Ingersoll Rand YSC033G, YSC120F, YSC063G, YZC048F, YZC036E Owner's Manual

...

SAFETYWARNING

Only qualified personnel should install and service the equipment.The installation,

starting up, and servicing of heating, ventilating, and air-conditioningequipment can

be hazardous and requiresspecific knowledge and training. Improperly installed,

adjusted or altered equipment byan unqualified person could result in death or

serious injury.When working on the equipment, observe all precautionsin the

literatureand on the tags, stickers, and labels that are attached to the equipment.

1

32

4 5

6 7

Owner Manual

Packaged Rooftop Air Conditioners

Precedent™ - Gas/Electric

3to10Tons-60Hz

Model Numbers:

YSC036E - YSC060E

YSC072F - YSC120F

YSC033G - YSC063G

YZC036E, YZC048F, YZC060E

YZC072F - YZC120F

YHC036E - YHC072E

YHC072F - YHC120F

Warnings, Cautions, and Notices

Read thismanual thoroughly before operating or servicing thisunit. Safety

advisories appearthroughout this manual asrequired.Your personalsafety

andthe proper operationof this machinedepend uponthe strict observance

of these precautions.

Important Environmental Concerns

Scientific research has shown that certain man-made chemicals can affect

the earth’snaturally occurringstratospheric ozone layer when released to

the atmosphere. In particular, several of the identified chemicals that may

affect the ozone layer are refrigerants that contain Chlorine, Fluorine and

Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs).Not all refrigerants containing these compounds havethe

same potentialimpact to the environment.Traneadvocates the responsible

handling of all refrigerants-including industry replacements for CFCs such

as HCFCs and HFCs.

Important Responsible Refrigerant Practices

Trane believes that responsible refrigerant practices are important to the

environment, our customers, and the air conditioning industry. All

technicianswho handle refrigerants mustbe certified.The Federal CleanAir

Act (Section 608) sets forth the requirements for handling, reclaiming,

recovering and recycling of certain refrigerants and the equipment that is

used inthese service procedures. In addition,some states or municipalities

may have additional requirements that must also be adhered to for

responsible management of refrigerants. Know the applicable laws and

follow them.

The three types of advisories are defined as follows:

WARNING

Indicates apotentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION

Indicates apotentially hazardous situation which,

if not avoided, could result in minor or moderate

injury.It could also beused to alertagainst unsafe

NOTICE

Indicates a situation that could result in

equipment or property-damage only accidents.

WARNING

Proper Field Wiring and Grounding Required!

Failure to followcode could result in death or seriousinjury. All field wiring

MUST beperformed by qualified personnel. Improperlyinstalled and grounded

field wiring poses FIRE and ELECTROCUTION hazards.To avoid these hazards,

you MUST follow requirementsfor field wiring installation and grounding as

described in NEC and your local/state electrical codes.

WARNING

Personal Protective Equipment Required!

Installing/servicing this unit could result in exposure to electrical, mechanical

and chemical hazards. Before installing/servicing this unit, technicians MUST

put on all Personal Protective Equipment (PPE) recommended for the work

being undertaken.ALWAYS refer toappropriate MSDS sheets and OSHA

guidelines for proper PPE.When working with or aroundhazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and OSHA guidelines for

information on allowable personal exposurelevels, proper respiratory

protection and handling recommendations. If there is a risk of arc or flash,

technicians MUSTput on all necessary Personal Protective Equipment (PPE) in

accordance with NFPA70Efor arc/flash protection PRIOR to servicing the unit.

Failure to followrecommendations could result in death or serious injury.

General Information

Important: Remember the following instructions at all times.

WARNING

Hazard of Explosion or Fire!

Do not store or use gasoline or other flammable vapors and liquids in the vicinity

of this or any other appliance.

IFYOU SMELL GAS, follow instructions below:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Open windows and doors.

• Alert others and evacuate building immediately.

• Froma phoneoutside of thebuilding, immediatelycall yourgas supplier.Follow

thegas supplier's instructions.If youcan not reachyour gassupplier,call the fire

department.

Failure to followinstructions listed above could result in death or serious injury

and equipment or property damage.

WARNING

Safety Hazards!

• Do not use this furnace if any portion has been under water as it may have

rendered the unit hazardous to operate.Immediately call a qualified service

technician toinspect the furnace and to replace anypart or the control system

and any gas control which has been under water.

• Should overheating occur,or the unit gas valve fail to shut off, close the gas

valve to the furnacebefore shutting off the electrical supply.

Failureto follow instructions couldresult in death, serious injuryand equipment or

property damage.

The unit has a complex design.To ensure that it performs safely and gives

long lastingservices, some of themaintenance work must be performedby

a qualified service person.

When aservice person is referred to inthis manual it is describing a service

technicianwho has had special training or a number ofyear sexperience in

servicingthis type of equipment.It is yourresponsibility to selecta qualified

service company that can provide a service person of this caliber.

WARNING

Safety Hazards!

• Never perform anymaintenance procedures until the electrical power to the

unit is turned off.

• Neverperform anymaintenance proceduresuntil thegas valveis the gassupply

line is turned off.

• Never remove anypanels from the unit while it isoperating.

• Never remove panels or parts fromthe unitthat arenot discussed in this

manual.

• Never cover the unit since it is designed to operate year round.

Failure to followinstructions could result in death or serious injury.

Thermostat

Room thermostats are delicate temperature sensing controls.Their main

function is to energize and de-energize the heating or cooling circuit to

maintain the temperature setting you select.

Manythermostats contain aroom thermometer toindicate theapproximate

room temperature and a temperature scale at the adjustment indicator to

select the desired indoor air temperature. In addition, most thermostats

have a selector mode switchwith Heat, Off and Cool positions and a fan

switch with On and Off positions.

When the switch is positioned atOff your unit will not operate in either the

heat or cool modes. If the selector switch is set at Heat the unit will

automatically cycle on andoff to maintain the desired temperature setting.

The unit will also operate automatically when the selector switch is

positioned at Cool.

The fan selector switchcan be used to operate the indoor fan continuously

by positioning it at On.When set toAuto the fan will only operate when

required during the heating or cooling cycles.

Toensure that the thermostat operates properly, it must be level and

positioned to avoid the influence of such external heat sources as lamps,

televisions or other heat producing appliances.

Note: Single Zone VAVis designed to be used with azone sensor. If a unit

is configured for Single ZoneVAV operation but is connected to a

thermostat, the control will revert to multi-speed (2-Speed) indoor fan

control and staged compressorcontrol. Thisdrastically reduces the energy

savings available with this design.

Note: eFlex™ is designed to be used with a zone sensor. If a unit is

configured for variable speed compressor operation but is connected to a

thermostat, the control will revert to multi-speed indoor fan control and

staged compressor control. This drastically reduces the energy savings

available with this design.

Note: Modulating gas heat is designed to be used with a zone sensor. If a

unit is configured for modulating gas heat operation but is connected to a

thermostat, the control will revertto a CV heating operation, but will utilize

the user selected discharge air heating setpoint for discharge air

temperature control of the modulating gas heat.

Air Filters

Filters are to be used with this unit. Units ship from the factory with filters

installed.

It is very important tok eep thecentral duct system air filters clean. Be sure

to inspect them at least once each month when the system is in constant

operation. (Innew homes, checkthe filters every week forthe first 4 weeks.)

See Table 1 for the required filter size(s).

If youhave disposable typefilters, replace them withnew filters of thesame

type and size. Do not attempt to clean disposable filters.

Permanent type filters can be cleaned by washing them with a mild

detergent and water. Ensure that the filters are thoroughly dry before

reinstalling them in the unit (or duct system).

It maybe necessary to replace permanentfilters annually if washing failsto

clean the filter, be sure to use the same type and size as was originally

installed.

Figure 1. Gas unit overview

RETURN AIR

SUPPLY AIR

PRESSURE SWITCH

GAS VALVE

COMPRESSOR

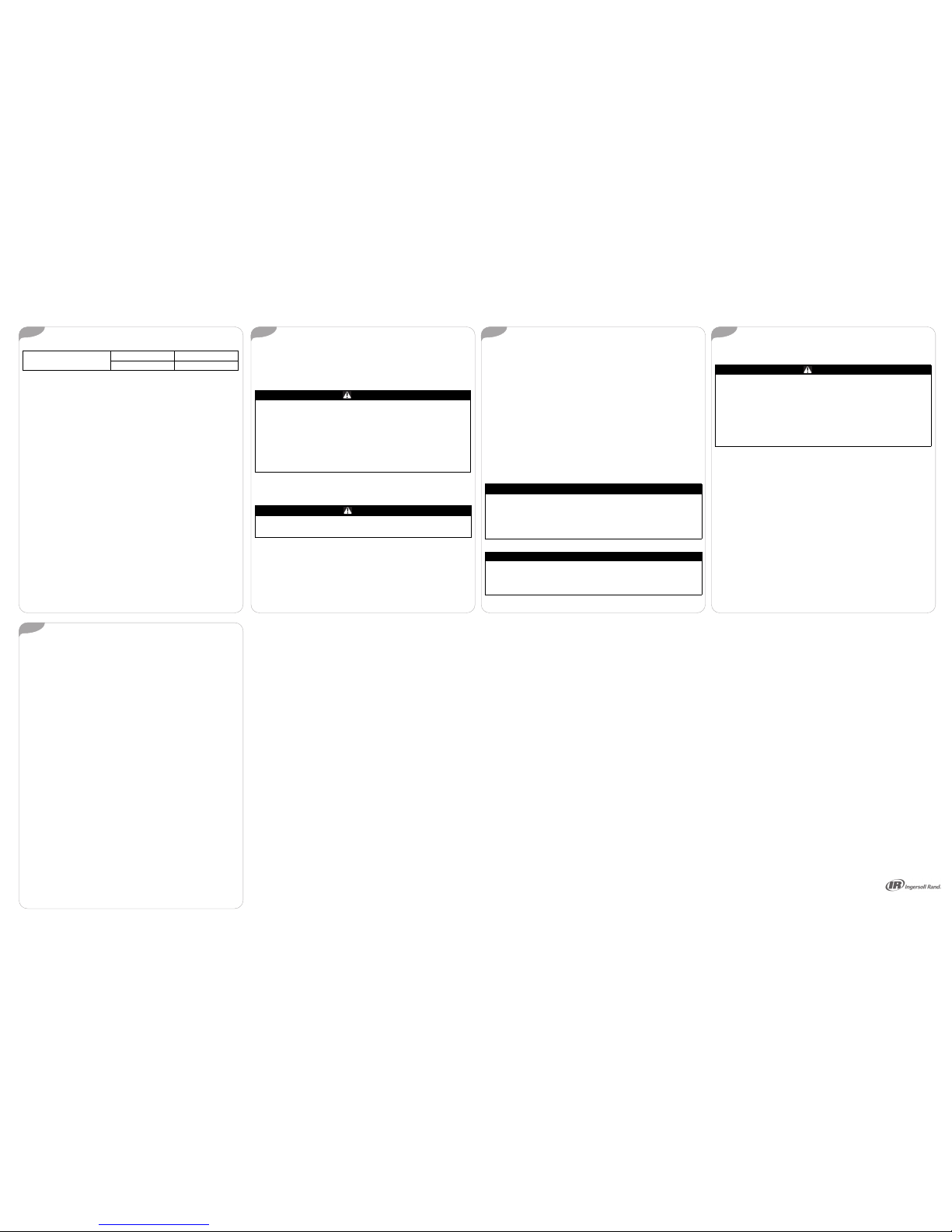

Table1. Recommended standard filters

Unit Model Number Filter Size

Inches Millimeters

YH/SC036E*, YHC037E* (2) 20x30x2 (2) 508x762x50

YZC036E* (2) 20x30x2 (2) 508x762x50

YSC048E* (2) 20x30x2 (2) 508x762x50

YZC048F* (4) 16x25x2 (4) 406x635x50

YSC060E* (2) 20x30x2 (2) 508x762x50

YZC060E* (4) 16x25x2 (4) 406x635x50

YZC072F* (4) 20x25x2 (4) 508x635x50

YZC090F* (4) 20x25x2 (4) 508x635x50

YZC102F* (4) 20x25x2 (4) 508x635x50

YZC120F*

(2) 20x30x2 (2) 508x762x50

(3) 20x25x2 (3) 508x635x50

YSC033-063G* (2) 20x35x2 (2) 508x635x50

YHC047E*, YHC048* (4) 16x25x2 (4) 406x635x50

YHC060*, YHC067E* (4) 16x25x2 (4) 406x635x50

YSC072F* (4) 16x25x2 (4) 406x635x50

YSC090F* (4) 16x25x2 (4) 406x635x50

YHC072F* (4) 20x25x2 (4) 508x635x50

YHC074F* (4) 20x25x2 (4) 508x635x50

YSC092F* (4) 20x25x2 (4) 508x635x50

YSC102F* (4) 20x25x2 (4) 508x635x50

YSC120F* (4) 20x25x2 (4) 508x635x50

YHC092F* (4) 20x25x2 (4) 508x635x50

YHC102F* (4) 20x25x2 (4) 508x635x50

January 2017

RT-SVU03L-EN

© 2017 Ingersoll Rand All Rights Reserved

Ingersoll Rand (NYSE:IR)advances the quality of life by creating comfortable,sustainable and efficient

environments. Ourpeople and our family of brands—including Club Car®, Ingersoll Rand®,Thermo

King®andTrane®—work together toenhance the quality and comfort of air inhomes and buildings;

transport andprotect food and perishables; and increase industrial productivity andefficiency. Weare a

global business committedto a world of sustainable progress and enduringresults. For more

information, visit www.ingersollrand.com.

Ingersoll Randhas a policy ofcontinuous product and productdata improvement andreser vesthe right to changedesign

and specificationswithout notice.

Weare committed to using

environmentally consciousprint

practices thatreduce waste.

9

1110

12 13

14 15

8

Heating System

Heating Cycle Operation

Yourunit's heating system has a solid-state electronic ignition control that

lights thefurnace burners eachtime the thermostat callsfor heat. Atthe end

of each heating cycle the furnace burners are extinguished.This type of

system is called Direct Spark Ignition (DSI).

A normal heating cycle begins when the air temperature drops below the

thermostat setting.The thermostat then energizes the heating electrical

circuit thatstarts and controlsthe furnace burners. Shortlyafter the burners

ignite theindoor fan starts and circulateswarm air through the conditioned

space.

When the airtemperature rises to the thermostat setting thethermostat deenergizes the heating electrical circuit, which in turn extinguishes the

burners.The indoor fan continues to circulate warm air until most of the

heat is removed from the unit's combustion chamber.

Safety Controls

• Yourunit is equipped with an automatic reset safety limit control to

prevent overheating. When this control opens, it shuts down the

heating electrical circuit until the unit cools down sufficiently.

Inadequate airflow (i.e., caused by dirty filters or defective fan motor)

maycause the unitto cycle onand off asthe limit tripsand automatically

resets. If you suspect that the unit is cycling on its limit control,

immediately contact a service person for instructions.

• If flames from the burner are not properly drawn into the heat

exchanger, a flame rollout protection control will open causing the

furnace to shut off. The cause must be investigated by a qualified

service person.

• If installed, the condensate overflow switch will shut down the unit

before a drain pan overflow occurs.

YHC120F*

(2) 20x30x2 (2) 508x762x50

(3) 20x25x2 (3) 508x635x50

Table1. Recommended standard filters (continued)

Heating System Start-Up

Because your unit has an automatic ignition system, it is easy to start the

heating cycle at the beginning of the heating season. In order for the unit

to operate properly and safely, the furnace needs air for both combustion

and ventilation. Check to make sure that all air openings are unobstructed

and there is adequate clearance around the unit to provide good air flow.

1. Set the thermostat's heating adjustment lever at its lowest setting.

2. Move the selector switch to the Off position.

3. Turn off all electric power to the unit.

4. This unit is equipped with an ignitiondevice whichautomatically lights

the burners.

5. Remove the access panel that contains the following label:

WARNING

HazardousVoltage w/Capacitors!

Failureto disconnect power and dischargecapacitors before servicing could result

in death or serious injury.Disconnect all electricpower, including remote

disconnects and discharge all motor start/runcapacitors before servicing. Follow

proper lockout/tagoutprocedures to ensure the power cannot be inadvertently

energized. For variablefrequency drives or other energy storing components

provided byTraneor others, referto the appropriate manufacturer’sliterature for

allowable waiting periods fordischarge of capacitors. Verifywith an appropriate

voltmeter that all capacitors have discharged.

For additional information regardingthe safe discharge of capacitors, see PRODSVB06A-EN

WARNING

Risk of Burn!

NEVER attempt to manually light the burner! Failureto follow this instruction

could result in serious injury.

Figure 2. Label

REMOVE THIS PANEL

TO GAIN ACCESS TO

THE GAS VALVE

6. Change the ON/OFF switch to the OFF position.

Note: Somevalves require the knobto be pushed in slightlybefore turning.

7. Wait (5) minutes to clear out any gas. If you then smell gas, STOP! Refer

to thewarnings provided in the “General Information”section. If you do

not smell gas, go to the next step.

8. Change the ON/OFF switch to the ON position.

9. Replace panel removed in step 5 above.

10.Turnon all electric power to unit.

11.Set thermostat to desired temperature and move the selector switch to

the ON position. The unit will now operate automatically.

12.If the unit will not operate, follow the instructions "ToTurn Off GasTo

Unit" (underHeating System Shutdown) andcall your service technician

or gas supplier.

Important: The unit is to be adjusted to obtain an air rise within that

specified on the nameplate.

Heating System Shutdown

Toshut down the heating systemfor brief periods of time simply adjust the

thermostat selector switch to the "Off" position.

NOTICE

Property Damage!

If the unit isshut down during the cold weather months, provisionsmust be taken

to prevent freeze-upof all waterpipes and water receptacles. Whenever your

house or building is to be vacant, arrangeto have someone inspect your structure

for proper temperature.This is veryimportant in below freezing weather. If forany

reason your furnace should failto operate, damage such as frozen water pipes

could result.

NOTICE

Coil Freeze-up!

Failure to followinstructions below could result in coil damage. Drain and vent

coils when not in use.Trane recommends glycol protection in all possible freezing

applications. Use a glycol approved for use with commercial cooling and heating

systems and copper tube coils.

HowToTurn Off Gas To Unit

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the unit if service is to be performed.

3. Remove the access panel that contains the label shown in Figure 2.

4. Change ON/OFF switch to the "OFF" position.

5. Replace panel removed in step 3 above.

WARNING

HazardousVoltage w/Capacitors!

Failureto disconnect power and dischargecapacitors before servicing could result

in death or serious injury.Disconnect allelectric power, including remote

disconnects and discharge all motor start/runcapacitors before servicing. Follow

proper lockout/tagoutprocedures to ensure the power cannot be inadvertently

energized. For variablefrequency drives or other energy storing components

provided byTraneor others, referto the appropriate manufacturer’sliterature for

allowable waiting periods fordischarge of capacitors. Verifywith an appropriate

voltmeter that all capacitors have discharged.

For additional information regardingthe safe discharge of capacitors, see PRODSVB06A-EN

Heating System Maintenance

Complete the following unit inspections and service routines at the

beginning of each heating season.

Refer to the warnings in “General Information” regarding combustible

materials and what to do if you smell gas.

Important: These steps should only be performed by a qualified service

technician.

1. Inspect the control panel wiring and heating controls to make sure

connections are tight and wiring insulation is intact.

2. Turn the unit on and off at the thermostat to be sure the ignition control

and spark electrode are operating properly.

3. Turn off the gas supply with the unit operating to verify that the gas

valves closes and that a re-ignition cycle is initiated by the ignition

control.

4. Check the operation of the gas ignition system.

5. Check the burner manifold pressure. A 1/8 inch pipe plug is provided in

the gas valve for this purpose.

6. Visuallyinspect all of the unit's flue product passageways for excessive

deposit build up and corrosion. If build up or corrosion is apparent,

perform the necessary repairs.

7. Arrange for aqualified serviceman toinspect the unitevery other heating

season to maintain safe and efficient operation.

8. Visuallycheckthe main burner flames.Theyshould be bright blueflames

extending into the heat exchangersections.

9. Never store anythingflammable or combustible around or near the unit.

Condensate Overflow Sensor (Optional)

If installed, the condensate overflow switch will shut down the unit before

a drain pan overflow occur s.

© 2017Ingersoll Rand All rights reserved

RT-SVU03L-EN 13 Jan2017

Supersedes RT-SVU03K-EN (06Nov 2015)

Loading...

Loading...