Page 1

CBI/CGI

CB BASIC

S5721-xxx

TECHNICAL REFERENCE

®

Intel

Pentium

or

®

Intel

Celeron

PROCESSOR-BASED

SBC

®

III

®

Page 2

Page 3

WARRANTY The product is warranted against material and manufacturing defects for two years from

date of delivery. Buyer agrees that if this product proves defective Chassis Plans is only

obligated to repair, replace or refund the purchase price of this product at Chassis Plans’

discretion. The warranty is void if the product has been subjected to alteration, neglect,

misuse or abuse; if any repairs have been attempted by anyone other than Chassis Plans;

or if failure is caused by accident, acts of God, or other causes beyond the control of

Chassis Plans. Chassis Plans reserves the right to make changes or improvements in any

product without incurring any obligation to similarly alter products previously

purchased.

In no event shall Chassis Plans be liable for any defect in hardware or software or loss or

inadequacy of data of any kind, or for any direct, indirect, incidental or consequential

damages arising out of or in connection with the performance or use of the product or

information provided. Chassis Plans’ liability shall in no event exceed the purchase

price of the product purchased hereunder. The foregoing limitation of liability shall be

equally applicable to any service provided by Chassis Plans

R

ETURN POLICY Products returned for repair must be accompanied by a Return Material Authorization

(RMA) number, obtained from Chassis Plans prior to return. Freight on all returned

items must be prepaid by the customer, and the customer is responsible for any loss or

damage caused by common carrier in transit. Items will be returned from Chassis Plans

via Ground, unless prior arrangements are made by the customer for an alternative

shipping method

To obtain an RMA number, call us at (858) 571-4330. We will need the following information:

Return company address and contact

Model name and model # from the label on the back of the board

Serial number from the label on the back of the board

Description of the failure

An RMA number will be issued. Mark the RMA number clearly on the outside of each

box, include a failure report for each board and return the product(s) to our San Diego,

CA facility:

Chassis Plans

8295 Aero Place, Suite 200

San Diego, CA 92123

Attn: Repair Department

858-571-4330

Page 4

TRADEMARKS IBM, PC, VGA, EGA, OS/2 and PS/2 are trademarks or registered trademarks of

International Business Machines Corp.

AMI and AMIBIOS are trademarks or registered trademarks of American

Megatrends Inc.

Intel, Pentium, Celeron and AGP are registered trademarks of Intel Corporation.

MS-DOS and Microsoft are registered trademarks of Microsoft Corp.

PICMG and the PICMG logo are registered trademarks of the PCI Industrial Computer

Manufacturers Group.

SCSISelect is a trademark of Adaptec, Inc.

All other brand and product names may be trademarks or registered trademarks of their

respective companies.

L

IABILITY

D

ISCLAIMER

This manual is as complete and factual as possible at the time of printing; however, the

information in this manual may have been updated since that time. Chassis Plans

reserves the right to change the functions, features or specifications of their products at

any time, without notice.

Copyright

© 2003 by Chassis Plans All rights reserved.

E-mail: support@chassisplans.com

Web: www.chassisplans.com

Chassis Plans, LLC

8295 Aero Place

Sales: (858) 571-4330

• Suite 200 • San Diego, California 92123

• Fax: (858) 57104330 • Web http://www.chassisplans.com

Page 5

CBI/CGI Technical Reference

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

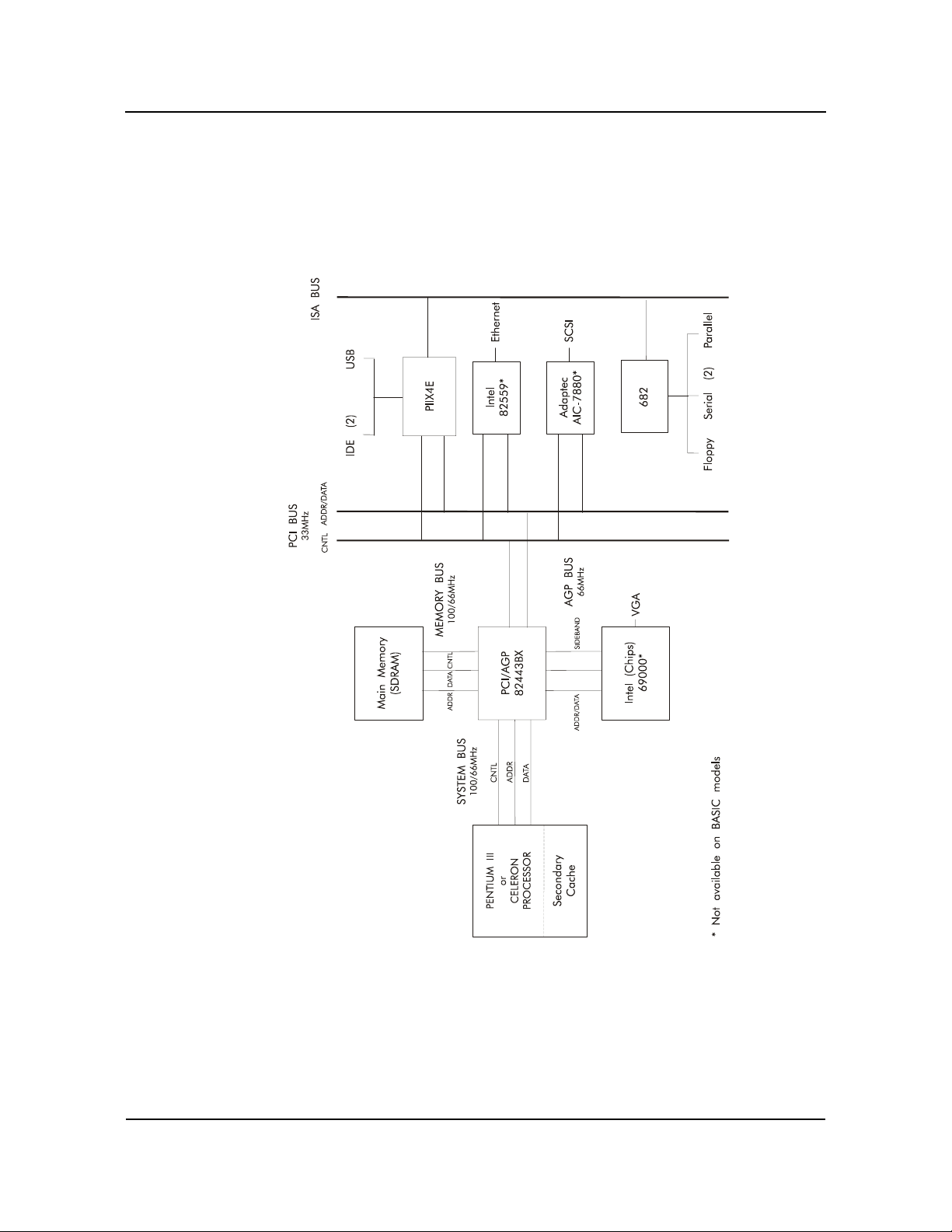

SBC Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

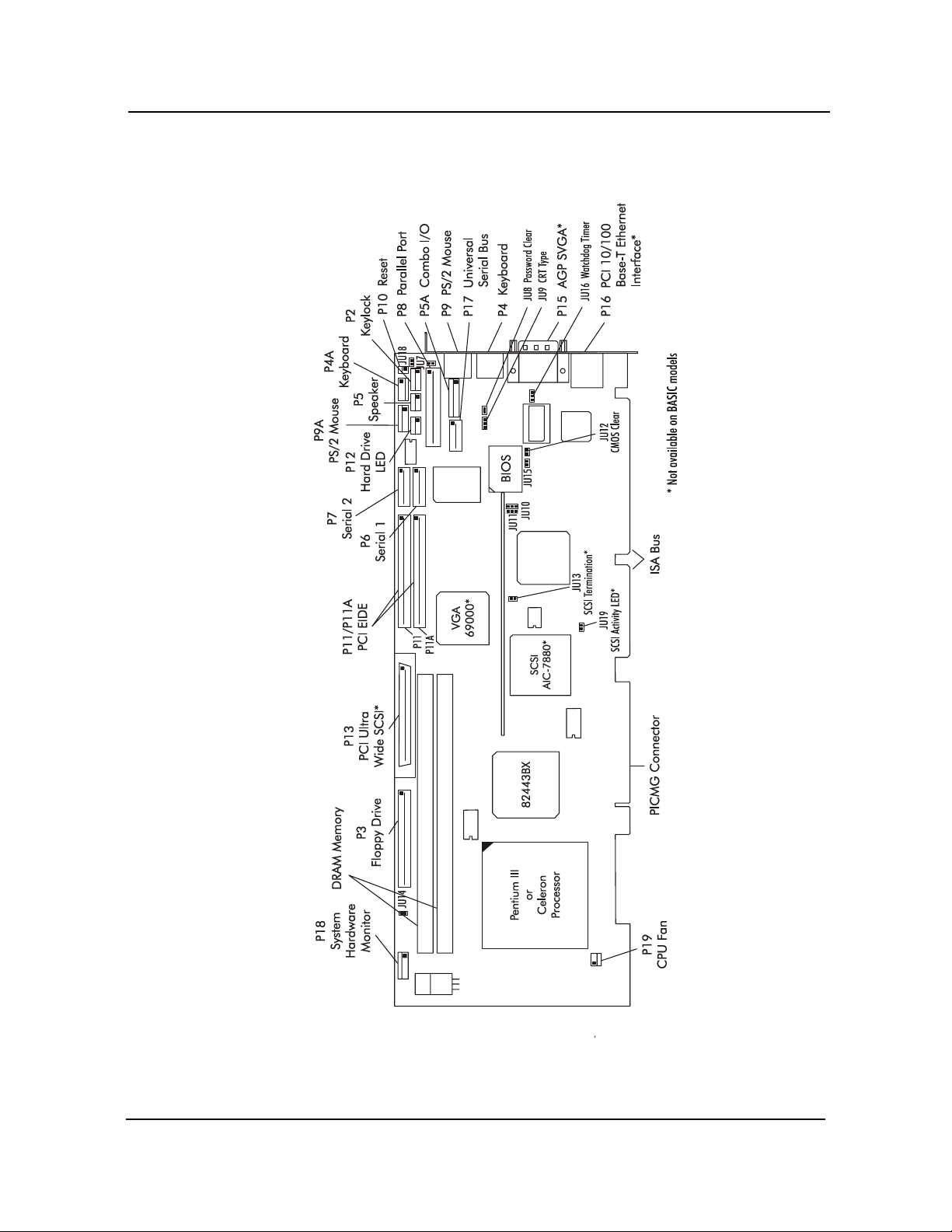

SBC Processor Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Bus Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Data Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Bus Speed - ISA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Bus Speed - PCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Bus Speed - System & Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

System & Memory Buses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

DMA Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

BIOS (Flash). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Cache Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

DRAM Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Memory Hole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Error Checking and Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

PCI Local Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Universal Serial Bus (USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Concurrent PCI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

AGP VGA Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

System Hardware Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

10/100Base-T Ethernet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

PCI Ultra Wide SCSI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

PCI Enhanced IDE Ultra DMA/33 Interfaces (Dual) . . . . . . . . . . .1-11

Floppy Drive Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Enhanced Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

PS/2 Mouse Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Keyboard Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Power Fail Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Table of Contents

Chassis Plans i

Page 6

CBI/CGI Technical Reference

Table of Contents

Specifications (continued)

Temperature/Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Mean Time Between Failures (MTBF) . . . . . . . . . . . . . . . . . . . . . .1-12

UL Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Configuration Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Ethernet LEDs and Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

System BIOS Setup Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

ISA/PCI Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

ISA Bus Pin Numbering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

ISA Bus Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

ISA Bus Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

I/O Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Interrupt Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

PCI Local Bus Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

PCI Local Bus Signal Definition . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

PCI Local Bus Pin Numbering. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

PCI Local Bus Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

PCI Local Bus Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . .2-14

PICMG Edge Connector Pin Assignments . . . . . . . . . . . . . . . . . . .2-18

System BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

BIOS Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Password Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

BIOS Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Running AMIBIOS Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

AMIBIOS Setup Utility Main Menu . . . . . . . . . . . . . . . . . . . . . . . .3-6

AMIBIOS Setup Utility Options . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Auto-Detect Hard Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Change Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Change Supervisor Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Change User Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Disabling the Password(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Auto Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Auto Configuration with Optimal Settings . . . . . . . . . . . . . . . . .3-13

Auto Configuration with Fail Safe Settings . . . . . . . . . . . . . . . .3-14

Chassis Plansii

Page 7

CBI/CGI Technical Reference

System BIOS (continued)

Save Settings and Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Exit Without Saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Key Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Standard CMOS Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Standard CMOS Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Boot Sector Virus Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Advanced Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Advanced CMOS Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Advanced Chipset Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

PCI/Plug and Play Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Table of Contents

Peripheral Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Appendix A - BIOS Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

BIOS Beep Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

BIOS Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

ISA BIOS NMI Handler Messages . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Port 80 Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Additional Bus Checkpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Appendix B - Adaptec, Inc. Software License . . . . . . . . . . . . . . . . . . .B-1

Appendix C - SCSISelect Configuration Utility. . . . . . . . . . . . . . . . . .C-1

Declaration of Conformity

Chassis Plans iii

Page 8

This page intentionally left blank.

CBI/CGI Technical Reference

Copyright 2003 by Trenton Technology Inc. All rights reserved.

Chassis Plansiv

Page 9

CBI/CGI Technical Reference

HANDLING

P

RECAUTIONS

S

OLDER-SIDE

C

OMPONENTS

_______________________________________________________________________

WA R NI N G : This product has components which may be damaged by electrostatic

discharge.

_______________________________________________________________________

To protect your single board computer (SBC) from electrostatic damage, be sure to

observe the following precautions when handling or storing the board:

• Keep the SBC in its static-shielded bag until you are ready to perform your

installation.

• Handle the SBC by its edges.

• Do not touch the I/O connector pins. Do not apply pressure or attach labels

to the SBC.

• Use a grounded wrist strap at your workstation or ground yourself

frequently by touching the metal chassis of the system before handling any

components. The system must be plugged into an outlet that is connected to

an earth ground.

• Use antistatic padding on all work surfaces.

• Avoid static-inducing carpeted areas.

This SBC has components on both sides of the PCB. It is important for you to observe

the following precautions when handling or storing the board to prevent solder-side

components from being damaged or broken off:

• Handle the board only by its edges.

• Store the board in padded shipping material or in an anti-static board rack.

• Do not place an unprotected board on a flat surface.

Chassis Plans v

Page 10

This page intentionally left blank.

CBI/CGI Technical Reference

Copyright 2003 by Trenton Technology Inc. All rights reserved.

Chassis Plansvi

Page 11

Chapter 1 Specifications

SpecificationsCBI/CGI Technical Reference

INTRODUCTION The CBI full-featured PCI/ISA processors are single board computers (SBCs) which

feature an Intel

®

Celeron® microprocessor or Intel® Pentium® III microprocessor, Intel

440BX AGPset, 66/100MHz system and memory buses, Intel Accelerated Graphics Port

(AGP) video interface, SDRAM, PCI Local Bus, cache, floppy controller, dual EIDE

(Ultra DMA/33) interface, PCI Ultra Wide SCSI controller, PCI 10/100Base-T Ethernet

controller, two serial ports, parallel port, speaker port, mouse port and keyboard port

on a single ISA-size card. These single-slot, high performance SBCs plug into PICMG

PCI/ISA passive backplanes and provide full PC compatibility for the system expansion

slots.

The CGI models of this SBC feature the Intel 440GX AGPset, supporting memory

configurations up to 1GB.

The CB BASIC model has all of the standard features of the CBI, but does not include

the Intel video interface, PCI Ultra Wide SCSI controller or PCI 10/100Base-T Ethernet

controller.

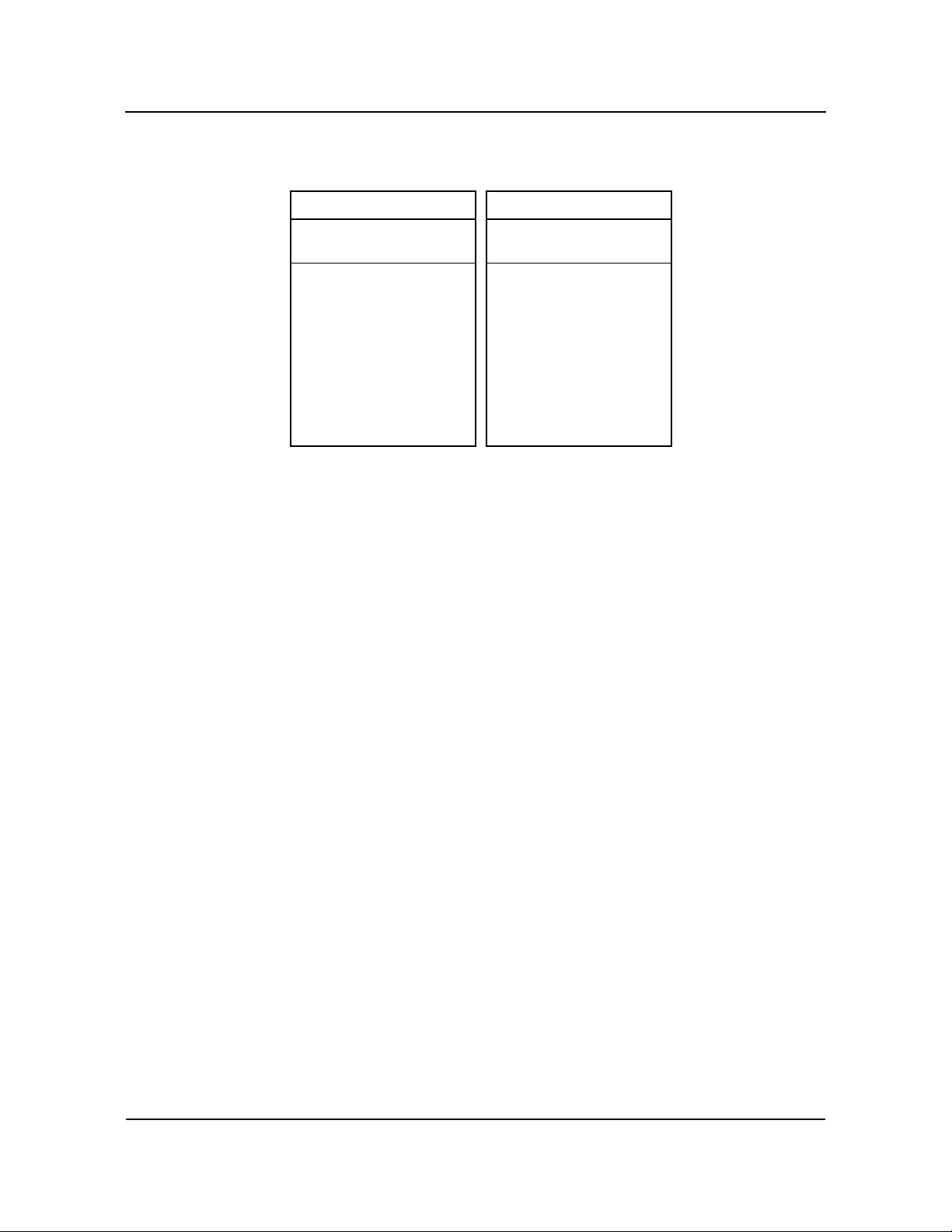

ODELS

M

Model # Model Name Speed

CBI - BX:

®

Intel

Pentium® III Processor - 100MHz FSB/256K cache:

S5721-110-xM

S5721-109-xM

S5721-108-xM

S5721-107-xM

S5721-106-xM

S5721-105-xM

S5721-104-xM

S5721-103-xM

S5721-102-xM

S5721-101-xM

CBI/1.0

CBI/900

CBI/850

CBI/800

CBI/750

CBI/700

CBI/650

CBI/600E

CBI/550E

CBI/500E

1.0GHz

900MHz

850MHz

800MHz

750MHz

700MHz

650MHz

600MHz

550MHz

500MHz

®

®

Intel

Celeron® Processor - 100MHz FSB/128K cache:

S5721-205-xM

S5721-204-xM

®

Intel

Celeron® Processor - 66MHz FSB/128K cache:

S5721-016-xM

S5721-015-xM

S5721-014-xM

S5721-013-xM

S5721-012-xM

S5721-011-xM

S5721-010-xM

S5721-009-xM

S5721-008-xM

S5721-007-xM

S5721-006-xM

CBI/900C

CBI/850C

CBI/800C

CBI/766

CBI/733

CBI/700C

CBI/667

CBI/633

CBI/600

CBI/566

CBI/533

CBI/500

CBI/466

900MHz

850MHz

800MHz

766MHz

733MHz

700MHz

667MHz

633MHz

600MHz

566MHz

533MHz

500MHz

466MHz

Chassis Plans 1-1

Page 12

Specifications CBI/CGI Technical Reference

MODELS

(

CONTINUED)

Model #

CBI - BX: (continued)

®

Intel

Celeron® Processor - 66MHz FSB/128K cache: (cont’d)

S5721-005-xM

S5721-004-xM

S5721-003-xM

S5721-002-xM

CGI - GX:

®

Intel

Pentium® III Processor - 100MHz FSB/256K cache:

S5721-150-xM

S5721-149-xM

S5721-148-xM

S5721-147-xM

S5721-146-xM

S5721-145-xM

S5721-144-xM

S5721-143-xM

S5721-142-xM

S5721-141-xM

Model Name Speed

CBI/433

CBI/400

CBI/366

CBI/333

CGI/1.0

CGI/900

CGI/850

CGI/800

CGI/750

CGI/700

CGI/650

CGI/600E

CGI/550E

CGI/500E

433MHz

400MHz

366MHz

333MHz

1.0GHz

900MHz

850MHz

800MHz

750MHz

700MHz

650MHz

600MHz

550MHz

500MHz

®

Intel

Celeron® Processor - 100MHz FSB/128K cache:

S5721-245-xM

S5721-244-xM

®

Intel

Celeron® Processor - 66MHz FSB/128K cache:

S5721-056-xM

S5721-055-xM

S5721-054-xM

S5721-053-xM

S5721-052-xM

S5721-051-xM

S5721-050-xM

S5721-049-xM

S5721-048-xM

S5721-047-xM

S5721-046-xM

S5721-045-xM

S5721-044-xM

S5721-043-xM

S5721-042-xM

CGI/900C

CGI/850C

CGI/800C

CGI/766

CGI/733

CGI/700C

CGI/667

CGI/633

CGI/600

CGI/566

CGI/533

CGI/500

CGI/466

CGI/433

CGI/400

CGI/366

CGI/333

900MHz

850MHz

800MHz

766MHz

733MHz

700MHz

667MHz

633MHz

600MHz

566MHz

533MHz

500MHz

466MHz

433MHz

400MHz

366MHz

333MHz

CB BASIC - BX:

®

Intel

Pentium® III Processor - 100MHz FSB/256K cache:

S5721-130-xM

S5721-129-xM

S5721-128-xM

CBB/1.0

CBB/900

CBB/850

1.0GHz

900MHz

850MHz

Chassis Plans1-2

Page 13

MODELS

(

CONTINUED)

Model #

Model Name Speed

CB BASIC - BX: (continued)

®

Intel

Pentium® III Processor - 100MHz FSB/256K: (cont’d)

S5721-127-xM

S5721-126-xM

S5721-125-xM

S5721-124-xM

S5721-123-xM

S5721-122-xM

S5721-121-xM

®

Intel

Celeron® Processor - 100MHz FSB/128K cache:

S5721-225-xM

S5721-224-xM

®

Intel

Celeron® Processor - 66MHz FSB/128K cache:

S5721-036-xM

S5721-035-xM

S5721-034-xM

S5721-033-xM

S5721-032-xM

S5721-031-xM

S5721-030-xM

S5721-029-xM

S5721-028-xM

S5721-027-xM

S5721-026-xM

S5721-025-xM

S5721-024-xM

S5721-023-xM

S5721-022-xM

CBB/800

CBB/750

CBB/700

CBB/650

CBB/600E

CBB/550E

CBB/500E

CBB/900C

CBB/850C

CBB/800C

CBB/766

CBB/733

CBB/700C

CBB/667

CBB/633

CBB/600

CBB/566

CBB/533

CBB/500

CBB/466

CBB/433

CBB/400

CBB/366

CBB/333

800MHz

750MHz

700MHz

650MHz

600MHz

550MHz

500MHz

900MHz

850MHz

800MHz

766MHz

733MHz

700MHz

667MHz

633MHz

600MHz

566MHz

533MHz

500MHz

466MHz

433MHz

400MHz

366MHz

333MHz

SpecificationsCBI/CGI Technical Reference

where xM indicates memory size (0M = 0MB memory,

8M =8MB memory, etc.)

F

EATURES • Intel

®

Pentium® III (FC-PGA) microprocessor

• 1.0GHz, 900MHz, 850MHz, 800MHz, 750MHz, 700MHz or 650MHz,

600EMHz, 550EMHz or 500EMHz with 256K cache and a 100MHz Front

Side Bus (FSB)

®

or Intel

Celeron® microprocessor

• 900MHz or 850MHz with 128K cache and a 100MHz FSB

• 800MHz, 766MHz, 733MHz, 700MHz, 667MHz, 633MHz, 600MHz,

566MHz, 533MHz, 500MHz, 466MHz, 433MHz, 400MHz, 366MHz or

333MHz with 128K cache and a 66MHz FSB

• Intel 440BX AGPset with 66/100MHz system and memory buses, and PCI

bandwidth greater than 100MB/second. 440GX AGPset also available.

Chassis Plans 1-3

Page 14

Specifications CBI/CGI Technical Reference

FEATURES

(

CONTINUED)

• Intel Accelerated Graphics Port (AGP) VGA on-board video interface

• PCI Local Bus supports off-board PCI option cards, PCI 10/100Base-T Ethernet

controller and on-board PCI Ultra Wide SCSI controller - Adaptec AIC-7880

• DRAM error checking and correction (ECC) support

• Compatible with PCI Industrial Computer Manufacturers Group (PICMG) 1.0

Specification

• Supports up to 512MB of Synchronous DRAM (SDRAM) on board; 440GX

AGPset supports up to 1GB

• Floppy drive and dual PCI EIDE Ultra DMA/33 drive interface

• Two serial ports and one parallel port

• Automatic or manual peripheral configuration

• Watchdog timer

• System hardware monitor

• Supports 1M x 64 to 32M x 64 DIMMs for non-ECC configurations; supports

1M x 72 to 32M x 72 DIMMs for ECC configurations. 440GX configurations

support up to 64M x 72 DIMMs.

• Shadow RAM for System BIOS and peripherals increases system speed and

performance

• Full PC compatibility

Chassis Plans1-4

Page 15

SBC BLOCK

D

IAGRAM

SpecificationsCBI/CGI Technical Reference

Chassis Plans 1-5

Page 16

Specifications CBI/CGI Technical Reference

SBC PROCESSOR

B

OARD LAYOUT

Chassis Plans1-6

Page 17

PROCESSORS • Intel® Pentium® III (FC-PGA) microprocessor

• 1.0GHz, 900MHz, 850MHz, 800MHz, 750MHz, 700MHz or 650MHz,

600EMHz, 550EMHz or 500EMHz with 256K cache and a 100MHz Front

Side Bus (FSB)

®

or Intel

Celeron® microprocessor

• 900MHz or 850MHz with 128K cache and a 100MHz FSB

• 800MHz, 766MHz, 733MHz, 700MHz, 667MHz, 633MHz, 600MHz,

566MHz, 533MHz, 500MHz, 466MHz, 433MHz, 400MHz, 366MHz or

333MHz with 128K cache and a 66MHz FSB

B

US INTERFACES ISA and PCI Local Bus compatible

D

ATA PATH DRAM/Memory - 64-bit

ISA Bus - 16-bit

PCI Bus - 32-bit

Video - 64-bit

SpecificationsCBI/CGI Technical Reference

B

US SPEED - ISA 8.33MHz

B

US SPEED - PCI 33MHz

B

US SPEED -

S

YSTEM &

M

EMORY

S

YSTEM &

M

EMORY BUSES

• Intel® Pentium® III - 100MHz

• Intel

®

Celeron® - 66MHz or 100MHz

The Intel 440BX/GX AGPset supports the system and memory buses at both 66MHz and

100MHz speeds. The 100MHz system and memory buses provide a higher bandwidth

path for transferring data between main memory/chip set and the processor.

DMA C

HANNELS The SBC is fully PC compatible with seven DMA channels, each supporting type F

transfers.

I

NTERRUPTS The SBC is fully PC compatible with interrupt steering for PCI plug and play compati-

bility.

BIOS (F

LASH) The BIOS is a Hi-Flex AMIBIOS with built-in advanced CMOS setup for system param-

eters, peripheral management for configuring on-board peripherals, PCI-to-PCI bridge

support and PCI interrupt steering. The BIOS chip is a boot block Flash device 28F002BX-T120. The BIOS may be upgraded from floppy disk by pressing <Ctrl> +

<Home> immediately after reset or power-up with the floppy disk in drive A:. Custom

BIOSs are available.

C

ACHE MEMORY For Pentium III processors, the processor includes an integrated on-die, 256K 8-way set

associative level two (L2) cache. The L2 cache implements the Advanced Transfer

Cache architecture with a 256-bit wide bus. The processor also includes a 16K level one

Chassis Plans 1-7

Page 18

Specifications CBI/CGI Technical Reference

(L1) instruction cache and 16K L1 data cache. These cache arrays run at the full speed

of the processor core.

For Celeron processors, a 128K unified, non-blocking second level (L2) cache improves

performance by reducing the average memory access time and providing fast access to

recently used instructions and data.

DRAM M

EMORY The DRAM interface consists of two dual in-line memory module (DIMM) sockets and

supports auto detection of memory up to 512MB of Synchronous DRAM (SDRAM) for

the 440BX or up to 1GB of SDRAM for the 440GX. Minimum memory size is 8MB.

The System BIOS automatically detects memory type, size and speed.

The SBC uses industry standard 64-bit or 72-bit wide gold finger DIMM SDRAM

modules in two 168-pin DIMM sockets.

______________________________________________________________________

NOTE: Memory can be installed in one or both DIMM sockets. If only one DIMM

module is used, it must be populated in the top DIMM socket (Bank 1 - BK1). If two

modules are used, they must be the same DIMM type, but may be different sizes (see

table below). EDO DIMMs are not supported. All DIMMs must have gold contacts.

______________________________________________________________________

The SBC supports DIMM memory modules which are PC-100 compliant and have the

following features:

• 168-pin DIMMs with gold-plated contacts

• 100MHz SDRAM

• Non-ECC (64-bit) or ECC (72-bit) memory

• 3.3 volt

• Single or double-sided DIMMs in the sizes listed below

• Buffered or Registered configuration

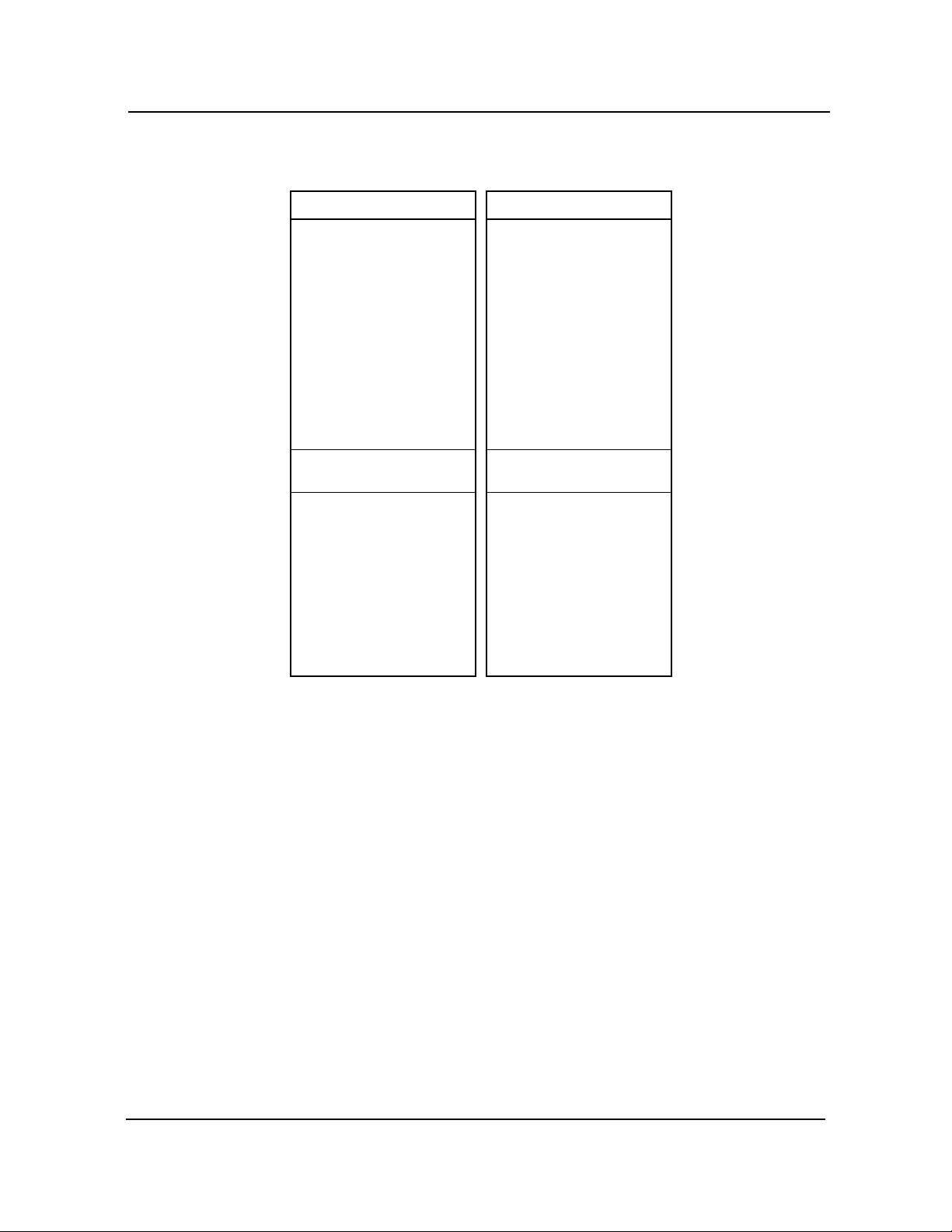

The following DIMM sizes are supported:

DIMM

Size

8MB

16MB

32MB

64MB

128MB

256MB

512MB

* CGI models only

All memory components and DIMMs used with the SBC must be PC-100 compliant,

which means that they comply with Intel's PC SDRAM specifications. These include the

PC SDRAM Specification (memory component specific), the PC Unbuffered DIMM

DIMM Type Non-ECC ECC

Unbuffered

Unbuffered

Unbuffered

Unbuffered

Unbuffered

Registered

Registered

1M x 64

2M x 64

4M x 64

8M x 64

16M x 64

32M x 64

64M x 64

1M x 72

2M x 72

4M x 72

8M x 72

16M x 72

32M x 72

64M x 72 *

Chassis Plans1-8

Page 19

SpecificationsCBI/CGI Technical Reference

Specification, the PC Registered DIMM Specification and the PC Serial Presence Detect

Specification.

M

EMORY HOLE The SBC supports a 1MB memory hole option at 512KB-640KB or 15MB-16MB.

RROR CHECKING

E

AND CORRECTION

PCI L

OCAL BUS

I

NTERFACE

The memory interface supports ECC modes via BIOS setting for multiple-bit error

detection and correction of all errors confined to a single nibble.

The SBC is fully compliant with the PCI Local Bus 2.1 Specification. It has optimized

the PCI interface to allow the processor to sustain the highest possible bandwidth

(greater than 100MB/sec sustained) and low latency of the PCI Bus. It supports PCI-toPCI bridge technology, a pipelined snoop ahead feature and improved PCI to DRAM

write-back policy. The PCI Local Bus interfaces to standard PCI option cards in the

backplane, and to the on-board PCI Ultra Wide SCSI controller and PCI 10/100Base-T

Ethernet controller. The PCI Local Bus interface to the backplane is compliant with the

PCI Industrial Computer Manufacturers Group (PICMG) 1.0 Specification.

U

NIVERSAL SERIAL

B

US (USB)

The SBC supports two USB 1.0 ports for serial transfers at 12 or 1.5Mbit/sec. The

Universal Serial Bus (USB) is an interface allowing for connectivity to many standard

PC peripherals via an external port.

C

ONCURRENT PCI Concurrent PCI maximizes system performance with simultaneous processor, PCI and

AGP Bus activities. It includes multitransaction timing, enhanced write performance, a

passive release mechanism and support for PCI 2.1 compliant delayed transactions.

AGP VGA

I

NTERFACE (NOT

AVAILABLE ON

BASIC

MODELS)

The 69000 HiQVideo video/graphic accelerator is an Accelerated Graphics Port (AGP)

device. AGP is designed to off-load the PCI Bus by allowing graphics data to move

directly from system memory. The 69000 integrates 2MB of high-speed SDRAM frame

buffer memory into the chip.

By embedding SDRAM and graphics controller logic on the same die, the 69000 delivers

uncompromising performance. The increase in the frame buffer bandwidth enables the

69000 to support high-color, high-resolution graphics modes and real-time video acceleration. The interface supports pixel resolutions up to 1600 x 1200 non-interlaced.

Software drivers for enhanced performance and resolution are available for most popular

operating systems.

S

YSTEM

H

ARDWARE

The system hardware monitoring system monitors system voltages, temperature and fan

speeds.

MONITOR

The circuitry is based on National Semiconductor's LM80. The LM80 monitors seven

system voltages, two fan speeds and the board ambient temperature. All of the voltages,

fan speeds and temperature measurements have associated programmable watchdog

limits. When any of these programmed limits are exceeded, the monitor software can be

used to notify the SBC. In addition, the externally available OS# signal can be used to

notify external hardware of any over-temperature condition.

Fan speed monitoring can be configured to monitor two system fans.

Chassis Plans 1-9

Page 20

Specifications CBI/CGI Technical Reference

The LM80 also monitors an external chassis intrusion switch via the system hardware

monitor connector (P18).

A general purpose output (GPO) is also provided at the system hardware monitor

connector. This signal can be used to provide a user-defined function.

The following system voltages are monitored by the LM80:

• -12 volts

• 3.3 volts provided by the on-board voltage regulator for components on the

SBC

• 3.3 volts backplane power used by the option slots

• +5 volts

• +12 volts

• VCC_CORE, voltage provided by on-board VRM

• 1.5 volt, VTT voltage used by processor's GTL+ bus

10/100B

E

THERNET

I

NTERFACE (NOT

AVAILABLE ON

BASIC

PCI U

SCSI I

ASE-T

MODELS)

LTRA WIDE

NTERFACE

(NOT AVAILABLE

ON BASIC

MODELS)

The PCI Ethernet interface is implemented using an Intel 82559 and operates in

10Base-T and 100Base-TX Fast Ethernet modes. The interface is compliant with

IEEE 802.3 and PCI Local Bus 2.1 Specifications.

The main components of the interface are:

• Intel 82559 for 10/100-Mb/s media access control (MAC) with SYM, a

serial ROM port and a PCI Bus Master interface

• Serial ROM for storing the Ethernet address and the interface configuration

and control data

• Integrated RJ-45/Magnetics module connector on the SBC's I/O bracket for

direct connection to the network. The connector requires a category 5

(CAT5) unshielded twisted-pair (UTP) 2-pair cable for a 100-Mb/s network

connection or a category 3 (CAT3) or higher UTP 2-pair cable for a 10-Mb/s

network connection.

• Link status and activity LEDs on the I/O bracket for status indication (See

Ethernet LEDs and Connector later in this section.)

Software drivers are supplied for most popular operating systems.

The SCSI interface is a PCI Bus Master device which supports Ultra Wide SCSI data

transfer up to 40MB per second and bursts data to the host at full PCI speeds. Active

termination is provided with terminator voltage protected by self-resetting fuses. A

jumper is provided to disable the termination. The SCSI controller is an Adaptec

AIC-7880. Software drivers are available for most popular operating systems.

The Adaptec SCSISelect Configuration Utility allows you to view and/or change the

default configuration settings for the Ultra Wide SCSI adapter. This utility is described

in Appendix C - SCSISelect Configuration Utility.

Chassis Plans1-10

Page 21

SpecificationsCBI/CGI Technical Reference

PCI ENHANCED

IDE U

LTRA

DMA/33

I

NTERFACE (DUAL)

F

LOPPY DRIVE

I

NTERFACE

ERIAL INTERFACE Two high-speed FIFO (16C550) serial ports with independently programmable baud

S

Dual high performance PCI Bus Master EIDE interfaces are capable of supporting two

IDE Type 4 disk drives each in a master/slave configuration. The interface supports

Ultra DMA/33 with synchronous DMA mode transfers up to 33MB per second.

The SBC supports two floppy disk drives. Drives can be 360K to 2.88MB, in any

combination.

rates are supported. The IRQ for each serial port has BIOS selectable addressing.

E

NHANCED

P

ARALLEL

I

NTERFACE

PS/2 M

I

NTERFACE

OUSE

The SBC provides a PC/AT compatible bidirectional parallel port and supports enhanced

parallel port (EPP) mode and extended capabilities port (ECP) mode. The ECP mode is

IEEE 1284 compliant. The IRQ for the parallel port has BIOS selectable addressing.

The SBC is compatible with a PS/2-type mouse. The mouse connection can be made by

using either the PS/2 mouse header or the bracket mounted PS/2 mouse mini DIN

connector. Mouse voltage is protected by a self-resetting fuse.

K

EYBOARD

I

NTERFACE

The SBC is compatible with an AT-type keyboard. The keyboard connection can be

made by using either the keyboard header or the bracket mounted keyboard mini DIN

connector. Keyboard voltage is protected by a self-resetting fuse.

W

ATCHDOG TIMER The watchdog timer is a hardware timer which resets the SBC if the timer is not

refreshed by software periodically. The timer is typically used to restart a system in

which an application becomes hung on an external event. When the application is hung,

it no longer refreshes the timer. The watchdog timer then times out and resets the SBC.

P

OWER FAIL

DETECTION

The watchdog timer has two levels of enable. First, the watchdog timer jumper must be

moved to the "enabled" position, which puts the watchdog timer under software control.

The second level involves software control of the watchdog's timer retriggering. Bit 6 of

the 82371EB GPOREG register at I/O address 437H must be set to a zero (0), which

blocks the triggering clock to the watchdog timer circuit, thus scheduling a hardware

reset in about 1.5 seconds.

To refresh the watchdog timer, the software in the application toggles bit 6 of the

GPOREG register. First the bit must be set to a one (1) to clear the watchdog timer

delay; then it must be set to a zero (0), which schedules a system reset in 1.5 seconds.

Toggling bit 6 of the GPOREG must occur within a period of less than 1.5 seconds to

insure that a system reset is not issued.

A set of watchdog timer software code and sample programs are available from

Technical Support.

A hardware reset is issued when on-board +5V voltage drops below 4.75 volts. In

addition, if the 3.3V Monitor jumper (JU15) is enabled, a reset is issued if 3.3V is below

tolerance. (See the Configuration Jumpers section later in this chapter.)

Chassis Plans 1-11

Page 22

Specifications CBI/CGI Technical Reference

BATTERY A built-in lithium battery is provided, for ten years of data retention for CMOS memory.

______________________________________________________________________

CAUTION: There is a danger of explosion if the battery is incorrectly replaced.

Replace it only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer's instructions.

______________________________________________________________________

P

OWER

R

EQUIREMENTS

The following are typical values:

Processor

Speed

+5V * +12V -12V

Intel® Pentium® III -100MHz FSB:

T

EMPERATURE/

E

NVIRONMENT

850MHz

800MHz

®

Intel

733MHz

667MHz

633MHz

Operating Temperature: 0º C. to 60º C.

Storage Temperature: - 40

7.6 Amps

7.1 Amps

< 100 mAmps

< 100 mAmps

Celeron® - 66MHz FSB:

6.5 Amps

6.1 Amps

5.6 Amps

< 100 mAmps

< 100 mAmps

< 100 mAmps

0

º C. to 55º C. for 700MHz Intel

º C. to 70º C.

Humidity: 5% to 90% non-condensing

M

EAN TIME

B

ETWEEN

F

AILURES (MTBF)

CBI/CGI:

66,000 POH (Power-On Hours) at 40° C., per MIL-HDBK-217F

CB BASIC:

95,000 POH (Power-On Hours) at 40° C., per MIL-HDBK-217F

UL R

ECOGNITION This SBC is a UL recognized product listed in file #E208896.

< 100 mAmps

< 100 mAmps

< 100 mAmps

< 100 mAmps

< 100 mAmps

®

Pentium® III and above

This board was investigated and determined to be in compliance under the Bi-National

Standard for Information Technology Equipment. This included the Electrical Business

Equipment, UL 1950, Third Edition, and CAN/CSA C22.22 No. 950-95.

Chassis Plans1-12

Page 23

SpecificationsCBI/CGI Technical Reference

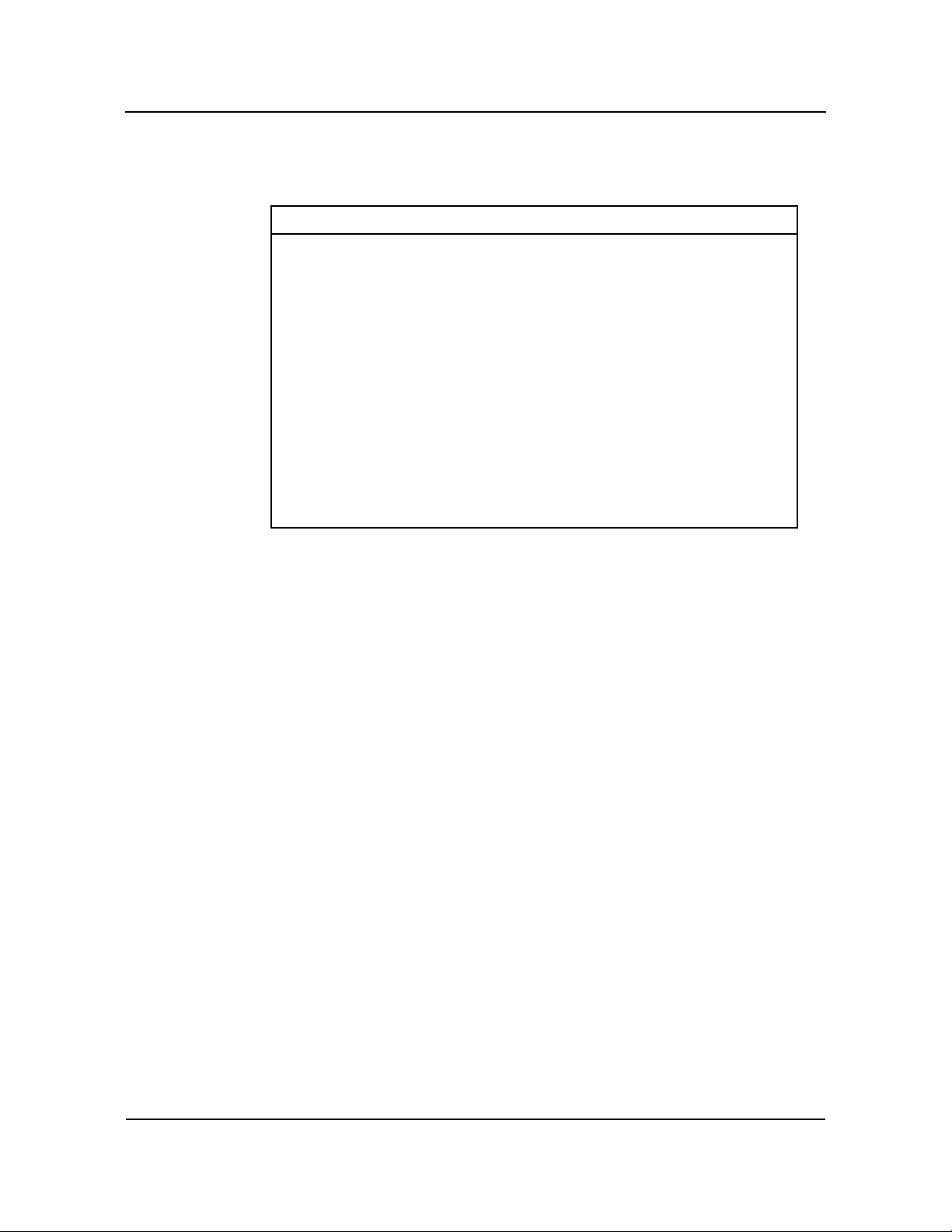

CONFIGURATION

J

UMPERS

The setup of the configuration jumpers on the SBC is described below. * indicates the

default value of each jumper.

______________________________________________________________________

NOTE: For two-position jumpers (3-post), "RIGHT" is toward the bracket end of the

board; "LEFT" is toward the memory sockets.

______________________________________________________________________

Jumper

JU7 Combo I/O (P5A) Speaker Connect

JU8 Password Clear

JU9 CRT Type Select

Description

(Also refer to JU18 - Combo I/O Reset Connect.)

Install to connect speaker data signal to pin 8 of the Combo

I/O connector (P5A). *

Remove to disconnect.

Install for one power-up cycle to reset the password to the

default (null password).

Remove for normal operation. *

Install on the LEFT for a monochrome CRT.

Install on the RIGHT for a color CRT. *

JU10/JU11 System Flash ROM Operational Modes

The Flash ROM has two programmable sections: the Boot

Block for “flashing” in the BIOS and the Main Block for the

executable BIOS and PnP parameters. Normally only the

Main Block is updated when a new BIOS is flashed into the

system.

JU10

Program All (Boot and Main) Bottom Bottom

Normal PnP (Program Main Block) Bottom * Top *

Write Protect Top Top

JU12 CMOS Clear

Install to clear.

Remove to operate. *

__________________________________________________

NOTE: The CMOS Clear jumper works on power-up. To

clear the CMOS, power down the system, install the jumper,

then turn the power back on. CMOS is cleared during the

POST routines. Then power down the system again and

remove the jumper before the next power-up.

__________________________________________________

JU11

Chassis Plans 1-13

Page 24

Specifications CBI/CGI Technical Reference

CONFIGURATION

J

UMPERS

(

CONTINUED)

Jumper

Description

JU13 SCSI Termination Enable (not available on BASIC models)

Install to disable on-board active termination for the SCSI

interface.

Remove to enable active termination. *

JU14 Fan Speed Monitor

This jumper must be removed (disabled).

JU15 3.3V Monitor Enable

Install to enable the 3.3V monitor.

Remove to disable the monitor. *

NOTE: On SBCs with revision L-07 and later, the position of

this jumper is horizontal; on earlier revisions it is vertical.

__________________________________________________

NOTE: JU15 enables the 3.3 volt monitor, which monitors

the 3.3V power plane of the backplane. This voltage is routed

to the SBC via the PICMG connector. The monitor generates

a RESET to the SBC if 3.3V is below tolerance. If your

system does not supply 3.3V to the backplane, this jumper

must be removed (disabled).

__________________________________________________

JU16 Watchdog Timer

Install on the LEFT for normal reset operation. *

Install on the RIGHT to enable watchdog timer operation.

JU18 Combo I/O (P5A) Reset Connect

(Also refer to JU7 - Combo I/O Speaker Connect.)

Install to connect reset data signal to pin 1 of the Combo I/O

connector (P5A). *

Remove to disconnect.

JU19 SCSI Activity LED Enable (not available on BASIC models)

Install to light the hard drive LED for SCSI drive activity. *

Remove if you do not have a SCSI drive (i.e., the SCSI

controller is not being used).

Chassis Plans1-14

Page 25

SpecificationsCBI/CGI Technical Reference

ETHERNET LEDS

AND CONNECTOR

(

NOT AVAILABLE

ON BASIC

MODELS)

The Ethernet interface has two LEDs for status indication and an RJ-45 network

connector.

LED/Connector

Description

Link/Activity LED Green LED which indicates the link status

Off The Ethernet interface did not find a valid link on the

network connection. Transmit and receive are not

possible.

On (solid) The Ethernet interface has a valid link on the network

connection and is ready for normal operation. The Speed

LED identifies connection speed.

On (flashing) Indicates network transmit or receive activity.

Speed LED Amber LED which identifies the connection speed.

Off Indicates a 10Mb/s connection.

On Indicates a 100Mb/s connection.

RJ-45 Network

Connector

The RJ-45 network connector requires a category 5

(CAT5) unshielded twisted-pair (UTP) 2-pair cable for a

100-Mb/s network connection or a category 3 (CAT3) or

higher UTP 2-pair cable for a 10-Mb/s network

connection.

S

YSTEM BIOS

S

ETUP UTILITY

The System BIOS is a Hi-Flex AMIBIOS with a ROM-resident setup utility. The BIOS

Setup Utility allows you to select the following options:

• Standard CMOS Setup

• Advanced CMOS Setup

• Advanced Chipset Setup

• Power Management Setup

• PCI/Plug and Play Setup

• Peripheral Setup

• Auto-Detect Hard Disks

• Change User Password/Change Supervisor Password

• Auto Configuration with Optimal Settings

• Auto Configuration with Fail Safe Settings

• Save Settings and Exit

• Exit Without Saving

Chassis Plans 1-15

Page 26

Specifications CBI/CGI Technical Reference

CONNECTORS ______________________________________________________________________

NOTE: Pin 1 on the connectors is indicated by the square pad on the PCB.

______________________________________________________________________

P2 - Keylock Connector

5 pin single row header, Amp #640456-5

Pin

Signal

1

LED Power

2

Key

3

Gnd

4

Keylock Data

5

Gnd

P3 - Floppy Drive Connector

34 pin dual row header, Robinson Nugent #IDH-34LP-S3-TR

Signal

Pin

1

Gnd

3

Gnd

5

Gnd

7

Gnd

9

Gnd

11

Gnd

13

Gnd

15

Gnd

17

Gnd

19

Gnd

21

Gnd

23

Gnd

25

Gnd

27

Gnd

29

Gnd

31

Gnd

33

Gnd

P4 - Keyboard Connector

6 pin mini DIN, Kycon #KMDG-6S-BS-PS

Pin

Signal

1

Kbd Data

2

Reserved

3

Gnd

4

Kbd Power (+5V fused) with self-resetting fuse

5

Kbd Clock

6

Reserved

Pin

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

Signal

N-RPM

NC

D-Rate0

P-Index

N-Motoron 1

N-Drive Sel2

N-Drive Sel1

N-Motoron 2

N-Dir

N-Stop Step

N-Write Data

N-Write Gate

P-Track 0

P-Write Protect

N-Read Data

N-Side Select

Disk Chng

Chassis Plans1-16

Page 27

CONNECTORS

(

CONTINUED)

P4A - Keyboard Header

5 pin single row header, Amp #640456-5

Pin

Signal

1

Kbd Clock

2

Kbd Data

3

Key

4

Kbd Gnd

5

Kbd Power (+5V fused) with self-resetting fuse

P5 - Speaker Port Connector

4 pin single row header, Amp #640456-4

Signal

Pin

1

Speaker Data

2

Key

3

Gnd

4

+5V

P5A - Combo I/O Connector

8 pin single row header, Amp #640456-8

SpecificationsCBI/CGI Technical Reference

Signal

Pin

1

Reset (See JU18 in the Configuration Jumpers section.)

2

Gnd

3

NC

4

Kbd Clock

5

Kbd Data

6

Kbd Lock Data

7

Kbd Power (+5V fused) with self-resetting fuse

8

Speaker Data

P6 - Serial Port 1 Connector

10 pin dual row header, 3M #30310-6002HB

Pin

Signal

1

Carrier Detect

3

Receive Data-I

5

Transmit Data-O

7

Data Terminal Ready-O

9

Signal Gnd

P7 - Serial Port 2 Connector

10 pin dual row header, 3M #30310-6002HB

Pin

Signal

1

Carrier Detect

3

Receive Data-I

5

Transmit Data-O

Pin

Signal

2

Data Set Ready-I

4

Request to Send-O

6

Clear to Send-I

8

Ring Indicator-I

10

NC

Pin

Signal

2

Data Set Ready-I

4

Request to Send-O

6

Clear to Send-I

Chassis Plans 1-17

Page 28

Specifications CBI/CGI Technical Reference

CONNECTORS

(

CONTINUED)

P7 - Serial Port 2 Connector (continued)

Signal

Pin

7

Data Terminal Ready-O

9

Signal Gnd

P8 - Parallel Port Connector

26 pin dual row header, 3M #30326-6002HB

Signal

Pin

1

Strobe

3

Data Bit 0

5

Data Bit 1

7

Data Bit 2

9

Data Bit 3

11

Data Bit 4

13

Data Bit 5

15

Data Bit 6

17

Data Bit 7

19

ACK

21

Busy

23

Paper End

25

Slct

P9 - PS/2 Mouse Connector

6 pin mini DIN, Kycon #KMDG-6S-BS-PS

Pin

Signal

8

Ring Indicator-I

10

NC

Pin

Signal

2

Auto Feed XT

4

Error

6

Init

8

Slct In

10

Gnd

12

Gnd

14

Gnd

16

Gnd

18

Gnd

20

Gnd

22

Gnd

24

Gnd

26

NC

Pin

Signal

1

Ms Data

2

Reserved

3

Gnd

4

Kbd Power (+5V fused) with self-resetting fuse

5

Ms Clock

6

Reserved

P9A - PS/2 Mouse Header

6 pin single row header, Amp #640456-6

Pin

Signal

1

Ms Data

2

Reserved

3

Kbd Gnd

4

Kbd Power (+5V fused) with self-resetting fuse

5

Ms Clock

6

Reserved

Chassis Plans1-18

Page 29

CONNECTORS

(

CONTINUED)

P10 - External Reset Connector

2 pin header, Amp #640456-2

Pin

Signal

1

Negative External Reset

2

Gnd

P11 - Primary IDE Hard Drive Connector

40 pin dual row header, Robinson Nugent #IDH-40LP-S3-TR

SpecificationsCBI/CGI Technical Reference

Signal

Pin

1

Reset

3

Data 7

5

Data 6

7

Data 5

9

Data 4

11

Data 3

13

Data 2

15

Data 1

17

Data 0

19

Gnd

21

DRQ 0

23

IOW

25

IOR

27

IORDY

29

DACK 0

31

IRQ 14

33

Add 1

35

Add 0

37

CS 1P

39

IDEACTP

P11A - Secondary IDE Hard Drive Connector

40 pin dual row header, Robinson Nugent #IDH-40LP-S3-TR

Pin

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

Signal

Gnd

Data 8

Data 9

Data 10

Data 11

Data 12

Data 13

Data 14

Data 15

NC

Gnd

Gnd

Gnd

+5V

Gnd

IOCS16

Gnd

Add 2

CS 3P

Gnd

Pin

1

3

5

7

9

11

13

15

17

19

21

23

25

27

Signal

Reset

Data 7

Data 6

Data 5

Data 4

Data 3

Data 2

Data 1

Data 0

Gnd

DRQ 1

IOW

IOR

IORDY

Pin

2

4

6

8

10

12

14

16

18

20

22

24

26

28

Signal

Gnd

Data 8

Data 9

Data 10

Data 11

Data 12

Data 13

Data 14

Data 15

NC

Gnd

Gnd

Gnd

+5V

Chassis Plans 1-19

Page 30

Specifications CBI/CGI Technical Reference

CONNECTORS

(

CONTINUED)

P11A - Primary IDE Hard Drive Connector (continued)

Signal

Pin

29

DACK 1

31

MIRQ 0

33

Add 1

35

Add 0

37

CS 1S

39

IDEACTS

P12 - Hard Drive LED Connector

4 pin single row header, Amp #640456-4

(This connector is used for both IDE and SCSI drives. See

JU19 in the Configuration Jumpers section.)

Pin

Signal

1

+5V Pull-up

2

Light

3

Light

4

+5V Pull-up

P13 - PCI Ultra Wide SCSI Controller Connector

(not available on BASIC models)

50/68 pin high density connector, Amp #749069-7

Signal

Pin

1

Gnd

2

Gnd

3

Gnd

4

Gnd

5

Gnd

6

Gnd

7

Gnd

8

Gnd

9

Gnd

10

Gnd

11

Gnd

12

Gnd

13

Gnd

14

Gnd

15

Gnd

16

Gnd

17

TERMPWR

18

TERMPWR

19

NC

20

Gnd

21

Gnd

22

Gnd

Pin

30

32

34

36

38

40

Pin

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

Signal

Gnd

IOCS16

Gnd

Add 2

CS 3S

Gnd

Signal

SCZDB12

SCZDB13

SCZDB14

SCZDB15

SCZDBPH

SCZDB0

SCZDB1

SCZDB2

SCZDB3

SCZDB4

SCZDB5

SCZDB6

SCZDB7

SCZDBP

Gnd

Gnd

TERMPWR

TERMPWR

NC

Gnd

SCZATN

Gnd

Chassis Plans1-20

Page 31

CONNECTORS

(

CONTINUED)

SpecificationsCBI/CGI Technical Reference

P13 - PCI Ultra Wide SCSI Controller Connector (continued)

Signal

Pin

23

Gnd

24

Gnd

25

Gnd

26

Gnd

27

Gnd

28

Gnd

29

Gnd

30

Gnd

31

Gnd

32

Gnd

33

Gnd

34

WIDEPS

P15 - PCI SVGA Interface Connector

(not available on BASIC models)

15 pin VGA connector, Amp #748390-5

Pin

Signal

Pin Signal

6Gnd

1Red

7Gnd

2 Green

8Gnd

3Blue

9NC

4NC

10 Gnd

5Gnd

Pin

57

58

59

60

61

62

63

64

65

66

67

68

Pin

11

12

13

14

15

Signal

SCZBSY

SCZACK

ASCRST

SCZMSG

SCZSEL

SCZCD

SCZREQ

SCZIO

SCZDB8

SCZDB9

SCZDB10

SCZDB11

Signal

NC

EEDI

HSYNC

VSYNC

EECS

P16 - PCI 10/100Base-T Ethernet Connector

(not available on BASIC models)

8 pin shielded RJ-45 connector, Pulse #J0035D21B

Signal

Pin

1

TD+

2

TD-

3

RX+

4

NC

5

NC

6

RX-

7

NC

8

NC

Chassis Plans 1-21

Page 32

Specifications CBI/CGI Technical Reference

CONNECTORS

(

CONTINUED)

P17 - Universal Serial Bus (USB) Connector

8 pin dual row header, Molex #702-46-0821

(+5V fused with self-resetting fuses)

Signal

Pin

1

+5V-USB0

3

USB0-

5

USB0+

7

Gnd-USB0

P18 - System Hardware Monitor Connector

6 pin single row header, Amp #640456-6

Signal

Pin

1

Gnd

2

GPO (General Purpose Output)

3

CI (Chassis Intrusion Input)

4

FAN1 (Fan 1 Tachometer Input)

5

FAN2 (Fan 2 Tachometer Input)

6

OS# (Temperature Sense Output)

P19 - CPU Fan

3 pin single row header, Molex #22-23-2031

Pin

Signal

1

Gnd

2

+12V

3

FanTach

Pin

2

4

6

8

Signal

+5V-USB1

USB1USB1+

Gnd-USB1

Copyright 2003 by Trenton Technology Inc. All rights reserved.

Chassis Plans1-22

Page 33

Chapter 2 ISA/PCI Reference

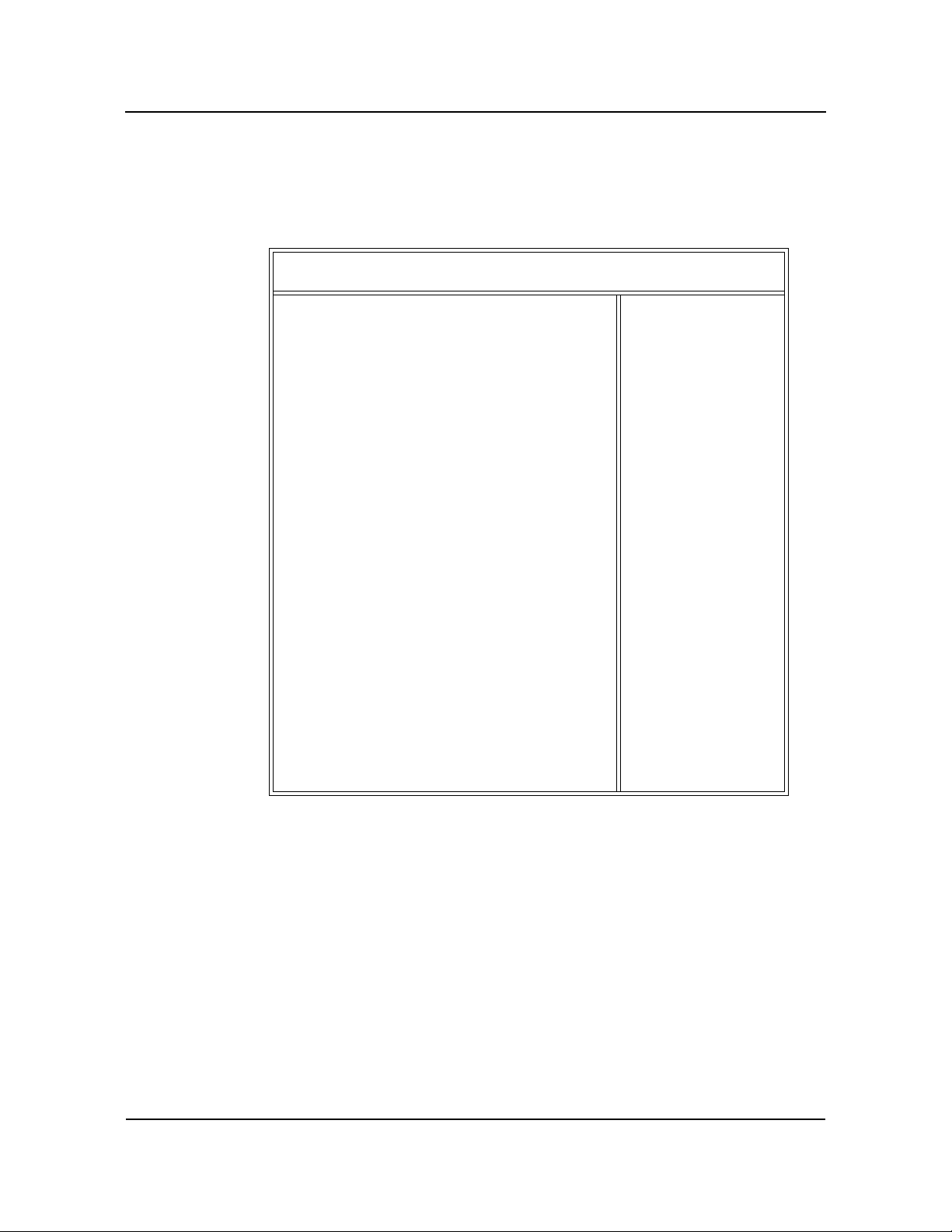

ISA BUS PIN

N

UMBERING

62-pin ISA Bus

Connector

ISA/PCI ReferenceCBI/CGI Technical Reference

Component Side

of Board

36-pin ISA Bus

Connector

Chassis Plans 2-1

Page 34

ISA/PCI Reference CBI/CGI Technical Reference

ISA BUS PIN

A

SSIGNMENTS

The following tables summarize pin assignments for the Industry Standard Architecture

(ISA) Bus connectors.

I/O Pin Signal Name I/O I/O Pin Signal Name I/O

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

IOCHK#

D7

D6

D5

D4

D3

D2

D1

D0

CHRDY

AEN

SA19

SA18

SA17

SA16

SA15

SA14

SA13

SA12

SA11

SA10

SA9

SA8

SA7

SA6

SA5

SA4

SA3

SA2

SA1

SA0

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I

O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

Gnd

RESDRV

+5V

IRQ9

-5V

DRQ2

-12V

NOWS#

+12V

Gnd

SMWTC#

SMRDC#

IOWC#

IORC#

DAK3#

DRQ3

DAK1#

DRQ1

REFRESH#

BCLK

IRQ7

IRQ6

IRQ5

IRQ4

IRQ3

DAK2#

T-C

BALE

+5V

OSC

Gnd

Ground

O

Power

I

Power

I

Power

I

Power

Ground

O

O

I/O

I/O

O

I

O

I

I/O

O

I

I

I

I

I

O

O

O

Power

O

Ground

I/O Pin Signal Name I/O I/O Pin Signal Name I/O

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

C17

C18

SBHE#

LA23

LA22

LA21

LA20

LA19

LA18

LA17

MRDC#

MWTC#

D8

D9

D10

D11

D12

D13

D14

D15

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

D16

D17

D18

M16#

IO16#

IRQ10

IRQ11

IRQ12

IRQ15

IRQ14

DAK0#

DRQ0

DAK5#

DRQ5

DAK6#

DRQ6

DAK7#

DRQ7

+5V

Master16#

Gnd

I

I

I

I

I

I

I

O

I

O

I

O

I

O

I

Power

I

Ground

Chassis Plans2-2

Page 35

ISA/PCI ReferenceCBI/CGI Technical Reference

ISA BUS SIGNAL

D

ESCRIPTIONS

The following is a description of the ISA Bus signals. All signal lines are TTLcompatible.

AEN (O)

Address Enable (AEN) is used to degate the microprocessor and other devices from the I/O

channel to allow DMA transfers to take place. When this line is active, the DMA controller has

control of the address bus, the data-bus Read command lines (memory and I/O), and the Write

command lines (memory and I/O).

BALE (O) (Buffered)

Address Latch Enable (BALE) is provided by the bus controller and is used on the system board

to latch valid addresses and memory decodes from the microprocessor. It is available to the I/O

channel as an indicator of a valid microprocessor or DMA address (when used with AEN).

Microprocessor addresses SA[19::0] are latched with the falling edge of BALE. BALE is forced

high during DMA cycles.

BCLK (O)

BCLK is the system clock. The clock has a 50% duty cycle. This signal should only be used for

synchronization. It is not intended for uses requiring a fixed frequency.

CHRDY (I)

I/O Channel Ready (CHRDY) is pulled low (not ready) by a memory or I/O device to lengthen I/

O or memory cycles. Any slow device using this line should drive it low immediately upon

detecting its valid address and a Read or Write command. Machine cycles are extended by an

integral number of clock cycles. This signal should be held low for no more than 2.5 microseconds.

D[15::0] (I/O)

Data signals D[15::0] provide bus bits 15 through 0 for the microprocessor, memory, and I/O

devices. D15 is the most-significant bit and D0 is the least-significant bit. All 8-bit devices on

the I/O channel should use D[7::0] for communications to the microprocessor. The 16-bit

devices will use D[15::0]. To support 8-bit devices, the data on D[15::8] will be gated to D[7::0]

during 8-bit transfers to these devices. 16-bit microprocessor transfers to 8-bit devices will be

converted to two 8-bit transfers.

DAK[7::5]#, DAK[3::0]# (O)

DMA Acknowledge DAK[7::5]# and DAK[3::0]# are used to acknowledge DMA requests

DRQ[7::5] and DRQ[3::0]. They are active low.

DRQ[7::5], DRQ[3::0] (I)

DMA Requests DRQ[7::5] and DRQ[3::0] are asynchronous channel requests used by

peripheral devices and the I/O channel microprocessors to gain DMA service (or control of the

system). They are prioritized, with DRQ0 having the highest priority and DRQ7 having the

lowest. A request is generated by bringing a DRQ line to an active level. A DRQ line must be

held high until the corresponding DMA Request Acknowledge (DAK) line goes active.

DRQ[3::0] will perform 8-bit DMA transfers; DRQ[7::5] will perform 16-bit transfers.

Chassis Plans 2-3

Page 36

ISA/PCI Reference CBI/CGI Technical Reference

IO16# (I)

I/O 16-bit Chip Select (IO16#) signals the system board that the present data transfer is a 16-bit,

1 wait-state, I/O cycle. It is derived from an address decode. IO16# is active low and should be

driven with an open collector or tri-state driver capable of sinking 20 mAmps.

IOCHK# (I)

I/O Channel Check (IOCHK#) provides the system board with parity (error) information about

memory or devices on the I/O channel. When this signal is active, it indicates an uncorrectable

system error.

IORC# (I/O)

I/O Read (IORC#) instructs an I/O device to drive its data onto the data bus. It may be driven by

the system microprocessor or DMA controller, or by a microprocessor or DMA controller

resident on the I/O channel. This signal is active low.

IOWC# (I/O)

I/O Write (IOWC#) instructs an I/O device to read the data on the data bus. It may be driven by

any microprocessor or DMA controller in the system. This signal is active low.

IRQ[15::14], IRQ[12::9], IRQ[7::3] (I)

Interrupt Requests IRQ[15::14], IRQ[12::9] and IRQ[7::3] are used to signal the microprocessor

that an I/O device needs attention. The interrupt requests are prioritized, with IRQ[15::14] and

IRQ[12::9] having the highest priority (IRQ9 is the highest) and IRQ[7::3] having the lowest

priority (IRQ7 is the lowest). An interrupt request is generated when an IRQ line is raised from

low to high. The line must be held high until the microprocessor acknowledges the interrupt

request (Interrupt Service routine).

LA[23::17] (I/O)

These signals (unlatched) are used to address memory and I/O devices within the system.

They give the system up to 16MB of addressability. These signals are valid when BALE is high.

LA[23::17] are not latched during microprocessor cycles and therefore do not stay valid for the

whole cycle. Their purpose is to generate memory decodes for 1 wait-state memory cycles.

These decodes should be latched by I/O adapters on the falling edge of BALE. These signals

also may be driven by other microprocessors or DMA controllers that reside on the I/O channel.

M16# (I)

M16# Chip Select signals the system board if the present data transfer is a 1<N>wait-state, 16bit, memory cycle. It must be derived from the decode of LA[23::17]. M16# should be driven

with an open collector or tri-state driver capable of sinking 20 mAmps.

Master16# (I)

Master16# is used with a DRQ line to gain control of the system. A processor or DMA controller

on the I/O channel may issue a DRQ to a DMA channel in cascade mode and receive a DAK#.

Upon receiving the DAK#, an I/O microprocessor may pull Master16# low, which will allow it to

control the system address, data, and control lines (a condition known as tri-state). After

Master16# is low, the I/O microprocessor must wait one system clock period before driving the

address and data lines, and two clock periods before issuing a Read or Write command. If this

signal is held low for more than 15<N>microseconds, system memory may be lost because of a

lack of refresh.

Chassis Plans2-4

Page 37

ISA/PCI ReferenceCBI/CGI Technical Reference

NOWS# (I)

The No Wait State (NOWS#) signal tells the microprocessor that it can complete the present bus

cycle without inserting any additional wait cycles. In order to run a memory cycle to a 16-bit

device without wait cycles, NOWS# is derived from an address decode gated with a Read or

Write command. In order to run a memory cycle to an 8-bit device with a minimum of two wait

states, NOWS# should be driven active on system clock after the Read or Write command is

active gated with the address decode for the device. Memory Read and Write commands to a

8-bit device are active on the falling edge of the system clock. NOWS# is active low and should

be driven with an open collector or tri-state driver capable of sinking 20 mAmps.

OSC (O)

Oscillator (OSC) is a high-speed clock with a 70-nanosecond period (14.31818 MHz). This

signal is not synchronous with the system clock. It has a 50% duty cycle.

REFRESH# (I/O)

The REFRESH# signal is used to indicate a refresh cycle and can be driven by a microprocessor on the I/O channel.

RESDRV (O)

Reset Drive (RESDRV) is used to reset or initialize system logic at power-up time or during a

low line-voltage outage. This signal is active high.

SA[19::0] (I/O)

Address bits SA[19::0] are used to address memory and I/O devices within the system. These

twenty address lines, in addition to LA[23::17], allow access of up to 16MB of memory.

SA[19::0] are gated on the system bus when BALE is high and are latched on the falling edge of

BALE. These signals are generated by the microprocessor or DMA Controller. They also may

be driven by other microprocessors or DMA controllers that reside on the I/O channel.

SBHE# (I/O)

System Bus High Enable (SBHE#) indicates a transfer of data on the upper byte of the data bus,

D[15::8]. 16-bit devices use SBHE# to condition data bus buffers tied to D[15::8].

SMRDC# (O), MRDC# (I/O)

These signals instruct the memory devices to drive data onto the data bus. SMRDC# is active

only when the memory decode is within the low 1MB of memory space. MRDC# is active on all

memory read cycles. MRDC# may be driven by any microprocessor or DMA controller in the

system. SMRDC is derived from MRDC# and the decode of the low 1MB of memory. When a

microprocessor on the I/O channel wishes to drive MRDC#, it must have the address lines valid

on the bus for one system clock period before driving MRDC# active. Both signals are active

low.

SMWTC# (O), MWTC# (I/O)

These signals instruct the memory devices to store the data present on the data bus. SMWTC#

is active only when the memory decode is within the low 1MB of the memory space. MWTC# is

active on all memory write cycles. MWTC# may be driven by any microprocessor or DMA

controller in the system. SMWTC# is derived from MWTC# and the decode of the low 1MB of

memory. When a microprocessor on the I/O channel wishes to drive MWTC#, it must have the

address lines valid on the bus for one system clock period before driving MWTC# active. Both

signals are active low.

Chassis Plans 2-5

Page 38

ISA/PCI Reference CBI/CGI Technical Reference

T-C (O)

Terminal Count (T-C) provides a pulse when the terminal count for any DMA channel is reached.

Chassis Plans2-6

Page 39

I/O ADDRESS MAP*

ISA/PCI ReferenceCBI/CGI Technical Reference

Hex Range Device

I

NTERRUPT

A

SSIGNMENTS*

000-01F

020-03F

040-05F

060-06F

070-07F

080-09F

0A0-0BF

0C0-0DF

0F0

0F1

0F8-0FF

1F0-1F8

200-207

278-27F

2F8-2FF

300-31F

360-36F

378-37F

380-38F

3A0-3AF

3B0-3BF

3C0-3CF

3D0-3DF

3F0-3F7

3F8-3FF

Interrupt Description

DMA Controller 1

Interrupt Controller 1, Master

Timer

8042 (Keyboard)

Real-time Clock, NMI (non-maskable interrupt) Mask

DMA Page Register

Interrupt Controller 2

DMA Controller 2

Clear Math Coprocessor Busy

Reset Math Coprocessor

Math Coprocessor

Fixed Disk

Game I/O

Parallel Printer Port 2

Serial Port 2

Prototype Card

Reserved

Parallel Printer Port 1

SDLC, Bisynchronous 2

Bisynchronous 1

Monochrome Display and Printer Adapter

Reserved

Color/Graphics Monitor Adapter

Diskette Controller

Serial Port 1

IRQ0

IRQ1

IRQ2

IRQ3

IRQ4

IRQ5

IRQ6

IRQ7

IRQ8

IRQ9

IRQ10

IRQ11

IRQ12

IRQ13

IRQ14

IRQ15

Timer Output 0

Keyboard (Output Buffer Full)

Interrupt 8 through 15

Serial Port 2

Serial Port 1

Parallel Port 2

Diskette Controller

Parallel Port 1

Real-time Clock Interrupt

Software Redirected to INT 0AH (IRQ2)

Unassigned

Unassigned

PS/2 Mouse

Coprocessor

Fixed Disk Controller

Unassigned (may be assigned by the system to the

secondary IDE)

* These are typical parameters, which may not reflect your current system.

Chassis Plans 2-7

Page 40

ISA/PCI Reference CBI/CGI Technical Reference

PCI LOCAL BUS

O

VERVIEW

The PCI (Peripheral Component Interconnect) Local Bus is a high performance, 32-bit or

64-bit bus with multiplexed address and data lines. It is intended for use as an interconnect mechanism between highly integrated peripheral controller components,

peripheral add-in boards and processor/memory systems.

The "local bus" moves peripheral functions with high bandwidth requirements closer to

the system’s processor bus and can produce substantial performance gains with graphical

user interfaces (GUIs) and other high bandwidth functions (i.e., full motion video, SCSI,

LANs, etc.).

The PCI Local Bus accommodates future system requirements and is applicable across

multiple platforms and architectures.

The PCI component and add-in card interface is processor independent, enabling an

efficient transition to future processor generations, by bridges or by direct integration,

and use with multiple processor architectures. Processor independence allows the PCI

Local Bus to be optimized for I/O functions, enables concurrent operation of the local

bus with the processor/memory subsystem, and accommodates multiple high performance peripherals in addition to graphics. Movement to enhanced video and multimedia

displays and other high bandwidth I/O will continue to increase local bus bandwidth

requirements. A transparent 64-bit extension of the 32-bit data and address buses is

defined, doubling the bus bandwidth and offering forward and backward compatibility of

32-bit (132MB/s peak) and 64-bit (264MB/s peak) PCI Local Bus peripherals.

Chassis Plans2-8

Page 41

ISA/PCI ReferenceCBI/CGI Technical Reference

PCI LOCAL BUS

S

IGNAL DEFINITION

The PCI interface requires a minimum of 47 pins for a target-only device and 49 pins for

a master to handle data and addressing, interface control, arbitration and system

functions. The diagram below shows the pins in functional groups, with required pins on

the left side and optional pins on the right side.

Required Pins:

Address & Data:

AD[31::00]

C/BE[3::0]#

PAR

Interface Control:

FRAME#

TRDY#

IRDY#

STOP#

DEVSEL#

IDSEL

Error Reporting:

PERR#

SERR#

Arbitration

(masters only):

REQ#

GNT#

System:

CLK

RST#

PCI

COMPLIANT

DEVICE

Optional Pins:

64-bit Extension

AD[63::32]

C/BE[7::4]#

PAR 64

REQ64#

ACK64#

Interface Control:

LOCK#

INTA#

INTB#

INTC#

INTD#

Cache Support:

SBO#

SDONE

JTAG (IEEE 1149.1):

TDI

TDO

TCK

TMS

TRST#

PCI Pin List

Chassis Plans 2-9

Page 42

ISA/PCI Reference CBI/CGI Technical Reference

PCI LOCAL BUS

P

IN NUMBERING

Component Side

of Board

5-volt/32-bit PCI Connector

Chassis Plans2-10

Page 43

ISA/PCI ReferenceCBI/CGI Technical Reference

PCI LOCAL BUS

P

IN ASSIGNMENTS

The PCI Local Bus pin assignments shown below are for the PCI option slots on the

backplane.

The PCI Local Bus specifies both 5-volt and 3.3-volt signaling environments. The

following bus pin assignments are for the 5-volt connector. The 3.3-volt connector bus

pin assignments are the same with the following exceptions:

* The pins noted as +V (I/O) are +5 volts or +3.3 volts, depending on which

connector is being used.

† Pins B12, B13, A12 and A13 are Gnd (ground) on the 5-volt connector, but

are Connector Keys on the 3.3-volt connector.

†† Pin B49 is Gnd (ground) on the 5-volt connector, but is M66EN on the 3.3-

volt connector.

††† Pins B50, B51, A50 and A51 are Connectors Keys on the 5-volt connector,

but are Gnd (ground) on the 3.3-volt connector.

I/O Pin Signal Name I/O Pin Signal Name

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

-12V

TCK

Gnd

TDO

+5V

+5V

INTB#

INTD#

PRSNT1#

Reserved

PRSNT2#

Gnd

†

Gnd †

Reserved

Gnd

CLK

Gnd

REQ#

+V (I/O) *

AD31

AD29

Gnd

AD27

AD25

+3.3V

C/BE3#

AD23

Gnd

AD21

AD19

+3.3V

AD17

C/BE2#

Gnd

IRDY#

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

TRST#

+12V

TMS

TDI

+5V

INTA#

INTC#

+5V

Reserved

+V (I/O) *

Reserved

Gnd

†

Gnd †

Reserved

RST#

+V (I/O) *

GNT#

Gnd

Reserved

AD30

+3.3V

AD28

AD26

Gnd

AD24

IDSEL

+3.3V

AD22

AD20

Gnd

AD18

AD16

+3.3V

FRAME#

Gnd

32-bit connector start

Chassis Plans 2-11

Page 44

ISA/PCI Reference CBI/CGI Technical Reference

PCI LOCAL BUS

P