Innovate Motorsports LM-2 User Manual

LM-2

Digital Air/Fuel Ratio Meter

User Manual

Note: This manual assumes that firmware version 1.10 or later is installed on your LM-2

Warning!

The Oxygen Sensor used in this device gets very hot in operation.

Do not touch the hot sensor. Do not let a hot sensor touch a combustible

surface. Do not use the sensor with or near flammable liquids or gases. Failure

to heed these warnings may result in severe burns, explosions or fires.

When installed in the exhaust, the oxygen sensor MUST be connected and

operating with the LM-2 whenever the car is running. An un-powered oxygen

sensor will be quickly damaged when exposed to hot exhaust gases.

TABLE OF CONTENT

1 LM-2.......................................................................................................................................................3

1.1 Main Screen.....................................................................................................................................5

1.2 Status Bar ........................................................................................................................................5

1.3 Configuration Menu Screen .............................................................................................................7

1.4 Recording.........................................................................................................................................8

1.5 Playback...........................................................................................................................................8

2 Air/Fuel Ratio Setup.............................................................................................................................10

2.1 Sensor Calibration..........................................................................................................................10

2.2 Sensor Placement..........................................................................................................................11

2.3 Calibration Schedule......................................................................................................................13

3 Software (LogWorks 3 and LM Programmer)......................................................................................14

3.1 Installing software and Connecting the LM-2 to computer.............................................................14

3.2 Updating Firmware.........................................................................................................................15

3.3 Downloading Logs from Memory Card ..........................................................................................16

4 OBD-II..................................................................................................................................................18

4.1 Locate the OBD-II Connector in your vehicle.................................................................................18

4.2 Selecting Channels on the LM-2....................................................................................................19

4.3 Selecting Channels with the LM Programmer software.................................................................20

4.4 OBD-II Channel Speed ..................................................................................................................21

4.5 Set the Priority of OBD-II Inputs (Optional)....................................................................................23

4.6 Check Vehicle Trouble Codes on the LM-2...................................................................................27

4.7 Clear Vehicle Trouble Codes on the LM-2.....................................................................................27

4.8 Check and Clear Vehicle Trouble Codes with LM Programmer....................................................28

4.9 OBD II Basics.................................................................................................................................29

5 Analog Cable .......................................................................................................................................31

5.1 RPM Input......................................................................................................................................31

5.1.1 Enable/Disable RPM.............................................................................................................31

5.1.2 Configure RPM......................................................................................................................31

5.2 Analog Inputs.................................................................................................................................33

5.2.1 Enable/Disable Analog Inputs...............................................................................................33

5.2.2 Wiring Analog Inputs.............................................................................................................33

5.3 Analog Outputs ..............................................................................................................................34

5.3.1 Programming the analog outputs..........................................................................................34

5.3.2 Advanced output programming.............................................................................................35

5.3.3 Wiring Analog Outputs ..........................................................................................................36

6 Tips, Tricks, & Troubleshooting...........................................................................................................37

6.1 Air/Fuel and Lambda......................................................................................................................37

6.2 General measurement requirements.............................................................................................38

6.3 Vehicles with ‘smog-pumps’...........................................................................................................38

6.4 Single Cylinder Engines.................................................................................................................38

6.5 Diesel Engines...............................................................................................................................38

6.6 Sensor Timing Errors.....................................................................................................................39

6.7 Connecting the LM-2 to simulate a narrow band oxygen sensor ..................................................39

6.8 Attenuating a Tach Signal..............................................................................................................41

6.9 OBD II connection diagnostic trace................................................................................................41

Appendix A: Specifications..........................................................................................................................42

Appendix B: Limited Warranty ....................................................................................................................43

Appendix C: Connectors.............................................................................................................................44

Appendix D: Supported PIDs......................................................................................................................46

Appendix E: Error Codes and Troubleshooting Tips ..................................................................................48

Appendix F: Kit Contents ............................................................................................................................49

2

Document # 31-0008 LM2_Manual_1.3.doc

1 LM-2

The LM-2 is a single or dual channel wideband controller with a built-in OBD II scan tool,

RPM input, four analog inputs, MTS serial I/O, SD memory card recording and two

analog outputs per wideband channel. The following screens will help you get familiar

with the unit.

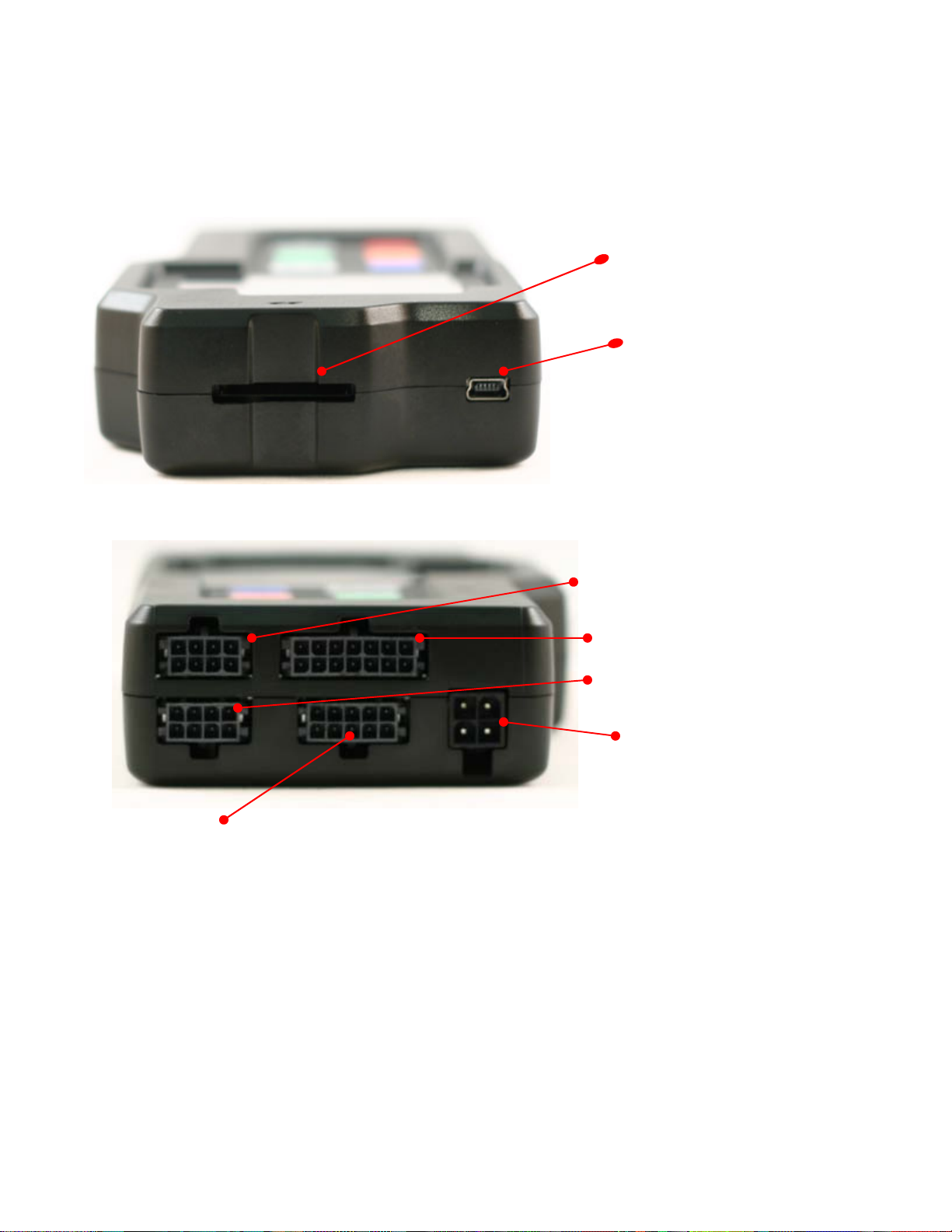

Front

Mode Button

Press once to

cycle through

channel display

screens. Press and

hold to enter menu.

Cancel Button

Press to cancel out

of menu or to stop

recording.

Record

Press once to

record or press again

to stop recording. Press

and hold to force a new log.

LCD Display

Up Arrow

Scroll through available

channels. Move through

menu

Enter

Accept an entry in the menu

screen.

Down Arrow

Scroll through available

channels. Move through

menu

Left

Inductive Clamp MTS Serial IN MTS Serial OUT

3

Document # 31-0008 LM2_Manual_1.3.doc

Top

Bottom

SD Memory Card Slot

USB Connector

Sensor Input # 2 (Enabled with

the Dual Channel version)

Analog Cable

Sensor Input # 1

Power

-

4

Document # 31-0008 LM2_Manual_1.3.doc

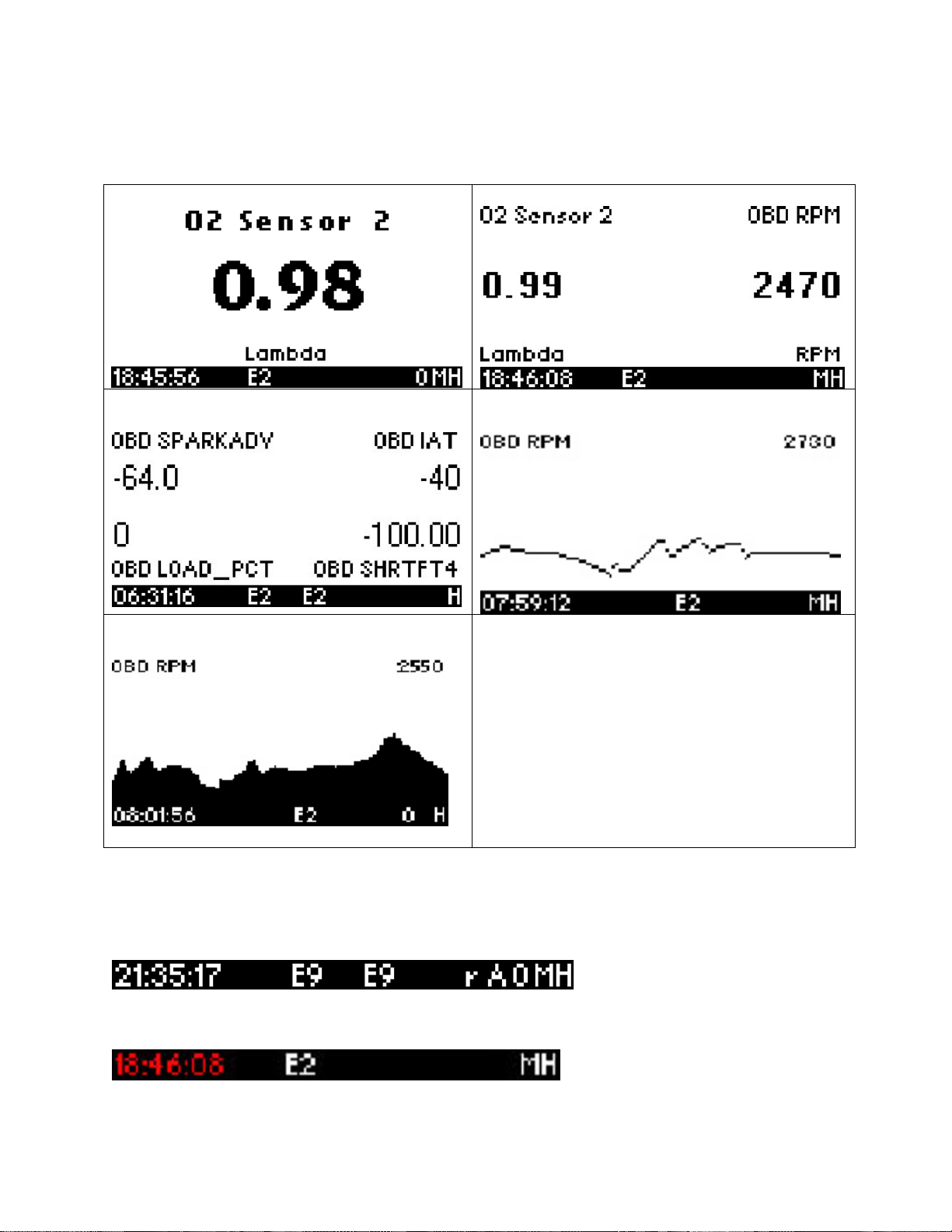

1.1 Main Screen

There are 5 different screen view options. These can be cycled by pressing the Mode

button.

One Channel Two Channels

Four Channels

One Channel Fill Graph

One Channel Line Graph

1.2 Status Bar

The bottom edge of the screen is the status bar and will look something like this:

The left most portion is the current time (which can be set via menu and is set

automatically by LM Programmer).

5

Document # 31-0008 LM2_Manual_1.3.doc

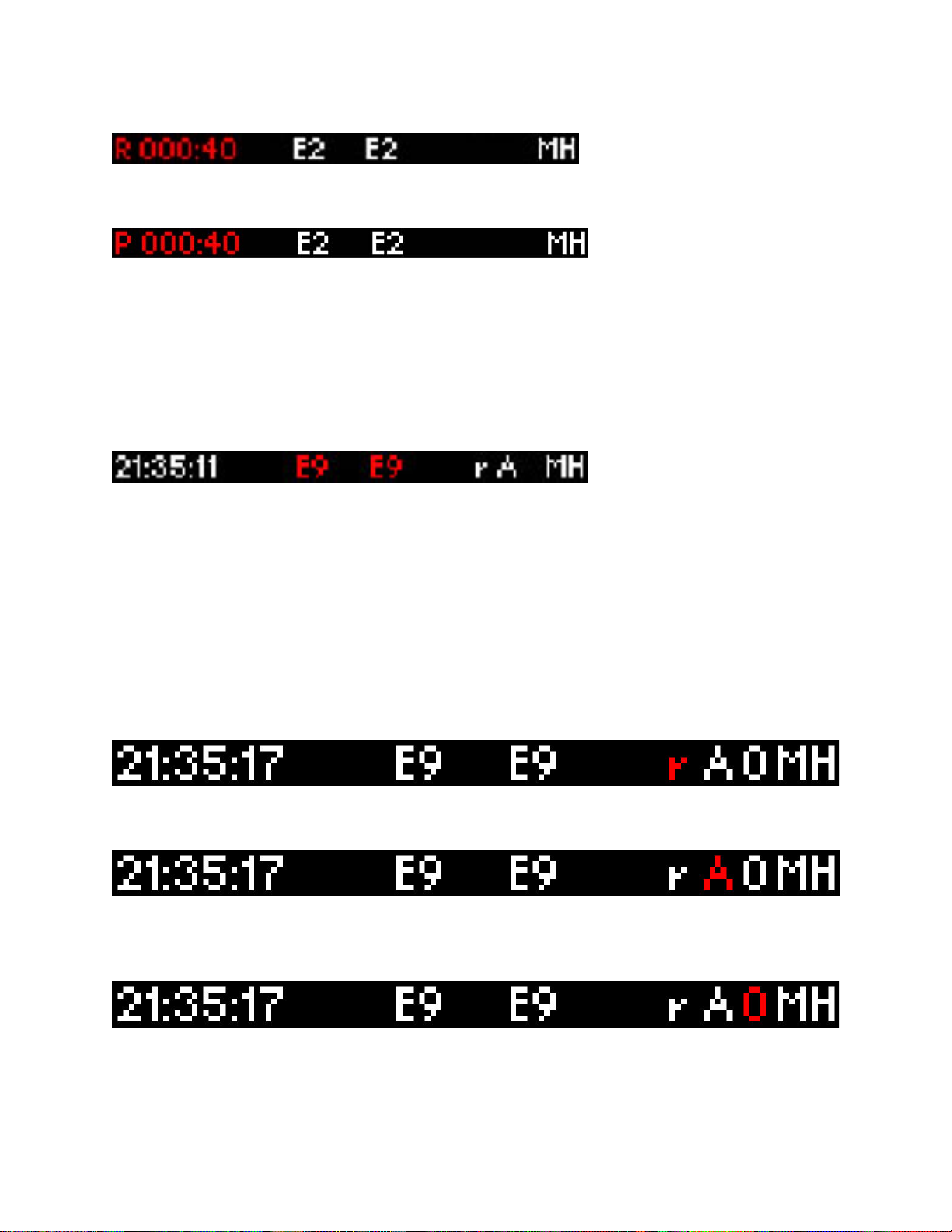

During Recording, an upper case ‘R’ and a counter will display on the lower left:

Counting minutes and seconds of recording.

Similarly, during playback a upper case ‘P’ and a counter will display:

Counting elapsed time during playback.

Note: If Recording does not start (see later section), also look here, the word “Card?”

will appear if no SD card is detected when Record is selected. The word “Full!” will

appear if you have either filled the SD card, or exhausted the available log names (see

section on recording).

Moving to the right, the next two indications are O2 sensor status, which can be one of

the following:

HW - Heater Warm-up

Cal - Calibrating

O2 - Reading O2 context (lambda over 8.something)

L - Reading Lambda (or AFR)

Ex - Error, Check Appendix E for error code meanings and trouble shooting tips

Note: If the LM-2 is a single channel model, the second indication will be blank, not an

error code.

The next indicator, “R”, will appear when a) RPM is selected for logging/use (see

menus) and b) an RPM signal is detected. Note, when RPM is enabled, but no RPM

signal is detected, this symbol will appear in lower case (“r”).

The “A” indicator means that the 4 Analog Inputs are selected for logging/Use (see

menus). It is all or nothing. The display will be blank if disabled.

The “O” indicates that an OBD-II connection is active. This indicator will blink at the

relative ‘sample rate’, which will vary on the number of channels selected and the

vehicle’s protocol. The display will be blank if the unit is not connected to an OBD-II port.

The blinking “M” indicates that MTS serial data is being generated. This will blink at the

relative MTS packet rate (for comparison with the O indicator). If the unit is not the

“head” unit, then this will only blink when packets are being received via the Serial In

6

Document # 31-0008 LM2_Manual_1.3.doc

connector.

Last, “H” indicates that the unit is the MTS head unit. If the unit is not head this indicator

will appear as a “-“

1.3 Configuration Menu Screen

To enter the Configuration Menu Screen press and hold the Mode button.

Navigating the Menu:

“Enter” Accepts

“Cancel” Returns one menu level

“Mode” Returns to Main Screen

Arrows adjust selection or value

“Record” has no effect

When “Mode” is first pressed, the following choices appear:

• Display AFR or Lambda. The factory default setting is AFR.

• Calibrate Sensors - Free Air Calibrate ALL O2 sensors connected will be

calibrated

• RPM – Enable/Disable RPM and Configure RPM.

• Analog Inputs- Enable/Disable Analog Inputs and Configure Inputs.

• OBD-II - Configure Number of Channels (0-16), Channel Use, Get/Clear DTC

codes Display in Metric/Imperial Units, and Start Trace File.

• Playback Log

• Reverse/Normal Display

• Set Date/Time - Set the current date/time

Important Note: Entering the Configuration Menus will stop recording and

suspend MTS packet output

7

Document # 31-0008 LM2_Manual_1.3.doc

1.4 Recording

To start a record session press the Record button. The LM-2’s display will then inverse

and the status bar will display an upper case ‘R’ and a counter on the lower left hand

corner of the screen. To stop the record session press the Record button a second time.

Note: Loss of power while the LM-2 is recording will lose all data from the current

session being recorded.

When recording is first activated, a file is created. The naming convention is:

mmddyyXX.d32

These are the month, day, and year that the file is created. The XX is to accommodate

multiple files on the same day (counting begins at “00”).

Once a file exists, sessions are appended to it for each additional recording. The

exceptions to this are:

1. The MTS channel count/type has changed

2. The user requests a new log file by pressing and holding “Record” (or holding the

record button on an external XD-16.)

The first instance will occur if devices are added or removed the MTS serial chain , or if

channels are enabled/disabled on the LM-2.

When a new file is created, it will be given the day’s date and a unique counter:

07010800.d32

07010801.d32

Etc

Note: When the LM-2 is recording the display will inverse. In the status bar, an upper

case ‘R’ and a counter will display on the lower left

1.5 Playback

1. Press and hold the Mode button to go into the Configuration Menu Screen.

2. Select Playback log and press the Enter button.

3. A list of available logs present on the memory card will be displayed. Make your

selection and press the Enter button.

Note: Depending on the size of the log the next screen some time to appear.

4. A list of available sessions will be displayed. Make your selection and press the

Enter button.

5. The selected session will now start playing. The status bar will display an upper

case ‘P’ and a counter on the lower left hand corner of the screen.

8

Document # 31-0008 LM2_Manual_1.3.doc

Note: While the session is being played back you can pres the Menu button to cycle

through the different display screens and you may also press the Arrow buttons to

change the displayed channels.

6. To stop the playback you may press the Cancel button at any time or allow the

playback to run it’s course.

9

Document # 31-0008 LM2_Manual_1.3.doc

2 Air/Fuel Ratio Setup

Innovate Motorsports’ ‘Direct Digital’ wideband measurement principal allows you to

calibrate the sensor to compensate for sensor wear. This procedure takes no more than

a couple seconds and it will insure the most accurate readings throughout the oxygen

sensor’s life.

2.1 Sensor Calibration

The calibration procedure requires that the oxygen sensor be in free air, not in the

exhaust.

1. Connect the oxygen sensor to the provided sensor cable and then to the

appropriate port on the LM-2. Note: The dual channel LM-2 model allows you to

connect both oxygen sensors to the unit at the same time to do the calibration

simultaneously.

2. Connect the LM-2 to the cigarette power plug with the provided cigarette power

adapter.

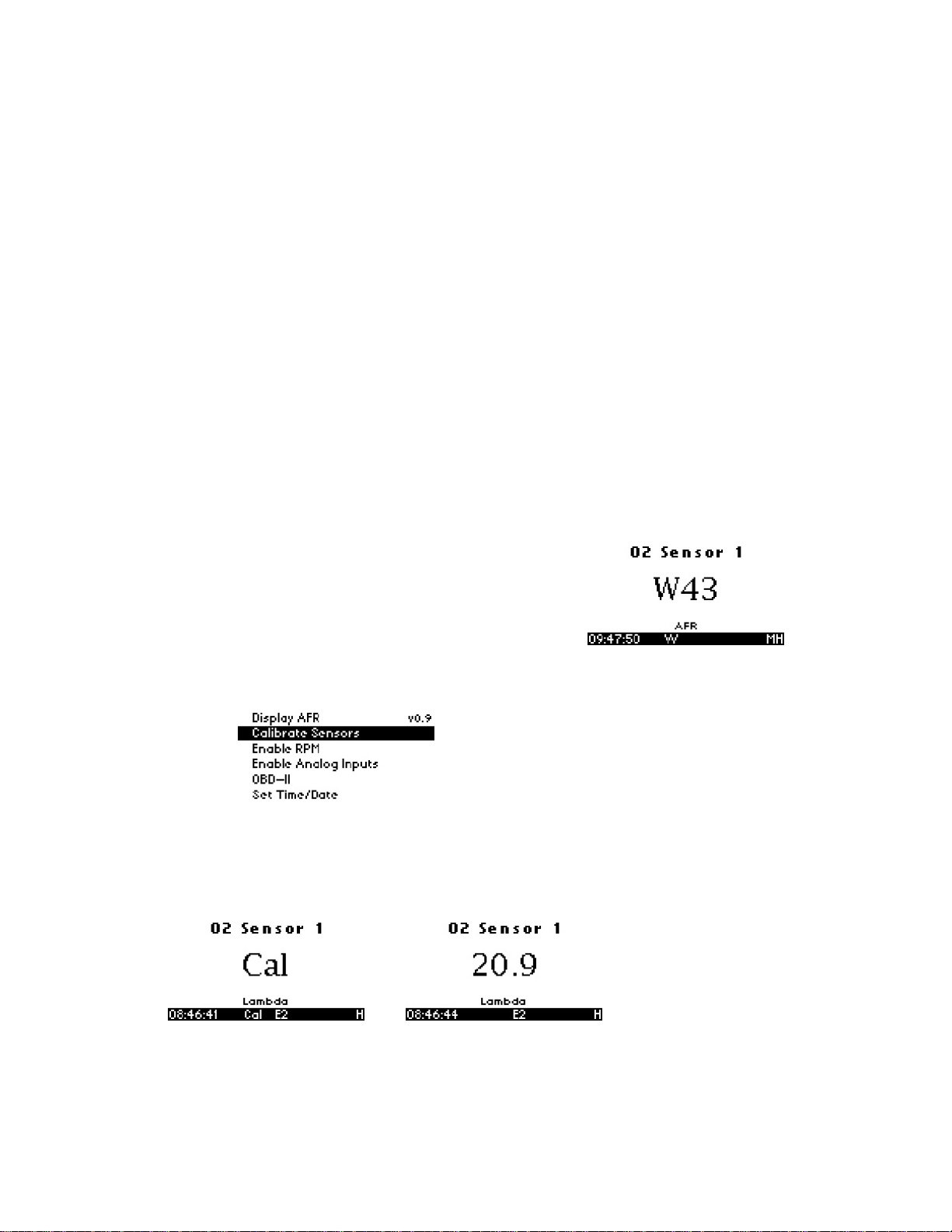

3. The sensor(s) will start warming up. The LM-2

will display WXX, where XX is the percentage of

temperature reached. Notice the status bar

displaying a ‘W’.

4. Next is the calibration procedure. Press and hold the Mode button until the

Configuration Menu appears. Select ‘Calibrate Sensors’ and press the Enter

button.

5. Confirm by selecting ‘Start Sensor Calibration’ and press the Enter button.

6. The display will momentarily display ‘Cal’ and then it will switch to reading a

percentage of oxygen. If the oxygen content now differs from 20.9% by more

than 0.4%, repeat the calibration.

7. The LM-2 is calibrated and ready for use.

10

Document # 31-0008 LM2_Manual_1.3.doc

The LM-2 must be powered by the cigarette adapter (12 volts) in order to

properly heat the Oxygen sensor and measure Air/Fuel. If the unit is only to be

used connected to the OBDII port it will properly function as a scan tool.

2.2 Sensor Placement

Using a bung is the preferred method for mounting the O2 sensor for both catalytic and

non-catalytic cars.

On CATALYTIC CONVERTER equipped vehicles:

Install the oxygen sensor’s bung upstream from the catalytic converter (a bung and

plug is included in the LM-2 kit). The bung must be installed in the exhaust pipe at

the side or on top, NOT on the bottom of the exhaust pipe. Any decent muffler or

exhaust shop can do this for you. The wide-band oxygen sensor is then installed into

the bung to take a reading. (Insert the plug into the bung when not in use). The ideal

position is between 10:00 and 2:00 position.

On NON-CATALYTIC converter vehicles:

You have the option with non-catalytic cars to also use an exhaust clamp as

described below. Use of a bung is the preferred method for mounting the 02 sensor

for both catalytic and non-catalytic cars.

On TURBO CHARGED vehicles:

Install the bung downstream from the turbo but before the catalytic converter. The

high exhaust pressure before the turbo interferes with the lambda measurement and

the high exhaust temperatures encountered there can damage the sensor.

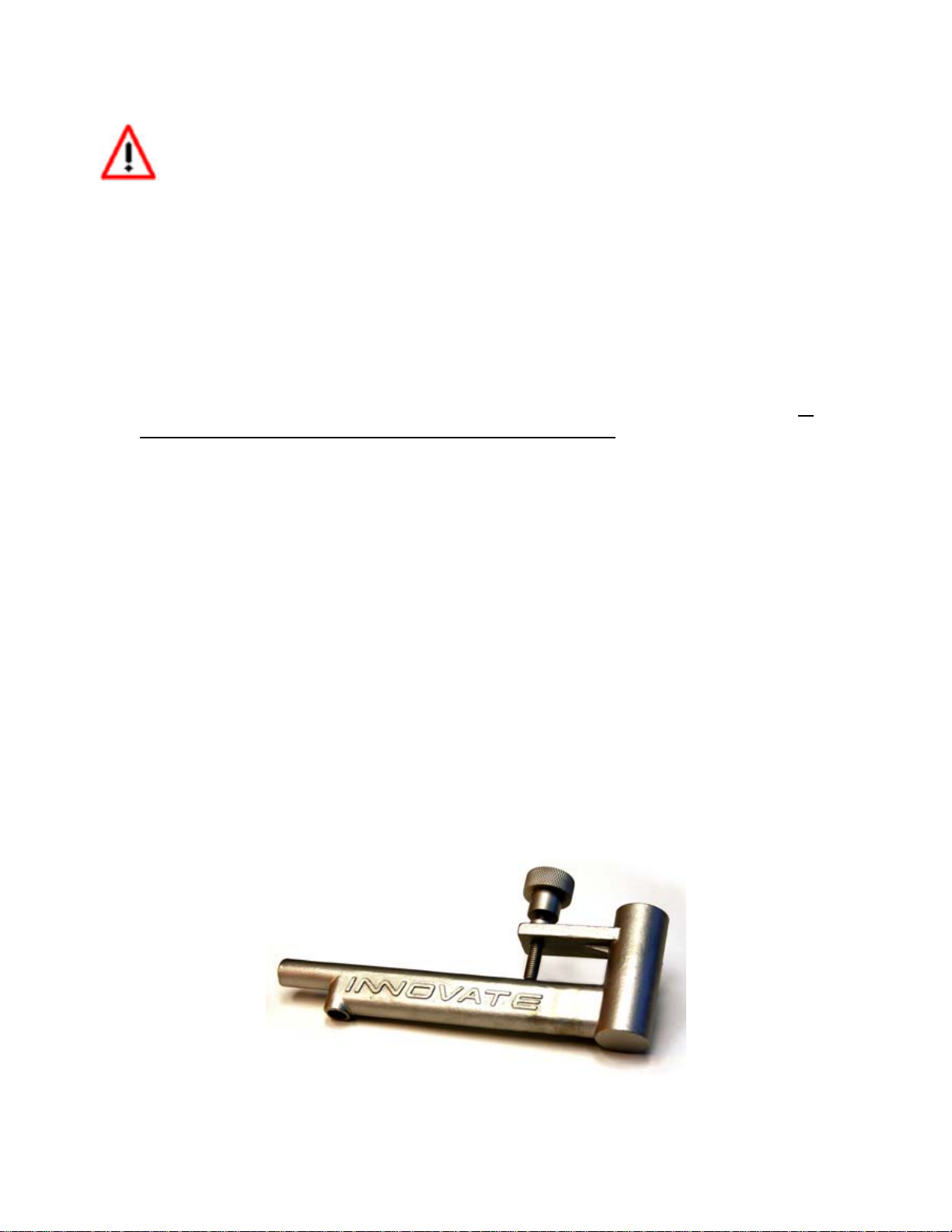

Alternatively you can also use the optional exhaust clamp (part number 3728) to sample

exhaust gases at the end of the tail pipe.

11

Document # 31-0008 LM2_Manual_1.3.doc

Do NOT install the Bung below the 3 o'clock or 9 o'clock position. Condensation

can form in the exhaust pipe and permanently damage the sensor. 6 o’clock is the

absolute worst position to mount the sensor.

Wide band oxygen sensors, like the one shipped with the LM-2, are designed to

work with unleaded gasoline. Use with leaded gasoline will significantly reduce the

lifespan of the sensor. The reduction is directly proportional to the metal content of the

fuel and the tune of the engine. In most cases, a wide band sensor will provide

accurate measurements somewhere between 50 hours and 500 hours with leaded fuel.

WHEN INSTALLED IN THE EXHAUST, THE OXYGEN SENSOR MUST BE

CONNECTED AND OPERATING WITH THE LM-2 WHENEVER THE CAR IS

RUNNING. AN UN-POWERED OXYGEN SENSOR WILL BE DAMAGED WHEN

EXPOSED TO EXHAUST GAS IF NOT PROPERLY POWERED.

The maximum temperature of the sensor at the bung (the sensor hexagon)

should not exceed 500 oC or 900 oF. If these temperatures are exceeded in your

application you should either install a double length bung (one inch) or the Innovate

Motorsports Heat-Sink Bung extender (HBX-1).

The double length bung is also recommended for situations where airflow is restricted.

It is NOT a good idea to do a sensor warm-up prior to starting the vehicle.

Depending on the climate and the sensor position in the exhaust, condensation can

form in the exhaust pipes. This condensation could then be blown by the exhaust

stream against the hot sensor when the car is started. The resulting heat shock can

permanently damage the sensor.

12

Document # 31-0008 LM2_Manual_1.3.doc

2.3 Calibration Schedule

Normally aspirated (daily driver)

- Calibrate before installation of new sensor

- Calibrate new sensor again after 3 month of use

- Thereafter calibrate once a year or every 20,000 miles, whichever comes first

Turbo Application, daily driver (tuned rich)

- Calibrate before installation of new sensor

- Calibrate new sensor again after 3 month of use

- Thereafter calibrate twice a year or every 10,000 miles, whichever comes first

Race Application

- Calibrate before first installation of new sensor

- Calibrate once per race weekend

- For added sensor life we also recommend our optional double length bung (part

number 3764

Dyno use:

- Calibrate a new sensor

- Calibrate every 2-3 days, depending on usage

13

Document # 31-0008 LM2_Manual_1.3.doc

3 Software (LogWorks 3 and LM Programmer)

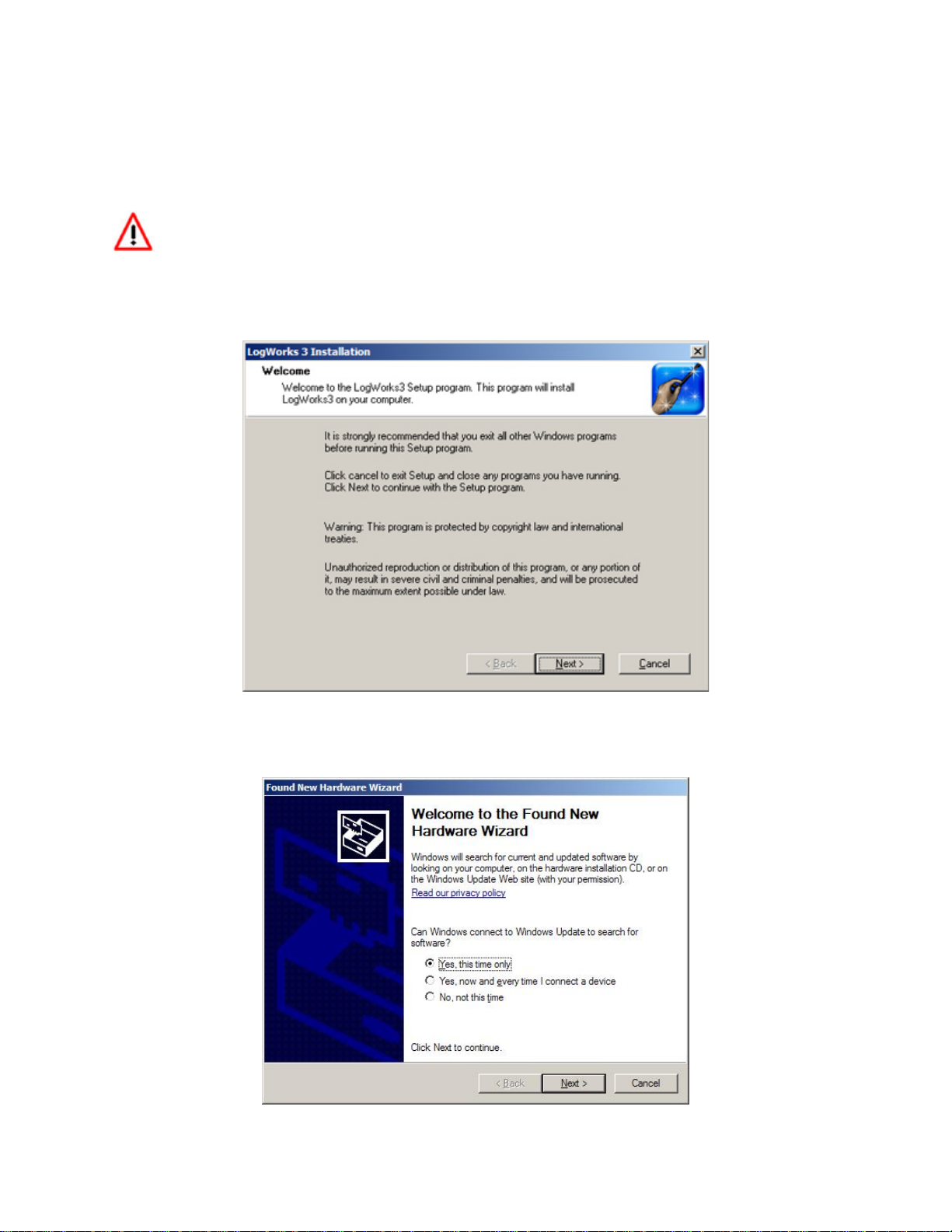

It is important to install the provided software on the computer prior to connecting

the LM-2. Failure to do so may lead to connection complications.

3.1 Installing software and Connecting the LM-2 to computer

1. Install the CD that came with your LM-2 in your personal computer.

2. The installer will automatically start, follow the prompts to install the software.

3. Connect one end of the USB cable to the LM-2 and the other end to your computer.

4. Power up the LM-2.

5. Windows will now recognize the device and prompt the “New Hardware Wizard.”

Click Next.

14

Document # 31-0008 LM2_Manual_1.3.doc

6. Select “Install the Device Automatically” and click Next.

7. A progress screen will appear. During this installation process the screen below will

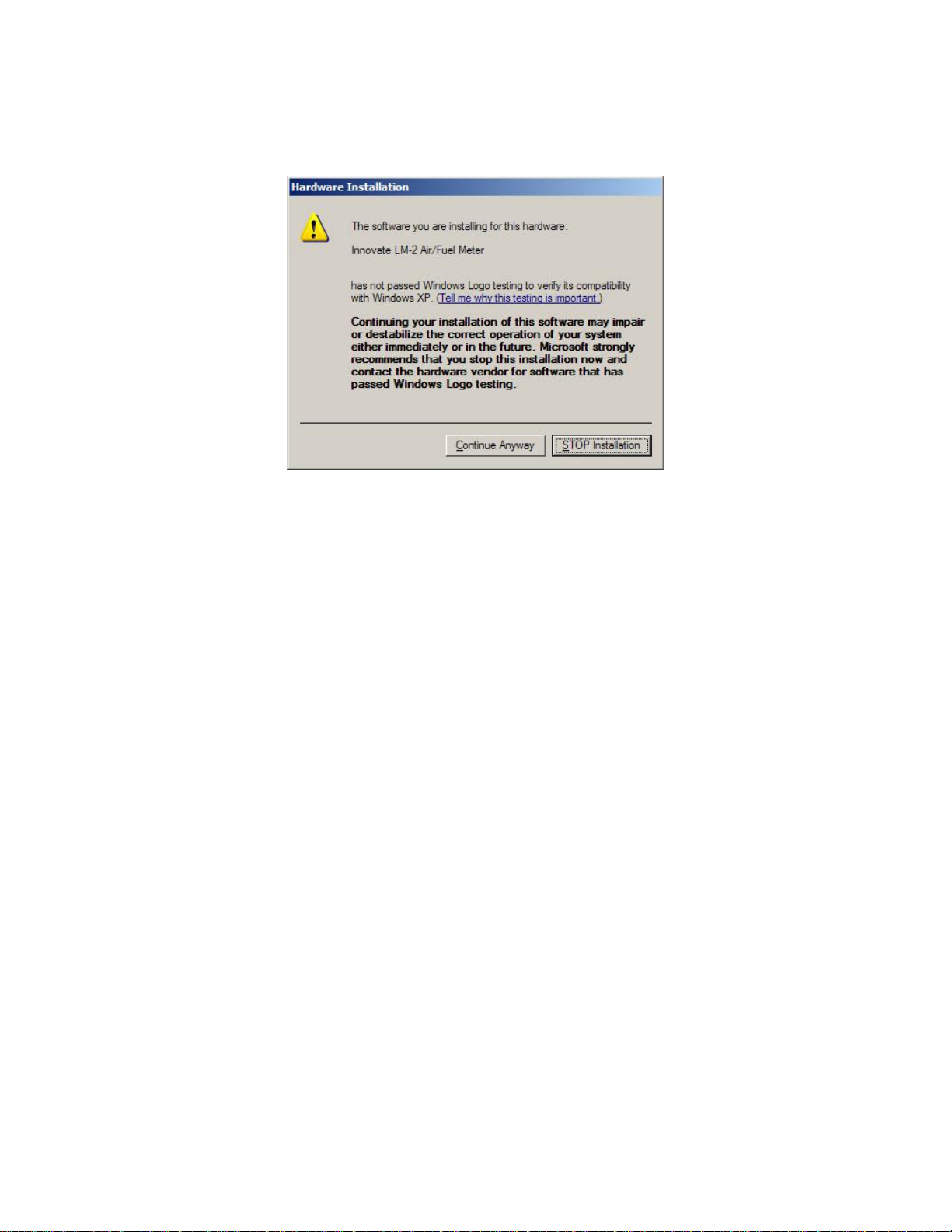

pop up. Click “Continue Anyway.”

8. The last screen will inform you that the unit has been successfully installed. Click

“Finish.” The unit is installed and ready to use.

3.2 Updating Firmware

1. Connect the LM-2 to your computer with the provided USB cable.

2. Power up the LM-2.

3. Launch LM Programmer. The LM Programmer application can be launched from

Start->Programs->LogWorks3->LM Programmer from the Windows task bar.

4. Once connected the LM Programmer will display the current version of the

firmware that is installed in the LM-2. Do not update the firmware if the versions

are the same. A firmware update should only be necessary if there has been a

new release.

5. On the very first tab of LM Programmer you will see a button labeled “Update

Firmware,” click this button.

15

Document # 31-0008 LM2_Manual_1.3.doc

Loading...

Loading...