Page 1

PROCEDURE

10

FAN

PROCEDURE

TO

ELECTRICAL

Unplug

>

"Τι

1

Ζ

Remove

Remove

op

Remove

BLY

5.

Remove

NOTE:

erly

6.

Remove

7.

Move

8,

Disconnect

9.

Remove

10.

Remove

10

PREVENT

OUTLET

unit.

cabinet

control

compressor

OR

CAPACITOR).

heat

Before

reinstalled

removing

the

fan

to

wires

GREEN

existing

to

four

access

REPLACING

-

ELECTRICAL

BEFORE

(Refer

panel

exchanger

secure

(4)

from

fan.

to

(Refer

assembly

the

heat

mounting

the

wires

spade

ground

COOLING

SHOCK,

SERVICING,

PROCEDURE

to

PROCEDURE

(Refer

(Refer

wire

to

four

(4)

mounting

exchanger.

screws

connected

connectors

from

CAUTION

ALWAYS

1 -

to

PROCEDURE

PROCEDURE

located

to

fan.

on

back

rear

of

fan

(FIGURE

FAN

DISCONNECT

REMOVING

9 - REMOVING

8 - REPLACING

clips,

note

under

by

sound

side

of

removing

1)

CABINET).

CONTROL

7 - REPLACING

HEAT

their

position.

box and

fan.

self-tapping

remove

CONCENTRATOR

PANEL).

COMPRESSOR

EXCHANGER).

These

screw

clips

mounting

on

fan

FROM

ASSEM-

must

be

prop-

clips.

assembly.

Fan

must

be

flow

arrow

11.

Reverse

12.

Reinstail

13.

Reinstall

on

STEPS

heat

compressor

CAPACITOR).

14.

Reinstall

15.

Plug

NOTE:

nical

Service.

16.

Reinstall

unit

Run

contro!

in

unit

cabinet

positioned

back

of

fan)

6-9

exchanger

panel

and

check

for

at

least

(Refer

properly

or

damage

to

install

(Refer

(Refer

(Refer

for

leaks

1/2

to

PROCEDURE

WARNING

so

air

from

to

the

NEW

fan.

to

PROCEDURE

to

PROCEDURE 7 -

to

PROCEDURE

(Refer

hour.

If

to

PROCEDURE

unit

runs

1 -

the

fan

unit

will

8 - REPLACING

REPLACING

9 - REMOVING

properly,

REMOVING

blows

occur.

19 - LEAK

replace

CABINET).

DOWN

onto

HEAT

COMPRESSOR

CONTROL

TEST).

cover.

the

compressor

EXCHANGER).

ASSEMBLY

PANEL).

If

not,

call

Invacare

(see

Tech-

air

OR

4-9

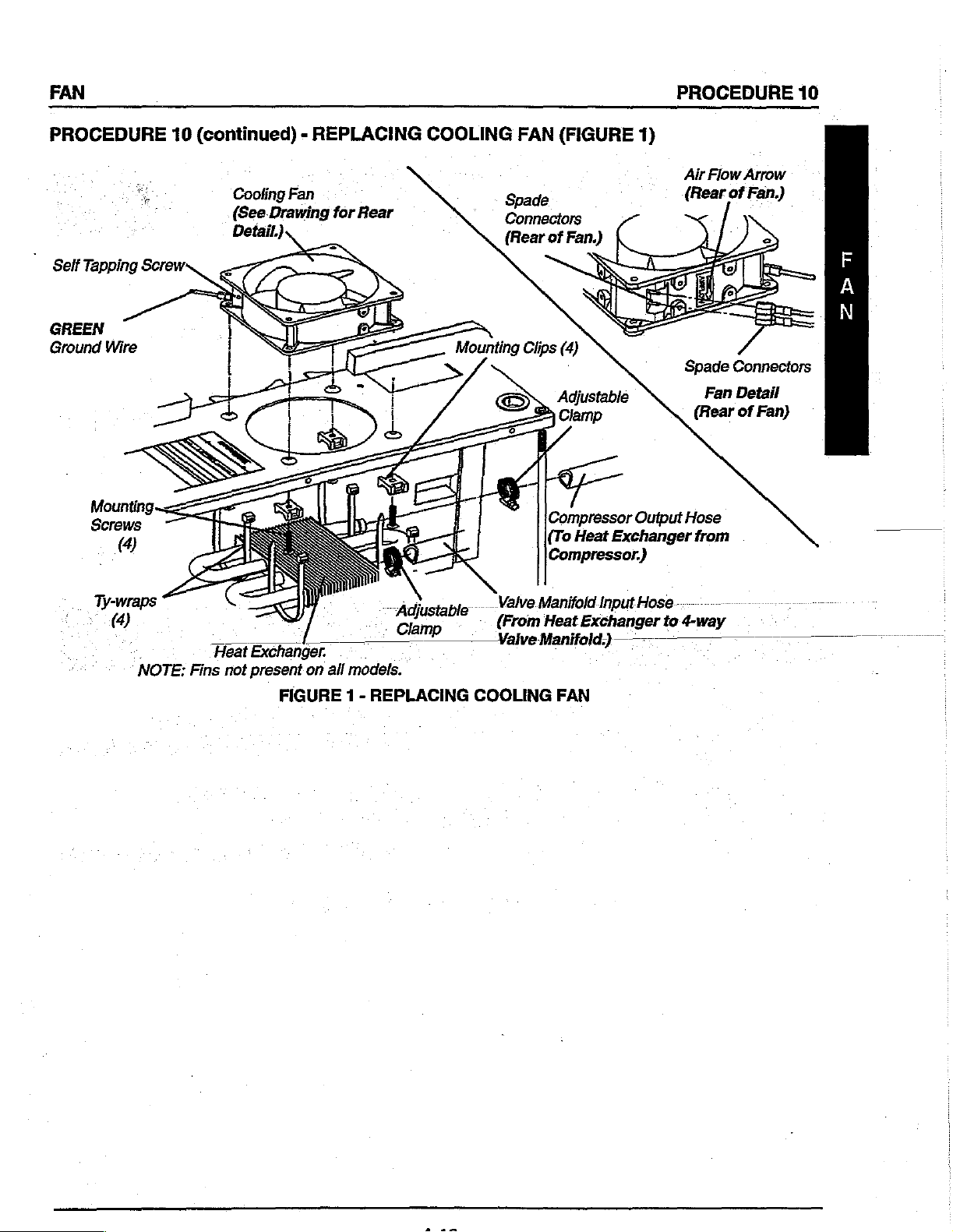

Page 2

FAN

PROCEDURE

10

PROCEDURE

GREEN

Ground

Wire

10

(continued) - REPLACING

Cooling

(See.Drawing

Detail.)

Fan

for

Rear

COOLING

FAN

(FIGURE

Spade

Connectors

(Rear

of

Fan.)

Adjustable

=

Clamp

Compressor

(To

Heat

Compressor.)

1)

Output

Exchanger

Air

Flow

(Rear

Spade

Fan

(Rear

Hose

from

Arrow

of

Fan.)

Connectors

Detail

of

Fan)

2pm

Ty-wraps

“4

.

NOTE:

DA

Heat

Fins

Exchanger.

not

present

on

FIGURE

all

models.

1 -

~

,

Cum

一

REPLACING

Valve

>

(From

—

ValveManifold)

COOLING

Manifold

Heat

Input

Exchanger

FAN

Hose

to

4-way

Page 3

PROCEDURE

11

P.C.

BOARD

REPLACEMENT

PROCEDURE

TO

P

ELECTRICAL

C

1.

B

2.

0

3.

A

R

D

ONLY

S

These

Before

the

tor

available.

When

solder

slight

Before

4, . Remove

PREVENT

Unplug

Remove

Remove

unit.

cabinet

control

QUALIFIED

are

precautions

handling

components

clip.

Electrical

Care

removing

joint

may

rocking

installing

Sensor

11 - REPLACING

ELECTRICAL

OUTLET

any

of

should

quick

occur.

motion

any

BEFORE

(Refer

panel

to

(Refer

SERVICE

that

P.

C.

boards,

the

board. A Static

conduit

or a water

be

taken

disconnects,

Hold

to

remove

P.

C.

boards,

Wiring

Hamess

PROCEDURE 1 -

TECHNICIANS

should

P.C.

SHOCK,

SERVICING.

to

PROCEDURE

be

you

to

ensure

down

the

the

ensure

Jumper

BOARD(S)

CAUTION

ALWAYS

REMOVING

WARNING

SHOULD

followed

need

to

Cuff

must

pipe

is

normally

that

DO

NOT

pull

P.

C.

board

terminals.

that

(P2)

Кот

(FIGURE

DISCONNECT

9 - REMOVING

MAKE

to

prevent

be

properly

be

worn

sufficient

alligator

all

insulators

Р.С.

clip

on

wire

with

one

board(s)

1)

CABINET).

CONTROL

ANY

CHANGES

damage

grounded

and

contact

itself

hand

are

to

be

to

properly

when a known

as

and

in

place.

replaced,

CONCENTRATOR

PANEL).

TO

THIS

the

P,

C.

to

prevent

grounded

good

with

bare

metal

damage

use

to

an

upward

EQUIPMENT.

boards:

static

damage

using

ground

surface.

the

connector

force

FROM

an

alliga-

is

with

to

not

or

a

5.

Disconnect

DO

NOT

sensor

3LX,

assembly

SLX

Sens02

a)

Sensor

CONTROL

Control

a)

Wiring

b)

Wiring

©)

Transformer connector(P3).

d)

Pressure

Integrated

a)

Wiring

b)

Wiring

©

Transformer

d)

Pressure

e)

Oxygen

CONTROL

f)

Wiring

the

remove

and

5LXO2

(Top)

tubing

PANEL).

(Bottom)

Hamess

Hamess

transducer

Board

Hamess

Hamess

transducer

Sensor

Hamess

following:

sensor

could

before

PC.

Board

from

P.C.

from

from

(5LXO2/5LXO2T/6LXO2/6L.XO2T)

from

from

connector(P3).

PANEL).

occur.

(SLXO2

“T*

Board

9-Pin

8-Pin

tubing

9-Pin

8-Pin

tubing

tubing

from

4-pin

tubing

from

P.C.

S/N97JXXXX

ONLY):

fitting

(3LX,

Wiring

Wiring

from

Wiring

Wiring

from

from

behind

SLX,

5LXO2):

Hamess

Hamess

producttank.

Hamess

Hamess

producttank.

“T°

fitting

wiring

Connector(P5).

behind

hamess

CAUTION

Board.

control

Connector

Remove

panel

(P1).

(Refer

Connector(P5).

After

S/N97JXXXX

Connector

connector

(P1).

control

panel

(P6)

from

to

(Refer

to

[5LXO2T,

tee

fitting

PROCEDURE

PROCEDURE

6LXO2T

Telemetry

ONLY.

Damage

9 - REMOVING

9 - REMOVING

Unit

to

ONLY].

Remote

a)

6.

Pinch

Display

Sensor

end

wiring

hamess

of

each

Board

if

not

stand-off

disconnected

with

needle-nose

in

STEP

pliers

4-11

1.

and

remove

the

P.C.

Board(s).

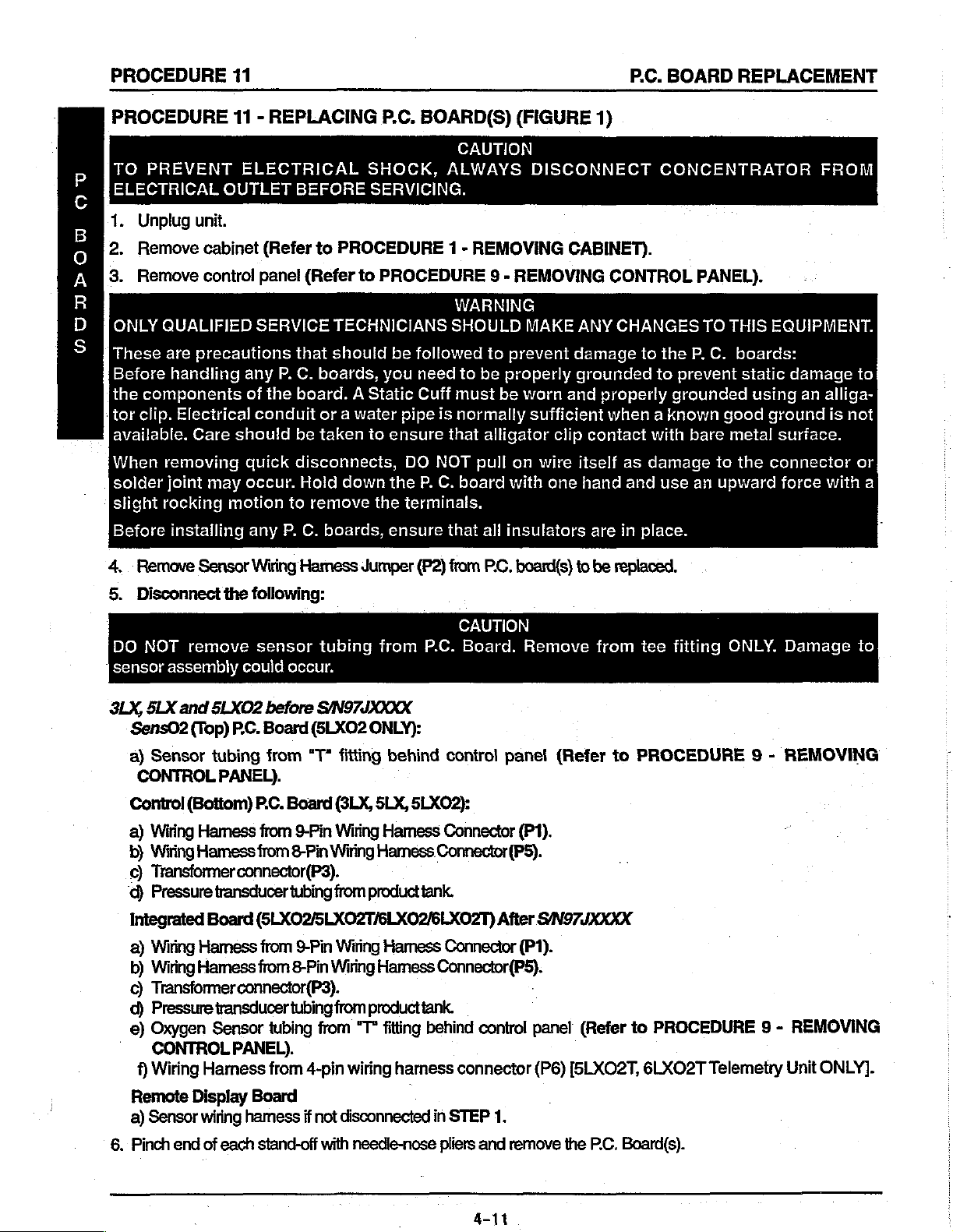

Page 4

P.C.

BOARD

PROCEDURE

11

PROCEDURE

7.

Position

8.

Snap

9,

3LX,

SensO2

a)

CONTROL

Control

a)

_-b)

c)

10.’

Reinstall

11.

Reconnect

12.

Settiming

13.

Run

NOTE:

TIMING

14.

Check

manual.

NEW

P.C.

Board(s)

SLX

and

or

integrated

Sensor

Wiring

Wiring

Transformer

THE

tubing

(Bottom)

Harness

Harness

Sensor

P6

switch

únitand

After

ensure

replacing

INVACARE

for

leaks

11

(continued)-

PCC.

board(s).

into

place.

SLXO2

after

(Top)

to

"T"

PANEL).

P.C.

Board

to

to

connector

Wiring

(4-pin

connector)

to

position

that

OXYGEN

at

transducer

^

SIN

97JXXXX.

P.C.

fitting

(IRC3LX,

9-Pin

Wiring

8-Pin

Wiring

(P3).

Hamess

concentrator

P.C.

Jumper(P2)

"F"

for

Board(s),

CONCENTRATOR.

tubing

REPLACING

а

Connect

Board

(5LXO2

behind

IRCSLX,

Harness

Hamess

on

wiring

3LX.

operates

retiming

on

product

ONLY}:

control

IRCSLXO2):

Connector

Connector

to

P.C.

harness

to

specification.

tank

P.C.

BOARD(S)

the

following:

panel

board(s).

may

cap

(Refer

(P1).

(P5).

on

Telemetry

be

-

(Refer

:

necessary.

to

(FIGURE

to

PROCEDURE

Units

ONLY.

(Refer

PROCEDURE

1)

9 - REMOVING

to.

PROCEDURE

19 - LEAK

.

TEST

in

18

-

this

Ou

OODUDPOU

15,

Reinstall

46.

Reinstall

P2

(Remove

Harness

Sensor

9

Pin

Connector

Jumper.)

Wiring

Wiring

(To P1)

control

cabinet

panel

(Refer

INTEGRATED

SETUP

5LXO2

SIN97JXXXX

Sensor

Hamess

Hamess

Wiring

Jumper

(Refer

to

PROCEDURE

to

PROCEDURE 1 -REMOVING

SensO2

(SLXOZ,

After

|

9-

REMOVING

PC.

(Top)

SLXOZT,

プン

”

ono

CONTROL

CABINET).

BOARD

6LXO2,

PANEL).

REAR

Stand-offs

Transformer

8-Pin

Wiring

Connector

Hamess

(To

P5)

4

F2

(Remove

FIGURE

1 -

REPLACING

Ὃ

Wiring

É

P.

—

C.

BOARD(S)

CONTROL

(8LX,5LX,

(Bottom)

5LXO2,

P.C.

5LXO2T,

BOARD

6LXO2,

BLXO2T)

Page 5

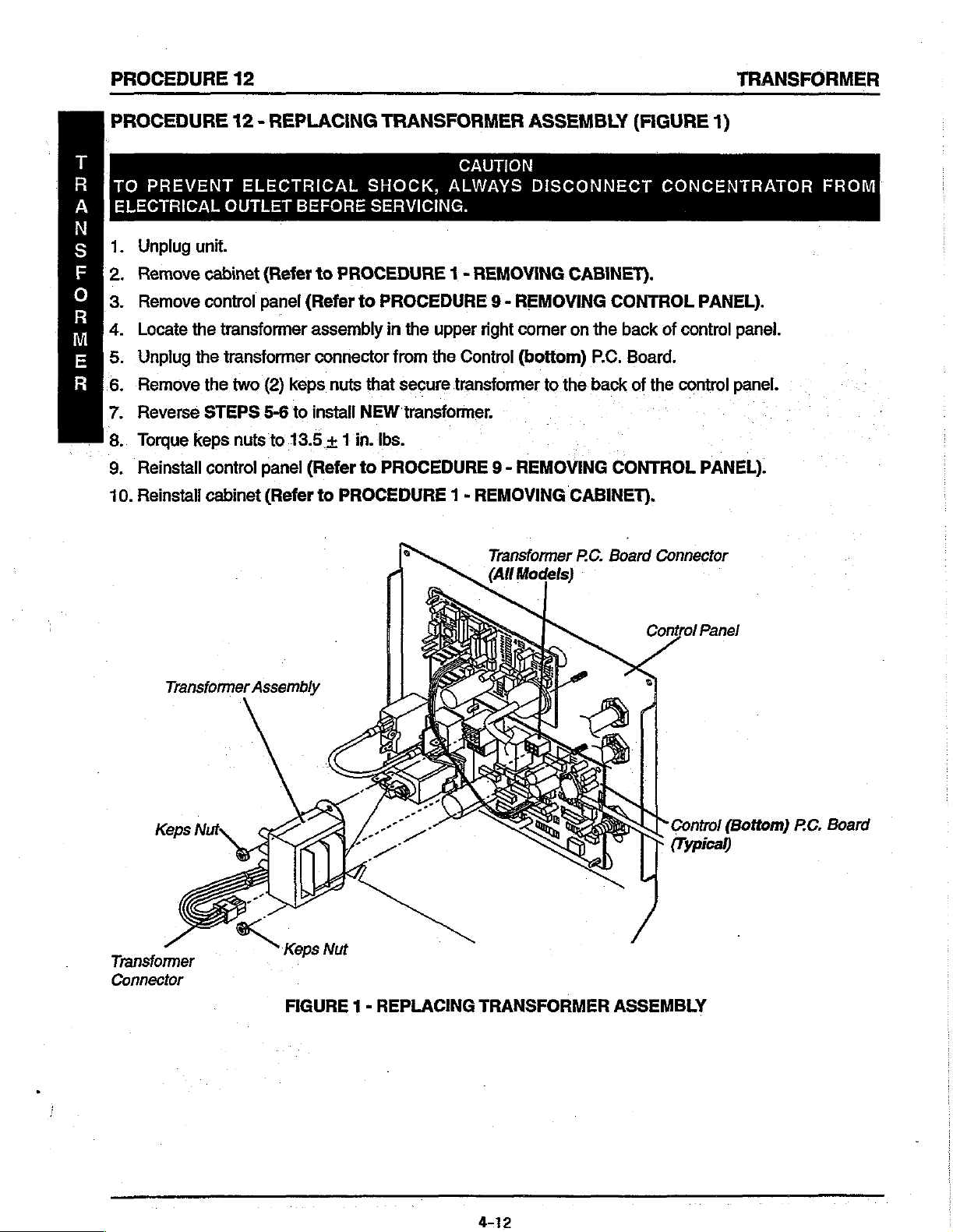

PROCEDURE

12

TRANSFORMER

PROCEDURE

TO

PREVENT

ELECTRICAL OUTLET

Unplug

>

Remove

Remove

ON

Locate

Unplug

DMSTONOZPIA

Remove

Oar

Reverse

Torque

DN

.

Reinstall

9

10.

Reinstall

unit.

cabinet

control

the

the

the

STEPS

keps

contro!

cabinet

12 - REPLACING

ELECTRICAL

BEFORE

(Refer

panel

transformer

transformer

two

(2)

5-6

nuts

panel

(Refer

(Refer

keps

to

to

13.5 + 1

to

assembly

connector

install

(Refer

to

TRANSFORMER

SHOCK,

SERVICING.

PROCEDURE

to

PROCEDURE

in

from

nuts

that

secure

NEW

in.

lbs.

to

PROCEDURE

PROCEDURE

CAUTION

ALWAYS

1 - REMOVING

9 - REMOVING

the

upper

the

transformer.

right

Conirol

transformer

9 - REMOVING

1 - REMOVING

Transformer

(All

ASSEMBLY

DISCONNECT

CABINET).

comer

(bottom)

Models)

on

to

the

CABINET).

PC.

(FIGURE

CONTROL

the

back

P.C.

Board.

back

of

CONTROL

Board

1)

CONCENTRATOR

PANEL).

of

control

the

control

Connector

panel.

panel.

PANEL).

FROM

Transformer

Transformer

Connector

Assembly

FIGURE 1 -

REPLACING

TRANSFORMER

Control

ASSEMBLY

Panel

Page 6

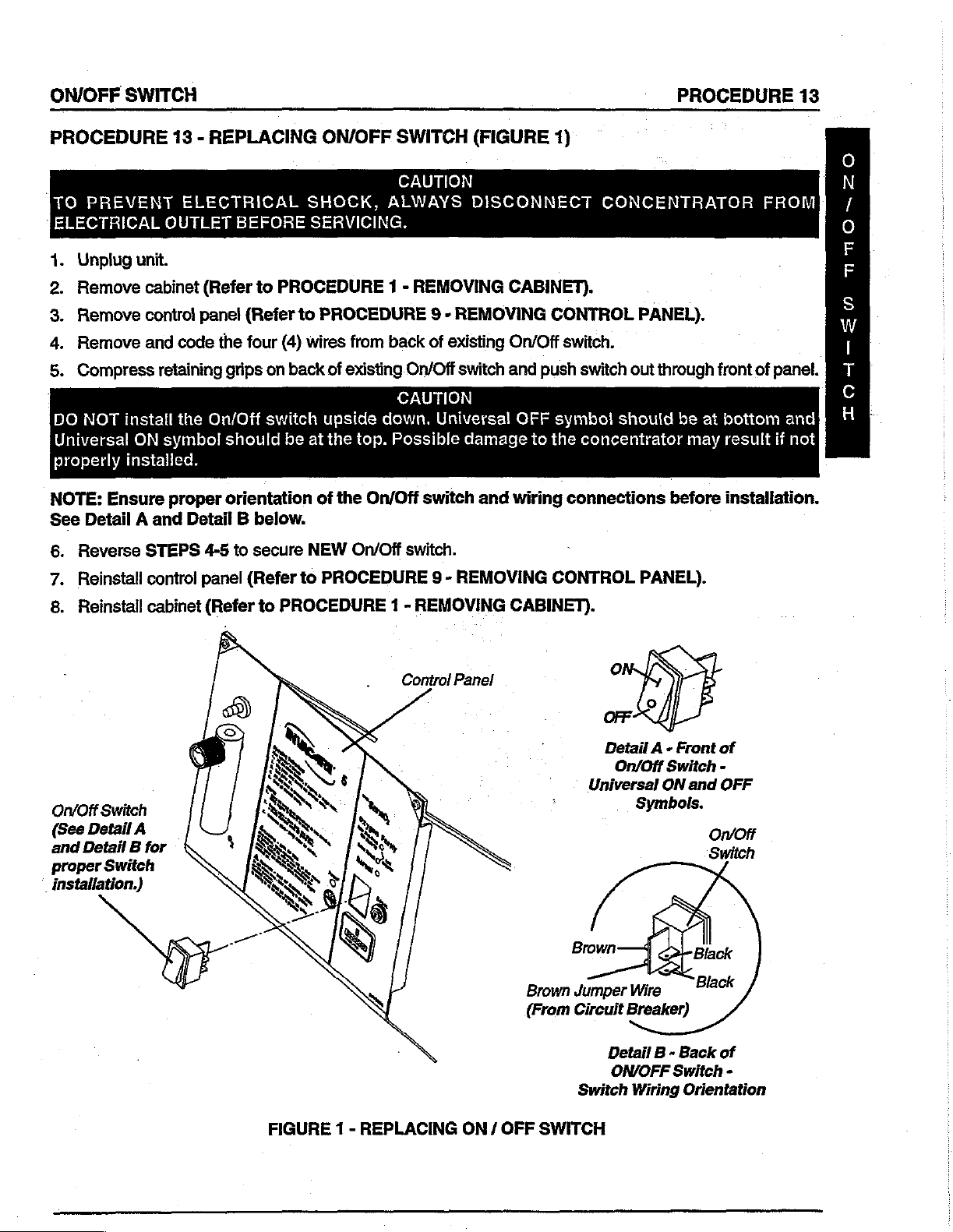

ON/OFF

SWITCH

PROCEDURE

13

PROCEDURE

TO

PREVENT

ELECTRICAL

Unplug

=

Remove

Remove

Remove

Compress

FREON,

DO

NOT

install

Universal

properly

NOTE:

See

6.

Reverse

7.

Reinstall

installed.

Ensure

Detail A and

13 - REPLACING

ELECTRICAL

OUTLET

unit.

cabinet

control

and

(Refer

panel

code

retaining

the

On/Off

ON

symbol

proper

Detail B below.

STEPS

control

4-5

panel

SHOCK,

BEFORE

(Refer

the

four

grips

should

to

SERVICING.

PROCEDURE 1 -

to

(4)

wires

on

back

switch

be

at

orientation

to

secure

(Refer

NEW

to

ON/OFF

PROCEDURE

from

of

existing.

upside

the

of

PROCEDURE

top.

the

On/Off

On/Off

dawn.

SWITCH

CAUTION

ALWAYS

REMOVING

9 - REMOVING

back

of

On/Off

CAUTION

Universal

Possible

switch

switch.

9 - REMOVING

(FIGURE

DISCONNECT

CABINET).

existing

switch

On/Off

and

damage

and

1)

CONTROL

switch.

push

OFF

symbol

to

the

wiring

CONTROL

CONCENTRATOR

PANEL).

switch

concentrator

out

through

should

connections

PANEL).

front

be

at

may

before

FROM

of

panel.

bottom

result

if

and

not

installation.

zo

nno-

E00

Io3-

8.

Reinstall

On/Off

(See

Detail

Detail

and

proper

installation.)

Switch

A

B

Switch

cabinet

for

(Refer

to

PROCEDURE

1 -

REMOVING

Control

Panel

CABINET).

Brown

(From

Detail À -

On/Off Switch

Universal

Brown

Jumper

Circuit

Detail B -

ON/OFF

Switch

Front

ON

Symbols.

Wire

Breaker)

Back

Switch

Wiring

Orientation

and

o

of

-

OFF

or

of

-

FIGURE 1 -

REPLACING

ON / OFF

SWITCH

Page 7

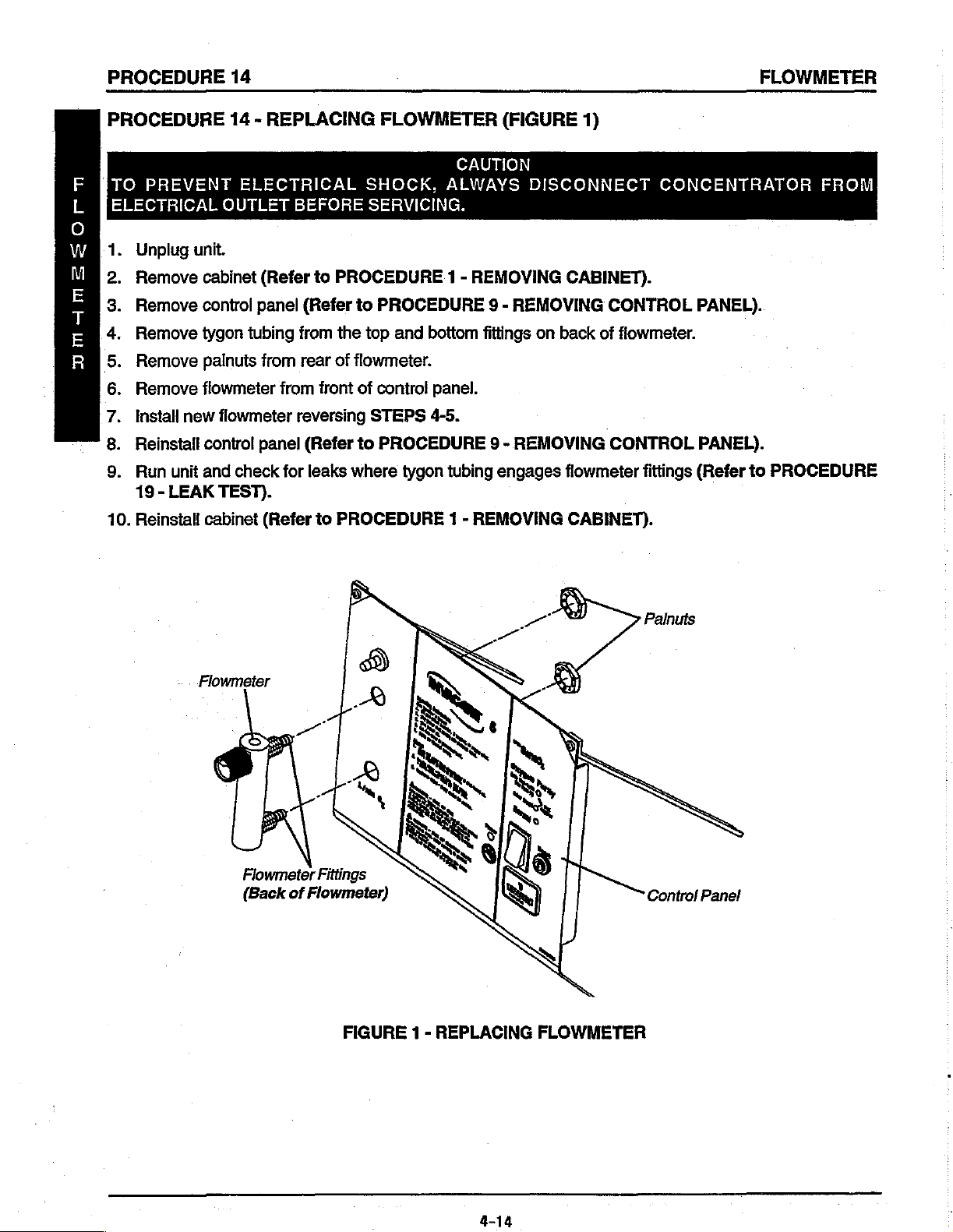

PROCEDURE

14

FLOWMETER

PROCEDURE

nmamesorm

10.

TO

PREVENT

ELECTRICAL

Unplug

Remove

Remove

Remove

Remove

Remove

Install

Reinstall

Run

PASAR»

new

unit

19 - LEAK

Reinstall

14 - REPLACING

ELECTRICAL

OUTLET

unit.

cabinet

control

tygon

palnuts

flowmeter

control

and

(Refer

panel

tubing

from

flowmeter

panel

check

TEST).

cabinet

(Refer

BEFORE

to

PROCEDURE

(Refer

from

rear

of

from

front

reversing

(Refer

for

leaks

to

FLOWMETER

SHOCK,

SERVICING.

to

PROCEDURE

the top

and

flowmeter.

of

contro!

STEPS

to

PROCEDURE

where

PROCEDURE

tygon

(FIGURE

CAUTION

ALWAYS

1 - REMOVING

9 - REMOVING

bottom

panel.

4-5.

fittings

9 - REMOVING

tubing

1 - REMOVING

engages

1)

DISCONNECT

CABINET).

CONTROL

on

back

of

|

CONTROL

flowmeter

CABINET).

CONCENTRATOR

flowmeter.

fittings

PANEL).

PANEL).

(Refer

to

FROM

PROCEDURE

Flowmeter

Flowmeter

(Back

Fittings

of

Flowmeter)

FIGURE 1 -

REPLACING

FLOWMETER

Control

Panel

4-14

Page 8

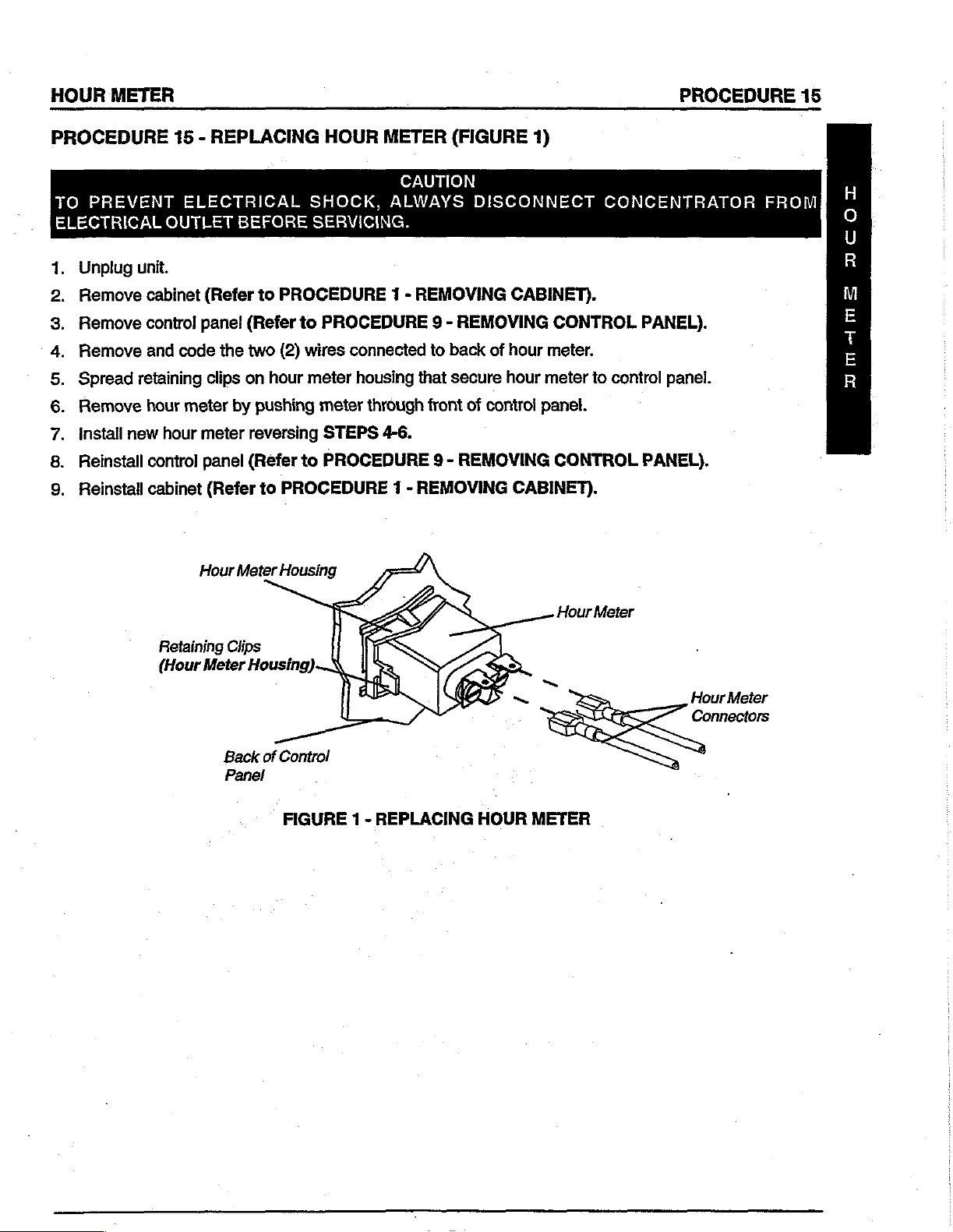

HOUR

METER

PROCEDURE

15

PROCEDURE

TO

PREVENT

ELECTRICAL

Unplug

Remove

Remove

Remove

Spread

Remove

Install

σσ.

new

Reinstall

Reinstall

op

15 - REPLACING

ELECTRICAL

OUTLET

unit.

cabinet

control

and

retaining

hour

control

cabinet

code

meter

hour

(Refer

panel

clips

meter

panel

(Refer

Hour

BEFORE

to

(Refer

the

two

on

by

pushing

reversing

(Refer

to

Meter

HOUR

METER

SHOCK,

SERVICING.

PROCEDURE

to

PROCEDURE 9 -

(2)

wires

connected

hour

meter

to

housing

meter

STEPS

through

4-6.

PROCEDURE 9 -

PROCEDURE 1 -

Housing

(FIGURE

CAUTION

ALWAYS

DISCONNECT

1 - REMOVING

REMOVING

to

back

that

secure

front

of

REMOVING

REMOVING

1)

CABINET).

of

hour

hour

control

panel.

CABINET).

CONTROL

meter.

meter

to

CONTROL

CONCENTRATOR

PANEL).

control

panel.

PANEL).

FROM

DCOT

μμ

Retaining

(Hour

Meter

Back

Panel

Clips

Housing)

of

Control

FIGURE

1 -

REPLACING

HOUR

Hour

~

METER

Meter

Hour

Meter

Connectors

Page 9

PROCEDURE

16

4-WAY

VALVE

PROCEDURE

TO

ELECTRICAL

Replacing

ES

1.

‘Position

oP oN

ш<гр<

valve

Torque

could

Tighten

6.

7.

The

8.

PREVENT

4-way

Unplug

Remove

Remove

Remove

Pre-torque

unit.

cabinet

control

the

NEW

and

sequence

result.

mounting

mounting

into

16 - REPLACING

ELECTRICAL

OUTLET

Valve

four

4-way

manifold

the

screws

BEFORE

(FIGURE

(Refer

panel

(Refer

(4)

mounting

valve

assembly.

and

specification

screws

mounting

can

to

screws

4-WAY

SHOCK,

SERVICING.

1)

PROCEDURE

to

PROCEDURE

screws

onto

manifold

MUST

in

the

sequence

to

be

now

be

VALVE/MANIFOLD

CAUTION

ALWAYS

1 - REMOVING

that

secure

assembly

CAUTION

BE

adhered

described

10 + 2

in.

torqued

lbs.

to

DISCONNECT

CABINET).

9 - REMOVING

the

4-way

and

loosely

to

or

below

using

the

27 + 3-in.

Ibs.

ASSEMBLY/PILOT

CONCENTRATOR

CONTROL

valve

to

the

manifold

install

mounting

possible

(FIGURE

torque

in

damage

1).

sequence.

the

same

PANEL).

assembly.

screws

to

the

sequence.

VALVES

through

4-way

FROM

4-way

valve

STOP!

Replacing

Unplug

Remove

Remove

Remove

Remove

Remove

POIANA

the

4-way

unit.

control

manifold

THIS

IS A MAINTENANCE

VOID

Valve

cabinet

panel

the

ty-wraps

hoses

and

from

code

assembly.

ANY

Manifold

(Refer

(Refer

from

manifold

the

four

AND

2)

ALL

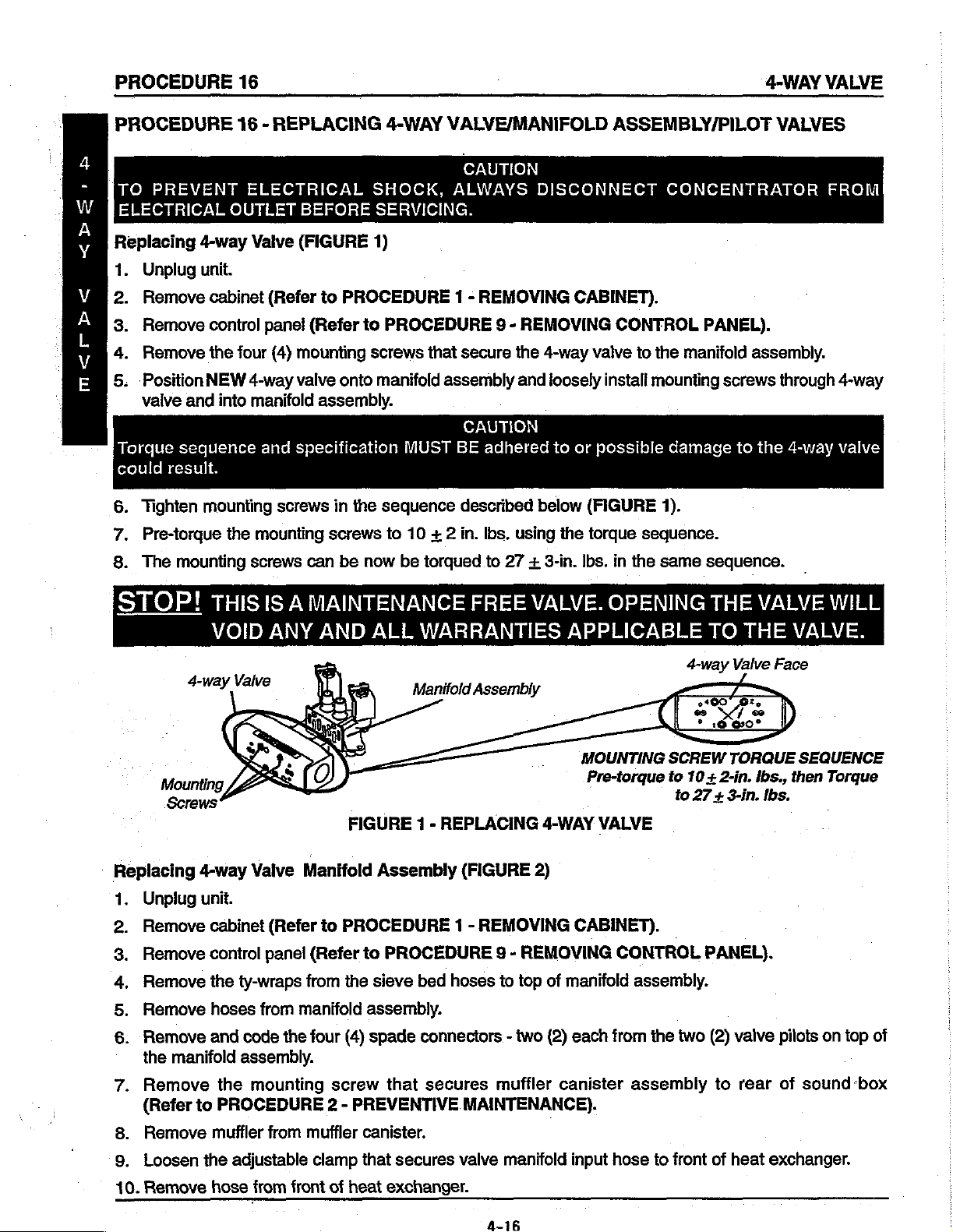

FIGURE 1 -

to

PROCEDURE

to

the

assembly.

(4)

spade

WARRANTIES

Manifold

Assembly

PROCEDURE

sieve

bed

connectors - two

FREE

Assembly

<<

REPLACING

(FIGURE

1 -

REMOVING

9 - REMOVING

hoses

to

top

VALVE.

APPLICABLE

MOUNTING

.

Pre-torque

4-WAY

2)

of

(2)

VALVE

CABINET).

manifold

each

OPENING

4-way

SCREW

to

10

to

CONTROL

assembly.

from

the

two

THE

TO

Valve

Sá

TORQUE

+ 2-in.

27

+ 3-in.

PANEL).

(2)

valve

VALVE

THE

Face

lbs.,

Ibs.

pilots

WILL

VALVE.

SEQUENCE

then

Torque

on

top

of

8.

9.

10.

Remove

(Refer

Remove

Loosen

Remove

the

to

PROCEDURE

muffler

the

adjustable

hose

mounting

from

muffler

clamp

from

front

screw

2 - PREVENTIVE

of

that

canister.

that

secures

heat

exchanger.

secures

muffler

MAINTENANCE).

valve

manifold

canister

input

assembly

hose

to

front

of

to

rear

heat

exchanger.

of

sound

«box

Page 10

4-WAY

VALVE

PROCEDURE

16

PROCEDURE

TO

PREVENT

ELECTRICAL

Spade

Connectors.

(STEP

i

'

Muffler

w/Exhaust

(STEP

16 - REPLACING

ELECTRICAL

OUTLET

Ty-wraps

(STEP

6)

4)

x

İSA

4-way

Valve

(STEP

13)

,

Canister

Hose

15)

BEFORE

N

¿(9

©

4-WAY

SHOCK,

SERVICING.

VALVE/MANIFOLD

à

Sieve

Mounting

A

5

__

Adjustable

Clamp

n

(STEP

Ty-wraps

(STEP

Compressor

Output

(STEP

Hose

17)

CAUTION

ALWAYS

Bed

Hoses

Detail

Assembly

16)

14)

ASSEMBLY/PILOT

DISCONNECT

(STEP

(STEP

5)

for

Manifold

11)

°

CONCENTRATOR

Heat

Exchanger

o

NOTE:

does

NEW

NOT

have

VALVES

FROME

(Typical)

Adjustable

Clamp

|

valve ” Manifold

Input

rose

(STEP

Heat

9)

Exchan

fins.

4

-

W

A

Y

V

A

上

WWA

Е

ger

11.

Remove

assembly

12.

The

straight

13.

Remove

4-WAY

14,

Remove

(Refer

15.

Remove

16.

Loosen

17.

Remove

18.

Reverse

19.

Slide

mounting

top

20.

Reverse

21.

Reinstall

22.

Plug

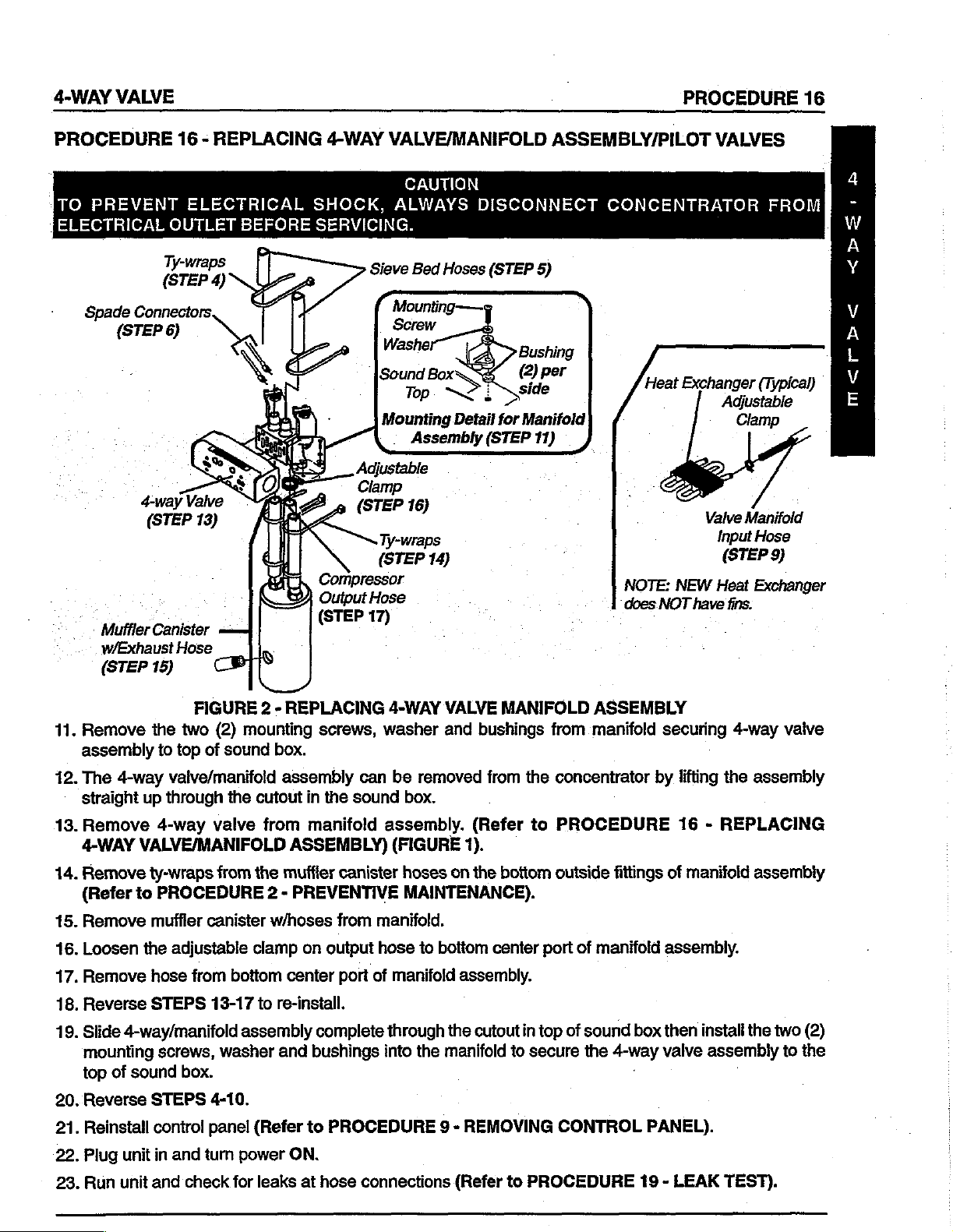

FIGURE 2 -

the

two

to

top

of

4-way

of

valve/manifold

up

through

4-way

VALVE/MANIFOLD

ty-wraps

to

PROCEDURE

muffler

the

hose

STEPS

4-way/manifold

screws,

sound

STEPS

controi

unit

in

valve

canister

adjustable

from

13-17

box.

4-10.

panel

and

turn

(2)

mounting

sound

the

cutout

from

the

clamp

bottom

to

assembly

washer

(Refer

power

REPLACING

screws,

box.

assembly

in

from

manifold

ASSEMBLY)

muffler

can

the

sound

canister

2 - PREVENTIVE

w/hoses

center

re-install.

and

on

output

complete

bushings

to

PROCEDURE

ON.

from

port

of

4-WAY VALVE

washer

be

assembly.

(FIGURE

removed

box.

hoses

and

1).

on

MAINTENANCE).

manifold.

hose

to

bottom

manifold

through

into

assembly.

the

the

manifold

9 - REMOVING

MANIFOLD

bushings

from

the

(Refer

the

cutout

to

boftom

center

in

to

secure

ASSEMBLY

from

manifold

concentrator

PROCEDURE

outside

port

top

of

CONTROL

fittings

of

manifold

sound

the

4-way

securing

by

lifting

16 - REPLACING

of

manifold

assembly.

box

then

install

valve

.

PANEL).

4-way

the

assembly

assembly

the

assembly

vaive

two

(2)

to

the

23.

Run

unit

and

check

for

leaks

at

hose

connections

(Refer

to

PROCEDURE

19 - LEAK

TEST).

Page 11

PROCEDURE

16

4-WAY

VALVE

PROCEDURE

VALVES

Replacing

24.

Check

25.

Re-install

Replacing

NOTE:

the

NOTE:

nectors

1.

2.

3.

Both

concentrator.

DO

aside

Hold

pilot

one

(1)

Unscrew

intact

on

Remove

STOP!

16

4-way

for

Valve

proper

cabinet

Pilot

Valve

pilot

NOT

remove

while

valve

complete

the

pilot

stem.

pilot

valve

DO

NOT

The

IS

NOT

will

(continued) - REPLACING

Manifold

system

(Refer

operation.

to

Poppets

valves

stem

can

spade

performing

with

turn.

valve

stem

poppet

REMOVE

Washer

DESIGNED

be

encountered

Assembly

(Refer

PROCEDURE 1 -

and

"O"

Rings

be

accessed

connectors

this

installation.

the

flat

blade

screwdriver

assembly

from

inside

from

the

THE

between

the

TO

that

4-WAY

(continued)

to

the

SPECIFICATION

REMOVING

(FIGURES 3 &

while

the

4-way

from

pilot

the

manifold

pilot

valve

COIL

YOKE

Bottom

BE

REMOVED

could

cause

VALVE/MANIFOLD

(FIGURE

2).

CABINET).

4).

valve

and

valve

and

stem.

coils.

turn

while

Simply

the

9/16-inch

leaving

FROM

of

the

Yoke

and

damage

ASSEMBLY/PILOT

section

sieve

THE

and

difficulty

of

this

bed

hoses

lay

coils

focknut

the

coil

with

COIL.

the

to

components.

Bottom

in

manual).

are

intact

with

spade

counterclockwise

yoke

and

of

on

con-

locknut

Coil

reassembly

4.

Set

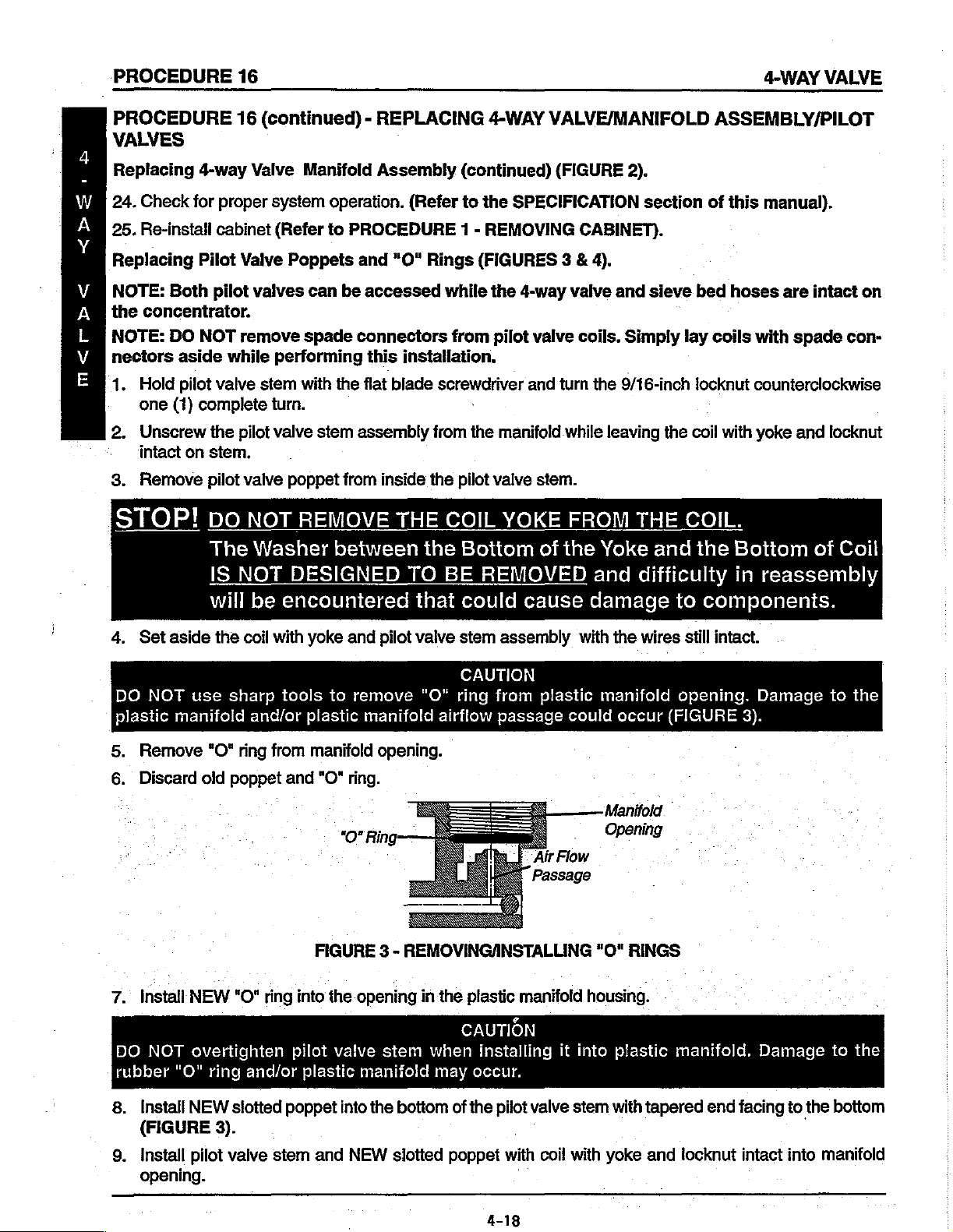

DO

NOT

plastic

5.

Remove

6.

Discard

7.

Install

DO

NOT

rubber

aside

the

use

manifold

"O"

old

NEW

overtighten

"O"

ring

coil

with

sharp

and/or

ring

from

poppet

"O"

ring

and/or

yoke

tools

to

plastic

manifold

and

"O"

FIGURE 3 -

into

the

pilot

plastic

and

pilot

remove

manifold

opening.

ring.

0

REMOVINGANSTALLING

opening

valve

stem

manifold

valve

"O"

airflow

in

the

when

may

stem

assembly

CAUTION

ring

from

passage

Air

Passage

plastic

manifold

CAUTION

installing

occur.

with

plastic

could

Flow

housing.

it

into

the

wires

manifold

occur

Manifold

Opening

"O"

RINGS

plastic

still

intact.

opening.

(FIGURE

manifold.

Damage

3).

Damage

to

to

the

the

8.

Install

(FIGURE

9.

Install

opening.

NEW

3).

pilot

valve

slotted

poppet

stem

and

into

the

NEW

bottom

slotted

of

the

poppet

4-18

pilot

valve

with

coil

with

stem

with

yoke

tapered

and

tocknut

end

facing

intact

to

the

into

bottom

manifold

Page 12

4-WAY

VALVE

PROCEDURE

16

PROCEDURE

VALVES

Sieve

Bed

Hoses.

Coil

Valve

Pilot

Body

‘Valve

(Reference)

FIGURE 3 -

16

(continued) - REPLACING

Valve

Pilot

р

Valve

(Reference)

REMOVINGANSTALLING

Body

PILOT

4-WAY

Yoke

Coit

_

VALVE

VALVE/MANIFOLD

oan

en

Pilot

Locknut

Spade

(Leave

Connectors

-L

>

T

ALP

Tapered

Manifold

Opening

POPPETS

AND

ASSEMBLY/PILOT

Stem

Valve

Connectors

Wire

Intact).

End

"O"

Slotted

"O"

Ring

RINGS

`

Poppet

10.

Use

to

25-inch

11.

Install

12.

Position

valve)

13.

Use

14.

Tighten

DO

DO

NOT

manifold

15.

Repeat

16.

Reposition

lower

sheet).

Ensure

lation.

the

flat

blade

Ibs. + 5-inch

NEW

pilot

to

ensure

the

flat

locknut

NOT

OVERTIGHTEN.

overtighten

may

the

FIGURE 3 PROCEDURE

lower

mounting

that

hoses

screwdriver

label

onto

valve

coil

spade

blade

screwdriver

clockwise

occur.

contro!

screws.

behind

ibs.).

pilot

valve

with

yoke

connectors

with

(Reference:

locknut

pane!

(Refer

control

and

tighten

coil

at

an

and

hold

the

9/16-inch

when

mounting

to

FIGURE 2 -

panel

pilot

yoke.

approximate

are

not

pulled

the

pilot

wrench

Torque

CAUTION

installing

for

other

screw

CAUTION

DO

NOT

valve

stem

60°

angle

or

tensioned

valve

stem

until

to

20-inch

it

onto

pilot

pilot

valve.

cut-outs.

REMOVING

contact

clockwise

to

the

after

in

place.

snug

to

secure

Ibs. + 3-inch

valve

behind

cooling

lower

CONTROL

until

snug.

left

(as

reinstallation.

the

stem.

mounting

PANEL

fan

after

(Reference:

viewed

stem

ibs.).

Damage

screws

in

control

from

and

to

this

panel

Torque

the

front

coil

with

yoke.

the

plastic

and

secure

instruction

reinstal-

of

17.

Reinstall

instruction

18.

Plug

19.

Reinstall

20.

If

any

(800)

upper

power

mounting

sheet).

cord

cabinet.

difficulties

832-4707

or

in

and

(Refer

are

encountered

in

Florida

screws.

tum

concentrator

to

FIGURE 1 -

1 -

(Refer

in

(407)

321-5630.

to

FIGURE 2 -

on

to

ensure

REMOVING

this

installation,

REMOVING

x

proper

CABINET

contact

CONTROL

operation.

in

this

instruction

Invacare

PANEL

sheet).

Technical

in

this

Service

at

Page 13

PROCEDURE

17

PURITY

SWITCH

PROCEDURE

で

ご

TO

コー

PREVENT

DISCONNECT

TRICAL

ゴー

Operation

The

の

an

the

concentrator.

コー

の

〇

indicator

の

NOTE:

warm-up

unit

will

initial

the

if

other

condition

tor

illuminate.

Indicator

GREEN

YELLOW

concentrator

supplier.

that

RED

IMMEDIATELY

Supplier

.

Invacare 5 and 6 with

oxygen

purity

Concentrator

is

initially

illuminate.

startup, a GREEN

Oxygen

the

concentration

indicator

may

BACKUP

LIGHT - Total

17 - SENSO2

CAUTION

ELECTRICAL

CONCENTRATOR

OUTLET

purity

level

lights

time

that

be

Lights

LIGHT - Normal

LIGHT - You

Cal!

IMMEDIATELY.

BEFORE

indicator.

of

the

If

purity

falls

on

the

(approx.

turned

Within 5 to

Purity

used

unless

Section

level

light

requires

while

(FIGURE

instructed

Supplier

OXYGEN

to

BACKUP

contro!

can

ON,

illuminating

IMMEDIATELY.

ALARM

SHOCK,

SERVICING.

SensO2

This

feature

oxygen

30

service.

Operation.

may

is

unit

generated

below

no

is

alarm

panel!

be

used

minutes).

oxygen

30

light

will

of

the

in

specification.

waiting

.

1)

continue

otherwise

nearby.

shutdown.

OXYGEN

INDICATORS

ALWAYS

FROM

is

equipped

will

during

minutes

illuminate

Control

will

The

for a light

ELEC- | Auto

monitors

by

thresholds,

illuminate.

When

purity

signal

concentra-

to

use

by

Be

certain

Switch

supply.

with

the

initial

the

lights

after

in

Panel

Any

a

to

the

your

Call

AND

SWITCH

Oxygen

Shut-

Down

Use

Backup

Below

Purity

1.

Unplug

2.

Remove

REMOVING

3.

Locate

Board.

4.

Settheindicator

is

olds

manual).

5.

‘Plug

6.

Run

in

PROCEDURE.

7.

If

8.

Refer

TION

of

9.

(Refer

Normal

Normal

FIGURE

Indicator

unit.

cabinet.

purity

factory

in

the

in

power

unit

and

accordance

problems

fo

Operating

AND

this

manual.

operation

to

PROCEDURE

=

Purity

y,

cal

@

©

1 -

INDICATOR

Switch - If

(Refer

CABINET).

switch

preset

cord.

check

exist,

SEQUENCE

is

on

switch

to

at

73%).

SPECIFICATION

the

with

specifications

call

Invacare

Sequence

within

specification,

Suppli

PP

LIGHTS

Installed

to

PROCEDURE

upper

left

either

73%

(Refer

indicator

to

section

lights

Technical

in

OF

OPERATION

1 -

REMOVING

_

RED

YELLOW

~*~

GREEN

(FIGURE

comer

or

85%.

Alarm

for

set

the

reinstall

2)

of

Sensor

(Switch

Thresh-

of

operation

forth

in

Support.

INSTALLA-

portion

cabinet.

CABINET).

1

-

this

this

GREEN

-

Oxygen

to

use

ATELY.

NOTE:

board

switch

purity

located

unit.

(FIGURE

Refer

TION

NOTE:

If

(See

to - Alarm

section

LIGHT - with

sensor

the

your

is

then

indicators

on

PURITY

2).

Indicator

malfunctioning;

concentrator.

Invacare

equipped

you

can

the

sensor

INDICATOR

Thresholds

of

this

lights

YELLOW

Call

Concentrator

with

an

set

the

will

activate.

board

manual.

are

visible

LIGHT

Supplier

alarm

level

near

you

The

FLASHING

may

SensO,

at

the top

SWITCH

in

the

SPECIFICA-

only

continue

IMMEDI-

Р.С.

threshold

which

switch

of

the

is

the

graphic)

when

lit.

4-20

TOP-LEFT

LI

FIGURE 2 -

73%

85%

~

PURITY

Purity

Switch

+.

INDICATOR

Settings

SWITCH

Page 14

TIMING

PROCEDURE

18

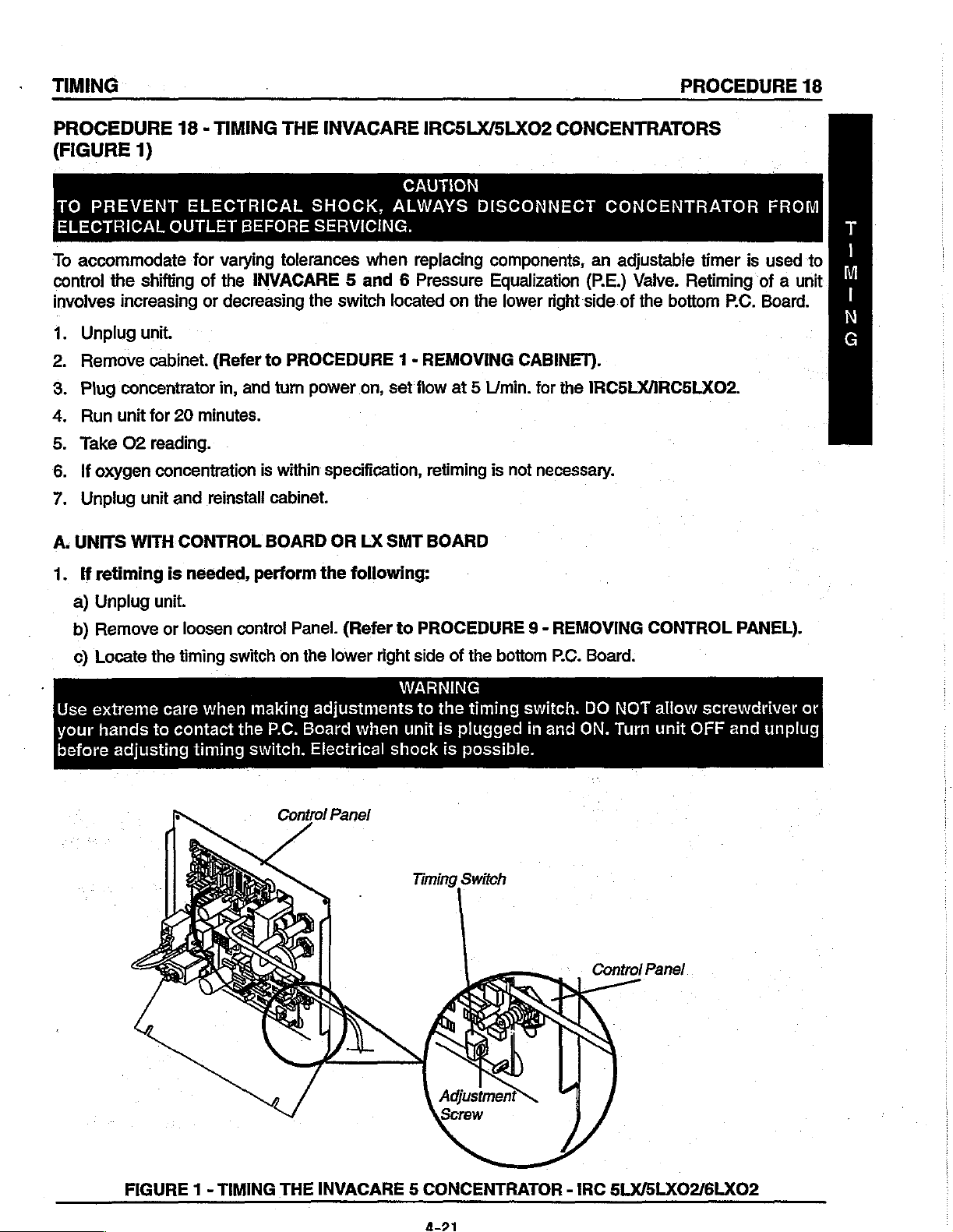

PROCEDURE

(FIGURE

TO

PREVENT

ELECTRICAL

To

accommodate

control

involves

1.

2.

A:

1.

Unplug

Remove

Plug

の

Run

Take

If

oxygen

の の か

ざさ

Unplug

UNITS

If

retiming

the

increasing

concentrator

unit

O2

WITH

18 - TIMING

1)

ELECTRICAL

OUTLET

for

varying

shifting

unit.

cabinet.

for

reading.

unit

of

the

or

decreasing

(Refer

in,

20

minutes.

conceniration

and

reinstall

CONTROL

is

needed, perform

THE

INVACARE

IRCSLX/5LXO2

CAUTION

BEFORE

tolerances

SHOCK,

SERVICING.

when

ALWAYS

replacing

INVACARE 5 and 6 Pressure

the

to

and

is

cabinet.

BOARD

PROCEDURE

tum

power

within

specification,

OR

the

switch

located

1 - REMOVING

on,

set

flow

retiming

LX

SMT

BOARD

following:

on

at 5 L/min.

CONCENTRATORS

DISCONNECT

components,

Equalization

the

lower

right

CABINET).

for

the

is

not

necessary.

CONCENTRATOR

an

adjustable

(P.E.)

side.of

Valve.

the

IRC5LX/IRC5LXO2.

Retiming

bottom

timer

P.C.

FROM

is

used

of a unit

Board.

to

OZ-E8-+

a)

Unplug

b)

Remove

c)

Locate

Use

extreme

your

before

hands

adjusting

unit.

or

loosen

the

timing

care

to

contact

switch

when

timing

contro!

Panel.

on

making

the

P.C.

switch.

Control

(Refer

the

lower

adjustments

Board

when

Electrical

Panel

to

PROCEDURE 9 -

right

side

of

WARNING

to

the

unit

is

plugged

shock

is

Timing

possible.

Switch

the

bottom

timing

REMOVING

P.C.

switch.

in

and ON.

Board.

DO

NOT

Turn

Control

CONTROL

allow

unit

Panel

screwdriver

OFF

PANEL).

and

unplug

or

FIGURE 1 -

TIMING

THE

INVACARE 5 CONCENTRATOR

-

IRC

5LX/5LX02/6LX02

Page 15

PROCEDURE

18

TIMING

PROCEDURE

IRC5LX/5LXO2

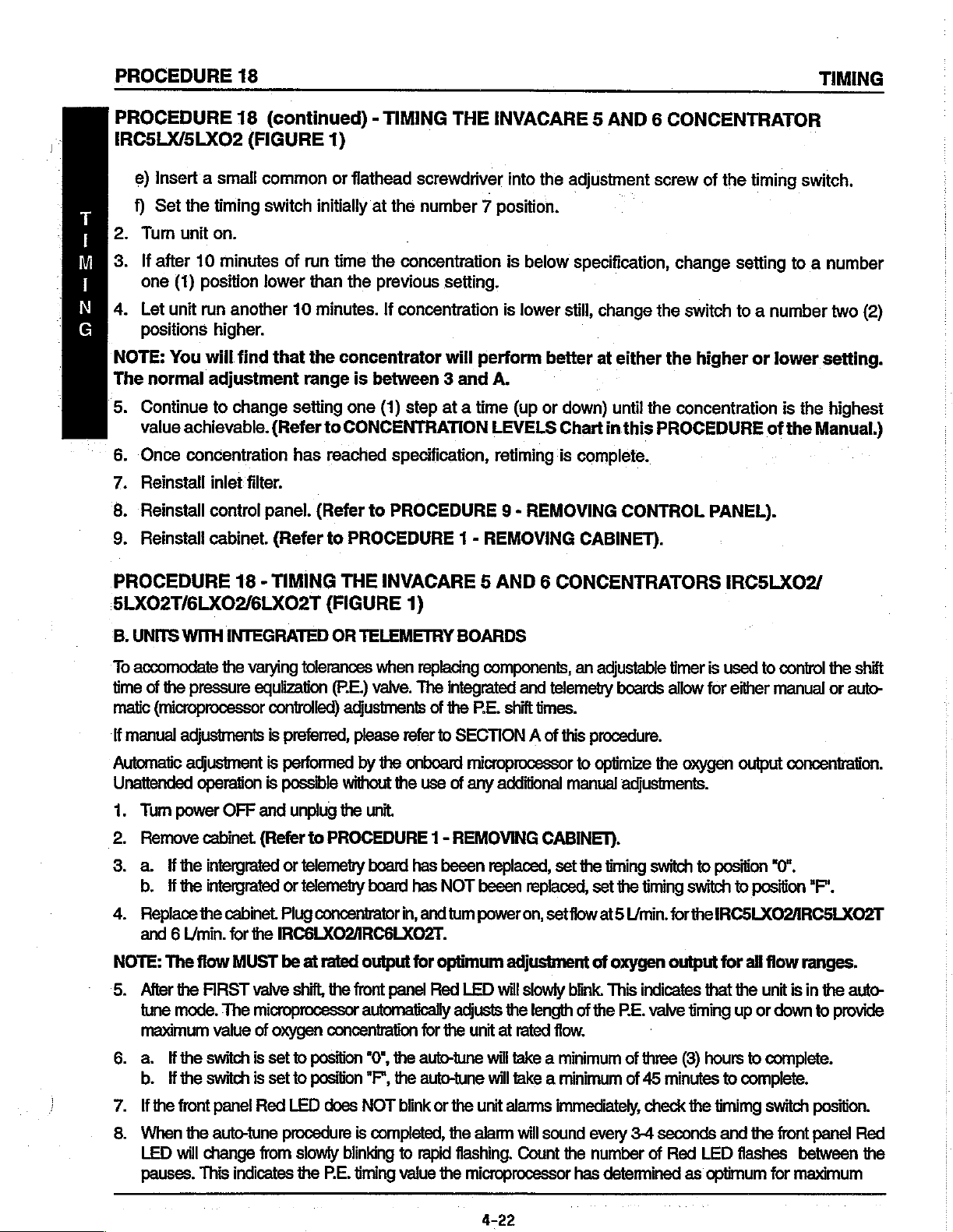

e)

Insert a small

f)

コ

ミー

テー

の 〇

Set

2.

Turn

3.

If

after

one

4.

Let

positions

NOTE:

The

normal

5.

Continue

value

Once

Reinstall

Reinstall

SENE

Reinstall

unit

You

18

(continued) - TIMING

(FIGURE

common

the

timing

unit

on.

10

(1)

position

run

higher.

will

adjustment

to

achievable.

concentration

inlet

control

cabinet.

switch

minutes

lower

another

find

change

filter.

panel.

initially

of

run

than

10

minutes.

that

the

range

setting

(Refer

has

(Refer

(Refer

1)

or

flathead

at

the

time

the

concentration

the

previous

If

concentration

concentrator

is

between 3 and

one

(1)

step

to

CONCENTRATION

reached

to

specification,

to

PROCEDURE

PROCEDURE

THE

INVACARE 5 AND 6 CONCENTRATOR

screwdriver

number 7 position.

setting.

will

at a time

1 - REMOVING

into

the

is

below

is

lower

perform

A.

(up

or

LEVELS

retiming

9 - REMOVING

better

down)

Chart

is

adjustment

specification,

still,

change

at

in

complete.

CABINET).

screw

the

either

until

the

this

PROCEDURE

CONTROL

the

of

the

timing

change

switch

concentration

setting

to a number

higher

PANEL).

or

lower

of

switch.

to a number

two

setting.

is

the

highest

the

Manual

(2)

.)

PROCEDURE

18 - TIMING

5LXO2T/GLXO2/6LXO2T

B.

UNITS

To

accomodate

time

matic

If

manual

Automatic

Unattended

1.

2.

3.

4.

NOTE:

5.

WITH

INTEGRATED

the

of

the

pressure

(microprocessor

adjustments

adjustment

operation

Tum

power

Remove

a.

If

b.

ff

Replace

and 6 L/min.

The

After

the

tune

mode.

maximum

OFF

cabinet.

the

intergrated

the

intergrated

the

cabinet.

for

flow

MUST

FIRST

The

value

varying

the

valve

microprocessor

tolerances

egulization

controlled)

is

preferred,

is

performed

is

possible

and

unplug

(Refer

or

telemetry

or

telemetry

Plug

IRC6LXO2ARC6LXO2T.

be

shift,

of

oxygen

THE

INVACARE 5 AND 6 CONCENTRATORS

(FIGURE

OR

TELEMETRY

when

(PE.)

valve.

adjustments

please

by

the

without

the

unit.

to

PROCEDURE

board

board

concentrator

at

rated

output

the

front

pane!

automatically

concentration

1)

replacing

The

of

refer

to

onboard

the

use

1 -

has

beeen

has

NOT

in,

and tum

for

optimum

Red

for

the

BOARDS

components,

integrated

the

SECTION A of

microprocessor

of

any

REMOVING

LED

adjusts

unit

and

P.E.

shift

additional

replaced,

beeen

power

replaced,

on,

adjustment

will

slowly

the

at

rated

times.

CABINET).

set

length

an

adjustable

telemetry

this

manual

set

flow

blink.

flow.

boards

procedure.

to

optimize

adjustments.

the

timing

set

the

at5

of

oxygen

This indicates

of

the PE.

timer

allow

the

switch

timing

L/min.

forthe

output

valve

IRC5LXO2/

is

used

to

control

for

either

manual

oxygen

switch

timing

output

to

position

to

IRCSLXO2/IRC5LXO2T

for

that

the

up

concentration.

"0".

position

all

flow

unit

is

or

down

the

shift

or

auto-

“F”.

ranges.

in

the

auto-

to

provide

a.

If

the

b.

ff

the

If

the

front

When

the

LED

will

pauses.

switch

switch

change

This indicates

is

set

is

set

pane!

Red

auto-tune

procedure

from

to

to

LED

slowly

the

position

position

"0",

*F",

does

NOT

is

completed,

blinking

P.E.

timing

the

auto-tune

the

auto-tune

blink

or

to

rapid

value

will

take a minimum

will

take a minimum

the

unit

alarms

the

alarm

will

flashing.

the

microprocessor

Count

4-22

of

of

immediately,

sound

every

the

number

has

determined

three

45

check

3-4

seconds

of

(3)

hours

minutes

the

timimg

Red

LED

as

optimum

to

complete.

to

complete.

switch

and

the

flashes

for

position.

front

panel

between

maximum

Red

the

Page 16

TIMING

PROCEDURE

18

oxygen

the

If

the

now

production.

manual

timing

function

-everytime

10.

If

the

timing

The

alarm

normally.

unit

is

turned

11.

The

timing

microprocessor

control

ing

by

to

SECTION A of

This

Red

mode.

switch

the

switch

should

The

switch

selecting

Record

was

normally.

unit

timimg

back

is

turned

was

stop

value

ON.

The

in

MUST

for

maximum

position

this

in

position

position

sounding

be

procedure.

CONCENTRATION

4

L/min.

LED

this

number.

timimg

back

is

stored

in

position

oxygen

"1"

to

LEVELS

count

"O"

corresponds

at

the

value

is

stored

ON.

"F"

at

the

start,

and

the

Red

in

the

microprocessor's

"0"

for

concentration.

"E".

Verification

CHART - (IRC5LX/SLXO2/6LXO2)

start,

tum

remove

LED

the

automatic

of

to

the

the

in

the

will

The

oxygen

same

numbers

unit

OFF

and

then

microprocessor's

the

cabinet

stop

memory

contro!

timing

production

and

flashing.

and

of

the

switch

can

MUST

02

95.6%

change

The

is

P.E.

Level

95.6%

95.6%

95.6%

on

the

BACK

memory

the

unit

will

recalled

valve

time

be

changed

be

performed

to

93%

to

93%

to

93%

to

91%

timing

on.

and

switch

The

is

recalled

position

now

function

everytime

by

the

to

in

unit

will

to

"0".

the

unit's

manual

accord-

|

O

5

L/min.

6

L/min.

95.6%

95.6%

to

to

87%

87%

Page 17

PROCEDURE

19

LEAK

TEST

L

E

A

K

7

E

EN

UN

PROCEDURE

(FIGURES

PREVENT

İTO

DISCONNECT

ELECTRICAL

Test

Leak

Unplug

1.

Remove

2.

REMOVING

3.

Turn

the

4.

Let

concentrator

Apply

tings

leak

for

4-way

to

small

only.

test

pressure

Valve.

enter

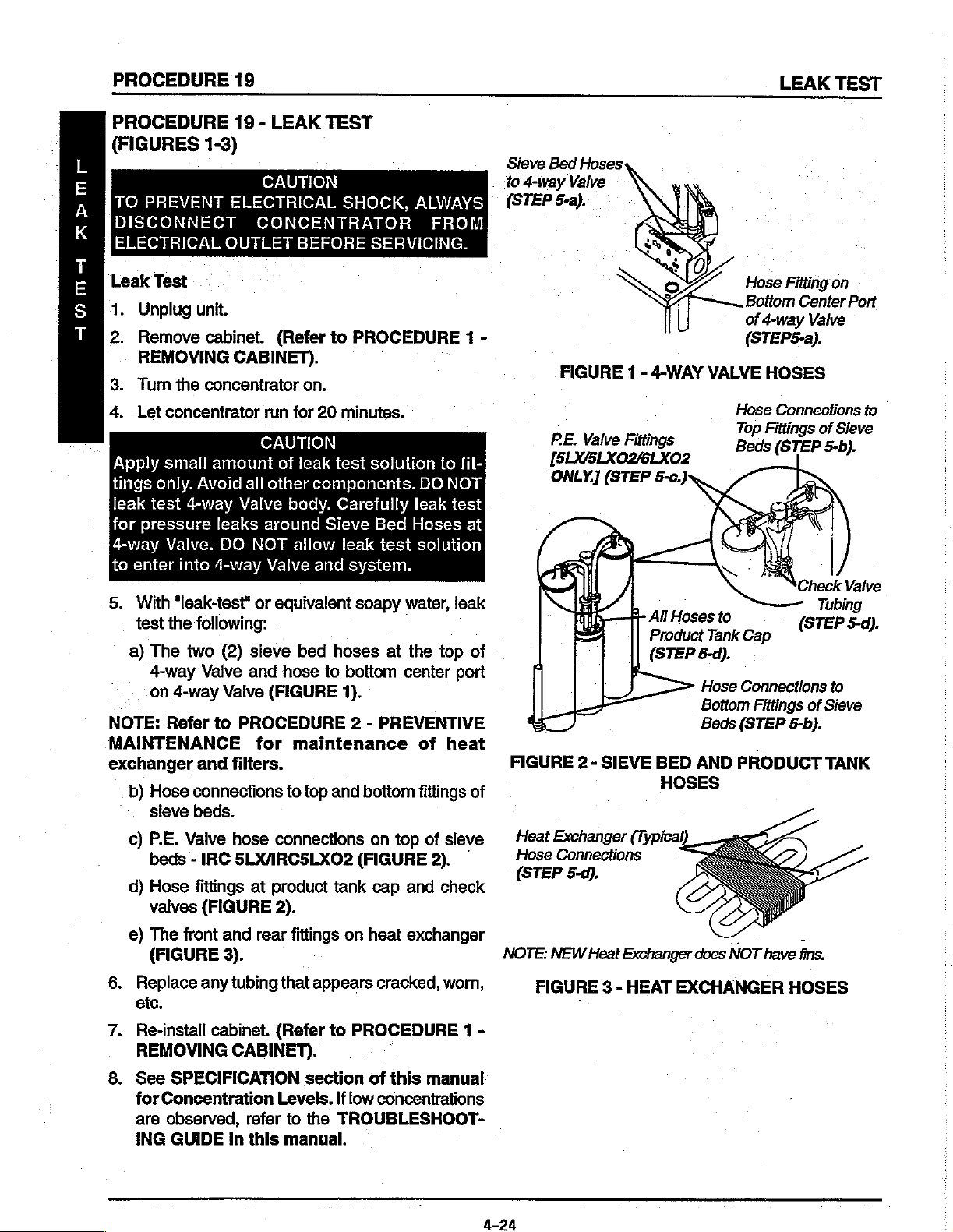

19

1-3)

ELECTRİCAL

OUTLET

.

'

unit.

cabinet.

CABINET).

concentrator

amount

Avoid

4-way

into

all

Valve

leaks

DO

4-way

NOT

LEAK

-

CAUTION

TEST

SHOCK,

CONCENTRATOR

BEFORE

(Refer

run

CAUTION

of

other

around

Valve

to

on.

for

20

minutes.

leak

test

components.

body.

Sieve

allow

and

Carefully

leak

ALWAYS

SERVICING.

PROCEDURE

solution

leak

Bed

Hoses

test

system.

FROM

1

to

fit-

DO

NOT

test

at

solution

Sieve

4-way

to

65Τερς-),

-

Bed

Hoses

Valve

FIGURE 1 -

PE.

[BLX/5LX02/6LX02

4-WAY

Valve

Fittings

Hose

Bottom

of

(STEPS-a).

VALVE

Hose

Top

Beds

Fitting

Center

Valve

4-way

HOSES

Connections

Fittings

(STEP

of

5b).

on

Port

to

Sie

5.

With

“leak-test*

test

the

following:

a)

The

two

4-way

on

4-way

NOTE:

MAINTENANCE

exchanger

6.

7.

Refer

and

b)

Hose

connections

sieve

beds.

c)

P.E.

Valve

beds - IRC

d)

Hose

fittings

valves

e)

The

front

(FIGURE

Replace

etc.

Re-install

REMOVING

or

(2)

sieve

Valve

(FIGURE

any

and

Valve

to

PROCEDURE

for

filters.

hose

5LXARC5LXO2

at

and

rear

3).

tubing

cabinet.

CABINET).

equivalent

bed

hoses

hose

to

bottom

(FIGURE

maintenance

to

connections

product

2).

fittings

that

(Refer

1).

2 - PREVENTIVE

top

and

tank

on

appears

to

PROCEDURE

soapy

(FIGURE

water,

at

center

bottom

on

top

cap

and

heat

exchanger

cracked,

leak

the

top

port

of

heat

fittings

of

sieve

2).

check

worn,

of

of

NOTE:

1 -

All

Hoses

FIGURE 2 -

Heat

Exchanger

Hose

(STEP

NEW

FIGURE 3 -

SIEVE

Connections

5-d).

Heat

Product

(STEP

BED

HOSES

(Typical)

Exchanger

HEAT

to

Tank

Cap

5-d).

Hose

Connections

Bottom

Beds

AND

Fittings

(STEP

PRODUCT

does

NOT

have

EXCHANGER

to

of

Sieve

5-b).

TANK

fins.

HOSES

8.

See

SPECIFICATION

for

Concentration

are

observed,

ING

GUIDE

refer

in

this

section

Levels.

to

the

manual.

of

this

manual

!f

low

concentrations

TROUBLESHOOT-

Page 18

ALARM

TEST

PROCEDURE

20

PROCEDURE

TO

PREVENT

ELECTRICAL

To

check

1.

POWER

mode

NOTE:

will

the

2.

LOW

a.

b.

Test

each

should

With

be

drained.

Battery

PRESSURE

Low

Failure

each

20 - ALARM

ELECTRICAL

OUTLET

alarm,

LOSS - With

sound

the

unit

If

power

Free™

product

in

the

tank

to

reach

following

circuit

BEFORE

CHECK

perform

the

the

audible

unplugged

failure

is

TEST-

pressure

the

set

AND

SHOCK,

SERVICING.

ALARMS

the

unit

running,

alarm

and

alarm

drained.

There

(pressure

point

pressure

manner:

SENSOR

CAUTION

ALWAYS

CAUTION

PERIODICALLY

following:

remove

immediately

inoperable

does

not

It

will

recharge

are

two

(2)

in

tank

within a prescribed

TEST

DISCONNECT

FOR

PROPER

the

line

cord

from

or

within

for a short

sound

when

seperate

failure

drops below a preset

period

with

unit

30

unit

modes

time

CONCENTRATOR

FUNCTION.

power

seconds.

is

Source,

of

time,

unplugged

plugged

for

Low

value,

limit,

or

The

power

the

Battery

and

in

and

Pressure.

typically 7 p.s.i).

Timeout

Free™

power

switched

Failure.

switch

FROM

loss

circuit

on.

alarm

on,

A

L

A

Β

M

T

同

S

T

Low

Pressure

cí.

With

unit

compressor

seconds.

c2.

With

unit

of

the

Shutdown

Time-Out

d.

NOTE:

Test

With

unit

unit

in

to

FIGURE 5 for

If

any

Test

(FIGURE

running,

relief

(Refer

product

to

running,

tank

Mode.)

(FIGURE

OFF,

and

turn

alarm

fails

1).

set

flow

valve

out

as

FIGURE 5 for

set

fiow

The

low

Replace

1)

disconnect

power

ON. The

Shutdown

to

perform

at

maximum

far

as

it

Shutdown

at

maximum

pressure

tubing

and

the

compressor

Time-Out

Mode.)

to

specification,

rating.

will

go

rating.

alarm

tywrap.

When

and

hold

Mode.)

Remove

should

activate

connector

Failure

the

main

it.

The

low

the

within

alarm

should

contact

valve

pressure

P.C.

board

30

seconds.

from

the

activate

Invacare

Compressor

[Disconnect

Harness(STEP

switches,

alarm

should

tubing

:

main

Technical

(tywrap)

(Refer

wiring

within

Molex

pull

the

activate

to

FIGURE 5 for

harness.

40

seconds.

Service.

Connector

from

2-b)].

stem

within

from

on

the

30

the top

Plug

(Refer

Relief

Valve

[Pull

Leak

FIGURE

Out

to

(STEP

1 -

Stem

Simulate

2-a)].

Compressor

LOW

PRESSURE

TEST

Page 19

PROCEDURE

3.

HIGH

23

Test

High

PRESSURE

psi + 1

in

the

Pressure

20

p.s.i.

following

Test

(FIGURE

-

Occurs

manner:

when

2).

pressure

in

product

tank

|

rises

beyond a preset

ALARM

value,

TEST

typically

3-a.

sEiprp

ο

NOTE:

With

unit

remove

within

should

40

Set

flow

remove

If

any

alarm

(SHOWN

running

one

seconds.

at 3 l/min.

one

activate

(1)

RED

(1)

RED

within

fails

and

ORANGE

Wires

NOT

(DO

Remove).

Valve

4-way

FOR

REFERENCE)

flow

set

wire

from

(Refer

for

to

to

3LX, 5 L/min.

wire

from

30

seconds.

perform

Pilot

Valve

Ts.

at 3 L/min.

the

FIGURE 5 for

the

to

specification,

top

of

for

top

of

(Refer

for

Pilot

SLX/5LXO2

Pilot

We

NL

2

3LX, 5 L/min.

Valve

Shutdown

to

FIGURE 5 for

1.

or 6 L/min.

Valve

contact

1

for

The

high

Mode.)

1.

Tum

Shutdown

Invacare

É

ES

5LX/5LX02

pressure

for

6LXO2.

unit

ON.

Technical

RED

[Remove

STEPS

Pilot

or 6 L/min.

alarm

Turn

The

high

Mode.)

Service.

Wires

Either

3-a

Valve

1

for

should

unit

OFF

pressure

Wire

and

3-b)].

6LX02,

activate

and

alarm

-

4.

OXYGEN

a

preset

component

Test

in

the

Oxygen

Ensure

INDICATOR

4-8.

4-b.

4-c.

4-d.

Sensor

that

Turn

Monitor

With

Slowly

than

the

4-е.

Use

Clamp

supply

SENSOR

value,

following

typically

mechanical

Test

Purity

AND

SWITCH

unit

ON.

the

O2

the

O2

level

adjust

75%

but

unit

will

continue

care

not

off

the

line

from

FIGURE 2 -

(5LXO2/6LXO2) - Alarm

73% + 3%

or

electrical.

manner:

(FIGURE

Switch

Set

level.

flow

less

to

1/8-inch

(SW1)

in

output

greater

beyond

than

to

cut

oxygen

the

product

this

oxygen

3)

flow

than

84%.

run.

or

This

is

set

manual).

at.5

85%

maximum

Within

sensor

sensor

tank.

HIGH

85% + 2%.

test

at

L/min.

after 5 minutes,

rated

30

tubing

tubing

PRESSURE

sequence

is

performed

73%.

(6LX0O2)

flow

min.

the

CAUTION

when

between

This

(Refer

until

YELLOW

TEST

occurs

failure

or 6 L/min.

the

you can

when

indicates a catastrophic

in a series

to

PROCEDURE

GREEN

achieve a concentration

panel

clamping

the

oxygen

concentration

of

STEPS.

17 - SENSO2

(61X02).

panel

LED

LED

indicator

the

oxygen

sensor

will

sensor

and

levels

:

illuminate.

will

the tee

fall

failure

level

illuminate

tubing.

in

the

below

of

any

ALARM

greater

and

4-26

Page 20

ALARM

TEST

PROCEDURE

20

44.

NOTE:

4-0.

Within

85%

Repeat

ALARM

4-h.

Unit

control

INDICATOR

4-i.

ai.

4k.

NOTE:

4-1.

4-m.

Your

NANCE

performed

Repeat

-

Within

Reset

If

Reinstail

If

Invacare

30

Setting

STEPS

INDICATOR

will

STEP

30

Purity

problems

any

alarm

concentrator

RECORD

on

the

1/8-inch

Oxygen

[Clamp

(STEP

min.,

the

Oxygen

is

NOT

available

4-a

again

pane!

AND

climb

LED

SWITCH

4-e.

min.,

the

Oxygen

Switch

arise

during

cabinet.

in

concentrator,

fails

to

this

LD.

Sensor

Off

4-e

(Refer

perform

manual

Flow

and

and

AND

to

will

to

desired

to

is

now

or

Tubing

4-i)].

Sensor

on

4-c

SWITCH

an

units

with

O2

Alarm

without

(SW1)

in

level

illuminate.

in

this

manual).

Sensor

test,

PROCEDURE

to

ready

to

record

any

Alarm

setting

contact

specification,

for

date

repairs

should

switch.

set

this

manual).

greater

(Refer

should

per

chart

Invacare

1 -

contact

an

additional

and

number

made.

activate.

at

85%.

than

85%

to

PROCEDURE

activate.

(FIGURE

Technical

REMOVING

Invacare

year.

of

(Refer

to

after 5 minutes

3).

Service

CABINET).

Technical

Use

the

hours

when

PROCEDURE

17 - SENSO2

for

further

Service.

PREVENTATIVE

preventive

17 - SENSO2.

and

the

GREEN

ALARM

assistance.

MAINTE-

maintenance

was

(STEP

4j)].)

Indicators

02

Purity

2%)

(+

85%

Over

73%

(+

3%)

to

85%

3%)

(+

73%

Below

|

Internal

{If

*Set

GREEN

(42%)

YELLOW

RED

Continuous

Alarm

Compressor

*

Factory

FIGURE 3 -

Switch

Present)

at

73%

Indicator

Indicator

Indicator

Sieve

Light

Audible

GARD™

Shutdown

Preset

OXYGEN

|

Light

Light}

-

at

SENSOR

Internal

(If

Present)

Set

GREEN

Indicator

RED

Continuous

Sieve

Alarm

Compressor

73%

TEST

Switch

at

85%

Indicator

Light

Audible

GARD™

Shutdown

NA

Light

-

Page 21

PROCEDURE

5-a.

A

Test

上

A

P.E.

R

5-b.

M

om

二

P.E.

Coil,

in

the

Valve

With

P.E.

20

Valve

following

Coil

Coil

Coil

connection

Test

the

unit

running

Alarm

(IRCSLXO2

or

P.C.

manner:

(FIGURE

and

should

after

Board

4)

activate

flow

Circuitry

set

within

S/N

97JXXXxX) - Alarm

has

failed.

at 5 L/min:,

10

remove

seconds.

one

(Refer

RE.

sequence

(1)

yellow

to

FIGURE 5 for

Valve

wire

Coil

occurs

from

ALARM

when

the

the

P.E.

Shutdown

TEST

P.E.

Valve

Valve.

Mode.)

The

ALARM

il

High

Pressure

Low

Pressure

Time-Out

(30

Secs.)

Low

02

All

alarms

ON

and

IRC5LXO2

3LX, 5LX,

(BEFORE

INTERNAL

have

Compressor

FIGURE 4 -

5LXO2

S/N

97JXXXX)

LED

RED

On

On On

On

on

.

Shutdown,

ONLY - RED

Panel

ALARM

GREEN

Off

On

off

LED

P.E.

Horn

Yellow

VALVE

COIL

MODES

8LX,

5LX,

ALARM

Three

(3)

Startup

Short

Long

Continuous

Continuous

Beeps

Beep,

Pause

|

.

Continuous

Wires

TEST

5LXO2/5LXO2T,

(AFTER

INTERNAL

at

S/N

LED

RED

0 0

0

1 1

1

1

6LXO2/6LXO2T

97JXXXX)

FLASHES

GREEN

No

Problems - System

ok

O

Main

Power

Low

Pressure:

Major

2

High

Pressure:

No

Switching

3

commer

Loss

Leak

.

ON.

FIGURE 5 -

Continuous

Continuous

Continuous

Continuous

Continuous

Continuous

Continuous

*No

Shutdown,

All

alarms

5LX02/5LXO2T,

LED

ON.

ALARM

4-28

MODES

Unit

have

Compressor

6LX02/6LXO2T

1

1

2

2

2 4

2

3

continues

4

5

1

3

5

1

Pilot

Valve 1 Coil

Pilot

Valve 2 Coil

73%

Shutdown:

PE Valve

Eprom

Ram

Failure

Oxygen

to

run.

Shutdown,

ONLY - RED

Coil

Failure

Sensor

Hom

Panel

Low

02

Failure

ON

and

Page 22

SIEVE

BED

PRESSURE

CHECK

PROCEDURE

21

PROCEDURE

PRESSURE

TO

PREVENT

ELECTRICAL

21 - SIEVE

CHECK

ELECTRICAL

OUTLET

BED

(FIGURES

BEFORE

PRESSURE

1, 2 &

SHOCK,

SERVICING.

3)

TAP-IN

CAUTION

ALWAYS

DISASSEMBLY

WARNING

Turn

power

1.

Remove

secure

cabinet

2.

Turn

3.

Loosen

product

4.

Pull

check

3LX

and

are

equipped

on the

from

restrictor.

the

the

the

from

unit

so

and

tank.

product

valve

5LX

left

top

rear.

Install

OFF

and

unplug

eight

cabinet

the

the

lower

tank

PVC

standard

with a restrictor

of

to

base

back

the

up

tubing.

CAUTION

the

DO

NOT

tap-in

(8)

5/8-inch

the

base

of

the

faces

adjustable

and

back

units

product

remove

kit

on the

unit.

screws

and

remove

concentrator.

you.

clamp

to

(without

assembly

tank

opposite

on

access

SensO2)

located

as

viewed

tubing

that

the

the

the

or

side.

KIT

INSTALLATION

DISCONNECT

INSTALLATION

1.

insert

the

"T"

fitting

Secure

2.

ing

3.

Attach

NEW

Insert

silicone

Secure

1/4-inch

“T”

fitting

the

1/4 x 2-inch

“T*

fitting

plug

into

tubing.

with a 1/4-inch

Pvc

Tubing

connection.

CONCENTRATOR

(FIGURE

into

clamps

and

secure

the

open

1/4"

*T*

AND

BED

2)

the

ends

of

to

each

end

silicone

with a 1/4-inch

end

of

the

」

clamp.

Clamp

Fitting

1/4 x 2-inch

Tubing

FROM

the

PVC

of

the

PVC

tubing

clamp.

1/4 x 2-inch

Silicone

tubing.

tub-

to

the

S

I

同

Vv

E

B

E

D

P

R

E

S

S

U

R

回

5.

Locate

right.

6.

Cut

in

half

Restrictor

SHOWN

Clarity

Adjus:

for

table

the

check

the PVC

valve

tubing

Clamp

FIGURE 1 -

:

i

and

PVC

tubing

below

the

Check

Cut

below

Valve

Tap-in

roduct

P

DISASSEMBLY

check

valve.

Valve

PVC

Tubing

Check

to

instail

Kit

to

your

Tank

PRESSURE

1.

Remove

1/4 x 2-inch

inch

clamp.

1/4"

Clamp

FIGURE 2 -

TESTING

plug

and

Connect

silicone

Plug

INSTALLATION

(FIGURE

tubing

and

pressure

3)

secure

gauge

to

with a 1/4-

the

Check

tight.

Turn

each

connection

the

concentrator

to

ON.

make

sure

they

are

Page 23

SIEVE

BED

PRESSURE

CHECK

PROCEDURE

21

PROCEDURE

5

PRESSURE

|

E

V

NOTE:

E

liter

and 6 ne

B

NOTE:

E

D

system

before

р

R

4.

E

S

S

υ

5.

Β

E

6.

Adjust

flow

Wait