Ipso BA4121 Top-Load Parts Diagram

Automatic

W162S

Washers

Refer to Page 6 for Model Numbers

Service

www.alliancelaundry.com

Part No. 32305R2

November 2016

Table of Contents

Section 1 – Safety Information

Locating an Authorized Servicer ............................4

Section 2 – Introduction

Customer Service ....................................................5

Nameplate Location ................................................5

Model Identification ................................................6

Section 3 – Troubleshooting

1. No Hot Water ...................................................7

2. No Cold Water .................................................7

3. No Warm Water ...............................................8

4. Water Fill Does Not Stop At Proper Level ......8

5. Timer Does Not Advance (Mechanical Timer

Models only) ....................................................8

6. No Agitation .....................................................9

7. Constant Agitation ...........................................9

8. Slow Spin Or No Spin ....................................10

9. Constant Spin .................................................10

10. Drive Motor Overload Protector Cycles

Repeatedly ......................................................10

11. Outer Tub Does Not Empty ...........................11

12. Excessive Vibration .......................................11

13. Water Leaking From Outer Tub ....................11

Section 4 – Grounding

14. Wall Receptacle Polarity Check ....................13

15. Power Cord to Cabinet Top, Cabinet Top to

Control Hood Mounting Bracket, Pressure

Switch Mounting Bracket and Ground Tab

on Graphic Panel (Models BA4121, BA4120

and BA3110) ..................................................13

16. Power Cord to Control Hood (Models

BA2411, BA2410 and BA2300) ....................14

17. Control Hood to Bottom Flange of Control

Panel (Models BA2411, BA2410 and

BA2300) .........................................................14

18. Main Wire Harness to Top Rear Corner

Gusset of Cabinet ...........................................15

19. Motor to Mounting Bracket to Base ..............15

Section 5 – Service Procedures

20. Control Hood Assembly (Models BA4121,

BA4120 and BA3110) ...................................17

To Remove Control Hood End Caps..............17

21. Control Panel (Models BA2411, BA2410

and BA2300) ..................................................18

22. Timer (Models BA4121, BA4120 and

BA3110) .........................................................19

23. Timer (Models BA2411, BA2410 and

BA2300) .........................................................20

24. Temperature Switch or Speed (Action)

Switch ............................................................20

25. Pressure Switch ..............................................20

26. Graphic Panel (Models BA4121, BA4120

and BA3110) ..................................................21

27. Loading Door .................................................21

28. Agitator (Short Post Models) .........................22

29. Agitator, Drive Bell And Seal Seat Assembly

(Short Post Models) .......................................22

To Reinstall Drive Bell...................................24

30. Agitator Post Assembly (Long Post

Models) ..........................................................24

31. Agitator Drive Shaft (Long Post Models) ......26

32. Front Panel .....................................................26

33. Pump Belt ......................................................26

34. Drive Belt ................................................ .......27

To Install No. 28808 Drive Belt.....................27

35. Motor And Mounting Bracket .......................29

36. Idler Lever And Pulley ..................................29

37. Motor Drive Pulley ........................................31

38. Motor Switch .................................................31

39. Pump Assembly .............................................31

40. Cabinet Top Assembly ...................................32

To Remove Cabinet Top From Washer..........32

41. Door And Out-of-balance Switch And

Bracket Assembly ................................... .......33

42. Mixing Valve Assembly ................................34

43. Washtub And Lint Filter ................................ 34

Short Post Models...........................................34

To Remove Lint Filter From Washtub............36

To Install Lint Filter In Washtub .................... 36

Long Post Models...........................................36

44. Water Seal and Hub Assembly ......................37

Short Post Models...........................................37

To Install No. 495P3 Hub and Seal Kit ..........38

To Install Drive Bell and No. 39508P Seal

Kit ...................................................................40

45. Water Seal Assembly .....................................41

Long Post Models...........................................41

To Install No. 356P3 Washer Seal Kit............41

46. Outer Tub .......................................................43

Short Post Models...........................................43

Long Post Models...........................................45

© Copyright 2016, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

47. Drive Pulley and Helix ...................................47

48. Brake Assembly .............................................50

49. Lower Bearing Housing .................................50

To Remove Bearing........................................52

50. Transmission Assembly .................................52

To Disassemble Transmission Assembly .......54

To Reassemble Transmission Assembly.........59

51. Balance Ring ..................................................60

52. Upper Bearing Assembly ...............................60

53. Snubber Pads ..................................................60

To Install No. 434P3 Snubber Pad Kit............60

Section 6 – Adjustments

54. Timer Knob Indicator ....................................65

55. Leveling Legs .................................................65

56. Pressure Switch ..............................................66

57. Belt (Agitate and Spin) ..................................66

58. Belt (Pump) ....................................................66

59. Out-of-Balance Switch Trigger ......................67

Section 7 – Test Procedures

60. To Check Continuity Through Motor

Harness and Motor .........................................69

61. To Check Continuity Through Base Harness,

Control Harness and Timer For Motor Start

Circuit .............................................................69

Section 8 – Cycle Sequence Charts

Timer No. 28918 Cycle Sequence

(Two Cycle)...........................................................71

Timer No. 31239 Cycle Sequence

(Three Cycle).........................................................72

Section 9 – Internal Wiring of Washer Motor

Switch

Section 10 – Wiring Diagrams

Models BA4121 and BA4120................................76

Model BA3110.......................................................77

Models BA2411 and BA2410................................78

Model BA2300.......................................................79

.....................................................................73

..........................75

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

Section 1

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or

property damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

WARNING

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING,” and “DANGER”) followed by specific instruc tions. These precauti ons are intende d for the person al

safety of the operator, user, servicer and those maintaining the machine.

DANGER

Danger indicates the presence of a hazard that wi ll cause severe personal injury, death or substantial property

damage if the danger is ignored.

WARNING

Warning indicates the presence of a hazard that can cause severe personal injury, death or substantial property

damage if the warning is ignored.

CAUTION

Caution indicates the presence of a hazard that will or can cause minor personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Section 1 Safety Information

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

W007

WARNING

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W008

WARNING

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the washer.

Always contact your dealer, distributor, service age nt or the manufac turer about any pro blems or condit ions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

Section 2

W162S

Nameplate

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call (920) 748-3121.

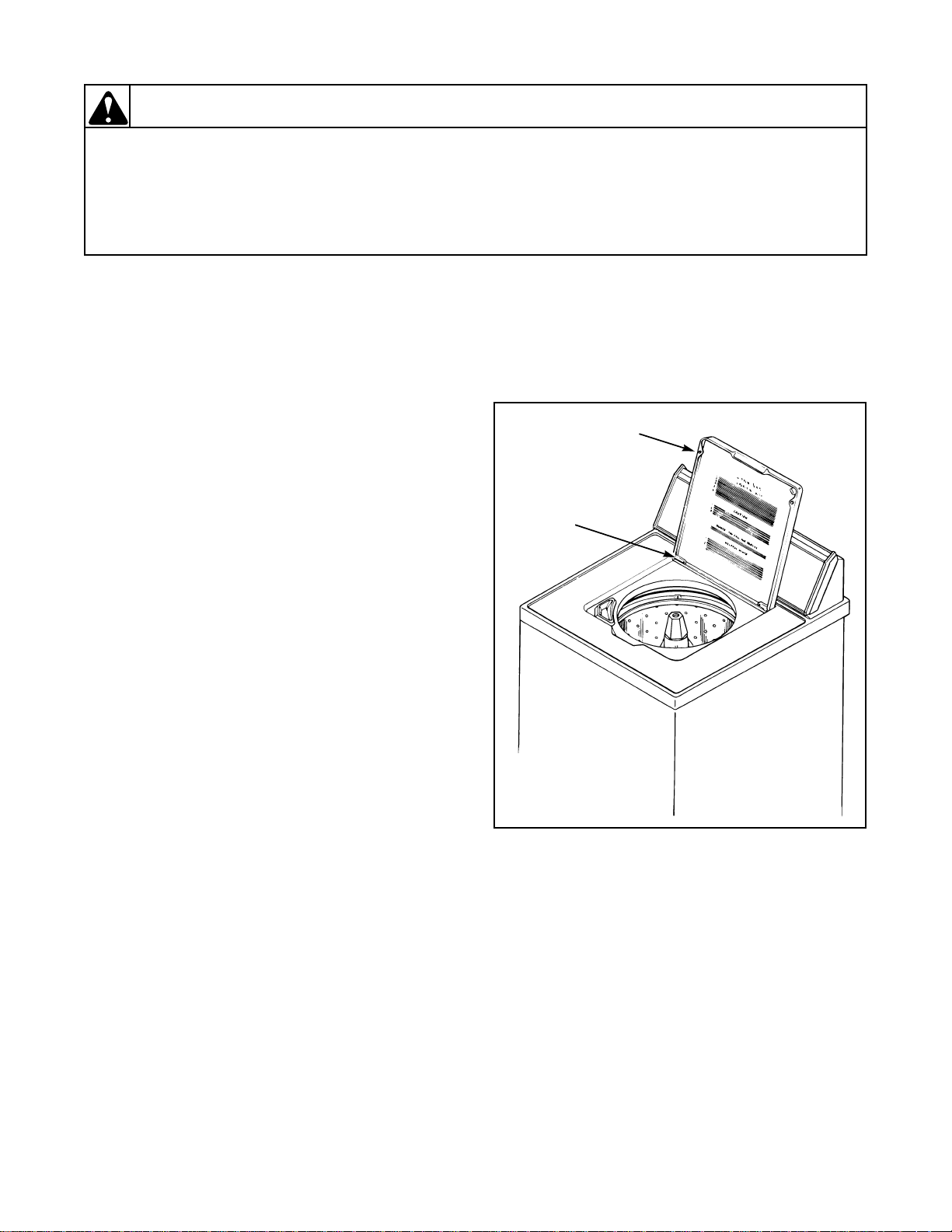

Nameplate Location

When calling or wri ting about your p rodu ct, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Section 2 Introduction

Model Identification

Information in this manual is applicable to these washer models.

BA4121 BA2411

BA4120 BA2410

BA3110 BA2300

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Section 3

Troubleshooting

IMPORTANT: Refer to appropriate Wiring Diagram for aid in testing washer components.

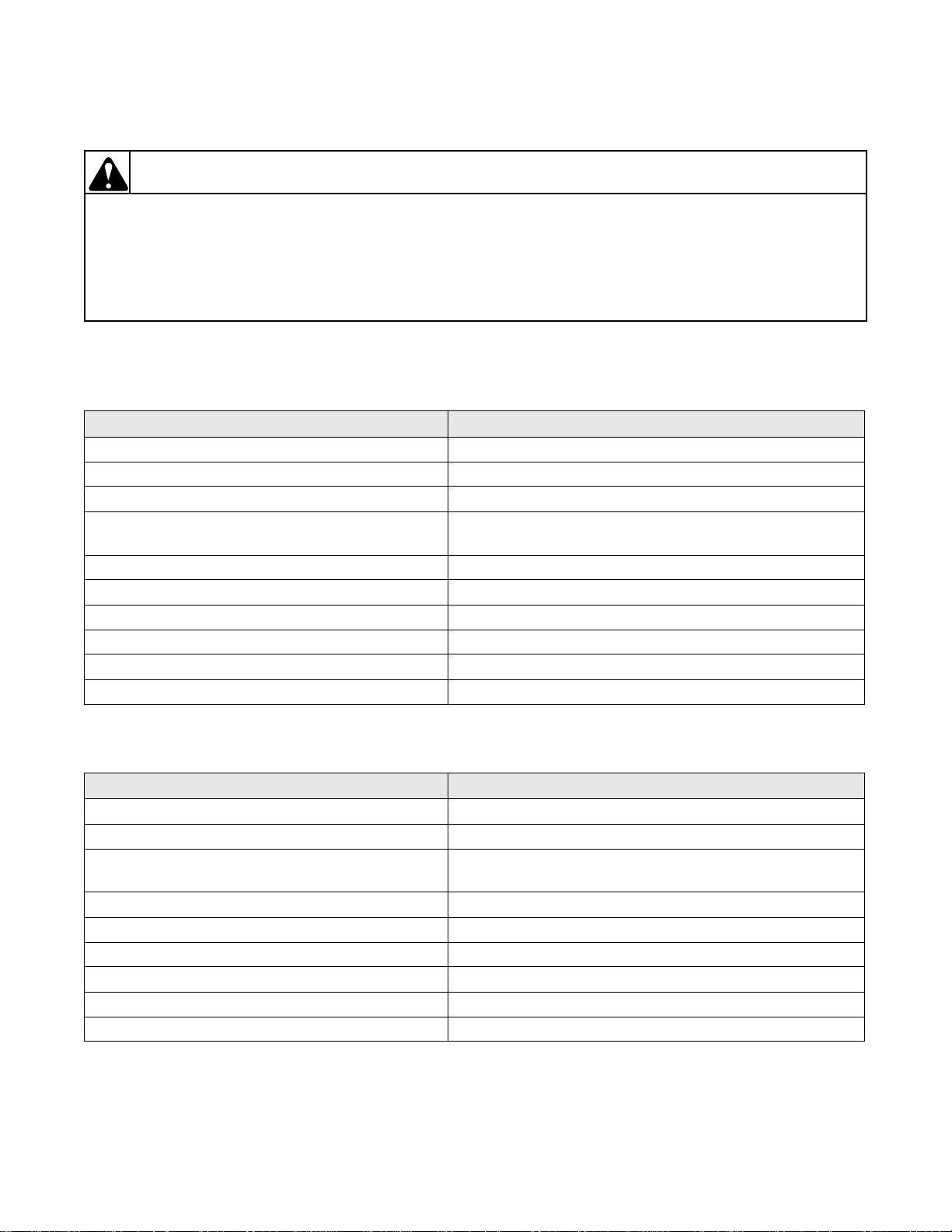

1. NO HOT WATER

POSSIBLE CAUSE TO CORRECT

Hot water su pply faucet is closed. • Open faucet.

Water supply is cold. • Check water heater.

Kinked hot water inlet hose. • Straighten or replace hose.

Clogged mixing valve screen, or screen in outer end

of inlet hose nearest water supply faucet.

Inoperative hot water mixing valve solenoid. • Test solenoid and replace if inoperative.

Inoperative timer. • Test timer and replace if inoperative.

Inoperative temperature switch. • Test switch and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Clogged pressure hose. • Remove and clean or replace hose.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

• Disconnect hot water inlet hose, and clean or replace

screen.

2. NO COLD WATER

POSSIBLE CAUSE TO CORRECT

Cold water supply faucet is closed. • Open faucet.

Kinked cold water inlet hose. • Straighten or replace hose.

Clogged mixing valve screen, or screen in outer end

of inlet hose nearest water supply faucet.

Inoperative cold water mixing valve solenoid. • Test solenoid and replace if inoperative.

Inoperative timer. • Test timer and replace if inoperative.

Inoperative temperature switch. • Test switch and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Clogged pressure hose. • Remove and clean or replace hose.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

• Disconnect cold water inlet hose, and clean or replace

screen.

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

3. NO WARM WATER

POSSIBLE CAUSE TO CORRECT

No hot water. • Refer to Paragraph 1.

No cold water. • Refer to Paragraph 2.

4. WATER FILL DOES NOT STOP AT PROPER LEVEL

POSSIBLE CAUSE TO CORRECT

Inoperative pressure switch. • Test switch and replace if inoperative.

Air leak in pressure hose. • Replace hose.

Sediment on or under mixing valve diaphragm,

defective diaphragm, or armature binding in

• Disassemble and clean mixing valve. Replace

deteriorated or not easily cleaned components.

armature guide.

Broken, weak or missing mixing valve armature

• Disassemble valve and replace spring.

spring.

A siphoning action started in washer will cause

water to be siphoned from washer during cycle due

• Install No. 562P3 Siphon Break Kit. Provide an air gap

around drain hose and drain receptacle.

to end of drain hose being lower th an cabine t top of

washer. Drain hose fits tight in standpipe or drain.

Water in pressure hose. • Blow air through hose to remove water.

Broken, loose, shorted or incorrect wiring. • Refer to appropriate w iring diagram.

5. TIMER DOES NOT ADVANCE (Mechanical Timer Models only)

POSSIBLE CAUSE TO CORRECT

Timer is designed to pause during fill periods. • Allow completion of fill period.

Inoperative timer. • Test timer, and replace if inoperative.

Loading door is open. • Close loading door. Loading door MUST be closed any

time the washe r is to agitate or spin.

Washer will not fill. • Timer pauses until pressure switch is satisfied. Refer to

Paragraph 1 and 2.

Timer motor lead wire off timer terminal. • Refer to appropriate wiring diagram and reattach wire.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

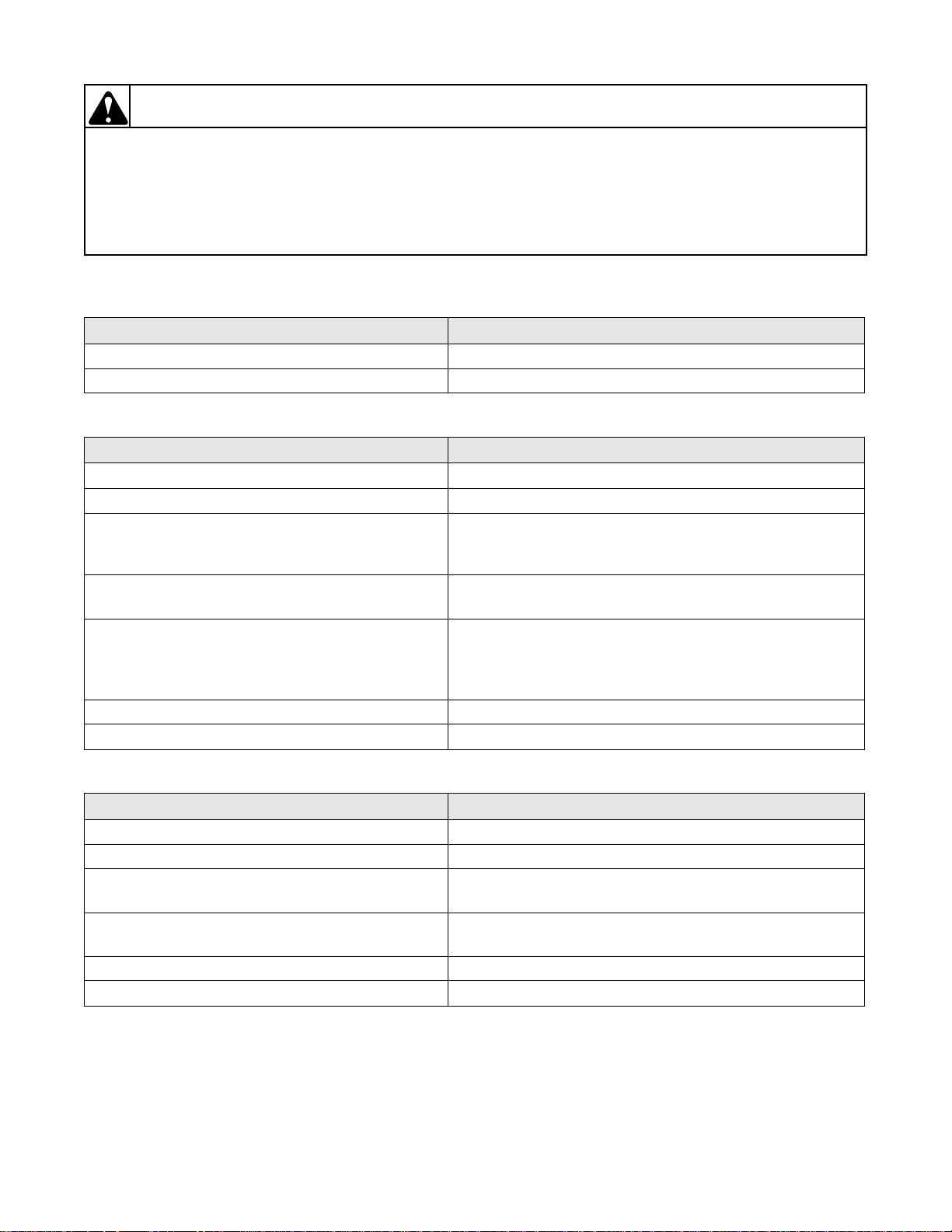

6. NO AGITATION

POSSIBLE CAUSE TO CORRECT

Inoperative timer. Timer is designed to pause

• Test timer and replace if inoperative.

(SOAK) during DELICATE cycle.

Inoperative motor. • Test motor and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Loose or broken drive belt. • Adjust or replace belt.

Inoperative transmission assembly. • Repair or replace transmission assembly.

Sheared motor pulley roll pin. • Remove drive motor and replace roll pin and any other

damaged parts.

Drive motor overload protector has cycled. • Refer to Paragraph 10.

Bind in pump. • Replace pump.

Loading door is open or door switch is inoperative. • Close door or test switch and replace if inoperative.

7. CONSTANT AGITATION

POSSIBLE CAUSE TO CORRECT

Inoperative timer. • Test timer and replace if inoperative.

Inoperative drive motor. • Test motor and replace if inoperative.

Shorted or incorrect wiring. • Refer to appropriate wiring diagram.

Inoperative transmission assembly. • Repair or replace transmission assembly.

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

8. SLOW SPIN OR NO SPIN

POSSIBLE CAUSE TO CORRECT

Inoperative timer. • Test timer and replace if inoperative.

On some model washers, the timer is programmed

• Use a different cycle.

for SLOW spin in the DELICATE CYCLE

regardless of the action switch setting.

Loading door is open or door safety switch is

inoperative.

• Close loading door, or test switch and replace if

inoperative.

Bind in water pump. • Replace pump.

Inoperative drive motor. • Test motor and replace if inoperative.

Loose or broken drive belt. • Adjust or replace spin belt.

Washer has gone out of balance. • Open loading door to reset out-of-balance switch.

Rearrange load in washtub.

No clearance or stuck brake pads. • Free sticky brake pads or replace pads.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Inoperative transmission assembly. • Repair or replace the transmission assembly.

9. CONSTANT SPIN

POSSIBLE CAUSE TO CORRECT

Inoperative timer. • Test timer and replace if inoperative.

Inoperative drive motor. • Test motor and replace if inoperative.

Excessive wear on brake pads, or missing brake

• Replace brake pads.

pads.

Shorted or incorrect wiring. • Refer to appropriate wiring diagram.

10. DRIVE MOTOR OVERLOAD PROTECTOR CYCLES REPEATEDLY

POSSIBLE CAUSE TO CORRECT

Excessive belt tension. • Adjust belts.

Inoperative motor overload protector. • Replace motor.

Bind in water pump. • Replace pump.

Bind in transmission. • Repair or replace transmission.

Brake pads binding. • Free binding pads, or replace pads.

Incorrect voltage. • Contact local utility company, or have a qualified

electrician check power supply.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

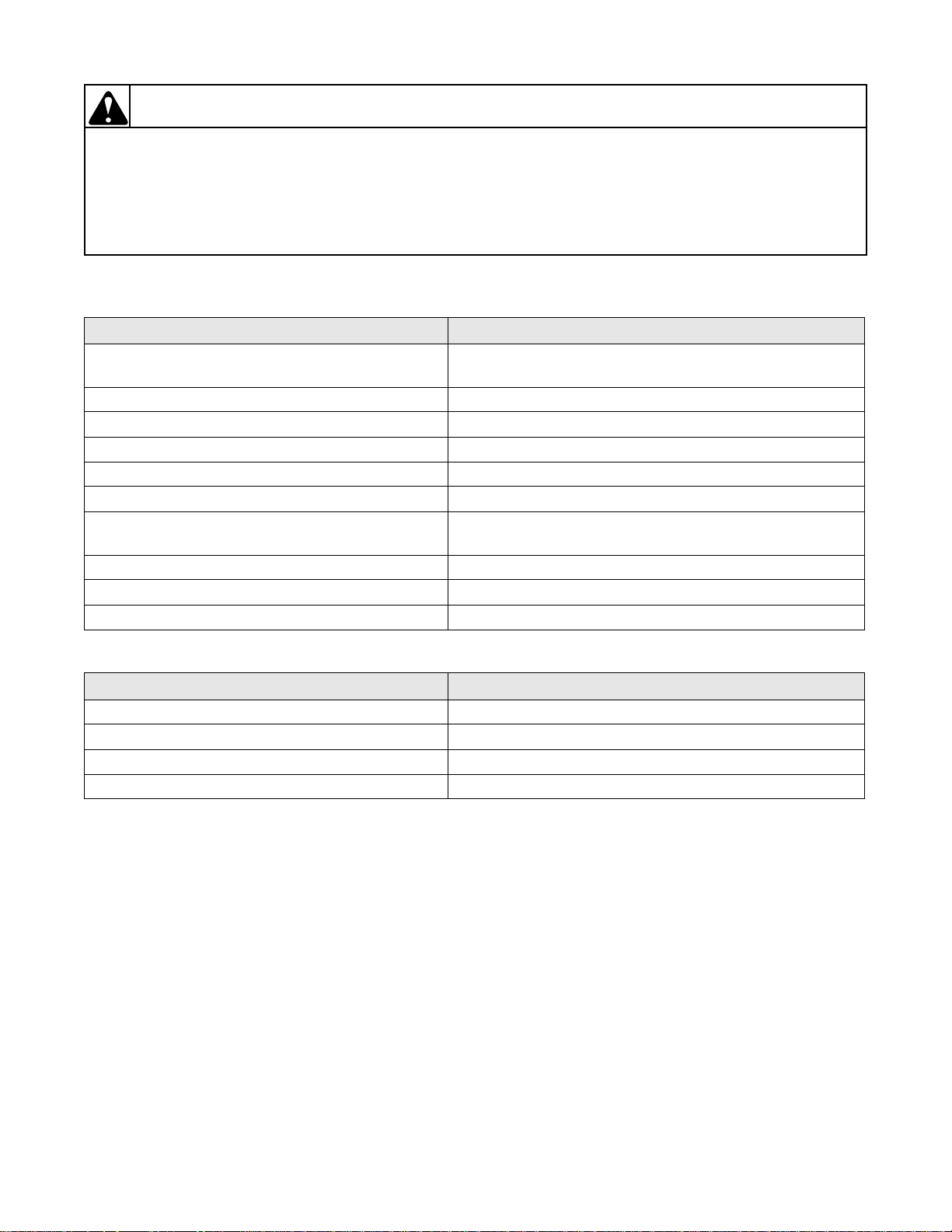

11. OUTER TUB DOES NOT EMPTY

POSSIBLE CAUSE TO CORRECT

Kinked drain hose. • Straighten hose.

Inoperative water pump. • Replace pump.

Obstruction in outer tub outlet hose. • Remove obstruction.

Loose or broken pump belt. • Adjust or replace belt.

12. EXCESSIVE VIBRATION

POSSIBLE CAUSE TO CORRECT

Unbalanced load in tub. • Stop washer, redistribute load, then restart washer.

Broken, disconnected or centering spring(s) out of

adjustment.

• Connect or replace centering spring(s). Spring should be

located in center notch. Refer to Figure 60.

Washer is not properly leveled. • Adjust leveling legs.

Washer is installed on weak, “spongy” or built-up

floor.

• Relocate washer, or support floor to eliminate weak or

“spongy” condition.

Incorrect or loose cabinet screws. • Replace with correct screws or tighten.

Base damaged (washer was dropped). • Replace base assembly.

Balance ring not positioned properly on

• Refer to Paragraph 51.

transmission assembly.

13. WATER LEAKING FROM OUTER TUB

POSSIBLE CAUSE TO CORRECT

Leaking water seal in outer tub. • Replace hub and seal kit assembly, Paragraph 44.

Hole in outer tub. • Replace outer tub.

Pressure hose or accumulator leaking. • Replace pressure hose and/or accumulator.

Outer tub cover gasket leaking. • Replace gasket.

Tub-to-pump hose leaking at clamp. • Tighten clamp.

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Section 3 Troubleshooting

Notes

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Section 4

W011G

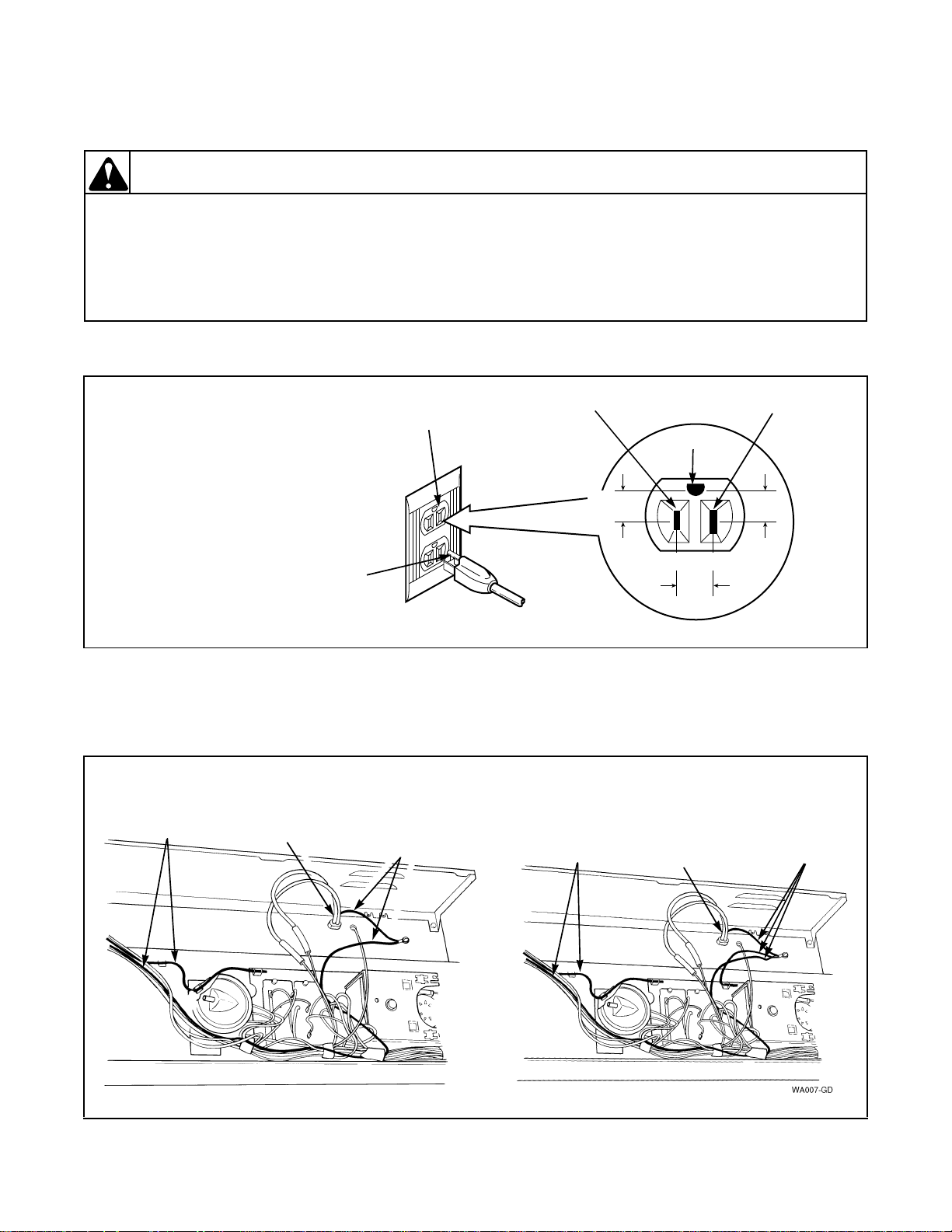

NOTE: For determining

the correct polarity of a

wall receptacle.

Neutral

Ground

L1

Neutral

Side

Round

Grounding

Prong

0

VAC

115 ± 12

VAC

115 ± 12

VAC

Standard 120 Volt, 60 Hertz

3-Wire Effectively Grounded

Circuit

MECHANICAL TIMER MODELS

Power

Cord

Ground

Wires

(Some models)

Ground

Wires

Ground

Wires

Power

Cord

Ground

Wires

(Some models)

Grounding

14. WALL RECEPTACLE POLARITY CHECK

Figure 1

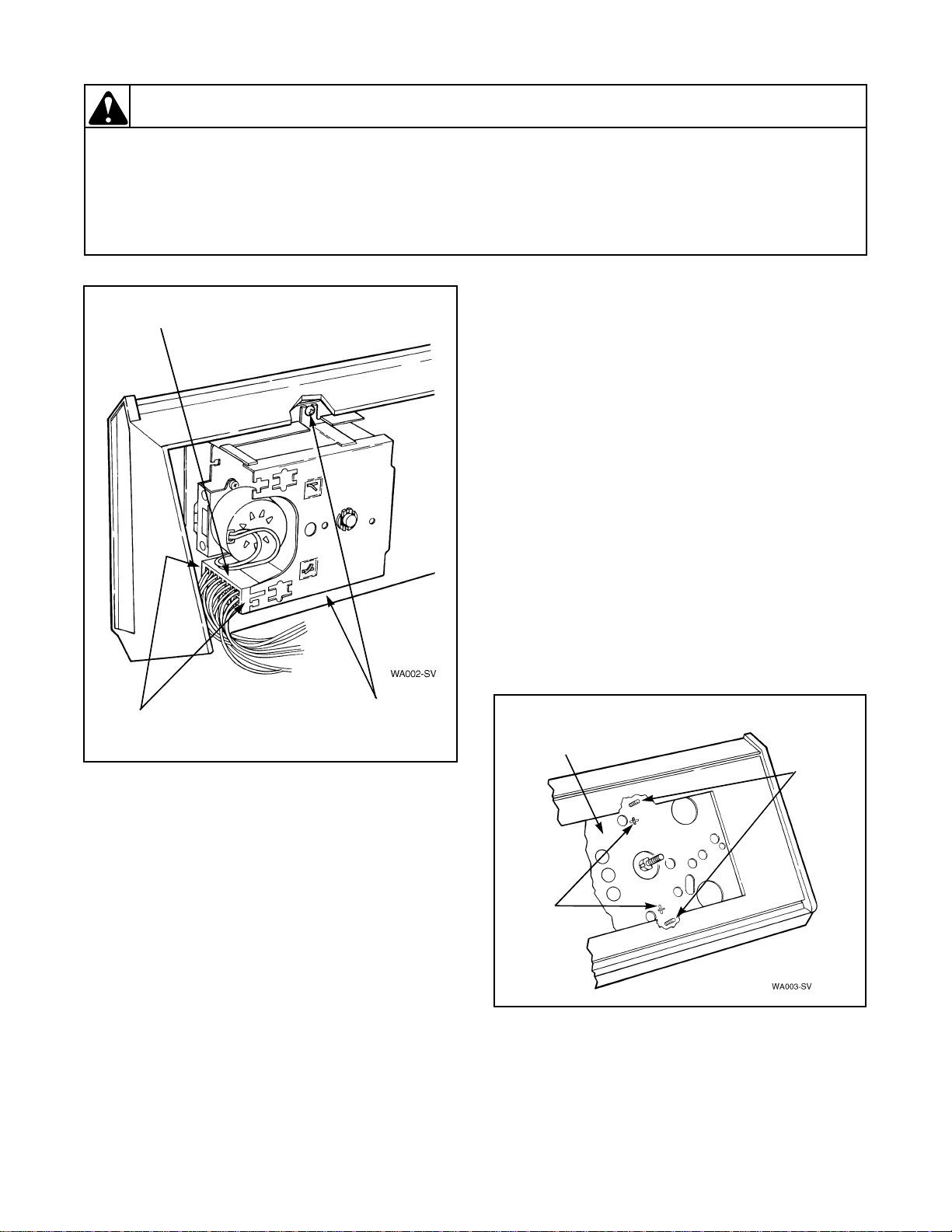

15. POWER CORD TO CABINET TOP, CABINET TOP TO CONTROL HOOD MOUNTING

BRACKET, PRESSURE SWITCH MOUNTING BRACKET AND GROUND TAB ON GRAPHIC

PANEL (Models BA4121, BA4120 and BA3110)

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 2

13

Section 4 Grounding

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

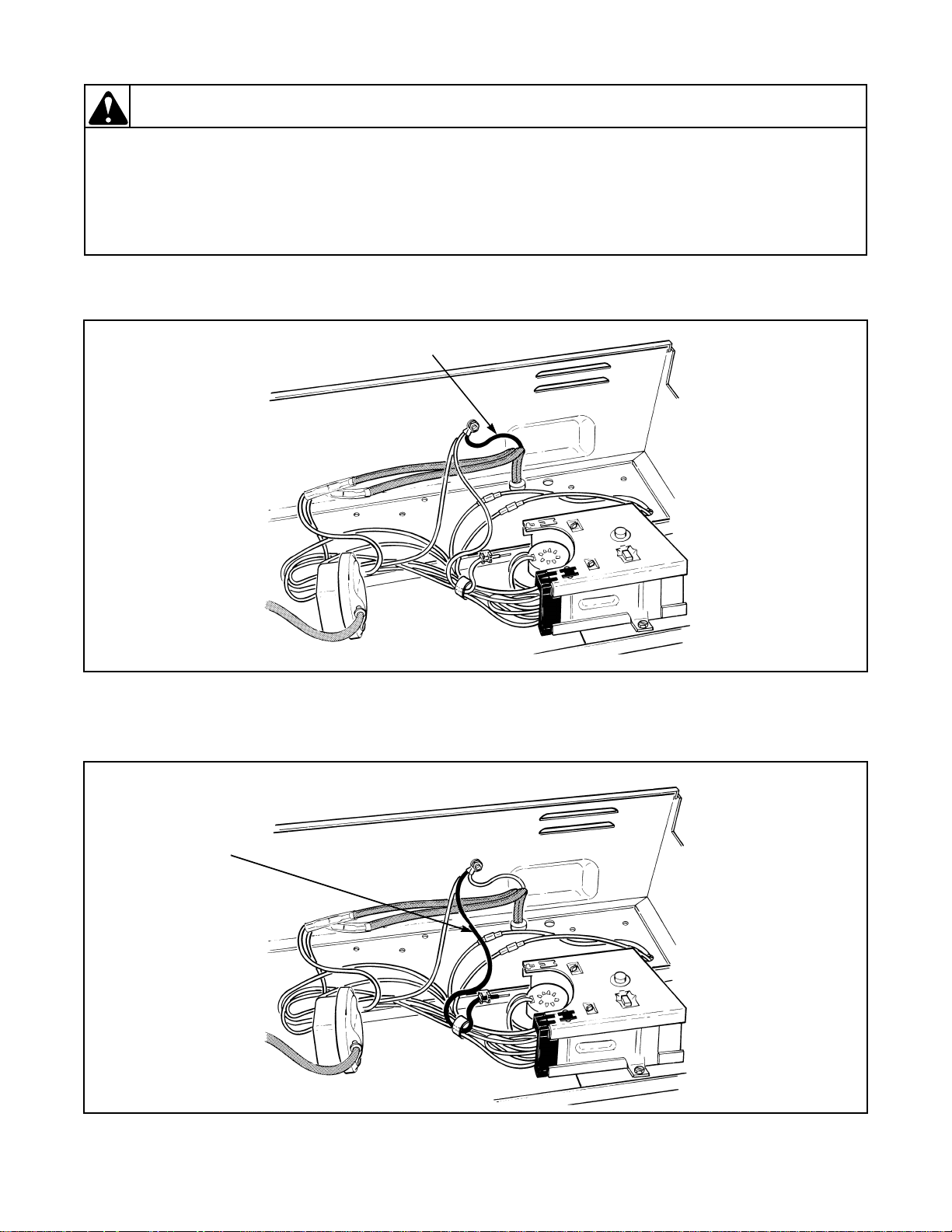

Ground

Wire

Ground

Wire

16. POWER CORD TO CONTROL HOOD (Models BA2411, BA2410 and BA2300)

Figure 3

17. CONTROL HOOD TO BOTTOM FLANGE OF CONTROL PANEL (Models BA2411, BA2410 and

BA2300)

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 4

32305

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

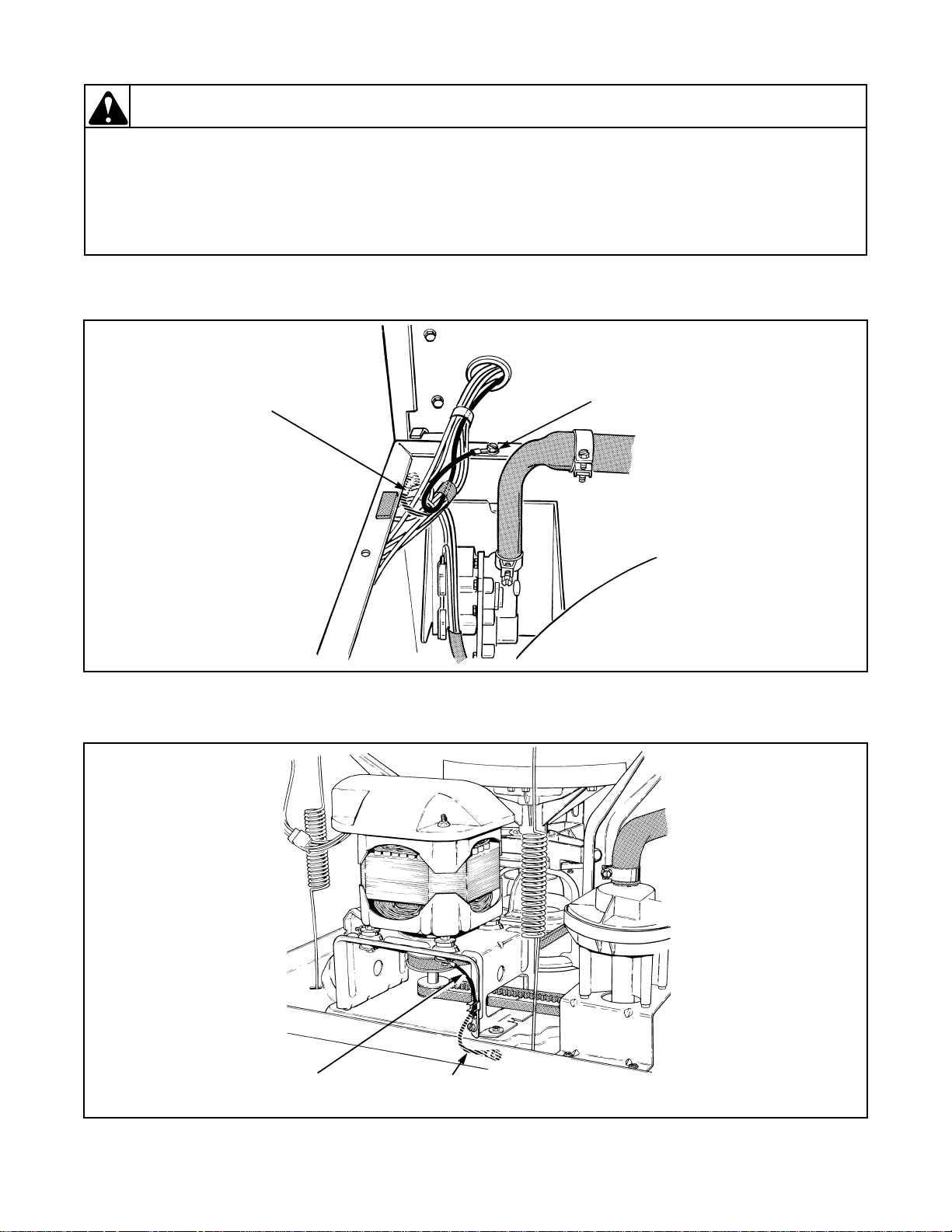

18. MAIN WIRE HARNESS TO TOP REAR CORNER GUSSET OF CABINET

Ground

Wire

on Cabinet

Corner

Gusset

(Some models)

Ground

Wire

on Cabinet

Flange

(Some models)

Ground

Wire

Ground Wire

(Some models)

Section 4 Grounding

Figure 5

19. MOTOR TO MOUNTING BRACKET TO BASE

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 6

15

Section 4 Grounding

Notes

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

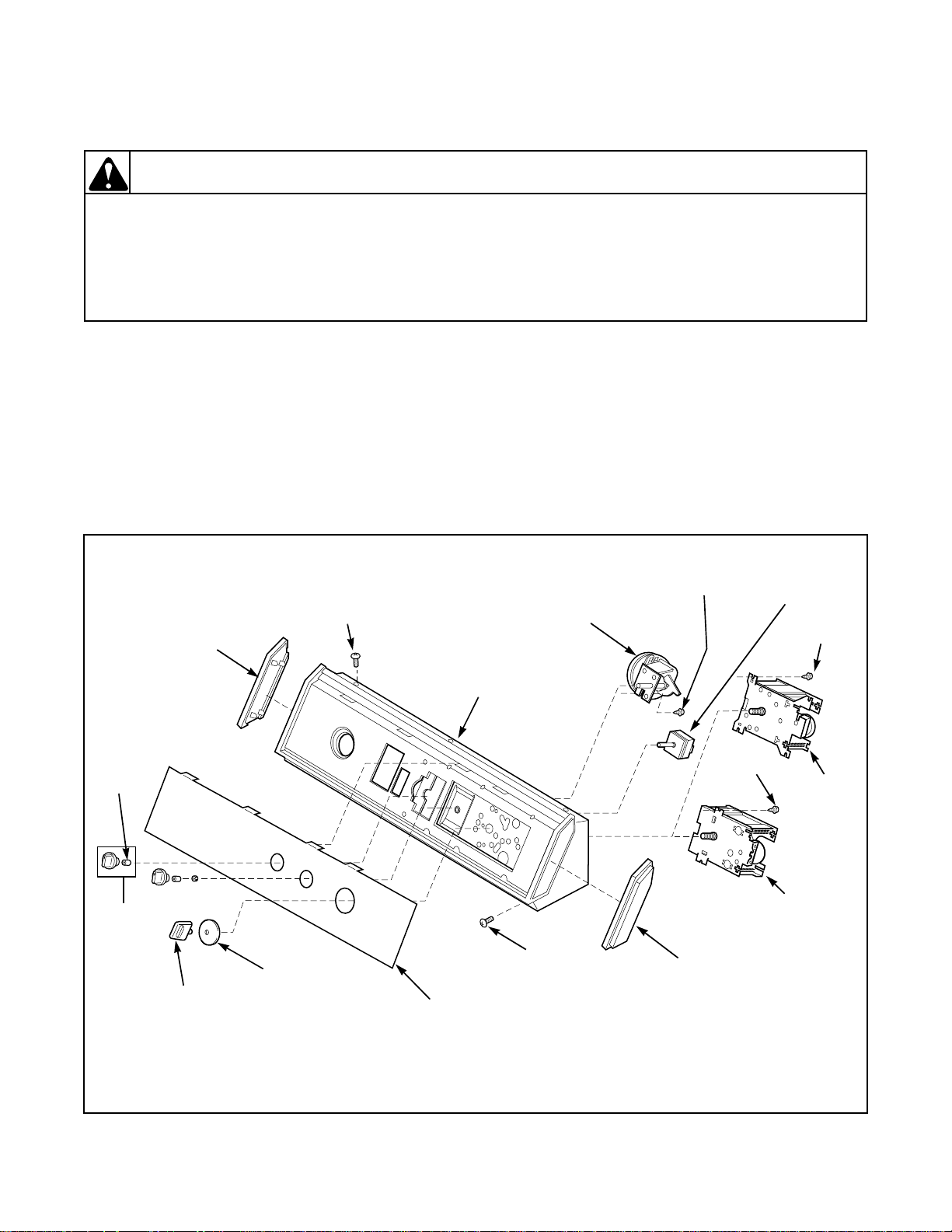

Section 5

W435P

Eaton

Timer

Screw

End Cap

(Right)

Screw

Screw

End Cap

(Left)

Pressure

Switch

Control Hood

Assembly

Graphic

Panel

Clip

Control

Knob

Assembly

Timer

Knob

Timer Knob

Skirt

Mallory

Timer

Screw

Screw

Temperature

Switch

Service Procedures

IMPORTANT: When reference is made to

directions (r ight or left) in this manual, it is from the

operator’s position facing the front of the washer.

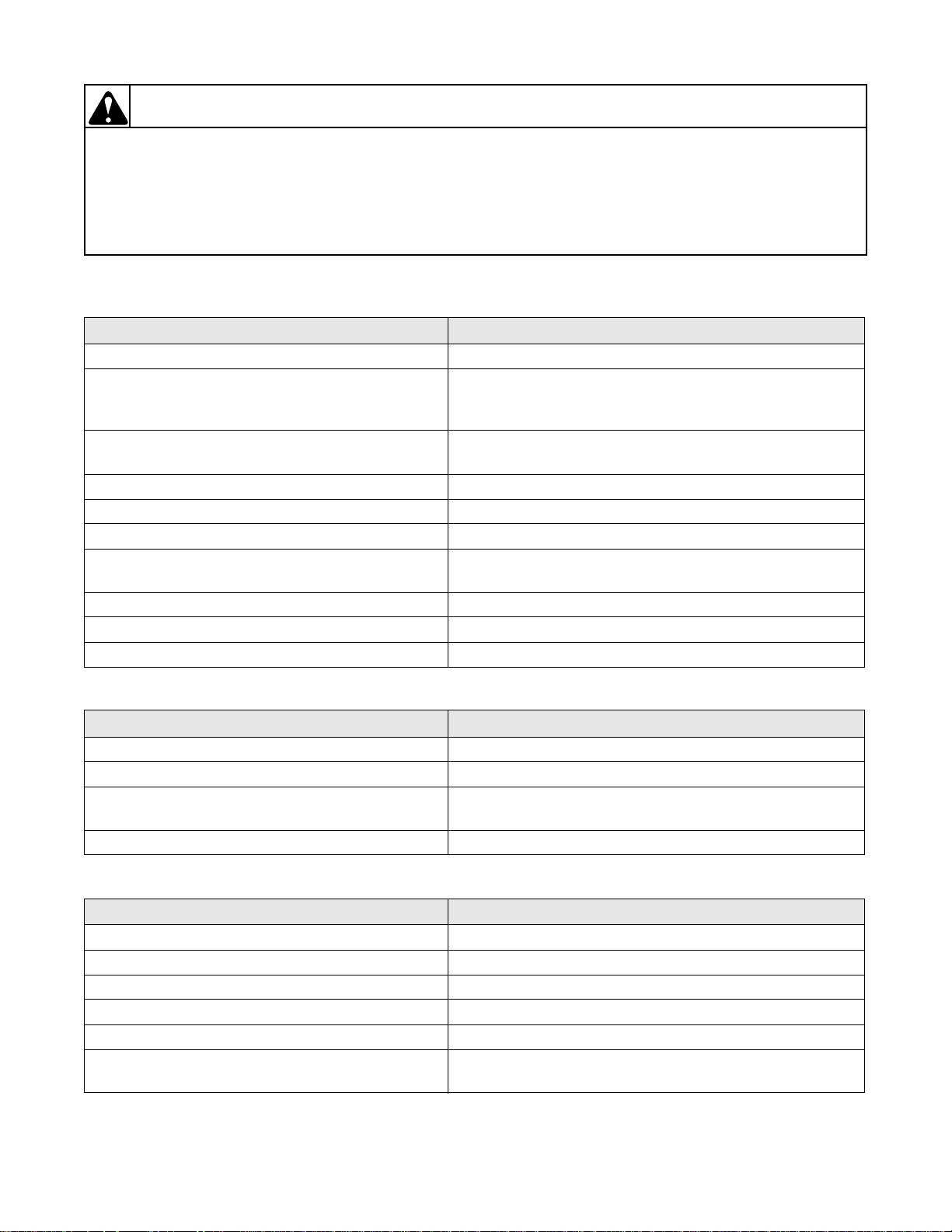

20. CONTROL HOOD ASSEMBLY (Models

BA4121, BA4120 and BA3110)

Refer to Figure 7.

a. Remove six screws (3 on top and 3 at lower

front) holding hood assembly to control hood

rear panel and cabinet top.

NOTE: Refer to appropriate wiring diagram when

rewiring component parts.

b. Disconnect wires from component parts and

carefully remove components from control

hood assembly.

TO REMOVE CONTROL HOOD END CAPS

Remove end caps by carefully prying caps out of

slots in ends of hood.

32305

GRAPHICS PANEL, CONTROL HOOD AND CONTROLS

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 7

17

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

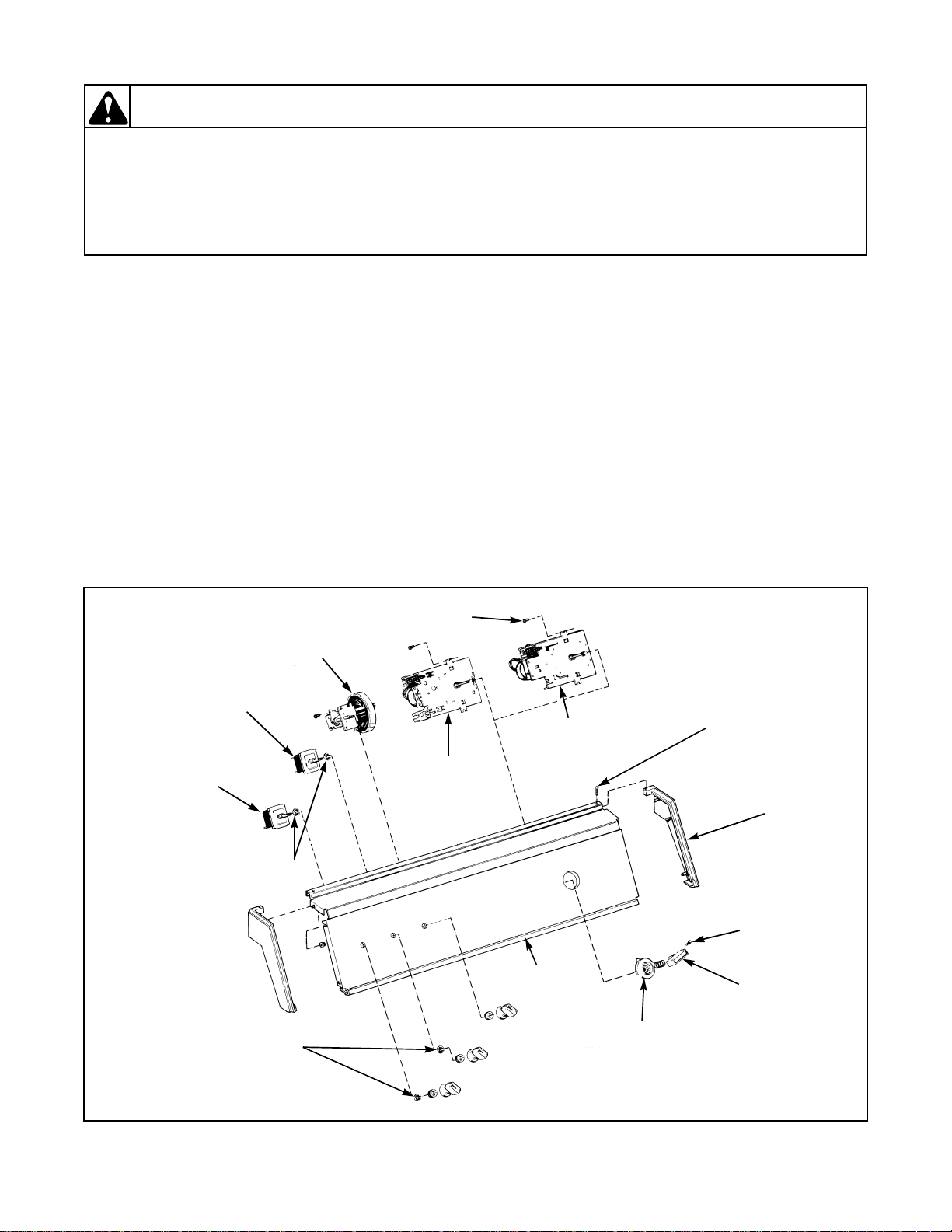

End

Cap

Pressure

Switch

Timer

(Mallory)

Temperature

Switch

Speed

Switch

(Action)

Timer

Attaching Screw

Timer

(Singer)

Panel

Assembly

Screw

Lockwashers

Lockwashers

Control

Panel

Timer Knob

Indicator

Timer Knob

Set Screw

Timer

Knob

21. CONTROL PANEL (Models BA2411, BA2410

and BA2300)

Refer to Figure 8.

a. Remove panel assembly screws and lift

assembly off panel support.

b. Remove end caps.

c. Remove timer knob assembly.

NOTE: When reinstalling timer knob assembly, pin

in timer shaft must be positi oned i n slot t imer kno b

indicator.

d. Pull knobs off temperature and speed (action)

switches (if present), and remove knurled nuts

and lockwashers holding switches to control

panel.

NOTE: Lockwashers must be between switch and

control panel when installing switch.

e. Pull knob off pressure switch and remove

screws holding switch to control panel.

f. Remove screws holding timer to control panel.

NOTE: When installing timers, shown in Figure 8,

the horizontal and vertical tabs on front plate of

timer must seat completely into the “cross shaped”

holes on the control panel bracket, Figure 8, and

that the two timer hex head attaching screws are

torqued down between 12 a nd 18 inch pounds (14 to

21 cm-kg).

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 8

32305

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

T erminal Blo ck

Plug

Timer

Attaching

Screws

Locking

Tabs

Control Hood

Mounting

Plate

Timer

Attaching

Screws

Cross

Shaped

Holes

IMPORTANT: To avoid an open circuit, DO NOT

pull on terminal block wir es wh en r emoving bloc ks

from timer as this could damage wires or terminal

crimping.

Before attachi ng wire harness terminal blocks to

timer, make sure all male terminals on timer are

straight and are capable of accepting terminals

from wire harness terminal blocks.

NOTE: When installing timer, be sure timer is

installed correctly and is securely mounted to

bracket on control hood. Refer to Figure 10.

e. The horizontal and vertical tabs on front plate

of timer must seat completely into the slots on

the control hood mounting br acket, and that the

two screws are torqued down between 12 and

18 inch pounds (14 to 21 cm-kg).

IMPORT ANT : T o avoid timer damage, do not allow

timer to be struck o n co rners, edges o f fra me, o r on

timer shaft.

Figure 9

22. TIMER (Models BA4121, BA4120 and

BA3110)

Refer to Figure 7.

a. Remove six screws (3 on top and 3 at lower

front) holding hood assembly to control hood

rear panel and cabinet top.

b. Unscrew timer knob from timer shaft (right

NOTE: DO NOT attempt to repair timer.

hand thread), then remove timer knob skirt.

c. Remove two screws holding timer to control

hood mounting plate. Refer to Figure 9.

Figure 10

d. Disengage wire harness terminal bloc k pl ug(s)

from timer by pressing in on movable locking

tabs (located on each side of terminal block

plug) and pulling away from timer. Refer to

32305

Figure 9.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Terminal

Block

Plug

Locking

Tabs

23. TIMER (Models BA2411, BA2410 and

BA2300)

Refer to Figure 8.

a. Remove panel assembly screws and lift

assembly off panel support.

b. Loosen setscrew holding timer knob to timer

shaft, then remove knob, spring and ti mer knob

indicator.

NOTE: DO NOT attempt to repair timer.

c. Disengage wire harness termi nal bloc k pl ug(s )

from timer by pressing in on movable locking

tabs (located on each side of terminal block

plug) and pulling away from timer. Refer to

Figure 11.

d. Remove the two hex head screws holdi ng timer

to rear of control panel bracket.

NOTE: When installing timer, be sure timer is

installed correctly and is securely mounted to

bracket on control hood. Refer to Figure 8.

e. The horizontal and vertical tabs on front plate

of timer must seat completely into the crossshaped holes on the control hood mounting

bracket. Torque down the screws between 12

and 18 inch pounds (14 to 21 cm-kg).

IMPORT ANT : T o avoid timer damage, do not allow

timer to be struck o n co rners, edges o f fra me, o r on

timer shaft.

24. TEMPERATURE SWITCH OR SPEED

(ACTION) SWITCH

Refer to Figure 7 or 8 for switch removal,

depending on model.

NOTE: Refer to appropriate wiring diagram when

rewiring switch.

25. PRESSURE SWITCH

Refer to Figure 7 or 8 for switch removal,

depending on model.

NOTE: Refer to appropriate wiring diagram when

rewiring switch.

IMPORTANT: When installing pressure switch,

blow air through pressure hose before connecting

Figure 11

IMPORTANT: To avoid an open circuit, DO NOT

pull on terminal block wir es when r emov ing blocks

from timer as this could damage wires or terminal

crimping.

hose to switch to remove any conde nsation that may

have accumulated in the hose.

When the pressure hose has been removed and

replaced several times, the end of the hose may

become enlarged, and does not seal properly.

If hose is enlarged, cut approximately 1/2" to 3/4"

off the end of the hose and rei nstall hose on pressur e

switch.

Before attaching wire harness terminal block to

timer, make sure all male terminals on timer are

straight and are capable of accepting terminals

from wire harness terminal block.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32305

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Loading

Door

Hinge

26. GRAPHIC PANEL (Models BA4121, BA4120

and BA3110)

Refer to Figure 7.

a. Remove six screws (3 on top and 3 at lower

front) holding hood assembly to control hood

rear panel and cabinet top.

b. Disconnect wires from component parts and

carefully remove components from control

hood assembly.

NOTE: Refer to appropriate wiring diagram when

rewiring component parts.

c. Bend tabs on graphic panel (located inside of

control hood) straight out toward rear of hood.

d. Carefully remove graphic panel off front of

control hood.

27. LOADING DOOR

Refer to Figure 12.

a. Depress tab on either hinge, then slide hinge out

of loading door and bushing in cabinet.

b. Tilt loading door slightly and slide door and

hinge out of opposite bushing.

Figure 12

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

No. 254P4P

Agitator Hooks

Agitator

To reduce the risk of electric shock or

injury to persons, disconnect the washer

power cord before servicing the washer. If

water is present in the washtub, spin and

pump out before attempting to remove t he

drive bell and seal seat assembly.

WARNING

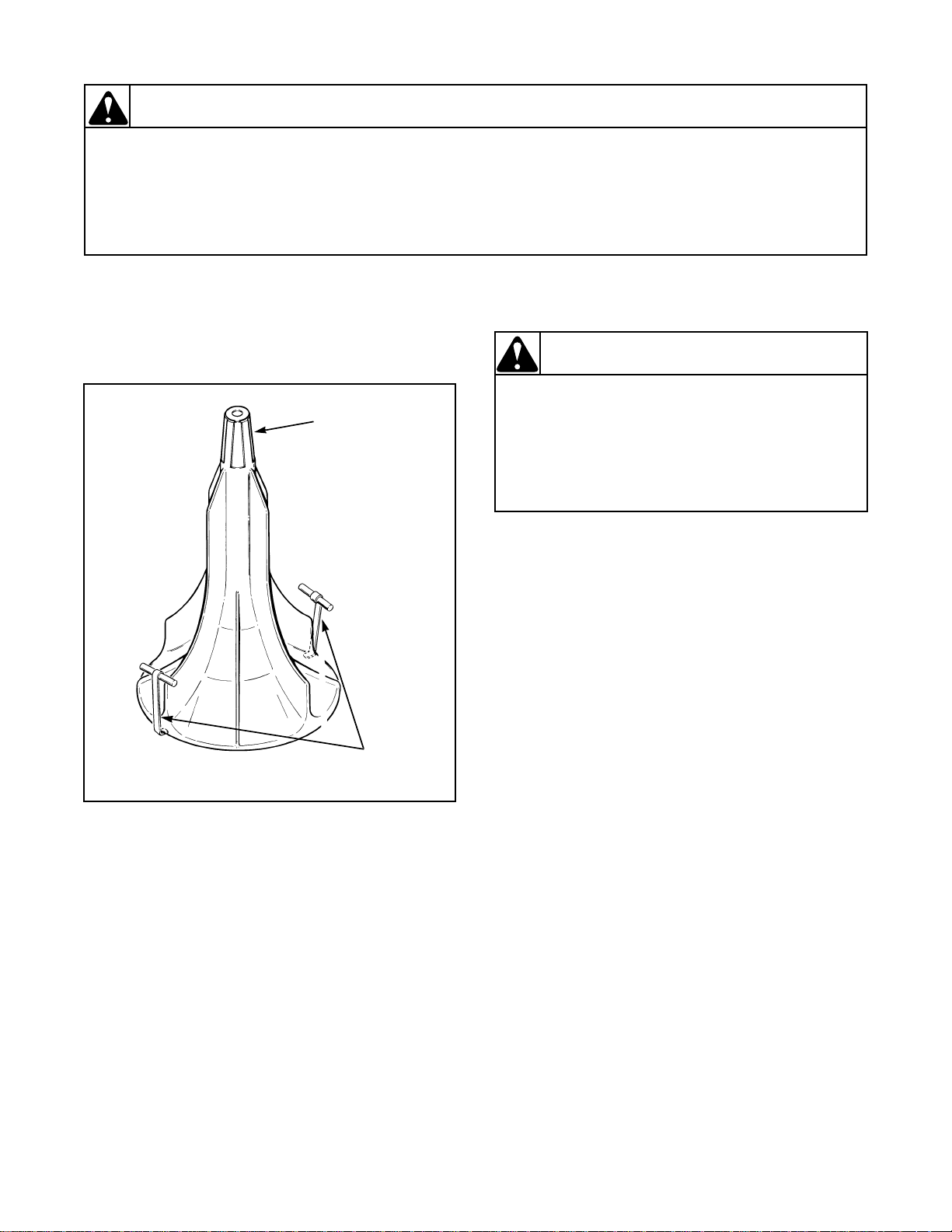

28. AGITATOR (Short Post Models)

a. Open loading door.

b. To remove agitator by hand, place two agi tator

hooks, No. 254P4P, under bottom edge of

agitator. Refer to Figure 13.

29. AGITATOR, DRIVE BELL AND SEAL

SEAT ASSEMBLY (Short Post Models)

a. Open loading door.

b. To remove agitator by hand, pla ce two agita tor

hooks, No. 254P4P, under bottom edge of

agitator. Refer to Figure 13.

IMPORTANT: Hooks should be positioned 180

degrees of each other, and must be placed under

agitator fin for great er stabi lity. If hooks are placed

between the fin ar ea, da mage to a gitat or may oc cur.

c. Using a rocking motion (back and forth)

carefully lift agitator off drive bell.

d. Remove the screw and o-ring washer from the

top side of the drive bell.

NOTE: To remove the drive bell from the

Figure 13

transmission shaft wi ll r equire using the No. 294P4

Drive Bell Tool. Refer to Figure 14.

IMPORTANT: Hooks should be positioned 180° of

each other, and must be placed under agitator fin

for greater st ability . If hooks ar e placed between th e

fin area, damage to agitator may occur.

e. Back bolt out of tool approximately three

quarters of the way.

f. Place tool over the bell, making sure indent on

jaw lines up with wide slots on the bell. Refer

c. Using a rocking motion (back and forth)

carefully lift agitator off drive bell.

to Figure 15.

g. Screw the bolt down through hole in top of bell

until bolt bottoms out in the hole in the

transmission shaft.

h. Place lip of each jaw under bottom edge of

drive bell, making sure indent on jaw lines up

with wide slots on bell. Then tighten the two

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

wing nuts to hold jaws firmly against drive bell.

Refer to Figure 15.

32305

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these grou nd wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

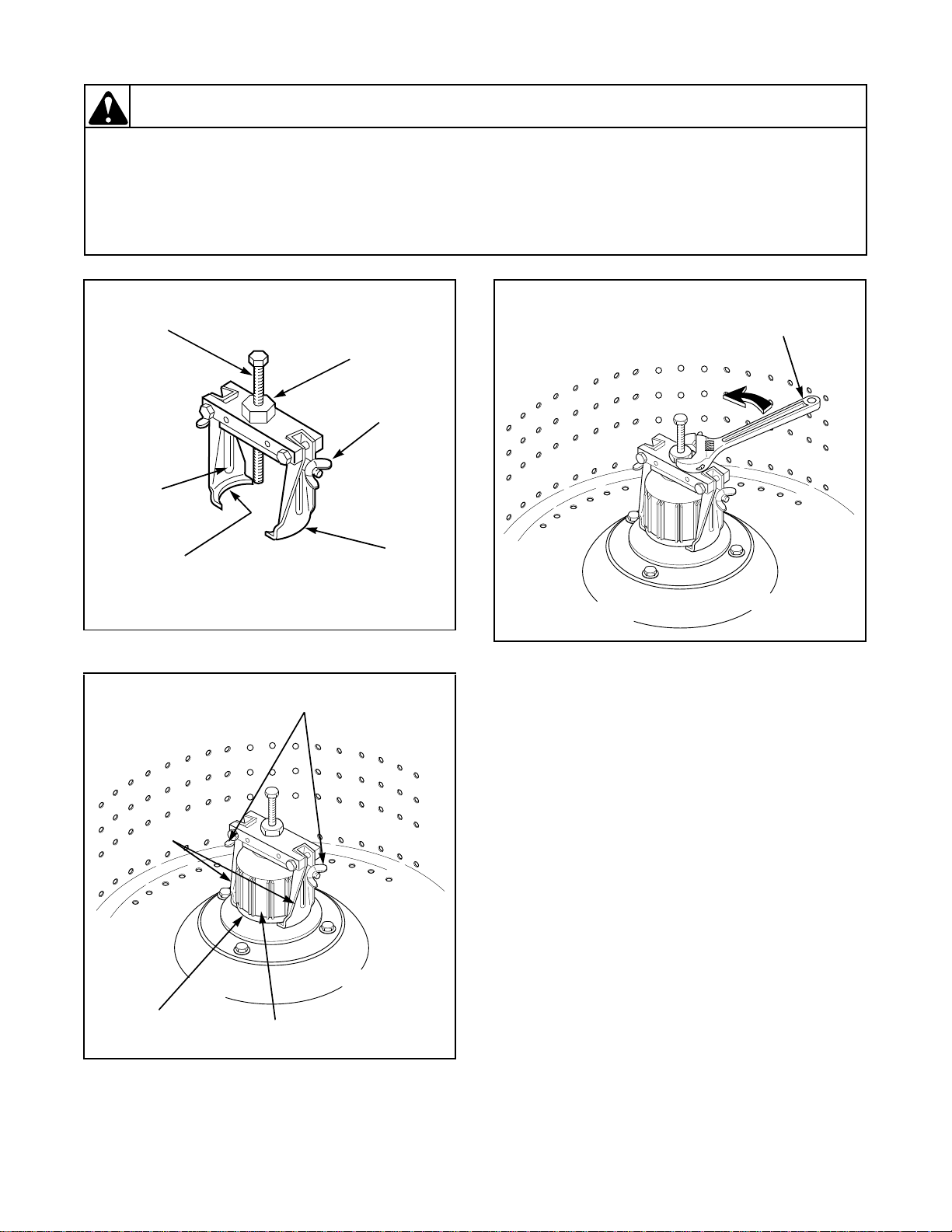

L021

Bolt

Large

Nut

Wing

Nut

Jaw

Jaw

Lip

Indent

WA189-SV

Wing

Nut

Jaws

Wide

Slot

Drive

Bell

WA190-SV

Turn Adjustable

Wrench Counterclockwise

to Remove Drive Bell

Figure 14

Figure 16

i. Use an adjustable wrench and turn the large nut

on tool COUNTERCLOCKWISE to pull

drive bell from transmis sion output shaft. Refer

to Figure 16.

IMPORTANT: If large nut is turned clockwise

when pulling drive bell, you will twist off the 1/4

inch bolt.

j. Turn the 1/4 inch bolt out of transmis sion shaf t

and remove tool and drive bell from washer.

k. Loosen the two wing nuts and remove drive bell

from tool.

l. Carefully pry the old seal out of the drive bell

and clean any foreign materials from the bell.

IMPORTANT: We recommend that both the seal

seat and the seal head be replace d together in pairs.

DO NOT replace only one of the two.

m. Install the new seal into the drive bell.

n. Remove the seal head from the hub and clean

Figure 15

any foreign material from the hub seal

mounting area.

32305

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Loading...

Loading...