Page 1

319.5 Crystal MaxLife Door/Window Sensor

Installation Instructions

Introduction

These are the 319.5 Crystal Maxlife Door/Window Sensor

Installation Instructions for models 60-362N-10-319.5 and

60-362N-11-319.5. Install the sensor (Figure 1

windows, and other objects that open and close. The sensor

transmits signals to the control panel when a magnet mounted

near the sensor is moved away from or closer to the sensor.

The sensor is equipped with a cover tamper microswitch for

additional security.

Figure 1. Sensor

Use the following installation guidelines:

• Mount the sensor on the door frame and the magnet on

the door. For double doors, mount the sensor on the leastused door and the magnet on the most-used door.

• Where possible, install sensors within 100 ft. (30 m) of the

panel. While a transmitter may have an open-air range of

500 ft. (150 m) or more, the environment at the installation

site may have a significant affect on operational range.

Changing a sensor location may improve wireless

communication.

• Line up the alignment mark on the magnet to one of the

alignment marks on the sensor.

• Mount sensors at least 4.7 in. (12 cm) above the floor to

avoid potential damage.

• Avoid mounting sensors in areas where they will be

exposed to moisture or where the operating temperature

range will exceed the specified range.

• If possible, mount directly to a stud. If a stud is not

available, use plastic anchors.

• Avoid mounting the sensor in areas with a large quantity of

metal or electrical wiring.

• Only one input can be used at any given time.

) on doors,

• You must mount the magnet within 3/8 in. (0.95 cm) of the

sensor.

• Mount sensors with screws, not double-sided tape.

• Only install the EOL resistor when an external contact is

used.

You will need the following tools and materials:

• Two #6 x 1.00 in. PPH (Phillips panhead) screws and two

plastic anchors for mounting the sensor (included).

• Two #6 x 0.625 in. PPH screws for mounting the magnet

(included).

• External contact 4.7 Kohm end-of-line (EOL) resistor

(included).

• Phillips screwdriver

Caution: You must be free of all static electricity when

handling electronic components. Touch a grounded, bare

metal surface before touching a circuit board or wear a

grounded wrist strap.

Programming

This section describes general guidelines for programming

(learning) the sensor into panel memory. Refer to the specific

panel or receiver documentation for complete programming

details.

To program the sensor:

1. Remove the sensor cover by squeezing the cover ends

firmly releasing the tab (Figure 2

Figure 2. Sensor tab

2. If required, insert the battery into the battery holder,

observing correct polarity (Figure 3

) from sensor base slot.

Tab

).

P/N 466-2298 • REV E • January 2011 1

Page 2

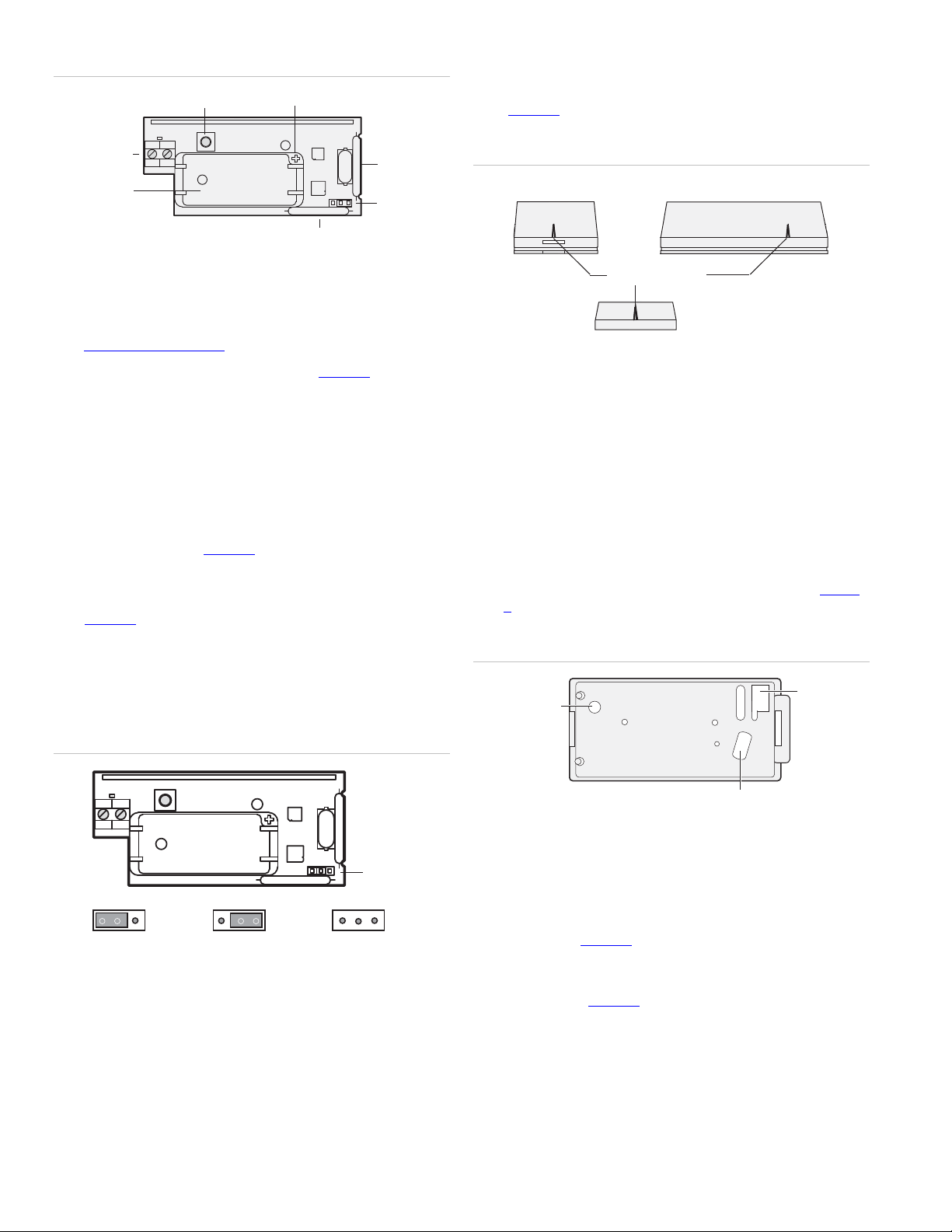

Figure 3.

A

External

Contact

Terminals

Battery

holder

Board components

Tamper switch

Positive

Reed B

Reed

Input

jumper

2. Take the sensor to the mounting location.

3. Hold the magnet next to the alignment mark on the sensor

(Figure 5

Figure 5. Alignment marks

) and then pull the magnet away from the sensor.

Sensor end view

Sensor side view

3. Set the panel to program mode.

4. Proceed to the Learn sensors menu.

5. Set the external contact in the alarm condition (see

External contact wiring

6. Press and release the tamper switch (Figure 3

).

) on the

sensor until the panel responds.

7. Select the appropriate sensor group and number.

8. Exit program mode.

Input selection

Only one door/window input can be used at any given time. For

example, if the external contact is used, internal reed switches

(Reed A and Reed B in Figure 3

Note: Power down the device before positioning the input

selection.

See Figure 4

and position the input selection jumper to select:

Reed B. Left two pins covered (default).

Reed A. Right two pins covered.

External contact. Jumper removed.

) cannot be used.

Alignment marks

Magnet

4. Listen for siren beeps to determine appropriate response

(refer to the specific panel/receiver documentation).

5. Exit sensor test mode.

Mounting

To mount the sensor:

1. Remove the sensor battery.

2. Remove the circuit board from the sensor base by pulling

back on the plastic tab.

3. Mount the sensor base using the screws provided (Figure

6).

Figure 6. Mounting holes

Mounting

hole

Wire

entry

Figure 4 Input selection jumper

Mounting

Jumper

location

hole

4. Replace the circuit board.

5. Remove the magnet from its base.

6. Line up the magnet alignment mark with the sensor

alignment mark, depending on the internal reed switch

Reed B

(default)

Reed A

External contact

being used (Figure 5

7. Mount the magnet base with the #6 x 0.625 in. PPH

).

screws no more than 3/8 in. (0.95 cm) away from the

sensor base (Figure 7

). Replace the magnet cover.

Verifying RF communication

Before mounting the sensor, verify the sensor mounting

location provides good RF panel communication.

To verify:

Put the panel/receiver into sensor test mode.

1.

2 319.5 Crystal MaxLife Door/Window Sensor Installation Instructions

Page 3

7. Mounted sensor

Figure

Magnet Sensor

Door Door frame

Sensor test

The sensor test verifies proper communication between the

sensor and the panel/receiver. To test the sensor, refer to the

specific panel/receiver documentation and do the following:

1. Put the panel/receiver into sensor test mode.

2. Open the door/window the sensor is protecting. The

sensor transmits a signal.

3. Listen for siren beeps to determine the appropriate

response.

4. Exit sensor test mode.

8. Insert the sensor battery observing correct polarity (Figure

3).

9. Attach the sensor cover to the base.

External contact wiring

Use the following specifications for the external contact:

• Maximum wire length: 26 ft. (8 m).

• Wire: Stranded, 22-gauge (0.7112 mm).

• Switches: Hermetically sealed external switches (sealed

reed switches) that supply a minimum 250 ms open or

close on alarm.

Note: Do not connect more than five external contacts to a

door/window sensor.

You can wire the sensor terminal blocks with leads from an

external contact (Figure 8

alarm and tamper indication. Wire the external contact with one

end-of-line (EOL) resistor in series with the external contact.

Caution: You must install the EOL resistor at the external

detection device for proper supervision. For UL listed

installations, the EOL resistor must be UL listed, manufactured

by Edwards part number EOL-4k7L, and rated 4.7Kohm.

). The door/window sensor provides

Battery replacement

Note: Battery replacement should be done by trained

personnel only.

When the system indicates low sensor battery, replace it

immediately. Use the recommended replacement batteries

(see Specifications

).

To replace the batteries:

1.

Remove the sensor cover.

2. Remove the battery. Follow local laws for battery disposal.

3. Insert the replacement battery, observing correct polarity

(Figure 3

4. Perform a sensor test with the panel. See Sensor test

).

.

Caution: The battery used in this device may present a fire or

chemical burn hazard if improperly handled. Do not recharge,

disassemble, heat above 100°C (212°F), or dispose of in fire.

Use only batteries listed in the Specifications

section. Use of

another battery may present a risk of fire or explosion.

Troubleshooting

This gives the following readings for each configuration:

Normally closed

Zero ohm/short = Tamper

4.7 Kohm = Normal

Open = Alarm

Normally open

Zero ohm/short = Tamper

4.7 Kohm = Alarm

Open = Normal

Figure 8 shows external contact wiring (normally closed and

normally open). For UL listed installations, use only UL listed

accessories/contacts.

Figure 8. External contact wiring

Door/Window

Sensor

EOL resistor

4.7 Kohm

319.5 Crystal MaxLife Door/Window Sensor Installation Instructions 3

Contacts

This information is provided to help you diagnose and solve

various problems that may arise while configuring or using the

door/window sensor.

Power up / battery

If the unit does

not power up properly:

• Make sure the battery is fully seated within the battery

bucket and the polarity is correct.

• Check the battery voltage (3.0 VDC nominal).

RF communication

If the control pane

l does not respond:

• Use the 60-401 RF Sniffer to make sure the transmitter is

sending messages for activation.

• Move or rotate the sensor position.

Page 4

Tamper (cover/external contact)

If a tamper condition does not restore:

• Make sure the cover tamper spring is properly installed.

The tamper spring must be properly seated into the switch

post groove.

Figure 9. Tamper spring

Switch post groove for proper

tamper spring installation

• Make sure the proper value end-of-line (EOL) resistor is

installed (4700 ohms series resistor).

Figure 10. External contact wiring

Door/Window

Sensor

EOL resistor

4.7 Kohm

Contacts

• Make sure the EOL resistor is properly seated in the

terminal block.

• Make sure the terminal block contacts are securely

fastened.

• Make sure the external contact wiring meets required

specification.

Open (reed switch/external contact)

If an open co

ndition does not restore:

• Make sure the input selection jumper is in the correct

position.

• Make sure the arrow on the magnet and the guide line on

the transmitter are aligned and within 3/8 in. (0.95 cm) of

each other.

• Verify that the external contact is operating properly in all

conditions of operation.

Specifications

Model number Brown: 60-362N-11-319.5 (NX-651N)

White: 60-362N-10-319.5 (NX-650N)

Frequency 319.5 MHz

Compatibility Interlogix 319.5 MHz control panels/receivers

Battery type 3.0 V, 1300 mAh lithium

Required batteries Duracell DL 123A, Energizer EL123, Sanyo

CR123A

Estimated battery life 5 to 10 years at 20°C (68°F) depending on

the number of activations per day

Magnet gap 3/8 in. (max.)

Supervisory interval 64 minutes

End-of-line resistor 4.7 Kohm

Typical RF output

power

Operating temperature 32 to 120°F (0 to 49°C)

Storage temperature -30 to 140°F (-34 to 60°C)

Relative humidity 0 to 85% noncondensing

Dimensions (LxWxD) 3.02 x 1.5 x 1.02in. (81 x 38 x 26 mm)

Weight 44 g

Listings UL 1023, UL 634

Replacement plastics

600-1063-60-362N-10

600-1063-60-362N-11

0.25mW EIRP

D/W sensor 60-362N-10 - 319..5

replacement enclosure, 5 pack, white

D/W sensor 60-362N-11 - 319..5

replacement enclosure, 5 pack, brown

Regulatory information

Manufacturer UTC Fire & Security Americas Corporation, Inc.

1275 Red Fox Rd., Arden Hills, MN 55112-6943,

USA

FCC compliance This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

Changes or modifications not expressly approved

by the party responsible for compliance could

void the user’s authority to operate the

equipment.

FCC ID: B4Z-914D-DWS

IC: 1175C-914EDWS

Contact information

www.utcfireandsecurity.com or www.interlogix.com

For customer support, see www.interlogix.com/customer-

support

Copyright © 2011 UTC Fire & Security. All rights reserved.

4 319.5 Crystal MaxLife Door/Window Sensor Installation Instructions

Loading...

Loading...