Page 1

INSTRUCTION BOOK

INSTRUCTION BOOK

Page 2

TABLE OF CONTENTS

SECTION I NAMES OF PARTS

Name of Parts ............................................................. 3

Screen Sharpness Adjusting Dial ............................... 4

Extension Table........................................................... 4

Standard Accessories ................................................. 5

SECTION II GETTING READY TO SEW

Connecting Machine to Power Supply ........................ 6

For Your Safety ........................................................... 6

Controlling Sewing Speed........................................... 6

Main Function of Buttons/Keys ................................... 7

Up/down needle position button........................ 7

Auto-lock button ............................................. 7

Reverse button ............................................... 7

Mode selection key......................................... 8

Twin needle key .............................................. 8

Editing key ...................................................... 8

Stitch width selection key ...............................8

Stitch length selection key.............................. 8

Message key .................................................. 9

Turn-over memory key ................................... 9

Elongation key ................................................9

Stock/call key ................................................. 9

Clear key ...................................................... 10

Memory key .................................................. 10

Direct pattern selection and number keys ... 10

Pattern selection and screen indication ....... 11

Number key selection................................... 11

Memory Mode/Buzzer Sound/Multiple

Language Settings .................................................... 12

To Raise or Drop the Feed Dogs .............................. 13

Pressure Dial............................................................. 13

Presser Foot Lifter .................................................... 13

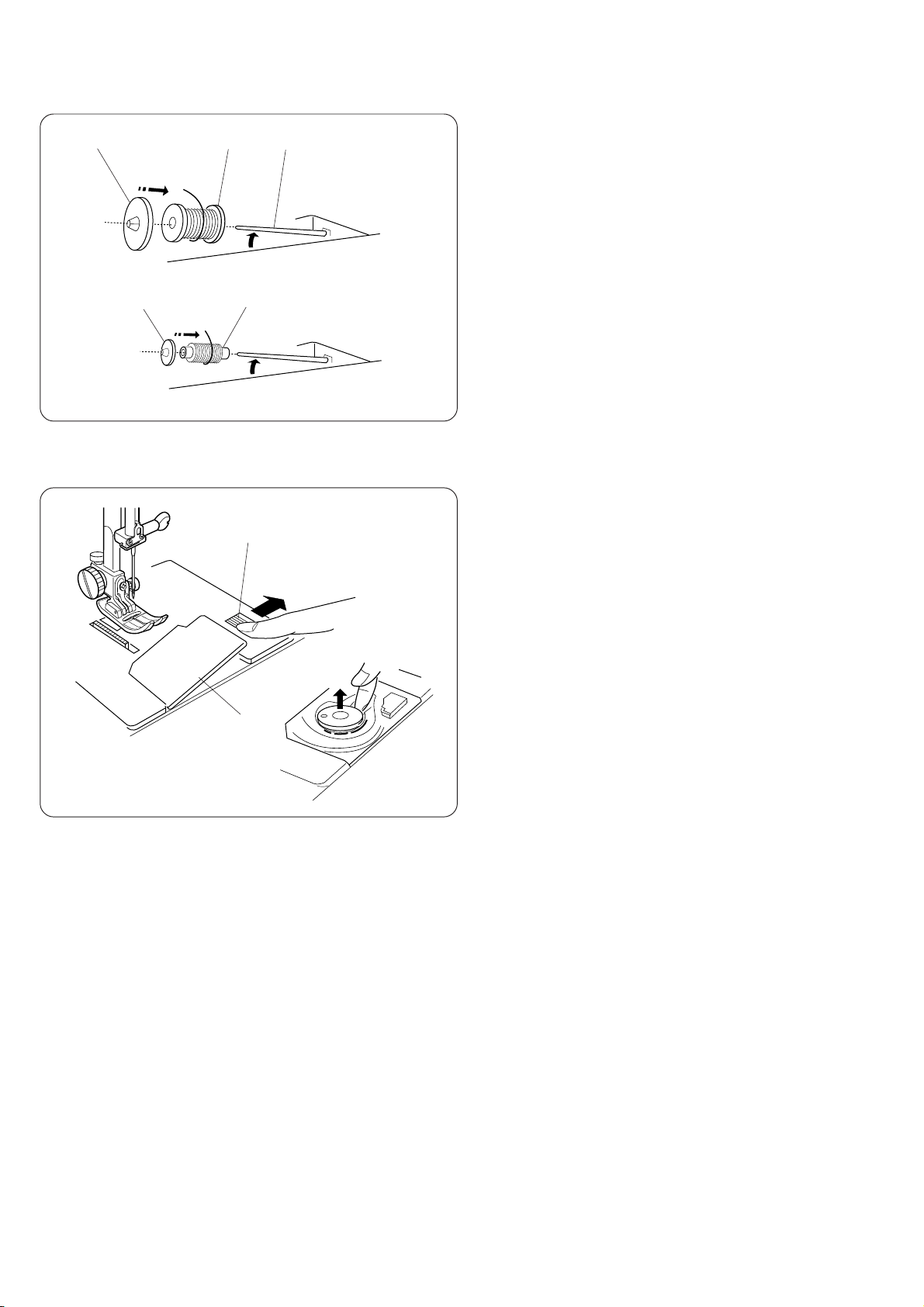

Changing Needles..................................................... 14

To Attach and Remove the Presser Foot.................. 14

To Remove and Attach the Foot Holder ................... 14

Selecting Needle and Thread ................................... 15

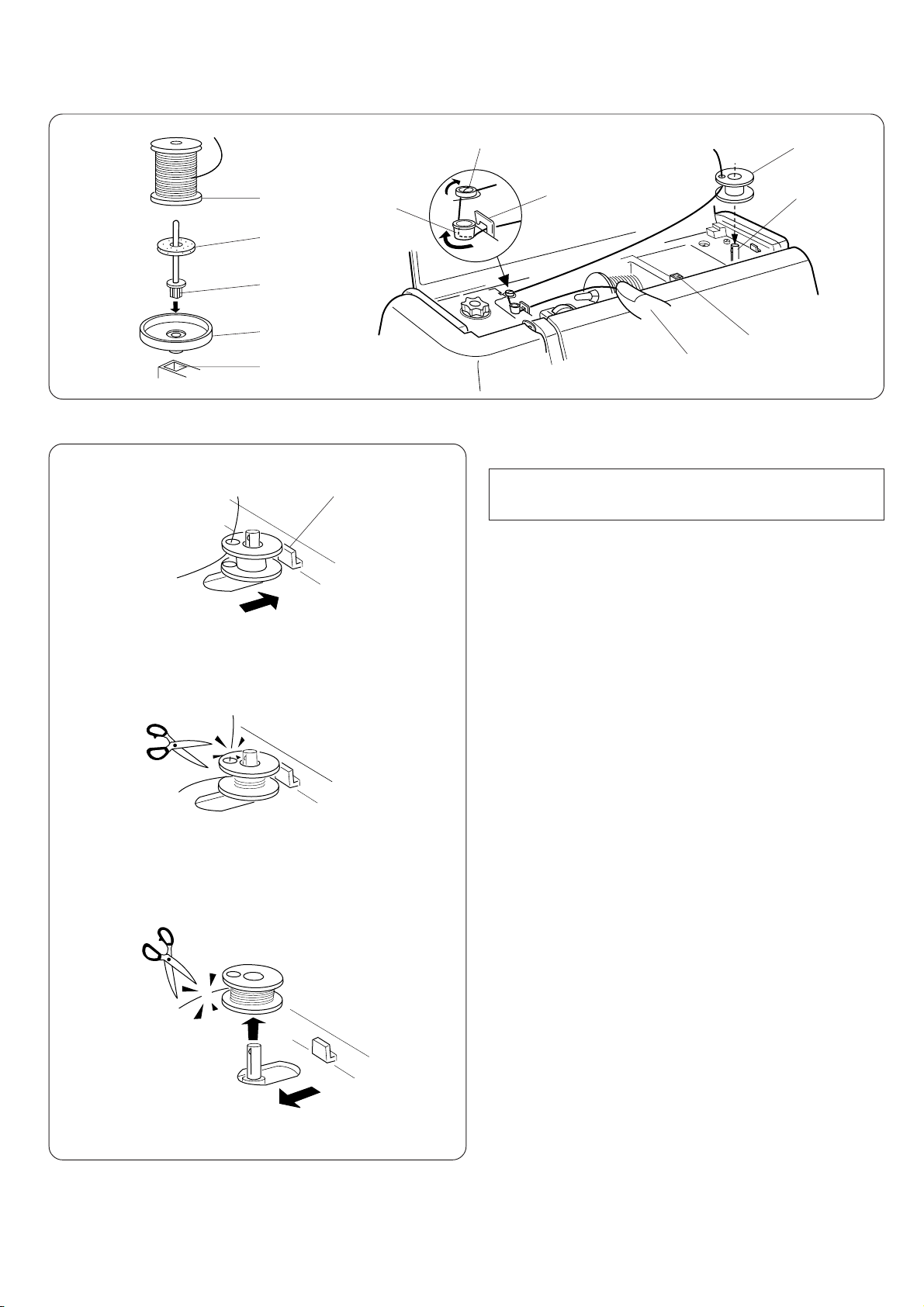

Winding the Bobbin................................................... 16

Set the spool ................................................... 16

Removing the bobbin ................................... 16

Winding the bobbin ...................................... 17

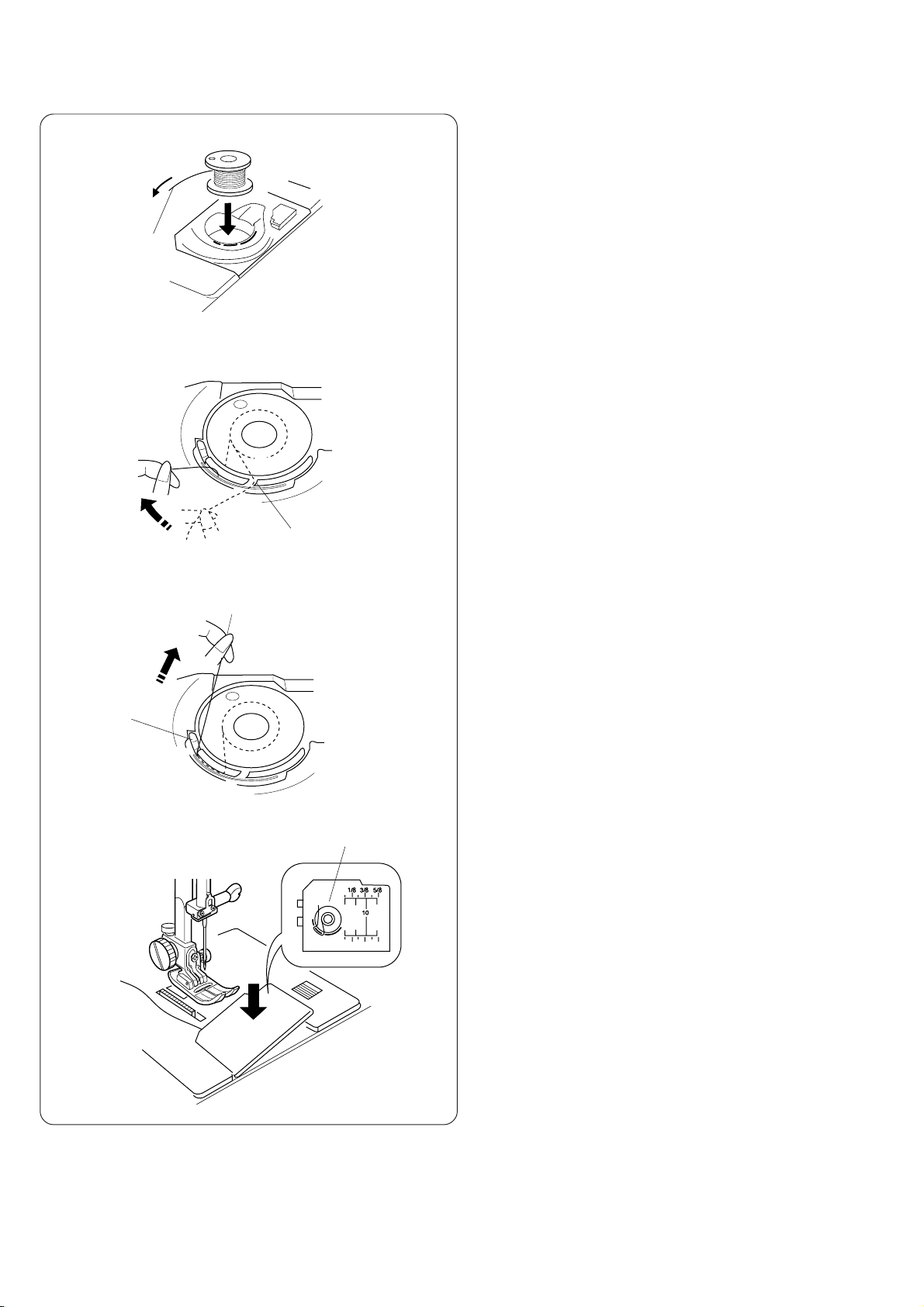

Inserting the bobbin...................................... 18

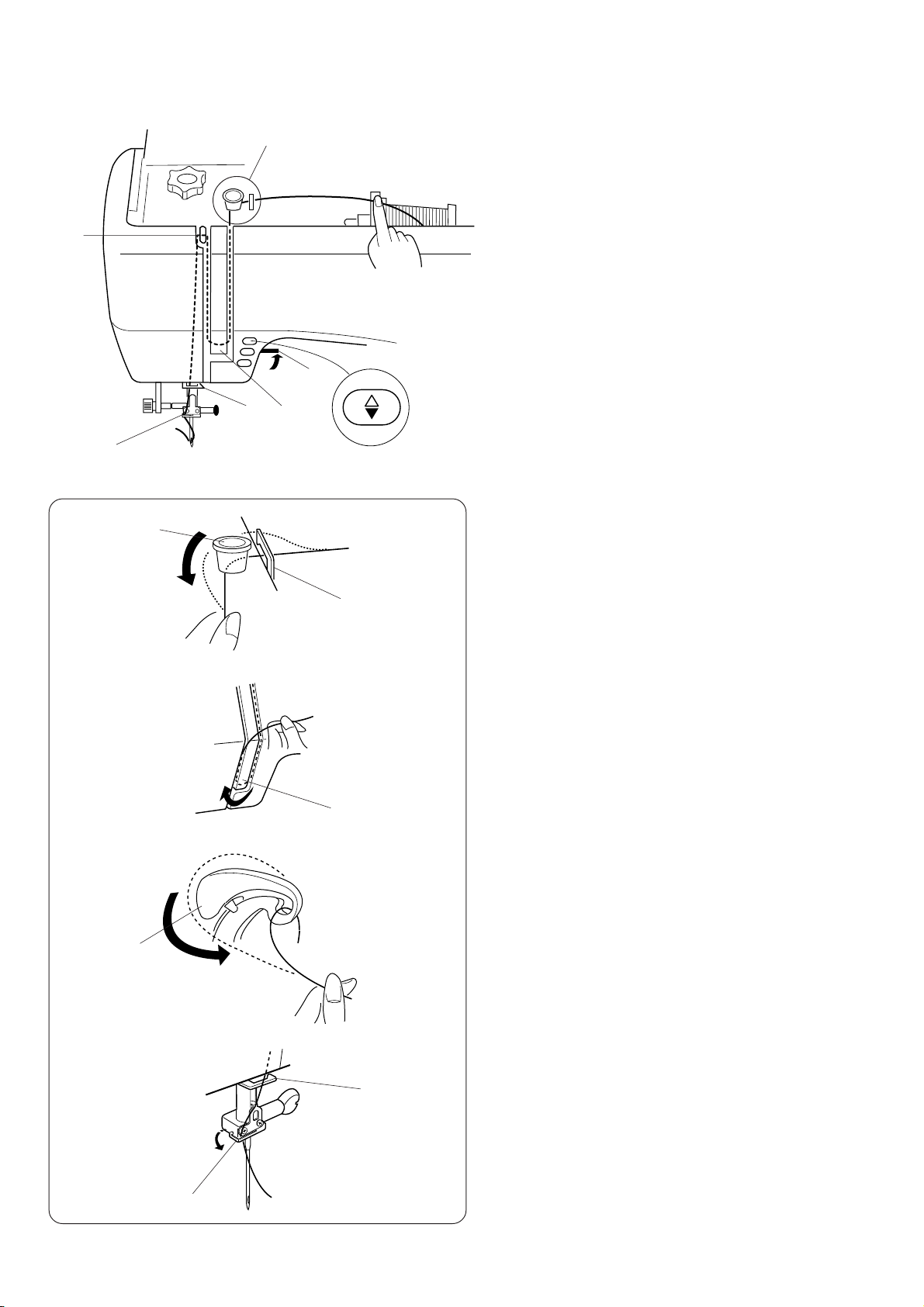

Threading the Machine................................. 19

Threading the machine ................................ 19

Needle threader............................................ 20

Drawing up the bobbin thread...................... 21

Balanced Thread Tension ............................. 22

Auto-thread tension ...................................... 22

Manual thread tension adjustment............................ 22

SECTION III BASIC SEWING

Straight Stitch Sewing............................................... 23

Starting to sew ................................................ 23

Changing sewing direction ........................... 23

Finishing sewing .......................................... 23

Practice Common Stitching Skills ............................ 24

Using the Seam Guides on the Needle Plate ........... 24

Turning Square Corners............................................ 24

Using the Quilting Bar ............................................... 24

Sewing on Heavy Fabrics ......................................... 24

Manual stitch length ........................................ 25

Variable needle position ............................... 25

Various Utility Stitch .................................................. 26

Basting ............................................................ 26

Straight stitches............................................ 27

Automatic reverse stitch............................... 27

Triple stretch stitch ....................................... 27

Auto-lock stitch ............................................. 27

Stretch stitch................................................. 28

Saddle stitch ................................................. 28

Sculpture stitch ............................................. 28

Zigzag Stitch ............................................................. 29

Interfacing ....................................................... 29

To change the width and length ................... 29

Variation of Zigzag Stitches ...................................... 30

Overcasting ..................................................... 30

Tricot stitch ...................................................30

Knit stitch ...................................................... 31

Overedge sewing (1).................................... 31

SECTION IV DECORATIVE STITCHING

TECHNIQUES

Overedge Sewing (2), (3) ......................................... 32

Sewing Buttons ......................................................... 33

Sensor Buttonhole................................................ 34-37

Automatic buttonholing ................................... 34

Sewing preparation ...................................... 35

Starting sewing............................................. 36

Adjusting Stitch Width and Density in Buttonholes .. 37

Sensor buttonhole 09 and 10 .......................... 38

Adjusting the stitch width and

density in buttonholes 09 and 10 ........................... 38

Corded Buttonholes .................................................. 39

Free Size Automatic Buttonhole 20 .......................... 40

Zipper Sewing ........................................................... 41

Put in a zipper ................................................. 41

Attaching the zipper foot .............................. 41

Fabric preparation ........................................ 41

To sew ....................................................................... 41

1

Page 3

Zipper Sewing, contÕd ............................................. 42

Darning ..................................................................... 43

To sew .................................................................. 43

For darning less than 2 cm ............................... 43

To memorize darning stitches ........................... 43

Adjusting the shape of darning stitches ............ 43

Bartacking ................................................................. 44

Memorizing bartacking ........................................ 44

Adjusting the evenness of bartacking stitches . 44

Rolled Hem ............................................................... 45

Blind Stitch Hemming ............................................... 46

How to fold the fabric ........................................... 46

How to sew ....................................................... 46

Changing the needle position ........................... 46

Pintucking ................................................................. 47

Quilting ..................................................................... 47

Shell Tack ................................................................. 48

Applique .................................................................... 48

Smocking .................................................................. 49

Fagoting .................................................................... 49

Scallop Stitch (A), (B) ............................................... 50

Patchwork ................................................................. 51

Satin Stitch Sewing .................................................. 51

Cross Stitch .............................................................. 52

Decorative Stitch ...................................................... 52

Cording ..................................................................... 53

Twin Needle Stitching............................................... 54

Adjusting Pattern Balance ........................................ 55

Adjusting distorted stretch stitch patterns ............ 55

Adjusting distorted letters or numbers in

B or C Mode ......................................................... 55

Adjusting the stitch density for buttonhole 20 ...... 55

Programming Decorative Stitch Patterns 61, 58...... 56

A programmed stitch sewing pattern finishing with .

auto-lock, stitches 61, 58, 98 ............................... 56

Cycle Stitching with Mirror Image Patterns .............. 57

Restarting Programmed Patterns ............................. 57

Elongation ................................................................. 58

Sewing sample, stitch pattern 51......................... 58

Sewing Letters in Block Style ................................... 59

Combining Letters in Script Style ............................. 60

Editing Function (1) .................................................. 61

Check and correct pattern combination

before sewing ....................................................... 61

Deleting a stitch pattern, letter or

number by editing ................................................ 61

Adding letters or space between letters............... 62

Editing Function (2) .................................................. 63

Uniform width, length adjustment ........................ 63

Editing Function (3) .................................................. 63

Custom stitch sizing ............................................. 63

SECTION V CARE OF YOUR MACHINE

Care of Your Machine ............................................... 64

Cleaning the Hook Race and Feed Dogs ................. 64

Replacing the Bobbin Holder .................................... 64

Replacing the Light Bulb ........................................... 65

Removing light bulb ............................................. 65

Attaching light bulb ........................................... 65

Troubleshooting .................................................. 66, 67

When message appears on the screen ............... 67

2

Page 4

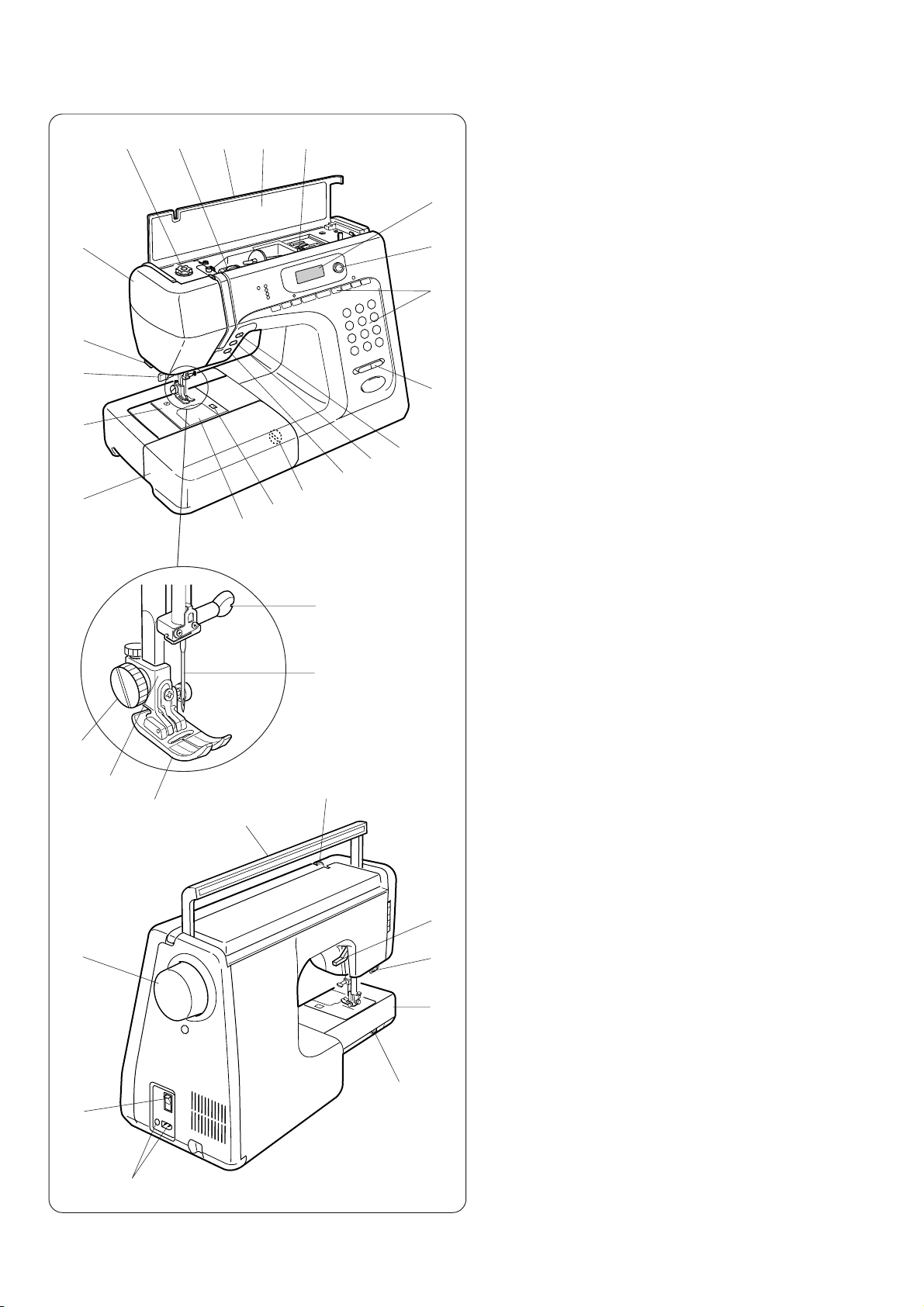

SECTION I NAME OF PARTS

Names of Parts

12345

1 Foot storage compartment

6

7

8

9

10

11

12

13

21

14

15

16

20

19

18

17

2 Flip-top sewing instruction panel

3 Top cover

4 Auto-tension dial

5 Pressure dial

6 Face plate

7 Thread cutter

8 Needle threader

9 Needle plate

10 Extension table

11 Hook cover plate

12 Hook cover plate release button

13 Feed balancing dial

14 Reverse button

15 Auto-lock button

16 Up/down needle button

17 Speed setting lever

18 Keyboard

25

28

29

24

23

77

22

26

31

34

33

32

19 Screen sharpness adjustment dial

20 LCD screen

21 Needle clamp

22 Needle

23 Presser foot

24 Foot holder

25 Thumb screw

26 Thread take-up lever

27 Carrying handle

28 Handwheel

29 Power switch

30 Machine sockets

31 Drop feed lever

32 Free arm

33 Buttonhole lever

34 Presser foot lifter

30

3

Page 5

Screen Sharpness Adjusting Dial

Use this to adjust the sharpness of the liquid crystal

display.

If no indication is shown on the screen after you switch

on the power, adjust the screen brightness with this dial.

Extension Table

The extension table provides added sewing surface and

can be easily removed for free arm sewing.

Detaching the table:

Pull the table away from the machine, as illustrated.

Free arm sewing

Free arm sewing is useful for darning socks or mending

knees, elbows or areas of wear in children’s cloths.

Attaching the table:

Push the extension table until it snaps into the machine.

2

1

1 Projection

2 Hole

4

Page 6

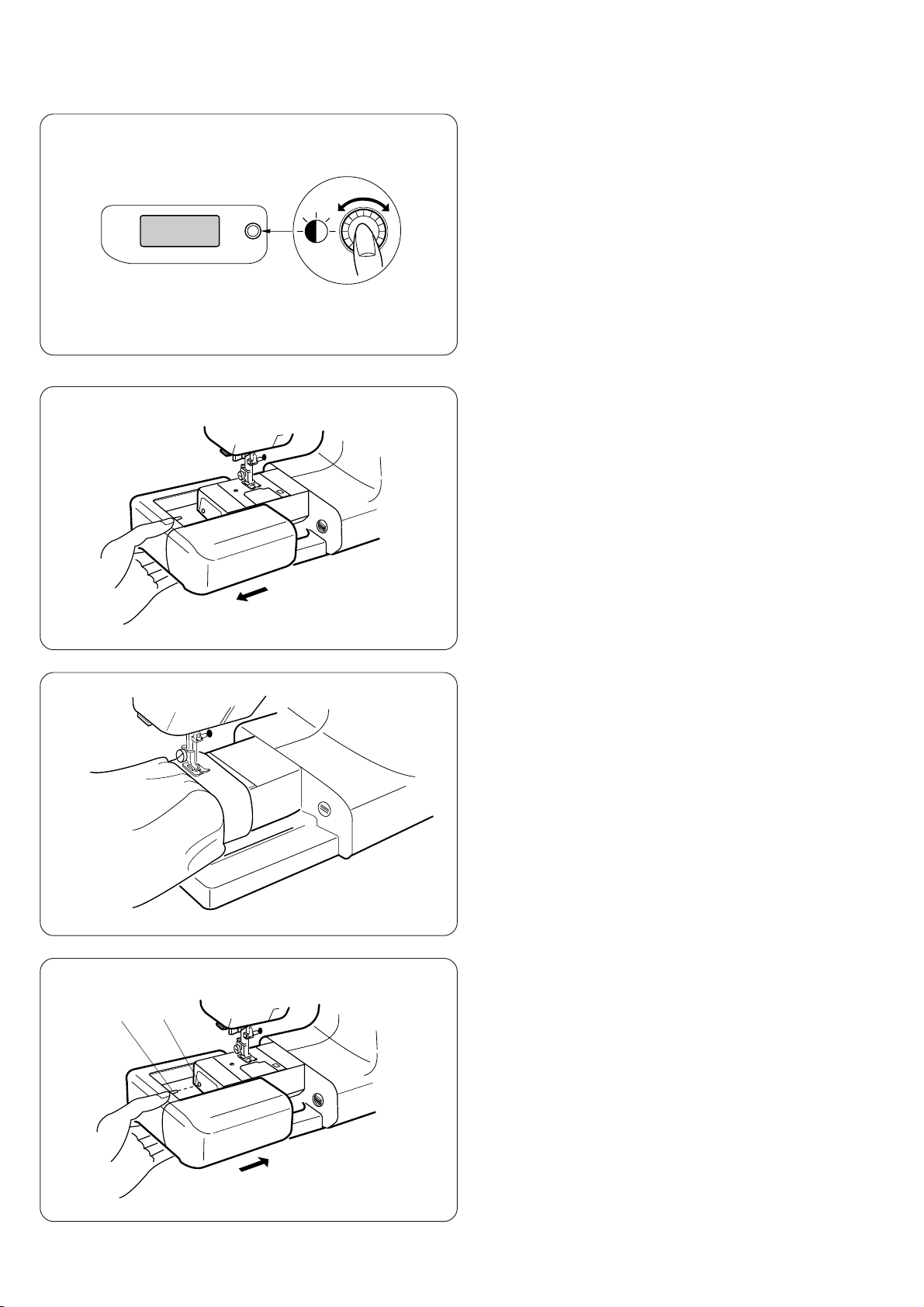

Standard Accessories

2

L

1

3

4

1 Set of needles

2 L: Quilting bar

3 G: Blind hem foot

G

D

C

F

E

A

5

6

4 D: Hemmer foot

5 C: Overedge foot

6 E: Zipper foot

7 A: Zigzag foot

*It is attached on the machine.

8 F: Satin stitch foot

7

8

22

9

11

13

14

18

15

19

23

16

20

10

17

12

24

21

o Screwdriver

!0 R: Automatic buttonhole foot

!1 Lint brush

!2 Bobbins

!3 Seam ripper

!4 Spool holder (Large)

* It is attached on the machine.

!5 Spool holder (Small)

!6 Additional spool pin

!7 Felt

!8 Spool base

!9 H: Cording foot

20 M: Overcasting foot

21 P: Basting foot

22 Foot control

23 Power supply cord

24 Carrying case

5

Page 7

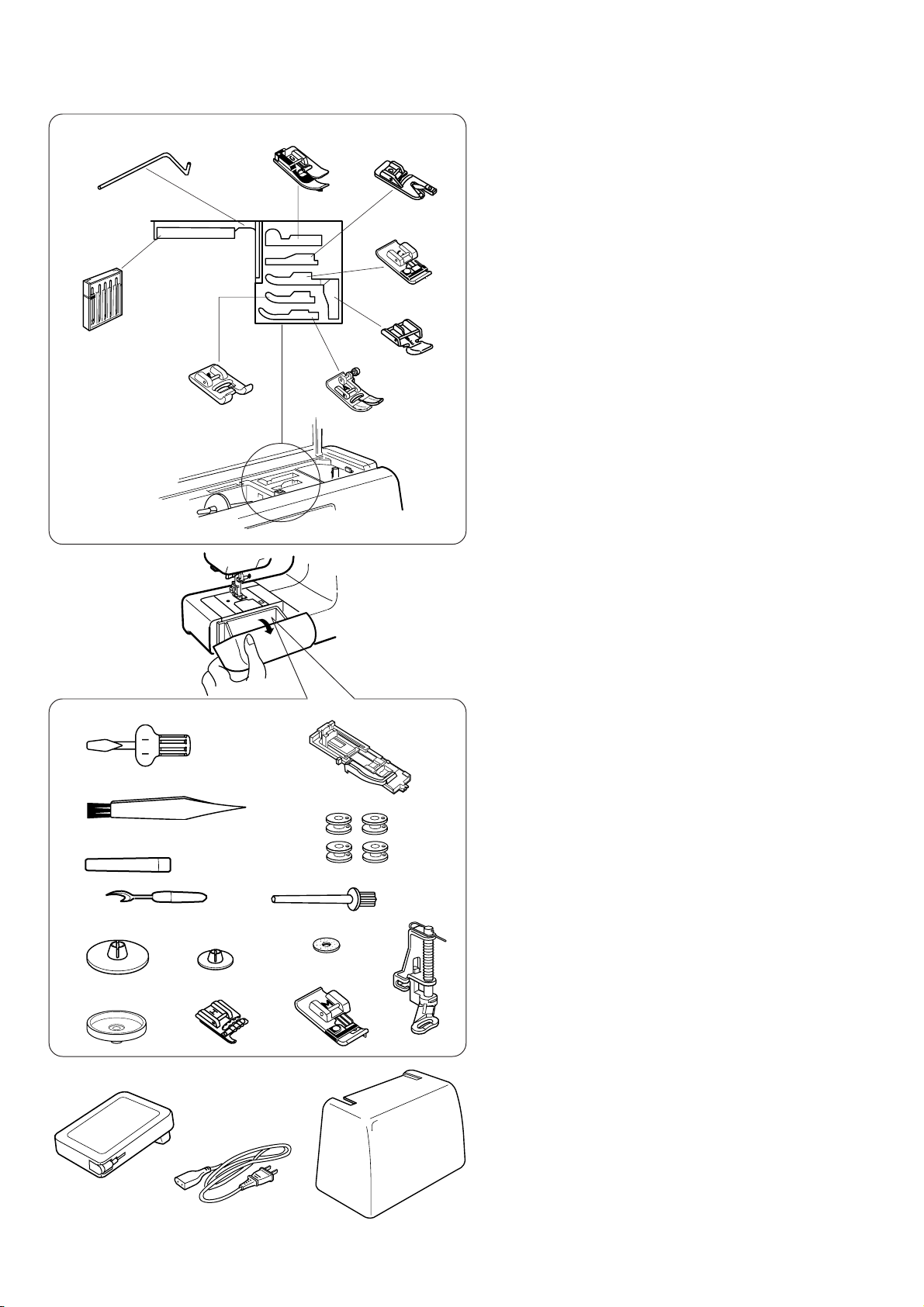

SECTION II GETTING READY TO SEW

Connecting Machine to Power Supply

4

Before connecting the power supply, make sure the

voltage and frequency shown on the machine conform to

your electrical power.

Turn off the power switch, and insert the foot control plug

1, machine plug 2, into the machine and power supply

2

5

1

6

plug 3 into the outlet in the following order.

1 Foot control plug

2 Machine plug

3 Power supply plug

4 Power switch

5 Power supply cord

6 Foot control

For Your Safety

* While in operation, always keep your eyes on the

sewing area. Do not touch any moving parts such as

3

the thread take-up lever, handwheel or needle.

* Always turn off the power switch and unplug from the

power supply:

- When leaving the machine unattended

- When attaching or removing parts

- When cleaning the machine

* Do not place anything on the foot control, when not

sewing.

Operating instructions

For appliances with a polarized plug (one blade wider than

the other), to reduce the risk of electric shock, this plug is

intended to fit in a polarized outlet only one way. If it does

not fit fully in the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install the proper

outlet. Do not modify the plug in any way.

Foot controller Model 21371 for use with Sewing Machine

MC4800.

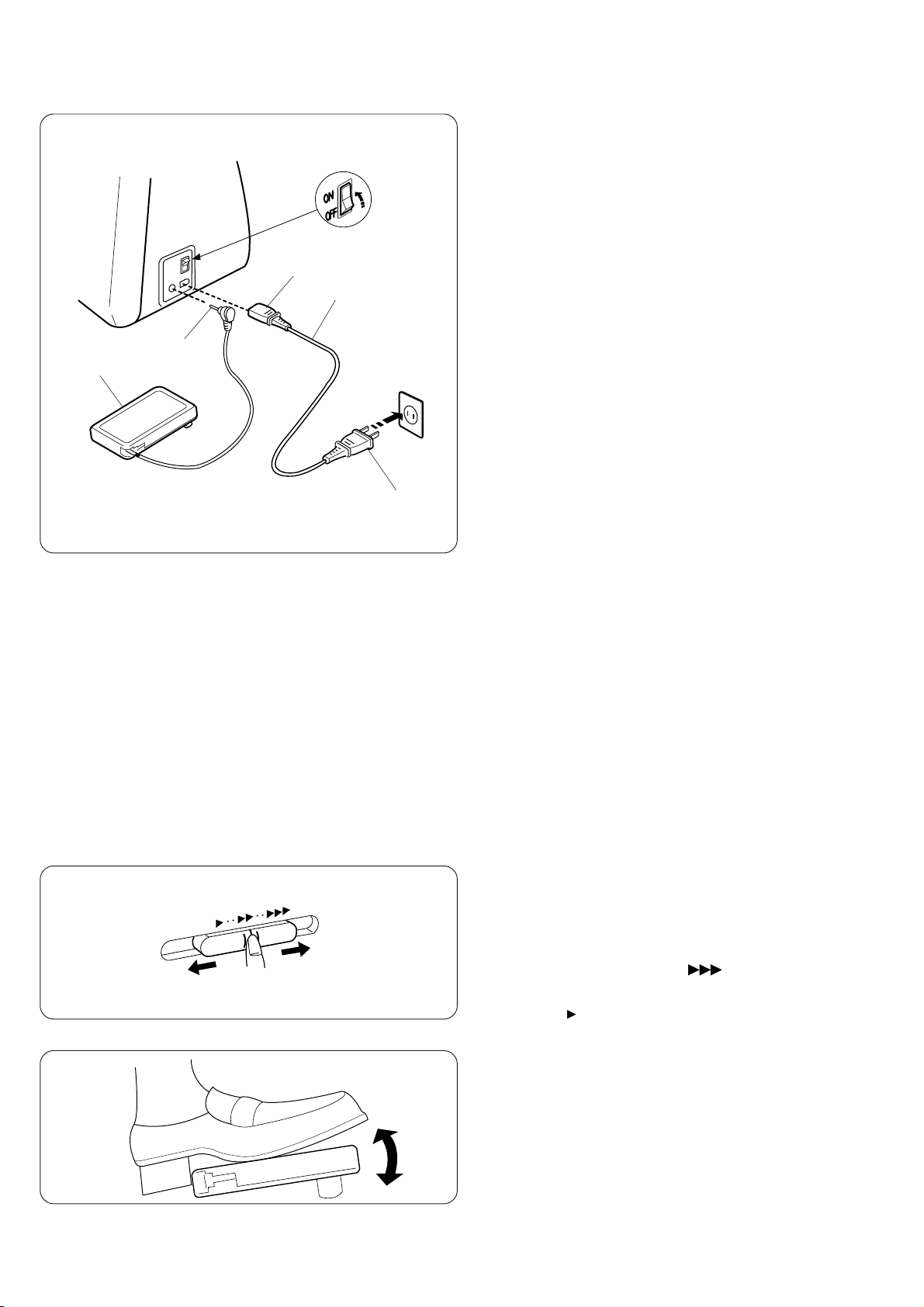

Controlling Sewing Speed

Speed setting lever

The maximum sewing speed can be controlled by the

speed setting lever. To increase the speed, slide the

lever to the right (toward “ “).

To decrease the sewing speed, slide the lever to the left

(toward “ “).

Foot control

Sewing speed can be varied by the foot control.

The harder you press on the control, the faster the

machine runs.

Note:The Memory Craft 4800 is equipped with a

protective circuit to prevent overheating.

The machine will stop automatically if it is running

overloaded for a long time. In such a case, follow

6

the message that appears on the LCD screen.

Page 8

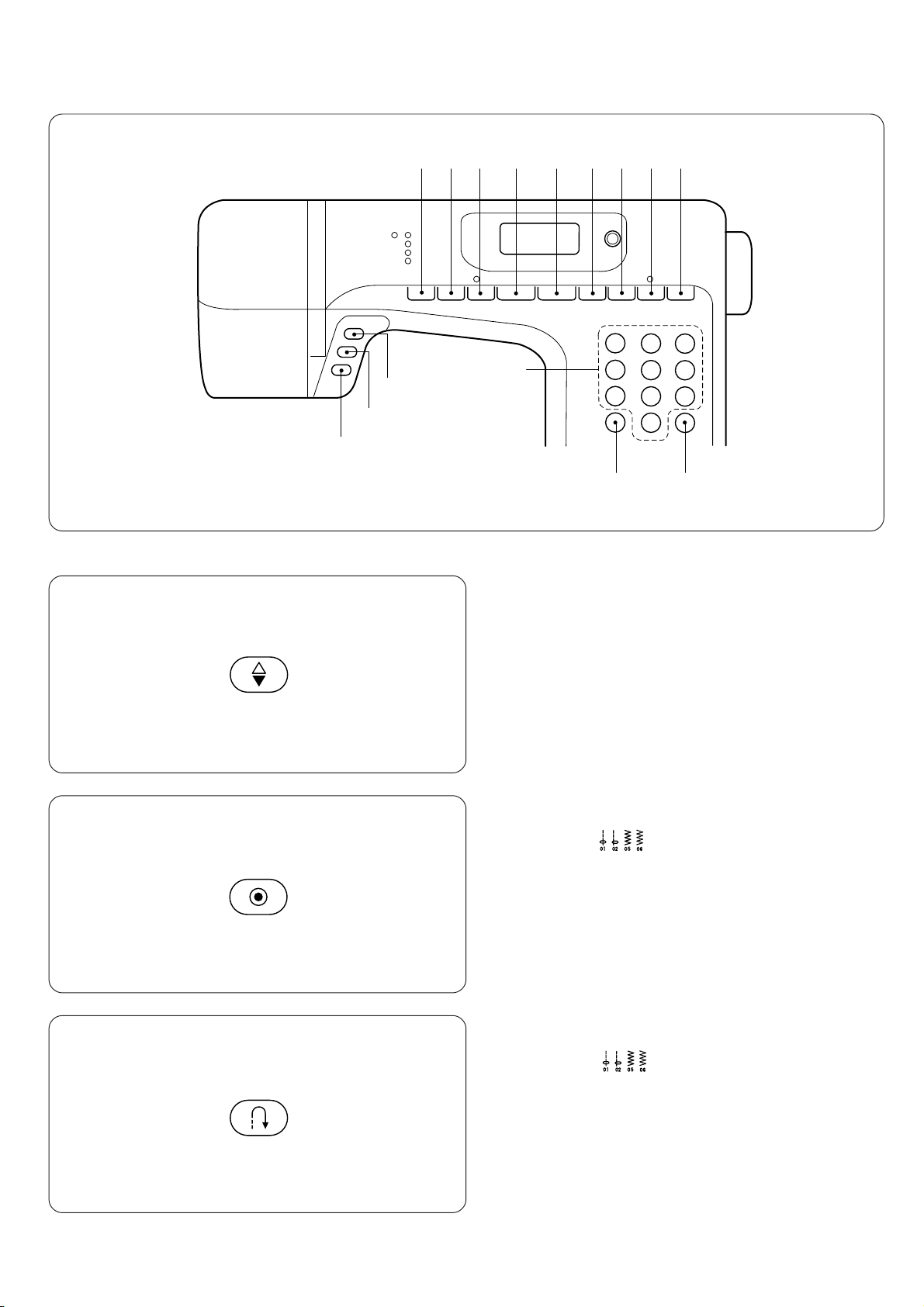

4

56 7 8 9101112

15

1

2

3

14

13

Main Function of Buttons / Keys

• Up/down needle position button

When the Up/down needle position button is pressed,

1

the needle bar goes down and stops in the lowest

position. When pressed again, the needle bar goes up

and stops in the highest position.

* When this button is pressed, the needle bar alter-

nates between up and down positions when the

machine stops.

• Auto-lock button

When stitches are selected, the machine will

immediately sew locking stitches when the auto-lock

button is pressed, then automatically stop.

2

When sewing all other stitches, the machine will sew

locking stitches at the end of the current pattern and

automatically stop.

• Reverse button

When stitches are selected, the machine will

sew in reverse while the reverse button is pressed.

3

If you press the reverse button when sewing all other

stitches, the machine will immediately sew locking

stitches and automatically stop.

7

Page 9

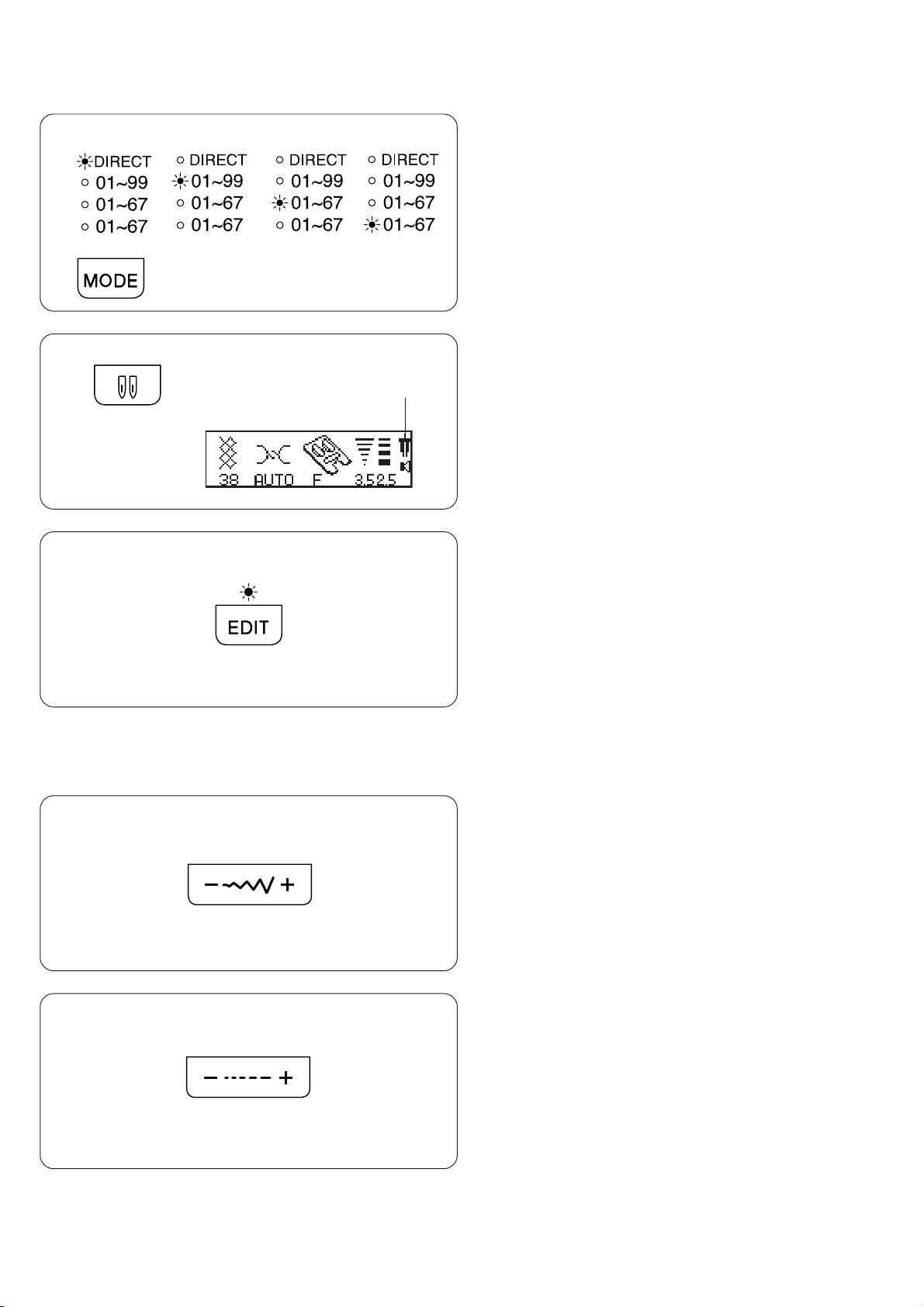

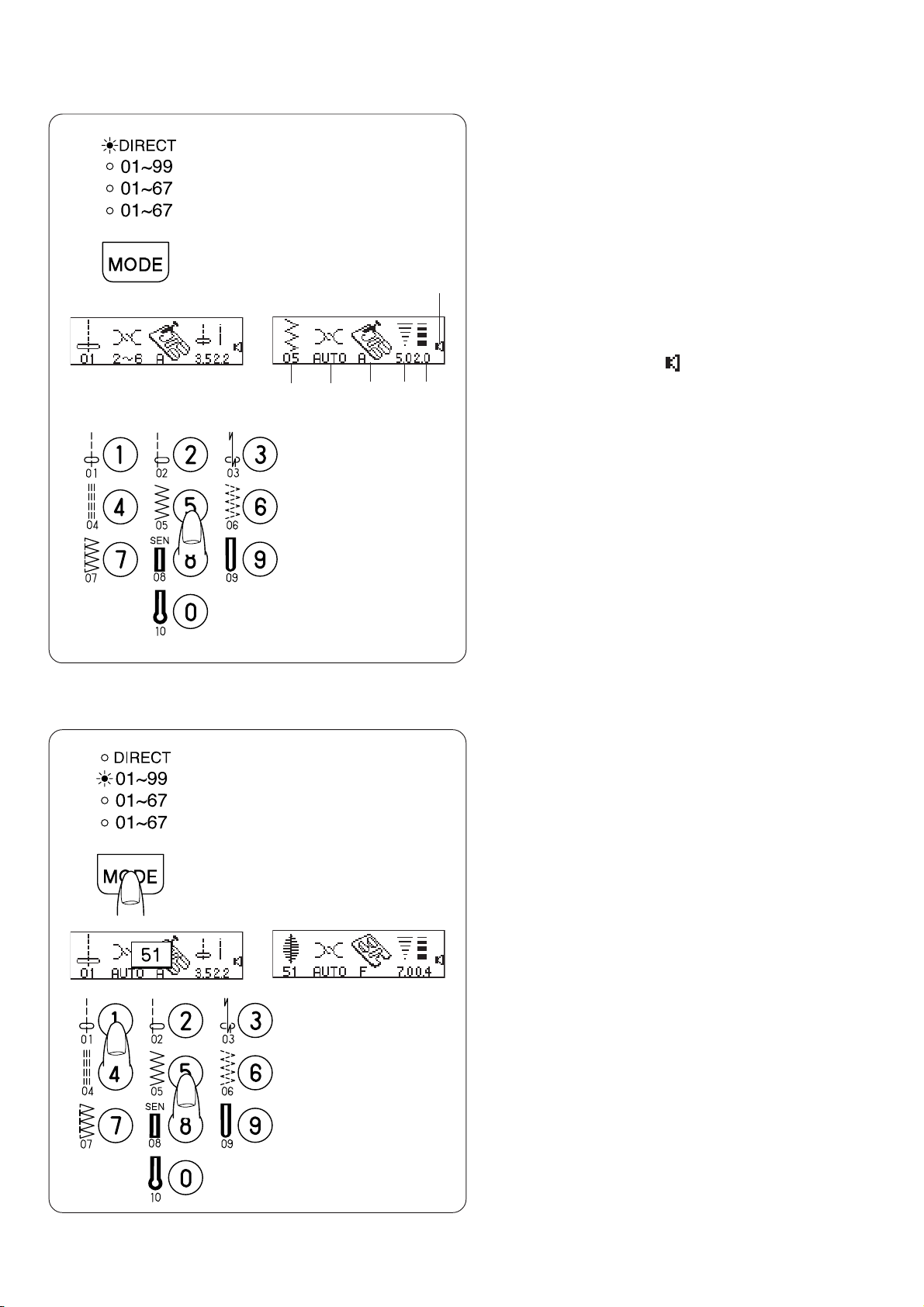

Direct ModeAA Mode

4

5

B Mode

C Mode

6

• Mode selection key

By pressing the key, LED light will move step by step to

select the stitch mode, as shown.

Direct Mode: Direct mode pattern selection

A Mode: Pattern selection using number keys utility

and decorative stitches)

B Mode: Character selection using number keys

(block type)

C Mode: Character selection using number keys

(script type)

• Twin needle key

Just press this button and “A” mark will appear on the

display screen.

Press button again for single needle sewing.

• Editing key

This button can be used for adding, deleting and chang-

ing combinations and monograms before sewing while

programming stitch patterns or monograms.

For editing, use the stitch width “+” or “-” key to select

editing position (see page 61, 62).

[Manual setting function of the zigzag width and stitch

length for programmed patterns]

The individual programmed zigzag pattern width or

stitch length can be changed (see page 63).

• Stitch width selection key

Press “+” or “-” to change the stitch width.

7

• Stitch length selection key

Press “+” or “-” to change the stitch length.

8

8

Page 10

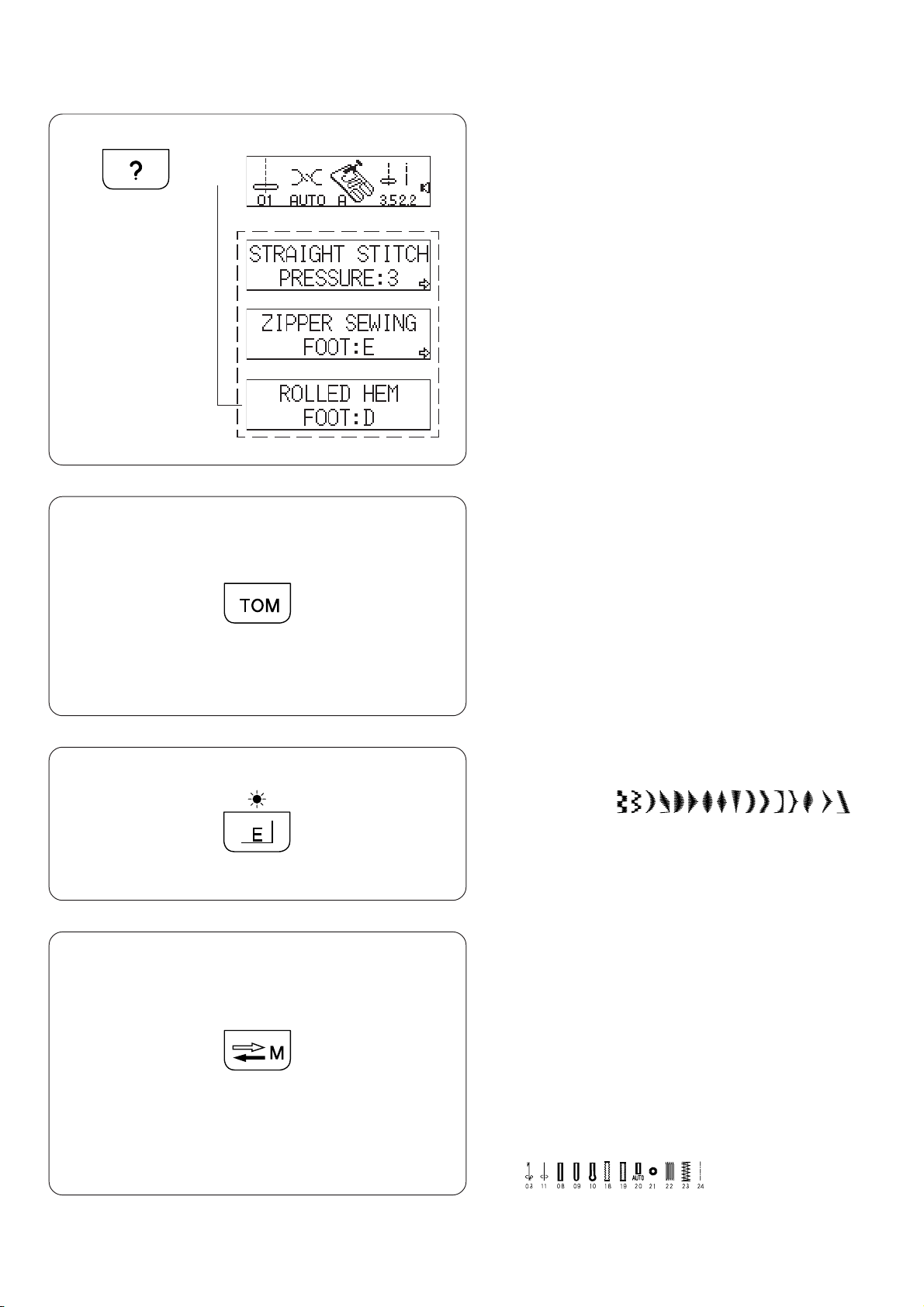

• Message key

When Message key is pressed, a detailed message will

9

,

display suitable stitches, patterns and machine settings.

,

• Turn-over memory key

(To memorize the pattern in mirror image)

Select a desired pattern and press TOM key so the

selected pattern’s mirror image will be shown on the

10

screen.

Use this key to memorize and sew patterns in a mirror

image. Programmed letters or numbers will be reduced

to 2/3 of their actual size when you press the TOM key.

!1

!2

• Elongation key

(For A Mode)

Stitches 45 to 60 ( )

can be elongated up to five times their normal length by

pressing this key.

• Stock/call key

When you press the Stock/call key after memorizing a

pattern or editing patterns, the currently registered

patterns will be deleted and new patterns will be stored.

Other than this, you can recall the stored patterns when

you press the Stock/call key.

You can store a maximum of 50 programmed patterns

and sew.

* You cannot store the Direct mode patterns and

buttonholes also you cannot memorize

( ) patterns by using

memory key (see page 10).

9

Page 11

13

14

• Clear key

If an incorrect pattern is memorized, pressing this key

will immediately clear it (like a backspace key).

• Memory key

When this key is pressed after selecting a pattern, the

pattern will be memorized as many times as the key is

pressed. When the key is pressed after selecting another pattern, that pattern will be memorized after the

previously memorized pattern.

(The maximum number of memory patterns is 50)

* The following patterns cannot be memorized.

* The Direct mode patterns and buttonholes cannot be

memorized.

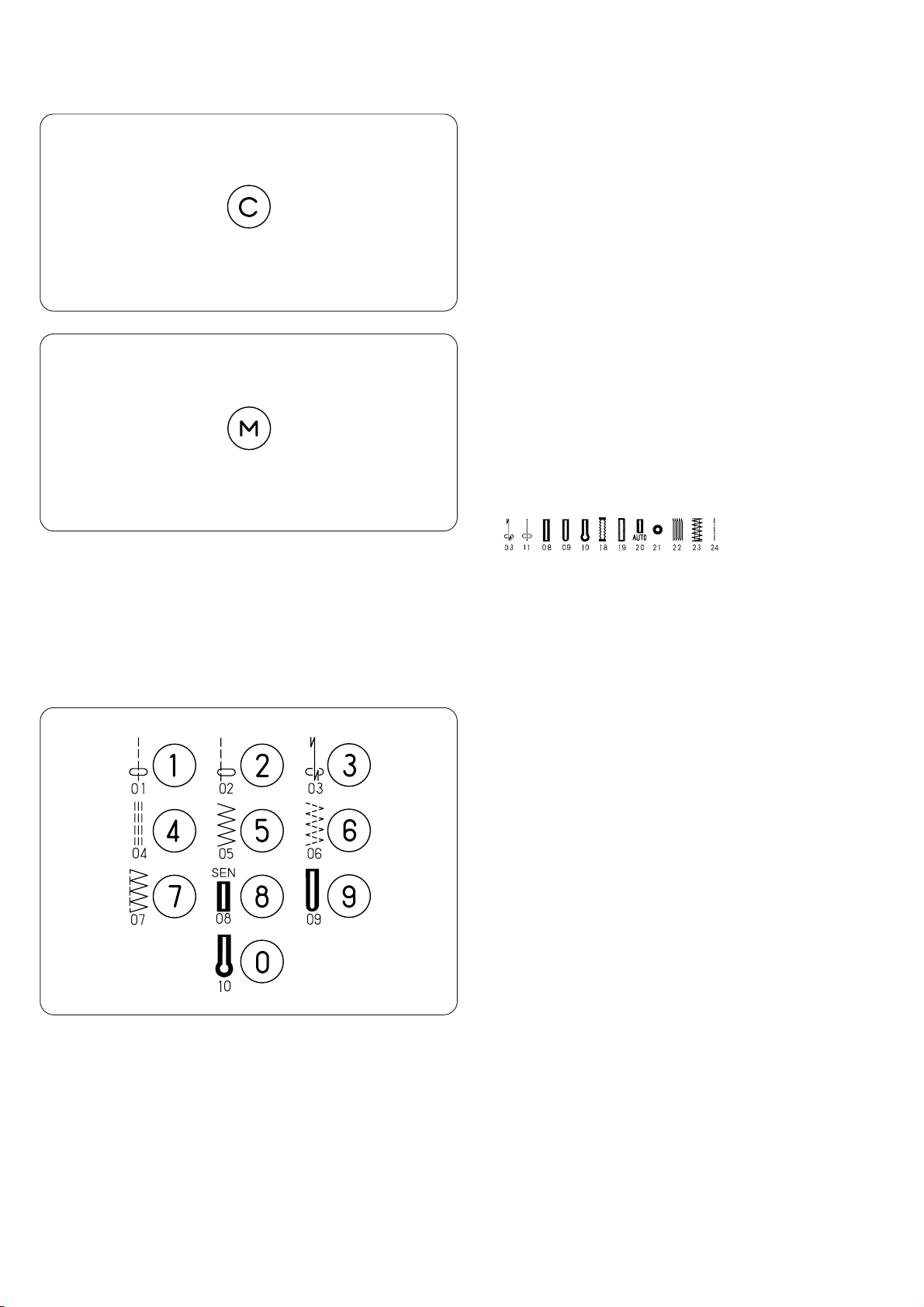

15

• Direct pattern selection and number keys

[Direct pattern selection]

You can select the patterns 1 to 10, also buttonhole

stitches, square buttonhole to keyhole buttonhole when

the mode key is set at the Direct mode.

In A Mode 01~96, the patterns 01 to 10 can be selected

by pressing two-digit numbers.

[Number keys]

Press number keys of the pattern number to select the

desired pattern.

10

Page 12

[1]

[2]

• Pattern selection and screen indication

Select the Direct mode pattern selection.

[1]

[2]Press the pattern key on the keyboard.

Example: Pattern 05, as shown.

[3]The display screens shows from left to right:

1 Stitch pattern: 05

6

[3]

\

345

2

1

2 Thread tension: AUTO

3 Presser foot: A

4 Stitch width: 5.0

5 Stitch length: 2.0

6 Buzzer sound on:

(see page 12 to mute the buzzer sound)

• Number key selection

You can select the patterns by pressing number keys.

Example: pattern number 51

\

11

Page 13

[1]

[2]

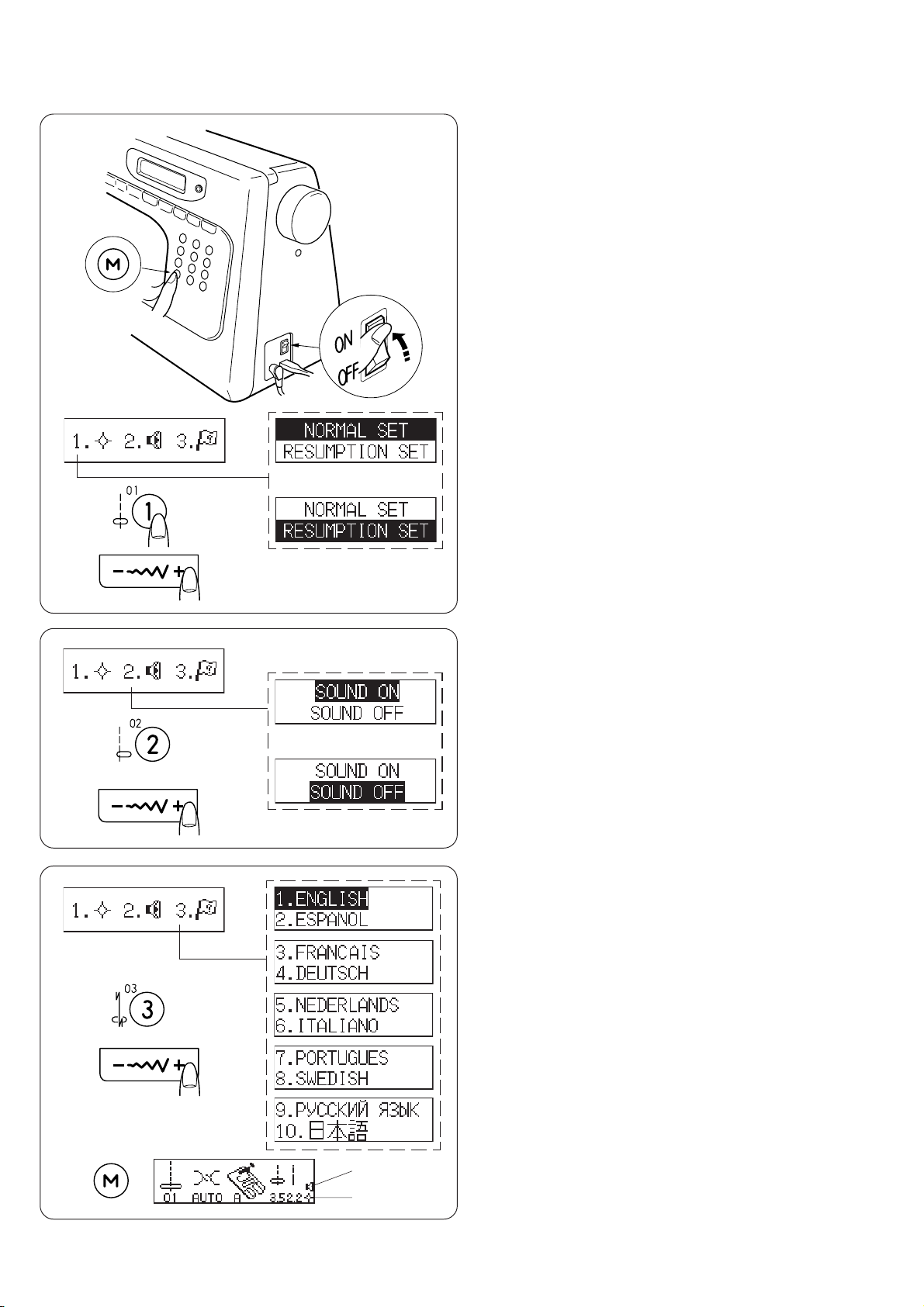

Memory Mode/Buzzer Sound/Multiple

Language Settings

NORMAL / RESUMPTION Mode

Turn on the power switch while pressing the memory

[1]

key.

1 Memory key

2 Power switch

2

1

\

\

[2]Select “1” on the number key to access the

NORMAL/RESUMPTION mode.

You can select the mode by pressing the stitch width

key “+” or “-”.

* NORMAL mode - The last selected pattern setting

will not be recalled when you turn on your machine.

Machine turns on in straight stitch 01, Direct mode.

* RESUMPTION mode - The last selected pattern

setting will always be recalled when you turn on

your machine. Machine turns on in A Mode.

[3]Select the desired mode: NORMAL SET or

RESUMPTION SET.

[4]Press the Memory key.

[3]

[1]

[2]

[2]

[3]

[4]

3

Buzzer

[1]

Turn on the power switch while pressing the memory

4

key.

1 Memory key

2 Power switch

[2]Select “ 2 “ by pressing the number key to access the

Buzzer mode.

\

\

You can select the mode by pressing the stitch width

“+” or “-”.

[3]Select desired mode “-” SOUND ON or “+” SOUND

OFF.

[4]Press the memory key.

* The Buzzer sound setting mark will appear on the

screen when you have set it .

Language selection setting

Turn on the power switch while pressing the memory

5

[1]

key.

1 Memory key

2 Power switch

[2]Select “ 3 “ by pressing the number key to access

language selection settings.

You can select the desired language by pressing

stitch width “+” or “-”.

[3]Select the desired language.

3 NORMAL / RESUMPTION

4 Buzzer sound “ ON “ or “ OFF”

5 Multiple language

[4]Press Memory key.

7

6 NORMAL / RESUMPTION

7 Buzzer sound setting mark

6

12

Page 14

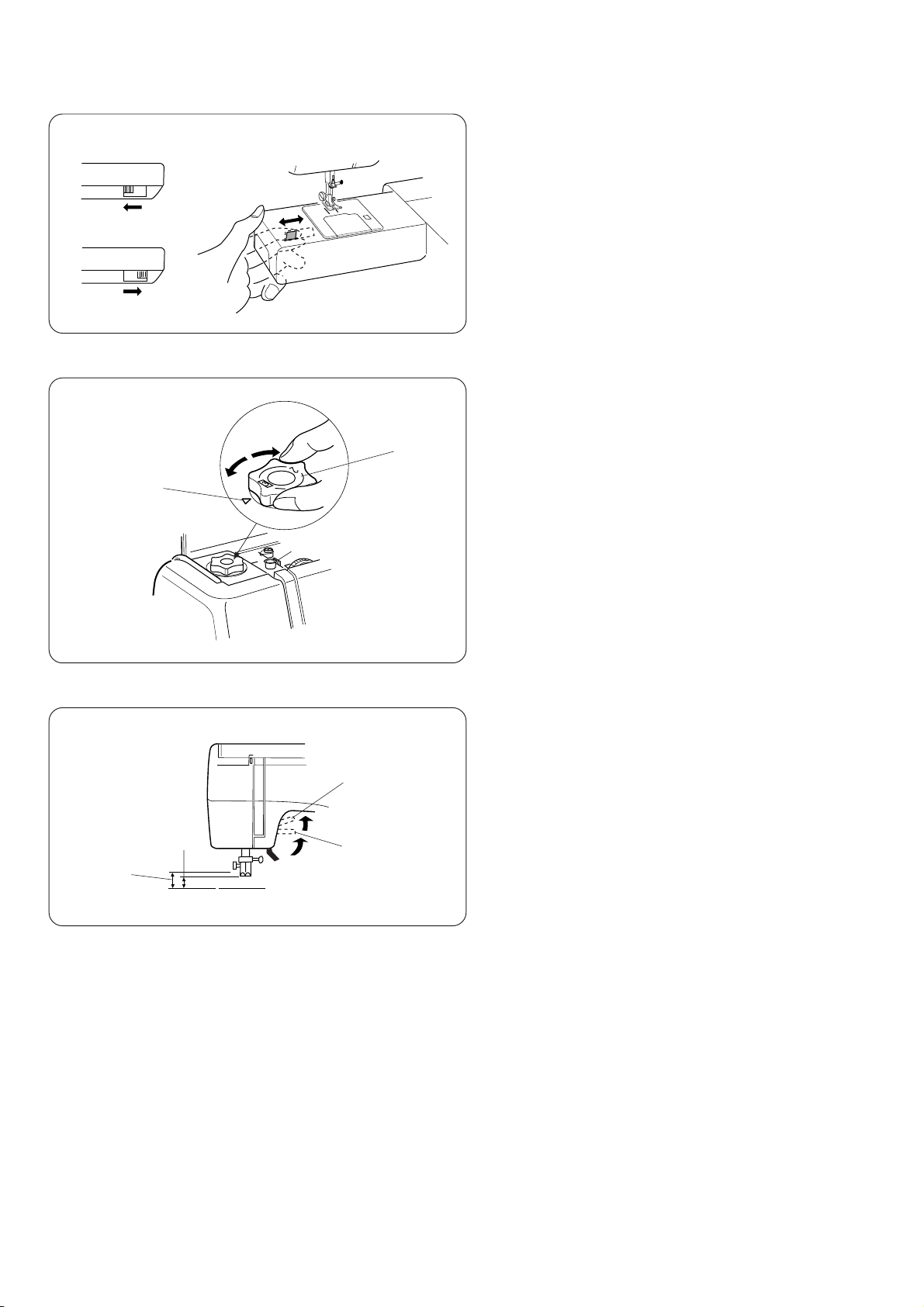

To Raise or Drop the Feed Dogs

1

1

2

2

• For button sewing etc., drop the feed dogs.

• When finished sewing, raise the feed dogs.

The feed dogs must always be up for normal sewing.

1 Lowered position

2 Raised position

Pressure Dial

The pressure dial should be set at “3“ for regular sewing.

1

2

Reduce the pressure to “2” for applique, cutwork, drawn

work, basting and embroidery.

Set the pressure to “1” when sewing chiffon, lace,

organdy and other fine fabrics. Velour and knit with a lot

of stretch may also require a “1” setting.

Align the number on the dial with the setting mark.

1 Pressure dial

2 Setting mark

Presser Foot Lifter

The presser foot lifter raises and lowers your presser

foot.

2

You can raise it about 0.6 cm (1/4ý) higher than the

normal up position for easy removal of the presser foot

1

1

2

or to help you place heavy fabric under the foot.

1 Normal up position

2 Highest position

13

Page 15

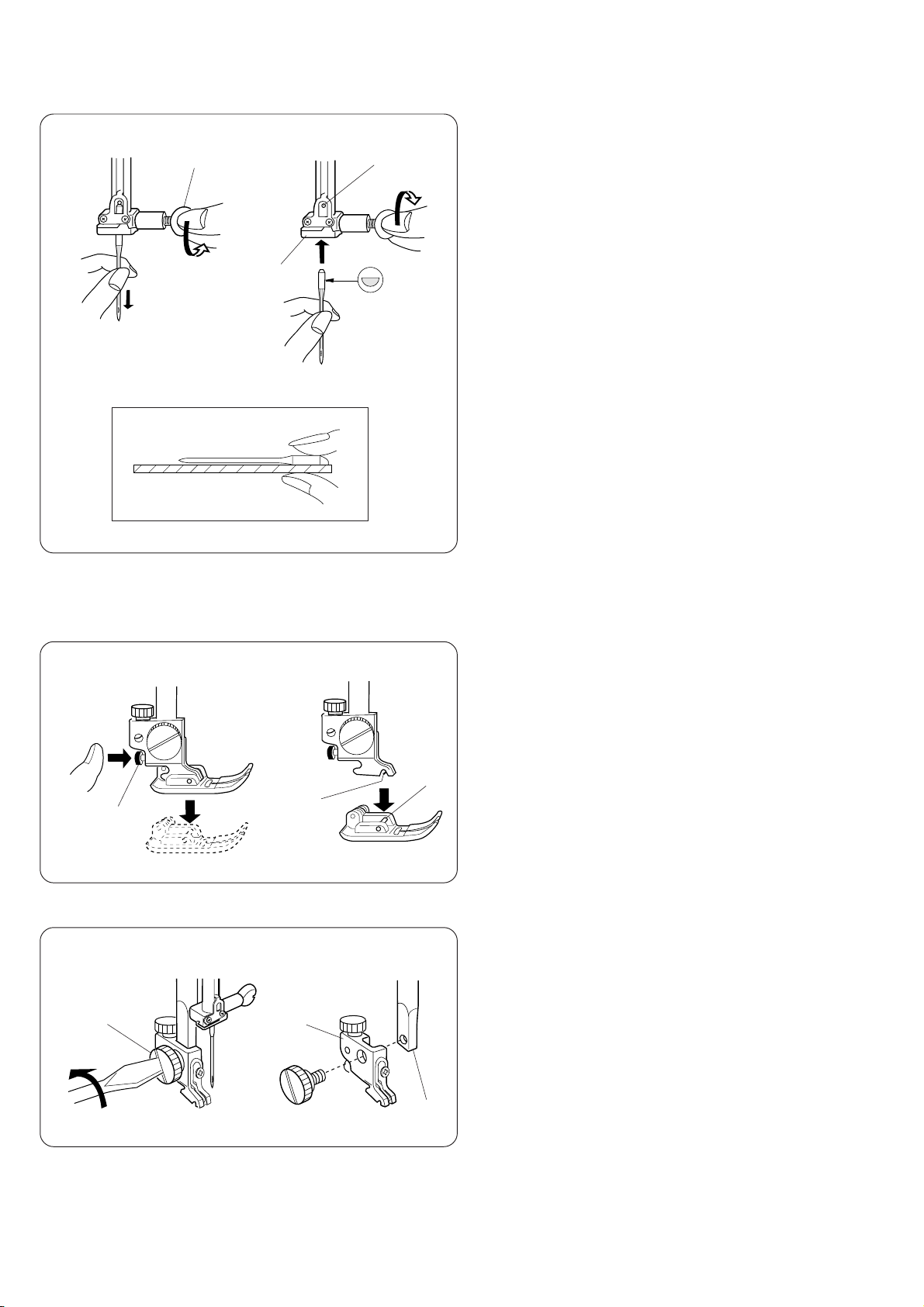

[1] [2]

1

3

[3]

Changing Needles

2

[1]Raise the needle by pressing the Up/down needle

position key and lower the presser foot.

Turn off the power switch.

Loosen the needle clamp screw by turning it

counterclockwise.

Remove the needle from the clamp.

[2]Insert the new needle into the needle clamp with the

flat side to the rear.

When inserting the needle into the clamp, push it up

as far as it will go. Tighten the clamp screw firmly by

turning it clockwise.

[3]To check for a good needle, put the flat side of the

needle onto something flat (the needle plate, glass

etc.).

The gap between the needle and the flat surface

should be consistent. Never use a bent or blunt

needle.

1 Needle clamp screw

2 Pin

3 Needle clamp

[1] [2]

1

[1] [2]

1

2

To Attach and Remove the Presser Foot

[1]Press the red button on the back of the foot holder.

The presser foot will drop off.

[2]Place the selected presser foot so the pin on the foot

3

2

lies just under the groove of the foot holder.

Lower the presser bar to lock the foot in place.

1 Red button

2 Groove

3 Pin

To Remove and Attach the Foot Holder

[1]To Remove:

Remove the thumb screw by turning the screw

counterclockwise with the screwdriver.

[2]To Attach:

Match the hole in the foot holder with the threaded

3

hole in the presser bar.

Fit the thumb screw into the hole.

Tighten the screw by turning it clockwise.

14

1 Thumb screw

2 Foot holder

3 Presser bar

Page 16

Selecting Needle and Thread

LIGHT WEIGHT

MEDIUM WEIGHT

HEAVY WEIGHT

NOTE:

FABRICS

Crepe de Chine,

Voile, Lawn,

Organdy,

Georgette,Tricot

Linens, Cotton,

Pique, Serge,

Double Knits,

Percale

Denim, tweed,

Gabardine, Coating,

Drapery, and

Upholstery Fabric

THREADS

Fine Silk

Fine Cotton

Fine Synthetic

Fine Cotton-covered Polyester

50 Silk

50 to 80 Cotton

50 to 60 Synthetic

Cotton-covered Polyester

50 Silk

40 to 50 Cotton

40 to 50 Synthetic

Cotton-covered Polyester

NEEDLE SIZE

9 or 11

11 or 14

14 or 16

* In general, fine threads and needles are used for sewing fine fabrics, and thicker threads and needles are used for sewing

heavy fabrics.

Always test thread and needle size on a small piece of fabric which will be used for actual sewing.

* Use the same thread for needle and bobbin.

* When sewing stretch, very fine fabrics and synthetics, use a blue tipped needle.

The blue tipped needle effectively prevents skipped stitches.

15

Page 17

321

4

5

1

Winding the Bobbin

• Set the spool

Lift up the spool pin and place the spool of thread on it

with the thread coming off the spool as shown.

Press the large spool holder firmly against the spool of

thread.

* The small spool holder is used with a small or narrow

spool of thread.

1 Spool pin

2 Ordinary spool

3 Large spool holder

4 Small spool holder

5 Small spool

• Removing the bobbin

Gently slide the hook cover plate release button to the

right and remove the cover plate.

Lift out the bobbin.

1 Hook cover plate release button

2 Hook cover plate

2

16

Page 18

“C”

[4]

“A”

3

5

[3]

“B”

[2]

[5]

1

4

[6]

[7]

,

7

6

• Winding the bobbin

2

For the bobbin winding, set the speed control lever at

the medium to high speed position.

[1]

6

[1] Hold the end of thread.

[2] Guide the thread through the thread guide “A”.

[3] Thread the thread guide “B”.

[4] Thread the thread guide “C”.

[5] Thread through the hole in the bobbin from the

inside to the outside.

1 Bobbin winder spindle

[6] Put the bobbin on the bobbin winder spindle, and

push it to the right.

2 Bobbin winder stopper

[7] Hold the free end of the thread in your hand and

depress the foot control.

Stop the machine when it has made a few turns,

and cut the thread close to the hole in the bobbin.

Depress the foot control again.

When the bobbin is fully wound, it will stop

automatiaclly.

, Return the bobbin winder to its original position by

moving the spindle to the left, and cut the thread as

shown.

* The machine will not sew until the spindle is in the

left position.

* You can also use the additional spool pin for the

bobbin winding as shown.

3 Spool

4 Additional spool pin

5 Felt

6 Additional spool pin hole

7 Spool base

17

Page 19

[1]

• Inserting the bobbin

[1]

Place the bobbin in the bobbin holder with the thread

running off counterclockwise.

1 End of thread

1

[2]

[3]

[2] Guide the thread into the notch on the front side

of the bobbin holder.

2 Notch

A

A

A

2

[3] Continue to draw the thread lightly. The thread slips

into notch .

Pull out about 15 cm (6”) of thread.

3 Notch

3

B

18

[4]

4

[4] Attach the hook cover plate.

Check the threading by referring to the chart shown

on the hook cover plate.

4 Threading chart

Page 20

[3]

[1]

[5]

4

“B”

[1]

Threading the Machine

• Threading the machine

* Raise the presser foot lever.

* Turn the power switch “ON”, press the needle

1

[2][4]

Up/down button twice to raise the needle, then turn

the power switch “OFF”.

1 Presser bar lifter

2 Needle Up/down button

2

[1] Raise the presser foot lifter.

Draw the thread from the spool and thread around

the upper thread guide “A” and “B”.

3 Thread guide “A”.

“A”

3

4 Thread guide “B”

[2]

[3]

[4]

[5]

[2] Then, down around the check spring holder.

5 Thread guide plate

5

[3] Turn the handwheel toward you to raise the thread

take-up lever.

Firmly draw the thread from right to left over the

take-up lever and down into the take-up lever eye.

6

“D”

7

6 Thread take-up lever

[4] Then, down through the lower thread guide.

7 Thread guide “D”

[5] Slide the thread behind the needle bar thread guide

on the left.

8 Needle bar thread guide

8

* Use the automatic needle threader (see page 20).

19

Page 21

[1]

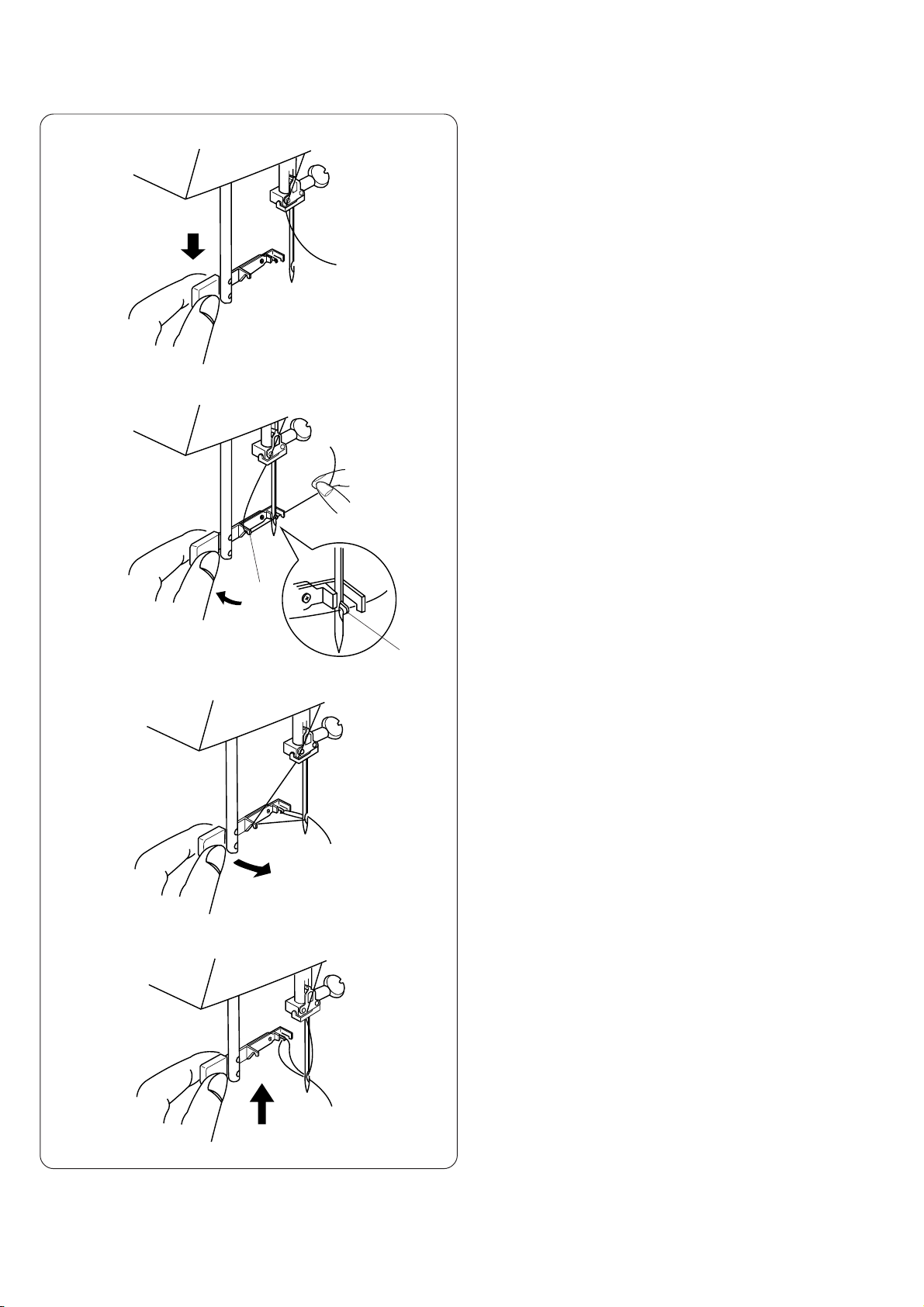

• Needle threader

Raise the needle to its highest position. Pull down the

[1]

needle threader knob as far as it will go.

[2]

[3]

[2]Push the knob in the direction of the arrow in the

illustration, inserting hook q into the needle eye.

Lead the thread around guide w and under the hook.

1 Hook

2 Guide

2

1

[3]Holding on to the thread firmly with your right hand,

pull the needle threader knob in the direction of the

arrow in the illustration, and then upwards to pull the

thread through the eye of the needle.

20

[4]

[4]Pull the thread through the needle eye.

The needle threader can be used with a #11 to #16

needle or #11 Blue tip needle.

Thread size 50 to 100 should work well.

Page 22

[1]

• Drawing up the bobbin thread

Raise the presser bar lifter, hold the end of the

[1]

thread as shown.

[2]

[3]

[2] Press the Up/down needle position button twice to

pick up the bobbin thread.

Draw up the needle thread together with a loop of

bobbin thread.

1 Up / down needle position button

1

[3] Pull both threads under the presser foot and to the

back of the presser foot leaving clear 10 to 15 cm

2

(4” to 6”) of the threads.

2 Needle thread

3 Bobbin thread

3

21

Page 23

[1]

Balanced Thread Tension

1

2

5

3

4

7

6

• Auto-thread tension

When the thread tension dial is set at “AUTO” for auto-

matic thread tension, the green light will be on.

The balanced thread tension is set automatically.

1 Set “AUTO” mark of thread tension dial with the

indication line.

2 Green light on or off.

3 Display screen shows “AUTO”.

For straight stitch sewing, both needle and bobbin

threads will join at the middle of the fabric.

For zigzag stitch sewing, the needle thread will appear

slightly on the wrong side of the fabric.

[1]Balanced thread tension:

4 Wrong side of fabric

5 Right side of fabric

6 Bobbin thread

7 Top thread (needle thread)

[3]

2

2

• Manual thread tension adjustment

[2]

4

5

7

If the thread tension doesn't balance, set the thread

tension dial at 0 to 9 and green light will disappear and

you can adjust the desired thread tension setting manually.

The screen shows the recommended tension setting for

normal sewing.

6

4

5

3

8

[2]If the top thread is too tight, the bobbin thread ap-

pears

on the right side of the fabric.

4 Wrong side of fabric

5 Right side of fabric

6 Bobbin thread

7 Top thread (needle thread)

8 Display screen tension setting

4

5

7

[4]

[5]

6

4

5

3

8

[3]Turn the thread tension dial in the direction of the

arrow to decrease the number.

[4]If the top thread is too loose, the bobbin thread

appears on the underside of the fabric.

4 Wrong side of fabric

5 Right side of fabric

6 Bobbin thread

7 Top thread (needle thread)

8 Display screen tension setting

[5]Turn the thread tension dial in the direction of the

arrow to increase the number.

22

Page 24

SECTION III BASIC SEWING

Straight Stitch Sewing

1

2

1 Stitch pattern: 01

2 Presser foot: Foot A or foot H

• Starting to sew

Raise the presser foot and position the fabric next to a

seam guide line on the needle plate (see page 24).

Lower the needle to the point where you want to start.

Lower the presser foot and pull the threads toward the

back. Depress the foot control. Gently guide the fabric

along a seam guide line letting the fabric feed naturally.

• Changing sewing direction

Stop the machine and bring the needle down into the

fabric by pressing the Up/down needle position button.

Raise the presser foot.

1

2

3

Pivot the fabric around the needle to change sewing

direction as desired. Lower the presser foot.

1 Up/down needle position button

2 Presser foot lifter

• Finishing sewing

To fasten the ends of seams, press the reverse button

and sew several reverse stitches.

Raise the presser foot. Remove the fabric, draw the

threads to the back and cut using the thread cutter.

The threads are cut at the proper length for starting the

next seam.

- When pattern is selected, reverse stitches are

sewn automatically at the beginning of the seam,

then sewing continue forward.

2

1

- When you reach the end edge of the fabric, press

the reverse button once.

The machine will sew four reverse stitches, four

forward stitches then stop sewing.

1 Reverse button

2 Thread cutter

3 Fabric

23

Page 25

Practice Common Stitching Skills

Using the Seam Guides on the Needle Plate

1

2

3

The seam guides on the needle plate are engraved to help

you measure seam width.

The lines are marked as follows.

24

Numbers on needle plate

Seam width center needle

position guide line (cm)

* The numbers indicate the width from the center needle

position to the edge of the fabric.

1

Needle drop position

2 Edge of fabric

1 Guide lines

15 20 4/8” 5/8” 6/8”

1.5 2.0 1.3 1.6 1.9

Turning Square Corners

Turning a square corner 1.5 cm (5/8 “) from the fabric edge:

1. Stop stitching and lower the needle by pressing the

Up/down needle position button when the fabric edge

facing you lines up with the cornering guides as shown.

2

3

1

2. Raise the presser foot and turn the fabric to line up to

the edge with the 1.5 cm (5/8”) seam guide.

3. Lower the presser foot and begin stitching in the new

direction.

1 Up/down needle button

2 Cornering guides

3 Presser bar lifter

Using the Quilting Bar

The stitch and its uses:

Quilting is stitching two layers of fabric together with batting

in between to add dimension and warmth.

You can use quilting on entire garments or parts of garments,

such as yokes, pockets, cuffs and collars.

1

2

3

It is also popular for table fashions.

In addition to straight stitch quilting, you can quilt with decorative stitches or stitch pattern combinations.

To do quilting successfully, follow these simple steps:

1. Loosen the quilter screw 1 on the back of the presser

foot holder as shown.

2. Slide the quilting bar w into the opening under the

screw to the width of quilting stitches you desire.

3. Tighten screw.

4. See page 47 for how to operate.

1 Screw

2 Quilter bar

3 Measurement lines

Sewing on Heavy Fabrics

The black button on foot A will lock the foot in a horizontal

position if you push it in before lowering the presser foot.

This ensures even feeding at the beginning of seams and

helps when sewing many layers of fabric such as sewing

over welt seams when hemming jeans.

1

2

When you reach the point of an increased thickness, lower

the needle and raise the presser foot. Press the toe of the

foot and push in the black button, then lower the foot and

continue sewing.

This button releases automatically after a few stitches.

Note: When sewing an edge, select stitch pattern 02.

1 Fabric

2 Black button

Page 26

• Manual stitch length

Press “-” or “+” to adjust the stitch length.

To decrease length, press “-”.

To increase length, press “+”.

The pre-programmed stitch length setting is suitable for

most of your sewing needs. However, you can change

these settings to accommodate different fabric characteristics or achieve a desired effect.

Hold down “-” or “+” until you reach the desired setting.

* The reverse stitch length cannot be set longer than

2.5 mm (1/8”).

• Variable needle position

These setting apply only to “straight” stitch patterns 01

through 04, and 11, 24, 29, 30.

You can adjust needle position of stitch patterns 01

through 04 and 11, 24, 29, 30 (see bottom of box on

left). When you press “-”, the needle position will move

to the left.

When you press “+”, the needle position will move to the

right.

1 Left (0.0)

2 Middle (3.5)

3 Rigth (7.0)

1

23

25

Page 27

[2]

Various Utility Stitches

3

1

2

4

[1]

1

2

• Basting

1

Stitch pattern : 24

2 Presser foot: Basting foot P

3 Thread tension dial : 1 to 4

4 Feed dogs : Down

* Set the manual thread tension at “1 to 4”.

Attaching the basting foot:

[1]Raise the needle.

[2] Remove the foot holder by loosening the thumb

screw.

[3]Attach the basting foot on the presser bar putting the

pin on the needle clamp.

Tighten the thumb screw firmly with a large

screwdriver.

[1]

[2]

2

[3] [4]

3

[3]

1 Foot holder

2 Thumb screw

3 Pin

4 Needle clamp

4

How to sew

[1]Put some fabric under the foot and press the Up/

down needle button twice to bring the needle thread

down through the hole in the foot. Pull the fabric and

thread to the rear. Lower the presser foot.

[2]While pressing down the foot control, hold the fabric

taut.

[3]When the machine is stopped after one stitch sewing,

pull the fabric with the thread to the back.

[4]Repeat steps 2 and 3 to sew. After finishing sewing,

pull the threads and fabric to the back and cut the

threads.

* After sewing, reset the thread tension dial at “AUTO “

and raise the feed dogs, slide the drop feed lever to

theleft.

26

Page 28

• Straight stitch

1

2

The common uses for the straight stitch are:

Regular seams and zippers:

1 Stitch pattern : 01

3

1

2

2 Presser foot : Foot A or zipper foot E

Edge sewing:

1 Stitch pattern : 02

2 Presser foot : Foot A

You can also use your basic straight stitch for pintucking

and rolled hems.

• Automatic reverse stitch

1 Select stitch pattern : 03

1

2

2 Presser foot : Foot A

This reverse stitch can be used for securing, mending

and reinforcement stitches.

At the end of seams, press “ “ (reverse button)

once, so that the machine will sew auto-lock stitch

immediately and stop automatically.

• Triple stretch stitch

1 Stitch pattern : 04

12

1

2

2 Presser foot : Foot A

This strong, durable stitch is recommended where both

elasticity and strength are needed for comfort and

durability.

Use it to reinforce areas such as crotch and armhole

seams. Also use it when constructing items such as

backpacks for extra reinforcement.

• Auto-lock stitch

1 Stitch pattern : 11

2 Presser foot : Foot A

Lower the needle close to the front edge of the fabric

and lower the presser foot.

The machine will sew several locking stitches in place

and continue sewing forward. By pressing the reverse

button, the machine will sew several locking stitches in

place, then stop sewing automatically.

27

Page 29

• Stretch stitch

1 Stitch pattern : 17

1

1

2

2

2 Presser foot : Foot A

This stitch is a narrow stretch stitch designed to eliminate puckering on knit fabrics and bias seam, while

permitting the seam to be pressed completely flat.

The stitch can also be used to simultaneously seam and

overcast when sewing on tricot and chiffon for a narrow,

almost invisible seam finish.

• Saddle stitch

1 Stitch pattern : 29

2 Presser foot : Foot A

This saddle stitch is formed with one stitch forward, two

stitches backward and a fourth stitch forward.

You can achieve a lovely hand-worked look when

topstitching suits, blazers, jumpers and denim outfits

with the saddle stitch.

• Sculpture stitch

This stitch can be used for decorative stitches.

1

2

Also, this stitch is useful for making a clear outline of a

design.

1 Stitch pattern : 30

2 Presser foot : Satin stitch foot F

3 Pressure dial : 2

* After sewing is finished, return the pressure dial

to “3 “.

3

28

Page 30

Zigzag Stitch

1

2

1 Stitch pattern: 05

2 Presser foot: Foot A

• Interfacing

You can get better sewing results using interfacing or

stabilizer on delicate or stretch fabric such as knit,

jersey, tricot etc.

12 34

6

• To change the width and length

Zigzag stitch is useful for overcasting, applique, mending etc. When you change the stitch width, make sure

the needle position is above the fabric.

1. Pre-programmed stitch settings will be displayed.

2. Press the stitch width key “+” , “-” or stitch length key

“+”, “-” to change the stitch width and length manually.

3. When the “+” or “-” key is pressed, the width and the

length will be changed accordingly.

1 Narrower width ( smaller number)

2 Wider width ( large number)

3 Denser stitch length ( smaller number)

4 Coarser stitch length ( larger number)

5 Width

6 Length

5

29

Page 31

Variation of Zigzag Stitches

12

• Overcasting

1

Stitch pattern: 05

2 Presser foot: Overedge foot C

This zigzag variation is very useful in garment construction and in finishing raw edges of any sewing project.

1. The black ridge and the guide wires on the overedge

foot keep the edge neat and the fabric straight.

2. Place your fabric so that the double guide wires

come to the edge.

The machine will stitch over these wires. The black

ridge and brush will keep the loose threads in so that

the needle can stitch over them.

3. As you sew, be sure your fabric edge pushes up

against the black ridge.

• Tricot stitch

12

Stitch pattern: 06

1

2 Presser foot: Foot A

This stitch can be used to prevent stretch material edges

from fraying, when sewing folded fabric.

A second method is to keep an extra space allowance

from the fabric edge and after finishing the sewing, cut

the extra seam allowance edge as shown.

30

Page 32

12

• Knit stitch

Stitch pattern: 12

1

2 Presser foot: Foot A

Keep an extra space allowance from the fabric edge and

after finishing the sewing, cut the extra seam allowance

edge as shown.

• Overedge sewing (1)

12

1

Stitch pattern: 07

2 Presser foot: Overedge foot C

This stitch pattern combines the straight and the zigzag

stitches, using the overedge foot, to stitch and overcast

seams in one step.

It is also a stretch stitch to provide elasticity for knits and

extra strength for woven fabrics.

Use this stitch when you want a narrow seam that you

do not have to press open flat.

It is ideal for 6 mm (1/4”) seams on knits. (when attaching ribbing) or on medium to heavyweight woven fabrics

where you want a narrow seam.

Place your fabric so that the raw edges fit under the wire

guides and touch the black ridge and brush guide.

Gently guide the fabric so that the raw edges always

touch the black ridge and brush guide.

Note: Stitch width should be set between 5.0 to 7.0.

The Blue tip needle is recommended for stretch

material.

31

Page 33

SECTION IV DECORATIVE STITCHING TECHNIQUES

Overedge Sewing (2)

12

1 Stitch pattern: 13

2 Presser foot: Overedge foot C

This stitch can be used for sewing heavier fabrics that

tend to fray extensively such as linens and gabardines.

Two rows of zigzag stitches are simultaneously sewn

over the edge to insure that your seams will not ravel.

Adjust the thread tension so both needle thread and

bobbin thread meet at the edge of the fabric.

Overedge Sewing (3)

12

1 Stitch pattern: 14

2 Presser foot: Overcasting foot M

3 Thread tension: 6-8

This stitch is more like the overlock stitch which is very

convenient to reinforce the fabric edge.

Place the fabric under the foot and guide it to the guide

ridge and lower the presser foot.

* The stitch width cannot be adjusted for this stitch

pattern.

32

Page 34

12

3

[1]

[2]

Sewing Buttons

1 Stitch pattern: 05

2 Presser foot: Satin stitch foot F

3 Feed dogs: Down

[1] Turn the handwheel by hand five times and raise the

needle to the highest point.

Match the holes on the button to the horizontal slot

on

the presser foot.

Lower the foot to hold the button in place.

Lower the feed dogs.

Press the stitch width button “+” or “-” so the needle

will enter the left hole of the button.

Turn the handwheel so the needle will enter the right

hole of the button.

* Readjust the stitch width if necessary.

[3]

[2] Place a pin on the foot and stitch ten times.

After you finish sewing, cut the thread but leave 20

cm(8 “) of thread on the wrong side of the fabric.

1 Pin

1

2

4

3

5

[3] Draw the thread to the wrong side of the fabric and

knot the threads.

Note: When sewing on the button is completed, raise

the feed dogs.

The feed dogs must always be up for normal

sewing.

2 Upper thread

3 Lower thread

4 Shank

5 Fabric

33

Page 35

08

Sensor Buttonhole

• Automatic buttonholing

Note:

* The size of the buttonhole is automatically set by

placing the button in the buttonhole foot, as shown.

* The button holder of the foot takes a maximum

button size of up to 2.5 cm (1”) in diameter.

* Before you sew the actual buttonholes on the actual

garment, make several practice buttonholes on a

scrap of the same fabric.

* Use interfacing on stretch fabrics and set the pres-

sure dial at 1 or 2 and sew.

08: Square buttonhole stitch

This buttonhole can be used for shirts and

blouses.

18/19:These bottonholes can be used for stretch

fabrics.

18

19

09

10

09: Rounded buttonhole stitch

This buttonhole can be used for shirts and

blouses of fine fabrics.

10: Keyhole buttonhole stitch

This buttonhole can be used for jackets of

heavy fabrics.

34

Page 36

[1]

• Sewing preparation

Stitch pattern: 08

1

2 Presser foot: Automatic buttonhole foot R

* When you select the buttonhole stitch, the screen

1

,

2

indicates the message: “PULL DOWN BH (Button

hole) LEVER” for a few seconds.

[1] Attach the automatic buttonhole foot R.

Make sure the groove on the holder catches the pin

on the foot, when lowering the presser foot.

1 Groove

1

2 Pin

2

[2]

[3]

[2] Pull the button holder to the back, and place the

button in it.

Push it together tightly on the button.

R

4

3 Button holder

If the button is extremely thick, make a test button-

hole.

If it is difficult to fit the button through the test

buttonhole, lengthen the size by pulling the button

holder on the back to increase length.

4 Gap

3

[3] Pull the buttonhole lever down as far as it will go.

5 Buttonhole lever

5

35

Page 37

[4]

[5]

[4]After attaching sensor buttonhole foot, raise the foot

lever once to assure spring is in proper position to

8

9

10

6

11

7

avoid any gap. Insert corner of fabric under the foot.

Press the Up/down needle button twice.

Remove the fabric to the left to draw both threads

under the foot.

Insert the garment under the foot, and lower the

needle at the starting point.

Then lower the automatic buttonhole foot.

If there is a gap, it may cause an uneven buttonhole

stitch length as shown.

6 Mark

7 Starting point

8 Foot holder

9 No gap

10 Spring holder

11 Uneven stitch results

Starting sewing

[5]

After sewing the buttonhole stitch, the machine stops

automatically.

............

,,

............

............

Sewing steps:

Step 1 The buttonhole will be automatically sewn first:

the front bartack and left row.

Step 2 Next, the right row.

Step 3 Last the back bartack and locking stitch.

Raise the presser foot.

To sew another buttonhole, press 08 on the number key,

then depress the foot control.

For buttonhole stitches ( ), you can repeat sewing

without pressing keys.

Raise the presser foot and lower the foot again.

,,

36

Page 38

[6]

[7]

12

13

14

15

[6] After sewing the buttonhole stitch, raise the button-

holelever until it stops.

12 Buttonhole lever

[7] Place a pin on the rear side of the bartack position

so that you donÕt need to worry about cutting the

end of the buttonhole stitch.

Cut the opening with the seam ripper in your accessorybox.

13 Pin

14 Seam ripper

15 Punch (use for keyhole buttonhole 10)

12 3 4

Adjusting Stitch Width and Density in Buttonholes

[To change the stitch width]

The stitch width key controls the stitch width.

The pre-set buttonhole widths are: square buttonhole

5.0, rounded buttonhole 4.0, keyhole buttonhole 7.0.

Press “+” or “-” to adjust the stitch width of the entire

buttonhole, ranging between 2.5 to 7.0 depending on the

selected buttonhole.

1 Narrower width by pressing “-”

2 Wider width by pressing “+”

[To Change Stitch Density]

The stitch length key controls the stitch density.

The pre-set density varies from 0.4 to 0.7 according to

the buttonhole selected.

Press “+” or “-” to adjust the stitch density of the entire

buttonhole between 0.2 to 1.0 depending on the selected

buttonhole.

Press “+” or “-” to adjust the stitch density between 0.5

to 1.0 for the buttonhole density for .

3 Denser stitch by pressing “-”.

4 Coarser stitch by pressing “+”.

37

Page 39

• Sensor buttonhole 09 and 10

1

2

Stitch pattern: 09 or 10

1

2 Presser foot: Automatic buttonhole R

[1]

4

* Sewing procedure is the same as 08.

[1] Sewing steps

3 Starting point

3

4 Bartacking

5 Stitch pattern 10

5

4

3

• Adjusting the stitch width and density in

buttonholes 09 and 10

[To change the stitch density]

The adjustment of the stitch density is between 0.2 to

0.8 the same as buttonhole 08.

Adjustment of the stitch width on buttonhole 09

When you press the zigzag width key, the pre-set

buttonhole width is set for the rounded buttonhole at 4.0.

6

9

78

10 11

Press “+” or “-” to adjust the stitch width of the entire

buttonhole between 2.5 to 5.5.

6 Width: 2.5

7 Width: 4.0

8 Width: 5.5

Adjustment of the stitch width on buttonhole 10

When you press the zigzag width key, the pre-set

buttonhole width is set for the keyhole buttonhole at 7.0.

Press “+” or “-” to adjust the stitch width of the entire

buttonhole between 5.5 to .7.0

9 Width: 5.5

10 Width: 6.0

11 Width: 7.0

38

Page 40

[1]

1

2

Corded Buttonholes

1 Stitch pattern: 08

2 Presser foot: Automatic buttonhole foot R

Use this procedure when you want to achieve a tailored,

more attractive raised buttonhole.

Use at least 40 cm (15”) of havy thread as filler cord.

Try a practice buttonhole first.

[1]Set the automatic buttonhole foot R on the foot

3

4

5

4

holder.

With the buttonhole foot raised, hook the filler cord

on the spur at the back of the buttonhole foot.

Bring the ends toward you under the buttonhole foot

until they clear the front end.

Hook the filler cord into the forks on the front of foot

R to hold them tight.

3 Spur

4 Filler cord

5 Forks

[2]

[3]

[2]Lower the needle into the garment where the button

hole will start and lower the foot.

Sew the buttonhole according to the buttonhole

sewing instructions on page 35.

4

6

Each side of the buttonhole and the back bartack will

be sewn over the filler cord.

Remove the fabric from the machine and cut the

sewing threads.

6 Needle thread

7 Bobbin thread

7

[3]Pull the left end of the filler cord to tighten it.

Thread the end through a darning needle, draw to the

4

bottom side of the fabric and cut.

39

Page 41

Free Size Automatic Buttonhole 20

1 Stitch pattern: 20

2 Presser foot: Automatic buttonhole R

,

12

[1]

[4]

[5]

[6]

[7]

[2]

[3]

A

[1] Pull the button holder to the back (direction of A).

[2] Insert the fabric under the foot. Press the Up/down

needle button twice. Remove the fabric to the left to

draw both threads under the foot.

[3] Insert the garment under the foot, and lower the

1

2

3

,

4

5

,

,,

needle at the starting point.

Then lower the automatic buttonhole foot.

1 Button holder

2 Needle thread

3 Bobbin thread

4 Starting point

[4] Sew down the left side stopping at the end of the

buttonhole mark. Press reverse button.

5 Reverse button

[5] Depress the foot control.

The machine will automatically bartack and sew up

the right side of the buttonhole.

Stop the machine when you are directly opposite the

first stitch on the left hand side.

Press the reverse button.

[6] Keep the foot control depressed. The machine will

bartack, knot the stitches and automatically stop

when the buttonhole is completed.

[7] Raise the presser foot.

To make the next buttonhole, position the fabric and

step down on the foot control.

The Memory Craft 4800 will sew another buttonhole

identical to the first each time you step down on the

foot control.

* If you would like to change the buttonhole size,

select buttonhole 20 again.

* If the right and left sides of density are not matching

(see page 55 ).

40

Page 42

Zipper Sewing

1

3

1

2

4

1

3

2

5

13

9

2

• Put in a zipper

1

Stitch pattern: 01

2 Presser foot: Zipper foot E

• Attaching the zipper foot

4

6

7

8

To sew on the left side of the zipper, attach the foot holder

to the right pin on the zipper foot.

To sew on the right side of the zipper, attach the foot holder

to the left pin on the zipper foot.

1 Groove

2 Pin

3 To sew left side

4 To sew right side

• Fabric preparation

Add 1 cm to the zipper size. This is the overall opening

size.

1 Right side of fabric 5 End of opening

2 Opening size 6 Slider

3 Zipper size 7 Zipper teeth

4 1 cm (3/8ý) 8 Zipper tape

Place right sides of fabric together and sew to the end of

the zipper opening. Reverse stitch to lock the stitches.

Manually increase the stitch length to 4.5 and sew the

zipper opening.

9 (4.5 stitch length) 12 (2.2 stitch length)

10 End of opening 13 2 cm (3/4”)

11 Reverse stitch

[1]

11

10

1

3

4

2

5

6

12

• To sew

[2]

Fold back the left seam allowance. Turn under the right

seam allowance to form a 0.2 to 0.3 cm (1/8”) fold.

Place the zipper teeth next to this fold and pin in place.

Attach the zipper foot holder to the right pin on the

zipper foot.

Lower the zipper foot on the top side at the bottom of

the zipper so that the needle pierces the fabric next to

the fold and the zipper tape.

7

1 Fold 5 Opening size

2 0.3 cm 6 Lower fabric

3 Stitch line 7 Wrong side of fabric

4 End of opening

41

Page 43

[2]

Zipper Sewing, cont’d

Sew through all layers next to fold. Stop 5 cm

[2]

before the top of the zipper just before the zipper

1

2

foot reaches the slider on the zipper tape. Lower the

needle slightly into the fabric. Raise the zipper foot

and open the zipper. Lower the foot and stitch the

remainder of the seam.

1 Slider

2 Stop sewing 5 cm (2”) before the top of the zipper.

[3]

[4]

[3] Close the zipper and spread the fabric flat with the

right side facing up. Baste the opened fabric and

4

5

3

zipper tape together.

3 Wrong side of upper fabric

4 Basting stitch

5 Right side of fabric

6 Zipper tape

5

6

4

5

[4] Move the zipper foot to the left pin.

Guide the edge of foot along the zipper teeth and

stitch

through the garment and zipper tape.

Stop 5 cm (2”) before the top of the zipper.

5

42

[5]

[5] Lower the needle slightly into the fabric, raise the

foot, remove the basting stitches and open the

zipper.

Lower the foot and stitch the remainder of the seam,

5

making sure the fold is even.

5

Page 44

1

1

[1][2][3]

Darning

2

1 Stitch pattern: 22

2 Presser foot: Automatic buttonhole foot R

3

3

2

4

2

[4]

3 Darning shape: (See below for settings.)

• To sew:

[1]

Pull the button holder to the rear.

[2] Place the garment under the foot. Press the Up/down

needle button twice. Raise the foot.

Remove the fabric to the left to draw both threads

under the foot and put the fabric back under the foot.

[3] Lower the foot. Press down the foot control. The

machine will lock stitch, sew 16 rows of darning, lock

stitch again and the machine will stop automatically.

* The size of one darn cycle is variable. However, the

maximum stitch length is 2 cm (3/4”) and the maxi-

mum stitch width is 7 mm (9/32”).

[4] Turn the fabric and repeat sewing for reinforcement.

1 Button holder

2 Starting point

3 2 cm (3/4”)

4 0.7 cm (9/32”)

5

6

• For darning less than 2 cm

Switch to “Low” speed setting. 4 lock stitches will be sewn

first. Then sew to the desired length and press the reverse

button. The desired length has now been determined.

Continue sewing until the machine stops automatically.

5 Reverse button

6 Desired stitch length

2

• To memorize darning stitches

When repeatedly sewing the same-size darn to repair a

side rip or belt loop, press “Memory” key and restart sewing.

• Adjusting the shape of darning stitches

If one side of the darn is higher than the other, make them

even by pressing the stitch length “+” or “-” key.

When you press the “+” or “-” key, d3 will be indicated

automatically.

7

8910

You can adjust the shape of the darn by pressing “+” or

“-” key, d1 to d5.

7 When the left side is lower

8 Select “d1” or “d2” to balance the stitches.

9 When the right side is lower.

10 Select “d4” to “d5” to balance the stitches.

43

Page 45

1

1

2

1 Stitch pattern: 23

2 Presser foot: Satin stitch foot F

Switch to “Low” speed setting. Four lock stitches will be

sewn first. Then sew to the desired length and press the

reverse button.

The desired length has been now determined. Continue

sewing until the machine stops automatically.

2

3

4

* This stitch is used for reinforcement of the heavily

strengthened part of a garment.

The maximum bartack length is 1.5 cm (5/8”) dependent

on fabric.

When you change the stitch length or stitch width, press

width key “+” or “-”, or length key “+” or “-”.

1 Starting position

2 Ending position

3 Pre-set 1.5 cm (5/8”)

To sew less than 1.5 cm (5/8”) of bartacking, sew the

length required, then press the reverse button. The

length is memorized. Depress the foot control until the

machine stops automatically.

Bartacking

9

4

5

○○○○○

6

11

10 14

8

○○○○○

• Memorizing bartacking

7

4

12

13

When repeatedly sewing the same size bartack, press

Memory key and restart sewing.

4 Length required

5 Reverse button

6 Starting position

7 Ending position

• Adjusting the evenness of bartacking stitches

Make a test on an extra piece of fabric to check your

settings.

If the bartacking is uneven, adjust the stitch length by

turning the feed balancing dial as shown.

8 Starting position

9 An extra length is left from the starting position.

10 Turn the feed balancing dial to “+” direction.

11 Matching the position. (Correct position)

12 An extra length is left at the returning position.

13 Returning position.

14 Turn the feed balancing dial to “-” position.

44

Page 46

1

2

1 Stitch pattern: 01

2 Presser foot: Hemmer foot D

Rolled Hem

[1]

[2]

[3]

2

4

3

1

5

6

7

[1] Make a double 0.3 cm (1/8”) fold approximately 6

cm (2”) in length.

* Use iron on the folded edge so that you can guide

the fabric easily.

1 Wrong side of fabric

2 Right side of fabric

3 6 cm(2”)

4 0.3 cm(1/8”)

[2] Trim about 0.7 cm(1/4”) from corners to reduce bulk.

5 Edge of fabric

6 Approximately 0.6 cm (1/4”)

7 Trimming part

[3] Lower the needle into the fabric at the point where

sewing is to begin. Then lower the hemmer foot.

Sew 3 to 4 stitches while holding the needle and

bobbin threads.

5

5 Edge of fabric

8 Guide

[4]

[5]

8

[4] Lower the needle into the fabric and lift the hemmer

foot. Insert the folded portion of the fabric into the

curl of the hemmer foot.

5

5 Edge of fabric

9 Curl of foot

9

[5] Lower the hemmer foot, then sew by lifting up the

edge of the fabric to keep it feeding smoothly and

evenly.

45

Page 47

1

2

1 Stitch pattern: 16 or 15

2 Presser foot: Blind hem foot G

• How to fold the fabric

Blind Stitch Hemming

[1]

[2]

2

1

1 Wrong side of fabric

2 0.4 to 0.7 cm (1/8” to 3/8”)

3 Overedge stitch

3

• How to sew

[1]

When the needle comes to the left hand side,

position the fabric so that the folded edge comes to

the left side of the guide. Lower the presser foot.

* Adjust the position of the needle swing with the

stitch width key so that the needle just pierces the

folded edge of the fabric when the needle comes to

the left side.

Sew guiding the folded edge along the guide.

[2] Open the fabric after sewing.

* For a professional looking hem, try not to let the

needle piece more than 0.2 cm (1/8”) into the fold.

If the folded edge is pierced too far to left side, you

can not expect a good seam on the right side of the

fabric.

46

• Changing the needle position

When the zigzag width key is pressed, the pre-set

needle position is shown at 0.6.

* The indication at 0.6 is the needle drop position from

the presser foot guide.

* When you select the stitch pattern 16, the stitch width

will not change, but the needle drop position from the

foot guide will be changed.

4 The needle drop position is shifted to the right side

4

56

5 The needle drop position is shifted to the left side.

6 Guide

7 When the needle comes to the left side

8 When the needle comes to the right side

7

8

Page 48

[1]

1

2

1 Stitch pattern: 02

2 Presser foot: Blind hem stitch foot G

[1] Attach the blind hem stitch foot.

Place the folded fabric under the presser foot.

Position the needle 0.1 to 0.2 cm (1/16”) inside

from the folded edge by turning the handwheel and

lower the presser foot.

Feed the folded edge smoothly against the sliding

guide.

Pintucking

[2]

12

3

1

3

2

4

[2] After sewing is finished, use an iron to make

pleats.

Quilting

1 Stitch pattern: 01

2 Presser foot: Foot A

3 Quilting bar L

Loosen the set screw on the back of the presser foot

as shown, sliding the quilting bar into the opening

under the screw to the width between lines of quilting

stitches you desire.

Tighten the screw.

Sew other rows, guiding the quilting bar over the

previous row of stitching.

1 Set screw

2 Quilting bar

3 Setting hole

4 Stitch interval

47

Page 49

12

Shell Tack

1 Stitch pattern: 25

2 Presser foot: Satin stitch foot F

* Use a light weight fabric such as tricot.

Fold and stitch on the bias. When the needle swings

to the right, allow the needle to just clear the folded

edge of the fabric.

Open the fabric and iron on one side of the fabric.

* For the shell stitch, be aware that thread tension may

have to be adjusted depending on the fabric for the

best sewing results.

1

1 Fold fabric

2 Folded edge

2

1

1

2

1 Stitch pattern: 26

2 Presser foot: Satin stitch foot F

3

2

3

3 Pressure dial: 2

* Stitch patterns, (27, 28) can also be used.

Applique, a technique for stitching fabric shapes onto

another fabric, opens limitless design possibilities.

Dimension and texture can be added by lightly stuffing

all or part of a design. This machine has several different patterns that can be used to enhance your applique.

In this type of applique raw edges are folded under.

To finish the raw edge, cut the applique design out of

cardboard. Fuse a lightweight interfacing to the wrong

side of the fabric then cut the fabric slightly larger than

the cardboard.

Fold the fabric around the cardboard and press to form a

perfectly shaped design.

Tape the applique in place and sew, guiding the slit on

foot F next to the finished edge of the applique.

Applique

48

1 Applique fabric

2 Slit

3 Edge

* After sewing, return the pressure dial to 3.

Page 50

Smocking

1

2

1 Stitch pattern: 38

2 Presser foot: Satin stitch foot F

* Stitch patterns (41, 65, 66, 88) can also be used.

For a delicate, decorative treatment, smocking can be

applied whenever gathers are used. Turn a child's dress

into something very special or smock a yoke on a

blouse.

Choose a soft, lightweight fabric such as batiste, gingham or challis. Cut the fabric three times the finished

width.

(Straight stitch)

With the manual stitch length at 0.3 to 0.4 cm (1/8”) sew

straight lines 1 cm (3/8”) apart, across the area to be

smocked.

A looser needle thread tension will make gathering

easier.

(Decorative sewing)

Knot the threads along one edge. Pull the bobbin

threads and distribute the gathers evenly. Secure the

threads at the other end.

Reduce the tension and pressure if necessary and sew

decorative pattern stitches between the straight seams.

Pull out the gathering stitches.

Fagoting

12

1 Stitch pattern: 36

2 Presser foot: Satin stitch foot F

* Stitch patterns (32, 37 and 40) can also be used.

Use this stitch to join two pieces of fabric to create an

open work appearance and add design interest.

Fold under each fabric edge 1.5 cm (5/8”) and press.

Pin the two edges to paper or tear away backing 0.3 cm

(1/8” )apart.

Sew slowly, guiding the fabric so the needle catches the

folded edge on each side.

After finishing the sewing, take off the paper.

49

Page 51

[1]

Scallop Stitch ( A )

1

1

2

1 Stitch pattern: 33

2 Presser foot: Foot A

[1]Fold hem with right sides together. Sew scallops 1

cm (3/8”) from folded edge.

[2]Trim close to stitching leaving 0.3 cm (1/8”) seam

allowance. Clip seams as shown or trim with pinking

shears. Turn the hem to right side and press.

2

[1]

[2]

Scallop Stitch ( B )

1

2

1 Stitch pattern: 34

2 Presser foot: Foot A

* Stitch pattern 47 can also be used.

[1]Sew the stitches approximately 1 cm (3/8”) inside of

the edge of fabric.

[2]Trim the outside of the stitches as shown. Make sure

you don’t cut the thread.

50

[2]

Page 52

Patchwork

12

1 Stitch pattern: 31

2 Presser foot: Satin stitch foot F

Sew seam with straight stitch and press seam allowance

to open.

Sew pattern stitch 31 on right side of garment centering

over the seam line.

11

1 Right side of fabric

Satin Stitch Sewing

1

2

1 Stitch pattern: 52

2 Presser foot: Satin stitch foot F

* Stitch patterns (45 to 64) can also be used.

To get fine sewing results, interfacing should be used on

the wrong side of fabric when you use stretch or elastic

garments.

Press Auto-lock button to finish the end of the pattern.

1 Auto-lock button

1

51

Page 53

Cross Stitch

12

1 Stitch pattern: 72

2 Presser foot: Satin stitch foot F

* These stitch patterns (74 to 76) can also be used.

You will love the beautiful designs you can sew with this

craft stitch pattern, and in half the time it would take if

embroidered by hand. Cross stitches can be effectively

combined with the other craft patterns for attractive

samplers and other sewing projects.

A plain close weave such as linen or wool flannel make

the best background fabric.

Support lightweight fabrics with a stabilizer backing.

* The size of cross stitch can be adjusted by pressing

the stitch width key “+”or “-”.

Decorative Stitch

12

1 Stitch pattern: 95

2 Presser foot: Satin stitch foot F

* Stitch patterns (35 to 44, 65 to 71, 77 to 97) can also

be used.

The satin stitches also are used for decorative stitches

on table linens, etc.

For the best sewing results, carefully align and guide the

fabric when you sew with decorative stitches.

Use a tear-away backing if necessary.

52

Page 54

1

2

1 Stitch pattern: 46

2 Presser foot: Cording foot H

Sew over one strand of cording to create a pretty swirled

design on a jacket or vest or sew over three strands of

cording for border trims. Pearl cotton, knitting yarn,

embroidery floss, lace thread, fine wool or lily yarn can

be used for cording.

(Triple cording)

Cording

[1]

[2][3]

[1]Mark the design on the right side of the fabric.

Slide the sewing threads to the left and insert three

strands of cording into the slots of foot H with 10 cm

(4ý) extending behind the foot.

[2]The slot on foot H will hold the lengths of cording in

place while the stitches form over the cording.

[3]Stitch slowly and smoothly turning the fabric as you

sew while guiding the cording over the marked line.

* You may want to reduce the pressure when sewing

curves.

1

2

(Single cording)

1 Stitch pattern: 05

2 Presser foot: Cording foot H

Use the center groove on the foot and adjust the zigzag

width to overlap the cord and sew.

53

Page 55

Twin Needle Stitching

1

3

1

2

1 Stitch pattern: 95

2 Presser foot: Satin stitch foot F

This machine is equipped with a twin needle that can be