Jenn-Air JDRP636HL, JDSP536HL, JDRP436HM, JDRP536HM, JDRP636HM Installation Instructions

...Page 1

INSTALLATION INSTRUCTIONS

CommerCial-Style Dual Fuel ConveCtion rangeS

30"(76.2Cm),36"(91.4Cm),anD48" (121.9 Cm)

For residential use only

INSTRUCTIONS D’INSTALLATION

CuiSinière à Double CombuStible à ConveCtion De Style CommerCial

De30po(76,2Cm),36po (91,4Cm) et48po (121,9Cm)

Pour utilisation résidentielle uniquement

INSTRUCCIONES DE INSTALACIÓN

eStuFaS De ConveCCión ComerCialeS De CombuStible Dual

De30"(76,2Cm),36"(91,4Cm) y48" (121,9 Cm)

Solo para uso residencial

Table of Contents/Table des matières/Tabla de contenidos

RANGE SAFETY ........................................ 2

INSTALLATION REQUIREMENTS ............ 4

Tools and Parts ....................................... 4

Water Filtration System Location

Requirements .......................................... 5

Water Supply Requirements ...................5

Location Requirements ........................... 6

Electrical Requirements: U.S.A. Only .....8

Electrical Requirements: CanadaOnly ...8

Gas Supply Requirements ...................... 8

INSTALLATION INSTRUCTIONS ............ 10

Unpack the Range ................................ 10

Remove Door ........................................ 11

Install Anti-Tip Bracket .........................12

Make Gas Connection .......................... 13

Verify Anti-Tip Bracket Location ...........13

Install Griddle Tray ................................ 13

Electronic Ignition System ....................14

Level Range .......................................... 14

Install Kick Plate ...................................15

Complete Installation ............................ 15

GAS CONVERSIONS ..............................16

Propane Gas Conversion ...................... 16

Natural Gas Conversion ........................ 20

SÉCURITÉ DE LA CUISINIÈRE .............. 24

EXIGENCES D’INSTALLATION ..............26

Outils et pièces ..................................... 26

Exigences d’emplacement du système

deltration d’eau .................................. 27

Spécications de l’alimentationen eau ... 28

Exigences d’emplacement ...................28

Spécications électriques: É.-U. seulement ..30

Spécications électriques:

Canadaseulement ................................ 31

Spécications de l’alimentationen gaz ... 31

INSTRUCTIONS D’INSTALLATION ........ 33

Déballage de la cuisinière ..................... 33

Retirer la porte ......................................34

Installation de la bride antibasculement .. 35

Raccordement au gaz ........................... 36

Vérication de l’emplacement dela

brideantibasculement ..........................36

Installer le plateau d’égouttement ........36

Système d’allumage électronique.........37

Ajustement de l’aplomb delacuisinière .. 37

Installer la plinthe .................................. 38

Terminer l’installation ............................ 38

CONVERSIONS POUR CHANGEMENT

DEGAZ .................................................... 39

Conversion pour l’alimentation aupropane ..39

Conversion au gaz naturel ....................43

SEGURIDAD DE LA ESTUFA..................48

REQUISITOS DE INSTALACIÓN ............ 50

Herramientas y piezas ..........................50

Requisitos de ubicación del sistema de

ltrado de agua ..................................... 51

Requisitos de suministro de agua ........51

Requisitos de ubicación .......................52

Requisitos eléctricos:

EnEE.UU.únicamente .........................54

Requisitos eléctricos: Exclusivamente

para Canadá .........................................54

Requisitos del suministro de gas .......... 54

INSTRUCCIONES DE INSTALACIÓN .... 56

Desembale la estufa .............................56

Quite la puerta ......................................57

Instalación del soporte antivuelco ........ 58

Conexión del suministro de gas ...........59

Vericación de la ubicación delsoporte

antivuelco ..............................................59

Instale la bandeja de la plancha ...........59

Sistema de encendido electrónico .......60

Nivelación de la estufa .......................... 60

Instale la placa de protección ............... 61

Finalización de la instalación ................ 61

CONVERSIONES DE GAS ......................62

Conversión a gas propano....................62

Conversión a gas natural ...................... 66

IMPORTANT:

Save for local electrical inspector’s use.

Installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

IMPORTANT:

Conserver ces instructions à l’usage de l’inspecteur des installations

électriques local.

Installateur: Remettre les instructions d’installation au propriétaire.

Propriétaire: Conserver les instructions d’installation pour référence

ultérieure.

W11521192A

IMPORTANTE:

Guarde para tener a disposición del inspector de electricidad local.

Instalador: Déjele las instrucciones de instalación al propietario.

Propietario: Guarde las instrucciones de instalación para futuras

consultas.

www.jennair.com (U.S.A.) www.jennair.ca (Canada)

Page 2

RANGE SAFETY

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

– Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

2

Page 3

IMPORTANT: Do not install a ventilation system that blows air downward toward this gas cooking appliance. This type of

ventilation system may cause ignition and combustion problems with this gas cooking appliance resulting in personal injury or

unintended operation.

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gas fitter qualified or licensed by

the State of Massachusetts.

■ Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

■ A flexible gas connector, when used, must not exceed 4 feet (121.9 cm).

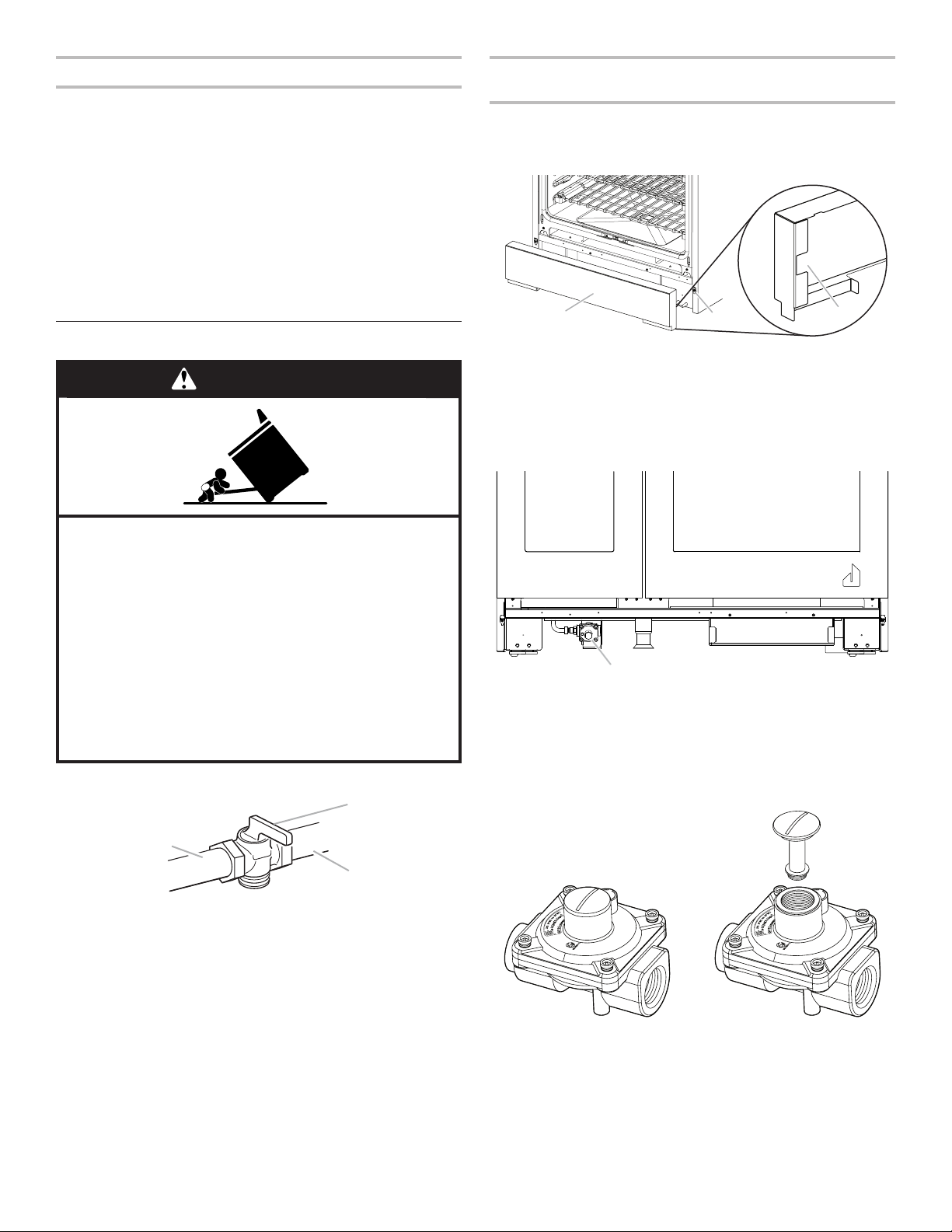

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage the anti-tip bracket if the range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

Anti-Tip

Bracket

Range Foot

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

Slide range back so rear range foot is under anti-tip bracket.•

• See installation instructions for details.

3

Page 4

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation. Read and follow the instructions provided with any tools listed here.

Tools Needed

Pipe wrench Adjustable wrench or

5/8"(16mm) wrench

Drill 3/8" (9.5 mm) drive ratchet 15/16" (24 mm)

Level Tubing cutter 1/4" (6.4 mm), 3/8" (9.5 mm),

3/16" (4.8 mm) carbide tip

masonry bit

Pipe-joint compound

resistanttopropanegas

1/8" (3.2 mm) drill bit

1/8" x 41/4" (3mmx100mm)

at-blade screwdriver

combinationwrench

5/16" (7.9 mm) nut drivers

Noncorrosive leak-detection

solution

#2 Phillips screwdriver

Pliers

Marker or pencil

Tape measure

For Propane/Natural Gas Conversions

Large at-blade screwdriver Adjustable wrench T20® Torx®† Driver Masking tape

1/2" (1.3 cm) open end

wrench

†®TORX and T20 are trademarks of Acument Intellectual Properties, LLC.

#1 Square Driver

4

Page 5

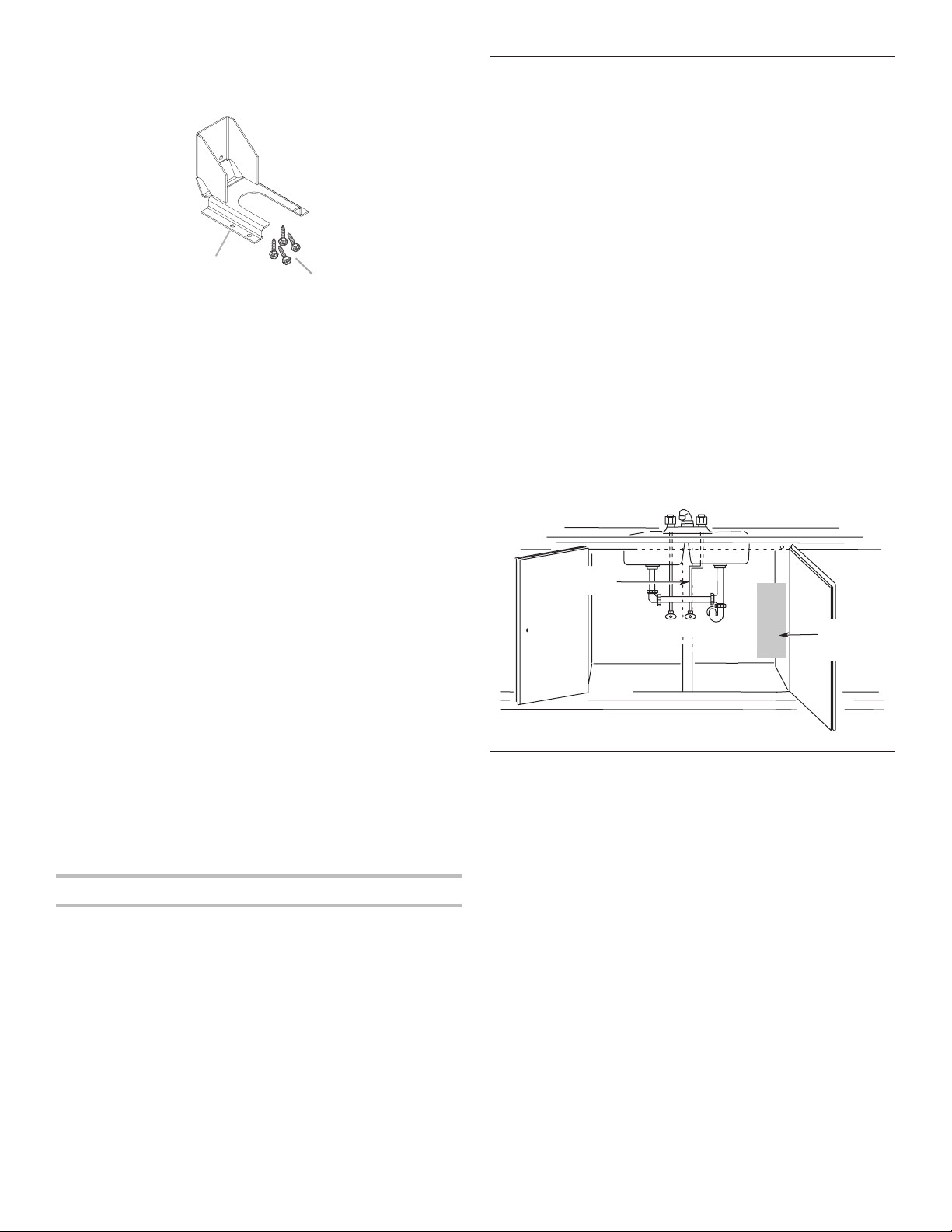

Parts Supplied

B

Check that all parts are included.

■ Anti-tip bracket kit

A

A. Anti-tip bracket

B. #8-18 x 1" (2.5cm) Phillips head screws (4)

NOTE: Anti-tip bracket must be securely mounted to

suboor. Thickness of ooring may require longer screws

toanchor bracket to suboor. Longer screws are available

from your local hardware store. See the “Install Anti-Tip

Bracket” section.

■ Burner grates

■ Burner caps

■ Griddle drip tray (on griddle models)

Additional Parts Supplied on Steam-Assist Models (on some

models)

■ Model W10049700 water lter kit

■ 1/4" (6.4 mm) to 1/4" (6.4 mm) water supply union

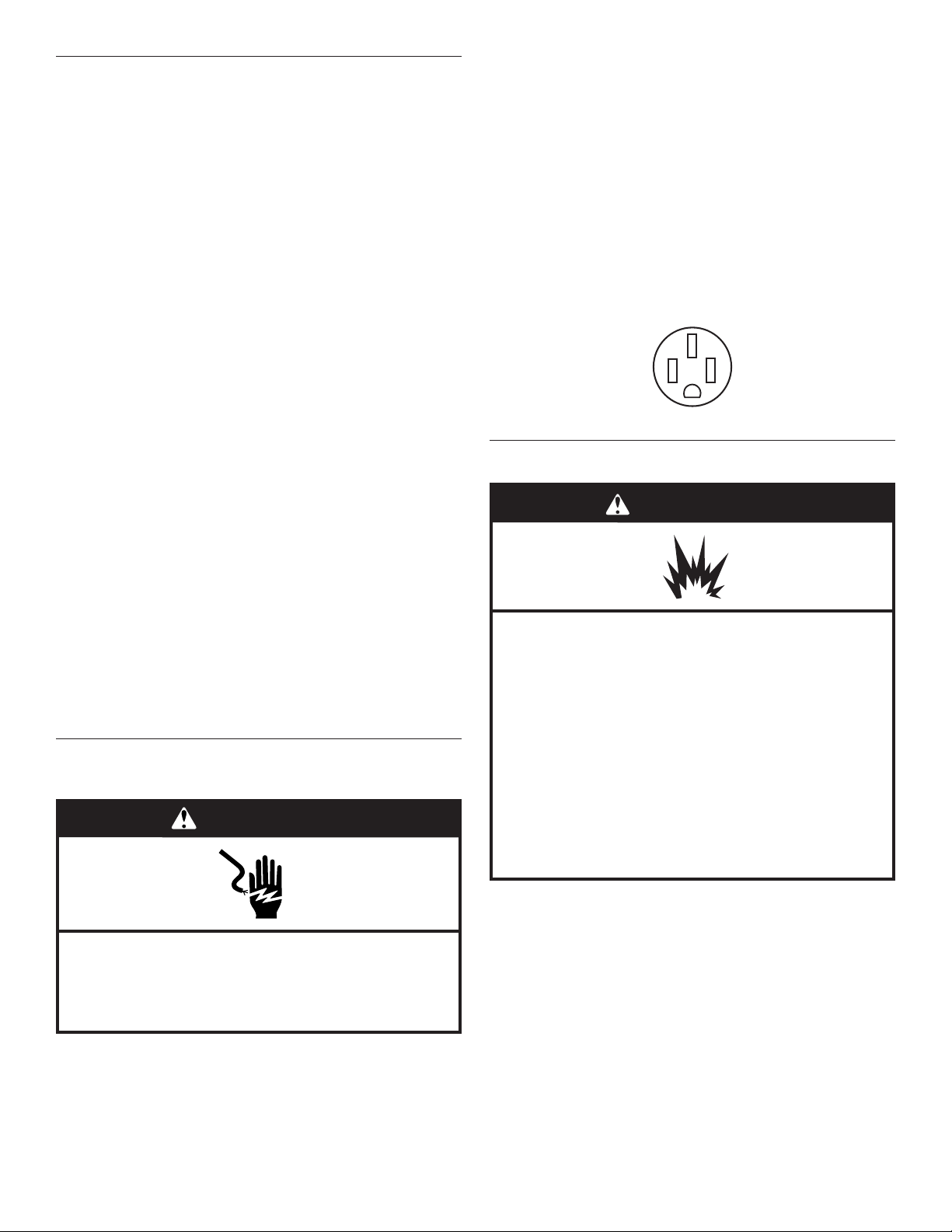

Water Filtration System Location

Requirements

(On some models)

For best results, do not install the water ltration system outside

or in extreme hot or cold temperatures. Temperature of water

supply to the water ltration system must be between 40°F (4°C)

and 100°F (38°C). Do not install on hot water supply line.

Locate the water ltration system near the cold water supply

pipe under the kitchen sink to lter cold water.

Make sure that the water lter assembly is installed in the upright

position.

It will be necessary to drill a 1/2" (1.3 cm) minimum diameter

hole in the upper-right or left rear corner of the side wall of the

cabinet under the sink to route the water supply tubing through

to the range.

Depending on your installation conguration, more routing holes

may be required.

Coil enough exible codes-approved water supply tubing behind

the range to allow for the connection to the range to be made

behind the range prior to setting the range in place.

Typical Installation Conguration

NOTE: For unique installations, contact a licensed plumber.

In Massachusetts, a licensed plumber is required and the

Commonwealth of Massachusetts Plumbing Code 248-CMR will

be adhered to.

Parts Needed

■ All models must be installed with a backguard if installing

at zero clearance to a combustible back wall surface such

as drywall. See “Cabinet Dimensions” in the “Location

Requirements” section for installation requirements.

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See the “Electrical Requirements”

and “Gas Supply Requirements” sections.

It is recommended that all electrical connections be made by

alicensed, qualied electrical installer.

Additional Parts Needed on Steam-Assist Models (on some

models)

■ Tubing staples/retainers

■ 1/4" (6.4 mm) O.D. exible codes-approved water supply

tubing (to make water connection)

■ Water connection device (to connect 1/4" (6.4 mm) O.D.

tubing to water source). Check local codes for type of

connection required.

High Altitude Conversion

Reoricing of this range/rangetop is not required for proper

operation. Low burner rates may require resetting for best

results.

Refer to the “Adjusting Simmer Low and Main Setting on

Surface Burner for Propane” section (page 18) for Propane Gas

Operation.

Refer to the “Adjusting Simmer Low and Main Setting on

Surface Burner for Natural Gas” section (page 22) for Natural

Gas Operation.

Cold water

supply

Hot

Cold

Filter

assembly

location

Water Supply Requirements

A cold water supply with water pressure between 30 and 120 psi

(207 and 827 kPa) is required to operate the steam feature. In

Massachusetts, plumbing code 248 CMR 3.00 and 10.00 must

be followed, and a licensed plumber will be used. If you have

questions about your water pressure, call a licensed, qualied

plumber.

Reverse Osmosis Water Supply

IMPORTANT: The pressure of the water supply coming out of

a reverse osmosis system going to the water inlet valve of the

range needs to be between 30 and 120 psi (207 and 827 kPa).

If a reverse osmosis water ltration system is connected to your

cold water supply, the water pressure to the reverse osmosis

system needs to be a minimum of 40 psi (276 kPa).

If the water pressure to the reverse osmosis system is less than

40 psi (276 kPa):

■ Check to see whether the sediment lter in the reverse

osmosis system is blocked. Replace the lter, if necessary.

■ Allow the storage tank on the reverse osmosis system to rell

after heavy usage.

If you have questions about your water pressure, call a licensed,

qualied plumber.

5

Page 6

Location Requirements

D

B

IMPORTANT: Observe all governing codes and ordinances.

Donot obstruct ow of combustion and ventilation air.

■ It is the installer’s responsibility to comply with installation

clearances specied on the model/serial/rating plate. The

model/serial/rating plate is located under the console on

theright-hand side.

■ It is recommended that a 585 CFM (993.9 m

range hood beinstalled above the range.

■ Follow the range hood or microwave hood combination

installation instructions for dimensional clearances above the

cooktop surface.

■ Recessed installations must provide complete enclosure

ofthe sides and rear of the range.

■ All openings in the wall or oor where range is to be installed

must be sealed.

■ Do not seal the range to the side cabinets.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see the “Install Anti-Tip

Bracket” section.

■ Grounded electrical supply is required. See the “Electrical

Requirements” section.

■ Proper gas supply connection must be available. See the

“Gas Supply Requirements” section.

■ Contact a qualied oor covering installer to check that the

oor covering can withstand at least 200°F (93°C). Use an

insulated pad or 1/4" (6.4 mm) plywood over carpet and

under range if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with

your builder or cabinet supplier to make sure that the materials

used will not discolor, delaminate, or sustain other damage. This

oven has been designed in accordance with the requirements

of UL and CSA International and complies with the maximum

allowable wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title24CFR,

Part 3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part 280).When such

standard is not applicable, use the Standard forManufactured

Home Installations, ANSI A225.1/NFPA 501A or local codes.

In Canada, the installation of this range must conform with

thecurrent standards CAN/CSA-A240-latest edition or with

localcodes.

Mobile Home Installations Require:

■ When this range is installed in a mobile home, it must be

secured to the oor during transit. Any method of securing

the range is adequate as long as it conforms to the

standards listed above.

3

/hr) or larger

Product Dimensions

NOTE: Cooktop features may differ.

30" (76.2 cm) models

A

B

D

C

A. 273/4" (70.5 cm) depth with control panel (See NOTE.)

B. 353/4" (90.8 cm) range height when sitting on the wheels

C. 297/8 " (75.7 cm) width

D. Model/serial/rating plate location/SAID label

(located on front side panel)

36" (91.4 cm) models

A

A. 271⁄8" (68.9 cm) depth with control panel (See NOTE.)

B. 353⁄4" (90.8 cm) range height when sitting on the wheels

C. 36" (91.4 cm) width

D. Model/serial/rating plate location/SAID label

(located on front side panel)

C

6

Page 7

48" (121.9 cm) models

C

D

B

A

Electrical

installation

area*

installation

NOTE: When installed in a 24" (61.0 cm) base cabinet with

25" (63.5 cm) countertop; front of oven door protrudes

17/8" (4.8 cm) beyond 24" (61.0 cm) base cabinet.

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth, and

36" (91.4 cm) countertop height. Dimensions must be met

in order to ensure a ush t to back wall.

IMPORTANT: If installing a range hood, hood liner, or microwave

hood combination above the cooking surface, follow the range

hood or microwave hood combination installation instructions for

dimensional clearances above the cooking surface.

A. 271⁄8" (68.9 cm) depth with control panel (See NOTE.)

B. 353⁄4" (90.8 cm) range height when sitting on the wheels

C. 48" (121.9 cm) width

D. Model/serial/rating plate location/SAID label

(located on front side panel)

Cabinet Requirements

C

**

D

B

O***

A

E

F

J

F

I

H

I

G

Gas

area

J

L

K

N

M

A. 18" (45.7 cm) upper cabinet to countertop

B. 30" (76.2 cm) model: 30" (76.2 cm) minimum upper cabinet

width

36" (91.4 cm) model: 36" (91.4 cm) minimum upper cabinet

width

48" (121.9 cm) model: 48" (121.9 cm) minimum upper cabinet

width

C. 13" (33 cm) maximum upper cabinet depth

D. For minimum clearance to top of range.**

E. 30" (76.2 cm) on 30" (76.2 cm) models

36" (91.4 cm) on 36" (91.4 cm) models

48" (121.9 cm) on 48" (121.9 cm) models

F. 12" (30.4 cm) minimum clearance from both sides of range to

side wall orother combustible material

G. 15" (38.1 cm)

H. 22" (55.9 cm) on 30" (76.2 cm) models

28" (71.1 cm) on 36" (91.4 cm) models

40" (101.6 cm) on 48" (121.9 cm) models

I. 4" (10.1 cm)

J. 3" (7.6 cm)

K. 5" (12.7 cm)

L. 6" (15.2 cm) on 30" (76.2 cm) models

12" (30.5 cm) on 36" (91.4 cm) models

24" (61.0 cm) on 48" (121.9 cm) models

M. 101/2" (26.7 cm)

N. 9" (22.9 cm)

O. 6" (15.2 cm)***

** If not using ventilation, Minimum Clearances

30" (76.2 cm) models: 42" (106.7 cm) minimum clearance

between the top of the cooking platform and the bottom of a

combustible surface.

36" (91.4 cm) models: 42" (106.7 cm) minimum clearance

between the top of the cooking platform and the bottom of a

combustible surface.

48" (121.9 cm) models: 48" (121.9 cm) minimum clearance

between the top of the cooking platform and the bottom of a

combustible surface.

*** If the surface of the back wall is constructed of a combustible

material and a backguard is not installed, a 6" (15.2 cm)

minimum clearance is required for all models.

7

Page 8

Electrical Requirements:

U.S.A. Only

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine

thatthe ground path and wire gauge are in accordance with

local codes.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

theground path is adequate.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code,

ANSI/NFPA 70 — latest edition — and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualied electrician or service technician if you are in doubt as

towhether the appliance is properly grounded. Do not modify

the power supply cord plug. If it will not t the outlet, have a

proper outlet installed by a qualied electrician.

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ Range must be connected to the proper electrical voltage

and frequency as specied on the model/serial/rating plate.

The model/serial/rating plate is located under the console

on the right-hand side. Refer to the illustrations in “Product

Dimensions” in the “Location Requirements” section.

■ This range is manufactured with a 4-wire power supply cord.

■ A circuit breaker is recommended.

■ Wire sizes and connections must conform with the rating

ofthe range.

NOTE: If your home does not have a 4-wire system, consult

your local qualied electrician.

Electrical Requirements:

Canada Only

WARNING

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

■ Check with a qualied electrical installer if you are not sure

the range is properly grounded.

■ When a 4-wire, single-phase 250 V, 60 Hz, AC-only electrical

supply is available, a 40 A minimum circuit protection is

required on 30" (76.2 cm) and 36" (91.4 cm) ranges and a

50 A minimum circuit protection is required on

48" (121.9 cm) ranges, fused on both sides of the line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a CSA International Certied

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range’s nal location.

■ Do not use an extension cord.

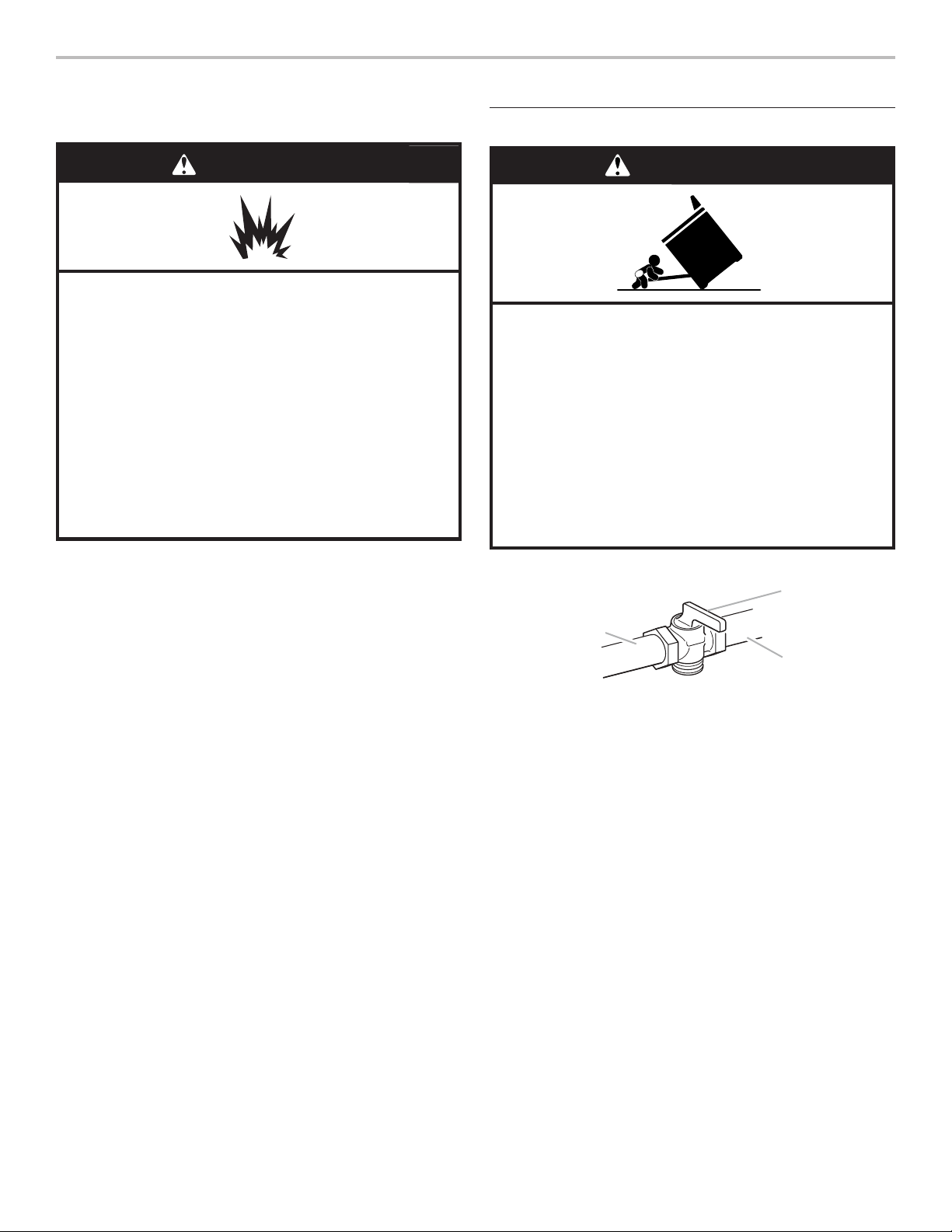

Gas Supply Requirements

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine

thatthe ground path and wire gauge are in accordance with

local codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with the CSA Standard C22.1, Canadian

Electrical Code, Part 1 — latest edition — and all local codes

andordinances.

8

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 — latest edition — or CAN/CGA B149 —

latest edition.

IMPORTANT: Range must be connected to a regulated

gassupply.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer’s instructions.

Page 9

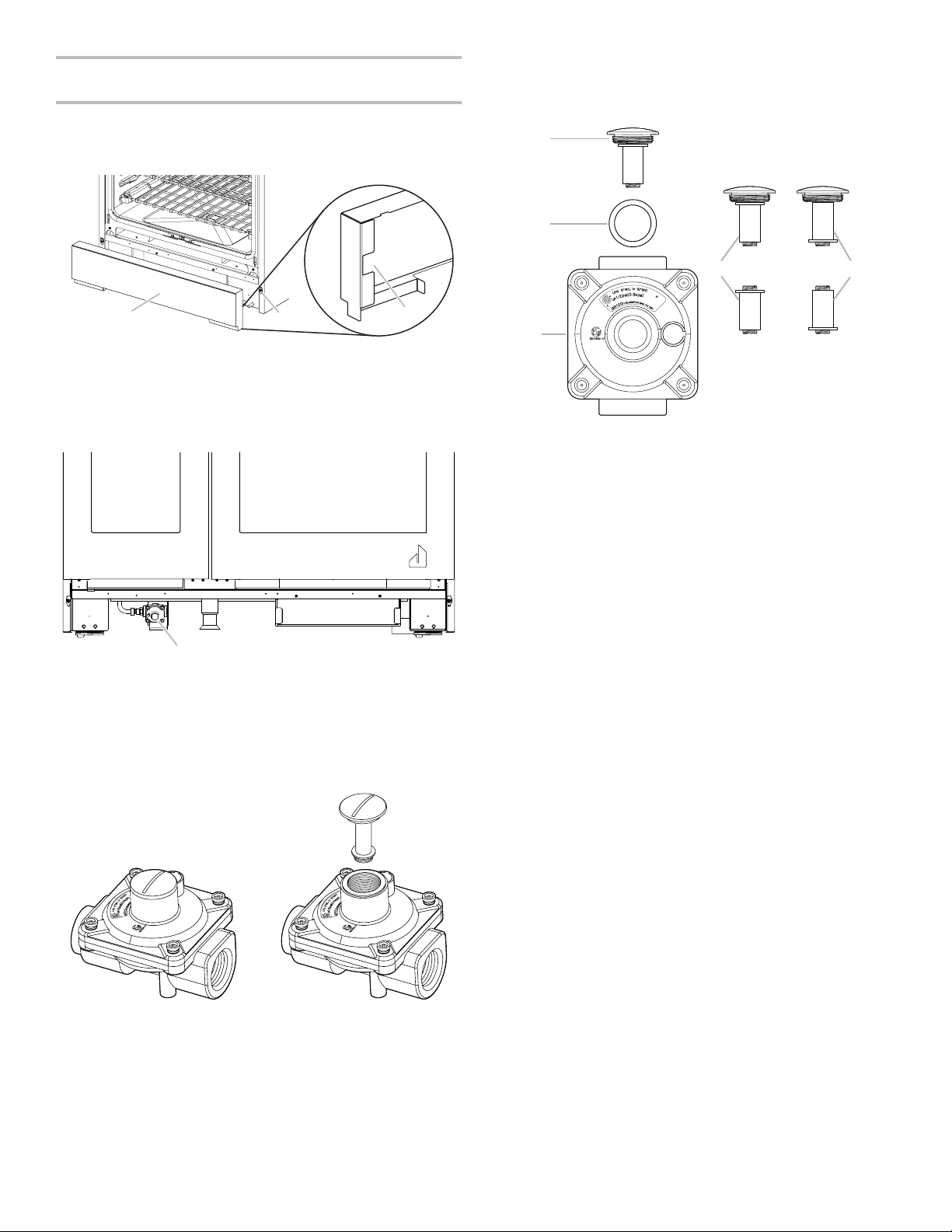

Type of Gas

A

C

Gas Pressure Regulator

Natural Gas:

This range is factory set for use with Natural gas. The

model/serial/rating plate, located under the console on the

right-hand side, has information on the types of gas that can be

used. If the types of gas listed do not include the type of gas

available, check with the local gas supplier.

Propane Gas conversion:

Conversion must be done by a qualied service technician.

No attempt shall be made to convert the range from the gas

specied on the model/serial/rating plate for use with a different

gas without consulting the serving gas supplier. To convert to

Propane gas, use the Propane gas conversion kit provided with

your range and see the “Gas Conversions” section. The parts for

this kit are in the package containing literature supplied with the

range.

Gas Supply Line

■ Provide a gas supply line of 3/4" (1.9 cm) rigid pipe to the

range location. A smaller size pipe on longer runs may result

in insufcient gas supply. With Propane gas, piping ortubing

size can be 1/2" (1.3 cm) minimum. Usually, Propane gas

suppliers determine the size and materials usedin the

system.

NOTE: Pipe-joint compounds that resist the action of

Propane gas must be used. Do not use TEFLON®† tape.

Flexible metal appliance connector:

■ If local codes permit, a new CSA design-certied, 4-5ft

(122-152 cm) long, 5/8" (1.6 cm) or 3/4" (1.9 cm) I.D.,

exible metal appliance connector may be used for

connecting the range to the gas supply line.

■ A 1/2" (1.3 cm) male pipe thread is needed for

connection to the female pipe threads of the inlet

totheappliance pressure regulator.

■ Do not kink or damage the exible metal tubing when

moving the range.

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas regulator too tight. Making

the connections too tight may crack the regulator and cause

a gas leak. Do not allow the regulator to turn or move when

tightening ttings.

■ Must include a shut-off valve:

Install a manual gas line shut-off valve in an easily accessible

location. Do not block access to shut-off valve. The valve is

for turning on or shutting off gas to the range.

B

The gas pressure regulator supplied with this range must

beused. The inlet pressure to the regulator should be as

followsforproper operation:

Natural Gas:

Minimum pressure: 5" (12.7 cm) WCP

Maximum pressure: 14" (35.6 cm) WCP

Propane Gas:

Minimum pressure: 10" (25.4 cm) WCP

Maximum pressure: 14" (35.6 cm) WCP

Contact local gas supplier if you are not sure about the

inletpressure.

Burner Input Rating — Altitude

Input ratings shown on the model/serial/rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings need to be

reduced at a rate of 4% for each 1,000 ft (304.8 m) above

sealevel (not applicable for Canada).

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" (2.5cm) water column pressure above the manifold pressure

shown on the model/serial/rating plate.

Line pressure testing above 1/2 psi (3.5 kPa)

gauge (14" [35.6cm]WCP)

The range and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2psi (3.5 kPa).

Line pressure testing at 1/2 psi (3.5 kPa)

gauge (14" [35.6cm]WCP) or lower

The range must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

A. Gas supply line

B. Shut-off valve open position

C. To range

†®TEFLON is a registered trademark of Chemours.

9

Page 10

INSTALLATION INSTRUCTIONS

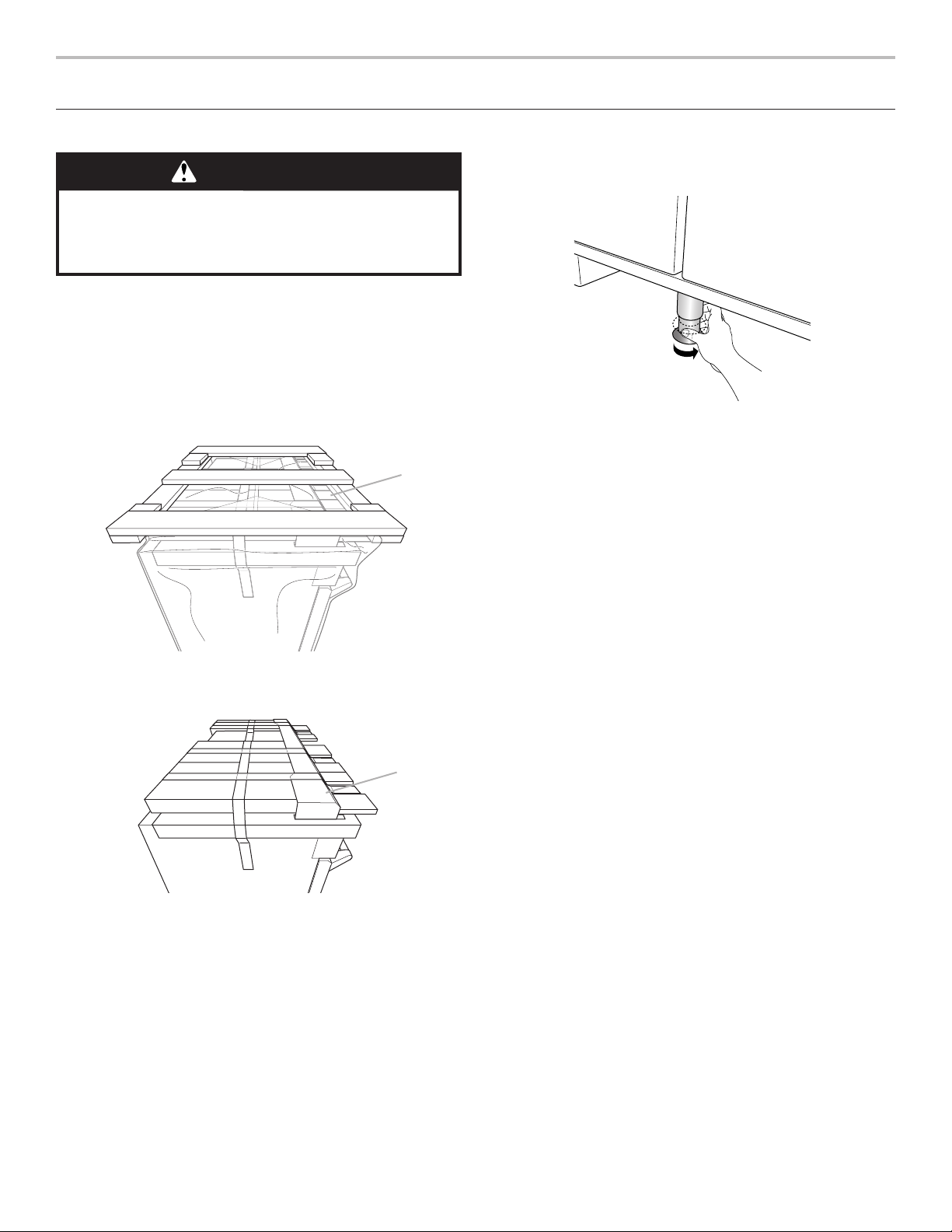

Unpack the Range

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

Remove shipping materials, tape, and lm from range.

Keepshipping pallet under range. Remove oven racks, and parts

package from inside oven. Remove grates from top of oven.

Remove Kick Plate

1. Your range will have the kick plate packaged on top of the

unit.

a. Remove kick plate from top of range and grate pack.

In packaging

A

2. For 48" (121.9 cm) models only, rotate center support

counterclockwise off the pallet until it stops.

NOTE: This support is used only for shipping and is not

needed for installation.

3. Lay a piece of cardboard from packaging on the oor behind

range. Using two or more people, rmly grasp each side of

range. Lift range up about 3" (8.0 cm) and move it back until

range is off shipping pallet. Set range oncardboard to avoid

damaging oor.

A. Kick plate

Packaging removed

A. Kick plate

b. Lay kick plate to the side to avoid scratching.

A

10

Page 11

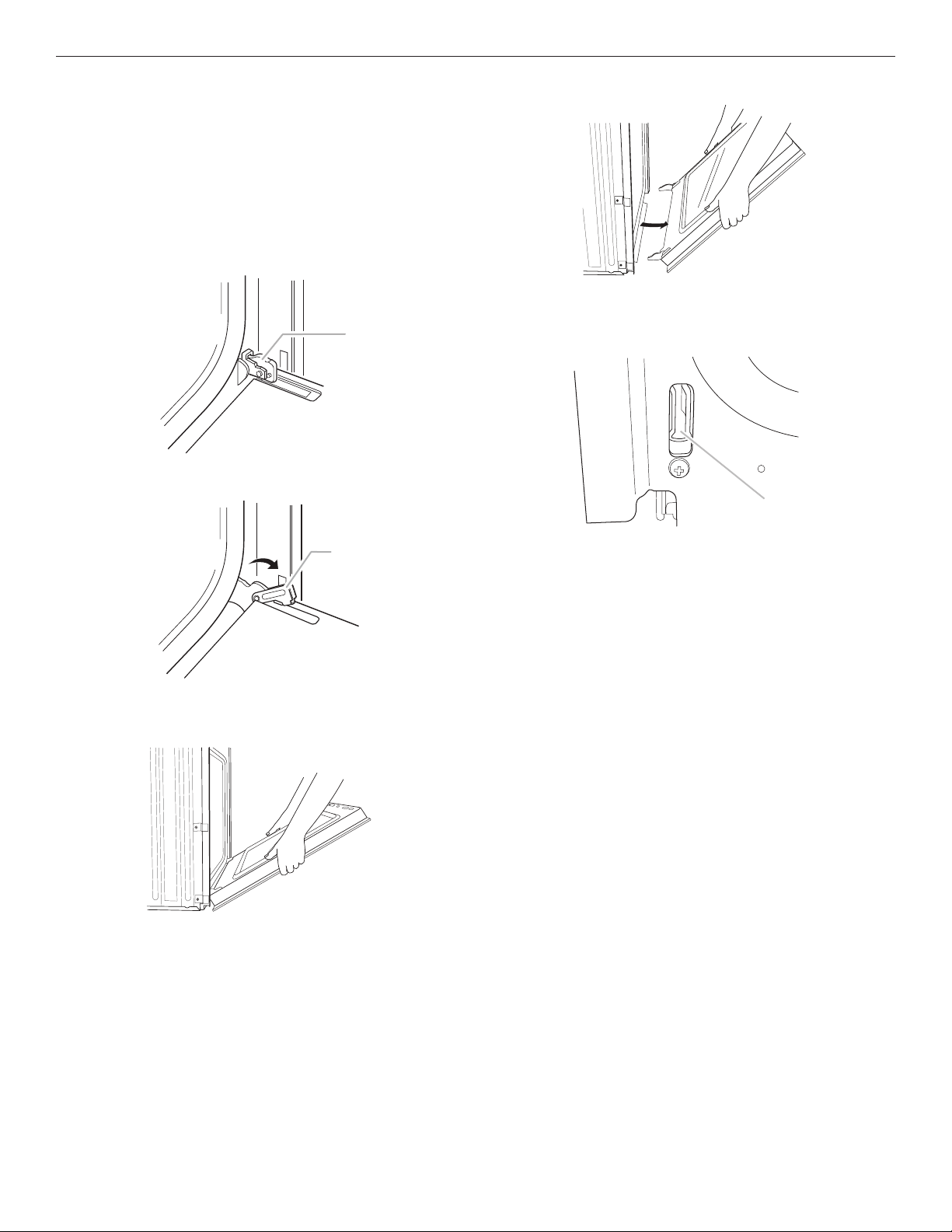

Remove Door

A

Door Removal

■ Do not remove the side door spacers until the range is ready

to install. Removing the door spacers could allow the door to

shift, damaging the door latch.

■ Do not lift or move the range by the door handle(s) or control

panel.

■ Prior to installing the range, you will need to remove the oven

door(s). Prepare a surface where you will place the door(s).

This surface should be at and covered with a soft blanket,

or use the corner posts from the packaging material.

A. Oven door hinge in the

locked position

Use two hands to remove and replace

the oven door(s). It may be necessary to

gently shift door from side to side.

A

B

B. Oven door hinge in the

unlocked position

Partially close the door to engage the

door latch locks. The door will stop at

this point.

A. Slot in the oven frame for the

door hinge lock

Replace the Door

■ To replace the oven door(s), locate the slots in the oven

cavity for the hinge locks and repeat the steps above in

reverse order. Make sure the door closes properly and there

is no interference from the door latch. If necessary, remove

the door and repeat the steps above. If power is connected

to the range, open and close the door to make sure the oven

light comes on and goes off appropriately.

■ The range is equipped with leveling legs and rollers. Once

the range is removed from the shipping pallet, make sure the

leveling legs are not touching the oor and use the rollers

to move the range into position. Always cover the ooring

surface to avoid damage to the oor. Do not roll the range

directly on the oor.

11

Page 12

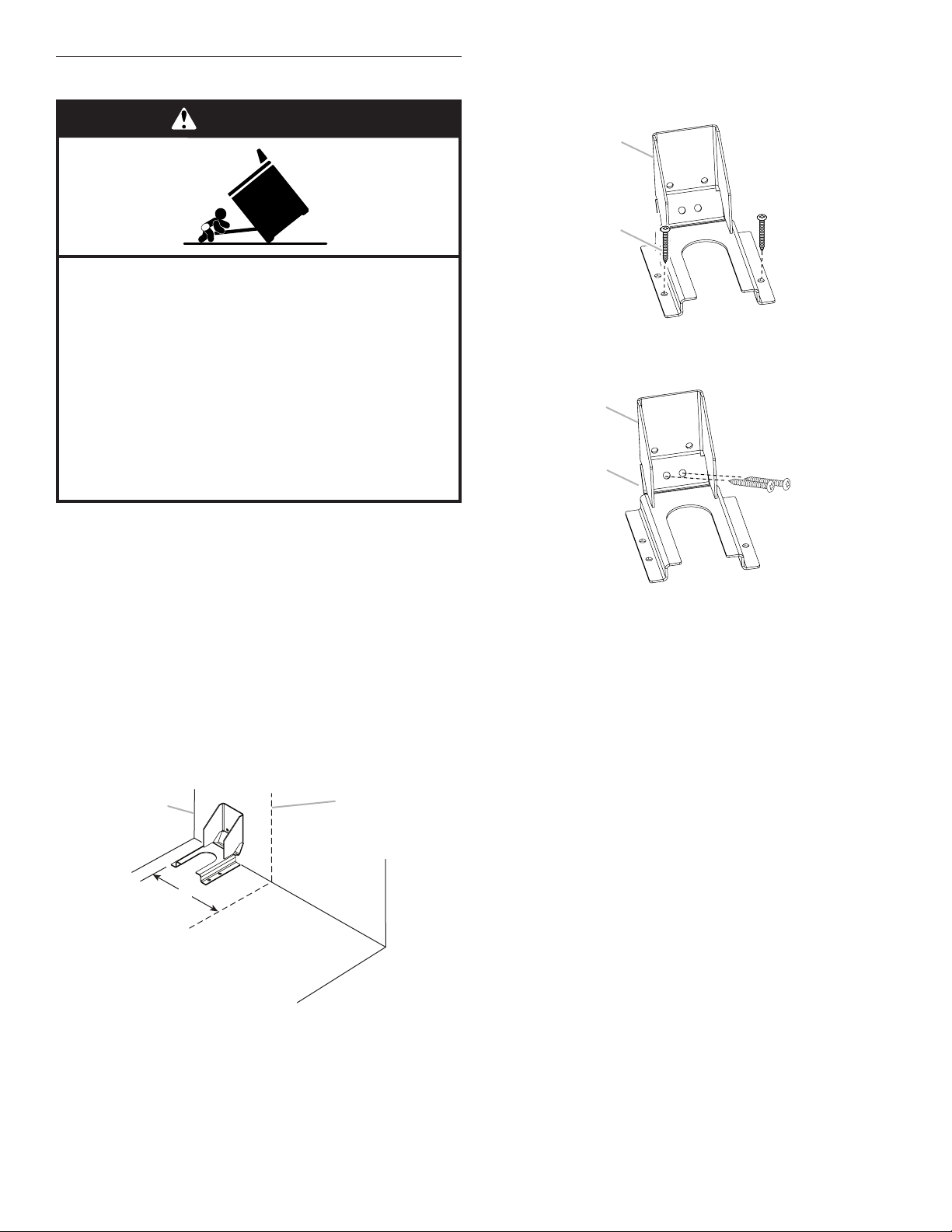

Install Anti-Tip Bracket

B

A

B

A

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

3. Drill two 1/8" (3.0 mm) holes that correspond to the bracket

holes of the determined mounting method. See the following

illustrations.

Floor Mounting

A. #12 x 15⁄8" (4.1 cm) screws

B. Anti-tip bracket

Wall Mounting

1. Determine which mounting method to use: oor or wall.

If you have a stone or masonry oor, you can use the

wallmounting method.

2. Determine and mark centerline of the cutout space. The

mounting bracket must be installed on the left side of the

cutout. Position mounting bracket in cutout as shown in the

following illustration.

Measurement B:

30" (76.2 cm) ranges: 13" (33.0 cm)

36" (91.4 cm) ranges: 16" (40.6 cm)

48" (121.9 cm) ranges: 22" (55.9 cm)

Measurement C:

Optional distance from back wall. If back wall is constructed

of a combustible material and a backguard is not installed, a

6" (15.2 cm) minimum clearance is required for all models.

Install anti-tip bracket accordingly.

C

B

A

A. #12 x 15⁄8" (4.1 cm) screws

B. Anti-tip bracket

4. Using a Phillips screwdriver, mount anti-tip bracket

tothewall or oor with the two #12 x 15⁄8" (4.1 cm)

screwsprovided.

Depending on the thickness of your ooring, longer screws

may be necessary to anchor the bracket to the suboor.

Longer screws are available from your local hardware store.

5. Move range close enough to opening to allow for electrical

connections to be made. Remove shipping base, cardboard,

or hardboard from under range.

6. Continue installing your range using the following

installationinstructions.

A. Centerline

B. Centerline of cutout to outside

12

edge of anti-tip bracket

C. Back wall to back of range

Page 13

Make Gas Connection

A

FG

A

B

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Complete Connection

1. Open the manual shut-off valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

2. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles

appear,aleak is indicated. Correct any leak found.

3. Remove range burner caps, and grates from parts package.

Place burner caps on burner bases. Place grates over

burners andcaps.

4. Check that the range is plugged into the appropriate

grounded outlet. (See the “Electrical Requirements” section.)

5. Turn on power supply. For further information, please refer

tothe user instructions located in the Use and Care Guide.

Verify Anti-Tip Bracket Location

1. Using a 5/16" (7.9 mm) socket or wrench, turn all four

leveling rods one full turn to raise the range and provide

enough clearance for the rear leveling leg to slide into the

anti-tip bracket.

1. Assemble exible connector from gas supply pipe to

pressure regulator located in the middle rear of the range.

2. Apply pipe-joint compound made for use with Propane gas

to the smaller thread ends of the exible connector adapters.

(SeeB and G in the following illustration.)

3. Attach one adapter to the gas pressure regulator and

the other adapter to the gas shut-off valve. Tighten both

adapters, being certain not to move or turn the gas pressure

regulator.

4. Use a 15/16" (2.4 cm) combination wrench and an adjustable

wrench to attach the exible gas supply to the adapters.

Check that connector is not kinked.

IMPORTANT: All connections must be wrench-tightened.

Donotmake connections to the gas regulator too tight. Making

the connections too tight may crack the regulator and cause a

gas leak. Do not allow the regulator to turn or move when

tightening ttings.

B

C

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have 1/2"

[1.3cm] male pipe thread)

D. Flexible connector

D

E

H

E. Manual gas shut-off valve

F. 1/2" (1.3 cm) or

3/4"(1.9cm) gas pipe

G. Use pipe-joint compound.

H. Adapter

2. Move range into its nal location, making sure rear leveling

leg slides into anti-tip bracket.

3. Use a ashlight to look underneath the bottom of the range

and visually check that the rear range foot is inserted into

theslot of the anti-tip bracket.

Install Griddle Tray

(On griddle models)

The griddle is factory installed.

1. Place drip tray in the well at the front of the griddle. Slide tray

toward the back until it stops.

A

B

A. Griddle drip tray

B. Griddle

2. Clean griddle before using. Refer to the Use and Care Guide.

13

Page 14

Electronic Ignition System

B

A

A

B

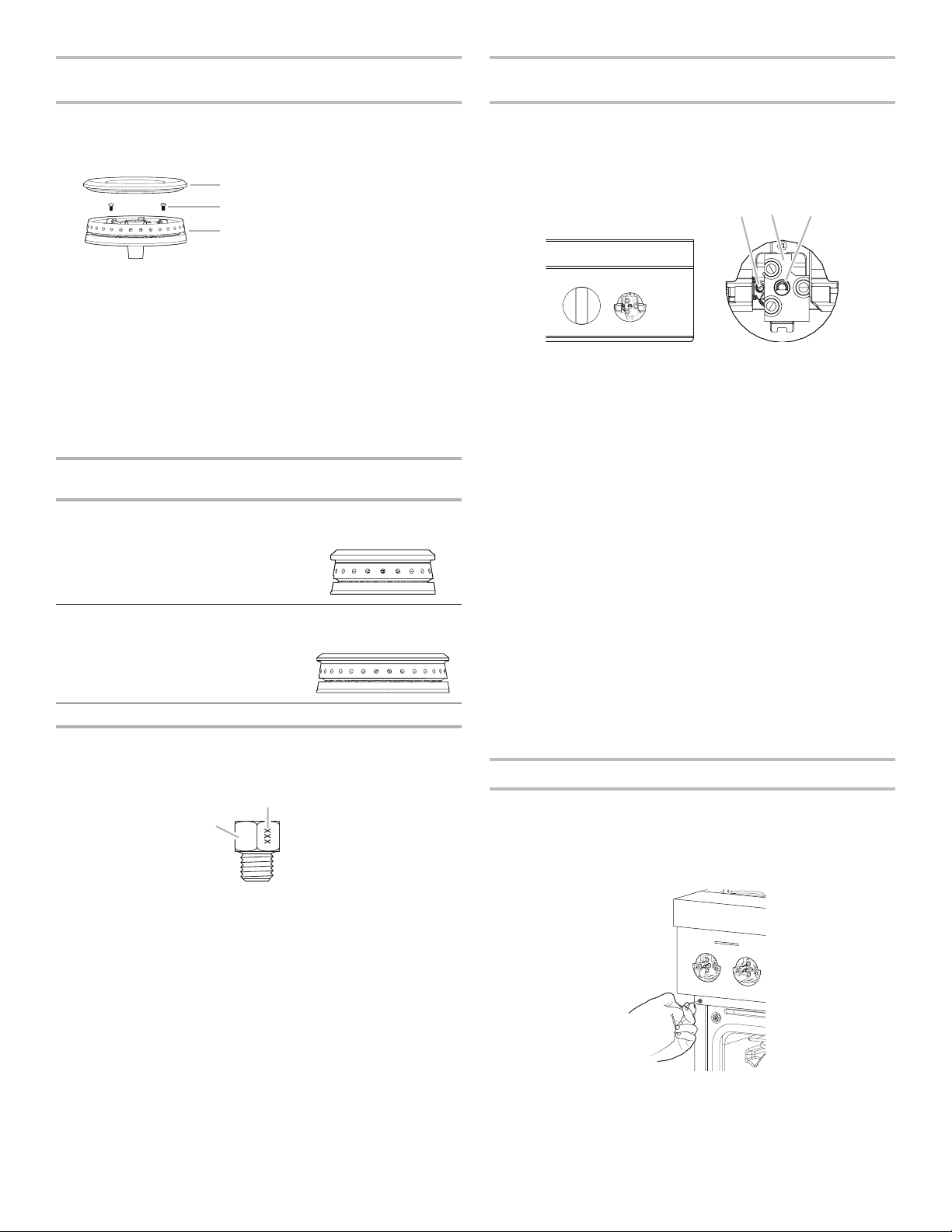

Install Burner Caps

Place burner caps on top of burner. If burner caps are not

properly positioned, surfaceburners will not light.

Burner

A

A. Incorrect

B. Correct

Level Range

NOTE: Range must be level for satisfactory baking performance.

1. Place rack in oven.

2. Place level on rack and check levelness of the range, rst

side to side, then front to back.

B

Initial Lighting and Gas Flame Adjustments

Range burners use electronic igniters in place of standing

pilots. When the range control knob is turned to any position,

the system creates a spark to light the burner. This sparking

continues until the ame is lit or the knob is turned to OFF.

NOTE: The rst time igniting the burners will take longer. This

allows the gas to reach the burners during the rst use.

Check Operation of Range Burners

Push in and turn each control knob to IGNITE.

NOTE: You will hear a clicking sound while the line clears.

The surface burners and grill ames should light within

4seconds. The rst time a burner is lit, it may take longer

than4seconds to light because of air in the gas line.

After verifying the proper burner operation, turn the control

knobs to OFF.

If burners do not light properly:

■ Turn range control knob to OFF.

■ Check that the range is plugged in and the circuit breaker

has not tripped or the fuse has not blown.

■ Check that the gas shut-off valves are set to the

openposition.

■ Check that burner caps are properly positioned on

burnerbases.

Repeat startup. If a burner does not light at this point, contact

your dealer or authorized service company for assistance.

3. If range is not level, adjust the leveling rods. Using a wrench,

turn leveling rods located behind the kick plate to level range

and to raise or lower range to the desired countertop height.

Leveling rods can be adjusted up to 11⁄2" (3.9 cm).

NOTE: All roller feet must be off the oor upon nal installation.

B

A

A. Rear leveling rod

B. Front leveling rod

NOTE: Turning clockwise raises the unit, whereas turning

counterclockwise lowers the unit.

Flame Height

The range ame should be a steady blue ame.

NOTE: Flame heights are factory set. If they don’t appear

correct, please contact your service provider.

Burner

A. Upper (main) ame

B. Lower (simmer) ame

14

Page 15

Install Kick Plate

B

NOTE: Door must be removed in order to remove or replace kick

plate. Refer to the “Remove Door” section.

Align kick plate over the kick plate slots and push kick plate

down.

A

A. Kick plate

B. Kick plate tab

C. Kick plate slot

C

Complete Installation

1. Check that all parts are now installed. If there is an extra

part, go back through the steps to see which step was

skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. For oven use and cleaning, read the Use and Care Guide.

Check Operation of Oven(s)

1. Turn power on.

2. Start a Bake cycle. See the Use and Care Guide for

operating instructions.

If oven(s) does not operate, check the following:

■ Household fuse is intact and tight or circuit breaker

hasnot tripped.

■ Electrical supply is connected.

■ See the “Troubleshooting” section in the Use and Care

Guide.

3. When oven has been on for 10–15 minutes, open the oven

door and feel for heat.

If you do not feel heat, turn off the oven and contact a

qualied technician.

If you need Assistance or Service:

Please reference the “Assistance or Service” section of the

Useand Care Guide or contact the dealer from whom you

purchased your range.

15

Page 16

GAS CONVERSIONS

A

B

C

IMPORTANT: Gas conversions from Natural gas to Propane gas

must be done by a qualied installer.

Propane Gas Conversion

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn the manual shut-off valve to the closed position.

A. To range

B. Shut-off valve (closed position)

C. Gas supply line

2. Unplug range or disconnect power.

16

Page 17

To Convert Gas Pressure Regulator from Natural Gas

B

C

DE

to Propane

NOTE: Door must be removed in order to remove or replace kick

plate. Refer to the “Remove Door” section.

1. Lift the kick plate up and off of the kick plate tab.

5. Remove spring retainer from the cap by turning the spring

retainer counterclockwise. Locate the “LP” and “NAT”

position on the spring retainer. Turn over the spring retainer

so the “LP” arrow is pointing toward the cap.

A

A

A. Kick plate

B. Kick plate tab

C. Kick plate slot

C

2. Gently lay kick plate aside to avoid scratching.

3. Locate the gas pressure regulator at the left rear of the range.

A

A. Gas pressure regulator

4. Remove the gas pressure regulator cap by using a

large at-blade screwdriver, turning the regulator cap

counterclockwise. When the cap is removed, do not lose the

metal seal.

NOTE: Do not remove the spring beneath the cap.

NAT

LP

NAT

LP

B

A. Access cap

B. Metal seal

C. Gas pressure regulator

LP

NAT

LP

NAT

D. Spring retainer in NAT

position

E. Spring retainer in LP

position

6. Tighten the gas pressure regulator cap by using a large

at-blade screwdriver, turning the regulator cap clockwise.

7. Test the gas pressure regulator and gas supply line.

The regulator must be checked at a minimum 1" (2.5 cm)

water column above the set pressure. The inlet pressure to

the regulator should be as follows for operation and checking

the regulator setting:

Propane Gas:

Minimum pressure: 10" (25.4 cm) WCP

Maximum pressure: 14" (35.6 cm) WCP

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" (2.5 cm) water column pressure above the manifold

pressure shown on the model/serial/rating plate.

Line pressure testing above 1/2 psi (3.5 kPa)

gauge (14" [35.6cm] WCP)

The range and its individual shut-off valve must be

disconnected from the gas supply piping system during

anypressure testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

Line pressure testing at 1/2 psi (3.5 kPa)

gauge (14" [35.6cm]WCP) orlower

The range must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

17

Page 18

To Convert Surface Burners from Natural Gas to

A

C

B

A

B

A B C

Propane

Adjusting Simmer Low and Main Setting on Surface

Burner for Propane

1. If the burner grates are installed, remove them.

2. Remove burner cap.

3. Remove the burner base by rst removing (2) T-20 screws.

Burner

A. Burner cap

B. Screws

C. Burner base

4. Apply masking tape to the end of a 1/4" (7 mm) nut driver

to help hold the gas orice spud in the nut driver while

changing it. Insert nut driver into the gas opening and press

down onto the gas orice spud and remove by turning the

gas orice spud counterclockwise and lifting out. Set gas

orice spud aside.

5. Replace with correct Propane gas orice spud. See the

“Propane Gas Orice Spud/Hood Chart”.

Use the following chart to nd the exact orice spud

placement.

Propane Gas Orice Spud/Hood Chart

Burner

Rating

7,400 BTUs 70

13,000 BTUs 99

16,000 BTUs 116 1.16 mm Grill burner

NOTE: Refer to serial tag for more information on burner ratings

and locations.

Stamp Size Burner Style

44

50

0.70 mm

0.44 mm

0.99 mm

0.50 mm

Small burner - main

Small burner - simmer

Large burner – main

Larger burner – simmer

Burner orice spud

A. Size stamp

B. Fuel type stamp (L or N)

1. Remove the surface burner control knobs and bezels (oven

control knobs and griddle control knobs do not have to be

removed).

2. Locate the Simmer low-turndown adjustment screw through

the bezel on the left side of the ignition switch.

A. Simmer low-turndown adjustment screw

B. Ignition switch

C. Main low-turndown adjustment screw (inside stem)

3. With the burner ON, and set to Simmer Lo, adjust the

simmer ame down to the proper BTU level. Using a

1/8" x 4

1

4

/

" (3.2 mm x 10.8 cm) at blade screwdriver, turn

the simmer low-turndown adjustment screw clockwise until

the ame height is below the bottom of the cap. If the ame

becomes unstable and ickers or appears to race around the

burner, the adjustment is too low and the screw should be

adjusted counterclockwise until the ame is stable. Repeat

this step for all surface burners, except the grill burner.

NOTE: Use a knob to adjust the burner valve.

NOTE: If your range has the IR grill, then skip ahead to the

Convert IR Grill Burner section.

NOTE: Adjust each burner individually.

4. With burner OFF, using the same at blade screwdriver, turn

the main low-turndown adjustment screw 120-135 degrees

clockwise. This will set the main low burner rate to a proper

level.

5. Replace the bezels using the 2 screws which attach to the

valve brackets.

6. Push the surface knobs onto the valve stems.

7. Replace burner grates.

To Convert IR Grill Burner for Propane

1. Unplug range or disconnect power.

2. Remove grill knob and bezel. The other surface knobs and

bezels should still be off the range.

3. Open the oven door and remove the two screws on each

side of the range that hold the control console in place.

6. Place Natural gas orice in plastic parts bag for future use

and keep with package containing literature.

NOTE: There may be extra orices in your kit.

7. Replace the burner base and screws. Tighten screws only

until burner is snug to cooktop, do not over-tighten.

8. Replace burner cap.

9. Repeat steps 2 through 8 for the remaining burners.

NOTE: Make sure to leave oven door open or the control

console will not rest in the side brackets properly once it is

detached.

18

Page 19

4. Pull up on the control console and let it drop forward into the

A

ve/replace

A

B

A

notched console brackets on each side.

A. Control console bracket

5. Remove the two screws holding the grill orice holder

bracket.

7. Using an adjustable wrench and a 1/2" (1.3 cm) open end

wrench remove the Natural (NG) gas orice spud and replace

with the correct Propane (L) orice spud.

Use 1/2" (1.3 cm)

open end wrench

to remo

orifice

Hold with adjustable

wrench here

8. Reposition the grill orice holder assembly back into the

burner box, and replace the grill orice holder bracket and

two holder screws.

9. Lift up on the control console and set it back into place. For

a proper t, the ange of the control console must hook over

the lip on the front of the range cooktop.

NOTE: It may be necessary to lift valve stems to align with

console holes.

B

A. Screws

B. Grill orice holder bracket

A

6. Pull the grill orice holder out of the burner box far enough

away to allow access to the orice with a wrench, using

caution not to kink the attached tubing.

A

B

A. Grill orice

B. Grill orice holder

A. Control console ange

B. Front lip of range cooktop

10. Check that the control console is ush with the top edge of

the range.

A. Flush with range top

11. Replace the screws on each side of the control console.

12. Replace the control knobs and bezels.

13. Replace burner grates.

19

Page 20

Complete Installation

A

B

C

B

1. Refer to the “Make Gas Connection” section for properly

connecting the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition, operation, and burner ame adjustments.

IMPORTANT: You may have to adjust the “LO” setting for

each range burner.

Checking for proper range burner ame is very important.

The small inner cone should have a very distinct blue ame

1/4" (6.4 mm) to 1/2" (1.3 cm) long. The outer cone is not as

distinct as the inner cone. Propane gas ames have a slightly

yellow tip.

3. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete this

procedure.

To Convert Gas Pressure Regulator from Propane to

Natural Gas

NOTE: Door must be removed in order to remove or replace kick

plate. Refer to the “Remove Door” section.

1. Lift the kick plate up and off of the kick plate tab.

A

C

Natural Gas Conversion

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn the manual shut-off valve to the closed position.

A. Kick plate

B. Kick plate tab

C. Kick plate slot

2. Gently lay kick plate aside to avoid scratching the stainless

steel.

3. Locate the gas pressure regulator at the left rear of the range.

A

A. Gas pressure regulator

4. Remove the gas pressure regulator cap by using a

large at-blade screwdriver, turning the regulator cap

counterclockwise. When the cap is removed, do not lose the

metal seal.

NOTE: Do not remove the spring beneath the cap.

A. To range

B. Shut-off valve (closed position)

C. Gas supply line

2. Unplug range or disconnect power.

20

Page 21

5. Remove spring retainer from the cap by turning the spring

C

DE

A

B

retainer counterclockwise. Locate the “LP” and “NAT”

position on the spring retainer. Turn over the spring retainer

so the “NAT” arrow is pointing toward the cap.

A

NAT

B

LP

LP

NAT

To Convert Surface Burners from Propane to

Natural Gas

1. If the burner grates are installed, remove them.

2. Remove burner cap.

3. Remove the burner base by rst removing (2) T-20 screws.

A

Burner

B

A. Burner cap

B. Screws

C

C. Burner base

A. Access cap

B. Metal seal

C. Gas pressure regulator

NAT

LP

D. Spring retainer in LP

position

E. Spring retainer in NAT

position

LP

NAT

6. Tighten the gas pressure regulator cap by using a large

at-blade screwdriver, turning the regulator cap clockwise.

7. Test the gas pressure regulator and gas supply line.

The regulator must be checked at a minimum 1" (2.5 cm)

water column above the set pressure. The inlet pressure to

the regulator should be as follows for operation and checking

the regulator setting:

Natural Gas:

Minimum pressure: 5" (12.7 cm) WCP

Maximum pressure: 14" (35.6 cm) WCP

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" (2.5 cm) water column pressure above the manifold

pressure shown on the model/serial/rating plate.

Line pressure testing above 1/2 psi (3.5 kPa)

gauge (14" [35.6cm] WCP)

The range and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psi (3.5 kPa).

Line pressure testing at 1/2 psi (3.5 kPa)

gauge (14" [35.6cm]WCP) orlower

The range must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

4. Apply masking tape to the end of a 1/4" (7 mm) nut driver

to help hold the gas orice spud in the nut driver while

changing it. Insert nut driver into the gas opening and press

down onto the gas orice spud and remove by turning the

gas orice spud counterclockwise and lifting out. Set gas

orice spud aside.

5. Replace with correct Natural gas orice spud. See the

“Natural Gas Orice Spud/Hood Chart.”

Use the following chart to nd the exact orice spud

placement.

Natural Gas Orice Spud/Hood Chart

Burner

Rating

9,200 BTUs 130

18,000 BTUs

(REAR)

20,000 BTUs

(FRONT)

16,000 BTUs 180 1.80 mm Grill burner

NOTE: Refer to serial tag for more information on burner ratings

and locations.

Stamp Size Burner Style

70

193

78

203

78

1.30 mm

0.70 mm

1.93 mm

0.78 mm

2.03 mm

0.78 mm

Small burner - main

Small burner - simmer

Large burner – main

Large burner – simmer

Large burner – main

Large burner – simmer

Burner orice spud

A. Size stamp

B. Fuel type stamp (L or N)

6. Place Propane gas orice spuds in plastic parts bag for

future use and keep with package containing literature.

7. Replace the burner base and screws. Tighten screws only

until burner is snug to cooktop, do not over-tighten.

8. Replace burner cap.

9. Repeat steps 2 through 8 for the remaining burners.

21

Page 22

Adjusting Simmer Low and Main Setting on Surface

A

Burner for Natural Gas

1. Remove the surface burner control knobs and bezels (oven

control knobs and griddle control knobs do not have to be

removed).

2. Locate the Simmer low-turndown adjustment screw through

the bezel on the left side of the ignition switch.

A B C

A. Simmer low-turndown adjustment screw

B. Ignition switch

C. Main low-turndown adjustment screw (inside stem)

3. With the burner ON, and set to Simmer Lo, adjust the

simmer ame down to the proper BTU level. Using a

1/8" x 4

turn the simmer low-turndown adjustment screw

counterclockwise until the ame becomes stable, does not

icker, or appear to race around the burner. Once the ame

is stable, turn the burner rate to SIMMER HIGH setting. The

ame should increase to approximately 2X the ame height.

If not, the low-turndown may be able to be adjusted low and

still remain stable. Repeat this step for all surface burners,

except the grill burner.

NOTE: Use a knob to adjust the burner valve.

NOTE: If your range has the IR grill, then skip ahead to the

Convert IR Grill Burner section.

NOTE: Adjust each burner individually.

4. With burner OFF, using the same at blade screwdriver, turn

the main low-turndown adjustment screw 120-135 degrees

counterclockwise. This will set the main low burner rate to a

proper level.

5. Replace the bezels using the 2 screws which attach to the

valve brackets.

6. Push the surface knobs onto the valve stems.

7. Replace burner grates.

1

4

/

" (3.2 mm x 10.8 cm) at blade screwdriver,

4. Pull up on the control console and let it drop forward into the

notched console brackets on each side.

A. Control console bracket

5. Remove the two screws holding the grill orice holder

bracket.

B

A. Screws

B. Grill orice holder bracket

A

6. Pull the grill orice holder out of the burner box far enough

away to allow access to the orice with a wrench, using

caution not to kink the attached tubing.

To Convert IR Grill Burner for Natural Gas

1. Unplug range or disconnect power.

2. Remove grill knob and bezel. The other surface knobs and

bezels should still be off the range.

3. Open the oven door and remove the two screws on each

side of the range that hold the control console in place.

NOTE: Make sure to leave oven door open or the control

console will not rest in the side brackets properly once it is

detached.

22

A

B

A. Grill orice

B. Grill orice holder

Page 23

7. Using an adjustable wrench and a 1/2" (1.3 cm) open end

ve/replace

A

B

A

wrench remove the Propane (L) orice spud and replace with

the correct Natural Gas (NG) orice spud. See Natural Gas

Orice Spud Chart.

Use 1/2" (1.3 cm)

open end wrench

to remo

orifice

Hold with adjustable

wrench here

8. Reposition the grill orice holder assembly back into the

burner box, and replace the grill orice holder bracket and

two holder screws.

9. Lift up on the control console and set it back into place. For

a proper t, the ange of the control console must hook over

the lip on the front of the range cooktop.

NOTE: It may be necessary to lift valve stems to align with

console holes.

10. Check that the control console is ush with the top edge of

the range.

A. Flush with range top

11. Replace the screws on each side of the control console.

12. Replace the control knobs and bezels.

13. Replace burner grates.

Complete Installation

1. Refer to the “Make Gas Connection” section for properly

connecting the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition, operation, and burner ame adjustments.

IMPORTANT: You may have to adjust the “LO” setting for

each range burner.

Checking for proper range burner ame is very important.

The small inner cone should have a very distinct blue ame

1/4" (6.4 mm) to 1/2" (1.3 cm) long. The outer cone is not as

distinct as the inner cone. Propane gas ames have a slightly

yellow tip.

3. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete this

procedure.

A. Control console ange

B. Front lip of range cooktop

23

Page 24

SÉCURITÉ DE LA CUISINIÈRE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT : Si les renseignements dans ces instructions ne sont pas

exactement observés, un incendie ou une explosion peut survenir, causant des

dommages au produit, des blessures ou un décès.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

– Ne pas entreposer ni utiliser de l’essence ou d’autres vapeurs ou liquides inflammables

à proximité de cet appareil ou de tout autre appareil électroménager.

– QUE FAIRE DANS LE CAS D’UNE ODEUR DE GAZ :

Ne pas tenter d’allumer un appareil.

•

Ne pas toucher à un commutateur électrique.

•

Ne pas utiliser le téléphone se trouvant sur les lieux.

•

Appeler immédiatement le fournisseur de gaz à partir du téléphone d'un voisin. Suivre

•

ses instructions.

À défaut de joindre votre fournisseur de gaz, appeler les pompiers.

•

– L’installation et l’entretien doivent être effectués par un installateur qualifié, une agence

de service ou le fournisseur de gaz.

AVERTISSEMENT : L’odorat ne permet pas toujours la détection d’une fuite de gaz.

Les distributeurs de gaz recommandent l’emploi d’un détecteur de gaz (homologation UL ou CSA).

Pour d'autres informations, contacter le fournisseur de gaz local.

En cas de détection d’une fuite de gaz, exécuter les instructions “Que faire dans le cas d’une odeur de gaz”.

24

Page 25

IMPORTANT : Ne pas installer un système de ventilation avec évacuation de l'air vers le bas, qui évacuerait l'air vers cet

appareil de cuisson à gaz. Ce type de système de ventilation peut causer des problèmes d'allumage et de combustion avec cet

appareil de cuisson à gaz et entraîner des blessures corporelles ou le fonctionnement non désiré de cet appareil.

Dans l’État du Massachusetts, les instructions d’installation suivantes sont applicables :

■ Les travaux d’installation et réparation doivent être exécutés par un plombier ou tuyauteur qualifié ou licencié, ou par le

personnel qualifié d’une entreprise licenciée par l’État du Massachusetts.

■ Remplacer par des dispositifs de fermeture acceptables : Les robinets de gaz et robinets à bille installés pour l'utilisation

devraient être indiqués.

■ Si un conduit de raccordement flexible est utilisé, sa longueur ne doit pas dépasser 4 pi (121,9 cm).

AVERTISSEMENT

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisinière, ce qui peut causer un décès.

Fixer la bride antibasculement au plancher ou au mur, conformément aux instructions

d’installation.

Faire glisser de nouveau la cuisinière de façon à ce que le pied arrière de la cuisinière se trouve

dans la fente de la bride antibasculement.

Réengager la bride antibasculement si la cuisinière a été déplacée.

Ne pas faire fonctionner la cuisinière si la bride antibasculement n’est pas installée et engagée.

Le non-respect de ces instructions peut causer un décès ou des brûlures graves aux enfants et

aux adultes.

La bride

antibasculement

Le pied de la cuisinière

Pour vérifier que la bride antibasculement est bien installée et engagée:

• Faire glisser la cuisinière vers l'avant.

• Vérifier que la bride antibasculement est bien fixée au plancher ou au mur.

Faire de nouveau glisser la cuisinière vers l’arrière de sorte que le pied de la cuisinière•

se trouve sous la bride antibasculement.

• Voir les instructions d’installation pour plus de détails.

25

Page 26

EXIGENCES D’INSTALLATION

Outils et pièces

Rassembler les outils et pièces nécessaires avant d’entreprendre l’installation. Lire et observer les instructions fournies avec chacun

des outils de la liste ci-dessous.

Outils nécessaires

Clé à tuyauterie Clé à molette ou clé

Perceuse Clé à cliquet de 3/8 po

Niveau Coupe-tube Tourne-écrou de 1/4 po

Foret de maçonnerie à pointe

carburée de 3/16 po (4,8mm)

Foret de 1/8 po (3,2mm)

de5/8po (16mm)

Composé d’étanchéité des

raccords letés résistant

augaz propane

(9,5mm)

Tournevis à tête plate de 1/8po

x 4 1/4 po (3mm x 100mm)

Clé mixte de 15/16 po (24mm) Pince

(6,4mm), 3/8 po (9,5mm)

et5/16 po (7,9mm)

Solution non corrosive de

détection des fuites

Tournevis cruciforme no2

Marqueur ou crayon

Ruban à mesurer

Pour les conversions gaz propane/naturel

Grand tournevis à lame plate Clé à molette Tournevis Torx®T-20

Clé ouverte de 1/2po

(1,3cm)

†® TORX et T20 sont des marques déposées de Acument Intellectual Properties, LLC.

26

Tournevis carré no1

®†

Ruban adhésif de masquage

Page 27

Pièces fournies

B

Emplacement

Vérier que toutes les pièces sont présentes.

■ Trousse de bride antibasculement

A

A. Bride antibasculement

B. (4) vis à tête cruciforme no8-18 x 1po (2,5 cm)

REMARQUE: La bride antibasculement doit être solidement

xée au sous-plancher. La profondeur du plancher peut

nécessiter des vis plus longues pour l’ancrage de la bride

dans le sous-plancher. Des vis plus longues sont offertes

chez votre quincaillerie locale. Voir la section “Installation

dela bride antibasculement”.

■ Grilles de brûleur

■ Chapeaux de brûleur

■ Plateau d’égouttement de la plaque à frire (sur modèles avec

plaque à frire)

Pièces supplémentaires fournies avec les modèles

àinjection de vapeur (sur certains modèles)

■ Trousse de ltre à eau, modèle W10049700

■ Raccord d’alimentation en eau de 1/4 po (6,4mm) à 1/4 po

(6,4mm)

Pièces nécessaires

■ Tous les modèles doivent être installés avec un dosseret

si l’installation se fait sans dégagement entre l’appareil

etune paroi arrière combustible comme un mur en gypse.

Voir “Dimensions de l’armoire” à la section “Exigences

d’emplacement” pour les spécications concernant

l’installation.

Vérier les codes locaux et consulter le fournisseur de gaz.

Vérier l’alimentation en gaz et l’alimentation électrique

existantes. Voir les sections “Spécications électriques”

et“Spécications de l’alimentation en gaz”.

Il est recommandé de faire réaliser tous les raccordements

électriques par un électricien qualié agréé.

Pièces supplémentaires requises avec les modèles à

injection de vapeur (sur certains modèles)

■ Agrafes/attaches de tuyau

■ Tuyau d’alimentation exible homologué par les codes en

vigueur de diamètre externe de 1/4 po (6,4mm) (pour la

réalisation du raccordement en eau)

■ Dispositif de raccordement de l’eau (pour raccorder le tuyau

de diamètre externe de 1/4 po [6,4mm] à l’alimentation

en eau). Vérier les codes locaux pour connaître le type de

raccordement exigé.

Conversion pour utilisation en haute altitude

Modier l’orice de la cuisinière/table de cuisson n’est pas

nécessaire pour un bon fonctionnement. L’intensité faible du

brûleur peut avoir besoin d’être réglée de nouveau pour obtenir

de bons résultats.

Consulter la section « Effectuer les réglages d’intensité faible

de mijotage et principal du brûleur de surface au propane »

(page41) pour l’utilisation du gaz propane.

Consulter la section « Effectuer les réglages d’intensité faible

de mijotage et principal du brûleur de surface au gaz naturel »

(page45) pour l’utilisation du gaz naturel.

Exigences d’emplacement du

système de ltration d’eau

(sur certains modèles)

Pour des résultats optimaux, ne pas installer le système de

ltration de l’eau à l’extérieur ou l’exposer à des températures

extrêmement élevées ou basses. La température en provenance

de l’alimentation en eau jusqu’au système de ltration de l’eau

doit être comprise entre 40°F (4°C) et 100°F (38°C). Ne pas

installer sur une canalisation d’alimentation en eau chaude.

Localiser le système de ltration de l’eau près de la canalisation

d’alimentation en eau froide situé sous l’évier de la cuisine pour

ltrer l’eau froide.

S’assurer que l’ensemble de ltre à eau est installé en position

verticale.

Il faudra percer un trou d’un diamètre minimum de 1/2 po

(1,3cm) dans le coin supérieur droit ou arrière gauche de la paroi

latérale de l’armoire sous l’évier pour acheminer la canalisation

d’alimentation en eau jusqu’à la cuisinière.

Selon la conguration d’installation, il faudra peut-être percer

davantage de trous pour l’acheminement des canalisations.

Enrouler sufsamment de tuyau d’alimentation exible

homologué par les codes en vigueur derrière la cuisinière

pourque le raccordement à la cuisinière puisse être réalisé

derrière la cuisinière avant la mise en place de celle-ci.

Conguration d’installation typique

REMARQUE: Pour des installations particulières, contacter un

plombier agréé.

Au Massachusetts, un plombier agréé est exigé et le code de

plomberie248–CMR du Commonwealth du Massachusetts doit

être respecté.

Arrivée d’eau

froide

Chaude Froide

du filtre

27

Page 28

Spécications de

l’alimentation en eau

Une alimentation en eau froide avec une pression comprise

entre 30 et 120lb/po² (207 et 827kPa) est nécessaire pour que

la caractéristique de cuisson à la vapeur puisse fonctionner.

AuMassachusetts, le code de plomberie248 CMR3.00 et

10.00doit être respecté et on doit faire appel à un plombier

agréé. Pour toute question au sujet de la pression de l’eau,

faireappel à un plombier qualié agréé.

Alimentation en eau par osmose inverse

IMPORTANT: La pression de l’alimentation en eau entre le

système d’osmose inverse et le robinet d’arrivée d’eau de la

cuisinière doit être entre 30 et 120lb/po² (207 et 827kPa).

Exigences d’emplacement

IMPORTANT: Observer les dispositions de tous les codes et

règlements en vigueur. Ne pas obstruer le ux de combustion

etde ventilation.

■ C’est à l’installateur qu’incombe la responsabilité de

respecter les distances de séparation spéciées sur la

plaque signalétique. La plaque signalétique se trouve sous

laconsole, du côté droit.

■ Il est recommandé qu’une hotte de cuisinière de 585 CFM

(993,9m3/h) ou plus soit installée au-dessus de la cuisinière.

■ Suivre les instructions d’installation de la hotte de cuisinière

ou de l’ensemble hotte/micro-ondes pour les dimensions

de dégagement à respecter au-dessus de la surface de la

tablede cuisson.

■ Dans le cas d’une cuisinière encastrée, l’enceinte doit

recouvrir complètement les côtés et l’arrière de la cuisinière.

■ Toutes les ouvertures dans le mur ou le plancher de

l’emplacement d’installation de la cuisinière doivent

êtrescellées.

■ Ne pas réaliser de scellement entre la cuisinière et les

armoires latérales.

■ Respecter les dimensions indiquées pour les ouvertures à

découper dans les meubles. Ces dimensions constituent

lesvaleurs minimums des dégagements.

■ La bride antibasculement doit être installée. Pour l’installation

de la bride antibasculement fournie avec la cuisinière, voir la

section “Installation de la bride antibasculement”.

■ Une source d’électricité avec liaison à la terre est nécessaire.

Voir la section “Spécications électriques”.

■ Un raccordement adéquat à l’alimentation en gaz doit être

disponible. Voir la section “Spécications de l’alimentation

en gaz”.

■ Contacter un installateur de revêtement de sol qualié,

quipourra déterminer si le revêtement de sol peut résister à

une température d’au moins 200°F (93°C). Dans le cas de

l’installation de la cuisinière par dessus un tapis, placer sous

la cuisinière une plaque d’appui isolée, ou une plaque de

contreplaqué de 1/4 po (6,4mm).

Si un système de purication de l’eau par osmose inverse est

raccordé à votre alimentation en eau froide, la pression de

l’eauau système par osmose inverse doit être d’un minimum

de40lb/po² (276kPa).

Si la pression de l’eau au système par osmose inverse est

inférieure à 40lb/po² (276kPa):

■ Vérier que le ltre à sédiment dans le système à osmose

inverse n’est pas obstrué. Remplacer le ltre si nécessaire.

■ Laisser le réservoir du système d’osmose inverse se remplir

après une utilisation intense.

Pour toute question au sujet de la pression de l’eau, faire appel

àun plombier qualié agréé.

IMPORTANT: Pour éviter d’endommager les armoires, consulter

le constructeur de la maison ou le fabricant des armoires pour

déterminer si les matériaux utilisés peuvent subir un changement

de couleur, une déstratication ou d’autres dommages. Ce four a

été conçu conformément aux exigences des normes UL et CSA

International et respecte les températures maximums permises

de194°F (90°C) pour les armoires en bois.

Résidence mobile – Spécications additionnelles à

respecter lors de l’installation

L’installation de cette cuisinière doit s’effectuer conformément

à la norme Manufactured Home Construction Safety Standards,

Title24 CFR, Part3280 (anciennement Federal Standard

for Mobile Home Construction and Safety, title24, HUD,

Part280).Lorsque cette norme n’est pas applicable, utiliser

la norme Standard for Manufactured Home Installations,

ANSIA225.1/NFPA501A ou les dispositions des codes locaux.

Au Canada, l’installation de cette cuisinière doit respecter la plus

récente version des normes CAN/CSA-A240 ou les dispositions

des codes locaux.

Autres critères à respecter pour une installation en

résidence mobile:

■ Dans le cas de l’installation de cette cuisinière dans une

résidence mobile, la cuisinière doit être xée au plancher

durant tout déplacement du véhicule. Toute méthode de

xation de la cuisinière est adéquate dans la mesure où elle

satisfait aux critères des normes mentionnées ci-dessus.

28

Page 29

Dimensions du produit

D