JKS 2002 User Manual

INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Quicker Disconnects™

Part Number: JKS2000 - JKS2001 - JKS2002

Welcome

CONGRATULATIONS on purchasing a set of new

Quicker Disconnects™ from JKS Manufacturing. We

are committed to providing you with the best products

available and your satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain

important installation and maintenance information.

Important

NOT COMPATIBLE WITH aftermarket swaybars. Install

product with Original Equipment swaybar only.

SOME VEHICLES MAY REQUIRE extended front brake

hoses or other modications to compensate for additional suspension travel.

NEVER DISCONNECT swaybar when operating vehicle

on public roads.

WHEN DISCONNECTED, swaybar must be secured to

prevent interference with other suspension components or axle.

Tools Required

Metric/Standard Socket Wrench Set

(17mm and 3/4” sockets)

Torque Wrench

Tie Rod End Remover *

6mm Allen Head Socket

6mm Allen Wrench

1/4" Allen Wrench *

15/16” Open-End Wrench

#1 Philips Screwdriver or Small Punch

F” Drill Bit (0.257” equiv.) *

5/16” x 18TPI Tap *

Angle Measuring Tool

Grease Gun with Zerk Fitting Coupler

Wheel Bearing Grease

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

JKS2000 / JKS2001 / JKS2002JKS Quicker Disconnect Installation

Page 1

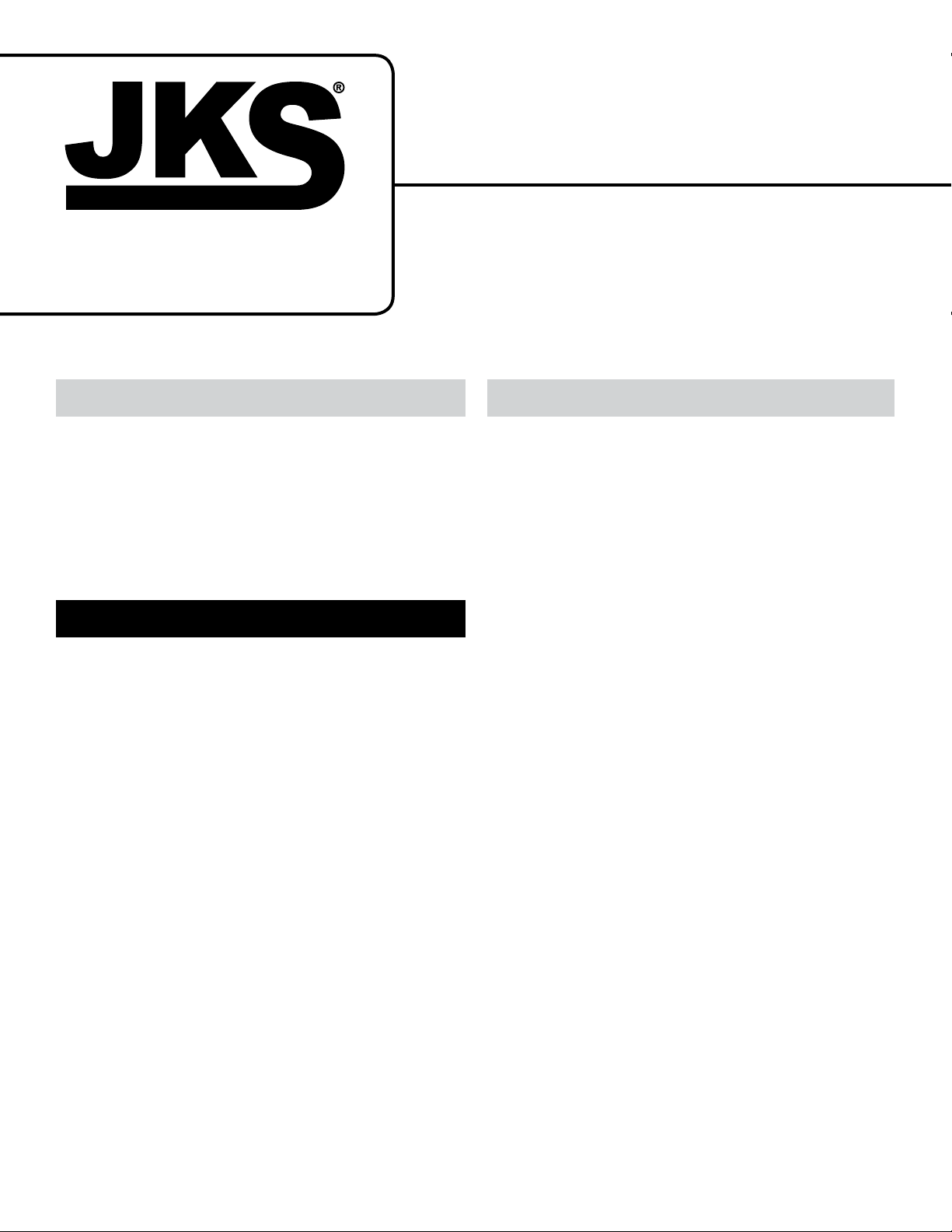

Parts

Installation

1. REMOVE ORIGINAL EQUIPMENT (OE)

SWAYBAR LINKS\

Remove front swaybar drop links and mounting

hardware per the factory service manual instructions for your vehicle. H I N T: If difcult to remove,

use special factory removal tool PN MB991113

(Miller Special Tools, 800-801-5420) or similar tie

rod end removal tool.

A

U-Strap

B

10mm x 35mm Button Head Bolt

C

10mm Nylock Nut

D

10mm x 50mm Button Head Bolt (with factory-applied

thread locking compound)

E

1.25” Aluminum Sleeve

F

Stainless Steel Post

G

Spherical Bushing

H

Click Pin

I

Grease Zerk Cap

J

Press-In Grease Zerk

K

1/2” NF Nylock Nut

L

Offset Polyurethane Spacer

M

5/8” Jam Nut

N

Upper Male Threaded End

O

Lower Female Threaded End

P

Flat Washer

Q

Storage Pin

R

5/16” x 1-1/2” NC Allen Bolt

S

10mm External Tooth Lock Washer

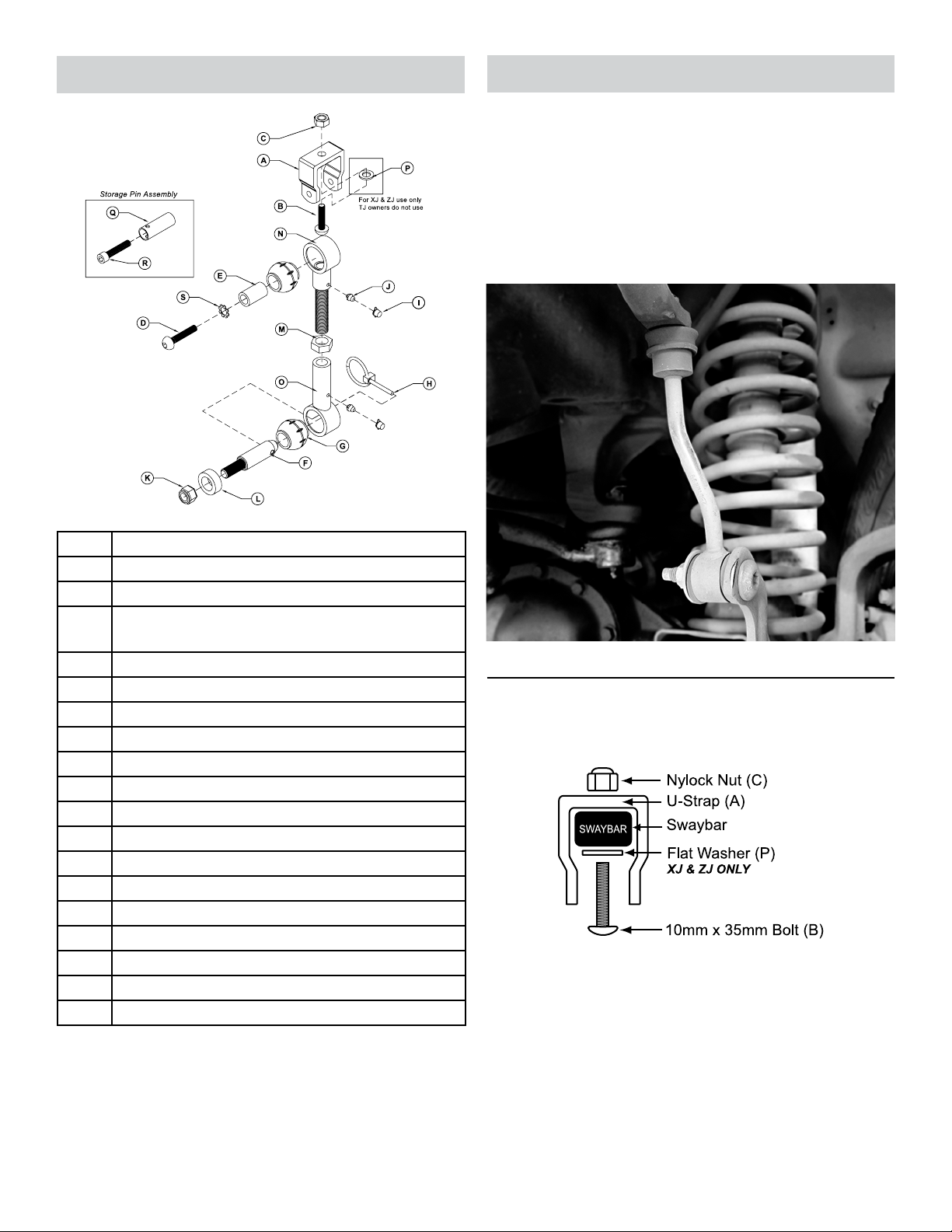

2. INSTALL UPPER U-STRAPS

Mount U-Strap (A) on top of swaybar with thread-

ed leg of U-Strap positioned inboard.

IMPORTANT: U-Strap must be mounted ABOVE

swaybar, NOT BELOW

Insert 10mm x 35mm Button Head Bolt (B) and

Flat Washer (P) – only if required – upward

through swaybar and U-Strap (A). Secure with

10mm Nylock Nut (C).

2 Page

JKS2000 / JKS2001 / JKS2002

JKS Quicker Disconnect Installation

Loading...

Loading...