Janome 990D Service Manual

SERVICE MANUAL

&

PARTS LIST

990D

TO CHANGE THE FACE PLATE UNIT ................................................................................................................... 1

TO CHANGE THE BELT COVER UNIT ....................................................................................................................2

TO CHANGE THE TOP COVER ...............................................................................................................................3

TO CHANGE THE FRONT COVER UNIT.................................................................................................................4

TO CHANGE THE SIDE COVER UNIT ....................................................................................................................5

TO CHANGE THE MACHINE BASE UNIT ...............................................................................................................6

TO CHANGE THE MACHINE SOCKET....................................................................................................................8

PREPARATION BEFORE THE ADJUSTMENT ........................................................................................................8

TO ADJUST THE NEEDLE HEIGHT ........................................................................................................................9

TO ADJUST THE PRESSER BAR HEIGHT ...........................................................................................................10

TO ADJUST THE FEED DOG HEIGHT..................................................................................................................11

TO ADJUST THE TIMING OF THE NEEDLE AND THE FEED DOG.....................................................................12

TO ADJUST THE TIMING OF THE NEEDLE AND THE UPPER KNIFE................................................................13

TO ADJUST THE HEIGHT OF THE LOWER LOOPER..........................................................................................14

TO ADJUST THE CLEARANCE BETWEEN THE NEEDLES AND THE LOWER LOOPER/NEEDLE GUARDS .. 15

TO ADJUST THE CLEARANCE BETWEEN THE NEEDLES AND THE LOWER LOOPER/NEEDLE GUARDS .. 16

TO ADJUST THE CLEARANCE BETWEEN THE NEEDLES AND THE FIXED NEEDLE GUARD .......................17

TO ADJUST THE POSITION OF THE CHAINING FINGER...................................................................................18

TO ADJUST THE POSITION OF THE UPPER LOOPER.......................................................................................19

TO ADJUST THE TIMING OF THE NEEDLE AND THE LOWER LOOPER...........................................................20

TO ADJUST THE TIMING OF THE UPPER AND LOWER LOOPERS ..................................................................21

TO ADJUST THE CLEARANCE BETWEEN THE LOOPERS................................................................................22

TO ADJUST THE CLEARANCE BETWEEN THE NEEDLES AND THE UPPER LOOPER................................... 23

TO ADJUST THE POSITION OF THE KNIVES......................................................................................................24

TO ADJUST THE POSITION OF THE LOWER LOOPER THREAD GUIDE..........................................................25

TO ADJUST THE STITCH LENGTH.......................................................................................................................26

TO ADJUST THE THREAD TENSION DIALS ........................................................................................................27

PARTS LIST .......................................................................................................................................................28-47

TABLE OF CONTENTS

1

990D

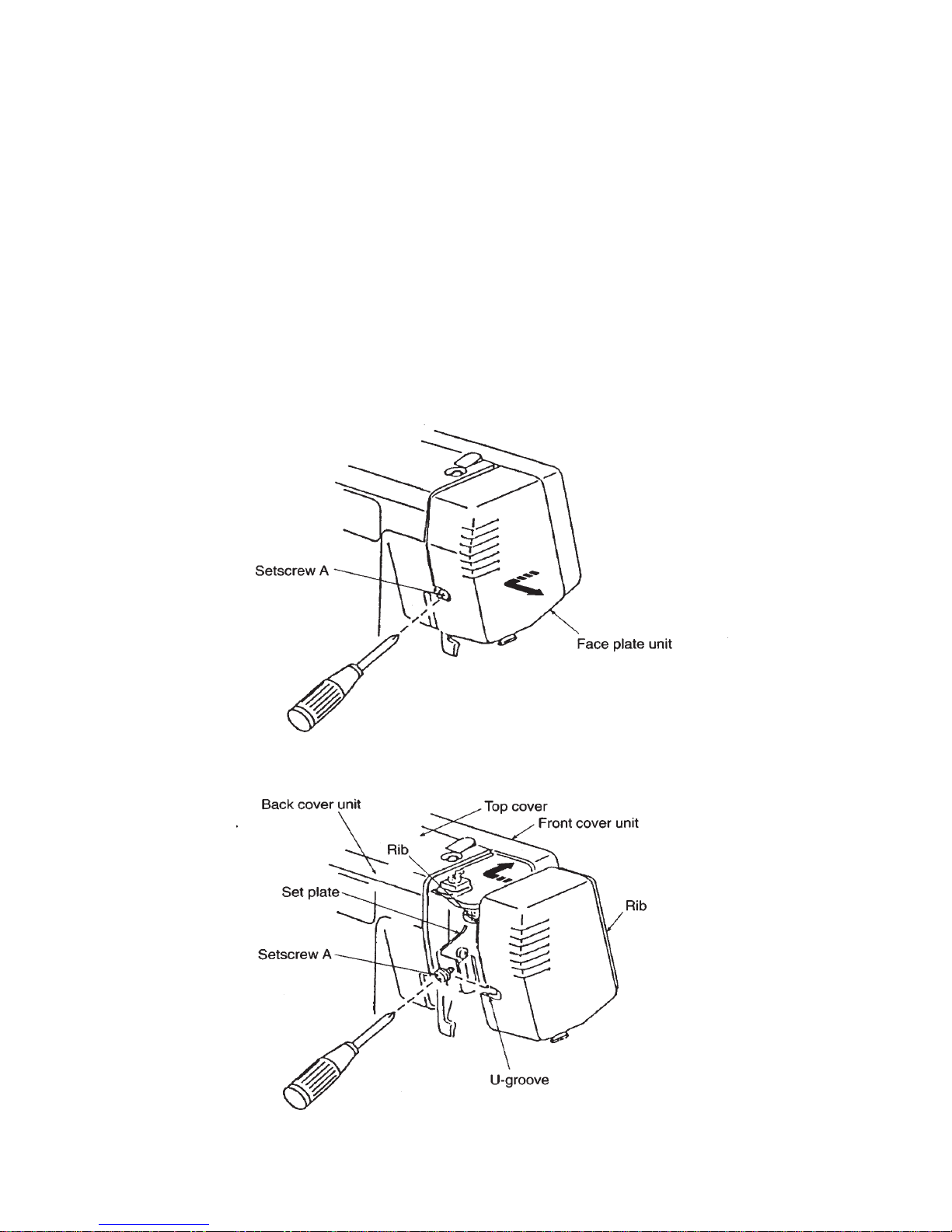

To remove:

1. Loosen the setscrew A and remove the face plate unit.

To attach:

2. Fit the U-groove of the face plate between the setscrew A and set plate, put the rib of the face

plate into the front cover unit and the back cover unit. Tighten the setscrew A.

TO CHANGE THE FACE PLATE UNIT

2

990D

Belt cover unit

Setscrew A

Setscrew B

Rib

Rib

To remove:

1. Loosen the setscrew A and remove the setscrew B.

2. Remove the belt cover unit.

To attach:

3. Put the ribs of belt cover into the front cover unit and tighten the setscrew A and B.

TO CHANGE THE BELT COVER UNIT

Front cover

3

990D

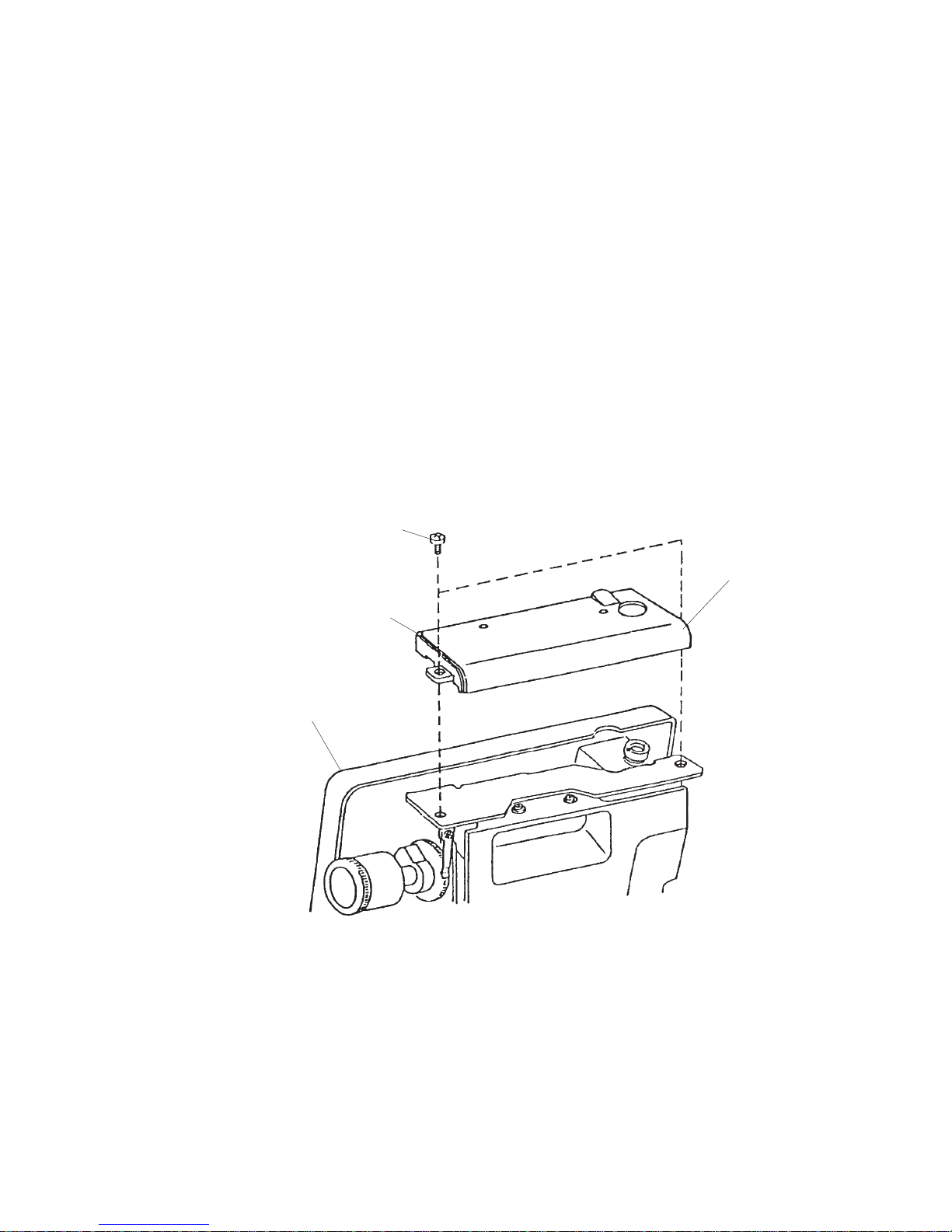

Top cover

Front cover unit

Setscrews A

Rib

To remove:

1. Remove the face plate unit and belt cover unit.

2. Remove the two setscrews A. Remove the top cover.

To attach:

3. Put the ribs of top cover into the front cover unit. Tighten setscrews A.

TO CHANGE THE TOP COVER

4

990D

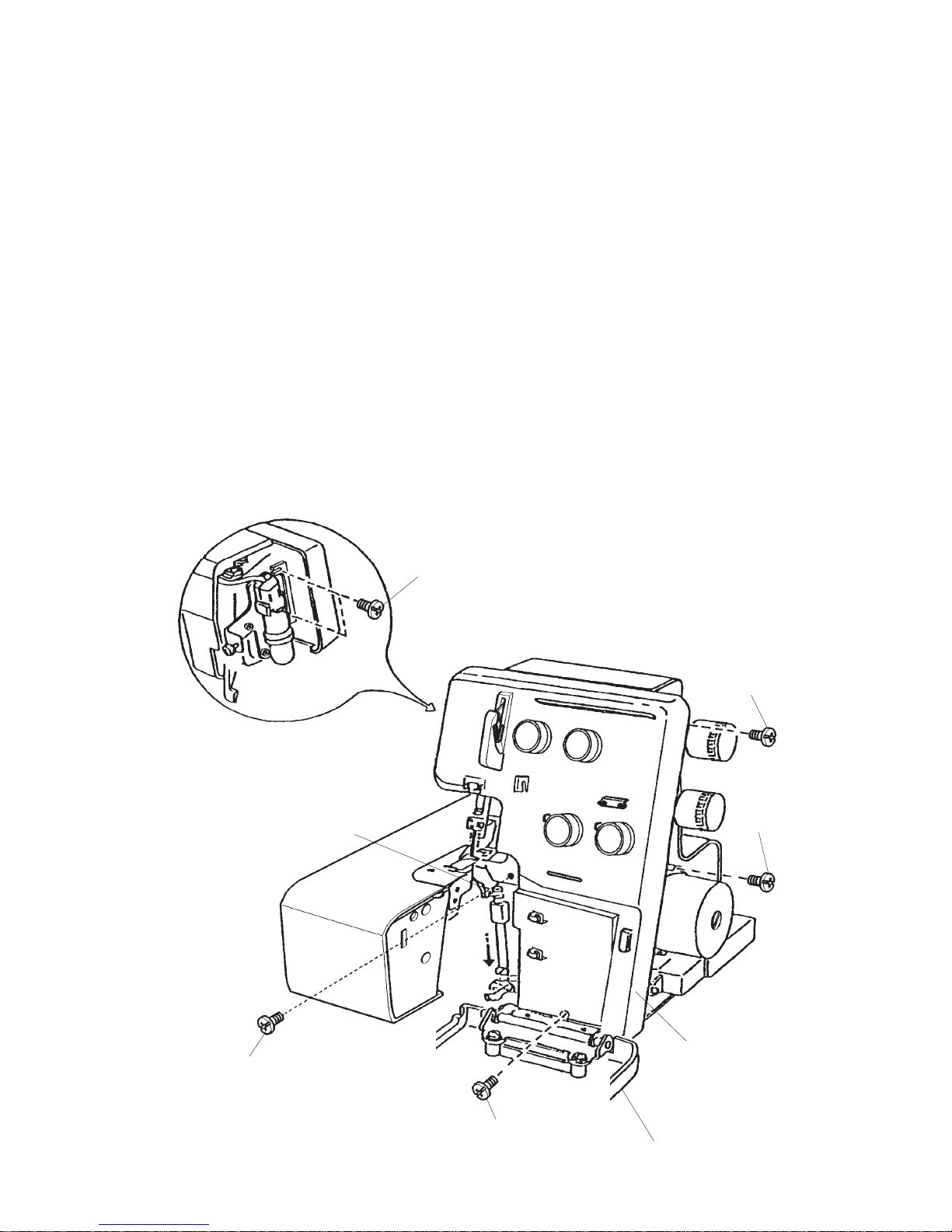

Setscrew B

Upper looper should be set

at its lowest position

Looper cover unit

Setscrew C

Setscrew D

Setscrews A

Front cover unit

Setscrew E

To remove:

1. Remove the face cover and belt cover unit.

2. Turn the handwheel toward you with your hand, and set the upper looper at its lowest position,

and remove the setscrews A, B, C, D, E and the front cover unit.

To attach:

3. Attach the front cov e r unit with setscrews A, B, C, D and E.

4. Attach the belt cover unit and face plate unit.

TO CHANGE THE FRONT COVER UNIT

5

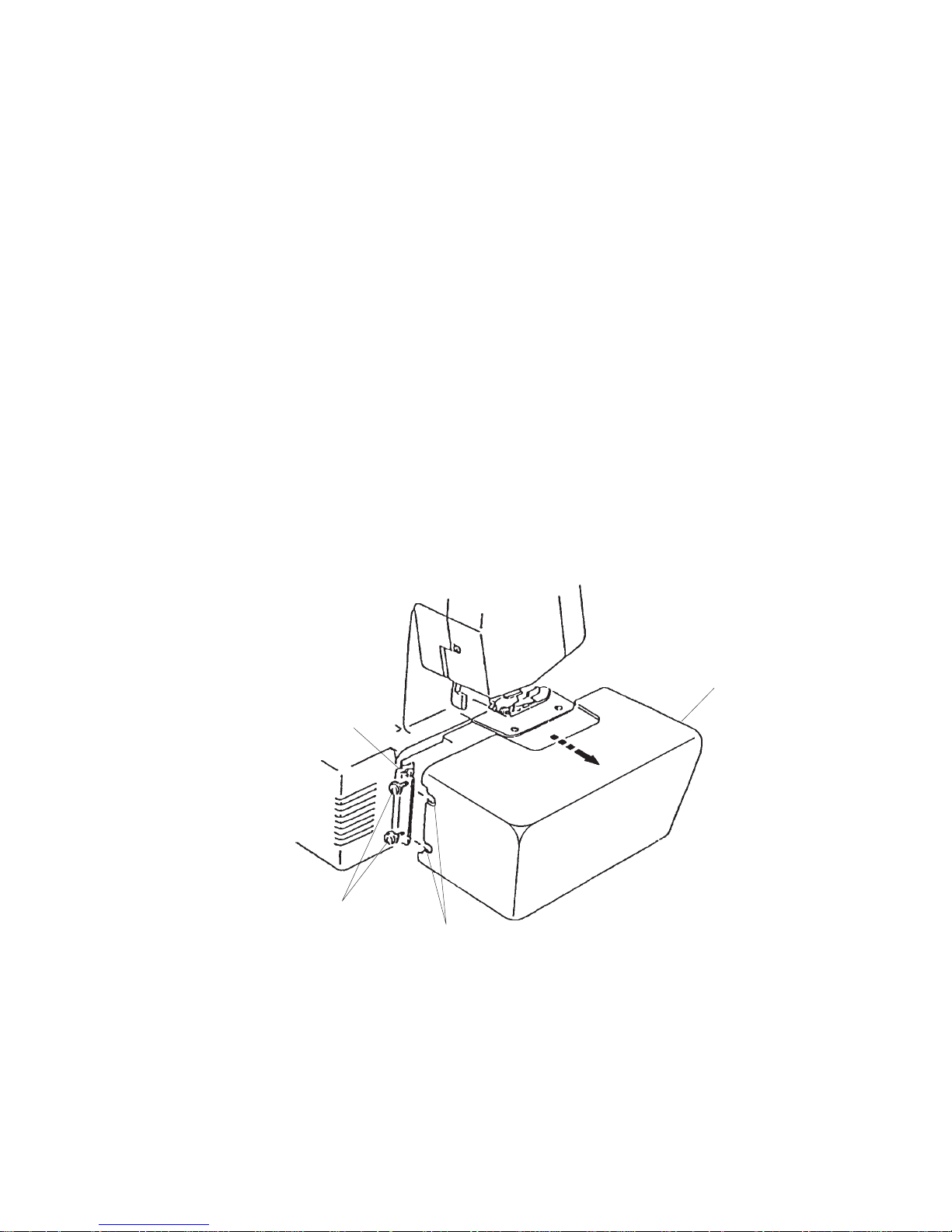

990D

Side cover unit

Set plate

Setscrews A

U-grooves

To remove:

1. Loosen the setscrew A and remove the side cover unit.

To attach:

2. Fit the U-grooves of the side cover between the setscrews A and the set plate.

3. Tighten the setscrews A.

TO CHANGE THE SIDE COVER UNIT

6

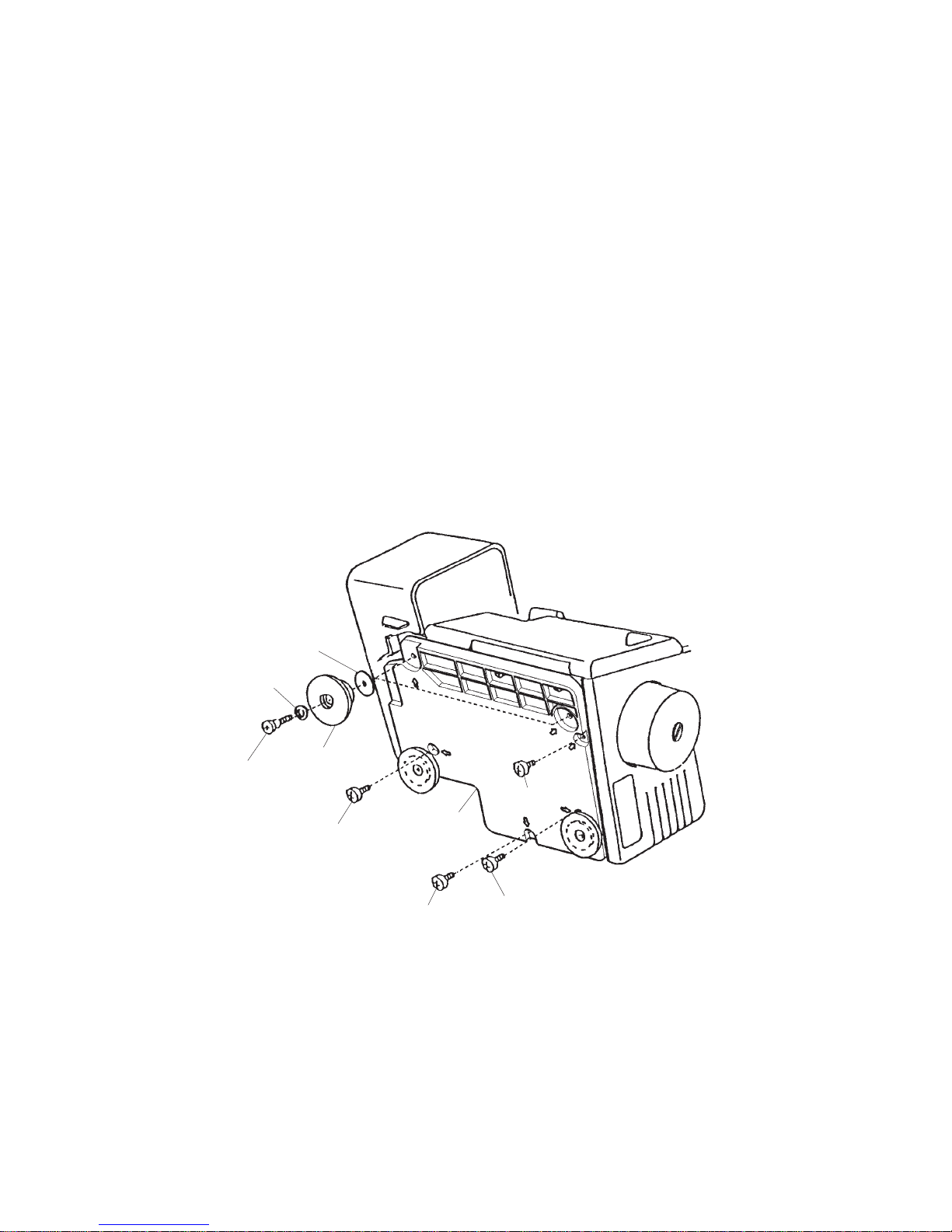

990D

Washer

Washer

Base

cushion F

Hinge screw E

Setscrew C

Setscrew B

Machine base

Setscrew A

Setscrew D

To remove:

1. Remove the setscrews A, B, C, D and two hinge screws E, and remove two base cushions F

and washers.

2. Remove the machine base.

NOTE: Do not remove another two base cushions.

To attach:

3. Attach the machine base unit, and tighten the setscrews A, B, C and D.

4. Attach the two base cushions F, washers, and tighten the hinge screws E.

TO CHANGE THE MACHINE BASE UNIT

7

990D

To remove:

1. Remove the belt cover unit.

2. Remove the setscrews A and pull out the cord connectors.

To attach:

3. Insert the cord connectors as shown below.

4. Attach the machine socket, and tighten two setscrews A and attach the belt cover unit.

TO CHANGE THE MACHINE SOCKET

Cord with ridge

Cord with ridge

8

990D

A

E

C

FB

D

787 - G05

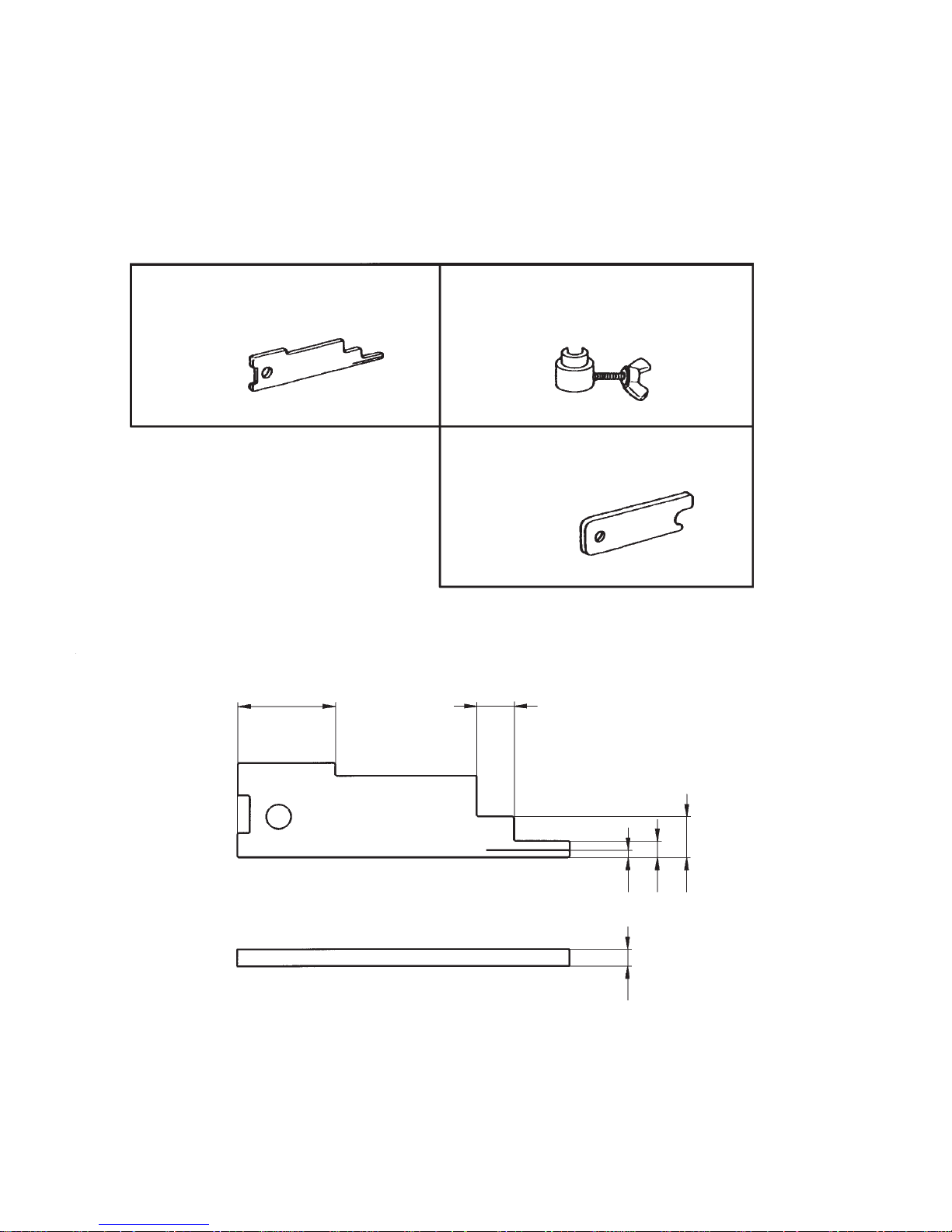

PREPARATION BEFORE THE ADJUSTMENT

Use the following gauges for the correct setting and adjustment.

Thickness gauge

No. 787-G05

Needle bar gauge

No. 787-G02

Thickness gauge

No. 787-G03

* Each part, indicated by an alphabet, of the thickness gauge No.787-G05 is used for the following

adjustments:

A: Adjustment of needle bar height

B: Adjustment of presser bar height

C: Adjustment of feed dog height

D: Adjustment of needle and upper looper timing

E: Adjustment of needle and upper looper timing

F: Adjustment of needle and feed dog timing

9

990D

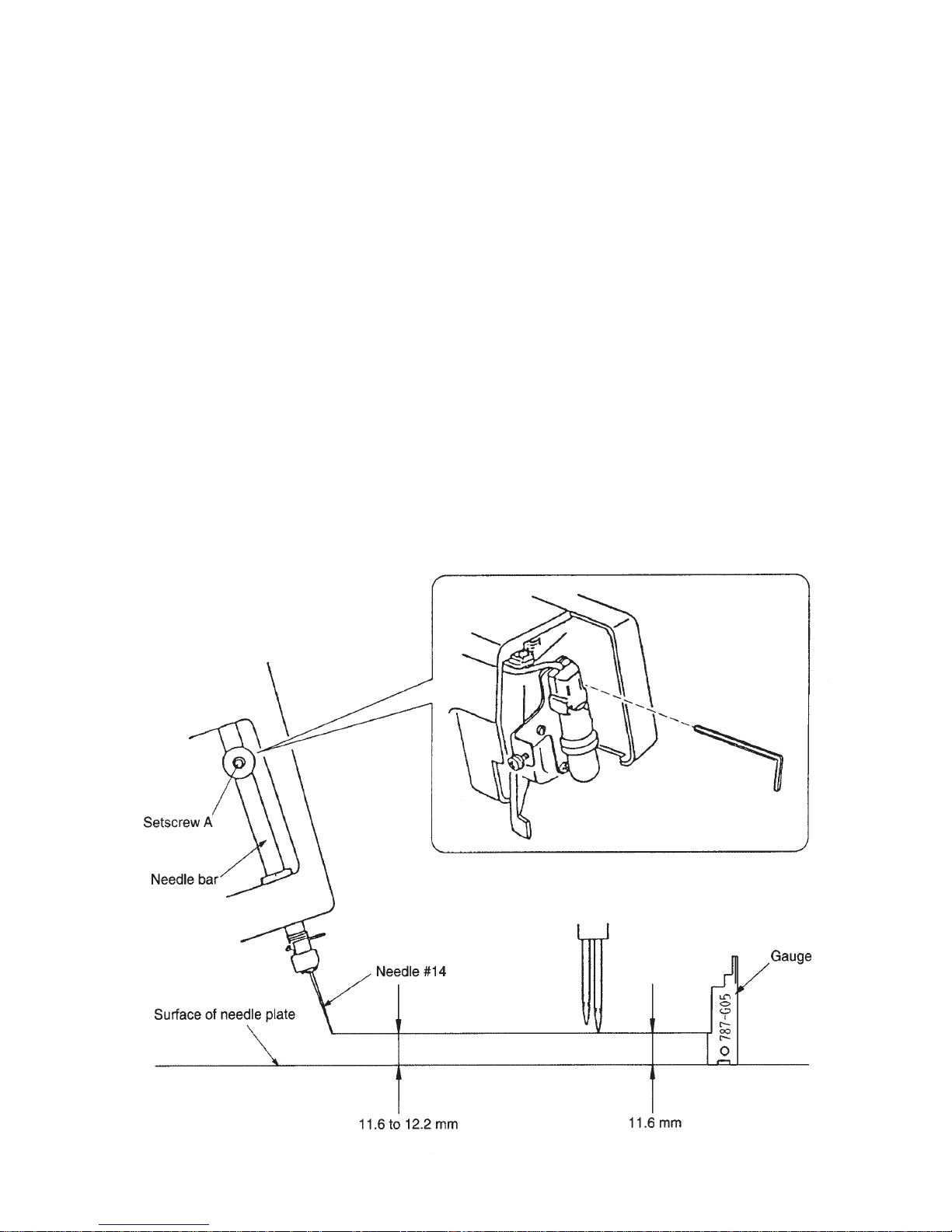

Correct Setting:

The distance between the tip of needle on the right and the surface of needle plate should be 11.6

to 12.2 mm when the needle bar is at the highest position.

To adjust:

1. Remove the face plate unit.

2. Turn the handwheel toward you with your hand, and set the needle bar at its highest position.

3. Loosen the setscrew A to adjust the height, and tighten the setscrew A after the adjustment is

done.

4. Turn the handwheel toward you one complete turn, and recheck the needle bar height.

5. Attach the face plate unit.

TO ADJUST THE NEEDLE HEIGHT

10

990D

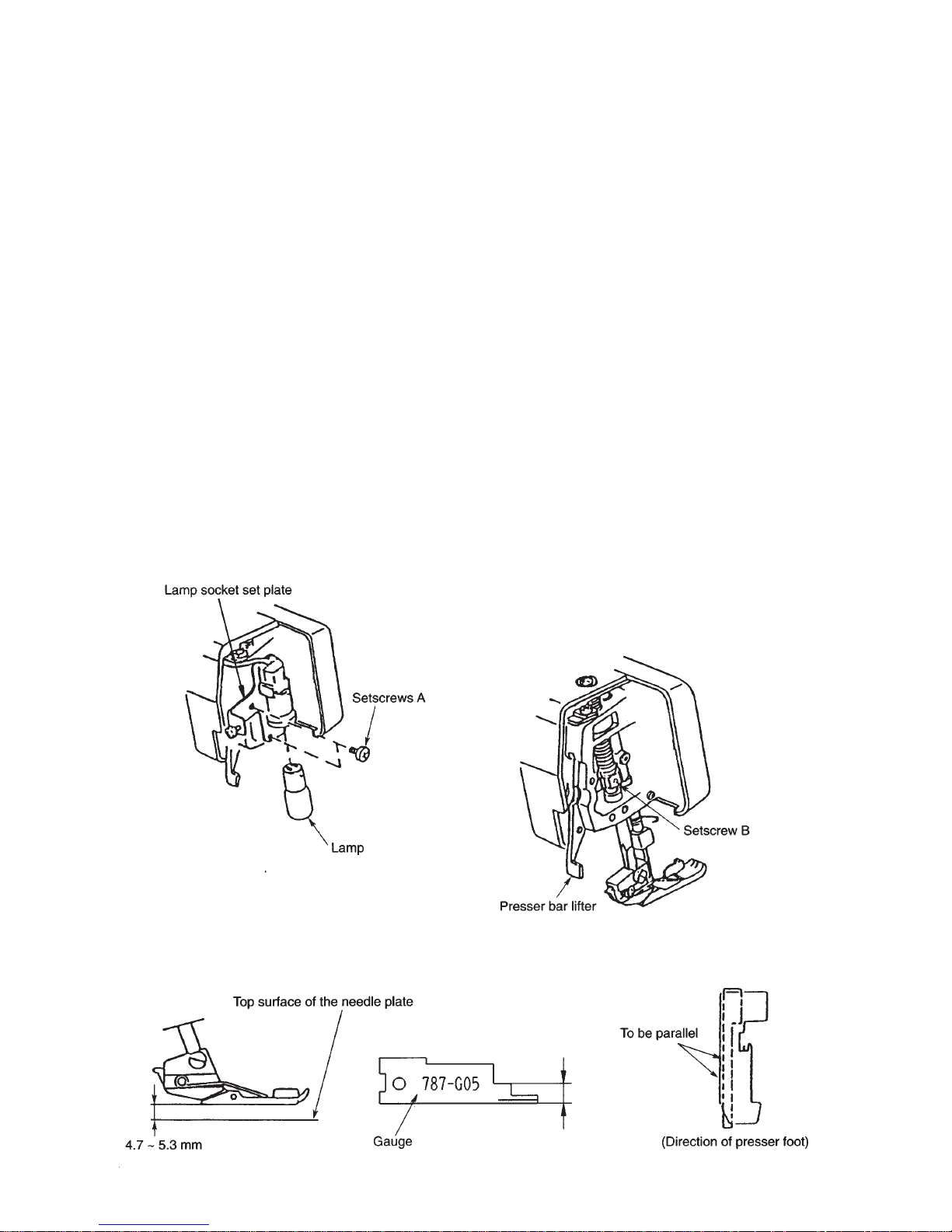

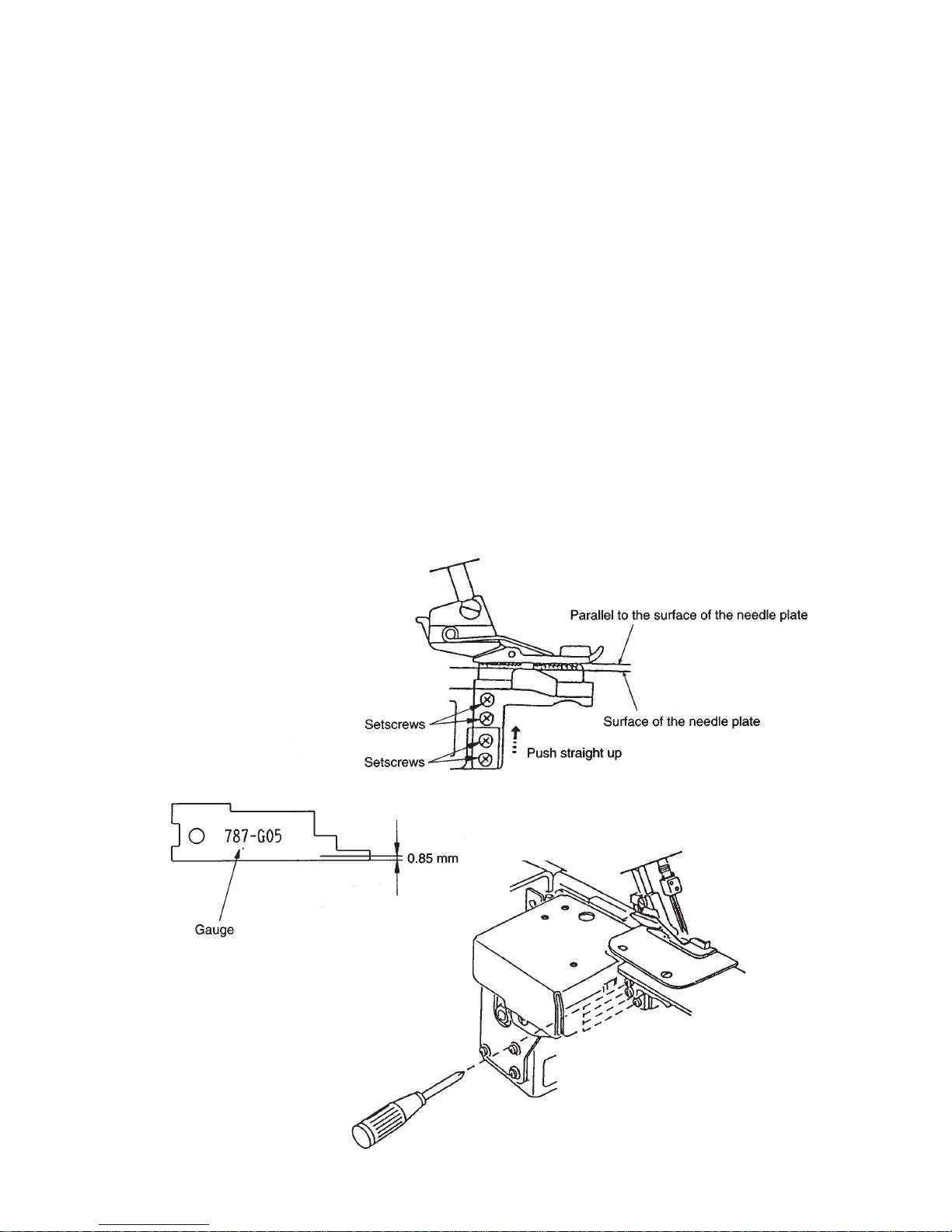

Correct Setting:

The distance between the surface of the needle plate and the bottom of presser foot should be 4.7

to 5.3 mm when the presser bar lifter is raised.

To adjust:

1. Remove the face plate unit. Remove the setscrews A and the lamp fixing plate.

2. Raise the presser bar lifter, and loosen the setscrews B.

Then adjust the presser bar height, the side of presser foot should be parallel with the hole of

needle plate.

3. Tighten the setscrew B.

4. Attach the lamp fixing plate with the setscrews A and attach the lamp.

5. Attach the face plate unit.

TO ADJUST THE PRESSER BAR HEIGHT

11

990D

Correct Setting:

When the presser foot is lowered and feed dog is at its highest position, the distance between the

surface of needle plate and bottom of presser foot should be 0.75 to 0.95 mm.

To adjust:

1. Set the stitch length dial at “3” and the differential feed dial at “1.0”.

2. Lower the presser foot and raise the feed dog to its highest position by turning the handwheel.

3. Loosen the feed dog screws A (2 pcs.).

4. Push the feed dog straight upward and adjust the distance between the surface of needle plate

and bottom of presser foot, then tighten the setscrews A (2 pcs.).

5. Check the feed dog height by turning the handwheel toward you.

TO ADJUST THE FEED DOG HEIGHT

12

990D

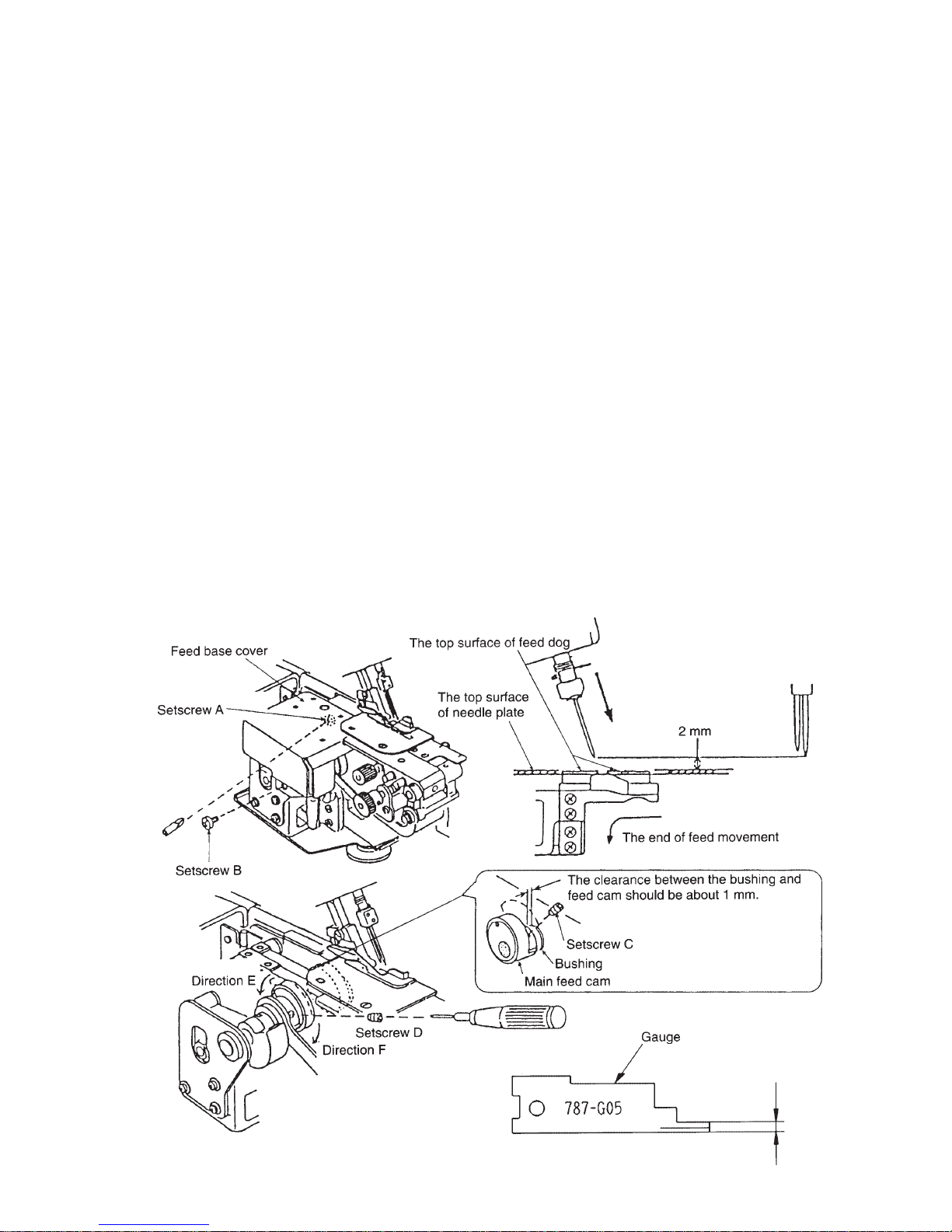

TO ADJUST THE TIMING OF THE NEEDLE AND THE FEED DOG

Correct Setting:

When the tip of right needle is at 2 ~ 4 mm above the needle plate in its downward motion,

and lowered presserr foot, the top of the feed dog teeth should be level to the top surface of needle

plate at their rearmost position.

Before adjustment, check if needle bar height and feed dog height are correct.

To adjust:

1. Loosen setscrew A and remove setscrew B, remove feed base cover.

2. Set the stitch length dial at “3” and differentiial feed dial at “1.0”.

3. Raise the presser foot and move the tip of right needle at 2 ~ 4 mm above the needle plate in its

downward motion by turning the handwheel.

4 Lower the presser foot, and loose two setscrews C for main feed cam, two setscrews D

for sub feed cam, annd adjust the position of the subb feed cam and tighten setscrews D.

* Turn the sub feed cam to the direction E if the feed dog is lower than the surface of the

needle plate.

* Turn the sub feed cam to the direction F if the feed dog is higher than the surface of the needle

plate.

5. Set the main feed cam to keep the clearance between the bushing and main feed cam to about

1 mm, and tighten two setscrewsss C.

Attach the feed base cover with setscrews A and B.

13

990D

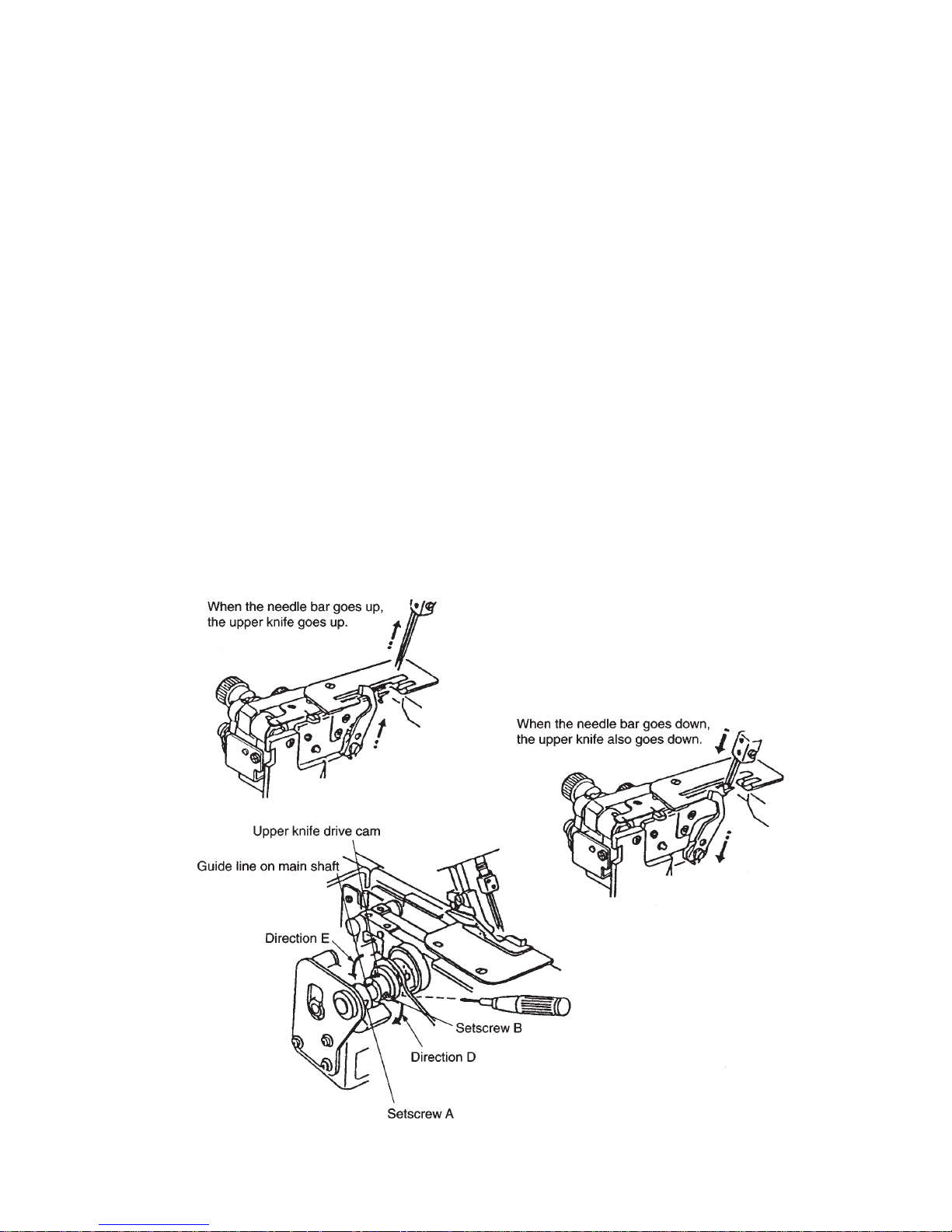

Correct Setting:

The upper knife timing is the same as that of the needle bar. In fact, when the needle bar is at

highest position, the upper knife should be also at its highest position.

To adjust:

1. Remove the feed base cover unit.

2. Loosen two setscrews A, and move the balance weight to left.

3. Loosen two setscrews B, and adjust the needle and upper knife timing is being delay.

# Turn the upper knife drive cam to the direction D when the upper knife timing is being delay.

# Turn the upper knife drive cam to the direciton E when the upper knife timing is too soon.

4. Tighten the two setscrews B firmly. Move the balance weight to right.

Match the guide line on the balance weight with the one of the main shaft correctly.

Thennn tighten the two screws A.

5. Turn the handwheel toward you one cycle, and recheck the needle and the upper knife timing.

6. Attach the feed base cover.

TO ADJUST THE TIMING OF THE NEEDLE AND THE UPPER KNIFE

Loading...

Loading...