Page 1

For DENSO Authorized

ECD Service Dealer Only

Diesel Injection Pump

No. E-03-04

SERVICE MANUAL

Common Rail System for OPEL

4EE2 Type Engine

Operation

August, 2003

-1

00400028

Page 2

FORWARD

To meet the high pressurization requirements for the engine to deliver cleaner exhaust gas

emissions, lower fuel consumption and reduced noise, advanced electronic control technology

is being adopted in the fuel injection system.

This manual covers the electronic control model Common Rail system with HP3 pump for the

ISUZU 4EE2 type engine which is used to OPEL CORSA and MERIVA. Complex theories, special functions and components made by manufacturers other than DENSO are omitted from this

manual.

This manual will help the reader develop an understanding of the basic construction, operation

and system configuration of the DENSO manufactured components and brief diagnostic information.

TABLE OF CONTENTS

1. Product Application ----------------------------------------------------------------------------------- 1

1.1 Application ----------------------------------------------------------------------------------------------------------------1

1.2 System Components Parts Numbers ------------------------------------------------------------------------------ 1

2. Outline ---------------------------------------------------------------------------------------------------- 2

2.1 Features of System ----------------------------------------------------------------------------------------------------- 2

[1] System Characteristics --------------------------------------------------------------------------------------------- 2

[2] Comparison to the Conventional System ----------------------------------------------------------------------- 3

2.2 Outline of System ------------------------------------------------------------------------------------------------------- 4

[1] Composition ----------------------------------------------------------------------------------------------------------- 4

[2] Operation --------------------------------------------------------------------------------------------------------------- 4

[3] Fuel System ------------------------------------------------------------------------------------------------------------ 5

[4] Control System -------------------------------------------------------------------------------------------------------- 5

3. Construction and Operation------------------------------------------------------------------------- 6

3.1 Description of Main Components ----------------------------------------------------------------------------------- 6

[1] Supply Pump (HP3) -------------------------------------------------------------------------------------------------- 6

[2] Description of Supply Pump Components ---------------------------------------------------------------------- 11

[3] Rail -----------------------------------------------------------------------------------------------------------------------14

[4] Injector ------------------------------------------------------------------------------------------------------------------ 16

3.2 Description of Control System Components --------------------------------------------------------------------- 19

[1] ECU (Electronic Control Unit) ------------------------------------------------------------------------------------- 19

[2] Description of Sensors ---------------------------------------------------------------------------------------------- 19

[3] EGR Valve (Exhaust Gas Recirculation Valve) --------------------------------------------------------------- 21

3-3 Various Types of Controls --------------------------------------------------------------------------------------------- 22

[1] Outline ------------------------------------------------------------------------------------------------------------------- 22

[2] Fuel Injection Quantity Control ------------------------------------------------------------------------------------ 23

[3] Fuel Injection Timing Control -------------------------------------------------------------------------------------- 25

[4] Fuel Injection Rate Control ----------------------------------------------------------------------------------------- 26

[5] Fuel Injection Pressure Control ----------------------------------------------------------------------------------- 26

[6] Other Controls --------------------------------------------------------------------------------------------------------- 26

4. External Wiring Diagram ----------------------------------------------------------------------------- 27

4.1 ECU External Wiring Diagram --------------------------------------------------------------------------------------- 27

4.2 ECU Connector Diagram ---------------------------------------------------------------------------------------------- 29

[1] ECU Connector Terminal Layout --------------------------------------------------------------------------------- 29

[2] Terminal Connections ----------------------------------------------------------------------------------------------- 29

0

Page 3

1. Product Application

1.1 Application

Vehicle Name Vehicle Model Engine Model Exhaust Volume Reference

Corsa S-Car

4EE2 1.7L Made in Germany

Meriva S-Mono

1.2 System Components Parts Number

Vehicle Model

Part Name

Corsa Meriva

DENSO Part

Number

Car Manufacturer

Part Number

Supply Pump {{HU294000-0071 97313 862

Rail {{HU095440-0411 97313 863

Injector {{HU095000-5082 97313 861

{ 112500-0151 97300 097

Engine ECU

{ 112500-0161 97350 948

Supply use 112500-0170 97364 132

Crankshaft Position Sensor {{949979-1200 97321 620

Cylinder Recognition Sensor {{949979-1200 97321 620

EGR Valve {{HU135000-7040 97355 042

1

Page 4

2. Outline

2.1 Outline of System

The common rail system was developed primarily to cope with exhaust gas regulations for diesel engines, and aimed for 1. further improved fuel economy; 2. noise reduction; and 3. high

power output.

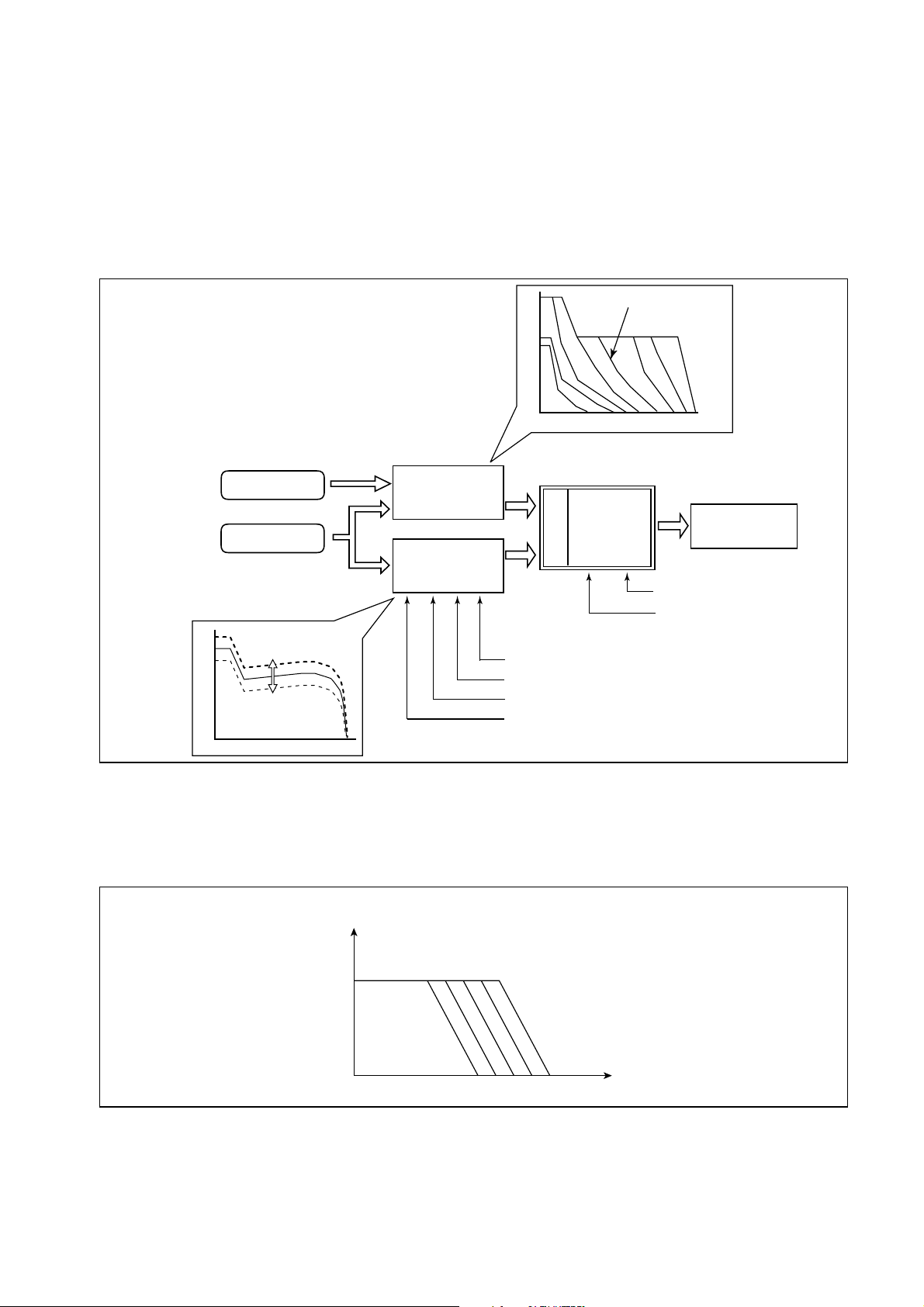

[1] System Characteristics

The common rail system uses a type of accumulation chamber called a rail to store pressurized

fuel, and injectors that contain electronically controlled solenoid valves to spray the pressurized

fuel into the cylinders. Because the engine ECU controls the injection system (including the injection pressure, injection rate, and injection timing), the injection system is unaffected by the

engine speed or load. This ensures a stable injection pressure at all times, particularly in the

low engine speed range, and dramatically decreases the amount of black smoke ordinarily

emitted by a diesel engine during start-up and acceleration. As a result, exhaust gas emissions

are cleaner and reduced, and higher power output is achieved.

(1) Injection pressure control

• Enables high-pressure injection even at low engine speeds.

• Optimizes control to minimize particulate matter and NOx emissions.

(2) Injection timing control

Enables finely tuned optimized control in accordance with driving conditions.

(3) Injection rate control

Pilot injection control sprays a small amount of fuel before the main injection.

Common Rail System

Injection Pressure Control

Optimization, High pressurization

Common rail system

Conventional

Injection pressure

pump

Speed

Particulate

Injection

pressure

Injection Timing Control

Optimization

Common rail system

NOx

Injection timing

Conventional

pump

Speed

Injection Rate Control

Injection rate

Crankshaft angle

Injection Quantity Control

Cylinder injection

volume correction

Speed

㧝㧟㧠㧞

Pilot injection

Main

injection

QD0734E

2

Page 5

[2] Comparison to the Conventional System

In-line, VE Pump

High-pressure pipe

Momentary high pressure

Timer

System

In-line pump

VE pump

Injection quantity control

Injection timing control

Pump (governor)

Pump (timer)

Rising pressure

Distributor Pump

Injection pressure control

Dependent upon speed and injection quantity

Governor

Pump

Common rail system

Rail

TWV

Nozzle

Supply pump

Usually high pressure

Delivery valve

Feed pump

SCV (suction control valve)

Injector

Fuel tank

Engine ECU, injector (TWV)*

Engine ECU, injector (TWV)*

1

1

Engine ECU, supply pump

Engine ECU, rail

Engine ECU, supply pump (SCV)*

2

*1 TWV: Two Way Valve *2 SCVSuction Control Valve

QD2341E

3

Page 6

2.2 Outline of System [1] Composition

The common rail system consists primarily of a supply pump, rail, injectors, and engine ECU.

Fuel temperature sensor

Vehicle speed

Accelerator opening

Intake air pressure

Intake air temperature

Coolant temperature

Crankshaft position

Cylinder recognition sensor

Engine ECU

Intake airflow rate

Fuel temperature

sensor

Rail pressure

sensor

Supply pump

Rail

SCV (suction

control valve)

Pressure

limiter

Fuel tank

Injector

Q000144E

[2] Operation

(1) Supply pump (HP3)

The supply pump draws fuel from the fuel tank, and pumps the high pressure fuel to the rail.

The quantity of fuel discharged from the supply pump controls the pressure in the rail. The

SCV (Suction Control Valve) in the supply pump effects this control in accordance with the

command received from the ECU.

(2) Rail

The rail is mounted between the supply pump and the injector, and stores the high-pressure

fuel.

(3) Injector

This injector replaces the conventional injection nozzle, and achieves optimal injection by effecting control in accordance with signals from the ECU. Signals from the ECU determine

the length of time and the timing in which current is applied to the injector. This in turn, determines the quantity, rate and timing of the fuel that is injected from the injector.

(4) Engine ECU

The engine ECU calculates data received from the sensors to comprehensively control the

injection quantity, timing and pressure, as well as the EGR (exhaust gas recirculation).

4

Page 7

[3] Fuel System

This system comprises the route through which diesel fuel flows from the fuel tank to the supply

pump, via the rail, and is injected through the injector, as well as the route through which the

fuel returns to the tank via the overflow pipe.

[4] Control System

In this system, the engine ECU controls the fuel injection system in accordance with the signals

received from various sensors. The components of this system can be broadly divided into the

following three types: (1) Sensors; (2) ECU; and (3) Actuators.

(1) Sensors

Detect the engine and driving conditions, and convert them into electrical signals.

(2) Engine ECU

Performs calculations based on the electrical signals received from the sensors, and sends

them to the actuators in order to achieve optimal conditions.

(3) Actuators

Operate in accordance with electrical signals received from the ECU. Injection system control is undertaken by electronically controlling the actuators. The injection quantity and timing

are determined by controlling the duration and the timing in which the current is applied to

the TWV (Two-Way Valve) in the injector. The injection pressure is determined by controlling

the SCV (Suction Control Valve) in the supply pump.

Sensor

Crankshaft Position Sensor (NE)

Cylider recognition sensor (G)

Accelerator position sensor

Other sensors and switches

Engine speed

Cylinder recognition

Load

Actuator

Injector

•Injection quantity control

•Injection timing control

•Injection pressure control

Engine

ECU

Supply pump (SCV)

•Fuel pressure control

EGR, air intake control relay, light

Q000047E

5

Page 8

3. Construction and Operation

3.1 Description of Main Components [1] Supply Pump (HP3)

(1) Outline

• The supply pump consists primarily of the pump body (eccentric cam, ring cam, and plungers),

SCV (Suction Control Valve), fuel temperature sensor, and feed pump.

Fuel temperature sensor

SCV (Suction Control Valve)

Q000145E

• The two plungers are positioned vertically on the outer ring cam for compactness.

• The engine drives the supply pump at a ratio of 1:2. The supply pump has a built-in feed

pump (trochoid type), and draws the fuel from the fuel tank, sending it to the plunger

chamber.

• The internal camshaft drives the two plungers, and they pressurize the fuel sent to the plunger

chamber and send it to the rail. The quantity of fuel supplied to the rail is controlled by the SCV,

using signals from the engine ECU. The SCV is a normally opened type (the intake valve

opens during de-energization).

6

Page 9

Injector

Rail

Return

Fuel overflow

Discharge valve

Intake valve

Plunger

Intake pressure

Feed pressure

High pressure

Return pressure

Return spring

Regulating valve

Fuel tank

Camshaft

Filter

Feed pump

Fuel inlet

Intake

Fuel filter (with priming pump)

QD0704E

7

Page 10

Pump body

Ring cam

SCV

Feed pump

Regulating valve

Filter

Drive shaft

Plunger

Q000146E

8

Page 11

(2) Supply Pump Internal Fuel Flow

The fuel that is drawn from the fuel tank passes through the route in the supply pump as illustrated, and is fed into the rail.

Supply pump interior

Regulating valve

Feed pump

Overflow

Fuel tank

SCV (Suction Control Valve)

Intake valve

Discharge valve

Pumping portion (plunger)

Rail

(3) Construction of Supply Pump

The eccentric cam is formed on the drive shaft. The ring cam is connected to the eccentric cam.

Drive shaft

Eccentric cam

Ring cam

As the drive shaft rotates, the eccentric cam rotates in the eccentric state, and the ring cam

moves up and down while rotating.

Plunger

QD0705E

QD0706E

Eccentric cam

Drive shaft

Ring cam

QD0727E

9

Page 12

The plunger and the suction valve are mounted on top of the ring cam. The feed pump is connected to the rear of the drive shaft.

Plunger A

Ring cam

Feed pump

Plunger B

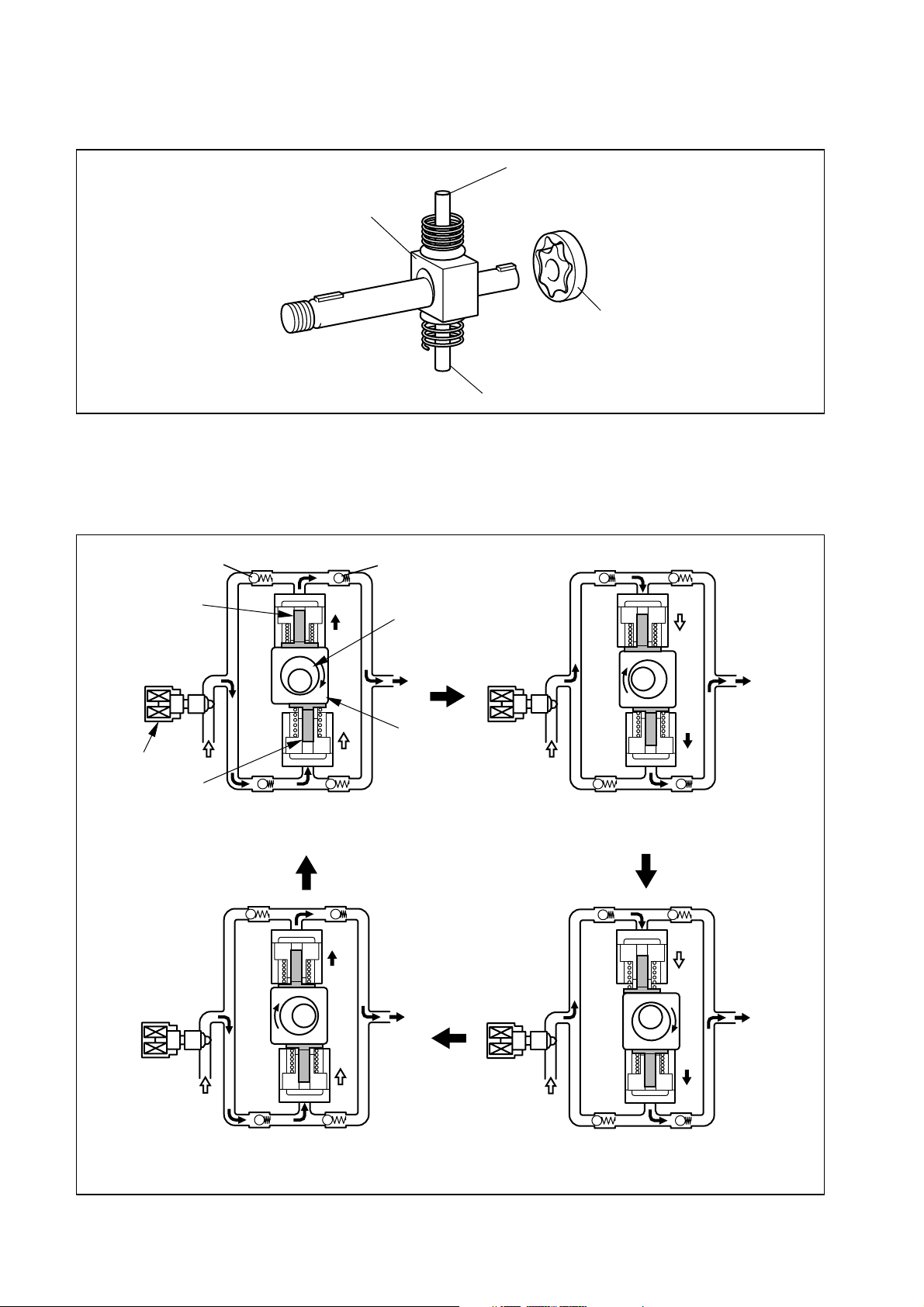

(4) Operation of the Supply Pump

As shown in the illustration below, the rotation of the eccentric cam causes the ring cam to

push Plunger A upwards. Due to the spring force, Plunger B is pulled in the opposite direction

to Plunger A. As a result, Plunger B draws in fuel, while Plunger A pumps it to the rail.

Suction valve

Plunger A

SCV

Plunger B

Plunger A: complete compression

Plunger B: complete intake

Delivery valve

Eccentric cam

Ring cam

Plunger A: begin intake

Plunger B: begin compression

QD0728E

Plunger A: begin compression

Plunger B: begin intake

Plunger A: complete intake

Plunger B: complete compression

QD0707E

10

Page 13

[2] Description of Supply Pump Components

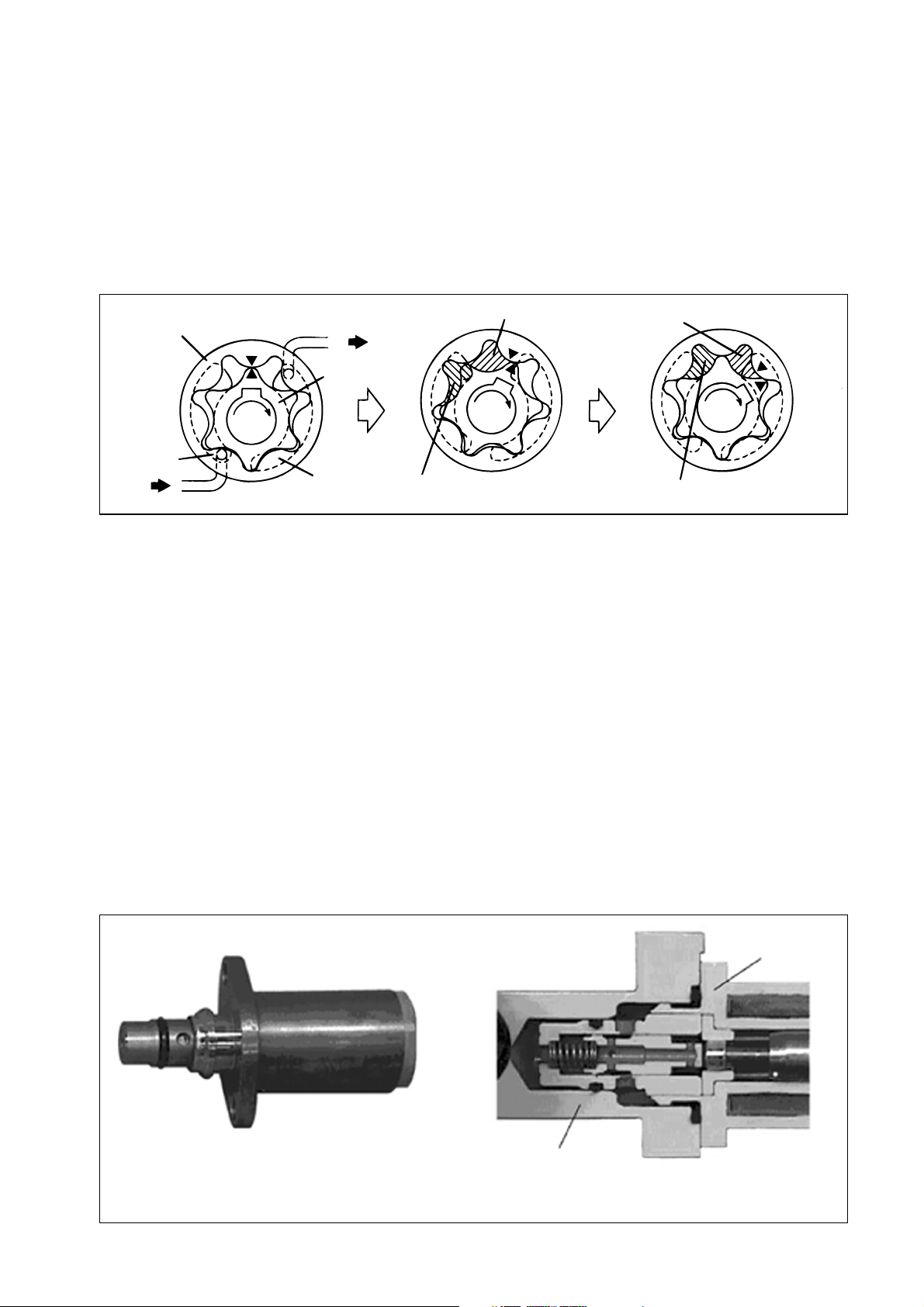

(1) Feed Pump

The trochoid type feed pump, which is integrated in the supply pump, draws fuel from the fuel

tank and feeds it to the two plungers via the fuel filter and the SCV (Suction Control Valve).

The feed pump is driven by the drive shaft. With the rotation of the inner rotor, the feed pump

draws fuel from its suction port and pumps it out through the discharge port. This is done in

accordance with the space that increases and decreases with the movement of the outer and

inner rotors.

Outer rotor

Intake port

from Fuel tank

to Pump chamber

Inner rotor

Discharge

port

Quantity decrease

Quantity increase

Quantity decrease (fuel discharge)

Quantity increase (fuel intake)

QD0708E

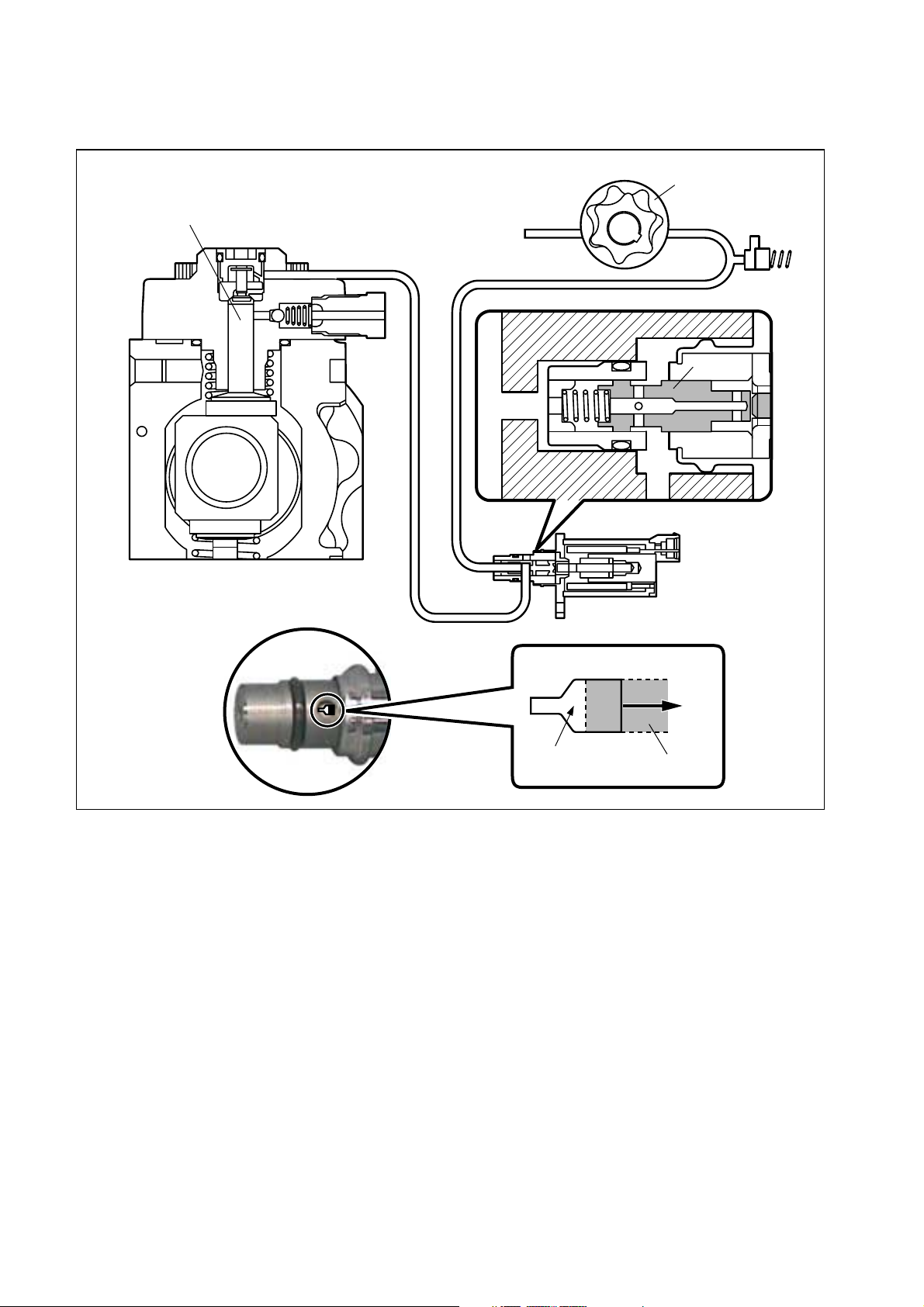

(2) SCV: Suction Control Valve

• A linear solenoid type valve has been adopted. The ECU controls the duty ratio (the length

of time that the current is applied to the SCV), in order to control the quantity of fuel that is

supplied to the high-pressure plunger.

• Because only the quantity of fuel that is required for achieving the target rail pressure is

drawn in, the drive load of the supply pump decreases.

• When current flows to the SCV, variable electromotive force is created in accordance with

the duty ratio, moving the armature to the left side. The armature moves the cylinder to the

left side, changing the opening of the fuel passage and thus regulating the fuel quantity.

• With the SCV OFF, the return spring contracts, completely opening the fuel passage and

supplying fuel to the plungers. (Full quantity intake and full quantity discharge)

• When the SCV is ON, the force of the return spring moves the cylinder to the right, closing

the fuel passage (normally opened).

• By turning the SCV ON/OFF, fuel is supplied in an amount corresponding to the actuation

duty ratio, and fuel is discharged by the plungers.

Exterior view of SCV

SCV

Pump body

Cross-section of SCV

Q000050E

11

Page 14

[In case of short duty ON]

Short duty ON → large valve opening → maximum intake quantity

Plunger

SCV

Feed pump

Cylinder

Large opening

Cylinder

Q000051E

12

Page 15

[In case of long duty ON]

Long duty ON → small valve opening → minimum intake quantity

Plunger

SCV

Feed pump

Cylinder

Small opening

Cylinder

Q000052E

13

Page 16

[3] Rail

(1) Outline

• Stores pressurized fuel (0 to 180 MPa) that has been delivered from the supply pump and

distributes the fuel to each cylinder injector. A rail pressure sensor and a pressure limiter are

adopted in the rail.

• The rail pressure sensor (Pc sensor) detects the fuel pressure in the rail and sends a signal

to the engine ECU, while the pressure limiter controls the fuel pressure in the rail.

Pressure limiter

Rail pressure (Pc) sensor

Q000147E

(2) Rail Pressure (Pc) Sensor

This sensor detects fuel pressure in the rail and sends a signal to the ECU. It is a semi-conductor type pressure sensor that utilizes the characteristic whereby electrical resistance

changes when pressure is applied to silicon.

Vcc

GND

Vout

Vcc

Pc

sensor

(supply voltage)

Vout

(output voltage)

GND (ground)

+5V

ECU

Vout [V]

4.2

1.0

0 200

Rail pressure [MPa]

Q000053E

14

Page 17

(3) Pressure Limiter

The pressure limiter relieves pressure by opening the valve if abnormally high pressure is

generated. The valve opens when pressure in rail reaches approximately 230 MPa, and

closes when pressure falls to approximately 50 MPa. Fuel leaked by the pressure limiter returns to the fuel tank.

To the fuel tank

Spring

Ball (valve)

Pc

QC0020E

15

Page 18

[4] Injector

(1) Outline

The injectors inject the high-pressure fuel from the rail into the combustion chambers at the

optimum injection timing, rate, and spray condition, in accordance with commands received

from the ECU.

(2) Characteristics

• A compact, energy-saving solenoid-control type TWV (Two-Way Valve) injector has been

adopted.

• QR codes displaying various injector characteristics are laser marked in the injector body,

and ID codes showing these in numeric form (22 alphanumeric figures) are laser marked on

the connector head.

• This system uses QR code information to optimize injection quantity control. When an injector

is newly installed in a vehicle, it is necessary to input the ID codes in the ECU.

(3) Construction

22-characters

Leak

passage

QR code

to Fuel tank

Solenoid valve

High pressure fuel

(from Rail)

Command piston

Valv e

spring

Nozzle spring

Seat area

Nozzle needle

Q000148E

16

Page 19

(4) Operation

The TWV valve opens and closes the outlet orifice to control the hydraulic pressure in the

control chamber, and the start and the end of injection.

[No injection]

• When no current is supplied to the solenoid, the valve spring force is stronger than the

hydraulic pressure in the control chamber. Thus, the TWV is pushed downward, effectively

closing the outlet orifice. For this reason, the hydraulic pressure in the control chamber is

applied to the command piston causes the nozzle spring to compress. This closes the nozzle

needle, and as a result, fuel is not injected.

[Injection]

• When the current is initially applied to the solenoid, the attraction of the solenoid pulls the

TWV up, effectively opening the outlet orifice and allowing the fuel to flow out of the control

chamber. After the fuel flows out, the hydraulic pressure in the control chamber decreases

pulling the command piston up. This causes the nozzle needle to rise and injection to start.

• The fuel that flows past the outlet orifice flows to the leak pipe and below the command

piston. The fuel that flows below the nozzle needle lifts the it upward, which helps to improve

the nozzle's opening and closing response.

• When current continues to be applied to the solenoid, the nozzle reaches its maximum lift,

where the injection rate is also at the maximum level. When current to the solenoid is turned

OFF, the TWV falls, causing the nozzle needle to close immediately and the injection to stop.

Solenoid

TWV

Outlet orifice

Inlet orifice

Command

piston

Nozzle

needle

Leak pipe

No injection

Actuation

current

Valve spring

Rail

Control chamber

pressure

Injection rate

Injection

Actuation

current

Control chamber

pressure

Injection rate

Actuation

current

Control chamber

pressure

Injection rate

End of injection

Q000149E

17

Page 20

(5) QR Code

QR (Quick Response) codes have been adopted to enhance the injection quantity precision

of the injectors. The adoption of QR codes enables injection quantity dispersion control

throughout all pressure ranges, contributing to improvement in combustion efficiency, reductions in exhaust gas emissions and so on.

QR Code Correction Point

180 MPa

140 MPa

P4-3

Injection

Quantity: Q

P4-1

P5-2

P5-1

P4-2

P3-2

P3-1

Actuating Pulse Width: Tq

90 MPa

64 MPa

P3-3

P2-1

P1-1

QR Code ( 9.9 mm)

ID Code

(22 sets of 16 alphanumeric figures)

25 MPa

18

Contents of Printing

TP

1-1 TP2-1 TP3-1

TP3-2 TP3-3 TP4-1

TP4-2 TP4-3 TP5-1

TP5-2 BCC

Q000150E

Page 21

3.2 Description of Control System Components [1] ECU (Electronic Control Unit)

This is the command center that controls the fuel injection system and engine operation in

general.

[Outline Diagram]

Sensor

Detection Calculation

Engine ECU

Actuator

Actuation

Q000152E

[2] Description of Sensors

(1) Crankshaft Position Sensor (NE sensor)

The NE sensor is an MRE (Magnetic Resistance Element) type sensor. It is positioned above

the crankshaft to detect the crankshaft position. The pulsar gear is composed of 56 gears with

4 gears missing (per 1 revolution), and the sensor outputs 56 pulses for each 1 revolution of

the crankshaft (360°CA).

Exterior Drawing

Vcc

NE-

Circuit Diagram

Vcc

NE+

NE-

ECU

Vcc

NE input circuit

NE+

Q000154E

(2) Cylinder Recognition Sensor (G sensor)

The cylinder recognition sensor (G sensor) is an MRE (Magnetic Resistance Element) type

sensor. It detects the engine cylinders, and outputs 5 pulses for every two revolutions of the

engine (720°CA).

Exterior View Diagram

Vcc

G-

G+

19

Circuit Diagram

Vcc

G+

G-

ECU

Vcc

G input circuit

Q000155E

Page 22

(3) Fuel temperature sensor (THF)

Detects the fuel temperature and sends a corresponding signal to the engine ECU. Based on

this information, the engine ECU calculates the injection volume correction that is appropriate

for the fuel temperature.

Resistance Value Characteristics

Temperature

(°C)

Thermistor

Resistance value

(kΩ)

-30 (25.4)

-20

-10 (9.16)

0 (5.74)

10 (3.70)

20

30 (1.66)

40 (1.15)

50 (0.811)

60 (0.584)

70 (0.428)

80 0.318±0.031

90 (0.240)

100 (0.1836)

110 (0.1417)

120

15.0±1.5

2.45±0.24

(0.1108)

Fuel temperature sensor

Q000156E

20

Page 23

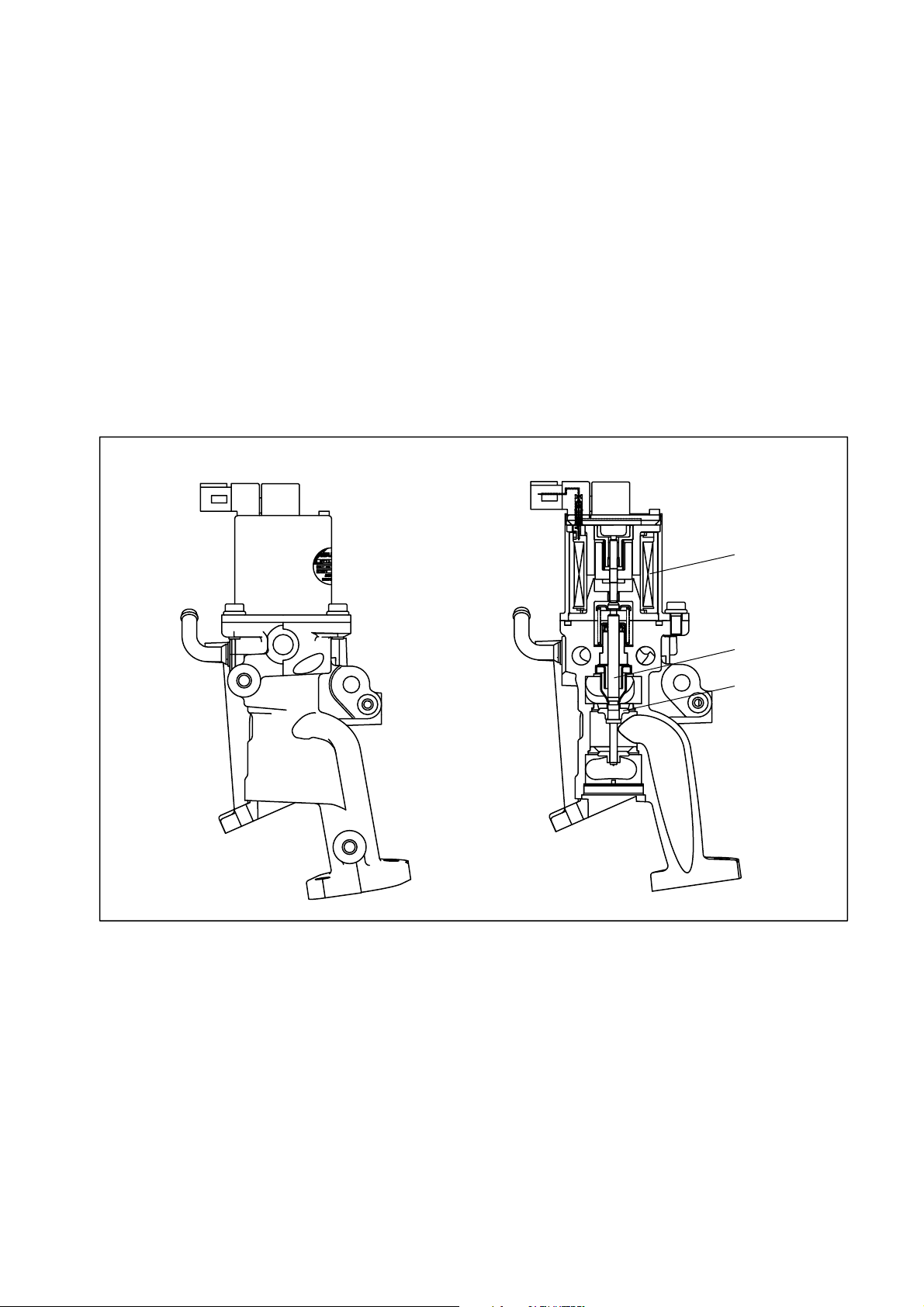

[3] EGR Valve (Exhaust Gas Recirculation Valve)

(1) EGR Valve Construction

An EGR valve is utilized as the system actuator for the electric exhaust gas recirculation (EEGR) system. It is constructed of an upper section and a lower section. The upper section

receives output signals from the engine ECU, and contains a solenoid that generates electromagnetic force. The lower section is constructed of a nozzle that moves up and down in

response to the electromagnetic force, and a valve with an opening that alters in response to

the nozzle position.

(2) EGR Valve Operation

The E-EGR system electronically controls the EGR. The EGR system reduces NOx by lowering the combustion temperature. This is done recirculating a portion of the exhaust gases

through the intake manifold. Because this system also reduces the engine output and affects

driveability, the E-EGR system effects computer control to achieve an optimal EGR volume

in accordance with the driving conditions.

Exterior View

Solenoid

Nozzle

Valve

Q000153E

21

Page 24

3.3 Various Types of Controls [1] Outline

This system effects fuel injection quantity and injection timing control more appropriately than

the mechanical governor and timer used in the conventional injection pump.The engine ECU

performs the necessary calculations in accordance with the sensors installed on the engine and

the vehicle. It then controls the timing and duration of time in which current is applied to the

injectors, in order to realize both optimal injection and injection timing.

(1) Fuel Injection Quantity Control Function

The fuel injection quantity control function replaces the conventional governor function. It

controls the fuel injection to an optimal injection quantity based on the engine speed and accelerator position signals.

(2) Fuel Injection Timing Control Function

The fuel injection timing control function replaces the conventional timer function. It controls

the injection to an optimal timing based on the engine speed and the injection quantity.

(3) Fuel Injection Rate Control Function

Pilot injection control injects a small amount of fuel before the main injection.

(4) Fuel Injection Pressure Control Function (Rail Pressure Control Function)

The fuel injection pressure control function (rail pressure control function) controls the discharge volume of the pump by measuring the fuel pressure at the rail pressure sensor and

feeding it back to the ECU. It effects pressure feedback control so that the discharge volume

matches the optimal (command) value set in accordance with the engine speed and the injection quantity.

22

Page 25

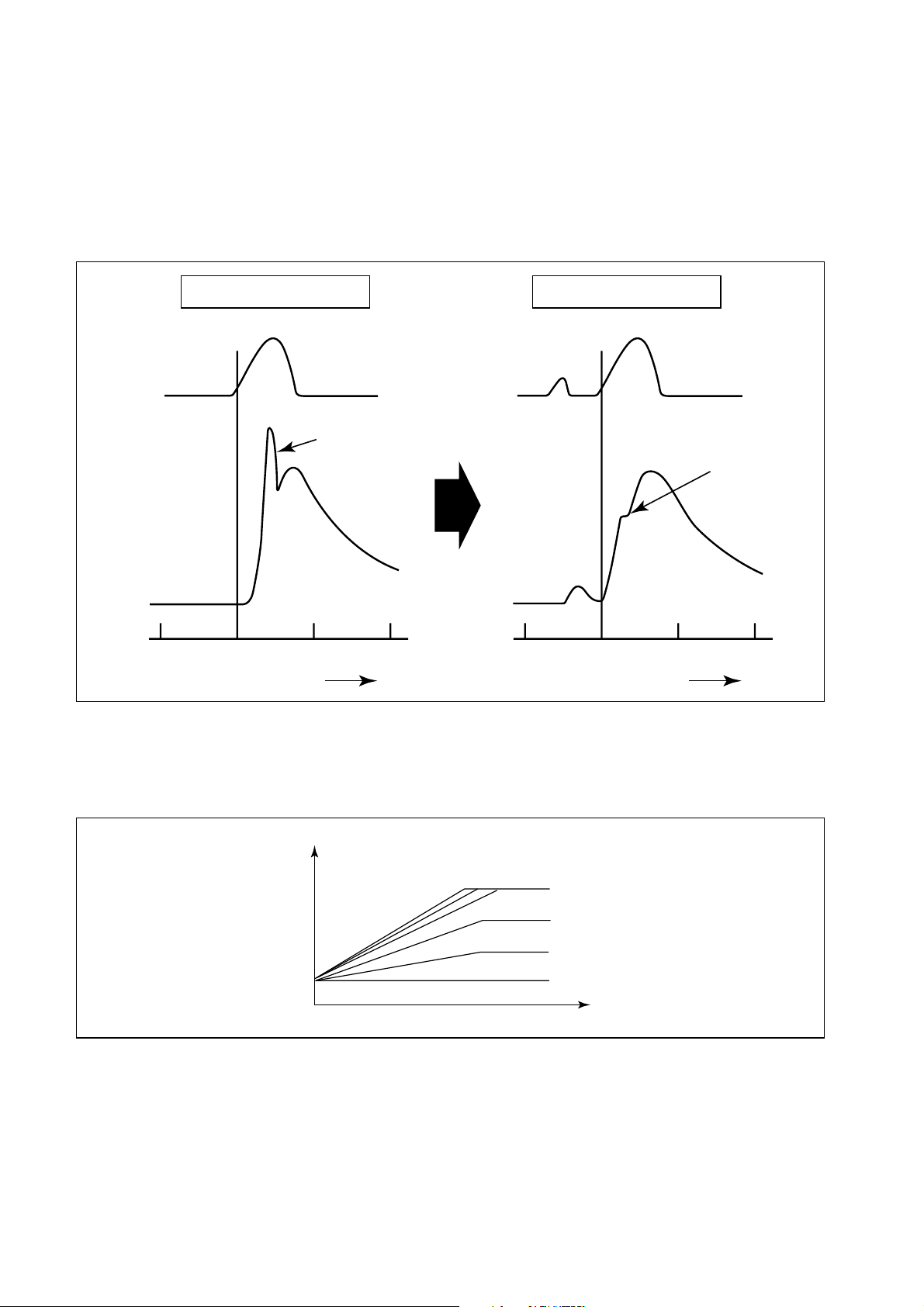

[2] Fuel Injection Quantity Control

(1) Outline

This control determines the fuel injection quantity by adding coolant temperature, fuel temperature, intake air temperature, and mass airflow corrections to the basic injection quantity

is calculated by the engine ECU, based on the engine operating conditions and driving conditions.

(2) Injection Quantity Calculation Method

The basic injection quantity is obtained through the governor pattern

calculated from the accelerator position and the engine speed.

The basic injection quantity is then compared to the maximum

injection quantity obtained from the engine speed, to which various

types of corrections are made. The smallest injection quantity is then

used as the basis for the final injection quantity.

Accelerator position

Engine speed

Injection quantity

Engine speed

Basic injection

quantity

Maximum injection

quantity

Mass airflow correction

Intake air temperature correction

Atmospheric pressure correction

Cold operation maximum injection quantity correction

Accelerator position

Injection quantity

Engine speed

Final injection

quantity after

correction

Smaller quantity

Driver actuation

timing calculation

Individual cylinder correction

Injection pressure correction

Q000061E

(3) Basic Injection Quantity

The basic injection quantity is determined by the engine speed (NE) and the accelerator position. The injection quantity is increased when the accelerator position signal is increased

while the engine speed remains constant.

Basic injection quantity

Accelerator position

Engine speed

QC0038E

23

Page 26

(4) Maximum Injection Quantity

The maximum injection quantity is calculated by adding the mass airflow correction, intake

air temperature correction, atmospheric pressure correction and the cold operation maximum injection quantity correction to the basic maximum injection quantity that is determined

by the engine speed.

Basic maximum injection quantity

Engine speed

(5) Starting Injection Quantity

When the starter switch is turned ON, the injection quantity is calculated in accordance with

the starting base injection quantity and the starter ON time. The base injection quantity and

the inclination of the quantity increase/decrease change in accordance with the coolant temperature and the engine speed.

QC0039E

Injection quantity

Base injection

quantity

STA ON duration

STA/ON

Injection quantity

Starting

Coolant temperature

High

STA ON duration

STA/ON

Low

Starting

(6) Idle Speed Control (ISC) System

This system controls the idle speed by regulating the injection quantity in order to match the

actual speed to the target speed that is calculated by the engine ECU.

The target speed varies according to the type of transmission (manual or automatic), whether

the air conditioner is ON or OFF, the shift position, and the coolant water temperature.

(7) Idle Vibration Reduction Control

To reduce engine vibrations during idle, this function compares the angle speeds (times) of

the cylinders and regulates the injection quantity for the individual cylinders if there is a large

the difference, in order to achieve a smooth engine operation.

QC0040E

Angle

speed

#1 #1 #3 #4 #2#3 #4 #2

Crankshaft angle

Correction

Crankshaft angle

QC0043E

24

Page 27

[3] Fuel Injection Timing Control

(1) Outline

Fuel injection timing is controlled by varying the timing in which current is applied to the injectors.

(2) Main and Pilot Injection Timing Control

[Main Injection Timing]

The engine ECU calculates the basic injection timing based on the engine speed the final

injection quantity, and adds various types of corrections in order to determine the optimal

main injection timing.

[Pilot Injection Timing (Pilot Interval)]

Pilot injection timing is controlled by adding a pilot interval to the main injection timing. The

pilot interval is calculated based on the final injection quantity, engine speed, coolant temperature (map correction). The pilot interval at the time the engine is started is calculated

from the coolant temperature and speed.

Pilot injection

Interval

(3) Injection Timing Calculation Method

[Outline of Control Timing]

01

NE pulse

Solenoid valve

control pulse

Nozzle needle lift

Top deadcenter

Pilot injection

Pilot

injection

timing

Main injection

QC0044E

Actual TDC

Main injection

Main

injection

timing

[Injection Timing Calculation Method]

Engine speed

Injection quantity

Basic injection

timing

25

Corrections

Pilot interval

Main injection

timing

Intake air temperature correction

Coolant temperature correction

Atmospheric pressure correction

QD0382E

Q000062E

Page 28

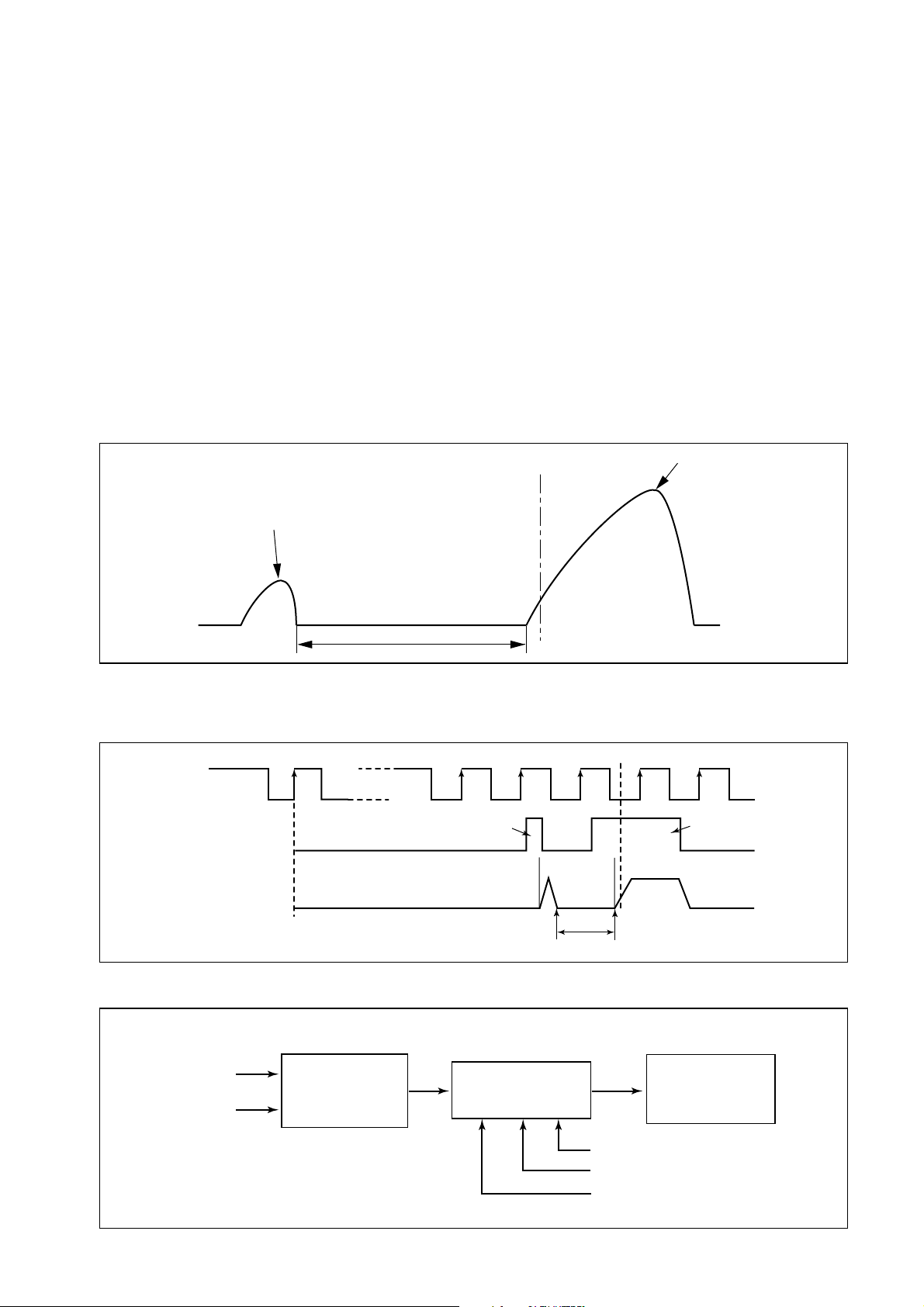

[4] Fuel Injection Rate Control

While the injection rate increases with the adoption of high-pressure fuel injection, the ignition

lag, which is the delay from the start of injection to the beginning of combustion, cannot be

shortened to less than a certain value. As a result, the quantity of fuel that is injected until main

ignition occurs increases, resulting in an explosive combustion at the time of main ignition. This

increases both NOx and noise. For this reason, pilot injection is provided to minimize the initial

injection rate, prevent the explosive first-stage combustion, and reduce noise and NOx.

Pilot Injection

Small first-stage

combustion

Crankshaft angle (deg)

QC0046E

Injection

rate

Heat release

rate

-20 TDC 20 40

Normal Injection

Large first-stage

combustion

(NOx and noise)

-20 TDC 20 40

Crankshaft angle (deg)

[5] Fuel Injection Pressure Control

A value that is determined by the final injection quantity, the water temperature and the engine

speed is calculated. During the starting of the engine, the calculation is based on the water temperature and the atmospheric pressure.

Rail pressure

Final injection quantity

Engine speed

[6] Other Controls

a: Limit maximum injection quantity b: Gradual acceleration injection quantity

c: Gradual deceleration injection quantity d: Post-acceleration damping injection quantity

e: Reference injection quantity f: Fuel cutoff

g: Turbo control h: Glow plug relay

i: EGR control

26

QC0047E

Page 29

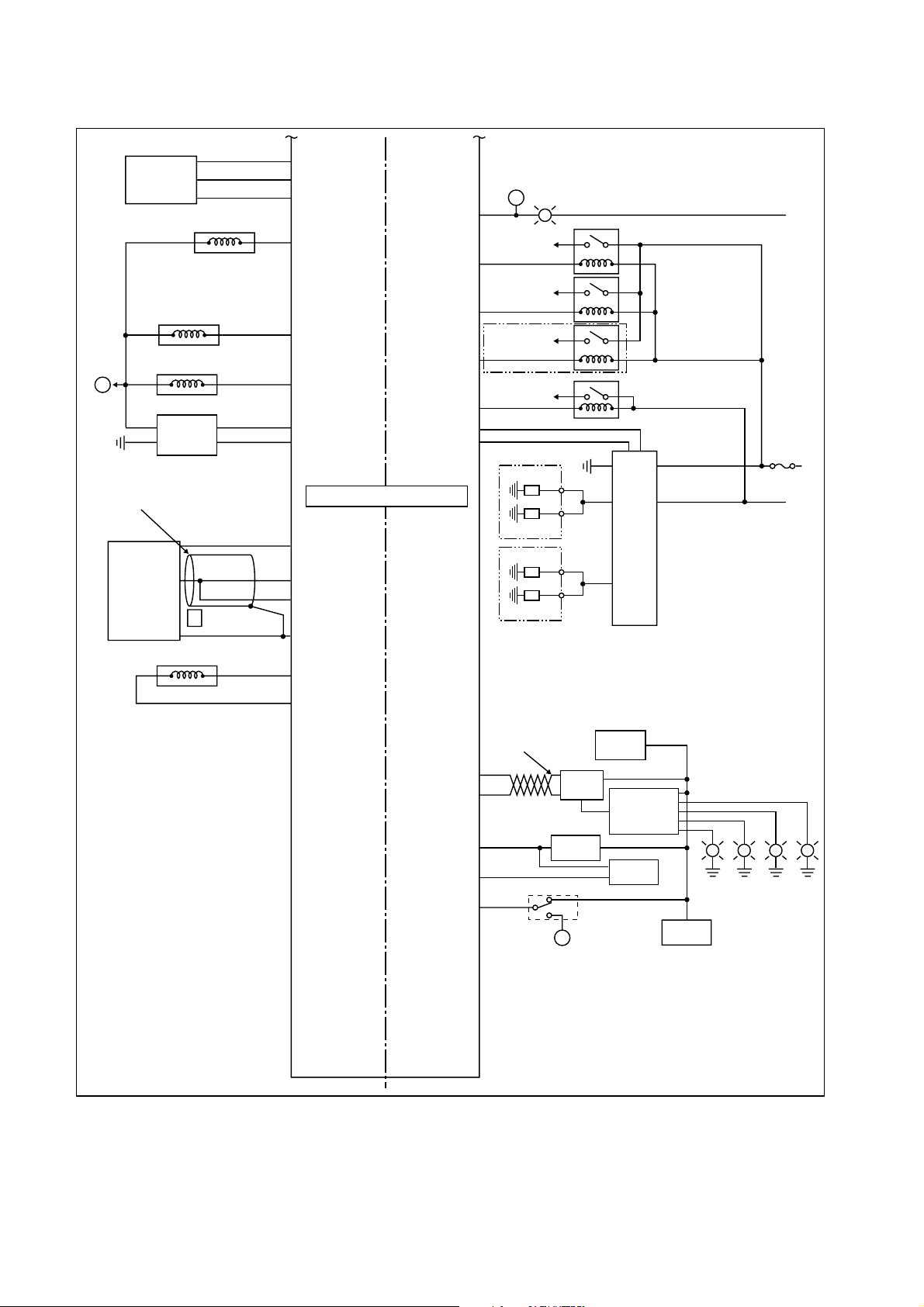

4. External Wiring Diagram

4.1 ECU External Wiring Diagram

Injector

Injector

Shield wire

CRANK

Shield wire

Fuel temp.

Boost pressure 1

Twist pair

CLY1

CLY4

CLY3

CLY2

Twist pair

CAM

Atmospheric

pressure

Coolant temp.

(COMMON1)

(COMMON2)

(NE-VCC)

(SH-GND)

(PATM-VCC)

(PATM-GND)

(THW-GND)

(THF-GND)

(PIM-VCC)

(PIM-GND)

(LOIL-SW)

Low oil level switch

(TWV1)

(TWV3)

(TWV2)

(TWV4)

(G+)

(G-)

(G-VCC)

(NE+)

(NE-)

(PATM)

(THW)

(THF)

(PIM1)

(Engine side)

E55:12V-REF

E52:O-PL-INVV1

E50:O-PL-INVV3

E51:12V-REF

E56:O-PL-INVV2

E53:O-PL-INVV4

E54

E49

E40:I-F-CAM

E3:S-R-5VRTN

E28:S-S-5VREF

(Vehicle Side)

V56:P-S-PROTBATT

V52:P-S-PROTBATT

V39:I-SL-STARTER

Electronic control unit

E27:CRANK

E15:S-R-5VREF

E39:S-S-5VREF

E16:GSFGND

V44:S-S-5VREF

V32:S-R-5VRTN

E18:S-S-5VREF

E31:I-AH-BAROT

E6:S-R-5VRTN

E17:S-R-5VRTN

E30:I-AH-CLT

E5:S-R-5VRTN

E43:I-AH-FUELT

E9:S-S-5VREF

E44:I-A-BOOSTP

E22:S-R-5VRTN

E25:I-SH-LOWOIL

V43:S-S-5VREF

V31:S-R-5VRTN

V41:S-S-5VREF

V29:S-R-5VRTN

V42:S-S-5VREF

V30:S-R-5VRTN

V16:I-SL-BRAKE2

V40:I-SL-GEARPOSN

V3: I-SL-BRAKE1

V50:BATT

V25:O-SL-MPR

V13:P-S-IGN

V37:P-S-IGN

V49:GSFGND

V53:GSFGND

V51:HSGGND

V55:HSGGND

V15:I-F-VSS

V7:I-A-PPS1

V6:I-A-PPS2

V19:I-A-MAT

V17:I-A-MAF

V5:I-A-A/C

(BATT)

(+B)

(+B)

(M-REL)

(IG-SW)

(IG-SW)

(STA-SW)

Starter switch

(GND)

(GND)

(P-GND)

(P-GND)

(SPD)

(ACCP1-VCC)

(ACCP1)

(ACCP1-GND)

(ACCP2-VCC)

(ACCP2)

(ACCP2-GND)

(THA)

(MAF-VCC)

(MAF)

(MAF-GND)

(PAC-VCC)

(PAC)

(PAC-GND)

(BK2-SW)

(CL-SW)

(BK1-SW)

Vehicle speed

sensor

Pedal

position

sensor 1

Pedal

position

sensor 2

Air mass flow

AC pressure

Brake switch 2 (N.C)

Clutch switch (N.C)

Main relay

Key switch

D

to IG

Brake switch 1 (N.O)

27

Q000158E

Page 30

(Joint to)

D

EGR position

VSS solenoid

Turbo solenoid

Inatake valve

controller

(LEGR-VCC)

(LEGR-GND)

EGR solenoid

(LEGR)

(EGR)

(VSS)

(VNT)

(I/T-ST)

(I/T)

E19:S-S-5VREF

E45:I-A-EGRP

E7:S-R-5VRTN

E48:O-PL-EGR

E12:O-PL-VSS

E35:O-PL-Turbo

E38:I-PL-I/T

E23:O-PL-I/T

V24:O-SL-DIAGLAMP

V23:O-SL-FAN1

V35:O-SL-FAN2

V47:O-SL-FAN3

V48:O-SL-ACCRLY

V11:O-SL-GLOWRLY

V27:I-SL-GLOWDIAG

A

(MIL)

Fan control relay 1

(FAN1-REL)

Fan control relay 2

(FAN2-REL)

Fan control relay 3

(FAN3-REL)

Available only with AC

A/C cut off relay

(ACT-REL)

(GL-ST)

(GLOW-DI)

MIL

to IG

+B

E

BATT (+)

Shield wire

Rail pressure

High pressure pump solenoid

(PFUEL-VCC)

(PFUEL)

(PFUEL)

(PFUEL-GND)

(SCV+)

(SCV-)

Electronic control unit

E8:S-S-5VREF

E21:I-A-RAILPS

E33:I-A-RAILPS

E20:S-R-5VRTN

E11:12V-REF

E24:O-PL-PRESSURE

V21:C-CANHI

V33:C-CANLO

V14:O-PL-TN

V1:O-PL-FC

V2:S-DATA1

Twist pair

(CAN-H)

(CAN-L)

(NEOUT)

(FUELOUT)

(ISO-K)

Immobilizer

to IG

Glow

controller

ABS/TC

BCM

IP-cluster

Glow

EPS

MID

A

K-line

SAE1962

Oil level

LED

SVS

Oil press.

warning

28

Q000159E

Page 31

4.2 ECU Connector Diagram [1] ECU Connector Terminal Layout

Vehicle Side (V)

V12V11V10V9 V8V7V6 V5V4 V3V2V1 V50V49

V24 V23 V22 V21 V20 V19 V18 V 17 V16 V1 5 V1 4 V13 V52 V51

V36V35 V34V33 V32V31 V30V29 V28V27 V26V25 V54V53

V48 V47 V46 V45 V44 V43 V42 V 41 V40 V3 9 V3 8 V37 V56 V 55

Engine Side (E)

E12E11E10E9 E8E7E6 E5E4 E3E2E1 E50E49

E24 E23 E22 E21 E20 E19 E18 E 17 E16 E1 5 E1 4 E13 E52 E 51

E36E35 E34E33 E32E31 E30E29 E28E27 E26E25 E54E53

E48 E47 E46 E45 E44 E43 E42 E 41 E40 E3 9 E3 8 E37 E56 E 5

[2] Terminal Connections

(1) Vehicle Side (V)

Wire

Cross-section

(proposal)

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Pin

Pin Name

(ISUZU)

Pin Name

(DENSO)

V29 S-R-5VRTN MAF-GND

V30 S-R-5VRTN PAC-GND

V31 S-R-5VRTN ACCP2-GND

V33 C-CANLO CAN-L

V34

V3 5 O-SL-FAN2 FAN2-RE L

V39 I-SL-STARTER STA-SW

I-SL-GEARPOSN

V40

CL-SW

V41 S-S-5VREF MAF-VCC

V42 S-S-5VREF PAC-VCC

V43 S-S-5VREF ACCP2-VCC

V44 S-S-5VREF ACCP1-VCC

V45

V4 7 O-SL-FAN3 FAN3-RE L

V49 GSFGND GND

V51 HSGGND P-GND

P-S-PROTBATT

V52

+B

V53 GSFGND GND

V55 HSGGND P-GND

P-S-PROTBATT

+B

Pin

Pin Name

(ISUZU)

Pin Name

(DENSO)

V1 O-PL-FC FUELOUT

V2 S-DATA1 ISO-K

V3 I-SL-BRAKE1 BK1-SW

V4 V32 S-R-5VRTN ACCP1-GND

V5 I-A-A/C PAC

V6 I-A-PPS2 ACCP2

V7 I-A-PPS1 ACCP1

V8 V36

V9 V37 P-S-IGN IG-SW

V10 V38

O-SL-GLOWRLY

V11

O-SL-WTGLOW1

V12

GL-ST

HEAT1-REL

V13 P-S-IGN IG-SW

V14 O-PL-TN NEOUT

V15 I-F-VSS SPD

V16 I-SL-BRAKE2 BK2-SW

V17 I-A-MAF MAF

V18 V46

V19 I-A-MAT THA

V20 V48 O-SL-ACCRLY ACT-REL

V21 C-CANHI CAN-H

V22 V50 BATT BATT

V2 3 O-SL-FAN1 FAN1-REL

O-SL-DIAGLAMP

V24

MIL

V25 O-SL-MPR M-REL

V26 V54

I-SL-GLOWDIAG

V27

GLOW-DI

V28 V56

5

Q000160E

Wire

Cross-section

(proposal)

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

1.5mm

1.5mm

1.5mm

1.5mm

1.5mm

1.5mm

1.5mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

29

Page 32

(2) Engine Side (E)

Wire

Cross-section

(proposal)

Pin

Pin Name

(ISUZU)

Pin Name

(DENSO)

Pin

Pin Name

(ISUZU)

Pin Name

(DENSO)

E1 E29

E2 E30 I-AH-CLT THW 0.75mm2

2

E3 S-R-12VRTN G-

0.75mm

E31 I-AH-BAROT PATM 0.75mm2

E4 E32

2

E5 S-R-5VRTN THF-GND

E6 S-R-5VRTN PATM-GND

E7 S-R-5VRTN LEGR-GND

E8 S-S-5VREF PFUEL-VCC

E9 S-S-5VREF PIM-VCC

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

E33 I-A-RAILPS PFUEL 0.75mm2

2

E34

2

E35 O-PL-Turbo VNT 0.75mm2

2

E36

2

E37

E10 E38 I-PL-I/T I/T-ST

E11 12V-REF SCV+

E12 O-PL-VSS VSS

0.75mm

0.75mm

2

E39 S-S-5VREF NE-VCC

2

E40 I-F-CAM G+

E13 E41

E14 E42

2

E15 I-F-CRANK Lo NE-

E16 GSFGND SH-GND

E17 S-R-5VRTN THW-GND

E18 S-S-5VREF PATM-VCC

E19 S-S-5VREF LEGR-VCC

E20 S-R-5VRTN PFUEL-GND

E21 I-A-RAILPS PFUEL

E22 S-R-5VRTN PIM-GND

E23 O-PL-I/T I/T

O-PL-PRESSURE

E24

SCV-

E25 I-SH-LOWOIL LOIL-SW

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

E43 I-AH-FUELT THF

2

E44 I-A-BOOSTP PIM1

2

E45 I-A-EGRP LEGR

2

E46

2

E47

2

E48 O-PL-EGR EGR

2

E49

2

E50 O-PL-INVV3 TWV3

2

E51 12V-REF COMMON2

2

E52 O-PL-INVV1 TWV1

2

E53 O-PL-INVV4 TWV4

E26 E54

2

E27 I-F-CRANK Hi NE+

E28 S-S-5VREF G-VCC

0.75mm

0.75mm

E55 12V-REF COMMON1

2

E56 O-PL-INVV2 TWV2

Wire

Cross-section

(proposal)

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

0.75mm

1.5mm

1.5mm

1.5mm

1.5mm

1.5mm

1.5mm

2

2

2

2

2

2

2

2

2

2

2

2

2

30

Loading...

Loading...