ITV Ice Makers IQ100C, IQ200C, IQ300C, IQ300, IQ500 Installation Manual

...

ICE QUEEN

USER MANUAL IQ MACHINES

MANUAL DEL USUARIO MÁQUINAS IQ

MANUEL DE L’ UTILISATEUR IQ MACHINES

ICE FLAKERS MAKERS

MÁQUINAS DE HIELO EN ESCAMAS

MACHINES A GLAÇONS EN CUBE

IQ100C

IQ200C

IQ300C

IQ300

IQ500

IQ900

IQ1300

IQ2700

IQ1300 REMOTE

IQ2700 REMOTE

ICE QUEEN

USER MANUAL IQ MACHINES

MANUAL DEL USUARIO MÁQUINAS IQ

MANUEL DE L’ UTILISATEUR IQ MACHINES

INDEX

WARNING 1

RECEPTION OF THE MACHINE 1

INSTALLATION 2

START-UP 6

MAINTENANCE AND CLEANING PROCEDURES 7

WIRING DIAGRAMS 9

ÍNDICE

ADVERTENCIAS 16

RECEPCIÓN DE LA MÁQUINA 16

INSTALACIÓN 17

PUESTA EN MARCHA 21

INSTRUCCIONES DE MANTENIMIENTO Y LIMPIEZA 22

ESQUEMAS ELÉCTRICOS 24

INDEX

ATTENTION 31

RECEPTION DE L’APPAREIL 31

INSTALLATION 32

MISE EN MARCHE 36

INSTRUCTIONS POUR L’ENTRETIEN ET LE NETTOYAGE 37

SCHÉMAS ÉLECTRIQUES 39

USER MANUAL IQ

THIS MANUAL IS PART OF THE PRODUCT. READ IT CAREFULLY IN ORDER TO USE AND MAINTAIN THE

EQUIPMENT CORRECTLY.

IT IS IMPORTANT TO KEEP IT FOR FUTURE TROUBLESHOOTING AND REFERENCE.

Warning

The installation of this equipment should be done by the Technical Assistance Service department.

The socket should always be placed on an accessible location.

ALWAYS disconnect the power supply from the machine BEFORE any cleaning or maintenance service.

Any change needed on the electrical installation for the appropriate connection of the machine, should be exclusively

performed by qualified and certified professional personnel.

Any use by the ice maker not intended to produce ice, using drinking water, is considered inappropriate.

It is extremely dangerous to modify or to intend to modify this machine, and shall make any type warranty void.

This appliance is not intended for used by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be monitored to assure that they should not play near the equipment.

This machine is not intended to be used outdoors nor exposed to the rain.

Connect the equipment to the drinking water network.

The machine should be connected using the power cable supplied with the equipment. The connection is not intended

for fixed cabling (not for the remote models, see electrical connection).

IT IS MANDATORY TO GROUND THE EQUIPMENT. To avoid possible discharges on individuals or damages to the

equipment, the machine should be grounded pursuant local and/or national regulations as the case may be.

THE MANUFACTURER SHALL BE HELD HARMLESS IN CASE OF DAMAGES ARISING DUE TO THE LACK OF THE

GROUND INSTALLATION.

In order to assure the proper operation and eciency of this equipment, it is of paramount importance to follow the

recommendations of the manufacturer, SPECIALLY THOSE RELATED TO CLEANING AND MAINTENANCE OPERATIONS,

which should be performed mostly by qualified personnel only.

CAUTION:

Do not try to perform repairs. The intervention of non-qualified personnel, besides of being dangerous, could result in

serious malfunctioning. In case of damages, contact your distributor. We recommend always using original replacement

and spare parts.

Perform all discharge and recovery of materials or waste according the national regulations in force.

Reception of the Machine

Inspect the outside packing. In case of damages, MAKE THE CORRESPONDING CLAIM TO THE CARRIER.

To confirm the existence of damages, UNPACK THE MACHINE IN THE PRESENCE OF THE CARRIER and state any

damage on the equipment on the delivery document or on a separate instrument.

As from May 1, 1998 complies with the European regulations on management of packing and packing waste, inserting

the “Green Dot Label” on all their packages.

1

USER MANUAL IQ

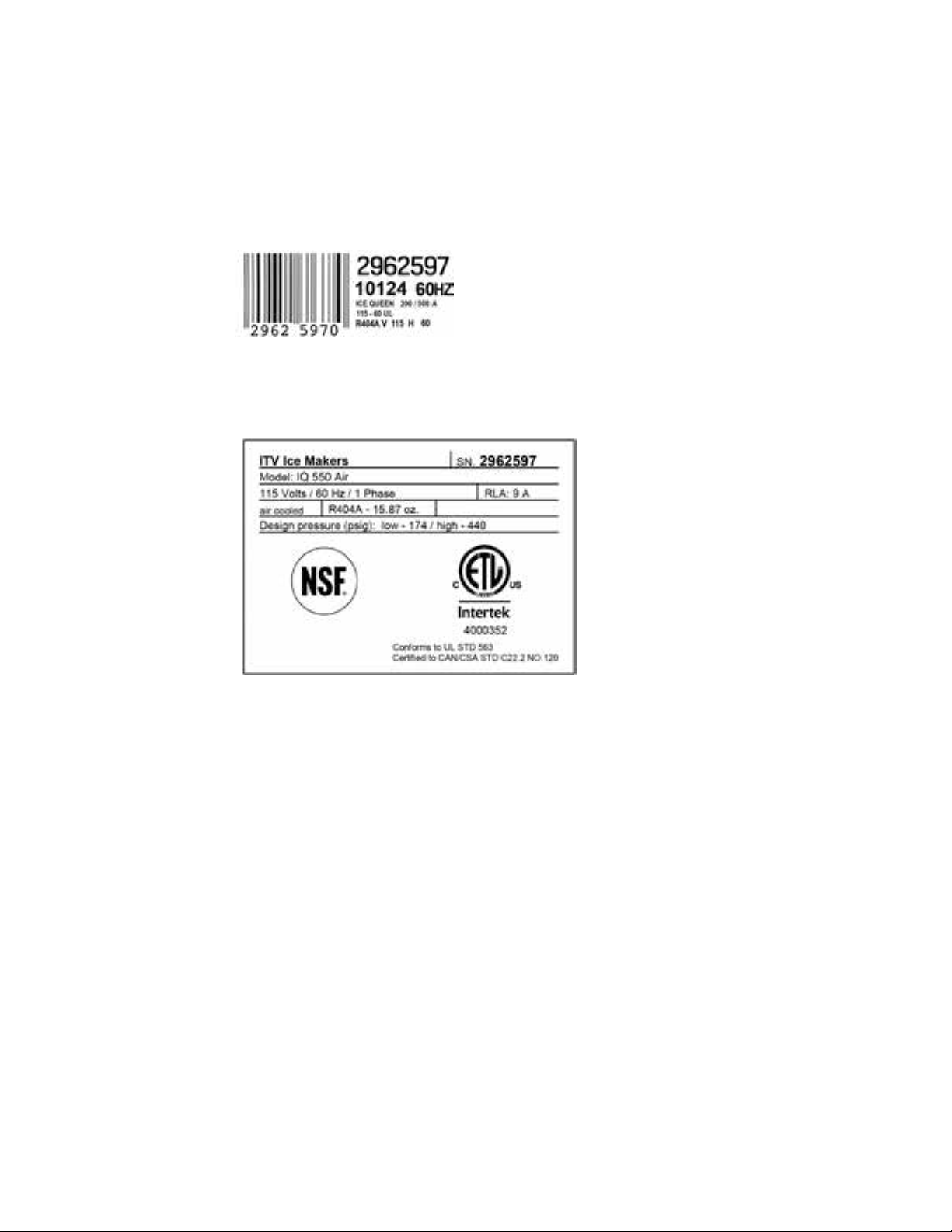

Always state the machine number and model. This number is printed on four locations:

(1) Packing: On the outside, it contains a label with the manufacturing number (1).

(2) Exterior of the equipment: On the back of the equipment, as the previous one.

(3) Nameplate: On the back of the machine.

(1)

Check that in interior of the machine the installation kit is complete and comprises:

• Ice scraper and manual.

• Warranty and serial number

• Drain hose.

CAUTION: All packing elements (plastic bags, carton boxes and wood pallets) should be kept outside the reach of

children, as they are a source of potential hazard.

Installation

THIS ICE MAKER IS NOT DESIGNED FOR OUTDOOR OPERATION.

An incorrect installation of the equipment may cause damages to individuals, animals or other materials, being

the manufacturer not responsible for such damages.

CAUTION:

The machines are designed to operate at room temperature between 5ºC (41ºF) and 43ºC (110ºF), with inlet water

temperature between 5ºC (41ºF) and 35ºC (95ºF). The gear motor is excessively forced if operated under the minimum

temperatures.

2

USER MANUAL IQ

Above the maximum temperature, the life of the compressor is shortened and the production is substantially lower.

Do not place anything over the maker or facing the front louver.

In case the front louver is not enough, the exit is either total or partially obstructed or due to its placement, it will receive

hot air from another device, we strongly recommend, in case it is not possible to change the location of the machine, to

install a water condenser.

IT IS IMPORTANT THAT THE WATER PIPING DO NOT PASS BY OR NEAR SOURCES OF HEAT SO AS NOT TO LOSE ICE

PRODUCTION.

IMPORTANT: Thread the support legs to the base of the machine on the housing set to such end, in case of machines

having this feature, and regulate the height as to have the equipment perfectly leveled.

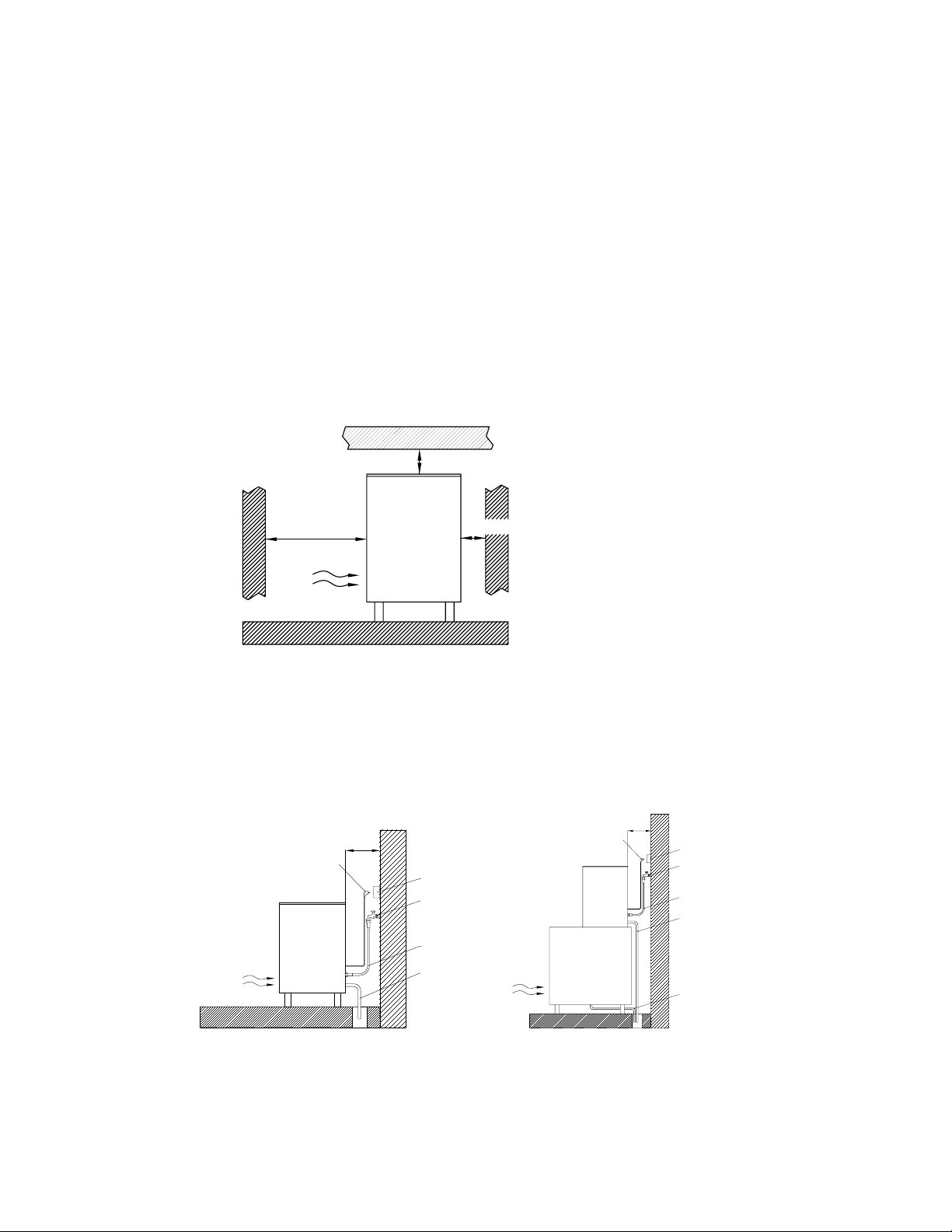

MINIMUM DISTANCE TO OBSTACLES

Side View

>75cm / >29”

* There’s no minimum distance to obstacles in the sides of the machine

CONNECTION DIAGRAM

FOR COMPACT MODELS FOR MODULAR MODELS

Plug

>10cm

>4”

>10cm / >4”

Socket

Tap

>10cm / >4”

Plug

>10cm

>4”

Socket

Tap

Water Connection Hose

Condensar Discharge Outlet

Water Connection Hose

Discharge Hose

3

Bin Drainage

USER MANUAL IQ

(1) Water and Drainage

Water quality has a remarkable influence on the appearance, hardness and flavor of the ice as well as, in the machines

condensed by water on the life of the condenser.

(2) Connections to the Water Network

Use a flexible food grade pipe.

Pressure should be established between 1 and 6 Bar (14 and 85 psi / 0.1 and 0.6 Mpa).

If pressures overpass such values, install the necessary corrective devices.

ATTENTION: The machine shall be plumbed (with adequate blackflow protection) according to applicable Federal State

and local regulations.

(3) Connection to Drainage

Drainage should be located below the level of the machine, at 150 mm (5.91 inches) minimum.

It is convenient that the drainage pipe is of 30 mm (1.18 in) of interior diameter and with a minimum gradient of 3 cm

(1.18 in) per meter (see figure).

CORRECT INCORRECT

Descending Ascending

INCORRECT

(4) Electrical Connection

IT IS MANDATORY TO GROUND THE EQUIPMENT: To avoid possible discharges on individuals or damages to the

equipment, the machine should be grounded pursuant local and/or national regulations as the case may be.

THE MANUFACTURER SHALL BE HELD HARMLESS IN CASE OF DAMAGES ARISING DUE TO THE LACK OF THE GROUND

INSTALLATION.

The machine is supplied with a 6 feet cable of length. In case the supply cable is damaged, it should be replaced by a

cable or a special kit to be furnished by the manufacturer or post-sale service. Such replacement should be performed

by qualified technical service only.

The machine should be placed in such a way as to allow a minimum space between the back and the wall to allow an

easy access and without risks to the cable plug.

It is convenient to install adequate switches and fuses.

Voltage and tension are indicated on the nameplate and in the technical specifications of this manual. Variation on

voltage above the 10% stated on the nameplate could result on damages or prevent the machine start-up.

The line up to the plug should have a minimum section of AWG16.

4

USER MANUAL IQ

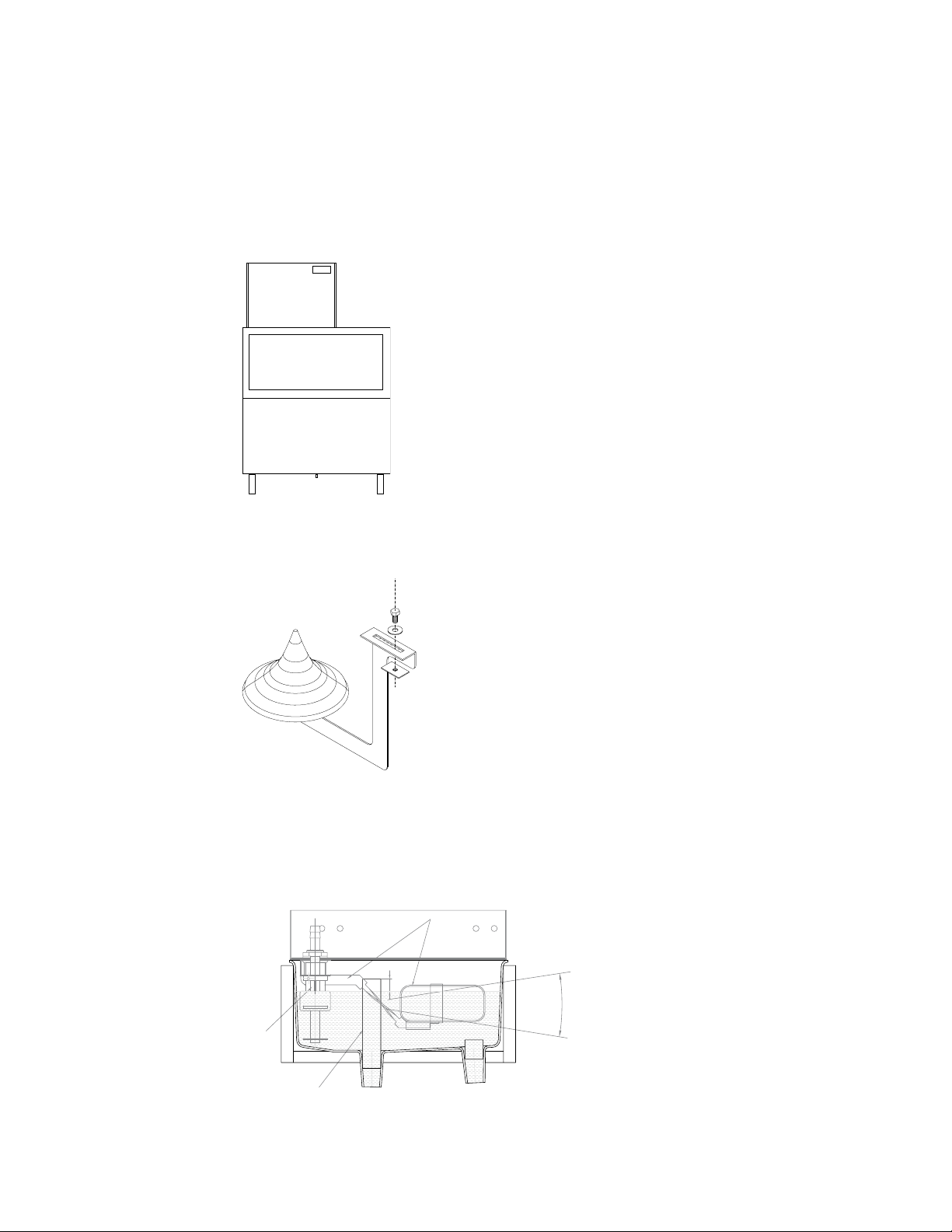

(5) Installation of Modular Equipments over Bin or Silos.

Modular makers should be installed over deposits or silos, following the instructions contained in this manual.

The resistance and stability of the container-machine/s assembly should be verified, as well as the fastening elements.

Follow bin manufacturer instructions.

(6) Assembly of the Dispersion Cone (Modular Models)

This device distributes the ice in the bin, and avoids ice compression under the exit pipe. Changing its position, the ice

could be directed to any direction.

(7) Water Level

The function of the water level is to maintain the necessary flow on the evaporator, and using the magnetic micro

device incorporated, stop the operation of the machine until the water reaches again the container.

The optimum level is located on the horizontal indicated in the figure, and its regulation is made following the indications

appearing below.

Float

Turn upwards to increase the level,

and downwards to decrease it. (Grab

from the metalic arm, NEVER FROM

THE FLOAT).

10

Probe

Safety Overflow

5

USER MANUAL IQ

(8) Remote Ice Queen Machine Installation: Connect to the Field-Installed Condensing Unit

Connect the pipes of a field-installed condensing unit (or a field-installed condenser located remote from the ice maker)

to the connections valves of the machine: the high pressure (liquid) line to the inlet connection valve (3/8” SAE) and the

low pressure (suction) line to the outlet connection valve (1/2” SAE).

Make vacuum to lines. Use allen wrench to open liquid and suction line connection valves. Unit is precharged with R404A

till positive pressure.

Connect the low pressure gauge to the service point of the KVP and, when unit started, adjust the KVP to -15ºC (2.6bar

/ 37.7psig).

(9) Remote Ice Queen Machine Installation: Connect to the Power Supply

The ice maker must be permanently connected to the power supply. There is a terminal box where the connections must

be made; it will be accessible removing the service cover of the outlet box.

All wiring must conform to local, state and national codes.

The ice machine must be grounded in accordance with national and local electrical code.

Start-Up

(1) Previous Checkup

a) Is the machine leveled?

b) Voltage and frequency are the same as those on the nameplate?

c) Are the discharges connected and operating?

d) If air condensed: Is the air circulation and its temperature appropriate?

ROOM WATER

MAXIMUM 43º C / 109º F 35ºC / 95º F

MINIMUM

e) Is water pressure appropriate?

MINIMUM 1 Bar (14 psi / 0.1 Mpa)

MAXIMUM

NOTE: In case input water pressure is higher that 6 bar (85 psi / 0.6 Mpa), install a pressure regulator.

(2) Start-Up

Once the installation instructions are followed (ventilation, site conditions, temperatures, water quality, etc.), proceed

as follows:

1) In the case of modular modules, remove the cover to access the installation kit .

2) In case of compact models, open the deposit door to access the installation kit.

3) Open the water inlet. Verify the no existence of leakages.

4) Connect the machine to the electrical network, and switch on the main switch placed on the front side..

5) For three-phase machine if sequence is not correct, red pilot will light and is necessary to change connection

sequence.

6) After 10 min. timer delay machine will start. (this delay will happen after every machine stop)

7) Verify that there are no vibrations or frictions on the elements.

8) After a few minutes, verify that the ice production has started.

9) In the case of modular models (mainly in three-phase equipments), having the cover removed, verify that the motor

is rotating in the correct direction (see arrow on steel frame).

10) Verify that after the final cycle, the frost on the aspiration pipe is at 20 mm (0.78 in) of the compressor.

5º C / 41º F

6 Bar (85 psi / 0.6 Mpa)

5ºC / 41º F

6

USER MANUAL IQ

The technical installer shall invoice traveling expenses, labour cost hours and materials used.

(3) Maneuver for model IQ 100C

Green led: Indicanting the machine is working. It could be stopped because the thermostat.

Black button: It starts the machine. It also re-starts the machine when it’s stopped because any safety element.

Red button: To stop the machine completely.

Green led

Black button

Red button

Maintenance and Cleaning Procedures

CAUTION: Instruct the user about maintenance, informing that maintenance and cleaning operation as well as damages

due to the lack of such operations are not included in the warranty.

If a good maintenance is performed, the machine will continue producing a good quality of ice and will be free of

damages.

Maintenance and cleaning intervals will depend on the conditions of the site and water quality.

CAUTION: At least, one revision and cleaning should be performed every six months.

On dusty environments, it might be necessary to clean the condenser on a monthly basis.

CAUTION: Unit should always be disconnected during maintenance/cleaning procedures.

CLEANING THE CONDENSER

(1) Air Condenser

1) Disconnect machine and close water faucet.

2) Remove front grid.

3) Clean condenser using a vacuum cleaner, soft brush or low pressure air. Clean from top to bottom, not side to side.

Be careful not to bend the condenser fins.

4) Carefully wipe o the fan blades and motor with a soft cloth. Do not bend the fan blades.

(2) Water Condenser

1) Disconnect machine and close water faucet.

2) Remove the front grid.

3) Disconnect water entry/exit from condenser.

4) Prepare a solution of 50% phosphoric acid in distilled water.

5) Distribute solution through condenser and make it circulate. Solution is more eective at 35°-40°C (95ºF-104ºF).

WARNING! DO NOT USE HYDROCHLORIC ACID

(3) Cleaning the Ice Bin

1) Disconnect machine, close water faucet and empty storage bin of ice

2) Wipe with a kitchen cloth soaked in bleach and detergent

3) If white lime stains do not vanish, rub with some lemon or vinegar, wait for a few minutes and wipe with the cloth

again.

4) Rinse with plenty of water, dry, and run the machine

7

USER MANUAL IQ

(4) Evaporator / Water Trough

1) Disconnect machine.

2) Remove water hose situated in lower bearing of evaporator. Use a container to collect water.

3) Allow water to flow for 2 to 3 minutes.

4) Close water faucet and replace hose in evaporator.

5) Prepare a solution of an appropriate product for the cleaning of ice machines (lime). Do not use hydrochloric acid.

We recommend the use of Scale-Kleen (Everpure) prepared according to the manufacture’s instructions. Slowly pour

solution into water trough. (Solution is more eective at 35°-40°C / 95ºF-104ºF).

6) Allow solution to stand for 20 minutes.

7) Remove lower hose and empty trough. Replace hose.

8) Fill trough with solution to maximum capacity. Connect machine and wait for unit to automatically shut o for lack

of water.

WARNING: Discard ice produced during cleaning procedure.

9) Disconnect machine, remove bearing hose and let water run.

**Sanitary cleaning

10) Replace bearing hose. Faucet must remain closed.

11) Prepare a solution of sanitizer (5-7 liters / 1.3-1.85 gal) using approved (EPA/FDA) sodium hypochlorite food

equipment sanitizer to form a solution with 100 t 200 ppm free chlorine yield. Below an example to calculate the

proper quantity of sanitizer to add to the water, for a household bleach 12,5%:

Blench to add = = 1.2 gr/L ® *0.133 = 0.16 oz/gal

15 15

% dis 12.5

12) Fill trough with solution. Connect machine and slowly add solution maintaining level in order to allow machine to

work for at least 15 minutes.

13) Empty trough and evaporator removing hose.

14) Replace hose. Open water faucet and allow machine run for 15 minutes.

WARNING: Discard ice produced during all cleaning procedure.

15) Disconnect unit, place cover and check for water leaks.

16) Replace filters if necessary. (Machines provided with 5mm wire gauze filters).

17) Reconnect machine.

(5) Cleaning the Outside of the Machine

1) Disconnect machine and close water faucet.

2) Wipe with a kitchen cloth soaked in bleach and detergent

3) If white lime stains do not vanish, rub with some lemon or vinegar, wait for a few minutes and wipe with the cloth

again.

4) Wipe with a damp cloth and then dry.

(6) Cleaning the Inlet Filters

They are easily obstructed during the first days of operation, mainly with new piping installations.

Loose the hose and clean it under water.

(7) Checking for Water Leaks

This must be done whenever maintenance is carried out on the machine: check all water connections, braces, tubes and

hoses in order to eliminate leaks and prevent breakages and flooding.

8

Wiring Diagrams

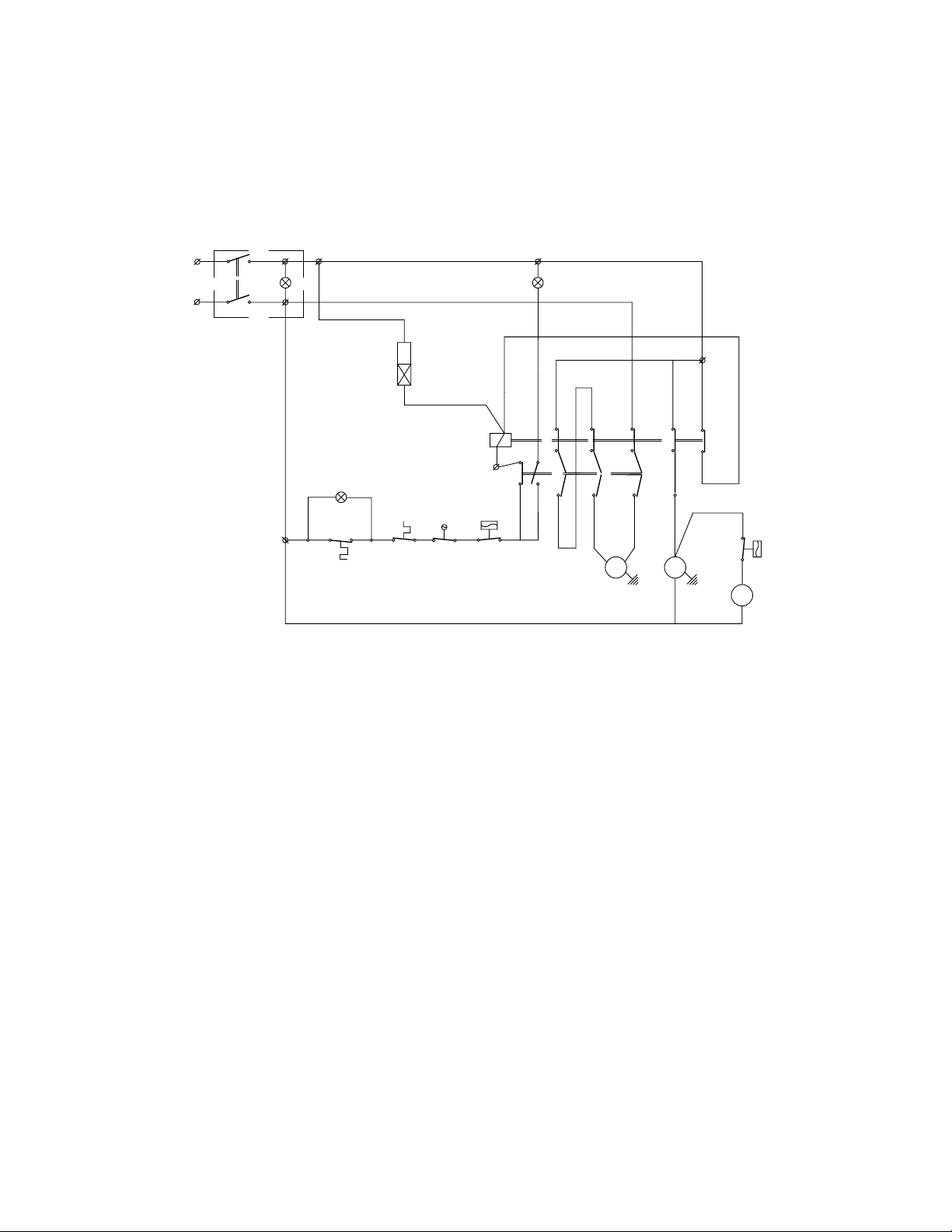

IQ 100C

Ps

USER MANUAL IQ

L

I

N

Components:

Pv Fan pressostat

V Fan

Ew Condenser water valve

S Compressor

Ir On switch

Is O switch

marrón/brown

Ir

13

Is

negro/black

Pt

Iw

violeta/violet

12

9

Ts

14

gris/grey

8

5

rojo/red

L

Pv

C

(1)

V

(2)

Ew

R S

azul/blue

20/01/11 . 24/10

Ts Full storage bin stop

Iw Water low level float switch

Ps High pressure safety pressostat

R Gearmotor

Pt Motor thermal protection

I Green - on

9

USER MANUAL IQ

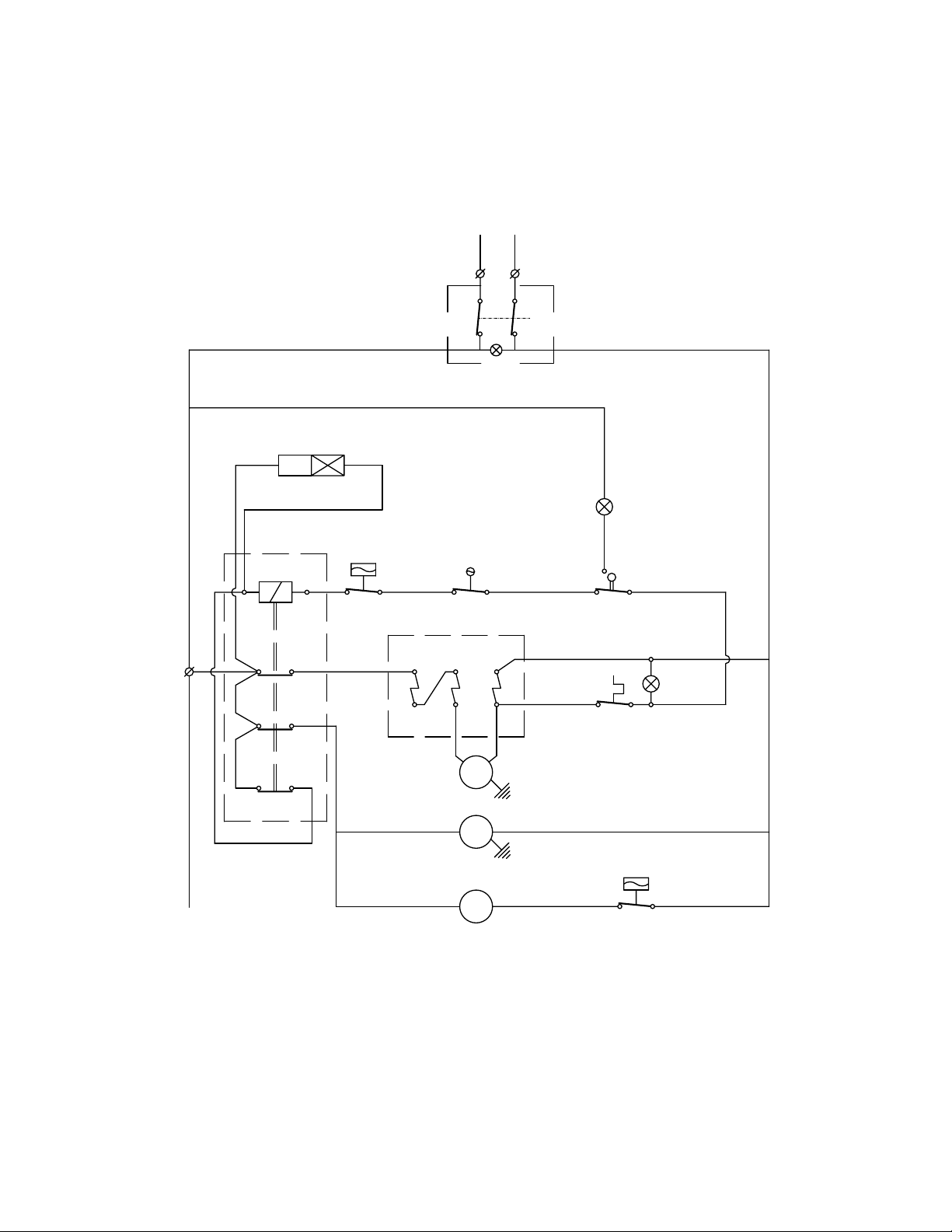

IQ 200C

Ip

N

L

I III

A1

Tem.

II

Ts

Components:

Tem Start timer

C1 Contactor

Pv Fan pressostat

V Fan

S Compressor

Ip On / O switch

Ts Full storage bin stop

Iw Water low level float switch

Ps High pressure safety pressostat

R Gearmotor

Pt Motor thermal protection

Ew Condenser water valve

I Green - on

II Yellow - full

III Thermic gearmotor

A2

A1

C1

A2

96

95

Iw Ps

Pt

LC

L1 L2 L3 L4

98

97

T1 T2 T3

gris/grey

gris/grey

marrón/brown

R

22

rojo/red

S

negro/black

3

Ca1

4

L

Pv

C

V

marrón/brown

20/01/11 . 24/10

10

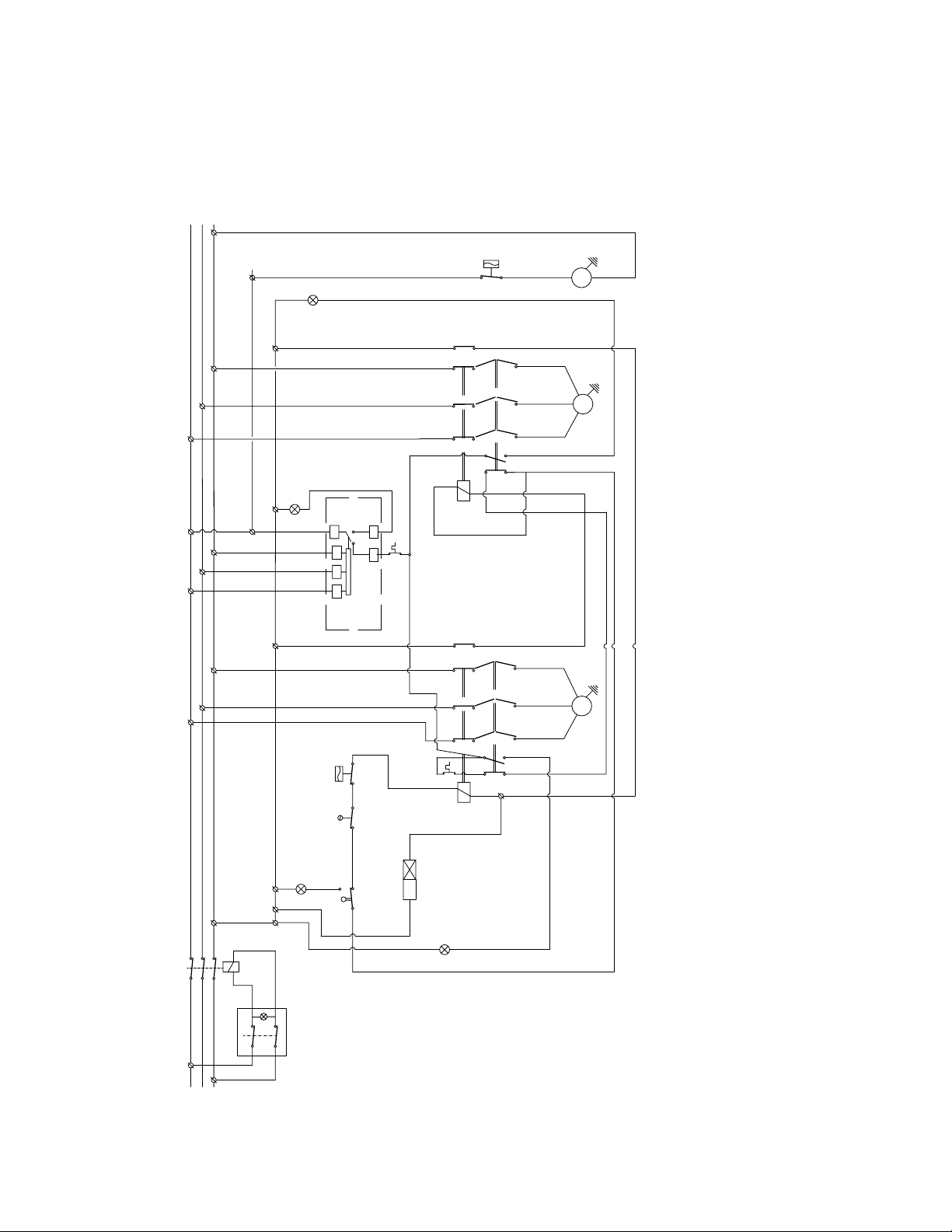

IQ - Single Phase

1

T

A1 A2

USER MANUAL IQ

L1 N

Ip

azul/blue

azul/blue

negro/black

negro/black

azul/blue

A1 A2

C1

L1

L2

L3

I

gris/grey

Ps

L C

marrón/brown

C

T1

rojo/red

C2

T2

C3

T3

rojo/red

L

1 L2 L3

T1

T2

Dis.

Iw

R

S

violeta/violet

T3

4

2

Pt

Ts

marrón/brown

1

marrón/brown

II

marrón/brown

Pv

rojo/red

V

L C

20/01/11 . 24/10

Components:

T1 Start timer

C Contactor

Dis Circuit breaker (gearmotor)

Pv Fan pressostat

V Fan

S Compressor

Ip On / O switch

Ts Full storage bin stop

Iw Water low level float switch

Ps High pressure safety pressostat

R Gearmotor

Pt Motor thermal protection

I Yellow - full

II Red - Breaker

11

USER MANUAL IQ

IQ - Three Phases

azul/blue

Pv

marrón/brown

L

C

V

20/01/11 . 24/10

II

rojo/red

Ca2

4

3

negro/black

T2 T3

L1 L2 L3

IV

rojo/red

11

12

T

Pt

14

A2

C2

T1

98

959796

A1

marrón/brown

R S

R

negro/black

marrón/brown

Ca2 Auxiliar contact feedback

I Thermic compressor

II Thermic gearmotor

III Yellow - full

azul/blue

IV Phase sequence

DF

4

3

negro/black

T2 T3

marrón/brown

959796

A1

T1

98

L1 L2 L3

C

Ps

Iw

violeta/violet

L

marrón/brownvioleta/violet

Pt

violeta/violet

A2

C1 Ca1

A2

III

azul/blue

negro/black

marrón/brown

azul/blue

gris/grey

4

Ts

T1

2

1

1

A

I

rojo/red

S

negro/black

marrón/brown

Ts Full storage bin stop

Iw Water low level float switch

Ps High pressure safety pressostat

R Gearmotor

Pt Motor thermal protection

Df Phase sequence relay

Ca1 Auxiliar contact gearmotor

marrón/brown

marrón/brown

C

A1 A2

RST

Ip

Components:

T1 Start timer

C1 Contactor (gearmotor)

C2 Contactor (compressor)

Pv Fan pressostat

V Fan

S Compressor

Ip On / O switch

12

Three Phases - IQ 2700

Ca1

3

1 L2 L3

L

A2

A1

T1

A1

C1

4

959796

A2

USER MANUAL IQ

II

Pv

L C

L

Ca2

3

4

azul/blue

T2 T3

S

rojo/red

T1

rojo/red

98

L1 L2 L3

979698

95

A2

A1

C2

V

azul/blue

T2 T3

negro/black

R

20/01/11 . 24/10

T1

negro/black

Pt

IV

L C

Ps

marrón/brown

1

11

12

T

rojo/red

14

1

marrón/brown

Iw

R S

DF

III

III

2

Ts

Ts

1

2

2

violeta/violet

violeta/violet

gris/grey

gris/grey

L C

Ps

marrón/brown

Ip

Ca2 Auxiliar contact feedback

L Electrical Interference Filter

I Thermic compressor

II Thermic gearmotor

III Yellow - full

IV Phase sequence

Ip

marrón/brown

II

Pv

L

C

L

Ca1

3

4

azul/blue

T2 T3

rojo/red

S

959796

A2

T1

rojo/red

98

I

azul/blue

L1 L2 L3

1

A2

A

T1

azul/blue

negro/black

marrón/brown

C

A1 A2

A1

C1

2

Ca

3

4

L1 L2 L3

959796

C2

A2

A1

V

azul/blue

T2 T3

negro/black

R

T1

negro/black

98

Ts Full storage bin stop

Iw Water low level float switch

Ps High pressure safety pressostat

R Gearmotor

Pt Motor thermal protection

Df Phase sequence relay

Ca1 Auxiliar contact gearmotor

Pt

RST

Ip

Components:

T1 Start timer

C1 Contactor (gearmotor)

C2 Contactor (compressor)

Pv Fan pressostat

V Fan

S Compressor

Ip On / O switch

13

Loading...

Loading...