Intermatic ET90000 Installation Manual

ET90000 Series

Electronic Timer

Installation and Programming Guide

WARNING

• Do not attempt to install or use your Intermatic product until you have read the safety instructions in this section. Save this

document and keep it in an easily accessible place.

• To avoid fire, shock, or death, turn off power at circuit breaker and test that power is off before wiring.

• Observe all national and local electrical and safety codes.

• Disconnect power when servicing or changing loads.

• Alterations or modifications to the device will create a hazard.

• Use copper conductors only. Use 10 AWG wire, minimum 105°C for 30 Amp loads.

• For outdoor locations, rainproof or wet location conduit hubs that comply with the requirements of UL 514B Conduit, Tubing,

and Cable Fittings for outdoor use, must be used.

Risk of Fire or Electric Shock

www.intermatic.com

7777 Winn Road

Spring Grove, IL 60081

Manual No. 158--01050-REVA

TABLE OF CONTENTS

Safety Information ....................................................2

Unpacking ................................................................2

Quick Start Guide .....................................................2

Product Description .................................................3

Installation ................................................................4

Mounting ..............................................................4

Wiring ...................................................................5

Door Assembly ....................................................8

Controls ....................................................................9

Programming ..........................................................10

Advanced Options ..................................................12

System Conguration Options ...............................14

Limited Three-Year Warranty ..................................16

Français ..................................................................17

Español ...................................................................33

SAFETY INFORMATION

WARNING

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

IMPORTANT is a statement that informs about

installation, operation, maintenance, performance issues,

or general tips that are important but do not create a

hazard or safety concern.

EMISSIONS: This device complies with Part 15 of the

FCC Rules.

This Class A digital apparatus complies with Canadian

ICES-003.

IMPORTANT: Changes or modications not expressly

approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

UNPACKING

Separate the timer from packaging materials and check

for any visual signs of damage. If you determine there

has been damage caused by shipping, le a claim

with the shipping company. If the device appears to

have been improperly assembled or does not operate

properly, return it for replacement or repair (see Limited

Three‑Year Warranty information at the end of this

manual).

QUICK START GUIDE

1. MOUNT UNIT

Mount the unit to a stable surface, as required (see

Mounting, page 4).

2. CONNECT TO POWER

WARNING

To avoid fire, shock, or death, turn off power at circuit breaker

and test that power is off before wiring.

Connect unit to power (see Connect to Power, page 5).

3. INSTALL WIRING

CAUTION

Some terminals in the ET90000-series electronic timer may be

energized even if the Status Screen is off. Check all terminals

and wires with an appropriate voltmeter before touching.

Wire applications to device as required (see Install

Wiring, page 6).

4. PROGRAM BASIC INFORMATION

Input the current date and time. To begin using an

application, program an event. For complete information,

see Programming, page 10.

2

ET90000 Series Electronic Timer

PRODUCT DESCRIPTION

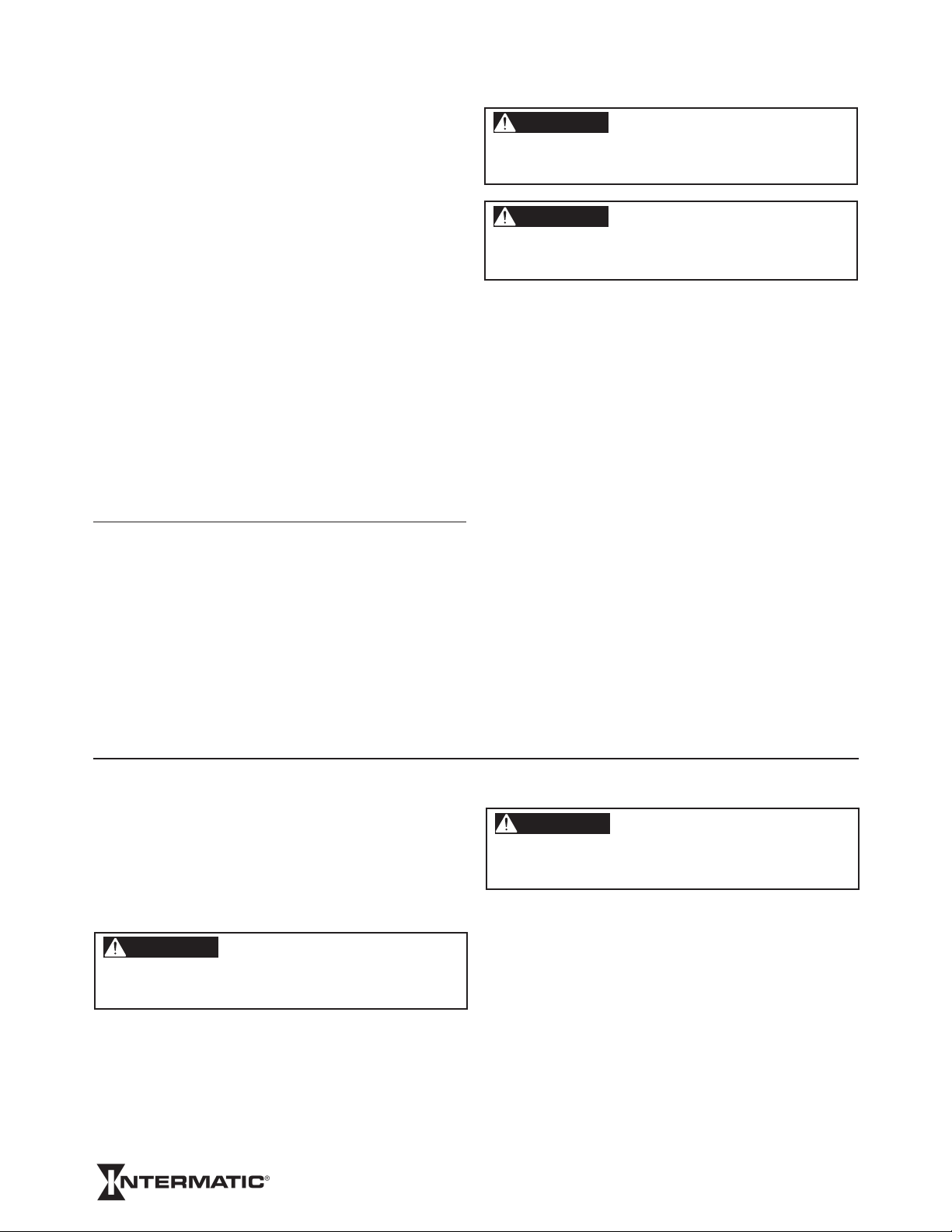

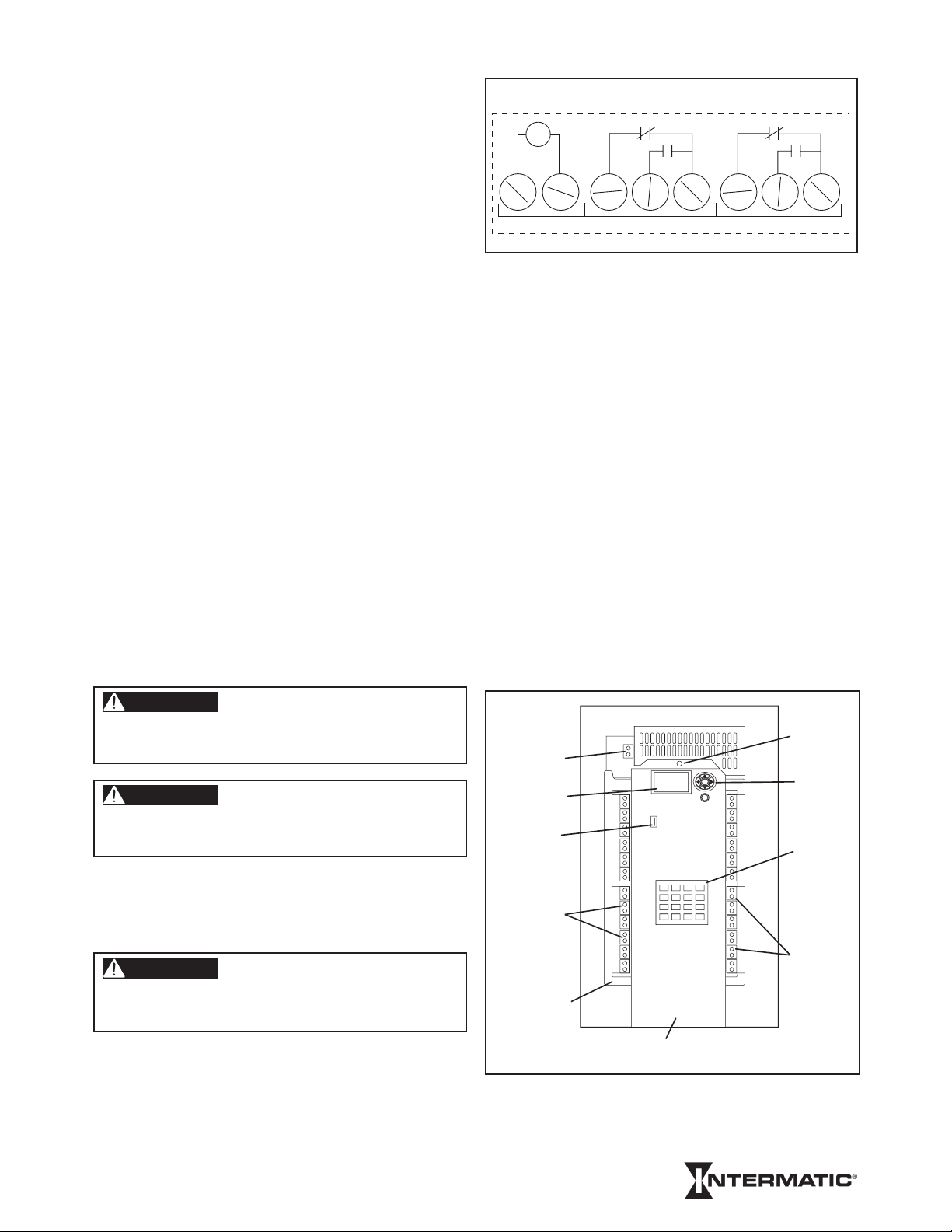

STATUS SCREEN

STATUS SCREEN

USB PORT

2-circuit control module

MANUAL

CIRCUIT ON/OFF KEYS

NAVIGATION KEYS

ENTER

ESC

ESCAPE KEY

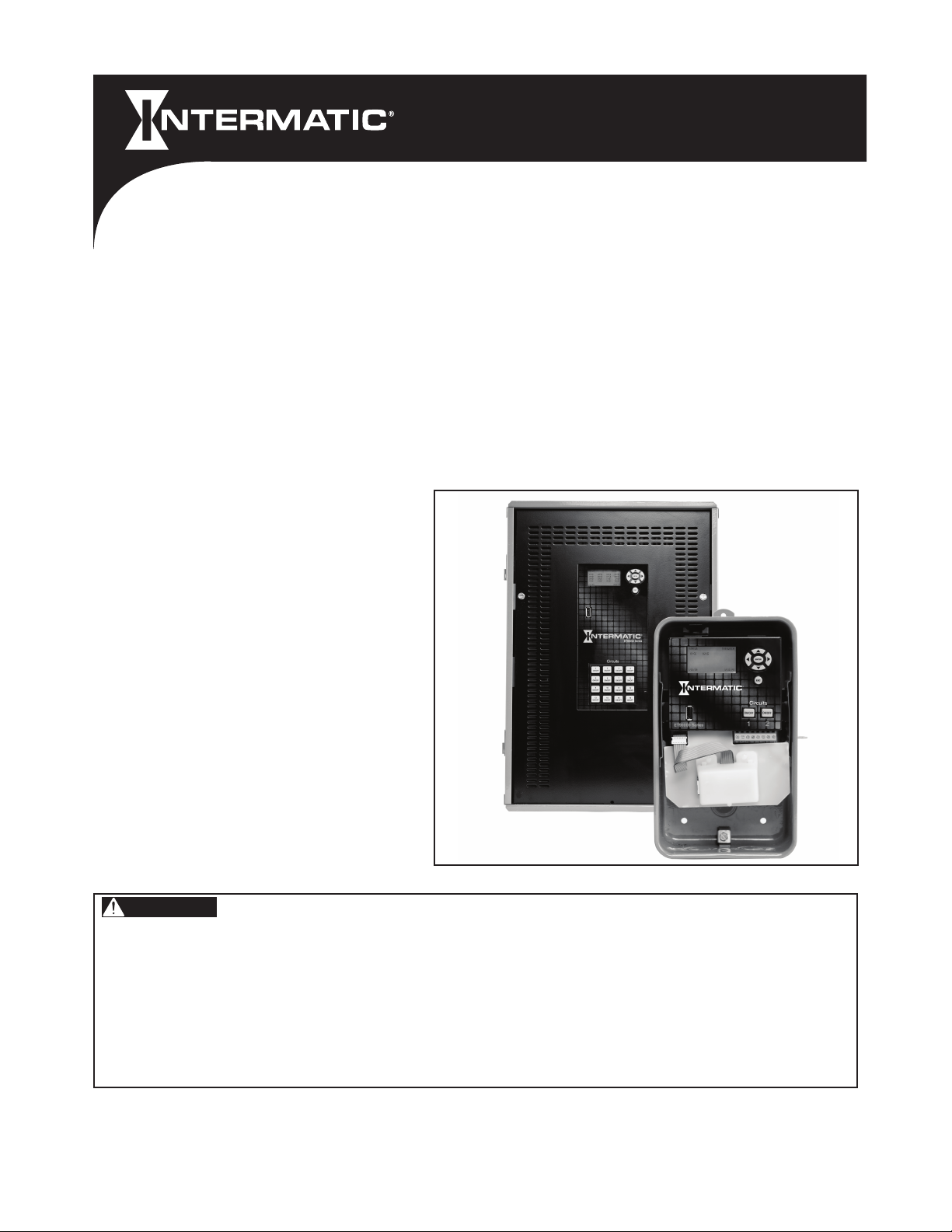

The ET90000-series electronic timer from Intermatic

is a microprocessor based unit that allows you to turn

your application ON or OFF automatically for worry-free

operation. Automatically bring up and shut down lights,

turn on or turn off heating and cooling systems, activate/

deactivate alarms, or start and stop pumps. From the

compact keypad, easily program, schedule, and track

these “events” by a specic date (January 1, 2014) or by

a relative date (for example, the rst Monday of January

of any year), and by a specic time (11:00 p.m. CST)

or by astronomical time (example: sunrise). Separately

program holidays and downtimes, too.

Choose whether your event is going to be a xed ON

or OFF (single ON or OFF time for lights, for example)

or pulsed ON (ON time with specied duration, such as

ringing an alarm).

You can congure ET90000-series electronic timers to t

your needs. They are available in 1 and 2 circuit models,

or 4, 8, 12, 16 circuit models. The smaller units are

housed in either a Type 1 indoor enclosure or a Type 3R

“rainproof” outdoor enclosure. All 4, 8, 12, and 16 circuit

models are housed in the Type 3R enclosure.

4 to 16-circuit control module

ENTER

ESC

USB PORT

NAVIGATION KEYS

ESCAPE KEY

MANUAL

CIRCUIT ON/OFF KEYS

POWER RATINGS

Input: 120-277 VAC, 50/60 Hz, 16 watts

Output: 1 and 2 circuit panel, 60 amps

General Purpose and

Resistive @ 12-240 VAC:

General Purpose and

Resistive @ 12-240 VAC:

Resistive @ 28 VDC: 20 amps (N.O.), 10 amps (N.C.)

Ballast @ 120-277 VAC: 20 amps (N.O.), 3 amps (N.C.)

Tungsten @ 12-120 VAC: 5 amps (N.O.)

Motor @ 120 VAC: 1 HP (N.O.), 1/4HP (N.C.)

Motor @ 240 VAC: 2 HP (N.O.), 1/2HP (N.C.)

Pilot duty 120-240 VAC: 470 VA (N.O.), 275VA (N.C.)

Maximum number of 30A

circuits (larger unit):

Maximum short circuit

rating both units:

max. for 1 and 2 circuit unit; 50

watts max. for larger unit

max.; 4-16 circuit panel, 350 amps

max. (both @25°C). Maximum

amperage for the 4-16 circuit panel

is reduced by 4.4A/°C above 25°C.

20 amps (N.O.), 10 amps (N.C.)

30 amps (N.O.)

11

5,000 amps

FEATURES

• Automatic input voltage selection (no switches or

DIP settings)

• Date and time retention via 100-hour

supercapacitor

• USB port for input

• Program up to 4000 events, 99 holidays

• Sunrise/sunset tracking without Photocontrol

• Automatically adjusts for daylight saving time

• Upgrade rmware on-site via USB and Ethernet

• Ethernet connection for PC control and connecting

multiple timers

• External device support with CAN and serial ports

ET90000 Series Electronic Timer

Notes:

• N.C = normally closed, N.O. = normally open

• All VAC ratings are for 50/60 Hz

MAXIMUM LOADING EXAMPLES

Example:

(30 amps x 11 circuits) = 30 x 11 = 330 amps

Example:

(30 amps x 5 circuits) + (20 amps x 10 circuits) =

(150) + (200) = 350 amps

3

TECHNICAL DATA

• Operating temperature: -40°F to 104°F (-40°C to

40°C)

• Dimensions 1 and 2 circuit unit (Type 1 encl.):

7-7/8H x 5 W x 3 inches D (20.0 H x 12.7 W x

7.6cmD)

• Dimensions 1 and 2 circuit unit (Type 3R encl.):

9-7/8 H x 5-5/8 W x 3-5/8 inches D (25.1 H x

14.3W x 9.2 cm D)

• Dimensions 4, 8, 12, 16 circuit unit: 19-1/8 H x

12-5/8 W x 5-3/8 inches D, including mounting

bracket; (48.6 H x 32.1 W x 13.7cm D)

• Knockout placement and sizes: for 1-2 circuit, 1/23/4 inch combo on back, each side, and two on

bottom; for 4-16 circuit, 1/2-3/4 inch combo on each

side and six on bottom, 3/4-1 inch combo on each

side and four on bottom

• Weight: 1 and 2 circuit device, Type 1 encl.: 2.5lbs.

(1.13 kg); 1 and 2 circuit device, Type 3R encl.:

3.4lbs. (1.54 kg); 4-16 circuit unit: 18.6 lbs. (8.4 kg)

INSTALLATION

CAUTION

For outdoor locations, rainproof, or wet location, you must use

conduit hubs that comply with the requirements of UL 514B

Conduit, Tubing, and Cable Fittings. For Outdoor Installation,

Fittings shall be identified with an enclosure type designation

(Type 3, 3X, 3S, 3SX, 3R, 3RX, 4, 4X, 6 or 6P) or as rain-tight

or liquid-tight on the carton. For indoor/outdoor locations,

provide sufficient space around the enclosure for convection

cooling.

IMPORTANT: See Connecting to Power and Installing

Wiring below if you are going to bring power wires and

wires for connecting to applications through the back of

the enclosure. Connect these wires before mounting unit.

4. Drill holes.

5. Install anchors in wall, if needed.

6. Install the top screw rst and then hang the

enclosure.

7. Install the remaining screws through the enclosure

and into the wall.

8. Close enclosure door.

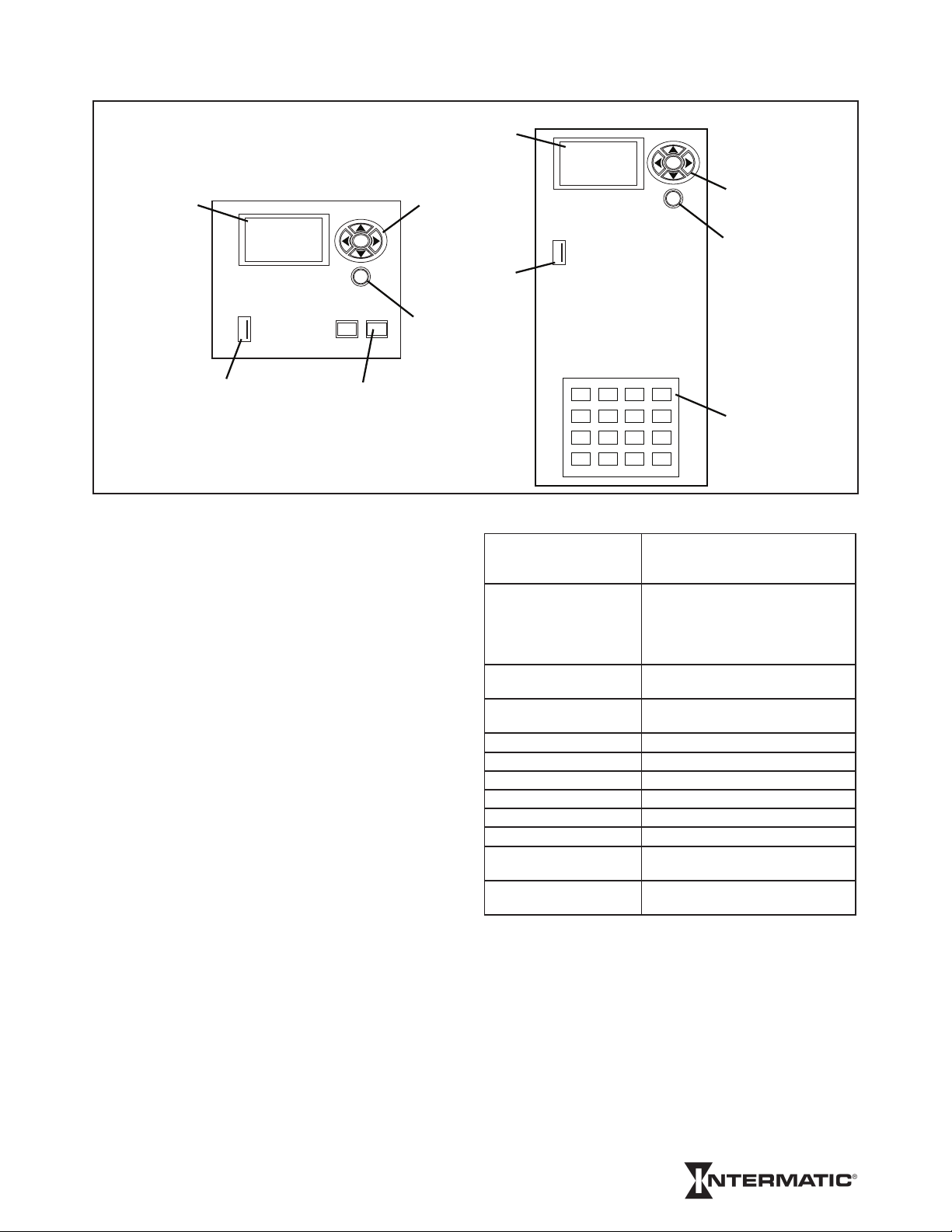

MOUNTING (4, 8, 12, 16 CIRCUIT ENCLOSURE)

IMPORTANT: Mounting screws and anchors not included.

Recommended screw size is #10; however, the type of

screw you select depends on the mounting surface.

1. INSTALL BRACKETS

BRACKET

MOUNTING

SCREWS (4)

MOUNTING

BRACKETS (2)

MOUNTING (1 AND 2 CIRCUIT ENCLOSURE)

IMPORTANT: Mounting screws and anchors not included.

1. Open the enclosure door.

2. Select the knockout you would like to use. Remove

the inner 1/2-inch knockout by inserting a athead

screwdriver in the slot; carefully punch the knockout

loose. Remove slug. If 3/4-inch knockout is required,

remove the outer ring with pliers after removing the

1/2-inch knockout. Smooth edge if necessary.

3. Place the enclosure in the desired mounting location

and mark mounting holes.

1. Remove the four hex head screws (5/16" slotted)

located on the top and bottom of the outside back of

the enclosure.

2. Using the screws that you just removed, install the

brackets with the keyhole portion extending past the

edge of the enclosure and providing an offset from

the back of the enclosure.

4

ET90000 Series Electronic Timer

2. MOUNT ENCLOSURE

1. Place the enclosure in the desired location and mark

the location of at least two of the keyhole openings

in the mounting bracket.

2. Drill holes.

3. Install anchors in wall, if needed.

4. Install screws at the keyhole locations.

5. Hang the enclosure on the screws.

6. Mark the location of at least two of the round holes

in the bottom bracket.

7. Remove the enclosure from the top screws and drill

holes for the bottom screws.

8. Install anchors in wall, if needed.

9. Select knockouts you would like to use. Remove the

inner 1/2 or 3/4-inch knockout by inserting a athead

screwdriver in the slot and carefully punch the

knockout loose. Remove slug. If a larger knockout

is required, remove the outer ring with pliers after

removing the inner knockout. Smooth edge if

necessary.

10. Place the enclosure on the wall using the keyholes

in the top mounting bracket.

11. Install the remaining screws through the bottom

bracket and tighten.

12. Tighten the screws through the top mounting bracket.

13. Close enclosure door before operating.

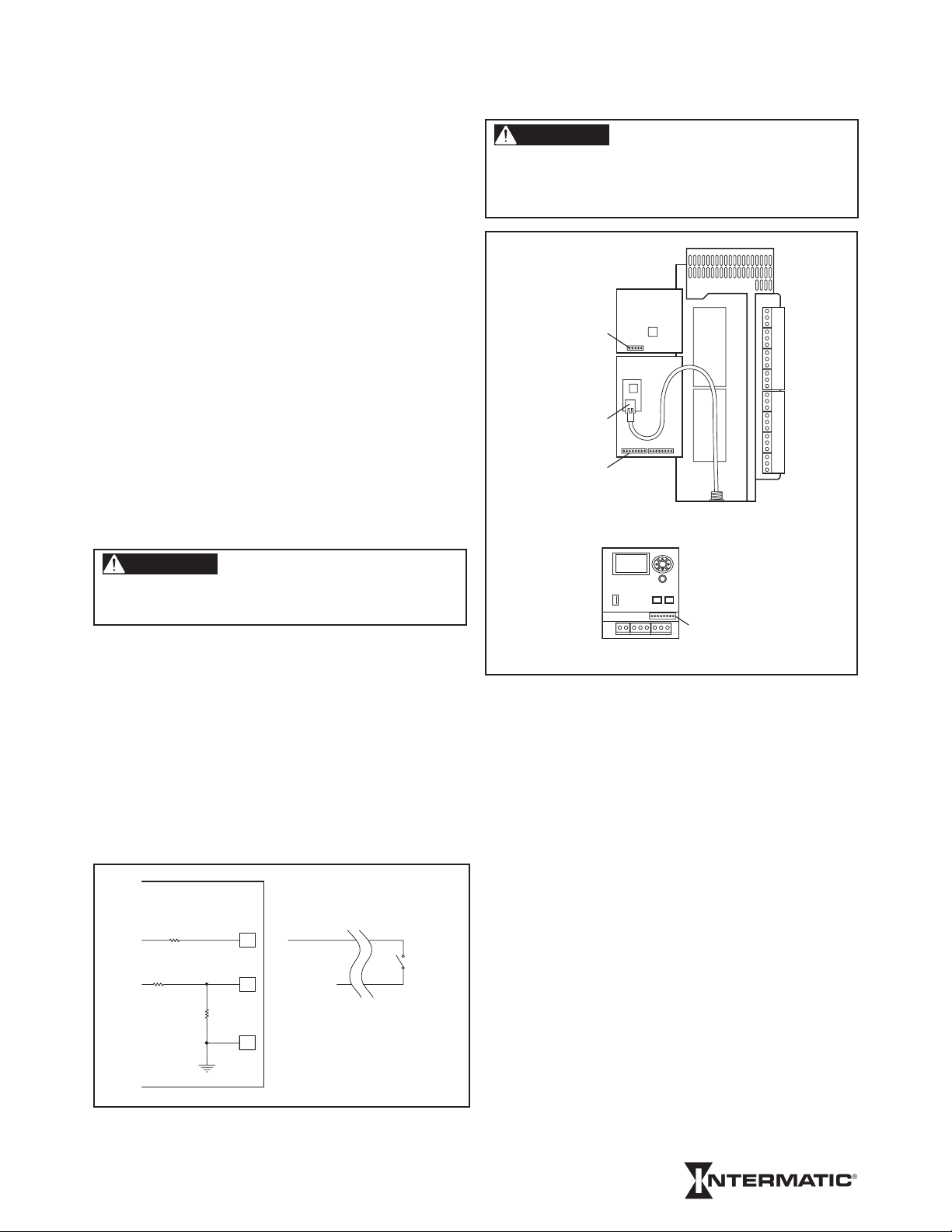

CONNECT TO POWER

ET90215 2-CIRCUIT TERMINALS

T

TIMER

INAC

COM1 COM2

1. Secure conduit connectors to conduit before

connecting the hubs to the enclosure. After inserting

connectors into enclosure, carefully tighten hub lock

nut. Do not over-torque.

2. Insert the black power wire into the power board

(marked “L1” or “AC”) and secure with a athead

screwdriver.

3. Insert the white neutral wire into the power board

(marked “L2/N” or “IN”) and secure with a athead

screwdriver.

IMPORTANT: Color of wires may vary.

4. 1 and 2 circuit system: Attach the green ground

wire to the green hex head screw at the bottom of

the enclosure and secure with a athead screwdriver.

4, 8, 12, 16 circuit system: Connect the input

power wires to the terminals at the top left corner

of the device. Connect the ground wire to the green

hex head screw at the lower left of the device (see

Figure1).

5. Close enclosure door.

NO-2NC-2NO-1NC-1

WARNING

To avoid fire, shock, or death, turn off power at circuit breaker

and test that power is off before wiring.

WARNING

Make sure there is no wire insulation under the clamping plate

and firmly tighten the terminal screws.

A 120 to 277 VAC power source supplies electricity to the

ET90000-series electronic timer, normally run through

conduit. To connect the power wires to the unit, follow

this procedure:

CAUTION

Wire in accordance with national and local electrical and

safety codes.

ELECTRICAL

POWER

TERMINALS

SCREEN

USB PORT

WIRING

TERMINALS

GROUNDING

CONNECTION

ENTER

ESC

CENTER KNOCKOUTS RESERVED FOR

LOW VOLTAGE WIRING

Model_TEMP

Figure 1: ET90000-Series Unit

(4, 8, 12, 16 circuit model)

DOOR

SCREW

KEYPAD

ON/OFF

SWITCHES

WIRING

TERMINALS

ET90000 Series Electronic Timer

5

INSTALL WIRING

WARNING

To avoid fire, shock, or death, turn off power at circuit breaker

and test that power is off before wiring.

Observe these regulations before connecting any

applications to the device.

• The circuit conductors shall have an ampacity

not less than the maximum total load to be

controlled.

• Over current protection shall have an interrupting

rating sufficient for the application control circuit

voltage and the total load current of the equipment

being controlled.

• A fuse or circuit breaker shall be connected in

series with each ungrounded conductor (and shall

be able to open each conductor simultaneously).

• Maximum current rating for each circuit is 30 amps

Resistive and General Purpose. Refer to the Power

Ratings section on page 3 for other ratings.

Wire components and applications to the terminal boards

as needed. Terminal boards are located underneath

the faceplate on the small unit, and on the right and left

sides of the large unit. Insert wires into slots; secure with

athead screwdriver.

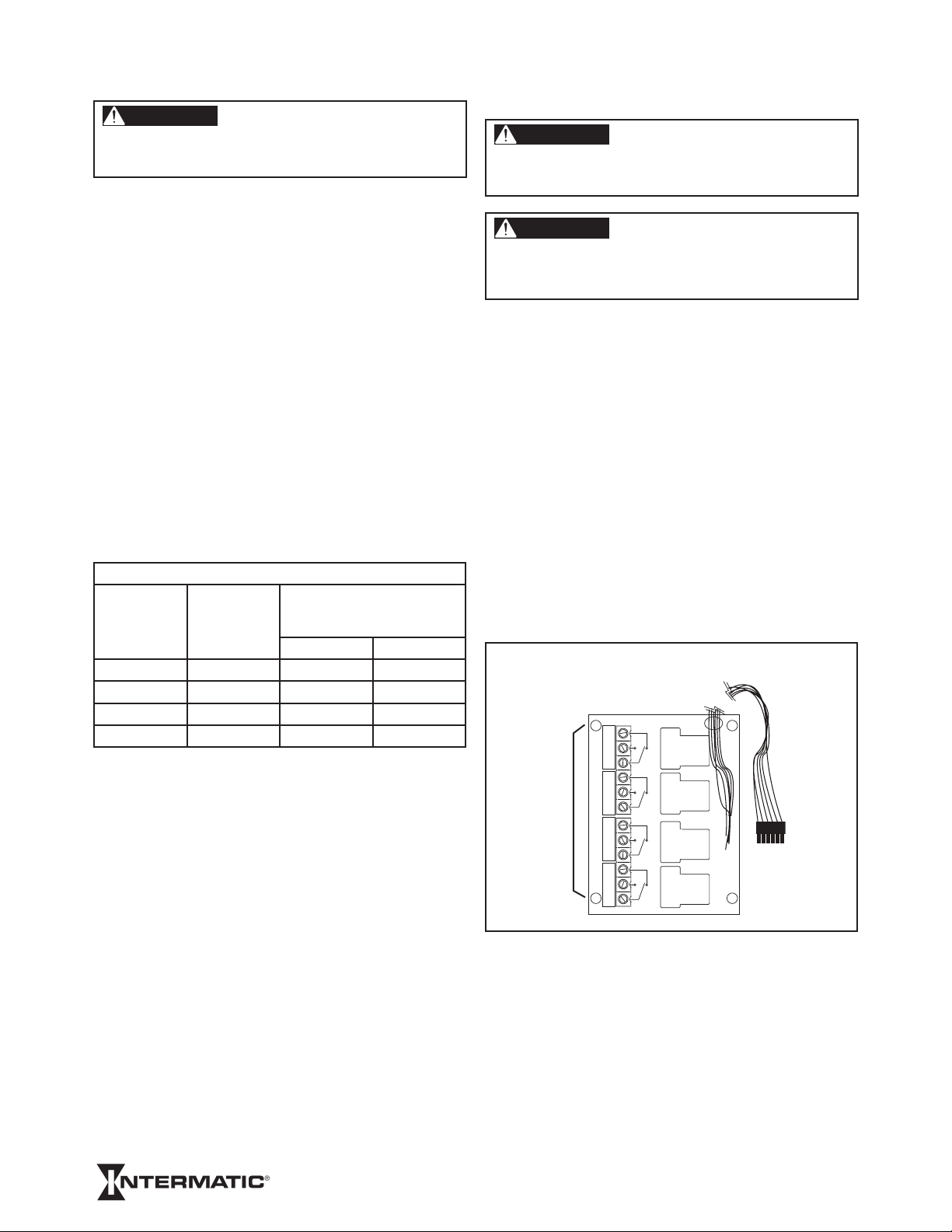

WIRING INFORMATION – COPPER CONDUCTORS ONLY

SUPPLY

WIRE SIZE

105°C MIN

INSULATION

AWG AMP HP HP

14 15 1/2 1

12 20 1 2

10 30 – –

CIRCUIT

BREAKER

RATING

MAX MOTOR LOAD

(CONTINUOUS DUTY)

120V 240V

ADDING RELAY BOARDS (4, 8, 12 CIRCUIT

SYSTEMS)

WARNING

To avoid fire, shock, or death, turn off power at circuit breaker

and test that power is off before wiring.

CAUTION

Some terminals in the ET90000-series electronic timer may be

energized even if the Status Screen is off. Check all terminals

and wires with an appropriate voltmeter before touching.

You can add additional four-circuit relay boards to the 4,

8 and 12 circuit model to a maximum of 16 circuits per

system.

IMPORTANT: Do not exceed 350 amps maximum panel

load.

1. Open outer door and remove and retain the two

screws that secure the interior deadfront to the

chassis.

2. Remove and retain the screw that secures the

controller door assembly.

3. Select the position to install the new relay board.

4. Remove and retain the outer two screws that secure

the ller panel.

5. Remove the ller panel by bending at the serration

until it breaks.

ET90000 SERIES 4-CIRCUIT RELAY BOARD

NC NO COM

Terminal block wire gauge range 20 to 6 AWG

CIRCUITS

1-4, 5-8, 9-12

OR 13-16,

DEPENDING

ON SLOT

USED

NC NO COM

NC NO COM NC NO COM

INDEXED PLUG FOR

CONNECTION TO

INTERFACE BOARD

6. Open the door assembly and remove and retain the

two screws just opposite of the ller panel screws.

7. Insert the new relay board assembly into the

opening, cable rst. The board should sit on top of

the brackets with its mounting holes positioned over

the holes of the previously-removed screws.

6

ET90000 Series Electronic Timer

8. Make sure there are no wires under the board. Use

the (4) original screws to secure the relay board to

the mounting bracket.

9. Connect the cable from relay board to the Interface

board. Use the next available open connector (to

maintain sequential numbering). Push the connector

into the mating connector until the connector latches.

10. Close the door assembly and secure with its screw.

11. Connect/wire the circuit(s) that the ET90000-series

timer will control to the relay board terminal blocks.

12. Check the wiring to ensure that there are no miswired circuits.

13. Reinstall the interior deadfront and secure with its

screws.

14. Remove the plastic cover over the keypads.

15. Apply power to the unit and program the new

channels. The ET90000 system recognizes the

new relay board, displays the circuits on the Status

Screen, and activates the correct ON/OFF keys.

16. Close enclosure door.

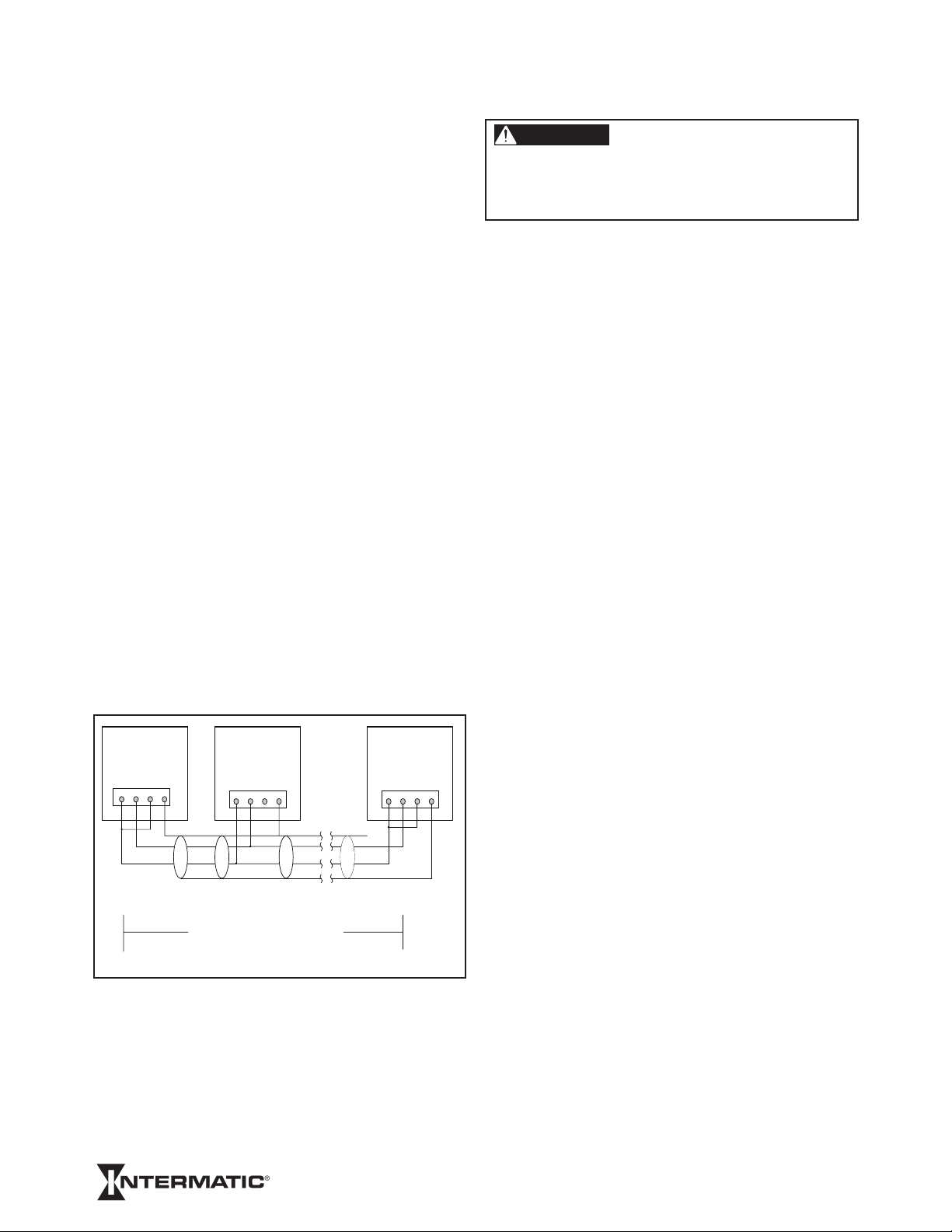

REMOTE SWITCH INSTALLATION

LOW-VOLTAGE WIRING FOR ETHERNET,

REMOTE SWITCH AND CAN BUS

CAUTION

Keep low-voltage wiring separate from high-voltage wiring,

including deadfront material between wiring areas. Use

separate conduit for low-voltage wiring with no line voltage

circuits included.

CAN BUS

CONNECTORS

ETHERNET

CONNECTION

REMOTE INPUT

CONNECTORS

4, 8, 12, AND 16 CIRCUIT MODELS

(DEADFRONT REMOVED)

WARNING

To avoid fire, shock, or death, turn off power at circuit breaker

and test that power is off before wiring.

The ET90000 system is equipped with remote switching

capability. There are 2 overrides for the 1 and 2 circuit

models and 8 overrides for the 4, 8, 12, and 16 circuit

models. The ET90000 system supplies ve-volt limited

current through terminal connections located on the

system interface board. The maximum length of a remote

switch circuit is 1000 feet using 20 AWG twisted pair wire.

The factory recommends 16 AWG through 26 AWG wire

sizes and low voltage SPST (single-pole, single-throw)

switches. Route the cable through one of the knockouts

at the bottom center of the enclosure (see illustration

below and Figure 2).

ET90000 SERIES

EXAMPLE REMOTE INPUT

5VDC

INPUT

100 OHM

100 K

10K

GND

5V

REMOTE (1 - 8)

GROUND

MANUAL

SWITCH

ENTER

ESC

CAN BUS AND REMOTE

1 AND 2 CIRCUIT MODELS

INPUT CONNECTORS

Figure 2: Low Voltage Wiring

Ethernet

1 and 2 circuit system: For the optional Ethernet

connection, attach the Ethernet module to the plastic

deadfront at the bottom of the enclosure; connect the

ribbon cable to the wiring port on the left side.

4, 8, 12, 16 circuit system: Locate the Ethernet module

underneath the deadfront and hinged door in the lowvoltage wiring area. The device uses standard Ethernet

connector cable. Ethernet cable range is 100 meters

between active devices.

Route the cable through one of the knockouts at the

bottom center of the enclosure. Push the connector onto

the module until the latch sets. See Figure 2.

Note:

• Power LED: illuminates while power is ON

• LED1 on RJ-45 model: Ethernet speed – 10 (OFF)

or 100 (ON)

• LED2 on RJ-45 model: link and data activity

ET90000 Series Electronic Timer

7

Remote Switch Installation

The serial port consists of multiple 2-wire inputs on

the terminal block. There are two 2-wire inputs on the

1 and 2 circuit models and eight 2-wire inputs on the

larger models. You can use a standard SPST wall switch

to make this connection. Install wiring for serial port

applications by inserting wiring into the available slot,

then securing with a athead screwdriver.

DOOR ASSEMBLY REMOVAL AND

INSTALLATION – 4 TO 16 CIRCUIT MODELS

CAUTION

Power to the ET90000 System must be OFF before adding or

removing any system components. Failure to remove power

could result in personal injury, damage to the equipment, and

voiding of the product warranty.

CAN Bus

CAN (controller area network) devices provide advanced

remote switch capabilities over a longer range.

1 and 2 circuit system: Connect devices through a fourwire interface on the terminal block above the deadfront.

4, 8, 12, 16 circuit system: Connect devices on the rear

of the interface PCB. Devices can be wired daisy-chain or

star. When the line is required to be “terminated,” connect

the TRM terminal to the C_H terminal with an external

jumper. Route the cable through one of the knockouts at

the bottom center of the enclosure.

CAN Bus Terminal Block

1 +5V

2 C_H

3 C_L

4 TRM (120 ohm termination)

5 GND

• Maximum bus length: 1,000 Meters (3280 Feet)

• Maximum number of remote devices: 16

• Wire type: 1 pair twisted with shield – UL Type CL2

• Wire gauge range: 16 to 26 AWG

Removal

1. Open outer door; remove and retain the two screws

that secure the interior deadfront to the chassis.

2. Remove and retain the screw that secures the

controller door assembly and open the door.

3. Disconnect the following cables from the controller

and interface boards and label each connector/wire

with its location.

• Cable between controller and interface

• Ethernet cable

• Channel 1-4, 5-8, 9-12, 13-16

• CAN bus connections

• Remote switch connections

Note: Some connectors have a latching feature; press to

remove.

4. Close the door; remove and retain the top hinge

screw located at the top of the assembly.

5. Lift up the assembly until it clears the hinge support,

then lift the assembly towards the top of the

enclosure until it is free of the bottom hinge support.

ET9XX15

CONTROLLER

77((5500,,11$$//%%//22&&..33

C_HC_L TRM

GND

1 PAIR TWISTED WITH SHIELD

UL TYPE CL2

CAN BUS

DEVICE #1

C_HC_L TRM GND C_HC_L TRM GNDC_HC_L TRM GND

MAX LENGTH = 1000 METERS

(3280 FEET)

CAN BUS

DEVICE #2

SHIELDSHIELDSHIELD

Figure 3: Example showing daisy-chain connections’

end units with termination

8

ET90000 Series Electronic Timer

Installation

01

E

01

E

1

ON/OFF2ON/OFF3ON/OFF4ON/OFF

5

ON/OFF6ON/OFF7ON/OFF8ON/OFF

9

ON/OFF10ON/OFF11ON/OFF12ON/OFF

13

ON/OFF14ON/OFF15ON/OFF16ON/OFF

1. Locate the bottom hinge pin; guide the bottom hinge

hole on the door assembly onto the pin.

2. Align the door assembly with the top hinge support

and secure with a screw.

3. Open the door assembly and connect the following

cables to the controller and interface boards:

IMPORTANT: The connectors are polarized and only t

in one direction. DO NOT FORCE them into a connector

location.

• Cable between controller and interface

• Ethernet cable

• Channel 1-4, 5-8, 9-12, 13-16

• CAN bus connections

• Remote switch connections

4. Close the door assembly and secure with its screw.

5. Reinstall the interior deadfront and secure with its

screws.

6. Congure the plastic covers over the keypads as

needed.

7. Apply power to the unit and reprogram.

USB PORT

The ET90000 is equipped with a hi-speed USB 2.0 port

for transferring updates and programs. Port functions are:

• transferring schedule programs

• updating the rmware

MANUAL ON/OFF KEYS

The ET90000 unit has a manual ON/OFF key for each

circuit in the system. Each key manually overrides the

associated circuit, turning the circuit OFF if it is ON and

ON if it is OFF. The condition of each circuit displays on

the default STATUS SCREEN.

number 1 is OFF and the circuit is ENABLED;

indicates circuit number 1 is ON and the circuit is

ENABLED. If the E is blocked out on the screen, the

circuit is DISABLED. Manual overrides can be used but

the schedule is not followed. ET90000 systems with 4, 8

or 12 circuits are shipped with all sixteen manual ON/

OFF keys installed. The keys for unused circuits are

inactive until you install the proper relay board in the

system. Inactive keys are shipped with a plastic cover

over them, which you can easily remove when you add

an additional relay board.

indicates circuit

CONTROLS

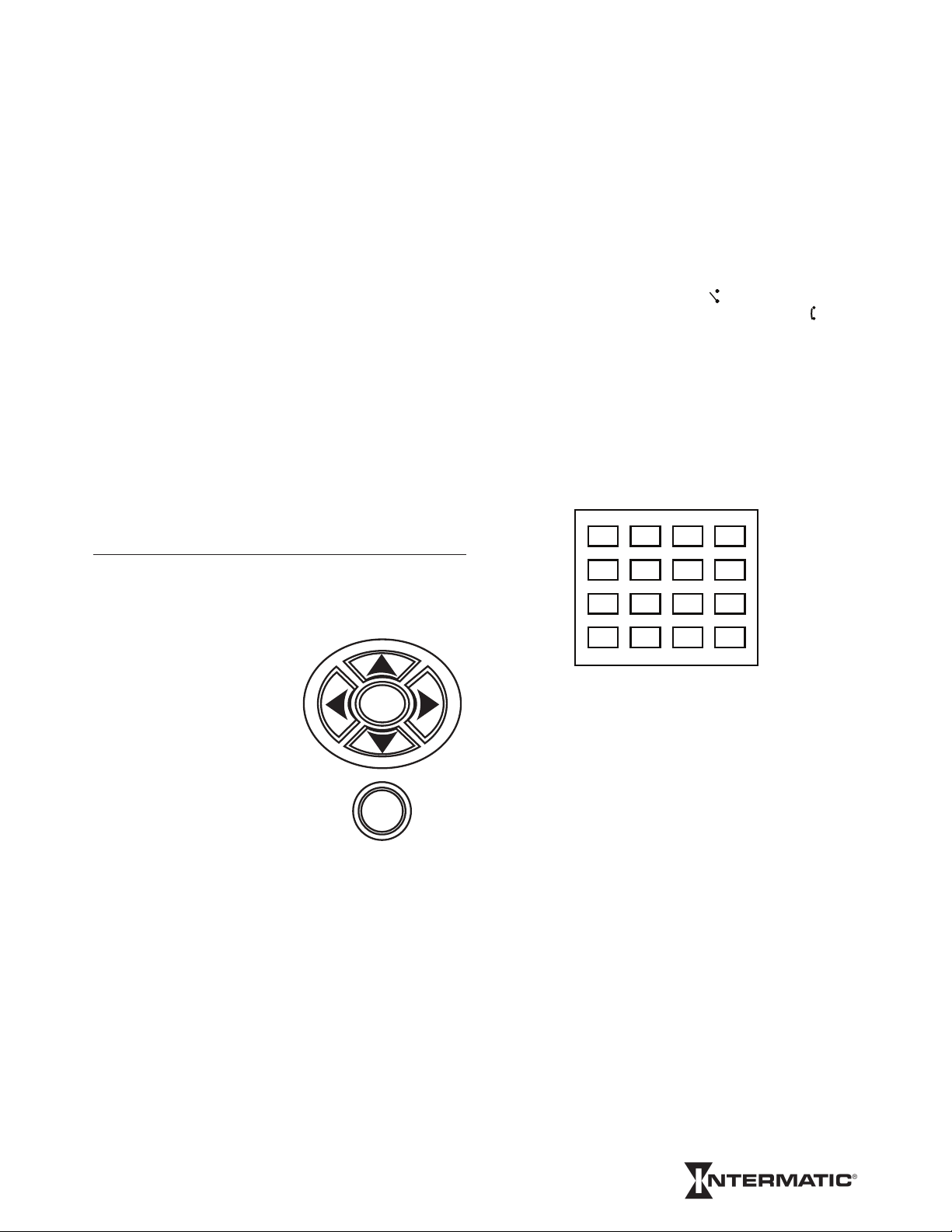

NAVIGATION KEYS

Use the ET90000 timer’s

navigation keys to scroll

through the display screens,

make selections, and enter

variables.

• Pressing the up, down,

left, or right keys moves

the highlight on the

display.

• Pressing ENTER accepts

your selection and

advances to the next

screen.

Figure 4: Navigation

• Pressing ESC cancels

the screen selection and

returns you to the previous screen. (Pressing ESC

several times returns you to the STATUS screen.)

ENTER

ESC

Keys

Figure 5: 16-Circuit System ON/OFF Keys

ET90000 Series Electronic Timer

9

PROGRAMMING

Program the ET90000-series electronic timer using the

navigation keys (see Figure 4). Some of the inputs you

program are simple choices: yes/no, enable/disable,

etc.; others involve inputting variables in alpha-numeric

characters.

INITIAL SETUP

From the STATUS screen, press ENTER. Use the

navigation keys to:

1. Choose INITIAL SETUP.

2. Input the current

date.

3. Input the correct

time (choose 12HOUR, example:

STATUS

E

01

7/14/11 2:20 PM

2:20 PM; or 24HOUR, example:

14 hours, 20 minutes).

4. Choose whether you would like the ET90000-series

timer to update the time automatically for daylight

saving time.

5. Select your time zone.

PROGRAMMING EVENTS

After you have set up the ET90000-series timer initially,

you can program an “event.” An event is something you

would like the device to control, such as turning ON lights

or turning OFF an alarm.

1. CHOOSE SPECIFIC OR RELATIVE DATE

To program an event, rst choose whether you would like

your event to occur on a specic or relative date. Program

a specic date by choosing the month and day; program

a relative date by choosing a date such as the 2nd week

of January, or the 10th day of each month.

Available Options:

1st-31st Mon-Sun Jan-Dec

Each Week Year

Last Weekday Month

First Weekend

Day

TIMESWITCH

E

02

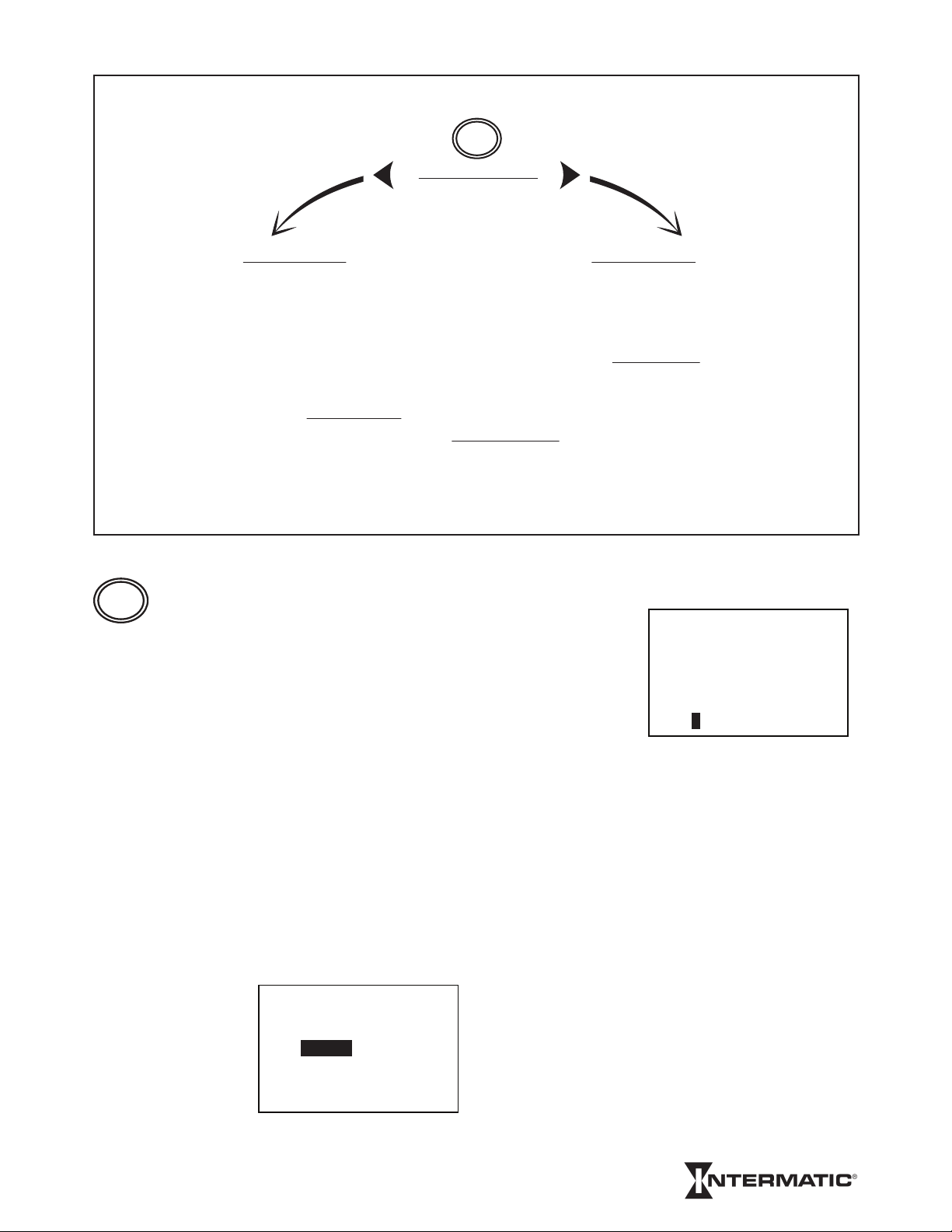

3. CIRCUIT TYPE

For your event, choose whether you would like the

ET90000-series electronic timer to turn your application

ON or OFF, then choose whether the circuit will have a

xed ON or a pulse ON.

Fixed means a steady

current. Pulse means a

EVENT 1

TYPE: PULSE

steady current which is

ON for a specied time

(input hours, minutes,

HH:MM:SS

00:01:00

and seconds of pulse)

and then turns OFF.

4. NAME YOUR EVENT

You can choose to give your event a name, such

as SLIGHTS or PUMP 1. Enter the name (up to 10

characters) using the

alpha-numeric display.

The ET90000 system

chooses a name for

you if you do not name

your event, for example

Event 1.

NAME: EVENT 1

ABCDEFGHIJKLM

NOPQUSTUVWYXZ

012345678 /-:

DEL ACCEPT

5. DETERMINE CIRCUIT CONTROL

After naming your event, select which circuit(s) the event

controls. Select as few as one circuit, or as many as 16

circuits on the large capacity device. (Note: Up to 32

external circuits will be available in the future.)

6. PROGRAM HOLIDAYS

If your event runs during times where there are one or

more holidays, which may supplant normal event times

and dates, you must program this information into the

device.

Similar to programming an event, you name the holiday,

set up date and time (in this case, choose the beginning

and end of the holiday), then program events into the

holiday. Also similar to programming primary event(s),

select your circuits and what they do: turn ON with a

xed or pulse duration or turn OFF.

2. SPECIFY TIME

Choose a time when

you want your event

to occur. Or choose

astronomic time, which

is sunrise or sunset,

plus or minus a variable

number of minutes

(up to ±120), per your

requirements.

ET90000 Series Electronic Timer

EVENT 1

TIME TYPE: ASTRO

SUNRISE

ADJUSTMENT +33 MINS

10

7. SELECT ASTRO(NOMIC) ZONES

If you have previously programmed an event or a

holiday based on astronomic time, you must select an

astronomic zone after you have programmed in all of

your variables, events, and holidays. Select from the

following regions:

• USA STATES

• MEXICO

• CANADA

• USA

TERRITORIES

Then select the

appropriate COUNTRY

LOCATION and LOCATION QUADRANT.

SELECT ASTRO ZONE

COUNTRY

UNITED STATES

COUNTRY LOCATION

ILLINOIS

LOCATION QUADRANT

CENTER

8. REVIEW YOUR EVENT

After you nish programming your events, you can

choose YES to review it. Review the program by circuit,

by event (ALL, HOLIDAY, or RELATIVE) and by specic

date. If the event requires changes, press ENTER with

the event highlighted to proceed directly to Advanced

Options. You can also edit or change your event from

ADVANCED OPTIONS on the SETUP screen.

TIPS ON PLANNING EVENTS

Depending on how complex your circuits are, you may

prefer to plan your events before programming using a

table similar to the one at the right.

EVENTS

Circuit(s)

HOLIDAYS

Circuit(s)

Event

Name

Name of

Holiday

Effective

Days

Begin

Date

Start

Time

End

Date

Type:

ON/OFF

FIXED/PULSE

Type:

ON/OFF

FIXED/PULSE

ET90000 Series Electronic Timer

11

SYSTEM CONFIG

REVIEW MODE

PROG COPY/RESTORE

PASSWORD SETUP

EDIT SYSTEM NAME

NETWORK SETUP

FIRMWARE UPDAT E

RESET TO FAC DEFAULT

EVENT CONFIG

ADD EVENT

MODIFY EVENT

DELETE EVENT

ADVANCED OPTIONS

ENTER

DATE/TIME CONFIG

DATE

TIME

DST

ASTRO

HOLIDAY CONFIG

ADD HOLIDAY

MODIFY HOLIDAY

DELETE HOLIDAY

CIRCUIT CONFIG

EDIT CKT NAME

ENABLE CKT EVENTS

MANUAL ACTIVATE MODE

EXTERNAL OVERRIDE

ZONE CONFIG

ADD ZONE

MODIFY ZONE

DELETE ZONE

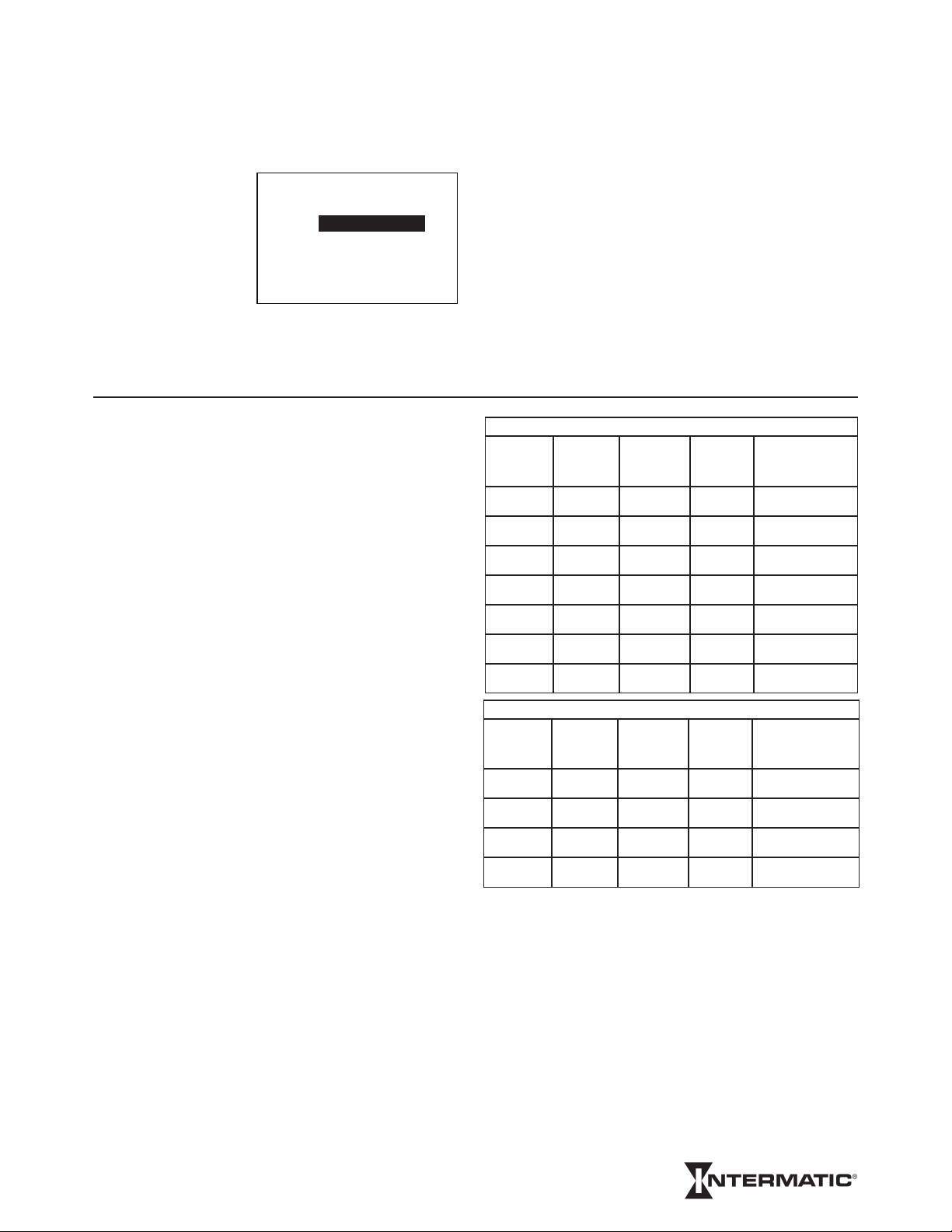

The conguration screens can be

navigated using the right or left keys. The

accompanying instructions are presented

based on a right-key sequence.

ENTER

ADVANCED OPTIONS

Use Advanced Options to edit already-existing

programming, congure circuits and zones, and set up

your system.

From the STATUS screen, press ENTER and navigate to

ADVANCED OPTIONS. Press ENTER to access DATE,

TIME, DST, or ASTRO on the DATE/TIME CONFIG

screen.

DATE

Press ENTER to correct the date.

TIME

Press ENTER to change the current time (hours,

minutes, AMor PM) or the display mode for the time

(12HOUR AM/PM or 24 HOUR).

DST (DAYLIGHT SAVING TIME)

Press ENTER to

enable/disable DST, set

the DST time zone, and

set up effective dates

(start and end date of

DST).

DT.DST.EFF—DATES

START DATE (SUN):

FOURTH WK OF FEB

END DATE (SUN):

FIRST WK OF OCT

ASTRO

From ASTRO, you can

dene an Astronomic

zone (country, location

in country, and

quadrant location).

Also, if you need to

adjust the time of the

astronomic zone, you

can do so against

the “calculated time” from the ASTRO ADJUSTMENT

screen.

DT.ASTRO .ADJUSTMENT

CALCULATED TIME

SUNRISE SUNSET

5:26 AM 5:29 PM

ENTER NEW TIME

SUNRISE SUNSET

5:26 AM 5:29 PM

ET90000 Series Electronic Timer

12

CIRCUIT CONFIG(URATION)

When you press the right key from TIME, DATE, DST, or

ASTRO, you have the following options under CIRCUIT

CONFIG:

• EDIT CKT (circuit) NAME

• ENABLE CKT EVENTS

• MANUAL ACTIVATE MODE

• EXTERNAL OVERRIDE

Each relay or output is dened as a circuit. Each circuit

can be independently congured using the following

options.

1. EDIT CKT NAME

Enter or change the name of the circuit(s). First select

the circuit you wish to change, then use the keypad to

enter or change the name (up to 10 characters; default

name is CIRCUIT 1, CIRCUIT 2, etc.).

2. ENABLE CKT EVENTS

When you enable a

circuit, it adheres to

the scheduled events.

However, events do not

turn a disabled circuit

ON or OFF but you can

still control disabled

circuits manually

via pushbuttons or

overrides. Add or remove the checkmark to enable/

disable the circuit.

3. MANUAL ACTIVATE MODE

This determines how the relays are controlled. If FIXED,

a pushbutton toggles the circuit ON and OFF normally. If

PULSE, after you turn the circuit on manually, the circuit

automatically turns OFF when the pulse duration expires.

(Note: You can always control circuits manually via the

pushbuttons.) To activate:

A. Select the circuit you would like to control.

B. Choose FIXED or PULSE.

C. If PULSE, input duration.

4. EXTERNAL OVERRIDE

You can use external

remote override

switches to control

circuits. 1 and 2

circuit models have

two overrides; 4 to 16

circuit units have up to

eight overrides. Select

which circuits you will

override, which zones,

and whether the override will be xed or pulse. If pulse,

set duration.

CIRCUIT . ENABLE

ENABLE/DISABLE CKTS

NONE

1: CIRCUIT 1

2: CIRCUIT 2

DONE

CIRCUIT . OVERRIDE

OVERRIDE 1

SELECT OVERRIDE

ACTIVATE MODE

FIXED

PULSE HH: MM: SS

00: 01: 00

ZONE CONFIG(URATION)

You will use these options to establish and dene zones.

You can set up a zone and use it to control one or more

circuits, including the circuit’s associated events and

holidays. For example, you may create Zone A, which is

comprised of circuits 1, 3 and 6 that have four events and

three holidays, including each event’s and each holiday’s

variables such as the dates, times, etc., associated with

them.

If events control zones instead of circuits, you can modify

the circuits in a zone without changing any events. To

congure, press the right key from CIRCUIT CONFIG to

land on ZONE CONFIG where your options are:

• ADD ZONE

• MODIFY ZONE

• DELETE ZONE

1. ADD ZONE

To add a zone, press ENTER from ADD ZONE where

your choices are:

• ENABLE A ZONE – You establish a zone by

enabling it. Disabling a zone causes it to ignore the

programmed schedule.

• EDIT ZONE NAME – Here you can give the zone

a name (up to 10 characters; default names are

ZONE 1, ZONE 2, etc.).

• EDIT ZONE CIRCUIT LIST – Choose the circuit(s)

you wish to include in the zone by placing a

checkmark next to the circuit(s).

2. MODIFY ZONE

Select the zone you would like to modify, then choose:

• ENABLE – Choose YES or NO.

• EDIT ZONE NAME – Edit the zone’s name (up to

10 characters; default names are ZONE 1, ZONE

2, etc.).

• EDIT ZONE CIRCUIT LIST– Choose the circuit(s)

you wish to include in the zone by placing a

checkmark next to the circuit(s).

3. DELETE ZONE

Select the zone you would like to delete, then press

ENTER.

13

ET90000 Series Electronic Timer

HOLIDAY CONFIG(URATION)

Press the right key again from ZONE CONFIG to land on

HOLIDAY CONFIG where your options are:

• ADD HOLIDAY

• MODIFY HOLIDAY

• DELETE HOLIDAY

1. ADD HOLIDAY

You create a holiday when you:

• ENABLE A HOLIDAY – Establish the holiday by

choosing YES or NO.

• EDIT HOLIDAY NAME – Give the holiday a name

(up to 10 characters; default names are HOLIDAY

1, HOLIDAY 2, etc.).

• EDIT HOLIDAY DATES – Choose from FIXED or

RELATIVE holiday, where xed is exact rst and

last days of the holiday (month and day); relative for

example, is 1st day = July 4th, length = 3 days.

2. MODIFY HOLIDAY

Select the holiday you would like to enable, change/add

name, and/or edit the holiday’s dates (same as above).

3. DELETE HOLIDAY

Choose any holiday(s) you would like to delete from the

zone.

EVENT CONFIG(URATION)

Press the right key again from HOLIDAY CONFIG to land

on EVENT CONFIG where your options are:

• ADD EVENT

• MODIFY EVENT

• DELETE EVENT

1. ADD EVENT

You add an event when you:

• ENABLE EVENT – Establish an event by choosing

YES or NO.

• EDIT EVENT NAME – Give the event a name (up

to 10 characters; default names are EVENT 1,

EVENT 2, etc.).

• EDIT EVENT TYPE – Choose whether this event

turns a circuit ON or OFF.

• EDIT EVENT DATE/TIME – Input a xed date

(month and day) or a relative date (example, 1st

day of each month); input a xed time (hour and

minute) or an astro time (sunrise or sunset, up to

±120 minutes allowable adjustment).

• CKT/ZONE/HOL LISTS – Select circuit(s), zone(s)

and holiday(s) for this event by placing checkmarks.

• EDIT ACTIVATION TYPE – Select activation mode,

either FIXED or PULSE. If PULSE, enter duration

in hours, minutes, and seconds.

2. MODIFY EVENT

To modify an event, rst select the event to modify then

change or edit the event under ENABLE EVENT, EDIT

EVENT NAME, EDIT EVENT TYPE, EDIT EVENT DATE/

TIME, CKT/ZONE/HOL LISTS, and/or EDIT ACTIVATION

TYPE (see above).

3. DELETE EVENT

Choose the event you would like to delete.

SYSTEM CONFIGURATION OPTIONS

Press the right key again from EVENT CONFIG to land

on SYSTEM CONFIG. Note: From the STATUS screen,

you can also press ENTER; navigate to ADVANCED

OPTIONS, press ENTER again, then press the left key

once.

Your options are:

• REVIEW MODE

• PROG COPY/RESTORE

• PASSWORD SETUP

• EDIT SYSTEM NAME

• NETWORK SETUP

• FIRMWARE UPDATE

• RESET TO FAC DEFAULT

IMPORTANT: Use the ESC key to return to the SYSTEM

CONFIG screen after entering these options.

1. REVIEW MODE

In REVIEW MODE, you can examine the parameters for

all your events by circuit and date.

ET90000 Series Electronic Timer

14

A) PROGRAMMED SCHEDULE

From REVIEW

MODE, you land

on PROGRAMMED

SCHEDULE. After you

choose which circuit’s

schedule you would

like to review, you land

on SELECT EVENT

SYS. REVIEW-MODE

CIRCUIT 1

SELECT EVENT TYPE

ALL EVENTS

HOLIDAY EVENTS ONLY

RELATIVE EVENTS ONLY

TYPE. From this

screen, select from the following:

• ALL EVENTS

• HOLIDAY EVENTS ONLY

• RELATIVE EVENTS ONLY

Select the date of the event you would like to review and

press enter. The screen shows any event scheduled.

B) EVENT LOG

You can also view an

EVENT LOG, such as

this example. The event

log stores the most

recent 1,000+ events

and can be saved to

USB.

EVENT LOG

PARKING L1

ON

-MANUALOFF

-SERIALON

12/31/12

5:00 PM

12/31/12

2:00 PM

12/31/12

10:00 AM

2. PROG COPY/RESTORE

Under this function, you can copy or restore a program

into the ET90000-series timer from the USB port. To copy

a program, insert a USB drive into the port and follow the

prompts. To restore a program, select which program you

would like to restore from the list on the screen; press

ENTER to delete the current schedule and replace it with

the saved USB schedule. Note: Backup your schedule to

USB in case it is unintentionally modied, reset, etc.

3. PASSWORD SETUP

On this screen, your choices are:

• ENABLE PASSWORD

• CHANGE PASSWORD

In ENABLE PASSWORD, your choices are ENABLED

and DISABLED. When you select ENABLED, it means

screens are viewable but you must enter the password

to change or add information. Choosing DISABLED

means no password is necessary to view, change or add

information.

To change the password, press CHANGE PASSWORD.

After you land on the SYS PSWORD CHANGE screen,

key in up to 10 alphanumeric characters; key in again to

conrm. Write down password!

Note: If the password is enabled, you can still reset the

device to factory defaults.

IMPORTANT: You can reset to factory defaults even if you

do not know the password; in fact, this is the only way

to start “from scratch,” and enter a new password, if the

password is permanently lost. Always copy the schedule

to USB prior to resetting the timer.

4. EDIT SYSTEM NAME

Use this for identication purposes to name your system

when networking multiple timers together. Change or

edit the system’s name using up to 10 alpha/numeric

characters, then press ACCEPT.

5. NETWORK SETUP

In NETWORK SETUP, you can:

• CONFIGURE NETWORK ADDRESS – If you

would like to connect to a network, you must

congure the network address. ENTER the IP

(internet protocol) address, the subnet mask, and

the default gateway.

• CONFIGURE REMOTE ADDRESS – To congure

a remote address, you must rst connect to an

Ethernet device (see page 7). Then you can

program up to 16 IP addresses.

• REMOTE CONNECT – Follow the prompts to

connect to another Ethernet device.

• REMOTE DISCONNECT – First connect to an

Ethernet device, then follow prompts.

• TIME SYNC – Sends the time information from

the current timer to all timers, so clocks are

synchronized. To synchronize timers, rst connect

to an Ethernet device, then follow the prompts.

6. FIRMWARE UPDATE

Firmware updates are available at

http://www.intermatic.com. To install an update from a

ash drive, insert drive into the USB port, then follow the

prompts.

7. RESET FACTORY DEFAULTS

Choose NO or YES. Be certain you want to do this!

IMPORTANT: Copy the schedule to USB prior to resetting

the timer. If you reset factory defaults, you lose all custom

programming.

15

ET90000 Series Electronic Timer

Loading...

Loading...