Page 1

Revision 1.0

Intel® Server System R2000LH2/T2

Product Family

Technical Product Specification

April 2013

Enterprise Platforms and Services Division

Page 2

Revision History Intel® Server System R2000LH2/T2 Product Family TPS

ii

Date

Revision

Number

Modifications

June 2012

0.8

Updates to images and all sections

Updates to images, environmental data,system boards,power supply section,

April 2013

1.0

Updates to Power Supply section, POST Codes, and formatting

Revision History

Nov 2012 0.95

IO Riser, GPGPU, Post Codes, and connector pinouts

Disclaimers

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL PRODUCTS. NO LICENSE,

EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS

GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR

SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER AND INTEL DISCLAIMS ANY EXPRESS OR

IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR

WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR

INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELL E CTUAL PROPERTY RIGHT.

A "Mission Critical Application" is any application in which failure of the Intel Product could result, directly or indirectly,

in personal injury or death. SHOULD YOU PURCHASE OR USE INTEL'S PRODUCTS FOR ANY SUCH MISSION

CRITICAL APPLICATION, YOU SHALL INDEMNIFY AND HOLD INTEL AND ITS SUBSIDIARIES,

SUBCONTRACTORS AND AFFILIATES, AND THE DIRECTORS, OFFICERS, AND EMPLOYEES OF EACH,

HARMLESS AGAINST ALL CLAIMS COSTS, DAMAGES, AND EXPENSES AND REASONABLE ATTORNEYS'

FEES ARISING OUT OF, DIRECTLY OR INDIRECTLY, ANY CLAIM OF PRODUCT LIABILITY, PERSONAL

INJURY, OR DEATH ARISING IN ANY WAY OUT OF SUCH MISSION CRITICAL A P P LICATION, WHETHER OR

NOT INTEL OR ITS SUBCONTRACTOR WAS NEGLIGENT IN THE DESIGN, MANUFA CTURE, OR WARNING OF

THE INTEL PRODUCT OR ANY OF ITS PARTS.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not

rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined". Intel reserves

these for future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from

future changes to them. The information here is subject to change without notice. Do not finalize a design with this

information.

The products described in this document may contain design defects or errors known as errata which may cause the

product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your

product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may

be obtained by calling 1-800-548-4725, or go to: http://www.intel.com/design/literature.htm

Revision 1.0

Page 3

Intel® Server System R2000LH2/T2 Product Family TPS Table of Contents

iii

Table of Contents

1. Introduction ........................................................................................................................ 1

1.1 Chapter Outline ...................................................................................................... 1

1.2 Server Board Use Disclaimer ................................................................................. 2

2. Product Family Overview ................................................................................................... 3

2.1 Chassis Dimensions ............................................................................................... 6

2.2 System Level Environmental Limits ........................................................................ 7

2.3 System Features and Options Overview ................................................................ 9

2.3.1 Hot Swap Hard Drive Bay and Front Panel Options ............................................... 9

2.3.2 Back Panel Features ............................................................................................ 10

2.3.3 Front Control Panel Options ................................................................................. 10

2.4 Server Board Features Overview ......................................................................... 12

2.5 Available Front Bezel Support .............................................................................. 13

2.6 Available Rack and Cabinet Mounting Kit Options ................................................ 14

3. Power Subsystem ............................................................................................................. 15

3.1 Mechanical Overview ........................................................................................... 16

3.2 Power Connectors ................................................................................................ 18

3.2.1 Power Supply Module Card Edge Connector ....................................................... 18

3.3 Power Supply Module Efficiency .......................................................................... 19

3.4 AC and DC Power Cord Specification Requirements ........................................... 20

3.5 AC Input Specifications ........................................................................................ 21

3.5.1 Power Factor ........................................................................................................ 21

3.5.2 AC Input Voltage Specification ............................................................................. 21

3.5.3 AC Line Isolation Requirements ........................................................................... 21

3.5.4 AC Line Dropout/Holdup ...................................................................................... 21

3.5.5 AC Line Fuse ....................................................................................................... 22

3.5.6 AC Inrush ............................................................................................................. 22

3.5.7 AC Line Transient Specification ........................................................................... 22

3.5.8 Susceptibility Requirements ................................................................................. 23

3.5.9 Electrostatic Discharge Susceptibility ................................................................... 23

3.5.10 Fast Transient/Burst ............................................................................................. 23

3.5.11 Radiated Immunity ............................................................................................... 23

3.5.12 Surge Immunity .................................................................................................... 23

3.5.13 Power Recovery ................................................................................................... 24

3.5.14 Voltage Interruptions ............................................................................................ 24

3.5.15 Protection Circuits ................................................................................................ 24

3.5.16 Over-current Protection (OCP) ............................................................................. 24

3.5.17 Over-voltage Protection (OVP) ............................................................................. 24

3.5.18 Over-temperature Protection (OTP) ..................................................................... 25

3.6 1600W DC Power Supply Support ....................................................................... 26

Revision 1.0

Page 4

Table of Contents Intel® Server System R2000LH2/T2 Product Family TPS

iv

3.6.1 Power Supply Module Efficiency .......................................................................... 26

3.6.2 DC Inlet Connector ............................................................................................... 26

3.6.3 DC Input Voltage Specification ............................................................................. 26

3.6.4 DC Holdup/Dropout Time ..................................................................................... 26

3.6.5 DC Line Fuse ....................................................................................................... 27

3.6.6 DC Inrush ............................................................................................................. 27

3.6.7 DC Line Surge Voltages (Line Transients) ........................................................... 27

3.6.8 Residual Voltage Immunity in Standby Mode ....................................................... 28

3.6.9 Protection Circuits ................................................................................................ 28

3.6.10 Over Temperature Protection (OTP) .................................................................... 29

3.7 Cold Redundancy Support ................................................................................... 30

3.7.1 Powering on Cold Standby Supplies to Maintain Best Efficiency .......................... 30

3.7.2 Powering on Cold Standby Supplies during a Fault or Over Current Condition..... 31

3.7.3 BMC Requirements .............................................................................................. 31

3.7.4 Power Supply Turn On Function .......................................................................... 31

3.8 Closed Loop System Throttling (CLST) ................................................................ 32

3.9 Smart Ride Through (SmaRT) .............................................................................. 32

3.10 Power Supply Status LED .................................................................................... 32

4. Thermal Management ....................................................................................................... 33

4.1 Thermal Operation and Configuration Requirements ............................................ 33

4.2 Thermal Management Overview .......................................................................... 35

4.2.1 Set Throttling Mode .............................................................................................. 35

4.2.2 Altitude ................................................................................................................. 35

4.2.3 Set Fan Profile ..................................................................................................... 36

4.2.4 Fan PWM Offset ................................................................................................... 36

4.2.5 Quiet Fan Idle Mode ............................................................................................. 36

4.2.6 Thermal Sensor Input for Fan Speed Control ....................................................... 37

4.3 System Fans ........................................................................................................ 39

4.3.1 Lower Fan Board .................................................................................................. 41

4.3.2 Upper Fans .......................................................................................................... 42

4.4 Power Supply Module Fan ................................................................................... 43

5. System Storage and Peripheral Drive Bays Overview ................................................... 44

5.1 2.5” Hard Disk Drive Support ................................................................................ 44

5.1.1 2.5” Drive Hot-Swap Backplane Overview ............................................................ 46

5.2 3.5” Hard Disk Drive Support ................................................................................ 48

5.2.1 3.5” Drive Hot-Swap Backplane Overview ............................................................ 49

5.3 Optical Drive Support ........................................................................................... 52

5.4 Solid State Drive (SSD) Support........................................................................... 53

5.5 Low Profile eUSB SSD Support ........................................................................... 54

5.6 SATA DOM Support ............................................................................................. 55

6. Storage Controller Options Overview ............................................................................. 56

Revision 1.0

Page 5

Intel® Server System R2000LH2/T2 Product Family TPS Table of Contents

v

6.1 Embedded SATA/SAS Controller Support ............................................................ 56

6.2 Embedded Software RAID Support ...................................................................... 58

6.2.1 Intel® Embedded Server RAID Technology 2 (ESRT2) ......................................... 58

6.2.2 Intel® Rapid Storage Technology (RSTe) ............................................................. 58

7. Front Control Panel and I/O Panel Overview .................................................................. 60

7.1 I/O Panel Features ............................................................................................... 60

7.2 Control Panel Features ........................................................................................ 61

8. Intel® Local Control Panel ................................................................................................ 65

8.1 LCD Functionality ................................................................................................. 66

8.2 Main Menu ........................................................................................................... 68

8.3 Event Menu .......................................................................................................... 69

8.4 View Menu ........................................................................................................... 70

8.4.1 System FW Version (SysFwVer) .......................................................................... 70

8.4.2 System Information (SysInfo) ............................................................................... 70

8.4.3 BMC IP Configuration ........................................................................................... 71

8.4.4 RMM4 IP Configuration ........................................................................................ 71

8.4.5 Power ................................................................................................................... 72

8.4.6 Last Post Code (Last PC) ..................................................................................... 72

8.5 Config Menu ......................................................................................................... 73

8.5.1 IP Version ............................................................................................................ 73

8.5.2 BMC IP................................................................................................................. 73

8.5.3 RMM4 IP .............................................................................................................. 75

8.5.4 Boot Device .......................................................................................................... 75

8.5.5 Banner ................................................................................................................. 76

9. PCI Riser Card Support .................................................................................................... 77

9.1 Riser Slot Overview .............................................................................................. 77

9.2 GPGPU Support on the PCIe Risers .................................................................... 79

9.2.1 GPGPU Power ..................................................................................................... 79

9.2.2 GPGPU Cable ...................................................................................................... 79

9.3 Wattage Limitation of the PCI Loading ................................................................. 80

9.4 Riser Slot Mapping .............................................................................................. 81

9.5 Riser Card Drawing .............................................................................................. 82

10. Additonal System Boards ................................................................................................ 83

10.1 Power Distribution Board (PDB) ........................................................................... 83

10.2 Setting the Power Supply Addressing for PMBus and FRU .................................. 83

10.3 12V Over Current Protection ................................................................................ 83

10.3.1 Over Current Protection Circuits ........................................................................... 83

10.4 Power Supply Keying ........................................................................................... 84

10.5 PDB Connectors .................................................................................................. 84

10.5.1 Grounding ............................................................................................................ 84

10.5.2 Power Supply Card Edge Connectors .................................................................. 84

Revision 1.0

Page 6

Table of Contents Intel® Server System R2000LH2/T2 Product Family TPS

vi

10.5.3 Motherboard Power Connectors ........................................................................... 85

10.5.4 Motherboard Signal from PDB .............................................................................. 86

10.5.5 GPGPU Power Connectors .................................................................................. 86

10.5.6 Upper Fan Connector ........................................................................................... 87

10.6 PDB Drawing........................................................................................................ 88

11. Front Panel ........................................................................................................................ 89

12. IO Module Support ........................................................................................................... 90

13. Intel® Intelligent Power Node Manager (NM) ................................................................... 92

13.1 Overview .............................................................................................................. 92

13.1.1 Hardware Requirements ...................................................................................... 92

13.1.2 Features ............................................................................................................... 92

13.1.3 Role of BMC in NM .............................................................................................. 93

13.1.4 ME System Management Bus (SMBus) Interface ................................................. 94

13.1.5 PECI 3.0 ............................................................................................................... 94

13.1.6 PECI Proxy .......................................................................................................... 94

13.1.7 ME Power and Firmware Startup.......................................................................... 95

13.1.8 ME Firmware Update ........................................................................................... 95

13.1.9 NM Discovery OEM SDR ..................................................................................... 95

13.1.10 SmaRT/CLST ....................................................................................................... 96

Appendix A: Integration and Usage Tip ................................................................................ 97

Appendix B: POST Code Diagnostic LED Decoder .............................................................. 98

Appendix C: POST Code Errors ........................................................................................... 104

Glossary ................................................................................................................................ 111

Reference Documents .......................................................................................................... 114

Revision 1.0

Page 7

Intel® Server System R2000LH2/T2 Product Family TPS List of Figures

vii

List of Figures

Figure 1. System Overview ......................................................................................................... 3

Figure 2. System Assembly......................................................................................................... 3

Figure 3. Chassis Dimensions ..................................................................................................... 6

Figure 4. System Components Overview .................................................................................... 9

Figure 5. 2.5" Hot Swap Hard Drive Bay - 8 Drive Configuration ................................................. 9

Figure 6. 3.5" Hotswap Hard Drive Bay - 4 Drive Configuration ................................................... 9

Figure 7. Back Panel Feature Identification ............................................................................... 10

Figure 8. Front Control Panel Options ....................................................................................... 10

Figure 9. Intel® Server Board S4600LH2/LT2 ............................................................................ 12

Figure 10. Optional Front Bezel (Intel Product Order Code – A2UBEZEL) ................................ 13

Figure 11. Installing the Front Bezel .......................................................................................... 13

Figure 12. Power Supply ........................................................................................................... 15

Figure 13. Power Supply Module Mechanical Drawing .............................................................. 16

Figure 14. Power Supply Module .............................................................................................. 16

Figure 15. AC and DC Power Supplies – Connector View ........................................................ 17

Figure 16. AC Power Cord ........................................................................................................ 20

Figure 17. DC Power Cord ........................................................................................................ 20

Figure 18. 75VDC Test ............................................................................................................. 27

Figure 19. 0VDC Test ............................................................................................................... 28

Figure 20. Fan Control Model .................................................................................................... 38

Figure 21. System Fan Identification ......................................................................................... 39

Figure 22. System Fan Assembly.............................................................................................. 40

Figure 23. Upper and Lower System Fan Connections ............................................................. 41

Figure 24. Lower Fan Board ...................................................................................................... 41

Figure 25. Lower Fan Board Dimensions .................................................................................. 42

Figure 26. Upper Fans Connectors on PDB .............................................................................. 42

Figure 27. 8 x 2.5" Hard Drive Configuration ............................................................................. 44

Figure 28. 2.5” Hard Disk Drive Assembly ................................................................................. 45

Figure 29. 2.5” Drive LEDs ........................................................................................................ 45

Figure 30. 2.5” Drive Hot-Swap Backplane Assembly ............................................................... 46

Figure 31. 2.5” Drive Hot-Swap Backplane – Front Side ........................................................... 46

Figure 32. 2.5” Drive Hot-Swap Backplane – Back Side ............................................................ 47

Figure 33. 4 x 3.5" Hard Drive Configuration ............................................................................. 48

Figure 34. 3.5” Hard Disk Drive Assembly ................................................................................. 48

Figure 35. 3.5” Drive LEDs ........................................................................................................ 49

Figure 36. 3.5” Drive Hot-Swap Backplane Assembly ............................................................... 50

Figure 37. 3.5” Drive Hot-Swap Backplane – Front Side ........................................................... 50

Figure 38. 3.5” Drive Hot-Swap Backplane – Back Side ............................................................ 51

Figure 39. Optical Drive Support ............................................................................................... 52

Revision 1.0

Page 8

List of Figures Intel® Server System R2000LH2/T2 Product Family TPS

viii

Figure 40. Optical Drive Assembly ............................................................................................ 52

Figure 41. 2.5" Solid State Drive (SSD) Mounting Option .......................................................... 53

Figure 42. Low Profile eUSB SSD Support ............................................................................... 54

Figure 43. InnoDisk* Low Profile SATA DOM ............................................................................ 55

Figure 44. Embedded SATA/SAS Controller Support ................................................................ 56

Figure 45. Front I/O Panel Features .......................................................................................... 60

Figure 46. Front Control Panel Features ................................................................................... 61

Figure 47. Intel® Local Control Panel Option ............................................................................. 65

Figure 48. LCP Background Color during Normal Operation ..................................................... 66

Figure 49. LCP Background Color during an Error .................................................................... 66

Figure 50. LCP Main Menu ....................................................................................................... 68

Figure 51. LCP Event Menu ...................................................................................................... 69

Figure 52. LCP View Menu ....................................................................................................... 70

Figure 53. System Firmware Versions Menu ............................................................................. 70

Figure 54. System Information Menu ........................................................................................ 70

Figure 55. LCP – BMC IP Configuration .................................................................................... 71

Figure 56. LCP – RMM4 IP Configuration ................................................................................. 71

Figure 57. LCP – Power Consumed by the System Currently ................................................... 72

Figure 58. LCP – Last BIOS Post Code .................................................................................... 72

Figure 59. LCP – Configure Menu Items ................................................................................... 73

Figure 60. LCP – IP Version Configuration Screen ................................................................... 73

Figure 61. LCP – BMC IP Configuration Menu .......................................................................... 73

Figure 62. LCP – BMC IP Source Configuration Menu .............................................................. 73

Figure 63. Screen shots for Configuring IP Address, Subnet Mask, and Gateway .................... 74

Figure 64. State Transition Diagram for Setting IP Address ...................................................... 75

Figure 65. Boot Options Configuration Menu ............................................................................ 75

Figure 66. Banner Configuration Menu ..................................................................................... 76

Figure 67. PCIe Risers and Add-in Cards ................................................................................. 78

Figure 68. GPGPU Cable .......................................................................................................... 79

Figure 69. IO Riser CPU Mapping ............................................................................................. 81

Figure 70. Right Riser Card Drawing ......................................................................................... 82

Figure 71. Left Riser Card Drawing ........................................................................................... 82

Figure 72. PDB ......................................................................................................................... 83

Figure 73. Upper Fans Connectors on PDB .............................................................................. 87

Figure 74. PDB Drawing ........................................................................................................... 88

Figure 75. SSI Common Front Panel Board .............................................................................. 89

Figure 76. Mezzanine Support .................................................................................................. 90

Figure 77. RMM4 Installation .................................................................................................... 91

Figure 78. PECI Proxy .............................................................................................................. 94

Figure 79. POST Diagnostic LED Location ............................................................................... 98

Revision 1.0

Page 9

Intel® Server System R2000LH2/T2 Product Family TPS List of Tables

ix

List of Tables

Table 1. Server System ............................................................................................................... 4

Table 2. System Feature Set ....................................................................................................... 4

Table 3. System Environmental Limits Summary ........................................................................ 7

Table 4 Front Control Panel Options ......................................................................................... 10

Table 5. Power Supply Module Output Power Connector Pin-out ............................................. 18

Table 6. 1600 Watt (AC) Power Supply Efficiency (Gold) .......................................................... 19

Table 7. AC Power Cord Specifications .................................................................................... 20

Table 8. Power Factor ............................................................................................................... 21

Table 9. AC Input Voltage Range .............................................................................................. 21

Table 10. AC Line Dropout/Holdup ............................................................................................ 22

Table 11. AC Line Sag Transient Performance ......................................................................... 22

Table 12. AC Line Surge Transient Performance ...................................................................... 23

Table 13. Performance Criteria ................................................................................................. 23

Table 14. Power Supply Over Current Protection ...................................................................... 24

Table 15. Over Voltage Protection (OVP) Limits ....................................................................... 25

Table 16. 1600 Watt (DC) Power Supply Efficiency (Platinum) ................................................. 26

Table 17. 1600 Watt (DC) Power Supply Efficiency (Platinum) ................................................. 26

Table 18. DC Holdup/Dropout Time .......................................................................................... 26

Table 19. Line Voltage Transient Limits .................................................................................... 28

Table 20. Over Current Protection............................................................................................. 29

Table 21. Over Voltage Protection Limits .................................................................................. 29

Table 22. Example Load Share Threshold for Activating Supplies ............................................ 30

Table 23. LED Indicators ........................................................................................................... 32

Table 24. Lower Fan Connector Pin-out .................................................................................... 41

Table 25. Upper Fan Connector Pin-out (Fans 8-11) ................................................................. 42

Table 26. 2.5” Drive Status LED States ..................................................................................... 45

Table 27. 2.5” Drive Activity LED States.................................................................................... 45

Table 28. 3.5” Drive Status LED States ..................................................................................... 49

Table 29. 3.5” Drive Activity LED States.................................................................................... 49

Table 30. Intel® RAID C600 Upgrade Key Options .................................................................... 57

Table 31. System Status LED State Definitions......................................................................... 62

Table 32. Power/Sleep LED Functional States .......................................................................... 64

Table 33. GPGPU Aux Connector Pin-out (J9 and J10) ............................................................ 79

Table 34. Wattage Limitation of PCIe Loading .......................................................................... 80

Table 35. Over Current Protection Circuits ................................................................................ 83

Table 36. Power Supply Card Edge Connector Pin-out P8 and P9 ........................................... 84

Table 37. Main Power (J8) Connector Pin-out ........................................................................... 85

Table 38. Main Power (J6) Connector Pin-out ........................................................................... 85

Table 39. Power Control Signals Pin-out (J5) ............................................................................ 86

Revision 1.0

Page 10

List of Tables Intel® Server System R2000LH2/T2 Product Family TPS

x

Table 40. GPGPU Aux Connector Pin-out (J9 and J10) ............................................................ 86

Table 41. Upper Fan Connector Pin-out (Fans 8-11) ................................................................ 87

Table 42. SSI Front Panel Connector Pin-out (Baseboard) ....................................................... 89

Table 43. Intel® I/O Modules ..................................................................................................... 90

Table 44. POST Progress Code LED Example ......................................................................... 99

Table 45. POST Progress Codes .............................................................................................. 99

Table 46. MRC Progress Codes ............................................................................................. 102

Table 47. MRC Fatal Error Codes ........................................................................................... 103

Table 48. POST Error Messages and Handling ....................................................................... 105

Table 49. POST Error Beep Codes ......................................................................................... 110

Table 50. Integrated BMC Beep Codes ................................................................................... 110

Revision 1.0

Page 11

Intel® Server System R2000LH2/T2 Product Family TPS List of Tables

xi

< This page intentionally left blank. >

Revision 1.0

Page 12

Page 13

Intel® Server System R2000LH2/T2 Product Family TPS Introduction

1

1.1 Chapter Outline

1. Introduction

This Technical Product Specification (TPS) provides system level information for the Intel®

Server System R2000LH2 and Intel

level features of both these product families are common, however the server board integrated

into them is different. The Intel

®

Intel

Server Board S4600LH2 and the Intel® Server System R2000LTH2 product family is

integrated with the Intel

®

Server Board S4600LT2.

®

Server System R2000LT2 product families. The system

®

Server System R2000LH2 product family is integrated with an

This document describes the functions and features of the integrated server system which

includes the chassis layout, system boards, power subsystem, cooling subsystem, storage

subsystem options, and available installable options. Server board specific details can be

obtained by referencing the Intel

®

Server Boards S4600LH2/T2 Product Specification.

In addition, design-level information related to specific server board components or subsystems

can be obtained by ordering External Product Specifications (EPS) or External Design

Specifications (EDS) related to this server generation. EPS and EDS documents are made

available under NDA with Intel and must be ordered through your local Intel representative. See

the Reference Documents

section for a complete list of available documents.

This document is divided into the following chapters:

Chapter 1 – Introduction

Chapter 2 – Product Family Overview

Chapter 3 – Power Subsystem

Chapter 4 – Thermal Management

Chapter 5 – System Storage and Peripherals Drive Bay Overview

Chapter 6 – Storage Controller Options Overview

Chapter 7 – Front Control Panel and I/O Panel Overview

Chapter 8 – Intel

Chapter 9 – PCI Riser Card Support

Chapter 10 – Additional System Boards

Chapter 11 – Front P anel

Chapter 12 – IO Module Support

Chapter 13 –Intel

Appendix A – Integration and Usage Tips

Appendix B – POST Code Diagnostic LED Decoder

Appendix C – Post Code Errors

Glossary

Reference Documents

®

Local Control Panel

®

Intelligent Power Node Manager (NM)

Revision 1.0

Page 14

Introduction Intel® Server System R2000LH2/T2 Product Family TPS

2

1.2 Server Board Use Disclaimer

Intel Corporation server boards support add-in peripherals and contain a number of high-density

Very Large Scale Integration (VLSI) and power delivery components that need adequate airflow

to cool. Intel ensures through its own chassis development and testing that when Intel

building blocks are used together, the fully integrated system will meet the intended thermal

requirements of these components. It is the responsibility of the system integrator who chooses

not to use Intel developed server building blocks to consult vendor datasheets and operating

parameters to determine the amount of airflow required for their specific application and

environmental conditions. Intel Corporation cannot be held responsible if components fail or the

server board does not operate correctly when used outside any of their published operating or

non-operating limits.

®

server

Revision 1.0

Page 15

Intel® Server System R2000LH2/T2 Product Family TPS Product Family Overview

3

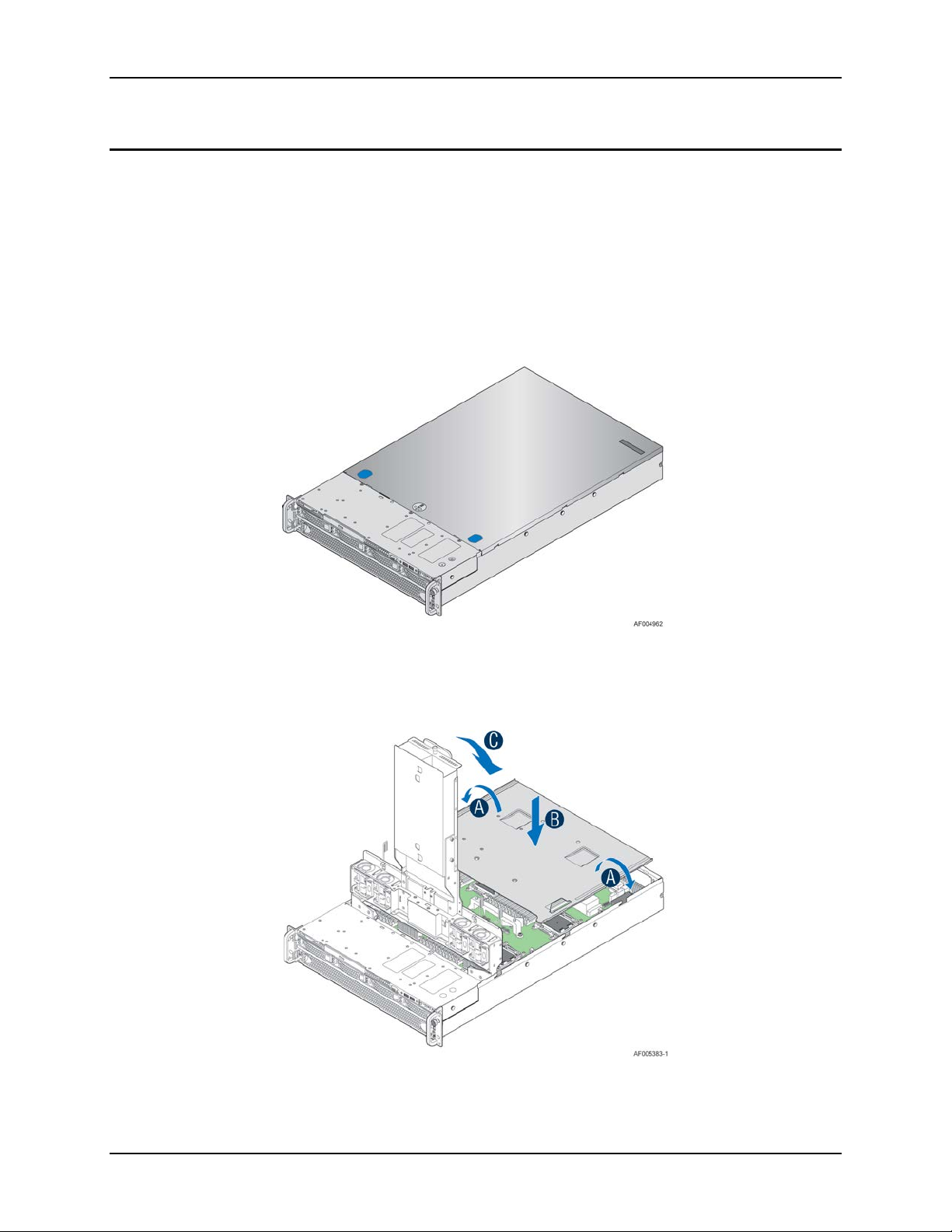

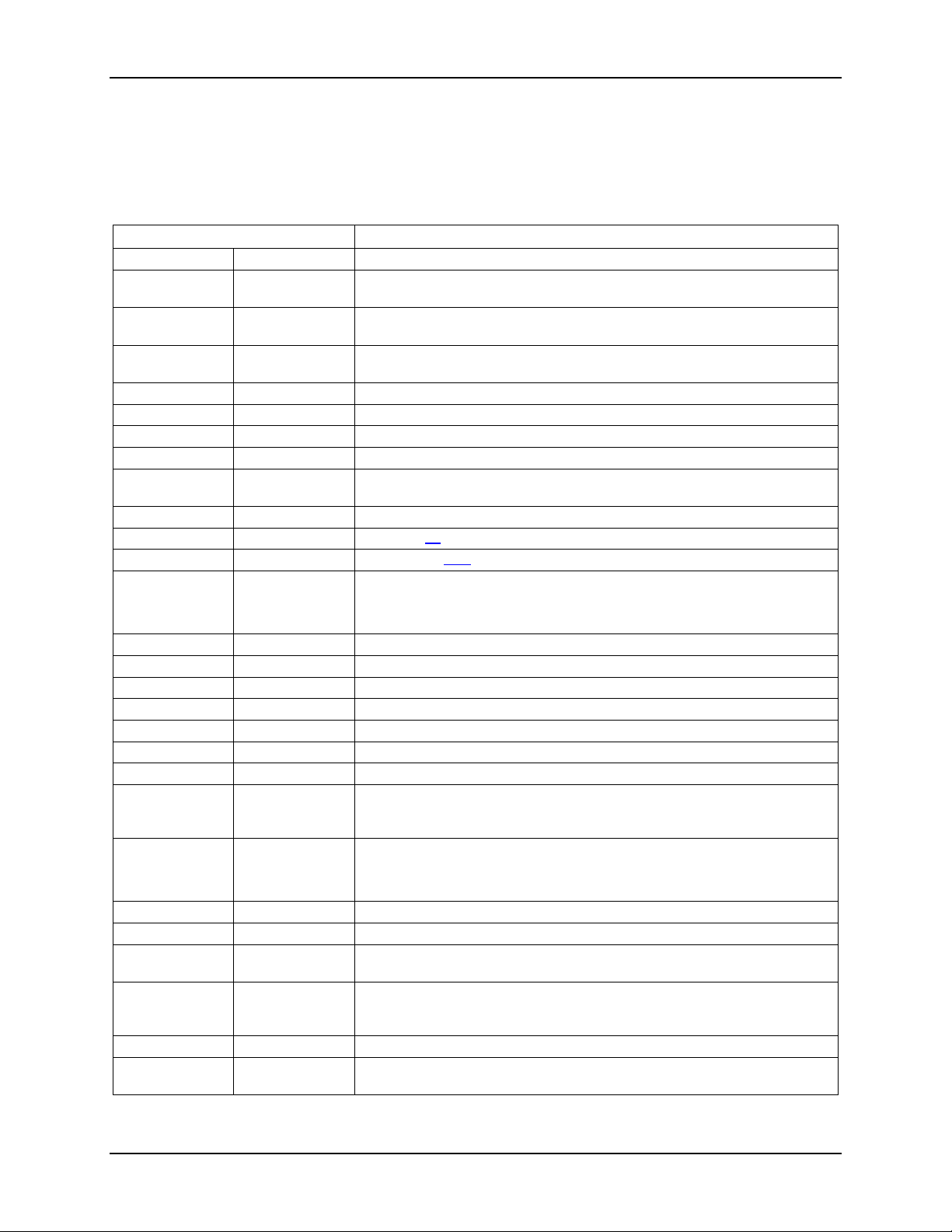

Figure 1. System Overview

Figure 2. System Assembly

2. Product Family Overview

This generation of Intel 2U server platforms offers a variety of system options to meet the varied

configuration r equirements of high-density high-performance computing environments. The

®

Intel

Server System R2000LH2 and Intel® Server System R2000LT2 servers are comprised of

several available 2U rack mount server systems that are integrated with either an Intel

Board S4600LH2 or Intel

®

Server Board S4600LT2.

This chapter provides a high-level overview of the system features and available options as

supported in different platform SKUs within this server family. Greater detail for each major

system component or feature is provided in the following chapters.

®

Server

Revision 1.0

Page 16

Product Family Overview Intel® Server System R2000LH2/T2 Product Family TPS

4

Table 1. Server System

Server System

Integrated Server Board

Intel® Server System R2000LH2

Intel® Server Board S4600LH2

Intel® Server System R2000LT2

Intel® Server Board S4600LT2

Table 2. System Feature Set

Feature

Description

Processor support

Support for up to four Intel® Xeon® processors E5-4600 product family with a Thermal

Memory

48 DIMM slots – 3 DIMMs / Channel – 4 memory channels per processor

Chipset

Intel® C600-A chipset with support for optional Storage Option Select keys

External I/O

DB-15 Video connector (Rear)

Internal I/O

One 2x5 pin connector providing front panel support for two USB ports

Optional I/O Module

The following I/O modules utilize a single proprietary on-board connector. An installed I/O

System Fans

11 managed system fan headers

Riser Cards

Two riser card slots:

Video Integrated 2D Video Controller

On-board storage

controllers and

One eUSB 2x5 pin connector to support 2mm low-profile eUSB solid state devices

Note: Table 2

lists features common to both server product families. Features that are unique to

one product family are identified by either denoting the server system name or the integrated

server board name.

Design Power (TDP) of up to 130 W

Unbuffered DDR3 (UDIMM), registered DDR3 (RDIMM), Load Reduced DDR3

(LRDIMM)

Memory DDR3 data transfer r ates of 800, 1066, 1333, and 1600 MT/s

DDR3 standard I/O voltage of 1.5V and DDR3 Low Voltage of 1.35V

connections

RJ-45 Serial Port A connector

S4600LH2 Dual-port Network Interface supporting 10/100/1000Mbps

S4600LT2 Dual-port Network Interface supporting 100/1000/10000Mbps

6 USB 2.0 connectors (4 rear + 2 front)

connectors / headers

support

One Type-A USB 2.0 connector

One 2x15 pin SSI-EEB compliant front panel header

One 2x7pin Front Panel Video connector

One DH-10 Serial Port B connector

module can be supported in addition to standard on-board features and any add-in

expansion cards.

Quad port 1 GbE based on Intel® Ethernet Controller I350 – RMS25CB0080

Dual port 10GBase-T Ethernet module based on Intel® Ethernet Controller I350

Dual SFP+ port 10GbE module based on Intel® 82500 10 GbE controller

Single Port FDR speed Infiniband* module with QSFP connector

Each riser card slot has a total of 48 PCIe lanes routed to them.

Each riser card slot supports various Full Height Full Length (FHFL) and Full Height

Half Length (FHHL) cards.

16 MB DDR3 Memory

Revision 1.0

Page 17

Intel® Server System R2000LH2/T2 Product Family TPS Product Family Overview

5

Feature

Description

options

Two 7-pin single port AHCI SATA connectors capable of supporting up to 6 GB/sec

Security

TPM Module AXXTPME5 (Accessory Option)

Server Management

Integrated Baseboard Management Controller, IPMI 2.0 compliant

Power Supply

The server system can have up to two power supply modules installed, providing

Storage Bay Options

8x – 2.5” SATA/SAS Hot Swap Hard Drive Bays

Available Rack

Tool-less rack mount premium rail kit – Intel Product Code – AXXPRAIL

Two SCU 4-port mini-SAS connectors capable of supporting up to 3 GB/sec

SAS/SATA

®

Intel

Support for Intel® Server Management Software

Intel® Remote Management Module 4 Lite – Accessory Option

Intel® Remote Management Module 4 Management NIC – Accessory Option

RAID C600 Upgrade Key support providing optional expanded SATA/SAS RAID

capabilities

Options

Mount Kit Options

support for the following power configurations: 1+0, 1+1 Redundant Power, and 2+0

Combined Power

Two power supply options:

AC 1600W

DC 1600W

4x – 3.5” SATA/SAS Hot Swap Hard Drive Bays

4x – 3.5” SATA/SAS Fixed Hard Drive Bays

Value rack mount rail kit – Intel Product Code – AXXVRAIL

Cable Management Arm – Intel Product Code – AXX1U2UCMA (*supported with

AXXPRAIL only)

2-post fixed mount bracket kit – Intel Product Code – AXX2POSTBRCKT

Revision 1.0

Page 18

Product Family Overview Intel® Server System R2000LH2/T2 Product Family TPS

6

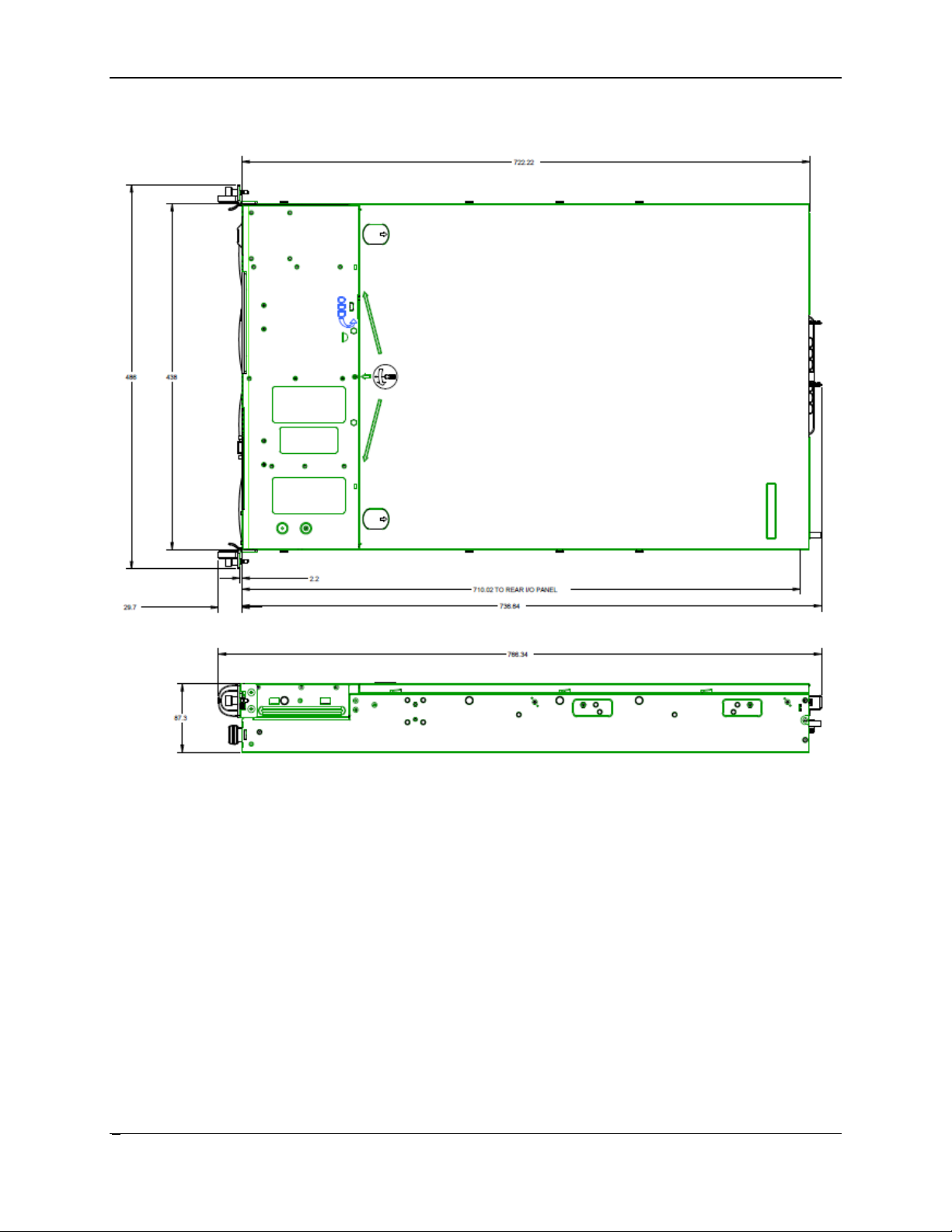

2.1 Chassis Dimensions

Figure 3. Chassis Dimensions

Revision 1.0

Page 19

Intel® Server System R2000LH2/T2 Product Family TPS Product Family Overview

7

2.2 System Level Environmental Limits

Table 3. System Environmental Limits Summary

Parameter

Limits

Temperature

Operating

ASHRAE Class A2 – Continuous Operation. 10ºC to 35ºC 1 (50ºF to 95ºF)

ASHRAE Class A3 – Includes operation up to 40ºC for up to 900 hrs. per

ASHRAE Class A4 – Includes operation up to 45ºC for up to 90 hrs. per

Shipping

-40ºC to 70ºC (-40ºF to 158ºF)

Altitude

Operating

Support operation up to 3050m with ASHRAE class deratings

Humidity

Shipping

50% to 90%, non-condensing with a maximum wet bulb of 28°C (at

Shock

Operating

Half sine, 2g, 11 mSec

Unpackaged

Trapezoidal, 25 g, velocity change is based on packaged weight

Packaged

Product Weight: ≥ 40 to < 80

Vibration

Unpackaged

5 Hz to 500 Hz 2.20 g RMS random

Packaged

5 Hz to 500 Hz 1.09 g RMS random

AC-DC

Voltage

90 Hz to 132 V and 180 V to 264 V

Frequency

47 Hz to 63 Hz

Source Interrupt

No loss of data for power line drop-out of 12 mSec

Surge Non-

Unidirectional

Line to earth

AC Leads 2.0 kV

ESD

Air Discharged

12.0 kV

Contact

8.0 kV

Acoustics

Power in Watts

<300 W ≥300 W ≥600 W ≥1000 W

Servers/Rack

7.0 7.0 7.0 7.0

The following table defines the system level operating and non-operating environmental limits.

with the maximum rate of change not to exceed 10°C per hour

year

year

temperatures from 25°C to 35°C)

Sound Power

Measured

operating and

operating

Only

Discharge

Non-palletized Free Fall Height = 18 inches

Palletized (single product) Free Fall Height = NA

I/O Leads 1.0 kV

DC Leads 0.5 kV

Mount BA

Revision 1.0

Page 20

Product Family Overview Intel® Server System R2000LH2/T2 Product Family TPS

8

Note:

1. Intel Corporation server boards contain a number of high-density VLSI and power delivery components that

need adequate airflow to cool. Intel ensures through its own chassis development and testing that when

®

server building blocks are used together, the fully integrated system will meet the intended thermal

Intel

requirements of these components. It is the responsibility of the system integrator who chooses not to use

Intel developed server building blocks to consult vendor datasheets and operating parameters to determine

the amount of airflow required for their specific application and environmental conditions. Intel Corporation

cannot be held responsible if components fail or the server board does not operate correctly when used

outside any of its published operating or non-operati ng limits.

Disclaimer Note: Intel ensures the unpackaged server board and system meet the shock

requirement mentioned above through its own chassis development and system configuration. It

is the responsibility of the system integrator to determine the proper shock level of the board

and system if the system integrator chooses different system configuration or different chassis.

Intel Corporation cannot be held responsible, if components fail or the server board does not

operate correctly when used outside any of its published operating or non-operating limits.

See the Intel® Server Board S4600LH2/T2 Power Budget and Thermal Configuration Guidelines

Tool for system configuration requirements and limitations.

Revision 1.0

Page 21

Intel® Server System R2000LH2/T2 Product Family TPS Product Family Overview

9

2.3 System Features and Options Overview

Figure 4. System Components Overview

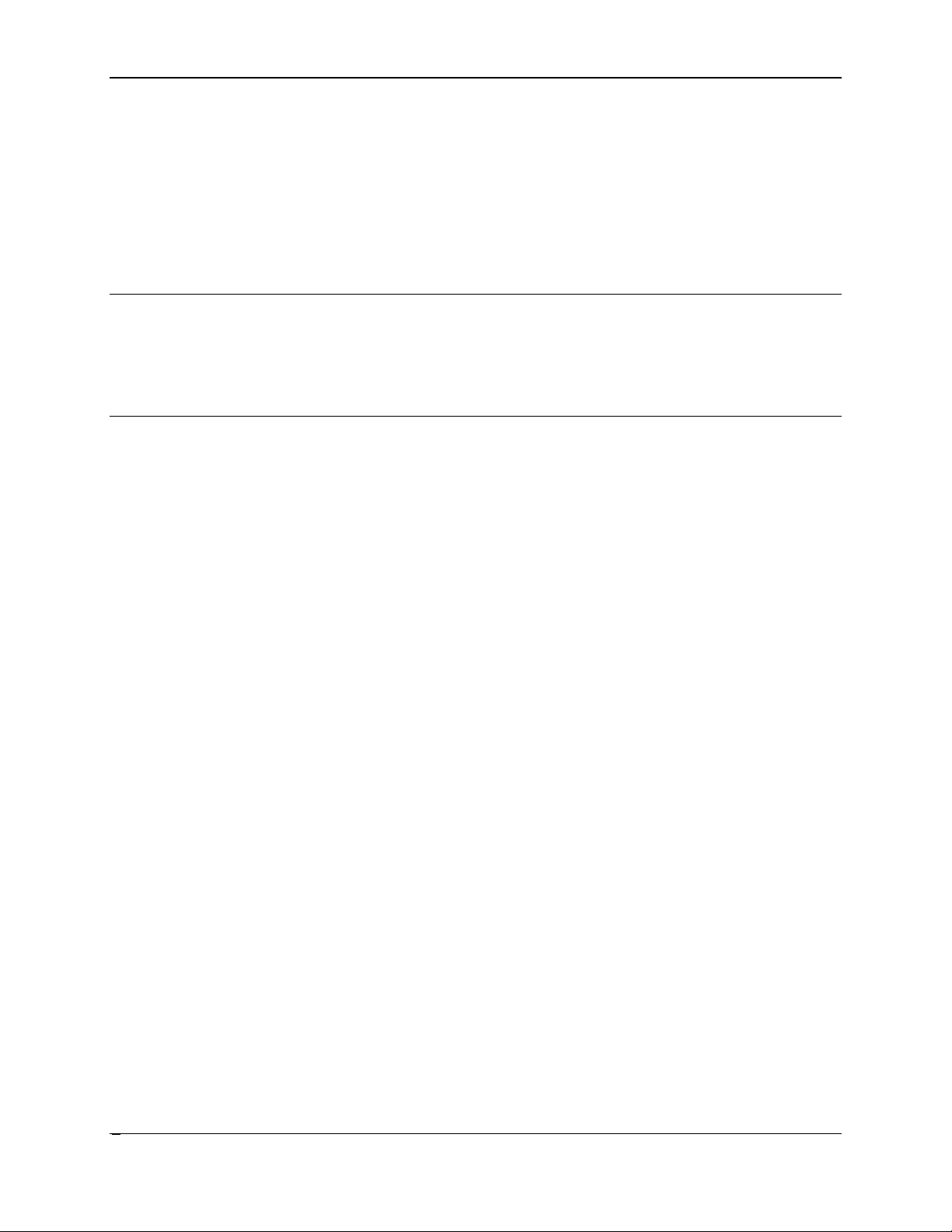

2.3.1

Hot Swap Hard Drive Bay and Front Panel Options

Figure 5. 2.5" Hot Swap Hard Drive Bay - 8 Drive Configuration

Figure 6. 3.5" Hotswap Hard Drive Bay - 4 Drive Configuration

Revision 1.0

Page 22

Product Family Overview Intel® Server System R2000LH2/T2 Product Family TPS

10

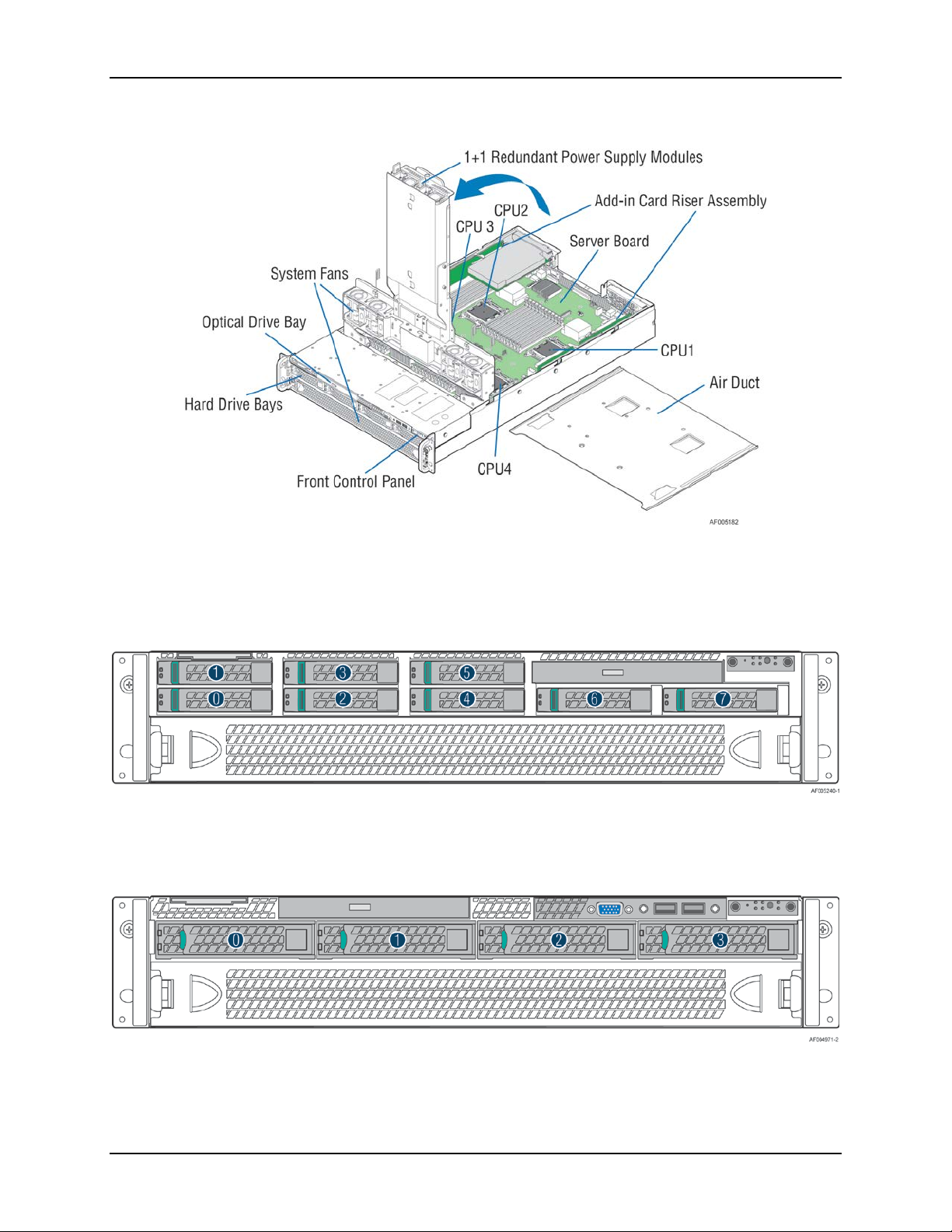

2.3.2

Back Panel Features

Figure 7. Back Panel Feature Identification

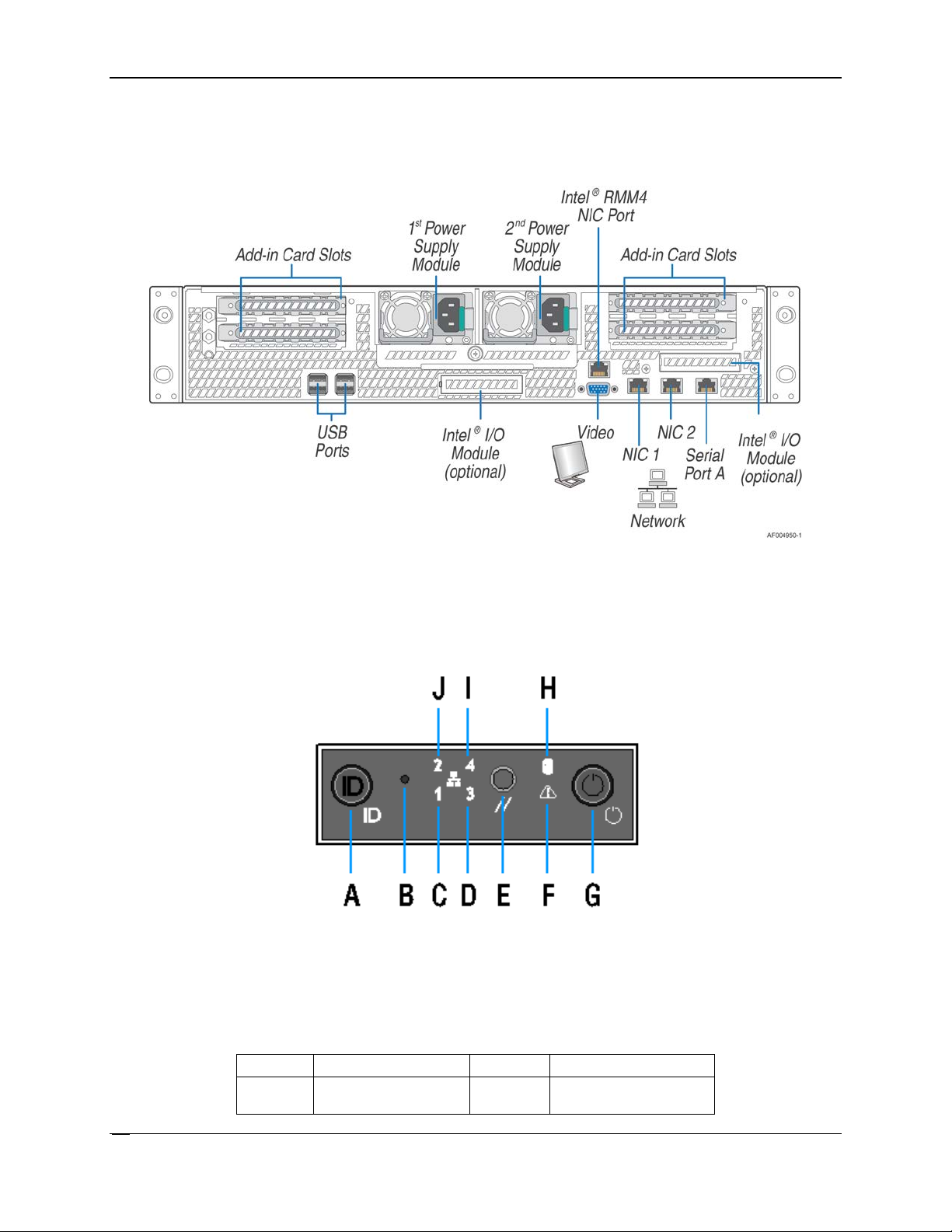

2.3.3

Front Control Panel Options

Figure 8. Front Control Panel Options

Table 4 Front Control Panel Options

Label

Description

Label

Description

A

System ID Button

F

System Status LED

w/Integrated LED

Revision 1.0

Page 23

Intel® Server System R2000LH2/T2 Product Family TPS Product Family Overview

11

Label

Description

Label

Description

B

NMI Button (recessed,

G

Power Button

C

NIC-1 Activity LED

H

Hard Drive Activity LED

D

Not used

I

Not used

E

System Cold Reset

J

NIC-2 Activity LED

tool required for use)

Button

w/Integrated LED

Revision 1.0

Page 24

Product Family Overview Intel® Server System R2000LH2/T2 Product Family TPS

12

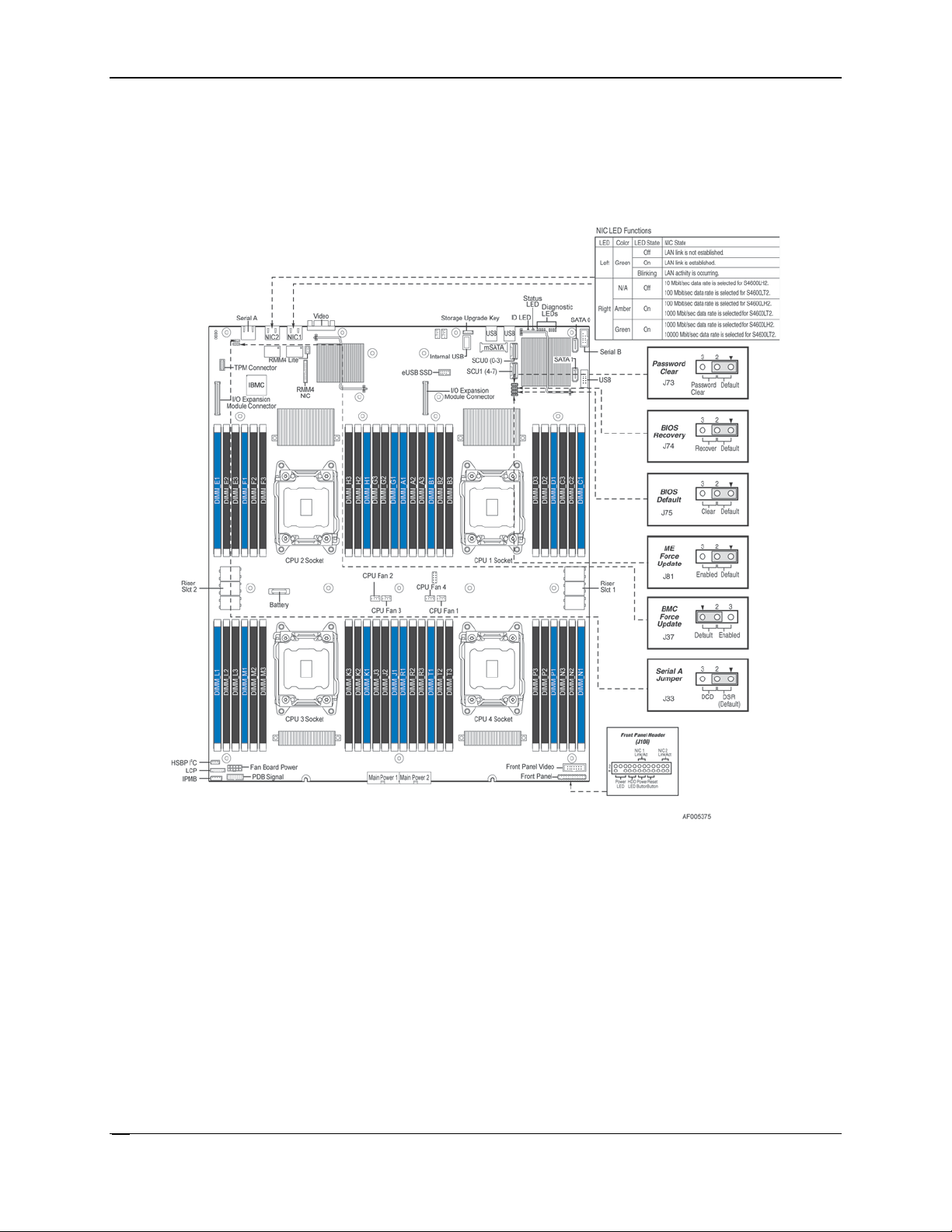

2.4 Server Board Features Overview

Figure 9. Intel® Server Board S4600LH2/LT2

The following illustration provides a general overview of the server board, identifying key feature

and component locations. The majority of the items identified are common for the Intel

®

Server

Board S4600LH2 and S4600LH2. The accompanying table identifies variations when present.

Revision 1.0

Page 25

Intel® Server System R2000LH2/T2 Product Family TPS Product Family Overview

13

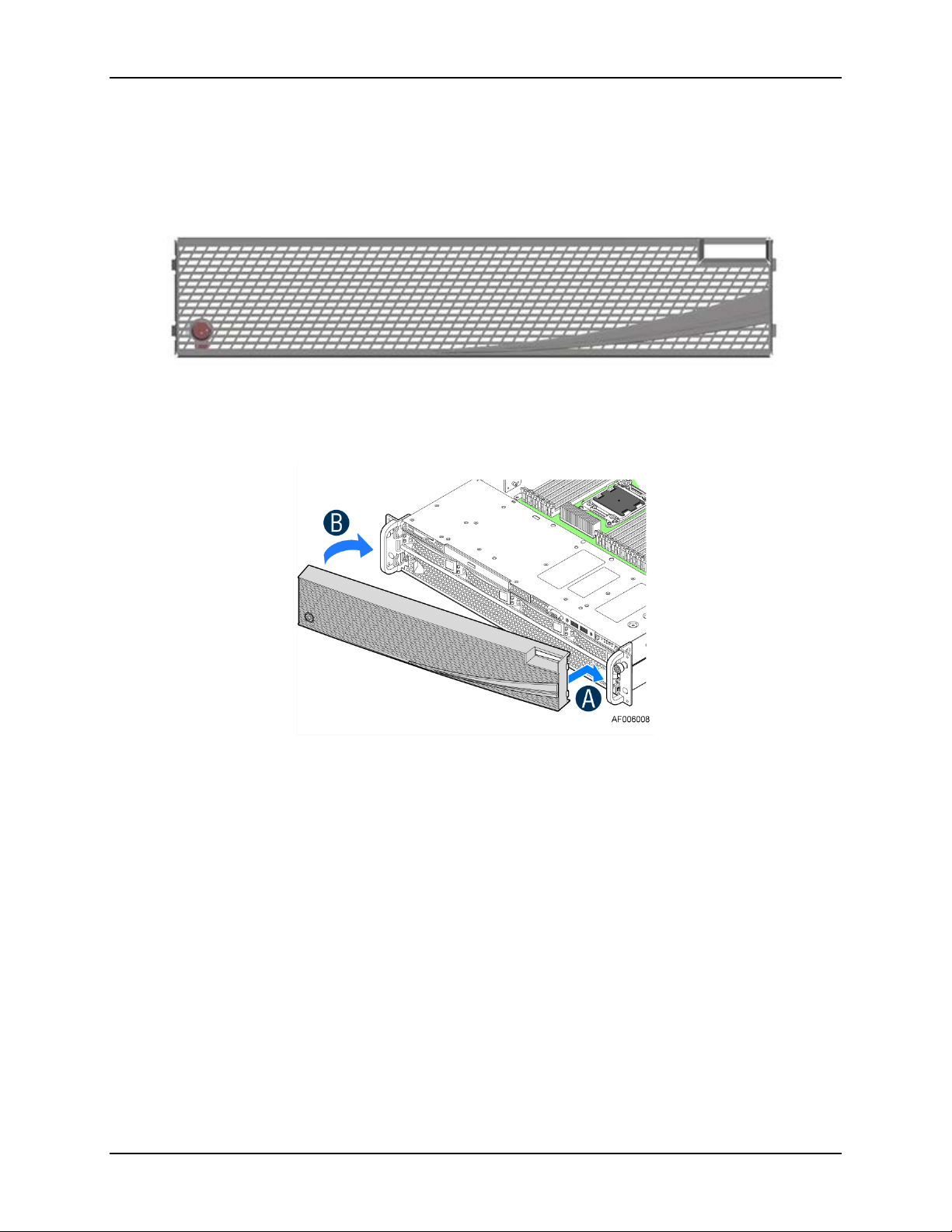

2.5 Available Front Bezel Support

Figure 10. Optional Front Bezel (Intel Product Order Code – A2UBEZEL)

Figure 11. Installing the Front Bezel

The optional front bezel is made of molded plastic and uses a snap-on design. When installed,

its design allows for maximum airflow to maintain system cooling requirements. The bezel

assembly includes snap-in options that can be used for customization.

Revision 1.0

Page 26

Product Family Overview Intel® Server System R2000LH2/T2 Product Family TPS

14

2.6 Available Rack and Cabinet Mounting Kit Options

Tool-less rack mount rail kit – Intel Product Code – AXXPRAIL

- 2U compatible

- 65 lbs. max support weight

- Tool-less installation

- Full extension from rack

- Drop in system install

- Optional cable management arm support

Cable Management Arm – Intel Product Code – AXX1U2UCMA (*supported with

AXXPRAIL only)

2-Post Fixed mount bracket kit – Intel Product Code – AXX2POSTBRCKT

Revision 1.0

Page 27

Intel® Server System R2000LH2/T2 Product Family TPS Power Subsystem

15

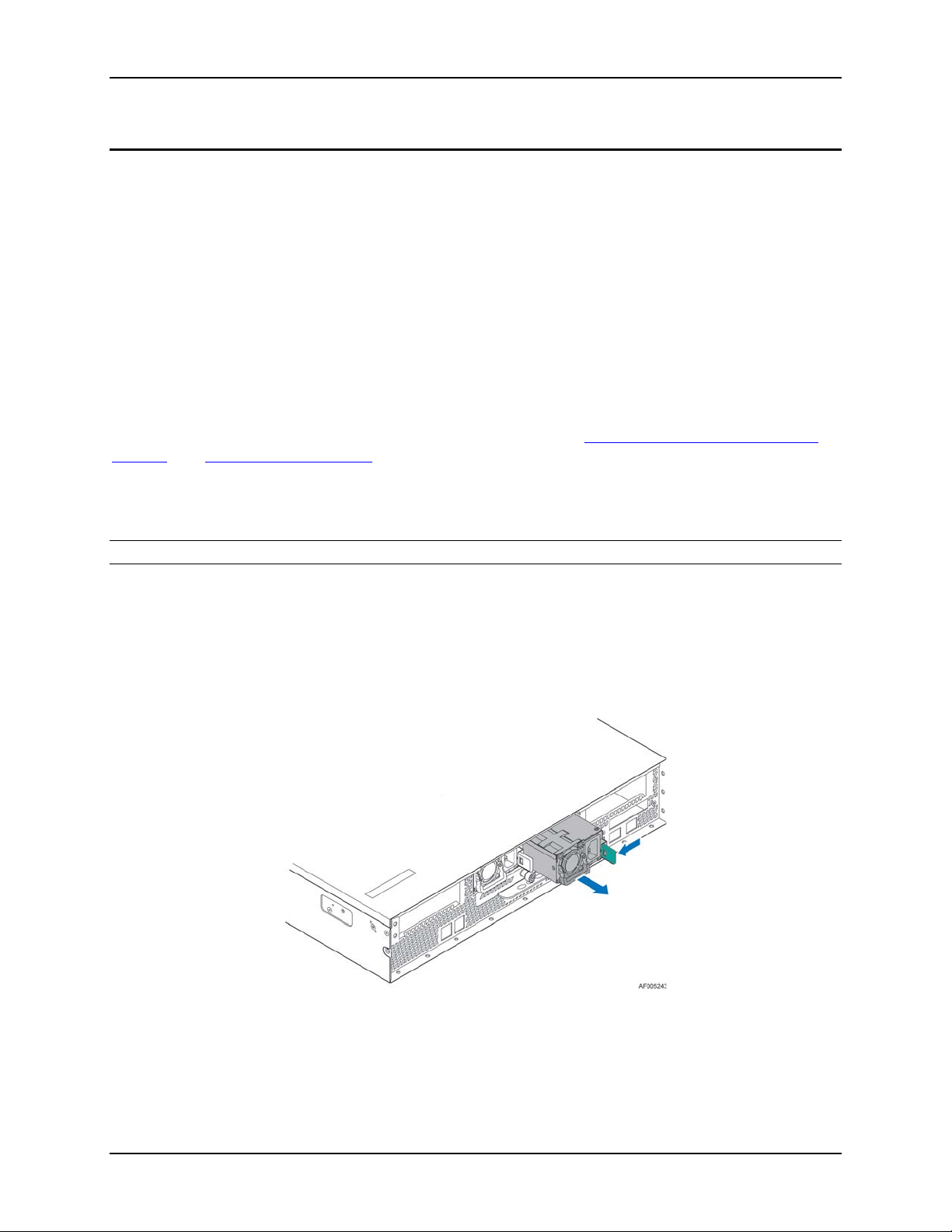

Figure 12. Power Supply

3. Power Subsystem

This chapter provides a high level overview of the power management features and

specification data for the power supply options available for this server product. Specification

variations are identified for each supported power supply.

The server system can have up to two power supply modules installed, supporting the following

power supply configurations: 1+0 (single power supply), 1+1 redundant power, and 2+0

combined power (non-redundant).The 1+1 redundant power and 2+0 combined power

configurations are automatically configured depending on the total power draw of the system. If

the total system power draw exceeds the power capacity of a single power supply module, the

power from the second power supply module will be utilized. If this occurs, power redundancy

will be lost. In a 2+0 power configuration, the total power available may be less than twice the

rated power of the installed power supply modules due to the amount of heat produced with

both supplies providing peak power. If system thermals exceed programmed limits, platform

management will attempt to keep the system operational. See

(CLST) and Thermal Management for det ails.

There are two power supply options available for this server product: 1600W AC and 1600W

DC.

Closed Loop System Throttling

Note: Mixing of AC and DC power supplies in the same system is unsupported.

The power supplies are modular, allowing for tool-less insertion and extraction from a bay in the

back of the chassis. When inserted, the card edge connector of the power supply mates blindly

to a matching slot connector on the server board.

In the event of a power supply failure, redundant 1+1 power supply configurations support hotswap extraction and insertion.

The AC input is auto-ranging and power factor corrected.

Revision 1.0

Page 28

Power Subsystem Intel® Server System R2000LH2/T2 Product Family TPS

16

3.1 Mechanical Overview

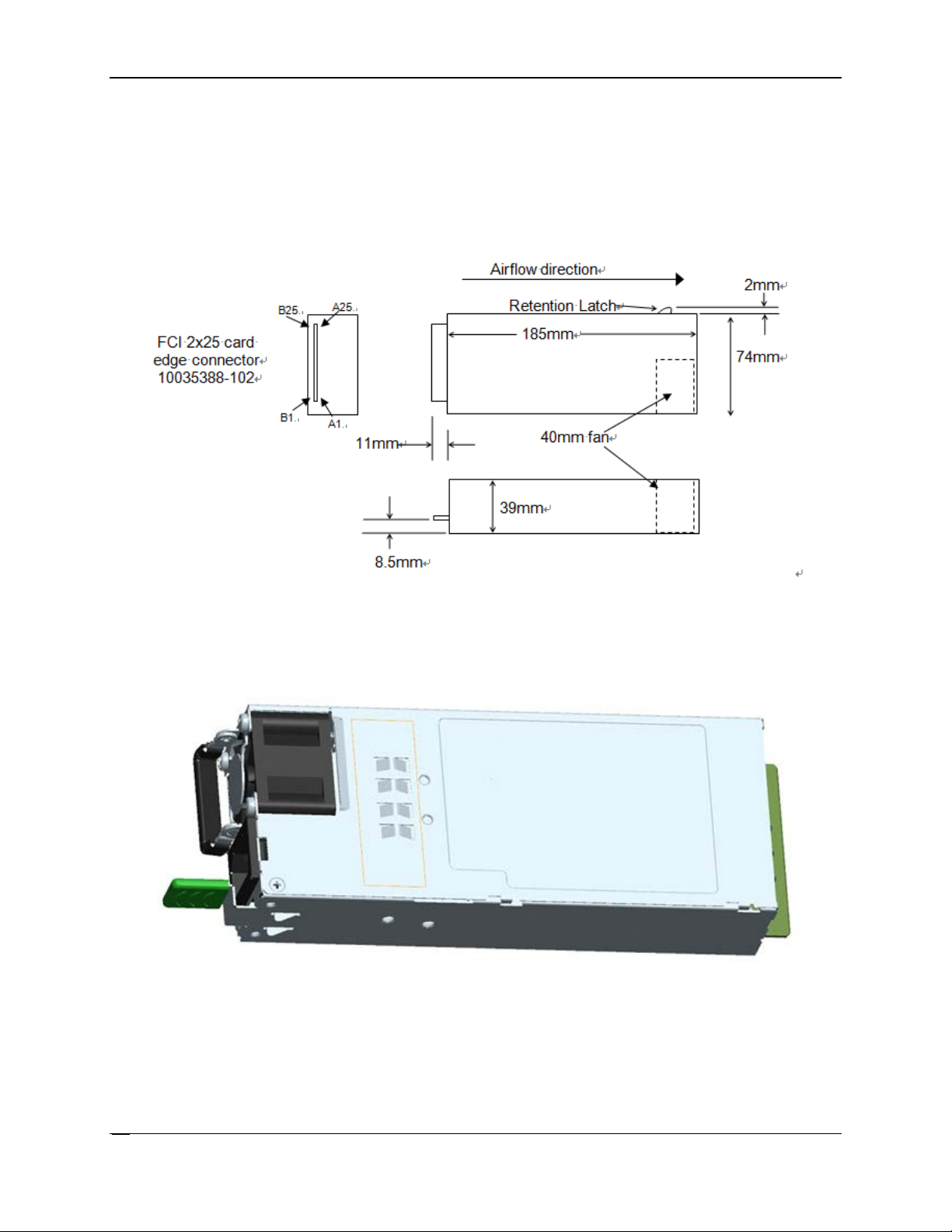

Figure 13. Power Supply Module Mechanical Drawing

Figure 14. Power Supply Module

The physical size of the power supply enclosure is 39/40mm x 74mm x 185mm. The power

supply contains a single 40mm fan. The power supply has a card edge output that interfaces

with a 2x25 card edge connector in the system. The AC plugs directly into the external face of

the power supply.

Revision 1.0

Page 29

Intel® Server System R2000LH2/T2 Product Family TPS Power Subsystem

17

Figure 15. AC and DC Power Supplies – Connector View

Revision 1.0

Page 30

Power Subsystem Intel® Server System R2000LH2/T2 Product Family TPS

18

3.2 Power Connectors

3.2.1

Power Supply Module Card Edge Connector

Table 5. Power Supply Module Output Power Connector Pin-out

Pin

Name

Pin

Name

A1

GND

B1

GND

A2

GND

B2

GND

A3

GND

B3

GND

A4

GND

B4

GND

A5

GND

B5

GND

A6

GND

B6

GND

A7

GND

B7

GND

A8

GND

B8

GND

A9

GND

B9

GND

A10

+12V

B10

+12V

A11

+12V

B11

+12V

A12

+12V

B12

+12V

A13

+12V

B13

+12V

A14

+12V

B14

+12V

A15

+12V

B15

+12V

A16

+12V

B16

+12V

A17

+12V

B17

+12V

A18

+12V

B18

+12V

A19

PMBus SDA

B19

A0 (SMBus address)

A20

PMBus SCL

B20

A1 (SMBus address)

A21

PSON

B21

12V stby

A22

SMBAlert#

B22

Cold Redundancy Bus

A23

Return Sense

B23

12V load share bus

A24

+12V remote Sense

B24

No Connect

A25

PWOK

B25

Compatibility Check

Each power supply module has a single 2x25 card edge output connection that plugs directly

into a matching slot connector on the server board. The connector provides both power and

communication signals to the server board. The following table defines the connector pin-out.

The connector pin out in table applies to the 1600W (AC) and 1600W (DC) power supplies.

Note: Mixing of AC and DC power supplies in the same system is unsupported.

pin*

Revision 1.0

Page 31

Intel® Server System R2000LH2/T2 Product Family TPS Power Subsystem

19

3.3 Power Supply Module Efficiency

Table 6. 1600 Watt (AC) Power Supply Efficiency (Gold)

Loading

100% of

maximum

50% of

maximum

20% of

maximum

10% of

maximum

Minimum

91%

94%

90%

82%

The following table provides the required minimum efficiency level at various loading conditions.

These are provided at three different load levels: 100%, 50%, and 20%. Efficiency is tested over

an AC input voltage range of 115 VAC to 220 VAC.

Efficiency

Revision 1.0

Page 32

Power Subsystem Intel® Server System R2000LH2/T2 Product Family TPS

20

3.4 AC and DC Power Cord Specification Requirements

Table 7. AC Power Cord Specifications

Cable Type

SJT

Wire S ize

16 AWG

Temperature Rating

105ºC

Amperage Rating

13 A

Voltage Rating

125 V

Figure 16. AC Power Cord

Figure 17. DC Power Cord

The AC and DC power cords used meet the specification requirements listed in the following

tables and figures.

Revision 1.0

Page 33

Intel® Server System R2000LH2/T2 Product Family TPS Power Subsystem

21

3.5 AC Input Specifications

3.5.1

Power Factor

Table 8. Power Factor

Output power

10% load

20% load

50% load

100% load

Power factor 1600w

> 0.80

> 0.90

> 0.90

> 0.95

3.5.2

AC Input Voltage Specification

Table 9. AC Input Voltage Range

Parameter

Min

Rated

Max

Start Up VAC

Power Off VAC

Voltage (110)

90 Vrms

100-127 Vrms

140 Vrms

85VAC +/-

70VAC +/Voltage (220)

180 Vrms

200-240 Vrms

264 Vrms

Frequency

47 Hz

50/60

63 Hz

3.5.3

AC Line Isolation Requirements

3.5.4

AC Line Dropout/Holdup

The power supply meets the power factor requirements stated in the Energy Star Program

Requirements for Computer Servers. These requirements are stated below.

AC

Note: Tested at 230VAC, 50Hz and 60Hz and 115VAC, 60Hz

The power supply operates within all specified limits over the following input voltage range.

Harmonic distortion of up to 10% of the rated line voltage does not cause the power supply to

go out of specified limits. Application of an input voltage below 85VAC does not cause damage

to the power supply, including a blown fuse.

4VAC

Note:

1. Maximum input current at low input voltage range is measured at 90VAC, at max load.

2. Maximum input current at high input voltage range is measured at 180VAC, at max load.

3. This requirement is not to be used for determining agency input current markings.

5VAC

The power supply meets all safety agency requirements for dielectric strength. Transformers’

isolation between primary and secondary windings complies with the 3000VAC (4242VDC)

dielectric strength criteria. If the working voltage between primary and secondary dictates a

higher dielectric strength test voltage, the highest test voltage will be used. In addition the

insulation system complies with reinforced insulation per safety standard IEC 950. Separation

between the primary and secondary circuits, and primary to ground circuits, complies with the

IEC 950 spacing requirements.

An AC line dropout is defined to be when the AC input drops to 0VAC at any phase of the AC

line for any length of time. During an AC dropout the power supply meets dynamic voltage

regulation requirements. An AC line dropout of any duration does not cause tripping of control

signals or protection circuits. If the AC dropout lasts longer than the holdup time, the power

supply will recover and meet all turn on requirements. The power supply meets the AC dropout

Revision 1.0

Page 34

Power Subsystem Intel® Server System R2000LH2/T2 Product Family TPS

22

Table 10. AC Line Dropout/Holdup

Power Supply

Loading

Holdup Time

1600W AC

70%

10.0 msec

3.5.4.1

AC Line 12VSB Holdup

3.5.5

AC Line Fuse

3.5.6

AC Inrush

3.5.7

AC Line Transient Specification

Table 11. AC Line Sag Transient Performance

AC Line Sag (10sec interval between each sagging)

Duration

Sag

Operating AC Voltage

Line Frequency

Performance Criteria

0 to 1/2 AC

95%

Nominal AC Voltage

50/60 Hz

No loss of function or

> 1 AC cycle

> 30%

Nominal AC Voltage

50/60 Hz

Loss of function acceptable,

requirement over rated AC voltages and frequencies. A dropout of the AC line for any duration

does not cause damage to the power supply.

The 12VSB output voltage stays in regulation under its full load (static or dynamic) during an AC

dropout of 70ms min (=12VSB holdup time) whether the power supply is in ON or OFF state

(PSON asserted or de-asserted).

The power supply has one line fused in the single line fuse on the line (Hot) wire of the AC

input. The line fusing is acceptable for all safety agency requirements. The input fuse is a slow

blow type. The AC inrush current does not cause the AC line fuse to blow under any conditions.

All protection circuits in the power supply will not cause the AC fuse to blow unless a component

in the power supply has failed. This includes DC output load short conditions.

The AC line inrush current does not exceed 65A peak, for up to one-quarter of the AC cycle,

after which, the input current is no more than the specified maximum input current. The peak

inrush current is less than the ratings of its critical components (including input fuse, bulk

rectifiers, and surge limiting device).

The power supply meets the inrush requirements for any rated AC voltage, during turn on at any

phase of AC voltage, during a single cycle AC dropout condition as well as upon recovery after

AC dropout of any duration, and over the specified temperature range (T

).

op

The AC line transient conditions are defined as sag and surge conditions. Sag conditions are

also commonly referred to as brownout; these conditions are defined as the conditions when the

AC line voltage drops below nominal voltage. Surge conditions are defined as the conditions

when the AC line voltage rises above nominal voltage.

The power supply meets the requirements under the following AC line sag and surge conditions.

cycle

ranges

ranges

performance

self-recoverable

Revision 1.0

Page 35

Intel® Server System R2000LH2/T2 Product Family TPS Power Subsystem

23

Table 12. AC Line Surge Transient Performance

AC Line Surge

Duration

Surge

Operating AC Voltage

Line Frequency

Performance Criteria

Continuous

10%

Nominal AC Voltages

50/60 Hz

No loss of function or

0 to 1/2 AC

30%

Mid-point of nominal AC

50/60 Hz

No loss of function or

3.5.8

Susceptibility Requirements

Table 13. Performance Criteria

Level

Description

A

The apparatus shall continue to operate as intended. No

B

The apparatus shall continue to operate as intended. No

C

Temporary loss of function is allowed provided the

3.5.9

Electrostatic Discharge Susceptibility

3.5.10

Fast Transient/Burst

3.5.11

Radiated Immunity

3.5.12

Surge Immunity

performance

cycle

Voltages

performance

The power supply meets the following electrical immunity requirements when connected to a

cage with an external EMI filter that meets the criteria defined in the SSI document EPS Power

Supply Specification. For further information on Intel standards, request a copy of the Intel

Environmental Standards Handbook.

degradation of performance.

degradation of performance beyond spec limits.

function is self-recoverable or can be restored by the

operation of the controls.

The power supply complies with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-2: Edition 1.2: 2001-04 test standard and performance criteria B defined in

Annex B of CISPR 24.

The power supply complies with the limits defined in EN55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-4: Second edition: 2004-07 test standard and performance criteria B defined in

Annex B of CISPR 24.

The power supply complies with the limits defined in EN55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-3: Edition 2.1: 2002-09 test standard and performance criteria A defined in

Annex B of CISPR 24.

The power supply is tested with the system for immunity to AC Unidirectional wave; 2kV line to

ground and 1kV line to line, per EN 55024: 1998/A1: 2001/A2: 2003, EN 61000-4-5: Edition

1.1:2001-04.

The pass criteria include:

Revision 1.0

Page 36

Power Subsystem Intel® Server System R2000LH2/T2 Product Family TPS

24

3.5.13

Power Recovery

3.5.14

Voltage Interruptions

3.5.15

Protection Circuits

3.5.16

Over-current Protection (OCP)

Table 14. Power Supply Over Current Protection

Power Supply

Output Voltage

Input voltage range

Over Current Limits

1600W AC

+12V

90 – 264VAC

180A min; 200A max

12VSB

90 – 264VAC

4A min; 5A max

3.5.17

Over-voltage Protection (OVP)

No unsafe operation is allowed under any condition.

All power supply output voltage levels to stay within proper spec levels.

No change in operating state or loss of data during and after the test profile.

No component damage under any condition.

The power supply complies with the limits defined in EN55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-5: Edition 1.1:2001-04 test standard and performance criteria B defined in

Annex B of CISPR 24.

The power supply recovers automatically after an AC power failure. AC power failure is defined

to be any loss of AC power that exceeds the dropout criteria.

The power supply complies with the limits defined in EN55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-11: Second Edition: 2004-03 test standard and performance criteria C defined

in Annex B of CISPR 24.

The protection circuits inside the power supply cause only the power supply’s main outputs to

shut down. If the power supply latches off due to a protection circuit tripping, an AC cycle OFF

for 15 seconds and a PSON# cycle HIGH for one second reset the power supply.

The power supply has current limit to prevent the outputs from exceeding the values shown in

table below. If the current limits are exceeded, the power supply will shut down and latch off.

The latch will be cleared by toggling the PSON# signal or by an AC power interr uption. The

power supply will not be damaged from repeated power cycling in this condition. 12VSB will be

auto-recovered after removing OCP limit.

The power supply over voltage protection is locally sensed. The power supply will shut down

and latch off after an over voltage condition occurs. This latch will be cleared by toggling the

PSON# signal or by an AC power interruption. The values are measured at the output of the

power supply’s connectors. The voltage will never exceed the maximum levels when measured

at the power connectors of the power supply connector during any single point of fail. The

voltage will never trip any lower than the minimum levels when measured at the power

connector. 12VSB will be auto-recovered after removing OVP limit.

Revision 1.0

Page 37

Intel® Server System R2000LH2/T2 Product Family TPS Power Subsystem

25

Table 15. Over Voltage Protection (OVP) Limits

Output Voltage

Min (V)

Max (V)

+12V

13.3

14.5

12VSB

13.3

14.5

3.5.18

Over-temperature Protection (OTP)

The power supply is protected against over temperature conditions caused by loss of fan

cooling or excessive ambient temperature. In an OTP condition the PSU will shut down. When

the power supply temperature drops to within specified limits, the power supply will restore

power automatically, while the 12VSB remains always on. The OTP circuit has built-in margin

so that the power supply will not oscillate on and off due to temperature recovering condition.

The OTP trip level has a minimum of 4°C of ambient temperature margin.

Revision 1.0

Page 38

Power Subsystem Intel® Server System R2000LH2/T2 Product Family TPS

26

3.6 1600W DC Power Supply Support

3.6.1

Power Supply Module Efficiency

Table 16. 1600 Watt (DC) Power Supply Efficiency (Platinum)

Loading

100% of

maximum

50% of

maximum

20% of

maximum

10% of

maximum

Minimum

88%

92%

88%

80%

3.6.2

DC Inlet Connector

3.6.3

DC Input Voltage Specification

Table 17. 1600 Watt (DC) Power Supply Efficiency (Platinum)

Parameter

Minimum

Rated

Maximum

Maximum Input

Current

DC Voltage

-38VDC

-48VDC/-60VDC

-75VDC

TBD

3.6.4

DC Holdup/Dropout Time

Table 18. DC Holdup/Dropout Time

Power Supply

Wattage

Loading

Holdup Time

1600W

1200W (75%)

0.2 msec

The following table provides the required minimum efficiency level at various loading conditions.

These are provided at three different load levels: 100%, 50%, and 20%. The input voltage is set

to -53VDC during the test.

Efficiency

The power supply has the -48VDC input fused. The fusing is acceptable for all safety agency

requirements. The DC inrush current does not caus e the fuse to blow under any conditions. No

protection circuits in the power supply will cause the DC fuse to blow unless a component in the

power supply has failed. This includes DC output load short conditions.

The power supply operates within all specified limits over the following input voltage range.

During a DC dropout of 0.2m s or less the power supply meets dynamic voltage regulation

requirements for every rated load condition. A DC line dropout of 0.2ms or less does not cause

tripping of control signals or protection circuits. Repeated every 10 seconds starting at the min

input voltage DC line dropout does not damage the power supply under any specified load

conditions. The PWOK signal does not go to a low state under these conditions. DC dropout

transients in excess of 0.2 milliseconds may cause shutdown of the PS or out of regulation

conditions, but do not damage the power supply. The power supply recovers and meets all turn

on requirements for DC dropouts that last longer than 0.2ms. The power supply meets the DC

dropout requirement over rated DC voltages and output loading conditions.

Revision 1.0

Page 39

Intel® Server System R2000LH2/T2 Product Family TPS Power Subsystem

27

3.6.5

DC Line Fuse

3.6.6

DC Inrush

3.6.7

DC Line Surge Voltages (Line Transients)

- 48VDC

<= 3.0ms

10.0ms

Rise TimeFall Time

<= 3.0ms

- 75VDC

Figure 18. 75VDC Test

The power supply has the -48VDC input fused. The fusing is acceptable for all safety agency

requirements. The DC inrush current does not cause the fuse to blow under any conditions. No

protection circuits in the power supply will cause the DC fuse to blow unless a component in the

power supply has failed. This includes DC output load short conditions.

The maximum inrush current from power-on is limited to a level below the surge rating of the

input line cable; input diodes, fuse, and EMI filter components. The inrush current does not

exceed the I²t curve shown in ETS 300 132-2 Equipment Engineering (EE); Power Supply

Interface at the Input to Telecommunication Equipment; Part2: Operated by Direct Current (DC).

To allow multiple power cycling events and DC line transient conditions, the maximum I²t value

does not exceed 20% of the fuse maximum rating. Repetitive ON/OFF cycling of the DC input

line voltage does not damage the power supply or cause the input fuse to blow.

The power supply demonstrates tolerance for transients in the input DC power line caused by

switching or lightning. The power supply is primarily tested and complies with the requirements

of EN61000-4-5: “Electrical Fast transients / Burst Requirements and Surge Immunity

Requirements” for surge withstand capability. The test voltage surge levels are to be 500Vpk for

each Line to Primary Earth Ground test (none required between the L1 and L2).

75VDC Line Transient Test

A standard line voltage momentary transient test is shown below. This test simulates a

momentary voltage overshoot. This does not affect the operation of the PSU, and the

output voltages remain in regulation.

This test is conducted every 10 sec for 30 min (180 times total).

0V Line Transient Test

A standard line voltage momentary blackout test is shown below. This test simulates a

momentary switch throw off-on. The power supply restarts, not latches.

This test is conducted 3 times in 10 min intervals. Refer to document TP76200MP

Section 8.05-b, page 14, for this transient test setup.

Revision 1.0

Page 40

Power Subsystem Intel® Server System R2000LH2/T2 Product Family TPS

28

<= 5.0ms 5.0ms <= 5.0ms

0V

- 48VDC

Rise Time Fall Time

Figure 19. 0VDC Test

Table 19. Line Voltage Transient Limits

Duration

Slope/Rate

Output

Performance Criteria

200µs max

-48V → -30V w/

Rated DC Voltages

No loss of function

-30V → -48V w/ -

Rated DC Voltages

No loss of function

3.6.8

Residual Voltage Immunity in Standby Mode

3.6.9

Protection Circuits

3.6.9.1

Current Limit (OCP)

Practically a blackout of any duration does not damage the power supply in any way and

not cause a latch off condition.

The power supply can also withstand the following transients.

+2V/µs

2V/µs

or performance

or performance

The power supply is immune to any residual voltage placed on its outputs (typically a leakage

voltage through the system from standby output) up to 500mV. There is neither additional heat