Page 1

™

®

PCW CONTROL

SYSTEM

User’s Guide

Page 2

PCW Control S Installation

2

Page 3

Table of Contents

Introduction – Getting Acquainted with the PCW Control System 2

Glossary 2

Chapter 1 - Getting Started 3

Chapter 2 - PCW Control Program Window Overview 5

The PCW Control Schedule Viewer 6

Calendar Control Panel 6

The Time Slot Editor 7

Operating Day Schedule 7

The Interval Schedule 8

The Even or Odd Date Schedule 9

The Weekday Schedule 9

The Zone Buttons 10

Adding Zones 10

Selecting Water Zone Properties 11

Selecting Lighting Zone Properties 12

Zone Control Options 13

The Scheduling AdvisorTM Panel 14

Advisor-Based Schedule 15

The Site Settings Panel 16

Manual Operations Panel 19

Multi-Zone Manual Program Setup 20

Chapter 3 – Hardware Features: PC-Remote and Controller Operations 21

Chapter 4 – Remote Master Valve / Pump Start Feature 22

Appendix 1 – Frequently Asked Questions 23

Appendix 2 – Advanced Adjustment Features 26

Global Seasonal Adjustment 26

Schedule Seasonal Adjustments

(Advanced Seasonal) 26

ET Adjustment 27

Appendix 3 – Transferring Irrigation Schedules 28

Troubleshooting Guide 30

FCC Part 15 Rule 31

PCW Control S Installation

1

Page 4

Introduction – Getting Acquainted with the PCW Control System

Irritrol’s PCW Control system brings simple, yet sophisticated control to your landscape’s automatic sprinkler

and lighting system, through the convenience of your personal computer and a wireless, hand-held PC Remote

transmitter.

Glossary

To start, take a moment to become familiar with the following list of terms used throughout the PCW Control

program software and user’s guide.

Active Schedule – The current schedule in use for the Site (also listed at the top of the program window). A

site can have any number of saved schedules such as Spring, Summer, and Fall schedules for a site labeled “My

House”.

Active Site – The current site in use (listed at the top of the screen). The average PCW Control application will

have only one site; the location of the yard or landscape controlled by the system. Professional irrigation installers may need multiple sites saved on their computers.

Controller – The electronic unit that stores the current operating program and controls the irrigation valves and/

or relays for lighting. As well as a Master Valve/Pump Start circuit and a sensor input, the controller provides connections for up to 12 zones, of which three can be lighting zones. The system can control up to four controllers.

Get Schedule – The function that retrieves and displays the current schedule in the controller.

Master Valve Circuit – A circuit that controls the valve that opens and closes the pipeline supplying the rest of

the valves on an irrigation system. The master valve electrical circuit opens the main line when the first valve

turns on and shuts off the mainline when the last valve turns off. The Master Valve is used as protection against

the continuous flow of an irrigation valve stuck open.

PC-Remote (PC-R) - A multi-function control unit that, connected via USB cord to the Windows-based PC, provides wireless communication with the controller. When disconnected, the handheld remote enables manual

operation of the system.

PIN – The 4-digit, personal identification number selectable for the system. The PCW Control software, PCRemote, and the controller all must have the same PIN. The user-selected PIN helps reduce the chance of unauthorized access to the system.

Pump Start Circuit – The same circuit for a Master Valve, however, instead of energizing a valve, the circuit closes and opens a relay for switching a pump on or off. One side of the relay is energized by 24VAC from the controller and closes a bigger relay between the pump’s power source and the pump motor.

Open Site – Clicking this button opens the list of saved sites.

Operating Day Schedule - The sequence of watering days and/or lighting nights selectable by zone.

Week Day – Operation on selected days of the week.

Odd/Even Date – Operation only on Odd or Even numbered dates.

Day Interval – Operation in repetitive days (every two days or every three days, etc.)

Remote Master Valve/Pump Start – The feature that allows a Master Valve or Pump Starter to be connected to

Controller #1 only. Other controllers in the system call #1 to activate the Master Valve or pump as needed.

Seasonal Adjust – A percentage increase or decrease in watering time to match seasonal watering needs of the

landscape.

Schedule - An automatic operating routine for the irrigation and/or lighting zones. Schedules can be selected,

created, edited, saved, and transmitted from the calendar screen.

Scheduling Advisor™ - A feature that allows the user to enter specific details about a watering zone into the

system and receive a recommended irrigation schedule. The user can elect to apply the schedule and can also

decide on automatic adjustments to the irrigation schedule based on weather updates.

Site - The location of an irrigation and/or lighting system under the PCW Control’s command. In most cases, only

one site is identified.

Station – Another term for zone (see Zone below).

Zone – A section of the landscape supplied by one irrigation valve (irrigation zone) or lit by one landscape light-

ing circuit (lighting zone). Irrigation systems are divided up into zones because water pressure and flow will not

allow watering all areas at one time and the wide variety of plant material, slope, soil type and sun exposure cre-

ate differing needs for water application.

PCW Control S Installation

2

Page 5

Chapter 1 - Getting Started

Irritrol’s PCW Control system brings simple yet sophisticated control to your automatic sprinkler and landscape

lighting system through the convenience of your personal computer.

The complete PCW Control system installation procedure is provided in the Installation and Setup Guide, form

number 373-0761. If you have already completed the

installation and setup procedures per the installation

guide, continue on to page 4.

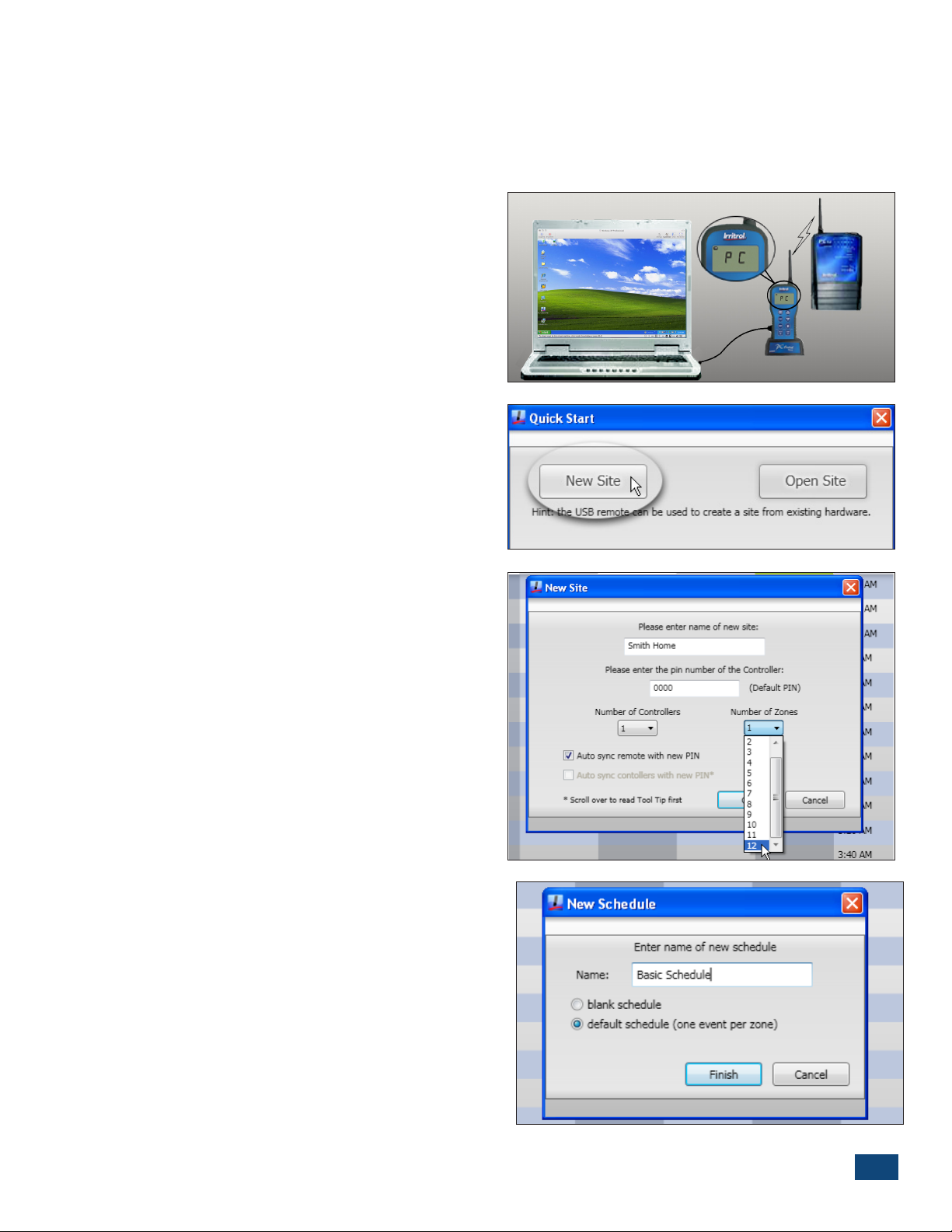

Install and Launch the PCW Control Program.

1. Insert the installation CD into your disc drive.

In the “My Computer” window, double-click the

PCW Control icon.

2. Double-click on setup.exe. The PCW Control

program and required support software will be

installed automatically. Respond to the software

installation prompts as necessary.

3. Using the provided USB cable, connect the PC-R to

the computer’s USB port.

The PC-R will display PC when the connection is

established (Figure 1.1).

4. From the Start menu, launch the PCW Control

program.

5. At the Quick Start dialog box, click the New Site

option button (Figure 1.2). The Open Site option is

used to open a previously saved site conguration

le.

Figure 1.1

Figure 1.2

Note: A “Site” le species how the PCW Control

system is congured. A Site requires a name, a PIN

code, the number of Controllers in use (1–4), and the

initial number of zones to be included in the operating schedule.

6. At the New Site dialog box (Figure 1.3), enter the

preferred site name.

7. In the PIN number eld, you may leave the default

0000 PIN code, or enter a preferred four-digit PIN.

(See Change PIN section, below).

8. The default number of controllers is one. If your

site utilizes more than one controller, select the applicable number from the drop-down list.

9. Select the number of zones to be scheduled. The

available zone count in the drop-down list will correlate with the number of controllers selected .

10. Click the OK button to save the Site le.

11. At the New Schedule dialog box (Figure 1.4), enter

your preferred Schedule name.

• A Schedule congures PCW Control system opera-

tion based on the active day(s), start time(s), and

Figure 1.3

Figure 1.4

PCW Control S Installation

3

Page 6

run time duration assigned to each zone.

• Any number of schedules can be dened and saved

to memory for later recall, however every schedule

must have a unique name assignment.

13. Select the Default Schedule option to open the

new schedule with a run time Blank Schedule to

start without presets.

14. Click the Finish Button.

• The site and schedule name will be displayed at

the top of the program window (Figure 1.5).

The PCW Control program should begin communicating with the Controller(s) at this time and will activate

the control system; indicated by green signal bars and

the Auto On controller status. If a communication link

is not established, Unknown Status will be displayed.

(Figure 1.6) This condition is usually caused by a

mismatching PIN. Verify the PC-R and Controller have

a matching PIN and the Controller(s) can be operated

manually with the PC-R.

Change PIN

Figure 1.5

Figure 1.6

Important PIN Information: As a security measure, the PC-Remote (PC-R) and Controller utilize a

four-digit PIN code to enable wireless communication. Both units are initially set to 0000 by default. This

is an optional feature and can remain 0000 if desired. If you wish to change the PIN to prevent unintended

system operation, read this section.

Changing the system’s PIN can only be done from the computer when all the PINs are the same to begin with.

The parts of the system, computer, PC-R, and Controller all have to be communicating for “Change PIN” to

function. In the case of mismatched PINs (and in the case of multiple Controllers in the system), the PIN and

controller number need to be set manually in each controller. See the procedure below:

1. On the front of the Controller, press the “MANUAL” and “AUTO ON” buttons simultaneously to start the

“POWER” light blinking and illuminate one of the station lights.

2. With the station lights 1 thru 9 representing PIN digits 1-9 and with 10 representing “0”, use the “MANUAL”

button to advance to and illuminate the rst digit desired for the PIN.

3. Press “AUTO ON” to move the light down from “POWER” to illuminate “SIGNAL”. The “SIGNAL” light represents

the second PIN digit. Again, use the “MANUAL” button to move to and illuminate the second, desired PIN

number and then press “AUTO ON”.

4. Repeat the above steps to set the third and fourth PIN digits with “SENSOR” and “MASTER VALVE / PUMP”

illuminated respectively.

5. The last digit, represented by the “TEST” light, is for the controller or Controller number. If there is only one

controller in the system, set or leave the controller number at “1”. If setting up a second controller for the

system, use the “MANUAL” button to move to #2 in the “STATION” lights. The controller number selection

only goes up to four.

6. Hold down the “AUTO ON” button until the lights start a sequential display and then release the button. The

Controller will demonstrate what was set for each of the four PIN numbers and the controller number and

will then return to AUTO mode on its own.

PCW Control S Installation

4

Page 7

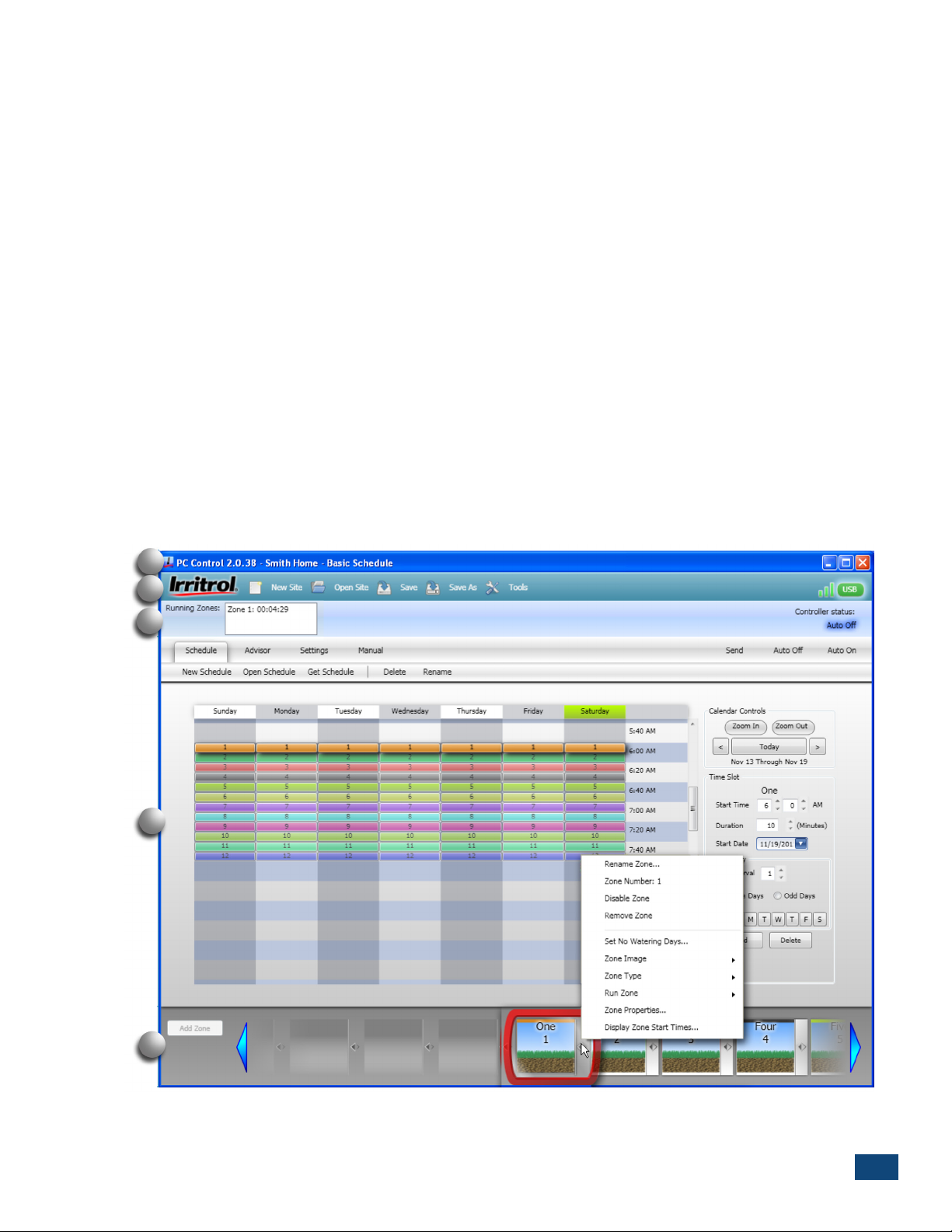

Chapter 2 - PCW Control Program Window Overview

The PCW Control program is designed for ease of scheduling, review and system operation. The

program window is organized so you can easily setup and review operating schedules, access the

weather data, fine-tune system operation, and manually operate the system as needed.

The program window is comprised of five main sections, shown below (Figure 2.1).

A – The dark blue title bar provides the PCW Control application version, currently open site and

schedule names, and the minimize/maximize/close window buttons.

B – Directly below is the turquoise Site Menu bar that provides direct access to the site resource

folders, save options and system tools. The PC-R remote USB connection and signal strength bars

are located on the far right.

C - The light blue section displays current Controller Status information including zone operation,

Auto On/Auto Off status, and system activity status.

D – The four main panel tabs of the light gray center section include the Schedule Viewer with Calendar Control center, schedule Advisor, Settings and Manual operation panel.

Located on the right are the Send, Auto Off and Auto On system control buttons. Below the Schedule tab are five schedule function buttons used to create a New schedule, Open a saved schedule,

Get Schedule (from Controller), and delete or rename a schedule.

E – The Zone Buttons are arranged across the bottom of the window. Each color-coded button is

linked to the corresponding colored/numbered zone segments in the Schedule Viewer. Modifications to individual zones are made through the Zone Button pop-up menu.

A

B

C

D

E

Figure 2.1

PCW Control S Installation

5

Page 8

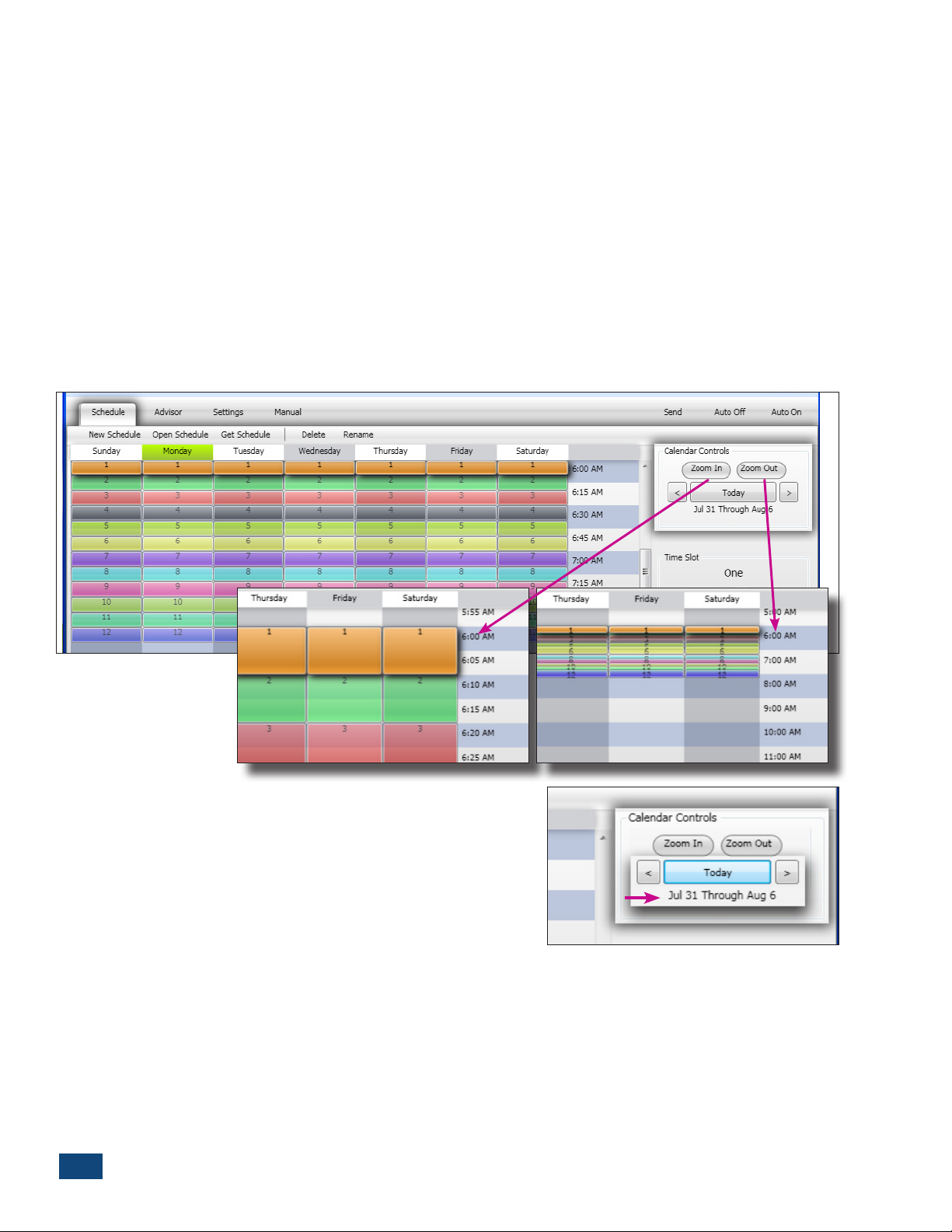

The PCW Control Schedule Viewer

The Schedule Viewer (Figure 2.2) is the primary panel where the scheduled operation of each zone

is established. The Schedule Viewer is arranged in a 7-day calendar format that initially displays

the schedule for the number of zones specified in the New Site dialog box. Each zone has a specific

color and number assignment that corresponds to the Zone Buttons at the bottom of the window,

and to the field output terminals of the Controller. When the default schedule is selected in the

dialog box, each zone will be scheduled to run for 10 minutes, every day, beginning at 6:00 a.m.

Calendar Control Panel

The Schedule Viewer is formatted with the days of the week arranged in columns starting on

Sunday, and Start Times arranged in rows, starting at 12:00 a.m. (Midnight). By default, start time is

displayed at a 30-minute increment resolution. The Zoom In and Zoom Out buttons enable the start

time resolution to be zoomed in to 5-minute increments, or zoomed out to a 1-hour increments.

Weekly

Figure 2.2

Calendar View

By default, the 7-day schedule will coincide with the current

date, verified by calendar dates displayed below the Today

button. The right and left arrow buttons are provided to

shift the schedule view forward and backward through the

calendar in 1-week increments. Selecting the Today button

resets the Schedule Viewer back to the current calendar week.

PCW Control S Installation

6

Page 9

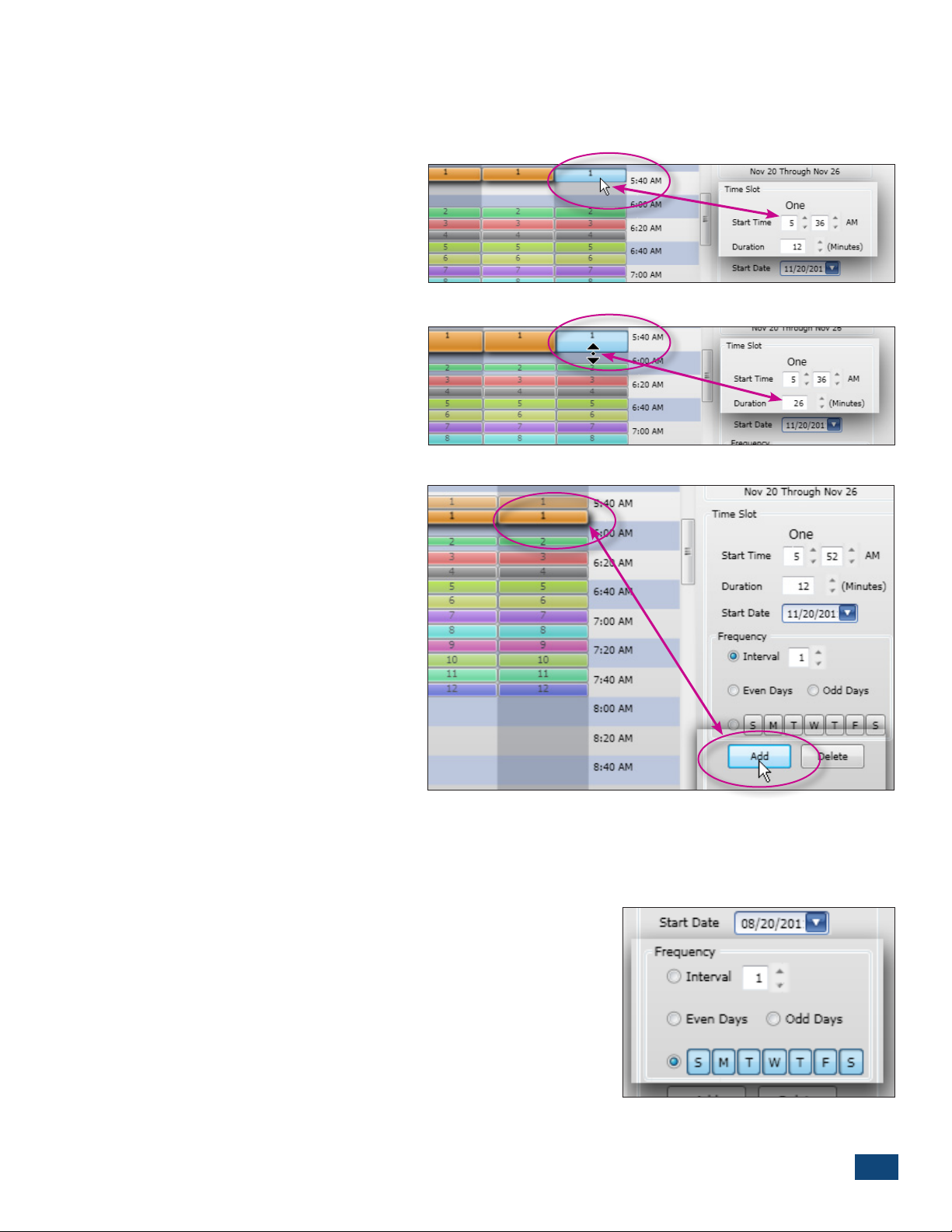

The Time Slot Editor

The zone Start Time and Run Time Duration can be configured directly within the Schedule Viewer,

or by selecting the desired values in the zone Time Slot editor.

To change a zone start time directly in

the Schedule Viewer, place the cursor over the desired zone segment to

highlight, then click and drag the segment to the desired start time (Figure

2.3).

To adjust the run time duration, place

the cursor on the bottom edge of the

segment, then Click and drag to adjust

the run time duration, (1–1400 minutes) (Figure 2.4).

To apply additional start times to a

zone, press the Add button (Figure

2.5). Each zone can have a maximum

of 10 start times. Remove a highlighted

start time by selecting the Delete button.

Note: By default, zone operation is limited

to one zone operating at any given

time. An Overlap Limit preference on

the Settings panel enables up to two

additional watering zones to operate

simultaneously.

See Site Settings Panel, p. 11, for

complete information.

Figure 2.3

Figure 2.4

Figure 2.5

Operating Day Schedule

The Operating Day schedule (Figure 2.6) determines which days a zone will be active. When the

default schedule is selected, all zones are scheduled to operate every day of the week, (based on a

1-day Interval schedule). Each zone operates independently and can be assigned to any one of the

following scheduling options:

•IntervalSchedule–Askip-dayfrequency,rangingfrom1–31;

where 1 equals every day, 2 equals every-other-day, etc., up

to one day every 31 days.

•Even- or Odd-Date Schedule – Schedules all even or odd cal-

endar dates as active watering days.

•Weekday Schedule – Schedules operation by days of the

week.

Note: Each zone can have only one operating day schedule. All

start times assigned to a zone are assigned to the same

operating day schedule.

PCW Control S Installation

Figure 2.6

7

Page 10

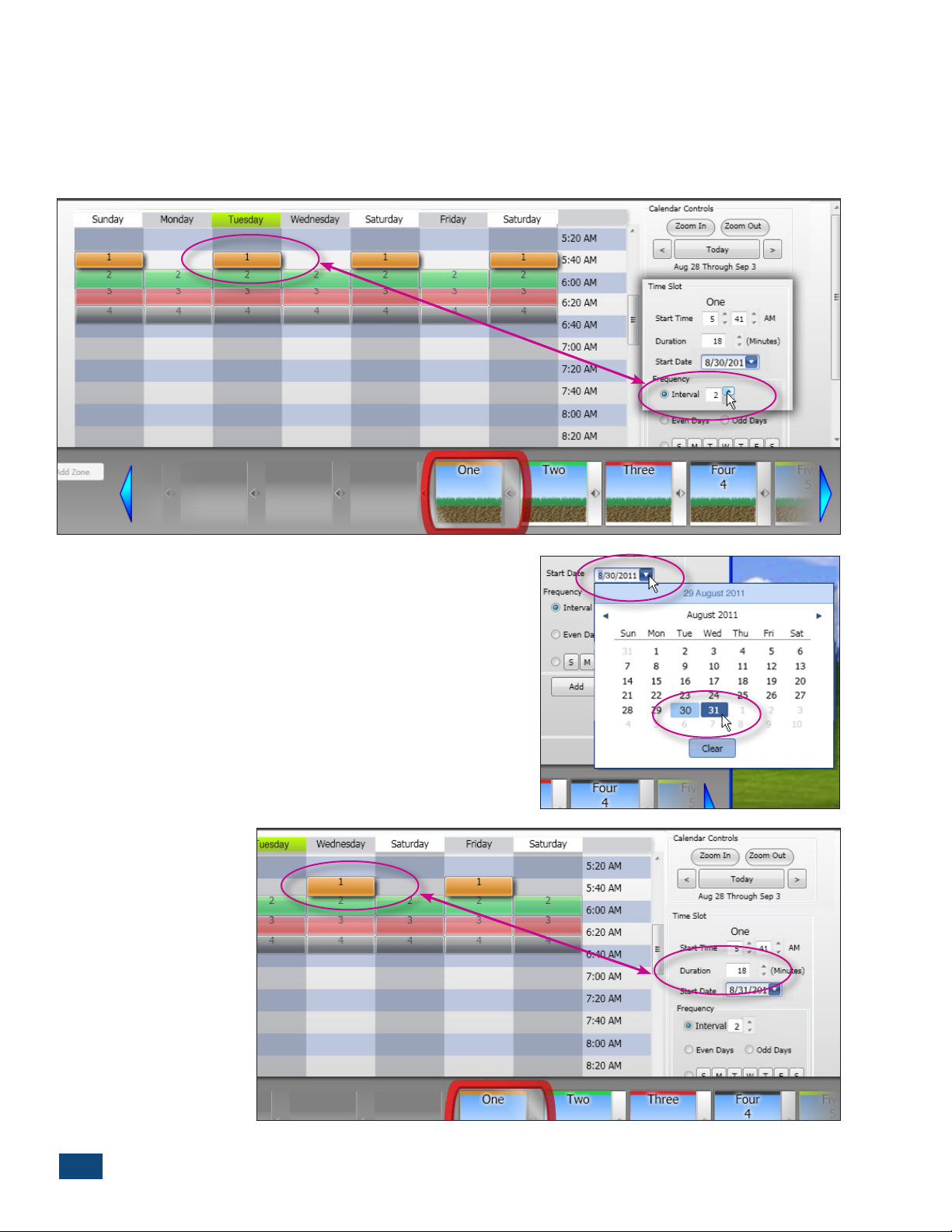

The Interval Schedule

To set an Interval schedule, highlight the zone by clicking on a segment bar, or on the corresponding Zone Button. Select the Interval option in the Time Slot editor. Use the up/down arrow scroll

box to select the preferred frequency (1–31) (Figure 2.7). Note the arrangement of the zone segment bars in the Schedule Viewer as the Interval frequency is changed.

Figure 2.7

To select an alternate Interval start day, click on the blue

down-arrow box to display the drop-down calendar. The

current Interval start date will be highlighted in dark blue.

Click on the preferred start date.

The new start date will be highlighted in dark blue and the

original start date will be highlighted in light blue (after the

calendar window is closed and reopened). Note the placement of the zone segment bars as the Interval start date is

changed. As shown in the screenshot (Figure 2.8) the start

date of the 2-day Interval has been changed from Tuesday

to Wednesday (Figure 2.9).

Figure 2.8

PCW Control S Installation

8

Figure 2.9

Page 11

The Even or Odd Date Schedule

Setting an Even- or Odd-date schedule is done in the same manner as setting an Interval schedule.

Simply select the corresponding button to choose the frequency schedule (Figure 2.10).

Note that in this Odd-day schedule, Wednesday and Thursday will be active. This circumstance will

occur at the end of all months with 31 days.

Figure 2.10

The Weekday Schedule

The Weekday schedule enables any day of the week to be selected as active. When initially selected

with the weekday button, all days are active. Click on the days of the week to remove them from the

schedule.

Figure 2.11

In the example above, a Weekday schedule has been selected for Zone 1 with Sunday and Friday as

non-operating days (Figure 2.11).

PCW Control S Installation

9

Page 12

The Zone Buttons

The individual Zone Buttons, located in the tray below the Schedule Viewer, are linked to the corresponding Zone Schedule bar segments. In addition, the zone configuration properties are accessed

through the Zone Button pop-up menus.

A zone must first be selected to enable it to be edited. Clicking on a

Zone Segment or the corresponding

Zone Button will position the Zone

Button into the Edit Frame. If a Zone

Button is not visible in the tray, clicking on the left or right blue arrow

buttons will scroll the Zone Buttons

into view. (Figure 2.12)

Figure 2.12

Adding Zones

Each site can schedule up to 12 zones.

If the site currently has less than 12

zones, selecting the Add Zone button

will open the Add New Zone dialog

box (Figure 2.13). All of the basic zone

setup properties can be applied to

the new zone through the dialog box.

The next zone in numeric sequence

will be added.

The default zone setup properties can

be changed as desired, including the

zone name, number, type (Water or

Lighting) and the Zone Box image

(Figure 2.14).

Click OK and the new zone will be

added to the Zone Box tray

(Figure 2.15).

Note: Refer to Time Slot Editor on page

2 to add a zone start time.

Figure 2.13

Figure 2.14

Figure 2.15

10

PCW Control S Installation

Page 13

Selecting Water Zone Properties

The Zone Properties configuration

menu is accessed by double-clicking

the preferred Zone Box. A specific set

of properties is provided for watering

and lighting applications. By default,

3

2

4

5

6

the zone property menu for watering

application will be displayed

1

(Figure 2.16).

(1)

Type – All zones are designated for

irrigation by default. To designate the

zone for landscape lighting, select the

Light button in the Type option box.

7

Note: For additional Lighting zone

setup options, continue at “Selecting

Lighting Zone Properties” on the

following page.

(2)

Zone Number – Enables the default

Figure 2.16

zone number to be reassigned to any currently unused zone number. The drop

down menu will list all currently available zone numbers.

Note: The default zone numbers corespond to the station output terminals in the controller

regardless of Zone Box content.

(3)

Name – Enables the zone to be labeled as preferred.

Note: Changes in the Zone Properties menu will not be reflected in the program until the

OK button has been selected.

(4)

Master Valve / Rain Sensor – Enable / disable the Master Valve / Pump circuit and/or

Rain Sensor for the zone as preferred.

(5)

No-Watering Days – Enables zone operation

to be restricted on specific days of the week. The

restricted days will be represented in the Schedule

Figure 2.17

Viewer with a striped segment (Figure 2.17).

(6)

Seasonal Adjustment – Changes the individual

zone run time duration (as indicated in the

Schedule Viewer) by a percentage value ranging

from 100% (unadjusted value) up to 200%, or

down to 10% in 5% increments.

(7)

Change Image – Enables the Zone Button

background image to be changed as desired. An

alternate image can be selected from the dropdown menu, or imported directly from your

computer by selecting the Custom option (Figure

2.18). The “My Pictures” folder opens when the

Custom button is clicked.

Figure 2.18

PCW Control S Installation

11

Page 14

Selecting Lighting Zone Properties

The Zone Properties configuration

menu is accessed by double-clicking

the preferred Zone Box. A specific set of

properties is provided for watering and

lighting applications. By default the zone

property menu for watering application

will be displayed (Figure 2.19).

(1)

Type – To designate the zone for a

lighting, select the Light button in the

Type option box.

(2)

Zone Number – Enables the default

zone number to be reassigned to any

currently unused zone number. The

drop down menu will list all currently

available zone numbers.

(3)

Name – Enables the zone name

label to be changed as preferred.

Note: Local ZIP code must be entered in

the Advisor Panel to enable the Sunset/

Sunrise lighting zone option. See “The

Scheduling Advisor Panel” on page 9 for

details.

3

2

4

5

1

Figure 2.19

(4)

Use Sunset Time to Start – Select this option to automatically begin lighting zone

operation at sunset (based on local ZIP code).

(5)

End Time – Select the Use Sunrise button to automatically end lighting zone operation

at sunrise. Select the Custom button to enter a

preferred end time.

(6)

Change Image – Enables the Zone Button

background image to be changed as desired. An

optional image can be selected from the dropdown menu (Figure 2.20), or imported directly

from your computer (“My Pictures” folder) by

selecting the Custom option. Simply double-click

the desired image from “My Pictures” and click

“OK” twice.

Note: The following image file formats can be

imported: jpg, jpeg, png, bmp, and gif.

Figure 2.20

12

PCW Control S Installation

Page 15

Zone Control Options

The Zone Control Options menu is accessed by

clicking on the gray bar, located on the right

side of the Zone button.

The Zone Control Options menu provides

an alternate selection path to access

specific zone property options. Additional

Zone Control options provided on this

menu included: Disable Zone, Remove

Zone, Run Zone, and Display Zone Start

Times (Figure 2.21).

Disable Zone: Select this option to disable

the zone from operation. Toggles the zone

off and on as needed, without deleting

the zone setup. The corresponding zone

segment will be grayed out and the control frame labeled nonoperation as illustrated at right.

Figure 2.21

Note: The Zone Properties menu is only

accessible through the Zone Control Options

menu when the zone is in the disabled mode.

Remove Zone: Removes the Zone Button

and all information for the zone from the

Schedule.

Important: When a zone is removed

from the schedule, it can be added back in,

but will be last in the Zone Button tray.

Run Zone: Enables the zone to be operated

manually for a selected or specified run

time duration (Figure 2.22).

Note: Once the zone has been started

manually, it can run to completion or can be

terminated at any time by selecting

Auto Off>Auto On or Manual>Stop.

Display Zone Start Times: Provides

an overview of the current start time

assignments for the selected zone. To edit a

start time, click the start time to highlight,

select Edit to display the Zone Start Time

edit box. Enter the preferred start time and

click OK (Figure 2.23).

Figure 2.22

Important: Zones assigned to the

Scheduling Advisor cannot be edited under

“Display Zone Start Times”.

Figure 2.23

PCW Control S Installation

13

Page 16

The Scheduling AdvisorTM Panel

The Scheduling Advisor is a powerful setup tool that automatically creates an effective watering

schedule based on specific sprinkler system and landscape parameters, in addition to local weather

factors retrieved from the internet.

The upper half of the Advisor panel provides convenient drop-down menus to select five specific

watering zone properties. Located to the right of the menus is the Advisor ET Adjustment slider, and

Earliest Advisor Start Time setting (Figure 2.24).

1

4

3

2

5

Figure 2.24

(1) Select the appropriate Advisor setting for each of the following characteristics:

• Sun Exposure – Full Sun, Part Sun, Part Shade, Full Shade or Custom (by % of exposure)

• Sprinkler Type – Single-Stream Rotor, Multiple-Stream Rotor, Fixed Spray, Drip, Bubbler, Microspray,

or Custom (by precipitation rate).

• Plant Type – Grass, Planter, Shrubs, Trees, or Custom (by plant root depth)

• Ground Slope – None, Low, Medium, or High

• Soil Type – Sand, Loam, or Clay

(2) Use Advisor check box must be selected to apply the Advisor-defined zone schedule.

(3) Advisor ET Adjustment: Use the adjustment slider to increase/decrease overall watering applica-

tion rate of an Advisor-based schedule.

(4) Earliest Advisor Start Time: Restricts the Advisor from scheduling a watering operation before a

specified time of day. By default, the earliest start time is set at 6:00 a.m.

(5) Weather – The specific weather information required by the Scheduling Advisor is entered in the

lower half of the panel. The local ZIP Code or City name is entered, and the current weather information is retrieved by selecting the Get Forecast button. If multiple site locations are to be used,

select the Add to Favorite Locations option. The selected locations will be retained in the Favorite

Locations drop-down list, and can be reinstated or removed as preferred. The Update Schedule

option enables the watering schedule to be automatically updated via the internet on a daily,

weekly, monthly or seasonal basis, with or without prior notification. Click the “Get Forecast” button

at the time of day you want the system to retrieve the weather data from then on (set for a time of

day that your computer is usually on).

14

PCW Control S Installation

Page 17

Advisor-Based Schedule

The watering schedule created by the Advisor is described on the Advisor panel and depicted in the

Schedule Viewer (Figure 2.25).

Figure 2.25

Note: The “Advisor” icon will be displayed in the lower corner of a Zone Button when the Scheduling

Advisor is controlling the zone watering schedule. The Use Advisor option must be unchecked to remove

or modify the Advisor-based zone schedule.

PCW Control S Installation

15

Page 18

The Site Settings Panel

The Site Settings panel provides an array of control options specific to the site configuration

(Figure 2.26).

Note: In order for any site configuration change to take effect, the Apply button and Send tab must be

selected. You will be prompted to save the site change(s) during the Send process.

Figure 2.26

Selecting Site Configuration Options

(1) Change PIN – The current PIN code can be changed as preferred using the Change

PIN option. The current PIN code assigned to the site will be indicated in the Change PIN dialog box

when opened (Figure 2.27). Type in a different four-digit PIN and select either of the following PIN

Options as preferred:

• Remote and Controller: (PINs must already

match to use this option.) This is the most

common selection when changing the PIN

code. Choosing this option changes the PIN

code in both the PC-Remote and the Controller

– ensuring that communication between the

components will not be lost.

• Remote Only: This selection changes the PIN

code in the PC-Remote only, and is generally

used by contractors when access to multiple

PC-Control irrigation systems is required.

(2) Hardware Information – Click to review

current controller hardware information

Figure 2.27

including firmware and hardware version,

model number and serial number.

16

PCW Control S Installation

Page 19

(3) Site Settings: Add/Remove Controller –

Manage multiple controller operation and

rain sensor input within this section of the

Settings panel. A check box is provided to

1

enable/disable up to four controllers per

site. Each additional controller increases

the displayed zone count in Controller 1

up to 12 zones, for a maximum a total of 48

3

2

zones.

• Rain Sensor Options – Also included

in this panel section are the Rain Sensor

configuration options. To utilize an auxiliary rain sensor with Controller 1, the Use

Rain Sensor box must be selected and the

rain sensor hardware must be connected to

the controller.

4

5

Note: When the rain sensor option is selected,

all zones will be assigned to the rain sensor

control, as indicated by RS in the lower right

corner of each Zone Box (Figure 2.28)

Figure 2.28

To isolate a zone from rain sensor operation,

such as watering areas not exposed to rainfall, deselect the rain sensor option within the individual

Zone Properties menu.

In systems where multiple controllers are utilized, the rain sensor connected to Controller 1 can be

linked electronically to each additional controller by selecting the Remote option. If an additional

controller has a dedicated rain sensor connection, select the Local option for that controller.

Note: The Rain Sensor option is selectable by zone within the Zone Properties menu, but must first be

enabled in the Site Settings panel to become available within the individual zone setup menu.

Note: Some of the selections in the Settings panel must be

saved and uploaded to the controller site to become effective. Selecting the Apply button followed by the Save and/

or Send button is required each time a selection is made.

(4) Overlap Limit – By default, the controller is restricted to operate one zone at a time, regardless

of the watering schedule. If the irrigation supply source is capable of providing sufficient capacity

to operate more than one watering zone at a time, the Overlap Limit can be set to enable up to two

additional zones to operate simultaneously. “0” equals no overlap, one zone at a time.

Caution: The maximum field output is 24 VAC, 0.4A per station, with a combined total not to

exceed 1.0A (including a master valve or pump start relay and zones designated for lighting).

Exceeding this limit will activate the controller’s automatic circuit breaker to restrict field

output.

(5) Rain Delay – Automatic controller operation can be manually set to prevent watering from 1 to

7 days by moving the sliding pointer to the right. Automatic operation will resume at the end of the

delay period, or can be reinstated at any time by moving the slider back to the left stop. (Not for use

with a rain sensor.)

PCW Control S Installation

17

Page 20

Note: The PCW Control program offers a variety of seasonal adjustment options that can be applied

globally to the Site and/or Schedule and/or individually to each zone. The percent adjustment for

seasonal changes are for systems not using Scheduling Advisor. Refer to Appendix 2– Advanced

Adjustment Features for detailed information

regarding Seasonal Adjustment options.

6 8

(6) Global Seasonal Adjustment is used to

apply a seasonal adjustment % factor globally to

any Schedule opened within the Site.

A % adjustment value, ranging from 100%

(unadjusted value) up to 200% or down to 10%

in 5% increments, can be applied globally to all

months of the year or to each month individually

as preferred. For individual months, select the

9

month’s radio button, then adjust the slider to

the % value as preferred. (Figure 2.29)

Each month selected will retain its corresponding adjustment % value after the selections have been applied, saved and sent to the

7

controller.

Note: When the All 12 Months option is selected,

the adjustment value will change to 10% (by

default) for all months. Be sure to set the adjustment slider to the preferred % value.

(7) Advanced Seasonal Adjustments enable

seasonal adjustment factors to be applied to

specified controllers (in multiple-controller

applications), to all zones or individual zones

within a schedule.

Note: A seasonal % value adjustment applied to

a zone within the Zone Properties configuration

menu will be reflected in the Advanced Season

Adjust Settings menu and vice-versa.

(8) Global No-Watering Days – Enables individual days of the week to be restricted from

operation for any schedule opened within

the site to comply with local water restrictions.

(9) Water Restriction Time – Enables a specific

window of time to be established that will

restrict all automatic watering operation. By

Figure 2.29

selecting the Use Restriction Window option,

the restriction window Start Time and End Time

can be established.

Note: When setting the Start Time and End Time, make sure the appropriate AM/PM reference is

displayed.

18

PCW Control S Installation

Page 21

Manual Operations Panel

1

3

2 4

Figure 2.30

Multiple-zone manual watering program are formatted and controlled in the Manual Operation Panel

(Figure 2.30).

(1) Multi-Manual Presets – Preset manual watering programs that the user creates are listed by

name in the drop-down menu for easy access and operation. The New and Delete buttons are used

to add and delete preset programs as preferred.

(2) Multi-Manual Zone List – The Zone Button in the red Edit Frame will be added to the program

list by selecting the Add button. The order in which Zones are added and listed determines the

zone operating sequence.

(3)Duration – Each zone is assigned a manual run time duration of 1 minute by default, with an

adjustment range of 1 minute to 99 hours.

(4) Start/Stop Buttons – The Start and Stop buttons are used to initiate the preset watering

program. To terminate the watering program at any time prior to automatic time-out, press the

Stop button.

Note: The Stop button is also used to terminate a single zone manual watering operation initiated in

the Zone Control Options menu.

PCW Control S Installation

19

Page 22

Multi-Zone Manual Program Setup

• SelecttheNew button to open the Manual Preset Name

dialog box (Figure 2.31).

• Enteraprogramname,thenclickOK(Figure2.32).

• ThemanualprogramnamewillbeenteredintheMulti-

Manual Presets drop-down menu (Figure 2.33).

• SelecttheZoneButtonfollowedbytheAddbuttonto

format the manual watering program list. The zone order

selected will be the order of operation during the watering

program. Continue to add as many zones to the list as

preferred (Figure 2.34).

Figure 2.31

Figure 2.32

Figure 2.33

• Clickonthezonenumber/nametohighlight.Selectthe

amount of zone run time using the scroll arrows. Repeat

to assign a run time duration for each zone on the list (as

required) (Figure 2.35)

• Aftersetup,themanualprogramcanbeaccessedbyname

at any time and started.

20

PCW Control S Installation

Figure 2.34

Figure 2.35

Page 23

Chapter 3 – Hardware Features: PC-Remote and Controller Operations

The system’s handheld remote (Figure 3.1) is the primary way to manually send

commands to the irrigation controller. The remote has several uses

and features.

1. When connected to the computer, the remote relays the schedule changes and

manual commands, wirelessly, to the Controller.

2. When handheld and disconnected from the computer, the device can

remotely perform the following:

a. Turn any zone or station ON or OFF (irrigation or lighting zones)

b. Turn the entire system to automatic mode or to system OFF mode

c. Turn on all landscape lighting zones (up to three zones maximum

at a time)

d. Indicate Rain OFF mode because of a wet rain sensor (rain cloud icon)

e. Indicate signal strength with the antenna icon

f. To preserve battery life, the remote turns itself off after a few seconds

of button inactivity (or just hold down STOP until “OFF” appears).

To use the remote, unplug the cord’s USB mini-connector from the side

of the handheld unit and reinsert the captive plug to help prevent

water entry.

1. Wake up the remote by pressing any button for one second. All

elements of the display will illuminate for a moment and the then

“AUTO” should be displayed (if the controller it found with the

same PIN is in automatic mode) or “OFF” for off mode.

Figure 3.1

2. Turn any station ON by selecting it with the UP or DOWN button

and pressing START. Press STOP to stop the station. To advance or change from one running station or zone to start another, use the UP or DOWN arrow button to move from the current station

and select a new station number. The previous station or zone will turn off and the selected station will start. Remote or Manual starts override a wet rain sensor and irrigate.

3. A remotely started station has a 10- minute default run time. To change the run, press the SHUTTLE button (arrows pointing both right and left) to start the “10 Min” blinking and then reset the

time from 1 to 59 minutes (in 1-minute increments) or from 1 to 4 hours (in 0.1-hour increments).

The operating countdown starts immediately for the selected station.

4. A lightning bolt icon in the display indicates a short circuit on one of the zones. The shorted zone

light will be blinking on the front of the Controller. The cause of the short must be corrected, then

run the station remotely or manually to clear the short indicator.

5. To turn on all landscape lighting zones (3 stations max.) wake the remote and let it find the controller and then press the light bulb button. The lighting zones will turn on for a default time of 1

hour or pressing the light bulb button again will shut them off.

6. To set the remote’s PIN, wake the remote and then hold down the two, top buttons for 3 seconds

simultaneously. Four digits will appear. Use the UP or DOWN arrow button to set the first digit in

the PIN. Then use the shuttle button to move to the next digit to the right. Repeat the steps to set

the rest of the 4-digit PIN. Then press START. When the remote finds the Controller with the same

PIN, “PIN OK” will appear in the display, then “AUTO” or “OFF” depending upon the Controller’s

mode.

PCW Control S Installation

21

Page 24

Chapter 4 – Remote Master Valve / Pump Start Feature

The Remote Master Valve / Pump Start Feature is only for systems with more than one controller.

A Master Valve (MV) is an automatic valve that shuts off the water supply pipe when the irrigation

system is idle. The master valve reduces the chance of flooding from a zone valve that leaks or has

failed while open. The controller turns on the MV when it turns on the first valve in a program and

turns off the MV when the last valve has timed out.

A Pump Start circuit is a circuit designed to energize a Master Valve or to operate a pump start

relay(24-volt AC). It allows a power source (120 VAC, 220 VAC, etc.) to connect to a pump motor. Like it

does for a master valve, the controller switches the pump on with the first station and off again once

the last valve closes.

For irrigation systems with one main supply line and multiple controllers, the Remote MV / Pump

Start feature allows the other controllers to use the master valve / pump start circuit on Controller

Number 1. This saves wire and trenching for multiple pump start circuits. In the system, each

controller (2, 3, or 4) is provided the choice of using itw own pump start circuit or that of controller

#1. In the same way, if controller #1 has a rain sensor, clicking the “Remote” radio button in controller

#2’s “Rain Sensor” box tells controller #2 to use controller #1’s rain sensor.

Below, the installer has set Controller #2 to use the master valve of Controller #1 and its rain sensor.

22

Figure 4.1

PCW Control S Installation

Page 25

Appendix 1 – Frequently Asked Questions

Q: What is the AdvisorTM?

A: The Advisor is a unique PCW Control program feature that will automatically formulates a zone watering

schedule based on specic parameters including, sun exposure, sprinkler type, plant type, terrain slope, and

soil type. Observed weather factors, including, temperature, humidity and wind condition can be entered as

well, or the local 9–10-day weather forecast, based on city name or ZIP code, is retrieved from weather.com

and factored into the schedule. The formulated schedule is then transferred to the Schedule Viewer panel.

Q: What weather data is used by the Advisor?

A: This version of the PCW Control software accesses data from a proprietary weather service. You can choose

to automatically update the weather data daily, weekly, monthly, seasonally, or never.

Q: Will the system shut o during rainfall?

A: The Controller is sensor-ready and compatible with most auxiliary rain or rain/freeze sensors. Irritrol rain

sensors are recommend and are available in three models: RS1000 - wireless rain sensor,

RFS1000 - wireless rain/freeze sensor, and RS500 - wired rain sensor. (Use of a sensor is recommended.)

Q: Can the system save water?

A: Yes, there are several ways the system can save water:

•Thesystemcanbeshutdownforthewintermonthsfromtheconvenienceofyourcomputer.(Infreezing

climates, this does not replace “winterizing” the system with compressed air blow-out.)

•TheschedulingAdvisor™willsavewaterbyadjustingtheirrigationscheduleperweatherconditions.

•Anoptimalrainsensorwillshutoirrigationduringadownpour.

Q: What PCW Control system components can be added or replaced?

A: The following PCW Control system components are available from your Irritrol distributor:

12-Station Indoor Controller w/Remote and Software Model# PCW-12 INT-PAK

12-Station Add-on Indoor Controller Model# PCW-12 ADD-INT

12-Station Outdoor Controller w/Remote and Software Model# PCW-12 EXT-PAK

12-Station Add-on Outdoor Controller Model# PCW-12 ADD-EXT

PC-Remote w/Stand, USB Cable and Software Model# PCW-R

The following service parts are also available:

Kit, Service Panel, Lower P/N 102-4973

Transformer, External, 115-120V, Outdoor Controller P/N 102-4788

Transformer, Internal, 115-120V, Indoor Controller P/N 363-4574

Kit, Service Door, Outdoor Controller P/N 102-4974

Q: Can I access my PCW Control irrigation from work or while traveling?

A: You can use a remote-access application, such as, GoToMy PC

computer from any other Internet-connected computer. As long as the PC-Remote is connected to your home

computer, you will have complete access to your PCW Control system.

®

that enables you to access your home

PCW Control S Installation

23

Page 26

Q: What’s the best way to get technical support?

A: Contact Irritrol Customer Support by phone at 1-800-634-8873, weekdays 7:30 a.m.–4:00 p.m., PST, or via

e-mail at: pccontrolsupport@irritrol.com. Visit the Irritrol Systems website at www.irritrol.com/pccontrol for

product support information.

Q: Why does it matter if a zone is designated for water or lighting?

A: When a zone is designated for lighting control, the optional watering control features; such as, rain sensor,

master valve/pump start, and scheduling Advisor options, are not factored into the zone operation. In addition, the PC- Remote handheld provides separate operating controls for watering and lighting zones.

Q: Do I set up a water feature as water zone or a lighting zone?

A: A fountain or water feature should be designated as a lighting zone, since the optional control features provided for irrigation would not be applicable. Make sure the controller station output is not connected directly

to the water pump. A 24 VAC relay rated at 0.4A maximum must be used. The Irritrol SR-1 relay unit is designed

for this type of application.

Q: How does the contractor change the homeowner’s PIN? Does it require a PC or can it be

done using just the remote?

A: To change the PIN, the contractor must know the old PIN and use his laptop with the PC remote to change

the PIN.

Q: How do I know what software version I have?

A: The software version is shown in the top left corner of the program window. You can also access the system

information by selecting Tools>About from the main menu.

Q: How do I know if I have the latest version of the software?

A: If you have registered your PCW Control system with Irritrol, you will receive a notice when an updated ver-

sion of the software is available.

Q: How many schedules can you have in the program? If you’re a contractor, how many

customer schedules can you save?

A: Currently there is no limit on how many schedules you can have at one time.

Q: Can you schedule a “no” irrigation day?

A: Yes, you have the option to prevent watering on any days of the week. (See No-Watering Days on page 18.)

Q: What happens if you have overlapping zone schedules

A: An overlap option is provided in the Settings panel that will enable you to schedule up to three zones to

run simultaneously. The defaut for this option is 0 overlap. Unless it is changed, a prompt will appear if you

attempt to schedule two or more zones to run at the same time. The overlap option is generally used to allow

lighting and irrigation zones to operate simultaneously.

Q: What is the maximum run time per station?

A: Each zone can be scheduled to run for 1 minute to 24 hours, in 1-minute increments.

Q: Does the controller supply power to the landscape lights?

A: No, the controller provides switching control for a 24 VAC relay with a maximum output of 0.4A per station.

The Irritrol SR-1 relay unit is designed to operate a pump starter or outdoor lighting control box from an irrigation system controller.

24

PCW Control S Installation

Page 27

Q: What if there is a power outage? Would everything still get watered?

A: The Controller will not operate the zones without 115/120 VAC. The “ash memory” in the Controller will

retain the current operating schedule indenitely in the absence of AC power. A fresh 9V battery will maintain

the current time/date for 48 continuous hours. Therefore, it’s recommended to change the battery at least

once a year–especially if the area is prone to frequent power outages. If the battery is dead (or is not installed),

the Controller time/date will be synchronized when contacted by the PCW Control computer program.

Q: If my computer goes down, can I still use the remote?

A: The last schedule uploaded to the Controller will reside indenitely in memory without being connected to

the computer. The system can be operated manually at any time using the hand-held Remote when disconnected from the computer.

Q: What if there is a power surge?

A: The Controller has built-in surge protection designed to divert strong electrical surges to earth ground.

Q: How do I know if there are any electrical short circuits?

A: A built-in electronic circuit breaker will shut down any eld output(s) when an over-current condition is

detected–generallycausedbyafaultyvalvesolenoidorashortedsolenoidwireconnection.Theoending

zone number(s) will be identied on the Controller with a ashing LED. The remaining zones will continue to

operate as scheduled.

Q: Can my system be reprogrammed even if my PC is down?

A: If you have your PCW Control system PIN, a professional irrigation contractor equipped with a laptop PC,

the remote, and the PCW Control program software can upload schedule changes to your control system.

Q: Can I transfer the PCW Control system setup to a new computer?

A: Yes. Install the software for the PCW Control system in your new computer, download your entire program

from the older computer to a CD or thumb drive, and upload that program (on the CD or thumb drive) to the

new computer. Use the current PIN to access your controller.

Q: How do I transfer my schedule information from an old computer to a new computer?

A: This is actually quite a lengthy process. See Appendix III for a detailed answer.

Q: I cannot change the PIN in my controller from my computer. The remote changed OK.

What should I do?

A: Unless all components (PC, Remote, and Controller) have the same PIN, the PIN in the controller cannot be

updated from the computer. (See the note at the end of Chapter 1.)

Q: Where do I nd an electronic version of the User’s Guide?

A: Click “Tools” and select “Help Manual”.

PCW Control S Installation

25

Page 28

Appendix 2 – Advanced Adjustment Features

There are multiple adjustment settings in the software.

1) Seasonal Adjustment, which can be individually set for each month (NOT if using Scheduling

Advisor)

2) Schedule Seasonal Adjustment, which adjusts all station runtimes on the current schedule

2) ET Adjustment, which adjusts the ET value used in scheduling calculations

4) Zone Seasonal Adjustment, which adjusts the selected zone’s runtimes

This appendix will discuss each setting in detail.

Global Seasonal Adjustment

The Global Seasonal Adjustment (Figure A2.1) will adjust all runtimes

in the system. The adjustment value is downloaded and stored in the

controller. The adjustment values for each month are independent

of the others. Once the calendar day rolls over to the next month the

controller will automatically start using the current month’s seasonal

adjustment value.

If you check the box “All 12 Months” the seasonal adjustment value will

drop to 10% (minimum value) to reflect that the user wants to set all

the months’ season adjustments. If you select an individual month then

the adjustment value will reflect the current seasonal adjustment on

that month.

Figure A2.1

Figure 2

Schedule Seasonal Adjustments

(Advanced Seasonal)

The Advanced Seasonal Adjust Settings allows the user

to modify a whole schedule or specific stations.

The Schedule Seasonal Adjustment (Figure A2.2)

affects all stations that have at least one event on the

current schedule. The adjusted runtime is a simple

multiplication of the percentage with respect to the

station’s runtime.

The Zone Seasonal Adjust affects all events for the

selected station. The adjusted runtime is a simple

multiplication of the percentage with respect to the

station’s runtime. The seasonal adjustment for each

station can be accessed through the Zone Properties

(Figure A2.3).

If there is more than one controller in the system,

change the “Select Controller” option to display the

selected controller’s stations.

26

Figure A2.2

PCW Control S Installation

Page 29

ET Adjustment*

The Advisor ET Adjustment (Figure A2.3) allows the user

to adjust the watering recommendations provided by the

scheduling advisor. The ET adjustment is NOT a simple

multiplication of the runtime. Instead, the adjustment

changes the ET value used to create the watering suggestions so a change of 10% in the adjustment might reflect

the advisor suggesting an increase of 20% to your runtime,

not a 10% increase.

If the Global Seasonal Adjustment is not at 100% the

Advisor will inform the user so that they can make more

accurate decisions when adjusting the ET value.

*(NOT compatible with Scheduling Advisor)

Working with Different Adjustments:

The user can affect the runtimes in various ways using

the different adjustment settings. In the example

below, each zone has a single watering event set

to run for ten minutes, and the global seasonal

adjustment set to 100%.

Figure A2.3

Figure A2.4

By changing the Schedule Seasonal Adjustment to

120% (Figure A2.4) the new runtimes for the stations

are twelve minutes.

Notice, that zone five is set to 115% for the Zone

Seasonal Adjustment. When viewing the schedule

zone five has a runtime of seventeen minutes, whereas

all the other stations have a twelve minute runtime

(Figure A2.5). This is consistent with the multiple

seasonal adjustments interacting with each other.

Figure A2.5

PCW Control S Installation

27

Page 30

Appendix 3 – Transferring Irrigation Schedules

It is possible to transfer irrigation schedule files from one computer to another. Irrigation schedule

files are XML files stored in a hidden folder on the hard drive of the host machine. If rights have not

been set to view hidden files and folders, that is the first step. Below are directions for Windows 7.

1. Set up View options to view hidden files and folders.

a. Double-click any folder icon to open a

Windows 7 window.

b. On the now visible window, click on the

Organize button (top left) (Figure A3.1).

c. Select “Folder and search options...”

d. Click the View tab.

e. In the Advanced Settings area, select

“Show hidden files, folders, and drives”

radio-button (Figure A3.2).

f. Click OK.

Figure A3.1

2. The default location for the XML file

installation is C:\Users\[login name]\

AppData. Navigate there.

If the AppData folder is not visible, go back

to step 1.

28

Figure A3.2

PCW Control S Installation

Page 31

3. Double-click the AppData folder, then

the Roaming folder, then the Irritrol

folder.

There is the default irrigation schedule

location.

4. Sweep all files in that window with your

mouse (Figure A3.3), copy (Ctrl-C), then

paste (Ctrl-V) them into a thumb drive

window.

5. Put the thumb drive into the new

computer.

6. Navigate to the same location on

this computer. C:\Users\[login name]\

AppData\Roaming\Irritrol.

If the AppData folder is not visible for this

computer, follow Step 1 for this computer.

7. Paste all files from the thumb drive into

this new window. “Copy and Replace” if

prompted.

Figure A3.3

8. Launch the PCW Control software and

click on “Open Site”.

9. All files should be present and ready to

use (Figure A3.4).

Figure A3.4

PCW Control S Installation

29

Page 32

Troubleshooting Guide

Symptom Possible Cause Solution

I have a new computer, or, I lost the

CD. Where do I get the software?

N/A Download the latest software at http://

www.pc-controller.com/PCW_Control.zip

How do I uninstall version 1.1.56 or

earlier?

My remote indicates there is no

communication when I turn it on.

All three signal bars in the software

are gray.

My remote displays “NO SIGNAL”

and “NOT ACCEPTED”.

The remote will not communicate

with additional controllers.

The remote displays “E1”. Most likely caused by a defective IC

The uninstall for versions 1.1.56 and

earlier does not work.

If the controllers are turned on

and match the PIN in the remote,

then most likely the cause is from

rmware.

Communication between the

software, remote, and controller(s)

is not working. Most likely the PIN

values do not match.

Controllerandremotehavedierent PIN codes.

Most likely caused by not manually

setting the additional controller’s

PIN and controller number.

in the remote.

Download our uninstall utility at http://

www.pc-controller.com/uninstall.exe.

When the remote is turned on, press the

top two buttons, side-to-side arrows and

the up arrow buttons. When your PIN is

displayed press the Start button. Your communication should be working now.

Check each hardware device and the PIN

value in the software to conrm that they

are the same.

See the Change PIN section in this User’s

Guide .

Check each controller and set the correct

PIN and controller number. All controllers

come from the factory set with PIN 0000

and as controller #1.

Please contact Irritrol Support for warranty

replacement.

Under “Display Zone Start Times”, I

highlight the start time but my edit

won’t change on the calendar.

The remote only displays 12 stations for a system that contains

multiple controllers and more than

12 stations.

Software displays “Invalid Data

Array” message when updating the

controllers.

The software displays “time out”

when sending a schedule or updating the controller(s).

Zones assigned to the Scheduling

Advisor cannot be edited in this

mode.

The main controller (controller #1)

has not been updated with the

additional controllers and station

information. This is the master controller of the system.

Possible invalid characters sent or

received from the controller(s).

Bad radio frequency interference in your environment, or the

controller(s) are too far away. The

range for communication is 1000

feet using line of sight. This will vary

depending on your environment.

Click on the Advisor tab, click on the zone

in question and then uncheck “Use Advisor”. Zone is now editable.

Open the XML le that you are using for

the multiple controller system, and after

establishing communication, update the

controllers by pressing the “Send” button.

Try pressing the “Send” button again. If the

message is still displayed contact Irritrol

Support so that you can send your XML le

for review.

If you have a laptop, move around your

property and see if you can establish a

more consistent connection. If you are using a desktop you can unplug the remote

anduseasimple“AutoOn/O”testby

walking around your property and conrming the communications are received by

the controller(s).

30

PCW Control S Installation

Page 33

Troubleshooting Guide (continued)

Symptom Possible Cause Solution

Where are my schedules and/or

les located?

The schedules are contained in the

XML les. Each XML le can contain

numerous schedules. You can save

these les to any directory, such as

My Documents.

Windows 7 - C:\Users\USER_ACCOUNT\AppData\Roaming\Irritrol

The software crashes or does not

respond when I open a le or when

using a default site.

The irrigation does not come on

according to the schedule shown

in the software.

I cannot click and hold the bottom edge of the zone segment to

change the watering duration.

I have most of my zones on the

Scheduling Advisor, and I have

checked “Update schedule changes without prompting”, but I do not

see scheduling changes with the

weather changes.

My system is using the Scheduling

Advisor, but keeps on watering

even when it’s raining.

Either the le you are trying to open

or the default le the software is

trying to open is missing some

information.

Most likely the controller(s)’ date

andtimeareo.

The zone is assigned to the Scheduling Advisor.

Thecomputeristurnedoatthe

time of day the system was told to

check the weather on the internet.

The internet weather is unaware of

local showers.

Open the le using MS Word or any other

text editor and see if there are any Schedules that are missing the <Events> tags. If

these schedules are present, then remove

them and save the le. If this does not work

then please contact Irritrol Support so that

they can review your le.

Under Tools->Preferences, click the option

to synchronize controller(s)’ time. Next, hit

the “Send” button in the software to update

the date and time in the controller(s).

To customize the zone, click on the ADVISOR tab, when the zone is highlighted,

uncheck “Use Advisor”.

Click on “Get Forecast” at the time you want

the system to regularly retrieve the weather

information. Make sure it is a time of day

your computer is on and connected to the

internet.

For the most water savings based on the

weather, we recommend the addition of an

Irritrol rain or rain/freeze sensor.

FCC Part 15 Rule

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment causes interference to radio or television reception, which can be determined by turning the

equipment on and off, the user is encouraged to try to correct the interference by one or more of the following

measures:

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

4. Consult the dealer or an experienced radio/TV technician for help.

The user may find the following booklet prepared by the Federal Communications Commission helpful: “How

To Identify and Resolve Radio-TV Interference Problems”. This booklet is available from the U.S. Government

Printing Office, Washington, DC 20402. Stock No. 004-000-00345-4 s.

© 2012 Irritrol • www.irritrol.com • 1-800-634-8873 Form Number 373-0762 Rev. A

PCW Control S Installation

31

Loading...

Loading...