Page 1

Second Edition: xx May 2018

SERVICE MANUAL

MODEL: AirThread 2000D

Page 2

Top Cove r

Required Tools ...................................................................................................................................... 1

Replacing External Parts

Top c o v e r ............................................................................................................................................... 2

Face plate (1) ......................................................................................................................................... 3

Face plate (2) ........................................................................................................................................ 4

Belt cover .............................................................................................................................................. 5

Base plate ............................................................................................................................................. 6

Looper cover ......................................................................................................................................... 7

Front cover ............................................................................................................................................8

Side cover ............................................................................................................................................. 9

Rear cover ........................................................................................................................................... 10

Mechanical Adjustment

To adjust the needle bar height ........................................................................................................... 11

To adjust the presser foot bar height ................................................................................................... 12

To adjust the feed dog height .............................................................................................................. 13

To adjust the differential feed .............................................................................................................. 14

To adjust the stitch length .................................................................................................................... 15

To adjust the timing of the needle and the upper knife ....................................................................... 16

To adjust the positions of the upper knife and the lower knife ............................................................ 17

To replace the lower looper ................................................................................................................. 18

To adjust the position of the lower looper (1) ....................................................................................... 19

To adjust the position of the lower looper (2) ...................................................................................... 20

To adjust the clearance of the needle and lower looper and the clearance of the needle and

needle guard (front) (1) ................................................................................................................... 21

To adjust the clearance of the needle and lower looper and the clearance of the needle and

needle guard (front) (2) .................................................................................................................. 22

To adjust the clearance of the needle and needle guard (rear) .......................................................... 23

To adjust the timing of the needle and the lower looper ...................................................................... 24

To replace the upper looper and to adjust the position of the tip of the upper looper ......................... 25

To adjust the leftmost position of the upper looper ............................................................................. 26

To adjust the timing of the upper looper and the lower looper ............................................................ 27

To adjust the clearance of the upper looper and the lower looper ...................................................... 28

To adjust the clearance between the needle and the upper looper .................................................... 29

To adjust the position of the chaining finger ........................................................................................ 30

To adjust the thread tensions .............................................................................................................. 31

To adjust the pre-tension ..................................................................................................................... 32

To adjust the position the looper thread take-up lever ........................................................................ 33

To adjust the looper threader (air) (1) .................................................................................................. 34

To adjust the looper threader (air) (2) .................................................................................................. 35

To adjust the needle threader .............................................................................................................. 36

To adjust the height of the rubber sole (rear left) ................................................................................ 37

Replacing External Parts

To replace the machine socket ............................................................................................................ 38

To replace the motor (1) ......................................................................................................................39

To replace the motor (2) ...................................................................................................................... 40

To replace the LED .............................................................................................................................. 41

To change the micro switch (to detect covers and the looper threader switch lever) .........................42

To change the micro switch (to detect the presser foot lifter).............................................................. 43

Page 3

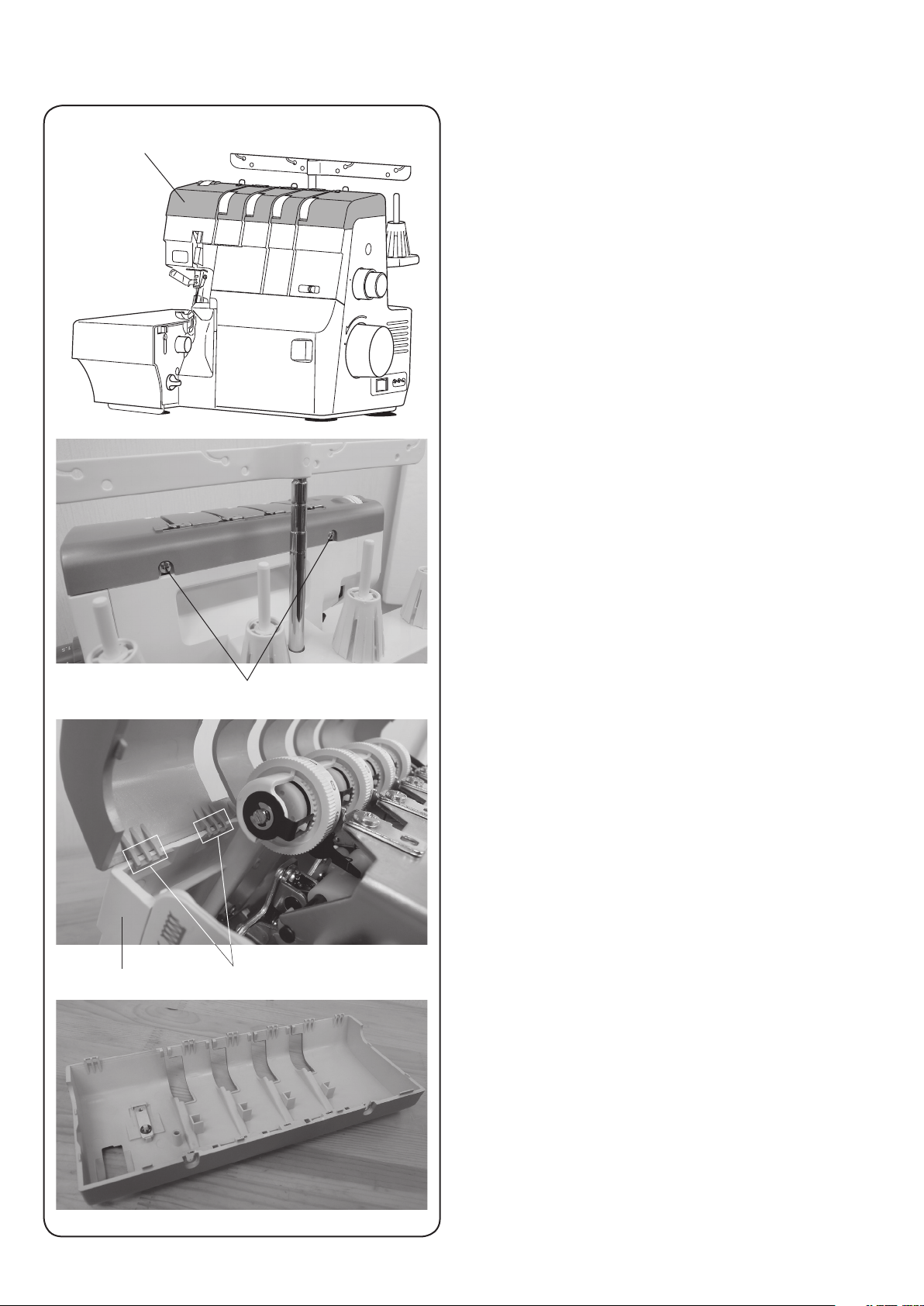

Plate gauge

Lower looper height gauge

Timing gauge

Needle bar gauge

Required Tools

Guide line

Position of the lower looper tip

Lower looper height

Travel

Upper looper tip gauge

Not gauge.

If threading special threads, such as wooly nylon.

Looper threading wire to clean the pipe of the looper.

A

C

D1

D2

Position of the upper looper tip

Bulge

F G

B

E

A: Needle bar height (Refer to page 11)

B: Presser bar height (Refer to page 12)

C: Feed dog height (Refer to page 13)

D1: Minimum stitch length (Refer to page 15)

D2: Maximum stitch length (Refer to page 15)

E: Overlap of the upper knife and the lower knife (Refer to page 17)

F: Leftmost position of the upper looper (Refer to page 26)

G: Timing of the upper looper and the lower looper (Refer to page 27)

1

Page 4

Top c o v e r

MODEL: AirThread 2000D

Replacing External Parts

Top cover

To remov e :

1. Remove the setscrews (2 pcs.) on the rear side of the

to p c over.

Setscrew

HookFront cover

2. Release the hooks of the top cover from the front

cov er.

3. Remove the top cover.

To attach:

Follow the above procedure in reverse.

2

Page 5

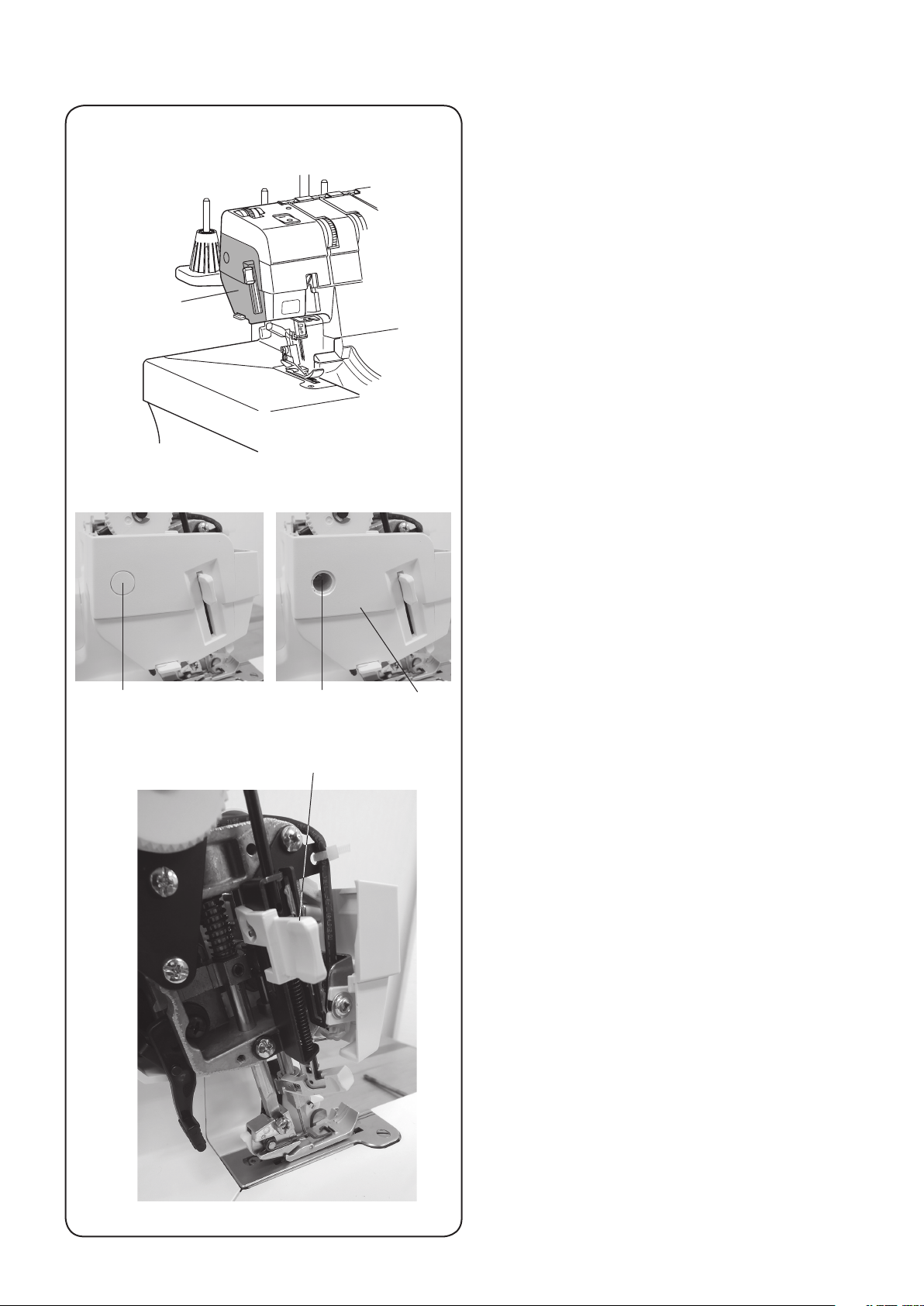

Face plate

MODEL: AirThread 2000D

Replacing External Parts

Face plate (1)

Cap Setscrew

Needle treader lever

To remov e :

1. Remove the top cover.

2. Remove the cap.

3. Remove the setscrew.

Face plate

4. Slightly lower the needle threader lever and remove

the face plate.

3

Page 6

Replacing External Parts

Face plate (2)

To attach:

1. Attach the face plate in place.

Hold the face plate with your finger.

MODEL: AirThread 2000D

Rib

Front cover

2. Pull the front cover lightly and place the ribs into the

inside of the front cover.

3. Tighten the setscrew and attach the cap.

Setscrew

Face plate

4

Page 7

Replacing External Parts

Belt cover

MODEL: AirThread 2000D

Looper cover

Cap

Belt cover

Setscrew A

To remov e :

1. Remove the top cover.

2. Open the looper cover.

3. Remove the cap.

4. Remove the setscrew A.

5. Loosen the setscrew B on the base.

6. Remove the belt cover.

Setscrew BBase plate

7. Close the looper cover.

To attach:

Follow the above procedure in reverse.

5

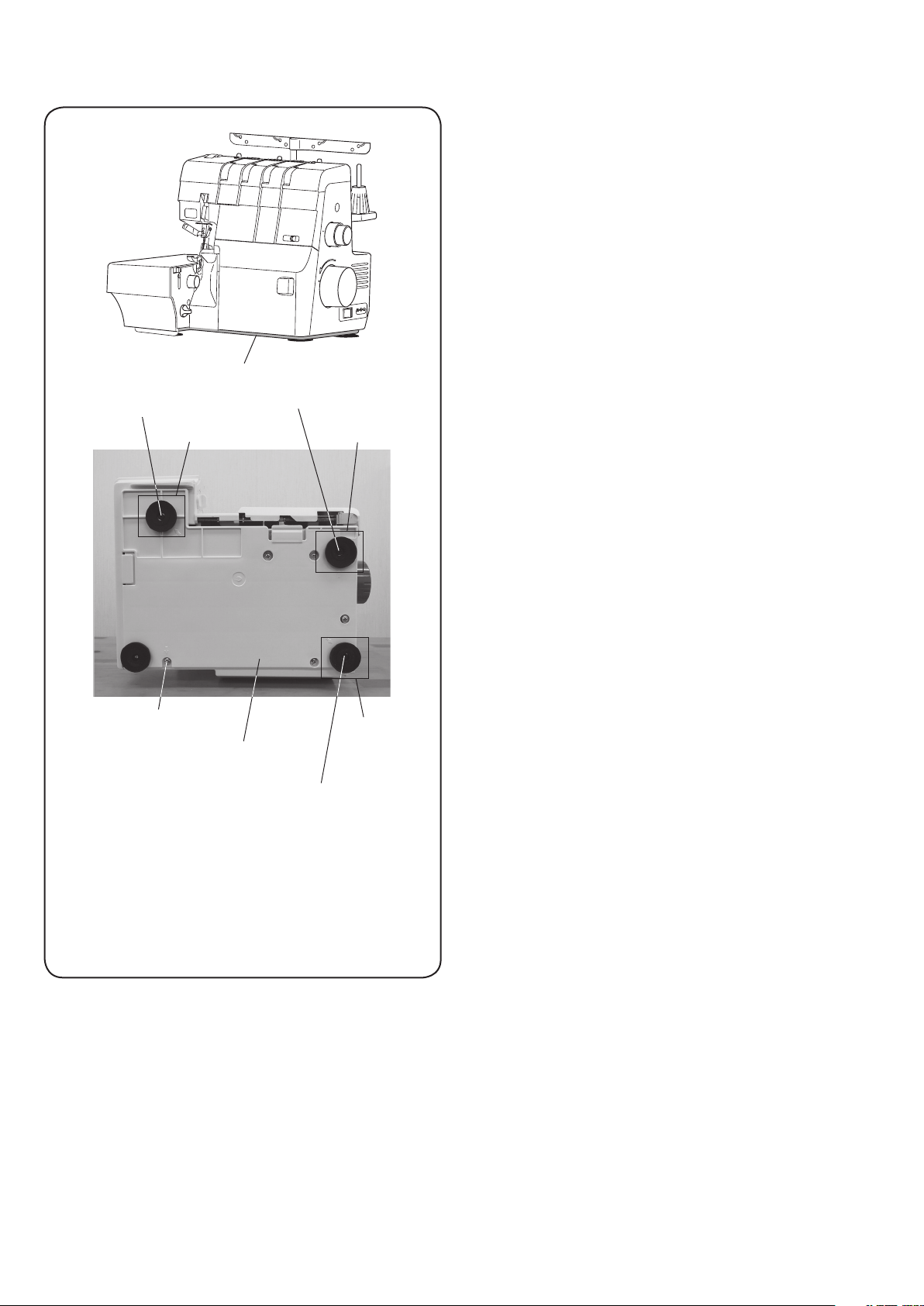

Page 8

Hinge screw

Rubber sole (unit)

MODEL: AirThread 2000D

Replacing External Parts

Base plate

Base plate

Hinge screw

Rubber

sole (unit)

To remov e :

1. Open the side cover.

2. Remove the hinge screw (3 pcs.) and remove the

rubber soles (unit).

3. Remove the setscrew.

4. Remove the base plate.

Setscrew

Base plate

To attach:

Follow the above procedure in reverse.

Rubber

sole (unit)

Hinge screw

6

Page 9

Replacing External Parts

Looper cover

MODEL: AirThread 2000D

Looper

cover shaft

Hook of looper cover position detecting arm

Looper cover

Setscrew

Hook of looper cover

position detecting arm

Setscrew

Looper cover shaft

To remov e :

1. Remove the base plate.

2. Remove the setscrews (2 pcs.).

3. Release the hook of looper cover position detecting

arm from the looper cover shaft.

4. Remove the looper cover.

To attach:

1. Set the looper threader switch lever to the

"THREADING" (right side).

Make sure that the looper cover position detecting

arm comes in front of the looper. threader switch

lever connecting lever (shown as the looper cover

position detecting arm on top the looper threader

switch lever connecting lever in the figure).

2. Put the hook of looper cover position detecting arm on

the looper cover shaft.

3. Tighten the setscrews (2 pcs).

4. Attach the base plate.

Looper threader switch lever

connecting lever

Looper cover

position detecting arm

7

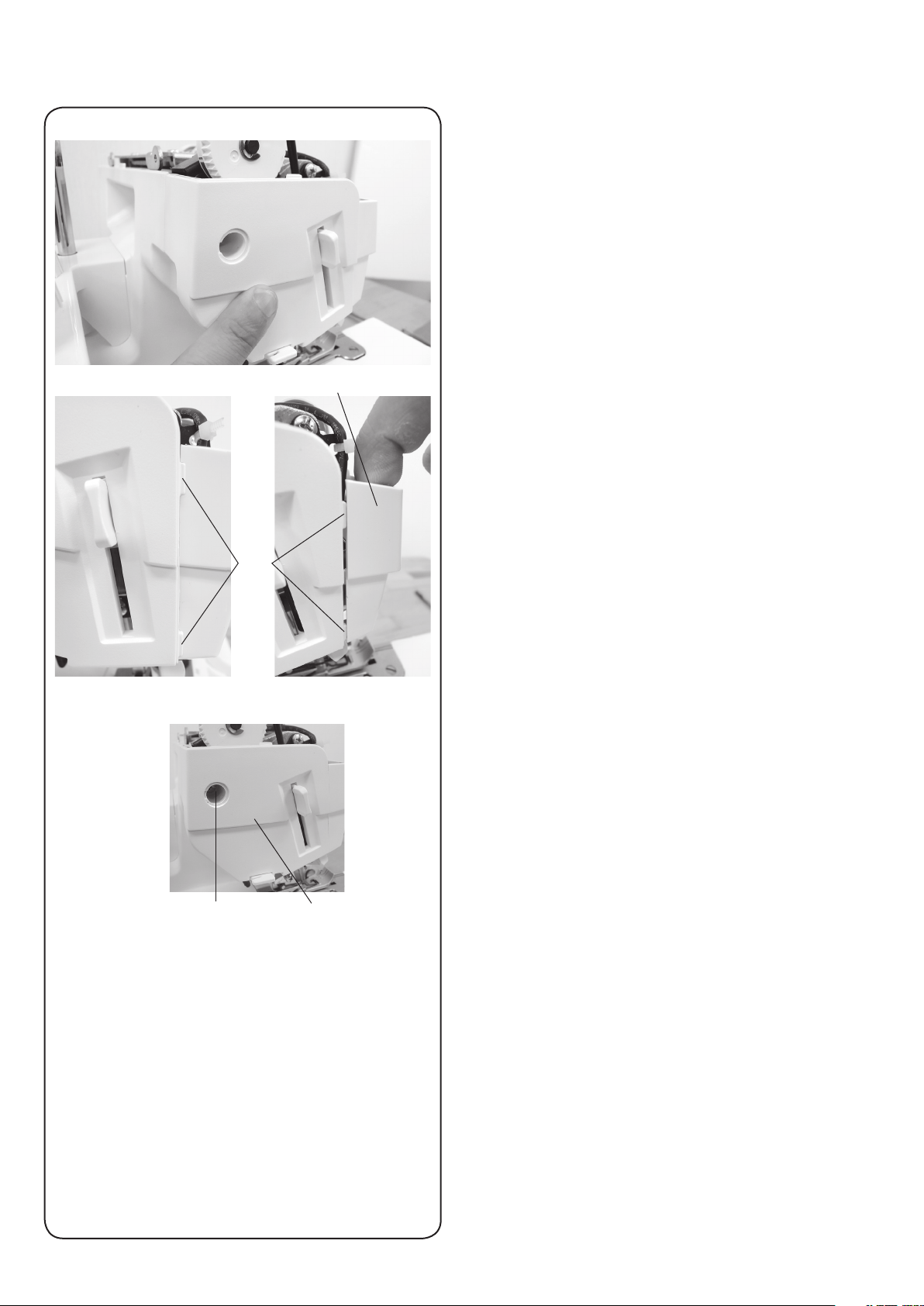

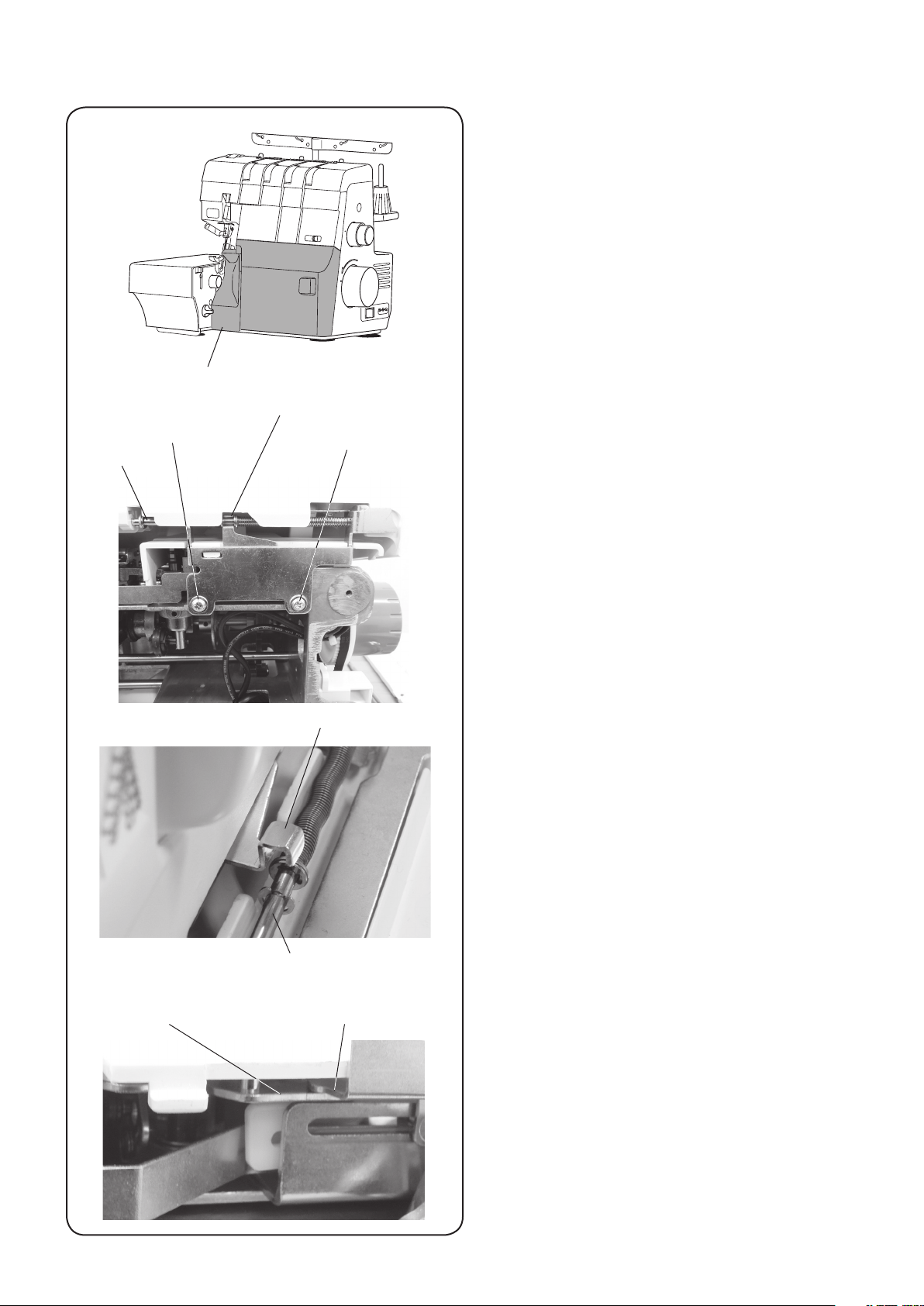

Page 10

Replacing External Parts

Front cover

MODEL: AirThread 2000D

Front cover

Setscrew A

To remov e :

1. Remove the top cover, the face plate, the belt cover,

the base plate and the looper cover.

2. Set the upper looper to the lowest position by turning

the handwheel toward you.

Handwheel

Front cover

3. Remove the setscrews A (2 pcs.).

Upper looper

Setscrew C

Setscrew A

Looper cover position detecting arm

Looper threader lever

Setscrew B

4. Loosen the setscrew B.

5. Loosen the setscrews C (2 pcs.).

6. Raise the looper threader lever halfway.

7. Set the looper cover position detecting arm to the right

and remove the front cover.

Setscrew C

To attach:

Follow the above procedure in reverse.

* Make sure that set the front cover into the catch of the

looper cover position detecting arm.

8

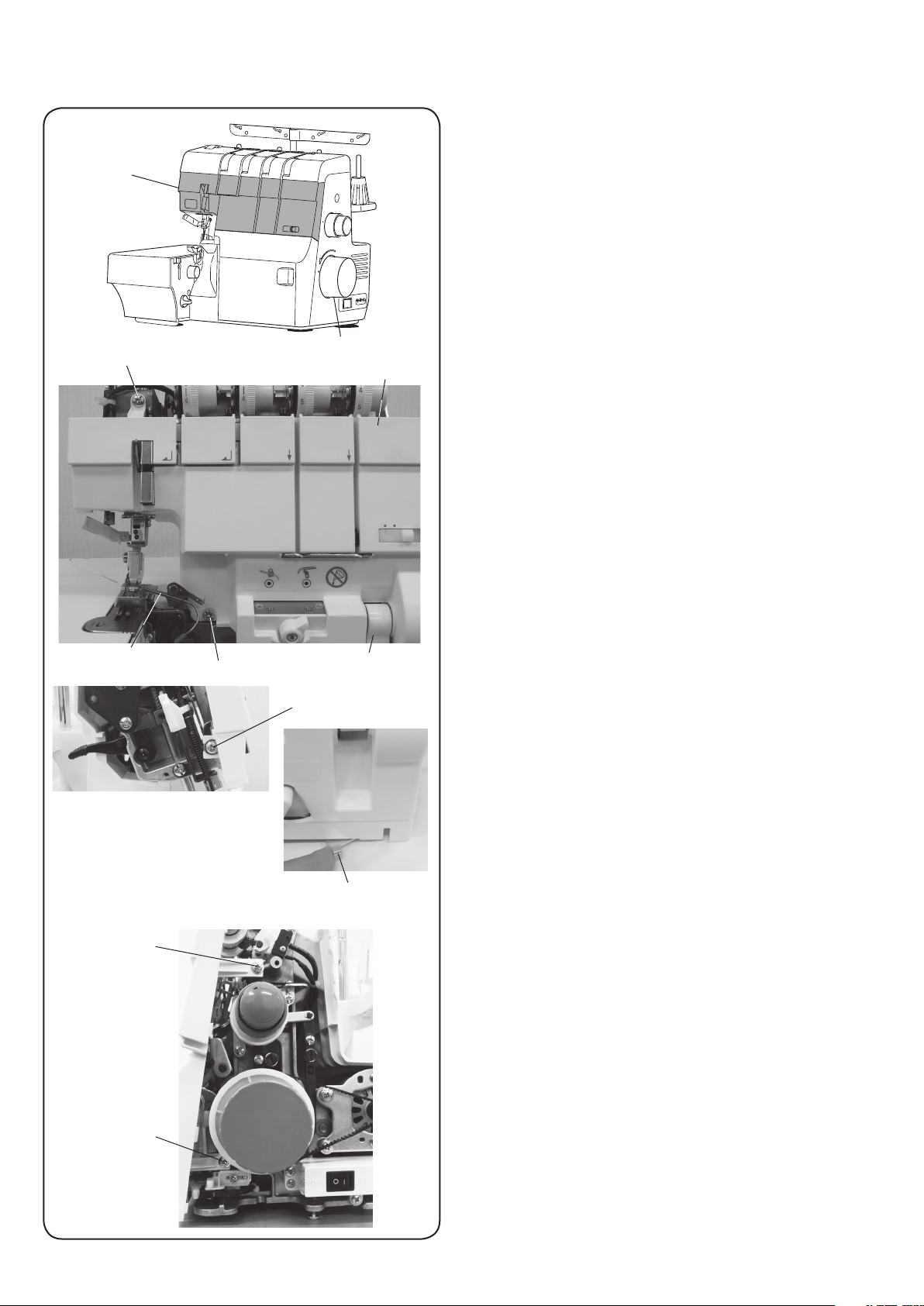

Page 11

Side cover

MODEL: AirThread 2000D

Replacing External Parts

Side cover

Setscrew

To remov e :

1. Open the side cover as far as it will go.

2. Remove the setscrews (2 pcs.).

3. Remove the side cover.

Setscrew

Groove of the rear cover

Edge of the side cover

Recess of the base plate

To attach:

1. Put the edge of the side cover on the groove of the

rear cover and partially tighten the setscrews (2 pcs.).

2. Open and close the side cover adjusting the position

vertically and horizontally. Make sure that there is no

gap with the needle plate, the rear cover or the looper

cover guide.

3. Make sure that the tab of the side cover is engaged

with the recess of the base plate.

4. Tighten the setscrews (2 pcs.).

Tab of the side cover

9

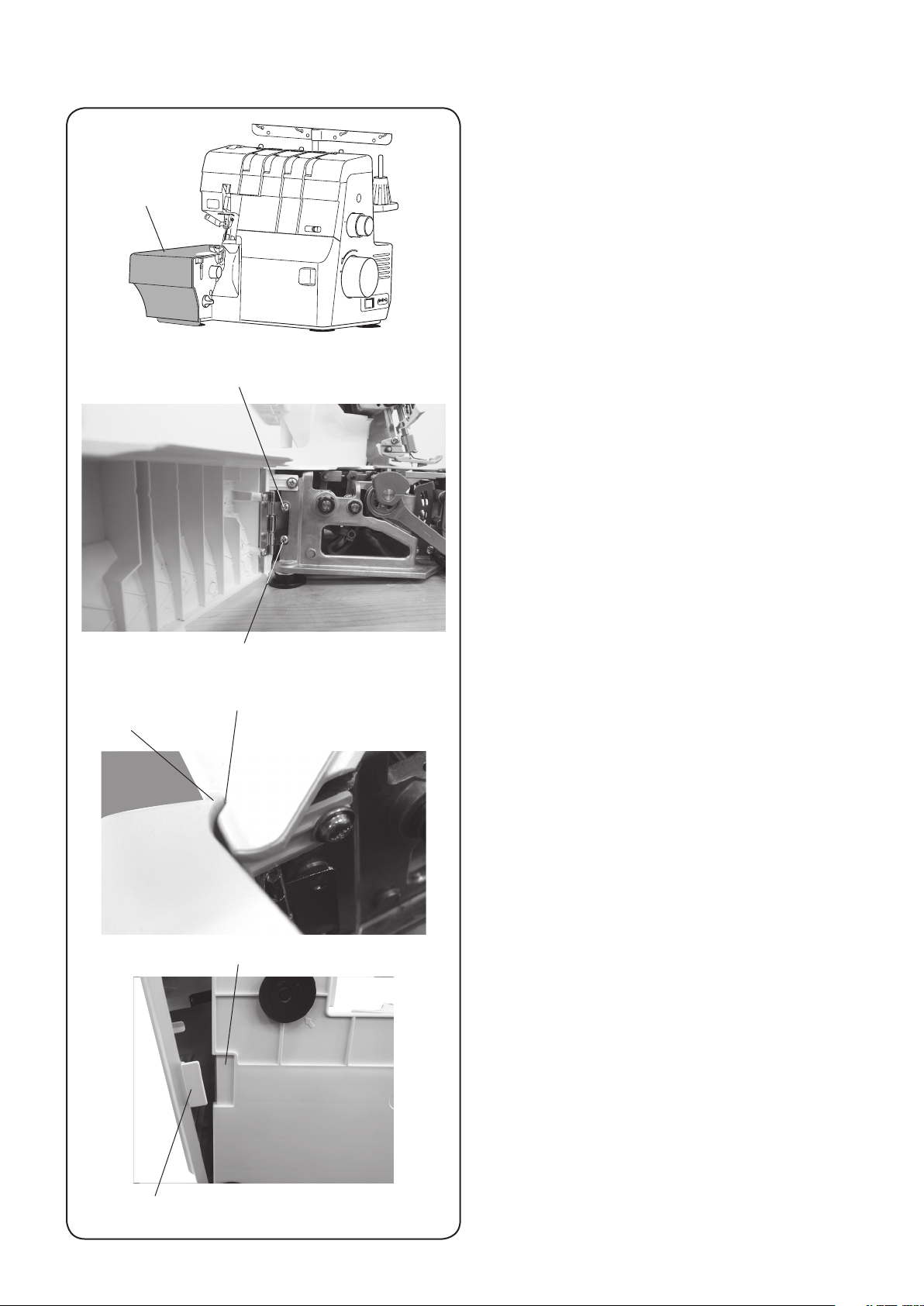

Page 12

Thread guide

base

Rear cover

MODEL: AirThread 2000D

Replacing External Parts

Rear cover

To remov e :

1. Remove the face plate, the belt cover and the side

cov er.

2. Remove the setscrews A (2 pcs.) on the carrying

handle.

Setscrew A

Setscrew B Setscrew B

Setscrew C

3. Remove the setscrews B (2 cps.) from the base.

4. Loosen the setscrew C.

5. Remove the rear cover.

To attach:

Follow the above procedure in reverse.

10

Page 13

MODEL: AirThread 2000D

Mechanical Adjustment

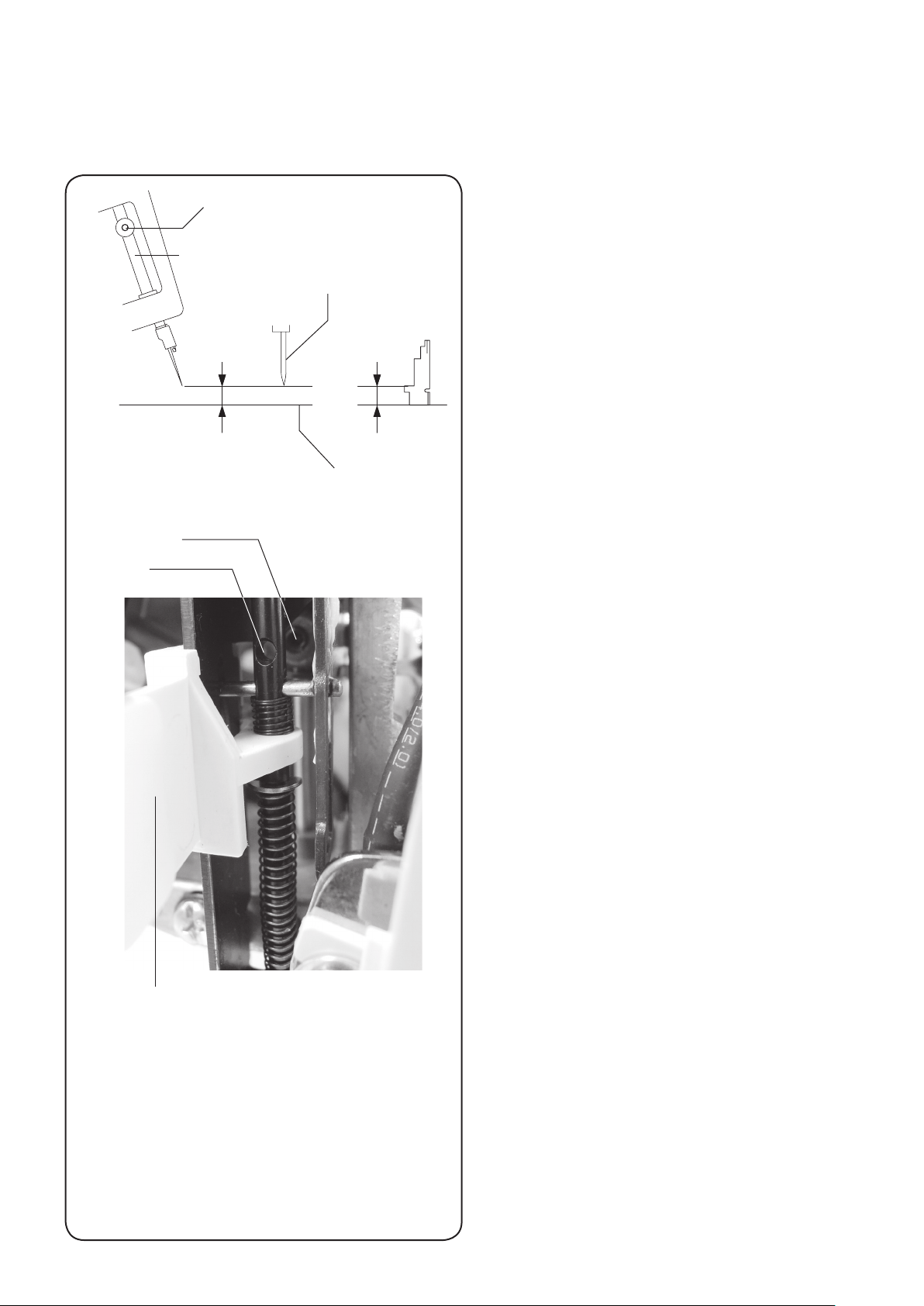

To adjust the needle bar height

The distance between the tip of the right needle (HA x 1SP#14) and the surface of the needle plate should be 11.6 to

12.2 mm when the needle is at the heighest position.

11.6〜12.2 mm

Setscrew

Hole

Setscrew

Needle bar

Right needle

11.9 mm

Surface of needle plate

Gauge

To check:

1. Remove the presser foot (unit).

2. Turn the handwheel toward you to raise the needle

bar at the highest poisition.

3. Use the gauge to check if the distance between the

tip of the right needle and the surface of the needle

plate is 11.6 mm to 12.2 mm.

4. If not, adjust as follows;

To adjust:

1. Remove the top cover and face plate.

2. Lower the needle threader lever to align the hole and

setscrew. Access the setscrew with the hexagonal

wrench (2 mm) through the hole.

3. Loosen the setscrew with the hexagonal wrench (2

mm), and adjust the needle bar height moving the

needle bar up or down. Be careful not to turn the

needle bar while moving it.

Tighten the setscrew after adjustment.

4. Turn the handwheel toward you.

Be sure that the distance between the tip of the right

needle and the needle plate is 11.6 mm to 12.2 mm.

5. Attach the face plate and the top cover.

Needle threader lever

11

Page 14

MODEL: AirThread 2000D

Mechanical Adjustment

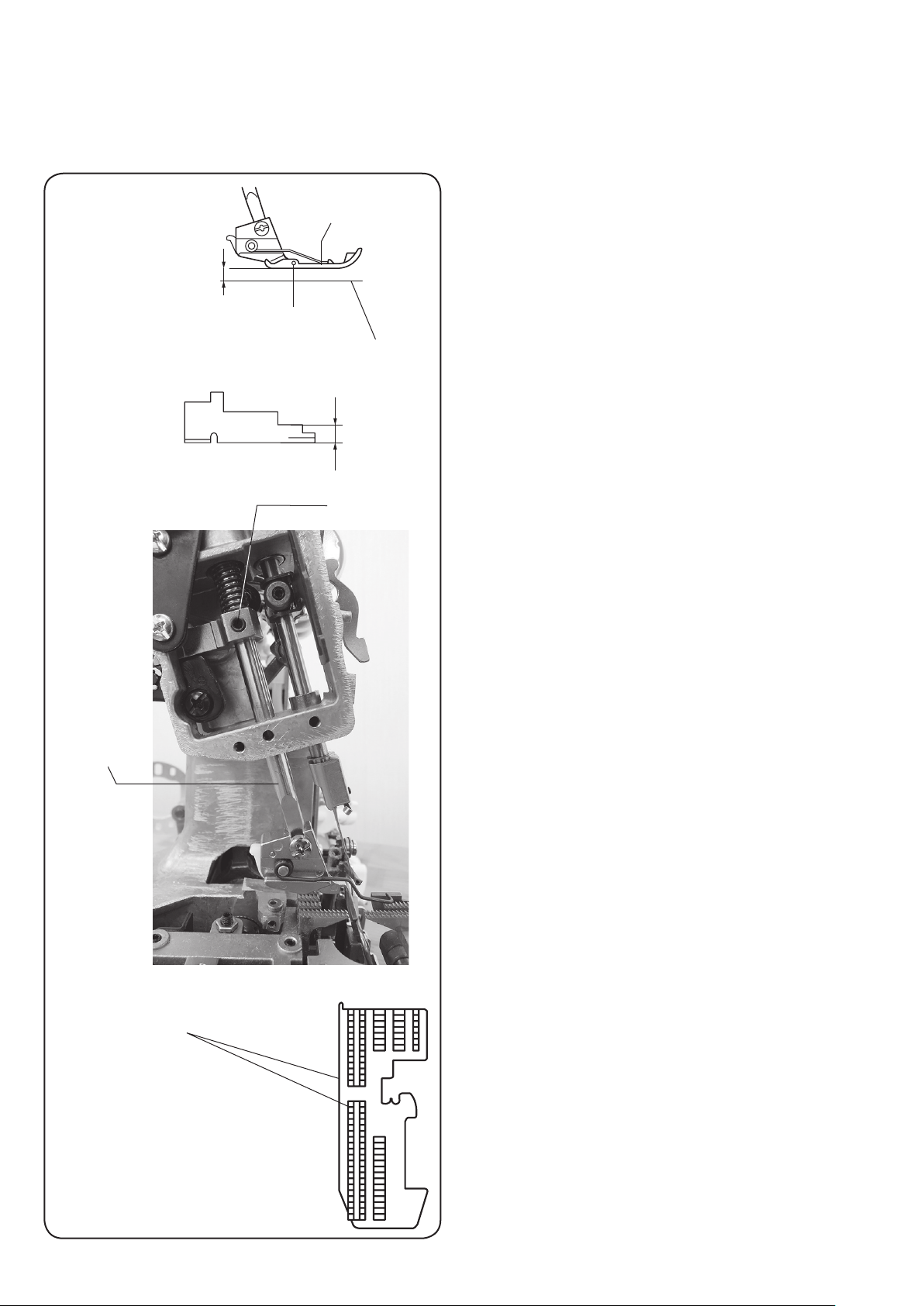

To adjust the presser bar height

The distance between the bottom of the presser foot and the surface of the needle plate should be in the range of 5.2

mm to 5.8 mm when the presser foot is raised.

To check:

Presser foot

5.2 to 5.8 mm

Measure just under the pin

Surface of needle plate

5.5 mm

Gauge

1. Raise the presser foot.

2. Use the gauge to check if the distance between the

bottom of the presser foot and the surface of the

needle plate is 5.2 mm to 5.8 mm.

3. If not, adjust as follows;

Presser bar

Setscrew

To adjust:

1. Remove the top cover and face plate.

2. Loosen the setscrew, and adjust the presser foot bar

height up or down. Be careful not to turn the presser

bar while moving it.

Tighten the setscrew after adjustment.

3. Lower and raise the presser foot again.

Be sure that the distance between the presser foot

and the needle plate is 5.2 to 5.8 mm.

4. Turn the handwheel toward you.

Make sure that the clearance between the needle and

the upper looper is appropriate.

5. Make sure that the presser foot and the feed dog

teeth are parallel.

6. Attach the face plate and the top cover.

The presser foot should be parallel

with the slots for feed dogs.

12

Page 15

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the feed dog height

The highest position of the feed dog should be 0.9 to 1.1 mm from the surface of the needle plate.

To check:

Presser foot

Feed dog

Measure just under the pin

1 mm

0.9 to 1.1 mm

Feed dog

Surface of needle plate

Gauge

1. Set the presser foot pressure dial to “N”.

2. Set the stitch length dial to “1” and the differential feed

dial to “1.0”.

3. Remove the side cover and rear cover.

4. Lower the presser foot lifter. Turn the handwheel

toward you to raise the feed dog teeth at the highest

position.

5. Push the gauge toward the feed dog teeth and check

the feed dog teeth height.

The feed dog height should be 0.9 to 1.1 mm from the

surface of the needle plate.

If not, adjust as follows;

Setscrew

Main feed dog

Hexagonal bolt (B)

To adjust:

1. Remove the top cover, the belt cover, the face plate

and the rear cover.

2. Loosen the setscrew.

3. If the feed dog is lower than the needle plate, turn the

adjusting screw clockwise.

If the feed dog is higher than the needle plate, turn the

adjusting screw counterclockwise.

After adjustment, tighten the setscrew.

4. Turn the handwheel toward you again and make sure

that the distance feed dog height is appropriate.

Adjusting screw

5. The main feed dog teeth and sub feed dog teeth

should be level. If not, loosen the hexagonal bolt with

a ball point hexagonel wrench and adjust the feed dog

teeth height.

6. Attach the rear cover, belt cover, face plate and the

top cover after adjustment.

Sub feed dog

13

Page 16

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the differential feed

Set the stitch length dial set to “3” and the differential feed dial to “1.0”.

The gap (a) is the gap between the main feed dog and the sub feed dog when ascending to the level of the needle

plate.

The gap (b) is the gap between the main feed dog and the sub feed dog when descending to the level of the needle

plate.

The difference of the gap (a) and the gap (b) should be 0.1 mm or less.

To adjust:

NOTE:

Adjust the differential feed, after adjusting the feed dog

height (Refer to page 13).

1. Set the stitch length dial to “3” and the differential feed

dial to “1.0”.

2. Open the looper cover and remove the belt cover.

Presser foot (unit)

Gap (a): Feed dog ascending to the level of the needle plate

Gap (b): Feed dog descending to the level of the needle plate

Needle plate

Main feed dog

Stitch length

adjusting pin

Sub feed dog

Setscrew

3. Remove the presser foot (unit).

4. Turn the handwheel toward you to raise the main feed

dog and the sub feed dog until the upper surface

of the feed dog aligns with the upper surface of the

needle plate.

5. Measure the gap (a) between the main feed dog and

the sub feed dog.

6. Turn the handwheel toward you to lower the main

feed dog and the sub feed dog until the upper surface

of the feed dog aligns with the upper surface of the

needle plate.

7. Measure the gap (b) between the main feed dog and

the sub feed dog.

8. If the difference between gaps (a) and (b) is larger

than 0.1 mm, loosen the setscrew and adjust the

differential feed as follows.

⇨ If the gap (a) is larger than the gap (b), turn the

stitch length adjusting pin to the direction where

the differential feed adjusting rod ascends.

⇨ If the gap (b) is larger than the gap (a), turn the

stitch length adjusting pin to the direction where

the differential feed adjusting rod descends.

9. Repeating the steps 4-7, adjust the differential feed

until the difference between gaps (a) and (b) becomes

0.1 mm or less.

10. After adjustment, tighten the setscrew.

11. Attach the presser foot (unit).

12. Attach the belt cover and close the looper cover.

Differential feed

adjusting rod

14

Page 17

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the stitch length

The actual stitch length should be 3.0 to 3.2 mm (30 to 32 mm for 10 stitches) when the stitch length dial is set to “3”

and the differential feed dial to “1.0”.

To adjust:

Right needle

3.0 to 3.2 mm

30 to 32 mm

Maximum stitch length: 32 mm

Minimum stitch length: 30 mm

Left needle

NOTE:

Adjust the stitch length, after adjusting the feed dog

height and the differential feed (Refer to pages 13 and

14).

1. Set the stitch length dial to “3” and the differential feed

dial to “1.0”.

2. Open the looper cover and remove the belt cover.

3. Sew 11 stitches on a piece of paper and measure the

distance between the first stitch and eleventh stitch

(10-stitch length). If the distance is not 30 to 32 mm,

loosen the setscrew and adjust as follows.

⇨ If the stitch length is longer than 32 mm, turn the

stitch length adjusting pin to the direction where

the differential feed adjusting rod ascends.

⇨ If the stitch length is shorter than 30 mm, turn the

stitch length adjusting pin to the direction where

the differential feed adjusting rod descends.

4. Measure the distance for 10 stitches again. Adjust

until distance becomes 30 to 32 mm.

5. After adjustment, tighten the setscrew

6. Attach the belt cover and close the looper cover.

Stitch length adjusting rod

Setscrew

Stitch length adjusting pin

15

Page 18

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the timing of the needle and the upper knife

The upper knife timing is the same as that of the needle bar. In fact, when the needle bar is at the highest position, the

upper knife should be also at the highest position.

To check:

1. Turn the handwheel toward you.

2. Check if the upper knife is also at the highest position

when the needle bar is at the highest position.

If not, adjust as follows.

Needle

Highest position

of the upper knife

Highest position

of the needle

Upper knife

(B)

Setscrew

Guide line

Setscrew

(A)

Upper knife drive cam

To adjust:

1. Open the side cover.

2. Set the needle bar to the highest position by turning

the handwheel toward you.

3. Loosen the setscrews (2 pcs.). Turn the upper knife

drive cam to adjust the timing. Tighten the setscrews (2

pcs.).

When the upper knife timing is late:

Turn the upper knife drive cam to the direction (A).

When the upper knife timing is early:

Turn the upper knife drive cam to the direction (B).

NOTE:

Make sure the guide line on the edge surface of the

upper drive cam and the guide line on the main shaft are

matched.

Loosen the setscrews (2 pcs.) and push the upper knife

drive cam to check the guide line on the main shaft.

4. Turn the handwheel toward you to check the timing of

the needle and the upper knife again.

5. Close the side cover.

16

Page 19

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the position of the upper knife and the lower knife

When the upper knife is at the lowest position, the front lower corner of the upper knife should be 1.0 to 2.0 mm below

the edge of the lower knife.

The distance between the left surface of the lower knife and the front lower corner of the upper knife should be 0.6 to 1.0

mm.

Edge of the lower knife

Edge of the

lower knife

Front lower

corner of the

upper knife

1.0 to 2.0 mm

Edge of the

lower knife

Gauge

Surface of the

needle plate

1.5 mm

Upper knife

0.6 to 1.0 mm

To check:

1. Open the looper cover (unit).

2. Set the upper knife to the lowest position by turning

the handwheel toward you.

3. Check if the front lower corner of the upper knife is 1.0

to 2.0 mm below the edge of the lower knife.

4. Check if the distance between the left surface of the

lower knife and the point of the upper knife is 0.6 to 1.0

mm.

If not, adjust as follows.

To adjust:

1. Open the looper cover (unit).

NOTE:

When replacing the upper knife:

(1) Set the upper knife to the highest position and remove

it.

(2) Attach the new upper knife and partially tighten the

bolt.

2. Set the upper knife to the lowest position by turning

the handwheel toward you.

3. Loosen the bolt.

Adjust the position of the upper knife so that the front

lower corner of the upper knife should be 1.0 to 2.0

mm below the edge of the lower knife.

4. While maintaining the height of the upper knife

unchanged, adjust the position of the upper knife and

the lower knife so that the distance between the left

surface of the lower knife and the point of the upper

knife is 0.6 to 1.0 mm.

Bolt

NOTE:

Do not move the upper knife vertically.

After adjustment, tighten the bolt.

While tightening the bolt, the upper knife may turn

clockwise. After tightening the bolt, re-check if the

distance is 0.6 to 1.0 mm.

Push the upper knife support plate (unit) to the right to

check if the upper knife supporter moves smoothly.

5. Check if the front lower corner of the upper knife is 1.0

to 2.0 mm below the edge of the lower knife.

Check if the distance between the left surface of the

lower knife and the point of the upper knife is 0.6 to 1.0

mm.

6. Close the looper cover.

17

Page 20

Mechanical Adjustment

To replace the lower looper

Upper knife

Bolt

Needle plate

Setscrew A

Looper cover guide

Setscrew B

Upper knife

Upper knife release knob

Chaining finger

Chaining finger switch knob

Lower looper

connecting pipe arm

Setscrew D

Setscrew C

Lower looper base

Lower looper (unit)

Mouth of the

lower looper

pipe

Tube

Lower looper

connecting pipe arm

Lower looper

connecting pipe (unit)

Lower looper

MODEL: AirThread 2000D

To remov e :

1. Open the looper cover (unit) and the side cover (unit).

2. Set the chaining finger switch knob to “R” and lower

the chaining finger.

3. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

4. Remove the left needle and the right needle.

5. Remove the presser foot (unit).

6. Remove the setscrew A and remove the needle plate.

7. Remove the setscrews B (2 pcs.) and remove the

looper cover guide.

8. Remove the bolt and remove the upper knife.

9. Set the lower looper to the rightmost position by

turning the handwheel toward you.

10. Remove the setscrew C and the setscrews D (2 pcs.).

Remove the lower looper connecting pipe arm with the

lower looper (unit) and the lower looper connecting

pipe (unit) connected.

NOTE:

Make sure that the looper does not hit the chaining finger.

Remove the lower looper pipe from the mouth of the

lower looper (unit).

11. Remove the tube from the lower looper (unit).

To attach:

1. Insert the mouth of the lower looper (unit) into the

tube and pull the tube upward until the upper end of

the tube aligns with the mouth of the lower looper (unit).

2. Turn the handwheel counterclockwise to move the

lower looper base to the rightmost position.

3. Insert the lower looper connecting pipe into the tube

on the mouth of the lower looper pipe and push the

edge of the lower looper connecting pipe into the

mouth of the lower looper pipe to engage them.

NOTE:

Make sure that the tube is not clipped between the

edge of the looper and the edge of the lower looper

connecting pipe.

4. Partially tighten the setscrews D (2 pcs.) to fix the

lower looper connecting pipe arm.

Aligning the the screw hole of the lower looper with

the screw hole of the lower looper base, artially

tighten the setscrew C to fix the lower looper.

5. Place the U groove of the lower looper height gauge

on the lower looper crank shaft.

Loosen the setscrew C and adjust the height of the

lower looper (unit).

Tighten the setscrew C. (Refer to pages 17 and 18.)

6. Attach the left needle and the right needle.

7. Check the clearance between the needle and the

lower looper, the timing of the needle and the lower

looper, the clearance between the upper looper and

the lower looper, and the timing of the upper looper

and the lower looper (Refer to pages 21, 23, 25 and

27.)

8. Loosen the setscrews D (2 pcs.). Adjust the position

of the mouth of the looper connecting pipe (unit) and

the slide pipe (refer to page 34). Check if the looper

can be threaded the the looper thrader (air) and

tighten the setscrews D (2 pcs.).

9. Tighten the bolt to fix the upper looper. (Refer to page

20).

10. Tighten the setscrews B (2 pcs.) to fix the looper

cover guide.

11. Tighten the setscrew A to fix the needle plate.

12. Attach the presser foot (unit).

13. While pressing the upper knife release knob, turn it

clockwise to activate the upper knife.

14. Close the looper cover and the side cover.

18

Page 21

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the position of the lower looper (1)

The tip of the lower looper is 65.6 to 65.9 mm from the center of the lower looper crank shaft as shown below.

To check:

1. Open the looper cover and the side cover.

2. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

Side cover

Upper knife

release knob

To set the upper knife in down position:

Press the

dial

knife.

3. Turn the handwheel counterclockwise to set the lower

looper to the rightmost position.

4. Place the lower looper height gauge to the lower

looper crank shaft as shown.

5. The tip of the lower looper should match with the

guide line of the gauge (65.7 mm).

If not, adjust the lower looper height position (see next

page).

Tip of the lower looper

Setting mark

Guide line

U groove

65.7 mm

Lower looper height gauge

Guide line

Lower looper height gauge

Lower looper crank shaft

19

Page 22

Mechanical Adjustment

To adjust the position of the lower looper (2)

MODEL: AirThread 2000D

Upper knife

Bolt

Needle plate

Setscrew A

Looper cover

guide

Setscrew B

Upper knife

Upper knife release knob

Upper knife

Tip of the

lower looper

Setscrew C

Guide line

To adjust:

1. Open the looper cover and the side cover.

2. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

3. Remove the presser foot (unit).

4. Remove the setscrew A and remove the needle plate.

5. Remove the setscrews B (2 pcs.) and remove the

looper cover guide.

6. Remove the bolt and remove the upper knife.

7. Set the lower looper to the rightmost position by

turning the handwheel toward you.

8. Place the U groove of the lower looper height gauge

down on the lower looper crank shaft and hold it.

9. Loosen the setscrew C and move the lower looper

vertically until the tip of the lower looper points at the

guide line of the lower looper height gauge.

10. Tighten the setscrew C.

11. Check the clearance between the needle and the

lower looper, the timing of the needle and the lower

looper, the timing of the upper looper and the lower

looper and the clearance between the upper looper

and the lower looper (Refer to pages 21, 22, 24, 27

and 28.)

12. Tighten the bolt to fix the upper knife.

13. Tighten the setscrews B (2 pcs.) to fix the looper

cover guide.

14. Tighten the setscrew A to fix the needle plate.

15. Attach the presser foot (unit).

16. While pressing the upper knife release knob, turn it

clockwise by half a rotation to activate the upper knife.

17. Close the looper cover and the side cover.

Bolt

Lower looper

crank shaft

Upper knife release knob

Setscrew C

Lower looper

height gauge

Upper knife

20

Page 23

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the clearance of the needle and the lower looper; and the clearance

of the needle and the needle guard (front) (1)

The standard clearance between the groove of the needle (HAx1 SP #14) and the tip of the lower looper is 0 to 0.05

mm when the needle and the lower looper intersect.

Upper knife

Upper knife release knob

Setscrew B

Needle bar gauge

Groove

Needle

guard (front)

0.05 - 0.25mm

Needle bar gauge

Needle bar

0 - 0.05mm

Lower looper

Needle

guard (rear)

Needle bar lower bushing

Setscrew A

Thumbscrew

Bolt

Bolt

To check:

1. Open the looper cover and the side cover.

2. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

3. Remove the left needle.

4. Attach an HAx1 SP #11 needle as the right needle.

5. Turn the handwheel toward you until the tip of the

lower looper comes from the left to the rear groove of

the right needle.

Check if the clearance between the rear groove of the

right needle and the tip of the lower looper is 0 to 0.05

mm when the needle and the lower looper intersect.

7. Attach an HAx1 SP #11 needle as the left needle.

8. Check if the clearance between the rear groove of the

left needle and the tip of the lower looper is 0 to 0.05

mm when the needle and the lower looper intersect.

If not, adjust as follows.

To adjust the clearance between the needle and the

lower looper

1. Open the looper cover (unit) and the side cover (unit).

2. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

3. Remove the presser foot (unit).

4. Remove the needle plate.

5. Remove the left needle.

6. Attach an HAx1 SP #11 needle as the right needle.

7. Turn the handwheel toward you until the tip of the

lower looper comes from the left to the rear groove of

the right needle.

8. Check if the clearance between the rear groove of the

right needle and the tip of the lower looper is 0 to 0.05

mm when the needle and the lower looper intersect.

NOTE:

If the needle guard (front) pushes the front surface of the

needle, temporarilly move the needle guard (front) to the

front.

9. Loosen the bolt slightly. Adjust the clearance by

moving the lower looper base. After adjustment,

tighten the bolt.

NOTE:

During adjustment, make sure that the lower looper base

does not turn or the handwheel does not rotate.

Otherwise, the timing of the needle and the lower looper

will be wrong.

Needle bar gauge

10. Attach an HAx1 SP #11 needle as the left needle.

11. Turn the handwheel toward you until the tip of the

lower looper comes from the left to the rear groove of

the left needle.

21

Page 24

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the clearance of the needle and the lower looper; and the clearance

of the needle and the needle guard (front) (2). To replace the needle guard (front).

The standard clearance between the groove of the needle (HAx1 SP #14) and the tip of the lower looper is 0 to 0.05

mm when the needle and the lower looper intersect.

12. Check if the clearance between the rear groove of the

Setscrew A

Needle bar

lower bushing

Thumbscrew

Needle

bar

Needle bar gauge

left needle and the tip of the lower looper is 0 to 0.05

mm when the needle anTd the lower looper intersect.

13. If the clearance is not correct, leaving the timing left

as is, remove the face plate and the front cover; and

adjust as follows.

14. Place the needle bar gauge on the needle bar . Pull

the needle bar gauge up against the lower surface

of the needle bar lower bushing and tighten the

thumbscrew slightly.

NOTE:

Do not tighten the thumbscrew too much. Otherwise, the

surface fo the needle bar may be damaged.

15. Loosen the setscrew A. Hold the thumbscrew to

prevent the needle bar goes down and adjust the

clearance by turning the needle bar.

16. Tighten the setscrew A.

17. Attach HAx1 SP #14 needles as the left and right

needles.

18. After adjustment, check the timing of the needle and

the lower looper, the timing of the upper looper and

the lower looper and the clearance between the upper

looper and the lower looper (Refer to pages 24, 27

and 28).

To adjust the clearance of the needle and needle

guard (front)

1. Turn the handwheel toward you until the tip of the

lower looper comes from the left to the rear groove of

the needle. Loosen the setscrews B (2 pcs.) and push

the needle guard (front) against the needle slightly so

that the clearance between the rear groove of the left

or right needle and lower looper is 0 to 0.05 mm.

2. Tighten the setscrews B (2 pcs.).

3. Turn the handwheel toward you to check the

clearance again.

To replace the needle guard (front):

1. Remove the setscrew B (2 pcs.).

2. Set the upper knife to the lowest position by turning

the handwheel toward you.

Pulling the feed base upward, remove the needle

guard (front).

Setscrew B

22

Page 25

MODEL: AirThread 2000D

Mechanical Adjustment

To replace the needle guard (front).

To adjust the clearance of the needle and the needle guard (rear).

With the needle deflected by the needle guard (front), the standard clearance between the part of the largest diameter

of the tip of the needle (HAx1 SP #14) and the needle guard (rear) is 0.05 to 0.25 mm.

To replace the needle guard (rear):

To remov e :

Groove

Needle

guard

(front)

Needle guard (rear)

Bolt

Needle bar gauge

0 - 0.05mm

Needle guard (rear)

Upper knife

Upper knife release knob

Lower looper

Remove the bolts (2 pcs.) and remove the needle guard

(rear).

To attach:

Attach the needle guard (rear) and tighten the bolts (2

pcs.).

To adjust:

1. Follow the procedure of “To adjust the clearance of

the needle and needle guard (front)” on the previous

page.

2. Turn the handwheel toward you until the tip of the

lower looper comes from the left to the rear groove

of the needle (with the HAx1 SP #14 needle slightly

deflected by the needle guard (front)). Check the

clearance between the part of the largest diameter of

the tip of the needle and needle guard (rear).

3. If the clearance is not correct, loosen the bolts (2

pcs.). Adjust the position of the needle guard (rear)

and tighten the bolts (2 pcs.).

4. Attach the face plate and the front cover.

5. Attach the needle plate.

6. Attach the presser foot (unit).

7. While pressing the upper knife release knob, turn it

clockwise by half a rotation to activate the upper knife.

8. Close the looper cover and the side cover.

0.05 - 0.25mm

23

Page 26

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the timing of the needle and the lower looper

When the needle comes up 3.4 to 3.8 mm from the lowest position, the tip of the lower looper comes to the left side of

the right needle (HAx1 SP #14).

Upper knife

Upper knife release knob

Needle bar lower bushing

Thumbscrew

Timing gauge

Needle bar gauge

Needle bar gauge

Lowest

needle

position

Timing gauge

Needle bar lower bushing

Thumbscrew

Needle bar gauge

Bolt

To adjust:

1. Remove the face plate.

2. Open the looper cover and the side cover.

3. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

4. Remove the presser foot (unit).

5. Remove the needle plate.

6. Remove the left needle.

7. Attach an HAx1 SP #14 needle as the right needle.

8. Set the needle bar to the lowest position by turning

the handwheel toward you.

9. Place the timing gauge at the base of the bushing.

than place the needle bar gauge directry under the

timing gauge.

Tighten needle bar gauge thumbscrew lightly.

NOTE:

Make sure that there is no gap between the needle bar

lower bushing and the timing gauge or between the

timing gauge and the needle bar guage. Do not tighten

the thumbscrew too much. Otherwise, the surface fo the

needle bar may be damaged.

10. Remove the timing gauge. Turn the handwheel toward

you to raise the needle bar until the needle bar gauge

touches the needle bar lower bushing.

11. Loosen the bolt slightly. Turn the lower looper base to

the left or right until the tip of the lower looper comes

to the left side of the right needle.

NOTE:

Make sure that the clearance between the tip of the lower

looper and rear groove of the right needle is 0 to 0.05

mm, with the needle deflected by the needle guard (front).

12. Loosen the bolt and remove the needle bar guage.

13. Check the timing of the upper looper and the lower

looper and the clearance between the upper looper

and the lower looper (Refer to pages 27 and 28).

14. Attach the left needle.

15. Attach the needle plate.

16. Attach the presser foot (unit).

17. While pressing the upper knife release knob, turn it

clockwise by half a rotation to activate the upper knife.

18. Close the looper cover and side cover.

19. Attach the face plate.

Upper knife

Upper knife release knob

24

Page 27

MODEL: AirThread 2000D

Mechanical Adjustment

To replace the upper looper and to adjust the position of the tip of the upper

looper

To replace the upper looper

To remov e :

1. Open the looper cover and the side cover.

2. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper knife.

3. Set the chaining finger switch knob to R.

4. Remove the left and right needles.

5. Remove the presser foot (unit).

6. Remove the needle plate.

7. Set the needle bar to the highest position by turning the

handwheel toward you.

8. Loosen the setscrew.

9. Pull the tube upward until the lower end of the tube aligns

with the lower end of the mouth of the upper looper.

10. Pulling up the upper looper, remove the mouth of the

upper looper from the upper looper connecting pipe.

11. Remove the spreader and attach it to the new upper

lo o p er.

To attach:

1. Insert the mouth of the upper looper into the tube and pull

the tube upward until the lower end of the tube aligns with

the lower end of the mouth of the upper looper.

2. Set the needle bar to the highest position by turning the

handwheel toward you.

3. Inserting the upper looper pin into the side hole of the upper

looper, insert the upper looper pipe into the mouth of the

upper looper.

4. Partially tighten the setscrew.

5. Pull the tube downward until the upper end of the tube

aligns with the mouth of the upper looper.

To adjust the position of the tip of the upper looper:

1. Set the upper looper to the leftmost position by turning the

handwheel toward you.

2. Loosen the setscrew. When the upper looper moves down

from the leftmost position, place the upper looper tip gauge

on the upper looper shaft guiding the gauge against the

lower surface of the upper looper. Slightly turn the gauge to

the direction of arrow until the bulge of the gauge touches

the upper looper pin.

3. Move the upper looper to the right or the left to adjust the

position of the upper looper so that the tip of the upper

looper comes to the guide of the upper looper tip gauge.

Partially tighten the setscrew and remove the upper looper

tip gauge.

4. Turn the handwheel toward you to adjust the clearance

between the tip of the upper looper and the rear surface

of the lower looper; and tighten the setscrew (refer to “To

adjust the clearance between the upper looper and the

lower looper”) (Refer to page 28).

5. Attach the needle plate.

6. Attach the presser foot (unit).

7. Attach the left and right needles.

8. While pressing the upper knife release knob, turn it

clockwise by half a rotation to activate the upper knife.

9. Close the looper cover and the side cover.

10. After adjustment, check the leftmost position of the upper

looper, the timing of the upper looper and lower looper, and

the clearance between the needle and the upper looper

(Refer to pages 26, 27 and 29).

Upper knife

Upper knife release knob

Upper looper body

Upper looper

connecting pipe

Mouth of the

upper looper

Upper looper

shaft

Upper looper tip gauge

Upper looper tip

Guide line

Upper

looper shaft

Upper looper

Setscrew

Upper looper pin

Tube

Needle plate setting knob: R

Spreader

Lower edge of

the upper looper

Bulge

Upper looper pin

25

Page 28

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the leftmost position of the upper looper

When the upper looper is at the leftmost position, the distance (front view) between the center of right needle and the

tip of the upper looper should be 7.8 to 8.2 mm.

To check:

Spreader

NOTE:

Adjust the position of the tip of the upper looper, after

Lower edge of

the upper looper

adjusting the position of the tip of the upper looper (Refer

to page 25).

Upper looper driving arm

Gauge

Gauge

8mm

Upper looper shaft

Upper surface of

the upper looper

shaft guide

Setscrew

Right needle

1. Remove the front cover.

2. Remove the left needle.

3. Attach an HAx1 SP #14 needle as the right needle.

4. Set the upper looper to the leftmost position by turning

the handwheel toward you.

5. Place the plate gauge on the tip of the upper looper

and the left side of the right needle (as shown in the

figure) to check the position of the tip of the upper

looper.

If adjustment is required, adjust the position as

follows.

To adjust:

1. Loosen the setscrews (2 pcs.). Adjust the position of

the tip of the upper looper by moving the upper looper

driving arm up or down.

2. Make sure not to move the upper looper driving arm

to the rear or the front. Otherwise, the upper looper

shaft may not move smoothly. Move the upper looper

driving arm slightly up and down to check it moves

smoothly; and partially tighten the setscrew.

3. Check the timing of the upper looper and the lower

looper, and the clearance between the needle and the

upper looper (Refer to pages 27 and 28.)

4. Tighten the setscrews (2 pcs).

5. Attach the left needle.

6. Attach the front cover. (Attach the other exterior

parts.)

Upper looper tip

26

Page 29

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the timing of the upper looper and the lower looper

When the lower looper moves to the right from the leftmost position and the tip of the upper looper meets the lower

edge of the lower looper as shown in the Fig. 1, the standard distance (front view) between the tip of upper looper and

the tip of the lower looper is 3.5 to 4.1 mm.

To adjust:

3.8 mm

Fig. 1

Upper looper tip

Fig. 2

Fig. 3

Gauge

Lower looper tip

3.5 to 4.1 mm

Upper looper cam

Setscrew

(A)

NOTE:

Adjust adjusting the timing of the needle and the lower

looper, the position of the tip of the upper looper and the

leftmost position of the upper looper, and the timing of

the upper looper and the lower looper (Refer to pages 24,

25 and 27).

1. Open the side cover and remove the base plate.

2. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

3. Turn the handwheel toward you to set the upper

looper and the lower looper to the phase shown in

the Fig. 1 (when the lower looper moves from left to

right and the upper looper moves upward). Turn the

spreader to the right.

4. Place the plate gauge on the lower looper and check

the position of the tip of the upper looper.

5. If the position of the tip of the upper looper is not

correct, loosen the setscrews (2 pcs.) and adjust the

position by turning the upper looper cam.

⇨ If the timing of the upper looper is early (as shown

in Fig. 2), turn the upper looper cam in the direction

(A) and tighten the setscrews (2 pcs.).

⇨ If the timing of the upper looper is late (as shown in

Fig. 3), turn the upper looper cam in the direction (B)

and tighten the setscrews (2 pcs.).

6. After adjustment, check the clearance between

the needle and the upper looper and the clearance

between the upper looper and the lower looper (Refer

to pages 26 and 29.)

7. Attach the base plate and close the side cover

8. While pressing the upper knife release knob, turn it

clockwise by half a rotation to activate the upper knife.

(B)

Setscrew

27

Page 30

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the clearance of the upper looper and the lower looper

When the lower looper moves to the right from the leftmost position, the upper looper moves upward from the lowest

position, and the tip of the upper looper comes behind the rear surface of the lower looper as shown in the figure, the

standard distance between the tip of upper looper and the rear surface of the lower looper is 0 to 0.1 mm.

To adjust:

Lower looper

0 to 0.1mm

Lower looper

Upper looper

Upper looper

Setscrew

NOTE:

Adjust adjusting the position of the tip of the upper

looper and timing of the upper looper and lower looper,

the timing of the needle and the lower looper, and the

clearance of the upper looper and the lower looper (Refer

to pages 25, 27 and 28).

1. Open the looper cover.

2. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

3. Turning the handwheel toward you so that the upper

looper intersects the lower looper.

4. Loosen the setscrew. Adjust the clearance between

the tip of the upper looper and the rear surface of the

lower looper by moving the upper looper to the front

or the rear,

NOTE:

Do not move the upper looper to the right or the left.

Otherwise, the timing will be wrong.

Lower looper

5. Partially tighten the setscrew and check the position of

the tip of the upper looper and the clearance between

the needle and the upper looper (Refer to pages 25

and 29.)

6. Tighten the setscrew.

7. Close the looper cover.

8. While pressing the upper knife release knob, turn it

clockwise by half a rotation to activate the upper knife.

Upper looper

28

Page 31

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the clearance between the needle and the upper looper

When the upper looper meets the right needle or the left needle, each clearance should be -0.05 to +0.05 mm.

To check:

Rear bulge of the upper looper

1. Turn the handwheel toward you until the upper looper

moves to the right from the leftmost position, the

needle bar goes down from the highest position and

the rear bulge of the upper looper intersects the left

needle and right needle.

2. Check if the clearance between the rear bulge of the

upper looper and the left needle or the right needle is

-0.05 to 0.05 mm.

Needle

Lower looper

Setscrew

Upper looper

NOTE:

Adjust after adjusting the timing of the needle and the

lower looper, the position of the tip of the upper looper

and the leftmost position of the upper looper, the timing of

the upper looper and the lower looper and the clearance

between the upper looper and the lower looper, and the

clearance between the needle and the upper looper (Refer

to pages 24 to 29.)

1. Open the looper cover.

2. Turn the handwheel toward you until the upper lower

moves to the right from the leftmost positon, the

needle bar moves upward from the lowest point and

the rear bulge of the upper looper intersects the left

needle or the right needle.

3. Loosen the setscrew and adjust the clearance

between the needle and the rear bulge of the upper

looper by moving the upper looper to the front or the

re a r.

NOTE:

Do not move the upper looper to the right or the left.

Otherwise, the timing will be wrong.

4. Partially tighten the setscrew and check the position

of the tip of the upper looper, and the clearance of the

upper looper and the lower looper (Refer to pages 25

and 28).

5. Tighten the setscrew.

6. Close the looper cover.

29

Page 32

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the position of the chaining finger

The standard distance between the side edge of the needle plate and the left edge of the chaining finger is 0.2 mm.

The side edge of the needle plate should not interfere with the left edge of the chaining finger. When setting the chaining

finger switch knob to “S”, the tip of the chaining finder should align with the point of the needles on the needle plate.

Upper knife release knob

Chaining finger switch

knob: R

Upper knife

Setscrew

Chaining finger switch

knob: S

To adjust:

1. Open the side cover.

2. Remove the presser foot (unit).

3. While pressing the upper knife release knob, turn it

clockwise by half a rotation to deactivate the upper

knife.

4. Set the chaining finger switch knob to “S”.

5. Loosen the setscrews (2 pcs.). Adjust the position of

the chaining finger by moving the chaining finger set

plate. Tighten the setscrews (2 pcs.).

6. Move the chaining finger switch knob to check if the

chaining finger moves smoothly.

7. Attach the presser foot (unit).

8. While pressing the upper knife release knob, turn it

clockwise by half a rotation to activate the upper knife.

9. Close the side cover.

Side edge of

the needle plate

Upper knife

Chaining finger switch set plate

Left edge of

the chaining finger

Upper knife release knob

30

Page 33

Mechanical Adjustment

To adjust the thread tensions

Use a standard thread #50. Do not pass the thread through the top cover thread guide.

Standard tension:

Left needle: Tension dial set to 3, 30-40 gf, Tension dial set to 9, 80 gf or more

Right needle: Tension dial set to 3, 15-19 gf, Tension dial set to 9, 50 gf or more

Upper looper: Tension dial set to 3, 9-13 gf, Tension dial set to 9, 30 gf or more

Lower looper: Tension dial set to 3, 18-22 gf, Tension dial set to 9, 55 gf or more

To adjust:

1. Use a standard thread to check the tension.

2. If the thread tension is not correct, turn the tension

dial so that the thread tension becomes the value

represented by “3” of the dial (ignore the real number

on the dial).

3. Remove the top cover.

4. Raise and hold the adjusting plate with a screwdriver.

Turn the dial to match the position of “3” with the notch

(position of the setting mark on the top cover).

5. Check the thread tension again. Repeat the procedure

of steps 2 and 4 until the thread tension becomes

correct.

6. Attach the top cover.

MODEL: AirThread 2000D

Thread tension

plate

Notch of

the thread

tension plate

Thread tension dial

Notch of

the thread

tension plate

Turn the dial to the

direction (A)

to loosen

the tension

To pull the thread to this direction

Thread

Holding the adjusting plate

raised with a screwdriver,

turn the dial.

Adjusting

0

plate

1

Turn the dial to the

direction (B)

to tighten

2

31

Page 34

Mechanical Adjustment

To adjust the pre-tension

Use a standard thread #50 to check the tension of the looper pre-tension.

Standard tension:

Lower looper pre-tension setting slider set to “STD.”: 1 gf or less.

Lower looper pre-tension setting slider set to “TIGHT”: 45-55 gf.

To check:

SlitSlit

1. Open the looper cover and remove the belt cover.

2. Check the tension of the lower looper pre-tension with

the standard thread.

3. If the thread tension is not correct, adjust the tension

by inserting a screwdriver in the slit of the thread

tension shaft and turning it.

⇨ If the tension is too tight, turn the thread tension

shaft counterclockwise.

⇨ If the tension is too loose, turn the thread tension

shaft clockwise.

4. Check the thread tension again. Repeat the procedure

of step 3 until the thread tension becomes correct.

5. Attach the belt cover and close the looper cover.

MODEL: AirThread 2000D

32

Page 35

Mechanical Adjustment

To adjust the needle threader

The hook of the needle threader should come through the eye of the needle.

MODEL: AirThread 2000D

Threader plate (unit)

Needle threader

switch lever

Setscrew B

Threader lever

Hook

Setscrew A

Needle threader

switch lever set

plate

Threader plate (unit)

Needle

Needle

hole

To check:

1. Attach HAx1 SP #11 needles as the left and right

needles.

2. Turn the handwheel toward you to match the mark of

the belt cover with the mark of the handwheel.

3. Lower the needle threader lever.

4. Loosen the setscrew A. Move the needle threader

switch lever set plate vertically so that the hook comes

through eye of the left needle or the right needle.

5. Loosen the setscrew B. Move the needle threader

switch lever set plate horizontally so that the hook

comes through eye of the left needle or the right

needle.

6. Loosen the setscrews C (2 pcs.). Adjust the position

of the

threader shaft guide plate by moving it to the front or

the rear so that the hook comes out from the hole of

the left and right needles.

(When the hook is lowered, the upper ribs above the

hook should touch the rear side of the needle slightly.)

7. Check if the needle threader works correctly.

Setscrew C

Setscrew C

Threader shaft guide plate

When the hook is

lowered, the upper ribs

above the hook should

touch the rear side of

the needle slightly

33

Page 36

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the position the looper thread take-up lever

When the upper looper is in the lowest position, the looper thread take-up lever should be upright.

In case the position of looper take-up lever cannot be adjusted completely after adjusting the looper threader (air),

adjustment of the looper threader (air) is preferable to adjustment of the looper take-up lever.

To check:

1. Open the looper cover.

2. Turn the handwheel toward you to set the upper

looper to the lowest position.

3. Loosen the setscrew. Turn the looper thread take-up

lever. Tighten the setscrew.

4. Check if you can thread the upper looper using the

looper threader.

(Refer to “To adjust the looper threader (air)” on pages

35 and 36.)

5. Close the looper cover.

Setscrew

Looper thread

take-up lever

34

Page 37

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the looper threader (air) (1)

When threading the upper looper or the lower looper with a standard thread #60, a thread of 30 mm or longer should come out

from the hole of the looper.

For threading with the looper threader (air), see the instruction manual.

Thread

Tip of the upper looper

Looper

threading wire

Slide pipe

Joint of the looper

connecting pipe

Failure

Upper looper

Tip of the lower looper

Looper threader

switch lever:

SEWING

Looper

threader lever

Threading hole

Lower looper

Thread

Looper threader

lever

Looper threader

switch lever:

THREADING

To c h e ck :

NOTE:

For checking the looper threader, do not use threads thicker

than #60, loosely twisted threads, special threads, moist or wet

threads. If the thread end is fluffed, trim it.

When you thread the looper with the looper threader (air), the

thread may be stained with grease or oil. Do not use it again.

Do not remove the thread pulling it from the threading hole.

1. Open the looper cover.

2. Thread the upper looper and the lower looper with the

looper threader (air).

If the thread does not come out from the hole of the looper

or the thread of less than 30 mm comes out of the hole of

the looper, remove both threads.

3. Set the looper threader switch lever to “SEWING”.

4. With the looper threader (air), thread the looper of which

thread does not come out from the hole correctly in the

step 2.

⇨ (a) If the thread of 100 mm or longer comes out:

Defect in the looper

⇨ (b) If the thread of less than 100 mm comes out:

Defect in the looper threader

5. Case (a)

5-1 There can be lint or objects stuck in the pipe of the looper.

Insert the looper threading wire into the mouth of the looper

connecting pipe to the tip of the looper to clean the pipe.

(Refer to page 53 in the instruction manual.)

5-2 Repeat the procedure from step 2.

5-3 If the problem is not solved yet, the slide pipe and the

looper connecting pipe may not be coaxial or straight.

6. Remove the top cover, the face plate, the belt cover, the

base plate, the looper cover and the front cover. Open the

side cover.

* To adjust:

・ Set the looper threader switch lever to “THREADING”

position.

Turn the handwheel toward you slowly until it clicks.

・ The slide pipe comes to the left and it is engaged with the

mouth of the looper connecting pige. Return the looper

threader switch lever to “SEWING” position to disengage

the slide pipe to the right.

・ Set the looper threader switch lever to “THREADING”

position and “SEWING” position slowly to check if the slide

pipe and the looper connecting pipe are getting coaxial and

straight.

Mouth of the upper

looper connecting pipe

Setscrews A

Mouth

Arm of the lower

looper connecting pipe

Setscrew B

Slide pipe

NOTE:

The mouth of the looper connecting pipe is conical. If the slide

pipe and the looper connecting pipe are not coaxial or straight,

the slide pipe will be delicately moving to the coaxial position.

[Upper looper]

・ Adjust the position of the upper looper connecting pipe

supporter after adjusting the position of the looper take-up

lever.

・ Loosen the setscrews A (2 pcs.) of the upper looper

connecting pipe supporter slightly.

Adjust the position of the upper looper connecting pipe

supporter to the opposition direction to which the slide pipe

moves at engagement.

・ Tighten the setscrews A (2 pcs.).

・ Thread the upper looper with the looper threader and check

the length of the thread coming out from the hole of the

upper looper tip.

35

Page 38

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the looper threader (air) (2)

When threading the upper looper or the lower looper with a standard thread #60, the thread of 30 mm or longer should

come out from the hole of the looper.

Threading hole

Slide pipe

Looper

threading wire

Looper threader (air) (unit)

Setscrews C

Cover

detecting base

Setscrew D

Setscrew DSetscrew D

Looper

threading wire

[Lower looper]

・ Loosen the setscrews B (2 pcs.) of the lower looper

connecting pipe supporter slightly.

Adjust the position of the upper looper connecting pipe

supporter to the opposition direction to which the slide pipe

moves at engagement.

・ Tighten the setscrews B (2 pcs.).

・ Thread the lower looper with the looper threader and check

the length of the thread coming out from the hole of the

lower looper tip.

7. Case (b) on the previous page

7-1 There can be lint or objects stuck in the pipe of the

looper.

Insert the looper threading wire into the mouth of the

looper connecting pipe to the tip of the looper to clean

the pipe. (Refer to page 53 in the instruction manual.)

7-2 Repeat the procedure from step 2.

7-3 If the problem is not solved yet, the looper threader

device (air) (unit) may be defective. Replace the

looper threader device (air) (unit).

7-4 To replace the looper threader device (air) (unit)

NOTE:

Set the looper threader switch lever is set to “SEWING”

(the slide pipe is disengaged from the looper connecting

pipe and set the upper looper to the lowest position for

attaching or removing the looper threader device (air).

・ Set the looper threader switch lever to “SEWING”

position.

・ Remove the front cover.

・ Remove the setscrews C (2 pcs.). Separate the cover

detecting base (unit) from the threader base (it cannot

be completely removed).

・ Remove the setscrews D (3 pcs.) and remove the

looper thrader device (air) (unit).

・ Placing the lower edge of the new looper thrader

device (air) (unit) behind the cover detecting base

(unit), fix it on the arm by tightening the setscrews D (3

pcs.).

・ Attach the cover detecting base (unit) and tighten the

setscrews C (2 pcs.).

・ Check and adjust the position of the slide pipe and

the looper connecting pipe (refer to the instructions of

“* To adjust:” in the clause 6.

8. Attach the front cover. (Attach the other exterior

parts.)

9. Close the looper cover.

36

Page 39

MODEL: AirThread 2000D

Mechanical Adjustment

To adjust the height of the rubber sole (rear left)

The adjustable rubber sole (rear left) is 0.6 mm higher (above the level) than the other 3 rubber soles.

To check:

1. Place the machine with the rear cover down.

2. Insert a screwdriver into the slit of the adjusting screw

of the real left rubber sole. Tighten the screw and

loosen the screw by a quarter rotation.

The height should be 0.6 mm above the level of the

other 3 rubber soles.

3. Place the machine upright. Check if the 4 rubber soles

are level. Check the vibration of the machine while

running.

Adjusting screw

37

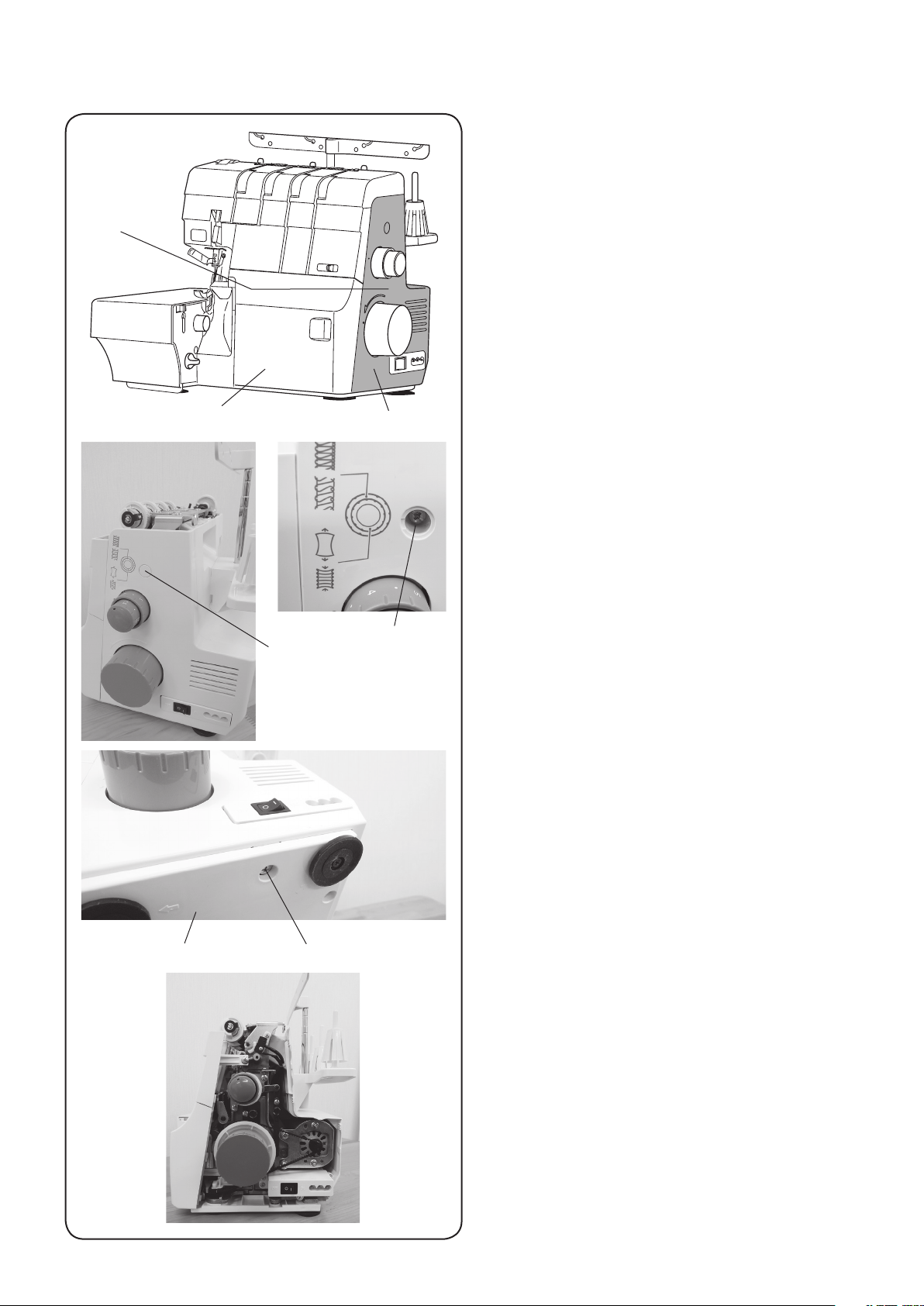

Page 40

Replacing External Parts

To replace the machine socket

Setscrew A

Setscrew A

Connector (LED)

MODEL: AirThread 2000D

To remov e :

1. Remove the belt cover and the rear cover.

2. Remove the setscrews A (2 pcs.). Pull the machine

socket by the allowance length of the cable, and

remove the connector (LED).

3. Remove the setscrew B (2 pcs.) and remove the

cable.

For removing and attaching each part, refer to the

instructions in the related section.

To attach:

1. Connect the cord of the replaced part to the machine

socket unit.

2. Tight the setscrews B (2 pcs.) to fix the machine

socket (unit).

3. Insert the machine socket (unit) under the motor (unit)

and insert the connector (LED).

4. Tighten the setscrews A (2 pcs.) to fix the machine

socket unit on the arm.

5. Attach the belt cover and the rear cover.

Machine socket cover

Setscrew B Machine socket

Setscrew B

38

Page 41

Replacing External Parts

To replacing the motor (1)

MODEL: AirThread 2000D

To remov e :

1. Remove the belt cover, the rear cover and the

machine socket (unit).

2. Remove the setscrews A (2 pcs.).

3. Remove the motor.

4. Remove the setscrews B (2 pcs.).

5. Remove the machine socket cover.

6. Remove the nuts.

7. Remove the motor terminals from the machine socket.

Setscrew B

Setscrew A

Machine socket cover

Machine socket

Motor terminals

Belt

Motor pulley

Setscrew B

Machine socket cover

To attach:

1. Connect the motor terminals to the machine socket.

2. Tighten the nuts.

3. Attach the machine socket cover to the machine

socket.

4. Tighten the setscrews B (2 pcs).

5. Tighten the setscrews A (2 pcs.) to fix the motor on

the arm.

Machine socket

Nut

Motor (unit)

39

Page 42

To replace the motor (2)

MODEL: AirThread 2000D

Replacing External Parts

To attach:

Follow the procedure on the previous page.

6. Attach the motor belt on the belt wheel and the motor

pulley. Check if the motor belt tension is correct.

*Standard tension*

The correct motor belt tension is when the deflection of

motor belt is about 5 - 6 mm, while pushing the motor belt

by finger with a 300 gf.

7. Loosen the setscrews A (2 pcs.) and adjust the

position of the motor to adjust the motor belt tension.

8. Attach the belt cover, the rear cover and the machine

socket (unit).

Setscrew A Motor pulleyMotor belt

Deflection 5 - 6 mm

300 gf

40

Page 43

To replace the LED

Replacing External Parts

To remov e :

1. Remove the top cover, the face plate, the belt cover,

Connector (LED)

the front cover, the rear cover and the machine socket

(unit).

2. Remove the connector (LED) from the machine socket

(unit).

3. Open the LED holder and remove the LED.

4. Cut the cord binders (2 pcs.and remove the LED cord

from the rear cord guide.

MODEL: AirThread 2000D

Cord binder

LED holder

Cord binder

To attach:

1. Insert the LED in the LED holder and close the hook.

2. Insert the LED cord in the rear cord guide.

3. Insert the LED connector in the machine socket (unit).

4. Fix the LED cord on the arm with the cord binders (2

pcs.).

5. Place the machine socket (unit) under the motor (unit).

6. Attach the machine socket (unit).

7. Attach the top cover, the face plate, the belt cover, the

front cover and the rear cover.

Cord guide

Motor

LED cord

41

Page 44

Replacing External Parts

To change the micro switch

(covers and looper threader switch lever)

Switch set plate 1

Setscrew A

Relay cable RF

Micro switch

Relay cable FF

MODEL: AirThread 2000D

To remov e :

1. Remove the belt cover.

2. Remove the setscrew A and remove the switch set

pla te 1.

3. Remove the setscrew B and remove the micro switch.

4. Remove the terminals from the relay cable RF (unit)

and the relay cable FF (unit).

To attach:

1. Insert the terminals into the relay cable RF (unit) and

the relay cable FF (unit).

2. Tighten the setscrew B to fix the micro switch to the

switch set plate 1.

3. Partially tighten the setscrew A to fix the switch set

plate 1 to the cover detecting base.

4. Close the side cover.

5. Adjust the position of the switch set plate 1 so that the

micro switch is set ON or OFF when the looper cover

is opened or closed.

6. Attach the belt cover.

Setscrew B

Cover positipn detecting base

42

Page 45

Replacing External Parts

To change the micro switch (presser foot lifter)

To remov e :

Micro switch

Thread tension set plate

Setscrew B

Relay cable FF

Switch set plate 2

Setscrew A

Relay cable RF

1. Remove the belt cover.

2. Remove the setscrew A and remove the switch set

plate 2.

3. Remove the setscrew B and remove the micro switch.

4. Remove the terminals from the relay cable RF (unit)

and the relay cable FF (unit).

To attach:

1. Insert the terminals into the relay cable RF (unit) and

the relay cable FF (unit).

2. Tighten the setscrew B to fix the micro switch to the

switch set plate 2.

3. Partially tighten the setscrew A to fix the switch set

plate 2 to the thread tension set plate.

4. Adjust the position of the switch set plate 2 so that the

micro switch is set ON or OFF when the presser foot

lifter is lowered or raised. Tighten the setscrew A.

5. Attach the belt cover.

MODEL: AirThread 2000D

43

Loading...

Loading...