Page 1

Before installing or starting this unit for the first

time, this manual should be studied carefully to

obtain a working knowledge of the unit and or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

More Than Air. Answers.

Online answers: http://www.air.irco.com

Ingersoll Rand

System Automation

X8I & X12I

Quick Setup Guide

C.C.N. : 80445067

REV. : A

DATE : DECEMBER 2008

Page 2

SECTION 1 — TABLE OF CONTENTS

SECTION1—TABLEOFCONTENTS.....................................1

SECTION2—INTRODUCTION.............................................2

SECTION3—SAFETY..........................................................2

INSTALLATION...........................................................................2

OPERATION..............................................................................2

MAINTENANCEANDREPAIR........................................................2

SECTION4—SYSTEMOVERVIEW.......................................4

SECTION5—INSTALLATIONOVERVIEW.............................5

SECTION6—BEFOREYOUSTART.......................................6

CHECKLIST..............................................................................6

CHECKLISTGUIDANCE...............................................................6

ASSISTANCE..............................................................................7

INTELLISYSCONTROLLERE‐PROMREFERENCELIST...........................7

SECTION7—MENUNAVIGATION......................................8

X8IUSERINTERFACE.................................................................8

X8IINFORMATIONDISPLAYS.....................................................11

X12IUSERINTERFACE.............................................................12

USERMENU...........................................................................14

X12IINFORMATIONDISPLAYS...................................................15

X8IANDX12IINDICATORS.......................................................18

COMPRESSORIDENTIFICATION...................................................19

X8I&X12ICONTROLKEYPADFUNCTIONS..................................19

SECTION8—QUICKSETUPCOMMISSIONING...................21

SECTION10WIRINGDIAGRAMS........................................28

X8I,EXP,EX,VSDMA,VSDV,I/O,CX,DX,SMGPOWERSUPPLY

CONNECTION.........................................................................28

X12IPOWERSUPPLYCONNECTION............................................28

X8I,X12IPRESSURETRANSDUCERCONNECTION..........................28

X8I,X12IRS485CONNECTION................................................29

EXBOXRS485CONNECTION...................................................29

VSDMA,VSDVBOXRS485CONNECTION................................29

I/OBOXRS485CONNECTION..................................................29

CXBOXRS485CONNECTION...................................................29

DXBOXRS485CONNECTION...................................................29

X8ITOEXPRS485CONNECTION..............................................29

X12ITOEXPRS485CONNECTION............................................29

IR485,IRV485GATEWAYCONNECTION.....................................30

IR‐485GATEWAYSWITCHSETTINGS..........................................31

IRV‐485GATEWAYSWITCHSETTINGS........................................32

IRPCBCONNECTION................................................................33

SMGBOXRS485CONNECTION................................................33

VXBOXCONNECTION..............................................................34

PHYSICALCHECKS....................................................................21

PRESSUREDISPLAY..................................................................21

QUICKSET‐UPCONFIGURATION................................................21

OPTIONALFEATURESANDFUNCTIONS........................................21

SECTION9—SYSTEMCONFIGURATION............................22

X8IORX12ICONFIGURATIONSCREENS......................................22

X8IORX12ICOMPRESSORCONNECTIVITYANDFUNCTIONALSETTINGS

............................................................................................25

Refer to Section Indicated

Note

Important or Caution, Safety

1

Page 3

SECTION 2 — INTRODUCTION

This manual is intended as a quick reference to establish

basic sequence control of the compressors with the X8I

or X12I. This document details the minimum required

hardware setup process for the product. Please refer to

the Operator’s Manual for complete setup and operating

SECTION 3 — SAFETY

WARNING :

!

WARNING :

WARNING :

!

WARNING :

• Before installing or operating the X8I or X12I,

take time to carefully read all the instructions

contained in this manual, all compressor

manuals, and all manuals of any other peripheral

devices that may be installed or connected to the

product.

• Electricity and compressed air have the potential

to cause severe personal injury or property

damage.

• The operator should use common sense and

good working practices while operating and

maintaining this system. All applicable codes

should be strictly adhered to.

• Maintenance must be performed by adequately

qualified personnel that are equipped with the

proper tools.

Risk of Danger

Risk of Electric Shock

Risk of High Pressure

Consult Manual

INSTALLATION

• Installation work must only be carried out by a

competent person under qualified supervision.

• A fused isolation switch must be fitted between

the main power supply and the X8I or X12I.

• The X8I or X12I should be mounted in such a

location as to allow operational and maintenance

access without obstruction or hazard and to

allow clear visibility of indicators at all times.

• If raised platforms are required to provide access

to the X8I or X12I they must not interfere with

normal operation or obstruct access. Platforms

and stairs should be of grid or plate construction

with safety rails on all open sides.

instructions. If you have any questions regarding the X8I

or X12I, please contact your local authorized and trained

Ingersoll Rand Service Center or contact Technical

Support Services at 800-820-0308 to speak one of our

Technical Support Engineers.

OPERATION

• The X8I or X12I must only be operated by

competent personnel under qualified

supervision.

• Never remove or tamper with safety devices,

guards or insulation materials fitted to the X8I or

X12I.

• The X8I or X12I must only be operated at the

supply voltage and frequency for which it is

designed.

• When main power is switched on, lethal voltages

are present in the electrical circuits and extreme

caution must be exercised whenever it is

necessary to carry out any work on the unit.

• Do not open access panels or touch electrical

components while voltage is applied unless it is

necessary for measurements, tests or

adjustments. Such work should be carried out

only by a qualified electrician equipped with the

correct tools and wearing appropriate protection

against electrical hazards.

• All air compressors and/or other equipment

connected to the unit should have a warning sign

attached stating ‘THIS UNIT MAY START

WITHOUT WARNING' next to the display panel.

• If an air compressor and/or other equipment

connected to the unit is to be started remotely,

attach warning signs to the equipment stating

‘THIS UNIT CAN BE STARTED REMOTELY’ in a

prominent location, one on the outside of the

equipment, the other inside the equipment

control compartment.

MAINTENANCE AND REPAIR

• Maintenance, repairs or modifications must only

be carried out by competent personnel under

qualified supervision.

• If replacement parts are required use only

genuine parts from the original equipment

manufacturer, or an alternative approved source.

• Carry out the following operations before

opening or removing any access panels or

carrying out any work on the X8I or X12I:

• Isolate the X8I or X12I from the main electrical

power supply. Lock the isolator in the 'OFF'

position and remove the fuses.

2

Page 4

• Attach a label to the isolator switch and to the

unit stating ‘WORK IN PROGRESS - DO NOT APPLY

VOLTAGE'. Do not switch on electrical power or

attempt to start the X8I or X12I if such a warning

label is attached.

• Make sure that all instructions concerning

operation and maintenance are strictly followed

and that the complete unit, with all accessories

and safety devices, is kept in good working

order.

• The accuracy of sensor devices must be checked

on a regular basis. They must be calibrated when

acceptable tolerances are exceeded. Always

ensure any pressure within the compressed air

system is safely vented to atmosphere before

attempting to remove or install a sensor device.

• The X8I or X12I must only be cleaned with a

damp cloth, using mild detergents if necessary.

Avoid the use of any substances containing

corrosive acids or alkalis.

• Do not paint the control faceplate or obscure any

indicators, controls, instructions or warnings.

3

Page 5

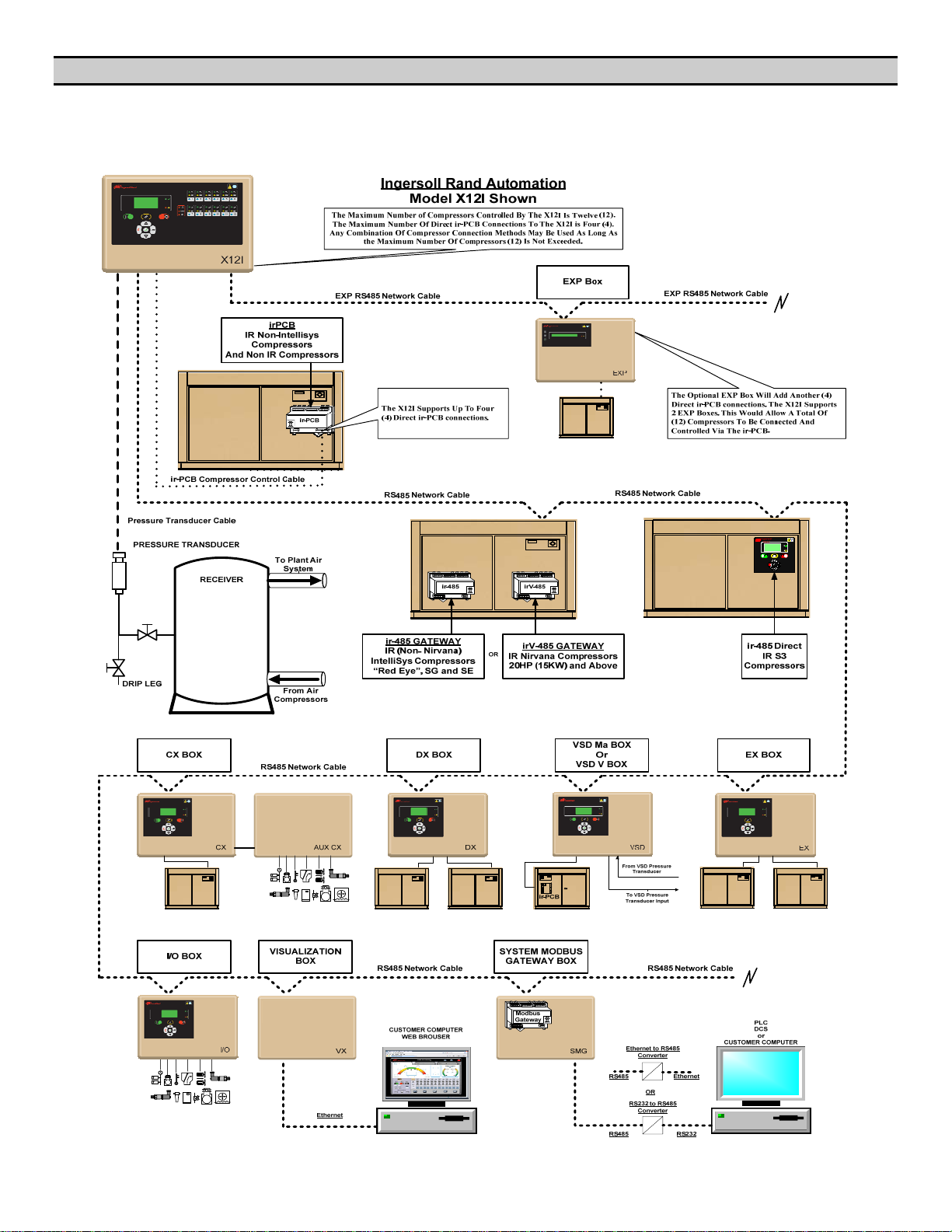

SECTION 4 — SYSTEM OVERVIEW

Refer to the X8I or X12I Operator’s Manual and the

Interconnect and Application Guide for installation

details.

4

Page 6

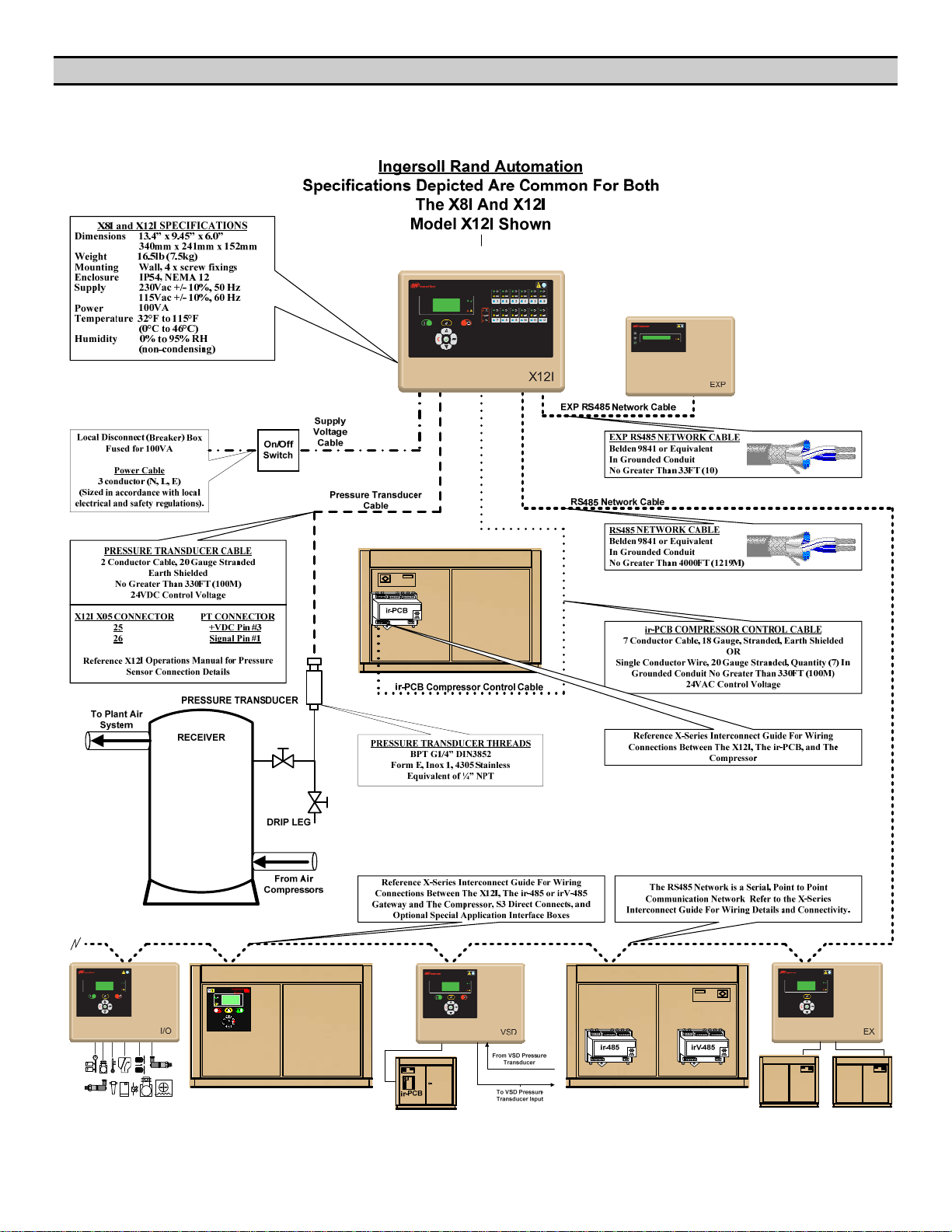

SECTION 5 — INSTALLATION OVERVIEW

Refer to the X8I or X12I Operator’s Manual and the

Interconnect and Application Guide for installation

details.

5

Page 7

SECTION 6 — BEFORE YOU START

CHECK LIST

Prior to attempting installation and commissioning of the

X8I or X12I please review the following check list:

o Quick Set Up Manual is available and has been

reviewed

o Application Guide is available and the correct

diagrams have been identified

o If the specific diagrams are not in the Application

Guide the specific compressor control wiring

schematic will be required to define the correct

interconnection

o Operator’s Manual is available and has been

reviewed

o Compressors to be connected can accept remote

load / unload commands

o Compressors to be connected have automatic

Start / Stop capability

o Correct compressor controller EPROM is installed

or available to allow Remote Control and Auto

Start/Stop (SE Controller) See Reference Table

Below.

o The correct wire is available to connect the X8I

or X12I with the Compressor / ir-PCB interface

o The correct wire is available to connect the X8I

or X12I with the Compressor / ir-485 and/or irV485 Gateway.

o The correct wire is available to connect the X8I

or X12I with the Optional Integration boxes

o The correct wire is available to connect the X8I

or X12I with the pressure sensor/transducer

o The X8I or X12I can be located within 330ft

(100m) of each compressor using the ir-PCB.

o The EXP must be located within 33ft (100m) of

X8I or X12I

o The EXP can be located within 330ft (100m) of

each compressor using the ir-PCB.

o The X8I or X12I can be located within 4000ft

(1219m) of each compressor using the ir-485

and/or irV-485 Gateway or Optional Integration

boxes. (The exception to this is connecting the

Optional EXP box to the X8I or X12I. The

maximum distance is 33ft (10m) in length.)

o The Pressure sensor/transducer can be located

appropriately within 330ft (100m) for the X8I or

X12I Controller

CHECK LIST GUIDANCE

o Electrical Drawing For Each Compressor: It is

important to have the Electrical drawing for each

compressor so that the correct interconnect

drawing can be referenced from the Interconnect

and Application Guide

o Types of Compressors To Be Sequenced: Refer

to the Interconnect and Application Guide for

specific details on the types of compressors that

can be sequenced and their individual

requirements such as Auto Restart, Intellisys

Software, etc.

o ir-PCB and ir-485 and/or irV-485 Gateway

Mounting: The ir-PCB and the Gateway module

is designed to be installed within the compressor

starter enclosure. The mounting location of the

ir-PCB should be away from any high voltage

connections, contactors, or transformers.

o ir-PCB, ir-485 and/or irV-485 Gateway and

Compressor Interconnections: Refer to the

Interconnect and Application Guide for specific

drawings for various compressors and the X8I or

X12I. If there is not a specific drawing available

for the compressor being sequenced at the site,

please contact Technical Support Services for

assistance.

o ir-PCB, ir-485 and/or irV-485 Gateway and

Compressor Interconnection Wire: The X8I or

X12I Installation kit contains 330 Ft (100m) of 18

gauge stranded wire (Orange) to use for the

connections between the ir-PCB and the

compressor. In most cases, this is sufficient for

most installations. If additional wire is required,

any 18 gauge stranded wire can be used in lieu

of the wire provided in the kit.

X8I or X12I Installation kit also contains an

interconnect cable for the connection between

the ir-485 Gateway and the Intellisys Controller.

o X8I or X12I, EXP, EX and ir-PCB Interconnect Wire:

The cable used between the X8I or X12I and the

compressor ir-PCB interconnection is designed to

use 7-conductor shielded cable or individual

wires run through earthed/grounded metal

conduit/tubing. (18 gauge wire).

o The cable used between the X8I or X12I, EXP, ir-

485 and/or irV-485 Gateway or any Optional

Integration Boxes is Belden 9841 (or equivalent).

It should be run in grounded conduit and should

not be greater than 4000 feet (1219 meters) in

length (The exception to this is connecting the

Optional EXP box to the X8I or X12I. The

maximum distance is 33ft (10m) in length.)

6

Page 8

o X8I or X12I and Pressure Transducer Wire: The

X8I or X12I and the pressure transducer

interconnection is designed to use 2-conductor

shielded cable. (18gauge)

o All external wiring to the X8I or X12I should be

made through the holes (grommets are provided)

in the X8I or X12I enclosure (8 in total). Drilling

or tapping additional holes in the enclosure can

result metal shavings making contact with the

circuit boards. Damage due to metal shavings in

the circuit boards is not covered by warranty.

o Power / Local Disconnect (Breaker): Incoming

power (115VAC/230VAC, single phase) should

be fused (100VA) and a local disconnect

provided. The power source should be regulated

and noise free. The use of a power supply

regulator might be required in applications

where unregulated power is an issue

o Confirm that all electrical connections are made

properly and tightened and conform to local

standards.

o Common Receiver: The X8I or X12I must have

its pressure transducer located in a common

receiver for proper Wet Side or Dry Side System

pressure control.

Pressure Transducer Installation: The pressure

transducer threads are BPT G1/4” DIN3852, Form

E, Inox 1, 4305 stainless. It is the equivalent of

¼” NPT.

ASSISTANCE

o Contacting Technical Support Services or Service

Bulletins listed on the IR ServiceNet can provide

further assistance if there are other questions or

concerns prior to Installation and Start-up.

INTELLISYS CONTROLLER E-PROM REFERENCE LIST

Minimum Recommended E-prom Levels - IntelliSys Controllers

IntelliSys - First Generation "Redeye"

SSR 50 - 450HP 1 & 2 stg 2.4

Sierra 100 - 200HP 2.7

Recip 1.62

IntelliSys - Second Generation "SG" IntelliSys - Second Edition "SE"

SSR 50 - 450 1 & 2 stg 1.5 SSR 15 - 100HP 1.75

SSR 75 - 350kW ESA

Sierra 125-400HP 1.35 SSR 22 - 150kW ESA

Recip 1.28 Sierra 50 - 100HP 1.3

IntelliSys - Nirvana "SGN"

Nirvana CC 100 - 200HP 1.45

IntelliSys - Nirvana "SGNe"

Nirvana CC 50 - 300HP 2.4

1.5 SSR - UP (Pegasus) 1.23

1.93

Nirvana OF 50 - 200HP 1.2

7

Page 9

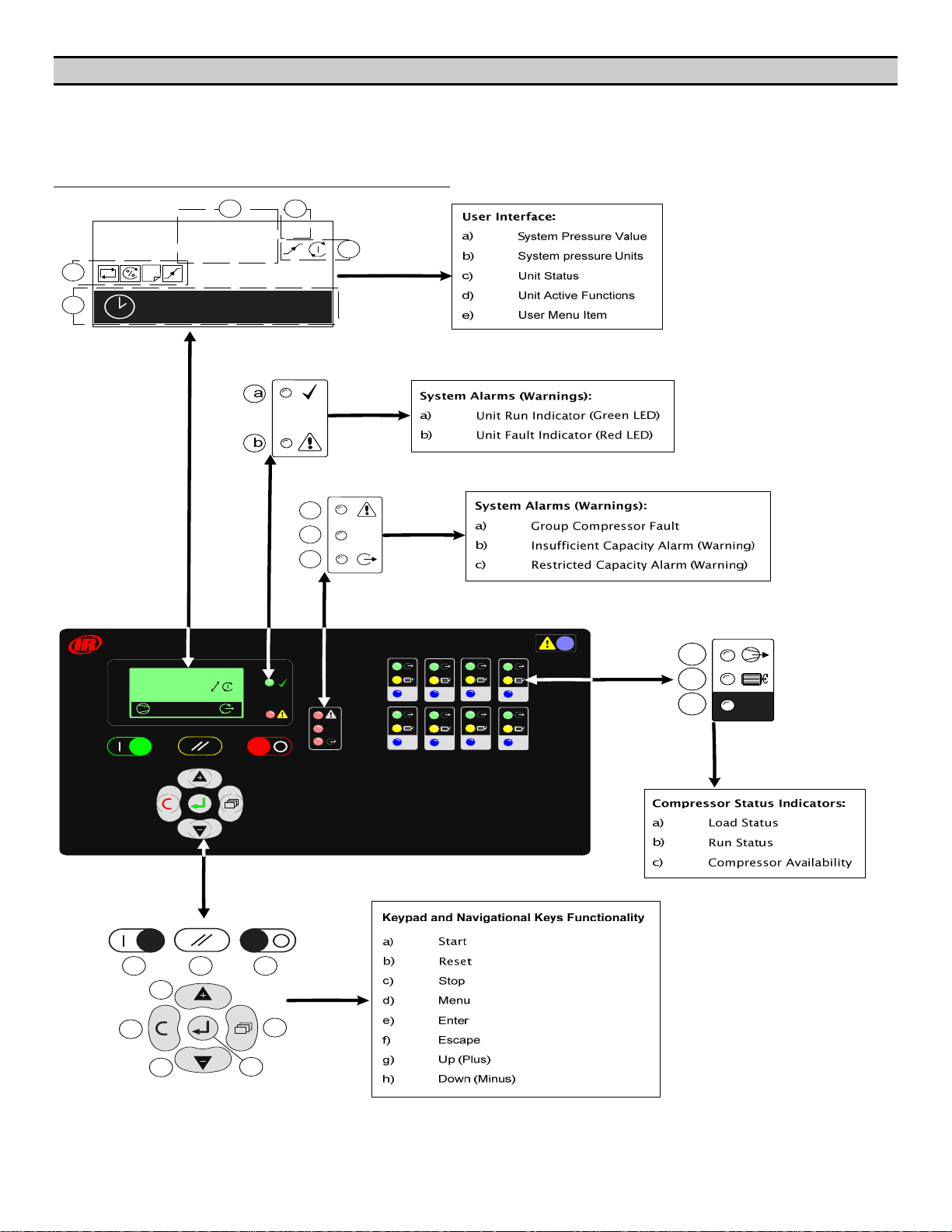

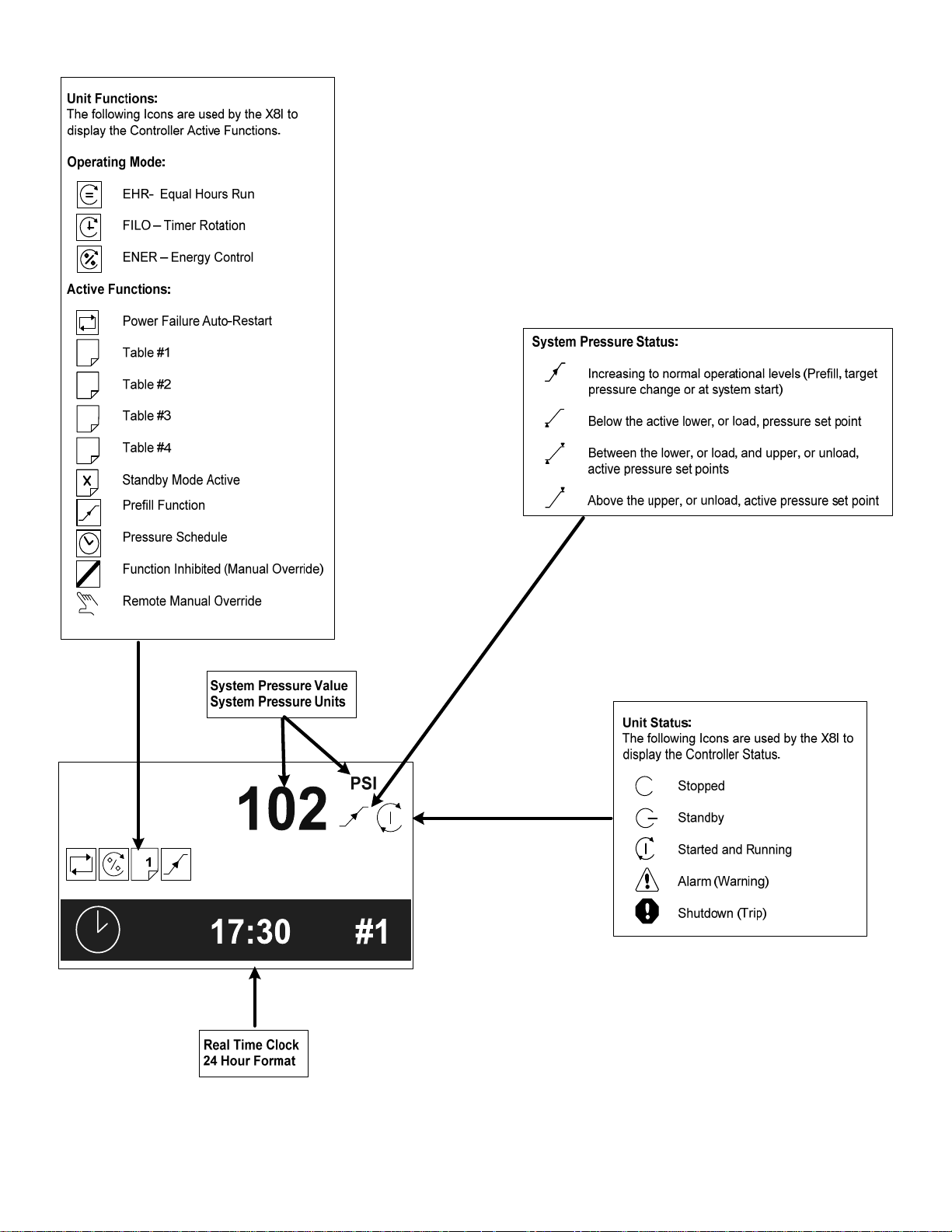

SECTION 7 — MENU NAVIGATION

The Main Display and the keypad and navigation buttons

on the X8I or X12I are depicted below and provide the

following functionality:

X8I User Interface

d

e

1

17:30 #1

a

102

b

PSI

c

a

Ingersoll Rand

1

102

A: 85%

b

c

psi

CAP

a

b

1

CAP

5

3

2

6

4

7

8

c

1

a

b

c

g

f

h

d

e

8

Page 10

1

2

3

4

9

Page 11

17:30 #1

1

#

A: 100%

102 psi

00:00 #1

10

Page 12

X8I Information Displays

P00

To view detailed information applicable to the

selected User menu display item press Enter.

Press Escape to return to the normal user menu

display items.

Real Time Clock:

P00

2

#1 18:30

T2

1

1

Shows the next Pressure Schedule event.

1: The Current Active Table

2: Day (#1=Monday, #7=Sunday)

3: Time (24hr system)

4: Table

3

4

psi

psi

psi

2

3

4

102

1

1

98

80

1: Active Table

2: Upper (Unload) Pressure Set Point

3: Lower (Load) Pressure Set Point

4: Minimum Pressure Alarm (Warning)

Sequence Rotation:

P00

#4 18:00

18 / 05 / 2006

A B C D

Items 2 and 3 show the day and time that the unit will

change to use the ‘Table’ shown in item 4.

Compressor Status:

P00

3

1

1

1

1

2

1: Compressor Number

2: Priority Setting

3: Zone Allocation Setting

4: Compressor/Connection Type

5: Maximum Capacity % Setting

6: Minimum Capacity % Setting

7: Minimum Efficiency % Setting

Item values 6 and 7 are only shown if compressor

type is IRV-485 (variable capacity/speed).

Primary Detected Pressure:

IRV-485

100 %

20 %

30 %

4

5

6

7

Day of the week (#4: Thursday), the time of

day (18:00) and the date (18/05/2006) of the next

automated sequence rotation event.

The active ‘mode’ of operation

“ABCD” The current active rotation sequence assignment.

Manual Sequence Rotation:

The sequence assignment can be manually rotated at any

time. When viewing the ‘Sequence Rotation’ information

screen press Enter:

The manual rotation symbols will appear and

flash. Press Enter again to execute a manual rotation or

Escape to abandon the manual rotation.

Automated sequence rotation is not disrupted by a

manual rotation; the next scheduled automated

sequence rotation event will still occur.

11

Page 13

X12I User Interface

d

e

1

17:30 #1

a

102

b

PSI

c

a

b

c

CAP

a

b

c

a

f

b

g

c

d

1

h

12

e

Page 14

1

2

3

4

13

Page 15

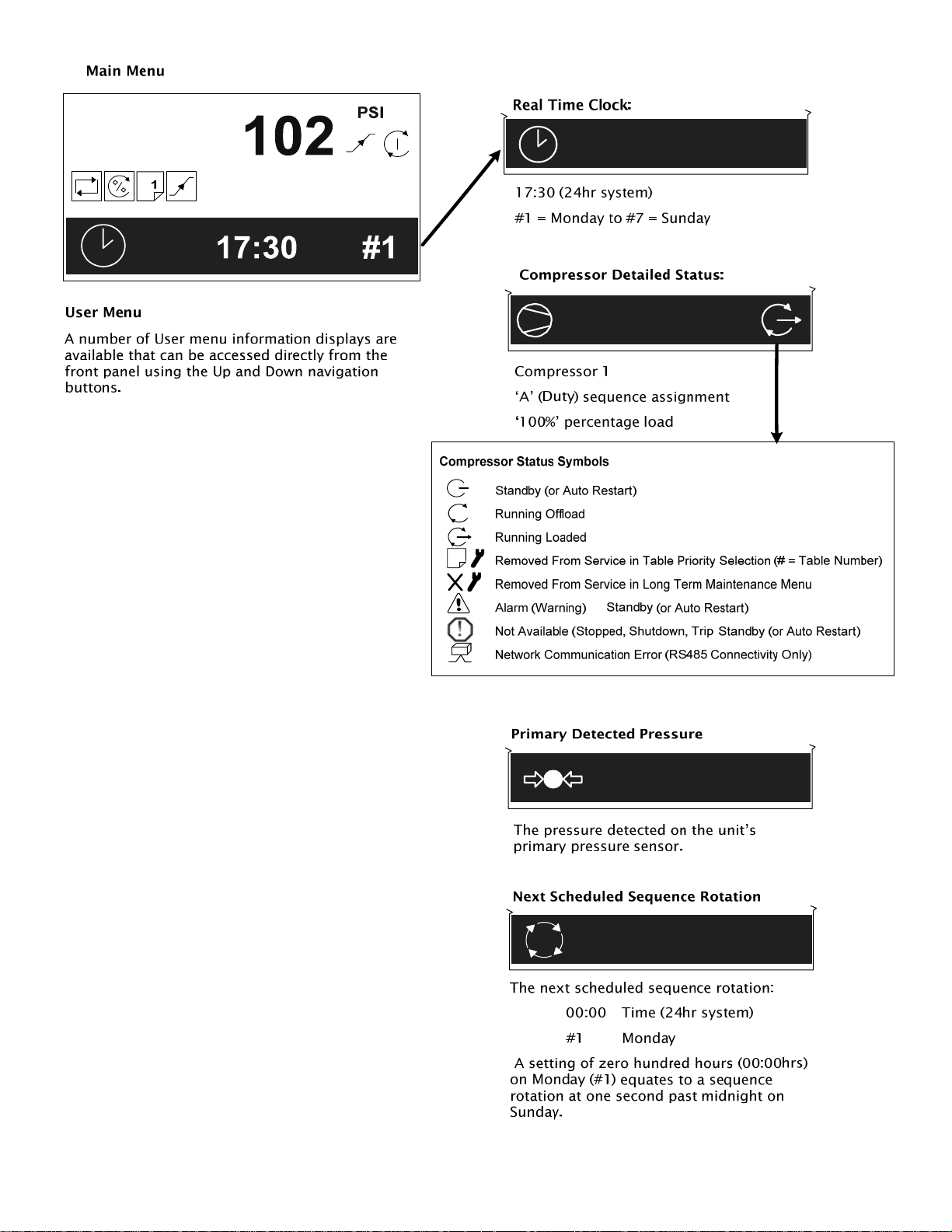

Main Menu

#

Removed From Service in Table Priority Selection

(# = Table Number)

User menu

A number of User menu information displays are

available that can be accessed directly from the front

panel using the Up and Down navigation buttons.

REAL TIME CLOCK:

17:30 #1

17:30 (24hr system)

#1 = Monday to #7 = Sunday

COMPRESSOR DETAILED STATUS:

Removed From Service in Long Term M

Menu

Removed From Service by Short Term IR-PCB

Maintenance Switch Function

Alarm (Warning)

Not Available, Shutdown (Trip), Stopped

Network Communications Error

(RS485 connectivity only)

The detailed status of each compressor in the system is

shown separately.

PRIMARY DETECTED PRESSURE:

aintenance

102 psi

The pressure detected on the unit’s primary pressure

sensor.

When using remote pressure balancing functions the

main display ‘control’ pressure may differ from the

primary detected pressure.

1

Compressor 1

‘A’ (Duty) sequence assignment

‘100%’ percentage load

Status Symbol:

Standby

Running, Offload

A: 100%

Running, Loaded

Pressure Balance Function

2ND PRESSURE INPUT:

101 psi

The second local pressure value.

Only displayed if the 2nd Pressure sensor function is

enabled.

2nd Pressure Sensor Input

14

Page 16

DIFFERENTIAL PRESSURE:

69 mBar

The differential pressure between the Primary and 2

Pressure sensor inputs.

Only displayed if the 2nd Pressure sensor function is

enabled and selected for air treatment pressure

differential monitoring.

Next Scheduled Sequence Rotation:

00:00 #1

The next scheduled sequence rotation:

nd

00:00 Time (24hr system)

#1 Monday

A setting of zero hundred hours (00:00hrs) on

Monday (#1) equates to a sequence rotation at one

second past midnight on Sunday.

2nd Pressure Sensor Input

REMOTE PRESSURE #1:

102 psi

The first remote pressure value from a remote source.

Used for the Pressure Balance Function.

Only displayed if the Pressure Balance Function is

activated and the first remote pressure has been

selected.

Pressure Balance Function

REMOTE PRESSURE #2:

100 psi

The second remote pressure value from a remote source.

Used for the Pressure Balance Function.

X12I Information Displays

To view detailed information applicable to the

selected User menu display item press Enter.

Press Escape to return to the normal user menu

display items.

REAL TIME CLOCK:

P00

2

#1 18:30

T2

1

1

Shows the next Pressure Schedule event.

1: The Current Active Table

2: Day (#1=Monday, #7=Sunday)

3: Time (24hr system)

4: Table

3

4

Only displayed if the Pressure Balance Function is

activated and the second remote pressure has been

selected.

Pressure Balance Function

15

Items 2 and 3 show the day and time that the unit

will change to use the ‘Table’ shown in item 4.

Page 17

COMPRESSOR STATUS:

P00

3

IRV-485

DIFFERENTIAL PRESSURE:

P00

4

1.0 bar

1

1

1

1

1

2

1: Compressor Number

2: Priority Setting

3: Zone Allocation Setting

4: Compressor/Connection Type

5: Maximum Capacity % Setting

6: Minimum Capacity % Setting

7: Minimum Efficiency % Setting

Item values 6 and 7 are only shown if compressor

type is IRV-485 (variable capacity/speed).

PRIMARY DETECTED PRESSURE:

100 %

20 %

30 %

5

6

7

P00

psi

psi

psi

2

3

4

102

1

1

98

80

30 sec

P2(SYS)

1: Alarm (Warning) Level

ime 2: Alarm (Warning) Delay T

3: Source of 2nd Pressure

Only show if the 2nd pressure sensor is activated in

air t

reatment pressure differential mode.

1ST REMOTE PRESSURE:

2

3

P00

B01

1: Source of 1

Only show if pressure balancing function active.

st

Remote Pressure

1

1: Active Table

2: Upper (Unload) Pressure Set Point

3: Lower (Load) Pressure Set Point

4: Minimum Pressure Alarm (Warning)

16

Pressure Balance Function

Page 18

2ND REMOTE PRESSURE:

P00

B02

1: Source of 2

Only show if pressure balancing function active and

nd

2

remote pressure in use.

Pressure Balance Function

SEQUENCE ROTATION:

nd

Remote Pressure

1

P00

#4 18:00

18 / 05 / 2006

A B C D

Day of the week (#4: Thursday), the time of

day (18:00) and the date (18/05/2006) of the next

automated sequence rotation event.

The active ‘mode’ of operation

“ABCD” The current active rotation sequence assignment.

MANUAL SEQUENCE ROTATION:

The sequence assignment can be manually rotated at any

time. When viewing the ‘Sequence Rotation’ information

screen press Enter:

The manual rotation symbols will appear and

flash. Press Enter again to execute a manual rotation or

Escape to abandon the manual rotation.

Automated sequence rotation is not disrupted by a

manual rotation; the next scheduled automated

sequence rotation event will still occur.

17

Page 19

X8I and X12I Indicators

COMPRESSOR STATUS INDICATORS:

INDICATOR LED’S

The X8I or X12I Indicator LED’s are as follows.

Off

On

Intermittent:

1sec

Slow Flash:

1sec

Fast Flash:

1sec

UNIT INDICATORS

Unit Run Indicator (Green LED)

OFF – Not Active, Stopped

a

b

c

Each compres r in the system has a set of dedicated

status indicators. The indicators will continuously show

the status of each compressor at all times.

a) Load Status

ON – Loaded

b) R un Status

OFF – Not Running

c) Available (Started)

1

so

OFF – Not Loaded, Offload

Slow Flash – The compressor has been requested

to load but is not loaded (load or re-load delay

period)

Slow Flash – The compressor has been requested

to load but is not running (blowdown delay or

other start delay)

ON – Running

OFF – No Compressor Connected

Fast Flash – Not Available, Shutdown Fault or

Stopped

Slow Flash: Active, Standby Mode

ON – Active, Running

Unit Fault Indicator (Red LED)

Fast Flash: Shutdown (Trip)

Slow Flash: Alarm (Warning)

The X8I or X12I fault indicator does not indicate

compressor fault states; see Compressor Status

Indicators.

Slow Flash – Alarm (Warning)

Intermittent Flash – The compressor has been

intentionally removed from service.

Available, OK

18

Page 20

SYSTEM ALARMS (WARNINGS):

a

b

CAP

c

a) Group Compressor Fault

OFF – All Compressors OK

The X8I or X12I will hold each compressor in an

offload state. If the compressor is equipped with a main

motor run-on-time function the compressor will run

offload for a period of time and then stop in to a

‘standby’ or ‘auto restart’ state.

The design of some air compressor control systems

may inhibit automatic transfer of pressure regulation

control to local operation mode. In this instance the

compressor will not continue production of compressed

air – consult the air compressor manual or your air

compressor supplier / specialist for details before

installing the X8I or X12I.

Fast Flash – One or more compressors Not

Available, Shutdown Fault or Stopped

Slow Flash – One or more compressors Alarm

(Warning)

b) Insufficient Capacity Alarm (Warning)

On – Insufficient Capacity

c) Restricted Capacity Alarm (Warning)

Slow Flash – Restricted Capacity

Compressor Identification

Each compressor connected to the X8I or X12I will have a

unique assigned compressor identification number;

starting at compressor 1 increasing sequentially to the

number of compressors connected to the X8I or X12I.

A: 85%

1234

START:

To start the X8I or X12I press Start.

If the ‘Start Function’ is enabled there will be a period of

time before any compressor is requested to load.

Start Function

To manually skip the Start function, press and hold

Start for several seconds.

If the Prefill function is enabled, and system pressure is

below the set prefill pressure, the system will enter Prefill

mode for the set Prefill time.

Prefill

To manually skip the Prefill function, press and hold

Start for several seconds.

When Prefill is complete, if applicable, the X8I or X12I will

enter normal operating mode.

The X8I or X12I will operate in accordance with the

parameters and options set in the active ‘Table’.

Tables

X8I & X12I Control Keypad Functions

Stop:

To stop the X8I or X12I press Stop.

The X8I or X12I will respond dependant on the setup of

item ‘CF’ in menu S02:

Pressure regulation control is automatically

transferred back to each compressor. The compressor(s)

will continue to operate using the pressure settings

programmed or set in the individual compressor

controller(s).

19

Each compressor in the system must be started

(running or in a standby or auto restart condition) before

X8I or X12I control of the compressor can be established.

The X8I or X12I will not start a compressor that is in a

stopped condition.

POWER FAILURE AUTO-RESTART

If the power failure auto-restart function is enabled

the X8I or X12I will automatically start, when power is

restored after a disruption or failure, if the X8I or X12I

was in a ‘started’ state when the power disruption or

failure occurred.

The X8I or X12I will not automatically restart if the X8I or

X12I was in a stopped state when the power disruption

or failure occurred.

Page 21

FAILURE MODE

If the X8I or X12I experiences a disruption to normal

control, or an X8I or X12I shutdown fault occurs,

pressure regulation control is automatically transferred

back to each compressor. The compressor(s) will

continue to operate using the pressure settings

programmed or set in the individual compressor

controller(s).

RESET

To reset an X8I or X12I Alarm (Warning) or

Shutdown condition press Reset.

Compressor Alarm (Warning) conditions are

automatically reset when the condition has been resolved

and reset on the compressor.

Compressor Not Available (Shutdown, Trip) conditions

are automatically reset when the condition has been

resolved and reset on the compressor; and the

compressor has been restarted.

20

Page 22

SECTION 8 — QUICK SETUP COMMISSIONING

When commissioning the X8I or X12I, carry out the

following procedures before attempting to start. It is

recommended that an authorized and trained Service

Technician performs the commissioning.

The Quick Setup Manual allows the user to enter the

basic required parameters to quickly start sequencing

the compressors with the X8I or X12I. Once sequencing

and basic control is established, the user can refer to the

Operator’s Manual for more detailed information on

other features and functionality of the unit.

PHYSICAL CHECKS

1. Before applying power to the X8I or X12I, ensure

that the power supply connections are correct

and secure and that the operating voltage

selector is set correctly for the power supply

voltage in use: 115Vac or 230Vac (+-10%),

50/60Hz.

2.

Open the front panel of the X8I or X12I and

check the location of the link wire(s) connected

to the “Voltage Selection” terminals of the power

supply PCB. If necessary, change the link wire

locations to those illustrated for the voltage in

use.

See the INSTALLATION section in the

Operator’s Manual for more information.

3. Switch on the power supply to the unit.

The control program identification will be displayed for a

short period followed by the normal operational user

display.

QUICK SET-UP CONFIGURATION

Before successful basic operation can be established the

following items must be set (in the order shown) to suit

installation requirements. The X8I or X12I can easily be

commissioned by simply setting the following

parameters.

NOTE: Leave all other parameters at factory defaults.

S02 - NC Number of Compressors

S02 - PM Maximum Pressure Alarm

S01 - Ct Real Time Clock Set

(X8I) C03 – 01/8 Compressor #1-8 Configurations

(X12I) C03 – 01/12 Compressor #1-12 Configurations

(X8I) C01 - 01/8 Compressor #1-8 Running Hours

(X12I) C01 - 01/12 Compressor #1-12 Running Hours

T01 - PH High Pressure Set Point

T01 - PL Low Pressure Set Point

T01 - Pm Minimum Pressure Alarm

(X8I) T01 – 01/8 Compressor #1-8 Priority

(X12I) T01 – 01/12 Compressor #1-12 Priority

PRESSURE DISPLAY

Check the displayed system pressure. If the pressure is

incorrect, or inaccurate, check the type and range of the

sensor and carry out the pressure sensor commissioning

and calibration procedure. If the display shows an error,

the error will need to be corrected before continuing.

See the Operator’s Manual for troubleshooting and

correcting the fault or error condition.

21

NOTE: By default, the pressure unit of measurement is

PSI. If the unit of measurement is BAR or kPA, please

refer to the Operator’s Manual for information on

changing the S02 P> Units Setting parameter.

Once set, the X8I or X12I will sequence all compressors

based on load demand using the ENER, Energy Mode.

Optional features and functions

Installation requirements may involve the

implementation of additional or optional functions and

features. Please refer to the appropriate Guide or Manual

as required.

Page 23

SECTION 9 — SYSTEM CONFIGURATION

Q

X8I or X12I Configuration Screens

T01

16 112

01 PH psi 102

02

psi

04 S

# = Table T01 to T06

T0# – PH High Pressure Set Point

The ‘upper’ or ‘unload’ pressure set point that will be

used when the ‘Table’ is active. The default setting for

this parameter is 102 PSI. The values for this

parameter are:

The highest value for the High Pressure setpoint = PM

“Maximum Pressure Alarm” minus 2 times TO

“Tolerance”.

If PM is set for 145 PSI and TO is set for 3.0 PSI, then the

highest value for the High Pressure setpoint would be

139 PSI.

The lowest value for the High Pressure setpoint = PL “Low

Pressure” setpoint plus TO “Tolerance”

If PL is set for 98 PSI and TO is set for 3.0 PSI, then the

lowest value for the High Pressure setpoint would be 101

PSI.

T0# - PL Low Pressure Set Point

The ‘lower’ or ‘load’ pressure set point that will be used

when the ‘Table’ is active. The default setting for this

parameter is 98 PSI. The values for this parameter are:

The highest value for the Low Pressure setpoint = PH

“High Pressure” setpoint minus TO “Tolerance”.

If PH is set for 102 PSI and TO is set for 3.0 PSI, then the

highest value for the Low Pressure setpoint would be 99

PSI.

The lowest value for the Low Pressure setpoint = Pm

“Minimum Pressure Alarm” setpoint plus 2 times TO

“Tolerance”

If Pm is set for 80 PSI and TO is set for 3.0 PSI, then the

lowest value for the Low Pressure setpoint would be 86

PSI...

Tables

98PL

003 Pm psi

ENER ( % )

PM

TO

P

r

e

s

s

u

r

e

Pressure Set-Point Illustration Summary

T0# - Pm Minimum Pressure Alarm

The miniumum pressure ‘Warning’ or ‘Alarm’ level that

will be used when the ‘Table’ is active. The default

setting for this parameter is 80 PSI. The values for this

parameter are:

The lowest Minimum Pressure Alarm setpoint = “The

minimum range of the pressure transducer used.“

The highest Minimum Pressure Alarm setpoint = “The

value from the Table PL – Low Pressure Setpoint” minus 2

times TO “Tolerance””

If PL in Table 1 (T01) is set for 100 PSI and TO is set for

3.0 PSI, then the highest Minimum Pressure setpoint

would be 94 PSI.

T0# - 01 Compressor #1 Priority

The ‘priority’ setting for compressor number 1 that will

be used when the table is active.

To

‘n’

T0# -

The ‘priority’ setting for compressor number ’n’ that will

be used when the table is active.

‘n’

maximum number of compressors for the X8I and 12 is

the maximum number of compressors for the X12I.

The default setting for this parameter is 1.

is active by selecting “X” priority. The compressor will be

held offload and will not be utilized under any

circumstances.

Compressor #’n’ Priority

= number of compressors in the system. 8 is the

Priority Settings:

: compressor(s) can be inhibited from use while a table

TO

PH + TO

PH

PT

PL

PL - TO

Pm

22

Page 24

A

06

BL

S01

08 Ct 1 . 18:00

08

PS

08

08

R

RP

1 . 00:00

5

X

12

ER

01 P>

02

NC

03

PM

04

CF

S02

X

psi

4

145

X

psi

Features and Functions

S01 - Ct Real Time Clock Set

Adjustment for the internal real time clock.

(Hours, Minutes, Date, Month, Year)

The ‘Day of the Week’ (1= Monday to 7=Sunday) is

automatically calculated and set in accordance with the

Day, Month and Year. The default setting for this

parameter is - --.--. (Represents the clock has not

been initialized))

The values for this parameter are:

“1” to “7” the ‘Day of the Week’ (1= Monday to

7=Sunday) which is automatically calculated and set

in accordance with the Day, Month and Year entered.

“00” to “23” the Hour for the Real Time Clock.

“0” to “59” the Minutes for the Real Time Clock.

“1” to “31” the Day for the Real Time Clock.

“1” to “12” the Month for the Real Time Clock.

“2005” to “2100” the Year for the Real Time Clock.

Pressure Control; Tables

S02 - NC Number of Compressors

This parameter sets the number of compressors

connected to, and controlled by, the X8I or X12I. This

value must be set to match the system at commissioning.

The default setting for this parameter is 4. The values

for this parameter are:

“1” for 1 compressor

To

“8” for 8 compressors (X8I)

“12” for 12 compressors (X12I)

S02 - PM Maximum Pressure Alarm

This parameter sets the High pressure ‘Fault’ level. This

value remains active at all times and is the same for all

‘Tables’. It should be set just below system pressure

relief value(s) and below the maximum system pressure

rating of all air system components. The default setting

for this parameter is 145. The values for this

parameter are:

The highest value for the Maximum Pressure Alarm

setpoint = “The maximum range of the pressure

transducer used”

The lowest value for the Maximum Pressure Alarm

setpoint = “The highest value from any Table “PH Pressure High” Setpoint plus 2 times the “To –

Tolerance”

If PH in Table 1 (T01) is set for 100 PSI, and PH

in Table 2 (T02) is set for 110 and TO is set for

3.0 PSI, then the lowest Maximum Pressure

setpoint would be 116 PSI.

23

Page 25

Control - Equal Hours Run Mode

C01 – 01 to C01 – ‘n’ Run Hours’

‘n’

= number of compressors in the system. 8 is the

maximum number of compressors for the X8I and 12 is

the maximum number of compressors for the X12I.

This parameter is set to match the running hours of each

compressor. Record of detected ‘running’ hours for each

compressor. The run hours value can be manually

adjusted, at any time, to match the running hours

meter/display value of each compressor. The default

setting for this parameter is 0 hours. The values for

this parameter are:

“0 to x” where x = the actual run hours for the

compressor

Installation – Compressor Connections

’

C03 – 01 to C03 – ‘n

‘n’

= number of compressors in the system. 8 is the

maximum number of compressors for the X8I and 12 is

the maximum number of compressors for the X12I

This parameter sets the type, method of connection, and

the control functionality, of each compressor connected

to the X8I or X12I. The default setting for this

parameter is ir-PCB.

Dependant on the regulation and connection type

selected the set-up screen will change to show applicable

settings.

Compressor Connection’

24

Page 26

X8I or X12I Compressor Connectivity and

Functional Settings

ir-PCB:

C03

1

2

irV-PCB:

C03

1

IRV-PCB

2

ir-485:

C03

1

01.01

1

IR-PCB

10 s

01.01 01

1

10 s

01.01

1

IR-485

01

100 %

+V=!

100 %

+V=!

10 s

01

100 %

5

4

5

4

3

5

1

Compressor Connectivity:

ir-PCB

Fixed speed, load/unload; connected to X8I OR

X12I using ‘ir-PCB’ module using 6-wire method.

(0/100%) 0% or 100% regulation

irV-PCB

using ‘ir-PCB’ module using the 7-wire ‘V’ terminal

method.

ir-485

X12I on RS485 network.

IrV-485

X12I on RS485 network.

2

Set to match the time that the compressor takes to start

its main motor and load. This time will typically be

equivalent to the compressors ‘Star/Delta’ time.

If unknown, the time can be established by experiment;

manually start the compressor, from a stopped

condition, and determine the time from pressing the

start button until the compressor loads and contributes

capacity output to the system.

of multiple compressors and other operational

calculations. An accurate time is important for successful

unit operation.

3

Variable Speed; connected to X8I OR X12I

(variable speed regulation)

Fixed speed, load/unload; connected to X8I OR

(0/100%) 0% or 100% regulation

Variable Capacity/Speed; connected to X8I OR

(0 . . 100%) variable %Load regulation

Compressor Start Sequence Time:

This time is used by the unit for ‘staggered starting’

Compressor Run-On Stop Time:

2

irV-485:

1

2

25

C03

IRV-485

10 s

01.01

1

10 s

01

100 %

50 %

60 %

5

6

7

This setting is only applicable to ‘irV-PCB’

connectivity and is not displayed for other connectivity

options.

The time that the compressor main motor will continue

to run when the compressor is offload (main motor runon-time).

If unknown, the time can be established by experiment;

start and load the compressor then arrange a condition

that will unload the compressor for a period of time.

Determine the time from the moment the compressor

unloads until the main motor stops and the compressor

enters a ‘Standby’ or ‘Auto Restart’ condition.

This time is used by the X8I or X12I for accurate

recording of ‘run hours’ (EHR mode), operational

calculations and other data recording applications. An

accurate time is important for successful X8I or X12I

operation.

Page 27

4

ir-PCB Alarm (Warning) Input:

Only applicable for ir-PCB connectivity. Not shown

for ‘485’ network types.

For ‘ir-PCB’ connectivity applications the voltage

detection function for the ‘ir-PCB’ Alarm (Warning) input

can be inverted.

+V=! An Alarm (Warning) condition is generated if the

‘ir-PCB’ Alarm input detects a voltage between 12250Vac/dc (default).

0V=! An Alarm (Warning) condition is generated if the

‘ir-PCB’ Alarm input detects no voltage.

5

% Maximum Output Capacity

The maximum output capacity of each compressor must

be set as a percentage with reference to the highest

output capacity (the largest) compressor in the system.

The highest output capacity compressor must be

assigned with 100% capacity. Equal capacity (equal sized)

compressors should be assigned the same % capacity

value. Calculate the output capacity of compressor(s) that

are smaller than the largest in the system as a

percentage of the largest in the system.

For example:

Compressor 1 700 cfm 100%

Compressor 2 700 cfm 100%

Compressor 3 420 cfm 60%

Compressor 4 420 cfm 60 %

Compressor 5 350 cfm 50%

Compressor 6 175 cfm 25%

For example 1:

For a variable speed compressor that has been assigned

a maximum capacity output percentage of 100%, and is

able to reduce speed to 30% of maximum speed:

Minimum Output Capacity = 30% (related to the largest

capacity)

Example Compressor 1 is a VSD

Max CFM = 700

Max Output Capacity 700/700 = 100%

Min CFM = 210 (30% or 700 x .30)

Min Output Capacity 210/700 = 30% (or 30% x 100%

= 30%)

For example 2:

For a variable speed compressor that has been assigned

a maximum capacity output percentage of 60% (related

to the largest capacity), and is able to reduce speed to

30% of maximum speed:

Example Compressor 4 is a VSD:

Max CFM = 420

Max Output Capacity 420/700 = 60%

Min CFM = 127 (30% or 420 x .30)

Min Output Capacity 127/700 = 18% (or 30% x 60% =

18%)

For example 3:

For a 3-step (0/50/100%) reciprocating compressor that

has been assigned a maximum capacity output

percentage of 60%, the minimum output capacity is the

half-output regulation step:

Minimum Output Capacity = 30%

6

% Minimum Output Capacity

Only applicable for a variable output compressor

(IRV-485). Not shown for other types.

The minimum output capacity of a variable output

compressor must be set as a percentage of the

compressor’s maximum output scaled in accordance

with the % maximum capacity output value. Minimum

output capacity is regarded as the output capacity at the

lowest possible speed (variable speed compressor) or the

minimal output achievable (stepping or other variable

regulation control).

26

Page 28

7

% Minimum Efficiency

Only applicable for a variable output compressor

(IRV-485). Not shown for other types.

The minimum efficiency point is regarded as the speed,

or step, below which another smaller capacity

compressor in the system could achieve the equivalent

output at a higher efficiency.

The percentage value is directly related, and scaled, to

the maximum and minimum output percentage values.

For example:

Example: A Compressor is a VSD:

Max CFM = 420 (Largest Compressor is 700 CFM)

Max Output Capacity 420/700 = 60%

Min CFM = 127 (30% or 420 x .30)

Min Output Capacity 127/700 = 18% (or 30% x 60% =

18%)

If another compressor in the system is able to provide

40% of the compressor’s full speed output more

efficiently, set the % Minimum Efficiency value to 24%

(40% x 60%). This percentage value represents 40% of the

full speed output of the compressor scaled to System

capacity.

When the compressor is detected as operating below the

% Minimum Efficiency value for a period of time the X8I

AND X12I will immediately re-evaluate utilization and reconfigure, if possible, to utilize a the smaller capacity,

more efficient compressor, or combination of

compressors. This process is automatic and executed

dynamically in accordance with prevailing operational

conditions at the time. The ENER control mode

algorithms will eventually conclude the best compressor

fit without this parameter; the % Minimum Efficiency

input will speed up this process.

The intent of this feature is to always operate the

smallest, most efficient compressor and to prevent a

variable output capacity compressor operating at

minimal speed, or minimal output, for prolonged periods

of time. Generally a variable output compressor

operating at minimal capacity is less efficient than a

smaller capacity compressor that is able to achieve the

same output at higher, or maximum, output capacity.

27

Page 29

SECTION 10 WIRING DIAGRAMS

Refer to the appropriate Manual for more detail on

the specifics for each of the followings components.

X8I, EXP, EX, VSD MA, VSD V, I/O, CX, DX,

SMG Power Supply Connection

N L

2 3 1 4

E

XPM-TAC24

X04

EE L N

X01

X04

2 3

1

VOLTAGE SELECT

1

2 3 4

VOLTAGE SELECT

4

230Vac

115Vac

X12I Power Supply Connection

XPM-TAC24

1

X04

X04

234

VOLTAGE SELECT

1

234

VOLTAGE SELECT

230Vac

115Vac

X8I, X12I Pressure Transducer Connection

Wire polarity is important.

Pressure Sensor Wiring and Location

28

Page 30

X8I, X12I RS485 Connection

X06

L2

L1

30

29

28

27

RS485

X8I to EXP RS485 Connection

L2

L1

EX Box RS485 Connection

X07

28

27

26

25

RS485

L1

L2

VSD Ma, VSD V Box RS485 Connection

L2

L1

X07

L2

L1

I/O Box RS485 Connection

X07

28

27

26

25

RS485

L1

L2

C1-4

X01

L1 L2

XPM485

C5-8

X06

29

28 3027

L1

L2 L2L1

X12I to EXP RS485 Connection

XPM-LED

X01

CX Box RS485 Connection

X07

L1

L2

RS485

DX Box RS485 Connection

X07

L1

L2

30

29

28

27

RS485

L1

L2

L1

L2

C1-4

X01

L1 L2

XPM485

XPM-LED

X01

C5-8 C9-12

X06

29

28 3027

L1

L2 L2L1

33ft (10m) max

28 3027

L2 L2L1

X06

29

L1

29

Page 31

Ir485, irV485 Gateway Connection

-24VDC

+24VDC

NC

-V +V

OUTPUT

24VDC 0.3A

idec

DC ON

V.ADJ

7.5

OUTPUT

W

POWER SUPPLY

PS5R-A24

50/60HZ

INPUT

100/240 VAC 0.17A

L

N

LNG

From Compressor

110 / 230VAC

+24VDC

0VDC

ir-485 / irV485

X01

+24VDC

-24VDC

12

+

Power Supply

X01

-

ir 485 Gateway

For IntelliSys “Red Eye”, SG and SE equipped with an RJ11

RS485 data communications connection port, use the

RJ11 Modbus cable supplied with the ir-485 Gateway.

RJ11

2

4

2

3

4

5

L1 (2)

1

2

3

4

5

L2 (4)

6

M4

Ring Tag

L1

L2

X02

irV-485 Gateway

For IntelliSys SGN, SGNe and Nirvana 15-30kW (20-40HP)

equipped with a Phoenix RS485 data communications

connector, use the RJ11 Modbus cable supplied with the

irV-485 Gateway and modify as shown by removing the

RJ11 Plug.

Intellisys Controller Connection

X8I, X12I RS485 Connection

L1

L2

X02

M4

Ring Tag

L2

L1

1

2

SGN / SGNe Phoenix

6Pin Connector

2

1

Consult the air compressor manual or your air

compressor supplier/specialist for details before

installing the X12I.

Consult the X-Series Interconnect and Application

Guide prior to the installation of the X12I and the ir-485

& irV-485 to the air compressor.

Consult the ir-485 & irV-485 Gateway Instruction

Manual for information regarding the use of the ir-485 &

irV-485 Gateway.

30

Page 32

ir-485 Gateway Switch Settings

Compressor Identification Number

Each compressor connected to the X8I or X12I will have a

unique assigned compressor identification number;

starting at compressor 1 increasing sequentially to the

number of compressors connected to the X8I or X12I.

Switch SW1 is used to assign this unique address on the

ir-485 Gateway

SW1

SW2 SW3

Compressor Type

Each compressor connected to the X8I or X12I must be

matched to a specific type and functionality. This is

unique to every compressor and the associated controller

used on it. Switch SW2 is used to assign this unique type

and functionality on the ir-485 Gateway

SW1

SW2

SW3

System Network Address

1 7

2 8

3 9 (for X12I only)

4 10 (for X12I only)

5 11 (for X12I only)

6 12 (for X12I only)

Function Selections

SW1 SW2

SW3

IR-BUS (9600 N-8-2)

0: SSR

1: SE_15_100

2: SE_PEGASUS (UP Series)

3: SE_ESA_22_150

4: not used 5: not used

6: not used 7: not used

8: SSR_PHASE_1 (status register only)

10: SIERRA_SE_50_100

11: SIERRA_125_200

SW3-2 to 4 are not used.

SW3-1: Software Version Display

31

MODBUS (9600 N-8-1)

9: SSR_SG

12: SIERRA_125_400

13: SIERRA_SG_BOOSTER

14: not used 15: not used

Page 33

irV-485 Gateway Switch Settings

Compressor Identification Number

Each compressor connected to the X8I or X12I will have a

unique assigned compressor identification number;

starting at compressor 1 increasing sequentially to the

number of compressors connected to the X8I or X12I.

Switch SW1 is used to assign this unique address on the

ir-485 Gateway

SW1

SW2 SW3

Compressor Type

Each compressor connected to the X8I or X12I must be

matched to a specific type and functionality. This is

unique to every compressor and the associated controller

used on it. Switch SW2 is used to assign this unique type

and functionality on the irV-485 Gateway

SW1

MODBUS (9600 N-8-1)

SW2

SW3

System Network Address

1 7

2 8

3 9 (for X12I only)

4 10 (for X12I only)

5 11 (for X12I only)

6 12 (for X12I only)

Function Selections

SW1 SW2

SW3-3 is not used.

SW3

0: NIRVANA_SGN

1: NIRVANA_SGNe

2: NIRVANA 20-40HP

IR-BUS (9600 N-8-2)

3: RECIP

4: RECIP_SG

5: RECIP_BOOSTE R

6: not used 7: not used

8: not used 9: not used

10: not used 11: not used

SW3-1: Software Version Display

SW3-2: Learning Mode

SW3-4: Nirvana 50HP and Greater 1psi Target

Offset Pressure

32

12: not used 13: not used

14: not used 15: not used

Page 34

irPCB Connection SMG Box RS485 Connection

C01 C02 C04

i-PCB

#1

C03

V

24613 5

C05

LED 1 LED 2

V

X01

246135

V1

Consult the air compressor manual or your air

compressor supplier/specialist for details before

installing the X12I.

Consult the X-Series Interconnect and Application

Guide prior to the installation of the X12I and the ir-PCB

to the air compressor.

3

2

1

X02

L2

L1

MODBUS

RS485

Customer Modbus Connection

X8I, X12I RS485 Connection

L1

(B)L2

(A)

Consult the ir-PCB Instruction Manual for

information regarding the use of the ir-PCB.

33

Page 35

VX Box Connection

VX Box Power Supply Connection

34

Loading...

Loading...