Page 1

Programmer’s

Reference Manual

SR60 Scanner

Page 2

Intermec Technologies Corporation

Corporate Headquarters

6001 36th Ave.W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is proprietary and is provided solely for the purpose of

allowing customers to operate and service Intermec-manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of Intermec.

Information and specifications contained in this document are subject to change without prior

noticed and do not represent a commitment on the part of Intermec Technologies Corporation.

© 2006 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, Beverage Routebook, CrossBar,

dcBrowser, Duratherm, EasyADC, EasyCoder, EasySet, Fingerprint, i-gistics, INCA (under

license), Intellitag, Intellitag Gen2, JANUS, LabelShop, MobileLAN, Picolink, Ready-to-Work,

RoutePower, Sabre, ScanPlus, ShopScan, Smart Mobile Computing, SmartSystems, TE 2000,

Trakker Antares, and Vista Powered are either trademarks or registered trademarks of Intermec

Technologies Corporation.

Throughout this manual, trademarked names may be used. Rather than put a trademark (™ or ®)

symbol in every occurrence of a trademarked name, we state that we are using the names only in

an editorial fashion, and to the benefit of the trademark owner, with no intention of

infringement.

There are U.S. and foreign patents pending.

ii SR60 Scanner Programmer’s Reference Manual

Page 3

Contents

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

About Cautions and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Global Services and Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Web Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Telephone Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Who Should Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Introduction to Programming the SR60 Scanner. . . . . . . . . . 1

1

Customizing Your Scanner’s Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

How to Program the SR60 Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What Is Programming Mode?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

What is a Programming Session? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Three Sample Programming Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Roadmap for Programming the Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

About the Scanner LEDs and Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Scanner LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Scanner Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Contents

Integrating the Scanner With Your Host System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Changing the Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Verifying that Your Scanner Supports the Interface. . . . . . . . . . . . . . . . . . . . 8

Removing and Replacing the Scanner Interface Cable . . . . . . . . . . . . . . . . . 8

Reconfiguring the Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Restoring Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Trouble Scanning the Bar Codes in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Configuring Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2

Wand Emulation Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wand Emulation Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wand Emulation Pre/Post-Noise Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SR60 Scanner Programmer’s Reference Manual iii

Page 4

Contents

RS-232 Interface/WN-RS-232 (SNI) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RS-232 Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Data Format Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Handshaking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Hardware Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Software Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

RS-232 ACK/NAK Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

RS-232 Intercharacter Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Keyboard Wedge Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PC Keyboard Interface Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connect to a Laptop or PC and Send Control/Function Characters . . . . . 33

Caps Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Country Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Intercharacter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Quiet Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configuring Label Transmit Settings . . . . . . . . . . . . . . . . . . . . . . 47

3

When to Configure Label Transmit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

How to Use the Prefix, Suffix, and Label ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Setting Global Prefix(es) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setting Global Suffix(es) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting a Single-Character Prefix or Suffix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Disabling a Global Prefix or Suffix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Setting a Label ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

About Symbology-Specific Label Identifiers. . . . . . . . . . . . . . . . . . . . . . . . 55

Setting the Label ID Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setting a Symbology-Specific Label ID . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Selecting the Symbology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Setting a Single-Character Label ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Disabling a Symbology-Specific Label ID . . . . . . . . . . . . . . . . . . . . . . . . . 63

iv SR60 Scanner Programmer’s Reference Manual

Page 5

Enabling and Configuring Symbologies . . . . . . . . . . . . . . . . . . .65

4

All Symbologies Supported by All Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Enabling Symbologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Code 39/PharmaCode 39 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

About Code 39 Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Start/Stop Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Code 39 Full ASCII. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Minimum Label Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Configuring the Code 39 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Minimum Label Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

About PharmaCode 39 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Transmit Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Start/Stop Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Configuring the PharmaCode 39 Options . . . . . . . . . . . . . . . . . . . . . . . . . 77

Code 128 and UCC/EAN 128 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

About Code 128 and UCC/EAN 128 Options. . . . . . . . . . . . . . . . . . . . . . 78

Setting Minimum Label Length. . . . . . . . . . . . . . . . . . . . . . . . . .78

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configuring the Code 128/and UCC/EAN 128 Options. . . . . . . . . . . . . . 79

Minimum Label Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Contents

Interleaved 2 of 5 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

About Interleaved 2 of 5 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Configuring the Interleaved 2 of 5 Options . . . . . . . . . . . . . . . . . . . . . . . . 84

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Variable Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Fixed Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Codabar Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

About Codabar Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Gap Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

SR60 Scanner Programmer’s Reference Manual v

Page 6

Contents

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Start/Stop Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Start/Stop Match . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Start/Stop Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Configuring the Codabar Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Variable Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Fixed Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

UPC/EAN Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

About UPC/EAN Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Data Format Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

UPC/EAN Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

UPC/EAN Add-ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Price/Weight Check Digit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Configuring the UPC/EAN Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

UPC Data Format Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

EAN Data Format Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

UPC/EAN Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

UPC/EAN Add-ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Custom Add-ons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Price/Weight Check Digit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Code 93 Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

About Code 93 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Minimum Label Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Configuring the Code 93 Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Minimum Label Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Standard 2 of 5/IATA Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

About Standard 2 of 5/IATA Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Configuring the Standard 2 of 5/IATA Options . . . . . . . . . . . . . . . . . . . 118

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Variable Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Fixed Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

vi SR60 Scanner Programmer’s Reference Manual

Page 7

IATA Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

MSI/Plessey Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

About MSI/Plessey Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Configuring the MSI /Plessey Options. . . . . . . . . . . . . . . . . . . . . . . . . . .126

Label Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Variable Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Fixed Length Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Read Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuring General Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5

Configuring the Green LED Idle State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Configuring the Beeper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Configuring the Marker Beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Configuring the Low Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Contents

Configuring the Low Power Shutdown Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Configuring the Half-Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Factory Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A

Factory Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

B

Sample Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Keypad Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

RS-232 Host Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

ASCII Character Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Contacting Intermec Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

SR60 Scanner Programmer’s Reference Manual vii

Page 8

Contents

viii SR60 Scanner Programmer’s Reference Manual

Page 9

Before You Begin

This section provides you with safety information, technical

support information, and sources for additional product

information.

About Cautions and Notes

Read and follow all cautions in this document before handling

and operating Intermec equipment. Equipment and data can be

damaged if you do not follow the cautions.

This section explains how to identify and understand cautions

and notes that are in this document.

A caution alerts you to an operating procedure, practice,

condition, or statement that must be strictly observed to

prevent equipment damage or destruction, or corruption or

loss of data.

Note: Notes either provide extra information about a topic or

contain special instructions for handling a particular condition or

set of circumstances.

Before You Begin

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the

Intermec web site at www.intermec.com and click Service &

Support > Warranty.

Disclaimer of warranties: The sample code included in this

document is presented for reference only. The code does not

necessarily represent complete, tested programs. The code is

provided “as is with all faults.” All warranties are expressly

disclaimed, including the implied warranties of merchantability

and fitness for a particular purpose.

Web Support

Visit the Intermec web site at www.intermec.com to download

our current manuals (in PDF). To order printed versions of the

Intermec manuals, contact your local Intermec representative or

distributor.

SR60 Scanner Programmer’s Reference Manual ix

Page 10

Before You Begin

Visit the Intermec technical knowledge base (Knowledge

Central) at

intermec.custhelp.com to review technical

information or to request technical support for your Intermec

product.

Telephone Support

These services are available from Intermec Technologies

Corporation.

In the U.S.A. and

Canada call 1-800755-5505 and

Services Description

Order Intermec

products

Order Intermec

media

Order spare

parts

Te c h n i ca l

Support

Service • Get a return authorization

Service contracts • Ask about an existing

• Place an order.

• Ask about an existing

order.

Order printer labels and

ribbons.

Order spare parts. 1 or 2 and then

Talk to technical support

about your Intermec

product.

number for authorized

service center repair.

• Request an on-site repair

technician.

contract.

•Renew a contract.

• Inquire about repair

billing or other service

invoicing questions.

choose this option

1 and then choose 2

1 and then choose 1

choose 4

2 and then choose 2

2 and then choose 1

1 or 2 and then

choose 3

Outside the U.S.A. and Canada, contact your local Intermec

representative. To search for your local representative, from the

Intermec web site, click Contact.

x SR60 Scanner Programmer’s Reference Manual

Page 11

Who Should Read This Manual

This programmer’s reference manual is for the person who is

responsible for installing, programming, configuring, and

maintaining the SR60 scanner.

This document explains how to program and configure the SR60

scanner.

Before you work with the SR60, you should be familiar with the

host system to which you will connect the SR60.

Related Documents

The Intermec web site at www.intermec.com contains our

documents (as PDF files) that you can download for free.

To d ownloa d docume nts

1 Visit the Intermec web site at www.intermec.com.

2 Click Service & Support > Manuals.

3 In the Select a Product field, choose the product whose

documentation you want to download.

To order printed versions of the Intermec manuals, contact your

local Intermec representative or distributor.

Before You Begin

SR60 Scanner Programmer’s Reference Manual xi

Page 12

Before You Begin

xii SR60 Scanner Programmer’s Reference Manual

Page 13

1

Introduction to

Programming the SR60

Scanner

This chapter explains how and why you program your SR60

scanner. You will find these sections in this chapter:

• Customizing Your Scanner’s Operation

• How to Program the SR60 Scanner

• About the Scanner LEDs and Beeper

• Integrating the Scanner With Your Host System

• Changing the Interface Cable

• Restoring Factory Default Settings

• Trouble Scanning the Bar Codes in This Manual

SR60 Scanner Programmer’s Reference Manual 1

Page 14

Chapter 1 — Introduction to Programming the SR60 Scanner

Customizing Your Scanner’s Operation

You can customize your SR60 scanner’s operation using the

programming bar codes in this manual.

• You can select and configure the settings that allow

communication with your host terminal, such as setting the

RS-232 baud rate and parity for the RS-232 interface. For

help, see Chapter 2, “Configuring Interface Settings.”

• You can configure the optional prefix, suffix, and label ID to

be sent with bar code data if your scanner is configured for the

RS-232 or Keyboard Wedge interface. For help, see Chapter

3, “Configuring Label Transmit Settings.”

• You can select and configure bar code symbologies. You can

give the scanner the capability to autodiscriminate as few as

one, and as many as all available symbologies. For optimal

scanner performance, enable only those symbologies required.

You may also program the scanner with the standard options

available for the symbologies, such as check digit, minimum

label length, and fixed and variable length bar codes. For help,

see Chapter 4, “Enabling and Configuring Symbologies.”

• You can configure general features. For example, you may

adjust the beeper volume. For help, see Chapter 5,

“Configuring General Features.”

How to Program the SR60 Scanner

There are two ways for you to program the scanner:

• You can scan programming bar codes to modify the scanner’s

programmable features and options. This manual provides the

bar codes and instructions necessary to configure the features

and options. To ensure full compatibility and proper

function, use only the programming bar codes in this manual.

• You can send commands directly from the host. A limited set

of host commands are available. For help, see “RS-232 Host

Commands” on page 157.

When you program the scanner, the scanner stores the changes

until reprogrammed or returned to factory defaults.

2 SR60 Scanner Programmer’s Reference Manual

Page 15

Chapter 1 — Introduction to Programming the SR60 Scanner

What Is Programming Mode?

The scanner must be placed in Programming mode in order to

accept programming commands. You place the scanner in

Programming mode by scanning the SET bar code, which

appears first in each set of programming bar codes in this manual.

While in the Programming mode, the scanner recognizes only the

special programming bar codes contained in this manual.

To understand how the LEDs and beeper behave while the

scanner is in Programming mode, see

and Beeper” on page 6.

What is a Programming Session?

A typical programming session is conducted as follows:

1 Scan the SET bar code at the beginning of each set of

programming bar codes to place the scanner in Programming

mode. The scanner emits three beeps, indicating it has read

the bar code, and the green LED flashes on and off slowly

while the scanner remains in Programming mode. Normal

scanning functions are disabled.

2 Scan the programming bar codes that are specially encoded to

make changes. With few exceptions, the scanner emits a triple

beep each time you scan a valid bar code. Be aware of these

considerations:

“About the Scanner LEDs

• Some features, such as Minimum Label Length, require

you to select the label length by scanning a series of singledigit bar codes. A single good read beep sounds when

scanning these single digits in Programming mode. Only

the final required digit in the sequence produces a triple

beep when scanned, indicating a successfully programmed

feature.

• Not all features are available for all interfaces. The scanner

sounds an error tone if you scan programming bar codes

for features invalid to the current interface. Only features

supported by the currently active interface are

implemented.

• If you scan a bar code that changes the interface type, all

previous configuration items scanned in the programming

session are lost.

SR60 Scanner Programmer’s Reference Manual 3

Page 16

Chapter 1 — Introduction to Programming the SR60 Scanner

• When programming a feature requiring you to scan single

digits to set a multi-digit number, such as Minimum Label

Length, scanning the END bar code (or any item tag/item

value bar code) before completing all input results in an

error tone and causes the scanner to exit Programming

mode. Under these circumstances, the features you were

trying to set are discarded; any previous bar codes scanned

during the session take effect.

• Intermec recommends that you limit each programming

session to one feature at a time. If you make a mistake in

the programming sequence, it can be difficult to discover

where an error has been made if several features are

programmed at once. Additionally, it can be confusing to

determine which features may or may not have been

successfully set following such a session.

3 Scan the END bar code to save any new settings and exit

Programming mode. The scanner sounds a beep and resets

upon exiting Programming mode, and the green LED returns

to its usual state (on steady or off).

Note: If you disconnect power before you scan the END bar

code, all the new settings are discarded. On power-up, the

scanner returns to the previous settings.

4 Maintain an accurate record of all changes you make. There is

a worksheet in Appendix A, “Factory Default Configuration”

on page 145, where you can record your changes.

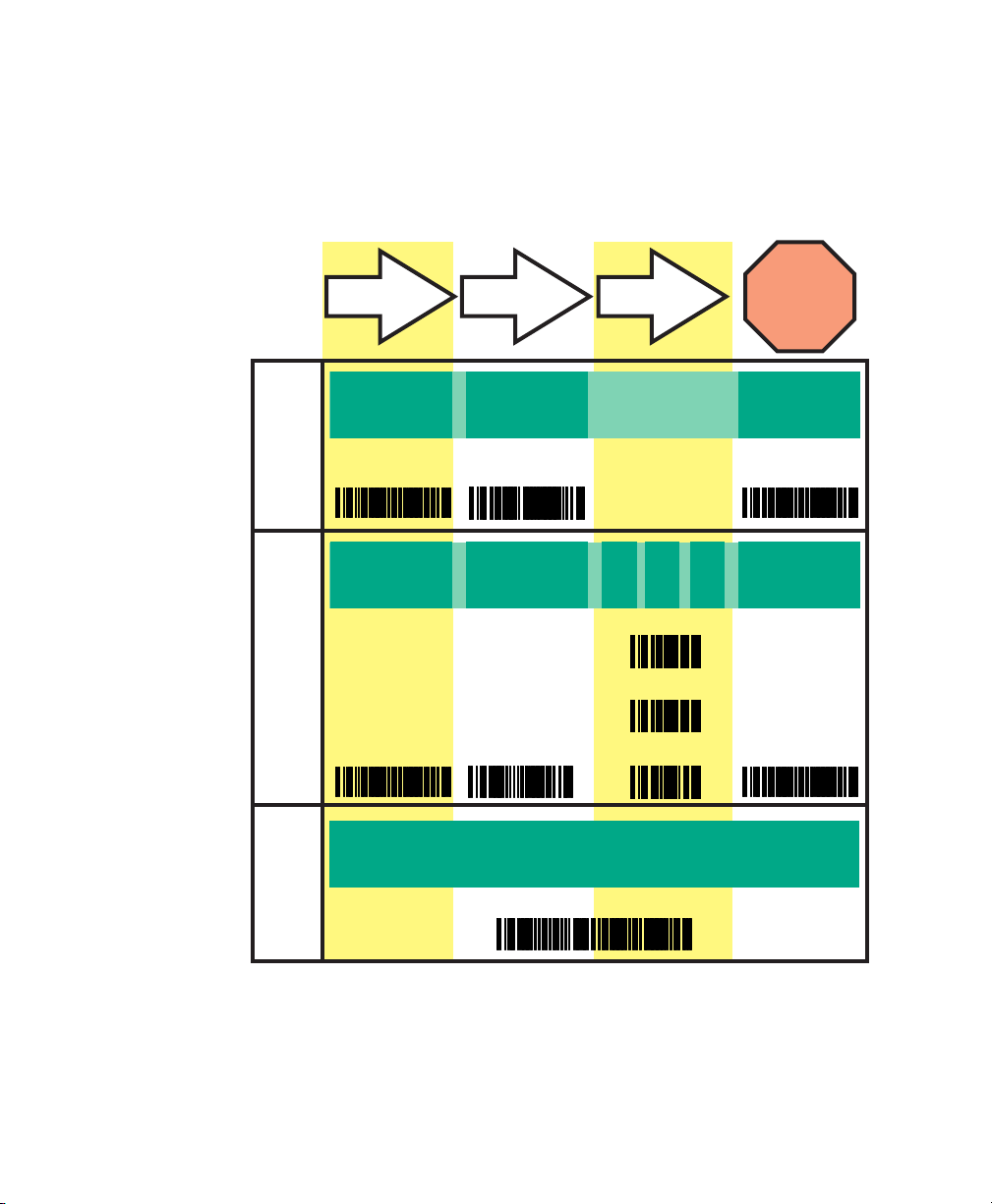

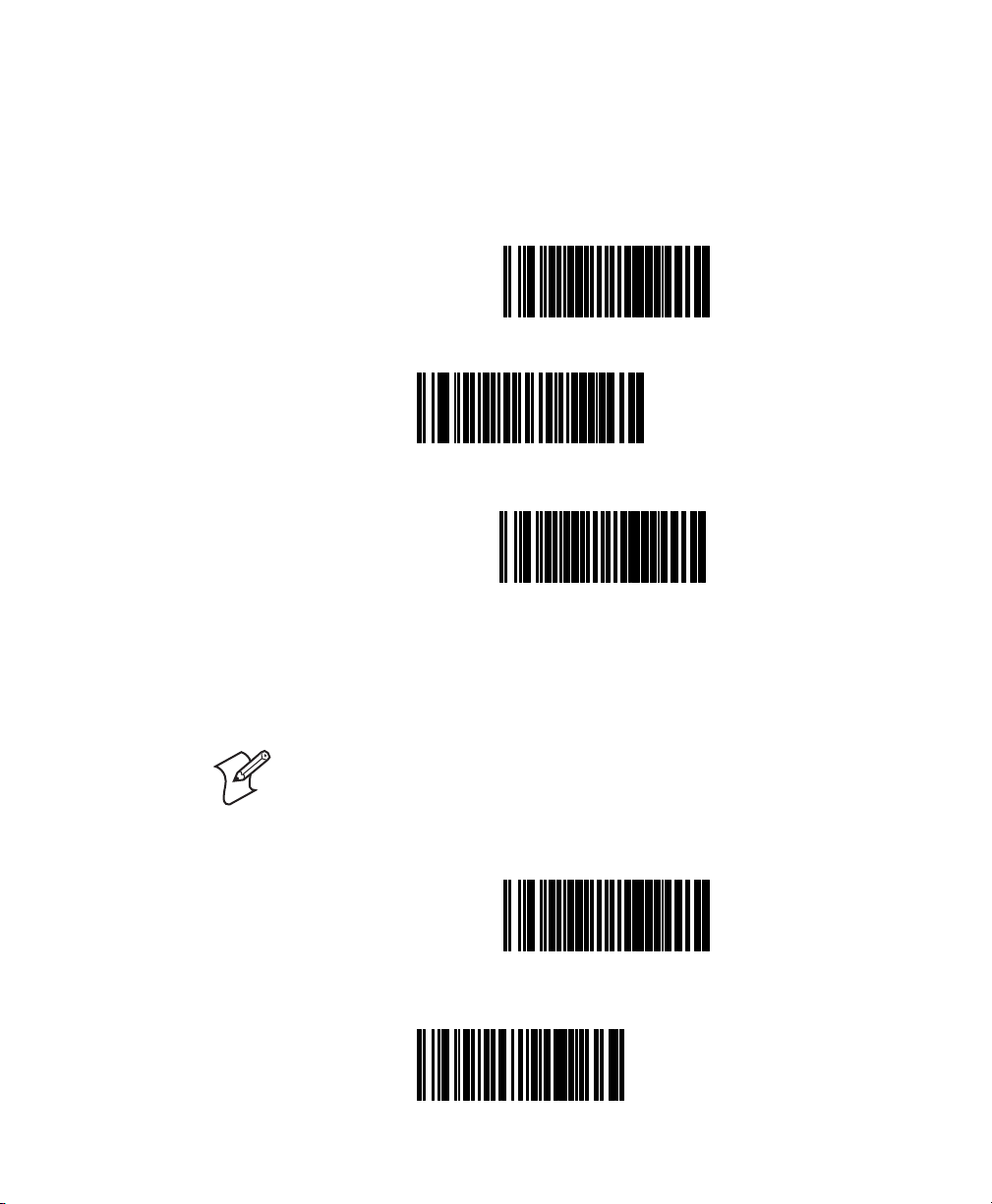

Three Sample Programming Sequences

To modify a scanner feature, you must scan the programming bar

codes in this manual in the correct sequence, depending upon the

feature being programmed. There are three programming

sequences, which are illustrated on the next page.

Sample A

Programming sample A is the most commonly used sequence and

demonstrates how three bar codes are scanned to accomplish

these tasks:

1 Enter Programming mode with the SET bar code.

2 Scan the Item Tag that enables the new feature.

4 SR60 Scanner Programmer’s Reference Manual

Page 17

Chapter 1 — Introduction to Programming the SR60 Scanner

The term Item Tag describes an assigned number encoded in

a programming bar code that selects, enables, or disables a

specific feature.

3 Exit Programming mode and reset the scanner with the END

bar code.

A

B

C

SET

1

SET

ITEM TAG ITEM VALUE END/RESET

23

ENABLE

NEW FEATURE

END

123456

0

ENABLE NEW

FEATURE

USING THE

FOLLOWING

SET END

SETTINGS...

0

8

1

ONE BAR CODE CONTAINS SET + ITEM TAG + ITEM VALUE + END

Three Sample Programming Sequences

Sample B

Programming sample B demonstrates how to enter a range value.

SR60 Scanner Programmer’s Reference Manual 5

Page 18

Chapter 1 — Introduction to Programming the SR60 Scanner

Like sample A, the scanner is placed in Programming mode and

an Item Tag is scanned. Then, a value must be entered before

ending the programming session. In the example, three digits

must be scanned from the number pad in Appendix C.

This type of format may require up to six programming bar codes

and is necessary to allow flexible programming with larger itemvalue numeric ranges.

Sample C

Programming sample C lets you scan a single, extended length

bar code. This special bar code contains all the data necessary to

enter Programming mode, set the Item Tag and Item Value, and

exit Programming mode all in one step.

Roadmap for Programming the Scanner

Follow this roadmap to program the SR60 scanner.

To program the scanner

1 Scan any feature bar codes that are unique to the interface you

are currently programming. These interface-specific

programming bar codes immediately follow each interface

selection bar code.

2 If you need to change any bar code symbologies or modify

any symbology-related features, see “Enabling Symbologies”

on page 66.

3 If you need to change or modify any other features (such as

beeper settings), see Chapter 5, “Configuring General

Features,” on page 133.

Once the necessary changes have been made, and you have

scanned the END bar code, you are ready to operate the SR60

scanner.

About the Scanner LEDs and Beeper

The scanner provides a set of indicators that verify or announce

scanner functions.

Note: The green LED and beeper are configurable features which

may have been modified or disabled. For help, see Chapter 5,

“Configuring General Features,” on page 133.

6 SR60 Scanner Programmer’s Reference Manual

Page 19

Scanner LEDs

Scanner Beeper

Chapter 1 — Introduction to Programming the SR60 Scanner

The amber Laser On LED is located on top rear of the scanner

and lights whenever laser power is on.

The green Good Read LED is located on top rear of the scanner

and flashes:

• once to indicate when a good read has occurred.

• slowly on and off to indicate the scanner is in Programming

mode.

The beeper operates differently when the scanner is in Scanning

mode and in Programming mode.

• When the scanner is in Scanning mode, the beeper sounds:

• four times at power-up.

• once following a good read.

• six rapid chirps to indicate an error (error tone).

• When the scanner is in Programming mode, the beeper

sounds:

• once when entering or exiting Programming mode.

• three times to indicate a successfully programmed feature.

• an error tone if you scan programming bar codes for

features that are not compatible with the current interface.

For example, you can set baud rate and parity only when

the current interface is RS-232.

Integrating the Scanner With Your Host System

Your scanner must be equipped with the correct hardware to

properly communicate with your host system. Contact your local

Intermec representative if you have questions about your scanner

hardware compatibility.

Intermec offers the following interface cables for the SR60

scanner:

• Wand emulation

•RS-232

SR60 Scanner Programmer’s Reference Manual 7

Page 20

Chapter 1 — Introduction to Programming the SR60 Scanner

• Keyboard wedge

•USB

Note: The part numbers for the keyboard wedge cables available

from Intermec are listed in the “PC Keyboard Interfaces and

Cables Supported ” table on page 31.

Changing the Interface Cable

If you need to move the scanner to a host terminal of a different

interface type, you simply connect the scanner to the new host

using the appropriate interface cable. The scanner automatically

changes to the interface functions specific to that cable.

Verifying that Your Scanner Supports the Interface

You must make sure that your SR60 scanner supports the

interface you want to change to. The following list indicates the

interfaces each SR60 scanner supports:

• SR60 scanner with C/N SR60AX01 supports the Wand

Emulation, RS-232, and Keyboard Wedge interfaces.

• SR60 scanner with C/N SR60AX02 supports the USB

interface.

You can find the scanner C/N on the label above the trigger.

Removing and Replacing the Scanner Interface Cable

You can change your scanner interface cable by following these

instructions.

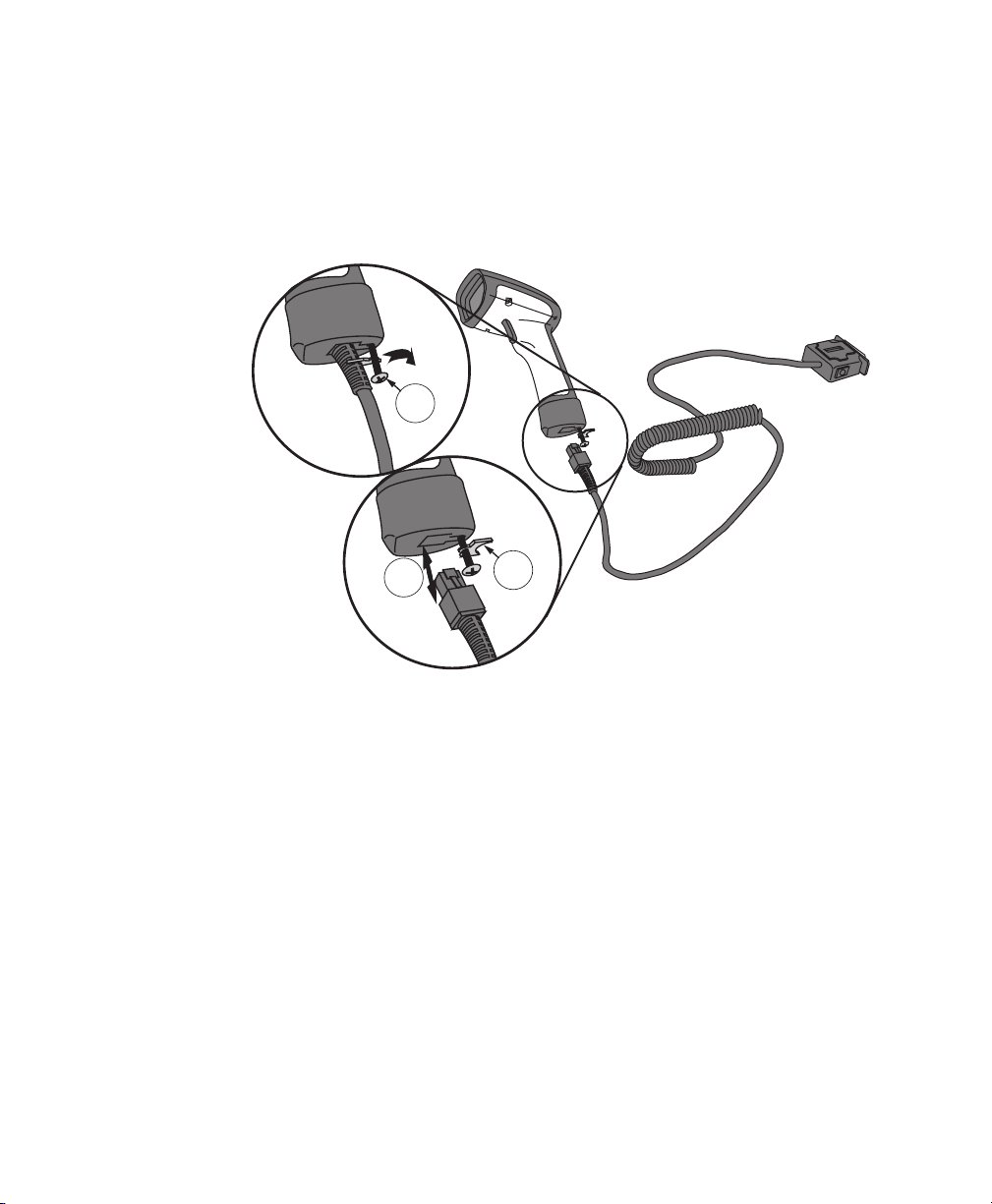

To change the scanner interface cable

1 Loosen the screw at the bottom of the handle. This screw is

captive and does not come all the way out.

Do not try to pull the end cap off, as this may damage the

scanner.

2 Swing the forked cable retainer clear of the square hole in the

end cap and rotate away from the cable.

8 SR60 Scanner Programmer’s Reference Manual

Page 21

Chapter 1 — Introduction to Programming the SR60 Scanner

3 Holding the scanner handle and end cap together in one

hand, pull the connector out of the handle end cap to free the

interface cable.

4 Connect the new interface cable at the scanner and rotate the

forked cable retainer to secure it. Tighten the screw to 0.67 to

1.13 Nm (6 to 10 in-lb).

1

3

Removing and Replacing an Interface Cable

Reconfiguring the Interface Settings

If you change the interface cable, you may need to reconfigure

the interface settings. For help, see Chapter 2, “

Interface Settings.”

After you reconfigure the interface settings, you should scan a bar

code to verify that the scanner communicates correctly with the

new host system. For sample bar codes, see

on page 152.

2

Configuring

“Sample Bar Codes”

SR60 Scanner Programmer’s Reference Manual 9

Page 22

Chapter 1 — Introduction to Programming the SR60 Scanner

Restoring Factory Default Settings

You can restore the factory default settings at any time by

scanning the Return to Factory Default Settings bar code in this

section. This bar code is typically used to return the scanner to a

known operating state when the present programming status is

not known, faulty, or suspect.

For a list of factory default settings, see Appendix A, “Factory

Default Configuration” on page 145.

Use this bar code with caution, since it resets all changes made

during previous programming sessions.

Note: This bar code does not reset the Low Power mode. For

details, see

To restore factory defaults

1 Scan the SET bar code.

2 Scan the Return to Factory Setting bar code.

“Configuring the Low Power Mode” on page 140.

3 Scan the END bar code.

SET ------------------------- ------------------

Return to Factory Default

Settings ---------

END ------------------------------------------

10 SR60 Scanner Programmer’s Reference Manual

Page 23

Chapter 1 — Introduction to Programming the SR60 Scanner

Trouble Scanning the Bar Codes in This Manual

If you are having trouble scanning the bar codes in this manual,

make sure you follow these guidelines:

• Review the scanning instructions in the SR60 Scanner Quick

Start Guide (P/N 930-141-001) which shipped with the

scanner.

• Hold the SR60 scanner at least 1.2 m (4 ft) from the bar code

because this is a long range scanner.

• If you see more than one red marker beam, aim the center

beam on the bar code.

• Move the marker beam horizontally across the page toward

the bar code to avoid passing the marker beam over other bar

codes.

SR60 Scanner Programmer’s Reference Manual 11

Page 24

Chapter 1 — Introduction to Programming the SR60 Scanner

12 SR60 Scanner Programmer’s Reference Manual

Page 25

2

Configuring Interface

Settings

This chapter contains the programming bar codes for selecting an

interface and programming the related interface settings. You will

find these sections in this chapter:

• Wand Emulation Interface

• Wand Emulation Settings

• RS-232 Interface/WN-RS-232 (SNI) Interface

• RS-232 Communication Parameters

• Keyboard Wedge Interface

•USB Interface

SR60 Scanner Programmer’s Reference Manual 13

Page 26

Chapter 2 — Configuring Interface Settings

Wand Emulation Interface

Scan the following bar codes to enable the Wand Emulation

Interface.

SET ------------------------- ------------------

Enable Wand Emulation ---------

END ------------------------------------------

Wand Emulation Settings

Scan the following bar codes to configure the settings for the

Wand Emulation Interface.

Note: You should enable Transmit C128 Function Characters

only when Data Format is set to Transmit in Normal Format or

Transmit in Code 128 Format.

SET ------------------------- ------------------

Polarity

Space Low, Bar High ---------

14 SR60 Scanner Programmer’s Reference Manual

Page 27

Space High, Bar Low ---------

Signal Speed

Low (660 µs) ---------

High (330 µs) ---------

Data Format

Transmit in Normal

Format ---------

Chapter 2 — Configuring Interface Settings

Transmit in C39

Format ---------

Transmit in C39 Full ASCII

Format ---------

Transmit in C128

Format ---------

SR60 Scanner Programmer’s Reference Manual 15

Page 28

Chapter 2 — Configuring Interface Settings

Idle State

Low ---------

High ---------

Transmit C128 Function Characters

Enable ---------

Disable ---------

END ------------------------------------------

16 SR60 Scanner Programmer’s Reference Manual

Page 29

Chapter 2 — Configuring Interface Settings

Wand Emulation Pre/Post-Noise Settings

You can independently configure the number of noise transitions

generated prior to or following label transitions.

To disable transmitting pre-noise or post-noise transitions

1 Scan the SET bar code.

2 Scan either the Don’t Transmit Pre-Noise bar code on page 17

or the Don’t Transmit Post-Noise bar code on page 18.

3 Scan the END bar code. You have disabled noise transitions.

To set pre-noise or post-noise transitions

1 Scan the SET bar code.

2 Scan either the Set Pre-Noise Transitions bar code on page 17

or the Set Post-Noise Transitions bar code on page 18.

3 From the “Keypad Bar Codes” on page 154, scan two digits

that represent the appropriate number of noise transitions.

You can choose from one to twenty noise transitions for either

pre-noise or post-noise. For example, scan the 0 and the 3 bar

codes for three transitions.

4 Scan the END bar code.

Pre-Noise Transitions Settings

SET ----------------------- --------------------

Don’t Transmit Pre-Noise ---------

Set Pre-Noise Transitions ---------

SR60 Scanner Programmer’s Reference Manual 17

Page 30

Chapter 2 — Configuring Interface Settings

Use the bar codes in “Keypad Bar Codes” on page 154 to scan two digits

representing the number of Pre-Noise Transitions padded with leading zeros.

For example, 03 = three transitions, 08 = eight, and 15 = fifteen.

END ------------------------------------------

Post-Noise Transitions Settings

SET ------------------------- ------------------

Don’t Transmit

Post-Noise ---------

Set Post-Noise

Transitions ---------

Use the bar codes in “Keypad Bar Codes” on page 154 to scan two digits

representing the number of Post-Noise Transitions padded with leading zeros.

For example, 03 = three transitions, 08 = eight, and 15 = fifteen.

END ------------------------------------------

18 SR60 Scanner Programmer’s Reference Manual

Page 31

Chapter 2 — Configuring Interface Settings

RS-232 Interface/WN-RS-232 (SNI) Interface

Scan the following bar codes to enable either the standard

RS-232 interface or the WN-RS-232 (SNI) Interface.

SET ----------------------- --------------------

Enable Standard

RS-232 ---------

Enable WN-RS-232 ---------

END ------------------------------------------

RS-232 Communication Parameters

This section describes these RS-232 communication parameters:

•Baud Rate

• Data Format Settings: Data Bit, Parity Bit, and Stop Bit(s)

•Handshaking

• Hardware Handshaking (CTS/RTS)

• Software Handshaking (XON/XOFF)

• ACK/NAK Options

• Intercharacter Delay

SR60 Scanner Programmer’s Reference Manual 19

Page 32

Chapter 2 — Configuring Interface Settings

For help changing other settings for this interface, see:

• Chapter 3, “Configuring Label Transmit Settings,” on

page 47

• “All Symbologies Supported by All Interfaces” on page 66

• Chapter 5, “Configuring General Features,” on page 133

Baud Rate

Scan the following bar codes to select the Baud Rate. Only one

Baud Rate selection may be active at any one time. The last Baud

Rate bar code you scan during a programming session is the

setting that is stored when you scan the END bar code.

SET ------------------------- ------------------

Baud Rate = 1200 ---------

Baud Rate = 2400 ---------

Baud Rate = 4800 ---------

Baud Rate = 9600 ---------

20 SR60 Scanner Programmer’s Reference Manual

Page 33

Baud Rate = 19200 ---------

Baud Rate = 38400 ---------

END ------------------------------------------

Data Format Settings

Scan the following bar codes to select the data format

configuration needed to communicate with your system.

Chapter 2 — Configuring Interface Settings

SET ----------------------- --------------------

Data Bit

Seven ---------

Eight ---------

SR60 Scanner Programmer’s Reference Manual 21

Page 34

Chapter 2 — Configuring Interface Settings

Parity Bit

None ---------

Even ---------

Odd ---------

Mark ---------

Space ---------

Stop Bit(s)

One ---------

22 SR60 Scanner Programmer’s Reference Manual

Page 35

Two ---------

END ------------------------------------------

Handshaking

Review your system documentation to identify handshaking

requirements, and scan the following bar codes to change the

settings if required. The following descriptions briefly explain

each selection.

Hardware Handshaking

You can choose either CTS/RTS Flow Control or CTS Scan

Control:

Chapter 2 — Configuring Interface Settings

• CTS/RTS Flow Control is a type of hardware handshaking.

The scanner activates the RTS (Request to Send) line when it

is ready to send data to the host. The scanner waits for an

active Clear to Send (CTS) signal from the host before

transmitting data. If hardware control is disabled, CTS/RTS

communication does not take place. If the host deactivates the

CTS line during data transmission, the host receives

additional characters for no more than 2 ms. (The timing

varies slightly, depending on the baud rate you select.)

Data

CTS

CTS/RTS Flow Control Illustration

Label Transmission Label TransmissionXmission

Active

Disabled

Inactive

• CTS Scan Control is a type of hardware handshaking. When

scan control is enabled, label scanning is disabled until CTS is

asserted and de-asserted, as shown in the next illustration.

SR60 Scanner Programmer’s Reference Manual 23

Page 36

Chapter 2 — Configuring Interface Settings

Data

CTS

CTS Scan Control Illustration

Label 1 Label 2Label 1

Disabled until

De-assert

Handshaking controls are mutually exclusive. You cannot enable

more than one of these features at a time, because enabling

multiple controls produces unpredictable results.

Note: Each handshaking feature requires a series of bar codes in

the sequence given. That is, you must enter Programming mode

by scanning the SET bar code, scan the Step #1 bar code, scan the

Step #2 bar code, and then scan the END bar code.

Enable CTS/RTS Flow Control

Will not scan again

until toggled

Assert

SET ------------------------- ------------------

Step #1 ---------

Step #2 ---------

24 SR60 Scanner Programmer’s Reference Manual

Page 37

END ------------------------------------------

Enable CTS Scan Control

SET ----------------------- --------------------

Step #1 ---------

Step #2 ---------

Chapter 2 — Configuring Interface Settings

END ------------------------------------------

Software Handshaking

XON/XOFF is software handshaking that allows the host to

control data transmission. If the host sends an XOFF command

to the scanner, the scanner does not send the bar code data until

it receives an XON command from the host. If the host sends the

XOFF command during data transmission, the host receives

additional characters for no more than 2 ms. (The timing varies

slightly, depending on the baud rate you select.)

SR60 Scanner Programmer’s Reference Manual 25

Page 38

Chapter 2 — Configuring Interface Settings

Enable XON/XOFF Control

SET ------------------------- ------------------

Step #1 ---------

Step #2 ---------

END ------------------------------------------

Disable both CTS/RTS and XON/XOFF Control

SET ------------------------- ------------------

Step #1 ---------

26 SR60 Scanner Programmer’s Reference Manual

Page 39

Step #2 ---------

END ------------------------------------------

To disable either CTS/RTS Control or XON/XOFF Control

1 Disable both CTS/RTS Flow Control and XON/XOFF

Control.

2 Enable one handshaking feature:

• To enable CTS/RTS Flow Control, see page 24.

• To enable XON/XOFF Control, see page 26.

RS-232 ACK/NAK Options

Scan the following bar codes to configure the RS-232 ACK/NAK

parameters for your scanner.

Chapter 2 — Configuring Interface Settings

RS-232 ACK/NAK Options

SET ----------------------- --------------------

Disable ACK/NAK ---------

SR60 Scanner Programmer’s Reference Manual 27

Page 40

Chapter 2 — Configuring Interface Settings

Enable for Bar Code

Transmission ---------

Enable for Host Command

Acknowledge ---------

Enable for Bar Code

Transmission and

Host Command

Acknowledge ---------

END ------------------------------------------

RS-232 Intercharacter Delay

Intercharacter Delay refers to the pause, if any, between each

character before it is sent to the host. This time delay controls the

flow of data from the scanner.

SET ------------------------- ------------------

None ---------

28 SR60 Scanner Programmer’s Reference Manual

Page 41

10 Milliseconds ---------

20 Milliseconds ---------

30 Milliseconds ---------

40 Milliseconds ---------

Chapter 2 — Configuring Interface Settings

50 Milliseconds ---------

100 Milliseconds ---------

200 Milliseconds ---------

SR60 Scanner Programmer’s Reference Manual 29

Page 42

Chapter 2 — Configuring Interface Settings

500 Milliseconds ---------

1 Second ---------

END ------------------------------------------

Keyboard Wedge Interface

This section describes these PC Keyboard Wedge interface

parameters:

• Interface Selection

• Connect to a Laptop

•Caps Lock

•Country Mode

• Intercharacter Delay

•Quiet Interval

For help changing other settings for this interface, see:

• Chapter 3, “Configuring Label Transmit Settings,” on

page 47

• “All Symbologies Supported by All Interfaces” on page 66

• Chapter 5, “Configuring General Features,” on page 133

Note: If you configure the transmission parameters so that a label

results in no actual data to send, the label will be accepted,

beeped, and no data transmitted.

30 SR60 Scanner Programmer’s Reference Manual

Page 43

PC Keyboard Interface Selection

The SR60 scanner supports a variety of PC keyboard interfaces.

Find your PC Keyboard Interface in the first column and note

the corresponding Interface Type in the second column.

For your convenience, the third column lists the corresponding

cable or cables you can use to connect the SR60 scanner.

PC Keyboard Interfaces and Cables Supported

PC Keyboard Interface

PC/XT with alternate key encoding A P/N 321-635-001

AT, PS/2 25-286, 30-286, 50, 50Z,

60, 70, 80, 90, and 95 with alternate

key encoding

PS/2 25 and 30 with alternate key

encoding

PC/XT with standard key encoding D P/N 321-635-001

AT, PS/2 25-286, 30-286, 50, 50Z,

60, 70, 80, 90, and 95 with standard

key encoding

PS/2 25 and 30 with standard key

encoding

PS/55 5530T with 104 keyboard I P/N 321-635-001

Chapter 2 — Configuring Interface Settings

Interface

Typ e

B P/N 321-635-001

C P/N 321-635-001

E P/N 321-635-001

F P/N 321-635-001

Cable(s)

P/N 321-636-001

P/N 321-636-001

P/N 321-636-001

P/N 321-636-001

P/N 321-636-001

Intermec recommends that you disconnect power before

plugging or unplugging cables to avoid any possibility of

equipment damage.

Scan the following bar codes to select the interface type you

identified from the previous table, “

PC Keyboard Interfaces and

Cables Supported.”

SR60 Scanner Programmer’s Reference Manual 31

Page 44

Chapter 2 — Configuring Interface Settings

PC Keyboard Interface Type

SET ------------------------- ------------------

A ---------

B ---------

C ---------

D ---------

E ---------

32 SR60 Scanner Programmer’s Reference Manual

Page 45

Chapter 2 — Configuring Interface Settings

F ---------

I ---------

END ------------------------------------------

Connect to a Laptop or PC and Send Control/Function Characters

You need to know if the scanner will be connected to a laptop

(with an integrated keyboard), connected to a PC (with an

external keyboard), or operated with no external keyboard. You

also need to know if you want to transmit control characters and

function characters.

• The Laptop/No External Keyboard bar code on page 34

provides the acknowledge signal to the PC. You should enable

this feature if the scanner is connected to a laptop or operated

with no external keyboard.

• The Keyboard Attached bar code on page 34 should be

enabled when the scanner is connected to a standard PC with

an external keyboard.

• The Enable Control Characters bar code on page 34 transmits

all ASCII characters except NUL (00h). Disabling this feature

limits the transmission of ASCII characters to this list:

• ASCII characters between 20h - 127h

• Carriage Return (CR=0Dh)

• BackSpace (BS=08h)

SR60 Scanner Programmer’s Reference Manual 33

Page 46

Chapter 2 — Configuring Interface Settings

• Right Tab (HT=09h)

•Left Tab (0Bh)

•Esc (1Bh)

• The Enable Function Characters bar code on page 34

transmits characters between 00H - IFH, which are not in the

normal ASCII set.

Scan the following bar codes to select the option for connecting

to a laptop or PC.

SET ------------------------- ------------------

Connect to Laptop or PC

Laptop/No External

Keyboard ---------

Keyboard Attached ---------

Send Control/Function Characters

Enable Control

Characters ---------

Enable Function

Characters ---------

34 SR60 Scanner Programmer’s Reference Manual

Page 47

Disable ---------

END ------------------------------------------

Caps Lock

You can set three Caps Lock settings:

• The Caps Lock Off bar code sends character data to the host

in normal format.

• The Caps Lock On bar code sends character data to the host

in reverse case:

• (a-z) = (A-Z)

Chapter 2 — Configuring Interface Settings

•(A-Z) = (a-z)

Use this feature if your keyboard Caps Lock key is on.

• The Caps Lock = Shift-Lock bar code sends character data to

the host in shifted case. This option may be used only with

interface type G (IBM 3xxx 122-keyboard) with the Shift

Lock key on.

SET ----------------------- --------------------

SR60 Scanner Programmer’s Reference Manual 35

Page 48

Chapter 2 — Configuring Interface Settings

Caps Lock Off ---------

Caps Lock On ---------

Caps Lock = Shift-Lock ---------

END ------------------------------------------

Country Mode

You can select the following countries only when the scanner is

configured for Interface Type E:

•Belgium

•Britain

•Denmark

•France

•Germany

•Italy

• Japanese 106-Key

•Norway

36 SR60 Scanner Programmer’s Reference Manual

Page 49

•Portugal

•Spain

•Sweden

•Switzerland

• U.S.A.

Scan the following bar codes to select the desired country.

SET ----------------------- --------------------

Belgium ---------

Chapter 2 — Configuring Interface Settings

Britain ---------

Denmark ---------

France ---------

SR60 Scanner Programmer’s Reference Manual 37

Page 50

Chapter 2 — Configuring Interface Settings

Germany ---------

Italy ---------

Japanese 106-Key ---------

Norway ---------

Portugal ---------

Spain ---------

Sweden ---------

38 SR60 Scanner Programmer’s Reference Manual

Page 51

Switzerland ---------

U.S.A. ---------

END ------------------------------------------

Intercharacter Delay

Intercharacter Delay refers to the pause, if any, between each

character before it is sent to the host. This time delay controls the

flow of data from the scanner. Scan the following bar codes to

select the Intercharacter Delay.

Chapter 2 — Configuring Interface Settings

SET ----------------------- --------------------

None ---------

5 Milliseconds ---------

SR60 Scanner Programmer’s Reference Manual 39

Page 52

Chapter 2 — Configuring Interface Settings

10 Milliseconds ---------

20 Milliseconds ---------

30 Milliseconds ---------

40 Milliseconds ---------

60 Milliseconds ---------

80 Milliseconds ---------

90 Milliseconds ---------

40 SR60 Scanner Programmer’s Reference Manual

Page 53

END ------------------------------------------

Quiet Interval

Quiet Interval is the amount of time to look for keyboard activity

before the scanner breaks the keyboard connection in order to

transmit data to the host.

SET ----------------------- --------------------

10 Milliseconds ---------

Chapter 2 — Configuring Interface Settings

20 Milliseconds ---------

50 Milliseconds ---------

100 Milliseconds ---------

SR60 Scanner Programmer’s Reference Manual 41

Page 54

Chapter 2 — Configuring Interface Settings

200 Milliseconds ---------

500 Milliseconds ---------

1 Second ---------

END ------------------------------------------

USB Interface

Scan the following bar codes to enable the USB interface and

configure the keyboard country code.

To enable the USB interface and configure the keyboard country code

1 Identify the keyboard country code you will use. See the

“Keyboard Country Code for USB Interface” table on

page 43.

2 Scan the START bar code on page 43.

3 Scan the Enable USB and Configure Keyboard Country

Code bar code.

4 Using the Digits bar codes on page 44, scan the digits to set

the keyboard country code you identified in Step 1.

5 Scan the END bar code on page 43.

42 SR60 Scanner Programmer’s Reference Manual

Page 55

Chapter 2 — Configuring Interface Settings

Keyboard Country Code for USB Interface

Country

Belgium 734 742

Denmark 738 746

France 523 526

Germany 525 528

Italy 529 530

Japan 759 Not available

Norway 737 745

Poland 733 Not available

Spain 732 741

Switzerland 736 744

United Kingdom 731 740

United States 524 527

START--------------------------------------

Code for

Windows 98/XP/2000

Code for

IMAC

Enable USB and Configure

Keyboard Country Code ---------

Use the bar codes on the next page to specify the three-digit keyboard country

code you identified in Step 1.

END ------------------------------------------

SR60 Scanner Programmer’s Reference Manual 43

Page 56

Chapter 2 — Configuring Interface Settings

Digits

0 ---------

1 ---------

2 ---------

3 ---------

4 ---------

5 ---------

44 SR60 Scanner Programmer’s Reference Manual

Page 57

6 ---------

7 ---------

8 ---------

9 ---------

Chapter 2 — Configuring Interface Settings

SR60 Scanner Programmer’s Reference Manual 45

Page 58

Chapter 2 — Configuring Interface Settings

46 SR60 Scanner Programmer’s Reference Manual

Page 59

3

Configuring Label Transmit

Settings

This chapter contains the programming bar codes for configuring

the optional prefix, suffix, and label ID which may be sent in

addition to bar code data if your SR60 scanner is configured for

the RS-232 or Keyboard Wedge interface. You will find these

sections in this chapter:

• When to Configure Label Transmit Settings

• How to Use the Prefix, Suffix, and Label ID

• Setting Global Prefix(es)

• Setting Global Suffix(es)

• Setting a Single-Character Prefix or Suffix

• Disabling a Global Prefix or Suffix

• Setting a Label ID

SR60 Scanner Programmer’s Reference Manual 47

Page 60

Chapter 3 — Configuring Label Transmit Settings

When to Configure Label Transmit Settings

If you need to send information in addition to bar code label

data, you can configure the scanner to transmit:

• global prefixes (or preambles).

• global suffixes (or postambles).

• symbology-specific identifier characters (or label IDs).

You may configure these Label Transmit settings only if your

SR60 scanner has been configured to use either the RS-232 or

Keyboard Wedge interface.

How to Use the Prefix, Suffix, and Label ID

The following table shows how you can use the prefix, suffix, and

label ID characters.

Note: Using these features requires a thorough understanding of

your specific system requirements. For help, contact Intermec

Product Support.

Global Prefix

1st

Char

00 00 None 0998875 None 00 00 0998875

50 51 None 0011223344 None 000 000 PQ0011223344

00 00 46 46 00210126 None 00 00 FF00210126

50 51 41 00a00210126 None 00 00 PQA210126

00 00 None $99.95 25 00

50 51 None 998875 25 00a00 00 PQ998875E

00 00 None 101234567891 None 53 57 10123456789SW

50 51 None Code39Test None 53 57 PQCode39TestSW

00 00 45 00

50 00 45 46 0998875 None 53 57 PFF09988875SW

00 00 None 0998875 46 46 53 57 0998875FFSW

50 51 None 0011223344 46 00a53 57 PQ0011223344FSW

a. The 00 indicates no second character.

Label ID

as Prefix Label Data

2nd

1st

Char

2nd

Char

Char Examples

a

Code128 None 53 00 ECode128S

Label ID

as Suffix Global Suffix

1st

2nd

1st

Char

Char

a

2nd

Char

Char Examples

00 00 $99.95%

Resulting Label

Format

48 SR60 Scanner Programmer’s Reference Manual

Page 61

Note: In the Global Prefix and the Global Suffix columns, 00

indicates no character.

Setting Global Prefix(es)

You may add one or two prefix characters to the standard label

format. To add more than two prefix characters, contact Intermec

Product Support for Full Label Edit (FLE) options.

To s et global prefixes

1 Identify your specific system requirements.

2 Using the ASCII chart on page 158, identify the ASCII

character(s) and the corresponding hex code(s) for the prefix.

For example, suppose you want to send the two prefix

characters STX (start transmit) and SP (Space). The ASCII

chart shows that STX equals 02 hex and SP equals 20 hex.

3 Scan the SET bar code on page 50.

4 Scan the Set Prefix bar code.

5 Using the list of bar codes that starts on page 154, scan the

four digits corresponding to the hex values you chose in

Step 2.

Chapter 3 — Configuring Label Transmit Settings

For this example, you would scan 0, 2, 2, and 0.

Note: Successful programming requires four digits for the

label ID.

Note: If you make a mistake or lose your place while setting

this option, scan the END bar code to exit Programming

mode. The scanner sounds a two-beep error tone to indicate

that programming was incomplete, and the setting remains as

it was before entering Programming mode.

6 Scan the END bar code.

SR60 Scanner Programmer’s Reference Manual 49

Page 62

Chapter 3 — Configuring Label Transmit Settings

You have added a two-character prefix to all bar code data,

regardless of label symbology. The prefix will be added to the

label data before it is sent to the host.

Setting Global Prefix(es)

SET ------------------------- ------------------

Set Prefix ---------

Use the ASCII chart on page 158 to identify the ASCII character(s) and the

corresponding hex code(s) for the prefix. Then use the bar codes on page 154

to scan the four digits corresponding to the hex values.

END ------------------------------------------

Setting Global Suffix(es)

You may add one or two suffix characters to the standard label

format. To add more than two suffix characters, contact Intermec

Product Support for Full Label Edit (FLE) options.

To s et global suffixes

1 Identify your specific system requirements.

2 Using the ASCII chart on page 158, identify the ASCII

character(s) and the corresponding hex code(s) for the ASCII

characters you plan to use as suffixes.

For example, suppose you want to send the two suffix

characters LF (Line Feed) and CR (Carriage Return). The

ASCII chart shows that LF equals 0A hex and CR equals 0D

hex.

50 SR60 Scanner Programmer’s Reference Manual

Page 63

Chapter 3 — Configuring Label Transmit Settings

3 Scan the SET bar code on page 51.

4 Scan the Set Suffix bar code.

5 Using the list of bar codes that starts on page 154, scan the

four digits corresponding to the hex values you chose in

Step 2.

For this example, you would scan 0, A, 0, and D.

Note: Successful programming requires four digits for the

label ID.

Note: If you make a mistake or lose your place while setting

this option, scan the END bar code to exit Programming

mode. The scanner sounds a two-beep error tone to indicate

that programming was incomplete, and the setting remains as

it was before entering Programming mode.

6 Scan the END bar code.

You have added a two-character suffix to all bar code data,

regardless of label symbology, that will be added to the label data

before it is sent to the host.

Setting Global Suffix(es)

SET ----------------------- --------------------

Set Suffix ---------

Use the ASCII chart on page 158 to identify the ASCII character(s) and the

corresponding hex code(s) for the suffix. Then use the bar codes on page 154

to scan the four digits corresponding to the hex values.

SR60 Scanner Programmer’s Reference Manual 51

Page 64

Chapter 3 — Configuring Label Transmit Settings

END ------------------------------------------

Setting a Single-Character Prefix or Suffix

The scanner does not transmit a prefix or suffix character if its

hex value is set to zero.

To set a prefix or suffix that has only one character

1 Using the ASCII chart on page 158, identify the ASCII

character and the corresponding hex code for the singlecharacter prefix or suffix.

For example, suppose you want to use the Space (SP)

character. The ASCII charts shows that SP equals 20 hex.

2 Scan the SET bar code on page 53.

3 Scan the Set Prefix or Set Suffix bar code.

4 Using the list of bar codes that starts on page 154, scan the

two digits corresponding to the hex value you chose in Step 1.

5 Scan the 0 digit twice to disable the transmission of a second

character.

6 For this example, you would scan 2, 0, 0, and 0.

Note: Successful programming requires four digits for the

label ID.

Note: If you make a mistake or lose your place while setting

this option, scan the END bar code to exit Programming

mode. The scanner sounds a two-beep error tone to indicate

that programming was incomplete, and the setting remains as

it was before entering Programming mode.

7 Scan the END bar code.

52 SR60 Scanner Programmer’s Reference Manual

Page 65

Setting a Single Character Prefix/Suffix

SET ----------------------- --------------------

Set Prefix ---------

Set Suffix ---------

Chapter 3 — Configuring Label Transmit Settings

END ------------------------------------------

Disabling a Global Prefix or Suffix

You can disable a global prefix or suffix.

To disable global prefix or suffix characters

1 Scan the SET bar code on page 54.

2 Scan the Set Prefix or Set Suffix bar code.

3 Scan the 0 digit four times to disable the prefix or suffix

characters.

4 Scan the END bar code.

SR60 Scanner Programmer’s Reference Manual 53

Page 66

Chapter 3 — Configuring Label Transmit Settings

Disabling Global Prefix/Suffix Characters

SET ------------------------- ------------------

Set Prefix ---------

Set Suffix ---------

0 ---------

END ------------------------------------------

54 SR60 Scanner Programmer’s Reference Manual

Page 67

Chapter 3 — Configuring Label Transmit Settings

Setting a Label ID

Setting the Label ID feature can be a complex task that requires

multiple steps to enable all necessary options.

About Symbology-Specific Label Identifiers

Symbology-specific label identifiers consist of one or two ASCII

characters that can precede or follow the bar code label data as it

is transmitted to the host. The host may use these characters as a

means of distinguishing between symbologies.

Industry standards have been established for symbology-specific

label identifiers, which are listed in the next table. Most scanners

have factory default identifiers preset to these standards.

Industry Standard Label Identifiers (Prefixes)

Symbology Identifier (ID)

UPC-A A

UPC-E E

EAN-8 FF

EAN-13 F

UPC-A (with 2 add-ons) A

UPC-A (with 5 add-ons) A

UPC-A (with 8 add-ons) A

UPC-E (with 2 add-ons) E

UPC-E (with 5 add-ons) E

UPC-E (with 8 add-ons) E

EAN-8 (with 2 add-ons) FF

EAN-8 (with 5 add-ons) FF

EAN-8 (with 8 add-ons) FF

EAN-13 (with 2 add-ons) F

EAN-13 (with 5 add-ons) F

EAN-13 (with 8 add-ons) F

Code 39 *

PharmaCode A

Codabar %

Interleaved 2 of 5 i

SR60 Scanner Programmer’s Reference Manual 55

Page 68

Chapter 3 — Configuring Label Transmit Settings

Industry Standard Label Identifiers (Prefixes) (continued)

Symbology Identifier (ID)

Standard 2 of 5 i

Code 93 &

Code 128 #

UPC/EAN 128 None

MSI/Plessey @

Setting the Label ID Location

You can specify the location where Label ID characters are to be

placed in relation to scanned label data. The location you choose

will be applied universally to all symbologies; you cannot specify

a symbology-specific label ID location.

The locations include:

• None (for example, prefix, label data, suffix)

• Prefix (for example, prefix, label ID, label data, suffix)

• Suffix (for example, prefix, label data, label ID, suffix)

To set the label ID location

1 Scan the SET bar code.

2 Scan the bar code for the location you chose.

3 Scan the END bar code

Setting Label ID Location

SET ------------------------- ------------------

Label ID = None ---------

56 SR60 Scanner Programmer’s Reference Manual

.

Page 69

Chapter 3 — Configuring Label Transmit Settings

Position Label ID as

Prefix ---------

Position Label ID as

Suffix ---------

END ------------------------------------------

Setting a Symbology-Specific Label ID

You can configure a label ID for each symbology.

To set a symbology-specific label ID

1 Using the ASCII chart on page 158, identify the ASCII

character(s) and the corresponding hex code(s) for the ASCII

characters you plan to use as the label ID.

For example, suppose you want to change the label ID for

UPC-A to A1. The ASCII chart shows that A equals 41 hex

and 1 equals 31 hex.

2 Scan the SET bar code on page 58.

3 Using the bar codes in “Selecting the Symbology” on page 58,

scan the bar code representing the symbology whose Label ID

you want to change.

For this example, you would scan the UPC-A symbology bar

code.

4 Using the list of bar codes that starts on page 154, scan the

four digits corresponding to the hex values you chose in

Step 1.

SR60 Scanner Programmer’s Reference Manual 57

Page 70

Chapter 3 — Configuring Label Transmit Settings

For this example, you would scan 4, 1, 3, and 1.

Note: Successful programming requires four digits for the

label ID.

5 Scan the END bar code.

You have changed the default Label ID for UPC-A from A to A1.

Selecting the Symbology

This section contains bar codes that represent each symbology.

You scan these bar codes when, for example, you configure a

symbology-specific label ID. You may scan only one symbology

per programming session.

Setting Label ID Characters by Symbology

SET ------------------------- ------------------

Code 39 ---------

PharmaCode 39 ---------

Code 128 ---------

58 SR60 Scanner Programmer’s Reference Manual

Page 71

UCC/EAN 128 ---------

Interleaved 2 of 5 ---------

Codabar ---------

UPC-A ---------

Chapter 3 — Configuring Label Transmit Settings

UPC-A

(2 digit add-ons) ---------

UPC-A

(with 5 digit add-ons) ---------

UPC-A

(with C128 add-ons) ---------

SR60 Scanner Programmer’s Reference Manual 59

Page 72

Chapter 3 — Configuring Label Transmit Settings

UPC-E ---------

UPC-E

(with 2 digit add-ons) ---------

UPC-E

(with 5 digit add-ons) ---------

UPC-E

(with C128 add-ons) ---------

EAN-13 ---------

EAN-13

(with 2 digit add-ons) ---------

EAN-13

(with 5 digit add-ons) ---------

60 SR60 Scanner Programmer’s Reference Manual

Page 73

EAN-13

(with C128 add-ons) ---------

EAN-8 ---------

EAN-8

(with 2 digit add-ons) ---------

EAN-8

(with 5 digit add-ons) ---------

Chapter 3 — Configuring Label Transmit Settings

EAN-8

(C128 add-ons) ---------

Code 93 ---------

Standard 2 of 5 ---------

SR60 Scanner Programmer’s Reference Manual 61

Page 74

Chapter 3 — Configuring Label Transmit Settings

MSI/Plessey ---------

END ------------------------------------------

Setting a Single-Character Label ID

The scanner does not transmit a label ID character if its hex value

is set to zero. If you need a Label ID that contains only a single

character, you can set a single-character label ID.

To set a single-character label ID

1 Using the ASCII chart on page 158, identify the ASCII

character and the corresponding hex code for the singlecharacter label ID.

For example, suppose you want to change the Label ID for

EAN-8 from the default setting FF to the single character 8.

The ASCII chart shows that ASCII 8 equals 38 hex.

2 Scan the SET bar code on page on page 58.

3 Using the bar codes in “Selecting the Symbology” on page 58,

scan the bar code representing the symbology whose Label ID

you want to change.

For this example, you would scan the EAN-8 bar code.

4 Using the list of bar codes that starts on page 154, scan the

two digits corresponding to the hex value you chose in Step 1.

5 Scan the 0 digit twice to disable transmission of a second

character.

For this example, you would scan 3, 8, 0, and 0.

Note: Successful programming requires four digits for the

label ID.

62 SR60 Scanner Programmer’s Reference Manual

Page 75

Chapter 3 — Configuring Label Transmit Settings