Page 1

ITI Part No. 60-620-01

Document Number: 466-1031-01 Rev. A August 2000

Product Summary

The SuperBus 2000 Energy Saver Mod ule (ESM) pr ovides a

money-saving and convenient way to monitor and control

temperatures. The ESM uses low- and high-temperature

limits to save energy by overriding the existing HVAC thermostat. When the ESM is on, temperature limits determine

when the heat or air-conditioning turns on. When the ESM

is off, the HVAC thermostat controls heat and air-conditioning.

For example, if the thermostat is set for 68°F and the ESM

high limit is 80°F, the ESM prevents the air-conditioner

from turning on until the temperature reaches 80°F. The

ESM limits may be set between 40° and 90°F.

A temperature sensor monitors the temperature and reports

a freeze alarm to the panel if the temperature drops below

the set freeze temperature (default = 42°F). A backup freeze

stat provides additional protection by activating the fur nace

if the temperature drops to 45°F (±6°F).

Note

Depending on where the ESM is located, additional

freeze sensors may need to be placed throughout the

residence to provide adequate freeze protection.

This device is backward compatible with Concord™ panels

with software versions 1.0–1.6 and UltraGard™ panels.

vs.

SuperBus 2000

Compatible panels (SuperBus 2000) have the ability to

auto-address module unit numbers. When the panel is powered up, the panel automatically reads the unique SuperBus

2000 device ID number and assigns a unit number to the

module. This eliminates manually setting DIP switches and

the chance of identical unit number conflicts.

Non-Compatible panels (SuperBus) communicate with

SuperBus 2000 modules but require the module unit number to first be set manually using DIP switches.

SuperBus 2000 Panels

❑ Concord (sof tware version s 2.0 and later)

SuperBus Panels

❑ UltraGard

❑ Concord (software versions 1.0–1.6)

SuperBus

8841G01A.DS4

Installation Instructions

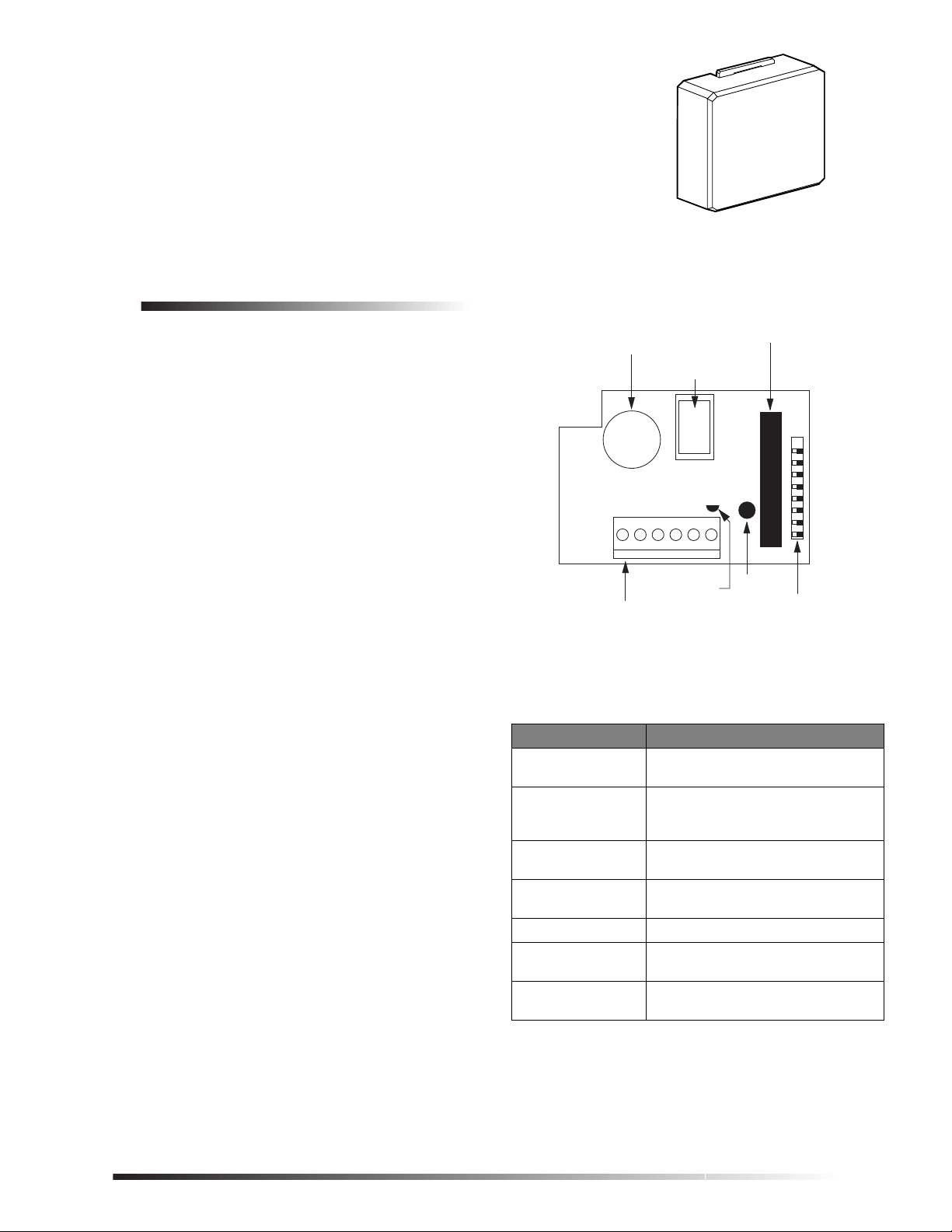

Figure 1 shows the main ESM components and Table 1

describes them.

BACKUP

FREEZE

STAT

SUPERBUS 2000

DEVICE ID

NUMBER LABEL

23456

1

TEMPERATURE

SENSOR

TERMINAL STRIP

Figure 1. ESM Component Locations

Table 1: ESM Component Descriptions

ESM Component Function

Backup Freeze Stat Activates furnace if temperature drops

to 45°F (±6°F).

SuperBus 2000

Device ID Number

Identifies unique device ID number

(SuperBus 2000 pane l s).

Label

ESM Software

Version Label

Identifies the installed software

version.

Terminal Strip Used for panel and HVAC thermostat

connections.

Temperature Sensor Monitors the premises temperature.

Bus LED Flashes constantly to indicate normal

communication to the panel bus.

Unit Number DIP

Switches

Used for manually setting unit

numbers (SuperBus panels).

ESM SOFTWARE

VERSION LABEL

BUS

LED

UNIT NUMBER

DIP SWITCHES

8557G31C.DS4

SuperBus® 2000 Energy Saver Module

1

Page 2

Installation Guidelines

PRESS DOWN

HERE

8857G46A.DS4

Installation Guide l ine s

Use the following guidelines when installing the ESM:

❑ For Concord systems, up to 16 bus devices can be

connected to the panel (alphanumeric touchpad, HIM,

ESM, etc.). UltraGard systems support up to eight bus

devices.

❑ Each bus device must have a different unit number.

❑ Concord systems allow one ESM per partition. For

UltraGard systems, only one ESM can be connected to

a panel.

❑ The ESM maximum current draw is 30 mA.

❑ Do not exceed the panel total power when using panel

power for bus devices a nd hardwired sensors t hat

require panel power (refer to the specific panel Instal-

lation Instructions).

❑ Use 4-conductor, 22-gauge or larger stranded wire

from the ESM to the panel.

❑ Use 22-gauge or larger stranded wire from the ESM to

the thermostat.

❑ Install the ESM on an inside wall next to or as close as

possible to the existing thermostat. This keeps th e temperature difference between the ESM and the thermostat to a minimum.

❑ Programmable thermostats that use a battery to keep

time and other programmed settings may lose time and/

or programmed settings when the ESM is turned on.

This can happen since the ESM relay is interrupting the

thermostat main power, forcing the thermostat to rely

on battery power to save time and programmed settings. As a result, the thermostat battery may need to be

replaced more often depending on how often and how

long the ESM is turned on.

❑ Refer to the specific panel Installation Instructions for

wire length limits.

Installation

Installation consists of mounting the ESM (next to or as

close as possible to the existing thermostat) and wiring it to

the panel and existing HVAC thermostat.

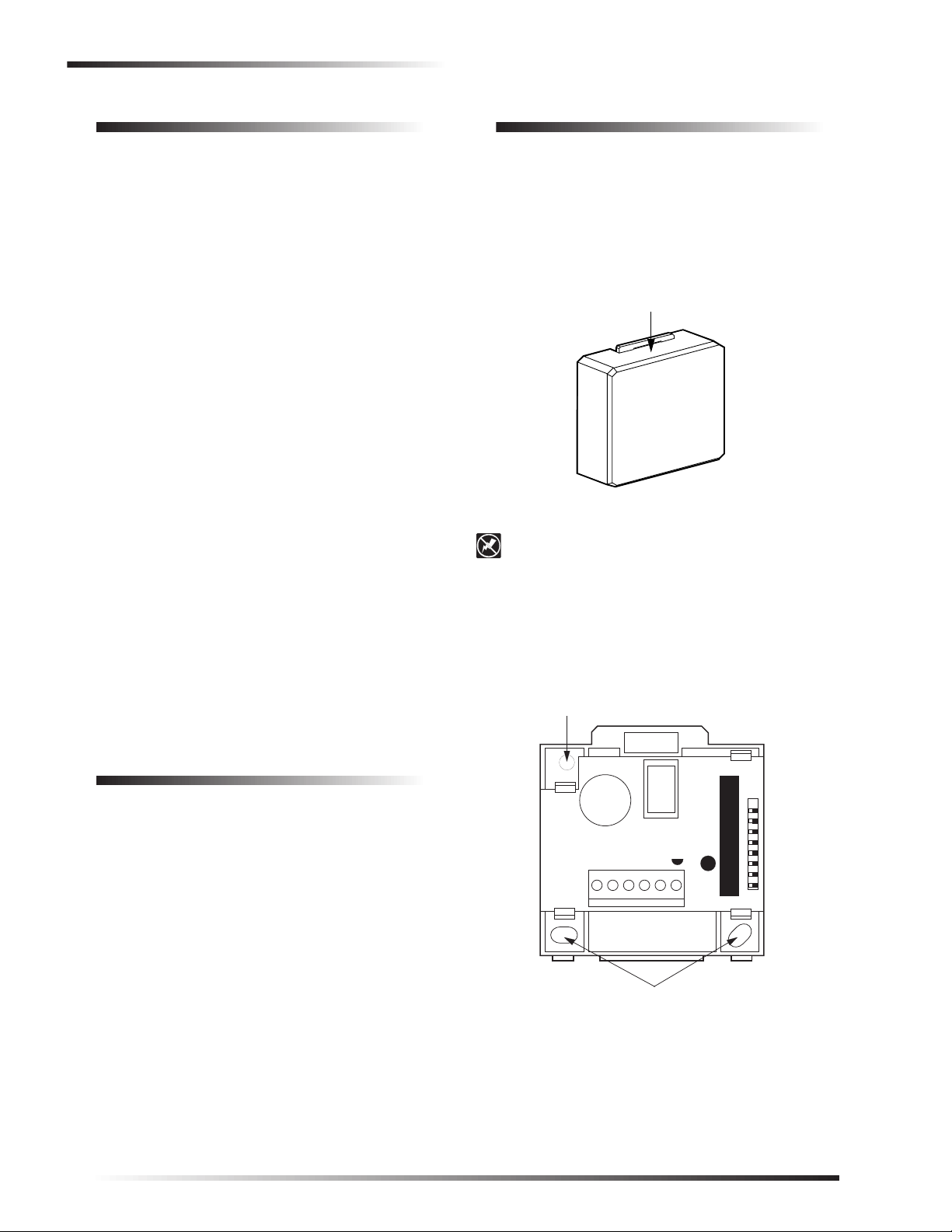

To mount the ESM:

1. Press down on the top center of the cover and pull it

away from the base (see Figure 2). Set the cover aside.

Figure 2. Removing the Enclosure Cover

CAUTION

You must be free of all sta tic electricity when han dli ng

electronic components. Touch a grounded bare metal

surface before touching the circuit board.

2. Place the ESM on the wall at the desired location and

mark the upper-left and lower mounting holes (see Figure 3).

MOUNTING

HOLE

Tools and Supplies

❑ Screwdrivers (Phillips and flat)

❑ Screws and anchors (included)

❑ Digital voltmeter

❑ Drill with bits

❑ Hammer

❑ Wire cutters/strippers

❑ 4-conductor, 22- gauge or larger stranded wire

❑ 22-gauge or larger stranded wire

❑ Pen or pencil

2

23456

1

MOUNTING HOLES

Figure 3. Mounting Hole Locations

8557G29C.DS4

3. Install anchors where studs are not present and secure

the ESM to the wall with the enclosed screws.

SuperBus® 2000 Energy Saver Module

Page 3

Wiring

Wiring

Some thermostats control heating and cooling, others control only heating. A heating/cooling thermostat uses four

wires and a heating-only thermostat usually has two.

Table 2: Four-Wire Thermostat Color Code

Wire Function

Red Power feed to thermostat

Green Fan control

Yellow Cooling

White Heating

Note

If the thermostat wire colors are different than those

described above, contact a qualified HVAC service

person for wiring information about the specific thermostat you are working with. Be sure to give the service person the manufacturer name and model

number of the thermostat.

To wire the ESM to a Concord panel:

1. Remove AC panel power and disconnect the backup battery.

2. Turn off the thermostat and remove its cover.

3. Route a 4-conductor, 22-gauge or larger, stranded wire from the ESM to the panel.

4. Connect terminals 3 t hro ugh 6 to the panel as sh own in Figure 4.

ESM TERMINALS

1 2 5

TO FURNACE

Figure 4. ESM Wiring Connections to the Thermostat and

THERMOSTAT

CONCORD

PANEL TERMINALS

Concord Panel Terminals

3 4 6

3 456

+12

VDC

BUSABUS

8573G09A.DSF

GND

B

To wire the ESM to the UltraGard panel:

1. Turn the power switch to off, unplug the AC power transformer, and disconnect the backup battery.

2. Turn off the thermostat and remove its cover.

3. Route a 4-conductor, 22-gauge or larger, stranded wire from the ESM to the panel.

4. Connect terminals 3 thro ugh 6 to the panel as shown in Figure 5.

ESM TERMINALS

1

2 3 4 5

TO FURNACE

Figure 5. ESM Wiring Connections to the Thermostat and

THERMOSTAT

ULTRAGARD

PANEL TERMINALS

UltraGard Panel Terminals

12

DC

OUT

13 14 15

BUS

A

6

BUSBGND

8557G30A.DS4

5. Route 22-gauge or larger, stranded wire from the ESM to the thermostat.

To connect a four-wire thermostat:

1. Remove the red wire (or power feed) from the thermostat and connect it to ESM terminal 1.

2. Connect a wire from ESM terminal 2, to the thermostat

terminal where the red wire (or power feed) was connected.

To connect a two-wire thermostat:

1. Remove one of the wires from the thermostat and connect it to ESM terminal 1.

2. Connect a wire from ESM terminal 2, to the terminal

on the thermostat where the original wire had been connected.

5. Route 22-gauge or larger, stranded wire from the ESM to the thermostat.

SuperBus® 2000 Energy Saver Module

3

Page 4

Setting the Module Unit Number

M

M

M

M

M

M

Setting the Module Unit Number

Setting the Unit Number on Concord Panels with Software Version 2.0 or Later

Setting the Unit Number On Concord (software versions 1.0–1.6) and UltraGard Panels

Module dip switches can be set to any unit number 0–15.

The default setting 0 can be used if no o ther bus dev ices are

installed in the system. When using one module per

partition (Concord only), the lower unit number will be

assigned to partition 1, while the higher unit number will be

assigned to partition 2.

Note

Do not use modu le number 15 if it is installed in a

Concord RF system since the built-in receiver is factory set to unit number 15 and cannot be changed.

To set the module unit number:

Locate the DIP switches on the ESM circuit board (see

Figure 1) and set them to the desired unit number (0–15)

before applying power (see Figure 6).

CAUTION

Do not change DIP switch settings once the panel is

powered up.

❑ 0-15 for Concord

❑ 0-7 for UltraGard

UNIT NUMBER 0

ON

A

1234

567

UNIT NUMBER 3

ON

A

1234

567

UNIT NUMBER 6

ON

A

1234

567

UNIT NUMBER 9

ON

A

1234

567

UNIT NUMBER 12

ON

A

1234

567

UNIT NUMBER 15--Do not use in Concord RF systems.

ON

A

1234

567

Figure 6. ESM Unit Number DIP Switch Settings

UNIT NUMBER 1

ON

M

A

1

234567

8

UNIT NUMBER 4

ON

M

A

1

34

2

8

UNIT NUMBER 7

ON

M

A

1234

8

UNIT NUMBER 10

ON

M

A

1

34

2

8

UNIT NUMBER 13

ON

M

A

1

34

2

8

8

56

56

56

56

UNIT NUMBER 2

ON

M

A

1

8

UNIT NUMBER 5

ON

M

A

1

8

7

UNIT NUMBER 8

ON

M

A

1

8

7

UNIT NUMBER 11

ON

M

A

1

8

7

UNIT NUMBER 14

ON

M

A

1

8

7

4

3

2

567

234567

34

2

56

234567

234567

9712G09A.DSF

8

8

8

7

8

8

The unit number will be automatically set when powering

up the system. No action is required by the installer. When

using one module per partition, the panel automatically

assigns each module with a partition number.

Power Up and Bus Communication

Use the following procedures for powering up the system

and verifying bus communication.

On Concord Panels (all software ver sions)

Note

In order to enter panel program mode to verify unit

numbers (optional), an alphanumeric touchpad must

be connected to Concord panels. Refer to the specific

Installation Instructions

1. Verify that all wiring at the panel and module is correct.

2. Connect the panel battery and plug in the panel AC

power transformer. Alphanumeric touchpad displays

should come on.

3. Verify that the ESM red bus LED is flashing.

4. If desired, enter panel program mode to verify the unit

number was learned and enrolled into the correct partition (see panel Installation Instructions for more information).

Note

If the ESM red bus LED does not flash, remove AC

panel power, disconnect the battery, and see Table 3

“Troubleshooting.”

On UltraGard Panels

1. Verify that all wiring at the panel and module are correct.

2. Connect the panel battery and plug in the panel AC power transformer.

3. Turn the panel power switch to on.

4. Set the panel RUN/PROGRAM switch to PROGRAM.

If the alphanumeric display reads 1-OFF and the 1 is flash-

ing, you must enter the installer code to place the p anel into

the program mode. Refer to the panel Installation

Instructions for more information.

The ESM red bus LED should be flashing continuously

which indicates successful communication to the panel.

for more information.

Note

If the ESM red bus LED is not flashing continuously,

set the RUN/PROGRAM switch to RUN, turn off the

panel power switch, unplug the panel AC power transformer, disconnect the backup battery, and see

Table 3 “Tr oubleshooting.”

4

SuperBus® 2000 Energy Saver Module

Page 5

Additional Information

Additional Information

For information on operating, programming, testing, and

deleting an ESM from panel memory, please refer to the

specific panel Installation Instructions or User’s Manual.

Note

The ESM must be installed and powered up for a minimum of 15 minutes before adjusting the ESM room

temperature to ensure consistent readings between

the ESM and house thermostat.

For best results, wait an hour before adjusting the

ESM room temperature.

Troubleshooting

Table 3 describes what to do if the module does not work correctly.

Table 3: Troubleshooting

Problem Action/Solution

The red bus LED

stays off.

1. Check fo r incorrect wiring connections.

2. Make sure the panel AC power

transformer is plugged in and

the backup battery is connected.

For UltraGard panels make sure

the panel power switch is on.

3. Verify that the panel recognizes the ESM and is enrolled

in the correct partition by entering program mode (see panel

Installation Instructions).

4. If the LED still remains off, replace the module.

Table 3: Troubleshooting (Continued)

Problem Action/Solution

The red bus LED

doesn’t flash.

Concord

1. Check fo r incorrect wiring connections.

2. For Concord (soft ware versions 1.0–1.6) panels make sure

that all bus devices are set with

different unit numbers.

3. If th e unit number dip switches

were changed, remove pa ne l

power and reapply it for the

panel and ESM to communicate

successfully. You will have to

go into panel programming to

delete the unit number previously assigned to the ESM (see

panel Installation Instructions).

4. If the LED still doesn’t flash, replace the module.

UltraGard

1. Set the RUN/PROGRAM switch to RUN and turn off the panel power switch.

2. Check fo r incorrect wiring connections.

3. Check that all bus dev ices are set with different unit numbers.

4. If th e unit number dip switches

were changed, turn off the

panel power switch, turn it back

on, then enter the program

mode for the pane l and E S M t o

communicate successfully. You

will have to go into panel

programming to delete the unit

number previously assigned to

the ESM (see panel Installa-

tion Instructions).

5. If the module still malfunctions, replace the module.

SuperBus® 2000 Energy Saver Module

The temperature is

incorrect or the

wrong furnace/AC

unit is being

controlled.

1. Check fo r incorrect wiring connections.

2. Verify the module is learned

into the correct partition by

entering program mo de (see

panel Installation Instructions).

3. Make sure that the ESM is

turned on (see panel Installa-

tion Instructions)

5

Page 6

Specifications

0

Specifications

Compatibility: Concord and UltraGard panels

Power Requirements: 12 VDC, 30 mA maximum

(from panel)

Storage Temperature: -30° to 140°F (-34° to 60°C)

Operating Temperature: 32° to 140°F (0° to 60°C)

Color: Belgian gray

Case Material: ABS plastic

Dimensions: 2.60" x 2.60" x 0.90" (L x W x D)

Installation: Wall mounting

UL Listings: UL 2017 General Purpose

Signaling Device

Notices

FCC Part 15 Information to the User

Changes or modifications not expressly approved by Interactive Technologies, Inc. can void the user’s authority to operate the equipment.

FCC Part 15 Class B

This equipment has been tested and found to comply with the lim its for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy

and, if not install ed and used in accordance with the i n s tructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference wi ll not occur in a particular installatio n .

If this equipment does ca use harmful interferenc e t o radio or television

reception, whic h ca n be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of

the following measures:

Reorient or relocate the receiving antenna.

❑

Increase the separation betwee n the equipment and receiver.

❑

Connect the affected equipment a nd the panel receiv er t o s epa rate

❑

outlets, on different branch circuits.

Consult the dealer or an experienced radio/T V technician for help.

❑

I

nteractive Technologies, Inc.

2266 Second Street North

North Saint Paul, MN 55109-290

T: 651/777-2690

F: 651/779-4890

1-800-777-1415

www.ititechnologies.com

Security

Automation

Fire Protection

©2000 Interactive Technologies, Inc. an Int e r logix™ company. Interlogix

is a trademark of Interlogix, Inc. ITI, UltraGard, and SuperBus are

registered trademarks of Interactive Technologies, Inc. Concord is a

trademark of Inte ractive Technologies, Inc.

6

Access Control

SuperBus® 2000 Energy Saver Module

Loading...

Loading...