Page 1

DPS-5.4

SERVICE MANUAL

Ref. No. 3767

SERVICE MANUAL

DVD PLAYER

MODEL DPS-5.4

Black model

JUL, 2003

RC-536DV

BMDD

120V AC, 60Hz

BMDC

BMUA

100-240V AC, 50/60Hz

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

www.denom.com

Page 2

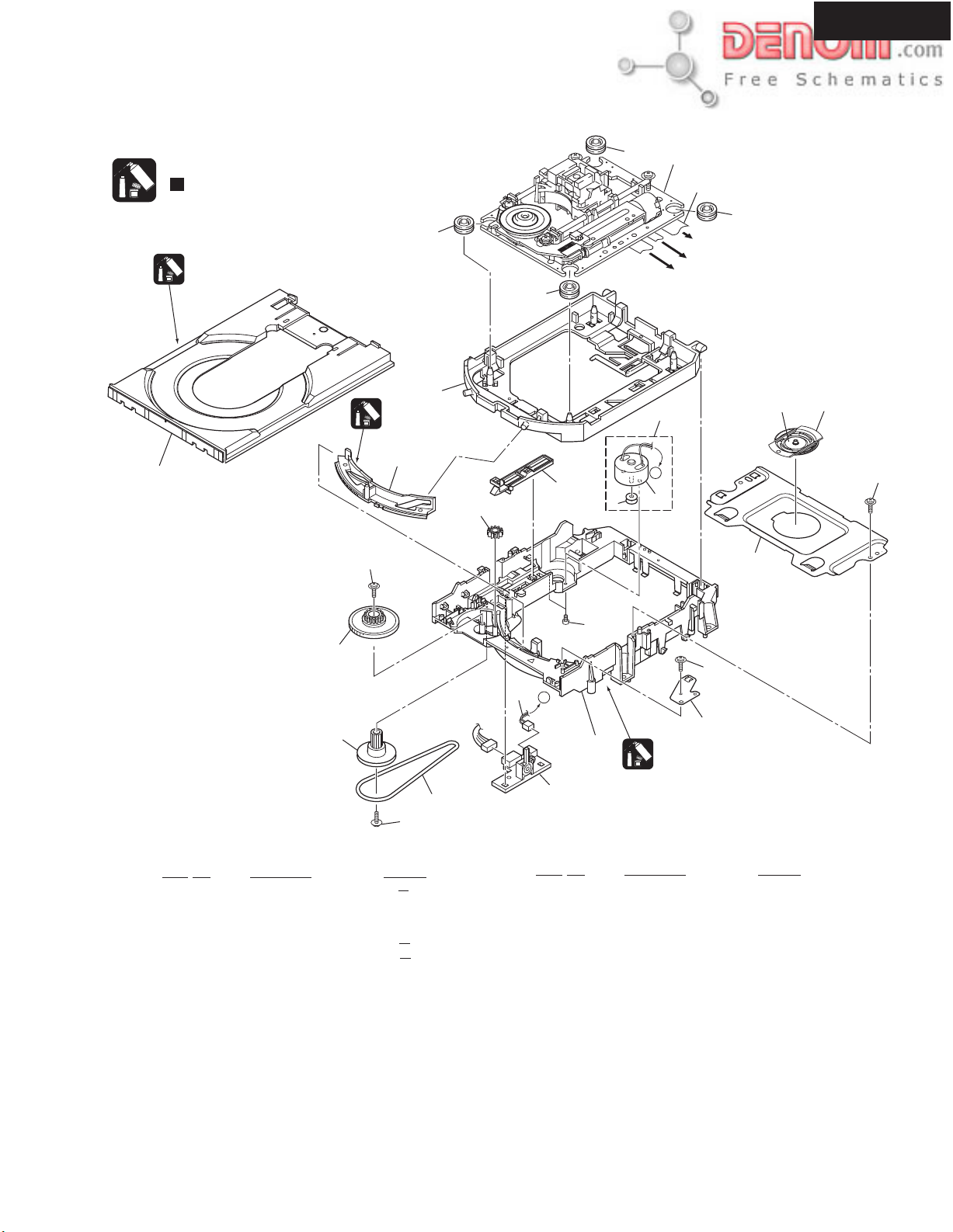

EXPLODED VIEW PARTS LIST ! : Safety part

Exploded V REF. NO. PART NAME PART NO. DESCRIPTION REMARK

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

A1 CHASSIS 27100425B

A3 LEG 27175316C LEG

A5 CUSHION 28141494

A10 HOLDER 27190428A KGLS-10RT

A11 SCREW 838130088 3TTB+8B

A11a WASHER 87643010 W3*10F(BC)

A12 HOLDER 27190657 KGLS-18RT

A13 HOLDER 27190772 KGLS-22RT

A15 LABEL(DVD2) 29362648

A16 CLAMP 27301394 HL-18-0

A20 F BRACKET 27111325A (B)

A21 KNOB 28325756 (STANDBY)

A22 CLEAR PLT 28191993

A23 B PLATE 28133410 DPS-5.4(B)

A24 TAPE 29110161

A27 ST SCREW 838126068 2.6TTB+6B

A30 KNOB 28325753 (POW)

A32 SCREW 82143010 3P+10FN(BC)

A35 KNOB 28326078 (CRS)

A51 DOOR 28148479A

A52 PLATE 27262651 (DVD)

A55 COVER 28184864 (B)

A56 SCREW 838430088 3TTB+8B(BC)

A57 CUSHION 28141542 HIME0.5*120*10

A41 F PANEL 27212527 DPS-5.4(B)

A43 BADGE 28135278

A44 FACET 28198906 (S)

A46 SCREW 838430088 3TTB+8B(BC)

A47 REAR PANEL 27123125 5.4MDD1N

A47 REAR PANEL 27123126 5.4MUA4P

A48 SCREW 838430088 3TTB+8B(BC)

A49 SCREW 838440089 4TTB+8C(BC)

F1 FUSE

F1 or FUSE

F1 FUSE

F1 or FUSE

252252 1.6A-T/UL-ST2

!

252147 1.6A-TSC

!

252273 1.6A-SE-TL250V

!

252073 1.6A-SE-EAK IEC FUSE

!

P501 FFC 2045301512 NCFC5-301512

P502 FFC 2045110612 NCFC5-110612

P503 FFC 2045180712 NCFC5-180712

P701 FFC 2045242012 NCFC5-242012

P702 SOCKET AS 20044391025 NSAS-10P1160

P901A CORE 230945 NFY-25 BLACK

P910 WIRE TIE 260208 (CLAMPER)UL

S731 JOY STICK 25035710 NPS-115-S673

Z1 DVD Main circuit PC board assy 24150042 DB-VPB501

Z10 DVD Mechanism assy 24801018 DB-VLD501-007

Z12 HOLDER 27191201 (ML)

Z13 HOLDER 27191202 (MR)

Z14 SCREW 801433 3SMS8W.SW+14B(BC)

Z15 SCREW 838130088 3TTB+8B

Z91A SCREW 830440089 4TTC+8C(BC)

U1 Output terminal PC board assy 1H505597-1G NAAR-7997-1G

U1 Output terminal PC board assy 1H505597-1H NAAR-7997-1H

U2 Display circuit PC board assy 1H505598-1G NADIS-7998-1G

U2 Display circuit PC board assy 1H505598-1H NADIS-7998-1H

U3 Standby switch PC boars assy 1H505599-1G NADIS-7999-1G

U3 Standby switch PC boars assy 1H505599-1H NADIS-7999-1H

U4 Power switch PC board assy 1H505500-1G NASW-8000-1G

U4 Power switch PC board assy 1H505500-1H NASW-8000-1H

U5 Inlet terminal PC board assy 1H505502-1G NAPS-8002-1G

DPS-5.4

<MDD, MDC>

<MUA>

<MDD, MDC>

<MDD, MDC>

<MUA>

<MUA>

<MDD, MDC>

<MUA>

<MDD, MDC>

<MUA>

<MDD, MDC>

<MUA>

<MDD, MDC>

<MUA>

<MDD, MDC>

www.denom.com

Page 3

Exploded V

A

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

Exploded V

U5 Inlet terminal PC board assy 1H505502-1H NAPS-8002-1H

U6 Support PC board 1H505503-1G NAETC-8003-1G

U6 Support PC board 1H505503-1H NAETC-8003-1H

U7 RS-232 terminal PC board assy 1H505505-1G NAETC-8005-1G

U7 RS-232 terminal PC board assy 1H505505-1H NAETC-8005-1H

U20 Power supply unit

U20 Power supply unit

24150040 NGPS-0040-100-120V

!

24150041 NGPS-0041-100-240V

!

NOTE: <MDD>: North American area

<MDC>: Canadian area

<MUA>: Australian area

<MUA>

<MDD, MDC>

<MUA>

<MDD, MDC>

<MUA>

<MDD, MDC>

<MUA>

PACKING PARTS LIST

Packing V REF. NO. PART NAME PART NO. DESCRIPTION REMARK

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

Packing V

A450 CARTON 29054065A DPS-5.4MDD

A451 LABEL 29363464 (RE)MUA4P

A455 UPC LABEL 29363446 DPS-5.4(B)

A530 WARRANTY CARD 29365089 (INTEGRA)

A601 PAD 29092099B (AS)

A604 POLY BAG 29100037-1A 650*500

A605 POLY BAG 29100097-1A 350*250

A607 PP TAPE 29110148 W48 OPP TAPE 1.3MT

A901 CORD AS 2010412 RCA3P(YWR)

A901 or PIN CORD AS 2010379 RCA3P(YWR)

A902 BATTERY 3010054 R6/AA(UM-3)

A903 PLUG CORD 2010200 3.5-MINI PLUG (RI)

A905 REMO CON 24140536 RC-536DV

A906 CORD AS 2010380 (S CORD)

A906 or CORD AS 2010360 TPX3000

A911 INS MANUAL 29343491 En(DPS-5.4)

P981 AC CORD

P981 or AC CORD

P981 AC CORD

253352TES AS-UC-2

!

253297KAW AS-UC-2

!

253311VOL AS-SAA

!

DPS-5.4

<MDD, MDC, MU

<MUA>

<MDD, MDC>

<MUA> supplied from

Sales Dep.

<MDD, MDC>

<MDD, MDC>

<MUA>

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

NOTE:

<MDD>: North American area

<MDC>: Canadian area

<MUA>: Australian area

PRINTED CIRCUIT BOARD PARTS LIST DPS-5.4

U1 : OUTPUT TERMINAL PC BOARD NAAR-7997

CIRCUIT NO. PART NAME PART NO. DESCRIPTION REMARK

Q352 IC 22274004HR2O TC74VHCU04FT

Q401 IC 22241448R2 NJM4580M-D

Q402 IC 22241448R2 NJM4580M-D

Q403 IC 22241448R2 NJM4580M-D

Q404 IC 22241448R2 NJM4580M-D

Q405 TR 2216141R2 HN1C03F-B

Q406 TR 2216141R2 HN1C03F-B

Q407 TR 2216141R2 HN1C03F-B

Q460 TR 2216480R2 DTA114YKA

Q460 or TR 2216360R2 RN2407

Q460 or TR 2216350R2 KRA107S

Q463 TR 2216470R2 DTC114YKA

Q463 or TR 2216260R2 RN1407

Q463 or TR 2216340R2 KRC107S

Q806 TR 2216706R2 UMG9N

Q920 TR 2216175R2 KTC3875-GR

Q920 or TR 2213145R2 2SC2712-GR

Q351 PHT CP 24120102 TOTX179L

Q801 PHT CP 24120043 ON3131

www.denom.com

Page 4

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

D101 ZENER D 224550510R2 UDZS5.1B

D101 or ZENER D 224490510R2 UDZ5.1B

D460 C-DIODE 223234R2 1SS352

D460 or C-DIODE 223269R2 1SS355

D801 C-DIODE 223234R2 1SS352

D801 or C-DIODE 223269R2 1SS355

D901 ZENER D 224550510R2 UDZS5.1B

D901 or ZENER D 224490510R2 UDZ5.1B

D920 ZENER D 224551100R2 UDZS11B

D921 C-DIODE 223234R2 1SS352

D921 or C-DIODE 223269R2 1SS355

D922 C-DIODE 223234R2 1SS352

D922 or C-DIODE 223269R2 1SS355

D923 C-DIODE 223234R2 1SS352

D923 or C-DIODE 223269R2 1SS355

D924 C-DIODE 223234R2 1SS352

D924 or C-DIODE 223269R2 1SS355

L351 EMIFIL 230958R1 BK1608LM182-T

L351 or EMIFIL 230968R1 FBM-10-160808-202T

L352 EMIFIL 230958R1 BK1608LM182-T

L352 or EMIFIL 230968R1 FBM-10-160808-202T

L353 EMIFIL 230958R1 BK1608LM182-T

L353 or EMIFIL 230968R1 FBM-10-160808-202T

L354 EMIFIL 230958R1 BK1608LM182-T

L354 or EMIFIL 230968R1 FBM-10-160808-202T

P351A SOCKET AS 2009990787UL NSAS-4P1148

P901 SOCKET AS 2004C193060UL NSAS-30P1102

CN901 SOCKET 25052524 NSCT-30P2421

CN901 or SOCKET 25051954 NSCT-30P1741

CN901 or SOCKET 25052330 NSCT-30P2227

CN902 SOCKET 25052505 NSCT-11P2402

CN902 or SOCKET 25051935 NSCT-11P1822

CN902 or SOCKET 25052311 NSCT-11P2208

CN903 SOCKET 25052512 NSCT-18P2409

CN903 or SOCKET 25051942 NSCT-18P1729

CN903 or SOCKET 25052318 NSCT-18P2215

P104 SOCKET 25052344 NSCT-7P2241

P104 or SOCKET 25051889 NSCT-7P1676

P104 or SOCKET 25052528 NSCT-7P2425

P701A SOCKET 25052518 NSCT-24P2415

P701Aor SOCKET 25051948 NSCT-24P1735

P701Aor SOCKET 25052324 NSCT-24P2221

P201 PIN JACK 25045660 NPJ-10PDBY459

P203 PIN JACK 25045661 NPJ-3PDGLR460

P205 BNC JACK 25045634 P2298

P350 PIN JACK 25045592 NPJ-1PDOR403

P352 PIN JACK 25045589 NPJ-2PDB400

P401 PIN JACK 25045662 NPJ-3PDBRW461

P402 PIN JACK 25045593 NPJ-2PDWR404

P851A PLUG 25055152 NPLG-8P136

C101 C-CERA C 332161040R1 CK725F1E-104Z1

C221 VR C 394624717 CE04W6.3V-470M(VR)

C222 C-CERA C 332121045R1 CK725B1C-104K1

C223 VR C 394624717 CE04W6.3V-470M(VR)

C224 VR C 394621027 CE04W6.3V-1000M(VR)

C225 VR C 394624717 CE04W6.3V-470M(VR)

C226 VR C 394624717 CE04W6.3V-470M(VR)

C227 VR C 394621027 CE04W6.3V-1000M(VR)

C228 VR C 394624717 CE04W6.3V-470M(VR)

C229 VR C 394624717 CE04W6.3V-470M(VR)

C251 VR C 394624717 CE04W6.3V-470M(VR)

C252 VR C 394624717 CE04W6.3V-470M(VR)

C253 C-CERA C 332121045R1 CK725B1C-104K1

www.denom.com

Page 5

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

C352 C-CERA C 332161040R1 CK725F1E-104Z1

C353 VR C 394621017 CE04W6.3V-100M(VR)

C357 C-CERA C 332121045R1 CK725B1C-104K1

C358 C-CERA C 342102204R1 CC725CH1H-220J1

C360 C-CERA C 332161040R1 CK725F1E-104Z1

C361 C-CERA C 332161040R1 CK725F1E-104Z1

C362 VR C 394621017 CE04W6.3V-100M(VR)

C363 C-CERA C 332152230R1 CK725F1H-223Z1

C364 C-CERA C 332152230R1 CK725F1H-223Z1

C401 VX C 393344707 CE04W16V-47M(VX)

C402 VX C 393344707 CE04W16V-47M(VX)

C403 TF C 374726814 ECQ-B50V-681J

C404 TF C 374726814 ECQ-B50V-681J

C405 TF C 374721524 ECQ-B50V-152J

C406 TF C 374721524 ECQ-B50V-152J

C407 TF C 374721024 ECQ-B50V-102J

C408 TF C 374721024 ECQ-B50V-102J

C409 C-CERA C 342104704R1 CC725CH1H-470J1

C410 C-CERA C 342104704R1 CC725CH1H-470J1

C411 VR C 394622217 CE04W6.3V-220M(VR)

C412 VR C 394622217 CE04W6.3V-220M(VR)

C413 VX C 393384707 CE04W50V-47M(VX)

C414 VX C 393384707 CE04W50V-47M(VX)

C415 VX C 393384707 CE04W50V-47M(VX)

C419 VX C 393384707 CE04W50V-47M(VX)

C420 VR C 394624717 CE04W6.3V-470M(VR)

C485 VR C 394642217 CE04W16V-220M(VR)

C486 VR C 394642217 CE04W16V-220M(VR)

C814 VR C 394621017 CE04W6.3V-100M(VR)

C815 TF C 374722234 ECQ-B50V-223J

C901 C-CERA C 332161040R1 CK725F1E-104Z1

C902 VR C 394642217 CE04W16V-220M(VR)

C903 C-CERA C 332161040R1 CK725F1E-104Z1

C904 VR C 394622217 CE04W6.3V-220M(VR)

C905 C-CERA C 332161040R1 CK725F1E-104Z1

C906 VR C 394642217 CE04W16V-220M(VR)

C907 C-CERA C 332161040R1 CK725F1E-104Z1

C908 VR C 394641027 CE04W16V-1000M(VR)

C909 C-CERA C 332161040R1 CK725F1E-104Z1

C910 VR C 394641027 CE04W16V-1000M(VR)

C911 VR C 394641017 CE04W16V-100M(VR)

C914 C-CERA C 332161040R1 CK725F1E-104Z1

C920 VR C 394641007 CE04W16V-10M(VR)

C921 VR C 394642217 CE04W16V-220M(VR)

C922 VR C 394642217 CE04W16V-220M(VR)

R1001 C-CARBON R 435030004R1 RN72K1J-000JE

R1002 C-CARBON R 435030004R1 RN72K1J-000JE

R1003 C-CARBON R 435030004R1 RN72K1J-000JE

R1004 C-CARBON R 435030004R1 RN72K1J-000JE

R1005 C-CARBON R 435030004R1 RN72K1J-000JE

R1006 C-CARBON R 435030004R1 RN72K1J-000JE

R1007 C-CARBON R 435030004R1 RN72K1J-000JE

R1008 C-CARBON R 435030004R1 RN72K1J-000JE

R1009 C-CARBON R 435030004R1 RN72K1J-000JE

R101 C-CARBON R 435031034R1 RN72K1J-103JE

R1010 C-CARBON R 435030004R1 RN72K1J-000JE

R1012 C-CARBON R 435030004R1 RN72K1J-000JE

R1013 C-CARBON R 435030004R1 RN72K1J-000JE

R1015 C-CARBON R 435030004R1 RN72K1J-000JE

R1016 C-CARBON R 435030004R1 RN72K1J-000JE

R1017 C-CARBON R 435030004R1 RN72K1J-000JE

R1018 C-CARBON R 435030004R1 RN72K1J-000JE

R1019 C-CARBON R 435030004R1 RN72K1J-000JE

www.denom.com

Page 6

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

R102 C-CARBON R 435034704R1 RN72K1J-470JE

R1020 C-CARBON R 435030004R1 RN72K1J-000JE

R103 C-CARBON R 435034704R1 RN72K1J-470JE

R104 C-CARBON R 435034704R1 RN72K1J-470JE

R106 C-CARBON R 435034704R1 RN72K1J-470JE

R107 C-CARBON R 435034704R1 RN72K1J-470JE

R108 C-CARBON R 435034704R1 RN72K1J-470JE

R115 C-CARBON R 435030004R1 RN72K1J-000JE

R117 C-CARBON R 435031034R1 RN72K1J-103JE

R118 C-CARBON R 435031034R1 RN72K1J-103JE

R119 C-CARBON R 435031034R1 RN72K1J-103JE

R121 C-CARBON R 435034704R1 RN72K1J-470JE

R122 C-CARBON R 435034704R1 RN72K1J-470JE

R123 C-CARBON R 435030004R1 RN72K1J-000JE

R124 C-CARBON R 435034704R1 RN72K1J-470JE

R125 C-CARBON R 435034704R1 RN72K1J-470JE

R126 C-CARBON R 435034704R1 RN72K1J-470JE

R127 C-CARBON R 435034704R1 RN72K1J-470JE

R134 C-CARBON R 435031034R1 RN72K1J-103JE

R135 C-CARBON R 435031034R1 RN72K1J-103JE

R136 C-CARBON R 435031034R1 RN72K1J-103JE

R137 C-CARBON R 435031034R1 RN72K1J-103JE

R221 C-CARBON R 435037504R1 RN72K1J-750JE

R222 C-CARBON R 435037504R1 RN72K1J-750JE

R223 C-CARBON R 435037504R1 RN72K1J-750JE

R224 C-CARBON R 435031034R1 RN72K1J-103JE

R225 C-CARBON R 435037504R1 RN72K1J-750JE

R227 C-CARBON R 435037504R1 RN72K1J-750JE

R229 C-CARBON R 435037504R1 RN72K1J-750JE

R231 C-CARBON R 435030004R1 RN72K1J-000JE

R232 C-CARBON R 435030004R1 RN72K1J-000JE

R233 C-CARBON R 435030004R1 RN72K1J-000JE

R234 C-CARBON R 435030004R1 RN72K1J-000JE

R235 C-CARBON R 435030004R1 RN72K1J-000JE

R236 C-CARBON R 435030004R1 RN72K1J-000JE

R241 C-CARBON R 435030004R1 RN72K1J-000JE

R242 C-CARBON R 435030004R1 RN72K1J-000JE

R243 C-CARBON R 435030004R1 RN72K1J-000JE

R244 C-CARBON R 435037504R1 RN72K1J-750JE

R245 C-CARBON R 435037504R1 RN72K1J-750JE

R246 C-CARBON R 435037504R1 RN72K1J-750JE

R251 C-CARBON R 435030004R1 RN72K1J-000JE

R252 C-CARBON R 435037504R1 RN72K1J-750JE

R253 C-CARBON R 435030004R1 RN72K1J-000JE

R254 C-CARBON R 435037504R1 RN72K1J-750JE

R255 C-CARBON R 435030004R1 RN72K1J-000JE

R256 C-CARBON R 435037504R1 RN72K1J-750JE

R257 C-CARBON R 435031034R1 RN72K1J-103JE

R351 C-CARBON R 435030004R1 RN72K1J-000JE

R353 C-CARBON R 435034744R1 RN72K1J-474JE

R354 C-CARBON R 435033314R1 RN72K1J-331JE

R355 C-CARBON R 435031814R1 RN72K1J-181JE

R356 C-CARBON R 435031814R1 RN72K1J-181JE

R357 C-CARBON R 435034714R1 RN72K1J-471JE

R401 C-CARBON R 435031524R1 RN72K1J-152JE

R402 C-CARBON R 435031524R1 RN72K1J-152JE

R405 C-CARBON R 435030004R1 RN72K1J-000JE

R406 C-CARBON R 435030004R1 RN72K1J-000JE

R407 C-CARBON R 435031034R1 RN72K1J-103JE

R408 C-CARBON R 435031034R1 RN72K1J-103JE

R409 C-CARBON R 435031034R1 RN72K1J-103JE

R410 C-CARBON R 435031034R1 RN72K1J-103JE

R411 C-CARBON R 435031524R1 RN72K1J-152JE

www.denom.com

Page 7

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

AR-7997

R412 C-CARBON R 435031524R1 RN72K1J-152JE

R413 C-CARBON R 435032234R1 RN72K1J-223JE

R414 C-CARBON R 435032234R1 RN72K1J-223JE

R415 C-CARBON R 435032234R1 RN72K1J-223JE

R416 C-CARBON R 435032234R1 RN72K1J-223JE

R417 C-CARBON R 435032234R1 RN72K1J-223JE

R418 C-CARBON R 435032234R1 RN72K1J-223JE

R419 C-CARBON R 435031524R1 RN72K1J-152JE

R420 C-CARBON R 435031524R1 RN72K1J-152JE

R421 C-CARBON R 435032234R1 RN72K1J-223JE

R422 C-CARBON R 435032234R1 RN72K1J-223JE

R423 C-CARBON R 435031524R1 RN72K1J-152JE

R424 C-CARBON R 435031524R1 RN72K1J-152JE

R427 C-CARBON R 435031034R1 RN72K1J-103JE

R428 C-CARBON R 435031034R1 RN72K1J-103JE

R429 C-CARBON R 435031034R1 RN72K1J-103JE

R430 C-CARBON R 435031034R1 RN72K1J-103JE

R431 C-CARBON R 435034714R1 RN72K1J-471JE

R432 C-CARBON R 435034714R1 RN72K1J-471JE

R433 C-CARBON R 435031014R1 RN72K1J-101JE

R434 C-CARBON R 435031014R1 RN72K1J-101JE

R435 C-CARBON R 435031014R1 RN72K1J-101JE

R441 C-CARBON R 435031044R1 RN72K1J-104JE

R442 C-CARBON R 435031044R1 RN72K1J-104JE

R443 C-CARBON R 435032714R1 RN72K1J-271JE

R444 C-CARBON R 435032714R1 RN72K1J-271JE

R445 C-CARBON R 435032224R1 RN72K1J-222JE

R446 C-CARBON R 435032224R1 RN72K1J-222JE

R447 C-CARBON R 435031014R1 RN72K1J-101JE

R448 C-CARBON R 435031014R1 RN72K1J-101JE

R449 C-CARBON R 435032224R1 RN72K1J-222JE

R450 C-CARBON R 435032224R1 RN72K1J-222JE

R452 C-CARBON R 435032224R1 RN72K1J-222JE

R453 C-CARBON R 435031014R1 RN72K1J-101JE

R454 C-CARBON R 435032224R1 RN72K1J-222JE

R455 C-CARBON R 435031044R1 RN72K1J-104JE

R456 C-CARBON R 435031044R1 RN72K1J-104JE

R457 C-CARBON R 435031044R1 RN72K1J-104JE

R458 C-CARBON R 435031544R1 RN72K1J-154JE

R459 C-CARBON R 435031544R1 RN72K1J-154JE

R460 C-CARBON R 435031544R1 RN72K1J-154JE

R461 C-CARBON R 435031544R1 RN72K1J-154JE

R462 C-CARBON R 435031024R1 RN72K1J-102JE

R463 C-CARBON R 435031024R1 RN72K1J-102JE

R481 NF CARBON R 415470224 R25J-2.2

R482 NF CARBON R 415470224 R25J-2.2

R820 C-CARBON R 435033324R1 RN72K1J-332JE

R821 C-CARBON R 435031034R1 RN72K1J-103JE

R822 C-CARBON R 435031034R1 RN72K1J-103JE

R823 C-CARBON R 435031014R1 RN72K1J-101JE

R902 C-CARBON R 435032224R1 RN72K1J-222JE

R920 C-CARBON R 435032214R1 RN72K1J-221JE

U2: DISPLAY CIRCUIT PC BOARD NADIS-7998

DIS-7998 CIRCUIT NO. PART NAME PART NO. DESCRIPTION REMARK

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

Q702 FL TUBE 212238 HNV-13SS12T

Q701 IC 22242005R3 MPD780232GC-092-8BT

Q703 IC 22241924R2 S-80130CLMC-JIP-T2

Q704 TR 2216230R2 KRA103S

Q704 or TR 2214540R2 RN2403

D701 C-DIODE 223234R2 1SS352

D701 or C-DIODE 223269R2 1SS355

D702 ZENER D 224550560R2 UDZS5.6B

N

www.denom.com

Page 8

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

D703 C-DIODE 223234R2 1SS352

D703 or C-DIODE 223269R2 1SS355

Q705 REMO SENS 241348 RPM7138-H9

P701B SOCKET 25052545 NSCT-24P2442

P701Bor SOCKET 25052361 NSCT-24P2258

P701Bor SOCKET 25051906 NSCT-24P1693

P731 SOCKET 25052344 NSCT-7P2241

P731 or SOCKET 25051889 NSCT-7P1676

P731 or SOCKET 25052528 NSCT-7P2425

JL703A WIRE HOL 25051088 NSCT-4P875

X701 CERA LOCK 3010242 CST5.00MGW

C701 ELECT C 355721019 CE04W6.3V-100M

C702 C-CERA C 332161040R1 CK725F1E-104Z1

C703 C-CERA C 332161040R1 CK725F1E-104Z1

C704 C-CERA C 332161040R1 CK725F1E-104Z1

C705 ELECT C 355782209 CE04W50V-22M

C706 ELECT C 355721019 CE04W6.3V-100M

R701 C-CARBON R 435031034R1 RN72K1J-103JE

R702 C-CARBON R 435030004R1 RN72K1J-000JE

R703 C-CARBON R 435031014R1 RN72K1J-101JE

R704 C-CARBON R 435030004R1 RN72K1J-000JE

R705 C-CARBON R 435030004R1 RN72K1J-000JE

R706 C-CARBON R 435030004R1 RN72K1J-000JE

R707 C-CARBON R 435030004R1 RN72K1J-000JE

R708 C-CARBON R 435030004R1 RN72K1J-000JE

R710 C-CARBON R 435031034R1 RN72K1J-103JE

R711 C-CARBON R 435031054R1 RN72K1J-105JE

R712 C-CARBON R 435034734R1 RN72K1J-473JE

R713 C-CARBON R 435032244R1 RN72K1J-224JE

R714 C-CARBON R 435031014R1 RN72K1J-101JE

R715 C-CARBON R 435031014R1 RN72K1J-101JE

R716 C-CARBON R 435031014R1 RN72K1J-101JE

R717 C-CARBON R 435030004R1 RN72K1J-000JE

R718 C-CARBON R 435030004R1 RN72K1J-000JE

R719 C-CARBON R 435031034R1 RN72K1J-103JE

R720 C-CARBON R 435031034R1 RN72K1J-103JE

R721 C-CARBON R 435031034R1 RN72K1J-103JE

R722 C-CARBON R 435031034R1 RN72K1J-103JE

R723 C-CARBON R 435031034R1 RN72K1J-103JE

R726 C-CARBON R 435030004R1 RN72K1J-000JE

R727 C-CARBON R 435030004R1 RN72K1J-000JE

R733 C-CARBON R 435031024R1 RN72K1J-102JE

R734 C-CARBON R 435030004R1 RN72K1J-000JE

R737 C-CARBON R 435031024R1 RN72K1J-102JE

R738 C-CARBON R 435030004R1 RN72K1J-000JE

R740 C-CARBON R 435030004R1

R741 C-CARBON R 435031024R1

R742 C-CARBON R 435030004R1

R743 C-CARBON R 435031024R1

RN72K1J-000JE <MDD>

RN72K1J-102JE <MUA>

RN72K1J-000JE <MUA>

RN72K1J-102JE <MDD>

R751 C-CARBON R 435032724R1 RN72K1J-272JE

R752 C-CARBON R 435033914R1 RN72K1J-391JE

R753 C-CARBON R 435034714R1 RN72K1J-471JE

R754 C-CARBON R 435038214R1 RN72K1J-821JE

R755 C-CARBON R 435031024R1 RN72K1J-102JE

R756 C-CARBON R 435031824R1 RN72K1J-182JE

R758 C-CARBON R 435032724R1 RN72K1J-272JE

R759 C-CARBON R 435033914R1 RN72K1J-391JE

R760 C-CARBON R 435034714R1 RN72K1J-471JE

R761 C-CARBON R 435038214R1 RN72K1J-821JE

R762 C-CARBON R 435031024R1 RN72K1J-102JE

R763 C-CARBON R 435031824R1 RN72K1J-182JE

R764 C-CARBON R 435033924R1 RN72K1J-392JE

R765 C-CARBON R 435031034R1 RN72K1J-103JE

www.denom.com

Page 9

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

DIS-7998

R766 C-CARBON R 435032724R1 RN72K1J-272JE

R767 C-CARBON R 435033914R1 RN72K1J-391JE

R768 C-CARBON R 435034714R1 RN72K1J-471JE

R769 C-CARBON R 435038214R1 RN72K1J-821JE

R770 C-CARBON R 435031024R1 RN72K1J-102JE

R771 C-CARBON R 435031824R1 RN72K1J-182JE

R772 C-CARBON R 435033924R1 RN72K1J-392JE

R773 C-CARBON R 435031034R1 RN72K1J-103JE

S701 PUSH SW 25035718 NPS-111-S681

S702 PUSH SW 25035718 NPS-111-S681

S703 PUSH SW 25035718 NPS-111-S681

S704 PUSH SW 25035718 NPS-111-S681

S705 PUSH SW 25035718 NPS-111-S681

S706 PUSH SW 25035718 NPS-111-S681

S707 PUSH SW 25035718 NPS-111-S681

S708 PUSH SW 25035718 NPS-111-S681

S709 PUSH SW 25035718 NPS-111-S681

S710 PUSH SW 25035718 NPS-111-S681

S712 PUSH SW 25035718 NPS-111-S681

S713 PUSH SW 25035718 NPS-111-S681

S714 PUSH SW 25035718 NPS-111-S681

S715 PUSH SW 25035718 NPS-111-S681

Q702A CUSHION 28141513 t3*10*25

U3 : STANDBY SWITCH PC BOARD NADIS-7999

DIS-7999 CIRCUIT NO. PART NAME PART NO. DESCRIPTION REMARK

DIS-7999

DIS-7999

DIS-7999

DIS-7999

DIS-7999

DIS-7999

DIS-7999

DIS-7999

Q708 TR 2216470R2 DTC114YKA

Q708 or TR 2216340R2 KRC107S

Q708 or TR 2216260R2 RN1407

D721 LED 225290 SEL4110R

JL703B WIRE HOL 25051088 NSCT-4P875

R757 C-CARBON R 435033924R1 RN72K1J-392JE

R779 C-CARBON R 435034714R1 RN72K1J-471JE

S716 PUSH SW 25035718 NPS-111-S681

U4 : POWER SWITCH PC BOARD NASW-8000

SW-8000 CIRCUIT NO. PART NAME PART NO. DESCRIPTION REMARK

SW-8000

SW-8000

SW-8000

S991 PUSH SW 25035703 NPS-111-L666P

S991 or P SW 25035550 NPS-111-L512P

C991 IS C 3500196S RE275V-103M

U5 : INLET TERMINAL PC BOARD NAPS-8002

PS-8002 CIRCUIT NO. PART NAME PART NO. DESCRIPTION REMARK

PS-8002

PS-8002

PS-8002

P981B AC INLET 25055960 NPLG-2P913

P982B SOCKET AS 2009990661UL NSAS-2P0921

P982A CRIMP AS 2069943301UL CRIMP AS

U7 : RS-232C TERMINAL PC BOARD NAETC-8005

ETC-8005 CIRCUIT NO. PART NAME PART NO. DESCRIPTION REMARK

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

Q802 IC 22241624R2 MPD789071MC-011-5A4

Q803 IC 22241537R2 MPD4721GS

L801 EMIFIL 230958R1 BK1608LM182-T

L801 or EMIFIL 230968R1 FBM-10-160808-202T

L802 EMIFIL 230958R1 BK1608LM182-T

L802 or EMIFIL 230968R1 FBM-10-160808-202T

L803 EMIFIL 230958R1 BK1608LM182-T

L803 or EMIFIL 230968R1 FBM-10-160808-202T

L804 EMIFIL 230958R1 BK1608LM182-T

L804 or EMIFIL 230968R1 FBM-10-160808-202T

L805 EMIFIL 230958R1 BK1608LM182-T

L805 or EMIFIL 230968R1 FBM-10-160808-202T

X801 CERA LOCK 3010242 CST5.00MGW

P851B SOCKET AS 2002341620 NSAS-16P0277

www.denom.com

Page 10

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

ETC-8005

P801 SOCKET 25052379 NSCT-9P2277

P802 ST JACK 25045647 HSJ1002-01-1020

C801 VR C 394680107 CE04W50V-1M(VR)

C802 VR C 394680107 CE04W50V-1M(VR)

C803 VR C 394680107 CE04W50V-1M(VR)

C804 VR C 394680107 CE04W50V-1M(VR)

C810 VR C 394621017 CE04W6.3V-100M(VR)

C811 C-CERA C 332161040R1 CK725F1E-104Z1

C812 C-CERA C 332161040R1 CK725F1E-104Z1

C813 VR C 394621017 CE04W6.3V-100M(VR)

R8001 C-CARBON R 435030004R1 RN72K1J-000JE

R801 C-CARBON R 435031054R1 RN72K1J-105JE

R802 C-CARBON R 435030004R1 RN72K1J-000JE

R803 C-CARBON R 435030004R1 RN72K1J-000JE

R804 C-CARBON R 435030004R1 RN72K1J-000JE

R805 C-CARBON R 435030004R1 RN72K1J-000JE

R806 C-CARBON R 435030004R1 RN72K1J-000JE

R807 C-CARBON R 435034704R1 RN72K1J-470JE

R808 C-CARBON R 435030004R1 RN72K1J-000JE

R809 C-CARBON R 435034704R1 RN72K1J-470JE

R810 C-CARBON R 435034704R1 RN72K1J-470JE

R811 C-CARBON R 435034704R1 RN72K1J-470JE

R812 C-CARBON R 435034704R1 RN72K1J-470JE

NOTE:

<MDD>: North American area

<MDC>: Canadian area

<MUA>: Australian area

www.denom.com

Page 11

SPECIFICATIONS

DPS-5.4

Video system

Region code

Laser

Frequency response

Signal-to-noise ratio (digital audio) 106 dB

Audio dynamic range (digital audio) 96 dB

Harmonic distortion (digital audio) 0.008%

Wow and Flutter Below measurable level (+/- 0.001% (W. PEAK) or less)

Operating conditions

Video outputs

Audio outputs

General

DVD linear audio

CD audio 4 Hz-20 kHz

Temperature 5 to 35 C (41 F to 95 F)

Installation Install horizontally

COMPONENT VIDEO

S VIDEO (S-Video)

VIDEO (composite video) 1.0 V (p-p), 75 ohm , negative sync, RCA/phono x 2

OPTICAL -22.5 dBm, optical connector x 1

COAXIAL 0.5 V (p-p), 75 ohm , RCA/phono x 1

ANALOG 2.0 V rms, 470 ohm , RCA/phono x 1

Power supply

Power consumption 15 W

Power consumption in

Standby mode

Weight 3.3 kg (7.3 lbs.)

Dimensions (W x H x D) 435 X 81 X 307 mm (17-1/8" X 3-3/16" X 12-1/16")

North American model: Standard NTSC,

Australian model: PAL/AUTO

North American model: 1,

Australian model: 4,

Semiconductor laser, wavelength 650 nm (DVD), 780 nm (CD)

4 Hz-20 kHz @ 48 kHz sampling rate

4 Hz-44 kHz @ 96 kHz sampling rate

Y: 1.0 V (p-p), 75 ohm , negative sync, RCA/phono x1, BNC x1

P

B/PR: 0.7 V (p-p), 75 ohm

Y: 1.0 V (p-p), 75 ohm, negative sync, 4-pin mini DIN x 2

C: 0.286 V (p-p), 75 ohm

North American model: 120 V AC, 60 Hz

Australian model: 100-240 V AC, 50/60 Hz

North American model: 1.6 W

Other models: 2.5 W

Specifications and features subject to change without notice.

www.denom.com

Page 12

SERVICE PROCEDURES-1

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs a laser. Therefore, be sure to follow

carefully the instructions below when servicing.

WARNING!!

SERVICE WARNING : DO NOT APPROACH THE

LASER EXIT WITH THE EYE TOO CLOSELY.

IN CASE IT IS NECESSARY TO CONFIRM LASER

BEAM EMISSION, BE SURE TO OBSERVE FROM

A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE

OPTICAL PICKUP BLOCK.

WARNING

Laser Diode Properties

Wavelength: 650/780nm (DVD/CD)

DPS-5.4

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR

MOISTURE.

CAUTION:

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT

REMOVE COVER (OR BACK). NO USER-SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

LASER WARNING

This unit contains a semiconductor laser system and is classified

as a "CLASS 1 LASER PRODUCT". So, to use this model

properly, read this Instruction Manual carefully. In case of any

trouble, please contact the store where you purchased the unit.

To prevent being exposed to the laser beam, do not try to open

the enclosure.

CAUTION:

VISIBLE LASER RADIATION WHEN OPEN AND INTERLOCK

FAILED OR DEFEATED. DO NOT STARE INTO BEAM.

CAUTION:

THIS PRODUCT UTILIZES A LASER. USE OF CONTROLS OR

ADJUSTMENTS OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN MA

HAZARDOUS RADIATION EXPOSURE.

Y RESULT IN

SERVICE PROCEDURE

1. Replacing the fuses

WARNING

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with arrowhead symbol, within an equilateral

triangle, is intended to alert the user to the presence of uninsulated

"dangerous voltage" within the product's enclosure that may be of

sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert

the user to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the appliance.

The label on the right

is applied on the rear

panel except for USA

and Canadian

models.

1. This unit is a CLASS 1 LASER PRODUCT and employs a

laser inside the cabinet.

2. To prevent the laser from being exposed, do not remove

the cover. Refer servicing to qualified personnel.

LASER BEAM CAUTION LABEL

AVIS

RISQUE DE CHOC ELECTRIQUE

NE PAS

OUVRIR

"CLASS 1 LASER

PRODUCT "

This symbol located near the fuse indicates that the

fuse used is show operating type, For continued protection against

fire hazard, replace with same type fuse , For fuse rating, refer to

the marking adjest to the symbol.

Ce symbole indique que le fusible utilise est e lent.

Pour une protection permanente, n'utiliser que des fusibles de meme

type. Ce demier est indique la qu le present symbol est apposre.

REF. NO.

F1

PART NO.

252252 or 1.6A-TL/T-ST2 <MDD>, <MDC>

DESCRIPTION

252147 1.6A-TSC

252273 or

252073

1.6A-SE-TL250V <MUA> F1

<MDD> : North American model

<MDC> : Canadian model

<MUA> : Australian model

www.denom.com

Page 13

SERVICE PROCEDURES-2

2. Safety-check out

(Only U.S.A. model)

After correcting the original service problem perform the

following safety check before releasing the set to the customer

Connect the insulating-resistance tester between the plug of

power supply cord and terminal GND on the back panel.

Specifications: More than 10M ohm at 500V

INITIALIZING

Factory-shipped condition.

Push button "ON" (Mechanical SW)

Press the [STOP] and [STANDBY] same time with NO DISC condition.

Push button "STANDBY".

DPS-5.4

REMOVE THE SOLDER OF LASER DIODE SHORT

When replace the mechanism or DVD main PC board.

Shorting the solder of Shot-circuit land. (2 positions)

Mechanism

Short Land

www.denom.com

Page 14

DPS-5.4

03

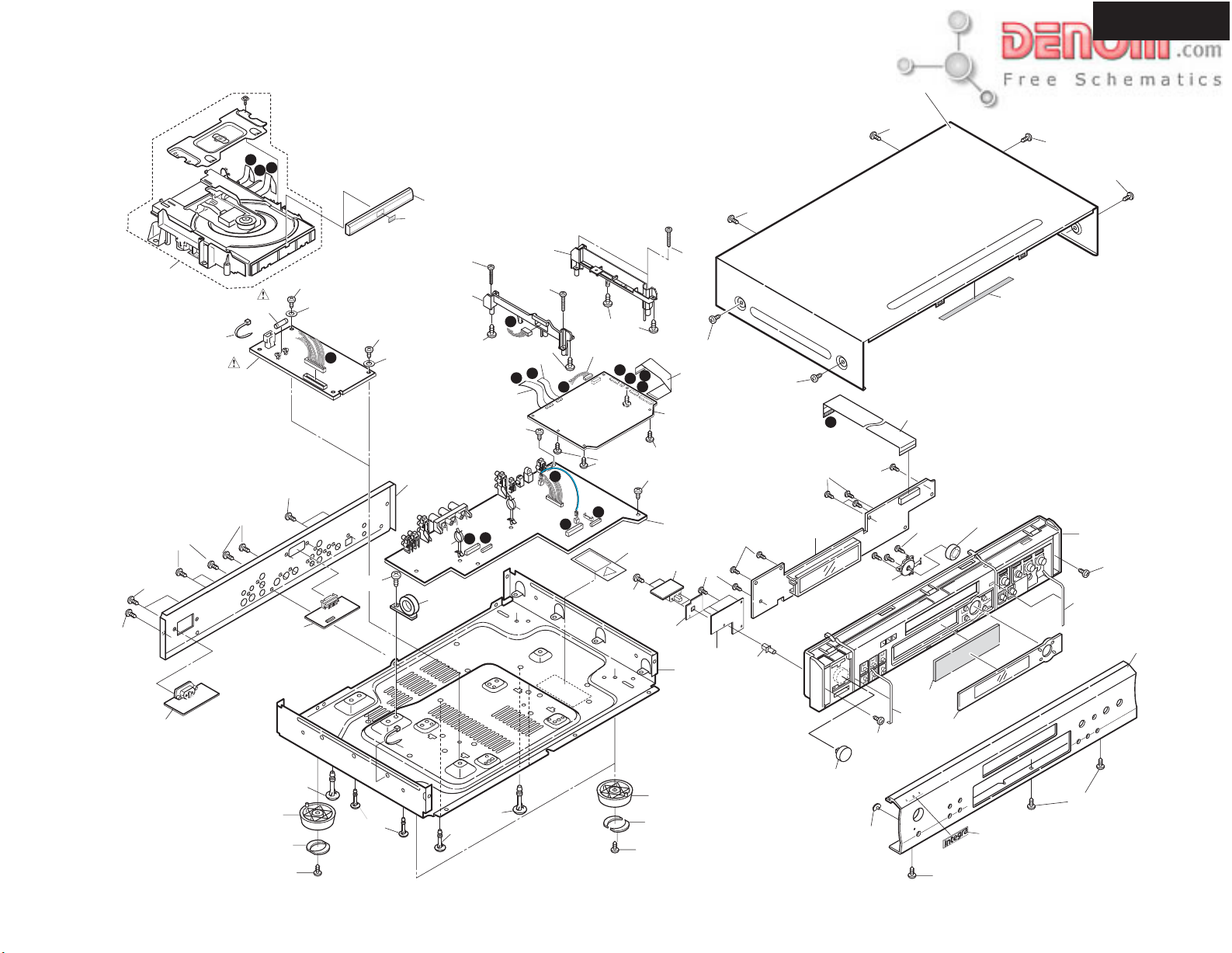

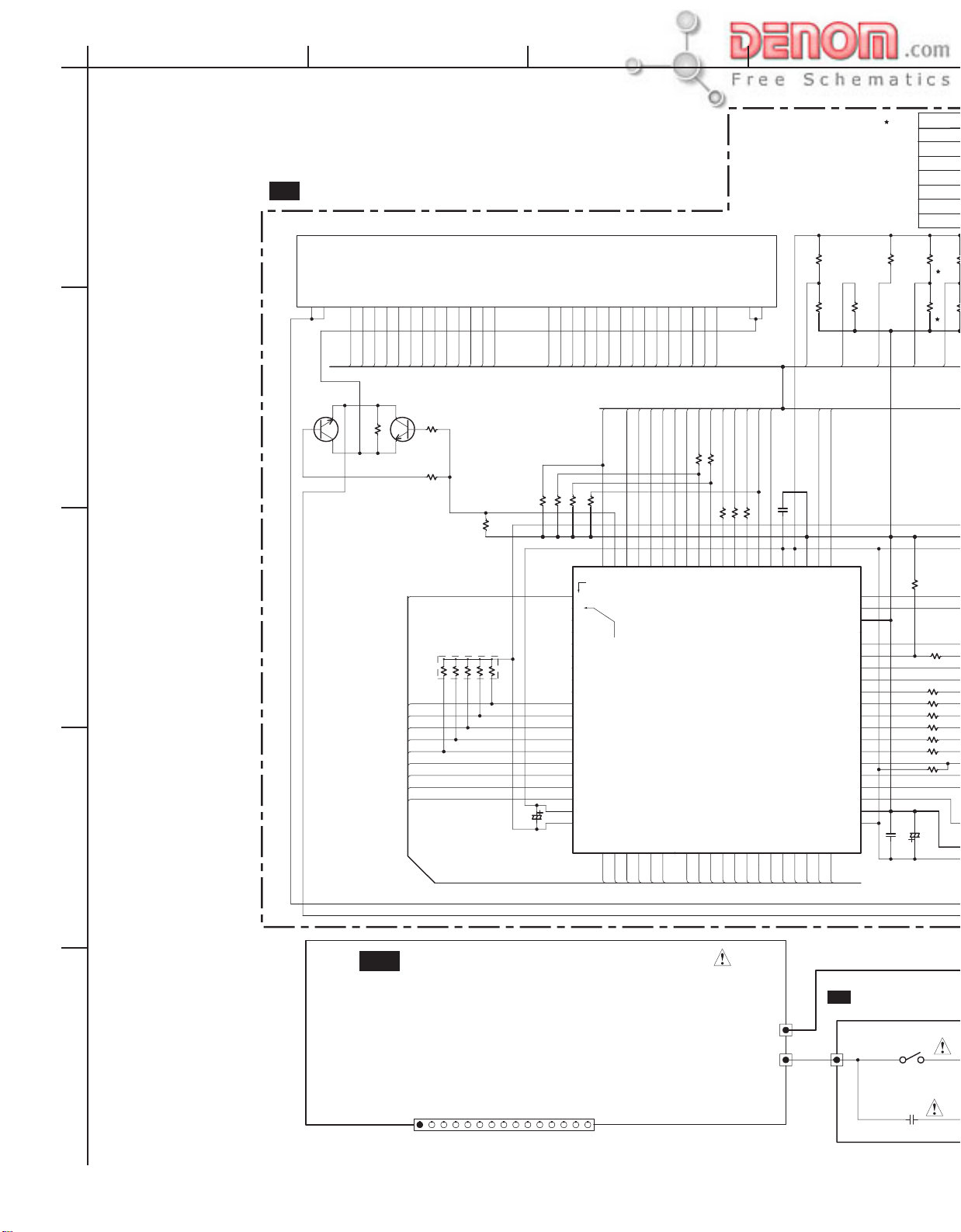

EXPLODED VIEW

a

Z10

P910

U20

A48

A48

A49

b

F1

A55

A56

A56

c

A48

A11

A11a

f

Z91A

EO

ID

V

A11

A11a

A52

A47

A51

Z14

Z12

A16

P901A

Z15

i

P503

A11

h

g

P502

i

A16

Z13

Z14

Z15

h

Z14

Z15

P702

a

d

g

b

c

A56

P501

Z1

A11

f

e

d

A11

A11

U1

A15

U4

A11

A32

A11

A56

A56

A11

U2

A57

e

P701

03

A11

A27 x 3

A35

S731

A56

A20

A11

A24

A48

U5

A3

A11

A13

A5

U7

A10

P910

A12

A13

U6

A3

A5

A11

www.denom.com

A1

U3

A30

A21

A11

A44

A24

A23

A22

A

IT

IG

D

CT

E

IR

D

A46

A41

4

.

5

-

S

P

D

A46

H

T

PA

L

A43

Page 15

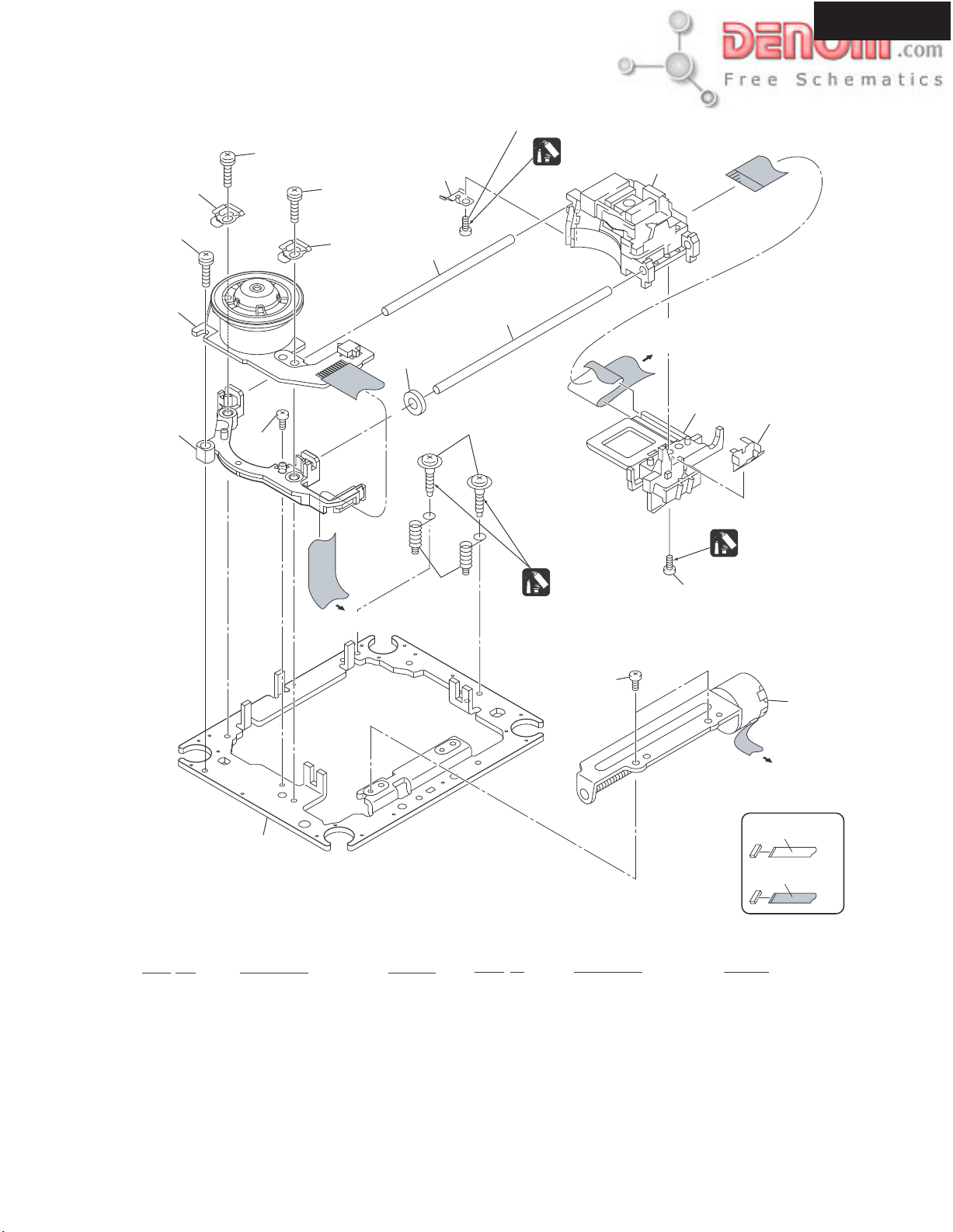

EXPLODED VIEW / PARTS LIST

DPS-5.4

TRAVERSE MECHANISM

17

17

10

13

10

17

1

16

12

8

7

4 (Adjustment screw)

15 (Torque : 0.15 +/- 0.01 N m)

Silicone Adhesive

GEM1037

6

3

To

DVDM CN101

(Pickup Assy)

14

9

Silicone Adhesive

GEM1037

(Adjustment

spring)

11

To DVDM CN102

(Spindle Motor)

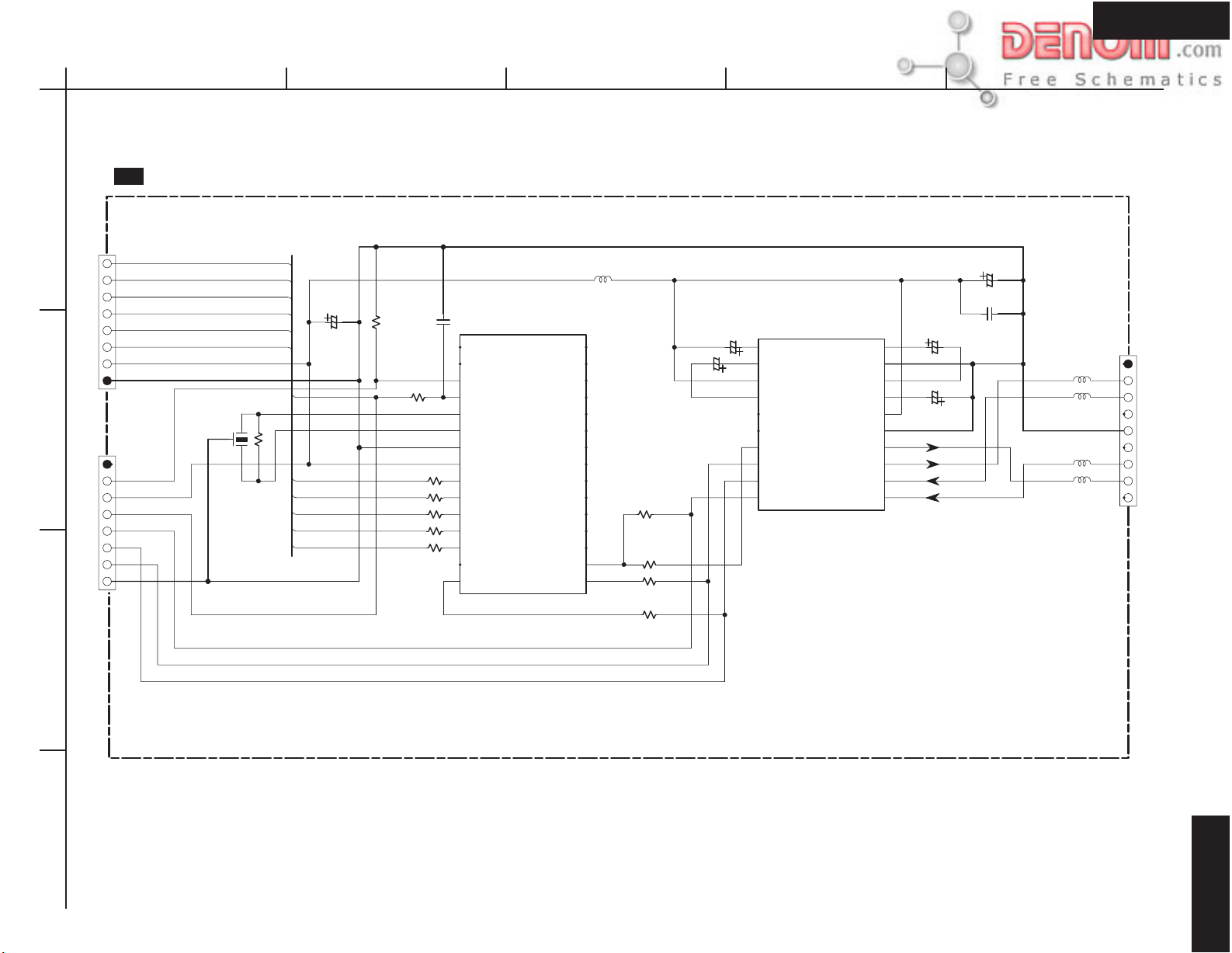

TRAVERSE MECHA. ASSY parts List

Mark No. Description Part No.

1 Spindle Motor VXM1099

2 Stepping Motor VXM1101

3 Pickup Assy-S OXX8005

4 Skew Screw VBA1080

5 Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Leaf Spring VNC1023

NSP : Not service parts

5

Screw Tight

GYL1001

15 (Torque : 0.15 +/- 0.01 N m)

16

Mark No. Description Part No.

9 Joint Spring VNC1019

10

NSP

Support Spring VNC1020

11 Mecha.Chassis VNE2248

12 Damper Sheet VEB1335

13 Spacer VNL1913

14 Joint 03 VNL1949

15 Tapping Screw OBA8016

16 Screw BBZ20P050FZK

17 Screw PMA26P100FMC

2

To

DVDM CN104

(Stepping Motor)

NON-CONTACT

SIDE

CONTACT SIDE

www.denom.com

Page 16

EXPLODED VIEW / PARTS LIST

LOADING MECHANISM

DPS-5.4

Note :

Refer to

" Application of Lubricant".

Daifree

GEM1036

23

Lubricating Oil

GYA1001

13

22

12

8

Refer to

2

"2.5 TRAVERSE MECHA. ASSY-S".

6

8

8

To DVDM CN101 (Pickup Assy-S)

To DVDM CN104 (Stepping Motor)

To DVDM CN102 (Spindle Motor)

8

20

18

22

16

17

3

A

4

5

19

15

14

22

LOADING MECHA. ASSY parts List

Mark No. Description Part No.

NSP 1 LOAB Assy

2 Traverse Mecha. Assy-S VXX2871

3 Loading Motor Assy VXX2872

4 Motor Pulley

5 Motor

6 Flexible Cable (24P) VDA1945

7 Connector Assy 2P VKP2253

8 Floating Rubber VEB1351

9 Belt VEB1330

10 Stabilizer VNE2253

11 Loading Base VNL1917

12 Float Base DVD VNL1918

13 Drive Cam VNL1919

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

16 Drive Gear VNL1923

21

22

7

A

10

11

Lubricating Oil

GYA1001

9

1

No. Description Part No.

Mark

17 SW Lever VNL1925

18 Clamper Plate VNE2251

19 Bridge VNE2252

20 Clamper VNL1924

21 Screw JGZ17P028FMC

22 Screw 801530

23 Tray VNL1920

NSP: Not service parts

www.denom.com

Page 17

DPS-5.4

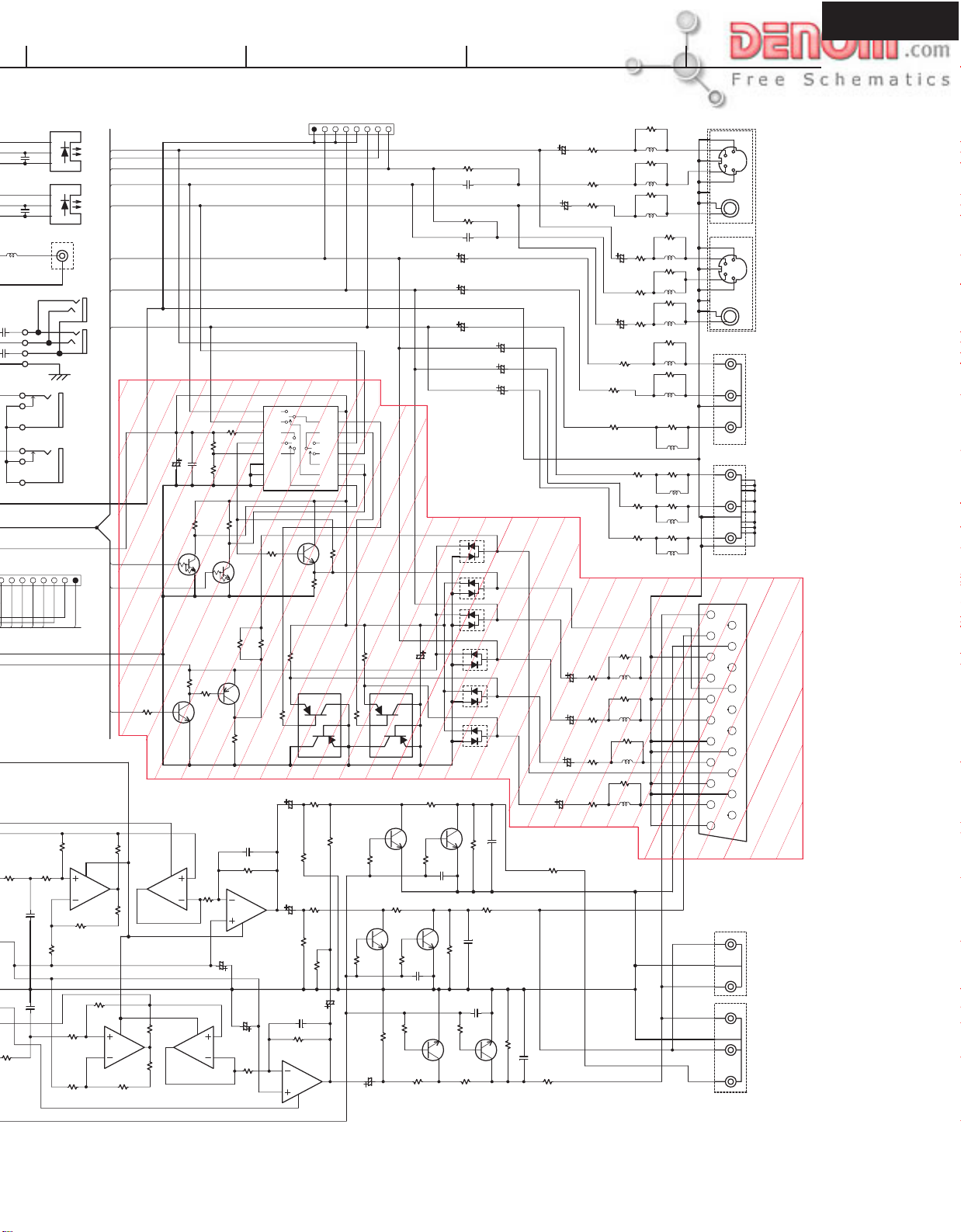

L354

232RE

1.5K

R412

232BU

C360

104Z

C367

104Z

232SCK

1

2

3

4

P802

232SI

102

102

OPTICAL_OUT

Q351 JFJ3000

3

2

1

Q356 JFJ3000

3

2

1

OPTICAL_OUT

RI_OUT

232SO

R413

22K

C407

22K

C408

P350

P352

IR_IN/OUT

232RESET

22K

R415

5

Q401

6

NJM4580M-D

R417

R421

R414

22K

R422

22K

P851A

4

-B

22K

22K

R416

NJM4580M-D

GND_VIDEO

RGBSW

68

R611

R609

470

C409

NJM4580M-D

Q403

-B

4

C412

R428

10K

P292A

TC4053BF

Q601

Y11

VCC16

Z13

Z4

Z05

EN6

VEE7

GND8

1K

R614

2SC2712

Q604

10K

V+12V

R610

R613

330 1/2W

R/C.DRV

1

100

25

R617

3

Q607

HN1A01F-GR

C415

R431

470

47/50

R432

150K

RR461

R443

C413

270

7

47/50

R461

150K

150K

47/50

470

C410

10K

R430

NJM4580M-D

6

Q404

+B

8

5

Y15Y02

X14

X113

X012

A11

B10

C9

R615

C419

7

Y Y

P/XI

ASPECT

C C

V

G/Y

B/CB

R/CR

2.2K

R603

1.8K

R601

C602

104Z

C601

100/16

SQUEEZE

VSEL2

4.7K

R606

R423

1.5K

8

1

7

R419

5

-B

Q402

6

R418

1.5K

4

22K

NJM4580M-D

1.5K

R424

7

R420

1.5K

Q403

2.2K

R602

10K

10K

R605

R604

Q602

Q603

DTC114EE

DTC114EE

SW+5V SW+5V

1.2K

22K

R608

R607

Q606

2SA1162

Q605 2SC2712

+B

1

NJM4580M-D

3

2

4

Q404

R427

-B

10K

56K

R429 10K

6

5

C411 220/6.3

3

220/6.3

2

NC

Y

V

R/C

Y/V

0

R626

R612

6

1

100

25

R616

4

3

HN1A01F-GR

Q407

HN1C03F

470

HN1C03F

Q405

2

R445

R458

2.2K

C414

47/50

MUTE_R

330 1/2W

Y/V.DRV

Q608

2

R452

2.2K

R447 100

6

1

150K

G/Y

6

1

HN1C03F

R449

R459

HN1C03F

5

2.2K

C416

102

Q406

R444

270

B/CB

C603

6

4

Q405

R446

2

100/16

R453

100

HN1C03F

5

R454

2.2K

C418

102

3

4

2.2K

R224 10K

C222 104K

R257 10K

C253 104K

C2241000/6.3

C2251000/6.3

C2261000/6.3

R441

1

HN1C03F

6

D601 1SS226

D603 1SS226

D605 1SS226

D606 1SS226

3

Q407

4

R455

100K

100

R433

C480

100K

C417

102

Q406

R450

2.2K

5

R448

100

D602

D604

C482

C2271000/6.3

C2281000/6.3

C2291000/6.3

4

3

1SS226

1SS226

R442

Y/V.DRV

100K

C481

NC

RGBSW

R/C.DRV

470/6.3

R435

100

100

R434

C221

470/6.3

C223

470/6.3

470/6.3

470/6.3

C614

470/6.3

C615

C613

C612

R221

R222

R223

R618

R619

R620

R621

P201

R231

C251

470/6.3

C252

470/6.3

R225

R229

75

R227

75

R622

L601

R623

L602

R624

L603

R625

L604

L201

L202

L203

R252

75

R254

75

R256

75

75

R24475R241

R245

75

R246

75

0

0

0

0

0

0

0

R236

R251

L210

R253

L211

R255

L212

R234

L204

L205

R235

L206

R242

L208

R243

L209

L207

0

0

0

0

0

R232

R233

0

0

0

0

1

3

5

4

2

7

8

1

3

5

4

2

7

8

DPS-5.4 only

75

75

75

75

75

75

75

G1

Y

G2

C

G3

G4

SIGNAL

P201

G1

VIDEO OUTPUT

Y

G2

C

G3

G4

SIGNAL

P203

4

Y

2

CB

1

3

P205

4

8

1

CR

COMPONENT 1

COMPONENT 2

P601

SCART

AUDIO_R1

2

AUDIO_L3

AGND4

VGND15

6

B7

F.SW8

VGND29

10

G11

12

VGND313

VGND414

R/C15

RGB.SW16

VGND517

VGND618

CV/Y19

20

VGND721

P402

2

L ch

1

3

R ch

R ch

3

1

L ch

2

MONO

4

P401

www.denom.com

Page 18

A

BCDEFGH

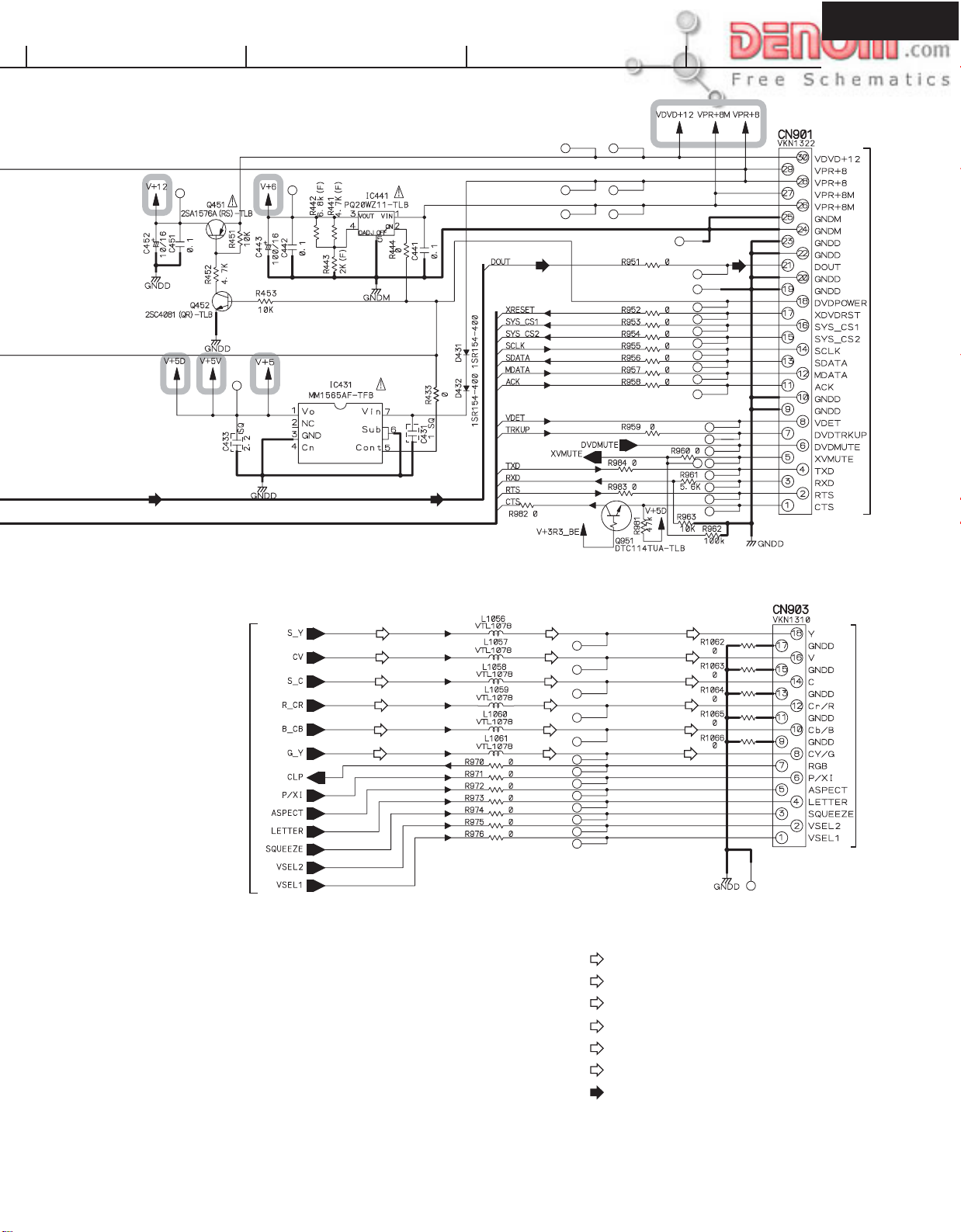

SCHEMATIC DIAGRAM-1

232SCK

232SI

232SO

232RE

232RESET

232BU

P701A

CN903

FLAC1

IRIN

EVER+5V

ACK

GND

SYSRESET

R102 47

R103 47

R104 47

R106 47

R107 47

R108 47

R121 47

R122 47

R125 47

R127 47

R123 0

R124 47

R126 47

R135 10K

R134 10K

-27V

RI

VDET

FLAC2

RESET

DEMO

P_ON

XSCK

XRDY

SI

SO

1

To Display circuit PC board

VSEL1 18

VSEL2 17

2

3

4

5

SQUEEZE 16

LETTER 15

ASPECT 14

P/XI 13

RGB 12

CY/G 11

GND1 10

CB/B 9

GND2 8

CR/R 7

DNG3 6

C5

From DVD Main circuit PC board

GND4 4

V3

GND5 2

Y1

GND4 11

Y10

GND3 9

V8

GND2 7

C6

GND1 5

DVDA2 4

DVDL 3

GNDA1 2

DVDR 1

CN902

From DVD Main circuit PC board

CTS 30

RTS 29

RXD 28

TXD 27

XVMUTE 26

DVDMUTE 25

DVDTRKUP 24

VDET 23

GNDD6 22

GNDD5 21

ARK 20

MDATA 19

SDATA 18

SCLK 17

SYS_CS2 16

SYS_CS1 15

XDVDRST 14

DVDPOWER 13

GNDD4 12

GNDD3 11

DOUT 10

GNDD2 9

GNDD 8

GNDM2 7

GNDM 6

From DVD Main circuit PC board

VPR+8M1 5

VPR+8M2 4

VPR+8A1 3

VPR+8A2 2

VDVD+12 1

CN901

P104

TXD 1

RXD 2

DTR 3

CTS 4

V+5D 5

GNDD 6

NC 7

For Download

1mm Pich FFC

U1 : OUTPUT TERMINAL PC BOARD

NAAR-7997

C360

C355

C354

020

1SS355

C920

470/6.3

Q352

D801

2SC2712

D922

1SS352

020

C356

020

C357

104K

8

9

101112

13

VCC 14

TC74VHCU04T

12345

GND

R822

10K

R821

10K

223

R820

C814

3.3K

100/6.3

IR

V+12V V+12V

R902

2.2K

Q920

D901

V+6V

AGND

C402 47/16

UDZS5.1B

R482

(1/4W)

C401

47/16

Q460

DTA114YKA

Q463

DTC144YKA

220/16

100K

100K

C485

104Z

C483

R402

1.5K

10/16

GND7

6

BK1608LM182-T

R357 470

C815

+6V

C923 104Z

C922 220/16

2.2

1.5K

R401

681

R457

V+6V

681

R456

330

R354

180

L352

12

SW+5V

V+11V

C921

C484

104Z

C486

220/16

C403

R403

NC

C404

180

220

220

R355

L353 BK1608LM182-T

220/16

C358

R356

C361

104Z

C362

4

53

NC

R404

(1/4W)

2.2

152

152

Q806

R405

R407

R408

UMG9N

R481

0

10K

C405

C406

R406

10K

ON3131

3

+B

Q401

2

3

0

Q402

2

C359

100/6.3

Q801

EVER+5V

GND

NJM4580M-D

8

R409

10K

NJM4580M-D

8

+B

R410

10K

L351 BK1608LM182-T

P351A

0

R351

C351

DVDMUTE

C904

220/6.3

+8V

GND

M+8V

MGND

SW+5V

P702B

RGB

MUP2P

OTHER

RESET

220/16

+8V

For FL tube

GND

SO

MRESET

DVDMUTE

C902

For Mecha.

-27V

DOUT

IC

P105

R115R116

0

--0

10K

R117

+5V

C901

104Z

C908

+8V

P901

RGB

R115

0

NC

R116

C903

104Z

C907

104Z

1000/16

C914

104Z

C911

100/16

-27V

GND

FLAC1

15 10 5 1

V+12V

FLAC2

To Power supply unit (CN2)

R101 10K

VSEL1

VSEL2

SQUEEZE

ASPECT

P/XI

RGB

G/Y

B/CB

R/CR

CSI

V XSCK

Y

CTS VSEL1

DTR

RXD

TXD

VDET

ACK

SI

SO

XSCK

XRDY

SYSRESET

P_ON

DOUT

C909

104Z

C910

1000/16

R137 10K

R136 10K

TXD

RXD

C101

DTR

CTS

104Z

R118

10K

DEMO

R119

10K

D101

UDZ5B

GND

C352 104Z

C905 104Z

R462

1K

+12V

P_ON

EVER+5V

C353 100/6.3

C906 220/16

D460

D923

D924

1K

R352 100K

R920

D920

R463

R353 470K

1SS352

1SS352

D921

1SS352

1SS352

+12V

220

UDZS11B

C420

104Z

C367

104Z

L354

BK1608LM182-T

C363

223Z

C364

223Z

AGND

R823

100

To U7: RS-232C terminal PC board

232RE

232BU

R411

1

1.5K

R412

1

1.5K

www.denom.com

Page 19

MDD

MUA

4

1

0

0

NC

NC

NC

0

1K

NC

0

NC

NC

1K

R739R738

R740 R741

R742 R743

INIT1

INIT2

R708 0 NC

R709 NC 0

SYSIN

VDET

SYSOUT

REMO

IRIN

ACK

DEMO -27V

SYSRESET

Q705

REMSENS

R727

REMO

Integra Others

47K

R712

D703

1SS352

Q704

RN2403

K1

R751

2.7K

0

C706

100/6.3

R713

220K

D702

UDZS5.6B

STB_L STB_L

K0 K0

R758

2.7K

2.7K

R766

R752

390

K1

CLEAR

T.MENU

K2

PAUSE

R753

470

R759

390

R767

390

S712

PLAY MODE

S704

RETURN

S701

STOP

GND

R754

820

R760

R768

470

470

S713

S705

S702

R755

DISPLAY

MENU

PLAY

1K

R761

820

R769

820

S714

S706

S703

R756

1.8K

SETUP

DIMMER

R762

1K

S707

R770

1K

S715

R763

1.8K

R771

1.8K

DOWN

U3 : STANDBY SWITCH

PC BOARD NADIS-7999

JL703B

R764

3.9K

R772

3.9K

JL703A

S708

R765

10K

UP

OPEN

S709

R773

10K

UP

RIGHT

DOWN

LEFT

S710

P731

R757

3.9K

STANDBY

7

6

5

4

3

2

1

S716

Q708

RN1407

ENTER

S731

NPS-115-S673

R779

D721

470

STANDBY

DPS-5.4

10K

R701

1M

R711

X701

P982A

5.00MHZ

R710 10K

104Z

P702A

D701

C703

S-80145

Q703

3

4

2

5

1

U5 : INLET TERMINAL

PC BOARD NAPS-8002

P981A

P982BP982A

AC INLET

P981

FLAC1

FLAC2

SO

P701A

DEMO

GND

ACK

XSCK

PON

SI

RESET

XRDY

GND

SYSRESET

20 10

E+5V

IRIN

FLAC1

VDET

To Output terminal PC board NAAR-7997

CAUTION

FOR CONTINUED PROTECTION

AGAINST FIRE HAZARD, REPLACE

ONLY WITH FUSE OF SAME TYPE

VA

AND RATING INDICATED.

ATTENTION

AFIN D'ASSURER UNE PROTECTION

PERMANENTE CONTRE LES RISQUES

D'INCENDIE, REMPLACER UNIQUEMENT

VA

PAR UN FUSIBLE DE MEME TYPE

ET CALIBRATION COMME INDIQUE.

THIS SYMBOL LOCATED NEAR THE FUSE INDICATES

THAT THE FUSE USED IS SLOW OPERATING TYPE

FOR CONTINUED PROTECTION AGAINST FIRE

HAZARD,REPLACE WITH SAME TYPE FUSE. FOR FUSE

RATING REFER TO THE MARKING ADJACENT TO THE SYMBOL.

CE SYMBOLE INDIQUE QUE LE FUSIBLE UTLISE EST

E LENT.POUR UNE PROTECTION PERMANENTE,N'UTILISER

QUE DES FUSIBLES DE MEME TYPE. CE DARNIER EST

INDIQUE LA QU LE PRESENT SYMBOL EST APPOSE.

FLAC2RI-27V

232BU

SRESET

232RE

232SO

232SI

232SCK

1

www.denom.com

Page 20

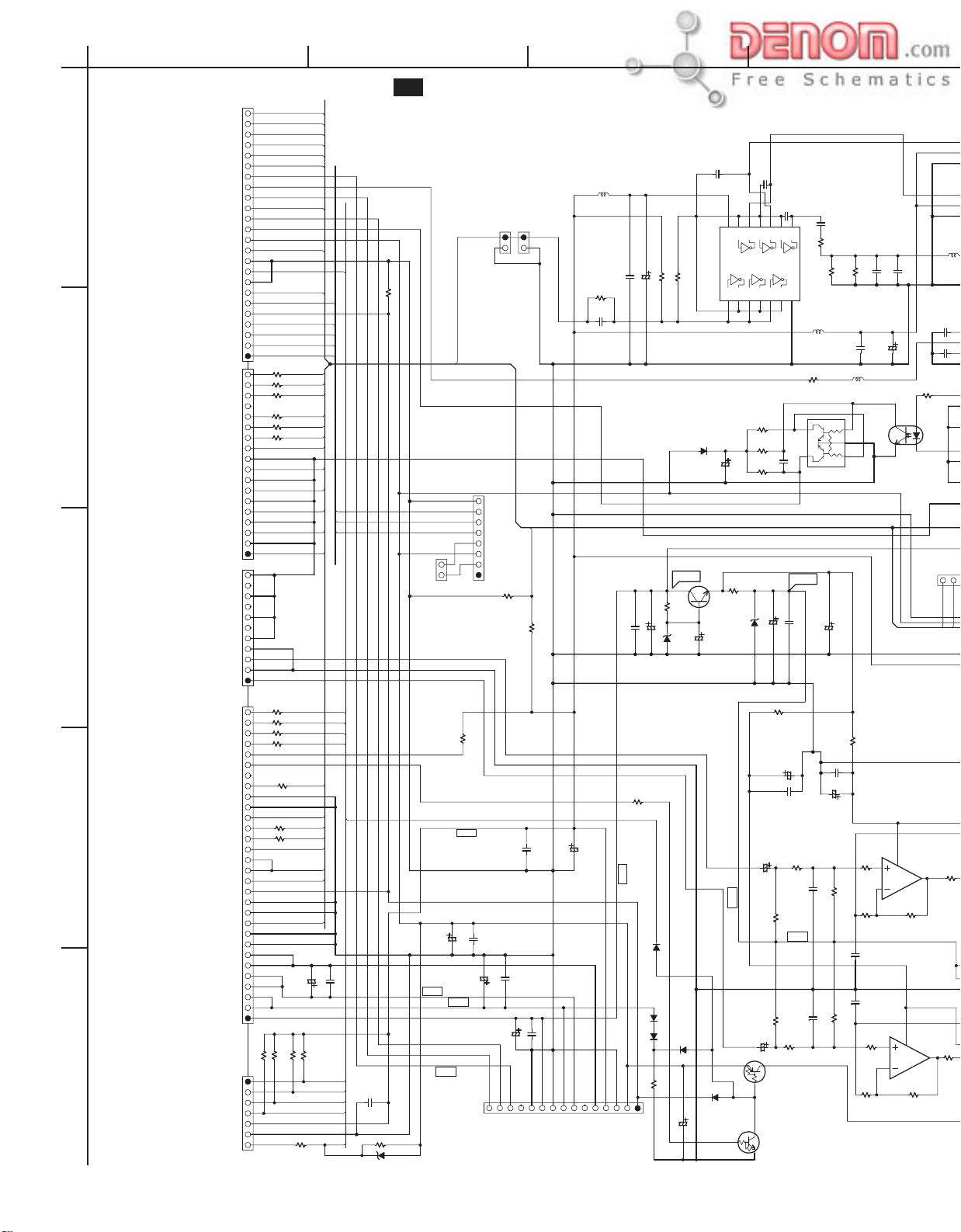

A

SCHEMATIC DIAGRAM-2

1

U2 : DISPLAY CIRCUIT PC BOARD NADIS-7998

BCDEFGH

: MARK

Region

Model Setup

DPS-5.4 Others

R736 NC 0

R737 1K NC

+5V

R738

R739

R740

R741

R742

R743

Q702HNV-13SS12T

1G41

2G40

3G39

4G38

5G37

6G36

7G35

8G34

F245

F2244

1G2G3G4G5G6G7G8G9G

2

2S

Q707

NC

0

R726

9G33

10G32

11G31

12G30

13G29

10G

11G

12G

13G

NC

Q706

R725

0

2S

R724

0

FL_ON/OFF ENTER

10K

R723

STB_L K2 RI

3

R

100KX5

P15 PON

P14 XRDY

P13 SO

P12 SI

P11 XSCK

P10

P9

P8

P7

4

P218

P317

P416

P119

P1P2P3P4P5P6P7P8P9

10K

10K

10K

10K

R720

R721

R722

+5V

41

42

NC543

NC644

NC745

NC846

NC947

NC1048

NC1149

P1550

P1451

P1352

P1253

P1154

P1055

P956

P857

P758

VDD259

VLOAD60

C705

22/50

P515

P614

P713

SRESET

MSO_0

R719

39

STBYLED

R232RES 40

FLON_OFF

42: NC4

P562

P661

P6P5P4P3P2

MSO_0 38

P463

P812

MSO_1

MSO_1 37

P364

P911

P10

MSO_2

MSO_2 36

P265

P1010

INIT0

INIT0 35

P166

P1

P119

P11

INIT1

INIT1 34

OPEN67

P128

P137

P146

P155

P12

P13

P14

P15

INIT2

232SO

232SCK

232SI

R7170

R7180

100

R716

INIT2 33

232SO 32

232SCK 31

Q701

MPD780232GC

11G70

12G69

13G68

13G

12G

11G

10G

F122

F11

232BU

232RE

SYSOUT

100

R714

R715 100

R232SI 30

SYSOUT 27

R232REQ 28

R232BUSY 29

10G71

7G74

8G73

9G72

9G8G7G6G5G4G3G2G1G

SYSIN

C704

104Z

+5V 24

VDD0 25

SYSIN 26

DISPKLAYMODE 13

4G77

5G76

6G75

1K

R737

NC

R736

MSO_0

K0

K1

K0 22

K1 21

VSS0 23

VDET 19

AVSS 18

VCOFF 17

REMO 16

IRIN 15

ACK 14

SYSRESET 12

PON 11

XRDY 10

XSCK 7

RESET 6

VSS1 2

VDD1 1

1G80

2G79

3G78

K2 20

SO 9

X2 4

X1 3

0

MSO_1

SI 8

IC 5

R734

MSO_2

C702

1K

104Z

R733

INIT0

NC

R709

R708 0

R707 0

R706 0

R705 0

R704 0

R703 100

R702 0

C701

R742 R743

INIT1

REMO

DEMO -27V

SYSRESET

10K

R701

1M

R711

100/6.3

U20 : POWER SUPPLY UNIT

NGPS-0040 AC100-120V 50Hz/60Hz

NGPS-0041 AC100-240V 50Hz/60Hz

AC G

5

FLAC1

-27V

CN2

P ON

GND

EVER+5V

GND

SW+5V

M+8V

NC

To Output terminal PC board NAAR-7997 (P901)

E+8V

GND

GND

NC

EVRE+12V

FLAC

AC H

U4 : POWER SWITCH

CN1

PC BOARD NASW-8000

S991

P982B

C991

103M/250V

www.denom.com

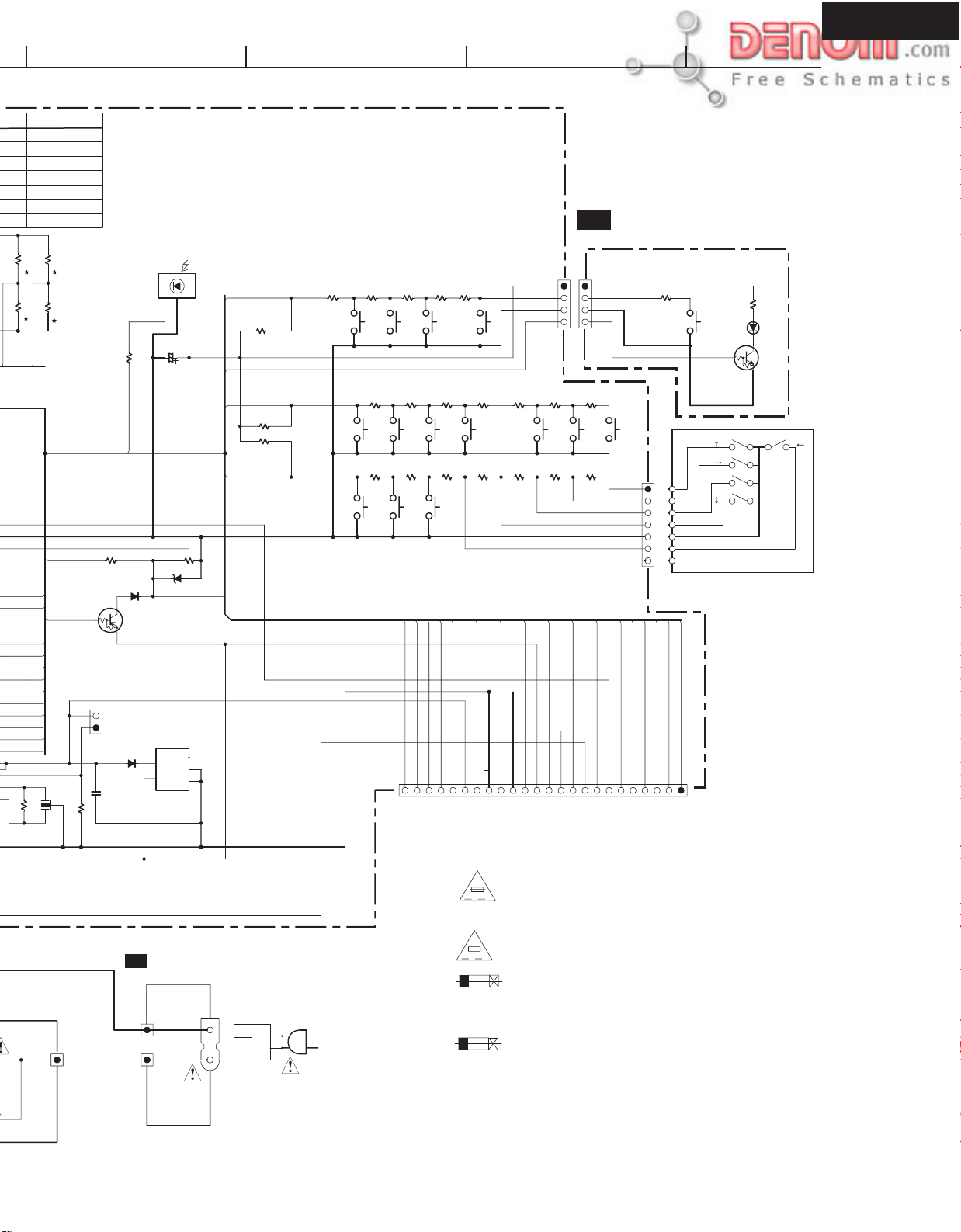

Page 21

DPS-5.4

A

SCHEMATIC DIAGRAM-6

U7 : RS-232C TERMINAL PC BPARD NAETC-8005

1

2

3

NCETC-8005

P851BP802

From Outpur terminal PC board

NC

RESET

SDATAOUT EVER+5V

SCK

SDATAIN

BUSY

REQ

X801

5.00MHZ

R801

1M

100/6.3

C810

RESET

SDATAOUT

SDATAIN

SCK

BUSY

REQ

BCDE

R808

R8060

R8050

R8040

R8020

R8030

R807

47

C811

104Z

GND

BK1608LM182-T

L801

1/50

C802

PORT14 30PORT151

PORT162

IC3

RESET4

X25

X16

VSS7

VDD8

SO9

SI10

SCK11

NC12

REQ13

BUSY14

RXD15

PORT13 29

PORT12 28

PORT11 27

PORT10 26

PORT9 25

PORT8 24

Q802MPD789071MC

PORT7 23

PORT6 22

PORT5 21

PORT4 20

PORT3 19

PORT2 18

PORT1 17

TXD 16

RTS_FL

TXD_FL

RXD_FL

R812

1/50

C801

CTS_FL

47

47

R809

47

R811

47

R810

1

2

3

4

5

6

7

8

9

10 11

MPD4721GS

Q803

1/50

C803

20

19

18

1/50

17

C804

16

15

14

13

12

100/6.3

C813

104Z

C812

BK1608LM182-T

BK1608LM182-T

BK1608LM182-T

BK1608LM182-T

(9PIN D-SUB CONNECTOR)

P801

RS-232C CONNECTOR

L805

L804

L803

L802

DPS-5.4

4

www.denom.com

Page 22

DPS-5.4

A

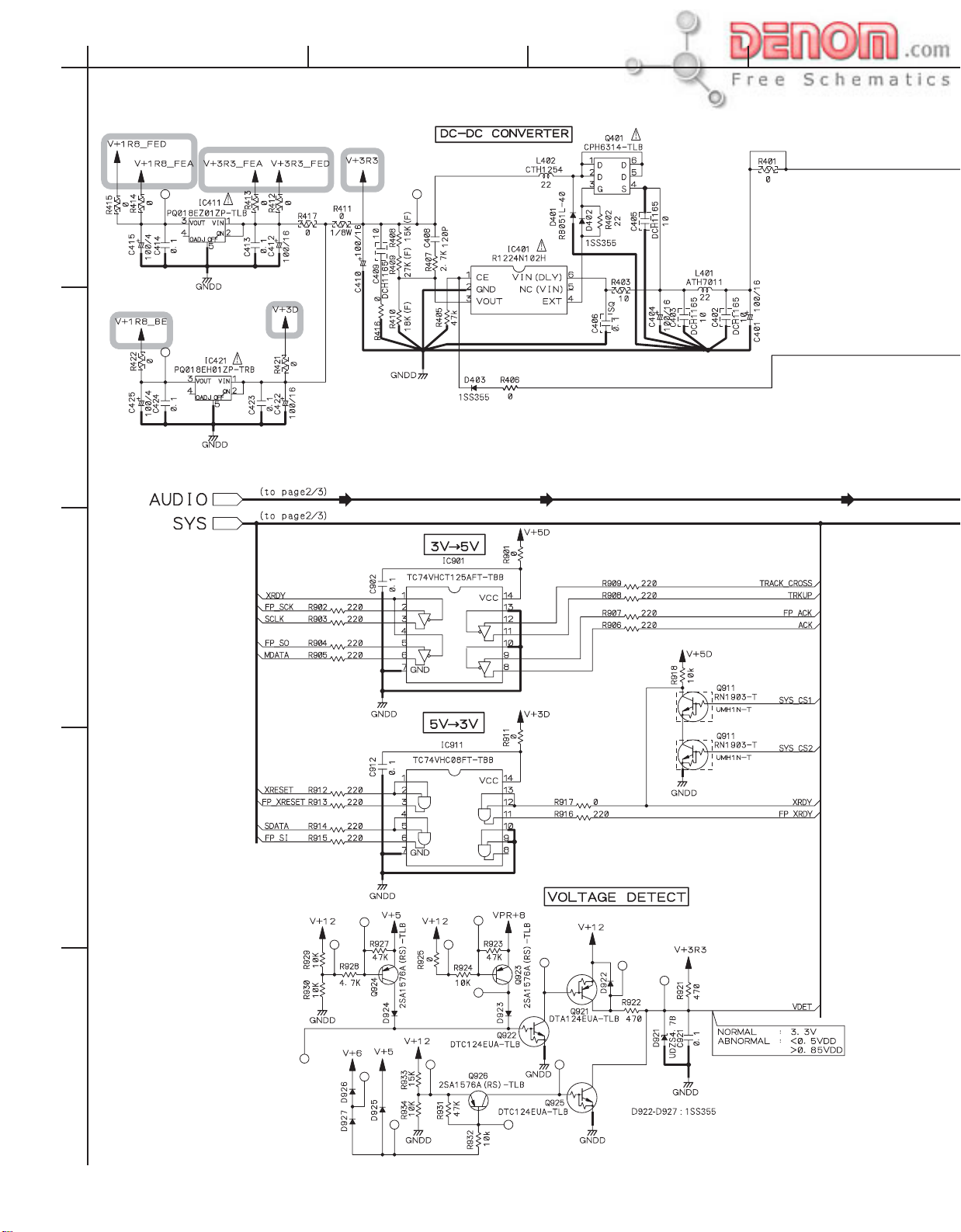

SCHEMATIC DIAGRAM-7

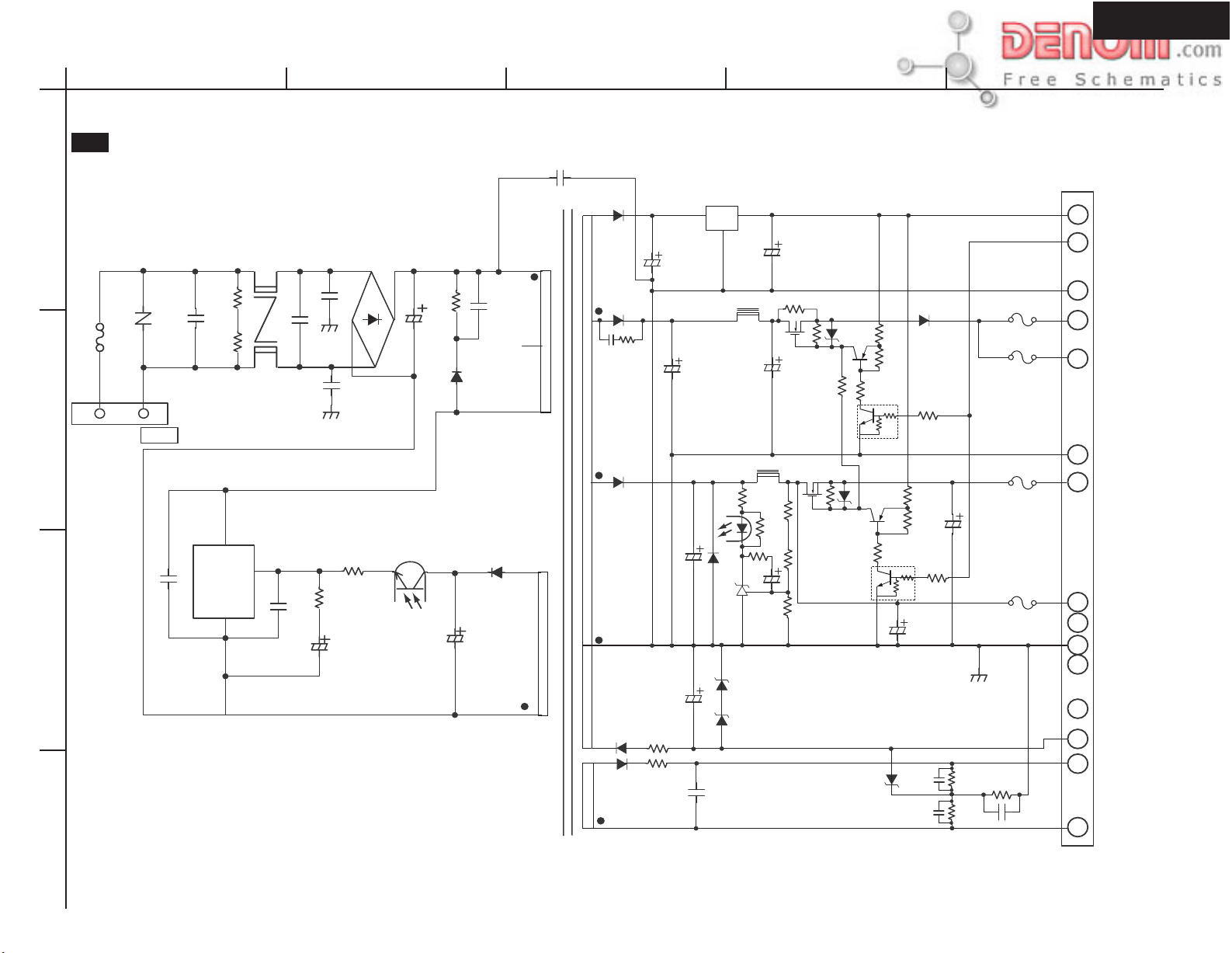

U20 : POWER SUPPLY UNIT

NGPS-0040-100-120V <MDD/ MDC>

NGPS-0041-100-240V Except <MDD/ MDC>

1

C4: 250WXA68M 16x20 <MDD>

400WXA68A 18x20 <MUA>

C2

L1

C1

CN1

R1

R2

C31

VS1

F1

2

AC-H

AC-G

3

C22

1

IC1

C8

3

2

D1-D4

C3

R4

R5

C7

BCDE

C28

CN2

C4

PHC1-1

R3

C5

D5

D6: 1SS133 <MDD/MDC>

05NU42 ExcepT <MDD/MDC>

D6

C5

D7

T1

8

18

17

D8

7

C30 R32

6

15 -16

D9

3

14

2

D11

D12

R29

R30

12

11

10

C9

C21

C27

C12

C14

1

IC4

2

L3

PHC1

R14

D14

IC3

D15

D16

3

C13

1

2

R16

L2

R17

R15

C15

C10

SJW1

5-6

Q3

4

7-8 1

Q3

R18

R19

10

EV+12V

P-con

1

GND

D13

3

2

R6

R31

R12

Q1

R9

Q2

D17

R22

Q5

D19

R7

R8

R10

R11

R21

C19

R23

C18

49101.6PAR

CP1

CP2

49101.6PAR

CP3

49101.6PAR

CP4

491.800PAR

11

7

9

4

2

6

3

8

SW+8V

SW+8V

GND

SW+5V

EV+5V

NC

GND

5

NC

12

EV -28V

13

14

15

FLAC

FLAC

D18

C24

C25

R24

R25

R26

C26

4

www.denom.com

Page 23

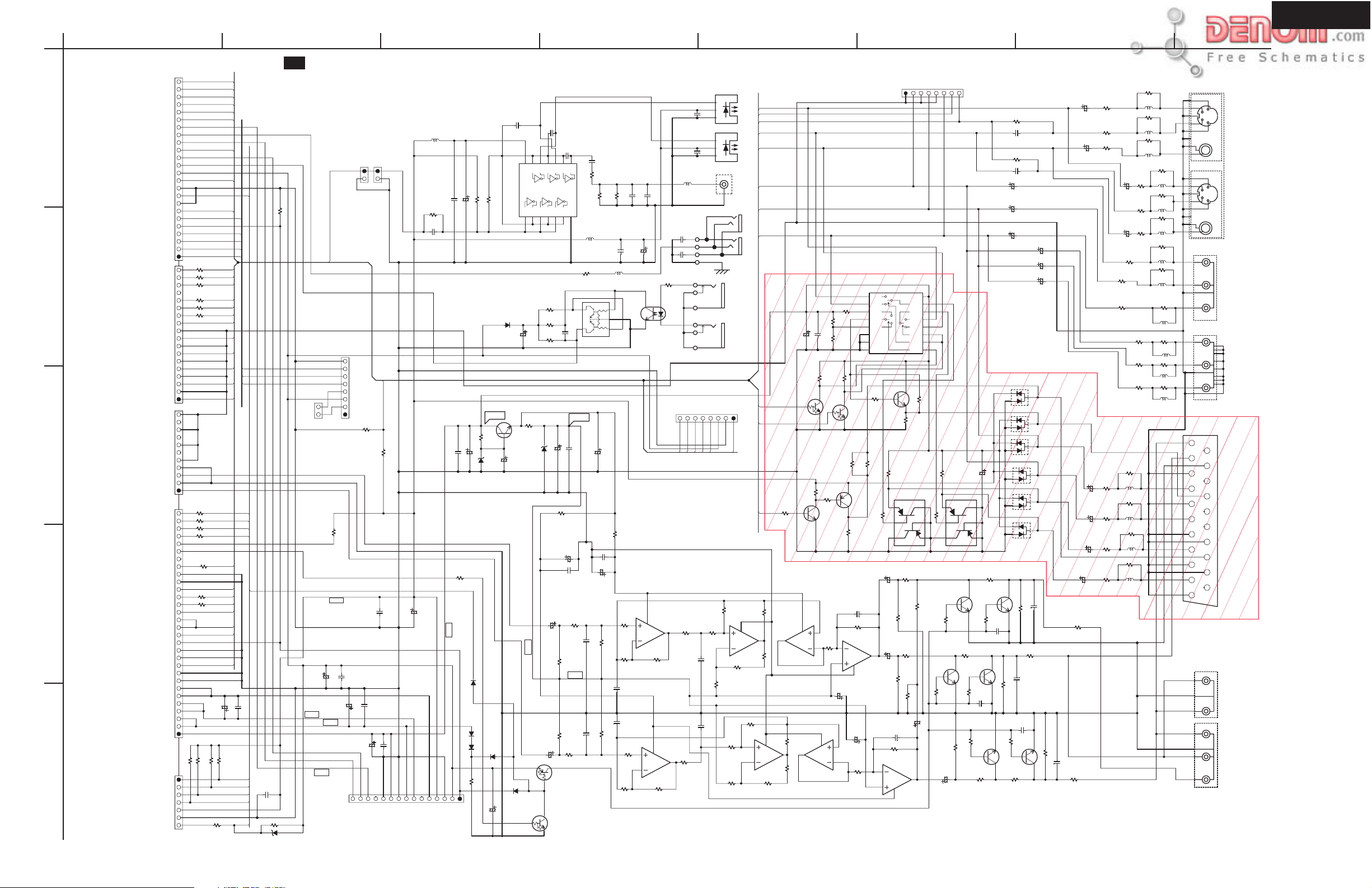

DPS-5.4

A

SCHEMATIC DIAGRAM-1

232SCK

232SI

232SO

232RE

232RESET

232BU

P701A

CN903

FLAC1

IRIN

EVER+5V

ACK

GND

SYSRESET

R102 47

R103 47

R104 47

R106 47

R107 47

R108 47

R121 47

R122 47

R125 47

R127 47

R123 0

R124 47

R126 47

R135 10K

R134 10K

-27V

RI

VDET

FLAC2

RESET

DEMO

P_ON

XSCK

XRDY

SI

SO

1

To Display circuit PC board

VSEL1 18

VSEL2 17

2

3

4

5

SQUEEZE 16

LETTER 15

ASPECT 14

P/XI 13

RGB 12

CY/G 11

GND1 10

CB/B 9

GND2 8

CR/R 7

DNG3 6

C5

From DVD Main circuit PC board

GND4 4

V3

GND5 2

Y1

GND4 11

Y10

GND3 9

V8

GND2 7

C6

GND1 5

DVDA2 4

DVDL 3

GNDA1 2

DVDR 1

CN902

From DVD Main circuit PC board

CTS 30

RTS 29

RXD 28

TXD 27

XVMUTE 26

DVDMUTE 25

DVDTRKUP 24

VDET 23

GNDD6 22

GNDD5 21

ARK 20

MDATA 19

SDATA 18

SCLK 17

SYS_CS2 16

SYS_CS1 15

XDVDRST 14

DVDPOWER 13

GNDD4 12

GNDD3 11

DOUT 10

GNDD2 9

GNDD 8

GNDM2 7

GNDM 6

From DVD Main circuit PC board

VPR+8M1 5

VPR+8M2 4

VPR+8A1 3

VPR+8A2 2

VDVD+12 1

CN901

P104

TXD 1

RXD 2

DTR 3

CTS 4

V+5D 5

GNDD 6

NC 7

For Download

1mm Pich FFC

BCDEFGH

U1 : OUTPUT TERMINAL PC BOARD

NAAR-7997

C355

C354

020

1SS355

C920

470/6.3

Q352

D801

2SC2712

D922

1SS352

020

C356

020

C357

104K

8

9

101112

13

VCC 14

TC74VHCU04T

12345

GND

R822

10K

R821

10K

223

R820

C814

3.3K

100/6.3

IR

V+12V V+12V

R902

2.2K

Q920

D901

V+6V

AGND

C402 47/16

UDZS5.1B

R482

(1/4W)

C401

47/16

Q460

DTA114YKA

Q463

DTC144YKA

220/16

100K

100K

C485

104Z

C483

R402

1.5K

10/16

GND7

6

BK1608LM182-T

R357 470

C815

+6V

C923 104Z

C922 220/16

2.2

1.5K

R401

681

R457

V+6V

681

R456

330

R354

180

L352

12

SW+5V

V+11V

C921

C484

104Z

C486

220/16

C403

R403

NC

C404

180

220

220

R355

L353 BK1608LM182-T

220/16

C358

R356

C361

104Z

C362

4

53

NC

R404

(1/4W)

2.2

152

152

Q806

R405

R407

R408

UMG9N

R481

0

10K

C405

C406

R406

10K

ON3131

3

+B

Q401

2

3

0

Q402

2

C359

100/6.3

Q801

EVER+5V

GND

NJM4580M-D

8

R409

10K

NJM4580M-D

8

+B

R410

10K

L354

BK1608LM182-T

C363

223Z

C364

223Z

AGND

R823

100

To U7: RS-232C terminal PC board

232RE

R411

1

1.5K

R412

1

1.5K

L351 BK1608LM182-T

P351A

0

R351

C351

DVDMUTE

C904

220/6.3

+8V

GND

M+8V

MGND

SW+5V

P702B

RGB

MUP2P

OTHER

RESET

220/16

+8V

For FL tube

GND

SO

MRESET

DVDMUTE

C902

For Mecha.

-27V

DOUT

IC

P105

R115R116

0

--0

10K

R117

+5V

C901

104Z

C908

+8V

P901

RGB

R115

0

NC

R116

C903

104Z

C907

104Z

1000/16

C914

104Z

C911

100/16

-27V

GND

FLAC1

15 10 5 1

V+12V

FLAC2

To Power supply unit (CN2)

R101 10K

VSEL1

VSEL2

SQUEEZE

ASPECT

P/XI

RGB

G/Y

B/CB

R/CR

CSI

V XSCK

Y

CTS VSEL1

DTR

RXD

TXD

VDET

ACK

SI

SO

XSCK

XRDY

SYSRESET

P_ON

DOUT

C909

104Z

C910

1000/16

R137 10K

R136 10K

TXD

RXD

C101

DTR

CTS

104Z

R118

10K

DEMO

R119

10K

D101

UDZ5B

GND

C352 104Z

C905 104Z

R462

1K

+12V

P_ON

EVER+5V

C353 100/6.3

C906 220/16

D460

D923

D924

1K

R352 100K

R920

D920

R463

R353 470K

1SS352

1SS352

D921

1SS352

1SS352

+12V

220

UDZS11B

C420

232BU

C360

104Z

C367

104Z

232SCK

102

102

1

2

3

4

P802

232SI

RI_OUT

R413

OPTICAL_OUT

Q351 JFJ3000

3

2

1

Q356 JFJ3000

3

2

1

OPTICAL_OUT

232SO

22K

22K

C407

22K

R421

C408

P350

P352

IR_IN/OUT

P851A

232RESET

R415

5

4

-B

Q401

6

NJM4580M-D

R417

R414

22K

R422

22K

22K

22K

R416

NJM4580M-D

GND_VIDEO

RGBSW

68

R611

R609

470

C409

NJM4580M-D

Q403

-B

4

C412

R428

10K

P292A

TC4053BF

Q601

Y11

VCC16

Z13

R614

Z4

Z05

EN6

VEE7

GND8

1K

R610

7

X113

X012

2SC2712

Q604

10K

V+12V

R613

330 1/2W

R/C.DRV

1

100

25

R617

3

Q607

HN1A01F-GR

C415

R431

470

47/50

R432

150K

RR461

R443

C413

270

47/50

R461

150K

150K

47/50

470

C410

10K

R430

NJM4580M-D

6

Q404

+B

8

5

Y15Y02

X14

A11

B10

C9

R615

C419

7

Y Y

P/XI

ASPECT

C C

V

G/Y

B/CB

R/CR

2.2K

R603

1.8K

R601

C602

104Z

C601

100/16

SQUEEZE

VSEL2

4.7K

R606

R423

1.5K

8

1

7

R419

5

-B

Q402

6

22K

R418

NJM4580M-D

1.5K

4

7

1.5K

R420

Q403

R424

1.5K

2.2K

R602

10K

10K

R605

R604

Q602

Q603

DTC114EE

DTC114EE

SW+5V SW+5V

1.2K

22K

R608

R607

Q606

2SA1162

Q605 2SC2712

+B

1

NJM4580M-D

3

2

Q404

4

R427

-B

10K

56K

R429 10K

6

5

C411 220/6.3

3

220/6.3

2

NC

Y

V

R/C

Y/V

0

R626

R612

6

1

100

25

R616

4

3

HN1A01F-GR

Q407

HN1C03F

470

HN1C03F

Q405

2

R445

R458

2.2K

C414

47/50

MUTE_R

330 1/2W

Y/V.DRV

Q608

2

R452

2.2K

R447 100

6

1

150K

G/Y

6

1

HN1C03F

R449

R459

HN1C03F

2.2K

Q405

5

C416

102

Q406

R444

270

B/CB

C603

6

4

R446

R453

R454

2.2K

2

100/16

100

HN1C03F

5

2.2K

C418

102

3

4

1

6

R224 10K

C222 104K

R257 10K

C253 104K

C2241000/6.3

C2251000/6.3

C2261000/6.3

D601 1SS226

D603 1SS226

D605 1SS226

D606 1SS226

3

4

C480

R441

100K

C417

R450

2.2K

HN1C03F

R448

100

Q407

R455

102

Q406

5

100K

100

R433

D602

D604

C482

4

3

C2271000/6.3

C2281000/6.3

C2291000/6.3

1SS226

1SS226

R442

Y/V.DRV

100K

C481

NC

RGBSW

R/C.DRV

470/6.3

R435

100

100

R434

C221

470/6.3

470/6.3

470/6.3

470/6.3

C614

470/6.3

C615

C223

C613

C612

R221

R222

R223

R618

R619

R620

R621

P201

R231

C251

470/6.3

C252

470/6.3

R225

R229

75

R227

75

R622

L601

R623

L602

L604

L201

L202

L203

R252

75

R254

75

R256

75

75

R24475R241

R245

75

R246

75

0

0

R624

0

L603

R625

0

0

0

0

R236

R251

L210

R253

L211

R255

L212

R234

L204

L205

L206

L208

R235

L207

R242

R243

L209

0

0

0

0

0

R232

R233

0

0

0

0

1

3

5

4

2

7

8

1

3

5

4

2

7

8

DPS-5.4 only

75

75

75

75

75

75

75

G1

Y

G2

C

G3

G4

SIGNAL

P201

G1

VIDEO OUTPUT

Y

G2

C

G3

G4

SIGNAL

P203

4

Y

2

CB

1

3

P205

4

8

1

CR

COMPONENT 1

COMPONENT 2

P601

SCART

AUDIO_R1

2

AUDIO_L3

AGND4

VGND15

6

B7

F.SW8

VGND29

10

G11

12

VGND313

VGND414

R/C15

RGB.SW16

VGND517

VGND618

CV/Y19

20

VGND721

P402

2

L ch

1

3

R ch

R ch

3

1

L ch

2

MONO

4

P401

www.denom.com

Page 24

DPS-5.4

A

SCHEMATIC DIAGRAM-2

1

U2 : DISPLAY CIRCUIT PC BOARD NADIS-7998

2

3

4

5

BCDEFGH

1G41

2G40

3G39

4G38

5G37

6G36

7G35

8G34

F245

F2244

1G2G3G4G5G6G7G8G9G

NC

2S

Q707

0

R726

9G33

10G32

11G31

12G30

13G29

10G

11G

12G

13G

NC

Q706

R725

0

2S

R724

0

FL_ON/OFF ENTER

10K

R723

STB_L K2 RI

R

100KX5

P15 PON

P14 XRDY

P13 SO

P12 SI

P11 XSCK

P10

P9

P8

P7

U20 : POWER SUPPLY UNIT

NGPS-0040 AC100-120V 50Hz/60Hz

NGPS-0041 AC100-240V 50Hz/60Hz

GND

SW+5V

EVER+5V

P ON

CN2

To Output terminal PC board NAAR-7997 (P901)

GND

E+8V

M+8V

NC

Q702HNV-13SS12T

P218

P317

P119

P1P2P3P4P5P6P7P8P9

10K

10K

10K

R720

R721

R722

+5V

41

42

C705

22/50

-27V

GND

FLAC

NC

EVRE+12V

GND

P416

P515

P614

SRESET

10K

R719

STBYLED

R232RES 40

NC543

NC644

42: NC4

NC745

NC846

NC947

NC1048

NC1149

P1550

P1451

P1352

P1253

P1154

P1055

P956

P857

P758

VDD259

VLOAD60

P661

P6P5P4P3P2

FLAC1

P713

P812

MSO_0

MSO_1

39

MSO_0 38

MSO_1 37

FLON_OFF

P364

P463

P562

P911

P10

MSO_2

MSO_2 36

P265

P1010

INIT0

INIT0 35

P166

P1

P119

P11

INIT1

INIT1 34

OPEN67

P128

P137

P146

P155

P12

P13

P14

P15

INIT2

232SO

232SCK

232SI

R7170

R7180

100

R716

INIT2 33

232SO 32

232SCK 31

Q701

MPD780232GC

11G70

12G69

13G68

13G

12G

11G

10G