Page 1

Intel® Server System S7000FC4UR

Product Guide

A Guide for Technically Qualified Assemblers of Intel® Identified Subassemblies/Products

Intel Order Number D93989-002

Page 2

Disclaimer

Information in this document is provided in connection with Intel® products. No license, express or implied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Intel's

Terms and Conditions of Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any

express or implied warranty, relating to sale and/or use of Intel products including liability or warranties relating to

fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property

right. Intel products are not designed, intended or authorized for use in any medical, life saving, or life sustaining

applications or for any other application in which the failure of the Intel product could create a situation where

personal injury or death may occur. Intel may make changes to specifications and product descriptions at any time,

without notice.

Intel server boards contain a number of high-density VLSI and power delivery components that need adequate

airflow for cooling. Intel's own chassis are designed and tested to meet the intended thermal requirements of these

components when the fully integrated system is used together. It is the responsibility of the system integrator that

chooses not to use Intel developed server building blocks to consult vendor datasheets and operating parameters to

determine the amount of airflow required for their specific application and environmental conditions. Intel Corporation

can not be held responsible if components fail or the server board does not operate correctly when used outside any

of their published operating or non-operating limits.

Intel, Intel Pentium, and Intel Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries in

the United States and other countries.

* Other names and brands may be claimed as the property of others.

Copyright © 2007, Intel Corporation. All Rights Reserved

ii Intel® Server System S7000FC4UR Product Guide

Page 3

Safety Information

Important Safety Instructions

Read all caution and safety statements in this document before performing any of the

instructions. See also Intel Server Boards and Server Chassis Safety Information on the

®

Server Deployment Toolkit CD 2 and/or at http://support.intel.com/support/

Intel

motherboards/server/sb/cs-010770.htm.

Wichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warnund Sicherheitshinweise in diesem Dokument, bevor

Sie eine der Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise zu

Intel-Serverplatinen und Servergehäusen auf der Intel

oder unter http://support.intel.com/support/motherboards/server/sb/cs-010770.htm.

®

Server Deployment Toolkit CD 2

Consignes de sécurité

Lisez attention toutes les consignes de sécurité et les mises en garde indiquées dans ce

document avant de suivre toute instruction. Consultez Intel Server Boards and Server

Chassis Safety Information sur le Intel

vous sur le site http://support.intel.com/support/motherboards/server/sb/cs-010770.htm.

®

Server Deployment Toolkit CD 2 ou bien rendez-

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de realizar

cualquiera de las instrucciones. Vea Intel Server Boards and Server Chassis Safety

Information en el Intel

support/motherboards/server/sb/cs-010770.htm.

®

Server Deployment Toolkit CD 2 y/o en http://support.intel.com/

Page 4

Warnings

重要安全指导

Heed safety instructions: Before working with your server product, whether you are

using this guide or any other resource as a reference, pay close attention to the safety

instructions. You must adhere to the assembly instructions in this guide to ensure and

maintain compliance with existing product certifications and approvals. Use only the

described, regulated components specified in this guide. Use of other products /

components will void the UL listing and other regulatory approvals of the product and

will most likely result in noncompliance with product regulations in the region(s) in which

the product is sold.

System power on/off: The power button DOES NOT turn off the system AC power. To

remove power from system, you must unplug the AC power cord from the wall outlet.

Make sure the AC power cord is unplugged before you open the chassis, add, or remove

any components.

Hazardous conditions, devices and cables: Hazardous electrical conditions may be

present on power, telephone, and communication cables. Turn off the server and

disconnect the power cord, telecommunications systems, networks, and modems attached

to the server before opening it. Otherwise, personal injury or equipment damage can

result.

Electrostatic discharge (ESD) and ESD protection: ESD can damage drives, boards,

and other parts. We recommend that you perform all procedures in this chapter only at an

ESD workstation. If one is not available, provide some ESD protection by wearing an

antistatic wrist strap attached to chassis ground any unpainted metal surface on your

server when handling parts.

ESD and handling boards: Always handle boards carefully. They can be extremely

sensitive to ESD. Hold boards only by their edges. After removing a board from its

protective wrapper or from the server, place the board component side up on a grounded,

static free surface. Use a conductive foam pad if available but not the board wrapper. Do

not slide board over any surface.

iv Intel® Server System S7000FC4UR Product Guide

Page 5

Installing or removing jumpers: A jumper is a small plastic encased conductor that slips

over two jumper pins. Some jumpers have a small tab on top that you can grip with your

fingertips or with a pair of fine needle nosed pliers. If your jumpers do not have such a tab,

take care when using needle nosed pliers to remove or install a jumper; grip the narrow

sides of the jumper with the pliers, never the wide sides. Gripping the wide sides can

damage the contacts inside the jumper, causing intermittent problems with the function

controlled by that jumper. Take care to grip with, but not squeeze, the pliers or other tool

you use to remove a jumper, or you may bend or break the pins on the board.

Intel® Server System S7000FC4UR Product Guide v

Page 6

vi Intel® Server System S7000FC4UR Product Guide

Page 7

Preface

About this Manual

Thank you for purchasing and using the Intel® Server System S7000FC4UR.

This manual is written for system technicians who are responsible for troubleshooting,

upgrading, and repairing this server chassis. This document provides a brief overview of

the features of the chassis, a list of accessories or other components you may need,

troubleshooting information, and instructions on how to add and replace components on

the Intel

manual, see http://support.intel.com/support/motherboards/server/S7000FC4UR/.

Manual Organization

®

Server System S7000FC4UR Product Guide. For the latest version of this

• Chapter 1 provides an overview of the Server System S7000FC4UR. In this chapter,

you will find a list of the server board and chassis features, and product diagrams to

help you identify components and their locations.

• Chapter 2 describes how to start up and shut down the server.

• Chapter 3 describes the Intel

®

Server System S7000FC4UR Deployment Toolkit CD.

• Chapter 4 provides instructions for using the utilities that are shipped with the server

system or that you might need to download to update the system. This includes how

to navigate through the BIOS Setup screens, how to perform BIOS and firmware

updates, and how to configure the server management features.

• Chapter 5 provides instructions for adding and replacing hot-swappable and user-

serviceable system components and memory DIMMs. You do not need a service

technician to perform these tasks.

• Chapter 6 provides instructions for adding and replacing processors, memory,

boards, and other components that require a certified service technician.

At the back of this book, you will find POST code information, safety and regulatory

information, “getting help” information, and the warranty.

vii

Page 8

Additional Information and Software

If you need more information about this product or information about the accessories that

can be used with this server chassis, use the following resources. These files are available

at http://support.intel.com/support/motherboards/server/S7000FC4UR/

Unless otherwise indicated in the table below, once on this Web page, type the document

or software name in the search field at the left side of the screen and select the option to

search “This Product.”

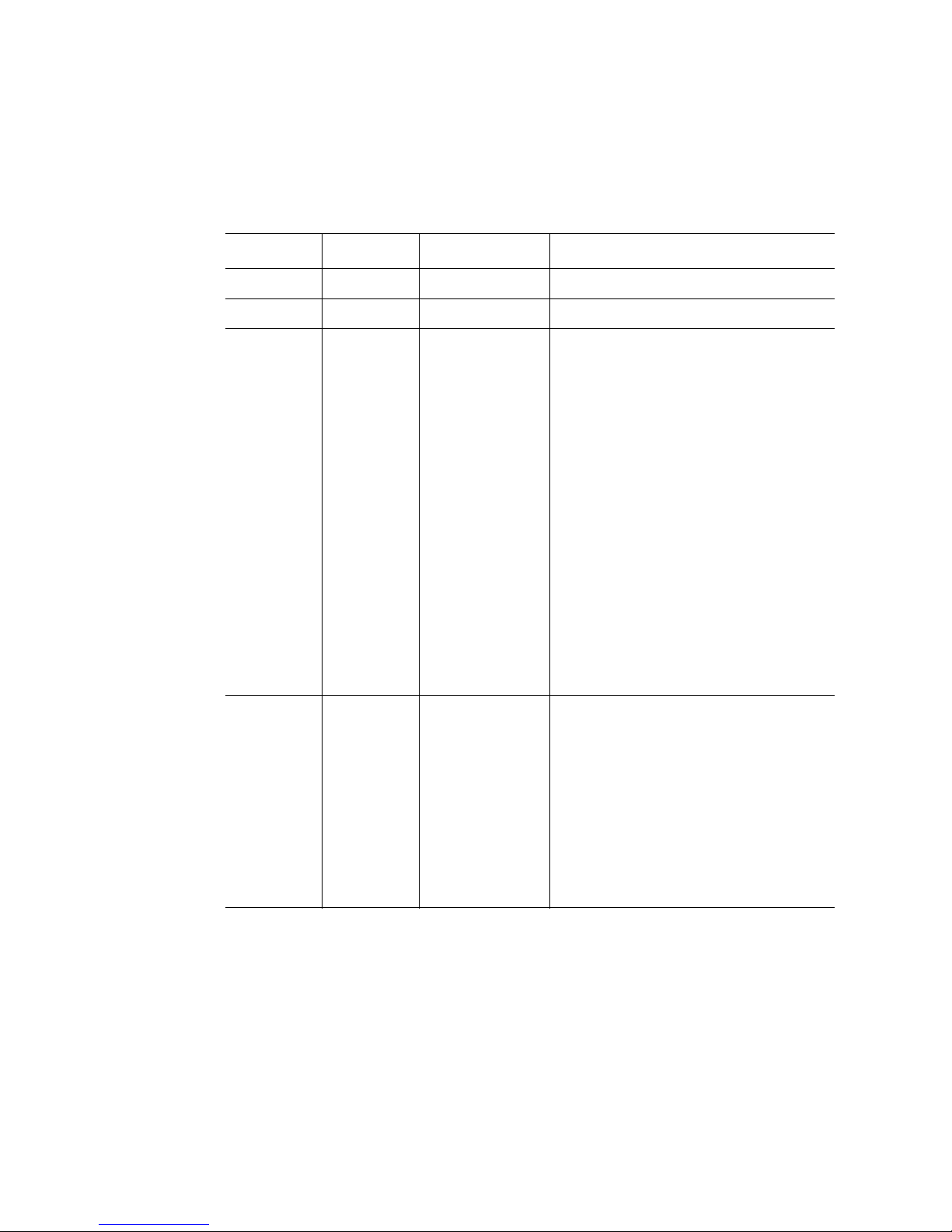

Table 1. Additional Information and Software

For this information or

software

For in-depth technical

information about this

product, including BIOS

settings and chipset

information

If you just received this

product and need to install

it

Accessories or other Intel

server products

Hardware (peripheral

boards, adapter cards) and

operating systems that

have been tested with this

product

Processors that have been

tested with this product

DIMMs that have been

tested with this product

To make sure your system

falls within the allowed

power budget

For diagnostics test

software

For drivers Driver (for an extensive list of drivers available)

For firmware and BIOS

updates

For software to manage

your Intel

®

server

®

Intel

Server System S7000FC4UR Technical Product Specification

Intel® Server System S7000FC4UR Quick Start User's Guide in the

product box

Spares and Configuration Guide

Tested Hardware Operating Systems List

Supported Processors

Supported Memory

Power Budget

Platform Confidence Tests (PCT)

Operating System Driver (for operating system drivers)

Firmware Update

Intel System Management Software

Use this Document or Software

viii Intel® Server System S7000FC4UR Product Guide

Page 9

Contents

Safety Information ................................................................................iii

Important Safety Instructions ..........................................................................iii

Wichtige Sicherheitshinweise .........................................................................iii

Consignes de sécurité ....................................................................................iii

Instrucciones de seguridad importantes .........................................................iii

Warnings ........................................................................................................iv

Preface ..................................................................................................vii

About this Manual ..........................................................................................vii

Manual Organization .....................................................................................vii

Additional Information and Software .............................................................viii

Chapter 1: System Description .............................................................1

System Features ............................................................................................ 2

System Front .................................................................................................. 4

System Rear ................................................................................................. 10

Processors ................................................................................................... 12

System Memory ............................................................................................ 12

Power Subsystem ......................................................................................... 14

Cooling Subsystem ....................................................................................... 18

Hot-swap PCI Slots ...................................................................................... 19

Peripherals ................................................................................................... 20

System Board Set ........................................................................................ 22

Server and Platform Management ................................................................ 35

Front Control Panel ................................................................................ 5

Power Supply Modules ........................................................................ 14

Power Supply Consumption ................................................................. 16

Hot-Swap Hard Drive ........................................................................... 21

Optical Drive Bay ................................................................................. 22

5 ¼-inch Half-height Drive Bay ............................................................ 22

Main Board ........................................................................................... 23

Memory Board ...................................................................................... 28

I/O Riser Board (optional) .................................................................... 30

SAS Riser Board (optional) .................................................................. 31

Front Panel Board ................................................................................ 32

SAS Backplane Board .......................................................................... 33

Power Distribution Board ..................................................................... 35

Chapter 2: Starting Up and Shutting Down the Server ....................37

Powering Up the Server ............................................................................... 37

Intel® Server System S7000FC4UR Product Guide ix

Page 10

Shutting Down the Server .............................................................................37

Chapter 3: Intel® Server Deployment Toolkit .................................... 39

Chapter 4: Server Utilities .................................................................. 41

Using the BIOS Setup Utility .........................................................................41

Navigating the BIOS Setup Utility .........................................................41

System Configuration Reset .........................................................................43

Rolling BIOS ..................................................................................................45

Booting from Backup Image .................................................................45

Console Redirection ......................................................................................46

Serial Configuration Settings ................................................................46

Keystroke Mappings .............................................................................47

Limitations .............................................................................................48

Interface to Server Management ..........................................................48

Platform Confidence Test ..............................................................................49

Running the Platform Confidence Test .................................................50

Intel® Deployment Assistant .........................................................................51

System Setup and Configuration Utilities ......................................................51

Save and Restore System Configuration (SYSCFG) ...........................52

FWPIAUPD Firmware Load Utility ........................................................52

One-boot Flash Update Utility (OFU) ....................................................53

IFLASH32 BIOS Load Utility .................................................................53

FRUSDR Load Utility ............................................................................53

Extensible Firmware Interface (EFI) Shell .....................................................54

Chapter 5: User-Serviceable Components ....................................... 57

Before You Begin ..........................................................................................57

Tools and Supplies Needed ..................................................................57

System References ..............................................................................57

Removing and Installing the Chassis Cover .................................................57

Removing the Top Cover ......................................................................58

Installing the Top Cover ........................................................................59

Hot-swapping a Front System Fan ................................................................59

Hot-swapping a Rear System Fan ................................................................60

Hot-swapping a Hard Drive ...........................................................................62

Removing a Hard Drive Carrier ............................................................63

Mounting a Hard Drive in a Carrier .......................................................63

Installing a Hard Drive Carrier ..............................................................65

Hot-swapping a Power Supply ......................................................................66

Installing and Removing PCI Express* Add-in Cards ...................................68

Removing a Hot-swap PCI Card, Operating System Interface .............69

Removing a Hot-swap PCI Card, Hardware Interface ..........................71

Installing a Hot-swap PCI Card .............................................................72

Removing a Non-hot-swap PCI Card ...................................................74

x Intel® Server System S7000FC4UR Product Guide

Page 11

Installing a Non-hot-swap PCI Card ..................................................... 75

Installing and Removing Memory Boards ..................................................... 75

Removing a Memory Board ................................................................. 76

Installing a Memory Board ................................................................... 78

Installing and Removing DIMMs ................................................................... 79

Installing DIMMs ................................................................................... 81

Removing DIMMs ................................................................................. 84

Chapter 6: Technician Maintenance ...................................................85

Before You Begin ......................................................................................... 85

Tools and Supplies Needed ................................................................. 85

System References .............................................................................. 85

Component Locations .......................................................................... 86

Removing and Installing the Top Cover ....................................................... 90

Removing the Top Cover ..................................................................... 90

Installing the Top Cover ....................................................................... 91

Removing and Installing the Processor Air Baffle ........................................ 92

Removing the Processor Air Baffle ...................................................... 92

Installing the Processor Air Baffle ........................................................ 94

Removing and Installing the Lower Air Baffle ............................................... 96

Removing the Lower Air Baffle ............................................................. 96

Installing the Lower Air Baffle ............................................................... 97

Installing and Removing the SAS Riser Board (optional) ............................. 98

Installing the SAS Riser Board ............................................................. 98

Removing the SAS Riser Board ........................................................... 99

Installing and Removing the Intel® RAID Activation Key and RAID DIMM 101

Installing the Intel® RAID Activation Key and RAID DIMM ................ 101

Removing the Intel® RAID Activation Key and RAID DIMM .............. 102

Installing and Removing the Intel® RAID Smart Battery AXXRSBBU4 ..... 104

Installing and Removing the CD-ROM / DVD-ROM Drive .......................... 104

Removing the CD-ROM / DVD-ROM Drive ........................................ 104

Installing a CD-ROM / DVD-ROM Drive ............................................. 106

Installing and Removing a 5 ¼-inch Peripheral Device .............................. 107

Installing a 5 ¼-inch Peripheral Device .............................................. 108

Removing a 5 ¼-inch Peripheral Device ............................................ 109

Servicing the Processors ............................................................................ 110

Handling the Intel

Installing and Removing a Processor Thermal Blank ................................. 111

Removing a Processor Thermal Blank ............................................... 111

Installing a Processor Thermal Blank ................................................. 112

Installing and Removing a Processor ......................................................... 113

Installing a Processor ......................................................................... 113

Removing a Processor ....................................................................... 115

Removing and Installing the Center Brace ................................................. 116

®

Xeon® Processor MP .......................................... 110

Intel® Server System S7000FC4UR Product Guide xi

Page 12

Removing the Center Brace ...............................................................116

Installing the Center Brace .................................................................117

Installing and Removing the I/O Riser Board ..............................................118

Installing the I/O Riser Board ..............................................................118

Removing the I/O Riser Board ............................................................118

Installing and Removing the Intel

®

Remote Management Module 2 (Intel®

RMM2) ................................................................................................119

Installing the Intel

Removing the Intel

®

RMM2 and NIC Module .......................................119

®

RMM2 and NIC Module .....................................121

Replacing the Main Board ...........................................................................122

Removing the Main Board ..................................................................122

Installing the Main Board ....................................................................124

Replacing the SAS Backplane Board ..........................................................127

Removing the SAS Backplane Board .................................................127

Installing the SAS Backplane Board ...................................................128

Replacing the Power Distribution Board .....................................................128

Removing the Power Distribution Board .............................................128

Installing the Power Distribution Board ...............................................130

Replacing the Front Panel Board ................................................................131

Removing the Front Panel Board .......................................................131

Installing the Front Panel Board .........................................................132

Replacing the CMOS Battery ......................................................................133

Appendix A: POST Codes ................................................................ 137

POST Progress Codes and Messages .......................................................137

POST Error Messages and Handling ..........................................................141

POST Error Beep Codes .............................................................................153

Appendix B: Installation / Assembly Safety Instructions .............. 155

English ........................................................................................................155

Deutsch .......................................................................................................157

Français ......................................................................................................159

Español .......................................................................................................161

Italiano .........................................................................................................163

Appendix C: Safety Information ....................................................... 167

English ........................................................................................................167

Server Safety Information ...................................................................167

Safety Warnings and Cautions ...........................................................167

Intended Application Uses ..................................................................168

Site Selection ......................................................................................168

Equipment Handling Practices ............................................................169

Power and Electrical Warnings ...........................................................169

System Access Warnings ...................................................................170

Rack Mount Warnings ........................................................................171

xii Intel® Server System S7000FC4UR Product Guide

Page 13

Electrostatic Discharge (ESD) ............................................................ 171

Other Hazards .................................................................................... 172

Sicherheitshinweise für den Server .................................................... 174

Sicherheitshinweise und Vorsichtsmaßnahmen ................................ 174

Zielbenutzer der Anwendung ............................................................. 175

Standortauswahl ................................................................................ 175

Handhabung von Geräten .................................................................. 176

Warnungen zu Netzspannung und Elektrizität ................................... 176

Warnhinweise für den Systemzugang ................................................ 177

Warnhinweise für Racks .................................................................... 178

Elektrostatische Entladungen (ESD) .................................................. 178

Andere Gefahren ................................................................................ 179

Français ...................................................................................................... 180

Consignes de sécurité sur le serveur ................................................. 180

Sécurité: avertissements et mises en garde ...................................... 180

Domaines d’utilisation prévus ............................................................ 181

Sélection d’un emplacement .............................................................. 181

Pratiques de manipulation de l’équipement ....................................... 181

Alimentation et avertissements en matière d’électricité ..................... 182

Avertissements sur l’accès au système ............................................. 183

Avertissements sur le montage en rack ............................................. 184

Décharges électrostatiques (ESD) ..................................................... 184

Autres risques .................................................................................... 185

Información de seguridad del servidor ............................................... 186

Advertencias y precauciones sobre seguridad .................................. 186

Aplicaciones y usos previstos ............................................................ 187

Selección de la ubicación ................................................................... 187

Manipulación del equipo .................................................................... 187

Advertencias de alimentación y eléctricas ......................................... 188

Advertencias el acceso al sistema ..................................................... 189

Advertencias sobre el montaje en bastidor ........................................ 190

Descarga electrostática (ESD) ........................................................... 190

Appendix D: Regulatory and Compliance Information ..................197

Product Regulatory Compliance ................................................................. 197

Product Safety Compliance ................................................................ 197

Product EMC Compliance - Class A Compliance .............................. 197

Certifications / Registrations / Declarations ....................................... 198

Product Regulatory Compliance Markings ......................................... 198

Electromagnetic Compatibility Notices ....................................................... 200

FCC Verification Statement (USA) ..................................................... 200

Industry Canada (ICES-003) .............................................................. 201

Europe (CE Declaration of Conformity) .............................................. 201

VCCI (Japan) ..................................................................................... 201

Intel® Server System S7000FC4UR Product Guide xiii

Page 14

BSMI (Taiwan) ....................................................................................202

RRL (Korea) ........................................................................................202

CNCA (CCC China) ............................................................................202

Regulated Specified Components ...............................................................203

Restriction of Hazardous Substances (RoHS) Compliance ........................203

End of Life / Product Recycling ...................................................................204

Appendix E: Equipment Log ............................................................ 205

Appendix F: Warranty ....................................................................... 207

Limited Warranty for Intel® Chassis Subassembly Products ......................207

Extent of Limited Warranty ..........................................................................208

Warranty Limitations and Exclusions ..........................................................208

Limitations of Liability ..........................................................................208

How to Obtain Warranty Service .................................................................209

Telephone Support .............................................................................209

Returning a Defective Product ............................................................209

Appendix G: Getting Help ................................................................. 211

World Wide Web .........................................................................................211

Telephone ...................................................................................................211

xiv Intel® Server System S7000FC4UR Product Guide

Page 15

List of Figures

Figure 1. Intel® Server System S7000FC4UR ................................................... 1

Figure 2. Front Components.............................................................................. 4

Figure 3. Front Panel Controls and Indicators ................................................... 6

Figure 4. Intel

Figure 5. System Rear..................................................................................... 12

Figure 6. Memory Boards ................................................................................ 13

Figure 7. Power Supply Indicators................................................................... 15

Figure 8. Power Consumption Selection Jumper............................................. 16

Figure 9. Rear Fan Locations .......................................................................... 18

Figure 10. Peripheral Area............................................................................... 20

Figure 11. Hard Drive Carrier........................................................................... 21

Figure 12. DVD-ROM / CD-ROM Drive Carrier ............................................... 22

Figure 13. Block Diagram ................................................................................ 23

Figure 14. Main Board Component Locations ................................................. 24

Figure 15. Main Board Jumpers....................................................................... 27

Figure 16. Memory Board LEDs and Connectors............................................ 29

Figure 17. I/O Riser Board Connectors............................................................ 31

Figure 18. SAS Riser Connectors.................................................................... 32

Figure 19. Front Panel Board Component Locations....................................... 32

Figure 20. SAS Backplane Connectors (Interior Side)..................................... 34

Figure 21. SAS Backplane Connectors (Drive Bay Side) ................................ 35

Figure 22. Removing the Chassis Cover ......................................................... 58

Figure 23. Installing the Chassis Cover ........................................................... 59

Figure 24. Removing a Front System Fan....................................................... 60

Figure 25. System Fan Module Installation...................................................... 60

Figure 26. Removing a Rear System Fan........................................................ 61

Figure 27. Hard Drive Carrier........................................................................... 62

Figure 28. Removing a Hard Drive Carrier ...................................................... 63

Figure 29. Removing the Air Baffle from the Hard Drive Carrier...................... 64

Figure 30. Attaching the Hard Drive to the Carrier........................................... 64

Figure 31. Installing Hard Drive into Server..................................................... 65

Figure 32. Power Supply Indicators................................................................. 66

Figure 33. Removing a Power Supply ............................................................. 67

Figure 34. Installing a Power Supply ............................................................... 68

Figure 35. Removing a PCI Card..................................................................... 70

Figure 36. PCI Slot Attention Button................................................................ 71

Figure 37. Installing a PCI Add-in Card ........................................................... 73

Figure 38. Opening Memory Board Latches.................................................... 76

Figure 39. Removing a Memory Board............................................................ 77

Figure 40. Installing a Memory Board.............................................................. 78

Figure 41. Minimum Memory Population ......................................................... 79

Figure 42. Memory Board A and B Population ................................................ 80

®

Local Control Panel................................................................... 8

Intel® Server System S7000FC4UR Product Guide xv

Page 16

Figure 43. Memory Board A, B, C, D Population.............................................. 81

Figure 44. Remove Memory Board DIMM Cover ............................................. 82

Figure 45. Install DIMMs................................................................................... 83

Figure 46. Main Board Component Locations.................................................. 87

Figure 47. SAS Backplane Connectors (Interior Side) ..................................... 88

Figure 48. SAS Backplane Connectors (Drive Bay Side)................................. 89

Figure 49. Front Panel Board Component Locations ....................................... 89

Figure 50. Removing the Top Cover ................................................................ 91

Figure 51. Installing the Top Cover .................................................................. 92

Figure 52. Removing the Processor Air Baffle ................................................. 93

Figure 53. Installing the Processor Air Baffle ................................................... 94

Figure 54. Engaging the Processor Air Baffle Guides...................................... 95

Figure 55. Removing the Lower Center Air Baffle............................................ 96

Figure 56. Installing the Lower Center Air Baffle.............................................. 97

Figure 57. Installing SAS Riser Board .............................................................. 98

Figure 58. Connecting SAS and SES Cables to SAS Riser Board .................. 99

Figure 59. Disconnecting SAS and SES Cables from SAS Riser Board........ 100

Figure 60. Removing SAS Riser Board .......................................................... 100

Figure 61. Installing the Intel® RAID Activation Key and DIMM..................... 102

Figure 62. Removing the CD-ROM / DVD-ROM Drive Carrier from the Server 105

Figure 63. Removing the CD-ROM / DVD-ROM Drive from the Carrier......... 105

Figure 64. Assembling the CD-ROM / DVD-ROM Drive and Carrier.............. 106

Figure 65. Inserting the CD-ROM / DVD-ROM Drive Carrier into the System 107

Figure 66. Removing 5 ¼-inch Peripheral Device from Server ...................... 108

Figure 67. Installing 5 ¼ Peripheral Device into Server ................................. 109

Figure 68. Removing a Thermal Blank........................................................... 111

Figure 69. Installing a Thermal Blank............................................................. 112

Figure 70. Open Processor Socket Release Lever ........................................ 113

Figure 71. Set Processor into Socket............................................................. 114

Figure 72. Close Processor Socket Lever...................................................... 114

Figure 73. Open Processor Socket Release Lever ........................................ 115

Figure 74. Removing the Center Brace.......................................................... 116

Figure 75. Installing the Center Brace............................................................ 117

Figure 76. Attaching the EMI Gasket.............................................................. 120

Figure 77. Installing the RMM2 NIC ............................................................... 120

Figure 78. Installing the Intel

®

RMM2............................................................. 121

Figure 79. Removing the PCI Dividers ........................................................... 123

Figure 80. Removing the Main Board............................................................. 124

Figure 81. Installing the Main Board............................................................... 125

Figure 82. Installing the PCI Slot Dividers...................................................... 126

Figure 83. Power Distribution Cable Location on SAS Backplane ................. 129

Figure 84. Removing the Power Distribution Board ....................................... 130

Figure 85. Installing the Power Distribution Board ......................................... 131

Figure 86. Removing the Front Panel I/O Board ............................................ 132

Figure 87. Installing the Front Panel I/O Board .............................................. 133

Figure 88. Removing the Battery.................................................................... 135

xvi Intel® Server System S7000FC4UR Product Guide

Page 17

Tables

Table 1. Additional Information and Software .................................................. viii

Table 2. Chassis Features ................................................................................. 2

Table 3. System Status LED States ................................................................... 9

Table 4. Hot-swap PCI Slot Power and Attention LED .................................... 19

Table 5. Setup Menu Key Use ......................................................................... 42

Table 6. Console Redirection Escape Sequences ........................................... 47

Table 7. EFI Shell Commands ......................................................................... 54

Table 8. Port 80 POST Code LEDs ............................................................... 137

Table 9. POST Progress Codes and Messages ............................................ 138

Table 10. POST Error Manager Messages and Handling ............................. 142

Table 11. Beep Codes ................................................................................... 153

Table 12. Product Regulatory Compliance Markings ..................................... 198

Intel® Server System S7000FC4UR Product Guide xvii

Page 18

xviii Intel® Server System S7000FC4UR Product Guide

Page 19

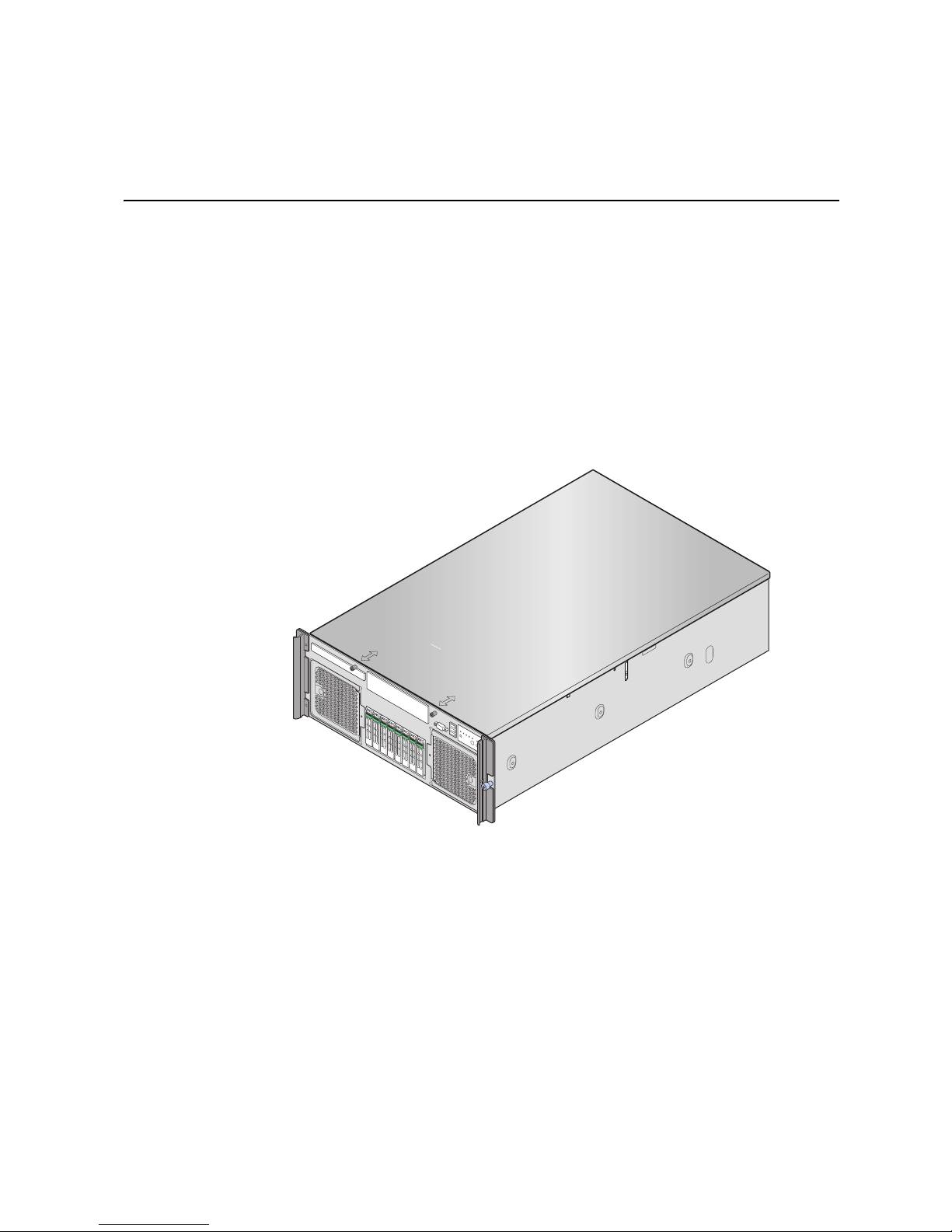

1 System Description

The Intel® Server System S7000FC4UR is a compact, high-density, 4U rack-mount

system with support for one to four Intel

533 MHz / 667 MHz FBDIMM memory. The system supports:

®

Xeon® processors MP and 256 GB of DDR2

• Hot-plug PCI Express* add-in cards

• Hot-swap, redundant power supply modules

• Hot-swap, redundant cooling fans

• Memory with RAS features

• Hot-swap hard drives

Figure 1. Intel

®

Server System S7000FC4UR

AF002228

1

Page 20

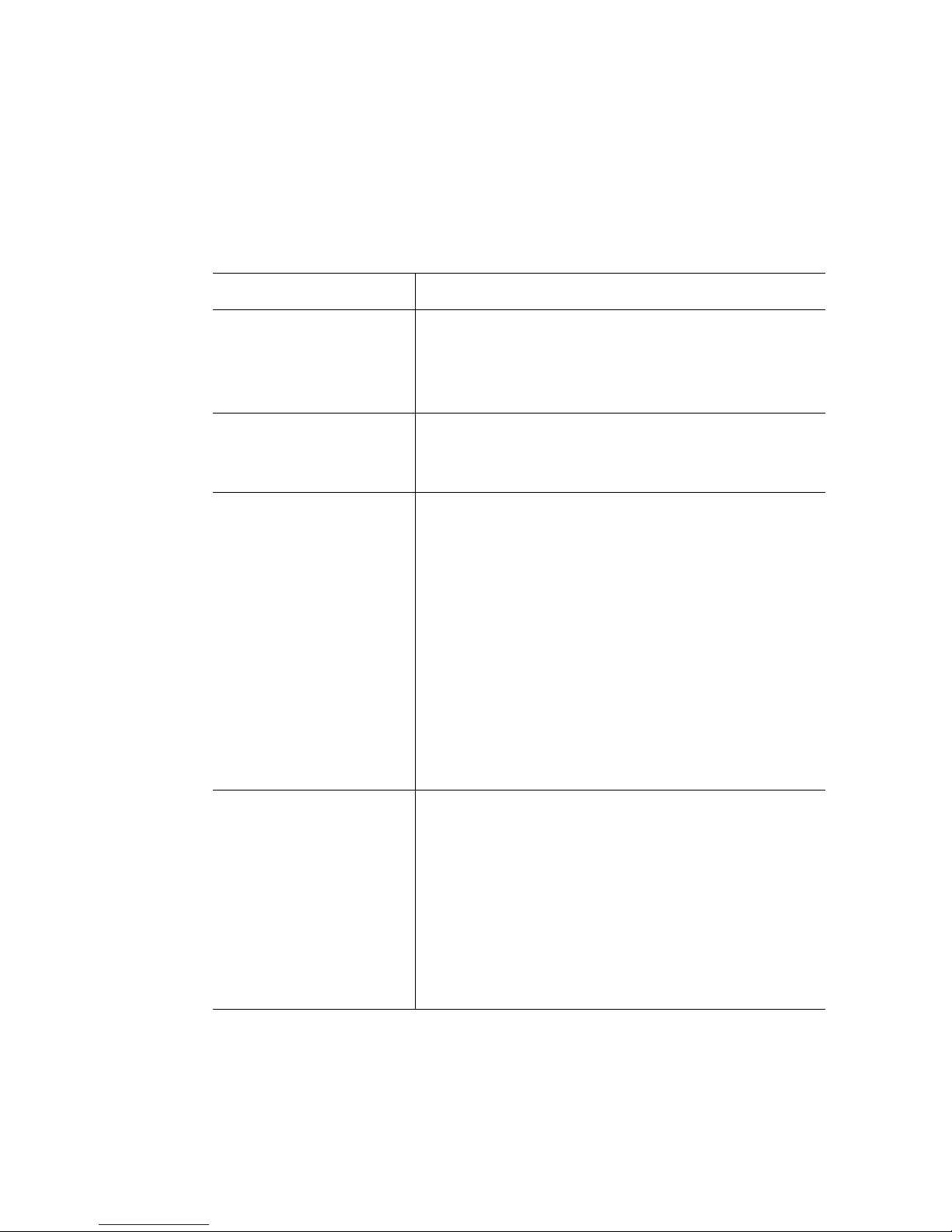

System Features

Feature Description

Dimensions Height: 6.8 inches (173 mm)

Clearance requirements Front clearance: 3 inches (76 mm)

Table 2. Chassis Features

Width: 17.6 inches (447 mm)

Depth: 27.8 inches (706 mm)

Weight of fully configured system: 90 lbs (40 kg)

Side clearance: 1 inch (25 mm)

Rear clearance: 6 inches (152 mm)

Configuration flexibility /

scaleability

Support for one to four processors

Support for at least two generations of processors

Support for up to four 2.5-inch SATA hard drives, or eight 2.5-

inch SAS hard drives with optional SAS riser board

Support for up to seven PCI-Express* adapters:

• Four x8 slots

• Three x4 slots

Support for up to 256 GB Fully Buffered DIMM (FBD) Double

Data Rate-2 (DDR2) 533 or 667 MHz memory

Support for two integrated gigabit LAN ports, or four integrated

gigabit LAN ports with optional I/O riser board

The optional Intel

display that allows you to configure and monitor the health of

the server independently from the operating system

Serviceability Front access to hot-swap hard drives

Front access to hot-swap fans

Rear access to hot-swap power supplies

System power and system status LEDs

System ID buttons and LEDs on front panel and rear of system

Memory status LEDs

Processor failure LEDs

Color-coded parts to identify hot-swap and non-hot-swap

serviceable components

®

Local Control Panel provides an LCD

2 Intel® Server System S7000FC4UR Product Guide

Page 21

Table 2. Chassis Features

Feature Description

Availability Two hot-plug PCI Express* slots.

Up to two 1570-watt power supplies in a redundant (1+1)

configuration. The second power supply is optional.

Dual power cords (1+1) when two power supplies are installed.

Up to eight hot-swap system fans in a redundant (7+1)

configuration. Two rear fans are optional; four rear fans are

required for redundancy.

Eight hot-swap 2.5-inch SAS hard drives.

SAS RAID riser board (optional) with a battery-backed DDR2

DIMM for disk cache.

Manageability Remote management

Emergency Management Port (EMP)

Intelligent Platform Management Interface (IPMI) 1.5 compliant,

partial IPMI 2.0 compliance

Wired For Management (WfM) 2.0 compliant

Remote diagnostics support

Optional Intel

KVM and media features (requires optional I/O riser)

®

Remote Management Module 2 provides remote

Front control panel System power button and LED

System reset button

NMI button

System ID button and LED

Optional Intel

®

Local Control Panel

System status LED

Hard drive status LED

LAN1 and LAN2 status LEDs

Video connector

Three USB 2.0 ports

Intel® Server System S7000FC4UR Product Guide 3

Page 22

System Front

A

B

C

G

Item Description

A CD-ROM / DVD-ROM drive bay

B 5 ¼-inch peripheral bay

C Video connector

E

D

FF

AF002229

D USB 2.0 ports

E Front control panel. Standard control panel shown.

F Hot-swap fan modules (2)

G Hot-swap hard drives (8)

Figure 2. Front Components

4 Intel® Server System S7000FC4UR Product Guide

Page 23

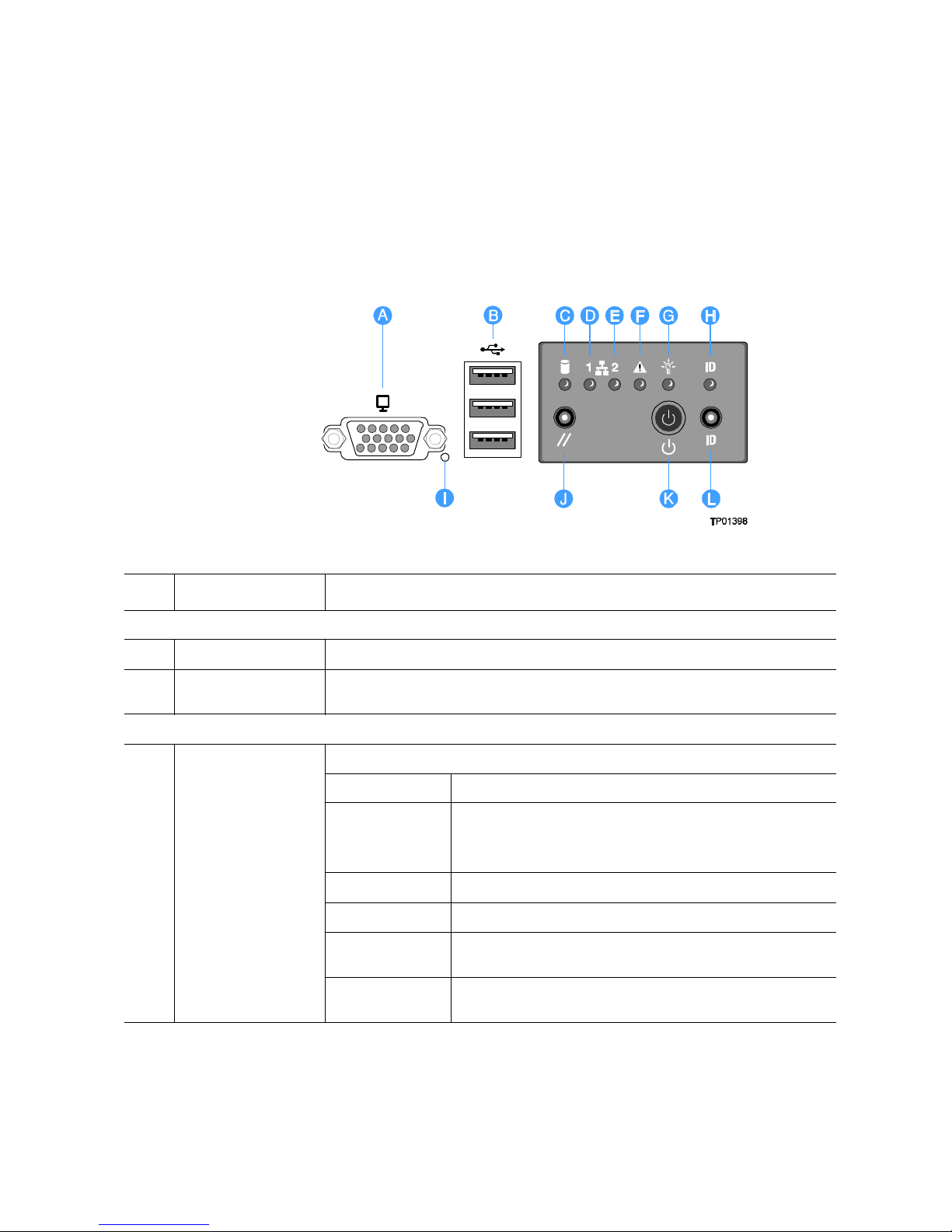

Front Control Panel

You can choose between the standard control panel or the Intel® Local Control Panel to

monitor and control your system locally.

The standard control panel provides the following user interface for system management

and status LEDs.

Item Feature Description

Front Panel Connectors

A Video connector Standard VGA-compatible video port

B Three USB

connectors

Front Panel Buttons and LED Indicators

C Hard drive activity

LED

2.0 port, 4-pin connectors

Green / amber LED that indicates hard drive activity and faults

LED State Drive State

Green on SAS drives are installed and functioning correctly

NOTE: LED may blink if all drives are active at the same

time.

Green blink SATA drives are installed and active

Amber on Drive / slot failure

Amber slow blink

(~1 Hz)

Amber fast blink

(~2.5 Hz)

Predictive hard drive / slot failure or rebuild in process

Rebuild interrupted or rebuild on empty slot

Intel® Server System S7000FC4UR Product Guide 5

Page 24

Item Feature Description

D

E

F System status / fault

G System power LED Green LED for system power status

LAN1, LAN 2 Status

LEDs

LED

Green LEDs

LAN1 shows status of either LAN port on the server board

LAN2 shows status of either LAN poor on the I/O riser board

LED State LAN State Activity

Off Idle No activity

Blinking Active Access

Green / amber LED for system status. See Table 3 for additional details.

LED System State Definition

Off Not ready AC power off

Green on Ok System is booted and ready

Green blink Degraded System is in a degraded

Amber blink Non-fatal System is likely to fail

Amber on Fatal System has failed

LED State System Power State ACPI

to operate

state

Off Power off No

On Power on No

Off S4 / S5 Yes

Blink S1 Yes

On S0 Yes

H System ID LED Blue ID that identifies the system through server management or locally

I NMI button Asserts NMI

J System reset button Press to reset the system

K System power button Press to turn the system power on or off

L System ID button Press to turn the system ID LED on or off

Figure 3. Front Panel Controls and Indicators

6 Intel® Server System S7000FC4UR Product Guide

Page 25

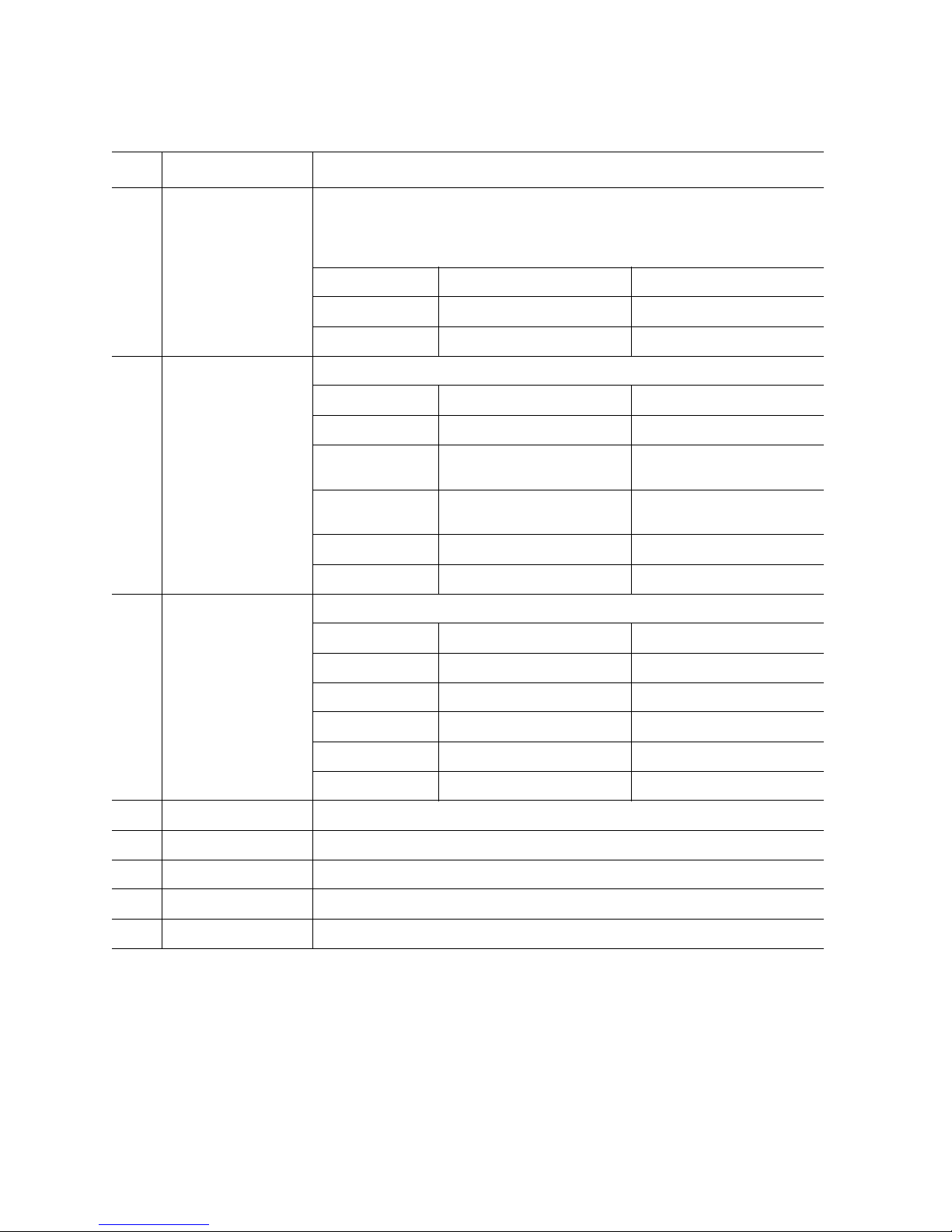

The optional Intel® Local Control Panel provides the following user interface for system

management and status LEDs.

A

B

C

D

E

M L K J I GH F

AF002230

Item Feature Description

A LCD display Video display

B Scroll up button Press to scroll up on the LCD

C Scroll down button Press to scroll down on the LCD

D Back button Press to move to the previous screen

E Select button Press to enter a command or select an option

F System ID LED Blue LED to identify the system through server management

software

G System power

LED

H System power

button

Green LED to show system status

LED State System Power State ACPI

Off Power off No

On Power on No

Off S4 / S5 Yes

Blink S1 Yes

On S0 Yes

Toggles system power on and off

Intel® Server System S7000FC4UR Product Guide 7

Page 26

Item Feature Description

I System status /

fault LED

J

K

L Hard drive status

LAN1, LAN 2

Status LEDs

LED

Green / amber LED for system status. See Table 3 for additional

details.

LED System State Definition

Off Not ready AC power off

Green on Ok System is booted and

ready to operate

Green blink Degraded System is in a degraded

state

Amber blink Non-fatal System is likely to fail

Amber on Fatal System has failed

Green LEDs

LAN1 shows status of either LAN port on the server board

LAN2 shows status of either LAN poor on the I/O riser board

LED State LAN State Activity

Off Idle No activity

Blinking Active Access

Green / amber LED that indicates hard drive activity and faults

LED State Drive State

M System reset

button

Green on SAS drives are installed and functioning correctly

NOTE: LED may blink if all drives are active at

the same time.

Green blink SATA drives are installed and active

Amber on Drive / slot failure

Amber slow

blink (~1 Hz)

Amber fast

blink (~2.5

Hz)

Resets the system

Predictive hard drive / slot failure or rebuild in

process

Rebuild interrupted or rebuild on empty slot

Figure 4. Intel® Local Control Panel

8 Intel® Server System S7000FC4UR Product Guide

Page 27

Both the standard and Intel® Local Control Panel provide the same Status LED

information:

Table 3. System Status LED States

LED Color LED State System Status Description

Off N/A Not ready The AC power is off

Green On OK System is ready to operate

Green Blink Degraded The system is in a degraded state because

of:

• Unable to use all of the installed

memory when more than one DIMM is

installed

• More than 10 correctable memory

errors occurred and data is migrating

to a spare DIMM (memory sparing or

mirroring is enabled)

• Loss of system memory redundancy

(memory sparing or mirroring is

enabled)

• PCI Express* correctable link errors

• Loss of power supply or fan

redundancy

• Processor disabled

• Non-critical threshold crossed

(temperature, voltage, power nozzle,

power gauge, PROCHOT1)

• Battery failed

Amber Blink Non-fatal Non-fatal alarm. The system is likely to fail

because of:

• More than 10 correctable memory

errors occurred and in a nonredundant memory configuration

• PCI Express uncorrectable link errors

• Critical threshold crossed

(temperature, PROCHOT)

• VRD hot-asserted

• Minimum number of fans not present

or too many fans failed

Intel® Server System S7000FC4UR Product Guide 9

Page 28

LED Color LED State System Status Description

Amber On Fatal Fatal alarm. The system has failed or shut

System Rear

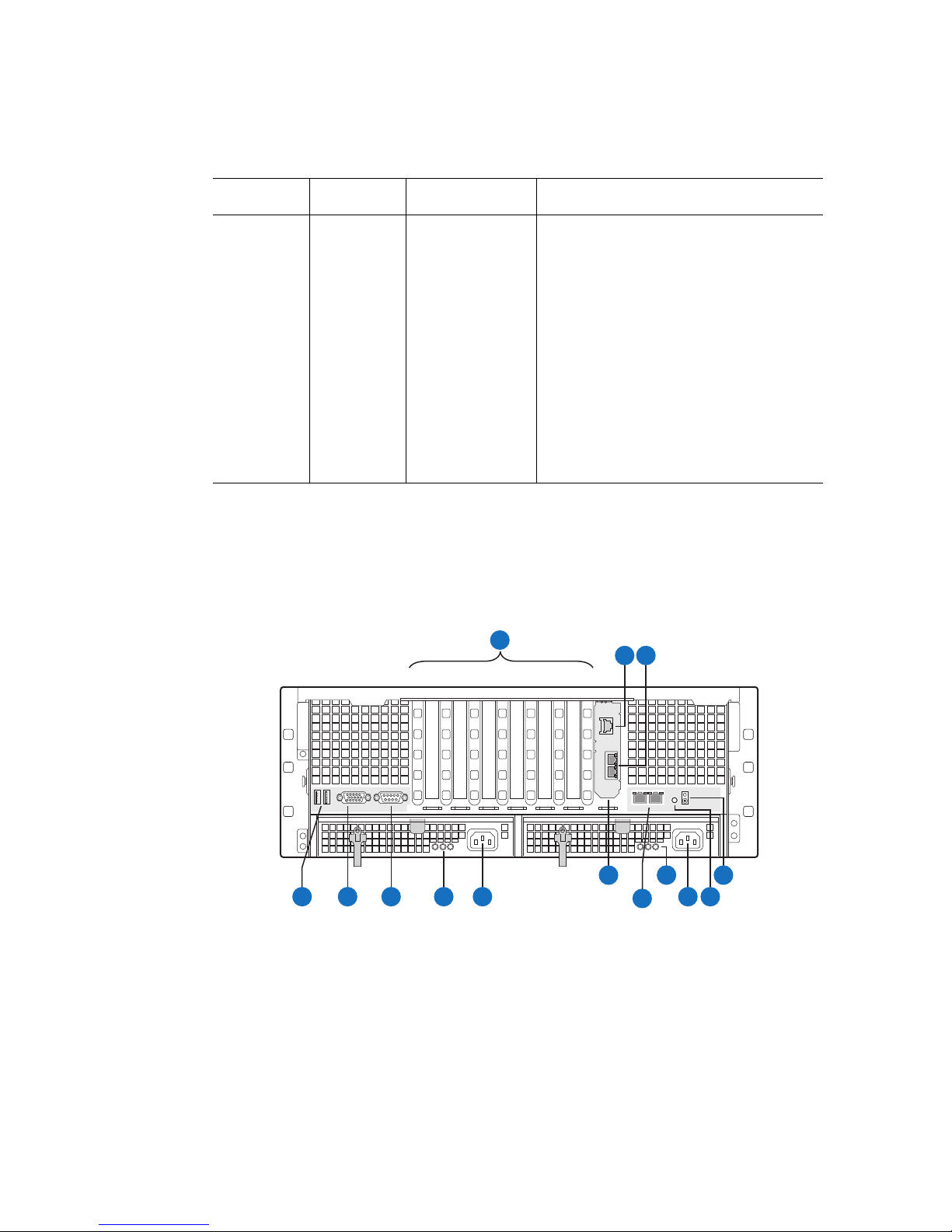

This diagram shows the system with the optional I/O panel installed.

Table 3. System Status LED States

down because of:

• DIMM failure with only one DIMM

present / no good memory present.

• Run-time memory uncorrectable error

in non-redundant memory mode.

• CPU IERR signal asserted.

• No processor present or processor

configuration errors

• CPU THERMTRIP

• No power good / power fault

• Power unit redundancy sensor.

Insufficient resources offset. Not

enough power supplies present

A

B C

1743256

I N

D

F

E

G

H

K

L

J

M

AF002231

10 Intel® Server System S7000FC4UR Product Guide

Page 29

Item Description

A PCI slots

Slot 1 PCI Express* x8, hot-plug

Slot 2 PCI Express* x8, hot-plug

Slot 3 PCI Express* x8, not hot-plug

Slot 4 PCI Express* x8, not hot-plug

Slot 5 PCI Express* x4, not hot-plug

Slot 6 PCI Express* x4, not hot-plug

Slot 7 PCI Express* x4, not hot-plug

B Intel

®

Remote Management Module 2 (Intel® RMM2) NIC

C I/O riser Ethernet ports (two)

D USB ports (two)

E Standard VGA-compatible video port with 15-pin connector

F Serial port B connector

G Power supply LEDs

Power Supply LED Power Supply Status

Left: Power good (green) Power supply is on

Center: Fault (amber) Power supply failure

Right: AC OK (green) Power supply is connected to AC

H AC input power connector

I I/O riser card (optional)

J LAN 1 (left), LAN 2 (right) RJ45 Ethernet connectors

LAN Port LED LAN Status

Status LED (green) Off: No Ethernet connected

On: Ethernet link detected

Blink: Ethernet link active

Speed LED (green / amber) Off: 10 Mbps

Green: 100 Mbps

Amber: 1000 Mbps

Intel® Server System S7000FC4UR Product Guide 11

Page 30

Item Description

K Power supply LEDs

L AC input power connector

M System ID button

N Blue system ID LED to identify the system from among many systems

Processors

One to four 64-bit Intel® Xeon® processors MP are supported.

Power Supply LED Power Supply Status

Left: Power good (green) Power supply is on

Center: Fault (amber) Power supply failure

Right: AC OK (green) Power supply is connected to AC

Figure 5. System Rear

System Memory

The memory boards connect to the main board through x16 PCI Express* connectors. One

to four memory boards can be installed, two on each side of the system. Memory board

baffles are not needed for empty memory board slots, but DIMM blanks are required for

each socket on each memory board in which a DIMM is not installed.

12 Intel® Server System S7000FC4UR Product Guide

Page 31

AF002235

Figure 6. Memory Boards

Each memory board has these features:

• Supports up to eight FBD Generation-1 DIMMs

• Supports FBD speeds of 533MT/s (4-4-4, 5-5-5 latencies) and 667MT/s (5-5-5

latency)

• Supports FBDIMM configurations of x8, x4, single, dual-rank DDR2 DRAMs

• Supports DDR2 DRAM technologies of 512 Mbit, 1 Gbit, and 2 Gbit

• Supports Closed Loop Thermal Throttling with FBDIMM AMB temperature

sensors

• LED fault indicators for each DIMM

• One field replaceable unit (FRU) EEPROM

• Supports memory mirroring and memory sparing

See “Memory Board” on page 28 for additional information.

Intel® Server System S7000FC4UR Product Guide 13

Page 32

Power Subsystem

The power subsystem consists of:

• Power supply modules (see below)

• Power distribution board (see “Power Distribution Board” on page 35)

1+1 power supply redundancy or operation with a single power supply is supported under

all configurations at 220 VAC. At 100 or 115 VAC, 1+1 power supply redundancy or

operation with only one power supply is supported only if the power supply DC limits are

not exceeded.

If your desired configuration exceeds the power supply limits, two power supplies are

required. The two power supplies will operate in current-sharing mode to deliver the

additional power needed for your configuration. The two power supplies must be sourced

from separate AC circuits so they do not exceed maximum AC inlet current. Exceeding

the maximum AC inlet current may cause a circuit breaker to trip.

In a redundant configuration, the system supports one fault at a time, either one fan fault

or one power supply fault, and it supports hot-swapping one component at a time.

Power Supply Modules

The output rating of each power supply is 1570 watts when operated between 180 VAC

and 264 VAC. It is current-sharing with auto-ranging input. The power supply is 7.75

inches wide, 14.5 inches deep, and 1.47 inches high. The power supply modules have

universal AC input with Power Factor Correction (PFC) Distributed Power Supplies

(DPS). The AC input receptacle is an IEC-320 C14.

The power supply has DC outputs of 12 V and 3.3 VSB. The 12 V main power is

distributed through the server and is converted locally at the point-of-load using

embedded VRM converters. The power supply is capable of power-safe monitoring.

The maximum AC input current is:

• 100 - 127 VAC: 12 A

• 200 - 240 VAC: 7 A

The maximum input current listed is the maximum AC inlet current that can be drawn by

the power supply / supplies. If two power supplies are installed, then this value is the

maximum combined input current for both AC inlets.

In an N+1 configuration, the 12 VDC outputs have active (forced) current-sharing. The

two externally enabled outputs have these maximum ratings:

• +12 VDC: 121 A

• +3.3 VDCSB: 5 A

14 Intel® Server System S7000FC4UR Product Guide

Page 33

Each power supply module requires one power cord to supply AC power to the system.

One power supply ships with the standard system. When two power supply modules and

two power cords are installed, the system supports (1+1) power cord redundancy. This

allows the system to be powered by two separate AC sources. In the 1+1 configuration,

the system continues to operate without interruption if one of the AC power sources fails.

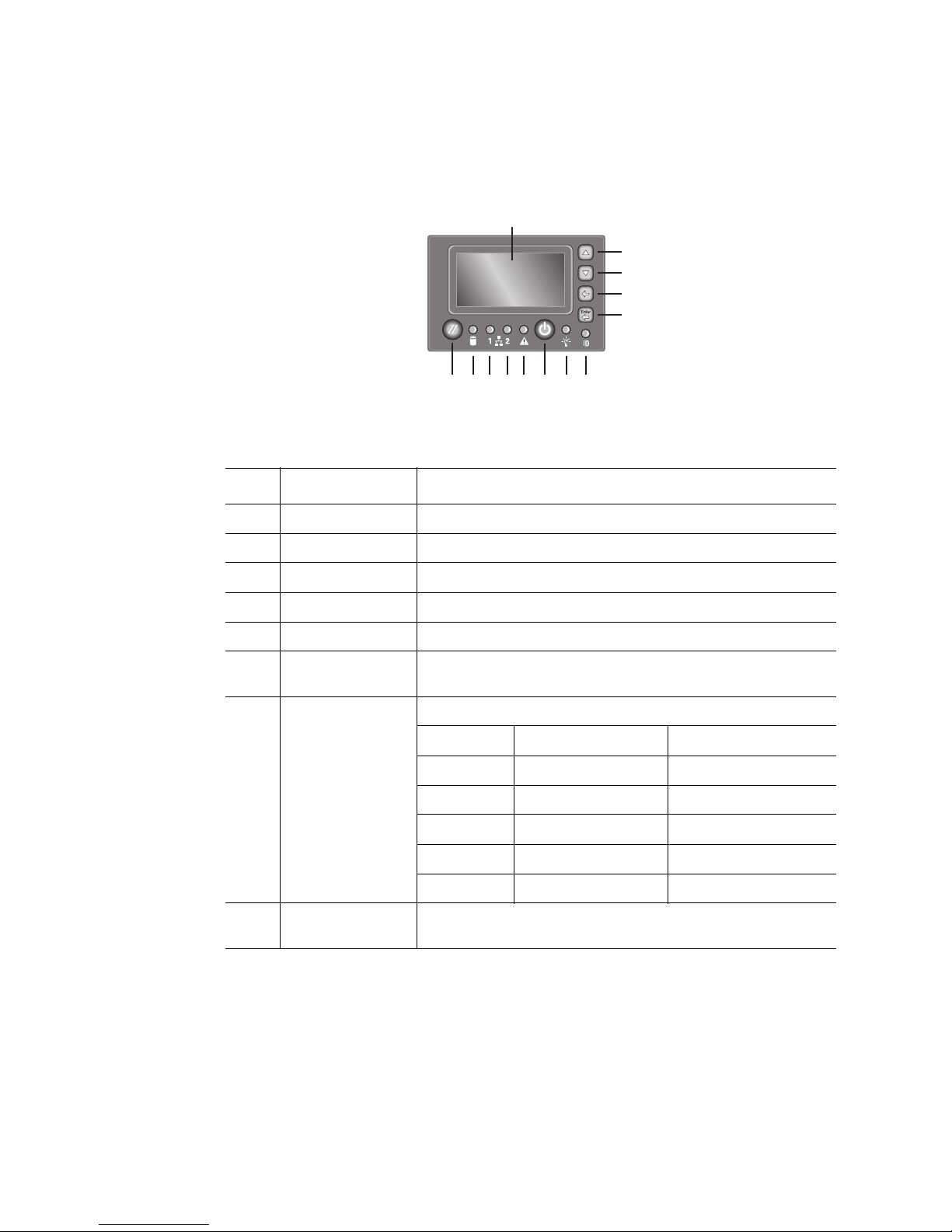

Each power supply module has three status LEDs next to the input connector.

A

B

C

AF002243

LED Location Purpose Description

A (left) Power Good LED (green) This green LED is driven by internal circuitry

and is lit whenever the power is turned on.

B (center) Fault LED (amber) This amber LED is driven by internal

circuitry and is lit when a power rail has

failed. The LED is lit even if the power

supply is in a latched state. The only time

(during a fault) when it is not lit is if the

+3.3VSB is lost.

The LED is not lit when the power supply is

turned off by powering down the system.

C (right) AC OK LED (green) This green LED is driven by internal circuitry

and is lit whenever the AC power cord is

plugged in to an active AC power source.

Figure 7. Power Supply Indicators

Intel® Server System S7000FC4UR Product Guide 15

Page 34

Note: The cooling system is non-redundant if only one power supply is installed.

Caution: Power supplies must be hot-swapped within two minutes. This time period applies only to

the time that the power supply is physically removed, not from the time of failure.

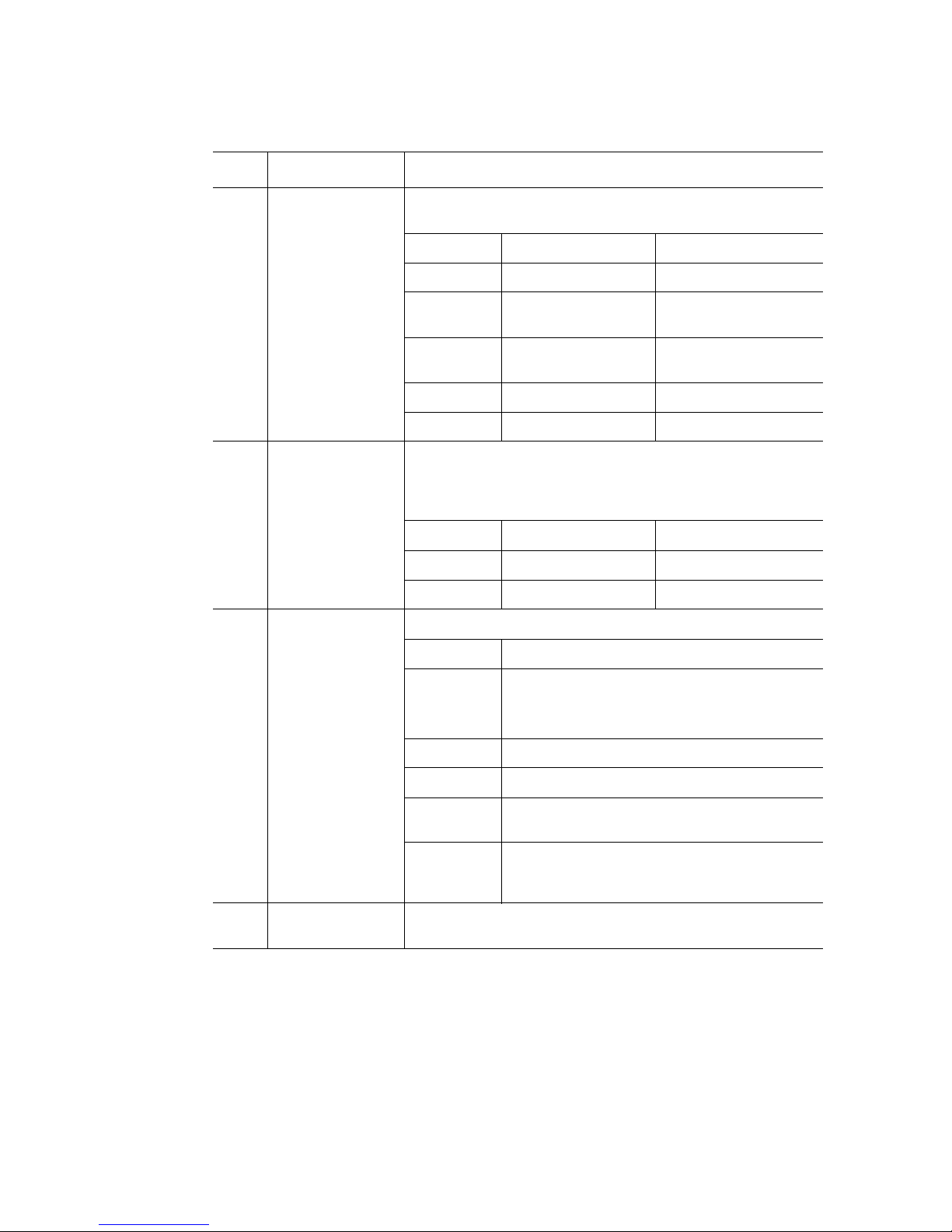

Power Supply Consumption

20A/110V

2

15A/100V

3

J6F1

Jumper J6F1 is used to set a threshold for power consumption when operating the server

with a single power supply on a low-line 100 / 110 / 115 / 120 / 127 VAC power circuit.

This threshold ensures the power consumption of the server does not exceed the power

that can be supplied by a single AC power circuit. When the system has two power

supplies, a separate AC power circuit is needed for each power supply to guarantee the

AC power circuit capability is not exceeded.

When a server is connected to low-line power, the J6F1 jumper sets these power

consumption thresholds:

• Pins 1-2 covered: Sets the power consumption threshold to 1180 watts

16 Intel® Server System S7000FC4UR Product Guide

AF002232

Figure 8. Power Consumption Selection Jumper

Page 35

• Pins 2-3 covered: Sets the power consumption threshold to 1030 watts

Power consumption is based on the power consumed within the system. Power factors for

inefficiency are not included in the above figures.

Servers connected to high-line power (200 / 208 / 220 / 230 / 240 VAC) do not have a

power consumption threshold. Under these conditions, jumper J6F1 should be set to:

• 100 / 110 VAC rated circuit: cover pins 2-3

• 115 / 120 / 127 VAC rated circuit: cover pins 1-2

• 200 / 208 / 220 / 230 / 240 VAC rated circuit: cover pins 1-2

The power consumption threshold is most likely to be exceeded when all of the following

conditions are met:

• The server is connected to a low-line power circuit

• The server has a single power supply installed

• The server is fully configured with four processors, 16 x4 GB DIMMs, and all PCI

slots are filled

• The server is running at maximum performance

If the power consumption threshold is crossed, the hardware throttles the processors to

reduce the power consumption to below the set threshold. The processor performance can

be returned to the full performance level by power cycling the server.

When two power supplies are installed, the required power is divided between them. By

using both circuits, the server can draw more power than the threshold limit for a single

power supply.

The hardware reduces the amount of power consumed if one of the power supplies fails.

This ensures the system consumes less power than the threshold from the single operating

power supply. When a failed power supply is replaced, the system is again able to share

the power load and operate at full performance.

If the J6F1 jumper is set incorrectly, the following may occur:

• If the jumper is covering pins 1-2 on a 100 / 110 VAC circuit, the server is allowed

to consume up to 1180 watts. This setting may cause a circuit breaker to trip.

• If the jumper is covering pins 2-3 on a 115 / 120 / 127 VAC circuit, the server power

consumption threshold is set to 1030 watts. The lower power threshold may be

exceeded, limiting system performance.

Intel® Server System S7000FC4UR Product Guide 17

Page 36

Cooling Subsystem

Caution: The chassis top cover must be installed for proper system cooling. Cooling components

must be hot-swapped within two minutes. This time period applies only to the time that the

cooling component is physically removed, not from the time of failure.

The cooling subsystem consists of hot-swap, redundant (7+1) fans. In a redundant

configuration, the system supports one fault at a time, either one fan fault or one power

supply fault, and it supports hot-swapping one component at a time. If a cooling

component fails, the system cooling is maintained and the system continues to operate

while the component is hot-swapped.

Each front fan assembly has one status LED. The LED is off when both fans are operating

normally. The LED illuminate amber if one or both of the fans fails. Failed front fans can

be hot-swapped from the front of the system.

Each rear fan has one status LED. The LED is off when the fan is operating normally and

illuminates amber if the fan fails. Failed rear fans can be replaced from the top of the

system when the top cover is removed.

18 Intel® Server System S7000FC4UR Product Guide

AF002242

Figure 9. Rear Fan Locations

Page 37

For proper processor cooling, the processor duct must always be in place. Systems that are

configured with fewer than four processors should have processor blanks installed to

maintain proper cooling.

Hot-swap PCI Slots

The two hot-swap PCI slots have power and attention LEDs. The attention button is used

to invoke a hot-swap sequence to remove or add an adapter without using the software

interface. The LEDs are identified by the green arrow on the PCI divider label.

Table 4. Hot-swap PCI Slot Power and Attention LED

Green Power LED State Definition

Off Power off: Power has been removed from the slot. A card can

On Power on: The slot is powered on. A card cannot be inserted or

Blinking Power transition: The slot is powering up or down. A card

Amber Attention LED

State

Off Normal: Normal operation.

On Attention: Power fault or operational problem has occurred with

Blinking Locate: The slot is being identified.

be inserted or removed.

removed.

cannot be inserted or removed.

Definition

this slot.

Note: If you hot-remove a PCI card without following the proper procedure, power is

automatically be turned off to the slot.

Intel® Server System S7000FC4UR Product Guide 19

Page 38

Peripherals

These peripheral devices are supported:

• Up to eight hot-swap 2.5-inch SAS hard drives or four 2.5-inch SATA hard drives

• One 1/2-inch IDE DVD-ROM / CD-ROM drive

• One 5 1/4-inch device bay

A

Item Description

A DVD-ROM / CD-ROM drive

B Tape drive (optional)

C Hard drives (eight)

B

C

Figure 10. Peripheral Area

AF002272

20 Intel® Server System S7000FC4UR Product Guide

Page 39

Hot-Swap Hard Drive

The hot-swap hard drive carrier and SAS backplane board accommodate 2.5-inch SAS or

SATA hard drives.

Item Description

A. Latch

C

B

A

AF002261

B. Green LED

Green on SAS drive is installed and working

Green blink Hard drive is active

C. Amber LED

Amber on Hard drive or slot failure

Amber slow blink (~1 Hz) Predictive hard drive / slot failure or rebuild

Amber fast blink (~2.5 Hz) Hard drive rebuild interrupted or rebuild on

correctly

is in process

empty slot

Figure 11. Hard Drive Carrier

Intel® Server System S7000FC4UR Product Guide 21

Page 40

Optical Drive Bay

The DVD-ROM / CD-ROM drive is installed in a sheet metal carrier that inserts from the

front of the system. You must power down the system and remove the top cover to remove

or install this device. A slimline IDE drive is supported if a SATA-to-IDE adapter board is

used. This board is connected to the drive and cabled to an internal SATA port on the main

board.

Figure 12. DVD-ROM / CD-ROM Drive Carrier

5 ¼-inch Half-height Drive Bay

The system supports one 5 ¼-inch, half-height device mounted at the front of the system.

A USB or SATA tape backup device can be cabled to the internal USB or SATA port

located on the main board. Alternatively, a SCSI or SAS tape backup device can be cabled

to a PCI Express* add-in card (not included).

System Board Set

The board set consists of these boards:

• Main board

• Memory boards

• I/O riser board (optional)

• SAS riser board (optional)

• Front panel board

• SAS backplane board

• Power distribution board

• SATA-to-IDE adapter board

22 Intel® Server System S7000FC4UR Product Guide

Page 41

Full Length Slot

Hot-Swap Capable

PCIe x8 (4Gb/s)

Slot # 1

Full Length Slot

Hot-Swap Capable

PCIe x8 (4Gb/s)

Slot # 2

Full Length Slot

PCIe x8 (4Gb/s)

Slot # 3

Half Length Slot

PCIe x8 (4Gb/s)

Slot # 4

Half Length Slot

PCIe x4 (2Gb/s)

Slot # 5

Note: x8 connector will be used for all x4 PCIe slots.

Full Length Slot

PCIe x4 (2Gb/s)

Slot # 6

Full Length Slot

PCIe x4 (2Gb/s)

Slot # 7

RAID

Battery

LSI* 1078

Controller

SAS and

DIMM VRs

RAID

Key

SAS Backplane

(8x 2.5” HS SAS HDD

SAS RAID5/6 DDR2 DIMM

SAS FW

SAS

Expander

Port # B

Port # C

Expander

Port # B

Port # C

CD-RW/DVD ROM

Note: PATA connector is

not on the baseboard.

SAS Riser

100-pin Front

Control Connector

Rear Video

Connector

PCIe

PCIe x8 (4Gb/s)

Port # A

PCIe

PCIe x8 (4Gb/s)

Port # A

PCIe x4 (2Gb/s)

SATA- PATA

Conversion

USB 2.0 Port # 6

Note: USB Hub on the Front

Panel I/O Board provides 3

Front Panel USB Ports

PCI 32-bit/33MHz

Misc.

A-Video #2

Video

(ATI RN50)

A-Video #1

Video Memory

(32 Mb, 16Mx16)

SATA # 0

(133 Mb/s)

1067 MT/s

Port #

4 and 5

Port #

6 and 7

Port # 1

1067 MT/s

North

Bridge

PE2

PE0 Port #

PE2

USB 2.0 Port # 2

USB 2.0 Port # 3

Rear

Rear

USB

USB

1067 MT/s

Port

Port

# 2

# 0

PCIe x4 (2 Gb/s)

Port #

4L (x4)

3 (ESI)

ESB2E

USB 2.0 Port # 4

Internal

USB

Header

CPU 1CPU 2CPU 3CPU 4

1067 MT/s

FSB 0FSB 1FSB 3FSB 2

FBD Channel 0

FBD 0

FBD Channel 1

FBD 1

FBD Channel 2

FBD 2

FBD Channel 3

FBD 3

Port

# 3

PCIe x4 “ESI” (2 Gb/s)

SATA # 5

SATA # 1-4

Internal

4

SATA

SATA

Ports

Memory

Memory

Riser A

Riser B

FBD DDR2

FBD DDR2

533/667

533/667

TPM

(ST Micro ST19WP18-TPM-C)

LPC

EMP/SOL

Kumeran

PCIe x4 (2 Gb/s)

Expansion Bus

BMC SDRAM + Flash

USB 2.0 Port # 0

FMLs, IPMB, SMBusses

DVO, DDC

Memory

Memory

Riser C

Riser D

FBD DDR2

FBD DDR2

533/667

533/667

SIO3

(PC87427)

Dual

GB

PHY

(Gilgal)

Intel

82575EB

Gigabit

Ethernet

Controller

I/O Riser

RMM2/ASMI

Intel Remote Management Module

GCM3 PHY

(General

MII

Communications

Module #3)

X-BUS

Gbit LAN

Gbit LAN

Gbit LAN

Gbit LAN

10/100 LAN

AF002283

Flash

(28F320C3 4Mb)

Flash

(28F320C3 4Mb)

Serial Port

(Back Panel)

Serial Port

(Internal)

RJ45

RJ45

RJ45

RJ45

RJ45

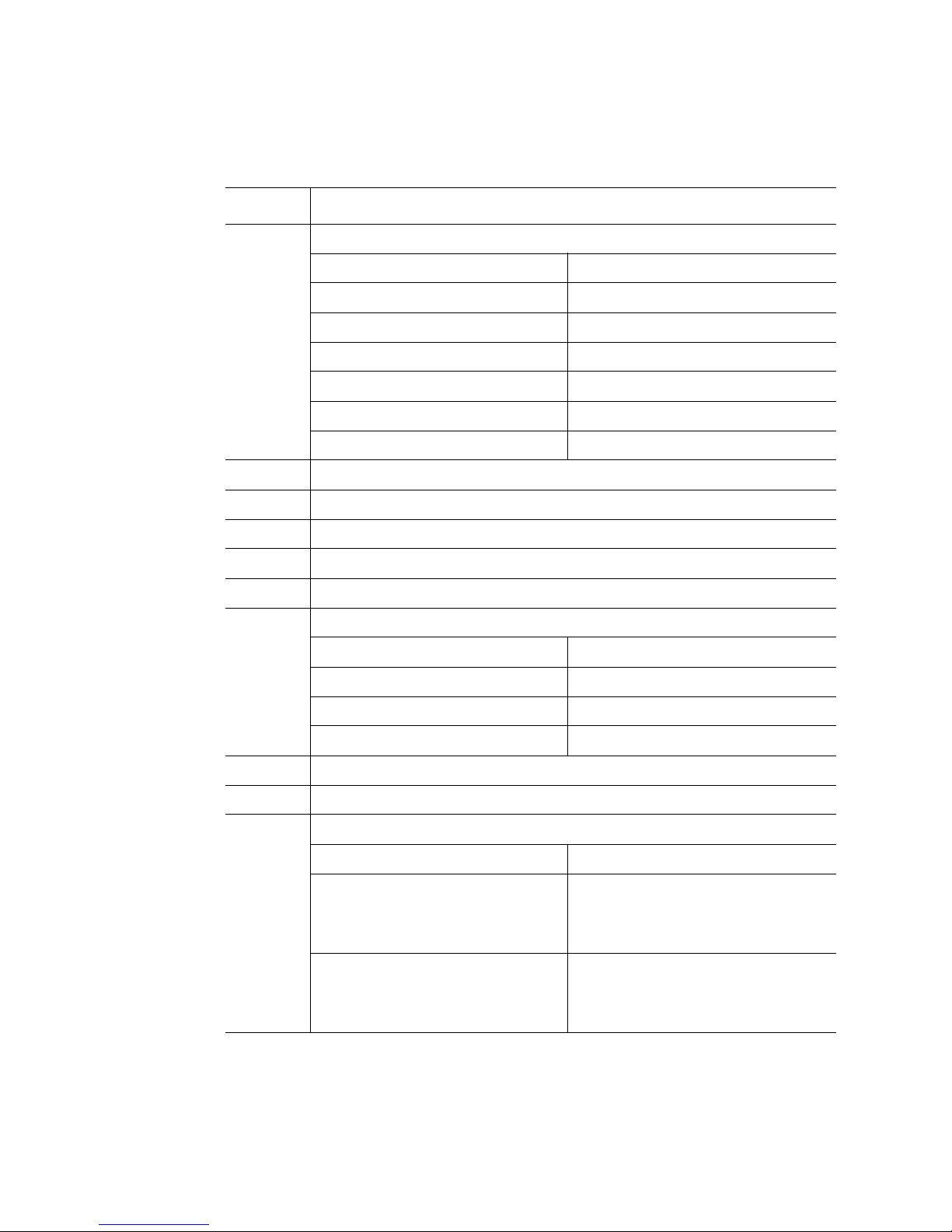

Main Board

The main board contains:

• Chipset north and south bridge components

• Processor sockets

• Four memory board connectors

• Video components

• Trusted Platform Module

• BIOS Flash components

Intel® Server System S7000FC4UR Product Guide 23

Figure 13. Block Diagram

Page 42

• Super I/O*

• Seven PCI Express* slots

• Back panel I/O connectors

• Many voltage regulators used by the components

• Many of the primary voltage rails used by the rest of the board set

D

CC

AA

Z

X

BB

Y

W

V

A

B C E F G

H

J

I

K

M

L

N

O

P

Q

f

Item Description Item Description

A Dual Ethernet ports P Front panel connector

B I/O riser slot Q Power distribution board connectors

C PCI Express* x4 (slot 7) R Processor socket 1

D Serial Port A S Processor socket 2

24 Intel® Server System S7000FC4UR Product Guide

U

T S R

Figure 14. Main Board Component Locations

(3)

AF002275

Page 43

Item Description Item Description

E PCI Express x4 (slot 6) T Processor socket 3

F PCI Express x4 (slot 5) U Processor socket 4

G PCI Express x8 (slot 4) V SAS riser slot

H PCI Express x8 (slot 3) W Chassis intrusion

I PCI Express x8 hot-plug (slot 2) X 4-port SATA connector

J PCI Express x8 hot-plug (slot 1) Y Internal USB port

K Serial port B Z Memory board (slot C)

L Video port AA Single port SATA connectors

M USB 1 (top), USB 2 (bottom) BB Memory board (slot D)

N Memory board (slot A) CC Real-time clock battery

O Memory board (slot B)

Intel® Server System S7000FC4UR Product Guide 25

Page 44

A

C D

B

E

F

AF002276

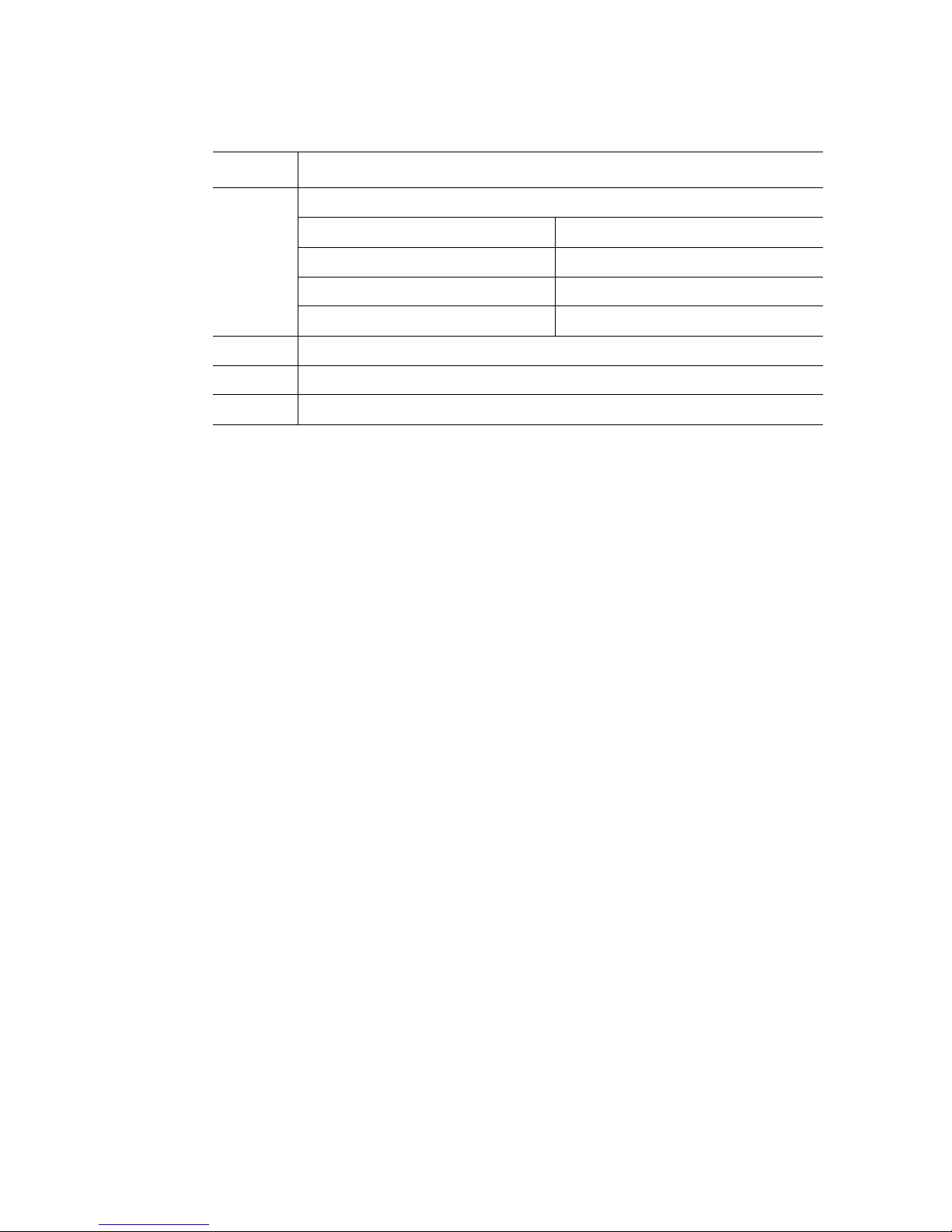

Label Name Location Default Stuffed Jumper State

A Rolling BIOS J3D1 Empty

Stuff

B Password disable or clear J3C2 Stuff

Empty

C Clear CMOS / NVRAM J3C3 Stuff

Empty

D BMC force update J5C1 Stuff

Empty

E BMC flash write protect J6D1 Stuff

Empty

26 Intel® Server System S7000FC4UR Product Guide

1 - 2 = Force other bank

2 - 3 = Normal mode

1 - 2 = Password protect

2 - 3 = Password disabled / cleared

1 - 2 = Normal

2 - 3 = Forced CMOS / NVRAM clear

1 - 2 = Disable BMC force update

2 - 3 = Enable BMC force update

1 - 2 = Disable flash write protect

2 - 3 = Enable flash write protect

Page 45

Label Name Location Default Stuffed Jumper State

F Circuit breaker J6F1 Empty

Stuff

Figure 15. Main Board Jumpers

SATA Device Support

The ESB2 provides six Serial ATA (SATA) ports with a transfer rate of up to 3.0GB/s. The

main board has two internal, industry-standard 7-pin vertical SATA connectors that can be

cabled directly to a SATA device.

As an alternative to using a SAS riser to support eight SAS hard drives, an internal x4

8086 SAS/SATA connector is provided to cable to the SAS backplane board to support

four SATA hard drives. SATA cables should be 1 meter (40 inches) or less in length.

The ESB2 Port configuration is:

• SATA0 to SATA connector1 goes to the SATA-to-PATA converter board, then to the

optical drive

• SATA1 to x4 connector Port0 goes to SATA Drive 0 on the SAS backplane board

• SATA2 to x4 connector Port1 goes to SATA Drive 1 on the SAS backplane board

1 - 2 = 20A/110V (USA)

2 - 3 = 15A/100V (Japan)

• SATA3 to x4 connector Port2 goes to SATA Drive 2 on the SAS backplane board

• SATA4 to x4 connector Port3 goes to SATA Drive 3 on the SAS backplane board

• SATA5 to SATA connector2 is an extra port that could be used for a SATA tape drive

Intel® Server System S7000FC4UR Product Guide 27

Page 46

Video Support

The main board uses the ATI* RN50 Embedded Video Controller with 32 MB of video

RAM. The RN50 provides these features:

• 2D/3D video accelerator

• Dual DAC for simultaneous port support (front / rear video support)

• Resolutions from VGA up to UXGA (1600 x 1200)

• Digital Video Input/Output (DVI/DVO) interface routed to the Intel