Page 1

6HQWURO,7,$3:

:LUHOHVV3,50RWLRQ

6HQVRU

Document Number: 466-1851 Rev. B

July 2001

Product Summary

A motion sensor (passive-infrared or PIR) detects movement by sensing the infrared energy emitted from a body as

it moves across its field of view. When this motion is

detected, the sensor transmits an alarm signal.

Install motion sensors to protect areas where door/window

sensors are impractical or not needed. For example, use a

motion sensor to protect large areas or open floor plans.

Motion sensors can also provide backup protection in areas

where door/window sensors exist.

This wireless motion sensor includes the following features:

Field-selectable coverage area; 33 or 50 feet

Field-selectable sensitivity modes; 2-pulse or 4-pulse

135-second transmitter lockout time after an alarm that

helps extend battery life

Cover-activated tamper

Supervisory signal transmitted every 64 minutes to the

control panel

Sensor low battery reports (trouble) to the control panel

Included with the sensor is a thin cardboard undercrawl

mask and snap-in plastic masks (installed at the factory).

Self-adhesive masking strips are also included.

Installation Guidelines

If possible, locate sensors within 100 feet of the panel.

While a transmitter may have an open-air range of 500

feet or more, the installation site can have a significant

effect on transmitter range. Changing the sensor location may help overcome adverse wireless conditions.

Mount the sensor permanently on a flat wall or in a cor-

ner. Do not set it on a shelf.

For installations without pets, the required mountin g

height is 7 1/2 feet.

Mount the motion sensor on an insulated, outside wall

facing in.

Mount the motion sensor on a rigid surface which is

free from vibrations.

Position the sensor so it faces a solid reference point,

like a wall.

Do not aim the sensor at windows, fireplaces, air condi-

tioners, heaters/heating vents, or place it in direct sunlight.

Position the sensor to protect an area where intruders

are most likely to walk across the detection pattern (s ee

Figure 1).

ITI Part No. 60-880-95

Installation Instructions

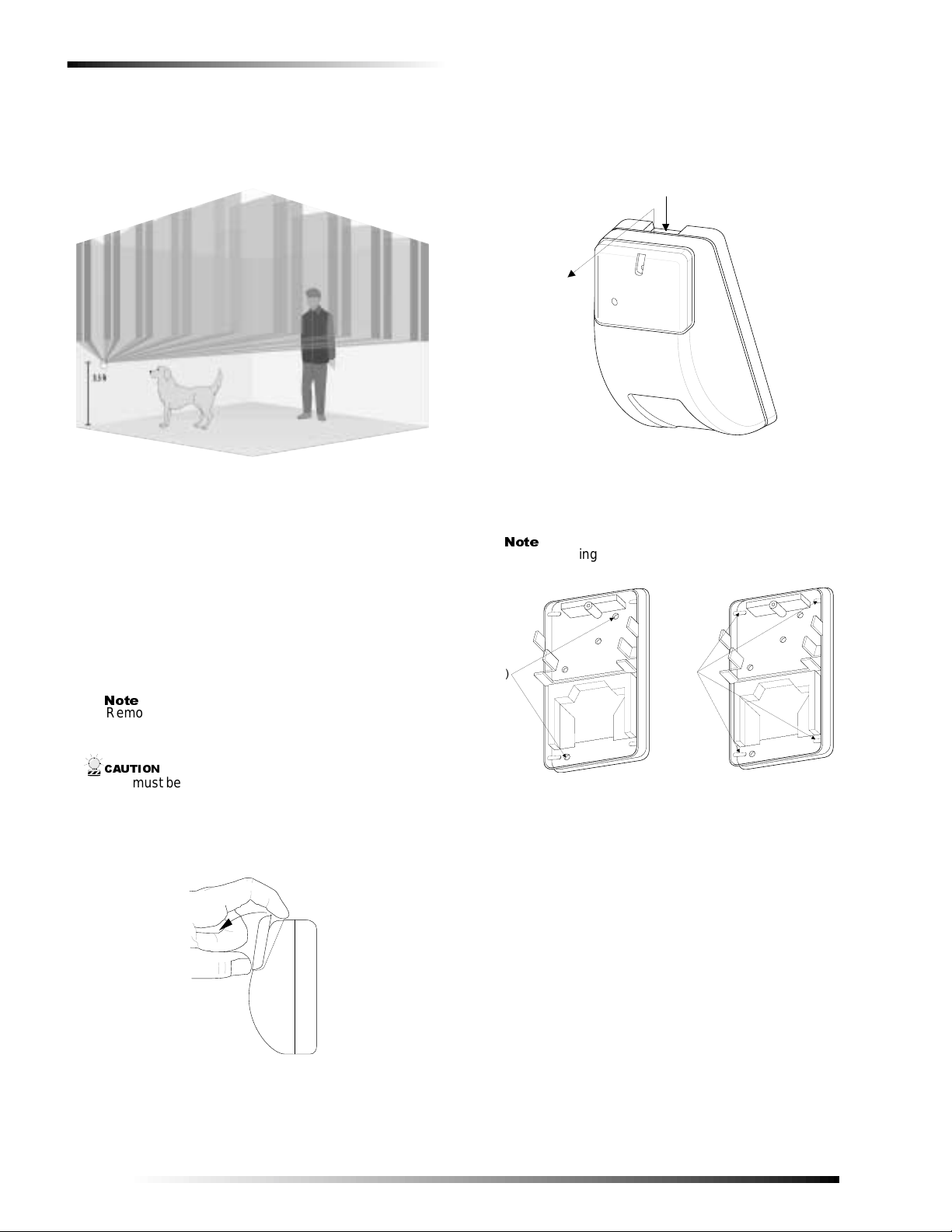

Person walking across detection path

8362G04B.DS4

Figure 1. Overhead View of Detection Pattern

Do not mount the sensor near duct work or other large

metallic surfaces which may affect the RF signals (see

“Final Testing” on page 4). Actual acceptable transmitter range should be verified for each installation.

Windows should be closed in any area which has an

armed motion sensor.

The cardboard undercrawl mask installed at the factory

(see Figure 2) blocks coverage within 5 feet of the sensor.

Figure 2. Cardboard Undercrawl Mask Location

1RWH

The cardboard undercrawl mask should remain

installed when sensor jumper J1 is set to the BI position. See the section “Setting the Sensor Coverage

Area and Sensitivity” for complete information on sensor jumper settings.

1

Page 2

Mounting the Sensor

1RWH

&$87,21

M

For installations where pets are present, mount the sen-

sor upside down about 3.5 feet ab ove the floor (s ee Figure 3). Leave the factory-installed undercrawl mask in

place to block any detection pattern directed at the ceiling.

Figure 3. Pet Alley Application

Tools and Supplies Needed

Phillips screwdriver

Anchors and screws for mounting (included)

Masks (included)

2. Open the sensor housing by pressing down on the top

rear and pulling the front cover at the top (see Figure

5). Set the front cover aside.

S T E P 1 :

P R E S S D O W N

W I T H I N D E X F I N G E R

S T E P 2 :

P U L L A W A Y

Figure 5. Opening the Sensor Housing

3. Mount the sensor on a flat wall or in a corner, using the

appropriate mounting holes (see Figure 6). Use wall

anchors and screws to secure the sensor.

1RWH

Avoid touching the mirror. Fingerpr in t s may af fe ct

detection coverage.

Mounting the Sensor

This section describes how to mount the sensor on a flat

wall or in a corner.

Remove the factory-installed plastic masks before

mounting. Re-install as desired after walk testing.

You must be free o f all static electricity be fore handlin g

sensor circuit boards. Touch a grounded, bare metal

surface before touching circuit boards or wear a

grounding strap.

1. Remove the small cover (see Figure 4).

Figure 4. Removing the Small Cover

F L A T

O U N T I N G

H O L E S

( 2 )

M I R R O R

Figure 6. Moun t i ng Hole Locati ons

C O R N E R

M O U N T I N G

H O L E S

( 4 )

M I R R O R

2

Page 3

Setting the Sensor Coverage Area and Sensitivity

Setting the Sensor Coverage Area

and Sensitivity

Jumper J1 determines the sensitivity mode of the sensor,

either standard or bi-curtain. Jumper J2 determines the coverage area of the sensor, either 33 or 50 feet. See Figure 7

for jumper positions.

Use the standard (STD) setting for wide-angle coverage and

single curtain pattern. Use the bi-curtain (BI) setting for

added stability to help reduce false alarms. This mode

requires intruders to be detected by two curtains of coverage.

1RWH

Do not use the bi-curtain mode for detection in areas

within 5 feet of the sensor. When selecting bi-curtain

mode, always leave the cardboard undercrawl mask

installed.

&$87,21

You must be free o f all static electricity be fore handlin g

sensor circuit boards. Touch a grounded, bare metal

surface before touching circuit boards or wear a

grounding strap.

1RWH

Excessive use of the walk test mode may reduce battery life. Use only for initial setup and maintenance

testing.

1RWH

In normal operation mode, the sensor only transmits

an alarm signal 135 se co nds af ter the previou s alarm .

This reduces unnecessary RF transmissions in high

traffic areas, thereby extending battery life.

Environment Testing

Activate the walk test mode, then turn on all heating or air

conditioning sources which would normally be active during the protection period. Stand away from the sensor and

outside the coverage pattern and watch for alarms.

Installing Masks

After determining the full coverage area and performing the

environment test, you may need or want to mask (block)

certain parts of the coverage.

Self-Adhesive Masks

Block the appropriate mirror sections with these masks.

Figure 8 shows an example of where to apply the masks and

the resulting coverage area.

J 1

J 2

J 1 - S E N S I T I V I T Y M O D E

J 1

J 2

Figure 7. Sensitivity Mode and Coverage Area Jumper

B I = J U M P E R O N T O P T W O P I N S

S T D = J U M P E R O N L O W E R T W O P I N S

J 2 - C O V E R A G E A R E A

5 0 F T = J U M P E R O N T O P T W O P I N S

3 3 F T = J U M P E R O N L O W E R T W O P I N S

Settings

Walk Testing

Walk testing should be done to determine the actual coverage area of the sensor. The edge of the coverage pattern is

determined by the first LED flash. This may change slightly

depending on the sensitivity setting. Walk test the unit from

both directions to determine the pattern boundaries.

1. Remove the sensor cover to activate the tamper switch,

then reattach it to activate the 2-minute walk test mode.

2. Walk across the coverage pattern to determine the coverage area, indicated by LED activation.

After 2 minutes, the walk test mode and the LED will no

longer activate when motion is detected.

&$87,21

To avoid damaging the mirror, do not remove masks

using a sharp tool. If necessary, remove masks by

carefully peeling them off with your fingers.

A

1 9

2 34567 8

1

B

B

9

8

Figure 8. Installing Self-Adhesive Masks

2 3456789

A

7

6

5

1

2

3

4

3

Page 4

Programming

1RWH

2

1

21

a

b

INSTALLING

PLASTIC

HALF COVERAGE-ONE

HALF COVERAGE-ONE

NARROW COVERAGE-BOTH

Plastic Masks

Install these masks for half coverage or narrow coverage

applications (see Figure 9).

Figure 9. Installing Plastic Masks

After inst alling masks, al w ay s conduct a walk test and

environment test to verify the coverage area is correct

for the application.

Programming

The following describes the basic steps for adding (learning) the sensor into panel memory. Refer to the specific

panel installation instructions for complete programming

information.

4. Move across the detection pattern until the sensor LED

turns on, then STOP your motion.

5. Listen for the appropriate system re sponse. If the sys-

tem does not respond, proceed to the “Troubleshoot-

ing” section.

Maintenance

At least once a year, the sensor should be tested to verify

correct operation. The end user should be instructed to put

the sensor in walk test mode and walk through the far end of

the coverage pattern to verify proper detection.

Replacing Batteries

When battery replacement is necessary, observe proper

polarity (positive +, negative -) when installing the new batteries, or the sensor may be damaged.

Use only exact replacement 3-volt lithium batteries

(CR123A).

&$87,21

You must be free of a ll static el ectricity before handling

sensor circuit boards. Touch a grounded, bare metal

surface before touching circuit boards or wear a

grounding strap.

1. Remove the sensor cover (see Figures 4 and 5) and set

it aside.

2. Remove the transmitter (upper) circuit board battery

(see Figure 10).

T R A N S M I T T E R

B O A R D

1. Put the panel into program mode.

2. Advance to the learn sensors menu.

3. Enter the appropriate sensor group and desired sensor

number.

4. When the panel prompts you to trip the sensor, activate

the sensor tamper switch by removing the sensor cover.

5. Reattach the sensor cover.

6. Exit from program m ode.

Final Testing

Final testing should be done to verify radio signal integ ri ty

and confirm control panel programming and response. The

actual transmitter range can be determined by performing a

sensor test as described below. Refer to the specific panel

installation instructions for complete sensor testin g information.

1. After the sensor has been mounted, remove the sensor

2. Replace the sensor cover.

3. Place the control panel in test mode.

cover to trip the tamper switch and activate the walk

test mode.

Figure 10.Removing the Transmitter Battery

4

Page 5

Lithium Battery Disposal

3. Remove the transmitter circuit board and place it inside

the cover (see Figure 11).

P U L L O U T O N

E I T H E R T A B

W H I L E P U L L I N G

T R A N S M I T T E R

B O A R D U P .

Figure 11.Removing the Transmitter Circuit Board

4. Carefully remove the PIR (lower) circuit board by

pressing outward on either side tab, then pull up on the

circuit board (see Figure 12).

8. Install a new battery in the transmitter circuit board,

observing polarity (marked in battery bucket).

After replacing batteries, wait at least 3 minutes before activating the walk test mode.

Lithium Battery Disposal

Lithium batteries that are no longer usable are considered

hazardous waste. Be sure to properly dispose of the old batteries. Contact your local city government for hazardous

waste disposal laws.

Troubleshooting

Use the following guidel ines if t he syst em does n ot respon d

correctly when the sensor is activated.

Check programming and re-program sensor into panel

if necessary.

Move the sensor to another location and test for correct

response.

Test a known good sensor at the same location.

If the system does not respond, avoid mounting a sen-

sor at that location.

If the replacement sensor functio ns, retur n the pro blem

sensor for repair or replacement.

1RWH

Avoid touching the mirror. Fingerprints may affect

detection coverage .

P U L L O U T O N

E I T H E R T A B . . .

. . . W H I L E P U L L I N G

T R A N S M I T T E R

B O A R D U P .

M I R R O R

Figure 12.Removing the PIR Circuit Board

5. Remove the PIR circuit board battery (located on opposite side of components) and install a new one, observing polarity (marked on the circuit board).

6. Re-install the PIR circuit board into the sensor plastic.

7. Re-install the transmitter circuit board onto the PIR circuit board.

5

Page 6

Specifications

466-1851 Rev. B

Printed in Mexico

Specifications

Compatibility: All ITI 319.5 MHz. Learn Mode Panels

Power source: Two 3-volt lithium (CR123A) batteries

T y pical battery life: 2-4 y ears at 6 8° F ( not veri f ied b y U.L.)

Operating temperature range: 10° to 110° F (-12° to 43° C)

Storage temperature: -40° to 140° F (-40° to 60° C)

Operating relative humidity: 5% to 95% non-condensing

Storage relative humidity: 95% maximum non-condensing

(up to 6 mont hs)

Dimensio ns: (L) 4.75 ” x (W) 2.60” x (D) 2.0”

Notices

These devices comply with part 15 of the FCC rules. Operation is subject

to the following two conditions:

1. These devices may not cause harmful interference.

2. These devices must accept any interference received, including interference that may cause unde sired operation.

Changes or modifications not expressly approved by Interactive Technologies, Inc.

can void the users’ authority to operate the equipment.

FCC ID: B4Z-779A-PIR

U.S. Patent Nos: 4,855,713, 4,864,636, 5,761,206, 5,805,063, 5,87 2, 512,

and 5,942,981

6

2266 SECOND STREET NORTH | NORTH SAINT PAUL MN | 800-777-2624 | www.interlogixinc.com

©2001 Interlogix,™ Inc. Interlogix is a trademark of Interlogix, Inc. ITI is a registered trademark of Interlogix, Inc.

Loading...

Loading...