Page 1

NEW 9030 SERIES TRACTORS

325 TO 530 ENGINE HORSEPOWER

Page 2

Choose from 10 models, unleash up to 500 horsepower.

All-new 9030 Series Tractors: Ready for the BIG TIME!

Since their launch in 1996,

John Deere 9000 Series Tractors

continue to be among the best

selling tractors in their class.

Why? The answer is simple –

dependability!

The all-new 9030 Series takes

this legendary performance to

greater heights.

A new 13.5 L engine provides

up to 583 peak horsepower* and

outstanding fuel economy.

™

A new AirCushion

suspension system lets you

operate at faster speeds, with

unmatched comfort.

The updated CommandView

cab is now quieter and more

user friendly than ever.

These powerful new tractors

are incredibly comfortable and

easy to operate. Ask your dealer

for a demonstration today.

tracks

™

LOADED WITH NEW FEATURES AND IMPROVEMENTS!

• New John Deere PowerTech Plus™ Tier III 13.5 L engine provides up to 530 engine

horsepower (583 peak hp*) and outstanding

fuel economy

• New tracks undercarriage and

single-piece frame delivers greater

durability

• New AirCushion tracks suspension

system enhances operator comfort

and reduces tractor wear and tear

• New double-reduction axle for

the 9530 and 9630 puts more power

to the ground

• Updated CommandView cab is quieter and more spacious

• Integrated Ag Management Solutions technology makes connecting

John Deere AMS components easy

• Newly refined 18-speed

Automatic PowerShift

Transmission provides more

power in the lower gears

4WD models

9230 – 325 hp

9330 – 375 hp

9430 – 425 hp

9530 – 475 hp

9630 – 530 hp

Scraper Special models

9430 – 425 hp

9530 – 475 hp

9630 – 530 hp

Track models

9430T – 425 hp

9530T – 475 hp

9630T – 530 hp

Note: Factory observed

horsepower levels at

2,100 rpm rated speed.

Engine 4-5

Cab 6-7

Controls 8-9

AMS 10-11

Hydraulics 12-13

Hitch, drawbar, PTO 14-15

Transmissions/axle 16-17

Track tractors 18-19

Track suspension 20-21

Row-crop solutions 22-23

Small-grain solutions 24-25

New 9030 Series Tractors:

• Decrease input costs

• Boost productivity

• Increase efficiency

*Factory observed with power bulge.

Scraper Special 26-27

Service/Dealer support 28-29

Specifications 30-31

Visit www.JohnDeere.com/9030 for more

details, or use the online product configurator

to build and price a new 9030 Series Tractor.

Page 3

Get up to 583 peak horsepower, plus outstanding fuel economy

The new John Deere PowerTech

Plus engines deliver Big Time

horsepower and outstanding fuel

economy. Plus, these fuel-injected

engines are Tier III emissions

certified and provide a 40 percent

reduction in nitrogen oxide

emissions compared to its

predecessor.

A 9.0 L engine – featured on

the 9230 – provides 325 hp. The

new 13.5 L powers all other 9030

Series Tractors. It delivers from

375 engine horsepower on the

9330 and up to 530 engine

horsepower (up to 583 peak hp*)

on the 9630.

Its new 4-valve, overhead

cam design produces tremendous

low-speed torque and throttle

response. Internal components

have been beefed up for greater

strength and reliability.

A new single-piece, lowfriction steel piston with directed

cooling, reduces parasitic load on

the engine, decreases internal

temperature, and helps improve

cylinder durability.

It all adds up to greater

durability, reliability, and lower

cost of ownership.

*Factory observed with power bulge.

Enormous power. As your field conditions change, the

new John Deere PowerTech Plus 13.5 L engine answers

the call. You get up to a 38 percent torque rise, and up to

a 10 percent power bulge – that’s an extra 32 to 53

horsepower!

Peak Torque 9030 Series

2000

1800

9630

9530

1600

9430

1400

9330

1200

9230

1000

ENGINE TORQUE (ft./lb.)

800

1300 1400 1500 1600 1700 1800 1900 2000 2100

ENGINE RPM

New 9030 Series Tractors reach peak torque up to 20 percent faster

than previous models so you can power through tough spots in the

field or accelerate up hills more quickly.

Field-proven Vari-Cool™ system

with variable-speed fan drive

automatically adjusts its speed

to keep the engine and hydraulic

system cool. It also improves fuel

economy and boosts pulling power.

New self-priming fuel system

eliminates messy hand priming

and filter pre-filling for fast, easy

filter changes.

John Deere PowerTech Plus 9.0 L engine

• Up to 38 percent PTO torque rise

• Up to 10 percent PTO power bulge

Meets Tier 3

emission standards.

New radiator is 29 percent larger

than previous models for increased

cooling capacity.

All-new John Deere

PowerTech Plus 13.5 L engine

• 375 to 530 engine hp*

• Peak torque rise of up to 38 percent – 20 percent faster than previous models

• Up to 10 percent power bulge on 9030 Series 4-wheel-drives

• Up to 9 percent power bulge on tracks

• Field-proven, high-capacity Vari-Cool cooling system

• New self-priming fuel system simplifies filter changes

• New heavy-duty stainless steel Exhaust Gas Recirculation cooler

• New cylinder liner material provides added liner strength and stiffness

• New 16:1 compression ratio improves cold-weather starts, and reduces emissions

• Low speed (1,000 rpm) torque – meets or exceeds previous model

• Improved throttle response

• Up to 375 hour engine-oil service interval with John Deere Plus-50™ Premium Oil

• Fuel filter regular service interval is 250 hours

• Dual fuel filter 10 micron/2 micron system with water separator

• Fuel pressure sensor indicates if filter is plugged

• 200 amp alternator

*Factory o bserved rated power mea sured at 2,100 eng ine rpm.

Page 4

CommandView cab takes comfort and convenience to new extremes

Big-Time comfort and

convenience await you inside

the CommandView cab.

The updated interior gives

you extra room to stretch your

legs. Plus, it’s quieter than

previous models.

A backlit instrument panel

makes controls and gauges easier

to see during night-time operation.

Available ClimaTrak™ temperature

control automatically keeps

temperatures right where you

like them.

And for an extra touch of

luxury you can add the optional

leather trim package and enjoy a

heated leather ActiveSeat™, and

leather-wrapped steering wheel.

The CommandView cab is a

real fatigue fighter that helps

operators stay fresh and alert,

increasing efficiency during long

days in the field.

Panoramic views surround you

Even with a larger engine and cooling system, the new 9030 Series hood remains neat and trim giving you outstanding visibility to the front of the tractor.

First-class comfort

• Quiet, spacious cab

• Available ActiveSeat suspension

• Easy-to-operate controls

• Uncompromised visibility

Are you looking for the ultimate in smooth-riding comfort? Choose the

optional John Deere ActiveSeat. It isolates the operator from up to 90 percent of

vertical movements as experienced in typical tractor operations. This reduces

operator fatigue, allows for faster field speeds, and increases overall productivity.

ActiveSeat not available for tracks.

Useful options enhance your comfort, efficiency

Dual outside mirrors – electric, adjustable

Comfort package with delayed lighting, auto temperature control

Adjustable ComfortCommand™ leather seat

Adjustable ActiveSeat (cloth or leather)

Business-band radio wiring-mounting bracket, antenna

Leather-wrapped steering wheel (requires leather seat)

Radar

Little things make a difference. Optional

external power mirror controls let you make

adjustments on-the-go.

Page 5

In a CommandView cab,

displays and controls encircle

you. Everything is within easy

reach and view.

The exclusive CommandARM

™

console places vital tractor

controls at your fingertips. Plus

its ergonomic design reduces

operator fatigue.

A large, illuminated cornerpost

monitor lets you check engine

speed, gear selection, ground

speed, and more in a glance.

An updated CommandCenter

™

LCD screen lets you program and

monitor more than 20 different

tractor functions.

It’s in-cab convenience that

will make every minute spent in

the field even more productive.

Convenient. Efficient. Productive.

• Push-button-easy controls

• Ergonomic fit for greater comfort

• Make on-the-go adjustments

Boost your efficiency with these easy-to-use controls

3

2

4

7

8

1. Electrohydraulic SCVs and 3-point hitch controls give you precise implement control. A fifth

and sixth SCV are optional providing the capacity necessary to control large air seeders and

other implements. See page 16.

2. The CommandCenter LCD display provides service and information alerts. Easily track engine,

transmission, electrical, and hydraulic performance. You can program tractor performance

settings, or set it to display readings in multiple languages if needed.

3. Control heating, cooling, extremity lighting, and wipers from the right-hand console.

4. Exclusive Implement Management System (IMS ) lets you operate multiple tractor functions

simultaneously. Two sequence buttons provide up to 20 learned commands. See page 17.

1

5

6

Total tractor control that is

easy to reach, easy to see

5. New electrohydraulic PTO switch provides

smooth, precise PTO engagement. See page 19.

6. The exclusive CommandARM console can be

raised or lowered to fine-tune comfort. You get

fingertip control of tractor hydraulics, throttle, gear

selection, rear hitch, and more.

7. Exclusive TouchSet

easily adjust hydraulic flow and timed-rate detents

for each individual hydraulic coupler. Make

adjustments on-the-go for added productivity.

9

11

10

See page 17.

8. Service ADVISOR™ port lets John Deere service

technicians plug in computers and quickly diagnose

and solve problems. This gets your equipment up

and running in less time.

9. Illuminated cornerpost monitor displays fuel

level, temperature, oil pressure, engine speed, gear

selection, ground speed, and stop-engine and

warning alerts.

10. GreenStar™-ready wiring harness and

implement connector ( ISO compatible). This makes

it easy to add John Deere guidance products such

as AutoTrac™ assisted steering.

11. ISO radar connector.

™

hydraulic control lets you

FieldVision™ HID lighting turns night into day

FieldVision High Intensity Discharge lighting is a must if you work much past sunset. For years HID

lights have been available for the front of your tractor. Now, you can enjoy the benefits of HID lights behind

your tractor.

When you choose the rear HID option, two of the four standard-equipped halogen lights (lower left) are

replaced with HID lights – 1 on each fender (lower right). These bright lights let you easily see from end to end

and from front to back of your largest implements.

Page 6

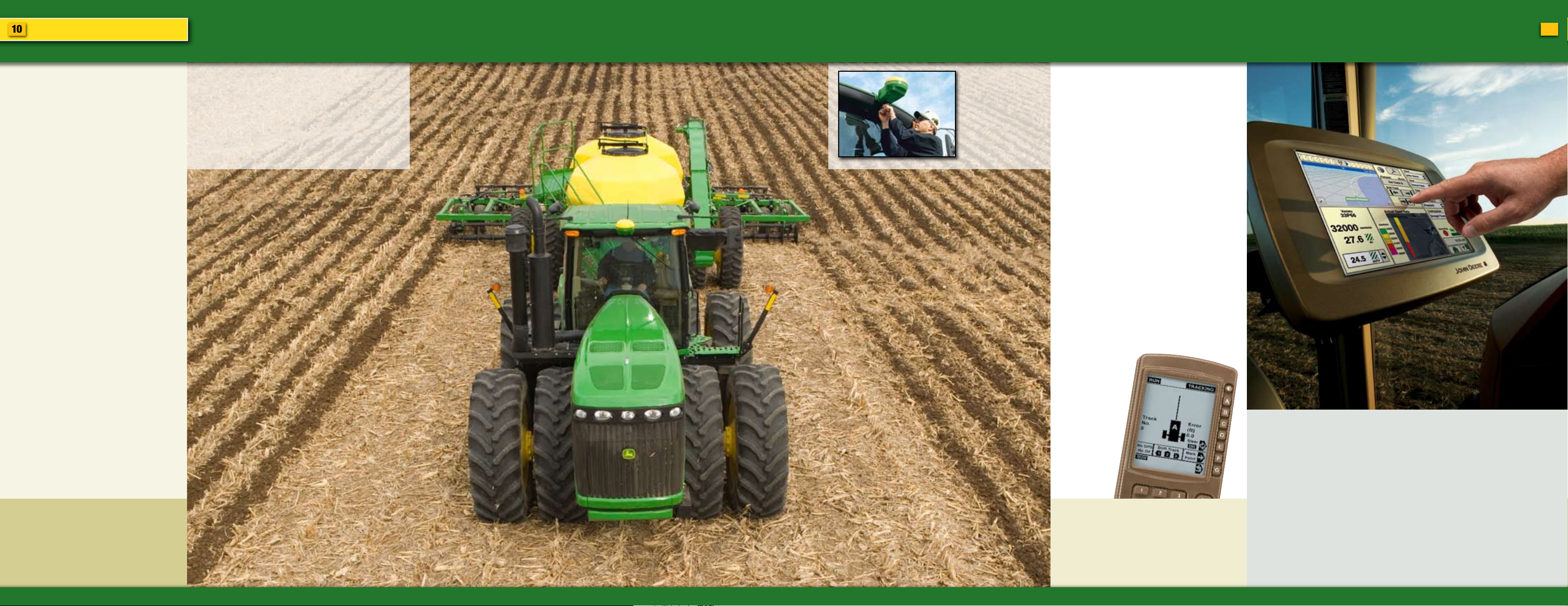

Make each pass more efficient with a GreenStar guidance system

Make every pass more

productive with integrated

guidance from John Deere

Ag Management Solutions.

™

Start with Parallel Tracking

and the free SF1 signal. This

hands-on system reduces

implement overlap and is ideal

for broad-acre tillage, seeding,

and spraying.

Ready for hands-free guidance?

Then upgrade to AutoTrac assisted

steering. It works with the free SF1

signal for broad-acre applications

or the subscriber-based SF2 signal.

It gives you pass-to-pass accuracy

of ± 4 in.

AutoTrac helps you work fast

so you finish more acres in less

time. Plus, by minimizing implement

overlap and skips, you can

decrease fuel, seed, chemical,

and fertilizer costs.

Visit your local John Deere

GreenStar certified dealer and

see how guidance can pay in

your operation.

Guidance benefits

• Reduce operator fatigue

• Save fuel with less overlap

• Increase operating speed

• Minimize crop input loss

Signal accuracy options

• SF1 – Free, pass-to-pass accuracy of about 1 ft.

•

SF2 – Pass-to-pass accuracy of ± 4 in.

•

StarFire RTK – ± 1-in. accuracy

Note: SF1 and SF2 – 15 minutes pass-to-pass, 95 percent of the time.

RTK ± within 6 mi. of base station and 68 percent of the time.

StarFire™ iTC

position receiver

with Integrated Terrain

Compensation corrects

all position calculations

to adjust for uneven

ground and slopes.

™

GreenStar guidance

Parallel Tracking

• Reduces overlap and skips

• Improves efficiency – saves time, chemicals,

and fuel

• Adjusts for satellite drift for precise applications

• Available on most equipment with 12-volt power

• Use on contours and with all three signal options

(SF1, SF2, and RTK)

AutoTrac

• Saves money, reduces fuel costs

• Increases field operating speeds

• Can help increase yields with more accurate

seed, fertilizer, and chemical placement

• Improves efficiency by maximizing full width

of implement

• Reduces operator fatigue

AutoTrac RTK

• Accurate guidance system

• Reduces input costs

• Improves efficiency

• Reduces operator fatigue

The original

GreenStar system

provides an

affordable option

for guidance

and field

documentation

applications.

John Deere offers you a complete zone-tillage

solution (left) with the all-new 2510S Strip-Till

Nutrient Applicator and AutoTrac RTK guidance.

You get repeatable 1-inch accuracy pass after

pass, season after season.

GreenStar 2 system

Reconfigurable GreenStar 2 display (above) with touch-screen navigation.

It comes pre-loaded with ISOBUS functionality, parallel tracking, and basic field

documentation programs to boost productivity. It can also act as a tractor performance monitor, providing you with instantaneous ground speed, wheel speed,

rear PTO speed, fuel efficiency, distance, total area, fuel consumption, engine

load readings, and more. With the GreenStar 2 Display, your 9030 Series Tractor

is fully prepared to optimize machine performance (guidance applications and

performance monitor), document all critical field tasks electronically (Field

Doc™), and control ISOBUS compatible implements.

Page 7

Exceptional hydraulics – plus all of the tools you need to maximize your efficiency

Only John Deere offers

TouchSet hydraulic controls.

As its name implies, just touch

and set hydraulic flow to

individual SCVs, on-the-go,

right from your seat.

Four electrohydraulic SCVs

are standard on all models, with

a fifth or sixth valve available as

a field-installed option. The SCV

control provides six-position

functions that include neutral,

extend, retract, extend detent,

retract detent, and float.

The 9030 Series comes with

a standard 48-gpm hydraulic flow

and an optional High-Flow system

with 78-gpm rated hydraulic flow

at the pump.

Internal valve parts are kept

to a minimum to reduce potential

wear points and to enhance

reliability. That means increased

uptime for your equipment.

Exclusive Implement Management System

When greater hydraulic capacity is needed

up to six SCV remotes are available as a fieldinstalled option.

Complete hydraulic control

• Four SCVs are standard

• Up to 78-gpm hydraulic flow

• Adjust hydraulic flow on-the-go

• Implement Management System

Exclusive TouchSet hydraulic control lets

you set and adjust hydraulic flow to individual

SCVs on-the-go right from your seat.

Set the Implement Management System (IMS) to

simultaneously perform up to 10 tractor functions per switch

(20 total) – push-button easy. You can simplify complicated

turn sequences and even less experienced operators can

become more productive in less time. IMS boosts efficiency,

enhances productivity, and reduces operator fatigue.

Page 8

Pull, lift, or power most anything on your farm

New 9030 Series Tractors give

you Big-Time versatility.

Multiple drawbar choices, plus

an optional 3-point rear hitch and

rear PTO, give you the versatility

to pull wide air seeders, lift heavy

plows, or power large grain carts.

Lift up to 15,300 lb. with your

choice of a Category 3/4N or

Category 4/4N, 3-point hitch with

quick coupler.

A heavy-duty 1¾-in. diameter,

1,000-rpm PTO gives you plenty

of power to drive tillers, grain

carts, and more. New electrohydraulic PTO engagement makes

operation push-button easy.

A Category 4 drawbar is

standard equipment on select

9030 Series Tractors (excludes

9530, 9630, 9530T, and 9630T).

A Category 4 conversion kit is

available for use with implements

requiring less than 475 hp.

To pull your extra-large

implements, a new Category 5

drawbar is standard on the 9530,

9530T, 9630, and 9630T.

Plenty of choices

• Multiple drawbar configurations

• Optional 3-point rear hitch

• Optional PTO power

• New push-button PTO control

A 20-spline, 1¾-in. diameter,

1,000-rpm PTO is optional for

the 9330, 9430, and 9430T.

New electrohydraulic

PTO option makes it pushbutton easy to control your

tractor’s PTO. Engagements

are smooth and precise.

Hitch Command enables your tractor to compensate for changes in

wheel or track slip when field conditions vary. A high setting makes the

tractor more responsive to changing field and soil conditions. If the

tractor exceeds the preset percentage of slip the hitch automatically

raises and lowers to compensate.

Drawbar and rear hitch options

A Category 4 drawbar is

standard on select 9030

Series Tractors (excludes

9530, 9630, 9530T, and

9630T). An optional Category

4 drawbar with heavy-duty

support is also available to

handle heavier draft loads.

Hitch-lift capacity has been

increased to 15,300 lb.

A 3-point rear hitch with

Quick-Coupler is available

on all models as a factory

or field-installed option.

A new Category 5 drawbar

is standard on the 9530,

9530T, 9630, and 9630T.

A 12,000-lb. vertical-load

carrying capacity, and

massive 2.75-inch hitch pin,

give you the added capacity

to pull heavy or extra-wide

implements.

External raise/lower

switch, located on the rear

fender, lets you adjust the

3-point hitch while outside of

the cab for easier hookups.

Page 9

Shift into action with push-button ease and field-proven reliability

Axle/Transmissions

17

Choose between two field-proven

transmissions – an 18-speed

PowerShift or a 24-speed

manual shift transmission.

The John Deere 18-speed

PowerShift has been updated

to accommodate the higher

horsepower levels of the 9030

Series. You get more lugging

power in the lower gears where

you need it most.

Shifts are clutch-free and

push-button easy. Robust

housing, shafts, and industrialstrength bearings make this a

rugged transmission you can

depend on year after year.

The 24-speed manual shift

transmission gives you a wide

range of speeds and a

powershiftable hi-lo for

tremendous versatility in

the field or on the road.

Legendary 18-speed PowerShift

The convenient shift lever on the CommandARM console

lets you smoothly move through 18 forward or six reverse

gears with just your thumb. Easily shift into park, neutral,

forward, or reverse, as well as change gears up or down.

Transport up to 24 mph (4WD).

Deluxe 24-speed transmission

The 24-speed Powr-sync transmission includes a

powershiftable hi-lo feature that lets you easily change

speeds as field conditions change.

New doublereduction axle

All-new double gear reduction in the planetary allows inputs into the rear differential to

turn faster. This results in lower torque loads on internal components and decreased wear

and loading of the power train – especially the ring gear and pinion. This added durability

provides longer wear life, keeping ownership costs low.

18-Speed PowerShift transmission

The updated 18-speed Automatic

PowerShift transmission

gives you 10 working

speeds between 3 and

8 mph, in ½ mph

speed increments.

You also get speed

matching between gears

13 and 18 to prevent

sudden jars while

downshifting

during transport.

Shifts are

electronically

modulated for ultra-

smooth performance.

Built-in reliability, efficiency

• Smooth, clutch-free shifts

• Automatic shifting improves efficiency

• More power in the lower gears

• Transport up to 24 mph (4WD)

A John Deere 9630 4-wheel-drive is an ideal

choice to handle your broad-acre tillage chores.

Disking, ripping, or plowing, a 9630 provides up to

530 engine horsepower (583 peak hp with power

bulge) – plenty of muscle to get the job done quickly

and efficiently.

Improve fuel economy and optimize productivity

with the Automatic PowerShift. It measures engine load,

throttle position, and gear selection to put you at just the

right speed . . . during field work or transport. Automatic

gear shifts also reduce operator fatigue and improve

pulling efficiency.

Transport up to

22.7 mph on

9030T Series

Track Tractors.

Page 10

Greater traction. Greater

flotation. And now you also

get improved operator comfort

and faster operating speeds

with a new 9030T Series Track

Tractor. Choose from three

models ranging from 425 to 530

rated horsepower.

The revolutionary new

AirCushion Suspension

system isolates the track

undercarriage from the tractor

frame. This provides you with a

super-smooth ride and allows for

fast field and transport speeds.

Other enhancements include

a rugged single-piece frame, a

new track-alignment system, and

a new drive-wheel pattern that

helps reduce slippage and increase track tension.

Plus, the wheelbase is

also five percent longer than

previous models.

All of these improvements

help improve ease of operation,

durability, and productivity.

Now enjoy supreme comfort with extra ground-gripping power and flotation

1

A new toolbox is built into the platform (left) for easy access and for storage of

tools, chains, or other equipment. New track-alignment mechanism (right)

makes adjustments easier and improves belt tracking.

Two track-width

options are available

for 9030T Series Track

Tractors. Choose from a

30- or 36-inch-wide

belt. Severe-duty

versions are also available.

2

3

Track tractor improvements

• New AirCushion suspension (p. 20)

• New track-alignment system

• New drive-wheel pattern

• New single-frame design

A new 60-degree drive wheel

pattern (right) grips the track belt

more efficiently, reducing slippage

for better performance.

(1) New mid rollers are 1.25 inches wider than previous models to help

reduce slippage and increase belt tension. (2) Twin nitrogen accumula-

tors and a larger tensioning cylinder increase track belt tension by 20

percent. (3) New guide lugs are 36 percent larger than previous

models. These improvements help reduce track belt wear and improve

tractor performance on steep hillside applications.

Page 11

Pump up your comfort and speed with the all-new AirCushion suspension system

Introducing the revolutionary

John Deere AirCushion tracks

suspension system. It’s the

ultimate in track tractor suspension

technology. Best of all, it’s standard

on all 9030T Series Track Tractors.

As the tractor passes over

bumps, or rough spots, trackframe

components are isolated from the

vehicle frame by the AirCushion

suspension system.

You get 13.7 inches of total

suspension travel at the front idler

wheels. As a result you’ll enjoy supreme operator comfort, while

being able to work and transport at

higher speeds. This helps you finish

your work in less time.

But that’s not all. The AirCushion

suspension combined with the

9030T’s longer wheelbase, also

helps limit wear and tear on the

tractor, improves reliability, and

puts more power to the ground.

It’s exclusive John Deere

suspension technology that

improves operator comfort,

boosts productivity, and helps

keep repair costs low.

4

5

1

2

Supreme comfort. Increased speed. More productivity.

The all-new John Deere AirCushion suspension system is the ultimate in track tractor suspension technology. You’ll appreciate the enhanced operator comfort and higher operating

speeds that are possible. Track frame components are isolated from the vehicle frame by the AirCushion suspension. Total travel range at the front idler wheels is 13.7 inches. This greatly

limits wear and tear on the tractor and improves reliability. Plus it helps put more tractor power to the ground.

(4) Heavy-duty reaction arm (above) attaches

to rear axle and pivots up and down.

(5) Heavy-duty damping cylinder (left)

provides additional cushion as the walking

beam travels vertically.

Pivot pin

(1) Massive pivot pin provides support for, and allows for the swingarm and walking beam

to pivot.

Swingarm

Walking beam

3

The AirCushion suspension system improves operator comfort and lets you work and transport at fast speeds for greater productivity.

(2) Two sets of air bags in front and behind

the front walking beam help cushion your ride.

(3) Heavy-duty bushing cushions the walking

beam and provides a pivot point for movement.

(6) 13.7 inches of total suspension travel

Page 12

New 9030 Series Tractors

help you work more row-crop

acres per day with optimum

efficiency.

Start in the spring and prepare

exceptional seedbeds with the

all-new 2310 Mulch Finisher or

field-proven 2210 Field Cultivator

equipped with AccuDepth™. You

get precise, incremental depth

control that conserves soil

moisture and saves fuel.

Then hook onto your largest

planter and plant all your corn

acres quickly and efficiently.

And after harvest you can put

the tremendous lugging power of

the 9030 Series to work in your

fall tillage operation.

Hitch onto the all-new

5-section 637 Disk. Or, shatter

soil compaction and size and bury

residue in a single, fuel-saving

pass with the 512 Disk Ripper or

2700 Mulch Ripper.

23

New 9030 Series Tractors: Extra versatility for today’s row-crop farms

Hitch onto the new John Deere 2510S Strip-Till Nutrient Applicator and you have a solution that lets you fertilizer big acres fast.

Spring tillage is a breeze with a new

9030 Series 4-wheel-drive and new

John Deere 2310 Mulch Finisher (shown

above). With working widths just over 45-ft.

wide, you can finish your big acres fast and

prepare planter-ready seedbeds in less time.

Add an aftermarket blade to

your new 9030 Series 4-wheeldrive and your set to push and

pack silage. See your dealer

for details.

For operations that require the ground-gripping performance and high-flotation capability of a track tractor look no further than a

new 9630T. With up to 530 engine horsepower, you can pull large implements like this new 2310 Mulch Finisher, with confidence.

Page 13

If you grow wheat, canola,

barley, or other small grains,

new 9030 Series Tractors can help

you get more from every acre.

It starts with seeding your

crop. These powerful tractors have

plenty of hydraulic flow to pull your

largest John Deere air-seeder and

commodity cart.

Whether you utilize convention

al-till or no-till practices on your

farm, there’s a John Deere airseeder that can get the job done.

At harvest, a PTO-equipped

9030 Series Tractor can be

hooked onto your high-capacity

grain cart to quickly unload

combines and transport grain.

Plus these big tractors have

plenty of lugging power to easily

handle your largest post-harvest

tillage jobs. Hook onto an all-new

five-section 637 Disk, or fieldproven 2410 Chisel Plow to size

and bury crop residue quickly and

efficiently.

John Deere makes big-acre

small-grain farming a snap.

Get big results from every acre with these John Deere small-grain farming solutions

A John Deere 9630 and 1835 Air Seeder will make short work of your large seeding

jobs. Add GreenStar AutoTrac assisted steering and you can work more quickly and more

accurately while decreasing input costs like seed, chemical, fuel, and fertilizer.

-

Here’s a terrific small-grain seeding

solution – a new 9030 Series Tractor

paired with a new 1870 Air-Hoe Drill with

exclusive Conserva Pak™ openers.

Wheels or tracks? John Deere gives you a choice in high-horsepower tractors. Choose between 4-wheel-drive tractors or the ground-gripping traction and flotation of a tracks tractor. Add

a John Deere ActiveSeat and you have the smoothest ride of any 4-wheel-drive tractor around. If you prefer tracks, the new AirCushion suspension system provides first-class ride comfort

and lets you operate at faster speeds than previous models. Your John Deere dealer can help you choose the right tractor for your operation.

Page 14

Scraper Special: built to handle the rigors of earthmoving

Want to boost productivity

without breaking the bank?

Consider a new 9030 Series

Scraper-Special Tractor teamed

with a John Deere Ejector or

Carry-all Scraper.

It’s the only fully integrated

tractor-scraper system on the

market and does as much or more

work as a self-propelled scraper

or truck and excavator – but at

one-third of the initial investment.

Operating costs are low too.

Unlike self-propelled units, you

don’t need a push dozer to help

load. In fact, without additional

operators and support equipment,

you can save as much as 30 to

50 cents per cubic yard.

You get added versatility, too.

Unhitch your scrapers and use

these powerful tractors to pull

disks, rippers, and other tools.

Dedicated scrapers can’t.

And now John Deere offers

an exclusive option you won’t

find anywhere else – AutoLoad.

This innovation automates the

scraper’s hydraulic-lift functions,

making it push-button easy to load

like a pro. You get consistent lifts

at the fill site and quick work

cycles that boost productivity.

Optional steel tow cable connects to the tractor

drawbar (dealer installed). It unhooks easily from the

front storage pin for quick hook-ups to the tow vehicle.

Scraper-Special

models include:

•

Gudgeon with tapered roller bearing

•

Greasable steering cylinder pins

•

Front-axle reinforcement

•

Rear-axle reinforcement (9530, 9630)

•

Hydraulic system without 3-point rear hitch

•

Secondary function hydraulic accumulator

•

Category 5 Drawbar support

•

Heavy-duty wheel equipment

•

Backup alarm

•

Flashing rotary beacon

Load like a pro with award-winning AutoLoad

The award-winning John Deere AutoLoad system makes it push-button easy for novice and experienced tractor/scraper

operators to consistently load like pros, time after time. The AutoLoad option also greatly reduces the time required for initial

operator training. You get maximum productivity from your workforce – even if operating conditions change. The result?

Consistent productivity throughout the workday and workweek. AutoLoad controls the scraper’s hydraulic-lift functions during

the load cycle. Push a button at the start of the cut. As the cut progresses, AutoLoad takes over and adjusts the blade height.

At the end of the cut, the system disengages through normal operation, providing consistently-filled scrapers time after time.

™

Page 15

Always there for you when you need us

New John Deere 9030 Series

Tractors are easy to operate

and built to deliver rock-solid

dependability, unmatched

uptime, and superior productivity.

When you invest in a new

John Deere tractor, you get more

than the latest high-performance

tractor technology.

You also get the unmatched

support of your local John Deere

dealer. He is part of a global

network of world-class dealers –

all backed by a company with

more than 170 years of experience in the farm-equipment

business.

So whether you need routine

service and parts, in-field repairs,

financing, or just some friendly

advice – John Deere, and your

local dealer are committed to

your continued success.

New “wide-open” hood gives you quick, easy access for routine maintenance

Routine maintenance is a part of owning any

tractor and John Deere makes it a quick and easy

task if you own a 9030 Series Tractor.

A new single-piece tilt hood gives you

unobstructed access to fluid-level check points,

site-gauges, and fluid fill points.

Regular service intervals are extended to save

you time and to help lower your maintenance costs.

Transparent fluid reservoirs let you quickly check

coolant and hydraulic fluid levels.

Enjoy up to a 375-hour engine oil change and oil

filter service interval with John Deere PLUS-50™ oil

and John Deere filter, or 250-hour service interval

with standard oil and filter.

Plus, a new self-priming fuel system eliminates

messy hand priming and filter pre-filling.

Whether you need a replacement filter, hydraulic

fluid, or any other part, your local John Deere dealer

has what you need to keep your new tractor running

in peak condition.

Service made simple

• World-class sales, service, support

• Unmatched parts availability

• Extended service intervals

• Factory-trained service technicians

Invest in John Deere equipment and enjoy the

benefits of a professional and knowledgeable staff

that are always willing to lend you a helping hand.

From the time you first walk into our store, until

we deliver that new tractor to your farm, we’re there

for you year after year.

Flip-up battery cover features an air

cylinder to hold it up during periodic

inspections or annual service.

Access to common service check points

is unobstructed making daily oil and coolant

level checks quick and easy.

Fuel fills are easy. A new 350-gal.

capacity on 4-wheel-drives means you can

stop less often to fill up. Capacity on tracks

models is now 330 gal.

Annual air filter replacements are a

breeze for all 9030 Series tractors. Filters

can be conveniently reached while standing

on the ground.

Page 16

Specifications by model – 4WD

Specifications by model – Tracks

Common specifications

ENGINE

Type

Aspiration

Engine air filter

Displacement - bore

and stroke

Compression ratio

Fuel injection system:

Lubrication

Oil filter

FUEL SYSTEM

Type

Filter system

Primary filter,

secondary filter

ELECTRICAL SYSTEM

Alternator, batteries

PowerGard ™ extended warranty

All John Deere tractors come with a 24

total month/2,000 total hour factory basic

warranty. You may elect to extend your

warranty for engine and powertrain related

components through the PowerGard Protection

Plan. See your dealer for pricing and details, or

go online to www.powergard.com.

John Deere PowerTech Plus diesel,

in-line, 6-cylinder

Variable geometry turbocharger

with air-to-air aftercooling and

exhaust gas recirculation

Dual stage with engine

cooling fan aspiration

549 cu . in. ( 9.0 L) - 4.66 x 5.3 5 in.

(118.4 x 136 mm ),

824 cu. in. (13.5 L) - 5.2 x 6.5 in.

(132 x 165 mm)

16:1

High Pressure Common Rail (9.0 L only),

Electronic unit injectors (13.5 L)

Full-pressure, full-flow filtration

Replaceable cartridge style oil filter

Self priming

Two stage with water separator

and service indicator light

10 micron replaceable cartridge,

2 micron with spin-on element

200 amp, 3 – 12 volt,

(2775 total cold cranking amps)

with battery boost terminal

protection plan

MODEL

ENGINE PERFORMANCE

Rated engine hp at 2,100 engine rpm 325 hp (2 39 kW ) 375 hp (276 kW) 425 hp (313 kW) 475 hp (349 kW) 530 hp (390 kW) 425 hp (313 kW) 475 hp (349 kW) 530 hp (390 kW)

Engine hp, 97/68/EC at 2,100 engine rpm 337 hp ( 248 kW) 388 hp (285 kW) 439 hp (323 kW) 491 hp (361 kW) 543 hp (399 kW) 439 hp (323 kW) 491 hp (361 kW) 543 hp (399 kW)

PTO hp at 1,89 5 rpm 263 hp (196 k W) 320 hp (238 k W) 320 hp (23 8 kW ) NA NA 320 hp (23 8 kW ) NA NA

FINAL DRIVES

TRANSMISSIONS

18-Speed Automatic P owerShift (18 For ward /6 Reverse) Optional Optional Optional Standard Standard Standard Standard Standard

24-Speed Manual Shift ( 24 For ward/6 Reverse ) Standard S tandard St andard NA NA NA NA NA

AXLES

100 mm x 3 045 mm (120 in.) Standard NA NA NA NA NA NA NA

110 mm x 3045 mm (120 in. ) Optional Standard Standard NA NA Standard NA NA

120 mm x 3045 mm (120 in. ) NA NA NA Standard Standard NA Standard Standard

DIFFERENTIAL LOCK

Hydraulic differential lock Optional Optional Optional Standard Standard Standard St andard Standa rd

HYDRAULIC SYSTEM (Closed-center, pressure/flow compensated)

Electrohydraulic selective control valves 4 standard, 5th and 6th optional 4 standard wi th 48 gpm (182 L/ min) f low, or 4 optional wit h Scraper High Flow 75 gpm (28 3.9 L /min)

Main pump, axial piston (displacement) 4.5 cu. in. (75 cm3) 4.5 cu. in. (75 cm3) 4.5 cu. in. (75 cm3) 4.5 cu. in. (75 cm3) 4.5 cu. in. (75 cm3)

Maximum pressure 2900 psi (20 000 kPa) 2900 psi (20 000 kPa) 2900 psi (20 000 kPa) 2900 psi (20 000 kPa) 2900 psi (20 000 kPa)

Maximum pump flow with PowerShift Transmission 48 gpm (182 L /min ) 48 gpm (182 L /min) 48 gpm (182 L /min ) 48 gpm (182 L /min) 48 gpm (182 L /min)

Maximum pump flow with Manual Shift Transmission 44 gpm (167 L/ min) 4 4 gpm (167 L /min ) 44 gpm (167 L /min) NA NA

Available flow available at 1 SCV 30 gpm (114 L/min ) 30 gpm ( 114 L/min ) 30 gpm (114 L/min ) 30 gpm (114 L /min ) 3 0 gpm ( 114 L/min )

Available flow available at 2 SCVs with PowerShift Transmission 48 gpm (182 L /min) 48 gpm (182 L /min) 48 gpm (182 L /min ) 48 gpm (182 L /min) 48 gpm (182 L /min)

Available flow available at 2 SCVs with

Manual Shift Transmission

3-POINT REAR HITCH WITH QUICK COUPLER

Category 3/4N with up to 15,300 lb. (6940 kg)

maximum hitch-lift capacity

Category 4/4N with up to15,300 lb. (6940 kg)

maximum hitch-lift capacity

DRAWBAR

Category 4 Drawbar Standard Standard Standard NA NA NA NA NA

Category 4 Heavy-duty drawbar support Optional Optional Optional NA NA NA NA NA

Category 4 Drawbar reinforcement up to 11,000 lb. (4990 kg) Optional Opt ional Opti onal N A N A NA NA NA

Secondary chain support Standard Standard Standard Standard Standard NA NA NA

Category 5 Drawbar up to 12,000 lb. (5443 kg) not compatible

with 3-point hitch or PTO

PTO (Fully independent Power Take-Off)

1¾-in. diameter, 20 spline, 45 mm, 1,000 rpm Optional Optional Optional NA NA NA NA NA

CAPACITIES

Fuel ta nk 350 gal. (1325 L) 350 gal. (1325 L) 350 gal. ( 1325 L) 35 0 gal. (1325 L) 350 gal. (1325 L ) 350 gal. (1325 L) 350 gal. (1325 L) 350 gal. (1325 L)

Cooling system 12.5 gal . (47.3 L) 14 gal. ( 53 L) 14 gal. (53 L) 14 ga l. (53 L) 14 gal. (53 L) 14 gal. (53 L) 14 gal. (5 3 L) 14 gal. (5 3 L)

Crankcase with filter 8.4 gal. (31.8 L) 11 gal. (41.6 L ) 11 gal. (41.6 L) 11 gal. ( 41.6 L) 11 gal. (41.6 L) 11 gal. (41.6 L) 11 gal. (41.6 L) 11 gal. (41.6 L)

Hydraulic system with 3-point rear hitch 28 gal. (106 L) 28 gal. (106 L) 28 gal. ( 106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. ( 106 L) 28 gal. (106 L)

Hydraulic system without 3-point rear hi tch 27 gal. ( 102.2 L ) 2 7 gal. (102.2 L) 27 gal. (102.2 L) 27 gal. (102.2 L) 27 gal. (102.2 L) 27 gal. (102. 2 L) 27 gal. (102. 2 L) 27 ga l. (102. 2 L)

BRAKES

Hydraulic power, we t disk, self adjusting

on fron t and r ear axle, plus secon dary brake

Hydraulic trailer brakes Optional Optional Optional Optional Optional Optional Optional Optional

ESTIMATED SHIPPING WEIGHT for tractor equipped with standard tires, with no PTO, and no 3-point rear hitch:

4WD 32,170 lb. (14 59 2 kg) 34,134 lb. (15 483 kg) 35,530 lb. (16 116 kg) 36,070 lb. (16 361 kg) 37,290 lb. (16 914 kg) 35,530 lb. (16 116 kg) 36,070 lb. (16 361 kg) 37,290 lb. (16 914 kg)

9230 9330 9430 9530 9630 9430 Scraper Special 9530 Scraper Special 9630 Scraper Special

Inboard planetary Inboard planetary Inboard planetary

44 gpm (167 L /min ) 44 gpm (167 L /min) 44 gpm (167 L /min) NA NA

Optional (N/A with 100 mm axle) Optional Optional Optional Optional NA NA NA

Optional (N/A with 100 mm axle) Optional Optional Optional Optional NA NA NA

Optional Optional Optional Standard Standard NA NA NA

Standard S tandard St andard Standa rd Standard Standard Standard St andard

Inboard planetary with

double-reduction axle

Inboard planetary with

double-reduction axle

Inboard planetary

Inboard planetary with

double-reduction axle

Inboard planetary with

double-reduction axle

Note: Specifications and design subject to change without notice.

MODEL

ENGINE PERFORMANCE

Rated engine hp at 2100 engine rpm 425 hp (313 kW) 475 hp (349 kW) 530 hp (390 kW)

Engine hp, 97/68/EC at 2100 engine rpm 439 hp (323 kW) 491 hp (361 kW) 543 hp (499 kW)

PTO hp at 1,89 5 rpm 302 hp (225 kW ) NA NA

TRANSMISSION

18-Speed Automatic P owerShift (18 For ward /6 Reverse) Standard Standard Standard

FRONT AXLE

Equipped with AirCushion suspension system Standard Standard Standard

REAR AXLE

Differential steer without outboard planetar y axle Standard Standard Standard

TRACK BELTS

30-in ch wide belt Standard Standard Standard

36-in ch wide belt Optional Optional Optional

HYDRAULIC SYSTEM (type)

Electrohydraulic selective control valves 4 base, 5th and 6th optional

Main pump, axial piston (displacement) 4.5 cu. in. (75 cm3) 4.5 cu. in. (75 cm3) 4.5 cu. in. (75 cm3)

Maximum pressure 2900 psi (20 000 kPa) 2900 psi (20 000 kPa) 2900 psi (20 000 kPa)

Maximum pump flow 48 gpm (182 L/min) 48 gpm (182 L/min) 48 gpm (182 L/min)

Available flow available at 1 SCV 30 gpm (114 L/min) 30 gpm (114 L/min) 30 gpm (114 L/min)

Available flow available at 2 SCVs 48 gpm (182 L/min) 48 gpm (182 L/min) 48 gpm (182 L/min)

3-POINT REAR HITCH WITH QUICK COUPLER

Category 4/4N with up to 15,300 lb. (6940 kg) maximum hitch-lift capacity Optional Optional Optional

DRAWBAR

Category 4 Drawbar with heavy-duty hammerstrap Optional NA NA

Category 4 Drawbar reinforcement up to 11,000 lb. (4990 kg) Optional NA NA

Category 4 Wide-swing drawbar on rollers Standard NA NA

Category 5 Wide-swing drawbar on rollers Optional St andard St andard

Category 5 Wide-swing drawbar with bottom rollers Optional Optional Optional

Category 5 Drawbar reinforcement up to 12,000 lb. (5443 kg) Optional Optional Optional

Secondary chain support Standard Standard Standard

PTO (Fully independent Power Take Off)

1¾-in. diameter, 20 spline, 45 mm, 1,000 rpm Optional NA NA

CAPACITIES

Fuel ta nk 330 gal. (1249 L ) 330 gal. (1249 L ) 330 gal. (1249 L )

Cooling system 14 gal. ( 53 L) 14 gal. ( 53 L) 14 gal. ( 53 L )

Crankcase with filter 11 gal. (41.6 L ) 15.8 gal. (59.8 L) 15.8 gal. (59.8 L)

Hydraulic system with 3-point rear hitch 27 gal. (102.2 L) 27 gal. (102.2 L) 27 gal. (102.2 L)

Hydraulic system without 3-point rear hi tch 27.5 gal. (104.1 L) NA NA

BRAKES

Hydraulic power, we t disk, self adjusting Standard Standard Standard

AVERAGE BASE WEIGHT less weights, with no PTO, and no 3-point rear hitch:

Tracks 43,000 lb. (19 504 kg) 43,000 lb. (19 504 kg) 43,000 lb. (19 504 kg)

9430T 9530T 9630T

(Closed-center, pressure/flow compensated)

Page 17

TM

Fast and easy credit

Why John Deere Credit?

Because they work with my dealer

to design the finance package that fits

my operation. It’s the most efficient

way to get the equipment I need.

And they understand my business,

which makes credit approvals

fast and easy.

w w w. J o hn De er eC re di t. c om • 1- 80 0 - 3 6 2- 8 5 8 0

A sk y our d eal e r f o r J ohn D eer e Cre d i t f i n anc i ng .*

*Subject to John Deere Credit approval.

This li terature has been compiled for worldwide circulation. While general info rmatio n, pic tures, and descript ions are prov ided, some ill ustra tions

This literature has bee n compi led for worldwi de circu lat ion. While ge neral i nfor mation, picture s, a nd d escript ions are pro vided, s ome illu strations

and tex t may include fina nce, ins urance, produc t options and ac cesso ries NOT AVAI LABLE i n all reg ions. P LEASE C ONTAC T YOUR LOC AL DE ALER

and te xt ma y incl ude finan ce, ins urance, pro duct optio ns and acce ssories NOT AVAIL ABLE in all regio ns. PLEASE CONTAC T YOUR LO CAL D EAL ER

FOR DETAIL S. John Deere re serves t he right to chang e sp ecif icat ions, de sign and price of product s de scrib ed in th is li terature without notice.

DSA A39488 L itho in U.S.A . (07-0 7)

FOR DETAILS. Jo hn Deer e reser ves t he rig ht to cha nge specif icati ons, de sign a nd p rice o f produ cts de scribe d in t his litera ture w ith out not ice.

www.JohnDeere.com/Ag

www.JohnDeere.com/Ag

We are proud

We are pro ud

to suppor t FFA

to suppor t FFA

®

®

®

Loading...

Loading...