ITV Ice Makers NG 75, NG 125, NG 175, NG 215, NG 285 Operator’s Manual

...

SPIKA

USER MANUAL SPIKA MACHINES

MANUAL DEL USUARIO MÁQUINAS SPIKA

MANUEL DE L’ UTILISATEUR SPIKA MACHINES

ICE CUBE MAKERS / UNDERCOUNTER MODELS

MÁQUINAS DE HIELO EN CUBITOS / MODELOS COMPACTOS MACHINES A GLAÇONS / MODELES COMPACTES

SPIKA NG 75

SPIKA NG 125

SPIKA NG 175

SPIKA NG 215

SPIKA NG 285

ICE CUBE MAKERS / MODULAR MODELS

MÁQUINAS DE HIELO EN CUBITOS / MODELOS MODULARES MACHINES A GLAÇONS / MODELES MODULAIRES

SPIKA MS 440

SPIKA MS 880

SPIKA

USER MANUAL SPIKA MACHINES

MANUAL DEL USUARIO MÁQUINAS SPIKA

MANUEL DE L’ UTILISATEUR SPIKA MACHINES

INDEX

INTRODUCTION |

1 |

WARNING |

1 |

RECEPTION OF THE MACHINE |

1 |

INSTALLATION |

2 |

START-UP |

8 |

MAINTENANCE AND CLEANING PROCEDURES |

10 |

USER TROUBLESHOOTING GUIDE |

16 |

WIRING DIAGRAMS |

18 |

ÍNDICE

INTRODUCCIÓN |

20 |

ADVERTENCIAS |

20 |

RECEPCIÓN DE LA MÁQUINA |

20 |

INSTALACIÓN |

21 |

PUESTA EN MARCHA |

27 |

INSTRUCCIONES DE MANTENIMIENTO Y LIMPIEZA |

29 |

GUÍA DE SOLUCIÓN DE PROBLEMAS PARA EL USUARIO |

35 |

ESQUEMAS ELÉCTRICOS |

37 |

INDEX

INTRODUCTION |

39 |

ATTENTION |

39 |

RECEPTION DE L’APPAREIL |

39 |

INSTALLATION |

40 |

MISE EN MARCHE |

46 |

INSTRUCTIONS POUR L’ENTRETIEN ET LE NETTOYAGE |

48 |

GUIDE DE RÉSOLUTION DE PROBLÈMES POUR L’UTILISATEUR |

54 |

SCHÉMAS ÉLECTRIQUES |

56 |

USER MANUAL SPIKA

Introduction

Thank you for purchasing a ‘Spika Series’ Ice Cube Maker by ITV. You have purchased one of the most reliable ice-making products on the market today.

Carefully read the instructions contained in this manual since they provide important information relative to safety during installation, use, and maintenance.

Warning

The installation of this equipment should be done by the Service Department. The socket should always be placed on an accessible location.

Always disconnect the power supply from the machine before any cleaning or maintenance service.

Any change needed on the electrical installation for the appropriate connection of the machine, should be exclusively performed by qualified and certified professional personnel only.

Any use by the ice maker not intended to produce ice, using potable water, is considered inappropriate. It is extremely dangerous to modify or intend to modify this machine, and will void warranty.

This machine should not be used by children or handicapped without the proper supervision and monitoring. This machine is not intended to be used outdoors nor exposed to the rain.

The machine should be connected using the power cord supplied with the equipment, except for SPIKA MS 880-3.

It is mandatory to ground the equipment to avoid possible electric shock on individuals or damages to the equipment. The machine should be grounded pursuant local and/or national regulations as the case may be. The manufacturer shall be held harmless in case of damages arising due to the lack of the ground installation.

In order to assure the proper operation and efficiency of this equipment, it is of paramount importance to follow the recommendations of the manufacturer, especially those related to cleaning and maintenance operations, which should be performed by qualified personnel only.

CAUTION: The intervention of non-qualified personnel, besides of being dangerous, could result in serious malfunctioning. In case of damages, contact your distributor. We recommend always using original spare parts.

ITV reserves the right to make changes in specifications and design without prior notice.

Reception of the Machine

Inspect the outside packing. In case of damages, MAKE THE CORRESPONDING CLAIM TO THE CARRIER.

To confirm the existence of damages, UNPACK THE MACHINE IN THE PRESENCE OF THE CARRIER and state any damage on the equipment on the reception document or freight document.

Always state the machine number and model. This number is printed on three locations:

1

USER MANUAL SPIKA

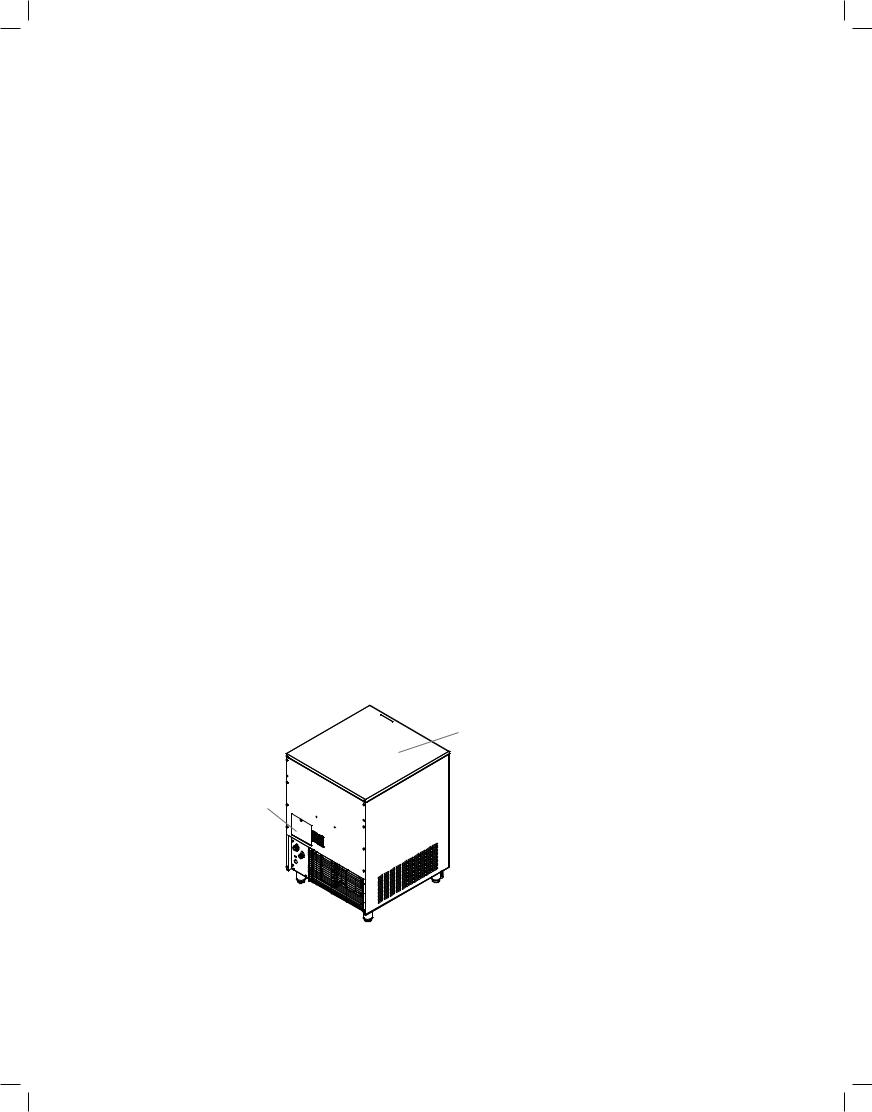

(1) Packing: On the outside, it contains a label with the manufacturing number.

(2)Exterior of the equipment: On the back of the equipment, there appears a label with the same characteristics as the previos one.

(3)Nameplate: On the back of the machine.

Check that in interior of the machine the installation kit is complete and comprises:

•Scoop, drain hose, four legs and manual.

•Warranty and serial number

CAUTION: All packing elements (plastic bags, carton boxes and wood pallets) should be kept outside the reach of children, as they are a source of potential hazard.

Installation

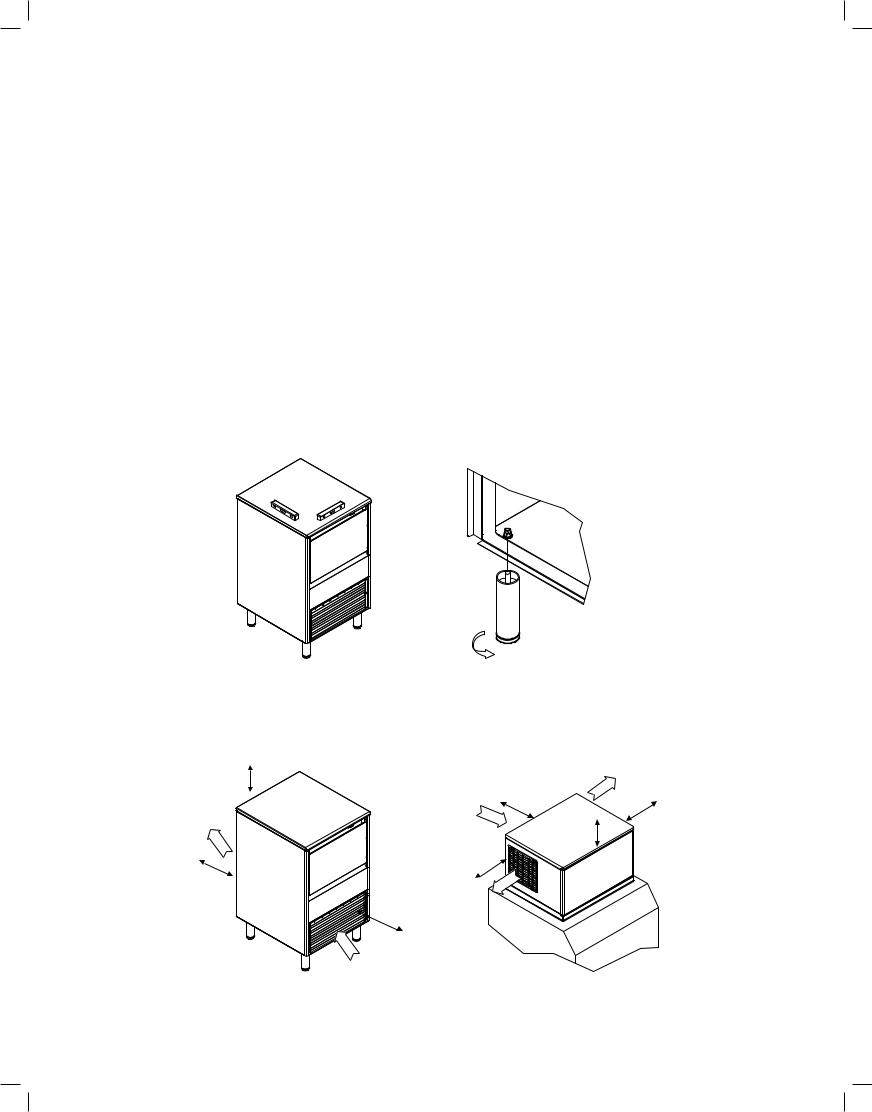

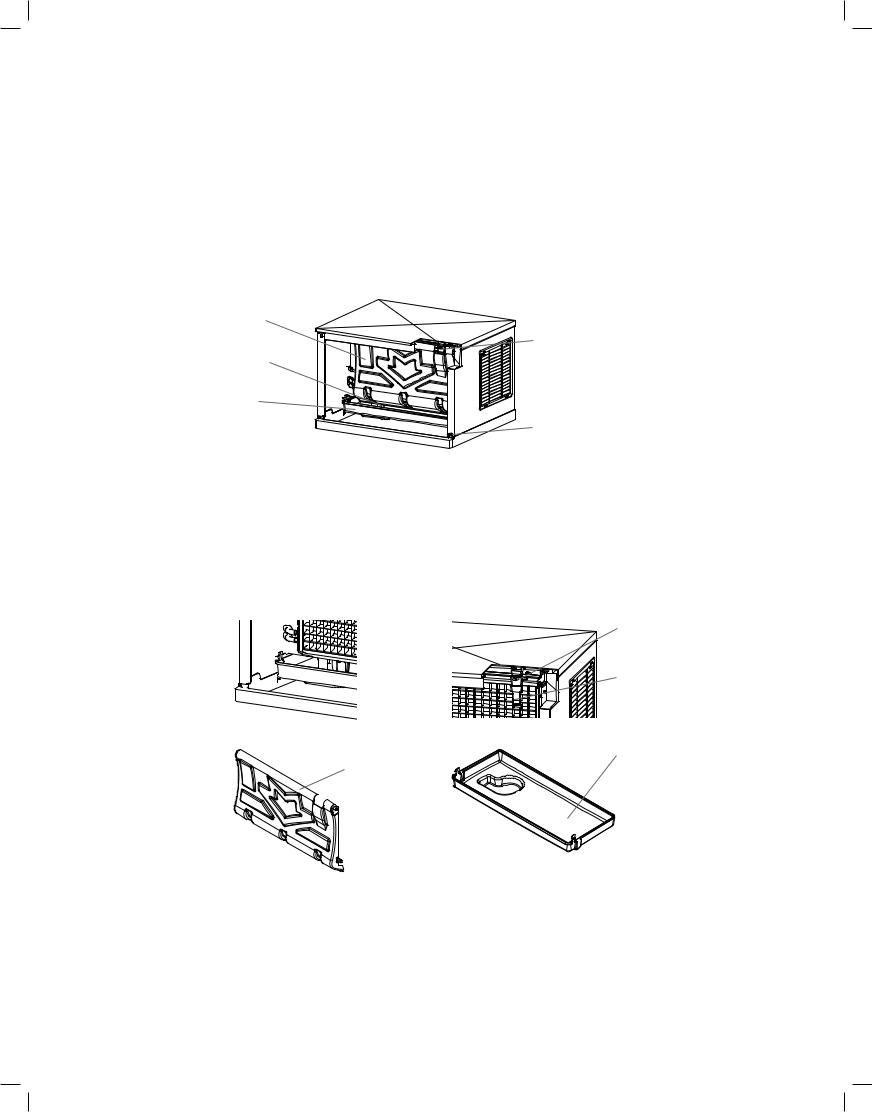

(1) LOCATION OF ICE MACHINE

This ice maker is not designed for outdoor operation. The icemaker should not be located next to ovens, grills or other high heat producing equipment.

The SPIKA machines are designed to operate at room temperature between 41ºF (5ºC) and 109.4ºF (43ºC). There may be some difficulties in ice slab removal under the minimum temperatures. Above the maximum temperature, the life of the compressor is shortened and the production is substantially lower.

The air cooled SPIKA NG (undercounter) ice makers take the air through the front section, and drive it off through the lateral, back and also front louvers due to their new oblique condenser structure and placement. Do not place anything on the top of ice maker or facing the front grille. In case the front grille is either total or partially obstructed, or due to its placement it receives hot air from another device, we recommend, in case it is not possible to change the location, to install a water cooled machine.

2

USER MANUAL SPIKA

The air cooled SPIKA MS (modular) ice makers take the air through the back section and drive it off through the two lateral louvers. In the case it is not possible to respect the minimum distances recommended (see the picture in point 3) for these machines we recommend to install a water cooled unit.

The location must allow enough clearance for water, drain and electrical connections in the rear of the ice machine. It is important that the water inlet piping do not pass near sources of heat so as not to lose ice production.

(2) LEVELING THE ICE MACHINE

Use a level on top of ice machine in order to ensure the equipment is perfectly leveled.

Only for SPIKA NG (undercounter) machines:

Screw the leveling legs onto the bottom of the ice machine as far as possible. Move the machine into its final position.

Use a level on top of the ice machine. Turn each foot as necessary to level the ice machine from front to back and side to side.

NOTE: An optional 3 1/2’’ (90mm) caster assembly is available for use in place of the legs. Installation instructions are supplied with the casters.

(3) MINIMUM DISTANCE TO OBSTACLES

The minimum clearance values you can see below are recommended for efficient operation and servicing.

UNDERCOUNTER MODELS |

MODULAR MODELS |

4’’ (10cm)

6’’ (15cm) |

6’’ (15cm) |

6’’ (15cm)

FRONT

6’’ (15cm)

FRONT

4’’ (10cm)

29,5’’ (75cm)

3

USER MANUAL SPIKA

(4) CONNECTION DIAGRAM

The location must allow enough clearance for water drain and electrical connections in the rear of the ice machine.

UNDERCOUNTER MODELS |

MODULAR MODELS |

|

|

6’’ (15cm) |

4’’ (10cm) |

|

Plug |

|

|

Socket |

Plug |

Socket |

Tap |

|

|

|

|

Tap |

Water Inlet |

|

|

|

|

|

Water Drain |

|

Water Inlet |

|

|

Bin Drain |

|

|

|

Bin Drain |

(5) WATER SUPPLY

The quality of the water supplied to the ice machine will have an impact on the time between cleanings and ultimately on the life of the product (mainly in water cooled units). It also will have a remarkable influence on the appearance, hardness and flavor of the ice.

Local water conditions may require treatment of the water to inhibit scale formation, improve taste and clarity. If you are installing a water filter system, refer to the installation instructions supplied with the filter system.

Use a flexible food grade hose.

Pressure should be between 14 and 85 psi (1 and 6 bar). If pressure overpasses such values, install a pressure regulator.

ATTENTION: The machine shall be plumbed (with adequate backflow protection) according to applicable Federal State and local regulations.

(6) DRAINAGE

Drainage should be located below the level of the machine, at 5,9’’ (150 mm) minimum.

It is convenient that the drainage pipe is 1,18’’ (30 mm) inside diameter and with a minimum gradient of 0,36’’/ft (3 cm/ meter), see figure.

CORRECT |

INCORRECT |

Descending |

Ascending |

|

INCORRECT |

4

USER MANUAL SPIKA

(7) ELECTRICAL CONNECTION

IT IS MANDATORY TO GROUND THE EQUIPMENT: To avoid possible discharges on individuals or damages to the equipment, the machine should be grounded pursuant local and/or national regulations as the case may be.

THE MANUFACTURER SHALL BE HELD HARMLESS IN CASE OF DAMAGES ARISING DUE TO THE LACK OF THE GROUND INSTALLATION.

In case the supply cable is damaged, it should be replaced by a cable of special assembly to be furnished by the manufacturer or after-sales service. Such replacement should be performed by qualified technical service only.

The machine should be places in such a way as to allow a minimum space between the back and the wall to allow an easy access and without risks to the cable plug.

Safeguard the socket. It is convenient to install adequate switches and fuses.

Voltage is indicated in the nameplate and on the technical specifications of this manual. Variation on voltage above the 10% stated on the nameplate could result on damages or prevent the machine start-up.

|

VOLTAGE |

TOTAL |

MAXIMUM FUSE / |

|

|

MODELS |

FREQUENCY |

AMPS |

CIRCUIT BREAKER |

POWER |

NEMA |

|

PHASE |

|

|

CORD |

|

|

(A) |

(A) |

|

||

|

|

|

|

||

|

|

|

|

|

|

SPIKA NG 125-1 |

115V / 60Hz / 1Ph |

6 |

15 |

3AWG16 |

5-15P |

|

|

|

|

|

|

SPIKA NG 175-1 |

115V / 60Hz / 1Ph |

5,5 |

15 |

3AWG16 |

5-15P |

|

|

|

|

|

|

SPIKA NG 215-1 |

115V / 60Hz / 1Ph |

6 |

15 |

3AWG16 |

5-15P |

|

|

|

|

|

|

SPIKA NG 285-1 |

115V / 60Hz / 1Ph |

8,7 |

15 |

3AWG16 |

5-15P |

|

|

|

|

|

|

SPIKA NG 440-1 |

115V / 60Hz / 1Ph |

14,5 |

14 |

3AWG16 |

5-20P |

|

|

|

|

|

|

SPIKA MS 440-2 |

208-230V / 60Hz / 1Ph |

9 |

15 |

3AWG16 |

6-15P |

|

|

|

|

|

|

SPIKA MS 880-2 |

208-230V / 60Hz / 1Ph |

10 |

15 |

3AWG16 |

6-15P |

|

|

|

|

|

|

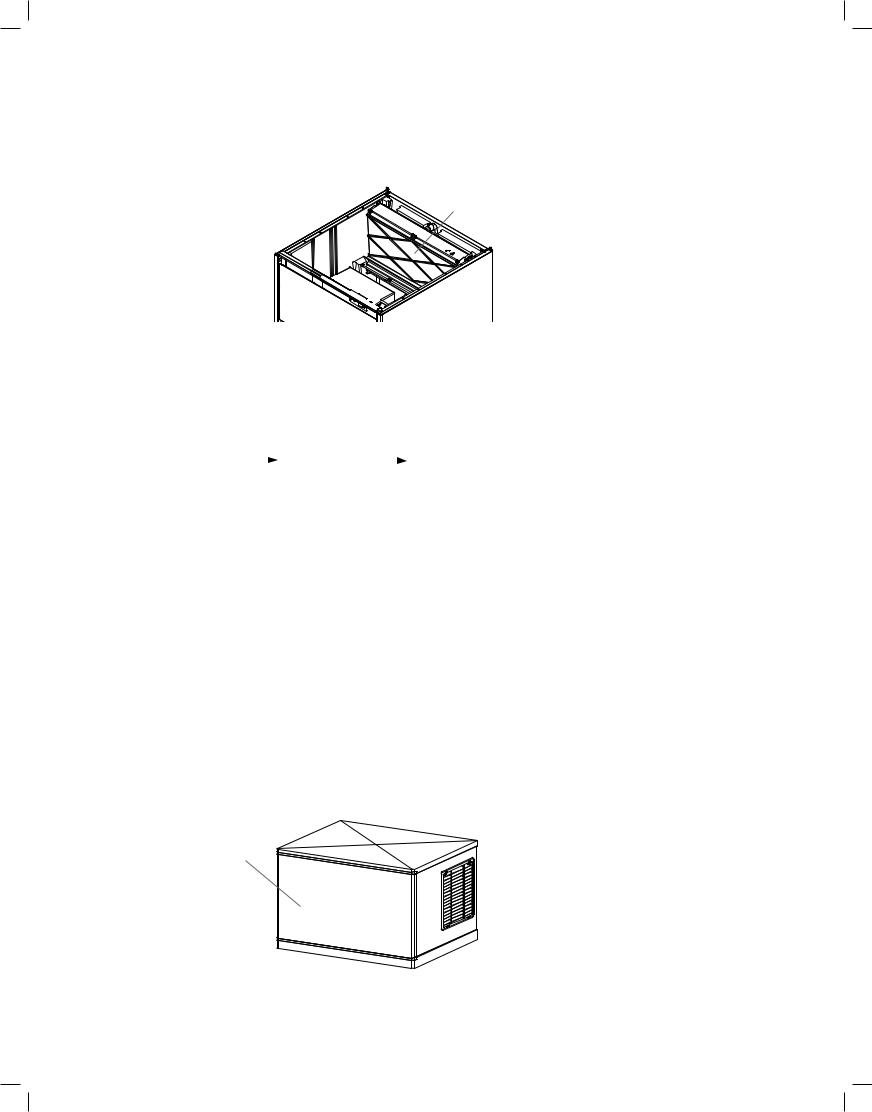

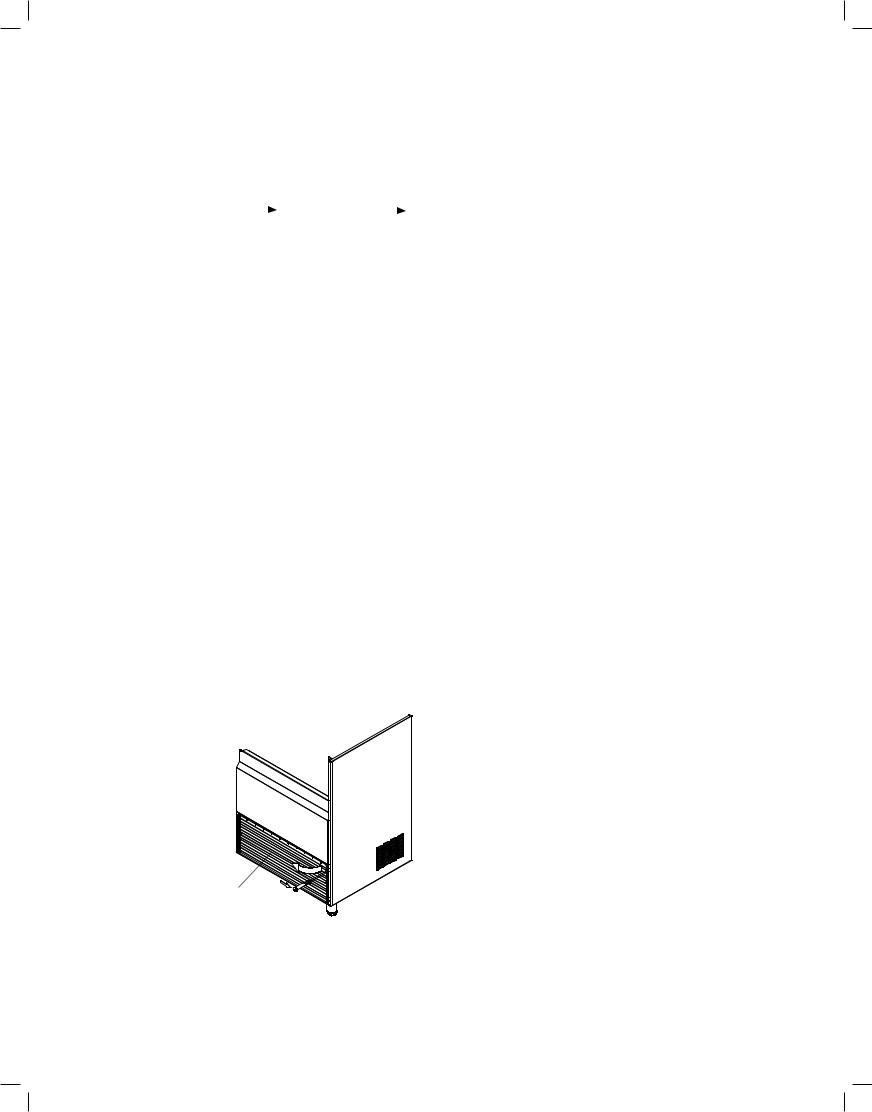

(8) INSTALLATION OF MODULAR EQUIPMENTS ON TOP OF BINS

Modular ice makers should be installed on top of bins, following the instructions contained in this manual.

The resistance and stability of the container-machine/s assembly should be verified, as well as the fastening elements. Follow bin manufacturer instructions.

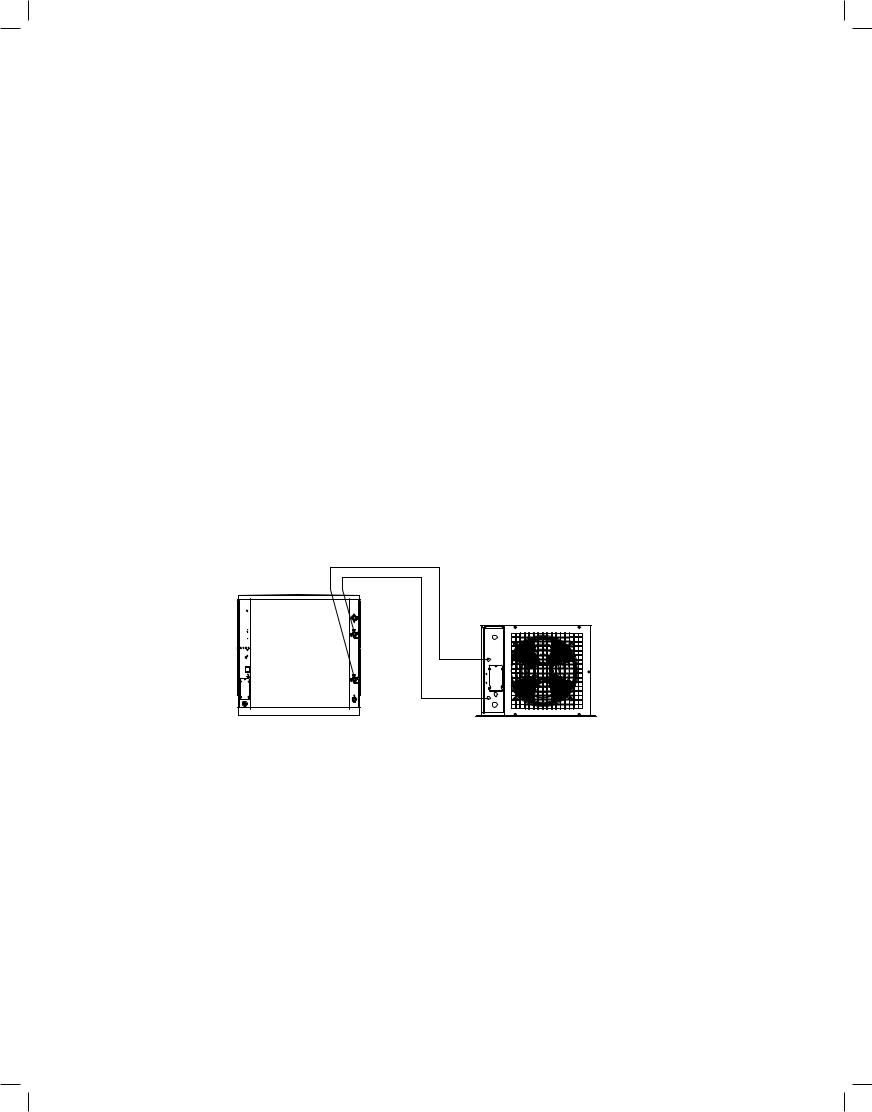

(9) REMOTE CONDENSER MODELS

Machines with remote condenser consist of an ice machine, remote condenser and interconnecting refrigerant pipes. Due to the remote condenser, these machines dissipate heat at a convenient location, away from the ice maker. The machines reduce the air conditioning loads.

SPIKA MS 500 – R1H/F 115/60 REMOTE + REMOTE CONDENSER RC5

SPIKA MS 1000 – R2H/F 208-230/60 REMOTE + REMOTE CONDENSER RC10

9.1 INSTALLATION AND CONDENSER LOCATION

To install the machine correctly, follow the instructions:

1) Ambient operating temperature -20°F (-28.9°C) to 120 ºF (48.9°C)

5

USER MANUAL SPIKA

2) Pipe diameter:

MS-500: liquid 1/4” – discharge 3/8” MS-1000: liquid 5/16” – discharge 1/2”

3) Line connection:

MS-500 3/8” – 3/8” SAE Condenser 1/4” – 3/8” ODS MS-1000 3/8” – 1/2” SAE Condenser 5/16” – 1/2” ODS

4) The pipeline length will be 16ft (5m) maximum. To increase the pipeline length, see point 9.2

Locate the condenser as near as possible to the ice machine. Remote condenser location must not exceed any of the following limits:

1)Maximum drop from the ice making head to the remote condenser: 16.4 physical ft (5 meters).

2)Maximum rise from the ice making head to the remote condenser: 35 physical ft (11 meters).

3)Maximum pipelines length: 100 physical ft (30 meters).

4)Maximum calculated pipelines length: 150 ft (45 meters).

Calculated pipeline length = Drop + Rise + Horizontal distance ≤ 150 ft (45 meters)

Drop = DD x 6.6 |

(DD = distance in feet) |

Rise = RD x 1.7 |

(RD = distance in feet) |

Horizontal distance = HD x 1 |

(HD = distance in feet) |

REMOTE CONDENSER LOCATION

Remote condenser located

ABOVE ice machine

HD

(11 m) |

|

RD |

Max. 35’ |

|

|

|

|

|

16.4’ (5 m) |

|

DD |

|

||

Max. |

|

|

|

|

|

|

|

|

Remote condenser located

BELOW ice machine

6

USER MANUAL SPIKA

9.2 PIPELINE LENGTH INCREASE

SPIKA MS 500 is filled with the necessary quantity of R404A for no more than 16.4 ft (5 m) pipeline length. To increase this length, add 2.82 oz. (80 g) R404A per 16.4 ft (5 m). The maximum pipeline length increase will be 82 ft (25 m).

SPIKA MS 1000 is filled with the necessary quantity of R404A for no more than 16.4ft (5 m) pipelines length. To increase this length, add 8.5 oz. (240 g) R404A per 16.4 ft (5 m). The maximum pipeline length increase will be 82 ft (25 m).

9.3 FACTORY SETTINGS

•Head pressure regulator: 10 bar.

•Pressure switch protection: 30 bar.

9.4 ELECTRICAL CONNECTION

Machines are non-cord-connected and the power line has to be connected at the rear of them. All the power requirements are on the data plate. Always use qualified personnel.

The power supply for the machine and the remote condenser are independent. This means no wiring between them is necessary.

Follow all applicable local, state and national codes

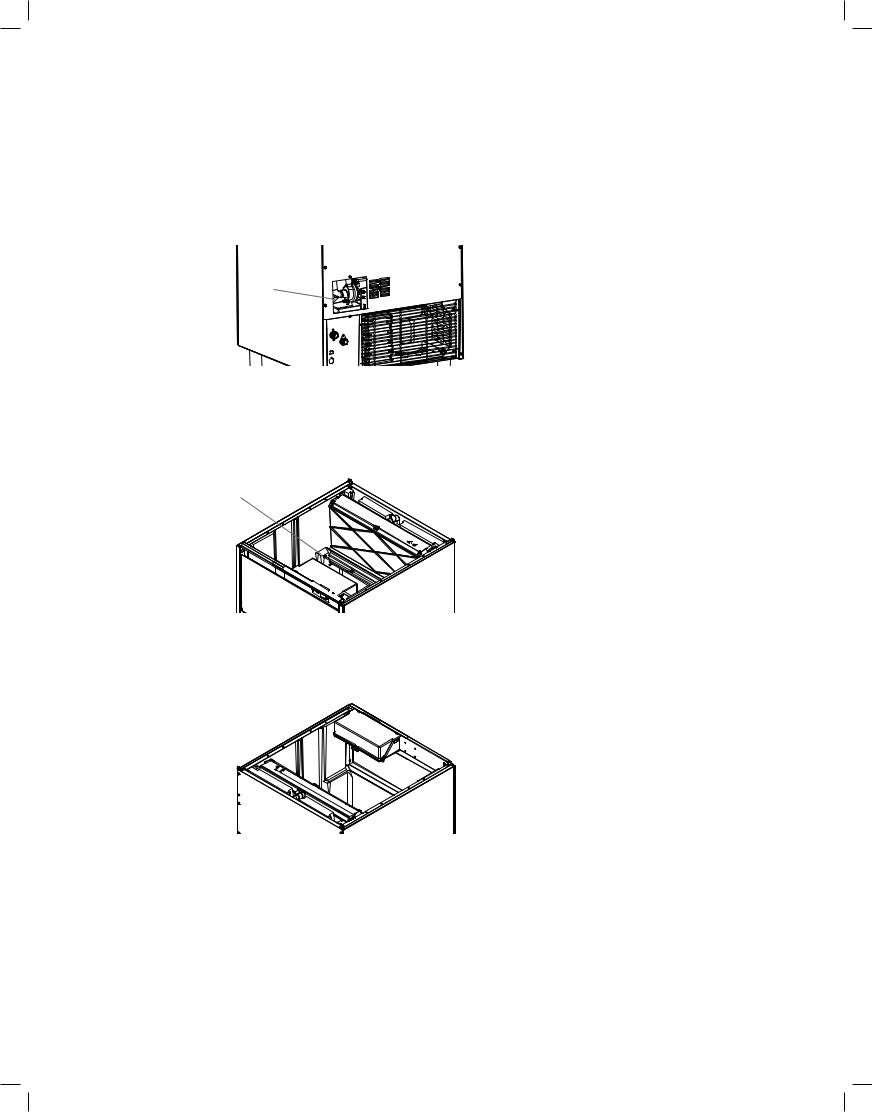

Image 2 shows how to connect the remote condenser.

SAE FLARE LIQUID

SAE FLARE DISCHARGE

LINE |

DISCHARGE LINE |

LIQUID |

|

ODS DISCHARGE

ODS

LIQUID

ICE MAKING HEAD |

REMOTE CONDENSER |

Figure 2. Remote condenser connection |

|

PIPE SIZE AND FITTINGS |

|

|

||

|

|

|

|

|

|

|

MS 1000R |

MS 500R |

|

|

|

|

|

|

LIQUID |

LIQUID LINE |

5/16’’ COOPER PIPE |

1/4’’ COOPER PIPE |

|

|

|

|

||

HEAD FITTING |

3/8’’ SAE FLARE |

3/8’’ SAE FLARE |

||

|

||||

|

|

|

|

|

|

CONDENSER FITTING |

5/16’’ ODS |

1/4’’ ODS |

|

|

|

|

|

|

DISCHARGE |

DISCHARGE LINE |

1/2’’ COOPER PIPE |

3/8’’ COOPER PIPE |

|

|

|

|

||

CONDENSER FITTING |

1/2’’ ODS |

3/8’’ ODS |

||

|

HEAD FITTING |

1/2’’ SAE FLARE |

3/8’’ SAE FLARE |

|

|

|

|

|

|

7

USER MANUAL SPIKA

Start-Up

(1) Previous Checkup

a)Is the machine leveled?

b)Voltage and frequency are the same as those on the nameplate?

c)Are the discharges connected and operating?

d)Will the ambient temperature and water temperature remain in the following range?

|

|

ROOM |

WATER |

|

|

|

|

|

MAXIMUM |

109º F / 43º C |

95º F / 35ºC |

|

|

|

|

|

MINIMUM |

41º F / 5º C |

41º F / 5ºC |

|

|

|

|

e) Is water pressure appropriate? |

|

|

|

|

|

|

|

|

MINIMUM |

14 psig (1 Bar) |

|

|

|

|

|

|

MAXIMUM |

85 psig (6 Bar) |

|

|

|

|

|

NOTE: In case input water pressure is higher than 85 psi (6 bar), install a pressure regulator.

For undercounter machines:

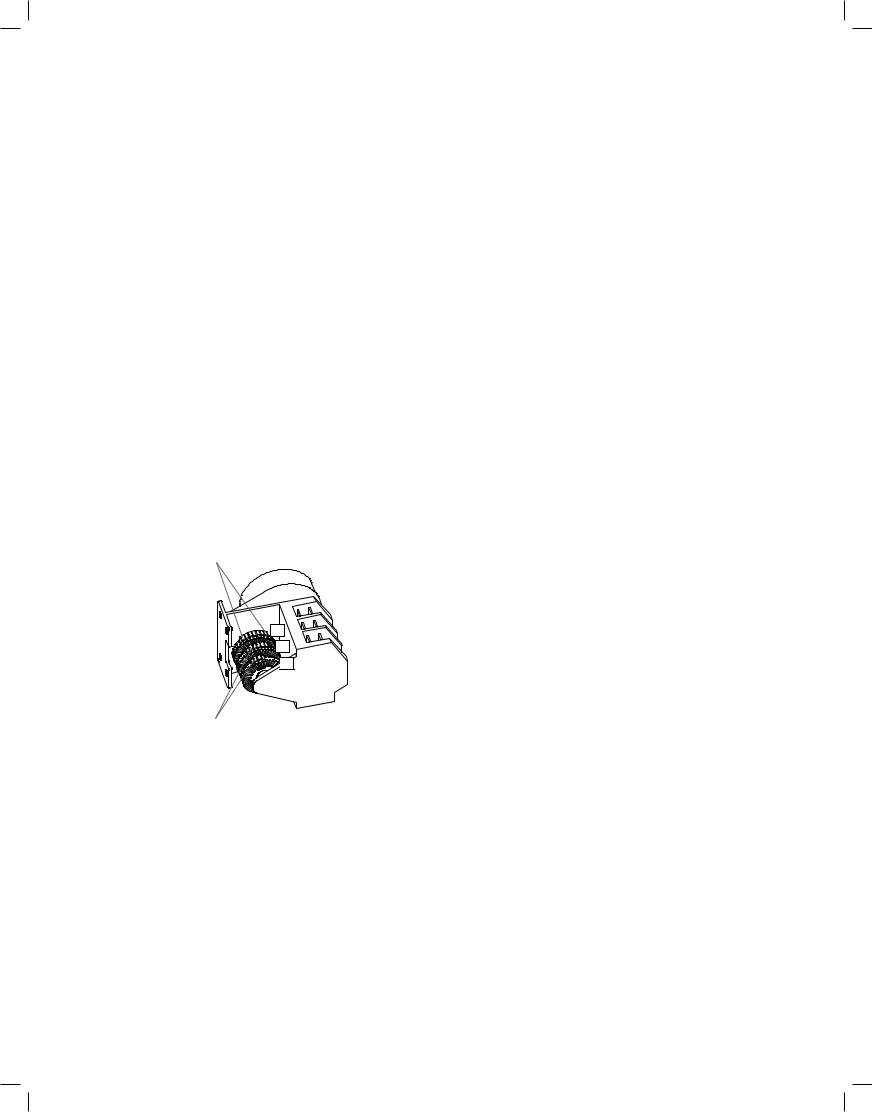

In case the room temperature exceeds 85ºF (29.5ºC) or water inlet temperature exceeds 68ºF (20ºC) the following adjustments should be made to ensure a proper efficiency.

The wheel G1 should have 2 more pins than G2, one by each side of those from the other.

G1

G2

G3

G3

The frist pin in G2 and G3 wheels must coincide in their position.

|

Air temp >85ºF |

Air temp <85ºF |

|

||||

|

Water temp >68ºF |

Water temp <68ºF |

|

||||

|

|

|

|

|

|

|

|

|

G1 |

G2 |

G3 |

G1 |

G2 |

G3 |

|

|

|

|

|

|

|

|

|

SPIKA NG 125 |

6 |

4 |

2 |

12 |

10 |

5 |

|

|

|

|

|

|

|

|

|

SPIKA NG 175 |

9 |

7 |

3 |

12 |

10 |

5 |

FIBER |

|

|

|

|

|

|

|

|

SPIKA NG 215 |

9 |

7 |

3 |

12 |

10 |

5 |

|

|

|

|

|

|

|

|

|

SPIKA NG 285 |

9 |

7 |

3 |

12 |

10 |

5 |

|

|

|

|

|

|

|

|

|

SPIKA 125 V2 |

6 |

4 |

2 |

8 |

6 |

5 |

|

|

|

|

|

|

|

|

|

SPIKA 175 |

11 |

9 |

5 |

14 |

12 |

8 |

CDC |

|

|

|

|

|

|

|

|

SPIKA 215 |

11 |

9 |

5 |

14 |

12 |

9 |

|

|

|

|

|

|

|

|

|

SPIKA 285 |

11 |

9 |

5 |

14 |

12 |

10 |

|

|

|

|

|

|

|

|

|

|

Indicating the number of white pins |

|

|

|

|||

(2) Start-Up

Once the installation instructions are followed (ventilation, site conditions, temperatures, water quality, etc.), proceed as follows:

1)Open the water inlet. Verify the no existence of leakages.

2)For undercounter models open the door and remove the protection elements on the shield. For modular models remove the two locking screws on top of machine, take off the front panel and remove protection elements on the shield and also on the thickness sensor.

3)Verify that the shield moves freely. For modular models verify also the thickness sensor moves freely.

4)Connect the machine to the power supply.

5)For undercounter models: push the blue switch on the machine front side. For modular models: push the blue switch found on the back of the machine and then set the ice-wash switch to the position I.

6)Verify that there are no vibrations or frictions on the elements.

7)Verify that the water fall to the evaporator is occurring uniformly and all ice cubes are properly watered.

8

USER MANUAL SPIKA

8)Close door (for undercounter models) / Replace the front panel in its place (for modular models).

9)Verify that after the final cycle, the frost on the aspiration pipe is at 20 mm (0.78 in) of the compressor.

10)For modular models: Verify the ice slab with the pictures below. In case the thickness sensor needs to be regulated, rotate the thickness adjustment screw CW to increase bridge thickness. Rotate CCW to decrease bridge thickness.

For undercounter models adjust the cycle thermostat.

Thickness Sensor

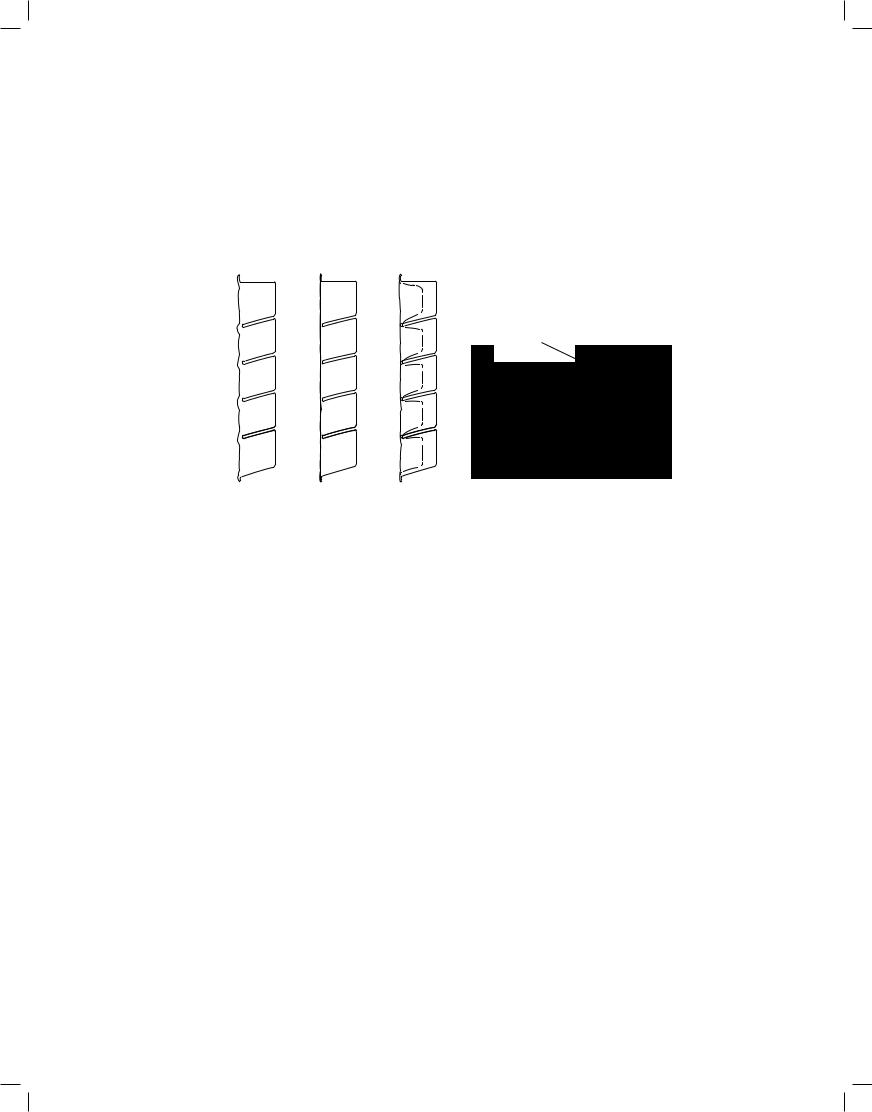

Too Big |

Just Right |

Too Small |

Damages due to the lack of maintenance and cleaning operations are not included on the warranty.

(3) Sequence of Operation

FOR UNDERCOUNTER MODELS:

Initial Start-up: It’s recommended that the first time the machine is started (or the water tray has been emptied) it begins with the harvest sequence to ensure the water tray is filled.

Freeze sequence: The compressor is energized. The timer G2 de-energizes the hot gas valve, so the evaporator begins to freeze. The timer G2 energizes the water pump so the water circulates from the water tray to the upper distributor, flowing through each cube cell, where it freezes.

Harvest sequence: The compressor will continue energized. The timer G2 energizes the hot gas valve during a certain time. The timer G3 at the same time energizes the water inlet valve during a certain time to fill the water tray with the appropriate quantity of water. The ice slab slides off the evaporator and into the bin. After this, the freeze sequence starts again.

When storage bin is full the stock thermostat detects a low temperature and the machine shuts off at the end of the freeze sequence. The ice machine remains off until enough ice has been removed from the storage bin and the stock thermostat doesn’t detect this low temperature.

FOR MODULAR MODELS:

Initial Start-up: The pump and the drain electrovalve are energized during 30 seconds to empty the water tray preventing the scale build-up in water. Then the pump and the drain electrovalve are de-energized, and the water inlet valve is energized filling the water tray until the water level sensor detects the water reaches the appropriate level. Then the freeze sequence starts.

Freeze sequence: The compressor is energized and the water pump is energized after 30 seconds. The water inlet valve is also energized at the same time that the water pump to replenish water level and then de-energized. The compressor and water pump will continue energized until the thickness sensor detects the thickness of the ice slab is the appropriate. Then the harvest sequence starts.

9

USER MANUAL SPIKA

Harvest sequence: The compressor will continue energized. The hot gas valve is energized throughout the harvest phase to divert hot refrigerant gas into the evaporator. The water pump and the drain electrovalve are energized during 45 seconds to empty the water tray and remove mineral deposits. After this (water pump and drain electrovalve deenergized) the water inlet valve is energized filling the water tray until the water level sensor detects water reaches the level. The ice slab slides off the evaporator and into the bin. The momentary opening and re-closing of the shield indicates the harvest sequence has finished and goes to the freeze sequence.

When the storage bin is full, the ice shield is held open during more than 30 seconds and the machine shuts off. The ice machine remains off until enough ice has been removed from the storage bin to allow the ice shield swings back to the operating position

Maintenance and Cleaning Procedures

It is the User’s responsibility to keep the ice machine and ice storage bin in a sanitary condition.

Ice machines also require occasional cleaning of their water systems with a specifically designed chemical. This chemical dissolves mineral build up that forms during the ice making process.

Sanitize the ice storage bin as frequently as local health codes require, and every time the ice machine is cleaned and sanitized.

The ice machine’s water system should be cleaned and sanitized at least twice a year. CAUTION: Do not mix Ice Machine Cleaner and Sanitizer solutions together.

WARNING: Wear rubber gloves and safety goggles when handling Ice Machine Cleaner or Sanitizer. WARNING: Unit should always be disconnected during maintenance/cleaning procedures.

CLEANING WATER DISTRIBUTION SYSTEM

(1) Cleaning Water Distribution System for Undercounter Models

1)Set the switch to the OFF position after ice falls from the evaporator at the end of a harvest cycle, or set the switch to the OFF position and allow the ice to melt off the evaporator.

CAUTION: Never use anything to force ice from the evaporator.

2)Remove the back metal lid and the top panel (if it need be to make easier the cleaning operations).

Top panel

Back metal lid

10

USER MANUAL SPIKA

3)Remove all ice from the bin.

4)Remove the auxiliary pipe for drain operations near the pump and empty the water tray. Return it to their original position to avoid water spill.

Pipe for drain

5)Prepare a solution of an appropriate product for the cleaning of ice machines (lime). Do not use

hydrochloric acid. We recommend the use of any NSF approved scale removal product prepared according to the manufacturer’s instructions.

6)Fill water tray with the solution.

Water tray

7)Switch compressor switch (see figure below) to position 0, and switch on machine in order to run water pump. Let solution stand for 30-40 minutes and then switch off the machine.

Compressor

switch

switch

8)Disconnect power and water supplies.

9)Remove the auxiliary pipe to drain and purge out the ice machine scale remover and residue. Replace it.

10)Mix enough cleaning solution (as in point 5) to clean parts and interior food zone surfaces.

11

USER MANUAL SPIKA

11) Remove shield.

Shield

12)Clean all surfaces of the shield with the cleaner solution using a brush (not a wire brush) or cloth. Rinse all areas with water.

13)Clean all the interior surfaces of the freezing compartment (including storage bin) with the cleaner solution using a brush or cloth. Rinse all areas with water.

14)Mix a solution of sanitizer using approved (EPA/FDA) sodium hypochlorite food equipment sanitizer to form a solution with 100 - 200 ppm free chlorine yield. Below an example to calculate the proper quantity of sanitizer to add to the water, for a household bleach 12,5%:

|

Bleach to add |

|

|

15 |

= |

15 |

= 1.2 gr/L |

|

*0.133 = 0.16 oz/gal |

|

|

|

|

% dis |

12.5 |

|

|

|

|

15) |

Sanitize all surfaces of the shield applying liberally the sanitizer solution using a cloth or sponge. |

||||||||

16) |

Sanitize all the interior surfaces of the freezing compartment (including the storage bin) applying liberally sanitizer |

||||||||

|

solution, using a cloth or sponge. |

|

|

|

|||||

17) |

Return shield to its position. |

|

|

|

|||||

18) |

Connect power and water supplies. |

|

|||||||

19) |

Fill water reservoir with the sanitizer solution. |

|

|||||||

20) |

Switch on machine in order to run water pump. Let solution stand for 20 minutes and switch off. |

||||||||

21) |

Remove the auxiliary pipe to drain and purge out the sanitizer solution and residue. Replace it. Fill the water |

||||||||

|

reservoir with water and switch on the machine to allow water to circulate for 5 minutes and then stop the |

||||||||

|

machine. Repeat this operation two more times to rinse thoroughly. |

||||||||

22) |

Remove the auxiliary hose to drain the water. Replace it and fill the tray with water to ensure the pump works |

||||||||

|

properly. |

|

|

|

|

|

|

||

23) |

Switch on compressor switch (position I). |

|

|||||||

24) |

Return the back metal lid and the top panel to their position. |

||||||||

25) |

Switch on machine and discard the first two harvests. |

||||||||

(2) Cleaning Water Distribution System for Modular Models

1)Set Ice-wash switch to the OFF position (position 0) after ice falls from the evaporator at the end of a harvest cycle, or set the ice-wash switch to the OFF position and allow the ice to melt off the evaporator.

CAUTION: Never use anything to force ice from the evaporator. Damage may result.

2)Remove the front panel.

Front panel

12

USER MANUAL SPIKA

3)Prepare a solution of an appropriate product for the cleaning of ice machines (lime). Do not use hydrochloric acid. We recommend the use of any NSF approved scale removal product. In modular machines the water bucket is filled automatically so we recommend to prepare a previous solution (for example 0,15 gal) according to the manufacturer’s instructions with the total quantity of product needed for the water tray (0,8 gal for MS 440 and 1,6 gal for MS 880).

4)To start a cleaning cycle, move the ice-wash switch to the WASH position (position II). The machine will drain the reservoir and refill it. Pour the scale remover solution into the reservoir.

Shield

Thickness sensor

Water level sensor

Water tray

Ice-wash switch

5)Allow the solution to circulate in the water system for 30-40 minutes and then set the ice-wash switch to the OFF position.

6)To purge out the ice machine scale remover and residue move the ice-wash switch to the WASH (the machine will drain the reservoir and refill it) and then set the ice-wash switch to the OFF position.

7)Disconnect power and water supplies.

8)Mix a cleaning solution.

9)Remove shield and water tray.

10)Clean the metal surfaces of the thickness sensor, water level sensor, the adjustment screw, the shield and the water tray with the cleaner solution using a brush (not a wire brush) or cloth.

Adjustment Water level screw  sensor

sensor

Thickness sensor

Water tray

Shield

11)Clean the interior surfaces of the freezing compartment (including walls, plastic parts of the evaporator, distributor...) and the front panel with the cleaner solution using a brush or cloth.

12)Mix a solution of sanitizer using approved (EPA/FDA) sodium hypochlorite food equipment sanitizer to form a solution with 100 t 200 ppm free chlorine yield.

13

USER MANUAL SPIKA

Below an example to calculate the proper quantity of sanitizer to add to the water, for household bleach 12,5%:

|

Bleach to add |

|

|

15 |

= |

15 |

|

= 1.2 gr/L |

|

*0.133 = 0.16 oz/gal |

|

|

|

|

% dis |

12.5 |

|

|

|

|

|

13) |

Sanitize all surfaces of the ice thickness sensor, water level sensor, shield and water tray applying liberally the |

|||||||||

|

sanitizer solution using a cloth or sponge. |

|

||||||||

14) |

Sanitize the interior surfaces of the freezing compartment (including walls, plastic parts of the evaporator, |

|||||||||

|

distributor...) and the front panel applying liberally the sanitizer solution using a cloth or sponge. |

|||||||||

15) |

Return the water tray and shield to their normal positions. |

|||||||||

16) |

Connect power and water supplies. |

|

||||||||

17) |

To start a sanitation cleaning cycle, move the ice-wash switch to the WASH position. The machine will drain the |

|||||||||

|

reservoir and refill it. Pour the sanitizer into the water reservoir to get a solution as in the point 12 (the volume in |

|||||||||

|

the water tray is approximately 1.6 gal for MS 880 and 0.8 gal for MS 440). |

|||||||||

18) |

Allow the solution to circulate in the water system for 20 minutes and then set the ice-wash switch to the OFF |

|||||||||

|

position. |

|

|

|

|

|

|

|

||

19) |

To purge out the sanitizer solution and residue move the ice-wash switch to the WASH position (drain and refill) |

|||||||||

|

and allow the water to circulate for 5 minutes and then move the switch to the OFF position (drain). Repeat this |

|||||||||

|

operation two more times to rinse thoroughly. |

|

||||||||

20) |

Return the panel to their position. |

|

|

|

||||||

21) |

Set the ice-wash switch to the ON position (position I) and discard the first two harvests. |

|||||||||

CLEANING THE ICE BIN (FOR UNDERCOUNTER MODELS)

1)Disconnect the machine, close water faucet and empty storage bin of ice

2)Use the cleaner/water solution to clean all surfaces of the bin. Use a nylon brush or cloth. Then rinse all areas thoroughly with clean water.

3)Use the sanitizer/water solution to sanitize all surfaces of the bin. Use a nylon brush or cloth.

4)Rinse with plenty of water, dry, run the machine and open water faucet.

CLEANING THE CONDENSER

(1) Air Condenser

1)Disconnect machine and close water faucet.

2)For undercounter models remove the front grid by pressing the two clips placed at right side (see figure).

Front grid

14

USER MANUAL SPIKA

For modular models remove the back panel (see figure).

Back panel

3)Clean condenser using a vacuum cleaner, soft brush or low pressure air. Clean from top to bottom, not side to side. Be careful not to bend the condenser fins.

(2) Water Condenser

The water condenser may require cleaning due to scale build-up. The cleaning procedures require special pumps and cleaning solutions. They must be performed by qualified maintenance or service personnel.

CLEANING THE OUTSIDE OF THE MACHINE

Clean the area around the ice machine as often as necessary to maintain cleanliness. Sponge any dust and dirt off the outside of the ice machine with mild soap and water. Wipe dry with a clean soft cloth. A commercial grade stainless steel cleaner/polish can be used as necessary.

CHECKING FOR WATER LEAKS

This must be done whenever maintenance is carried out on the machine: check all water connexions, braces, tubes and hoses in order to eliminate leaks and prevent breakages and flooding.

15

USER MANUAL SPIKA

User Troubleshooting Guide

UNDERCOUNTER MODELS:

PROBLEM |

|

PROBABLE CAUSE |

SOLUTION |

|

|

|

|

|

|

|

|

None of the electrical parts work. |

|

The machine is unplugged. |

Plug in the machine and |

|

|

|

verify shocket power. |

|

|

|

|

|

|

Bin thermostat open. |

Remove ice from the bin. |

|

|

Ice touching bin tube. |

|

|

|

|

|

|

|

Bin thermostat open. |

Adjust thermostat (electric |

|

|

No ice touching bin tube. |

box under top cover). |

|

|

|

|

All the electrical parts work but not |

|

Compresor switch is in the |

Switch to “ICE” position (1). |

compressor. (water doesn´t get frozen). |

|

“WASH” position (0). |

|

|

|

|

|

No water in tray. |

|

Not incoming water. |

Check water supply. |

|

|

|

|

|

|

Inlet strain at water valve blocked. |

Check an clean. |

|

|

|

|

Bin full and ice touching thermostat |

|

Bin thermostat doen´t open (only |

Adjust thermostat (electric |

tube, but machine doesn´t stop. |

|

operates at harvest time). |

box under top cover). |

|

|

|

|

Ice slab empty or too thick . |

|

Desadjusted cycle time. |

Adjust thermostat (electric |

|

|

|

box under top cover). |

|

|

|

|

Difficult to release ice slab at harvest. |

|

Unit bad leveled (tilted to back). |

Level; down front. |

|

|

|

|

|

|

Not enough harvest time. |

Add more pins to cam timer |

|

|

|

wheels (as label indications). |

|

|

|

|

Not uniform flow pattern at evaporator. |

|

Dirty or scaled distributor. |

Perform descaling procedure. |

|

|

|

Remove and clean distributor (pull |

|

|

|

from two clips at distributor sides). |

|

|

|

|

Unit run and stops alternatively itself |

|

Safety presostat opens. |

Clean air condenser (behind front grid). |

|

|

|

|

|

For further problems call aftersales service. |

||

|

|

|

|

16

Loading...

Loading...