Page 1

Revision 1.42

November 2015

Intel® Storage Server System JBOD

2000 Family

Hardware Guide

Page 2

Revision History Intel® Storage Server System JBOD 2000 Family Hardware Guide

ii

Date

Revision

Number

Modifications

December 2012

0.9

Pre-production release.

March 2013

1.0

First release.

July 2013

1.05

Removed Chapter 9 and Appendix A.

September 2013

1.1

Restructured the document.

Added chapter for external connection mode.

November 2013

1.2

Removed JBOD2224S2SP( 2.5”, single port SKU) related content

March 2014

1.3

Removed original section 4.6.13 about power recovery

September 2014

1.4

Removed the description of SMBus connector on the HSBP, as they are not

used.

January 2015

1.41

Removed qualified mini-SAS cable list as many models have been EOL’ed by

vendors

November 2015

1.42

Removed PSU Cold Redundancy support

Added verbiage mentioning the spare PSU does not include a power

cord and added reference to the Config. Guide.

Revision History

Revision 1.42

Page 3

Intel® Storage Server System JBOD 2000 Family Disclaimers

iii

Disclaimers

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL PRODUCTS. NO LICENSE,

EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS

GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR

SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER AND INTEL DISCLAIMS ANY EXPRESS OR

IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR

WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR

INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

A "Mission Critical Application" is any application in which failure of the Intel Product could result, directly or indirectly,

in personal injury or death. SHOULD YOU PURCHASE OR USE INTEL'S PRODUCTS FOR ANY SUCH MISSION

CRITICAL APPLICATION, YOU SHALL INDEMNIFY AND HOLD INTEL AND ITS SUBSIDIARIES,

SUBCONTRACTORS AND AFFILIATES, AND THE DIRECTORS, OFFICERS, AND EMPLOYEES OF EACH,

HARMLESS AGAINST ALL CLAIMS COSTS, DAMAGES, AND EXPENSES AND REASONABLE ATTORNEYS'

FEES ARISING OUT OF, DIRECTLY OR INDIRECTLY, ANY CLAIM OF PRODUCT LIABILITY, PERSONAL

INJURY, OR DEATH ARISING IN ANY WAY OUT OF SUCH MISSION CRITICAL APPLICATION, WHETHER OR

NOT INTEL OR ITS SUBCONTRACTOR WAS NEGLIGENT IN THE DESIGN, MANUFACTURE, OR WARNING OF

THE INTEL PRODUCT OR ANY OF ITS PARTS.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not

rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined". Intel reserves

these for future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from

future changes to them. The information here is subject to change without notice. Do not finalize a design with this

information.

The products described in this document may contain design defects or errors known as errata which may cause the

product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your

product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may

be obtained by calling 1-800-548-4725, or go to: http://www.intel.com/design/literature.

Revision 1.42

Page 4

Table of Contents Intel® Storage Server System JBOD 2000 Family Hardware Guide

iv

Table of Contents

1. Introduction ........................................................................................................................ 1

1.1 Server Product Use Disclaimer .............................................................................. 1

1.2 Product Errata ........................................................................................................ 1

2. Product Family Overview ................................................................................................... 2

2.1 Chassis Dimensions ............................................................................................... 4

2.2 System Level Environmental Limits ........................................................................ 5

2.3 System Features and Options Overview ................................................................ 7

2.3.1 Hot Swap Hard Drive Bay and Front Panel Options ............................................... 7

2.3.2 Front Panel Options ............................................................................................... 8

2.3.3 Back Panel Features ............................................................................................ 10

3. System Storage and Peripheral Drive Bays Overview ................................................... 11

3.1 2.5” Hard Disk Drive Support ................................................................................ 11

3.1.1 2.5” Drive Hot-Swap Backplane Overview ............................................................ 13

3.1.2 Cypress* CY8C22545 Enclosure Management Controller .................................... 14

3.2 3.5” Hard Disk Drive Support ................................................................................ 15

3.2.1 3.5” Drive Hot-Swap Backplane Overview ............................................................ 16

3.2.2 Cypress* CY8C22545 Enclosure Management Controller .................................... 17

4. Power Subsystem ............................................................................................................. 18

4.1 Power Distribution Board (PDB) ........................................................................... 19

4.2 Mechanical Overview ........................................................................................... 23

4.3 Power Connectors ................................................................................................ 24

4.3.1 Power Supply Module Card Edge Connector ....................................................... 24

4.3.2 Hot-Swap Backplane Power Connector................................................................ 25

4.4 Power Supply Module Efficiency .......................................................................... 25

4.5 AC Power Cord Specification Requirements ........................................................ 25

4.6 AC Input Specifications ........................................................................................ 26

4.6.1 Power Factor ........................................................................................................ 26

4.6.2 AC Input Voltage Specification ............................................................................. 26

4.6.3 AC Line Isolation Requirements ........................................................................... 26

4.6.4 AC Line Dropout/Holdup ...................................................................................... 26

4.6.5 AC Line Fuse ....................................................................................................... 27

4.6.6 AC Inrush ............................................................................................................. 27

4.6.7 AC Line Transient Specification ........................................................................... 27

4.6.8 Susceptibility Requirements ................................................................................. 28

4.6.9 Electrostatic Discharge Susceptibility ................................................................... 28

4.6.10 Fast Transient/Burst ............................................................................................. 28

4.6.11 Radiated Immunity ............................................................................................... 28

4.6.12 Surge Immunity .................................................................................................... 28

4.6.13 Voltage Interruptions ............................................................................................ 29

Revision 1.42

Page 5

Intel® Storage Server System JBOD 2000 Family Hardware Guide Table of Contents

v

4.6.14 Protection Circuits ................................................................................................ 29

4.6.15 Over Current Protection (OCP) ............................................................................ 29

4.6.16 Over Voltage Protection (OVP) ............................................................................ 29

4.6.17 Over Temperature Protection (OTP) .................................................................... 30

4.7 Power Supply Status LED .................................................................................... 31

5. Thermal Management ....................................................................................................... 32

5.1 Thermal Operation and Configuration Requirements ............................................ 32

5.2 Thermal Management Overview .......................................................................... 32

5.3 Thermal Sensor Input for Fan Speed Control ....................................................... 33

5.4 System Fans ........................................................................................................ 33

5.5 Power Supply Module Fan ................................................................................... 34

6. JBOD 2000 Internal Connection Overview ...................................................................... 35

6.1 Expander Board ................................................................................................... 35

6.2 JBOD SAS Interface Board .................................................................................. 37

6.2.1 JBOD SAS Interface Board Port Numbering ........................................................ 37

6.3 Pin-outs ................................................................................................................ 38

6.3.1 JBOD2312S2SP Interconnection ......................................................................... 39

6.3.2 JBOD2224S2DP Interconnection ......................................................................... 42

7. JBOD 2000 External SAS Connection Mode Overview .................................................. 45

7.1 External SAS Controller Support .......................................................................... 45

7.2 External SAS Cable.............................................................................................. 45

7.3 Hard Drive Type ................................................................................................... 46

7.4 JBOD Cascade .................................................................................................... 46

7.5 Single-port JBOD 2000 External Connection Mode .............................................. 46

7.5.1 Single JBOD 2000 Connection ............................................................................. 46

7.5.2 Two JBOD 2000 Cascade .................................................................................... 47

7.5.3 Dual-path Connection ........................................................................................... 48

7.5.4 Dual-path with Cascaded JBOD 2000 .................................................................. 48

7.6 Dual-port JBOD 2000 External Connection Mode ................................................ 49

7.6.1 Dual-domain SAS for Dual-port JBOD 2000 ......................................................... 49

7.6.2 Dual-domain SAS for Cascaded Dual-port JBOD 2000 ........................................ 50

7.6.3 Dual-domain SAS for Two-node Cluster ............................................................... 51

Reference Documents ............................................................................................................ 53

Revision 1.42

Page 6

List of Figures Intel® Storage Server System JBOD 2000 Family Hardware Guide

vi

List of Figures

Figure 1. 24 x 2.5” Drive JBOD 2000 Product Drawing ............................................................... 2

Figure 2. 12 x 3.5” Drive JBOD 2000 Product Drawing ............................................................... 3

Figure 3. Chassis Dimensions ..................................................................................................... 4

Figure 4. System Components Overview .................................................................................... 7

Figure 5. 12 x 3.5" Drive JBOD2000 Front View ......................................................................... 7

Figure 6. 24 x 2.5" Drive JBOD2000 Front View ......................................................................... 7

Figure 7. Front Panel Options ..................................................................................................... 8

Figure 8. Single-port Backplane JBOD2000 Back View ............................................................ 10

Figure 9. Dual-port Backplane JBOD2000 Back View ............................................................... 10

Figure 10. 2.5" Hard Drive Bay – 24-Drive Configuration .......................................................... 11

Figure 11. 2.5” Drive Tray Assembly ......................................................................................... 11

Figure 12. Status and Activity LED on 2.5” Drive Tray ............................................................... 12

Figure 13. 2.5” Hot-Swap Backplane and Drive Bay Assembly ................................................. 13

Figure 14. SFF-8482 Connector on HSBP ................................................................................ 13

Figure 15. Components on dual port 2.5” HSBP ....................................................................... 14

Figure 16. 3.5” Hard Drive Bay – 12-Drive Configuration .......................................................... 15

Figure 17. 3.5” Drive Tray Assembly ......................................................................................... 15

Figure 18. Status and Activity LED on 3.5” Drive Tray ............................................................... 15

Figure 19. 3.5” Hot-Swap Backplane and Drive Bay Assembly ................................................. 16

Figure 20. SFF-8482 Connector on 3.5” HSBP ......................................................................... 16

Figure 21. Components on 3.5” HSBP ...................................................................................... 17

Figure 22. Power Supply Assembly ........................................................................................... 18

Figure 23. Power Distribution Board (PDB) ............................................................................... 19

Figure 24. PDB Component Placement .................................................................................... 20

Figure 25. Fan Fault LED Block Diagram .................................................................................. 22

Figure 26. Power Supply Module Mechanical Drawing .............................................................. 23

Figure 27. Power Supply Module .............................................................................................. 23

Figure 28. AC Power Supply – Connector View ........................................................................ 23

Figure 29. AC Power Cord ........................................................................................................ 25

Figure 30. System Fan Identification ......................................................................................... 33

Figure 31. System Fan Assembly.............................................................................................. 34

Figure 32. Internal SAS Expander Location .............................................................................. 36

Figure 33. JBOD 2000 SAS Interface Board Port Number ........................................................ 37

Figure 34. 12x3.5” Single-port JBOD 2000 Interconnection Diagram ........................................ 39

Figure 35. Primary SAS Expander ............................................................................................ 40

Figure 36. 2U 24x2.5” Dual-port JBOD2000 Interconnection Diagram ...................................... 42

Figure 37. Secondary SAS Expander ........................................................................................ 44

Figure 38. SFF-8088 mini-SAS Cable ....................................................................................... 45

Figure 39. Single JBOD 2000 Connection ................................................................................. 46

Revision 1.42

Page 7

Intel® Storage Server System JBOD 2000 Family Hardware Guide List of Figures

vii

Figure 40. Two Single-port JBOD 2000 Cascade ...................................................................... 47

Figure 41. Two Groups of Cascaded Single-port JBOD 2000 ................................................... 47

Figure 42. Dual-path Connection .............................................................................................. 48

Figure 43. Dual-path with Cascaded JBOD 2000 ...................................................................... 48

Figure 44. Dual-domain SAS for Dual-port JBOD 2000 ............................................................. 49

Figure 45. Two SAS Controllers Dual-domain SAS Connection ................................................ 50

Figure 46. Dual-domain SAS for Cascaded Dual-port JBOD 2000 ............................................ 50

Figure 47. Dual-domain SAS for a Two-node Cluster ................................................................ 51

Figure 48. Cascaded JBOD 2000 for a Two-node Cluster ......................................................... 52

Revision 1.42

Page 8

List of Tables Intel® Storage Server System JBOD 2000 Family Hardware Guide

viii

List of Tables

Table 1. System Feature Set ....................................................................................................... 2

Table 2. System Environmental Limits Summary ........................................................................ 5

Table 3. Power LED Functional States ........................................................................................ 8

Table 4. System Status LED State Definitions............................................................................. 8

Table 5. Drive Status LED States .............................................................................................. 12

Table 6. Drive Activity LED States............................................................................................. 12

Table 7. Status LED Status ....................................................................................................... 15

Table 8. Activity LED Status ...................................................................................................... 16

Table 9. Power Supply Module Output Power Connector Pin-out ............................................. 24

Table 10. Hot-swap Backplane Power Connector Pin-out (“HSBP PWR”) ................................. 25

Table 11. 460 Watt Power Supply Efficiency (Gold) .................................................................. 25

Table 12. AC Power Cord Specifications................................................................................... 25

Table 13. Power Factor ............................................................................................................. 26

Table 14. AC Input Voltage Range ............................................................................................ 26

Table 15. AC Line Dropout/Holdup ............................................................................................ 27

Table 16. AC Line Sag Transient Performance ......................................................................... 27

Table 17. AC Line Surge Transient Performance ...................................................................... 28

Table 18. Performance Criteria ................................................................................................. 28

Table 19. 460 Watt Power Supply Over Current Protection ....................................................... 29

Table 20. Over Voltage Protection (OVP) Limits ....................................................................... 30

Table 21. LED Indicators ........................................................................................................... 31

Table 22. System Fan Connector Pin-out .................................................................................. 34

Table 23. SGPIO Headers Pin-out ............................................................................................ 38

Table 24. 12x3.5” Single-port JBOD 2000 Internal Components ............................................... 40

Table 25. Primary SAS Expander in 12x3.5” Single-port JBOD 2000 Connector Mapping ........ 41

Table 26. 2U 24x2.5” Dual-port JBOD2000 Components .......................................................... 43

Table 27. Primary SAS Expander in 24x2.5” Dual-port JBOD 2000 Connector Mapping ........... 44

Table 28. Second SAS Expander in 24x2.5” Dual-port JBOD 2000 Connector Mapping ........... 44

Revision 1.42

Page 9

Intel® Storage Server System JBOD 2000 Family Hardware Guide List of Tables

ix

< This page intentionally left blank. >

Revision 1.42

Page 10

Page 11

Intel® Storage Server System JBOD 2000 Family Hardware Guide Introduction

1

1. Introduction

This Hardware Guide provides system-level information for the Intel® Storage Server System

JBOD 2000 Family.

This document describes the functions and features of JBOD product that includes the chassis

layout, system boards, power subsystem, cooling subsystem, storage subsystem options, and

available installable options.

This document is divided into the following chapters:

Chapter 1 – Introduction

Chapter 2 – Product Family Overview

Chapter 3 – System Storage and Peripheral Drive Bays Overview

Chapter 4 – Power Subsystem

Chapter 5 – Thermal Management

Chapter 6 – JBOD 2000 Internal Connection Overview

Chapter 7 – JBOD 2000 External SAS Connection Mode Overview

Appendix A – Qualified External Mini-SAS Cable List

Reference Documents

1.1 Server Product Use Disclaimer

It is the responsibility of the system integrator who chooses not to use Intel-developed server

building blocks to consult vendor datasheets and operating parameters to determine the amount

of airflow required for their specific application and environmental conditions. Intel Corporation

cannot be held responsible if components fail to operate correctly when used outside any of

their published operating or non-operating limits.

1.2 Product Errata

The products described in this document may contain design defects or errors known as errata

which may cause the product to deviate from published specifications. Product Errata are

documented in the Intel® Storage Server System JBOD 2000 Family Monthly Specification

Update which can be downloaded from http://www.Intel.com.

Revision 1.42

Page 12

Product Family Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

2

Intel® Storage Server System JBOD

2000 Family

Description

JBOD2224S2DP

2U JBOD supports 24 x 2.5” drives, with a dual-port backplane.

JBOD2312S2SP

2U JBOD supports 12 x 3.5” drives, with a single-port backplane.

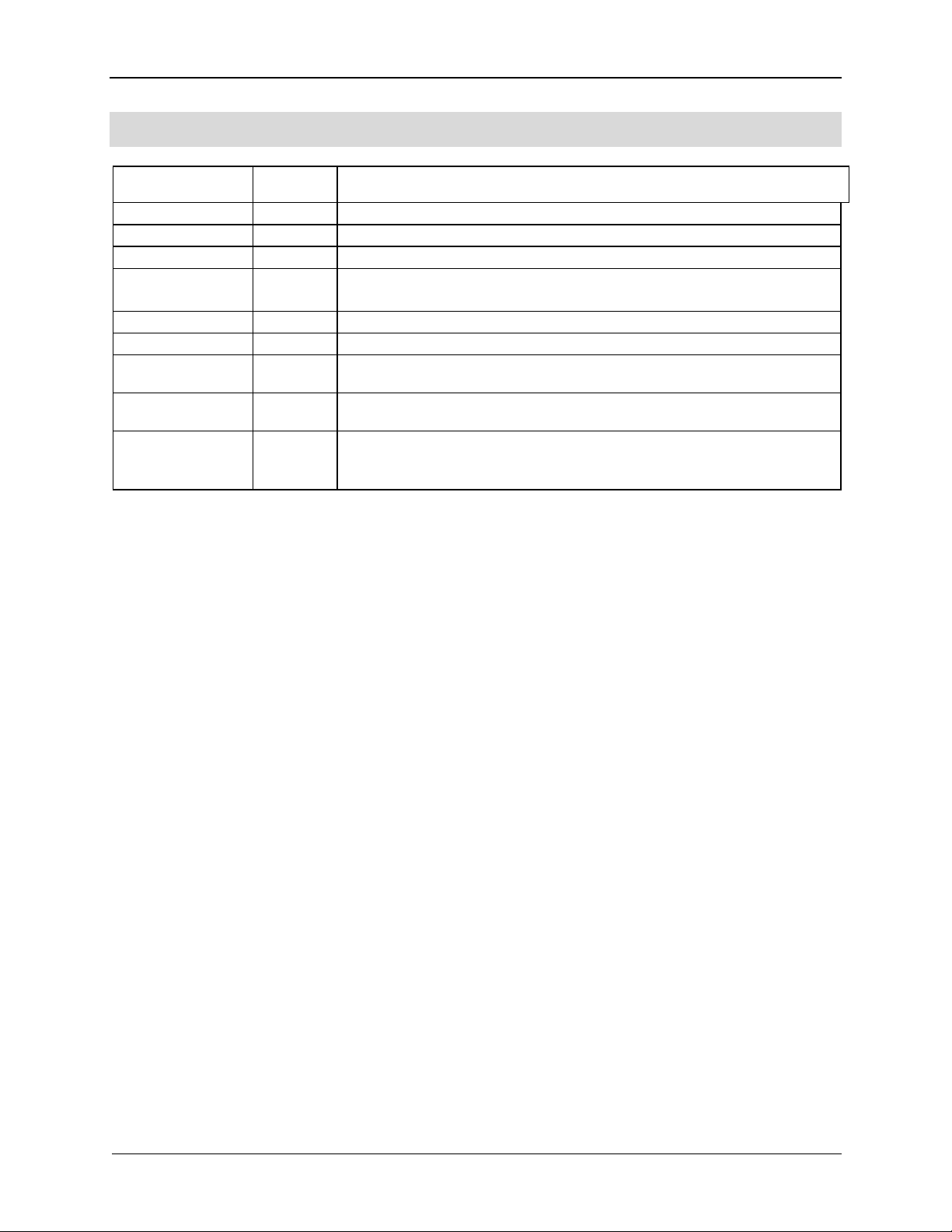

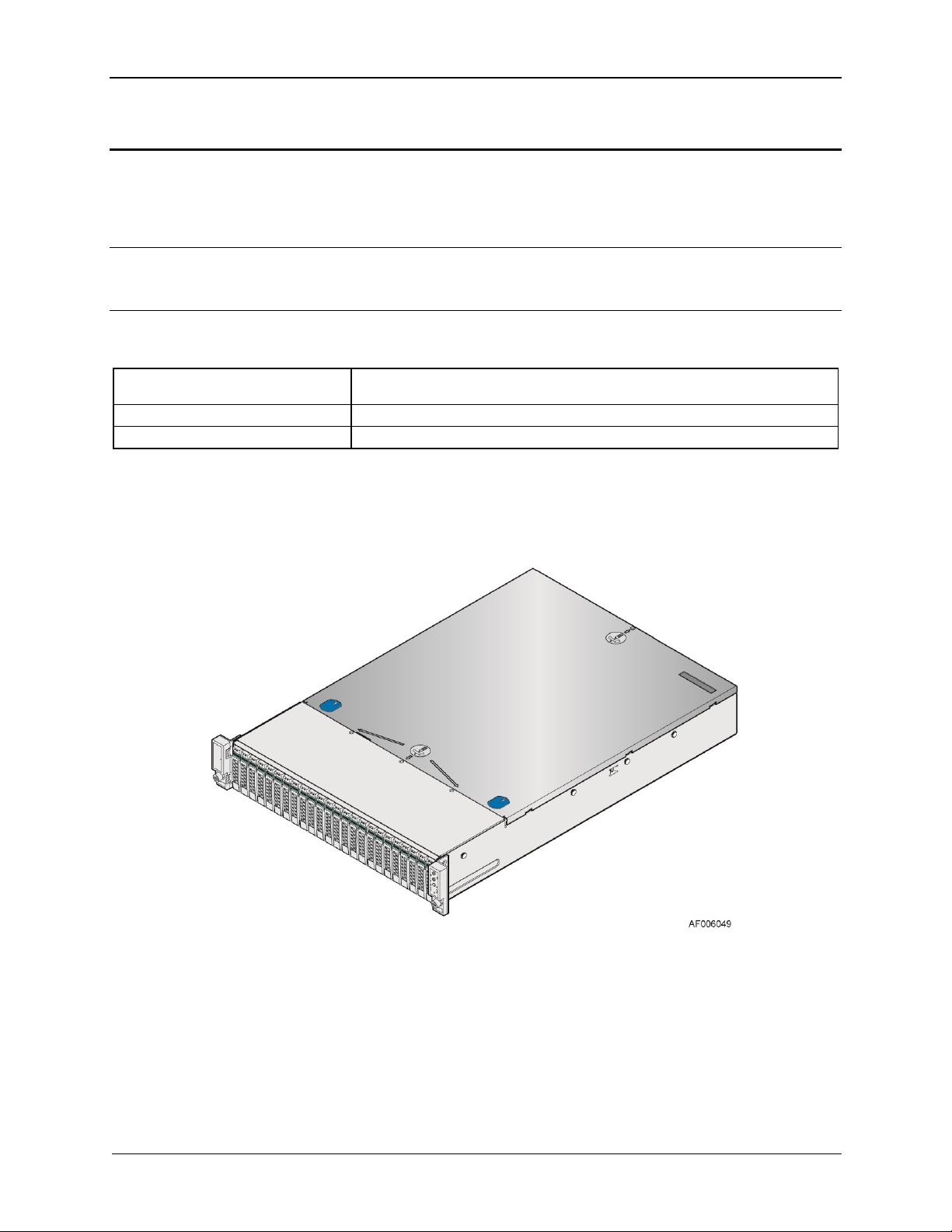

2. Product Family Overview

This generation of Intel® Storage Server System JBOD 2000 Family offers a variety of options to

meet the configuration requirements of high-density high-performance computing environments.

The Intel® Storage Server System JBOD 2000 Family is comprised of three product offerings.

Note: The following table lists features common to the Intel® Storage Server System JBOD 2000

Family. Features that are unique to one product in the family are identified by denoting the full

JBOD Product Code name.

Table 1. System Feature Set

This chapter provides a high-level overview of the Intel® Storage Server System JBOD 2000

Family features and available options as supported in different JBOD SKUs. Greater detail for

each major system component or feature is provided in the following chapters.

Figure 1. 24 x 2.5” Drive JBOD 2000 Product Drawing

Revision 1.42

Page 13

Intel® Storage Server System JBOD 2000 Family Hardware Guide Product Family Overview

3

Figure 2. 12 x 3.5” Drive JBOD 2000 Product Drawing

Revision 1.42

Page 14

Product Family Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

4

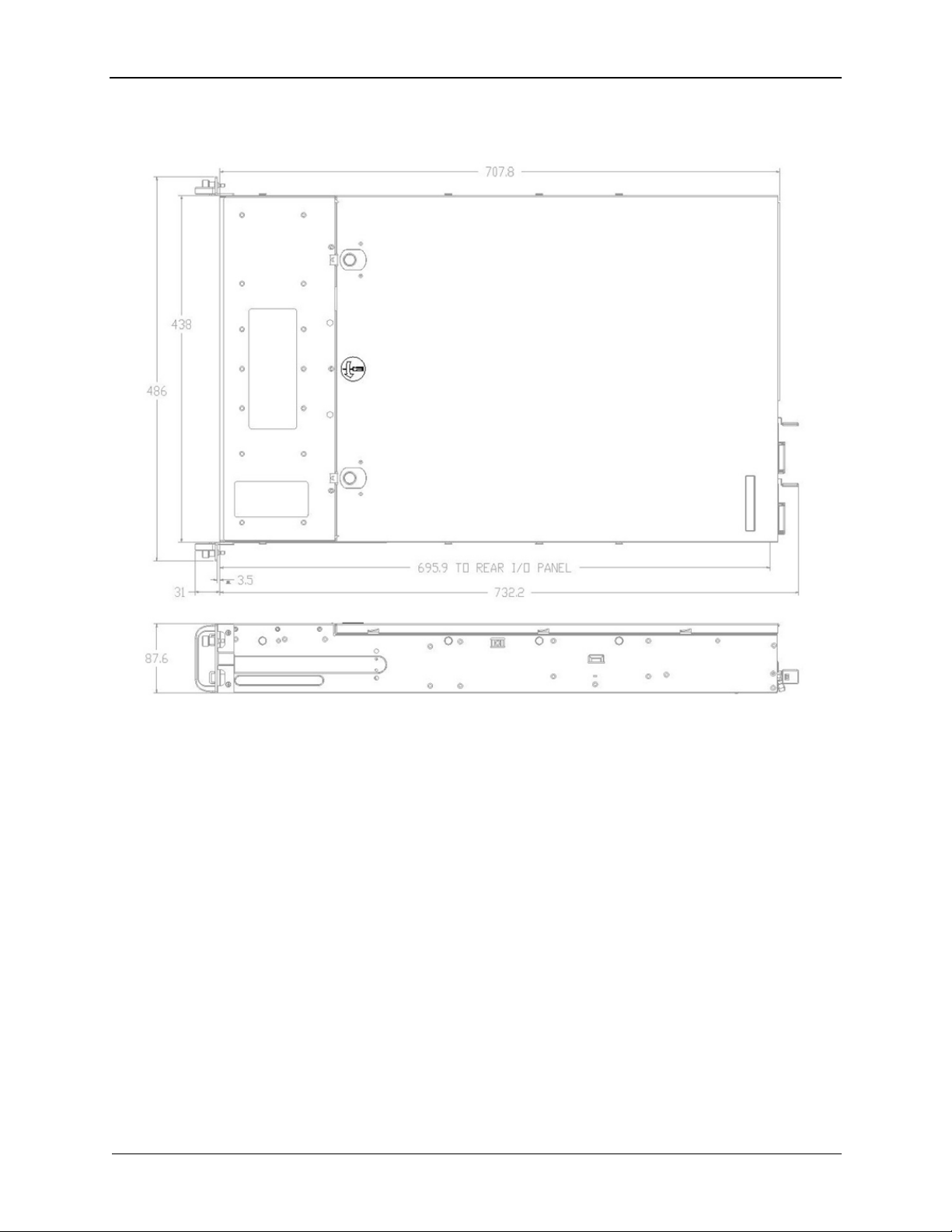

2.1 Chassis Dimensions

Figure 3. Chassis Dimensions

Revision 1.42

Page 15

Intel® Storage Server System JBOD 2000 Family Hardware Guide Product Family Overview

5

Parameter

Limits

Temperature

Operating

ASHRAE Class A2 – Continuous Operation. 10ºC to 35ºC 1 (50ºF to 95ºF) with

the maximum rate of change not to exceed 10ºC per hour.

ASHRAE Class A3 – Includes operation up to 40ºC for up to 900 hrs per year.

ASHRAE Class A4 – Includes operation up to 45ºC for up to 90 hrs per year.

Shipping

-40ºC to 70ºC (-40ºF to 158ºF)

Altitude

Operating

Support operation up to 3050m with ASHRAE class deratings.

Humidity

Shipping

50% to 90%, non-condensing with a maximum wet bulb of 28ºC (at

temperatures from 25ºC to 35ºC)

Shock

Operating

Half sine, 2g, 11 mSec

Unpackaged

Trapezoidal, 25g, velocity change is based on packaged weight

Packaged

Product Weight: ≥ 40 to < 80

Non-palletized Free Fall Height = 18 inches

Palletized (single product) Free Fall Height = NA

Vibration

Unpackaged

5 Hz to 500 Hz 2.20 g RMS random

Packaged

5 Hz to 500 Hz 1.09 g RMS random

AC-DC

Voltage

90 V AC to 132 V AC and 180 V AC to 264 V AC

Frequency

47 Hz to 63 Hz

Source Interrupt

No loss of data for power line drop-out of 12 mSec

Surge Nonoperating and

operating

Unidirectional

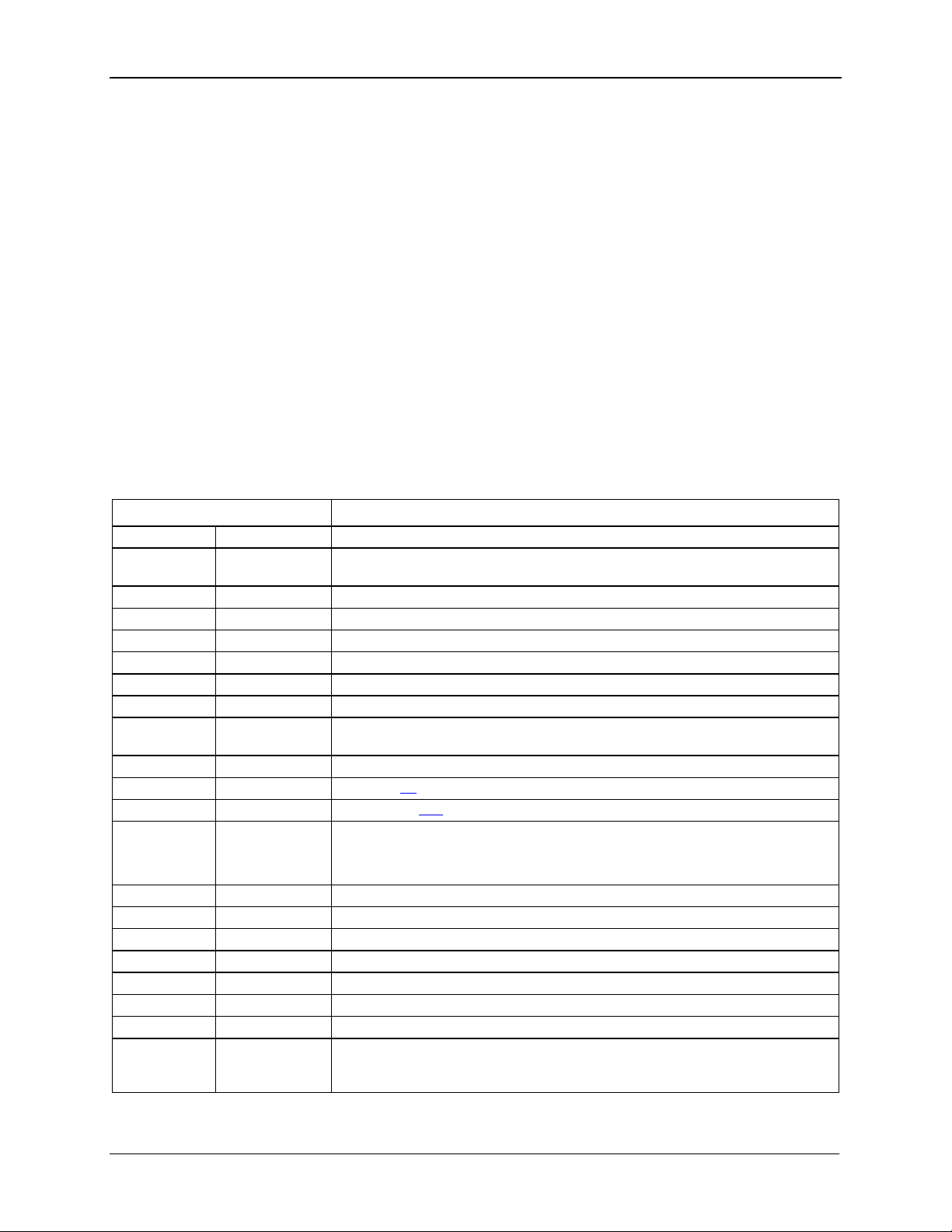

2.2 System Level Environmental Limits

To keep the system operating within supported maximum thermal limits, the system must meet

the following operating and configuration guidelines:

The system operating ambient is designed for sustained operation up to 35ºC (ASHRAE

Class A2) with short-term excursion-based operation up to 45ºC (ASHRAE Class A4).

- The system can operate up to 40ºC (ASHRAE Class A3) for up to 900 hours per

year.

- The system can operate up to 45ºC (ASHRAE Class A4) for up to 90 hours per year.

- When operating within the extended operating temperature range, the system

performance may be impacted.

- There is no system reliability impact when operating at the extended temperature

range within the approved limits.

The following table defines the system level operating and non-operating environmental limits.

Table 2. System Environmental Limits Summary

Revision 1.42

Page 16

Product Family Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

6

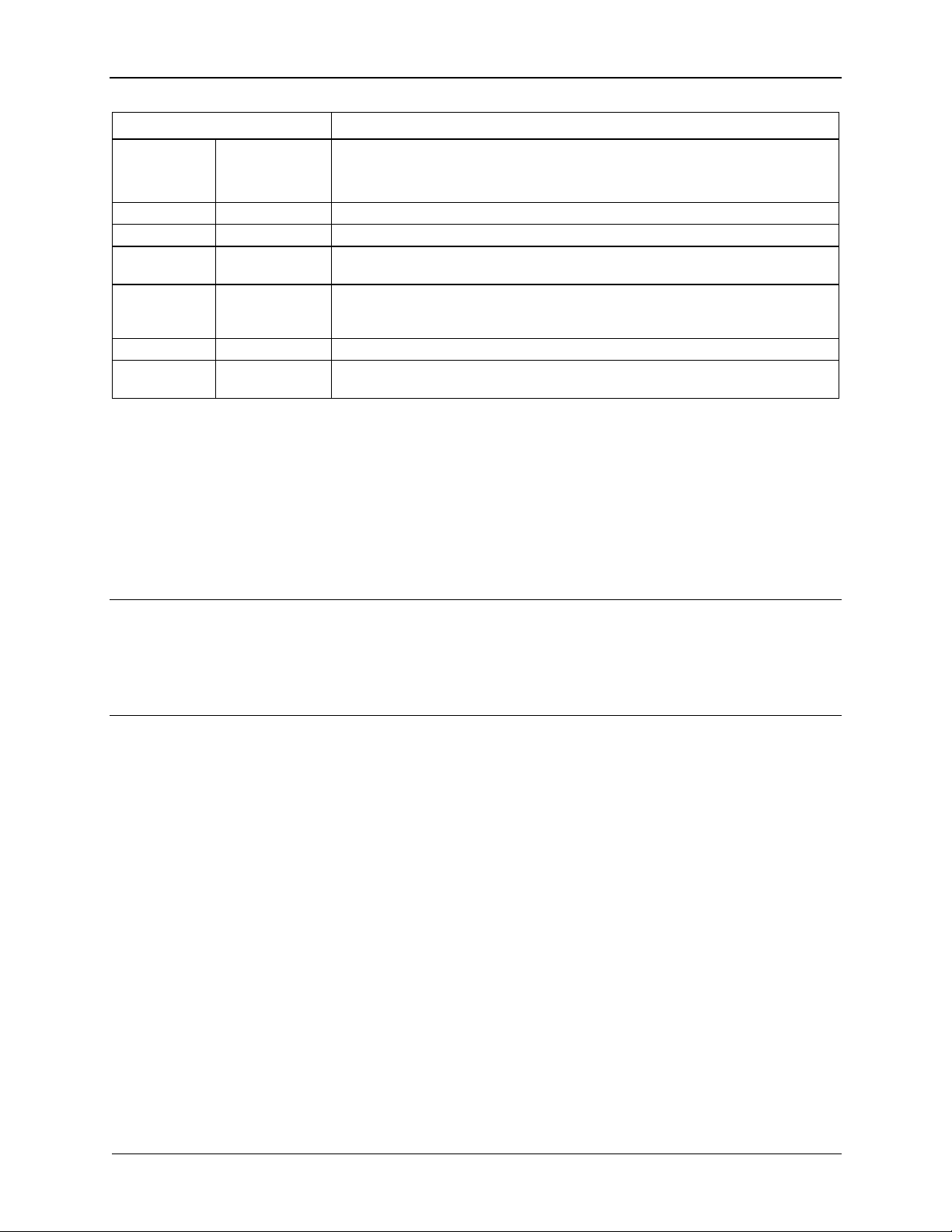

Parameter

Limits

Line to earth

Only

AC Leads 2.0 kV

I/O Leads 1.0 kV

DC Leads 0.5 kV

ESD

Air Discharged

12.0 kV

Contact

Discharge

8.0 kV

Acoustics

Sound Power

Measured

Power in Watts

<300 W ≥300 W ≥600 W ≥1000 W

Servers/Rack

Mount BA

7.0 7.0 7.0 7.0

Note:

1.

Intel Corporation server boards contain a number of high-density VLSI and power delivery components

that need adequate airflow to cool. Intel ensures through its own chassis development and testing that

when Intel server building blocks are used together, the fully integrated system will meet the intended

thermal requirements of these components. It is the responsibility of the system integrator who

chooses not to use Intel developed server building blocks to consult vendor datasheets and operating

parameters to determine the amount of airflow required for their specific application and environmental

conditions. Intel Corporation cannot be held responsible if components fail or the server board does not

operate correctly when used outside any of its published operating or non-operating limits.

Disclaimer Note: Intel ensures the unpackaged server board and system meet the shock

requirement mentioned above through its own chassis development and system configuration. It

is the responsibility of the system integrator to determine the proper shock level of the board

and system if the system integrator chooses different system configuration or different chassis.

Intel Corporation cannot be held responsible, if components fail or the server board does not

operate correctly when used outside any of its published operating or non-operating limits.

Revision 1.42

Page 17

Intel® Storage Server System JBOD 2000 Family Hardware Guide Product Family Overview

7

2.3 System Features and Options Overview

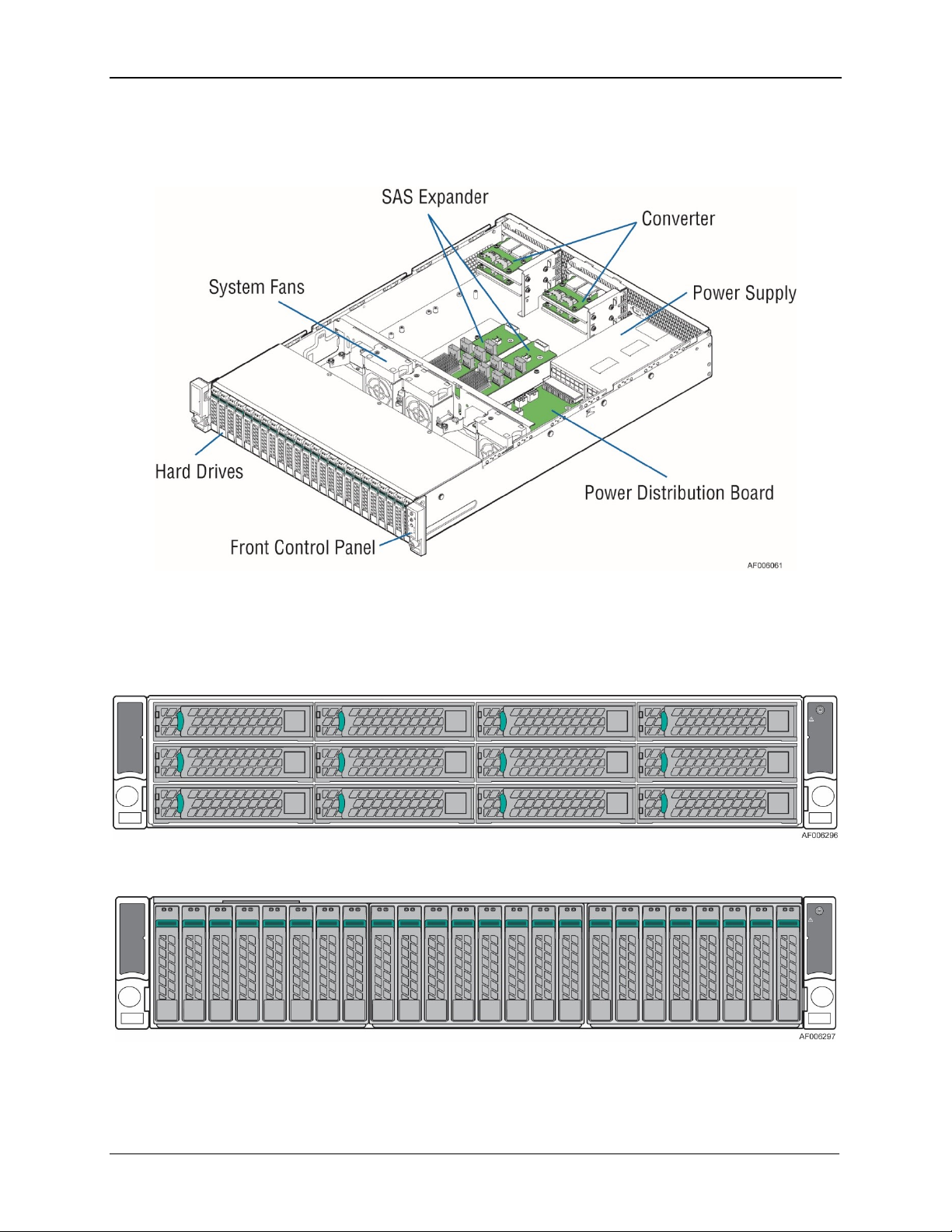

Figure 4. System Components Overview

2.3.1 Hot Swap Hard Drive Bay and Front Panel Options

Figure 5. 12 x 3.5" Drive JBOD2000 Front View

Figure 6. 24 x 2.5" Drive JBOD2000 Front View

Revision 1.42

Page 18

Product Family Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

8

Label

Description

A

Power Button w/Integrated LED

B

System Status LED

State

Power Mode

LED

Description

Power-off

Non-ACPI

Off

System power is off.

Power-on

Non-ACPI

On

System power is on.

Color

State

Criticality

Description

Off

System is not

operating

Not ready

The system is powered off (AC and/or DC).

Green

Solid on

Ok

Indicates that the system status is “healthy”. The system is not

exhibiting any errors. AC power is present and the system is

either in a standby state or has been powered on.

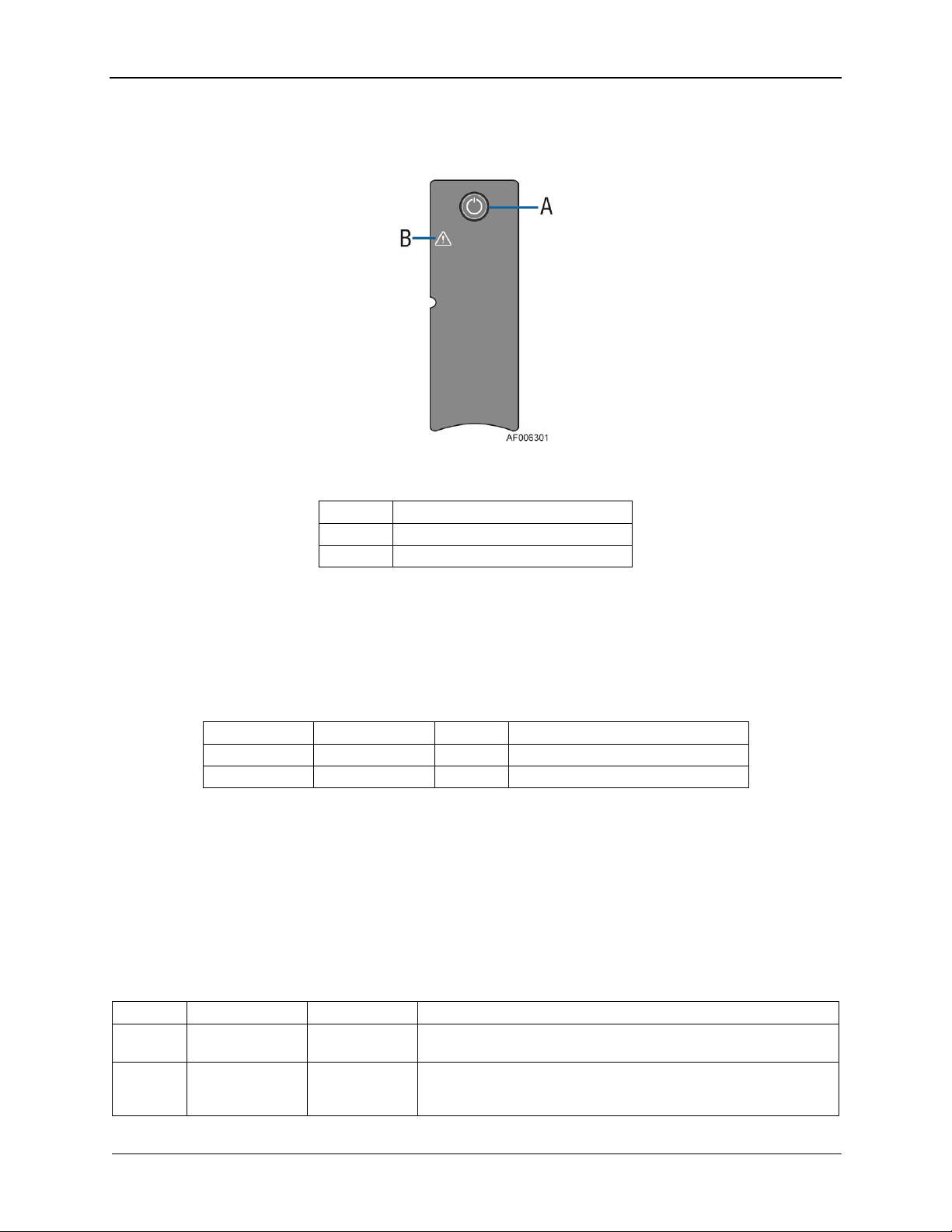

2.3.2 Front Panel Options

Figure 7. Front Panel Options

The Power Button toggles the system power on and off. Pressing this button sends a signal to

the integrated PDB board, which either powers on or powers off the system. The integrated LED

is a single-color (Green) indicator that supports different states as defined in the following table.

Table 3. Power LED Functional States

The System Status LED is a bi-color (Green/Amber) indicator that shows the current health of

the server system. The system provides two locations for this feature: one is located on the

Front Control Panel, and the other is located on the back edge of the server board, viewable

from the back of the system. Both LEDs are tied together and show the same state. The System

Status LED states are driven by the on-board platform management subsystem. The following

table provides a description of each supported LED state.

Table 4. System Status LED State Definitions

Revision 1.42

Page 19

Intel® Storage Server System JBOD 2000 Family Hardware Guide Product Family Overview

9

Color

State

Criticality

Description

Amber

Solid on

SMBUS Alert

Event

Encountered

P12V is out of its limits.

P5V is out of its limits.

A fan fault has been detected.

An over temperature event has been detected.

P3V3 is out of its limits.

Remote 1 and/or Remote 2 temperature sensor is either

open or shorted.

Revision 1.42

Page 20

Product Family Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

10

Label

Description

A

SFF-8088 receptacle (label: A PRI)

B

SFF-8088 receptacle (label: B PRI)

C

PSU

Label

Description

A

SFF-8088 receptacle (label: A PRI)

B

SFF-8088 receptacle (label: B PRI)

C

SFF-8088 receptacle (label: A SEC)

D

SFF-8088 receptacle (label: B SEC)

E

SFF-8088 receptacle (label: C SEC)

F

SFF-8088 receptacle (label: C PRI)

G

PSU 1

H

PSU 2

2.3.3 Back Panel Features

Figure 8. Single-port Backplane JBOD2000 Back View

Figure 9. Dual-port Backplane JBOD2000 Back View

Revision 1.42

Page 21

Intel® Storage Server System JBOD 2000 Family Hardware Guide System Storage and Peripheral Drive Bays Overview

11

3. System Storage and Peripheral Drive Bays Overview

The Intel® Storage Server System JBOD2000 product family supports the following storage

device options:

Hot-swap 2.5” hard disk drives

Hot-swap 3.5” hard disk drives

3.1 2.5” Hard Disk Drive Support

The server is available in 2.5” hard disk configurations of 24 drives as illustrated below.

Figure 10. 2.5" Hard Drive Bay – 24-Drive Configuration

The drive bay can support either SATA or SAS hard disk drives. Mixing of drive types within a

common hot-swap backplane is not supported. Systems with multiple hot-swap backplanes can

support different drive type configurations as long as the drives attached to a common

backplane are the same and the installed controller attached to the given backplane can support

the drive type. Hard disk drive type is dependent on the type of host bus controller used, SATA

only or SAS.

Each 2.5” hard disk drive is mounted to a drive tray, allowing for hot-swap extraction and

insertion. Drive trays have a latching mechanism that is used to extract and insert the drives

from the chassis, and lock the tray in place.

Figure 11. 2.5” Drive Tray Assembly

Revision 1.42

Page 22

System Storage and Peripheral Drive Bays Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

12

Amber

Off

No access and no fault.

Solid on

Hard drive fault has occurred.

Blink

RAID rebuild in progress (1 Hz);

Identify (2 Hz).

Green

Condition

Drive Type

Behavior

Power on with no drive

activity

SAS

LED stays on.

SATA

LED stays off.

Power on with drive

activity

SAS

LED blinks off when processing a command.

SATA

LED blinks on when processing a command.

Power on and drive

spun down

SAS

LED stays off.

SATA

LED stays off.

Power on and drive

spinning up

SAS

LED blinks.

SATA

LED stays off.

Light pipes integrated into the drive tray assembly direct the light emitted from Amber drive

status and Green activity LEDs located next to each drive connector on the backplane, to the

drive tray faceplate, making them visible from the front of the system.

Figure 12. Status and Activity LED on 2.5” Drive Tray

Table 5. Drive Status LED States

Table 6. Drive Activity LED States

Revision 1.42

Page 23

Intel® Storage Server System JBOD 2000 Family Hardware Guide System Storage and Peripheral Drive Bays Overview

13

3.1.1 2.5” Drive Hot-Swap Backplane Overview

Depending on the number of hard disk drives supported by a given system SKU, a system can

be configured with one, two, or three 8-drive backplanes. Each backplane is attached to the

back of the drive bay assembly.

Figure 13. 2.5” Hot-Swap Backplane and Drive Bay Assembly

On the front side of each backplane are mounted eight hard disk drive interface connectors (A),

each providing both power and I/O signals to the attached hard disk drives.

Figure 14. SFF-8482 Connector on HSBP

Revision 1.42

Page 24

System Storage and Peripheral Drive Bays Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

14

Label

Description

A

SMBus-Out cable connector (not used)

B

mini-SAS cable connectors

C

SMBus-In cable connector (not used)

D

Power connector

On the back side of each backplane are several connectors. The following illustration identifies

each.

Figure 15. Components on dual port 2.5” HSBP

B – Multi-port Mini-SAS Cable Connectors – The backplane includes two pair of multi-port mini-

SAS cable connectors. Each pair contains primary SAS port and second SAS port providing

SGPIO and I/O signals for four SAS/SATA hard drives on the backplane. Cables can be routed

from matching connectors on the server board, installed add-in SAS/SATA RAID cards, or

optionally installed SAS expander cards for drive configurations of greater than eight hard

drives.

D – Power Harness Connector – The backplane includes a 2x2 connector supplying power to

the backplane. Power is routed to each installed backplane via a multi-connector power cable

harness from the server board.

3.1.2 Cypress* CY8C22545 Enclosure Management Controller

The backplanes support enclosure management using a Cypress* CY8C22545 Programmable

System-on-Chip (PSoC*) device. The CY8C22545 drives the hard drive activity/fault LED, hard

drive present signal, and controls hard drive power-up during system power-on.

Revision 1.42

Page 25

Intel® Storage Server System JBOD 2000 Family Hardware Guide System Storage and Peripheral Drive Bays Overview

15

Amber

Off

No access and no fault.

Solid on

Hard drive fault has occurred.

Blink

RAID rebuild in progress (1 Hz);

Identify (2 Hz).

3.2 3.5” Hard Disk Drive Support

The server is available in 3.5” hard disk configurations of 12 drives as illustrated below.

Figure 16. 3.5” Hard Drive Bay – 12-Drive Configuration

The drive bay can support either SATA or SAS hard disk drives. Mixing of drive types within the

hard drive bay is not supported. Hard disk drive type is dependent on the type of host bus

controller used, SATA only or SAS. Each 3.5” hard disk drive is mounted to a drive tray,

allowing for hot-swap extraction and insertion. Drive trays have a latching mechanism that is

used to extract and insert the drives from the chassis, and lock the tray in place.

Figure 17. 3.5” Drive Tray Assembly

Light pipes integrated into the drive tray assembly direct the light emitted from Amber drive

status and Green activity LEDs located next to each drive connector on the backplane, to the

drive tray faceplate, making them visible from the front of the system.

Figure 18. Status and Activity LED on 3.5” Drive Tray

Table 7. Status LED Status

Revision 1.42

Page 26

System Storage and Peripheral Drive Bays Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

16

Green

Condition

Drive Type

Behavior

Power on with no drive

activity

SAS

LED stays on.

SATA

LED stays off.

Power on with drive

activity

SAS

LED blinks off when processing a command.

SATA

LED blinks on when processing a command.

Power on and drive

spun down

SAS

LED stays off.

SATA

LED stays off.

Power on and drive

spinning up

SAS

LED blinks.

SATA

LED stays off.

Table 8. Activity LED Status

3.2.1 3.5” Drive Hot-Swap Backplane Overview

Systems with 12-drive configurations have their own unique backplane. The backplanes mount

to the back of the drive bay assembly.

Figure 19. 3.5” Hot-Swap Backplane and Drive Bay Assembly

On the front side of each backplane are mounted 12 hard disk drive interface connectors, each

providing both power and I/O signals to the attached hard disk drives.

Figure 20. SFF-8482 Connector on 3.5” HSBP

Revision 1.42

Page 27

Intel® Storage Server System JBOD 2000 Family Hardware Guide System Storage and Peripheral Drive Bays Overview

17

Label

Description

A

4-port mini-SAS connectors

B

Power connectors

C

SMBus connector (not used)

On the back side of each backplane are several connectors. The following illustration identifies

each.

Figure 21. Components on 3.5” HSBP

A – 4-port Mini-SAS Connectors – The backplane includes two or three multi-port mini-SAS

cable connectors, each providing SGPIO and I/O signals for four SAS/SATA hard drives on the

backplane. Cables can be routed from matching connectors on the server board, add-in

SAS/SATA RAID cards, or an optionally installed SAS expander card. Each mini-SAS connector

includes a silk-screen identifying which drives the connector supports: Drives 0-3, Drives 4-7,

and Drives 8-11.

B – Power Harness Connector – The backplane includes a 2x2 connector supplying power to

the backplane. Power is routed to the backplane via a power cable harness from the server

board.

3.2.2 Cypress* CY8C22545 Enclosure Management Controller

The backplanes support enclosure management using a Cypress* CY8C22545 Programmable

System-on-Chip (PSoC*) device. The CY8C22545 drives the hard drive activity/fault LED, hard

drive present signal, and controls hard drive power-up during system power-on.

Revision 1.42

Page 28

Power Subsystem Intel® Storage Server System JBOD 2000 Family Hardware Guide

18

4. Power Subsystem

This chapter provides a high-level overview of the power management features and

specification data for the power supply options available for Intel® Storage Server System JBOD

2000 Family. Specification variations are identified for each supported power supply.

Although the Intel® Storage System JBOD2000 ships with only one power supply, a second one

can be installed and have up to two power supply modules installed, supporting the following

power supply configurations: 1+0 (single power supply), 1+1 Redundant Power, and 2+0

Combined Power non-redundant (although this system cannot be loaded high enough to hit this

mode). The 1+1 redundant power and 2+0 combined power configurations are automatically

configured depending on the total power draw of the system. If the total system power draw

exceeds the power capacity of a single power supply module, then power from the second

power supply module will be utilized. If this occurs, power redundancy is lost. In a 2+0 power

configuration, total power available maybe less than twice the rated power of the installed power

supply modules due to the amount of heat produced with both supplies providing peak power. If

system thermals exceed programmed limits, platform management will attempt to keep the

system operational. Thermal support is open loop based on ambient temp sensor on the front

panel.

The only power supply option validated for the Intel® Storage Server System JBOD2312S3SP is

the 460W AC PS. The 750 W AC PS will fit and operate, but will not be validated in the JBOD or

plan of record. Note: the power cord is not included with the spare power supply and must be

ordered separately. Please refer to the Spares, Parts List and Configuration Guide for ordering

information (http://www.intel.com/support/motherboards/server/jbod2000/sb/CS-034094.htm)

The power supplies are modular, allowing for tool-less insertion and extraction from a bay in the

back of the chassis. When inserted, the card edge connector of the power supply mates blindly

to a matching slot connector on the PDB board.

In the event of a power supply failure, redundant 1+1 power supply configurations have support

for hot-swap extraction and insertion.

Figure 22. Power Supply Assembly

The AC input is auto-ranging and power factor corrected.

Revision 1.42

Page 29

Intel® Storage Server System JBOD 2000 Family Hardware Guide Power Subsystem

19

4.1 Power Distribution Board (PDB)

Figure 23. Power Distribution Board (PDB)

Revision 1.42

Page 30

Power Subsystem Intel® Storage Server System JBOD 2000 Family Hardware Guide

20

Label

Description

Label

Description

A

HSBP power header

F

2x15-pin storage mini front

panel header

B

Expander SES-2 header

G

2x12-pin front panel header

C

Expander power header

H

1x5 aux header

D

FAN header

J

2x12 SSI power connector

E

HSBP power header

K

power supply connector

The PDB provides power from the power supply modules to the JBOD components, and

provides thermal monitoring and fan control, and includes the following features:

The PDB connects to the power supply canister through two CRPS card edge

Revision 1.42

Figure 24. PDB Component Placement

connectors.

Page 31

Intel® Storage Server System JBOD 2000 Family Hardware Guide Power Subsystem

21

Optional 2x12-pin SSI and 1x5-pin SSI power control headers (for potential future use

with 4U JBOD fixed power supply).

Power for up to two internal 36-port SAS expander cards (RES2CV360R) for the 2U

JBOD with two additional connectors for future use.

Two 2x4-pin 12V power headers and an additional two 2x4-pin 12V power headers for

future use. Each cable is used to connect power to a single 12x 3.5” HSBP or up to three

8x 2.5” HSBPs.

Support for hot-swap redundant fan speed control solutions up to three system fans and

identification of fan failures at front panel fault LED indicator with communication over

SES2 interface to host PC.

SMB interface for communicating enclosure status through the expander board to the

host system external host controller via SES interface. Monitoring capabilities include:

- Fan tachs

- 12V voltage out from PSU

- 12V current from PSU

- Temperature on front panel, HDDs, and on the board behind drives

- Ambient overtemp protection: Reported to host system and fan boost only. No

shutdown.

- Degraded (PSU, FAN) state reportable to host system and on JBOD status LED

The ADT7476 thermal controller on the PDB can measure and control the speed of up to three

fans. The controller provides acoustic enhancements to ensure the fans run at the lowest

possible speed for the given temperature. The controller interfaces with two remote temp

sensors and a local temp sensor built into the chip.

The thermal controller on the PDB is programmed using the SAS expander that comes with the

Intel® Storage Server System JBOD 2000 Family. The SAS expander in the Intel® Storage

System JBOD 2000 Family uses a firmware that programs the thermal controller when the

system is turned on. If the SAS expander is not plugged into the PDB using the I2C cable, the

fans will run at 100% and the thermal controller will not be programmed correctly.

The cable must be connected to the I2C port B (Port C will not program the PDB) on the

expander board and then either of the I2C connectors on the PDB before the system is turned

on.

If the fan runs at 100% at room temperature, there is an issue with the SMBUS connection, the

SAS expander is not getting power, or the incorrect firmware is on the expander.

When a fan fails in the Intel® Storage Server System JBOD 2000 Family, an interrupt register bit

is set in the ADT7476 Thermal Controller that signals the fan fault (register shown below). The

LSI expander chip on the SAS expander monitors this register, and when a fan fault bit is set in

the interrupt register, this information is sent to the host system through SES. The ADT7476

controller also sends a signal out of its GPIOs to light the LED on the failed fan’s hot-swap

housing which makes replacing/diagnosing the failed fan much easier.

Revision 1.42

Page 32

Power Subsystem Intel® Storage Server System JBOD 2000 Family Hardware Guide

22

Interrupt Register 2 for ADT7476 (Bits 2, 3, and 4 used for fan faults):

Figure 25. Fan Fault LED Block Diagram

Revision 1.42

Page 33

Intel® Storage Server System JBOD 2000 Family Hardware Guide Power Subsystem

23

4.2 Mechanical Overview

The physical size of the power supply enclosure is 39/40mm x 74mm x 185mm. The power

supply contains a single 40mm fan. The power supply has a card edge output that interfaces

with a 2x25 card edge connector in the system. The AC plugs directly into the external face of

the power supply.

Figure 26. Power Supply Module Mechanical Drawing

Figure 27. Power Supply Module

Figure 28. AC Power Supply – Connector View

Revision 1.42

Page 34

Power Subsystem Intel® Storage Server System JBOD 2000 Family Hardware Guide

24

Pin

Name

Pin

Name

A1

GND

B1

GND

A2

GND

B2

GND

A3

GND

B3

GND

A4

GND

B4

GND

A5

GND

B5

GND

A6

GND

B6

GND

A7

GND

B7

GND

A8

GND

B8

GND

A9

GND

B9

GND

A10

+12V

B10

+12V

A11

+12V

B11

+12V

A12

+12V

B12

+12V

A13

+12V

B13

+12V

A14

+12V

B14

+12V

A15

+12V

B15

+12V

A16

+12V

B16

+12V

A17

+12V

B17

+12V

A18

+12V

B18

+12V

A19

PMBus SDA

B19

A0 (SMBus address)

A20

PMBus SCL

B20

A1 (SMBus address)

A21

PSON

B21

12V stby

A22

SMBAlert#

B22

Cold Redundancy Bus

A23

Return Sense

B23

12V Load Share Bus

A24

+12V Remote Sense

B24

No Connect

A25

PWOK

B25

Compatibility Check pin*

4.3 Power Connectors

4.3.1 Power Supply Module Card Edge Connector

Each power supply module has a single 2x25 card edge output connection that plugs directly

into a matching slot connector on the server board. The connector provides both power and

communication signals to the server board. The following table defines the connector pin-out.

Table 9. Power Supply Module Output Power Connector Pin-out

The JBOD’s PDB provides several connectors to provide power to various system options. The

following sub-sections identify the location, provide the pin-out definition, and provide a brief

usage description for each.

Revision 1.42

Page 35

Intel® Storage Server System JBOD 2000 Family Hardware Guide Power Subsystem

25

Pin

Signal Description

Pin

Signal Description

1

Ground

5

P12V_240VA

2

Ground

6

P12V_240VA

3

Ground

7

P12V_240VA

4

Ground

8

P12V_240VA

Loading

100% of

Maximum

50% of

Maximum

20% of

Maximum

10% of

Maximum

Minimum efficiency

88%

92%

88%

80%

Cable Type

SJT

Wire Size

16 AWG

Temperature Rating

105ºC

Amperage Rating

13 A

Voltage Rating

125 V

4.3.2 Hot-Swap Backplane Power Connector

The JDOB’s PDB board includes four white 2x4-pin power connectors, used to provide power to

the hot-swap backplanes. On the JBOD PDB, this connector is labeled as “HSBP PWR”. The

following table provides the pin-out for this connector.

Table 10. Hot-swap Backplane Power Connector Pin-out (“HSBP PWR”)

4.4 Power Supply Module Efficiency

The following table provides the required minimum efficiency level at various loading conditions.

These are provided at four different load levels: 100%, 50%, 20%, and 10%. Efficiency is tested

over an AC input voltage range of 115 VAC to 220 VAC.

Table 11. 460 Watt Power Supply Efficiency (Gold)

4.5 AC Power Cord Specification Requirements

The AC power cord used meets the specification requirements listed in the following table.

Table 12. AC Power Cord Specifications

Figure 29. AC Power Cord

Revision 1.42

Page 36

Power Subsystem Intel® Storage Server System JBOD 2000 Family Hardware Guide

26

Output Power

10% Load

20% Load

50% Load

100% Load

Power factor

> 0.65

> 0.80

> 0.90

> 0.95

Parameter

Min

Rated

Vmax

Start-up VAC

Power-off VAC

Voltage (110)

90 Vrms

100-127 Vrms

140 Vrms

85VAC +/-4VAC

70VAC +/-5VAC

Voltage (220)

180 Vrms

200-240 Vrms

264 Vrms

Frequency

47 Hz

50/60 Hz

63 Hz

4.6 AC Input Specifications

4.6.1 Power Factor

The power supply meets the power factor requirements stated in the Energy Star Program

Requirements for Computer Servers. These requirements are stated below.

Table 13. Power Factor

Tested at 230VAC, 50Hz and 60Hz and 115VAC, 60Hz

4.6.2 AC Input Voltage Specification

The power supply operates within all specified limits over the following input voltage range.

Harmonic distortion of up to 10% of the rated line voltage does not cause the power supply to

go out of specified limits. Application of an input voltage below 85VAC does not cause damage

to the power supply, including a blown fuse.

Table 14. AC Input Voltage Range

1. The maximum input current at low input voltage range is measured at 90VAC, at max load.

2. The maximum input current at high input voltage range is measured at 180VAC, at max load.

3. This requirement is not to be used for determining agency input current markings.

4.6.3 AC Line Isolation Requirements

The power supply meets all safety agency requirements for dielectric strength. Transformers’

isolation between primary and secondary windings complies with the 3000VAC (4242VDC)

dielectric strength criteria. If the working voltage between primary and secondary dictates a

higher dielectric strength test voltage, the highest test voltage will be used. In addition the

insulation system complies with reinforced insulation per safety standard IEC 950. Separation

between the primary and secondary circuits, and primary to ground circuits, complies with the

IEC 950 spacing requirements.

4.6.4 AC Line Dropout/Holdup

An AC line dropout is defined to be when the AC input drops to 0VAC at any phase of the AC

line for any length of time. During an AC dropout the power supply meets dynamic voltage

regulation requirements. An AC line dropout of any duration does not cause tripping of control

signals or protection circuits. If the AC dropout lasts longer than the holdup time, the power

supply will recover and meet all turn-on requirements. The power supply meets the AC dropout

requirement over rated AC voltages and frequencies. A dropout of the AC line for any duration

does not cause damage to the power supply.

Revision 1.42

Page 37

Intel® Storage Server System JBOD 2000 Family Hardware Guide Power Subsystem

27

Loading

Holdup Time

70%

12msec

AC Line Sag (10sec interval between each sagging)

Duration

Sag

Operating AC Voltage

Line Frequency

Performance Criteria

0 to 1/2 AC cycle

95%

Nominal AC Voltage ranges

50/60 Hz

No loss of function or

performance

> 1 AC cycle

> 30%

Nominal AC Voltage ranges

50/60 Hz

Loss of function acceptable,

self recoverable

Table 15. AC Line Dropout/Holdup

4.6.4.1 AC Line 12VSB Holdup

The 12VSB output voltage stays in regulation under its full load (static or dynamic) during an AC

dropout of 70ms min (=12VSB holdup time) whether the power supply is in ON or OFF state

(PSON asserted or de-asserted).

4.6.5 AC Line Fuse

The power supply has one line fused in the single line fuse on the line (Hot) wire of the AC

input. The line fusing is acceptable for all safety agency requirements. The input fuse is a slow

blow type. The AC inrush current does not cause the AC line fuse to blow under any conditions.

All protection circuits in the power supply will not cause the AC fuse to blow unless a component

in the power supply has failed. This includes DC output load short conditions.

4.6.6 AC Inrush

The AC line inrush current does not exceed 55A peak, for up to one-quarter of the AC cycle,

after which, the input current is no more than the specified maximum input current. The peak

inrush current is less than the ratings of its critical components (including input fuse, bulk

rectifiers, and surge limiting device).

The power supply meets the inrush requirements for any rated AC voltage, during turn-on at any

phase of AC voltage, during a single cycle AC dropout condition as well as upon recovery after

AC dropout of any duration, and over the specified temperature range (Top).

4.6.7 AC Line Transient Specification

The AC line transient conditions are defined as sag and surge conditions. Sag conditions are

also commonly referred to as “brownout”; these conditions are defined as the conditions when

the AC line voltage drops below nominal voltage. Surge conditions are defined as the conditions

when the AC line voltage rises above nominal voltage.

The power supply meets the requirements under the following AC line sag and surge conditions.

Table 16. AC Line Sag Transient Performance

Revision 1.42

Page 38

Power Subsystem Intel® Storage Server System JBOD 2000 Family Hardware Guide

28

AC Line Surge

Duration

Surge

Operating AC Voltage

Line Frequency

Performance Criteria

Continuous

10%

Nominal AC Voltages

50/60 Hz

No loss of function or

performance

0 to ½ AC cycle

30%

Mid-point of nominal AC

Voltages

50/60 Hz

No loss of function or

performance

Level

Description

A

The apparatus continues to operate as intended. No degradation of performance.

B

The apparatus continues to operate as intended. No degradation of performance beyond spec

limits.

C

Temporary loss of function is allowed provided that the function is self-recoverable or can be

restored by the operation of the controls.

Table 17. AC Line Surge Transient Performance

4.6.8 Susceptibility Requirements

The power supply meets the following electrical immunity requirements when connected to a

cage with an external EMI filter that meets the criteria defined in the SSI document EPS Power

Supply Specification. For further information on Intel standards, request a copy of the Intel

Environmental Standards Handbook.

Table 18. Performance Criteria

4.6.9 Electrostatic Discharge Susceptibility

The power supply complies with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-2: Edition 1.2: 2001-04 test standard and performance criteria B defined in

Annex B of CISPR 24.

4.6.10 Fast Transient/Burst

The power supply complies with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-4: Second edition: 2004-07 test standard and performance criteria B defined in

Annex B of CISPR 24.

4.6.11 Radiated Immunity

The power supply complies with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-3: Edition 2.1: 2002-09 test standard and performance criteria A defined in

Annex B of CISPR 24.

4.6.12 Surge Immunity

The power supply is tested with the system for immunity to AC unidirectional wave, 2kV line to

ground and 1kV line to line, per EN 55024: 1998/A1: 2001/A2: 2003, EN 61000-4-5: Edition

1.1:2001-04.

Revision 1.42

Page 39

Intel® Storage Server System JBOD 2000 Family Hardware Guide Power Subsystem

29

Output Voltage

Input Voltage Range

Over Current Limit

+12V

90–264VAC

47A min; 55A max

12VSB

90–264VAC

2A min; 2.5A max

The pass criteria include: no unsafe operation is allowed under any condition; all power supply

output voltage levels to stay within proper spec levels; no change in operating state or loss of

data during and after the test profile; no component damage under any condition.

The power supply complies with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-5: Edition 1.1:2001-04 test standard and performance criteria B defined in

Annex B of CISPR 24.

4.6.13 Voltage Interruptions

The power supply complies with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003 using

the IEC 61000-4-11: Second Edition: 2004-03 test standard and performance criteria C defined

in Annex B of CISPR 24.

4.6.14 Protection Circuits

The protection circuits inside the power supply cause only the power supply’s main outputs to

shut down. If the power supply latches off due to a protection circuit tripping, an AC cycle OFF

for 15 seconds and a PSON# cycle HIGH for one second reset the power supply.

4.6.15 Over Current Protection (OCP)

The power supply has a current limit to prevent the outputs from exceeding the values shown in

the table below. If the current limit is exceeded, the power supply will shut down and latch off.

The latch will be cleared by toggling the PSON# signal or by an AC power interruption. The

power supply will not be damaged from repeated power cycling in this condition. 12VSB will be

auto-recovered after removing the OCP limit.

Table 19. 460 Watt Power Supply Over Current Protection

4.6.16 Over Voltage Protection (OVP)

The power supply over voltage protection is locally sensed. The power supply will shut down

and latch off after an over voltage condition occurs. This latch will be cleared by toggling the

PSON# signal or by an AC power interruption. The values are measured at the output of the

power supply’s connectors. The voltage never exceeds the maximum levels when measured at

the power connectors of the power supply connector during any single point of fail. The voltage

never trips any lower than the minimum levels when measured at the power connector. 12VSB

will be auto-recovered after removing the OVP limit.

Revision 1.42

Page 40

Power Subsystem Intel® Storage Server System JBOD 2000 Family Hardware Guide

30

Output Voltage

Min (V)

Max (V)

+12V

13.3

14.5

12VSB

13.3

14.5

Table 20. Over Voltage Protection (OVP) Limits

4.6.17 Over Temperature Protection (OTP)

The power supply is protected against over temperature conditions caused by loss of fan

cooling or excessive ambient temperature. In an OTP condition the PSU will shut down. When

the power supply temperature drops to within specified limits, the power supply will restore

power automatically, while the 12VSB remains always on. The OTP circuit has a built-in margin

so that the power supply will not oscillate on and off due to temperature recovering conditions.

The OTP trip level has a minimum of 4ºC of ambient temperature margin.

Revision 1.42

Page 41

Intel® Storage Server System JBOD 2000 Family Hardware Guide Power Subsystem

31

Power Supply Condition

LED State

Output ON and OK

Green

No AC power to all power supplies

Off

AC cord unplugged or AC power lost, with a second

power supply in parallel still with AC input power

Amber

Power supply warning events where the power supply

continues to operate; high temp, high power, high

current, slow fan

1 Hz Blink Amber

Power supply critical events causing a shutdown;

failure, OCP, OVP, fan fail

Amber

Power supply FW updating

2 Hz Blink Green

Power supply Off – In Stand-by – AC applied

1 Hz Blink Green

4.7 Power Supply Status LED

There is a single bi-color LED to indicate power supply status. The LED operation is defined in

the following table.

Table 21. LED Indicators

Revision 1.42

Page 42

Thermal Management Intel® Storage Server System JBOD 2000 Family Hardware Guide

32

5. Thermal Management

The Intel® Storage Server System JBOD 2000 Family is designed to operate at external

ambient temperatures of between 10ºC and 35ºC with limited excursion-based operation up to

45ºC and limited performance impact. Working with integrated platform management, several

features within the system are designed to move air in a front-to-back direction, through the

system and over critical components to prevent them from overheating and allow the system to

operate with best performance.

The installation and functionality of several JBOD components are used to maintain system

thermals. They include up to three managed 60-mm system fans and one integrated 40-mm fan

for each installed power supply module. Hard drive carriers can be populated with a hard drive

or supplied drive blank.

5.1 Thermal Operation and Configuration Requirements

To keep the system operating within supported maximum thermal limits, the system must meet

the following operating and configuration guidelines:

The system operating ambient is designed for sustained operation up to 35ºC (ASHRAE

Class A2) with short-term excursion-based operation up to 45ºC (ASHRAE Class A4).

- The system can operate up to 40ºC (ASHRAE Class A3) for up to 900 hours per

year.

- The system can operate up to 45ºC (ASHRAE Class A4) for up to 90 hours per year.

- System performance may be impacted when operating within the extended operating

temperature range.

- There is no long-term system reliability impact when operating at the extended

temperature range within the approved limits.

All hard drive bays must be populated. Hard drive carriers can be populated with a hard

drive or supplied drive blank.

In single power supply configurations, the second power supply bay must have the

supplied filler blank installed at all times.

The system must be configured with dual power supplies for the system to support fan

redundancy.

The system top cover must be installed at all times when the system is in operation. The

only exception to this requirement is to hot replace a failed system fan, in which case the

top cover can be removed for no more than three minutes at a time.

5.2 Thermal Management Overview

In order to maintain the necessary airflow within the system, all of the previously listed

components and top cover need to be properly installed. For best system performance, the

external ambient temperature should remain below 35ºC and all system fans should be

operational. The system is designed for fan redundancy when the system is configured with two

power supplies.

Revision 1.42

Page 43

Intel® Storage Server System JBOD 2000 Family Hardware Guide Thermal Management

33

5.3 Thermal Sensor Input for Fan Speed Control

The power distribution board uses various sensors as inputs to fan speed control. Some of the

sensors are actual physical sensors and some are virtual sensors derived from calculations.

The following thermal sensor is used as an input to fan speed control:

Front Panel Temperature Sensor

5.4 System Fans

Three 60x38-mm fans and an embedded fan for each installed power supply, provide the

primary airflow for the system. The system is designed for fan redundancy when configured with

two power supply modules. If a single fan fails (system fan or power supply fan), platform

management will adjust the airflow of the remaining fans and manage other platform features to

maintain system thermals. Fan redundancy is lost if more than one fan is in a failed state.

Figure 30. System Fan Identification

The system fan assembly is designed for ease of use and supports several features:

Each fan is hot-swappable.

Each fan is designed for tool-less insertion and extraction from the fan assembly. For

instructions on installing or removing a fan module, see the Intel® JBOD 2000 Family

Service Guide.

Fan speed for each fan is controlled by integrated platform management controlled by

the PDB board. When system thermals fluctuate high and low, the PDB firmware will

increase or decrease the speeds of specific fans within the fan assembly to regulate

system thermals.

Each fan has a tachometer signal that allows the PDB to monitor its status.

On top of each fan is an integrated fault LED, although currently this feature is not

supported.

Revision 1.42

Page 44

Thermal Management Intel® Storage Server System JBOD 2000 Family Hardware Guide

34

SYS_FAN 1

SYS_FAN 2

SYS_FAN 3

Pin#

Signal Description

Pin#

Signal Description

Pin#

Signal Description

1

FAN_TACH1_IN

1

FAN_TACH3_IN

1

FAN_TACH5_IN

2

FAN_BMC_PWM0_R_BUF

2

FAN_BMC_PWM1_R_BUF

2

FAN_BMC_PWM2_R_BUF

3

P12V_FAN

3

P12V_FAN

3

P12V_FAN

4

P12V_FAN

4

P12V_FAN

4

P12V_FAN

5

FAN_TACH0_IN

5

FAN_TACH2_IN

5

FAN_TACH4_IN

6

GROUND

6

GROUND

6

GROUND

7

GROUND

7

GROUND

7

GROUND

8

FAN_SYS0_PRSNT_N

8

FAN_SYS1_PRSNT_N

8

FAN_SYS2_PRSNT_N

9

LED_FAN_FAULT0_R

9

LED_FAN_FAULT1_R

9

LED_FAN_FAULT2_R

10

LED_FAN0

10

LED_FAN1

10

LED_FAN2

Each fan has a 10-pin wire harness that connects to a matching connector on the PDB.

Figure 31. System Fan Assembly

Table 22. System Fan Connector Pin-out

5.5 Power Supply Module Fan

Each installed power supply module includes one embedded (non-removable) 40-mm fan. It is

responsible for airflow through the power supply module. If this fan fails, the power supply will

continue to operate until its internal temperature reaches an upper critical limit. The power

supply will be protected against over temperature conditions caused by loss of fan cooling or

excessive ambient temperature. In an over temperature protection condition, the power supply

module will shut down.

Revision 1.42

Page 45

Intel® Storage Server System JBOD 2000 Family Hardware Guide JBOD 2000 Internal Connection Overview

35

6. JBOD 2000 Internal Connection Overview

The Intel® Storage Server System JBOD 2000 contains the SAS expander board, power

distribution board, HSBP, SAS interface board, and fans in its chassis. This chapter provides

specification of the SAS expander board and SAS converter, and interconnection between

those components.

6.1 Expander Board

The Intel 36-port expander is mounted vertically in the chassis and is designed on LSI’s Bobcat

expander technology. The expander has nine SFF8087 mini-SAS connectors that connect to

either the backplane or the SAS converter boards via SFF8087 to SFF8087 cables. The dualport backplane of the JBOD contains two 36-port expanders, while the single-port backplane

contains one 36-port expander.

Features of the Intel® RAID Expander are as follows:

SAS protocol, described in the Serial Attached SCSI (SAS) Standard, version 2.0

Serial SCSI Protocol (SSP) to enable communication with other SAS devices

Serial Tunneling Protocol (STP) support for SATA II through expander interfaces

Serial Management Protocol (SMP) to share topology management information with

expanders

Supports SES for enclosure management

Output mini-SAS connectors support sideband SGPIO as per SFF-8485 specification

Supports both Serial Attached SCSI and Serial ATA device targets

6.0 Gb/s, 3.0 Gb/s, and 1.5 Gb/s data transfer rate

SFF-8087 mini-SAS connectors

Provides a low-latency connection to create and maintain transparent access to each

connected SAS/SATA physical drive

Staggered spin-up

Hot-plug

Native Command Queuing

Allows multiple initiators to address a single target (in a fail-over configuration)

All JBOD SKUs use the 36-port SAS expander card. Single-port JBOD 2000 SKU has one 36port SAS expander card; dual-port JBOD 2000 SKU has two 36-port expander cards.

Revision 1.42

Page 46

JBOD 2000 Internal Connection Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

36

Figure 32. Internal SAS Expander Location

Revision 1.42

Page 47

Intel® Storage Server System JBOD 2000 Family Hardware Guide JBOD 2000 Internal Connection Overview

37

Item

Description

A1

External SFF 8088 connector 0. Internally wired to B1.

A2

External SFF 8088 connector 1. Internally wired to B2.

B1

Internal SFF 8087 connector 0. Internally wired to A1

B2

Internal SFF 8087 connector 1. Internally wired to A2.

6.2 JBOD SAS Interface Board

The JBOD SAS interface board is an independent product – Intel® 8087-8088 Cable Connector

Converter AXXSAS88CNVRT converts two internal SFF8087 x4 mini-SAS connectors to two

external SFF8088 SAS x4 connectors. The 8x ports of 6Gb SAS can be supported with this

adapter.

The converter includes a PCI mounting bracket that allows the converter to be mounted and

retained in a rear panel PCI mounting location.

No power rails, power consumers, or temperature sensors are on the JBOD SAS interface

board.

6.2.1 JBOD SAS Interface Board Port Numbering

Following is a suggestion for the JBOD SAS interface board port numbering for internal and

external connections.

Figure 33. JBOD 2000 SAS Interface Board Port Number

Revision 1.42

Page 48

JBOD 2000 Internal Connection Overview Intel® Storage Server System JBOD 2000 Family Hardware Guide

38

Description

1x5-pin SATA SGPIO

Pin

Signal Description

1

SGPIO_CLOCK_0

2

SGPIO_LOAD_0

3

GND

4

SGPIO_DATAOUT_0

5

SGPIO_DATAIN_0

6.3 Pin-outs

See the SAS Gen2 specification for correct pin-out for the SAS internal and external connectors.

The connection between the internal mini-SAS and external mini-SAS needs to be one-to-one

direct connection of differential pairs with length matching on the board. The internal mini-SAS

connectors should use the controller mini-SAS pin-out. The sideband signals within the internal

mini-SAS connectors need to conform to the SFF-8448 specification. You do not need to do the

pull-ups or pull-downs on any sideband signals (including sideband 6 and 7) when cabling

externally; sidebands are only for potential debug purposes on this board.

See the following pin-out for SGPIO debug headers.

Table 23. SGPIO Headers Pin-out

Revision 1.42

Page 49

Intel® Storage Server System JBOD 2000 Family Hardware Guide JBOD 2000 Internal Connection Overview

39

6.3.1 JBOD2312S2SP Interconnection

The Intel® Storage Server System JBOD2312S2SP has a 12x3.5” single-port HSBP, a primary

SAS expander, a dual-port SAS interface board, a PDB, a PSU, and three fans in its chassis.