Page 1

Intel NetStructure® MPCMM0002 Chassis Management Module

Hardware Technical Product Specification

July 2007

Order Number: 309247-004US

Page 2

Legal Lines and Disclaimers

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR

OTHERWISE, TO ANY IN TELLEC TUA L PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN INTEL ’S TERMS AND CONDITIONS

OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER, AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING

TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE,

MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for

use in medical, life saving, life sustaining, critical control or safety systems, or in nuclear facility applications.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not rely on the absence or characteristics

of any features or instructions marked “reserv ed” or “undefined.” Intel reserves these for fut ure definition and shall ha ve no responsibility whatsoever for

conflicts or incompatibilities arising from future changes to them. The information here is subject to change without notice. Do not finalize a design with

this information.

The products described in this document may contain design defects or errors known as errata which may cause the product to deviate from published

specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained by calling 1-800-548-

4725, or by visiting Intel’s Web Site.

Intel processor numbers are not a measure of performance. Processor numbers differentiate features within each processor family, not across different

processor families. See http://www.intel.com/products/processor_number for details.

BunnyPeople, Celeron, Celeron Inside, Centrino, Centrino logo, Core Inside, FlashFile, i960, InstantIP, Intel, Intel logo, Intel386, Intel486, Inte l7 40 ,

IntelDX2, IntelDX4, IntelSX2, Intel Core, Intel Inside, Intel Inside logo, Intel. Leap ahead., Intel. Leap ahead. logo, Intel NetBurst, Intel NetMerge, In tel

NetStructure, Intel SingleDriver, Intel SpeedStep, Intel StrataFlash, Intel Viiv, Intel vPro, Intel XScale, Itanium, Itanium Inside, MCS, MMX, Oplus,

OverDrive, PDCharm, Pentium, Pentium Inside, skoool, Sound Mark, The Journey Inside, VTune, Xeon, and Xeon Inside are trademarks of Intel

Corporation in the U.S. and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2007, Intel Corporation. All rights reserved.

Intel NetStructure® MPCMM0002 Chassis Management Module

Hardware TPS July 2007

2 Order Number: 309247-004US

Page 3

Contents—MPCMM0002 CMM

Contents

1.0 Document Organization.............................................................................................8

1.1 Acronyms and Terms.............................. .................................. .........................10

2.0 Introduction............................................................................................................11

2.1 Architecture Specification...................................................................................11

2.2 User Documentation..........................................................................................11

2.3 Product Definition..............................................................................................11

3.0 Getting Started........................................................................................................ 13

3.1 Installing the CMM.............................................................................................13

4.0 Module Components ................................................................................................15

4.1 Block Diagram ..................................................................................................15

4.2 Intel® 80321 Processor ................................ ..................................................... 17

4.3 Memory ...........................................................................................................19

4.4 Ethernet ..........................................................................................................19

4.5 Serial Port UARTs............................... .................................. .. ...........................19

4.6 FPGA...............................................................................................................20

4.7 Redundancy and Hot Swap CPLD.........................................................................20

4.8 Watchdog Timer................................................................................................20

4.9 Real-Time Clock......................... .. ................................. .................................. ..20

4.10 ADM1026 Controller ..........................................................................................21

4.11 Hot Swap Controller...........................................................................................21

4.12 Ride-Through Support................................. ... .. ................................. ... .. .. ..........21

4.13 IPMB Isolation Logic ..........................................................................................21

5.0 Mechanical Information...........................................................................................24

5.1 Dimensions ...................................................................................................... 24

5.2 Front Panel Hardware ...................................... .. .. ..............................................26

5.3 Rear Connector Placement..................................................................................27

5.4 ESD Discharge Strip ..........................................................................................27

6.0 Backplane Considerations........................................................................................28

6.1 IPMB Routing....................................................................................................28

6.2 CMM Power ...................................................................................................... 28

7.0 Rear Connections ....................................................................................................32

7.1 CMM Connector Pinouts......................................................................................32

7.2 Guide Post........................................................................................................41

7.3 CMM Redundancy..............................................................................................41

8.0 Chassis Data Modules (CDMs)..................................................................................43

8.1 CDM Overview..................................................................................................43

8.2 CDM LED..........................................................................................................43

8.3 CDM Management.............................................................................................43

8.4 CDM Power.......................................................................................................44

8.5 CDM Redundancy..............................................................................................44

9.0 Front Panel.............................................................................................................. 45

9.1 Serial Port Pinouts.......................................................................... .. ... .. ............45

9.2 Ethernet Port Pinouts....................................... .. .................................. .. ............47

9.3 Telco Alarm Connector.......................................................................................48

9.4 Alarm Quiet Switch............................................................................................51

9.5 LEDs................................................................................................................52

10.0 Grounding Considerations .......................................................................................54

July 2007 Hardware TPS

Order Number: 309247-004US 3

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 4

MPCMM0002 CMM—Contents

10.1 ESD Discharge Protection....................................................................................54

10.2 Chassis Ground and Logic Ground.............................. .. .................................... .. ..54

11.0 Thermals..................................................................................................................55

11.1 Processor Heat Sink...........................................................................................55

11.2 Module Orientation.............................................................................................55

11.3 Module Airflow Path ...........................................................................................55

11.4 Airflow Requirements .........................................................................................57

11.5 Board Resistance Curve.............................................. .. .................................. .. ..57

11.6 Thermal Sensors................ .. .................................................................. ............58

12.0 Management Module Specifications..........................................................................59

12.1 Feature Summary..............................................................................................59

12.2 Dimensions and Weight......................................................................................60

12.3 Environmental Characteristics .............................................................................60

12.4 Product Reliability Estimate.................................................................................60

12.5 Agency Certifications..........................................................................................61

13.0 Guidelines for Third Party Chassis Vendors..............................................................62

13.1 High Level Design..............................................................................................62

13.2 IPMB Buses.......................................................................................................63

13.3 GPIO Pins.........................................................................................................66

13.4 Interfacing FRUs to the CMM...............................................................................67

13.5 Intelligent FRUs.................................................................................................68

13.6 Non-Intelligent FRUs with I2C* Support................................................................68

13.7 Non-Intelligent FRUs without I2C Support........................................ .. ...................69

13.8 FRU Data Storage for Non-Intelligent Devices........................................................69

13.9 Controllers and I/O Ports for Non-Intelligent Devices..............................................70

13.10 Temperature Sensors Fronted by the CMM........................................... .. ... ............70

13.11 Related Documents............................... .. ...........................................................70

14.0 Warranty Information..............................................................................................71

®

14.1 Intel NetStructure

Compute Boards & Platform Products Limited Warranty ... ...........71

14.2 Returning a Defective Product (RMA)....................................................................71

14.3 For the Americas .............................. .. .. .................................. .. .. .......................72

15.0 Customer Support....................................................................................................74

15.1 Customer Support..............................................................................................74

15.2 Technical Support and Return for Service Assistance ..............................................74

15.3 Sales Assistance................................................................................................74

15.4 Product Code Summary......................................................................................74

16.0 Certifications ...........................................................................................................75

16.1 Material Declaration Data Sheet...........................................................................75

17.0 Agency Information .................................................................................................77

17.1 North America (FCC Class A)...............................................................................77

17.2 Canada – Industry Canada (ICES-003 Class A) (English and French-translated below) 77

17.3 Safety Instructions (English and French-translated below).......................................78

17.4 Taiwan Class A Warning Statement......................................................................78

17.5 Japan VCCI Class A............................................................................................79

17.6 Korean Class A..................................................................................................79

17.7 Australia, New Zealand.......................................................................................79

18.0 Safety Warnings ......................................................................................................80

18.1 Mesures de Sécurité...........................................................................................81

18.2 Sicherheitshinweise............................................................................................83

18.3 Norme di Sicurezza............................................................................................85

®

Intel NetStructure

Hardware TPS July 2007

4 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 5

Contents—MPCMM0002 CMM

18.4 Instrucciones de Seguridad.................................................................................87

18.5 Chinese Safety Warning ............................................................................... .. .. ..89

Figures

1 Top View of the Intel NetStructure® MPCMM0002 CMM ......................... ........................ 13

2 CMM Block Diagram .................................................................................................15

3 CMM Top View Layout........................................ ... ................................. ...................16

4 Intel® 80321 Processor Internal Block Diagram ..... ......................................................17

5 IPMB Dual Star Isolation ...................... .....................................................................22

6 Dual Bus IPMB Isolation............................................................................................23

7 CMM Component Side 1 Dimensions ...........................................................................24

8 CMM Backing Plate Dimensions..................................................................................25

9 CMM Side View Dimensions.......................................................................................26

10 CMM ESD Strip Electrical Definition.............................................................................27

11 Power System Block Diagram ....................................................................................29

12 CDM Power Input.....................................................................................................30

13 Ethernet Port Poaching .............................................................................................31

14 CMM Power Connector..............................................................................................32

15 CMM Data Connector................................................................................................ 36

16 Cross-Connected CMM Signals ................................................................................... 41

17 Guide Post to Backplane . .. ................................. ... ................................. .. ... ..............41

18 Chassis Data Module I2C Routing...............................................................................43

19 CMM Front Panel......................................................................................................45

20 Serial Port RJ-45 Connector....................................................................................... 46

21 Serial Port RJ-45 Cabling........................................................................................... 46

22 Ethernet Port RJ-45 Connector Front View...................................................................47

23 DB-15 Telco Alarm Connector.................................................................................... 48

24 Telco Alarm Contact Wiring for Dual Connectors........................................................... 49

25 Failure Scenario with Dual Telco Alarm Connectors .......................................................50

26 Parallel Inputs to Telco Alarm Connectors.................................................................... 50

27 Cascaded Telco Alarm Cables.....................................................................................51

28 CMM Front Panel with Labels .....................................................................................52

29 CMM Heat Sink........................................................................................................55

30 Side-to-Side Air Flow................................................................................................ 56

31 Front-to-Back Air Flow..............................................................................................57

32 High Level CMM Design.............................................................................................62

33 I/O Signals of the CMM.............................................................................................63

34 Radial Bus Topology ............................................. ................................. .. .................65

35 Shared Bus Topology................................................................................................66

36 FRU That Uses the ADM1026 ..................................................................................... 69

Tables

1 Acronyms and Terms................................................................................................10

2 Processor Features........................................ .................................. .. .......................17

3 FPGA Features.........................................................................................................20

4 Voltage Usage .........................................................................................................29

5 Chassis Elements Directly Driven by CMM Hardware ........................................... .. .. .. .. ..31

6 Power Connector Pinouts...........................................................................................33

7 Power Connector Pinouts Matrix.................................................................................34

8 Pin Staging .............................................................................................................34

9 Power Connector Receptacle Pin Placement .................................................................34

10 Power Connector Header Pin Placement ...................................................................... 35

11 Data Connector Pinouts ........................... .. .................................... ...........................37

12 Data Connector Pinouts Matrix................................................................................... 38

13 Pin Staging ............................................................................................................. 40

July 2007 Hardware TPS

Order Number: 309247-004US 5

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 6

MPCMM0002 CMM—Contents

14 CDM Health LED States.............................................................................................43

15 RTM Serial Port Pinout...............................................................................................46

16 Ethernet Port Pinouts............................... .. .. .................................. .. .........................47

17 Ethernet Port LED States.......................... .................................. ...............................48

18 Telco Alarm Pinout....................................................................................................49

19 Ganged Telco Alarm Cable Pinouts with Cabling............................................................51

20 CDM Health LED States.............................................................................................52

21 CMM Health LED States.............................................................................................53

22 CMM Hot Swap LED States.........................................................................................53

23 Typical Airflow and Cooling Requirements......................................... .. .. .......................57

24 Airflow Guidelines.............................. .. ................................. .. ..................................58

25 Dimensions and Weight.............................................................................................60

26 Environmental Characteristics ....................................................................................60

27 Reliability Estimate Data............................................................................................61

28 Physical Bus Number Mapping....................................................................................64

29 Related Documents...................................................................................................70

30 MPCMM0002 Product Code Summary ..........................................................................74

®

Intel NetStructure

Hardware TPS July 2007

6 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 7

Revision History—MPCMM0002 CMM

Revision History

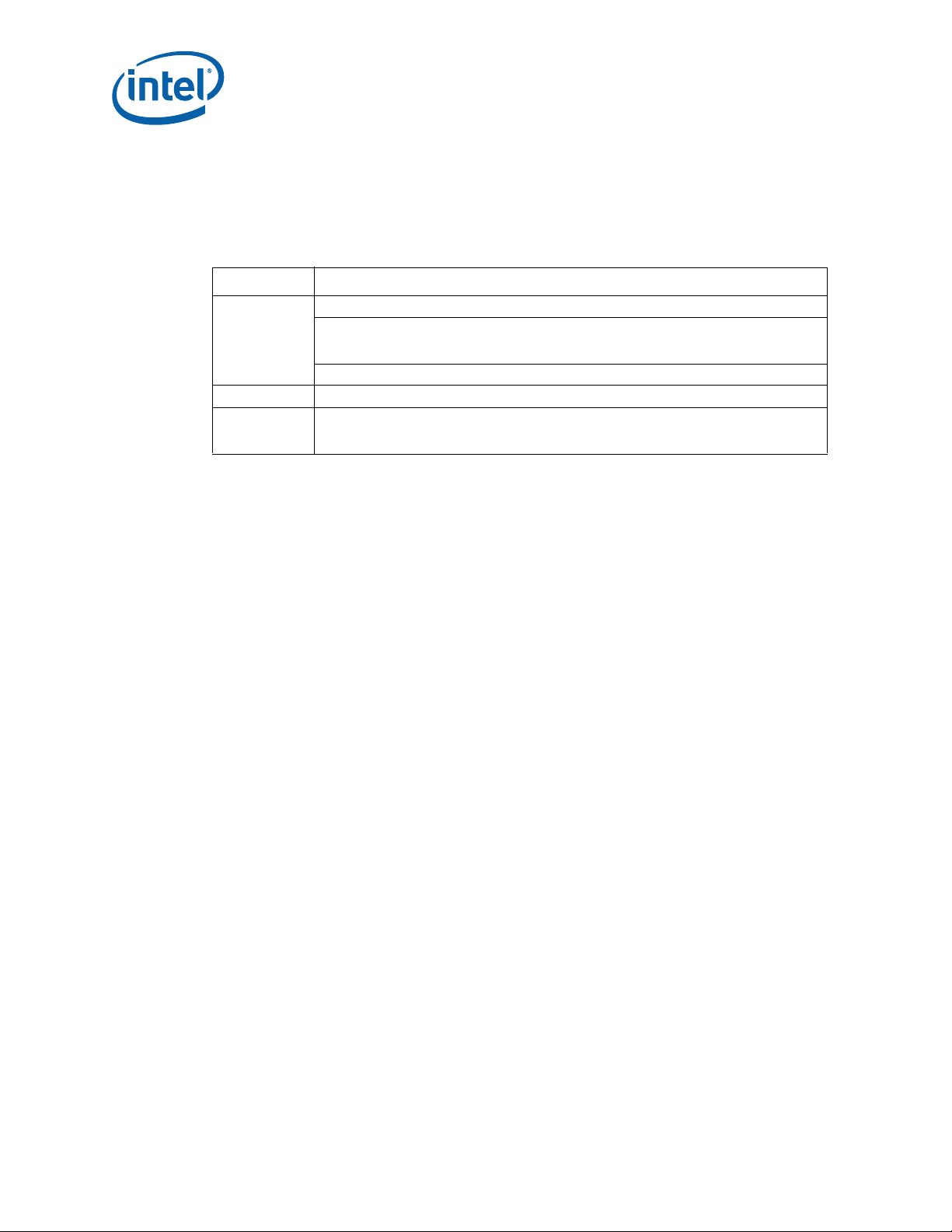

Date Revision Description

July 2007 004 CMM drawings updated

July 2007 003 Failure Rate and MTBF values updated.

May 2007 002

April 2006 001 Initial release of this document.

Quick Start section updated with new CMM remo val procedure.

CMM dimension drawings updated.

July 2007 Hardware TPS

Order Number: 309247-004US 7

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 8

1.0 Document Organization

This document describes the operation and use of the Intel NetStructure® MPCMM0002

CMM.

The following topics are covered in this document.

Chapter 2.0, “Introduction” introduces the key features of the MPCMM0002 CMM. This

chapter includes a product definition and a list of product features.

Chapter 3.0, “Getting Started” provides installation and setup information for the

MPCMM0002 CMM. This chapter should be read before using the management module.

Chapter 4.0, “Module Components” describes the major components of the CMM and

how the components are interconnected.

MPCMM0002 CMM—Document Organization

Chapter 5.0, “Mechanical Information” provides information on the critical dimensions

of the CMM.

Chapter 6.0, “Backplane Considerations” identifies the IPMB routing requirements,

power distribution options, and Ethernet routing information for chassis designers to

build the MPCMM0002 CMM into their shelves.

Chapter 7.0, “Rear Connections” details the pinouts for the two connectors that

interface with a backplane or coplanar mating board.

Chapter 8.0, “Chassis Data Modules (CDMs)” provides information on how the CMM

accesses the Chassis Data Module (shelf FRU repository).

Chapter 9.0, “Front Panel” details the cable connections and LEDs on the CMM’s front

panel

Chapter 10.0, “Grounding Considerations” provides information on grounding jumpers

and ESD discharge features.

Chapter 11.0, “Thermals” provides information on the cooling requirements for the

CMM.

Chapter 12.0, “Management Module Specifications” contains the electrical,

environmental, and mechanical specifications for the CMM.

Chapter 13.0, “Guidelines for Third Party Chassis Vendors” provides a high-level design

of the MPCMM0002 CMM to help third party chassis vendors incorporate it into their

chassis.

Chapter 14.0, “Warranty Information” defines the warranty for the MPCMM0002 CMM.

Chapter 15.0, “Customer Support” provides information on reaching Intel customer

support.

Chapter 16.0, “Certifications” lists the various applicable product certifications of the

CMM.

®

Intel NetStructure

Hardware TPS July 2007

8 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 9

Document Organization—MPCMM0002 CMM

Chapter 17.0, “Agency Information” contains notices from various certifying agencies.

Chapter 18.0, “Safety Warnings” lists important safety warnings in various languages.

1.1 Acronyms and Terms

The following special acronyms and terms are used in this specification:

Table 1. Acronyms and Terms

Acronym/Term Meaning

Board Front Board as defined in PICMG 3.0 specification

CDM Chassis Data Module

CFM Cubic Feet per Minute

Chassis Physical structure containing boards, backplane, PEMs, etc,; same as shelf

CMM Chassis Management Module

COM

Component Side 1 Primary side of PCB, used for synergy with PICMG 3.0 terminology

Component Side 2 Secondary side of PCB

EMI Electromagnetic Interferen ce

ESD Electrostatic Discharge

ETSI European Telecommunications Standards Institute

Frame Structure in which chassis is mounted; could be enclosed or open; same as rack

FRU Field Replaceable Unit

2

I

C Inter-Integrated Circuit Bus

IPMB Intelligent Platform Management Bus

IPMI Intelligent Platform Management Interface

LED Light Emitting Diode

LFM Linear Feet per Minute

MLBF

NC No Connect [exception: in Section 9.3, refers to Normally Closed relay contacts]

NEBS Network Equipment Building Standards

NO Normally Open [for relay contacts in Section 9.3]

PCB Printed Circuit Board

PEM Power Entry Modules

PICMG

Rack Structure in which chassis is mounted; could be enclosed or open; same as frame

RTM Rea r Transition Module

SCap Super Capacitor

SEL System Event Log

Shelf See Chassis

ShMC Shelf Management Controller

SSI Server System Infrastructure

Common connection [used with relay contacts in Section 9.3, “Telco Alarm

Connector” on page 48.

Mate Last, Break First. Refers to the shortest pin. Used to enable a Hot Swap

controller to cut or connect power to a board.

PCI Industrial Computers Manufacturers Group, sponsor of AdvancedTCA

specification

July 2007 Hardware TPS

Order Number: 309247-004US 9

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 10

Introduction—MPCMM0002 CMM

2.0 Introduction

This chapter provides an overview of the Intel NetStructure® MPCMM0002 CMM (CMM).

It includes a product definition and summaries of the module’s hardware features.

The CMM’s software features are detailed in the Intel NetStructure® MPCMM0001

Chassis Management Module and Intel NetStructure

Management Module Software Technical Product Specification for version 6.1. That

document also describes how to configure the firmware to work in a third-party

chassis.

2.1 Architecture Specification

The MPCMM0002 CMM is designed to be compatible with AdvancedTCA* products,

which are based on the PICMG* 3.0 specification. A short form of the PICMG 3.0

specification and other AdvancedTCA information can be found on PICMG’s

AdvancedTCA web site at:

http://www.advancedtca.org/

2.2 User Documentation

The Intel NetStructure® MPCMM0002 CMM is part of the Intel NetStructure family of

products. The latest Intel NetStructure product information and documentation are

available at:

http://www.intel.com/design/network/products/cbp/index.htm

Documents that are not available on Internet web sites may be obtained from your

Intel Business Link (IBL) account, or contact your Intel Field Sales Engineer (FSE) or

Field Application Engineer (FAE) to obtain access.

Refer to the following documentation for more information about the components that

may be in your system.

• Intel NetStructure

NetStructure

version 6 .1.

• Intel NetStructure® MPCBL0001 High-Performance Single Board Computer

Technical Product Specification

®

®

MPCMM0001 Chassis Management Module and Intel

MPCMM0002 CMM Software Technical Product Specification for

®

MPCMM0002 Chassis

2.3 Product Definition

The MPCMM0002 CMM is one of several telecom building blocks from Intel, providing

OEM equipment designers with carrier-grade, standards-based, high-availability

solutions built on the PICMG* 3.x series of specifications. This management module is

designed to be used in certain third-party shelves.

July 2007 Hardware TPS

Order Number: 309247-004US 11

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 11

MPCMM0002 CMM—Introduction

Key carrier-grade features of the MPCMM0002 CMM include the following:

• Full Shelf Management Controller and Shelf Manager capability as defined in the

PICMG 3.0 specification .

• Support for up to 16 board slots in an AdvancedTCA* chassis.

• Hybrid dual IPMB star topology support for improved reliability, security, and

throughput.

• Compact 4U x 280 mm x 3HP size to simplify integration into shelves.

• Comprehensive management interfaces including CLI, SNMP, RPC, and RMCP.

• Dual 10/100 Mbps Ethernet controllers with support for individually routing

connections via software to the front panel, optional rear transition modules

(RTMs), or PICMG 3.0 backplane.

• Dual serial ports (one out front; one out the RTM) for local console support.

• Isolated telecom alarm connections front or rear to connect to standard telecom

alarm systems.

• Direct –48 VDC inputs with on-board power regulation for maximum uptime.

• Low power design, using less than 30 W.

• High-temperature design to survive 70° C incoming (pre-heated) air to CMM for

NEBS-style temperature excursions with the proper airflow.

• Dedicated communication paths between dual CMMs for active-standby operation.

• Support for chassis data modules (FRU modules), fan trays, PEMs, and external

temperature sensors.

• Integrated backing plate to help meet the full range of standard NEBS and ETSI

tests including earthquake, fire, immunity, and safety.

®

80321 processor with Intel® XScale® technology , 128 MByte RAM, and 64 MByte

Intel

flash memory to provide headroom for future expansion and space for custom user

applications on board.

®

Intel NetStructure

Hardware TPS July 2007

12 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 12

Getting Started—MPCMM0002 CMM

3.0 Getting Started

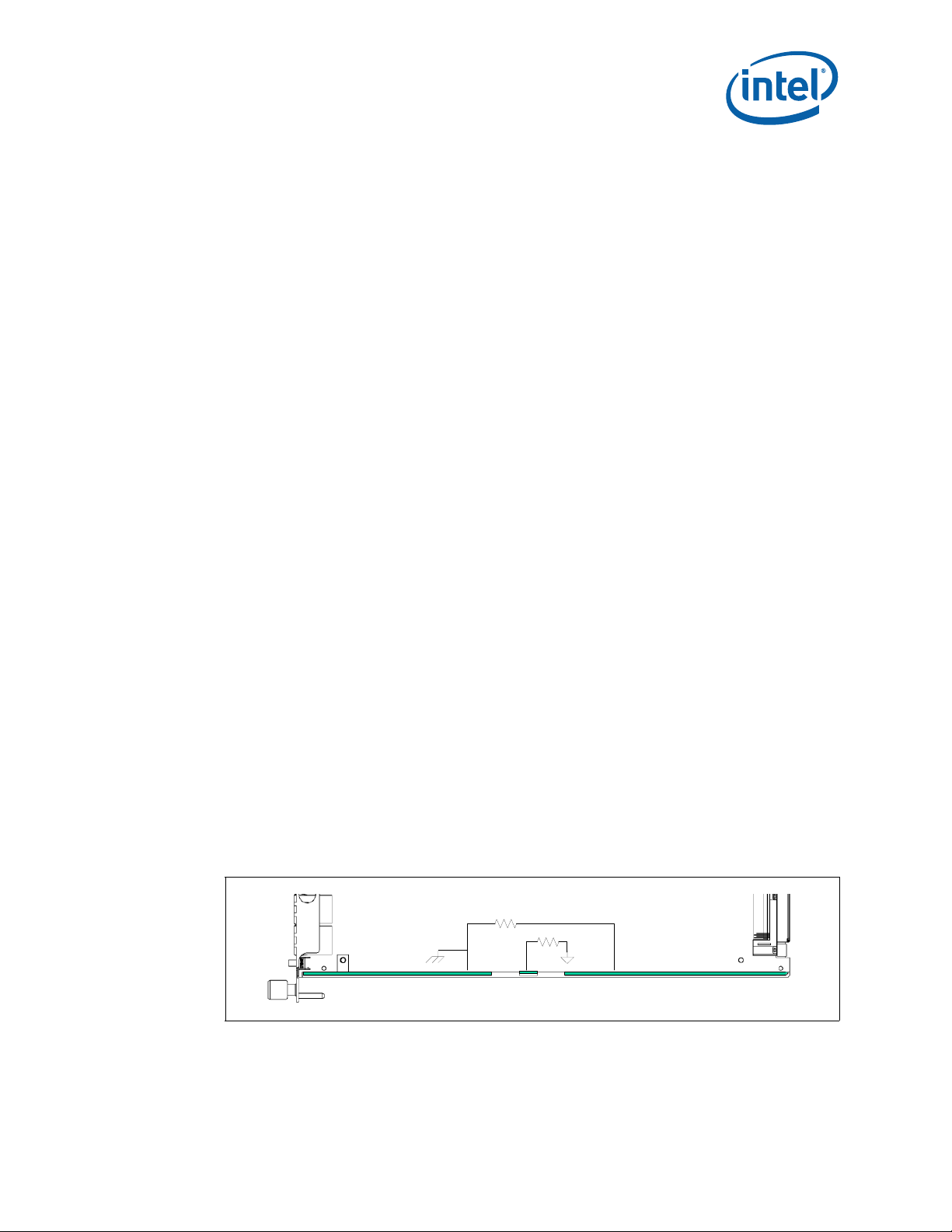

3.1 Installing the CMM

The Intel NetStructure® MPCMM0002 CMM is designed to fit in a variety of compatible

chassis and orientations. This chapter provides some useful information for installing

the management module in a chassis (shelf), but you will also need to read the thirdparty documentation provided by the chassis manufacturer or system vendor for your

chassis before you install the module.

In addition to the information provided in the third-party documentation just

mentioned, you should also read and follow the precautions below:

Caution: As noted in the PICMG* 3.0 specification, AdvancedTCA* products (including the

MPCMM0002 CMM) are designed to be installed and serviced by trained service

personnel only, not equipment operators. The primary reason for this is the high

voltage level (over 60 VDC) that can be present in AdvancedTCA systems.

Caution: Many components in the system contain sensitive electronic components. Service

personnel should follow proper grounding procedures when installing or servicing this

equipment.

Figure 1. Top View of the Intel NetStructure

®

MPCMM0002 CMM

July 2007 Hardware TPS

Order Number: 309247-004US 13

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 13

3.1.1 Quick Start

MPCMM0002 CMM—Getting Started

1. Open the packing material, find the packing list, and ensure that all the necessary

components are present for the Intel NetStructure

®

MPCMM0002 CMM.

2. Take the MPCMM0002 CMM to the chassis in which it will be installed.

3. Following standard ESD protection procedures, remove the CMM from its anti-static

bag.

4. Insert the management module into the card guides for the dedicated CMM slot.

Follow the chassis manufacturer’s or system vendor’s directions for the proper

orientation of the CMM.

5. As the CMM is being pushed into the slot, keep the ejector handle open until it

engages with the card guide. Ensure the alignment pins on the faceplate engage

the receptacles on the card cage. When the ejector handle engages, rotate the

ejector handle toward the faceplate until the card is fully seated.

6. Use a screwdriver or pair of pliers to tighten the retention screws on both ends of

the faceplate.

7. If the chassis power is on, the CMM will turn on automatically.

8. Connect the appropriate cables to the front or rear serial port, LAN ports. Connect

the telco alarm connector, if desired.

9. If a second CMM is to be installed in the chassis, follow the same instructions in this

procedure.

To remove the CMM:

1. Loosen the retention screws with a screw driver (Type#1 Philips head screw

driver).

2. Pull the ejector away from the faceplate (unlatch condition for ejector) enough to

ensure that the blue LED on the faceplate begins to flash. At this stage, the CMM

remains attached to the chassis (the backplane connector of CMM is still mated

with the chassis’s connector).

3. When the blue hot swap LED turns solid blue, pull the ejector farther out in order to

eject the CMM from the chassis.

Note: The hot swap LED will turn solid blue only when the redundancy feature is fully

enabled.

®

Intel NetStructure

Hardware TPS July 2007

14 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 14

Module Components—MPCMM0002 CMM

4.0 Module Components

4.1 Block Diagram

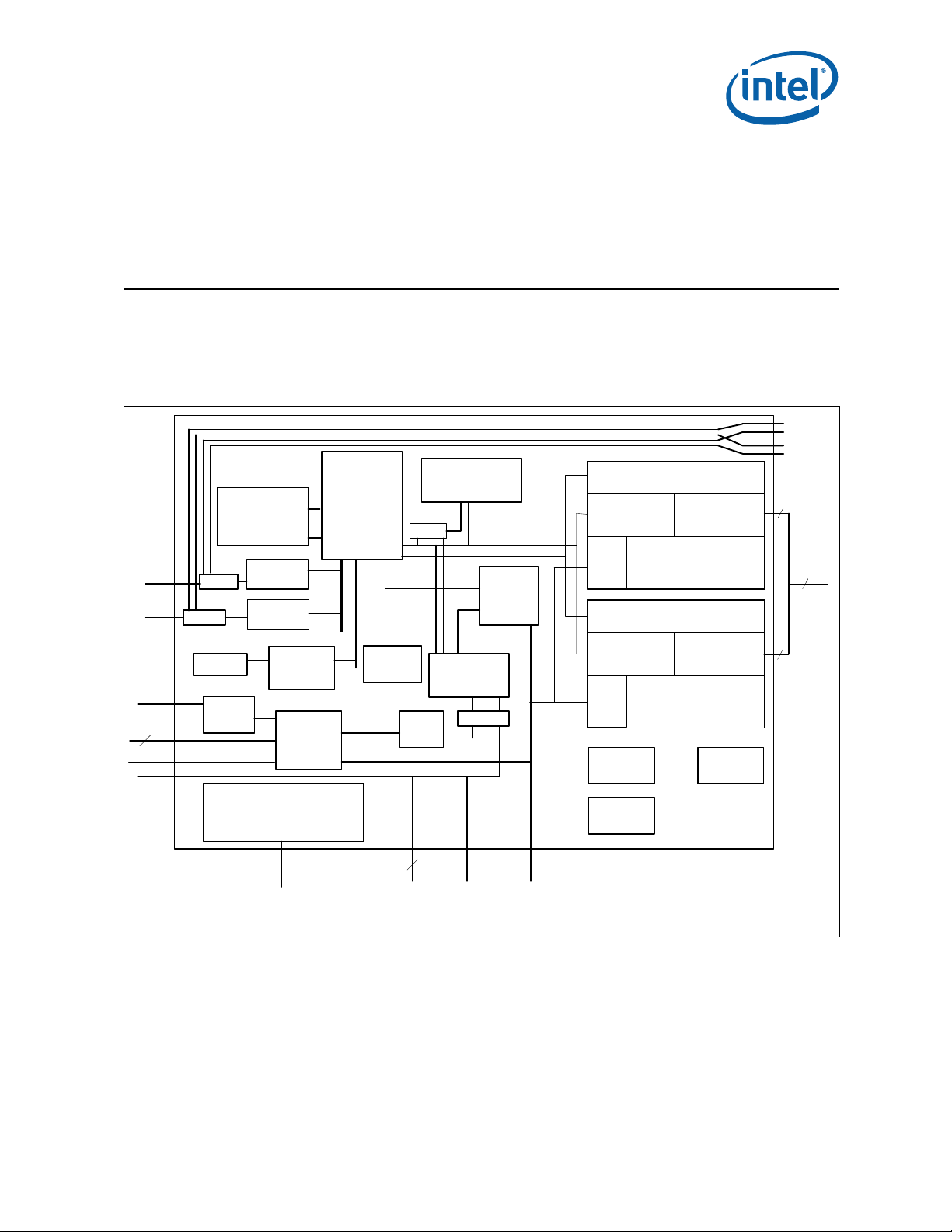

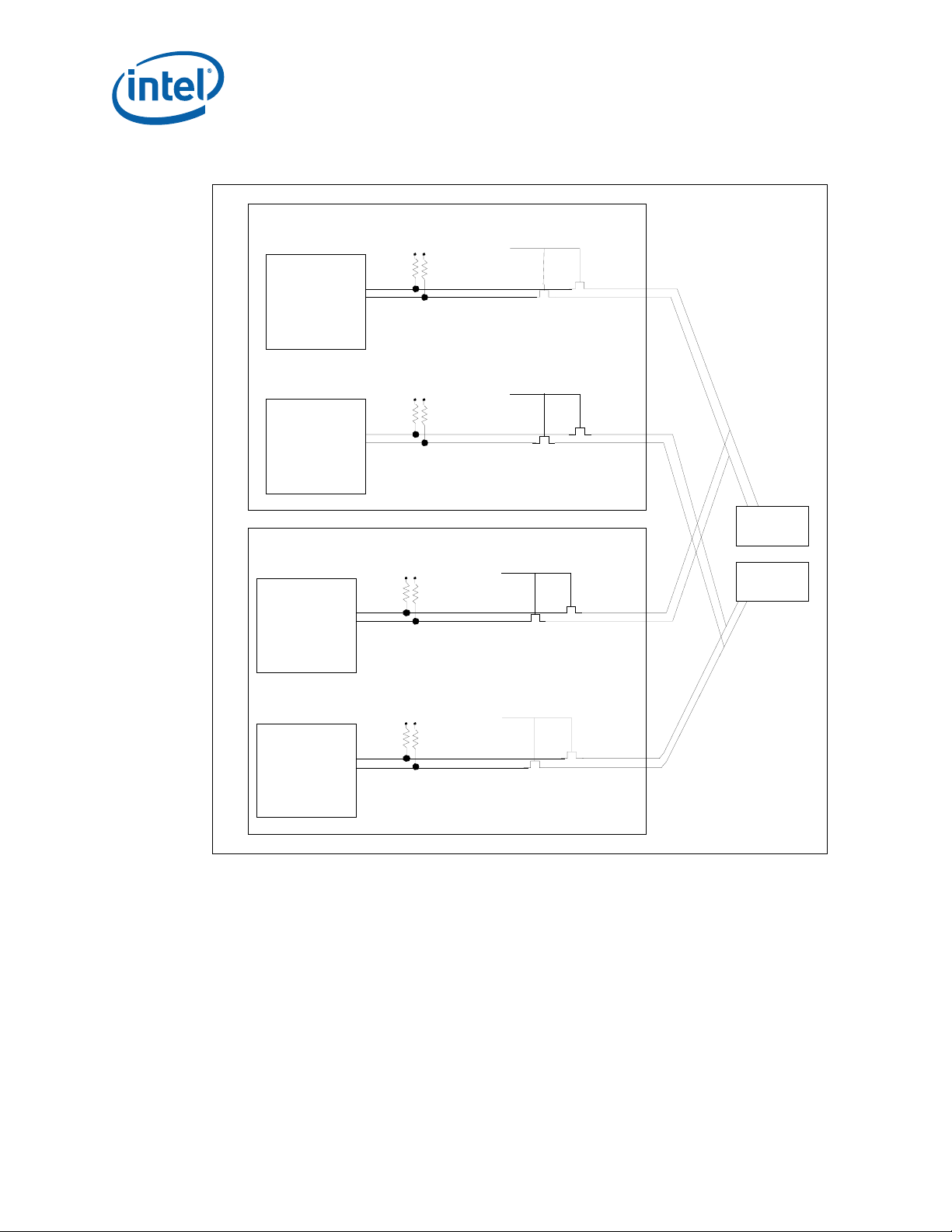

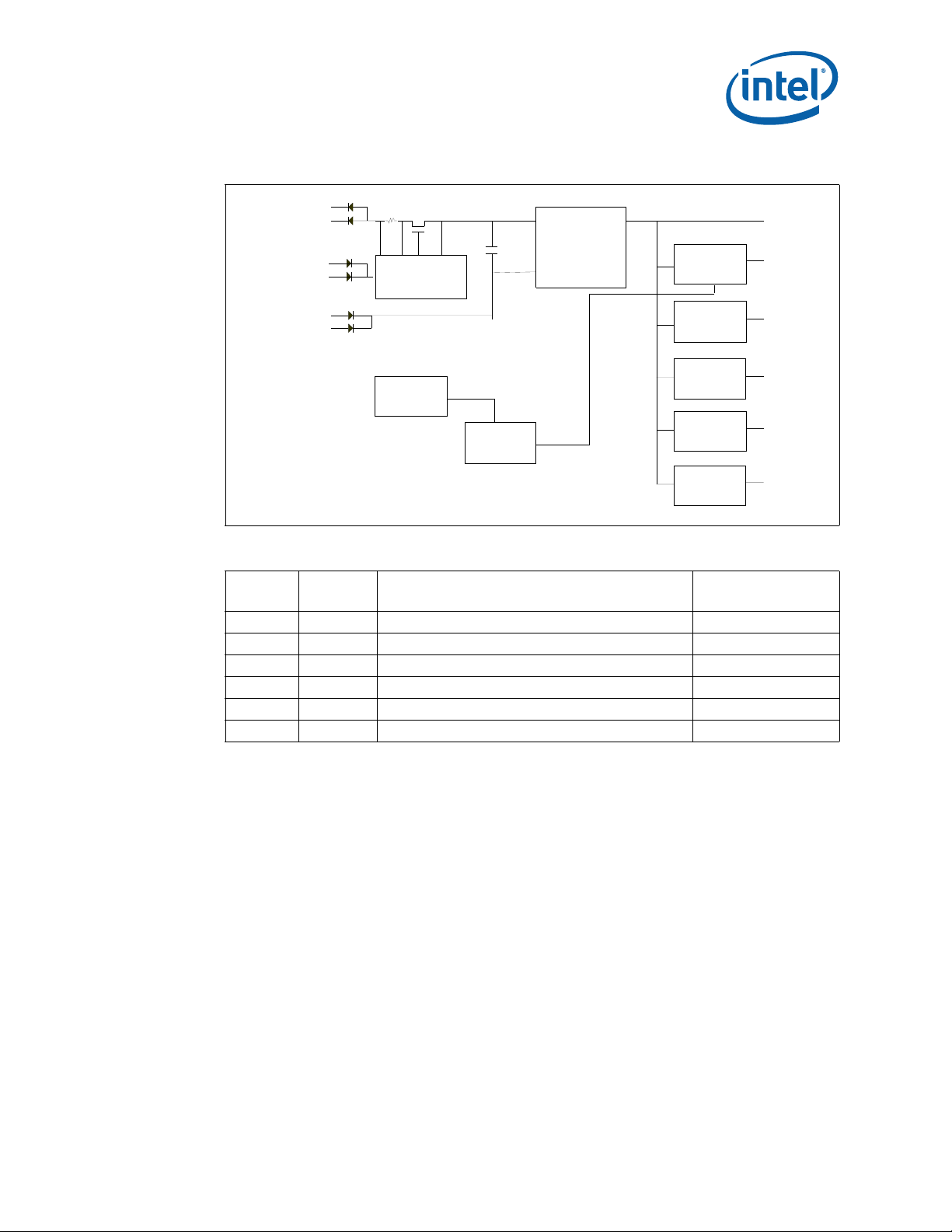

The block diagram for the Intel NetStructure® MPCMM0002 CMM is shown in Figure 2.

Figure 2. CMM Block Diagram

RJ45

RJ45

Alarm

Alarm

LEDs

3

Button

RS-232

Mux

Mux

Battery

Telco

Relays

SODIMM

Socket

128MB

10/100

NIC

10/100

NIC

RTC

-48VDC Power

Control

80321

Intel®

XScale™

Core

and IOP

w/ PCI

Bridge

I2C

ADM1026

GPIO

8/16/32/64 MB

flash

Latch

SIO Serial

Controller

Debug

LEDs

Debug

Drivers

CPLD

Control

Address

Decode

GPIO

Control

Address

Decode

GPIO

Clocks

OCS

FRU

Interrupt

router

FPGA 1

Interrupt

router

FPGA 2

I2C

Engines

I2C

Engines

Debug

RTM

BP

Switch

I2C[0:20]

42 I2C

I2C[21:41]

4

Health/

User

LEDs

July 2007 Hardware TPS

Order Number: 309247-004US 15

Fault

LED

Ejector

Blue LED

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 15

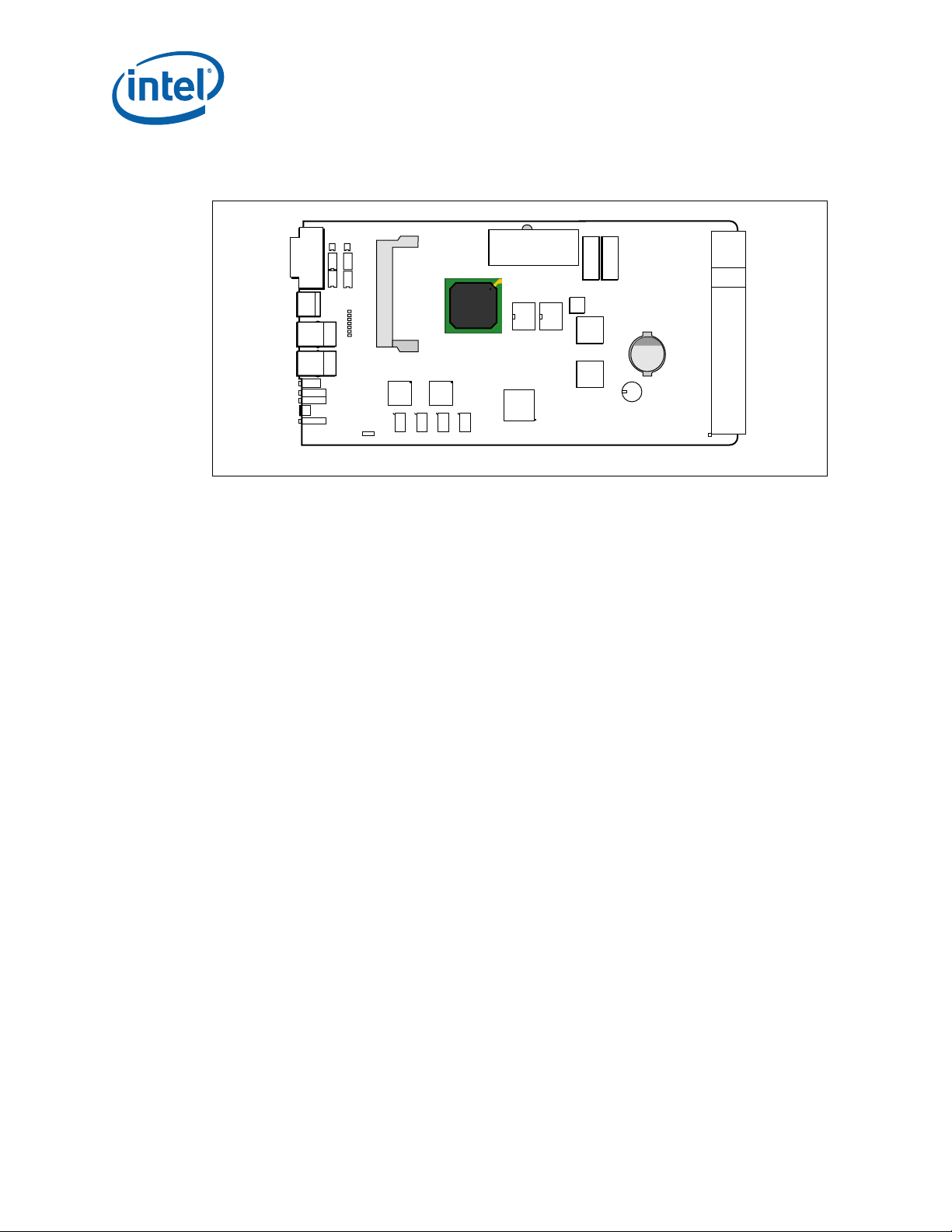

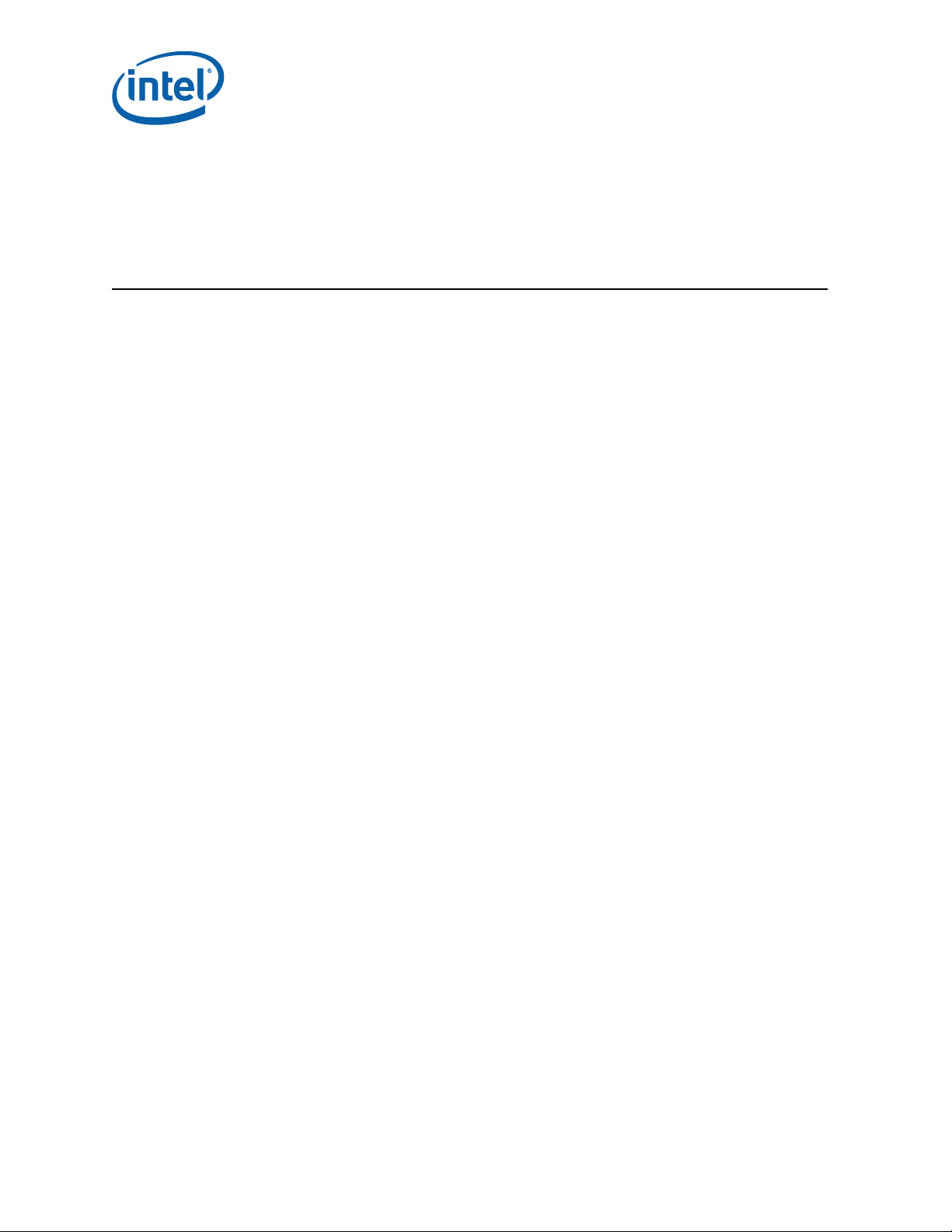

The major components of the CMM are arranged as shown in Figure 3.

Figure 3. CMM Top View Layout

MPCMM0002 CMM—Module Components

Telco

Serial

LAN B

LAN A

LED

Opto

Relay RAM

Debug

LED

NIC1

J3

NIC2

CPU

M

Power Brick

Flash

CPLD

+ +

S2 switch

FPGA

Bulk Cap

Battery

Super Cap

Power

Guide

Pin

Data

B5106-01

The PCB is composed of 10 layers of FR406 (or equivalent material). The outer layers

(1 and 10) are 0.5 ounce copper (plated to 1.6 ounces); all other layers are 1 ounce

copper.

Note: S2 abov e is a four-pole DIP switch block. The first switch in the DIP, S2-1 (1:8), is used

for password reset; the other three switches, S2-2, S2-3, and S2-4, are currently not

used. The default position for S2-1 is the ‘off’ position (open). See the Intel

NetStructure

®

MPCMM0001 Chassis Management Module and Intel NetStructure®

MPCMM0002 CMM Software Technical Product Specification for procedures on resetting

the CMM password.

®

Intel NetStructure

Hardware TPS July 2007

16 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 16

Module Components—MPCMM0002 CMM

Internal Bus

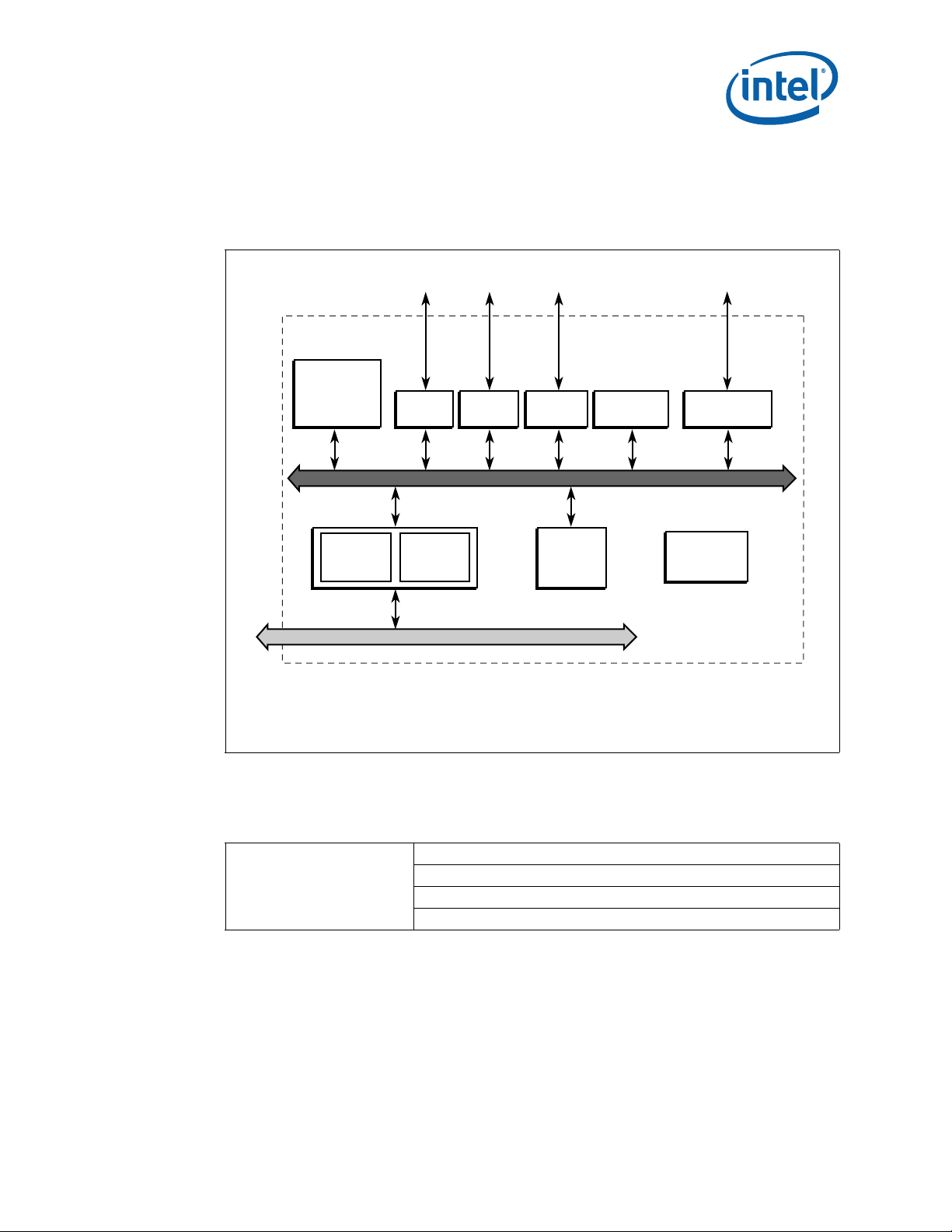

4.2 Intel® 80321 Processor

The CPU in the MPCMM0002 CMM is an Intel® 80321 Processor/PCI Application Bridge

with Intel

Figure 4. Intel

XScale® technology. The internal block diagram is shown in Figure 4.

®

80321 Processor Internal Block Diagram

2

C

I

Serial Bus

I2C Bus

Interface

Two

DMA

Channels

Application

Accelerator

Intel

Serial Bus

Serial Bus

Performance

Monitoring

Unit

®

80321 I/O Processor

®

Intel

XScale

Core

Messaging

Unit

72-Bit

I/F

®

DDR I/F

Unit

Address

Translation

Unit

64-bit / 32-bit PCI Bus

32-Bit

I/F

PBI Unit

(Flash)

SSP

Notes:

®

XScale® Microarchitecture is ARM* Architecture compliant.

Intel

* Other brands and names are the property of their respective owners.

B3063-01

This processor runs at 600 MHz and has an integrated chipset for lower power usage;

the typical power consumption of the CPU is 4 W. Other features are given in Table 2.

Table 2. Processor Features (Sheet 1 of 2)

ARM* V5T Instruction Set

Integrated Intel XScale® Core

July 2007 Hardware TPS

Order Number: 309247-004US 17

ARM V5E DSP Extensions

400 MHz and 600 MHz

Write Buffer, Write-back Cache

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 17

Table 2. Processor Features (Sheet 2 of 2)

PCI Local Bus Specification, Rev. 2.2 compliant

PCI-X Addendum to the PCI Local Bus Specification, Rev. 1.0a

64-bit/66 MHz Operation in PCI Mode

PCI Bus Interface

Memory Controller

Address Translation Unit

DMA Controller

Application Accelerator Unit

2

I

C Bus Interface Units

SSP Serial Port

Peripheral Performance

Monitoring Unit

Timers

544-Ball, Plastic Ball Grid Array

(PBGA)

Eight General Purpose I/O Pins

64-bit/133 MHz Operation in PCI-X Mode

Support 32-bit PCI Initiators and Targets

Four Split Read Requests as Initiator

Eight Split Read Requests as Target

64-bit Addressing Support

PC200 Double Data Rate (DDR) SDRAM

Up to 1 GByte of 64-bit DDR SDRAM (128 MBytes on MPCMM0002)

Up to 512 MBytes of 32-bit DDR SDRAM

Single-bit Error Correction, Multi-bit Support (ECC)

1024 Byte Posted Memory Write Queue

40- and 72-bit wide Memory Interface

2 KByte or 4 KByte Outbound Read Queue

4 KByte Outbound Write Queue

4 KByte Inbound Read and Write Queue

Connects Internal Bus to PCI/PCI-X Bus

Two Independent Channels Connected to Internal Bus

Up to 1064 MByte/s Burst Support in PCI-X Mode

Up to 1600 MByte/s Burst Support for Internal Bus

Two 1 KB Queues in Ch-0 and Ch-1

232 Addressing Range on Internal Bus Interface

264 Addressing Range on PCI Interface

Performs XOR on Read Data

Compute Parity Across Local Memory Blocks

1 KByte/512 Byte Store Queue

Two Separate I

Serial Bus

Master/Slave Capabilities

System Management Funct ions

Full-duplex Synchronous Serial Interface

Supports 7.2 KHz to 1.84 MHz Bit Rates

One Dedicated Global Time Stamp Counter

Fourteen Programmable Event Counters

Three Control/Status Registers

Two Dual-programmable 32-bit Timers

Watchdog Timer

MPCMM0002 CMM—Module Components

2

C Units (one used on MPCMM0002)

®

Intel NetStructure

Hardware TPS July 2007

18 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 18

Module Components—MPCMM0002 CMM

4.3 Memory

The CMM has a SODIMM (Small Outline Dual Inline Memory Module) socket on board.

The SODIMM is populated with a 128 MByte unbuffered memory module.

The CMM also has four separate 16 MByte flash modules. These are Intel® E28F128

flash memory modules. Each memory module has multiple lockable regions within the

flash.

4.4 Ethernet

The CMM has two Intel® 82551QM Fast Ethernet Multifunction Controllers with

integrated media access controllers and physical interfaces. The output from each of

these chips is passed to a dedicated multiplexing device (mux), the SN74CBT16124.

Each mux can be individually controlled to send the Ethernet signals to one of three

destinations: the front panel, an optional RTM connection, or a separate backplane

connection. Separate magnetics (six total) provide magnetic coupling for the 10BASE- T

or 100BASE-TX signaling commonly associated with 10/100 MByte/s Ethernet.

In Figure 3, “CMM Top View Layout” on page 16, the four magnetics for the RTM and

backplane connections are at the bottom of the board. The two magnetics for the front

panel are integrated into the front panel RJ-45 connectors.

4.5 Serial Port UARTs

The UART (Universal Asynchronous Receiver/Transmitter) controller on the CMM board

is a T exas Instruments* TL16C752B dual UAR T chip. The first serial port is connected to

an RJ-45 connector on the front panel; the second serial port is passed to the rear of

the card for an optional RTM connection. Full modem hardware signals are passed

through to the RTM.

The UART driver provides 15 kV of ESD protection (8 kV contact, 15 kV air discharge).

July 2007 Hardware TPS

Order Number: 309247-004US 19

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 19

4.6 FPGA

The MPCMM0002 CMM has two redundant field-programmable gate arrays (FPGAs) on

board. These two Xilinx* Spartan* II XC2S200 FPGAs have identical internal design,

but different addresses. A brief summary of the FPGA functions is shown in Table 3.

Table 3. FPGA Features

Signal Description

IPMI 1.5-compliant buses, pulled up to 3.3 V and operating at 100 kHz

IPMB

compatible

buses

Bus 50nS basic memory bus with data, address, chip select, output enable, and write enable

Interrupt

Router

20 IPMB ports per FPGA (40 total): 32 IPMBs for dual star routing to up to 16

AdvancedTCA* slots, 2 shared buses for PEMs and fan trays, 2 buses for communication

between CMMs, and 4 spare IPMBs for future expansion

2

One I

C port per FPGA (2 total) for communication to CDMs

The FPGA is responsible for identifying and routing interrupt requests from multiple sources

on the CMM, including the following: internal IPMB engine, other FPGA, both UARTs, the

ADM1026 controller, the CPLD, and both LAN controllers

4.7 Redundancy and Hot Swap CPLD

A Xilinx XC95144XL CPLD is used on the CMM to control the redundancy failover logic,

Hot Swap logic, FPGA control, and address decode for simple devices on the CMM. This

CPLD also contains the PCI arbitration circuitry for the 80321 processor and the

Ethernet controllers.

MPCMM0002 CMM—Module Components

4.8 Watchdog Timer

A Maxim* MAX6374KA-T watchdog timer is used to protect against CPU lockups. The

CMM firmware strobes the watchdog periodically; if the CPU fails to strobe the

watchdog within a given time interval, the watchdog sends a signal to the CPLD that

forces the CPU to reset. This allows the processor to automatically recover to a known

good state in the case of lockup.

Note: If the watchdog timer fires, the IPMB signals are not affected by the CPU timer reset.

The other CMM automatically takes over and manages the chassis.

4.9 Real-Time Clock

The CMM time-stamps certain events as they occur within the system, particularly

entries into the System Event Log (SEL). A Dallas Semiconductor* DS1307 real-time

clock provides this capability.

To avoid losing the current time, the CMM provides independent power to the DS1307

with an on-board battery (size CR2032). The battery provides approximately five years

of run time for the clock in case of a power failure or if the CMM is removed from a

chassis.

Batteries have limited shelf lives. After many years in storage, a battery may not be

able to hold a charge. To supplement the battery, a super capacitor (SCap) is also

provided on the CMM; this provides a mechanism to get up to two hours of backup

power for the clock in case of a power failure. Though the SCap will not hold a charge

for even a full day, the ability to power the clock circuit during a power failure even

after years in storage is a reliability feature of the CMM.

The battery and SCap are both diode-OR’d to ensure that either one can supply the

power for the clock without being affected by the other backup power source.

®

Intel NetStructure

Hardware TPS July 2007

20 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 20

Module Components—MPCMM0002 CMM

4.10 ADM1026 Controller

An Analog Devices* ADM1026 controller monitors the on-board voltages and manages

the thermal sensors. The processor communicates with the ADM1026 through an I

bus.

4.11 Hot Swap Controller

The CMM uses an LTC4250AH* Hot Swap controller to ramp voltages and watch for

over-current conditions. If the CMM draws more than 2.5 A for more than 500 µs, the

Hot Swap controller terminates.

The Hot Swap controller waits for the enable signals (short pins tied to each return) to

connect before ramping up the circuitry on the CMM. Similarly, if a CMM is pulled out of

the system, the Hot Swap controller immediately cuts power to the board.

4.12 Ride-Through Support

Many carriers require equipment to survive a 5 ms period without any power in order to

survive power glitches due to short circuit, power switchovers, etc. Section 4.1.4.3 of

the PICMG 3.0 specification requires boards to survive this 5 ms drop-out and

recommends that other chassis elements also have capability to ride through these

transients.

The MPCMM0002 CMM module meets this requirement. The CMM will survive the zero

volt transient described in Table 4-4 of the PICMG 3.0 specification. Large bulk

capacitors next to the DC-DC power converters provide this hold-up capacity.

4.13 IPMB Isolation Logic

2

C

In a carrier-grade system it is important to prevent cascaded failures; that is, a failure

in one element that affects other system elements and causes them to fail or lose

significant functionality . A shared bus is more sensitive to a single item impacting other

elements than a simple point-to-point system. This is one reason the MPCMM0002 CMM

chassis management module implements the hybrid dual IPMB star topology outlined in

Section 6.1, “IPMB Routing” on page 28.

Some IPMB channels are dedicated links between the CMMs and an individual blade;

this type of link is called a star. Some IPMB channels are shared among several devices,

and this type of link is called a bus. The star and bus elements have different isolation

logic in the CMM.

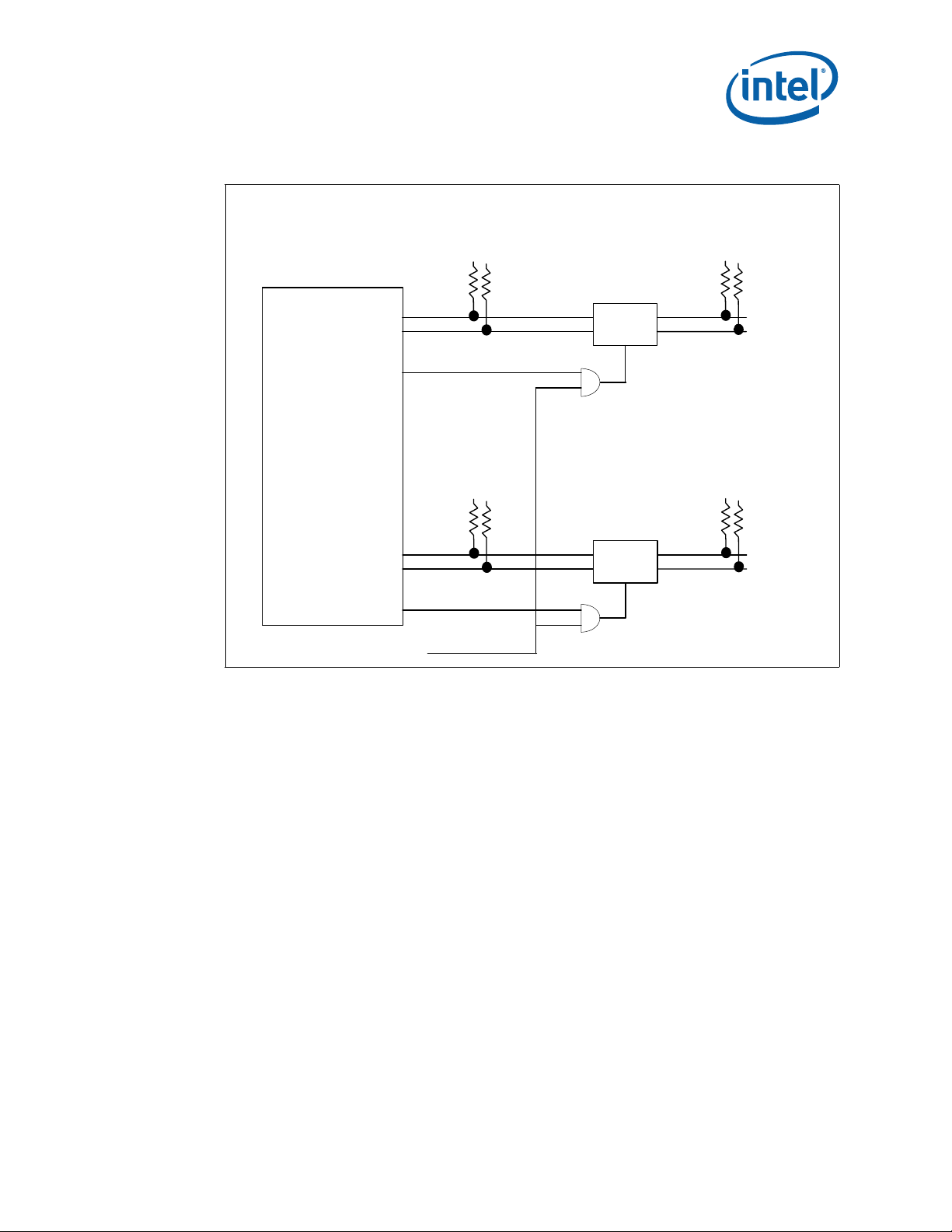

4.13.1 Dual Star IPMB Isolation

The dual star IPMBs on the MPCMM0002 CMM use MOSFET-controlled isolators to

disconnect all the radial IPMB signals automatically if power fails on a CMM. The

isolation circuit is pictured in Figure 5. The hardware ensures that the CMM is isolated

from the dual star IPMBs if power fails.

July 2007 Hardware TPS

Order Number: 309247-004US 21

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 21

Figure 5. IPMB Dual Star Isolation

MPCMM0002 CMM—Module Components

CMM 1

FPGA 1

FPGA 2

CMM 2

FPGA 1

IPMBa

IPMBa

IPMBb

IPMBb

IPMB_ P W R

IPMB_ P W R

IPMB_ P W R

IPMB_PWRGOOD

IPMB_ P W RG O O D

IPMB_PW RG O OD

SLOT a

or

CDM a

SLOT b

or

CDM b

IPMB_ P W R

IPMB_ P W RGO OD

FPGA 2

IPMBb

IPMBb

4.13.2 Dual Bus IPMB Isolation Requirements

The isolation requirements for a dual bus IPMB are more stringent. In addition to the

power failure isolation needed by radial IPMBs, dual bus IPMBs must be able to

selectively enable and disable the is olation on each bus. Furtherm ore, each element on

the bus must protect against errors that can cause the bus to hang. Finally, there are

electrical drive and rise time requirements that are more difficult to meet on a shared

bus.

An LTC4300 on each bus provides the necessary individually selectable isolation

mechanisms in addition to rise time acceleration. A watchdog timer is also used to

ensure the bus is isolated if the CPU locks up and resets so that glitches are not

propagated to other controllers on the bus. See Figure 6.

®

Intel NetStructure

Hardware TPS July 2007

22 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 22

Module Components—MPCMM0002 CMM

Figure 6. Dual Bus IPMB Isolation

FPGA 2

IPMBa

GPIO_0

IPMBb

GPIO_1

IPMB _PWR

INHIB ITa#

IPMB _PWR

INHIB ITb#

WDT

Local

Local

LTC4300A

ENA

LTC4300A

ENA

Local

IPMB_PWR

IPMB a to

Back p lan e

Local

IPMB_PWR

IPMBb

to

Back p lan e

July 2007 Hardware TPS

Order Number: 309247-004US 23

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 23

5.0 Mechanical Information

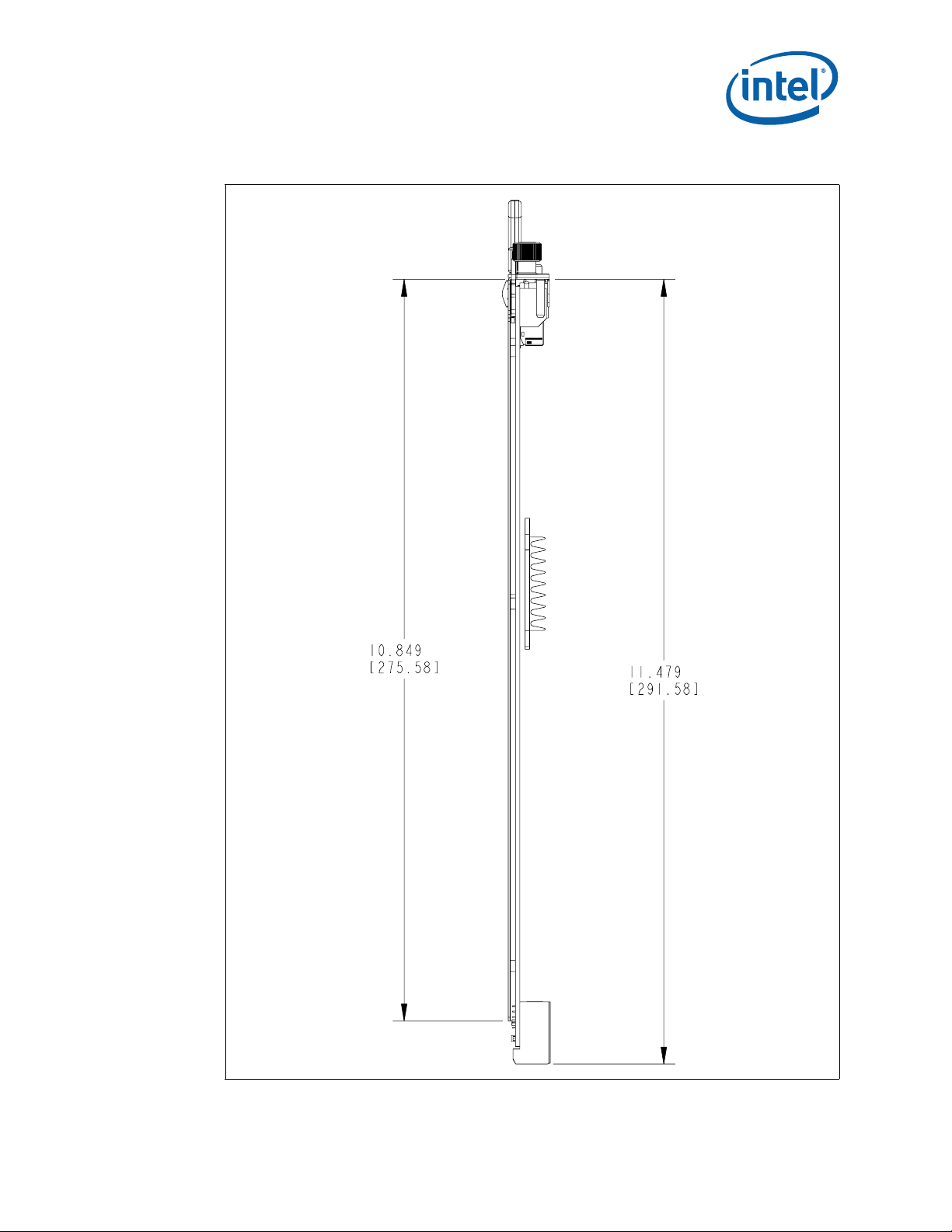

5.1 Dimensions

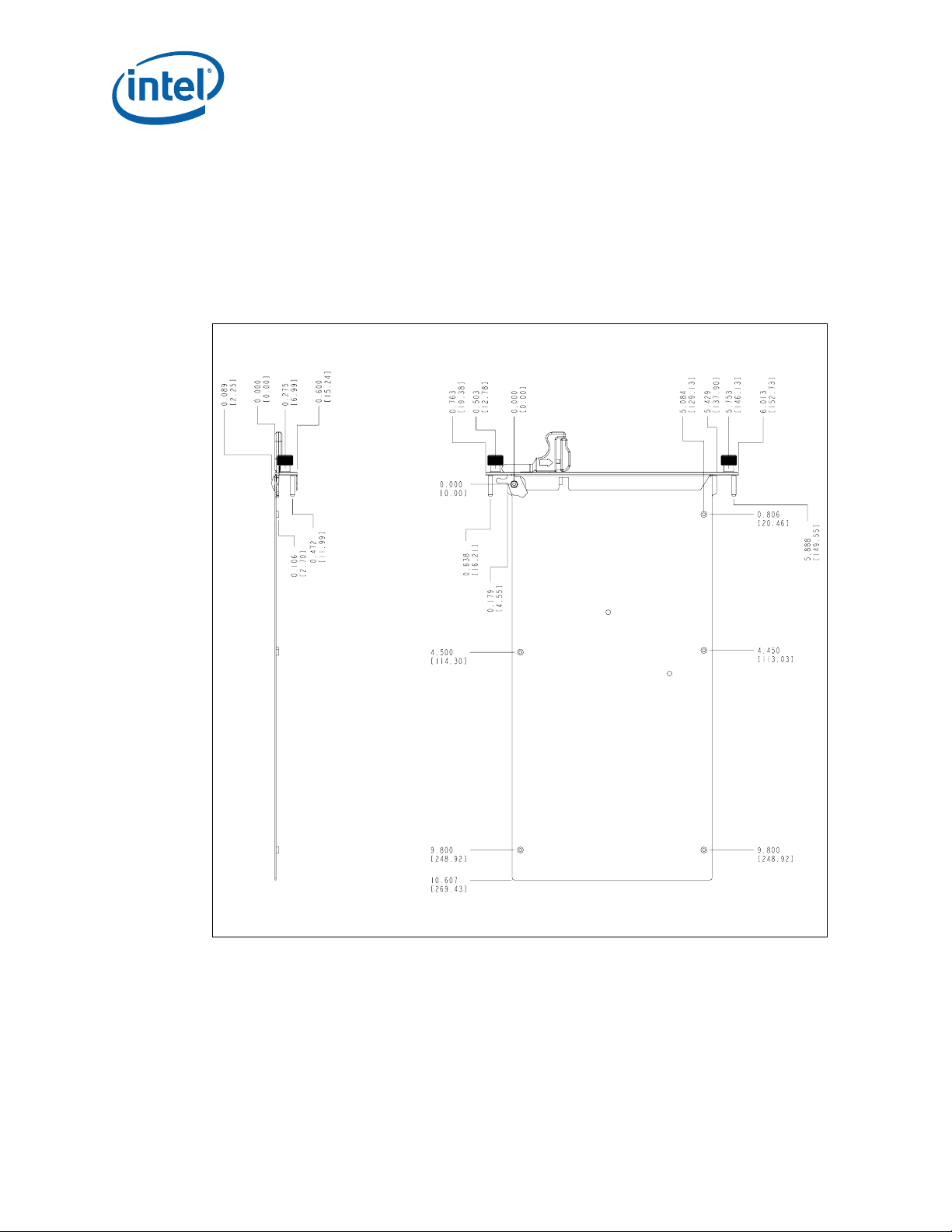

Dimensions for the CMM are shown in Figure 7. The origin is in the lower right corner.

All dimensions are shown in millimeters.

The form factor of the CMM PCB has a height of 144.4 mm and a depth of 282.5 mm.

The faceplate has a horizontal slot pitch (width) of 3 HP (0.6 inches).

Dimensions for the CMM backing plate are shown in Figure 8. The origin for these

Figure 7. CMM Component Side 1 Dimensions

dimensions is based on the mounting hole in the upper left corner.

MPCMM0002 CMM—Mechanical Information

®

Intel NetStructure

Hardware TPS July 2007

24 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 24

Mechanical Information—MPCMM0002 CMM

Figure 8. CMM Backing Plate Dimensions

July 2007 Hardware TPS

Order Number: 309247-004US 25

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 25

The gasket is on the secondary side of the backing plate and extends over the pitch

line, just as PICMG 3.0 boards extend their gasket over the pitch line. The outer face of

the backing plate is 0.15 mm (0.0059 inches) inside the nearest pitch line. Since the

gasket has a nominal compressed size of 1.53 mm (0.0602 inches) and a four-sigma

range of 0.99 mm (0.0390 inches) to 2.07 mm (0.0815 inches), the gasket must seal

on a surface that is between 0.84 mm (0.0331 inches) and 1.92 mm (0.0756 inches)

from the left side pitch line.

Figure 9. CMM Side View Dimensions

MPCMM0002 CMM—Mechanical Information

5.2 Front Panel Hardware

Table 18, “Telco Alarm Pinout” on page 49 shows two retention screws and two

alignment posts on the MPCMM0002 CMM faceplate. Like the hardware used with

PICMG* 3.0 boards, these items are M3 hardware. However, since the 15.24 mm (0.6

inches) pitch of the CMM does not allow sufficient room to put the retention screws and

alignment posts side by side, the alignment posts are offset slightly.

®

Intel NetStructure

Hardware TPS July 2007

26 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 26

Mechanical Information—MPCMM0002 CMM

There is only one ejector on the CMM, but it matches the subrack interface geometry

defined in Section 2.2.7 of the PICMG 3.0 specification. Note, however, that the ejector

handle is 2 mm (0.0787 inches) thick, not the 2.5 mm (0.0984 inches) thickness that

many PICMG 3.0 boards use.

A switch on Component Side 2 of the PCB detects the opening and closing of the ejector

handle.

5.3 Rear Connector Placement

5.3.1 MPCMM0002 CMM Rear Connectors

The CMM uses three connectors (for power, data, and a guide pin) that can mate with

either vertical (backplane) connectors or coplanar connectors. The power connector is

an FCI* 85719-107LF (or equivalent) connector. As shown in Table 14, “CMM Power

Connector” on page 32, the A1 pin on the connector is located at coordinates (2.37,

96.34). The data connector is an FCI 89095-102LF (or equivalent). Pin 1 on the data

connector is located at coordinates (13.7, 64.65). The guide pin connector is an FCI

73474-201 (or equivalent).

5.3.2 Coplanar Mating Connectors

In a coplanar mating arrangement, a FCI* HM1L54LDP000H6P connector with FCI*

72019-101 guide pin is mated to the data connector on the CMM, while a FCI*

HM1L52LDP493H6P (or equivalent) connector mates with the power connector.

5.3.3 Vertical Mating Connectors

When a CMM board mates directly into a backplane, vertical mating connectors are

used. The data connector that mates to the CMM is a FCI* 89009-116 with FCI*

70295-001 guide pin and 73475-101 shroud, while the power connector is an FCI*

HM1W52ZPR493H6P (or equivalent). Since they are mounted on a backplane, the rear

of these two connectors must be in the same plane.

Example: If mounted horizontally with Component Side 1 up, the bottom row of holes

for the data connector is 1.775 mm (0.0699 inches) lower than the power connector.

5.4 ESD Discharge Strip

The ESD strip along the bottom of the CMM follows the guidelines in Section 2.2.5 of

the PICMG* 3.0 specification. The electrical definition of the ESD discharge strip is

shown below.

Figure 10. CMM ESD Strip Electrical Definition

Dimensions of the ESD strips are shown in Table 16, “Ethernet Port Pinouts” on

page 47.

10MΩ

10MΩ

July 2007 Hardware TPS

Order Number: 309247-004US 27

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 27

6.0 Backplane Considerations

6.1 IPMB Routing

The Intel NetStructure® MPCMM0002 CMM is designed to support a hybrid dual IPMB

star topology.

The CMMs can support up to 16 slots, the maximum number of boards in a PICMG* 3.0

chassis. Each board in the subrack has two dedicated IPMBs going to it. Each IPMB is

arranged in a ‘Y’ pattern: the connection from the board is split to two legs, one going

to each CMM. Each CMM is present on both buses to each board. In addition, there are

two shared IPMB buses routed between the CMMs for private, dedicated IPMB traffic

between the two CMMs. While the CMMs theoretically can talk between themselves

over any of 30+ IPMBs, the private IPMB traffic between CMMs is normally over these

two inter-CMM links.

MPCMM0002 CMM—Backplane Considerations

Note: A shared dual IPMB bus is used for chassis elements such as PEMs and one or more fan

trays. This shared dual bus allows the CMM to support varying numbers of PEMs, fan

trays, and other intelligent chassis elements.

In compliance with the PICMG 3.0 specification, the shared bus IPMB signals have an

isolating buffer device (LTC4300) to ensure proper bus isolation in a shared bus

environment. The radial (star) IPMB connections to each node are not required to have

this same isolation circuitry since each node is effectively isolated already by the star

topology.

6.2 CMM Power

6.2.1 DC Power Input

Each CMM receives dual -48 VDC power feeds on its power connector. Since the

maximum power draw is 28 W, the maximum power draw from each CMM is less than 1

A. The typical power draw for each CMM is 17 W. Most of the power is derived from the

3.3 V converter.

®

Intel NetStructure

Hardware TPS July 2007

28 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 28

Backplane Considerations—MPCMM0002 CMM

Figure 11. Power System Block Diagram

-48V

Power

Enable

(MLBF)

-48V Return

Table 4. Voltage Usage

Voltage

12 V 0.3 A Op Amp and IPMB isolation circuit ADM1026

5 V 1 A Misc components that cannot use 3.3 V ADM1026

3.3 V 4 A Most logic ADM1026

2.5 V 5 A Memory interface ADM1026

1.3 V 3 A IOP321 core ADM1026

1.25 V 1 A DDR Termination ADM1026

Current

Max

Hotswap

Controller

ADM1026

Filter

Cap

-48 V t o

3.3V

Power

Bri ck

LT1371

LT1930

PG33

CPLD

PG5

TPS54610

TPS54610

Discrete

Linear

Regulator

Where Used Monitored By

3.3V

5V

12V

2.5V

1.3V

1.25V

The CMM supports an input voltage range of –34 VDC to –72 VDC. However, the 5 ms

ride-through capability (see Section 4.12, “Ride-Through Support” on page 21)

assumes a prior minimum voltage of –43 VDC.

6.2.2 CDM Power

The CMM provides a few powered outputs that chassis designers can use as they see

fit. The chassis data modules (sometimes called shelf FRUs) are described in more

detail in Section 8.0, “Chassis Data Modules (CDMs)” on page 43. Each CMM provides a

diode-OR’d 5 V output at 50 mA maximum current to the CDMs. Chassis designers can

use this 5 V output to power simple EEPROMs in a CDM. The CMMs can both drive a

tricolor LED on the CDM as well.

July 2007 Hardware TPS

Order Number: 309247-004US 29

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 29

Figure 12. CDM Power Input

6.2.3 Filter Tray

The CMM also provides direct support for a filter tray. The CMM provides signals to

handle a filter presence switch, two thermistors, and a tricolor LED.

MPCMM0002 CMM—Backplane Considerations

CDM 1 CDM 2

The filter presence switch is typically a mechanical switch that connects the AF_PRES#

signal to ground when an air filter is installed in the chassis. The switch is debounced in

software.

The two thermistor inputs provide redundant temperature readings to the CMM. The

thermistors should be a NTC (negative thermocouple) device like the US Sensor*

USX2257 thermocouple (http://www.ussensor.com/). For maximum accuracy, a

dedicated logic ground reference signal AFTREF is provided to isolate localized

perturbations to logic ground. Chassis designers should use the AFTREF signal

exclusively for these thermocouples and should route the two temperature signals and

the reference signal in close proximity.

6.2.4 Power Switch

The CMM has support for an optional soft power switch. This dual-pole input signal can

be used to signal the CMM to gracefully shut down the elements within the chassis.

Both poles of this switch are debounced in software. If only one contact on the switch

closes, the CMM flags this as an error and generates a system event log entry.

These direct drive capabilities of the CMM are summarized in the table below. All the

outputs are protected via OR-ing diodes, as shown in Figure 12.

®

Intel NetStructure

Hardware TPS July 2007

30 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 30

Backplane Considerations—MPCMM0002 CMM

Table 5. Chassis Elements Directly Driven by CMM Hardware

Chassis

Element

CDM

Filter Tray

Power switch Dual pole switch Soft power switch to CMMs

LAN ports 2 LEDs each (4 total) Speed on one LED, Link and Activity on the other

Component Notes

EEPROM + others

LED Tricolor LEDs driven by CMM

2 Thermistors NTC sensors, such as US Sensor USX2257

LED Red plus green LEDs driven by CMM

6.2.5 Ethernet Routing

Each CMM provides two Ethernet channels that can be routed to the base interface of

PICMG* 3.0 hub slots. The PICMG 3.0 specification only allocates space for one ShMC

slot, but the backplane can typically be set up to “poach” an unused slot in order to

provide a connectivity option.

A 14-slot chassis typically uses 14 base interface channels (13 for other slots plus one

for the ShMC). However, the specification defines 16 total channels for the base

interface. The second port from each CMM can be routed to an unused upper channel of

the opposite hub or fabric board.

Figure 13. Ethernet Port Poaching

50 mA @ 5 V max; typically uses series resistance to drop

voltage to 3.3.V.

CMM 1

LAN A LAN B

Ethernet

Fabric A

Port 0

Port 1

...

Port 14

Port 15

CMM 2

LAN A LAN B

Ethernet

Fabric B

Port 0

Port 1

...

Port 14

Port 15

July 2007 Hardware TPS

Order Number: 309247-004US 31

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 31

7.0 Rear Connections

7.1 CMM Connector Pinouts

Each CMM has a power connector and a data connector.

7.1.1 CMM Power Connector

The CMM power connectors are standard J12 power receptacles as shown in Figure 14.

Figure 14. CMM Power Connector

12

MPCMM0002 CMM—Rear Connections

1

E

A

®

Intel NetStructure

Hardware TPS July 2007

32 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 32

Rear Connections—MPCMM0002 CMM

The pinout of each CMM power connector is shown in Table 6.

Table 6. Power Connector Pinouts

Pin Signal Purpose Pin Length

B12, D12 SGND Shelf ground, mostly for safety Long

A5, C5, E5 GND Logic ground for signal returns Long

C1, E1 -48 V_A A power feed Medium

B2, D2 -48 V_B B power feed Medium

C3, E3 -48 VRTNA Return path for A feed Medium

B4, D4 -48 VRTNB Return path for B feed Medium

A1 -48VRTN_A_MLBF

A3 -48VRTN_B_MLBF

D6 PWRALRM_NO Power alarm relay, normally open Medium

E9 MNRALRM_COM Minor alarm relay, common path Medium

C9 MJRALRM_COM Major alarm relay, common path Medium

A9 CRTALRM_COM Critical alarm relay, common path Medium

B6 PWRALRM_COM Power alarm relay, common path Medium

E7 MNRALRM_NO Minor alarm relay, normally open Medium

C7 MJRALRM_NO Major alarm relay, normally open Medium

A7 CRTALRM_NO Critical alarm relay, normally open Medium

E11 MNRALRM_NC Minor alarm relay, normally closed Medium

C11 MJRALRM_NC Major alarm relay, normally closed Medium

A11 CRTALRM_NC Critical alarm relay, normally closed Medium

D10 MNRRES+ Minor alarm reset, positive polarity Medium

B10 MNRRES- Minor alarm reset, negative polarity Medium

D8 MJRRES+ Major alarm reset, positive polarity Medium

B8 MJRRES- Major alarm reset, negative polarity Medium

Return path for A feed (mate last, break first pin)

that allows Hot Swap controller to turn system

power on and off

Return path for B feed (mate last, break first pin)

that allows Hot Swap controller to turn system

power on and off

Short

Short

July 2007 Hardware TPS

Order Number: 309247-004US 33

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 33

Table 7 labels the pins on the power connector at the intersection of each row (A-E) and

column (1-12).

Table 7. Power Connector Pinouts Matrix

MPCMM0002 CMM—Rear Connections

1 -48V_A -48V_A -48_A_RTN_MLBF

2 -48V_B -48V_B

3 -48_A_RTN -48_A_RTN -48_B_RTN_MLBF

4 -48_B_RTN -48_B_RTN

5 GND GND GND

6 PWRALRM_NO PWRALRM_COM

7 MNR_NO MJR_NO CRT_NO

8 MJR+ MJR-

9 MNR_COM MJR_COM CRT_COM

10 MNR+ MNR-

11 MNR_NC MJR_NC CRT_NC

12 SGND SGND

Table 8 shows the staging of the power connector pins. Table 9 and Table 10 (for the

receptacle and for the header) show the physical locations of the pins identified by pin

code.

Table 8. Pin Staging

ED C B A

Order

First Mate 8 mm 4.3mm 19

Second Mate 7.25 mm 4.3mm 4

Third Mate 6.5 mm 4.3mm 3

Fourth Mate 5.75 mm 4.3mm 2

Last Mate 5 mm 4.3mm 1

Empty

Mating

Length

Tail

Length

Pin Code

Table 9. Power Connector Receptacle Pin Placement (Sheet 1 of 2)

1 4 4 1

2 3 3

3 4 4 1

4 3 3

®

Intel NetStructure

Hardware TPS July 2007

34 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

ED C B A

Page 34

Rear Connections—MPCMM0002 CMM

Table 9. Power Connector Receptacle Pin Placement (Sheet 2 of 2)

5 4 4 4

6 2 2

7 2 2 2

8 2 2

9 22 2

10 2 2

11 2 2 2

12 19 19

ED C B A

Table 10. Power Connector Header Pin Placement

1 1 4 4

2 3 3

3 1 4 4

4 3 3

AB C D E

5 4 4 4

6 2 2

7 2 2 2

8 2 2

9 22 2

10 2 2

11 2 2 2

12 19 19

July 2007 Hardware TPS

Order Number: 309247-004US 35

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 35

7.1.2 CMM Data Connector

The CMM data connector is a J16 signal connector. See Figure 15.

Figure 15. CMM Data Connector

48

A

MPCMM0002 CMM—Rear Connections

1

E

A

®

Intel NetStructure

Hardware TPS July 2007

36 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 36

Rear Connections—MPCMM0002 CMM

The pinouts for the data connector are shown in Table 11.

Table 11. Data Connector Pinouts (Sheet 1 of 2)

Signal Name Count Type Description Pin Name From Table 12

BP_AFT1 1 I Filter tray ambient temperature thermistor A E16

BP_AFT2 1 I Filter tray ambient temperature thermistor B E17

BP_AFTREF 1 I Filter tray ambient temperature thermistor return E18

BP_AFLED[1:2] 2 O

BP_AFPRES# 1 I

RP_ENET1_LNK# 1 O Ethernet port 1 to RTM Link LED drive A29

RP_ENET1_ACT# 1 O Ethernet port 1 to RTM Activity LED drive A30

RP_ENET1_SPD# 1 O Ethernet port 1 to RTM speed indicator A31

RP_ENET2_LNK# 1 O Ethernet port 2 to RTM Link LED drive B29

RP_ENET2_ACT# 1 O Ethernet port 2 to RTM Activity LED drive B30

RP_ENET2_SPD# 1 O Ethernet port 2 to RTM speed indicator B31

FRU0_STATUS[0:1] 1 O

FRU1_STATUS[0:1] 1 O

PWRSW[1:2] 2 I

BP_N_SCL[0..15]A and B 32 OD Node IPMB clock A2-A17, C2-C17

BP_N_SDA[0..15]A and B 32 OD Node IPMB data B2-B17, D2-D17

BP_CF_SCL_A and B 2 OD Chassis FRU IPMB clock A18, C18

BP_CF_SDA_A and B 2 OD Chassis FRU IPMB data B18, D18

BP_SH_SCL_A and B 2 OD Shared Bus IPMB clock A19, C19

BP_SH_SDA_A and B 2 OD Shared Bus IPMB data B19, D19

BP_RED_SCL_A and B 2 OD Redundant CMM IPMB serial clock A20, C20

BP_RED_SDA_A and B 2 OD Redundant CMM IPMB serial data B20, D20

BP_RP_SCL_A and B 2 OD Reserved IPMB clocks for RTM A21, C21

BP_RP_SDA_A and B 2 OD Reserved IPMB data for RTM B21, D21

BP_SP_SCL_A and B 2 OD RESERVED FOR FUTURE USE A22, C22

BP_SP_SDA_A and B 2 OD RESERVED FOR FUTURE USE B22, D22

BP_ENET1_TX0(+-) 2 I/O Ethernet port 1 to RTM A33, B33

BP_ENET1_RX0(+-) 2 I/O Ethernet port 1 from RTM A35, B35

BP_ENET2_TX0(+-) 2 I/O Ethernet port 2 to RMT A37, B37

BP_ENET2_RX0(+-) 2 I/O Ethernet port 2 from RTM A39, B39

BP_ENET1_TX1(+-) 2 I/O Reserved for GbE to RTM D33, E33

BP_ENET1_RX1(+-) 2 I/O Reserved for GbE from RTM D35, E35

BP_ENET2_TX1(+-) 2 I/O Reserved for GbE to RTM D37, E37

BP_ENET2_RX1(+-) 2 I/O Reserved for GbE from RTM D39, E39

Filter tray status tri-color LED control. Bit 1

controls the red LED. Bit 2 controls th e green LED .

Filter tray presence. This signal is pulled up to

+3.3V and is de-bounced by software.

Control signals for ShFRU status tri-color LED 1.

Bit 0 controls the red LED. Bit 1 controls the green

LED.

Control signals for ShFRU status tri-color LED 2.

Bit 0 controls the red LED. Bit 1 controls the green

LED.

Power switch input A or B from system power on/

off switch. These two signals have to be

debounced by software.

E19, E20

E21

D30, D31

C30, C31

E30, E31

July 2007 Hardware TPS

Order Number: 309247-004US 37

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 37

MPCMM0002 CMM—Rear Connections

Table 11. Data Connector Pinouts (Sheet 2 of 2)

Signal Name Count Type Description Pin Name From Table 12

CFG_STX 1 O Serial transmit A28

CFG_SRX 1 I Serial receive D28

CFG_SCTS 1 I Serial clear to send E28

CFG_SRTS 1 O Serial request to send C28

CFG_SDSR 1 I Serial data set ready E29

CFG_SDTR 1 O Serial data terminal ready B28

BP_CMC_TX0(+-) 2 I/O Ethernet port 0 to switch A41, B41

BP_CMC_RX0(+-) 2 I/O Ethernet port 0 from switch A43, B43

BP_CMCX_TX0(+-) 2 I/O Ethernet port 1 to switch A45, B45

BP_CMCX_RX0(+-) 2 I/O Ethernet port 1 from switch A 47, B47

BP_CMC_TX1(+-) 2 I/O Reserved for GbE to switch D41, E41

BP_CMC_RX1(+-) 2 I/O Reserved for GbE from switch D43, E43

BP_CMCX_TX1(+-) 2 I/O Reserved for GbE to switch D45, E45

BP_CMCX_RX1(+-) 2 I/O Reserved for GbE from switch D47, E47

BP_NGO 1 O Negotiate output to other CMM E14

BP_NGOI 1 I Negotiate input from other CMM E15

BP_HLY# 1 O Healthy output to other CMM E12

BP_HLYI# 1 I Healthy input from other CMM E13

BP_PRESI# 1 I Other CMM is present (0V) E11

BP_PRES# 1 O Tie to ground E10

GA[0:7] 8 I Hardware Address E2-E9

A1-E1, A23-C23, A32-E32,

GND 61 I Ground

FRU_VCCA and B 2 I

RESV[1:11] 11 Reserved A26-E26, A27-E27, D23

GPIO[1:10] 10 I General Purpose Input Only A24-E24, A25-E25

BP_CMM_RESET# 1 O Inter CMM reset output to another CMM C29

BP_CMM_RESETI# 1 I Inter CMM reset input from another CMM D29

Power to CDMs (shelf FRUs) and distribution

board

C33, A34-E34, C35, A36-E36,

C37, A38-E38, C39, A40-E40,

C41, A42-E42, C43, A44-E44,

C45, A46-E46, C47, A48-E48

E22, E23

Table 12 identifies each pin on the data connector at the intersection of each row (A-E)

and column (1-48).

Table 12. Data Connector Pinouts Matrix (Sheet 1 of 3)

ED CBA

1 GND GND GND GND GND

2 GA0 BP_N_SDA_[1]_B BP_N_SCL_[1]_B BP_N_SDA_[1]_A BP_N_SCL_[1]_A

3 GA1 BP_N_SDA_[2]_B BP_N_SCL_[2]_B BP_N_SDA_[2]_A BP_N_SCL_[2]_A

4 GA2 BP_N_SDA_[3]_B BP_N_SCL_[3]_B BP_N_SDA_[3]_A BP_N_SCL_[3]_A

®

Intel NetStructure

Hardware TPS July 2007

38 Order Number: 309247-004US

MPCMM0002 Chassis Management Module

Page 38

Rear Connections—MPCMM0002 CMM

Table 12. Data Connector Pinouts Matrix (Sheet 2 of 3)

ED CBA

5 GA3 BP_N_SDA_[4]_B BP_N_SCL_[4]_B BP_N_SDA_[4]_A BP_N_SCL_[4]_A

6 GA4 BP_N_SDA_[5]_B BP_N_SCL_[5]_B BP_N_SDA_[5]_A BP_N_SCL_[5]_A

7 GA5 BP_N_SDA_[6]_B BP_N_SCL_[6]_B BP_N_SDA_[6]_A BP_N_SCL_[6]_A

8 GA6 BP_N_SDA_[7]_B BP_N_SCL_[7]_B BP_N_SDA_[7]_A BP_N_SCL_[7]_A

9 GA7 BP_N_SDA_[8]_B BP_N_SCL_[8]_B BP_N_SDA_[8]_A BP_N_SCL_[8]_A

10 BP_PRES# BP_N_SDA_[9]_B BP_N_SCL_[9]_B BP_N_SDA_[9]_A BP_N_SCL_[9]_A

11 BP_PRESI# BP_N_SDA_[10]_B BP_N_SCL_[10]_B BP_N_SDA_[10]_A BP_N_SCL_[10]_A

12 BP_HLY# BP_N_SDA_[11]_B BP_N_SCL_[11]_B BP_N_SDA_[11]_A BP_N_SCL_[11]_A

13 BP_HLYI# BP_N_SDA_[12]_B BP_N_SCL_[12]_B BP_N_SDA_[12]_A BP_N_SCL_[12]_A

14 BP_NGO BP_N_SDA_[13]_B BP_N_SCL_[13]_B BP_N_SDA_[13]_A BP_N_SCL_[13]_A

15 BP_NGOI BP_N_SDA_[14]_B BP_N_SCL_[14]_B BP_N_SDA_[14]_A BP_N_SCL_[14]_A

16 BP_AFT1 BP_N_SDA_[15]_B BP_N_SCL_[15]_B BP_N_SDA_[15]_A BP_N_SCL_[15]_A

17 BP_AFT2 BP_N_SDA_[16]_B BP_N_SCL_[16]_B BP_N_SDA_[16]_A BP_N_SCL_[16]_A

18 BP_AFTREF# BP_CF_SDA_B BP_CF_SCL_B BP_CF_SDA_A BP_CF_SCL_A

19 BP_AFLED1 BP_SH_SDA_B BP_SH_SCL_B BP_SH_SDA_A BP_SH_SCL_A

20 BP_AFLED2 BP_RED_SDA_B BP_RED_SCL_B BP_RED_SDA_A BP_RED_SCL_A

21 BP_AFPRES BP_RP _SDA_B BP_RP_SCL_B BP_RP_SDA_A BP_RP_SCL_A

22 FRU_VCCA BP_SP_SDA_B BP_SP_SCL_B BP_SP_SDA_A B P_SP_SCL_A

23 FRU_VCCB Reserved for future use GND GND GND

24 GPIO5 GPIO4 GPIO3 GPIO2 GPIO1

25 GPIO10 GPIO9 GPIO8 GPIO7 GPIO6

26 RESV5 RESV4 RESV3 RESV2 RESV1

27 RESV10 RESV9 RESV8 RESV7 RESV6

28 CFG_SCTS CFG_SRX CFG_SRTS CFG_SDTR CFG_STX

29 CFG_SDSR BP_CMM_RESETI# BP_CMM_RESET# RP_ENET2_LNK# RP_ENET1_LNK#

30 BP_PWRSW1 BP_FRU0_STATUS0 BP_FRU1_STATUS0 RP_ENET2_ACT# RP_ENET1_ACT#

31 BP_PWRSW2 BP_FRU0_STATUS1 BP_FRU1_STATUS1 RP_ENET2_SPD# RP_ENET1_SPD#

32 GND GND GND GND GND

33 RP_ENET1_TX1- RP_ENET1_TX1+ GND RP_ENET1_TX0- RP_ENET1_TX0+

34 GND GND GND GND GND

35 RP_ENET1_RX1- RP_ENET1_RX1+ GND RP_ENET1_RX0- RP_ENET1_RX0+

July 2007 Hardware TPS

Order Number: 309247-004US 39

Intel NetStructure® MPCMM0002 Chassis Management Module

Page 39

MPCMM0002 CMM—Rear Connections

Table 12. Data Connector Pinouts Matrix (Sheet 3 of 3)

ED CBA

36 GND GND GND GND GND

37 RP_ENET2_TX1- RP_ENET2_TX1+ GND RP_ENET2_TX0- RP_ENET2_TX0+

38 GND GND GND GND GND

39 RP_ENET2_RX1- RP_ENET2_RX1+ GND RP_ENET2_RX0- RP_ENET2_RX0+

40 GND GND GND GND GND

41 BP_CMC_TX1- BP_CMC_TX1+ GND BP_CMC_TX0- BP_CMC_TX0+

42 GND GND GND GND GND

43 BP_CMC_RX1- BP_CMC_RX1+ GND BP_CMC_RX0- BP_CMC_RX0+

44 GND GND GND GND GND

45 BP_CMCX_TX1- BP_CMCX_TX1+ GND BP_CMCX_TX0- BP_CMCX_TX0+

46 GND GND GND GND GND

47 BP_CMCX_RX1- BP_CMCX_RX1+ GND BP_CMCX_RX0- BP_CMCX_RX0+

48 GND GND GND GND GND

Table 13 shows the staging of the power connector pins.