Invicta SFI-80 Operator's Manual

OPERATORS MANUAL

Band Saw

by

INVICTA

Model

SFI-80

INVICTA USA English Version

(877) 308-6423 - East

(800) 499-4682 - West

1

Band Sa

w

Mod. SFI-80

General Instructions

Thank you for purchasing this quality machine from INVICTA.

As with all equipment, safety is to be the priority. The operator should understand the safety features as well as

apply good safety habits in transportation, adjustment, maintenance and operation of the machine. Practice and

teach others the safe operating procedures of this machine and help to prevent the possibility of accidents.

Safety Rules

1. For your own safety, read carefully the Instruction Manual before attempting to operate the machine.

2. If you are not thoroughly familiar and comfortable with the adjustment and operation of the machine, ask for

instruction from your supervisor or a fully qualified person. You may also contact Invicta USA.

3. Before the initial operation of the machine, remove all packaging, shipping grease and fully assemble the

machine. Pay special attention to the assembly of safety components.

4. Wear proper apparel while operating the machine. Never wear loose fitting clothing, gloves or ties. Always

remove rings or other jewelry before operating the machine. It is strongly suggested the operator wear

shoes with non-slip soles and also wear a protective hair net to prevent hair entanglement in moving parts.

5. Always wear personal safety equipment. Follow the safety regulations of your country and your company.

6. Have a certified person make all wiring connections to power source and properly ground the machine.

7. Always disconnect the machine from the power source and use lockout procedures before servicing,

changing cutting tools and during cleaning of the machine.

8. Before starting the machine, have the work area clean and free of debris. Cluttered areas are invitations for

accidents to occur.

9. Keep all safety guard(s) of the machine in place and in proper working condition. Never operate machinery

without safety equipment in place. Report any damage to your supervisor.

10. Keep children and visitors a safe distance from the working area.

11. Never leave the machine running while unattended. Turn off the power source during breaks. Before

walking away, allow the machine to come to a complete stop.

12. Do not operate the machine under the influence of drugs or alcohol. Consult your physician when taking

medications.

13. Do not force the machine beyond its limitations. It will produce a nicer and safer job at the rate it was

designed to operate.

Loading and Unloading

During loading and unloading, the machine should not be lifted by

components which could become damaged and affect it’s functioning.

The correct procedure is shown in figure 1.

NOTE: To remove the upper cover “A”, us e the ey e bolt “B ” Figur e 1. D o

not transport the machine through any point other than the eye bolts.

After this, reassemble and cover all the non painted surfaces with a

good quality paste wax.

A

B

Fig. 1

2

Band Sa

w

Mod. SFI-80

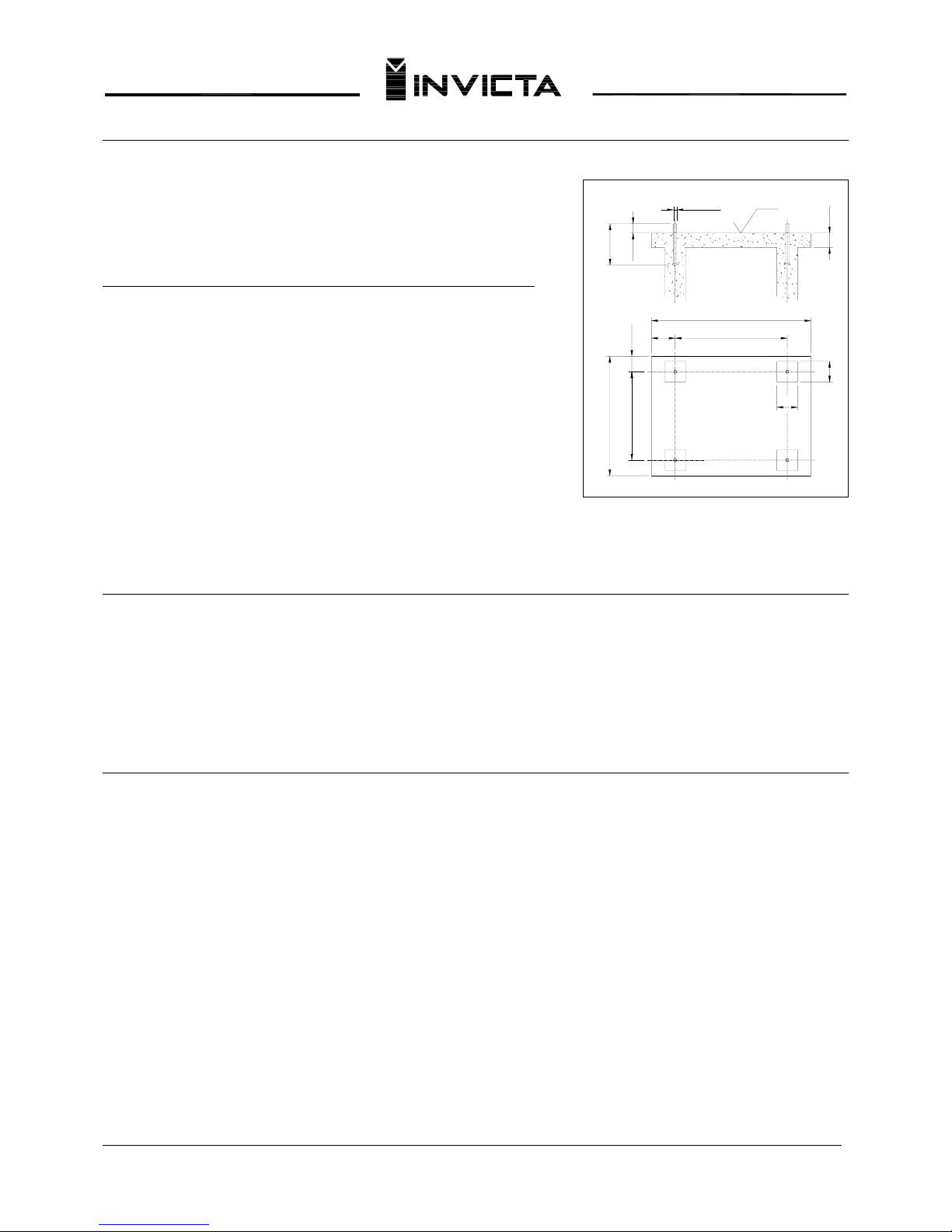

Fastening the Machine to the Floor

To prevent vibration, set the machine correctly on the floor. The spacing

of concrete anchors is shown in figure 2 sketch.

Electrical Connection

The machine name plate supplies the specifications of the motor and

voltage requirements. Check the name plate for the voltage

requirements and cycles (Hz) before connecting the electrical power.

After completing the connection of the power lines, switch the machine

on and off quickly to see if the rotation of the wheel is clockwise while

standing at the operator’s position. If not, reverse any two of three

phases of power line, without changing the internal wiring of the

machine.

NOTE: If the machine has manual star delta starter, turn it to the start

position (star) and as soon as the motor reaches its maximum speed,

change over to the run position. Never do any work with the switch at

the start position.

Lubrication

Your machine requires periodic lubrication as follows:

1. Remove the guard “G” (Page 05). Lubricate the screw “H” with standard grease.

2. The threaded adjustment tee “43” should be lubricated with the same standard grease used for the screw.

3. The top wheel supporting slide “J” (Page 05) should be lubricated with standard grease.

Adjusting the Guide

W.5/8"

150

45

130

1030

510

770

130

770

100

100

Level

70

Fig. 2

1. To adjust the cutting height, loosen knob “P” (Page 06), then move the guide up to the desired height and

tighten knob again.

2. The screw “S” and “T” (Page 06) are used to adjust the blade guide for blade width and fine tracking.

3. To adjust the top blade guide bearings “Q”, loosen the locking screw “V” (Page 06) with a 3mm Allen

wrench. Adjustment is made by turning the eccentric shafts which the bearings are mounted using a 6mm

Allen wrench. For the axial adjustment “Q”, pull the shafts forward till you met the blade and lock screw.

4. To adjust the lower blade guide, loosen screws “X” (Page 06) with a 3mm Allen wrench until the bearing

lightly touches the saw blade. Then retighten.

NOTE: The guide pins “Y” should center the saw blade. If it is necessary, center the pins to the desired position

and fasten the lock screws again.

3

Band Sa

w

Mod. SFI-80

Adjusting the Belts

The belt tension adjustment is changed by bolt “N” and nut “O”, as shown in figure page 06. Do not over tighten or

premature belt wear will occur. Use just enough tension so that the belt does not slip under heavy cutting.

Adjusting the Table

Your machine is equipped with a fixed stop at 90º. To readjust this setting, loosen nut “L” and turn bolt “M” (Page

06) to the desired position. Relock nut “L” correctly.

Adjusting the Table Tilt

The work table will tilt up to 45º to the right. To adjust this feature, proceed as follows: loosen nut “K”, tilt the table

to the desired position and retighten (Page 05)

Adjusting the Rip Fence

Loosen the adjustable handle “E” and move the rip fence “D” (Page 05) in the desired direction to achieve the

proper cutting dimension. Lock in position using handle “E”.

Installing the Saw Blade

1. Turn the blade tension adjusting knob “I” (Page 05), and lower the top blade wheel.

NOTE: Safety guard “R” must be removed to install the saw blade (Page 06). Replace the safety guard when blade

is in place.

2. Tensioning the saw blade “F” (Page 05) is achieved by turning knob “I” to the correct setting.

NOTE: Correct blade tensioning is necessary for the blade to remain on the wheels when cutting. Release the saw

blade tension if the machine will not be used for an extended period of time. This will increase the blade life.

3. Perfect alignment of the saw blade on the rubber covered wheel is reached by turning screw “C” (Page 05) with

the 8mm Allen wrench. Blades should normally track center of the wheel.

Replacement Parts

Every INVICTA machine has a serial number which enables the manufacturer to identify the exact type and date of

its manufacture. At the end of this manual you will find a list of parts which compose your machine with their names

and numbers. Use only genuine INVICTA parts and on your order alwa ys mention the serial number, part number

and quantity desired.

4

Band Sa

w

Mod. SFI-80

Technical Specifications

Diameter of Wheels…………………………………………………………………………………… 31 ½”

Width of Wheels………………………………………………………………………………………

2”

Speed of Wheels………………………………………………………………………………………… 600 RPM

Maximum Cutting Height……………………………………………………………………………… 18 ½”

Maximum Cutting Width……………………………………………………………………………… 30 45/64”

Minimum Saw Blade Length………………………………………………………………………… 218 37/64”

Maximum Saw Blade Length………………………………………………………………………… 226 27/32”

Maximum Saw Blade Width…………………………………………………………………………… 1 37/64”

Table Size………………………………………………………………………………………………… 30 45/64”x39 3/8”

Table Tilting to Right…………………………………………………………………………………… 45º

Working Height………………………………………………………………………………………… 36 7/32”

Three Phase Motor Power…………………………………………………………………………… 7.5 HP

5

Band Sa

w

Mod. SFI-80

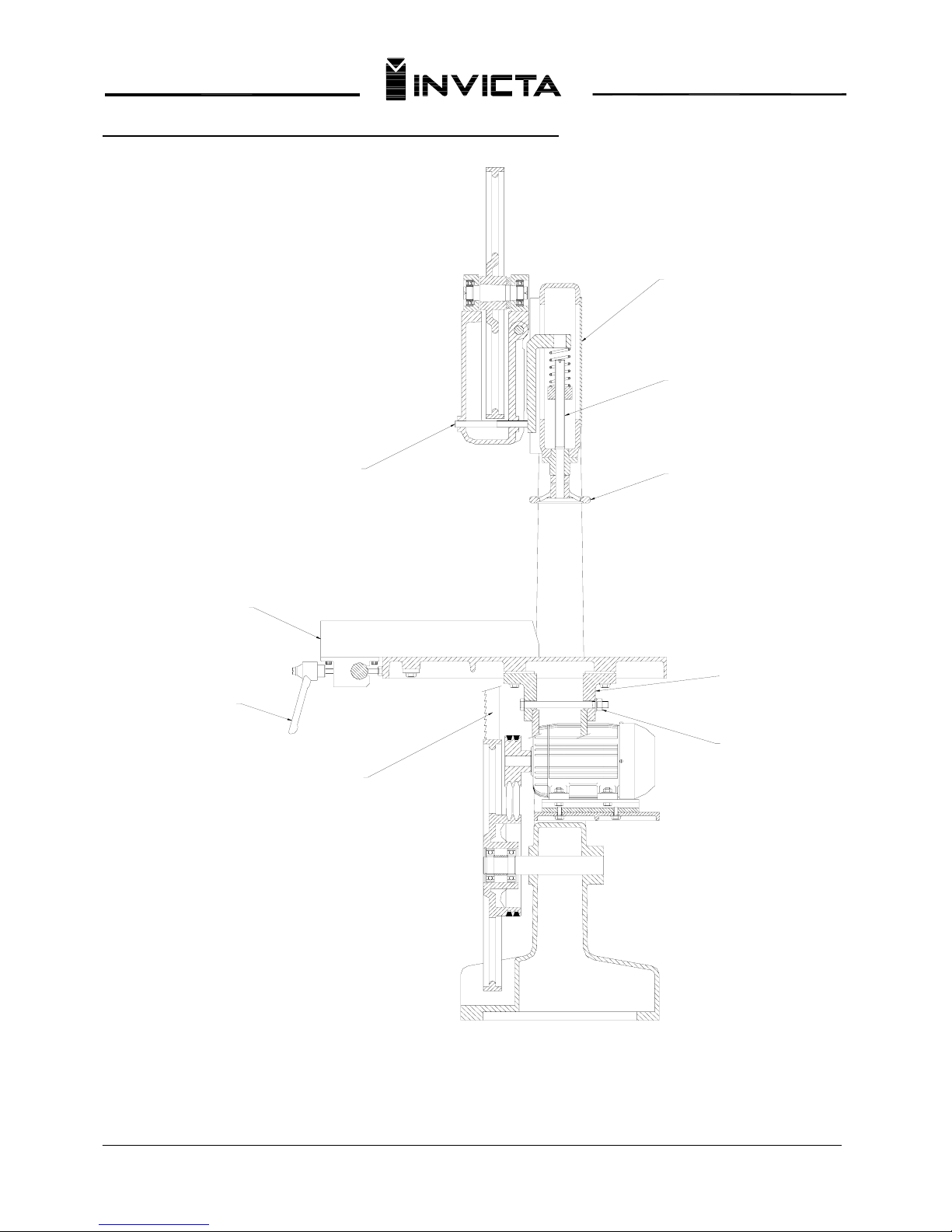

Side View Showing Adjustment and Lubrication Points

E

D

F

J

C

G

I

H

K

Loading...

Loading...