Page 1

2008-2011MY

WORKSHOP MANUAL

GENERAL INFORMATION

Page 2

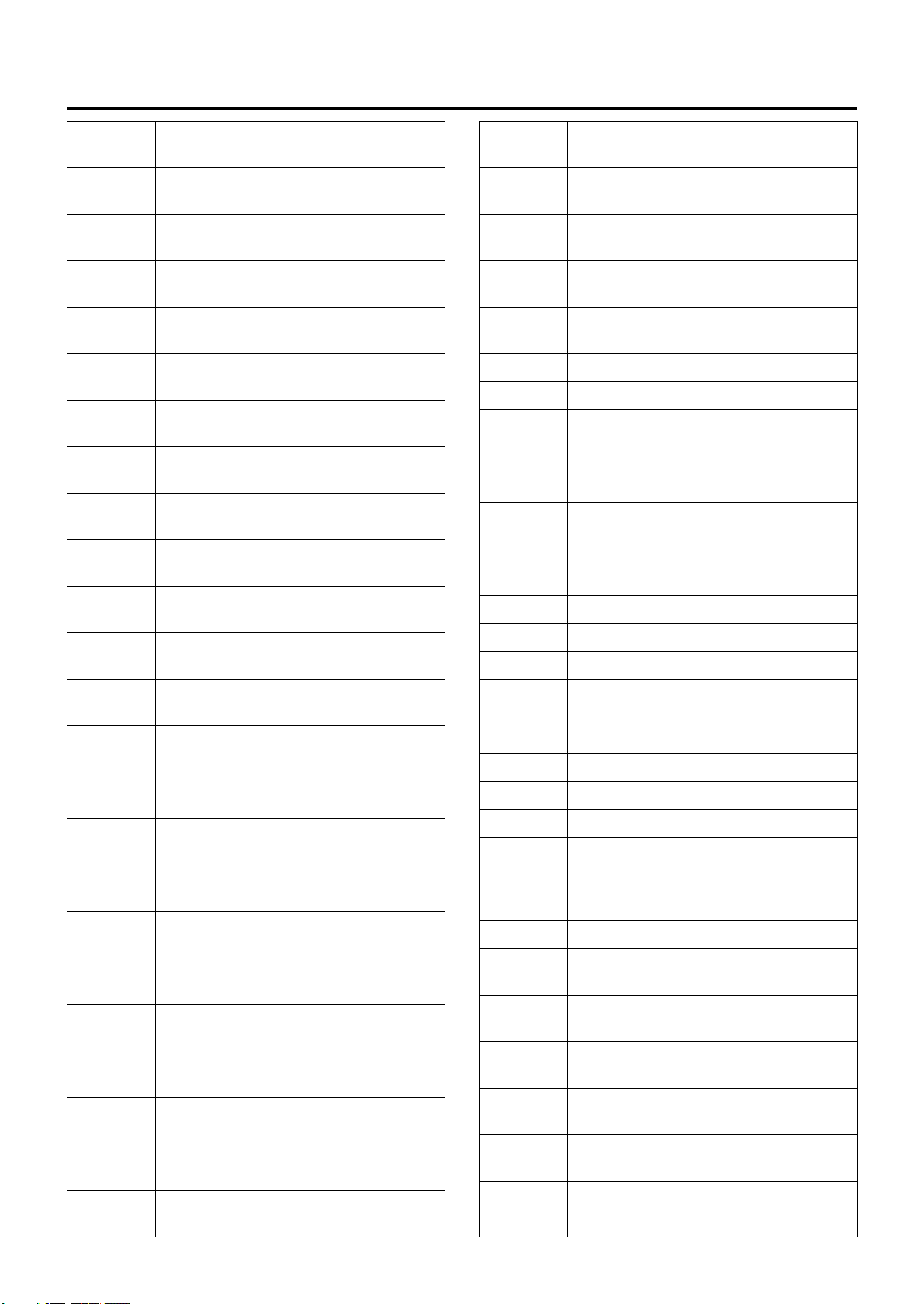

This Workshop Manual deals only with the screen toned section(s) in the table below.

Section Sub Section

0 GENERAL INFORMATION 0A General Information

1 ENGINE 1A Engine Control System

1B Engine Mechanical

1C Engine Cooling

1D Engine Fuel

1E Engine Electrical

1F Emission Control

1G Engine Exhaust

1H Engine Lubrication

1I Engine Speed Control System

1J Induction

1K Pre-Heating System

1L Power Take-Off (PTO)

2 SUSPENSION 2A1 Air Suspension Control System

2B Front Suspension

2C Rear Suspension

2D Wheel and Tire System

3 DRIVELINE/AXLE 3A1 Front Differential

3A2 Rear Differential

3C1 Propeller Shaft

3C2 Front Axle

3C3 Rear Axle

3D Transfer Case

4 BRAKES 4A2 Brake Control System (Air Over)

4A3 Brake Control System (Full Air)

4B2 Brake (Air Over)

4B3 Brake (Full Air)

4C Anti-Lock Brake (ABS)

4C1 Anti-Lock Brake (ABS)/Anti-Slip Regulator (ASR)

4D Parking Brake

4E Hill Start Aid (HSA)

4F Speed Retarder System

4G Trailer Brake

5 TRANSMISSION/TRANSAXLE 5A Transmission Control System

5B Automatic Transmission

5C Manual Transmission

5E Clutch

5G Power Take-Off (PTO)

5G1 Side Power Take-Off

6 STEERING 6B Power Steering

7 HVAC 7A Heating and Ventilation

7B Manual Air Conditioning

7C Automatic Air Conditioning

8 RESTRAINTS 8A Seat Belt

8B Supplemental Restraint System (SRS)

8C SRS Control System

9 BODY, CAB AND ACCESSORIES 9A Lighting System

9B Wiper/Washer System

9C Entertainment

9D Wiring System

9E Instrumentation/Driver Info.

9F Body Structure

9G Cab

9H Seats

9I Security and Lock

9K Exterior/Interior Trim

9L Cab Mounting

10 CONTROL SYSTEMS 10B Vehicle Control

11 FRAME AND FRAME ACCESSORIES 11A Frame

Page 3

Page 4

General Information 0A-1

GENERAL INFORMATION

General Information

TABLE OF CONTENTS

General Information . . . . . . . . . . . . . . . . . . . . . . . 0A-2

General Repair Instructions . . . . . . . . . . . . . . . 0A-2

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-3

Chassis Number/Engine Number Stamping

Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-3

Option Code List . . . . . . . . . . . . . . . . . . . . . . . . 0A-4

Vehicle Identification Number (VIN) . . . . . . . . 0A-11

General Precaution . . . . . . . . . . . . . . . . . . . . . . 0A-15

General Precautions . . . . . . . . . . . . . . . . . . . . 0A-15

Lifting Instruction . . . . . . . . . . . . . . . . . . . . . . . . 0A-17

Lifting Instruction . . . . . . . . . . . . . . . . . . . . . . . 0A-17

Caution for The Maintenance of Electrical Parts 0A-20

Battery Cable . . . . . . . . . . . . . . . . . . . . . . . . . 0A-20

Connector Handling Requirements . . . . . . . . . 0A-20

Handling Electronic Parts . . . . . . . . . . . . . . . . 0A-23

Cable Harness . . . . . . . . . . . . . . . . . . . . . . . . 0A-23

Regarding The Scan Tool. . . . . . . . . . . . . . . . . . 0A-25

Trouble Diagnosis Using The Scan Tool . . . . . 0A-25

Recommended Liquid Gasket . . . . . . . . . . . . . . 0A-31

Recommended Liquid Gasket. . . . . . . . . . . . . 0A-31

Recommended Thread Locking Agent. . . . . . . . 0A-33

Recommended Thread Locking Agent . . . . . . 0A-33

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . 0A-34

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-34

Maintenance Schedule

(for Euro4 specification except Europe) . . . . . 0A-35

Maintenance Schedule

(for Euro2, Euro3 specification). . . . . . . . . . . . 0A-41

Maintenance Schedule (for Europe) . . . . . . . . 0A-45

Maintenance Schedule

(CNG engine for Australia) . . . . . . . . . . . . . . . 0A-50

Maintenance Schedule

(CNG engine for Thailand) . . . . . . . . . . . . . . . 0A-54

Transmission Oil - ZF6S1000/ZF9S1110 Type 0A-58

Transmission Oil - FS8209A/FSO5206B Type 0A-65

RS23/RS40 Type Axle . . . . . . . . . . . . . . . . . . 0A-67

RS25 Type Axle . . . . . . . . . . . . . . . . . . . . . . . 0A-68

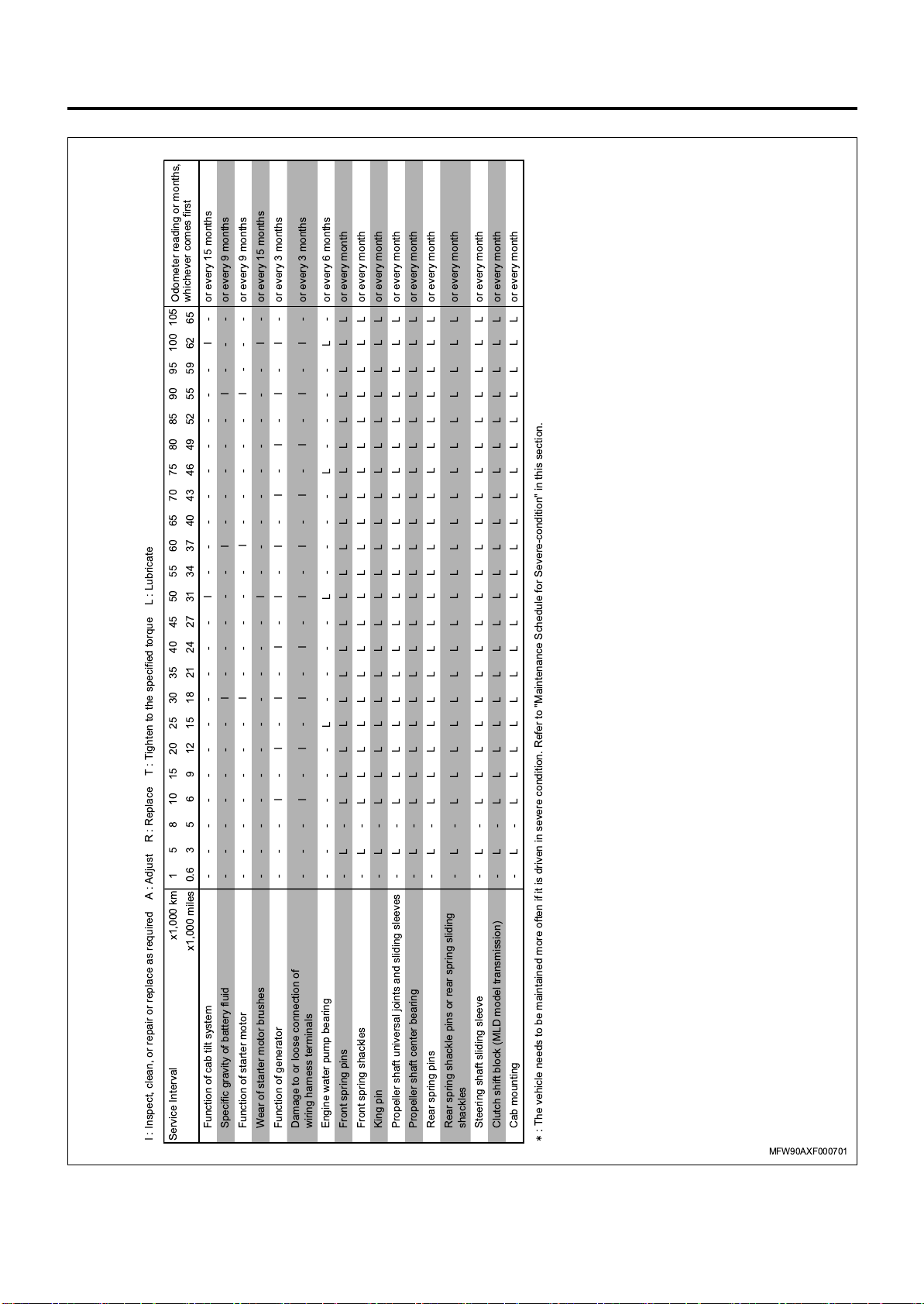

Maintenance Schedule for Severe-condition . . . 0A-69

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-69

Maintenance Schedule for Severe-condition . 0A-69

Recommended Fluids, Lubricants and

Diesel Fuels (except Europe). . . . . . . . . . . . . . . 0A-73

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-73

Diesel Engine Crankcase with DPD

(Low Ash Oil). . . . . . . . . . . . . . . . . . . . . . . . . . 0A-73

Diesel Engine Crankcase without DPD. . . . . . 0A-74

CNG Engine Crankcase (for Australia) . . . . . . 0A-74

CNG Engine Crankcase (for Thailand) . . . . . . 0A-74

Manual Transmission (MZX/MZW/MLD

models), Transfer Case, Differential

(without LSD) and Oil Lubricated Hub

Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-75

Manual Transmission (MZZ models). . . . . . . . 0A-75

Differential (with LSD) . . . . . . . . . . . . . . . . . . . 0A-75

Smoother Clutch Oil (Smoother) . . . . . . . . . . . 0A-75

Automatic Transmission, Power Steering . . . . 0A-76

Center Bearing, Clutch Shift Block,

Grease Lubricated Hub, Water Pump,

Propeller Shaft Sliding Yoke, Universal

Joint (Multi Purpose Grease) . . . . . . . . . . . . . 0A-76

Multi-Purpose Grease Containing

Molybdenum . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-76

Engine Cooling System . . . . . . . . . . . . . . . . . . 0A-76

Electric-hydraulic Cab Tilt Pump . . . . . . . . . . . 0A-77

Clutch and Brake Fluid Reservoir . . . . . . . . . . 0A-77

Diesel Fuel / Applicable Standard . . . . . . . . . . 0A-77

Diesel Fuel / Applicable Standard

(Sulfur content below 50 ppm) . . . . . . . . . . . . 0A-78

Recommended Fluids, Lubricants and

Diesel Fuels (for Europe) . . . . . . . . . . . . . . . . . . 0A-79

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-79

Diesel Engine Crankcase with DPD

(Low Ash Oil). . . . . . . . . . . . . . . . . . . . . . . . . . 0A-79

Diesel Engine Crankcase without DPD. . . . . . 0A-79

Manual Transmission (MZX/MZW/MZZ/MLD

models), Differential (without LSD) and Oil

Lubricated Hub Bearing . . . . . . . . . . . . . . . . . 0A-80

Differential (with LSD) . . . . . . . . . . . . . . . . . . . 0A-80

Smoother Clutch Oil (Smoother) . . . . . . . . . . . 0A-80

Power Steering . . . . . . . . . . . . . . . . . . . . . . . . 0A-80

Center Bearing, Clutch Shift Block,

Grease Lubricated Hub, Water Pump,

Propeller Shaft Sliding Yoke, Universal

Joint (Multi Purpose Grease) . . . . . . . . . . . . . 0A-81

Engine Cooling System . . . . . . . . . . . . . . . . . . 0A-81

Electric-hydraulic Cab Tilt Pump . . . . . . . . . . . 0A-81

Clutch and Brake Fluid Reservoir . . . . . . . . . . 0A-82

Diesel Fuel / Applicable Standard . . . . . . . . . . 0A-82

Diesel Fuel / Applicable Standard

(Sulfur content below 50 ppm) . . . . . . . . . . . . 0A-82

Oil Viscosity Chart . . . . . . . . . . . . . . . . . . . . . . . 0A-83

Oil Viscosity Chart . . . . . . . . . . . . . . . . . . . . . . 0A-83

Lubrication Chart . . . . . . . . . . . . . . . . . . . . . . . . 0A-84

Lubrication Chart . . . . . . . . . . . . . . . . . . . . . . . 0A-84

Greasing Point . . . . . . . . . . . . . . . . . . . . . . . . . . 0A-97

Greasing Point . . . . . . . . . . . . . . . . . . . . . . . . 0A-97

Page 5

0A-2 General Information

General Information

General Repair Instructions

1. Park the vehicle on level ground and chock the

front or rear wheels before lifting the vehicle.

2. Use covers on the vehicle body, seats, and floor to

prevent damage and/or contaminations.

3. Disconnect the grounding cable from the battery

before performing service operations.

This will prevent cable damage or burning due to

shortcircuiting.

4. Raise the vehicle with a jack set against the axle or

the frame.

5. Support the vehicle on chassis stands.

6. Handle brake fluid and antifreeze solution with

great care.

Spilling these liquids on painted surfaces will

damage the paint.

7. The use of the proper tool(s) and special tool(s)

where specified is efficient, reliable, and safe

service operations.

8. Always use genuine ISUZU replacement parts.

9. Discard used cotter pins, gasket, O-rings, oil seals,

lock washers, and self-locking nuts at disassembly.

Normal function of these parts cannot be

guaranteed if they are reused.

10. Keep the disassembled parts neatly in groups.

This will facilitate smooth and correct reassembly.

11. Keep fixing nuts and bolts separate.

Fixing nuts and bolts vary in hardness and design

according to installation positions.

12. Clean all parts before inspection or reassembly.

13. Clean the oil ports and other openings with

compressed air to make certain that they are free

of dirt and obstructions.

14. Lubricate the rotating and sliding faces of all

moving parts with oil or grease before installation.

15. Use the recommended liquid gasket to prevent

leakage.

16. Be sure to tighten nuts and bolts to the specified

torque, using a properly maintained torque wrench.

17. When service operation is completed, male a final

check to be sure service has been done properly

and problem has been corrected.

18. When removing or replacing parts that require

refrigerant to the discharged from the Air

conditioning system, be sure to use the ACR4 or

equivalent to recover and recycle Refrigerant 134a (HFC-134a), to promote the movement for

the protection of the ozone layer covering the

earth.

19. To assure safety, always slowly release air

pressure from the air tanks before disconnecting

pipes, hoses or other parts from any unit under

pressure.

20. Prior to start the welding work, the following

operations are required:

• Disconnect all connectors of electronic control

unit.

• Disconnect battery ground terminal.

• Welding machine ground cable must be

connected near the welding point.

• Turn off the all switches.

Page 6

Identification

General Information 0A-3

Chassis Number/Engine Number Stamping Position

Chassis number

It is stamped on the front right-hand side face of the

chassis side member.

MFW70ASH000101

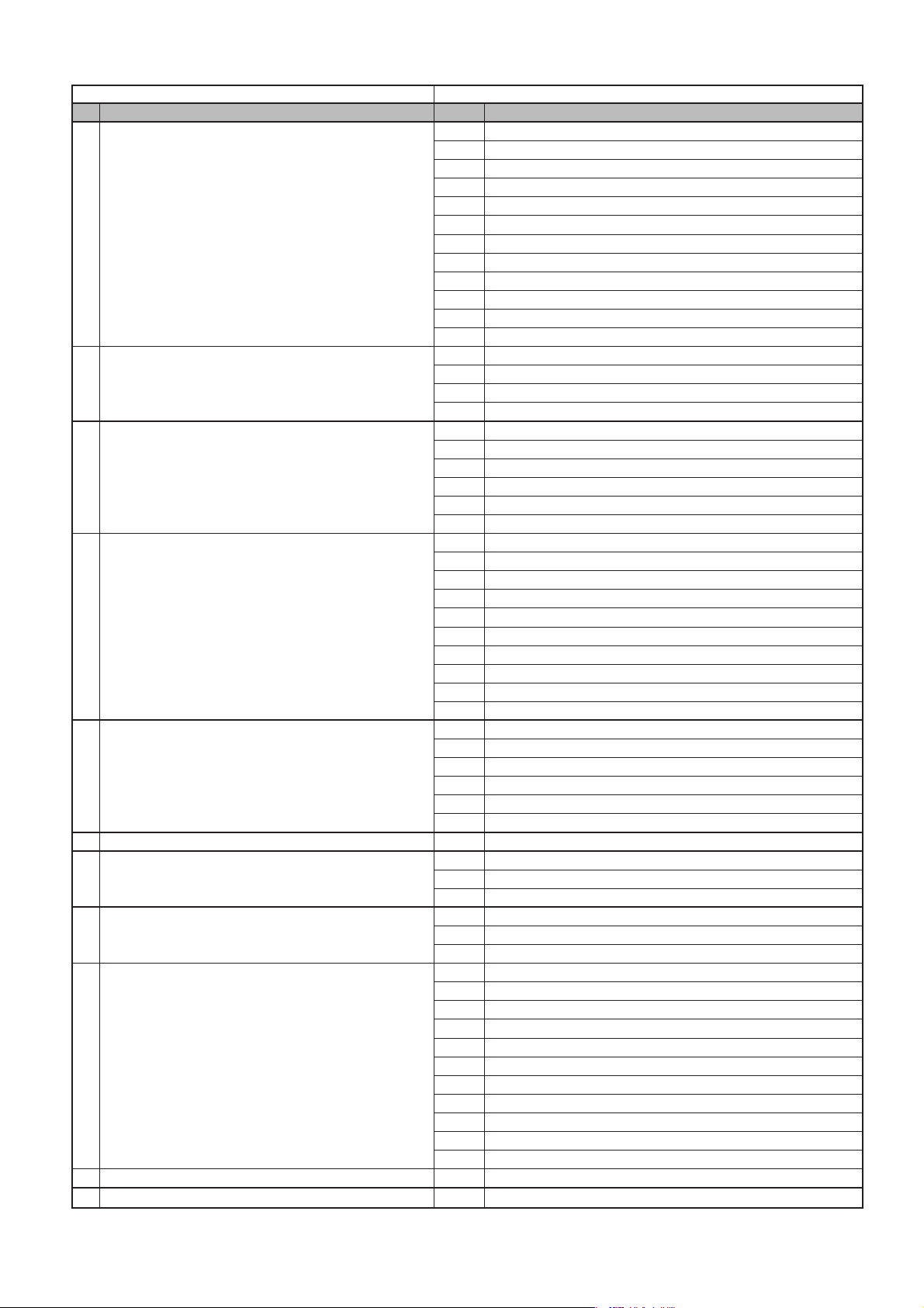

Engine number (4HK1 Engine)

The engine number is stamped on the right side of the

cylinder body.

Engine number (6HF1 Engine)

The engine number (1) is stamped on the right side of

the cylinder body.

1

MFW90ASH000101

Engine number (6HK1 Engine)

The engine number is stamped on the right side of the

cylinder body.

LNWB0ASH000101

MFW80ASH000401

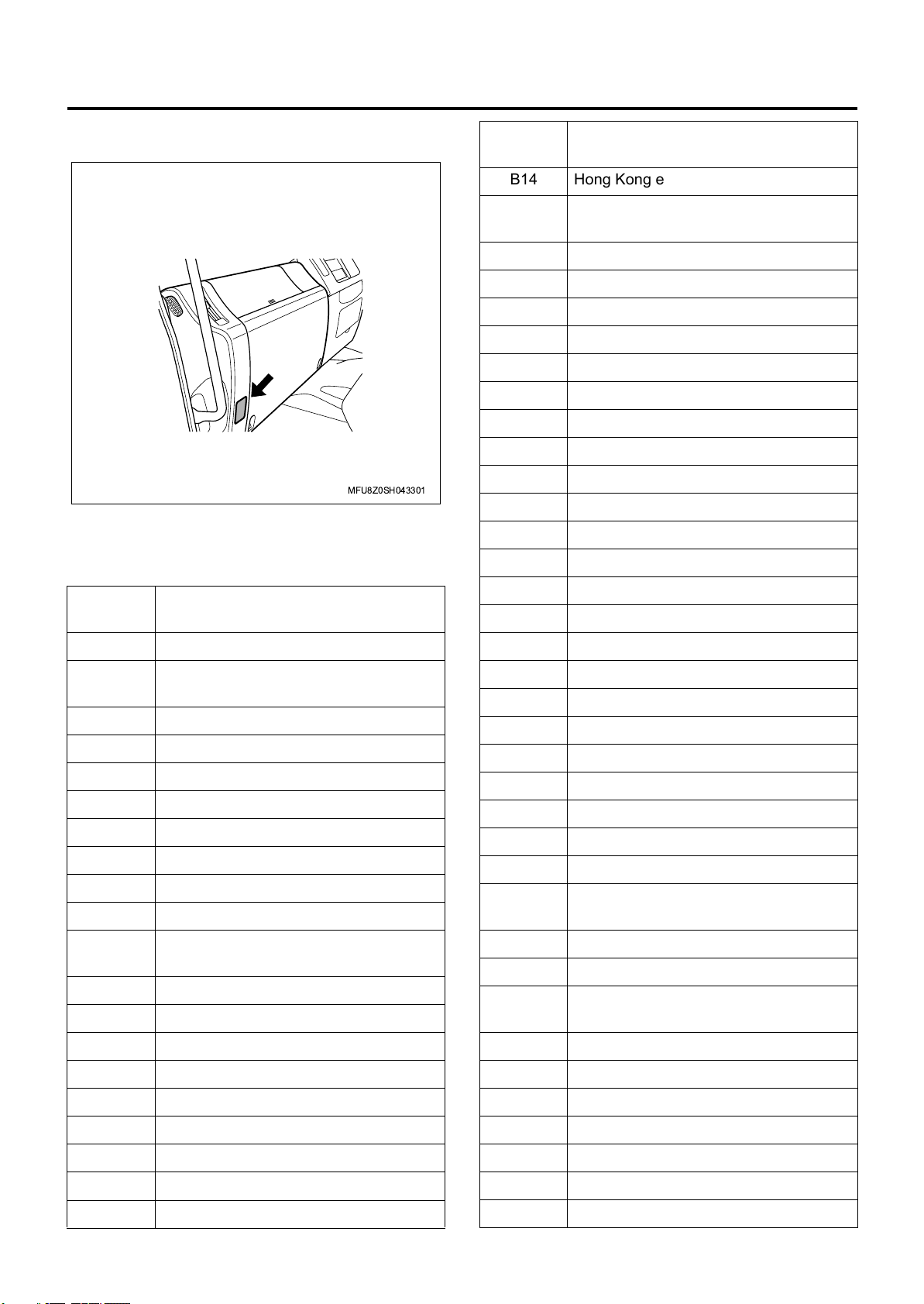

Service Parts ID Plate

The service parts ID plate is attached to the passenger

side lower dashboard.

The service parts ID plate has the following information;

• Vehicle identification number (VIN)

• Wheelbase dimensions

• Paint information

• Production options or special equipment installed

on the vehicle at the factory

Page 7

0A-4 General Information

Refer to the service parts ID plate when ordering

replacement parts.

MFU8Z0SH043301

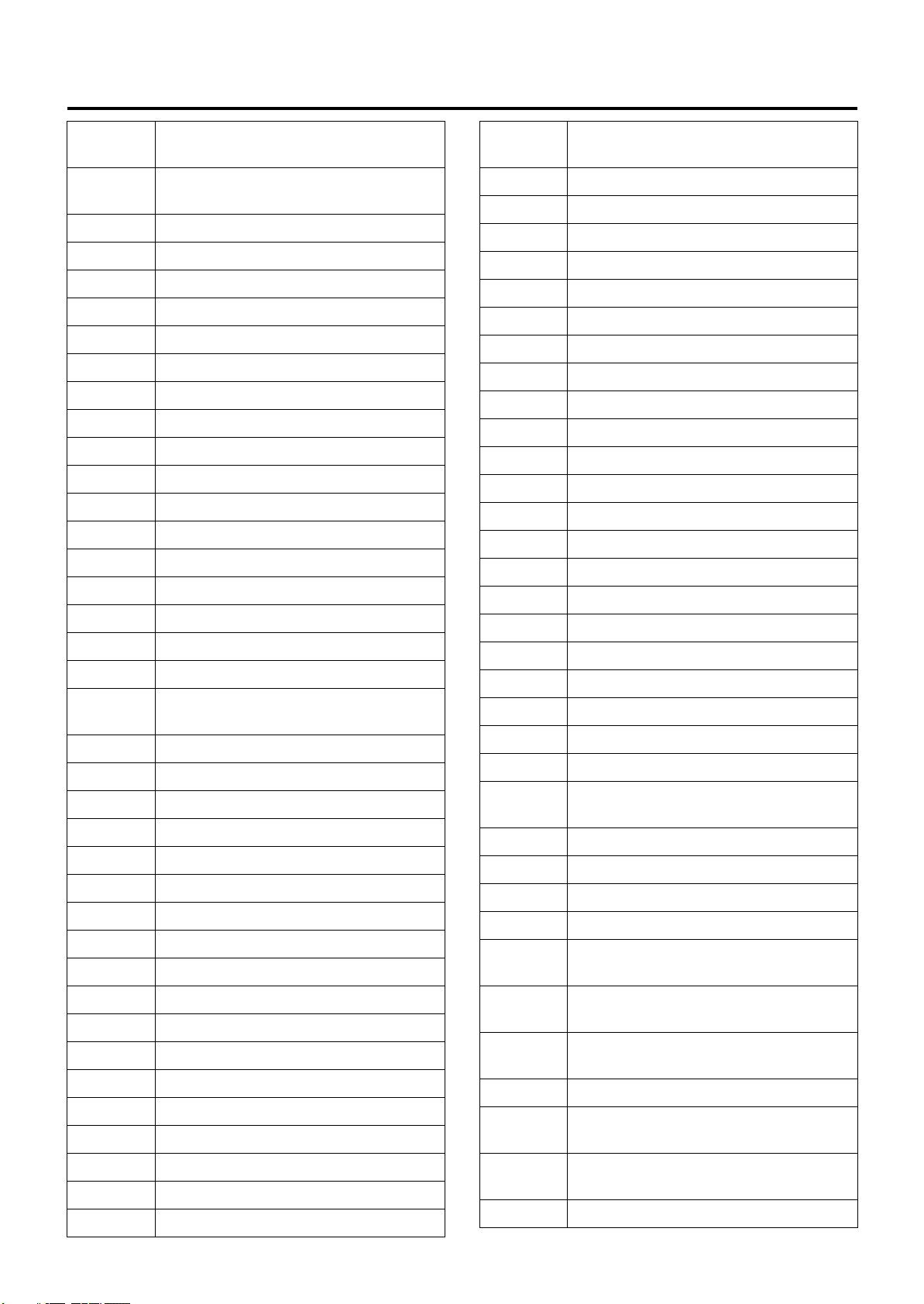

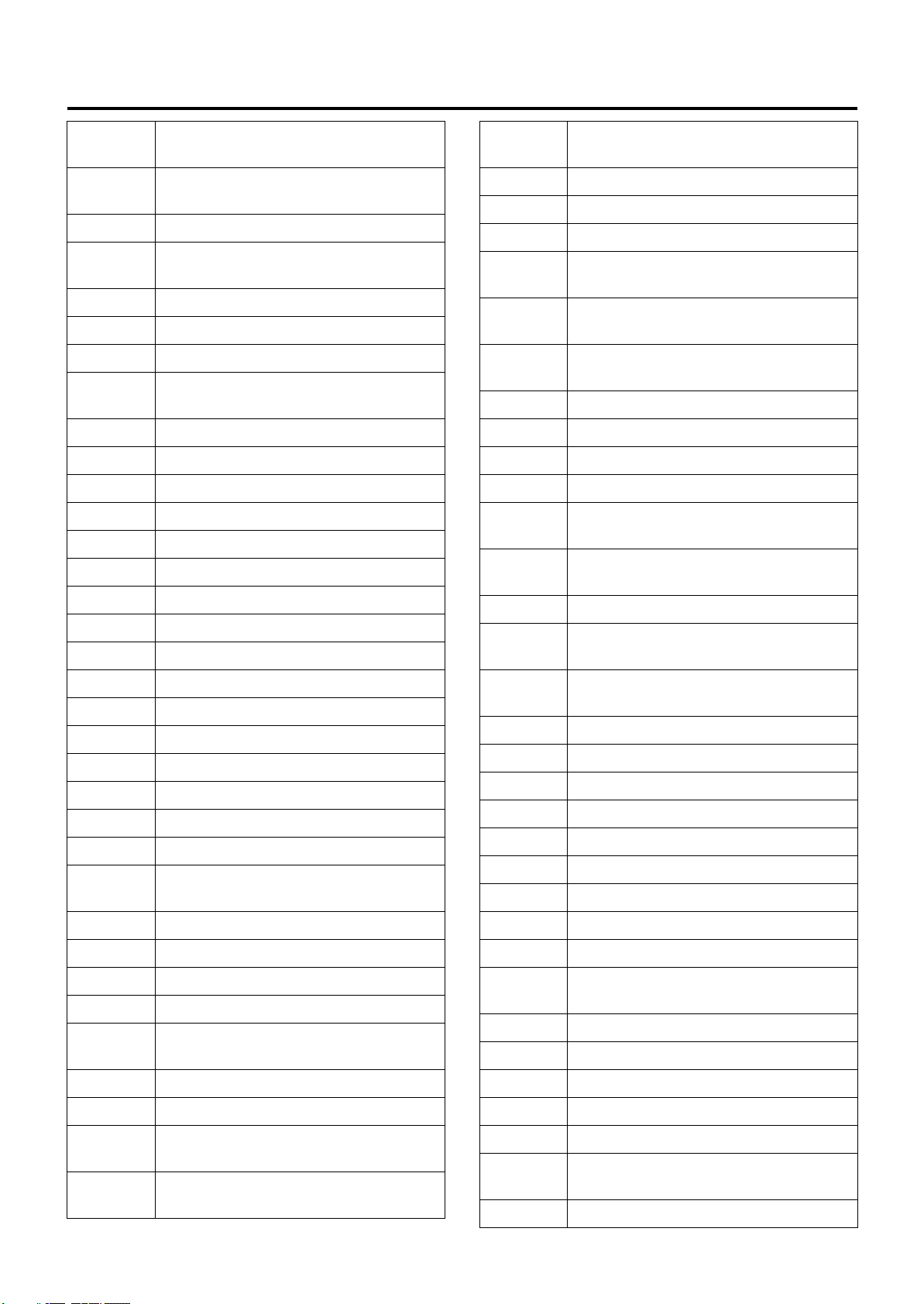

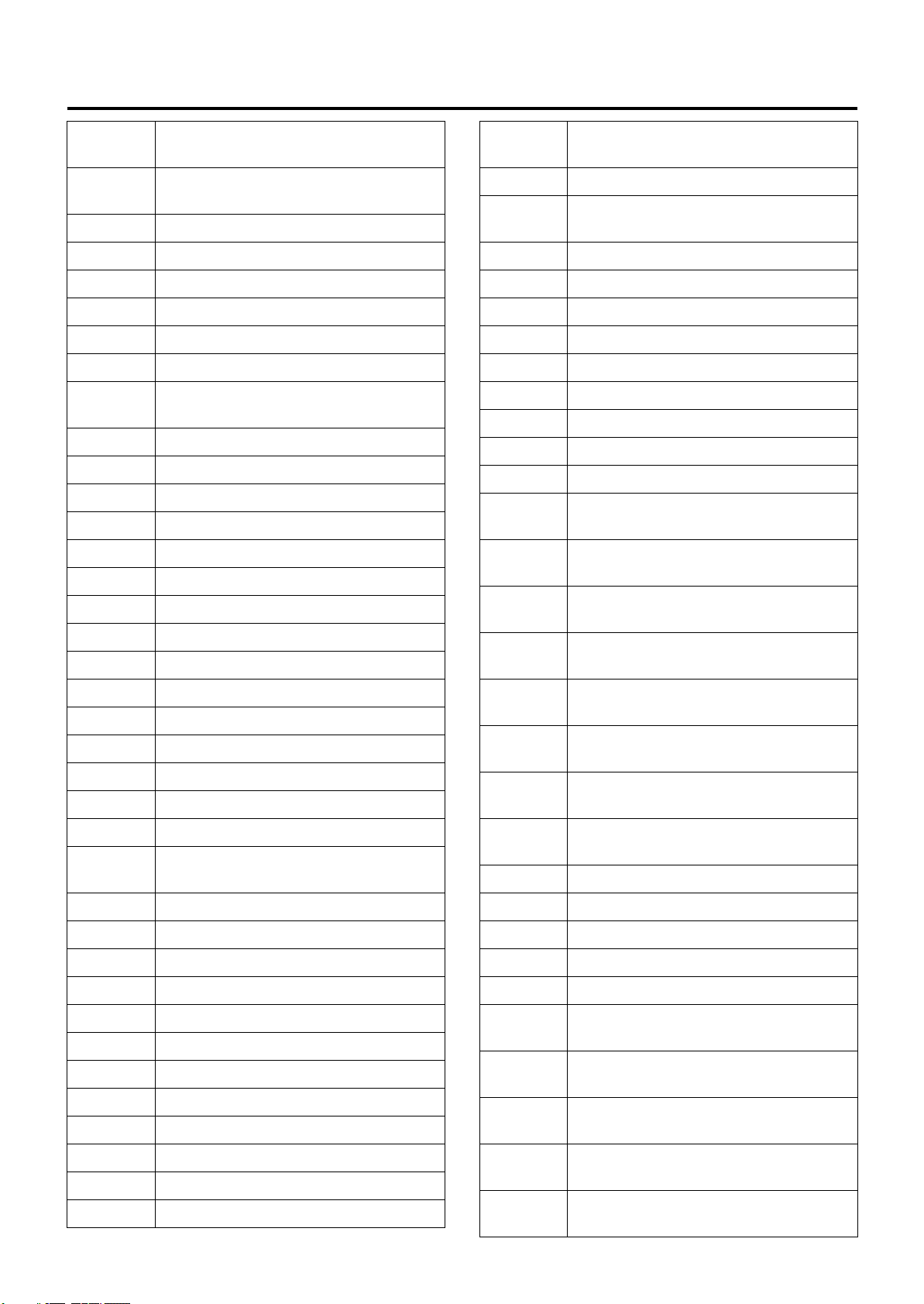

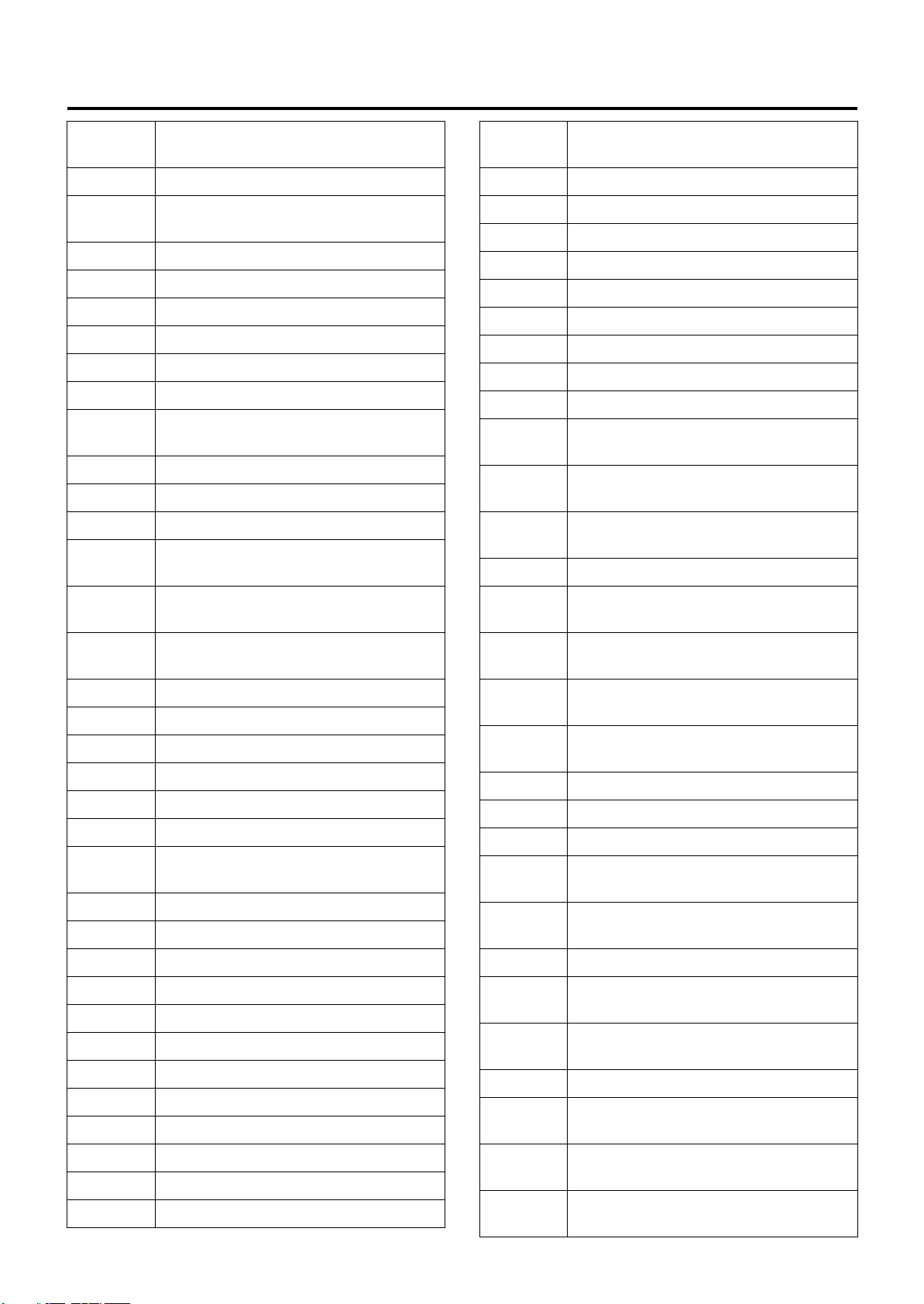

Option Code List

Option

Code

B14 Hong Kong equipment

B3A

B30 Floor carpet - vinyl

B84 Body side molding

CB7 Colombia equipment

CE4 Head lamp washer

CGA Morocco equipment

CJ6 Country - Ireland

CK1 Pakistan equipment

CL1 Kenya equipment

CT6 Country - Italy

CU9 Country - United Kingdom

CV4 Country - Israel

CX6 Country - New Zealand

Rear wheel parking brake - air

control

Option Description

Option

Code

AJ3 Driver side air bag

AK3

AK5 Driver and passenger side air bag

AU4 Automatic door lock

A31 Power window - front & rear door

A32 Power window - front door

A56 Driver seat - air suspension

A83 Vinyl seat with reclining

BDM Power take off - transmission rear

BFK Transfer TF56

BHW

BJR Brake adjuster - manual

B02 South Africa equipment

Front seat belt & shoulder

with retractor

Power take off - engine rear,

electromagnetic clutch

Option Description

C13 Wiper with intermittent

C2C Transmission oil cooler

C2M Propeller shaft - P60 type

C3N Final differential lock

C3U Air suspension - high control

C4M Air breather with flex hose

C4Z Propeller shaft - P46 type

C41 Heater & defroster

C5K Hub lubrication - oil bath

C5T Propeller shaft - P90 type

C60 Manual air conditioning

C65

C68 Automatic air conditioning

DH2 O/S rear view mirror - long arm

DL8

Manual air conditioning

without heater core

O/S rear view mirror - remote control

with heated

B03 Thailand equipment

B04 Taiwan equipment

B1S Parking brake drum - 8.5 inch

B1T Parking brake drum - 10 inch

B10 Malaysia equipment

B12 Russia equipment

B13 Australia equipment

DNB O/S rear view mirror - pillar mounted

D20 Assist side sun visor

D31 Rear view mirror

D37 Mirror - Outside rear view

D6M User - export government

D8T Iran equipment

D94 Touch-up paint

Page 8

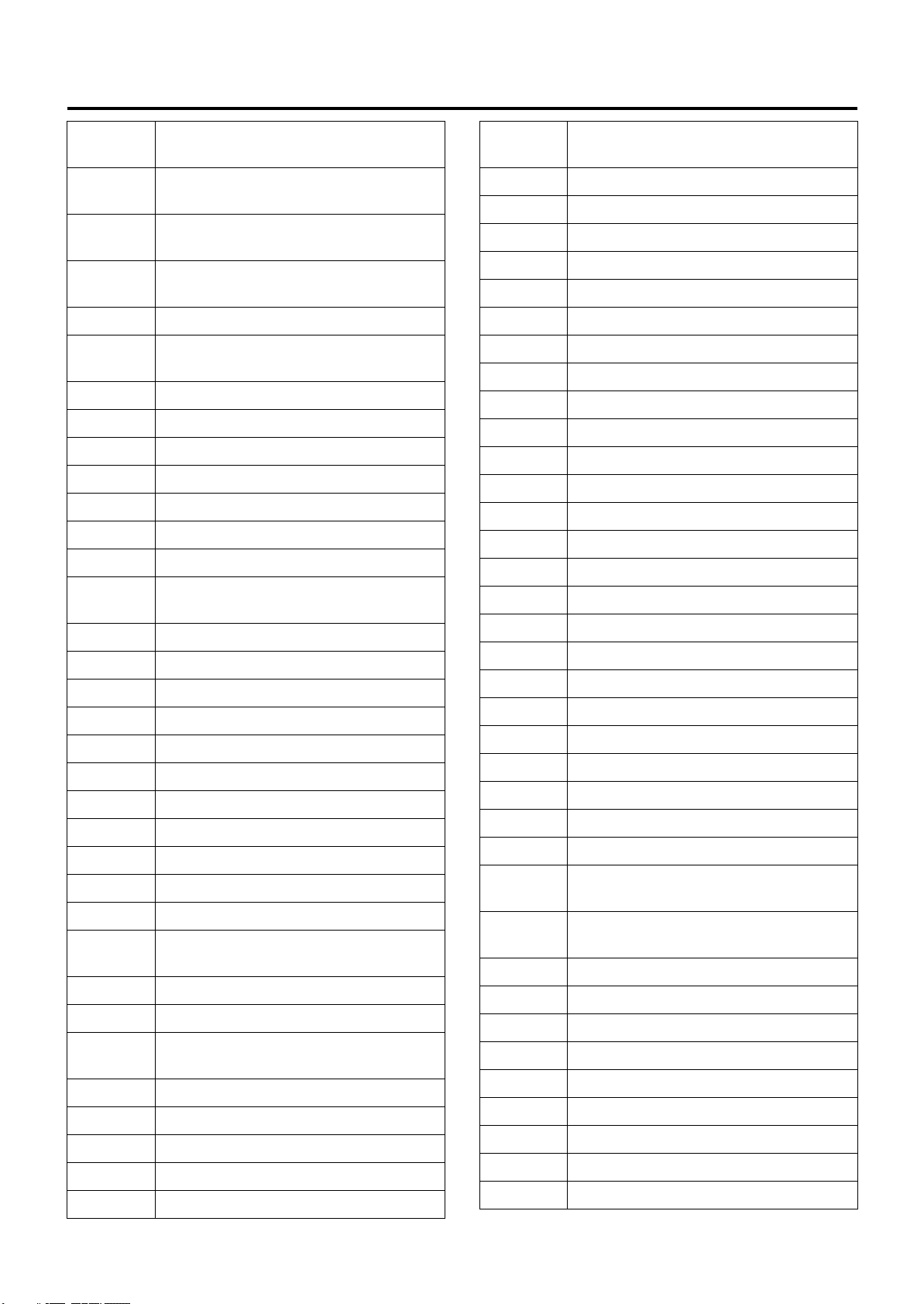

General Information 0A-5

Option

Code

EAK

EBB Digital tachograph

EBE Front under run protector

ECF Speed limiter - 60km/h

ECY Speed limiter - 70km/h

EDG Header console - driver & assist

EDH Round curtain rail

EDW Speed limiter - 80km/h

EDX Speed limiter - 85km/h

EFE Regulation ECE R29

EFK Floor mat - vinyl mat Var.2

E09 Europe equipment

E11 Mexico equipment

E13 New Zealand equipment

E2N Fuel pipe - steel

E29 Auxiliary steps

E40 Sleeper cab with mattress

E46 Ecuador equipment

FJC

F59 Front stabilizer

GH3 Saudi Arabia equipment

GL6 Rear shock absorber

GN1 Rear stabilizer

G86 Limited slip differential - no spin

JAQ Lighting system - Saudi Arabia

JBF Tire - KD special

JBZ Lighting system - Japanese standard

JCA Anti-noise equipment - ECE R51.02

Disc wheel - 6 studs 19.5x6.75

(136-12)

Disc wheel - 10 studs 20x8.50V

(138-13)

Option Description

Option

Code

K30 Auto cruise

K44 Generator 24V-90A

K89 Generator 24V-50A

M9A Owners manual - Not required

NCR Memory system - Runnig condition

NF7 Fuel tank 200L + 200L

NJW Ireland KD special

NMJ Speed limiter - 90km/h

NMU Speed limiter - 100km/h

NNR 3 speaker system

NT2 Emission system - Euro2

NT3 Emission system - Euro3

NT4 Emission system - Euro4

N02 Fuel tank 100L - frame side mount

N05 Fuel tank cap with key lock

N19 Fuel tank - 140L frame side

N20 Fuel tank 200L - frame side mount

N79 Spare disc wheel

PM1 Rear hook - double

PP7 Pintle hook

PR2 Driving position - wide leg space

PS7 Air dryer

PT1

PT6 Thailand KD special

P10 Spare tire carrier - frame rear mount

P13 Spare tire carrier - frame side mount

P38 Tire delete

QM8

Disc wheel - 8 studs 22.5x6.75

(145-11)

Disc wheel - 10 studs 22.5 x 8.25

(165-13)

Option Description

JDN Compartment - I/P assist side with lid

JDP Compartment - I/P assist side without lid

JE5 Anti-lock brake system

J55 Brake system - heavy duty Var.1

J91 Trailer brake control

KC5 Receptacle - accessory

KE1 Chile equipment

KF0 Fuel filter - low quality

KG2 Generator 24V60A

Q47

Q87

Q5T Turbo - conventional

Q50

Q54

Q58 Disc wheel - 10 studs 20x7.00T

Disc wheel - 8 studs 20x6.50T

(145-10)

Disc wheel - 10 studs 22.5x7.50

(162-12)

Disc wheel - 8 studs 20x6.50T

(152-11)

Disc wheel - 8 studs 20x7.00T

(162-12)

Page 9

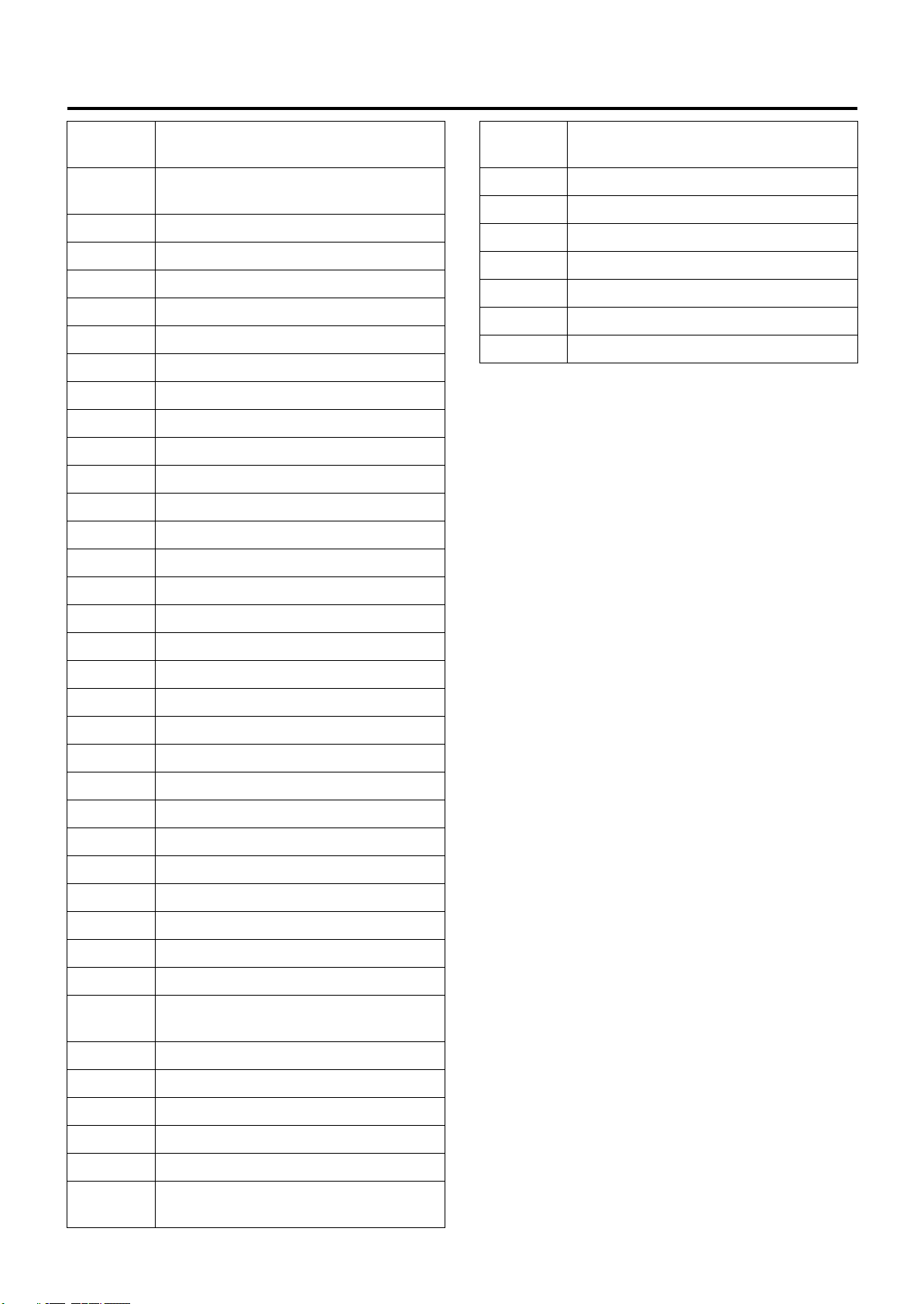

0A-6 General Information

Option

Code

Q62

Q64 Disc wheel - 10 studs 20 x 7.50V

Q87

RC4 Dump control lever

RC5 Tool box with key lock

RE3 Spare tire fixing

RE9

RDV 4HK1-TCC engine

RJS 4HK1-TCS engine

RQZ G.V.W. - 8.0-11.0 ton

RRA G.V.W. - 11.0-14.0 ton

RR9 O/S rear view mirror - under

RSA Manual transmission - MZZ6W

RSW Manual transmission - MZX6P

RSZ Manual transmission - MZW6P

RWE Chevrolet brand

Disc wheel - 8 studs 20x7.50V

(165-13)

Disc wheel - 10 studs 22.5x7.50

(162-12)

Clutch - 15 inch single plate

strap drive

Option Description

Option

Code

SDF Room lamp with all door switch

SDH Fuel tank 400L

SDK Cab suspension - semi floating type

SDP

SEG

SFC

SFT Electric outlet - one

SGA Front under spoiler delete

SGX Vietnam equipment

SG4 Tire inflator device

SG7

SH5

SJA Driver seat - Isringhausen

SKU

Disc wheel - 8 studs 20x7.00T

(152-12)

Disc wheel - 8 studs 205x7.50V

(130-13)

Disc wheel - 6 studs 17.5x6.75

(137-10)

Disc wheel - 6 studs 16x6.00GS

(135-9)

Power take off - transmission side

without lever

Disc wheel - 8 studs 22.5x7.50

(162-13)

Option Description

R32 KD frame

R46 Spare tire & disc wheel

R9A Service cab with electric

R9B Service cab without electric

R9C Deletion - service cab with electric

R9D Deletion - service cab without electric

R9E Service cab conversion with electric

R9F

R9Z Thailand localization spec.

SAQ Front suspension - multi leaf spring

SAR Front suspension - taper leaf spring

SAS Rear suspension - multi leaf spring

SAU

SAY Standard cab

SAZ Ventilator & defroster

Deletion - service cab conversion

without electric

Rear helper suspension - taper leaf

spring

SKV

SK4 Engine overrun buzzer

SLB Front bumper with headlamp

SLC Lighting system - ECE

SLK Anti-noise equipment - ECE

SMS Rear bumper - steel wide

SP9 Assist seat without center seat

SR6 Rearward double tire

SV6 Power take off control

SY8 Spare tire carrier - lifting type

TAF

TAK Anti-noise equipment - Var.2

TAZ Driver seat - rigid without arm rest

TDU Brake regulation - ADR

TDV Brake regulation - ECE

Disc wheel - 8 studs 22.5 x 8.25

(165-13)

O/S rear view mirror - under & side

under

SBB

SBG

Disc wheel - 8 studs 20x6.00S

(135-10)

Disc wheel - 6 studs 17.5x6.00

(135-9)

TEC Roof marker lamp

TEE

TFD Cab all painting

Disc wheel - 8 studs 19.5x6.75

(147-12)

Page 10

General Information 0A-7

Option

Code

TFN

TGL Anti corrosion package

TM1 Battery - 80D26L

TR6 Headlamp leveling system - manual

TR7 Headlamp leveling system - automatic

TT5 Halogen headlamp

TT6 High intensity discharge headlamp

T1A

T62 Battery - dry

T64 Battery delete

T79 Rear fog lamp

T87 Cornering lamp

T96 Front fog lamp

UC1 Speedometer - miles per hour (MPH)

UC9 Tachograph- Kienzle

UF3 Map lamp

UG3 Engine oil temperature gauge

Driver’s seat belt with pre-tension

reducer

Injection pump Q set - special

+5%Q

Option Description

Option

Code

WC7 Tachograph - 140km/h

WF6

WG3 Brake system - heavy duty Var.2

WH2 Spare tire - front tire

WJ7 Cautions - Arabian

WJ8 Cautions - French

WL5 Inspection lamp

WM3 Interior trim - full trimming

WV2 Automatic cab tilt

WX8 Shift control - assister

W02 Highland zone package

W1G

W1H

W1J

W1K

Clutch - 14 inch single plate

strap drive

Final drive gear ratio - 6.143 (43/7)

14.5 inch hypoid

Final drive gear ratio - 5.571 (39/7)

14.5 inch hypoid

Final drive gear ratio - 6.500 (39/6)

14.5 inch hypoid

Final drive gear ratio - 6.833 (41/6)

14.5 inch hypoid

Option Description

UL5 Radio delete

UT3 AM/FM radio with CD player

U01 Roof marker - 5 lamps

U18 Speedometer - kilometer

U69 AM/FM radio

U95 2 speaker system

VG7

VP1 Front under spoiler

VR7 Two eye rear hook

VTK Owners manual - Arabic language

VTL Owners manual - French language

VTS Owners manual - Spanish language

VT7 Owners manual - English language

VZA VIN model year - 2010

VZB VIN model year - 2011

V22 Radiator grille - chrome

Front bumper reinforcement

- heavy duty

W1L

W1R

W1T

W1U

W12 Front locking hub - manual

W14 Deluxe cab

W16 Cab suspension - full floating

W18 Transfer TF36

W20 Disc wheel special painted (white)

W3B

W3D

W3F

Final drive gear ratio - 6.500 (39/6)

16.5 inch hypoid

Final drive gear ratio - 6.143 (43/7)

15.5 inch hypoid

Final drive gear ratio - 6.500 (39/6)

15.5 inch hypoid

Final drive gear ratio - 4.875 (39/8)

14.5 inch hypoid

Final drive gear ratio - 5.571 (39/7)

16.5 inch hypoid

Final drive gear ratio - 4.875 (39/8)

18.5 inch hypoid

Final drive gear ratio - 6.167 (37/6)

18.5 inch hypoid

V4F Chassis for fire car

V76 Hook - tow

WB7 Electrical horn

W3G

W3K

Final drive gear ratio - 6.667 (40/6)

18.5 inch hypoid

Final drive gear ratio - 5.571 (39/7)

15.5 inch hypoid

Page 11

0A-8 General Information

Option

Code

W3L

W3M

W3N

W3P

W3S

W3U

W3X

W3Y

W3Z

W4A

W4B

Option Description

Final drive gear ratio - 6.143 (43/7)

16.5 inch hypoid

Final drive gear ratio - 5.125 (41/8)

18.5 inch hypoid

Final drive gear ratio - 4.556 (41/9)

18.5 inch hypoid

Final drive gear ratio - 5.125 (41/8)

16.5 inch hypoid

Final drive gear ratio - 5.857 (41/7)

15.5 inch hypoid

Final drive gear ratio - 7.167 (43/6)

17.5 inch hypoid

Final drive gear ratio - 6.429 (45/7)

17.5 inch hypoid

Final drive gear ratio - 6.143 (43/7)

17.5 inch hypoid

Final drive gear ratio - 5.571 (39/7)

17.5 inch hypoid

Final drive gear ratio - 5.125 (41/8)

17.5 inch hypoid

Final drive gear ratio - 4.875 (39/8)

17.5 inch hypoid

Option

Code

W6M

W6N

W6R

W6S

W66 Disc wheel with step

W71 Cab suspension - rigid type

W8C

W8D

W8F

W8L

X5J Manual transmission - MLD6Q

X7W Manual transmission - MLD6S

X9C Transmission - manual

Final drive gear ratio - 6.43 (45/7)

18.0 inch hypoid Rockwell

Final drive gear ratio - 6.83 (41/6)

18.0 inch hypoid Rockwell

Final drive gear ratio - 4.30 (43/10)

18.0 inch hypoid Rockwell

Final drive gear ratio - 6.14 (43/7)

15.0 inch hypoid Rockwell

Final drive gear ratio - 4.56 (41/9)

18.0 inch hypoid Rockwell

Final drive gear ratio - 6.43 (45/7)

15.0 inch hypoid Rockwell

Final drive gear ratio - 4.555 (41/9)

14.5 inch hypoid

Final drive gear ratio - 6.83 (41/6)

15.0 inch hypoid Rockwell

Option Description

W4C

W4F

W4H

W4T

W4W

W4X

W5M

W5V

W5Z

W6A

W6B

W6C

Final drive gear ratio - 4.556 (41/9)

17.5 inch hypoid

Final drive gear ratio - 5.125 (41/8)

14.5 inch hypoid

Final drive gear ratio - 5.125 (41/8)

15.5 inch hypoid

Final drive gear ratio - 4.333 (39/9)

18.5 inch hypoid

Final drive gear ratio - 6.833 (41/6)

17.5 inch hypoid

Final drive gear ratio - 4.333 (39/9)

14.5 inch hypoid

Final drive gear ratio - 4.100 (41/10)

14.5 inch hypoid

Final drive gear ratio - 6.833 (41/6)

16.5 inch hypoid Rockwell

Final drive gear ratio - 4.89 (44/9)

18.0 inch hypoid Rockwell

Final drive gear ratio - 5.38 (43/8)

18.0 inch hypoid Rockwell

Final drive gear ratio - 5.63 (45/8)

18.0 inch hypoid Rockwell

Final drive gear ratio - 6.14 (43/7)

18.0 inch hypoid Rockwell

X9D Transmission - automatic

YC4

YK3 Rearward single tire

YM9 Reversing warning buzzer

YN1 Caution - Spanish

YS1 O/S rear view mirror - flat type

YT9 Pakistan KD special

Y2C Manual transmission - MLD6W

Y21 Light duty package truck

Y3A

Y3B

Y4F

Y4G

Y4V

Y48 Heavy duty package truck

Y5D Manual transmission - ZF 6S1000

Injection pump - high altitude

compensator, aneroid type

Manual transmission

- Fuller FS8209

Automatic transmission

- Allison MD3560P

Automatic transmission

- Allison LCT2000

Automatic transmission

- Allison MD3060P

Manual transmission

- Fuller FSO5206B

Page 12

General Information 0A-9

Option

Code

Y5E Manual transmission - ZF 9S1110

Z05

Z06 Brake system - full air dual circuit

Z1V Equipment - additional key

01D KD package - South Africa

01R Tire - front & rear 8.25-20-14 lug

02E KD package - Taiwan

05R Tire - front & rear 8.25R20-14 rib

09X

1D7 6HF1-TCN engine

1D9 6HF1-TCC engine

10T Tire - front & rear 9.00-20-14 rib

10X

Brake system - air over hydraulic

dual circuit

Tire - front 8.25-20-14 rib,

rear 8.25-20-14 lug

Tire - front 9.00-20-14 rib,

rear 9.00-20-14 lug

Option Description

Option

Code

42W Wheel base 4,200mm

43P Tire - front & rear 9R22.5-14

43W Wheel base 4,300mm

45N Tire - front & rear 11R22.5-14 rib

45P Tire - front & rear 275/70R22.5

45R Tire - front & rear 10.00R20-14 rib

46W Wheel base 4,600mm

48W Wheel base 4,800mm

49W Wheel base 4,900mm

49P

5D9

5E0

5E1 Tire - front & rear 10R22.5-14

Tire - front & rear 8.25R20-14

exp block

Tire - front & rear

295/80R22.5-152/148K rib/lug

Tire - front & rear

295/80R22.5-152/148J rib

Option Description

11X

12X

15N Tire - front & rear 9R22.5-14 rib

155 Interior color - Charcoal gray

2G0 Singapore equipment

20D Thailand KD deletion parts

21R Tire - front & rear 9.00-20-14 lug

25R Tire - front & rear 9.00R20-14 rib

27X

30T Tire - front & rear 10.00-20-14 rib

34W Wheel base 3,400mm

35N Tire - front & rear 10R22.5-14 rib

36W Wheel base 3,600mm

37W Wheel base 3,700mm

38W Wheel base 3,800mm

39W Wheel base 3,900mm

40S Tire - front & rear 8.25-16-14 rib

40T Tire - front & rear 10.00-20-16 rib

Tire - front 10.00-20-14 rib,

rear 10.00-20-14 lug

Tire - front 10.00-20-16 rib,

rear 10.00-20-16 lug

Tire - front 11.00-20-16 rib,

rear 11.00-20-16 lug

5G2

5H1

5J6

5J7

5J8 Tire - front & rear 245/70R19.5 rib

5J9 Tire - front & rear 235/75R17.5 rib

5K0 Tire - front & rear 265/70R19.5 rib

5K4

5K5

5L1 Tire - front & rear 12.00R20-18

5L4

5L7

5L8 Tire - front & rear 10.00R-20-16 lug

5N5

Tire - front 295/80R22.5,

rear 11R22.5-16

Tire - front 10.00-20-16 rib,

rear 10.00-20-16 lug

Tire - front 9.5R17.5 129/127L rib,

rear 9.5R17.5 129/127L traction

Tire - front & rear 11R22.5 148/145L

rib

Tire - front & rear 11R22.5 148/145K

rib/lug

Tire - front & rear 12R22.5 152/148K

rib/lug

Tire - front & rear 275/70R22.5

148/145M rib

Tire - front & rear 9.00R-20-14

exp lug

Tire - front & rear 265/70R19.5 140/

138M rib (BS brand)

40W Wheel base 4,000mm

41R Tire - front & rear 10.00-20-14 lug

41W Wheel base 4,100mm

5N6

5P0

Tire - front & rear 235/75R17.5 132/

130M rib (BS brand)

Tire - front & rear 235/75R17.5 132/

130M rib (BS brand)

Page 13

0A-10 General Information

Option

Code

5P1

5P2

5P3

5P6 Tire - front & rear 225/70R19.5

5P7

50W Wheel base 5,000mm

51R Tire - front & rear 10.00-20-16 lug

51W Wheel base 5,100mm

517 Body color - AL. gray

53W Wheel base 5,300mm

538 Body color - Tool-IPEC yellow

55N Tire - front & rear 11R22.5-16 rib

55P

55R Tire - front & rear 10.00R20-16 rib

55W Wheel base 5,500mm

58N Tire - front & rear 11.00R20-16 rib

58W Wheel base 5,800mm

59W Wheel base 5,900mm

6DY Rear under run protector

6EP HSA system

6HF KD preparatory package

6KK Horn - heavy duty (dual)

6ND OK window

6NF Remote control door lock

6PH

6SZ Power take off - flywheel

6UC Fluorescent lamp

6UH

6VE O/S rear view mirror - door mount

6WX Floor mat - vinyl

6XH ASR system

60W Wheel base 6,000mm

609 Body color - FT orange

Tire - front 295/80R22.5,

rear 11R22.5-16 (6x2, BS brand)

Tire - front 295/80R22.5,

rear 11R22.5-16 (BS brand)

Tire - front & rear 10R22.5-14

exp rib/lug (BS brand)

Tire - front & rear 8.25R16 128/126L

exp rib/lug

Tire - front & rear 295/80R22.5

152/148M rib

LSPV - Load sensing proportioning

valve

O/S rear view mirror - assist side short

stay

Option Description

Option

Code

61P Tire - front & rear 225/90R17.5

63E KD package - Italy

63W Wheel base 6,300mm

64E KD package - Vietnam

64N Tire - front & rear 8.25R20-14 rib

65W Wheel base 6,500mm

668 Body color - Purplish blue

681 Body color - Geranium red

695 Body color - Dark blue

7BC Assist seat with center seat

7DM Tuner band - Latin America

7FL Seat material - cloth

7HZ Rear bumper

7KC Immobilizer system

7NY Multi information display

7SV O/S rear view mirror - heated

7TV KD preparatory package

70T Tire - front & rear 11.00-20-14 rib

71R Tire - front & rear 11.00-20-14 lug

71S Tire - front & rear 7.50-20-12 lug

71W Wheel base 7,100mm

729 Body color - Arc white

736 Body color - Cardinal red

78N Tire - front & rear 8.25R16

79R Tire - front & rear 11.00R20-14

8AA

8AC

8EJ Battery - 65D23L

8GF Transmission with Smoother

8GJ Transmission without Smoother

8JM Diesel particulate diffuser

8LF Rear window glass

8LX Ash tray - assist side

8MA Battery 115E41L

8MH Fuel tank 370L

8ML O/S rear view mirror - middle arm

Good quality ethylene glycol

antifreeze 50%

Good quality ethylene glycol

antifreeze 30%

Option Description

Page 14

General Information 0A-11

Option

Code

8MV

8NG Decal - vehicle & pet name

8NH Decal - pet name

8NV Bio diesel fuel B10

80L 6HK1-TCS engine

80R Tire - front & rear 11.00-20-16 rib

800 Body color - In white

807 Body color - Woodland green

81L 6HK1-TCC engine

81R Tire - front & rear 11.00-20-16 lug

81U Tire - front & rear 8.25-16-14 lug

812 Body color - Wheatland yellow

82L 6HK1-TCN engine

829 Body color - Sahara beige

O/S rear view mirror - extended long

arm

Option Description

Option

Code

982 Body color - Polar white

989 Body color - Sunbelt green

99D KD package - United Kingdom

99N Tire - front & rear 11R22.5-16

909 Body color - middle bronze green

919 Body color - olive drab

999 Body color - trans blue

Option Description

Vehicle Identification Number (VIN)

The ID plate indicates the vehicle identification number

(VIN).

This single number contains multiple pieces of

information including the vehicle and engine model

codes as shown below.

83N Tire - front & rear 9.5R17.5

84D Colombia Var.2

85N Tire - front & rear 11R22.5-16

85R Tire - front & rear 11.00R20-16 rib

85U Tire - front & rear 8.25R16-14 rib

87N Tire - front & rear 10.00R20-14PR rib

89N Tire - front & rear 9.00R20-14PR rib

89R Tire - front & rear 11.00R20-16PR

89T Tire - front & rear 11.00R20-16

890 Body color - Marine blue

90S Tire - front & rear 8.25-20-14 rib

904 Body color - golden yellow

91D KD package - Philippine Var.2

915 Body color - fire red

92N Tire - front & rear 8.25R16-14PR rib

93N

Tire - front 12.00R20-18,

rear 12.00R20-18 lug

94K Tire - front & rear 10.00R20-16

94N Tire - front & rear 12.00R20-16

944 Body color - Highway orange

95D KD package - Ireland

951 Body color - arc white

97N

Tire - front 295/80R22.5,

rear 11R22.5-16

Page 15

0A-12 General Information

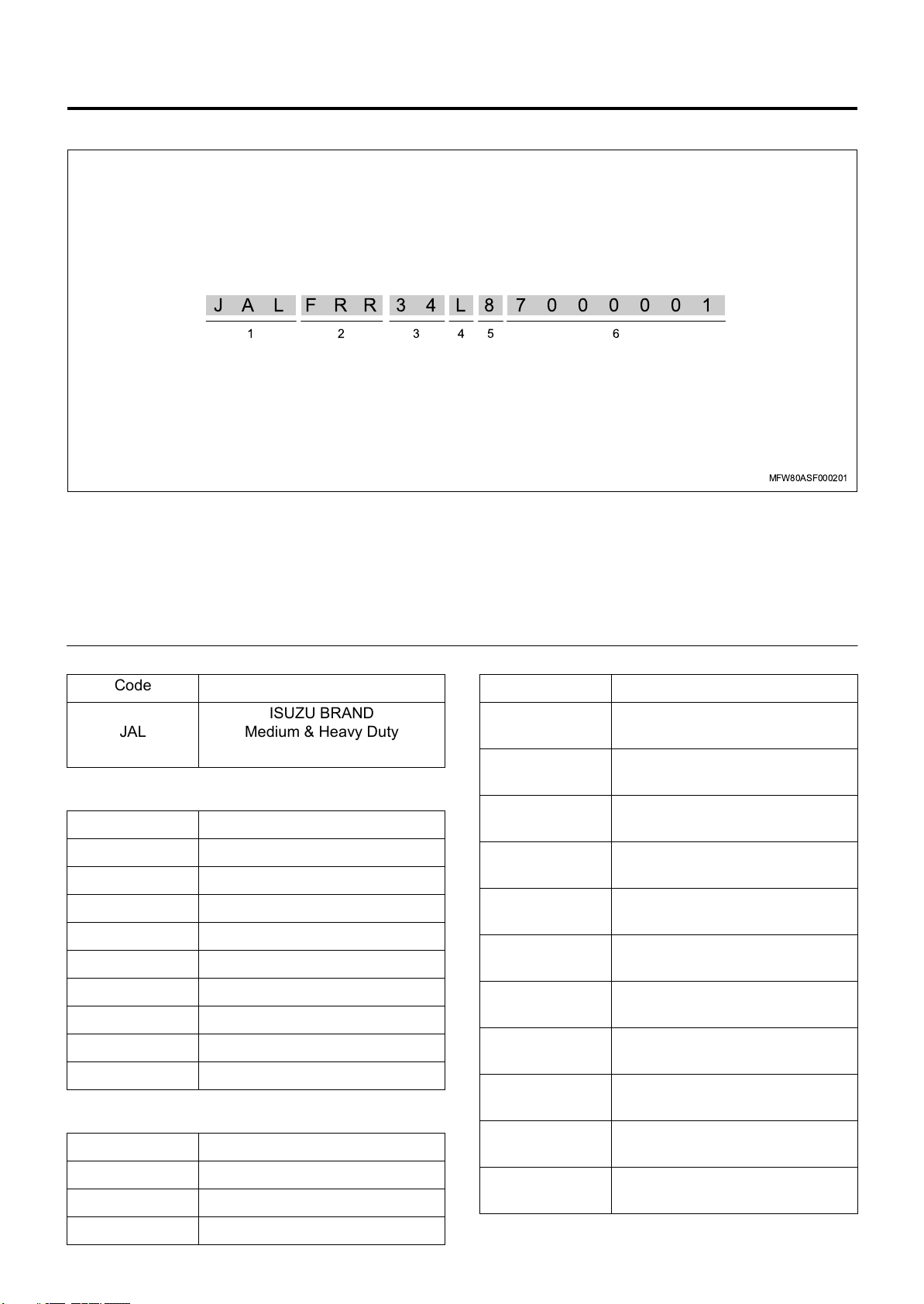

Typ e 1

JALFRR34L87000001

Legend

1. World manufacturer identifier (WMI)

2. Vehicle model code

3. Engine code

4. Wheel base code

5. Model year code

6. Chassis number

1. World manufacturer identifier (WMI)

654321

MFW80ASF000201

4. Wheel base code

Code

JAL

2. Vehicle model code

Code

FRR 4x2 Truck FRR model

FSR 4x2 Truck FSR model

FTR 4x2 Truck FTR model

FVR 4x2 Truck FVR model

FVZ 6x4 Truck FVZ model

FVM 6x2 Truck FVM model

GVR 4x2 Tractor GVR model

FSS 4x4 Truck FSS model

FTS 4x4 Truck FTS model

3. Engine code

Code

34 6HK1 Engine

86 6HF1 Engine

ISUZU BRAND

Medium & Heavy Duty

Incomplete Vehicle

Code

H

J

K

L

M

N

P

7

R

S

T

3,201 - 3,500 mm

(126.02 - 137.80 in)

3,501 - 3,800 mm

(137.83 - 149.61 in)

3,801 - 4,100 mm

(149.65 - 161.42 in)

4,101 - 4,400 mm

(161.46 - 173.23 in)

4,401 - 4,700 mm

(173.27 - 185.04 in)

4,701 - 5,000 mm

(185.08 - 196.85 in)

5,001 - 5,300 mm

(196.89 - 208.66 in)

5,301 - 5,600 mm

(208.70 - 220.47 in)

5,601 - 5,900 mm

(220.51 - 232.28 in)

5,901 - 6,200 mm

(232.32 - 244.09 in)

6,201 - 6,500 mm

(244.13 - 255.91 in)

90 4HK1 Engine

Page 16

General Information 0A-13

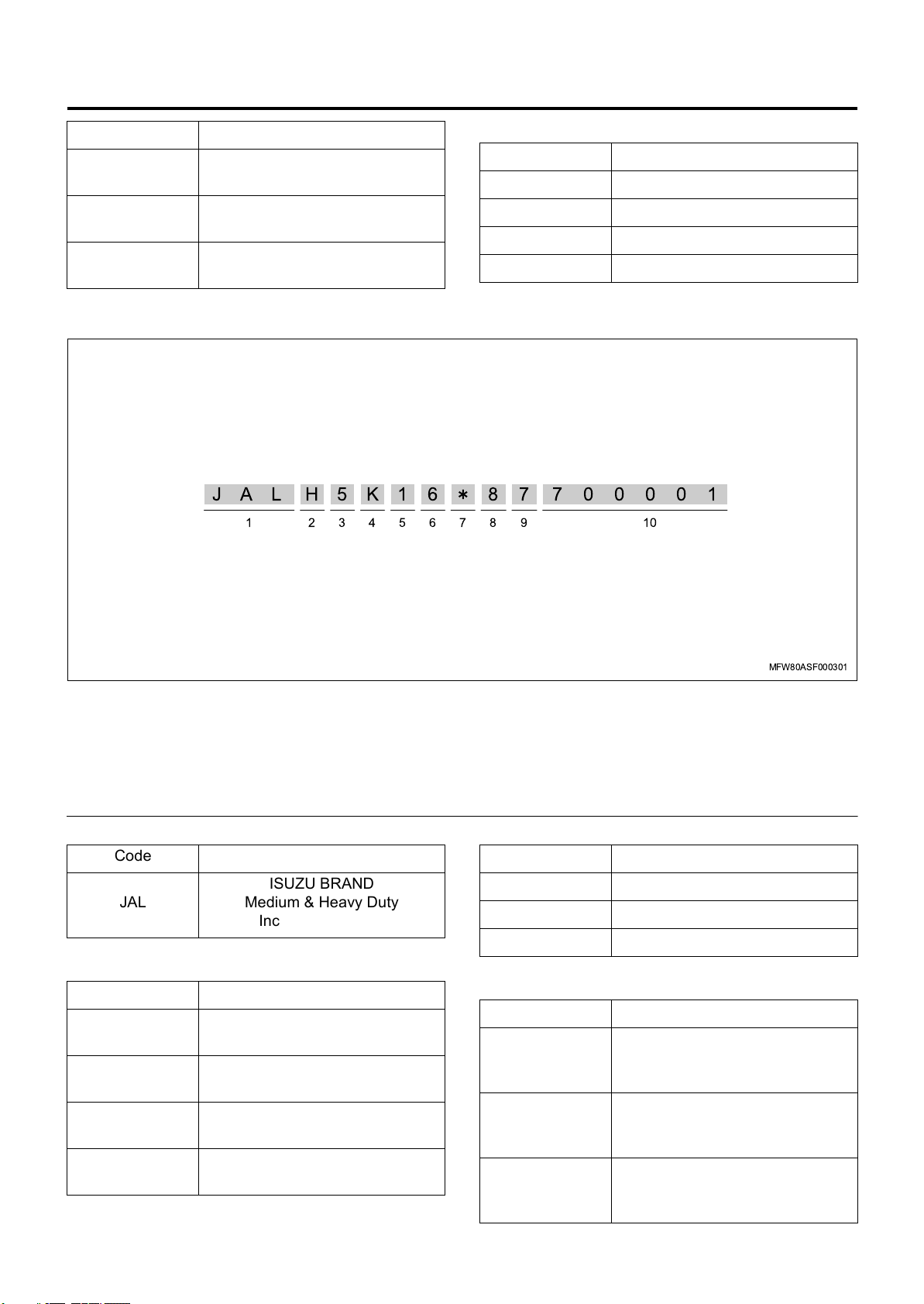

Typ e 2

Code

U

V

W

5. Model year code

6,501 - 6,800 mm

Code

(255.94 - 267.72 in)

6,801 - 7,100 mm

(267.76 - 279.53 in)

7,101 - 7,400 mm

(279.57 - 291.34 in)

JAL 5K16 87

H

2 431

8 9765

8 2008MY

9 2009MY

A 2010MY

B 2011MY

700001

10

Legend

1. World manufacturer identifier (WMI)

2. Gross vehicle weight (GVW) and brake system

3. Series code

4. Line/Cab type code

5. Chassis code

1. World manufacturer identifier (WMI)

Code

ISUZU BRAND

JAL

Medium & Heavy Duty

Incomplete Vehicle

2. Gross vehicle weight (GVW) and brake system

Code

H

K

M

P

8,846 - 10,659 kg

(19,501 - 23,500 lb)

10,660 - 11,793 kg

(23,501 - 26,000 lb)

11,794 - 14969 kg

(26,001 - 33,000 lb)

14,970 - 18,370 kg

(33,001 - 40,500 lb)

6. Engine code

7. Check digit

8. Model year code

9. Plant code

10. Production sequential number

3. Series code

Code

5FRR

6FSR

7 FTR, FTS, FVR

4. Line/Cab type code

Code

K

M

S

BBC = 1,726 mm (67.95 in),

BBC = 2,066 mm (81.34 in),

BBC = 2,066 mm (81.34 in),

MFW80ASF000301

Tilt cab,

Narrow Cab

Tilt cab,

Narrow Cab

Tilt cab,

Wide Cab

Page 17

0A-14 General Information

5. Chassis code

Code

1 4x2, 2 Axles, 1 driving

2 4x4, 2 Axles, 1 driving

4 6x4, 3 Axles, 2 driving

6. Engine code

Code

36HK1-TC

64HK1-TC

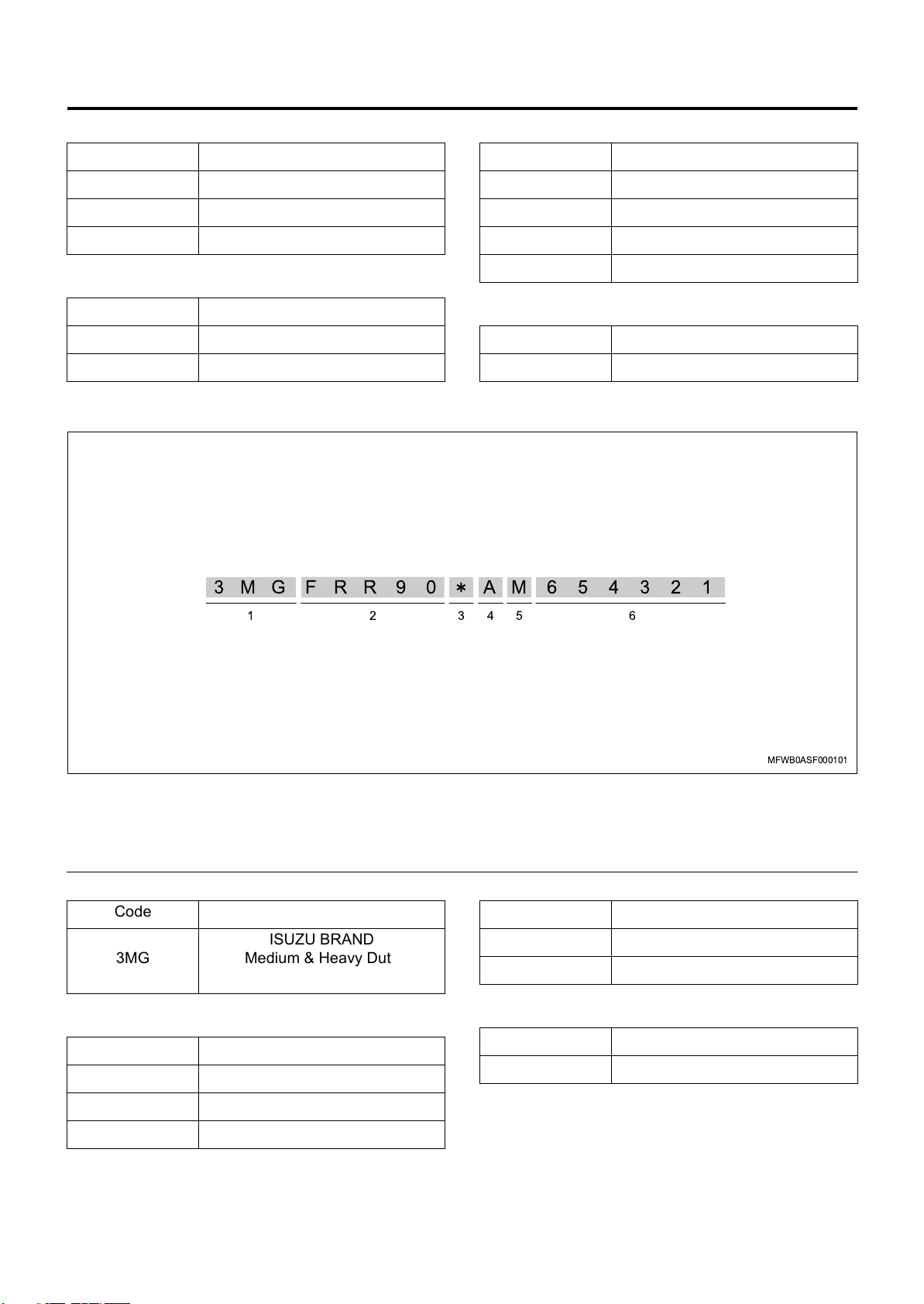

Typ e 3

8. Model year code

Code

8 2008MY

9 2009MY

A 2010MY

B 2011MY

9. Plant code

Code

7 Fujisawa

3MG FRR 9 0 AM654321

Legend

1. World manufacturer identifier (WMI)

2. General attributes

3. Check digit

1. World manufacturer identifier (WMI)

Code

ISUZU BRAND

3MG

2. General attributes

Code

FRR90 FRR90

Medium & Heavy Duty

Incomplete Vehicle

643 521

MFWB0ASF000101

4. Model year code

5. Plant code

6. Production sequential number

4. Model year code

Code

A 2010MY

B 2011MY

5. Plant code

Code

MMexico (IMEX)

FTR34 FTR34

FVR34 FVR34

Page 18

General Precautions

General Information 0A-15

General Precaution

Legend

1. Clean and safe costume

2. Installation of Chock blocks

1

2

3

MFW70AMF000201

3. Support by stand after jack up

Work preparations

• Prepare the tools, instruments, and special tools in

advance.

• Prepare the parts that require replacement and

parts that cannot be re-used in advance.

Clothing

• The service technician must wear a clean service

technician uniform, hat, and safety footwear.

Protect the vehicle.

• Make sure to use a seat cover, etc.

• Disconnect the terminal of the battery (–) in

advance.

Always focus on safety

• Make sure to use chock block when the vehicle is

jacked up.

• After jacking up, make sure to support the

specified position using a stand.

• When lifting up the vehicle using a lift, make sure

to set the safety device.

• When performing a procedure with two or more

people, make sure to ensure each other's safety

before performing an action.

• Do not leave the engine running for an extended

period of time or perform painting in a poorly

ventilated working environment.

• Make sure to use only the special tools if the

procedure requires them for the work. Performing

the procedure using other tools may cause

damage to parts or personal injury.

• Do not use tools such as a wrench that has lost its

edges, a hammer with frayed edges, or a chipped

chisel.

• When performing work using a device such as a

grinder, crane, or welder, make sure that a

qualified technician performs the procedure while

paying sufficient attention to the handling

precautions.

Page 19

0A-16 General Information

• When performing maintenance on fuel systems,

make sure that there is no fuel leakage. (may

possibly catch fire)

• When handling volatile materials, take care that

they do not catch fire.

Also make sure to wipe away any oil that sticks to

rubber parts, as it can cause deterioration.

Work Precaution

• Arrange removed parts in the correct order and

ensure they do not get mixed up with parts that

cannot be re-used.

• Perform sufficient cleaning and washing when

performing assembly / installation.

Also perform sufficient grease removal for areas to

apply liquid gasket, etc.

After-procedure check

• After completing the procedure, perform a final

check to confirm that the problem has been solved.

• Check that there is no fuel, oil, or coolant leakage.

Page 20

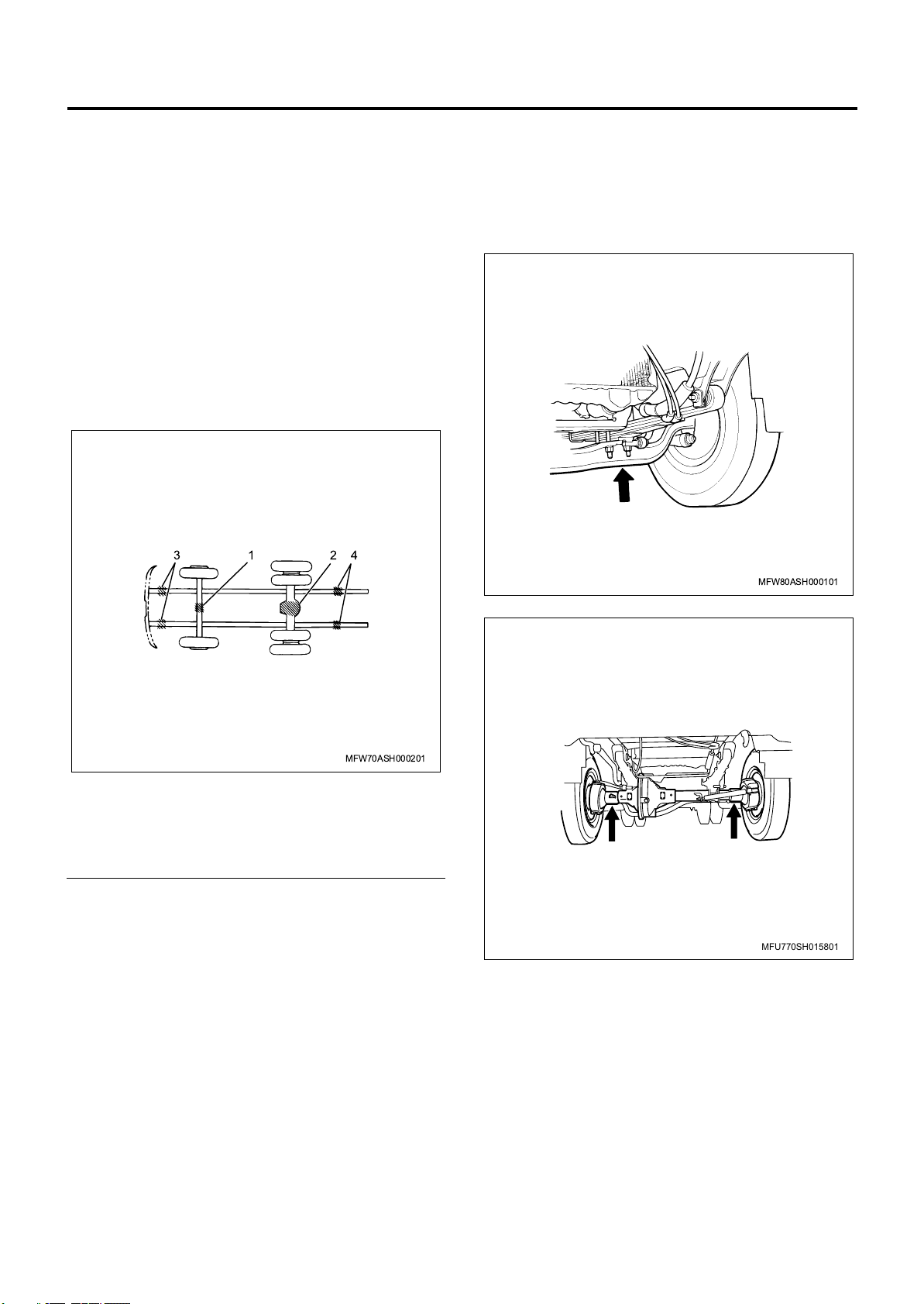

Lifting Instruction

General Information 0A-17

Lifting Instruction

If it necessary to use a lifting device other than the

original equipment jack, see illustration for acceptable

lifting points.

Lifting should only be done at the positions indicated to

prevent possible damage to the vehicle.

CAUTION:

Failure to observe the acceptable lift points may result

in unsatisfactory vehicle performance or a durability

failure which may result in loss of control of the vehicle.

Garage Jack and Safety Stand

Lifting Point and Supportable Point Location

31 24

Lifting Point Positions - Front side

CAUTION:

Do not lift or support on engine oil pan.

F*R/FVM/FVZ/GVR models

MFW80ASH000101

FSS model

Legend

1. Front axle

2. Rear axle center

3. Side member front side

4. Side member rear side

MFW70ASH000201

MFU770SH015801

Page 21

0A-18 General Information

FTS model

Lifting Point Positions - Rear side

CAUTION:

Do not lift or support on rear axle tube.

FRR/FSR/FTR/FVR/GVR models (with leaf spring

suspension), FSS/FTS models (except rear singletire model)

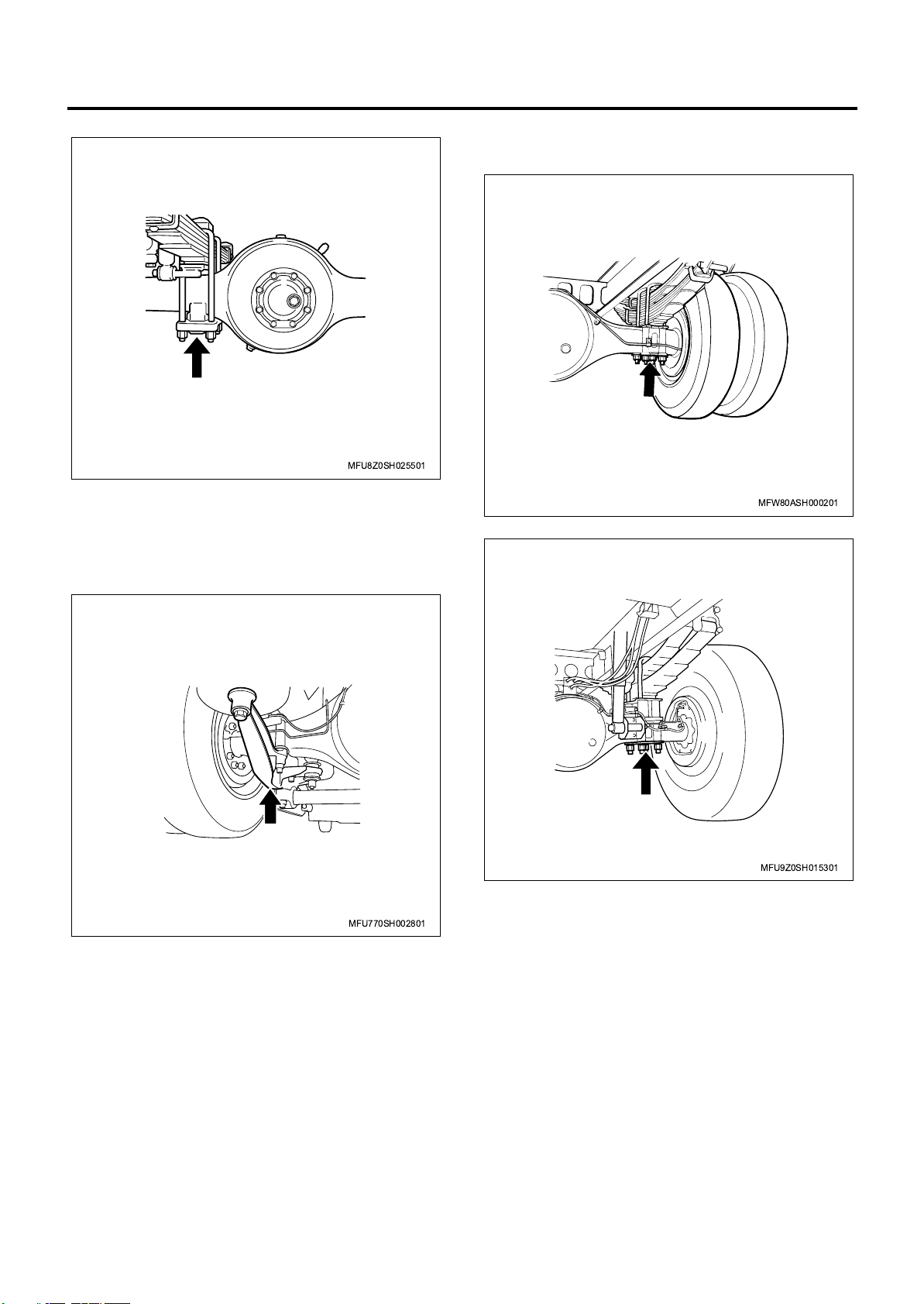

MFU8Z0SH025501

MFW80ASH000201

FSS/FTS models (rear single-tire model)

FRR/FSR models (with air suspension)

MFU9Z0SH015301

MFU770SH002801

Page 22

General Information 0A-19

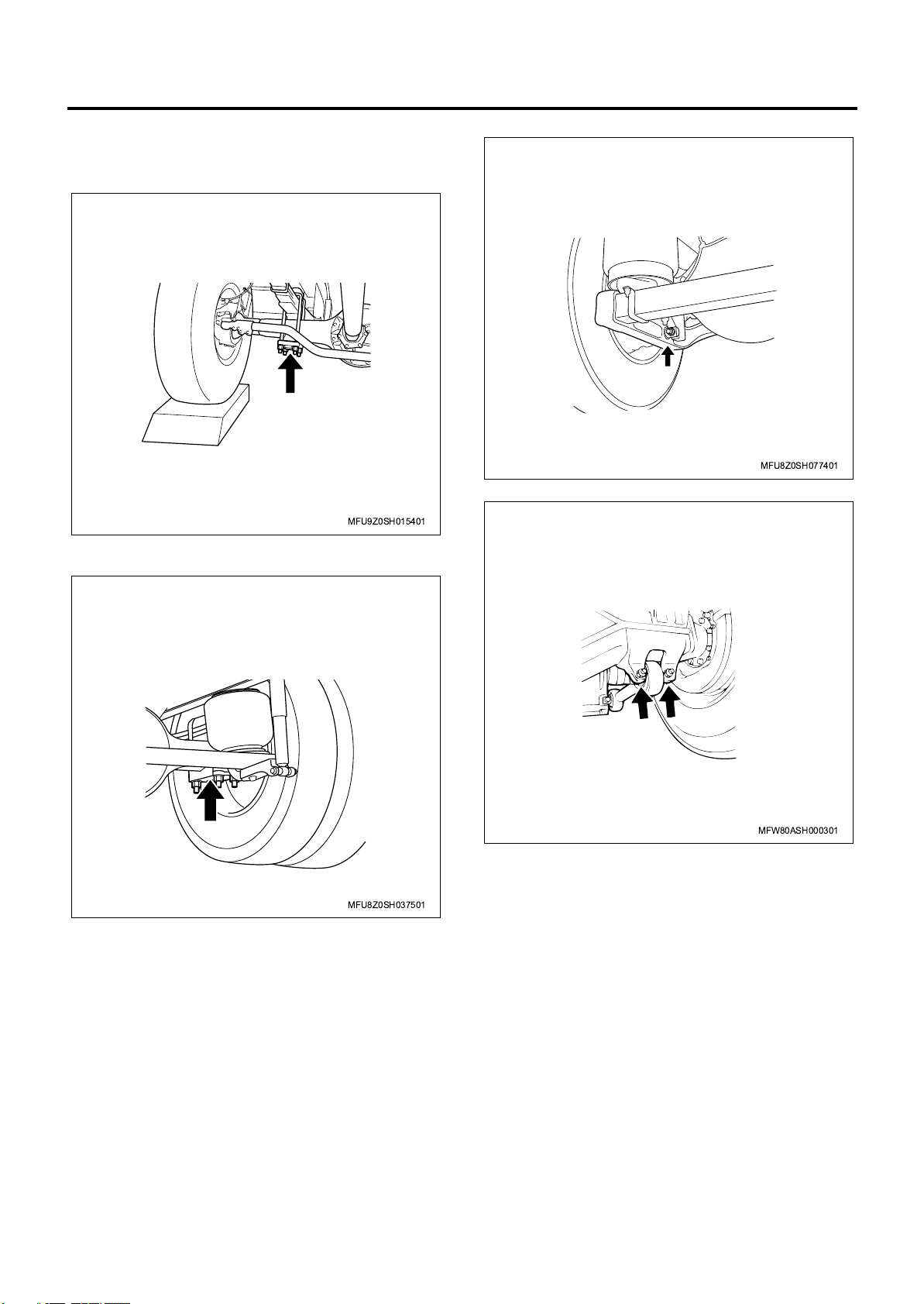

NOTE:

Let the tire run over a piece of block, etc., and apply the

jack.

FTS model(rear single-tire model)

MFU9Z0SH015401

FVR/FVM/FVZ/GVR models (with air suspension,

except Europe)

FVR model (with air suspension, for Europe)

MFU8Z0SH077401

FVM/FVZ models (with leaf spring suspension)

MFU8Z0SH037501

MFW80ASH000301

Page 23

0A-20 General Information

Caution for The Maintenance of Electrical Parts

Battery Cable

Disconnecting the battery cables

1. Turn all the switches "OFF".

2. Disconnect the battery ground cable (1).

3. Disconnect the battery plus cable (3).

4. Disconnect the battery cable (2).

CAUTION:

Make sure to disconnect the battery ground cable first.

Disconnecting the plus cable first may cause a short

circuit.

3

1

2

MFW70ASH000401

Connecting the battery cables

Connect the battery cables in the reverse order of the

disconnection procedure.

CAUTION:

Clean the area surrounding the battery terminal, and

apply a thin layer of grease to the terminal to prevent

corrosion.

• Check that no foreign material or water has

entered the inside of the connectors.

Remove any foreign material or water that has

entered the connector using an air brush, etc. If the

material cannot be removed, replace them.

• Check that no foreign material is stuck to the

terminals, and there is no corrosion or

deformation.

Remove any foreign material by cleaning with an

air brush, or clean rag, etc. If the material cannot

be removed by cleaning, or there is corrosion or

deformation, replace them.

• Gently pull the wires to check that no terminals are

missing from the connector and there is no

breakage in the terminal area.

If a terminal is missing, reinsert it until it locks into

place. If you find a disconnection, replace them.

• Insert the male connector into the same female

connector, and check that there is no abnormality

in the terminal contact pressure.

If you find an abnormality, replace them.

• For waterproof connectors, check that there is no

damage or foreign material stuck to the seal parts

(wire seal of wiring, O-ring or waterproofing seal of

connector, etc.) or seal area of the connector

housing.

Remove any foreign material by cleaning with an

air brush, or clean rag, etc. If the material cannot

be removed by cleaning, or there is damage,

replace them.

CAUTION:

• Do not perform polishing that would remove the

plating of the terminals, nor wash the inside of the

connector. If there is dirt that requires washing,

replace them.

• Be careful when attaching the seal areas of

waterproof connectors, as some have specific

positions and directions they must be attached.

Also do not attach them in a twisted state.

Connector Handling Requirements

Visual inspection

With the male and female connectors connected

• Gently pull the connector and check whether the

connector becomes disconnected or partially

disconnected, and that the lock is properly set.

If a problem is found, reconnect the connectors.

• Check that there is no damage to the connector

housing.

If a problem is found, perform replacement.

With the male and female connectors disconnected

Regarding vehicle washing

Even for electric parts that are installed outside the cab

and are waterproofed, try to avoid exposing them

directly to high pressure water when washing the

vehicle (cover them with plastic sheets, etc.) as much

as possible.

Page 24

General Information 0A-21

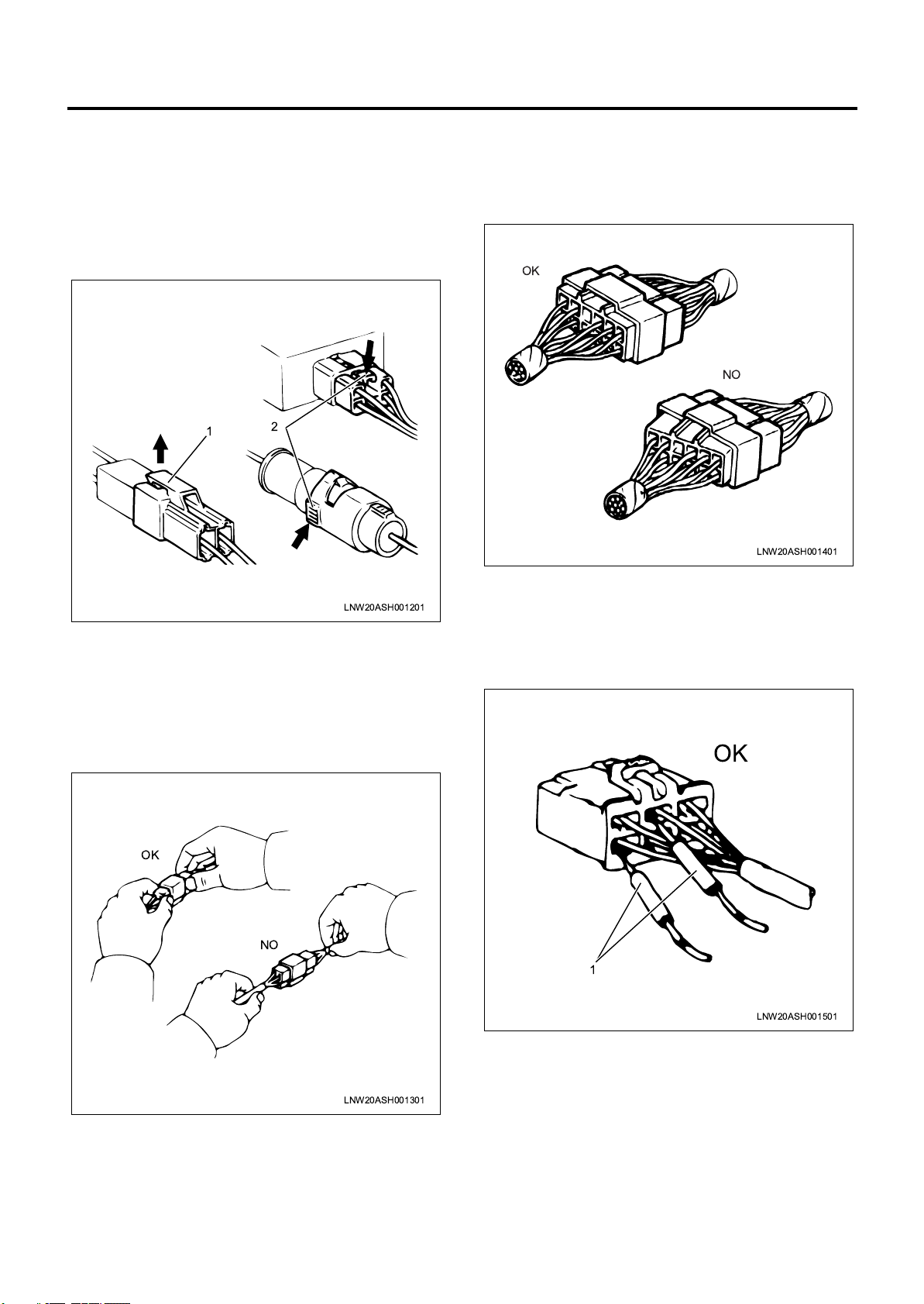

Disconnecting the connector

Many connectors have a lock to ensure secure

connections.

The two types of locks generally used are those that

open by lifting the release area of the lock (1), and

those that open by pressing the release area (2).

Before disconnecting the connector, determine in

advance which type of lock the connector is using.

1

2

Connecting the connector

Securely grasp the female side and male side of the

connector, and align them correctly.

Firmly push them together until both sides click into

place.

OK

NO

LNW20ASH001401

LNW20ASH001201

When disconnecting the connector, first securely grasp

the male side and female side of the connector.

Release the lock, and carefully disconnect the

connector.

Do not pull the harness when disconnecting the

connector, as this may cause wires to come out or

break.

OK

NO

Connector circuit inspection requirements

Check the continuity of the connector using a circuit

tester. Insert the probes (1) of the tester from the

harness side of the connector, as indicated in the

diagram.

OK

1

LNW20ASH001501

LNW20ASH001301

Page 25

0A-22 General Information

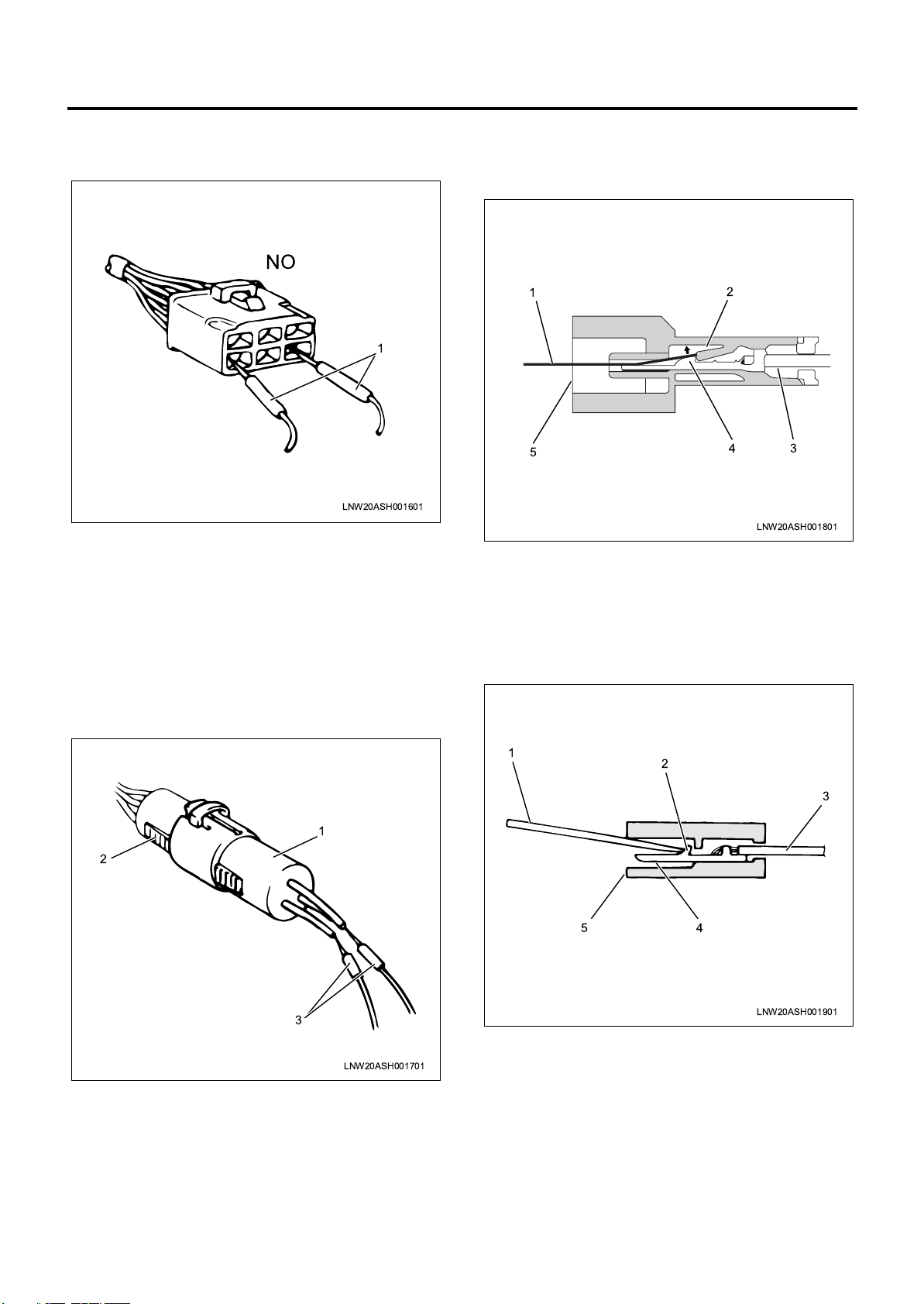

Never insert the probes (1) from the connection closure

area of the connector, as this will cause the connector

terminals to break.

NO

1

LNW20ASH001601

Inspection requirements for waterproof connector

circuit

For waterproof connectors, the probes of the tester

cannot be inserted from the wiring side, due to the

structure of the connectors.

Therefore, perform the continuity inspection as

indicated in the diagram, by connecting a testing

connector (1) prepared in advance to the connector (2)

to test, and connect the probes (3) of the tester to the

harness of the testing connector.

2. Push the lock (2) up in the direction of the arrow

using the metal rod to release the lock. In that

state, pull out the harness (3) together with the

terminal (4).

1

5

2

4

LNW20ASH001801

3

—Terminal lock type

1. Insert a metal rod (1) from the connector closure

area (5).

2. As indicated in the diagram, release the terminal

lock (2) by pushing it to the harness side, pull out

the harness (3) together with the terminal (4).

1

2

3

LNW20ASH001701

Disconnecting connector terminals

—Built-in lock type

1. As indicated in the diagram, insert a thin

screwdriver-shaped metal rod (1) from the

connector closure area (5).

1

2

3

45

LNW20ASH001901

Connecting connector terminals

1. Check that the terminal lock (1) area is raised fully

and can be locked.

2. Insert the terminal (3) from the harness (2) side of

the connector, and push it in until the lock area

clicks.

Page 26

General Information 0A-23

3. Gently pull the harness and check whether the

terminal is completely locked inside the connector.

1

2

3

LNW20ASH002001

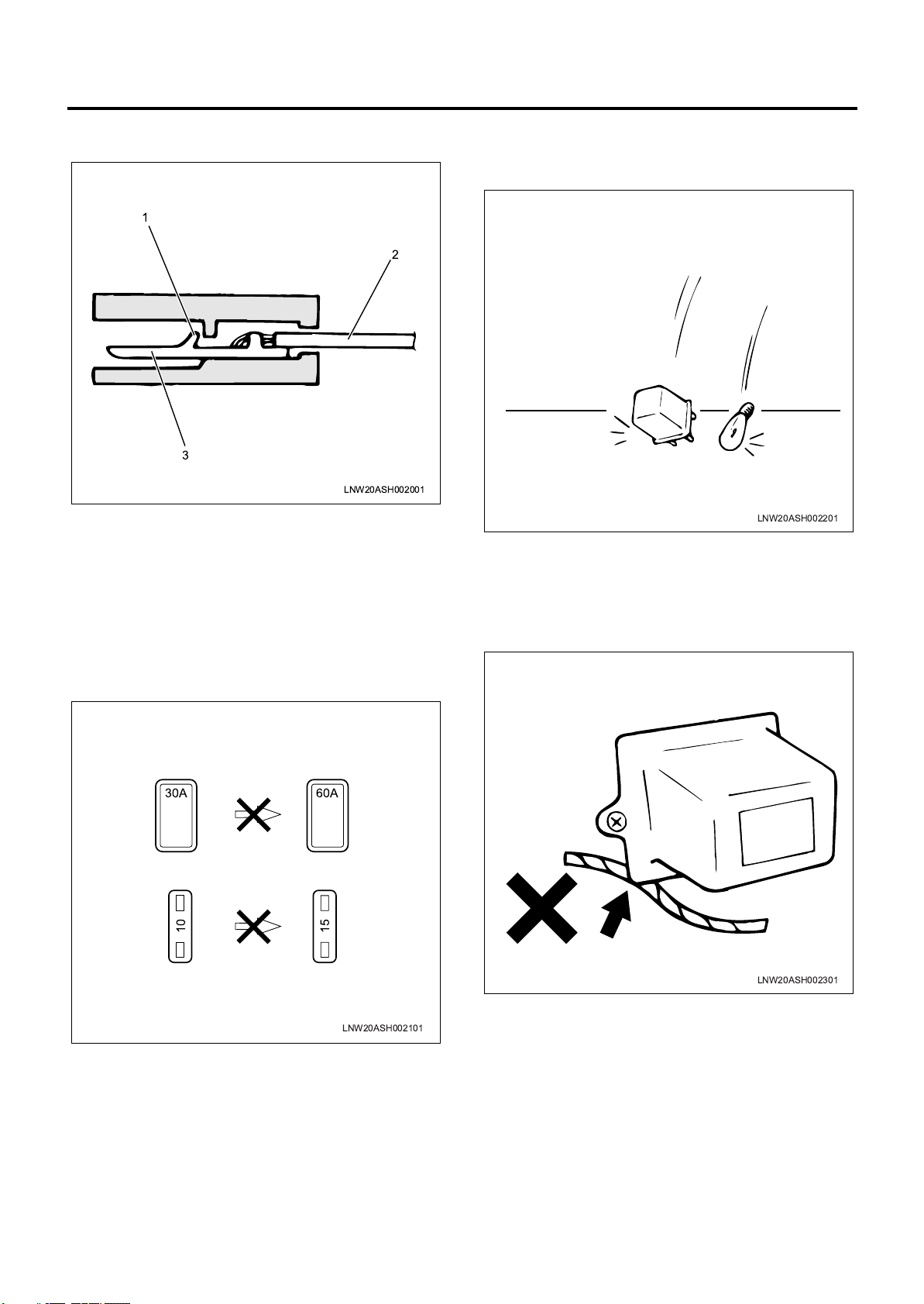

Replacing the fuse

WARNING:

If a fuse melts down, make sure to replace it with a nondefective fuse of the same capacity, after identifying the

cause of the melt down.

If you use a fuse with high capacity, the fuse will not

perform its function when excess current flows. This

may cause parts or wires, etc. to burn, and can result in

a vehicle fire.

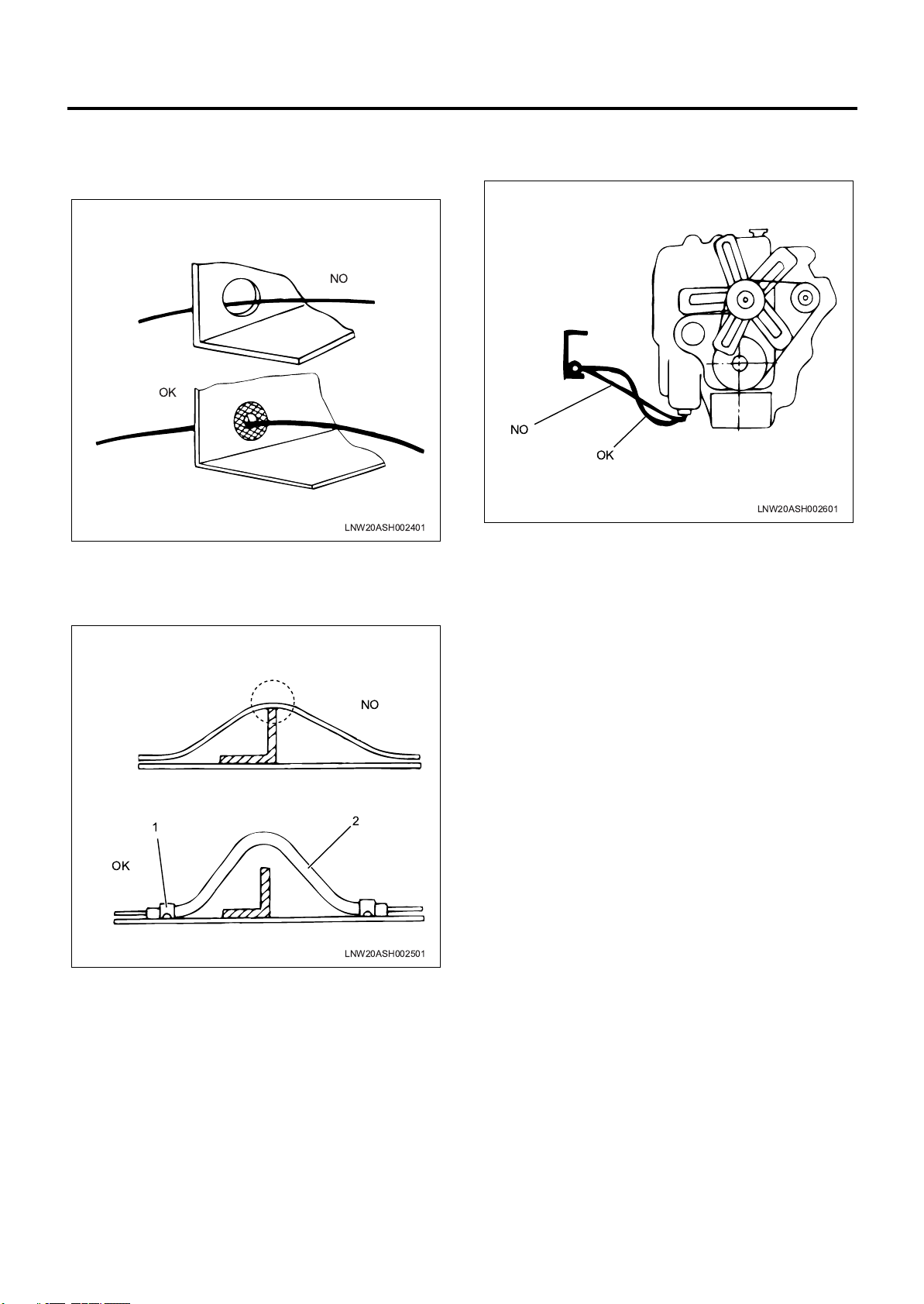

Handling Electronic Parts

Handle electronic parts with sufficient care, and do not

damage the parts by dropping or throwing them.

LNW20ASH002201

Cable Harness

1. When installing electronic parts, take care to

ensure the harness does not get stuck and do not

forcibly push the harness in.

30A 60A

10

15

LNW20ASH002101

LNW20ASH002301

2. Make sure that all connections are clean and

secure.

Page 27

0A-24 General Information

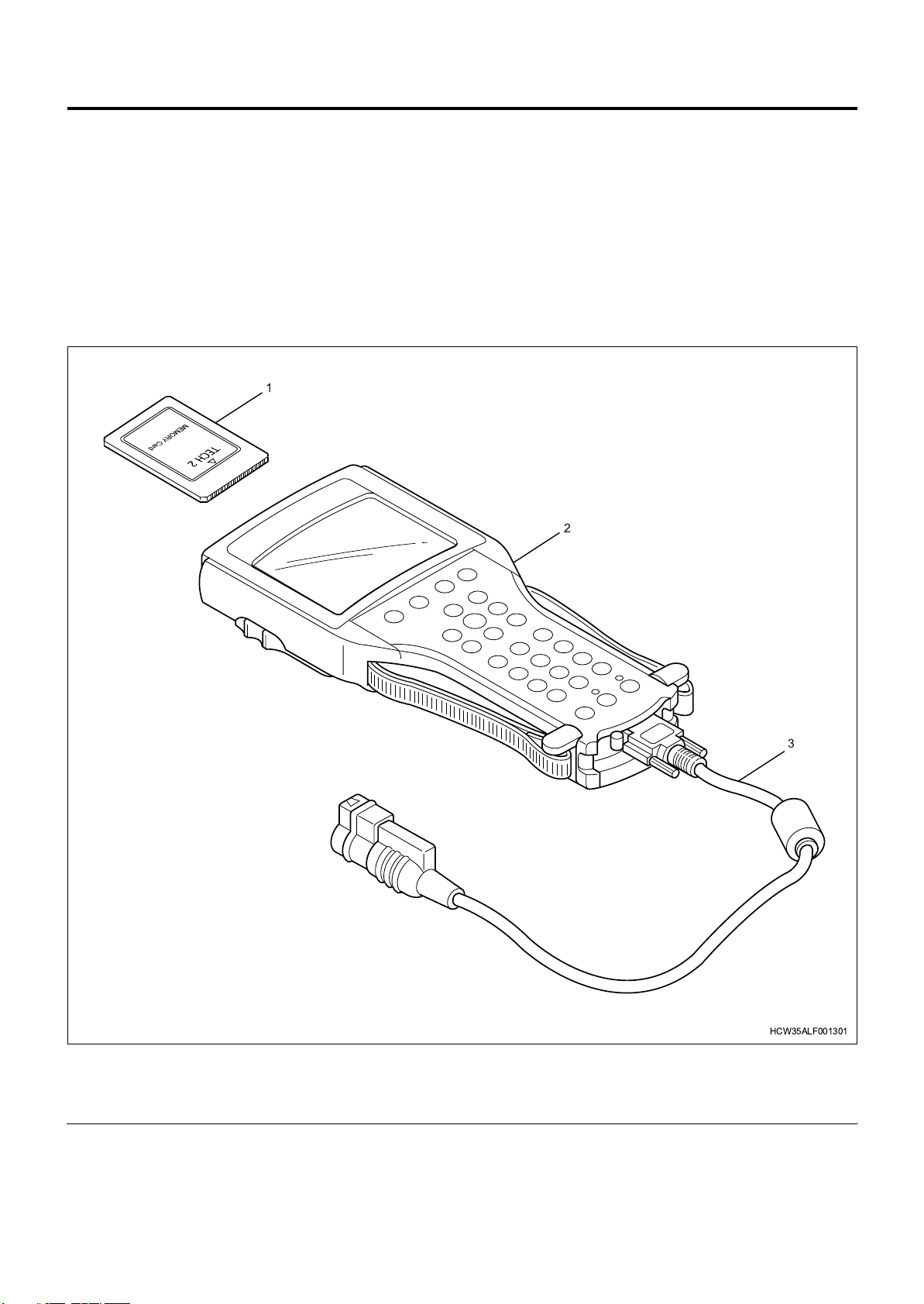

3. When the harness will be contacting sharp edges

or surfaces of other parts, protect the harness

using a grommet or tube to prevent damage due to

the contact.

NO

OK

LNW20ASH002401

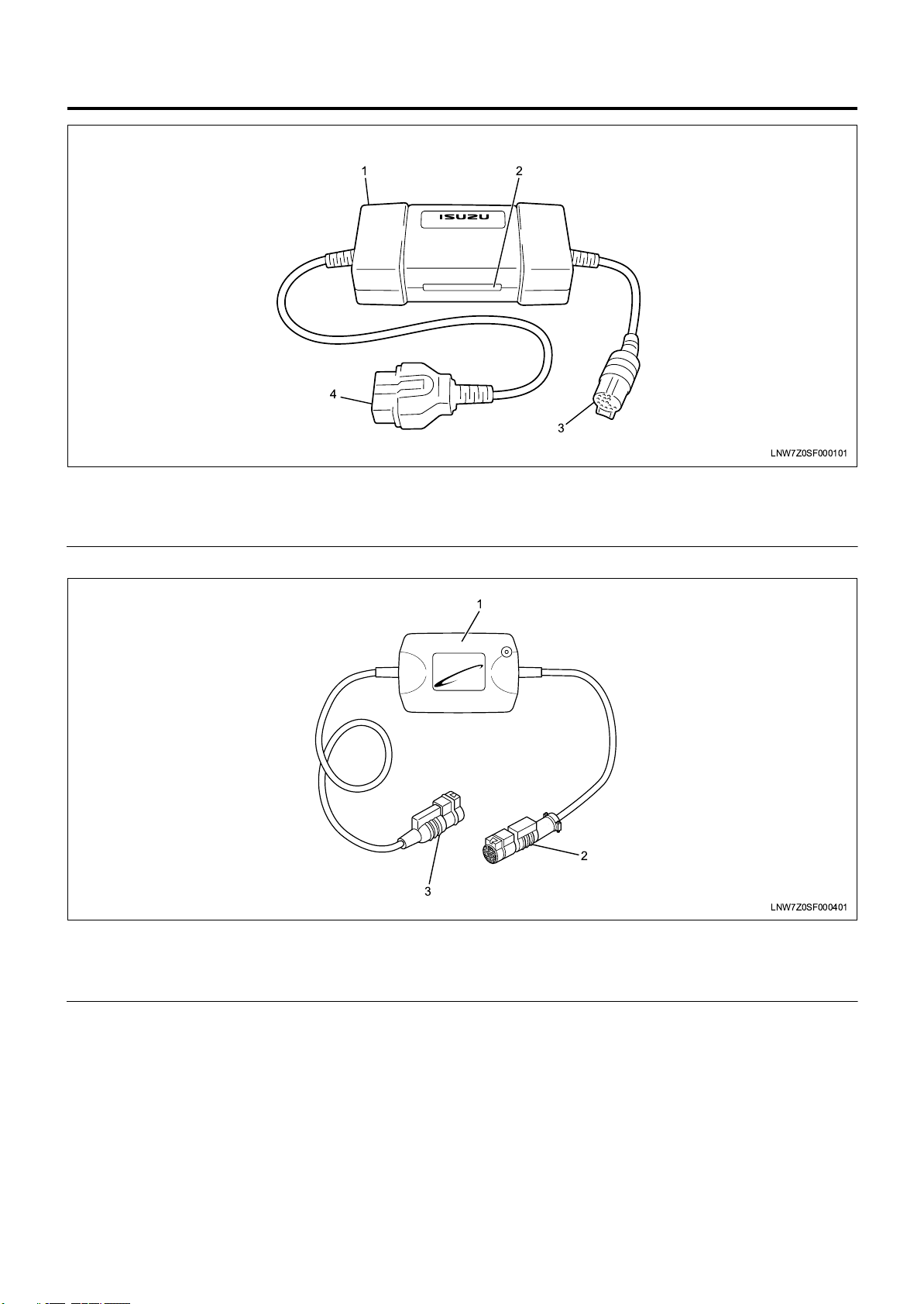

4. When wiring the harness by diverting it around

other parts, give the harness a sufficient amount of

free length, and use a protective tube (2) and clip

(1) to ensure it does not contact surrounding parts.

5. For wiring between the engine and chassis, give

the wiring sufficient free length to prevent wear and

damage caused by vibrations.

NO

OK

LNW20ASH002601

OK

NO

1

2

LNW20ASH002501

Page 28

Regarding The Scan Tool

Trouble Diagnosis Using The Scan Tool

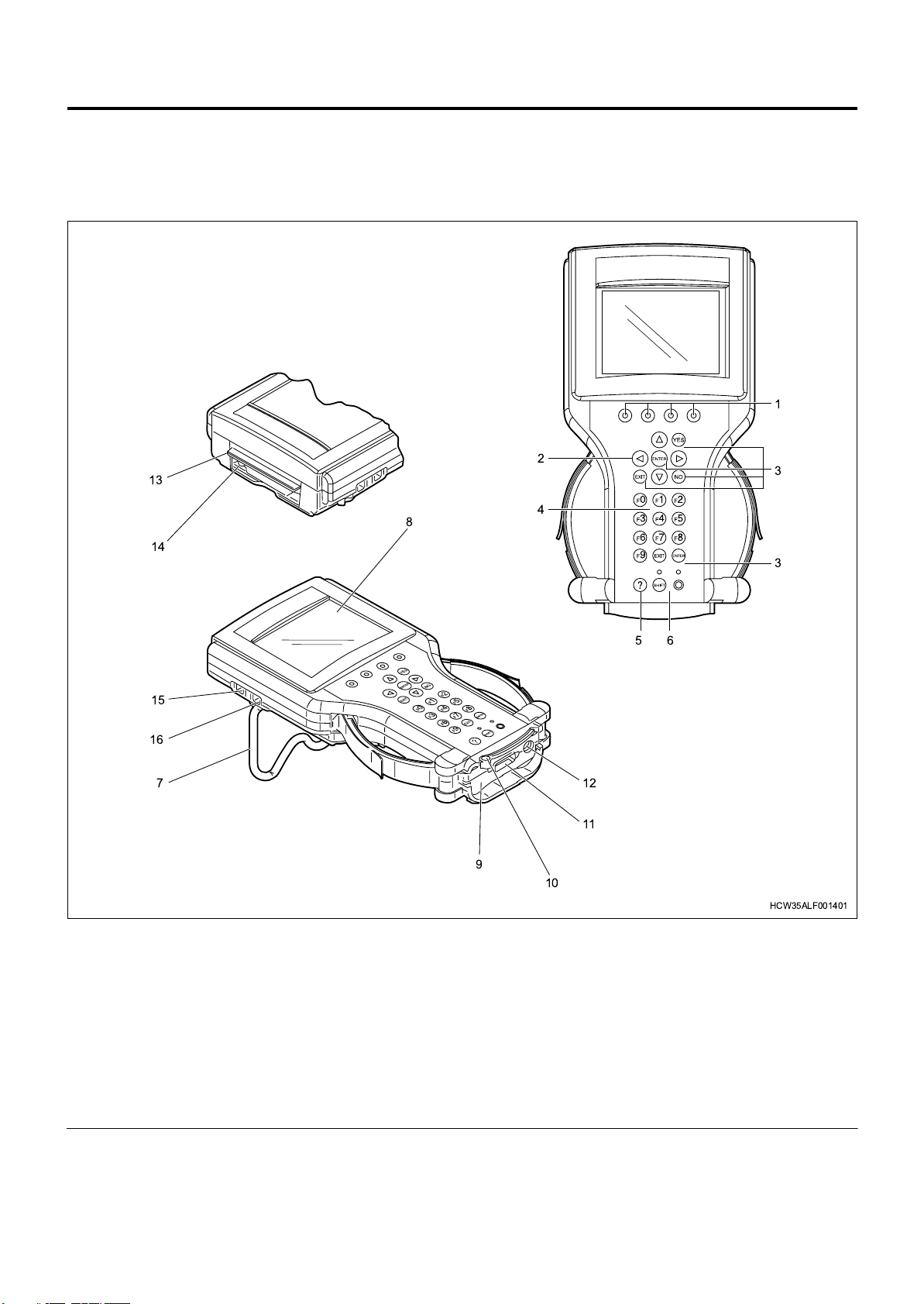

Regarding the scan tool (Tech2) / Tech2 24 volt

adaptor 2 /CAN-di module

This tool is effective for diagnosing electrical failures in

electronic control units and performing system checks.

If you connect the Tech2 to the DLC installed in the

vehicle, it performs communication with the control

units of the vehicle, and enables various diagnoses and

tests to be performed.

1

General Information 0A-25

2

Legend

1. PCMCIA card (dedicated)

2. Tech2 (body)

3

HCW35ALF001301

3. DLC cable

Page 29

0A-26 General Information

Legend

1. Tech2 24V adaptor 2 (body)

2. Signal change switch

[Euro4 specification]

1 2

4

3

LNW7Z0SF000101

3. Tech2 connecting cable

4. DLC connecting cable

3

Legend

1. CAN-di module (body)

2. Tech2 connecting cable

Features and cautions regarding the scan tool

(Tech2) / Tech2 24 volt adaptor 2 / CAN-di module

[Euro4 specification]

• The Tech2 has a 12 V power system. Do not

directly use 24 V power. Do not directly supply

power from the cigar lighter.

• Remove/install the PCMCIA card after turning the

power off.

• The Tech2 has the capacity for two snapshots.

• As the PCMCIA card is sensitive to magnetism and

static electricity, take care when handling it.

1

2

LNW7Z0SF000401

3. DLC connecting cable

• The Tech2 is able to draw graphs of snapshots.

• To select a menu, press the selection key or

choose a menu with a function key and press the

ENTER key.

• You can return to the main menu at any time by

pressing the EXIT key.

• To clear the diagnostic trouble codes (DTC), open

the application menu and select "Clear DTC

Information".

• The Tech2 adaptor 2 has a built-in DC to DC

converter (that converts 24 V to 12 V).

Page 30

General Information 0A-27

• The Tech2 adaptor 2 has a selector for switching

signals (the signals for each electronic control unit

(ECU)).

Parts of the Tech2

13

14

• The CAN-di module has a built-in signal converter

(that converts CAN serial data to keyword serial

data)

1

2

4

8

3

3

15

16

7

Legend

1. Soft key

2. Selection key (arrow key)

3. Action keys (YES, NO, ENTER, EXIT)

4. Function key (F0 – F9)

5. Help key (?)

6. Control key (PWR or SHIFT)

7. Wide stand

8. Display (liquid crystal display)

9. Vehicle communication interface (VCI) Module

1. Soft keys

When operating the Tech2, the selection box is

displayed on the top of the screen. The soft keys

correspond to that selection box. The soft keys

cannot be used unless the selection box is

56

12

11

9

10

HCW35ALF001401

10. VCI module fastening bar

11. DLC cable connecting connector

12. AC adaptor connector

13. PCMCIA card insertion opening (with cover)

14. PCMCIA card release (removal) button

15. Connector for external communication (RS-485

port)

16. Connector for external communication (RS-232

port)

displayed on the screen.

2. Selection key (arrow key)

Selects menu items on the Tech2 screen, and

switches the display. The highlighted area of the

screen display indicates what is being selected.

Page 31

0A-28 General Information

3. Action keys (YES, NO, ENTER, EXIT)

Confirm Tech2 operations, respond to screen

instructions/questions, switch/move to the various

menu screens.

4. Function keys (F0 - F9)

Confirm menu functions displayed on the screen.

Also when "F0" etc., is displayed on the menus on

the screen, the keys correspond to that display.

5. Help key (?)

Displays a screen explaining the Tech2 function

being used.

6. Control key (PWR or SHIFT)

The PWR key turns the power of the Tech2 ON/

OFF. The SHIFT key is used when adjusting the

screen contrast. The LED (orange) lights up when

the SHIFT key is available. At this time, the key

and functions other than the selection key are

locked. The LED (green) lights up when the power

is turned ON.

7. Wide stand

Used as a stand. The operating angle of the stand

is 0 to 180°.

8. Display (liquid crystal display)

The liquid crystal display has a contrast

adjustment function. Displays the ECM information

and the various instruction screens.

9. Vehicle communication interface (VCI) module

The module that enables communication between

the vehicle and Tech2.

10. VCI module fastening bar

Operate the bar to attach/fix, or remove the VCI.

11. DLC cable connecting connector

Connector for using (connecting) the Tech2 with

the vehicle. Connect the DLC cable.

12. AC adaptor connector

Connector for connecting the included AC adaptor.

Enables the Tech2 to be used away from the

vehicle.

13. PCMCIA card insertion opening (with cover)

Open the cover to insert a PCMCIA card into the

Tech2. Insert the PCMCIA card with the cover

opened. Never insert/remove the PCMCIA card

with the Tech2 turned ON.

14. PCMCIA card release (removal) button

Used when removing the PCMCIA card from the

Tech2. The PCMCIA card can be removed when

the button is pressed. Never remove the PCMCIA

card with the Tech2 turned ON.

15. Connector for external communication

(RS-485 port)

This port is for connecting to a telephone line, but

is currently not used for the Tech2. Do not connect

a telephone line, etc., to this port.

16. Connector for external communication

(RS-232 port)

This port is for connecting the Tech2 to another

computer.

Parts of the Tech2 24 V adaptor 2

2

1. Signal change switch

The Tech2 adaptor 2 has a selector for switching

signals (the signals for each electronic control unit

(ECU)).

(The position of the switch is free for other than the

following device)

•“1” : —

•“2” : HSA

1

3

LNW7Z0SF000301

• “3” : —

2. DLC connecting cable

Connects the Tech2 adaptor 2 to the vehicle DLC

(pole 16, blue).

3. Tech2 connecting cable

Connects the Tech2 adaptor 2 to the Tech2.

Page 32

Parts of the CAN-di module [Euro4 specification]

General Information 0A-29

1

1. Tech2 connecting cable

Connects the CAN-di module to the Tech2.

2. DLC connecting cable

Connects the CAN-di module to the Tech2 adaptor

2.

Connection method

1. Insert the ISUZU system PCMCIA card into the

Tech2 unit.

2. Connect the DLC cable to the Tech2 unit.

3. Connect the CAN-di module to the DLC cable.

[Euro4 specification]

4. Connect the Tech2 24 V adaptor 2 to the CAN-di

module. [Euro4 specification]

Connect the Tech2 24 V adaptor 2 to the DLC

cable. [Except Euro4 specification]

5. Confirm that the ignition is turned "OFF".

6. Connect the Tech2 24 V adaptor 2 to the vehicle

side DLC connector (pole 16, blue).

RHD model

9

1

10

2

11

3

12

4

13

5

14

6

15

7

16

8

2

LNW7Z0SF000501

LHD model

9

1

10

2

11

3

12

4

13

5

14

6

15

7

16

8

MFW82ASH000401

NOTE:

The CNG engine becomes sensitive to fluctuation of

the power voltage when the temperature of ECM unit is

high while or after driving, and communication failures

may occur.

To avoid this situation, input 12 V power supply from a

12 V battery using a battery power cable, separately

from the power for the Tech2 24 V adaptor 2.

• Do not input 24 V battery power supply to the Tech2

unit. Do not use the cigar lighter power supply on

the vehicle side, which is also 24 V.

MFA7Z0SH000201

Page 33

0A-30 General Information

1

2

3

4

5

MFW90ASH000401

Legend

1. Tech2

2. Battery power cable

3. 3 A fuse

4. Clip (black)

5. Clip (red)

• If the power supply is not input, check the 3 A fuse.

7. Turn the ignition "ON", and press the "PWR" key of

the Tech2.

8. Confirm the display of the Tech2.

Press (ENTER) To Continue

HCW46ESH001901

CAUTION:

Remove/install the PCMCIA card after confirming that

power is not being supplied to the Tech2.

Page 34

Recommended Liquid Gasket

Recommended Liquid Gasket

Type Product name Manufacturer name Area used (reference)

General Information 0A-31

ThreeBond 1207B

Silicon type

(Room temperature

vulcanization process)

ThreeBond 1207C

ThreeBond 1215

ThreeBond 1216

ThreeBond 1281

Water Base ThreeBond 1141E ThreeBond

ThreeBond 1102

Solvent

ThreeBond 1104

ThreeBond 1194

LOCTITE 515

Anaerobic

LOCTITE 518

LOCTITE 17430

FMD127

• Make sure to use a liquid gasket with the above

product name or equivalent.

• Do not use LOCTITE 515, 518 or FMD 127, as

they are anaerobic, and do not provide sufficient

effect when there is a gap larger than 0.25 mm

(0.010 in) between the contact surfaces of metals.

• Use an appropriate amount of liquid gasket. Follow

the handling precautions for the product.

ThreeBond

ThreeBond

ThreeBond

ThreeBond

ThreeBond

ThreeBond

ThreeBond

ThreeBond

LOCTITE

LOCTITE

LOCTITE

LOCTITE

Application method

1. Wipe any water or oil from the contact surface.

2. Apply liquid gasket of the specified bead width to

Engine oil seal retainer

Engine oil pan

Timing gear case

Cylinder head cover

Fuel pump

Water pump

Rear axle

Etc.

Engine oil seal retainer

Water pump

Transaxle

Etc.

Make sure the contact surface is dry.

one side of the contact surface. Make sure there

are no cuts in the beads.

1.Completely remove lubricant and moisture from the connecting surfaces.

The surfaces must be perfectly dry.

2.Apply specified bead width of liquid gasket to one of the connecting surfaces.

There must be no gaps in the bead.

mm (in)

SCREW

HOLE

13

(0.040.12)

13

(0.040.12)

DEPRESSION

More than

2 (0.08)

JUDGE

MENT

OK

OK

NG

Depression

Apply liquid gasket to

the bolt hole interior

Example

Anaerobic Type:2-3 mm (0.08-0.12 in)

Others :2-6 mm (0.08-0.24 in)

Specified

bead width

MFW70AMF000101

Page 35

0A-32 General Information

NOTE:

If the repair manual specifies an application method,

follow that method.

Page 36

Recommended Thread Locking Agent

Recommended Thread Locking Agent

Type Color

LOCTITE 242 Blue

LOCTITE 262 Red

LOCTITE 271 Red

Work procedure

1. Completely wipe off any water or oil from the

contact surface of the bolt and bolt hole, and the

threaded portion of nut. Make sure the contact

surface is dry.

2. Apply LOCTITE to the end 1/3 of the screw.

General Information 0A-33

LNW20ASH003201

3. Tighten the bolt at the specified torque.

CAUTION:

After tightening, do not apply excessive torque or

vibrations for at least an hour until the Loctite hardens.

Page 37

0A-34 General Information

Maintenance Schedule

Introduction

When performing the checks on the following items,

regular inspection items should also be checked.

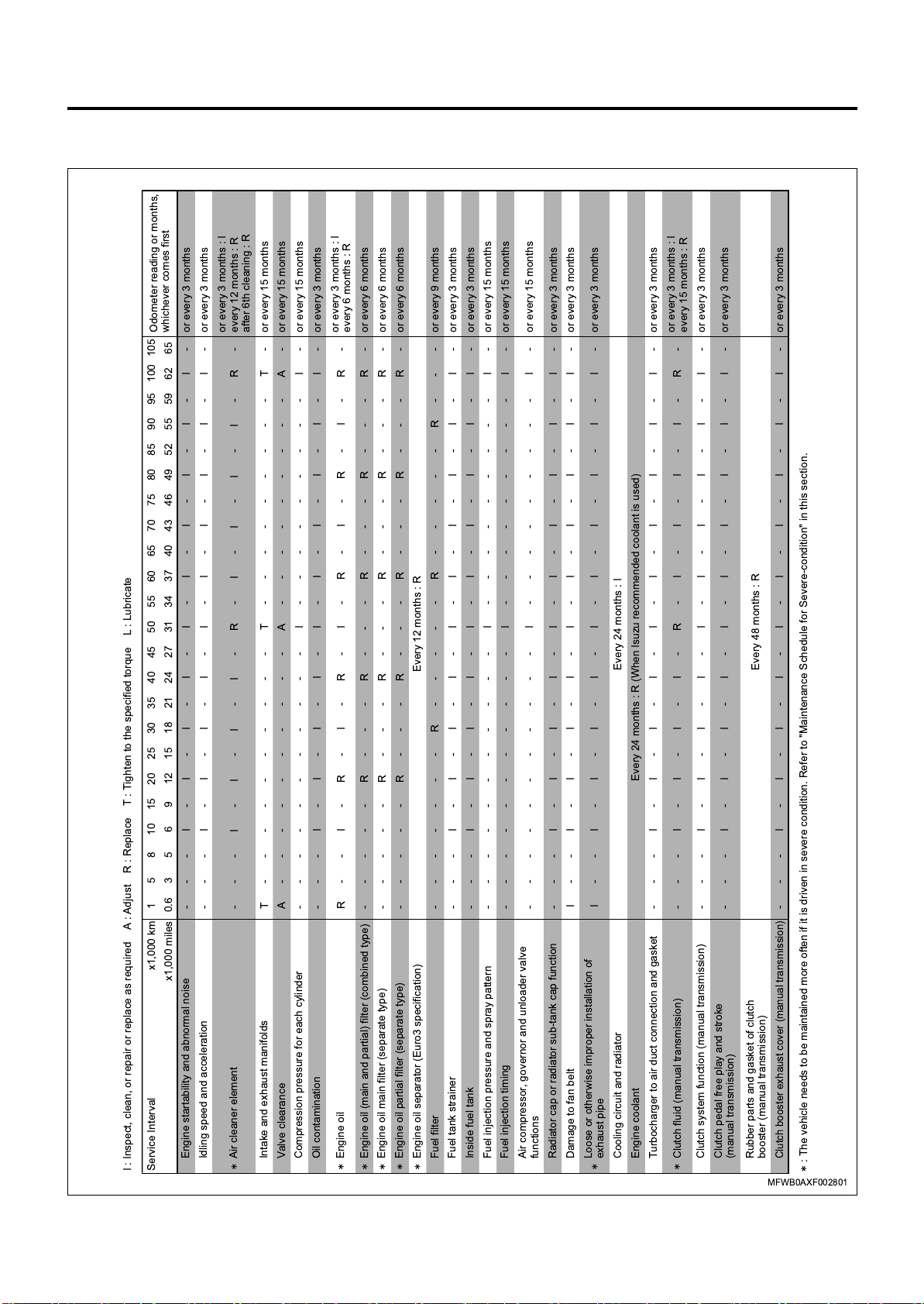

Abbreviations Used in This Manual

I : Inspect, clean, or repair or replace as required

A : Adjust

R : Replace

T : Tighten to the specified torque

L : Add lubricant

Page 38

Maintenance Schedule (for Euro4 specification except Europe)

for Euro4 specification except Europe (1/6)

Odometer reading or months,

whichever comes first

or every 15 months

or after 6th cleaning : R

Every 6 months : I

or every 3 months : I

every 6 months : R

or every 6 months

General Information 0A-35

or every 3 months : I

every 15 months : R

x1,000 miles 0.6 3 5 6 9 12 15 18 21 24 27 31 34 37 40 43 46 49 52 55 59 62 65

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

-----------R---------R-

T----------T---------T-orevery 15 months

A----------A---------A-orevery 15 months

-----------I---------I-orevery 15 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

R-- I-R- I-R- I-R- I-R-I-R-

- - - - - R - - - R - - - R - - - R - - - R - or every 6 months

- - - - - R - - - R - - - R - - - R - - - R - or every 6 months

-----R---R---R---R---R-

-----R---R---R---R---R-

Every 12 months : R

-------R-----R-----R---orevery 9 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

I - - I - I - I - I - I - I - I - I - I - I - or every 3 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

I - - I - I - I - I - I - I - I - I - I - I - or every 3 months

Every 24 months : I

Every 24 months : R (When Isuzu recommended coolant is used)

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

--- I- I- I- I-R-I- I- I- I-R-

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

Every 48 months : R

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

I : Inspect, clean, or repair or replace as required A : Adjust R : Replace T : Tighten to the specified torque L : Lubricate

Service Interval x1,000 km 1 5 8 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Engine startability and abnormal noise

Idling speed and acceleration

Air cleaner element

Valve clearance

Intake and exhaust manifolds

Compression pressure for each cylinder

Oil contamination

Fuel injection timing

Air compressor, governor and unloader valve

functions

Radiator cap or radiator sub-tank cap function

Damage to fan belt

Loose or otherwise improper installation of

exhaust pipe

Engine oil (main and partial) filter (combined type)

Engine oil main filter (separate type)

Engine oil partial filter (separate type)

Engine oil separator (6HK1 engine model)

Engine oil

Engine oil separator (4HK1 engine model)

Fuel filter

Fuel tank strainer

Inside fuel tank

Fuel injection pressure and spray pattern

Cooling circuit and radiator

Engine coolant

Turbocharger to air duct connection and gasket

Clutch fluid (manual transmission)

Clutch pedal free play and stroke

(manual transmission)

Clutch system function (manual transmission)

Clutch booster exhaust cover (manual transmission)

Rubber parts and gaskets of clutch booster

(manual transmission)

: The vehicle needs to be maintained more often if it is driven in severe condition. Refer to "Maintenance Schedule for Severe-condition" in this section.

MFWB0AXF002001

Page 39

0A-36 General Information

for Euro4 specification except Europe (2/6)

or 2,000 hours

or 24 months : R

or 2,000 hours

Odometer reading or months,

whichever comes first

or every 3 months : I

every 15 months : R

or every 3 months : I

every 15 months : R

or 24 months : R

or 1,000 hours

or 12 months : R

or 1,000 hours

or 12 months : R

or every 3 months : I

or every 3 months : I

every 15 months : R

or every 3 months : I

every 15 months : R

every 15 months : R

or every 3 months : I

every 15 months : R

or every 3 months : I

every 15 months : R

Replace the filter at overhaul

Refer to Maintenance Schedule (Transmission Oil - FS8209A/FSO5206B Type)

Refer to Maintenance Schedule (Transmission Oil - ZF6S1000/ZF9S1110 Type)

Refer to Maintenance Schedule (Transmission Oil - FS8209A/FSO5206B Type)

-----------------R-----orevery 24 months

--R--------------R-----

-----------------R-----

--R------R-------R-----orevery 12 months

--R------R-------R-----

Refer to Maintenance Schedule (Transmission Oil - ZF6S1000/ZF9S1110 Type)

R--I-I-I-I-R-I-I-I-I-R-

R--I-I-I-I-R-I-I-I-I-R-

x1,000 miles 0.6 3 5 6 9 12 15 18 21 24 27 31 34 37 40 43 46 49 52 55 59 62 65

Replace the filter at overhaul

---------R-------R-----

R--I-I-I-I-R-I-I-I-I-R-

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

R--I-I-I-I-R-I-I-I-I-R-

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

R--I-I-I-I-R-I-I-I-I-R-

Refer to Maintenance Schedule (RS23/RT40 type Axle)

R--I-I-I-I-R-I-I-I-I-R-

R--I-I-I-I-R-I-I-I-I-R-

-----------R---------R-orevery 15 months

I : Inspect, clean, or repair or replace as required A : Adjust R : Replace T : Tighten to the specified torque L : Lubricate

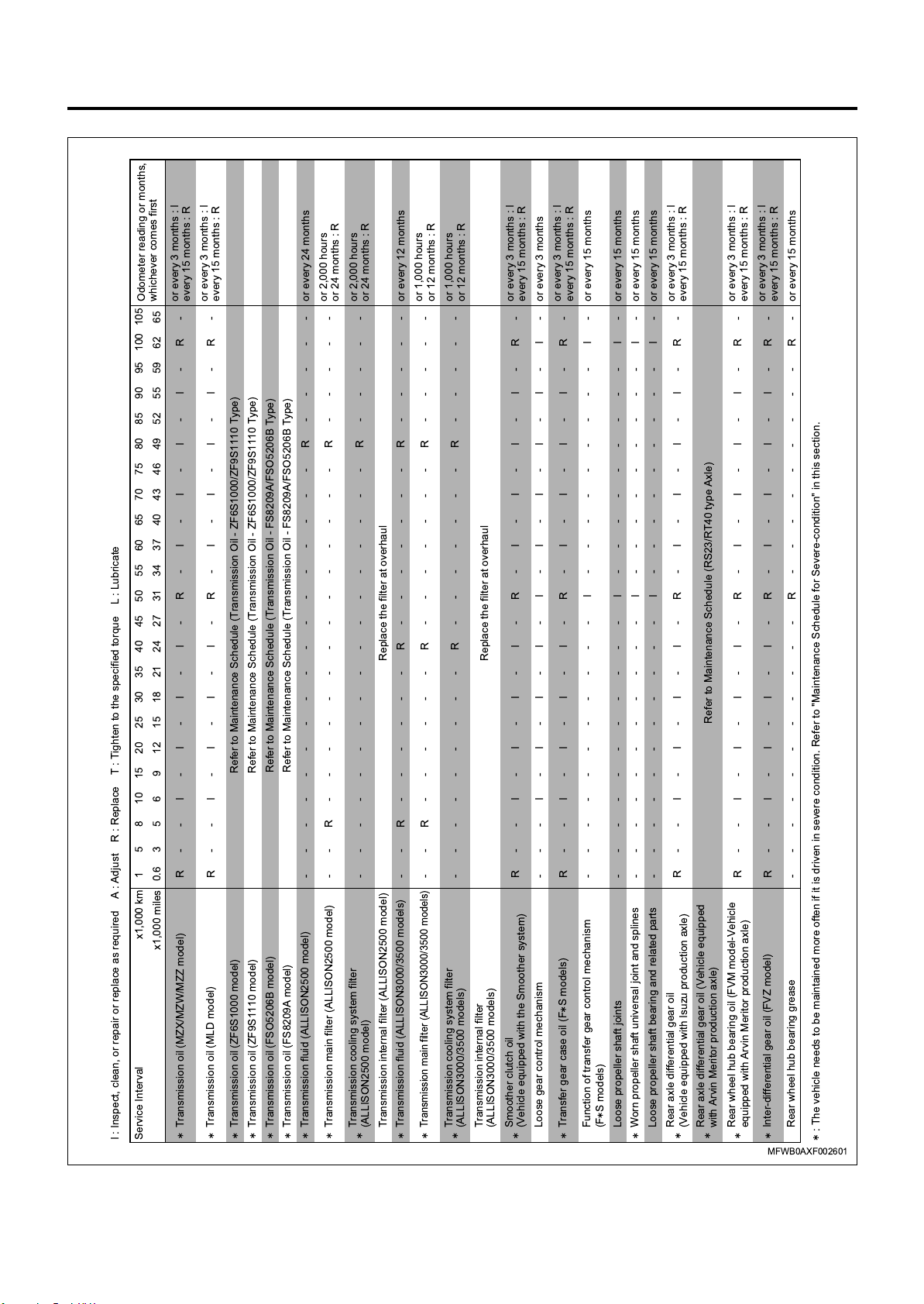

Service Interval x1,000 km 1 5 8 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Transmission oil (MZX/MZW/MZZ model)

Transmission oil (MLD model)

Transmission oil (ZF9S1110 model)

Transmission oil (ZF6S1000 model)

Transmission oil (FSO5206B model)

Transmission oil (FS8209A model)

Transmission fluid (ALLISON2500 model)

Transmission main filter (ALLISON2500 model)

Transmission cooling system filter

(ALLISON2500 model)

Transmission internal filter (ALLISON2500 model)

Transmission main filter (ALLISON3000/3500 models)

Transmission fluid (ALLISON3000/3500 models)

Transmission cooling system filter

(ALLISON3000/3500 models)

Transmission internal filter

(ALLISON3000/3500 models)

Smoother clutch oil

(Vehicle equipped with the Smoother system)

Loose gear control mechanism

Transfer gear case oil (F S models)

Function of transfer gear control mechanism

Loose propeller shaft joints

(F S models)

Worn propeller shaft universal joint and splines

Loose propeller shaft bearing and related parts

Rear axle differential gear oil

(Vehicle equipped with Isuzu production axle)

Rear axle differential gear oil (Vehicle equipped

with Arvin Meritor production axle)

Rear wheel hub bearing oil (FVM model-Vehicle

equipped with Arvin Meritor production axle)

Inter-differential gear oil (FVZ model)

MFWB0AXF002601

Rear wheel hub bearing grease

: The vehicle needs to be maintained more often if it is driven in severe condition. Refer to "Maintenance Schedule for Severe-condition" in this section.

Page 40

for Euro4 specification except Europe (3/6)

or every 3 months : I

every 15 months : R

or every 3 months : I

Odometer reading or months,

whichever comes first

every 15 months : R

General Information 0A-37

or every 3 months : I

every 15 months : R

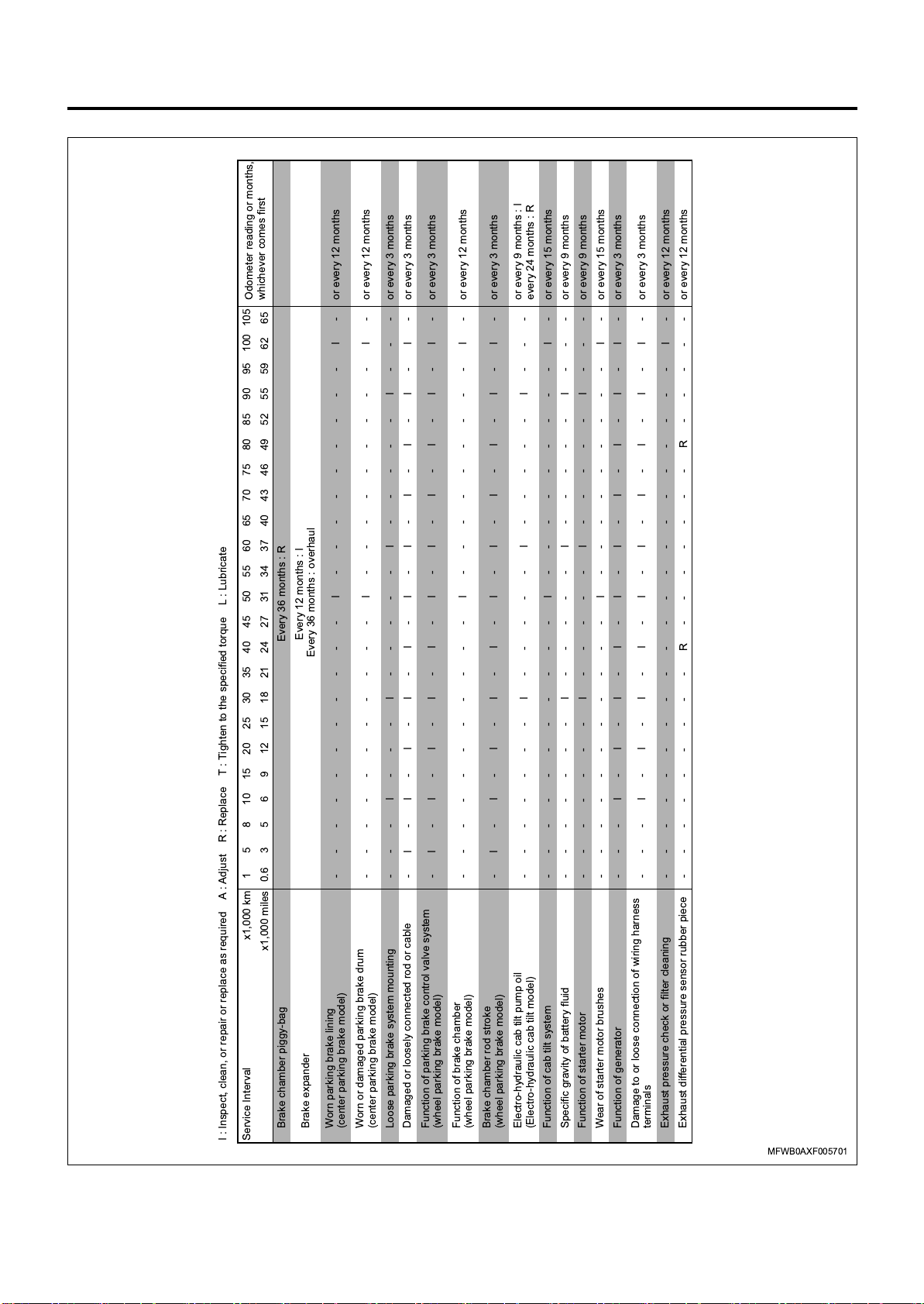

I : Inspect, clean, or repair or replace as required A : Adjust R : Replace T : Tighten to the specified torque L : Lubricate

Service Interval x1,000 km 1 5 8 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

x1,000 miles 0.6 3569121518212427313437404346495255596265

-----------I---------I-orevery 15 months

Damaged or distorted rear axle case

-----------R---------R-orevery 15 months

R--I-I-I-I-R-I-I-I-I-R-

Front wheel hub bearing grease

Front axle differential gear oil (F S models)

R--I-I-I-I-R-I-I-I-I-R-

Front wheel hub bearing oil

)

Vehicle equipped with Arvin Meritor production axle

(

-----------I---------I-orevery 15 months

T----------T---------T-orevery 15 months

Damaged or distorted front axle case

Leaf spring U-bolt nuts

T----------T---------T-orevery 15 months

Air suspension's beam bolt nuts/U-bolt nuts

(Air suspension model)

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

-----------I---------I-orevery 15 months

Damaged leaf spring

Uneven suspension due to leaf spring fatigue

-------I-----I-----I---orevery 9 months

-------I-----I-----I---orevery 9 months

Loose or damaged leaf spring mounting

Spring leaves for misalignment

-------I-----I-----I---orevery 9 months

-------I-----I-----I---orevery 9 months

Oil leaks from or damage to shock absorbers

Loose shock absorber mounting

Loose or damaged air suspension main support

-----------I---------I-orevery 15 months

members (Air suspension model)

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

Air leaks from air suspension (Air suspension model)

Damaged air spring (Air suspension model)

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

-----------I---------I-orevery 15 months

Loose or damaged air suspension mounting

(Air suspension model)

Air spring height (Air suspension model)

-----------I---------I-orevery 15 months

Function of height sensor or leveling valve

(Air suspension model)

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

- - - - - I - - - I - - - I - - - I - - - I - or every 6 months

Loose or damaged torque rod (if so equipped)

Loose or damaged traverse rod (if so equipped)

Loose or damaged V-rod (if so equipped)

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

T - - T - T - T - T - T - T - T - T - T - T - or every 3 months

Wheel nuts

Foreign object in wheels

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

-----------I---------I-orevery 15 months

Damaged disc wheels

Loose front wheel hub bearings

-----------I---------I-orevery 15 months

--- I- I- I- I-R-I- I- I- I-R-

Loose rear wheel hub bearings

Power steering fluid

MFWB0AXF005001

: The vehicle needs to be maintained more often if it is driven in severe condition. Refer to "Maintenance Schedule for Severe-condition" in this section.

Page 41

0A-38 General Information

for Euro4 specification except Europe (4/6)

Odometer reading or months,

whichever comes first

or every 3 months

or every 3 months : I

every 12 months : R

or every 3 months

or every 3 months : I

every 24 months : R

x1,000 miles 0.6 3 5 6 9 12 15 18 21 24 27 31 34 37 40 43 46 49 52 55 59 62 65

-----------I---------I-orevery 15 months

--- I- I- I- I- I- I- I- I- I- I-

-----------I---------I-orevery 15 months

-- I- I- I- I- I- I- I- I- I- I-

I or every 3 months

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

-----------I---------I-orevery 15 months

- - - - - - - - - - - I - - - - - - - - - I - or every 15 months

---I-I-I-I-R-I-I-I-I-R-

- - - - - - - - - - - I - - - - - - - - - I - or every 12 months

--- I- I- I- I- I- I- I- I- I- I-

---I-I-I-I-R-I-I-I-I-R-

- - - - - - - - - - - I - - - - - - - - - I - or every 12 months

- - - I - I - I - I - I - I - I - I - I - I - or every 12 months

- - - I - I - I - I - I - I - I - I - I - I - or every 3 months

- - - - - - - - - - - I - - - - - - - - - I - or every 15 months

- I - I - I - I - I - I - I - I - I - I - I - or every 3 months

- - - - - - - - - - - I - - - - - - - - - I - or every 12 months

- - - - - - - - - - - I - - - - - - - - - I - or every 12 months

Change the desiccant, filter and rubber parts of air dryer

Every 24 months : RABS modulator (Vehicle equipped with ABS)

at 100,000 km (62,000 miles) or every 12 months.

Every 12 months : RRubber parts of wheel cylinder

Every 24 months : R

Every 3 months : I

Every 24 months : R

Every 24 months : R

I : Inspect, clean, or repair or replace as required A : Adjust R : Replace T : Tighten to the specified torque L : Lubricate

Service Interval x1,000 km 1 5 8 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Power steering fluid filter

Excessive play in power steering bearing

Loose power steering system mounting

Damage to, loose or excessive play in power

steering joints

Knuckle-to-front axle clearance

Wheel alignment

Steering angle range for right and left turns

King pin-to-bearing clearance

Brake fluid (Vehicle equipped with the air-over

hydraulic brake system)

Brake lining wear

Brake drum wear or damage

Brake hose

Function of brake valves (Vehicle equipped with

the air-over hydraulic brake system)

Brake booster exhaust cover (Vehicle equipped

with the air-over hydraulic brake system)

Leaks from, damage to, or loose connection of

brake hose or pipe

Excessively worn cams and wheel brakes (Vehicle

equipped with Arvin Meritor production axle)