Page 1

NX-591NE-GSM NetworX GSM 3G HSPA+

Module Installation Sheet

Description

The NX-591NE-GSM is a microprocessor-controlled GSM

interface module used to connect the NetworX series of control

panels to GSM cellular networks for event reporting. The

module is compatible with the latest 3G and HSPA+ (4G)

networks, as well as backward compatible with 2G networks,

and can be used for primary or backup reporting. Flexible

event selection allows only specific messages to be reported,

keeping airtime to a minimum. The module interfaces with the

NetworX panel data bus and has 9 LEDs to provide extensive

diagnostic and setup information.

Activation

Before installing the module, it must be activated on an existing

dealer account. If you do not have a dealer account, please

contact Interlogix directly to initiate the account set-up

procedure. The activation process automatically activates the

module within a few hours. If you already have a dealer

account, you can activate and manage the module via our

website address: https://login.uplink.com/ge/login.aspx.

1. Enter your login name and password, then click

Login.

2. Click on Activate Unit on the left side of the page.

3. Enter the serial number of the module from label on

the front of the unit (10-digit number preceded by S/N)

and select Interlogix SMS Plan from the drop-down

menu, then click Activate.

Mounting

Inside the can, several two-holed insertion points have been

constructed. This allows for either vertical or horizontal

placement of the modules. The insertion points have two sizes

of holes, a larger hole and a smaller hole. The black plastic

PCB guides are grooved on one edge where the PC board will

be seated. The end with the half-moon protrusion fits into the

larger hole. The smaller hole is for the screw.

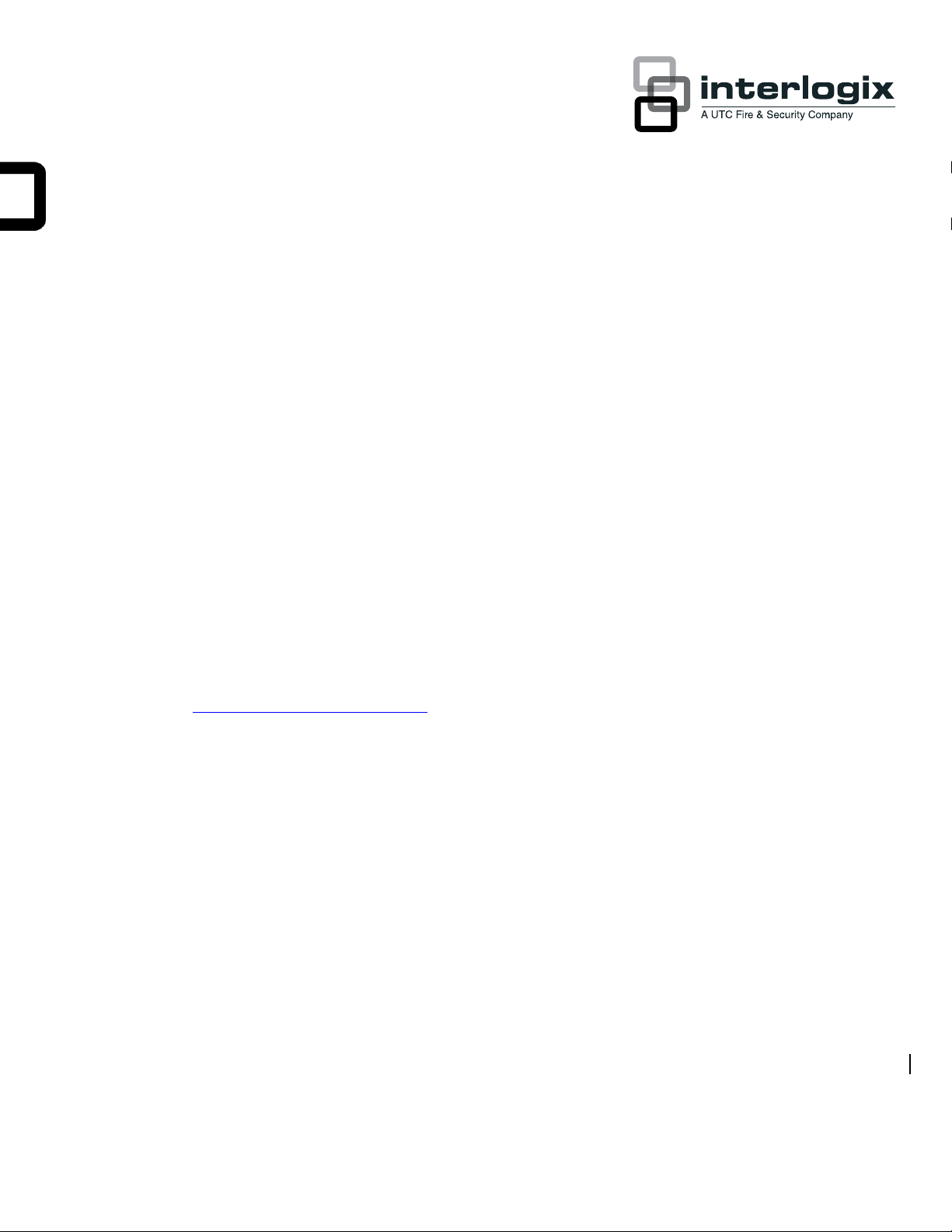

To mount the board, see Figure 1 and do the following:

1. Hold the board vertically, with antenna bracket facing to the

left, near the top of the inside of the panel enclosure to identify

the hole knockout that must be removed to allow for the

antenna to protrude through the top of the can. Note the two

insertion points that align with the board.

2. Remove the knockout from the hole with appropriate tools.

3. Place the first black plastic PCB guide in the top insertion

point, grooved edge downward. The half-moon protrusion will

be in the large hole. It does not require force.

4. Insert one of the provided screws into the smaller hole

(from the inside of the can) to secure it in place. A screwdriver

should reach through the notch that runs the length of the

guide to tighten the screw.

5. Position the second PCB guide opposite of the first

(grooved edge up) and placed in the lower insertion point,

using the same procedure.

4. Fill out the required information and select reporting

options, then click Update.

Installation

To install the module you will need to mount the unit in the

panel enclosure and wire the unit to the main security panel

within the enclosure.

P/N 466-4433 • REV A • 25MAR13 1

6. Once mounted, screw it in securely.

7. Slide the board in the grooves of both guides with antenna

bracket facing left.

Note: Older style enclosures did not provide an exit hole for the

antenna included with the GSM module. In such cases, you must

either drill a new hole (5/8 in.) on top of the can or use an optional

external antenna (NX-501E-GSM).

Page 2

Figure 1: Mounting the unit

Gauge

Maximum wire length to panel

20 gauge

10 ft. (3.1 m)

18 gauge

50 ft. (15.2 m)

16 gauge

100 ft. (30.5 m)

Terminal

Description

DATA

Connect to the KP DATA terminal of panel

COM

Connect to the KP COM terminal of panel

POS

Connect to the KP POS terminal of panel

TAM

Unused on this design

. .

. .

. .

. .

. .

NX-591NE-GSM

BUSS

XMIT

SVC

BEST

GOOD

FAIR

POOR

RXD

TXD

TAM

POS

COM

DATA

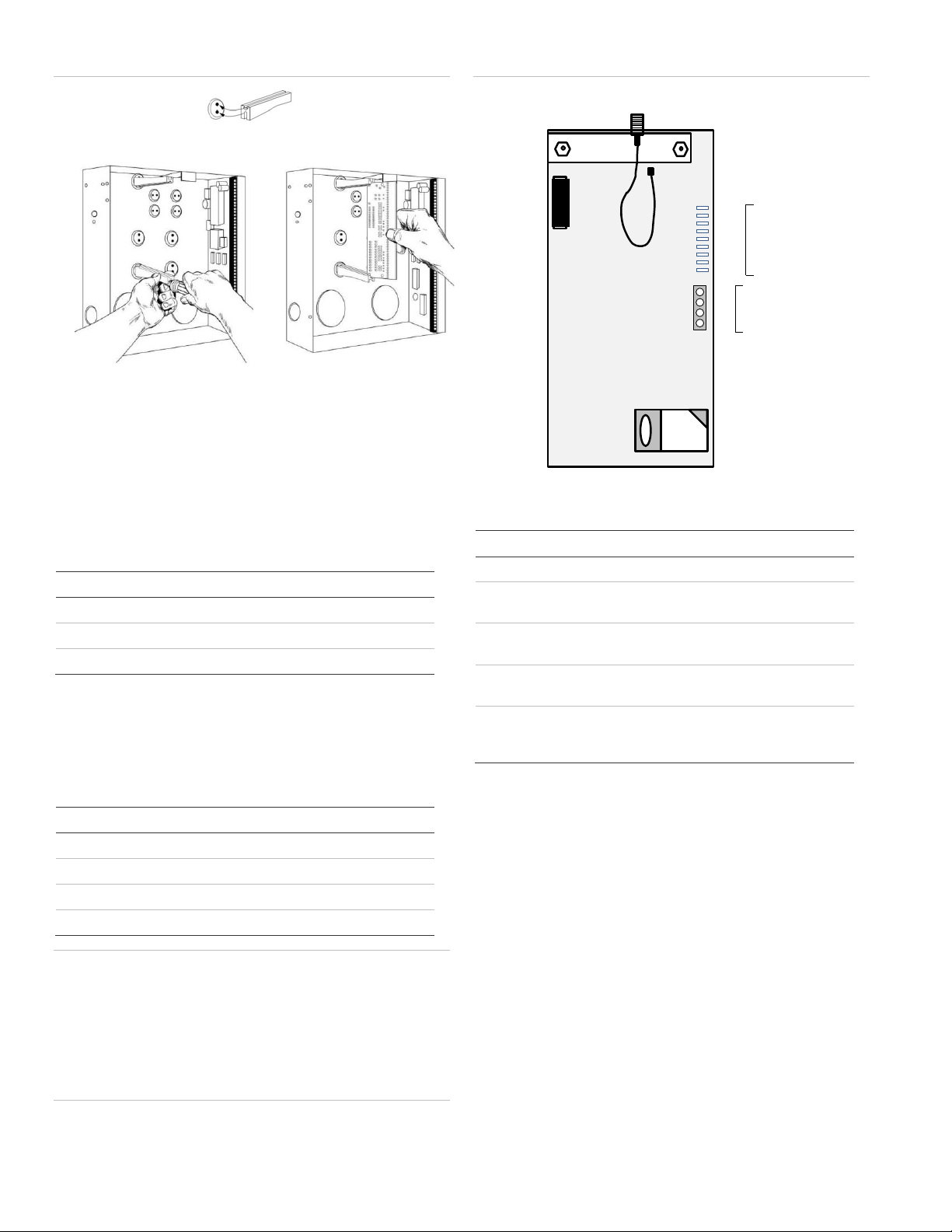

Wiring

Terminals

SIM Card

GSM Antenna Connector

Status

LEDs

Component

Function

SIM Card

Identifies the module to the local network

Wiring terminals

Provides panel wiring connections to attach

module to the data bus

Antenna Connector

Provides mounting location for GSM

antenna

GSM status LEDs

Indicates communication with the GSM

network, traffic, and signal strength

Serial number

10-digit number preceded with S/N – found

on label on front of module or on top of

antenna mounting bracket.

Wiring

Figure 2: Main Board Components

Use three-conductor, 20-guage or larger stranded wire to

connect the module to the control panel or to the NX-320E

power supply. Table 1 below shows the maximum wire length

for each gauge.

Table 1: Maximum wire length

Refer to Figure 2 to identify the wiring terminals of the module

and wire from these terminals to the main control panel or NX320E power supply based on Table 2 below.

Table 2: Wiring Terminals

Table 3: Main Board Components

Module LEDs

The module has 9 status LEDs oriented in a vertical column on

the front of the board. These LEDs provide valuable

information about the status of the module and the GSM

network. Please refer to Figure 2 above and Table 4 below for

more details.

Caution: You must be free of static electricity before handling

electronic components. Touch a grounded metal surface

before touching the circuit board.

Caution: To prevent damaging the panel or module, you must

remove panel AC power and disconnect the backup battery

before making or changing wiring connections.

2 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 3

Table 4: Module LEDs

LED

Description

BUSS

ON = proper connection to data bus of control panel

XMIT

ON = transmitting message packet(s) to GSM tower

SVC

ON = Cellular service available

BEST

The LEDs will either be OFF, ON, Flashing Slow or

Flashing Fast depending on the signal strength of

the GSM signal. Refer to Table 5 below for details.

GOOD

FAIR

POOR

RXD

Receiving data from GSM radio

TXD

Sending data to GSM radio

dB

POOR

FAIR

GOOD

BEST

-110 or worse

OFF

OFF

OFF

OFF

-109 to -104

SLOW

OFF

OFF

OFF

-103 to -100

FAST

OFF

OFF

OFF

-99 to -94

ON

OFF

OFF

OFF

-93 to -88

ON

SLOW

OFF

OFF

-87 to -84

ON

FAST

OFF

OFF

-83 to -78

ON

ON

OFF

OFF

-77 to -72

ON

ON

SLOW

OFF

-71 to -68

ON

ON

FAST

OFF

-67 to -62

ON

ON

ON

OFF

-61 to -56

ON

ON

ON

SLOW

-55 to -52

ON

ON

ON

FAST

-51 or better

ON

ON

ON

ON

Table 5 describes the signal strength level. This power level is

denoted in dB and the larger the number, the better the signal

strength from the GSM tower.

Enrolling the module

The NetworX control panels have the ability to automatically

find and store in memory the presence of all keypads, zone

expanders, wireless receivers, and any other device on the

keypad bus. This allows these devices to be supervised by the

control panel.

To enroll the devices, enter program mode of the NX control

panel using the procedure described in the control panel

documentation. When you exit program mode, the control

panel will automatically enroll all the devices. The enrolling

process takes about 12 seconds, during which time the service

LED will illuminate. When using the LCD keypad, the “Service

Required” message will be displayed. User codes will not be

accepted during the enrolling process. Once a module is

enrolled, if the control panel does not detect it, the service LED

will illuminate.

Table 5: Signal Strength Level

Power up

You will need to power up the panel and module to begin the

enrolling and programming process.

Module Address

The GSM module has a fixed address of 76. When

programming the module, enter program mode and select the

device address as 76.

Programming

You can program the module using the LED keypad or the

LCD keypad. To program the module using the LED keypad,

do the following:

Enter program mode

To enter program mode, press * 8. The Stay, Chime, Exit,

Bypass, and Cancel LEDs on the keypad will flash. Enter the

“go to program code”. The factory default is 9 7 1 3. If the code

is valid, the Service LED on the keypad will flash and the five

function LEDs will illuminate steady. You are now in program

mode and can select the module to program.

Select the module to program

To select the module to program, press 7 6 # (the address of

this GSM module). The Armed LED on the keypad will

illuminate while it is waiting for a programming location to be

entered.

To power up:

1. Verify that all wiring between the panel and module is

correct.

2. Connect the backup battery and restore AC power to the

panel.

NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Factory default the module

To return the module to factory defaults, press 9 1 0 #. The

keypad will beep three times indicating that loading is in

progress. Remember you will erase any values you may have

entered previously.

Programming a location

Once the number of the module to be programmed has been

entered, the Armed LED on the keypad will illuminate while it is

waiting for a programming location to be entered.

Page 4

Note: If an attempt is made to program an invalid entry for a

particular segment , the keypad sounder will emit a triple error beep,

and remain in that segment waiting for a valid entry.

To enter a location, enter the location number (1 to 13) and

press #. The Armed LED will flash. If the location is valid, the

Armed LED will extinguish, the Ready LED will illuminate, and

the zone LEDs will show the data for the first segment of this

location.

To change location data, enter the changed data. The Ready

LED will flash to indicate a data change in progress and will

continue until the data is saved. Press * to save the new data.

The keypad will advance to the next segment and display its

data. These steps are repeated until the last segment is

reached.

To exit a location, press #. The Ready LED will extinguish. The

Armed LED will illuminate waiting for a new programming

location to be entered.

To review the data, enter the location number and press #. The

Armed LED will flash. If the location number is valid, the Armed

LED will extinguish, the Ready LED will illuminate, and the

zone LEDs will show the binary data for the first segment of

this location. Press * to display the next segment data. Each

time you press *, the data of the next segment will be displayed

for review.

Exit program mode

data in a programming location. The numeric equivalents of

these LEDs are as follows:

Zone 1 LED = 1 Zone 2 LED = 2 Zone 3 LED = 4

Zone 4 LED = 8 Zone 5 LED = 16 Zone 6 LED = 32

Zone 7 LED = 64 Zone 8 LED = 128

For example, if the numerical data to be programmed in a

location is “66”, press 6 6 on the keypad. The LEDs for Zone 2

and Zone 7 will illuminate indicating 66 is in that location (2 +

64 = 66). Once the data is programmed, press * to enter the

data and advance to the next segment of that location.

After the last segment of a location is programmed, press * to

exit that location, turn the Ready LED off, and the Armed LED

on. You are now ready to enter another programming location.

If an attempt is made to program a number too large for a

particular segment, the keypad sounder will emit a triple beep,

indicating an error, and remain in that segment waiting for a

valid entry.

Feature selection data

Feature selection data will display the current condition (on or

off) of eight features associated with the programming location

and segment selected. Pressing a button on the touchpad (1

through 8) that corresponds to the feature number within a

segment will toggle (on/off) that feature. Pressing any numeric

key between 1 and 8 for selection of a feature will make the

corresponding LED illuminate (feature on). Press the number

again, and the LED will extinguish (feature off).

Press Exit to exit this programming level. Press Exit a second

time to completely exit programming.

LCD keypad programming

All steps required for programming are the same as those

described for the LED keypad. The LCD keypad display will

prompt you for the data required. While in programming mode,

and not in a location, the number in parenthesis is the location

you were previously changing. For example, if the display

reads, “Enter location, then # (5)”, it is reminding you that

location 5 was the last location you programmed.

Programming data

Programming data is either numerical data, or feature selection

data.

Numerical data

To program numerical data, enter a number from 0 to 255 on

the numeric keys of the keypad. To view the data in a location,

a binary process is used. With this process, the LEDs for

zones 1 through 8 are used, and the numeric equivalents of

their illuminated LEDs are added together to determine the

You will see that numerous features can be selected from

within one segment. For instance, if all eight features of a

segment are desired, pressing 1 2 3 4 5 6 7 8 will turn on LEDs

1 through 8 as you press the keys, indicating that those

features are enabled.

Note: On LCD keypads, the numbers of the enabled features will be

displayed. However, the features not enabled will display a hyphen (-).

After you select the desired setting for this segment, press * to

enter the data and automatically advance to the next segment

of the location. When you are in the last segment of a location

and press * to enter the data, you will exit that location. The

Ready LED will turn off and the Armed LED will turn on. You

are now ready to enter another programming location.

Location 0 – this location is not used.

Location 1, feature selection

This location has four segments. Segment 1 contains the

options to be programmed for the functioning of this module.

Factory default for all Segment 1 options is off. Table 6

describes the options:

4 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 5

Table 6: Segment 1 options

Option

Description

ON

OFF 1 Format

SIA

Contact ID

2

Test Signal

Daily1

Weekly2

3

Reserved for future use

4

Reserved for future use

5

Reserved for future use

6

Disable Cellular Service LEDs

Disabled

Enabled

7

Reserved for future use

8

Disable SIA DCS area modifier3

Disabled

Enabled

Option

Description

ON

OFF

1

Central Station Messages

Enabled

Disabled

2

Email Messages

Enabled

Disabled

3

Pager Messages

Enabled

Disabled

4

Periodic test signals

Enabled

Disabled

5 to 8

Reserved for future use

Segment

Description

1

Alarms

2

Open/Close

3

Bypass

4

Zone Trouble

5

Power Trouble (AC failure or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Failure to communicate

15

Zone activity monitor

16

Reserved for future use

Segment

Description

1

Alarm restores

2

Telephone fault

3

Start download

4

Failure to communicate, data lost

5 to 8

Reserved for future use

1 Daily test will be performed 24 hours (± 10 minutes) from time this

option is programmed.

2 Weekly test will be performed 168 hours (± 10 minutes) from time

this option is programmed.

3 Some older SIA DCS compatible receivers may not support the

use of area (partition) modifiers. In such cases, the area modifier must

be disabled (Option 8 on).

Segment 2 programs host acknowledgement requirements.

Factory default for all Segment 2 options is off. Table 7

describes the options:

Table 8: Location 2 options

Location 3, special events to report to

Table 7: Segment 2 options

Segments 3 and 4 are reserved for future use.

Location 2, events to report to central

station – phone fault detected

Note: Reporting must be enabled in the control panel for this

location to function.

This location has 16 segments and selects the partitions to

include when reporting to the central station. To exclude any

partition from reporting, turn off the LED corresponding to that

particular partition number. Enter the numbers of the partitions

to include for each type of report found in segments 1 through

16. Factory default is all partitions on for segment 1; all

partitions off for segments 2 to 16. Table 8 describes the

segment options:

central station – phone fault detected

This location has 8 segments and selects the partitions to

include when reporting special events to the central station. To

exclude any partition from reporting, simply turn off the LED

corresponding to that particular partition number. Enter the

numbers of the partitions to include for each type of report

found in segments 1 through 4. Factory default is all partitions

off for segment 1 and 3; all partitions on for segments 2 and 4.

Segments 5 to 8 are reserved for future use. Table 9 describes

the segment options:

Table 9: Location 3 options

Location 4, events to report to email –

phone fault detected

Note: Reporting must be enabled in the control panel for this

location to function.

NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 6

This location has 16 segments and selects the partitions to

Segment

Description

1

Alarms

2

Open/Close

3

Bypass

4

Zone Trouble

5

Power Trouble (AC failure or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Failure to communicate

15

Zone activity monitor

16

Reserved for future use

Segment

Description

1

Alarm restores

2

Telephone fault

3

Start download

4

Failure to communicate, data lost

Segment

Description

5 to 8

Reserved for future use

Segment

Description

1

Alarms

2

Open/Close

3

Bypass

4

Zone Trouble

5

Power Trouble (AC failure or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Failure to communicate

15

Zone activity monitor

16

Reserved for future use

include when reporting to email. To exclude any partition from

reporting, turn off the LED corresponding to that particular

partition number. Enter the numbers of the partitions to include

for each type of report found in segments 1 through 16.

Factory default is all partitions off for all segments. Table 10

describes the segment options:

Location 6, events to report to pager –

phone fault detected

Table 10: Location 4 options

Note: Reporting must be enabled in the control panel for this

location to function.

This location has 16 segments and selects the partitions to

include when reporting to a pager. To exclude any partition

from reporting, turn off the LED corresponding to that particular

partition number. Enter the numbers of the partitions to include

for each type of report found in segments 1 through 16.

Factory default is all partitions off for all segments. Table 12

describes the segment options:

Table 12: Location 6 options

Location 5, special events to report to email

– phone fault detected

This location has 8 segments and selects the partitions to

include when reporting special events to email. To exclude any

partition from reporting, turn off the LED corresponding to that

particular partition number. Enter the numbers of the partitions

to include for each type of report found in segments 1 through

4. Factory default is all partitions off for all segments.

Segments 5 to 8 are reserved for future use. Table 11

describes the segment options:

Table 11: Location 5 options

Location 7, special events to report to

pager – phone fault detected

This location has 8 segments and selects the partitions to

include when reporting special events to a pager. To exclude

any partition from reporting, turn off the LED corresponding to

that particular partition number. Enter the numbers of the

partitions to include for each type of report found in segments 1

through 4. Factory default is all partitions off for all segments.

6 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 7

Segments 5 to 8 are reserved for future use. Table 13

Segment

Description

1

Alarm restores

2

Telephone fault

3

Start download

4

Failure to communicate, data lost

5 to 8

Reserved for future use

Segment

Description

1

Alarms

2

Open/Close

3

Bypass

4

Zone Trouble

5

Power Trouble (AC failure or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Failure to communicate

15

Zone activity monitor

16

Reserved for future use

Segment

Description

1

Alarm restores

2

Telephone fault

3

Start download

4

Failure to communicate, data lost

5 to 8

Reserved for future use

Segment

Description

1

Alarms

2

Open/Close

3

Bypass

4

Zone Trouble

5

Power Trouble (AC failure or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

describes the segment options:

Table 13: Location 7 options

Location 9, special events to report to

central station – phone line is good

This location has 8 segments and selects the partitions to

include when reporting special events to the central station. To

exclude any partition from reporting, simply turn off the LED

corresponding to that particular partition number. Enter the

numbers of the partitions to include for each type of report

found in segments 1 through 4. Factory default is all partitions

off for all segments. Segments 5 to 8 are reserved for future

use. Table 15 describes the segment options:

Location 8, events to report to central

station – phone line is good

Note: Reporting must be enabled in the control panel for this

location to function.

This location has 16 segments and selects the partitions to

include when reporting to the central station. To exclude any

partition from reporting, turn off the LED corresponding to that

particular partition number. Enter the numbers of the partitions

to include for each type of report found in segments 1 through

16. Factory default is all partitions off for all segments. Table

14 describes the segment options:

Table 14: Location 8 options

Table 15: Location 9 options

Location 10, events to report to email –

phone line is good

Note: Reporting must be enabled in the control panel for this

location to function.

This location has 16 segments and selects the partitions to

include when reporting to email. To exclude any partition from

reporting, turn off the LED corresponding to that particular

partition number. Enter the numbers of the partitions to include

for each type of report found in segments 1 through 16.

Factory default is all partitions off for all segments. Table 16

describes the segment options:

NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Table 16: Location 10 options

Page 8

Segment

Description

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Failure to communicate

15

Zone activity monitor

16

Reserved for future use

Location 11, special events to report to

Segment

Description

1

Alarm restores

2

Telephone fault

3

Start download

4

Failure to communicate, data lost

5 to 8

Reserved for future use

Segment

Description

1

Alarms

2

Open/Close

Segment

Description

3

Bypass

4

Zone Trouble

5

Power Trouble (AC failure or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Failure to communicate

15

Zone activity monitor

16

Reserved for future use

Segment

Description

1

Alarm restores

2

Telephone fault

3

Start download

4

Failure to communicate, data lost

5 to 8

Reserved for future use

email – phone line is good

This location has 8 segments and selects the partitions to

include when reporting special events to email. To exclude any

partition from reporting, turn off the LED corresponding to that

particular partition number. Enter the numbers of the partitions

to include for each type of report found in segments 1 through

4. Factory default is all partitions off for all segments.

Segments 5 to 8 are reserved for future use. Table 17

describes the segment options:

Table 17: Location 11 options

Location 13, special events to report to

pager – phone line is good

This location has 8 segments and selects the partitions to

include when reporting special events to a pager. To exclude

any partition from reporting, turn off the LED corresponding to

that particular partition number. Enter the numbers of the

partitions to include for each type of report found in segments 1

through 4. Factory default is all partitions off for all segments.

Segments 5 to 8 are reserved for future use. Table 19

describes the segment options:

Location 12, events to report to pager –

Table 19: Location 13 options

phone line is good

Note: Reporting must be enabled in the control panel for this

location to function.

This location has 16 segments and selects the partitions to

include when reporting to a pager. To exclude any partition

from reporting, turn off the LED corresponding to that particular

partition number. Enter the numbers of the partitions to include

for each type of report found in segments 1 through 16.

Factory default is all partitions off for all segments. Table 18

describes the segment options:

Table 18: Location 12 options

8 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 9

Specifications

Compatibility

NX-4v2, NX-6v2, NX-8v2 and NX-8E

Voltage

12 V nominal, 25 mA (continuous) 700 mA

(instantaneous peaks) maximum (from panel

or auxiliary power supply)

Cellular network

GSM, 2G, 3G and HSPA+ (4G)

Power/data bus

One three-wire NetworX

power/communication data bus

Dimensions (D × H ×

W)

1.5 × 4.2 × 1.8 in. (38 × 107 × 45 mm)

Operating temperature

32 to 120ºF (0 to 49ºC)

Storage temperature

-30 to 140ºF (-34 to 60ºC)

Relative humidity

90% noncondensing (maximum)

Listings

FCC Part 15, IC, PTCRB, Numerex network

2. This device must accept any interference received,

including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to

operate the equipment.

In accordance with FCC requirements of human exposure to

radiofrequency fields, the radiating element shall be installed

such that a minimum separation distance of 20 cm is

maintained from the general population.

FCC ID: QIPPHS8-US

IC ID: 7830A-PHS8US

Regulatory information

FCC

This device complies with part 15 of the FCC rules. Operation

is subject to the following conditions.

1. This device may not cause harmful interference.

Contact information

www.utcfireandsecurity.com or www.interlogix.com

For customer support, see www.interlogix.com/customer-

support

Copyright © 2013 UTC Fire & Security. All rights reserved.

NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 10

Programming Worksheets

Segment

Description

Default

Data

1 Feature

Selection

1 = SIA format (off = Contact ID)

OFF

2 = Daily test signal (off = weekly)

OFF

3 = Reserved for future use

OFF

4 = Reserved for future use

OFF

5 = Reserved for future use

OFF

6 = Disable cellular service LEDs

OFF

7 = Reserved for future use

OFF

8 = Disable SIA DCS area modifier

OFF

2 Host

acknowledgement

required

1 = Host acknowledgement for central station messages

OFF

2 = Host acknowledgement for e-mail messages

OFF

3 = Host acknowledgement for pager messages

OFF

4 = Host acknowledgement for periodic test signals

OFF

5 to 8 = Reserved for future use

Segment

Partition

Description

1 2 3 4 5 6 7 8 1

Alarms

2

Open/close

3

Bypass

4

Zone trouble

5

Power trouble (AC fail or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Fail to communicate

15

Zone activity monitor

16

Reserved for future use

Location 1, feature selection

Table 20: Location 1 Worksheet

Location 2, events to report to central station – phone fault detected

Table 21: Location 2 Worksheet

10 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 11

Location 3, special events to report to central station – phone fault detected

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarm restores

2

Telephone fault

3

Start download

4

Fail to communicate, data lost

5 to 8

Reserved for future use

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarms

2

Open/close

3

Bypass

4

Zone trouble

5

Power trouble (AC fail or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Fail to communicate

15

Zone activity monitor

16

Reserved for future use

Table 22: Location 3 Worksheet

Location 4, events to report to email – phone fault detected

Table 23: Location 4 Worksheet

NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 12

Location 5, special events to report to email – phone fault detected

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarm restores

2

Telephone fault

3

Start download

4

Fail to communicate, data lost

5 to 8

Reserved for future use

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarms

2

Open/close

3

Bypass

4

Zone trouble

5

Power trouble (AC fail or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Fail to communicate

15

Zone activity monitor

16

Reserved for future use

Table 24: Location 5 Worksheet

Location 6, events to report to pager – phone fault detected

Table 25: Location 6 Worksheet

12 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 13

Location 7, special events to report to pager – phone fault detected

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarm restores

2

Telephone fault

3

Start download

4

Fail to communicate, data lost

5 to 8

Reserved for future use

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarms

2

Open/close

3

Bypass

4

Zone trouble

5

Power trouble (AC fail or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Fail to communicate

15

Zone activity monitor

16

Reserved for future use

Table 26: Location 7 Worksheet

Location 8, events to report to central station – phone line is good

Table 27: Location 8 Worksheet

NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 14

Location 9, special events to report to central station – phone line is good

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarm restores

2

Telephone fault

3

Start download

4

Fail to communicate, data lost

5 to 8

Reserved for future use

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarms

2

Open/close

3

Bypass

4

Zone trouble

5

Power trouble (AC fail or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Fail to communicate

15

Zone activity monitor

16

Reserved for future use

Table 28: Location 9 Worksheet

Location 10, events to report to email – phone line is good

Table 29: Location 10 Worksheet

14 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 15

Location 11, special events to report to email – phone line is good

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarm restores

2

Telephone fault

3

Start download

4

Fail to communicate, data lost

5 to 8

Reserved for future use

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarms

2

Open/close

3

Bypass

4

Zone trouble

5

Power trouble (AC fail or low battery)

6

Siren and telephone fault

7

Test reports

8

Program, download and log full

9

Tampers

10

Short circuit and ground fault

11

Sensor lost

12

Sensor low battery

13

Expander trouble

14

Fail to communicate

15

Zone activity monitor

16

Reserved for future use

Table 30: Location 11 Worksheet

Location 12, events to report to pager – phone line is good

Table 31: Location 12 Worksheet

NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Page 16

Location 13, special events to report to pager – phone line is good

Segment

Partition

Description

1 2 3 4 5 6 7

8

1

Alarm restores

2

Telephone fault

3

Start download

4

Fail to communicate, data lost

5 to 8

Reserved for future use

Table 32: Location 13 Worksheet

16 NX-591NE-GSM NetworX GSM 3G HSPA+ Module Installation Sheet

Loading...

Loading...