Page 1

C.C.N. : 80445596 en

REV. : A

DATE : JULY 2009

Ingersoll Rand

X-IRI Communications Gateway

Operator’s Manual

Before installing or starting this unit for the first

time, this manual should be studied carefully to

obtain a working knowledge of the unit and or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

More Than Air. Answers.

Online answers: http://www.ingersollrandproducts.com

Page 2

2

SECTION 1 TABLE OF CONTENTS

SECTION 1 TABLE OF CONTENTS .............................2

SECTION 2 INTRODUCTION ...................................... 3

SECTION 3 SAFETY PRECAUTIONS .........................3

SAFETY PRECAUTIONS ............................................................3

INSTALLATION .............................................................................3

OPERATION ...................................................................................3

MAINTENANCE AND REPAIR .................................................4

SECTION 4 COMPRESSOR CONNECTION AND

CONTROL ......................................................................... 5

COMPRESSOR CONNECTION AND CONTROL ................ 5

INTELLISYS SOFTWARE REQUIREMENTS .......................... 5

MODBUS RTU ..............................................................................6

SECTION 5 INSTALLATION .......................................... 9

INSTALLATION .............................................................................9

UNIT LOCATION ..........................................................................9

POWER SUPPLY ...........................................................................9

DCS OR PLC CONNECTION ...................................................10

COMPRESSOR IRBUS CONNECTION ...............................10

DCS OR PLC COMMUNICATIONS .......................................11

COMPRESSOR COMMUNICATIONS: .................................11

OPERATIONAL INDICATIONS ...............................................11

RS485 NETWORK ....................................................................13

MODBUS ADDRESS SELECTION .........................................14

MODBUS PORT SETUP SELECTION ...................................15

GATEWAY SOFTWARE VERSION DISPLAY .......................16

COMMISSIONING PROCEDURE ..........................................17

SECTION 6 PARTS LIST ..............................................18

SECTION 7 TECHNICAL DATA ..................................18

SECTION 8 INTELLISYS MODBUS TABLES ............19

TABLE 1 SSR REDEYE CONTROLLER ...............................19

TABLE 2 SSR SG CONTROLLER .........................................22

TABLE 3 SSR SE 15100HP

CONTROLLER .............................................................................27

TABLE 4 SIERRA REDEYE 125200 HP

CONTROLLER .............................................................................30

TABLE 5 SIERRA SE 50100 HP

CONTROLLER .............................................................................33

TABLE 6 SIERRA SG 125400 HP

CONTROLLER .............................................................................36

TABLE 7 SSR SG CONTACT COOLED RETROFIT

CONTROLLER .............................................................................40

TABLE 8 RECIP REDEYE CONTROLLER ...........................45

TABLE 9 RECIP SG CONTROLLER .....................................49

TABLE 10 RECIP BOOSTER REDEYE

CONTROLLER .............................................................................53

TABLE 11 NIRVANA SGN CC CONTACT COOLED

CONTROLLER .............................................................................57

TABLE 12 NIRVANA SGNE CC CONTACT COOLED

CONTROLLER .............................................................................61

TABLE 13 NIRVANA SGNE OF OILFREE

CONTROLLER .............................................................................66

TABLE 14 SSR UP SE CONTROLLER .................................70

TABLE 15 ESA SE 22 150 KW

CONTROLLER .............................................................................73

TABLE 16 RSERIES S3 CONTROLLER .............................76

TABLE 17 NIRVANA 1530 KW 2040 HP DF

CONTROLLER .............................................................................78

Refer to Section Indicated

Note

Important or Caution, Safety

Page 3

SECTION 2 INTRODUCTION

!

WARNING : Risk of Danger

WARNING : Risk of Electric Shock

!

WARNING : Risk of High Pressure

WARNING : Consult Manual

Before installing or operating theX-IRI GATEWAY, take

time to carefully read all the instructions contained

in this manual, all compressor manuals, and all

manuals of any other peripheral devices that may be

installed or connected to the unit.

Electricity and compressed air have the potential to

cause severe personal injury or property damage.

The operator should use common sense and good

working practices while operating and maintaining

this system. All applicable codes should be strictly

adhered to.

Maintenance must be performed by adequately

qualified personnel that are equipped with the

proper tools.

INSTALLATION

Installation work must only be carried out by a

competent person under qualified supervision.

A fused isolation switch must be fitted between the

main power supply and the product.

The X-IRI GATEWAY should be mounted in such a

location as to allow operational and maintenance

access without obstruction or hazard and to allow

clear visibility of indicators at all times.

If raised platforms are required to provide access

to the X-IRI GATEWAY, they must not interfere with

normal operation or obstruct access. Platforms and

stairs should be of grid or plate construction with

safety rails on all open sides.

•

•

•

•

•

•

•

•

OPERATION

The X-IRI GATEWAY must only be operated by

competent personnel under qualified supervision.

Never remove or tamper with safety devices, guards

or insulation materials fitted to the X-IRI GATEWAY.

The X-IRI GATEWAY must only be operated at

the supply voltage and frequency for which it is

designed.

When main power is switched on, lethal voltages are

present in the electrical circuits and extreme caution

must be exercised whenever it is necessary to carry

out any work on the unit.

Do not open access panels or touch electrical

components while voltage is applied unless it is

necessary for measurements, tests or adjustments.

Such work should be carried out only by a qualified

electrician equipped with the correct tools and

wearing appropriate protection against electrical

hazards.

All air compressors and/or other equipment

connected to the unit should have a warning sign

attached stating “THIS UNIT MAY START WITHOUT

WARNING” next to the display panel.

If an air compressor and/or other equipment

connected to the unit is to be started remotely,

attach two warning signs to the equipment stating

“THIS UNIT CAN BE STARTED REMOTELY”.

Attach one sign in a prominent location on the

outside of the equipment, and the other sign inside

the equipment control compartment.

•

•

•

•

•

•

•

The X-IRI Communication Gateway is designed to

in

terface the Intellisys Controllers on Ingersoll Rand

Compressors with a Distributed Control System (DCS),

Programmable Logic Controller (PLC), or any other

device that is capable of communicating using the

MODBUS RTU communications protocol.

SECTION 3 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The X-IRI provides MODBUS connectivity to Ingersoll

Rand controllers that do not have built-in MODBUS

capability. The X-IRI also provides address filtering and

communication buffering capabilities to protect the

integrity of the serial data network.

The X-IRI is designed to be DIN Rail mounted within the

compressor control gear enclosure but can alternatively

be mounted remotely within a separate enclosure.

3

Page 4

MAINTENANCE AND REPAIR

M

aintenance, repairs or modifications must only

•

be carried out by competent personnel under

qualified supervision.

If replacement parts are required, use only genuine

•

parts from the original equipment manufacturer, or

an alternative approved source.

Carry out the following operations before opening

•

or removing any access panels or carrying out any

work on the X-IRI GATEWAY:

Isolate the X-IRI GATEWAY from the main

i.

electrical power supply. Lock the isolator in the

“OFF” position and remove the fuses.

Attach label to the isolator switch and to the

ii.

unit stating “WORK IN PROGRESS - DO NOT

APPLY VOLTAGE”. Do not switch on electrical

power or attempt to start the X-IRI GATEWAY if

such a warning label is attached.

Make sure that all instructions concerning

•

operation and maintenance are strictly followed

and that the complete unit, with all accessories and

safety devices, is kept in good working order.

The accuracy of sensor devices must be checked

•

on a regular basis. They must be calibrated when

acceptable tolerances are exceeded. Always ensure

any pressure within the compressed air system is

safely vented to atmosphere before attempting to

remove or install a sensor device.

•

The X-IRI GATEWAY must only be cleaned with a

damp cloth, using mild detergents if necessary.

Avoid the use of any substances containing

corrosive acids or alkalis.

Do not paint the control faceplate or obscure any

•

indicators, controls, instructions or warnings.

4

Page 5

SECTION 4 COMPRESSOR CONNECTION AND CONTROL

Setting a MODBUS polling rate of less than 500

milliseconds will not cause a quicker response from X-IRI.

The PLC or DCS communicates to the X-IRI Gateway via

a two wire, RS-485 network utilizing the MODBUS RTU

protocol.

The X-IRI Gateway module is installed within the

compressor control cabinet and connected to the PLC or

DCS using Belden 9841 or equivalent RS-485 cable.

INTELLISYS SOFTWARE REQUIREMENTS

Each Intellisys controller must have its controller

software revision at or above a certain minimum level

to work with the IRI.

The machine types and required software EPROM

minimum version levels are listed below. Check the

machine to be connected to an IRI for the appropriate

EPROM. If the EPROM is not of the correct minimum

version level, the appropriate EPROM may be ordered

from your local Ingersoll Rand Distributor or Air Center.

Machine Type EPROM Minimum Version Level

SSR 50-450 Horsepower - 1 stage (Red Eye) 2.3

SSR 50-450 Horsepower - 2 stage (Red Eye) 2.3

SSR SG 1.0

15-50 Horsepower 1.4

Sierra 50-100 Horsepower (SE) 1.2

Sierra 100-200 Horsepower (Red Eye) 2.5

Sierra 125-400 HP SG 1.0

Recip (Red Eye) 1.6

Recip SG 1.0

Nirvana SGN 1.0

Nirvana SGNe CC 2.0

Nirvana SGNe OF 1.0

Pegasus 1.0

ESA SE 22-150 KW 1.6

When monitoring compressor data only, no options

are required to be installed in the Intellisys controller. If

machine control is desired, the Remote Start/Stop and

Sequence options must be installed and turned “On”.

COMPRESSOR CONNECTION AND CONTROL

T

he X-IRI Gateway module is designed to interface to

any Ingersoll Rand Intellisys controlled compressor. All

Ingersoll Rand compressors equipped with Intellisys

controllers must use this interface when communicating

with MODBUS masters.

The X-IRI gateway prevents the compressor controller

from seeing any communications that aren’t directed

toward the controller’s network address. Additionally, the

X-IRI will buffer communications so that the compressor

controller will not receive a command greater than once

every 500 milliseconds.

5

Page 6

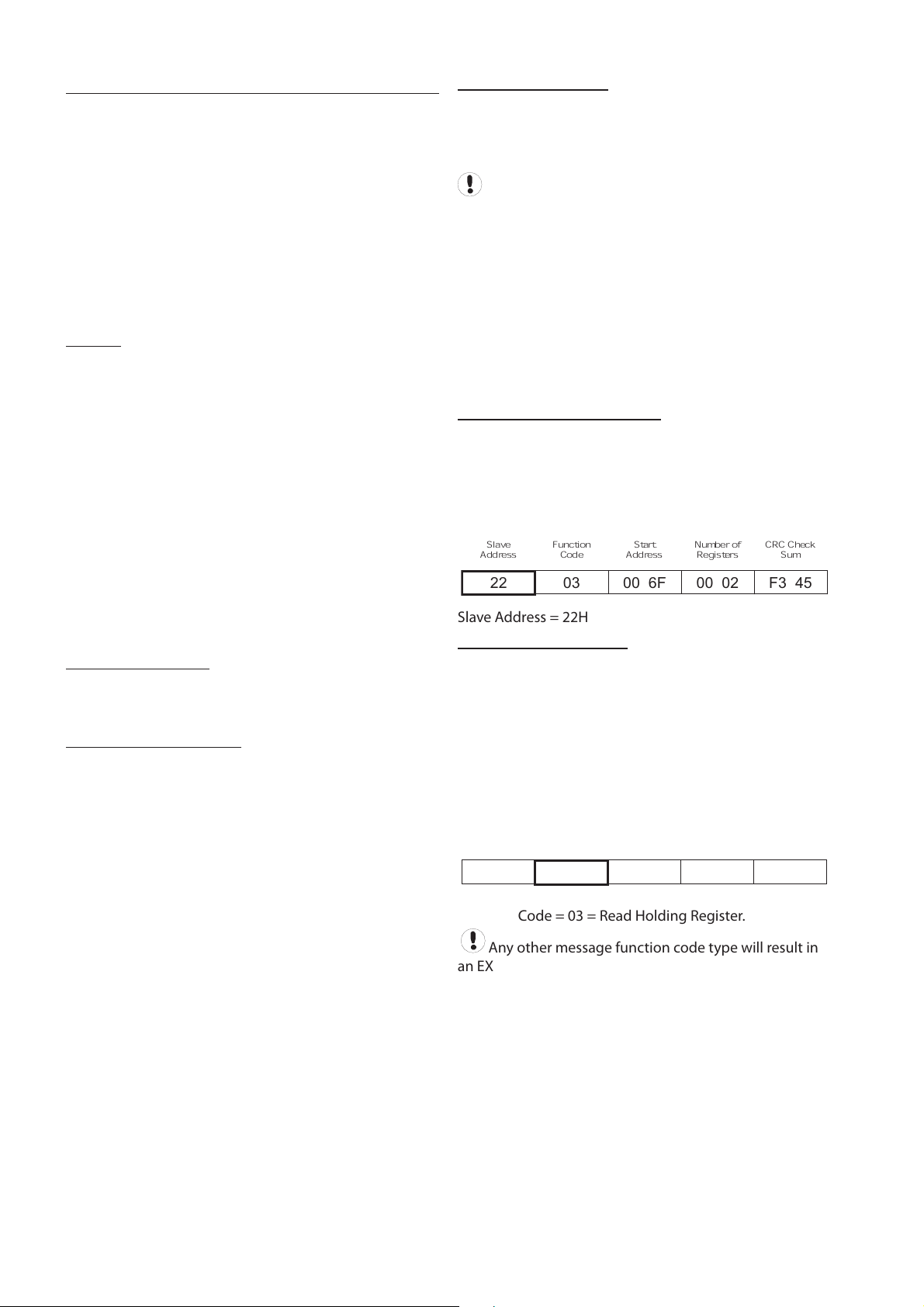

MODBUS RTU

A pause longer than 1.5 byte-times will render the

message invalid and it will be ignored.

Message data format is dependent on function and will

consist of a combination of the following elements:

1) Destination address (slave network address)

2) Function Code

3) Data start address (slave register start address)

4) Number of registers, number of bytes of data

5) Message data

6) CRC checksum

Message Destination Address

The ‘destination address’ must be correct for the ‘slave’

controller device for which the message is intended. An

address can be from 1 to 127 decimal (01Hex to 7FHex).

The SMG Box is transparent and addresses must be for the

destination ‘slave’ controller or unit. Each controller or unit

must be set with a unique address.

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

22 03 00 6F 00 02 F3 45

Slave Address = 22Hex = 34 Decimal

Message Function Codes

The message function code defines the required data

processing operation of the slave controller. Although

several types of message function codes are defined by

the MODBUS standard, only the message function code

types working directly with registers are implemented on

controller units:

03H Read Holding Register(s) – Read

06H Preset Single Register - Write

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

22 03 00 6F 00 02 F3 45

Function Code = 03 = Read Holding Register.

Any other message function code type will result in

an EXCEPTION response.

This document discusses generic MODBUS

communications and how to implement the software

specific ‘MODBUS Table’ information. MODBUS

communication formatting may differ from controller to

controller and you may require more than one ‘MODBUS

Table’.

Always check the software variant identification and

version number for a controller with the variant and

version of the ‘MODBUS Table’ supplied. In some instances

the information contained in a ‘MODBUS Table’ may not

be applicable to a controller installed with the same

software variant but a different version number.

General

MODBUS RTU (Remote Terminal Unit) is a master-slave

type protocol. An Intellisys Controller functions as the

slave device. Information requests or commands are

communicated from master to slave only through the

X-IRI.

The X-IRI will always respond to communications from a

remote master device in accordance with the MODBUS

RTU protocol standard.

The MODBUS protocol is used to communicate with

personal computers (PC), Programmable Logic Controllers

(PLC’s), or Distributed Control Systems (DCS) over the

Network port. The X-IRI only responds to two MODBUS

commands, Read Holding Register 03 (03 Hex) and Preset

Single Register 06 (06 Hex). (See Modicon MODBUS

Protocol Reference Guide, PI-MBUS-300 Rev. J or later, for

more details on MODBUS).

Communication Link

MODBUS is implemented using a two-wire RS485

industry standard communications link operating in

master-slave mode.

RS485 Serial Data Format

The RS485 MODBUS port is a 2-wire operating with an

asynchronous serial data format: 8 data bits / no parity / 1

or 2 stop bits (8,N,1 or 8,N,2) - transmitted at 9600 baud.

Message Data Format

The bytes of the MODBUS RTU message must be sent

in one message package. The RTU protocol allows for a

maximum pause of 1.5 byte-times between 2 consecutive

bytes of a message.

6

Page 7

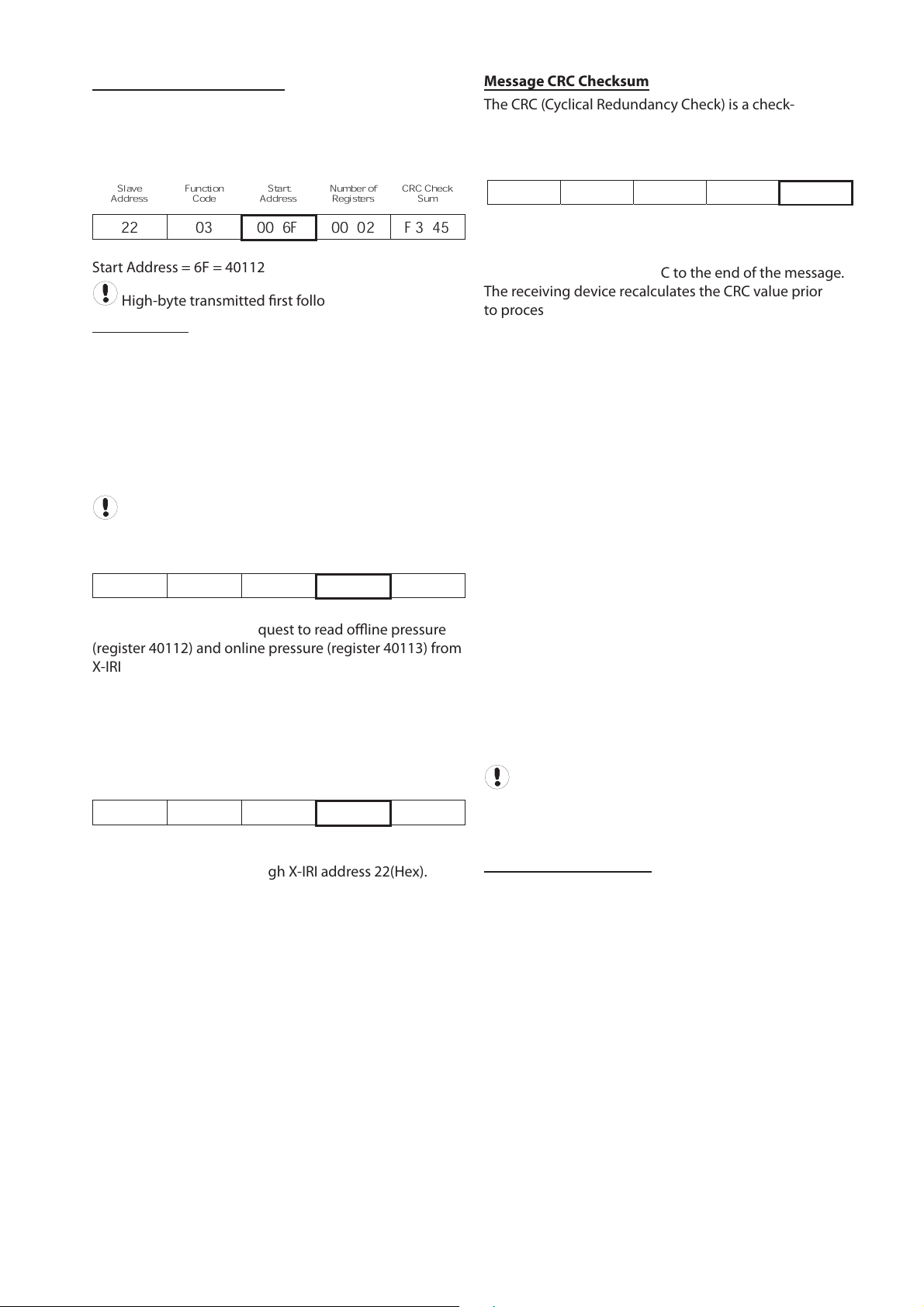

Message Data Start Address

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

22 03 00 6F 00 02 F3 45

Start Address = 6F = 40112

High-byte transmitted first followed by low-byte.

Message Data

The message data content depends on the message

function code type.

03H Read Holding Register(s)

The Number of Registers designates the 16bit integer

value that determines the size (in 16bit ‘word’ registers)

of the message data being requested. This is the number

of 16bit registers to read. This information is contained in

the ‘MODBUS Table’.

A maximum of 32 registers can be read at one time.

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

22 03 00 6F 00 02 F3 45

The example above is a request to read offline pressure

(register 40112) and online pressure (register 40113) from

X-IRI address 22(Hex)

06H Preset Single Register

The Data byte 0 byte 1 designates the value of the 16bit

integer word to be written to the Intellisys controller. This

information is contained in the ‘MODBUS Table’.

Slave

Address

Function

Code

Start

Address

DATA

byte 0 byte 1

CRC Check

Sum

22 06 00 6F 00 5F FE BC

The example above is a request to set offline pressure

(register 40112) to 95 through X-IRI address 22(Hex).

Message CRC Checksum

The CRC (Cyclical Redundancy Check) is a check-sum

generated by means of ‘A001H polynomial’.

Slave

Address

Function

Code

Start

Address

DATA

byte 0 byte 1

CRC Check

Sum

22 06 00 6F 00 5F FE BC

The CRC is two bytes containing a 16-bit binary value

(word). The CRC value is calculated by the transmitting

device that appends the CRC to the end of the message.

The receiving device recalculates the CRC value prior

to processing of a received message and compares the

result to the actual CRC value appended to the message.

If the two values do not match the message is regarded

as invalid.

The CRC is initiated by first preloading a 16bit register

to all 1’s (FFFF Hex). Then a process begins of applying

each consecutive 8bit byte of the message to the register

contents using an exclusive ‘OR’ calculation. The result is

shifted one bit in the direction of the least significant bit

(LSB), with the most significant bit (MSB) set at ‘0’. The LSB

is then examined; if ‘1’ the register content is applied to

the polynomial value ‘A001’ Hex (1010 0000 0000 0001)

using an exclusive ‘OR’ calculation - if ‘0’ no exclusive OR

takes place.

This process is repeated until eight ‘bit’ shifts have

been performed. After the eighth bit shift, the next 8bit

message byte is applied to the register contents using an

exclusive ‘OR’ calculation. The bit shift and re-calculation

process is then repeated again. When all message bytes

have been processed the final content of the 16bit

register is the message CRC value.

Only the 8bits of ‘data’ in each message character is used

for generating the CRC; start, stop and parity bits are

ignored.

When the 16bit CRC value is appended to a message,

the low order byte must be transmitted first followed by

the high order byte. An incorrect or byte reversed check

sum will render the message invalid and it will be ignored.

Slave Response Timeout

A slave controller may not answer immediately. Ensure

the ‘slave timeout’ setting of the ‘master’ device is set

to a value no less than 500ms. If the ‘slave’ device fails

to receive a valid message due to a communication

disruption, parity error, CRC error or other reasons, no

response is given and the master must process a timeout

condition in this instance. If the ‘slave’ receives a valid

message that cannot be processed an exception response

will be returned.

T

he message data start address (16bit word) designates

the initial register address location in the controller from

which the data is processed. Start address information is

contained in the ‘MODBUS Table’.

7

Page 8

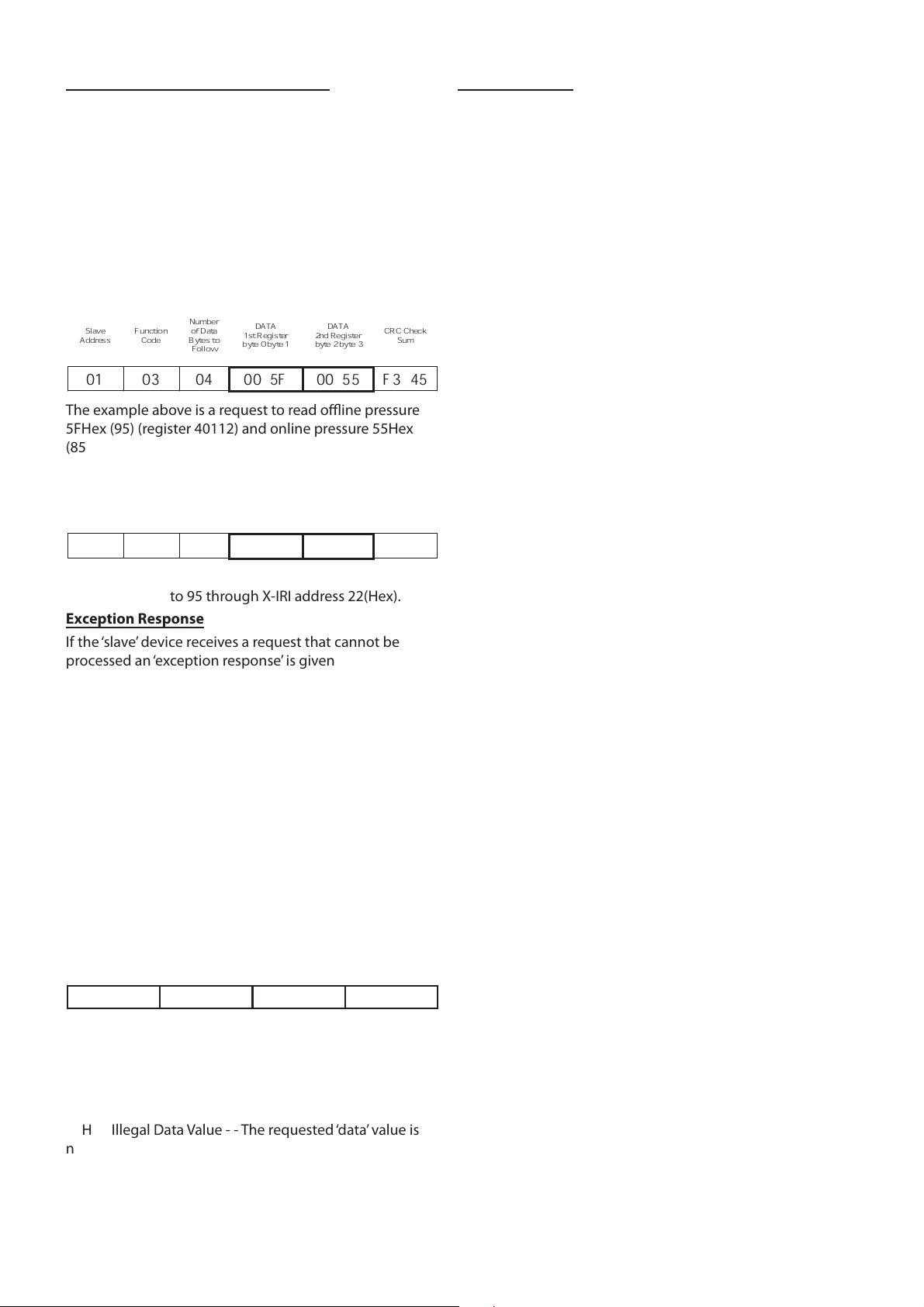

Message Answer From Slave to Master

Slave

Address

Function

Code

Number

of Data

Bytes to

Follow

DATA

1st Register

byte 0 byte 1

DATA

2nd Register

byte 2 byte 3

CRC Check

Sum

01 03 04 00 5F 00 55 F3 45

The example above is a request to read offline pressure

5FHex (95) (register 40112) and online pressure 55Hex

(85) (register 40113) from X-IRI address 22(Hex).

06Hex - Preset Single Register

Slave

Address

Function

Code

Number

of Data

Bytes to

Follow

DATA

1st Register

byte 0 byte 1

DATA

2nd Register

byte 2 byte 3

CRC Check

Sum

01 03 04 00 5F 00 55 F3 45

The example above is a request to set offline pressure

(register 40112) to 95 through X-IRI address 22(Hex).

Exception Response

If the ‘slave’ device receives a request that cannot be

processed an ‘exception response’ is given. An exception

response message consists of the following elements:

Slave Network Address (1 byte): Slave address

identification

Function Code (1 byte): In a normal response, the

slave repeats the function code of the original

master request. All function codes have an MSB

(most significant bit) of 0 (values are all below 80

hexadecimal). In an exception response, the slave

sets the MSB of the function ‘code’ to 1. This makes

the ‘code’ value 80 Hex greater than the received

‘code’ value from the master.

Data (1 byte): The ‘data’ response will contain a ‘1

byte’ value exception code.

CRC Checksum (2 byte).

01 90 04 4D C3

CRC Check SumSlave Address Function Code Error Code

Exception Codes:

01H Illegal Function Code - - The requested ‘code’

function is not supported.

02H Illegal Data Address - - The requested ‘data start

address’ is not supported.

03H Illegal Data Value - - The requested ‘data’ value is

not supported.

04H Function Error - - The slave cannot execute the

request or the request type is inhibited.

•

•

•

•

Troubleshooting

Problem:

No ‘slave’ response or corrupt MODBUS message

Solution:

Check that the ‘slave’ controller is set for the

anticipated slave address

Check that all ‘slave’ controllers are set with a unique

system address

Check that the controller is set for MODBUS RTU

mode (if applicable)

Check that the ‘master’ is operating in MODBUS RTU

mode

Check that the ‘master’ baud rate, parity bit and

number of stop bits are correct

Check that the ‘master ‘response timeout is set for a

minimum of 500ms

Check that the ‘master’ is implementing the specified

CRC check sum process

Check RS485 wiring polarity and security of

connections

Problem:

Last character of MODBUS message is corrupted

Solution:

Add a delay of 2ms after last character received

before releasing RTS signal

Problem:

The MODBUS master message is reflected in the

slave answer

Solution:

Inhibit RX/TX echo on ‘master’ device

communications port

•

•

•

•

•

•

•

•

•

•

•

•

•

T

he format of the ‘slave’ controller answer is similar to the

original master request format; the message data content

depends on the message function code type.

The ‘address’ and ‘code’ of the slave answer is identical

to the original request message; the address is the ‘slave’

device address and the ‘code’ is a repeat of received

function code type from the master. The remainder of the

message is dependent on the requested function code

type. The CRC checksum is re-calculated for the answer

message characters using the specified CRC process.

03H Read Holding Register(s)

8

Page 9

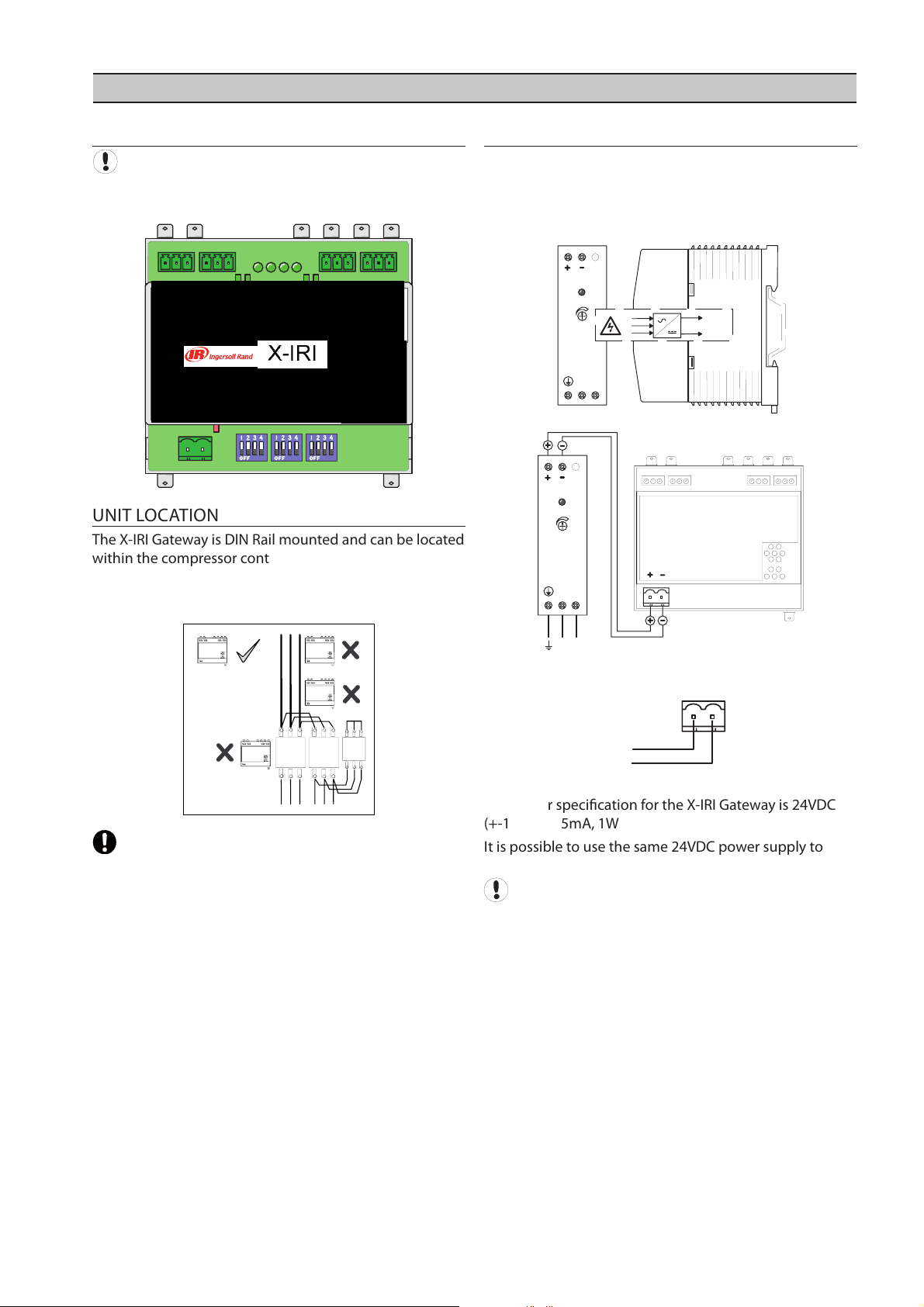

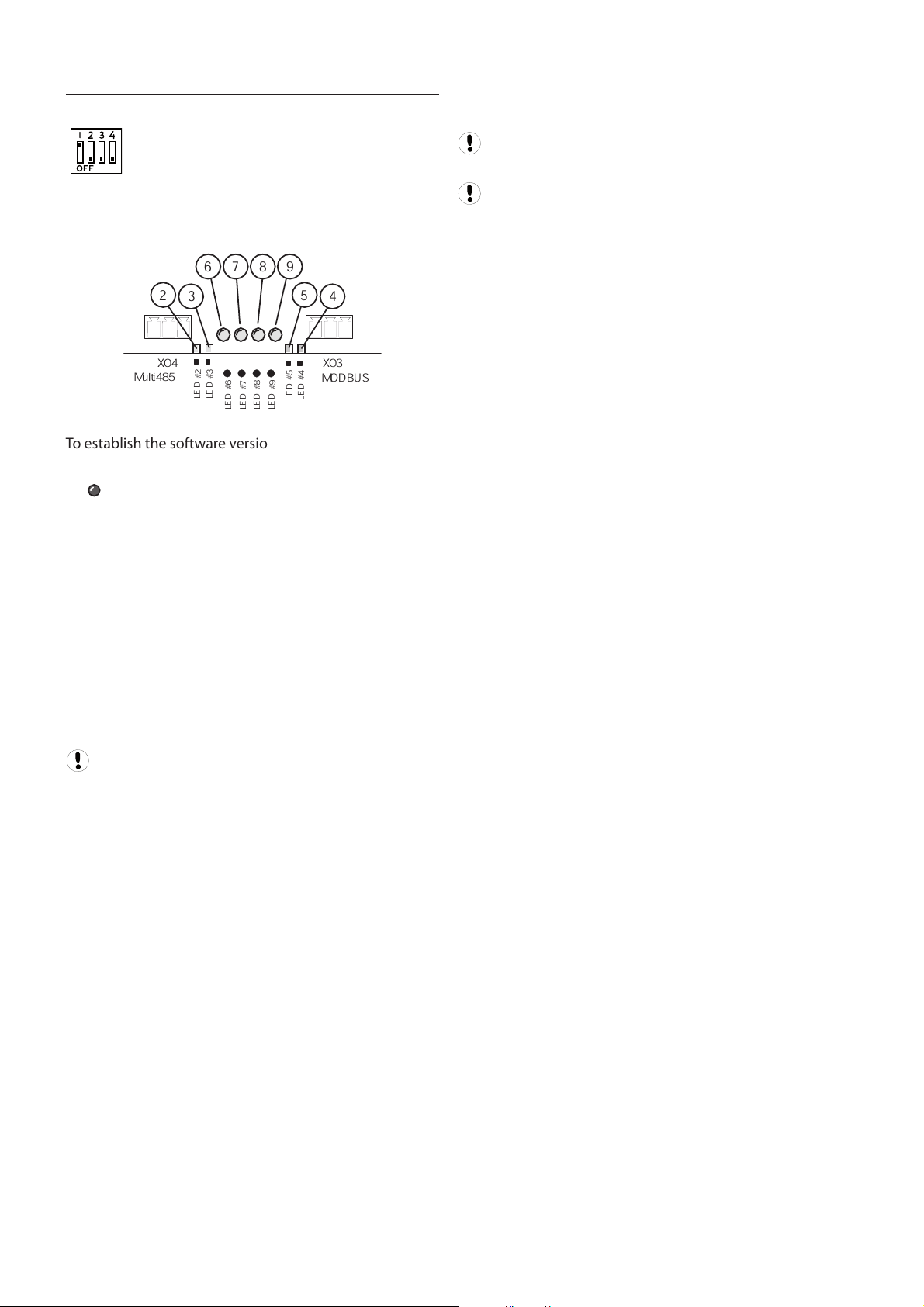

SECTION 5 INSTALLATION

It is recommended that installation and

commissioning be carried out by an authorized and

trained product supplier.

L

E

D

#

6

L

E

D

#

7

L

E

D

#

8

L

E

D

#

9

s

c

r

e

e

n

L

2

L

1

12 13 23

Multi485

X05

s

c

r

e

e

n

L

2

L

1

12 13 23

MODBUS

X03

1 2

+

2

4

V

a

c

/

d

c

0

V

a

c

/d

c

X01

X02

X04

L

E

D

#

1

2

3

4

1

ON

OFF

6

7

8

5

1

0

1

1

1

2

9

SW1 SW2 SW3

L

E

D

#

2

L

E

D

#

3

L

E

D

#

5

L

E

D

#

4

Avoid mounting the X-IRI Gateway near high voltage

cables, high voltage devices or equipment or motor

starter contactors.

POWER SUPPLY

The X-IRI Gateway is powered by an external 24VDC

power supply. The AC supply voltage for the 24VDC

power supply is derived from the compressor’s 110VAC or

230VAC internal AC supply.

DC

+V.ADJ

LN

24V DC

100-240VAC

50/

60Hz

E

N

L

0VDC

+24VDC

1

2

X01

GATEWAY

LN

DC

+V.ADJ

L

N

24V DC

100-240VAC

50/60Hz

24V

AC/DC

X01

1 2

+24VDC

0VDC

+

-

The power specification for the X-IRI Gateway is 24VDC

(+-10%) @ 35mA, 1W

It is possible to use the same 24VDC po

wer supply to

power multiple X-IRI Gateway devices.

Wire polarity is important

INSTALLATION

UNIT LOCATION

The X

-IRI Gateway is DIN Rail mounted and can be located

within the compressor control enclosure or remotely

within a separate enclosure. X-IRI Gateway must be

located within 1000ft (10m) of the compressor controller.

9

Page 10

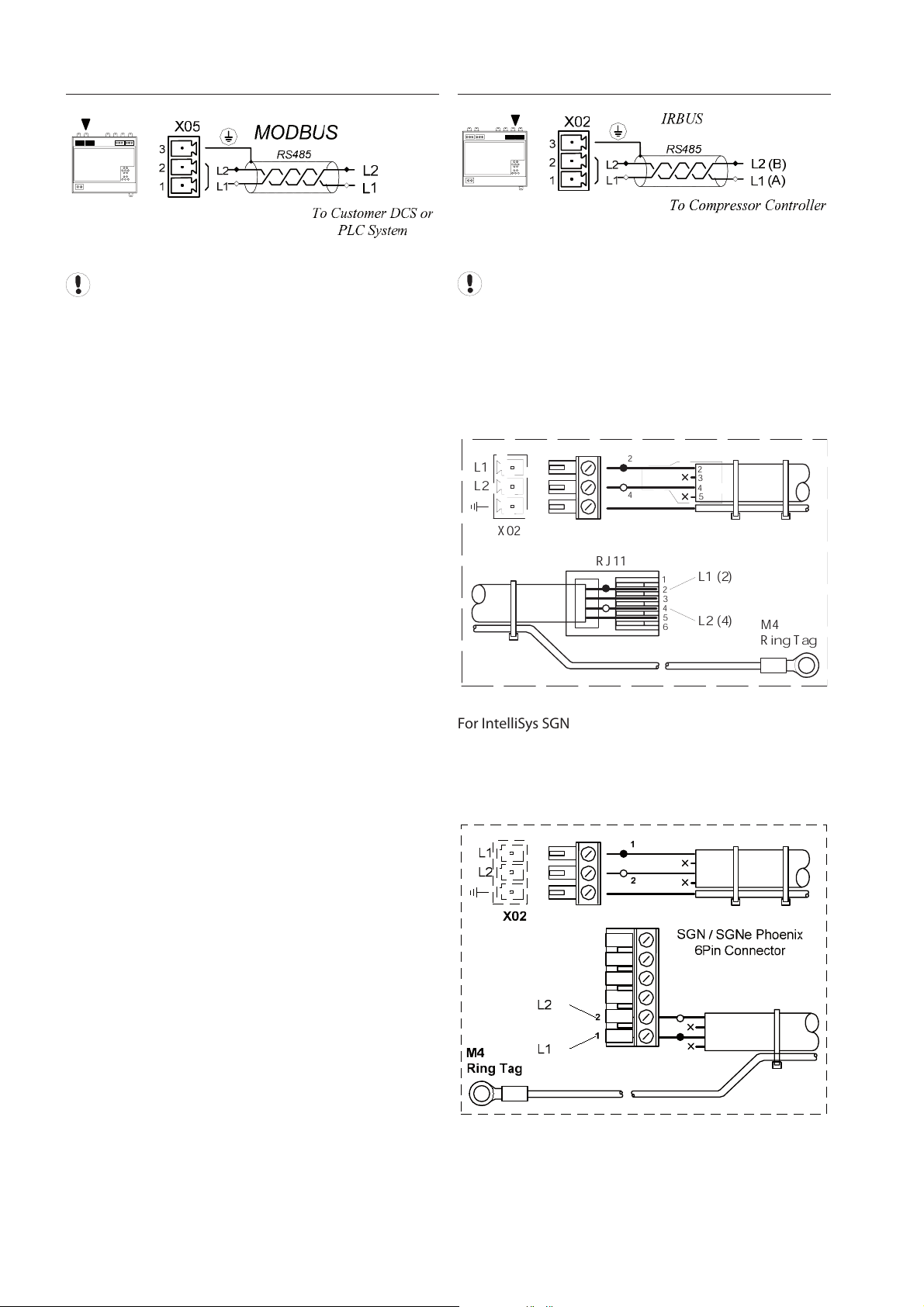

DCS OR PLC CONNECTION

Wire polarity is important

Use 2-wire, 24 gauge (Belden 9841 or equivalent), twisted

pair, earth shielded, data cable with a total system

network length no greater than 4000ft (1219m).

COMPRESSOR IRBUS CONNECTION

1

6

2

3

5

4

RJ11

2

4

3

5

L1

L2

M4

Ring Tag

L1 (2)

L2 (4)

2

4

X02

For IntelliSys SGN, SGNe and Nirvana 15-30kW (20-40HP)

equipped with a Phoenix RS-485 data communications

connector, use the RJ11 Modbus cable supplied with the

X-IRI Gateway and modify as shown by removing the RJ11

Plug.

Wire polarity is important

Use 2-

wire, 24 gauge (Belden 9841 or equivalent), twisted

pair, earth shielded, data cable with a length no greater

than 1000ft (10m).

For IntelliSys “Red Eye”, SG and SE equipped with an RJ11

RS-485 data communications connection port, use the

RJ11 Modbus cable supplied with the X-IRI Gateway.

10

Page 11

11

DCS OR PLC COMMUNICATIONS

50ms

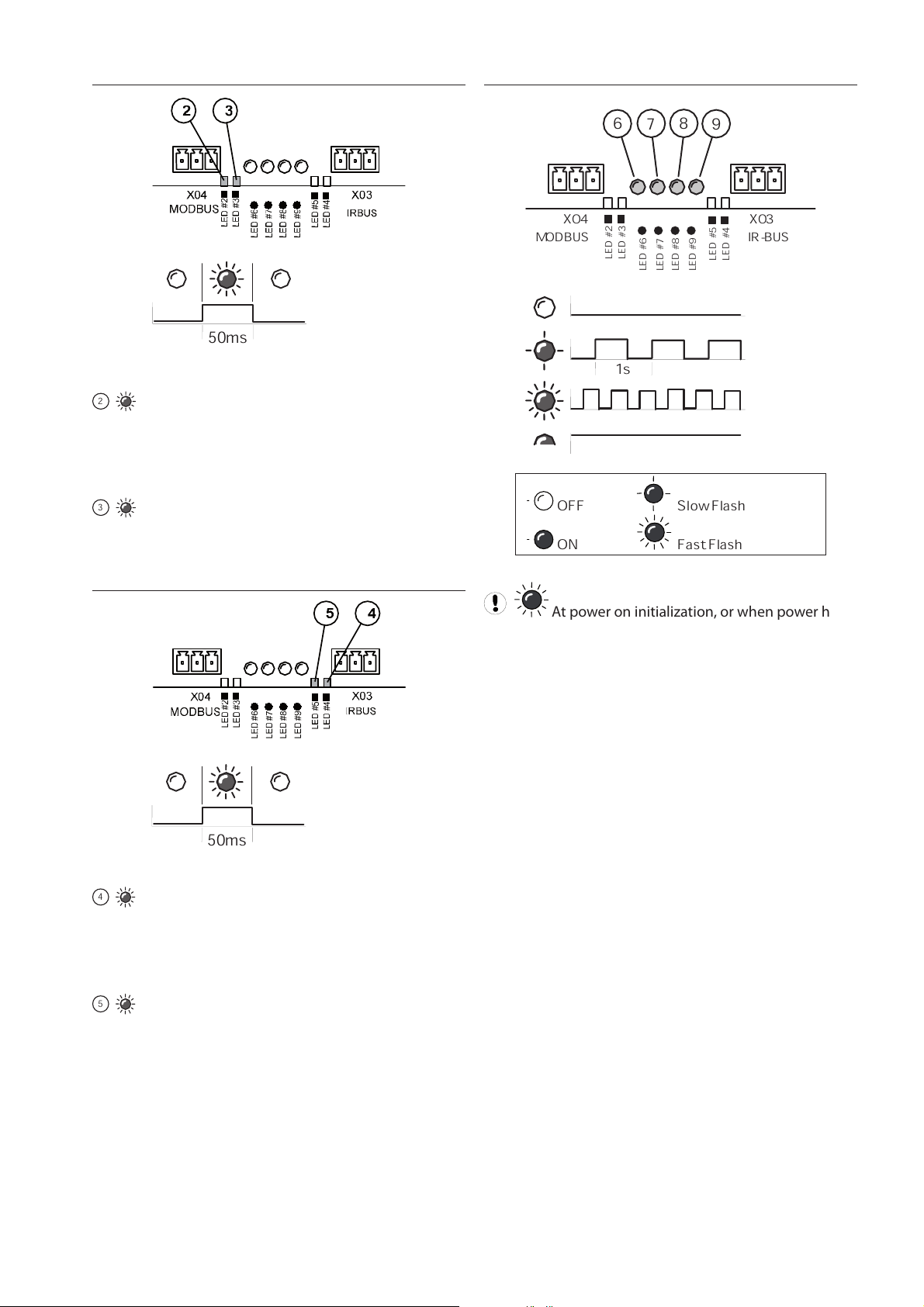

RX – Data Received:

2

A valid MODBUS communication has just been

received from the DCS or PLC unit. In normal operation

this event should occur periodically depending on the

polling rate.

TX – Data Transmitted:

3

A MODBUS broadcast or message has just been

sent. To keep the link active, a MODBUS message must be

sent at least once every 10 seconds.

COMPRESSOR COMMUNICATIONS:

50ms

RX – Data Received:

4

A valid IRBUS communication has just been

received from the compressor controller. In normal

operation this event should occur at least once every ½

second.

TX – Data Transmitted:

5

An IRBUS message has just been sent to the

compressor controller. In normal operation this event

should occur at least once every ½ second.

OPERATIONAL INDICATIONS

OFF Slow Flash

ON Fast Flash

L

E

D

#

6

L

E

D

#

7

L

E

D

#

8

L

E

D

#

9

Multi485

X04

L

E

D

#

2

L

E

D

#

3

L

E

D

#

5

L

E

D

#

4

MODBUS

X03

7

6

9

8

1s

MODBUS IR-BUS

At power on initialization, or when power has

been removed, all operational indicators will fast flash for

several seconds.

Page 12

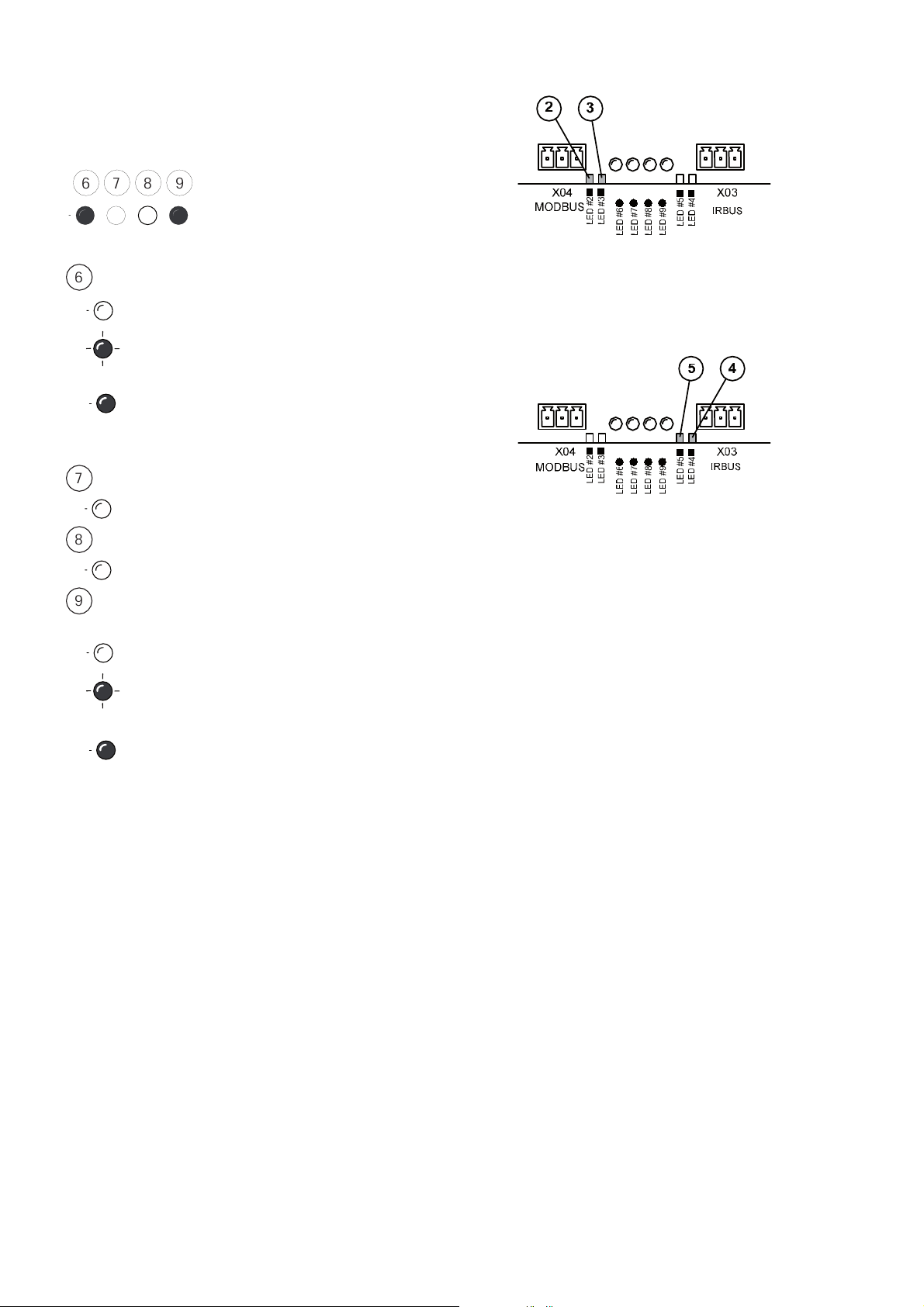

Normal O

6 7 8 9

Normal operation function:

6

Modbus Communications with MODBUS master.

OFF

No valid communications with a MODBUS

master

ON: Valid communication with a MODBUS

master, at least one read/write operation once

every 10 seconds.

7

No function

Always OFF: no other defined function

8

No function

Always OFF: no other defined function

9

IR-BUS communication with a compressor

controller

OFF

No valid communications with the compressor

controller.

ON: IR-BUS compressor controller detected and

communication link established.

Led#2: Every flash indicates reception of a valid MODBUS

messsage from the MODBUS master.

Led#3: Every flash indicates transmission of a valid

MODBUS messsage to the MODBUS master.

Led#5: Every flash indicates transmission of a valid IRBUS

messsage to the IR-BUS compressor controller.

Led#4: Every flash indicates reception of a valid IR-BUS

message from the IR-BUS compressor controller.

peration Example:

When there is valid communication with a MODBUS

master and an IR-BUS compatible compressor controller

the main operation indicators will light up as shown

below.

12

Page 13

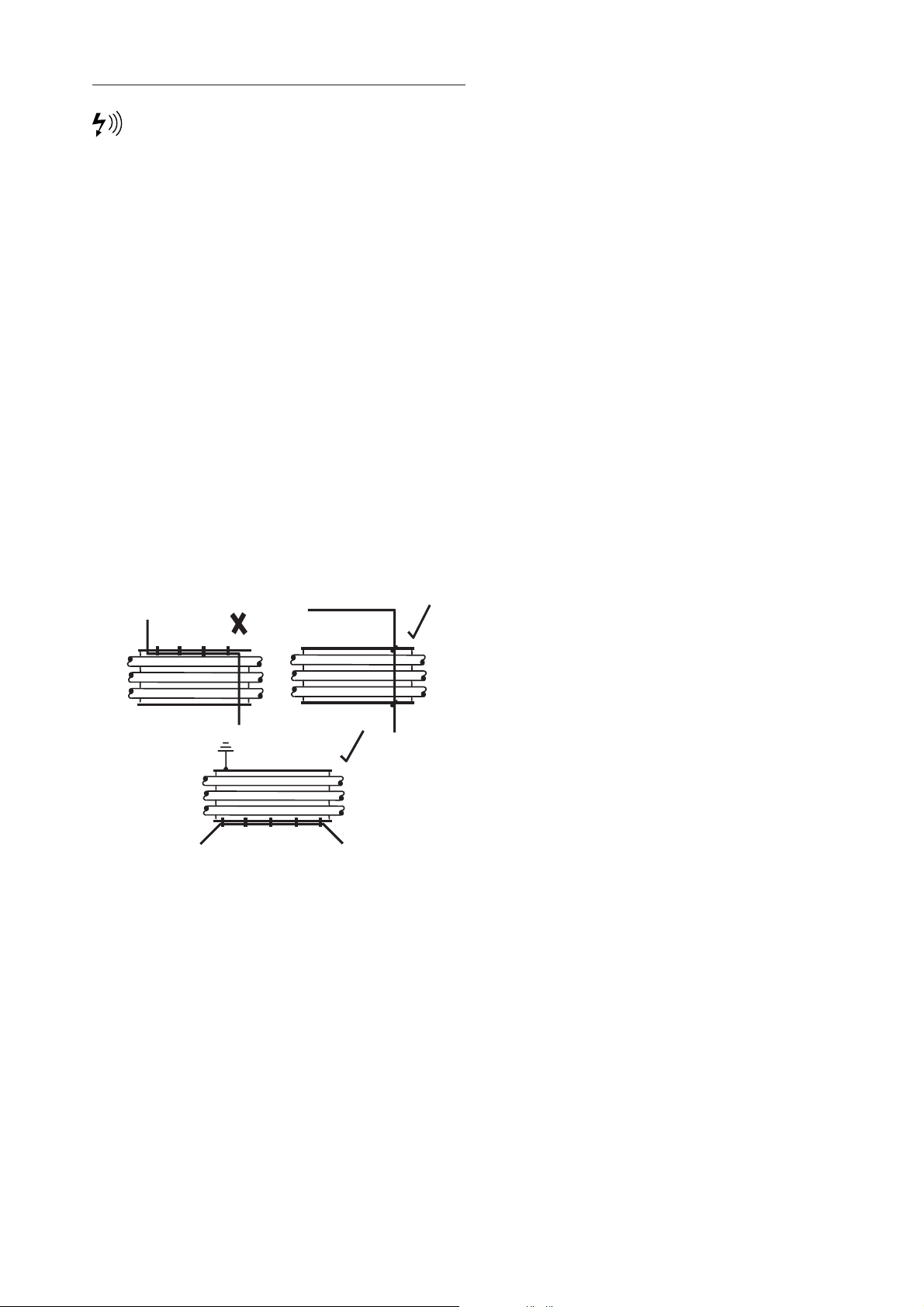

RS485 NETWORK

RS-485 data communications and other low

voltage signals can be subject to electrical interference.

This potential can result in intermittent malfunction

or anomaly that is difficult to diagnose. To avoid this

possibility always use earth shielded cables, securely

bonded to a known good earth at one end. In addition,

give careful consideration to cable routing during

installation.

1) Never route an RS-485 data communications or low

voltage signal cable alongside a high voltage 3-phase

power supply cable. If it is necessary to cross the path of a

power supply cable(s), always cross at a right angle.

2) If it is necessary to follow the route of power supply

cables for a short distance (for example: from a

compressor unit to a wall along a suspended cable tray)

attach the RS- 485 or signal cable on the outside of an

earthed cable tray such that the cable tray forms an

earthed electrical interference shield.

3) Where possible, never route an RS-485 or signal cable

near to equipment or devices that may be a source of

electrical interference (for example: 3-phase power

supply transformer, high voltage switchgear unit,

frequency inverter drive module, radio communications

antenna).

13

Page 14

14

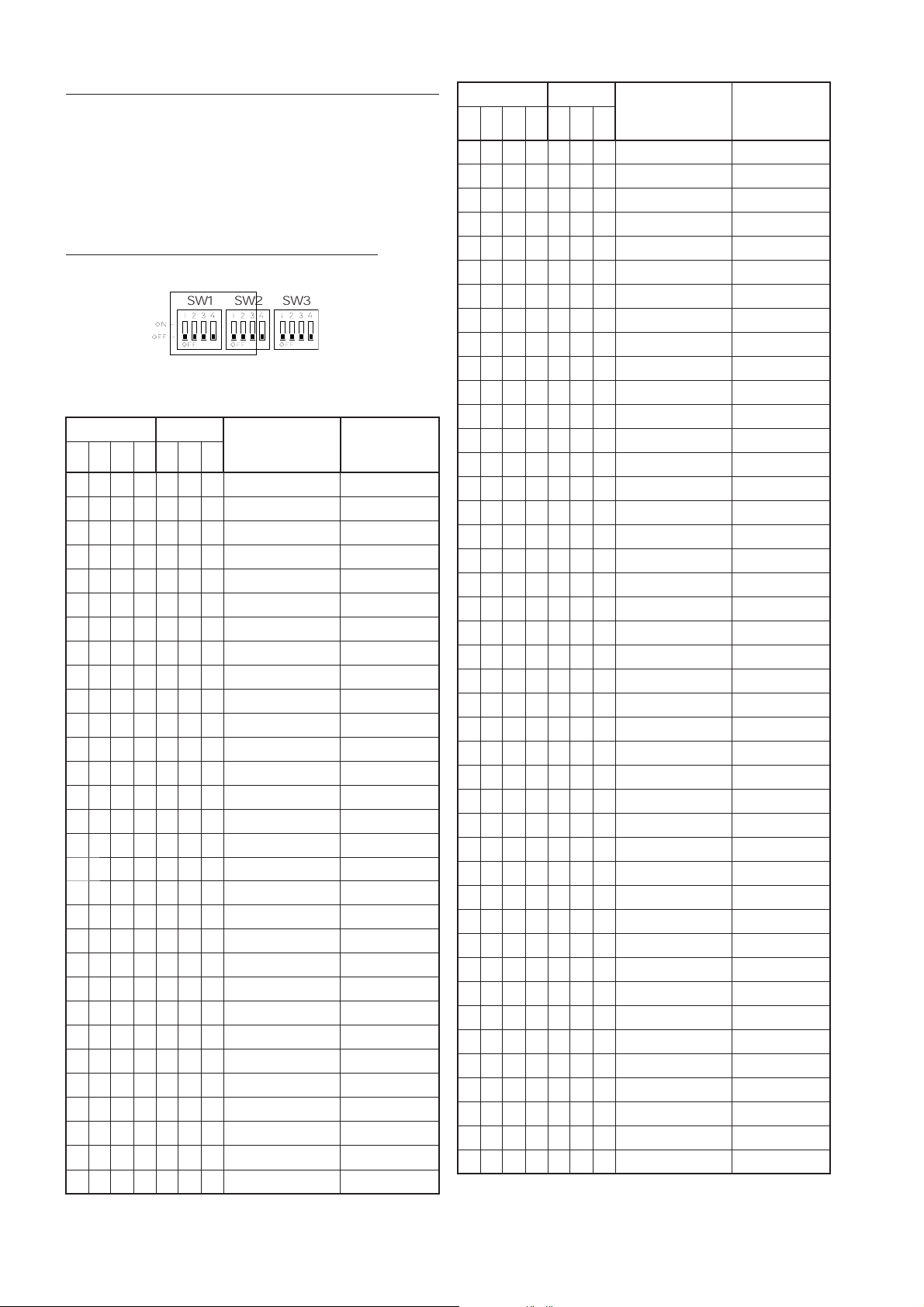

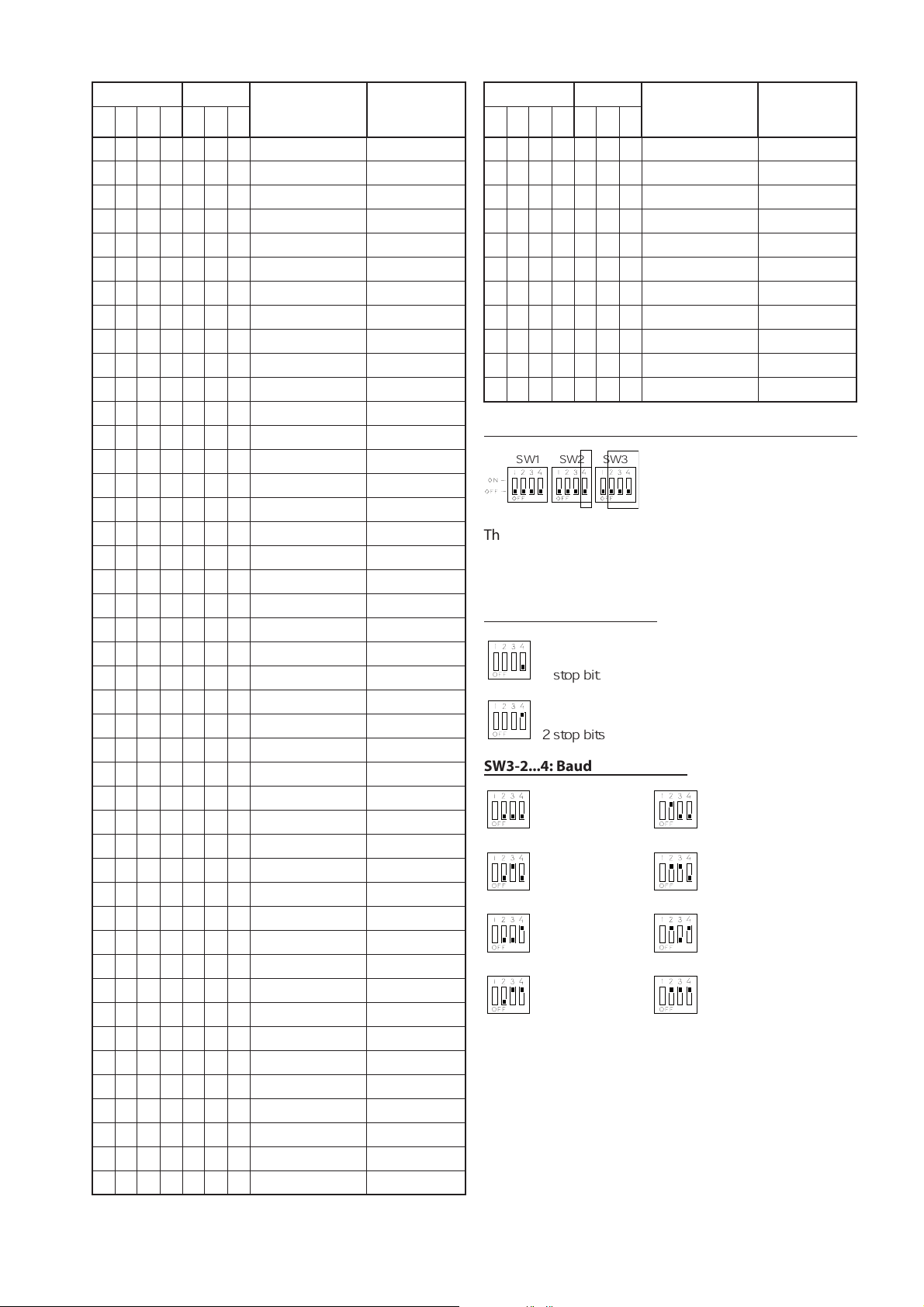

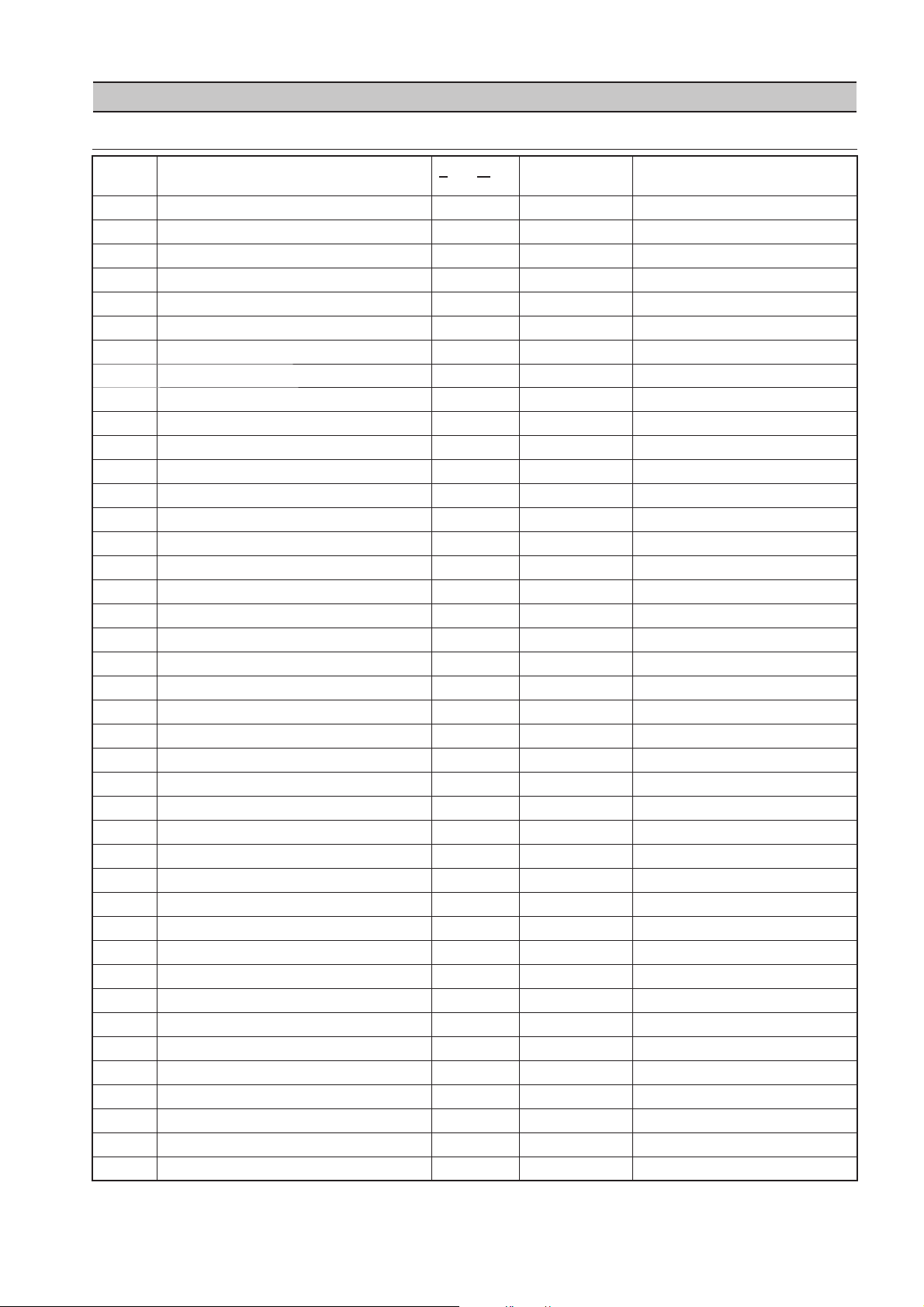

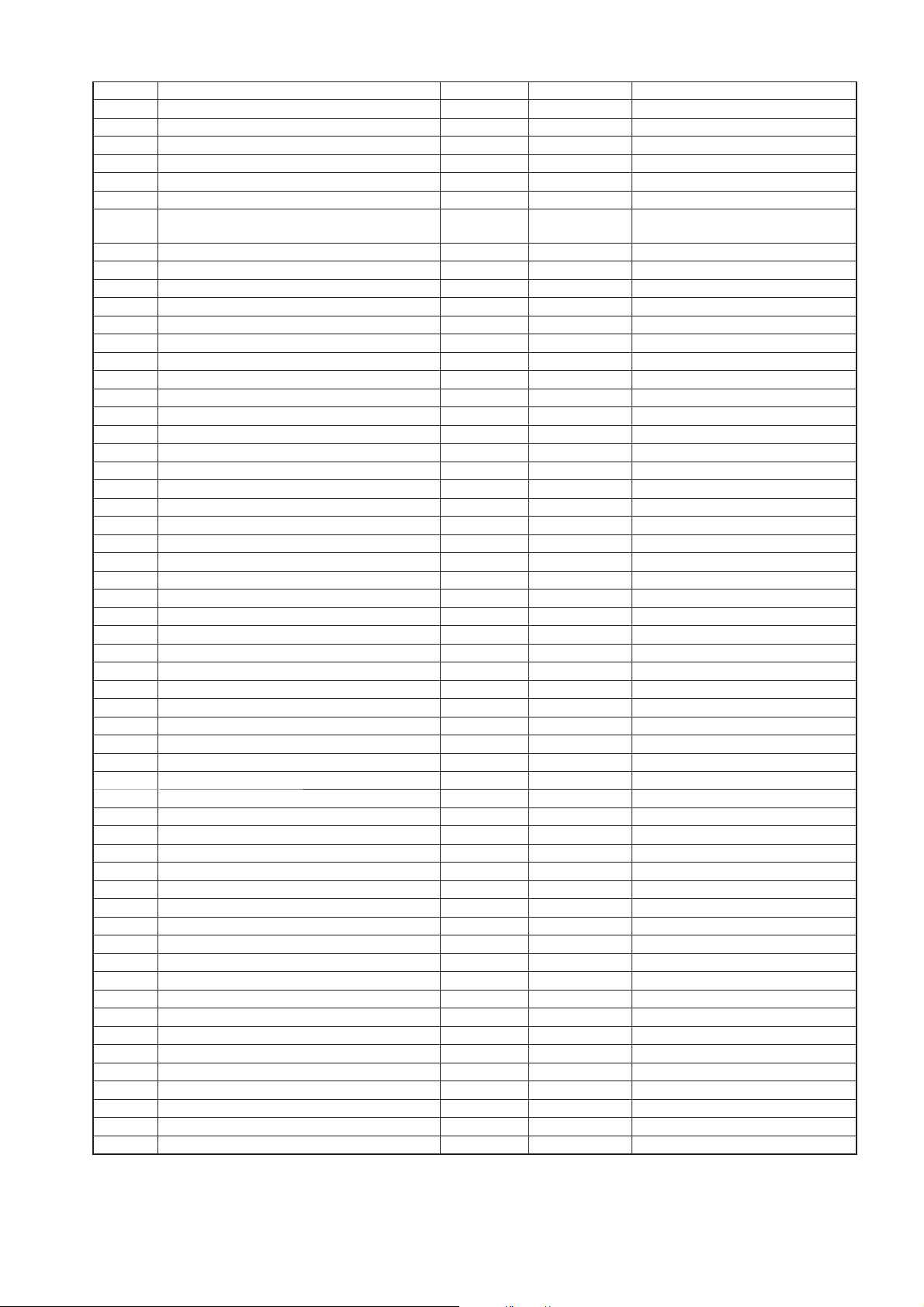

MODBUS ADDRESS SELECTION

Each compressor connected to the MODBUS network will

have a unique assigned address, starting at compressor

1 increasing sequentially to the number of compressors

connected to the MODBUS network. The MODBUS

address is selected by using DIP switches 1, 2, 3, and 4

on SW1, and switches 1, 2, and 3 on SW2 on the X-IRI

Gateway.

SW1, 1 to4 and SW2, 1 to 3: Address Selection

The addresses are selected as shown in the following

table: (Note: ON = 1, OFF = 0 )

SW1 SW1 MODBUS

Address

(Decimal)

MODBUS

Address

(Hexl)1 2 3 4 1 2 3

0 0 0 0 0 0 0 1 1

1 0 0 0 0 0 0 1 1

0 1 0 0 0 0 0 2 2

1 1 0 0 0 0 0 3 3

0 0 1 0 0 0 0 4 4

1 0 1 0 0 0 0 5 5

0 1 1 0 0 0 0 6 6

1 1 1 0 0 0 0 7 7

0 0 0 1 0 0 0 8 8

1 0 0 1 0 0 0 9 9

0 1 0 1 0 0 0 10 A

1 1 0 1 0 0 0 11 B

0 0 1 1 0 0 0 12 C

1 0 1 1 0 0 0 13 D

0 1 1 1 0 0 0 14 E

1 1 1 1 0 0 0 15 F

0 0 0 0 1 0 0 16 10

1 0 0 0 1 0 0 17 11

0 1 0 0 1 0 0 18 12

1 1 0 0 1 0 0 19 13

0 0 1 0 1 0 0 20 14

1 0 1 0 1 0 0 21 15

0 1 1 0 1 0 0 22 16

1 1 1 0 1 0 0 23 17

0 0 0 1 1 0 0 24 18

1 0 0 1 1 0 0 25 19

0 1 0 1 1 0 0 26 1A

1 1 0 1 1 0 0 27 1B

0 0 1 1 1 0 0 28 1C

1 0 1 1 1 0 0 29 1D

SW1 SW1

MODBUS

Address

(Decimal)

MODBUS

Address

(Hexl)

1 2 3 4 1 2 3

0 1 1 1 1 0 0 30 1E

1 1 1 1 1 0 0 31 1F

0 0 0 0 0 1 0 32 20

1 0 0 0 0 1 0 33 21

0 1 0 0 0 1 0 34 22

1 1 0 0 0 1 0 35 23

0 0 1 0 0 1 0 36 24

1 0 1 0 0 1 0 37 25

0 1 1 0 0 1 0 38 26

1 1 1 0 0 1 0 39 27

0 0 0 1 0 1 0 40 28

1 0 0 1 0 1 0 41 29

0 1 0 1 0 1 0 42 2A

1 1 0 1 0 1 0 43 2B

0 0 1 1 0 1 0 44 2C

1 0 1 1 0 1 0 45 2D

0 1 1 1 0 1 0 46 2E

1 1 1 1 0 1 0 47 2F

0 0 0 0 1 1 0 48 30

1 0 0 0 1 1 0 49 31

0 1 0 0 1 1 0 50 32

1 1 0 0 1 1 0 51 33

0 0 1 0 1 1 0 52 34

1 0 1 0 1 1 0 53 35

0 1 1 0 1 1 0 54 36

1 1 1 0 1 1 0 55 37

0 0 0 1 1 1 0 56 38

1 0 0 1 1 1 0 57 39

0 1 0 1 1 1 0 58 3A

1 1 0 1 1 1 0 59 3B

0 0 1 1 1 1 0 60 3C

1 0 1 1 1 1 0 61 3D

0 1 1 1 1 1 0 62 3E

1 1 1 1 1 1 0 63 3F

0 0 0 0 0 0 1 64 40

1 0 0 0 0 0 1 65 41

0 1 0 0 0 0 1 66 42

1 1 0 0 0 0 1 67 43

0 0 1 0 0 0 1 68 44

1 0 1 0 0 0 1 69 45

0 1 1 0 0 0 1 70 46

1 1 1 0 0 0 1 71 47

0 0 0 1 0 0 1 72 48

SW1

SW2 SW3

Page 15

15

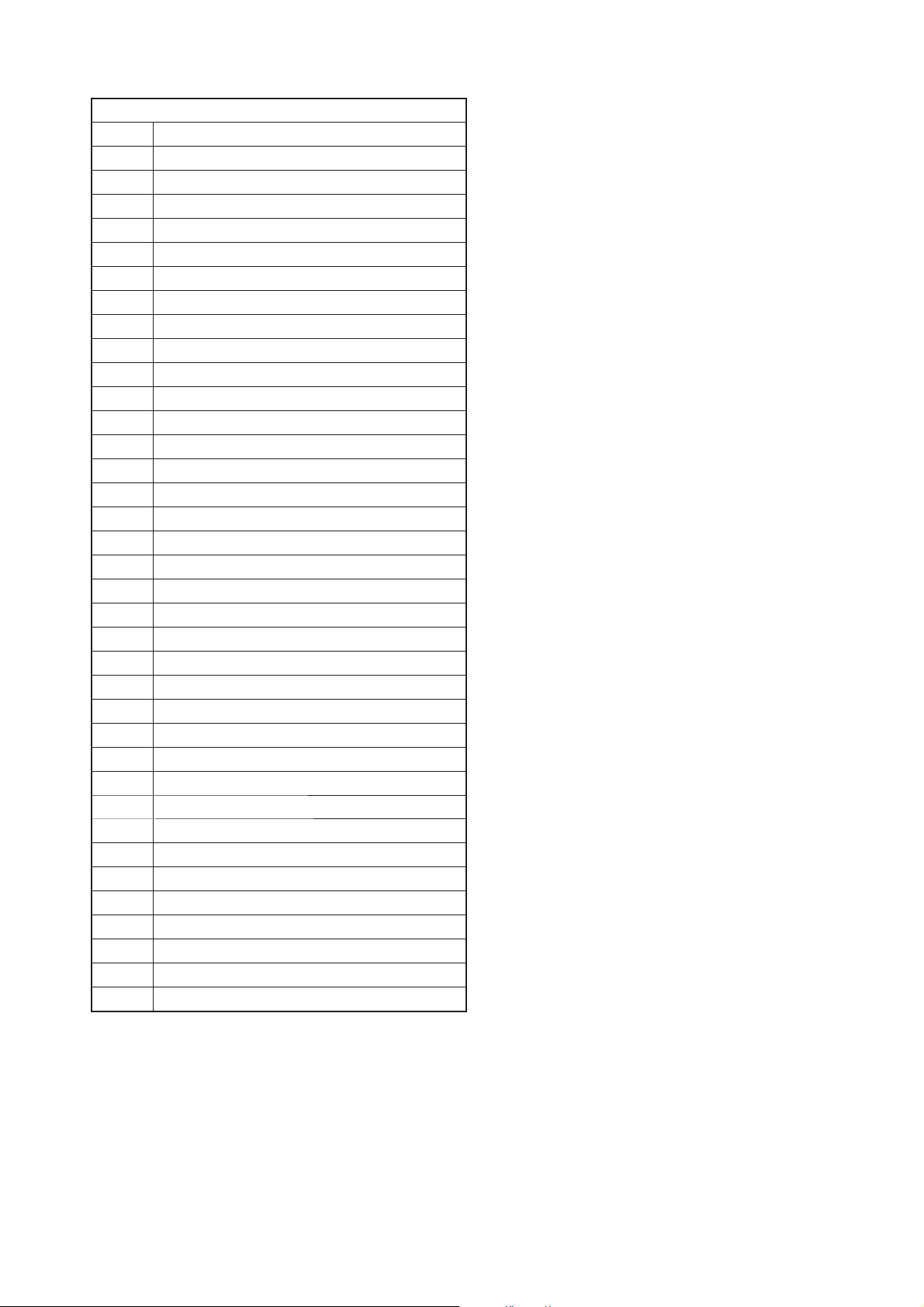

SW1 SW1

MODBUS

Address

(Decimal)

MODBUS

Address

(Hexl)1 2 3 4 1 2 3

1 0 0 1 0 0 1 73 49

0 1 0 1 0 0 1 74 4A

1 1 0 1 0 0 1 75 4B

0 0 1 1 0 0 1 76 4C

1 0 1 1 0 0 1 77 4D

0 1 1 1 0 0 1 78 4E

1 1 1 1 0 0 1 79 4F

0 0 0 0 1 0 1 80 50

1 0 0 0 1 0 1 81 51

0 1 0 0 1 0 1 82 52

1 1 0 0 1 0 1 83 53

0 0 1 0 1 0 1 84 54

1 0 1 0 1 0 1 85 55

0 1 1 0 1 0 1 86 56

1 1 1 0 1 0 1 87 57

0 0 0 1 1 0 1 88 58

1 0 0 1 1 0 1 89 59

0 1 0 1 1 0 1 90 5A

1 1 0 1 1 0 1 91 5B

0 0 1 1 1 0 1 92 5C

1 0 1 1 1 0 1 93 5D

0 1 1 1 1 0 1 94 5E

1 1 1 1 1 0 1 95 5F

0 0 0 0 0 1 1 96 60

1 0 0 0 0 1 1 97 61

0 1 0 0 0 1 1 98 62

1 1 0 0 0 1 1 99 63

0 0 1 0 0 1 1 100 64

1 0 1 0 0 1 1 101 65

0 1 1 0 0 1 1 102 66

1 1 1 0 0 1 1 103 67

0 0 0 1 0 1 1 104 68

1 0 0 1 0 1 1 105 69

0 1 0 1 0 1 1 106 6A

1 1 0 1 0 1 1 107 6B

0 0 1 1 0 1 1 108 6C

1 0 1 1 0 1 1 109 6D

0 1 1 1 0 1 1 110 6E

1 1 1 1 0 1 1 111 6F

0 0 0 0 1 1 1 112 70

1 0 0 0 1 1 1 113 71

0 1 0 0 1 1 1 114 72

1 1 0 0 1 1 1 115 73

0 0 1 0 1 1 1 116 74

SW1 SW1

MODBUS

Address

(Decimal)

MODBUS

Address

(Hexl)1 2 3 4 1 2 3

1 0 1 0 1 1 1 117 75

0 1 1 0 1 1 1 118 76

1 1 1 0 1 1 1 119 77

0 0 0 1 1 1 1 120 78

1 0 0 1 1 1 1 121 79

0 1 0 1 1 1 1 122 7A

1 1 0 1 1 1 1 123 7B

0 0 1 1 1 1 1 124 7C

1 0 1 1 1 1 1 125 7D

0 1 1 1 1 1 1 126 7E

1 1 1 1 1 1 1 127 7F

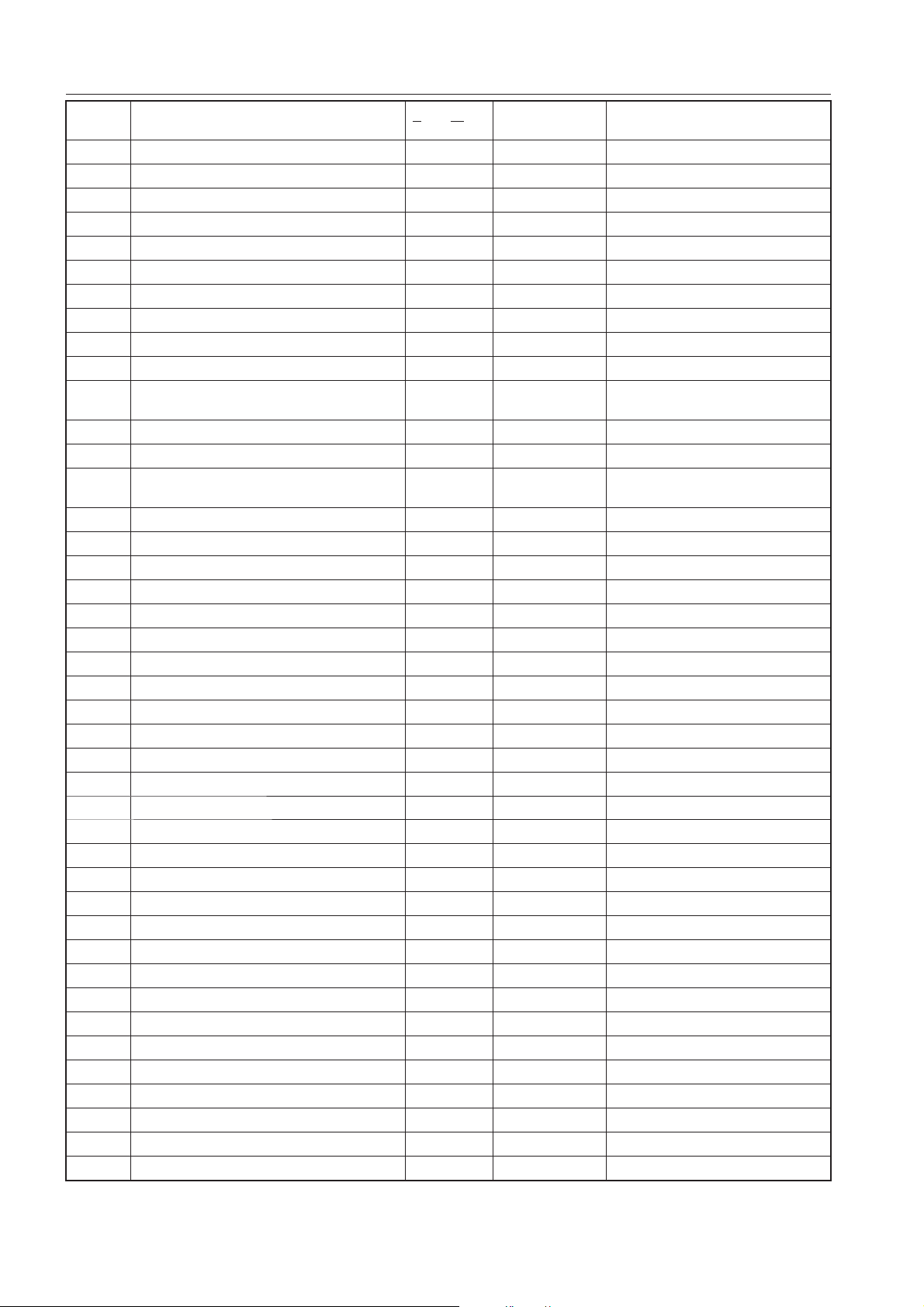

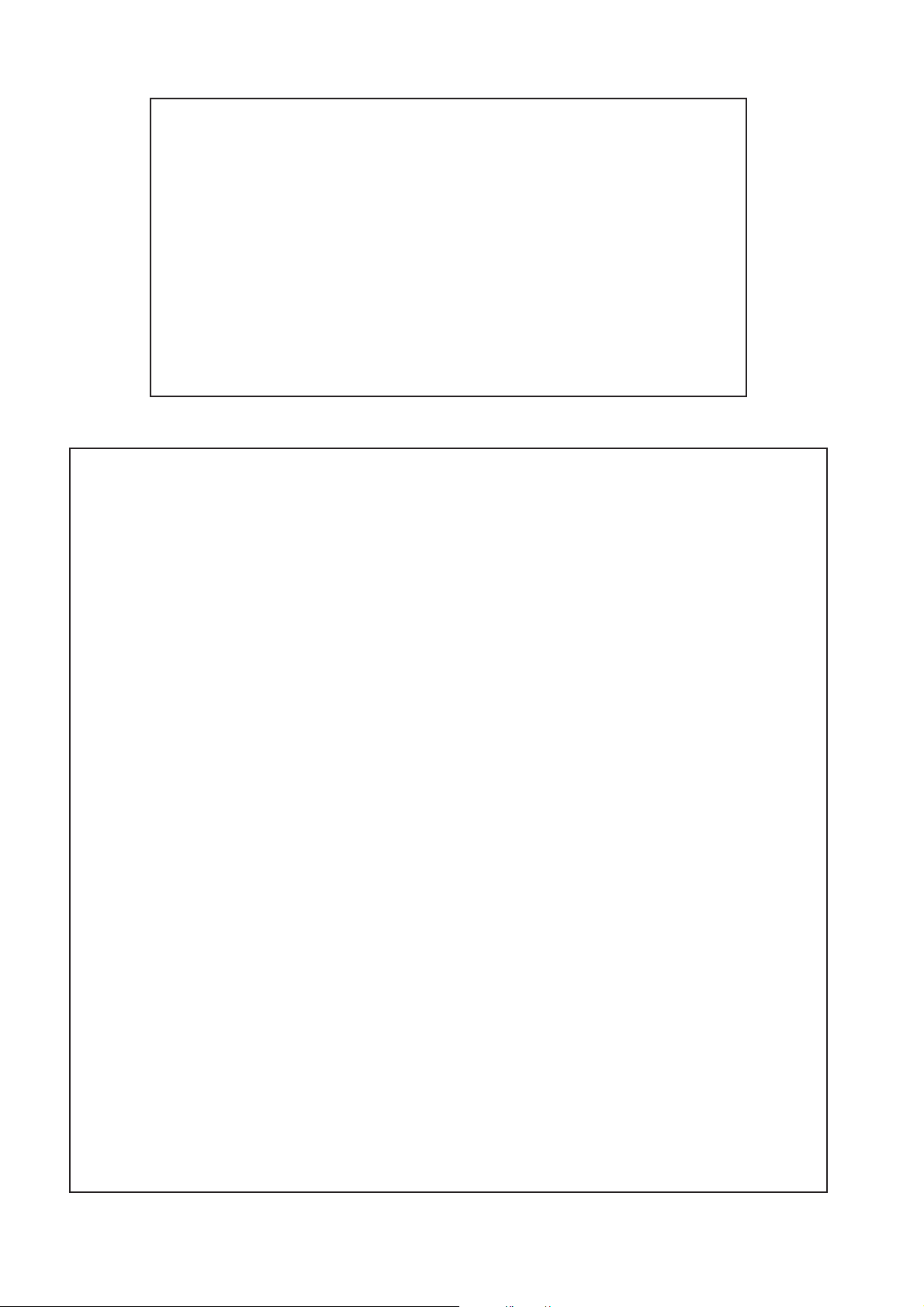

MODBUS PORT SETUP SELECTION

SW1 SW2

SW3

The MODBUS port setup is determined by means of DIP

switch 4 on SW2 and DIP switches 2,3 and 4 on SW3. The

selectable items are: baudrate and number of stop bits.

Parity is not selectable and fixed at “no parity”

SW2-4: Stop Bit Selection

1 stop bit

2 stop bits

SW3-2...4: Baudrate Selection

1200 baud 2400 baud

48

00 baud 9600 baud

19200 baud 38400 baud

57600 baud 115200 baud

Page 16

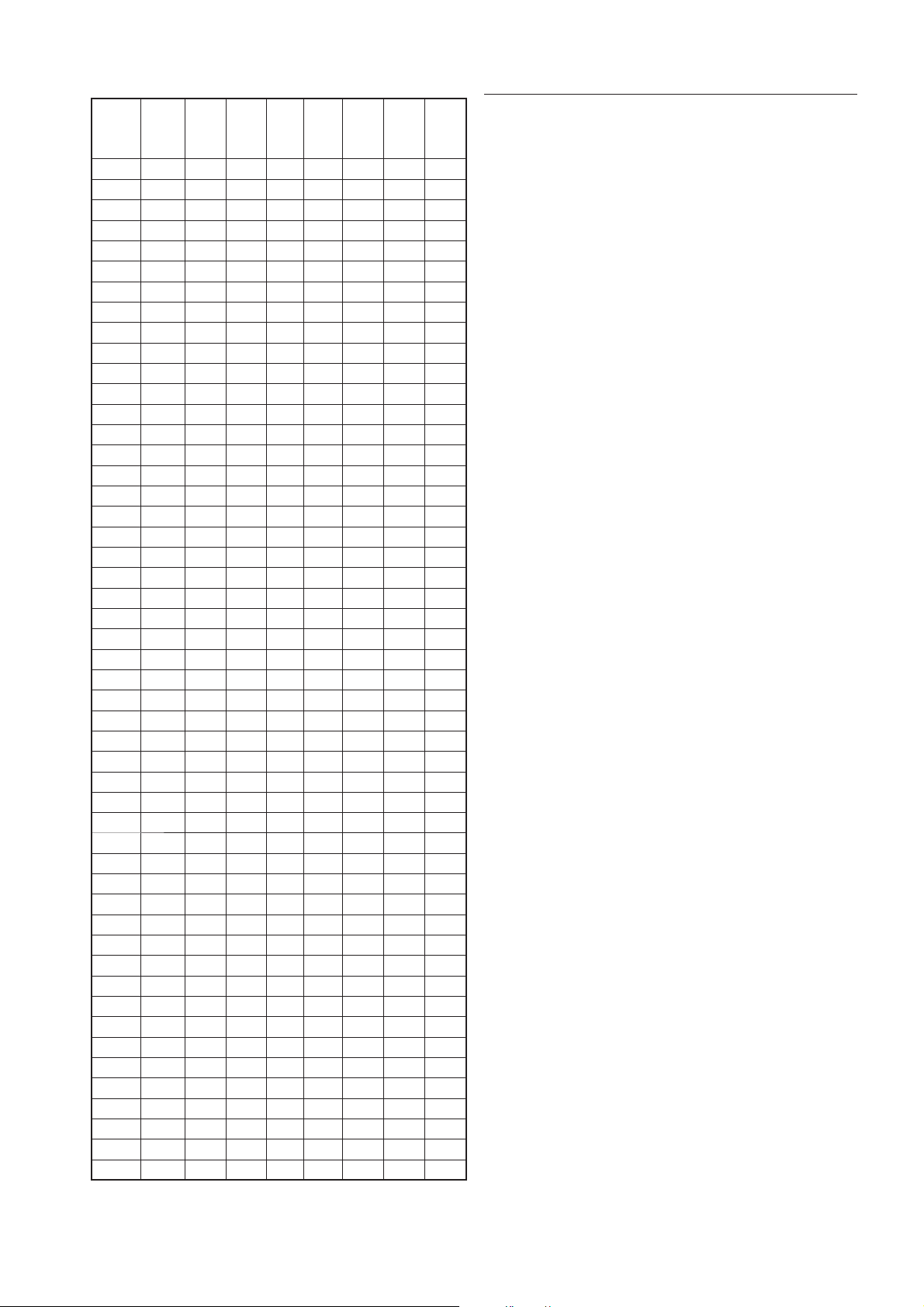

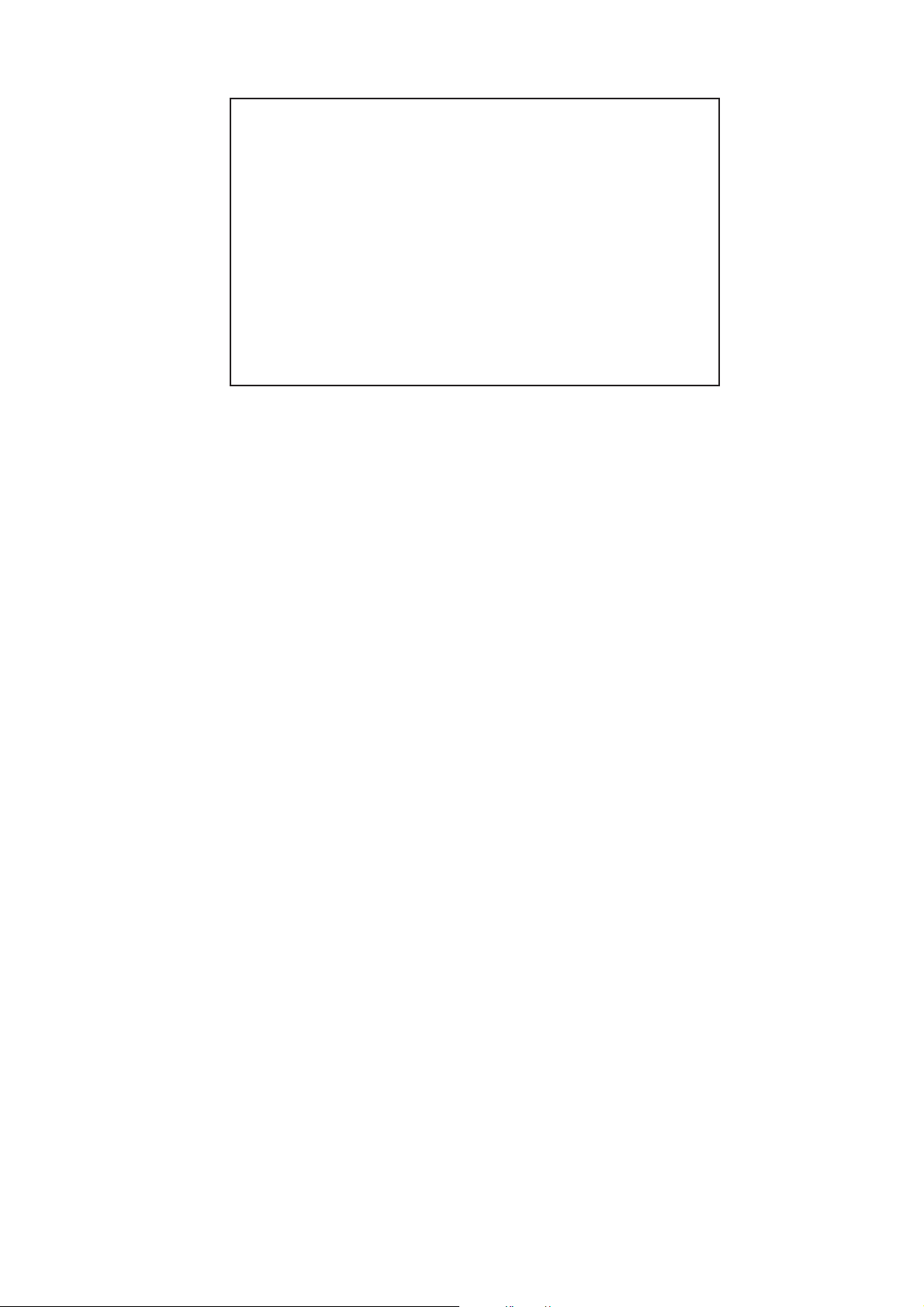

GATEWAY SOFTWARE VERSION DISPLAY

SW3-1

When DIP Switch 1 on SW3 is set to the ‘on’ possition the

LED indicators (LED 2 to 9) will show the software version:

L

E

D

#

6

L

E

D

#

7

L

E

D

#

8

L

E

D

#

9

Multi485

X04

L

E

D

#

2

L

E

D

#

3

L

E

D

#

5

L

E

D

#

4

MODBUS

X03

4

5

6 7 8 9

3

2

To establish the software version number (01 to 255) add

together the ‘value’ associated with each illuminated LED.

LED # Value

6 =1

7 =2

8 =4

9 =8

2 =16

3 =32

5 =64

4 =128

Ignore LED 1 (power on indicator), located adjacent

to X01; this LED will always be on when power is applied.

For example:

1) LED 6 and 8 = ON; all others off

LED 6 = 1

LED 8 = 4

total = 5

Software Version = ‘E05’

2) LED 7 and 8 = ON; all others off

LED 7 = 2

LED 8 = 4

total = 6

Software Version = ‘E06’

3) LED 6, 7, 9 and 2 = ON; all others off

LED 6 = 1

LED 7 = 2

LED 9 = 8

LED 2 = 16

total = 27

Software Version = ‘E27’

The LED indicators will continue to display the the

software version, regardless of operation, until switch 1

on SW3 is set to the ‘off’ possition.

DIP Switch 1 on SW3 must always be set to the ‘off’

position for normal operation.

DIP Switch 1 on SW3 has no function with earlier

software versions; if the LED indicators continue to

operate normally when SW3-1 is switched on, the

software is an earlier version; update the software.

Please refer to the table on the following page to assist in

decoding the software version number.

16

Page 17

oding The Software Version Number

Dec

LED#2

LED#3

LED#6

LED#7

LED#8

LED#9

LED#5

0 0 0 0 0 0 0 0 0

0 0 1 0 0 0 0 0 1

0 0 0 1 0 0 0 0 2

0 0 1 1 0 0 0 0 3

0 0 0 0 1 0 0 0 4

0 0 1 0 1 0 0 0 5

0 0 0 1 1 0 0 0 6

0 0 1 1 1 0 0 0 7

0 0 0 0 0 1 0 0 8

0 0 1 0 0 1 0 0 9

0 0 0 1 0 1 0 0 10

0 0 1 1 0 1 0 0 11

0 0 0 0 1 1 0 0 12

0 0 1 0 1 1 0 0 13

0 0 0 1 1 1 0 0 14

0 0 1 1 1 1 0 0 15

1 0 0 0 0 0 0 0 16

1 0 1 0 0 0 0 0 17

1 0 0 1 0 0 0 0 18

1 0 1 1 0 0 0 0 19

1 0 0 0 1 0 0 0 20

1 0 1 0 1 0 0 0 21

1 0 0 1 1 0 0 0 22

1 0 1 1 1 0 0 0 23

1 0 0 0 0 1 0 0 24

1 0 1 0 0 1 0 0 25

1 0 0 1 0 1 0 0 26

1 0 1 1 0 1 0 0 27

1 0 0 0 1 1 0 0 28

1 0 1 0 1 1 0 0 29

1 0 0 1 1 1 0 0 30

1 0 1 1 1 1 0 0 31

0 0 0 0 0 0 0 0 32

0 0 1 0 0 0 0 0 33

0 0 0 1 0 0 0 0 34

0 0 1 1 0 0 0 0 35

0 0 0 0 1 0 0 0 36

0 0 1 0 1 0 0 0 37

0 0 0 1 1 0 0 0 38

0 0 1 1 1 0 0 0 39

0 0 0 0 0 1 0 0 40

0 0 1 0 0 1 0 0 41

0 0 0 1 0 1 0 0 42

0 0 1 1 0 1 0 0 43

0 0 0 0 1 1 0 0 44

0 0 1 0 1 1 0 0 45

0 0 0 1 1 1 0 0 46

0 0 1 1 1 1 0 0 47

1 1 0 0 0 0 0 0 48

1 1 1 0 0 0 0 0 49

LED#4

COMMISSIONING PROCEDURE

1) B

efore applying power to the X-IRI Gateway ensure:

a)

Version

The MODBUS address is set to the correct value

(switches 1-4 on SW1 and switches 1- 3 on SW2)

b)

The MODBUS port setup matches the MODBUS

master’s requirements. Switches 4 on SW2 and

switches 2-4 on SW3.

c)

The communication link wires from the Gateway

to the compressor controller and the MODBUS

master are connected, secure and the wire

polarities are correct (L1, L2).

2) Apply power to the X-IRI Gateway

3) Ensure communications with the compressor controller

is established – ensure indicator (9) is ON permanently.

4) Once the IR-BUS compressor controller communication

link is established the MODBUS master unit can start

operating. Any attempt from the MODBUS master to

communicate before the IR-BUS link is established will

simply result in the gateway not responding to the

MODBUS master.

5) Once the MODBUS master communicates with the

compressor controller through the gateway it should

keep on doing so at least once every 10 seconds to keep

indicator (6) from flashing.

6) In case the MODBUS master does not communicate at

least once every 10 seconds the communication link is

considered inactive: indicator (6) flashes and any earlier

commands for the compressor controller to operate in

“Host” mode are cancelled => the machine reverts back

to local start/stop and load/unload control mode.

17

Page 18

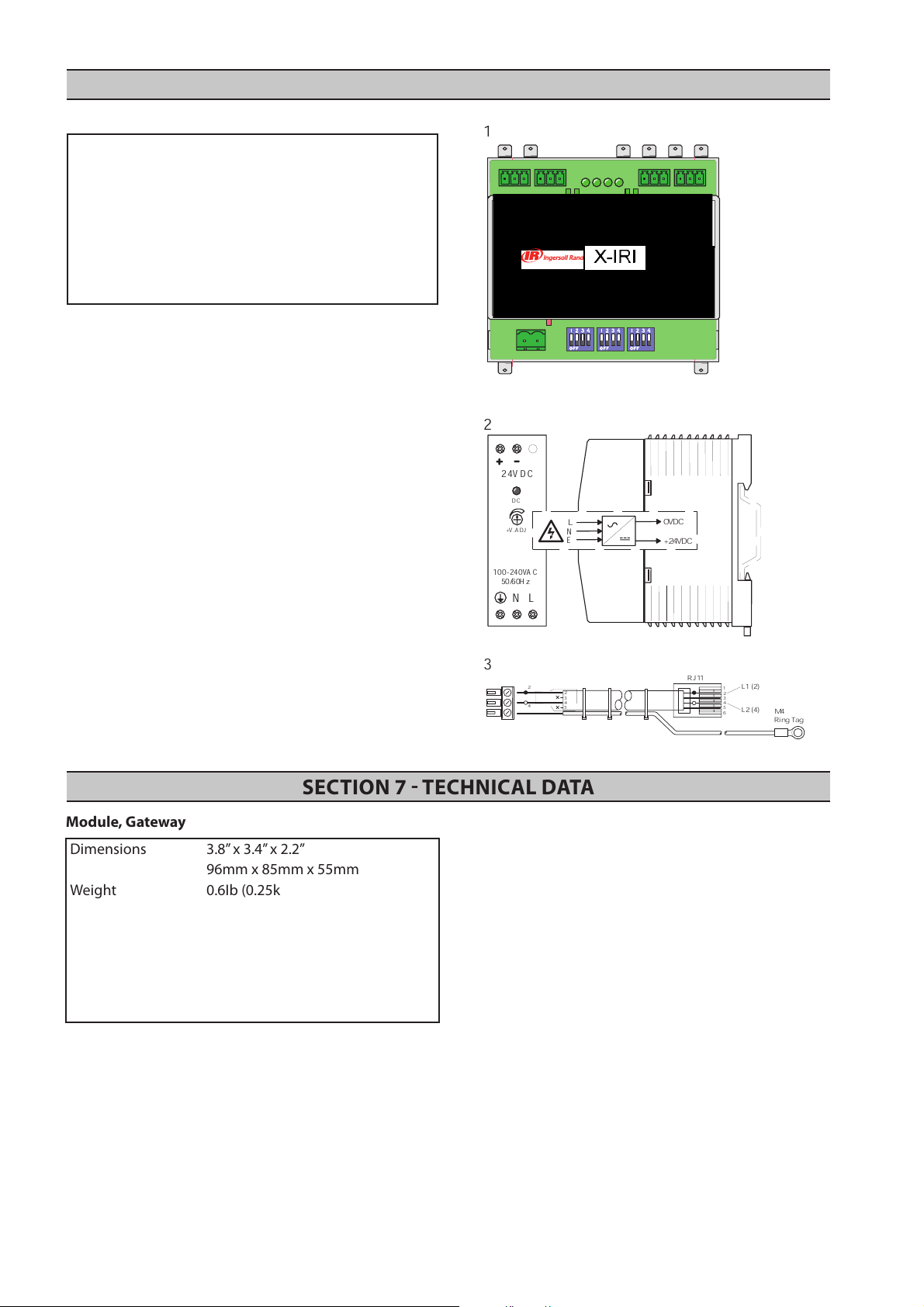

SECTION 6 PARTS LIST

1

L

E

D

#

6

L

E

D

#

7

L

E

D

#

8

L

E

D

#

9

s

c

r

e

e

n

L

2

L

1

12 13 23

Multi485

X05

s

c

r

e

e

n

L

2

L

1

12 13 23

MODBUS

X03

1 2

+

2

4

V

a

c

/

d

c

0

V

a

c

/

d

c

X01

X02

X04

L

E

D

#

1

2

3

4

1

ON

OFF

6

7

8

5

1

0

1

1

1

2

9

SW1 SW2 SW 3

L

E

D

#

2

L

E

D

#

3

L

E

D

#

5

L

E

D

#

4

2

3

DC

+V.ADJ

L

N

24V DC

100-240VAC

50/60Hz

E

N

L

0VDC

+24VDC

1

6

2

3

5

4

RJ11

2

4

3

5

M4

Ring Tag

L1 (2)

L2 (4)

2

4

SECTION 7 TECHNICAL DATA

Module, Gateway

Dimensions 3.8” x 3.4” x 2.2”

96mm x 85mm x 55mm

Weight 0.6Ib (0.25kg)

Mounting DIN, 35mm

Enclosure IP20

Supply 24VDC/ac +/-15%

Power 1.0VA

Temperature 0°C to 46°C (32°F to 115°F)

Humidity 95% RH non-condensing

X

-IRI Communication Gateway

Item Part No. Description

-

- 80445604 Manual, User CD

- 23462005 DIN Rail, Mounting

1 23461890 Module, X-IRI Gateway

2 39266101 Module, PSU-24VDC

3 39266135

23461908 KIT, X-IRI Gateway

Cable, RJ11 Modbus

18

Page 19

SECTION 8 INTELLISYS MODBUS TABLES

TABLE 1 SSR REDEYE CONTROLLER

Register

(40X

64 Total Hours (hours) R

65 Loaded Hours (hours) R

96 Language Selection R See FIGURE 1-2

97 Units of Measure R See FIGURE 1-2

98 Rated Pressure R

99 Rated Horse Power R See FIGURE 1-2

112 Offline Pressure R/W 75 - (rated+3) rated = rated pressure

113 Online Pressure R/W 65-(offline-10) offline = offline pressure

114 Display Timer (seconds) R/W 10-600

115 Star-Delta Time (seconds) R

116 Auto Start/Stop (AS/S) Time (minutes) R/W Feb-60 No Write if AS/S is off

117 Auto Start/Stop (AS/S) On/Off R 0 or 1 0=Off, 1=On

118 Sequence Control On/Off R 0 or 1 0=Off, 1=On

119 Remote Start/Stop On/Off R 0 or 1 0=Off, 1=On

120 Mod Only On/Off R/W 0 or 1 0=Off, 1=On

121 Power Out Restart Option (PORO)On/Off R 0 or 1 0=Off, 1=On

122 PORO Time (seconds) R/W 10-120 No Write if PORO is off

123 Load Delay Time (seconds) R/W 0-60

124 Min. Cooler Out Load Temp R/W 30-150 Low Ambient Option

125 Unloaded Stop Time R/W 10-30

255 Warning Code R See FIGURE 1-4

256-270 Alarm Code History R See FIGURE 1-4

272-286 Inlet Vacuum Alarm History R

288-302 Sump Pressure Alarm History R

304-318 Discharge Pressure Alarm History R

320-334 Coolant Temperature Alarm History R

336-350 Airend Temperature Alarm History R

352-366 Discharge Temperature Alarm History R

368-382 Low Ambient Coolant Temp. History R Low Ambient Option

384-398 Run Hours Alarm History R

400-414 Load Hours Alarm History R

512-526 Status Alarm History R See FIGURE 1-3

999 IRI Version Number R Reads from IRI only

Variable

XX)

1 Status/Control R/W See FIGURE 1-1

3 Discharge Pressure R

4 Sump Pressure R

5 Inlet Vacuum R

6 Coolant Temperature R

7 Airend Temperature R

8 Discharge Temperature R

9 Low Ambient Coolant Temp. R Low Ambient Option

Read/Write Range Not

es

19

Page 20

FIGURE 11 REGISTER 40001 STATUS / CONTROL

Bit 0: Host/Local (R/W) Bit 6: A

larm (R)

0 = Local 0 = No Alarms

1 = Host 1 = Alarms

Bit 1: Run/Stop (R/W) Bit 7: Warning (R)

0 = Stop 0 = No Warnings

1 = Run 1 = Warnings

Bit 2: Load/Unload (R/W) Bit 8: On/Off Line Mode (R)

0 = Unload 0 = Not in On/Off Line Mode

1 = Load 1 = On/Off Line Mode

Bit 3: Modulating (R) Bit 9: Mod/ACS or Mod Only (R)

0 = Not Modulating 0 = Not in Mod/ASC Mode

1 = Modulating 1 = Mod/ASC Mode

Bit 4: Unused Bits 10-12: Unused

Bit 5: Stopped in Auto Restart (R) Bits 13-15: Unit Type (R)

0 = Not Stopped in Auto Restart 001 = SSR controller

FIGURE 12 REGISTER CODES

Register 096: Language Regist

er 097: Units of Measure

0 = English 0 = °F and PSI

1 = Spanish 1 = °C and PSI

2 = French 2 = °C and Bar

3 = Portuguese 3 = °C and kPa

4 = °C and kg/cm

2

Register 99: Rated Horse Power/Kilowatt

0 = 50hp 7 = 250hp

1 = 60hp 8 = 300hp

2 = 75hp 9 = 350hp

3 = 100hp 10 = 400hp

4 = 125hp 11 = 450hp

5 = 150hp 12 = 500hp

6 = 200hp

FIGURE 13 REGISTER STATUS ALARM HISTORY

Bit 0: Run/Stop (R) Bit 4: S

topped Auto Restart (R)

0 = Stop 0 = Not Stopped in Auto Restart

1 = Run 1= Stopped in Auto Restart

Bit 1: On/Off Line Mode (R) Bit 5: Unused

0 = Not in On/Off Line Mode

1 = On/Off Line Mode

Bit 2: MOD/ACS Mode (R) Bit 6: Unused

0 = Not in Mod/ACS Mode

1 = Mod/ACS Mode

Bit 3: Load/Unload (R) Bit 7: Unused

20

Page 21

IGURE 14 REGISTER ALARM / WARNING CODES

F

SSR (Redeye) Controller

C

ode Description

01 Sensor Failure 1AVPT

02 Sensor Failure 3APT

03 Sensor Failure 4APT

04 Sensor Failure P4 (Spare)

05 Sensor Failure P5 (Spare)

06 Sensor Failure P6 (Spare)

07 Sensor Failure P7 (Spare)

08 Sensor Failure P8 (Spare)

09 Sensor Failure 2CTT

10 Sensor Failure 2ATT

11 Sensor Failure 4ATT

12 Sensor Failure 3CTT (Optional)

13 Sensor Failure T5 (Spare)

14 Sensor Failure T6 (Spare)

15 Sensor Failure T7 (Spare)

16 Sensor Failure T8 (Spare)

17 Starter Fault

18 Motor Overload (Main)

19 Fan Motor Overload

20 Door Open (Starter)

21 Stepper Limit Switch

22 Check Motor Rotation

23 Check Inlet Control System

25 Remote Stop Failure

26 Remote Start Failure

27 Check Inlet Control

28 Low Unload Sump Pressure

29 High Air Pressure

30 Low Sump Air Pressure

31 High A/E Discharge Temperature

32 Emergency Stop

33 Change Inlet Filter

34 Change Separator Element

35 Change Coolant Filter

36 1AVPT Sensor Error (Calibration)

37 Memory Fault

21

Page 22

TABLE 2 SSR SG CONTROLLER

Register

(40X

10 Separator Pressure Drop R

11 Spare Pressure Input 4 R

12 Dry Side Sump Pressure R Spare Pressure Input #5 if no

13 Spare Pressure Input 6 R

14 Spare Pressure Input 7 R

15 Remote Pressure R Spare Pressure Input #8 if no

16 Spare Temperature Input 5 R

17 Spare Temperature Input 6 R

18 Spare Temperature Input 7 R

19 Spare Temperature Input 8 R

20 % Load Modulation R

64 Total Hours (hours) R 0 – 9999 Less Than 10000

65 Loaded Hours (hours) R 0 – 9999 Less Than 10000

66 Ten Thousand Total Hours R Multiply by 10000

67 Ten Thousand Loaded Hours R Multiply by 10000

96 Language Selection R 0 – 11 See FIGURE 2-2

97 Units of Measure R 0 – 4 See FIGURE 2-2

98 Rated Pressure R

99 Rated Horse Power /Kilowatt R 0 – 21 See FIGURE 2-2

100 Starter Type R 0 - 4 See FIGURE 2-2

101 Service Level R 0 or 1 0=Level 1, 1=Level 2

102 Service Type R 0 or 1 0=Hours, 1=Months

103 Service Interval R 0 - 3 3, 6, 9, or 12 months

112 Offline Pressure R/W 75 - (rated+3) rated = rated pressure

113 Online Pressure R/W 65-(offline-10) offline = offline pressure

114 Mode of Operation R/W 0 – 2 See FIGURE 2-2

115 Star-Delta Time (seconds) R 5 – 20

116 Auto Start/Stop (AS/S) Time (minutes) R/W 2 – 60 No Write if AS/S is off

117 Auto Start/Stop (AS/S) On/Off R 0 or 1 0=Off, 1=On

118 Sequence Control On/Off R 0 or 1 0=Off, 1=On

119 Remote Start/Stop On/Off R 0 or 1 0=Off, 1=On

120 Solenoid Delta-P R 0 or 1 0=Off, 1=On

121 Power Out Restart Option (PORO)On/Off R 0 or 1 0=Off, 1=On

122 PORO Time (seconds) R/W 10-120 No Write if PORO is off

Variable

XX)

1 Status/Control R/W See FIGURE 2-1

3 Discharge Pressure R

4 Sump Pressure R

5 Inlet Vacuum R Divided by 10

6 Coolant Temperature R

7 Airend Temperature R

8 Discharge Temperature R

9 Low Ambient Coolant Temp. R Low Ambient Option

Read/Write Range Not

separator delta-p sensor option

remote sensor option

es

22

Page 23

123 Auto Start/Stop Delay Time (seconds) R/W 0-60

124

125 Unloaded Stop Time R/W 10-30t

126 Low Ambient Option On/Off R 0 or 1 0=Off, 1=On

127 Contrast R 0 - 10

128 Lead/Lag R/W 0 or 1 0=Off, 1=On

129 Lag Offset R/W 0 - 10

130 Max Modulation Pressure R/W (Online+10) –

131 Lead/Lag Cycle Length (Hours) R/W 0 – 750

132 Scheduled Start (Hour) R/W 0 – 23

133 Scheduled Start (Minute) R/W 0 – 59

134 Scheduled Stop (Hour) R/W 0 – 23

135 Scheduled Stop (Minute) R/W 0 – 59

136 Modbus Protocol R 0 or 1 0=Off, 1=On

137 Modbus Address R 1 – 247

138 High Dust Filter R 0 or 1 0=Off, 1=On

139 Integral Sequencing Lead R/W 0 – 3 0=Off, 1=On, 2=Always, 3=Never

140 Integral Sequencing Address R/W 1 – 4

141 Integral Sequencing Total R/W 2 – 4

142 Integral Sequencing Load Delay R/W 10 – 60

143 Integral Sequencing Lead Change (Hours) R/W 0 – 750

144 Integral Sequencing Lead Change – Day R/W 0 – 9 See FIGURE 2-2

145 Integral Sequencing Lead Change – Hour R/W 0 – 23

146 Integral Sequencing Lead Change – Min R/W 0 – 45 Steps of 0, 15, 30, 45

147 Separator Delta-P Sensor R 0 or 1 0=Off, 1=On

148 Variable Frequency Drive R 0 or 1 0=Off, 1=On

149 Scheduled Start (Day) R/W 0 - 9 See FIGURE 2-2

150 Scheduled Stop (Day) R/W 0 - 9 See FIGURE 2-2

151 Remote Sensor R 0 or 1 0=Off, 1=On

250 Options R See FIGURE 2-2

251 Unloaded Inlet Vacuum R

252 Software Part Number – Most Significant R High Digits

253 Software Part Number – Least Significant R Low Digits

254 Software Version Number R

255 Warning Code R See FIGURE 2-4

256-270 Alarm Code History R See FIGURE 2-4

272-286 Inlet Vacuum Alarm History R

288-302 Sump Pressure Alarm History R

304-318 Discharge Pressure Alarm History R

320-334 Coolant Temperature Alarm History R

336-350 Airend Temperature Alarm History R

352-366 Discharge Temperature Alarm History R

368-382 Low Ambient Coolant Temp. History R Low Ambient Option

384-398 Total Hours Alarm History R Less Than 10000 Hours

400-414 10000 Total Hours Alarm History R Multiply by 10000

416-430 Loaded Hours Alarm History R Less Than 10000 Hours

432-446 10000 Loaded Hours Alarm History R Multiply by 10000

448-462 Unloaded Inlet Vacuum Alarm History R

464-478 Coolant Pressure Alarm History R

480-494 Dry Side Sump Pressure Alarm History R

496-510 Remote Pressure Alarm History R

512-526 Status Alarm History R See FIGURE 2-3

528-542 Real Time Clock Alarm History – Hours R

544-558 Real Time Clock Alarm History – Minutes R

560-574 Real Time Clock Alarm History – Month R

576-590 Real Time Clock Alarm History – Date R

592-606 Real Time Clock Alarm History – Year R

999 IRI Version Number R Reads from IRI only

Min. Cooler Out Load Temp R/W 30-150 Low Ambient Option

(Offline + 7)

23

Page 24

FIGURE 21 REGISTER 40001 STATUS / CONTROL

Bit 0: Host/Local (R/W) Bit 6: A

larm (R)

0 = Local 0 = No Alarms

1 = Host 1 = Alarms

Bit 1: Run/Stop (R/W) Bit 7: Warning (R)

0 = Stop 0 = No Warnings

1 = Run 1 = Warnings

Bit 2: Load/Unload (R/W) Bit 8: On/Off Line Mode (R)

0 = Unload 0 = Not in On/Off Line Mode

1 = Load 1 = On/Off Line Mode

Bit 3: Modulating (R) Bit 9: Mod/ACS or Mod Only (R)

0 = Not Modulating 0 = Not in Mod/ASC Mode

1 = Modulating 1 = Mod/ASC Mode

Bit 4: Unused Bits 10-12: Unused

Bit 5: Stopped in Auto Restart (R) Bits 13-15: Unit Type (R)

0 = Not Stopped in Auto Restart 001 = SSR controller

1 = Stopped in Auto Restart

FIGURE 22 REGISTER CODES

Register 096: Language

Register 097: Units of Measure

0 = English 0 = °F and PSI

1 = Spanish 1 = °C and PSI

2 = Portuguese 2 = °C and Bar

3 = French 3 = °C and kPa

4 = Italian 4 = °C and kg/cm

5 = Dutch

6 = German

7 = Danish

8 = Norwegian

9 = Swedish

10 = Finnish

11 = Turkish

2

Register 99: Rated Horse Power/Kilowatt Register 100: Starter Type

0 = 50hp 11 = 450hp 0 = Star-Delta

1 = 60hp 12 = 500hp 1 = Full Voltage

2 = 75hp 13 = 75kw 2 = Remote Star-Delta

3 = 100hp 14 = 90kw 3 = Remote Full Voltage

4 = 125hp 15 = 110kw 4 = Soft Starter

5 = 150hp 16 = 132kw

6 = 200hp 17 = 150kw

7 = 250hp 18 = 200kw

8 = 300hp 19 = 250kw

9 = 350hp 20 =300kw

10 = 400hp 21 = 250kw

Register 114: Mode of Operation Register 144: Integral Sequencing Lead Change - Day

0 = MOD/ACS Register 149: Schedule Start - Day

1 = On/Off Line Register 150: Schedule Stop - Day

2 = Modulation Only 0= Sunday

1 = Monday

2 = Tuesday

3 = Wednesday

4 = Thursday

5 = Friday

6 = Saturday

7 = Daily

8 = Weekdays

9 = Weekends

Register 250: Options

Bit 0: Power Out Restart and Scheduled Start/Stop

0 = Off

1 = On

24

Page 25

IGURE 23 REGISTER STATUS ALARM HISTORY

F

Bit 0: Run/Stop (R) Bit 4: S

0 = Stop 0 = Not Stopped in Auto Restart

1 = Run 1 = Stopped in Auto Restart

Bit 1: On/Off Line Mode (R) Bit 5: Unused

0 = Not in On/Off Line Mode

1 = On/Off Line Mode

Bit 2: MOD/ACS Mode (R) Bit 6: Unused

0 = Not Modulating

1 = Modulating

Bit 3: Load/Unload (R) Bit 7: Unused

0 = Unload

1 = Load

topped Auto Restart (R)

25

Page 26

IGURE 24 REGISTER ALARM / WARNING CODES

F

SSR (SG) Controller

C

ode Description

01 Sensor Failure 1AVPT

02 Sensor Failure 3APT

03 Sensor Failure 4APT

04 Sensor Failure 5CPT (Optional)

05 Sensor Failure 6APT (Optional)

06 Sensor Failure P6 (Spare)

07 Sensor Failure P7 (Spare)

08 Sensor Failure P8 (Spare)

09 Sensor Failure 2CTT

10 Sensor Failure 2ATT

11 Sensor Failure 4ATT

12 Sensor Failure 3CTT (Optional)

13 Sensor Failure T5 (Spare)

14 Sensor Failure T6 (Spare)

15 Sensor Failure T7 (Spare)

16 Sensor Failure T8 (Spare)

17 Starter Fault

18 Motor Overload (Main)

19 Fan Motor Overload

20 Control Power Loss

21 Stepper Limit Switch

22 Check Motor Rotation

23 Check Inlet Control System

25 Remote Stop Failure

26 Remote Start Failure

27 Check Inlet Control

28 Low Unload Sump Pressure

29 High Air Pressure

30 Low Sump Air Pressure

31 High A/E Discharge Temperature

32 Emergency Stop

33 Change Inlet Filter

34 Change Separator Element

35 Change Coolant Filter

36 1AVPT Sensor Error (Calibration)

37 Memory Fault

38 100 Hours/14 Days To Service

39 Service Required

40 Alarm - Service Required

41 Auxiliary 2

42 Auxiliary 1

43 High Line/Sump Differential

44 Communication Failure 1

45 Communication Failure 2

46 Communication Failure 3

47 Communication Failure 4

48 Low Coolant Pressure

26

Page 27

TABLE 3 SSR SE 15100HP CONTROLLER

Register

(40X

64 Total Hours (hours) R

65 Loaded Hours (hours) R

96 Language Selection R See FIGURE 3-2

97 Units of Measure R See FIGURE 3-2

98 Rated Pressure R

99 Starter Type R See FIGURE 3-2

100 Star-Delta Timer (seconds) R

101 Contrast R

102 Modulation On/Off (v1.5 or higher) R 0 or 1 0=Off, 1=On

112 Offline Pressure R/W 75 - (rated+3)

113 Online Pressure R/W 65-(offline-10)

114 Mode of Operation R/W 0-2 See FIGURE 3-2

115 Display Timer (seconds) R/W 10-600

116 Auto Start/Stop (AS/S) On/Off R 0 or 1 0=Off, 1=On

117 Auto Start/Stop Time (minutes) R/W 2-20 No Write if AS/S is off

118 Sequence Control On/Off R 0 or 1 0=Off, 1=On

119 Remote Start/Stop On/Off R 0 or 1 0=Off, 1=On

120 Power Out Restart Option(PORO) On/Off R 0 or 1 0=Off, 1=On

121 PORO Time (seconds) R/W 10-120 No Write if PORO is off

122 Load Delay Time (seconds) R/W 0-60

123 Lead/Lag (v1.5 or higher) R/W 0 or 1 0=Lead, 1=Lag

124 Lag Offset (v1.5 or higher) R/W 0-45 psi

125 Low Ambient Option (v1.6 or higher) R 0 or 1 0=Off, 1=On

252 Part Number (v1.5 or higher) R High 16-bits

253 Part Number (v1.5 or higher) R Lower 16-bits

254 Software Version (v1.5 or higher) R

255 Warning Code R See FIGURE 3-4

256-270 Alarm Code History R See FIGURE 3-4

272-286 Discharge Pressure Alarm History R

288-302 Sump Pressure Alarm History R

304-318 Airend Temperature Alarm History R

320-334 Separator Pressure Alarm History R

336-350 Run Hours Alarm History R

352-366 Load Hours Alarm History R

368-382 Status Alarm History R See FIGURE 3-3

999 IRI Version Number R Reads from IRI only

Variable

XX)

1 Status/Control R/W See FIGURE 3-1

3 Discharge Pressure R

4 Sump Pressure R

5 Separator Pressure Drop R

6 Airend Temperature R

Read/Write Range Not

es

27

Page 28

IGURE 31 REGISTER 40001 STATUS / CONTROL

F

Bit 0: Host/Local (R/W) Bit 6: A

larm (R)

0 = Local 0 = No Alarms

1 = Host 1 = Alarms

Bit 1: Run/Stop (R/W) Bit 7: Warning (R)

0 = Stop 0 = No Warnings

1 = Run 1 = Warnings

Bit 2: Load/Unload (R/W) Bit 8: On/Off Line Mode (R)

0 = Unload 0 = Not in On/Off Line Mode

1 = Load 1 = On/Off Line Mode

Bit 3: Modulating (R) Bit 9: Mod/ACS or Mod Only (R)

0 = Not Modulating 0 = Not in Mod/ASC Mode

1 = Modulating 1 = Mod/ASC Mode

Bit 4: Sump Pressure (R/W) Bits 10-12: Unused

1 = Get Sump Pressure

Bit 5: Stopped in Auto Restart (R) Bits 13-15: Unit Type (R)

0 = Not Stopped in Auto Restart 010 = SE controller

1 = Stopped in Auto Restart

FIGURE 32 REGISTER CODES

Register 096: Language

Register 097: Units of Measure

0 = English 0 = °C and Bar

1 = Spanish 1 = °C and PSI

2 = French 2 = °C and kPa

3 = Portuguese 3 = °F and PSI

4 = °C and kg/cm

2

Register 99: Starter Type Register 114: Mode of Operation

0 = Full Voltage 0 = MOD/ACS

1 = Star-Delta 1 = Modulation Only

2 = No Starter 2 = On/Off Line

FIGURE 33 REGISTER STATUS ALARM HISTORY

Bit 0: Run/Stop (R) Bit 4: S

topped Auto Restart (R)

0 = Stop 0 = Not Stopped in Auto Restart

1 = Run 1= Stopped in Auto Restart

Bit 1: On/Off Line Mode (R) Bit 5: Unused

0 = Not in On/Off Line Mode

1 = On/Off Line Mode

Bit 2: MOD/ACS Mode (R) Bit 6: Unused

0 = Not Modulating

1 = Modulating

Bit 3: Load/Unload (R) Bit 7: Unused

0 = Unload

1 = Load

28

Page 29

IGURE 34 REGISTER ALARM / WARNING CODES

F

SSR (SE) 15-100HP CONTROLLER

C

ode Description

01 Pressure Sensor Failure

02 Temperature Sensor Failure 1

04 Starter Fault

05 Motor Overload

06 Reverse Rotation

07 Remote Stop Failure

08 Remote Start Failure

09 Calibration Error

10 High Airend Discharge Temperature

12 High Pressure

15 Separator Element

16 Control Power Loss

17 Fan Motor Overload

18 Emergency Stop

19 Low Sump Pressure

20 Memory Fault

21 Low Unloaded Sump Pressure

29

Page 30

TABLE 4 SIERRA REDEYE 125200 HP CONTROLLER

Register

(40X

112 Offline Pressure R/W 75 - (rated+3) rated = rated pressure

113 Online Pressure R/W 65-(offline-10) offline = offline pressure

114 Display Timer (seconds) R/W 10-600

115 Condensate Time (seconds) R/W 90-270

116 Start-Delta Time (seconds) R 10-20

117 Auto Start/Stop Time (seconds) R/W 2-60 No Write if AS/S is off

118 Max. 1st Stage Temperature R/W 310-410

119 Max. 2nd Stage Temperature R/W Variable Refer to Sierra’s Manual

120 PORO Time (seconds) R/W 10-120 No Write if PORO is off

121 Auto Start/Stop On/Off R 0 or 1 0=Off, 1=On

122 PORO On/Off R 0 or 1 0=Off, 1=On

123 Remote Start/Stop On/Off R 0 or 1 0=Off, 1=On

124 Sequence Control On/Off R 0 or 1 0=Off, 1=On

125 Condensate Level On/Off R 0 or 1 0=Off, 1=On

126 Water Unit Yes/No R 0 or 1 0=No, 1=Yes

255 Warning Code R See FIGURE 4-4

256-270 Alarm Code History R See FIGURE 4-4

272-286 Inlet Vacuum Alarm History R

288-302 2nd Stage Inlet Pressure Alarm History R

304-318 2nd Stage Discharge Press. Alarm History R

320-334 Package Discharge Press. Alarm History R

336-350 Oil Filter In Pressure Alarm History R

352-366 Bearing Oil Pressure Alarm History R

368-382 1st Stage Discharge Temp Alarm History R

384-398 2nd Stage Inlet Temp Alarm History R

400-414 2nd Stage Discharge Temp Alarm History R

512-526 Bearing Oil Temp Alarm History R

528-542 Package Discharge Air Temp Alarm History R

544-558 Run Hours Alarm History R

560-574 Run Hours, Ten Thousand, Alarm History R

576-590 Load Hours Alarm History R

592-606 Load Hours, Ten Thousand, Alarm History R

608-622 Status Alarm History R See FIGURE 4-3

999 IRI Version Number R Reads from IRI only

Variable

XX)

1 Status/Control R/W See FIGURE 4-1

3 Discharge Pressure R

4 2nd Stage Inlet Pressure R

5 2nd Stage Discharge Pressure R

6 Inlet Vacuum R

7 Oil Filter In Pressure R

8 Bearing Oil Pressure R

9 1st Stage Discharge Temp. R

10 2nd Stage Inlet Temp. R

11 2nd Stage Discharge Temp. R

12 Bearing Oil Temp. R

13 Package Discharge Temp. R

64 Running Hours (<10,000 hours) R

65 Ten Thousand Running Hours R Multiply value by 10,000

66 Load Hours (<10,000 hours) R

67 Ten Thousand Load Hours R Multiply value by 10,000

96 Language Selection R See FIGURE 4-2

97 Units of Measure R See FIGURE 4-2

98 Rated Pressure R

Read/Write Range Not

es

30

Page 31

IGURE 41 REGISTER 40001 STATUS / CONTROL

F

Bit 0: Host/Local (R/W) Bit 6: A

larm (R)

0 = Local 0 = No Alarms

1 = Host 1 = Alarms

Bit 1: Run/Stop (R/W) Bit 7: Warning (R)

0 = Stop 0 = No Warnings

1 = Run 1 = Warnings

Bit 2: Load/Unload (R/W) Bit 8: On/Off Line Mode (R)

0 = Unload 0 = Not in On/Off Line Mode

1 = Load 1 = On/Off Line Mode

Bit 3: Unused Bit 9: Unused

Bit 4: Unused Bits 10-12: Unused

Bit 6: Stopped in Auto Restart (R) Bits 13-15: Unit Type (R)

0 = Not Stopped in Auto Restart 100 = Sierra controller

1 = Stopped in Auto Restart

FIGURE 42 REGISTER CODES

Register 096: Language Regist

er 097: Units of Measure

0 = English 0 = °F and PSI

1 = Spanish 1 = °C and PSI

2 = Portuguese 2 = °C and Bar

3 = °C and kPa

4 = °C and kg/cm

2

FIGURE 43 REGISTER STATUS ALARM HISTORY

Bit 0: Run/Stop (R) Bit 4: S

topped Auto Restart (R)

0 = Stop 0 = Not Stopped in Auto Restart

1 = Run 1 = Stopped in Auto Restart

Bit 1: On/Off Line Mode (R) Bit 5: Unused

0 = Not in On/Off Line Mode Bit 6: Unused

1 = On/Off Line Mode Bit 7: Unused

Bit 2: Unused

Bit 3: Load/Unload (R)

0 = Unload

1 = Load

31

Page 32

IGURE 44 REGISTER ALARM / WARNING CODES

F

SIERRA (REDEYE) 125-200 HP CONTROLLER

C

ode Description

01 Sensor Failure 1AVPT

02 Sensor Failure 2APT

03 Sensor Failure 3APT

04 Sensor Failure 4APT

05 Sensor Failure 5OPT

06 Sensor Failure 6OPT

07 Sensor Failure P7 (Spare)

08 Sensor Failure P8 (Spare)

09 Sensor Failure 2ATT

10 Sensor Failure 3ATT

11 Sensor Failure 4ATT

12 Sensor Failure 5OTT

13 Sensor Failure 7ATT

14 Sensor Failure T6 (Spare)

15 Sensor Failure T7 (Spare)

16 Sensor Failure T8 (Spare)

17 Starter Fault

18 Motor Overload (Main)

19 Fan Motor Overload

20 High 1st Stage Discharge Temp.

21 High 2nd Stage Discharge Temp.

22 High Bearing Oil Temp.

23 High I/C Air Temp,

24 Unused

25 Remote Stop Failure

26 Remote Start Failure

27 High Vacuum

28 High Loaded Vacuum

29 High Discharge Air Pressure

30 Low Bearing Oil Pressure

31 High I/C Pressure (Loaded)

32 Emergency Stop

33 Change Inlet Filter

34 High I/C Pressure (Unloaded)

35 Change Coolant Filter

36 High 2nd Stage Pressure

37 Memory Fault

38 Low Water Flow

39 High Condensate

32

Page 33

TABLE 5 SIERRA SE 50100 HP CONTROLLER

Register

(40X

100 Star-Delta Timer (seconds) R

101 Contrast R

112 Offline Pressure R/W 75 - (rated+3)

113 Online Pressure R/W 65-(offline-10)

114 Display Timer (seconds) R/W 10-600

115 Auto Start/Stop On/Off R 0 or 1 0=Off, 1=On

116 Auto Start/Stop Time (minutes) R/W 2-60 No Write if AS/S is off

117 Condensate Switch On/Off R 0 or 1 0=Off, 1=On

118 Sequence Control On/Off R 0 or 1 0=Off, 1=On

119 Remote Start/Stop On/Off R 0 or 1 0=Off, 1=On

120 PORO On/Off R 0 or 1 0=Off, 1=On

121 PORO Time (seconds) R/W 10-120 No Write if PORO is off

122 Load Delay Time (seconds) R/W 0-60

123 Lead/Lag R/W 0 or 1 0=Lead, 1=Lag

124 Lag Offset R/W 0-45 psi

125 Condensate Discharge Time (seconds) R/W 2-10

126 Condensate Interval Time (seconds) R/W 90-270

252 Part Number R High 16-bits

253 Part Number R Lower 16-bits

254 Software Version R

255 Warning Code R See FIGURE 5-4

256-270 Alarm Code History R See FIGURE 5-4

272-286 Discharge Pressure Alarm History R

288-302 Package Disch. Temp. Alarm History R

304-318 Bearing Oil Temp. Alarm History R

320-334 2nd Stage Inlet Temp. Alarm History R

336-350 2nd Stage Disch. Temp. Alarm History R

352-366 1st Stage Disch. Temp. Alarm History R

368-382 Run Hours Alarm History R

384-398 Load Hours Alarm History R

400-414 Status Alarm History R See FIGURE 5-3

999 IRI Version Number R Reads from IRI only

Variable

XX)

1 Status/Control R/W See FIGURE 5-1

3 Discharge Pressure R

4 Package Discharge Temp. R

5 Bearing Oil Temp. R

6 2nd Stage Inlet Temp. R

7 2nd State Discharge Temp. R

8 1st Stage Discharge Temp. R

64 Total Hours (hours) R

65 Loaded Hours (hours) R

96 Language Selection R See FIGURE 5-2

97 Units of Measure R See FIGURE 5-2

98 Rated Pressure R

99 Starter Type R See FIGURE 5-2

Read/Write Range Not

es

33

Page 34

IGURE 51 REGISTER 40001 STATUS / CONTROL

F

Bit 0: Host/Local (R/W) Bit 6: A

larm (R)

0 = Local 0 = No Alarms

1 = Host 1 = Alarms

Bit 1: Run/Stop (R/W) Bit 7: Warning (R)

0 = Stop 0 = No Warnings

1 = Run 1 = Warnings

Bit 2: Load/Unload (R/W) Bit 8: On/Off Line Mode (R)

0 = Unload 0 = Not in On/Off Line Mode

1 = Load 1 = On/Off Line Mode

Bit 3: Unused Bit 9: Unused

Bit 4: Sump Pressure (R/W) Bits 10-12: Unused

1 = Get Sump Pressure Bits 13-15: Unit Type (R)

Bit 5: Stopped in Auto Restart (R) 110 = Sierra SE controller

0 = Not Stopped in Auto Restart

1 = Stopped in Auto Restart

FIGURE 52 REGISTER CODES

Register 096: Language Regist

er 097: Units of Measure

0 = English 0 = °C and Bar

1 = Spanish 1 = °C and PSI

2 = French 2 = °C and kPa

3 = Portuguese 3 = °F and PSI

4 = °C and kg/cm

2

Register 99: Starter Type

0 = Full Voltage

1 = Star-Delta

2 = No Starter

FIGURE 53 REGISTER STATUS ALARM HISTORY

Bit 0: Run/Stop (R) Bit 4: S

topped Auto Restart (R)

0 = Stop 0 = Not Stopped in Auto Restart

1 = Run 1 = Stopped in Auto Restart

Bit 1: On/Off Line Mode (R) Bit 5: Unused

0 = Not in On/Off Line Mode Bit 6: Unused

1 = On/Off Line Mode Bit 7: Unused

Bit 2: Unused

Bit 3: Load/Unload (R)

0 = Unload

1 = Load

34

Page 35

IGURE 54 REGISTER ALARM / WARNING CODES

F

SIERRA (SE) 50-100 HP CONTROLLER

C

ode Description

01 Pressure Sensor Failure

02 Package Disch. Temp. Sensor Failure

03 Bearing Oil Temp. Sensor Failure

04 Starter Fault

05 Motor Overload

06 2nd Stage Inlet Temp. Sensor Failure

07 Remote Stop Failure

08 Remote Start Failure

09 Calibration Error

10 2nd Stage Disch. Temp. Sensor Failure

11 1st Stage Disch. Temp. Sensor Failure

12 High Pressure

13 Oil Pressure Switch

14 Condensate Level

15 High Package Disch. Temp.

16 Control Power Loss

17 High Bearing Oil Temp.

18 Emergency Stop

19 High 2nd Stage Inlet Temp.

20 Memory Fault

21 High 1st Stage Disch. Temp.

22 High 2nd Stage Disch. Temp.

35

Page 36

TABLE 6 SIERRA SG 125400 HP CONTROLLER

Register

(40X

100 Power Type R 0 - 1 0=50 Hz, 1=60 Hz

112 Offline Pressure R/W 75 - (rated+3) rated = rated pressure

113 Online Pressure R/W 65-(offline-10) offline = offline pressure

114 Condensate Release Time (seconds) R/W 2-10

115 Condensate Interval Time (seconds) R/W 90-270

116 Start-Delta Time (seconds) R 10-20

117 Auto Start/Stop Time (seconds) R/W 2-60 No Write if AS/S is off

118 Max. 1st Stage Temperature R/W 310-410

119 Max. 2nd Stage Temperature R/W Variable Refer to Sierra’s Manual

120 PORO Time (seconds) R/W 10-120 No Write if PORO is off

121 Auto Start/Stop On R 1 Always On

122 PORO On/Off R 0 or 1 0=Off, 1=On

123 Remote Start/Stop On/Off R 0 or 1 0=Off, 1=On

124 Sequence Control On/Off R 0 or 1 0=Off, 1=On

125 Condensate Level On/Off R 0 or 1 0=Off, 1=On

126 Load Delay Time (seconds) R/W 0 - 60

127 Lead/Lag R/W 0 or 1 0=Lead, 1=La

128 Lag Offset R/W 0 - 45 psi

129 Contrast R 0 - 10

130 Lead/Lag Cycle Length (Hours) R/W 0 - 750

131 Scheduled Start (Hours) R/W 0 - 23

132 Scheduled Start (Minutes) R/W 0 - 59

133 Scheduled Stop (Hours) R/W 0 - 23

134 Scheduled Stop (Minutes) R/W 0 - 59

135 Real Time Hours R 0 - 23

136 Real Time Minutes R 0 - 59

137 Month of Year R 1-12

138 Day of Month R 1-31

139 Year R 0 - 99

140 Integral Sequencing Lead R/W 0 – 3 0=Off, 1=On, 2=Always, 3=Never

141 Integral Sequencing Total R/W 2 – 4

142 Integral Sequencing Address R/W 1 – 4

143 Integral Sequencing Load Delay R/W 10 – 60

144 Integral Sequencing Lead Change (Hours) R/W 0 – 750

145 Integral Sequencing Lead Change – Day R/W 0 – 9 See FIGURE 6-2

Variable

XX)

1 Status/Control R/W See FIGURE 6-1

3 Discharge Pressure R

4 2nd Stage Inlet Pressure R

5 2nd Stage Discharge Pressure R

6 Inlet Vacuum R Value Divided by 10

7 Oil Filter In Pressure R

8 Bearing Oil Pressure R

9 2nd Stage Inlet Temp. R

10 1st Stage Discharge Temp. R

11 2nd Stage Discharge Temp. R

12 Bearing Oil Temp. R

13 Package Discharge Temp. R

14 P6 Spare Pressure Input R 0 - 1023 0 volts = 0, 5 volts = 1023

64 Running Hours (<10,000 hours) R

65 Ten Thousand Running Hours R Multiply value by 10,000

66 Load Hours (<10,000 hours) R

67 Ten Thousand Load Hours R Multiply value by 10,000

93 Service Level R 0 or 1 0=Level 1, 1=Level 1

94 Service Type R 0 or 1 0=Hours, 1=Months

95 Service Interval R 0 - 3 3, 6, 9, or 12 months

96 Language Selection R See FIGURE 6-2

97 Units of Measure R See FIGURE 6-2

98 Rating Pressure R

99 Starter Type R 0 -3 See FIGURE 6-2

Read/Write Range Not

es

36

Page 37

146 Integral Sequencing Lead Change - Hour R/W 0 – 23

147

148 Scheduled Start - Day R/W 0 – 9 See FIGURE 6-2

149 Scheduled Stop - Day R/W 0 – 9 See FIGURE 6-2

150 High Dust Filter R 0 or 1 0=Off, 1=On

252 Part Number R High 16-bits

253 Part Number R Lower 16-bits

254 Software Version R

255 Warning Code R See FIGURE 6-4

256-270 Alarm Code History R See FIGURE 6-4

272-286 Inlet Vacuum Alarm History R

288-302 2nd Stage Inlet Pressure Alarm History R

304-318 2nd Stage Discharge Press. Alarm History R

320-334 Package Discharge Press. Alarm History R

336-350 Oil Filter In Pressure Alarm History R

352-366 Bearing Oil Pressure Alarm History R

368-382 1st Stage Discharge Temp Alarm History R

384-398 2nd Stage Inlet Temp Alarm History R

400-414 2nd Stage Discharge Temp Alarm History R

512-526 Bearing Oil Temp Alarm History R

528-542 Package Discharge Air Temp Alarm History R

544-558 Run Hours Alarm History R

560-574 Run Hours, Ten Thousand, Alarm History R

576-590 Load Hours Alarm History R

592-606 Load Hours, Ten Thousand, Alarm History R

608-622 Status Alarm History R See FIGURE 6-4

999 IRI Version Number R Reads from IRI only

Integral Sequencing Lead Change – Min R/W 0 – 45 Steps of 0, 15, 30, 45

37

Page 38

IGURE 61 REGISTER 40001 STATUS / CONTROL

F

Bit 0: Host/Local (R/W) Bit 6: A

larm (R)

0 = Local 0 = No Alarms