Intermec EasyCoder 501XP, EasyCoder 601XP, EasyCoder F2, EasyCoder F4, Direct Protocol v7.80 Programmer's Reference Manual

Page 1

Programmer’s

Reference Manual

Intermec

Direct Protocol

v7.80

Page 2

Intermec Technologies Corporation

Corporate Headquarters

6001 36th Ave. W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is proprietary and is provided solely

for the purpose of allowing customers to operate and service Intermecmanufactured equipment and is not to be released, reproduced, or used

for any other purpose without written permission of Intermec.

Information and specifi cations contained in this document are subject to

change without prior notice and do not represent a commitment on the

part of Intermec Technologies Corporation.

© 2004 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, CrossBar,

Data Collection Browser, dcBrowser, Duratherm, EasyCoder, EasyLAN,

Enterprise Wireless LAN, EZBuilder, Fingerprint, i-gistics, INCA (under

license), InterDriver, Intermec Printer Network Manager, IRL, JANUS,

LabelShop, Mobile Framework, MobileLAN, Nor*Ware, Pen*Key,

Precision Print, PrintSet, RoutePower, TE 2000, Trakker Antares, UAP,

Universal Access Point, and Virtual Wedge are either trademarks or registered trademarks of Intermec Technologies Corporation.

Throughout this manual, trademarked names may be used. Rather than

put a trademark (™ or ®) symbol in every occurrence of a trademarked

name, we state that we are using the names only in an editorial fashion,

and to the benefi t of the trademark owner, with no intention of infringement.

There are U.S. and foreign patents pending.

The name Centronics is wholly owned by GENICOM Corporation.

Kimdura is a registered trademark of Kimberly Clark.

Microsoft is a registered trademark of Microsoft Corporation.

TrueDoc is a registered trademark of Bitstream, Inc.

TrueType is a trademark of Apple Computer Inc.

Unicode is a trademark of Unicode Inc.

Windows is a trademark of Microsoft Corporation.

Page 3

Intermec Direct Protocol v7.80 Programmer’s Reference Manual iii

Contents

Contents

1

Introduction

1.1 Introduction .........................................................................2

2

Getting Started

2.1 Computer Connection .........................................................4

2.2 Media and Ribbon Supply ....................................................4

2.3 Switch On the Printer ...........................................................5

2.4 Intermec Shell Startup Program ............................................5

2.5 No Startup Program ............................................................. 6

2.6 Serial Communication Test ..................................................6

3

Principles of Operation

3.1 Entering from Intermec Shell .............................................10

3.2 Entering from Immediate Mode .........................................10

3.3 Special Intermec Direct Protocol Features ...........................10

3.4 Sending Instructions ...........................................................11

3.5 Fields ..................................................................................14

3.6 General Formatting Instructions .........................................14

3.7 Field-Related Formatting Instructions ................................15

3.8 Layout Instructions ............................................................ 16

3.9 Printable Data Instructions .................................................16

3.10 Feeding and Printing Instructions .......................................16

3.11 Setting Up the Printer ........................................................17

3.12 Reading Printer’s Status ......................................................18

3.13 File-Handling Instructions .................................................18

3.14 Syntax Descriptions ............................................................19

4

Label Design

4.1 Introduction .......................................................................22

4.2 General Formatting Instructions .........................................23

4.3 Text Fields ..........................................................................29

4.4 Bar Code Field ...................................................................32

Page 4

iv Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Contents

4.5 Image Field .........................................................................37

4.6 Box Field ............................................................................39

4.7 Line Field ...........................................................................40

4.8 Layout Instructions ............................................................ 41

4.9 Printable Data Instructions .................................................43

5

Feeding and Printing Instructions

5.1 Media Feed .........................................................................50

5.2 Label Printing .....................................................................53

5.3 Batch Printing ....................................................................54

6

Setting Up the Printer

6.1 Enabling/Disabling Intermec Direct Protocol .....................58

6.2 Selecting Standard I/O Channel .........................................58

6.3 Setting Time and Date ........................................................59

6.4 Selecting Format for Time and Date ...................................60

6.5 Changing Separators ...........................................................62

6.6 Creating Counters .............................................................. 63

6.7 Enabling/Disabling Label Taken Sensor ..............................64

6.8 Enabling/Disabling Automatic Cutting ..............................65

6.9 Enabling/Disabling the Print Key .......................................65

6.10 Producing Audible Signals ..................................................65

6.11 Formatting the Printer’s Memory ........................................66

6.12 Preprocessing Input Data ....................................................67

6.13 Selecting Character Set .......................................................68

6.14 Rebooting the Printer .........................................................69

6.15 Setting Verbosity Level .......................................................69

6.16 Selecting Type of Error Message .........................................69

6.17 Error Handling ...................................................................70

6.18 Setting Break for Batch Printing .........................................72

6.19 Changing the Printer’s Setup ..............................................73

6.20 Selecting Centronics Type ...................................................75

6.21 Clearing Media Feed Data at Headlift ................................75

6.22 Minimum Gap Length .......................................................75

6.23 Equal Safe for TESTFEED .................................................75

6.24 Overriding Media Feed Setup .............................................70

Page 5

Intermec Direct Protocol v7.80 Programmer’s Reference Manual v

Contents

7

Reading the Printer’s Status

7.1 Introduction .......................................................................78

7.2 Returning Information to Host ..........................................78

7.3 Reading Date and Time ......................................................78

7.4 Testing the Printer’s Memory .............................................. 78

7.5 Testing the Printhead ..........................................................79

7.6 Reading System Counters ...................................................79

7.7 Reading Sensors and Straps ................................................ 80

7.8 Reading Printer’s Status ......................................................80

8

File Handling

8.1 Reading the Printer’s Memory ............................................84

8.2 Removing Fonts, Images, and Files .....................................84

8.3 Copying Files .....................................................................85

8.4 Downloading Binary Files ..................................................85

8.5 Downloading Image Files ...................................................85

9

Advanced Features

9.1 Specifying Complex Bar Codes ........................................... 88

9.2 Using International Character Sets .....................................89

10

Character Sets and Fonts

10.1 Character Sets .....................................................................94

10.2 Resident Fonts ..................................................................118

11

Error Messages

11.1 Interpretation Table ..........................................................120

12

Reference Lists

12.1 Instructions in Alphabetical Order ...................................124

12.2 Instruction Syntax List .....................................................129

Page 6

vi Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Contents

Page 7

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 1

1

Introduction

This chapter gives a quick introduction to the

Intermec Direct Protocol.

Page 8

2 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 1 — Introduction

1.1 Introduction

Intermec Direct Protocol v7.80 is an easy-to-use printer protocol that

has been developed for use with the EasyCoder 501 XP/601 XP and

EasyCoder F2/F4 direct thermal and/or thermal transfer printers manufactured by Intermec Technologies Corp.

The Intermec Direct Protocol can be used in two ways:

• To create label layouts consisting of fi elds with fi xed or variable

information. A layout can then be selected and provided with variable

input from the host computer in the form of a simple string of data.

• To send input data and formatting instructions as a continuous string

of data directly from the host computer.

In both cases, the Intermec Direct Protocol provides a fl exible error

handler, which allows you to compose your own error messages in any

language.

The Intermec Direct Protocol has been created with two main types of

application in mind:

• Applications, where the end-user requires a simple printer control

program, and has little or no use for the sophistication and fl exibility offered by Intermec’s BASIC-inspired programming language

Intermec Fingerprint, yet needs a versatile error handler.

• Applications, which are provided with a comprehensive printer

control program in the host computer, making the use of Intermec

Fingerprint programming more or less an overkill.

Intermec Direct Protocol v7.80 is a subset of the Intermec Fingerprint

v7.80 fi rmware and can be selected using Intermec Shell.

Refer to Chapter 12 at the end of this manual for lists of the various

instructions in the Intermec Direct Protocol.

We recommend that you have the following manuals accessible:

• The User’s Guide for the printer model in question.

• This Programmer’s Reference Manual.

• Intermec Fingerprint v7.80, Programmer’s Reference Manual (useful,

but not necessary).

Page 9

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 3

2

Getting Started

This chapter how to connect the printer to a

computer using the serial interface, switch on the

printer, use Intermec Shell to select the Direct

Protocol, and how to check that the communication

between printer and the host computer is working.

Page 10

4 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 2 — Getting Started

2.1 Computer Connection

The Intermec Direct Protocol is included in the Intermec Fingerprint

fi rmware, which is stored in the Flash SIMM package fi tted on the

printer’s CPU board at delivery. No operative system, such as Microsoft

Windows, is required. The printer only needs to be connected to an

AC supply and to some device, which can transmit characters in ASCII

format. It can be anything from a non-intelligent terminal to a mainframe computer system.

For running the printer, we recommend a computer or terminal with a

screen, an alphanumeric keyboard, and a communication program, that

provides two-way serial communication using RS-232.

It is possible to use a parallel communication board in the printer for

receiving data. However, since the parallel interface provides one-way

communication only, no data or messages can be returned to the host.

For the same reason, the printer’s USB port is not recommended.

Connect the printer and host as described in the printer’s User’s Guide.

If the printer has several serial communication ports, it is recommended

to use the serial port "uart1:" for controlling the printer. It is possible to

set up the printer’s communication protocol to fi t the host computer, as

described in the User’s Guide. However, until you have become familiar

with the Intermec Direct Protocol, it may be easier to adapt the host to

the printer’s default setup parameters.

Default serial communication setup on "uart1:"

• Baud rate: 9600

• Character length: 8

• Parity: None

• No. of stop bits: 1

• Flow control: none

• New line: CR/LF (Carriage Return + Line Feed)

2.2 Media and Ribbon Supply

Check that the printer has an ample supply of media (that is, paper or

similar) and, in case of thermal transfer printing, of thermal transfer

ribbon. Also check that the printer is set up accordingly in regard of

media size, media type, and paper type. Refer to the User’s Guide for

setup and loading instructions.

Page 11

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 5

Chapter 2 — Getting Started

2.3 Switch On the Printer

Check that the printhead is lowered. Switch on the power using the

On/Off switch, which is fi tted on the printer’s rear plate, and check that

the “Power” control lamp comes on. Then check the display window.

What happens next depends on what kind of startup program there is in

the printer.

If you have an EasyCoder 501XP/601 XP printer fi tted

with a paper cutter, make sure the cutter is locked in closed

position. The cutter will be activated when the power is

switched on!

2.4 Intermec Shell Startup Program

After about 30 seconds, when the printer has performed certain self-diagnostic tests and loaded the startup program, a countdown menu will be

displayed:

ENTER=SHELL

5 sec. v.4.6

This menu indicates that the printer is fi tted with the Intermec Shell

startup program. Before the 5 seconds countdown is completed, you

should take action as to select the Intermec Direct Protocol by means

of Intermec Shell as described in the Installation & Operation manual.

Should you fail to take any action before the 5 seconds countdown

runs out, you can start all over again by simply cycling the power to the

printer.

Note: Once you have selected Intermec Direct Protocol, the

printer will automatically enter it again at each startup, until

you select another application in Intermec Shell.

Page 12

6 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 2 — Getting Started

2.5 No Startup Program

If the printer starts up in the immediate mode of Intermec Fingerprint (because you have already selected the Fingerprint application in

Intermec Shell, or because the printer for some reason is not fi tted with

any startup program at all), the display window should show the following message directly after power-up:

Fingerprint

7.80

To use the Intermec Direct Protocol, you will have to send an INPUT ON

instruction to the printer as described in Chapter 3.2.

2.6 Serial Communications Test

Check that you have a working two-way serial communication by sending a simple instruction from the host to the printer. On the host, type:

? VERSION$ ↵ (↵ = Carriage Return key)

Provided you have a serial two-way communication, the printer should

respond by immediately returning the version of the installed Intermec

Fingerprint software to the screen of the host:

Fingerprint 7.50

Ok

This indicates that the communication is working both ways.

If the communication does not work, switch off the printer and check

the connection cable. Also check if the communication setup in the host

corresponds to the printer’s setup and if the connection is made between

the correct ports. Then try the communication test again.

Once you know that the communication is working, you may proceed

by sending a line of text to make sure that characters transmitted from

the terminal are interpreted as expected by the printer’s fi rmware:

FT "Swiss 721 BT" ↵

PT "ABCDEFGHIJKLM" ↵

PF ↵

Page 13

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 7

Chapter 2 — Getting Started

Each line will be acknowledged by an “Ok” on the screen, provided it has

been entered correctly. When you press the “Carriage Return” key the

third time, the printer will feed out a label, ticket, tag, or piece of continuous stock with the text printed in the lower left corner of the printable

area.

ABCDEFGHIJKLM

You can try using other characters between the quotation marks in the

third line, especially typical national characters like ÅÄÖÜ¿¢¥ç, etc.

Should any unexpected characters be printed, you may need to select

another character set, see Chapter 6.13.

Page 14

8 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 2 — Getting Started

Page 15

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 9

3

Principles of Operation

This chapter explains how to enter the Direct Protocol

from Intermec Shell and from the Immediate Mode.

It also describes the special features of the Direct

Protocol and shows how to send instructions to the

printer. Finally, it provides a quick overview of the

instructions used for various purposes in the Direct

Protocol. These are explained more comprehensively

in the chapters that follow.

Page 16

10 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 3 — Principles of Operation

3.1 Entering from Intermec Shell

In Intermec Shell, select the “Intermec Direct Protocol” option under the

“Select Application” headline. After a few seconds, the display will show

the message:

Direct Protocol

7.80

3.2 Entering from Immediate Mode

If you want to enter the Direct Protocol from the immediate mode of

Intermec Fingerprint, issue the following instruction:

INPUT ON ↵ (↵ is carriage return, ASCII 13 dec. )

The display will show the message:

Direct Protocol

7.80

By default, no messages or characters will be returned to the host (see

Chapter 6.15) until you leave the Intermec Direct Protocol.

3.3 Special Intermec Direct Protocol Features

If you are familiar with Intermec Fingerprint, you will notice that the

Intermec Direct Protocol is rather similar to the Immediate Mode. There

are, however, some important differences:

• The Intermec Direct Protocol has a built-in error handler, that can

indicate selected error conditions and produce error-messages of your

own creation in any language you like.

• The Intermec Direct Protocol is able to receive variable input data in a

special format to fi elds in a predefi ned layout.

• The Intermec Direct Protocol allows you to create counters without

extensive programming.

• The Intermec Direct Protocol provides a simple way to enable the

Print key to produce printouts.

• By default, verbosity is off in the Intermec Direct Protocol. While you

develop your Direct Protocol fi les, we recommend setting the verbosity to ON using a SYSVAR (18) instruction, see Chapter 6.15

Page 17

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 11

Chapter 3 — Principles of Operation

• Some instructions only work in the Intermec Direct Protocol:

COUNT&

ERROR

FORMAT INPUT

INPUT ON|OFF

LAYOUT END

LAYOUT INPUT

LAYOUT RUN

PRINT KEY ON|OFF

3.4 Sending Instructions

The Intermec Direct Protocol allows you to send instructions to the

printer in two ways:

• You can send instructions that the printer will act upon directly. This

method is used for setting up the printer, for reading various data

from the printer back to the host, and for managing fi les, fonts, and

images.

Examples:

PRINT KEY ON ↵ (enable Print key)

? DATE$ ↵ (read printer’s calendar)

KILL "LAYOUT1" ↵ (delete a layout or fi le)

This method can also be used for creating label layouts including all

the printable data as illustrated below.

• The other method is only intended for creating labels. First create a

layout containing formatting instructions for a number of variable

fi elds. Also include such fi elds that you do not need to change. Then

send a string of printable data to the empty variable fi elds plus a print

instruction. You can create a number of different layouts, select the

one you need, and then add the variable data.

Page 18

12 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 3 — Principles of Operation

Layout and Printable Data in One Sequence

Continuous String

Enter the instructions as a continuous string, where the instructions are

separated by colons (:).

BF ON:BF "Swiss 721 BT",6:PP 10,10:

PX 430,340,15:PP 30,30:PM "GLOBE.1":

PP 75,270:BT "CODE39":PB "ABC":PP 75,220:

FT "Swiss 721 BT",6:PT "My FIRST label":PF ↵

Line-by-Line

You can also send the same string line by line:

BF ON ↵ (enable bar code interpretation)

BF "Swiss 721 BT",6 ↵ (select bar code interpr. font)

PP 10,10 ↵ (insertion point for box fi eld)

PX 430,340,15 ↵ (create a box)

PP 30,30 ↵ (insertion point for image fi eld)

PM "GLOBE.1" ↵ (select image)

PP 75,270 ↵ (insertion point for bar code fi eld)

BT "CODE39" ↵ (select bar code type)

PB "ABC" ↵ (input data to bar code fi eld)

PP 75,220 ↵ (insertion point for text fi eld)

FT "Swiss 721 BT",6 ↵ (select font for text fi eld)

PT "My FIRST label" ↵ (input data to text fi eld)

PF ↵ (print one label)

A label looking like this should be printed regardless if you use a continuous string or send the instructions line-by-line:

Page 19

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 13

Chapter 3 — Principles of Operation

Layout and Variable Input Data in Separate Sequences

All necessary commands for setting up the printer (see Chapter 6) should

be issued before the LAYOUT INPUT...LAYOUT END sequence. The only

exceptions are

NASC and NASCD, see Chapters 6.13 and 9.2.

Creating the Layout

LAYOUT INPUT "tmp:LABEL1" ↵ (start layout recorder)

BF ON ↵ (enable bar code interpretation)

BF "Swiss 721 BT",6 ↵ (select bar code interpretation font)

PP 10,10 ↵ (insertion point for box fi eld)

PX 430,340,15 ↵ (create a box)

PP 30,30 ↵ (insertion point for image fi eld)

PM "GLOBE.1" ↵ (select image)

PP 75,270 ↵ (insertion point for bar code fi eld)

BT "CODE39" ↵ (select bar code type)

PB VAR1$ ↵ (variable input data to bar code fi eld)

PP 75,220 ↵ (insertion point for text fi eld)

FT "Swiss 721 BT",6 ↵ (select font for text fi eld)

PT VAR2$ ↵ (variable input data to text fi eld)

LAYOUT END ↵ (save layout)

COPY "tmp:LABEL1","c:LABEL1" ↵ (save layout in "c:")

The layout was created in the printer’s temporary memory ("tmp:")

because it is faster and then, as a safety measure, copied to the permanent

memory ("c:") which is slower but safer than ("tmp:"). The instructions

could also have been sent as a continuous string rather than line-by-line.

Add Variable Data and Print

COPY "c:LABEL1","tmp:LABEL1" ↵ (copy layout)

LAYOUT RUN "tmp:LABEL1" ↵ (select layout)

<STX> (start of input data, ASCII 02 dec)

ABC ↵ (variable input data to VAR1$)

My FIRST label ↵ (variable input data to VAR2$)

<EOT> (end of input data, ASCII 04 dec)

PF ↵ (print one label)

This should produce a label looking exactly like the one shown on the

previous page.

Page 20

14 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 3 — Principles of Operation

Note: If a label has been printed using a predefi ned layout

and you want to return to the method of printing labels using

layout and printable data in one sequence, the predefi ned

layout must fi rst be cleared from the printer’s working memory

using the instruction:

LAYOUT RUN ""

3.5 Fields

The printable information on a label, ticket, tag, or piece of strip consists

of various types of fi elds. A fi eld can consist of:

• A single line of text

• Several lines of text with line-wrap and hyphenation optionally surrounded by a box

• A bar code with or without human readable interpretation

• An image, for example picture or logotype, in bitmap format

• A box, that is a hollow square or rectangle

• A line

3.6 General Formatting Instructions

Any type of fi eld should be specifi ed in regard of:

• Position

• Alignment

• Direction

Refer to Chapter 4.2 for more information.

Page 21

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 15

Chapter 3 — Principles of Operation

3.7 Field-Related Formatting Instructions

Depending on type of fi eld, additional formatting instructions can be

used before you enter the input data:

Type of Field Formatting Instructions

Single-Line Font (typeface, size, slant, width)

Text Field [Magnifi cation, (obsolete)]

Normal Image/Inverse Image

Multi-Line

Text Field

Font (typeface, size, slant, width)

[Magnifi cation, (obsolete)]

Normal Image/Inverse Image

Bar Code Field

1

Bar Code Type

Height (height of bar pattern)

Ratio (wide bars/narrow bars)

Magnifi cation (bar pattern)

Bar Code Interpretation On/Off

Interpretation Font (typeface, size, slant, width)

Image Field Magnifi cation

Normal Image/Inverse Image

Box Field Size

Line Field Size

1

/. Refers to one-dimensional bar codes. Complex two-dimensional bar or dot codes may

have other formatting parameters.

Text, bar code, and image fi elds also require some input data:

• Single-Line Text Field: Alphanumeric text

• Multi-Line Text Field: Box size, alphanumeric text, horizontal offset,

vertical offset, hyphenation specifi cations

• Bar Code Field: Alphanumeric or numeric value (depending

on type of code)

• Image Field: Name of the image

The input data to text and bar code fi elds may either be provided by the

host, or be read from the printer’s fi rmware, for example counter values

or various data related to the printer’s clock/calendar.

In the Intermec Direct Protocol, you can either specify the fi elds both in

regard of formatting parameters and input data in the same string, or you

can create a layout to which you can send variable data later.

Page 22

16 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 3 — Principles of Operation

3.8 Layout Instructions

The layout should contain formatting parameters for all fi elds and input

data to such fi elds that will always contain the same information. When

the variable input data are added, they will be inserted into their respective fi elds in a way similar to fi lling out a preprinted form.

When creating predefi ned layouts, you must use special instructions for:

• Clearing the working memory and starting the layout recorder.

• Saving the layout and clearing the working memory.

3.9 Printable Data Instructions

Depending on type of fi eld and type of bar code, printable data to text,

and bar code fi elds may consist of:

• Alphanumeric data (text)

• Numeric data

• Counter values

• Current date

• Current time

• Current date +/- nn days

• Current time +/- nn seconds

• Current week number

• Current weekday

3.10 Feeding and Printing Instructions

There are some instructions that control the printing and media feed, for

example used for:

• Printing one label or a batch of labels (or similar)

• Activating an optional paper cutter

• Speeding up batch printing

• Reprinting lost labels after interruption of batch print jobs

• Enable/disable reprinting

Page 23

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 17

Chapter 3 — Principles of Operation

• Rotating the platen roller during cleaning

• Feeding out an empty label, ticket, tag, or piece of strip

• Adjusting the label stop/black mark sensor

3.11 Setting Up the Printer

You can control how the printer will work, for example:

• Enable/disable Intermec Direct Protocol

• Select standard IN and OUT channels

• Set the printer’s clock/calendar

• Set formats for the printing of date and time

• Set separators for input data strings to predefi ned layouts

• Create label counters

• Enable/disable the optional label taken sensor

• Enable/disable automatic cut-off operation

• Enable/disable Print key

• Produce audible signals

• Format the printer’s permanent memory or a memory card

• Remap certain incoming characters

• Select character set

• Restart the printer

• Select verbosity level

• Select type of error message

• Enable error handling and create customized error messages

• Select method for breaking the printing of a batch of labels

• Change the printer’s setup

Page 24

18 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 3 — Principles of Operation

3.12 Reading Printer’s Status

Provided you have a two-way serial communication between printer and

host, you can read the printer’s status regarding a number of functions

back to the screen of the host, for example:

• Current date and time

• Memory status

• Printhead status and characteristics

• Value of various system counters

• Status of various sensors and straps

• Software and hardware version

3.13 File-Handling Instructions

A number of instructions are used to control the printer’s memory, for

example to:

• Read the number of free bytes in the printer’s memory

• Read the names of fi les, fonts, or images stored in the printer’s

memory

• Remove fi les, fonts and images

• Copy fi les

• Download binary fi les

• Download .PCX fi les and convert them to images

Page 25

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 19

Chapter 3 — Principles of Operation

3.14 Syntax Descriptions

Many commonly used instructions have a shorthand version to minimize the transfer of data. In the explanations of the various instruction

that follow, both the full name and the shorthand version will be shown,

separated by a thin vertical line, for example:

PRPOS | PP

Unless otherwise indicated, upper- and lowercase characters can be used

at will. Parameters for the instruction are shown like this:

<parameter> = numeric value

"<parameter>" = alphanumeric text (enclosed by quotation

marks)

• Compulsory space characters are indicated by double-headed arrows

(

↔

).

• Square brackets [ ] indicate optional parameters.

• Thin vertical bars (|) indicate alternatives.

• Always enter parentheses, commas, colons, semicolons, minus signs,

quotation marks and period characters exactly as shown.

• Negative values are indicated by leading minus signs (-).

The various instructions are described in as simple terms as possible.

Complete syntax descriptions and comprehensive information on each

instruction can be found in the Intermec Fingerprint v7.80, Programmer’s

Reference Manual.

Page 26

20 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 3 — Principles of Operation

Page 27

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 21

4

Label Design

This chapter describes how a label layout is made up

of various types of fi elds and explains the instructions

used for creating each type of fi eld.

Page 28

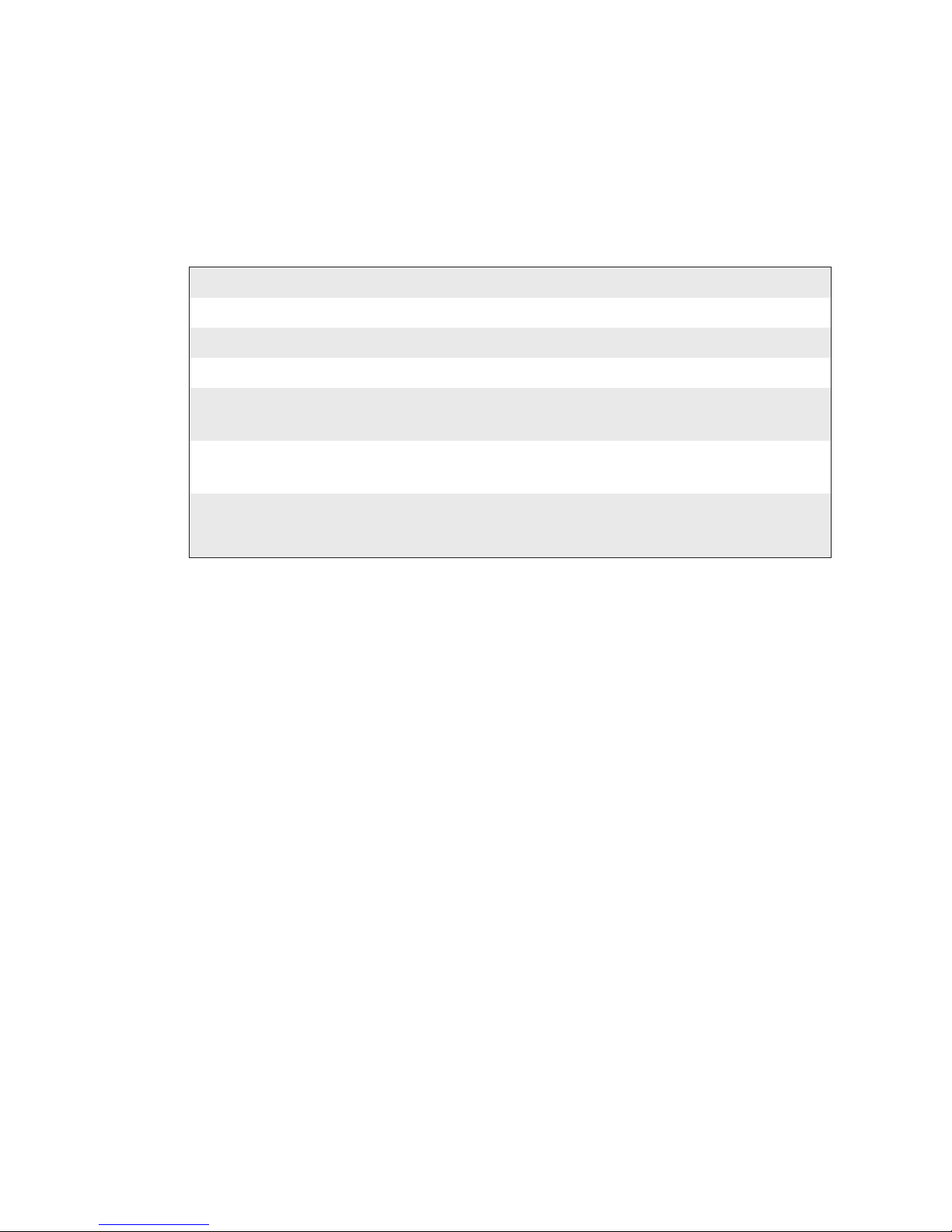

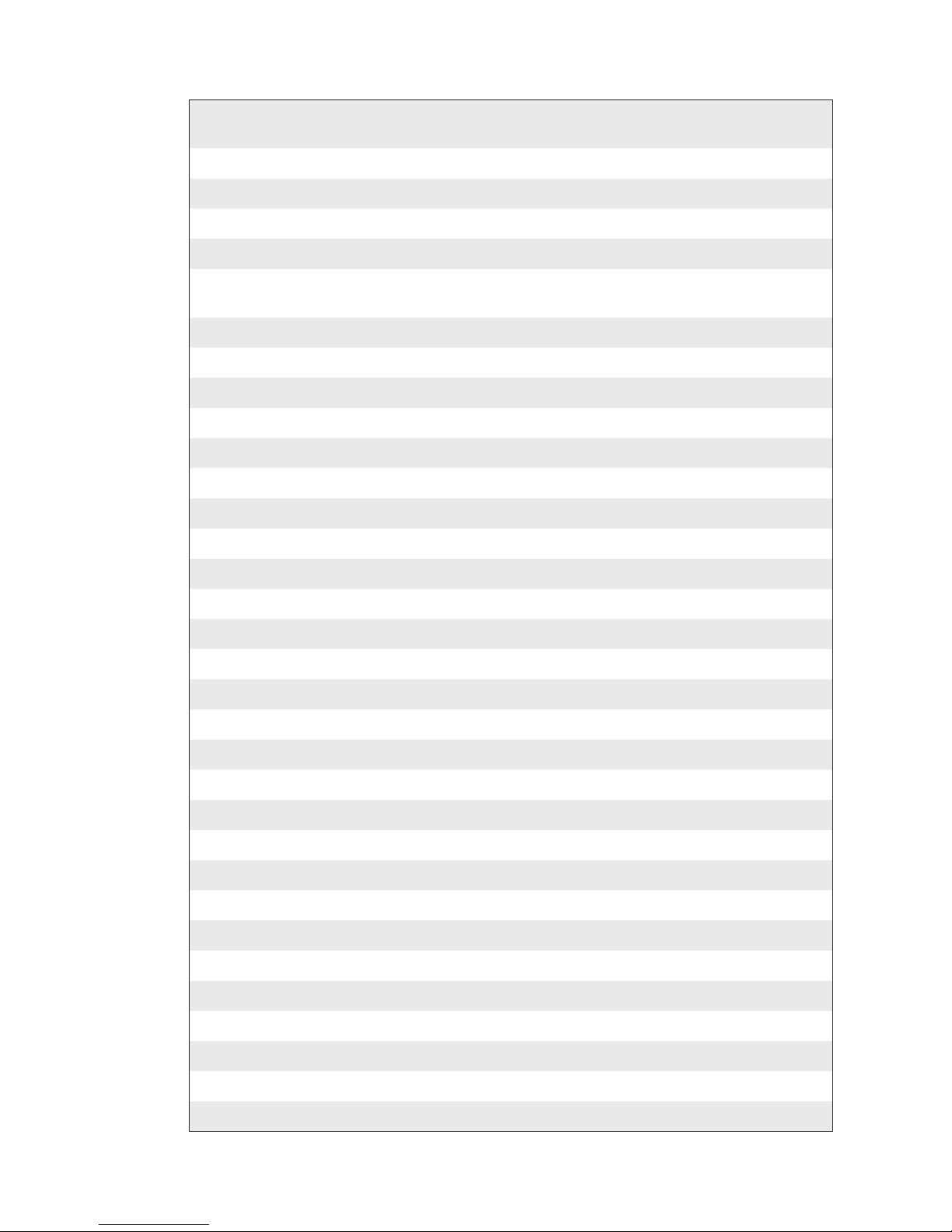

This is a multiline text field

with line-wrap

and hyphenation

Multi-Line

Text Field

Single-Line

Text Field

Line Field

Ima

g

e Field

Box Field

Bar Code Field

(w. interpretation)

22 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

4.1 Field Types

A label layout is made up of a number of fi elds. There are six different

types of fi eld:

• Single-Line Text Field A single-line text fi eld consists of a single line

of text.

• Muli-Line Text Field A multi-line text fi eld consists of one or

more lines of text with line-wrap and

hyphenation, optionally surrounded by a

black border line.

• Bar Code Field A bar code fi eld consists of a single bar code,

with or without a human readable bar code

interpretation.

• Image Field An image fi eld is a picture, drawing, logotype, or other type of illustration.

• Box Field A box fi eld is a square or rectangular white

area surrounded by a black border line.

• Line Field A line fi eld is a black line that goes either

along or across the media path.

There are no restrictions, other than the size of the memory, regarding

the number of fi elds on a single label.

Page 29

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 23

Chapter 4 — Label Design

4.2 General Formatting Instructions

Origin

The positioning of all printable objects on the label, that is text fi elds, bar

code fi elds, images, boxes, and lines, uses a common system. The starting

point is called “origin” and is the point on the media that corresponds

to the innermost active dot on the printhead at the moment when the

printing is started.

The location of the origin is affected by the following factors:

• Position across the media path (X-axis):

The position of the origin is determined by the X-Start value in the

setup.

• Position along the media path (Y-axis):

The position of the origin is determined by the Feed adjustment in

the setup (and any

FORMFEED instruction executed before the current

PRINTFEED instruction or after the preceding PRINTFEED).

Coordinates

Starting from origin, there is a coordinate system where the X-axis runs

across the media path from left to right (as seen when facing the printer)

and the Y-axis runs along the media path from the printhead and back

towards the media supply.

Units of Measure

The unit of measure is generally “dots”, which means that all measurements depend on the density of the printhead, see the Info box to the

left. The only exception is outline font heights, which are specifi ed in

points.

A dot has the same size along both the X-axis and the Y-axis.

Printhead density 8 dots/mm = 203.2 dots/inch:

Dot size: 0.125 mm = 4.92 mils

Printhead density 12 dots/mm = 304.8 dots/inch:

Dot size: 0.083 mm = 3.28 mils

Page 30

24 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

Insertion Point

The insertion point of any printable object is specifi ed within the coordinate system by means of PRPOS (PP). The coordinates must be selected

so the fi eld fi ts completely inside the printable area.

PRPOS | PP <x-coordinate>,<y-coordinate>

<x-coordinate> is the distance in dots along the x-axis from origin to insertion point

<y-coordinate> is the distance in dots along the y-axis from origin to insertion point

Default value: PRPOS 0,0

Reset to default by: PRINTFEED (PF)

Example:

PP 100, 200 ↵

Alignment

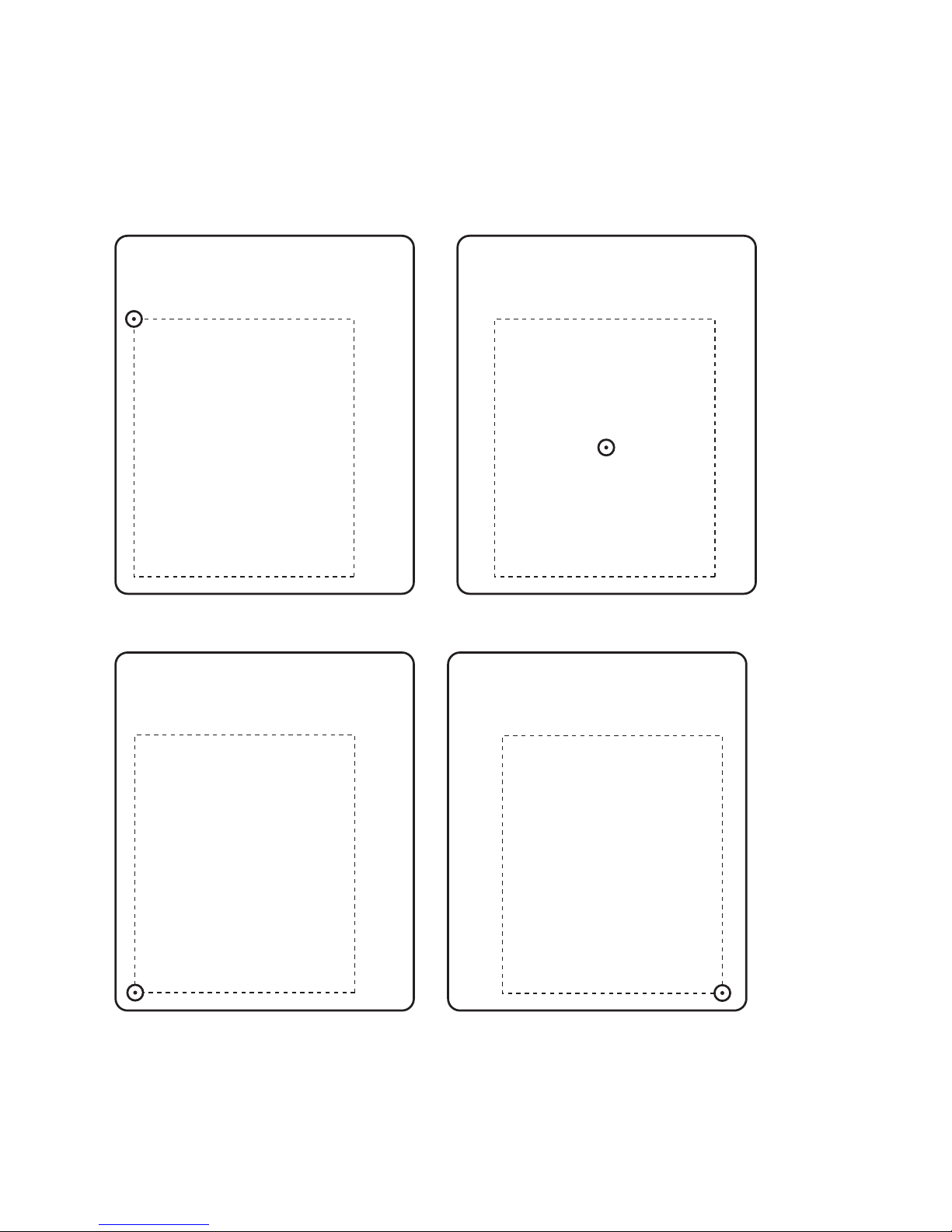

Once the insertion point is specifi ed, you must also decide which part

of the object should match the insertion point. For example, a text fi eld

forms a rectangle. There are 8 anchor points along the borders and one

in the center, numbered 1-9 and specifi ed by means of the instruction

ALIGN:

ALIGN | AN <anchor point>

<anchor point> is a number 1-9

Default value: 1

Reset to default by: PRINTFEED (PF)

Example:

AN 1 ↵

This instruction will place the lower left corner of the text fi eld at the

insertion point specifi ed by PRPOS. Refer to the illustration below, and

to the Intermec Fingerprint v7.80, Programmer’s Reference Manual;

ALIGN

statement, for detailed information on the anchor points for various

types of printable objects.

Page 31

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 25

Chapter 4 — Label Design

Page 32

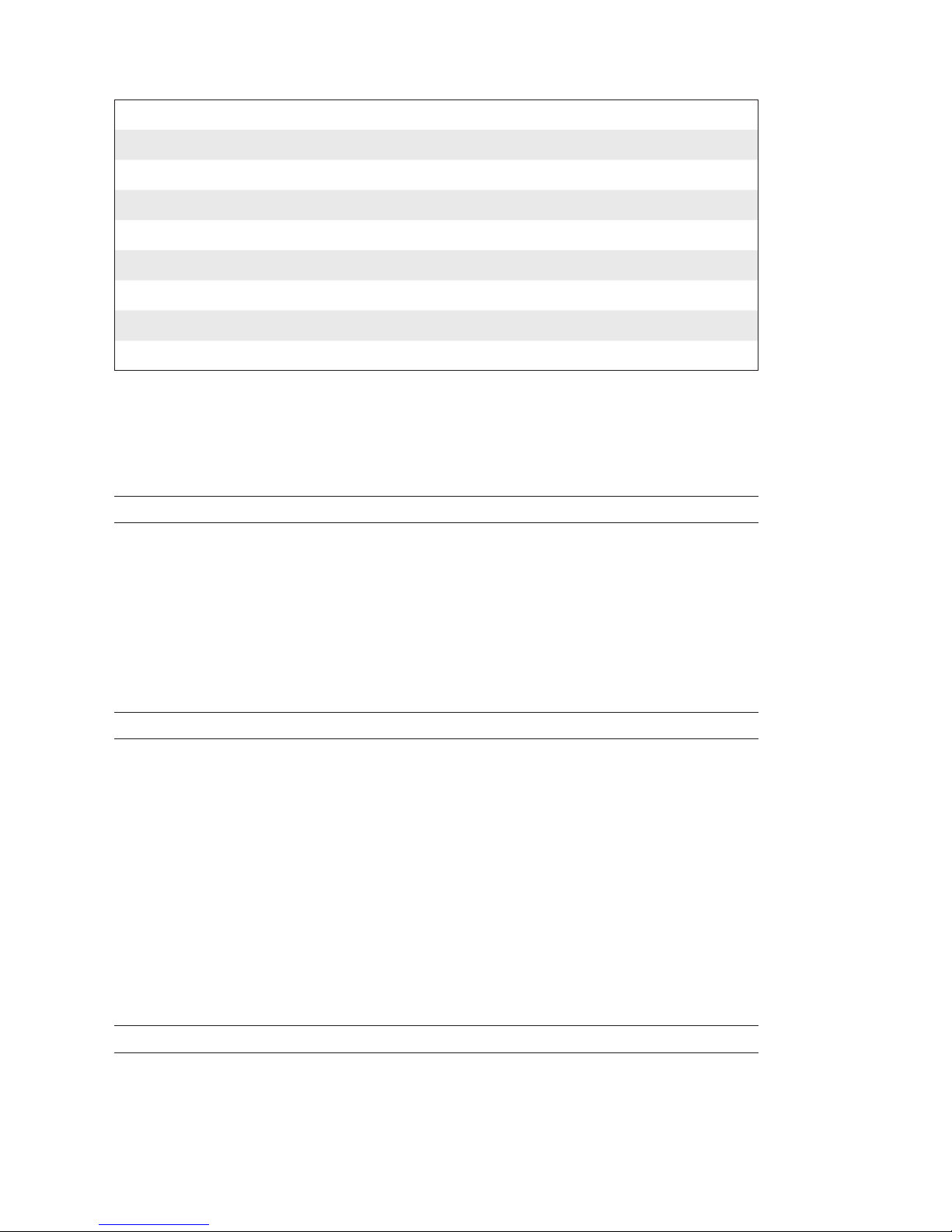

This is line number 1

and this is line 2

and now comes line 3

followed by No. 4.

ALIGN 7

This is line number 1

and this is line 2

and now comes line 3

followed by No. 4.

ALIGN 5

This is line number 1

and this is line 2

and now comes line 3

followed by No. 4.

ALIGN 1 ALIGN 3

This is line number 1

and this is line 2

and now comes line 3

followed by No. 4.

26 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

In case of multi-line text fi elds, the alignment will not only decide the

anchor point of the box that surrounds the text (there are nine anchor

points, similar to image fi elds), but also the alignment of the text inside

box. This becomes more evident if you use a black border around the

box. Here are a few examples:

Page 33

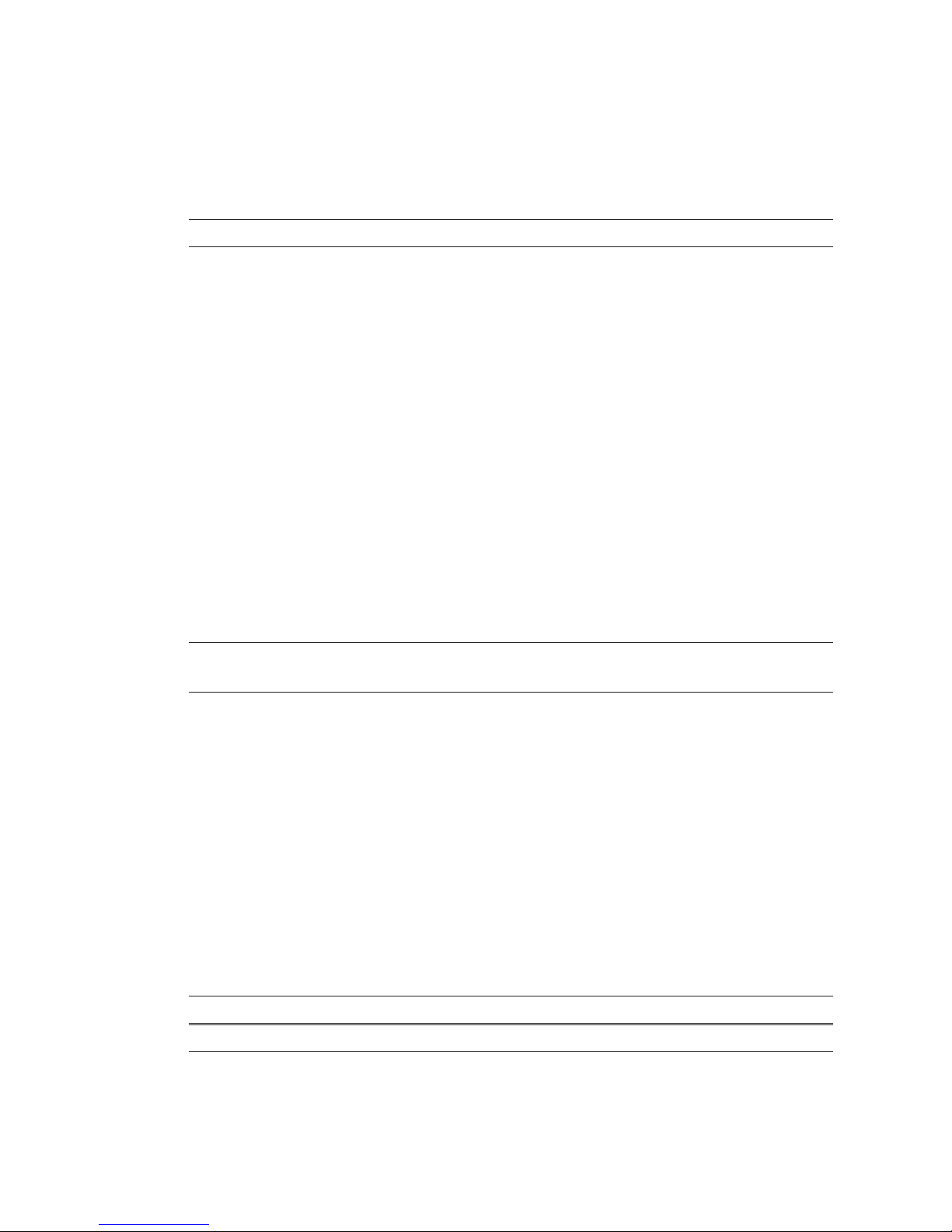

Dot-line on printhead

X-CoordinateX-start

X-Coordinate

Dot 0

Insertion point =

Anchor point

Origin

DIR 1

DIR 2

DIR 3

DIR 4

FEED

DIRECTION

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 27

Chapter 4 — Label Design

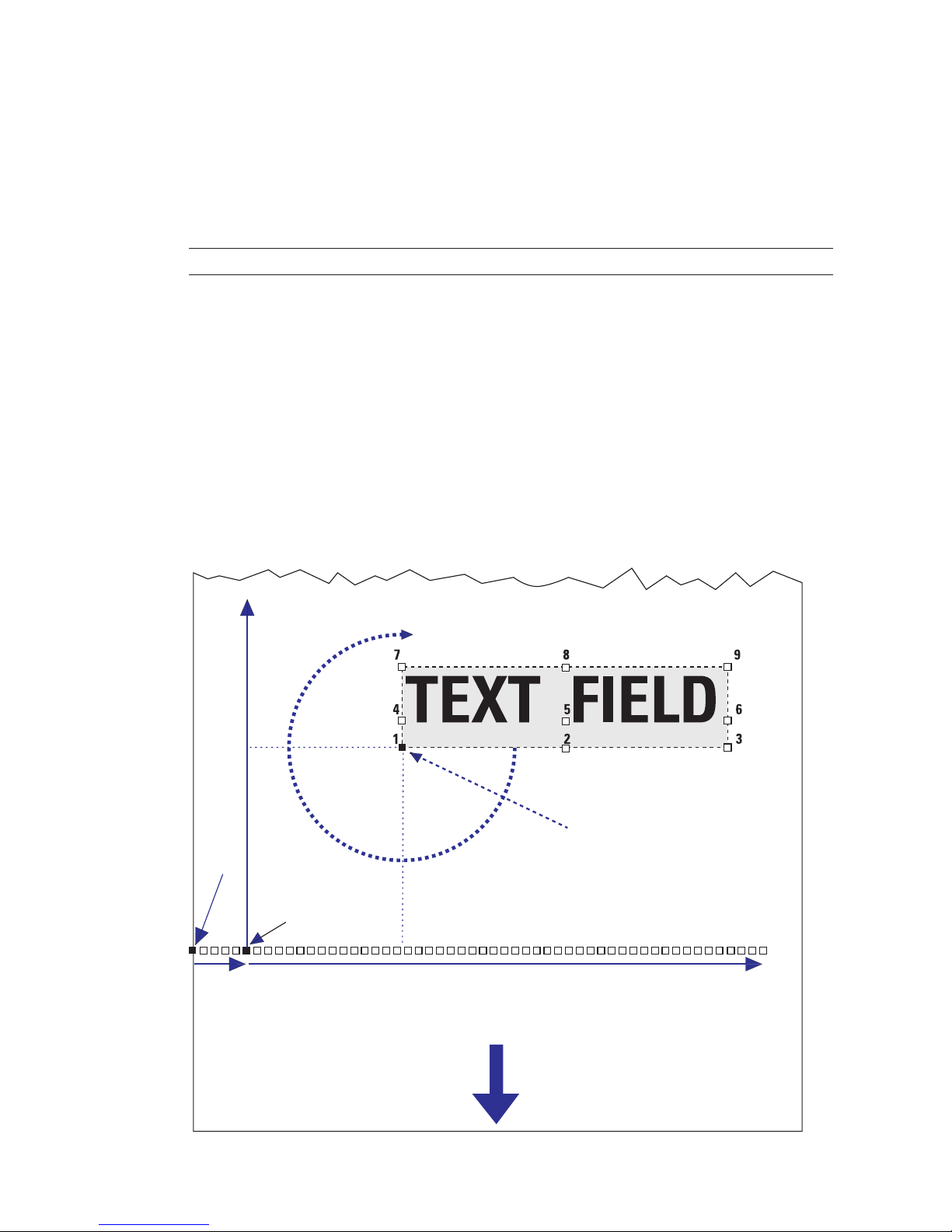

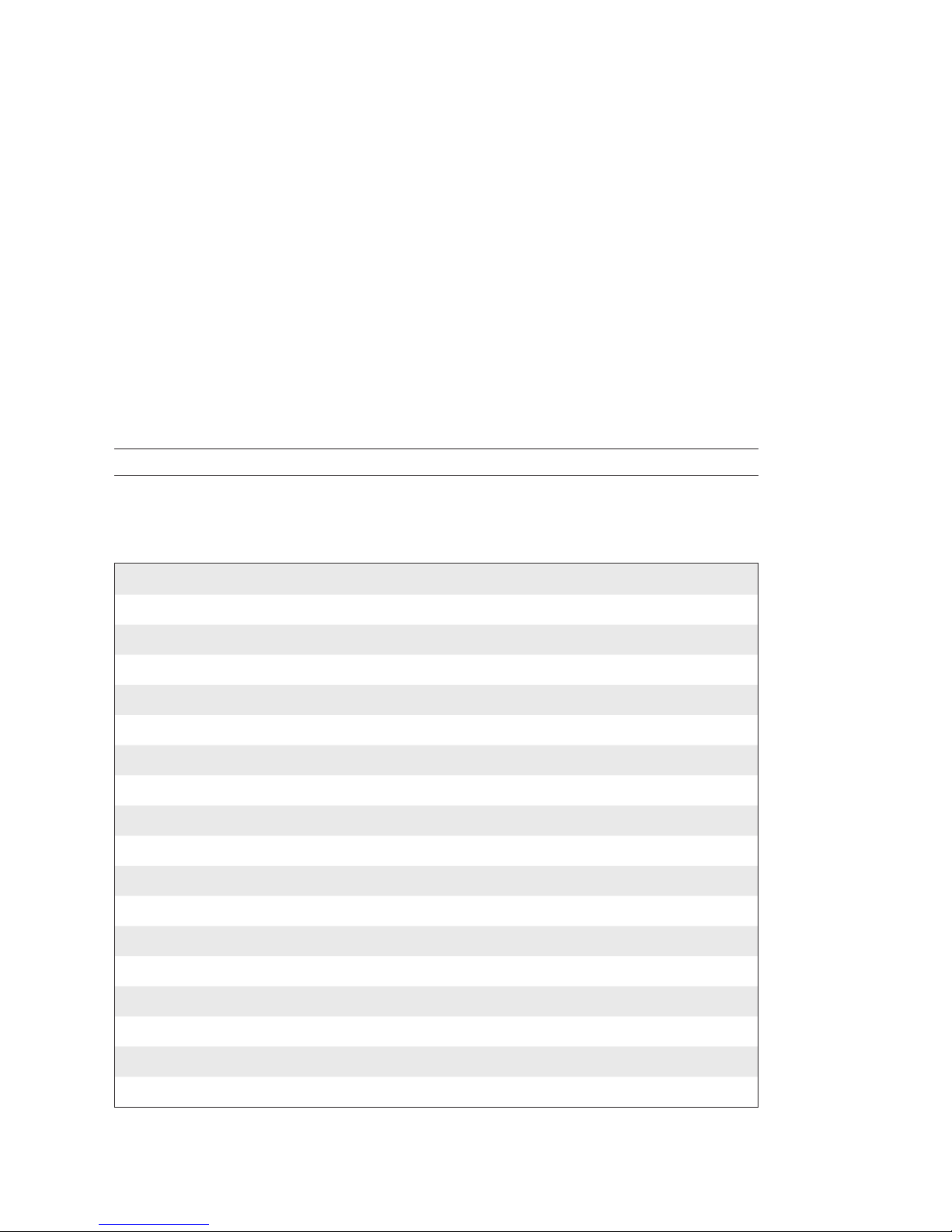

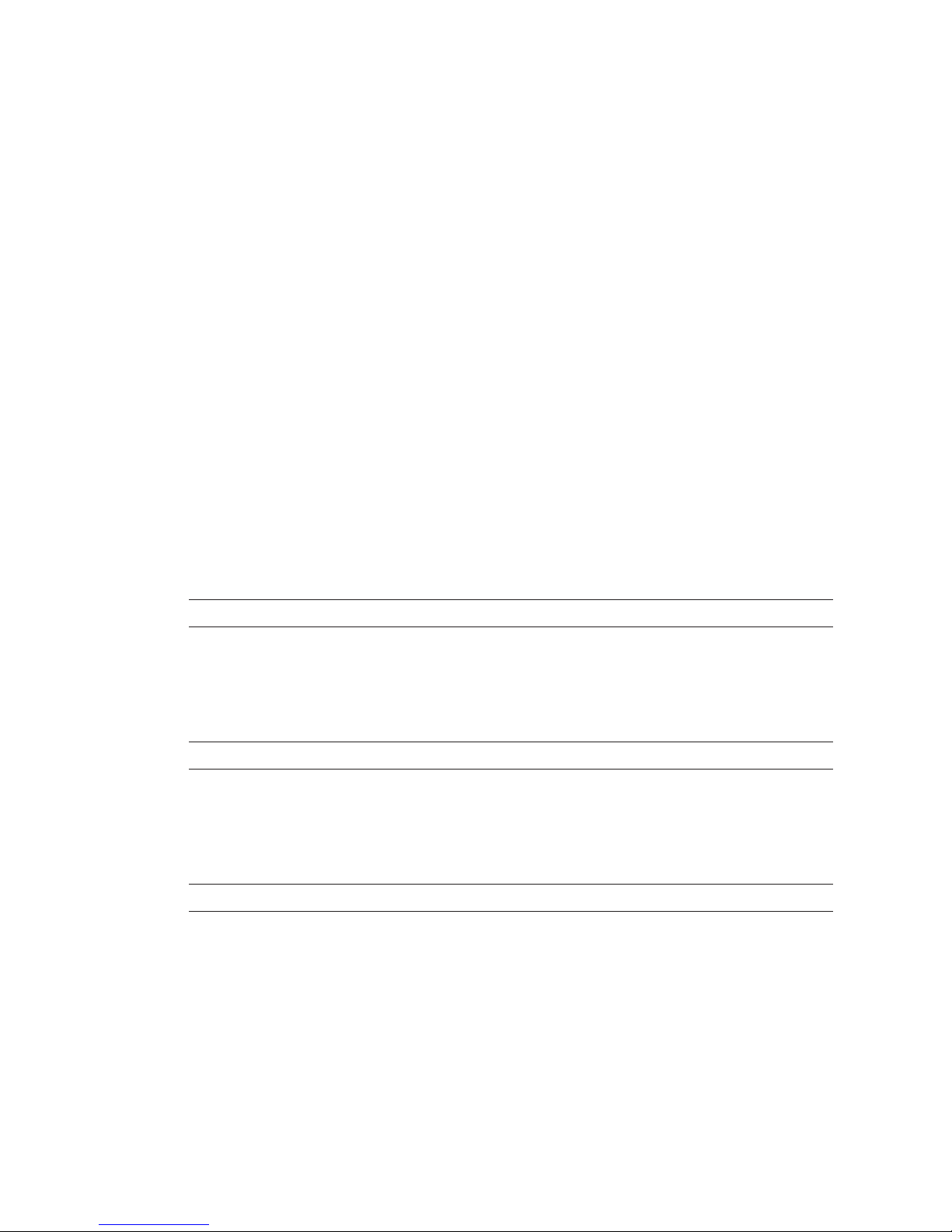

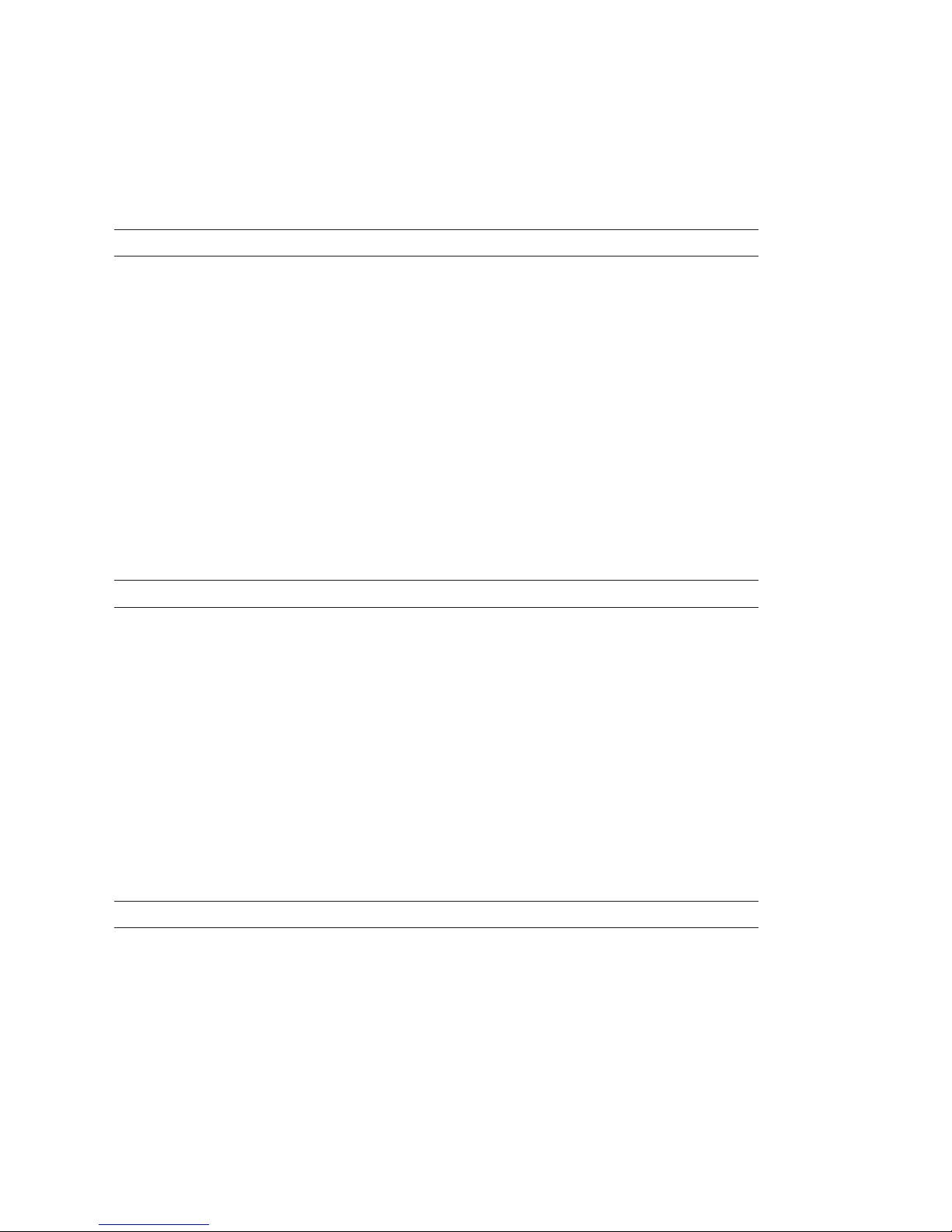

Directions

Intermec Direct Protocol allows printing in four different directions. You

can rotate the printable object clockwise around the anchor point/insertion point with a 90° increment (0°, 90°, 180°, or 270°) using a

DIR

instruction:

DIR <direction>

<direction> is a number 1–4 (DIR 1 = 0°; DIR 2 = 90°; DIR 3 = 180°; DIR 4 = 270°)

Default: 1

Reset to default by: PRINTFEED (PF)

Example:

DIR 3 ↵

This instruction rotates all printable fi elds that follow to be printed

across the media path and upside down in relation to how the media is

fed out from the printer.

This illustration summarizes the three general formatting instructions

PRPOS (PP), ALIGN (AN), and DIR:

Page 34

28 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

Enabling/Disabling Partial Fields

Normally, any fi eld that extends outside the print window, as specifi ed

by the printer’s setup in regard of media size (X-start, width, and length),

will cause Error 1003 “Field out of label.” This can easily happen while

you design your label layout, for example when changing the font,

font size, direction, alignment, etc. Even “invisible” parts of a fi eld, for

example “transparent” parts of an image may cause such errors.

If your label layout contains many fi elds, it may be diffi cult to grasp

all implications of a change. However, it is possible to enable so called

“partial fi elds.”

CLIP ON/CLIP OFF is suffi cient for partial text, image,

line, and box fi elds. For partial bar code fi elds, a more complex syntax is

required.

When partial fi elds are enabled, a fi eld that extends outside the print

window will not cause Error 1003, but will be clipped at the edge of the

window and not included in the printout. Thus, you can print a sample

and more easily determine what is wrong.

CLIP [BARCODE [HEIGHT|INFORMATION|X|Y]] [ON|OFF]

BARCODE Toggles between partial bar code enable/disable.

HEIGHT clips the height of the bars.

INFORMATION clips the bar code lengthwise.

X clips the part of the bar code that comes outside the print window in the

X-dimension.

Y clips the part of the bar code that comes outside the print window in the

Y-dimension.

Default: CLIP OFF

Example:

Only the last part of the text fi eld will be printed, since the fi eld is rightaligned and the insertion point is close to the left-hand edge of the print

window.

CLIP ON ↵

PP 350,100 ↵

AN 6 ↵

PT "INTERMEC PRINTERS" ↵

PF ↵

XOR Mode

The instruction XORMODE controls how intersecting fi elds will be printed.

At

XORMODE OFF (default), the intersection will be black, and at XORMODE

ON, the intersection will be white.

Page 35

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 29

Chapter 4 — Label Design

4.3 Text Fields

A single-line text fi eld consists of one or several alphanumeric characters

on the same line. There is no practical limit other than the size of the

printable area on the media. Text is not wrapped to a new line, but each

line must be specifi ed as a separate text fi eld.

A multi-line text fi eld consists of one or more lines with line-wrap and

hyphenation inside a visible or imaginary box

In addition to the instructions

PRPOS, ALIGN, and DIR (see Chapter 4.2),

a text fi eld can contain the following instructions:

Select Font

The FONT instruction specifi es the typeface, size, slant, and width of the

simgle-byte Unicode font to be printed. The printer may contain various font sets, depending on market area and customer’s requirements.

Double-byte Unicode fonts can be used for single-line text fi elds by

means of the FONTD instruction, see Chapter 9, “Advanced Features.”

Once a font has been specifi ed, it will be used in all text fi elds until a new

FONT instruction is executed.

FONT | FT "<font name>"[,<size>[,<slant>[,<width>]]]

<font name> is the name of a font enclosed by quotation marks. Default: "Swiss 721

BT".

<size> in points (1 point = 1/72 inch ≈ 0.352 mm) (not for bitmap fonts). Default:

12

<slant> is the angle of the characters in degrees (not for bitmap fonts). Default: 0

<width> is the width in percent relative the size (not for bitmap fonts). Default: 100

The standard set of fonts contains the following 15 typefaces from Bitstream, Inc. The names are case-sensitive:

"Century Schoolbook BT" "DingDings SWA"

"Dutch 801 Roman BT" "Dutch 801 Bold BT"

"Futura Light BT" "Letter Gothic 12 Pitch BT"

"Monospace 821 BT" "Monospace 821 Bold BT"

"OCR-A BT" "OCT-B 10 Pitch BT"

"Prestige 12 Pitch Bold BT" "Swiss 721 BT"

"Swiss 721 Bold BT"

"Swiss 721 Bold Condensed BT"

"Zurich Extra Condensed BT"

Page 36

NORIMAGE

INVIMAGE

30 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

Select Magnifi cation

Fonts can be magnifi ed 1-4 times independently in regard of height and

width by means of a MAG instruction. However, for outline fonts the

printout quality will be better if you use a larger font size and/or width.

Use MAG in connection with bitmap fonts.

MAG <height mag>,<width mag>

<height mag> is the magnifi cation factor 1, 2, 3, or 4 times in regard of height.

<width mag> is the magnifi cation factor 1, 2, 3, or 4 times in regard of width.

Default: 1,1

Reset to default by: PRINTFEED (PF).

Select Normal/Inverse Printing

Normally, text is printed in black on a transparent background (NORIM-

AGE

). By using INVIMAGE, the printing can be inversed so the characters

become transparent, whereas the background will be black. The size of

the background is decided by the character cell. A NORIMAGE instruction

is only needed when changing back from

INVIMAGE printing.

NORIMAGE | NI

INVIMAGE | II

Default: NORIMAGE.

Reset to default by: PRINTFEED (PF).

Page 37

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 31

Chapter 4 — Label Design

Summary

To create a text fi eld, the following formatting instructions must be given

(in most cases default values may substitute missing parameters). Input

data to the fi eld and printing instructions are explained in Chapters 4.9

and 5.2 respectively.

Purpose Instruction Default Remarks

X/Y Position PP (PRPOS) 0/0 Number of dots

Alignment AN (ALIGN) 1 Select AN 1-9

Direction DIR 1 Select DIR 1-4

Font FT (FONT) Swiss 721 BT,

12,0,100

[Magnifi cation] MAG 1,1 Height 1-4, Width

1-4

Appearance II (INVIMAGE)

NI (NORIMAGE )

off

on

White-on-black

Black-on-white

Example:

PP 200,500:AN 7:DIR 2:FT "Swiss 721 BT",18:II ↵

Page 38

32 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

4.4 Bar Code Field

The Intermec Direct Protocol supports 53 of the most common bar code

symbologies. 38 of these bar code symbologies are standard, whereas

15 are available as a dynamic module (see Intermec Fingerprint v7.80,

Programmer’s Reference Manual). Each bar code (optionally including its

human readable interpretation) makes up a bar code fi eld. In addition to

the general formatting instructions PRPOS, ALIGN, and DIR (see Chapter

4.2), a bar code fi eld can contain the following instructions:

Select Bar Code Type

The type of bar code is specifi ed by a BARTYPE instruction containing an

abbreviation of the bar code name.

BARTYPE | BT "<bar code name>"

<bar code name> is the designation of the bar code type according to the list below.

Default: "INT2OF5"

Reset to default by: PRINTFEED (PF)

Bar Codes Designation

Codabar "CODABAR"

Code 11 "CODE11"

Code 16K "CODE16K"

Code 39 "CODE39"

Code 39 full ASCII "CODE39A"

Code 39 w. checksum "CODE39C"

Code 49 "CODE49"

Code 93 "CODE93"

Code 128 "CODE128"

Code 128 subset A "CODE128A"

Code 12 subset B "CODE128B"

Code 128 subset C "CODE128C"

Data Matrix (dynamic module only) "DATAMATRIX"

DUN-14/16 "DUN"

EAN-8 "EAN8"

EAN-8 Composite with CC-A or CC-B (dynamic module only) "EAN8_CC"

EAN-13 "EAN13"

Page 39

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 33

Chapter 4 — Label Design

EAN-13 Composite with CC-A or CC-B (dynamic module

only)

EAN13_CC"

EAN 128 "EAN128"

EAN 128 subset A "EAN128A"

EAN 128 subset B "EAN128B"

EAN 128 subset C "EAN128C"

EAN 128 Composite with CC-A or CC-B (dynamic module

only)

"EAN128_CCAB

EAN128 Composite with CC-C (dynamic module only) "EAN128_CCC"

Five-Character Supplemental Code "ADDON5"

Industrial 2 of 5 "C2OF5IND"

Industrial 2 of 5 w. checksum "C2OF5INDC"

Interleaved 2 of 5 "INT2OF5"

Interleaved 2 of 5 w. checksum "INT2OF5C"

Interleaved 2 of 5 A "I2OF5A"

Matrix 2 of 5 "C2OF5MAT"

MaxiCode "MAXICODE"

MicroPDF417 "MICROPDF417"

MSI (modifi ed Plessey) "MSI"

PDF 417 "PDF417"

Plessey "PLESSEY"

Postnet "POSTNET"

QR Code (dynamic module only) "QRCODE"

RSS-14 (dynamic module only) "RSS14"

RSS-14 Truncated (dynamic module only) "RSS14T"

RSS-14 Stacked (dynamic module only) "RSS14S"

RSS-14 Stacked Omnidirectional (dynamic module only) "RSS14SO"

RSS-14 Limited (dynamic module only) "RSS14L"

RSS-14 Expanded (dynamic module only) "RSS14E"

RSS-14 Expanded Stacked (dynamic module only) "RSS14ES"

Straight 2 of 5 "C2OF5"

Two-Character Supplemental Code "ADDON2"

UCC-128 Serial Shipping Container Code "UCC128"

UPC-5 digits Add-On Code "SCCADDON"

UPC-A "UPCA"

Page 40

34 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

UPC-A Composite with CC-A or CC-B (dynamic module only) "UPCA_CC"

UPC-D1 "UPCD1"

UPC-D2 "UPCD2"

UPC-D3 "UPCD3"

UPC-D4 "UPCD4"

UPC-D5 "UPCD5"

UPC-E "UPCE"

UPC-E Composite with CC-A or CC-B (dynamic module only) "UPCE-CC"

UPC Shipping Container Code "UPCSCC"

Specify Bar Code Height

The height of the bars that make up the bar code can be specifi ed using

the BARHEIGHT instruction.

BARHEIGHT | BH <height>

<height> is the height of the bars in dots.

Default: 100

Reset to default by: PRINTFEED (PF)

Specify Bar Code Ratio

The ratio between the wide and the narrow bars can be set using a BAR-

RATIO instruction.

BARRATIO | BR <wide bars>,<narrow bars>

<wide bars> is a relational factor wide bars vs narrow bars

<narrow bars> is a relational factor narrow bars vs wide bars

Default: 3:1

Reset to default by: PRINTFEED (PF)

Specify Bar Code Magnifi cation

The magnifi cation of the bar code and the bar code ratio decide the

actual thickness of the bars. For example, if BARRATIO is 3:1 and BARMAG

is 2, then the wide bars will be 6 dots thick (3×2) and the narrow bars

will be 2 dots (1×2). Magnifi cation also affects interpretations that are

integrated in the code, for example EAN and UPC codes.

BARMAG | BM <magnifi cation>

<magnifi cation> is the enlargement of the bar code pattern.

Default: 2

Reset to default by: PRINTFEED (PF)

Page 41

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 35

Chapter 4 — Label Design

Specify Bar Codes (combined instruction)

The BARSET instruction is primarily intended for complex bar codes (see

Chapter 8.1), but can also be used to specify simple one-dimensional bar

codes with a single instruction:

BARSET "<code name>",<ratio wide bars>,<ratio narrow bars>,<magn.>,<height>

<code name> is the bar code designation

(default "INT2OF5")

<ratio wide bars> specifi es thickness of wide bars

(default 3)

<ratio narrow bars> specifi es thickness of narrow bars

(default 1)

<magnifi cation> specifi es magnifi cation

(default 2)

<height> specifi es height of bars in dots

(default 100)

All parameters reset to default by PRINTFEED (PF)

Bar Code Interpretation

Most bar codes do not automatically include any bar code interpretation.

If a bar code interpretation is required, it must be enabled and the singlebyte font to be used for the interpretation must be specifi ed.

BARFONT | BF [#<start parameter>,]"<font name>"[,<font height>[,<font slant>[,<vert.

off set>[,<height mag>[,<width mag>[,<width in %>]]]]]][ON]

<start parameter> specifi es where in the syntax the command starts (default 1)

<font name> specifi es a single-byte bar code font (default: Swiss 721 BT)

<font height> specifi es the size of the font in points (default: 12)

<font slant> specifi es the slant of the font in degrees (default: 0)

<vert. off set> specifi es distance from bar code to interpretation (default: 6)

<height mag> specifi es vertical font magnifi cation (default: 1)

<width mag> specifi es horizontal font magnifi cation (default: 1)

<width in %> specifi es the width in % relative the font height (default: 100)

<ON> enables printing of bar code interpretation (default: OFF)

All parameters reset to default by PRINTFEED (PF)

Bar code interpretation printing can also be enabled or disabled using

these instructions:

BARFONT ↔ON | BF↔ON

BARFONT

↔

OFF | BF↔OFF

By default, bar code interpretation is disabled.

Page 42

36 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

Summary

To create a bar code fi eld, the following formatting instructions must be

given (in most cases default values may substitute missing parameters).

Input data and printing instructions are explained in Chapters 4.9 and

5.2 respectively.

Purpose Instruction Default Remarks

X/Y Position PP (PRPOS) 0/0 Number of dots

Alignment AN (ALIGN) 1 Select ALIGN 1-9

Direction DIR 1 Select DIR 1-4

Bar Code Select BARSET see above Can be replaced by BT,

BH, BR, BM

Interpretation BF...ON Off Can be omitted

Example:

PP 100,100:AN 7:DIR 4:BARSET "CODE39",2,1,3,120:

BF #2,"Swiss 721 BT",5,1,1 ON ↵

Page 43

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 37

Chapter 4 — Label Design

4.5 Image Field

An image fi eld is a fi eld containing some kind of picture or logotype in

.PCX format. The image can either be stored in the permanent memory

or in a memory card, or be downloaded as a fi le by means of an

IMAGE

LOAD

instruction, see Chapter 8.5.

In addition to the general formatting instructions

PRPOS, ALIGN, and

DIR, an image fi eld can contain the following instructions:

Select an Image

An image is selected by the full name under which it is stored in the

printer’s memory, either as plain text or as a variable (also see Chapter

4.9).

PRIMAGE | PM "<image name>"

<image name> is the full name of the image incl. extension, enclosed by quotation marks.

Default: None

The Fingerprint image name convention includes an extension (.1 or .2),

where .1 indicates that the image is intended for print directions 1 and

3, whereas .2 indicates print directions 2 and 4. For example, the image

"GLOBE.1" is suited for directions 1 and 3.

Select Magnifi cation

Images can be magnifi ed 1-4 times independently in regard of height and

width by means of a

MAG instruction.

MAG <height mag>,<width mag>

<height mag> is the magnifi cation factor 1, 2, 3, or 4 times in regard of height.

<width mag> is the magnifi cation factor 1, 2, 3, or 4 times in regard of width.

Default: 1,1

Reset to default by: PRINTFEED (PF)

To obtain the best printout appearance, use a larger image rather than

magnifying a smaller one.

Page 44

38 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

Select Normal/Inverse Printing

Normally, an image is printed in black on a transparent background, just

as it was created. Using INVIMAGE, the black and transparent parts can be

switched. The size of the background is decided by the actual size of the

image including “invisible” background. A

NORIMAGE statement is only

needed when changing back from

INVIMAGE printing.

NORIMAGE | NI

INVIMAGE| I I

Default: NORIMAGE

Reset to default by: PRINTFEED (PF)

Summary

To create an image fi eld, the following formatting instructions must be

given (in most cases default values may substitute missing parameters).

Image selection by means of variable input, and printing instructions are

explained in Chapters 4.9 and 5.2 respectively.

Purpose Instruction Default Remarks

X/Y Position PP (PRPOS) 0/0 Number of dots

Alignment AN (ALIGN) 1 Select ALIGN 1- 9

Direction DIR 1 Select DIR 1- 4

Magnifi cation MAG 1,1 Height 1-4, Width

1-4

Appearance II (INVIMAGE)

NI (NORIMAGE)

off

on

Black/white inversed

Normal (revokes

INVIMAGE)

Image name PM (PRIMAGE) n.a. Full name incl.

extension

Example:

PP 200,500:AN 3:DIR 3:MAG 2,2:II:PM "GLOBE.1" ↵

Page 45

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 39

Chapter 4 — Label Design

4.6 Box Field

A box is a hollow square or rectangle that can be rotated with an increment of 90° according to the print direction. If the line thickness is

suffi ciently large, the box will appear to be fi lled (another method is to

print an extremely thick short line).

In addition to the general formatting instructions

PRPOS, ALIGN, and

DIR, a box fi eld is specifi ed by a single instruction.

Specify Size of the Box

The size of the box is specifi ed in regard of height, width, and line weight

(thickness).

PRBOX | PX <height>,<width>,<line thickness>

<height> is the height in dots perpendicular to the selected direction.

<width> is the length in dots along the selected direc-tion.

<line thickness> is the line weight in dots (minimum 1 dot.

No default values.

Note: The PRBOX instruction is also used to format and provide

input data to a multi-line text fi eld, see Chapter 4.9.

Summary

To create a box fi eld, the following formatting instructions must be given

(in most cases default values may substitute missing parameters). Printing

instructions are explained in Chapter 5.2.

Purpose Instruction Default Remarks

X/Y Position PP (PRPOS) 0/0 Number of dots

Alignment AN (ALIGN) 1 Select ALIGN 1-9

Direction DIR 1 Select DIR 1-4

Box size PX (PRBOX) n.a. Height, width, and

line thickness (dots)

Example:

PP 250,250:AN 1:DIR 3:PX 200,200,10 ↵

Page 46

40 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

4.7 Line Field

A line can be printed in right angles along or across the media path

according to the print direction.

In addition to the general formatting instructions

PRPOS, ALIGN, and

DIR, a line fi eld is specifi ed by a single instruction.

Specify Size of the Line

The size of the line is specifi ed in regard of length and line weight (thickness).

PRLINE | PL <length>,<line thickness>

<length> is the line length in dots along the selected direction.

<line thickness> is the line weight in dots.

No default values.

Summary

To create a line fi eld, the following formatting instructions must be given

(in most cases default values may substitute missing parameters). Printing

instructions are explained in Chapter 5.2.

Purpose Instruction Default Remarks

X/Y Position PP (PRPOS) 0/0 Number of dots

Alignment AN (ALIGN) 1 Select ALIGN 1-9

Direction DIR 1 Select DIR 1-4

Line size PL (PRLINE) n.a. Length and thick-

ness (dots)

Example:

PP 100,100:AN 1:DIR 4:PL 200,10 ↵

Page 47

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 41

Chapter 4 — Label Design

4.8 Layout Instructions

Start Layout Recorder

The LAYOUT INPUT instruction clears the printer’s working memory,

starts the layout recorder, and allows you to assign a name and a device

to the layout. The layout should be created in the printer’s temporary

memory ("tmp:"). Once the layout has been created in "tmp:", it can be

copied to "c:" so it will be saved at power off.

LAYOUT INPUT "<tmp:><layout name>"

<layout name> Max. 30 characters incl. extension enclosed by quotation marks

Example:

COPY "c:Shipping Label","tmp:Shipping Label" ↵

LAYOUT INPUT "tmp:Shipping Label" ↵

Assign Input Variables to Fields

The layout may consist of both fi xed fi elds and fi elds for variable information. In the layout, you must give a reference to each fi eld, that is

intended to receive variable data, so the input data can be inserted into

the correct fi eld. The variable

VAR<n>$ should be used to indicate vari-

able input, where

<n> specifi es the number of the fi eld. The fi rst variable

input data block will be combined with the fi eld containing VAR1$, the

second block with

VAR2$, etc. Fixed data and variable data can be com-

bined in the same fi eld. Also refer to Chapter 4.9.

VAR<n>$

<n> is the number of the fi eld (1-nnnn...)

Examples:

PT VAR1$ ↵ (text fi eld with variable input)

PT "Price: ";VAR2$ ↵ (text fi eld with fi xed & variable input)

PB VAR3$ ↵ (bar code fi eld with variable input)

PM VAR4$ ↵ (image fi eld with variable input)

Page 48

42 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

Save the Layout

After having completed the layout, save it in the printer’s temporary

memory ("tmp:"), turn off the layout recorder, and clear the printer’s

working memory by means of a

LAYOUT END instruction. The layout

could then be copied to the printer’s permanent memory ("c:") so it will

not be deleted when the power is turned off.

LAYOUT END

Example:

LAYOUT END ↵

COPY "tmp:Shipping Label","c:Shipping Label" ↵

Page 49

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 43

Chapter 4 — Label Design

4.9 Printable Data Instructions

Select a Layout

Before any variable data can be transmitted to a preprogrammed layout,

the layout must be selected by means of a

LAYOUT RUN instruction. If

the layout has been saved in the printer’s permanent memory ("c:") as

described in Chapter 4.8, it should be copied to the temporary memory

("tmp:"), and run from there.

LAYOUT RUN "<tmp:><layout name>"

<layout name> is the name given to the layout in the LAYOUT INPUT instruction and must

be enclosed by quotation marks.

Example:

COPY "c:Shipping Label","tmp:Shipping Label" ↵

LAYOUT RUN "tmp:Shipping Label" ↵

Transmit Variable Data to a Layout

After having selecting a layout using a LAYOUT RUN instruction, you can

transmit the variable data to their respective layout fi elds:

• The transmission starts with a start-of-text separator.

• Then comes a block of data to the fi eld containing

VAR1$.

• A fi eld separator separates the blocks of data.

• Next block goes to the fi eld containing

VAR2$.

• A fi eld separator separates the blocks of data and so on.

• The last block must also end with a fi eld separator.

• The end of transmission is indicated by an End-of text separator.

By default, the following separators should be used:

• Start separator: STX (ASCII 02 dec)

• Field separator:

CR (ASCII 13 dec)

• End separator:

EOT (ASCII 04 dec)

All separators can be changed at will by means of a

FORMAT INPUT

instruction, see Chapter 6.5.

Page 50

44 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

<STX> <Input data to VAR1$> <CR> <Input data to VAR2$> <CR>.....<EOT>

Input data must not be enclosed by quotation marks.

Example:

<STX> Abcdefg <CR> 123456789 <CR> <EOT>

Note: If a label has been printed using a predefi ned layout

and you want to return to the method of printing labels using

layout and printable data in one sequence, the predefi ned

layout must fi rst be cleared from the printer’s working memory

using the instruction:

LAYOUT RUN ""

Input Data to Single- and Multi-Line Text Fields

The input data to a text fi eld is given by means of a PRTXT or PRBOX

instruction. You can add various types of data to a text fi eld:

• Plain text, by typing for example "Abcdefgh" or "012345"

• Variable input data using variables, for example

VAR1$

• Counter values, for example CNT1$

• Current date, using DATE$ or DATE$ ("F")

• Current time, using TIME$ or TIME$ ("F")

• The weekday of the current or specifi ed date, using WEEKDAY$

• The number of the current or specifi ed date, using WEEKNUMBER

• A future date, using DATEADD$ or DATEADD$ ("F")

• A future time, using TIMEADD$ or TIMEADD$ ("F")

PRTXT

is used for single line text fi elds. You can combine different types

of data in a single

PRTXT instruction. The different parts are placed adja-

cently by means of separating semicolons (;). Note that plain text must

be enclosed by quotation marks.

PRTXT | PT "<input data>"[;"<input data>"...]

Examples:

PT "Price: $1.99" ↵

PT "Price: ";VAR1$;" per dozen" ↵

PT "Box No. ";CNT15$;" Packed: ";DATE$ ("F") ↵

PT WEEKDAY$(DATE$);", ";DATE$("F") ↵

PT "Week Number ";WEEKNUMBER(DATE$) ↵

PT "Expiry date: ";DATEADD$ (30,"F") ↵

Page 51

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 45

Chapter 4 — Label Design

PRBOX is used for multi-line text fi elds.

PRBOX | PX <box height>,<box width>,<line thickness>,"<input data>"[,<hor.

off set>[,<vert. off set>[,"<line delimiter>"[,"<control string>"]]]]]

<box height> is the height of the box in dots (1-6000).

<box width> is the width of the box in dots.

<line thickness> is the line thickness in dots (0-6000).

<input data> is max. 20 lines of text, each with max. 300 single-byte characters.

<hor. off set> is the horizontal distance between the box line and the text frame (-100 to

+100 dots). Default: 0.

<vert. off set> is the vertical distance between the box and the text frame and between

each text line (-100 to +100 dots). Default: 0.

<line delimiter> is a string used to replace the default carriage return or line feed character.

<control string> is a string for hypenation control, see Intermec Fingerprint v7.80, Programmer’s

Reference Manual.

The height, width, and line thickness parameters are the same as when

creating an ordinary box fi eld, see Chapter 4.6. However, you can set the

line thickness to 0, which gives an invisible box.

The input data allow max. 20 lines with max. 300 characters on each

line. Double-byte fonts cannot be used. In all other respects, this parameter corresponds to the input data in

PRTXT (PT).

The horizontal and vertical offset is used to specify the position of the

text frame in relation to the inner edge of the border line. The vertical

offset also controls the line spacing, which means the distance between

the bottom of the character cells on one line and the top of the character

cells on the next line. Note that the alignment affects both how the box

is located in relation to the insertion point and how the text frame is

located in relation to the box, see Chapter 4.2.

By default, the input data wraps to a new line each time a carriage return

or linefeed character is entered. You can optionally replace those characters with another character or a series of characters.

By default, text lines are hyphenated from the last space or position

marked by a hyphen sign (-). The hyphen sign will only be printed as the

last character on a line. There are many advanced features for controlling the hyphenation and handling of long-spelling words. Refer to the

Intermec Fingerprint v7.80, Programmer’s Reference Manual for syntax and

explanations of the hyphenation control string.

Page 52

46 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

Input Data to Bar Code Fields

The input data to a bar code fi eld is given by means of a PRBAR instruction. You can add the same types of data to a bar code fi eld as to a text

fi eld, provided the type of data (numeric/alphanumeric), number of

characters, etc. comply with the bar code specifi cation.

You can combine different types of data in a single

PRBAR instruction.

The different parts are placed adjacently by means of separating semicolons (;). Note that alphanumeric input must be enclosed by quotation

marks, whereas numeric input must not.

PRBAR | PB <input data>[;<input data>...]

Examples:

PB 71543;VAR5$ ↵

PB "Intermec" ↵

PB DATE$;TIME$ ↵

Input Data to Image Fields

An image can be selected either by name in plain text (for example

"GLOBE.1"), or in the form of a variable (for example VAR1$), also see

Chapter 4.5. Note that plain text input must be enclosed by quotation

marks.

PRIMAGE | PM "<image name>"

Examples:

PM VAR5$ ↵

PM "LOGOTYPE.2" ↵

Input Data from Counters

Using a COUNT& instruction, various counters can be created, see Chapter

6.6. You can read the present value of a counter and use it as input data

by including a reference to the counter in the PRTXT, PRBOX, or PRBAR

instructions in the form of a variable.

CNT<Counter No.>$

<Counter No.> is the number is assigned to the counter in the COUNT& instruction.

Example:

PT "Label number: ";CNT1$ ↵

PB CNT2$ ↵

Page 53

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 47

Chapter 4 — Label Design

Input Data from the Printer’s Clock/Calendar

The printer’s clock/calendar can be used to provide input data to text

and bar code fi elds by including any of the following instructions in the

PRTXT, PRBOX, or PRBAR instructions:

DATE$

Returns the current date according to the printer’s calendar in the standard format YYMMDD, where YY

is the last two digits of the year, MM is the number of the month (01-12), and DD is the number of the

day (01-31).

Example:

PT DATE$ ↵

DATE$ ("F")

Returns the current date according to the printer’s calendar in the format specifi ed by FORMAT DATE$,

see Chapter 6.4.

Example:

PT DATE$("F") ↵

TIME$

Returns the current time according to the printer’s clock in the standard time format HHMMSS, where

HH is the hour (00-24), MM is the minute (00-59) and SS is the second (00-59).

Example:

PT TIME$ ↵

TIME$ ("F")

Returns the current time according to the printer’s clock in the format specifi ed by FORMAT TIME$, see

Chapter 6.4.

Example:

PT TIME$("F") ↵

WEEKDAY$ ("<date>")

Returns the name of the weekday in plain text according to NAME WEEKDAY$ (see Chapter 6.4) from a

given date or the current date.

<date> can be specifi ed in the standard format “YYMMDD” or by a DATE$ instruc-

tion.

Examples:

PT WEEKDAY$("041201") ↵

PT WEEKDAY$(DATE$) ↵

Page 54

48 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 4 — Label Design

WEEKNUMBER ("<date>"[,<calculating function>])

Returns the weeknumber from a given date or the current date.

<date> can be specifi ed in the standard format “Y YMMDD” or by a DATE$ instruction.

By default, the week number is calculated according to ISO 8601, but there

are 14 other methods (see Intermec Fingerprint v7.80, Programmer’s Reference

Manual).

Examples:

PT WEEKNUMBER("041201") ↵

PT WEEKNUMBER(DATE$) ↵

DATEADD$ (["<original date>",]<number of days>[,"F"])

Adds or subtracts a certain number of days to the current date or optionally to a specifi ed date.

<original date> is optional and is entered in the standard date format “YYMMDD”. Note that

the original date must be enclosed by quotation marks.

<number of days> specifi es the number of days to be added to or subtracted from the current

date or, optionally, the date specifi ed by <original date>. In case of subtraction, the <number of days> should be preceded by a minus sign (-).

"F" is an optional fl ag specifying that the result should be returned in the format

specifi ed by FORMAT DATE$ instead of the standard format “YYMMDD.”

Example:

PT DATEADD$("040801",-15,"F") ↵

TIMEADD$ (["<original time>",]<number of sec’s>[,"F"])

Adds or subtracts a certain number of seconds to the current time or optionally to a specifi ed moment

of time.

<original time> is optional and is entered in the standard date format “HHMMSS”. Note that

the original time must be enclosed by quotation marks.

<number of sec’s> specifi es the number of seconds to be added to or subtracted from the current

time or, optionally, the moment of time specifi ed by <original time>. In

case of subtraction, the <number of sec’s> should be preceded by a minus

sign (-).

"F" is an optional fl ag specifying that the result should be returned in the format

specifi ed by FORMAT TIME$ instead of the standard format “HHMMSS.”

Example:

PT TIMEADD$("123026",100,"F") ↵

Page 55

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 49

5

Feeding & Printing

Instructions

This chapter describes the various instructions used

for controlling the media feed and the printing of

labels.

Page 56

50 Intermec Direct Protocol v7.80 Programmer’s Reference Manual

Chapter 5 — Feeding & Printing Instructions

5.1 Media Feed

In order to provide maximum fl exibility, there are several instructions for

controlling the media feed and an optional paper cutter:

CLEANFEED <feed length in dots>

Runs the printer’s media feed mechanism in order to facilitate cleaning of the platen roller.

FORMFEED | FF [<feed length in dots>]

Feeds out a blank label or optionally feeds out (+) or pulls back (-) a certain amount of media without

printing.

TESTFEED [<feed length>]

Feeds out a number of blank labels, or optionally a specifi ed amount of media, while adjusting the

sensitivity of the label stop/black mark sensor and detecting the front edges of the labels. If a feed length

is specifi ed, make sure that at least one gap or mark passes the label stop/black mark sensor.

CUT

Makes an optional paper cutter perform a cutting cycle.

The media is fed past the printhead by a rubber-coated platen roller

driven by a stepper motor. The movement of the media is detected by the

label stop sensor (LSS) or black mark sensor (BMS), except when various

types of continuous stock are used.

The printer’s setup in regard of “Media Size; Length” and ”Media Type”

is essential for how the media feed will work. There are fi ve different

Media Type options (also see the User’s Guide for the printer):

• Label (w gaps)

• Ticket (w mark)

• Ticket (w gaps)

• Fix length strip

• Var length strip

When a

FORMFEED, TESTFEED, or PRINTFEED instruction is executed,

the photoelectric label stop sensor (LSS) detects the forward edge of each

new label or the forward edge of each detection gap, and the black mark

sensor (BMS) detects the rear edge of each black mark, as the media is

moved past the sensor.

By performing a

TESTFEED operation after loading a new supply of

media, the fi rmware is able to measure the distance between, for example, the forward edges of two consecutive labels, thereby determining

the label length, and can adjust the media feed accordingly. The same

principle applies to tickets or tags with detection gaps, and to tickets with

Page 57

Intermec Direct Protocol v7.80 Programmer’s Reference Manual 51

Chapter 5 — Feeding & Printing Instructions

black marks. At the same time, the sensitivity of the sensor is adjusted

according to the characteristics of the media, for example the transparency of the liner.

In case of continuous stock, the LSS will only detect possible outof-paper conditions and the amount of media feed is decided in two

different ways:

• Fixed length strip