Page 1

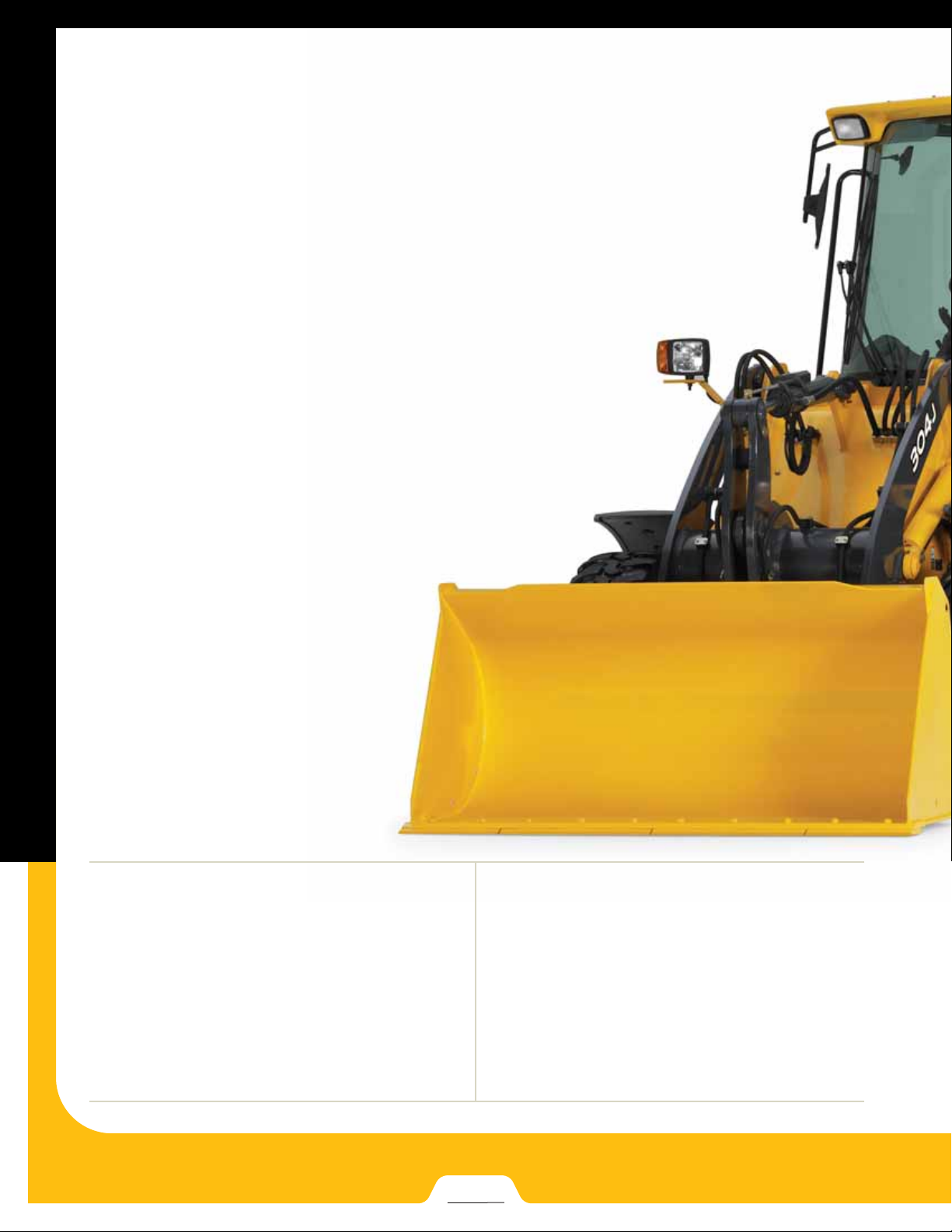

73 SAE NET HORSEPOWER

LOADER

J

304J

Page 2

Agile, productive,

Agile, productive,

Agile, productive,

po

powerful, and ready

powerful, and ready

werful, and ready

for anything.

for anything.

for anything.

Need a compact loader to get big results?

Choose the 304J. This versatile 73-hp machine

combines outstanding maneuverability, travel

speed, breakout force, reach, and stability in an

innovative package. Its oscillating stereo steering

delivers a turning radius that’s 20-percent tighter

than comparable loaders for fast work cycles.

Delivers smooth moves and better material

retention over rough terrain, too. Add to that a

redesigned, more spacious cab, and extra uptime

from sealed electrical connections, more durable

axles, and extended service intervals, and you’ve

got a multi-purpose machine that’s ready, able,

and willing to take on your many tasks.

PAGES

2–3

Page 3

304J Loader key specifications

Operating Weight.....................................13,404 lb.

Net Horsepower.......................................73 hp

Full Turn Tip Load....................................9,315 lb.

Bucket Size..............................................1.4 cu. yd.

Bucket Breakout Force...........................12,364 lb.

Unique stereo steering makes this compact loader

even more productive, for tight turns and extra agility

in close quarters.

Comes with standard items others call options —

return to dig, quick-coupler, high travel-speed range,

and 1.4-cubic-yard bucket.

Extended service intervals help maximize uptime.

100-percent manual differential lock helps you dig

down deep for more power.

Tier 3 emissions-certified five-cylinder turbocharged

John Deere diesel delivers power without compromise.

Page 4

Unlike comparable-size machines, return-to-dig

is standard on the 304J.

Oscillating stereo steering combines machine

articulation and rear-axle steering, giving the

304J the tightest turn radius in its class.

Twenty-inch tires are standard.

1

1. Boom float allows easy backdragging for

finish grading and cleaning up jobsites.

2. The 304J’s unique design turns tight but

articulates less, keeping the center of

gravity and ballast in line to counteract

load forces — for superior full-turn

tipping load capacity.

3. An oscillating rear axle and elastic

articulation at the pivot smoothes the

ride for greater material retention and

2

reduced operator fatigue.

4. 304J’s long reach lets it easily dump

to the center of tandem-axle trucks

for quicker and easier loading.

5. Manual low-speed differential

lock delivers the traction needed

to go deeper into the pile for bigger

bucket loads.

3

4

5

Page 5

Give crowded

Give crowded

Give crowded

conditions the

conditions the

conditions the

runaround.

runaround.

runaround.

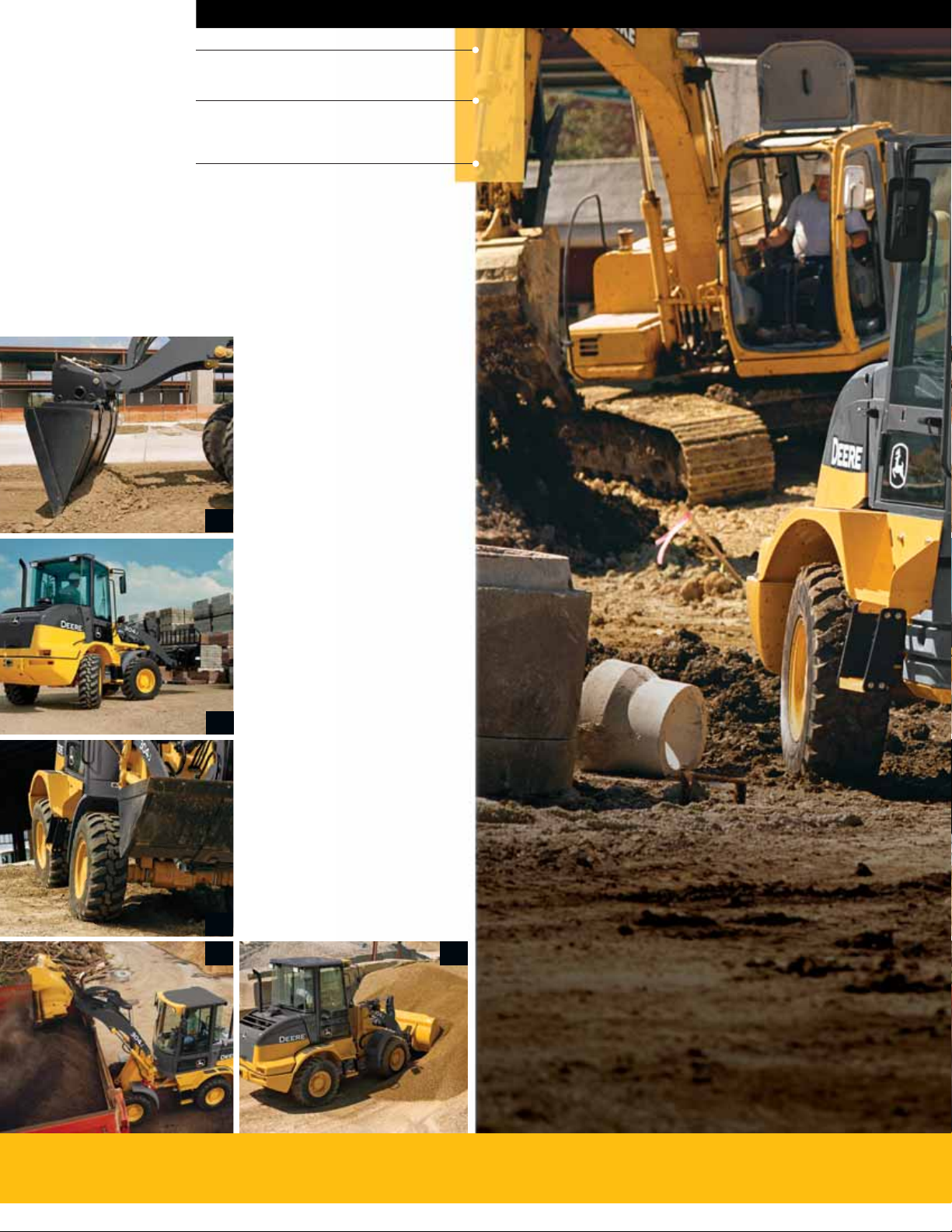

When the going gets rough, get your

hands on a 304J and get going. Unlike

other machines that are frequently

forced into three-point turns (or worse), this

nimble loader’s stereo steering allows a

tight 148-inch turn radius for unsurpassed

maneuverability. Delivers higher tipping

load capacities, too. What’s more, the

PAGES

4–5

hydrostatic drivetrain’s infinitely variable

range lets you precisely match travel speed

to the work at hand. So you can inch ahead

while maintaining full hydraulic power.

Or max out at a fastest-in-class 19 mph. The

304J lets you move more materials, more

quickly, and more efficiently. Without running

you ragged.

Page 6

Efficient interior

Efficient interior

Efficient interior

provides plenty of

provides plenty of

provides plenty of

room for productivity.

room for productivity.

room for productivity.

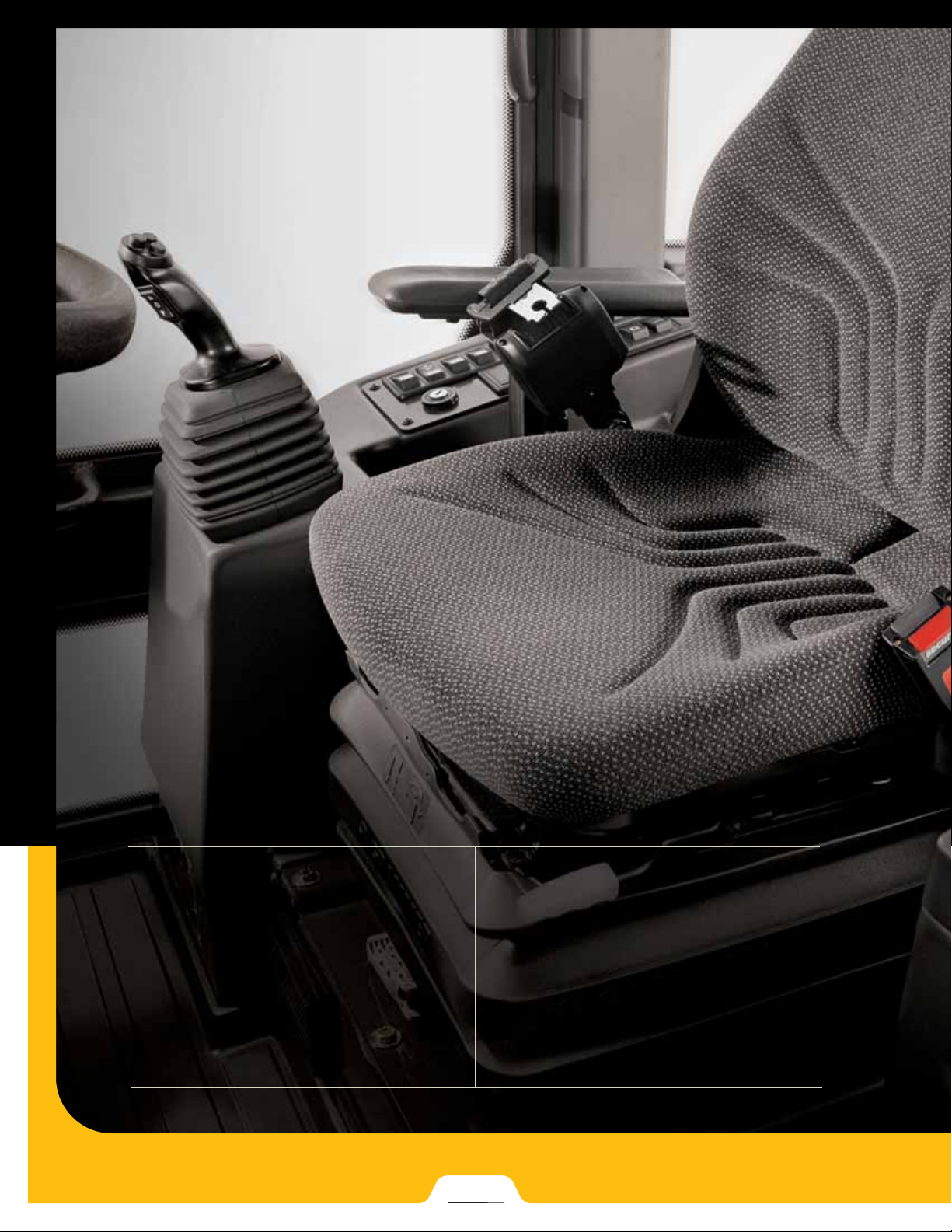

When operation is easy, maximum pro-

ductivity becomes second nature. The 304J’s

sound-suppressed spacious cab provides

ample leg- and headroom, best-in-class

all-around visibility, and one smooth ride.

A single lever with FNR switch controls

all boom and bucket functions, and standard

return-to-dig is just a flick-of-the-wrist

away. Gauges in the forward console are

clearly visible, intuitive, and easy to read.

Tilt steering, multi-adjustable high-back

suspension seat, electronic monitor, and

many more productivity-boosting features

also are standard.

PAGES

6–7

Page 7

Inching/brake pedal lets you slow travel speed while keeping

engine rpm high for optimum hydraulic response and control.

Interior and exterior convex mirrors further enhance the

304J’s best-in-class visibility.

Add a highly efficient HVAC system and make your operator

even more productive. Automotive-type louvers help keep

the view clear, the cab comfortable.

1. Walk-through cab lets you enter or

exit easily from either side.

2. Boom and bucket control, FNR, and

differential lock are on the same

low-effort lever for convenient singlehanded control.

3. Easy-to-read monitor tracks rpm,

time, hours, engine oil pressure,

and more. Issues both visible

and audible warnings.

4. Low- and high-speed ranges provide

infinitely variable travel speeds from

standstill to a best-in-class 19 mph.

5. Oscillating axle/elastic articulation

reduces cab tilt by as much as 50

percent for a smoother ride that’s

easier on both machine and operator.

5

1

2

3

4

3

Page 8

Wet-disc brakes in the heavy-duty axles self-adjust

and are sealed from moisture and contaminants for

long, trouble-free life.

Proportional fan runs only as needed to provide

optimal cooling — for reduced wear-and-tear

on cooling components, reduced noise, and lower

fuel consumption.

Turbocharged Deere PowerTech™diesel runs

quiet and meets EPA Tier 3 non-road emissions

regulations. So it can work where rigid soundand air-quality regulations exist.

Remote test ports enable technicians to quickly

troubleshoot problems.

1. Steering linkage is positioned where it’s

protected, and supported by brackets

with easily replaceable wear strips.

2. Angled self-cleaning steps and

ergonomically positioned grab

bars make getting in and out of

the cab easier.

3. A/C condenser tilts out and away

from the radiator for easier cleanout. Doesn’t require draining fluids

1

or disconnecting hoses.

4. Articulation joints and major structures

are so strong and durable, they’re

covered by a three-year/10,000-hour

StructurAll

™

warranty.

2

3

4

Page 9

Built to handle the

Built to handle the

Built to handle the

toughest jobs – yours.

toughest jobs – yours.

toughest jobs – yours.

The hard-working 304J limits downtime with

its toughness and improves your bottom line

with its long-term reliability. Incorporating

many of the same features found on our larger

loaders, it’s built to keep downtime down with

sealed electrical connectors, flat-face O-ring

seal hydraulic couplings, and self-adjusting

wet-disc brakes. The 304J helps keep your

operator out of harm’s way, too, with numerous

safety features such as an automatic park brake,

bypass-start protection, slip-resistant steps,

and convenient handholds. If it’s uptime you

demand, the 304J provides all you and your

operator need to stay productive.

PAGES

8–9

Page 10

If it’s not one thing,

If it’s not one thing,

If it’s not one thing,

it’

it’

it’s another.

s another.

s another.

Why invest in a bunch of specialized

machines when the highly versatile 304J

can do the job? With its standard pin-type

hydraulic quick-coupler, the 304J lets you

go from bucket to forks, quickly and easily.

Or opt for the Worksite Pro

coupler that enables this jack-of-all-trades

™

skid-steer-style

machine to utilize an even wider array of

skid-steer-compatible Worksite Pro attach-

ments. Operation is easy, with joystick and

third- and fourth-function pilot controls con-

veniently located at your fingertips. Regardless

of how you equip it, the 304J will be the most

versatile compact machine on your worksite.

PAGES

10–11

Page 11

Change hydraulic flow with a twist of your wrist.

Unobstructed line of sight to attachments makes

switchover quick and easy.

The optional fourth-function valve delivers plenty of

flow for running hydraulic-driven attachments like

power rakes and augers.

1. If you change attachments often, you’ll

appreciate the hydraulic-actuated skidsteer-style coupler that lets you attach

and release attachments quickly, without tools or leaving the seat.

Attachments shown:

2. Utility/sno

3. Scrap grapple

4. Utility bucket

5. Pallet fork

6. Auger

w blade

1

2

Available attachments:

• Power rakes

• Utility/snow blades

• Augers

• Bale spears

• Construction or utility buckets

• Tooth buckets

• Pallet forks

• Scrap and brush-tined grapples

• Pick-up brooms

6

3

4

5

5

Page 12

Fuel-efficient Tier 3

emission-certified

John Deere diesel runs

500 hours between oil

changes. Hydraulic valve

lifters and serpentine belt

never require adjustment.

Remote lube bank puts

rear axle zerks within

easy reach. Convenient

maintenance chart helps

ensure that nothing gets

overlooked.

Locking fuel cap and

electrical disconnect

switch help prevent

theft or vandalism.

Easily accessible

maintenance-free

batteries are connected

in parallel for reliable

electrical power.

Easy-lift hood and

transverse-mounted

engine provide convenient

ground-level access to

daily checkpoints.

Page 13

Lower operating costs,

Lower operating costs,

Lower operating costs,

raise expectations.

raise expectations.

raise expectations.

We spared no expense to help keep the 304J’s

operating costs low. From the transverse-mounted

John Deere diesel that provides convenient

ground-level service access, to easy-to-change

vertical spin-on filters, this versatile loader will

1. Hydraulically driven fan runs only as needed

for efficient cooling, reduced noise, and lower

fuel consumption.

4. Hydraulic fluid sight gauge and see-through

coolant reservoir let you check fluid levels

at a glance.

2. Easy-access fuse panel accommodates quick

checks and changes.

5. Easy access vertical spin-on filters and

environmental drains make fluid changes

quicker and cleaner.

require less of your time and attention. Extended

service intervals, environmentally friendly drains,

sight gauges — the list of J-Series features that

help minimize maintenance go on and on. And so

will the daily operating cost savings you’ll enjoy.

3. Electronic control unit lets service technicians

easily retrieve vital operating information and

helps diagnose problems more quickly.

6. Nobody backs you better than the 400-plus

John Deere dealers throughout North America.

1

4

2

5

PAGES

12–13

3

6

Page 14

Specifications

Specifications

Specifications

Engine 304J

Manufacturer and Model . . . . . . . . . . . . . . . . . . .John Deere PowerTechTM 5030T

Non-Road Emission Standards . . . . . . . . . . . . . . .certified to EPA Tier 3 emissions

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Valves per Cylinder . . . . . . . . . . . . . . . . . . . . . . .2

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184 cu. in. (2.9 L)

Net Rated Power @ 2,800 rpm, SAE . . . . . . . . . . 73 hp (54 kW)

Net Peak Power @ 2,800 rpm, SAE . . . . . . . . . . .75 hp (56 kW)

Maximum Net Torque @ 1,500 rpm . . . . . . . . . . .195 lb.-ft. (265 Nm)

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pressure system with full-flow spin-on filter

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronically controlled unit injection pump

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .turbocharged

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual safety element dry type

Cooling

Hydraulically driven, proportionally controlled fan

Engine Coolant Rating . . . . . . . . . . . . . . . . . . . . .–34 deg. F (–37 deg. C)

Powertrain

Hydrostatic (HST) with infinitely variable speed control over full range of operating speeds; two speed ranges; joystick-mounted F-N-R; acceleration pedal; HST inching pedal, which

allows infinitely reduced travel speeds while maintaining full engine rpm and hydraulic flow

Two Travel Speeds In Forward and Reverse

(equipped with 405/70R20 tires)

Gear 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.3 mph (6.9 km/h)

Gear 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18.6 mph (29.9 km/h)

Axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .rear center-pivot axle with 10-deg. rear axle oscillation and 10-deg. frame oscillation

Rear Axle Oscillation Versus Front Axle . . . . .20 deg. total, stop to stop

Differentials . . . . . . . . . . . . . . . . . . . . . . . . . . . . manual (push-button) locking front, conventional rear

Maximum Rise and Fall, Single Wheel . . . . . .11 in. (290 mm)

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .hydraulic power steering (SAE J1511); 26-deg. rear-wheel steering tied mechanically to articulation; equivalent of 97-deg. conventional

steering system articulation

Articulation Angle . . . . . . . . . . . . . . . . . . . . .56-deg. arc (28 deg. each direction)

Final Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .heavy-duty outboard planetary

Brakes (SAE J1473 and ISO 3450)

Service Brakes . . . . . . . . . . . . . . . . . . . . . . . hydraulically actuated, self-adjusting internal wet-disc brake and driveline drum brake

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . .automatically spring-applied, hydraulically released, internal wet disc

Hydraulics

Main Pump (loader and steering) . . . . . . . . . . . . .fixed-displacement gear pump; open-center system

Maximum Rated Flow @ 1,000 psi (6895 kPa) . . . .25 gpm (95 L/m)

System Relief Pressure (loader and steering) . . . .2,750 psi (18 961 kPa)

Hydraulic Cycle Times

Raise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.3 sec.

Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6 sec.

Lower

Float Down . . . . . . . . . . . . . . . . . . . . . . .4.5 sec.

Power Down . . . . . . . . . . . . . . . . . . . . . .6.3 sec.

Total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13.2 sec.

Maximum Lift Capacity . . . . . . . . . . . . . . . . . . . with 1.4-cu.-yd. (1.1 m

Lift at Ground Level . . . . . . . . . . . . . . . . . . . .12,136 lb. (5510 kg)

Lift at Maximum Height . . . . . . . . . . . . . . . . .7,868 lb. (3572 kg)

Turning Radius

Measured to Centerline of Outside Tire . . . . .12 ft. 5 in. (3.78 m)

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pilot-operated, 3-function valve with single-lever control for boom and bucket, and auxiliary level for standard pin disconnect and

auxiliary hydraulics, with control-lever lockout feature; optional additional 4-function valve with push-button control

3

) stockpiling/general-purpose bucket with bolt-on cutting edge

PAGES

14–15

Page 15

Electrical 304J

Electrical load center with blade-type multi-fused circuits

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volt

Battery Capacity . . . . . . . . . . . . . . . . . . . . . . . . . .1,700 CCA

Reserve Capacity . . . . . . . . . . . . . . . . . . . . . . . . .160 min.

Alternator Rating . . . . . . . . . . . . . . . . . . . . . . . . .65 amp

Lights (SAE 99) . . . . . . . . . . . . . . . . . . . . . . . . . . driving/front working lights (2), turn signals, flashers, stop- and taillights

Tires/Wheels

Tread Width Width Over Tires Change In Vertical Height

Standard-Size, 405/70R20 Tires on

Single-Piece Rims . . . . . . . . . . . . . . . . . . . .65.4 in. (1661 mm) 81.7 in. (2075 mm) 0 in. (0 mm)

Serviceability

Refill Capacities

Cooling System (engine and radiator) . . . . . .12.7 qt. (12.0 L)

Differential and Planetary Axle

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.7 qt. (7.3 L)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.1 qt. (6.7 L)

Engine Oil with Filter . . . . . . . . . . . . . . . . . . .11.9 qt. (11.0 L)

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . .21.5 gal. (81.0 L)

Hydraulic/Hydrostatic Reservoir with

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . .21.1 gal. (80.0 L)

Hydrostatic Motor Gearbox . . . . . . . . . . . . . .0.8 qt. (0.8 L)

Front/Rear Axle Planetary Hubs (each) . . . . . .0.9 qt. (0.9 L)

Operating Weights

With standard equipment, 405/70R20 tires, standard counterweight, cab, 175-lb. (79 kg) operator, and full fuel tank

With Quick-Coupler and 1.4-cu.-yd.

(1.1 m

Bucket with Bolt-On Edge . . . . . . . . . . . .13,404 lb. (6080 kg)

With Quick-Coupler and Fork . . . . . . . . . . . . .13,058 lb. (5923 kg)

Optional Components

Bucket, 1.4 cu. yd. (1.1 m

piling/General Purpose . . . . . . . . . . .946 lb. (429 kg)

3

) Stockpiling/General-Purpose

3

), Stock-

Machine Dimensions

DIMENSIONS WITH QUICK-COUPLER AND BUCKET

A Height to Top of Cab . . . . . . . . . . . . . . . . . . . .9 ft. 2 in. (2.79 m)

B Height to Top of Exhaust . . . . . . . . . . . . . . . . .8 ft. 9 in. (2.67 m)

C Ground Clearance . . . . . . . . . . . . . . . . . . . . . .15.2 in. (386 mm)

D Length from Centerline of Front Axle . . . . . . . .29.5 in. (749 mm)

E Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . .7 ft. 7 in. (2.30 m)

F Dump Clearance, 42-deg. Full Height . . . . . . . ▲ (see page 16)

G Height to Hinge Pin, Fully Raised . . . . . . . . . . .11 ft. 0 in. (3.35 m)

H Dump Reach, 42-deg., 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . .▲▲ (see page 16)

I Maximum Digging Depth . . . . . . . . . . . . . . . . .2.7 in. (69 mm)

J Overall Length . . . . . . . . . . . . . . . . . . . . . . . . .▲▲▲ (see page 16)

K Maximum Rollback at Full Height . . . . . . . . . .56 deg.

L Bucket Dump at Full Height . . . . . . . . . . . . . . .42 deg.

M Maximum Rollback at Ground Level . . . . . . . .40 deg.

K

L

H

G

F

M

D

I

J

C

E

Cab and Canopy

A

B

Page 16

BUCKET SIZE cu yd (m )

3

Machine Dimensions (continued) 304J

DIMENSIONS WITH QUICK-COUPLER AND FORK

A Reach, Fully Raised . . . . . . . . . . . . . . . . . . . . . 22.4 in. (569 mm)

B Fork Height, Fully Raised . . . . . . . . . . . . . . . . . 10 ft. 6 in. (3.19 m)

C Maximum Reach, Fork Level . . . . . . . . . . . . . .5 ft. 0 in. (1.52 m)

D Fork Height, Maximum Reach . . . . . . . . . . . . .4 ft. 6 in. (1.36 m)

E Reach, Ground Level . . . . . . . . . . . . . . . . . . . .29.5 in. (749 mm)

F Depth Below Ground . . . . . . . . . . . . . . . . . . . .1.4 in. (36 mm)

G Tine Length . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ft. 11 in. (1.20 m)

H Overall Length . . . . . . . . . . . . . . . . . . . . . . . . .20 ft. 2 in. (6.14 m)

As Measured with Fork Level, Load Centered

on Tine

Tipping Load, Straight . . . . . . . . . . . . . . . . . .7,877 lb. (3573 kg)

Tipping Load, Full Turn . . . . . . . . . . . . . . . . . 7,165 lb. (3250 kg)

A

C

B

E

D

F

Standard Z-Bar Pin-On Bucket

G

H

Stockpiling/General

Bucket Type/Size Purpose w/Bolt-on Edge

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . .1.4 cu. yd. (1.1 m

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . 1.2 cu. yd. (0.9 m

3

)

3

)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . .7 ft. 3 in. (2.20 m)

Breakout Force, SAE J732C . . . . . . . . . . . . . .12,364 lb. (5608 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . .10,241 lb. (4645 kg)

Tipping Load, Full Turn, SAE . . . . . . . . . . . . .9,315 lb. (4225 kg)

▲▲ Reach, 42-Deg. Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . 4 ft. 3 in. (1.30 m)

▲▲ Reach, 42-Deg. Dump, Full Height . . . . . . . .34.8 in. (884 mm)

▲ Dump Clearance, 42 Deg., Full Height . . . . . .8 ft. 9 in. (2.67 m)

▲▲▲ Overall Length, Bucket on Ground . . . . . . . . .18 ft. 11 in. (5.76 m)

Loader Clearance Circle, Bucket Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . .27 ft. 3 in. (8.30 m)

Loader operating information is based on machine with standard equipment, 405/70R20 tires, standard counterweight, cab, 175-lb. (79 kg) operator, and full fuel tank. This information

is affected by tire size, ballast, and different attachments.

PAGES

16–17

Page 17

Bucket Selection Guide* 304J

3.0

(2.3)

2.5

(1.9)

3

BUCKET SIZE cu. yd. (m )

2.0

(1.5)

1.5

(1.0)

1.0

(0.8)

lb./cu.yd.

3

kg/m

Deere 2.0-cu. yd. (1.6 m )

Light-Material Bucket

1,000

900

3

Deere 1.4-cu. yd. (1.1 m )

General-Purpose Bucket

1,500 2,000 2,500 3,000

1,134

2,700

2,943

1,701

2,160

1,458

1,350

2,052

3,105

2,592

3,834

2,646

2,835

2,295

3,510

2,970

3,510

2,214

2,295

3,294

2,430

2,700

3

kg/m

486

288

673

1602

1746

1009

1282

865

801

1218

1843

1538

2275

1570

1682

1362

2083

1762

2083

1314

1362

1955

1442

1602

LOOSE MATERIALS

Chips, pulpwood

Cinders (coal, ashes, clinkers)

Clay and gravel, dry

Clay, compact, solid

Clay, dry in lump loose

Clay, excavated in water

Coal, anthracite, broken, loose

Coal, bituminous, moderately wet

Earth, common loam, dry

C

o

n

s

e

r

v

a

t

i

v

e

M

N

a

o

x

i

r

m

m

u

a

m

l

L

L

o

o

a

a

d

2100

d

3,500 4,000

2400 2700

4,500

3000

L

o

a

d

3

180015001200

Earth, mud, packed

Granite, broken

Gypsum

Limestone, coarse, sized

Limestone, mixed sizes

Limestone, pulverized or crushed

Sand, damp

Sand, dry

Sand, voids, full of water

Sandstone, quarried

Shale, broken crushed

Slag, furnace granulated

Stone or gravel, 1-1/2" to 3-1/2" size

Stone or gravel, 3/4" size

*

This guide, representing bucket sizes not necessarily manufactured by

Deere, will help you in selecting proper bucket size for material density,

loader configuration, and operating conditions. Optimum bucket size

is determined after adding or subtracting all tipping load changes due

to optional equipment. The “conservative load” line on this guide is

recommended when operating in conditions such as soft ground and

unlevel surfaces. The “maximum load” condition on this guide is

sometimes utilized when operating on firm ground and level surfaces.

lb./cu. yd.

Page 18

304J LOADER

Key: ● Standard equipment ▲ Optional or special equipment *See your John Deere dealer for further information.

304J

304J

Engine

● Certified to EPA Tier 3 emissions

● Antifreeze, –34°F (–37°C)

● Coolant recovery tank

● Fan safety guard

● Fan, suction type, hydraulically driven, proportional

speed

● Muffler, under hood with curved end exhaust stack

● Environmentally friendly engine oil drain

● Spin-on engine oil and fuel filter

● Engine oil cooler

● Quick-release fuel filter and water separator

● Under-hood dual-element air cleaner with restric-

tion indicator

● Under-hood prescreened air intake with dust

evacuator valve

● Serpentine drive belt with automatic tensioner

▲ Engine coolant heater, 1,000 watts, 110 volts

▲ Special application: Trash screens, etc.*

Electrical

● Starter switch with electric fuel cutoff

● 12-volt system

● Electrical load center with blade-type fuses

● Standard batteries (2), 12 volt with 1,700 CCA

● Master electrical disconnect switch

● Alternator, 12 volts, 65 amps

● Horn (conforms to SAE J994, J1446)

● Lights (conform to SAE 99): Driving / Front work-

ing (2) / Turn signals / Flashers / Stop / Taillights

● Pre-wired for rear worklights

▲ Worklights, rear (2)

● Reverse warning alarm (conforms to SAE J994,

J1446)

● Multifunction monitor with audible and visual

warnings: Low engine oil pressure / Engine

coolant temperature / HST transmission oil

temperature / Parking brake indicator / Gauges

and indicators: Engine coolant temperature, fuel

level, speedometer, clock, and hour meter

● Indicator lights: Engine air filter / Fasten seat belt /

Parking brake actuated / Forward/reverse travel /

1st or 2nd speed range / Turn signal and hazard

lights / High-beam indicator / Battery voltage

Electrical (continued)

● Radio-ready cab, fused 12-volt radio electrical

lead and speakers, power port

● By-pass starter safety cover on starter, positive

terminal battery cover

● Pre-wired for roof beacon

● Sealed external electrical connectors

Powertrain/Brakes

● Hydrostatic (HST) transmission: Electric shift

control / Single-lever joystick F-N-R / Hydrostatic

oil cooler / Inching pedal / Two speeds forward

and reverse / Infinitely variable speed control

● Service brakes, hydraulically actuated, self-

adjusting internal wet-disk brake and driveline

drum brake

● Parking brake, spring applied, hydraulically

released, switch operated

● Axles, manual locking front and conventional rear

differentials, heavy-duty outboard planetaries

Hydraulic System

● Hydraulic system oil cooler

● Automatic bucket return-to-dig control

● Boom float function

● Reservoir sight gauge for hydraulic/hydrostatic oil

● Fine-micron hydraulic filter, vertical mounting

● Hydraulic lever lockout

● Pilot-operated three-function valve with single

joystick lever control for boom and bucket, and

auxiliary lever for standard pin disconnect and

auxiliary hydraulics

▲ Four-function hydraulic valve with pilot joystick

control and pilot auxiliary lever for third function,

and push buttons for fourth function

▲ Hydraulic conversion kits, four-function valve

● Quick-coupler diagnostic ports: Priority pressure /

Hydraulic pump pressure / Control valve pressure /

HST pressure

Operator’s Station

● Cab (conforms to SAE J1040, SAE J231, ISO3471,

ISO3449): ROPS/FOPS / Heater/defroster / Rubber plane isolation mounted for noise/vibration reduc tion / Intermittent front and rear windshield

304J

Operator’s Station (continued)

wipers and washers / Tinted safety glass / Full width adjustable sun visor / Pre-wired for radio

speakers / Deluxe high-back cloth seat with

mechanical and 2-inch (51 mm) retractable seat

belt / Left and right doors / One sliding window

in each door

▲ AM/FM/WB radio

▲ AM/FM/WB radio with cassette player

▲ AM/FM/WB radio with CD player

▲ Air conditioning (factory or dealer installed)

● Storage compartment

● Rubber floormat

● Tilt steering column

● Rearview mirrors, outside (2) and inside (1)

(conform to SAE J985)

● Handholds and steps, ergonomically located and

slip resistant (conform to SAE J185)

Loader Linkage

● Z-bar loader linkage

● Loader boom service locking bar (conforms to

SAE J38)

Buckets and Attachments

▲ Full line of buckets with selection of bolt-on

cutting edges and teeth

● Standard quick-coupler, less bucket

▲ Worksite Pro

TM

skid-steer-style coupler

▲ Full line of construction utility forks, pallet forks,

extendible boom with hook, and other attachments*

Tires

● 405/70R20 tires on single-piece rims

Other

● Fenders, front and rear

● Articulation locking bar (conforms to SAE J276)

● Vandal protection, includes lockable engine

enclosure and fuel fill

● Counterweight, full

● Rear bottom guard

● Drawbar, with locking pin

▲ Material-weighing system*

▲ Ride control

▲ JDLink

TM

wireless communication system

CONTROL OWNING AND OPERATING COSTS

Customer Personal Service (CPS) is part of John Deere’s proactive, fix-before-fail strategy on machine maintenance that will help control costs, increase profits, and reduce

stress. Included in this comprehensive lineup of ongoing programs and services are:

Fluid analysis program – tells you what’s going on inside all of your machine’s

major components so you’ll know if there’s a problem before you see a decline in

performance. Fluid analysis is included in most extended coverage and preventivemaintenance agreements.

Component life-cycle data – gives you vital information on the projected life

span of components and lets you make informed decisions on machine maintenance

by telling you approximately how many hours of use you can expect from an engine,

transmission, or hydraulic pump. This information can be used to preempt catastrophic

downtime by servicing major components at about 80 percent of their life cycle.

Preventive Maintenance (PM) agreements – give you a fixed cost for maintain-

ing a machine for a given period of time. They also help you avoid downtime by ensur-

Specifications and design subject to change without notice. Wherever applicable, specifications are in accordance with SAE

standards. Except where otherwise noted, these specifications are based on a unit with all standard equipment, 405/70R20 tires,

ROPS cab, full fuel tank, and 175-lb. (79 kg) operator.

DKA304J Litho in U.S.A. (09-03)

Net engine power is with standard equipment including air

cleaner, exhaust system, alternator, and cooling fan, at standard conditions per SAE J1349 and DIN 70 020, using No. 2-D

fuel at 35 API gravity. No derating is required up to 5,000-ft.

(1500 m) altitude. Gross power is without cooling fan.

ing that critical maintenance work gets done right and on schedule. On-site preventive

maintenance service performed where and when you need it helps protect you from

the expense of catastrophic failures and lets you avoid waste-disposal hassles.

Extended coverage – gives you a fixed cost for machine repairs for a given

period of time so you can effectively manage costs. Whether you work in a severeservice setting or just want to spread the risk of doing business, this is a great way

to custom-fit coverage for your operation. And an extended coverage contract also

travels well because it’s backed by John Deere and is honored by all Deere construction dealers.

Customer Support Advisors (CSAs) – Deere believes the CSA program lends

a personal quality to Customer Personal Service (CPS). Certified CSAs have the knowledge and skills for helping make important decisions on machine maintenance and

repair. Their mission is to help you implement a plan that’s right for your business

and take the burden of machine maintenance off your shoulders.

Loading...

Loading...