Page 1

Before installing or starting this unit for the first

time, this manual should be studied carefully to

obtain a working knowledge of the unit and/or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

Ingersoll Rand

X-Series System Automation

Interconnect Guide

Ingersoll Rand Compressors

C.C.N. :

More Than Air. Answers.

Online answers: http://www.air.irco.com

REV. : A

DATE : APRIL 2007

1

Page 2

SECTION 1 — TABLE OF CONTENTS

SECTION 1 — TABLE OF CONTENTS.................................2

SECTION 2 — INTRODUCTION.........................................3

SECTION 3 — SAFETY......................................................3

INSTALLATION ................................................................3

OPERATION.....................................................................3

MAINTENANCE AND REPAIR ............................................4

SECTION 4 — X4I SYSTEM OVERVIEW ..............................5

SECTION 5 — X8I SYSTEM OVERVIEW ..............................6

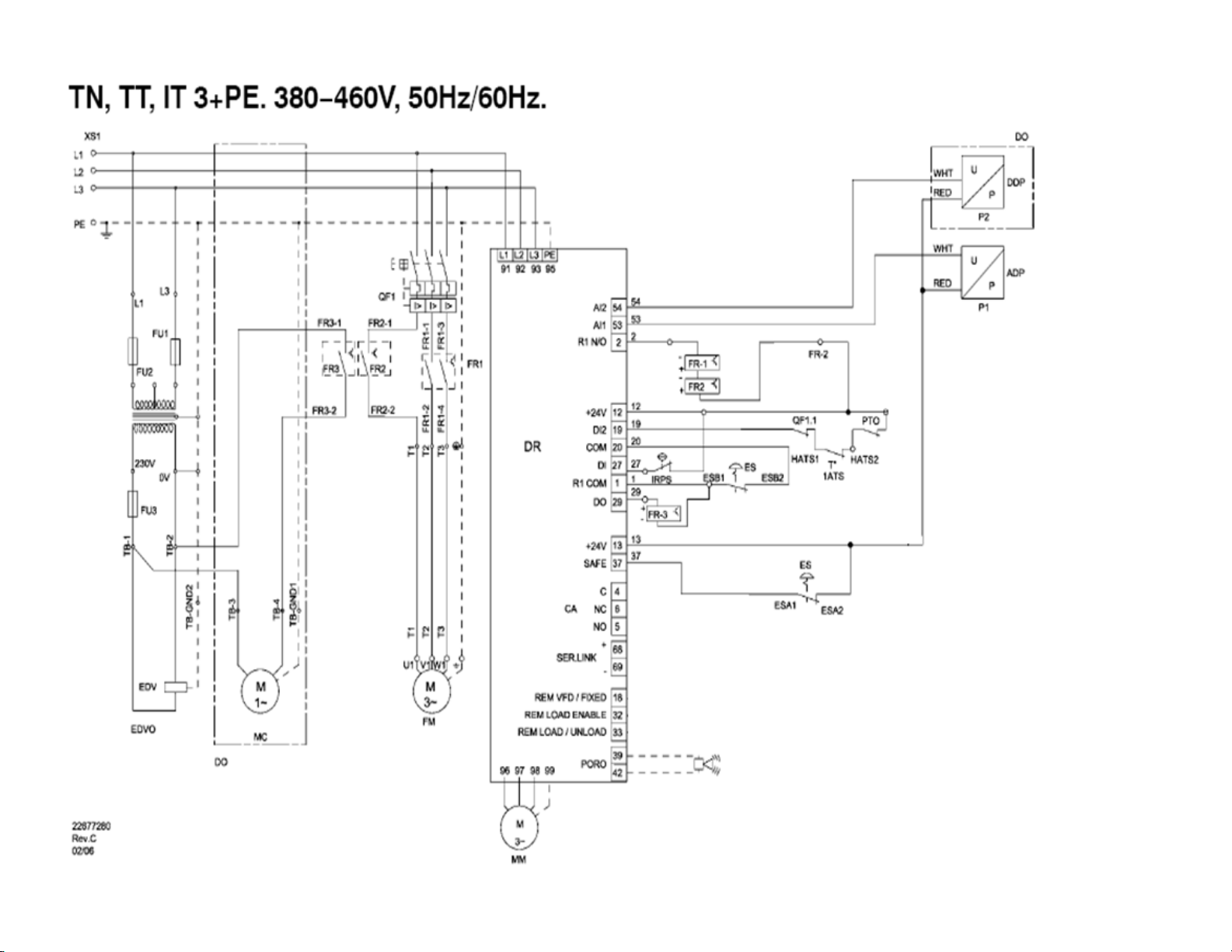

SECTION 6 — VSD OVERVIEW ..........................................7

SECTION 7 — ASSISTANCE ..............................................8

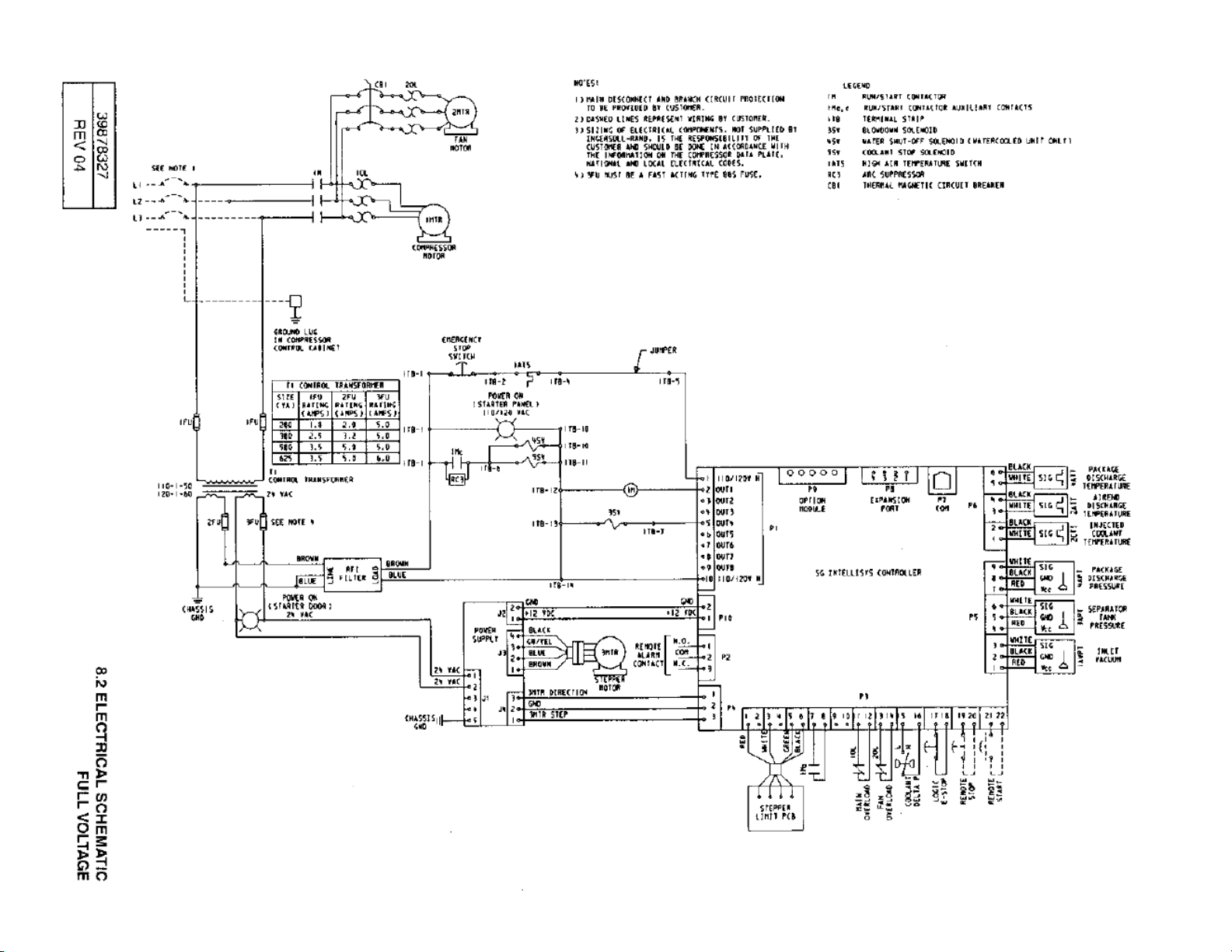

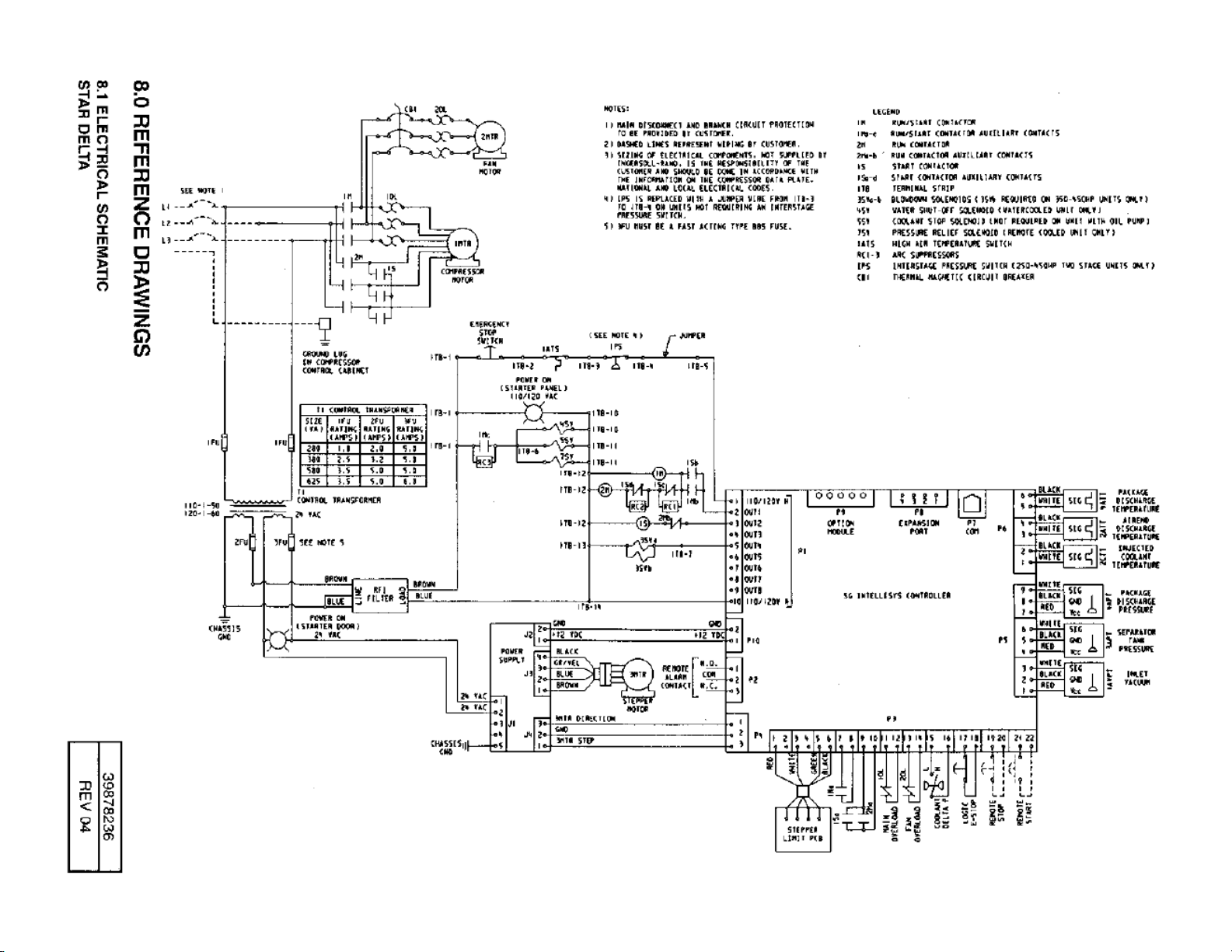

SECTION 8 — INTERCONNECT DRAWINGS .......................8

INTELLISYS CONTROLLER E-PROM

RECOMMENDATIONS.......................................................8

INTELLISYS CONTROLLER INTERCONNECT

RECOMMENDATIONS.......................................................8

APPENDIX A — ir-485, irV-485, and RS485 Direct

Interconnect Drawings To Ingersoll Rand Intellisys

Controlled Compressor ............................................9

APPENDIX B — ir-PCB Interconnect Drawings To

Ingersoll Rand Intellisys Controlled And CMC Sierra

Compressors ..........................................................17

APPENDIX C — ir-PCB Interconnect Drawings To

Ingersoll Rand Pressure Switch Controlled

Compressors ..........................................................51

APPENDIX D — VSD Box Interconnect Drawings To

Ingersoll Rand Non-Nirvana VSD Compressors .......92

2

Page 3

SECTION 2 — INTRODUCTION

The X - SERIES AUTOMATION is a family of specialized

controllers designed to provide safe, reliable, and

energy-efficient control of your compressed air system.

X4I

The X4I is capable of controlling positive displacement

air compressors. The compressors may have electropneumatic or microprocessor based controls. The X4I is

completely customizable to meet the specific needs of

your compressed air system.

SECTION 3 — SAFETY

WARNING :

!

WARNING :

WARNING :

!

WARNING :

INSTALLATION

Risk of Danger

Risk of Electric Shock

Risk of High Pressure

Consult Manual

• Before installing or operating the X-

Series Automation System, take time to

carefully read all the instructions

contained in this manual, all compressor

manuals, and all manuals of any other

peripheral devices that may be installed

or connected to the unit.

• Electricity and compressed air have the

potential to cause severe personal injury

or property damage.

• The operator should use common sense

and good working practices while

operating and maintaining this system.

All applicable codes should be strictly

adhered to.

• Maintenance must be performed by

adequately qualified personnel that are

equipped with the proper tools.

• Installation work must only be carried

out by a competent person under

qualified supervision.

• A fused isolation switch must be fitted

between the main power supply and the

X-Series Automation System.

• The X-Series Automation System should

be mounted in such a location as to

allow operational and maintenance

X8I

The X8I is an advanced system controller designed to

provide safe, reliable, and energy-efficient management

of your compressed air system. The X8I is capable of

controlling up to eight (8) positive displacement air

compressors. The compressors may be fixed speed,

variable speed or multi-step and have electro-pneumatic

or microprocessor based controls. The X8I is uniquely

configurable and customizable to meet the specific

needs of some of the most complex compressed air

system. Additionally, the X8I control network can expand

to include monitoring and control of various compressed

air system components.

access without obstruction or hazard

and to allow clear visibility of indicator

at all times.

• orms are required to

If raised platf

provide access to the X-Series

Automation System, they must not

interfere with normal operation or

obstruct access. Platforms and stair

should be of grid or plate construction

with safety rails on all open sides.

OPERATION

• The X-Series Automation System must

only be operated by competent

personnel under qualified superv

•

Never remove or tamper with safety

devices, guards or insulation materia

fitted to the X-Series Automation System

•

The X-Series Automation System must

only be operated at the supply voltage

and frequency for which it is designed.

•

When main power is switched on, lethal

voltages are present in the electrical

circuits and extreme caution must be

exercised whenever it is necessary to

carry out any work on the unit.

• uch

Do not open access panels or to

electrical components while voltage is

applied unless it is necessary for

measurements, tests or adjustment

Such work should be carried out only b

a qualified electrician equipped with the

correct tools and wearing appropriate

protection against electrical hazards.

•

All air compressors and/or other

equipment connected to the unit s

have a warning sign attached stating

“THIS UNIT MAY START WITHOUT

WARNING” next to the display pane

3

s

s

ision.

ls

.

s.

y

hould

l.

Page 4

• If an air compressor and/or other

equipment connected to the unit is to be

started remotely, attach two warning

signs to the equipment stating “THIS

UNIT CAN BE STARTED REMOTELY”.

Attach one sign in a prominent location

on the outside of the equipment, and

the other sign inside the equipment

control compartment.

MAINTENANCE AND REPAIR

• Maintenance, repairs or modifications

must only be carried out by competent

personnel under qualified supervision.

• If replacement parts are required, use

only genuine parts from the original

equipment manufacturer, or an

alternative approved source.

• Carry out the following operations

before opening or removing any access

panels or carrying out any work on the

X-Series Automation System:

i. Isolate the X-Series Automation

System from the main electrical

power supply. Lock the isolator

in the “OFF” position and remove

the fuses.

ii. Attach labels to the isolator

switch and to the unit stating

“WORK IN PROGRESS - DO NOT

APPLY VOLTAGE”. Do not switch

on electrical power or attempt to

start the X-Series Automation

System if such a warning label is

attached.

• Make sure that all instructions

concerning operation and maintenance

are strictly followed and that the

complete unit, with all accessories and

safety devices, is kept in good working

order.

• The accuracy of sensor devices must be

checked on a regular basis. They must

be calibrated when acceptable tolerances

are exceeded. Always ensure any

pressure within the compressed air

system is safely vented to atmosphere

before attempting to remove or install a

sensor device.

• The X-Series Automation System must

only be cleaned with a damp cloth, using

mild detergents if necessary. Avoid the

use of any substances containing

corrosive acids or alkalis.

• Do not paint the control faceplate or

obscure any indicators, controls,

instructions or warnings.

4

Page 5

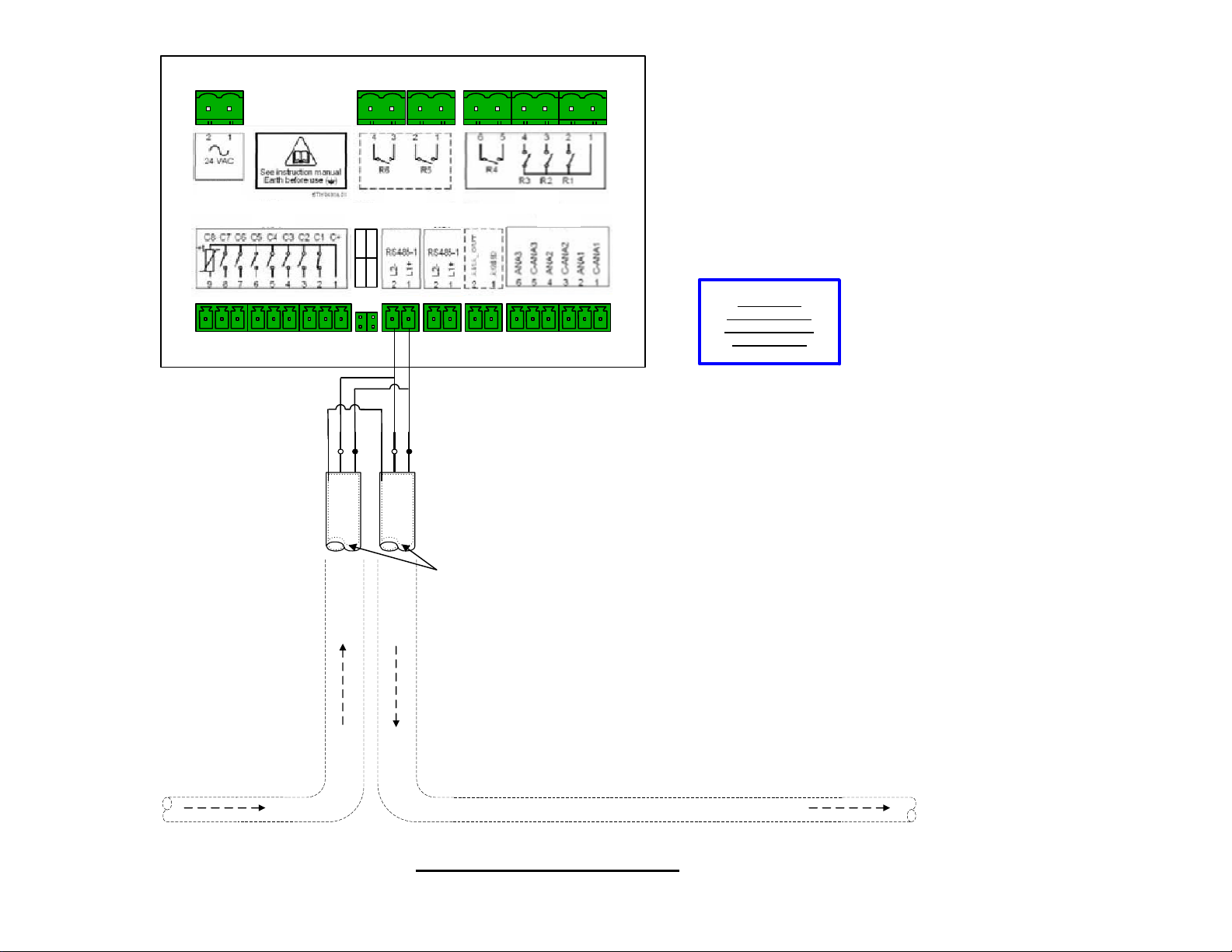

SECTION 4 — X4I SYSTEM OVERVIEW

It is recommended that installation and commissioning be carried out by an authorized and trained product supplier.

Ingersoll Rand Automation

Model X4I

Dimensions 11.45” x 9.45” x 6.0”

291mm x 241mm x 152mm

Weight 14lb (6.4kg)

Mounting Wall, 4 x screw fixings

Enclosure IP65, NEMA 4

Supply 230Vac +/- 10%, 50 Hz

115Vac +/- 10%, 60 Hz

Power 50VA

Temperature 32°F to 115°F

(0°C to 46°C)

Humidity 0% to 95% RH

(non-condensing)

Local Disconnect (Breaker) Box

electrical and safety regulations).

X4I X05 CONNECTOR

SPECIFICATIONS

Fused for 50VA

Power Cable

3 conductor (N, L, E)

(Sized in accordance with local

PRESSURE TRANSDUCER CABLE

2 Conductor Cable, 18 Gauge Stranded

Reference X4I Operations Manual for Pressure

Earth Shielded

No Greater Than 330FT (100M)

24VDC Control Voltage

25 +VDC Pin #3

26 Signal Pin #1

Sensor Connection Details

PT CONNECTOR

On/Off

Switch

Supply

Voltage

Cable

Pressure

Transducer

Cable

ir-PCB ir-PCB

The Maximum Number of Compressors Controlled By The X4I Is Four (4).

The Maximum Number Of Direct ir-PCB Connections To The X4I is Four (4).

ir-PCB COMPRESSOR CONTROL CABLE

7 Conductor Cable, 18 Gauge, Stranded, Earth Shielded

Single Conductor Wire, 18 Gauge Stranded, Quantity (7)

In Grounded Conduit No Greater Than 330FT (100M)

OR

24VAC Control Voltage

PRESSURE TRANSDUCER

To Plant Air

System

Reference X4I Application and Interconnect Guide For

Wiring Connections Between The X4, The ir-PCB, and

RECEIVER

Compressors

The Compressor

DRIP LEG

From Air

Ir-PCB Compressor #1

Control Cable

ir-PCB ir-PCB

Ir-PCB Compressor #4

Control Cable

Ir-PCB Compressor #2

Control Cable

Ir-PCB Compressor #3

Control Cable

5

Page 6

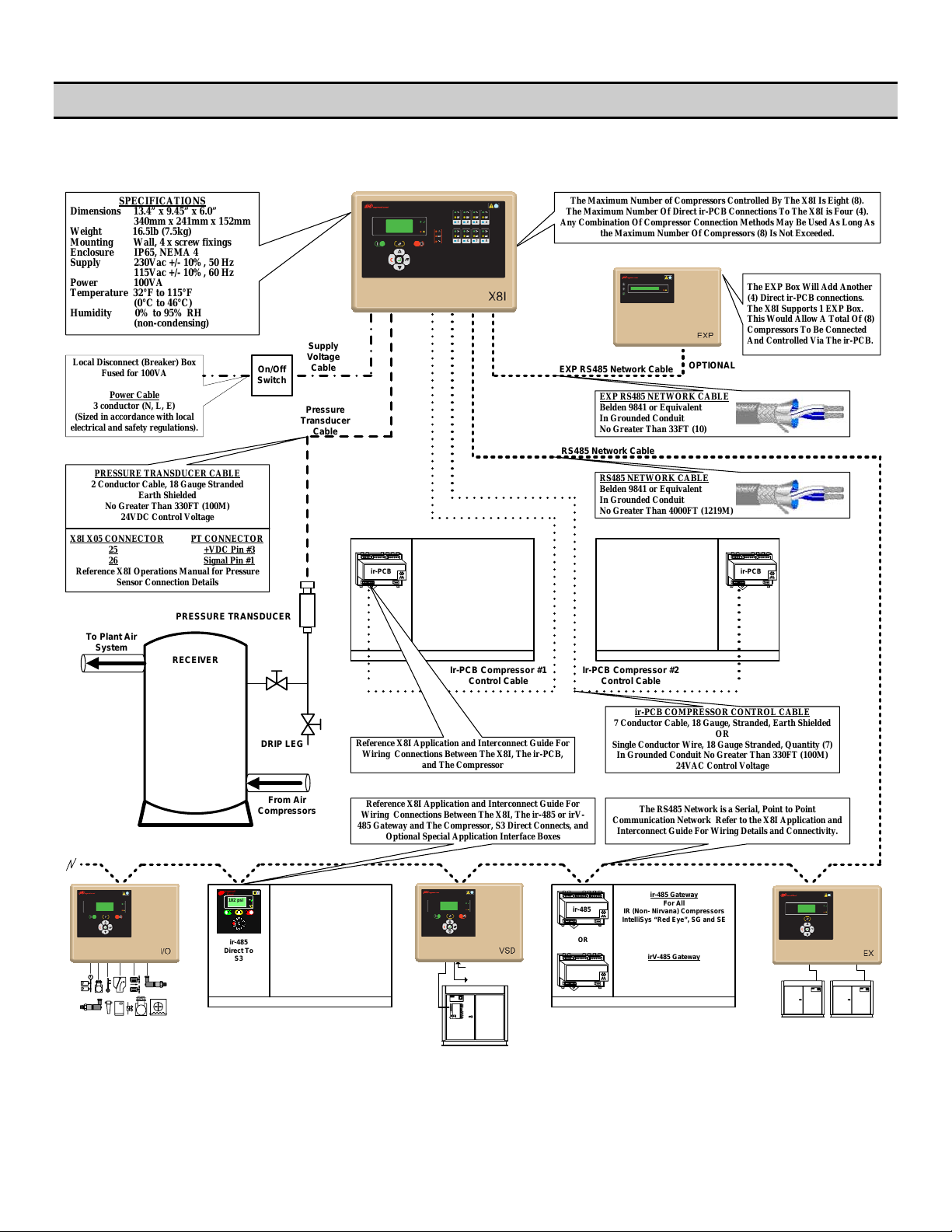

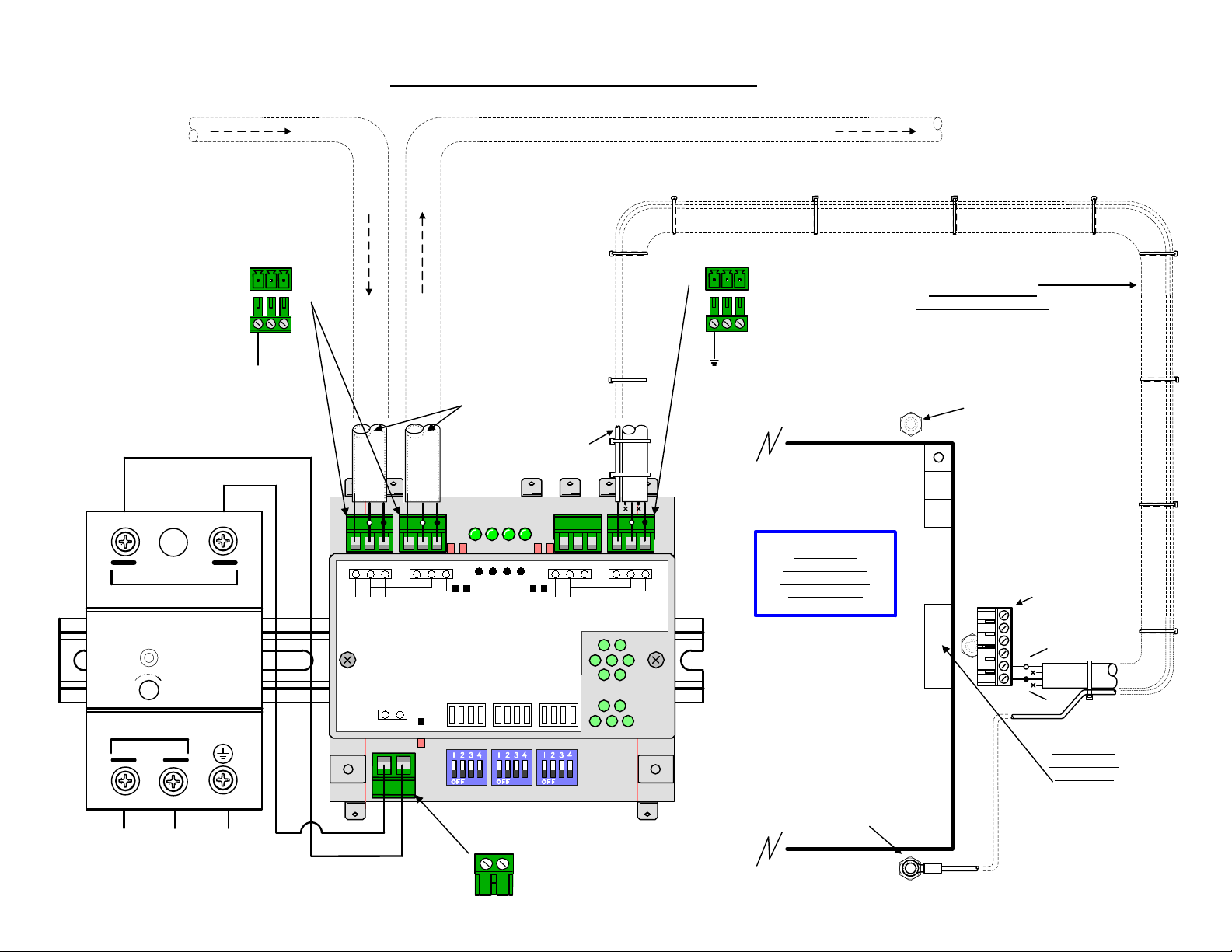

SECTION 5 — X8I SYSTEM OVERVIEW

It is recommended that installation and commissioning be carried out by an authorized and trained product supplier.

Ingersoll Rand Automation

Model X8I

Dimensions 13.4” x 9.45” x 6.0”

340mm x 241mm x 152mm

Weight 16.5lb (7.5kg)

Mounting Wall, 4 x screw fixings

Enclosure IP65, NEMA 4

Supply 230Vac +/- 10%, 50 Hz

115Vac +/- 10%, 60 Hz

Power 100VA

Temperature 32°F to 115°F

(0°C to 46°C)

Humidity 0% to 95% RH

(non-condensing)

electrical and safety regulations).

X8I X05 CONNECTOR PT CONNECTOR

SPECIFICATIONS

Local Disconnect (Breaker) Box

Fused for 100VA

Power Cable

3 conductor (N, L, E)

(Sized in accordance with local

PRESSURE TRANSDUCER CABLE

2 Conductor Cable, 18 Gauge Stranded

Reference X8I Operations Manual for Pressure

Earth Shielded

No Greater Than 330FT (100M)

24VDC Control Voltage

25 +VDC Pin #3

26 Signal Pin #1

Sensor Connection Details

On/Off

Switch

Supply

Voltage

Cable

Pressure

Transducer

Cable

ir-PCB ir-PCB

The Maximum Number of Compressors Controlled By The X8I Is Eight (8).

The Maximum Number Of Direct ir-PCB Connections To The X8I is Four (4).

Any Combination Of Compressor Connection Methods May Be Used As Long As

the Maximum Number Of Compressors (8) Is Not Exceeded.

The EXP Box Will Add Another

(4) Direct ir-PCB connections.

The X8I Supports 1 EXP Box.

This Would Allow A Total Of (8)

Compressors To Be Connected

And Controlled Via The ir-PCB.

EXP RS485 Network Cable

EXP RS485 NETWORK CABLE

Belden 9841 or Equivalent

In Grounded Conduit

No Greater Than 33FT (10)

OPTIONAL

RS485 Network Cable

RS485 NETWORK CABLE

Belden 9841 or Equivalent

In Grounded Conduit

No Greater Than 4000FT (1219M)

To Plant Air

System

PRESSURE TRANSDUCER

RECEIVER

DRIP LEG

From Air

Compressors

Ingersoll

Rand

102 psi

ir-485

Direct To

S3

Ir-PCB Compressor #1

Control Cable

Reference X8I Application and Interconnect Guide For

Wiring Connections Between The X8I, The ir-PCB,

Reference X8I Application and Interconnect Guide For

Wiring Connections Between The X8I, The ir-485 or irV-

485 Gateway and The Compressor, S3 Direct Connects, and

and The Compressor

Optional Special Application Interface Boxes

From VSD Pressure

Transducer

To VSD Pressure

Transducer Input

1

D

2

LE

D

LE

ir-

PCB

ir-485

irV-485

Ir-PCB Compressor #2

Control Cable

ir-PCB COMPRESSOR CONTROL CABLE

7 Conductor Cable, 18 Gauge, Stranded, Earth Shielded

Single Conductor Wire, 18 Gauge Stranded, Quantity (7)

In Grounded Conduit No Greater Than 330FT (100M)

The RS485 Network is a Serial, Point to Point

Communication Network Refer to the X8I Application and

Interconnect Guide For Wiring Details and Connectivity.

ir-485 Gateway

For All

IR (Non- Nirva na ) Comp res so rs

IntelliSys “Red Eye”, SG and SE

OR

irV-485 Gateway

For All

Nirvana Compressors

20HP (15KW) and Above

OR

24VAC Control Voltage

34

6

Page 7

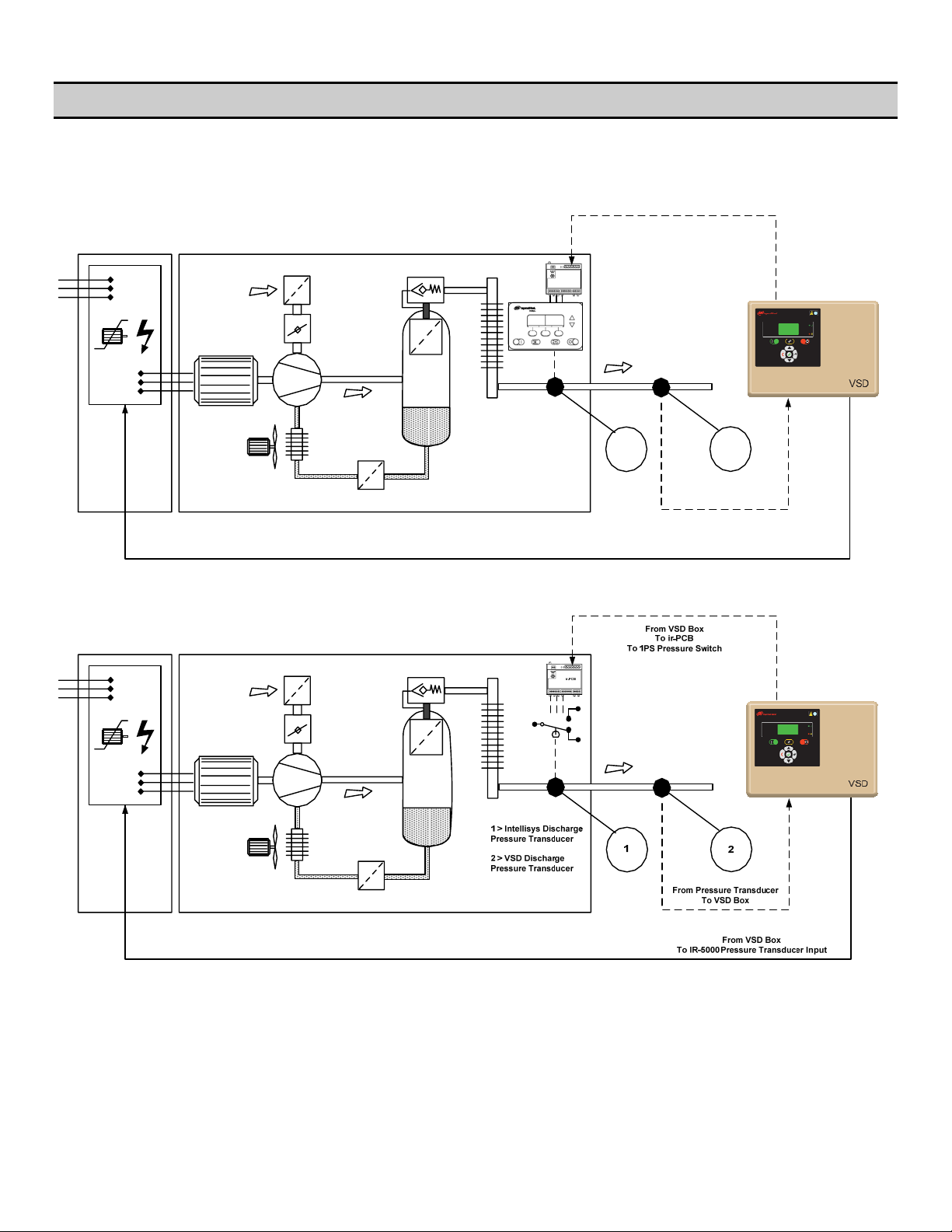

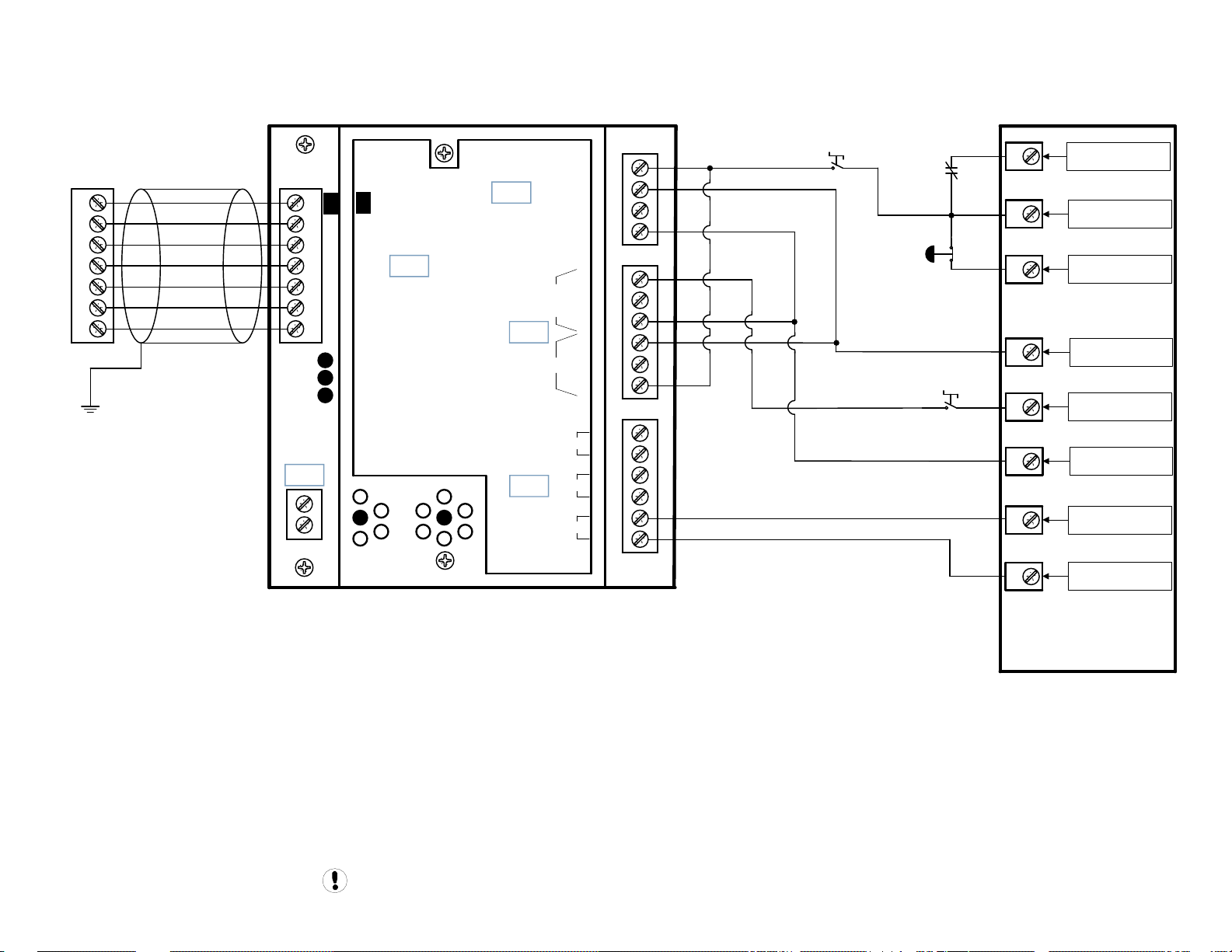

SECTION 6 — VSD OVERVIEW

It is recommended that installation and commissioning be carried out by an authorized and trained product supplier.

Ingersoll Rand Automation

VSD Box

From VSD Box

To ir-PCB

LED 1

LED 2

ir-PCB

1 > Intellisys Discharge

Pressure Transducer

2 > VSD Discharge

Pressure Transducer

To Intellisys Controller

1

From Pressure Transducer

2

To VSD Box

From VSD Box

To IR-5000 Pressure Transducer Input

7

Page 8

SECTION 7 — ASSISTANCE

Contacting Technical Support Services or Service Bulletins listed on the IR ServiceNet can provide further assistance if there

are other questions or concerns during Installation and Start-up. Also, additional Application and Compressor Interconnect

Guides will be posted and available on the IR ServiceNet as they are developed and created.

SECTION 8 — COMPRESSOR INTERCONNECT DRAWINGS

The following Appendix’s contain reference drawings designed to assist with the connection of the X – Series Automation

System to Ingersoll Rand Air Compressors as well as Non-Ingersoll Rand Air Compressors. These drawings are for

Guidance Only; connections may differ with date, model, type, variant, special, custom or concession builds. This

information is intended to be used in conjunction with the compressor’s original control circuit diagram.

INTELLISYS CONTROLLER E-PROM ROMMENDATION REFERENCE LIST

Minimum Recommended E-prom Levels - IntelliSys Controllers

IntelliSys - Firs t Generation

SSR 50 - 450HP

Sierra 100 - 200HP

Recip

IntelliSys - Second Generation

SSR 50 - 450 (1 & 2 Stage)

SSR 75 - 350kW (ESA)

Sierra 125-400HP

Recip

Redeye SE

2.4 1.75

2.7 1.23

1.62 1.93

SG SGN

1.5 1.45

1.5 SGNe

1.35 2.4

1.28 1.2

IntelliSys - Second Edition

SSR 15 - 100HP (DSA)

SSR - UP (Pegasus)

SSR 22 - 150kW (ESA)

Sierra 50 - 100HP

IntelliSys - Nirvana

Nirvana CC 100 - 200HP

IntelliSys - Nirvana

Nirvana CC 50 - 300HP

Nirvana OF 50 - 200HP

1.3

INTELLISYS CONTROLLER INTERCONNECT RECOMMENDATION

When using the X8I Automation System, the ir-485 and irV-485 Gateway is the “recommended and preferred” method when

interfacing and connecting to the FG (redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and Nirvana 1530KW (20-40HP) Compressors. See Appendix A for interconnect drawings for these applications

When using the X4I Automation System, the ir-PCB is the only method when interfacing and connecting to the FG (redeye),

SG, SGN and SGNe, SE IntelliSys controlled compressors and Nirvana 15-30KW (20-40HP) Compressors. See Appendix B for

interconnect drawings for these applications

8

Page 9

APPENDIX A

ir-485, irV-485, and RS485 DIRECT TO INGERSOLL RAND

INTELLISYS AND NIRVANA 15-30KW (20-40HP)

COMPRESSOR INTERCONNECT DRAWINGS

IR-485, IRV-485, AND RS485 DIRECT to Ingersoll Rand

Intellisys and Nirvana 15-30kw (20-40hp) ................... A1

irV-485 Interconnect To Ingersoll Rand Intellisys SGN /

SGNe Controlled Compressors ..................................... A2

ir-485 Interconnect To Ingersoll Rand Intellisys SG

Controlled Compressors .............................................. A3

ir-485 Interconnect To Ingersoll Rand Intellisys SE

Controlled Compressors .............................................. A4

ir-485 Interconnect To Ingersoll Rand Intellisys Redeye

Controlled Compressors .............................................. A5

RS485 Direct Interconnect To Ingersoll Rand Intellisys S3

Controlled Compressors .............................................. A6

irV-485 Interconnect To Ingersoll Rand Nirvana 15-30kw

(20-40HP) .................................................................... A7

9

Page 10

ir-485, irV-485, and RS485 DIRECT To Ingersoll Rand

Intellisys and Nirvana 15-30KW (20-40HP) Compressors

All Intellsys and Nirvana 15-30KW (20-40HP) Compressors

All compressors must have Automatic Start / Stop

ir-485

ir-485

ir-485

irV-485

No Modbus Functionality in Controller

Redeye Controller

Operates in irbus mode

Sequence Control Set To “ON”

Remote Start / Stop Set To “OFF”

SG Recip Controller

No Modbus Functionality in Controller

Operates in irbus mode

Sequence Control Set To “ON”

Remote Start / Stop Set To “OFF”

`SE Controller

No Modbus Functionality in Controller

Operates in irbus mode

Sequence Control Set To “ON”

Remote Start / Stop Set To “OFF”

SG Controller

Modbus Functionality in Controller

Set Modbus To ON

Set Modbus Address To Unique

Modbus Address

1-8 For X8I 1-12 For x12I

Sequence Control Set To “ON”

Remote Start / Stop Set To “OFF”

irV-485

RS485 Direct

From X8I or X12I

Automation

System

Modbus Functionality in Controller

SGN Controller

Set Modbus To ON

Set Modbus Address To Unique

Modbus Address

1-8 For X8I 1-12 For x12I

Sequence Control Set To “ON”

Remote Start / Stop Set To “OFF”

S3 Controller

Modbus Functionality in Controller

Set Modbus To ON

Set Modbus Address To Unique

Modbus Address

1-8 For X8I 1-12 For x12I

Remote Control Set To “ON”

Remote Start / Stop Set To “OFF”

Appendix A - Page A1

Page 11

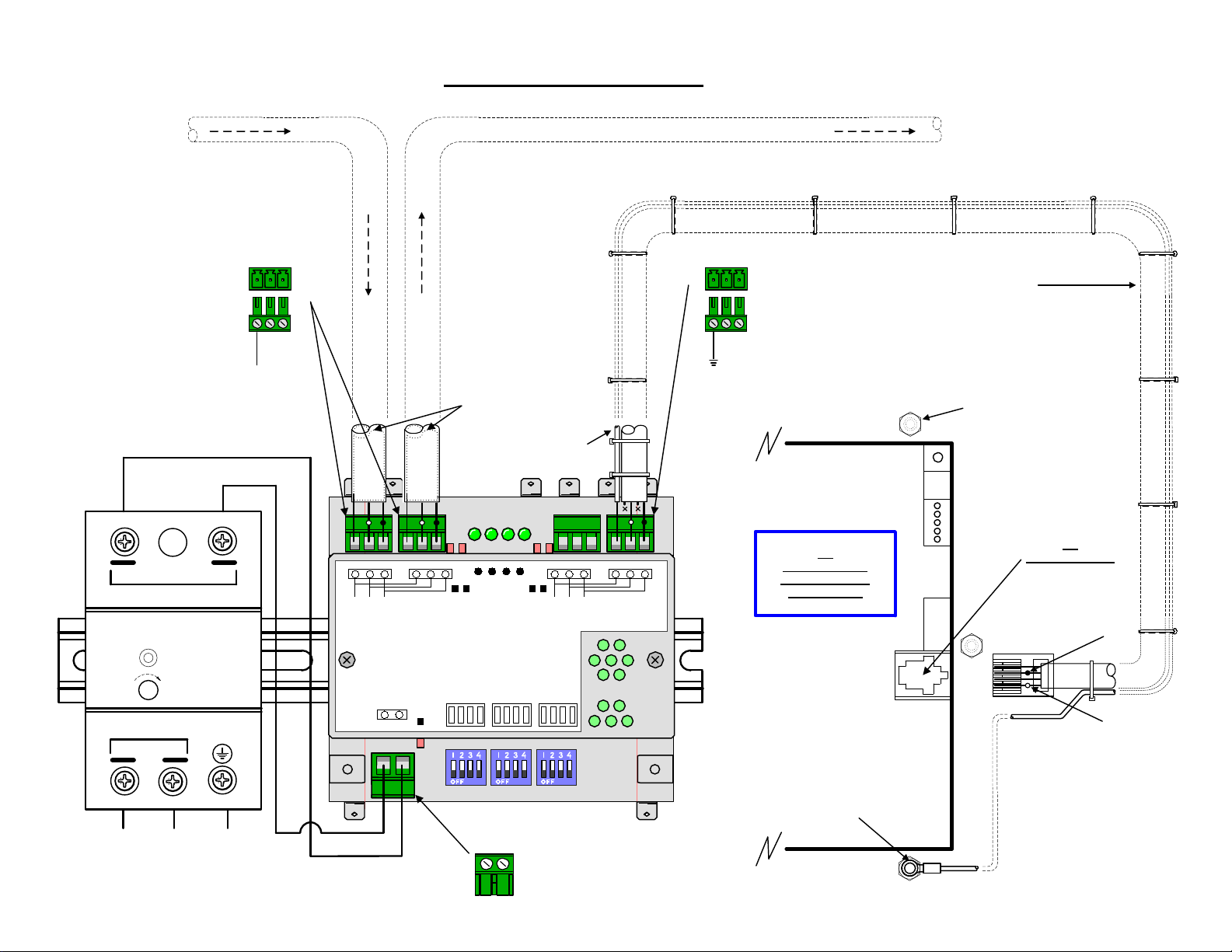

From Previous X8I or X12I

Automation Network

Component

irV-485 To INTELLISYS SGN / SGNe

RS485 RS485

X04

And

X02

X05

To Next

X8I or X12I Automation

Network Component

RJ11 Modbus Cable

Supplied With The

irV-485 Gateway

Modify As Shown By

Removing The RJ11 Plug.

0VDC

-V

NC

OUTPUT

idec

DC ON

V.ADJ

INPUT

100/240 VAC 0.17A

50/60HZ

L

L N G

From Compressor

110 / 230VAC

24VDC 0.3A

7.5

POWER SUPPLY

PS5R-A24

N

+24VDC

+V

WOUTPUT

SHIELD

L1L2

L1L2

GROUND

SHIELD

SGN/SGNe

Mounting Bolt

GROUND

WIRE

2121

P10

P8

P7

Phoenix 6Pin

CONNECTOR

6

5

43

21

L2

2

1

L1

SGN / SGNe

Phoenix 6Pin

COM PORT

On Right Side

As Viewed From

The Back

n

e

e

r

c

s

X01

+24VDC

0VDC

2

L

X05

123 123

1

L

c

d

/

c

c

d

a

/

V

c

4

a

2

V

+

0

1 2

1212

X04

ir485

irV-485

1

#

D

E

L

ON

OFF

6

7

8

#

#

#

D

D

D

E

E

2

#

D

E

L

SW1 SW2

E

3

L

L

L

#

D

E

L

2

341

+24

0

V

V

DC

DC

12

SGN / SGNe

As Viewed From

The Back Side Of

The Controller

4

#

D

E

L

SW3

9

n

e

e

r

c

s

101

1

2

L

X03

2

1

123 123

1

L

X02

irbus /

Modbus

9

#

D

E

5

L

#

D

E

L

6

785

Place Ground

Wire Lug Behind

SGN/SGNe

Mounting Bolt

Appendix A - Page A2

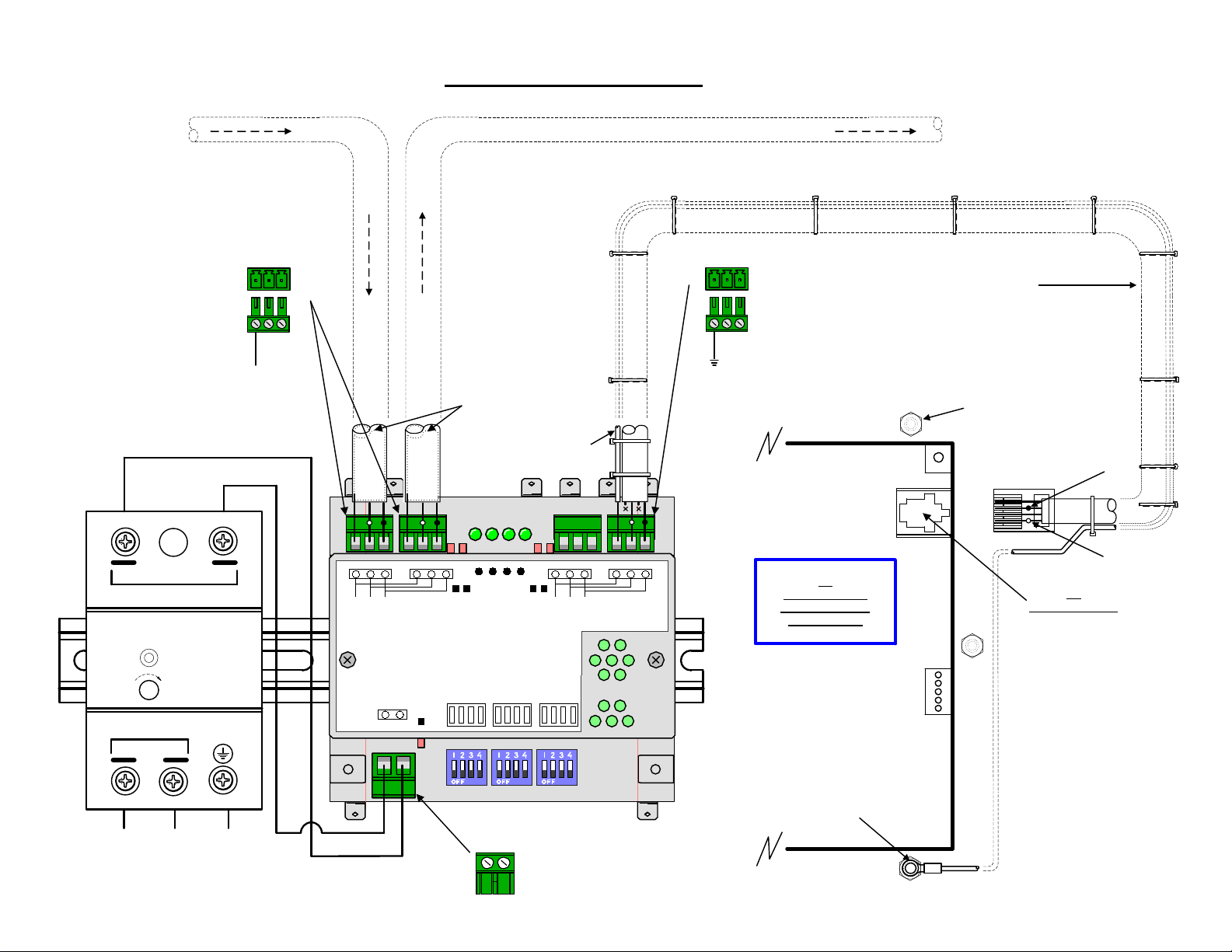

Page 12

From Previous X8I or X12I

Automation Network

Component

ir-485 To INTELLISYS SG

RS485 RS485

To Next

X8I or X12I Automation

Network Component

0VDC

-V

OUTPUT

idec

DC ON

V.ADJ

INPUT

100/240 VAC 0.17A

L

NC

24VDC 0.3A

7.5

POWER SUPPLY

PS5R-A24

50/60HZ

N

+24VDC

+V

WOUTPUT

SHIELD

X04

And

X02

X05

L1L2

L1L2

RJ11 Modbus Cable

Supplied With The

irV-485 Gateway

GROUND

SHIELD

SG

Mounting Bolt

GROUND

WIRE

21

P10

n

e

e

r

c

s

X01

2

L

X05

123 123

1

L

c

d

/

c

c

d

a

/

V

c

4

a

2

V

+

0

1 2

X04

ir485

1

#

D

E

L

ON

OFF

1212

6

#

D

E

2

3

L

#

#

D

D

E

E

L

L

ir-485

SW1 SW2

2

341

4

#

D

E

L

SW3

9

n

e

e

r

c

s

101

1

2

L

X03

2

1

123 123

1

L

8

9

7

#

#

#

D

D

D

E

E

E

5

L

L

L

#

D

E

L

6

785

X02

irbus /

Modbus

12

SG

As Viewed From

The Back Side Of

The Controller

P7

P9

P8

SG

RJ11 COM PORT

On Right Side

As Viewed From

RJ11

The Back

L2 (4)

43

2

1

CONNECTOR

6

5

4

3

2

1

L1 (2)

L N G

From Compressor

110 / 230VAC

+24VDC

0VDC

+24

DC

Place Ground

Wire Lug Behind

0

V

V

DC

SG Mounting Bolt

Appendix A - Page A3

Page 13

From Previous X8I or X12I

Automation Network

Component

ir-485 To INTELLISYS SE

RS485 RS485

To Next

X8I or X12I Automation

Network Component

0VDC

-V

OUTPUT

idec

DC ON

V.ADJ

INPUT

100/240 VAC 0.17A

L

NC

24VDC 0.3A

7.5

POWER SUPPLY

PS5R-A24

50/60HZ

N

SHIELD

+24VDC

+V

WOUTPUT

X04

And

X02

X05

L1L2

L1L2

RJ11 Modbus Cable

Supplied With The

irV-485 Gateway

GROUND

SHIELD

SG

Mounting Bolt

GROUND

WIRE

n

e

e

r

c

s

X01

2

L

X05

123 123

1

L

c

d

/

c

c

d

a

/

V

c

4

a

2

V

+

0

1 2

X04

ir485

1

#

D

E

L

ON

OFF

1212

6

#

D

E

2

3

L

#

#

D

D

E

E

L

L

ir-485

SW1 SW2

2

341

RJ11

CONNECTOR

6

5

4

12

7

9

8

#

#

#

D

D

D

E

E

E

5

L

L

L

#

D

E

L

123 123

SE

4

1

n

2

#

e

L

e

D

r

E

c

L

s

X03

X02

L

irbus /

Modbus

As Viewed From

The Back Side Of

The Controller

J8

3

2

1

RJ11 COM PORT

On Right Side

As Viewed From

The Back

SW3

2

1

1

101

6

785

9

J11

L2 (4)

L1 (2)

SE

L N G

From Compressor

110 / 230VAC

+24VDC

0VDC

+24

DC

Place Ground

Wire Lug Behind

0

V

V

DC

SE Mounting Bolt

Appendix A - Page A4

Page 14

From Previous X8I or X12I

Automation Network

ir-485 To INTELLISYS REDEYE

Component

RS485 RS485

To Next

X8I or X12I Automation

Network Component

0VDC

-V

NC

OUTPUT 24VDC 0.3A

idec

DC ON

V.ADJ

INPUT

100/240 VAC 0.17A

L

7.5

POWER SUPPLY

PS5R-A24

50/60HZ

N

+V

W

SHIELD

+24VDC

OUTPUT

X04

And

X05

L1L2

X02

L1L2

RJ11 Modbus Cable

Supplied With The

irV-485 Gateway

GROUND

SHIELD

GROUND

L2 (4)

L1 (2)

WIRE

Redeye

Starter Interface

Board

Mounting Bolt

X02

irbus /

Modbus

12

Test Port

1212

123 123

1

n

2

e

L

e

r

c

s

X05

X04

L

ir485

6

7

8

9

#

#

#

#

D

D

D

D

E

E

E

2

3

#

#

D

D

E

E

L

L

E

L

5

L

L

L

#

D

E

L

123 123

4

1

n

2

#

L

e

L

e

D

r

E

c

L

s

X03

ir-485

RJ11

CONNECTOR

J2

1

6235

4

Sequencer Port

Place Ground

Wire Lug Behind

Starter Interface

Board Mounting

Screw

J3

c

X01

d

/

c

a

V

4

2

+

1 2

c

d

/

c

a

V

0

1

#

D

E

L

ON

OFF

SW1 SW2

2

341

SW3

2

1

1

101

9

6

785

REDEYE STARTER

INTERFACE BOARD

RJ11 COM PORT

On Top Center

BTS

As Viewed Facing Board

L N G

From Compressor

110 / 230VAC

+24VDC

0VDC

+24

DC

0

V

V

DC

REDEYE STARTER

INTERFACE BOARD

As Viewed Facing Board

Appendix A - Page A5

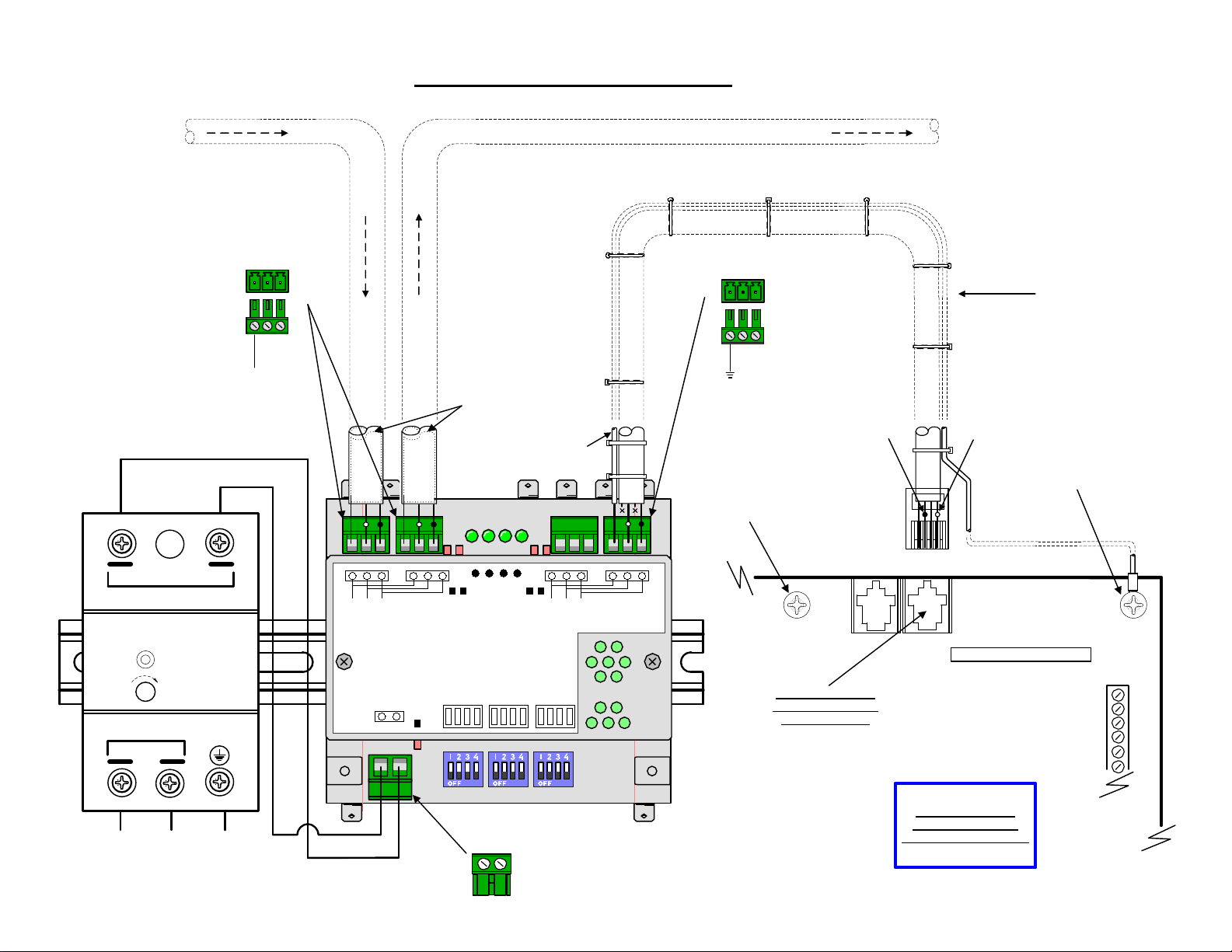

Page 15

X01

X01

X04

X04

X02

X02 X03

X09

X07 X08

GND

Vcc

TxD RxD

1212

SHIELD

X03

X06 X05

X05X06X07 X08

IntelliSys S3

As Viewed From

The Back Side Of

The Controller

RS485 RS485

From Previous X8I or X12I

Automation Network

Component

RS485 To INTELLISYS S3

To Next

X8I or X12I Automation

Network Component

Appendix A - Page A6

Page 16

From Previous X8I or X12I

Automation Network

irV-485 To NIRVANA 15-30KW (20-40HP)

Component

RS485 RS485

To Next

X8I or X12I Automation

Network Component

0VDC

-V

NC

OUTPUT 24VDC 0.3A

idec

DC ON

V.ADJ

INPUT

100/240 VAC 0.17A

L

7.5

POWER SUPPLY

PS5R-A24

50/60HZ

N

+V

W

SHIELD

+24VDC

OUTPUT

X04

And

X05

L1L2

X02

L1L2

RJ11 Modbus Cable

Supplied With The

irV-485 Gateway

NIRVANA 15-30KW

(20-40HP)

SHIELD

GROUND

CONTROL BOARD

As Viewed Facing Board

GROUND

WIRE

n

e

e

r

c

s

X01

2

L

X05

123 123

1

L

c

d

/

c

c

d

a

/

V

c

4

a

2

V

+

0

1 2

X04

ir485

1

#

D

E

L

ON

OFF

1212

3

2

#

#

D

D

E

E

L

L

ir-485

SW1 SW2

2

341

4

#

D

E

L

SW3

9

n

e

e

r

c

s

101

1

2

L

X03

2

1

123 123

1

L

6

7

8

9

#

#

#

#

D

D

D

D

E

E

E

E

L

5

L

L

L

#

D

E

L

6

785

X02

irbus /

Modbus

12

NIRVANA

15-30KW

(20-40HP)

COM PORT

On Right

Side As

Viewed

From The

2 1

68 6961

L1

Back

68 6961

L2

L N G

From Compressor

110 / 230VAC

+24VDC

0VDC

+24

V

DC

DC

0

V

Phoenix 3Pin

CONNECTOR

Place Ground Wire Lug

Behind

NIRVANA 15-30KW

(20-40HP) Mounting Bolt

Appendix A - Page A7

Page 17

APPENDIX B

ir-PCB TO INGERSOLL RAND INTELLISYS CONTROLLED

COMPRESSOR INTERCONNECT DRAWINGS

ir-PCB Interconnect Requirements For Ingersoll Rand

Unigy & Nirvana 15-30KW (20-40HP) Compressors .......B1

Unigy 1 1of2.................................................................B2

Unigy 1 2of2.................................................................B3

Unigy 2/3 1of2 ............................................................. B4

Unigy 2/3 2of2 ............................................................. B5

Nirvana 15-30KW (20-40HP) 1of2..................................B6

Nirvana 15-30KW (20-40HP) 2of2..................................B7

ir-PCB Interconnect Requirements For Ingersoll Rand

Intellisys Redeye Controlled Compressors ....................B8

SSR Redeye 1of3 ...........................................................B9

SSR Redeye FV 2of3 ....................................................B10

SSR Redeye SD 3of3 ....................................................B11

ir-PCB Interconnect Requirements For Ingersoll Rand

Intellisys SE Controlled Compressors .......................... B12

SE UP 1of2 ..................................................................B13

SE UP 2of2 ..................................................................B14

SE ESA 1of2 ................................................................B15

SE ESA 2of2 ................................................................B16

SE DSA 1of2................................................................B17

SE DSA 2of2................................................................B18

ir-PCB Interconnect Requirements For Ingersoll Rand

Intellisys SG Controlled Compressors..........................B19

SG SSR 1of2 ................................................................ B20

SG SSR 2of2 ................................................................ B21

SG Sierra 1of2.............................................................B22

SG Sierra 2of2.............................................................B23

ir-PCB Interconnect Requirements For Ingersoll Rand

Intellisys SGN / SGNe Controlled Compressors ........B24

Nirvana SGN/SGNe 1of3 .............................................. B25

Nirvana SGN/SGNe 2of3 .............................................. B26

Nirvana SGN/SGNe 3of3 .............................................. B27

SI1 Interface to Redeye, SE, SG Controllers.................. B28

ir-PCB Interconnect Requirements For Ingersoll Rand

Intellisys S3 ................................................................B29

Intellisys S3 1of2 ........................................................B30

Intellisys S3 2of2 ........................................................B31

ir-PCB Interconnect Requirements For Ingersoll Rand CMC

Sierra 1of2.................................................................. B32

ir-PCB Interconnect Requirements For Ingersoll Rand CMC

Sierra 2of2.................................................................. B33

17

Page 18

ir-PCB Interconnect To Ingersoll Rand

Unigy & Nirvana 20-40 HP Compressors

FOR UNIGY COMPRESSORS:

All Unigy Phase 1 compressors “MUST” be converted to Phase 2 or higher. Contact Technical Support Services for the

CCN's required for this conversion.

FOR NIRVANA 20-40HP COMPRESSORS:

When using the X8I Automation System, the ir-485 and irV-485 Gateway is the “recommended and preferred” method

when interfacing and connecting to the FG (redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and

Nirvana 15-30KW (20-40HP) Compressors. See Appendix A for interconnect drawings for these applications

When using the X4I Automation System, the ir-PCB is the only method when interfacing and connecting to the FG

(redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and Nirvana 15-30KW (20-40HP) Compressors. See

Appendix B for interconnect drawings for these applications

Remote Control “MUST” be set to “ON”.

Remote Start / Stop must be set to “OFF”.

Check the Nirvana Software revision level. It “MUST” be updated to Version 1.10 or greater. Contact Technical Support

Services to acquire the update.

DRAWING NOTES FOR UNIGY PHASE 1 MACHINES:

Note: All Unigy Phase 1 compressors “MUST” be converted to Phase 2 or higher. Contact Technical Support Services

for the CCN's required for this conversion. The Drawing “Unigy Phase 1 1of2” is a representation for “AFTER” the

conversion is completed.

Note: The Unigy Target Pressure “MUST” be set equal to the “midpoint” of the X - Series Automation pressure control

band.

DRAWING NOTES FOR UNIGY PHASE 2/3 MACHINES:

Note: The Unigy Target Pressure “MUST” be set equal to the “midpoint” of the X - Series Automation pressure control

band.

DRAWING NOTES FOR NIRVANA 20-40HP MACHINES:

Note: Remote Control “MUST” be set to on.

Note: The Nirvana Target Pressure “MUST” be set equal to the “midpoint” of the X - Series Automation pressure

control band.

Appendix B Page B1

Page 19

Unigy Phase 1

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

2

3

4

5

6

1

2

V

SEQ CONT

LOAD UNL

GND

C03

D11

D12

+20V

LED 5 V

LED 2 LOAD

LED 1 SEQ

LED 4

READY

LED 3

RUN

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

+VDC

VFD/fixed

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

D13

+24VDC

SA1

HATS

10

13

E-STOP

14

EN

C

12

DI-4

C

VFD/FIX

11

9

5

17

+24VDC

DI-2

0V

NO

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

Unigy 1

7.5 - 15 HP

5.5 – 11 kW

Appendix B Page B2

Page 20

Unigy Phase 1

Appendix B Page B3

Page 21

Unigy Phase 2/3

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 V

LED 2 LOAD

LED 1 SEQ

READY

1

2

V

LED 4

C03

RUN

LED 3

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

+VDC

VFD/fixed

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

D13

+24VDC

SA1

10

HATS

13

E-STOP

14

EN

C

12

DI-4

C

VFD/FIX

11

9

5

17

+24VDC

DI-2

0V

NO

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

Unigy

7.5 - 15 HP

5.5 – 11 kW

Appendix B Page B4

Page 22

Unigy Phase 2/3

Appendix B Page B5

Page 23

Nirvana 15 – 30KW

(20 – 40HP)

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 V

LED 2 LOAD

LED 1 SEQ

READY

1

2

12

+24VDC

+VDC

VFD/fixed

V

C01

Load Enable

Load/Unload

C03

NO

OUT

18

32

33

Remote

VFD / FIXED

Remote

LOAD ENABLE

Remote

LOAD / UNLOAD

C

IN

NC

NO

C

C02

NC

SAFE

C

COM

LED 4

RUN

LED 3

C04

ALARM

RUN

READY

37

4

20

IR-PCB

6

NC

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

Nirvana

20 - 40 HP

15 – 30 kW

37

SAFE

Appendix B Page B6

Page 24

Nirvana 15 - 30KW

(20-40HP)

Appendix B Page B7

Page 25

ir-PCB Interconnect To Ingersoll Rand

First Generation IntelliSys “Redeye” Controlled Compressors

FOR REDEYE INTELLISYS CONTROLLED MACHINES:

When using the X8I Automation System, the ir-485 and irV-485 Gateway is the “recommended and preferred” method

when interfacing and connecting to the FG (redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and

Nirvana 15-30KW (20-40HP) Compressors. See Appendix A for interconnect drawings for these applications

When using the X4I Automation System, the ir-PCB is the only method when interfacing and connecting to the FG

(redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and Nirvana 15-30KW (20-40HP) Compressors. See

Appendix B for interconnect drawings for these applications

The ‘MASTER CONTROL’ setting of the Intellisys controller must be set to ‘ON’

The 'SEQUENCER' setting of the Intellisys controller must be set to 'ON'.

Remote Start / Stop must be set to “OFF”.

Auto Restart must be turned 'ON’ to allow the machines to stop in Auto restart when unloaded by the X - Series

Automation.

The Intellisys must be run in the Online/Offline regulation mode. Do not use Modulation or ACS.

Check the Intellisys software revision level. Always update to the latest revision prior to operation.

FOR DSA REDEYE CONTROLLERS, the 'SEQUENCER Option’ must be purchased. installed and then turned on.

CCN: 39225099

FOR ESA REDEYE INTELLISYS CONTROLLERS, the SI1 interface (CCN: 42425710) must be used to allow the Redeye to

be controlled by the X - Series Automation

FOR SIERRA REDEYE INTELLISYS CONTROLLERS, the SI1 interface (CCN: 42425710) must be used to allow the Redeye

Controller to be sequenced/controlled by the X - Series Automation

DRAWING NOTES FOR REDEYE INTELLISYS CONTROLLED MACHINES:

Note: For Star Delta starter wiring the X - Series Automation Run signal should be connected directly to the 1M coil.

Note: For Full voltage wiring the 1S (1Sb) interlock will not be used. The X - Series Automation Run signal can be

connected directly to the Intellisys BTS1-28 terminal.

Appendix B Page B8

Page 26

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

SSR Redeye

Analog Barrier Board

BTS311

+VDC

VFD/fixed

V

C03

LED 4

RUN

LED 3

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

0VAC

110VAC

E-STOP

1M

HATS

12

16

18

BTS1-

1

BTS1-

34

Remote Load/Unload

(was Remote Start)

Remote Load Enable

(was Remote Stop)

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

110VAC

E-STOP

HATS

BTS2-

1

2

3

Starter Interface Board

BTS2

34

Appendix B Page B9

Page 27

SSR Redeye FV

Appendix B Page B10

Page 28

SSR Redeye SD

Appendix B Page B11

Page 29

ir-PCB Interconnect To Ingersoll Rand

Second Edition Intellisys “SE” Controlled Compressors

FOR ALL SE INTELLISYS CONTROLLED MACHINES:

When using the X8I Automation System, the ir-485 and irV-485 Gateway is the “recommended and preferred” method

when interfacing and connecting to the FG (redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and

Nirvana 15-30KW (20-40HP) Compressors. See Appendix A for interconnect drawings for these applications

When using the X4I Automation System, the ir-PCB is the only method when interfacing and connecting to the FG

(redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and Nirvana 15-30KW (20-40HP) Compressors. See

Appendix B for interconnect drawings for these applications

The 'SEQUENCER' setting of the Intellisys controller must be set to 'ON'.

Remote Start / Stop must be set to “OFF”.

Auto Restart must be turned 'ON’ to allow the machines to stop in Auto restart when unloaded by the X - Series

Automation.

The Intellisys must be run in the Online/Offline regulation mode. Do not use Modulation or ACS.

Check the Intellisys software revision level. Always update to the latest revision prior to operation.

FOR UP SE INTELLISYS CONTROLLERS

Minimum Software Version 1.11

CCN: 39217047 (w/o PORO)

CCN: 39217039 (w PORO)

When installing the Sequence Option to enable Remote Load/Unload, the Remote Start/Stop input terminals

are now used for the Remote Load inputs. Remote Start Stop will no longer be functional. The SI1 interface (CCN: 42425710)

can be used in place of the Sequence Option to allow the SE controlled machines to function with both Remote Load Unload

and Remote Start Stop.

Software Version 1.20 and Greater

The 'CONTACT SEQUENCE' setting of the Intellisys controller must be set to 'ON'.

DRAWING NOTES FOR UP SE INTELLISYS CONTROLLED MACHINES:

Note: For Star Delta starter wiring the X - Series Automation Run signal should be connected directly to the 1M coil.

Note: For Full voltage wiring the 1S (1Sb) interlock will not be used. The X - Series Automation Run signal can be

connected directly to the Intellisys J5-1 terminal.

Note: For Pegasus machines wiring may be factory installed connecting the Intellisys Alarm Relay J5-9, J5-10 and J5-11

to a terminal strip but unused. Remove any factory installed wiring from the Intellisys Alarm Relay contacts and connect

the X - Series Automation Interface board wiring directly to the Intellisys Alarm Relay terminals J5-9 and J5-10.

FOR ESA SE INTELLISYS CONTROLLERS

Minimum Software Version 1.40

CCN: 39217047 (w/o PORO)

CCN: 39217039 (w PORO)

When installing the Sequence Option to enable Remote Load/Unload, the Remote Start Stop input terminals

are now used for the Remote Load inputs. Remote Start Stop will no longer be functional. The SI1 interface (CCN: 42425710)

can be used in place of the Sequence Option to allow the SE controlled machines to function with both Remote Load Unload

and Remote Start Stop.

DRAWING NOTES FOR ESA SE INTELLISYS CONTROLLED MACHINES:

Note: For Star Delta starter wiring the X - Series Automation Run signal should be connected directly to the 1M coil.

Note: For Full voltage wiring the 1S (1Sb) interlock will not be used. The X - Series Automation Run signal can be

connected directly to the Intellisys J5-1 terminal.

FOR DSA SE INTELLISYS CONTROLLERS

CCN: 22179238

When installing the Sequence Option to enable Remote Load/Unload, the Remote Start Stop input terminals

are now used for the Remote Load inputs. Remote Start Stop will no longer be functional. The SI1 interface (CCN: 42425710)

can be used in place of the Sequence Option to allow the SE controlled machines to function with both Remote Load Unload

and Remote Start Stop.

DRAWING NOTES FOR DSA SE INTELLISYS CONTROLLED MACHINES:

Note: For Star Delta starter wiring the X - Series Automation Run signal should be connected directly to the 1M coil.

Note: For Full Voltage wiring, the 1S (1Sb) interlock will not be used. The X - Series Automation Run signal can be

connected directly to the Intellisys terminal 42.

,

, the 'SEQUENCER Option’ must be purchased. installed and then turned on.

, the 'SEQUENCER Option’ must be purchased. installed and then turned on.

FOR SIERRA SE INTELLISYS CONTROLLERS

be sequenced/controlled by the X - Series Automation

, the SI1 interface (CCN: 42425710) must be used to allow the SE Controller to

Appendix B Page B12

Page 30

SE UP

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

J1

+VDC

VFD/fixed

V

C03

LED 4

RUN

LED 3

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

0VAC

110VAC

E-STOP

1M

11

12

13

14

J5

1

J5

7

J5

9

10

11

Remote Load/Unload

(was Remote Start)

Remote Enable

(was Remote Stop)

Intellisys SE

UP Series

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

110VAC

E-STOP

J5

7

Appendix B Page B13

Page 31

SE UP

Appendix B Page B14

Page 32

SE ESA

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

V

LED 4

C03

LED 3

RUN

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

+VDC

VFD/fixed

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

J1

11

12

13

14

C

C

J5

1

J5

7

J5

9

10

11

110VAC

0VAC

MCB2

HAT

1M

E-STOP

Remote Load/Unload

(was Remote Start)

Remote Enable

(was Remote Stop)

Intellisys SE

ESA Series

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

110VAC

E-STOP

J5

7

Appendix B Page B15

Page 33

SE ESA

Appendix B Page B16

Page 34

SE DSA

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

J1

+VDC

VFD/fixed

V

C03

LED 4

RUN

LED 3

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

0VAC

110VAC

E-STOP

1M

1ATS

6

5

4

3

J5

42

J5

36

J5

34

33

32

Remote Load/Unload

(was Remote Start)

Remote Enable

(was Remote Stop)

Intellisys SE

DSA Contact

Cooled

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

110VAC

E-STOP

J5

38

Appendix B Page B17

Page 35

SE DSA

Appendix B Page B18

Page 36

ir-PCB Interconnect To Ingersoll Rand

Second Generation IntelliSys “SG” Controlled Compressors

FOR SG INTELLISYS CONTROLLED MACHINES:

When using the X8I Automation System, the ir-485 and irV-485 Gateway is the “recommended and preferred” method

when interfacing and connecting to the FG (redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and

Nirvana 15-30KW (20-40HP) Compressors. See Appendix A for interconnect drawings for these applications

When using the X4I Automation System, the ir-PCB is the only method when interfacing and connecting to the FG

(redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and Nirvana 15-30KW (20-40HP) Compressors. See

Appendix B for interconnect drawings for these applications

The 'SEQUENCER' setting of the Intellisys controller must be set to 'ON'.

Remote Start / Stop must be set to “OFF”.

Auto Restart must be turned 'ON’ to allow the machines to stop in Auto restart when unloaded by the X - Series

Automation.

The Intellisys must be run in the Online/Offline regulation mode. Do not use Modulation or ACS.

Check the Intellisys software revision level. Always update to the latest revision prior to operation.

FOR SIERRA SG INTELLISYS CONTROLLERS, the SI1 interface (CCN: 42425710) can be used as an alternative to allow

the SG Controller to be sequenced/controlled by the X - Series Automation

DRAWING NOTES FOR SG INTELLISYS CONTROLLED MACHINES:

Note: For Star Delta starter wiring the X - Series Automation Run signal should be connected directly to the 1M coil.

Note: For Full Voltage wiring, the 1S (1Sb) interlock will not be used. The X - Series Automation Run signal can be

connected directly to the Intellisys P1-2 terminal.

Appendix B Page B19

Page 37

SG SSR

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

P3

+VDC

VFD/fixed

V

C03

LED 4

RUN

LED 3

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

1Sb

0VAC

110VAC

1M

1ATS

E-STOP

25

26

27

28

P1

2

P1

1

P2

3

2

1

Remote Load Enable

Remote Load/Unload

Intellisys SG

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

110VAC

E-STOP

1ATS

P!

1

Appendix B Page B20

Page 38

SG SSR

Appendix B Page B21

Page 39

SG Sierra

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

P3

+VDC

VFD/fixed

V

C03

LED 4

RUN

LED 3

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

1Sb

0VAC

110VAC

1M

1ATS

E-STOP

25

26

27

28

P1

2

P1

1

P2

3

2

1

Remote Load Enable

Remote Load/Unload

Intellisys SG

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

110VAC

E-STOP

1ATS

P!

1

Appendix B Page B22

Page 40

SG Sierra

Appendix B Page B23

Page 41

ir-PCB Interconnect To Ingersoll Rand

Nirvana IntelliSys “SGN / SGNe” Controlled Compressors

FOR SGN/SGNE INTELLISYS CONTROLLED MACHINES:

When using the X8I Automation System, the ir-485 and irV-485 Gateway is the “recommended and preferred” method

when interfacing and connecting to the FG (redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and

Nirvana 15-30KW (20-40HP) Compressors. See Appendix A for interconnect drawings for these applications

When using the X4I Automation System, the ir-PCB is the only method when interfacing and connecting to the FG

(redeye), SG, SGN and SGNe, SE IntelliSys controlled compressors and Nirvana 15-30KW (20-40HP) Compressors. See

Appendix B for interconnect drawings for these applications

The SI1 interface (CCN: 42425710) must be used to allow the SGN/SGNe Controller to be sequenced/controlled by the X Series Automation

The 'SEQUENCER' setting of the Intellisys controller must be set to 'ON'.

Remote Start / Stop must be set to “OFF”.

Auto Restart must be turned 'ON’ to allow the machines to stop in Auto restart when unloaded by the X - Series

Automation.

The Intellisys must be run in the Online/Offline regulation mode. Do not use Modulation or ACS.

Check the Intellisys software revision level. Always update to the latest revision prior to operation.

DRAWING NOTES FOR NIRVANA MACHINES:

Note: The Nirvana Target Pressure “MUST” be set equal to the Midpoint of the X - Series Automation pressure control

band.

Refer to the X - Series Automation Overview Drawing for the X - Series Automation Compressor 2 through 4 X01 to IRPCB terminal connections

Appendix B Page B24

Page 42

Nirvana SGN/SGNe

Sequence Interface 1

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

1

Remote Load / Unload

+VDC

VFD/fixed

V

C03

LED 4

LED 3

RUN

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

H

N

110 VAC

Supply

HATS

P!

1

110VAC

110VAC

E-STOP

E-STOP

1ATS

2

3

Run

4

Remote Load Enable

5

Neutral

6

Neutral

7

Hot

SGN/

SGNe

P1

1

SGN/

SGNe

P2

3

2

1

Intellisys Controller

COM

COM

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

Appendix B Page B25

Page 43

Nirvana SGN/SGNe

Appendix B Page B26

Page 44

Nirvana SGN/SGNe

Appendix B Page B27

Page 45

SI1 Interface to Redeye, SE, SG Controllers

Sequence Interface 1

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

V

V

1

SEQ CONT

LOAD UNL

2

GND

3

4

5

6

C05

1

2

Alternate Connection Metthod For

READY Input If Alarm Contacts Are

Being Used

C03

D11

D12

+20V

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

LED 4

READY

RUN

LED 3

C01

IR-PCB

110VAC

+VDC

VFD/fixed

Load Enable

Load/Unload

NO

OUT

IN

ALARM

READY

E-STOP

NC

NO

NC

RUN

C02

C04

C

C

1ATS

Redeye

BTS134 36

110VAC

SE

DSA

J5

E-STOP

SE

ESA/UP

J5

7

N

110 VAC

Supply

HATS

SG

P1

1

1

Remote Load / Unload

2

3

Run

4

Remote Load Enable

5

Neutral

6

Neutral

7

Hot

H

Redeye

BTS1-

34 36

Redeye

BTS2-

1

2

3

SE

DSA

J5

SE

DSA

J5

34

33

32

Intellisys Controller

SE

ESA/UP

J5

7

SE

ESA/UP

J5

9

10

11

COM

COM

SG

P1

1

SG

P2

3

2

1

READY

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

Appendix B Page B28

Page 46

a

n

d

o

l

l

e

r

o

I

c

t

o

n

n

t

e

r

P

C

B

i

r

-

I

n

c

e

T

n

g

s

R

t

s

o

s

o

r

r

i

e

s

-Se

t

he

X

y

e

a

b

d

d

l

o

.

.

n

t

i

o

per

a

o

s

p

r

C

o

l

l

e

o

n

t

r

s

s

y

i

n

e

t

a

p

u

o

con

t

o

s

i

on mode

d

a

t

3

/

S

C

f

”

w

O

H

1

C

:

S

E

I

N

H

e

t

I

e

n

l

l

i

n

A

E

a

m

r

e

e

lways

:

S

c

gul

i

h

t

h

t

he

f

f

l

.

l

I

N

y

s

L

t

’

O

i

S3

9

3

E

A

M

D

C”

o

“

R

o

F

“

F

O

l

o

t

a

o

l

e

l

i

n

n

l

eve

n

i

o

s

C

A

M

0

9

2

9

5

1

0

t

e

l

l

i

T

N

'

s

t

b

ned

n

a

LLI

3

:

C

S

L

O

R

t

t

e

i

ng

set

e

N

O

'

t

he

i

n

r

r

e

e

v

S

Y

S

9

4

2

0

3

:

N

C

I

n

O

C

S

Y

I

S

L

L

S3

t

R

k

E

T

I

N

L

O

R

T

N

O

C

E

T

O

M

E

s

t

a

a

r

n

y

I

E

R

r

t

/

must

t

.

s

mu

t

e

n

S

a

e

l

a

S

l

l

i

O

F

y

B

y

op mu

b

e

s

t

b

ys

s

N

I

R

I

C

R

a

s

e

t

u

r

e

r

u

s

o

f

t

w

E

T

N

C

I

R

–

e

t

S

t

e

s

a

t

i

o

t

e

l

l

i

s

e

t

h

T

O

N

1

Rel

R

1

R

L

L

A

R

O

F

R

'

e

h

T

e

o

R

m

t

o

u

A

u

A

m

t

o

I

n

e

h

T

h

C

e

c

G

N

I

W

A

R

D

:

t

e

o

N

:

t

e

o

N

d

l

l

e

r

mu

t

r

o

i

A

n

t

op

s

.

o

D

t

o

t

he

l

e

a

m

t

b

set

e

s

est

u

t

o

r

s

e

u

t

o

n

t

e

v

s

r

e

t

e

'

.

N

O

'

o

t

n

e

u

a

i

n

r

t

h

w

l

a

u

t

n

i

o

d

o

M

i

o

s

r

i

p

o

n

r

Appendix B Page B29

Page 47

Intellisys S3

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

X04

+VDC

VFD/fixed

V

C03

LED 4

RUN

LED 3

C01

Load Enable

Load/Unload

C02

C04

IR-PCB

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

KM2

Contact

0VAC

R1

Contact

KM1

1

7

Remote Load Enable

8

Remote Load/Unload

X03

2

X02

R1

Coil

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

110VAC

3

4

Intellisys S3

Appendix B Page B30

Page 48

Intellisys S3

Appendix B Page B31

Page 49

CMC Sierra

X4I / X8I / X12I

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

1

2

Terminal

Strip

2TB

+VDC

VFD/fixed

V

C03

LED 4

LED 3

RUN

C01

Load Enable

Load/Unload

C02

C04

NO

OUT

NC

NO

IN

NC

ALARM

RUN

READY

C

C

1Sb

1TB12

1M

1

2TB

5

2TB

6

1TB

5

Remote Load Enable

Remote Load/Unload

BCM

+24VDC

IR-PCB

The CMC Controller must be updated with Release Version 1.42 or greater.

The file can be found on the ServiceNet. Select Centrifugal, then select CMC Files, then select V320.

The Executable file is 22458368.exe

Guidance only; connections may differ with date, model, typ e, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

CMC

Appendix B Page B32

Page 50

Appendix B Page B33

Page 51

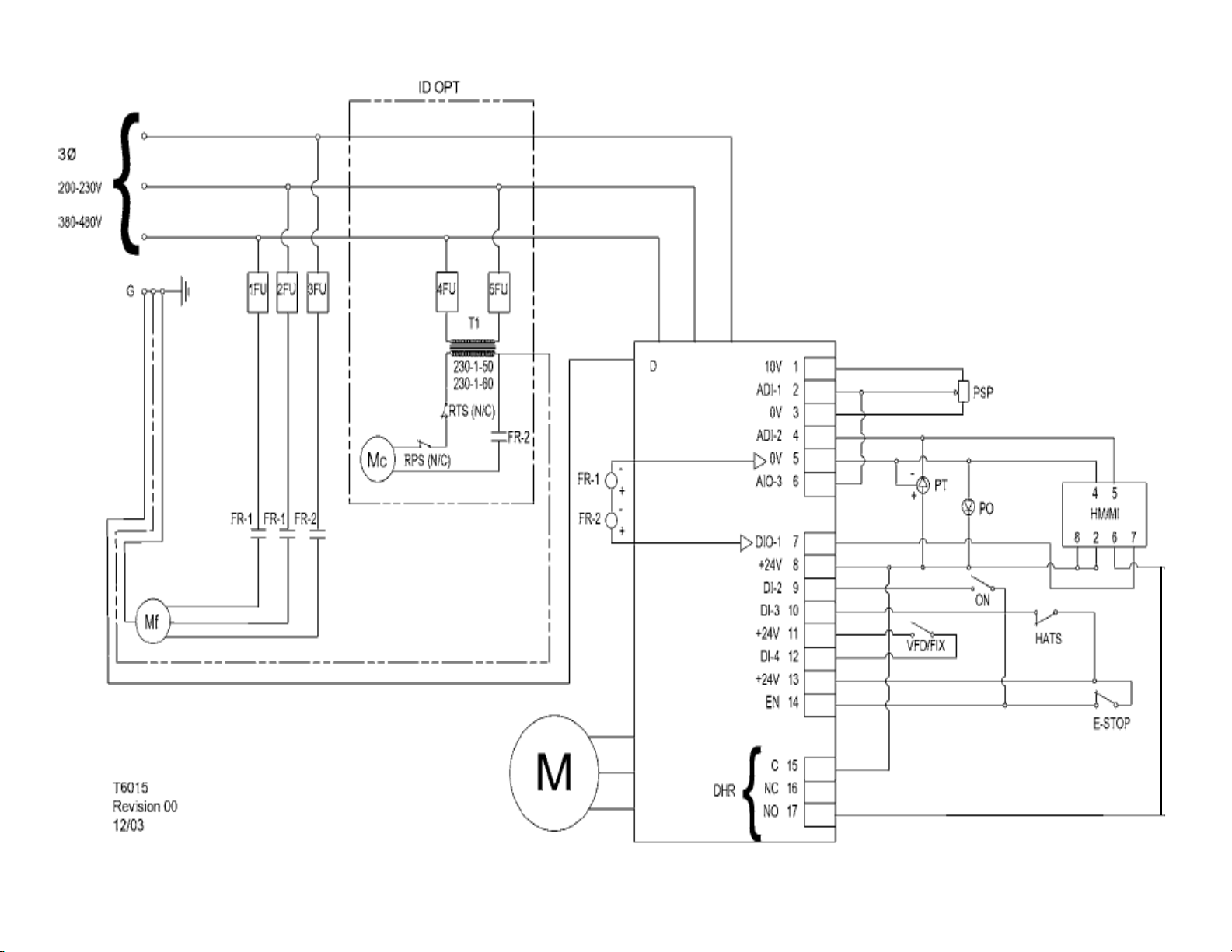

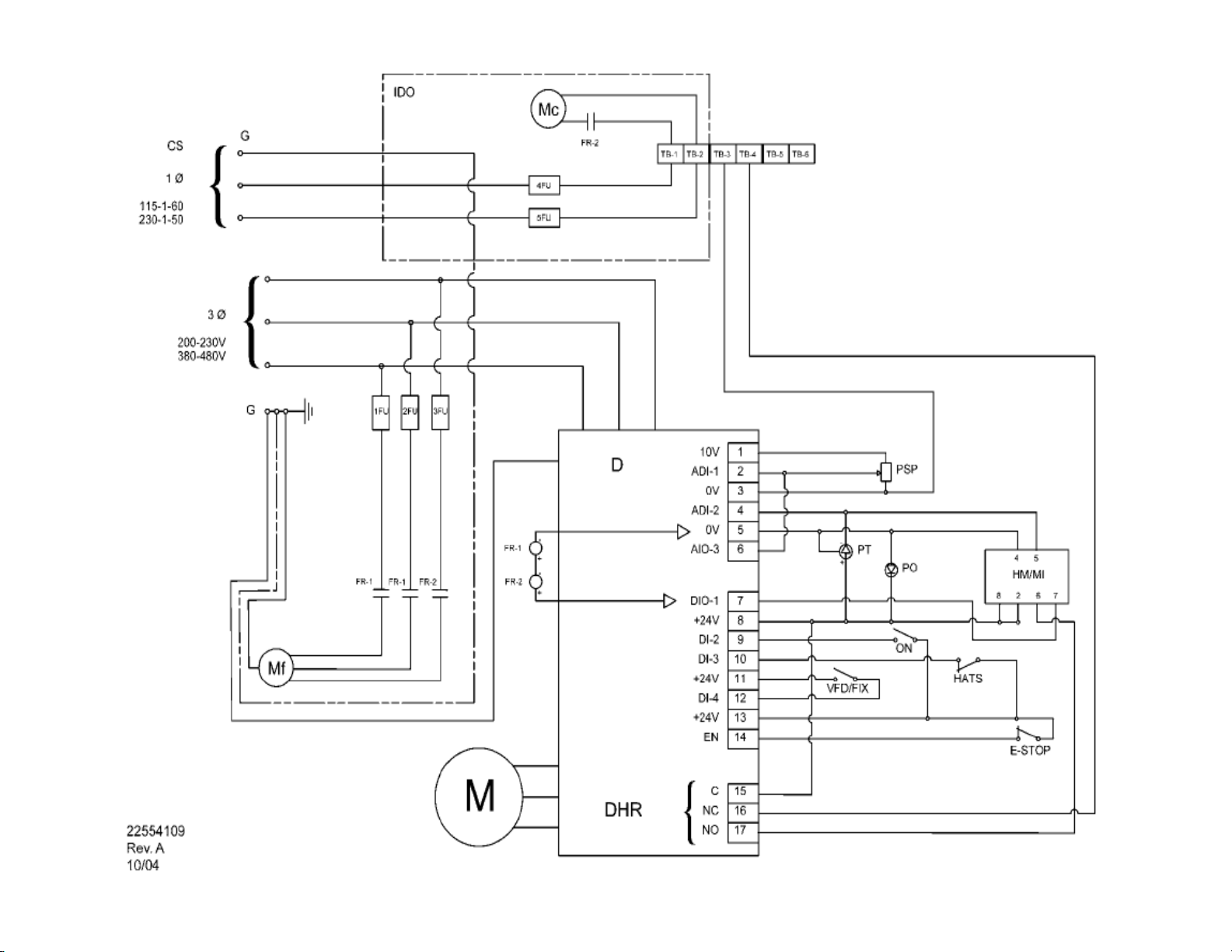

APPENDIX C

ir-PCB TO INGERSOLL RAND PRESSURE SWITCH CONTROLLED

COMPRESSOR INTERCONNECT DRAWINGS

ir-PCB Interconnect Requirements For Ingersoll Rand

Pressure Switch Controlled Compressors ..................... C1

SSR UP5 11-22 SD 1of2 ................................................ C2

SSR UP5 11-22 SD 2of2 ................................................ C3

SSR UP5 22-37 SD 1of2 ................................................ C4

SSR UP5 22-37 SD 2of2 ................................................ C5

SSR UP6 15-30 FV 1of2 ................................................ C6

SSR UP6 15-30 FV 2of2 ................................................ C7

SSR UP6 15-30 SD 1of2 ................................................ C8

SSR UP6 15-30 SD 2of2 ................................................ C9

SSR UP6 40-50 FV 1of2 .............................................. C10

SSR UP6 40-50 FV 2of2 .............................................. C11

SSR UP6 40-50 SD 1of2 .............................................. C12

SSR UP6 40-50 SD 2of2 .............................................. C13

UP6 5-15 FV 1PH 60Hz 1of2 ...................................... C14

UP6 5-15 FV 1PH 60Hz 2of2 ...................................... C15

UP6 5-15 FV 3PH 60Hz 1of2 ...................................... C16

UP6 5-15 FV 3PH 60Hz 2of2 ...................................... C17

UP6 5-15 SD 3PH 60Hz 1of2 ...................................... C18

UP6 5-15 SD 3PH 60Hz 2of2 ...................................... C19

UP6 5-15 FV 3PH 50Hz 1of2 ...................................... C20

UP6 5-15 FV 3PH 50Hz 2of2 ...................................... C21

UP6 5-15 SD 3PH 50Hz 1of2 ...................................... C22

UP6 5-15 SD 3PH 50Hz 2of2 ...................................... C23

SSR M15-22c 20-30HP XF EP HP HXP

50-60Hz 1of2 ............................................................ C24

SSR M15-22c 20-30HP XF EP HP HXP

50-60Hz 2of2 ............................................................ C25

M37-50 1of2.............................................................. C26

M37-50 2of2.............................................................. C27

EP 20-30 ESP FV 1of2 ................................................. C28

EP 20-30 ESP FV 2of2 ................................................. C29

EP 20-30 ESP SD 1of2................................................. C30

EP 20-30 ESP SD 2of2................................................. C31

ir-PCB Interconnect Requirements For Ingersoll Rand

Small Reciprocating Air Compressors ........................C32

UP6RE 7.5–15 175, UP6RX 7.5–15 175 1of3 ...............C33

UP6RE 7.5–15 175, UP6RX 7.5–15 175 2of3 ...............C34

UP6RE 7.5–15 175, UP6RX 7.5–15 175 3of3 ...............C35

Models 2340, 2475, 2545, 7100,

15T & 3000 10f3 ........................................................C36

Models 2340, 2475, 2545, 7100,

15T & 3000 20f3 ........................................................C37

Models 2340, 2475, 2545, 7100,

15T & 3000 30f3 ........................................................C38

Excessive Pressure Shutdown Switch Example Before

Installation ................................................................C39

Excessive Pressure Shutdown Switch Example After

Installation ................................................................C40

51

Page 52

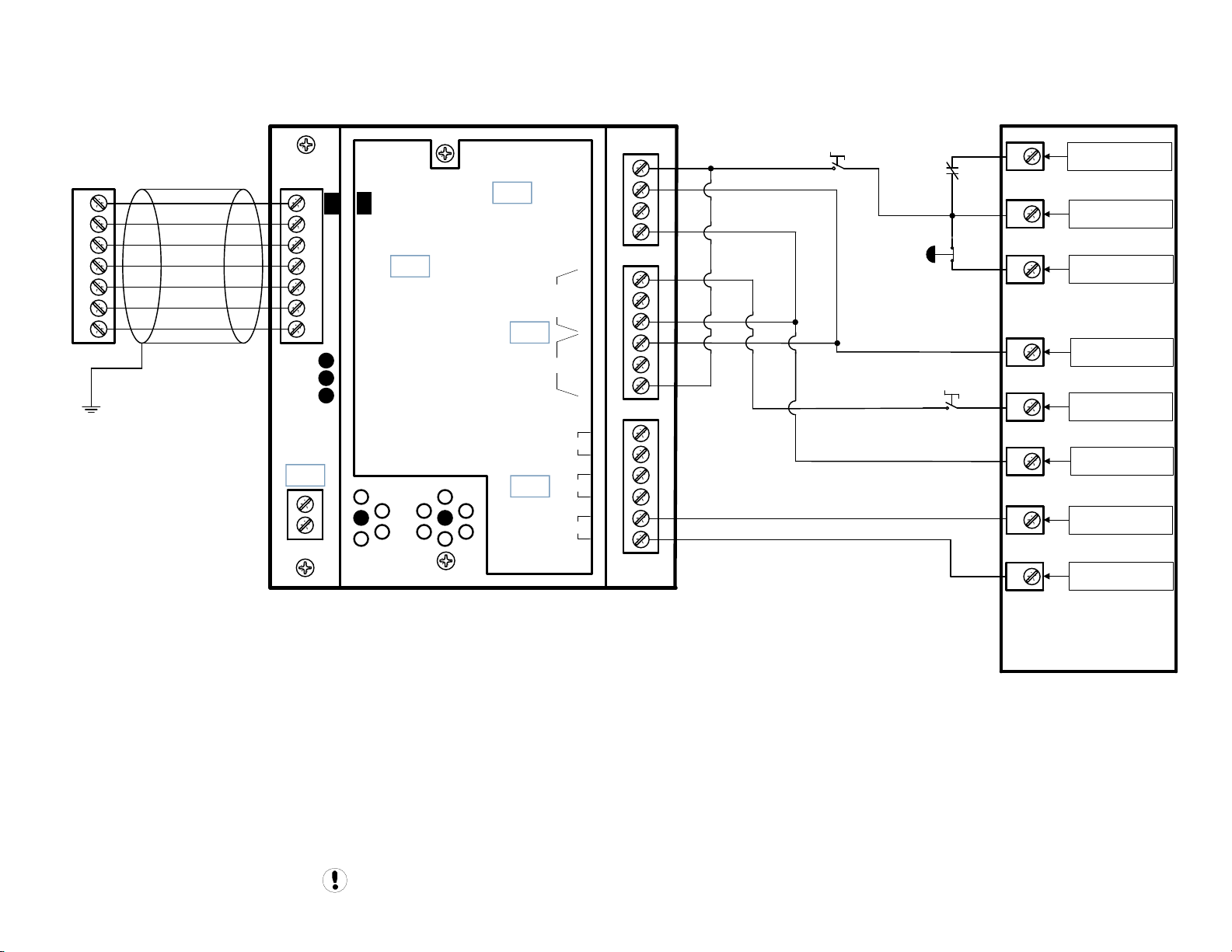

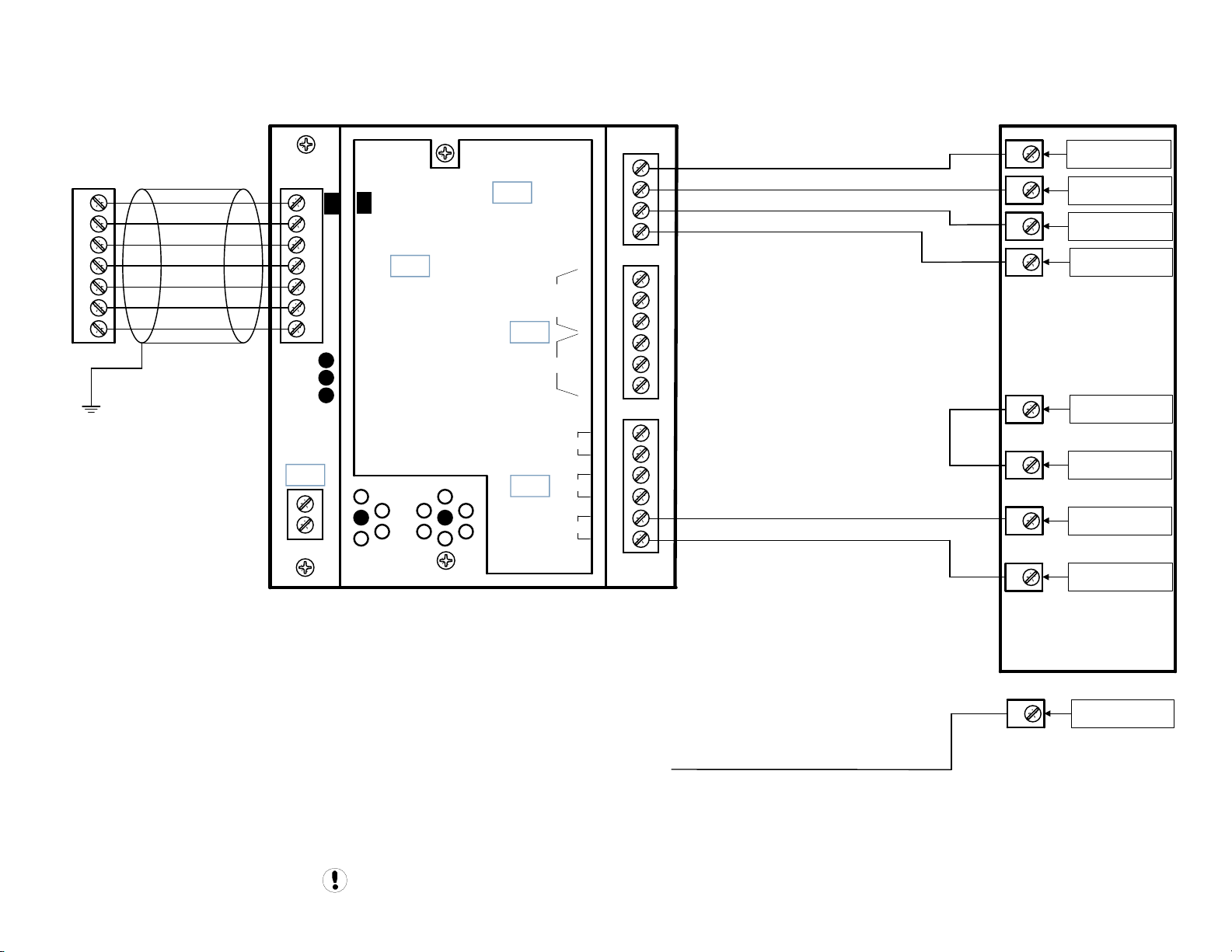

ir-PCB Interconnect To Ingersoll Rand

Pressure Switch Controlled Compressors

FOR ALL COMPRESSORS:

Compressors to be connected must have automatic Start / Stop capability .

DRAWING NOTES FOR PRESSURE SWITCH CONTROLLER MACHINES:

Ensure each compressor is equipped with independent Excessive Pressure Shutdown Switch. An increase in pressure

differential across air treatment equipment can result in excess compressor discharge pressure. See Appendix A, Page

70 and 71 for application drawings. In most applications, the model and type of pressure switch supplied with the

compressor can be used as the Excessive Pressure Shutdown Switch

is not readily available, any pressure switch can be utilized as long as it equals or exceeds the specifications of the

pressure switch found on the compressor.

Set the Excessive Pressure Shutdown Switch to “OPEN” 5 PSI less than the maximum discharge pressure

recommended by the compressor manufacturer.

. If this is specific model/type of pressure switch

Appendix C Page C1

Page 53

SSR UP5 11-22 SD

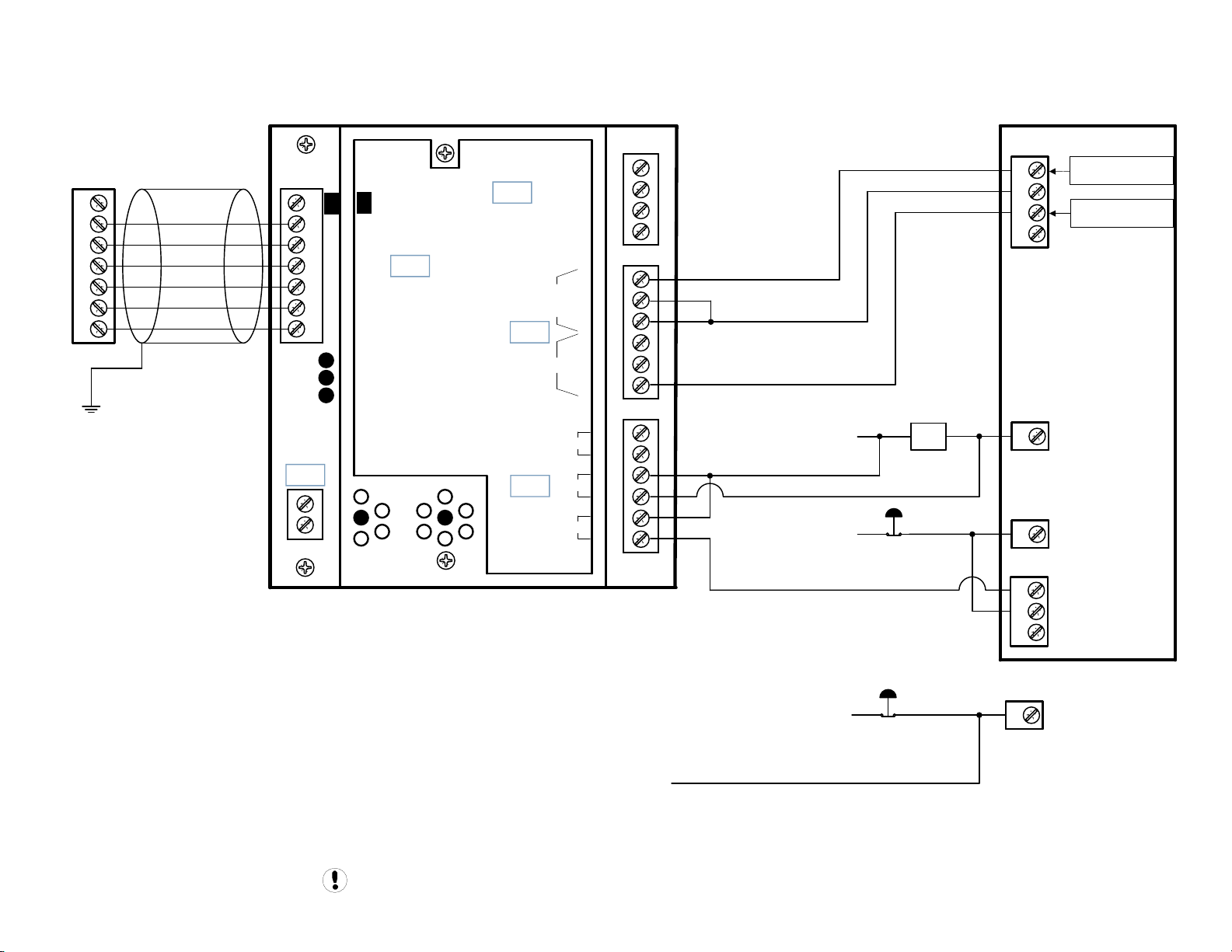

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

C05

V

1

2

3

4

5

6

1

2

V

SEQ CONT

LOAD UNL

GND

C03

D11

D12

+20V

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

LED 4

READY

E-STOP

110VAC

+VDC

VFD/fixed

C01

Load Enable

Load/Unload

NO

OUT

C

C02

LED 3

RUN

C04

NC

NO

IN

NC

ALARM

RUN

READY

C

MOL

Contact

SS

P

KM1 Relay

Contact

HATR

Contact

KM1

Restart TD

Relay

Contact

To TM2 Relay

To KM1 Contact

To KM2 Contact

0 VAC

IR-PCB

Guidance only; connections may differ with date, model, type, variant, special, custom or concession builds.

This information is intended to be used in conjunction with the compressor’s original control circuit diagram.

UnLoad

1PS

To Avoid Potential Wiring Issues, Always Break / Make ir-PCB

Wire Connections At The Pressure Switch Or Cut / Splice The

Actual Pressure Switch Wires

Wire Per The Above Schematic

Load

Appendix C Page C2

Page 54

SSR UP5 11-22 SD

Appendix C Page C3

Page 55

X - SERIES AUTOMATION

COMPRESSOR #1

X01 TERMINAL

V1

1

2

3

4

5

6

V

1

SEQ CONT

LOAD UNL

2

GND

3

D11

4

D12

5

+20V

6

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

READY

SSR UP5 22-37 SD

E-STOP

110VAC

+VDC

VFD/fixed

V

C03

LED 4

LED 3

RUN

C01

Load Enable

Load/Unload

C02

NO

OUT

NC

NO

IN

NC

ALARM

C

C

MOL

Contact

MMS

Contact

KM1

Relay

Contact

TM3

Relay

Contact

SS

P

KM1 Relay

Contact

HATR

Contact

KM1

Restart TD

Relay

Contact

To TM2 Relay

To KM1 Contact

To KM2 Contact

0 VAC

C05

C04

RUN

1

2

IR-PCB