Owner’s Operator and Maintenance Manual

®

Crossfire

Series

Wheelchairs

Crossfire T6

Crossfire Titanium

Crossfire All Terrain

™

DEALER: This manual MUST be given to

the user of the wheelchair.

USER:

this manual and save for future reference.

BEFORE using this wheelchair, read

For more information regarding

Invacare products, parts, and services,

please visit www.invacare.uk

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT FIRST READING

AND UNDERSTANDING THIS MANUAL. IF YOU ARE UNABLE TO

UNDERSTAND THE WARNINGS, CAUTIONS AND

INSTRUCTIONS, CONTACT YOUR INVACARE DEALER OR

INVACARE CUSTOMER SUPPORT BEFORE ATTEMPTING TO USE

THIS EQUIPMENT - OTHERWISE INJURY AND/OR EQUIPMENT

DAMAGE MAY OCCUR.

NOTE: Updated versions of this manual are available on www.invacare.uk.

Crossfire™Series Wheelchairs 2 Part No 1148078

TABLE OF CONTENTS

TABLE OF CONTENTS

SPECIAL NOTES ................................................................................ 6

TYPICAL PRODUCT PARAMETERS .................................................... 8

Tyre Pressure Conversion .....................................................................................................................10

SECTION 1—GENERAL GUIDELINES ................................................. 11

Stability Warning.......................................................................................................................................11

Operating Information.............................................................................................................................12

Tyre Pressure and Information .............................................................................................................13

Weight Training ........................................................................................................................................13

Weight Limitation.....................................................................................................................................13

SECTION 2—SAFE HANDLING ......................................................... 14

Stability and Balance.................................................................................................................................14

Coping with Everyday Obstacles......................................................................................................15

A Note to Wheelchair Assistants....................................................................................................16

Reaching, Leaning and Bending - Forward......................................................................................16

Reaching, Leaning - Backwards .........................................................................................................16

Tipping.........................................................................................................................................................17

Tipping - Curbs .........................................................................................................................................17

Stairways.....................................................................................................................................................18

Transferring To and From Other Seats..............................................................................................19

SECTION 3—SAFETY INSPECTION ................................................... 20

Safety Inspection Checklist.....................................................................................................................20

Inspect Initially ......................................................................................................................................20

Inspect/Adjust Weekly........................................................................................................................21

Inspect/Adjust Monthly.......................................................................................................................21

Inspect/Adjust Periodically.................................................................................................................22

Troubleshooting........................................................................................................................................22

Maintenance...............................................................................................................................................23

Maintenance Safety Precautions .......................................................................................................23

Suggested Maintenance Procedures ................................................................................................23

SECTION 4—FOOTREST ................................................................... 25

Adjusting/Replacing Standard Footrest................................................................................................25

Replacing the Footrest........................................................................................................................25

Adjusting the Footrest........................................................................................................................25

Installing/Adjusting Optional Clamp on Raised Footrest ................................................................26

Installing..................................................................................................................................................26

Part No 1148078 3 Crossfire™Series Wheelchairs

TABLE OF CONTENTS

TABLE OF CONTENTS

Adjusting ................................................................................................................................................26

Replacing/Adjusting Optional Adjustable Angle Footrest...............................................................26

Replacing the Footrest........................................................................................................................26

Adjusting Footplate Angle..................................................................................................................27

Adjusting Footplate Depth.................................................................................................................27

SECTION 5—ARMS ......................................................................... 28

Installing the Swingaway Padded Armrest Socket Assembly..........................................................28

Adjusting Swingaway Padded Armrest Height...................................................................................29

SECTION 6—BACK ......................................................................... 30

Unfolding/Folding the Back.....................................................................................................................30

Back Angle Adjustment...........................................................................................................................30

Adjustable Tension Back Upholstery...................................................................................................32

The Adjustable Tension Straps.........................................................................................................32

The Back Upholstery Cover..............................................................................................................32

Replacing Adjustable Tension Back Upholstery............................................................................32

Removing/Installing Foldover Back Upholstery .................................................................................33

Removing Foldover Back Upholstery..............................................................................................34

Installing Foldover Back Upholstery ................................................................................................34

Back Height Adjustment (Adjustable Backs Only)............................................................................35

SECTION 7—SEAT ........................................................................... 36

Replacing Adjustable Tension Seat Upholstery.................................................................................36

SECTION 8—WHEELS ....................................................................... 38

Removing/Installing Rear Wheels .........................................................................................................38

Adjusting Quick-Release Axles..............................................................................................................39

Replacing Quad-Release Axles ..............................................................................................................39

Adjusting Quad-Release Handles..........................................................................................................40

In and/or Out........................................................................................................................................40

Removing Play from Rear Wheels ...................................................................................................40

Handrim Replacement.............................................................................................................................41

Repairing/Replacing Rear Wheel, Tyre/Tube.....................................................................................42

Adjusting Wheelbase Length (Adjusting Center of Gravity)..........................................................42

Repositioning the Camber Tube Mounting Brackets ..................................................................44

Repositioning the Camber Tube Mounting Bracket Socket Screws........................................44

Reversing the Camber Tube Mounting Bracket Direction........................................................45

Adjusting Wheelbase Width..................................................................................................................46

Removing/Installing/ the Camber Tube ...............................................................................................47

Crossfire™Series Wheelchairs 4 Part No 1148078

TABLE OF CONTENTS

TABLE OF CONTENTS

Removing the Camber Tube .............................................................................................................47

Installing the Camber Tube ...............................................................................................................47

Adjusting the Camber Tube...................................................................................................................48

Determining Toe In/Toe Out................................................................................................................49

Adjusting Fork Tension...........................................................................................................................50

Removing/Installing/Repositioning the Caster Assemblies..............................................................51

Standard Forks......................................................................................................................................51

Removing Front Caster ................................................................................................................51

Installing Front Caster ...................................................................................................................51

Suspension Forks..................................................................................................................................51

Removing the Caster .....................................................................................................................51

Installing the Caster .......................................................................................................................52

Removing/Installing the Fork Assembly...............................................................................................52

Removing Fork Assembly...................................................................................................................52

Installing Fork Assembly.....................................................................................................................53

Removing/Installing the Elastomers (Suspension Forks Only) .......................................................54

Removing the Elastomer ....................................................................................................................54

Installing the Elastomer.......................................................................................................................54

SECTION 9—WHEEL LOCKS ............................................................. 55

Replacing/Adjusting the Wheel Locks .................................................................................................55

Replacing the Wheel Lock.................................................................................................................55

Adjusting the Wheel Lock .................................................................................................................55

Changing Wheel Lock Handle Position...............................................................................................56

Converting Wheel Lock From Push-to-Lock to

Pull-to-Lock or Pull-to-Lock to Push-to-Lock..........................................................................................57

Converting From Push-to-Lock to Pull-to-Lock...........................................................................57

Converting From Pull-to-Lock to Push-to-Lock...........................................................................57

SECTION 10—ANTI-TIPPER ............................................................. 58

Adjusting/Replacing Anti-tipper.............................................................................................................58

Adjusting Anti-tipper...........................................................................................................................58

Replacing Anti-tipper...........................................................................................................................59

LIMITED WARRANTY ..................................................................... 60

Part No 1148078 5 Crossfire™Series Wheelchairs

SPECIAL NOTES

SPECIAL NOTES

Signal words are used in this manual and apply to hazards or unsafe practices which

could result in personal injury or property damage. Refer to the table below for

definitions of the signal words.

SIGNAL WORD MEANING

DANGER

WARNING

CAUTION

Danger indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

NOTICE

THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO

CHANGE WITHOUT NOTICE.

Serial number information is located under the seat of the chair.

As a manufacturer of wheelchairs, Invacare endeavors to supply a wide variety of

wheelchairs to meet many needs of the end user. However, final selection of the

type of wheelchair to be used by an individual rests solely with the user and his/her

healthcare professional capable of making such a selection.

Some countries require product returned for service be cleaned and sanitised.

Please consult your dealer prior to returning product.

WHEELCHAIR TIE-DOWN RESTRAINTS AND SEAT POSITIONING STRAPS

Invacare recommends that wheelchair users not be transported in vehicles of any

kind while in wheelchairs. As of this date, the Department of Transportation has not

approved any tie-down systems for transportation of a user while in a wheelchair, in

a moving vehicle of any type.

It is Invacare’s position that users of wheelchairs should be transferred into

appropriate seating in vehicles for transportation and use be made of the restraints

made available by the auto industry. Invacare cannot and does not recommend any

wheelchair transportation systems.

WARNING

Invacare products are specifically designed and manufactured for use in conjunction

with Invacare accessories. Accessories designed by other manufacturers have not

been tested by Invacare and are not recommended for use with Invacare products.

Crossfire™Series Wheelchairs 6 Part No 1148078

SPECIAL NOTES

WARNING

SEAT POSITIONING STRAP

ALWAYS wear your seat positioning strap. Inasmuch as the seat positioning strap is

an option on this wheelchair (you may order with or without the seat positioning

strap), Invacare Top End strongly recommends ordering the seat positioning strap

as an additional safeguard for the wheelchair user. The seat positioning strap is a

positioning belt only. It is not designed for use as a safety device withstanding high

stress loads such as auto or aircraft safety belts. If signs of wear appear, seat

positioning strap MUST be replaced IMMEDIATELY.

Invacare products are specifically designed and manufactured for use in conjunction

with Invacare accessories. Accessories designed by other manufacturers have not

been tested by Invacare and are not recommended for use with Invacare products.

Because TOP END wheelchairs are made to the specifications of the original owners it is unlikely that refurbished product would be suitable to other user’s needs.

Part No 1148078 7 Crossfire™Series Wheelchairs

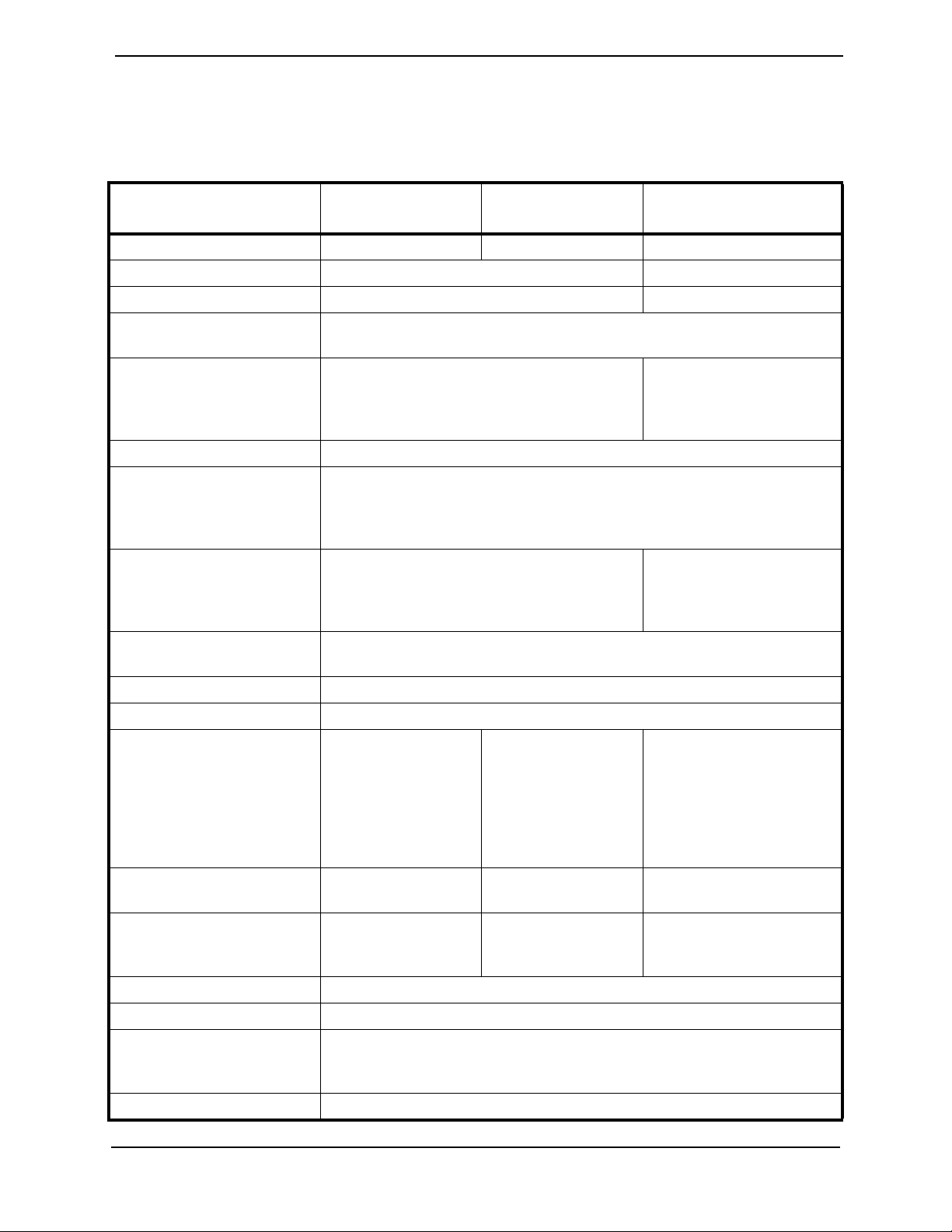

TYPICAL PRODUCT PARAMETERS

TYPICAL PRODUCT PARAMETERS

NOTE: All specifications are approximate.

CROSSFIRE T6 CROSSFIRE

TITANIUM

FRAME: 6061T6 Aluminum Grade 9 Titanium 6061T6 Aluminum

FRONT FRAME: Tapered front end (Standard), V-Style (Optional) Tapered front end (Standard)

FRONT FRAME ANGLE: 70°, 75°, 80°, 85° or 90° 90°

FOOTREST: Tubular footrest in same material as frame (Standard),

Adjustable Angle NCO, Plastic or Carbon Fiber Cover (Optional)

SEAT HEIGHT Front: 16 to 21 inches (40.64 to 53.34 cm)

(Fixed)

Rear: 14 to 20 Inches (35.56 to 50.8 cm) (Fixed),

Ergo Level Seat (Optional)

ARMS (OPTIONAL): Swing-away Style

SIDE GUARDS

(OPTIONAL)

FOLDING BACK:

FIXED BACK:

SEAT WIDTH: 12 to 18 inches (30.48 to 45.72 cm) (Standard),

(48.26 to 50.8 cm ) (Optional),

Tapered Seat Width (Optional)

SEAT DEPTH: 14 to 18 inches (35.56 to 45.72 cm) (Standard), 19 to 20 inches

BACK STYLE: Folding (Standard), Fixed (Optional)

Removable, Folding, Removable with Fender

Fixed Aluminum, Fixed Carbon Fiber

19 to 20 inches

(48.26 to 50.8 cm) (Optional)

CROSSFIRE ALL

TERRAIN

Front:19 to 21 inches (48.26

to 53.34 cm) (Fixed)

Rear:15** to 20 Inches (38.10

to 50.8 cm) (Fixed)

12 to 18 inches (30.48 to

45.72 cm) (Standard), 19 to

20 inches (48.26 to 50.8 cm )

(Optional),

BACK HEIGHT

ADJUSTABLE: 8 to 11, 10 to 14, 12 to

16, 14 to 18, or 16 to

20 inches

(20.32 to 27.94, 25.4 to

35.56, 30.48 to 40.64,

35.56 to 45.72, 40.64

to 50.8 cm)

FIXED: Not Available 20.32 to 40.64 (8 to 16

BACK ANGLE

FOLDING:

FIXED:

BACK UPHOLSTERY: U850 Black - Adjustable Tension by Straps

SEAT UPHOLSTERY: U850 Black - Adjustable Tension by Straps

AXLE POSITIONS/CENTER OF GRAVITY:

REAR WHEEL AXLE: Quick Release (Standard), Quad-Release or Titanium (Optional)

Crossfire™Series Wheelchairs 8 Part No 1148078

-15°, -10°, -5°, 0° and 5°

Not Available

Adjustable to 4¼ inches (10.8 cm) in two positions:

Amputee Position: -2¼ to 2 inches (-5.72 to 5.08 cm)

Active Position: 1¼ to 5½ inches (3.18 to 13.97 cm)

8 to 11, 10 to 14, 12 to

16, 14 to 18, or 16 to

20 inches

(20.32 to 27.94, 25.4 to

35.56, 30.48 to 40.64,

35.56 to 45.72, 40.64

to 50.8 cm)

inches)

-15°, -10°, -5°, 0° and 5°

0°, 3°, 6°, and 9°

8 to 11, 10 to 14, 12 to 16,

14 to 18, or 16 to 20 inches

(20.32 to 27.94, 25.4 to

35.56, 30.48 to 40.64, 35.56

to 45.72, 40.64 to 50.8 cm)

20.32 to 40.64 (8 to 16

inches)

-15°, -10°, -5°, 0° and 5°

0°, 3°, 6°, and 9°

TYPICAL PRODUCT PARAMETERS

CROSSFIRE T6 CROSSFIRE

TITANIUM

REAR WHEEL CAMBER

CAMBER TUBE: 0°, 3°, 6°, or 9°

REAR WHEELS*

REAR WHEEL TYPE:

REAR WHEEL SIZE:

HANDRIMS: Aluminum Anodized (Standard)

WHEEL LOCKS: Push to Lock (Standard) or Scissor lock (Optional)

FRONT FORKS: Non-Suspension (Standard), Suspension (Optional)

CASTERS

CASTER SIZE:

CASTER TYPE:

ANTI-TIPPERS: Optional

WEIGHT: 8.85 kg (19.5 lbs) 8.39 kg (18.5 lbs) 13.61 Kg (30 lbs)

SHIPPING WEIGHT: 30 lbs (13.6 kg)

High Performance with Primo Tyres (Standard),

Spinergy® Spox, knobby, KIK® and Kenda Tyres

22, 24 or 25 inch (55.88, 60.96, or 63.5 cm)

(Standard), 26 inch

(66.04 cm) (Optional)

3, 4 or 5 inch (7.62, 10.16, 12.7 cm )

Semi-pneumatic (Standard), Soft Roll or Lighted

(Optional)

Titanium, Coated, Natural Fit® (Optional)

(Optional)

CROSSFIRE ALL

TERRAIN

High Performance with

Knobby tyres (Standard)

Spinergy® Spox (Optional)

24 inch (60.96) or

25 inch (63.5 cm)

8 inch

Pneumatic (Standard)

WEIGHT LIMITATION: 250 lbs (113.4 kg)

NOTE: 40.64 x 40.64 cm seat, rear wheels and minimal options are included in the weight.

*NOTE: Refer to Tyre Pressure Conversion.

**NOTE: 15 inch rear seat height only available with 24 inch rear wheels.

Part No 1148078 9 Crossfire™Series Wheelchairs

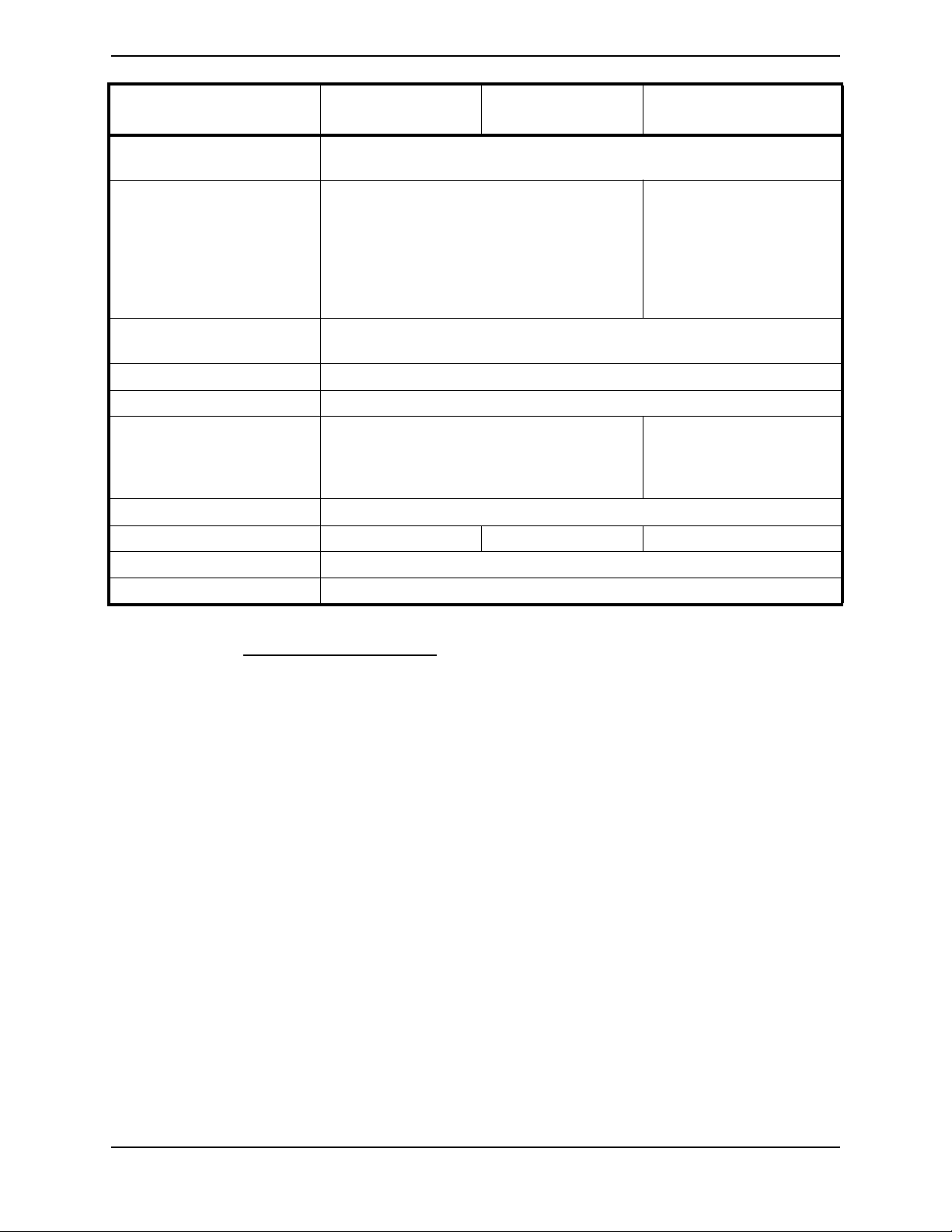

TYPICAL PRODUCT PARAMETERS

Tyre Pressure Conversion

NOTE: PSI rating is printed on the side of the tyre.

NOTE: Conversion formula: 1 psi = 6.895 kPa (appox. 7 kPa).

PSI KILOPASCALS

50 345

55 379

60 414

65 448

70 483

75 517

80 552

85 586

90 621

95 655

100 690

105 724

110 758

115 793

120 827

Crossfire™Series Wheelchairs 10 Part No 1148078

SECTION 1—GENERAL GUIDELINES

SECTION 1—GENERAL GUIDELINES

WARNING

SECTION 1 - GENERAL GUIDELINES contains important information for the safe

operation and use of this product. DO NOT use this product or any available

optional equipment without first completely reading and understanding these

instructions and any additional instructional material such as Owner’s Manuals,

Service Manuals or Instruction Sheets supplied with this product or optional

equipment. If you are unable to understand the Warnings, Cautions or Instructions,

contact a healthcare professional, dealer or technical personnel before attempting

to use this equipment - otherwise, injury or damage may occur.

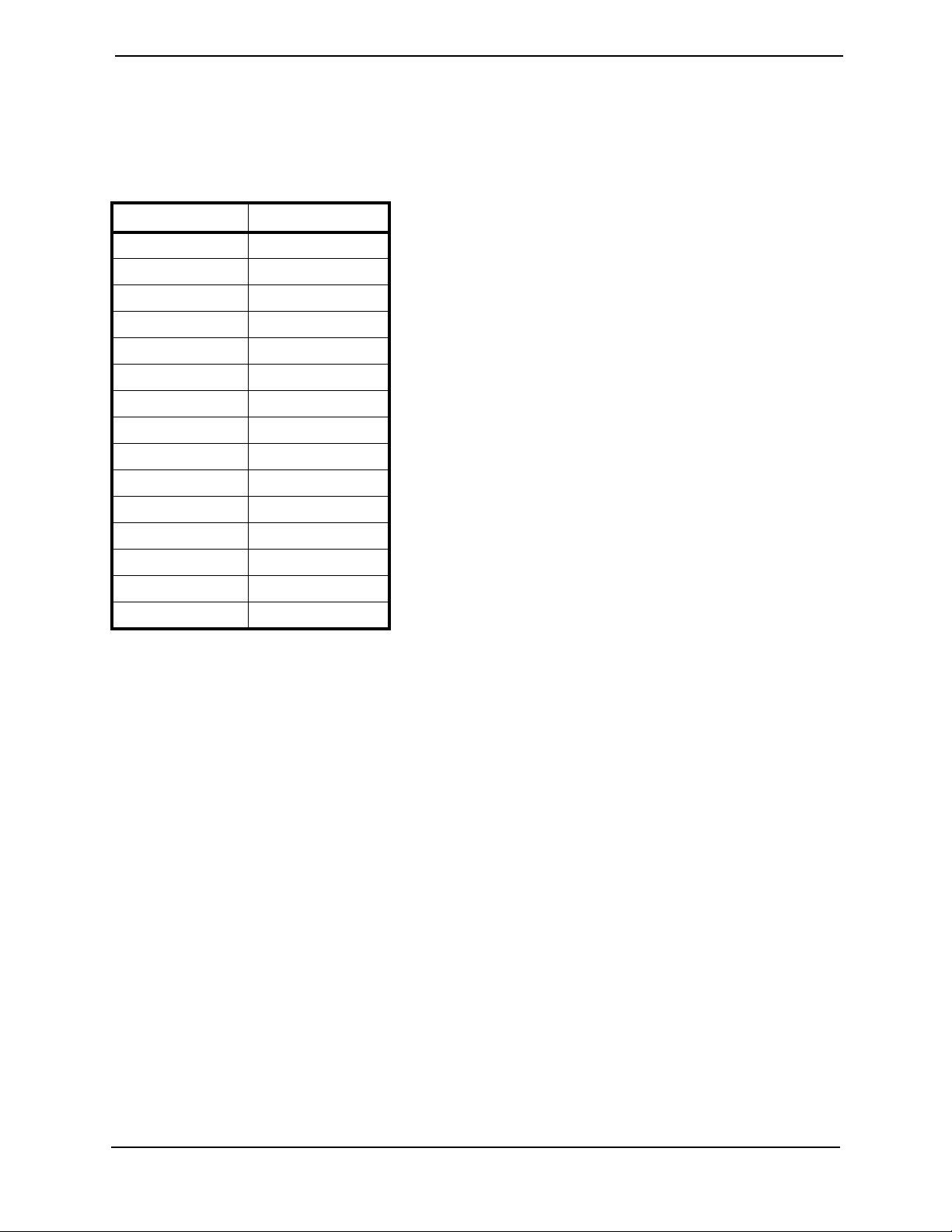

Stability Warning

The position of the footrest, camber tube, back angle, the tautness of the back upholstery

as well as the user's condition are directly related to the wheelchairs stability. Any change

to one or any combination of the five may cause the wheelchair to decrease in stability.

Use EXTREME caution when using a new seating position. The addition of anti-tippers

may be required.

FOOTREST POSITION

CAMBER TUBE

BACK ANGLE

BACK UPHOLSTERY

USER CONDITION

FOOTREST POSITION ●

CAMBER TUBE ●

BACK ANGLE

BACK UPHOLSTERY

USER CONDITION

✓

✓✓✓✓

✓✓

✓✓

●

✓✓

●

✓

✓

●

NOTE: When changes to the left hand column occur, follow across the chart and refer to the ✓

procedure to maintain the proper stability, safety and handling of the racing chair.

Part No 1148078 11 Crossfire™Series Wheelchairs

SECTION 1—GENERAL GUIDELINES

Operating Information

To determine and establish your particular safety limits, practice bending, reaching and

transferring activities in several combinations in the presence of a qualified healthcare

professional before attempting active use of the wheelchair.

DO NOT attempt to reach objects if you have to move forward in the seat.

DO NOT attempt to reach objects if you have to pick them up from the floor by reaching

down between your knees.

DO NOT lean over the top of the back upholstery to reach objects from behind as this may

cause the wheelchair to tip over.

DO NOT shift your weight or sitting position toward the direction you are reaching as the

wheelchair may tip over.

DO NOT tip the wheelchair without assistance.

DO NOT attempt to stop a moving wheelchair with wheel locks. Wheel locks are not brakes.

NEVER leave an unoccupied wheelchair on an incline.

DO NOT use an escalator to move a wheelchair between floors. Serious bodily injury may

occur. Before attempting to transfer in or out of the wheelchair, every precaution should be

taken to reduce the gap distance. Turn both casters parallel to the object you are transferring

onto. Also be certain the wheel locks are engaged to prevent the wheels from moving.

DO NOT operate on roads, streets or highways.

DO NOT climb, go up or down ramps or traverse slopes greater than 9°.

DO NOT attempt to move up or down an incline with a water, ice or oil film.

DO NOT attempt to ride over curbs or obstacles. Doing so may cause your wheelchair to

turn over and cause bodily harm or damage to the wheelchair.

Invacare products are specifically designed and manufactured for use in conjunction with

Invacare accessories. Accessories designed by other manufacturers have not been tested

by Invacare and are not recommended for use with Invacare products.

Because TOP END wheelchairs are made to the specifications of the original owners it is

unlikely that refurbished product would be suitable to other user’s needs.

DO NOT attempt to lift the wheelchair by any removable (detachable) parts. Lifting by

means of any removable (detachable) parts of a wheelchair may result in injury to the user

or damage to the wheelchair.

DO NOT stand on the frame of the wheelchair.

Check all Allen screws that secure the footrest/raised footrest system to the wheelchair

frame before using the wheelchair, especially if engaging in any contact sport.

Anti-tippers MUST be used at all times. When outdoors on wet, soft ground or on gravel

surfaces, anti-tippers may not provide the same level of protection against tip over. Extra

caution MUST be observed when traversing such surfaces. Inasmuch as the anti-tippers are an

option on this wheelchair (you may order with or without the anti-tippers), Invacare strongly

recommends ordering the anti-tippers as an additional safeguard for the wheelchair user.

Crossfire™Series Wheelchairs 12 Part No 1148078

SECTION 1—GENERAL GUIDELINES

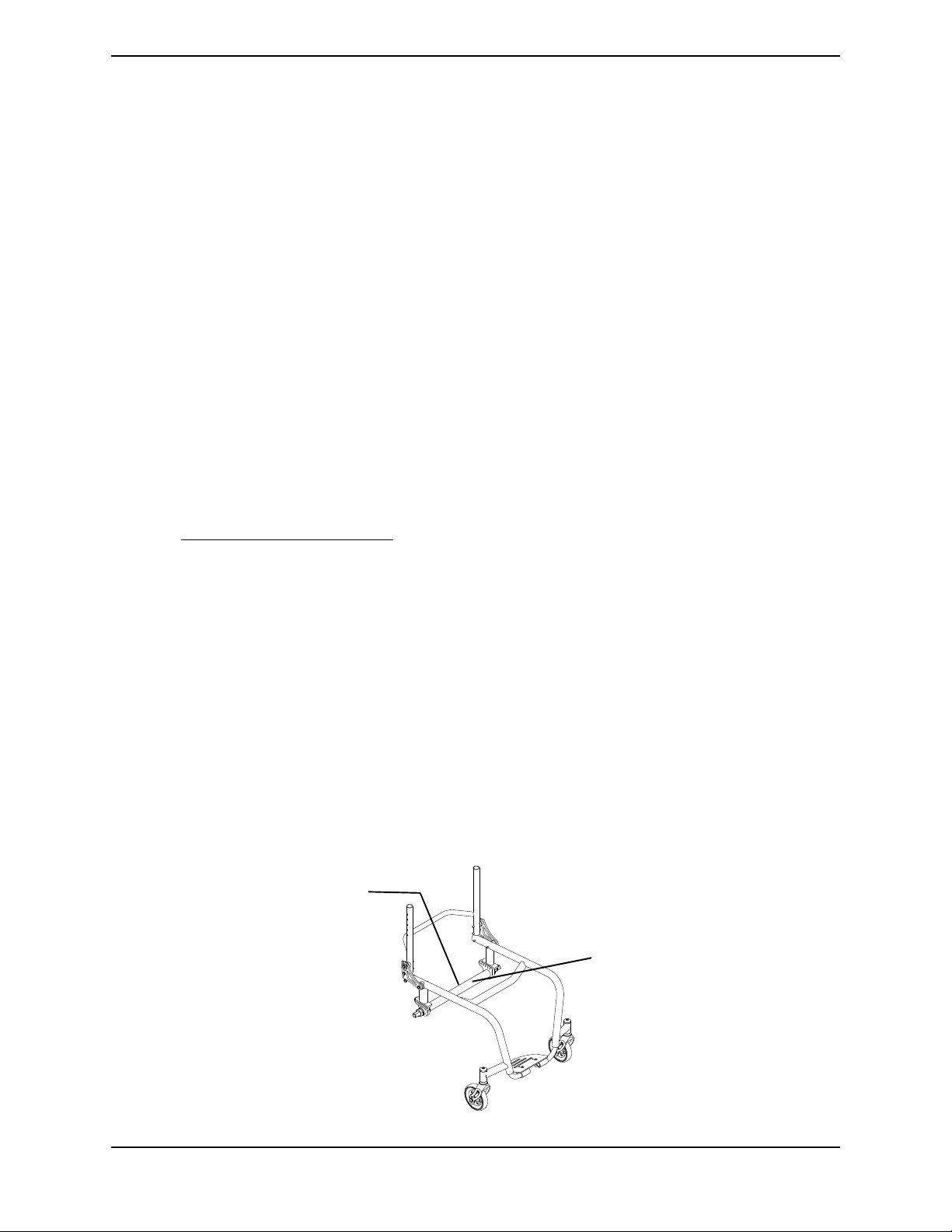

Weight

Capacity

Label

Camber

Tube

NOTE: Wheels

removed for clarity.

Unless otherwise noted, all service and adjustments should be performed while the

wheelchair is unoccupied.

ALWAYS wear your seat positioning strap. Inasmuch as the seat positioning strap is an

option on this wheelchair (you may order with or without the seat positioning strap),

Invacare Top End strongly recommends ordering the seat positioning strap as an

additional safeguard for the wheelchair user. The seat positioning strap is a positioning

belt only. It is not designed for use as a safety device withstanding high stress loads such

as auto or aircraft safety belts. If signs of wear appear, seat positioning strap MUST be

replaced IMMEDIATELY.

ALWAYS use the handrims for self-propulsion. Inasmuch as the handrims are an option

on this wheelchair (you may order with or without the handrims), Invacare strongly

recommends ordering the handrims as an additional safeguard for the wheelchair user.

DO NOT use the footplate as a platform when getting in or out of the wheelchair.

Tyre Pressure and Information

DO NOT use your wheelchair unless it has the proper tyre pressure (p.s.i.). DO NOT

overinflate the tyres. Failure to follow these suggestions may cause the tyre to explode

and cause bodily harm. The recommended tyre pressure is on the sidewall of the tyre.

Refer to Tyre Pressure Conversion on page 10.

Replacement of the tyre or tube MUST be performed by a qualified technician.

Weight Training

Invacare DOES NOT recommend the use of its wheelchairs as a weight training

apparatus. Invacare wheelchairs have not been designed or tested as a seat for any kind

of weight training. If occupant uses said wheelchair as a weight training apparatus,

Invacare shall not be liable for bodily injury and the warranty is void.

Weight Limitation

Invacare's Top End Crossfire T6 and Crossfire Titanium wheelchairs have a weight

limitation of 250 lbs.

A weight limitation label is on the camber tube of the chair.

Part No 1148078 13 Crossfire™Series Wheelchairs

FIGURE 1.1 Weight Capacity Label

SECTION 2—SAFE HANDLING

SECTION 2—SAFE HANDLING

“Safety and Handling” of the wheelchair requires the close attention of the wheelchair

user as well as the assistant. This manual points out the most common procedures and

techniques involved in the safe operation and maintenance of the wheelchair. It is

important to practice and master these safe techniques until you are comfortable in

manoeuvering around the frequently encountered architectural barriers.

Use this information only as a “basic” guide. The techniques that are discussed on the

following pages have been used successfully by many.

Individual wheelchair users often develop skills to deal with daily living activities that

may differ from those described in this manual. Invacare recognises and encourages each

individual to try what works best for him/her in overcoming architectural obstacles that

they may encounter, however, ALL WARNINGS and CAUTIONS given in this manual

MUST be followed. Techniques in this manual are a starting point for the new wheelchair

user and assistant with “safety” as the most important consideration for all.

Stability and Balance

WARNING

ALWAYS wear your seat positioning strap. Inasmuch as the seat positioning strap is

an option on this wheelchair (you may order with or without the seat positioning

strap), Invacare Top End strongly recommends ordering the seat positioning strap

as an additional safeguard for the wheelchair user. The seat positioning strap is a

positioning belt only. It is not designed for use as a safety device withstanding high

stress loads such as auto or aircraft safety belts. If signs of wear appear, seat

positioning strap MUST be replaced IMMEDIATELY.

Anti-tippers MUST be attached at all times. Inasmuch as the anti-tippers are an

option on this wheelchair (you may order with or without the anti-tippers), Invacare

strongly recommends ordering the anti-tippers as an additional safeguard for the

wheelchair user.

To assure stability and proper operation of your wheelchair, you must at all times

maintain proper balance. Your wheelchair has been designed to remain upright and

stable during normal daily activities as long as you do not move beyond the center of

gravity.

Virtually all activities which involve movement in the wheelchair have an effect on the

center of gravity. Invacare recommends using seat positioning straps for additional safety

while involved in activities that shift your weight.

DO NOT lean forward out of the wheelchair any further than stability will allow. Make

sure casters are pointing in the forward position whenever you lean forward. This can be

achieved by advancing the wheelchair and then reversing it in a straight line.

Crossfire™Series Wheelchairs 14 Part No 1148078

SECTION 2—SAFE HANDLING

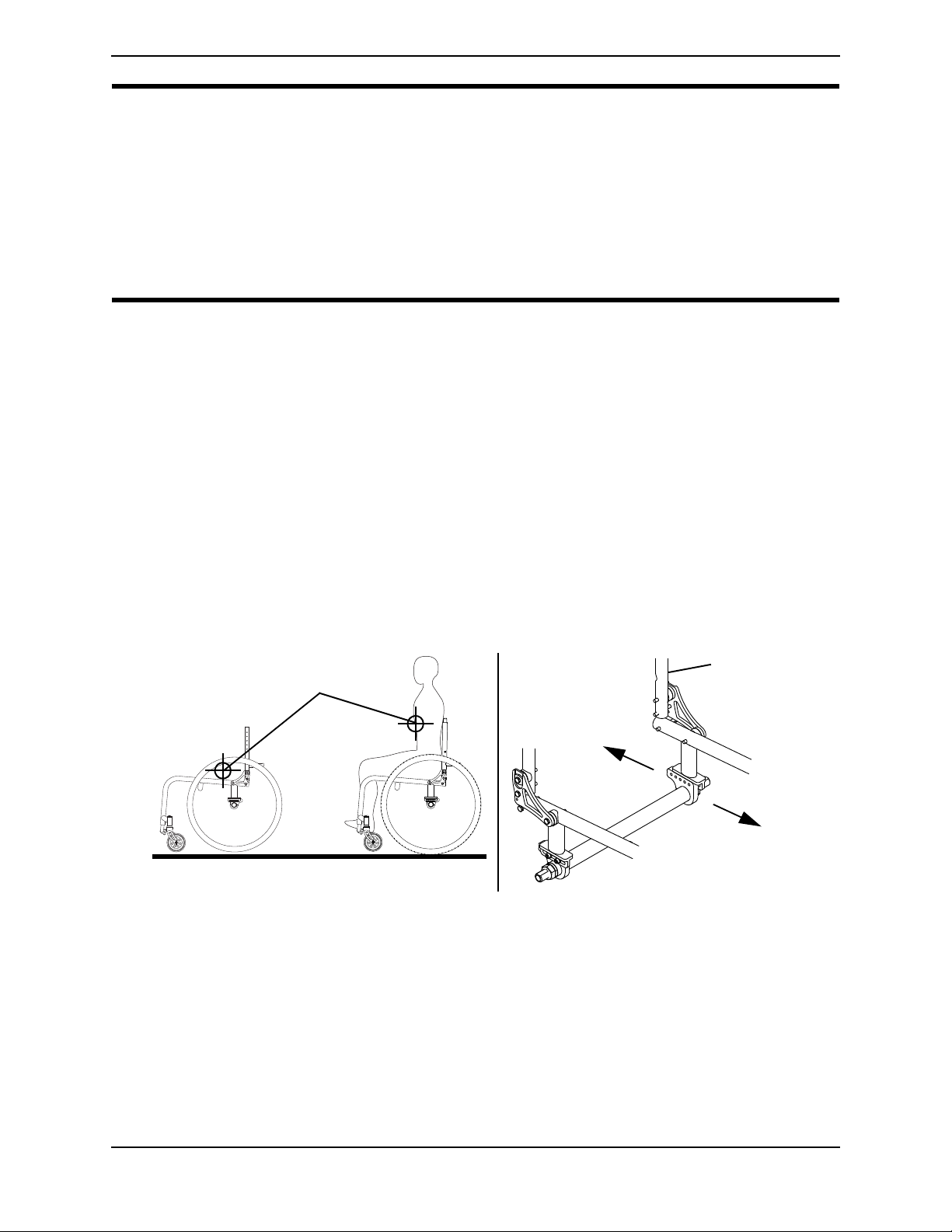

Center of

Gravity

Unoccupied

Occupied

Lengthening the

Wheelbase

Shortening the

Wheelbase

Rear of

Wheelchair

WARNING

DO NOT attempt to reach objects if you have to move forward in the seat or pick

them up from the floor by reaching down between your knees.

The position of the footrest, camber tube, back angle, the tautness of the back

upholstery as well as the user's condition are directly related to the wheelchair's

stability. Any change to one or any combination of the five may cause the wheelchair to decrease in stability. Use EXTREME caution when using a new seating position. The addition of anti-tippers may be required.

NOTE: For this procedure, refer to FIGURE 2.1.

Many activities require the wheelchair owner to reach, bend and transfer in and out of the

wheelchair. These movements will cause a change to the normal balance, the center of

gravity, and the weight distribution of the wheelchair.

To determine and establish your particular safety limits, practice bending, reaching and

transferring activities in several combinations in the presence of a qualified health-care

professional before attempting active use of wheelchair.

Proper positioning is essential for your safety. When reaching, leaning, bending forward,

it is important to use the front casters as a tool to maintain stability and balance.

• Lengthening the wheelbase will increase the stability and maintain standard

manoeuvrability of the wheelchair.

• Shortening the wheelbase will decrease the stability, increase the manoeuvrability and

distribute additional weight onto the rear wheels.

FIGURE 2.1 Stability and Balance

Coping with Everyday Obstacles

Part No 1148078 15 Crossfire™Series Wheelchairs

Coping with the irritation of everyday obstacles can be alleviated somewhat by learning

how to manage your wheelchair. Keep in mind your center of gravity to maintain stability

and balance.

SECTION 2—SAFE HANDLING

Reaching, Leaning, and Bending - Forward

Reaching, Leaning, and Bending - Backwards

A Note to Wheelchair Assistants

When assistance to the wheelchair user is required, remember to use good body

mechanics. Keep your back straight and bend your knees whenever tilting the wheelchair

or traversing curbs, or other impediments.

WARNING

DO NOT attempt to lift a wheelchair by lifting on any removable (detachable)

parts. Lifting by means of any removable (detachable) parts of a wheelchair may

result in injury to the user or damage to the wheelchair.

Also, be aware of any removable (detachable) parts. These must NEVER be used to move

the wheelchair or as lifting supports, as they may be inadvertently released, resulting in

possible injury to the user and/or assistant(s).

When learning a new assistance technique, have an experienced assistant help you before

attempting it alone.

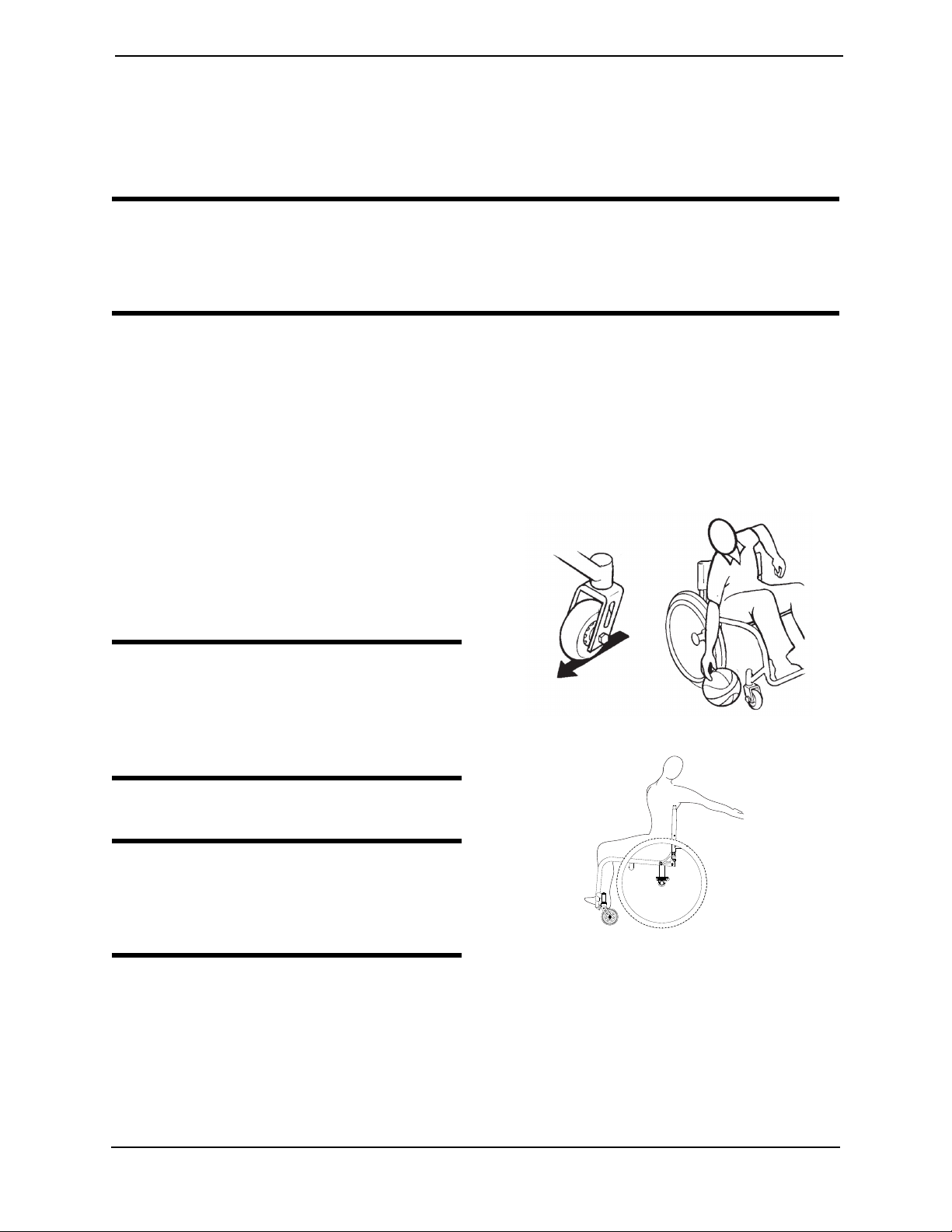

Reaching, Leaning and Bending - Forward

NOTE: For this procedure, refer to

FIGURE 2.2.

Position the front casters so that they are

extended as far forward as possible and

engage wheel locks.

WARNING

DO NOT attempt to reach objects if

you have to move forward in the seat or

pick them up from the floor by reaching

down between your knees.

Reaching, Leaning - Backwards

WARNING

DO NOT lean over the top of the back

upholstery. This will change your center

of gravity and may cause you to tip over.

Crossfire™Series Wheelchairs 16 Part No 1148078

FIGURE 2.2 Reaching, Leaning and Bending

- Forward

SECTION 2—SAFE HANDLING

Tipping

WARNING

DO NOT tip the wheelchair without assistance.

DO NOT let the wheelchair drop the last few inches to the ground. This could result

in injury to the occupant.

When tipping the wheelchair, an assistant should grasp the back of the wheelchair on a

non-removable (non-detachable) part. Inform the wheelchair occupant before tilting the

wheelchair and remind him/her to lean back. Be sure the occupant’s feet and hands are

clear of all wheels and/or pinch points. Apply a continuous motion until the balance point

is achieved. At this point, the assistant will feel a difference in the weight distribution.

Turn the wheelchair in the desired direction if necessary. Slowly lower the wheelchair in

one continuous movement.

Tipping - Curbs

WARNING

Invacare does not recommend that sport wheelchairs be used where traversing

curbs present an obstacle. Possible injury to occupant and/or assistant(s) can occur.

Transfer to an everyday use wheelchair is recommended if any such obstacles may

be encountered.

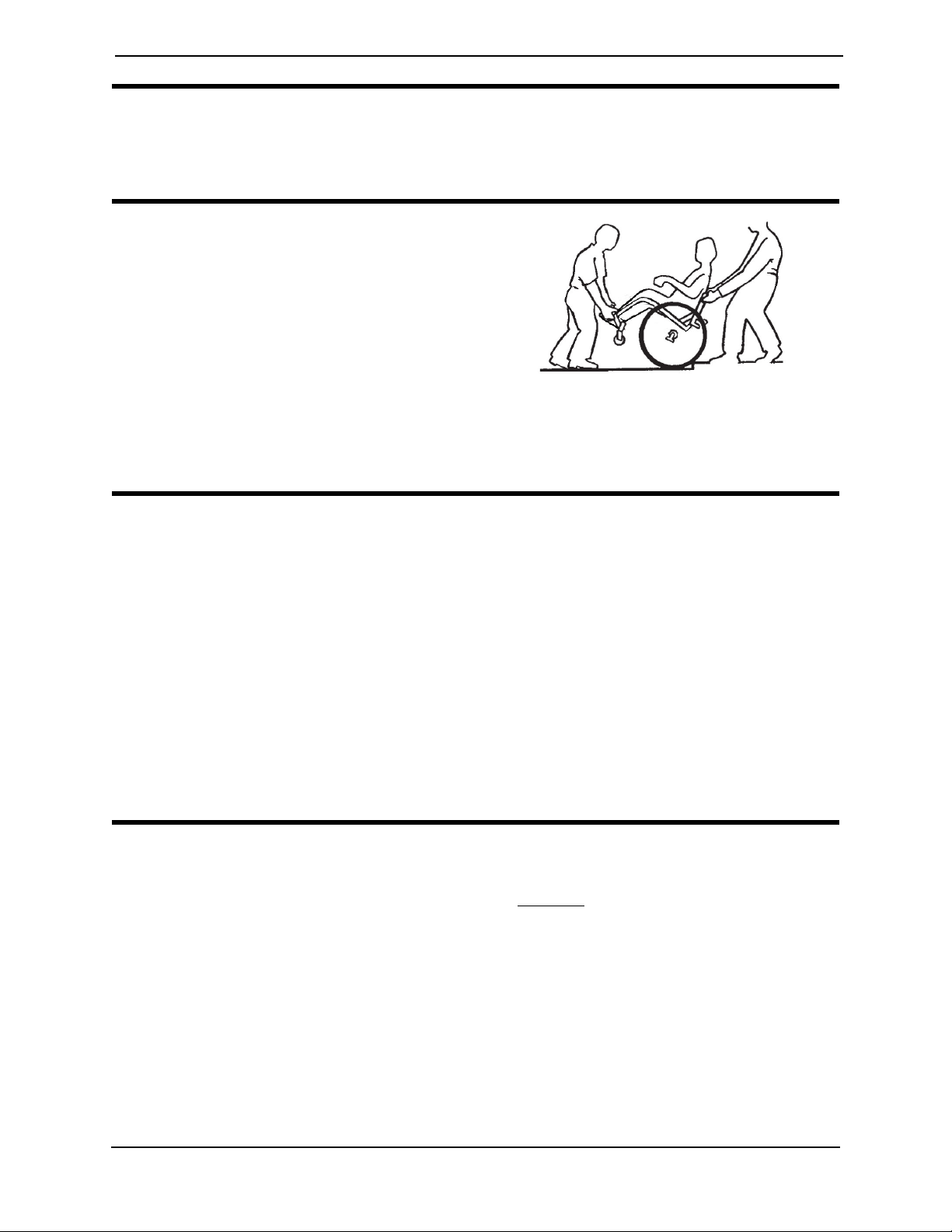

NOTE: For this procedure, refer to FIGURE 2.3 on page 18.

After mastering the techniques of tipping the wheelchair, use the following method to

tackle curbs, short stairs, etc.

Turn the anti-tippers, if equipped, so the wheels are facing UP. Unless the first assistant

has exceptional upper body strength, it is recommended that two assistants perform this

operation. The second assistant should be positioned at the front of the wheelchair lifting

upward on a non-removable (non-detachable) part of the wheelchair frame when lifting

the wheelchair and stabilising the wheelchair when the wheelchair is being lowered to the

ground.

The first assistant should stand on the sidewalk and turn the wheelchair so that the rear

wheels are against the curb. The wheelchair should be tilted back to the balance point and,

in one continuous upward movement, the rear wheels should be pulled up and over the

curb. DO NOT return the front casters to the ground until the wheelchair has been pulled

backward far enough for the front casters to clear the edge of the curb.

Part No 1148078 17 Crossfire™Series Wheelchairs

SECTION 2—SAFE HANDLING

WARNING

When lowering the front casters of the wheelchair, DO NOT let the wheelchair

drop the last few inches to the ground. This could result in injury to the occupant

and/or damage to the wheelchair.

Roll the wheelchair backward and slowly

lower the wheelchair in one continuous

movement. DO NOT let the wheelchair

drop the last few inches to the ground. This

could result in injury to the occupant. Turn

the anti-tippers so the wheels are facing

down.

FIGURE 2.3 Tipping - Curbs

Stairways

WARNING

Concerning stairway access: Invacare does not recommend that wheelchairs be

transported up or down stairways with occupant in the wheelchair. Possible injury

to occupant and/or assistant(s) can occur. Transfer to an everyday use wheelchair is

recommended.

DO NOT attempt to lift the wheelchair by any removable (detachable) parts.

Lifting by means of any removable (detachable) parts of a wheelchair may result in

injury to the user or damage to the wheelchair.

Extreme caution is advised when it is necessary to move an occupied wheelchair up

or down a stairway. Invacare recommends that, if possible, the user be removed

from the wheelchair prior to moving. Invacare recommends using two assistants

and making thorough preparations. Make sure to use only secure, non-detachable

parts for hand-held supports.

Follow this procedure for moving the wheelchair between floors when an elevator is NOT

available:

1. If equipped, turn the anti-tippers up. Refer to Footrest on page 25.

2. After the wheelchair has been tilted back to the balance point, one assistant (in the

rear) backs the wheelchair up against the first step, while securely grasping a

non-removable (non-detachable) part of the wheelchair for leverage.

3. The second assistant, with a firm hold on a non-detachable part of the framework, lifts

the wheelchair up and over the stair and steadies it as the first assistant places one foot

on the next stair and repeats procedure.

4. The wheelchair should not be lowered until the last stair has been negotiated and it

has been rolled away from the stairway.

Crossfire™Series Wheelchairs 18 Part No 1148078

SECTION 2—SAFE HANDLING

5. If equipped, turn the anti-tippers down. Refer to Footrest on page 25 in this manual.

WARNING

DO NOT use an escalator to move a wheelchair between floors. Serious bodily

injury may occur.

Transferring To and From Other Seats

WARNING

BEFORE attempting to transfer in or out of the wheelchair, every precaution should

be taken to reduce the gap distance. Turn both casters parallel to the object you are

transferring onto. Also be certain the wheel locks are engaged to help prevent the

wheels from moving.

When transferring, position yourself as far back as possible in the seat. This will

prevent damaged upholstery and the possibility of the wheelchair tipping forward.

NOTE: For this procedure, refer to FIGURE 2.4.

NOTE: This activity may be performed independently provided you have adequate mobility and

upper body strength.

Position the wheelchair as close as possible along side the seat to which you are

transferring, with the front casters parallel to it. Remove the armrest, if installed. Engage

wheel locks. Shift body weight into seat with transfer.

During independent transfer, little or no seat platform will be beneath you. Use a transfer

board if at all possible.

FIGURE 2.4 Transferring To and From Other Seats

Part No 1148078 19 Crossfire™Series Wheelchairs

SECTION 3—SAFETY INSPECTION

SECTION 3—SAFETY INSPECTION

NOTE: Every six months, take your wheelchair to a qualified technician for a thorough inspection

and servicing. Regular cleaning will reveal loose or worn parts and enhance the smooth operation

of your wheelchair. To operate properly and safely, your wheelchair must be cared for just like any

other vehicle. Routine maintenance will extend the life and efficiency of your wheelchair. Clean

upholstery with mild soap and water or spray disinfectant using a sponge. DO NOT use bleach or

wash in a washing machine.

Safety Inspection Checklist

WARNING

In cases of inactivity longer then six months, a comprehensive initial inspection

MUST be performed.

CAUTION

As with any vehicle, the wheels and tyres should be checked periodically for cracks

and wear, and should be replaced if damaged.

Initial adjustments should be made to suit your personal body structure and preference.

Thereafter follow these maintenance procedures:

Inspect Initially

❑ Ensure wheelchair rolls straight (no excessive drag/pull to one side).

❑ Ensure wheel locks DO NOT interfere with tyres when rolling.

❑ Ensure pivot points are free of wear and looseness.

❑ Ensure wheel locks are easy to engage and prevent the wheels from moving.

❑ Ensure that the casters are free of debris.

❑ Inspect seat and back upholstery for rips or sagging.

❑ Inspect upholstery fastening flaps to ensure they securely latch.

❑ Inspect seat positioning strap for any signs of wear. Ensure buckle latches. Verify

hardware that attaches strap to frame is secure and undamaged. Replace if necessary.

❑ Ensure hand grips (if equipped) are not loose.

❑ Ensure quick release axles and camber inserts are clean.

❑ Ensure camber bar mounting clamps are securely tightened.

❑ Ensure quick/quad release axles lock properly.

❑ Ensure no excessive side movement or binding when lifted and spun.

❑ Inspect handrims for signs of rough edges or peeling.

Crossfire™Series Wheelchairs 20 Part No 1148078

SECTION 3—SAFETY INSPECTION

❑ Inspect spokes for bent or broken spokes.

❑ Ensure all spokes are uniformly tight.

❑ Clean upholstery and armrests.

❑ Inspect wheel/fork assembly for proper tension by spinning caster; caster should come

to a gradual stop.

❑ Loosen/tighten locknut if wheel wobbles noticeably or binds to a stop.

❑ Ensure wheel bearings are clean and free of moisture.

❑ Inspect tyres for flat spots and wear.

❑ If pneumatic tyres check for proper inflation.

❑ Ensure casters are free of debris.

❑ Check that all labels are present and legible. Replace if necessary.

Inspect/Adjust Weekly

❑ Ensure wheel locks are easy to engage and prevent the wheels from moving.

❑ Ensure that the casters are free of debris.

❑ Ensure hand grips (if equipped) are not loose.

❑ Ensure quick release axles and camber inserts are clean.

❑ Ensure quick/quad release axles lock properly.

❑ Inspect handrims for signs of rough edges or peeling.

❑ Inspect spokes for bent or broken spokes.

❑ Ensure All spokes uniformly tight.

❑ Inspect wheel/fork assembly for proper tension by spinning caster; caster should come

to a gradual stop.

❑ Inspect tyres for flat spots and wear.

❑ If pneumatic tyres check for proper inflation.

❑ Ensure casters are free of debris.

Inspect/Adjust Monthly

❑ Ensure wheel locks DO NOT interfere with tyres when rolling.

❑ Ensure that the casters are free of debris.

❑ Ensure pivot points are free of wear and looseness.

❑ Inspect upholstery fastening flaps to ensure they securely latch.

❑ Inspect seat positioning strap for any signs of wear. Ensure buckle latches. Verify

hardware that attaches strap to frame is secure and undamaged. Replace if necessary.

❑ Ensure camber bar mounting clamps are securely tightened.

Part No 1148078 21 Crossfire™Series Wheelchairs

SECTION 3—SAFETY INSPECTION

❑ Loosen/tighten locknut if wheel wobbles noticeably or binds to a stop.

❑ Ensure wheel bearings are clean and free of moisture.

❑ Ensure casters are free of debris.

❑ Check that all labels are present and legible. Replace if necessary.

Inspect/Adjust Periodically

❑ Ensure wheelchair rolls straight (no excessive drag/pull to one side).

❑ Ensure wheel locks are easy to engage.

❑ Ensure that the casters are free of debris.

❑ Inspect seat and back upholstery for rips or sagging.

❑ Ensure camber bar mounting clamps are securely tightened.

❑ Ensure no excessive side movement or binding when lifted and spun.

❑ Inspect handrims for signs of rough edges or peeling.

❑ Clean upholstery and armrests.

❑ Ensure wheel bearings are clean and free of moisture.

❑ Ensure casters are free of debris.

❑ Check that all labels are present and legible. Replace if necessary.

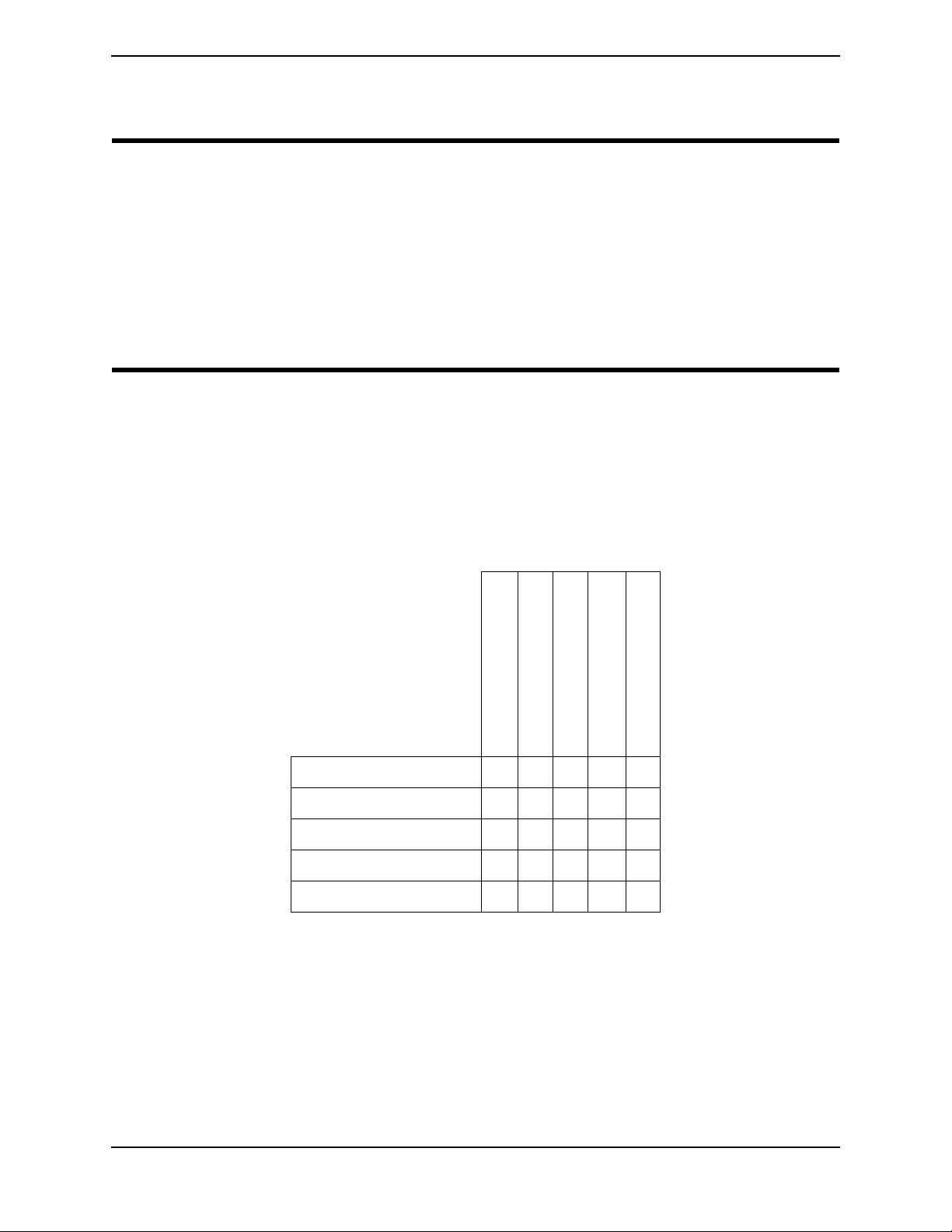

Troubleshooting

OR

RATTLES

CHAIR VEERS RIGHT

X X X X Check tyres for correct and equal pressure.

CHAIR VEERS LEFT

X X X X Check for loose stem nuts.

CASTER FLUTTERS

PERFORMANCE

SLUGGISH TURN

SQUEAKS AND

LOOSENESS IN CHAIR

X X Check spokes and nipples.

SOLUTIONS

XX X

Crossfire™Series Wheelchairs 22 Part No 1148078

Check that both casters contact the ground at

the same time.

SECTION 3—SAFETY INSPECTION

Maintenance

Maintenance Safety Precautions

WARNING

After ANY adjustments, repair or service and BEFORE use, make sure all attaching

hardware is tightened securely - otherwise injury or damage may occur.

CAUTION

DO NOT overtighten hardware attaching to the frame. This could cause damage to

the frame tubing.

Suggested Maintenance Procedures

1. Before using your wheelchair, make sure all nuts and bolts are tight. Check all parts

for damage or wear and replace. Check all parts for proper adjustment.

2. Keep quick/quad-release axles free of dirt and lint to ensure positive locking and

proper operation. Refer to Adjusting Quick-Release Axles on page 39 or Adjusting

Quad-Release Handles on page 40.

WARNING

DO NOT use WD-40®, 3-in-1 oil®, or other penetrating lubricants on quick-release

axles or camber inserts. Otherwise, binding and/or damage to the wheelchair may

occur.

3. Clean quick-release axles and camber inserts once a week with a Teflon® lubricant.

WARNING

DO NOT use your wheelchair unless it has the proper tyre pressure (p.s.i.).

DO NOT overinflate the tyres. Failure to follow these suggestions may cause the

tyre to explode and cause bodily harm. The recommended tyre pressure is on the

sidewall of the tyre.

4. Recommended tyre pressure is listed on the sidewall of the tyre.

CAUTION

As with any vehicle, the wheels and tyres should be checked periodically for cracks

and wear, and should be replaced if damaged.

5. The wheels, casters and tyres should be checked periodically for cracks and wear, and

should be replaced when necessary. Contact a qualified technician or Invacare

customer support at the telephone numbers on the back of this manual.

Part No 1148078 23 Crossfire™Series Wheelchairs

SECTION 3—SAFETY INSPECTION

6. Regularly check for loose spokes in the rear wheels. If loose, have them adjusted.

Contact a qualified technician or Invacare customer support at the telephone numbers

on the back of this manual.

7. Periodically check handrims to ensure they are secured to the rear wheels. Refer to

Handrim Replacement on page 41.

8. Periodically adjust wheel locks as tyres wear. Refer to Replacing/Adjusting the Wheel

Locks on page 55.

9. Periodically check caster wheel bearings to make sure they are clean and free from

moisture. Use a Teflon® lubricant if necessary.

10. Check upholstery for sagging, rips or tears.

11. Clean upholstery with mild soap and water.

12. Replace any labels that are missing, worn or torn.

NOTE: Some countries require product returned for service be cleaned and sanitised. Please

consult your dealer prior to returning product.

Crossfire™Series Wheelchairs 24 Part No 1148078

SECTION 4—FOOTREST

Footrest

Clamps (Allen Screws)

Wheelchair

Frame

SECTION 4—FOOTREST

WARNING

After ANY adjustments, repair or service and BEFORE use, make sure all attaching

hardware is tightened securely - otherwise injury or damage may occur.

ALWAYS perform this procedure in the presence of an assistant. The position of

the footrest, camber tube, back angle, the tautness of the back upholstery as well as

the user's condition are directly related to the wheelchairs stability. Any change to

one or any combination of the five may cause the wheelchair to decrease in stability.

Use EXTREME caution when using a new seating position. The addition of

anti-tippers may be required.

Check ALL allen screws that secure the footrest/raised footrest system to the

wheelchair frame to make sure they are securely tightened BEFORE using the

wheelchair. ESPECIALLY if engaging in ANY contact sport.

The footrest assembly MUST be at least 1-3/4-inches (4.45 cm) above the

ground/floor to avoid hitting protruding objects when using this wheelchair.

Adjusting/Replacing Standard Footrest

NOTE: For this procedure, refer to

FIGURE 4.1.

1. Loosen the allen screw of the two

clamps that secure the footrest to the

wheelchair frame.

Replacing the Footrest

1. Remove existing footrest.

2. Install new footrest.

WARNING

The standard footrest has an open hoop. A footplate cover is recommended for

wheelchair users that have leg spasticity or whose feet have a possibility of falling

through the footrest hoop. A calf strap is provided with each wheelchair to prevent

the feet from slipping backwards off of the footrest. Be sure the calf strap is secure

when using the wheelchair.

FIGURE 4.1 Adjusting/Replacing Standard

Footrest

Adjusting the Footrest

1. Position new/existing footrest to desired height.

2. Tighten the allen screw of the two clamps that secure the footrest to the wheelchair

frame.

Part No 1148078 25 Crossfire™Series Wheelchairs

SECTION 4—FOOTREST

Allen

Screws

Wheelchair Frame

Outside

Footrest

Hoop

Half Clamp

Raised

Footrest

Installing/Adjusting Optional Clamp on Raised Footrest

NOTE: For this procedure, refer to FIGURE 4.2.

Installing

1. Install the two half clamps onto either

side of the wheelchair frame

approximately 2-inches (5.08 cm) above

existing footrest with two provided

allen screws.

2. Repeat for the opposite side of the

wheelchair.

3. Slide the clamp on raised footrest into

the half clamps to the desired height.

4. Securely tighten the four allen screws.

FIGURE 4.2 Installing/Adjusting Optional

Clamp on Raised Footrest

Adjusting

1. Loosen the four allen screws.

2. Adjust clamp on raised footrest to the desired height.

3. Securely tighten the four allen screws.

Replacing/Adjusting Optional Adjustable Angle

Footrest

NOTE: For this procedure, refer to FIGURE 4.3 on page 27.

Replacing the Footrest

1. Loosen, but DO NOT the allen screw of the two clamps that secure the footrest to the

wheelchair frame.

2. Slide the existing footrest tubes out of the wheelchair frame and install new footrest

by reversing this step.

3. Position the new footrest to a determined height.

4. Tighten the allen screw of the two clamps that secure the footrest to the wheelchair

5. Adjust the footplate to the desired position. Refer to Adjusting Footplate Angle on

Crossfire™Series Wheelchairs 26 Part No 1148078

frame.

page 27 and/or Adjusting Footplate Depth on page 27.

SECTION 4—FOOTREST

Footrest

Tube

Mounting

Positions

Footplate

Locknut

(Not Shown)

Angle

Depth

Height

Clamp

(Allen

Screw)

Mounting

Screws

Adjustments

Wheelchair

Frame

Clamp

(Allen Screw)

Adjusting Footplate Angle

1. Loosen, but DO NOT remove the two mounting screws and locknuts (not shown) that

secure the footplate to the two footrest tubes.

2. Position the footplate to the necessary angle to accommodate the user.

3. Retighten the two mounting screws and locknuts.

NOTE: The locknuts should lie in the channel of the footplate clamp.

Adjusting Footplate Depth

1. Remove the two mounting screws and locknuts (not shown) that secure footplate to

the footrest tubes.

NOTE: Observe the angle of footplate for reinstallation.

2. Move the footplate to one of two mounting positions to accommodate the user.

3. Using the two mounting screws and locknuts, secure the footplate to the footrest

tubes.

NOTE: The locknuts should lie in the channel of the footplate half clamp.

FIGURE 4.3 Replacing/Adjusting Optional Adjustable Angle Footrest

Part No 1148078 27 Crossfire™Series Wheelchairs

SECTION 5—ARMS

Long Mounting

Screws

Back Cane

Mounting Bracket

Wheelchair

Frame

Locknuts

Locknuts

Arm Socket

Short Mounting

Screws

Coved

Washer

Arm Socket

Plate

SECTION 5—ARMS

WARNING

After ANY adjustments, repair or service and BEFORE use, make sure all attaching

hardware is tightened securely - otherwise injury or damage may occur.

DO NOT attempt to lift or tilt a wheelchair by using any removable (detachable)

parts. Lifting by means of any removable (detachable) parts of a wheelchair may

result in injury to the user or damage to the wheelchair.

Installing the Swingaway Padded Armrest Socket

Assembly

NOTE: For this procedure, refer to FIGURE 5.1.

1. Fold down the back. Refer to Unfolding/Folding the Back on page 30.

2. Install the arm socket on the arm socket plate using the two short mounting screws

and locknuts.

3. Remove the two mounting screws, coved washers and locknuts located on the back

NOTE: Position arm socket towards outside and rear of the wheelchair frame.

4. Align the mounting holes in the arm socket plate and wheelchair frame.

5. Using the two long mounting screws, coved washers and locknuts, secure the arm

6. Repeat STEPS 2-5 for the opposite arm socket.

cane mounting bracket.

socket plate to the wheelchair frame. Securely tighten.

FIGURE 5.1 Installing the Swingaway Padded Armrest Socket Assembly

Crossfire™Series Wheelchairs 28 Part No 1148078

SECTION 5—ARMS

Swingaway Padded Armrest

Arm Socket

Mounting Bolt

Locknut

Washer

Three Mounting Positions

Washer

Adjusting Swingaway Padded Armrest Height

NOTE: For this procedure, refer to FIGURE 5.2.

1. Remove the half arm from the arm socket.

2. Remove the mounting bolt, two washers and locknut mounted in the arm socket that

determine the swingaway padded armrest height.

3. Reposition mounting bolt and one washer to one of three positions in the arm socket

depending on the desired height.

4. Retighten the mounting bolt and washer to the arm socket with the remaining washer

and locknut.

5. Reinstall the half arm into the arm socket.

6. Repeat STEPS 1-5 for the opposite side, if necessary.

FIGURE 5.2 Adjusting Swingaway Padded Armrest Height

Part No 1148078 29 Crossfire™Series Wheelchairs

SECTION 6—BACK

Front of

Wheelchair

Rear of

Wheelchair

Back Cane

Back Release Cord

(Not Shown)

NOTE: Back upholstery

removed for clarity.

SECTION 6—BACK

WARNING

ALWAYS perform these procedures in the presence of an assistant. The position of

the footrest, camber tube, back angle, the tautness of the back upholstery as well as

the user's condition are directly related to the wheelchairs stability. Any change to

one or any combination of the five may cause the wheelchair to decrease in stability.

Use EXTREME caution when using a new seating position. The addition of

anti-tippers may be required.

After ANY adjustments, repair or service and BEFORE use, make sure all attaching

hardware is tightened securely - otherwise injury or damage may occur.

Unfolding/Folding the Back

WARNING

Back MUST be locked securely in place before using the wheelchair.

NOTE: For this procedure, refer to FIGURE 6.1

1. To unfold the back, lift up on the back canes and pull back towards the rear of the

2. To fold the back, pull up on the back release cord and push the back canes forward

Back Angle Adjustment

wheelchair until it locks into place.

toward the front of the wheelchair.

FIGURE 6.1 Unfolding/Folding the Back

NOTE: For this procedure, refer to FIGURE 6.2 on page 31.

NOTE: Perform this procedure on both sides of the wheelchair at the same time.

Crossfire™Series Wheelchairs 30 Part No 1148078

SECTION 6—BACK

95° Back Angle to Seat Rail 90° Back Angle to Seat Rail

80° Back Angle to Seat Rail85° Back Angle to Seat Rail

75° Back Angle

to Seat Rail

Back Cane

Indexing

Notch

Cam

Seat Rail

Back Angle

Bracket

TOP Hex

Screw and

Locknut

Back Cane

Indexing

Notch

Cam

Seat Rail

Back Angle

Bracket

TOP Hex Screw

and Locknut

Back Cane

Indexing

Notch

Cam

Seat Rail

Back Angle Bracket

TOP Hex

Screw and

Locknut

Back

Cane

Indexing Notch

Cam

Seat Rail

Back Angle Bracket

TOP Hex Screw

and Locknut

Back Cane

Indexing

Notch

Cam

Seat Rail

Back Angle Bracket

TOP Hex Screw

and Locknut

1. Loosen, but DO NOT remove the locknuts and hex screws that secure the back angle

bracket to the seat rail and the back cane.

2. Loosen the top locknut and slide the top hex screw away from the back angle bracket

to adjust the cam.

3. Adjust back canes to back angle required.

4. Adjust cam to achieve desired position.

NOTE: An indexing notch has been put on the cam to help determine cam position for desired back

angle adjustment.

5. Secure cam in desired position. Torque all hex screws and locknuts to 960-1020 inch

pounds (80-85 foot-pounds) (1105920 - 1175040 gram-centimeters).

NOTE: As shown in FIGURE 6.2, the adjustment cam can be rotated to several different positions

thus changing the overall back angle relative to the seat rail.

Part No 1148078 31 Crossfire™Series Wheelchairs

FIGURE 6.2 Back Angle Adjustment

SECTION 6—BACK

Fastening Strap

Back Upholstery Cover

Fastening Straps

Adjuster Strap

Anchor

Loop

Back

Cane

Upper

Grommet

Hole

Back Upholstery

Anchor Loop Section

Mounting Screw

Back Upholstery Adjuster Strap Section

Adjustable Tension Back Upholstery

WARNING

The position of the footrest, seat angle, back angle, seating system/upholstery,

caster size and position, rear wheel size and position, use of anti-tippers, as well as

the user condition directly relate to the stability of the wheelchair. Any change to

one or any combination of the ten may cause the wheelchair to decrease in stability.

EXTREME care MUST be taken when changing the stability of the wheelchair. Refer

to the chart in General Guidelines on page 11 of this manual.

NOTE: For this procedure, refer to FIGURE 6.3.

The Adjustable Tension Straps

The straps can be adjusted at various levels

of tension to accommodate individual

end-users. The bottom two straps can be

adjusted tightly to support and/or assist

the extensor muscles.

The Back Upholstery Cover

NOTE: The back upholstery cover is designed

for three reasons:

• The first is as a modesty cover.

• The second is to keep the cushion from

• The third is a sacral support depending

Replacing Adjustable Tension Back Upholstery

1. Remove the back height adjustment screws that secure the back canes to the back

2. Slide the back canes out of the back uprights.

3. Remove the two screws and washers that secure the existing back upholstery to the

4. Slide the existing back upholstery down and off the back canes.

sliding out of the back of the

wheelchair.

upon how far or tight the flap is pulled

under the seat cushion.

uprights.

back canes.

FIGURE 6.3 Back Height Adjustment

(Adjustable Backs Only)

Crossfire™Series Wheelchairs 32 Part No 1148078

SECTION 6—BACK

5. Stand behind the wheelchair and perform the following:

A. Slide anchor loop section of adjustable tension back upholstery up onto the left

back cane with the upper grommet hole facing the rear of the wheelchair.

B. Slide adjuster strap section of adjustable tension back upholstery up onto the right

back cane with the upper grommet hole facing the rear of the wheelchair.

6. Align the mounting hole in each back cane with the desired mounting hole in each

back upright.

NOTE: Both back canes should be adjusted to the same height.

7. Install the two back height adjustment screws through the back upright mounting

holes determined in STEP 6 and the back cane mounting holes.

8. Slip adjuster straps through corresponding anchor loops and adjust the back

upholstery. Secure with the fastening straps.

WARNING

After the adjustable tension back upholstery has been positioned to the end-users

individual needs, the fastening straps MUST be securely fastened BEFORE applying

the back upholstery cover. The adjustable back should be checked whenever entering the wheelchair to ensure that the fastening straps are securely fastened.

9. Secure the back upholstery cover (fastening strap) to the back of the adjustable back

upholstery (fastening strap).

10. Flip the back upholstery cover over the adjustable back upholstery and secure the

fastening straps to the front of the adjustable back upholstery.

11. Lay the front portion of the back upholstery cover on the seat pan.

12. Adjust the slack in the back upholstery cover and then secure to the seat pan fastening

straps.

Removing/Installing Foldover Back Upholstery

WARNING

The position of the footrest, seat angle, back angle, seating system/upholstery,

caster size and position, rear wheel size and position, use of anti-tippers, as well as

the user condition directly relate to the stability of the wheelchair. Any change to

one or any combination of the ten may cause the wheelchair to decrease in stability.

EXTREME care MUST be taken when changing the stability of the wheelchair. Refer

to the chart in General Guidelines on page 11 of this manual.

NOTE: For this procedure, refer to FIGURE 6.4 on page 34.

Part No 1148078 33 Crossfire™Series Wheelchairs

SECTION 6—BACK

Fastening Flap

Back Upholstery

Fold

Fastening Flap

Back Canes

Fastening Strips

Loops

Front of Wheelchair

Removing Foldover Back Upholstery

1. Unfasten the two fastening flaps that secure the bottom of the existing back upholstery

to the back canes.

2. Unfold the top of the back upholstery.

3. Lift up on the existing back upholstery and remove from the wheelchair.

Installing Foldover Back Upholstery

1. Install the new back upholstery onto the back canes.

2. Wrap the end of a fastening flap around the back cane.

3. Insert the end of the fastening flap through the loop.

4. Wrap the fastening flap around the back cane again and press firmly to secure.

5. Fold the top of the back upholstery down over the back canes towards the front of the

wheelchair.

6. Press firmly to secure the fastening strips.

FIGURE 6.4 Removing/Installing Foldover Back Upholstery

Crossfire™Series Wheelchairs 34 Part No 1148078

SECTION 6—BACK

Back

Cane

Insert

Hole Number

4

3

2

1

5

Adjustment

Pin

Back Height Adjustment (Adjustable Backs Only)

NOTE: For this procedure, refer to FIGURE 6.5

NOTE: Observe the tautness of the back upholstery for reinstallation.

1. Unlatch the two fastening flaps that secure the top of the back upholstery to the back

canes and remove from the back canes.

WARNING

Adjustment pin MUST be protruding through hole in back cane.

Ensure that both back cane inserts are at the same height BEFORE reassembling

the wheelchair.

2. Press the adjustment pin on the back cane insert tube in and adjust the back height to

one of four heights depending on original back height:

HOLE* NUMBER BACK HEIGHT IN INCHES AND CENTIMETERS

(20.32 - 27.94 CM)

8 - 11

1 8 (20.32 cm) 10 (25.4 cm) 14 (35.56 cm)

2 9 (22.86 cm) 11 (27.94 cm) 15 (38.1 cm)

3 10 (25.4 cm) 12 (30.48 cm) 16 (40.64 cm)

4 11 (27.94 cm) 13 (33.02 cm) 17 (43.18 cm)

5 NA 14 (35.56 cm) 18 (45.72 cm)

(25.4 - 35.56 CM)

10 - 14

(35.56 - 45.72 CM)

14 - 18

*NOTE: Holes numbered from bottom to top for reference only. (There are no numbers on the back

canes.)

3. Reinstall the fastening flaps onto the back canes.

NOTE: The fastening flap with logo is for the left back cane.

NOTE: Right and left is determined by sitting in the wheelchair.

4. Adjust the new back upholstery to the desired tautness. Refer to Back Height

Adjustment (Adjustable Backs Only) on page 35.

FIGURE 6.5 Back Height Adjustment (Adjustable Backs Only)

Part No 1148078 35 Crossfire™Series Wheelchairs

SECTION 7—SEAT

SECTION 7—SEAT

WARNING

After ANY adjustments, repair or service and BEFORE use, make sure all attaching

hardware is tightened securely - otherwise injury or damage may occur.

Replacing Adjustable Tension Seat Upholstery

WARNING

The seat upholstery and/or cushion MUST be cleaned regularly and/or replaced if

incontinence is frequent. The risk of pressure sores is significantly higher with seat

upholstery that is wet and/or soiled.

NOTE: For this procedure, refer to FIGURE 7.1 on page 37.

1. Remove the seat cushion and back upholstery from the wheelchair.

2. Place the wheelchair onto its two rear wheels and back canes.

3. Unlatch the five adjusting straps that secure the seat upholstery to the wheelchair

frame.

4. Remove the existing seat upholstery.

5. Place the wheelchair back onto all four wheels.

NOTE: Right and left is determined by sitting in the wheelchair.

NOTE: The seat upholstery MUST be positioned with the three rear adjusting straps towards the

rear of the top crossbar for proper installation.

NOTE: Make sure the rear retaining flap is between the wheelchair frame and the back cane

support brackets (adjustable backs only).

6. Position new seat upholstery onto the wheelchair frame, ensuring the five adjusting

straps hang over the right and left sides of the wheelchair.

7. Pull the front adjuster straps around and under the wheelchair frame top bars.

8. Slip front adjuster strap through corresponding anchor loop and adjust the seat

upholstery to desired tension. Secure the adjustment straps.

9. Place the wheelchair onto its two rear wheels and back cane.

10. Securely latch the four remaining adjuster straps together.

11. Return wheelchair to upright position.

12. Reinstall the seat cushion and back upholstery.

Crossfire™Series Wheelchairs 36 Part No 1148078

SECTION 7—SEAT

Fastening Flaps

Seat

Upholstery

Adjuster

Straps (Rear)

Wheelchair Frame

(Top Bar)

Top Crossbar

Anchor Loop

FIGURE 7.1 Replacing Adjustable Tension Seat Upholstery

Part No 1148078 37 Crossfire™Series Wheelchairs

SECTION 8—WHEELS

Wheelchair Frame

Rear

Wheel

Locking Pins

Quick-Release

Axle

Detent Pin

NOTE: Quad-Release Axle

not shown. Locking pins on

the Quad-Release Axle are

the same as Quick-Release

Axle.

SECTION 8—WHEELS

WARNING

After any adjustments, repair or service and before use, make sure all attaching

hardware is tightened securely - otherwise injury or damage may result.

Removing/Installing Rear Wheels

CAUTION

Changing the size of the rear wheels can affect the performance of the wheelchair.

Contact Invacare at the telephone numbers on the back of this manual before

changing rear wheel size.

NOTE: For this procedure, refer to FIGURE 8.1.

1. Perform one of the following:

• Quick-Release - Push in the tip of the quick-release axle and pull axle and wheel

away from the wheelchair.

• Quad-Release - Lift up on the handle of the quad-release axle and pull axle and

wheel away from the wheelchair.

2. Repeat STEP 1 for the opposite rear wheel.

3. Reinstall the rear wheels onto the wheelchair by reversing STEPS 1-2.

WARNING

Pull on the rear wheel to make sure the detent pin and locking pins of the quick/

quad-release axle are fully released before operating wheelchair.

Keep locking pins clean.

4. If there is too much movement of the rear wheel assembly in a back and forth motion,

refer to Adjusting Quick-Release Axles on page 39 or Adjusting Quad-Release

Handles on page 40.

Crossfire™Series Wheelchairs 38 Part No 1148078

FIGURE 8.1 Removing/Installing Rear Wheels

SECTION 8—WHEELS

Locking

Pins

Quick-Release

Axle

Detent

Pin

Locknut

Adjustable Axle

Position Camber Bar

Wheel

Hub

NOTE: End of Quick Release axle is shown

for reference only. It is not visible when

inserted into camber bar.

NOTE: End of Quick Release axle is shown

for reference only. It is not visible when

inserted into camber bar.

Quick-Release Axle

Rear Wheel Hub

Locking Collar

Allen Screw

Adjusting Quick-Release Axles

NOTE: For this procedure, refer to FIGURE 8.2.

1. Remove rear wheel and quick-release axle from the wheelchair. Refer to

Removing/Installing Rear Wheels on page 38.

2. Depress detent pin in the quick-release

axle and slide axle through the wheel

hub.

3. Release detent pin ensuring that the

locking pins are fully released.

4. Increase or decrease end play by

adjusting the locknut on the end of the

quick-release axle.

5. Reinstall rear wheel onto the

wheelchair. Refer to

Removing/Installing Rear Wheels on

page 38.

FIGURE 8.2 Adjusting Quick-Release Axles

Replacing Quad-Release Axles

NOTE: For this procedure, refer to FIGURE 8.3.

1. Remove rear wheel and the existing quick-release axle from the wheelchair. Refer to

Removing/Installing Rear Wheels on page 38.

2. Remove existing quick-release axle from rear wheel.

3. Insert new quad-release axle through rear wheel hub.

4. Slide locking collar onto quad-release axle until it is snug against rear wheel and

tighten securely with allen screw.

5. Reinstall rear wheel and the

quad-release axle onto the wheelchair.

Refer to Removing/Installing Rear

Wheels on page 38.

6. Flip the handle of the quad-release axle

down to release the detent pin ensuring

that the locking pins are fully released.

7. If detent pin does not fully release,

proceed to Adjusting Quad-Release

Handles on page 40.

8. Repeat STEPS 1-7 for the opposite rear

wheel.

Part No 1148078 39 Crossfire™Series Wheelchairs

FIGURE 8.3 Replacing Quad-Release Axles

SECTION 8—WHEELS

Adjusting Locknut

(On Quick-Release Axle)

Length

Adjustment

Screw

Removing

Play from

Rear Wheels

Adjusting Quad-Release

Handle In and/or Out

Locking Pins

Camber Bar

Locking

Screw

Quad Release

Handle

Adjusting Quad-Release Handles

NOTE: For this procedure, refer to FIGURE 8.4.

In and/or Out

1. Remove rear wheel and the

quad-release axle from the wheelchair.

Refer to Removing/Installing Rear

Wheels on page 38.

2. Loosen the locking screw.

3. Make one or both of the following

adjustments:

• If the quad-release handle is not

releasing the locking pins

completely, rotate the quad-release

handle approximately one-quarter

turn clockwise.

• If the quad-release handle hits the

spokes of the rear wheel when

assembled, rotate the quad-release

handle approximately one-quarter

turn counterclockwise.

4. Tighten the locking screw.

5. Reinstall the rear wheel and quad-release axle onto the wheelchair. Refer to

Removing/Installing Rear Wheels on page 38.

6. Flip the handle of the quad-release axle down to release the detent pin ensuring that

the locking pins are fully released.

7. Repeat the above procedures until the quad-release axle locks correctly.

Removing Play from Rear Wheels

1. With the rear wheel and quad-release axle still mounted onto the wheelchair, make the

following adjustment:

• Tighten the length adjusting screw until there is no in and out movement of the

quad-release axle and rear wheel.

FIGURE 8.4 Adjusting Quad-Release

Handles

Crossfire™Series Wheelchairs 40 Part No 1148078

SECTION 8—WHEELS

Allen Screw

Locknut

Handrim

Handrim Replacement

NOTE: For this procedure, refer to FIGURE 8.5.

1. Remove the rear wheel from the wheelchair. Refer to Removing/Installing Rear

Wheels on page 38.

WARNING

Tyre MUST be fully deflated before any disassembly procedures are performed.

Otherwise injury or damage may result.