Page 1

CELLROLL and CELLSPIN

Operating instructions

183411_V12

Page 2

2

Declaration of Conformity | Konformitätserklärung | Déclaration de conformité

INTEGRA Biosciences AG – 7205 Zizers, Switzerland

declares on its own responsibility that the products |

erklärt in alleiniger Verantwortung, dass die Produkte |

déclare sous sa responsabilité exclusive, que les produits

in accordance with the EC directives | gemäß der EU-Richtlinien |

sont conforme au terme de la directives CE

are in compliance with the following standards or normative documents: |

mit den folgenden normativen Dokumenten übereinstimmen: |

aux documents normatifs ci-après :

Standards for Canada and USA

Zizers, December 9th 2013

ledom ,epyTnoitpircseD

500681 ,100681LLORLLEC

100381NIPSLLEC

2006/95/EC Low voltage equipment

2004/108/EC Electromagnetic compatibility

2011/65/EC Restriction of Hazardous Substances

2002/96/EC Waste Electrical and Electronic Equipment

EN 61010-1 Safety requirements for electrical equipment

for measurement, control and laboratory use,

Part 1: General requirements.

EN 61326-1 Electrical equipment for measurement, control

and laboratory use - EMC requirements.

CAN/CSA-C22.2 No. 61010-1 Safety requirements for electrical equipment

for measurement, control and laboratory use,

Part 1: General requirements.

UL Std. No. 61010-1 Safety requirements for electrical equipment

for measurement, control and laboratory use,

Part 1: General requirements.

FCC, Part 15, Class A Emission

Elmar Morscher

CEO

Thomas Neher

Quality Manager

Page 3

2.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Contents

1. Safety precautions

2. Technical data

4. Assembly and installation CELLROLL/CELLSPIN

3. Abridged operating instructions CELLROLL/CELLSPIN

3.1 Instrument parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Description of keys and functions . . . . . . . . . . . . . . . . . . . . . 10

3.3 Abridged instructions CELLROLL . . . . . . . . . . . . . . . . . . . . . 11

3.4 Abridged instructions CELLSPIN . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Equipment provided - CELLROLL . . . . . . . . . . . . . . . . . . . . . 15

4.2 Equipment provided - CELLSPIN . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Control unit CELLROLL/CELLSPIN . . . . . . . . . . . . . . . . . . . . 16

4.4 Designation of individual instrument parts . . . . . . . . . . . . . . 17

4.5 Vertical assembly - CELLROLL . . . . . . . . . . . . . . . . . . . . . . . 18

4.6 Horizontal assembly - CELLROLL . . . . . . . . . . . . . . . . . . . . . 19

4.7 Disassembly - CELLROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.8 Stirring unit - CELLSPIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.9 Connecting the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.10 Equipment disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation of CELLROLL/CELLSPIN: location and conditions . . . . . . . . . . . . 5

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conditions of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dangers involved when safety precautions are not observed . . . . . . . . . . . . . 6

Safety at work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Qualification of operating personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety aspects for user company . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changes in configuration/design by user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3

Page 4

4

5.1 Operating steps

Starting and stopping the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Switching on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Selecting outputs (OUTPUT 1/OUTPUT 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configuration of connected instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 CELLSPIN - specific CELLSPIN functions

Stirring - "SPEED" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pendular stirring angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Interval mode "––" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3 CELLROLL - specific CELLROLL functions

Rolling speed - "SPEED" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rocking angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4 CELLROLL/CELLSPIN - common functions

Running time mode "" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Cycle mode "CYCLES" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Printout and overview of program parameters "PRINT . . . . . . . . . . . . . . . . . . . 30

Storing programs "STORE" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Recalling and viewing programs "RECALL" . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6. Troubleshooting

7. Guarantee/Cleaning

5. Detailed operating instructions

8. Manufacturer and Service Contacts

Page 5

5

General

Throughout the manual, the following symbols will be used to indicate general precautionary measures:

Indication: information on the correct use of

CELLROLL/CELLSPIN.

Warning: Warning that, if safety precautions are not

observed, damage may result to the instruments.

Please read all documentation.

Danger: Warning that, if safety precautions are not

observed, injury to personnel may result.

Installation: Location and conditions

CELLROLL/CELLSPIN are intended for use in a laboratory.

Ambient conditions for the devices CELLROLL/

CELLSPIN see chapter Technical data

Warning: Always locate the control unit outside of an incubator if used.

Avoid exposing the control unit and power supply to direct

sunlight or high humidity.

Locate CELLROLL in such a way that personnel

cannot come in contact with the cogs.

Transport

Always grip CELLROLL on the base when transporting

1. Safety precautions

Page 6

6

Conditions of use

CELLROLL is a modular and expandable roller system for cell cul-

tivation and preparation of cell products in roller bottles. It is suitable for use with adherent cells and cell suspensions. The instrument is not designed for any other applications and should therefore not be used for such.

CELLSPIN is a spinning system comprising four stirring units for

the gentle cultivation of cells and the preparation of cell products in

spinning vessels. It is suitable for use with cell suspensions and immobilised adherent cells (e.g. microcarriers/alginate inclusion). The instrument is not designed for any other applications and should therefore not be used for such.

Dangers involved when safety precautions are not

observed

CELLROLL/CELLSPIN are state-of-the-art instruments with respect

to current technology and are safe to use. Some danger may exist

if the instruments are used by untrained personnel. Any person given

the task of operating CELLROLL/CELLSPIN must first read the operating and safety instructions and understand them fully or be thoroughly trained by a superior in the use of the instruments before

operating the instrument.

Safety at work

Independent of any safety precautions listed here, all other relevant

safety aspects - e.g. GLP, GMP, professional trade associations,

Department of Health, trade supervisory authorities - must be

observed.

Qualification of operating personnel

Normally, a technical qualification is required. Specialist knowledge

is required when using CELLROLL/CELLSPIN if all danger is to be

avoided.

Personnel without formal technical qualifications do not as a rule

possess such specialised information and should therefore only be

allowed to operate CELLROLL/CELLSPIN if properly trained and

under the supervision of suitably qualified personnel.

Safety aspects for the user company

The supervisors of operating personnel must have read and understood all the safety precautions involved and must ensure that these

are adhered to. They must also ensure that operating personnel also

understand and observe all safety rules.

Prior to operating CELLROLL/CELLSPIN, the supervisor must ensure

that no other dangers exist, especially if other instruments and systems are also being used.

If necessary, additional safety instructions must be compiled by the

supervisor. The user company must, if necessary, in order to exclude

all possible danger, compile explicit safety instructions and have these

signed by the staff responsible. In addition, clear competences must

be established as to who is responsible for the operation of CELLROLL/CELLSPIN so that these potential dangers can be reduced

to an absolute minimum.

Page 7

7

Changes in configuration/design by user

No changes may be made to CELLROLL/CELLSPIN. Any parts that

become defective must be replaced by original INTEGRA Biosciences

parts.

CELLROLL/CELLSPIN may not be altered in design or in any of their

safety aspects without the express written permission of INTEGRA

Biosciences. In particular, no alterations may be made to any of the

protective functions. Any alteration made releases INTEGRA

Biosciences from any liability for damage caused.

Power requirements

Checking the power supply

Check the power supply at the location and ensure that it complies

with that of the instrument.

Indication: Using the wrong power supply may damage

electronic components in the instrument.

Connecting to the power supply

Connect CELLROLL/CELLSPIN to the power supply using the cable

provid ed.

Danger: The instrument may not be used if insufficient

protection is provided as this may expose personnel

to the danger of electrical current injury.

NB: When connecting or disconnecting the instrument

from the control unit the latter must always first be

switched off otherwise the electronics may be damaged or a program interrupted.

Page 8

8

2. Technical data

CELLROLL

Width Depth Height

1 Deck 295 mm 360 mm 240 mm

2 Decks 295 mm 360 mm 400 mm

3 Decks 295 mm 360 mm 560 mm

4 Decks 295 mm 360 mm 720 mm

Control unit: 295 mm 80 mm 60 mm

Speed: "Motor unit": 0.1 – 2.0 rpm

"Motor unit fast": 2.0 – 6.0 rpm

Power Supply:

Input: 100 – 240 VAC/47 – 63 Hz/1.6 A

Output: 9.5 VDC/4.0 A/38 W

Weight:

Motor unit: 1.85 kg

Deck: 1.7 kg

Operating Condition:

Operation

Motor-unit/ Deck: 5 – 40 °C/max. 99% RH/max. 10% CO

2

Operation Control unit: 5 – 40 °C/max. 80% RH

Storage: -10 – 50 °C/max. 95% RH

Degree of protection:

Motor-unit/Deck: IP54

Control unit: IP21

2.1 Technical data

CELLSPIN

Width Depth Height

Drive: 295 mm 330 mm 60 mm

Control unit: 295 mm 80 mm 60 mm

Speed: 5 – 75 rpm

Power Supply:

Input: 100 – 240 VAC/47 – 63 Hz/1.6 A

Output: 9.5 VDC/4.0 A/38 W

Weight:

Control unit: 0.5 kg

Stirrer unit: 2.9 kg

Operating Condition:

Operation Stirrer unit: 5 – 40 °C/max. 99% RH/max. 10% CO

2

Operation Control unit: 5 – 40 °C/max. 80% RH

Storage: -10 – 50 °C/max. 95% RH

Degree of protection:

Stirrer unit: IP54

Control unit: IP21

Page 9

9

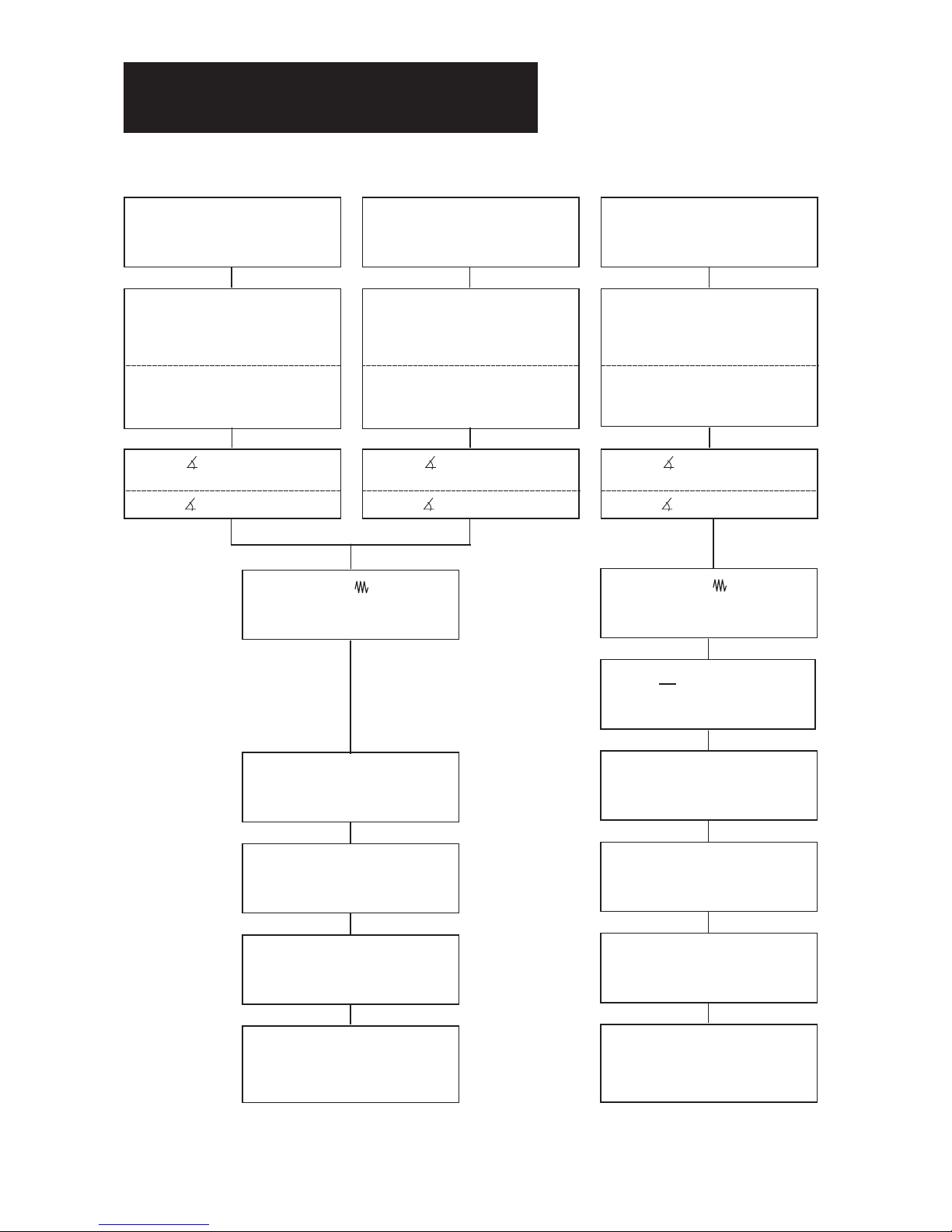

3.1 Instrument parameters

3. Abridged operating instructions

CELLROLL /CELLSPIN

Storing of programs – "STORE"

Memories Pr. 01 – Pr. 10

Recalling programs – "RECALL"

Pr. 01 – Pr. 10

CELLROLL

Motor unit fast (2 – 6 rpm)

"SPEED" for continuous rolling

(rolling with no directional change)

2.0 – 6.0 in steps of 0.25

and for rocking

(rolling with directional change)

ANGLE " " for rocking

(180° – 1440° in steps of 180°)

ANGLE ""for rolling = 0°

CELLSPIN

"SPEED" for continuous stirring

(= continuous stirring)

5.0 – 40.0 rpm in steps of 2.5

40.0 – 75.0 rpm in steps of 5.0

"SPEED" for pendular stirring

(= stirring with directional change)

5.0 – 40.0 rpm in steps of 2.5

ANGLE " " for pendular stirring

(180° – 1440° in steps of 180°)

ANGLE ""continuous stirring = 0°

RUNNING TIME ""

(00.05 h.min. - 99.59 h.min.) or

unlimited = Con

Cycles – "CYCLES"

for programming

1 – 9999

CELLROLL

Motor unit (0.1 – 2 rpm)

"SPEED" for continuous rolling

(rolling with no directional change)

0.1 – 1.0 in steps of 0.1

1.0 – 2.0 in steps of 0.5

and for rocking

(rolling with directional change)

ANGLE " " for rocking

(180° – 1440° in steps of 180°)

ANGLE ""for rolling = 0°

Print-out of protocols – "PRINT"

For viewing stored programs P1

Protocol print-out P2

Print-out of stored programs P3

Storing of programs – "STORE"

Memories Pr. 01 – Pr. 10

Recalling programs – "RECALL"

Pr. 01 – Pr. 10

RUNNING TIME ""

(00.05 h.min. - 99.59 h.min.) or

unlimited = Con

PAUSE " "

(00.00 h.min. - 99.59 h.min.)

Cycles – "CYCLES"

for programming

1 – 9999

Print-out of protocols – "PRINT"

For viewing stored programs P1

Protocol print-out P2

Print-out of stored programs P3

Page 10

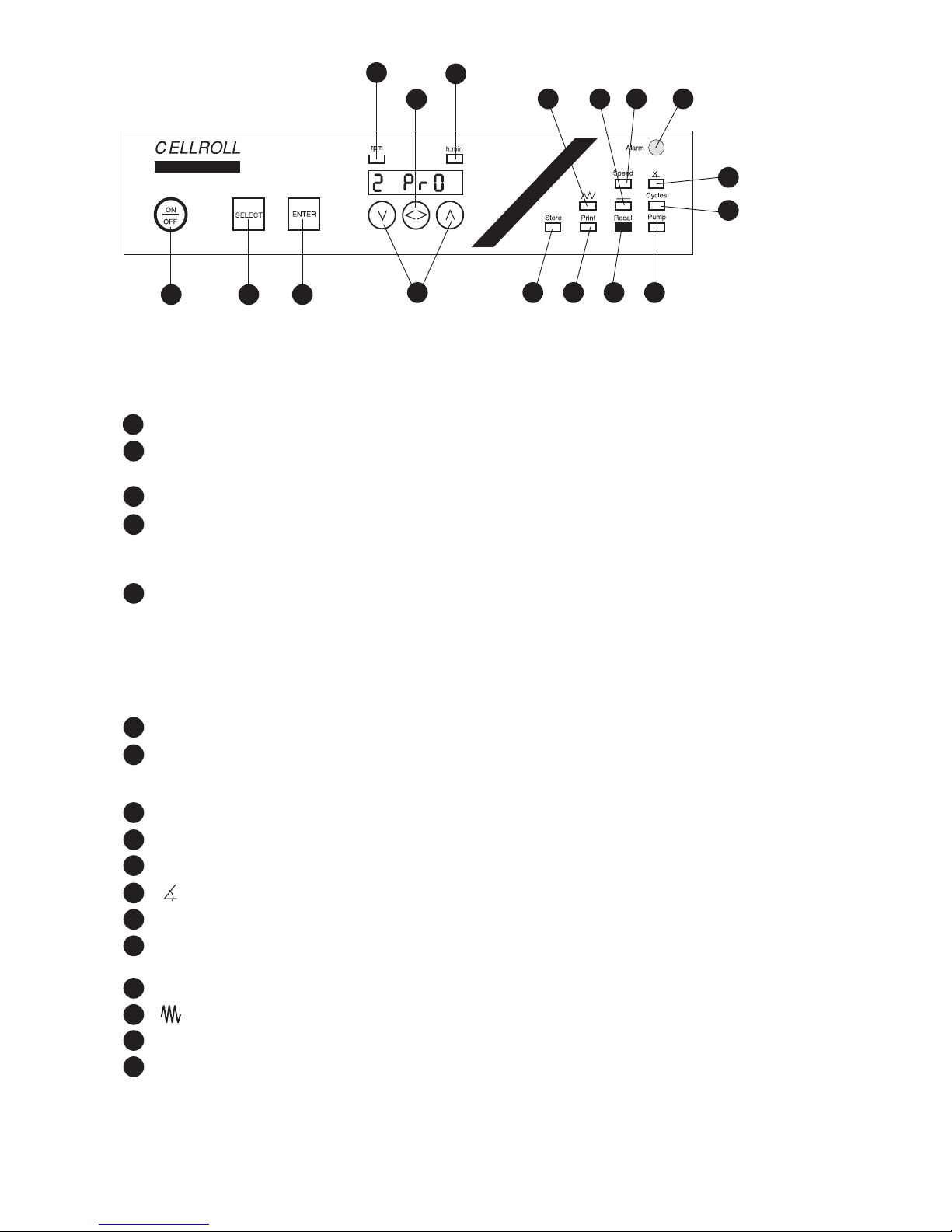

3.2 Brief description of keys and functions

Keys:

ON/OFF: Switches the instrument on/off

SELECT: Switches between parameters. The corresponding green LED will light and the most

recently set value will appear in the display.

ENTER: For confirming the value entered.

∨/∧: Keys "∨" and "∧" alter the corresponding parameters stepwise, the values being shown on

the display.

By keeping keys "∨" and "∧" pressed, all parameter values are displayed in rapid sequence.

< >: For:

a) Changing e.g. from hours to minutes and vice versa when setting time.

b) Switching between OUTPUT 1 and OUTPUT 2 in the functions "SPEED" and "RECALL".

c) Activating/deactivating the print options P2 and P3 in the function "PRINT".

Function LED’s :

STORE: Storing of programs

PRINT: P1: Display of stored programs

P2: Setting the printing interval

P3: Print out of stored programs

RECALL: Recalling stored programs

PUMP: Additional function

CYCLES: Number of times a program should be repeated

: Angle for pendular/circular stirring and rocking/rolling

ALARM: Red lamp lights if there is malfunction

SPEED: Speeds for pendular/circular stirring and rocking/rolling and for selecting between

OUTPUT 1 and OUTPUT 2

–––– : Pause between two programmed runs

: Running time (specific/continuous) for pendular or continuous stirring, rocking or rolling

h/min: Activated during entry of time parameter

rpm: Activated during entry of speed

2

4

3

4

1

17

12

5

16

11

6

13

7

15

8

14

9

17

16

10

10

11

7

1213

6

8

14

9

10

2

3

5

15

1

Page 11

NB: The control unit must always be located outside the incubator!

– Connect C ELLRO LL t o the control u nit with the cable

provided.

If connection has not been made, "Err 02" will appear on the

dis play on starting the instrument. Check the connection and

cancel the error message by pressing "ENTER".

– In the event of a power failure, any unstored data of both out-

puts will be automatically stored and recalled once the power has

been restored. The "Err 03" in the display can be cancelled by

pressing "ENTER".

Entering the program for working with CELLROLL

☞ Switch on the instrument by pressing the ON/OFF key. The

green LED under "RECALL" will light.

☞ Press "SELECT" and select the function "SPEED".

In the function "SPEED":

Selecting the output:

☞ Select OUTPUT 1 or OUTPUT 2 via key "< >".

Setting the rolling speed:

CELLROLL is equipped with two different motors. The control unit

will always select the right one.

"CELLROLL" Motor unit (0.1-2.0 rpm):

☞ Set the speed within the range 0.1 - 2.0 rpm via "∨" and "∧".

Confirm by pressing "ENTER".

"CELLROLL" Motor unit fast (2.0-6.0 rpm):

☞ Set the speed within the range 2.0 - 6.0 rpm via "∨" and "∧".

Confirm by pressing "ENTER".

In the function " ":

Selecting the pendular angle:

☞ For continuous rolling (no directional change), set the

pendulum angle to "0°" via "∨". Confirm by pressing "ENTER".

☞ For rocking (with directional change), set the pendulum angle

within the range 180° - 1440° (= 0.5 - 4.0 bottle revolutions).

Confirm by pressing "ENTER".

NB: If "rocking" has been selected, please observe the restrictions

impos ed below under " " and "–".

In the function "":

Set the rolling duration:

The duration of continuous rolling or rocking can be set to:

- A limited time between 00.05 (h/min) - 99.59 (h/min), or

- An unlimited time as "Con".

☞ To select a specific rolling duration

, set hours and/or minutes

via the "< >" key and alter via "∨" and "∧". Confirm by pressing

"ENTER".

☞ To select continuous rolling or rocking operation, activate the

h/min function and press the "∨" key until the display shows

less than 0.05 and "Con" appears. Confirm by pressing

"ENTER".

11

3.3 Abridged operating instructions - CELLROLL

Page 12

In the function " – ":

The pause interval cannot be selected for either motor unit and is

overrun.

In the function "CYCLES":

Repeating programs:

Programs can be set to repeat within the range 1 - 9999.

☞ Select the required value via "∨" and "∧". Confirm by pressing

"ENTER".

NB: If in the function " " continuous stirring has been selected,

"Con" will appear automatically under "CYCLES".

In the function "STORE":

Storing programs:

Up to 10 programs can be stored in separate memories.

☞ Select a memory between Pr. 01 and Pr. 10 via keys "∨" and

"∧". Confirm by pressing "ENTER".

In the function "RECALL":

Recalling stored programs:

☞ Select a memory between Pr. 01 and Pr. 10 via keys "∨" and

"∧". Confirm by pressing "ENTER". Three beeps will be given

and the program will start.

NB: When recalling a program, please remember to take the output into account.

Selecting the output:

☞ Key "< >" can be used to select OUTPUT 1 or 2.

Additional functions: "PRINT" and "PUMP":

Information on the operating steps for these functions along with the

options

P1 = view stored programs

P2 = entering print interval

P3 = Print-out of stored programs

is given in the detailed operating instructions.

12

Page 13

NB: The control unit must always be located outside the incubator!

– Connect CELLSPIN to the control unit with the cable provided.

If connection has not been made, "Err 02" will appear on the

display on starting the instrument. Check the connection and

cancel the error message by pressing "ENTER".

– In the event of a power failure, any unstored data of both out-

puts will be automatically stored and recalled once the power has

been restored. The "Err 03" in the display can be cancelled by

pressing "ENTER".

Entering the program for working with CELLSPIN:

☞ Switch on the instrument by pressing the "ON/OFF" key. The

green LED under "RECALL" will light.

☞ Select the function "SPEED" by pressing "SELECT".

In the function "SPEED":

Selecting the required output:

☞ Select OUTPUT 1 or OUTPUT 2 via key "< >".

Selecting the stirring speed:

NB: In the "SPEED" mode, the rpm limit for pendular stirring must

be taken into account so that the pendulum angle " " can be

set.

☞ For continuous stirring (no directional change), set the

speed within the range 5 - 75 rpm and for pendular stirring

(stirring with directional change) within 5 - 40 rpm via "∨" and

"∧". Confirm by pressing "ENTER".

In the function " ":

NB: The function " " can only be selected when the set speed is

<

40 rpm. If a value > 40 rpm has been selected, the " " function

will be overrun and the angle automatically set to "0".

Selecting the pendular angle:

☞ For continuous stirring, set the pendulum angle to "0°" via "∨".

Confirm by pressing "ENTER".

☞ For pendular stirring, set the pendulum angle via keys "∨"

and "∧" within the range 180° - 1440°. Confirm by pressing

"ENTER".

In the function " ":

Setting the stirring duration:

The duration of stirring can be set to:

- A limited time between 00.05 (h/min) - 99.59 (h/min), or

- An unlimited time as "Con".

☞ To select a specific stirring duration

, set hours and/or minutes

via the "< >" key and alter via "∨" and "∧". Confirm by pressing

"ENTER".

☞ To select continuous stirring, activate the h/min function with

the "< >" key and press the "∨" key until the display shows

less than 0.05 and "Con" appears. Confirm by pressing

"ENTER".

13

3.4 Abridged operating instructions - CELLSPIN

Page 14

In the function " – ":

Setting the interval:

Within any program, an interval can be freely selected within the range

00.00 (h/min) - 99.59 (h/min).

☞ Choose the position for hours and minutes via key "< >" and

set the interval via keys "∨" and "∧". Confirm by pressing

"ENTER".

In the function "CYCLES":

Repeating programs:

Programs can be set to repeat within the range 1 - 9999.

☞ Select the required value via "∨" and "∧". Confirm by pressing

"ENTER".

NB: If in the function " " continuous stirring has been selected,

"Con" will appear automatically under "CYCLES".

In the function "STORE":

Storing programs:

Up to 10 programs can be stored in separate memories.

☞ Select a memory between Pr. 01 and Pr. 10 via keys "∨" and

"∧". Confirm by pressing "ENTER".

In the function "RECALL":

Recalling stored programs:

☞ Select a memory between Pr. 01 and Pr. 10 via keys "∨" and

"∧". Confirm by pressing "ENTER". Three beeps will be given

and the program will start.

NB: When recalling a program, please remember to take the output into account.

Selecting the output:

☞ OUTPUT 1 or OUTPUT 2 can be selected via key "< >".

Additional functions: "PRINT" and "PUMP":

Information on the operating steps for these functions along with the

options

P1 = view stored programs

P2 = entering print interval

P3 = Print-out of stored programs

is given in the detailed operating instructions.

14

Page 15

Accessories:

Part No.

Deck for system extension (2 roller bottles per deck) 186 026

Storage deck for horizontal extension, with drive belt, 186 030

spacers and deck cover (Deck 186 026 not included)

Control cable for 2nd output, length 2 m 186 050

Interface cable for connection to printer or PC 186 041

Drive unit standard (0.1 - 2.0 rpm), incl. control cable 186 015

Drive unit fast (2.0 - 6.0 rpm), incl. control cable 186 020

Control unit incl. mains adapter 186 013

Mains adapter 186 238

4.1 Equipment provided - CELLROLL

4. Assembly and installation

CELLROLL/CELLSPIN

CELLROLL (Part. No. 186 001) or

CELLROLL fast (Part. No. 186 005) comprises:

1 Control unit

1 "Drive unit", 0.1-2.0 rpm (for 186 001)

or

1 "Drive unit fast ", 2.0-6.0 rpm (for 186 005)

2 Decks for 4 roller bottles

(incl. connectors for assembly)

1 Power cable

1 Mains adapter

1 Control cable, length 2 m

1 Operating instructions

15

Page 16

4.3 Control unit for CELLROLL/CELLSPIN

The CELLROLL/CELLSPIN control unit includes:

① Connection for power cable and integrated interface

RS 232 C for connecting a printer/PC (activated via Y-cable)

to POWER IN.

Two asynchronous outputs - OUTPUT 1 and OUTPUT 2

for connecting: – 1 CELLSPIN and 1 CELLROLL

– or 2 CELLSPINS or 2 CELLROLLS

4.2 Equipment provided - CELLSPIN

①

Accessories: Article No.

Control cable for 2nd output, length 2 m 186 050

Control unit incl. mains adapter 183 013

Interface cable for connection to printer or PC 186 041

Stirring platform 183 015

Mains adapter 186 238

Conversion kit for using CELLSPIN 183 260

with impeller-type flasks

Spinner flasks (www.integra-biosciences.com)

CELLSPIN (Part No. 183 001) comprises:

1 Stirring platform incl. control cable

1 Control unit incl. mains adapter

1 Power cable

1 Mains adapter

1 Control cable, length 2 m

1 Operating instructions

9,

5

V

,

3

A

9,5 V ,3 A

16

Page 17

4.4 Designation of individual instrument parts

CELLROLL - Motor unit

① Socket

➁ Deck

CELLSPIN -stirring unit with 4 stirrers

③ Left cable channel

④ Socket

⑤ Right cable channel

Control cable

⑥ Socket

⑦ Plug

Mains cable

⑧ Socket

⑥⑦

⑧

17

Page 18

4.5 Vertical assembly - CELLROLL

☞ Insert 4 connectors and 4 end pieces each into the bottom and

the top of the first deck until they audibly fit into position.

Via further connectors, up to four decks may be connected vertically. The top deck of a tower remains without connectors.

The gears of the decks mesh together automatically. Locate

CELLROLL in such a way that personnel do not come in contact

with the cogs.

NB: Never stack more than 4 decks at any one time.

NB: When transporting CELLROLL, always grip the lower

deck.

☞ Place the CELLROLL motor unit with its ex-factory fitted con-

nectors on the last free deck and ensure that it engages in position.

If running special applications in which the usual cell culture conditions (temperature, humidity etc.) are not necessary, the control

unit can be fitted directly to the guide slot on the motor unit.

NB: Before locating CELLROLL/CELLSPIN, please read

and observe the safety conditions listed in section 1.

☞ Connect the plug of the low voltage cable ① to "POWER IN"

at the rear of the control unit and tighten.

☞ Place the power cable in the cable clips located at the side of

the shelf of the motor unit. If necessary, mount additional clips

at the rear of the tower. Insert cable.

Take care that the cable does not come into contact with

the cogs.

☞ Connect the power supply to power.

NB: Always locate the control unit outside of the incubator.

18

Page 19

4.6 Horizontal assembly - CELLROLL

☞ Place two modules furnished with end pieces/intermediaries

next to each other.

☞ Snap two double-clips onto the round stud of the right module.

☞ Place synchronous belt on both crown gears.

☞ Snap the mounted double-clips onto the round stud of the left

modu-le.

Now the synchronous belt is stretched.

Up to three additional decks may be added vertically if they are

connected with intermediaries.

The individual module's composition gears mesh together automatically.

The top deck or each tower remains without intermediaries.

Continue assembly following the instructions.

☞ Place the CELLROLL motor unit with its ex-factory fitted con-

nectors on the top deck of one of the towers and ensure that

it engages in position.

☞ Connect the control cable to the flange socket of the motor unit

and to OUTPUT 2 of the electronics unit.

NB: Never stack more than 4 decks at any one time.

NB: When transporting CELLROLL, always grip the lower

deck.

19

Page 20

☞ Connect the low voltage cable plug ① to "POWER IN" at the

rear of the instrument and tighten.

☞ Insert the low voltage cable in the side clips of the motor unit.

NB: Ensure that the cable does not come into contact

with the cogs.

☞ Add more cable clips on the back of one of the towers as it

appears appropriate and use them to guide mains cable.

☞ Mount stacker plate onto the second tower with intermediaries.

☞ Connect the power pack to the source of electricity.

NB: Always locate the control unit outside of the incubator.

4.7 Disassembly - CELLROLL

☞ Disconnect the power cable.

☞ Remove the low voltage cable from the clips.

☞ Disconnect the plug of the low voltage cable from control unit.

☞ Press the green knobs on the framework and disconnect the

decks.

☞ Disassemble motor unit and decks.

20

Page 21

4.8 Putting a CELLSPIN stirring unit into

operation

☞ Insert the low voltage cable into the right hand duct on the base

of the stirring unit housing.

☞ Connect the low voltage cable to "POWER IN" at the rear of

the control unit and tighten.

☞ Connect control cable to OUTPUT 1/2 of the control unit to the

flange socket of the stirring unit.

If running special applications in which the usual cell culture conditions (temperature, humidity etc.) are not necessary, the control

unit can be fitted directly to the guide slot on the motor unit. Ensure

that it engages.

NB: In setting up CELLROLL/CELLSPIN, please observe

the conditions for location and setting up as outlined in

section 1.

☞ Connect power supply to source of electricity.

NB: Always locate the control unit outside of the incubator.

If two stirring units are used, these should be connected via two

control cables to OUTPUTS 1/2 of the electronics unit.

21

Page 22

4.9 Connection to a printer or PC

☞ Connect the female, 4-pin socket ➊ of the Y-cable (186.041) to

the power input of the control unit.

☞ Connect the male, 4-pin plug ➋ of the Y-cable to the power

supply.

Printer with serial interface

☞ Connect the Sub-D9 plug ➌ to the serial interface of the printer.

Printer with parallel interface

☞ Connect the Sub-D9 plug ➌ to the printer using the delivered

female-female adapter (gender changer) ➍ and a serial-parallel converter.

PC with hyperterminal software

☞ Connect the Sub-D9 plug ➌ to the serial port of the PC using

the delivered female-female adapter (gender changer) ➍ and the

delivered Null Modem adapter ➎.

RS 232 parameters setting for the printer/hyperterminal software

Baud rate: 2400

Parity: none

Data bits: 8

Start bit: 1

Stop bit: 1

4.10 Equipment disposal

The CELLROLL and CELLSPIN motor units and

the control unit are labelled with the "crossed-out

wheeled bin" symbol to indicate that this equipment

must not be disposed of with unsorted municipal

waste. Instead, it is your responsibility to correctly dispose of your waste equipment by handing it

over to an authorised facility for separate collection and recycling. It is also your responsibility to

decontaminate the equipment in case of biological,

chemical, and/or radiological contamination so as to protect from

health hazards the persons involved in the disposal and recycling

of equipment.

For more information about where you can drop off your waste equipment for recycling, please contact your local dealer from whom you

originally purchased the product or your local council.

By doing so, you will help conserve natural resources and you will

ensure that your waste equipment is recycled in a manner that protects human health and the environment. Thank you!

22

Page 23

Please read and observe the safety precautions

listed on page 5.

1. If, during entry of a new program or alteration of

individual parameters a pause >120 sec arises, the

current speed will appear in the display.

2. Alterations in the functions are indicated by the display blinking. The new entry is confirmed by pressing

the ENTER key resulting in the display stopping to

blink.

5.1 Operating steps

Starting and stopping the system

Switching on the instrument:

☞ Press the "ON/OFF" key. All LEDs will blink and the display will

briefly show 8.8.8.8.8.8. The green light under "RECALL" will

light. The last selected output (OUTPUT 1 or OUTPUT 2) will

appear at the left-hand side of the display. The last activated

program number will appear, blinking, at the right-hand side of

the display.

Switching off the instrument:

☞ Press the "ON/OFF" key; the instrument is switched off after

about 5 sec. which is indicated by the appearance of a red point

in the display.

Selection of OUTPUT 1 or OUTPUT 2

These outputs can be selected in the function "SPEED".

If only one instrument has been connected, the control unit will automatically select the correct output.

If two instruments are connected:

☞ Press the "SELECT" key until the green light under "SPEED"

and "rpm" lights.

The selected OUTPUT will appear at the left-hand side of the display whilst the current set stirring speed will appear at the righthand side.

☞ By pressing key "< >" either OUTPUT 1 or OUTPUT 2 can be

se lected.

5. Detailed Operating Instructions

23

Page 24

24

5.2 CELLSPIN –

Instrument-specific functions

Stirring speed - "SPEED"

In the function "SPEED", the speed for

circulatory stirring = continuous stirring

or for pendular stirring = stirring with directional change

can be set according to the following table:

Circulatory „SPEED“ rpm Angle

stirring

5 – 40 rpm in steps of 2.5 0°

40.0 – 75 rpm in steps of 5.0 0°

Pendular „SPEED“ rpm Angle

stirring

5.0 - 40.0 rpm in steps of 2.5 180°– 1440°

N.B.: The function "angle" can only be activated if a speed

of 40 rpm or less has been selected. If an entry of > 40

rpm is made, the angle function can not be used and will

be overrun automatically.

Setting the pendular and stirring speeds:

☞ Press the "SELECT" key until the green light under "SPEED" and

"rpm" lights. The currently set speed will appear in the display.

☞ Set the required speed using keys "∨" or "∧". The display will blink.

☞ Press the "ENTER" key to confirm entry.

Allocation of connected instruments

If CELLSPIN/CELLROLL is located in an incubator, the display of

the externally located control unit will indicate which instrument is

connected to which OUTPUT.

Procedure:

☞ Select the required OUTPUT 1 or OUTPUT 2 (in the func tion

"SPEED") by briefly pressing the "< >" key.

By continuously pressing key "< >", the instrument allocation will

appear in the display:

– CS for CELLSPIN

– Cr for CELLROLL with "motor unit" 0.1 to 2.0 rpm

– CrF for CELLROLL with "motor unit fast": 2.0 to 6.0 rpm

Page 25

25

Setting the angle for pendular stirring

In the function " " the angle for pendular stirring can

be set.

Pendular Angle „SPEED“ rpm

stirring

180°–1440° 5.0 – 40.0 rpm in steps of 2.5

*

If values > 40 rpm are entered, the angle " "will automaticallybe overrun.

Pendular stirring:

☞ Press the "SELECT" key until the green light under " " lights.

☞ Set the required value using keys "∨" or "∧".

☞ Press the "ENTER" key to confirm the values.

Circulatory stirring:

☞ Press the "SELECT" key until the green light under " " lights.

☞ Enter "0" using the "∨" key.

☞ Press the "ENTER" key. The value entered will be confirmed.

Page 26

26

5.3 CELLROLL –

Instrument-specific functions

The roller system CELLROLL is available with two types

of motor unit:

"Motor unit" (0.1 to 2.0 rpm)

"Motor unit fast" (2.0 to 6.0 rpm)

The control unit automatically recognises the type of motor unit

connected and indicates the appropriate ranges in the display.

Setting the speed for continuous rolling and

rocking - "SPEED":

In the function SPEED, the speeds for

continuous rolling = rolling without directional change

and rocking = rolling with directional change

can be set according to the following table:

Continuous "SPEED" rpm Bottles turns per Angle

rolling minute

"Motor unit" 0.1 - 2.0 rpm 0.1 – 2.0 0°

"Motor unit fast" 2.0 - 6.0 rpm 2.0 – 6.0 0°

Rocking "SPEED" rpm Bottles turns per

rocking cycle Angle

"Motor unit" 0.1 – 2.0 rpm 0.5 – 4.0 180° – 1440°

"Motor unit fast" 2.0 – 6.0 rpm 0.5 – 4.0 180° – 1440°

Interval mode "–––––"

In the function "––", the time interval between repetition of the program can be set.

For both motor units of CELLROLL the function pause

can not be selected and will be automatically overrun.

The interval between program runs can be set for CELLSPIN within the range 00.00 h.min to 99.59 h.min.

☞ Press the "SELECT" key until the green light under "––" and

"h.min" lights. The current setting will be shown in the display.

The "< >" key can be used to switch from hours to minutes. Set

the required values using keys "∨" or "∧".

☞ Press the "ENTER" key to confirm the settings.

For entry of functions running time, cycles, print, see following

pages.

Page 27

27

Setting the speed for continuous rolling and rocking:

☞ Press the "SELECT" key until the green light under "SPEED"

and "rpm" lights. The currently set and speed will appear in the

display.

☞ Set the required speed using the "∨" or "∧" keys. The display

will blink.

☞ Press the "ENTER" key to confirm. Function will be carried out.

Setting the angle for rocking

In the function " " the pendular angle rocking can be

set.

Continuous rolling: set the rocking angle to 0°.

Rocking:

☞ Press the "SELECT" key until the green light under " " lights.

☞ Set the required value using key "∨" or "∧".

☞ Press the "ENTER" key to confirm. Function will be carried out.

Continuous rolling:

☞ Press the "SELECT" key until the green light under " "lights.

☞ Set "0" using the "∨" key.

☞ Press the "ENTER" key to confirm the value. Function will be

carried out.

For setting running time, cycles, see following pages.

Page 28

28

Running time mode " "

The running time is the duration of stirring or rolling and can be

set from:

- 00.05 h.min to 99.59 h.min or

- unlimited = Con

In the mode " ", the key "< >" can be used to change between

hours and minutes.

Entry of a specified running time

Example: Running time of 12 hours 15 minutes:

☞ Press the "SELECT" key until the green light under " " and

"h.min." lights.

☞ Press the "< >" key. This activates the minute setting. Both right-

hand numerals will blink.

☞ Set a value of 15 using keys "∨" or "∧".

☞ Press key "< >". This activates the hour setting. Both left-hand

numerals will blink.

☞ Set the value of 12 using keys "∨" or "∧".

☞ Press the "ENTER" key. The running time starts immediately.

Entry of unlimited running time

☞ Press the select key until the green light under " " and under

"h.min." lights. The current value will appear in the display.

☞ Press the "< >" key to activate hours/minutes entry.

☞ Press the "∨" key until "Con" appears in the display below 0.05.

☞ Press the "ENTER" key. "Con" will appear in the display.

5.4 CELLROLL/CELLSPIN - common functions

Page 29

29

Cycle mode "CYCLES"

In the "CYCLES" mode, the number of cycles can be set from 1

to 9999. One cycle is the combination of the set running time and

the set interval (see CELLSPIN).

N.B.: If continuous running time has been entered, "Con" will appear in the display automatically in the mode CYCLES.

Setting the number of cycles:

☞ Press the "SELECT" key until the green light under "CYCLES"

lights.

☞ Set the required number of cycles using keys "∨" or "∧".

Page 30

30

PRINT - print-out and overview of program

parameters

Options of the function PRINT:

- Viewing stored programs - P1

- Print-out of protocols- P2

- Print-out of stored programs - P3

Selecting options:

☞ Press the "SELECT" key until the green light under "PRINT"

lights. "P1" will appear in the display.

Keys "∨" and "∧" can be used to switch between options P1, P2

and P3.

Confirm the selected option by pressing the "ENTER" key.

P1 - Viewing stored programs:

In this option, the individual parameters of a stored program can

be viewed.

☞ Select option P1 using key "∨ " or "∧" and confirm by pressing

the "ENTER" key.

☞ Enter the required program number between Pr. 01 and Pr. 10

using key "∨" or "∧".

☞ Press the "ENTER" key to confirm. The LED under "PRINT"

and "SPEED" will light. The speed of the selected program will

appear in the display.

The "SELECT" key can be used to call up the program parameters which than can be read off the display.

☞ Press the "SELECT" key until the green light under "PRINT"

lights again.

At this point, either further programs can be viewed or the

"PRINT" mode left.

a) To view further programs:

☞ Press the "ENTER" key. Select the required program number

between Pr. 01 and Pr. 10. Use the "SELECT" key to view the

required parameters.

b) To leave the "PRINT" mode:

☞ Press the "SELECT" key to move to the next required functions.

Page 31

31

P2 - Print-out of protocol

The print interval specifies the intervals at which the parameters

of an activated program are printed out.

☞ Select option P2 using keys "∨" or "∧" and confirm by pressing

"ENTER". The display for time entry will appear.

☞ Press the "< >" key to activate the hours/minutes entry. Set the

required printing interval using key "∨" or "∧" and confirm by

pressing "ENTER". "P2" will reappear in the display.

Briefly press key "< >" to activate print-out of the protocol. "≡ P2"

will appear at the right hand side of the display and the protocols

will be printed out at the required intervals.

Repressing key "< >" deactivates the protocol mode and "P2" will

reappear in the display.

N.B.: Any changes in parameter during the running of a program

are automatically and immediately noted on the print-out.

P3 - Print-out of stored programs:

In this option, all stored programs can be printed out. For each of

the system components, i.e.

• CELLSPIN

• CELLROLL "Motor unit"

• CELLROLL "Motor unit fast"

• External device

there are 10 memories available for each; these are noted on the

print-out.

N.B.: If two identical system components (e.g. 2 CELLROLLS, 2

CELLSPINS) have been connected, each will be allocated 5 memories.

☞ Select option P3 using key "∨" or "∧" and confirm by pressing

"ENTER".

The appropriate data will then be transmitted immediately to the

printer or PC connected.

Page 32

32

Storing programs - "STORE" mode

For each of the connected system components, 10 memories

(Pr. 01 to 10) are available for program storing.

N.B.: If two identical system components (e.g. two Cellrolls, two Cellspins) have been connected, each will be allocated 5 memories.

In addition, one further memory is provided with the following function: In the case of power failure, all data of the current program

for both outputs which have not been stored under "STORE" are

stored in this memory. Once power has returned, the programs automatically continue.

☞ Once all of the parameters have been entered, press the

"SELECT" key until the green light under "STORE" lights.

☞ Select a memory between 01 and 10 using key "∨" or "∧".

Confirm the number by pressing "ENTER".

N.B.: Should another parameter have been stored under this particular number, it will be overwritten by the new parameter entries.

Calling-up programs - RECALL mode

☞

Press the "SELECT" key until the green light under "RECALL"

lights.

☞ Set the required program number (Pr. 01 to Pr. 10) using keys

"∨" or "∧".

☞ Press the "ENTER" key. An acoustic signal will be given three

times in succession and the program will start.

After 120 sec., the current speed will appear in the display and

the instrument will move into function "SPEED".

Page 33

33

Problem Probable cause Remedial measure

CELLROLL or CELLSPIN control • Power interruption • Check all connections between control

unit doesn't switch on by unit, power supply and wall socket.

pressing the "ON/OFF" key

• Faulty power supply • Replace the power supply with a new one.

An error message appears:

- Err 02 • Electronic unit disconnected • Check the connection between control unit

and device. Make sure that the screw tops

are fastened when using a control cable.

If this measure is unsuccessful, replace the

control cable with a new one.

Press "ENTER" to quit Err 02.

- Err 03 • Power failure • A power interruption has appeared during a

program run.

Press "ENTER" to quit Err 03.

Printer doesn't work • Printer disconnected • Check power connection and connection

between control unit and printer. You have to

use a special Y-cable (art.-no.: 186 041)

• Incorrect settings • Make sure that a printer with a serial

interface is connected. Settings:

Baudrate: 2400

Parity: none

Databits: 8

Startbit: 1

If you like to use a printer with a parallel

interface you have to connect

a serial/parallel converter additionally

• No printing interval time • See manual

entered/printer mode

deactivated

Selected program doesn't run • Incorrect settings • Check all program settings, make sure

that the value of the entered speed is > "0".

Display shows indefinable • Line transient (e.g. by flash RESET the control unit:

characters of lightning) - Connect the control unit to power.

or • Data loss in random - Switch the unit off by pressing the

input data will not be accepted access memory "ON/OFF" key.

• Software crash - Press "∨" once until "––" appears while

switching on

Press "<>" twice

Press "∧" three times till the display

shows " _ _ _ _ _ _"

The "Reset" is finished automatically, the

display will show "LL" for 2 seconds.

Disconnect the control unit from power

supply for a few seconds afterwards,

then connect it again.

WARNING!

All stored programs are deleted after a

RESET!

6. Troubleshooting

Page 34

7. Guarantee/Cleaning

Guarantee

All instruments are guaranteed for 1 year.

Cleaning

Cleaning of the instruments

Always switch off the instrument and disconnect it from

the mains when carrying out maintenance/cleaning

work.

34

8. Manufacturer and Service Contacts

Manufacturer:

INTEGRA Biosciences AG

CH-7205 Zizers

Switzerland

www.integra-biosciences.com

info@integra-biosciences.com

Customer service:

Please contact your local INTEGRA Biosciences representive.

To find out name and address of your local representive go to

www.integra-biosciences.com.

Further information is available from info@integra-biosciences.com.

© 2015 INTEGRA Biosciences AG

All rights to this documentation are reserved. In particular the rights of reproduction, processing,

translation and the form of presentation lie with INTEGRA Biosciences AG. Neither the complete

documentation nor parts thereof may be reproduced in any way, or stored and processed using

electronic media or distributed in any other way without the written consent of INTEGRA Biosciences AG.

This operating instruction manual has the article number 183 411, version number V12.

To clean the instruments, use a cloth moistened with customary

cleansing agents like soapy water, a 70 % ethanol solution or

isopropanol. Do not spray directly on the instrument but use a cloth

and wipe dry directly after cleaning. Never use acetone!.

Page 35

03/2015 183411_V12_OI_CELLROLL_CELLSPIN

Loading...

Loading...