Page 1

Solara Contracture Footplate Retro Fit Kit

Assembly, Installation and Operating Instructions

Kit Nos. 1095340, 1095341, 1095342, 1095343, 1095344, 1095345, 1095346

SAVE THESE INSTRUCTIONS

NOTE: Check all parts for shipping damage. In case of

damage, DO NOT use. Contact Carrier/Invacare for further instructions.

3. Remove the back canes. Refer to

4. Remove the allen screw, spacer and locknut that

SAFETY SUMMARY

The following recommendations are made for the safe

and proper installation and use of the Contracture

Footplate Retro Fit Kit:

GENERAL WARNINGS

DO NOT install this equipment without first reading and understanding this instruction sheet. If you

are unable to understand the W arnings, Cautions

and Instructions, contact a healthcare professional, dealer or technical personnel if applicable,

before attempting to install this equipment - otherwise, injury or damage may occur.

INST ALLATION WARNINGS

After ANY adjustments, repair or service and BEFORE use, make sure that all attaching hardware

is tightened securely.

This kit contains the following:

DESCRIPTION QTY

Contracture Assembly (Right Side) 1

Contracture Assembly (Left Side) 1

Insert Tube (Crossmember Assembly) 1

Outer Tube (Crossmember Assembly) 1

5. Remove the shoulder screw and locknut securing

6. Repeat STEPS 4-5 for opposite side of seat frame.

7. Lift up to remove the seat frame from the base frame.

NOTE: When reassembling the seat frame, the front

crossbrace will be replaced with the crossmember assembly (insert tube and outer tube) provided in this kit

and will be secured with the EXISTING mounting screws.

NOTE: Right and left sides of the seat frame are determined by sitting in the wheelchair.

8. On the left hand side of the seat frame, remove the

9. Pull the left hand side of the seat frame away from

10. Remove the EXISTING mounting screw, and locknut

INSTALLING THE CONTRACTURE

FOOTPLATE ASSEMBLY

Installing the Crossmember Assembly

(FIGURE 1)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

instruction sheet.

NOTE: Invacare recommends that two (2) people perform this procedure.

SAFETY SUMMARY of this

11. Remove the front crossbrace from the brace support

12. Insert one end of the insert tube into the front right

13. Align mounting holes in the end of the insert tube with

14. Slide the outer tube over the insert tube as shown in

REMOVING/INSTALLING THE BACK CANES in PROCEDURE 5

of the Service Manual, part number 1085787.

secure the link bracket to the lower seat frame as

shown in DETAIL “A” of FIGURE 1.

the rear of the seat frame to the bearing housing as

shown in DETAIL “A” of FIGURE 1.

two (2) EXISTING mounting screws and locknuts that

secure the front and rear crossbraces to the brace

supports of the seat frame as shown in DETAIL “B”

of FIGURE 1.

the front and rear crossmembers.

that secures the other end of the front crossbrace to

the front right hand side brace support of the seat

frame as shown in DETAIL “B” of FIGURE 1.

and discard.

hand side brace support.

the brace support and secure with the EXISTING

mounting screw and locknut.

DETAIL “B” of FIGURE 1.

NOTE: Take note of position and orientation of the mounting hardware for reassembly.

1. If necessary, remove the seating system from the

wheelchair. Refer to the seating systems Owner’s

Manual supplied with the wheelchair.

2. Remove the seat pan. Refer to

STALLING THE SEAT PAN in PROCEDURE 4 of

the Service Manual, part number 1085787.

REMOVING/IN-

15. Align the brace supports of the left hand side of the

seat frame with the front and rear crossmembers.

16. Insert the front and rear crossmembers into the brace

supports of the left hand side of the seat frame. Reinstall

the two (2) EXISTING mounting screws and locknuts.

1

Page 2

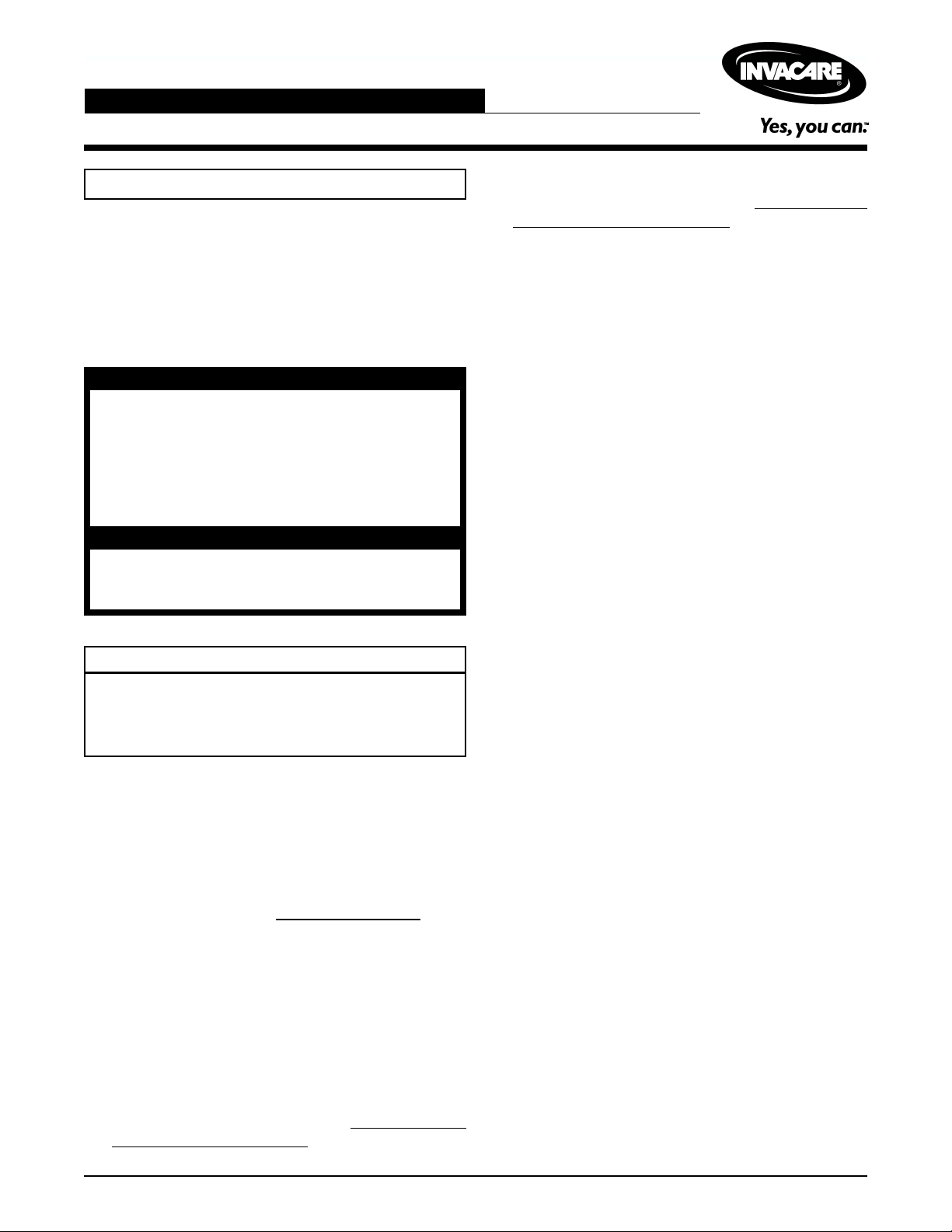

Seat Frame

(Rear)

DETAIL “A”

Seat Frame

2. Align the mounting holes of the contracture footplate

assembly with two (2) desired mounting positions of

the crossmember assembly.

3. Secure the contracture assembly to the crossmember

assembly with two (2) mounting screws, washers and

locknuts provided. Securely tighten.

4. If necessary, repeat STEPS 1-6 for the other contracture assembly.

Bearing

Housing

Lower Seat Frame

Shoulder Screw

Locknut

Base

Frame

DETAIL “B”

Crossbrace

(Rear)

Seat

Frame

Brace Support

Locknut

Seat Frame

Mounting Screws

Lock Nuts

Spacer

Allen

Screw

Link

Bracket

Brace Support

Outer Tube

Insert Tube

FIGURE 1 - INST ALLING THE CROSSMEMBER

ASSEMBL Y

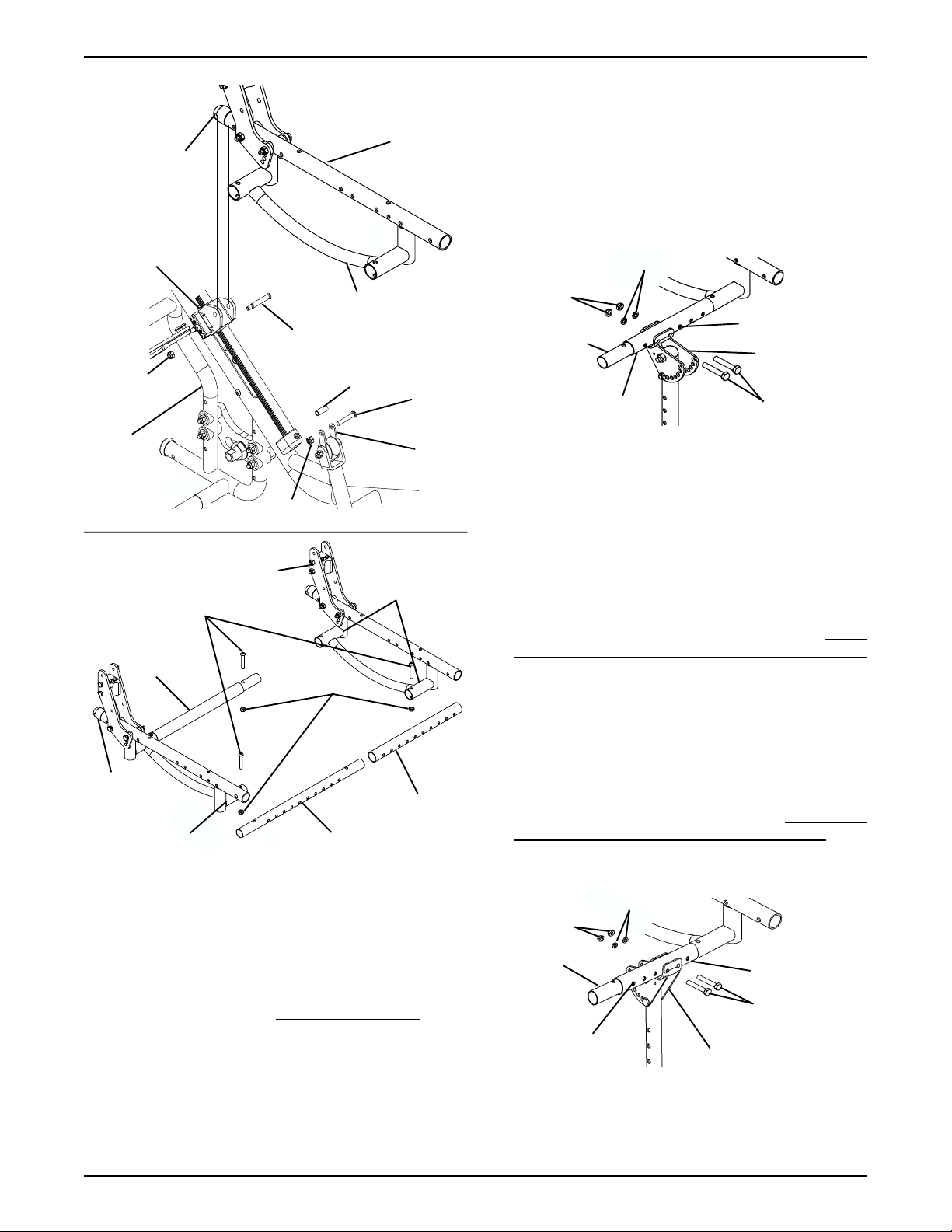

Installing the Contracture Assembly - Forward

Mount (FIGURE 2)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

instruction sheet.

NOTE: The number of mounting positions on the contracture assembly may vary due to the width of the wheelchair.

1. Align the mounting holes of the outer tube with the

mounting holes of the insert tube of the crossmember

assembly.

SAFETY SUMMARY of this

Washers

Lock Nuts

Mounting Holes

Insert Tube

Outer Tube

Contracture

Assembly

Mounting Screws

FIGURE 2 - REMOVING/INST ALLING THE

CONTRACTURE ASSEMBLY - FORWARD MOUNT

Installing the Contracture Assembly Reversed Mount (FIGURE 3)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

instruction sheet.

1. Remove the contracture footplate. Refer to CONTRACTURE FOOTPLATE HEIGHT ADJUSTMENT

in this instruction sheet.

2. Align the mounting holes of the contracture footplate

assembly with two (2) desired mounting positions of

the crossmember assembly.

3. Secure the contracture assembly to the crossmember

assembly with two (2) mounting screws, washers and

locknuts provided. Securely tighten.

4. Reinstall the contracture footplate. Refer to

TURE FOOTPLATE HEIGHT ADJUSTMENT.

5. If necessary, repeat STEPS 1-4 for the other contracture assembly.

Washers

Lock Nuts

Insert

Tube

Mounting

Holes

SAFETY SUMMARY of this

CONTRAC-

Outer Tube

Mounting

Screws

Contracture Assembly

FIGURE 3 - REMOVING/INST ALLING THE

CONTRACTURE ASSEMBLY - REVERSED MOUNT

2

Page 3

CONTRACTURE ASSEMBLY ANGLE

ADJUSTMENT (FIGURE 4)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the SAFETY SUMMARY of this

instruction sheet.

Angle Adjustment

Bracket

Pop Rivet

1. Remove the mounting screw and locknut used to lock

the angle adjustment of the contracture assembly.

2. Lift the contracture support UP/DOWN to achieve

the desired angle.

3. Align the mounting hole in the contracture support

with one (1) of seven (7) mounting holes on the angle

adjustment bracket.

4. Reinstall the mounting screw and locknut used to lock

the angle adjustment of the contracture assembly.

Securely tighten.

5. If necessary repeat STEPS 1-4 on remaining contracture assembly.

Mounting Screw

Angle

Adjustment

Bracket

Mounting

Hole

Locknut

Contracture Support

FIGURE 4- CONTRACTURE ASSEMBLY ANGLE

ADJUSTMENT

USING THE OPTIONAL QUICK

RELEASE PIN (FIGURE 5)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

instruction sheet.

SAFETY SUMMARY of this

Button

Quick Release Pin

Contracture

Support

FIGURE 5 - USING THE OPTIONAL QUICK

RELEASE PIN

ANGLE ADJUSTMENT OF THE

CONTRACTURE FOOTPLATE

(FIGURE 6)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

instruction sheet.

1. Loosen, but DO NOT, remove the two (2) flat screws,

washers and locknuts that secure contracture

footplate to the footplate hinge.

2. Tilt the contracture footplate UP/DOWN to achieve

desired angle.

3. Retighten the two (2) flat screws, washers and locknuts that secures the contracture foot plate to the

footplate hinge.

4. If necessary repeat STEPS 1-3 on remaining contracture footplate.

Contracture

Assembly

SAFETY SUMMARY of this

Flat Screws

Contracture

Footplate

NOTE: The Quick Release Pin replaces the mounting

screw that is used to lock the angle adjustment of the

contracture support.

NOTE: If not installed at time of shipment, the quick release

pin must be installed by a qualified technician only, using a

1/8-inch pop rivet.

1. Press the button on the quick release pin and insert

through the contracture support and the angle adjustment bracket.

2. If necessary adjust the angle of the contracture assembly. Refer to CONTRACTURE ASSEMBLY

ANGLE ADJUSTMENT in this instruction sheet.

3. Repeat STEPS 1-2 on the remaining contracture assembly.

Footplate

Hinge

NOTE: Mounting hardware

shown removed for clarity

only.

FIGURE 6 - ANGLE ADJUSTMENT OF THE

CONTRACTURE FOOTPLATE

3

Washers

Lock Nuts

Page 4

CONTRACTURE FOOTPLATE

DEPTH ADJUSTMENT (FIGURE 7)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

SAFETY SUMMARY of this

instruction sheet.

NOTE: Observe the angle of the contracture footplate for

reinstallation.

1. Remove the two (2) flat screws, washers and locknuts that secure the contracture footplate to the

footplate hinge.

2. Move the contracture footplate to one (1) of four (4)

mounting hole.

3. Reinstall the two (2) flat screws, washers and locknuts that secures the contracture foot plate to the

footplate hinge.

Flat Screws

Mounting

Hole

Contracture

Footplate

Washers

Footplate Hinge

Lock Nuts

FIGURE 7 - CONTRACTURE FOOTPLATE DEPTH

ADJUSTMENT

CONTRACTURE FOOTPLATE

HEIGHT ADJUSTMENT (FIGURE 8)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

instruction sheet.

SAFETY SUMMARY of this

4. Secure the footplate bracket to the contracture support with the mounting screw, two (2) coved washers,

washer and locknut. Securely tighten.

5. If necessary repeat STEPS 1-4 on remaining contracture footplate.

Mounting

Contracture Support

Holes

Mounting Screws

Lock Nut

Coved Washers

Washers

Footplate

Bracket

FIGURE 8 - CONTRACTURE FOOTPLATE HEIGHT

ADJUSTMENT

REPLACING THE CONTRACTURE

FOOTPLATE HEEL LOOP (FIGURE 9)

NOTE: Refer to the GENERAL WARNINGS and INSTALLATION WARNINGS in the

instruction sheet.

1. Tilt the contracture footplate forward to gain access to the

mounting screws that secure the heel loop to the underside of the contracture foootplate. Refer to angle adjustment of the contracture footplate in this instruction sheet.

2. Remove the four (4) mounting screws and washers

that secure the EXISTING heel loop to the contracture footplate.

3. Reverse STEPS 1-2 to install the NEW heel loop.

Mounting

Screws

SAFETY SUMMARY of this

Washers

Contracture

Footplate

1. Remove the mounting screw, two (2) coved washer,

washer and locknut that secure the footplate bracket

to the contracture support.

2. Move the footplate bracket UP/DOWN to achieve

desired height.

3. Align the mounting hole in the footplate bracket with

one (1) of seven (7) mounting holes on the contracture support.

Invacare Corporation www.invacare.com

USA Canada

One Invacare Way 5970 Chedworth Way Invacare and "Yes, you can" are trademarks of Invacare

Elyria, Ohio USA Mississauga, Ontario Corporation.

44036-2125 L5R 3T9, Canada © 2000 Invacare Corporation

800-333-6900 905-890-8838 Form No. 00-97 Part No. 1095349 Rev A (1) 5/00

Washers

Heel Loop

FIGURE 9 - REPLACING THE CONTRACTURE

FOOTPLATE HEEL LOOP

Loading...

Loading...