Page 1

®

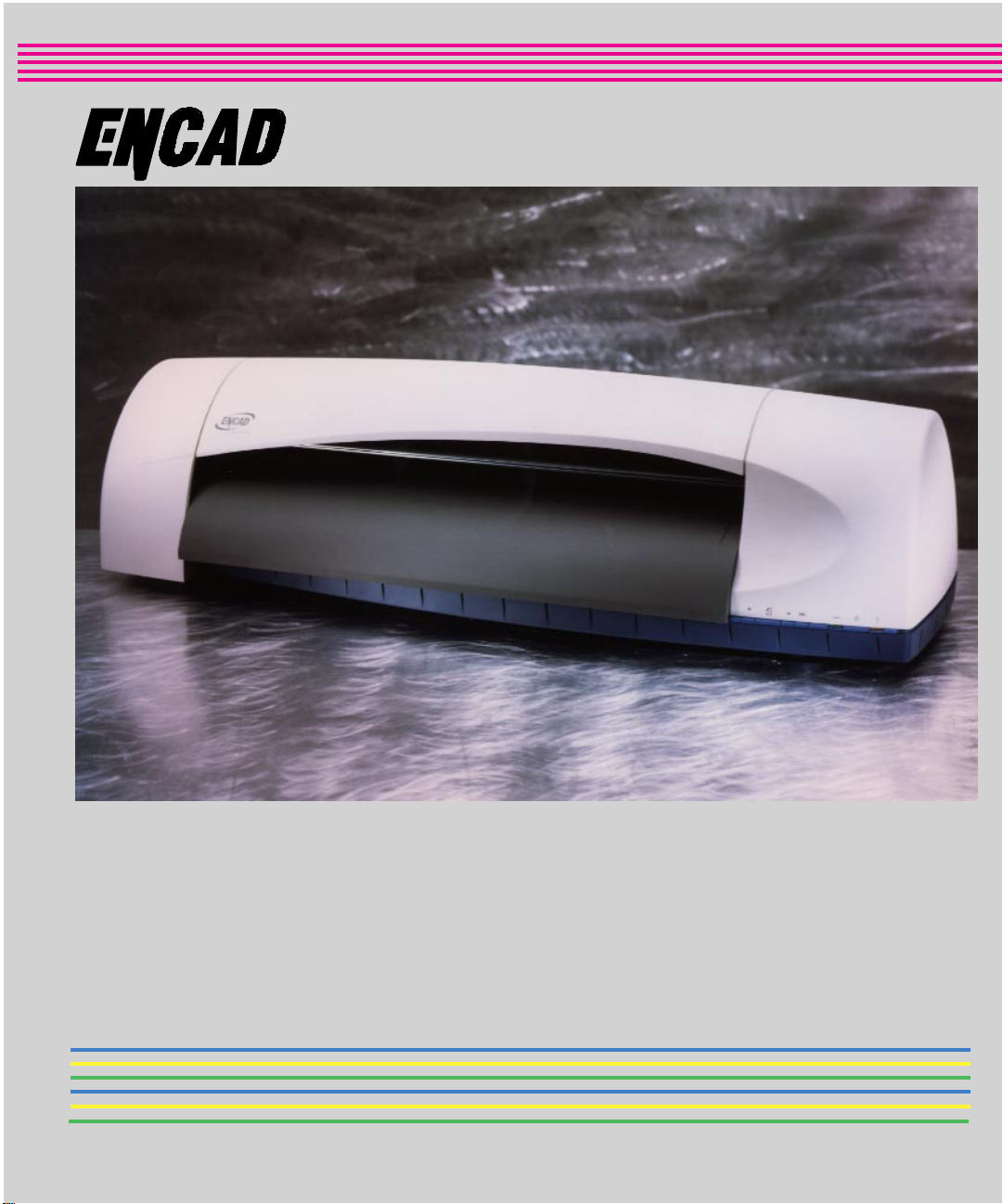

CROMA24

COLOR PRINTER

SERVICE MANUAL

Page 2

This Page Intentionally Left Blank

Page 3

®

Croma24™

COLOR INKJET

PRINTER

SERVICE MANUAL

Part Number 208817

Page 4

Croma24 Service Manual

Copyright © 1995 and 1996 ENCAD®, Inc. All rights

reserved.

ENCAD is a registered trademark of ENCAD, Inc.

CROMA24™ is a trademark of ENCAD, Inc.

Other trademarks and registered trademarks are the

property of their respective owners.

No part of this manual may be copied or distributed,

transmitted, transcribed, stored in a retrieval system, or

translated in any human or computing language, in any

form or by any means, electronic, mechanical, magnetic or otherwise, or disclosed to a third party without

the express written permission of ENCAD, Inc., 6059

Cornerstone Court West, San Diego, CA 92121, U.S.A.

Printing history

1st Edition Rev A May 1997

4

Page 5

FCC Statement (U.S.A.)

The United States Federal Communications Commision has specified

that the following notice be brought to the attention of the users of the

Croma24 printers.

FEDERAL COMMUNICATIONS COMMISION RADIO AND TELEVISION INTERFERENCE FOR CLASS B DEVICE

This equipment has been tested and found to comply with the limits for a

class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications.

User Instructions:

If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one of the

following measures:

Croma24 Service Manual

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

Changes or modifications not expressly approved by ENCAD, Inc. could

void the user’s authority to operate the equipment.

5

Page 6

Croma24 Service Manual

VDE Statement

Hiermit wird bescheinigt, daß der

den Bestimmungen der BMPT-AmstbIVfg 234/1991 funkentstört ist. Der

vorschriftsmäßige Betrieb mancher Geräte (z.B. Meßsender) kann

allerdings gewissen Einschränkungen unterliegen. Beachten Sie

deshalb die Hinweise in der Bedienungsanleitung.

Dem Zentralamt für Zulassungen im Fernmeldewesen würde dan

Inverkehrbringen dieses Gerätes angezeigt und die Berechtigung zur

Überprüfung der Serie auf die Einhaltung der Bestimmungen

eingeräumt.

ENCAD, Inc.

U.S.A

CROMA24

in Übereinstimmung mit

6

Page 7

Material Safety Data Sheet

Croma24 Service Manual

CROMA24

no special disposal handling. It can be harmful if swallowed and should

be kept away from children.

To obtain a Material Safety Data Sheet, contact

International users should contact their local dealer or distributor.

QIS (Quality Image Supplies) ink is nonhazardous, requiring

ENCAD, Inc.

6059 Cornerstone Court West

San Diego, CA 92121-3734

(619) 452-4350

at:

7

Page 8

Croma24 Service Manual

WARRANTY OR DAMAGE CLAIMS

United States

ENCAD®, Inc., warrants its printers ("PRODUCT") to be free from defects in workmanship

and materials for a period of one year from the date of purchase. In order to submit a

Warranty claim, please contact the ENCAD Help Desk at (619) 452-4350.

ENCAD reserves the right to make changes or improvements to Products, without

incurring any obligation to similarly alter Products previously purchased.

Buyer's sole and exclusive rights pursuant to this Warranty shall be for the repair or

replacement of defective Product. ENCAD specifically disclaims any and all other

warranties, expressed or implied, including but not limited to, implied warranties of

merchantability and fitness for a particular purpose. In no event shall ENCAD be liable

for any loss of profit or other commercial damages, special, incidental or consequential

damages, or any other damages or claims, whatsoever.

This Warranty gives Buyer specific legal rights, and Buyer may also have other rights

that vary from state to state.

This Warranty applies only to printers purchased from ENCAD, or authorized ENCAD

distributors or dealers. The intent of this Warranty is to repair or replace defective

Products subjected to normal wear and tear, when operated according to ENCAD

instructions.

This Warranty does not cover damage to the Product resulting from the following:

• Accident or negligence.

• Unauthorized modification of the Product.

• Adverse environmental conditions.

• Service of the Product by other than an ENCAD authorized service provider.

• Unauthorized or improper use, including but not limited to:

– Use in applications for which the Product was not designed.

– Using cartridges or ink other than those supplied by ENCAD or authorized

ENCAD resellers.

– Using media other than that supplied by ENCAD or authorized ENCAD

resellers.

– Lubricating any part of the printer.

Internationally: Contact your dealer or distributor for warranty information.

8

Page 9

Croma24 Service Manual

Table of Contents

Chapter 1 General Description............................................................. 17

Introduction ...............................................................................................................17

Overview ...................................................................................................................18

Related Publications ...........................................................................................18

Electrostatic Discharge (ESD) Sensitivity ..................................................................18

Warnings, Cautions, and Notes.................................................................................19

Printer Specifications ................................................................................................20

Contents of this Service Manual................................................................................21

Technical Support .....................................................................................................2 3

Chapter 2 Theory of Operation............................................................. 25

Introduction ...............................................................................................................25

Croma24 Printer General Block Diagram ..................................................................25

Paper (Media) Axis Drive ..........................................................................................27

The Carrier Axis Drive...............................................................................................28

Main Printed Circuit Board (MPCB)...........................................................................29

Microprocessor ...................................................................................................3 0

Gate Array ..........................................................................................................3 0

Memory Circuits..................................................................................................31

Stepper Motor Controller.....................................................................................33

Servo Motor Controller........................................................................................34

Interface Circuits: Serial & Parallel......................................................................36

Carrier Assembly Circuits..........................................................................................37

Power Supply............................................................................................................38

System Grounding ....................................................................................................38

Front Key Controls ....................................................................................................40

Chapter 3 Maintenance ......................................................................... 43

Introduction ...............................................................................................................43

Scheduled Maintenance............................................................................................43

Cleaning Procedures ..........................................................................................44

External Cleaning .........................................................................................44

Slide Shaft Cleaning.....................................................................................44

9

Page 10

Croma24 Service Manual

Table of Contents (cont)

Chapter 3 Maintenance (cont)

Service Station Cleaning ..............................................................................45

Linear Encoder Strip Cleaning......................................................................46

Cartridge Dimple Cleaning ...........................................................................47

Flex Cable Contact Cleaning........................................................................48

Clean and Inspect Stepper Motor Gears ......................................................48

Clean and Inspect MPCB .............................................................................49

Clean and Inspect Carrier Assembly ............................................................49

Reseat Connectors on MPCB and Carrier Board................................................50

Replace Carrier Bushings...................................................................................52

Servo Motor Winding Resistance Check...................................................................52

Stepper Motor Winding Resistance Check................................................................53

Banding: Hardware vs Software................................................................................53

Alignments/Adjustments............................................................................................55

Color Calibration .................................................................................................55

Deadband Alignment ..........................................................................................56

X-Axis Calibration ...............................................................................................57

Pinch Roller Adjustment Procedure ....................................................................57

Head Height Alignment Procedure......................................................................60

Croma24 Control Panel.............................................................................................65

Manufacturing Menu ...........................................................................................66

Print Quality T est..........................................................................................67

Deadband.....................................................................................................67

Diagnostics Menu ...............................................................................................68

Paper Sensor Test........................................................................................69

Fan Test .......................................................................................................69

Carriage Vibration Test.................................................................................70

Color Test .....................................................................................................70

Keypad Test .................................................................................................71

LED Test ......................................................................................................72

Servo Motor Test ..........................................................................................72

Paper Motor Test..........................................................................................73

Service Menu......................................................................................................74

Built In Test (BIT) ......................................................................................................75

10

Page 11

Croma24 Service Manual

Table of Contents (cont)

Chapter 3 Maintenance (cont)

Firmware/Software Upgrades....................................................................................76

Internal Cabling and Signal Flow Diagram ................................................................77

Chapter 4 Troubleshooting................................................................... 79

Introduction ...............................................................................................................79

No Power ..................................................................................................................79

Media Does Not Move...............................................................................................80

Carrier Axis Failure ...................................................................................................81

Does Not Print...........................................................................................................82

Ink Cartridge Misfiring ...............................................................................................82

Paper Skewing ..........................................................................................................83

Printer Output is Banding ..........................................................................................84

Fan Does Not Power Up ...........................................................................................85

Chapter 5 Assembly\Disassembly ....................................................... 87

Introduction ...............................................................................................................87

Remove the Left, Middle (Lid), and Right Covers......................................................88

Install the Left, Middle, and Right Covers ..................................................................89

Remove the MPCB (Main Printed Circuit Board) and Actuator Assembly .................90

Install the MPCB and Actuator Assembly ..................................................................91

Remove Servo Motor ................................................................................................92

Install Servo Motor ....................................................................................................94

Remove the Carrier Assembly, Carrier Belt, and the Frame T ensioner .....................95

Install the Carrier Assembly, Carrier Belt, and the Frame Tensioner ........................98

Remove the Carrier PCB ........................................................................................100

Install the Carrier PCB ............................................................................................102

Remove the Paper Sensor or the Encoder Sensor .................................................102

Install the Paper Sensor or the Encoder Sensor .....................................................104

Remove the Trailing Cable Cover Assembly ...........................................................105

Install the Trailing Cable Cover Assembly ...............................................................107

Replacing the Carrier Bushings...............................................................................108

Remove the Service Station, Seals, and Wipers..................................................... 110

Install the Service Station, Seals, and Wipers ......................................................... 1 11

11

Page 12

Croma24 Service Manual

Table of Contents (cont)

Chapter 5 Assembly\Disassembly (cont)

Remove the Lower Roller Assembly and Stepper Motor ......................................... 112

Install the Lower Roller Assembly and Stepper Motor ............................................. 115

Remove the Power Supply and AC Entry Module ...................................................117

Install the Power Supply and AC Entry Module .......................................................120

Chapter 6 Parts List ............................................................................ 123

Index..................................................................................................... 131

12

Page 13

Croma24 Service Manual

List of Illustrations

Figure Page

Chapter 1 General Description

Chapter 2 Theory of Operation

2-1. General Block Diagram ...................................................................................26

2-2. Paper (Media) Axis Drive.................................................................................27

2-3. Carrier Axis Drive ............................................................................................28

2-4. Main Printed Circuit Board...............................................................................29

2-5. Gate Array.......................................................................................................30

2-6. Stepper Motor Controller .................................................................................33

2-7. Servo Motor Controller ....................................................................................34

2-8. Quadrature Signal Generation.........................................................................35

2-9. Interface Circuits .............................................................................................36

2-10. Carrier Assembly Circuits ................................................................................37

2-11. Croma24 System Ground Network (Left Side) ................................................39

2-12. Croma24 System Ground Network (Right Side) ..............................................40

2-13. Front Key Controls...........................................................................................40

Chapter 3 Maintenance

3-1. Encoder Strip Cleaning....................................................................................46

3-2. Cartridge Dimple Region .................................................................................47

3-3. Flex Cable Contacts ........................................................................................48

3-4. MPCB Connection Locations...........................................................................50

3-5. Carrier PCB Connection Locations ..................................................................51

3-6. Ribbon Connector Locking Mechanism ...........................................................51

3-7. Servo Motor.....................................................................................................52

3-8. Stepper Motor..................................................................................................53

3-9. Examples of Banding ......................................................................................54

3-10. Color Calibration ..............................................................................................55

3-1 1. Deadband Fast/Slow .......................................................................................56

3-12. Upper Roller Support Description ....................................................................57

3-13. Upper Roller Mounting.....................................................................................59

3-14. Gap of Pinch Roller .........................................................................................59

3-15. Upper Roller Adjustment .................................................................................60

3-16. Carrier Head Height Tolerance........................................................................61

13

Page 14

Croma24 Service Manual

List of Illustrations (cont)

Figure Page

Chapter 3 Maintenance (cont)

3-17. Setting Up Tools from Height Gauge Kit..........................................................61

3-18. Zeroing the Micrometer Gauge........................................................................62

3-19. Test Cartridge Installed....................................................................................62

3-20. Carrier Positions for Head Height Adjustment .................................................63

3-21. Maintenance Menu ..........................................................................................66

3-22. Manufacturing Menu........................................................................................66

3-23. Deadband Options Menu.................................................................................67

3-24. Deadband Slow/Fast Display...........................................................................68

3-25. Diagnostics Menu ............................................................................................68

3-26. Paper Sensor Reported Data Dialog Box ........................................................69

3-27. Fan Test Menu Panels.....................................................................................69

3-28. Color Test........................................................................................................70

3-29. Keypad T est.....................................................................................................71

3-30. LED Test..........................................................................................................72

3-31. Servo Motor Test.............................................................................................72

3-32. Paper Motor Test.............................................................................................73

3-33. Service Menu ..................................................................................................74

3-34. ROM Info .........................................................................................................74

3-35. Service Special Information .............................................................................75

3-36. Signal Wiring Diagram.....................................................................................78

Chapter 4 Troubleshooting

Chapter 5 Assembly/Disassembly

5-1. Cover Removal/Installation..............................................................................89

5-2. Frame Tensioner .............................................................................................92

5-3. Electronics Cover Removal .............................................................................95

5-4. Strain Relief Removal/Installation from Carrier................................................96

5-5. Carrier Belt Clamp...........................................................................................97

5-6. Installation of Frame Tensioner .......................................................................99

5-7. Carrier PCB Removal/Installation ..................................................................101

5-8. Paper and Encoder Sensor Removal ............................................................103

5-9. Paper and Encoder Sensor Installation .........................................................104

14

Page 15

Croma24 Service Manual

List of Illustrations (cont)

Figure Page

Chapter 5 Assembly/Disassembly (cont)

5-10. Trailing Cable Assembly Removal/Installation ...............................................106

5-11. Carrier Bushing Removal ..............................................................................108

5-12. Carrier Bushing Installation............................................................................109

5-13. Service Station, Exploded View .....................................................................110

5-14. C-Bracket Assembly and Platen Removal ..................................................... 113

5-15. Stepper Motor Removal/Installation............................................................... 114

5-16. Installing Lower Roller Assembly ...................................................................116

5-17. Ground Stud with Ground Lugs Attached ......................................................118

5-18. Power Supply Assembly ................................................................................119

Chapter 6 Parts List

6-1. Croma24 Assembly Parts (Platen and Above)...............................................125

6-2. Croma24 Assembly Parts (Below Platen)......................................................126

6-3. Carrier Assembly Breakdown ........................................................................127

6-4. C-Bracket Assembly Breakdown ...................................................................128

6-5. Lower Roller Assembly Breakdown ...............................................................129

15

Page 16

Croma24 Service Manual

List of Tables

Table Page

Chapter 1 General Description

Chapter 2 Theory of Operation

2-1. Front Key Control LED Codes .........................................................................41

Chapter 3 Maintenance

3-1. Pinch Roller Adjustments ................................................................................58

3-2. Keypad Test Indications...................................................................................71

Chapter 4 Troubleshooting

4-1. Troubleshooting Table .....................................................................................79

Chapter 5 Assembly/Disassembly

Chapter 6 Parts List

6-1. Parts List .......................................................................................................123

16

Page 17

General Description

Introduction

This manual provides service information for the ENCAD, Inc.

Croma24 Color Inkjet Printer.

There are three versions to the Croma24 Color Inkjet Printer

family:

CAD version GA & CAD version GA version

for: CAD market GA & CAD GA

I/O: parallel serial & parallel serial & parallel

includes: ENCAD software RIP

All versions will have an ADI Windows driver and print utility.

This manual is written for service personnel who possess analog

and digital circuitry experience. Chapter 2, Theory of Operation,

should be read and thoroughly understood before troubleshooting/

calibrating the printers.

The printers support pre-cut and roll media. Media size is automatically determined and hardclip limits are set accordingly. Precut media uses different maximum plotting areas than roll media.

See the Printer Specifications for more details.

1

DESCRIPTION

GENERAL

Both RS-422 serial and Centronics parallel connections are provided to interface with the host computer on the GA (Graphic Arts)

compatable versions. Only the Centronics parallel connection

exists on the CAD only version. Commands sent from the host

computer are in Encad RTL format.

Drivers are supplied to support Windows-based PC’s (3.XX, 95, and

NT) as well as Macintosh and Power PC computers.

These printers expand upon ENCAD’s tradition of delivering fast,

high-quality color or monochrome graphics for a variety of applications. ENCAD has made significant advances in designing these

17

Page 18

Croma24 Service Manual

plotters to respond to and anticipate our customers’ needs. Principal

features are summarized below.

Three Versions: CAD, GA (Graphic Arts), GA & CAD

ENCAD’s software RIP supplied with the GA (Graphic Arts) version

Remotely Configured via Host Computer

25" (63.6 cm) Maximum Media Width

600 x 600 dpi (mono) addressable

300 x 300 dpi (color)

Overview

Printers draw according to instructions issued from a “host” computer. Every printer is engineered to understand a specific set of

instructions and to execute each instruction in a precise manner.

In addition, most printers are designed to execute predetermined

characters automatically without a specific line-by-line instruction

from the program. These characters are part of the printer’s

permanent memory.

Related Publications

The following publication contains additional information which may

be useful in servicing the ENCAD, Inc. Croma24 Color Inkjet

Printers:

• ENCAD, Inc. Croma24 User Guide, P/N 207103

Copies of this and other ENCAD, Inc. publications may be obtained

by contacting your nearest authorized ENCAD, Inc. dealer or by

contacting ENCAD’s Technical Support and Service Department.

Electrostatic Discharge (ESD) Sensitivity

All PCBs (Printed Circuit Boards) associated with the Croma24

printers have components sensitive to ESD (electrostatic discharge). Care must be taken to avoid damage to any of the components by following current ESD handling procedures and practices.

Always use an approved ESD grounding strap when handling or

working with PCBs.

18 General Description

Page 19

Croma24 Service Manual

W arnings, Cautions, and Notes

Warnings, cautions, and notes are used when additional information, instructions, or care should be observed. In this manual,

warnings cautions, and notes precede the text to which each applies. The definition of each is provided below.

WARNINGS - Warnings are used to stress that the following steps

or procedure has the potential to cause serious harm or death to

service personnel. Extreme care should be observed when following

the procedures and to exercise standard safety procedures. They

are indicated by:

Followed by a paragraph describing the concern.

CAUTION - Cautions depict that the following steps or procedures

can cause damage to the equipment if not properly followed. Extreme care should be observed when following the procedures and

to exercise standard safety procedures. They are indicated by:

DESCRIPTION

GENERAL

Followed by a paragraph describing the concern.

NOTE - Notes are placed before a procedure to inform the service

personnel of specific details to improve quality, to give reminders of

interrelated parts, and to provide other helpful information. They

are indicated by:

NOTE

Followed by a paragraph describing the concern.

General Description 19

Page 20

Croma24 Service Manual

Printer Specifications

The specifications and performance characteristics of the Croma24

Color Inkjet Printers are as follows:

Max Printing Area:

Norm 23.8” 60.9cm

Extend 24.6” 62.9cm

Language Emulation:

ENCAD RTL

Buffer:

2 MB permanently

installed

(not upgradable)

Power Requirements:

Input Voltage:

90 - 246 VAC

47 - 63 Hz

Output Power:

24 W typical

63 W maximum

Baud Rates:

38400

1MByte High Speed

Serial (MAC only)

Resolution:

Mono 600x600 dpi

addressable

Color 300x300 dpi

Accuracy:

0.2% line length (with

ROLL mode off)

Interface:

Centronics parallel

RS-422 serial

(GA and GA/CAD

versions only)

Environment:

Operating:

41° to 104° F

(5° to 40° C)

10% to 70% RH

non-condensing

Storage:

-40° to 140° F

(-40° to 60° C)

5% to 80% RH

non-condensing

Dimensions:

Height 12” (305mm)

Width 43.5” (1105mm)

Dept h 14” (356mm)

20 General Description

Page 21

Croma24 Service Manual

Contents of this Service Manual

Figures are used in this manual to clarify procedures. They are

for illustrative purposes only and may not necessarily be drawn to

scale.

Material in this manual may be repeated in various sections so

that each section can “stand alone”. This allows information to be

located without having to refer back and forth between sections.

Figures and tables are easily located and cross-referenced, and are

listed in the front of the manual under List of Illustrations and

List of Tables.

This manual is divided into six chapters as:

Chapter 1 GENERAL DESCRIPTION - Contains a general

description of the ENCAD Croma24 printer. This

includes printer specifications, and related materials.

Also included is a description of the use of Warnings,

Cautions and Notes as used in this manual and chapter

contents.

Chapter 2 THEORY OF OPERATION - Functional

descriptions of the overall printer and major assemblies

are contained in this chapter.

DESCRIPTION

GENERAL

Chapter 3 MAINTENANCE - This chapter covers the

scheduled maintenance, cleaning procedures and

alignment/adjustments recommended to perform on the

printers. Diagnostics and a signal flow diagram are also

listed.

General Description 21

Page 22

Croma24 Service Manual

ORIENTATION - Instructions in this manual are based on the

assumption that the service person is facing the front of the

printer. References to top view, back view, and so forth are consistent with this engineering standard. References to the X Axis and

Y Axis (Paper Axis and Carrier Axis, respectively) follow the standard of AutoCAD™ absolute coordinates: up and down for X, left

to right for Y.

Chapter 4 TROUBLESHOOTING - A table containing

problems that could occur and possible causes and repairs

is found in this chapter. This table is not intended to be a

complete listing of troubleshooting procedures. It will

isolate the problem down to the lowest replacable

assembly. If the problem happens to be the wiring

between assemblies, standard troubleshooting techniques

will have to be implemented to correct the problem.

Chapter 5 ASSEMBLY/DISASSEMBLY - Contains detailed

procedures to remove and replace printer parts and

assemblies.

Chapter 6 PARTS LIST - Contains a complete listing of all

field replacable parts and assemblies for the Croma24

Color Inkjet Printer. Illustrated parts breakdown

drawings are included to help clarify and identify parts for

ordering. Special kits and adjustment jigs may be

required.

22 General Description

Page 23

Croma24 Service Manual

T echnical Suppor t

ENCAD offers full technical support and service for its various

products. If you are unable to find the answer to your question in

either the User’s Guide, Service Manual, or other related publications, check out ENCAD’s Technical Bulletins located on

ENCAD’s bulletin board or the Internet:

ENCAD BBS: (619) 452-2653 or

ENCAD Website: http://www.encad.com

Additional information is available though our Technical Support

and Service Department’s Help Desk.

ENCAD, Inc.

Technical Support & Service Dept.

6059 Cornerstone Court West

San Diego, CA 92121

Help Desk Telephone: (619) 452-4350

Help Desk FAX: (619) 546-0659

DESCRIPTION

GENERAL

(619) 452-3768

International Users contact your local ENCAD service provider.

see details on your ENCAD registration card.

General Description 23

Page 24

Croma24 Service Manual

This Page Intentionally Left Blank

24 General Description

Page 25

Theory of Operation

Introduction

This chapter explains the mechanical and electrical theory of operation of the ENCAD Croma24 D-Size Color Inkjet printer.

The Croma24 is a MC68322 microprocessor-based digital printer

that receives plotting instructions from a host computer through

either the RS-422 serial interface or the Centronics parallel interface.

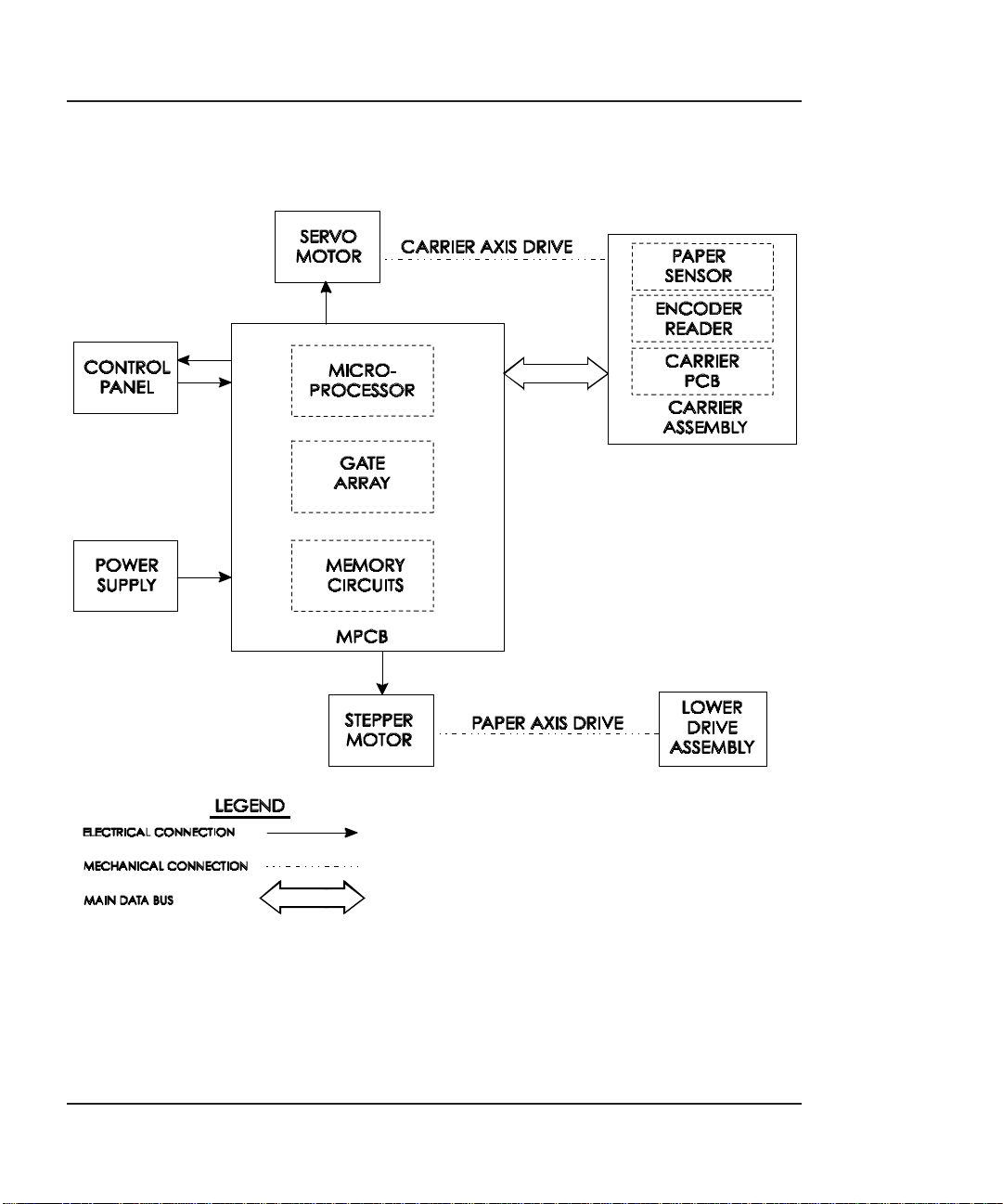

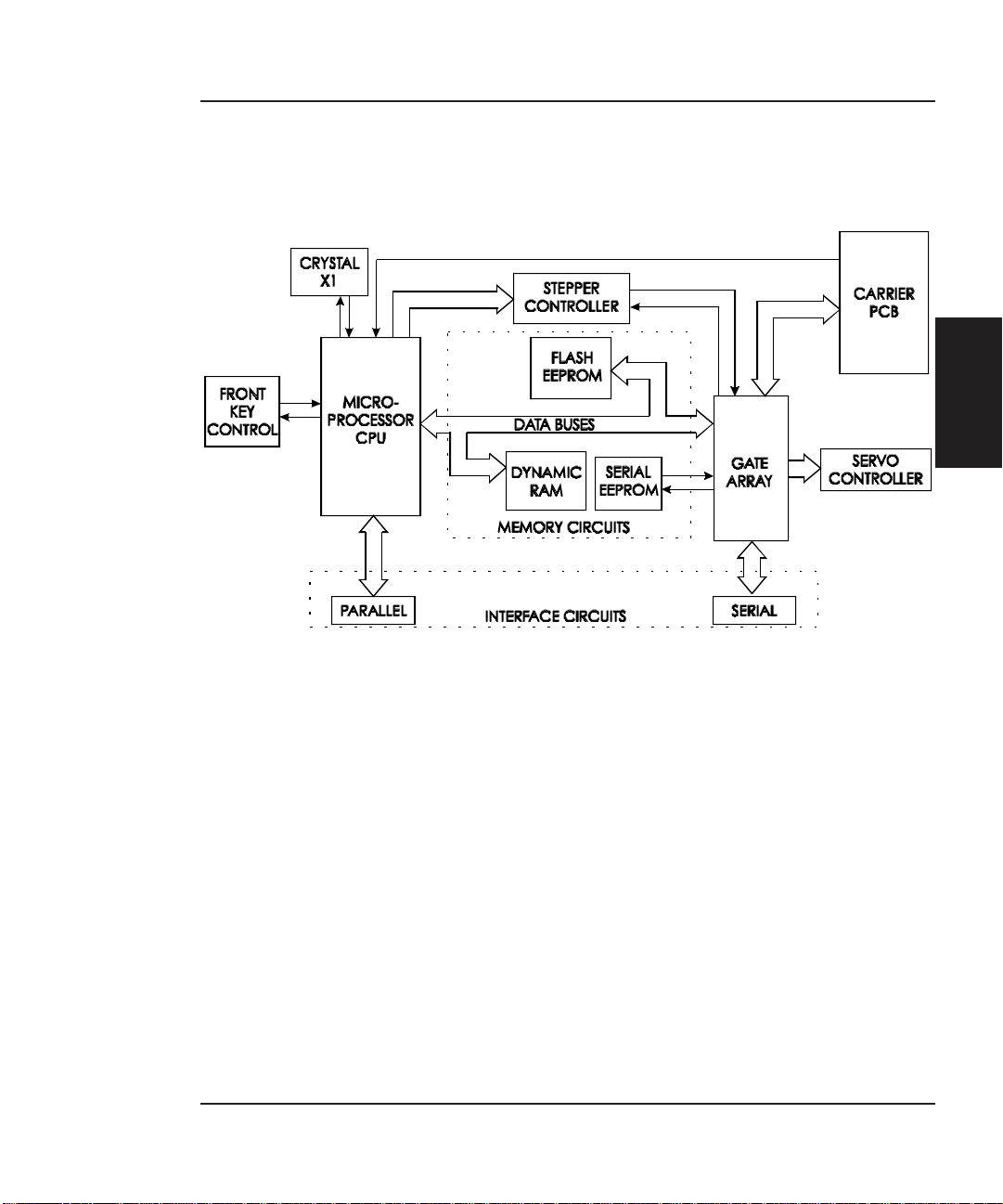

Croma24 Printer General Block Diagram

Figure 2-1 illustrates the major functional areas of the printer.

The Croma24 printer consists of two mechanical drives:

1. Paper (Media) Axis Drive

2. Carrier Axis Drive

2

THEORY OF

OPERATION

and three main electrical assemblies:

1. MPCB (Main Printed Circuit Board)

2. Carrier Assembly

3. Power Supply

25

Page 26

Croma24 Service Manual

Figure 2-1. General Block Diagram.

26 Theory of Operation

Page 27

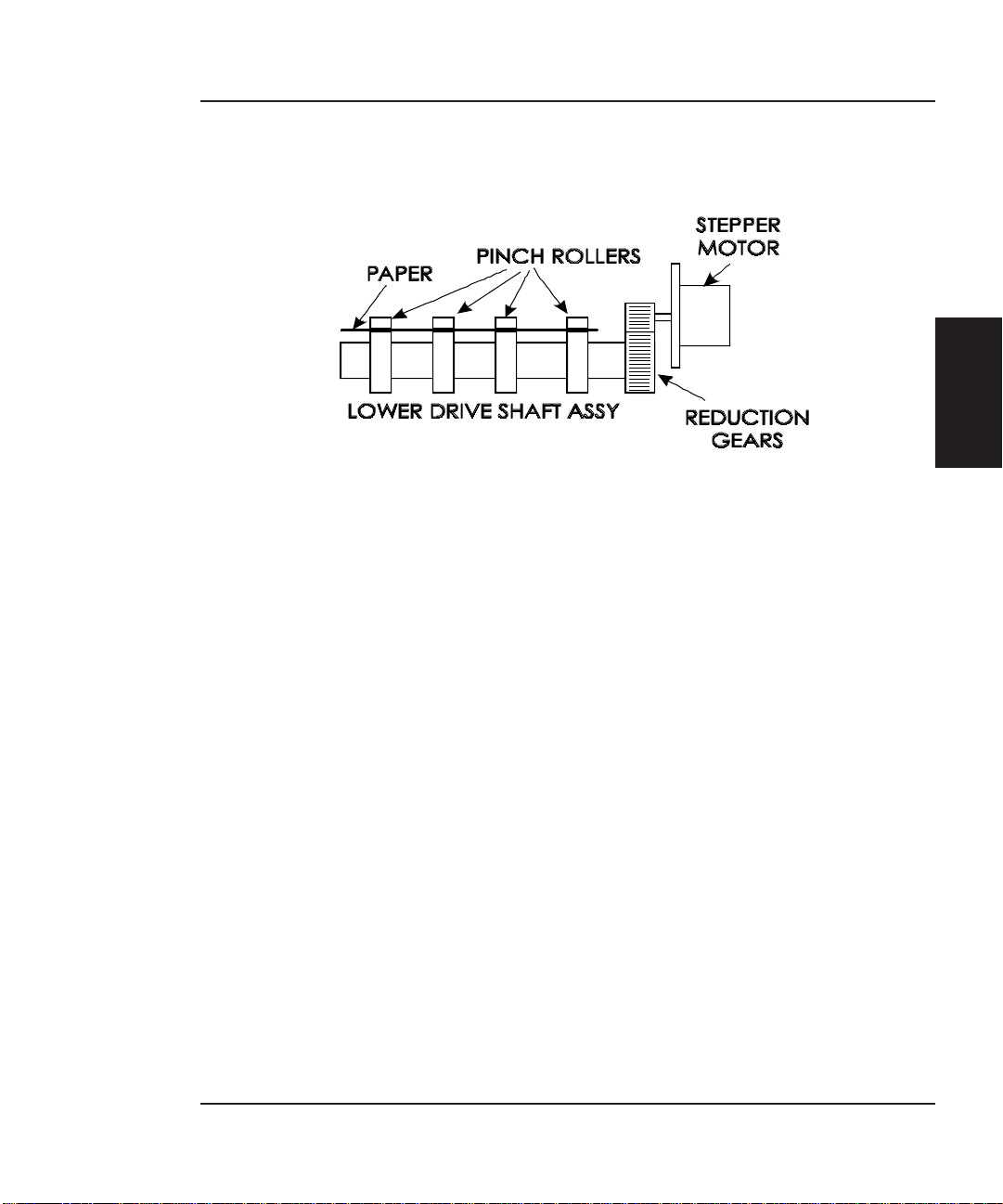

Paper (Media) Axis Drive

Figure 2-2. Paper (Media) Axis Drive.

The Paper (Media) Axis Drive moves the plotting media in a direction perpendicular to the length of the printer. This friction drive

utilizes a micro-step drive technology and consists of a stepper

motor, reduction gears, lower drive shaft assembly, and pinch

wheels. This can be seen in Figure 2-2.

Croma24 Service Manual

THEORY OF

OPERATION

The micro-step technology associated with the stepper motor gives

the capability of a resolution up to 600 dpi.

The reduction gear meshes the stepper motor to the lower drive

shaft assembly which allows the media to advance or retract.

The purpose of the pinch wheels is to apply pressure to the media

onto the drive shaft assembly to reduce the chance of slipping.

Misaligned pinch wheels is the main cause of skewing of the media.

Theory of Operation 27

Page 28

Croma24 Service Manual

The Carrier Axis Drive

Figure 2-3. Carrier Axis Drive.

The Carrier Axis Drive moves the printer’s carrier assembly along

the length of the printer. The drive consists of a servo motor, linear

encoder strip, drive belt, and tension assembly. These items are

illustrated in Figure 2-3.

The servo motor, drive belt, and tension assembly are the components that actually drive the carrier assembly. The servo motor

drives the belt back and forth allowing the attached carrier assembly

to be repositioned as required. The tension assembly is spring

controlled and allows the proper amount of tension on the belt.

The linear optical encoder strip is used to obtain the printers accuracy along the axis of the printer. It is made with 150 parallel lines

per inch etched into it. By utilizing two optical encoder sensors that

are slightly off set from each other, and reading the leading and

trailing edges of the lines, a resolution of 600 dpi can be obtained.

The stepper and servo motors are controlled from the main printed

circuit assembly by the microprocessor.

28 Theory of Operation

Page 29

Main Printed Circuit Board (MPCB)

Croma24 Service Manual

THEORY OF

OPERATION

Figure 2-4. Main Printed Circuit Board.

The Main Printed Circuit Board (MPCB) consists of six functional

areas:

1. Microprocessor (CPU)

2. Gate Array

3. Memory Circuits

4. Stepper Motor Controller

5. Servo Motor Controller

6. Interface Circuits: Serial & Parallel

Theory of Operation 29

Page 30

Croma24 Service Manual

Microprocessor

The microprocessor (a Motorola MC68322) is the central processor

unit which supervises system functions, executes the printer firmware, manipulates data, and controls input/output data busses. It

has a built-in parallel port, a two channel DMA (Direct Memory

Access) controller, timer module, clock generator, and an on-board

chip select generator. One DMA channel supplies data to the gate

array for jet firing; the other DMA channel is used to receive data

through the serial port via the gate array, or the serial port when

using a high speed serial mode. One timer generates a servo interrupt every millisecond.

The microprocessor halves the 40MHz crystal reference (X1) signal

to create the 20MHz system clock that is used for timing of all

internal circuitry.

The chip select generator is programmed to generate chip selects at

the appropriate addresses, with the appropriate data size (byte,

word) and with the appropriate number of wait states.

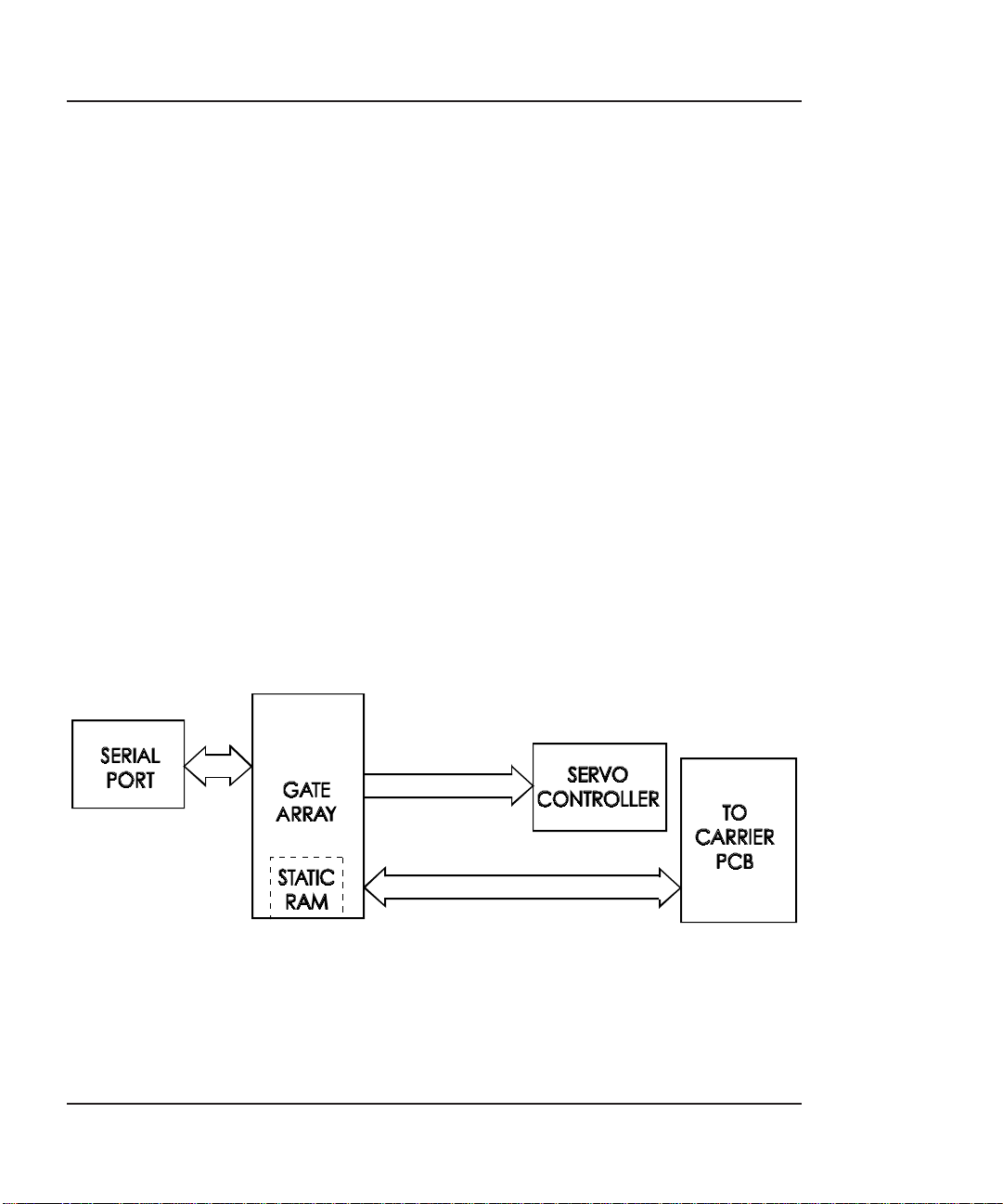

Gate Array

30 Theory of Operation

Figure 2-5. Gate Array.

Page 31

The gate array contains the hardware logic for dot firing, monitoring changes in the Carrier Assembly position, controlling DMA for

the serial port, and generating the PWM (Pulse Width Modulation)

waveforms for the servo controller.

The gate array is a Xilinx device. It is a static RAM-based field

programmable gate array. This means that the logic that it implements is determined by configuration information in internal RAM

storage. Each time power is turned on, this information must be

downloaded from the system ROM. This type of gate array allows

for the flexibility of upgrading the logic by simply downloading the

new system software.

Memory Circuits

Memory is used to retain large amounts of information. This

information is stored in the device memory in the form of binary

bits.

Printer memory consists of Flash EEPROM, DRAM, and

EEPROM.

Croma24 Service Manual

THEORY OF

OPERATION

Maximum installable memory is as follows:

DRAM = 2 MB

Flash EEPROM = 1 MB

Serial EEPROM = 1 KB

Flash EEPROM

Flash EEPROM is Electrically Erasable, Programmable, Read Only

Memory used to store instructions and data constants which the

microprocessor can access and interpret. This set of instructions

and data constants is called the “firmware” of the plotter.

The term “Flash” means that bytes cannot be individually erased.

A block or the whole device is erased at the same time and the

block or whole device is then reprogrammed. It can be erased and

reprogrammed more than 10,000 times.

Theory of Operation 31

Page 32

Croma24 Service Manual

The system firmware is stored in Flash EEPROM and can be upgraded by opening the Control Panel located on the host computer.

Once the Control Panel has been executed, it first starts an initialization and status communication sequence with the printer. The

Control Panel requires ink levels and deadband information to load

correctly. At the same time, it checks the version of firmware that is

loaded on the printer.

The flash EEPROM is a volitile memory in that it will lose updated

information after a loss of power and revert back to the firmware

that was initially installed at the factory. If the Control Panel

contains a newer version of the firmware than the printer is currently loaded with, it automatically updates the firmware at the

startup of the Control Panel.

DRAM

DRAM is Dynamic Random Access Memory which provides temporary storage of the microprocessor calculation and input/output data.

It is also a faster type of memory then the Flash EEPROM. Thats

why the printer control program is also copied from the Flash

EEPROM to RAM, where it can be executed faster.

The printer is supplied with 2 Megabytes of DRAM permanently

installed on the Main PC Board. Memory expansion is not available

for this printer. Since it only supports EN-RTL language, additional

memory is not required or beneficial.

Serial EEPROM

Serial EEPROM is an Electrically Erasable, Programmable, Read

Only Memory which provides storage for calibration constants and

user configuration data entered from the host computer.

A 1K bit serial nonvolatile EEPROM stores calibration and configuration information. It retains data while the unit is off.

32 Theory of Operation

Page 33

Stepper Motor Controller

Croma24 Service Manual

Figure 2-6. Stepper Motor Controller.

The media is driven by a Stepper Motor, which drives the media in

a direction perpendicular to the length of the printer. The media

in the printer can advance forward and backward, depending upon

the commands which the Stepper Motor receives from the microprocessor.

The Stepper Motor Controller contains two identical circuits, one

for each winding of the stepper motor. The circuit is a combination

of two simpler types of circuits and can be thought of as a variation

of either one.

A digital-to-analog (D/A) converter receives digital data from the

CPU and generates a sine wave output. This signal is fed into a

comparator circuit that measures the current through the winding

of the stepper motor. If the current is too low, a pulse of 24 V is

generated. When the current goes above the output of the waveform generator, the pulse turns off. Every time the output of the

waveform generator is changed by the microprocessor, the motor

moves 1 “micro-step”.

Each circuit contains four main blocks (see Figure 2-6):

1. Reference waveform generator

THEORY OF

OPERATION

The microprocessor uses a D/A (digital to analog) converter to

set the desired level for the current in the stepper motor

winding. The output of the D/A converter varies in time to

create a reference waveform. This reference waveform is

centered around 10 V.

Theory of Operation 33

Page 34

Croma24 Service Manual

2. Motor current sense

The voltage across a series current sense resistor is measured

and level shifted so that it is centered around 5 V.

3. Comparator

This portion divides the output of the reference waveform gen-

erator by two and compares it to the output of the motor current

sensor. Logic inside the gate array generates the control signals

for the power driver that applies voltage across the motor winding in order to make the actual current match the reference

waveform.

4. Power driver

An H-bridge allows the supply voltage to be applied across the

winding in either polarity to drive the current to the desired

value.

Servo Motor Controller

Figure 2-7. Servo Motor Controller.

The Carrier Assembly is driven by the Servo Motor. The speed of the

Carrier Assembly is controlled by varying the duty cycle of the power

applied to the controller. The microprocessor checks the position of

the Carrier Assembly approximately 1,000 times per second (during

the servo interrupt). It then updates the PWM (pulse width modula-

34 Theory of Operation

Page 35

Croma24 Service Manual

tor) register in the gate array which sets the duty cycle to make

adjustments to the Carrier Assembly speed. A linear optical encoder

is used to monitor the Carrier Assembly position.

The optical encoder strip runs the length of the Stabilizer Bracket

and contains 150 lines and spaces per inch. Thus there are 300

edges per inch. The detector circuit actually consists of two optical

edge detectors. They are separated from each other by one half the

width of one of the optical lines on the encoder strip. This allows 4

evenly spaced pulses to be developed for each line on the encoder

strip. This is known as quadrature signals. It gives an effective

resolution of 600 lines per inch. See Figure 2-8 for a graphical

representation of quadrature signals.

THEORY OF

OPERATION

Figure 2-8. Quadrature Signal Generation.

Theory of Operation 35

Page 36

Croma24 Service Manual

The direction that the Carrier Assembly is moving is known based

upon the state of one detector’s output and the direction of the

transition of the other detector’s output.

A hardware counter in the gate array increments as the Carrier

Assembly moves left and decrements as the Carrier Assembly moves

right. The hardware counter is only eight bits wide, so it cannot

store a value large enough to represent an absolute Carrier Assembly

position. Instead, it is read during the servo interrupt and its value

compared with that from the previous interrupt. This difference is

used to update the absolute position value in the software.

Interface Circuits: Serial & Parallel

Data from the host computer is received either through the

Centronics parallel port or the serial port (on the GA/CAD or GA

versions only). The gate array provides the control signals for DMA

transfers from the serial port to DRAM.

Figure 2-9. Interface Circuits.

The serial port is designed primarily to interface to a Macintosh

printer port. It has an eight pin Mini-DIN connector. The data

(TXD, RXD) signals meet RS-422 electrical specifications, and the

control signal (DTRCLK) meets the RS-423 electrical specifications.

The control signal can be configured as a 1 MHz clock for high speed

serial communications with a Macintosh.

The serial port is compatible with RS-422 devices when an appropriate adapter cable is used. This cable is available from ENCAD.

36 Theory of Operation

Page 37

Carrier Assembly Circuits

Croma24 Service Manual

THEORY OF

OPERATION

Figure 2-10. Carrier Assembly Circuits.

The Carrier Assembly contains:

1) Carrier PCB

2) Optical Sensors

3) Paper Sensor

4) Inkjet Cartridges

The Carrier PCB contains the logic and drive circuitry for the firing

of the inkjet cartridges. It also establishes an interface path for the

optical sensor and paper sensor to communicate with the MPCB.

The optical sensors receive their inputs from the optical encoder strip

and sends this data to the MPCB. The MPCB uses this information

to determine the horizontal position of the carrier assembly so that

accurate printing can be established.

The paper sensor circuitry senses for the presence of loaded media.

It does this automatically during the start-up and load sequences. It

Theory of Operation 37

Page 38

Croma24 Service Manual

also constantly monitors the media during printing to determine if

the media has run out.

If no paper is sensed, the paper sensor sends this information to the

MPCB, which immediately begins an ‘out of paper’ subroutine. This

subroutine starts the LEDS on the printer to blink (green blinks slow

while yellow blinks faster.) It also informs the host computer of the

situation and stops the printer from printing until more media is

loaded.

The sensor also checks for the size of the media loaded so it can

determine the proper printing parameters.

Power Supply

An internal UL recognized switching power module supplies power

for the Croma24 printer. It provides a constant 5 VDC and 24 VDC

output from input voltage in the range of 90-264 VAC. The 24 V

supply is used for: the stepper controller (which advances the

paper); the servo controller (which moves the Carrier); and power to

fire the inkjets. The 5V supplies power to the logic circuits.

The power supply is fused using a 2 A 250 V fast blow type fuse.

The outputs share a common ground which is isolated from earth

ground within the supply itself. Earth ground and DC ground are

connected external to the power supply.

The power supply will shut down under overload/short circuit conditions on any output over the full range of input voltage. Overvoltage

protection is 20%-30% above nominal for the 5 V and 24 V outputs.

System Grounding

Due to the amount of plastics used in the manufacturing of the

printer, a system of grounding the metal assemblies to each other is

required. If no common ground was in place, the potential of electric

shock could exist due to static voltage buildup on the individual

assemblies. The system grounding network ensures that all metallic

assemblies have the same ground potential. Figures 2-11 and 2-12

show how the ground straps are implemented on the printers.

38 Theory of Operation

Page 39

Croma24 Service Manual

THEORY OF

OPERATION

Figure 2-11. Croma24 System Ground Network (Left Side).

Theory of Operation 39

Page 40

Croma24 Service Manual

Figure 2-12. Croma24 System Ground Network (Right Side).

Front Key Controls

The Control Panel (see Figure 2-13) is located on the lower right side

of the printer and consists of five controls and two LED indicators.

The controls are (from left to right): Backward, Load, Forward, Cut,

and Power. Table 2-1 lists all possible indications allowed using the

LEDs and the conditions that generated that indication.

Figure 2-13. Front Key Controls.

40 Theory of Operation

Page 41

Croma24 Service Manual

Table 2-1. Front Key Control LED Codes.

THEORY OF

OPERATION

Theory of Operation 41

Page 42

Croma24 Service Manual

This Page Intentionally Left Blank

42 Theory of Operation

Page 43

Maintenance

Introduction

This chapter contains general maintenance and cleaning instructions for the Croma24 printer.

Scheduled Maintenance

Scheduled maintenance consists of a list of checks that are planned

to be performed on a regular basis or when conditions warrant it.

3

Scheduled maintenance can be thought of as preventive maintenance since its purpose is to prolong the life of the printer. It is not

intended to repair or isolate an existing problem, though it can

sometimes be helpful in detecting a condition due to a weakened

component that has not yet completely failed.

Below is a list of scheduled maintenance checks and their periodicity.

Clean external areas: weekly, or

as required

Clean slide shaft: monthly

Clean service station: biweekly

Clean encoder strip: monthly

Clean cartridge dimples: if prime fails

Clean flex cable contacts: if prime fails,

or cartridge

is replaced

Clean and inspect motor gears: annually

Clean and inspect MPCB: annually

Clean and inspect carrier assembly: annually

Reseat connectors on MPCB: annually

Reseat connectors on carrier board: annually

Replace carrier bushings: biannually

MAINTENANCE

43

Page 44

Croma24 Service Manual

Cleaning Procedures

External Cleaning

Always turn the printer OFF, remove the power cord

and the interface cable before cleaning the printer. An

electrical shock hazard may be present if these procedures are not followed.

Do not use abrasive cleansers of any sort on the surfaces of the printer. Damage to the surface may result.

The exterior surfaces of the printer may be cleaned with a soft cloth

which has been dampened. For more persistent stains, a small

amount of liquid detergent may be used. Cleaning intervals are

determined by the environment in which the printer is used.

Slide Shaft Cleaning

Use only isopropyl alcohol on the slide shaft of the

printer. Damage to the stainless steel slide shaft may

result if cleaned with water and not completely dried

off.

44 Maintenance

Page 45

Croma24 Service Manual

Printer problems can be caused by an accumulation of dirt or other

contamination on the slide shaft. This contamination may lead to

drag on the carrier. Extreme drag results in a “carrier axis failure”

fault and will stop the carrier motion. These problems may be

eliminated by maintaining and cleaning the slide shaft at intervals

determined by the environmental conditions. Do not use any

lubrication.

To clean the slide shaft:

1. Remove the power cord.

2. Raise the middle cover.

3. Moisten a clean cloth or paper wipe with isopropyl alcohol.

4. Wipe the length of the slide shaft with the moistened cloth

or wipe.

5. Manually move the carrier assembly from side to side.

6. Wipe the shaft again to remove any deposits left from the

carrier.

7. Lower the cover and reconnect the power cord, perform the

PRIME plot. Be sure that the carrier moves freely over the

slide shaft.

Service Station Cleaning

Ink and dust may build up on the service station, resulting in

contamination which may smear the prints. The service station is

cleaned as follows:

1. Disconnect the power cord and interface cable.

2. Raise the middle cover.

MAINTENANCE

3. Carefully move the carrier toward the center of the printer.

Maintenance 45

Page 46

Croma24 Service Manual

4. Using a cotton swab dampened with distilled water, wipe the

5. With a dry swab, wipe all moisture from the seals and

6. Close the cover and reconnect the power cord and interface

Linear Encoder Strip Cleaning

Clean the linear encoder strip monthly, or as necessary, to remove

any buildup of debris. Distilled water or isopropyl alcohol may be

used. You may notice that it tends to fog the encoder strip; however,

no detrimental effect has been observed in the field.

To clean the Encoder Strip:

1. Disconnect the power cord and interface cable.

seals and the rubber wiper in the service station until no

more ink residue or dust can be removed.

wipers.

cable.

2. Slightly dampen a cotton swab with distilled water or

isopropyl alcohol and wipe along the length of the encoder

strip on both sides.

3. Reconnect the power cord and interface cable.

Figure 3-1. Encoder Strip Cleaning.

46 Maintenance

Page 47

Cartridge Dimple Cleaning

Croma24 Service Manual

Figure 3-2. Cartridge Dimple Region.

The cartridge dimple area can easily be contaminated by oils and

dirt on fingers and hands or ink spilled onto them. This causes the

cartridges to not receive some of the electrical signals for a proper

firing of the jets. This can be seen as a misfiring of the cartridge.

NOTE

Care should be used when handling the cartridges.

Avoid touching the cartridges on the dimple area or

on the inkjet holes on the bottom. The oils and dirt on

fingers and hands can contaminate the area and result in misfiring of the inkjets.

Clean the cartridge dimple area by gently dabbing the area with a

lint free cloth or cotton swab saturated with isopropyl alcohol.

MAINTENANCE

Maintenance 47

Page 48

Croma24 Service Manual

Flex Cable Contact Cleaning

Cleaning the flex cable contact area is very important due to the ease

of which this area can become dirty. This also causes the cartridges

to not receive all of the electrical signals for a proper firing of the

jets. This can be seen as a misfiring of the cartridge.

Figure 3-3. Flex Cable Contacts.

Clean the flex cable contacts by gently dabbing the area with a

cotton swab soaked with isopropyl alcohol.

Clean and Inspect Stepper Motor Gears

The stepper motor gears can become dirty and after time if not

cleaned, could cause wide banding in the print or paper skewing.

This will reduce the quality of the intended output. Clean the motor

48 Maintenance

NOTE

Care should be used when handling the flex cable contact area. Avoid touching the contact area because the

oils on your skin can contaminate the area and result

in misfiring of the inkjets.

Page 49

Croma24 Service Manual

gears with a stiff brush to knock off any debris. A cotton swab

soaked with isopropyl alcohol can be used to remove any ink that

may have accumulated on the gears.

Clean and Inspect MPCB

Foreign material on the MPCB could short out electrical signals

being developed on the MPCB and cause erroneous prints or even

damage to the MPCB. All electrical circuits should be free of foreign

material, especially those with conductive properties.

Clean the MPCB by blowing the objects away or gently brush them

aside with a soft brush if required.

Inspect the MPCB for any damage to the board, connections, or any

of the components on the board. Replace board if inspection reveals

any damage or flaws that could effect the function of the MPCB.

Clean and Inspect Carrier Assembly

Foreign material on the carrier assembly could short out signals

being developed on the carrier assembly and cause erroneous prints

or even damage to the carrier assembly. A very common problem is

where ink has been spilled onto the carrier assembly. All electrical

circuits should be free of foreign material, especially those with

conductive properties.

Clean the carrier assembly by blowing the objects away or gently

brush them aside with a soft brush if required. Be careful not to let

anything to fall into the printer as you clean or it could cause a new

problem later.

Inspect the carrier assembly for any damage to the boards, connections, or any of the components on the assembly.

MAINTENANCE

Maintenance 49

Page 50

Croma24 Service Manual

Reseat Connectors on MPCB and Carrier Board

Many problems can be corrected simply by removing and reseating

connections found in circuit assemblies. This process helps to clean

the contacts and can dissipate any static electrical charges that

might have developed.

Integrated circuits may become weakened or damaged

by electrical discharge. Do not touch or work near integrated circuits without wearing an ESD wrist strap.

Ribbon connectors can be easily damaged if incorrectly

handled. Observe extreme caution when handling the

ribbon connectors to avoid damage.

Figure 3-4. MPCB Connection Locations.

50 Maintenance

Page 51

Croma24 Service Manual

Figure 3-5. Carrier PCB Connection Locations.

Figures 3-4 and 3-5 shows the locations of all the connectors on the

MPCB and carrier board respectively. To remove the ribbon cables

from their connectors, lift the connector’s ribbon locking mechanism

as shown in Figure 3-6. To reattach, depress the locking mechanism

back into the locking position after inserting the ribbon cable end.

MAINTENANCE

Figure 3-6. Ribbon Connector Locking Mechanism.

Maintenance 51

Page 52

Croma24 Service Manual

Replace Carrier Bushings

The carrier bushings are rated for approximately 1500 hours of

operational usage. Given an average of about 3 hours a day of

printing for 104 weeks, results in 1560 hours. Therefore, it is safe to

approximate 1500 hours into 2 years of continuous service.

If not replaced, the wear on the bushings can result in erratic carrier

motion and/or carrier axis failures. It can even cause cartridge

headheight to become uneven.

To replace the carrier bushings, follow the Replacing the Carrier

Bushing procedures in Chapter 5.

Servo Motor Winding Resistance Check

1. Disconnect the servo motor connection from the MPCB.

2. Using a standard ohmmeter or multimeter, connect the

3. While manually rotating the servo motor, monitor the

5. If the measurement is found to be unsatisfactory, replace the

52 Maintenance

Figure 3-7. Servo Motor.

meter leads to the two wires going to the motor.

readings on the meter. The acceptable range is 10-20 ohms.

Typically, the reading is 12-16 ohms.

servo motor.

Page 53

Croma24 Service Manual

Stepper Motor Winding Resistance Check

Figure 3-8. Stepper Motor.

MAINTENANCE

1. Disconnect the stepper motor connection from the MPCB.

2. Using a standard ohmmeter or multimeter, measure

between pins 1 (yellow wire) and 3.

3. The reading should indicate 7.2 - 8.0 ohms.

4. Continue by measuring between pins 4 and 6.

5. Reading should also indicate 7.2 - 8.0 ohms.

6. If either measurement is out of tolerance, replace the

stepper motor.

Banding: Hardware vs Software

The technician must be able to identify whether the banding that

is being observed is related to either a hardware or a software

problem. The two examples in Figure 3-9 represent classic types of

hardware and software banding errors.

Maintenance 53

Page 54

Croma24 Service Manual

Hardware banding is usually characterized by consistent banding

strips as shown. It signifies a slippage in the media’s normal movement that is possibly due to the stepper motor, lower drive shaft

assembly, or the rollguides on the back of the printer. All these

possible faulty areas deal with a rotational movement that, if faulty,

will generate a consistent banding pattern. The MPCB and Carrier

PCB can also cause this type of error to incur.

Figure 3-9. Examples of Banding.

Software banding is characterized by inconsistent banding lines.

These banding lines are generated by the software when incorrectly

interpreting the paper advancing/ink firing sequence of the expected

print file. Because it is not directly tied to a mechanical movement,

the bands become inconsistent in both frequency and duration. The

possible causes are the printer driver, the original software package,

or the RIP, if used. To eliminate the chance that it is the printer

driver:

1) Remove any RIP or network systems and connect the printer

directly to the computer.

2) Print a test file approved by ENCAD that uses only the

printer driver software and the ENCAD printer.

If the test file prints correctly, the problem lies in either the software

package that generated the print or the RIP, if used.

54 Maintenance

Page 55

Alignments/Adjustments

The ENCAD Croma24 printers are designed with a minimum of

maintenance requirements in mind. Most of the adjustments are

controlled and performed via software/firmware interaction that

require you to run a subroutine and enter values on the computer.

Programmed calibrations include: color calibration, deadband

alignment, and X-axis calibration. The mechanical adjustment

requirements include the pinch roller adjustments and the encoder

strip height adjustments. No electrical alignments are required.

Color Calibration

Croma24 Service Manual

This procedure describes how to check that the cartridges are

properly aligned for color plotting & should be followed each time

the ink cartridges are installed. Figure 3-10 is a representation of

how a color calibration looks when printed.

MAINTENANCE

Figure 3-10. Color Calibration.

Maintenance 55

Page 56

Croma24 Service Manual

The “Current Heads (Y, M, C)” view represents the alignment of the

heads as they are currently entered. This is just an overview of all

heads and how they are aligned. Do not attempt to align the heads

using this view.

The “Color Horizontal Head-to-Head Calibration” checks the alignment of the nozzles horizontally and allows corrections when required. Just enter the value below the set of lines that are correctly

aligned. Be careful that you are aligning the correct color by observing the C (cyan), M (magenta), and Y (yellow) on the right side of the

plot.

The “Color Vertical Head-to-Head Calibration” checks the alignment

of the nozzles vertically and allows corrections when required. Just

enter the value below the set of lines that are correctly aligned. Be

careful that you are aligning the correct color by observing the C

(cyan), M (magenta), and Y (yellow) on the right side of the plot.

Deadband Alignment

Deadband calibration compensates for minute differences created

when bidirectional printing is used. Unidirectional printing is not

affected by deadband. There are four types of deadband tests: slow

deadband, fast deadband, fast deadband; vertical lines (all), and fast

deadband; vertical lines (one).

Figure 3-11 shows what the display will look like when printing

either the fast or slow test if it is out of alignment. A correctly

aligned printer will appear as if there is only a series of vertical lines

printed. No difference between the three segments of lines would be

apparent.

The SLOW DEADBAND calibration is a precision test that checks

the firing time of the jets as related to the forward and reverse

direction.

56 Maintenance

Figure 3-11. Deadband Slow/Fast.

Page 57

Croma24 Service Manual

X-Axis Calibration

The X-axis calibration procedure ensures that the processing that

drives the stepper motor is correct to minimize line length accuracy

errors.

Pinch Roller Adjustment Procedure

The purpose of the Paper Skew Adjustment is to make certain that

the Pinch Roller in the Upper Roller Support stays centered on its

shaft and/or has a gap when the Lower Roller is rotated forward

for approximately two full revolutions. In other words, the Pinch

Roller should not drift rapidly to the left or to the right when the

Lower Roller is rotated forward for two full revolutions. (Slow

drifting is acceptable.)

Use the torque screwdriver with the P0 bit to adjust the Pinch

Roller mounting screws. The maximum torque requirement is

1 in-lbs ± 0.5.

MAINTENANCE

Figure 3-12. Upper Roller Support Description.

1. Figure 3-12 shows the Upper Roller Support and the

mounting screws. Stand behind the printer in order to

adjust the mounting screws on the Upper Roller Supports.

Maintenance 57

Page 58

Croma24 Service Manual

2. Become familiar with the actions and results shown in

Table 3-1. Note that these actions are performed from

behind the printer.

Table 3-1. Pinch Roller Adjustments.

ACTION RESULT

1. Turn mounting screw

counterclockwise (ccw).

2. Turn mounting screw

clockwise (cw).

3. Loosen left mounting screw

(turn ccw).

4. Tig hten left monting screw

(turn cw).

5. Loosen right mounting screw

(turn ccw).

6. Tig hten right mo unting screw

(cw).

7. Not maintaining downw ard

pressure (towards the flo or) on

the head of each mounting screw

at the same time as you loosen or

tighten the screw.

1. Screw is loosened.

2. Screw is tigh tened .

3. Roller moves to the right.

4. Roller moves to the left.

5. Roller moves to the left.

6. Roller moves to the right.

7. Th e upper roller sup port

will not be perfectly level and

will not perform its func tion

properly.

Each m ou nting screw m ust be

completely at the bottom

edge of its hole in the back

of the C -bracket as you

loosen or tighten th e screw.

See Figure 3-13.

58 Maintenance

Page 59

Croma24 Service Manual

Figure 3-13. Upper Roller Mounting.

3. If you loosen one of the mounting screws and the roller

moves in one direction, and you need to move the roller in

the opposite direction, tighten the screw that was loosened

to its maximum torque (1 in.-Lbs. ± 0.5) BEFORE loosening

the other screw to move the roller in the opposite direction.

NEVER LOOSEN OR TIGHTEN BOTH MOUNTING

SCREWS AT THE SAME TIME ON THE SAME UPPER

ROLLER SUPPORT.

MAINTENANCE

4. Following all of the above information precisely will ensure

that the Upper Roller Support springs are deflected and the

lower tail of the springs will always be pressed against the

C-bracket’s vertical wall (without a gap) as shown in

Figure 3-13.

Figure 3-14. Gap of Pinch Roller.

Maintenance 59

Page 60

Croma24 Service Manual

Figure 3-15. Upper Roller Adjustment.

Figure 3-15 shows how the motion (rapid drifting to the right or to

the left) of the roller determines which mounting screw should be

tightened in order to eliminate the motion of the roller so that the

roller stays in the center of the shaft and/or there is a gap when the

Lower Roller is rotated forward.

Head Height Alignment Procedure

Perform this procedure only when the encoder strip stabilizer has

been removed from the C-Bracket or whenever the alignment is in

question. The head height alignment procedure is to ensure that a

0.065” +/- 0.003” difference exists between the cartridge jet plate and

the Platen. See Figure 3-16.

60 Maintenance

Page 61

Croma24 Service Manual

Figure 3-16. Carrier Head Height Tolerance.

1. Remove the lid and the right cover of the printer. See

Chapter 5 for procedures.

MAINTENANCE

2. Obtain the 3 tools (Micrometer Dial Gauge, Test Cartridge,

and Measuring Tip Extender) from the Height Gauge Kit.

Assemble the tools as shown in Figure 3-17.

Figure 3-17. Setting Up Tools from Height Gauge Kit.

Maintenance 61

Page 62

Croma24 Service Manual

3. Place the test cartridge upright on a flat surface and ‘zero’

4. Remove the Cyan ink cartridge. Snap the test cartridge with

the gauge by loosening the knob near the top and turning the

dial until the needle is at the ‘0’ position on the dial. Tighten

the knob. See Figure 3-18.

Figure 3-18. Zeroing the Micrometer Gauge.

the micrometer gauge into the position vacated by the Cyan

ink cartridge. See Figure 3-19. Ensure that the micrometer

can be read from the BACK of the printer.

5. Remove the trailing cable assembly.

6. Loosen the three screws located on the back of the C-bracket

62 Maintenance

Figure 3-19. Test Cartridge Installed.

that secures the stabilizer to the C-bracket.

Page 63

Croma24 Service Manual

Damage may occur to the micrometer

gauge if the Carrier is moved without

lifting up on the measuring tip. This

action could also take the micrometer

out of alignment and foul the results of

the alignment.

7. While lifting up the measuring tip of the micrometer, slide

the Carrier to the center of the stabilizer as shown in Figure

3-20. Position it as close to the screw as possible and drop the

measuring tip onto the platen. Do this a couple of times to

ensure an accurate reading.

MAINTENANCE

Figure 3-20. Carrier Positions for Head Height Adjustment.

8. Move the left and right ends of the stabilizer bracket until a

reading of 0.075 +/- 0.003” is observed. Read only the RED

numbers on the micrometer gauge. The measurement of

0.075 +/-0.003” is used because the test cartridge being used

does not have a print head attached. A 0.010” difference had

to be added to compensate for the lack of a print head.

9. Tighten the screw on the center of the stabilizer.

Maintenance 63

Page 64

Croma24 Service Manual

10. While lifting up the measuring tip of the micrometer, slide

11. Move the left end of the stabilizer bracket until a reading of

12. Tighten the screw on the left end of the stabilizer.

13. While lifting up the measuring tip of the micrometer, slide

14. Move the right end of the stabilizer bracket until a reading of

the Carrier to the left of the stabilizer as shown in Figure 3-

20. Position it as close to the screw as possible and drop the

measuring tip onto the platen. Do this a couple of times to

ensure an accurate reading.

0.075” +/- 0.003” is observed. Read only the RED numbers on

the micrometer gauge.

the Carrier to the right of the stabilizer as shown in Figure 3-

20. Position it as close to the screw as possible and drop the

measuring tip onto the platen. Do this a couple of times to

ensure an accurate reading.