Page 1

Intel NetStructure® MPRTM0020 Rear Transition Module

Technical Product Specification

April 2006

Order Number: 309383-004

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PRO PERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEV ER, AND INTEL DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING T O FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER

INTELLECTUAL PROPERTY RIGHT. This document and the software described in it are furnished under license and may only be used or copied in

accordance with the terms of the license. The information in this document is furnished for informational use only, is subject to change without notice,

and should not be construed as a commitment by Intel Corporation. Intel Corporation assumes no responsibility or liability for any errors or

inaccuracies that may appear in this document or any software that may be provided in association with this document. Except as permitted by such

license, no part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the express

written consent of Intel Corporation.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by calling

1-800-548-4725 or by visiting Intel's website at http://www.intel.com.

Intel, Intel logo, and Intel NetStructure are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other

countries.

*Other names and brands may be claimed as the property of others.

Copyright © Intel Corporation, 2006. All rights reserved.

2 Intel NetStructure

®

MPRTM0020 Technical Product Specification – April 2006

Page 3

Contents

1 Document Organization....................................... ... .... ... ... ... .... ... ... ... ... .... ... ... ...............................7

1.1 Acronyms and Terms......... .... ... ... ... ... .... ... .......................................... ..................................7

2 Functional Overview .....................................................................................................................9

3 Operating the Unit .......................................................................................................................11

3.1 Introduction.........................................................................................................................11

3.2 RTM Installation Procedure ................................................................................................11

3.3 RTM Removal Procedure ...................................................................................................11

3.4 Digital Ground to Chassis Ground Connection...................................................................12

4 Module Components...................................................................................................................14

4.1 Block Diagram ....................................................................................................................14

4.2 Physical Layout...................................................................................................................15

4.3 Components Description .......................................... ... .... ... ................................................17

4.3.1 Serial Port Interface...............................................................................................17

4.3.2 USB Interface ........................................ ... ....................................... ... ... ... ... .... ... ...18

4.3.3 Gigabit Ethernet Interface......................................................................................18

4.3.4 SAS Connector Interface.......................................................................................19

4.3.5 T1/E1 Connector Interface.................................. ... ... ... ... .... ... ................................20

4.3.6 Zone 3 Rear Transition Module Power Connector (P30).......................................21

4.3.7 Zone 3 Rear Transition Module Data/Control Connectors.....................................23

4.3.7.1 Zone 3 Rear Transition Module Data/Control Connector (P31).............23

4.3.7.2 Zone 3 Rear Transition Module Data Connector (P32) .........................24

4.3.7.3 Zone 3 Rear Transition Module Data Connector (P33) .........................24

4.3.8 Alignment Blocks ...... ... ... ... ....................................................................................25

4.3.9 ADM1026 Controller .............................................................. ................................25

4.3.10 Power Supplies......................................................................................................26

4.3.11 SAS Redriver.........................................................................................................27

4.3.12 Board Status LEDs ......... ... ... .... ... ... ... .... ... .............................................................27

4.3.13 RJ-45 Gigabit Ethernet Port LEDs.........................................................................28

5 RTM Management Architecture..................................................................................................30

5.1 Introduction.........................................................................................................................30

5.2 RTM FRU Control...............................................................................................................30

5.3 M-state Machine ... .... ... ... ... .... ...................................... .... ... ... ... ... .... ... ................................30

5.4 Power Budget Management ...............................................................................................31

5.5 LED Management...............................................................................................................31

5.6 SDR Proxy......................................... .... ... ... ... ....................................... ... .... ... ... ... ... ..........31

5.7 RTM Sensor Proxy .............................................................................................................31

6 Detailed Specifications ...............................................................................................................33

6.1 Dimensions and Weight......................................................................................................33

6.2 Environmental Specification ............................................ ... ... ... ... .... ... ... ... .... ... ...................33

6.3 Mechanical Specifications .............................. .... ... ... ... .......................................................33

6.3.1 Board Outline............... ... ... ... .... ...................................... .... ... ... ... .... ... ... ................33

6.4 Reliability Specifications ........ ... ... ... ... .... ... ... ... .... .......................................... ... ... ... .............35

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 3

Page 4

6.4.1 Mean Time Between Failure (MTBF) Specifications .............................................35

6.4.1.1 Environmental Assumptions..................................................................35

6.4.1.2 General Assumptions...................................................... .... ...................35

6.4.1.3 General Notes........................... ... ... ... .... ... ... ... ... ....................................36

6.5 Power Consumption ...........................................................................................................36

7 Warranty Information................................. ... ..............................................................................37

7.1 Intel NetStructure

7.2 Returning a Defective Product (RMA) ................................................................................37

7.2.1 For the Americas ............................................................ ... .... ... ... ... .... ... ... ... ..........37

7.2.2 For Europe, Middle East, and Africa (EMEA)........................................................38

7.2.3 For Asia and Pacific (APAC)..................................................................................38

7.2.4 Limitation of Liability and Remedies......................................................................39

8 Customer Support.......................................................... .............................................................40

8.1 Customer Support...............................................................................................................40

8.2 Technical Support and Return for Service Assistance .......................................................40

8.3 Sales Assistance ................................................................................................................40

8.4 Product Code Summary .....................................................................................................40

9 Certifications................................................................................................................................41

10 Agency Information..................................................................................................................... 42

10.1 North America (FCC Class A).............................................................................................42

10.2 Canada – Industry Canada (ICES-003 Class A) ................................................................42

10.3 European Union..................................................................................................................42

®

Compute Boards and Platform Products Limited Warranty.................37

11 Safety Warnings ................................................................ ... ... .... ... ... ... ... .... ... .............................44

11.1 Safety Precautions..............................................................................................................44

Figures

1 Relationship of RTM to Front Board.............................................................................................9

2 Default Grounding on MPRTM0020 ...........................................................................................12

3 Digital Ground Connected to Chassis Ground .............................................. ... ... .... ... ... ... ..........13

4 RTM Functional Block Diagram..................................................................................................14

5 Rear Transition Module (RTM)...................................................................................................15

6 RTM Faceplate Connectors and LEDs.......................................................................................16

7 Serial Port Connector .................................................................................................................17

8 USB Connector (J2) ............................................... ... .... ... ... ... .... ... .............................................18

9 RJ-45 Gigabit Ethernet Connector .............................................................................................19

10 SAS Connector...........................................................................................................................20

11 RJ-48 Connector ........................................................................................................................21

12 P30 Connector............................................................................................................................22

13 RTM Power Distribution..............................................................................................................26

14 Physical Breakdown of SAS Ports Distribution...........................................................................27

15 RJ-45 Ethernet Port LEDs..........................................................................................................28

16 RTM Temperature Sensor Locations .........................................................................................32

17 Component Layout.....................................................................................................................34

4 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 5

Tables

1 Acronyms and Terms....................................................................................................................7

2 Serial Port Connector Pinout......................................................................................................18

3 USB Connector Pinout................................................................................................................18

4 RJ-45 Ethernet Connector Pinout........................ .......................................................................19

5 SAS Connector Pinout .. ..............................................................................................................20

6 T1/E1 Connector Pinout .............................................................................................................21

7 P30 Connector Pinout.................................................................................................................22

8 P30 Signal Descriptions..............................................................................................................22

9 RTM Connector (Zone 3) P31 Pinout.........................................................................................23

10 P31 Signal Descriptions..............................................................................................................23

11 RTM Connector (Zone 3) P32 Pinout.........................................................................................24

12 RTM Connector (Zone 3) P33 Pinout.........................................................................................25

13 GPIO Signal Mapping.................................................................................................................25

14 Board Status LED Descriptions..................................................................................................28

15 Sensor Data Record for RTM.....................................................................................................32

16 Environmental Specifications......................................................................................................33

17 Board Components.....................................................................................................................35

18 Reliability Estimate Data.............................................................................................................35

19 Product Codes..... ... ... ... .... ... .......................................... ... ... .......................................... .............40

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 5

Page 6

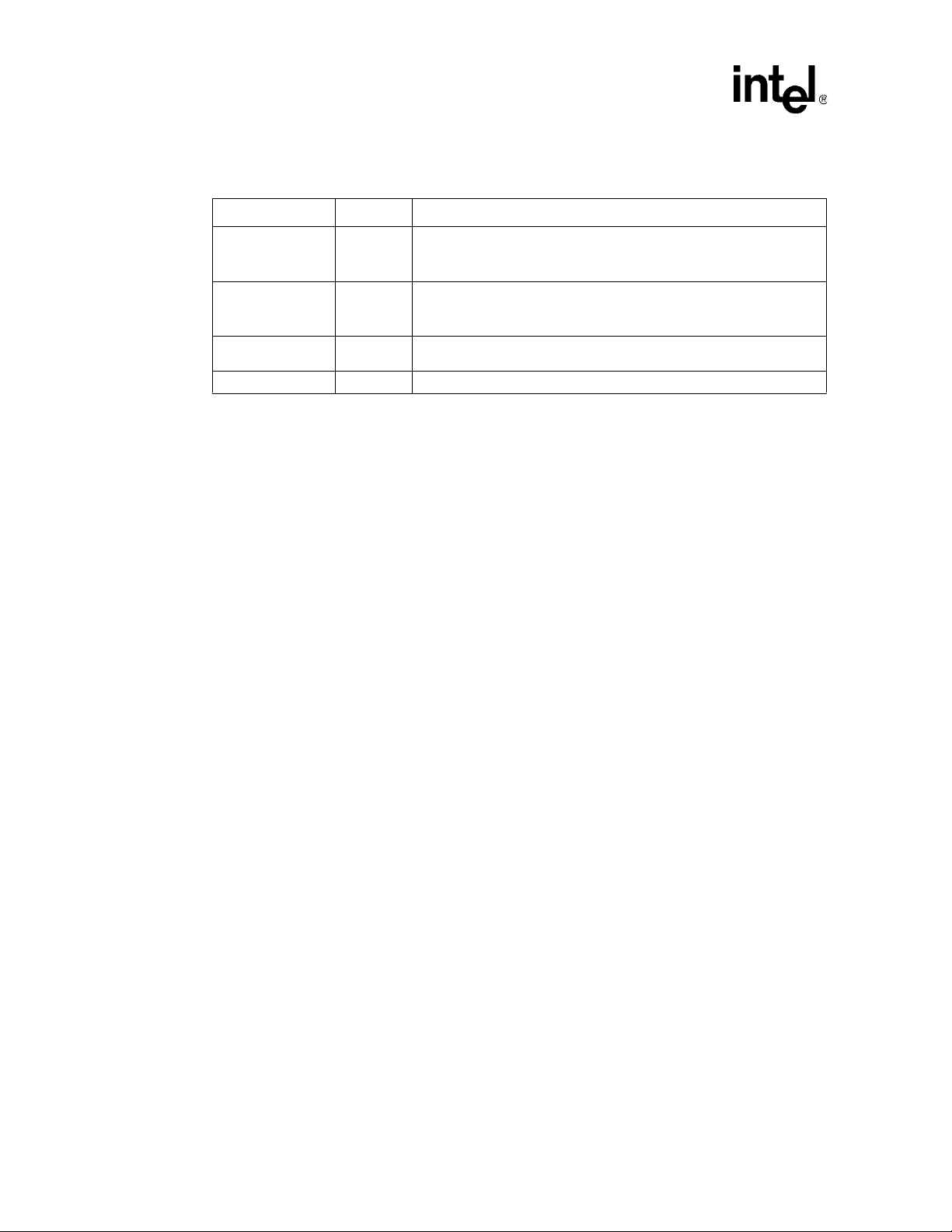

Revision History

Date Revision Description

April 2006 004

January 2006 003

December 2005 002

September 2005 001 Initial release of this document.

Updated values for temperature sensor thresholds in “Sensor Data

Record for RTM” table.

Updated faceplate illustration.

Initial production release.

Added new info on grounding procedure, power supplies, SAS redriver,

faceplate LEDs, and RTM sensors. Updated P31 pinout.

Added “Operating the Unit”, “RTM Management Architecture”, and

“Detailed Specifications” chapters

6 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 7

Document Organization

Document Organization 1

The Intel NetStructure® MPRTM0020 Rear Transition Module Technical Product Specification is

organized as follows:

• Chapter 1, “Document Organization” provides a table of acronyms and terms that are used

throughout the document.

• Chapter 2, “Functional Overview” describes the features of the Rear Transition Module.

• Chapter 3, “Operating the Unit” includes information about installing and removing the Rear

Transition Module.

• Chapter 4, “Module Components” describes the functional components of the Rear Transition

Module.

• Chapter 5, “RTM Management Architecture” describes support for a non-intelligent Rear

Transition Module in an IPMC environment.

• Chapter 6, “Detailed Specifications” includes detailed environmental, mechanical and

reliability specifications for the Rear Transition Module.

• Chapter 7, “Warranty Information” includes product warranty information.

• Chapter 8, “Customer Support” offers technical and sales assistance information for the Rear

Transition Module.

• Chapter 9, “Certifications” provides information about product certifications.

• Chapter 10, “Agency Information” provides product compliance information.

• Chapter 11, “Safety Warnings” includes several safety warnings about working with the Rear

Transition Module.

1.1 Acronyms and Terms

Table 1. Acronyms and Terms (Sheet 1 of 2)

Term Definition

AdvancedTCA* Advanced Telecommunications Computing Architecture

Blade, Board

CPU Central Processing Unit. A microprocessor.

DPM Defects Per Million

ENA Enable

FIT Failures In Time

FRU

HA Highly Available.

These terms are used interchangeably to refer to an assembled PCB card that plugs into a

chassis slot.

Field Replaceable Unit. Logically represents an entity that can be queried for sensor data,

and perhaps an entity that has a satellite management controller. Example FRUs can

include an entire SBC or a power supply.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 7

Page 8

Document Organization

Table 1. Acronyms and Terms (Sheet 2 of 2)

Term Definition

Hot Swap A specific specification from the PICMG 3.0 Spec.

2

C A two-wire serial bus. Licensed by Phillips Semiconductors.

I

®

IA-32 32-bit Intel

I/O Input/Output

IPMB

Intelligent Platform Management Bus. The bus that interconnects all boards in the chassis

to the Shelf Manager.

Intelligent Platform Management Bus Channel 0 as defined in the IPMI v1.5 specification.

IPMB-0

This is the logical aggregation of IPMB-A and IPMB-B. The use of IPMB Channels 1 through

7 are not defined in this specification.

IPMB-R

IPMC

IPMI

Local IPMI link that is on the “carrier” side of the IPMC device. The IPMC shall proxy for all

IPMB-R devices (AMCs and RTM).

Intelligent Platform Management Controller. The portion of a FRU that interfaces to the

AdvancedTCA* IPMB-0 and represents that FRU and any device subsidiary to it.

Intelligent Platform Management Interface. The overall specification for doing point-to-point

management communication within the chassis over and I

JBOD Just a Bunch of Drives

Node Slot Any standard slot other than a fabric slot

OOS Out of Service

PCI

Peripheral Component Interconnect. Bus technology used to interconnect components in a

computer.

PICMG PCI Industrial Computer Manufacturers Group

PMC PCI Mezzanine Card

Power Module Either a power supply or a power entry module

RMC RTM Management Controller. The IPMI controller on an RTM, similar to an MMC.

RMCP Remote Management Control Protocol. Defined by IPMI 1.5.

RMD

RTM Management Device. A non-intelligent device (typically an ADM1026) that

communicates over I

RTM Rear Transition Module

SAS Serial Attached SCSI

SDR

Sensor Data Record. An IPMI term. Used to describe the name, meaning, and units of

measure for a particular data value provided by a PM or BMC.

SEL Sensor Event Log. An IPMI defined term. Maintained by the BMC.

Shelf A shelf is equivalent to a chassis.

A pluggable board that provides management functions, allowing the chassis backplane to

remain passive. Although the term implies a dedicated module, the Shelf Manager may be

Shelf Manager

one function of a multi-function module. For example, the Shelf Manager and a switch can

be combined in a single physical module. The Shelf Manager performs the BMC function

within the chassis and provides remote management capabilities.

SMBus

SMC

A two-wire serial bus with slightly different electrical and timing characteristics than I

technology is owned by Intel Corporation.

Satellite Management Controller. Defined by IPMI. Also known as a peripheral controller or

peripheral management controller.

Switch Slot See “Fabric Slot”

TPS Technical Product Specification

Architecture

2

C to the Front Board IPMC, rather than using IPMB like an RMC does.

2

C bus.

2

C. This

8 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 9

Functional Overview

Functional Overview 2

Rear Transition Modules (RTM) are important components in many telecommunications and

embedded systems. These environments place most of the active components on a Front Board and

most of the cable connections (especially copper cables) are made from the RTM. This allows the

Front Board to be replaced without the need to reinsert a large number of cables in the correct

order.

In AdvancedTCA* systems, the Front Board mates directly with the RTM, as shown in Figure 1:

Figure 1. Relationship of RTM to Front Board

Front Board

The Intel NetStructure

with the Intel NetStructure MPCBL0020 Single Board Computer.

The MPRTM0020 RTM includes the following interfaces and features:

®

MPRTM0020 Rear Transition Module is designed specificall y to work

• One serial port

• One USB 1.1 port

• T wo Gigabit Ethernet (RJ45) ports from the Fabric Interface

RTM

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 9

Page 10

Functional Overview

• One SAS x4 connector to support external SAS JBOD. (Only three of these SAS ports on the

RTM are usable; the first SAS port is used by the MPCBL0020 Single Board Computer’ s local

SAS drive.)

• Six T1/E1 ports with transformer and protection circuitry (designed primarily for intra-

building applications)

2

• I

• OOS and Health LEDs

• Hot Swap status LED. This LED mirrors the indication of the HS status LED on the

MPCBL0020 Single Board Computer since the MPRTM0020 RTM itself is not hot swappable.

• P30 power connector

• P31, P32, and P33 HM- ZD connectors for SBC signals

• On-board power conversion from +12V supplied by the SBC via P30 connector

• ADM1026 for voltage monitoring, storing FRU and SDR data.

C connectivity to the SBC for remote management capabilities

10 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 11

Operating the Unit

Operating the Unit 3

3.1 Introduction

The Intel NetStructure® MPRTM0020 Rear Transition Module is a non-intell igen t RTM. A nonintelligent FRU does not have a remote management controller (RMC) on board to communicate

with the SBC IPMC. Instead, all of the non-intelligent RTM sensors and FRU device information is

made available to the IPMC through direct device access. This is usually done via dummy I

sensor and storage devices. It is the responsibility of the IPMC to make the non-intelligent RTM

look like a separate intelligent FRU controller to the rest of the system.

3.2 RTM Installation Procedure

The MPRTM0020 RTM is mechanically compliant with the PICMG*3.0 specifications Revision 2

ECN1.

2

C

The RTM must be installed in an AdvancedTCA* chassis prior to installing the MPCBL0020

Single Board Computer.

Install the RTM as follows:

1. Remove the rear air management blade from an AdvancedTCA chassis (where applicable).

2. Locate the slot where the RTM is to be installed in the chassis. The RTM must be installed in

the same slot number as the MPCBL0020 Single Board Computer.

3. Open the top and bottom ejector latches and slide the RTM into the chassis by aligning to the

guide rails on the top and bottom of the chassis cage.

4. Ensure that the RTM is fully installed in the chassis by locking the top and bottom ejector

handles.

5. Tighten the faceplate retention screws on the top and bottom of the RTM faceplate. Ensure that

the screws are torqued to ~6 in-lbs using a torque screwdriver.

3.3 RTM Removal Procedure

Removal of the RTM from the chassis uses the following procedure:

1. Because the MPRTM0020 is not an intelligent RTM, removing the RTM causes the SBC to be

shut down. Ensure that the SBC is ready to be shut down before opening the bottom ejector

handle of the RTM.

2. Remove all interface cables from the RTM faceplate connectors.

3. Loosen the RTM faceplate retention screws with a screwdriver.

4. Open the top and bottom ejector handles on the RTM.

5. Remove the RTM from the chassis slot.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 11

Page 12

Operating the Unit

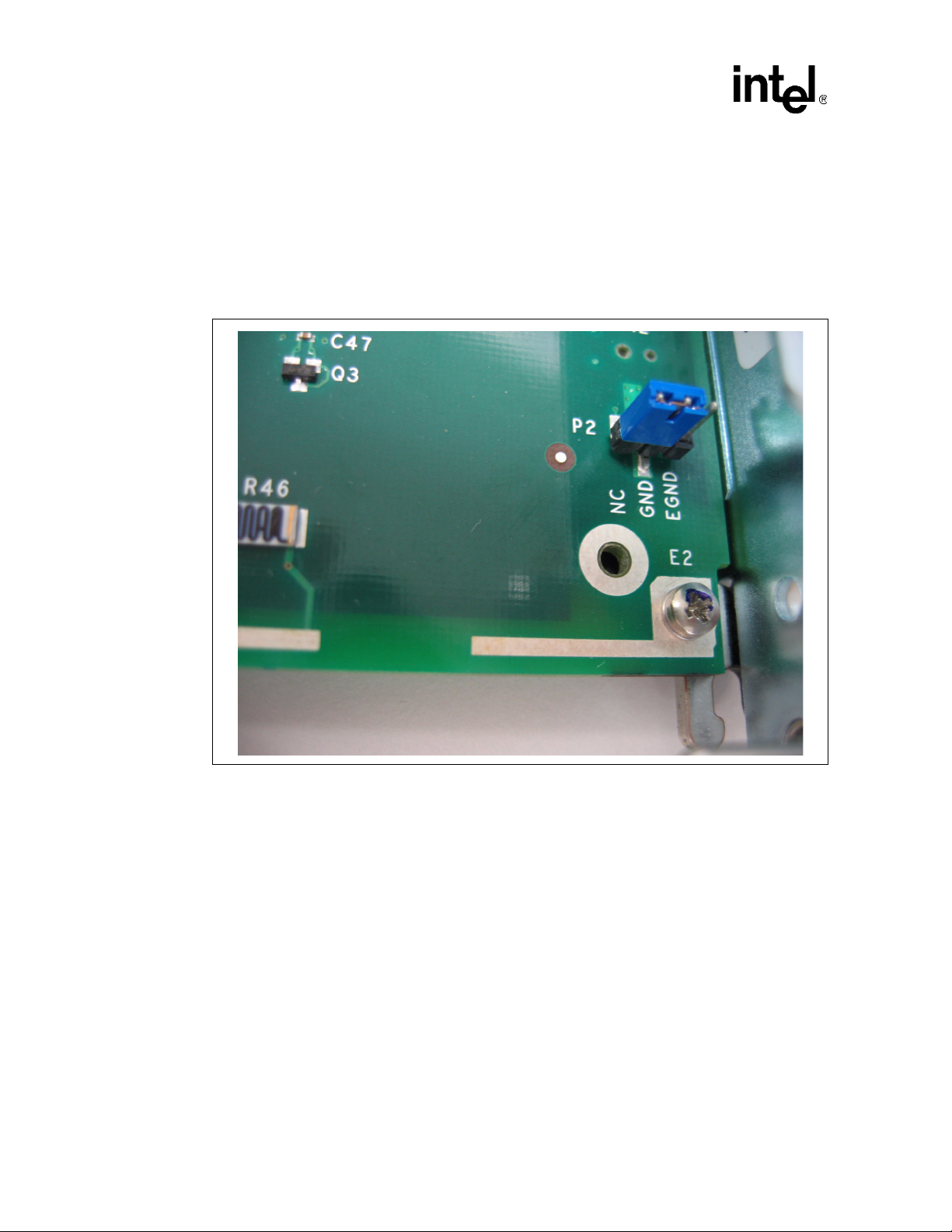

3.4 Digital Ground to Chassis Ground Connection

Digital ground can be tied to chassis ground through a jumper (P2) located near the bottom, right

corner of the RTM.

In the default grounding for the MPRTM0020, digital ground is isolated from chassis ground

(jumper link connecting “NC” to “GND”) as shown in Figure 2.

Figure 2. Default Grounding on MPRTM0020

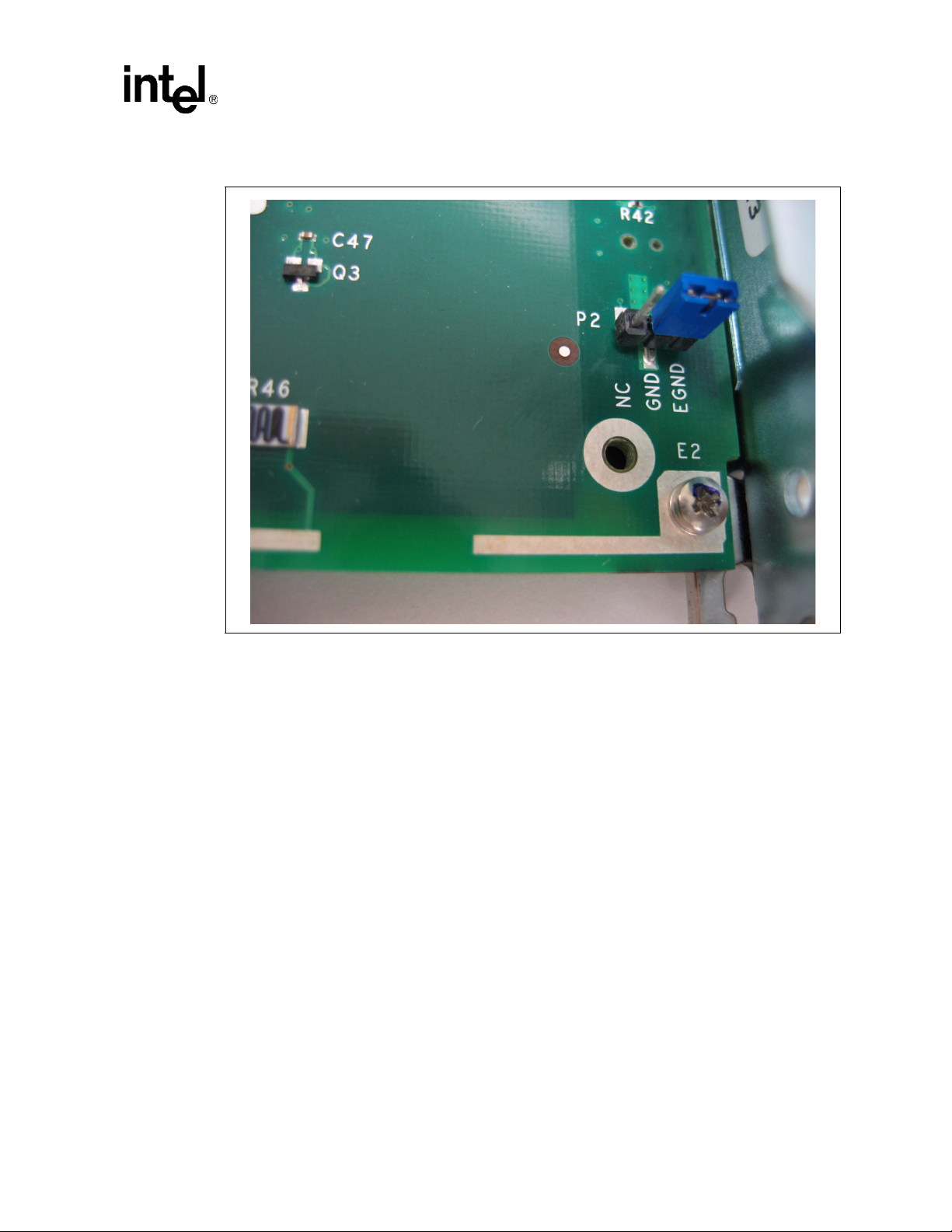

T o connect the digital ground to the chassis ground, follow this procedure:

1. Remove the jumper link from the default location on P2 (connecting “NC” & “GND”).

2. Place the jumper link over pins 2 & 3 to connect “GND” to “EGND” as shown in Figure 3.

12 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 13

Figure 3. Digital Ground Connected to Chassis Ground

Operating the Unit

Note: Digital ground is also called “logic ground”. Chassis ground is also known as “shelf ground”.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 13

Page 14

Module Components

Module Components 4

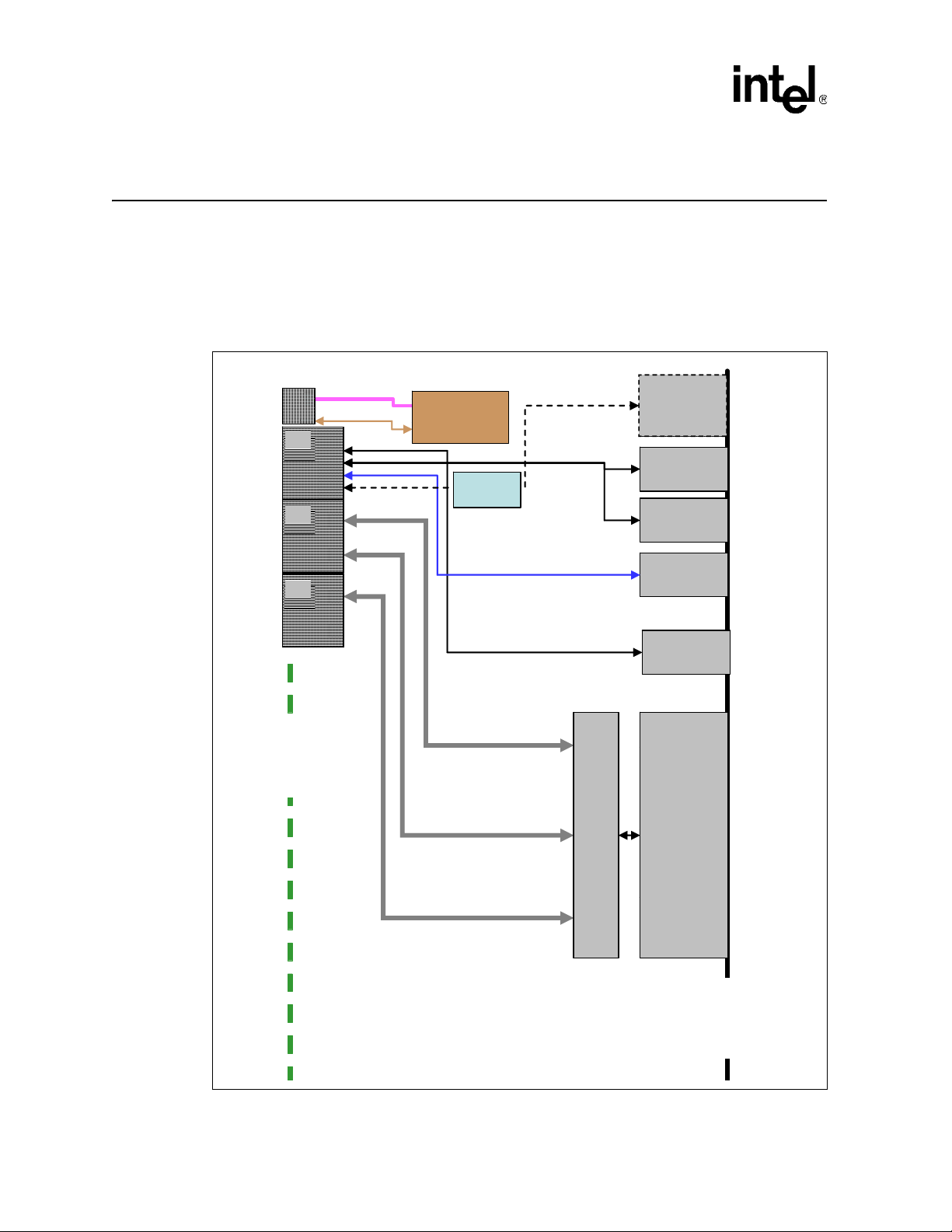

4.1 Block Diagram

Figure 4 shows a functional block diagram of the RTM.

Figure 4. RTM Functional Block Diagram

P30

P31

P32

P33

Backplane

Power

IPMB/I2C

ADM1026

RMD

Redriver

2xT1/E1

From Mezz. #1

2xT1/E1

From Mezz. #2

SAS

(x3)

2xGbE

(from

Fabric

Interface)

USB

Serial

Transformers / Sidactors

3 SAS

Port

RJ-45 GbE

Port

RJ-45 GbE

Port

USB Port

RJ-45 Serial

Port

1x6

RJ-48C

T1/E1

Ports

2xT1/E1

From Mezz. #3

Rear Panel

14 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 15

4.2 Physical Layout

Figure 5. Rear Transition Module (RTM)

Module Components

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 15

Page 16

Module Components

Figure 6 identifies the connectors and LEDs on the RTM faceplate.

Figure 6. RTM Faceplate Connectors and LEDs

SAS Connector

Fabric Interface

Port A

Fabric Interface

Port B

USB Connector

Serial Port

Connector

T1/E1 RJ48C

from PMC1

T1/E1 RJ48C

from PMC2

T1/E1 RJ48C

from PMC3

OOS LED

Health LED

Hot Swap LED

16 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 17

4.3 Components Description

The following sections describe the components shown in Figure 4 through Figure 6.

4.3.1 Serial Port Interface

One serial port (RS-232) connector is present on the RTM. This connector provides access to the

COM1 serial port from the MPCBL0020 Single Board Computer, which is also routed to the front

panel of the SBC. Both connections are active, but only one can be used at any given time.

The line driver/receiver for the serial port resides on the SBC. The RTM only provides a connector

along with EMI/EMC filtering. The serial port uses an RJ-45 connector, which is located on the

RTM faceplate as shown in Figure 6 on page 16. Figure 7 shows the serial port connector’s outline,

and Table 2 provides the pin-out information for this connector.

Because this serial port is the COM port from the MPCBL0020 Single Board Computer, the port is

inactive when the Serial Over LAN feature is activated on the SBC (the serial port data from

COM1 is routed to the Base Interface Gigabit Ethernet adapter in this situation).

Figure 7. Serial Port Connector

Module Components

Optional Top Ground Tabs

Optional Side

Ground tabs

(2 places)

Shielded Modular Jack Assembly

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 17

Page 18

Module Components

Table 2. Serial Port Connector Pinout

Pin Signal Name

1RTS

2DTR

3TXD

4GND

5GND

6RXD

7DSR

8CTS

4.3.2 USB Interface

One USB port is provided on the RTM. 5V power is available through this USB port with a current

limit of 400mA. Figure 8 illustrates the USB connector and Table 3 provides pinout information.

Figure 8. USB Connector (J2)

Table 3. USB Connector Pinout

Pin Signal Name

15V_USB

2USB–

3USB+

4GND

4.3.3 Gigabit Ethernet Interface

T wo Gigabit Ethernet ports with LEDs are present on the RTM. Figure 9 shows the physical outline

of the RJ-45 connector used for each port, and Table 4 provides the standard pinout information.

18 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 19

Figure 9. RJ-45 Gigabit Ethernet Connector

Module Components

Table 4. RJ-45 Ethernet Connector Pinout

Pin Signal Name

1MDI0+

2MDI0–

3MDI1+

4MDI2+

5MDI2–

6MDI1–

7MDI3+

8MDI3–

4.3.4 SAS Connector Interface

One x4 SAS (Serial Attached SCSI) connector is present on the RTM. When the MPRTM0020 is

connected to a MPCBL0020 Single Board Computer, only three of the four high-speed serial

interfaces is available on the SAS connector, because one port is already used for the on-board

local SAS drive on the SBC. The remaining three ports are available as ports 0-2 on the SAS

connector (as shown in Figure 14 on page 27) to enable users to connect to a SAS JBOD for remote

storage purposes. Figure 10 shows the outline of the SAS connector and Table 5 provides pinout

information for the connector.

Refer to the Intel NetStructure® MPCBL0020 Single Board Computer Compatibility Report for

information on specific SAS cable and SAS JBOD models that have been tested and validated by

Intel.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 19

Page 20

Module Components

Figure 10. SAS Connector

Table 5. SAS Connector Pinout

Pin Signal Name Pin Signal Name

1 GND 14 SAS_TX3–

2 SAS_RX0+ 15 SAS_TX3+

3 SAS_RX0– 16 GND

4 GND 17 SAS_TX2–

5 SAS_RX1+ 18 SAS_TX2+

6 SAS_RX1– 19 GND

7 GND 20 SAS_TX1–

8 SAS_RX2+ 21 SAS_TX1+

9 SAS_RX2– 22 GND

10 GND 23 SAS_TX0–

11 SAS_RX3+ 24 SAS_TX0+

12 SAS_RX3– 25 GND

13 GND

Pin 23

Pin 2

Pin 1Pin 3Pin 24Pin 25

Note: The SAS_RX3 and SAS_TX3 interfaces are not physically connected to the SAS controller on

MPCBL0020. The physical routing for these signals exists on the MPRTM0020 but is not

supported on the SBC. See Figure 14 “Physical Breakdown of SAS Ports Distribution” on page 27

for further details.

4.3.5 T1/E1 Connector Interface

Six T1/E1 RJ-48 connectors are present on the RTM. These connectors are designed primarily for

intra-building applications. Figure 11 shows the physical outline of the E1/T1 connectors and

Table 6 shows pinout information for each connector.

20 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 21

Figure 11. RJ-48 Connector

Table 6. T1/E1 Connector Pinout

Pin T1 Signal E1 Signal

1RX_RNG RL1

2RX_TIP RL2

3 Not Used Not Used

4 TX_RNG XL1

5TX_TIP XL2

6 Not Used Not Used

7 Not Used Not Used

8 Not Used Not Used

Module Components

4.3.6 Zone 3 Rear Transition Module Power Connector (P30)

The P30 connector is a bladed connector originally developed for FutureBus* applications.

Figure 12 illustrates the connector outline and Table 7 provides pinout information. Table 8

provides additional descriptions of the signals on the connector.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 21

Page 22

Module Components

Figure 12. P30 Connect or

Table 7. P30 Connector Pinout

Pin Signal Pin Signal

A1 (L) Logic_GND A2 (L) Shelf_GND

B1 (L) Logic_GND B2 (L) +3.3V_MP

C1 (M) IPMI_Sclk C2 (M) IPMI_Sdata

D1 (S +12V D2 (S) +12V

E1 (S) PS1# E2 (S) ENABLE#

Table 8. P30 Signal Descriptions

Pin Signal Comments

A1 Logic_GND

A2 Shelf_GND

B1 Logic_GND Logic ground connection (long contact); see above.

B2 +3.3V_MP

C1 IPMI_Sclk IPMB/I

C2 IPMI_Sdata

D1 12V 12V RTM payload power (short contact); provides up to 420mA to power active

D2 12V

E1 PS1#

E2 ENABLE#

Logic ground connection (long contact); provides return path for power and signal

connections.

Shelf ground connection (long contact); provides safety ground contact between

SBC and RTM.

Management power (long contact); provides up to 100mA to power management

system on RTM. Used exclusively for management power.

IPMB/ I

ADM1026 for temperature and voltage monitoring on the RTM.

devices (other than management system) on RTM. See additional requirements

below.

Presence Signal, active low (short contact); the RTM connects this signal to

Logic_GND through a 100 Ohm resistor (to facilitate manufacturing test). The Front

Board reads this signal to understand if an RTM is fully inserted.

Module enable signal, active low (short contact); the Front Board sets this signal high

to reset the RMC/RMD.

2

C clock signal (medium contact)

2

C data signal (medium contact); This signal is connected to the on board

22 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 23

Module Components

4.3.7 Zone 3 Rear Transition Module Data/Control Connectors

The MPRTM0020 implementation includes three data connectors (P31, P32, P33) that mate

directly to the MPCBL0020 Single Board Computer without connecting through the backplane.

Each Zone 3 data/control connection consists of 120-pin HM-Zd connector with 40 differential

pairs which allows high-speed signals to be passed between the boards.

4.3.7.1 Zone 3 Rear Transition Module Data/Control Connector (P31)

The signals that are routed through P31 are the IEEE 1149.1 JT AG signals, SAS storage ports, USB

2.0 signals, and serial and fabric interface Ethernet ports. Table 9 provides the basic pinout of the

connector, and Table 10 provides more detail abou t the signal s .

Table 9. RTM Connector (Zone 3) P31 Pinout

PinABCDEFGH

1 RMD_INT# Reserved Reserved TDI Reserved TDO Blue HS LED Reserved

2 SA[1]TX+ SA[1]TX- SA[1]RX+ SA[1]RX- SA[2]TX+ SA[2]TX- SA[2]RX+ SA[2]RX-

3 SA[3]TX+ SA[3]TX- SA[3]RX+ SA[3]RX- No Connect No Connect No Connect No Connect

4 FI_DA1+ FI_DA1- FI_DB1+ FI_DB1- FI_DC1+ FI_DC1- FI_DD1+ FI_DD1+

5 FI_DA2+ FI_DA2- FI_DB2+ FI_DB2- FI_DC2+ FI_DC2- FI_DD2+ FI_DD2+

6 LNK[0]- ACT[0]- SPD1000[0]- LNK[1]- ACT[1]- SPD1000[1]- Reserved Reserved

7 Reserved Reserved Reserved Reserved Reserved Reserved PCIe_CLK+ PCIe_CLK-

8 Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

9 Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

10 USB[0]+ USB[0]- DSR# RXD# RTS# TXD# CTS# DTR#

Table 10. P31 Signal Descriptions (Sheet 1 of 2)

Pin Signal Comments

A1 RMD_INT#

B1, C1 Reserved Reserved

D1 TDI

E1 Reserved Reserved

F1 TDO Test Data Out signal as defined in JTAG. See TDI comments above. Output of RTM

G1 Blue HS LED Blue Hot Swap LED

H1 Reserved Reserved

A2-D3

E3-H3 No Connect No Connect

A4-H5 FI_Dxy+, FI_Dxy-

SA[x]TX+, SA[x]TX-,

SA[x]RX+, SA[x]RX-

This signal is driven by the RMD on non-intelligent RTMs to alert the SBC that there is a

sensor needing attention. It is required on all SBCs and RTMs.

Test Data In signal as defined in JTAG. SBCs must connect this signal into the test data chain

(i.e., in line with TDO connections from other chips), but must have a means to bypass this

connection if an RTM is not installed.

Storage architecture signals for transmit and receive portions of differential pairs. Three SAS

ports are routed to the RTM.

PHY -level 10/100/1000Base-T signaling routed to the RTM. Row 4 is for the first Ethernet port,

row 5 is for the second Ethernet port. These Ethernet ports are routed from the “Physical

Level” Fabric Interface of the MPCBL0020 Single Board Computer, and have gone through

the magnetics on the SBC.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 23

Page 24

Module Components

Table 10. P31 Signal Descriptions (Sheet 2 of 2)

Pin Signal Comments

A6-F6

G6, F7 Reserved Reserved

G7, H7

A8-H9 Reserved Reserved

A10-

B10

C10 DSR# Data Set Ready signal for COM1 RS-232 connection.

D10 RXD# Received Data signal for COM1 RS-232 connection.

E10 RTS# Ready to Send signal for COM1 RS-232 connection.

F10 TXD# Transmit Data signal for COM1 RS-232 connection.

G10 CTS# Clear to Send signal for COM1 RS-232 connection.

H10 DTR# Data Terminal Ready signal for COM1 RS-232 connection.

LNK[x], ACT[x],

SPD1000[x]

PCIe_CLK+,

PCIe_CLK-

USB[0]+, USB[0]-

Represent the link, activity, and speed LEDs for the Fabric Interface Gigabit Ethernet that are

routed to the RTM

PCI Express reference clocks. Any SBC providing PCI Express (pins A3-H4) must provide

these signals.

* Not supported for the MPRTM0020 RTM.

USB data signals. Note that the RTM’s 5 V power for the USB connections must be derived off

the 12 V rail.

4.3.7.2 Zone 3 Rear Transition Module Data Connector (P32)

The P32 connector on the RTM connects to J32 on the MPCBL0020 Single Board Computer and is

used to route the T1/E1 signals from the PMC slots (on the SBC) to the RTM.

Table 11 provides the pinout of the P32 connector. AP1[x] designates T1/E1 signals that are routed

n

from PMC 1 while AP2[x] designates T1/E1 signals routed from PMC 2.

Table 11. RTM Connector (Zone 3) P32 Pinout

Pin A B C D E F G H

1 AP1[0]TX+ AP1[1]TX- AP1[0]RX+ AP1[0]RX- AP1[1]TX+ AP1[1]TX- AP1[1]RX+ AP1[1]RX-

2 AP1[2]TX+ AP1[2]TX- AP1[2]RX+ AP1[2]RX- AP1[3]TX+ AP1[3]TX- AP1[3]RX+ AP1[3]RX-

3 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

4 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

5 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

6 AP2[0]TX+ AP2[1]TX- AP2[0]RX+ AP2[0]RX- AP2[1]TX+ AP2[1]TX- AP2[1]RX+ AP2[1]RX-

7 AP2[2]TX+ AP2[2]TX- AP2[2]RX+ AP2[2]RX- AP2[3]TX+ AP2[3]TX- AP2[3]RX+ AP2[3]RX-

8 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

9 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

10 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

4.3.7.3 Zone 3 Rear Transition Module Data Connector (P33)

The P33 connector on the RTM connects to J33 on the MPCBL0020 Single Board Computer and is

used to route the remainder of the T1/E1 signals from PMC slot 3 on the SBC to the RTM. Table 12

provides the pinout of the P33 connector.

24 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 25

Module Components

AP3[x] indicates that these T1/E1 signals are routed from PMC 3.

Table 12. RTM Connector (Zone 3) P33 Pinout

Pin A B C D E F G H

1 AP3[0]TX+ AP3[1]TX- AP3[0]RX+ AP3[0]RX- AP3[1]TX+ AP3[1]TX- AP3[1]RX+ AP3[1]RX-

2 AP3[2]TX+ AP3[2]TX- AP3[2]RX+ AP3[2]RX- AP3[3]TX+ AP3[3]TX- AP3[3]RX+ AP3[3]RX-

3 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

4 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

5 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

6 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

7 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

8 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

9 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

10 No Connect No Connect No Connect No Connect No Connect No Connect No Connect No Connect

4.3.8 Alignment Blocks

The MPRTM0020 Rear T ransition Module implements the rK1 and A2 alignment blocks at the top

of Zone 2 and Zone 3, as required in Section 2.4.4 of the PICMG 3.0 Specification. The Zone 2

alignment block (rK1) is assigned a keying value of 11, and uses Tyco* 1-1469373-1 (or

equivalent). The Zone 3 alignment block (A2) is assigned a keying value of 7-3, and uses Tyco

7-1469373-3 (or equivalent).

4.3.9 ADM1026 Controller

The RTM has an ADM1026 controller that collects sensor information from the board using the

SMBus interface. It also has memory to store FRU and user information.

The ADM1026 is managed by the MPCBL0020 Single Board Computer IPMC connected via the

2

I

C bus. These I2C signals are routed from the SBC IPMC through the P30 connector on the

Zone 3.

The SBC IPMC communicates with the ADM1026 using an I

management perspective, the RTM can be managed using the IPMB address fronted by the SBC

(MPCBL0020) with a FRU Device ID of 0x04.

Refer Section 5 for further information regarding management of the FRU and SDR data of the

RTM.Table 13 shows mapping between GPIO signal name and pin on the ADM1026.

Table 13. GPIO Signal Mapping (Sheet 1 of 2)

GPIO Signals Pin on ADM1026

Hotswap_Switch 3

OOS Green LED Control 6

OOS Red LED Control 5

Health Green LED Control 10

2

C address of 0x5C. From the Shelf

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 25

Page 26

Module Components

Table 13. GPIO Signal Mapping (Sheet 2 of 2)

GPIO Signals Pin on ADM1026

Health Red LED Control 9

USB_OC Monitor 12

Payload Power Enable 2

Payload PowerGood 43

4.3.10 Power Supplies

The MPRTM0020 RTM needs several voltages that are not available from the SBC. The P30

connection to the SBC only provides two power supplies:

• +12 V voltage rail (420 mA maxi mum current) is used as the main input voltage for the RTM

• +3.3 V SUS voltage powers the management circuitry on the RTM (ADM1026, I

etc.)

Voltage regulation on the RTM is used to generate the additional required voltages, as shown in

Figure 13.

2

C pullup,

Figure 13. RTM Power Distribution

Input via P 30 (from

M P C B L0020)

12V

The four voltages that are generated on the RTM are used as follows:

• +5V_SUS: The +5V_SUS is mainly used as an input voltage to drive the blue Hot Swap LED.

It is generated from the +3.3V_SUS using a boost regulator.

• +5V: The 5 V payload voltage is generated from the +12 V power. To increase the power

conversion efficiency, a switching regulator is added. The 5 V is mainly used for USB power

and also used as a supply to 5 V/3.3 V linear regulator.

+3.3V _S U S

3.3V /5V

Converter

12V /5V

Converter

+5V_SUS

For M anagem ent Circuitry

5V /3.3V

Converter

+5V

3.3V /1.8V

Converter

+3.3V

+1.8V

• +3.3V: The 3.3 V voltage is used to drive the components on the SAS re-driver circuitry. This

voltage is also used to drive the Gigabit Ethernet LINK/ACTIVITY LEDs on the RTM.

26 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 27

• +1.8V: The 1.8 V voltage is used as the input voltage to the SAS re-driver IC.

4.3.11 SAS Redriver

The MPCBL0020 Single Board Computer implements optional SAS storage access via the

MPRTM0020 RTM. SAS is a 3-Gbps SERDES style bus, and a redriver is added on the RTM to

effectively detect and correct the SAS OOB signals at a proper amplitude.

The specific SAS re-driver that was used is the PMC-Sierra* PM8380 Quad SMX 3G SATA/SAS

Mux/Demux. The RTM implements the PM8380 device as a 1:1 re-driver. The four host ports are

connected to the SBC via the Zone 3 connector.

The four SAS ports of the “B” Load-side Mux-port are connected to the External SAS connector.

The “A” Load-side Mux-port is left unconnected. The PM8380 has its configuration straps set to

operate in re-driving mode, rather than in Mux mode. The “B” Load-side Mux-port is configured

for the default SAS amplitude, pre-emphasis, and equalization.

Figure 14 illustrates the SAS port distribution on the RTM.

Note: Only three SAS ports are routed to the MPRRTM0020 RTM because the first SAS port from the

SAS HBA (port 0) is used for the on-board SAS hard drive on the MPCBL0020 SBC.

Module Components

Figure 14. Physical Breakdown of SAS Ports Distribution

MPRTM0020 RTMMPRTM0020 RTMMPCBL0020 SBCMPCBL0020 SBC

SAS

SAS

Re-driver

Re-driver

0

SAS HDD

4-Port

4-Port

SAS HBA

SAS HBA

0

J31P31

0

1

2

3

1

2

3

Port

Host

A-Port (Not

Connected)

4.3.12 Board Status LEDs

0

1

2

B-Port

3

SAS Connector

External cable

to a SAS JBOD

The Hot Swap, Out of Service, and Health LEDs on the RTM faceplate are fronted by the

MPCBL0020 Single Board Computer. These LEDs have identical state to the LEDs on the SBC

faceplate and allow service personnel to verify the state of the board when servicing the board from

the rear of the chassis.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 27

Page 28

Module Components

Table 14. Board Status LED Descriptions

LED Function

Hot Swap

Out of Service

Health

Function: Hot Swap as defined in AdvancedTCA 3.0 Specification

It is also possible for a user to override the default behavior of the LED using

AdvancedTCA FRU LED Control commands.

Possible States: OFF / BLUE / SHORT BLINK / LONG BLINK

Blinking Blue: Preparing for removal/insertion. Long blink indicates activation is in

progress, short blink when deactivation is in progress

Function: Out of Service (AdvancedTCA LED 1).

RED: The board is out of service.

OFF: The board is running.

It is possible for a user to override the default IPMC behavior of the LED using

AdvancedTCA FRU LED Control commands.

Possible States: OFF / RED / AMBER

Function: Health (AdvancedTCA LED 2). The SBC health is based on an aggregation of

IPMI sensors, like board temperature and voltage.

Green: The SBC is healthy.

Red: The SBC is not healthy.

It is possible for the user to override the default IPMC behavior of the LED using

AdvancedTCA FRU LED Control commands.

Possible States: OFF / GREEN / RED / AMBER

4.3.13 RJ-45 Gigabit Ethernet Port LEDs

The RJ-45 connector for each of the Gigabit Ethernet ports on the RTM has two indicator LEDs

integrated in the connector body.

As shown in Figure 15, the top LED represents the LINK LED while the bottom LED represents

the SPEED LED.

Figure 15. RJ-45 Ethernet Port LEDs

28 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 29

Module Components

The LINK LED has the following indications and meanings:

• LED Off – Link not established

• Steady green – Link established but not active

• Flashing green – Link established and currently active

When the LINK LED is illuminated, the SPEED LED has the following indications and meanings:

• Steady green – 10/100 Mbps connection

• Steady amber – 1000 Mbps connection

Note: When the Fabric Interface Gigabit Ethernet links from the MPCBL0020 Single Board Computer

are routed to the switch slots, the Ethernet connections on the RTM are not active. However, the

Speed and Link LEDs on the connectors will still indicate the operational status of the Ethern et

ports.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 29

Page 30

RTM Management Architecture

RTM Management Architecture 5

5.1 Introduction

This section describes the management support for a non-intelligent Rear Transition Module

(RTM) such as the MPRTM0020. A non-intelligent RTM FRU does not have a controller on board

to communicate with the SBC IPMC. Instead, all of the non-intelligent RTM sensors and the nonintelligent RTM FRU storage device are connected directly to the SBC IPMC. This is usually done

via dummy I

non-intelligent RTM look like a separate intelligent FRU controller to the rest of the system.

The feature that is not supported for RTMs is E-keying, since there are no PICMG requirements

defined for non-intelligent RTMs.

5.2 RTM FRU Control

2

C sensor and storage devices. It is the responsibility of the SBC IPMC to make the

Since the non-intelligent RTM does not have a payload, the SBC IPMC only needs to implement

the Cold Reset version of the FRU control command. This command does not cause the IPMC to

reset. Instead the command causes all of the sensor and state information for the non-intelligent

RTM to be set back to startup values, simulating a controller reset.

5.3 M-state Machine

The SBC IPMC is responsible for implementing the M-State machine for the non-intelligent RTM.

From the perspective of the Shelf Manager the non-intelligent RTM looks like a separate managed

FRU device with its own M-state that is separate from that of the IPMC. In order to do this, the

IPMC sends M-State transition messages to the Shelf Manager, accepts activation/deactivation

requests from the Shelf Manager, and negotiates power budgeting as if it were a separate RTM

controller.

The non-intelligent RTM is not intended to be hot-swapped in or out of the system. For this reason

the handle switch on the non-intelligent RTM is combined with the handle switch on the SBC. If

either handle switch is opened, both the non-intelligent RTM and the SBC will take the appropriate

action for removal.

When the SBC is inserted into the system the non-intelligent RTM is initialized to M0 state. The

SBC IPMC then checks for the presence of the non-intelligent RTM. If the non-intelligent RTM is

present then the non-intelligent RTM M-State is set to M1. In the M1 state the SDR records in the

non-intelligent RTM FRU device are incorporated with the IPMC SDR records. The nonintelligent RTM then remains in M1 until the SBC IPMC reaches M4. At that point the nonintelligent RTM transitions to M2 and waits for activation from the Shelf Manager. Once the Shelf

Manager activates the non-intelligent RTM, the non-intelligent RTM transitions to M3 and waits

for its power budget to be granted. Once the power budget is granted the non-intelligent RTM

transitions to M4 and stays there until a deactivation is received from the Shelf Manager or a

handle switch is opened.

30 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 31

5.4 Power Budget Management

The SBC IPMC has inherent knowledge of the non-intelligent RTM power requirements. The

IPMC will handle power negotiation commands from the Shelf Manager that are targeted for the

non-intelligent RTM FRU ID. By doing this, the Shelf Manager should see the non-intelligent

RTM as a separate controller negotiating for a power budget.

5.5 LED Management

The SBC IPMC has direct control over the LEDs on the non-intelligent RTM. Control of these

LEDs is done through the IPMC system attention manager in the same way as other IPMCcontrolled LEDs. Special fault classes are added to system attention manager tables to handle the

failure and status state of the non-intelligent RTM. The non-intelligent RTM sensors and M-State

machine are the contributors to the failure and status state. When the non-intelligent RTM is

present, its failures will contribute to the overall failure state of the IPMC. Thus, the non-intelligent

RTM LEDs will match the SBC LEDs.

5.6 SDR Proxy

RTM Management Architecture

The SDR records for the non-intelligent RTM are stored in a proprietary format in the internal use

area of the non-intelligent RTM FRU storage device. When the non-intelligent RTM reaches M1

state the non-intelligent RTM SDR records are read out of the FRU device and stored in the IPMC.

The non-intelligent RTM SDR records are then merged with the IPMC SDR records and made

available through the Device SDR IPMI commands.

5.7 RTM Sensor Proxy

The non-intelligent RTM sensors are included in the sensor compliment programmed in the SBC

IPMC. The only difference is that the non-intelligent RTM sensors are turned on and off with

respect to the non-intelligent RTM M-State. When the non-intelligent RTM is in M4 state the

sensors are turned on and scanned by the IPMC. In any other M-state the sensors are not scanned

and will return a “sensor not found” completion code to sensor commands. When the nonintelligent RTM sensors are turned on the IPMC handles event generation and sensor access

commands for the non-intelligent RTM sensors just as it does for any other IPMC sensor.

Below is a list of the current non-intelligent RTM sensors:

• RTM +1.8V

• RTM +3.3V

• RTM +3.3V Standby

• RTM +5.0V

• RTM +5.0V Standby

• RTM +12V

• RTM Temp1

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 31

Page 32

RTM Management Architecture

• RTM Temp2

• RTM Temp3

• RTM Power Status

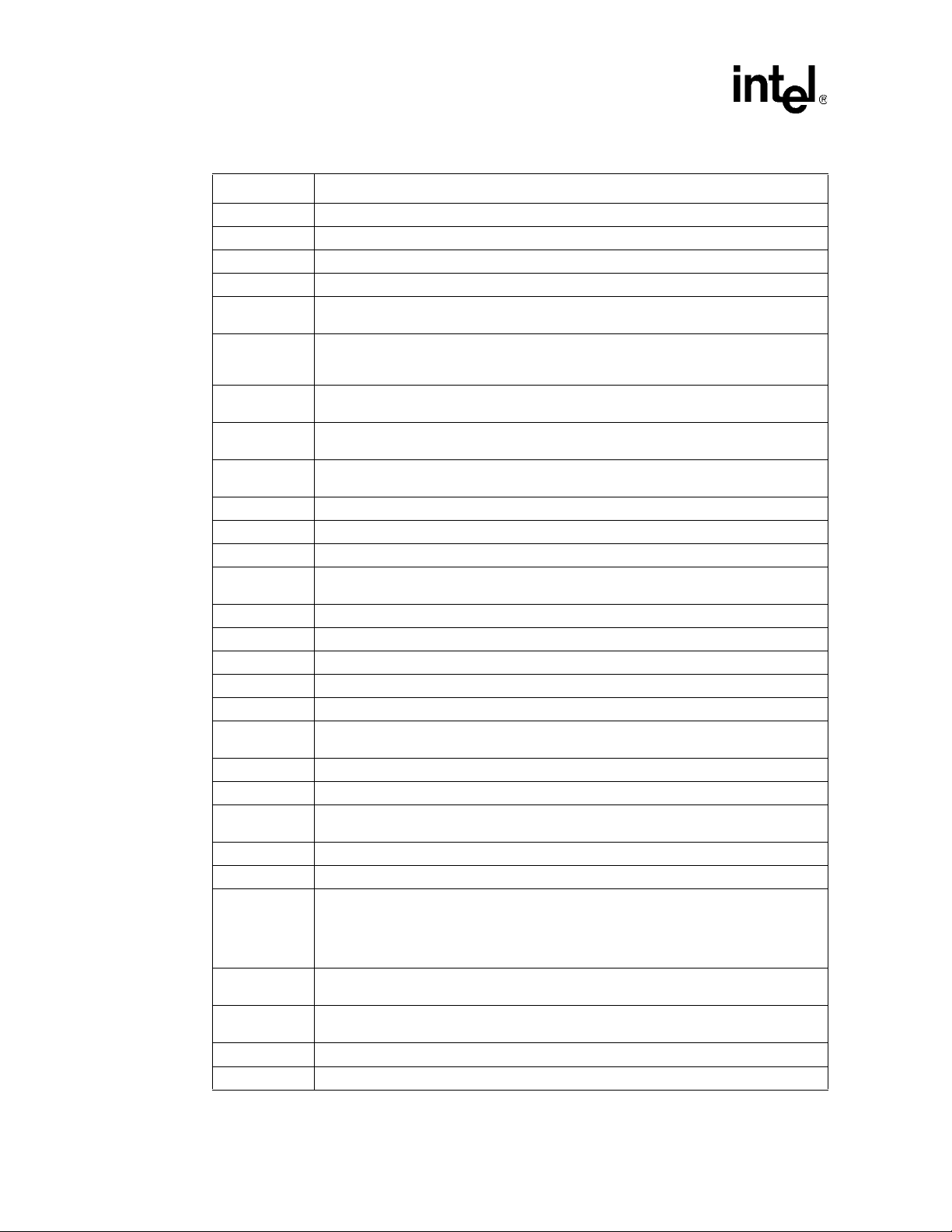

Table 15. Sensor Data Record for RTM

Sensor Name Description

RTM +1.8V For SAS Retimer 1.71 – – 1.89

RTM +3.3V For other Integrated Circuits 3.10 – – 3.47

RTM +3.3V SUS Early voltage for ADM1026 3.11 – – 3.46

RTM +5.0V For USB Interface 4.71 – – 5.23

RTM +5V SUS Early voltage for Hotswap LED 4.73 – – 5.25

RTM +12V Main voltage rail for other ICs/

peripherals

RTM Temp 1 Internal ADM1026 (U3)

[see Figure 16 for location]

RTM Temp 2 External Thermal Diode (Q3)

[see Figure 16 for location]

RTM Temp 3 External Thermal Diode (Q2)

[see Figure 16 for location]

Figure 16. RTM Temperature Sensor Locations

Lower

Critical

10.71 – – 13.10

-5 – 70 75

-5 – 70 75

-5 – 70 75

Lower Non

Critical

Upper Non

Critical

Upper

Critical

32 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 33

Detailed Specifications

Detailed Specifications 6

6.1 Dimensions and Weight

The weight of the baseboard is 1.14 kg (2.5 lbs.) with packaging materials.

6.2 Environmental Specification

The test methodology is a combination of Intel and NEBS test requirements with the intent that the

product will pass pure system-level NEBS testing. The following table summarizes environmental

limits, both operating and nonoperating.

Table 16. Environmental Specifications

Parameter Conditions Detailed Specification

Operating (Normal 5°C to 40°C

Temperature

(Ambient)

Humidity

Altitude

Unpackaged

Vibration

Shock

Operating (Short term) -5°C to 55°C

Storage -40°C to 70° C

Operating 15%-90% (non-condensing) at 55° C

Storage 5%-95% (non-condensing) at 40° C

Operating

Storage 15,000 m (49,200 ft.)

Operating

Storage

Operating 30 G/11 ms half sine

Storage 50 G, 170 inches/second trapezoidal

4,000 m (13,100 ft.)

Note: may require additional cooling above 1800 m (5,900 ft.)

Sine sweep:

• 5 to 100 Hz: 1G @ 0.25 Octave/minute

• 100 to 500 Hz: 1G @ 1 Octave/minute

Random profile:

2

• 5 Hz @ 0.01 g

• 20 Hz to 500 Hz @ 0.02 g

• 3.13 g RMS, 10 minutes per axis for all three axes

5 Hz to 50 Hz: 0.5 G @ 0.1 Octave/minute

50 Hz to 500 Hz: 3 G @ 0.25 Octave/minute.

/Hz to 20 Hz @ 0.02 g2 /Hz (slope up)

2

/Hz (flat)

6.3 Mechanical Specifications

6.3.1 Board Outline

The MPRTM0020 printed circuit board (PCB) is mechanically compliant with the PICMG 3.0

Specification dimensions of 322.25 mm x 70.00 mm. The board pitch is 6HP.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 33

Page 34

Detailed Specifications

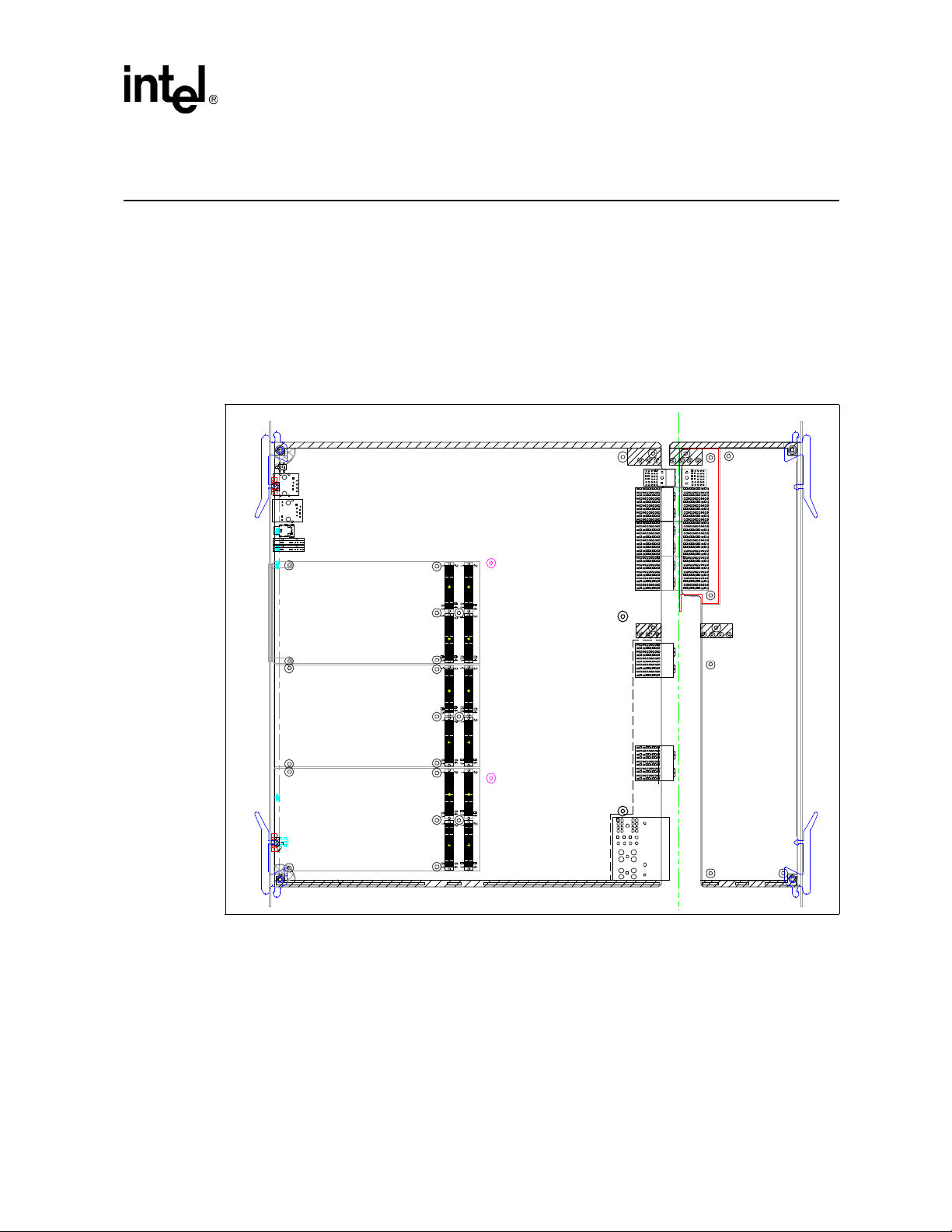

Figure 17 below shows the locations of major components of the MPRTM0020. Table 17 lists the

components shown in the illustration.

Figure 17. Component Layout

34 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 35

Detailed Specifications

Table 17. Board Components

Component/Function

A SAS Retimer

RMD/ENA jumper. Used to bypass the manageability by the MPCBL0020 SBC IPMC for debugging

B

purposes. Not intended to be use in any field deployment, because changing this default jumper affects

the RTM manageability from the ShMC.

C ADM1026

D Digital/Chassis Ground Jumper

6.4 Reliability Specifications

6.4.1 Mean Time Between Failure (MTBF) Specifications

Calculation Type: MTBF/FIT Rate

Standard: Telcordia* Standard SR-332 Issue 1

Methods: Method I, Case I, Quality Level II

The calculation results were generated using the references and assumptions listed. This report and

its associated calculations supersede all other released mean time between failures (MTBF) and

Failure in Time (FIT) calculations of earlier report dates. The reported failure rates do not represent

catastrophic failure. Catastrophic failure rates will vary based on application environment and

features critical to the intended function.

Table 18. Reliability Estimate Data

Failure Rate (FIT) 913 failures in 109 hours

MTBF 1,095,000 hours

6.4.1.1 Environmental Assumptions

•

Failure rates are based on a 40° C ambient temperature.

• Applied component stress levels are 50% (voltage, current, and/or power).

• Ground, fixed, controlled environment with an environmental adjustment factor equal to 1.0.

6.4.1.2 General Assumptions

• Component failure rates are constant.

• Board-to-system interconnects included within estimates.

• Non-electrical components (screws, mechanical latches, labels, covers, etc.) are not included

within estimations.

• Printed circuit board is considered to have a 0 FIT rate.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 35

Page 36

Detailed Specifications

6.4.1.3 General Notes

Method I, Case I = Based on parts count. Equipment failure is estimated by totaling device

•

failures rates and quantities used.

• Quality Level II = Devices purchased to specifications, qualified devices, vendor lot-to-lot

controls for AQLs and DPMs.

Where available, direct component supplier predictions or actual FIT rates have been u s ed.

6.5 Power Consumption

The maximum power consumption of the MPRTM0020 is 5 watts. The typical power consumption

is 4 watts (with SAS re-timer and USB consuming 2 watts each).

36 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 37

Warranty Information

Warranty Information 7

7.1 Intel NetStructure® Compute Boards and Platform Products Limited Warranty

Intel warrants to the original owner that the product delivered in this package will be free from

defects in material and workmanship for two (2) year(s) following the latter of: (i) the date of

purchase only if you register by returning the registration card as indicated thereon with proof of

purchase; or (ii) the date of manufacture; or (iii) th e r egistration date if by electronic means

provided such registration occurs within 30 days from purchase. This warranty does not cover the

product if it is damaged in the process of being installed. Intel recommends that you have the

company from whom you purchased this product install the product.

THE ABOVE WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, WHETHER

EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, ANY

WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, ANY

WARRANTY OF INFRINGEMENT OF ANY OTHER PARTY'S INTELLECTUAL PROPERTY

RIGHTS, OR ANY WARRANTY ARISING OUT OF ANY PROPOSAL, SPECIFICATION OR

SAMPLE.

This warranty does not cover replacement of products damaged by abuse, accident, misuse,

neglect, alteration, repair, disaster, improper installation or improper testing. If the product is found

to be otherwise defective, Intel, at its option, will replace or repair the product at no charge except

as set forth below, provided that you deliver the product along with a return material authorization

(RMA) number (see below) either to the company from whom you purchased it or to Intel. If you

ship the product, you must assume the risk of damage or loss in transit. You must use the original

container (or the equivalent) and pay the shipping charge. Intel may replace or repair the product

with either a new or reconditioned product, and the returned product becomes Intel's property. Intel

warrants the repaired or replaced product to be free from defects in material and workmanship for a

period of the greater of: (i) ninety (90) days from the return shipping date; or (ii) the period of time

remaining on the original two (2) year warranty.

This warranty gives you specific legal rights and you may have other rights which vary from state

to state. All parts or components contained in this product are covered by Intel's limited warranty

for this product. The product may contain fully tested, recycled parts, warranted as if new.

7.2 Returning a Defective Product (RMA)

Before returning any product, contact an Intel Customer Support Group to obtain either a Direct

Return Authorization (DRA) or Return Material Authorization (RMA). Return Material

Authorizations are only available for products purchased within 30 days.

7.2.1 For the Americas

Return contact information by geography:

Return Material Authorization (RMA) credit requests e-mail address: requests.rma@intel.com

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 37

Page 38

Warranty Information

Direct Return Authorization (DRA) repair requests e-mail address: uspss.repair@intel.com

DRA on-line form: http://support.intel.com/support/motherboards/draform.htm

Intel Business Link (IBL): http://www.intel.com/ibl

Telephone No.: 1-800-INTEL4U or 480-554-4904

Office Hours: Monday - Friday 0700-1700 MST Winter / PST Summer

7.2.2 For Europe, Middle East, and Africa (EMEA)

Return Material Authorization (RMA) e-mail address EMEA.Returns@Intel.com

Direct Return Authorization (DRA) for repair requests e-mail address: EMEA.Returns@Intel.com

Intel Business Link (IBL): http://www.intel.com/ibl

Telephone No.: 00 44 1793 403063

Fax No.: 00 44 1793 403109

Office Hours: Monday - Friday 0900-1700 UK time

7.2.3 For Asia and Pacific (APAC)

RMA/DRA requests e-mail address: apac.rma.front-end@intel.com

T elephone No.: 604-859-3111 or 604-859-3325

Fax No.: 604-859-3324

Office Hours: Monday - Friday 0800-1700 Malaysia time

Return Material Authorization (RMA) requests e-mail address: rma.center.jpss@intel.com

T elephone No.: 81-298-47-0993 or 81-298-47-5417

Fax No.: 81-298-47-4264

Direct Return Authorization (DRA) for repair requests, contact the JPSS Repair center.

E-mail address: sugiyamakx@intel.co.jp

T elephone No.: 81-298-47-8920

Fax No.: 81-298-47-5468

Office Hours: Monday - Friday 0830-1730 Japan time

If the Customer Support Group verifies that the product is defective, they will have the Direct

Return Authorization/Return Material Authorization Department issue you a DRA/RMA number

to place on the outer package of the product. Intel cannot accept any product without a DRA/RMA

number on the package.

38 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 39

7.2.4 Limitation of Liability and Remedies

INTEL SHALL HAVE NO LIABILITY FOR ANY INDIRECT OR SPECULATIVE DAMAGES

(INCLUDING, WITHOUT LIMITING THE FOREGOING, CONSEQUENTIAL, INCIDENTAL

AND SPECIAL DAMAGES) ARISING FROM THE USE OF OR INABILITY TO USE THIS

PRODUCT, WHETHER ARISING OUT OF CONTRACT, NEGLIGENCE, TORT, OR UNDER

ANY WARRANTY, OR FOR INFRINGEMENT OF ANY OTHER PARTY'S INTELLECTUAL

PROPERTY RIGHTS, IRRESPECTIVE OF WHETHER INTEL HAS ADVANCE NOTICE OF

THE POSSIBILITY OF ANY SUCH DAMAGES, INCLUDING , BUT NOT LIMITED T O LOSS

OF USE, BUSINESS INTERRUPTIONS, AND LOSS OF PROFITS. NOTWITHSTANDING

THE FOREGOING, INTEL'S TOTAL LIABILITY FOR ALL CLAIMS UNDER THIS

AGREEMENT SHALL NOT EXCEED THE PRICE PAID FOR THE PRODUCT. THESE

LIMITATIONS ON POTENTIAL LIABILITIES WERE AN ESSENTIAL ELEMENT IN

SETTING THE PRODUCT PRICE. INTEL NEITHER ASSUMES NOR AUTHORIZES

ANYONE TO ASSUME FOR IT ANY OTHER LIABILITIES.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitations or exclusions may not apply to you.

Warranty Information

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 39

Page 40

Customer Support

Customer Support 8

8.1 Customer Support

This chapter offers technical and sales assistance information for this product.

8.2 Technical Support and Return for Service Assistance

For all product returns and support issues, please contact your Intel product distributor or Intel

Sales Representative for specific information.

8.3 Sales Assistance

If you have a sales question, please contact your local Intel NetStructure Sales Representative or

the Regional Sales Office for your area. Address, telephone and fax numbers, and additional

information is available at Intel’s web site located at:

http://www.intel.com/network/csp/sales/

Intel Corporation

T elephone (in U.S.) 1-800-755-4444

Tele phone (Outside U.S.) 1-973-993-3030

FAX 1-973-967-8780

8.4 Product Code Summary

Table 19 lists the MPRTM0020 product code:

Table 19. Product Codes

Product Code MM# Description

MPRTM0020S01Q 882004 MPRTM0020 Rear Transition Module

40 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 41

Certifications

Certifications 9

Safety:

• IEC60950-1

• EN60950

• UL/CSA 60950-1

Hazardous substances:

• The Intel NetStructure

European Directive 2002/95/EC, officially titled “The Restriction on the Use of Hazardous

Substances (RoHS) in Electrical and Electronic Equipment” or RoHS. Specifically, this

product uses only RoHS compliant parts and Pb-free solder and may take advantage of certain

exemptions referenced within the Directive.

Electromagnetic Compatibility (EMC) emissions:

• CISPR22/EN55022 Class A

• EN300386

• FCC Rules CFR 47 Part 15B Class A

®

MPRTM0020S00Q has been verified to be compliant with the

• ICES-003 Class A

Electromagnetic Compatibility (EMC) immunity:

• CISPR24/EN55024

• EN300386

Network Equipment Building System (NEBS) compliance:

• The MPCBL0020 SBC meets the board-level specifications as specified in the Intel

Environmental Standar ds Handbook – Telco Specification Document No. A78805-01. The test

methodology is a combination of Intel and NEBS test requirements with the intent that the

product will pass pure system-level NEBS testing. Intel has performed limited NEBs testing.

Among these are GR-1089-CORE: ESD, radiated emissions (E- and H-field), conducted

emissions, radiated immunity, and conducted immunity.

Telecom Comp liance of T1/E1 Ports:

• The T1/E1 ports of the MPRTM0020 have not been tested for compliance against any

telecommunications standards. It is the responsibility of the final integrator to obtain telecom

attachment approvals for their combination of PMC and RTM T1/E1 configuration.

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 41

Page 42

Agency Information

Agency Information 10

10.1 North America (FCC Class A)

Federal Communications Commission (FCC) Part 15 Rules

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his own expense.

10.2 Canada – Industry Canada (ICES-003 Class A)

Industry Canada ICES-003 Issue 3

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matérial

brouilleur du Canada.

10.3 European Union

The products covered by this notice meet the following European Directives:

• 73/23/EECLow Voltage Directive

• 89/336/EECEMC Directive

To achieve CE compliance, be sure to select a host that already meets the EMC and Low Voltage

Directives before the addition of any optional board. Remember that the use of option boards

declared compliant with the Directives by their manufacturer only gives “presumption of

compliance” for the whole system. It is the responsibility of the system supplier to verify that the

requirements of the listed Directives are still met by the final system, as supplied to the end-user.

System integrators should take notice of further conditions expressed in the sections below and the

Safety Information sheet supplied with each board.

Warning: This is a class A product. In a domestic environment this product may cause radio int erference in

which case the user may be required to take adequate measures.

42 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Page 43

Agency Information

Compliance with the R&TTE Directive

The R&TTE Directive includes its own safety and EMC requirements. Although equipment

declared compliant to the R&TTE Directive does not require explicit declaration of conformity to

EMC and Low Voltage Directives, above conditions must also be met to satisfy the safety and

EMC requirements of the R&TTE Directive.

Intel Declarations of Conformity for the products covered by this notice can be found under the

“Network Building Blocks” heading at http://developer.intel.com/design/litcentr/ce_docs.

Manufacturer's office in European Union:

Intel Corporation (UK) Ltd.

Pipers Way

Swindon, Wiltshire SN3 1RJ

UK

Tel: +44 (0)1793 403000

Fax: +44 (0)1793 641440

Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006 43

Page 44

Safety Warnings

Safety Warnings 11

11.1 Safety Precautions

Review the following precautions to avoid personal injury and prevent damage to this product or

products to which it is connected. To avoid potential hazards, use the product only as specified.

Read all safety information and understand the precautions associated with safety symbols, written

warnings, and cautions before accessing parts or locations within the unit.

System for Restricted Access Use Only!

Warning: To avoid the risk of electrical shock hazard, special measures and precautions must be taken when

using these products:

— Access to this equipment must be restricted by locating this equipment where access can

only be gained by SERVICE PERSONNEL who have been informed about the reasons

for the restrictions applied to the location and about any precautions that shall be taken.

Access is through the use of a TOOL, lock and key, or ot her means of security and is

controlled by the authority responsible for the location.

— This product should only be used by SERVICE PERSONNEL who have the knowledge

and training required to work with products of this type.

— To avoid shock, ensure that the chassis power cables are connected to a properly wired

and grounded receptacle.

— The system containing these boards should not be operated with the faceplates, blank

panels, or covers removed. Some voltages, that are on the board and inside the chassis,

present an electrical shock and/or energy hazard to the user . Keep hands out of the chassis

when power is applied or when performing hot swap of the boards.

44 Intel NetStructure® MPRTM0020 Technical Product Specification – April 2006

Loading...

Loading...