Page 1

INSTRUCTION BOOK

MC 200E

Page 2

IMPORTANT SAFETY INSTRUCTIONS

This sewing machine is not a toy. Do not allow children to play with this machine.

The machine is not intended for use by children or mentally infirm persons without supervision.

This sewing machine is designed and manufactured for household use only.

Read all instruction before using this sewing machine.

DANGER – To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing machine from the

electric outlet immediately after using and before cleaning.

2. Do not reach for the appliance that has fallen into water. Unplug immediately.

3. Do not place or store appliance where it can fall or be pulled into a tub or sink. Do not place in or drop into water

or other liquid.

WARNING – To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow children to play with the machine. The machine is not intended for use by children or infirm

persons without proper supervision.

Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near

children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water.

4. Never operate the appliance with any air opening blocked. Keep ventilation opening of this sewing machine and

foot controller free from accumulation of lint, dust and loosen cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as threading the

needle, changing the needle, threading the bobbin or changing the presser foot, and the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or when making

any other adjustments mentioned in this owner’s manual.

SA VE THESE INSTRUCTIONS

The design and specifications are subject to change without a prior notice.

Please note that on disposal, this product must be safely recycled in accordance with relevant National legislation

relating to electrical/electronic products. If in doubt please contact your retailer for guidance. (European Union only.)

Page 3

Table of contents

Name of parts ..............................................................2

Standard accessories ..................................................3

GETTING READY TO SEW

Connecting the power supply....................................... 4

For your safety .............................................................4

Polarized plug............................................................... 4

Start/stop button........................................................... 5

Presser foot lifter ..........................................................5

Winding the bobbin ...................................................... 6

Removing the bobbin............................................... 6

Setting the spool of thread....................................... 6

Additional spool pin.................................................. 6

Winding the bobbin ..................................................7

Inserting the bobbin ................................................. 8

Threading the machine ................................................ 9

Needle threader ......................................................... 10

Drawing up the bobbin thread ....................................11

Changing the needle ..................................................12

Adjusting the thread tension.......................................13

Balanced thread tension ........................................13

When the needle thread tension is too tight ..........13

When the needle thread tension is too loose......... 13

Adhesive (iron-on) stabilizer.......................................14

Stabilizers...................................................................14

Types of stabilizer ..................................................14

Usage ....................................................................14

Template..................................................................... 14

Saving the file.............................................................39

Saving in internal memory .........................................39

Name of file ...........................................................39-40

Saving in USB memory (optional) .............................. 41

Creating a new folder ................................................. 42

Opening a file from the internal memory.................... 43

Deleting a file ............................................................. 43

Opening a file from USB memory (optional) .............. 44

CARE AND MAINTENANCE ..................................... 45

Cleaning the hook race ..............................................45

Assembling the hook race.......................................... 45

TROUBLESHOOTING ..........................................46-47

DESIGN CHARTS.................................................48-50

KEY OPERATIONS ...............................................15-21

Adjusting the brightness of LCD screen..................... 15

Function panel.......................................................15-16

Setting mode .............................................................. 17

Machine settings ...................................................17-20

HELP key ................................................................... 21

Setting the fabric in the embroidery hoop .................. 22

Attaching the embroidery hoop to the machine .........23

Selecting built-in designs ........................................... 24

Ready to sew screen..................................................24

Color list screen ......................................................... 24

Starting to sew embroidery ................................... 25-26

When the upper thread has broken or run out while

sewing.................................................................... 26

Lettering embroidery .............................................27-30

Selecting fonts ....................................................... 27

Entering characters................................................ 27

To enter lettering .................................................... 28

Ready to sew screen ............................................. 29

Color change .........................................................29

Placement of lettering embroidery ......................... 29

Maximum number of characters ............................ 29

To view a long lettering .......................................... 30

Deleting a letter...................................................... 30

Inserting a letter ..................................................... 30

Editing mode ........................................................31- 38

Selecting the hoop ................................................. 31

Selecting the pattern to edit ................................... 32

Magnifier key..........................................................33

Flipping the pattern ................................................ 33

Resizing the pattern............................................... 34

Rotating the pattern ............................................... 34

Combining patterns...........................................35-38

1

Page 4

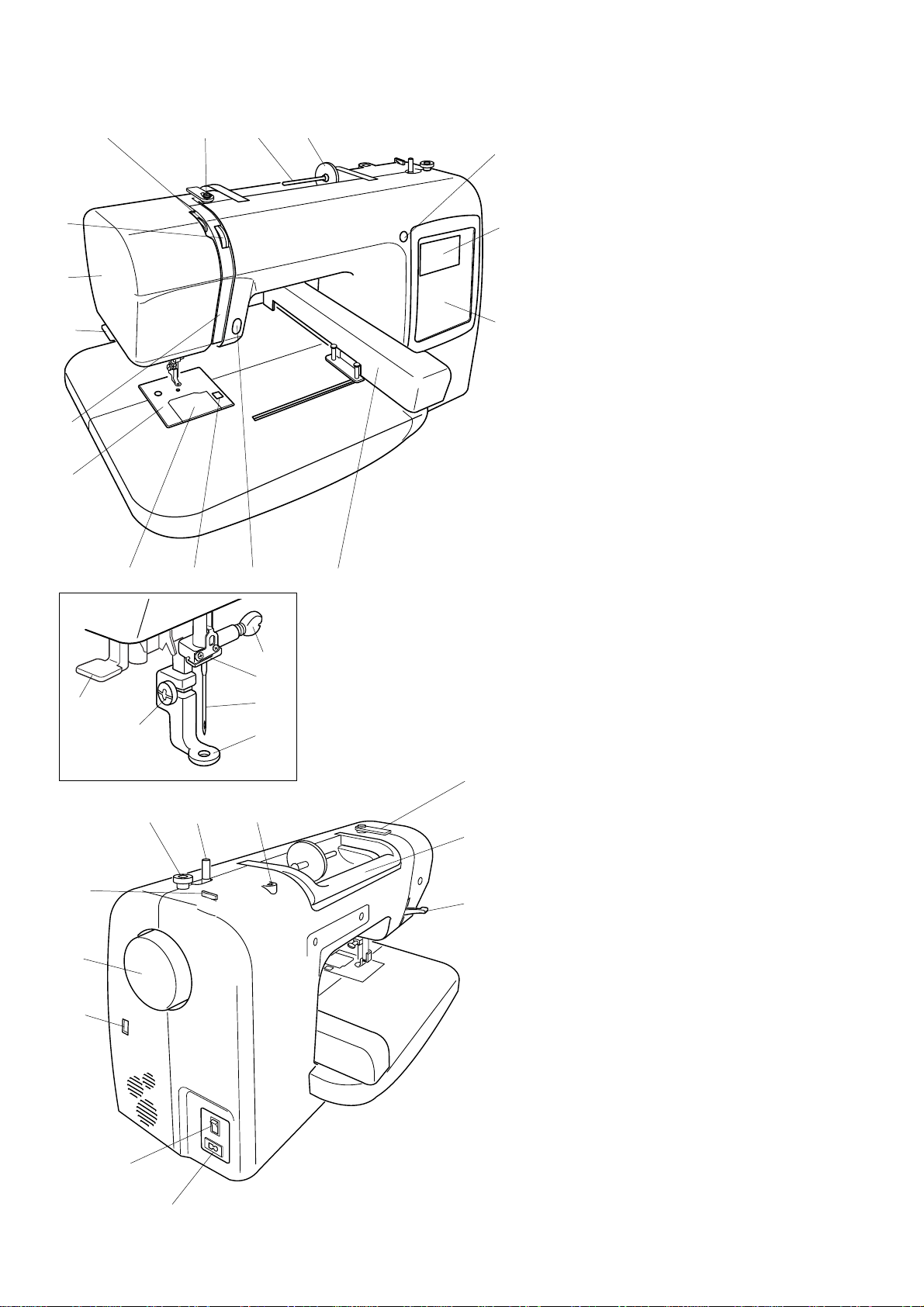

Name of parts

8

9

10

11

12

22

26

7

13 14 15

21

2425

23

17

18

19

20

456

3

2

1

16

33

32

31

1 Function panel

2 LCD screen

3 LCD brightness adjusting dial

4 Spool holder (large)

5 Spool pin

6 Bobbin thread guide

7 Thread take-up lever

8 Thread tension dial

9Face plate

10 Thread cutter & thread holder

11 Thread guide plate

12 Needle plate

13 Hook cover plate

14 Hook cover plate release button

15 Start/stop button

16 Carriage

17 Needle clamp screw

18 Needle bar thread guide

19 Needle

20 Presser foot

21 Setscrew

22 Needle threader

23 Hole for additional spool pin

24 Bobbin winder spindle

25 Bobbin winder stopper

26 Thread cutter

27 Handwheel

28 USB socket

29 Power switch

30 Machine socket

31 Presser foot lifter

32 Carrying handle

33 Thread guide cover

27

28

29

30

2

Page 5

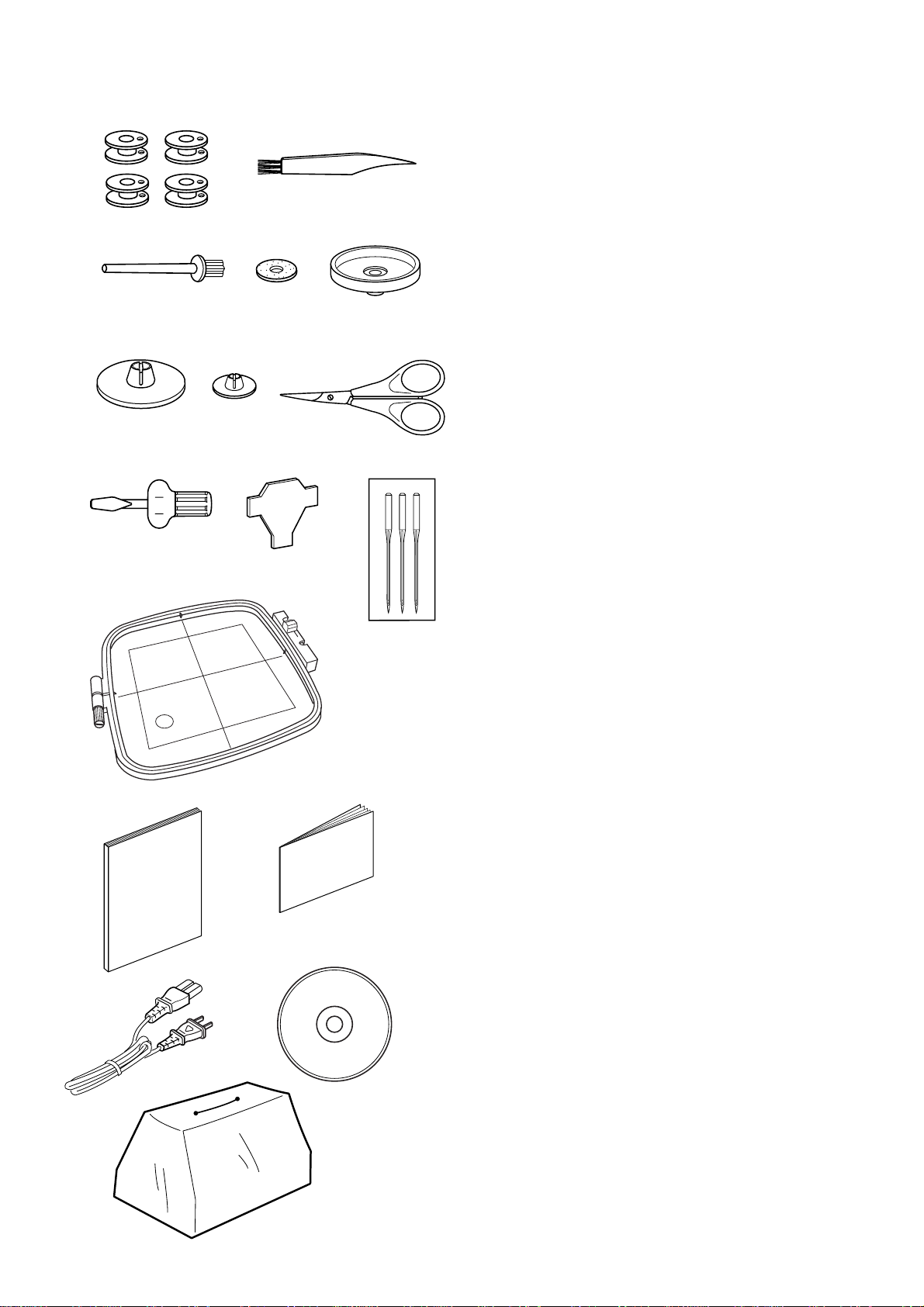

Standard Accessories

1

3

6

91011

78

2

4

5

10 Screwdriver

11 Set of needles

12 Embroidery hoop

13 Instruction book

14 Template sheets

15 Power supply cord

16 Instructional movie CD

17 Soft cover

1 Bobbin

2 Lint brush

3 Additional spool pin

4Felt

5 Spool stand

6 Spool holder (Large)

7 Spool holder (Small)

8 Scissors

9 Screwdriver

12

13

15

14

16

17

3

Page 6

q

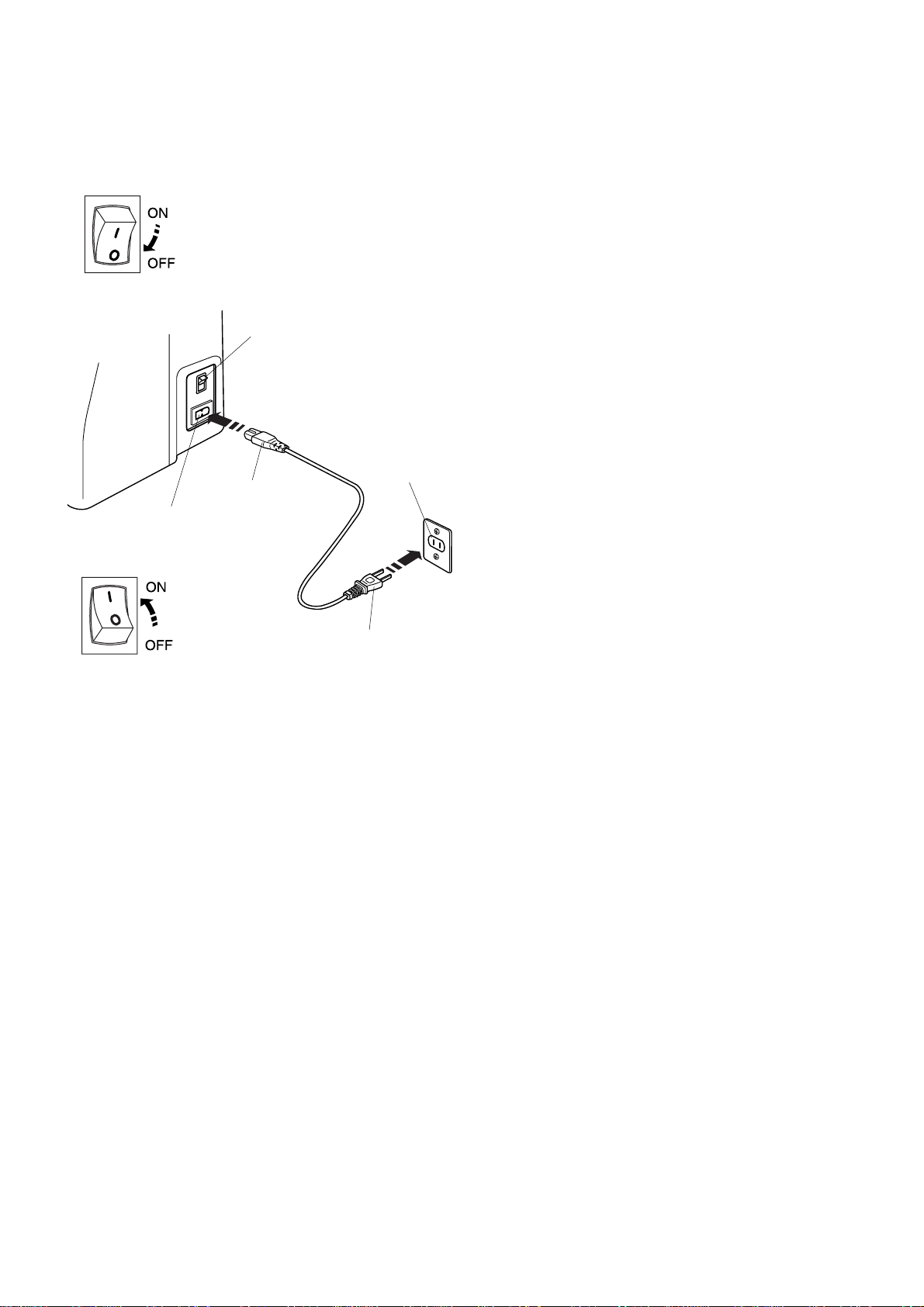

GETTING READY TO SEW

Connecting the power supply

Turn off the power switch and insert the machine plug

into the machine socket.

Insert the power supply plug into the wall outlet and turn

the power switch on.

q Power switch

w Machine plug

e Machine socket

r Power supply plug

t Wall outlet

NOTE:

After turning on the power, it takes approximately ten

seconds for boot-up.

e

w

r

t

For Y our Safety

While in operation, always keep your eyes on the sewing

area, and do not touch any moving parts such as the

thread take-up lever, handwheel or needle.

Always turn off the power switch and unplug the power

supply:

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Polarized plug (for U.S.A and Canada only)

The symbol “O” of a switch indicates the “off” position of

a switch.

For appliances with a polarized plug (one blade wider

than the other). To reduce the risk of electric shock, this

plug is intended to fit in a polarized outlet only one way. If

it does not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install the

proper outlet. Do not modify the plug in any way.

4

Page 7

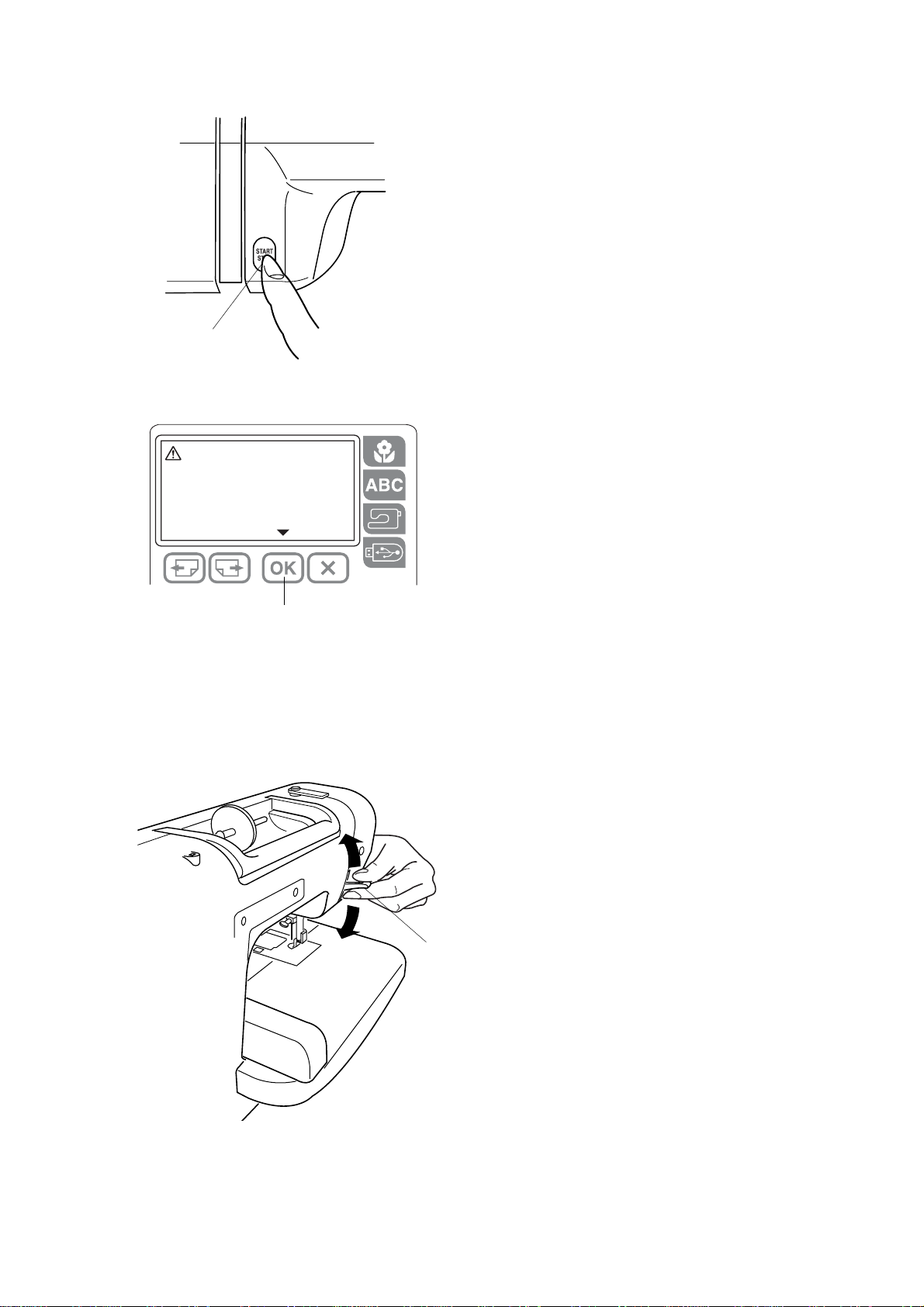

q

Lower the

Presser Foot.

Start/stop button

Press this button to start or to stop the machine.

q Start/stop button

NOTE:

If you press the start/stop button without lowering the

presser foot, a warning message appears on the LCD

screen.

Lower the presser foot and press the OK key to return to

the previous display.

w OK key

w

Presser foot lifter

q Presser foot lifter

The presser foot lifter raises and lowers the presser foot.

You can raise it higher than the normal up position for

easy removal of the presser foot or to set the embroidery

hoop.

q

5

Page 8

z

q

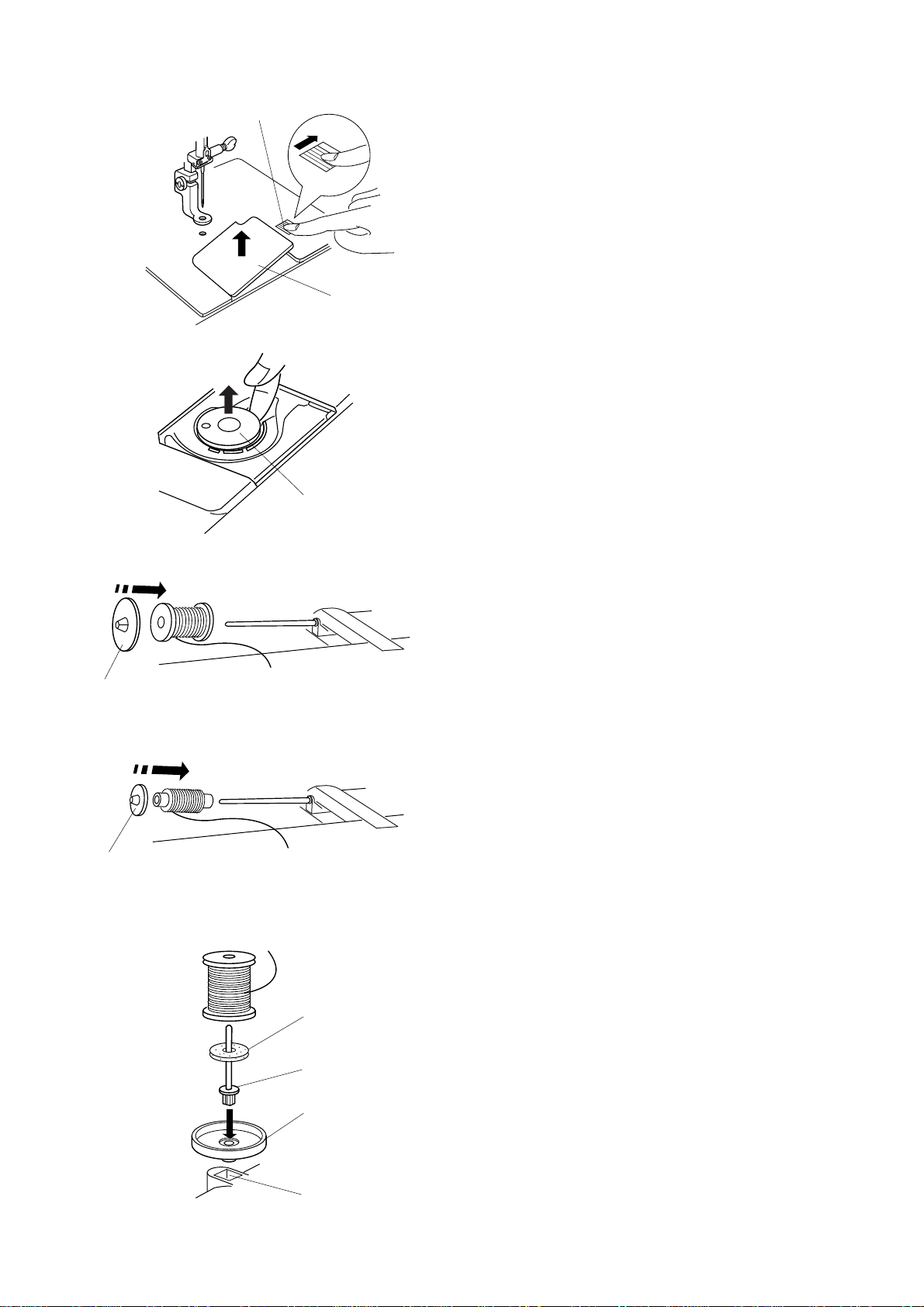

Winding the bobbin

Removing the bobbin

z Slide the hook cover plate release button to the right,

and remove the hook cov er plate.

w

x

z

x

x Lift out the bobbin from the bobbin holder.

q Hook cover plate release button

w Hook cover plate

e Bobbin

e

Setting the spool of thread

z Place the spool of thread on the spool pin with the

thread coming off the spool as shown. Attach the large

spool holder, and press it firmly against the spool of

thread.

q Large spool holder

q

x Use the small spool holder to hold narrow or small

spools of thread.

w Small spool holder

w

r

q

w

e

Additional spool pin

Use the additional spool pin when you need to wind the

bobbin without unthreading the machine while working

on an embroidery.

Insert the additional spool pin into the spool stand and

then into the hole beside the horizontal spool pin.

Place the felt on the spool pin and place a spool of

thread on it as shown.

q Additional spool pin

w Spool stand

e Hole

r Felt

6

Page 9

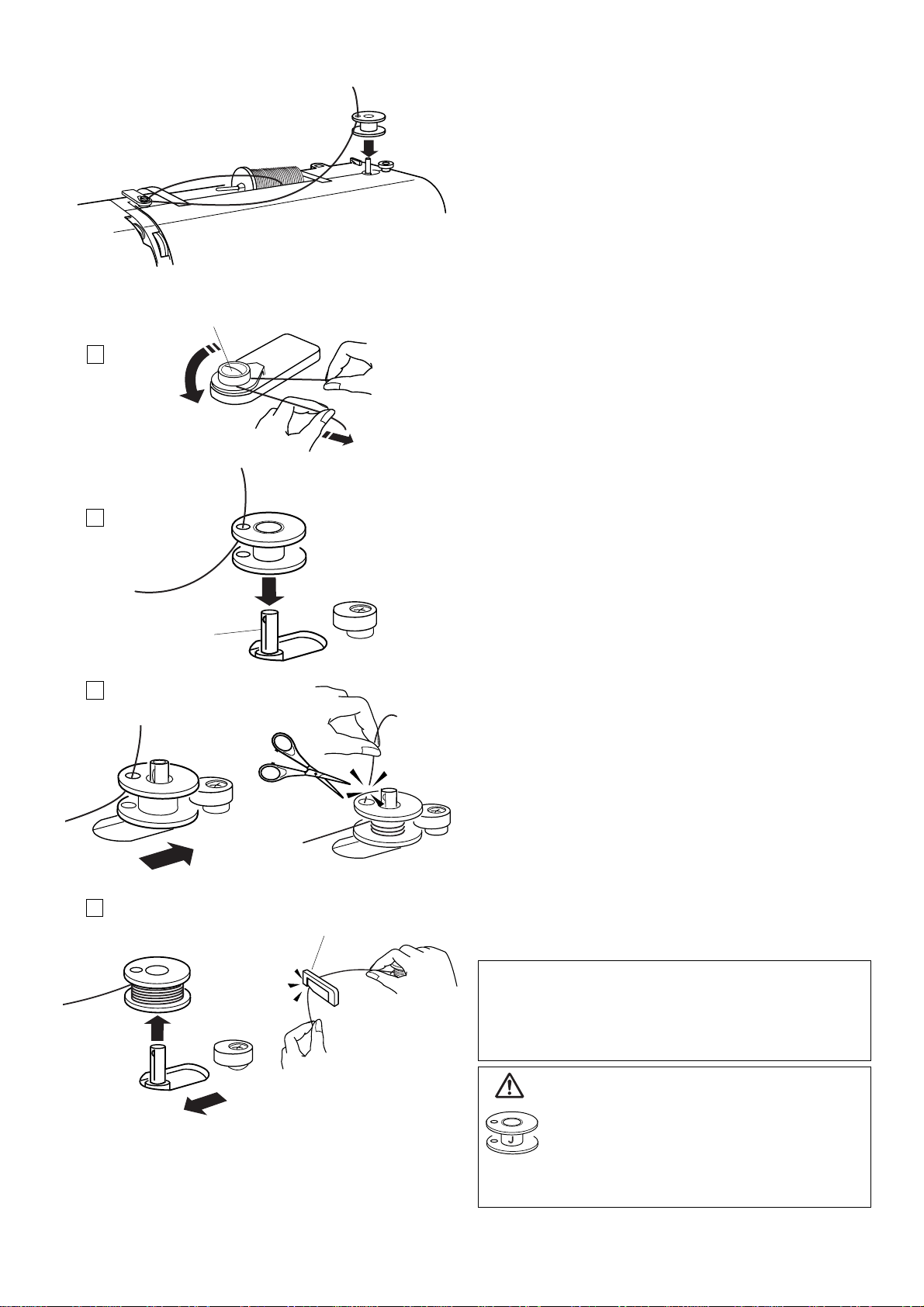

q

Winding the bobbin

1

2

w

3

z Guide the thread around the bobbin winder thread

guide while holding the thread with both hands.

q Bobbin winder thread guide

x Thread through the hole in the bobbin from the

inside to the outside. Put the bobbin on the bobbin

winder spindle.

w Bobbin winder spindle

c Push the spindle to the right. Press the start/stop

button while holding the end of the thread. Stop

the machine after the bobbin is wound a few layers.

Cut the thread close to the hole in the bobbin.

v Press the start/stop button again. When the bobbin is

fully wound it will stop automatically.

Press the start/stop button to stop the machine

then return the bobbin winder spindle to the left.

4

e

Remove the bobbin and cut the thread with the

bobbin thread cutter.

e Bobbin thread cutter

NOTE:

Do not move the bobbin winder spindle while the

machine is running.

For safety purposes, the motor will stop automatically

after running for two minutes.

CAUTION

Use the Janome plastic bobbin for horizontal

hook machines (marked with J). Using other

bobbins, such as prewound paper bobbins,

may cause stitching problems or damage the

bobbin case.

7

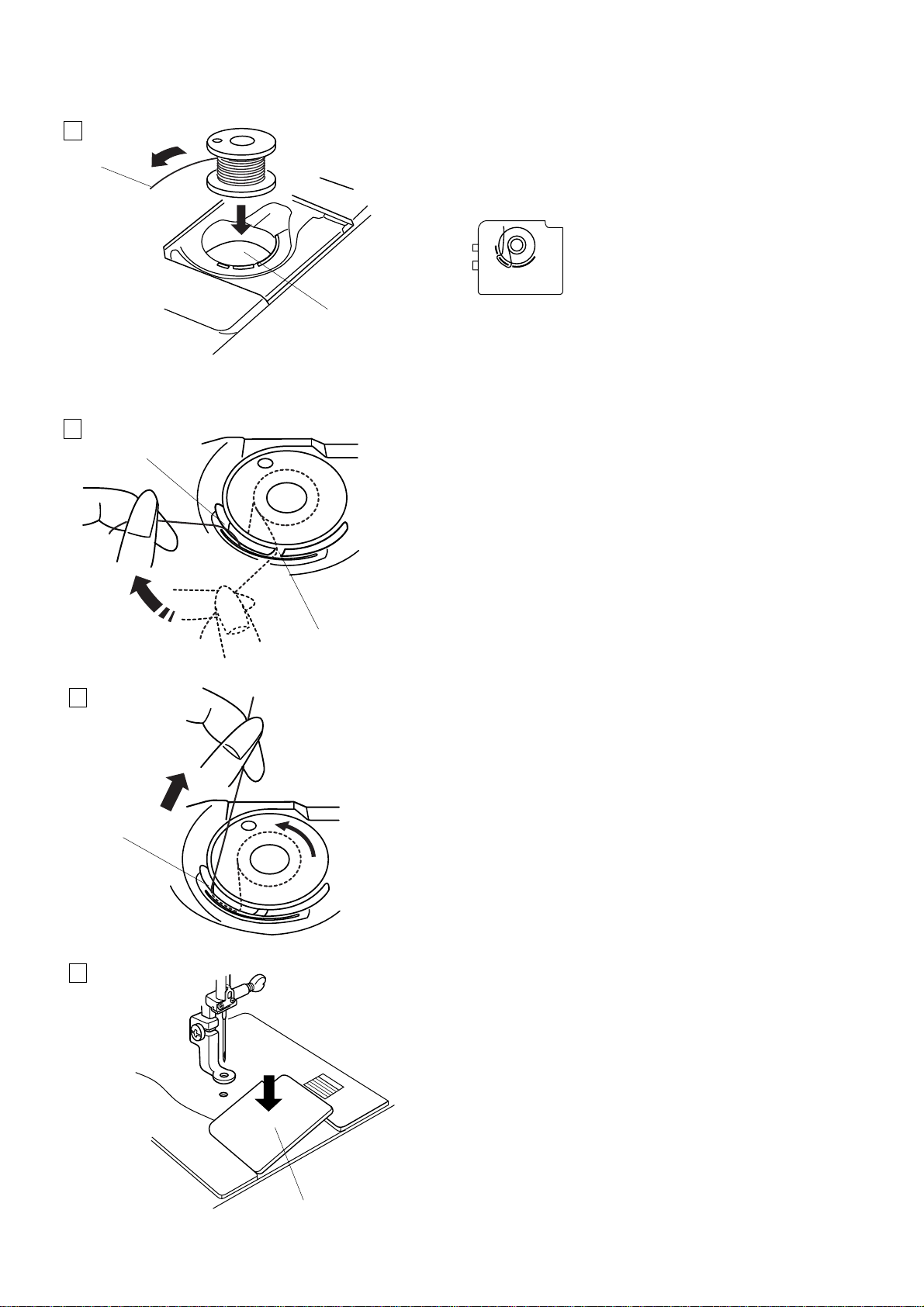

Page 10

Inserting the bobbin

1

q

z Place the bobbin in the bobbin holder with the

thread running off in a counterclockwise direction.

q Thread

w Bobbin holder

* Refer to the threading chart shown on

the hook cover plate.

w

2

r

x Guide the thread into the notch on the front of

the bobbin holder.

Draw the thread to the left, sliding it between the

tension spring blades.

e Front notch

e

3

c Continue to draw the thread lightly until the

thread slips into the side notch.

Pull out about 10 cm (4˝) of thread to the rear.

r Side notch

r

4

v Reattach the hook cover plate.

t Hook cover plate

t

8

Page 11

1

3

Threading the machine

4

5

1

2

q

2

z Raise the presser foot lifter. Turn the handwheel

to bring the needle to its highest position. Draw

the thread around and under the thread guide

while holding the thread at the spool. Then draw the

thread down through the right channel of the thread

tension dial.

q Thread guide

x Firmly draw the thread around the thread guide

plate and up to the thread take-up lever.

w Thread guide plate

w

3

4 5

e

t

r

c Slip the thread through the slit and down into the

eye of the take-up lever as shown. Draw the

thread down through the left channel.

e Slit

r Eye of the take-up lever

v Slip the thread behind the lower thread guide

from the right.

b Slip the thread in the needle bar thread guide

from the left.

t Needle bar thread guide

Thread the needle from front to back by hand or use the

built-in needle threader.

NOTE:

Refer to page 10 for built-in needle threader.

9

Page 12

Needle threader

1

q

2

w

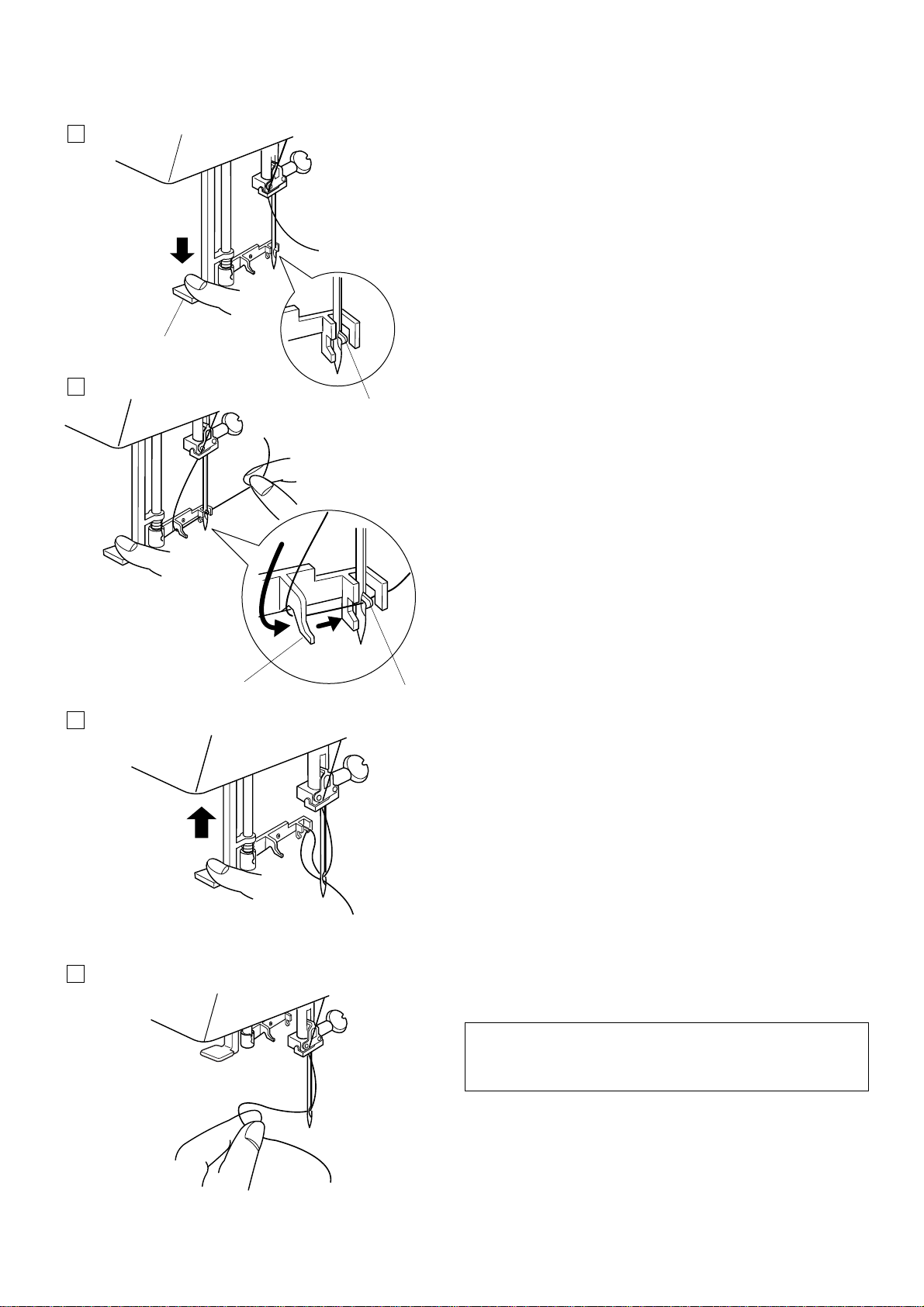

z Lower the presser foot. Depress the needle

threader knob as far as it will go. The hook comes

out through the needle eye from behind.

q Needle threader knob

w Hook

x Draw the thread down around the threader guide

and under the hook.

e Threader guide

e

3

4

w

c Release the threader knob slowly while holding

the thread end with your hand. A loop of the thread

is pulled up through the needle eye.

v Remove the loop from the threader and pull out the

thread end from the needle eye.

NOTE:

The needle threader works well with the threads #50-90

and needles #11-14, as well as the blue tip needles.

10

Page 13

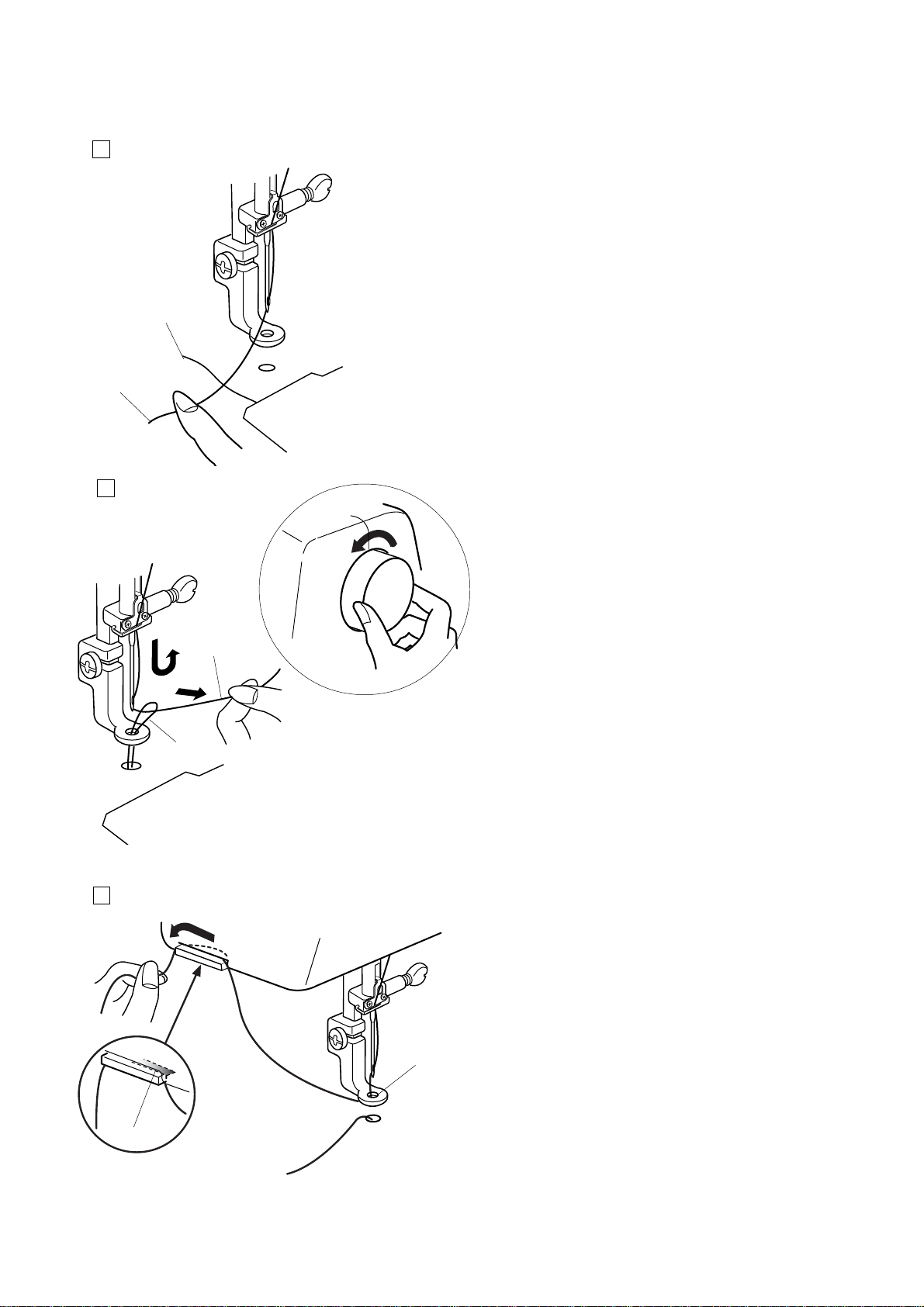

Drawing up the bobbin thread

1

z Raise the presser foot lifter. Hold the needle thread

with your finger.

q Needle thread

w Bobbin thread

w

q

2

x Turn the handwheel one complete turn towards you.

Draw the needle thread to bring up a loop of the

bobbin thread.

q

w

3

c Pass the needle thread through the hole in the

embroidery foot and draw it up to the thread holder

leaving an inch of free thread.

e Hole

r Thread holder

e

r

11

Page 14

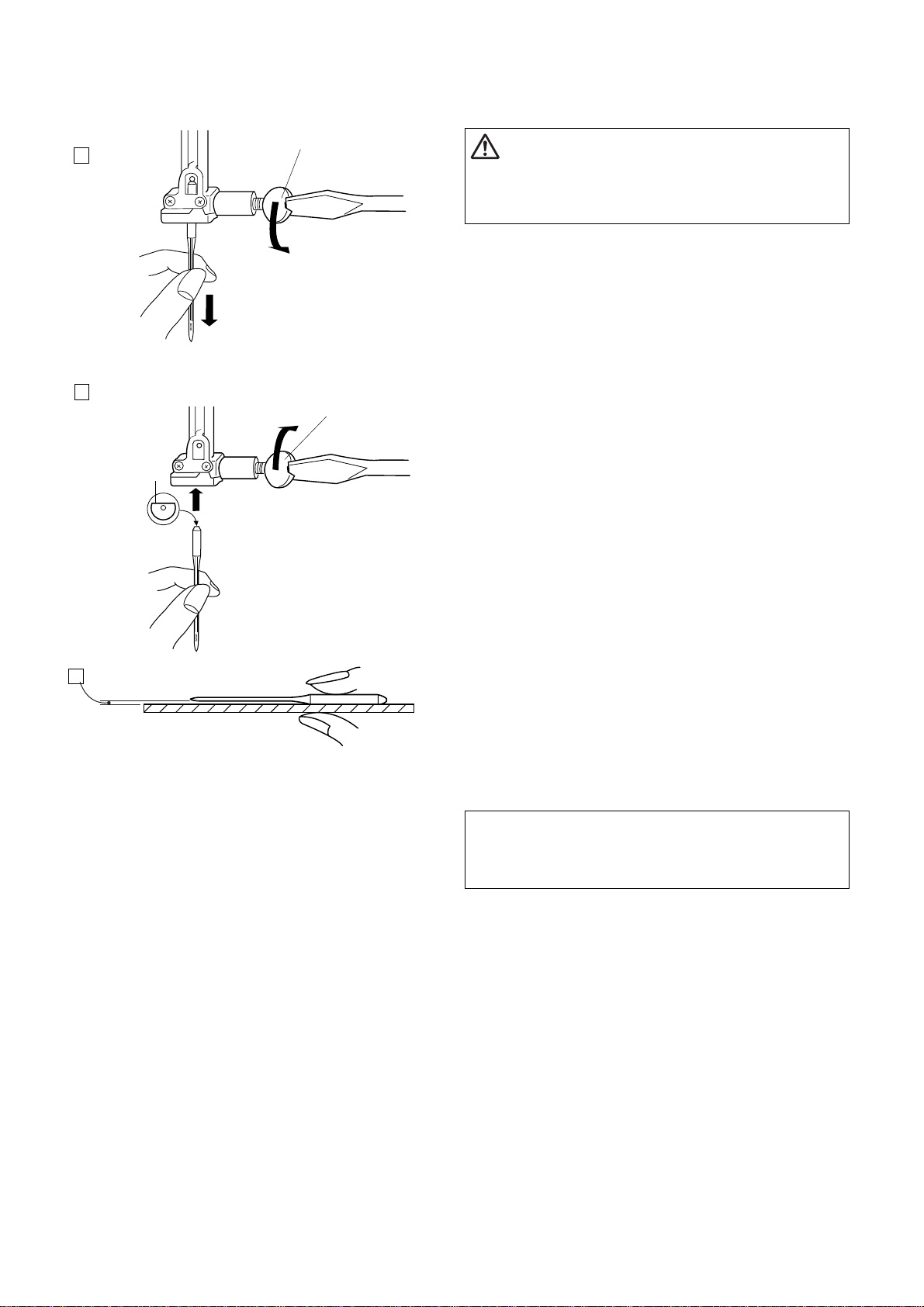

Changing the needle

1

2

q

q

w

CAUTION

Always make sure to turn the power switch off and

disconnect the machine from the power supply before

changing the needle.

z Turn off the power switch. Raise the needle by

turning the handwheel and lower the presser foot.

Loosen the needle clamp screw by turning it

counterclockwise.

Remove the needle from the clamp .

x Insert a new needle into the needle clamp with the flat

side of the needle to the rear.

q Needle clamp screw

w Flat side of the needle

When inserting the needle into the needle clamp, push it

up as far as it will go and tighten the needle clamp screw

firmly.

3

To check needle straightness, place the flat side of the

needle onto something flat (a needle plate, glass etc.)

The gap between the needle and the flat surface should

be consistent.

e Gap

Never use a blunt needle.

NOTE:

Use size 11 blue tipped needles for fine fabrics.

For medium to heavy weight fabrics, use size 14

needles.

12

Page 15

q

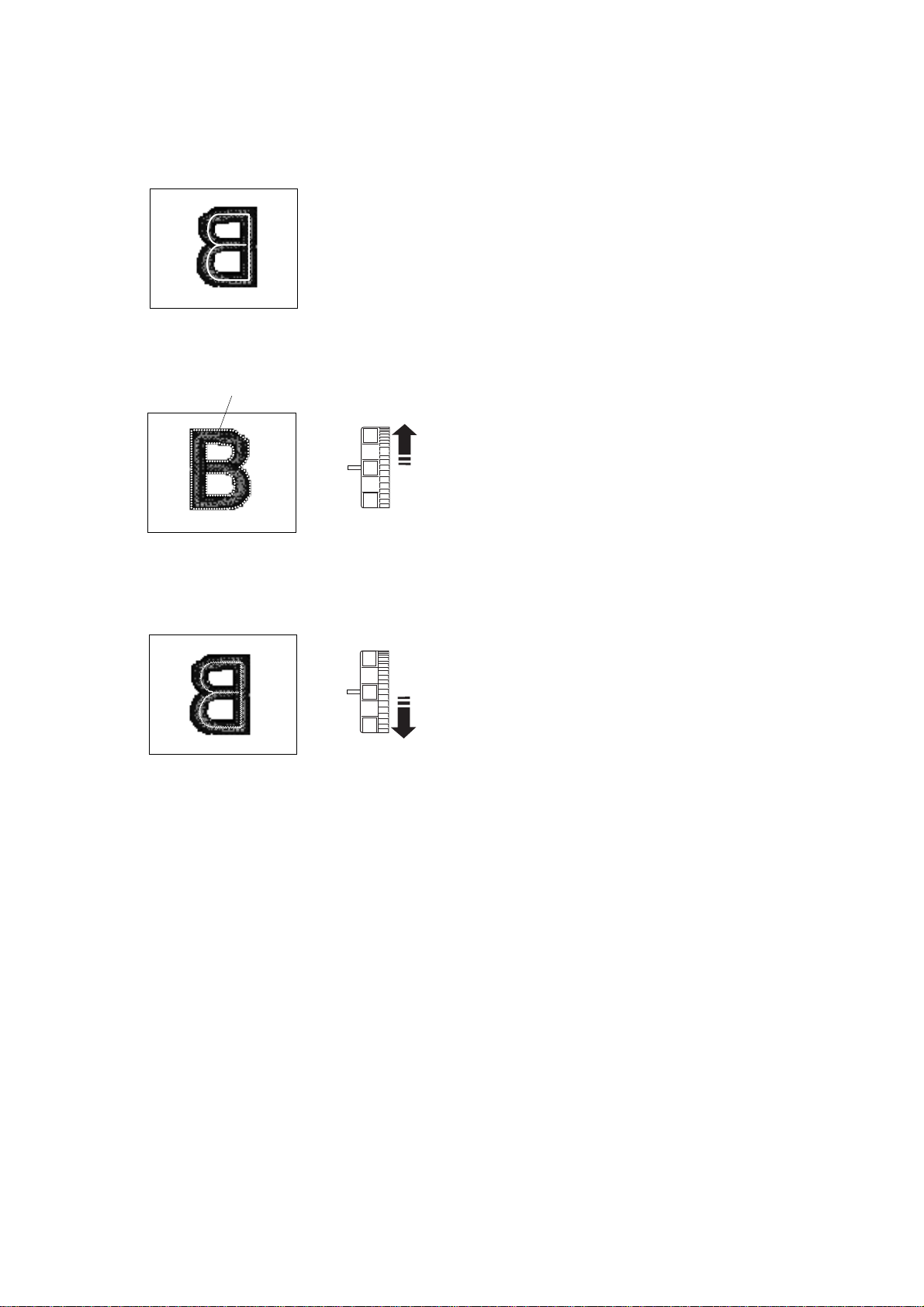

Adjusting the thread tension

Balanced thread tension

A small amount of needle thread shows on the wrong

side of the fabric.

5

4

3

5

4

3

When the needle thread tension is too tight

The bobbin thread shows on the right side of the fabric.

Reduce the tension by turning the tension dial to a lower

number.

q Bobbin thread

When the needle thread tension is too loose

The needle thread forms loops and the stitches look

shaggy.

Increase the tension by turning the dial to a higher

number.

13

Page 16

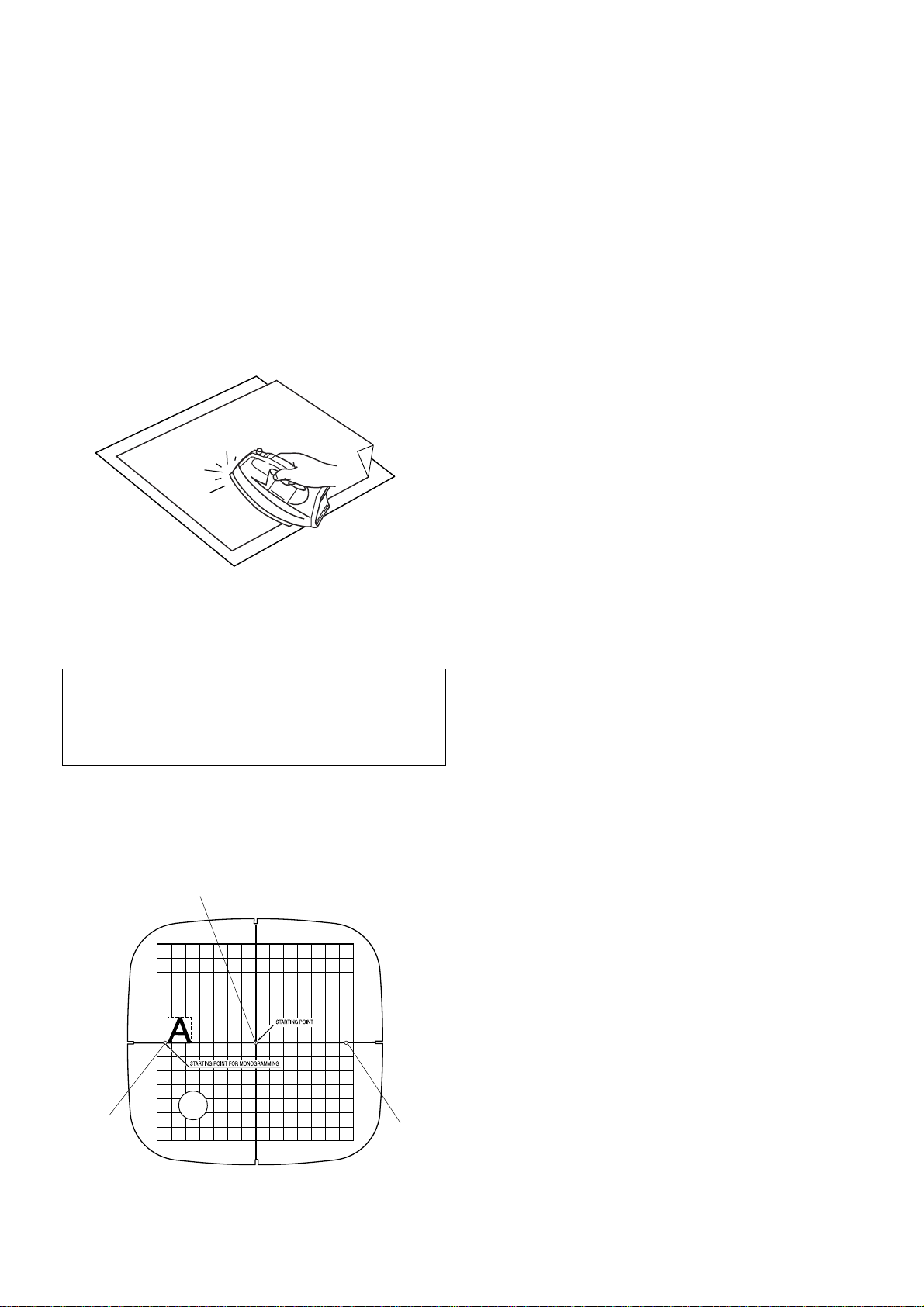

Adhesive (Iron-on) stabilizer

Place the wrong side of fabric and the glossy side of

the stabilizer together. Fold up a corner of the stabilizer and fuse it with an iron.

NOTES:

Fold up a corner of the stabilizer, to make it easier to

peel off the excess stabilizer after stitching.

Ironing temperatures vary depending on the type of

adhesive type stabilizer being used.

Stabilizers

To obtain the best quality embroidery, it is important to

use stabilizers.

Types of stabilizer

Tear-away Stabilizer is made from a fiber that will tear

easily. Use tear-away stabilizers for stable woven

fabrics. After stitching, tear away the stabilizer so that

the small portion left in the back of the stitching will not

affect the wear.

Iron-on Stabilizer is an adhesive type stabilizer for knits

and all kinds of unstable fabrics. Fuse it to the wrong

side of fabric with an iron.

Cut-away Stabilizer is a non-woven fabric that does not

tear. Cut the excess portion after stitching. Use cutaway

stabilizers for knits and all kinds of unstable fabrics.

Water Soluble Stabilizer will dissolve in water. Use this

stabilizer for cutwork or lace embroidery, and also for

the right side of looped fabrics such as toweling to avoid

loops coming through the embroidery.

Sticky Stabilizer is a sticky paper used for securing a

small fabric or work that cannot be secured in the hoop.

It is also used for velvet and other napped fabric that

would be permanently marked by the hoop.

Usage

The stabilizer should be attached to the wrong side of

fabric. More than one layer may be required.

Felt or stable fabrics do not need to be stabilized and you

may embroider directly on them.

For firm fabrics, you may place a thin paper under the

fabric.

The non-adhesive type should be used when

embroidering fabric, which cannot be ironed or for

sections, which are difficult to iron.

Cut the stabilizer larger than the embroidery hoop and

set it on the hoop so that the entire piece is fastened

within the hoop to prevent looseness of the fabric.

w

q

Template

When positioning the fabric into the hoop, use the

template to align the centerlines on the fabric with the

center of the hoop. First mark the centerlines on the

fabric and place the fabric on the outer hoop. Place the

inner hoop and template over the fabric and adjust the

fabric placement.

q Center point for embroidery and center justified

lettering embroidery

w Leftmost point for left justified lettering embroidery

e Rightmost point for right justified lettering embroidery

e

14

Page 17

KEY OPERATIONS

Adjusting the brightness of the LCD screen

q LCD brightness adjustment dial

w LCD screen

q

w

q

w

e

r

CAUTION:

Do not press the surface of the LCD Screen or function

panel with a hard or sharp object such as a pencil,

screwdriver or the like.

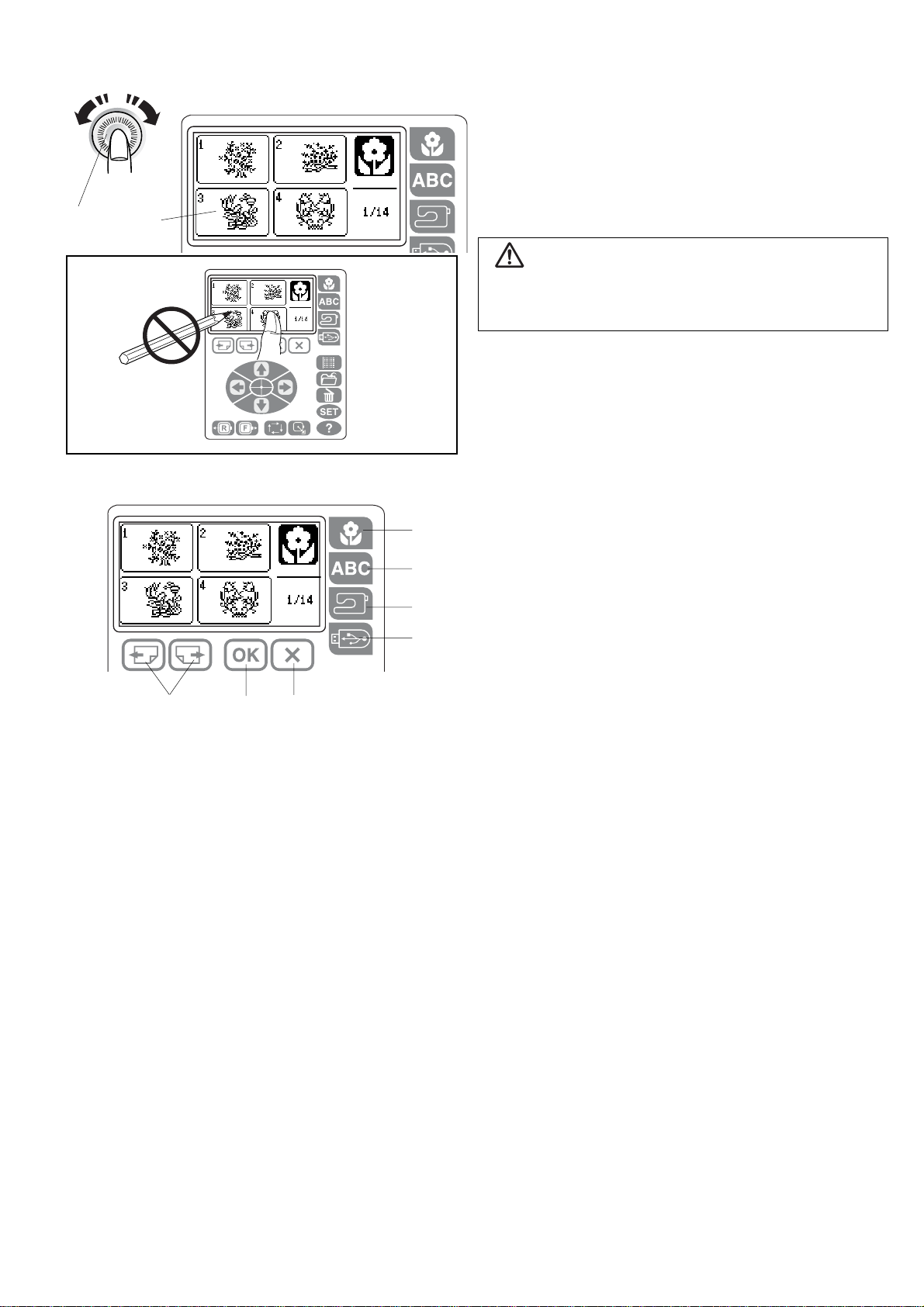

Function panel

q Built-in design key

Press this key to display the pattern selection window

for the built-in designs. The LCD screen displays up to

4 patterns. Press the page keys to show the next or

previous 4 patterns. Press the icon key to select the

desired pattern. The LCD screen shows the ready to

sew window.

t

áA

á@

áB

áC

áD

áE

y

u

w Lettering key

Press this key to select one of the 3 fonts for the

lettering embroidery or border designs. To enter the

characters, press the letter key until the desired

character appears on the LCD screen.

e Internal memory key

Press this key to open the pattern file stored in the

machine’s internal memory.

r USB memory key

Press this key to open the pattern file stored in the

USB memory.

t Page keys

Press the next page key to display the next page and

press the previous page key to go back to the

previous page.

y OK key

Press this key to confirm the setting and return to the

previous window.

u Exit key

Press this key to close the current window and return

to the previous display.

áF

15

Page 18

!3

!4

i

i Editing key

Press this key to open the editing window. You can

resize, rotate, flip and combine the pattern to create

your own original embroidery design.

áG

áH

áI

áJ

o

!0

!1

!2

!6!5!7!8

o File save key

Press this key to save the lettering or edited design as

a file.

!0 Delete key

Press this key to delete the selected pattern.

!1 SET key

Press this key to open the custom setting windows.

You can set the machine functions to your preference

(See page 17-20).

!2 Help key

Press this key to view the step by step illustrated

instructions of the following basic operations:

1. Changing needle

2. Inserting the bobbin

3. Threading the machine

4. Winding the bobbin

!3 Jog keys

Press one of the 4 keys to move the hoop in the

direction of the arrow on the key. In the editing mode,

press these keys to move the selected pattern in the

editing window.

áK

áL

áM

áN

áO

áL-1

!4 Centering key

Press this key to move the hoop to the center.

!5 Trace key

Press this key to trace the embroidery pattern without

stitching.

!6 Carriage return key

Press this key to return the carriage to the home

position.

!7 Stitch forward key

Press this key to move the hoop forward. The hoop

will move forward 10 stitches each time you press this

key.

!8 Stitch back key

Press this key to move the hoop backward. The hoop

will move backward 10 stitches each time you press

this key.

áP

16

Page 19

Setting mode

Machine settings

Pressing the SET key will open the custom setting

windows. You can set the following 8 functions to your

preference.

Maximum

speed setting

Maximum

speed setting

spm

650

650

spm

wq e

1

1

q Page keys

Press the next page key to display the next page and

press the previous page key to go back to the

previous key.

w OK key

Press the OK key to confirm the setting and return to

the previous window.

e Exit key

Press the Exit key to return to the previous window

without changing the setting.

1. Maximum speed

The maximum sewing speed can be set from 400 to 650

spm.

The default setting is 650 spm.

Press the – key to reduce the maximum sewing speed.

Press the + key to increase the maximum sewing speed.

NOTE:

Reduce the sewing speed when sewing small

embroidery patterns, as distortions tend to occur at high

speeds.

inch/mm

ON

inch

OFF

mm

2

2. Buzzer sound

The buzzer sound can be turned ON or OFF.

The default setting is ON.

Press the ON key to switch on the buzzer sound.

Press the OFF key to switch off the buzzer sound.

3

3. Inch/millimeter

You can set your machine’s measuring unit to either

inches or millimeters.

The default unit setting is millimeters.

Press the inch or mm key to select the preferred unit.

17

Page 20

q

Thread

selection

Janome Madeira

Mettler

Format

Robison-Anton

4

4. Thread selection

There are four brands of embroidery threads to choose

from. Press the corresponding key of the thread you wish

to use. The color code of the selected brand will be

shown on the embroidery screen.

5. Formatting the memory

5

If the internal memory or USB memory does not function

due to damage to the memory bank, you need to

re-enable it by formatting the memory.

w

To format the memory, select the memory location by

pressing the corresponding icon key and press OK key.

q Built-in memory

w USB memory

1

2

Format Memory?

Key Position

Adjustment

Press

YES

key

5

NOTE:

Formatting will erase all data stored in the memory.

6. Key position adjustment

6

If you think the touch panel keys are unaligned, you can

correct it in the key position adjustment window.

z Press the YES key.

x Follow the guidance that appears in the window.

6

Press the previous page key.

18

Page 21

3

6

c Press the OK key.

OK

key

v Press the USB file open key.

6

key

Press

4

Press

5

b Press the cross mark.

6

Press mark

6

n Press the trace key.

6

Press

7

Key Position

Adjustment

key

m Press the OK key to confirm the adjustments and exit

6

the setting mode.

END

19

Page 22

q

r

y

u

o

!1

English

Italiano

Deutsch

Suomi

Francais

Espanol

Nederlands

i

Svenska

Portugues

7. Language Selection

w

You can select one of the following 11 languages

7

e

t

8

by pressing the corresponding key.

q English

w French

e Spanish

r Italian

t Dutch

y German

u Japanese

i Swedish

o Russian

!0 Portuguese

!1 Finnish

Press the OK key to confirm your selection.

Reset

all to defaults

!0

8. Default setting

9

When you press the YES key, all settings except

language setting will return to default (the same settings

as when you purchased the machine).

YES

20

Page 23

1

HELP key

Press this key to view the help topics for basic operations.

z Press the help key.

q Help key

q

w

2

Changing

needles

Threading

the machine

3

Inserting

the bobbin

Winding

the bobbin

1/2

x Press the help topic you want to see.

w Help topics

c Press the page key to turn the page.

e Page key

v Press the exit key to return to the previous window.

4

2/2

r Exit key

21

Page 24

Setting the fabric in the embroidery hoop

1

q

w

e

2

t

r

3

u

y

z Attach a stabilizer to the wrong side of the fabric. Mark

the centerlines on the right side of the fabric with

tailor’s chalk.

q Fabric

w Centerlines

e Stabilizer

x Place the inner hoop with the template on the fabric,

matching the centerlines.

r Inner hoop

t Template

c Loosen the hoop tightening screw of the outer hoop.

y Outer hoop

u Hoop tightening screw

4

5 6

u

v Lay the fabric and the inner hoop on the outer hoop.

Push the inner hoop into the outer hoop.

b Tighten the hoop tightening screw.

Pull fabric corners to remove wrinkles.

n Tighten the hoop tightening screw securely.

t

7

m Remove the template.

22

Page 25

1 2

w

w

Attaching the embroidery hoop to the machine

e

To attach

z Raise the presser foot.

x Place the prepared hoop on the machine.

Position the hoop by aligning the notches of the hoop

with the carriage pins.

q Notch

w Carriage pin

e Carriage

w

q

3

5 6

r

r

w

4

c Shift the lever in the direction of the arrow.

r

t

Attach the hoop by pushing it against the carriage

pins.

r Lever

v Release the lever to lock the hoop in place.

To remove

b Raise the presser foot.

n Shift the lever in the direction of the arrow and remove

the hoop.

r Lever

e

CAUTION:

• Be careful not to place the excess of fabric between

the carriage and machine body t.

•Never try to move the carriage by hand or touch the

carriage while it is moving.

23

Page 26

w

2

Selecting built-in designs

z Your Memory Craft provides you with 14 pages of 55

1

q

e

ready-to-sew built-in designs. Press the pattern

selection key to select the pattern you wish to sew.

To view the ne xt page, press the next page key.

q Built-in design key

w Pattern selection key

e Page keys

To select the embroidery design, press the desired

pattern selection key.

w Pattern selection keys

x The carriage goes to the starting position and the

ready to sew screen will be shown.

Ready to sew screen

z The LCD screen shows the following information.

q Image of the selected design

w Sewing time in minutes

e Number of colors

r Spool icon key

z

w

e

r

t Design size

y Hoop

q

u

x

i

!0

o

19 min

4 Colors

90x99mm

140x140

!1

!2

Press the spool icon key to display a list of thread

colors employed in the selected design.

ty

Color list screen

x Press the OK key or exit key to return to the original

window.

If the design contains more than 4 colors simply

press the next pgae key display the rest.

u Sewing order of the thread color

i Color code of the thread

o Name of the color

!0 Page keys

!1 OK key

!2 Exit key

!3 Jog key

!3

!3

24

Page 27

Starting to sew embroidery

1

19 min

4 Colors

90x99mm

140x140

pattern.

2

x Adjust the hoop position with the jog keys q so that

the needle drop position comes right above the

center of the centerlines w on the fabric.

q Jog keys

w Centerlines

z Press the pattern selection key to select the desired

w

q

e

3

c Press the tracing key to trace the outline of the

selected design so that you can check the sewing

position without stitching.

e Tracing

25

Page 28

4 5 6

7

v Lower the presser foot. Press the Start/Stop button

and sew 5 to 6 stitches.

b Press the start/stop button again to stop the

machine. Raise the presser foot. Trim the thread.

n Lower the presser foot and press the start/stop

button. The machine will sew the first color section

and stop automatically when it has finished.

m Change the thread and sew the next section.

w

r

q

When the upper thread has broken or run out

while sewing

z Raise the presser foot and rethread the needle

thread.

* If the carriage position makes threading difficult,

you can move the hoop for easier threading by

pressing the home position key q.

After rethreading the needle thread, press the home

position key q again to return the carriage to the

previous position.

q Home position key

x Press the stitch back key w or stitch forward key r

to move the embroidery hoop to where the thread

has broken or run out e

Press the stitch back key once w to move the hoop

back by 10 stitches.

w Stitch back key

e Broken point

r Stitch forward key

e

c Lower the presser foot, and press the start/stop

button and sew 5 to 6 stitches. Stop the machine and

trim the thread.

v Press the start/stop button and start the machine

again.

26

Page 29

Lettering embroidery

1

Selecting fonts

q

2

r

w

A

e

t

AB

CDE

PQ

RST

C

y

You can select one of 3 styles of font and border

patterns.

Press the lettering key q. The font selection window will

open w.

q Lettering key

w Font selection window

Press one of the following keys to select the desired

font or border pattern.

e Gothic font

r Script font

t Cheltenham font

y Border pattern

z

w

e

AB

CDE

PQ

RST

AB

CDE

PQ

RST

FG

HIJ

UV Z.

WXY

q

FG

HIJ

UV Z .

WXY

w

KL

MNO

KL

MNO

1/7

1/7

SIZE

M

SIZE

Entering characters

A

C

A

C

M

Select the desired font, and the window for upper case

letters will open.

Press the next page key to display lower case letters,

numbers and European accented letters.

The size of characters can be changed by pressing the

letter size key r.

To enter the character, press the letter or number key

until the desired character appears.

q Uppercase letter keys

w Cursor keys

e Cursor

r Letter size key

t Clear key

q

r

t

27

Page 30

q

1

1/7

SIZE

A

C

M

G

CDE

RST

AB

PQ

FG

HIJ

UV Z.

WXY

KL

MNO

To enter lettering (For example: “Green”)

z Press the q key twice to select “G”.

x Press the page key w to select lower case letters.

2 3

e

4

r

5

G

G

G

r

ab

cde

pq

rst

r

ab

cde

pq

rst

r

ab

cde

pq

rst

e

e

fg

hij

uv z.

wxy

fg

hij

uv z.

wxy

y

fg

hij

uv z.

wxy

kl

mno

kl

mno

kl

mno

w

c Press the e key 3 times to select “r”.

2/7

A

SIZE

C

M

v Press the r key 5 times to select “e”.

b Press the cursor key t to shift the cursor y.

2/7

A

SIZE

C

M

t

2/7

A

SIZE

C

M

n Press the r key 5 times to select “e”.

6

r

7 8

9

e

G

r

ab

cde

pq

rst

ee

G

r

ab

cde

pq

rst

een

G

r

4min

1Color

67x19mm

e

fg

hij

uv z.

wxy

n

fg

hij

uv z.

wxy

i

kl

mno

kl

mno

140x140

2/7

SIZE

M

u

2/7

SIZE

M

change

A

C

A

C

color

ABC

m Press the u key 4 times to select “n”.

, Press the OK key i.

* Press the file save key to save the letter

combination.

. The display will change to the ready to sew screen.

A

28

Page 31

c

q

u

Ready to sew screen

v

q

w

e

r

een

G

r

4min

1Color

67x19mm

een

G

r

4min

1Color

67x19mm

een

G

r

4min

1Color

67x19mm

140x140

t

140x140

140x140

color

change

ABC

y

A

color

change

ABC

A

color

change

ABC

A

w Sewing time in minutes

e Number of colors

r Lettering size

t Hoop size

y Justification key

u Color change key

Color change

You can sew a multi-colored lettering embroidery by

changing the thread color of each letter if you press the

color change key before sewing.

The machine will stop automatically when each letter has

been sewn.

Change the thread to the next color and start sewing

again.

Placement of lettering embroidery

You can select one of the 3 placements for lettering

embroidery: left justify, center justify and right justify.

Press the justification key to change the placement for

lettering embroidery.

q Lettering embroidery design

b

w

e

een

G

r

4min

1Color

67x19mm

q

CDEFG

AB

FG

CDE

HIJ

PQ

UV Z.

RST

WXY

140x140

KL

MNO

change

1/7

SIZE

M

color

ABC

A

C

q Left justify

w Center justify

e Right justify

A

Maximum number of characters

The maximum number of characters varies depending on

the font and size. If you enter more characters than the

maximum number, the last entered character will be

highlighted.

Press the clear key to delete the highlighted character.

q Highlighted character

w Clear key

w

29

Page 32

r

w

e

w

ABCDEFGHI

6min

1Color

94x11mm

CDEFGHIJK

6min

1Color

94x11mm

ABC

AB

CDE

PQ

RST

ABC

AB

CDE

PQ

RST

140x140

FG

HIJ

UV Z.

WXY

FG

HIJ

UV Z.

WXY

140x140

KL

MNO

KL

MNO

A

color

change

ABC

color

change

ABC

1/7

SIZE

M

1/7

SIZE

M

To view a long lettering

If the lettering is too long to display on the ready to sew

screen, press the page key to show the hidden

characters.

Example: Letters from A to K in S size.

The character shows letters from A to I. Press the next

A

page key and letters C to K will be shown.

Deleting a letter

A

Pressing the clear key q will delete the letter e above

the cursor w or the letter r in front of the cursor w.

C

q

q Clear key

w Cursor key

e Letter above the cursor key

r Letter in front of the cursor key

A

C

1

2

1

2

y

ABC

AB

CDE

HIJ

PQ

RST

UV Z.

WXY

AC

AB

CDE

PQ

RST

FG

HIJ

UV Z .

WXY

ABC

AB

CDE

RST

HIJ

PQ

WXY

ADBC

AB

CDE

HIJ

PQ

RST

WXY

FG

MNO

MNO

FG

UV Z.

FG

MNO

UV Z.

KL

KL

KL

MNO

KL

1/7

1/7

1/7

SIZE

M

SIZE

M

1/7

SIZE

SIZE

z Press the cursor key to shift the cursor under the

A

letter to delete.

t Cursor keys

t

C

x Press the clear key to delete the letter.

A

C

q

q Clear key

Inserting a letter

A

You can insert the desired letter in front of the cursor.

t

C

M

z Press the cursor key t to shift the cursor under the

letter “B”.

A

x Press the key 4 times to insert the letter “D” y.

C

M

30

Page 33

w

Editing mode

The editing function allows you to modify and combine

embroidery patterns from the built-in memory or USB

memory to create your own original designs.

q

Press the edit key q and the editing window w for the

standard hoop will open.

q Edit key

w Editing window

The “+” mark indicates the center of the embroidery

hoop.

e Center mark

e

140x140

q

Selecting the hoop

When you use the optional hoop, press the hoop icon q

140x140

to open the hoop selection window.

Select the desired hoop and press the OK key w.

140x140 50x50

w

31

Page 34

1

q

Selecting the pattern to edit

Example: Select the embroidery #51.

z Press the built-in design key.

q Built-in design key

140x140

2

w

u

r

y

140x140

100%

x Select the pattern #51.

w Pattern #51

The editing window shows the relative size and

placement of the pattern with a square block y

instead of the pattern image.

* To move the pattern, press the jog key.

e Jog key

* Press the center key to place the embroidery in the

center of the hoop.

r Center key

i

u

y

140x140

e

100%

t

*To delete the pattern, press the delete key.

t Delete key

If there are 2 or more patterns in the editing window,

press the next or previous page key to select the

pattern to edit.

The selected pattern is displayed with a solid line.

The patterns not selected are displayed with a dotted

line.

y Selected pattern

u Page keys

i Patterns not selected

32

Page 35

Magnifier key

1

100%

z Press the magnifier key to view the design image of

the selected pattern.

q Magnifier key

140x140

q

2

e

r

w

t

x The center of the magnified image will be displayed.

w Center part of the magnified image

3

c Press the jog key (up) to scroll up the image.

e Jog key (up)

4

v Press the jog key (down) to scroll down the image.

r Jog key (down)

Press the exit key to return to the editing window.

t Exit key

1

2 3

w

140x140

100%

r

e

t

q

Flipping the pattern

You can flip the embroidery pattern horizontally.

z Press the flip key. The flip window will open.

q Flip key

x Press the flip to the right key e.

w Flip to the left key

e Flip to the right key

r OK key

t Exit key

c Press the OK key r to flip the selected pattern.

Press the exit key t to exit the flip window without

any change.

33

Page 36

q

1

Resizing the pattern

2 3

w

100

140x140

e

100%

You can change the size of the embroidery pattern from

90% to 120% of the original pattern size. The size will

change 10% each time you press – or + key.

z Press resize key q.

q Resize key

x The resize window will open.

Press - or + key w.

c Press the OK key e to resize the selected pattern.

Press the exit key r to exit the resizing window

without any change.

1

2 3

w

q

140x140

0

err

100%

Rotating the pattern

You can rotate the selected embroidery pattern either

clockwise or counterclockwise.

z Press the rotate key q.

q Rotate key

x The the rotate window will open.

Press – or + key w to rotate the selected embroidery

pattern. The pattern will rotate 45 degrees clockwise

or counterclockwise when pressing one of the keys.

c Press the OK key e to rotate the selected pattern.

Press the exit key r to exit the rotate window without

any change.

34

Page 37

1

Combining patterns

(For example: pattern #51 and lettering)

z Press the edit key q.

q

2

140x140

w

3

x Press the built-in design key w.

c Select the pattern #51 e.

e

4

v Press the jog key r to move the embroidery pattern

to the right.

100%

140x140

r

35

Page 38

5

100%

140x140

w

b Press the built-in design key w.

6

7

8 9

e

140x140

100%

y

n Select the pattern #51 e.

m Press the flip key t.

t

, Press the flip to the right key y to flip the embroidery

pattern.

. Press the OK key u.

10

u

⁄0 Press the jog keys i to move the embroidery pattern

to the left.

100%

140x140

i

36

Page 39

⁄1

⁄1 Press the magnifier key o and view the placement of

the embroidery patterns.

100%

140x140

⁄2

⁄3

⁄4

!2

o

140x140

⁄2 Press the exit key !0 to return to the editing window.

!0 Exit key

!0

⁄3 Press the lettering key !1.

!1 Lettering key

100%

!1

⁄4 Press the Gothic font key !2.

A

AB

CDE

PQ

RST

C

⁄5 ⁄6 ⁄5 Enter the letters (For example: LEAF).

LEAF

AB

PQ

FG

HIJ

UV Z.

WXY

CDE

RST

u

KL

MNO

1/7

SIZE

M

A

C

⁄60 Press the OK key u.

37

Page 40

17

⁄7 Press the jog keys !3 to move the letters down.

!3 Jog keys

100%

140x140

!3

18

19

20

⁄8 Confirm the layout of the embroidery by pressing the

magnifier key o.

o Magnifier key

100%

140x140

o

⁄9 Press the exit key !0 to return to the editing window.

!0 Exit key.

!0

¤0 Press the OK key u.

u OK key

21

140x140

u

6 min

2 Colors

112x25mm

140x140

100%

¤1 Start sewing.

38

Page 41

Saving the file

1

100%

An original embroidery design created in the editing

mode can be saved as a file in the built-in memory or

USB memory.

140x140

q

2

M_001

z Press the file-save key q.

x The save file window will open.

Press the internal memory key w.

Press the OK key to save the file e.

The file name will automatically be assigned starting

from M_001…in order.

Saving in internal memory

1

2 3

w

M_001

AB

CDE

PQ

RST

e

w

FG

HIJ

UV Z _

WXY

KL

MNO

1/2

Name of file

You can assign a desired name to your own file.

(8 characters can be entered for the file name.)

q

C

For example, assign “U_2” for the file name.

z Press the name key q.

x The window for entering the name will open.

Press the letter keys w and enter “U_”.

c Press the next page key e.

e

39

Page 42

v Enter “2”.

4 5

6

0 1

2 3 4

U_2

b Press the OK key r.

2/2

5 6

789

C

r

n Press the OK key r to save the file under the new

name.

The same file

name exists,

overwrite it?

r

When you attempt to save a file when the name already

exists, the confirmation message will appear.

Press OK key r to overwrite the existing file.

Press the exit key t if you do not wish to overwrite it.

rt

40

Page 43

v Enter “2”.

4 5

6

0 1

2 3 4

U_2

b Press the OK key r.

2/2

5 6

789

C

r

n Press the OK key r to save the file under the new

name.

The same file

name exists,

overwrite it?

r

When you attempt to save a file when the name already

exists, the confirmation message will appear.

Press the OK key r to overwrite the existing file.

Press the exit key t if you do not wish to overwrite it.

rt

40

Page 44

Saving in USB memory (Optionl)

1

q

w

2

100%

USB memory can be used to save the stitch data.

z Insert the USB memory q into the USB socket w.

q USB memory

w USB socket

x Press the file save key.

The file-save screen will open.

e File-save key

140x140

CAUTION:

Do not turn the power off, or remove the USB memory

e

M_001

3

EMBF

1/1

r

4

EMBF

1/1

while a warning message has been displayed on the

screen.

Otherwise the saved data will be lost or the memory

will be damaged.

c Press the USB memory key.

The folder list will be displayed on the screen.

r USB memory key

NOTE:

The EMBF folder will automatically be created when

inserting the USB memory for the first time.

v Press the folder icon to open.

t Folder icon

t

5

M_001

EMBF

b Press the OK key to save the file. The file name will

be automatically assigned from M_001.

y OK key

y

6

100%

140x140

n The screen returns to the previous display.

41

Page 45

Creating a new folder

You can create your own folder and assign the desired

1

EMBF

1/1

q

name to it.

z Press the folder key q.

q Folder key

x Enter the folder name.

(Only 8 characters can be entered).

3

2

1/2

AB

CDE

PQ

RST

FG

HIJ

UV Z _

WXY

KL

MNO

C

For example, enter “ABC” for the folder name.

c Press the OK key w.

w OK key

w

4

ABC

e

5

EMBF

M_001

r

1/1

ABC

v Press the ABC folder to open.

e ABC folder

b Press the OK key w to save the file in a new folder.

w OK key

t

w

6

100%

140x140

n The screen returns to the previous screen.

42

Page 46

1

Opening a file from the internal memory

To open the saved files, press the internal memory key

and the open file window will open.

z Press the internal memory key q.

q

2

w

x File list will be displayed.

Press the icon key to open the file you wish to sew.

3

6 min

2 Colors

112x25mm

140x140

1

c The screen will display the ready to sew window of

the saved design. Lower the presser foot and start

sewing.

Deleting a file

You can delete the file no longer needed.

z Press the internal memory key q.

q

q Internal memory key

3

2

x File list will be displayed.

Press the delete key w.

e

w Delete key

c Select the file e you wish to delete.

w

Are you sure

you want to

delete this file?

r

v The confirmation window will appear. Press the OK

key r to delete the selected file.

Press the exit key t instead of the OK key to return

to the previous screen without deleting the file.

r OK key

t

t Exit key

43

Page 47

Opening a file from USB memory (Optional)

1

z Insert the USB memory q into the USB socket w.

q USB memory

w USB socket

q

w

2

x Press the USB memory key.

The file-open window will open.

e USB memory key

e

3

r

c Press the desired folder r to open.

r Folder icon

t

4

v The file list will be displayed.

Press the icon key t to open the file.

t Icon

5

6 min

2 Colors

112x25mm

140x140

b The ready to sew screen will be displayed.

44

Page 48

1

e

t

CARE AND MAINTENANCE

Cleaning the hook race

q

WARNING:

Turn the power switch off and unplug the machine

before cleaning.

w

2

r

y

3

u

y

4

u

i

NOTE:

Do not dismantle the machine in any way other than

what is explained in this section.

Clean the outside of the machine with a soft cloth and

mild soap.

z Remove the setscrews with the screwdriver

supplied with the machine. Remove the needle

plate and presser foot.

q Setscrew

w Presser foot

e Screwdriver

r Setscrew

t Needle plate

x Lift up the bobbin holder y and remove it.

y Bobbin holder

c Clean the bobbin holder with the lint brush u.

u Lint brush

e

r

5

v Clean the hook race with the lint brush.

i Hook race

b Clean the hook race with a dry cloth.

(You may also use a vacuum cleaner.)

i

1

e

w

Assembing the hook race

z Insert the bobbin holder so that the knob fits next to

the stopper in the hook race.

q Knob

w Stopper

q

r

3

t

y

x Reattach the presser foot and needle plate.

Align the needle plate guide pins with the guide

holes on the needle plate and tighten the screw.

e Needle plate guide pins

NOTE:

u

After cleaning the machine, make sure the needle and

presser foot are attached.

45

Page 49

TROUBLESHOOTING

Problem: Cause: Reference:

The machine is noisy 1 Threads have been caught in the hook mechanism. See page 45.

The needle thread breaks. 1 The needle thread is not threaded properly. See pages 9.

2 The needle thread tension is too tight. See page 13.

3 The needle is bent or blunt. See page 12.

4 The needle is inserted incorrectly. See page 12.

5 The needle thread is not set in the thread holder See page 11.

when starting the machine.

The bobbin thread breaks. 1 The bobbin thread is not threaded properly in the bobbin See page 8.

holder.

2 Lint has collected in the bobbin holder. See page 45.

3 The bobbin is damaged and does not turn smoothly. Replace the bobbin.

The needle breaks. 1 The needle is inserted incorrectly See page 12

2 The needle is bent or blunt. See page 12.

3 The needle clamp screw is loose. See page 12.

4 The needle thread tension is too tight. See page 13.

Visual Touch Screen is 1 The screen contrast of the visual touch screen is not See page 15.

not clear. adjusted correctly.

Skipped stitches. 1 The needle is inserted incorrectly. See page 12.

2 The needle is bent or blunt. See page 12.

3 The needle thread is not threaded properly. See pages 9

4 The defective needle (rusted, burred needle eye) is used. Replace the needle.

5 The embroidery hoop is not set properly. See page 23.

6 The fabric is not tightly pulled on the embroidery hoop. See page 22.

7A stabilizer is not being used. See page 14.

The machine does not 1 A thread is caught in the hook race. See page 45.

run. 2 The control circuit is not working correctly. Turn the switch off and

turn it on again.

3 The machine is not connected to the power supply. See page 4.

Abnormal noise occurs 1 Something is caught between the carriage and the arm. Remove the object.

when the machine is

switched on.

Patterns are distorted. 1 The fabric is not pulled tightly on the embroidery hoop. See page 22.

2 The embroider hoop is not fixed securely. See page 23.

3 The carriage is bumping into something around the See page 23.

machine.

4 The fabric is caught or pulled for some reason when Stop the machine and

sewing embroidery. free the fabric.

5 The needle thread tension is too tight. See page 13.

6A stabilizer is not used. See page 14.

46

Page 50

Problem: Cause: Reference:

Pattern selection keys 1 Key position is not adjusted properly. See page 18.

do not work. 2 The control circuit is not working correctly. Turn the switch off and

turn it on again.

3 The bobbin winder spindle is in the winding position. See page 7.

USB memory 1 The USB memory is not inserted correctly. See pages 41

does not work 2 The USB memory is damaged. See page 18

47

Page 51

DESIGN CHARTS

24513

67

11

16 17

12

8

13 14 15

18

9

19

10

20

21

26

22 23 24

27

28 29

48

25

30

Page 52

31 32 33 34 35

36

41

46 47

42

37

3938

43

48 49

40

4544

50

5251

53

49

5554

Page 53

GOTHIC

SCRIPT

FONTS

CHELTENHAM

BORDER

12 345

DESIGNS

67

11 12 13

16 17

8

18

9

14

10

15

50

Page 54

856-800-005

Loading...

Loading...