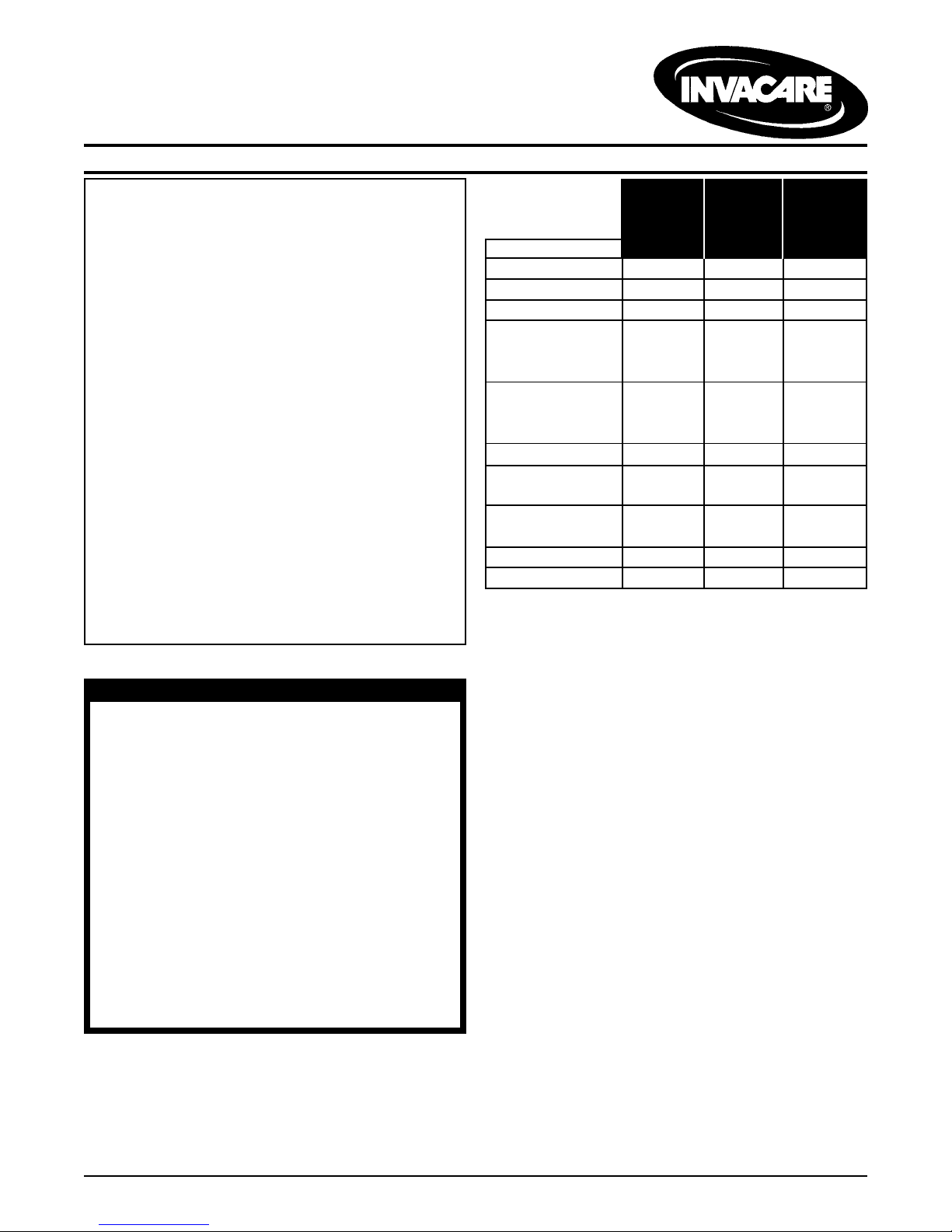

KSS SEA TING SYSTEM

CHILD/JUNIOR SIZES: 10R, 12R, 14R, 16R

ADUL T SIZES: 16T, 18T, 20T

STORM JR. TRANSPORT READY OPTION (TRRO) 12R, 14R, 16R

Assembly, Installation, and Operating Instructions

SPECIAL NOTES

WHEELCHAIR TIE-DOWN RESTRAINTS AND SEA T RESTRAINTS Invacare recommends that wheelchair

users NOT be transported in vehicles of any kind

while in wheelchairs. As of this date, the Department of Transportation has not appr oved any tiedown systems for transportation of a user while in

a wheelchair, in a moving vehicle of any type.

It is Invacare’s position that users of wheelchairs

should be transferred into appropriate seating in

vehicles for transportation and use be made of

the restraints made available by the auto

industry. Invacare cannot and does not recommend any wheelchair transportation systems.

AS REGARDS RESTRAINTS - SEAT POSITIONING

STRAPS - IT IS THE OBLIGATION OF THE DME DEALER,

THERAPISTS AND OTHER HEALTH CARE PROFESSIONALS TO DETERMINE IF A SEAT POSITIONING STRAP IS

REQUIRED TO ENSURE THE SAFE OPERA TION OF THIS

EQUIPMENT BY THE USER. SERIOUS INJURY CAN OCCUR IN THE EVENT OF A F ALL FROM A WHEELCHAIR.

SAFETY SUMMARY

WARNING

DO NOT install this equipment without first reading and understanding this instruction sheet. If you

are unable to understand the W ARNINGS, CAUTIONS and INSTRUCTIONS, contact a health-care

professional , dealer or technical personnel before attempting to install this equipment - otherwise, injury or damage may occur .

Ensure that the seat is fixed to the wheelchair. A

loose seat may lead to potentially dangerous

situations with positioning devices.

It is strongly recommended that the lap belt be

strapped across the hip area with an angle of

o

45

to the seating surface. Angles less than 45

make it easier for the user to slip under the belt if

it is improperly tightened.

NOTE: The KSS seating system is defined as a

seating system which includes the following:

o

CHILD/ STORM Jr .

JUNIOR ADUL T (TRRO)

10R, 12R, 16T,18T 12R, 14R

FEATURES 14R, 16R 20T 16R

Curved Back Standard Standard Standard

Ulti-Mate Base Standard Standard Standard

Neck Support Standard Standard Standard

Lateral Supports:

Fixed Standard Standard Standard

Swingaway Optional Optional Optional

Growth Bracket: Standard N/A Standard

900 Angle Standard Standard Standard

Adj. Angle Optional Optional N/A

Lap Belt Standard Standard Standard

Twist Release

Cane Clamp Standard Standard Standard

Quick Release

Rail Clamp Standard Standard Standard

Abductor Optional Optional Optional

Shoulder Support Optional Optional Optional

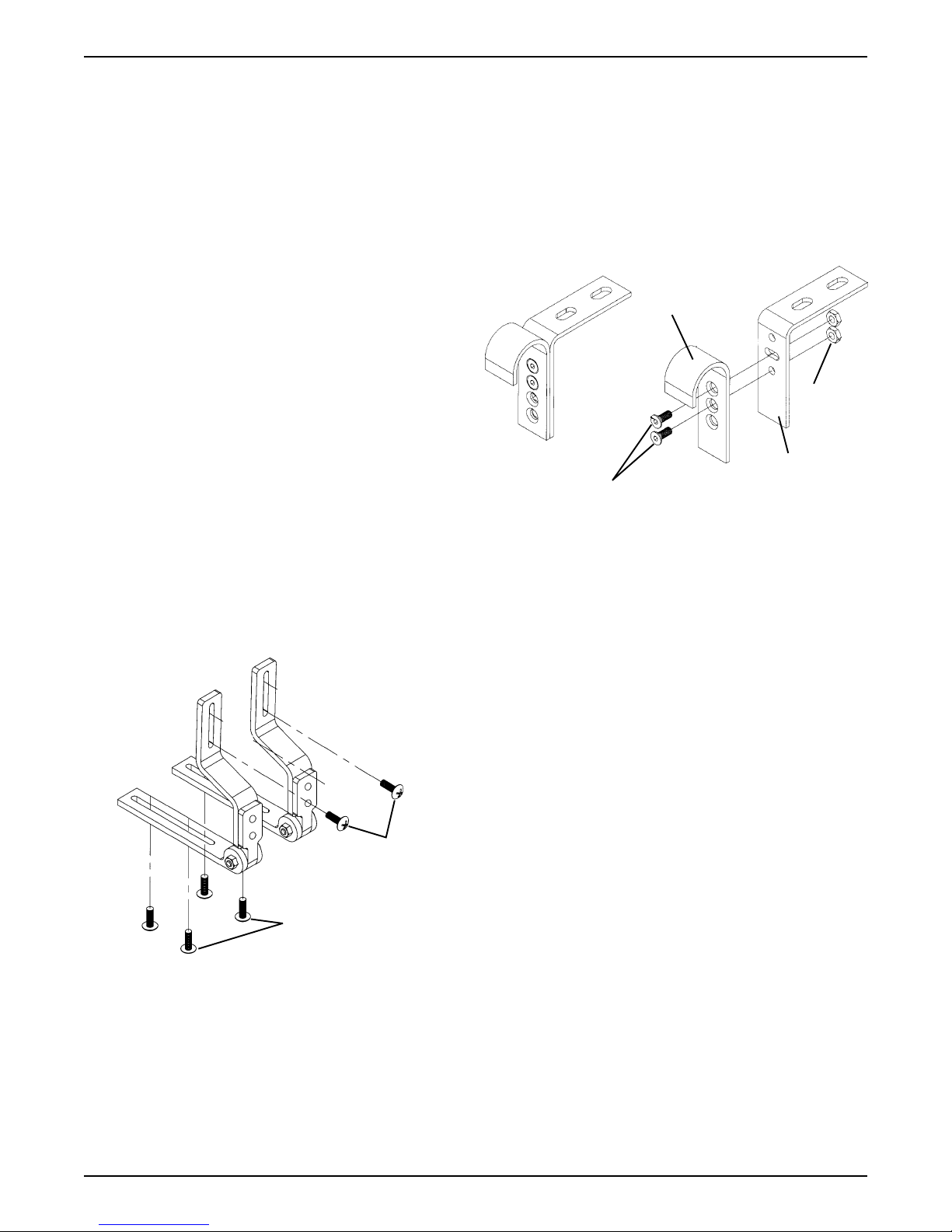

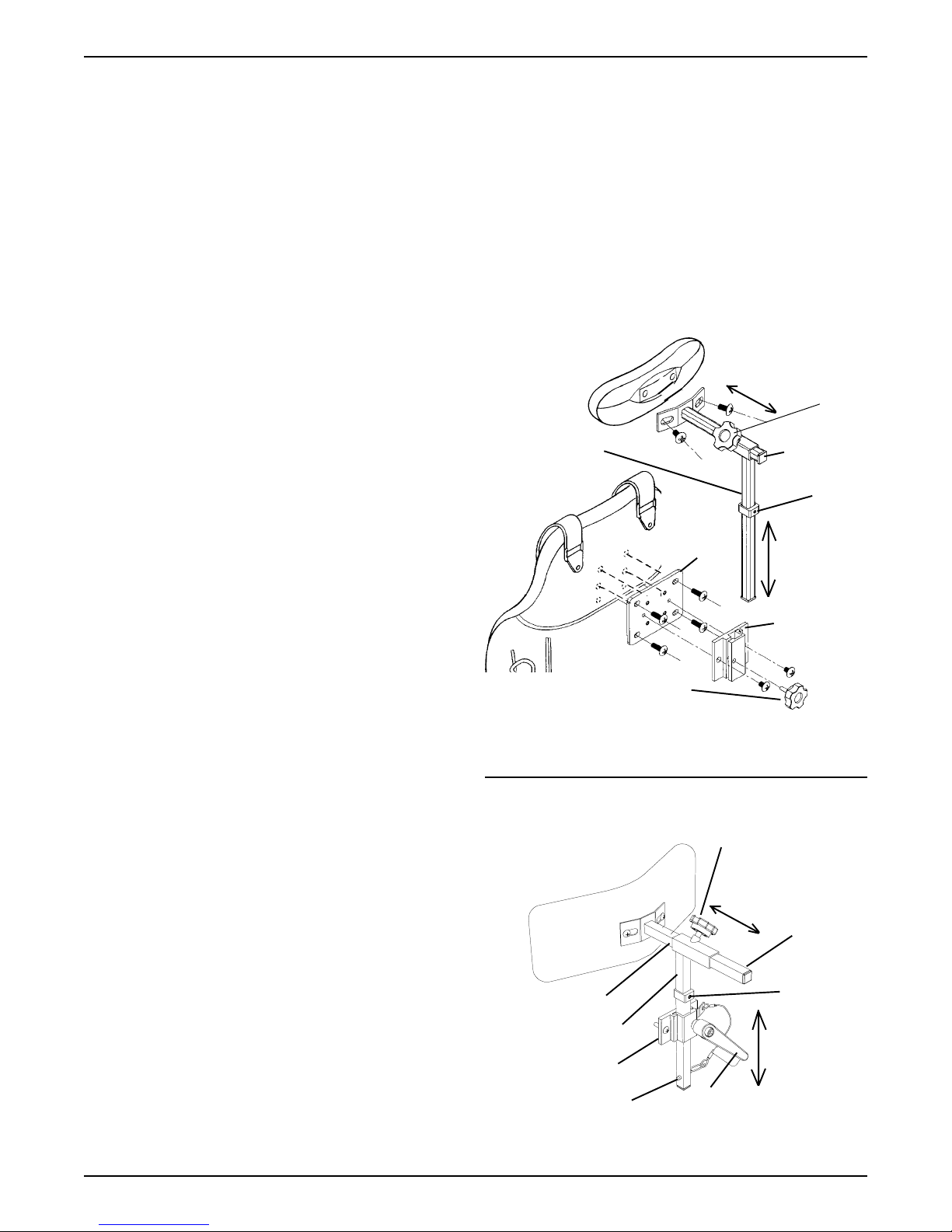

ATTACHING/ADJUSTING THE

FIXED GROWTH BRACKET

NOTE: This procedure only applies the Child/Junior Sizes.

All other procedures are applicable to both the Child/

Junior and Adult Sizes.

Attaching the Growth Bracket

NOTE: Additional mounting hooks and mounting screws

are supplied for the Ulti-Mate Seat and Curved Back.

This additional hardware is taking the place of the growth

bracket.

1. Remove the curved back, Ulti-Mate Base, and growth

bracket from their respective packages.

2. Unzip center panel of the back cover, exposing the

six (6) T-nutted mounting holes.

NOTE: Make sure the growth bracket is positioned correctly . The flat portion of the growth bracket provides depth

adjustment for the Ulti-Mate Base. The angled portion of

the growth bracket provides height adjustment for the

Curved Back. See FIGURE 1.

3. Install four (4) of the mounting screws through the

holes in the growth bracket and into the back shell.

Securely tighten.

1

NOTE: On the back, the standard attachment points are

the top and bottom sets of holes. Refer to the A TTACH-

MENT POINTS chart in this instruction sheet for optional

attachment points.

4. Install four (4) of the mounting screws through the

holes in the growth bracket and into the underside of

the Ulti-Mate Base. Securely tighten.

NOTE: On the seat, the standard attachment points are

the front and back sets of holes. Refer to the ATT ACH-

MENT POINTS chart in this instruction sheet for optional

attachment points.

5. If adjustment is required, refer to ADJUSTING THE

GROWTH BRACKET in this instruction sheet. Otherwise, continue on with A TTACHING/ADJUSTING

THE LA TERAL SUPPORTS in this instruction sheet.

ADJUSTING THE ULTI-MATE BASE

DEPTH.

1. Remove the four (4) mounting screws that secure

the growth bracket to the Ulti-Mate Base.

2. Adjust the seat forward or back until the desired

mounting position is obtained.

3. Reinstall the four (4) mounting screws through the

growth bracket and into the seat. Securely tighten.

chart

Refer to the ATTACHMENT POINTS

instruction sheet for standard and optional attachment points.

in this

ATTACHING / ADJUSTING THE

ADJUSTABLE ANGLE GROWTH

BRACKET (FIGURE 2)

Curved

Back

Center Panel

Top Set

Bottom Set

Ulti-Mate

Base

Adjustment

Holes

NOTE: Your Growth Bracket may have SLOTS instead of Adjustment Holes.

FIGURE 1 - FIGURE 1 -

FIGURE 1 -

FIGURE 1 - FIGURE 1 -

GRGR

GR

GRGR

AA

A

AA

OO

WTH BRAWTH BRA

O

WTH BRA

OO

WTH BRAWTH BRA

T TT T

AA

CHING/ADJUSTING CHING/ADJUSTING

T T

A

CHING/ADJUSTING

T TT T

AA

CHING/ADJUSTING CHING/ADJUSTING

CKETCKET

-CHILD/JUNIOR SIZES-CHILD/JUNIOR SIZES

CKET

-CHILD/JUNIOR SIZES

CKETCKET

-CHILD/JUNIOR SIZES-CHILD/JUNIOR SIZES

Six (6) T-nutted

Mounting Holes

Mounting

Screws

Growth Bracket

THE FIXEDTHE FIXED

THE FIXED

THE FIXEDTHE FIXED

Adjusting the Growth Bracket (FIGURE 1)

NOTE:The growth bracket provides up to a 3-inch depth

adjustment and up to a 3-inch height adjustment.

ADJUSTING THE BACK HEIGHT.

1. If necessary, unzip center panel of the back cover.

2. Remove the four (4) mounting screws that secure

the growth bracket to the back.

3. Adjust the back up or down until the desired mounting position is obtained.

4. Reinstall the four (4) mounting screws through the

growth bracket and into the back shell. Securely

tighten. Refer to the ATTACHMENT POINTS

in this instruction sheet for standard and optional

attachment points.

5. If all attachments and adjustments are complete, zip

center panel of back cover closed.

chart

ATTACHING THE ADJUSTABLE ANGLE

GROWTH BRACKET

NOTE: The growth bracket attaches to the child/junior

sized curved back ONLY.

1. Remove the adjustable angle growth bracket and

attaching hardware from the packaging.

2. Unzip the center panel of the back cover, exposing

the six (6) T-nutted mounting holes.

NOTE: Make sure that the growth bracket is positioned

correctly . The flat portion of the adjustable angle bracket

growth bracket provides depth adjustment for the Ultimate base. The angled portion of the adjustable angle

bracket height adjustment for the curved back

(FIGURE 1).

3. Install four (4) of the mounting screws through the

slots in the adjustable angle growth bracket and into

the underside of the Ulti-mate base. Securely tighten.

NOTE: On the Ulti-mate base, the standard attachment

points are the front and rear four (4) holes. Refer to the

ATTACHMENT POINTS

optional attachment points.

4. Install two (2) of the mounting screws through the

slots on the adjustable angle growth bracket and

into the back shell. Securely tighten.

NOTE: On the curved back, the standard attachment

points are the MIDDLE set of holes. Refer to the

ATTACHMENT POINTS

optional attachment points.

5. If adjustment is required, refer to ADJUSTING THE

GROWTH BRACKET in this instruction sheet.

in this instruction sheet for

in this instruction sheet for

ADJUSTING THE GROWTH BRACKET

ADJUSTING THE BACK HEIGHT.

1. If necessary, unzip center panel of the back cover.

2

2. Loosen the two (2) mounting screws that secure the

growth bracket to the back.

1. Remove the two (2) attaching screws and nuts on

the adjustable angle back hooks.

3. Adjust the back up or down until the desired mounting position is obtained.

4. Securely tighten the two (2) mounting screws.

5. If more adjustment is needed, the adjustment screws

can be completely removed, and the bracket set to

a NEW T-nutted hole location. Refer to the

A TTACHMENT POINTS

optional attachment points.

6. Zip center panel of back cover closed.

in this instruction sheet for

ADJUSTING THE ULTI-MATE BASE DEPTH.

1. If necessary, unzip center panel of the back cover.

2. Loosen the four (4) mounting screws that secure the

growth bracket to the Ulti-Mate Base.

3. Adjust the seat forward or back until the desired

mounting position is obtained.

4. Securely tighten the two (2) mounting screws.

5. If more adjustment is needed, the adjustment screws

can be completely removed, and the bracket set to

a NEW T-nutted hole location. Refer to the

A TTACHMENT POINTS

optional attachment points.

6. Zip center panel of back cover closed.

in this instruction sheet for

2. Recline the back to the desired angle.

3. Align one (1) round hole and one (1) slotted hole on

the back L-bracket with two (2) of the holes on the

hook portion.

4. Reinstall the two (2) screws and nuts and securely

tighten.

Hook Portion

Nuts

L-Bracket

Attaching Screws

FIGURE 3 - FIGURE 3 -

FIGURE 3 -

FIGURE 3 - FIGURE 3 -

ADJUSTING ADJUSTING

ADJUSTING

ADJUSTING ADJUSTING

THE THE

ANGLE OF ANGLE OF

THE

ANGLE OF

THE THE

ANGLE OF ANGLE OF

THE BTHE B

THE B

THE BTHE B

AA

A

AA

CKCK

CK

CKCK

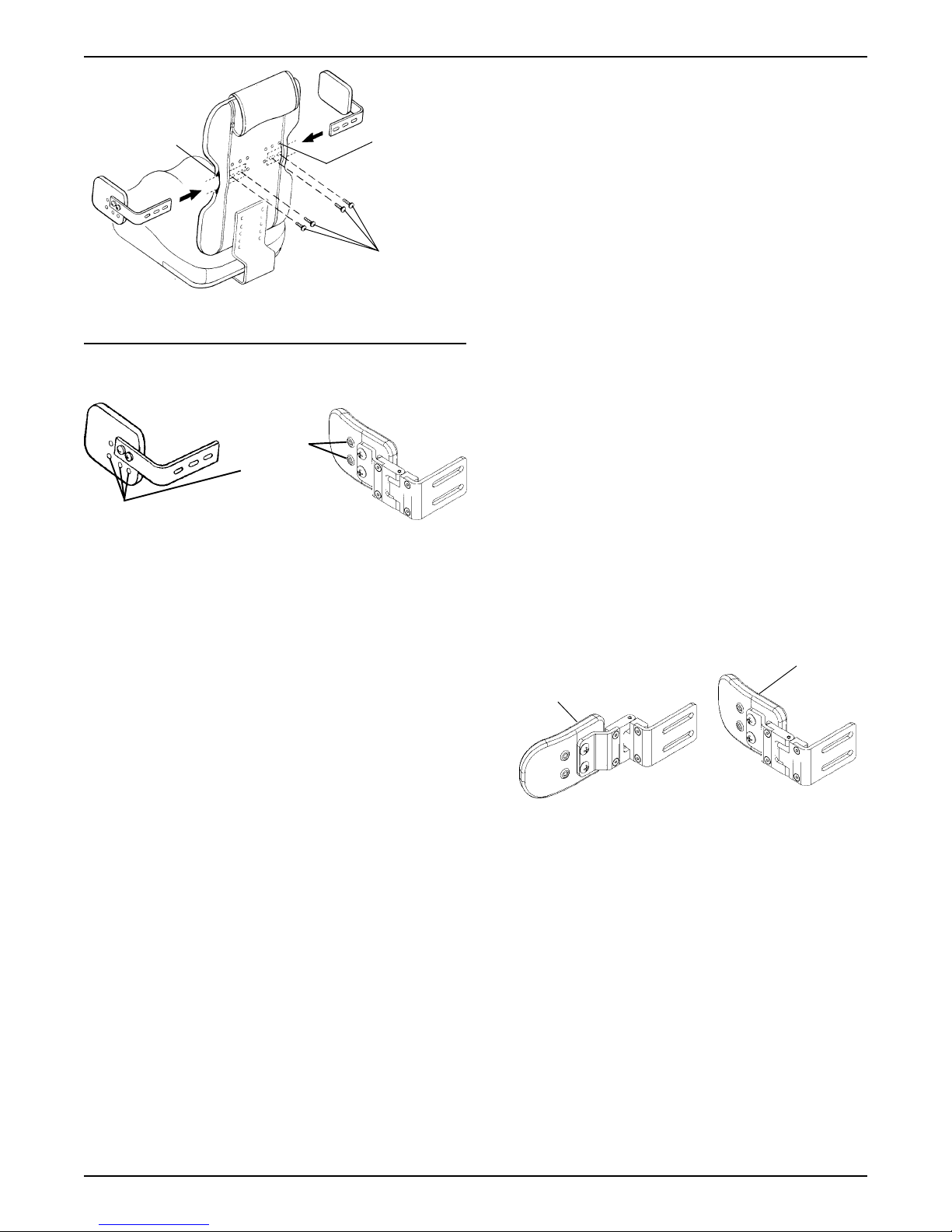

ATTACHING/ADJUSTING THE

LATERAL SUPPORTS (FIGURE 4)

Attaching

1. Remove lateral support and mounting hardware from

packaging.

Top Mounting

Screws

Bottom Mounting

Screws

FIGURE 2 - FIGURE 2 -

FIGURE 2 -

FIGURE 2 - FIGURE 2 -

ADJUSTADJUST

ADJUST

ADJUSTADJUST

AA

A

AA

ABLE ABLE

ABLE

ABLE ABLE

TTTT

AA

CHING / CHING /

TT

A

CHING /

TTTT

AA

CHING / CHING /

ANGLE GRANGLE GR

ANGLE GR

ANGLE GRANGLE GR

ADJUSTING ADJUSTING

ADJUSTING

ADJUSTING ADJUSTING

OO

WTH BRAWTH BRA

O

WTH BRA

OO

WTH BRAWTH BRA

THETHE

THE

THETHE

CKETCKET

CKET

CKETCKET

ADJUSTING THE ANGLE OF THE BACK

(FIGURE 3)

NOTE: The adjustable angle growth bracket is infinitely

angle adjustable. The back-to-seat angle is set by the

location of the mounting points for the back in relation to

the base and by changing the hole positions of the adjustable angle back hooks.

2. Feed lateral support bracket through the slots provided in the back cover.

3. Attach lateral support bracket to back shell as shown

in FIGURE 2 with the two (2) mounting screws pro-

vided. Repeat for opposite side.

4. If adjustment is required, refer to ADJUSTING THE

LATERAL SUPPORTS in this instruction sheet. If

so equipped continue with USING THE SWING-

AW A Y LATERAL SUPPORTS.

Adjusting

NOTE: Lateral supports provide adjustment up to 2inches for height; 2-inches for width, and 1-inch for depth.

STANDARD ADJUSTMENTS.

NOTE: There are additional mounting holes located on

the back shell to provide width and height adjustment for

a more comfortable fit. Only the child/junior size is shown

for clarity . Refer to the ATTACHMENT POINTS chart in

this instruction sheet for standard and optional attachment points.

3

Slot

Standard

Adjustment

T-nutted

Mounting

Holes

3. For height adjustment on adult sizes, remove the

two (2) mounting screws.

4. Raise or lower the lateral support and align the slots

with the back holes in the desired mounting positions.

5. Reinsert the two (2) mounting screws and securely

retighten.

6. Zip center panel of back cover closed.

Mounting

Screws

NOTE: Your Growth Bracket may have SLOTS instead of Adjustment Holes.

FIXED LAFIXED LA

FIXED LA

FIXED LAFIXED LA

SUPPORSUPPOR

SUPPOR

SUPPORSUPPOR

FIGURE 4 - FIGURE 4 -

FIGURE 4 -

FIGURE 4 - FIGURE 4 -

1. If necessary, unzip the center panel of back cover.

2. For minimal width adjustment, loosen the mounting

screws and slide support bracket in or out and retighten mounting screws.

3. For further width and/or height adjustment, remove

the two (2) mounting screws.

TERALTERAL

TERAL

TERALTERAL

TT

T

TT

AA

A

AA

THE LATHE LA

THE LA

THE LATHE LA

SWINGASWINGA

SWINGA

SWINGASWINGA

Optional

Adjustment

Holes

TTTT

AA

CHING/ADJUSTINGCHING/ADJUSTING

TT

A

CHING/ADJUSTING

TTTT

AA

CHING/ADJUSTINGCHING/ADJUSTING

TERAL SUPPORTERAL SUPPOR

TERAL SUPPOR

TERAL SUPPORTERAL SUPPOR

WW

AA

W

A

WW

AA

SUPPORSUPPOR

SUPPOR

SUPPORSUPPOR

TSTS

TS

TSTS

Y LAY LA

Y LA

Y LAY LA

TERALTERAL

TERAL

TERALTERAL

TT

T

TT

Pad Adjustment

1. Unzip the hideaway cover and pull the cover partially off the pad to expose the mounting screws.

2. Remove the two (2) pad mounting screws.

3. Reposition the pad depth to the desired position.

4. Reinsert the two (2) mounting screws and securely

tighten.

5. Zip the hideaway cover over the pad.

USING THE SWINGAWAY

LATERAL SUPPORTS (FIGURE 5)

NOTE: The swingaway lateral supports were designed

for ease in removing the individual from the KSS seating

system.

1. Lift up on the lateral support and push outward, away

from the wheelchair.

2. T o lock lateral support in place, pull back inward until

lateral support snaps in place.

Locked

Position

Unlocked

Position

4. Place the lateral support in the desired mounting

position.

5. Reinsert the two (2) mounting screws. Securely

tighten.

6. If all attachments and adjustments are complete, zip

center panel of back cover closed.

OPTIONAL ADJUSTMENT (FIGURE 4).

1. Fixed lateral supports have height and depth ad-

justment holes on the outside of the padded portion

of the lateral support. Follow STEPS 3-5 in STAN-

DARD ADJUSTMENTS in this section of the instruction sheet. Repeat for opposite lateral support.

SWINGAWAY LATERAL SUPPORTS

Bracket Adjustment

1. Unzip center panel of back cover.

2. For width adjustment, loosen the mounting screws

and slide the support bracket in or out and retighten

the mounting screws.

FIGURE 5 - USING FIGURE 5 - USING

FIGURE 5 - USING

FIGURE 5 - USING FIGURE 5 - USING

LALA

TERAL SUPPORTERAL SUPPOR

LA

TERAL SUPPOR

LALA

TERAL SUPPORTERAL SUPPOR

THE SWINGATHE SWINGA

THE SWINGA

THE SWINGATHE SWINGA

TSTS

TS

TSTS

WW

AA

YY

W

A

Y

WW

AA

YY

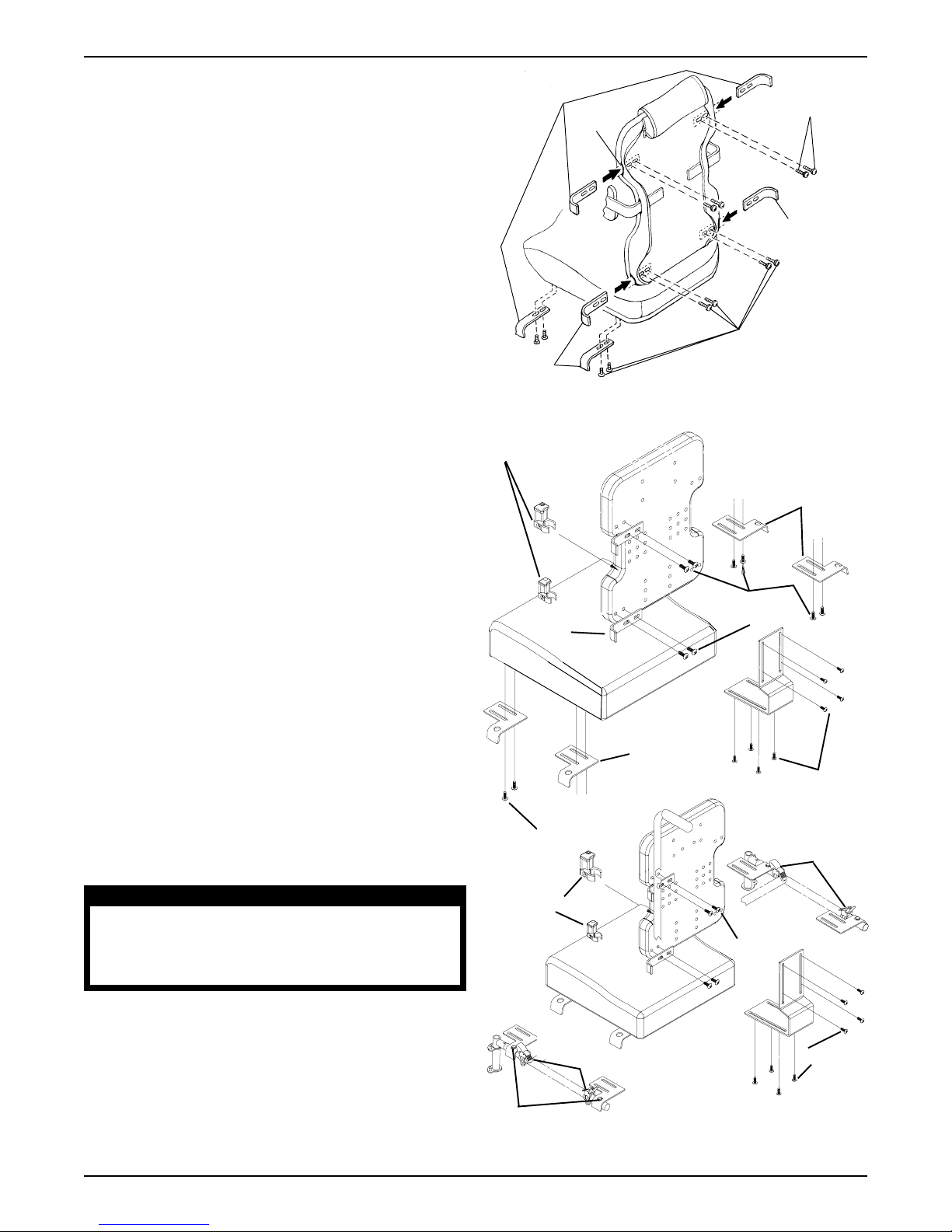

ATTACHING/ADJUSTING THE

MOUNTING HOOKS (FIGURE 6)

Attaching the Mounting Hooks

CHILD/JUNIOR SIZES.

1. Remove four (4) mounting hooks from packaging.

2. Slide one (1) hook through the slot provided in the

back cover. Attach to the upper corner , on either side

of the back, with two (2) of the mounting screws provided. Repeat for opposite side.

3. Attach one (1) mounting hook to the front corner , on

either side of the seat, with two (2) of the mounting

screws provided. Repeat for opposite side.

4

ADULT SIZES.

1. Remove eight (8) mounting hooks from the packaging.

2. Slide one (1) hook through the slot provided in the

back cover. Attach to the upper corner , on either side

of the back, with two (2) of the mounting screws provided. Repeat for opposite side.

3. Slide one (1) hook through the slot provided in the

back cover. Attach to the lower corner , on either side

of the back, with two (2) of the mounting screws provided. Repeat for procedure for opposite side.

4. Attach one (1) mounting hook to the front corner , on

either side of the seat, with two (2) of the mounting

screws provided. Repeat for opposite side.

5. Attach one (1) mounting hook to the back corner , on

either side of the seat, with two (2) of the mounting

screws provided. Repeat for opposite side.

Adjusting the Mounting Hooks

NOTE: Refer to the ATTACHMENT POINTS chart in

this instruction sheet for adjustment locations.

1. If necessary, unzip the back cover.

2. CHILD/JUNIOR AND ADULT SIZES - For minimal

width adjustment, loosen the mounting screws and

adjust the hooks in or out and retighten the mounting screws.

3. ADULT SIZE ONL Y - If further adjustment is needed:

a. Remove the mounting screws that secure the

mounting hooks to the back/seat.

b. Adjust the mounting hooks to desired mounting

position.

c. Reinsert the mounting screws. Securely tighten.

4. TRANSPORT OPTION - For seat adjustment, loosen

the mounting screws and adjust the hooks back and

forth.

NOTE: Some configurations for seat depth changes may

require REVERSING seat mounting hooks.

For back adjustment, loosen the mounting screws

and adjust the hooks side-to-side. Retighten the

mounting screws.

Mounting Hooks

Slot

* Mounting

Hooks

* These items are only

needed on the adult size.

Mounting

Screws

* Mounting

Hook

* Mounting

Screws

TRANSPORT READY OPTION (TRRO)

Twist Release

Clamp

Four (4) Mounting

Hooks

Seat

Mounting

Hooks

Mounting

Screws

Seat Mounting

Hooks

Mounting

Screws

Mounting

Screws

Quick Release

Clamps

WARNING

Ensure the seating system mounting brackets are

correctly positioned and clamps are securely

engaged. Failure to do so may result in serious

bodily injury.

5. If all attachments and adjustments are complete, zip

the back cover closed.

n

NOTE: For 12 and 14-inch seat depth ALL four

(4) mounting holes will be used.

n

NOTE: For 16-inch seat depth the FRONT two

(2) mounting holes will be used.

Twist Release

Clamp

n

See NOTES

FIGURE 6 - FIGURE 6 -

FIGURE 6 -

FIGURE 6 - FIGURE 6 -

5

Quick Release Clamps

AA

TTTT

AA

CHING/ADJUSTING CHING/ADJUSTING

A

TT

A

CHING/ADJUSTING

AA

TTTT

AA

CHING/ADJUSTING CHING/ADJUSTING

MOUNTING HOOKSMOUNTING HOOKS

MOUNTING HOOKS

MOUNTING HOOKSMOUNTING HOOKS

Mounting

Screws

Mounting

Screws

THETHE

THE

THETHE

ATTACHING/ADJUSTING THE

NECK SUPPORT (FIGURE 7)

Attaching the Neck Support

CURVED BACK.

1. Remove neck support bracket from packaging.

2. Unzip back cover on both sides of center panel.

3. Lift center panel.

NOTE: If a NEW neck support is used on an EXISTING

Curved Back than the adapter plate and support bracket

MUST be used.

NOTE: If a NEW neck support is used on a NEW Curved

Back than the support bracket can be used WITHOUT

the adapter plate.

4. Perform Steps 4a. and 4b. or 4c.:

a. Secure neck adapter plate to the back shell

with the four (4) mounting screws provided (If

applicable).

b. Then secure the neck support bracket to the

neck adapter plate using the two (2) mounting

screws provided.

c. Secure the vertical neck post to the back shell

using the two (2) mounting screws provided.

5. Close center panel with the vertical neck post exposed through the slot provided in upholstery.

6. Zip the back cover closed.

7. Insert horizontal post into vertical post and secure

with thumbscrew knob.

8. Insert vertical post into neck support bracket.

9. Secure with a thumbscrew knob or adjustable lever.

10. Insert detent pin into through both walls of vertical

post (Transport Ready Option [TRRO]).

11. If adjustment is required, refer to ADJUSTING THE

NECK SUPPORT in this instruction sheet.

ULTI-MATE AIR BACK.

NOTE: The standard attachment points are where the

eyelets are located in the upholstery.

1. If there are no eyelets, pierce a hole pattern in the

fabric, that resembles the pattern found on the neck

support bracket. Ensure the pattern is aligned with

the T-nutted holes found on the back shell.

NOTE: The cover may need to be removed to get a

more precise location of the T-nutted holes before piercing the hole pattern in the fabric.

NOTE: There is an extra set of T-nutted holes found on the

back shell for optional height adjustment. T o make these holes

accessible, pierce a hole in the fabric aligned with the T-nutted hole in the back shell. Repeat for opposite hole.

NOTE: If a NEW neck support is used on an EXISTING

Curved Back than the adapter plate and support bracket

MUST be used.

NOTE: If a NEW neck support is used on a NEW Curved

Back than the support bracket can be used WITHOUT

the adapter plate.

2. Secure neck adapter plate to the back shell with the

four (4) long mounting screws provided.

3. Attach neck support bracket to the adapter plate using

the two (2) short mounting screws provided.

4. Insert horizontal post into vertical post and secure

with thumbscrew.

5. If adjustment is required, refer to ADJUSTING

THE NECK SUPPORT in this instruction sheet.

Depth

Adjustment

Vertical Post

Neck

Adapter

Plate

Neck Support

Thumbscrew Knob

NOTE: Only the curved back is shown for clarity. The

neck support on the Ulti-mate Air Back adjusts in the

same manner.

NOTE: Ensure that the retaining screw is located

in the end of the horizontal post.

Thumbscrew Knob

Depth

Adjustment

Horizontal Post

Vertical Post

Neck Support

Bracket

Detent Pin

NOTE: Neck Adapter Plate NOT shown.

FIGURE 7 - FIGURE 7 -

FIGURE 7 -

FIGURE 7 - FIGURE 7 -

ADJUSTING ADJUSTING

ADJUSTING

ADJUSTING ADJUSTING

Adjustment Lever

THE NECK SUPPORTHE NECK SUPPOR

THE NECK SUPPOR

THE NECK SUPPORTHE NECK SUPPOR

Thumb-

screw

Knob

Horizontal

Post

Height

Adjustment

Stop

Height

Adjustment

Bracket

Retaining

Screw

Height

Adjustment

Stop

Height

Adjustment

TT

T

TT

6

ADJUSTING THE NECK SUPPORT

Curved Back and Ulti-Mate Air Back

1. Height Adjustment - Loosen the thumbscrew knob

or adjustment lever on the neck support bracket.

Loosen the height adjustment stop setscrew. Adjust

the neck support to the desired height and retighten

the thumbscrew knob or adjustment lever. Slide

height adjustment stop to the top of the support

bracket and retighten setscrew.

Insert detent pin into through both walls of vertical post (Transport Ready Option [TRRO]).

NOTE: The height adjustment stop allows the neck support to be removed for transfers, then reinstalled back to

the exact height set by the location of the height adjustment stop.

2. Depth Adjustment - Loosen the thumbscrew knob

on the horizontal post, adjust the neck support to the

desired depth and retighten the thumbscrew knob.

NOTE: On the Ulti-Mate Air Back further adjustment can

be obtained by utilizing the extra set of T-nutted holes in

the back shell. Refer to A TT ACHING THE NECK SUP-

PORT in this instruction sheet.

ATTACHING/ADJUSTING THE

HEIGHT/REVERSING THE

PAD/USING THE FLIP DOWN

ABDUCTOR (FIGURE 8)

Reversing the Cushion of the Flip

Down Abductor (FIGURE 8-DETAIL "B")

1. To unlock and flip down abductor, press release

button (FIGURE 8-DETAIL "C").

2. Using a socket key, remove the adjustment

screw and washer on the vertical portion of the

mounting bracket.

3. Completely remove the top tube from the telescoping tube assembly.

4. Rotate top portion 180

5. Reinstall top tube portion.

6. Follow STEPS 4-5 in ADJUSTING THE FLIP

DOWN ABDUCTOR.

DETDET

AIL "A"AIL "A"

DET

AIL "A"

DETDET

AIL "A"AIL "A"

Flip-Down

Abductor

Flip-Down

Abductor

DETDET

AIL "B"AIL "B"

DET

AIL "B"

DETDET

AIL "B"AIL "B"

Flip-Down

Abductor

Bracket

o.

Seat

Mounting

Screws

Attaching the Flip Down Abductor (FIGURE

8-DETAIL "A")

NOTE: Refer to the ATTACHMENT POINTS chart in

this instruction sheet for attachment location.

1. Remove the flip down abductor and attaching hardware from packaging.

2. Attach the flip down abductor bracket to the underside

of the seat with the four (4) mounting screws provided.

3. To remove the flip down abductor reverse STEP 2.

Adjusting the Height of the Flip Down

Abductor (FIGURE 8-DETAIL "B")

1. To unlock and flip down abductor, press release button (FIGURE 8-DET AIL "C").

2. Using a socket key , loosen the adjustment screw on

the vertical portion of the mounting bracket.

3. Adjust the flip down abductor to the desired height.

4. Securely tighten the adjustment screw and then

check pad height.

5. Repeat Steps 1 through 4 until proper height is

obtained.

Mounting

Screws

Telescoping

Tube Assembly

DETDET

AIL "C"AIL "C"

DET

AIL "C"

DETDET

AIL "C"AIL "C"

FIGURE 8 - FIGURE 8 -

FIGURE 8 -

FIGURE 8 - FIGURE 8 -

HEIGHT/REVERSING HEIGHT/REVERSING

HEIGHT/REVERSING

HEIGHT/REVERSING HEIGHT/REVERSING

USING USING

USING

USING USING

AA

A

AA

THE FLIP DOTHE FLIP DO

THE FLIP DO

THE FLIP DOTHE FLIP DO

Flip-Down

Abductor

Bracket

Release

Button

TTTT

AA

CHING/ADJUSTING CHING/ADJUSTING

TT

A

CHING/ADJUSTING

TTTT

AA

CHING/ADJUSTING CHING/ADJUSTING

Adjusting Screw

Locked

Position

Unlocked

Position

THE CUSHION/THE CUSHION/

THE CUSHION/

THE CUSHION/THE CUSHION/

WN WN

WN

WN WN

ABDUCTABDUCT

ABDUCT

ABDUCTABDUCT

OROR

OR

OROR

THETHE

THE

THETHE

Using the Flip-Down Abductor

(FIGURE 8-DETAIL "C")

1. To unlock and flip down press release button.

2. To lock in place pull up on abductor until an audible click is heard.

7

ATTACHING/USING THE LAP

BELT (FIGURES 9 AND 10)

Attaching the Lap Belt

WARNING

It is strongly recommended that the lap belt

be strapped across the hip area with an

angle of 45o to the seating surface. Angles

less than 45o make it easier for the user to slip

under the belt if it is improperly tightened.

1. The lap belt can be anchored in one (1) of the

two (2) possible locations:

a. In one (1) of the T-nutted holes located on

the underside of the seat.

b. In one (1) of the holes in the side frame of

the wheelchair.

NOTE: DO NOT reposition the lap belt mounting

location from the factory installation on the TRANSPORT READY OPTION (TRRO).

NOTE: The most desirable location for the mounting screws will be determined by the size of the

client involved and the angle achieved by trying the

various attachment points with the client seated

comfortably in the wheelchair.

SEASEA

T T

ATTATT

AA

FRAME FRAME

FRAME

FRAME FRAME

ATTATT

ATT

ATTATT

AA

CHMENTCHMENT

A

CHMENT

AA

CHMENTCHMENT

SEA

SEASEA

T

T T

ATT

ATTATT

CHMENTCHMENT

A

CHMENT

AA

CHMENTCHMENT

2. Determine the most suitable attachment point. Put

the padded side of the belt toward the seating

surface.

3. Align the hole located at the anchor end of the

belt with the chosen attachment point and insert

one (1) of the mounting screws provided. HAND

TIGHTEN ONLY. Repeat for opposite side.

Using the Lap Belt

WARNING

Ensure that the seat is fixed to the wheelchair .

A loose seat may lead to potentially dangerous situations with positioning devices.

It is strongly recommended that the lap belt

be strapped across the hip area with an

angle of 45

less than 45o make it easier for the user to slip

under the belt if it is improperly tightened.

NOTE: Stabilize from the ground up. A stable base

(seat) and footrest are the first steps to a stable

pelvis. Also, the user should be lightly clothed for

the initial adjustment.

NOTE: A belt angle of 45

best stability and positioning. The belt will apply its

pressure directly to the hips, usually allowing more

force to be applied without discomfort.

o

to the seating surface. Angles

o

will usually provide the

Mounting

Screws

Lap Belt

Wheelchair

Frame

Lap Belt (Acceptable lap belt angle is 45o)

B

a

c

k

Seat

45

o

B

a

c

k

Seat

Mounting Screws

B

a

c

k

Seat

Lap

Belt

1. Adjust the slide, located at each end of the belt,

to fit the client with proper tension.

2. The plastic D-rings, located at the front of the belt,

can be pulled or released to conveniently tighten

the belt to provide extra tension if needed or

loosen the belt to allow for bulky clothing, etc.

NOTE: When all final adjustments have been made

and the client is comfortable with the fit of the lap

belt, any excess lengths of material can be cut off,

keeping in mind the potential future growth of the

client. The cut end can be melted slightly to prevent fraying.

NOTE: Only the Child/Junior lap belt is shown for clarity .

Anchor

End

Padded

Portion

D-Rings

Buckle

Slider

FIGURE 9 - FIGURE 9 -

FIGURE 9 -

FIGURE 9 - FIGURE 9 -

AA

TTTT

A

TT

AA

TTTT

AA

CHING CHING

A

CHING

AA

CHING CHING

THE LAP BELTHE LAP BEL

THE LAP BEL

THE LAP BELTHE LAP BEL

FIGURE 10 - USING FIGURE 10 - USING

FIGURE 10 - USING

TT

T

TT

FIGURE 10 - USING FIGURE 10 - USING

THE LAP BELTHE LAP BEL

THE LAP BEL

THE LAP BELTHE LAP BEL

TT

T

TT

8

POSITIONING/ADJUSTING THE KSS

SEATING SYSTEM IN THE

WHEELCHAIR

HARDWARE REFERENCE CHART

NOTE: This chart is a general guideline for recommended mounting hardware.

With the individual positioned in the KSS seating system:

1. Check that the width and height of the system is

fitted properly to the individual using the system. If

adjustment is needed, refer to ADJUSTING THE

GROWTH BRACKET in this instruction sheet.

2. Check to make sure the neck support is properly

positioned, with the correct height and depth, for the

individual using the system. If adjustment is needed,

refer to ADJUSTING THE NECK SUPPORT in this

instruction sheet.

3. Check to make sure the lateral supports are properly positioned, with the correct width and height, for

the individual using the system. If adjustment is

needed, refer to ADJUSTING THE LA TERAL SUP-

PORTS in this instruction sheet.

4. Check to make sure the flip-down abductor is securely tightened.

5. Check to make sure the lap belt is securely fastened.

Is the lap belt uncomfortably compressing the abdomen when properly tightened? You can mount the

anchor points further forward to increase the belt

angle. If adjustment is necessary , refer to A TT ACH-

ING/USING THE LAP BEL T in this instruction sheet.

SECURING THE KSS SEATING SYSTEM

TO THE WHEELCHAIR FRAME

The following recommendations are made for the safe

installation and use of mounting hardware on seating

systems:

SAFETY SUMMARY

GENERAL W ARNING

Hardware Clamps

With With Out

Growth Bracket Growth Bracket

BACK Twist Release Twist Release

(SEE FIGURE 11) Fixed Release

(SEE FIGURE 13)

SEAT Quick Release Quick Release

(SEE FIGURE 12) Fixed Release

(SEE FIGURE 14)

PROCEDURE 1 - INSTALLING

CLAMPS ON SEATING SYSTEMS

WITH A GROWTH BRACKET

Twist Release Clamps For Back (FIGURE 11)

NOTE: Refer to INSTALLATION WARNING in the

SAFETY SUMMARY before proceeding.

1. Make sure that the back mounting hooks are flush

against the back canes.

2. Loosen the socket screw that opens the twist release clamp.

NOTE: There is a right and left twist release clamp.

Make sure when installing that the socket screw

adjustment is on the outside of the wheelchair

frame.

NOTE: FOR TRANSPORT READY OPTION (TRRO) There is a right and left twist release clamp. Make sure

when installing that the socket screw adjustment is on

the INSIDE of the wheelchair frame.

3. Install the open end of the twist release clamp below

the back mounting hook so that the locking mechanism rests on top of the back mounting hook.

Ensure that the seat and back of the seating system are fixed to the wheelchair. A loose seat or

back may lead to potentially dangerous situations with positioning devices.

Ensure that ALL hardware is tight at ALL times.

INST ALLATION WARNING

DO NOT install twist, quick, and fixed release

clamps in any other locations than specified in

this instruction sheet - otherwise, the seating system will not be secured properly to the wheelchair and bodily injury may occur.

4. Loosely tighten the socket screw.

5. Repeat STEPS 1- 4 for the other side.

6. Make sure both twist release clamps are flush

against the back mounting hooks and that the locking mechanism rests on top of the back mounting

hooks.

7. Torque socket screw to 75 - inch pounds.

9

Locking Mechanism

7. Once quick release mounting clamps are secured,

do one (1) of following:

Twist Release

Cane Clamp

Socket Screw

Inside

Back Cane

Seat Rail

NOTE: For TRANSPORT READY OPTION (TRRO)

Twist Release Cane Clamp is REVERSED.

FIGURE 11- FIGURE 11-

FIGURE 11-

FIGURE 11- FIGURE 11-

8. Once twist release mounting clamps are secured, do

one (1) of following:

A. Refer to QUICK RELEASE CLAMPS FOR

B. Refer to USING CLAMPS in this instruction

TWIST RELEASE CLAMPS FOR BTWIST RELEASE CLAMPS FOR B

TWIST RELEASE CLAMPS FOR B

TWIST RELEASE CLAMPS FOR BTWIST RELEASE CLAMPS FOR B

SEAT in PROCEDURE 1 of this instruction sheet.

sheet.

Back Mounting

Hook

AA

CKCK

A

CK

AA

CKCK

Quick Release Clamps For Seat

(FIGURE 12)

A. Refer to TWIST RELEASE CLAMPS FOR

BACK in PROCEDURE 1 of this instruction

sheet.

B. Refer to USING CLAMPS in this instruction

sheet.

DETDET

AIL AIL

DET

Insert

Lock Washer

Sleeve

Back Cane

Fixed

Portion

Mounting Hook

FIGURE 12- QUICK RELEASE CLAMPS FOR SEAFIGURE 12- QUICK RELEASE CLAMPS FOR SEA

FIGURE 12- QUICK RELEASE CLAMPS FOR SEA

FIGURE 12- QUICK RELEASE CLAMPS FOR SEAFIGURE 12- QUICK RELEASE CLAMPS FOR SEA

Quick Release

Rail Clamp

DETDET

““

AIL

“

AIL AIL

““

Internal

Mounting

Screw

Release

Portion

PROCEDURE 2 - INSTALLING

CLAMPS ON SEATING SYSTEMS

WITHOUT A GROWTH BRACKET

A”A”

A”

A”A”

TT

T

TT

NOTE: Refer to INSTALLATION WARNING in the

SAFETY SUMMARY before proceeding.

NOTE: The quick release clamps are designed to fit

either 1-inch rail tubing or, with insert provided, 7/8-inch

rail tubing.

1. Remove the sleeve, lock washer, and internal

threaded mounting screw from the quick release

clamp (DET AIL “A”).

2. Place the quick release clamp on the seat rail.

3. If quick release clamp is not tightly fitted around seat

rail tubing, install insert provided as shown in DE-

T AIL “A”.

4. Install the quick release clamp onto the seat rail so

that the fixed portion is flush against and rests on top

of the mounting hook and the release portion is between the front riggings and the mounting hook.

5. Reinstall the sleeve, lock washer , and internal mounting screw into the quick release rail clamp and torque

to 75 - inch pounds.

6. Repeat STEPS 1- 5 for other side.

Twist Release Clamps For Back

(FIGURE 11)

NOTE: Refer to INSTALLATION WARNING in the

SAFETY SUMMARY before proceeding.

1. Make sure that the back mounting hooks are flush

against the back canes.

2. Loosen the socket screw that opens the twist release clamp.

NOTE: There is a right and left twist release clamp. Make

sure when installing that the socket screw adjustment is

on the outside of the wheelchair frame.

3. Install the open end of the twist release clamp below

the back mounting hook so that the locking mechanism rests on top of the mounting hook.

4. Loosely tighten the socket screw.

5. Repeat STEPS 1- 4 for the other side.

6. Make sure both twist release clamps are flush against

the back mounting hooks and that the locking mechanism rests on top of the back mounting hooks.

10

7. Torque socket screw to 75 - inch pounds.

8. Once twist release mounting clamps are secured,

do one (1) of following:

A. Refer to FIXED RELEASE CLAMPS FOR

BACK in PROCEDURE 2 of this instruction

sheet.

B. Refer to USING CLAMPS in this instruction

sheet.

DETDET

AIL AIL

DET

AIL

DETDET

AIL AIL

Mounting

Hook

Back Cane

“B”“B”

“B”

“B”“B”

Sleeve

Lock

Washer

Fixed

Portion

Internal Mounting

Screw

Fixed Release Clamps For Back (FIGURE 13)

NOTE: Refer to INSTALLATION WARNING in the

SAFETY SUMMARY before proceeding.

NOTE: The fixed release rail/cane clamps are designed

to fit either 1-inch rail tubing or, with insert provided, 7/8inch rail tubing.

1. Remove the mounting screw, lock washer, and

internal threaded mounting screw from the fixed

release clamps (DET AIL “B”).

2. Place the fixed release clamp on the back cane.

3. If fixed release clamp is not tightly fitted around back

cane tubing, install insert provided as shown in DE-

T AIL “A”.

4. Install the fixed release clamp onto the back rail so

that the fixed portion is flush against and rests on top

of the mounting hook and is located between the

seat rail and the bottom of the mounting hook.

5. Reinstall the mounting screw, lock washer, and

internal mounting screw into the fixed release rail/

cane clamp and torque to 75 - inch pounds.

6. Repeat STEPS 1 - 5 for other side.

7. Once fixed release mounting clamps are secured,

do one (1) of following:

A. Refer to QUICK RELEASE CLAMPS FOR

SEAT in PROCEDURE 2 of this instruction sheet.

B. Refer to USING CLAMPS in this instruction sheet.

Twist Release

Mounting

Hooks

Clamp

Inside of Back Cane

FIGURE 13- FIXED RELEASE CLAMPS FOR BFIGURE 13- FIXED RELEASE CLAMPS FOR B

FIGURE 13- FIXED RELEASE CLAMPS FOR B

FIGURE 13- FIXED RELEASE CLAMPS FOR BFIGURE 13- FIXED RELEASE CLAMPS FOR B

AA

A

AA

CKCK

CK

CKCK

Quick Release Clamps For Seat

(FIGURE 14)

NOTE: Refer to INSTALLATION WARNING in the

SAFETY SUMMARY before proceeding.

NOTE: The quick release and fixed release clamps are

designed to fit either 1-inch rail tubing or, with insert provided, 7/8-inch rail tubing.

1. Remove the sleeve, lock washer, and internal threaded

mounting screw from the quick release clamp (DE-

T AIL “C”).

2. Place the quick release clamp on the seat rail.

3. If quick release clamp is not tightly fitted around seat

rail tubing, install insert provided as shown in DE-

T AIL “C”.

4. Install the quick release clamp onto the seat rail so

that the fixed portion is flush against and rests on top

of the mounting hook and the release portion is between the front riggings and the mounting hook.

5. Reinstall the sleeve, lock washer, and internal mounting screw into the quick release clamp and torque to

75 - inch pounds.

6. Repeat STEPS 1- 5 for other side.

7. Once quick release mounting clamps are secured,

do one (1) of following:

A. Refer to FIXED RELEASE CLAMPS FOR

SEAT in PROCEDURE 2 of this instruction

sheet.

B. Refer to USING CLAMPS in this instruction

sheet.

Fixed Release

Clamp

Seat Rail

FIGURE 13- FIXED RELEASE CLAMPS FOR BFIGURE 13- FIXED RELEASE CLAMPS FOR B

FIGURE 13- FIXED RELEASE CLAMPS FOR B

FIGURE 13- FIXED RELEASE CLAMPS FOR BFIGURE 13- FIXED RELEASE CLAMPS FOR B

AA

A

AA

CKCK

CK

CKCK

11

Fixed Release Clamps For Seat

(FIGURE 14)

NOTE: Refer to INSTALLATION WARNING in the

SAFETY SUMMARY before proceeding.

NOTE: The quick release and fixed release clamps are

designed to fit either 1-inch rail tubing or, with insert provided, 7/8-inch rail tubing.

1. Remove the sleeve, lock washer, and internal

threaded mounting screw from the fixed release

clamp (DETAIL “C”).

USING CLAMPS

Twist Release (FIGURE 15)

1. To unlock the cane clamp, twist away from the

back cane.

2. To lock the cane clamp, twist in toward the back.

TT

OP OP

VIEWVIEW

T

OP

VIEW

TT

OP OP

VIEWVIEW

Twist Release

Cane Clamp

2. Place the fixed release clamp on the seat rail.

3. If fixed release clamp is not tightly fitted around seat rail

tubing, install insert provided as shown in DET AIL “C”.

4. Install the fixed release clamp onto the back rail so

that the fixed portion is flush against and rests on top

of the mounting hook and is located between the

seat rail and the bottom of the mounting hook.

5. Reinstall the sleeve, lock washer , and internal mounting screw into the fixed release clamp and torque to

75 - inch pounds.

6. Repeat STEPS 1-5 for other side.

7. Once fixed release mounting clamps are secured,

do one (1) of following:

A. Refer to QUICK RELEASE CLAMPS FOR

SEAT in PROCEDURE 2 of this instruction

sheet.

B. Refer to USING CLAMPS in this instruction sheet.

DETDET

AIL AIL

AIL

AIL AIL

“C”“C”

“C”

“C”“C”

Insert

Lock Washer

Sleeve

DET

DETDET

Internal Mounting Screw

Unlock

Mounting

Hook

Back Cane

NOTE: For TRANSPORT READY OPTION (TRRO)

Twist Release Cane Clamp is REVERSED.

FIGURE 15 - USING CLAMPS - FIGURE 15 - USING CLAMPS -

FIGURE 15 - USING CLAMPS -

FIGURE 15 - USING CLAMPS - FIGURE 15 - USING CLAMPS -

TWIST RELEASETWIST RELEASE

TWIST RELEASE

TWIST RELEASETWIST RELEASE

Back

Quick Release (FIGURE 16)

1. T o unlock, push down on the release tab of the quick

release rail clamps.

2. To lock, push down on the thumb-like feature of the

quick release rail clamps.

TO LOCK APPLY

PRESSURE HERE

TO UNLOCK APPLY

PRESSURE HERE

Back Cane

Fixed

Portion

Fixed Release

Clamp

NOTE: For TRANSPORT READY OPTION (TRRO) use

ONLY Quick Release Clamps on Seat Rails.

FIGURE 14 - QUICK RELEASE FIGURE 14 - QUICK RELEASE

FIGURE 14 - QUICK RELEASE

FIGURE 14 - QUICK RELEASE FIGURE 14 - QUICK RELEASE

RELEASE CLAMPS FOR SEARELEASE CLAMPS FOR SEA

RELEASE CLAMPS FOR SEA

RELEASE CLAMPS FOR SEARELEASE CLAMPS FOR SEA

Mounting

Hooks

Quick Release

Fixed

Portion

Clamp

AND FIXEDAND FIXED

AND FIXED

AND FIXEDAND FIXED

TT

T

TT

Release

Portion

Wheelchair

Frame

Quick Release

Rail Clamp

FIGURE 16 - USING CLAMPS - QUICK RELEASEFIGURE 16 - USING CLAMPS - QUICK RELEASE

FIGURE 16 - USING CLAMPS - QUICK RELEASE

FIGURE 16 - USING CLAMPS - QUICK RELEASEFIGURE 16 - USING CLAMPS - QUICK RELEASE

Mounting

Hook

12

ATTACHMENT POINTS FOR CURVED BACK

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

CHILD/JUNIOR SIZE

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

Top of Back

NN

N

NN

EE

E

EE

CC

C

CC

KK

K

KK

SS

S

SS

UU

U

UU

PP

P

PP

PP

P

PP

OO

O

OO

RR

R

RR

TT

T

TT

Bottom of Back

LL

L

LL

AA

A

AA

TT

T

TT

EE

E

EE

RR

R

RR

AA

A

AA

LL

L

LL

Top of Back

ADULADUL

T SIZET SIZE

ADUL

T SIZE

ADULADUL

T SIZET SIZE

Top of Back

Bottom of Back

Top of Back

SS

S

SS

UU

U

UU

PP

P

PP

PP

P

PP

OO

O

OO

RR

R

RR

TT

T

TT

GG

G

GG

RR

R

RR

OO

O

OO

WW

W

WW

TT

T

TT

HH

H

HH

Two (2) Mounting screws on each side.

BB

B

BB

RR

R

RR

AA

A

AA

CC

C

CC

KK

K

KK

EE

E

EE

TT

T

TT

Bottom of Back

Top of Back

Any combination.

Bottom of Back

Bottom of Back

The Adult Size does not require

a Growth Bracket. Extra mounting

hooks and mounting screws will be

supplied for the Curved Back and

Ulti-Mate Base

13

ATTACHMENT POINTS FOR CURVED BACK

(Continued)

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

CHILD/JUNIOR SIZE

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

ADULADUL

ADUL

ADULADUL

T SIZET SIZE

T SIZE

T SIZET SIZE

Top of Back

SS

S

SS

HH

H

HH

Optional

OO

O

OO

UU

U

UU

LL

L

LL

DD

D

DD

EE

E

EE

RR

R

RR

SS

S

SS

Optional

UU

U

UU

PP

P

PP

PP

P

PP

RR

R

RR

OO

O

OO

TT

T

TT

Standard location is the two (2) holes not

used by the growth bracket

Standard

Bottom of Back

Top of Back

MM

M

MM

OO

O

OO

UU

U

UU

NN

N

NN

TT

T

TT

II

I

II

NN

N

NN

GG

G

GG

Optional

Optional

Top of Back

OptionalStandard StandardOptional

Standard Standard

Top of Back

HH

H

HH

OO

O

OO

OO

O

OO

KK

K

KK

SS

S

SS

Bottom of Back

Bottom of Back

14

ATTACHMENT POINTS FOR ULTI-MATE BASE

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

CHILD/JUNIOR SIZE

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

GG

G

GG

RR

R

RR

OO

O

OO

WW

W

WW

TT

T

TT

HH

H

HH

Two (2) Mounting screws on each side.

BB

B

BB

RR

R

RR

AA

A

AA

CC

C

CC

KK

K

KK

EE

E

EE

TT

T

TT

LL

L

LL

AA

A

AA

PP

P

PP

Standard location is the two (2) holes

BB

B

BB

EE

E

EE

LL

L

LL

TT

T

TT

not used by the growth bracket)

Front of Seat

Any combination.

Rear of Seat

Front of Seat

ADULADUL

T SIZET SIZE

ADUL

T SIZE

ADULADUL

T SIZET SIZE

The Adult Size does not require

a Growth Bracket. Extra mounting

hooks and mounting screws will be

supplied for the Ulti-Mate Base

Front of Seat

Use either of the holes not being

use by the mounting hooks.

Rear of Seat

Lap Belt

(Optional)

Front of Seat

AA

A

AA

BB

B

BB

DD

D

DD

UU

U

UU

CC

C

CC

TT

T

TT

OO

O

OO

RR

R

RR

Rear of Seat

Rear of Seat

Front of Seat

Rear of Seat

15

ATTACHMENT POINTS FOR ULTI-MATE BASE

(Continued)

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

CHILD/JUNIOR SIZE

CHILD/JUNIOR SIZECHILD/JUNIOR SIZE

MM

M

MM

OO

O

OO

UU

U

UU

NN

N

NN

TT

T

TT

II

I

II

NN

N

NN

GG

G

GG

HH

H

HH

OO

O

OO

OO

O

OO

KK

K

KK

SS

S

SS

Front of Seat

Rear of Seat

ADULADUL

T SIZET SIZE

ADUL

T SIZE

ADULADUL

T SIZET SIZE

Front of Seat

Rear of Seat

16

FRONT VIEW BACK VIEW

Neck

Support

KSS SYSTEM FEATURES

Shoulder

Support

Mounting

Hook

Neck

Support

Curved

Back

Curved

Back

Mounting

Hook

Lateral

Support

Mounting

Support

Hook

Ulti-mate

Base

Lateral

Support

Ulti-mate Base

Lap Belt

(Transport Ready

Option [TRRO]

NOT shown.)

Abductor

CHILD/JUNIOR SIZE

Lateral

Support

Mounting

Hook

Lap Belt

FRONT VIEW BACK VIEW

Neck

Shoulder

Support

Curved

Back

Shoulder

Support

Growth Bracket

Neck

Support

Curved

Back

Mounting

Hook

Lateral

Support

Mounting

Hook

Ulti-mate

Base

Lateral

Support

Lap Belt (Transport

Ready Option [TRRO]

NOT shown.)

Abductor

Lateral

Support

Ulti-mate Base

Mounting

Hooks

ADULT SIZE

17

Mounting

Hooks

Shoulder

Support

Lap Belt

WASHING INSTRUCTIONS - COVERS

Outer Cover

1. Can be machine washed and dried.

2. DO NOT use bleach.

3. We DO NOT recommend machine washing or drying for colored NEOPRENE child cushion covers.

NOTE: We recommend cleaning the cover on a regular

basis.

Inner Cover (If applicable)

1. Hand wash with a damp cloth.

2. We DO NOT recommend machine washing or drying.

Neoprene Cover

1. Hand Wash in luke warm water (80OF) in mild detergent.

2. Drip dry in sun.

3. No bleach or toluene.

4. NOT recommended for machine drying.

18

PARTS LIST - CHILD/JUNIOR AND ADULT ONLY

(NOT FOR TRANSPORT READY OPTION [TRRO])

Mounting Hooks available:

3-Inch Drop

2-Inch Drop

1-Inch Drop

Flush Mount

99

9

99

88

8

88

1111

11

1111

1212

12

1212

33

3

33

99

9

99

1111

11

1111

1212

12

1212

11

1

1212

12

1212

1111

11

1111

1212

12

1212

11

55

5

55

44

4

44

1212

12

1212

1111

11

1111

12

1212

1212

1010

10

1010

55

5

55

22

2

22

1212

12

1212

66

6

66

NOTE: Your Growth

Bracket may have

SLOTS instead of

Adjustment Holes.

1212

12

1212

P ARTS LIST

QUANTITY

ITEM DESCRIPTION CHILD/JUNIOR ADUL T

1 CURVED BACK 1 1

2 SEAT 1 1

3 NECK SUPPORT ASSEMBLY 1 1

4 NECK SUPPORT BRACKET 1 1

5 LATERAL SUPPORT 2 2

6 GROWTH BRACKET 1 N/A

7 LAP BELT* 1 1

8 ABDUCTOR 1 1

9 TWIST RELEASE CANE CLAMP ASSEMBLY 2 2

10 QUICK RELEASE RAIL CLAMP ASSEMBLY 2 4

11 MOUNTING HOOKS** 4 8

12 MOUNTING SCREWS INCL INCL

* Lap belt not shown

** Mounting hooks available for the seat are: flush mount, 1-inch drop, 2-inch drop, and 3-inch drop

Mounting hooks available for the back are: flush mount, 1-inch recess, 2-inch recess, and 3-inch recess

19

LIMITED W ARRANTY

PLEASE NOTE: THE WARRANTY BELOW HAS BEEN DRAFTED TO COMPLY WITH FEDERAL LAW APPLICABLE TO PRODUCTS MANUF ACTURED AFTER JULY 4, 1975.

This warranty is extended only to the original purchaser/user of our products.

This warranty gives you specific legal rights and you may also have other legal rights which vary

from state to state.

Invacare warrants its product to be free from defects in materials and workmanship for the period

of two (2) years of use by original purchaser. All covers are warranted for 90 days only. If within

such warranty period any such product shall be proven to be defective, such product shall be

repaired or replaced, at Invacare's option. This warranty does not include any labor or shipping

charges incurred in replacement part installation or repair of any such product. Invacare's sole

obligation and your exclusive remedy under this warranty shall be limited to such repair and/or

replacement.

For warranty service, please contact the dealer from whom you purchased your Invacare product. In the event you do not receive satisfactory warranty service, please write directly to Invacare

at the address on the next page. Provide dealer's name, address, model number, date of purchase, indicate nature of the defect and, if the product is serialized, indicate the serial number.

Invacare Corporation will issue a return authorization. The defective unit or parts must be returned

for warranty inspection using the serial number , when applicable, as identification within thirty (30)

days of return authorization date. DO NOT return products to our factory without our prior consent.

C.O.D. shipments will be refused; please prepay shipping charges.

LIMIT ATIONS AND EXCLUSIONS: THE WARRANTY SHALL NOT APPLY TO PROBLEMS ARISING FROM

NORMAL WEAR OR FAILURE TO ADHERE TO THE ENCLOSED INSTRUCTIONS. IN ADDITION, THE FOREGOING W ARRANTY SHALL NOT APPLY TO SERIAL NUMBERED PRODUCTS IF THE SERIAL NUMBER HAS

BEEN REMOVED OR DEFACED; PRODUCTS SUBJECTED TO NEGLIGENCE, ACCIDENT, IMPROPER

OPERATION, MAINTENANCE OR STORAGE; OR PRODUCTS MODIFIED WITHOUT INV ACARE'S EXPRESS

WRITTEN CONSENT INCLUDING, BUT NOT LIMITED TO: MODIFICATION THROUGH THE USE OF UNAUTHORIZED P ARTS OR ATTACHMENTS: PRODUCTS DAMAGED BY REASON OF REPAIRS MADE TO ANY

COMPONENT WITHOUT THE SPECIFIC CONSENT OF INVACARE; PRODUCTS DAMAGED BY CIRCUMSTANCES BEYOND INVACARE'S CONTROL; PRODUCTS REPAIRED BY ANYONE OTHER THAN AN AUTHORIZED INVACARE DEALER, SUCH EVALUATION SHALL BE SOLELY DETERMINED BY INVACARE.

THE FOREGOING W ARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS W ARRANTIES, IF ANY,

INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

IT SHALL NOT EXTEND BEYOND THE DURATION OF THE EXPRESSED WARRANTY PROVIDED HEREIN

AND THE REMEDY FOR VIOLATIONS OF ANY IMPLIED WARRANTY SHALL BE LIMITED TO REPAIR OR

REPLACEMENT OF THE DEFECTIVE PRODUCT PURSUANT TO THE TERMS CONT AINED HEREIN. INV ACARE

SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENT AL DAMAGES WHATSOEVER.

THIS WARRANTY SHALL BE EXTENDED TO COMPLY WITH STATE/PROVINCIAL LAWS AND REQUIREMENTS.

INVINV

AA

CC

ARE CORPORAARE CORPORA

INV

A

C

ARE CORPORA

INVINV

AA

CC

ARE CORPORAARE CORPORA

INVACARE CANADA

TION TION

TION l

TION TION

l 5970 Chedworth Way l Mississauga, Ontario Canada L5R 3T9

Phone (905) 890-8300, 1-800-668-5324, Fax (905)-890-5244

For m No. 96-306 Part No. 1068446 Rev. C (1) - 7/99 Printed in U.S.A.

ONE INVONE INV

ONE INV

ONE INVONE INV

AA

CC

ARE ARE

C

CC

ARE

ARE ARE

WW

W

WW

A

AA

Phone 1-(800)-333-6900Phone 1-(800)-333-6900

Phone 1-(800)-333-6900

Phone 1-(800)-333-6900Phone 1-(800)-333-6900

AA

A

AA

Y Y

Y l

Y Y

PP

.O.O

..

Bo Bo

.O

.O.O

.

Bo

..

Bo Bo

x 4028 x 4028

x 4028 l

x 4028 x 4028

P

PP

ElyrElyr

ia,ia,

Ohio 44036-2125 Ohio 44036-2125

Elyr

ia,

Ohio 44036-2125 l

ElyrElyr

ia,ia,

Ohio 44036-2125 Ohio 44036-2125

l

Loading...

Loading...