Page 1

APDD 739

June 1999

XF 20 - 30

EP 20 - 30

HP 20 - 30

HXP 20 - 30

OPERATORS/

INSTRUCTION MANUAL

OPTIONS

Before installation or starting the compressor for

the first time, this manual should be studied carefully to obtain a clear knowledge of the unit and of the

duties to be performed while operating and maintaining the unit.

RETAIN THIS MANUAL WITH UNIT.

This Technical manual contains IMPORTANT SAFETY DATAand should be kept with the air compres-

®

Page 2

©INGERSOLL-RAND COMPANY

AIR COMPRESSOR GROUP

BONDED WARRANTY & REGISTERED START UP

Warranty

The Company warrants that the equipment manufactured by it and delivered hereunder will be free of defects in

material and workmanship for a period of twelve months (see extended airend warranty) from the date of placing

the Equipment in operation or eighteen months (see extended airend warranty) from the date of shipment from

Davidson, NC, whichever shall first occur. The Purchaser shall be obligated to promptly report any failure to conform to this warranty, in writing to the Company in said period, whereupon the Company shall, at its option, correct

such nonconformity, by suitable repair to such equipment or, furnish a replacement part F.O.B. point of shipment,

provided the Purchaser has stored, installed maintained and operated such Equipment in accordance with good

industry practices and has complied with specific recommendations of the Company. Accessories or equipment furnished by the Company, but manufactured by others, shall carry whatever warranty the manufacturers have conveyed to the Company and which can be passed on to the Purchaser. The Company shall not be liable for any

repairs, replacements, or adjustments to the Equipment or any costs of labor performed by the Purchaser or others

without Company’s prior written approval.

The effects of corrosion, erosion and normal wear and tear are specifically excluded. Performance warranties are

limited to those specifically stated within the Company’s proposal. Unless responsibility for meeting such performance warranties are limited to specified tests, the Company’s obligation shall be to correct in the manner and for

the period of time provided above.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR APARTICULAR PURPOSE, ARE HEREBY DISCLAIMED.

Correction by the Company of nonconformities whether patent or latent, in the manner and for the period of time

provided above, shall constitute fulfillment of all liabilities of the Company for such nonconformities whether based

on contract, warranty negligence, indemnity, strict liability or otherwise with respect to or arising out of such

Equipment.

The purchaser shall not operate Equipment which is considered to be defective, without first notifying the Company

in writing of its intention to do so. Any such Equipment will be at Purchaser’s sole risk and liability.

Limitation or Liability

The remedies of the Purchaser set forth herein are exclusive, and the total liability of the Company with respect to

this contract or the Equipment and services furnished hereunder, in connection with the performance or breach

thereof, or from the manufacture, sale, delivery, installation, repair or technical direction covered by or furnished

under this contract, whether passed on contract, warranty negligence, indemnity, strict liability or otherwise, shall

not exceed the purchase price of the unit of Equipment upon which such liability is based.

The Company and its suppliers shall in no event be liable to the Purchaser, any successors in interest or any beneficiary or assignee of this contract for any consequential, incidental, indirect, special or punitive damages arising

out of this contract or any breach thereof, or any defect in, or failure of, or malfunction of the Equipment hereunder,

whether based upon loss of use, lost profits or revenue, interest, lost goodwill, work stoppage, impairment of other

goods, loss by reason of shutdown or non-operation, increased expenses of operation, cost of purchase of replacement power or claims of Purchaser or customers of Purchaser for service interruption whether or not such loss or

damage is based on contract, warranty, negligence, indemnity, strict liability or otherwise.

EXTENDED AIREND WARRANTY

The Ingersoll-Rand Company Rotary Screw Air Compressor that has been

filled prior to its original shipment from Ingersoll-Rand Company with ULTRA

COOLANT and which has been operated solely on ULTRA COOLANT thereafter shall have its AIREND warranted for twenty four (24) months from the

date of placing the COMPRESSOR in operation or thirty (30) months from the

date of shipment, whichever occurs first.

Except for the above warranty period, the standard warranty provisions shall

apply and the conditions outlined herein are understood to be a supplement to

the standard Ingersoll-Rand Company warranty.

Page 3

1

ROTARY SCREW AIR COMPRESSOR

This unit was purchased from

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Ingersoll-Rand Company reserves the right to make changes or add

improvements without notice and without incurring any obligation to make

such changes or add such improvements to products sold previously.

No. of units on order:

Customer Order No:

Ingersoll-Rand Co. Order No.:

For ready reference:

Record the serial number and model number of your unit here.

Serial Number:

Model Number:

TYPICAL UNIT

Page 4

2

TABLE OF CONTENTS

0.0 SAFETY AND WARNINGS

0.1 safety instructions

0.2 safety precautions

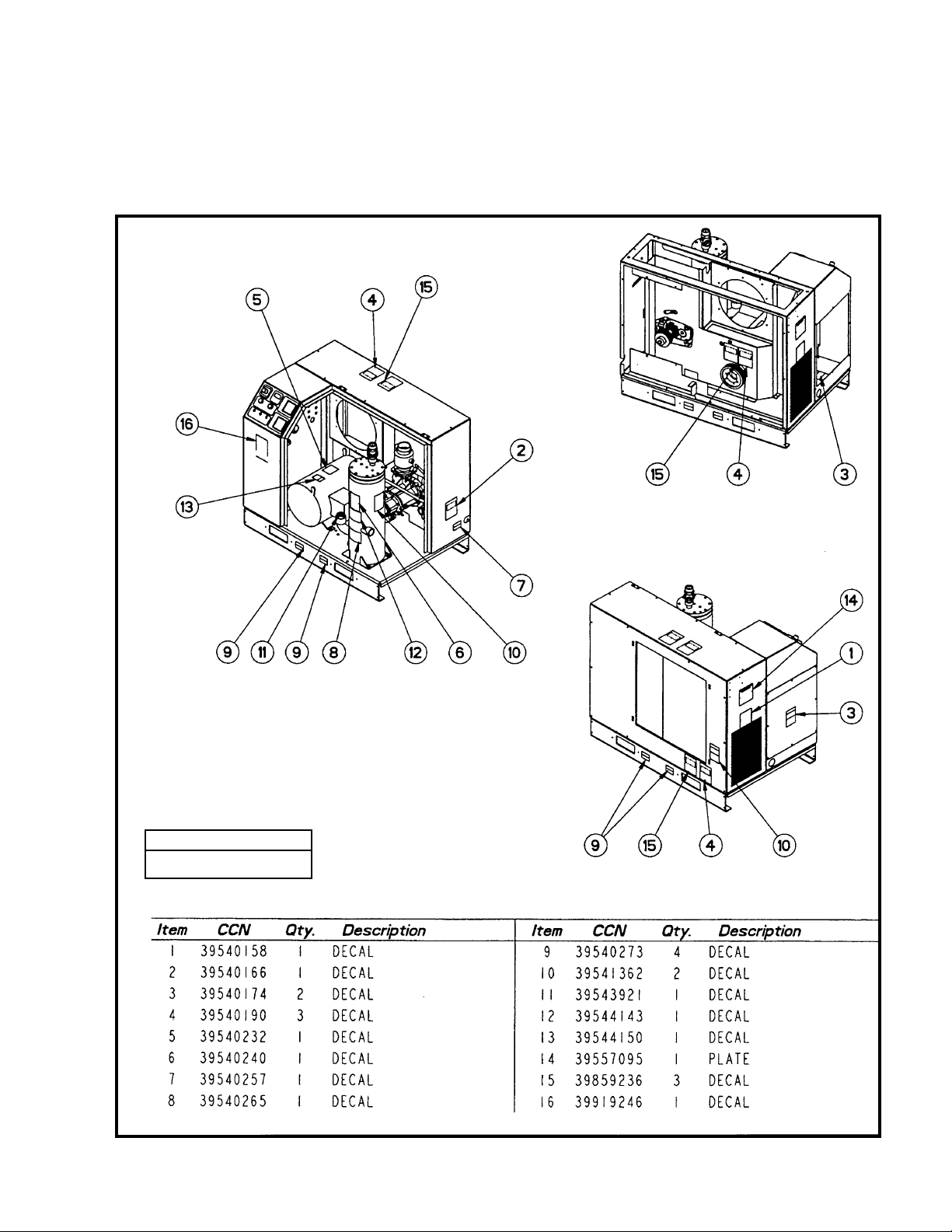

0.3 decals

1.0 RECEIPT OF EQUIPMENT

1.1 inspection

1.2 unpacking and handling

1.3 tools

2.0 INSTALLATION

2.1 ventilation

2.2 foundation requirements

2.3 piping

2.4 electrical installation

2.5 voltage conversion

2.6 rotation check

2.7 before starting - starting - stopping

2.8 outdoor sheltered installation

3.0 SYSTEMS

3.1 general system information

3.2 aircooled compressors

3.3 coolant system

3.4 air system

3.5 electrical system

3.6 capacity control

3.7 pressure switch adjustment

3.8 modulation control (optional)

3.9 ACS control (intellisys modulation option only)

3.10 modulate control valve adjustment (optional)

4.0 INTELLISYS

4.1 emergency stop switch

4.2 power indicator light

4.3 push buttons

4.4 setpoint procedure

4.5 warnings

4.6 alarms

5.0 MAINTENANCE

5.1 maintenance schedule

5.2 maintenance records

5.3 maintenance procedures

5.4 pressure relief valve check

5.5 sheave alignment

5.6 drive belt

5.7 belt tension

5.8 belt tension spring replacement

5.9 shaft seal replacement

5.10 inlet air filter element

5.11 coolant filter

5.12 coolant change

5.13 coolant hoses

5.14 airend discharge hose

5.15 coolant separator filter element

5.16 separator tank scavenge

check valve/screen/orifice

4.17 cooler cores

4.18 motor lubrication

4.19 intellisys removal

6.0 TROUBLE SHOOTING

6.1 standard control

6.2 intellisys control

7.0 OPTIONS

7.1 remote start/stop

7.2 remote start/stop and power outage restart option

7.3 sequencer control

8.0 REFERENCE DRAWING

8.1 electrical schematic - full voltage - standard control

8.2 electrical schematic - star delta - standard control

8.3 electrical schematic - full voltage - intellisys control

8.4 electrical schematic - star delta - intellisys control

8.5 foundation plan - base mounted - unenclosed

8.6 foundation plan - base mounted -enclosed

8.7 foundation plan - 120 gal. tank mounted - unenclosed

8.8 foundation plan - 120 gal. tank mounted - enclosed

8.9 foundation plan - 240 gal. tank mounted - unenclosed

8.10 foundation plan - 240 gal. tank mounted - enclosed

8.11 basic flow schematic - standard control

8.12 basic flow schematic - intellisys control

8.13 typical system flow diagrams

9.0 MAINTENANCE RECORD

GENERAL INFORMATION

Cooling Air Flow:

60 Hz: 2060 cfm (3500m

3

/hr.)

50 Hz: 1710 cfm (2905m

3

/hr.)

Ambient Temperature Limit: 35°F to 115°F (2°C to 46°C)

Coolant: Factory Filled ULTRACOOLANT

Coolant Change: 8,000 hours or two years, whichever

comes first, when using ULTRACOOLANT

Coolant Capacity: 3.2 GAL (12L)

Discharge Temperature Limit: 228°F (109°C)

Tools: U.S. Standard and metric are required to perform

maintenance

Page 5

3

0.0 SAFETY AND WARNINGS

0.1 SAFETY INSTRUCTIONS Before you install this air compressor you should take the time to carefully read all the instructions contained in this manual.

Electricity and compressed air have the potential to cause

severe personal injury or property damage.

Before installing, wiring, starting, operating or making any

adjustments, identify the components of the air compressor

using this manual as a guide.

The operator should use common sense and good working

practices while operating and maintaining this unit. Follow all

codes, pipe adequately, understand the starting and stopping

sequence. Check the safety devices by following the procedure contained in this manual.

Maintenance should be done by qualified personnel, adequately equipped with proper tools. Follow the maintenance

schedules as outlined in the operators manual to ensure problem free operation after start up.

Safety instructions in the operators manual are bold-faced for

emphasis. The signal words DANGER, WARNING and CAUTION are used to indicate hazard seriousness levels as follows:

Danger is used to indicate the presence of

a hazard which will cause severe personal

injury, death, or substantial property damage if the warning is ignored.

Warning is used to indicate the presence of

a hazard which can cause severe personal

injury, death, or substantial property damage if the warning is ignored.

Caution is used to indicate the presence of

a hazard which will or can cause minor personal injury or property damage if the warning is ignored.

Notice is used to notify people of installation, operation, or maintenance information

which is important but not hazard-related.

D! DANGER

! WARNING

! CAUTION

NOTICE

SAFETY PRECAUTIONS

BEFORE PROCEEDING, READ CAREFULLY BEFORE INSTALLING THE

COMPRESSOR OR PERFORMING ANY MAINTENANCE

WARNING

COMPRESSED AIR AND ELECTRICITY

ARE DANGEROUS.

BEFORE DOING ANY WORK ON THIS

UNIT, BE SURE THE ELECTRICAL SUPPLY HAS BEEN CUT OFF–LOCKED &

TAGGED AND THE ENTIRE COMPRESSOR SYSTEM HAS BEEN VENTED OF

ALL PRESSURE.

1. Do not remove the covers, loosen or

remove any fittings, connections or

devices when this unit is in operation.

Hot liquid and air under pressure that

are contained within this unit can cause

severe injury or death.

2. The compressor has high and dangerous voltage in the motor starter and

control box. All installations must be in

accordance with recognized electrical

codes. Before working on the electrical

system, be sure to remove voltage from

the system by use of a manual-disconnect-switch. A circuit breaker or fuse

safety switch must be provided in the

electrical supply line leading to the

compressor.

Those responsible for installation of

this equipment must provide suitable

grounds, maintenance clearance and

lightning arrestors for all electrical components as stipulated in O.S.H.A.

1910.308 through 1910.329.

3. Do not operate the compressor at

higher discharge pressure than those

specified on the Compressor Nameplate

or motor overload will occur. This condition will result in compressor motor

shutdown.

4. Use only safety solvent for cleaning

the compressor and auxiliary equipment.

5. Install a manual shut off valve (isolation type) in the discharge line. When a

safety valve is installed between the isolation valve and the compressor, it must

have sufficient capacity to relieve the

full capacity of the compressor(s).

6. Whenever pressure is released

through the pressure relief valve, it is

due to excessive pressure in the system. The cause for the excessive pressure should be investigated immediately.

7. Before doing any mechanical work on

the compressor:

a.) Shut the unit down.

b.) Electrically isolate the compressor

by use of the manual disconnect switch

in the power line to the unit. Lock and

tag the switch so that it cannot be operated.

c.) Vent pressure from the compressor

and isolate the unit from any other

source of air.

8. There can be adverse effects if compressor lubricants are allowed to enter

plant air systems.

Air line separators, properly selected

and installed, will minimize any liquid

carry-over.

The use of plastic bowls on line filters

without metal guards can be hazardous.

From a safety standpoint, metal bowls

should be used on any pressurized system. Review of your plant air line system is recommended.

9. When a receiver is installed, it is recommended that occupational safety and

health standards as covered in the

Federal Register, Volume 36, number

105, part 11, paragraph 1910.169 be

adhered to in the installation and maintenance of this receiver.

10. Before starting the compressor, its

maintenance instructions should be

thoroughly read and understood.

11. After maintenance functions are

completed, covers and guards must be

replaced.

0.2 SAFETY PRECAUTIONS

Page 6

4

There is a high discharge air temperature shutdown function built into the Intellisys on each compressor.

It is factory pre-set at 228°F (109°C). This function should be checked at regular intervals for proper operation, once a month is recommended.

PROCEDURE:

1. Block off the cooling air discharge.

2. The compressor discharge temperature will rise at a rapid rate. Shutdown should occur when the discharge temperature reaches the pre-set maximum discharge air temperature setting.

Failure to adhere to these recommendations can result in mechanical failure, property damage and serious

injury or death.

All air and water inlet, and air and water discharge pipework to and from the inlet and discharge port connections must take into account vibration, pulsations, temperature, maximum pressure applied, corrosion

and chemical resistance. In addition, it should be noted that lubricated compressors will discharge some

oil into the air stream; therefore, compatibility between discharge piping, system accessories and software

must be assured.

For the foregoing reasons, the use of plastic piping, soldered copper fittings and rubber hose as discharge

piping is not recommended. In addition, flexible joints and/or flex lines can only be considered for such purposes if their specifications fit the operating parameters of the system.

It is the responsibility of the installer and owner to provide the appropriate service pipework to and from

the machine.

“Ingersoll-Rand air compressors are not designed, intended, or approved for breathing air applications.

Ingersoll-Rand does not approve specialized equipment for breathing air application and assumes no

responsibility or liability for compressors used for breathing air services.”

! WARNING

! WARNING

! SAFETY SHUTDOWN CHECK HIGH AIR TEMPERATURE

Page 7

5

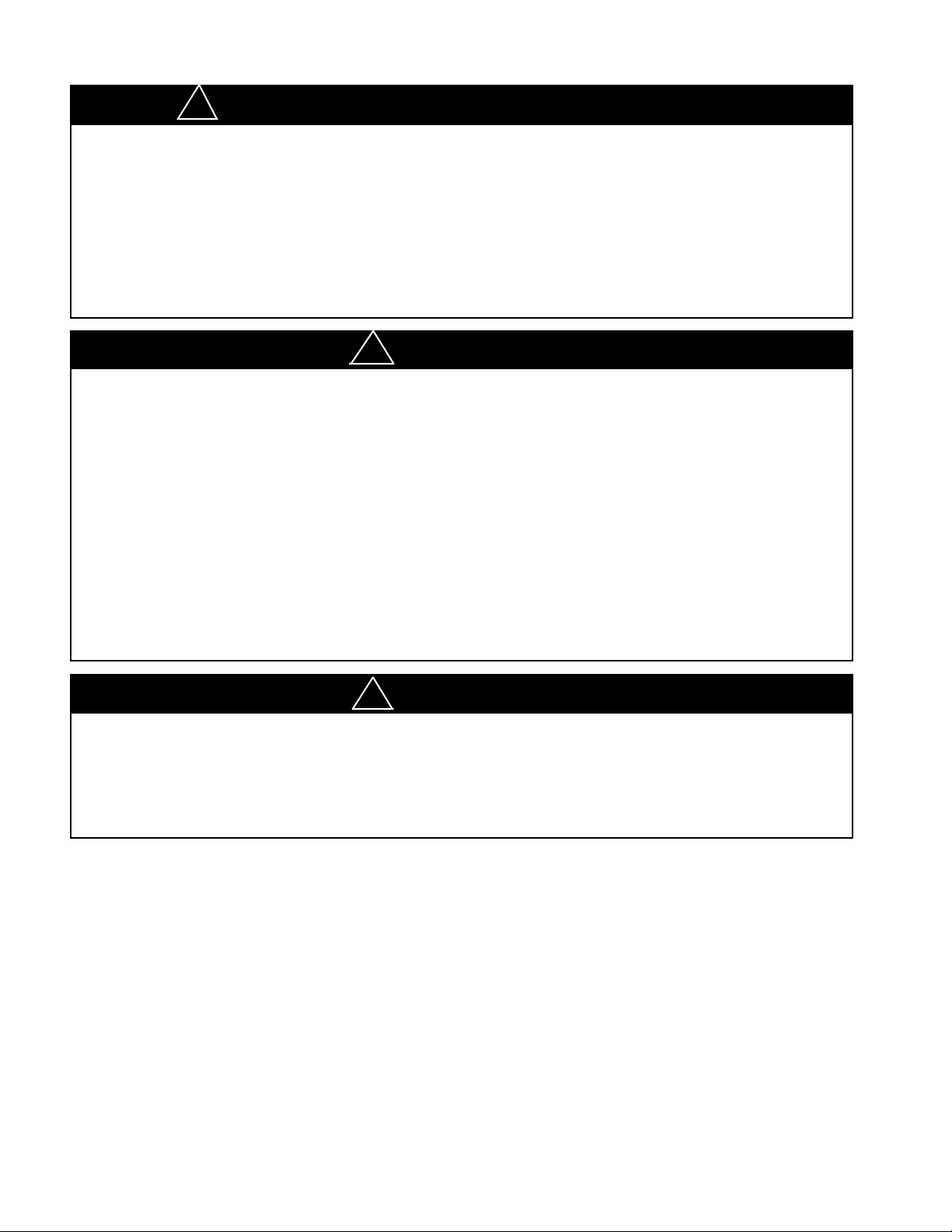

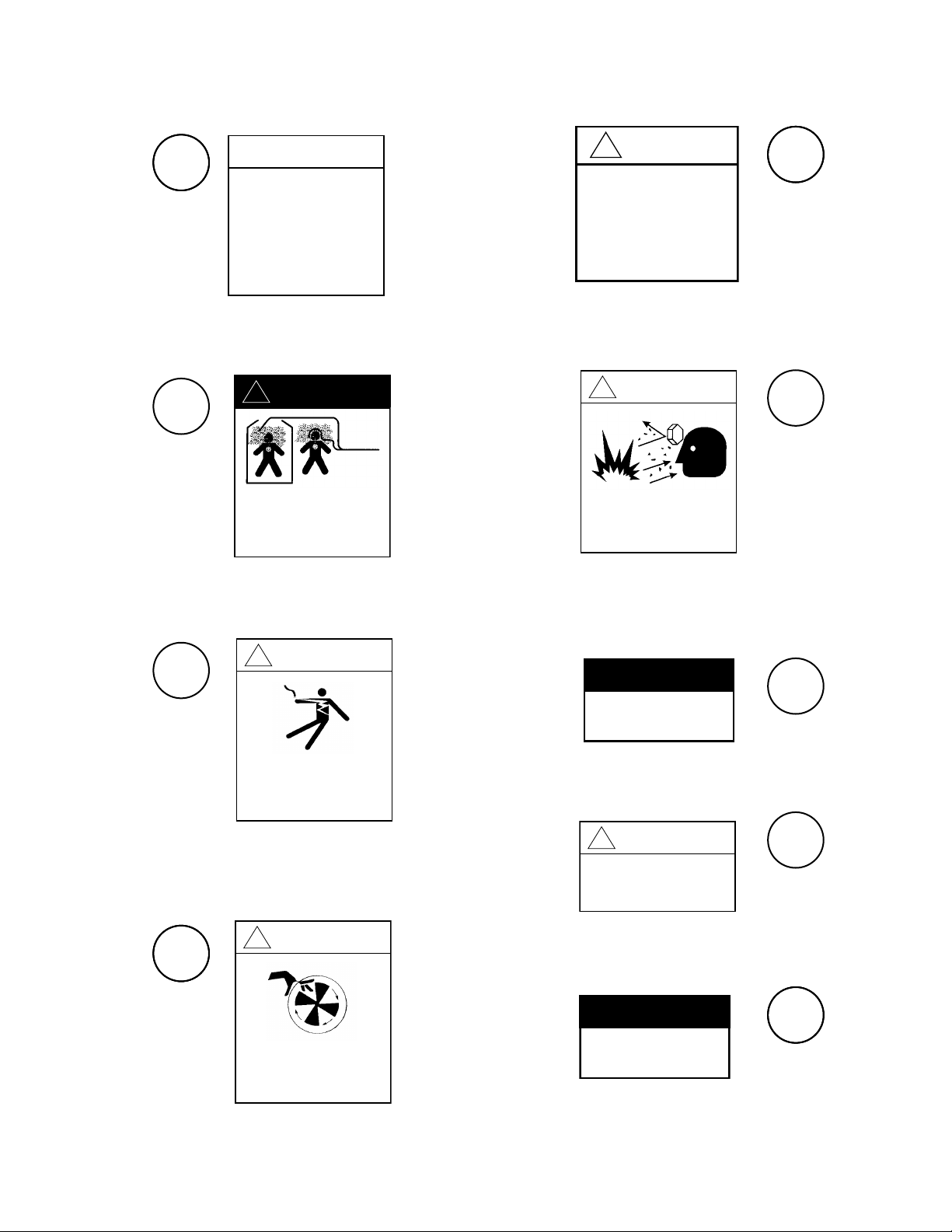

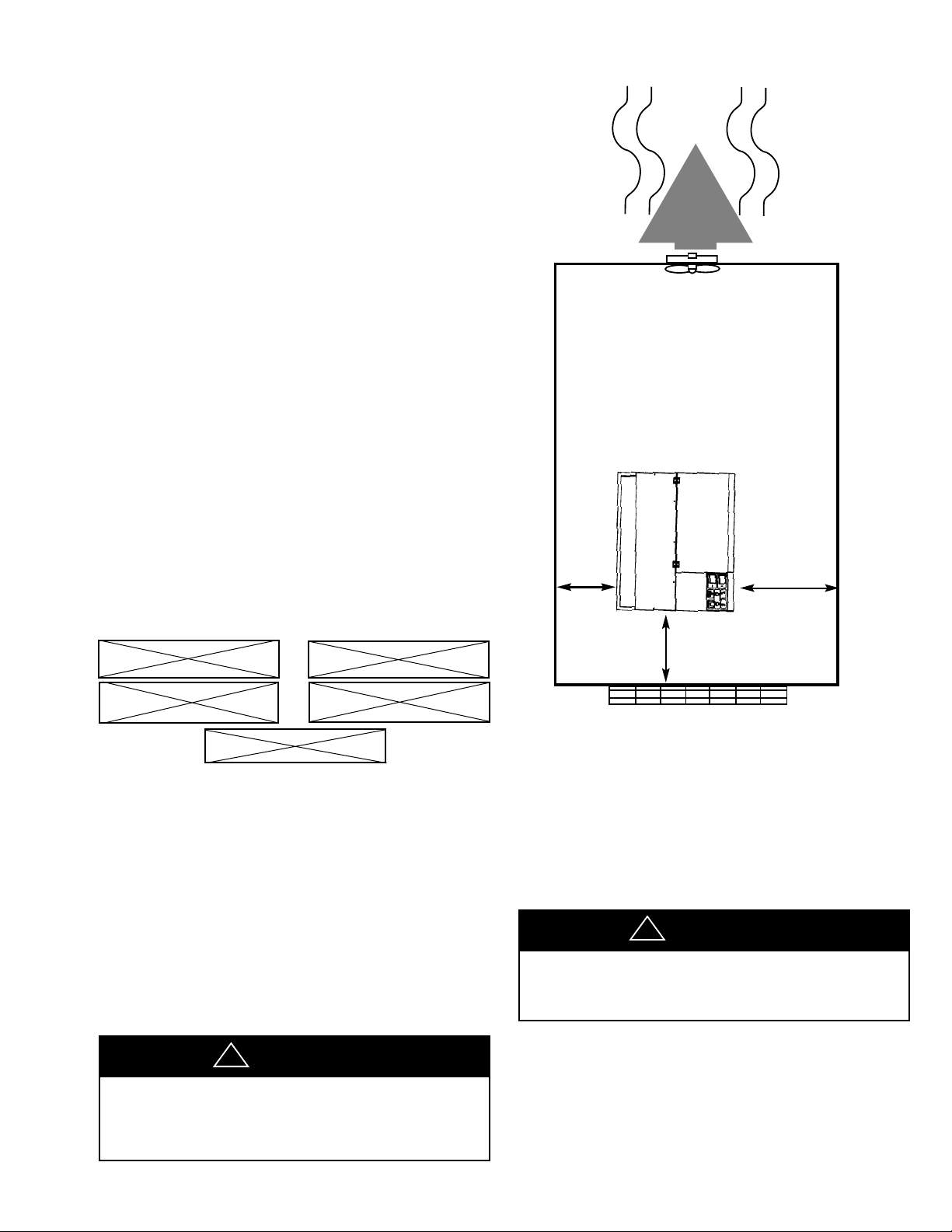

0.3 DECALS

This section contains representative examples of

decals which will be appearing throughout this manual

and are applied to the compressor unit.

If for some reason a decal is defaced, parts are

replaced or painted over, we recommend that you

obtain a replacement (See Parts manual APDD 742

for Decal Kit Number).

39264734

REV A

Page 8

6

3954190

39540232

39540174

39540166*

39540257*

3

1

2

7

5

6

4

8

9

39540158

39540240

39540265

39540273

NOTICE

To obtain satisfactory compressor

operation and maintenance a

minimum of 3 feet clearance on 3

sides is required 3-1/2 feet is

required in front of the control panel

(or minimum required by latest

National Electrical code or applicable

local codes).

Refer to the Instruction / Operators

Manual before performing any

maintenance.

INGERSOLLrAND ®

!

DANGER

!

CAUTION

Incorrect lifting of

machine can cause injury

or property damage.

Lift only from base

channels.

I

!

WARNING

Discharge air.

Can contain carbon monoxide or

other contaminants.Will cause

severe injury or death.

Do not breathe this air.

INGERSOLLrAND ®

!

WARNING

Hazardous voltage. Can cause

severe injury or death.

Disconnect power before servicing.

Lockout/Tagout machine.

INGERSOLLrAND ®

!

WARNING

High pressure air.

Can cause severe injury or death.

Relieve pressure before removing filter

plugs / caps, fittings or covers.

INGERSOLLrAND ®

NOTICE

Air discharge.

INGERSOLLrAND®

!

CAUTION

Use of incorrect coolant can cause

system contamination.

Use only SSR ULTRA COOLANT.

INGERSOLLrAND ®

Exposed fan blade. Can cause severe

injury.

Do not operate with covers removed.

Disconnect power.Lock and tag.

INGERSOLLrAND ®

NOTICE

Lift here.

INGERSOLLrAND®

Page 9

7

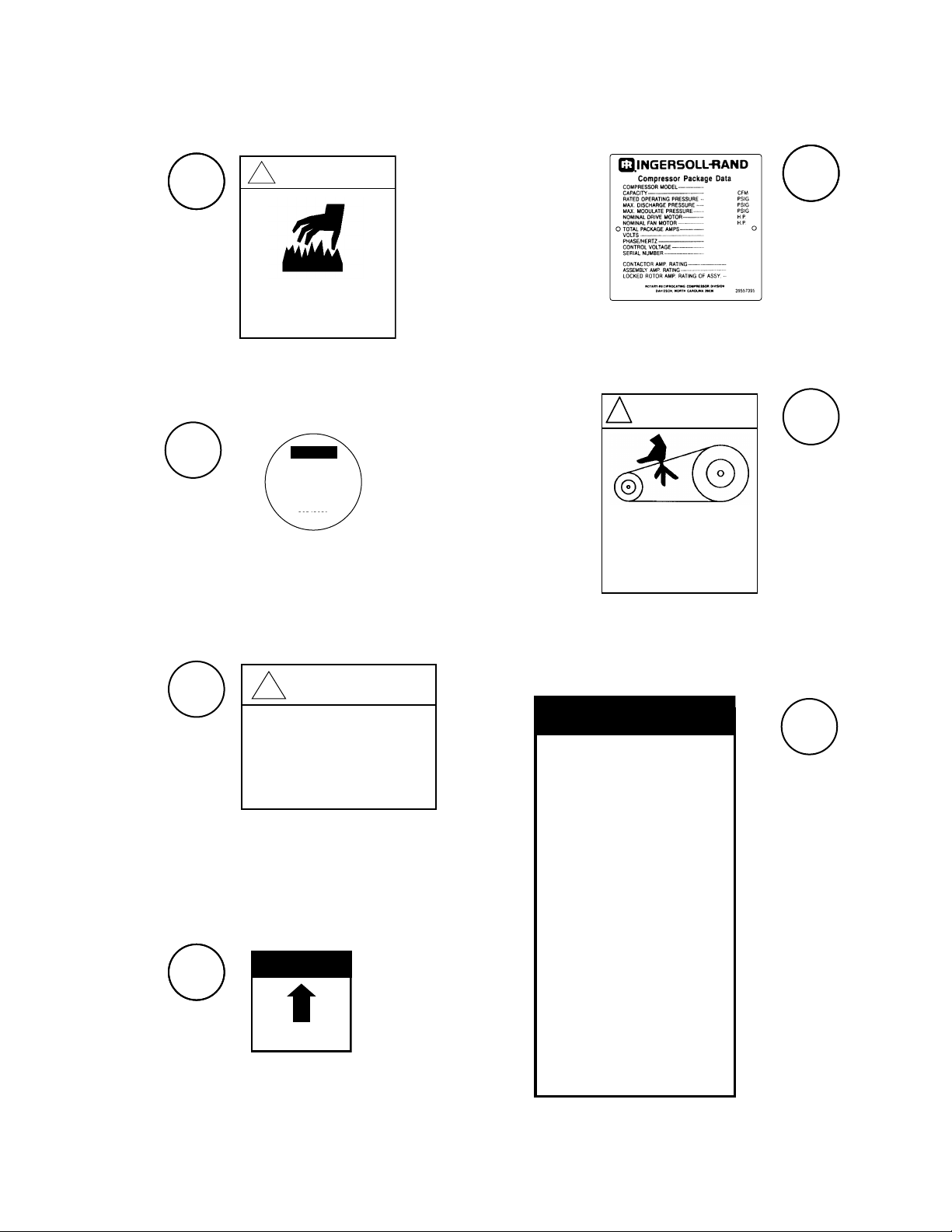

39859236

39541362

39544143

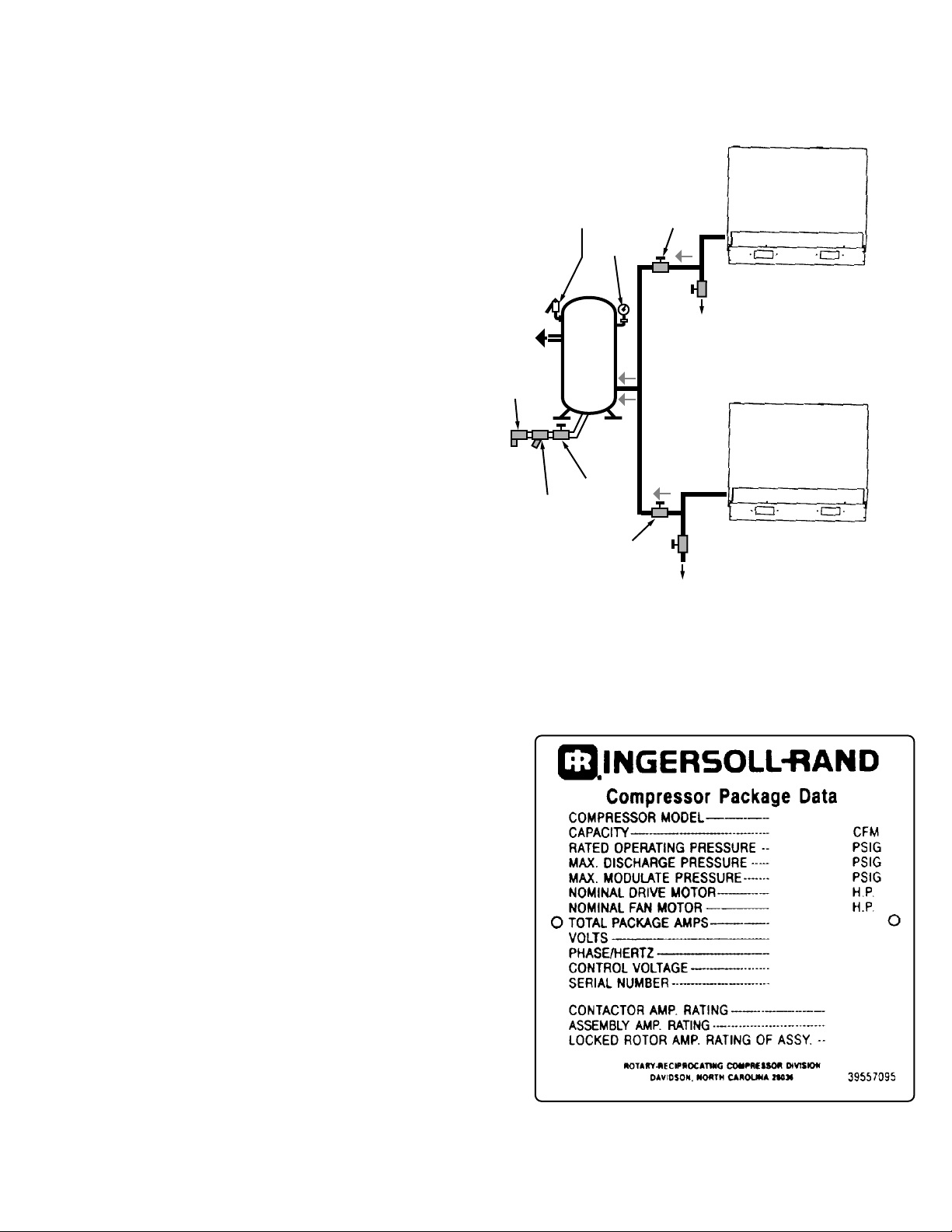

39557095

INGERSOLLrAND®

39544150

NOTICE

Filler Cap.

Use only recommended

coolant.

Read instruction book

before servicing.

39543921

39540281

12

10

11

16

14

15

13

!

WARNING

Hot surface.

Can cause severe injury.

Do not touch. Allow to cool before

servicing.

INGERSOLLrAND ®

!

CAUTION

Improper coolant filter replacement

will cause compressor damage.

Replace filter element after first 150

hours of operation and every 2000

hours thereafter or when coolant is

changed.

INGERSOLLrAND ®

! WARNING

Exposed moving belts and sheaves.

Can cause severe injury or death.

Do not operate with guards removed.

Disconnect power, lock and tag out

machine before servicing.

NOTICE

Before installing, operating, or

performing any maintenance on

this unit, read and understand

the instructions in the

Operators/Instruction Manual.

Before Starting

1. Check coolant level and add

coolant if necessary.

2. Verify that main isolation

valve is open.

3. Close main disconnect switch.

39859236

NOTICE

Rotation.

INGERSOLLrAND ®

Starting

1. Push START button. Compresor

will start and load automatically.

2. Air Pressure will rise if

there is sufficient demand

for air.

Stopping

1. Pushing STOP button.

Compressor will stop

after 7-10 seconds.

2. Open main disconnect switch.

INGERSOLLrAND ®

39919246

Page 10

1.0 RECEIPT OF EQUIPMENT

1.1 INSPECTION

When you receive the compressor please inspect it

closely. Any indication of careless handling by the carrier

should be noted on the delivery receipt especially if the

compressor will not be immediately uncrated. Obtaining

the delivery man’s signed agreement to any noted damages will facilitate any future insurance claims.

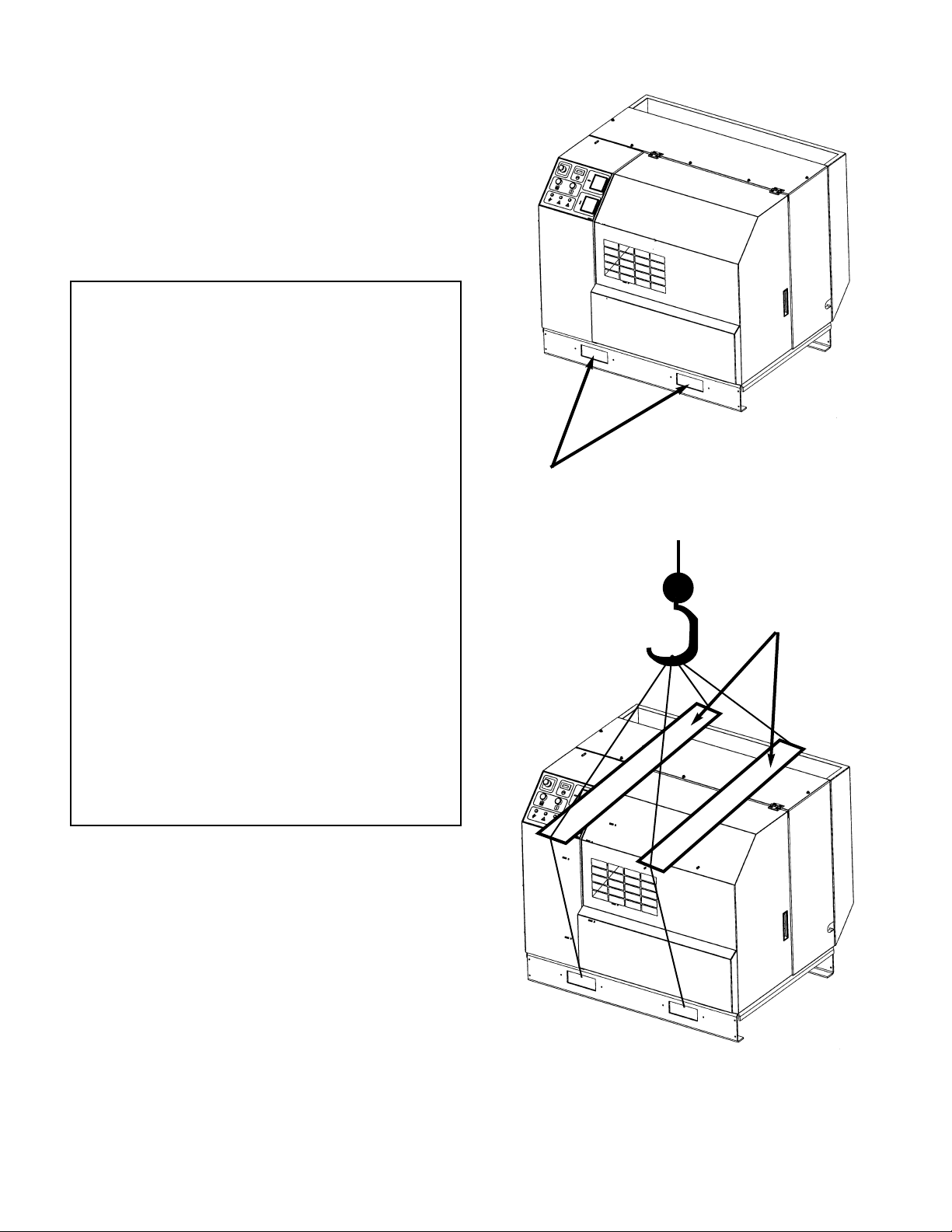

1.2 UNPACKING AND HANDLING

The compressor package has been mounted on a base

which provides for forklifting between the two side channels to facilitate handling during shipment. Care in positioning the forklifts is important because the location of

the center of gravity is strongly affected by the location of

the compression module and drive motor.

Slings can be used to lift the crates, but spreader bars

must be used to prevent the slings from exerting a force

against the sides of the crates.

1.3 TOOLS

Remove compressor unit from wooden skid. Acrowbar

and hammer will be needed.

IMPORT ANT

READ THIS

LOST OR DAMAGED GOODS

THOROUGHLY INSPECT THIS SHIPMENT

IMMEDIA TELY UPON ARRIV AL

OUR RESPONSIBILITY FOR THIS SHIPMENT

CEASED WHEN THE CARRIER SIGNED

BILL OF LADING

If goods are received short or in damaged condition, it is important that

you notify the carrier and insist on a notation of the loss or damage

across the face of the freight bill. Otherwise no claim can be enforced

against the transportation company.

If concealed loss or damage is discovered, notify your carrier at once

and request an inspection. This is absolutely necessary. Unless you do

this the carrier will not entertain any claim for loss or damage. The agent

will make an inspection and grant a concealed damage notation. If you

give the transportation company a clear receipt for goods that have been

damaged or lost in transit, you do so at your own risk and expense.

WE, ATI-R, ARE WILLING TO ASSIST YOU IN EVERY POSSIBLE

MANNER TO COLLECT CLAIMS FOR LOSS OR DAMAGE, BUT THE

WILLINGNESS ON OUR PARTDOES NOT MAKE US RESPONSIBLE

FOR COLLECTION OF CLAIMS OR REPLACEMENT OF MATERIAL.

THE ACTUALFILING AND PROCESSING OF THE CLAIM IS YOUR

RESPONSIBILITY.

Ingersoll-Rand Company

Davidson, North Carolina

APDDGFO-99-79

FORKLIFT PADDING

WILL REDUCE SCRATCHES

AND MARS

SPREADER

BARS

8

Page 11

2.0 INSTALLATION

2.1 VENTILATION

Oil flooded rotary air compressors produce large

amounts of heat. Because of this large heat production,

the compressor must be placed in a room with adequate

ventilation. Aroom in which the amount of air that is

drawn in and exhausted is equal to or greater than the

cooling fan air flow requirement for the compressor that

is installed.

If heated air from the compressor exhaust is allowed to

recirculate back to the compressor, the compressor will

overheat and shut down. This heat must be exhausted

from the room. You should take this into consideration

when you decide where to place the compressor within

your plant. Consider that the required maintenance clearance is 3 ft (.9 m) all around the compressor.

However 42” (1.06m), or minimum required by latest

NEC or applicable local codes, must be maintained in

front of control panel.

Ambient temperatures higher than 115°F (46°C)

should be avoided as well as areas of high humidity.

Consider also the environment surrounding or near

the compressor. The area selected for the location of

the compressor should be free of dust, chemicals,

metal filings, paint fumes and overspray.

2.2 FOUNDATION REQUIREMENTS

Refer to the foundation plan for the particular model compressor to be installed. See Section 8.0.

The compressor can be installed on any level floor that is

capable of supporting it. Compressor weights are listed

on the foundation plans.

When sound transmission is of particular importance it is

often helpful to install a sheet of rubber-fabric-matting, or

cork under the compressor to reduce the possibility of

resonant sounds being transmitted or amplified through

the floor.

2.3 PIPING

The use of plastic bowls on line filters without metal

guards can be hazardous. Their safety can be affected

by either synthetic lubricants or the additives used in mineral oil. From a safety standpoint, metal bowls should be

used on any pressurized system. Review of your plant air

line system is recommended.

The built-in aftercooler reduces the discharge air temperature well below the dew point (for most ambient conditions), therefore, considerable water vapor is condensed.

To remove this condensation, each compressor with

built-in aftercooler is furnished with a combination condensate separator/trap.

DUST

CHEMICALS

METAL

FILINGS

PAINT

SPRAY

OVERSPRAY

Do not use plastic pipe, soldered copper

fittings or rubber hose for discharge piping.

WARNING

Never elevate the compressor unit

above the floor level. This may allow air

to enter the cabinet under the base.

Performance will be affected.

NOTICE

!

!

36”

(.9 m)

36” (.9 m)

42” (1.06 m) OR

CODE MINIMUM

9

AIR INTAKE

Page 12

10

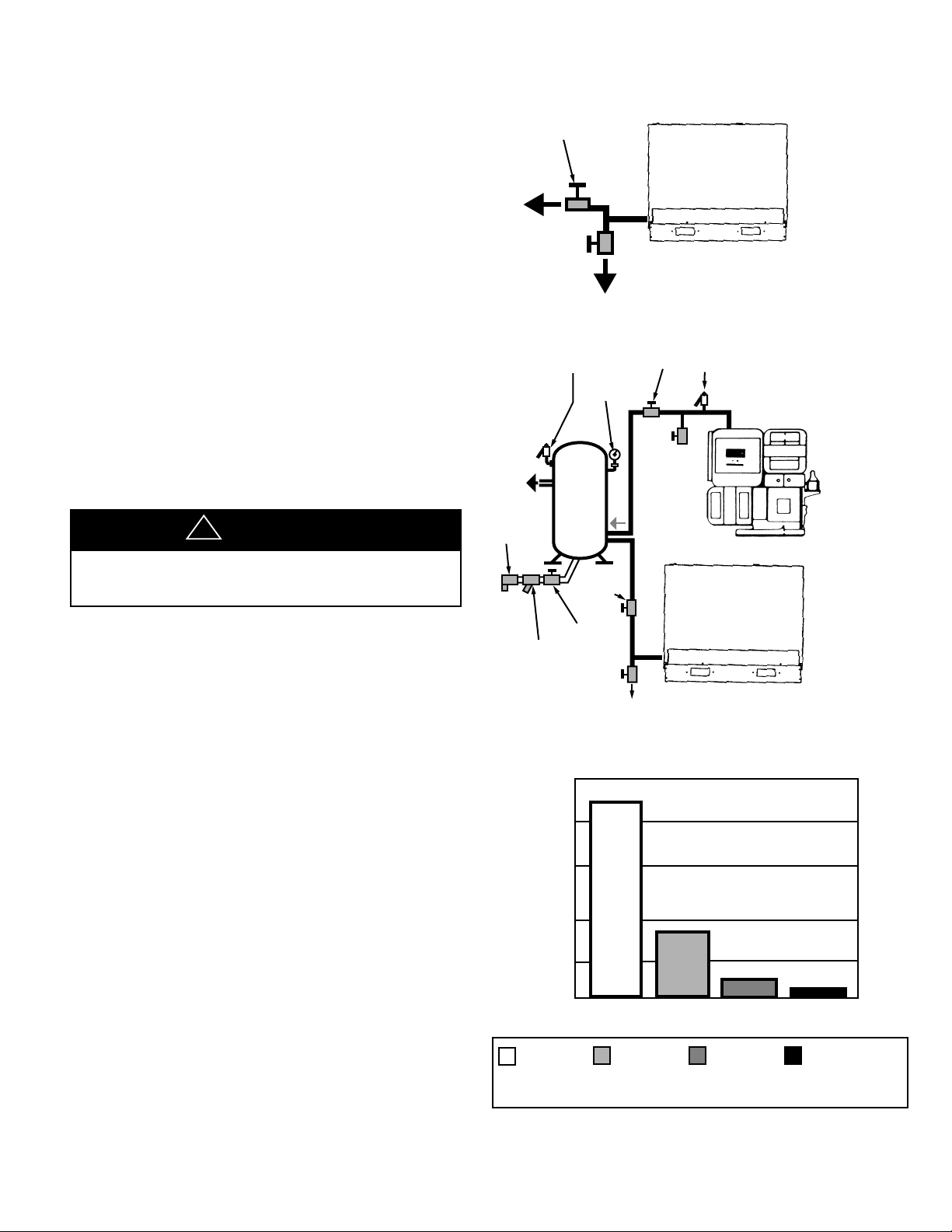

DISCHARGE PIPING WITH AFTERCOOLER

ROTARY-RECIP IN PARALLEL

Do not use the compressor

to support the discharge pipe.

Careful review of piping size from the compressor connection point is essential. Length of pipe, size of pipe,

number and type of fittings and valves must be considered for optimum efficiency of your compressor.

It is essential when installing a new compressor to review

the total plant air system. This is to ensure a safe and

effective total system.

Liquid water occurs naturally in air lines as a result of

compression. Moisture vapor in ambient air is concentrated when pressurized and condenses when cooled in

downstream air piping.

Moisture in compressed air is responsible for costly problems in almost every application that relies on compressed air. Some common problems caused by moisture are rusting and scaling in pipelines, clogging of

instruments, sticking of control valves, and freezing of

outdoor compressed air lines. Any of these could result in

partial or total plant shutdown.

Compressed air dryers reduce the water vapor concentration and prevent liquid water formation in compressed air lines. Dryers are a necessary companion to

filters, aftercoolers, and automatic drains for improving

the productivity of compressed air systems.

NOTICE

!

2.3 PIPING (Continued)

A dripleg assembly and isolation valve should be mounted near the compressor discharge. Adrain line should be

connected to the condensate drain in the base.

IMPORT ANT: The drain line must slope downward from

the base to work properly.

NOTE: For ease of inspection of the automatic drain trap

operation, the drain piping should include an open funnel.

It is possible that additional condensation can occur if the

downstream piping cools the air even further and low

points in the piping systems should be provided with driplegs and traps.

IMPORT ANT: Discharge piping should be at least as

large as the discharge connection at the compressor

enclosure. All piping and fittings must be suitable for the

maximum operating temperature of the unit and, at a

minimum, rated for the same pressure as the compressor sump tank.

MOISTURE CONTENT OF COMPRESSED AIR

200

160

120

80

40

0

DEW POINT

without

Aftercooling

100°F/38°C

(with

Aftercooler)

35°F /1.7°C

(Refrigerated

Dryer)

-40°F/-40°C

(Desiccant

Dryer)

Gallons of Water/24

hours/1000 acfm

ROTARY

COMPRESSOR

ISOLATION

VALVE

DRIP LEG

SAFETY

VALVE

PRESSURE

GAUGE

ISOLATION

VALVE

DRIP

LEG

SAFETY

VALVE

RECIPROCATING

COMPRESSOR

TRAP

ISOLATION

VALVE

ISOLATION

STRAINER

NOTE:

SEPARATE LINES

GOING TO THE

RECEIVER

VALVE

DRIP

LEG

ROTARY

COMPRESSOR

Page 13

11

2.4 ELECTRICAL INSTALLATION

Before proceeding further, we recommend that you

review the safety data in the front of this manual.

Locate the compressor data plate on the left end of the

cooler box next to the control box.

The data plate lists the rated operating pressure, the

maximum discharge pressure and the electric motor

characteristics and power.

Confirm that the line voltage and compressor nameplate

voltage are the same and that the standard starter box

meets the intent of NEMA 1 guidelines.

A hole is provided for incoming power connection. If it is

necessary to make a hole in the control box in a different

location, care should be taken to not allow metal shavings to enter the starter and other electrical components

within the box. After making the power inlet hole, all

shavings and debris must be removed from inside of

control box before power is turned on.

Incoming power should be connected per the electrical

schematic on the starter box door. Confirm that all electrical connections are made and tightened. Confirm that

the control transformer is wired correctly for supply voltage (See Figure 2.5-1).

Inspect the motor and control wiring for tightness. Close

the panel front.

Two types of dryers, refrigerated or desiccant, are used

to correct moisture related problems in a compressed air

system. Refrigerated dryers are normally specified where

compressed air pressure dew points of 33°F (1°C) to

39°F (4°C) are adequate. Desiccant dryers are required

where pressure dew points must be below 33°F (1°C).

Contact your local Ingersoll-Rand distributor for assistance in selecting correct Ingersoll-Rand filtration or drying products.

NOTE: Screw type compressors should not be installed

in air systems with reciprocating compressors without a

means of pulsation isolation, such as a common receiver

tank. We recommend both types of compressor units be

piped to a common receiver utilizing individual air lines.

When two rotary units are operated in parallel, provide

an isolation valve and drain trap for each compressor

before the common receiver.

ROT ARY TWO COMPRESSOR SYSTEM

SAFETY

VALVE

PRESSURE

GAUGE

ISOLATION

VALVE

ROTARY

COMPRESSOR

TRAP

DRIP

LEG

ISOLATION

STRAINER

VALVE

ISOLATION

VALVE

DRIP

LEG

COMPRESSOR

ROTARY

Page 14

12

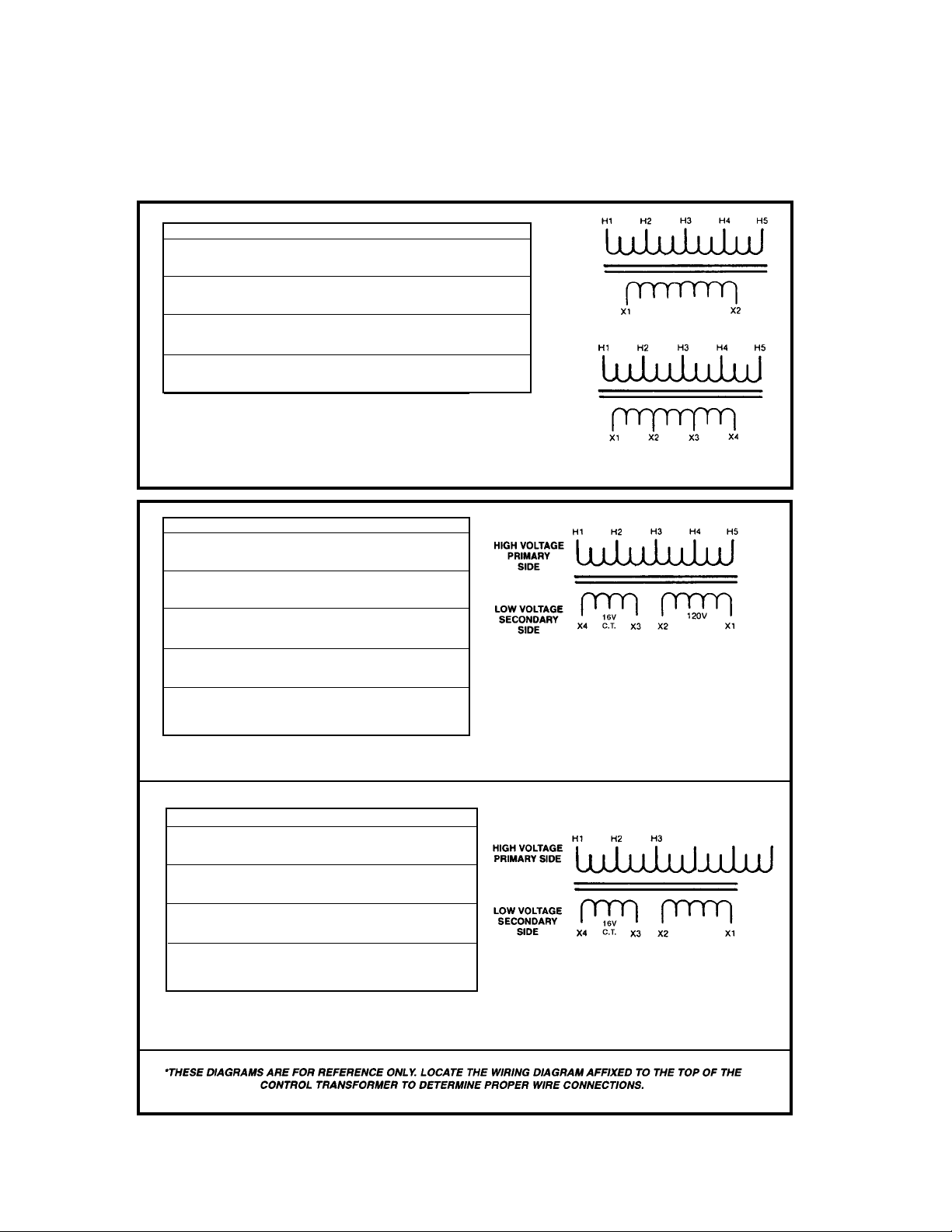

2.5 VOLTAGE CONVERSION

IMPORTANT: This procedure should only be carried

out by a qualified electrician, electrical contractor or

your local Ingersoll Rand Distributor or Air Center

NOTE: This procedure applies only to units manufactured to multi-voltage specifications. Motor nameplate

must indicate multiple voltatges.

FIGURE 2.5-1 TYPICAL CONTROL TRANSFORMER WIRING

110V

LINE VOLTS HZ LINE SEC VOLTS LINE

200 60 H4-H5 120 X1-X2

8 X3-X4

8 X4-X5

220/230 60 H3-H5 120 X1-X2

8 X3-X4

8 X4-X5

380 60 H3-H5 120 X1-X2

8 X3-X4

8 X4-X5

440/460 60 H2-H5 120 X1-X2

8 X3-X4

8 X4-X5

575 60 H1-H5 120 X1-X2

8 X3-X4

8 X4-X5

LINE VOLTS HZ LINE SEC VOLTS LINE

220 50 H5-H6 110 X1-X2

8 X3-X4

8 X4-X5

380 50 H4-H6 110 X1-X2

8 X3-X4

8 X4-X5

415 50 H2-H6 110 X1-X2

8 X3-X4

8 X4-X5

550 50 H1-H6 110 X1-X2

8 X3-X4

8 X4-X5

LINE VOLTS HZ LINE SEC VOLTS LINE REFERENCE

200 60 H4-H5 120 X1-X2 Quad Type

220/230 50/60 H1-H2 120 X1-X4 Universal Type

380 50/60 H1-H3 120 X1-X4 Universal Type

415 50 H1-H3 120 X1-X4 Universal Type

440/460 50/60 H1-H4 120 X1-X4 Universal Type

550/575 60 H1-H5 120 X1-X4 Universal Type

*TYPICAL 60 HZ

CONTROL TRANSFORMER

(INTELLISYS OPTION)

*TYPICAL 50 HZ

CONTROL TRANSFORMER

(INTELLISYS OPTION)

H4

H5

H6

HIGH

VOLTAGE

PRIMARY

SIDE

HIGH

VOLTAGE

PRIMARY

SIDE

LOW

VOLTAGE

SECONDARY

SIDE

LOW

VOLTAGE

SECONDARY

SIDE

UNIVERSAL TYPE TRANSFORMER

(ALL VOLTAGES EXCEPT 200V/60 HZ)

QUAD TYPE TRANSFORMER (200V/60 HZ)

*TYPICAL CONTROL TRANSFORMER

(STANDARD OPTION)

Page 15

If the compressor is operated in the

opposite direction of rotation, airend damage

can result and is not warrantable.

CAUTION

Open the motor junction box on the side of the motor.

Reconnect the motor to the desired voltage. Use the con-

nection decal provided on the motor as a guide.

Reconnect the primary side of the control transformer for

the desired voltage, as shown on the control transformer

wiring decal.

Refer to the motor nameplate for full load amps. Set

main fan the dial position of the overload relay to the corresponding setting.

Make sure all wiring connections are tight.

Put main disconnect in the ON position and check main

motor and fan motor rotation, as outlined in Section 2.6

of this manual.

2.6 ROTATION CHECK

Locate the rotation decal on the motor and check for correct rotation. The correct rotation when viewed from the

non-drive end of the motor is clockwise (See Figure 2.6-

1).

!

FIGURE 2.6-1 DRIVE MOTOR ROTATION

NON-DRIVE

END

DRIVE

END

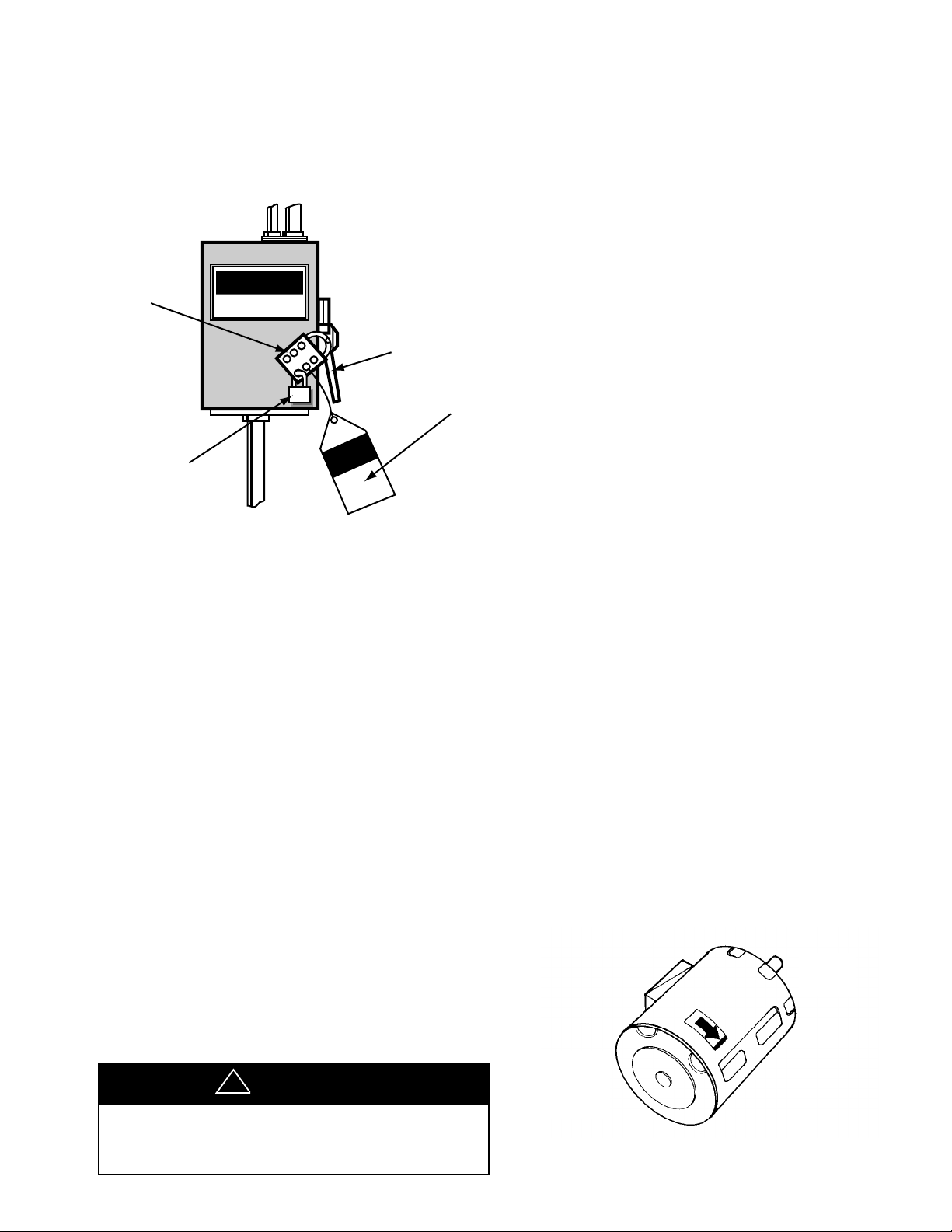

FIGURE 2.5-2 MAIN DISCONNECT

LOCKED AND TAGGED

DANGER

Procedure:

Put main disconnect in the OFF position, lock and tag

(See Figure 2.5-2).

For the compressor motor and fan rotation check, the

motor jogging should be as short a time as possible.

1. Assure that the Emergency Stop button is in the

stop (depressed) position.

2. Check coolant level. To check coolant level, slowly

loosen the fill plug one complete turn. As the fill plug is

unscrewed approximately one complete turn, a small

amount of pressure may be released. Do not remove

the fill plug until all pressure has been vented. Once

pressure is vented, finish removing the fill plug. The

proper coolant level is when the coolant is even with

the top of the fill port. Add coolant if necessary.

3. Replace and tighten fill plug.

4. Close the main disconnect switch (ON position).

5. Verify that the main isolation valve is open.

6. Open the canopy enclosure if machine is so

equipped. Push the red unloaded Stop/Reset Button.

Push the Start button to start the unit and immediately

depress (push) the Emergency Stop button to stop

the unit (See Figure 2.7-1 for Control Panel layout).

NOTE: Do not use the Unloaded Stop Button for this

procedure; it is equipped with a time delayed stop circuit and damage may occur to the compression module if operated in wrong direction.

Observe the compressor drive motor shaft. The rotation should be in accordance with the directional arrow

decal on the motor. Observe the cooling fan (s). The

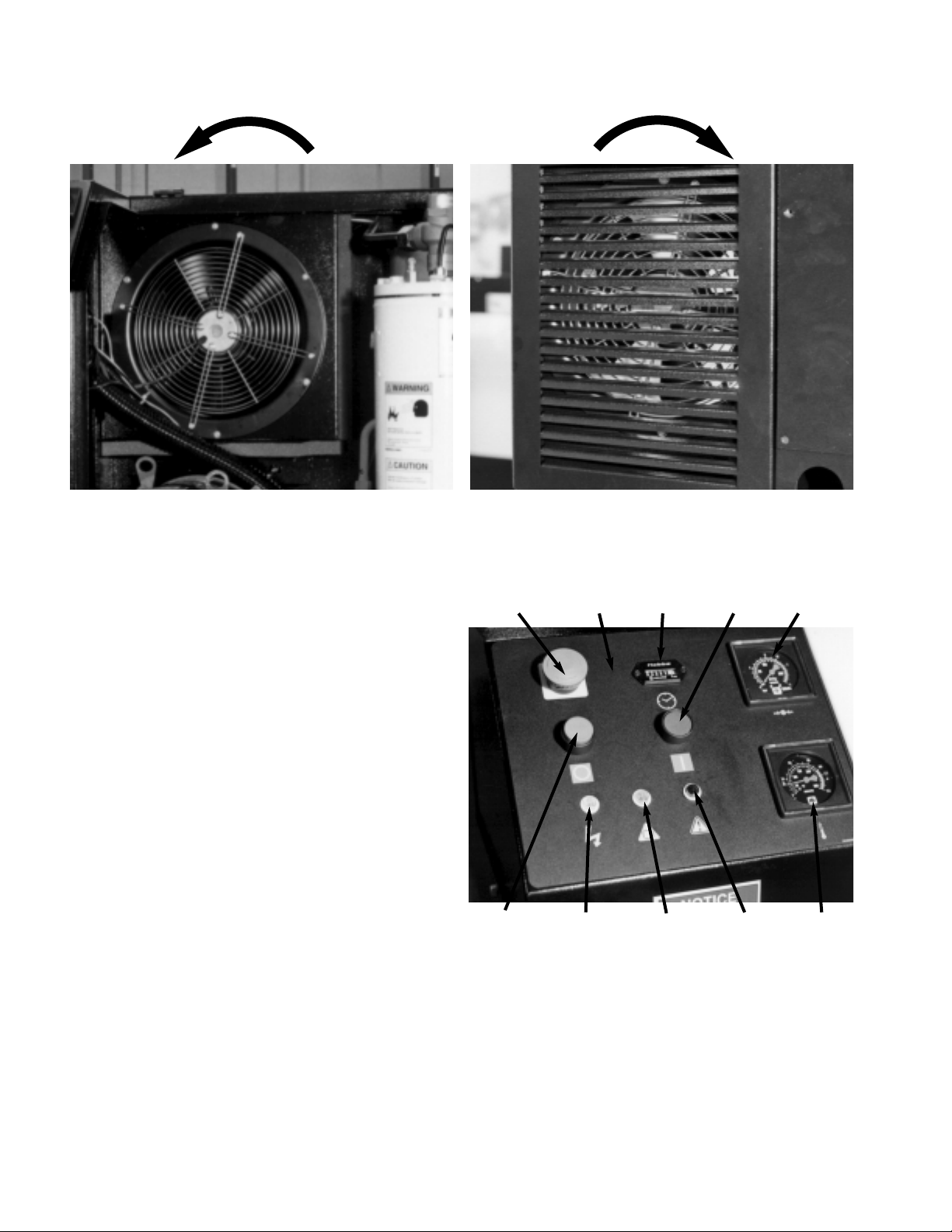

rotation of the main fan should be counter-clockwise.

The auxiliary fan rotation should be clockwise. (See

Figures 2.6-2 and 2.6-3.

Should the main motor or fan rotation be incorrect, put

the main disconnect in the OFF position, lock and tag.

Interchange any two line connections (L1, L2, or L3) at

the starter panel for the appropriate component. Close

the control box cover. Recheck for correction rotation.

13

DANGER

HASP

KEY LOCK

HIGH VOLTAGE

LEVER

DANGER

TAG

Page 16

14

2.7 BEFORE STARTING - STARTING - STOPPING Read and understand the following instructions

before operating or performing any maintenance

on this unit

Before Starting:

1. Ensure that Emergency Stop push button is in the

OFF (depressed) position (See Figure 2.7-1).

2. Check coolant level. To check coolant level, slowly

loosen the fill plug one complete turn. As the fill plug is

unscrewed approximately one turn, a small amount of

pressure may be released. Do not remove the fill plug

until all pressure has been vented. Once pressure is

vented, finish removing the fill plug. The proper

coolant level is when the coolant is even with the top

of the fill port. Add coolant if necessary.

3. Replace and tighten fill plug.

4. Close the main disconnect switch (ON position).

5. Verify that the main isolation valve is open.

Starting

1. Push the unloaded Stop/Reset Button (red fault

indicator will go out).

2. Push the Start button and release. The compressorwill start and then load automatically if line pressure is

below the lower setting of the pressure switch.

FIGURE 2.6-2 MAIN FAN

FIGURE 2.6-3 AUXILIARY FAN

CORRECT ROTATION CORRECT ROTATION

Stopping

1. Depress the Stop button to the OFF position.

Compressor will unload for approximately 7 seconds

and then stop.

2. Open the main disconnect switch (OFF position).

FIGURE 2.7-1 CONTROL PANEL

EMERGENCY

STOP

BUTTON

CONTROL

PANEL

HOUR

METER

START

BUTTON

PRESSURE

GAUGE

UNLOADED

STOP/RESET

BUTTON

POWER ON

INDICATOR

AUTO

RESTART

INDICATOR

FAULT

ALARM

INDICATOR

TEMP

GAUGE

Page 17

15

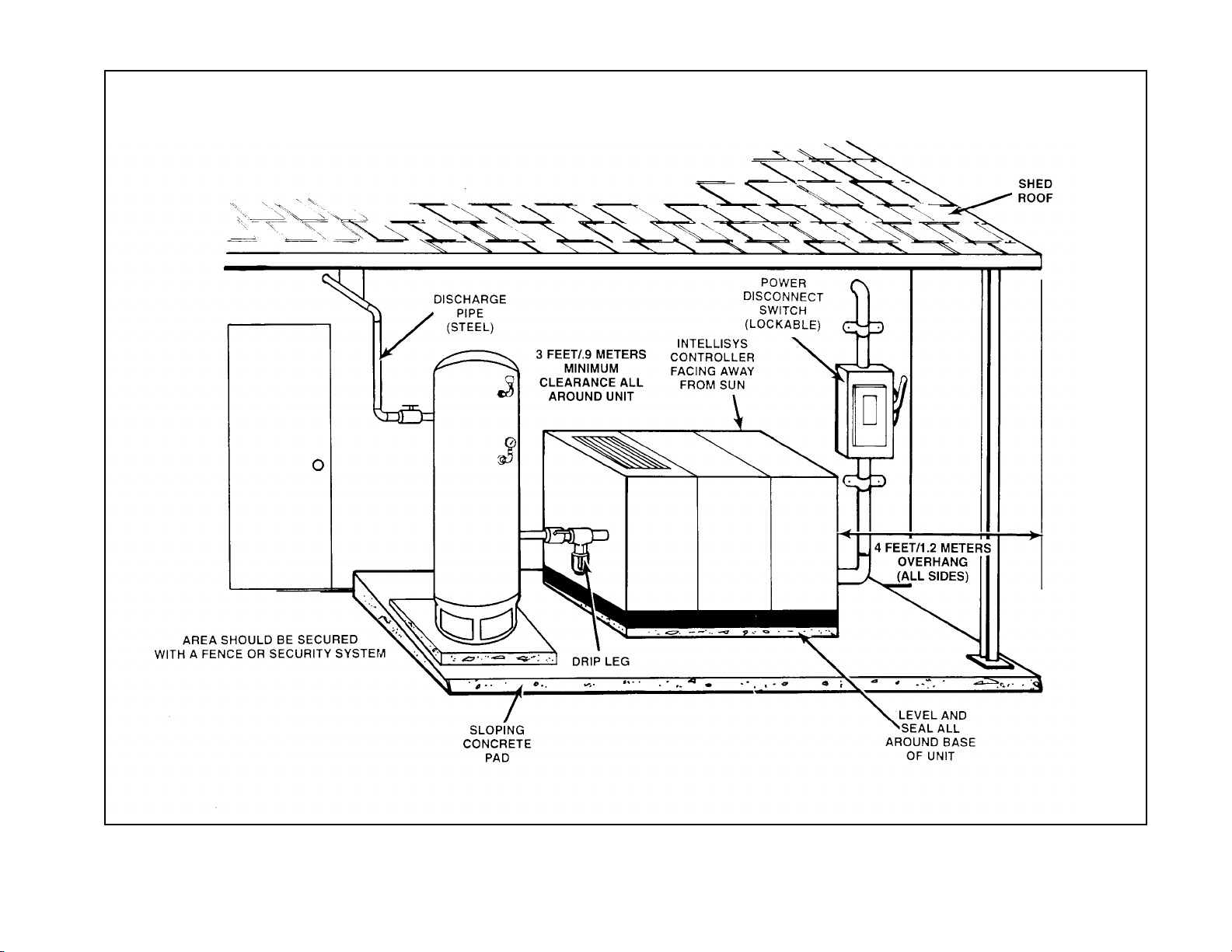

2.8 OUTDOOR SHELTERED INSTALLATION

Many times a compressor must be installed outside due

to jobsite conditions or limited space within a manufacturing facility. When this occurs there are certain items that

should be incorporated into the installation to help ensure

trouble free operation. These items have been listed

below plus Figure 2.8-1 has been included to show a typical outdoor sheltered installation. The unit must be purchased with the Outdoor Modification Option to provide

watertight electrics and a TEFC motor.

■ The compressor should be on a concrete pad

designed to drain water away. If the concrete pad is

sloped, then the compressor must be leveled. In order

to properly pull cooling air through the aftercooler, the

base/skid must be sealed to the concrete pad.

■ The roof of the shelter should extend a minimum of

4 ft (1.2 m) around all sides of the compressor to prevent direct rain and snow from falling on the unit.

■ Air-cooled machines must be arranged under the

shelter in a way that prevents air recirculation (i.e. hot

exhaust back to the package inlet).

■ If the installation includes more than one compressor,

the hot air exhaust should not be directed towards the

fresh air intake of the second unit or an Air Dryer.

■ If a standard machine is to be installed outside, the

ambient temperature must never drop below 35°F

(1.7°C).

■ Arrange the machine with the Intellisys con-

troller/starter enclosure facing away from the sun as

radiant heat can affect starter/lntellisys performance.

Also direct sunlight and UV rays will degrade the

membrane touch panel. This is not a warrantable situation.

■ Power disconnect switch should be within line of sight

and in close proximity to the unit. N.E.C. and local

electrical codes must be followed when installing the

power disconnect switch.

■ Condensate drains must never be allowed to dump on

the ground. Run to a suitable sump for future collection and disposal or separation of lubricant and water

mixture.

■ Incoming power connections must use suitable con-

nectors for outdoor weather tight service.

■ A minimum of 3 ft (.9 m) clearance must be allowed

on all four sides of the unit for service access.

However 42” (1.06m), or minimum required by latest

NEC or applicable local code, must be maintained in

front of control panel.

■ If possible, access by a forklift and/or an overhead

beam hoist should be kept in mind (for eventual service to airend or motor).

■ If the area around the installation contains fine air-

borne dust or lint and fibers etc., then the unit should

be purchased with the High Dust Filter Option and

TEFC motor option.

■ Some type of protection such as a fence or security

system, should be provided to prevent unauthorized

access.

Page 18

16

FIGURE 2.8-1 TYPICAL OUTDOOR SHELTERED INSTALLATION

Page 19

17

3.0 SYSTEMS

3.1 GENERAL SYSTEM INFORMATION

The compressor is an electric motor driven, single

stage, rotary screw compressor, complete with supporting components to make a fully functional unit. Astandard compressor is composed of the following:

Inlet air filter

Drive motor

Airend

Pressurized coolant system with cooler & filter

Cooling fan (s)

Capacity control

Instruments

Safety devices

Compression in the rotary screw type air compressor is

created by the meshing of two helical rotors (male and

female) on parallel shafts, enclosed in a heavy duty

iron housing, with air inlet and outlet ports located on

opposite ends. The grooves of the female rotor mesh

with and are driven by the male rotor. Bearings on both

ends of the rotors are used to support the rotor both

laterally and axially.

3.2 AIRCOOLED COMPRESSORS

Design Temperatures

The standard compressor is designed for operation in

an ambient range of 35°F. to 115°F. (1.7°C. to 46°C.).

When conditions other than design levels described

are encountered, we recommend you contact your

nearest Ingersoll-Rand representative for additional

information.

The standard maximum temperature 115°F. (46°C)

is applicable up to an elevation of 3300 ft. (1000

meters) above sea level. Above this altitude, significant reductions in ambient temperature are required if

a standard drive motor is to be used.

Coolant Cooler

The cooler is an integral assembly of core, fan and

fan-motor, mounted in the compressor. The cooling

air flows in through the front corners of the enclosure,

through the vertically mounted cooler core, and discharges upward through the top of the enclosure.

Aftercooler

The discharge air aftercooling system consists of a

heat exchanger (located at the cooling air discharge

of the machine), a condensate separator, and an

automatic drain trap.

By cooling the discharge air, much of the water

vapor naturally contained in the air is condensed

and eliminated from the downstream plant-piping

and equipment.

3.3 COOLANT SYSTEM

The coolant system consists of a separator tank,

thermostatic element, coolant filter, coolant cooler

with fans, and a separator element. When the unit

is operating, the coolant is pressurized and forced

to the compressor bearings. The compressor is

provided with a temperature switch which will shut

the unit down in case of excessive temperature,

228°F (109°C). Effective coolant filtration is provided by the use of a screw on, automotive type,

heavy duty coolant filter.

The compressor is designed for operation in an

ambient range of 35°F to 115°F (2°C to 46°C).

Coolant

Rotary screw compressor fluids have a triple function to perform. They lubricate the bearings and

contacting surfaces of the rotors, seal internal

clearances within the rotor chamber, and provide

for the cooling of the compression process. The

bulk of the fluid is actually used for cooling, with

only small amouts used for lubrication and sealing.

SSR air compressors are factory filled with

SSR ULTRA COOLANT which is designed to

operate for 8,000 hours or two years, whichever comes first. The coolant must be changed at

these intervals to avoid breakdown and equipment damage.

Circulation of Coolant

Coolant is forced by air pressure from the separator tank to the thermostatic element. The position

of the element (a direct result of coolant temperature) will determine whether the coolant circulates

through the cooler, bypasses the cooler, or mixes

the two paths together to maintain an optimum

compressor injection temperature. This temperature is controlled to preclude the possibility of

water vapor condensing. By injecting coolant at a

sufficiently high temperature, the discharge air

coolant mixture temperature will be kept above the

dew point.

Page 20

18

Before being injected into the airend, all coolant flows

through the coolant filter. If tis an aubomotive type full

flow filter with a single replacement spin-on element,

rated at 4 micron. There is a differential-pressure

bypass valve set to open in the event that the pressure drop across the filter rises to as high as 15 psi (1

bar), which indicates an excessively fouled element as

well as poor maintenance practice.

Coolant/Air Separation System

The coolant/air separation system is composed of a

separator tank with specially designed internals and a

coslescing type separator element located inside the

tank.

The air-coolant mixture discharges from the airend into

the separator tank. The majority of coolant is separted

while in the separator tank and the coalescing separator filter element is used for final cleaning of the air

prior to the customer’s system. The system removes

nearly all of the coolant from the discharge air. The

separated coolant is returned to the coolant system

and the air passes to the compressed air system.

3.4 AIR SYSTEM

Components and Flow

The air system is composed of:

Inlet air filter

Inlet control valve (ICV)

Airend (rotors)

Coolant/Air separator

Minimum pressure check valve (MPCV)

Aftercooler

Moisture separator/drain trap (optional)

The direction of flow is from the inlet filter to the aftercooler. Refer to procedure and instrumentation diagrams in Section 8.0.

Functions of Components

Inlet air filter, filters the incoming air, trapping 99.9% of

particles 3 micron and larger.

Inlet valve opens full for on-line opeation.

The valve closes in the off-line mode and at shutdown

which prevents back flow of the compressed air.

The airend compresses the air.

The separator tank removes most of the coolant from

the air.

The separator element performs the final separation of

coolant and cleaning of the air prior to leaving the

compressor.

The minimum pressure check valve keeps the separator tank and separator element at a minimum pressure

to ensure adequate oil flow and proper coolant/air separation. It also prevents line pressure from exhausting

back through the airend at shutdown and during periods of unloaded operation.

The aftercooler cools the air prior to leaving the package.

3.5 ELECTRICAL SYSTEM

The electrical system of each SSR compressor is built

with electro-pneumatic controls as standard, or with

the micro-processor based Intellisys controller as an

option.

The standard electrical/electronic components,

enclosed in a readily accessible enclosure include:

1. Push buttons control w/analog gauges

2. Neon indicators

3. Switching relays/timers

4. Control transformers and fuses

5. Compressor motor starter, with auxiliary contacts

and overload relays

6. Optional Intellisys controller in place of #1, 2, and 3

By use of a built-in Automatic Across-The-Line type

starter, the compressor can be started using full voltage electric current. The starter is completely automatic and controlled by the Intellisys controller. Refer to

the electrical schematic, Section 8.0 schematic 8.1

(Standard controller) or 8.3 (Intellisys controller).

By use of an optional built-in Star-Delta type starter,

the compressor motor can be started and accelerated

using a greatly reduced “inrush” electric current. The

starter is completely automatic and controlled by the

Intellisys controller. Refer to the electrical schematic,

Section 8.0 schematic 8.2 (Standard control) or 8.4

(Intellisys control).

Options such as remote start/stop or power outage

restart with remote start/stop can be added by

installing a plug-in module in the controller.

Page 21

3.6 CAPACITY CONTROL

The SSR compressor is supplied with on-line/off-line

and automatic start/stop controls as standard.

Optional modulation control enables the compressor

to operate with a throttled inlet flow for air systems

which have a relatively high constant demand relative

to compressor capacity.

On-Line/Off-Line With Automatic Start/Stop

Control

The compressor will deliver air at full capacity, (the

compressor maximum efficiency condition) or will

operate at zero capacity with high receiver pressure

(the compressor minimum power condition), while the

unit continues to run.

When the compressor starts and line pressure is

below the lower setting of the line pressure switch,

control solenoid 1SV will be energized (close), inlet

control valve ICV will open, and the compressor will

load. When the line pressure reaches the upper setting of the pressure switch, the compressor will

unload by de-energizing (opening) 1SV and closing

ICV. Solenoid 1SV relieves the internal pressure of

the compressor back to the inlet filter. The only

adjustment required is setting of the pressure switch.

A time delay relay is energized and begins to time

out. The timer, mounted in the control box, is factory

set at 10 minutes. It will continue to operate for as

long as its time setting, after which a relay contact

opens to de-energize the compressor starter coil. At

the same time, an amber light (1LT) on the control

box is lit to indicate the compressor has shut down

automatically and will restart automatically. The automatic restart will take place when the line pressure

drops to the lower setting of the pressure switch.

Adjusting the adjustable timer below the 10

minute factory setting may shorten the life of the

compressor drive motor.

3.7 PRESSURE SWITCH ADJUSTMENT

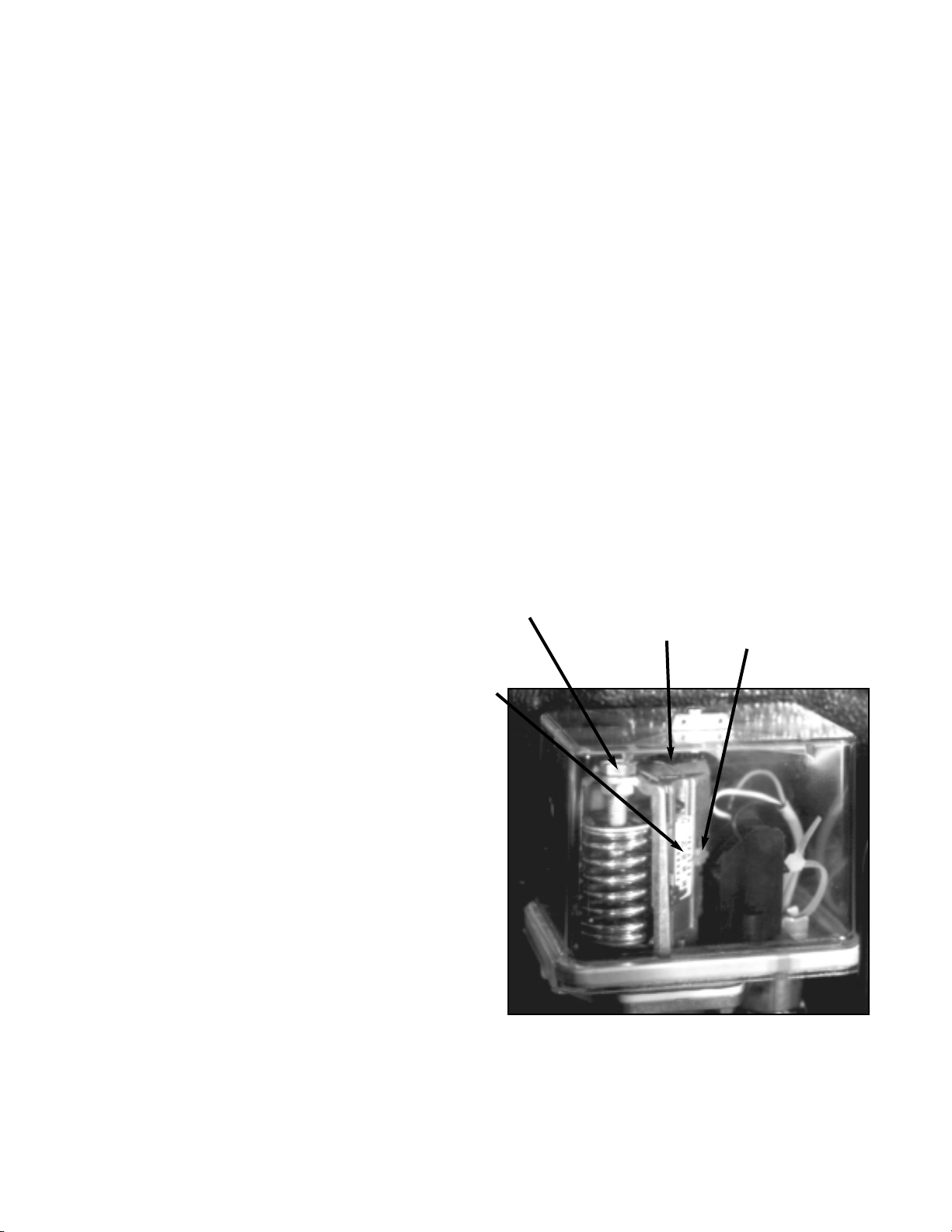

Locate the pressure switch as shown in Figure 3.7-1.

The pressure switch can be adjusted using the following procedure:

1. Open, lock and tag the main electrical disconnect.

Do not adjust the pressure switch with power on or

machine operating.

FIGURE 3.7-1 PRESSURE SWITCH ADJUSTMENT

5

2

3

4

2. Remove pressure switch cover by turning the cover

screw counterclockwise.

NOTE: It is required that the load or on-line pressure

be set first, before the unload or off-line pressure is

set.

3. Set the on-line pressure by turning screw 5 (See

Figure 3.7-1). Turn clockwise to increase setting or

counter-clockwise to decrease setting (indicated by

pointer 4).

4. Set the off-line pressure by turning screw 2. Turn

screw counter-clockwise to increase setting or clockwise to decrease setting (indicated by pointer 3).

CAUTION:

DO NOT EXCEED NAMEPLATE RATING OF THE

COMPRESSOR.

5. Start compressor and test adjustment(s) made. If

necessary, readjust according to steps 1-4 above.

19

Page 22

3.8 MODULATION/ACS CONTROL (OPTIONAL)

For those plants which have relatively high constant

air demand, relative to the compressor capacity, the

recommended control mode is modulation.

The modulation control system retains the features

of the on-line/off-line control, but also provides for

throttling of the inlet flow up to the off-line air pressure setpoint value.

By applying line pressure to an adjustable modulator

valve, the throttling position of the inlet valve is controlled, thus allowing the modulator to "trim" the inlet

valve position as dictated by the line pressure.

The modulating pressure range is about 4 psig (0.3

BAR) and the modulator is factory set to straddle the

compressor rated pressure. Modulation begins when

the line pressure reaches about 99 percent of the

compressor rated pressure and continues as/if the

line pressure rises. Modulation becomes stable

when the compressor output equals the plant air

demand. When the modulation is at the factory setting, the maximum capacity reduction will be approximately 60 percent of the compressor rated capacity

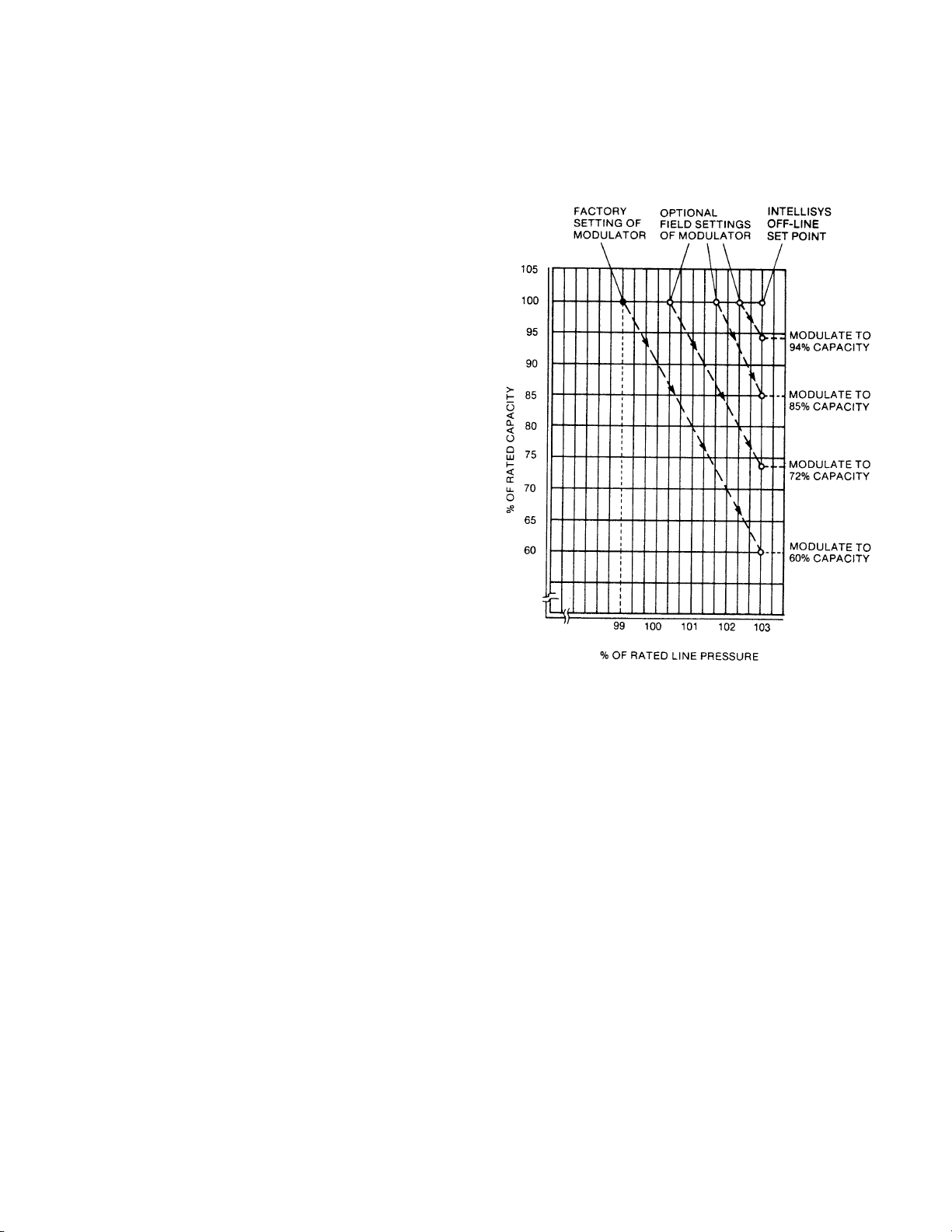

(as indicated in Figure 3.8-1).

FIGURE 3.8-1

Capacity control of machines supplied with standard

electro-pneumatic controls and the modulation option

can be manually switched from on-line/off-line with

auto start/stop to modulation via a rotary selector

switch located adjacent to the pressure switch.

3.9 ACS CONTROL (INTELLISYS MODULATION

OPTION ONLY)

For compressors supplied with Intellisys control and

modulation options, ACS control will allow the compressor to automatically switch between on-line/offline and modulation control, depending on air

demand.

If the air demand has decreased to a level below

the 60 percent modulated output, the line pressure

will increase slightly to actuate the Intellisys. The

compressor will then shift to the off-line control

position, and operate unloaded with the compressor

vented.

20

It is sometimes desirable to begin modulation at a

higher pressure than the standard factory setting,

thereby increasing the modulated capacity at the

time the Intellisys is actuated. Refer to Figure 3.81 for modulated capacities available when this is

done.

The compressor will then operate to deliver full

capacity air to the plant system. If the plant air

system pressure rises to that of the Intellisys offline set point, pressurized air will be sent to the

inlet valve causing it to close, and to the blowdown valve, causing it to open.

The compressor will continue to run unloaded, but

since pressure levels have reduced, it will do so

with a minimum power draw.

Page 23

The Intellisys®has a fixed minimum differential of 10

psi between the off-line air pressure setting and the

on-line air pressure setting. The differential may be

increased by adjusting the on-line air pressure setting of the Intellisys

®

.

Refer to Section 4.4 for instructions.

The automatic control selector (ACS) is designed to

continuously monitor the plant air demand and

select either the on-line/off-line, or the modulate

control mode - whichever is most desirable at anytime during an operating day.

It allows the compressor to operate in its most

efficient mode without attendance, thereby reducing

power costs to a minimum.

When the compressor operates in the on-line/off-line

control mode, the length of time the compressor

remains in the "off-line" condition is an indication of

the plant air demand. Intellisys controller is sensing

and awaiting a sufficient line pressure decrease

before signaling a shift to the on-line mode. If the

"off-line" time period is relatively short, thereby indicating a high demand for air, it is preferable to shift

the control system to upper range modulation.

The Intellisys

®

does this, and does it automatically if

the compressor unloads 3 times within a 3 minute

time period.

If later, the plant demand decreases, and even

under modulate control the line pressure reaches

the setting of the Intellisys

®

controller, and the

control shifts to the "off-line" mode, the time in this

mode will still be monitored. Along "off-line" timeperiod indicates a low plant air demand, indicating

the desirability of operating in the on-line/off-line

mode.

The Intellisys

®

then does this, and does it

automatically if the compressor operates unloaded

for more than 3 minutes.

Modulation Only

If MODULATION ONLY is turned on in the setpoint

routine, the unit will shift to Modulation control mode

immediately when the unit is running. The 3 cycles

within 3 minutes time period required for ACS to

change to Modulation mode is bypassed. The unit

will stay in Modulation mode until the unit runs

unloaded for 3 minutes (the unit then returns to ACS

control) or MODULATION ONLY is turned off via the

set routine.

Delay Load Time

This is the amount of time the line pressure must

remain below the on-line setpoint before the compressor will load or start (if the unit was stopped due

to an auto start/stop situation). Setting the load delay

time to 0 will cause no delay. When the delay load

timer becomes active, the display will switch to package discharge pressure (if not displaying package

discharge pressure at that time) and then display the

delay load count down. Once the count down reaches 0, the unit will load or start and the display will

return to line pressure. The display select button is

inactive during the delay load count down.

21

Page 24

3.10 Modulate Control Valve Adjustment (Optional)

Ensure that the compressor is isolated from the

compressed air system by closing the isolation

valve and venting pressure from the drip leg.

Ensure that the main power disconnect switch is

locked open and tagged.

1. Enter the setpoint routine and put the compressor

in the MODULATION mode. Refer to Section 4.4 for

instructions.

2. Remove 1/8" NPT plug from the tee in the control

piping on the side of the airend support. Connect a

pressure gauge to this port.

3. Loosen the adjustment screw locknut and back

out adjusting screw 3 turns. See Figure 3.9-1.

4. Open the isolation valve and start the compressor.

5. Adjust the isolation valve to bring the discharge

air pressure to the rated discharge pressure (100,

125, 140, or 200 psig).

6. While MAINTAINING the rated discharge

pressure, turn the adjustment screw on the modulation valve (see Figure 3.9-1) so that the test pressure gauge reads:

30 psig for modulate 60% cfm (star-delta units)

Tighten the adjustment screw locknut.

7. Press UNLOADED STOP. Wait for sump pressure

to go 0 psig. Close the isolation valve or bleed off all

system air.

8. Enter the setpoint routine and put the compressor

in the desired control mode (Intellisys units only).

9. Remove the test pressure gauge and replace the

1/8" NPT plug using Loctite

®

PST or similar thread

sealant.

*Loctite is a registered trademark.

FIGURE 3.9-1 MODULATION VALVE

22

!

WARNING

Hazardous voltage. Can cause

severe injury or death.

Disconnect power before servicing.

Lockout/Tagout machine.

!

WARNING

High pressure air.

Can cause severe injury or death.

Relieve pressure before removing filter

plugs / caps, fittings or covers.

LOCKNUT

ADJUSTING SCREW

Page 25

•

ALARM

•

•

•

•

•

•

AIREND DISCHARGE TEMPERATURE •

SUMP PRESSURE •

SEPARATE PRESSURE DROP •

TOTAL HOURS •

LOADED HOURS •

UNLOAD •

POWER

START

UNLOAD

/LOAD

DISPLAY

SELECT

STOP

SET

4.0 INTELLISYS

INTELLISYS CONTROLLER

INGERSOLLrAND

INTELLISYS

(OPTIONAL)

23

•

•

SET OFFLINE AIR PRESURE

SET ONLINE AIR PRESSURE

SELECT CONTROL MODE

SET DISPLAY TIME

SELECT OPTIONS

•

•

•

•

•

•

•

INGERSOLrAND

INTELLISYS

RESTART

AUTOMATIC

SET

DISPLAY

POWER

•

SELECT

•

STOP

UNLOADED

/LOAD

UNLOAD

START

TOTAL HOURS •

SUMP PRESSURE •

PACKAGE DISCHARGE PRESSURE •

AIREND DISCHARGE TEMPERATURE •

LOADED HOURS •

SEPARATE PRESSURE DROP •

UNLOAD •

Page 26

4.0 INTELLISYS

4.1 EMERGENCY STOP SWITCH

Pressing this switch stops the compressor immediately. Compressor cannot be restarted until switch

is manually reset. Turn clockwise to reset.

4.2 POWER INDICATOR LIGHT

Indicates voltage is available to the intellisys controller.

4.3 PUSH BUTTONS

Start

If the display shows READY TO START, pressing

this button will start the compressor. The compressor will start and load automatically if there is a

demand for air.

If in the display table press this button to exit the display table. Display will show “CHECKING

MACHINE” then “READY TO START”.

Unload Stop

Pressing this button will activate the unload stop. If

the compressor is running loaded, it will unload.

Seven seconds later it will stop. if the compressor is

running unloaded, it will stop immediately. Pressing

this button with the unit stopped will flash all L.E.D.’s

for a light check and flash the software version number in the display.

Unload/load

If the unit is running loaded, pressing this button will

cause the unit to unload, the unload indicator light

will be on. The unit will not load until the button is

pressed again. If the unit is running unloaded,

pressing this button will load the unit in the ON/OFF

LINE or MOD/ACS control mode previously operating.

24

EMEG

STOP

UNLOADED

STOP

POWER

START

UNLOAD

/LOAD

Page 27

4.3 PUSH BUTTONS (Continued)

Display Select

Pressing this button will change the information

selected for the display. The display table will be

incremented. If the button is held, this display table

will scroll. This button can also be used to exit the

set point procedure.

NOTE: For readings less than 1 hr., hourmeter

display minutes. After 1 hr. the hourmeter displays

hours.

Set

The SET button is used to enter the setpoint procedure. The set button is also used to reset warnings

and alarms. Pressing this button once will reset a

warning, twice will clear an alarm.

Arrows

These buttons have several functions. If the

Intellisys is in the setpoint mode, the ARROWS are

used to change the setpoint values. If the unit has

multiple alarms or warnings, the ARROWS are used

to scroll through these conditions. The ARROWS

have a function in the calibration routine, which will

be described later.

Pressure Sensor Calibration (Zeroing) Routine

This routine is entered if the unit is not running and

both the up and down arrows button are pressed at

the same time. Make sure all pressure is relieved

from the compressor before calibration. The display

will flash the message “CALIBRATING”. After calibration is completed the display will indicate

“READY TO START”. Zeroing should only be done

after a pressure sensor has been replaced or any

controller change.

25

DISPLAY

SELECT

SET

Page 28

4.5 WARNINGS

When a warning occurs, the alarm indicator will flash

and the display will alternate between the current

message and the warning message. If multiple

warnings exist, the message

SCROLL FOR WARN

will be substituted for the warning messages. The up

and down arrows can be used to obtain the warnings

A warning needs to be reset by an operator. The

warning will clear when the SET button is pressed

once. The following is a list of the warning messages.

1) CHG SEPR ELEMENT

This warning will occur if the pressure on the

Separator is 12 psig (.8 bar) greater than the pressure at the Package discharge and the unit is fully

loaded.

2) HIGH AIREND TEMP

This will occur if the Airend Discharge Temperature

(2ATT) exceeds 221°F (105°C).

4.4 SETPOINT PROCEDURE

This procedure allows the customer to modify 11

variables in the controller logic.

At this time, press the SET button to enter the setpoint routine. The SET OFFLINE AIR PRESSURE

indicator will light and the display will show:

XXXX PSI

OFFLINE AIR PRESSURE is the first setpoint and

XXXX stands for the value of the setpoint. Press the

SET button to select the setpoint to be adjusted.

Press the up or down arrow buttons to raise or lower

the setpoint value. Press the SET button to move to

the next setpoint. If the setpoint value has been

adjusted, press the SET button to enter the new

value. The display will flash to acknowledge.The

next setpoint will then be displayed. If the value of

the setpoint was not changed, pressing the SET button will only step to the next setpoint. When the

SELECT OPTIONS setpoint is entered, the SELECT

OPTIONS indicator will light, and the setpoints for

options Auto Start/Stop or Remote Start/Stop will

only be accessible and displayed if the option module is installed in the unit. The Power Outage Restart

setpoints will only be accessible and displayed if the

combination Auto/Remote Start/Stop/Power Outage

Restart option module is installed in the unit. The

setpoint routine can be exited by pressing the DISPLAY/SELECT button or exit will be automatic after

30 sec.

The following is a list of the setpoints. Also included

are maximum and minimum limits, step size, and

units of measure.

MIN MAX STEP UNIT

OFFLINE PRESSURE 75 RATED + 3 1 PSI

ONLINE PRESSURE 65 OFFLINE - 10 1 PSI

CONTROL MODE MOD/ACS - MODULATION - ON/OFF LINE

DISPLAYTIME 10 600 10 SEC

AUTO RESTART OFF ON --- --AUTO RESTART TIME 2 60 1 MIN

SEQUENCER OFF ON --- --REMOTE START/STOP * OFF ON --- --POWER OUT/RESTART* OFF ON --- --POWER OUT RESTART 10 120 1 SEC

TIME *

DELAY LOAD TIME 0 60 1 SEC

LEAD/LAG** --- --- --- --LAG OFFSET 0 45 1 PSI

*Optional

** The lead/lag feature allows the customer to choose

one compressor as the “lead” compressor and any others as the “lag” compressor (simulates the mode of a

sequencer). The lag compressor’s on-line and off-line

pressures are determined by subtracting the lag offset

setpoint from the on-line and off-line pressure set-points

of the lead compressor.

26

Page 29

4.6 ALARMS

When an alarm occurs, the alarm indicator will light

and display will show actual alarm message. If alternately multiple alarms have occurred the display will

show SCROLL FOR ALARM. In this situation the up

and down arrows will be used to view the alarm

messages. All alarms (with the exception of the

emergency stop) will be reset by twice pressing the

SET button. Any exceptions to the above will be

explained in the alarm description.

The following is a list of the alarm messages.

1) LOW SUMP PRESS

This will occur if the unit is running and sump pressure is too low.

2) HIGH AIR PRESS

This will occur if the unit is running and sump pressure is greater than unit rated operating pressure

plus 20 psig (1.4 bar), plus the separator pressure

drop, or the line pressure is 15 psig (1.0 bar) above

the rated pressure.

3) HIGH AIREND TEMP

This will occur if airend discharge temperature is

greater than 228°F (109°C).

4) STARTER FAULT

This alarm will occur if the starter contacts open

while the unit is running. This alarm will also occur if

the unit is given the stop command and the starter

contacts do not open.

5) MAIN MTR OVERLD

This will occur if a motor overload is sensed.

6) FAN MTR OVERLOAD

This will occur if a fan motor overload is sensed.

7) TEMP SENSOR FAIL

This will occur when the sensor temperature is

recognized as missing or broken.

8) REMT STOP FAIL

This will occur if the momentary remote stop switch

does not disengage by the time the unit attempts to

start.

9) REMT START FAIL

This will occur if the momentary remote start switch

does not disengage by the time star-delta transition

occurs.

10) CK MTR ROTATION

This alarm will occur if a unit is started and compressor has incorrect rotation.

11) CALIBRATION FAIL

This alarm will occur if the sensor calibration routine

is executed and the sensor reading exceeds 10% of

scale.

12) NO CONTROL POWER

This alarm will occur when the controller senses a

loss of control power.

13) PRES SENSOR FAIL

Whenever the pressure sensor is recognized as

missing or broken, a pressure sensor failure alarm

will occur.

INITIAL CHECK ALARMS

14) HIGH AIREND TEMP

This will occur if airend discharge temperature is

greater than 217°F (103°C).

This alarm will only occur when the machine is not

running. When it occurs, the message MUST COOL

DOWN is added to the alternating group of alarm

messages.

Emergency Stop

This will occur when the EMERGENCY STOP button

is engaged. The alarm indicator will light and display

will show:

EMERGENCY STOP

Disengage the EMERGENCY STOP button and

press the SET button twice to reset this alarm.

27

Page 30

28

5.2 MAINTENANCE RECORDS

It is very important that you, the owner, keep accurate

and detailed records of all maintenance work you or the

Ingersoll-Rand Distributor or Air Center perform on your

compressor. This includes, but is not limited to, coolant,

coolant filter, separator element, inlet air filter, drive

belts, shaft seals and so forth. This information must be

kept by you, the owner, should you require warranty

service work by your Ingersoll-Rand Distributor or Air

Center. Maintenance record sheets are located at the

back of this manual.

5.3 MAINTENANCE PROCEDURES

Before starting any maintenance, be certain the following is heeded.

Read Safety Instructions.

Have a well equipped mechanic’s tool box with English

and Metric sockets. (Special tools when needed will be

listed under each appropriate procedure).

Have an OSHA approved air nozzle and compressed

air. (International - local codes may apply).

Have spare parts on hand (See Parts Manual APDD

742.

5.0 SCHEDULED PREVENTATIVE MAINTENANCE

5.1 MAINTENANCE SCHEDULE

THE MAINTENANCE SCHEDULE SPECIFIES ALLRECOMMENDED MAINTENANCE REQUIRED TO KEEP THE

COMPRESSOR IN GOOD OPERATING CONDITION. SERVICE AT THE INTERVAL LISTED OR AFTER THAT

NUMBER OF RUNNING HOURS, WHICHEVER OCCURS FIRST.

SPECIAL NOTE:

Replace separator element when the separator differential pressure ( ▲▲ P) reaches three times the ini-

tial pressure drop or a maximum pressure differential of 12 psi (.8 bar) at full load or if the Intellisys

warning “CHG SEPR ELEMENT” is displayed. See

Section 5.15.

Running Time Interval (whichever comes first)

Action Part or Item Hours 1 Week 1 Mo. 3 Mo. 6 Mo. Yearly 2 Years

Inspect Coolant level Weekly x

Inspect Discharge temperature (air) Weekly x

Inspect Separator element differential Weekly x

Inspect Air filter Delta P (at full load) Weekly x

Replace Coolant filter* 150 x (initial change only)

Check Temperature sensor (intellisys option) 1000 x

Replace Food grade coolant (when used) 1000 x

Inspect Hoses 1200 x

Replace Coolant filter* 2000 x (subsequent changes)

Inspect Drive belt 2000 x

Clean Separator scavenge screen and orifice 4000 x

Clean Cooler cores** 4000 x

Replace Air filter* 4000 x

Replace Separator element* *See special note

Replace SSR Coolant 6000 x

Replace Ultra Coolant* 8000 x

Inspect Starter contactors 8000 x

Service Drive Motor Lubrication See Section 5.18

* In very clean operating environments and where inlet filter is changed at the above prescribed intervals.

In extremely dirty environments change V-belts, coolant, filters, and separator elements more frequently.

** Clean cooler cores if discharge air temperature is excessive or if unit shutdown occurs on high air temperature.

Page 31

29

Before beginning any work on the compressor,

open, lock and tag the main electrical disconnect

and close the isolation valve on the compressor

discharge. Wait 2 minutes after stopping to allow

internal pressure to dissipate. Vent residual pressure from the unit by slowly unscrewing the

coolant fill plug one turn. Unscrewing the fill plug

opens a vent hole, drilled in the plug, allowing the

pressure to release to atmosphere (See Figure

5.3-1). A slight mist or oil droplets may be visible

during venting. Do not remove fill plug until all

pressure has vented from the unit. Also vent piping by slightly opening the drip leg valve. When

opening the drain valve or removing the coolant fill

plug, stand clear of the valve discharge, wear work

gloves and appropriate eye protection.

5.4 PRESSURE RELIEF VALVE CHECK

Under normal operating condition a “try lever test”

must be performed every month . Under severe service conditions, or if corrosion and/or deposits are

noticed within the valve body, testing must be performed more often. A“try lever test” must also be performed at the end of any non-service period. CAU-

TION! High pressure air will discharge through the

discharge ports of the valve during “try lever test”.

Wear ample clothing, gloves, safety glasses and

ear protection during valve testing. Run the com-

pressor for about 10 minutes by venting air from the

system to let the unit warm up. With the unit running,

test at or near maximum operating pressure by holding

the test lever fully open for at least 5 seconds to flush

the valve seat free of debris. Then release lever and

permit the valve to snap shut. If lift lever does not activate, or there is no evidence of discharge, discontinue

use of equipment immediately and contact a licensed

contractor or qualified service personnel.

5.5 SHEAVE ALIGNMENT

Any degree of sheave misalignment will result in a

reduction of belt life. Misalignment of belt drive should

not exceed 1/16 in. (1.6 mm).

Parallel misalignment occurs when the drive and driven shafts are parallel, but the two sheaves lie in different planes (See Figure 5.5-1).

Angular misalignment occurs when the two shafts are

not parallel (See Figure 5.5-2).

FIGURE 5.3-1 FILL PLUG WITH VENT HOLE

FIGURE 5.5-1 PARALLEL MISALIGNMENT

FIGURE 5.5-2 ANGULAR MISALIGNMENT

VENT

O-RING

1/16” (1.6mm) MAX

1/16” (1.6mm) MAX

STRAIGHTEDGE

STRAIGHTEDGE

1/16" MAX

AIREND

STRAIGHT EDGE

MOTOR

1/16" MAX

AIREND

STRAIGHT EDGE

MOTOR

Page 32

30

Align Sheaves

Ensure that the compressor is isolated from the

compressed air system by closing the isolation

valve and venting pressure from the drip leg.

Ensure that the main power disconnect switch is

locked and tagged.

An easy and effective method of checking alignment in

both directions between the driver and driven sheaves

utilizes an accurate straightedge.

Lay the straightedge across the face of the driver

(motor) sheave and check alignment of the driven

(airend) sheave. Then lay the straightedge across the

driven sheave and check that the driver sheave is

aligned.

Alignment should be within 1/16” (1.6 mm) maximum

when measuring the gap between the straightedge

and the rim of the opposite sheave in each direction.

This alignment is factory set and should only require