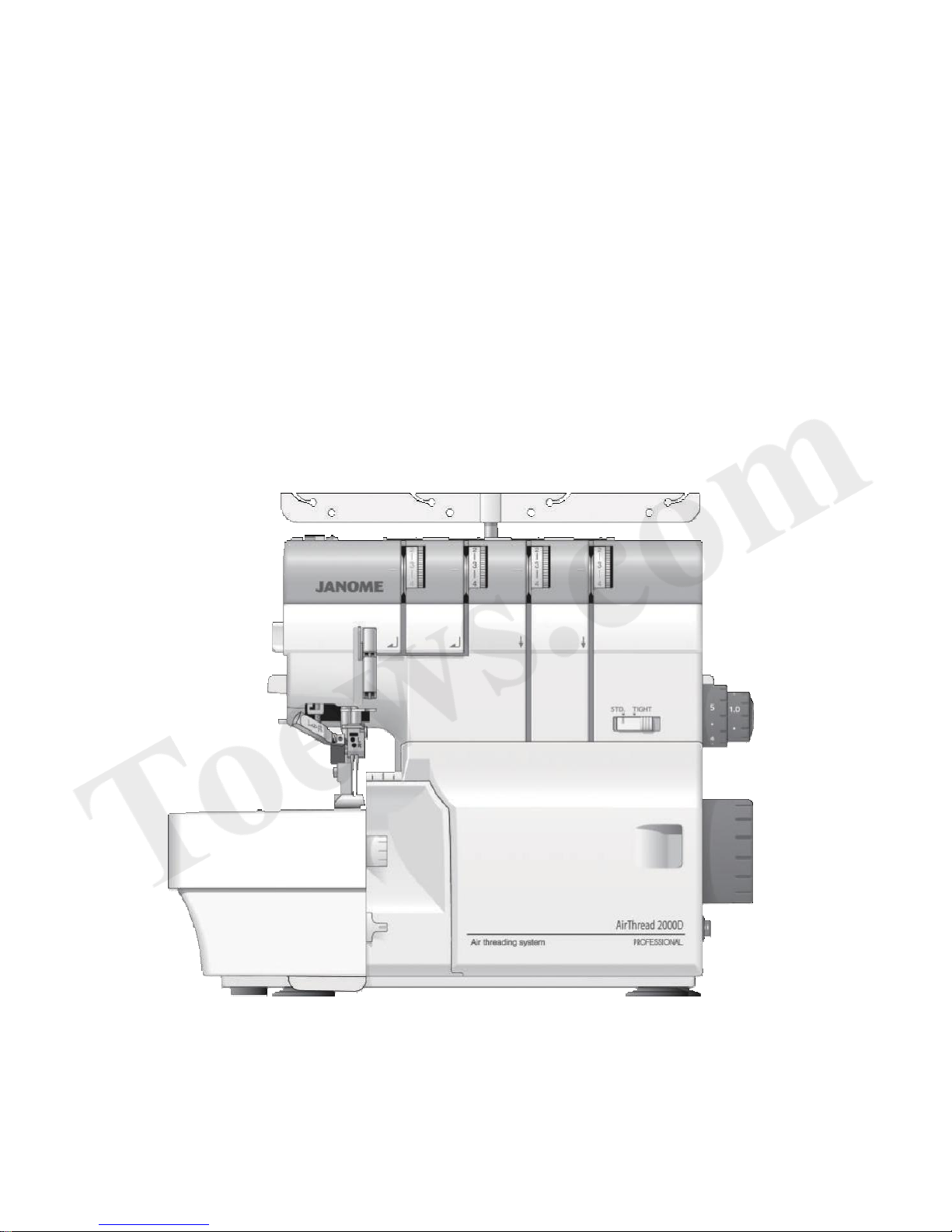

Page 1

Instruction Book

AirThread 2000D Professional

Janome 2000D Air Threading Serger Owners Manual

Janome Air Thread Instruction Book

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

following:

This Serger/Overlocker/Overlock machine is designed and manufactured for household use only.

Read all instructions before using this Serger/Overlocker/Overlock machine.

DANGER

—

To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug

this Serger/Overlocker/Overlock machine from the electric outlet immediately after

using and before cleaning.

WARNING

—

To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this Serger/Overlocker/Overlock

machine is used by or near children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this Serger/Overlocker/Overlock machine if it has a damaged cord or plug, if it is not

working properly, if it has been dropped or damaged, or dropped into water.

Return this Serger/Overlocker/Overlock machine to the nearest authorized dealer or service center

for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this

Serger/Overlocker/Overlock machine and foot controller free from accumulation of lint, dust and

loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the Serger/Overlocker/

Overlock machine needle and/or cutting blade.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this Serger/Overlocker/Overlock machine off (“O”) when making any adjustment in the

needle area, such as threading the needle, changing the needle or changing the presser foot, and

the like.

15. Always unplug this Serger/Overlocker/Overlock machine from the electrical outlet when removing

covers, lubricating, or when making any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

Please note that on disposal, this product must be safely recycled in accordance with relevant

National legislation relating to electrical/electronic products. If in doubt please contact your

retailer for guidance. (European Union only)

For Europe only:

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

For outside Europe (except U.S.A and Canada):

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

1

Page 3

2

ESSENTIAL PARTS

Names of Parts............................................................... 3

Safety Device ................................................................. 4

Standard Accessories .................................................... 5

Waste Chip Box.............................................................. 6

GETTING READY TO SEW

Connecting the Power Supply ........................................ 7

Before Using Your Machine............................................ 7

Operating Instructions: ................................................... 7

Controlling Sewing Speed .............................................. 7

Handwheel ..................................................................... 8

Looper Cover.................................................................. 8

Side Cover...................................................................... 8

Presser Foot Lifter.......................................................... 9

Removing or Attaching the Presser Foot ....................... 9

Presser Foot Guide Lines............................................... 9

Presser Foot Pressure Dial .......................................... 10

Changing the Needle.................................................... 10

Checking the needle .................................................. 10

Stitch Length Adjustment ..............................................11

Differential Feed Ratio Adjustment ..............................11

How to adjust...............................................................11

Gathering.....................................................................11

To Deactivate or Activate the Upper Knife ................... 12

Cutting Width Adjustment............................................. 12

Chaining Finger Switch Knob Adjustment (Changing to

Standard Serging or Rolled Hemming) ........................ 13

Standard serging ........................................................ 13

Rolled hemming ......................................................... 13

Position of Thread Guide Bar ....................................... 14

Attaching the Spool Holder Cap and Net ..................... 14

MACHINE THREADING

Threading the Machine (4 threads) .............................. 15

Preparation................................................................. 15

Lower looper pre-tension setting slider ...................... 15

Threading the Machine (3 threads) .............................. 16

Threading the Machine (2 threads) .............................. 17

Using the Spreader for Two-thread Serging................. 18

Raising the spreader .................................................. 18

Lowering the spreader................................................ 18

Threading the Lower Looper ................................... 19-21

Threading the Upper Looper ................................... 22-25

Adjusting the looper threader switch lever ................... 23

Threading Loopers with the Looper Threading Wire or

Standard Thread ..................................................... 26-27

Using the looper threading wire ................................. 26

Using a standard thread ............................................. 27

Replacing threaded looper thread.............................. 27

Threading the Right Needle ....................................28-30

Using the needle threader .......................................... 30

Threading the Left Needle....................................... 31-32

Thread and Needle Chart............................................. 33

TEST STITCHING

Starting Sewing ............................................................ 34

Finishing Sewing .......................................................... 34

Sewing Continuously.................................................... 35

Using Guide Lines ........................................................ 35

Securing Ends .............................................................. 36

At the beginning of the seam...................................... 36

At the end of the seam ............................................... 36

Cutting the Seams........................................................ 36

Thread Tension (4 threads) .......................................... 37

TABLE OF CONTENTS

Thread Tension (3 threads) .......................................... 39

Thread Tension (2 threads) .......................................... 40

ROLLED HEMMING, PICOT EDGING AND NARROW

HEMMING

Tension Dial and Machine Settings According to the

Thread and Fabric ........................................................ 42

For Better Results ........................................................ 43

Thread Tension........................................................44-45

ADVANCED TECHNIQUES

Decorative Overedging................................................. 46

Gathering...................................................................... 47

Pintucking..................................................................... 48

Flatlock ....................................................................49-50

Sewing Corners............................................................ 51

CARE OF YOUR MACHINE

Cleaning the Upper Knife Area .................................... 52

Cleaning the Feed Dog ................................................ 52

Cleaning the Lo oper Threader Pipe ............................. 53

Replacing the Upper Knife ........................................... 54

Oiling the Machine........................................................ 55

Troubleshooting............................................................ 56

Optional Accessories ................................................... 57

EC DECLARATION OF CONFORMITY ....................... 58

Page 4

NOTE:

Serger/Overlocker/Overlock machine design and

specifications are subject to change without prior

notice.

ESSENTIAL PARTS

Names of Parts

q Left needle thread tension dial

w Right needle thread tension dial

e Upper looper thread tension dial

r Lower looper thread tension dial

t Lower looper pre-tension setting slider

y Stitch length dial

u Differential feed dial

i Ventilation openings

o Handwheel

!0 Machine socket

!1 Power switch

!2 Looper cover

!3 Side cover

!4 Presser foot pressure dial

!5 Thread guide

!6 Thread guide bar

!7 Spool holder

!8 Ventilation openings

!9 Spool pin

@0 Hole of rear arm

@1 Top cover thread guide

@2 Needle threader lever

@3 Face plate

@4 Thread cutter

@5 Presser foot lifter

@6 Needle threader switch lever

@7 Presser foot

@8 Upper looper

@9 Spreader

#0 Lower looper

#1 Looper threader hole

#2 Looper selection lever

#3 Looper threader switch lever

#4 Looper threader lever

#5 Upper knife release knob

#6 Looper cover guide

#7 Cutting width adjusting dial

#8 Chaining finger switch knob

#9 Lower knife

$0 Upper knife

$1 Chaining finger

@2

@3

@4

@5

@6

@7

q w e r

t

y

u

i

o

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

@0

@1

#0

#1

#2

#3

#4

#6

#5

#7

#8

@8

@9

#99

$0

$1

3

Page 5

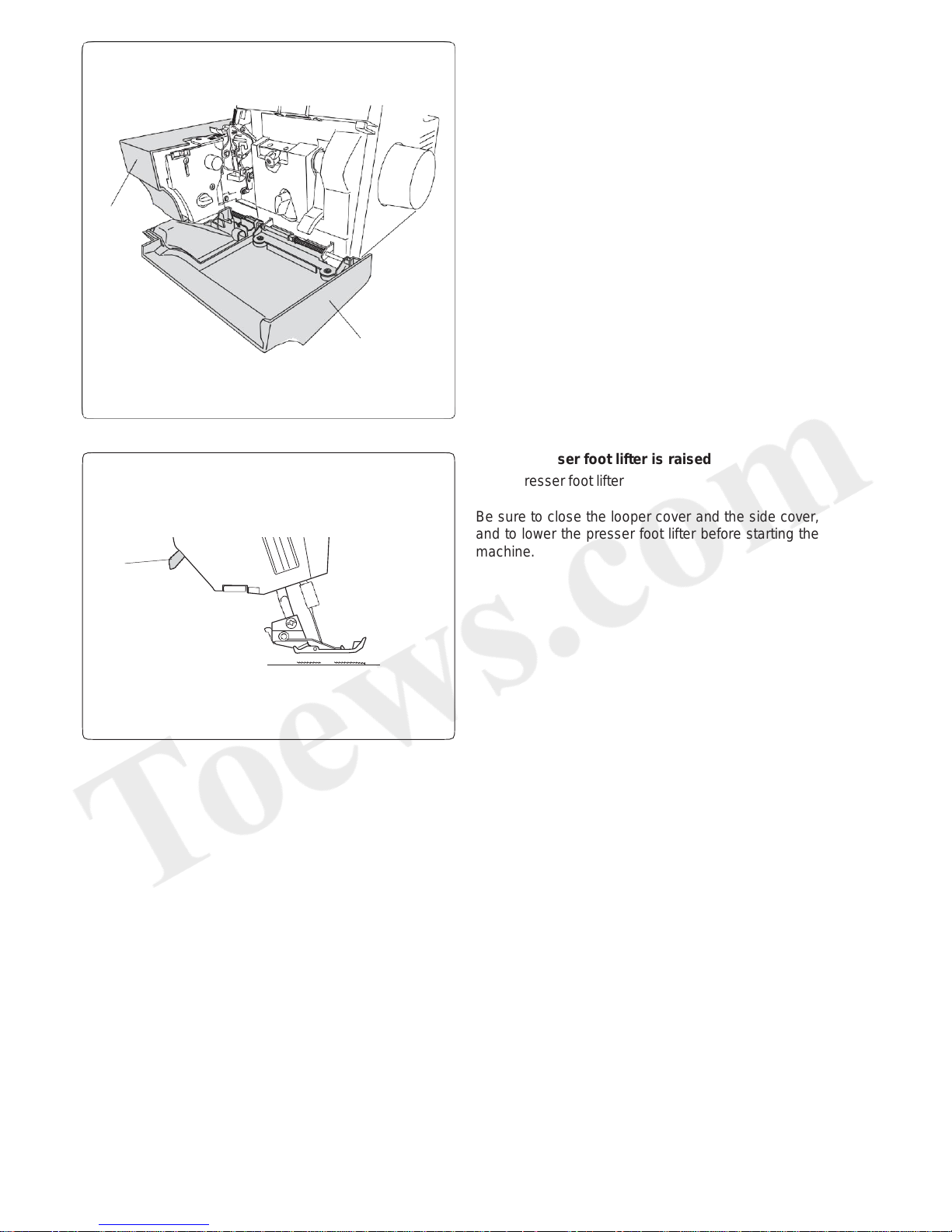

Safety Device

This machine is equipped with a safety device that

prevents the machine from starting in the following

conditions:

• The looper cover or the side cover is open

q Looper cover

w Side cover

q

4

w

e

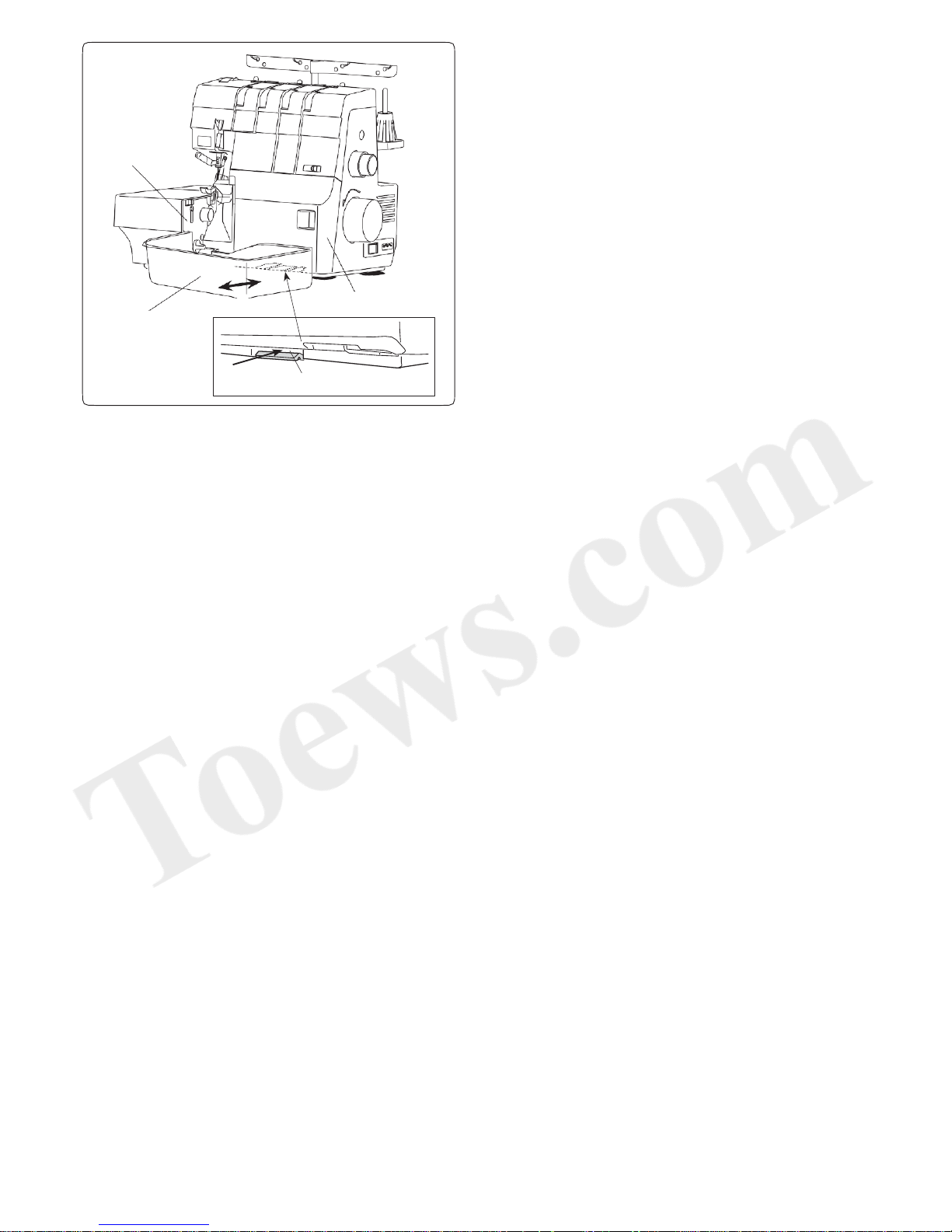

• The presser foot lifter is raised

e Presser foot lifter

Be sure to close the looper cover and the side cover,

and to lower the presser foot lifter before starting the

machine.

Page 6

q w

e

r

t y

u

i

o

!

0

!

1

!

2

!

3

!

4

!

5

!

6

!

7

!

8

Standard Accessories

5

*The foot control included may differ from the illustration.

No.

Part Name

Part No.

1

Screwdriver (large)

784810002

2

Screwdriver (small)

647803004

3

Double-ended spanner

799807002

4

Tweezers

624801001

5

Needle set

(HAx1 SP#11) x 2

(HAx1 SP#14) x 3

784860100

6

Net

624806006

7

Spool holder cap (Large)

822020503

8

Lint brush

802424004

9

Oil

741814003

10

Needle holder/spreader pin

799802007

11

Upper knife

799096000

12

Looper threading wire (Looper

threader)

799803008

13

Accessory box

366401400

14

Waste chip box

799801006

15

Instruction manual

799800005

16

Instructional DVD

799804009

17

Cover

797608005

18

Foot control*

U.S.A and Canada

C-1028

U.K.

C-2085-1

Australia

C-2065

Continental Europe

C-2060

Page 7

Waste Chip Box

The waste chip box collects trimmings.

Dispose trimmings after sewing.

To attach:

Sliding the waste chip box along the looper cover guide,

insert the tabs into the slit under the looper cover.

q Looper cover

w Waste chip box

e Looper cover guide

r Slit

To remove:

Pull the waste chip box toward you.

6

q

w

e

r

Page 8

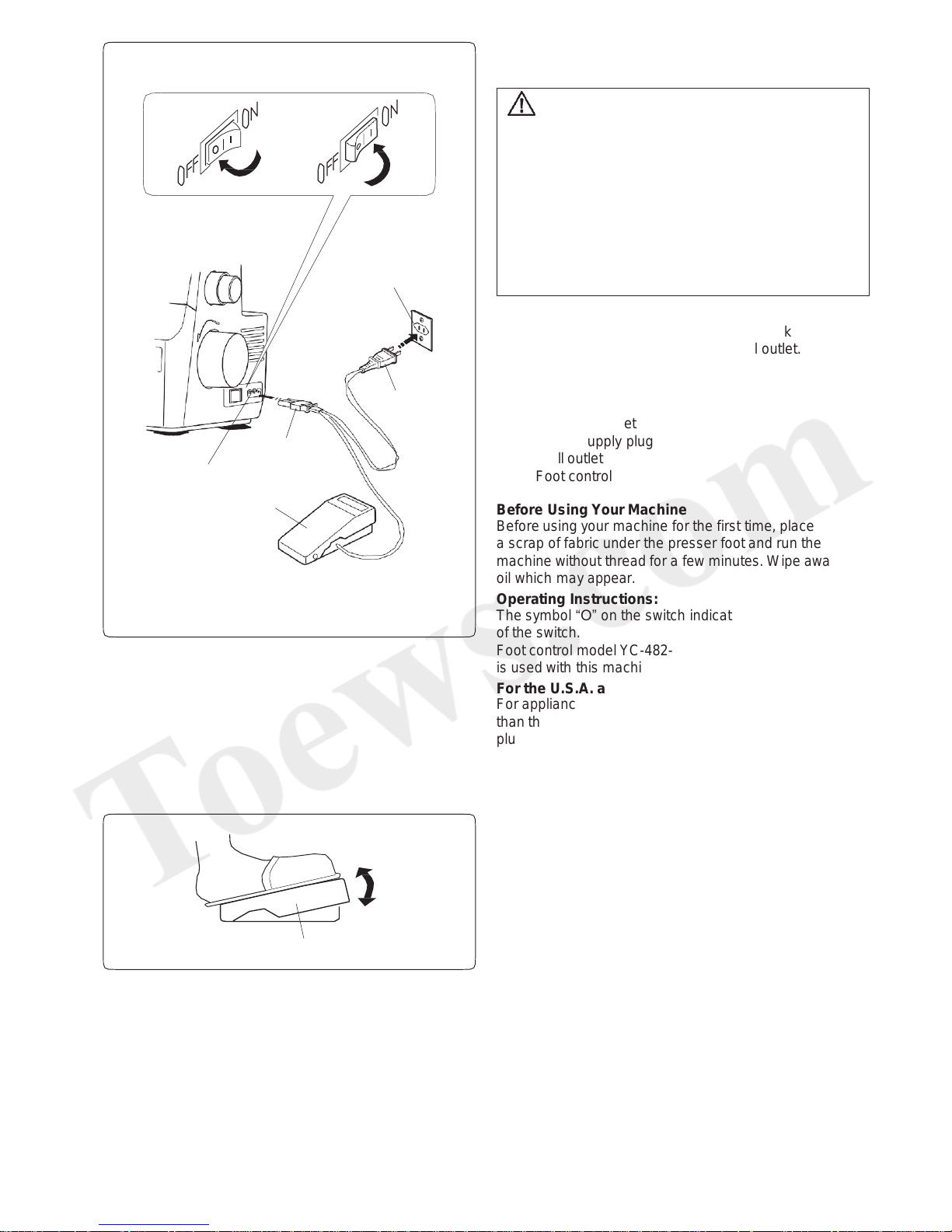

GETTING READY TO SEW

Connecting the Power Supply

WARNING

While in operation, always keep your eyes on the

sewing area, and do not touch any moving parts

such as the thread take-up lever, handwheel, knives,

loopers or needles.

Always turn off the power switch and unplug the

machine from the power supply:

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Do not place anything on the foot control.

Turn the power switch off.

Insert the machine plug into the machine socket.

Insert the power supply plug into the wall outlet.

Turn the power switch on.

q Power switch

w Machine plug

e Machine socket

r Power supply plug

t Wall outlet

y Foot control

Before Using Your Machine

Before using your machine for the first time, place

a scrap of fabric under the presser foot and run the

machine without thread for a few minutes. Wipe away any

oil which may appear.

Operating Instructions:

The symbol “O” on the switch indicates the “off” position

of the switch.

Foot control model YC-482-J-1 (U.S.A and Canada only)

is used with this machine.

For the U.S.A. and Canada only:

For appliances with a polarized plug (one blade wider

than the other): To reduce the risk of electric shock, this

plug is intended to fit in a polarized outlet only one way. If

it still does not fit, contact a qualified electrician to install

the proper outlet. Do not modify the plug in any way.

Controlling Sewing Speed

Depress the foot control to start the machine.

The further down you press on the foot control, the faster

the machine runs.

q Foot control

q

q

t

r

w

e

y

7

Page 9

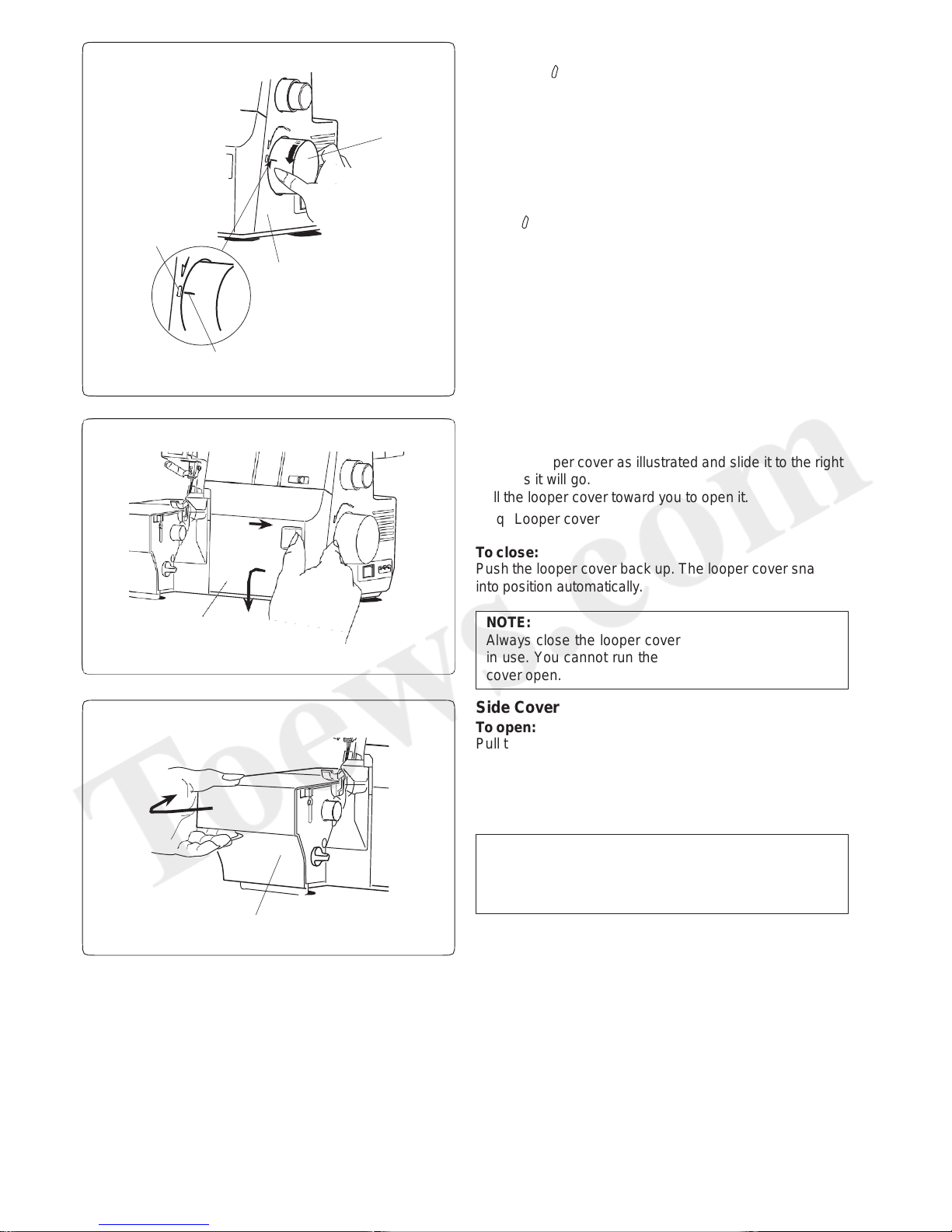

Handwheel

Match the “ ” mark of the belt cover with the “–” mark

of the handwheel when threading needles, adjusting

the chaining finger switch knob or raising/lowering the

spreader.

Always turn the handwheel toward you

(counterclockwise).

q Handwheel

w Belt cover

e “ ” mark

r “–” mark

Looper Cover

To open:

Hold the looper cover as illustrated and slide it to the right

as far as it will go.

Pull the looper cover toward you to open it.

q Looper cover

To close:

Push the looper cover back up. The looper cover snaps

into position automatically.

Side Cover

To open:

Pull the side cover to the left.

q Side cover

To close:

Push the side cover to the right.

q

q

q

e

w

r

NOTE:

Always close the looper cover when the machine is

in use. You cannot run the machine with the looper

cover open.

NOTE:

Always close the side cover when the machine is in

use. You cannot run the machine with the side cover

open.

8

Page 10

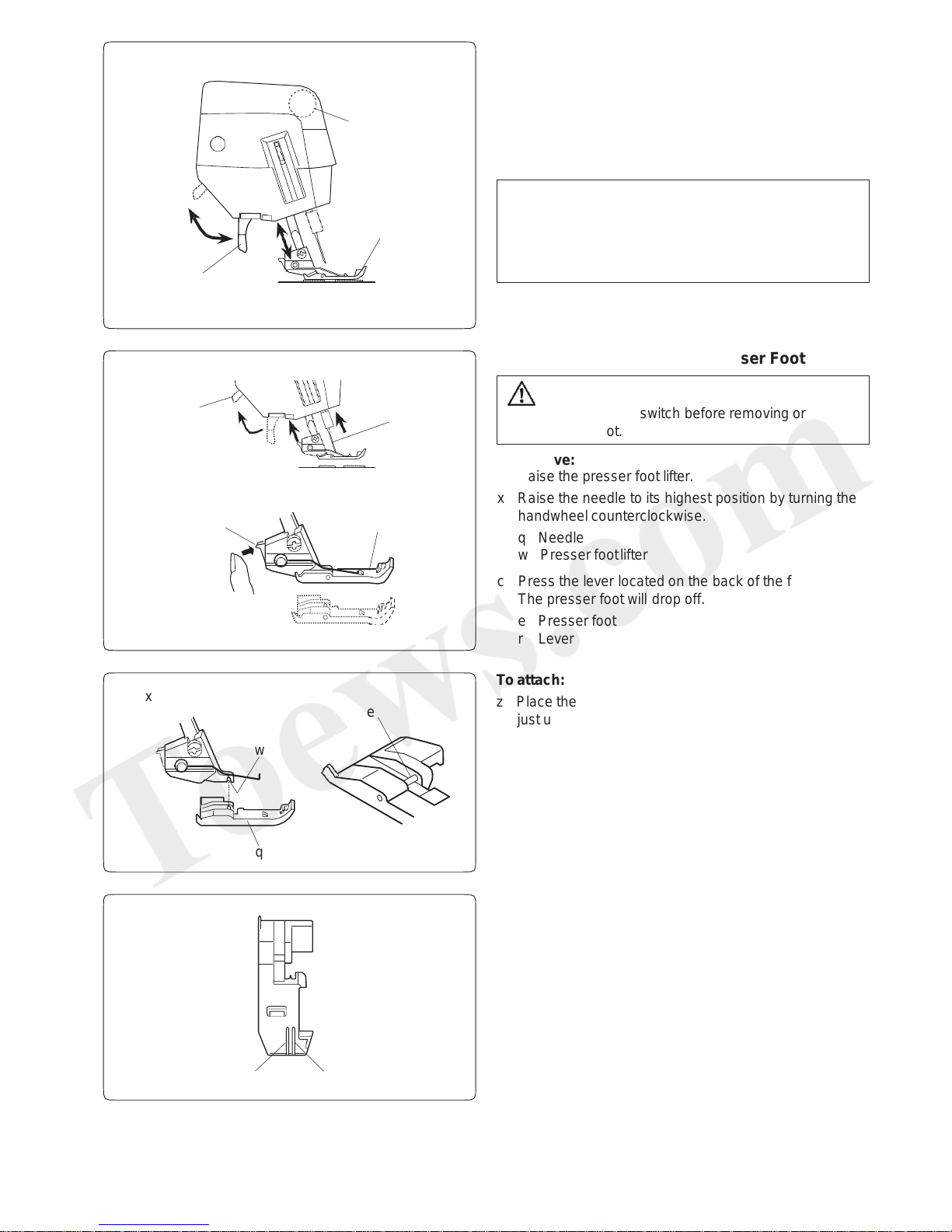

Removing or Attaching the Presser Foot

CAUTION:

Turn OFF the power switch before removing or

attaching the foot.

To remove:

z Raise the presser foot lifter.

x Raise the needle to its highest position by turning the

handwheel counterclockwise.

q Needle

w Presser foot lifter

c Press the lever located on the back of the foot holder.

The presser foot will drop off.

e Presser foot

r Lever

To attach:

z Place the presser foot so that the pin on the foot is

just under the groove on the foot holder.

Lower the foot holder to lock the foot into place.

x Raise the presser foot lifter.

Make sure that the presser foot is secured.

q Presser foot

w Groove

e Pin

Presser Foot Guide Lines

The guide lines on the toe of the presser foot are marked

with two needle positions.

The left guide line is marked at the left needle position.

The right guide line is marked at the right needle position.

q Left needle position

w Right needle position

z x

z x

c

q

w

e

r

q

q

w

w

e

e

q

w

Presser Foot Lifter

The presser foot lifter raises and lowers the presser foot.

Raise the presser foot lifter before you thread the

machine.

Always lower the presser foot lifer when you start sewing.

q Presser foot

w Presser foot lifter

9

NOTE:

Tension disks open when the presser foot lifter is

raised. Raise presser foot lifter when you pass the

thread between the tension disks.

e Presser foot lifter

Page 11

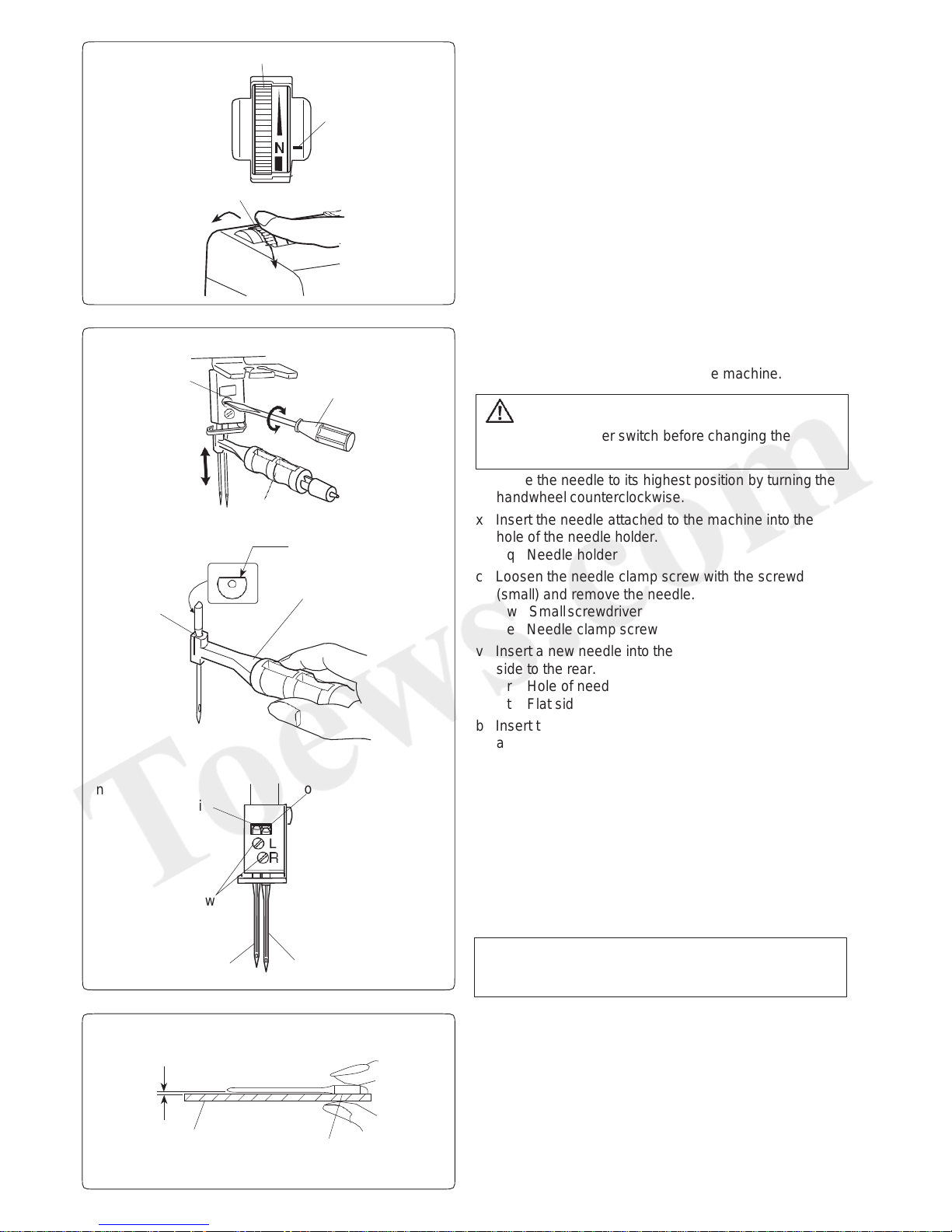

CAUTION

Turn OFF the power switch before changing the

needle.

z Raise the needle to its highest position by turning the

handwheel counterclockwise.

x Insert the needle attached to the machine into the

hole of the needle holder.

q Needle holder

c Loosen the needle clamp screw with the screwdriver

(small) and remove the needle.

w Small screwdriver

e Needle clamp screw

v Insert a new needle into the needle holder with the flat

side to the rear.

r Hole of needle holder

t Flat side

b Insert the needle into the needle clamp and push it up

as far as it will go.

n The top of the right needle should touches the bottom

of the needle bar and the top of the left needle should

touches the edge of the needle bar.

y Left needle

u Right needle

i Edge of needle bar

o Bottom of needle bar

m Firmly tighten the needle clamp screw with the

screwdriver (small) while holding the holder in place.

Pull the needle holder down to remove the needle.

Checking the needle

To see if the needle is in good condition, place the flat

side of the needle onto something flat (needle plate, glass

etc.). The gap between the needle and the flat surface

should be consistent. Never use a bent or blunt needle.

q Flat side

w Something flat

e Gap

Changing the Needle

* Use an HA-1 SP #14 or #11 needle.

* An HA-1 SP #14 needle is set on the machine.

q

w

e

q

w

q

e

r

y

u

i

o

w

e

w

q

r

10

t

q

x c b m

n

Presser Foot Pressure Dial

Foot pressure can be adjusted by turning the presser foot

pressure dial.

Set the pressure to “N” for ordinary fabrics.

Turn the dial toward you for light weight fabrics .

Turn the dial away from you for heavy weight fabrics.

q Presser foot pressure dial

w Setting mark

e To increase

r To decrease

You do not need to adjust the presser foot pressure for

normal sewng.

After making an adjustment, sew and check the pressure.

v

NOTE:

Partially tighten the needle clamp screw on the side

that is not being used to prevent losing the screw.

Page 12

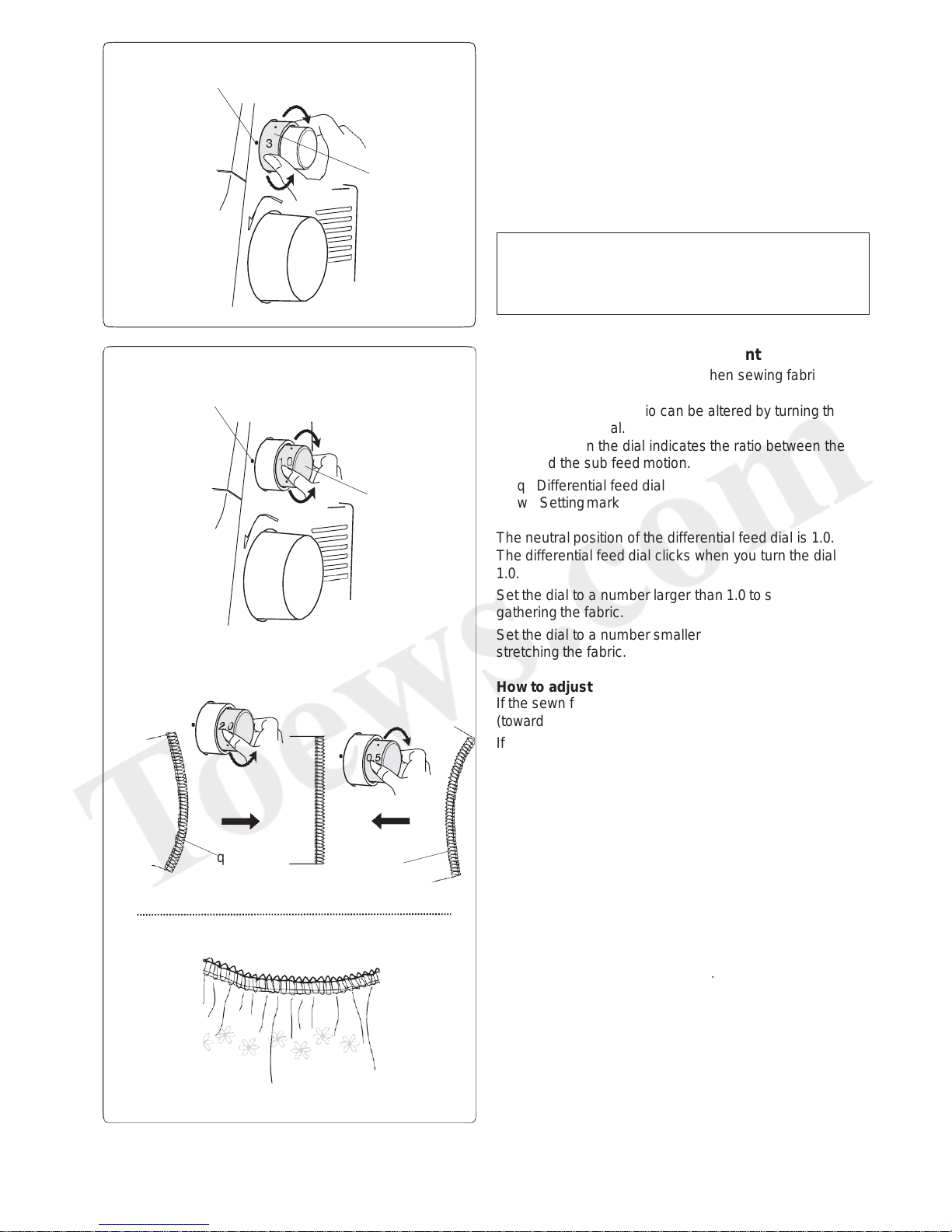

Stitch Length Adjustment

To adjust the stitch length, turn the stitch length dial.

The larger the number, the longer the stitch.

q Stitch length dial

w Setting mark

The standard stitch length setting for serging stitch is “3”

(approximately 3 mm).

The dial clicks when you turn the dial to 3.

The stitch length can be adjusted while sewing.

Differential Feed Ratio Adjustment

Adjust the differential feed ratio when sewing fabrics that

tend to stretch or pucker.

The differential feed ratio can be altered by turning the

differential feed dial.

The number on the dial indicates the ratio between the

main and the sub feed motion.

q Differential feed dial

w Setting mark

The neutral position of the differential feed dial is 1.0.

The differential feed dial clicks when you turn the dial at

1.0.

Set the dial to a number larger than 1.0 to sew while

gathering the fabric.

Set the dial to a number smaller than 1.0 to sew while

stretching the fabric.

How to adjust

If the sewn fabric stretches, turn the dial counterclockwise

(toward 2.0).

If the sewn fabric is gathered, turn the dial clockwise

(toward 0.5).

q Stretched

w Gathered

q

q

w

w

w

q

NOTE:

• The stitch length can be adjusted from 1 to 5 mm.

• Position “R” is for rolled hemming and narrow

hemming (approximately 1.5 mm).

11

Gathering

You can sew gathering with a single layer of light weight

or medium weight fabric.

Set the differential feed dial to 2.0

Set the stitch length dial to 4.

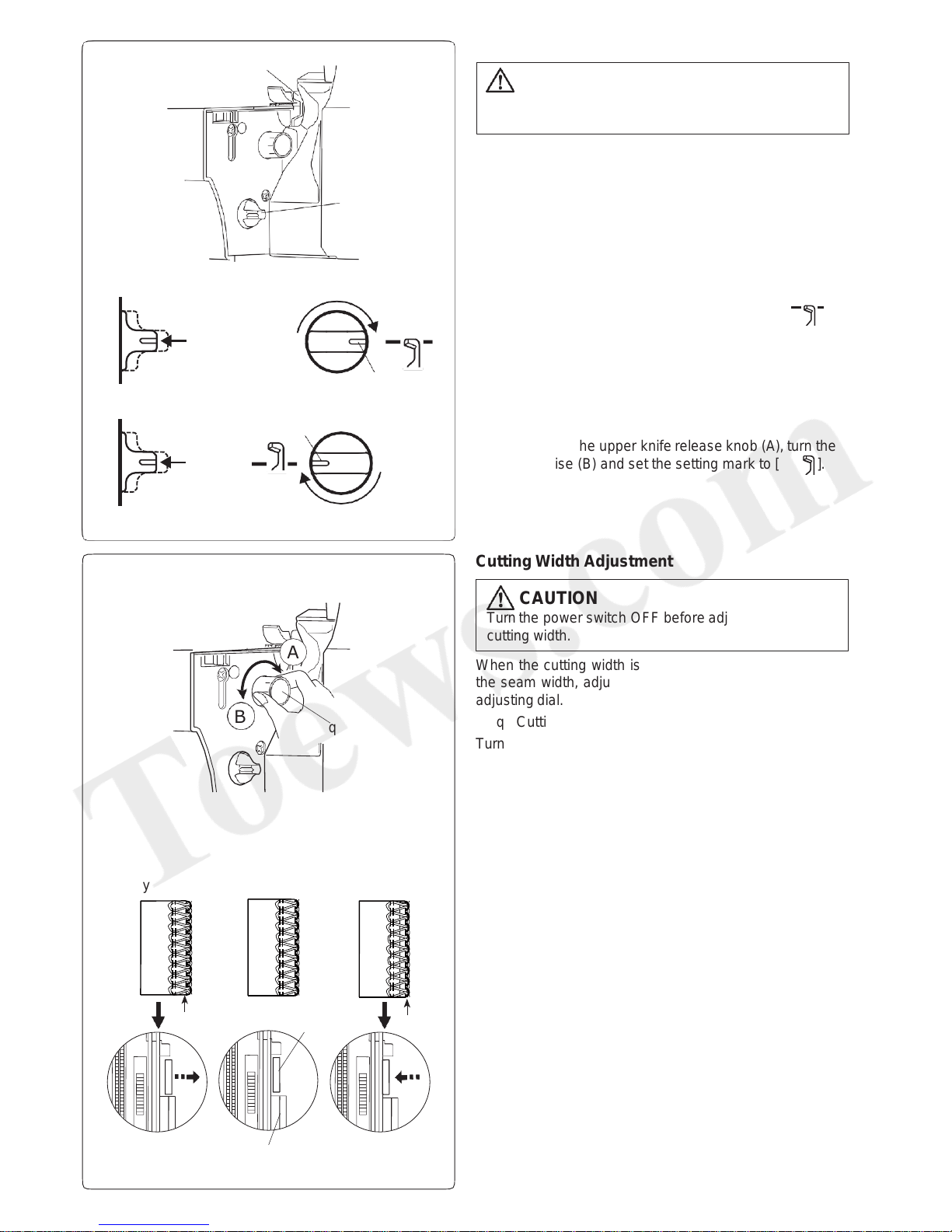

Page 13

Deactivate the upper knife for flatlock, pintucking, etc.

q Upper knife release knob

w Upper knife

To Deactivate or Activate the Upper Knife

Cutting Width Adjustment

When the cutting width is too narrow or too wide for

the seam width, adjust it by turning the cutting width

adjusting dial.

q Cutting width adjusting dial

Turn the cutting width adjusting dial to get the desired

position of the lower knife.

When the lower knife is set to the standard position, the

right edge of the lower knife is aligned with the guide line

on the needle plate.

w Standard position

e Lower knife

r Guide on the needle plate

t Edge of fabric

If the cutting width is too narrow y, turn the cutting width

adjusting dial clockwise (to the direction of A).

The lower knife moves to right.

If the cutting width is too wide u , turn the cutting width

adjusting dial counterclockwise (to the direction of B).

The lower knife moves to left.

Sew and check the cutting width.

(A)

(B)

(A)

(B)

A

B

q

w

e

e

CAUTION

Turn the power switch OFF before deactivating or

activating the upper knife.

CAUTION

Turn the power switch OFF before adjusting the

cutting width.

q

w

e

r

t

t

y u

To deactivate:

While pressing the upper knife release knob (A), turn the

knob clockwise (B) and set the setting mark to [ ].

e Setting mark

12

To activate:

While pressing the upper knife release knob (A), turn the

knob clockwise (B) and set the setting mark to [ ].

Page 14

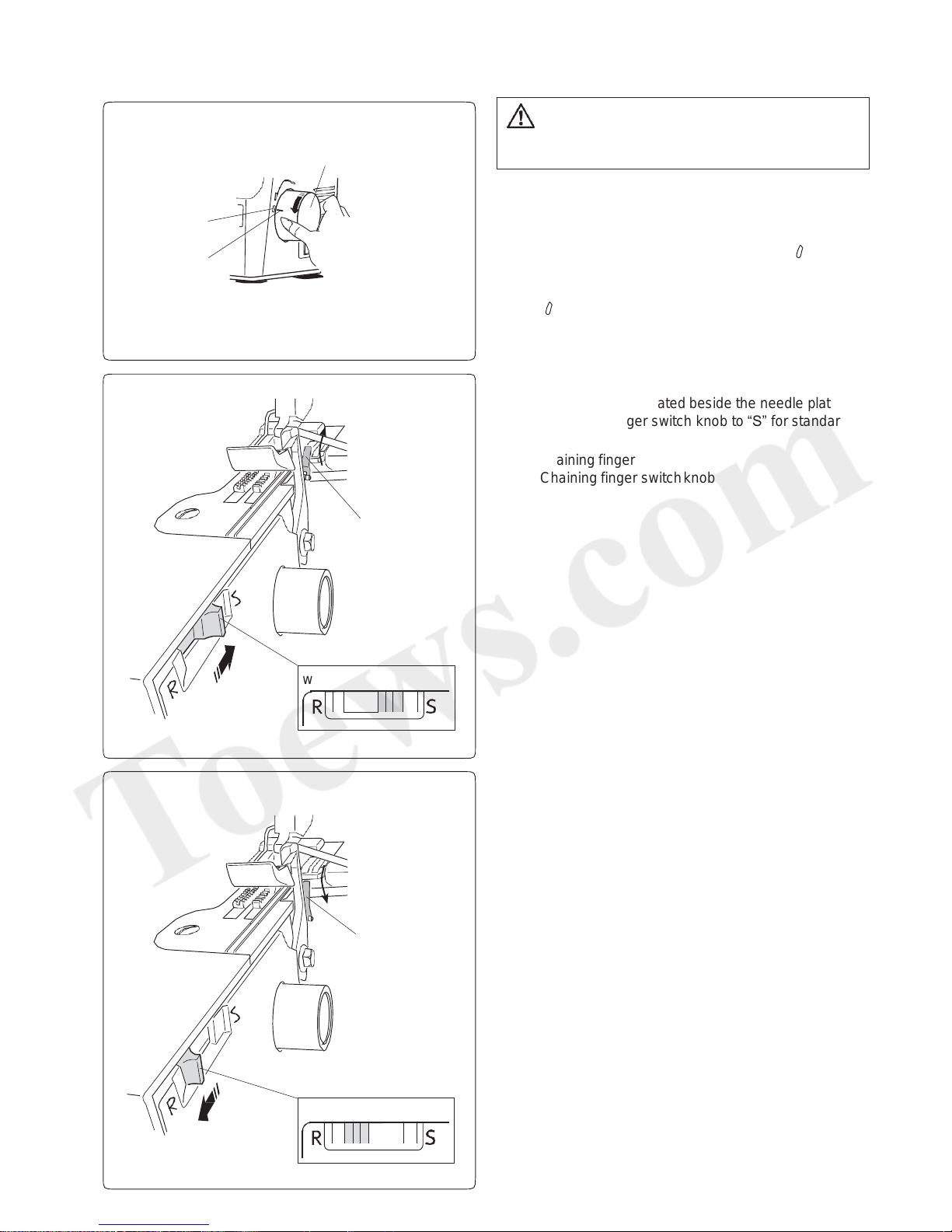

Chaining Finger Switch Knob Adjustment

(Changing to Standard Serging or Rolled

Hemming)

Standard serging

The chaining finger is located beside the needle plate.

Turn the chaining finger switch knob to “S” for standard

serging.

q Chaining finger

w Chaining finger switch knob

Rolled hemming

Turn the chaining finger switch knob to “R” for rolled for

hemming, picot edging or narrow hemming sewing.

q Chaining finger

w Chaining finger switch knob

CAUTION

Turn the power switch OFF before adjusting the

chaining finger switch knob.

q

q

w

w

q

w

e

The chaining finger switch knob is connected to the

chaining finger.

The chaining finger slides back and forth when you set

the chaining finger switch knob to “S” or “R”.

Turn the handwheel toward you to match the “ ” mark on

the belt cover with the “–” mark on the handwheel.

q Handwheel

w “ ” mark

e “–” mark

13

Page 15

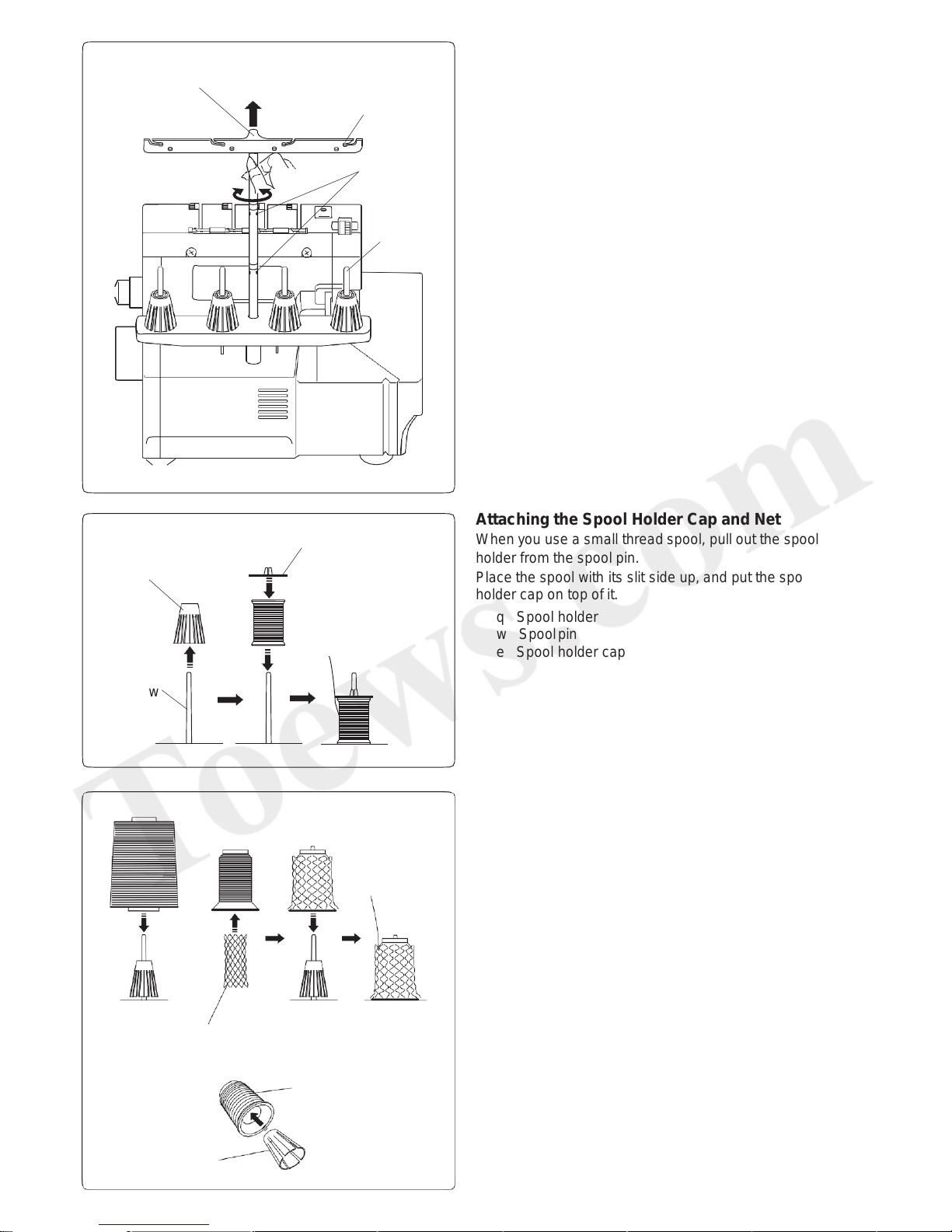

Position of Thread Guide Bar

Pull the thread guide bar up as far as it will go.

q Thread guide bar

Turn the thread guide bar until it snaps into place.

Be sure to snap both stoppers into places.

The thread guide bar is placed right above the spool pins

as shown.

w Thread guide

e Stopper

r Spool pin

Attaching the Spool Holder Cap and Net

When you use a small thread spool, pull out the spool

holder from the spool pin.

Place the spool with its slit side up, and put the spool

holder cap on top of it.

q Spool holder

w Spool pin

e Spool holder cap

If the thread slips down from the spool during threading

and/or sewing, put a net on the spool as illustrated to

prevent jamming.

r Net

q

w

e

r

14

e

q

w

q

r

t

* Firmly insert the spool holder into the spool.

q Spool holder

t Spool

Page 16

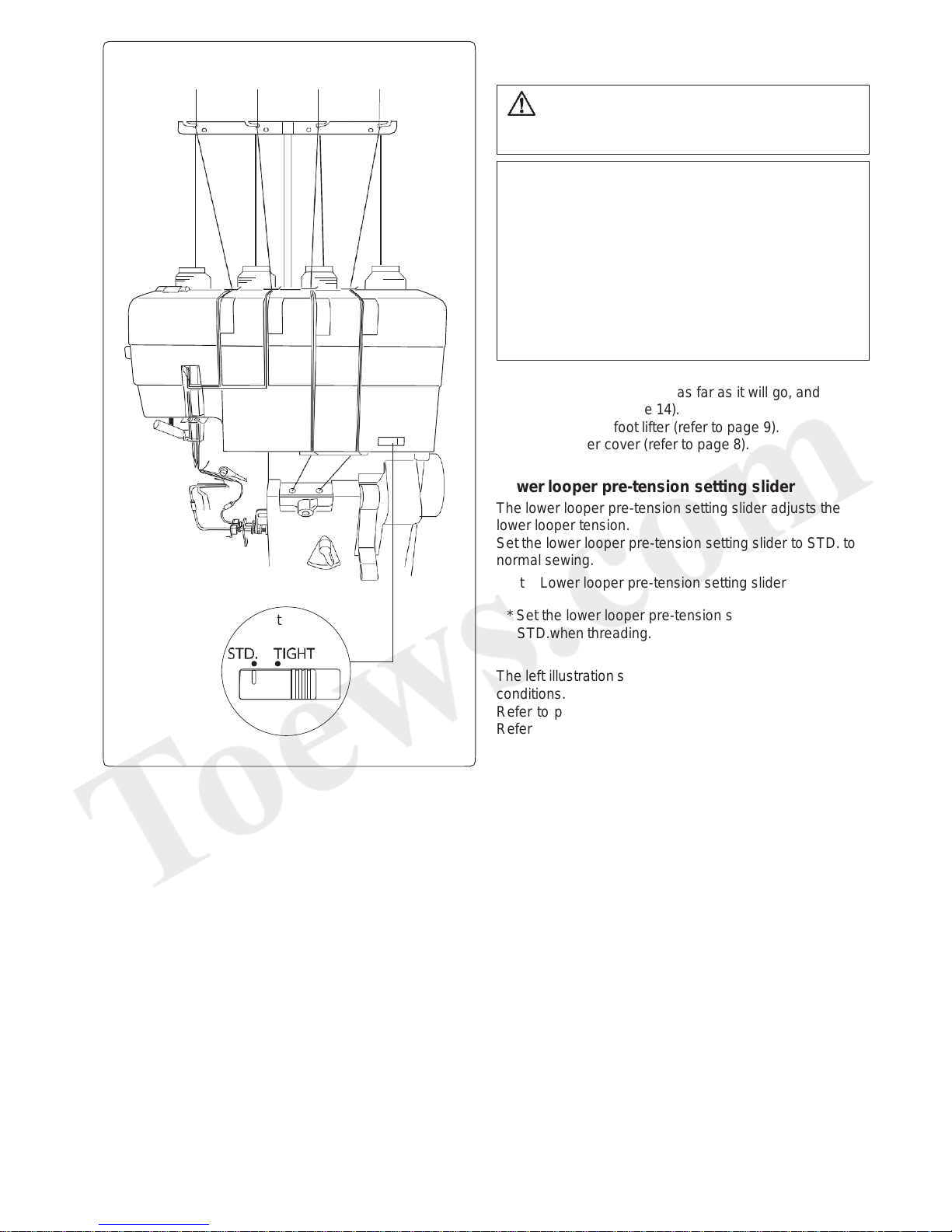

MACHINE THREADING

Threading the Machine (4 threads)

q w e r

t

CAUTION

Turn the power switch OFF before threading the

machine.

15

NOTE:

• The looper threader can be used with standard

threads #60 - #100.

• The looper threader cannot be used with special

threads, such as wooly nylon, gold thread, etc.

For threading, refer to “Using the looper threading

wire”

(page 26) or “Using a standard thread” (page 27).

• For general sewing, standard threads #60 - #100

are used as needle thread.

• Do not use poor quality thread.

Preparation

Pull the thread guide bar up as far as it will go, and set

the spools (refer to page 14).

Raise the presser foot lifter (refer to page 9).

Open the looper cover (refer to page 8).

Lower looper pre-tension setting slider

The lower looper pre-tension setting slider adjusts the

lower looper tension.

Set the lower looper pre-tension setting slider to STD. to

normal sewing.

t Lower looper pre-tension setting slider

* Set the lower looper pre-tension setting slider to

STD.when threading.

The left illustration shows the completed threading

conditions.

Refer to pages 19-21 for threading the lower looper.

Refer to pages 22-24 for threading the upper looper.

Refer to pages 28-30 for threading the right needle.

Refer to pages 31-32 for threading the left needle.

q Left needle thread

w Right needle thread

e Upper looper thread

r Lower looper thread

Page 17

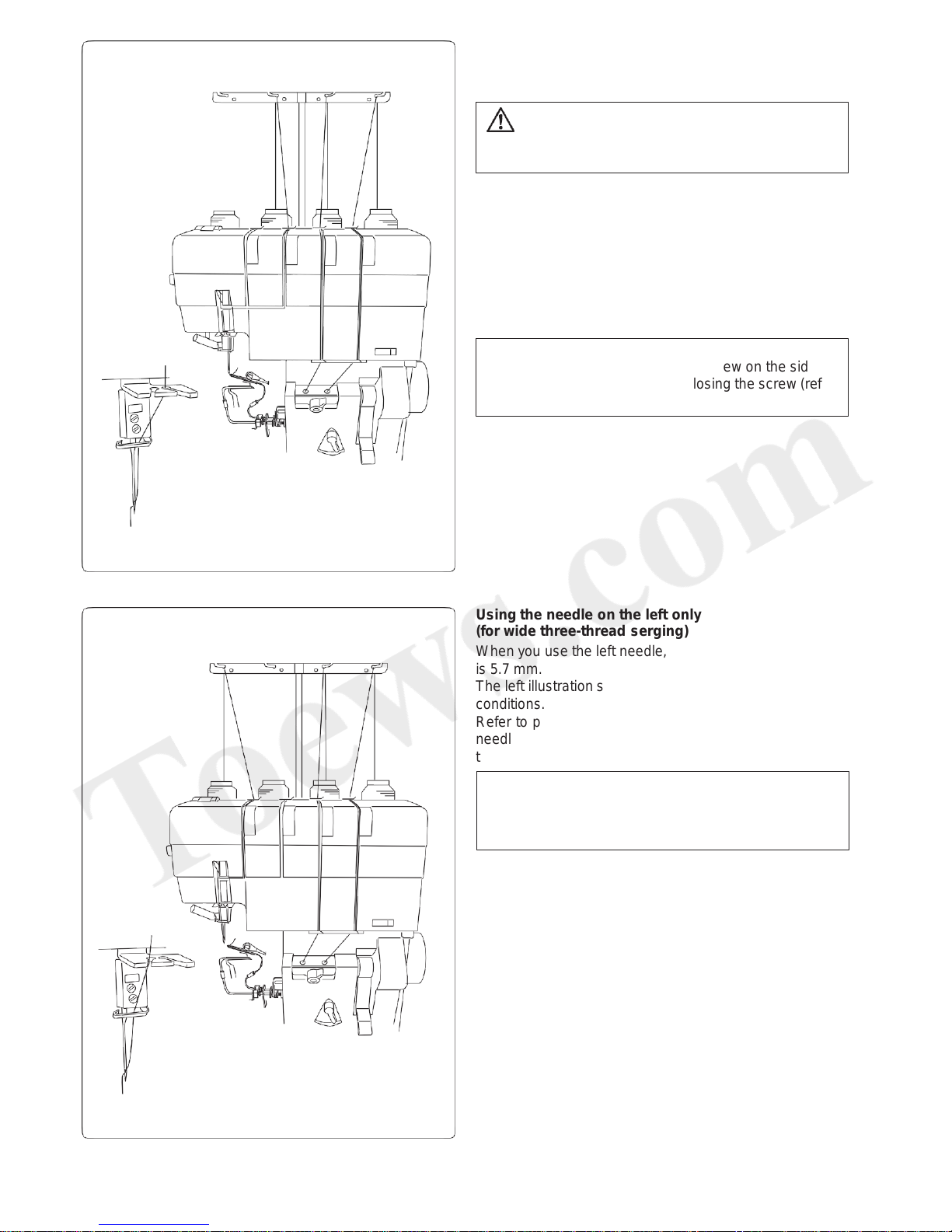

NOTE:

Partially tighten the needle clamp screw on the side

that is not being used to prevent losing the screw (refer

to page 10).

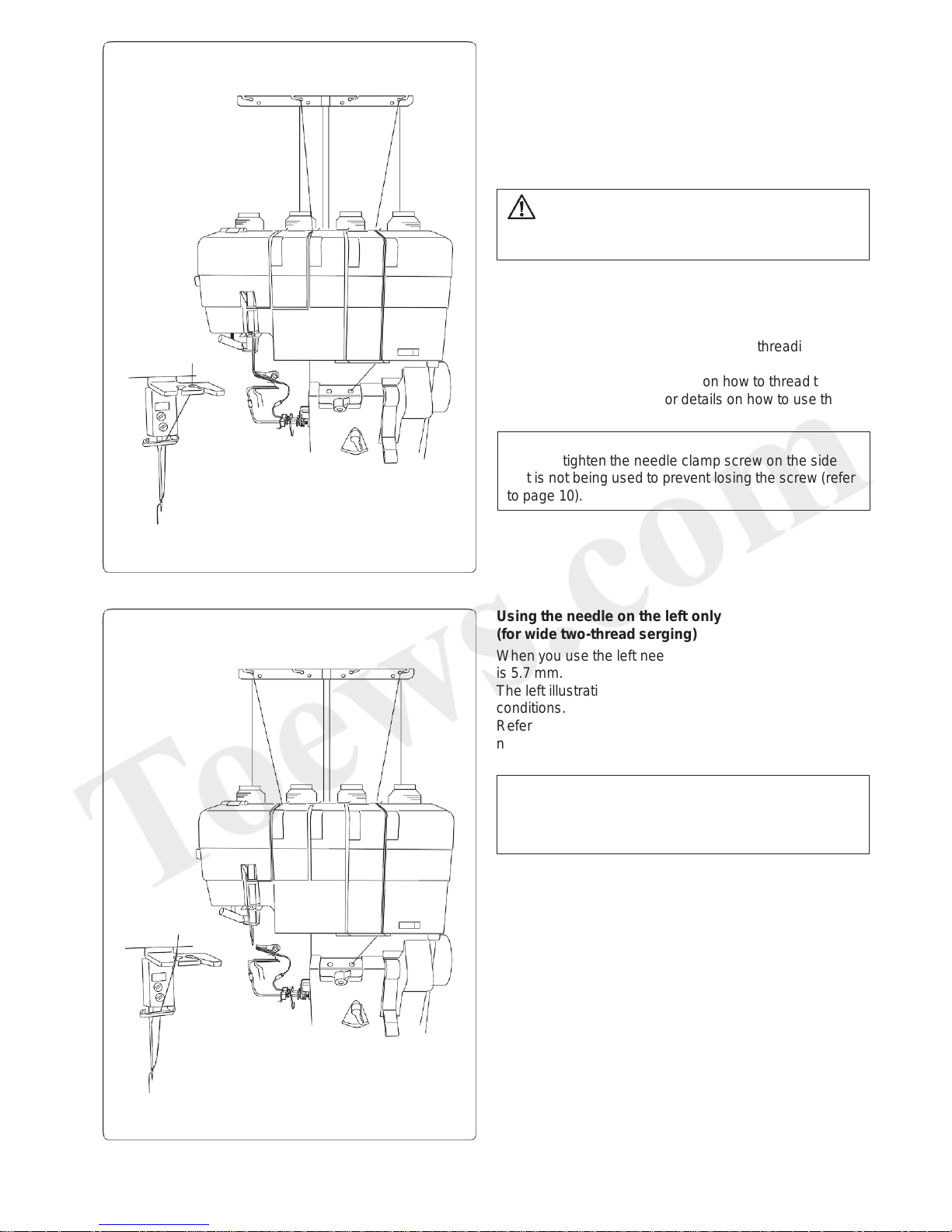

Threading the Machine (3 threads)

You can sew three-thread serging using the right needle

or the left needle.

Using the needle on the right only

(for regular three-thread serging)

When you use the right needle, the standard sewing

width is 3.5 mm.

The left illustration shows the completed threading

conditions.

Refer to pages 28-29 for details on how to thread the

right needle and page 30 for details on how to use the

needle threader.

CAUTION

Turn the power switch OFF before threading the

machine.

16

Using the needle on the left only

(for wide three-thread serging)

When you use the left needle, the standard sewing width

is 5.7 mm.

The left illustration shows the completed threading

conditions.

Refer to pages 31-32 for details on how to thread the left

needle and page 30 for details on how to use the needle

threader.

NOTE:

Partially tighten the needle clamp screw on the side

that is not being used to prevent losing the screw (refer

to page 10).

Page 18

Threading the Machine (2 threads)

You can sew two-thread serging using the right needle or

the left needle.

Use the lower looper and the spreader.

Refer to page 18 for details on how to raise and lower the

spreader.

Using the needle on the right only

(for regular two-thread serging)

When you use the right needle, the standard sewing

width is 3.5 mm.

The left illustration shows the completed threading

conditions.

Refer to pages 28-29 for details on how to thread the

right needle and page 30 for details on how to use the

needle threader.

CAUTION

Turn the power switch OFF before threading the

machine.

17

Using the needle on the left only

(for wide two-thread serging)

When you use the left needle, the standard sewing width

is 5.7 mm.

The left illustration shows the completed threading

conditions.

Refer to pages 31-32 for details on how to thread the left

needle and page 30 for details on how to use the needle

threader.

NOTE:

Partially tighten the needle clamp screw on the side

that is not being used to prevent losing the screw (refer

to page 10).

NOTE:

Partially tighten the needle clamp screw on the side

that is not being used to prevent losing the screw (refer

to page 10).

Page 19

Using the Spreader for Two-thread Serging

Use the spreader pin (needle holder) to raise or lower the

spreader.

Raising the spreader

z Turn the handwheel toward you to match the “ ” mark

on the belt cover with the “–” mark on the handwheel.

Raise the needle.

q Handwheel

w “ ” mark

e “–” mark

x Insert the spreader pin into the small hole in the

spreader and turn the spreader pin counterclockwise

until the hook comes to the tip of the upper looper.

(Slightly turn the needle holder so that the needle

holder does not touch the upper knife.)

r Spreader pin

t Hook

y Small hole

u Spreader

i Upper looper

o Upper knife

c Slightly push the spreader pin so that the hook goes

behind the bulge of the upper looper and into the hole

in the upper looper.

!0 Bulge

v Remove the spreader pin from the spreader.

!1 Hole of upper looper

(Upper view of the upper looper)

q

w

e

r

r

t

t

(Rear view of the upper looper)

t

y

u i

i

i

o

!0

!0

!1

z

z

x

x c

c v

CAUTION

Turn the power switch OFF before raising or lowering

the spreader.

Lowering the spreader

z Insert the spreader pin into the small hole in the

spreader.

Slightly push the spreader and turn it clockwise so

that the hook comes over the bulge.

(Slightly turn the needle holder so that the needle

holder does not touch the upper knife.)

r Spreader pin

i Upper looper

!0 Bulge

x Turn the spreader clockwise to the original position

(until the spreader clicks).

c Remove the spreader pin from the spreader.

Correct Wrong

18

Page 20

NOTE:

Raise the presser foot lifter for easier threading.

z Draw the thread through the right side thread guide

from back to front: (A)

q Thread guide

Threading the Lower Looper

CAUTION

Turn the power switch OFF before threading the

machine.

z

x

c

b

v

(A)

(B)

q

e

r

r

t

z

19

x

w

c

v

y

b

u

x Slide the thread under the top cover thread guide as

illustrated.

w Top cover thread guide

c Pull the thread along the slit.

Using both hands, insert the thread between the

tension disks of the lower looper thread tension dial.

e Thread

r Tension disk

t Lower looper thread tension dial

v Set the lower looper pre-tension setting slider to STD.

y Lower looper pre-tension setting slider

b Draw the thread along the slit and pass it through the

right slit of the looper thread guide.

u Right slit of looper thread guide

NOTE:

If the thread tends to slip away from the guide while

sewing, pass the thread through both thread guide

holes as shown: (B)

Page 21

Looper selection lever

Turn the looper selection lever to the right to

thread the lower looper.

Turn the looper selection lever to the left to

thread the upper looper.

⁄ 0 Using the tweezers, insert the end of the thread 2 cm

or more into the threading hole on the right.

!2 Tweezers

!3 Threading hole on the right

!4 Thread (30 cm or longer)

!5 Thread end (2 cm or longer)

!2

!3

!4

!5

⁄0

n Pull out approximately 12˝ (30 cm) of thread. Make

sure that the thread does not get tangled around the

lever or the cover.

i Thread

m Set the looper threader switch lever to the

“THREADING” position.

o Looper threader switch lever

Adjusting the looper threader switch lever

Set the looper threader lever to the

“THREADING” position by turning it to the

right.

Set the looper threader lever to the “SEWING”

position by turning it to the left.

i

o

n m

,

!0

.

!1

,

20

⁄0

.

n m

, Turn the handwheel toward you slowly until it clicks.

This locks the handwheel in place.

!0 Handwheel

. Turn the looper selection lever to the “LOWER LOOPER”

position.

!1 Looper selection lever

NOTE:

• Trim the thread end so that it can be inserted into

the threading hole smoothly.

• If threading special threads, such as wooly nylon,

etc., refer to pages 26 and 27.

Page 22

⁄ 1 Raise the looper threader lever until it clicks into

place.

!6 Looper threader lever

!6

⁄1

!6

⁄2

!7

!8

!9

@0

@1

⁄3

⁄4

@2

⁄5

o

⁄ 2 Lower the looper threader lever until it knocks into

place.

21

⁄ 3 Make sure that the thread comes out from the hole of

the lower looper tip.

!7 Thread end

!8 Hole of lower looper tip

* If the thread does not come out from the hole,

follow the procedure from step ⁄1 again.

* If the thread comes out behind the pipe, use the

tweezers to draw the thread toward you between

the lower looper and the pipe.

!9 Thread (behind the pipe)

@0 Pipe

@1 Lower looper

⁄ 4 Draw 4˝ (10 cm) of the thread under the toe of the foot,

and pull it to the rear between the foot and the upper

knife.

@2 Upper knife

⁄ 5 Return the lower threader switch lever to the “SEWING”

position.

o Lower threader switch lever

Close the looper cover and lower the presser foot

lifter.

Page 23

z

c

z

x

c

v

(A) (B)

q

x

w

e

r

r

t

v

y

Threading the Upper Looper

z Draw the thread through the thread guide from back

to front: (A)

q Thread guide

x Slide the thread under the top cover thread guide as

illustrated.

w Top cover thread guide

c Pull the thread along the slit.

Using both hands, insert the thread between the

tension disks of the upper looper thread tension dial.

e Thread

r Tension disk

t Upper looper thread tension dial

v Draw the thread along the slit and pass it through the

left slit of the looper thread guide.

y Left slit of looper thread guide

NOTE:

Raise the presser foot lifter for easier threading.

CAUTION

Turn the power switch OFF before threading the

machine.

22

NOTE:

If the thread tends to slip away from the guide while

sewing, pass the thread through both thread guide

holes as shown: (B)

Page 24

Turn the looper selection lever to the left to

thread the upper looper.

. Using the tweezers, insert the end of the thread 1˝

(2 cm) or more into the threading hole on the right.

!1 Tweezers

!2 Threading hole on the right

!3 Thread (12˝ (30 cm) or longer)

!4 Thread end (1˝ (2 cm) or longer)

b Pull out approximately 12˝ (30 cm) of thread. Make

sure that the thread does not get tangled around the

lever or the cover.

u Thread

n Set the looper threader switch lever to the

“THREADING” position.

i Looper threader switch lever

Adjusting the looper threader switch lever

Set the looper threader lever to the

“THREADING” position by turning it to the right.

Set the looper threader lever to the “SEWING”

position by turning it to the left.

m Turn the handwheel toward you slowly until it clicks.

This locks the handwheel in place.

o Handwheel

, Turn the looper selection lever to the “UPPER LOOPER”

position.

!0 Looper selection lever

Looper selection lever

Turn the looper selection lever to the right to

thread the lower looper.

NOTE:

• Trim the thread end so that it can be inserted into

the threading hole smoothly.

• If threading special threads, such as wooly nylon,

etc., refer to pages 26 and 27.

u

i

b n

m

o

,

!0

.

!1

!2

!3

!4

m

23

.

,

b n

Page 25

⁄0

⁄4

⁄2

⁄3

!5

⁄1

!5

!8

!6

!7

i

⁄ 0 Raise the looper threader lever until it clicks into

place.

!5 Looper threader lever

24

⁄ 1 Lower the looper threader lever until it knocks into

place.

⁄ 2 Make sure that the thread comes out from the hole of

the upper looper tip.

!6 Thread end

!7 Hole of lower looper tip

⁄ 3 Draw 4˝ (10 cm) of the thread under the toe of the foot,

and pull it to the rear between the foot and the upper

knife.

!8 Upper knife

⁄ 4 Return the lower threader switch lever to the “SEWING”

position.

i Lower threader switch lever

Close the looper cover and lower the presser foot

lifter.

NOTE:

If the thread does not come out from the hole, follow

the procedure from step ⁄0 again.

Page 26

Instructions for using the looper threader

1. If either the upper or lower looper thread breaks while sewing, cut both of the upper and lower threads in front of

the threading holes, and remove the thread from the holes. Rethread both of the threads.

2. When the looper threader switch lever is in the “THREADING” position, the handwheel is locked. Even if the foot

control is depressed, the handwheel does not rotate.

Do not turn the handwheel. Doing so may cause malfunction.

3. After threading loopers, lower the looper threader lever and return the looper threader switch lever to “SEWING”

position.

25

Page 27

Threading Loopers with the Looper Threading

Wire or Standard Thread

If the looper threads are made from materials that are

difficult to thread, such as wooly nylon, there are 2

ways to thread the looper threads:

• Use the looper threading wire (looper threader)

• Tie the thread to standard thread, which you then

use to thread.

q

e

r

t

t

z x

c

q

w

v b

n m

,

CAUTION

Turn the power switch OFF before threading the

machine.

Using the looper threading wire

z Pass the thread up to the looper thread guide (before

the looper threader hole).

x Set the looper threader switch lever to the

“THREADING” position.

q Looper threader switch lever

c Turn the handwheel toward you slowly until it clicks.

This locks the handwheel in place.

w Handwheel

v Pass the straight end (not the loop end) through the

looper threader hole until it comes out from the the

hole of the looper tip.

e Loose end of looper threading wire

r Looper threader hole

b Pass approximately 2˝ (5 cm) thread through the loop

of the looper threading wire.

t Thread

n Pull the loose end of the looper threading wire until

the thread comes out from the hole of the looper tip.

m Remove the thread from the looper threading wire.

, Return the looper threader switch lever to the

“SEWING” position.

CAUTION

Do not raise or lower the looper thread lever while

threading.

26

Page 28

Using a standard thread

z Pass the thread up to the looper thread guide (in front

of the looper threader hole).

q Looper thread

x Prepare 12˝ (30 cm) of a standard thread and tie it 5

cm from the end of the looper thread as shown.

w Standard thread

e Knot

r 5 cm

t

c

y

v

u

i

b

Figure A

,

t

q

m

q

e

z x

q

w

e

r

x

o

n

z

q

q

27

NOTE:

when tying the standard thread to the looper thread,

tie a knot as small as possible and cut any excess

standar thread.

c Set the looper threader switch lever to “THREADING”

position.

t Looper threader switch lever

v Turn the handwheel toward you slowly until it clicks.

This locks handwheel in place.

y Handwheel

b Using the tweezers, insert approximately 1˝ (2 cm) of

the standard thread into the threading hole.

u Tweezers

i Looper threader hole

n Raise the looper threader lever until it clicks into

place.

Lower the looper threader lever until it knocks into

place.

o Looper threader lever

m Pull out approximately 4˝ (10 cm) of the standard

thread from the hole in the looper tip and trim it at the

knot.

* When the knot reaches the looper threader hole,

fold the loose end of the looper thread as illustrated

by figure A in procedure b.

, Return the looper threader switch lever to the

“SEWING” position.

Replacing threaded looper thread

z Cut the threaded looper thread between the thread

guide and the top cover thread guide.

q Thread guide

w Top cover thread guide

w

x Set a new spool of looper thread.

Pass the new looper thread through the thread guide,

and tie it to the end of the threaded looper thread.

Tie a knot as small as possible.

e Knot

c

e

c Slowly pull the threaded looper thread out from the

hole of the looper tip until the knot comes out.

Page 29

(A) (B)

q

e

r

r

t

z

x

c

z

x

w

c

Threading the Right Needle

z Draw the thread through the thread guide from back

to front: (A)

q Thread guide

x Slide the thread under the top cover thread guide as

illustrated.

w Top cover thread guide

c Pull the thread along the slit.

Using both hands, insert the thread between the

tension disks of the right needle thread tension dial.

e Thread

r Tension disk

t Right needle thread tension dial

NOTE:

Raise the presser foot lifter for easier threading.

CAUTION

Turn the power switch OFF before threading the

machine.

28

NOTE:

If the thread tends to slip away from the guide while

sewing, pass the thread through both thread guide

holes as shown: (B)

Page 30

v Pull the thread down along the slit and draw it to the

left through the thread path.

y Slit

u Thread path

b Pull the thread up and along the left side of the thread

take-up lever cover and pass it over the take-up lever

thread guide.

i Thread take-up lever cover

o Thread take-up lever thread guide

v b

v

b

n

m

n m ,

. ⁄0

y

u

u

i

o

o

i

!0

!1

!2

!3

29

n Pass the thread through the right slit of the needle

thread guide.

!0 Needle thread guide

m Pass the thread through the needle bar thread guide

from left to right.

!1 Needle bar thread guide

, Thread the right needle from front to back.

!2 Right needle

* Use the needle threader (refer to page 30).

. Pull out approximately 4˝ (10 cm) of thread from the

needle and slide it under the foot so that it runs in

between the foot and the upper knife.

!3 Upper knife

⁄ 0 Close the looper cover and lower the presser foot

lifter.

* Refer to pages 31 and 32 for details on how to

thread the left needle.

Page 31

Using the needle threader

Following the procedure m on page 29 or page 32,

thread the needles with the needle threader shown

below.

z Turn the handwheel toward you to match the “o” mark

on the belt cover with the “-” mark on the handwheel.

q Handwheel

x Lower the presser foot lifter.

w Presser foot lifter

CAUTION

Turn the power switch OFF before threading the

machine.

q

R

L

e

r

u

z

30

x

w

c

v

r

b

t

y

n

m

c Set the needle threader switch lever to R when

threading the right needle.

Set the needle threader switch lever to L when

threading the left needle.

e Needle threader switch lever

v Pull down the needle threader lever as far as it will go.

r Needle threader lever

b Draw the thread along the guide on the needle

threader switch lever from the left and under the hook.

t Guide

y Hook

* Make sure that the thread or your finger does not

touch the upper looper or the upper knife.

n Slowly raise the threader lever so that a loop of the

thread is pulled up through the needle.

r Needle threader lever

u Loop

m Pull the thread loop and draw out the thread end to

the rear through the needle eye.

Page 32

z

c

(A)

(B)

q

x

w

e

r

r

t

z

x

c

Threading the Left Needle

z Draw the thread through the thread guide from back

to front: (A)

q Thread guide

x Slide the thread under the top cover thread guide as

illustrated.

w Top cover thread guide

c Pull the thread along the slit.

Using both hands, insert the thread between the

tension disks of the left needle thread tension dial.

e Thread

r Tension disk

t Left needle thread tension dial

NOTE:

Raise the presser foot lifter for easier threading.

CAUTION

Turn the power switch OFF before threading the

machine.

31

NOTE:

If the thread tends to slip away from the guide while

sewing, pass the thread through both thread guide

holes as shown: (B)

Page 33

v Pull the thread down and along the slit and draw it to

the left through the thread path.

y Slit

u Thread path

b Pull the thread up and along the left side of the thread

take-up lever cover and pass it over the take-up lever

thread guide.

i Thread take-up lever cover

o Thread take-up lever thread guide

v b

n m ,

. ⁄0

b

v

n

m

i

o

u

u

y

i

!0

!1

!2

!3

32

o

n Pass the thread through the left slit of the needle

thread guide.

!0 Needle thread guide

m Pass the thread through the needle bar thread guide

from left to right.

!1 Needle bar thread guide

, Thread the left needle from front to back.

!2 Left needle

* Use the needle threader (refer to page 30).

. Pull out approximately 4˝ (10 cm) of thread from the

needle and slide it under the foot so that it runs in

between the foot and the upper knife.

Refer to pages 28 and 29 for details on how to thread

the right needle.

⁄ 0 Close the looper cover and lower the presser foot

lifter.

Page 34

Thread and Needle Chart

Type of fabric

Thread

Needle

Stitch

length dial

Differential

feed dial

Chaining

finger switch

knob

Lower looper

pre-tension

setting slider

Upper knife

Light weight

Organdy,

Georgette,

Lawn,

Crepe de chine,

Lining

Synthetic

#80-100

HAx1SP

#11-14

2.0-3.0

0.5-1.0

S

STD.

Activated

Medium weight

Cotton, Linen,

Satin,

Ordinary fabric

Synthetic

#60-100

HAx1SP

#14

2.5-3.5

1.0

Heavy weight

Tweed,

Coating, Denim,

Doeskin,

Thick fabric

Synthetic

#50-100

HAx1SP

#14

3.0-5.0

1.0

Knits

Knitted fabric

Synthetic

#60-90

Woolly nylon

(for upper

looper)

HAx1SP

#11-14

2.5-3.5

1.0-2.0

* For details on how to adjust the stitch length and the differential feed ratio, refer to pages 37-38 (4 threads), page 39 (3

threads) or page 40 (2 threads).

* Use wooly nylon thread as upper looper thread for rolled hemming, picot edging and narrow hemming.

33

Page 35

TEST STITCHING

Starting Sewing

z Close the side cover and the looper cover.

Turn the power switch ON.

x Make sure that the upper knife is activated (in the

raised position).

c Lower the presser foot lifter.

v Draw all of the threads back under the foot. Slowly

run the machine and produce a 2˝ (5 cm) thread chain

while gently pulling the thread chain to the back.

Check the chain.

b Insert the fabric under the toe of the foot. (You do

not need to raise the foot.) Start sewing slowly. The

fabric will automatically be fed. Guide the fabric in the

desired direction.

* For heavyweight fabric, raise the presser foot and

insert the fabric in front of the knife. Lower the foot

and start to sew while guiding the fabric.

Finishing Sewing

z After stitching is complete, continue to slowly produce

approximately 5˝ (12 cm) of thread chain while gently

pulling the thread chain to the back.

q

34

z

x

x Cut the threads with the thread cutter as illustrated,

leaving a thread chain approximately 2˝ (5 cm) long

on the end of the fabric.

q Thread cutter

Page 36

Sewing Continuously

Insert the next piece of the fabric under the toe of the

foot, and start sewing. You do not need to raise the

presser foot for ordinary fabric.

* For heavyweight fabric, raise the presser foot and insert

the fabric in front of the knife. Lower the foot and start

sewing while guiding the fabric.

35

q

Using Guide Lines

The guide lines on the top of the looper cover help you to

measure the distance from the right needle drop position.

The numbers on the top of the looper cover indicate the

distance from the right needle position in inches.

q 5/8˝ to the right of the right needle position

* The cutting width between the right needle position and

the upper knife when in the standard position (refer to

page 12) is 3.5 mm.

Page 37

Securing Ends

To avoid raveling, you need to leave a thread chain

approximately 2˝ (5 cm) long at the beginning and at the

end of a seam. To secure the beginning and end of a

seam, choose one of the following methods.

At the beginning of the seam

A. Separate and tie the thread ends together.

B. Thread the chain through a large eyed needle, and

weave that chain through the overlock stitches on the

fabric.

C. Cut the chain at the edge of the fabric, and apply a

small amount of seam sealant (Fray Check™ or Fray-

No-More™) to the thread ends.

D. Securing the beginning w ith the machine

z Before putting your fabric in the machine, sew a

thread chain approximately 2˝ (5 cm) long behind

the needle.

x Put your fabric on the machine. Serge a few

stitches and stop.

c Raise the presser foot and bring the thread chain

to the left around and under the presser foot.

v Place the thread chain between the presser foot

and upper knife, holding it in position as you lower

the presser foot to sew.

b After sewing approximately 1˝ (2.5 cm), move the

chain to the right and under the upper knife, cutting

the chain as you sew.

D

A

B

C

At the end of the seam

Securing the seam end with the machine

z Serge one stitch off the end of the seam.

x Raise the needle and presser foot, and gently pull the

threads off the chaining finger.

c Turn the fabric over so that the under side is up.

v Serge approximately 1˝ (2.5 cm) over the stitching and

angle off the fabric.

E

Cutting the Seams

Cut the upper looper thread with a seam ripper (not

included with the machine) to cut the seams.

q Upper looper thread

w Seam ripper

q

36

w

z

z

x c v b

x

c

v

Page 38

Thread Tension (4 threads)

Correct tension

The illustration to the left shows a seam sewn at the

correct tension. Note that you may need to adjust the

thread tension depending on the fabric and thread being

used.

q Wrong side of fabric

w Right side of fabric

e Right needle thread

r Left needle thread

t Upper looper thread

y Lower looper thread

Left needle thread tension is too loose

The illustration to the left shows a seam sewn when the

left needle thread tension is too loose.

Remedy:

Tighten the left needle thread tension.

!1 Left needle tension dial

Right needle thread tension is too loose

The illustration to the left shows a seam sewn when the

right needle thread tension is too loose.

Remedy:

Tighten the right needle thread tension.

!2 Right needle tension dial

Thread tension adjustment

Set all four thread tension dials to “3”.

Sew and check the thread tension.

If the tension on the test piece is not satisfactory, you can

adjust the thread tension with the thread tension dial.

u Thread tension dial

i Setting mark

o Loosen

!0 Tighten

u

i

o

!0

q

w

e

r

t

y

q

e

r

w

t

y

!1

!2

37

q

e

r

w

t

y

Page 39

Looper thread tension is out of balance (1)

The illustration shows sewing results when the lower

looper thread tension is too tight and/or upper looper

thread tension is too loose.

38

Remedy:

Loosen lower looper thread tension and/or tighten upper

looper thread tension.

q Wrong side of fabric

w Right side of fabric

e Right needle thread

r Left needle thread

t Upper looper thread

y Lower looper thread

!3 Upper looper thread tension dial

!4 Lower looper thread tension dial

Looper thread tension is out of balance (2)

The illustration to the left shows a seam sewn when the

upper looper thread tension is too tight and/or the lower

looper thread tension is too loose.

Remedy:

Loosen the upper looper thread tension and/or tighten

the lower looper thread tension.

!3 Upper looper thread tension dial

!4 Lower looper thread tension dial

q

w

e

r

t

y

!3

!3

!4

!4

q

w

e

r

t

y

Page 40

Thread Tension (3 threads)

Correct tension

The illustration to the left shows a seam sewn at the

correct tension. Note that you may need to adjust the

thread tension depending on the fabric and thread being

used.

q Wrong side of fabric

w Right side of fabric

e Right or left needle thread

r Upper looper thread

t Lower looper thread

q

w

e

r

t

y

39

u

i

o

q

w

e

r

t

!0 !1

q

w

e

r

t

!2 !3

q

w

e

r

t

!2 !3

Thread tension adjustment

Set the three thread tension dials to “3”.

Sew and check the thread tension.

If the tension on the test piece is not satisfactory, you can

adjust the thread tension with the thread tension dial.

y Thread tension dial

u Setting mark

i Loosen

o Tighten

Needle thread tension is too loose

The illustration to the left shows a seam sewn when the

left needle thread tension is too loose.

Remedy:

Tighten the needle thread tension.

!0 Left needle tension dial

!1 Right needle tension dial

Looper thread tension is out of balance (1)

The illustration to the left shows a seam sewn when the

lower looper thread tension is too tight and/or the upper

looper thread tension is too loose.

Remedy:

Loosen the lower looper thread tension and/or tighten the

upper looper thread tension.

!2 Upper looper thread tension dial

!3 Lower looper thread tension dial

Looper thread tension is out of balance (2)

The illustration to the left shows a seam sewn when the

upper looper thread tension is too tight and/or the lower

looper thread tension is too loose.

Remedy:

Loosen the upper looper thread tension and/or the tighten

lower looper thread tension.

!2 Upper looper thread tension dial

!3 Lower looper thread tension dial

Page 41

Thread Tension (2 threads)

Correct tension

The illustration to the left shows a seam sewn at the

correct tension. Note that you may need to adjust the

thread tension depending on the fabric and thread being

used.

q Wrong side of fabric

w Right side of fabric

e Right or left needle thread

r Lower looper thread

Thread tension adjustment

Set the lower looper pre-tension setting slider to TIGHT.

Set the two thread tension dials to “3”.

Sew and check the thread tensions.

If the tension on the test piece is not satisfactory, you can

adjust the thread tension with the thread tension dial.

t Thread tension dial

y Setting mark

u Loosen

i Tighten

Needle/Lower looper thread tension is out of

balance (1)

The illustration to the left shows a seam sewn when the

lower looper thread tension is too tight and/or the needle

thread tension is too loose.

Remedy:

Loosen the lower looper thread tension and/or the tighten

upper looper thread tension.

o Left needle thread tension dial

!0 Right needle thread tension dial

!1 Lower looper thread tension dial

q

w

e

r

t

y

u

i

q

w

e

r

o !0 !1

Needle/Lower looper thread tension is out of

balance (2)

40

The illustration to the left shows a seam sewn when the

needle thread tension is too tight and/or the lower looper

thread tension is too loose.

Remedy:

Loosen the needle thread tension and/or tighten the

lower looper thread tension.

o Left needle thread tension dial

!0 Right needle thread tension dial

!1 Lower looper thread tension dial

q

w

e

r

o !0 !1

Page 42

Correct tension for rolled hem

The illustration to the left shows a seam sewn at the

correct tension. Note that you may need to adjust the

thread tension depending on the fabric and thread being

used.

41

Use synthetic thread for the needle thread and woolly

nylon thread for the lower looper thread.

Set the lower looper pre-tension setting slider to STD.

Other settings are same as the 3-threads rolled hem (refer

to page 42).

For best results, make a test run using the fabric

and threads you want to use and adjust the tension

accordingly.

q Wrong side of fabric

w Right side of fabric

e Needle thread

r Lower looper thread

q

w

e

r

Page 43

Rolled Hemming

Picot Edging

Narrow Hemming

Lower looper

pre-tension setting

slider

TIGHT

* Set the lower looper

pre-tension setting slider to

TIGHT after threading.

TIGHT

* Set the lower looper

pre-tension setting slider to

TIGHT after threading.

STD.

Standard setting of

tension dials

Right

needle

Upper

looper

Lower

looper

Right

needle

Upper

looper

Lower

looper

Right

needle

Upper

looper

Lower

looper

(Syntheti

c) 3-4

(Syntheti

c) 3

(Syntheti

c) 3

(Syntheti

c) 2-4

(Syntheti

c) 3

(Syntheti

c) 3

(Syntheti

c) 4

(Syntheti

c) 3

(Syntheti

c) 3

(Syntheti

c) 4

(Wooly

nylon

) 1

(Syntheti

c) 3

-

-

-

(Syntheti

c) 4

(Wooly

nylon

) 1

(Syntheti

c) 3

(Syntheti

c) 4

(Wooly

nylon

) 1

(Wooly

nylon

) 3

(Syntheti

c) 4

(Wooly

nylon

) 1

(Wooly

nylon

) 3

Stitch length dial

R

3-4

R

Differential feed

dial

1.0

1.0

1.0

Chaining finger

switch knob

R R R

Upper knife

Activated

Needle

Using the right needle: HA -1 SP No. 11

(Remove the left needle.)

Needle thread

Synthetic: No. 80 - 100

Fabric

Lightweight fabric such as organdy, crepe de chine, lawn and georgette

ROLLED HEMMING, PICOT EDGING AND NARROW HEMMING

Tension Dial and Machine Settings According to the Thread and Fabric

The setting of tension dials may vary depending on the

type and thickness of fabric and thread being sewn.

* Refer to page 10 for details on how to remove the needle.

* Refer to page 11 for details on how to adjust the stitch length.

* Refer to page 11 for details on how to adjust the difference ratio.

* Refer to page 13 for details on how to adjust the chaining finger switch knob.

* Refer to page 12 for details on how to deactivate and activate the upper knife.

CAUTION

Make sure to turn the power switch off before

changing the needle or setting the chaining finger

switch knob.

42

Page 44

For Better Results

Rolled hemming

Gently pull the end of thread chain to the back at the

beginning and end of sewing.

43

Picot edging

Gently pull the fabric to the back while sewing.

NOTE:

The sewing procedure of narrow hemming is the same

as that for standard overedging.

Page 45

Thread Tension

Correct tension

The illustration to the left shows a seam sewn at the

correct tension. Note that you may need to adjust the

thread tension depending on the fabric and thread being

used.

q Wrong side of fabric

w Right side of fabric

e Right needle thread

r Upper looper thread

t Lower looper thread

Thread tension adjustment

1. Set the tension dials as shown on page 42.

2. Sew and check the tension.

3. If the tension on the test piece is not satisfactory, you

can adjust the thread tension with thread tension dial.

Rolled hemming

Picot edging

q

w

e

r

t

q

t

w

e

r

Narrow hemming

q

w

e

r

t

44

Page 46

For rolled hemming and picot edging

* Thread tension adjustment for narrow hemming is the

same as that for 3-thread overedging (refer to page 39).

q Wrong side of fabric

w Right side of fabric

e Right needle thread

r Upper looper thread

t Lower looper thread

The lower looper thread tension is too tight and/or

the right thread tension is too loose

Remedy:

Tighten the right needle thread tension and/or loosen the

lower looper thread tension.

y Right needle thread tension dial

i Lower looper thread tension dial

q

w

e

r

t

y i

q

w

e

r

t

u

q

45

w

e

r

t

u i

The upper looper thread tension is too loose

Remedy:

Tighten the right needle thread tension.

u Upper looper thread tension dial

The lower looper thread tension is too loose and/or

the upper looper thread tension is too tight

Remedy:

Loosen upper looper thread tension and/or tighten lower

looper thread tension.

u Upper looper thread tension dial

i Lower looper thread tension dial

Page 47

Machine Setting

Lower looper

pre-tension

setting slider

STD.

Standard setting

of tension dials

Left

needle

Right

needle

Upper

looper

Lower

looper

5

5

1-2

6

Stitch length dial

3-4

Differential feed

dial

1.0

Chaining finger

switch knob

S

Upper knife

Activated

Needle

Use both the right and left needles:

HA-1 SP No. 14

Needle thread

Synthetic: No. 60 - 80

Upper looper

thread

Decorative thread

* Use the looper threading wire or a

standard thread for threading.

Lower looper

thread

Synthetic: No. 60 - 100

Fabric

Medium weight or heavy weight

ADVANCED TECHNIQUES

Decorative Overedging

q Left needle thread tension dial

w Right needle thread tension dial

e Upper looper thread tension dial

r Lower looper thread tension dial

t Chaining finger switch knob

y Upper knife release knob

u Stitch length dial

i Differential feed dial

o Lower looper pre-tension setting slider

* Refer to page 10 for details on how to remove the

needle.

* Refer to page 11 for details on how to adjust the

stitch length.

* Refer to page 11 for details on how to adjust the

difference ratio.

* Refer to page 12 for details on how to deactivate/

activate the upper knife.

* Refer to page 13 for details on how to adjust the

chaining finger switch knob.

CAUTION

Make sure to turn the power switch off before

changing the needle, deactivating/activating the upper

knife or setting the chaining finger switch knob.

w

q

46

e

r

t

y

u

i

o

NOTE:

• You may need to adjust the thread tension.

• For best results, gently pull the thread chain to the

back at the beginning and end of sewing.

Page 48

Gathering

Sew and check the thread tensions.

If the tension balance on the test piece is not satisfactory,

you can adjust the thread tension with the thread tension

dial.

* Adjust the differential feed dial between 1.0 and 2.0 for

gathering.

CAUTION

Make sure to turn the power switch off before

changing the needle, deactivating/activating the upper

knife or setting the chaining finger switch knob.

q

q Left needle thread tension dial

w Right needle thread tension dial

e Upper looper thread tension dial

r Lower looper thread tension dial

t Chaining finger switch knob

y Upper knife release knob

u Stitch length dial

i Differential feed dial

o Lower looper pre-tension setting slider

* Refer to page 10 for details on how to remove the

needle.

* Refer to page 11 for details on how to adjust the

stitch length.

* Refer to page 11 for details on how to adjust the

difference ratio.

* Refer to page 12 for details on how to deactivate/

activate the upper knife.

* Refer to page 13 for details on how to adjust the

chaining finger switch knob.

w e

r

t

y

u

i

o

Machine Setting

Lower looper

pre-tension

setting slider

STD.

Standard setting

of tension dials

Left

needle

Right

needle

Upper

looper

Lower

looper

3

3

3

3

Stitch length dial

3-4

Differential feed

dial

2.0

Chaining finger

switch knob

S

Upper knife

Activated

Needle

Use both the right and left needles:

HA-1 SP No. 14 or No. 11

Needle thread

Synthetic: No. 60 - 80

Upper looper

thread

Synthetic: No. 60 - 100

Lower looper

thread

Synthetic: No. 60 - 100

Fabric

Medium weight, light weight

47

Page 49

Sewing

z Sew the folded edge while guiding it along the guide

line.

q Right side of fabric

w Folded edge

e Guide line on the needle plate

x Open the fold flat and press the pintucks to one side.

* After you finish sewing, return the upper knife to the

original position (activated).

w

q

e

r

t

y

u

i

o

q

w

e

z

x

Machine Setting

Lower looper

pre-tension

setting slider

STD.

Standard setting

of tension dials

Left

needle

Right

needle

Upper

looper

Lower

looper

-

4

5-7

2-4

Stitch length dial

R

Differential feed

dial

1.0

Chaining finger

switch knob

R

Upper knife

Deactivated

Needle

Use the right needle:

HA-1 SP No. 14 or No. 11

Needle thread

Synthetic: No. 80 - 100

Upper looper

thread

Synthetic: No. 80 - 100

Lower looper

thread

Synthetic: No. 80 - 100

Fabric

Light weight, knit fabric

Pintucking

NOTE:

• You may need to adjust the thread tension

depending on the type of fabric and thread being

used.

• If the tension balance on the test piece is not

satisfactory, you can adjust the thread tension with

the thread tension dial.

CAUTION

Make sure to turn the power switch off before

changing the needle, deactivating/activating the upper

knife or setting the chaining finger switch knob.

q Left needle thread tension dial

w Right needle thread tension dial

e Upper looper thread tension dial

r Lower looper thread tension dial

t Chaining finger switch knob

y Upper knife release knob

u Stitch length dial

i Differential feed dial

o Lower looper pre-tension setting slider

* Refer to page 10 for details on how to remove the

needle.

* Refer to page 11 for details on how to adjust the

stitch length.

* Refer to page 11 for details on how to adjust the

difference ratio.

* Refer to page 12 for details on how to deactivate/

activate the upper knife.

* Refer to page 13 for details on how to adjust the

chaining finger switch knob.

48

Page 50

Flatlock

CAUTION

Make sure to turn the power switch off before

changing the needle, deactivating/activating the upper

knife or setting the chaining finger switch knob.

q

q Left needle thread tension dial

w Right needle thread tension dial

e Upper looper thread tension dial

r Lower looper thread tension dial

t Chaining finger switch knob

y Upper knife release knob

u Stitch length dial

i Differential feed dial

o Lower looper pre-tension setting slider

* Refer to page 10 for details on how to remove the

needle.

* Refer to page 11 for details on how to adjust the

stitch length.

* Refer to page 11 for details on how to adjust the

difference ratio.

* Refer to page 12 for details on how to deactivate/

activate the upper knife.

* Refer to page 13 for details on how to adjust the

chaining finger switch knob.

* Refer to page 18 for details on how to raise and

lower the spreader.

w e

r

t

y

u

i

o

Machine Setting

Lower looper

pre-tension

setting slider

STD.

Standard setting

of tension dials

(1 needle 3

threads)

Left

needle

Right

needle

Upper

looper

Lower

looper

0-2

-

0

6-7

Standard setting

of tension dials

(1 needle 2

threads)

Left

needle

Right

needle

Upper

looper

Lower

looper

0-2

-

-

7

Spreader

(1 needle 2

threads)

Stitch length dial

3-4

Differential feed

dial

1.0

Chaining finger

switch knob

S

Upper knife

Deactivated

Needle

Use the left needle:

HA-1 SP No. 14 or No. 11

Needle thread

Synthetic: No. 60 - 100

Upper looper

thread

Left

needle

Right

needle

Upper

looper

Lower

looper

Synthetic:

No.60-

100

Decorati

ve

thread

Synthetic:

No.60100

Lower looper

thread

Left

needle

Right

needle

Upper

looper

Lower

looper

Synthetic:

No.60100

Decorati

ve

thread

* Use the looper threading wire or a standard thread for

threading.

Fabric

Medium weight

49

NOTE:

• You may need to adjust the thread tension

depending on the type of fabric and thread being

used.

• If the tension balance on the test piece is not

satisfactory, you can adjust the thread tension with

the thread tension dial.

Page 51

r

Sewing

z Fold the fabric wrong sides together.

q Wrong side of fabric

50