Page 1

Intel® Carrier Grade Server TIGI2U User

Guide

®

A Guide for Technically Qualified Assemblers of Intel

Subassemblies/Products

Order Number: D15006-003

Identified

Page 2

Disclaimers

Disclaimer

Information in this document is provided in connection with Intel

otherwise, to any intellectual property rights is granted by this document. Except as provided in Intel’s Terms and Conditions

of Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating

to sale and/or use of Intel products including liability or warranties relating to fitness for a particular purpose, merchantability,

or infringement of any patent, copyright or other intellectual property right. Intel products are not designed, intended or

authorized for use in any medical, life saving, or life sustaining applications or for any other application in which the failure of

the Intel product could create a situation where personal injury or death may occur. Intel may make changes to

specifications and product descriptions at any time, without notice.

Intel server boards contain a number of high-density VLSI and power delivery components that need adequate airflow for

cooling. Intel’s own chassis are designed and tested to meet the intended thermal requirements of these components when

the fully integrated system is used together. It is the responsibility of the system integrator that chooses not to use Intel

developed server building blocks to consult vendor datasheets and operating parameters to determine the amount of airflow

required for their specific application and environmental conditions. Intel Corporation can not be held responsible if

components fail or the server board does not operate correctly when used outside any of their published operating or nonoperating limits.

Intel, Intel Pentium, and Intel Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the

United States and other countries.

®

products. No license, express or implied, by estoppel or

* Other names and brands may be claimed as the property of others.

Copyright © 2007, Intel Corporation. All Rights Reserved.

®

Carrier Grade Server TIGI2U User Guide

ii

Intel

Page 3

Preface

Preface

About this Manual

Thank you for purchasing and using the Intel® Carrier Grade Server TIGI2U (Telecom

Industrial Grade Intel

®

Xeon™ processor 2U Server).

This manual is for system technicians who are responsible for troubleshooting, upgrading,

and repairing this Carrier Grade Server. This document provides a brief overview of the

features of the board/chassis, a list of accessories or other components you may need,

troubleshooting information, and instructions on how to add and replace components on

the Intel

®

Carrier Grade Server TIGI2U. For the latest version of this manual, refer to

http://support.intel.com/support/motherboards/server/TIGI2U.

Manual Organization

Chapter 1 provides a brief overview of the Carrier Grade Server TIGI2U. In this chapter,

you will find a list of the server board features, chassis features, photos of the product, and

product diagrams to help you identify components and their locations.

Chapter 2 provides instructions on adding and replacing components. Use this chapter for

step-by-step instructions and diagrams for installing or replacing components such as the

memory, processor, front panel board, the battery, and other components.

Chapter 3 provides instructions on using the utilities that are shipped with the board or that

may be required to update the system. This includes how to navigate through the BIOS

(Basic Input/Output System) Setup screens, how to perform a BIOS update, and how to

reset the password or CMOS (Complementary Metal Oxide Semiconductor). Information

about the specific BIOS settings and screens is available in the Intel

TIGI2U Technical Product Specification. See “

Additional Information and Software” for a

link to the Technical Product Specification.

®

Server Board

Chapter 4 provides troubleshooting information. In this chapter, you will find BIOS error

messages and POST (Power-on Self Test) code messages. You will also find suggestions

for performing troubleshooting activities to identify the source of a problem.

®

Carrier Grade Server TIGI2U User Guide

Intel

iii

Page 4

Preface

What Your Platform Includes

Your Intel® Carrier Grade Server TIGI2U includes the following components:

One Intel

One 2U rack-mount chassis

Two hard disk drive carriers

One bracket for installing a CD ROM or DVD-ROM drive

One 600 W SSI (Server System Infrastructure) PFC (Power Factor Correction)

Four-fan assembly for cooling the processor, DIMMs (Dual Inline Memory Modules),

PCI slot and other internal components

One processor air duct

Front panel I/O board

Cables and connectors

CD-ROM drive

One IMM Advanced Module

See the Intel® Carrier Grade Server TIGI2U Hardware Reference Guide for initial

installation instructions.

®

Server Board SE7502JR2

Product Accessories

You may need or want to purchase one or more of the following accessory items for your

server:

One Intel

One processor heat sink

DDR2-400 memory DIMMs

Hard disk drives (HDDs)

PCI (Peripheral Component Interconnect) add-in card

Rack mount kit

Power cord (If not included with the platform. This product ships with a power cord in

North America only.)

For information about the accessories, memory, processors, and third-party hardware that

has been tested and can be used with your board, and for ordering information for Intel

products, see

®

Xeon™ Processor: 3.2 GHz with an 800 MHz system bus

http://support.intel.com/support/motherboards/server/TIGI2U/compat.htm.

iv

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 5

Preface

Additional Information and Software

If you need more information about this product or information about the accessories that

can be used with this Carrier Grade Server, go to

http://support.intel.com/support/motherboards/server/TIGI2U/index.htm

In-depth technical information about the server board included with this Carrier

Grade Server, including BIOS settings and chipset information

The latest product information

Accessories or other Intel server products

Hardware (peripheral boards, adapter cards) and operating systems that have been

tested with this product

DIMMs that have been tested with this product

The power budget for this product

Software to manage your Carrier Grade Server

Diagnostics testing software

Firmware and BIOS updates

System drivers

Safety Information

WARNING

Although you may be using this guide or another resource as a

reference, before working with your server product pay close attention

to the safety instructions. You must adhere to the assembly

instructions in this guide to ensure and maintain compliance with

existing product certifications and approvals. Use only the described,

regulated components specified in this guide. Use of other products /

components will void the UL listing and other regulatory approvals of

the product and will most likely result in noncompliance with product

regulations in the region(s) in which the product is sold.

WARNING

All LAN ports of the equipment are considered Type 2 or Type 4 intrabuilding ports as described in NEBS GR-1089-CORE, Issue 4. The

LAN ports are suitable for connection to intra-building or unexposed

wiring or cabling only. The LAN ports of the equipment MUST NOT

be metalically connected to interfaces that connect to the OSP or its

wiring. The addition of primary protectors is not sufficient protection in

order to connect these interfaces metalically to OSP wiring. All LAN

ports must be installed with shielded cabling which must be grounded

at both ends.

®

Carrier Grade Server TIGI2U User Guide

Intel

v

Page 6

Preface

Emissions Disclaimer

To ensure EMC (Electromagnetic Compatibility) compliance with your local regional rules

and regulations, the final configuration of your end system product may require additional

EMC compliance testing. For more information, please contact your local Intel

Representative.

See “

Regulatory and Integration Information” for product Safety and EMC regulatory

compliance information. This is an FCC (Federal Communications Commission) Class A

device.

Intended Uses

This product was evaluated as Information Technology Equipment (ITE), which may be

installed in Central Offices, Telecommunication Centers, offices, schools, computer

rooms, and similar commercial type locations where the National Electrical Code (NEC)

applies. The suitability of this product for other product categories and environments

(medical, industrial, OSP telecommunications, residential, alarm systems, test equipment,

etc.), other than an ITE application, may require further evaluation.

WARNING

Anchor the equipment rack: The equipment rack must be anchored to

an unmovable support to prevent it from falling over when one or

more servers are extended in front of the rack on slides. You must

also consider the weight of any other device installed in the rack. A

crush hazard exists should the rack tilt forward which could cause

serious injury.

If AC power supplies are installed:

Mains AC power disconnect: The AC power cord(s) is considered the

mains disconnect for the server and must be readily accessible when

installed. If the individual server power cord(s) will not be readily

accessible for disconnection then you are responsible for installing an

AC power disconnect for the entire rack unit. This main disconnect

must be readily accessible, and it must be labeled as controlling

power to the entire rack, not just to the server(s).

Grounding the rack installation: To avoid the potential for an electrical

shock hazard, you must include a third wire safety ground conductor

with the rack installation. If the server power cord is plugged into an

AC outlet that is part of the rack, then you must provide proper

grounding for the rack itself. If the server power cord is plugged into a

wall AC outlet, the safety ground conductor in the power cord provides

proper grounding only for the server. You must provide additional,

proper grounding for the rack and other devices installed in it.

vi

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 7

Preface

Overcurrent protection: The server is designed for an AC line voltage

source with up to 20 amperes of overcurrent protection per cord feed.

If the power system for the equipment rack is installed on a branch

circuit with more than 20 amperes of protection, you must provide

supplemental protection for the server. The overall current rating of a

configured server is less than 6 amperes. It is intended that an

external Surge Protective Device (SPD) will be utilized at the AC

power service for the equipment.

If DC power supplies are installed:

Connection with a DC (Direct Current) source should only be

performed by trained service personnel. The server with DC input is to

be installed in a Restricted Access Location in accordance with

articles 110-16, 110-17, and 110-18 of the National Electric Code,

ANSI/NFPA 70. The DC source must be electrically isolated by double

or reinforced insulation from any hazardous AC source. The DC

source must be capable of providing up to 600 Watts of continuous

power per feed pair.

Main DC power disconnect: You are responsible for installing a

properly rated DC power disconnect for the server system. This mains

disconnect must be readily accessible, and it must be labeled as

controlling power to the server. The circuit breaker of a centralized DC

power system may be used as a disconnect device when easily

accessible and should be rated no more than 10 amps.

Grounding the server: To avoid the potential for an electrical shock

hazard, you must reliably connect an earth grounding conductor to the

server. The earth grounding conductor must be a minimum 14AWG

connected to the earth ground stud(s) on the rear of the server. The

safety ground conductor should be connected to the chassis stud with

a Listed closed two-hole crimp terminal having 5/8 inch pitch. The

nuts on the chassis earth ground studs should be installed with a

10 in/lbs torque. The safety ground conductor provides proper

grounding only for the server. You must provide additional, proper

grounding for the rack and other devices installed in it. The battery

return input terminal is designed as an isolated DC return (DC-I) from

the frame earth ground per NEBS GR-1089-CORE.

Overcurrent protection: Overcurrent protection circuit breakers must

be provided as part of each host equipment rack and must be

incorporated in the field wiring between the DC source and the server.

The branch circuit protection shall be rated minimum 75Vdc, 10 A

maximum per feed pair. If the DC power system for the equipment

rack is installed with more than 10 amperes of protection, you must

provide supplemental protection for the server. The overall current

rating of a server configured is 10 amperes.

®

Carrier Grade Server TIGI2U User Guide

Intel

vii

Page 8

Preface

WARNING

Do not attempt to modify or use an AC power cordset that is not the

exact type required. You must use a power cordset that meets the

following criteria:

• Rating: In the U.S. and Canada, cords must be UL (Underwriters

Laboratories, Inc.) Listed/CSA (Canadian Standards

Organization) Certified type SJT, 18-3 AWG (American Wire

Gauge). Outside of the U.S. and Canada, cords must be flexible

harmonized (<HAR>) or VDE (Verband Deutscher

Electrotechniker, German Institute of Electrical Engineers)

certified cord with 3 x 0.75 mm conductors rated 250 VAC (Volts

Alternating Current).

• Connector, wall outlet end: Cords must be terminated in

grounding-type male plug designed for use in your region. The

connector must have certification marks showing certification by

an agency acceptable in your region and for U.S. must be Listed

and rated 125% of overall current rating of the server.

• Connector, server end: The connectors that plug into the

AC receptacle on the server must be an approved IEC

(International Electrotechnical Commission) 320, sheet C13, type

female connector.

• Cord length and flexibility: Cords must be less than 4.5 meters

(14.76 feet) long.

CAUTION

Temperature: The temperature, in which the server operates when

installed in an equipment rack, must not go below 5 °C (41 °F) or rise

above 40 °C (104 °F). Extreme fluctuations in temperature can cause

a variety of problems in your server.

Ventilation: The equipment rack must provide sufficient airflow to the

front of the server to maintain proper cooling. The rack must also

include ventilation sufficient to exhaust a maximum of 1023 BTU's

(British Thermal Units) per hour for the server. The rack selected and

the ventilation provided must be suitable to the environment in which

the server will be used.

viii

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 9

Preface

Safety Cautions

Read all caution and safety statements in this document before performing any of the

instructions. See also Intel Server Boards and Server Chassis Safety Information on the

Resource CD and/or at

http://support.intel.com/support/motherboards/server/sb/CS-010770.htm.

Wichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warn- und Sicherheitshinweise in diesem Dokument, bevor

Sie eine der Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise

zu Intel-Serverplatinen und -Servergehäusen auf der Ressourcen-CD oder unter

http://support.intel.com/support/motherboards/server/sb/CS-010770.htm.

重要安全指导

在执行任何指令之前,请阅读本文档中的所有注意事项及安全声明。参见 Resource

CD(资源光盘) 和/或

http://support.intel.com/support/motherboards/server/sb/CS-010770.htm 上的

Server Boards and Server Chassis Safety Information

(《Intel

Intel

服务器主板与服务器机箱安全信息》)。

Consignes de sécurité

Lisez attention toutes les consignes de sécurité et les mises en garde indiquées dans ce

document avant de suivre toute instruction. Consultez Intel Server Boards and Server

Chassis Safety Information sur le CD Resource CD ou bien rendez-vous sur le site

http://support.intel.com/support/motherboards/server/sb/CS-010770.htm.

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de

realizar cualquiera de las instrucciones. Vea Intel Server Boards and Server Chassis

Safety Information en el CD Resource y/o en

http://support.intel.com/support/motherboards/server/sb/CS-010770.htm.

®

Carrier Grade Server TIGI2U User Guide

Intel

ix

Page 10

Contents

Contents

Preface .................................................................................................................iii

Intel® Carrier Grade Server TIGI2U Features .................................................. 16

Server Platform Components................................................................................................19

Server Platform Back Panel..................................................................................................20

Server Platform Front Panel..................................................................................................21

Server Platform Peripherals..................................................................................................22

Server Board Connector and Component Locations ............................................................23

Configuration Jumpers..........................................................................................................24

Front Panel IO (FPIO) System Board ...................................................................................25

Features.......................................................................................................................25

FPIO SCSI Subsystem Status LEDs............................................................................25

Peripheral Bay.......................................................................................................................26

Hard Disk Drives...................................................................................................................26

Interconnect System (SysCon) Board...................................................................................26

Power Supply........................................................................................................................27

System Cooling.....................................................................................................................28

Hardware Requirements.......................................................................................................28

Processor.....................................................................................................................28

Memory ........................................................................................................................29

Platform Installations and Upgrades............................................................... 33

Before You Begin..................................................................................................................33

Tools and Supplies Needed.........................................................................................33

System References......................................................................................................33

Cable Routing Reference.............................................................................................33

Removing and Installing the Chassis Cover .........................................................................35

Removing the Chassis Cover.......................................................................................35

Installing the Chassis Cover.........................................................................................36

Removing and Installing the Front Bezel ..............................................................................37

Removing the Front Bezel............................................................................................37

Installing the Front Bezel..............................................................................................38

Removing and Installing the Processor Air Duct...................................................................39

Removing the Processor Air Duct................................................................................39

Installing the Processor Air Duct..................................................................................40

Installing and Removing Memory DIMMs .............................................................................41

Installing DIMMs...........................................................................................................41

Removing DIMMs.........................................................................................................42

Replacing the Processor.......................................................................................................42

Removing the Processor..............................................................................................43

Installing the Processor................................................................................................44

Installing or Removing a Hard Drive .....................................................................................46

Installing a Hard Drive..................................................................................................46

Removing a Hard Drive................................................................................................48

Replacing the CD-ROM Drive...............................................................................................48

Removing the CD-ROM / DVD-ROM Drive..................................................................49

Installing the CD-ROM / DVD-ROM Drive....................................................................50

10

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 11

Contents

Installing or Removing a PCI Add-in Card ............................................................................51

Installing a PCI Add-in Card.........................................................................................51

Removing a PCI Add-in Card.......................................................................................53

Replacing the Power Supply.................................................................................................55

Removing the Power Supply........................................................................................55

Installing the Power Supply..........................................................................................56

DC Power In Male Connector Configuration................................................................56

Grounding a DC Powered System...............................................................................57

Replacing the Four-Fan Assembly........................................................................................57

Removing the Four-Fan Assembly...............................................................................58

Installing the Four-Fan Assembly.................................................................................59

Replacing the Mini-Bezel ......................................................................................................60

Replacing the Front Panel I/O Board....................................................................................61

Removing the Front Panel I/O Board...........................................................................61

Replacing the Light Pipe ..............................................................................................63

Installing the Front Panel I/O Board.............................................................................64

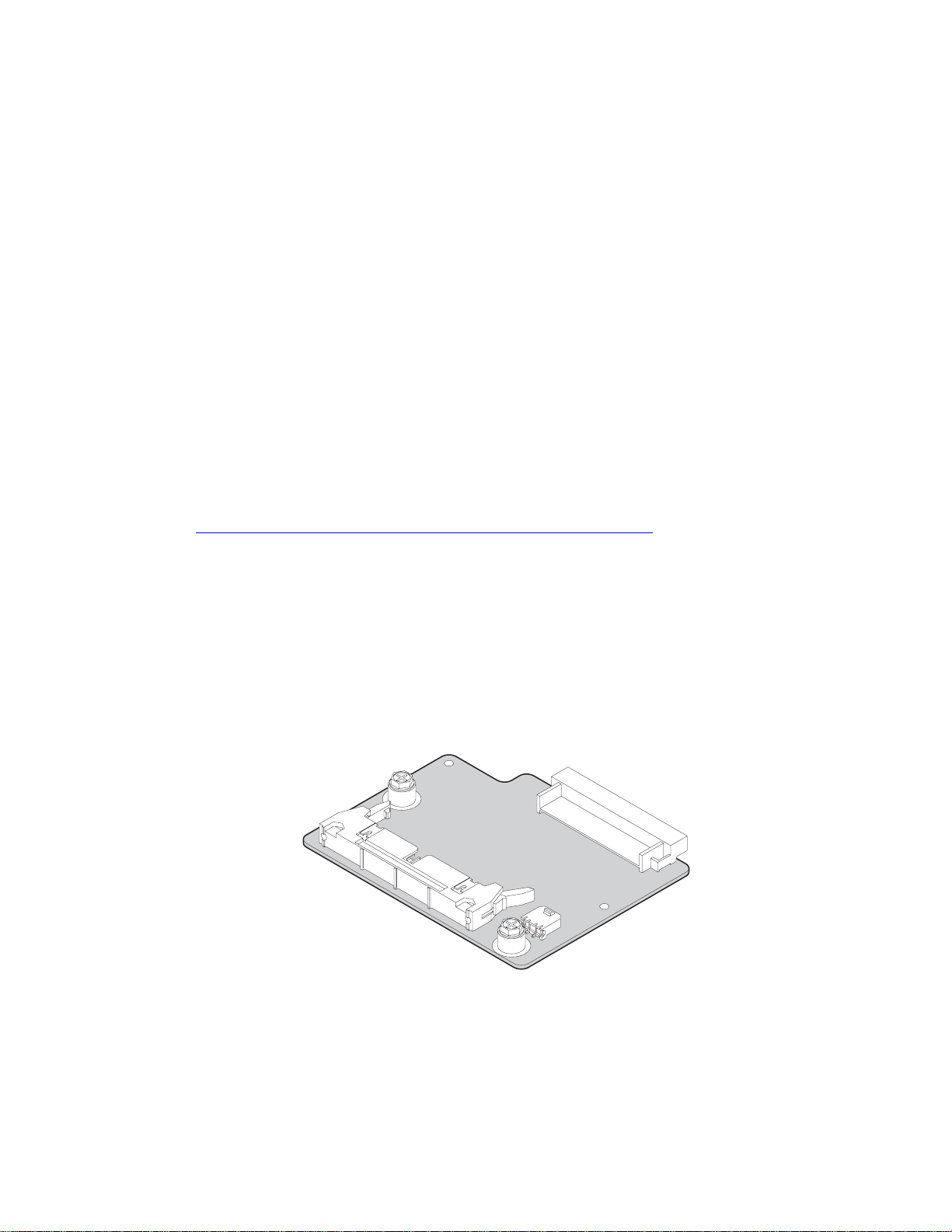

Replacing the PCI Riser Board.............................................................................................66

Replacing the Power Interface Board ...................................................................................68

Removing the Power Interface Board ..........................................................................69

Installing the Power Interface Board ............................................................................70

Replacing the Serial/Alarms Cable .......................................................................................70

Removing the Serial/Alarms Cable ..............................................................................71

Installing the Serial/Alarms Cable ................................................................................72

Replacing the Server Board..................................................................................................73

Removing the Server Board.........................................................................................73

Installing the Server Board...........................................................................................75

Replacing the Backup Battery...............................................................................................77

Installing or Replacing the Power Cord........................................................................79

Installing the Platform into a Rack.........................................................................................79

Equipment Rack Precautions................................................................................................79

Server Utilities ................................................................................................... 82

Using the BIOS Setup Utility.................................................................................................82

Starting Setup ..............................................................................................................82

If You Cannot Access Setup ........................................................................................82

Setup Menus................................................................................................................82

Upgrading the BIOS..............................................................................................................84

Preparing for the Upgrade............................................................................................84

Upgrading the BIOS.....................................................................................................85

Clearing the Password..........................................................................................................85

Clearing the CMOS...............................................................................................................86

Troubleshooting................................................................................................ 87

Resetting the System............................................................................................................87

Problems following Initial System Installation .......................................................................88

First Steps Checklist.....................................................................................................88

Hardware Diagnostic Testing................................................................................................89

Verifying Proper Operation of Key System Lights........................................................89

Confirming Loading of the Operating System ..............................................................90

Specific Problems and Corrective Actions............................................................................90

Power Light Does Not Light..........................................................................................90

®

Carrier Grade Server TIGI2U User Guide

Intel

11

Page 12

Contents

No Characters Appear on Screen................................................................................91

Characters Are Distorted or Incorrect...........................................................................91

System Cooling Fans Do Not Rotate Properly.............................................................92

CD-ROM Drive or DVD-ROM Drive Activity Light Does Not Light ...............................92

Cannot Connect to a Server .........................................................................................92

Problems with Network.................................................................................................93

System Boots when Installing PCI Card.......................................................................93

Problems with Newly Installed Application Software....................................................94

Problems with Application Software that Ran Correctly Earlier....................................94

Devices are not Recognized under Device Manager (Windows* Operating System)..95

Hard Drive(s) are not Recognized................................................................................95

Bootable CD-ROM Is Not Detected..............................................................................95

LED Information ...........................................................................................................96

BIOS Error Messages...........................................................................................................97

BIOS POST Beep Codes.............................................................................................98

Regulatory and Certification Information..................................................... 100

Product Regulatory Compliance .........................................................................................100

Product Safety Compliance........................................................................................100

Product EMC Compliance – Class A Compliance......................................................100

Certifications / Registrations / Declarations................................................................101

Product Regulatory Compliance Markings.................................................................101

Electromagnetic Compatibility Notices................................................................................102

FCC (USA).................................................................................................................102

Industry Canada (ICES-003)......................................................................................103

Europe (CE Declaration of Conformity)......................................................................103

VCCI (Japan) .............................................................................................................104

BSMI (Taiwan)............................................................................................................104

Korean RRL Compliance............................................................................................104

Regulated Specified Components ..............................................................................105

Getting Help..................................................................................................... 106

Intel® Server Issue Report Form.................................................................... 107

Warranty........................................................................................................... 111

Limited Warranty for Intel® Chassis Subassembly Products...............................................111

Extent of Limited Warranty..................................................................................................111

Warranty Limitations and Exclusions..................................................................................112

Limitations of Liability.................................................................................................112

How to Obtain Warranty Service.........................................................................................113

Telephone Support.....................................................................................................113

Returning a Defective Product ...................................................................................114

®

Carrier Grade Server TIGI2U User Guide

12

Intel

Page 13

Contents

Figures

Figure 1. Intel® Carrier Grade Server TIGI2U ......................................................................16

Figure 2. System Components.............................................................................................19

Figure 3. Platform Back........................................................................................................20

Figure 4. Front of Server Platform........................................................................................22

Figure 5. Optional Peripheral CD-ROM or DVD-ROM Drive................................................22

Figure 6. Intel® Server Platform TIGI2U Board Diagram......................................................23

Figure 7. Configuration Jumper Location.............................................................................24

Figure 8. SysCon Board.......................................................................................................26

Figure 9. System Cable Routing..........................................................................................34

Figure 10. Removing the Chassis Cover .............................................................................35

Figure 11. Installing the Chassis Cover ...............................................................................36

Figure 12. Removing the Front Bezel ..................................................................................37

Figure 13. Installing the Front Bezel ....................................................................................38

Figure 14. Removing the Processor Air Duct.......................................................................39

Figure 15. Installing the Processor Air Duct.........................................................................40

Figure 16. Installing Memory DIMMs ...................................................................................41

Figure 17. Removing Heat Sink............................................................................................43

Figure 18. Open the Processor Socket Lever.......................................................................44

Figure 19. Installing the Processor in the Processor Socket.................................................44

Figure 20. Close Processor Socket Lever.............................................................................45

Figure 21. Installing Heat Sink.............................................................................................45

Figure 22. Removing Hard Drive Carrier from Chassis........................................................46

Figure 23. Attaching a Hard Disk Drive to a Carrier.............................................................47

Figure 24. Inserting Hard Disk Drive Assembly into Chassis...............................................48

Figure 25. Removing CD-ROM / DVD-ROM Drive Assembly from Chassis........................49

Figure 26. Install CD-ROM Drive or DVD-ROM Drive Assembly into Chassis ....................50

Figure 27. Removing Riser Assembly from Chassis............................................................51

Figure 28. Installing Low-Profile PCI Card into Riser...........................................................52

Figure 29. Installing Full Length PCI Card into Riser...........................................................53

Figure 30. Removing a Low-Profile PCI Card......................................................................54

Figure 31. Removing a Full Height PCI Card.......................................................................54

Figure 32. Removing the Power Supply...............................................................................55

Figure 33. Installing the Power Supply.................................................................................56

Figure 34. DC Power In Male Connector Configuration.......................................................56

Figure 35. Connecting the Terminal Lug..............................................................................57

Figure 36. Removing the Four-Fan Assembly .....................................................................58

Figure 37. Installing the Four-Fan Assembly .......................................................................59

Figure 38. Removing the Mini Bezel....................................................................................60

Figure 39. Removing the Front Panel Board........................................................................62

Figure 40. Replacing the Light Pipe.....................................................................................63

Figure 41. Inserting the Front Panel Board..........................................................................64

Figure 42. Cabling to Front Panel Board..............................................................................65

Figure 43. Removing the Low-Profile PCI Riser Board........................................................66

Figure 44. Removing the Full Height PCI Riser Board.........................................................67

Figure 45. Installing the Low-Profile PCI Riser Board..........................................................67

Figure 46. Installing the Full Height PCI Riser Board...........................................................68

Figure 47. Removing the Power Interface Board.................................................................69

Figure 48. Installing the Power Interface Board...................................................................70

Figure 49. Removing the Serial/Alarms Cable Threaded Standoffs ....................................71

®

Carrier Grade Server TIGI2U User Guide

Intel

13

Page 14

Contents

Figure 50. Removing the Serial/Alarms Connector from the Chassis..................................71

Figure 51. Installing the Serial/Alarms Connector into Chassis...........................................72

Figure 52. Installing the Serial/Alarms Cable Threaded Standoffs ......................................72

Figure 53. Removing the Server Board................................................................................74

Figure 54. Installing the Server Board..................................................................................75

Figure 55. Securing SCSI Cable to Server Board Connector..............................................76

Figure 56. Replacing the Battery..........................................................................................78

Figure 57. Password Recovery Jumper...............................................................................85

Figure 58. CMOS Recovery Jumper....................................................................................86

14

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 15

Contents

Tables

Table 1. Server Platform Features .................................................................................17

Table 2. NIC LEDs..........................................................................................................20

Table 3. Configuration Jumper [J1H2]............................................................................24

Table 4. LED Activity Definitions ....................................................................................25

Table 5. Keyboard Commands.......................................................................................83

Table 6. BIOS Error Messages.......................................................................................97

Table 7. POST Error Beep Codes..................................................................................98

Table 8. Error Beep Codes Provided by Intel® Management Modules..........................98

Table 9. Product Certification Markings........................................................................101

®

Carrier Grade Server TIGI2U User Guide

Intel

15

Page 16

Server Platform Features

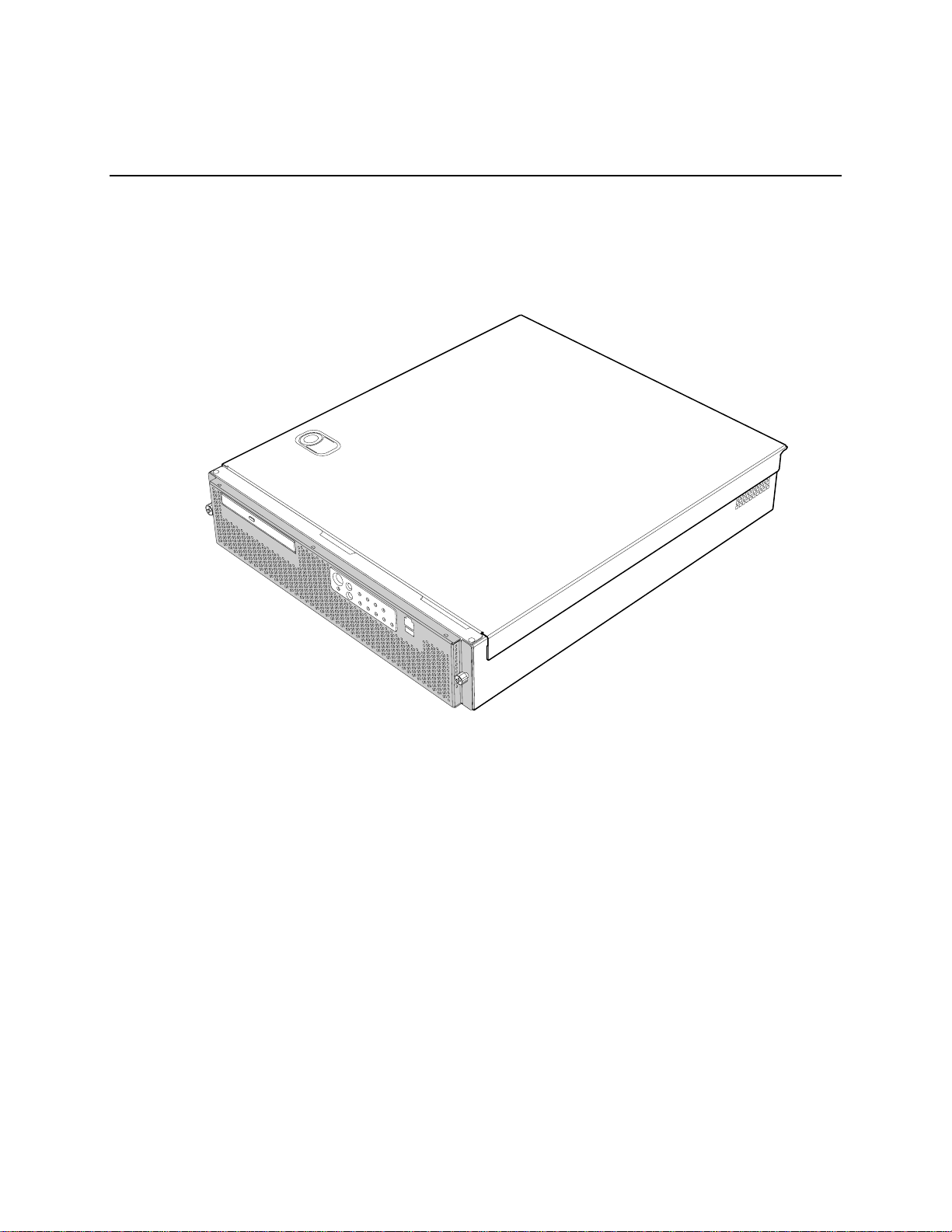

Intel® Carrier Grade Server TIGI2U Features

This chapter briefly describes the main features of the Intel® Carrier Grade Server TIGI2U.

This chapter provides a diagram of the product, a list of the server features, and diagrams

showing the location of important components and connections on the server platform.

The Intel

®

Carrier Grade Server TIGI2U is shown in the following diagram.

16

Figure 1. Intel® Carrier Grade Server TIGI2U

®

Carrier Grade Server TIGI2U User Guide

Intel

TP01642

Page 17

Server Platform Features

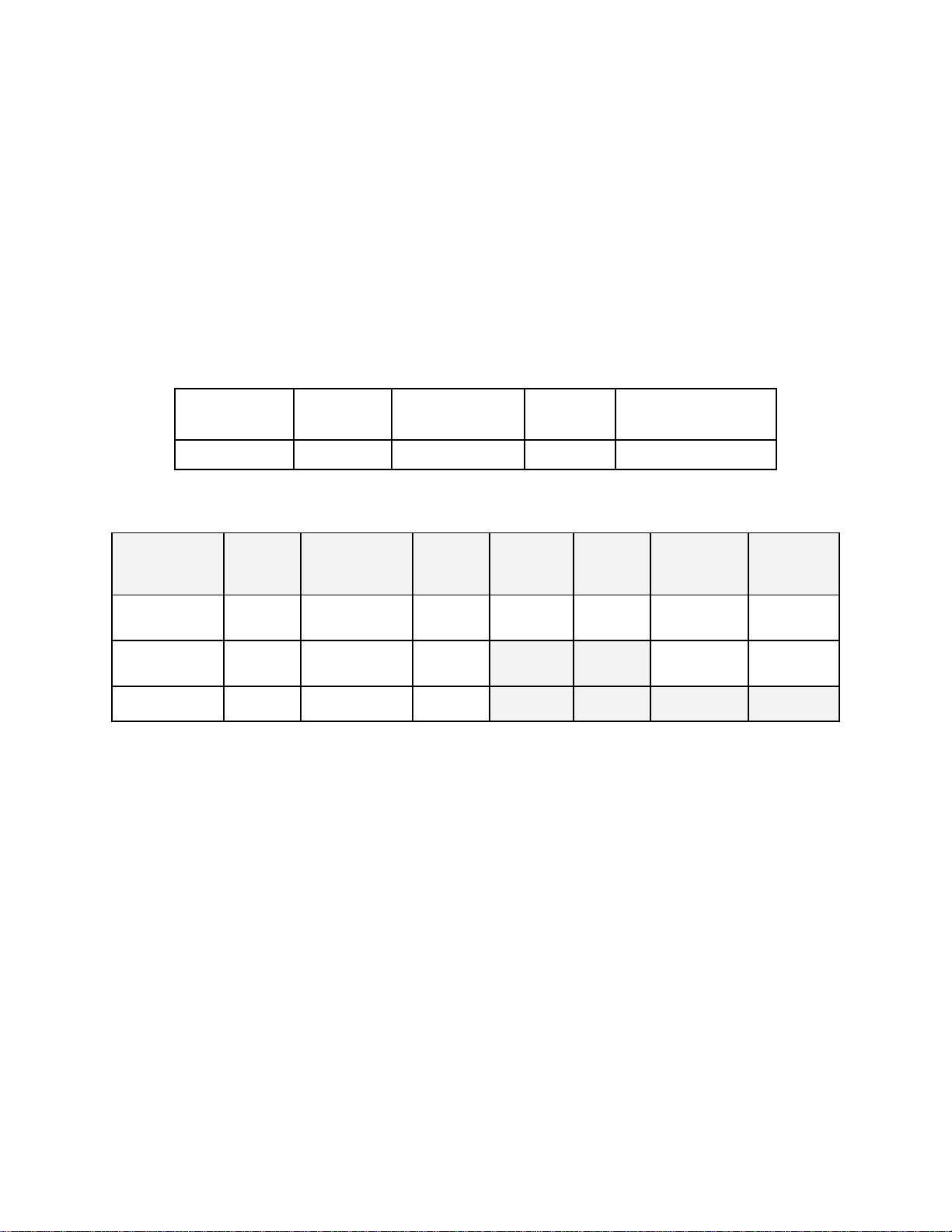

Table 1 summarizes the major features of the server platform.

Table 1. Server Platform Features

Feature Description

Processors Support for up to two Intel® Xeon™ processors with an 800 MT/s MHz front side

bus at frequency 3.2 GHz with 2MB cache.

Memory

Chipset Intel® E7520 chipset, including:

Memory mirroring and memory sparing options

Six DIMM slots supporting DDR-2 400MHz memory

E7520 MCH

PXH

Intel® 82801ER I/O Controller Hub 5-R (ICH-5R)

I/O Control External connections:

Stacked PS/2 ports for keyboard and mouse

RJ45 Serial B port

Two RJ45 NIC connectors for 10/100/1000 Mb connections

Two rear USB 2.0 ports

One front USB port - USB 2.0 compliant with less than ten feet of

external cable

U320 high-density 80-pin SCSI connector (channel B)

Internal connections:

Two USB port headers, each of which supports two USB 2.0 ports

One DH10 Serial A header

One Ultra320 80-pin SCSI connector (Channel A)

One ATA-100 connector

SSI-compliant 34-pin, high-density 100-pin, and alternate 50-pin control

panel headers

Intel® Management Module 120-pin connector, supporting the

Professional and Advanced server management modules

Add-in Card

One low-profile riser slot that supports a riser card capable of supporting

upto three low-profile PCI-X 64/100MHz add-in cards.

One full-height riser slot, utilizing Intel® Adaptive Slot technology. Capable

of supporting riser cards that follows PCI-X specifications. The riser card

can support up to three full-height, full-length PCI-X 64/100 MHz add-in

cards.

Video On-board ATI* RAGE XL video controller with 8MB SDRAM

®

Carrier Grade Server TIGI2U User Guide

Intel

Continued

17

Page 18

Server Platform Features

Feature Description

Hard Drive SCSI support:

LAN Dual Intel® 82546GB 10/100/1000 NICs

Fans

Server Management /

Diagnostics

Server Management

Dual-channel LSI Logic* 53C1030 Ultra320 SCSI controller

⎯ Implements LSI Logic* Fusion-MPT architecture

⎯ Supports LSI Logic* Integrated Mirroring and Striping technology

Zero-channel RAID supporting the RUBI-2 specification

Two 80mm x 38mm fans

Two 40mm x 28mm fans

On-board Platform Instrumentation using the National Semiconductor*

PC87431M mini-Baseboard Management Controller (mBMC) (Default).

Support for optional Intel® Management Module - Advanced Edition or

Professional Edition

Support for Intel® Server Management 8.x

Intel® Light-Guided Diagnostics on all field replaceable units (F RUs)

®

Server Management 5.8 support

Intel

Telco Alarm Manager (TAM)

18

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 19

Server Platform Features

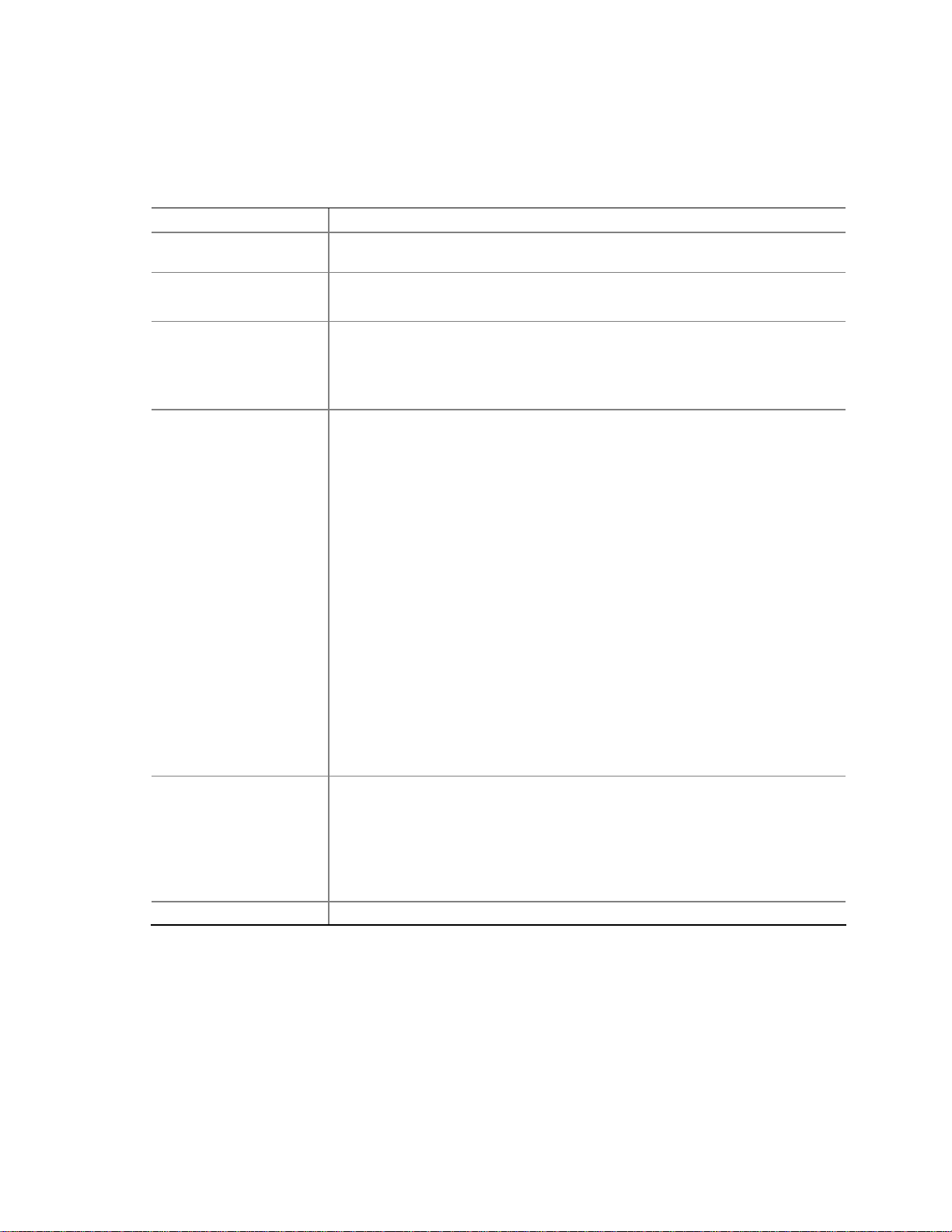

Server Platform Components

B

A

C

D

I

E

H

F

G

TP01643

A. Power Distribution Board F. System Fans

B. Processor Air Duct G. Front Panel I/O Board

C. Power Supplies H. SCSI Hard Disk Drive Carriers

D. PCI Riser Card Assembly I. Peripheral Bay (CD-ROM or DVD-ROM drive)

®

E. Intel

Server Board SE7520JR2

Figure 2. System Components

®

Carrier Grade Server TIGI2U User Guide

Intel

19

Page 20

Server Platform Features

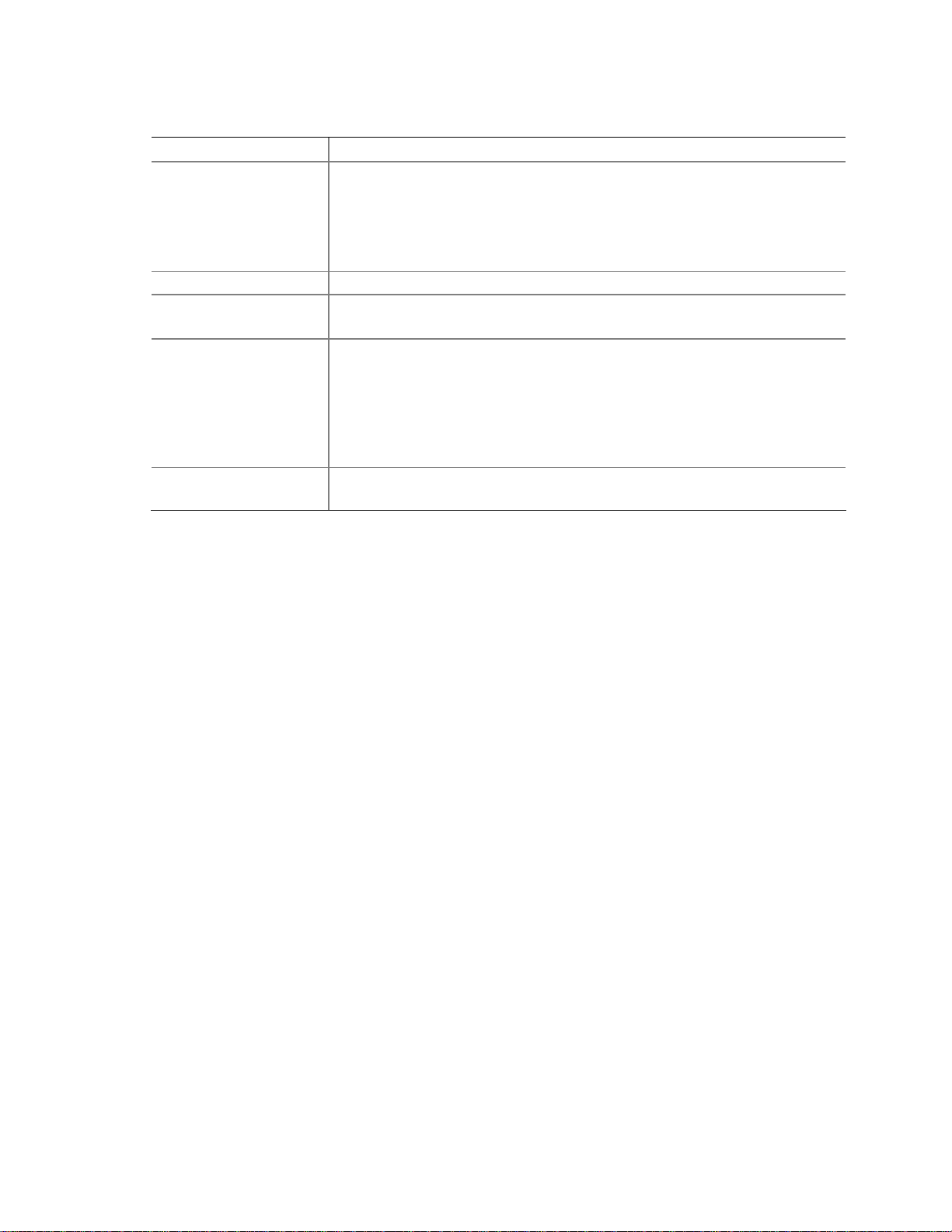

Server Platform Back Panel

A

F J

H

G

B C D

I

K

L

M N

A DB15 Alarms Connector H RJ45 NIC 1 Connector

B PCI Card Bracket (low-profile) I RJ45 NIC 2 Connector

C PCI Card Bracket (full-height) J Video Connector

D Optional second power supply or filler

panel (filler panel shown)

E Power Supply L USB 0

F PS/2 Mouse and Keyb oard Connectors M Server Management Port

G Rear Serial Port N SCSI Channel B

Figure 3. Platform Back

K USB 1

E

TP01644

The NIC LEDs at the right and left of each NIC provide the following information.

Table 2. NIC LEDs

NIC LED Color LED State Description

Off No network connection

Solid Amber Network connection in place

Blinking Amber Transmit/receive activity

Off 10 Mbps connection (if left LED is on or

blinking)

Solid Amber 100 Mbps connection

Solid Green 1000 Mbps connection

®

Carrier Grade Server TIGI2U User Guide

Intel

20

NIC1 / NIC2

(Gigabit)

Left LED

Right LED

Page 21

Server Platform Features

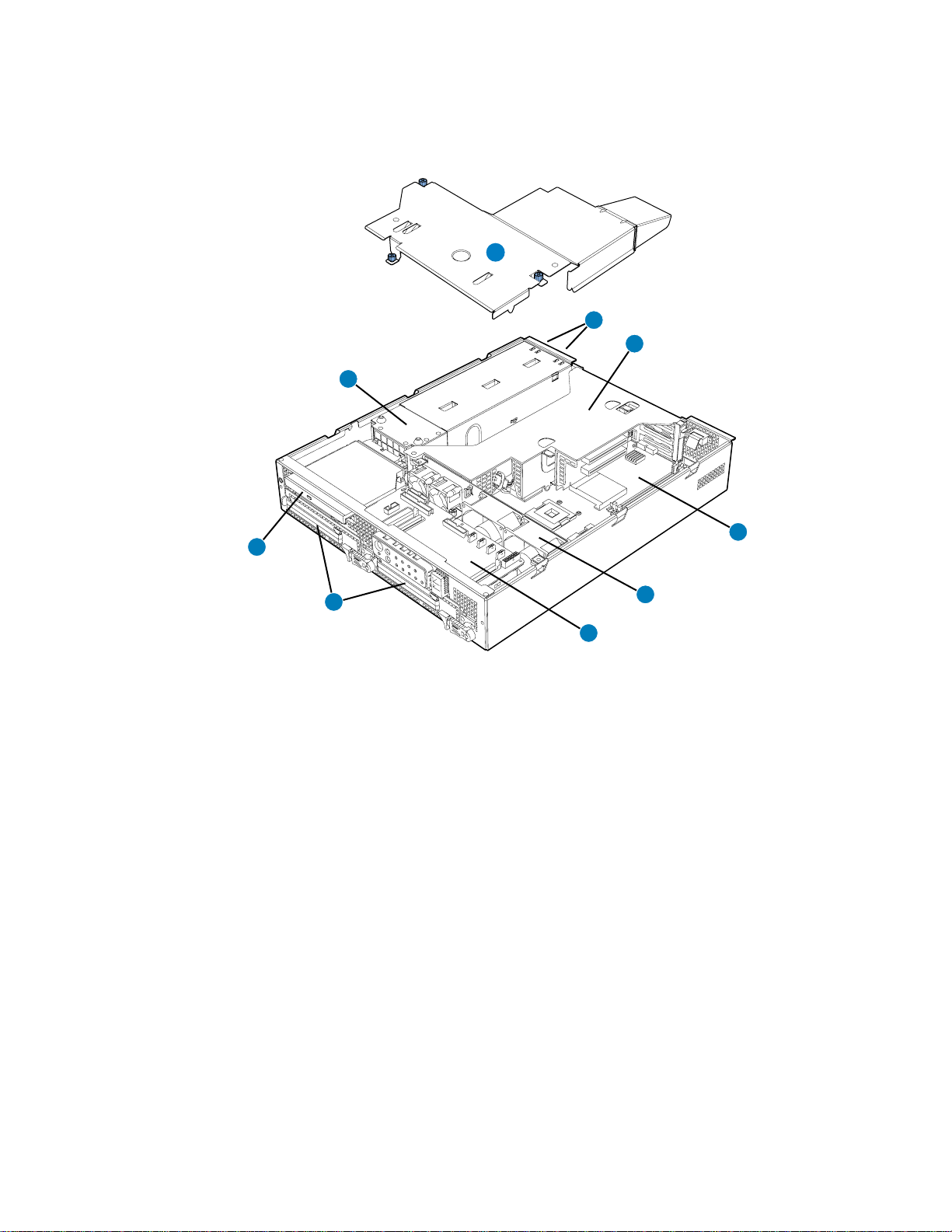

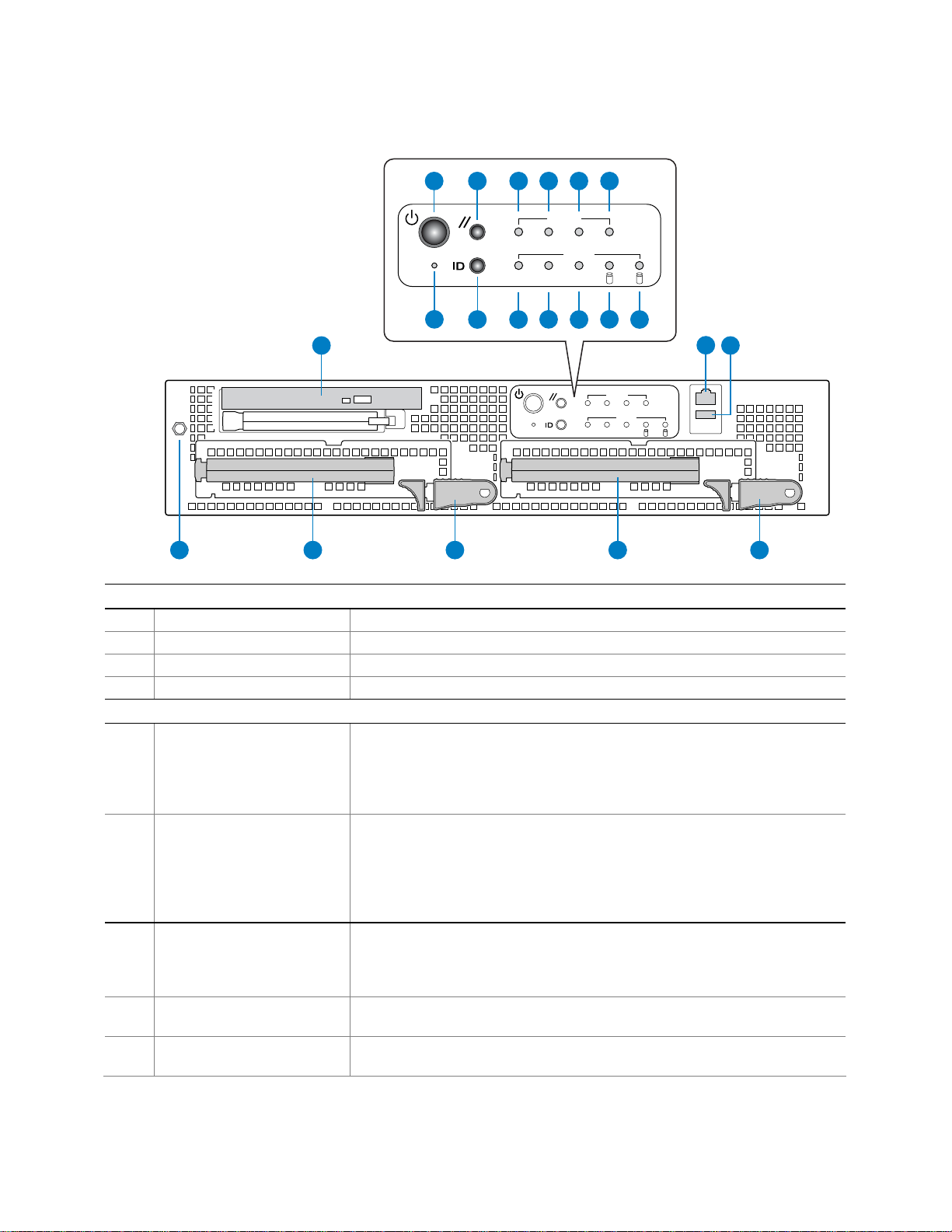

Server Platform Front Panel

A

G

N

Q

R

S

C ED F

B

CRT MNR PWRMJR

ID ONNIC

H

I

Alarms

Status

J

K M

1 0

L

Alarms

CRT MNR PWRMJR

Status

ID ONNIC

1 0

T U

O

P

TP01645

Front Panel Buttons

A Power button Toggles the system power

B Reset button Resets the system

G NMI button Assert NMI to baseboard

H ID button Toggles system ID LED

Front Panel LEDs

C Critical (amber ) When continuously lit, indicates the presence of a Critical System Fault. A

critical system fault is an error or event that is detected by the system with a

fatal impact to the system. In this case, the system cannot continue to

operate. An example is the loss of a large section of memory that renders the

system not operational. The front panel critical alarm relay will be engaged.

D Major (amber) When continuously lit, indicates the presence of a Major System Fault. A

major system fault is an error or event that is detected by the system that has

discernable impact to system operation. In this case, the system can continue

to operate but in a “degraded” fashion (reduced performance or loss of nonfatal feature reduction). An example is the loss of one of two mirrored disks.

The front panel major alarm relay will be engaged.

E Minor (amber) When continuously lit, indicates the presence of a Minor System Fault. A

minor system fault is an error or event that is detected by the system but has

little impact on actual system operation. An example is a correctable ECC

error. The front panel minor alarm relay will be engaged.

F Power (amber) When continuously lit, indicates the presence of a Power System Fault. The

front panel power alarm relay will be engaged.

I System ID LED (white) Continuously lit when activated either by a software command or by the front

panel ID button.

®

Carrier Grade Server TIGI2U User Guide

Intel

continued

21

Page 22

Server Platform Features

J NIC activity LED (green) Indicates activity on either NIC.

K Main power LED (green) When continuously lit, indicates the presence of DC power in the server. The

LED goes out when the power is turned off or if the power source is

disrupted.

L Disk 1 Activity/Fault LED

(green/amber)

M Disk 0 Activity/Fault LED

(green/amber)

Front of Server Platform

N Optional CD-ROM or DVD-ROM Drive

O Serial B via RJ45

P USB 2

Q Anti-static Connection

R Drive Carrier 0

S Drive Release Lever

T Drive Carrier 1

U Drive Release Lever

Indicates disk 1 SCSI hard drive activity when green, or a disk 1 SCSI hard

drive fault when amber.

Indicates disk 0 SCSI hard drive activity when green, or a disk 0 SCSI hard

drive fault when amber.

Figure 4. Front of Server Platform

Server Platform Peripherals

The platform provides for a peripheral location to install either a CD-ROM or a DVD-ROM

drive. The platform comes with a CD-ROM drive installed. For information on replacing the

CD-ROM drive, see “

Replacing the CD-ROM Drive”.

TP01647

Figure 5. Optional Peripheral CD-ROM or DVD-ROM Drive

22

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 23

Server Platform Features

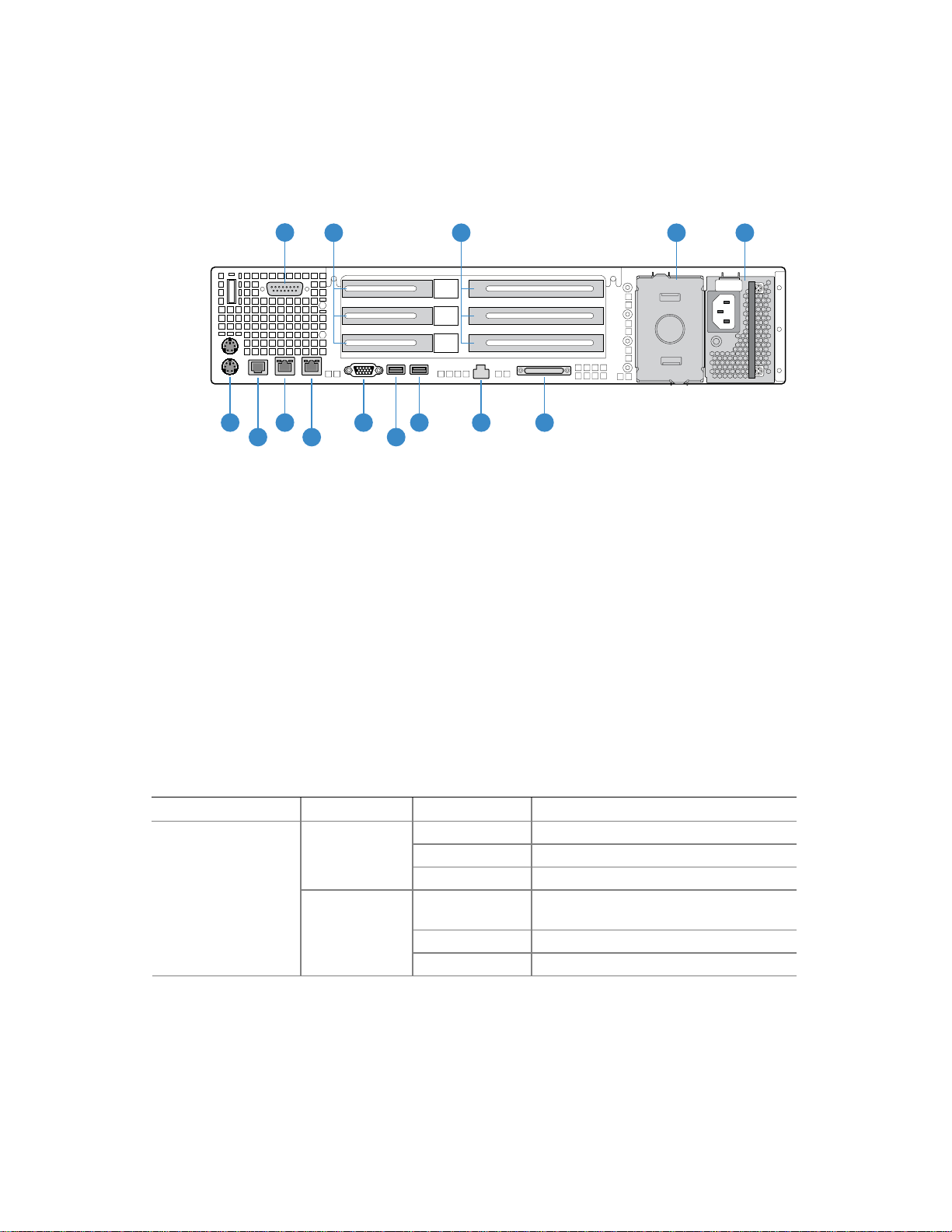

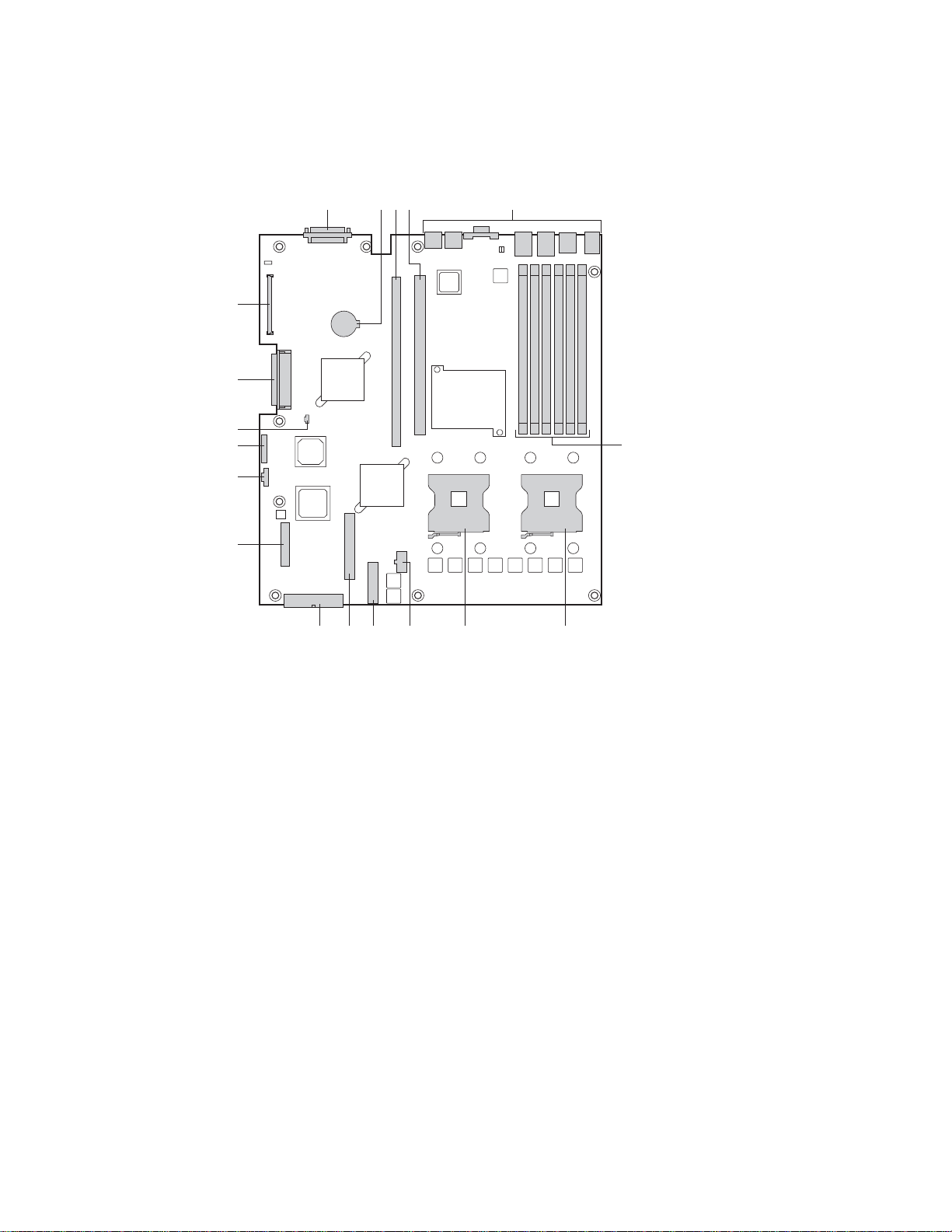

Server Board Connector and Component Locations

BA CD E

R

Q

P

O

F

N

M

L

K

J

A. SCSI Channel B J. Fan board connector

B. Battery K. Secondary IDE channel

C. Full-height riser slot

D. Low-profile riser slot

E. Back panel I/O ports

F. DIMM sockets

G. Processor socket 1

H. Processor socket 2

I. +12V processor power R. 120-pin connector for Intel® Management Module

L. 24-pin SSI power connector

M. 50-pin control panel connector

N. Power supply signal cable

O. USB header (1 x 10)

P. IDE power connector

Q. SCSI channel A

GHI

TP01646

Figure 6. Intel® Server Platform TIGI2U Board Diagram

®

Carrier Grade Server TIGI2U User Guide

Intel

23

Page 24

Server Platform Features

Configuration Jumpers

J1H2

C

B

A

1-2: Default

32

A1-A2: CMOS Clear by BMC

A2-A3: CMOS Clear Force Erase

B1-B2: Recovery Boot Disable (Normal Boot)

B2-B3: Recovery Boot Enable

C1-C2: Password Clear Protect

C2-C3: Password Clear Erase

Figure 7. Configuration Jumper Location

Table 3. Configuration Jumper [J1H2]

Jumper Name Pins What happens at system reset…

1-2 These pins should be jumpered for normal system operation. Password Clear

(line “A” in figure

above)

(line “B” in figure

above)

“C” in figure

above)

2-3 If these pins are jumpered, administrator and user passwords will be cleared on the

next reset. These pins should not be jumpered for normal operation.

1-2 These pins should be jumpered for normal system operation. Recovery Boot

2-3 If these pins are jumpered, the system will attempt to recover the BIOS by loading the

BIOS code into the flash device from a floppy disk. This jumper is typically used when

the BIOS has become corrupted. These pins should not be jumpered for normal

operation.

1-2 These pins should be jumpered for normal system operation. CMOS Clear (line

2-3 If these pins are jumpered, the CMOS settings will be cleared on the next reset.

These pins should not be jumpered for normal operation.

TP01652

24

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 25

Server Platform Features

Front Panel IO (FPIO) System Board

Features

The TIGI2U server system has the following FPIO features:

• Four switches to control power-on, reset, NMI, and the system ID LED

• One system ID LED that can be controlled remotely or by the system ID switch

• Two system activity LEDs that indicate power-on and NIC activity

• Two hard drive activity/fault LEDS that indicate activity/fault status for drives 1 and 2

• Four system fault LEDs that indicate critical, major, minor, and power system fault

status

• Four system fault relays for external critical, major, minor, and power fault indicators

• One SCSI bus with hot-swap circuitry for controlling hot-swap SCSI disk drives 1 and 2

• IDE Bus from IDE Connector to blind mate connector

• One blind mate connector for interfacing to CDROM or floppy drive carrier assembly

• Connectors for interfacing to the power supply, server baseboard, drive carrier

assemblies, and hot plug disk drives 1 and 2

FPIO SCSI Subsystem Status LEDs

The status LEDs give the user a visual indication of the drives’ condition. There is a single

LED for each drive. The LEDs are bi-colored and use a combination of color and blinking

frequency to indicate multiple conditions. The LEDs are mounted on the FPIO board, and

the light is directed to the front panel through the use of a light pipe assembly. See

4

for LED activity definitions. See the Firmware EPS for definitions of the different blink

rates.

Table 4. LED Activity Definitions

LED State Drive Active Fault Condition

Solid Green

Blinking Green X

Blinking

Yellow/Green

Blinking

Yellow/Blank

Blank

X

X

Table

®

Carrier Grade Server TIGI2U User Guide

Intel

25

Page 26

Server Platform Features

Peripheral Bay

One peripheral drive (either a slim-line CD-ROM drive or a slim-line DVD-ROM drive) can

be mounted in the system using a blind-mate peripheral drive carrier inserted into the

peripheral drive bay. The peripheral drive bay is located above the hard drive tray and to

the left.

Hard Disk Drives

The platform ships with two drive carriers for mounting hot swap Ultra320 SCSI hard disk

drives in the chassis.

For information on how to install these drives, see “

Installing or Removing a Hard Drive”.

NOTE

The Intel® Carrier Grade Server TIGI2U does not support all SCSI

hard drives. For a list of validated hard drive manufacturers and hard

drive types, see

http://support.intel.com/support/motherboards/server/TIGI2U

Drives can consume up to 17 watts of power each. Drives must be

specified to run at a maximum ambient temperature of 45 °C.

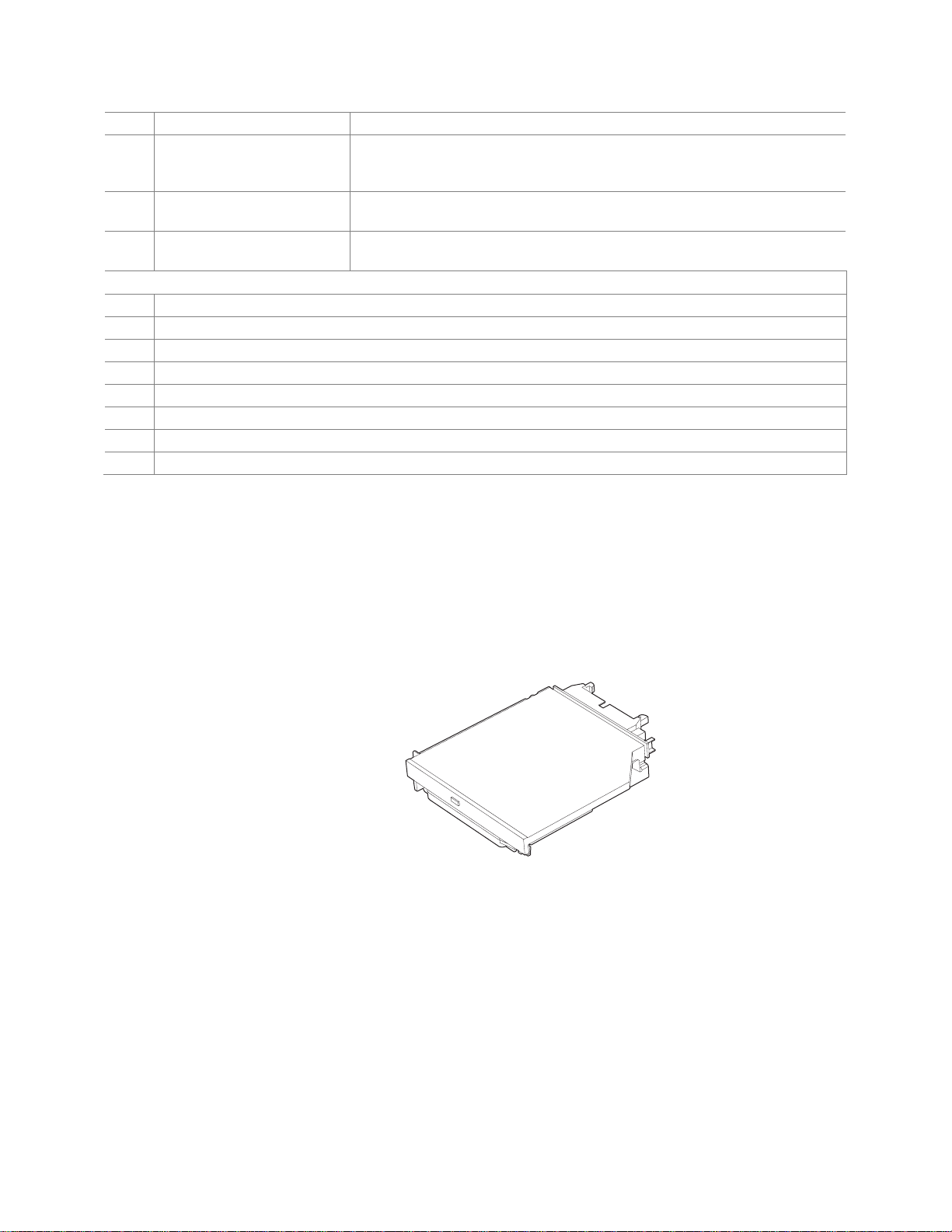

Interconnect System (SysCon) Board

The interface board is used in the CD-ROM drive carrier assembly as the signal and

power interface between the CD-ROM drive and the FPIO system board. The interface

board has standard IDE and power connectors for interfacing to the CD-ROM drive, and

has a high-density blind-mate connector for interfacing to the FPIO system board.

26

TP01691

Figure 8. SysCon Board

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 27

Server Platform Features

Power Supply

The power supply cage supports up to two hot-swap power supplies (either AC input or

DC input) in a (1+1) redundant configuration. A power supply filler module for the empty

power supply site is supplied for systems without redundancy. Only the DC input version

is NEBS certified.

The power subsystem supports the implementation of remote management features

including remote enable, which permits power to be activated from a variety of sources.

The power supply is rated for 600 watts of power at the following voltages.

AC Power Supply:

PARAMETER MIN RATED MAX Max Input Current

DC Voltage -38 VDC -48VDC/ -60VDC -75VDC 20.5ADC

DC Power Supply:

PARAMETER MIN RATED MAX

Start-up

Vac

Power

Off

Vac

Max Input

AC Current

Max Rated

Input AC

Current

Line Voltage

(110)

Line Voltage

(220)

Frequency 47 Hz 50/60Hz 63 Hz

90V

180V

rms

rms

100-127 V

200-240 V

rms

rms

140V

264V

85Vac

rms

±4Vac

- -

rms

75Vac

±5Vac

Notes:

1. Maximum input current at low input voltage range shall be measured at 90Vac,

at max load.

2. Maximum input current at high input voltage range shall be measured at

180VAC, at max load.

3. This is not to be used for determining agency input current markings.

4. Maximum rated input current is measured at 100VAC and 200VAC

10.0

A

rms

5.0 A

1,3

rms

2,3

8.9A

4.5A

rms

rms

4

4

®

Carrier Grade Server TIGI2U User Guide

Intel

27

Page 28

Server Platform Features

System Cooling

All system components except the power supply cage are cooled by a set of fans mounted

near the middle of the chassis and behind the hard drive bays. The TIGI2U system comes

in a non-redundant, four-fan configuration that consists of two 80mm x 38mm fans and two

40mm x 28mm fans.

Air flows in through the front bezel over the peripheral bay and the hard drive bays,

passes through the fans and over the baseboard, and exhausts through the rear of the

chassis. Each fan provides tachometer signal output to the server baseboard to indicate a

fan failure.

The cooling subsystem contains a fan array consisting of two 80 x 38 mm fans and two 40

x 28 mm fans to cool the server board and other components. A fan failure is indicated by

one of the fault LEDs located on the front panel.

Hardware Requirements

To avoid integration difficulties and possible board damage, your system must meet the

requirements outlined below. For a list of qualified components, see the links under

“

Additional Information and Software.”

Processor

The server board accommodates two Intel® Xeon™ 3.2 GHz processors operating at 800

MHz FSB with 2MB cache.

28

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 29

Server Platform Features

Memory

The Server Board SE7520JR2 provides six DIMM sockets across two channels, Channel

A and Channel B. Channel A consists of DIMM sockets 1A, 2A, and 3A. Channel B

consists of DIMM sockets 1B, 2B, and 3B.

If six DIMMs are installed, the following maximum capacitites are possible:

For DDR-2 400: Maximum capacity of 16 GB

A minimum of one 256MB DIMM is required in DIMM socket 1A or 1B. This uses singlechannel interleave. However, for dual-channel interleave, providing optimum performance,

a minimum of two DIMMs should be installed in DIMM sockets 1A and 1B. Except for the

option of installing a single DIMM in socket 1A or 1B, DIMMs must be installed in pairs and

populated as follows:

DIMM1A and DIMM 1B: Populate these two sockets together first

DIMM 2A and DIMM 2B: Populate these sockets in addition to DIMM 1A and DIMM 2A

if four DIMMs are to be used.

DIMM 3A and DIMM3B: Populate these sockets after DIMM 1A, DIMM1B, DIMM2A,

and DIMM2B have been populated.

DIMMs must meet the following requirements:

Use only DDR2-400 ECC, registered DDR DIMM modules

Use only DIMMs that comply with the DDR specifications.

Use only DIMMs with DIMM organization of x72 ECC

Use only 240pin DIMMs

NOTE

When using DDR2-400 DIMM technologies, a maximum of four loads per memory channel

is supported. When all DIMMs used in the system match this technology, a maximum of

four DIMMs can be populated. Refer to the Intel

Product Specification for additional information regarding the memory sub-system.

In determining your memory requirements, the need for memory sparing or memory

mirroring must be considered.

Memory Sparing and Mirroring

The Intel® E7520 chipset includes hardware that supports memory mirroring and memory

on-line sparing. Both memory mirroring and memory on-line sparing provide a way to

prevent data loss in case a DIMM fails.

With memory mirroring the system maintains two copies of all data in the memory

subsystem. If a DIMM fails, the data is not lost because the second copy of the data is

available from the mirrored DIMM in the opposite channel. The system will not fail due to

memory error unless both the primary and the mirrored copy of the data become corrupt at

the same time.

®

Server Board SE7520JR2 Technical

®

Carrier Grade Server TIGI2U User Guide

Intel

29

Page 30

Server Platform Features

In a mirrored system, the maximum usable memory is one-half of the installed memory,

with a minimum of four DIMMs installed. Since the data is duplicated across DIMMs, it

means that up to one-half of the installed DIMMs are actively in use at any one time. The

remaining DIMMs are used for mirroring.

Two methods for memory mirroring are available:

Four identical DIMMs are used in DIMM sockets 1A, 1B, 2A, and 2B.

⎯ If the DIMM in socket 1A fails, the DIMM in socket 2B takes over.

⎯ If the DIMM in socket 1B fails, the DIMM in socket 2A takes over.

Four DIMMs are used with identical single-ranked DIMMs in Banks 2 and 3. DIMMs in

sockets 1A and 1B must be dual-ranked and identical.

⎯ If the DIMM in socket 1A fails, the DIMM in socket 1B takes over.

⎯ If the DIMM in socket 2A fails, the DIMM in socket 3B takes over.

⎯ If the DIMM in socket 2B fails the DIMM in socket 3A takes over.

For memory on-line sparing, one DIMM per channel is used as the memory spare. The spare

DIMM is not available for use, but is kept in reserve. If a DIMM begins to fail, the content of the

failing DIMM is copied to the spare DIMM in that channel. When all of the data is copied to the

spare DIMM, the primary DIMM is removed from service and the spare DIMM takes its place.

When memory on-line sparing is used, the spare DIMMs must be equal to or larger than the

largest in-service DIMM in that channel.

NOTE

Memory mirroring and memory sparing are mutually exclusive. Only

one can be active at a time. Refer to the Intel

SE7520JR2 Technical Product Specification for additional information

regarding the memory sub-system.

All memory components and DIMMs used with the Intel

must comply with the DDR specifications. For a complete list of supported memory

DIMMs, see the links under “

Additional Information and Software.”

®

Server Board

®

Carrier Grade Server TIGI2U

30

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 31

Server Platform Features

NOTES

Although the server board architecture allows the user to mix various

sizes of DIMMs between channels, DIMMs must be identical within

each bank.

To be fully compliant with all applicable DDR SDRAM memory

specifications, the board should be populated with DIMMs that

support the Serial Presence Detect (SPD) data structure. This allows

the BIOS to read the SPD data and program the chipset to accurately

configure memory settings for optimum performance. If non-SPD

memory is installed, the BIOS will attempt to correctly configure the

memory settings, but performance and reliability may be impacted or

the DIMMs may not function under the determined frequency.

For ECC functionality, all installed DIMMs must be ECC.

®

Carrier Grade Server TIGI2U User Guide

Intel

31

Page 32

Page 33

Platform Installations and Upgrades

Platform Installations and Upgrades

Before You Begin

Before working with your server product, pay close attention to the safety instructions at

the beginning of this manual. See “

Tools and Supplies Needed

Phillips* (cross head) screwdriver (#1 bit and #2 bit)

Needle nosed pliers

Antistatic wrist strap and conductive foam pad (recommended). To mitigate damage

to equipment from static electricity discharge an antistatic wriststrap connected to

earth ground must be worn be service personnel.

Safety Information.”

System References

All references to left, right, front, top, and bottom are based on the reader facing the front

of the platform as it would be positioned for normal operation.

Cable Routing Reference

It is important for cables to be connected correctly. The diagram below provides

information about the location of the cable connections. Use this diagram as a reference

when following the installation steps in this chapter.

Intel® Carrier Grade Server TIGI2U User Guide 33

Page 34

Platform Installations and Upgrades

Connections

Front Panel I/O to CD-ROM

A

Front Panel I/O to HDD 2

B

Front Panel I/O to HDD 1

C

Power Supply to Front Panel I/O

D

Front Panel USB

E

IDE

F

Aux. Power

G

Front Panel

H

Main Power

I

Power to PCI Riser

J

CPU Power

K

Fan Module Monitor

L

Telco Alarms - back panel

M

SCSI

N

Individual Fan Power

O

Cable Legend

BLUE indicates Data Cable

RED indicates Power Cable

RED/BLUE indicates

Power and Data Cable

3

System Components

Power Supply

1

Power Distribution Module

2

CD-ROM Module

3

SCSI Hard Drive

4

Front Panel I/O Board

5

Fan Module

6

Server Board

7

1

G

2

H

I

A

D

F

E

J

7

K

L

M

6

34

4

B

N

O

5

4

C

TP01668

Figure 9. System Cable Routing

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 35

Platform Installations and Upgrades

Removing and Installing the Chassis Cover

Removing the Chassis Cover

The Intel® Carrier Grade Server TIGI2U must be operated with the top cover in place to

ensure proper cooling. You will need to remove the top cover to add or replace

components inside of the platform. Before removing the top cover, power down the server

system and unplug all peripheral devices and the AC power cable or disconnect the DC

mains. None of the components inside the platform are hot-swappable.

To mitigate damage to equipment from static electricity discharge an antistatic wriststrap

connected to earth ground must be worn be service personnel.

NOTE

A nonskid surface or a stop behind the platform may be needed to

prevent the platform from sliding on your work surface.

1. Observe the safety and ESD precautions at the beginning of this section.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord or disconnect the DC mains.

4. While holding the blue button at the top of the chassis in (see letter “A”), slide the top

cover back until it stops (see letter “B”).

5. Lift the cover straight up to remove it from the platform.

A

B

TP01648

Figure 10. Removing the Chassis Cover

®

Carrier Grade Server TIGI2U User Guide 35

Intel

Page 36

Platform Installations and Upgrades

Installing the Chassis Cover

1. Place the cover over the chassis so that the side edges of the cover sit just inside the

chassis sidewalls, with the front of the cover with about 1/8-inch gap showing between

the chassis cover and the sheet-metal at the front of the chassis.

2. Press down slightly on the chassis cover behind the CD-ROM / DVD-ROM drive area

and slide the cover forward until it clicks into place (see letter “A”).

3. Reconnect all peripheral devices and the AC power cord or the DC mains.

A

TP01649

Figure 11. Installing the Chassis Cover

36

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 37

Platform Installations and Upgrades

Removing and Installing the Front Bezel

The front bezel needs to be removed only to install or remove hot-swap hard drives or the

CDROM drive.

Removing the Front Bezel

1. Loosen the captive screws at the left and right edges of the front bezel (one screw at

the right and one screw at the left; see letter “A”).

NOTE

Hold the bezel in place while you loosen the screws. After both

screws are loosened, the bezel will drop from the chassis.

2. Remove the front bezel from the chassis (see letter “B”).

A

B

A

TP01650

Figure 12. Removing the Front Bezel

®

Carrier Grade Server TIGI2U User Guide 37

Intel

Page 38

Platform Installations and Upgrades

Installing the Front Bezel

1. While holding the front bezel in place (see letter “A”), tighten the captive screws at the

left and right edges of the bezel (see letter “B”).

B

A

B

Figure 13. Installing the Front Bezel

TP01651

38

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 39

Platform Installations and Upgrades

Removing and Installing the Processor Air Duct

The air duct must be removed to access the processor assembly and the four-fan

assembly. The processor air duct is required for proper airflow within the chassis. Be sure

the air duct is in place before installing the chassis cover.

Removing the Processor Air Duct

1. Power down the server system and unplug all peripheral devices and the AC power

cable or the DC mains.

2. Remove the chassis cover. For instructions, see “

3. Remove the screws at the top of the air duct (see letter “A”).

4. Lift the air duct from the server platform (see letter “B”).

Removing the Chassis Cover.”

A

B

Figure 14. Removing the Processor Air Duct

TP01670

®

Carrier Grade Server TIGI2U User Guide 39

Intel

Page 40

Platform Installations and Upgrades

Installing the Processor Air Duct

1. Place the processor air duct over the processor socket and four-fan assembly, using

caution to make sure you do not pinch any wires beneath the edges of the air duct

(see letter “A”).

2. Tighten the screws at the top of the air duct (see letter “B”). The top of the installed air

duct should be flush with the top surface of PCI adapter assembly.

3. Replace the chassis cover if you have completed all work inside of the chassis. For

instructions, see “

Installing the Chassis Cover.”

B

A

TP01671

Figure 15. Installing the Processor Air Duct

40

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 41

Platform Installations and Upgrades

Installing and Removing Memory DIMMs

The silkscreen on the board for the DIMMs displays DIMM1B, DIMM1A, DIMM2B,

DIMM2A, DIMM3B and DIMM3A, starting from the outside of the board. DIMM1B is the

socket closest to the outside edge of the server board.

Installing DIMMs

To install DIMMs, follow these steps:

1. Power down the server system and unplug all peripheral devices and the AC power

cable or the DC mains.

2. Remove the chassis cover. For instructions, see “

3. Locate the DIMM sockets. See below.

Removing the Chassis Cover.”

DIMM 2A

DIMM 3B

DIMM 3A

DIMM 2B

DIMM 1A

DIMM 1B

TP01661

Figure 16. Installing Memory DIMMs

4. Push the clips at each end of the DIMM socket(s) outward to the open position. See

Figure 16.

5. Holding the DIMM by the edges, remove it from its anti-static package.

6. Position the DIMM above the socket. Align the small notch in the bottom edge of the

DIMM with the keys in the socket.

7. Insert the bottom edge of the DIMM into the socket.

8. Push down on the top edge of the DIMM until the retaining clips snap into place. Make

sure the clips are firmly in place.

®

Carrier Grade Server TIGI2U User Guide 41

Intel

Page 42

Platform Installations and Upgrades

9. Replace the chassis cover if you have completed all work inside of the platform. For

instructions, see “

Installing the Chassis Cover.”

Removing DIMMs

To remove a DIMM, follow these steps:

1. Power down the server system and unplug all peripheral devices and the AC power

cable or the DC mains.

2. Remove the chassis cover. For instructions, see “

3. Locate the DIMM(s). See

Figure 16.

4. Push the clips at each end of the DIMM socket(s) outward to the open position. The

DIMM lifts from the socket.

5. Holding the DIMM by the edges, lift it away from the socket, and store it in an antistatic package.

6. Replace the chassis cover if you have completed all work inside of the platform. For

instructions, see “

Installing the Chassis Cover.”

Removing the Chassis Cover.”

Replacing the Processor

NOTE

Use the instructions provided below to replace a processor instead of

using the instructions that came with the processor.

CAUTIONS

Processor must be appropriate: You may damage the server board

if you install a processor that is inappropriate for your server. See

“

Additional Information and Software” for a link to the list of compatible

processors.

ESD and handling processors: Reduce the risk of electrostatic

discharge (ESD) damage to the processor by doing the following:

(1) Touch the metal chassis before touching the processor or server

board. Keep part of your body in contact with the metal chassis to

dissipate the static charge while handling the processor. (2) Avoid

moving around unnecessarily.

Follow the instructions below to remove and then install a processor.

42

®

Carrier Grade Server TIGI2U User Guide

Intel

Page 43

Platform Installations and Upgrades

Removing the Processor

1. Power down the server system and unplug all peripheral devices and the AC power

cable or the DC mains.

2. Remove the chassis cover. For instructions, see “

3. Remove the processor air duct that covers the processor. For instructions, see

Removing the Processor Air Duct.”

“

4. Loosen the four captive screws on the corners of the heat sink.

Removing the Chassis Cover.”

TP01660

Figure 17. Removing Heat Sink

5. Twist the heat sink slightly to break the seal between the heat sink and the processor.

6. Lift the heat sink from the processor. If it does not pull up easily, twist the heat sink

again. Do not force the heat sink from the processor. Doing so could damage the

processor.

7. Lift the processor lever.

8. Remove the processor.

®

Carrier Grade Server TIGI2U User Guide 43

Intel

Page 44

Platform Installations and Upgrades

Installing the Processor

To install a processor, follow these instructions:

1. Power down the server system and unplug all peripheral devices and the AC power

cable or the DC mains.

2. Remove the chassis cover. For instructions, see “