Page 1

Installation and operation manual

CALEC® ST II

Table of contents

1 Safety 2

2 Structure of a measuring point 4

3 Scope of delivery, installation accessories 5

4 Installation 6

5 Controls and operation 32

6 Maintenance and repair 49

7 Disposal 49

8 Technical specifications 50

9 CE Declaration of Conformity 54

10 Appendix 55

VD 3-126e 01.2018

Page 2

1 Safety

1.1 Intended use

CALEC® ST II is a high precision instrument designed for the collection, analysis, presentation and transmission

of information. Improper or non-intended use of the device may compromise operational safety. We accept no

liability for any resulting damages.

1.2 Notes on safety instructions and symbols

The device has been designed to fulfil modern safety requirements. It has been tested and delivered in a condition

that ensures safe operation. However, improper or non-intended use of the device may result in it becoming

dangerous. Please always pay attention to the safety instructions in this manual which are accompanied by the

following symbols:

2

CALEC® ST II

WARNING!

WARNING indicates an action or measure which, if performed incorrectly, can cause

potentially life-threatening injuries and lead to a high safety risk. Always follow the

instructions and proceed with caution.

NOTE!

NOTE indicates an action or measure which, if performed incorrectly, may have an

indirect effect on the operation of the device, or trigger an unexpected response.

COMMENT!

COMMENT provides information and recommendations for efficient and trouble-free

operation.

CAUTION!

CAUTION indicates an action or measure which, if performed incorrectly, can cause

minor injuries and/or incorrect operation or destruction of the device. Always follow the

instructions.

REFERENCE!

REFERENCE refers to additional documents.

Page 3

3

CALEC® ST II

1.3 Installation, startup and operation

General hazards and warnings

This device is intended for permanent installation with a fixed electrical connection. The installation, connection

to the electricity supply, startup and maintenance must be carried out by trained, qualified personnel who are

authorised to perform this type of work. The respective specialist personnel must have read and understood this

installation and operation manual, and follow the instructions contained therein. The operator must ensure that

the measuring system is wired correctly in accordance with the wiring diagrams. Contact protection is deactivated

when the cover is removed (risk of electric shock). The housing may only be opened by qualified personnel.

Disconnect the power supply prior to electrical installation, and ensure that it cannot be reconnected

without your consent.

Pay attention to the following points during installation:

• Voltage, operating data

• Maximum transmission length

• Cable cross-section and length

• Ambient temperature and installation position

1.4 Technical progress

We reserve the right to modify the technical specifications without prior notice.

WARNING!

Danger of electrocution!

Touching or gripping live electrical parts can cause an electric shock, which may

result in burns, paralysis or death.

• The device should only be opened, installed or repaired when the power has

been switched off.

• Only specialist technicians are authorised to work on or with mains voltage.

They must comply with the applicable regulations.

• Only the intended terminals should be used to connect the device to the mains

supply.

REFERENCE!

Latest version of this manual!

The latest version of this manual is available at:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

Page 4

4

CALEC® ST II

2 Structure of a measuring point

A complete measuring point for thermal energy consists of the CALEC® ST II energy calculator, paired temperature

sensors and flow sensor.

The applicable regulations and recommendations for installation and operation must also be complied with,

e.g. Section 6 of EN 1434, and the recommendations of professional associations such as the „Merkblätter der

Fernwärmeversorgung“ [fact sheets for district heating] issued by the German Energy Efficiency Association for

District Heating, Cooling and CHP (AGFW). The installation of control immersion sleeves is mandatory in some

countries (e.g. in France after FDE 39-007).

NOTE!

Type of temperature sensor, pulse value, installation side!

Check whether the temperature sensor type (e.g. Pt100), pulse value and installation

side (cold, hot) of the flow sensor match the nameplate on the CALEC® ST II.

NOTE!

Calibrated device!

Depending on the version, the CALEC® ST II is a calibrated measuring device

(see calibration markings on the nameplate).

Calibration is rendered invalid if any changes are made to the calibration parameters.

The parameters can only be accessed once the verification seal has been destroyed.

Parameters related to the calibration of calibrated devices can only be adjusted by

the manufacturer or by a designated calibration centre. The commissioning of a calibrated

measuring point must be made by an authorized organisation according to the valid regulations.

After commissioning of the meter, the components (the calculator, the flow meter and two

temperature sensors) must be sealed.

Page 5

5

CALEC® ST II

3 Scope of delivery,

installation accessories

The supplied assembly and connection accessories

are located on the top of the housing:

The yellow piercing awl 1) can be used to pass the

cables through the membrane seals easily

The strain on the wire can be eased using the

white strain-relieving discs 2).

The two red plugs 3) are used to secure the two screws in the front cover.

Unauthorised opening of the device can be detected if these safety caps have been installed.

Removing the protective caps:

Pierce with a sharp tool and lever them out. This damages the cap, which needs to be replaced.

NOTE!

Calibrated device!

The unit can be damaged if not stored correctly!

This precision measuring device can be damaged by heat, moisture, dirt and vibration,

which can cause malfunctions.

The device must be stored in accordance with the specifications and only removed from

the packaging immediately prior to installation.

Page 6

6

CALEC® ST II

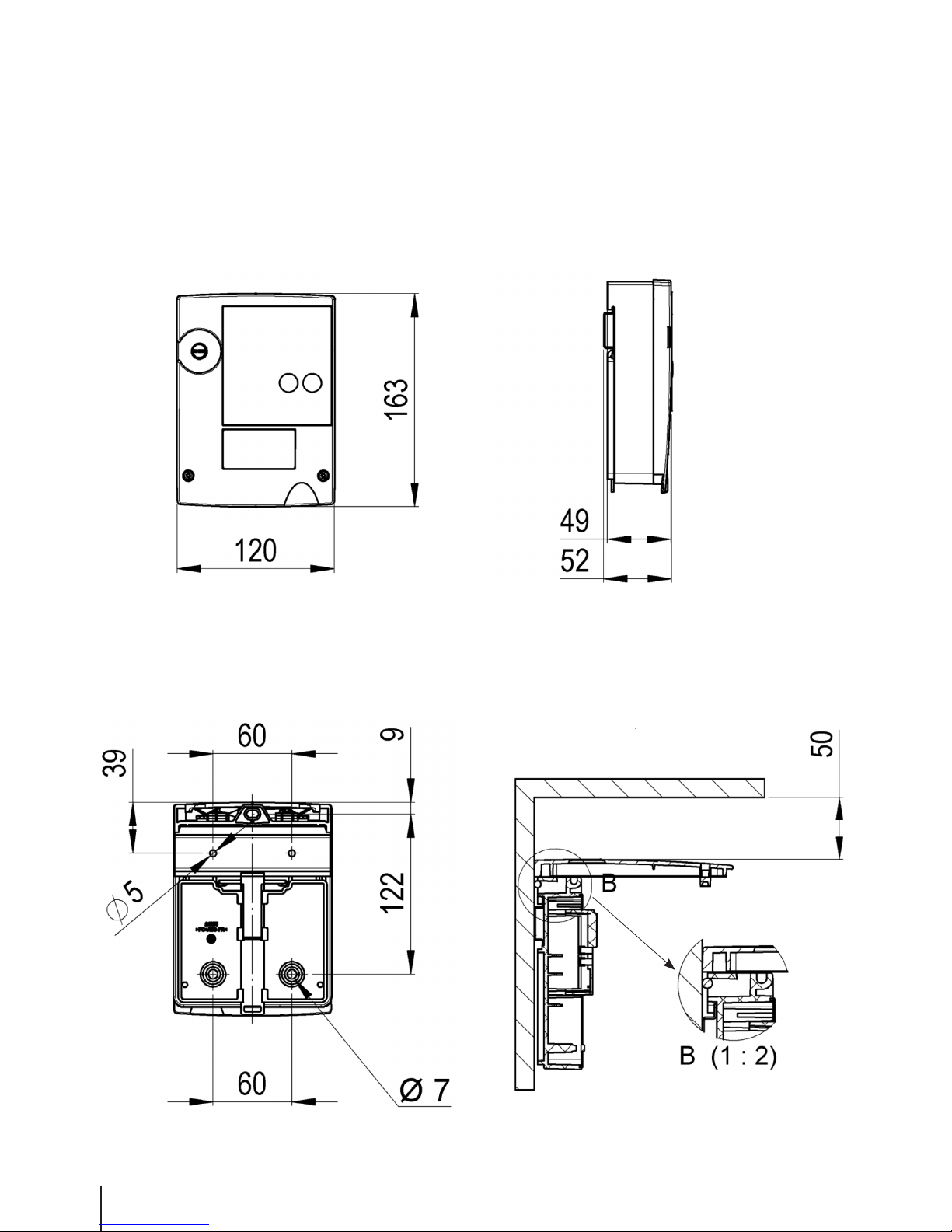

4 Installation

The CALEC® ST II can be mounted on a mounting rail or on a flat wall. Suitable mounting rails are available as

an accessory (article number 19838). Please refer to the last page of this document for a hole template for both

installation types.

Device dimensions

Hole dimensions for wall mounting Clear height

(for clipping on the housing cover)

Page 7

7

CALEC® ST II

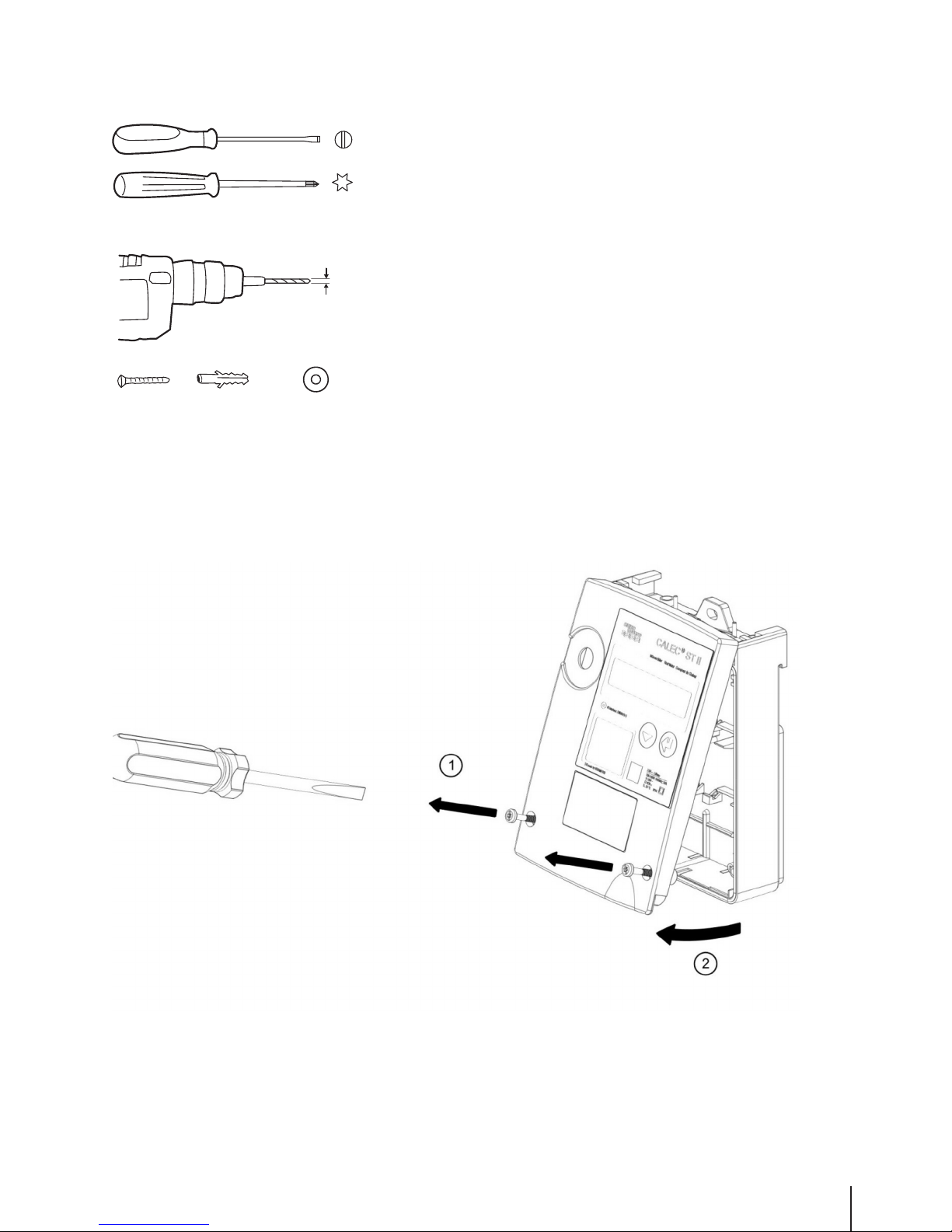

Tools, assembly materials

(Not included in the scope of delivery)

Opening the housing

3 x Ø

4

3 x Ø6

Torx T15

Ø6

3 x 4.3 x 12

3.5 x 0.6

Page 8

8

CALEC® ST II

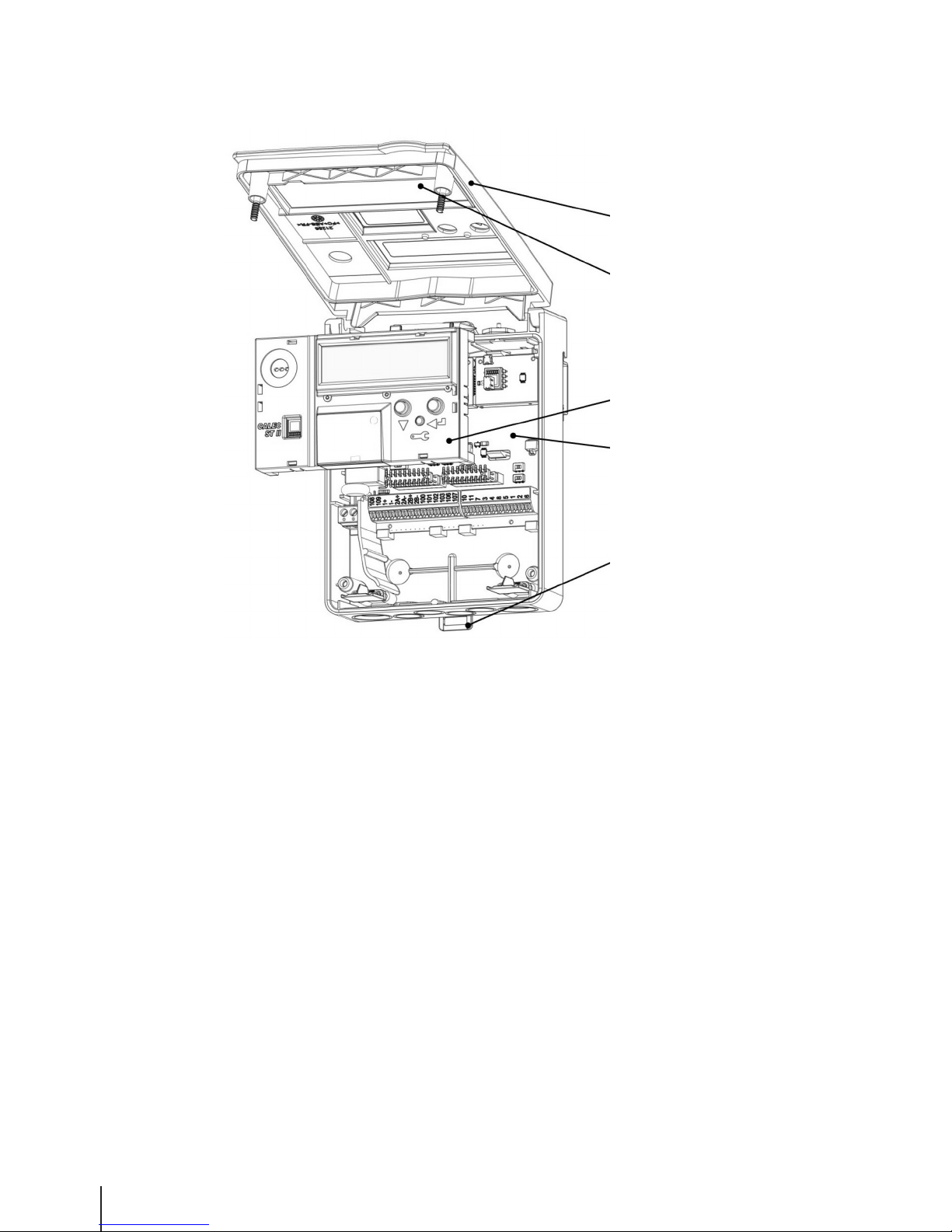

Unit design

À

The front cover can be locked into the lower section of the housing

Á

The connection diagram is located on the inside of the front cover

Â

The motherboard can be accessed by removing the plug-in totaliser

Ã

Motherboard with terminals and microswitches for configuring inputs and outputs

Ä

Clip-on holder for mounting rail

À

Á

Â

Ã

Ä

Page 9

9

CALEC® ST II

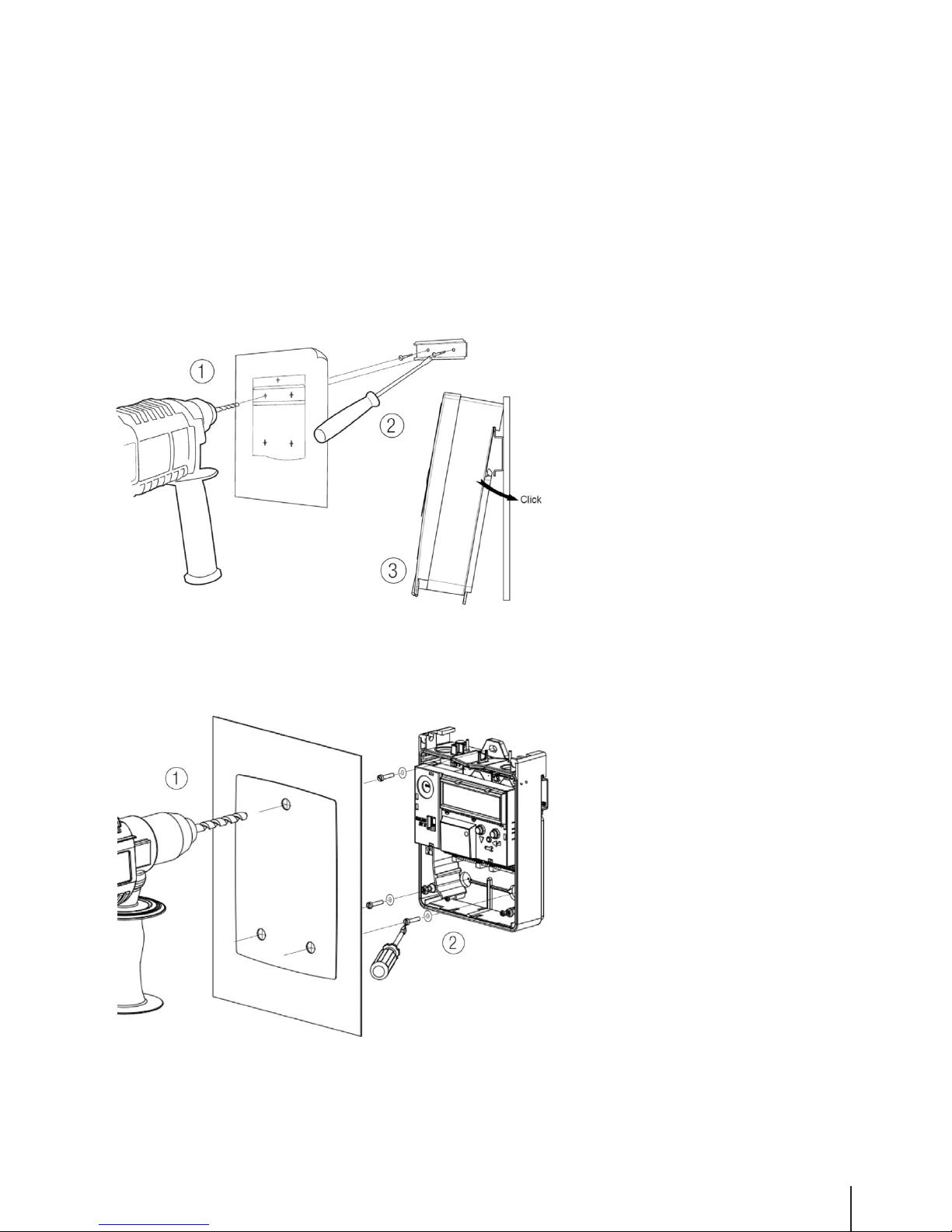

4.1 Installation

Installation instructions

Select the installation point:

• protected from moisture, heat, direct sunlight and damage

• easily accessible for reading, operation and installation

• at a sufficient distance from sources of electromagnetic interference

Mounting on rail DIN-EN 50222

À

Drill holes Ø6

Á

Screw in the mounting rail

Â

Clip the device onto the

mounting rail

Wall mounting

Only mount the device on

a flat surface!

À

Drill holes Ø6

Á

Screw in the device

Page 10

10

CALEC® ST II

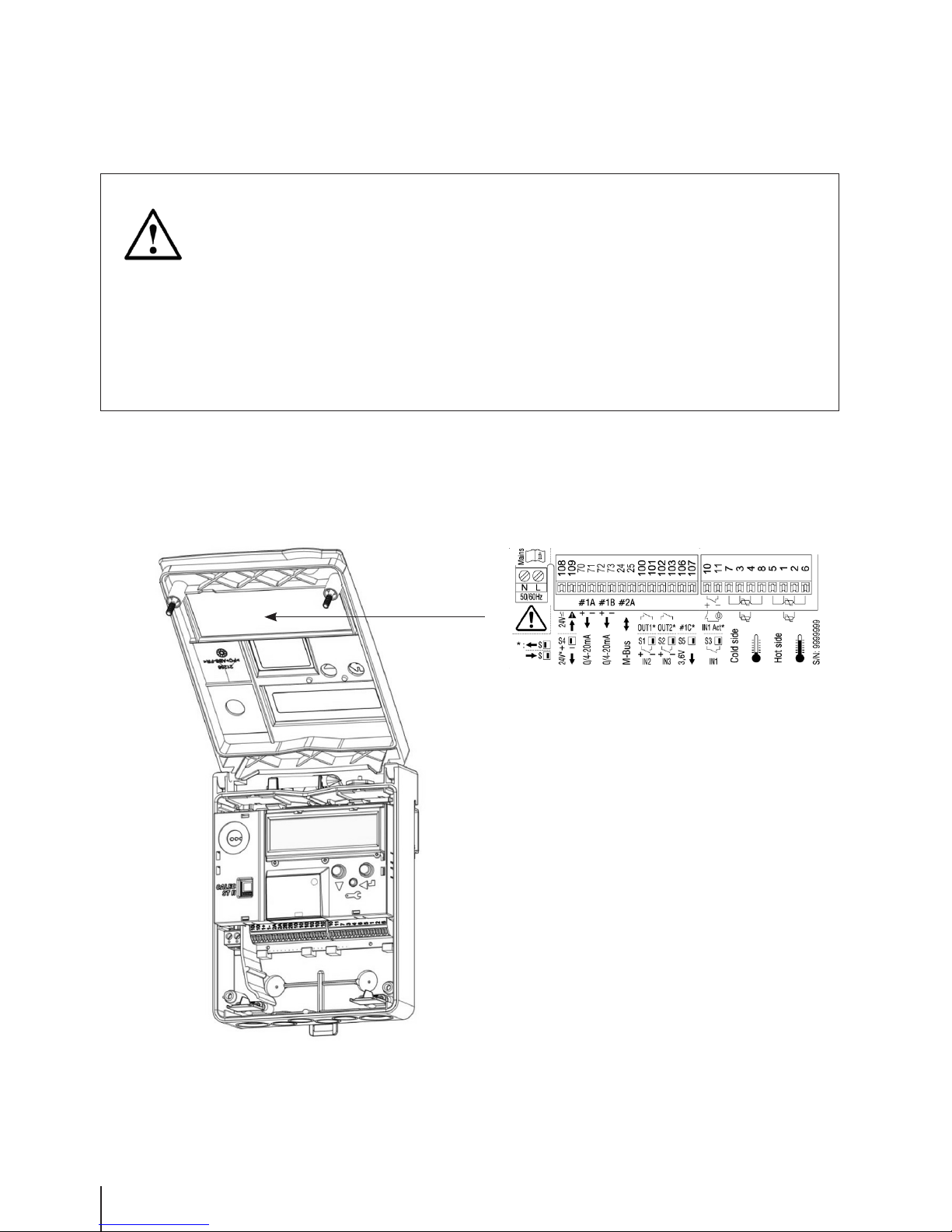

4.2 Electrical connection

Hazard warning

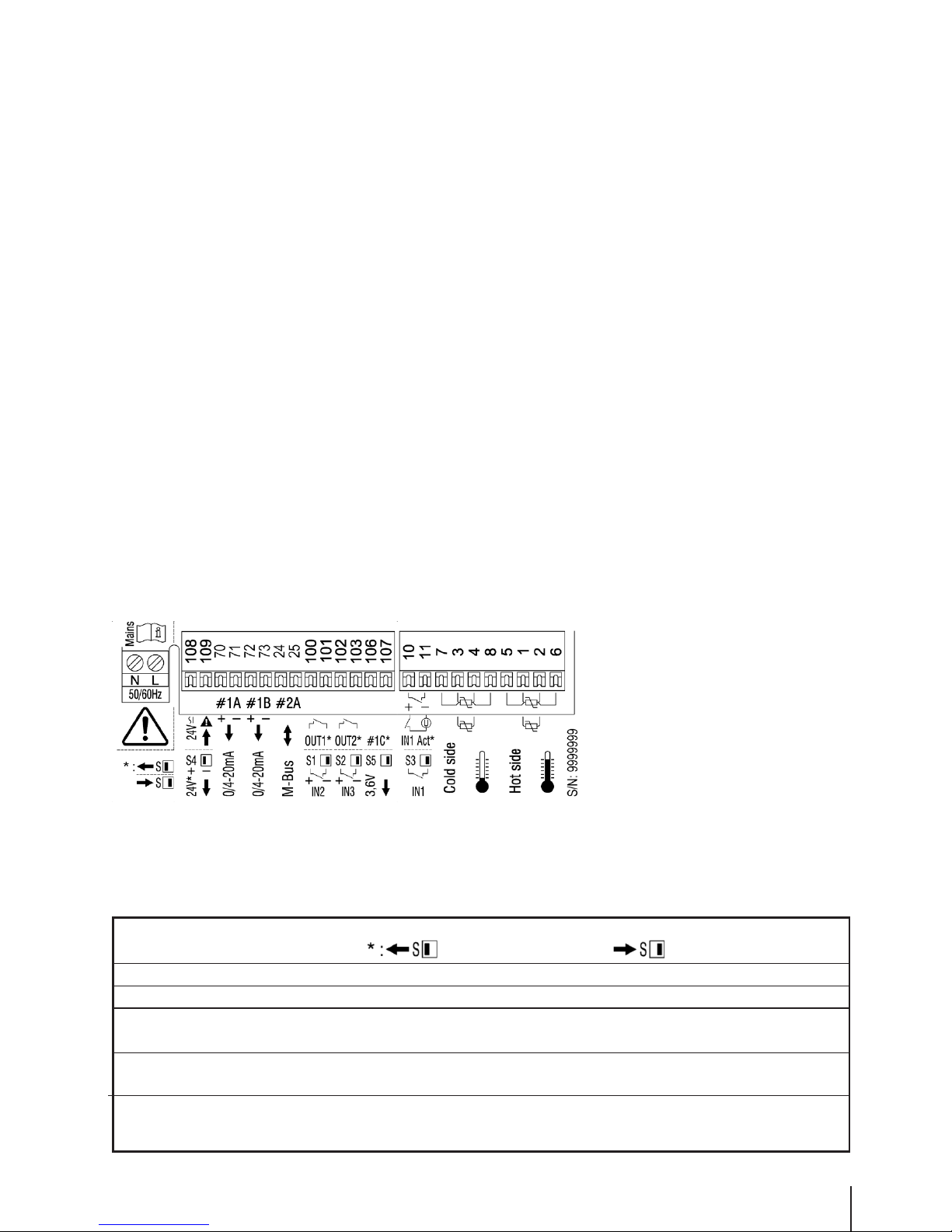

Connection diagram

The connection diagram is located on the inside of the front cover.

Sample connection diagram:

Analogue outputs in socket #1 and M-Bus

in socket #2.

WARNING!

Danger of electrocution!

Touching or gripping live electrical parts can cause an electric shock, which may

result in burns, paralysis or death.

• The device should only be opened, installed or repaired when the power has been

switched off.

• Only specialist technicians are authorised to work on or with mains voltage.

They must comply with the applicable regulations.

• Only the screw-type terminals in the separated area on the left in the terminal

compartment should be used to connect the device to the mains supply.

Page 11

11

CALEC® ST II

Terminal technology

The CALEC® ST II is equipped with direct plug-in terminal connectors based on the “push-in” principle. Stripped

rigid conductors or flexible conductors with crimped ferrules (AEH) can be plugged directly into the spring terminal

to create a reliable, vibration-resistant and gas-tight connection. The release button has to be pressed for finestranded conductors, or to release the conductors.

Connectable conductors:

Single-conductor connection:

• Single-wire mm2: 0.50…1.50

• Finely stranded mm2: 0.50…1.50

• Finely stranded with AEH mm2: 0.25…1.50

• AEH with plastic collar mm2: 0.25…0.75

Stripping length mm: 8.0 + 1.0

AWG: 24-16

Functionality of connections

Connection diagram

The functionality of different connections can be configured with microswitches S1 - S5. The original factory

status is documented on the connection diagram. If required, the alternative functionality shown in the connection

diagram can be made available by switching the corresponding microswitch.

Sample connection diagram:

Analogue outputs in socket #1

and M-Bus in socket #2.

Overview of configuration options using microswitches

Terminals Switch Left function position Right function position

100 - 101 S1 OUTPUT#1 INPUT#2

102 - 103 S2 OUTPUT#2 INPUT#3

10 - 11 S3 INPUT#1: Active transmitter signal INPUT#1: Passive transmitter signal

(5 - 48 VDC) (e.g. reed)

108 - 109 S4 Sensor supply voltage Note: Consider section low voltage

supply (page 13)

106 - 107 S5 OUTPUT #1C Sensor supply voltage

3.6 V DC

Page 12

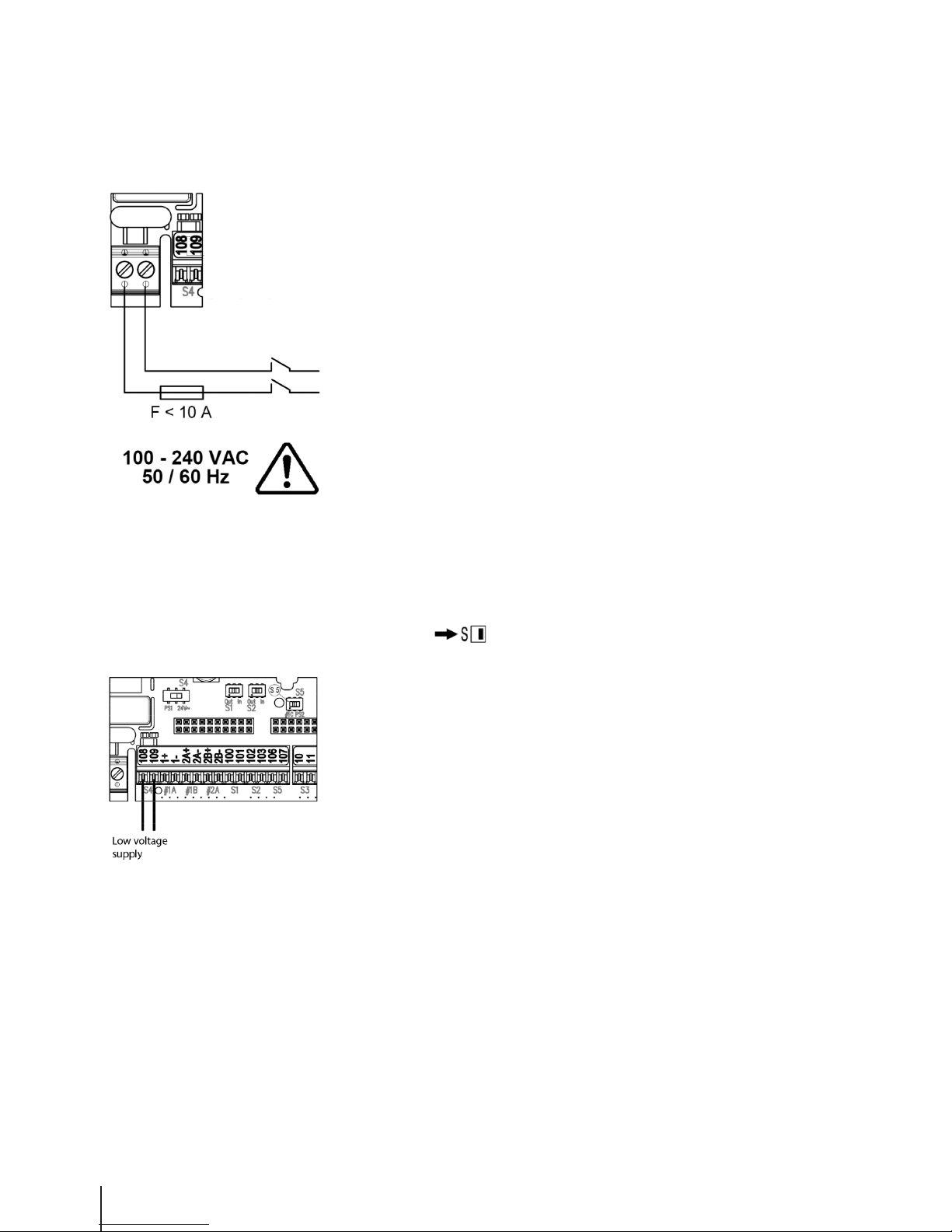

Supply voltage 100 - 240 V AC 50/60 Hz

l

Connections: L and N The supply voltage is connected via the two screw terminals in

accordance with on-site regulations.

The cable is passed through the diaphragm seal using

the enclosed piercing awl.

Voltage range: 100 - 240 V AC

Frequency range: 50/60 Hz

Power requirements: max. 15 VA

Connection cross-section: max. 2.5 mm

2

Cladding diameter: max. 8 mm

Heat resistance: min. 65°C

Connection to circuit with protection of max. 10A and

double-pole isolating element.

Low voltage supply 12 - 42 V DC or 12 - 36 V AC 50/60 Hz or 24 VDC ± 20%

l

Connections: 108 and 109 Switch S4 (24 V ~ )

The CALEC® ST II can be supplied with safe extra-low voltage via these

terminals.

Voltage range: 12 - 42V DC / 12 - 36V AC

Frequency range: 50/60 Hz

Power requirements: max. 1 VA

With adapter « insulated supply 24V-24V» (Art. no. 80828))

Voltage range: 24VDC ± 20%

Frequency range: 50/60 Hz

Performance range: max 1 W

12

CALEC® ST II

Page 13

13

CALEC® ST II

NOTE!

In low voltage applications of CALEC® ST II, in which a multiple grounding (PE) exists in field

installation, the adapter “insulated supply 24V-24V» (Art. no. 80828) must be positioned

upstream.

Examples for grounding:

• Grounded pulse input (e.g. pulser AMFLO® MAG Basic)

• Grounded sensor supply 3.6V and / or 24V

• Grounded pole of the low voltage supply

Procedure:

1. Disconnect CALEC® ST II from power supply

2. Set switch S4 from left to right

3. Connect adapter:

108+ from adapter to clamp 108 on CALEC® ST II

109- from adapter to clamp 109 on CALEC® ST II

IN+ and IN- from adapter to the external measuring point supply

Additionally the low voltage and sensor supply is possible with the adapter “insulated supply

24V-24V». Therefore the sensor shall be connected with OUT2+ and OUT2- (max. 150 mA).

If the switch is not correctly set, the device is later may not working properly or getting

destroyed.

The function low voltage supply shall only be used with the switch S4 in the position “right”!

Page 14

14

CALEC® ST II

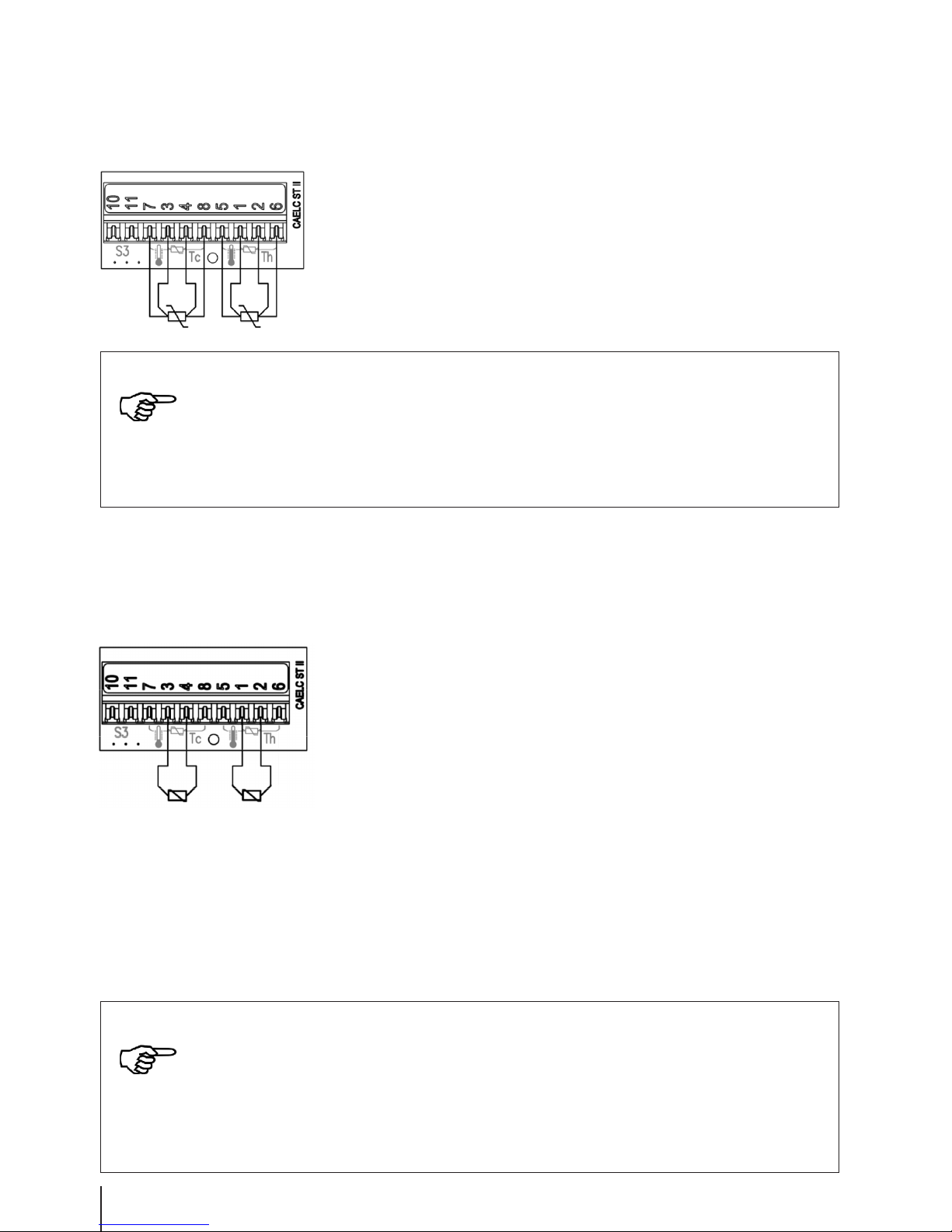

4-wire temperature sensor

l

Connections: 1 to 8

Check that the temperature sensor type (e.g. Pt500) corresponds to

the specifications of the CALEC® ST II.

Connection cross-sections: min. 0.22 mm

2

Cable length: max. 100 m

2-wire temperature sensor

l

Connections: 1, 2 and 3, 4

Check that the temperature sensor type (e.g. Pt500) corresponds to the

specifications of the CALEC® ST II.

Connection cross-sections:

Head sensor: min. 0.8 mm

2

Cable sensor: min. 0.22 mm

2

Cable length: shorter than 50 m (recommended)

Please note that the following maximum cable lengths are permitted for

2-wire technology, according to EN 1434-2:

Cable cross-section: Cable length:

Pt100 Pt500

min. 0.22 mm2 2.5 m 12.5 m

min. 0.50 mm2 5.0 m 25.0 m

min. 0.75 mm2 7.5 m 37.5 m

min. 1.5 mm2 15.0 m 75.0 m

NOTE!

Please check the connections carefully and ensure that the sensors are not reversed.

T

hot

terminals 1/5 and 2/6

T

cold

terminals 3/7 and 4/8

Temperature sensor cables must not be routed near power lines or electromagnetic inter-

ference sources (min. 50 cm distance).

NOTE!

The length of signal cable supplied by the manufacturer must not be changed.

Please check the connections carefully and ensure that the sensors are not reversed.

T

hot

terminals 1 and 2

T

cold

terminals 3 and 4

Temperature sensor cables must not be routed near power lines or electromagnetic inter-

ference sources (min. 50 cm distance).

Page 15

15

CALEC® ST II

Sensor supply voltage 24 V DC

l

Connections: 108 and 109 Switch S4 (PS1)

When switch S4 is in the left-hand position (PS1), terminals 108/109

have a 24 V DC power supply for supplying a flow transmitter, e.g.

AMFLO® MAG Smart.

Output voltage: 24 VDC, electrically isolated

from all other outputs

Load: max. 150 mA

Electrical isolation: max. 48 VDC

Sensor supply voltage 3.6 V DC

l

Connections: 106 and 107 Switch S5 (PS2)

When switch S5 is in the right-hand position (PS1), terminals 106/107

have a 3.6 V DC power supply for supplying a flow transmitter, e.g.

AMFLO® SONIC UFA113.

Output voltage: 3.6 VDC, not electrically isolated

Load: max. 2 mA

NOTE!

When the sensor power supply is not needed, it can also be used for the active supply

of the current outputs (optional). If multiple current outputs are supplied, please note

that these are no longer electrically isolated from each other.

NOTE!

Terminal 107 is connected to terminal 11 and establishes the reference potential

for the flow transmitter.

Page 16

16

CALEC® ST II

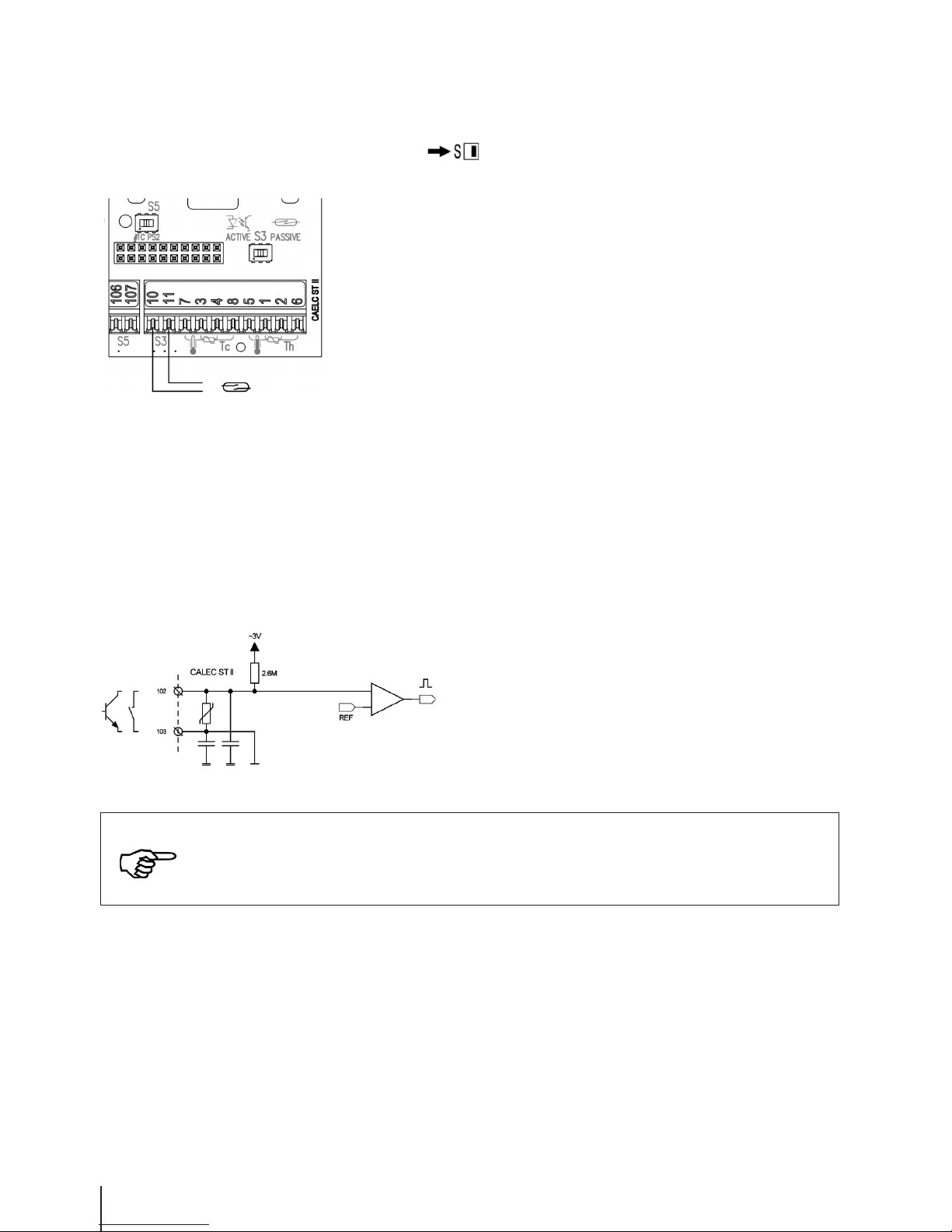

Flow transmitter with passive signal on pulse input #1

l

Connections: 10 and 11 Switch S3 (PASSIVE)

When switch S3 is set to the right-hand position (PASSIVE), a flow

transmitter with passive pulse signals, such as a reed relay or SSR

(solid state relay), can be connected to terminals 10 and 11.

The pulse signal from the flow transmitter must comply with the

following specifications:

Open-circuit voltage: 8 V

Short-circuit current: 8 mA

Switching level: <1.5 mA, >2.1 mA

Input capacity: 20 nF

Frequency range: 0…20 Hz 0…200 Hz

Min. OFF (toff): 20 ms 2 ms

Min. ON (ton): 3 ms 300 μs

The programming options for this input are described in the “InPutS”

of chapter „Operation“.

Diagram of input circuit

NOTE!

Flow transmitter cables must not be routed near power lines or electromagnetic interfe-

rence sources (min. 50 cm distance).

Page 17

17

CALEC® ST II

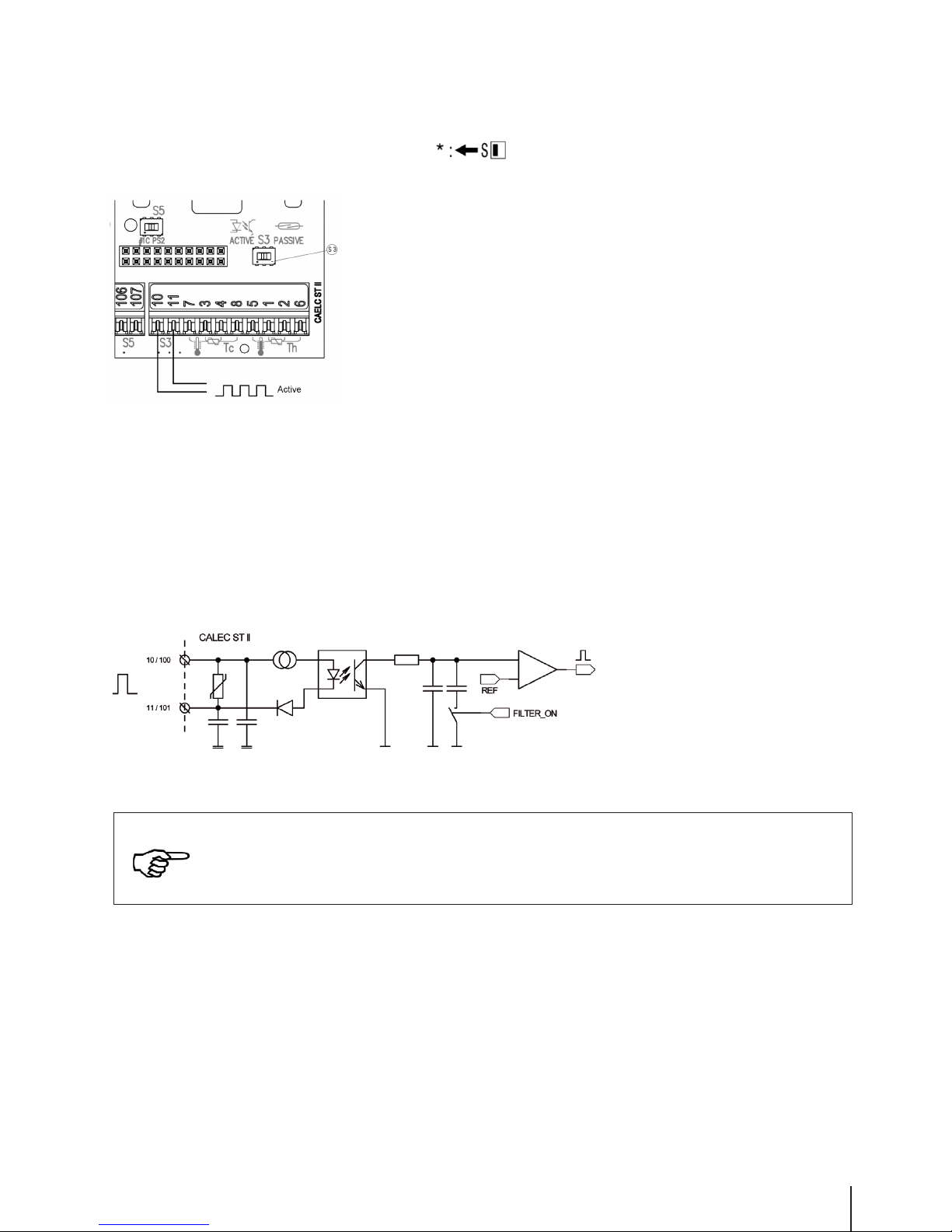

Flow transmitter with active signal on pulse input #1

l

Connections: 10 and 11 Switch S3 (ACT)

Switch S3 must be moved to the left-hand position (ACT) for flow

transmitters with an active signal.

The pulse signal from the flow transmitter must comply with the

following specifications:

Voltage range: 3...48 VDC

Current signal: > 2 mA

Reverse polarity protection: -48 V

Electrical isolation: 48 V

Frequency range: 0…20 Hz 0…200 Hz

Min. OFF (toff): 20 ms 2 ms

Min. ON (ton): 3 ms 300 μs

The programming options for this input are described in “InPutS”

of chapter „Operation“.

Diagram of input circuit

NOTE!

Flow transmitter cables must not be routed near power lines or electromagnetic interfe-

rence sources (min. 50 cm distance).

Page 18

18

CALEC® ST II

Connection examples for flow transmitters on pulse input #1

a) Connection example for TOPAS PMG/PMH flow transmitter

l

Connections: 10 and 11 Switch S3 (PASSIVE)

The TOPAS PMH transmits a

passive pulsed signal when

switch S3 is in the right-hand

position (PASSIVE).

b) Flow transmitter AMFLO® SONIC UFA113 with supply

l

Connections: 10, 11 and 106, 107 Switch S5 (PS2)

Switch S3 (PASSIVE)

The AMFLO® SONIC UFA113

is supplied with 3.3 V DC via

terminal 106 and 107 when

switch S5 is in the right-hand

position (PS).

The AMFLO® SONIC UFA113

transmits a passive pulsed signal

when switch S3 is in the

right-hand position (PASSIVE).

Connections 11 and 107 are

connected internally, which

means that the connection

can be made using only

3 wires.

+

–

Page 19

19

CALEC® ST II

c) AMFLO® MAG Smart / MAG Basic flow transmitter with grounding (standard)

l

Connections: 108, 109, 10 and 11 Switch S4 (PS1)

Switch S3 (PASSIVE)

Set switch S4 to the left-hand

position (PS) so that the

AMFLO® MAG Smart is supplied

with 24 V DC via terminals

108 and 109.

The AMFLO® MAG Smart

transmits a passive pulsed

signal when switch S3 is in

the right-hand position (PASSIVE).

d) AMFLO® MAG Smart / MAG Basic flow transmitter with two groundings

l

OUT2+, OUT2-, 10 and 11 Switch S4 (=24V)

Switch S3 (PASSIVE)

CALEC® ST II is supplied with 24

VDC via the adapter «insulated sup ply 24V-24V» (Art. no. 80828) IN+

and IN- over the clamps 108 and

109. Therefore the switch S4 needs

to be switched to the “right” (24V).

AMFLO® MAG Smart is supplied

with 24 VDC via OUT2+ and OUT2-

at the adapter «insulated supply

24V-24V».

AMFLO® MAG Smart is emitting

a passive pulse signal,

for which the switch S3 shall be

switched to the „right“ (PASSIVE).

NOTE!

See note low voltage supply (page 13)

Page 20

20

CALEC® ST II

Pulse input #2

l

Connections: 100 and 101 Switch S1 (in)

Terminals 100 and 101 can be used as the 2nd pulse input

when switch S1 is set to the right-hand position (In).

The data correspond to pulse input 1 for passive pulse

transmitters on terminal 10 and 11.

The programming options for this input are described in the

“InPutS” of chapter „Operation“.

Pulse input #3

l

Connections: 102 and 103 Switch S2 (in)

Terminals 102 and 103 can be used as the 3rd pulse input

when switch S2 is set to the right-hand position (In).

The pulse signal from the pulsed transmitter must comply

with the following specifications:

Frequency range: 0…20 Hz

ton: ≥ 50 µs

t

off

: ≥ 50 µs

Switching thresholds:

RON: ≤ 20 Ω

R

OFF

: ≥ 1 MΩ

The programming options for this input are described in the

“InPutS” of chapter „Operation“.

Diagram of input circuit

Page 21

21

CALEC® ST II

Digital output (pulse, status, alarm) #1

l

Connections: 100 and 101 Switch S1 (Out)

Terminals 100 and 101 are used as digital output 1 when

switch S1 is set to the left-hand position (Out).

Switching voltage: max. 48 V DC, 36 V AC

Switching current: max. 100 mA

RON: < 25 Ω

R

OFF

: > 1 MΩ

Electrical isolation: max. 48 V DC

Pulse frequency: max. 4 Hz

Pulse width: 100 ms

The programming options for this input are described in the

“OutPutS” of chapter „Operation“.

Diagram of input circuit

Digital output (pulse, status, alarm) #2

l

Connections: 102 and 103 Switch S2 (Out)

Terminals 102 and 103 are used as digital output 2 when

switch S2 is set to the left-hand position (Out).

Data as per digital output signal 1.

Page 22

Module slots

Connection diagram

CALEC® ST II is equipped with 2 separate slots for optional communication or function modules. Depending on

the equipment fitted to the device, these 2 slots provide various connection options on outputs #1A, #1B and

#2A. The connection diagram and the terminal numbers shows the optional communication or function modules

which are fitted to the device.

Sample connection diagram:

Analogue outputs in socket #1 and M-Bus in socket #2.

Function overview of outputs #1A, #1B and #2A

Optional communication and function modules

Communications modules can be connected to either slot #1 or #2.

It is preferable to use the function module with 2 analogue outputs in slot #1, because both channels are connected to terminals. In principle, the analogue output can also be used in slot #2. However, only one analogue output is

available on the terminals in this case. It is therefore preferable to use slot #2 for the first communication module.

22

CALEC® ST II

Function Terminals Available on output

M-Bus 24 - 25 #2A and / or #1A

Modbus RTU (RS 485) 90a - 91b #2A and / or #1A

BACnet MS/TP (RS 485) 90a - 91b #2A and / or #1A

N2Open (RS 485) 90a - 91b #2A and / or #1A

LON TP/FT-10 90a - 97b #2A and / or #1A

4 - 20 mA / 0 - 20 mA 70 - 71 #1A and / or #2A

4 - 20 mA / 0 - 20 mA 72 - 73 #1B

Page 23

23

CALEC® ST II

Analogue module in socket #1

For devices with 2 analogue outputs, the analogue module is fitted to socket #1.

l

Connections: 70, 71, 72 and 73

If an analogue module is connected to socket #1, there are 2 passive

analogue outputs via terminals 70/71 (#1A) and 72/73 (#1B).

The analogue outputs are electrically isolated.

Current range: 4...20 mA or 0...20 mA

Supply voltage: 6...24 V DC

Electrical isolation: max. 48 V DC

Resistance: ≤ 837 ohms at 24 V DC

The programming options for this output are described in “I-OUT”

of chapter „Operation“.

Analogue module in socket #2

l

Connections: 70 and 71 (#2A)

If an analogue module is connected to socket #2,

there is one analogue output via terminals 70 and 71 (#2A).

Data as per the analogue module in socket #1.

Resistance

Page 24

24

CALEC® ST II

M-Bus Modul

M-Bus-Modul in Socket #2

Slot #2 is used for the first communication module.

l

Connections: 24 and 25 (#2A)

M-bus is connected via terminals 24 and 25 (#2A).

The primary and secondary address, and the baud rate,

can be set under “M-BuS”.

The interface is electrically isolated.

Factory settings:

Primary address: 0

Secondary address: Serial number

Baud rate: 2,400 baud

M-Bus module in socket #1

l

Connections: 24 and 25 (#1A)

The wiring for the second M-Bus interface is via terminals

24 and 25 (#1).

The specifications are the same as for the first M-Bus.

The settings for the first and second M-Bus can be programmed

independently.

REFERENCE!

The M-Bus protocol is described in detail in a separate document,

which is available on the following website:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

Page 25

25

CALEC® ST II

LON-Modul

LON module in socket #2

Slot #2 is used for the first communication module.

l

Connections: 96a and 97b (#2A)

The twisted pair wiring is via terminals 96a and 97b (# 2A) and

is not poled.

The interface is electrically isolated.

The service PIN and the Wink LED are available for identification

on the LON network.

The service LED provides information about the system

status.

LON module in socket #1

l

Connections: 96 and 97 (#1A)

The twisted pair wiring for the second LON interface is via terminals

96a and 97b (#1A).

The specifications are the same as for the first LON interface.

REFERENCE!

The LON TP-FT 10 interface is described in detail in a separate

document, which is available on the following website:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

An XIF file is also available at www.lonmark.org

Wink LED

Service PIN

Service LED

Page 26

BACnet MS/TP Modul

BACnet MS/TP module in socket #2

Slot #2 is used for the first communication module.

l

Connections: 90a+ and 91B- (#2A)

The twisted pair wiring is via terminals 90a and 91b (#2A).

The BACnet MAC address, device instance number, mode and baud rate

can all be set under “BACnet”. If the CALEC® ST II is at the end of the

BACnet-segment, the internal termination resistor can be used.

The interface is electrically isolated.

Factory settings:

Aquametro manufacturer ID: 431

BACnet device profile: B-ASC

BACnet MAC address: Last 2 digits of the serial number

Device instance number: Last 5 digits of the serial number

Mode: Master

Baud rate: Automatic

BACnet MS/TP module in socket #1

l

Connections: 90a+ and 91b- (#1A)

The twisted pair wiring for the second BACnet inter-face is via terminals

90a+ and 91b- (#1A).

The specifications correspond to the first BACnet interface.

26

CALEC® ST II

REFERENCE!

The BACnet MS/TP protocol is described in detail in a separate

document, which is available on the following website:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

The PICS document can also be found there.

Page 27

27

CALEC® ST II

Modbus RTU Modul

Modbus RTU module in socket #2

Slot #2 is used for the first communication module.

l

Connections: 90a+ and 91b- (#2A)

The twisted pair wiring is via terminals 90a+ and 91b- (#2A).

The address, baud rate and parity can be set under “ModbuS”.

If the CALEC® ST II is at the end of the Modbus-segment, the internal

termination resistor can be used.

The interface is electrically isolated.

Factory settings:

Modbus address: 1

Baud rate: 19200 baud

Parity: Even

Modbus RTU module in socket #1

l Connections: 90a+ and 91b- (#1A)

The twisted pair wiring for the second Modbus interface is via

terminals 90a+ and 91b- (#1A).

The specifications are the same as for the first Modbus interface.

REFERENCE!

The Modbus RTU interface is described in detail in a separate

document, which is available on the following website:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

Page 28

28

CALEC® ST II

METASYS® N2Open Modul

METASYS® N2Open module in socket #2

For devices with a communication module, this is fitted to socket #2.

l

Connections: 90a+ and 91b- (#2A)

The twisted pair wiring is via terminals 90a and 91b (# 2A). The address

and the baud rate can be set under “n2-buS”.

If the CALEC® ST II is at the end of the N2Open-segment, the internal

termination resistor can be used.

The interface is electrically isolated.

Factory settings:

N2Open address: 1

Baud rate: 9600

METASYS® N2Open module in socket #1

l

Connections: 90a+ and 91b- (#1A)

The twisted pair wiring for the second N2Open interface is via

terminals 90a+ and 91b- (#1A).

The specifications are the same as for the first N2Open interface.

REFERENCE!

The METASYS® N2Open Interface is described in detail in a separate

document, which is available on the following website:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

Page 29

29

CALEC® ST II

Connecting the mains voltage

Hazard warning

WARNING!

Danger of electrocution!

Touching or gripping live electrical parts can cause an electric shock, which may result

in burns, paralysis or death.

• The device should only be opened, installed or repaired when the power has

been switched off.

• Only specialist technicians are authorised to work on or with mains voltage.

They must comply with the applicable regulations.

• Only the screw-type terminals in the separated area on the left in the terminal

compartment should be used to connect the device to the mains supply.

NOTE!

Calibrated device!

• The device must be protected by an external overcurrent protective device

(max. 10A) so that the unit shuts down safely in the event of an electrical fault.

The power supply must be designed to ensure that it has adequate protection

against intentional interruption and that it can be shut down for maintenance.

• A marked 2-pole isolating device is mandatory. Alternatively, a 2-pole isolating

overcurrent protective device can be used. However, it must not be possible to the

circuit for the totaliser to be disconnected independently of the heating or cooling

system.

• The connection cable must have a temperature resistance > 65°C.

Page 30

30

CALEC® ST II

(A) Power supply terminal

(B) External isolating device

(C) External protection

The power supply is connected to the screw terminals (A).

After tightening the terminals, check that the wires are clamped securely.

Tighten the strain relief, check that it is functioning correctly.

Page 31

31

CALEC® ST II

Closing the housing

Insert the cover into the hinge from above and turn to close.

Tighten the two fixing screws.

The screws can be secured. Once the security sealing caps stored

on the top of the housing have been fitted, any unauthorised opening

of the device can be detected. Engage the security sealing caps with

the smooth side on the outside.

Page 32

32

CALEC® ST II

5 Controls and operation

5.1 Content of this manual

This manual only contains details of the operating steps required to perform a function check.

5.2 Controls

Cover

Liquid crystal display

(LCD)

Enter key

Select key

Nameplate, if verified with

calibration

Optical M-Bus interface /

alarm signal display

(flashing red)

Service key

Nameplate of totaliser module

Housing screws covered by

safety caps

REFERENCE!

Related documents!

Related documents can be found on the following website:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

Page 33

33

CALEC® ST II

5.3 Display

5.4 Operating modes

The operating keys and display enable all relevant settings to be carried out without using peripheral units.

The settings are arranged in three security levels (lock levels).

Various data can therefore be altered depending on the operating mode.

User mode:

When the housing is closed, freely accessible data can be shown in the display using the keys.

Service mode:

This can be activated by pressing the service key when the cover is open. It also enables all necessary but

non-verifiable startup parameters to be set and displayed.

Programming mode:

This enables the complete range of settings, including calibrated values, to be made.

This can be activated only if the leaded seal has been destroyed. It is not described in these instructions.

Flow

indication

Alarm indication

Places after the

decimal point

Service

mode

Edit

mode

User

mode

Memory

Identification 8 character decimal field Units

Page 34

34

CALEC® ST II

5.5 Key functions

When the device is switched on, the display shows the energy reading in the Counter loop. Additional readings

can be displayed by pressing the Select button. The “Counter” menu is displayed once you have scrolled through

all readings. Press the Enter button to display the Counter loop again. The other available main menus can be

selected by pressing the Select button. Press the Enter button to display the relevant menu loop.

The main loop shows the key readings and allows you to navigate through the sub-loops. In addition, highresolution meter readings can be displayed by pressing the two buttons simultaneously.

Keys Function

Next field

Higher value

Accept the set value

Accept the selected value

Hold + for longer than 1s Return to the standard “Counter” display

Hold , press High-resolution display

Hold , press Previous field

Lower value

The Service button activates Edit mode

Page 35

35

CALEC® ST II

5.6 Display and menu structure

The following double pages shows the menu structure.

Legend:

Note!

Fields marked with * are only visible when the device has the corresponding option

(Mass, PDA, TGR, tariff & BDV, Flow, GLY).

Field visible

Field visible under certain

conditions

Field in service mode

editable

Field in programming mode

editable

Field in Init mode

editable

white

grey 15%

grey 35%

Page 36

36

CALEC® ST II

Menu description

Display Definition

Counter Counters

E Energy meter reading

V Volume meter reading

M Mass meter reading (optional)

E2 Energy meter 2 reading (optional BDE/TGR)

V2 Volume meter 2 reading (optional BDE)

E3 Energy meter 3 reading (optional TGR)

H1 Auxiliary counter 1 reading (optional Flow)

H2 Auxiliary counter 2 reading

H3 Auxiliary counter 3 reading

Imp Pulse value flowmeter

Sid Installation side flowmeter

Display Definition

INFO Error messages

SYSt-Err Error system

U-Err Error supply

th-Error Error temperature sensor hot side

tc-Error Error temperature sensor cold side

MEM-Err Memory error (HW)

OPT-Err Error on one of the option modules (HW)

th-ALArM Temperature on hot side outside the permitted range

tc-ALArM Temperature on cold side outside the permitted range

dt-ALArM Temperature difference outside the permitted range

Ext-AL External Alarm

XX888XXX Display test

Page 37

37

CALEC® ST II

Display Definition

Instant Current values

Th Temperature hot side

(For cooling = Return line)

Tc Temperature cold side

(For cooling = Supply line)

dT Temperature difference

P Power

Qv Flow

Qm Mass flow

KF Specific heat factor

DEN Density

Display Definition

TIME Time-parameters

DAT Date

TiM Time

DAY Day

SEA Summer or Winter time

Hr Operating hours

AL Hours of alarm

Err Hours of error

Pb Calibration year

Page 38

38

CALEC® ST II

Menu description

Display Definition

Stich Billing date values

Nr Billing date number 1 - 12

St Billing date 1 - 12

DAT Date

E Energy meter reading

V Volume meter reading

M Mass meter reading

E2 Energy meter reading 2,

in options BDE / BDV

V2 Volume meter reading 2,

in options BDE / BDV

E3 Energy meter reading 3,

in option TGR

H1 Auxiliary meters reading 1,

in option Flow

H2 Auxiliary meters reading 2

H3 Auxiliary meters reading 3

AL Alarm hours

ERR Error hours

Display Definition

LOGGEr Logger data

Nr Logger number

Per memory interval

DAT Date

E Energy meter reading

V Volume meter reading

M Mass meter reading

E2 Energy meter reading 2

in options BDE / BDV

V2 Volume meter reading 2

in options BDE / BDV

E3 Energy meter reading 3

in option TGR

H1 Auxiliary meters reading 1,

in option Flow

H2 Auxiliary meters reading 2

H3 Auxiliary meters reading 3

Page 39

39

CALEC® ST II

Display Definition

Inputs Parameters for input signals

Nr Input number

Fct Input Function

ImP Puls value of the flow meter

Sid Installation side of the flow meter

(th = hot side, tc = cold side)

F Maximum frequency

STA Actual status

MAX Upper limit for th / tc alarm

MiN Lower limit for th / tc alarm

Tr Threshold for return temperature

in option TGR

Overstepping: register E2

Undercutting: register E3

Page 40

40

CALEC® ST II

Menu description

Display Definition

Outputs Parameters for digital output signals

Nr Output number

Fct Output Function

SIG Type of the output

ImP Pulse value of the output

GW1 Limit 1

GW2 Limit 2

Hys Hysteresis

Cnt Pulse counter / Seconds of overstepped

limit value

Act Direction of action

STA Actual status

Display Definition

I-Out Parameters for analogue output signals

Nr Output number

Fct Output Function

SIG Type of the output

0/4 Value at 0 mA

20 Value at 20 mA

do Simulation mA value

Err Current output in case of error

STA Current value

Page 41

41

CALEC® ST II

Page 42

42

CALEC® ST II

Menu description

Display Definition

UnitS Units

Eu Energy unit

Ed Number of decimal places on the display for energy

V Number of decimal places on the display for volume

M Number of decimal places on the display for mass

P Power unit

Q Volume flow unit

T Temperature unit

EP Pulse value for energy pulse output

VP Pulse value for volume pulse output

Display Definition

M-BuS M-Bus parameters

Nr M-Bus number

(1 = Socket #1, 2 = Socket #2,

3 = optical interface)

Adr Primary M-Bus address

SEK Secondary M-Bus address

BAU Baud rate

Acc Access counter

APP M-Bus application reset

Page 43

43

CALEC® ST II

Display Definition

ModbuS Modbus-Parameter

Nr Modbus number (1 = Socket #1, 2 = Socket #2)

Adr Modbus address

BAU Baud rate

Par Parity

TRN Termination resistor ON / OFF

n2-buS N2Open parameters

Nr Number (1 = Socket #1, 2 = Socket #2)

Adr Address

TRN Termination resistor ON / OFF

Display Definition

BAcnEt BACnet-parameters

Nr Number (1 = Socket #1, 2 = Socket #2)

Adr Address

Mod Mode (Master /Slave)

DIN BAcnEt Device Instance Number

TRN Termination resistor ON / OFF

Page 44

44

CALEC® ST II

Menu description

Display Definition

CONFIG

TYP Type temperature sensors (PT 100 etc.)

MEd Heat carrier (medium) in option Glycol

Con Concentration of heat carrier in option Glycol

SMU Low flow cut off

Rem Remanence (time of display of

instantaneous Values)

Display Definition

CONFIG

dPQ Attenuation factor for power and flow

dPt Attenuation factor for temperature

Loc Lock levels

RES Reset of alarms and counters

(depending on lock level)

dt- Adjustment of minimal temperature difference alarm

dtc Sensor alignment

Page 45

45

CALEC® ST II

Display Definition

SYStEM

FNr Fabrication number

SYS Functionality of the calculator

DAT Date of manufacture

FW Firmware version

HW Hardware version

CS Checksum

Page 46

46

CALEC® ST II

NOTE!

Unit!

If the option once-only on-site adjustment of the calibration-related input variables

“IMP EBS” is used, ensure that the selected unit can display the amount of energy

accumulated during the calibration period without counter overflow.

Init-Mode: Once-only on-site adjustment

Menu description

Display Definition

INIT Depending on the model it is possible to program

in the „INIT-Mode“ ImP/Sid/Eu/Ed once-only

Go After conforming the settings they can‘t be

changed any longer

Page 47

47

CALEC® ST II

5.7 Commissioning

Startup

• Check the electrical connections.

• Turn on the power supply.

• Any error/alarms which appear must be fixed, (see Info loop and error messages).

• Press the select button until the display shows “ImP”, and check the pulse value of the flow transmitter.

• Press the select button until the display shows “Sid”, and check the installation side of the flow transmitter.

• Following startup, close the housing and secure the screws with the protective plugs.

(Sealing of calibrated measuring points)

• Give this operation manual to the user or leave it with the device.

Function control

• Check the main input unit, or set it up for an auxiliary meter (see Units loop).

• Check the pulse value of the main input, or set it up for an auxiliary meter (see Input loop).

• Check and/or set the date and time (see Time loop).

• If there is a flow, the wave symbol flashes in the top left of the display.

• Check whether plausible instantaneous values are displayed during unit operation (see Instant loop).

• The display reset time (to zero) and the filter characteristics for the instantaneous values of Q and/or

P can be set in the Config loop.

Page 48

48

CALEC® ST II

5.8 Error messages, alarms

If a fault occurs, the message “Alarm” will appear on the display above the number pad. The optical M-Bus interface also flashes red to indicate the alarm message.

The short message in the information loop gives details of the reason for the fault/alarm.

Message Error/alarm Possible cause Corrective measures

th-ERROR Temperature error • Sensor connected • Check wiring

on hot side, incorrectly • Check disconnected

no measurement • Interruption/short circuit sensor wires with ohm

possible in sensor cables meter

• If OK, check the input

input with a resistor:

Pt 100: 100 - 150Ω

Pt 500: 500 - 620Ω

tc-ERROR Temperature error As above As above

on cold side,

no measurement

possible

SYSt-Error EEPROM Component/device error Send the device to

memory error be checked

th-ALArM Temperature on the Temperature of the heat Check the current

hot side is outside cycle is too high or temperature in the InStAnt

the permitted too low submenu

measuring range

tc-ALArM Temperature on the As above As above

cold side is outside

the permitted

measuring range

dt-ALArM Temperature difference • Temperature difference Check the current

is outside the permitted in the heat cycle temperature difference

measuring range is too large or is negative in the InStAnt submenu

• Sensor problem

Page 49

49

CALEC® ST II

6 Maintenance and repair

6.1 Recalibration

In accordance with national legislation on weights and measures, periodic recalibration is required for devices in

commercial use which are subject to mandatory verification. The recalibration interval for energy meters is usually

5 years.

All calibration-related functions on the CALEC® ST II can be found on the plug-in totaliser module. This means

that recalibration can be carried out by simply replacing the totaliser module. The lower section of the housing

containing the field wiring does not have to be removed during calibration. The parameter settings specific to the

device are stored redundantly in the lower section of the housing and are loaded automatically when a replacement

totaliser module is plugged in. Reparametrisation of the device is not required. When processing the readings,

however, remember to ensure that the readings on the replacement totaliser module are reset to 0.

Plug-in totaliser module

7 Disposal

The device contains electronic components and must therefore be disposed of as

electronic waste.

Aquametro takes back its old devices and will dispose of them. Please also note

your local regulations in this respect.

Page 50

50

CALEC® ST II

8 Technical data

The following tables contain information on the technical data of the available functions. Please refer to the price

list for possible combinations.

Standards

CE directives

20

14/32/EU Measuring Instruments Directive (MID)

20

14/30/EU Electromagnetic compatibility (EMC)

20

14/35/EU Low voltage (LVD)

20

12/19/EU Waste Electrical and Electronic Equipment (WEEE) Directive

Standards EN 1434, EN 61000-6-1, EN 61000-6-2, EN 61010, DIN 43863-5

Housing and operating conditions

Dimensions W x H x D = 120 x 163 x 49 mm

Ambient temperature +5...+55 °C, EN 1434 class C

Storage temperature 0...60 °C

Humidity Max. 95% rel. humidity (non-condensing)

Operating altitude Up to 2,000 m above sea level

Protection rating IP 54

Terminals 1.5 mm2 spring terminals, Power connection 2.5 mm2 screw terminals

Basic data for calculator

Temperature measuring range 0...+200 °C (heat carrier: water)

-40...+180 °C (special heat carrier)

Temperature difference 0...190 K, Approval 3...190 K, on demand 2...190 K

Temperature sensor Pt100 or Pt500 in accordance with IEC 751 paired in accordance

with EN 1434, 2-wire or 4-wire connection. Max. sensor cable length

2-wire connection 10 m, 4-wire connection 15 m.

Temperature measurement 20-bit resolution, typical ±0.005 K (Ta = 5...55 °C)

resolution

Installation side Hot or cold side

Pulse value of the flow sensor 0.001...9999.999 litres

Pulse values and units for Volume: 0.001...9999.999 ml, l, m3 , GAL

auxiliary inputs and Energy: 0.001...9999.999 Wh, kWh, MWh, MJ, KBTU

contact outputs

Error limits Better than those required for calculators in accordance with EN 1434-1.

Suitable for combined class 2 heat meters in accordance with

EN 1434-1 when used with suitable volume metering units.

Optical interface IEC 870-5, M-Bus protocol

Page 51

51

CALEC® ST II

Mains version

Power supply 100 - 240 V AC, 50/60 Hz, max. 15 VA (in accordance with EN 1434)

12 - 42 VDC or 12 - 36 VAC, max. 1 VA (according to EN 1434)

At supply via adapter «insulated supply 24V-24V» (Art. no. 80828)

24 VDC ±20%, max. 7 Watt (at adapter)

Calculation cycle 1 s

Backup battery 3.6 V lithium battery

Additional functions

Adjustable low flow cut-off Function for stopping the energy calculation when the temperature

(SMU) difference is too low, ΔT SMU adjustable ΔT = 0 - 2.99 K

Limit-value monitoring One-sided or two-sided, hysteresis 0 - 10%,

action of the output signal is selectable

Display

Display units: volume m3, USGal

Display units: energy kWh, MWh, MJ, GJ, KBTU, MBTU

Data backup in the event of In EERPOM >10 years

a power failure

Data logger 500 values from all readings with a time stamp, stored in ring memory

Logger interval: 1 min, 1 hour, 1 day, 1 week, 1 month

Low-voltage power supply for flow transmitter

Terminals 108 / 109 (depending

on the version) Terminals 106/ 107

Supply voltage 24 V DC, max.150 mA, 3.6 VDC, max. 2 mA

el. isolation max. 48V V DC

Flow transmitter e.g. AMFLO® MAG Smart or e.g. AMFLO® SONIC UFA 113

active sensors

Page 52

52

CALEC® ST II

Pulse inputs and outputs

Main input #1 Connecting a pulse generator according to NAMUR, with potential-free contact

(10/11) (reed relay) or SSR (solid state relay), or for active sensors with the following

values.

Input passive Input active

Open-circuit voltage 8 V Voltage range 3...48 V DC

Short-circuit current 8 mA Current signal > 2 mA

Switching level <1.5 mA, >2.1 mA Reverse polarity protection -48 V

Min. OFF (t off) 20 Hz 20 ms Electrical isolation 48 V

Min. ON (t on) 20 Hz 3 ms Min. OFF (t off) 20 Hz 20 ms

Min. OFF (t off) 200 Hz 2 ms Min. ON (t on) 20 Hz 3 ms

Min. ON (t on) 200 Hz 300 µs Min. OFF (t off) 200 Hz 2 ms

Input capacity 20 nF Min. ON (t on) 200 Hz 300 µs

Switchable Input Output

input and output Open-circuit voltage 8 V Max. Contact rating 48 VDC, 100 mA

Output #1/ input #2 Switching level <1.5 mA, >2.1 mA Electrical isolation 48 V

(100/101) Min. OFF (t off) 20 Hz 20 ms Contact resistance (on) <30 ohms

Min. ON (t on) 20 Hz 3 ms Contact resistance (off) >10 MOhm

Min. OFF (t off) 200 Hz 2 ms Pulse frequency max. 4 Hz

Min. ON (t on) 200 Hz 300 μs Pulse width 100 ms

Input capacity 20 nF

Switchable Input Output

input and output Open-circuit voltage 8 V Contact rating 48 VDC, 100 mA

Output #2/ input #3 Short-circuit current 800 µA Electrical isolation 48 V

(102/103) Switching level <1.4, >3.2 kOhm Contact resistance (on) <30 ohms

Pulse length t off : 20 ms Contact resistance (off) >10 MOhm

Pulse length t on: 3 ms Pulse frequency max. 4 Hz

Max. frequency 20 Hz Pulse width 100ms

Input capacity 20 nF

Page 53

53

CALEC® ST II

Option M-Bus Factory settings

M-Bus Interface in accordance with EN 13757-2/-3

Addresses Primary address: 0

Secondary address: Serial number

Baud rate 2400 Baud

Option 2 analogue outputs

Output signal 4...20 mA or 0...20 mA

Supply voltage 6...24 V DC

Electrical isolation max. 48 V DC

Maximum resistance ≤ 837 ohms at 24 V DC, 0 ohms at 6 V

Maximum transformer error 0.15% of measured value + 0.15% of end value

Option Modbus RTU Factory settings

Physical layer and address RS 485, / address: 1

Baud rate 19200

Address range (slave) 1...247

Parity Even

Function code 03: Read holding register

Option N2Open Factory settings

Physical layer and address RS 485 / address: 1

Baud rate 9600

Option BACnet MS/TP Factory settings

Physical layer and AMT ID RS 485 / ID: 431

BACnet device profile and instance B - ASC / the last 5 digits of the serial number

BACnet MAC address The last 2 digits of the serial number

Baud rate and mode Automatic / master

Option LON Interface Factory settings

Type LON TP-FT 10 free topology (2-wire twisted pair),

certified in accordance with LONMARK® 3.4

Baud rate 78 kBaud

Maximum bus length 500 m / 2700 m with/without termination resistors,

64 nodes per segment

Page 54

54

CALEC® ST II

9 CE Declaration of Conformity

REFERENCE!

CE Declaration of Conformity!

The CE Declaration of Conformity is available at:

http://www.aquametro.ch/qr/prod/calec-st/11111.html

Page 55

55

CALEC® ST II

10 Appendix

10.1 Hole template

Page 56

Änderungen vorbehalten / Sous réserve de modifications Modification

rights reserved / Copyright © INTEGRA METERING AG

Loading...

Loading...