IPSO HF055, HF165, HF035, HF045, HF100 User Manual

...

On-premises laundries face enough daily challenges, wrestling with complicated, inefficient

equipment shouldn’t be one of them. IPSO’s HF model washer-extractors combine proven

designs with user-friendly controls to streamline the laundry process. Our goal is building

equipment that’s simple to own and even more simple to operate.

Simplifying Ownership

VERSATILE. The PS40 microprocessor offers managers the highest level of control to set spin

speeds and water levels, while a simple design ensures employees are quickly trained on its

operation. It comes with 10 preprogrammed cycles and room to customize 30 additional cycles.

Programming easily is accomplished by uploading from a PC through an infrared connection.

EFFICIENT. With a maximum extract of 475 G-Force, the HF significantly reduces drying time —

in some cases, by up to 80%. As a result, operations benefit from lower utility consumption.

RUGGED RELIABILITY. A heavy-duty steel frame, with a minimum of welds, provides one of

the most stable bases in the market. That translates into years of worry-free operation. In addition,

three layers of paint protect the frame from corrosion, while heavy-duty bearings and a rugged

housing ensure longevity.

PEACE OF MIND. Our commitment to you comes with a 3/5-year limited parts warranty.

WASHABILITY. While the HF is designed to increase productivity and efficiency,

managers don’t have to sacrifice quality. IPSO washer-extractors deliver superior

consistent finished results.

TIME SAVINGS. The HF’s automatic supply

injection system — which supports up to 12

pumps — eliminates the need for staff to

manually add chemicals. This saves time and

allows them to concentrate on other laundry

tasks. In addition, for laundries utilizing finishing

equipment, the high extract speed of the HF

allows pieces to go directly from the washer

to ironers with no drying necessary.

THE BOTTOM LINE. We believe the

efficiency in design and operation of our

washer-extractors combined with the

features of our intuitive controls will have

the ultimate impact on your laundry’s

productivity and bottom line. Put simply,

IPSO gets results.

On-Premises Laundry

HF Series Washer-Extractor

HF035 - 35 lb Washer-Extractor

HF045 - 45 lb Washer-Extractor

HF055 - 55 lb Washer-Extractor

HF075 - 75 lb Washer-Extractor

HF100 - 100 lb Washer-Extractor

HF135 - 135 lb Washer-Extractor

HF165 - 165 lb Washer-Extractor

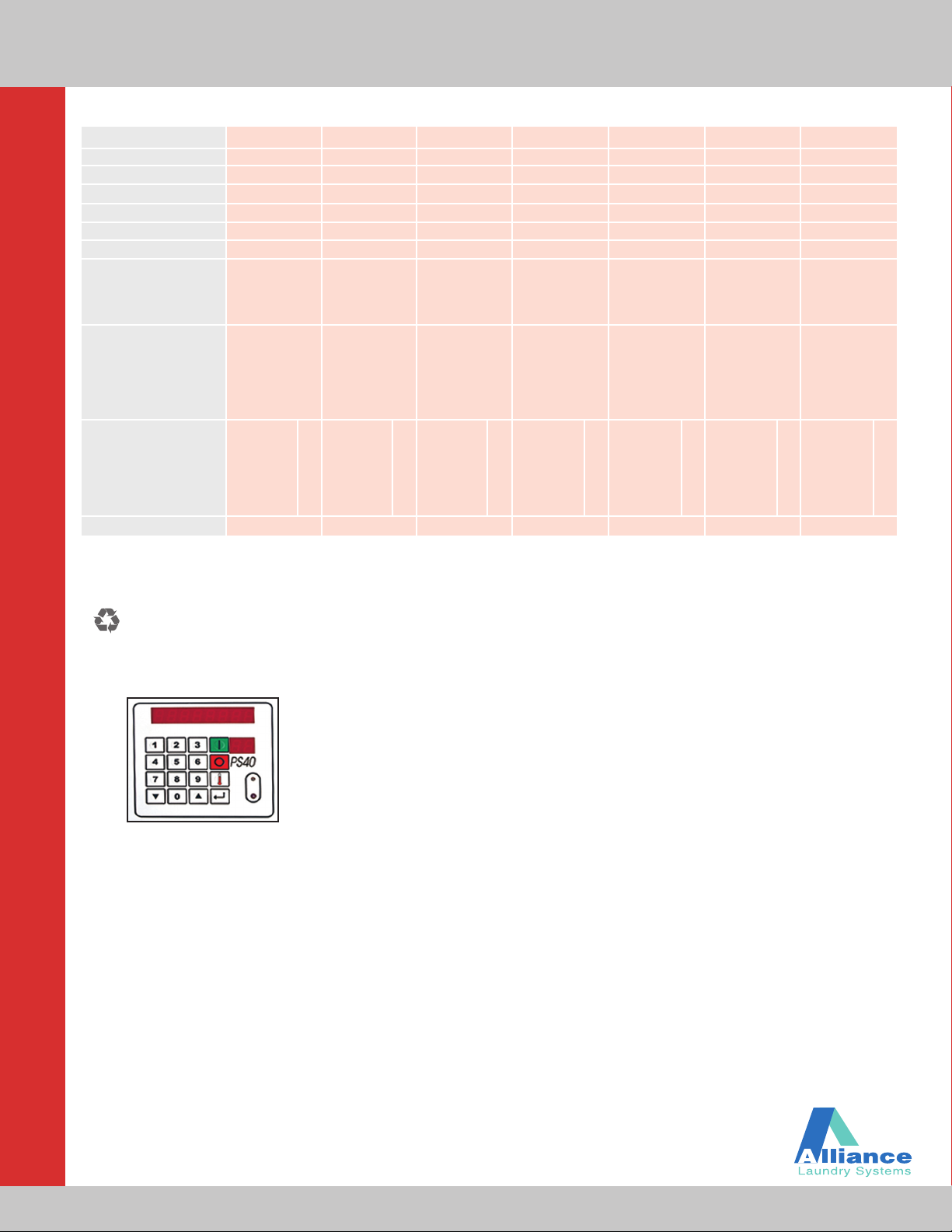

HF Series Washer-Extractor Specifications

Questions? Contact us at:

1 800 USA IPSO or www.ipsousa.com

1 800 (872-4776)

AP07-217

PS40 Microprocessor

HF035 HF045 HF055 HF075 HF100 HF135 HF165

Capacity - lb (kg) 35 (15) 45 (18.5) 55 (23.4) 75 (30.4) 100 (45.5) 135 (57.5) 165 (73)

Height - in (mm) 51 5/8" (1310) 51 5/8" (1310) 59 1/4" (1276) 60 1/4" (1530) 75 9/16" (1919) 75 9/16" (1919) 85 1/16" (2178)

Width - in (mm) 33 1/2" (850) 33 1/2" (850) 35 7/16" (902) 41 3/4" (1060) 47 1/4" (1200) 47 1/4" (1200) 51 1/16" (1553)

Depth - in (mm) 35 13/16" (910) 40 5/8" (1030) 39 1/2" (1003) 48 1/4" (1226) 52 9/16" (1335) 59 1/16 " (1500) 63 3/4 " (1619)

Door Opening - in (mm) 16" (400) 16" (400) 16" (400) 16" (400) 16" (400) 16" (400) 24 1/2" (622)

Net Weight - lb (kg) 764 (347) 847 (385) 1257 (571) 1907 (866) 3344 (1518) 3619 (1643) 4630 (2102)

Crated Weight - lb (kg) 831 (377) 915 (415) 1389 (630) 2194 (996) 3741 (1698) 4017 (1824) 5181 (2352)

Cylinder Dimensions

Diameter - in (mm) 27" (680) 27" (680) 29 1/2" (750) 33 7/16" (850) 38 5/8" (904) 38 9/16" (903) 43 1/8" (1092)

Depth - in (mm) 16" (400) 19 3/4" (500) 20 7/8" (530) 21 1/8" (537) 23 3/16" (590) 30 1/2" (775) 30 1/2" (775)

Volume - cu.ft. (liters) 5.3 (150) 6.54 (185) 8.27 (234) 10.76 (304) 15.9 (450) 20.31 (575) 25.78 (730)

Cylinder Speed

Wash - RPM 10-50 10-50 10-50 10-50 10-50 10-50 10-50

Extract - RPM 250-1000 1000 1000 1000 800 800 750

G-Force - RPM 380 380 419 475 350 350 350

Drain Size - in (mm) 3" (76) 3" (76) 3" (76) 3" (76) 3" (76) 3" (76) 3" (76)

Water Inlet - (std/opt) 2/3 2/3 2/3 2/3 2/3 2/3 2/3

Voltage/Hz/Phase

Circuit Breaker - FLA

(N)

440-480/50-60/3ph 20 440-480/50-60/3ph 20 440-480/50-60/3ph 20 440-480/50-60/3ph 20 440-480/50-60/3ph 30 440-480/50-60/3ph 30 440-480/50-60/3ph 40

(P)

380-415/50-60/3ph 20 380-415/50-60/3ph 20 380-415/50-60/3ph 20 380-415/50-60/3ph 20 380-415/50-60/3ph 30 380-415/50-60/3ph 30 380-415/50-60/3ph 40

(Q)

200-240/50-60/3ph 20 200-240/50-60/3ph 20 200-240/50-60/3ph 20 200-240/50-60/3ph 30 200-240/50-60/3ph 50 200-240/50-60/3ph 50 200-240/50-60/3ph 80

(X)

200-240/50-60/1-3 20 200-240/50-60/1-3 20 200-240/50-60/1-3 20 200-240/50-60/1-3 N/A 200-240/50-60/1-3 N/A 200-240/50-60/1-3 N/A 200-240/50-60/1-3 N/A

Agency Approvals ETL ETL ETL ETL ETL ETL ETL

Due to continuous improvements, design and specifications subject to change without notice. The quality management systems at all Alliance Laundry Systems manufacturing facilities

are registered as ISO 9001:2000 compliant. Features and certifications may vary by model.

©Copyright 2007 Alliance Laundry Systems LLC

Printed in the U.S.A.

Printed on paper manufactured with virgin pulp from certified

sources and a minimum of 10% post-consumer recovered fiber.

Control Options

Loading...

Loading...