Page 1

Chevrolet/GMC Class T6500/7500/8500

i

Low Cab Forward

MODEL SYMBOL CHART ...................................................................................................................................................................................1

CHASSIS

& Isuzu Class FTR/FTV/FTX

PAGE

General Arrangement – T6/T7/T8 F042 ....................................................................................................................................................

General Arrangement – T8F064 .................................................................................................................................................................

Body Payload Weight Distribution – T6/T7/T8 F042 ...............................................................................................................................

Body Payload Weight Distribution – T8F064 ............................................................................................................................................

Formulas for Calculating Height Dimensions to Top of Frame – Front Axle .......................................................................................

Formulas for Calculating Height Dimensions to Top of Frame – Rear Axle ........................................................................................

BODY

Cab Exterior – Front, Rear, Side Views – (Cab Tilt, Bumper, Rear Window, Step Heights,

Bumper To BOC, Bumper To Air Induction – Effective CA)....................................................................................................................8

Cab Exterior – Mirrors ................................................................................................................................................................................

Cab Exterior – Door Swings .....................................................................................................................................................................

Cab Interior – Seating ...............................................................................................................................................................................

FRAME

General Information ..................................................................................................................................................................................

Section Modulus ...............................................................................................................................................................................

Yield Strength ....................................................................................................................................................................................

2

3

4

5

6

7

9

10

11

12

12

12

Resisting Bending Moment (RBM) .................................................................................................................................................

Frame Rail – Material and Weldability ............................................................................................................................................

Body Mounting Concerns ................................................................................................................................................................

Single Axle Medium Duty Conventional .........................................................................................................................................

Strength

Frame Material Properties ...............................................................................................................................................................

Frame Lengths with Reinforcements .....................................................................................................................................................

Frame Lengths with Reinforcements – Charts (042) ............................................................................................................................

Low Cab Forward — Revised 10/2006

..............................................................................................................................................................................................15

12

13

14

14

16

17

18

Page 2

Low Cab Forward

FRAME – (Continued)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

ii

PAGE

Frame Lengths with Reinforcements – Charts (064) ............................................................................................................................

Frame and Crossmember Locations (042) .............................................................................................................................................

Frame and Crossmember Locations (064) .............................................................................................................................................

AXLE/SUSPENSION

Front Axle Track and Suspension Drawing ............................................................................................................................................

Front Axle Track Charts ............................................................................................................................................................................

Front Suspension Charts ..........................................................................................................................................................................

Rear Axle and Suspension – Drawing (042) ...........................................................................................................................................

Rear Axle and Suspension – Formulas (042) .........................................................................................................................................

Rear Axle / Suspension – Chart (042) Option Description and Bottom of Differential Bowl ...........................................................

Rear Axle / Wheel – Chart (042) Track Widths .......................................................................................................................................

Rear Axle / Suspension – Chart (042) Heights .......................................................................................................................................

Rear Axle / Suspension – Chart (042) Heights .......................................................................................................................................

Rear Axle and Suspension – Drawing (064) ...........................................................................................................................................

Rear Axle and Suspension – Formulas (064) .........................................................................................................................................

Rear Axle / Suspension – Chart (064) Option Descriptions, Bottom of Differential Bowl and Heights .........................................

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

BRAKES

Air Tank Location – (042) Truck – RQ2 ....................................................................................................................................................

Air Tank Location – (042) Tractor – RQ3 .................................................................................................................................................

Air Tank Location – (064) Truck – RQ2 ....................................................................................................................................................

Air Tank Location – (064) Tractor – RQ3 .................................................................................................................................................

BATTERY BOX LOCATION ................................................................................................................................................................................38

FUEL TANKS

Dual 50 Gallon (opt. NJ8) & Single 50 Gallon LH (opt. NK8)

Dual 50 Gallon LH and 25 Gallon RH (opt. NJ7) & Single 50 Gallon LH (opt. NK6) ...........................................................................

Low Cab Forward — Revised 11/2007

................................................................................................................39

34

35

36

37

40

Page 3

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

AIR INDUCTION .................................................................................................................................................................................................41

EXHAUST

& Isuzu Class FTR/FTV/FTX

iii

PAGE

Single Horizontal Exhaust w/RH exit tailpipe & cooler, opt. N1B & 7.8 Isuzu Diesel LHP & 140´´ WB opt. FQT

Single Horizontal Exhaust w/RH exit tailpipe & cooler, opt. N1B & 7.8 Isuzu Diesel HHP & 140´´ WB opt. FQT

Single Horizontal Exhaust, opt. NB5 & 7.8 Isuzu Diesel LHP & 152´´ and longer WB

Single Horizontal Exhaust, opt. NB5 & 7.8 Isuzu Diesel HHP & 152´´ and longer WB

Exhaust LH Vertical DPF, Tailpipe and Heat Shield – Exhaust opt. NEP, with Engine opt. LF8, 7.8L LHP Isuzu ...........................

Exhaust LH Vertical DPF, Tailpipe and Heat Shield – Exhaust opt. NEP, with Engine opt. LF8, 7.8L HHP Isuzu ..........................

Horizontal Tailpipe, Nozzle, Hangers and Cooler – opt. LF8, 7.8L Isuzu ............................................................................................

PTO

Manual Transmission PTO Location Charts

Automatic Transmission PTO Location Charts

WHEEL & TIRE SPECIFICATIONS ................................. QUICK LINKS – www.gmfleet.com/See Medium Duty Online Order Guide/

Technical Data/Gray Tabs

MODEL & OPTIONS WEIGHTS .......................................QUICK LINKS – www.gmfleet.com/See Medium Duty Online Order Guide/

select model/CALCULATORS

..........................................................................................................................................49

.....................................................................................................................................50

.......................................................................44

......................................................................45

...........................42

..........................43

46

47

48

Low Cab Forward — Revised 11/2007

Page 4

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

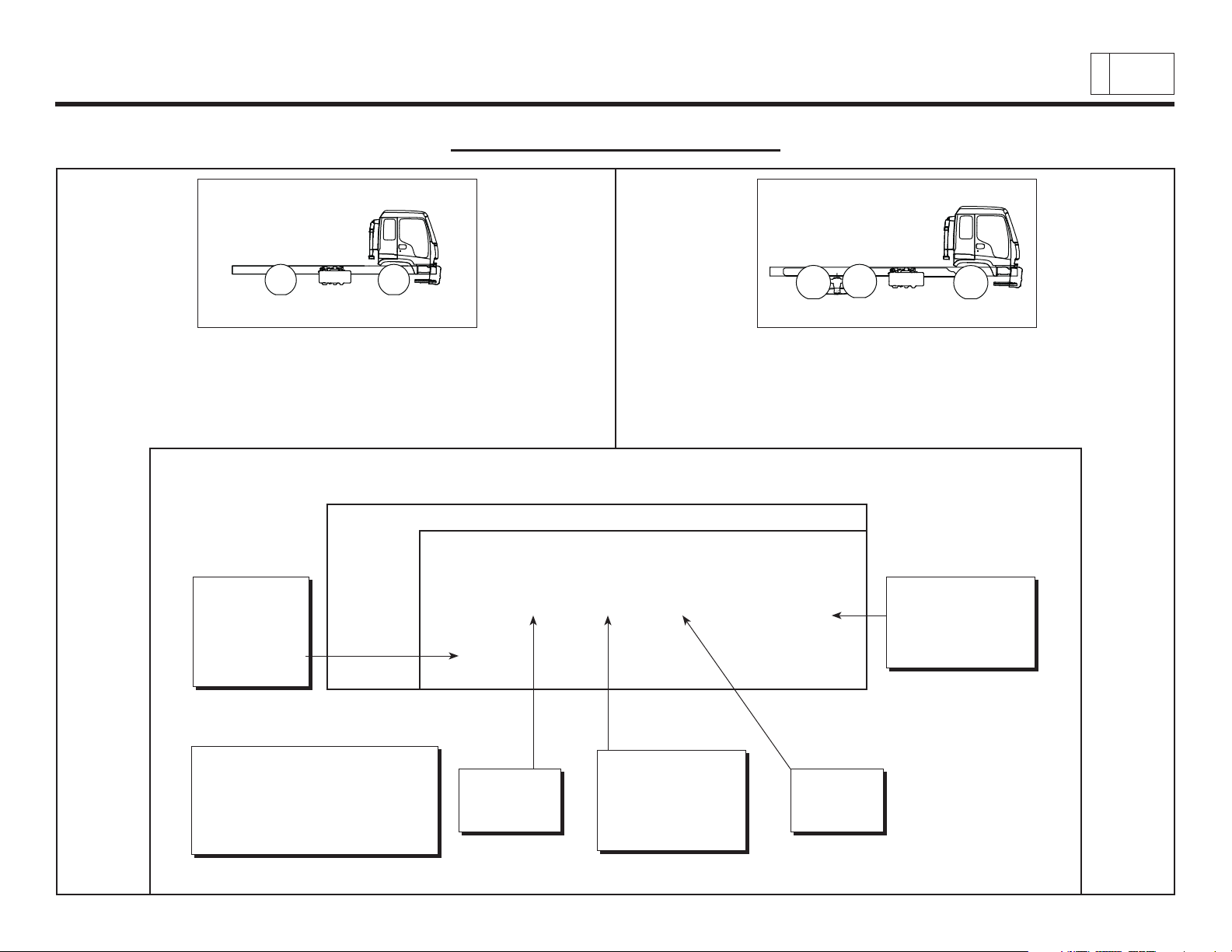

MODEL SYMBOL CHART

T Series – 2-wheel drive T Series – Tandem

T6F042 T8F064

T7F042

T8F042

MODEL DESIGNATOR KEY:

Position 1 2 3 4 5 6, 7

1

PAGE

Division:

C = Chevrolet

T = GMC

J = Isuzu

General Information:

RPO Code VDS Books

X88 = Chevrolet 11 = Family 3

Z88 = GMC 11 = T Series

Z89 = Isuzu

Low Cab Forward — Revised 10/2006

Division Model GVW Cab Constant Chassis

Line Range Style Type

______ ______ ______ ______ ______ ______

not 0

shown

GVW Range:

Model Line:

T = T Series

6 = 19501 - 26000

7 = 26001 - 33000

8 = Over 33000

Cab Style:

F = Tilt

Chassis Type:

42 = 2 wheel drive

64 = Tandem

Page 5

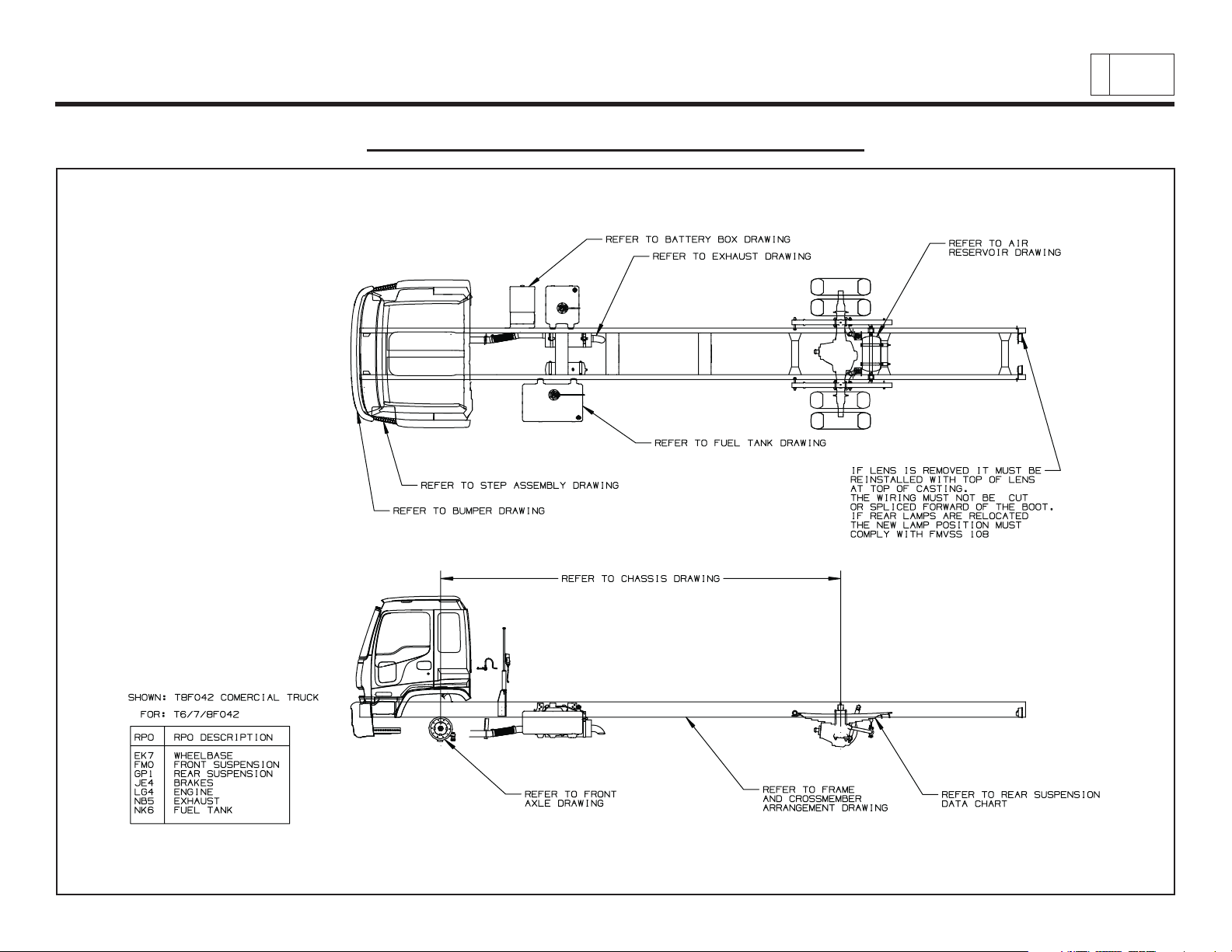

Low Cab Forward

General Arrangement – T6/T7/T8 F042

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

2

PAGE

Low Cab Forward — Revised 10/2006

TD006041a

Page 6

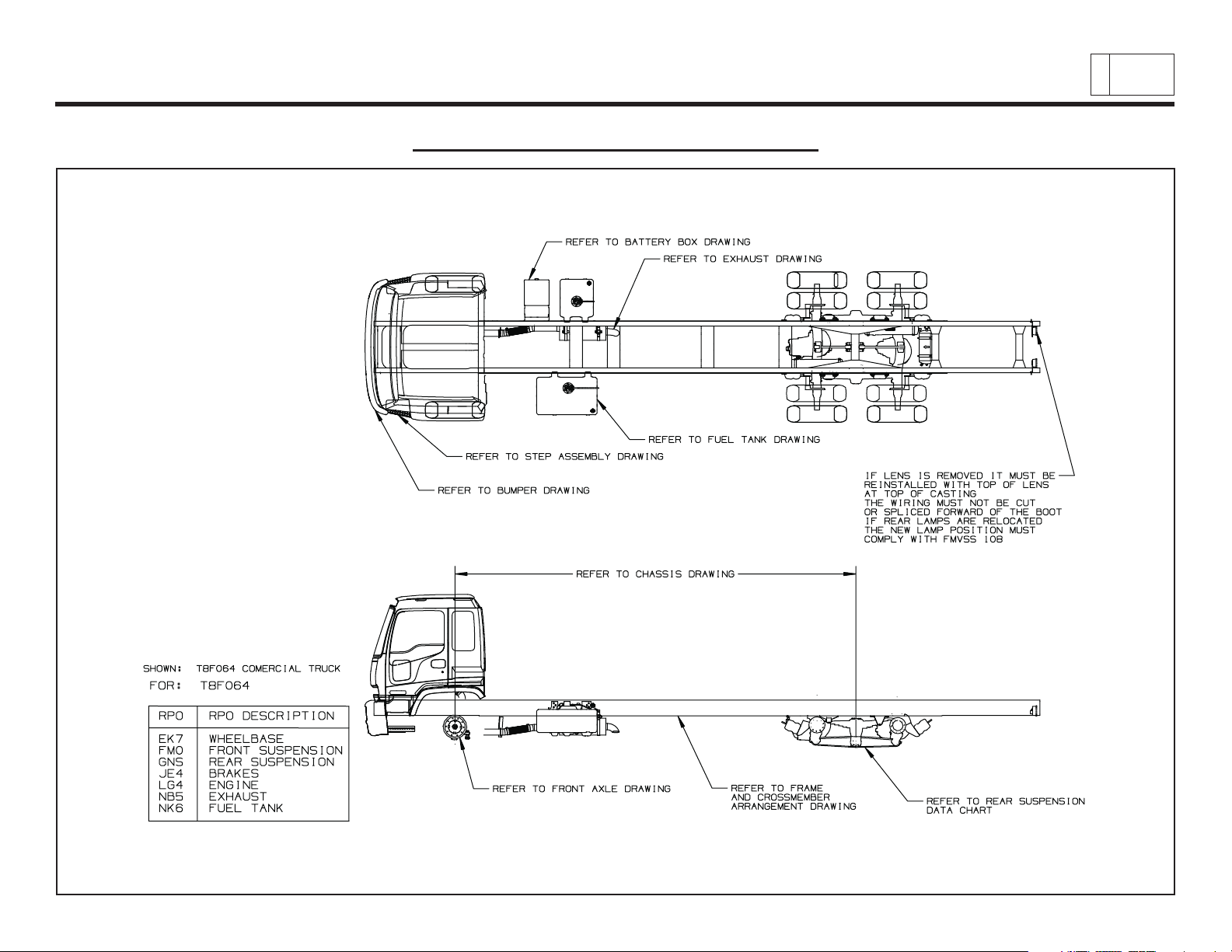

Low Cab Forward

General Arrangement – T8F064

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

3

PAGE

Low Cab Forward — Revised 10/2006

TD006041b

Page 7

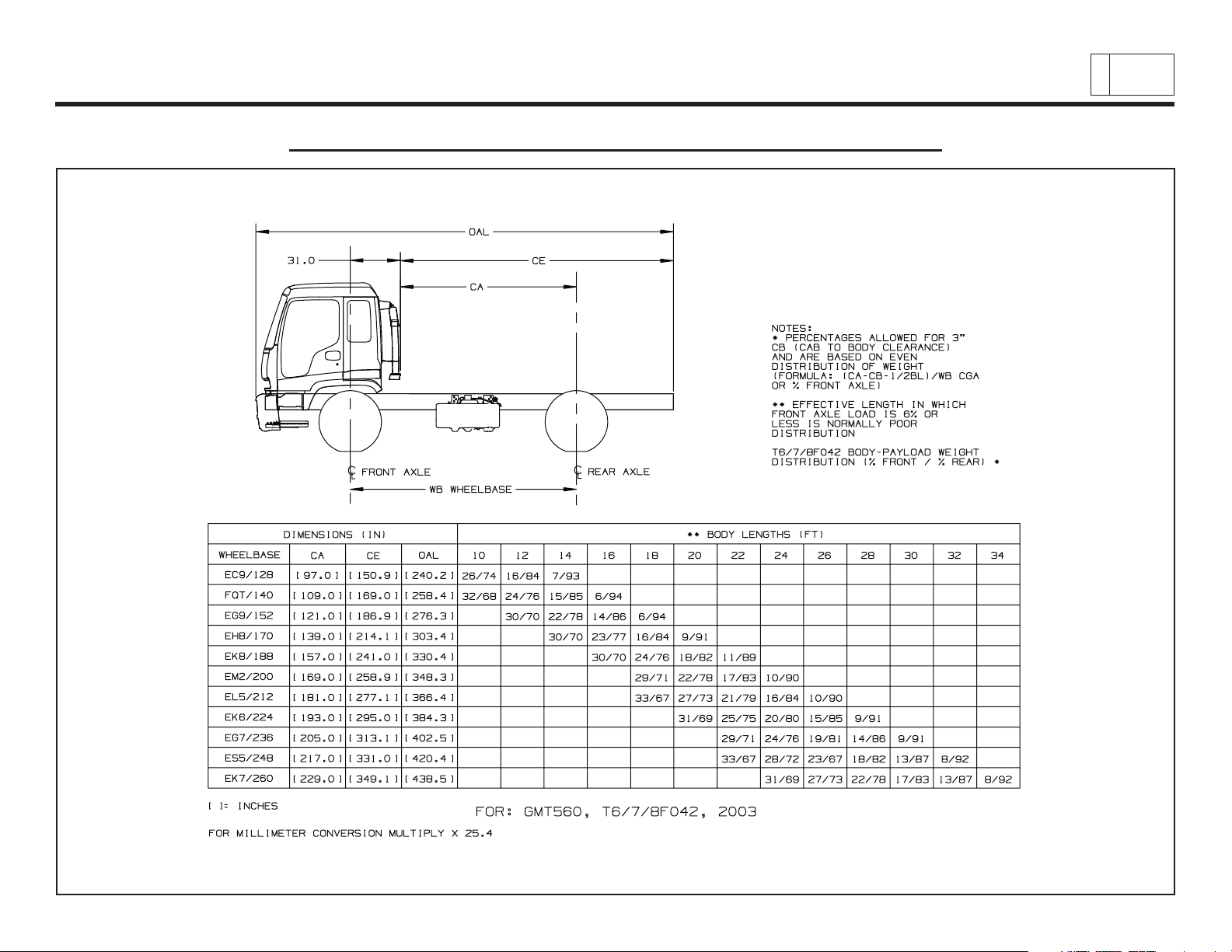

Low Cab Forward

Body Payload Weight Distribution – T6/T7/T8 F042

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

4

PAGE

Low Cab Forward — Revised 10/2006

TD006055a

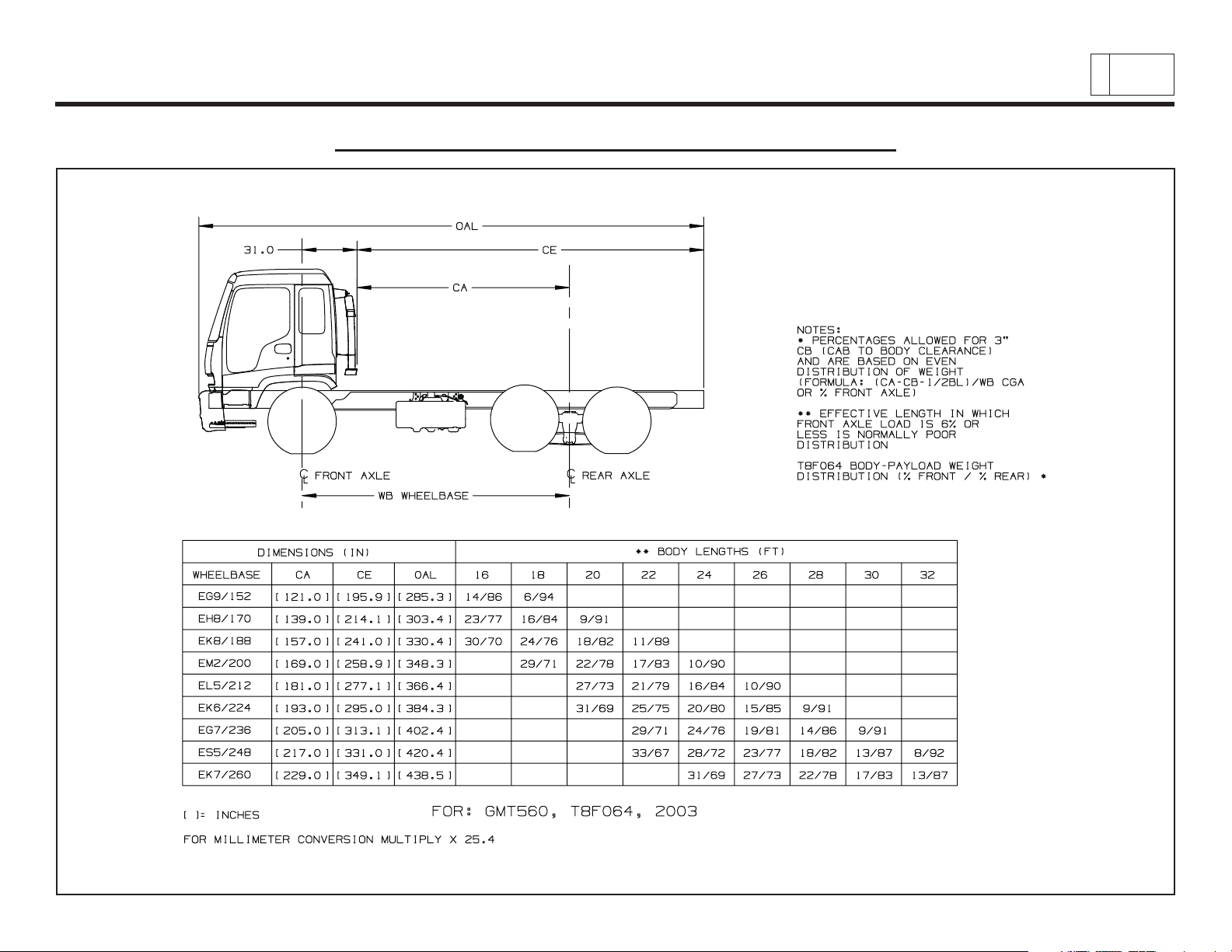

Page 8

Low Cab Forward

Body Payload Weight Distribution – T8F064

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

5

PAGE

Low Cab Forward — Revised 10/2006

TD006055b

Page 9

Sample Data:

Model Tire Tire Loaded Radius LH C D

T7F042

275/80R22.5G (XSH)

18.6" 9.69" 7.35" 5.75"

Frame Reinforcement RPO Wheelbase Suspension RPO Axle RPO

F20 152" (EG9) F28 (12,000 lb) FS7 (12,000 lb)

Formulas:

CH = C + Tire Static Loaded Radius + LH CH = 7.35" + 18.6" + 9.69" = 35.64"

DH = D + Tire Static Loaded Radius + LH DH = 5.75" + 18.6" + 9.69" = 34.04"

Definitions:

C – Centerline of axle to bottom inside of rail at curb position

D – Centerline of axle to bottom inside of rail at design load

LH – Distance from the bottom inside rail to the top of the rail

NOTE: For Tire, Static Loaded Radius (SLR) / QUICK LINKS – www.gmfleet.com /

See Medium Duty Online Order Guide / select Technical Data/Gray Tab from the upper tool bar /

select Wheel-Tire Specification / select print to view.

For the C & D values see the Front Axle and Suspension Chart.

For the LH values see the Frame Length with Reinforcements section.

Step Height Dimensions:

When calculating step height dimensions see the step assembly location, and the frame drawings for values.

R4L/S3L (Michelin) S4L

Low Cab Forward

Formulas for Calculating Height Dimensions to Top of Frame – Front Axle

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

6

PAGE

Low Cab Forward — Revised 10/2006

Page 10

Sample Data:

Model Tire Tire Loaded Radius LH C D

T7F042

275/80R22.5G (YSH)

19.0" 9.69" 11.41" 7.94"

S3H (Michelin) S4L

Frame Reinforcement RPO Wheelbase Suspension RPO Axle RPO

F20 152" (EG9) GNB (21,000 lb) HPN (21,000 lb)

F

ormulas:

CH = C + Tire Static Loaded Radius + LH CH = 19.0" + 11.41" + 9.69" = 40.11"

DH = D + Tire Static Loaded Radius + LH DH = 19.0" + 7.94" + 9.69" = 36.63"

D

efinitions:

C – Centerline of axle to bottom inside of rail at curb position

D – Centerline of axle to bottom inside of rail at design load

LH – Distance from the bottom inside rail to the top of the rail

NOTE: For Tire, Static Loaded Radius (SLR) / QUICK LINKS – www.gmfleet.com /

See Medium Duty Online Order Guide / select Technical Data/Gray Tab from the upper tool bar /

select Wheel-Tire Specification / select print to view.

For the C & D values see the Rear Axle and Suspension Chart.

For the LH values see the Frame Length with Reinforcements section.

Step Height Dimensions:

When calculating step height dimensions see the step assembly location, and the frame drawings for values.

Low Cab Forward

Formulas for Calculating Height Dimensions to Top of Frame – Rear Axle

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

7

PAGE

Low Cab Forward — Revised 10/2006

Page 11

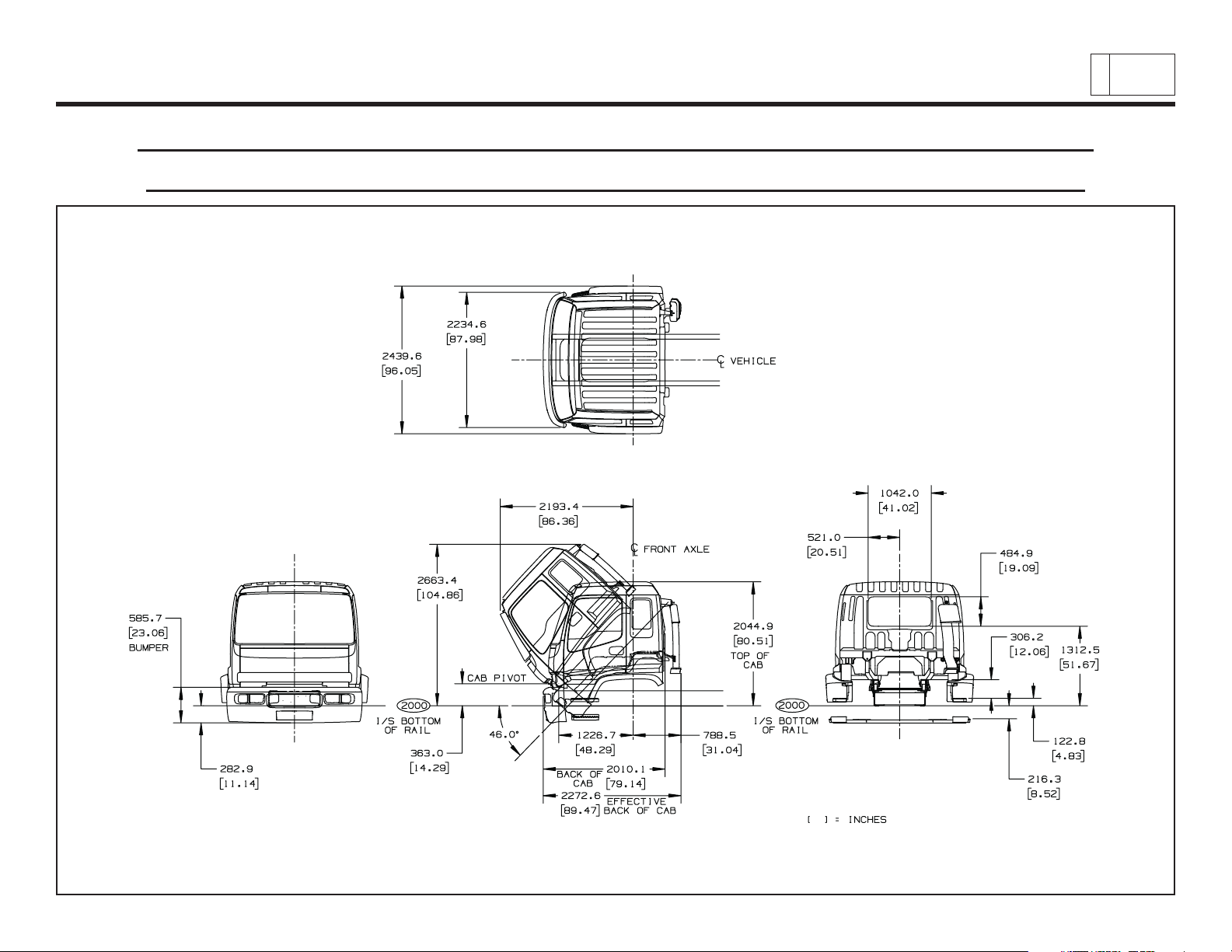

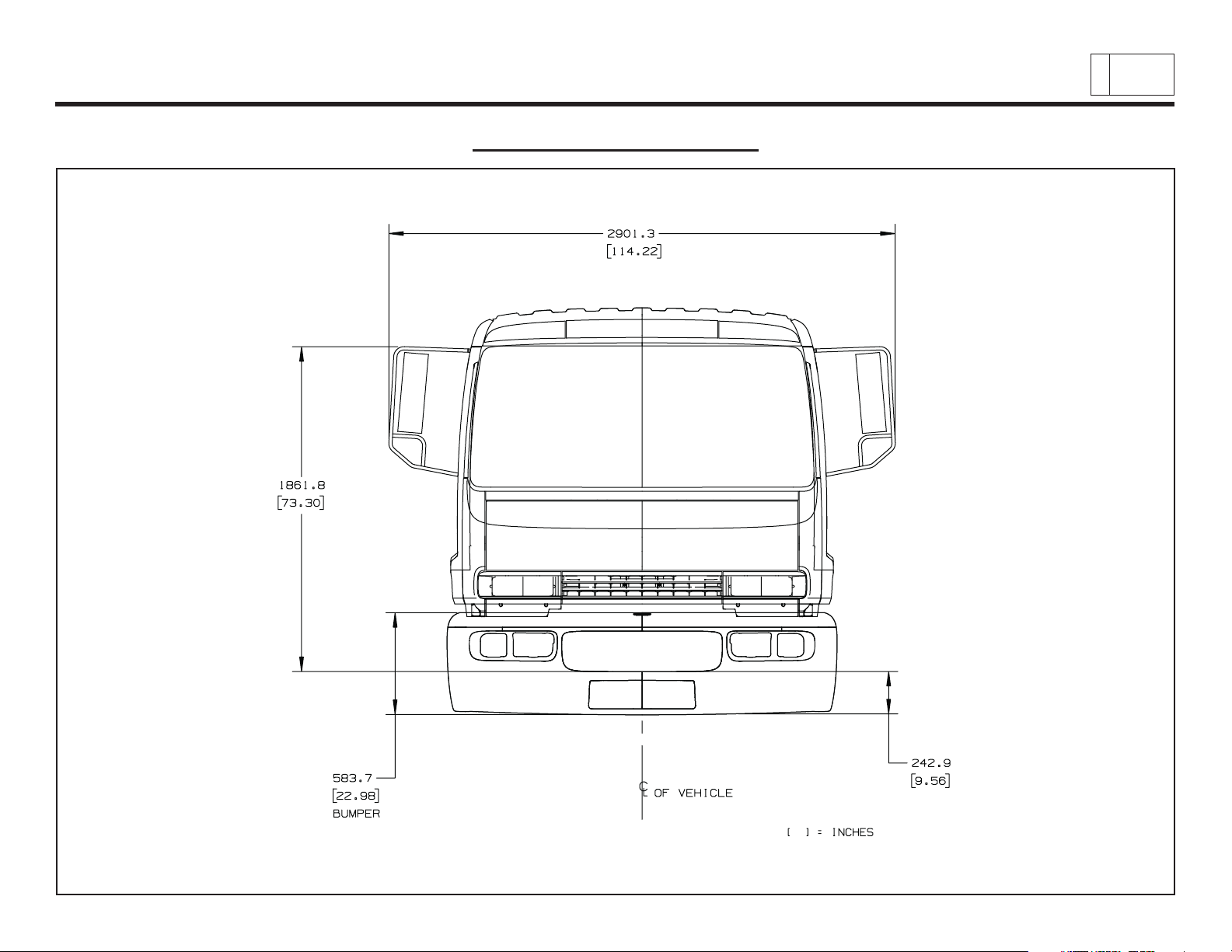

Low Cab Forward

Cab Exterior – Front, Rear, Side Views – (Cab Tilt, Bumper, Rear Window,

Step Heights, Bumper To BOC, Bumper To Air Induction – Effective CA)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

8

PAGE

Low Cab Forward — Revised 10/2006

TD006045a

Page 12

Low Cab Forward

Cab Exterior – Mirrors

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

9

PAGE

Low Cab Forward — Revised 10/2006

TD006045b

Page 13

Low Cab Forward

Cab Exterior – Door Swings

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

10

Low Cab Forward — Revised 10/2006

TD006045c

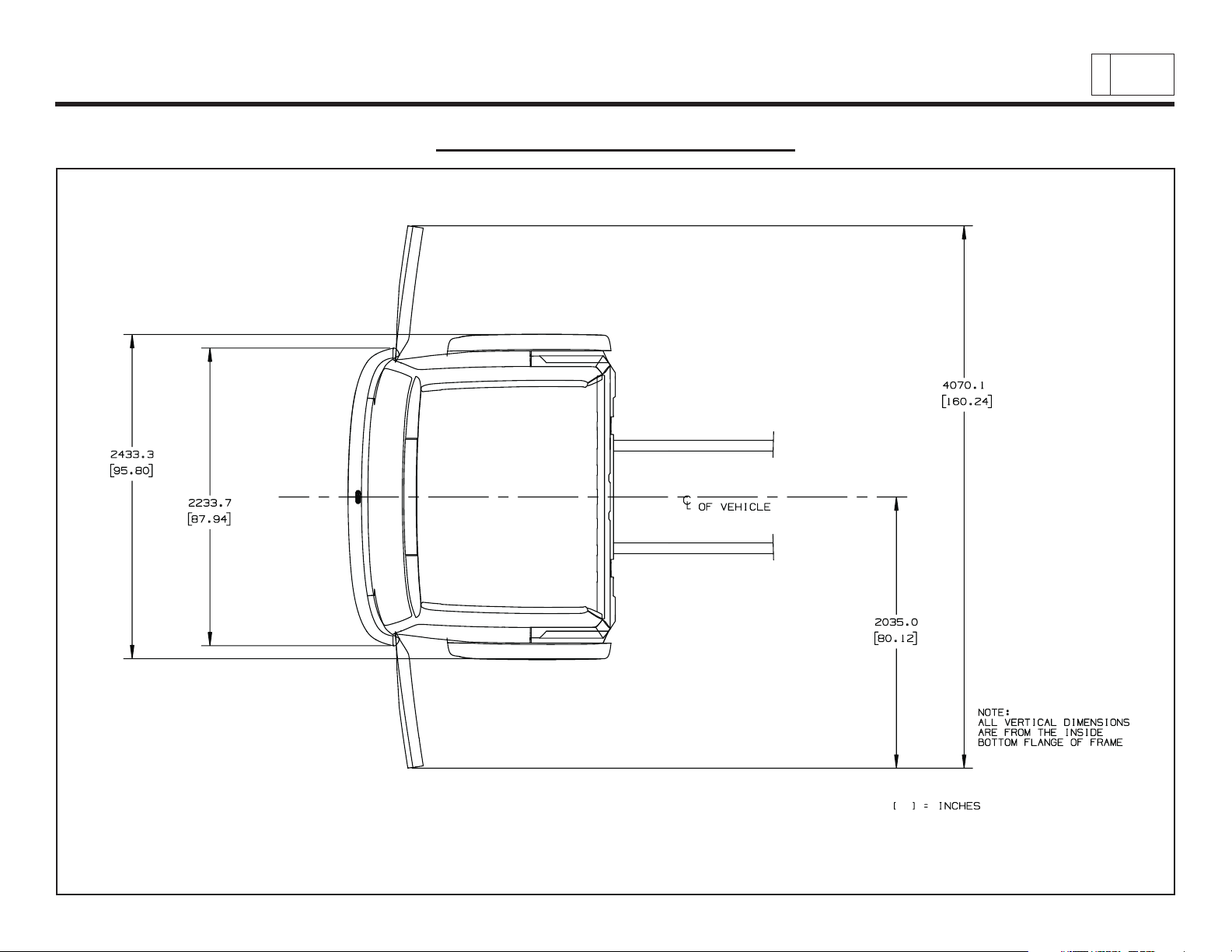

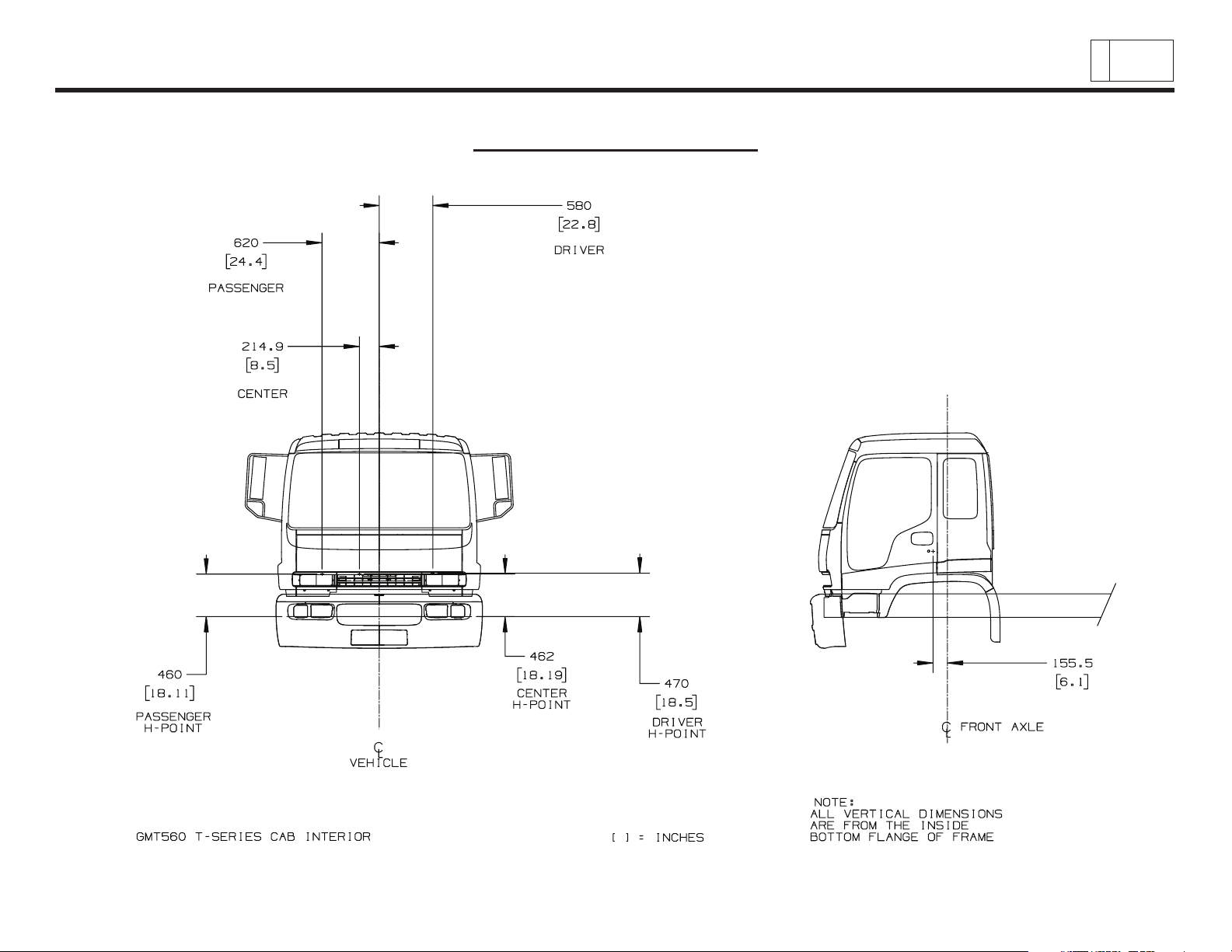

Page 14

Low Cab Forward

Cab Interior – Seating

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

11

Low Cab Forward — Revised 10/2006

TD006044.3

Page 15

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

General Information

Section Modulus

• Section modulus is a measure of the frame strength based solely on the height, width, thickness, and configuration of the side

rails. It is calculated at the point of maximum stress, which is usually directly behind the cab.

• Section modulus is not a measure of material strength and can only be used by itself to compare frames of like materials.

• Frame reinforcements will increase the section modulus because they increase the strength by adding to the thickness of the

section.

• Consult the Frame Properties for all section modulus ratings.

Yield Strength

• Yield strength is a measurement of the frame material’s strength. It is maximum load (PSI) that can be placed on the material and

still have it return to its original position when the load is removed without being bent out of shape.

• It can be used only to compare frames of identical section. Two yield strength frames are available for the T-Series. They are

80,000 psi (551,600 kPa) and 120,000 psi (827,400 kPa).

PAGE

12

RBM-Resisting Bending Moment

• Since Section Modulus can only be used to compare frames of like materials and yield strength can only indicate relative strengths

of identical frames, some measurement is necessary to compare frames of different materials and different sections. The RBM,

or Resisting Bending Moment, can be used for this comparison as it utilizes section modulus and yield strength in its makeup.

• RBM = Section Modulus x Yield Strength

• This measurement will show that a smaller section frame of higher strength steel will be just as strong as a larger section frame

of lower strength of steel.

• It is readily apparent that both section modulus and yield strength are equally important so that their product, RBM, is the correct

figure to use for frame comparisons. The RBMs for all standard and optional frames are shown on the Frame Properties charts.

• Frames are designed to torsional stiffness and beaming criteria as well as fatigue strength.

Low Cab Forward — Revised 10/2006

Page 16

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

General Information (continued)

Frame Rail – Material and Weldability

• The frames on GM Trucks are built for strength, durability, and adaptability. They are available in tensile strengths of 80,000 psi

(551,600 kPa) and 120,000 psi (827,400 kPa) ratings.

• The 80,000 psi (551,600 kPa) frames are made from hot rolled steel that is pierced and formed to produce a finished side rail.

Following the procedure outlined in the GM Truck Service Manual these frames can be subjected to welding without affecting

frame integrity.

• The 120,000 psi (827,400 kPa) frame rails are made from steel with an initial yield strength of 35,000-40,000 psi. The chemistry

of the steel is slightly different to allow for better handling characteristic.Because the heat treating operation causes molecular

movement in the steel, the only holes pierced in the side rails prior to heat treating are near the front-end hole. Growth can be

predicted in this area and adjustments in hole placement can be made accordingly. The balance of the required holes are pierced

in the frame rail after heat treating.

• The 120,000 psi (827,400 kPa) frame rails are heat treated by an electric induction heat treating process. During this process,

the formed side rails are moved through a series of three induction coils and brought to a temperature of about 1650º F, (898.9º

C). Once at this temperature, the side rail passes through a cold-water quench. After the frame goes through the cold-water

quench, it is very hard but also brittle. Thus, the rails continue to roll through the final “tempering” electric coil and are brought to a

temperature of about 900º F, (482.2º C). Then the frame is allowed to cool to room temperature. This tempering operation “draws”

some of the hardness out of the material, but it now becomes very tough and durable. Once through the tempering operation, the

side rail passes through a “shot peen” operation. This process hurls millions of 1/8-inch, (0.3175 cm), diameter spherical-shaped

balls at the side rails. Shot peening significantly increases the fatigue life of the frame rail, as well as providing a clean surface.

PAGE

13

• Welding should not be preformed on the heat treated 120,000 psi (827,400 kPa) frame rails. Welding depends on heat for a good

adherence. Applying heat or welding on hardened side rails will create a “soft zone” where the heat was applied. Since the heated

area is now softer than the balance of the side rail, the general area would become more susceptible to failure of the frame rail.

Low Cab Forward — Revised 10/2006

Page 17

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

General Information (continued)

Body Mounting Concerns

• The great variety of truck bodies and applications is difficult to appreciate. GM has tried to offer frame equipment suitable for the

greatest number of configurations, but some concerns do exist. To assist sales personnel and customers, we remind everyone

to review and follow data presented in:

• TRUCK BODY BUILDER BOOK Located at gmupfitter.com

• SERVICE MANUAL

• OWNERS MANUAL

• Each publication contributes to an understanding of the complex issues of good vehicle / body application.

• The amount of load carried by the front axle is the most significant consideration. Front Gross Axle Weight Ratings (FGAWR) are

sometimes controlled by the frame.

• The front frame limit is defined by wheelbase and frame choice for each model. The attachment method and the structural

character of the body will also affect the final vehicle performance.

PAGE

14

• Based on experience, GM has determined that

Back-of-Cab. This will assure that ride, handling and load carrying ability are maintained for high customer satisfaction.

Single Axle Medium Duty Conventional

• T6500 single-axle model frames feature straight full-channel side rails over the total length of the frame. Channel type

crossmembers are web mounted to leave side rail flanges clear for body mounting.

• T7500 single-axle model frames are similar to the T6500 frames.

• Optional heat-treated sidemembers (F06) are also available on T7500 truck (RQ2) models.

• “L” shaped reinforcements are available to increase the section modulus.

• Heat-treated sidemembers (F06) and “L” shaped reinforcements are standard for tractor (RQ3).

• Rear side rail taper is standard for tractor.

Low Cab Forward — Revised 10/2006

the first body mounting point should be within 12 inches or (30.5 cm) of the

Page 18

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

General Information (continued)

Strength

• The frame has a straight, full-depth, C-shaped side member rail design and a ladder-type frame assembly.

• The overall frame length on sizes similar to those previously offered has increased by about 1 inch or (2.54 cm) to accommodate

a slight increase in front overhang (related to improved aerodynamics and visibility).

• Basic frame dimensions.

• The T6500-T7500 Series models (unlike the 4500-5500 Series) allow customers to select the frame strength they want and tailor

it to their particular requirements.

• The (RPO F05) 8mm thick frame with 80,000 psi (551,600 kPa), strength is available on all single-axle trucks. Because of its

widespread availability and strength, it has, by far, been the most popular choice, accounting for nearly 80 percent of total frame

selection.

• The (RPO F06) 8mm thick frame with 120,000 psi (827,400 kPa) strength is available on all wheelbase models. It is now also

the standard frame for the tandem axle models and tractor models. This provides more value (extra strength) for customers and

simplifies manufacturing for GM.

• The frame crossmembers all have a 50,000 psi (344,750 kPa) material strength. Their thickness varies, depending on their

application.

PAGE

15

• Customers can also choose frame reinforcements for extra strength to meet their GVW/gross axle weight rating (GAWR) needs.

• The reinforcements can make a considerable difference in front axle loading capability. For example, if a customer selects a 224inch (569 cm) wheelbase and (RPO F05) frame, the maximum load rating allowed on the front is 12,000 pounds (5443 kg). Adding

the L-shaped frame reinforcement option increases front axle load rating 14,600 pounds (6622 kg).

• Basically, the “L” shaped reinforcement gives the 8mm-thick/80,000-psi frame a front axle load rating equal to a 8mm thick/

120,000 psi (827,400 kPa) strength frame.

• The T6500-T7500 Series offer two frame reinforcements. Both have the “L” shaped (with the flange at the bottom) to fit this Series'

particular design requirements. Both are also 8mm thick.

• (RPO F08) and (RPO FSA) with 80,000 psi (551,600 kPa) strength “L” shaped reinforcement on the T6500-T7500 single-axle truck

models.

• (RPO F20) and (RPO FSC) which are made of heated treated material to match the heat-treated frame option.

• RPO F08 and F20 start under the cab and run to approximately the rear of the rear spring hanger.

• RPO FSA and FSC start under the cab and run to the end of the rail.

Low Cab Forward — Revised 10/2006

Page 19

Low Cab Forward

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

16

Frame Material Properties

T6500 & T7500 Single-Axle Truck Models T7500 Models

Frame Material and Physical Properties Frame RPO “F05” Frame RPO “F06”

Material Steel No. or Type SAE J1392 (-080 XLF) H.T. SAE 1027

Material Thickness – in. (mm) 0.32 (8) 0.32 (8)

Physical Properties:

Min. Tensile or Ultimate Strength psi (kPa) 95,000 (655,000) 125,000 (861,800)

Minimum Yield Strength psi (kPa) 80,000 (551,600) 120,000 (827,400)

Resisting Bending Moment (RBM)

(Rated Yield Strength x Section Modulus) 80,000 x SM 120,000 x SM

Section Modulus in

Rated RBM 1,015,000 1,522,800

Optional Reinforcement RPO F08 or FSA F20 or FSC

Reinforcement Type “L” Shape “L” Shape

Material Thickness – in. (mm) 0.32 (8) 0.32 (8)

Combined Section in

Rated Combined RBM 1,938,000 2,907,600

* Grade 80 is rated equivalent to Heat Treated SAE 1027

**SECTION MODULUS BASED ON Square C-Channel. (Actual parts contain radius)

110K Heat Treated Versus 80K HSLA

GM Truck is the only major OEM to offer 80K HLSA material on all T-Series.

This offering is based on fatigue testing which shows equivalency to heat treated steel.

Frames fail in fatigue, not yield, and therefore the materials are equivalent with respect to service life.

3

(cm3) 12.69 (208) 12.69 (208)

Frame Reinforcements Available

3

(cm3) 24.23 (397) 24.23 (397)

Low Cab Forward — Revised 10/2006

Page 20

Low Cab Forward

Frame Lengths with Reinforcements

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

17

Low Cab Forward — Revised 10/2006

TD006051a

Page 21

Low Cab Forward

Frame Lengths with Reinforcements – Charts (042)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

18

Low Cab Forward — Revised 10/2006

TD006051b

Page 22

Low Cab Forward

Frame Lengths with Reinforcements – Charts (064)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

19

Low Cab Forward — Revised 10/2006

TD006051c

Page 23

Low Cab Forward

Frame and Crossmember Locations (042)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

20

Low Cab Forward — Revised 10/2006

TD006046.3

Page 24

Low Cab Forward

Frame and Crossmember Locations (064)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

21

Low Cab Forward — Revised 10/2006

TD0060464.4

Page 25

Low Cab Forward

Front Axle Track and Suspension Drawing

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

22

Low Cab Forward — Revised 10/2006

TD006059a

Page 26

Low Cab Forward

Front Axle Track Charts

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

23

Low Cab Forward — Revised 10/2006

TD006059.4

Page 27

Low Cab Forward

Front Suspension Charts

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

24

Low Cab Forward — Revised 10/2006

TD006059.5

Page 28

Low Cab Forward

Rear Axle and Suspension – Drawing (042)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

25

Low Cab Forward — Revised 10/2006

TD006060a

Page 29

Low Cab Forward

Rear Axle and Suspension – Formulas (042)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

26

Low Cab Forward — Revised 10/2006

TD006060b

Page 30

Chevrolet/GMC Class T6500/7500/8500

27

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

PAGE

Rear Axle / Suspension – Chart (042) Option Description and Bottom of Differential Bowl

Low Cab Forward — Revised 10/2006

TD006060.5

Page 31

Low Cab Forward

Rear Axle / Wheel – Chart (042) Track Widths

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

28

Low Cab Forward — Revised 10/2006

TD006060.6

Page 32

Low Cab Forward

Rear Axle / Suspension – Chart (042) Heights

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

29

Low Cab Forward — Revised 10/2006

TD006060.7

Page 33

Low Cab Forward

Rear Axle / Suspension – Chart (042) Heights

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

30

Low Cab Forward — Revised 10/2006

TD006060f

Page 34

Low Cab Forward

Rear Axle and Suspension – Drawing (064)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

31

Low Cab Forward — Revised 10/2006

TD006047a

Page 35

Low Cab Forward

Rear Axle and Suspension – Formulas (064)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

32

Low Cab Forward — Revised 10/2006

TD006047b

Page 36

Chevrolet/GMC Class T6500/7500/8500

33

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

PAGE

Rear Axle / Suspension – Chart (064) Option Descriptions, Bottom of Differential Bowl and Heights

Low Cab Forward — Revised 10/2006

TD006047c

Page 37

Low Cab Forward

Air Tank Location – (042) Truck – RQ2

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

34

Low Cab Forward — Revised 10/2006

TD006043a

Page 38

Low Cab Forward

Air Tank Location – (042) Tractor – RQ3

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

35

Low Cab Forward — Revised 10/2006

TD006043b

Page 39

Low Cab Forward

Air Tank Location – (064) Truck – RQ2

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

36

Low Cab Forward — Revised 10/2006

TD006043c

Page 40

Low Cab Forward

Air Tank Location – (064) Tractor – RQ3

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

37

Low Cab Forward — Revised 10/2006

TD006043d

Page 41

Low Cab Forward

BATTERY BOX LOCATION

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

38

Low Cab Forward — Revised 10/2006

TD006042a

Page 42

Low Cab Forward

Dual 50 Gallon (opt. NJ8) & Single 50 Gallon LH (opt. NK8)

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

39

Low Cab Forward — Revised 11/2007

TD006056.3

Page 43

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

Dual 50 Gallon LH and 25 Gallon RH (opt. NJ7) & Single 50 Gallon LH (opt. NK6)

PAGE

40

Low Cab Forward — Revised 11/2007

TD006056.4

Page 44

Low Cab Forward

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

AIR INDUCTION

PAGE

41

Low Cab Forward — Revised 10/2006

TD006057a

Page 45

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

Single Horizontal Exhaust w/RH exit tailpipe & cooler, opt. N1B & 7.8 Isuzu Diesel LHP & 140´´ WB opt.

PAGE

42

Low Cab Forward — Revised 08/2007

AND20446.19

Page 46

Low Cab Forward

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

43

Single Horizontal Exhaust w/RH exit tailpipe & cooler, opt. N1B & 7.8 Isuzu Diesel HHP & 140´´ WB opt. FQT

Low Cab Forward — Revised 08/2007

AND20446.18

Page 47

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

Single Horizontal Exhaust, opt. NB5 & 7.8 Isuzu Diesel LHP & 152´´ and longer WB

PAGE

44

Low Cab Forward — Revised 05/2007

AND20446.17

Page 48

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

Single Horizontal Exhaust, opt. NB5 & 7.8 Isuzu Diesel HHP & 152´´ and longer WB

PAGE

45

Low Cab Forward — Revised 05/2007

AND20446.16

Page 49

Low Cab Forward

Exhaust LH Vertical DPF, Tailpipe and Heat Shield –

Exhaust opt. NEP, with Engine opt. LF8, 7.8L LHP Isuzu

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

46

Low Cab Forward — Revised 08/2007

AND20446.21

Page 50

Low Cab Forward

Exhaust LH Vertical DPF, Tailpipe and Heat Shield –

Exhaust opt. NEP, with Engine opt. LF8, 7.8L HHP Isuzu

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

47

Low Cab Forward — Revised 08/2007

AND20446.20

Page 51

Chevrolet/GMC Class T6500/7500/8500

Low Cab Forward

& Isuzu Class FTR/FTV/FTX

Exhaust LH Vertical DPF, Tailpipe and Heat Shield – Option LF8, 7.8L LHP Isuzu

PAGE

48

Low Cab Forward — Revised 05/2007

AND20446.22

Page 52

Low Cab Forward

Manual Transmission PTO Location Charts

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

49

Low Cab Forward — Revised 05/2007

AND77068.8

Page 53

Low Cab Forward

Automatic Transmission PTO Location Charts

Chevrolet/GMC Class T6500/7500/8500

& Isuzu Class FTR/FTV/FTX

PAGE

50

Low Cab Forward — Revised 05/2007

AND77068.9

Loading...

Loading...