Page 1

446PR / 446PRI

IRRIGATION CONTROLLER

INSTALLATION AND OPERATING GUIDE

Page 2

FEATURES

SIX ZONE CONTROL: Turns up to six sprinkler valves on and off

automatically in sequence.

DUAL PROGRAMMING: Allows you to water your lawn and landscape

on separate schedules.

EASY AT-A-GLANCE SETTINGS: Makes it simple to set watering

lengths and days.

MULTIPLE START TIMES: Lets you water up to four times per day -

ideal for new lawns.

EXTENDED WATERING PERIODS: Allows you to water up to 99 min-

utes a day per zone.

PAUSE FUNCTION: Makes it easy to interrupt watering cycles for yard

activities.

MANUAL OPERATING MODE: Allows you to water manually when an

automatic watering cycle is not in progress.

ELECTRONIC CIRCUIT BREAKER: Prevents controller shut-down in

the case of a short circuit in a valve; diagnostic feature displays malfunctioning valve number for easy trouble-shooting.

MASTER VALVE/PUMP START CONNECTION: Automatically turns a

pump or a master valve on and off. (Requires a pump start relay, Model

SR-1, if used with a pump).

TO USE YOUR NEW CONTROLLER MOST EFFECTIVELY, PLEASE

READ THIS MANUAL CAREFULLY AND REFER TO THE MANUAL IF

ANY DIFFICUL TIES ARISE.

NOTE:

trical surges caused by unstable power supply, consult your local supplier

or contractor for additional protection devices which may be required.

For areas which are vulnerable to lightning strikes, or transient elec-

2

Page 3

TABLE OF CONTENTS

Controller Components . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Installation Procedures

• Selecting The Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• Mounting The Controller . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

• Connecting The Valve Wires . . . . . . . . . . . . . . . . . . . . . 7–8

• Connecting APump Start Relay Or Master Valve . . . . . . . . 8

• Connecting The Power Source (Outdoor Models) . . . . 9–10

• Connecting The Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Planning Your Watering Schedule

• Guidelines For Watering . . . . . . . . . . . . . . . . . . . . . . . . . . 11

• Selecting The Right Program . . . . . . . . . . . . . . . . . . . . . . 11

• Filling In The Watering Schedule Form . . . . . . . . . . . . . . . 11

• Watering Schedule Forms . . . . . . . . . . . . . . . . . . . . . . . . 12

Programming Steps

• Setting Correct Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

• Assigning Zones To AProgram . . . . . . . . . . . . . . . . . . . . . 13

• Setting Program Start Times . . . . . . . . . . . . . . . . . . . . 14–15

• Setting Zone Run Time . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

• Setting Program Cycle Days . . . . . . . . . . . . . . . . . . . . . . 15

Manual And Semi-Auto Operation

• Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

• Semi-Auto Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Controller Shut-down / Circuit Breaker

• Controller Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• Electronic Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . 17

Voltage Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electro-Magnetic Compatibility . . . . . . . . . . . . . . . . . . . . 19

3

Page 4

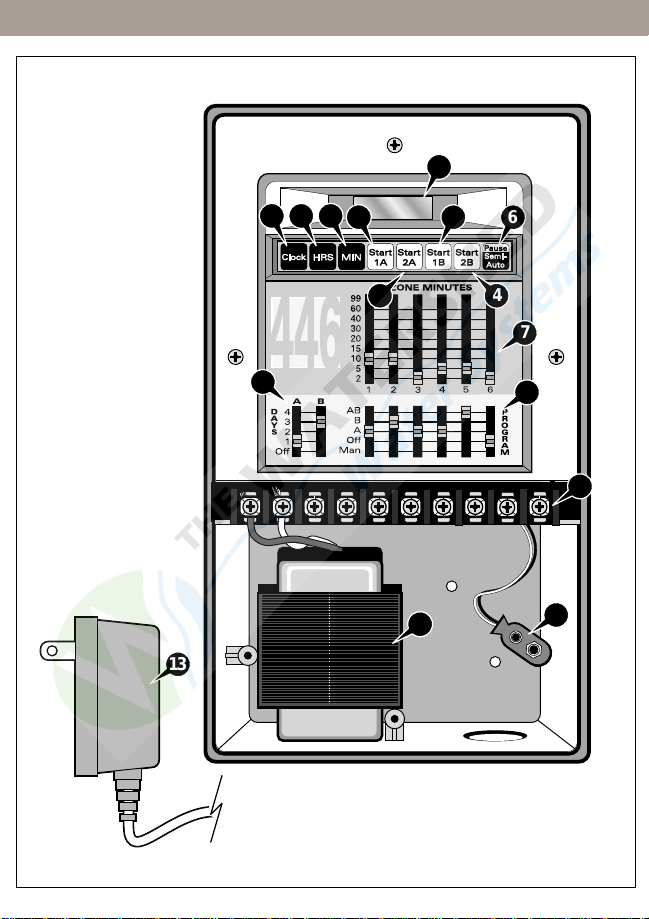

1

2

3

4

5

4

6

44

7

8

9

10

11

12

13

Figure 1

CONTROLLER COMPONENTS

4

Page 5

CONTROLLER COMPONENTS

CLOCK - DAY NOW KEY

1

Allows you to set the current time and day

2

HOURS KEY

Allows you to set the correct hour for the current time as well as the

hour for the desired start times.

MINUTES KEY

3

Allows you to set the correct minute for the current time as well as

the minute for the desired start times.

4

START KEYS

Enable you to set the start times of each programs (two start times

for program A and two for program B).

5

CONTROLLER DISPLAY

It displays the current time or the zone number being watered with its

watering run time when a program is in progress. It also indicates

programming errors and short circuits when detected.

6

PAUSE - SEMI-AUTO KEY

Temporarily interrupts a watering cycle in progress or allows you to

start a semi-automatic watering cycle

7

ZONE MINUTES SWITCHES

Allows you to select the watering time duration for each zone from

2–99 minutes

8

PROGRAM SWITCHES

Allows you to designate each zone to program (A, B, or AB).

9

DAYS SWITCHES

Allows you to set the day interval for each watering program.

TERMINAL SCREWS

10

Terminal connections for the power source, zone 1–6, pump

start/master valve and valve common.

11

BA TTERY CONNECTOR

Connects a 9 volt battery to retain stored watering cycle programs in

case of a power failure.

12

INTERNAL TRANSFORMER (Outdoor models)

Enables the controller to connect to a 120 V a.c., 60 Hz source

(220/240 V a.c., 50 Hz source for the international units).

13

PLUG-IN TRANSFORMER (Indoor Models)

Supplied with 120 V a.c., 60 Hz.

5

Page 6

INSTALLATION PROCEDURE

WARNING: All electrical components must meet applicable

national and local electrical codes including installation by

qualified personnel. These codes may require an external junction

box mounted on the transformer 1/2" nipple and a means, in the

fixed wiring, of disconnecting AC power having a contact separation of at least 0.120" (3 mm) in the line and neutral poles. Ensure

the AC power source is OFF prior to connecting to the controller.

The wire used for connection to the controller must have insulation

rated at 105° C minimum.

STEP 1 : Selecting The Location

For the 446 PRI (indoor models), choose an indoor location near a standard

120 V a.c. wall outlet. Install the controller in an area protected from weather, such as a garage, and within 5' (1.5 m) of a grounded electrical outlet.

The 446 PR (outdoor model) can be installed almost anywhere, but avoid

exposure to direct sun or irrigation spray. The controller must be powered

by a well grounded AC circuit.

CAUTION: Do not place the controller where temperatures may

exceed 60° Centigrade (140° Fahrenheit) or on a circuit controlled by a

switch or on the same circuit with a high power user (refrigerator, air conditioner, garage door opener, etc.). Malfunctions may result.

STEP 2 : Mounting 446 PR Controller (Outdoor Model)

1. Mount the hanger kit (1 hanger and 1 screw) on the top rear of the con-

troller.

2. Position the controller on the wall slightly below eye level. Mark the

mounting screw location at the top of the hanger’s keyhole slot.

3. Install a #8 mounting screw into the wall at the marked location leaving

the screw head about 1/4" (6 mm) out from the wall.

4. Remove the screw from the controller’s bottom panel. Pull the panel out

to access the two bottom screw holes.

5. Hang the controller on the mounting screw while making sure the screw

head is secured at the top of the keyhole slot. Install the two bottom

mounting screws, then tighten the top keyhole screw securely.

6. Replace the lower bottom to the controller.

6

Page 7

INSTALLATION PROCEDURE

Mounting 446 PRI Controller (Indoor Model)

1. Install a #8 mounting screw at eye

level on the wall, leaving the screw

head extended 1/4" (6 mm) out from

the wall.

2. Hang the controller on the mounting

screw. Make sure the screw head is

secured at the top of the keyhole slot.

See

Figure 2.

3. Install the lower mounting screws.

4. Replace the controller’s bottom panel.

STEP 3 : Connecting The Valve Wires

CAUTION:

The power transformer is protected by an electronic circuit

breaker. Do not connect a combination of valves requiring an inrush current

above 1 Amp at 24 V a.c. to one zone terminal.

1. Route valve control wires

between the valves and the

controller.

Note: An 18 AWG (0.75

mm) multi-wire cable is rec-

ommended. This cable is

24V

AC

123456

ZONES

P

C

U

O

M

M

P

M

Pump Start Relay or

Master Valve

insulated for direct burial

and color coded to simplify

installation.

2. Attach the white color-coded

wire to one of the wires from

each valve solenoid (either

Zone 3

solenoid wire can be used).

The white wire is designated

as the valve common wire.

Zone 2

(continued to the next page)

Zone 1

Figure 2

Figure 3

Wire

Connector

Grease Cap

7

Page 8

INSTALLATION PROCEDURE

3. Attach a separate color-coded wire to the remaining wire from each

valve solenoid. Make a note of the wire color used for each valve and

the watering zone it controls. You will need this information when connecting the valve wires to the controller.

4. Secure all wire splices using a twist-on wire connectors. To prevent cor-

rosion and possible short circuit, use a grease cap or similar waterproofing method to insulate each wire splice connection. See

on page 7.

5. Remove the controller’s bottom panel and route the valve cable into the

controller through the conduit opening at the base of the cabinet. Strip

back the wire insulation, about 1/2" (13 mm), from all cable wires to be

connected.

Note: The identification label for each of the terminal screws are located

at the backside of the controller’s bottom plastic panel.

6. Secure the valve common wire to the terminal labeled

the individual valve wires to the valve terminals labeled 1–6 in the order

you wish the valve zones to operate.

7. Replace the controller’s bottom panel and test each valve for proper

operation using the

connecting the AC power source.

STEP 4 : Connecting A Pump Start Relay Or Master Valve

When a pump relay is required to be operated by the controller, a compatible relay must be used. The relay coil will be connected to the PUMP termi-

nal. Refer to the Voltage Specification on page 19 of this Installation Guide

for power requirements. The relay contacts will be connected to the pump

start terminals and must be rated for use with that particular pump.

CAUTION: To prevent controller damage, ensure the relay’s current

draw does not exceed 1A. Do not connect the controller directly to the

pump starter. The pump start relay must be installed at least 5' (1.5 m)

away from the controller.

1. Route a twisted pair cable from the pump relay or the master valve into

the controller housing through the conduit opening.

2. Connect one of the wires to the

to the terminal labeled PUMP.

3. Test for proper operation after connecting the AC power source.

MAN option under the PROGRAM switches after

COMM terminal and the remaining wire

Figure 3 insert

COMM. Connect

8

Page 9

INSTALLATION PROCEDURE

STEP 5 : Connecting The Power Source

The outdoor controller model has a built-in transformer which must be connected to a grounded AC power source. Refer to the POWER SPECIFICA-

TIONS on page 18 for the proper power requirements. Electrical conduit

and adapters are not supplied with the controller but are generally required.

Check local building codes and install conduit accordingly.

CAUTION: Before wiring the internal transformer, switch off power at

the source. Do not link two or more controllers via a common transformer or

common wire.

PR (Outdoor Model)

1. Verify that the power has been turned

off at the power source by using an

appropriate AC voltage meter.

2. For the power wire connection, install

a 3/4" (19 mm) NPT threaded conduit

to the transformer assembly nipple.

Install electrical conduit from the con-

duit body to the AC power source cir-

cuit breaker panel.

Note: Figure 4 applies to 120 V a.c.,

60 Hz models only. For international

models, connect in accordance to

local and national electrical codes.

3. Route a three wire cable through the conduit and out from the conduit

body .

4. Splice the mating wires. Connect and insulate the wires with proper size

wire connectors. See

Figure 4.

5. Close and secure the conduit cover.

6. Apply power to the controller and test each valve for proper operation

using the

MAN option under the PROGRAM switches.

Figure 4

Neutral Line

White or Blue

Hot Line

Black or Brown

Conduit Body

Ground Line

Green or

Green/Yellow

9

Page 10

INSTALLATION PROCEDURE

PRI (Indoor Model)

Note:

The plug-in transformer is supplied with the 120 V a.c., 60 Hz indoor

controller models only. See page 18 for the controller’s proper power specifications.

CAUTION: Make sure the transformer is unplugged during installation.

1. Lift out the the controller’s bottom plastic panel.

2. Route the plug-in transformer cable into the controller through the pro-

vided conduit opening at the base of the cabinet.

3. Attach the transformer cable to the 24 V a.c. terminals. Make sure the

transformer leads do not make contact.

4. Replace the bottom panel of the controller.

5. Plug in the transformer to apply power to the controller and test each

valve for proper operation using the

switches.

STEP 6 : Connecting The Battery

1. Remove the bottom panel of the controller.

2. Connect a 9 volt alkaline battery (not supplied) to the battery connector

found inside the wiring compartment. Installing a battery enables the

controller to retain watering programs stored in the controller’s memory

during power failures. See

3. Replace the bottom panel.

CAUTION: Batteries contain hazardous materials. Always handle and

discard batteries properly in accordance with the battery manufacturer’s

recommendations.

Figure 2 on page 7.

MAN option under the PROGRAM

10

Page 11

PLANNING YOUR WATERING SCHEDULE

Guidelines For Watering

There are several factors to be considered when deciding when and how

long to water. For example, the soil type (i.e. clay, loam, etc.), the part of the

landscape being watered, climate conditions and the type of sprinklers

being used. Because of these variables, we cannot provide an exact schedule to follow, but here are some general watering guidelines to help you get

started.

• Water early in the morning, one to two hours before sunrise. You will

have the best water pressure at this time and the water can soak into

the plant root zone while evaporation is minimal. Watering during midday or in the evening may cause plant damage or mildew.

• For new lawns where frequent watering is required, take advantage of

the multiple start time feature of the 446 PR/PRI controller. Each

watering program cycle can be initiated twice a day.

• If under- or over-watering signs are observed, adjust program immedi-

ately .

Select The Right Program

On the following pages are some guidelines for planning your automatic

watering programs. We recommend taking a few moments to review this

information and filling in the watering schedule form provided.

Filling In The Watering Schedule Form

It is always helpful to plan your watering schedule on paper before beginning the programming steps. When completed, you will have a guide to use

during programming, and a record of your watering schedule which can be

kept with the controller for future reference.

Here are the information you will need to program your controller for automatic operation:

•

Location - Identify the location of each valve’s watering zone number.

•

Zone Run Time - Indicate the amount of watering run time required for

each zone (2–99 minutes).

•

Watering day schedule

Identify the watering day schedule for each program (everyday, every

other day, every third day or every fourth day interval).

•

Program Start Times Indicate the time of day you wish each watering

program to start.

11

Page 12

WATERING SCHEDULE FORMS

1

2

3

4

5

6

STATION

STATION RUN TIME

STATION RUN TIME

1

2

1

2

LOCATION

WATERING

DAY SCHEDULE

2nd

Every 2nd,

3rd or 4th Day

Everyday Off

3rd

PROGRAM

START TIMES

PROGRAM AWatering Schedule Form

PROGRAM B

4th

2nd

3rd

4th

Everyday Off

1

2

3

4

5

6

STATION

STATION RUN TIME

STATION RUN TIME

1

2

1

2

LOCATION

WATERING

DAY SCHEDULE

2nd

Every 2nd,

3rd or 4th Day

Everyday Off

3rd

PROGRAM

START TIMES

PROGRAM AWatering Schedule Form

PROGRAM B

4th

2nd

3rd

4th

Everyday Off

12

Page 13

PROGRAMMING STEPS

STEP 1 : Setting The Correct Time

The controller’s clock features a 12-hour format where 1200P represents

12:00 p.m. (noon) and 1200A represents 12:00 a.m. (midnight). When

power is first applied, the controller automatically resets the day and time to

Day 1 and 400P.

1. Press the

2. Advance the hour digit by holding down or by pressing the

repeatedly until the correct hour and A (a.m.) or P (p.m.) is displayed.

3. Advance the minute digit by holding down or by pressing the

repeatedly until the current minute is displayed.

4. Once the current time is set, the procedure is completed. If no additional

key is pressed within 15 seconds, the controller will revert back to time

mode.

STEP 2 : Assigning Zones To AProgram

The controller provides several options that allow simple, flexible programming. The dual program feature provides the ability to water individual

areas of the yard on separate schedules.

A typical example of how these programs might be used would be to assign

all lawn zones to program

watering demands are generally quite different for lawns and shrubs, dual

programming enables watering days and start times to be tailored specifically for each type of plant material.

1. Select each zone’s watering program by simply moving each zone’s

program switch to

bination of program A and B.

2. To disable a zone, simply move its designated zone switch into the

position.

Note: If a zone switch is placed in the AB position, the zone will start watering at every start time programmed in both A and B. Unused zones should

be placed in the OFF position.

Clock key to place the controller in time setting mode.

HRS key

MIN key

A and all shrub zones to program B. Since

A for program A, B for program B or AB for the com-

OFF

13

Page 14

PROGRAMMING STEPS

STEP 3 : Setting Program Start Times

A program start time is the designated time when the programmed automatic watering cycle begins. Sometimes it is necessary to run a program more

than once within the same day, for example, when growing a new lawn.

The controller has the ability to start each program twice a day.

Refer to the following guidelines when programming the start times:

• A start time (

individual zone.

• A program requires only one start time to operate automatically.

• When a program starts, each zone assigned to the program will water

in numerical order,

• Enough time should be provided between program start times to allow

all zones assigned to the program to be watered. If a start time produces a watering cycle that runs beyond the next start time, the controller will delay the next start time(s) to allow completion of the previous watering cycle.

• If a start time produces a watering cycle that runs past midnight, any

remaining start times scheduled to start before midnight will be cancelled.

• Start times begin according to the time they are programmed to water,

and not by the order at which they were programmed. For example,

the first start time programmed on

watering time to occur if it is programmed to water at 11:00 p.m., and

the last start time programmed on ST ART A may actually be the first

to occur if programmed to water at 5:00 a.m.

To Set Start Time

1. Press START 1A key. The display will show the current start time programmed in START 1A or OFF if it has been disabled.

2. Hold down or repeatedly press the

hour until the desired hour and A (a.m.) or P (p.m.) are displayed.

3. Hold down or repeatedly press the

the desired minute is displayed.

4. Repeat the process to program the other

5. To disable a start time, advance the start time hour until

played. OFF comes after 1100P.

6. Press the

NOTE: Once you have pressed a START key, you must press the HRS or

MIN key within 10 seconds. Otherwise, the controller will revert back to time

mode

14

ST ART A or START B) activates a watering cycle, not an

one at a time until its designated run time.

ST ART A may actually be the last

HRS key to advance the start time

MIN key to advance the minute until

ST ART times as needed.

OFF is dis-

Clock key to return the controller back to time mode.

Page 15

PROGRAMMING STEPS

STEP 4 : Setting The Zone Run Time

The zone run time is the duration the zone will water during a watering

cycle. Each of the six zones can be set to run at different duration between

2–99 minutes.

1. To set each zone’s run time, simply align each

the desired run time along the time indicator. Do not place the switch

between the indicated run times. During watering, the zone number and

its current run time will appear on the display

IMPORT ANT: Make sure the switches are placed on the minute marks and

not between the marks. Improper run time may occur.

STEP 5 : Setting Program Cycle Days

The DAYS switch sets the day interval for the program to cycle.

1. Move the

ing interval. Slide the switch to 4 for every 4th day, 3 for every 3rd day, 2

for every other day or 1 for everyday.

For example, if the

water every fourth day. After the switch is moved to 4, the display shows

day 1, which indicates a watering day. This means that program A will

water today if the watering time has not been missed.

By pressing the

day 1 to one of the following options:

day 0 - No more watering today.

day 1 - Water today.

day 2 - Water tomorrow.

day 3 - Water the day after tomorrow

day 4 - Water on the 4th day.

This option can be used when both programs are set to the same watering

cycle interval so program

To return the controller into time mode, press the

onds after the last keystroke.

2. Move the switch to

Note: The controller counts down from the day interval set to the designated active watering day. Day changeover occurs at 1200P.

DAYS switch for each program (A or B) to the desired water-

DAYS switch on program A is set to 4, the controller will

HRS key while the display shows day 1, you can change

A will water on a different day than program B.

OFF if a program is unused.

ZONE MINUTE switch to

Clock key or wait 10 sec-

15

Page 16

MANUAL AND SEMI-AUTO OPERATION

Step 1 : Manual Operation

1. To water your yard manually, move the PROGRAM switch of the zone

you wish to water to MAN. The controller will allow only one zone at any

given time to be watered manually. If more than one zone switch is

placed in the MAN position, only the lowest zone number will water.

When the switch is moved off the MAN position, the second lowest

zone number set to MAN will start to water. The MAN setting will override any automatic watering cycle including any watering cycle in

progress.

NOTE: When a zone switch is placed in MAN, the controller will water

continuously until the switch is moved.

Step 2 : Semi-Auto Operation

1. Semi-auto operation can be initiated by pressing the PAUSE - SEMI-

AUTO key. The controller will energize all the zones, one zone at a

time, starting from zone 1 until zone 6. The controller will skip any zones

that are disabled (zones placed in the OFF position within the PROGRAM switches). The zones will continue to water until their designated

time duration expires, then the next zone in sequence will start. The

controller will revert back to the time mode after watering the last zone

in the sequence.

2. Pressing the

sequence.

To pause the cycle, press the

play will alternately flash “P AUSE” as well as the station number and

run time. To resume the watering cycle, press PAUSE - SEMI-AUTO

key again and the station run time countdown will continue.

3. To exit the semi-auto operation, first pause the operation by pressing

the

PAUSE - SEMI-AUTO key. After pausing the semi-auto operation,

press the CLOCK key followed by the PAUSE - SEMI-AUTO key to ter-

minate the operation. When terminated successfully, OFF will be displayed. Pressing the MIN key repeatedly until the time mode is displayed will also exit the semi-auto operation.

Min key will advance the watering to the next zone in

PAUSE - SEMI-AUTO key once. The dis-

16

Page 17

CONTROLLER SHUT-DOWN / CIRCUIT BREAKER

Controller Shut-Down

When automatic watering is not needed, you can prevent the programmed

watering cycles from starting by moving the DAYS switches into the OFF

position.

NOTE: Manual watering is still possible even when the DAYS switches are

in the OFF position.

Electronic Circuit Breaker

The 446 PR/PRI controller is equipped with an electronic circuit breaker that

can detect short circuits in the valve zone terminals. If the controller detects

a short circuit, the shorted valve will automatically turn off. The display will

then alternately flash FUS with the shorted zone number. The controller will

continue to automatically water the remaining zones in the current watering

cycle as well as execute the next watering cycles.

After repairing the short circuit, press the

keys to return the controller to its current operating mode.

CLOCK or any of the START

17

Page 18

VOLTAGE SPECIFICATION / TROUBLESHOOTING

Voltage Specifications

Power Input Station Output Pump Output

Domestic Models

International Models 250 V a.c., 50 Hz., 18W 24 V a.c., 1 VA 24 V a.c., 9 VAmax.

Troubleshooting

120 V a.c., 60 Hz., 35W 24 V a.c., 1 VA 24 V a.c., 9 VAmax.

Problem

One or more valves do not

operate.

Display is stuck on a zone

FUS is flashing on the

and

display.

Continuous loss of time.

Zones turn on when they are

NOT programmed to start.

The clock has the correct

time and the zones appear to

be functioning properly, but

none of the valves are on.

Zone does not shut

OFF.

Possible Cause

1. Faulty solenoid.

2. Poor wire connection.

3. Possible break in wire.

4. Valve flow stem is screwed down too far.

1. Faulty solenoid.

2. Shorted or poor wire connection.

1. No battery.

2. Weak or bad battery.

3. Controller is on an electrical circuit controlled by a switch.

4. Controller is on the same circuit as a

high power user (refrigerator, air conditioner, etc.).

1. Start times and the total combined zone

run times have overlapped.

1. One or more zone switches are in the

OFF position.

2. The common wire is not hooked up.

3. Valve flow stem is screwed down too far.

1. Zone switch is in

2. Faulty valve.

3. Particles of dirt or debris are preventing

proper valve operation.

MAN.

18

Page 19

ELECTROMAGNETIC COMPATIBILITY

Domestic: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does harmful interference

to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

4. Consult the dealer or an experienced radio/TV technician for help.

The user may find the following booklet prepared by the Federal Communications Commission helpful:

“How To Identify and Resolve Radio-TV Interference Problems”. This book-

let is available from the U.S. Government Printing Office, Washington, DC

20402. Stock No. 004-000-00345-4.

International: This is a CISPR 22 Class B product.

19

Page 20

Irritrol Systems offers an entire family of products

for commercial and residential applications:

Controllers and Controller Accessories

Valves and Valve Accessories

Rotors, Spray heads, and Nozzles

U.S.A.:

P.O. Box 489

Riverside, California 92502

Tel: (909) 785-3623

(800) 634-8873

Europa:

Irritrol Systems Europe s.p.a.

Via dell’Artigianato, 1/3-Loc Prato della Corta

00065 Fiano Romano (Roma), Italia

Tel: (39) 0765 455201

© 2001 Irritrol Systems Form No. 373-0154 Rev. A

Australia:

Irritrol Systems PTY Ltd.

53 Howards Road

Beverley SA 5009

Tel: (08) 8300 3633

Loading...

Loading...