Invicta TI-14 Operator's Manual

OPERATORS MANUAL

SHAPER

by

INVICTA

Model

TI-14

INCLUDES VERSIONS:

TI-14 V.02 NON-TILTING

TI-14 V.03 TILTING SPINDLE

TI-14 V.04 SLIDING TABLE

TI-14 V.05 TILTING SPINDLE / SLIDING TABLE

INVICTA USA English Version

(8

77) 308-6423 – East

Revision Nº 01

(800) 499-4682 - West

SHAPER

Model TI-14

General Instructions

As with all equipment, safety is to be a priority. The operator should understand the safety features and apply good

safety habits in transportation, adjustment, maintenance and operation of the machine. Practice and teach others

the safe operating procedures of this machine and help to prevent the possibility of accidents.

Safety Rules

1. For your own safety, read carefully the Instruction Manual before attempting to operate the machine.

2. If you are not thoroughly familiar and comfortable with the adjustment and operation of the machine, ask for

instruction from your supervisor or a fully qualified person. You may also contact Invicta USA.

3. Before the initial operation of the machine, remove all packaging, shipping grease and fully assemble the

machine. Pay special attention to the assembly of safety components.

4. Wear proper apparel while operating the machine. Never wear loose fitting clothing, gloves or ties. Always

remove rings or other jewelry before operating the machine. It is strongly suggested the operator wear

shoes with non-slip soles and also wear a protective hair net to prevent hair entanglement in moving parts.

5. Always wear personal safety equipment. Follow the safety regulations of your country and your company.

6. Have a certified person make all wiring connections to power source and properly gro und the machine.

7. Always disconnect the machine from the power source and use lockout procedures before servicing,

changing cutting tools and during any cleaning of the machine.

8. Before starting the machine, be aware that the work area is clean and free of debris. Cluttered areas are

invitations for accidents to occur. .

9. Keep the safety guard(s) of the machine in place and in proper working condition. Never operate

machinery without safety equipment in place. Report any damage to your supervisor. Keep children and

visitors a safe distance from the working area.

10. Never leave the machine running while unattended. Turn off the power source during breaks. The machine

should come to a complete stop before walking away.

11. Do not operate the machine under the influence of drugs or alcohol. Consult your physician when taking

medications.

12. Do not force the machine beyond its limitations. It will produce a nicer and safer job and at the rate it was

designed to operate.

Additional Safety Rules for the Operation of Shapers

1) Avoid Kickbacks. “Kickback” can occur when the workpiece is forced back by the cutter during improper

operation. When “Kickback” occurs an injury can result. Some of the causes of Kickback are:

A- Improper tooling

B- Knots, Nails or Imperfections in the workpiece.

C- Heavier Cuts than the machine was designed for.

D- Failure to use the material hold downs and or a powerfeeder with thin or narrow workpieces.

2) Always maintain the proper relationship of in-feed fence and the out-feed fence in relation to the Cutterhead.

3) Never start the work-piece into the cutterhead before allowing it to reach operation speed.

4) Keep the cutter sharp and free of rust and pitch

5) Never use an unbalanced cutterhead or an improper speed fo r the cutterhead.

6) Support and control the workpiece properly all times during the operation.

7) Never reverse the direction of the workpiece after beginning operation. Kickback can occur.

8) Always use the diameter spindle that is the correct size for your cutter.

9) When changing cutterheads be sure to replace the cutter guard before operation.

10) Check for proper rotation after each cutter change and the beginning of work.

11) Mounting of large diameter cutterheads should be as close to the base of the spindle as possible.

12) Keep the work area as clean as possible to avoid slipping or tripping.

13) Never place loose items on the table top while in operation.

14 Never continue to operate equipment that is in need of repair.

15) Safety glasses are strongly recommended during operation.

01

S

HAPER

Mod. TI-14

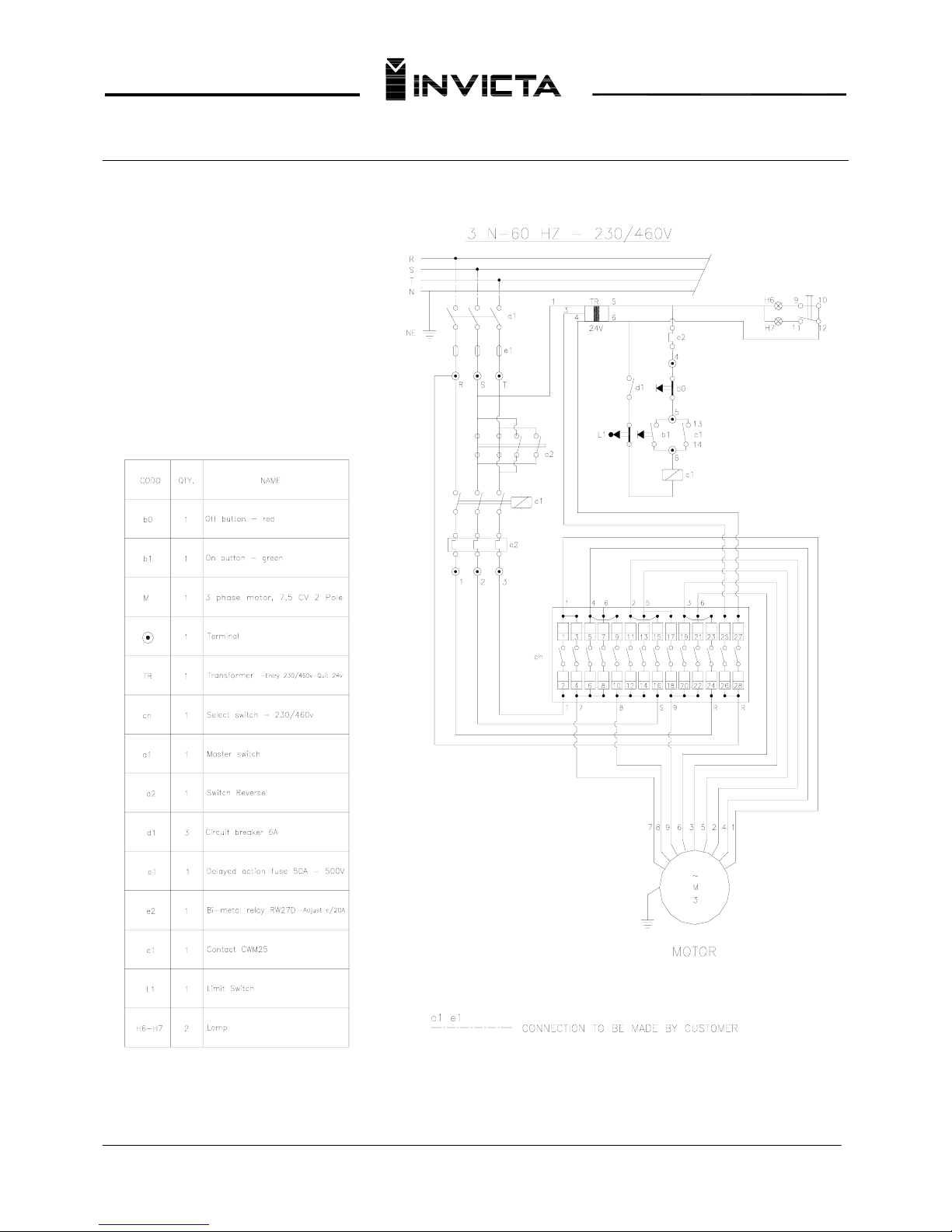

Electrical Connections of the Machine

Each machine is provided with a reference plate that

indicates the requirements of the electrical service

needed for the machine to properly operate. Before

you call a certified electrician to make the wiring

connections, be sure that the voltage and cycle

(phase) stated on this reference plate are the same

as provided in your building.

(Electrician) Remove the electrical box cover and

connect the electrical supply wires to the proper

terminals. Rapidly turn on and off the machine and

then visibly check the rotation direction of the

cutterhead. It should correspond to the direction

indicated on reversing switch. If not, proceed with the

instructions below:

For three-phase machines: invert two wires of the

power source without changing the internal

connections of the machine. See the electrical

diagrams for three-phase on page 08. If further

information is needed or contact Invicta USA.

Loading and unloading

When loading and unloading the machine there

should be no pressure on areas which could affect its

functioning. On figure 01 we show correct procedure

for handling.

Installing the Machine

Place the machine on a level and structurally sound

floor to avoid vibration. On figure 02 we display a

foundation layout for your reference.

CAUTION: The machine comes with a reverse rotation

switch, set it as shown (Clockwise) on the display in the

front panel before testing the rotation direction.

CUTTERHEAD ROTATION DIRECTION

Fig. 01

Fig. 02

0

2

S

HAPER

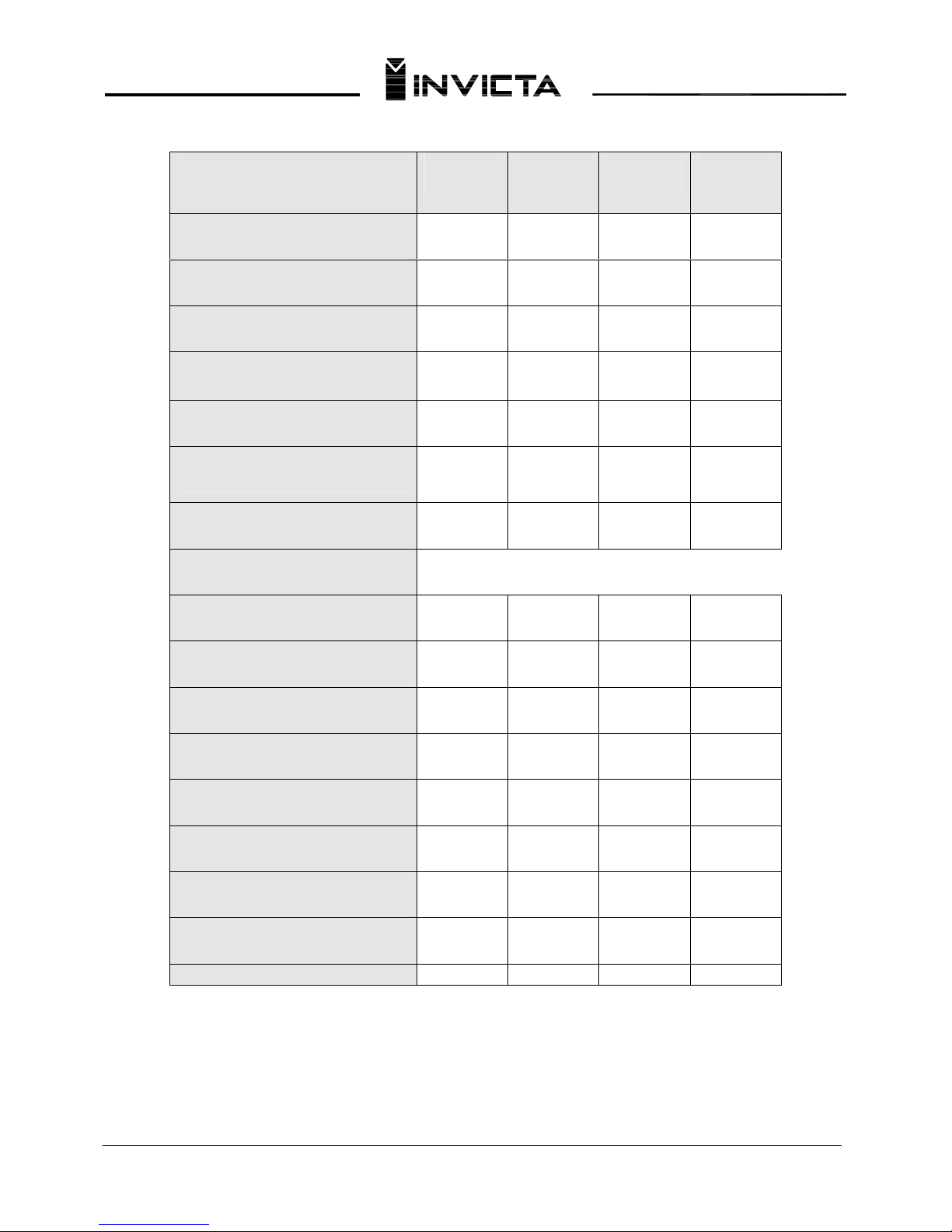

Technical Specification

Version

02

03

04

05

35.43 x 43.3 35.43 x 43.3 35.43 x 43.3 35.43 x 43.3

Table dimensions (in)

33.46

33.46

33.46

33.46

Working height (in)

Spindle vertical travel (in)

5.51

5.51

5.51

5.51

Morse taper

#5

#5

#5

#5

Spindle diameter (in)

.75 & 1.25 .75 & 1.25 .75 & 1.25 .75 & 1.25

Useable spindle length (in)

5.31

5.31

5.31

5.31

Table insert diameter (in)

16.53

16.53

12.99

12.99

Spindle speeds (rpm)

Three phase motor power

7.5 HP

7.5 HP

7.5 HP

7.5 HP

Sliding table travel (in)

-

-

39.37

39.37

Brake

YES

YES

YES

YES

Micro-adjustable fence

YES

YES

YES

YES

Sliding table (in)

-

-

10.82x54.13 10.82x54.13

Spindle Tilting

-

YES - YES

Net weight

1257 lbs 1257 lbs 1389 lbs 1433 lbs

Gross weight

1425 lbs 1433 lbs 1566 lbs 1621lbs

0

3

SHAPER

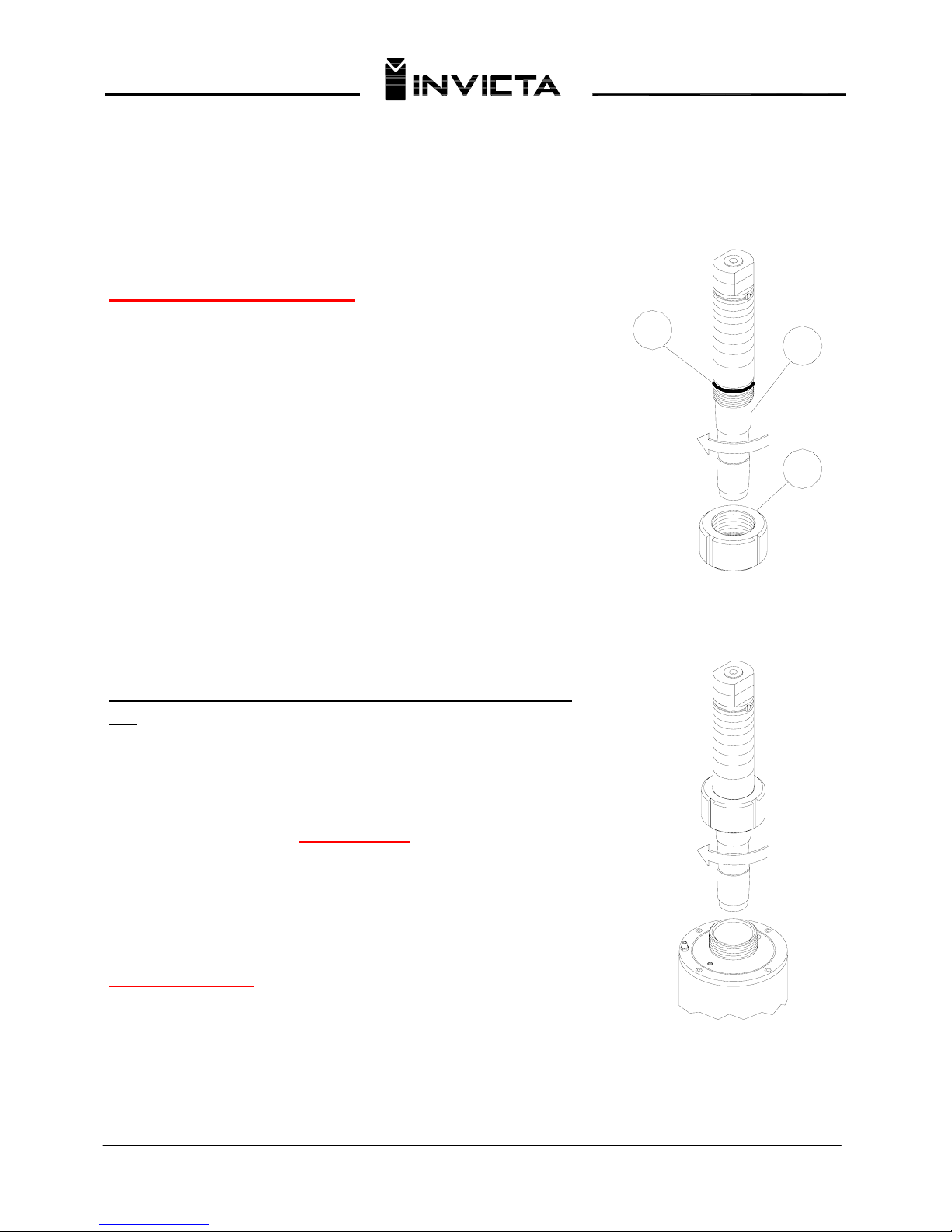

Changing the Spindle

INVICTA TECHNICAL BULLETIN

Subject: Correct Procedure for Changing Spindles

Pre-installation Instructions

Remove all cosmoline from interchangeable spindle and

mating main spindle before mounting tooling. It is very

important that the locking nut, threads and taper be

clean. Make sure O-ring is in place just below the

bottom lip of the spindle. This acts as a dust shield.

Failure to have O-ring in place will allow dust and

debris to filter down into spindle threads, making it

very difficult to remove the spindle. Lightly oil lower

spindle with 10wt oil before seating.

1. Screw the locking nut (A) up on the fine threads of

the interchangeable spindle (B) until the rubber O-ring

(C) is flush with the bottom lip of the spindle.

2. Then place the interchangeable spindle assembly into

the main spindle and tighten by turning with the nut.

IMPORTANT: Allow spindle assembly to turn with the

nut. Turn until hand tight.

3. Take the spindle nut wrench and turn nut ¼ turn

clockwise to tighten.

CAUTION!!

Do not turn the spindle separately and always return

the locking nut to contact the bottom of rubber O-ring

each time the spindle is removed.

IMPORTANT: All tooling used on the spindle

must be balanced.

C

B

A

04

SHAPER

Mod. TI-14

Accessories

1 Special wrench

1 Open end wrench 38 mm

1 Open end wrench 10 x 13 mm

1 Open end wrench 19 x 24 mm

1 Open end wrench 24 x 27 mm

1 Allen wrench 5 mm

1 Cutter Shaft(Spindle) Ø3/4” with rings

1 Cutter Shaft(Spindle) Ø1 1/4” with rings

1 Allen wrech 14 mm

1 Instruction manual

Lubrication

Your machine requires lubrication as follows:

The upper bearing should be lubricated every

48 hours of use with a high quality grease,

through point A. Below are makes and types

of greases that can be used on this bearing:

• Darina Grease nº 2 - SHELL

The lower bearing does not need

greasing as it is shielded.

Machine Identification and Replacement Parts

A

Every machine has a manufacturing code (tag) which provides the manufacturer serial number and production

date. This manual gives listing numbers of parts that form your machine. They provide description and order

numbers. When needed, use original parts; always mention the manufacturing code, part number and quantity

desired.

05

SHAPER

Mod. TI-14

Adjustment Instructions

Controls

1 – On (Green) and Off (Red) Switches 6 – Spindle lock lever

2 - Vertical Height Adjusting Handwheel 7 - Tilt Adjustment Handwheel (Ver. 3 and 5)

3 – Handwheel Lock 8 – Brake

4 – Sliding Table Lock (Ver. 4 and 5) 9 – Spindle Reversing Switch

5 - Belt tension lever

C

D

F

E

A

B

Inserting the Interchangeable Spindles (Cutter Shafts)

Fig. 3

Turn Lever nº 6 to its horizontal position locking the drive shaft.

Loosen knob nº 3 and turn handwheel nº 2 until the shaft reaches its

maximum height. Screw nut “A” onto the interchangeable spindle shaft

to be used until tightening up against rubber ring “B”. Then screw this

assembly into the drive shaft turning the nut until the assembly is

securely tightened. Finally unlock the drive shaft by lever nº 6.

IMPORTANT:

1. When assembling the nut to the spindle, face “C” should be slightly

higher than face “D”.

2. When changing spindles, the locknut face “E” should never come

in contact with surface “F”. If this occurs, change the relation of the

locknut to the shaft before tightening.

3. Never allow debris to come between shaft and the spindle housing.

4. Protect the spindle mating surfaces from damage at all times.

Fig. 4

06

SHAPER

Mod. TI-14

G

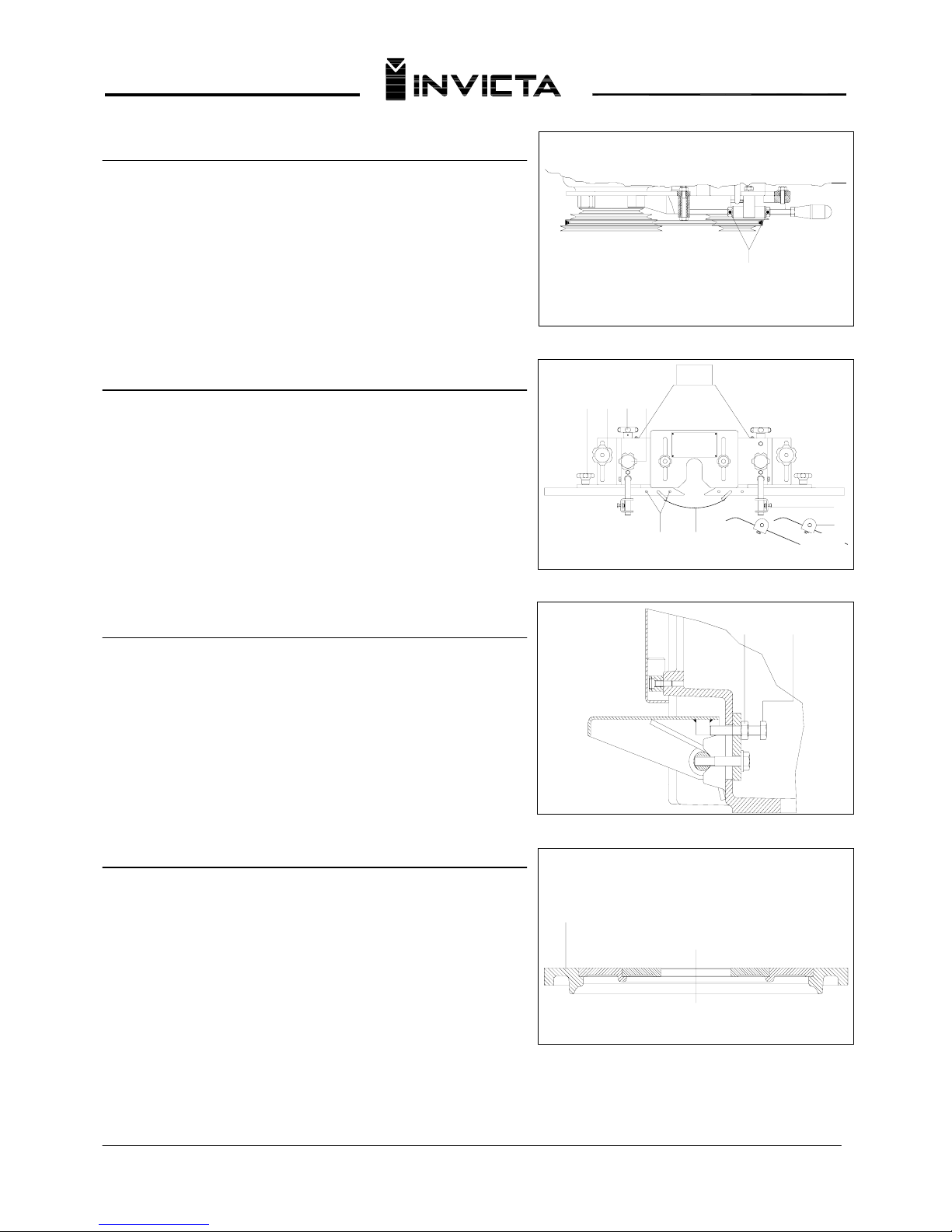

Change Speeds and Adjustment of Belt Tension

To change the spindle speed, pull lever nº 5 (fig.3 pg.6) and

loosen the belt. Change the belt position both pulleys, and tighten

the belt by returning the lever to its original position. Adjust belt

tension as belt wears by nuts “G” when necessary.

Micro -Adjustable Fence Assembly

The fence assembly is fastened directly to the table using knobs

“I” at points “R”. Fine adjustment of the infeed and outfeed fence

around the cutter is done by knobs “J”. Once adjusted, the fence

is locked in position by knobs “K”.

Note: Keep the wood guide close to the cutter.

The front and upper flexible metal spring holddown feet, “N” and

“O” should be adjusted to press the wood correctly against the

fence and the table. Top guard “M” comes with the fence and can

be positioned many different ways by holes “L”.

Brake Adjustment

When it is necessary to adjust the brake, loosen nut “P” and

adjust the steel cable by screw “Q” until the assembly is adjusted

properly. Finally, lock the screw by nut “P”.

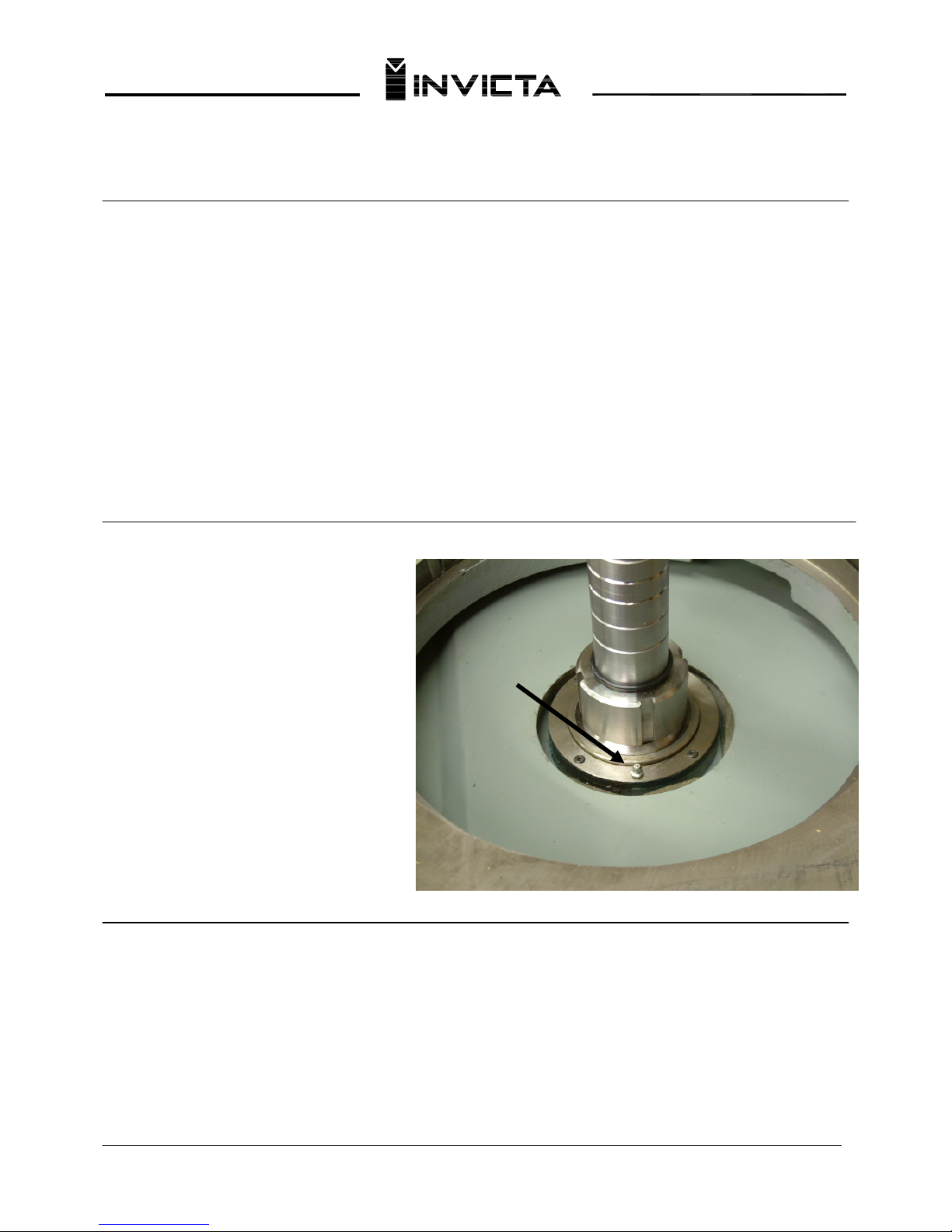

Table Inserts

Fig. 5

J

N

O

HI K

ML

Fig. 6

P

Q

Fig. 7

R

The machine is equipped with three inserts “R”, which allow the

accomodation of various size cutters. Alignment marks on each

insert are to assure the correct positioning. The inserts can be

locked in place to avoid rotating by turning the lock with an allen

wrench. The largest diameter insert is supplied with four leveling

screws which allow it to be leveled to the table. If an adjustment

is necessary, place a straight edge on the insert and across the

table, then tighten or loosen the four leveling screws until the

correct relationship of the rings to the table is achieved.

NOTE: Cam lock nº 4 (fig.3 pag.6) must be loose when making this adjustment.

Fig. 8

07

S

HAPER

Mod. TI-14

ELECTRICAL DIAGRAM

IMPORTANT

SELECT THE VOLTAGE (230/460V) OF YOUR

INTERNAL ELECTRIC NETWORK.

THE VOLTAGE SELECTION KEY IS LOCATED ON

THE ELECTRICAL BOX.

FOR YOU SAFETY THE VOLTAGE SELECTION

KEY IS ON NEUTRAL POSITION.

08

Loading...

Loading...