Page 1

Ingersoll Rand

Operator’s Manual

System Automation

X8I

Before installing or starting this unit for the first

time, this manual should be studied carefully to

obtain a working knowledge of the unit and or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

More Than Air. Answers.

Online answers: http://www.air.irco.com

C.C.N. : 80444060

REV. : B

DATE : MAY 2008

Page 2

SECTION 1 TABLE OF CONTENTS

SECTION 1 TABLE OF CONTENTS ..........................2

CTION 2 INTRODUCTION

SE

...................................3

SECTION 3 SAFETY ....................................................3

INSTALLATION .............................................................................3

OPERATION

MAINTENANCE AND REPAIR

.................................................................................. 3

.................................................3

SECTION 4 COMPRESSOR CONNECTION AND

CONTROL ........................................................................5

COMPRESSOR CONNECTION AND CONTROL ..............5

OPTIONAL CONNECTION METHODS

PRESSURE DETECTION AND CONTROL

X8I MAIN DISPLAY

....................................................................7

.................................5

............................6

SECTION 5 INSTALLATION OVERVIEW ................. 8

INSTALLATION .............................................................................9

PRESSURE DISPLAY

X8I QUICK SETUP CONFIGURATION

OPTIONAL FEATURES AND FUNCTIONS.........................26

.................................................................26

...............................26

SECTION 9 SYSTEM CONFIGURATION ...............27

DISPLAY ITEM STRUCTURE...................................................27

NORMAL OPERATIONAL DISPLAY MENU PAGE P00

ACCESSING THE X8I CONFIGURATION SCREENS

USER LEVEL MENUS ................................................................29

SERVICE LEVEL MENUS ..........................................................30

X8I CONFIGURATION SCREENS

X8I COMPRESSOR CONNECTIVITY AND FUNCTIONAL

SETTINGS

.....................................................................................41

.........................................31

27

........27

SECTION 10 FAULT CODES ....................................46

X8I COMPRESSOR FAULT INDICATIONS, TYPES, AND

CODES: ..........................................................................................46

UNIT LOCATION

POWER SUPPLY

PRESSURE SENSOR LOCATION

PRESSURE SENSOR CONNECTION

IRPCB INTERFACE MODULE ................................................10

IR485 AND IRV485 GATEWAY MODULE........................11

IR485 COMMUNICATION PROTOCOL ...............................11

RS485 NETWORK

..........................................................................9

........................................................................... 9

.............................................9

....................................10

......................................................................11

SECTION 6 CONTROL FEATURES AND

FUNCTIONS ...................................................................13

STANDARD CONTROL FEATURES AND

FUNCTIONALITY .......................................................................13

STANDARD CONTROL FEATURES AND

FUNCTIONALITY

ALTERNATE CONTROL FEATURES AND

FUNCTIONALITY

.......................................................................15

.......................................................................18

SECTION 11 — PARTS LIST….. ...............................48

SECTION 12 — DIAGRAMS…... ...............................49

WIRING DIAGRAM……….…….....................................49

CONNECTION DIAGRAM……... ...................................50

XPM-TAC24...................................... ...................................51

X8I COMMISSIONING FORM… ...............................52

SECTION 7 DISPLAY AND MENU OPERATION ..20

INDICATORS ...............................................................................23

SECTION 8 COMMISSIONING ...............................26

PHYSICAL CHECKS ...................................................................26

2

Page 3

SECTION 2 INTRODUCTION

!

!

The X8I is an advanced system controller designed to

provide safe, reliable, and energy-efficient management

of your compressed air system. The X8I is capable of

controlling up to eight (8) positive displacement air

compressors. The compressors may be fixed speed,

variable speed or multi-step and have electro-pneumatic

SECTION 3 SAFETY

WARNING : Risk of Danger

WARNING : Risk of Electric Shock

WARNING : Risk of High Pressure

WARNING : Consult Manual

Before installing or operating the X8I, take time to

•

carefully read all the instructions contained in this

manual, all compressor manuals, and all manuals of

any other peripheral devices that may be installed or

connected to the unit.

Electricity and compressed air have the potential to

•

cause severe personal injury or property damage.

The operator should use common sense and good

•

working practices while operating and maintaining

this system. All applicable codes should be strictly

adhered to.

Maintenance must be performed by adequately

•

qualified personnel that are equipped with the

proper tools.

INSTALLATION

Installation work must only be carried out by a

•

competent person under qualified supervision.

A fused isolation switch must be fitted between the

•

main power supply and the X8I.

The X8I should be mounted in such a location as to

•

allow operational and maintenance access without

obstruction or hazard and to allow clear visibility of

indicators at all times.

If raised platforms are required to provide access

•

to the X8I they must not interfere with normal

operation or obstruct access. Platforms and stairs

should be of grid or plate construction with safety

rails on all open sides.

or microprocessor based controls. The X8I is uniquely

configurable and customizable to meet the specific needs

of some of the most complex compressed air system.

Additionally, the X8I control network can expand to

include monitoring and control of various compressed air

system components.

OPERATION

The X8I must only be operated by competent

•

personnel under qualified supervision.

Never remove or tamper with safety devices, guards

•

or insulation materials fitted to the X8I.

The X8I must only be operated at the supply voltage

•

and frequency for which it is designed.

When main power is switched on, lethal voltages are

•

present in the electrical circuits and extreme caution

must be exercised whenever it is necessary to carry

out any work on the unit.

Do not open access panels or touch electrical

•

components while voltage is applied unless it is

necessary for measurements, tests or adjustments.

Such work should be carried out only by a qualified

electrician equipped with the correct tools and

wearing appropriate protection against electrical

hazards.

All air compressors and/or other equipment

•

connected to the unit should have a warning sign

attached stating ‘THIS UNIT MAY START WITHOUT

WARNING’ next to the display panel.

If an air compressor and/or other equipment

•

connected to the unit is to be started remotely,

attach warning signs to the equipment stating ‘THIS

UNIT CAN BE STARTED REMOTELY’ in a prominent

location, one on the outside of the equipment, the

other inside the equipment control compartment.

MAINTENANCE AND REPAIR

Maintenance, repairs or modifications must only be

•

carried out by competent personnel under qualified

supervision.

If replacement parts are required use only genuine

•

parts from the original equipment manufacturer, or

an alternative approved source.

Carry out the following operations before opening or

•

removing any access panels or carrying out any work

on the X8I:

Isolate the X8I from the main electrical power

i.

supply. Lock the isolator in the ‘OFF’ position

and remove the fuses.

3

Page 4

Attach a label to the isolator switch and to the

ii.

unit stating ‘WORK IN PROGRESS - DO NOT

APPLY VOLTAGE’. Do not switch on electrical

power or attempt to start the X8I if such a

warning label is attached.

Make sure that all instructions concerning operation

•

and maintenance are strictly followed and that

the complete unit, with all accessories and safety

devices, is kept in good working order.

The accuracy of sensor devices must be checked

•

on a regular basis. They must be calibrated when

acceptable tolerances are exceeded. Always ensure

any pressure within the compressed air system is

safely vented to atmosphere before attempting to

remove or install a sensor device.

The X8I must only be cleaned with a damp cloth,

•

using mild detergents if necessary. Avoid the use of

any substances containing corrosive acids or alkalis.

Do not paint the control faceplate or obscure any

•

indicators, controls, instructions or warnings.

4

Page 5

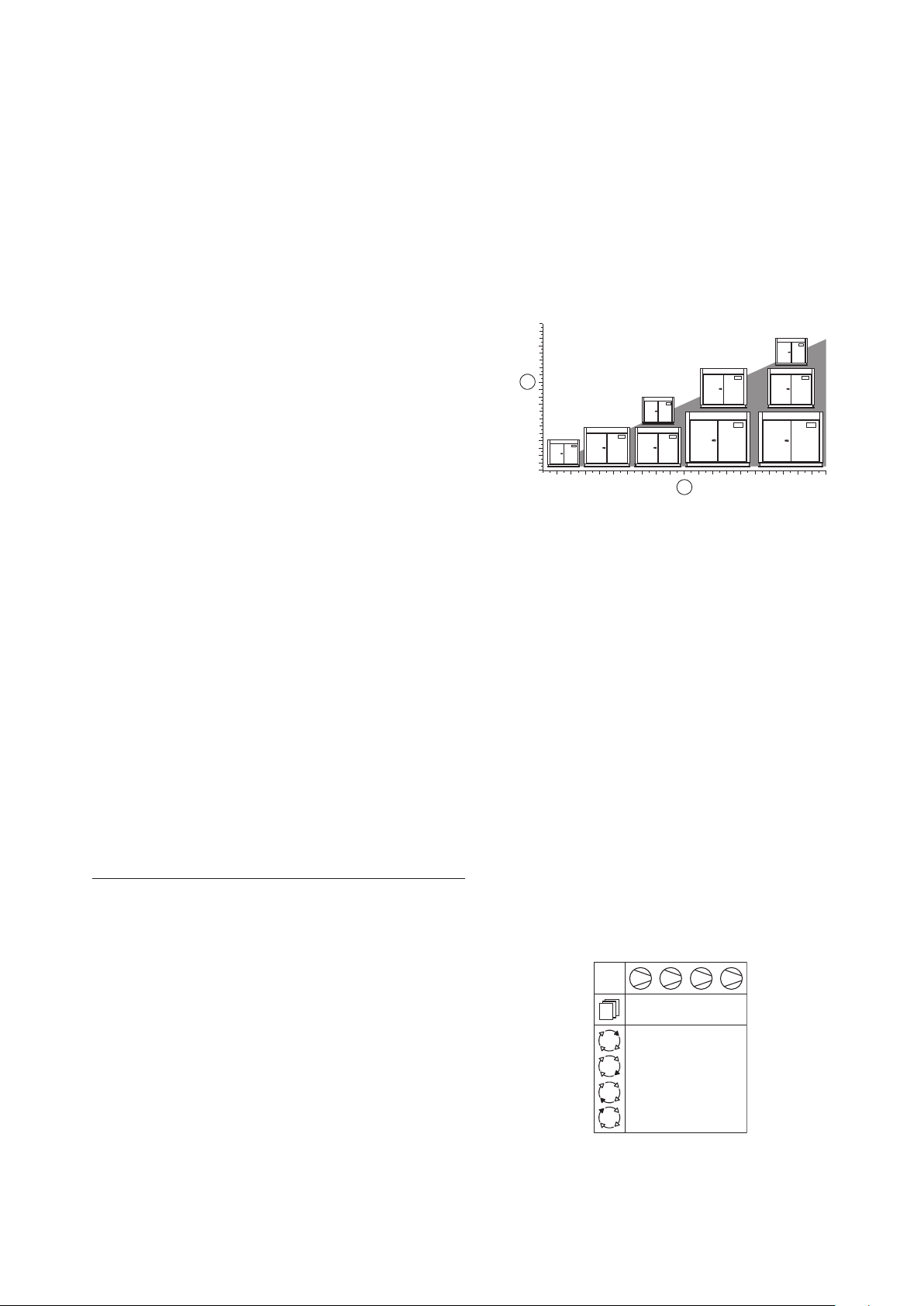

SECTION 4 COMPRESSOR CONNECTION AND CONTROL

ir-485

irV-485

Ingersoll Rand

102

psi

1 3

1

2 4

CAP

18:35 #2

5 7

6 8

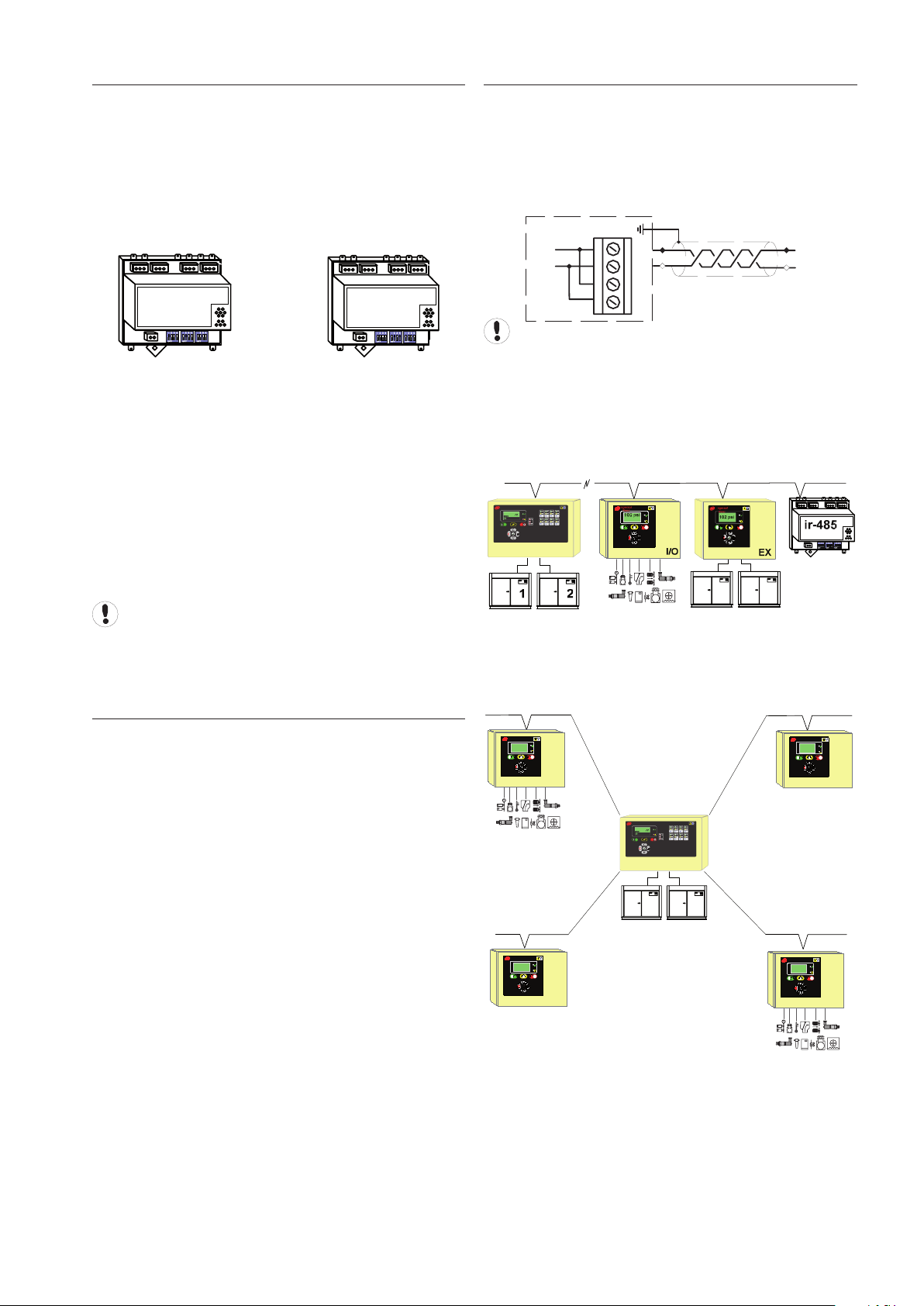

COMPRESSOR CONNECTION AND

CONTROL

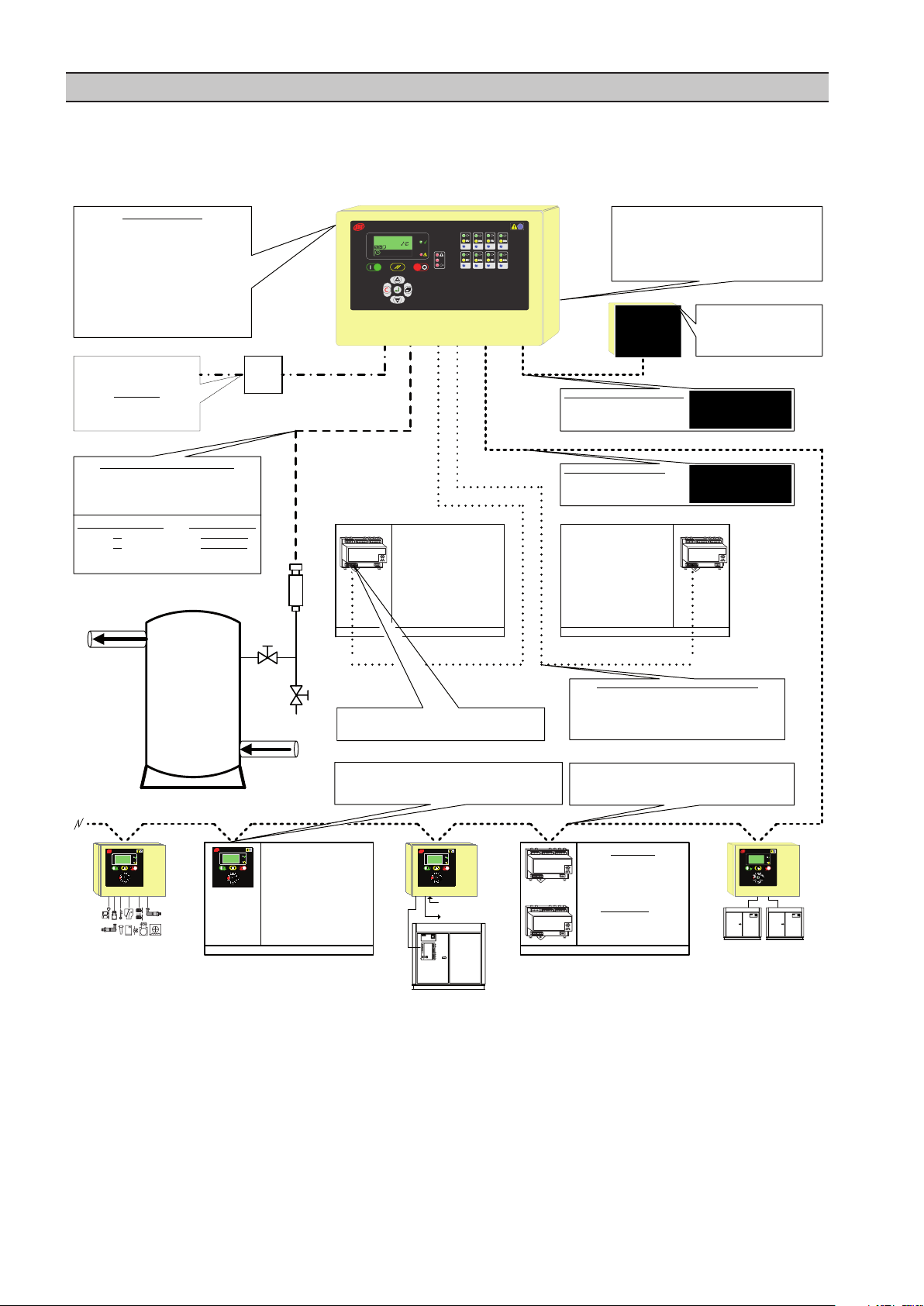

Each air compressor in your system must be interfaced to

the X8I. Interface methods may vary depending on the

compressor type and/or local control configuration. The

following are main methods for interfacing compressors

to the X8I:

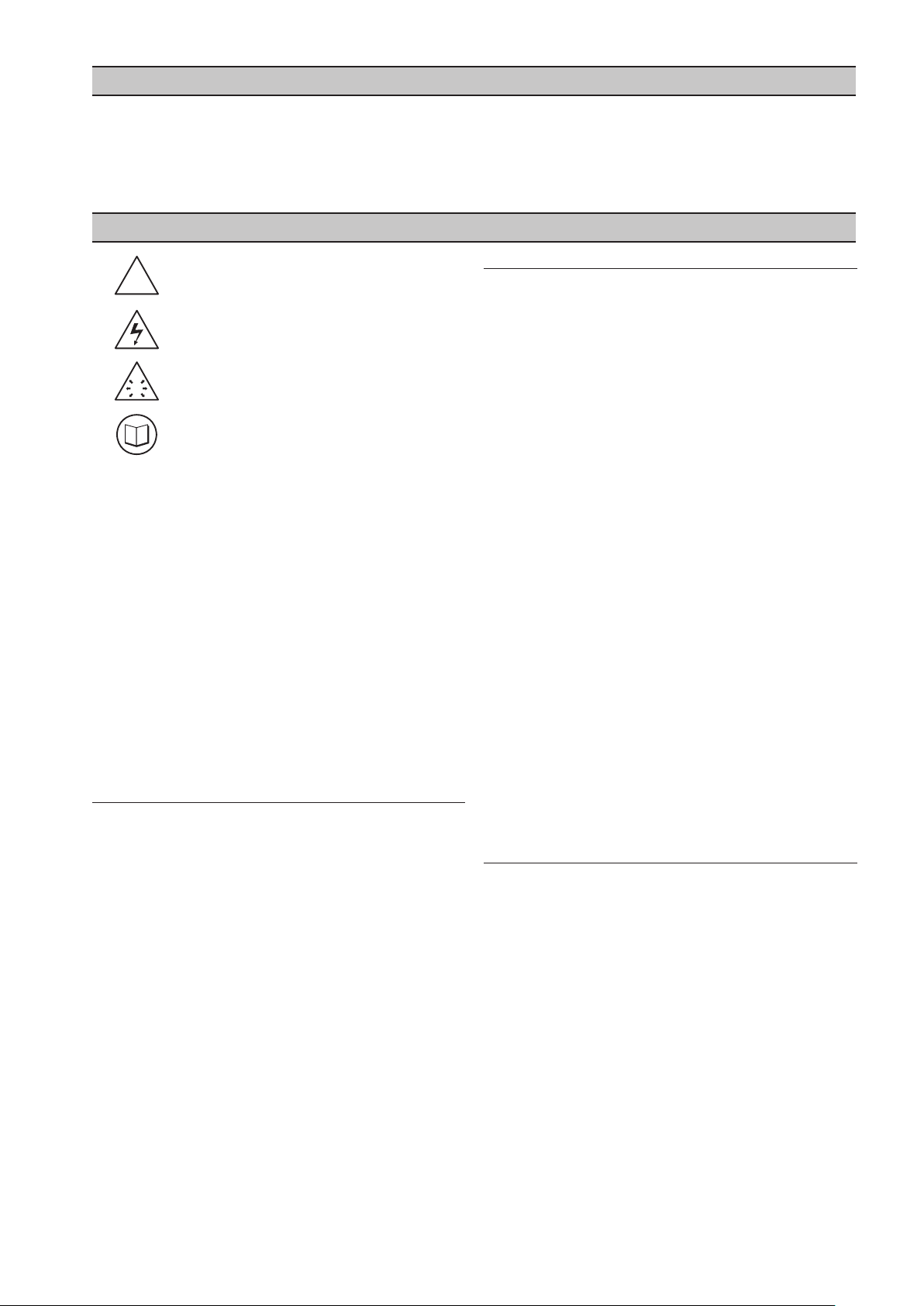

1) The ir-PCB Interface module that is designed to

interface to any positive displacement air compressor

(regardless of make or manufacturer) with an available

control voltage of 12-250V (either 50Hz or 60Hz).

The ir-PCB interface module is installed within the

compressor control area and connected to the X8I using

a six (6) wire cable, (seven (7)-wire cable for Nirvana 7.5 to

15HP (5.5 to 11KW).

Each air compressor must be equipped with an online/

offline pressure regulation system capable of accepting a

remote load/unload signal through a volt-free switching

contact or a single electro-mechanical pressure switch.

Consult the air compressor manual or your air

compressor supplier/specialist for details before installing

the X8I.

2) The ir-485 Gateway Interface module that is designed

to interface to any Ingersoll Rand Intellisys controlled

(Non-Nirvana) compressor. The X8I communicates to the

ir-485 Gateway via a two wire, RS485 network utilizing the

ir485 protocol. All IR compressors equipped with Intellisys

controllers (Non-Nirvana) require this interface.

The irV-485 Gateway interface module is installed within

the compressor control cabinet and connected to the X8I

using Belden 9841 or equivalent RS485 cable.

Nirvana 7.5 to 15HP (5.5 to 11KW) connect via the

ir- PCB using seven (7)-wire cable.

4) Direct Connect via RS485 to any Ingersoll Rand

compressor that has an integrated RS485 network port

utilizing the ir485 protocol. The X8I communicates to

these compressors via a two wire, RS485 network. The

compressor is connected to the X8I using Belden 9841 or

equivalent RS485 cable.

4) Special Application Interface uses integration boxes

designed to accommodate various types of compressor

and regulation methods and system monitoring.

OPTIONAL CONNECTION METHODS

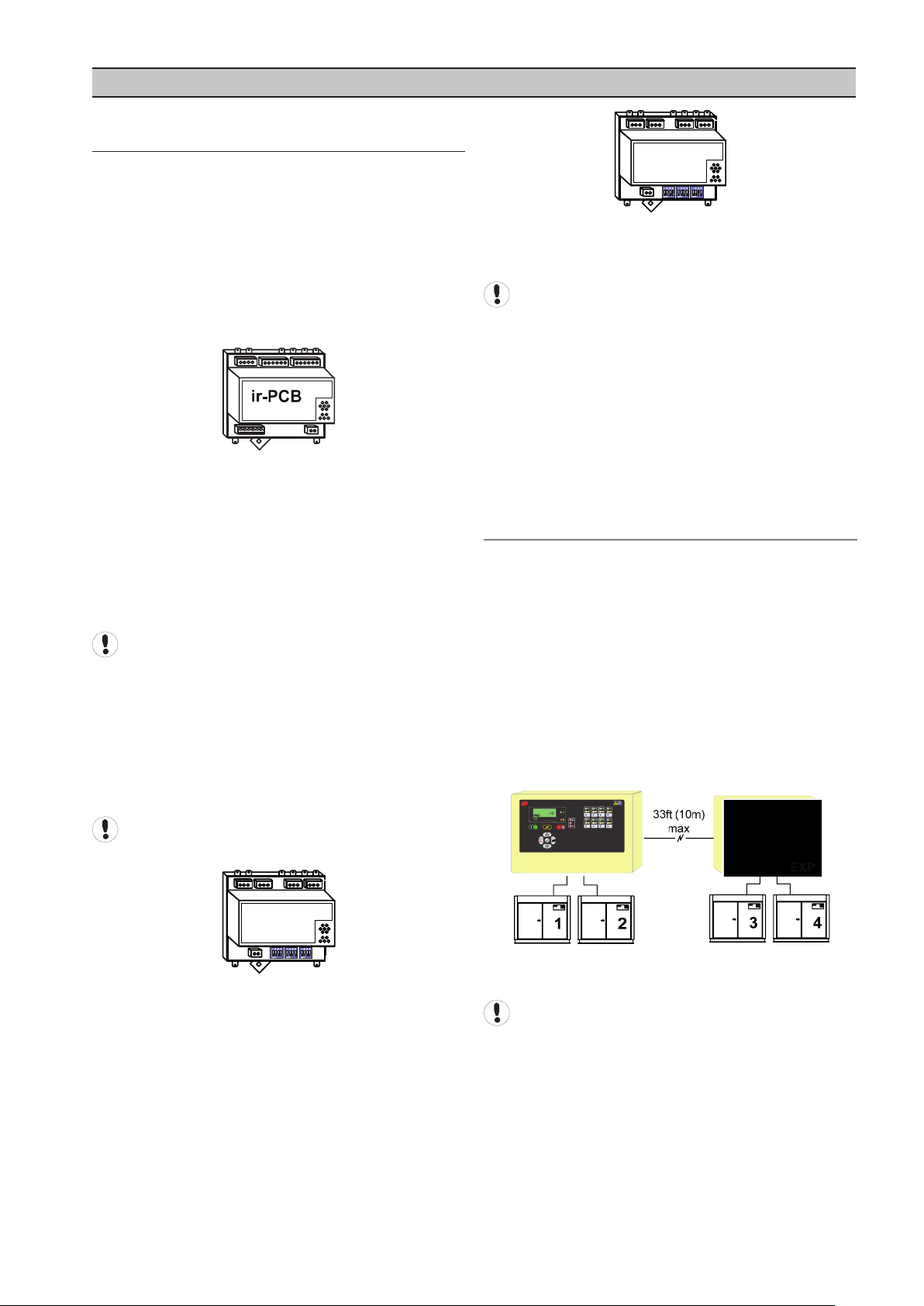

Expansion Module: EXP Box (Option)

As standard the X8I has four direct connect ‘ir-PCB’

terminal connections. This capability can be extended

with the use of an optional EXP Box. The EXP Box will add

another four direct connect ‘ir-PCB’ connection terminals.

This would allow a total of 8 compressors to connected

and controlled via ‘ir-PCB’ integration.

Compressors 1-4 connect via the X8I and Compressors 5-8

connect via the EXP Box

The EXP Box is suitable for wall mounting and must be

located adjacent to the X8I unit (max 33ft or 10m).

All Nirvana Compressors, 20 HP (15KW) and above

require the irV-485 Gateway.

The ir-485 Gateway interface module is installed within

the compressor control cabinet and connected to the X8I

using Belden 9841 or equivalent RS485 cable.

3) The irV-485 Gateway Interface module that is

designed to interface to any Ingersoll Rand Nirvana

compressor. The X8I communicates to the irV-485

Gateway via a two wire, RS485 network utilizing the ir485

protocol. All Nirvana Compressors, 20 HP (15KW) and

above, require this interface.

The EXP Box connects to the X8I controller via a two wire,

dedicated RS485 network

Use Belden 9841 or Equivalent In Grounded Conduit

No Greater Than 33ft (10m)

Up to four air compressors can be connected to the EXP

Box using a 6 or 7 wire cable and a compressor interface

ir-PCB (330ft (100m) max). The ‘ir-PCB’ connections are

identical to the X8I.

5

Page 6

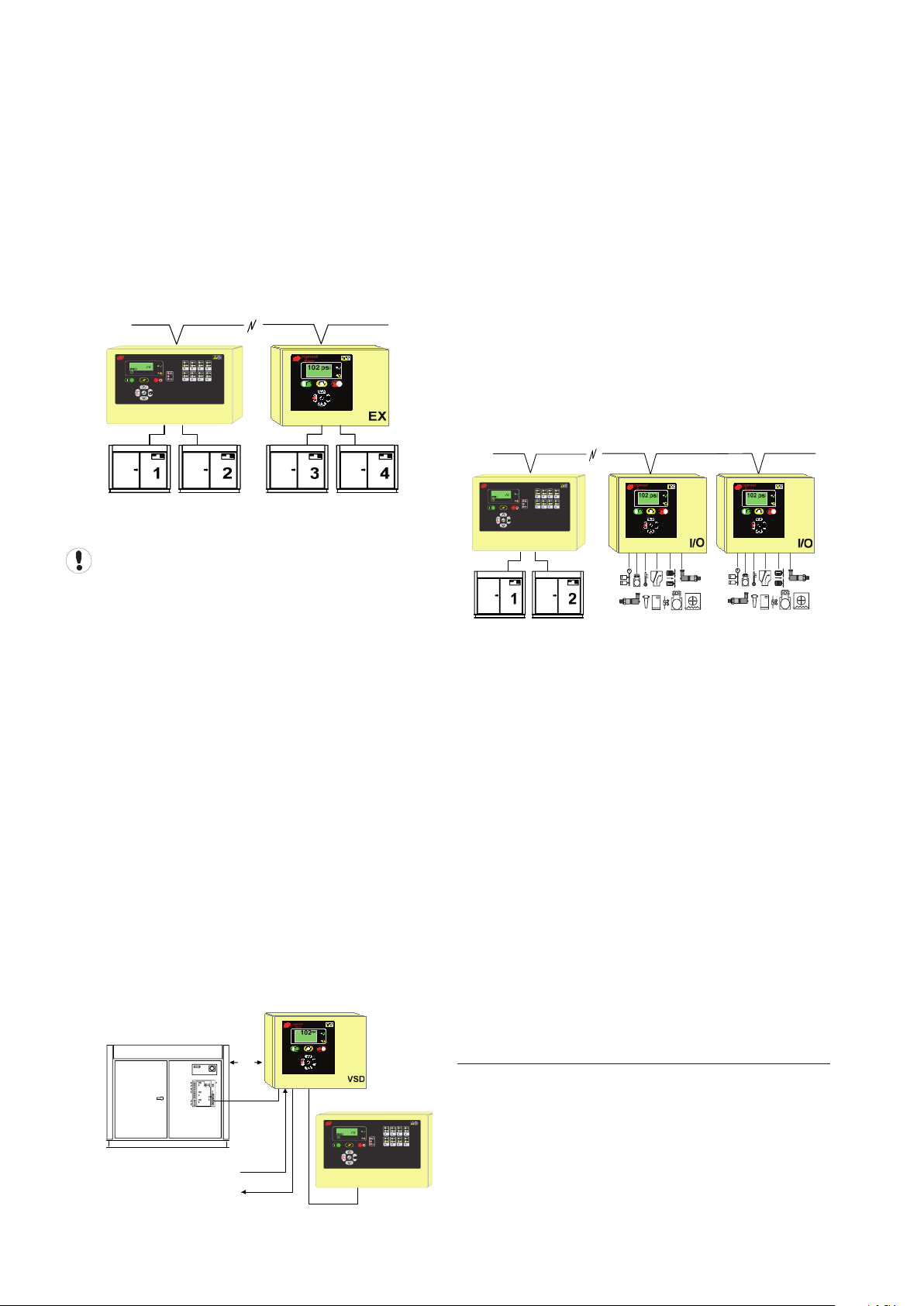

Remote Compressor Management; EX Box (option)

Ingersoll Rand

102

psi

1

CAP

1

5

2

6

3

7

4

8

18:35 #2

4000ft (1219m) max

From VSD Pressure Transducer

30ft

max

ir-PCB

o VSD Pressure Transducer Input

Ingersoll Rand

102

psi

1 3

2 4

1

CAP

18:35 #2

5 7

6 8

4000ft (1219) max

Ingersoll Rand

102

psi

1 3

1

2 4

CAP

18:35 #2

5 7

6 8

The EX Box is an ‘EXtension’ to the X8I providing

additional ‘ir-PCB’ connectivity.

The EX Box will typically be used to provide ‘ir-PCB’

connectivity at a remote location beyond the maximum

distance specification of compressors that require ‘ir-PCB’

type connection; 330ft (100m). This effectively expands

the hardwire connection scheme of the ‘ir-PCB” to the full

RS485 distance specification.

The EX box is suitable for wall mounting and can be

located up to 4000ft (1219m) from the X8I unit.

The EX Box connects to the X8I controller via a two wire,

RS485 network utilizing the IR485 protocol

The VSD Box connects to the X8I controller via a two wire,

RS485 network utilizing the ir485 protocol

Each air compressor in a system, that requires VSD Box

integration, must be equipped with an individual VSD

Box. Multiple VSD Boxes can be connected to the X8I as

long as the number of compressors does not exceed the

maximum number of compressors (8).

Remote Input & Output: I/O Box (option)

An I/O Box provides additional general purpose I/O

(input/output) for a system enhancing monitoring

capabilities and providing distributed system automation.

Up to two I/O Boxes can be connected to the X8I

controller. Each I/O Box features:

8 Digital Inputs

5 Analog Inputs

6 Relay Outputs

Use Belden 9841 or Equivalent In Grounded Conduit

No Greater Than 4000ft (1219m)

One (1) or two (2) air compressors can be connected

to the EX Box using a 6-wire cable and a compressor

interface ir-PCB (330ft (100m) max). The ‘ir-PCB’

connections are identical to the X8I.

The EX Box also provides optional ‘local pressure sensor’

connections. The compressor delivery pressure, local

system pressure and air treatment differential pressure

can be displayed.

Multiple EX Boxes can be connected to the X8I as long

as the number of compressors does not exceed the

maximum number of compressors (8).

Bolt-On VSD Control Integration: VSD Box (optional)

The VSD Box is intended to provide a method of

system integration for a VSD (Variable Speed Drive) air

compressor that is not equipped with any accessible

means of remote connectivity (such as IR- Nirvana). The

VSD Box will provide required functionality to enable

system integration and efficient control using the X8I

automation system.

The I/O Box connects to the X8I controller via a two wire,

RS485 network utilizing the ir485 protocol

Digital inputs can be used to monitor switching contact

devices. Each input can be set to act as an Alarm or

High Level Alarm input. Digital inputs can also be used

for metering (for example m3, ft3, kWh) providing an

accumulative count of pulses from a metering device.

Analog inputs can be used to monitor sensor devices (for

example: pressure differential, temperature, dewpoint,

flow, current, power, bearing condition). Each input is

equipped with adjustable high or low level detection that

can be used to activate an Alarm or High Level Alarm.

Relay outputs use ‘Virtual Relay Automation’ technology

and are totally configurable with duel input logic

functions. Relay functions can be assigned utilizing any

status or condition information available on a system

network from any compatible unit connected to the

network.

PRESSURE DETECTION AND CONTROL

The X8I utilizes the signal from a 4-20 ma pressure sensor

that is mounted remotely from the X8I in a suitable

location in the compressed air system.

The factory default settings for the pressure sensor is

0–232 PSI (16 bar), but the X8I can accept any pressure

sensor with a 4–20 ma output and a range of up to 8700

PSI (600 bar).

6

Page 7

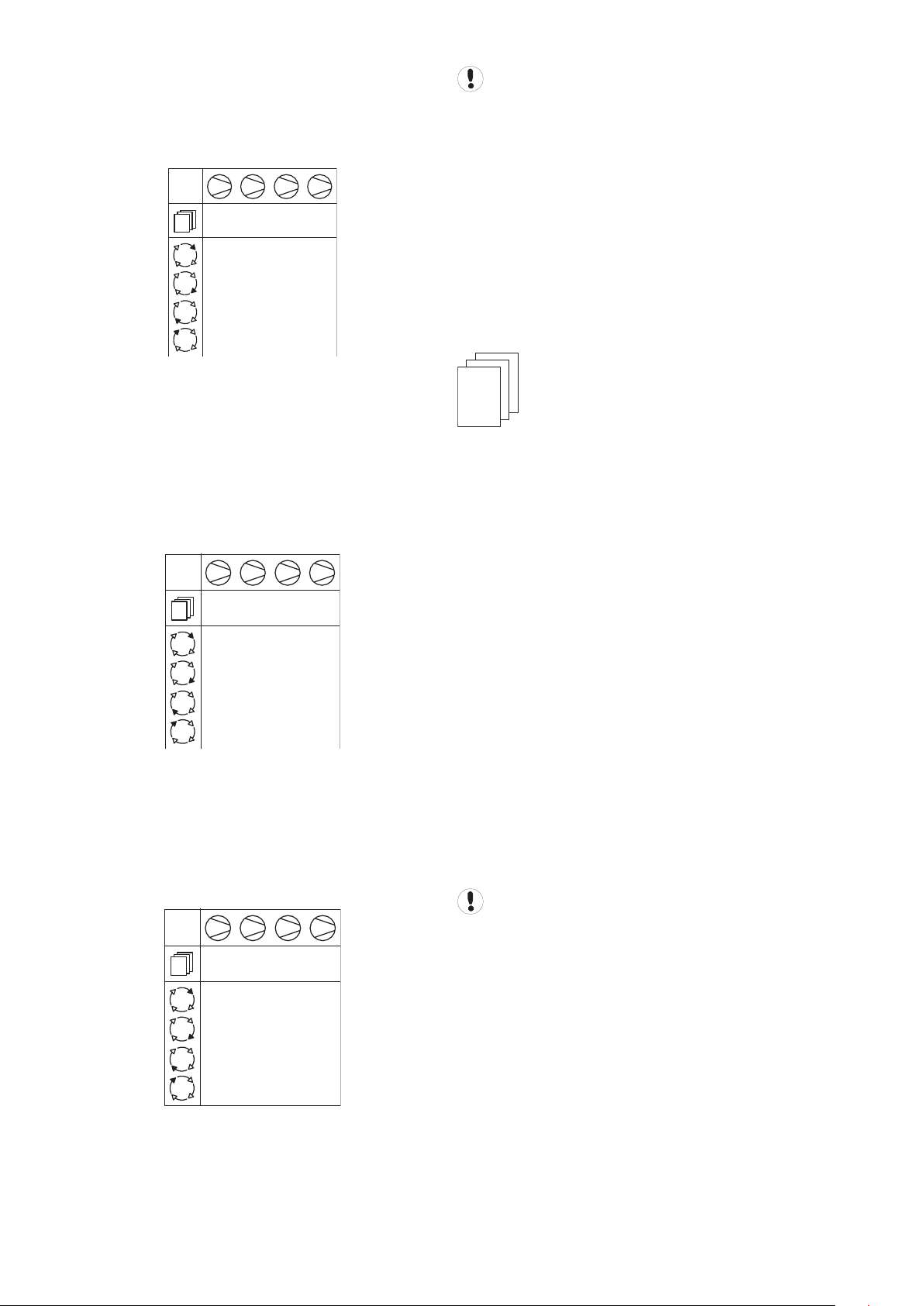

X8I MAIN DISPLAY

a

b

c

d

f

g

h

e

Ingersoll Rand

102

psi

A: 85%

1

CAP

1

5

2

6

3

7

4

8

102

PSI

1

a

b

c

d

e

17:30 #1

a

b

c

CAP

a

b

c

1

Keypad and Navigational Keys Functionality

a) Start

b) Reset

c) Stop

d) Menu

e) Enter

f) Escape

g) Up (Plus)

h) Down (minus)

Compressor Status Indicators :

a) Load Status

b) Run Status

c) Compressor Availability

System Alarms (Warning) :

a) Group Compressor Fault

b) Insufficient Capacity Alarm (Warning)

c) Restricted Capacity Alarm (Warning)

System Alarms (Warning) :

a) Unit Run Indicator (green LED)

b) Unit Alarm Indicator (Red LED)

User Interface :

a) System Pressure Value

b) System Pressure Units

c) Unit Status

d) Unit Active Functions

e) User Menu Item

7

Page 8

SECTION 5 INSTALLATION OVERVIEW

DRIP LEG

PRESSURE TRANSDUCER

RECEIVER

PRESSURE TRANSDUCER CABLE

2 Conductor Cable, 18 Gauge Stranded

Earth Shielded

No Greater Than 330FT (100M)

24VDC Control Voltage

X8I X05 CONNECTOR

PT CONNECTOR

25 +VDC Pin #3

26 Signal Pin #1

Reference X8I Operations Manual for Pressure

Sensor Connection Details

RS485 Network Cable

Ir-PCB Compressor #1

Control Cable

Ir-PCB Compressor #2

Control Cable

Pressure Transducer Cable

SPECIFICATIONS

Dimensions

13.4” x 9.45” x 6.0”

340mm x 241mm x 152mm

Weight

16.5lb (7.5kg)

Mounting

Wall, 4 x screw fixings

Enclosure

IP65, NEMA 4

Supply

230Vac +/- 10%, 50 Hz

115Vac +/- 10%, 60 Hz

Power

100VA

Temperature 32°F to 115°F

(0°C to 46°C)

Humidity 0% to 95% RH

(non-condensing)

Model X8I

Ingersoll Rand Automation

Supply Voltage Cable

Local Disconnect (Breaker) Box

Fused for 100VA

Power Cable

3 conductor (N, L, E)

(Sized in accordance with local

electrical and safety regulations).

On/Off

Switch

From Air

Compressors

To Plant Air

System

ir-PCB COMPRESSOR CONTROL CABLE

7 Conductor Cable, 18 Gauge, Stranded, Earth Shielded

OR

Single Conductor Wire, 18 Gauge Stranded, Quantity (7)

In Grounded Conduit No Greater Than 330FT (100M)

24VAC Control Voltage

Reference X8I Application and Interconnect Guide For

Wiring Connections Between The X8I, The ir-PCB,

and The Compressor

EXP

EXP RS485 Network Cable

The Maximum Number of Compressors Controlled By

The X8I Is Eight (8).

The Maximum Number Of Direct ir-PCB Connections

To The X8I is Four (4)

.

Any Combination Of Compressor Connection Methods

May Be Used As Long As the Maximum Number Of

Compressors (8) Is Not Exceeded.

OPTIONAL

Ingersoll Rand

102

psi

1 3

2 4

1

CAP

18:35 #2

5 7

6 8

EXP RS485 NETWORK CABLE

Belden 9841 or Equivalent

In Grounded Conduit

No Greater Than 33FT (10)

RS485 NETWORK CABLE

Belden 9841 or Equivalent

In Grounded Conduit

No Greater Than 4000FT (1219M)

EX

Ingersoll

Rand

102 psi

ir-485

Direct To

S3

Ingersoll

Rand

102 psi

OR

Ingersoll

Rand

102 psi

LE

D

1

LE

D

2

ir-PCB

From VSD Pressure

Transducer

To VSD Pressure

Transducer Input

I/O

Ingersoll

Rand

102 psi

VSD

Reference X8I Application and Interconnect Guide For

Wiring Connections Between The X8I, The ir-485 or irV-

485 Gateway and The Compressor, S3 Direct Connects, and

Optional Special Application Interface Boxes

The EXP Will Add Another (4)

Direct ir-PCB connections. This

Would Allow A Total Of (8)

Compressors To Be Connected

And Controlled Via The ir-PCB.

ir-PCB ir-PCB

The RS485 Network is a Serial, Point to Point

Communication Network Refer to the X8I Application and

Interconnect Guide For Wiring Details and Connectivity.

ir-485 Gateway

For All

IR (Non- Nirvana) Compressors

IntelliSys “Red Eye”, SG and SE

irV-485 Gateway

For All

Nirvana Compressors

20HP (15KW) and Above

irV-485

ir-485

8

Page 9

INSTALLATION

XPM-TAC24

1

P

P

2

1

P

2

P

1

P

2

P

P

It is recommended that installation and

commissioning be carried out by an authorized and

trained product supplier.

UNIT LOCATION

The X8I can be mounted on a wall using conventional

bolts. The X8I can be located remotely from the

compressors as long as it is within 330 feet (100 meters)

of cable length when connecting compressors directly

with ir-PCB’s. When connecting the X8I over the RS485

communication network the distance is up to 4000 feet

(1219 meters) The X8I must be located within 330 feet

(100 meters) of the system pressure transducer.

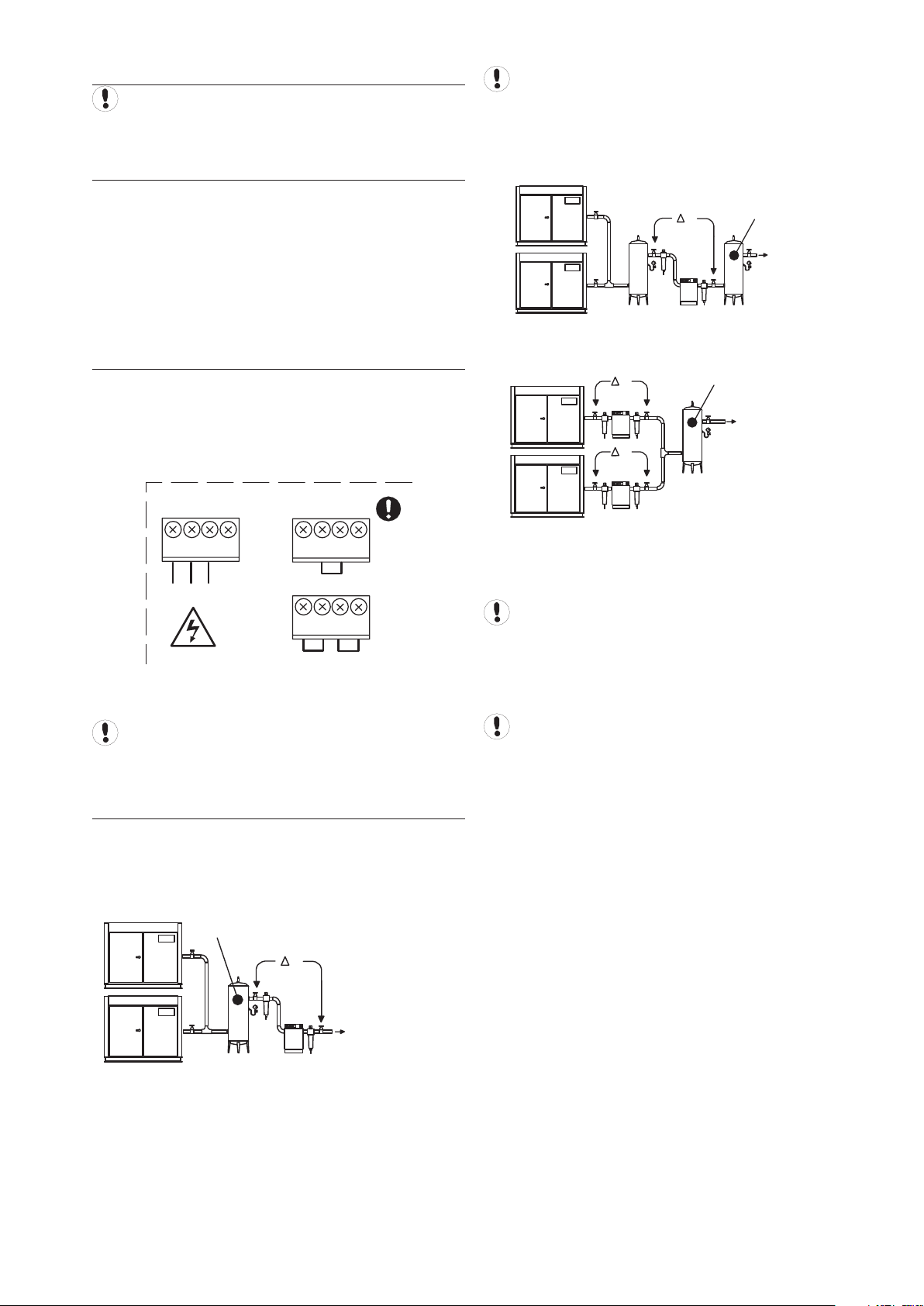

POWER SUPPLY

A fused switching isolator must be installed to the main

incoming power supply, external to the X8I. The isolator

must be fitted with a properly sized fuse to provide

adequate protection to the power supply cable used (in

accordance with local electrical and safety regulations).

1

1 2 3 4

N L E

X04

X01

X04

Power Supply Terminals

2 3 4

VOLTAGE SELECT

1

2 3 4

VOLTAGE SELECT

230Vac

115Vac

Dry side pressure will be lower than the system

pressure due to pressure differential losses across air

treatment equipment. The nominal system pressure will

reduce as the air treatment differential pressure increases.

DEMAND (DRY) SIDE PRESSURE CONTROL

Pressure Sensor Located After Shared Cleanup

Equipment

Pressure Sensor Located After Individual Cleanup

Equipment

Ensure each compressor is equipped with

independent excess pressure shutdown. An increase in

pressure differential across air treatment equipment can

result in excess compressor discharge pressure.

Ensure that the voltage select input is properly

jumpered for the incoming power. Default voltage

configuration is 230Vac.

PRESSURE SENSOR LOCATION

The system pressure sensor (P) must be located where

it will see the air pressure that is common to all of the

compressors.

SUPPLY (WET) SIDE PRESSURE CONTROL

Pressure Sensor Located Before Cleanup Equipment

Regular routine monitoring of pressure differential

across air treatment equipment is recommended.

9

Page 10

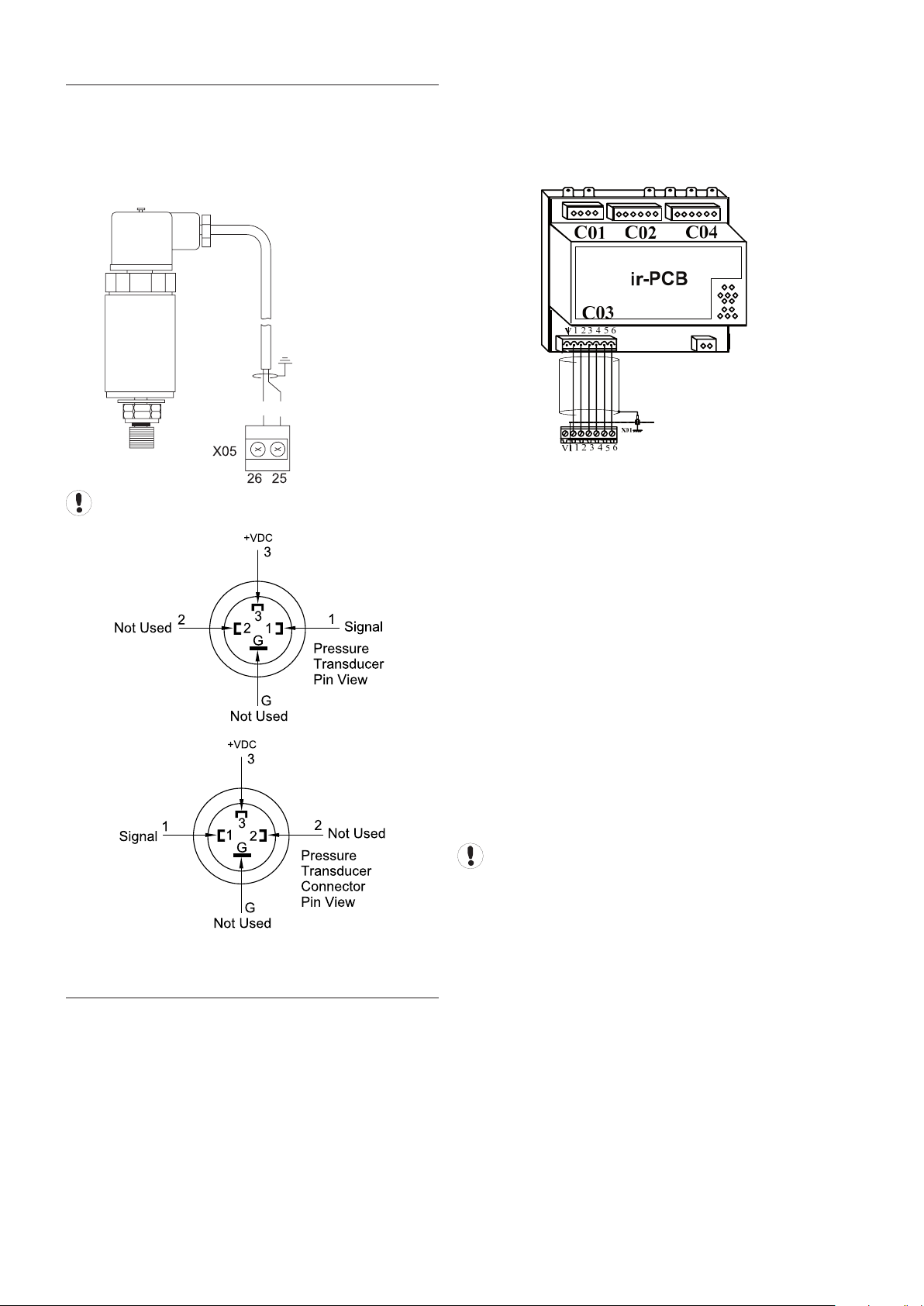

PRESSURE SENSOR CONNECTION

Cable Earth Shield

The pressure sensor connects to terminal X05 of the X8I

terminal PCB using a shielded 18 AWG maximum 2conductor cable no more than 330 feet (100 meters) in

length. The transducer threads are BPT. It is the equivalent

of ¼” NPT.

Wire polarity is important.

For each compressor utilizing an ir-PCB, connection to

the X8I the signal wires must be made to the correct

X8I terminals for that compressor number. Compressor

1 should be wired to terminal X01 on the terminal PCB,

Compressor 2 should be wired to terminal X02 on the

terminal PCB, etc.

ir-PCB Interface Module

The ir-PCB is a DIN rail mountable module designed to be

installed within the compressor starter enclosure.

Pressure Sensor Wiring and Location

IRPCB INTERFACE MODULE

Each air compressor must be equipped with a load/

unload regulation system and, if not regulated with a

single electro-mechanical pressure switch, have a facility

for a remote load/unload control with the ability to

accept a volt-free switching contact input for remote

load/unload. Each air compressor must have Auto Restart

capability.

The ir-PCB accepts a 12V to 250V input voltage detection

system and utilizes universal relay contact control outputs

(250V “CE” / 115V “UL” @ 5A maximum) integrated directly

into the circuits of an air compressor. The ir-PCB avoids

the need for additional relays or remote inputs. The ir-PCB

also acts as an electrical barrier between the compressor

and the X8I providing protection and voltage isolation.

Consult the X8I Interconnect and Application Guide

prior to the installation of the X8I and the ir-PCB to the air

compressor.

The ir-PCB is designed to interface a compressor with

the X8I using a seven (7)-conductor shielded cable or

individual wires run through grounded conduit no

greater than 330 feet (100 meters) in length.

Each compressor in the system must be assigned a

unique identification number from 1 up to the number

of compressors in the system. The identification number

should be clearly indicated on each compressor for

operational reference.

10

Page 11

IR485 AND IRV485 GATEWAY MODULE

ir-485

irV-485

28

30

27

29

X06

Ingersoll Rand

102

psi

1 2 3 4

1

CAP

18:35 #2

5 7

6 8

4000ft (1219m) max

I/O

Ingersoll

Rand

102 psi

Ingersoll Rand

102

psi

1

CAP

1

5263748

18:35 #2

1 2

Ingersoll

Rand

102 psi

EX

Ingersoll

Rand

102 psi

EX

I/O

Ingersoll

Rand

102 psi

RS485 NETWORK

The ir-485 and irV-485 Gateways are designed to

interface the Intellisys Controller on the Ingersoll Rand

Compressors and the Nirvana compressors, 20 HP (15KW)

and above, with the X8I via the RS485 Network utilizing

the ir485 protocol. The ir-485 and irV-485 Gateways

are DIN Rail mounted and can be located within the

compressor control gear enclosure or remotely within a

separately enclosure.

ir-485 Gateway irV-485 Gateway

The cable used between the X8I and the ir-485 and irV485 Gateways is Belden 9841 (or equivalent). It should be

run in grounded conduit and should not be greater than

4000 feet (1219 meters) in length.

The cable used between the ir-485 Gateway and irV-485

Gateways and the Intellisys Controller is included with the

Installation Kit

The cable used between the ir-485 Gateway and the

Intellisys Controller is included with the Installation Kit

The X8I is equipped with an RS485 network

communications capability using the ir485 protocol. This

facility can be used for remote connectivity to optional

networked units and modules with ir485 communications

capabilities or compressor controllers equipped with the

ir485 capability.

L2

L

1

RS485

L

L1

2

The RS485 Network is a Serial, Point to Point

Communication Network. Refer to the X8I Application

and Interconnect Guide For Wiring Details and

Connectivity.

The following example details the “correct” method of

wiring the RS485 Network

Consult the X8I Interconnect and Application Guide

and the ir-485 or irV-485 Gateway Manual prior to the

installation of the X8I and the Compressor Gateway to the

air compressor.

The following example details the “incorrect” method of

wiring the RS485 Network

Correct RS485 Network Example

IR485 COMMUNICATION PROTOCOL

ir485 is a unique communication protocol designed

specifically for Compressor and Air System control. ir485

is a Multi-Master vs. a Master–Slave protocol that enables

faster, more effective control of network components.

ir485 also features distributed control capabilities and has

inherent resistance to communication faults due to noise

Note: Follow RS485 Network installation

recommendations.

11

Incorrect RS485 Network Example

Page 12

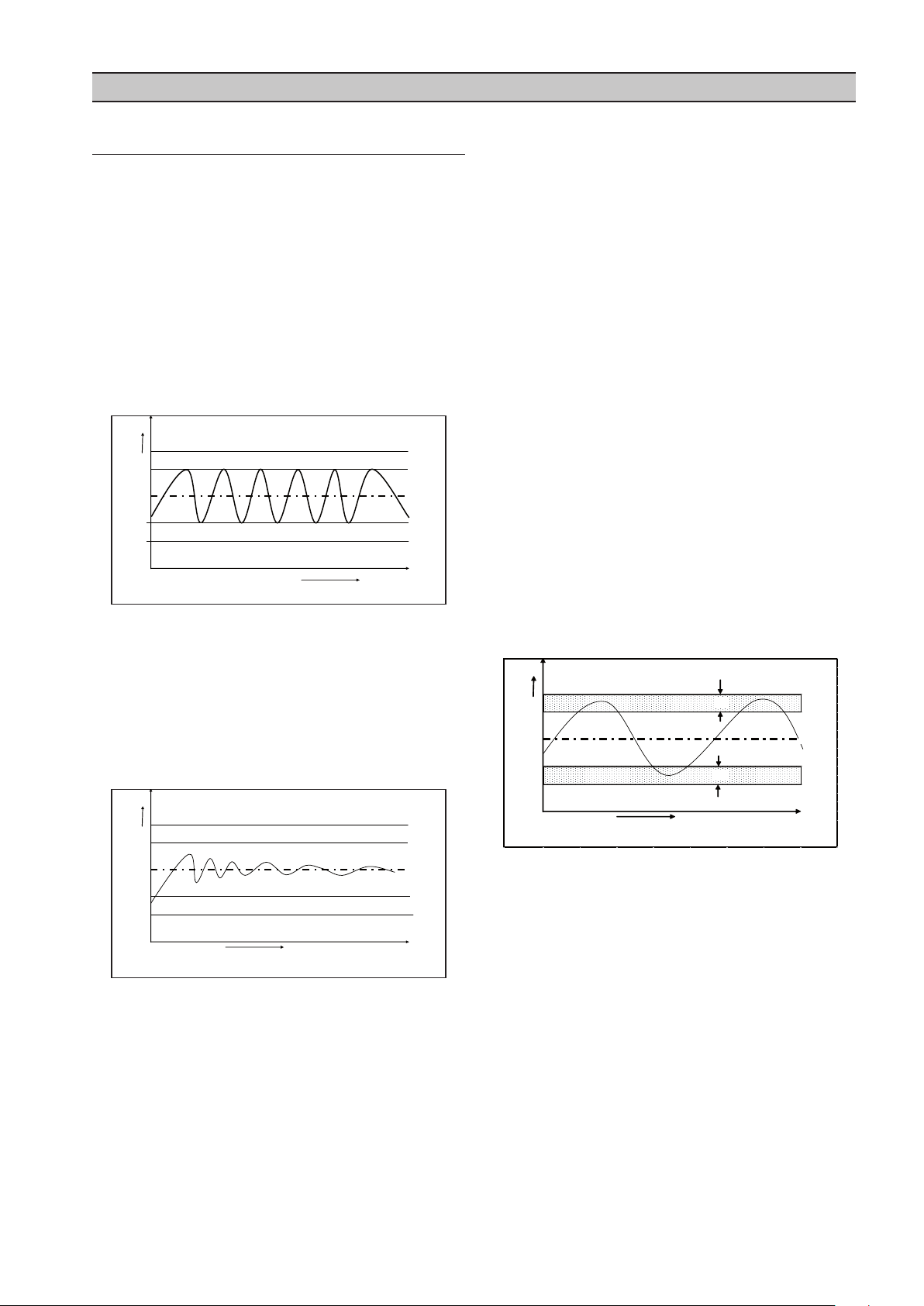

RS485 data communications and other low

voltage signals can be subject to electrical interference.

This potential can result in intermittent malfunction

or anomaly that is difficult to diagnose. To avoid this

possibility always use earth shielded cables, securely

bonded to a known good earth at one end. In addition,

give careful consideration to cable routing during

installation.

a) Never route an RS485 data communications or low

voltage signal cable alongside a high voltage or 3-phase

power supply cable. If it is necessary to cross the path of a

power supply cable(s), always cross at a right angle.

b) If it is necessary to follow the route of power

supply cables for a short distance (for example: from a

compressor X8I to a wall along a suspended cable tray)

attach the RS485 or signal cable on the outside of an

earthed cable tray such that the cable tray forms an

earthed electrical interference shield.

c) Where possible, never route an RS485 or signal cable

near to equipment or devices that may be a source of

electrical interference (for example: 3-phase power

supply transformer, high voltage switchgear unit,

frequency inverter drive module, radio communications

antenna).

12

Page 13

SECTION 6 CONTROL FEATURES AND FUNCTIONS

PH

PL

PT

a

b

PH

PL

PT

PH

PT

PL

PH + TO

PL - TO

TO

TO

STANDARD CONTROL FEATURES AND

FUNCTIONALITY

PRESSURE CONTROL

Pressure control is achieved by maintaining the system pressure

within an acceptable range, or pressure band, which is defined and

programmed by the user. Pressure will rise in the band when system

demand is less than the loaded compressor’s output. Pressure will

fall in the band when system demand is greater than the loaded

compressor’s output.

Simply stated, pressure control is achieved by unloading and

loading compressors to closely match compressor output with

system demand within a specified pressure band defined by PL and

PH. See Figure 1.

Variable speed compressors also operate within the pressure band

and actively match compressor output with system demand by

speeding up and slowing down around a target pressure defined by

the exact midpoint of the pressure band defined by PT. See Figure 2.

Figure 1 — Typical System Pressure vs. Time

As pressure rises to point “a”, the compressor will unload

based on the sequencing algorithm. System pressure is

then allowed to decrease due to the drop in supply until

point “b” is reached. Once point “b” is reached, the X8I will

load the next compressor in the sequence to match the

air demand. This cycle will repeat as long as the X8I is able

to keep the system air pressure between PH and PL.

ANTI-CYCLING CONTROL

The most efficient way to utilize most air compressors is

either fully loaded or off, with the exception of variable

speed compressors which can operate efficiently at

reduced loading. Compressor cycling (start-load-unloadstop, etc.) is essential to maintain pressure control.

Excessive cycling, however, can result in poor compressor

efficiency as well as increased maintenance.

Anti-cycling control is incorporated to help ensure

that only the compressors that are actually required

are started and operating while all others are kept off.

Anti-cycling control includes a pressure tolerance range

or band, defined by the user, which is outside of the

primary pressure band. Inside the tolerance band, an

active control algorithm continually analyzes pressure

dynamics to determine the last possible second to add or

cycle another compressor into the system. This control is

further enhanced by the ability to fine tune the tolerance

band settings and algorithm processing time (Damping).

TOLERANCE

Tolerance is a user adjustable setting that determines

how far above the PH setpoint and below the PL setpoint

system pressure will be allowed to stray. Tolerance

keeps the X8I from overcompensating in the event of

a temporary significant increase or decrease in system

demand.

Figure 2 — Typical VSD Pressure Control vs. Time

The variable speed compressors in the system will run

on their target pressure and smooth out the variations in

system pressure. This assumes that system demand does

not vary more than the capacity of the variable speed

compressor.

A variable speed compressor will be included in the

load/unload sequence and be controlled exactly as a

fixed speed machine with the exception of speed control

to maintain target pressure.

Figure 3 — Tolerance in Relation to PH and PL

Tolerance (TO) is expressed as a pressure defining the

width of the band above PH and below PL in which

energy efficient control will be in effect.

When system pressure is in the tolerance band, the

X8I will continuously calculate the moment at which

compressors will be loaded or unloaded based on the rate

of change of system pressure. When the system pressure

strays outside of the tolerance band, the X8I will abandon

energy efficiency and begin to protect the system air

pressure by loading or unloading the compressors.

Loading will be delay controlled.

13

Page 14

When the compressed air system storage is relatively

+

-

small compared to the system demand, and fluctuations

are large and quick, the tolerance band setting should

be increased to maintain energy efficient operation and

avoid a situation in which multiple compressors are

loaded just to be unloaded moments later.

When the compressed air system is relatively large

compared to system demand and fluctuations are

smaller and slower, the tolerance band can be reduced to

improve pressure control and maintain energy efficient

operation.

The factory default setting for tolerance is 3.0 PSI (0.2Bar).

This setting is user adjustable.

DAMPING

Any time the pressure is within the Tolerance band the

Anti-Cycling algorithm is active, sampling the rate of

pressure change and calculating when to load or unload

the next compressor. The damping (DA) setting is a user

adjustable setpoint that determines how quickly the

controller samples and recalculates, effectively speeding

up or slowing down the reaction time.

The X8I’s factory default DA setting of “1” is adequate for

the majority of compressed air systems but may need

to be adjusted in the following circumstances involving

aggressive and disproportionate system pressure

changes:

Inadequate air storage

•

High pressure differential across the air

•

treatment equipment

Incorrectly sized piping

•

Slow or delayed compressor response

•

In these circumstances, the X8I may overreact and

attempt to load additional compressors that may not

be necessary if the system was given time to allow the

system pressure to stabilize after the initial compressor

is given time to load. If the tolerance has already been

increased and the X8I is still overreacting, then increasing

the damping factor is the next step.

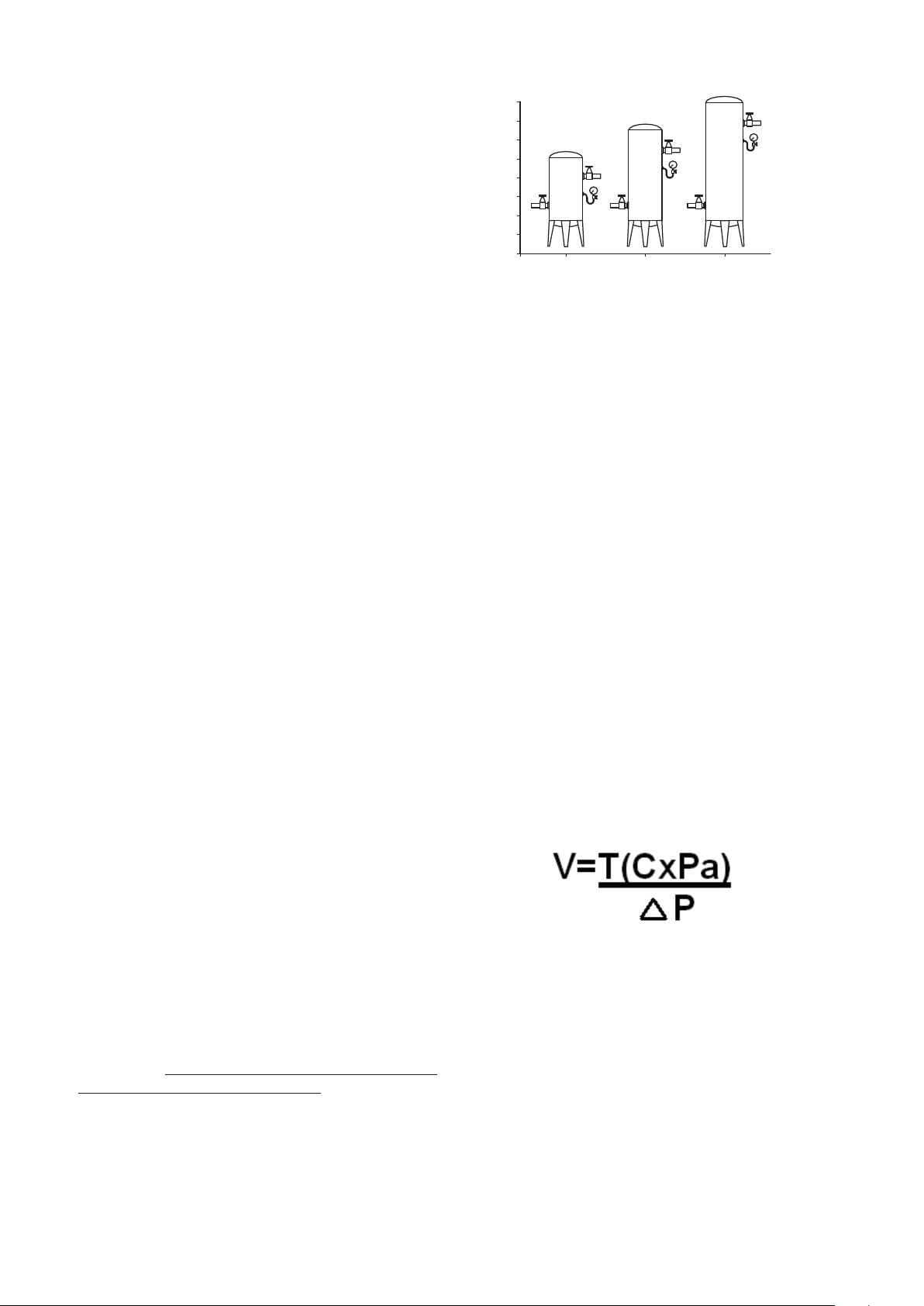

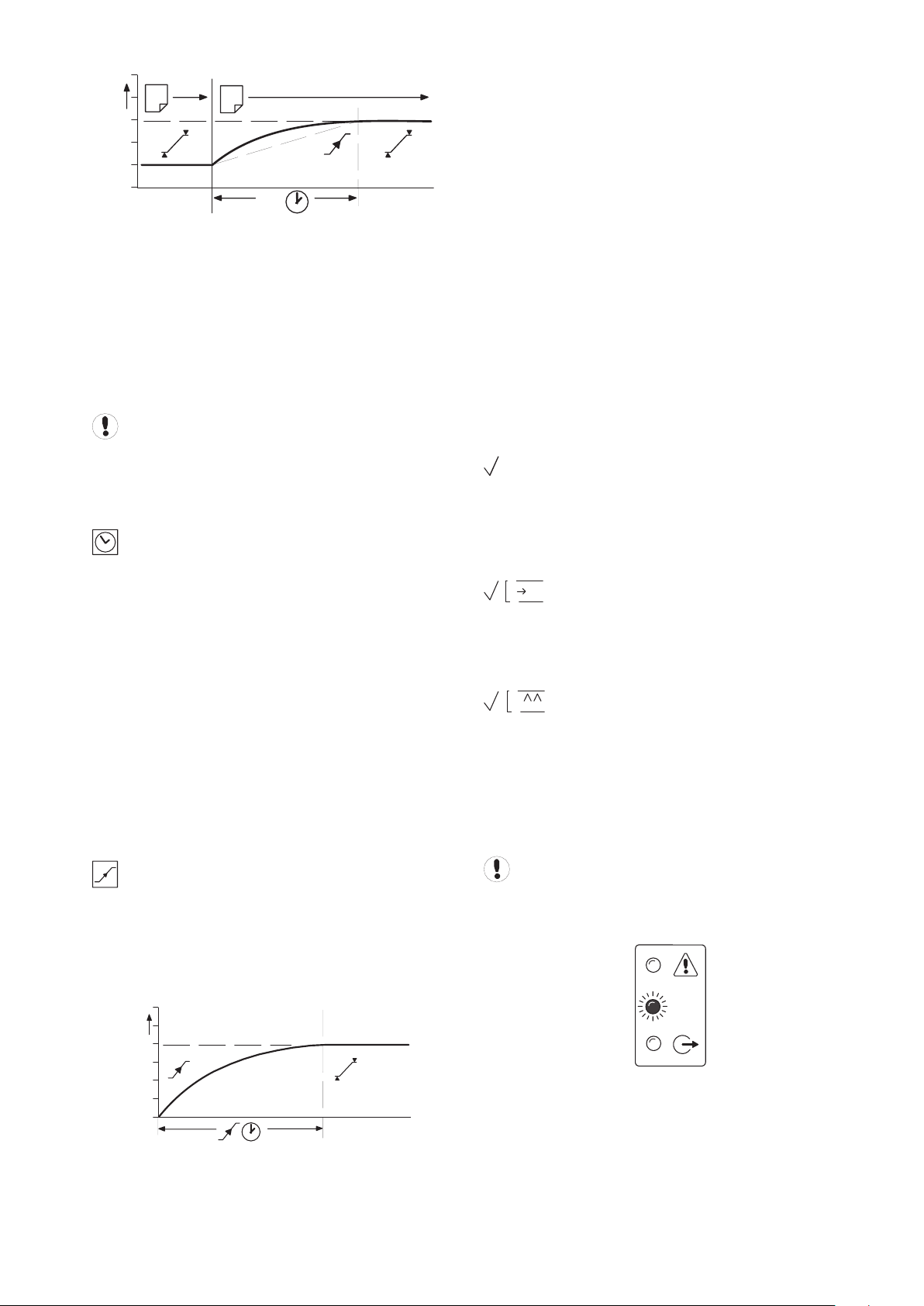

SYSTEM VOLUME

Assorted Receiver Tanks

System volume defines how fast system pressure will rise

or fall in reaction to either increased/decreased demand

or increased/decreased supply. The larger the system

volume, the slower the pressure changes in relation to

increased/decreased demand or supply. Adequate system

volume enables effective pressure control and avoids

system over-pressurization in response to abrupt pressure

fluctuations. Adequate system volume is created by

correctly sizing and utilizing air receivers.

The most accurate way to determine the size of air

receivers or the additional volume required would

be to measure the size and duration of the largest

demand event that occurs in the system, then size the

volume large enough to ride through the event with

an acceptable decrease in system pressure. Sizing the

volume for the worst event will ensure system stability

and effective control over all other normal operating

conditions.

If measurement is not available, then estimating the

largest event is a reasonable alternative. For example,

assume that the largest demand event could be equal to

the loss of the largest operating air compressor. System

volume would be sized to allow time for a back-up

compressor to be started and loaded with an acceptable

decrease in pressure.

The following formula determines the recommended

minimum storage volume for a compressed air system:

Damping is adjustable and is scaled from 0.1 to 10 with

a factory default of 1. A factor of 0.1 is a reaction time

10 times faster than the default and a factor of 10 is a

reaction time 10 times slower than the default.

NOTE: There are many variables that go into determining the stability and control of the system pressure, only some of which are able to be controlled by

the X8I. System storage, air compressor capacity, and

air demand all need to be analyzed by experienced

professionals to determine the best installation for

your system. Tolerance (TO) and damping (DA) can be

used for minor tuning of the system.

V — “Volume of Required Storage” (Gal, Ft3, m3, L)

T — “Time to Start Back-up Compressor” (Minutes)

C — “Lost Capacity of Compressed Air” (CFM, m3/min)

Pa — “Atmospheric pressure” (PSIa, BAR)

∆P — “Allowable Pressure Drop” (PSI, BAR)

14

Page 15

Example 1: Find Required Storage Volume in Ft3 and US

20%

40%

80%

100%

100%

0%

0%

2

1

1 2 3 4

#1

#2

#3

#4

A B C D

A C D B

A D B C

A B C D

1 2 2 2

Gal.

(4) - 100 Hp Compressors at 450 CFM (12.7 m3) each /

15 seconds to start and load a compressor. 5PSIG is the

maximum allowable pressure drop.

T=15 Seconds (.25 minute)

C=450 ft3

Pa = 14.5 PSI

Delta P = 5 PSI

V = [.25 x (450 x 14.5)]/5

V = (.25 x 6525)/5

V = 1631/5

V = 326 Ft3

1 ft3 = 7.48 Gal

Gal= 326 Ft3 x 7.48

Gal = 2440

Example 2: Find Required Storage Volume in m3 and L.

(4) - 100 Hp Compressors at 450 CFM (12.7 m3) each / 15

seconds to start and load a compressor. 0.34 BAR is the

maximum allowable pressure drop.

T=15 Seconds (.25 minute)

C=12.7 m3

Pa = 1BAR

Delta P = .34 BAR

V = [.25 x (12.7 x 1)]/.34

V = (.25 x 12.7)/.34

V = 3.2/.34

V = 9.33m3

1m3 = 1000 L

L= 9.33 m3 x 1000

L = 933

STANDARD CONTROL FEATURES AND

FUNCTIONALITY

STANDARD SEQUENCE CONTROL STRATEGIES

The standard configuration of the X8I provides ENER

(Energy Control) sequence control strategy, Priority

Settings, Table Selection, Pressure Schedule, and Pre-fill

operation.

ENER: Energy Control Mode

Control and Rotation:

Compressor control and utilization is dynamically

automated with adaptive control logic and therefore

does not follow pre-determined schedules, rotation

configurations or time intervals. Energy Control mode

can, however be operator influenced by the Priority

functionality which is discussed later in this manual.

Energy Control mode is enabled by the ability of the

X8I to process individual compressor capacity, variable

capacity capabilities, and changes in system pressure to

dynamically implement and continuously review ‘best fit’

configurations as demand variations occur.

1: Demand

2: Supply

PRIORITY SETTINGS

The sequence assignment pattern can be modified by

using the priority settings.

Priority settings can be used to modify the rotation

sequence assignments. Compressors can be assigned

a priority of 1 to 8, where 1 is the highest priority. Any

compressor can be assigned any priority and any number

of compressors can share the same priority.

Priorities allow you to set up rotation groups. All

compressors that have the same priority number will

rotate inside their own group. The group with the highest

priority will always be in the front of the sequence.

For example, in a four compressor system including one

variable speed compressor in the compressor 1 position

you may want the variable speed compressor to always

be in the Lead position. By assigning compressor 1 a

priority of 1 and the other three compressors a priority

of 2, the variable speed compressor will always remain at

the front of the sequence:

The primary function of Energy Control mode is to:

1/ Dynamically match compressed air supply with

compressed air demand.

2/ Utilize the most energy efficient set/combination of air

compressors to achieve 1/.

Energy Control mode is designed to manage systems that

include compressors of different capacities and different

air compressor types (fixed speed, variable speed and

variable capacity) in any combination or configuration.

Compressor 1 has priority 1, all other compressors have

priority 2

15

Page 16

In another example, there is a four compressor system

1 2 3 4

#1

#2

#3

#4

A B C D

B C A D

C A B D

A B C D

1 1 1 2

1 2 3 4

#1

#2

#3

#4

A B C D

A C B D

A B C D

A C B D

1 2 2 3

1 2 3 4

#1

#2

#3

#4

A B C D

B A D C

A B C D

B A D C

1 1 2 2

T01

PH

PL

Pm

SQ

- - - -

- - - -

- - - -

- - - -

that includes a compressor in the compressor 4 spot

that is used only as an emergency backup compressor.

To accomplish this, simply assign compressor 4 a lower

priority than any other compressor in the system:

Compressor 4 has priority 2, all other compressors have

priority 1

In a third example, there is a four compressor system

that includes a variable speed compressor designated

compressor 1 and a fixed speed compressor that is an

emergency backup assigned as compressor 4. To ensure

that compressor 1 is always at the front of the sequence

and compressor 4 is always at the end of the sequence,

set the priority as shown below:

Priority control will also work with ENER control

mode. Recall that ENER control automatically selects

the most efficient set of compressors to dynamically

match compressed air demand. Priority will force the

X8I controller to select from all “priority 1” compressors

and make sure that they are loaded in the sequence

before utilizing any priority 2 compressors. All priority

2 compressors must be utilized before priority 3

compressors can be loaded and so on. Priority allows

a system to be segregated to backup and primary use

compressors when using ENER control.

Note: Using the Priority function with ENER Control can

affect system efficiency.

TABLES AND THE PRESSURE SCHEDULE

The X8I operates based on settings that are

configured into one of three tables. Each table defines

the operational settings and sequence control mode

of the X8I. The X8I can be instructed to change among

the tables at any time based on the configuration of the

pressure schedule.

This functionality allows the X8I to switch among

multiple different system configurations without any

disruption to control. This is particularly useful in the case

of shift changes, or weekends when the system is to be

deactivated.

Compressor 1 has priority 1, compressor 4 has priority 3

and all other compressors have priority 2

A last example involves another four compressor system

that will be assigned into two independently rotation

groups. Compressors 1 and 2 are given priority 1 and

compressors 3 and 4 are given priority 2. This results in

the rotation sequence shown below:

Each table consists of the following parameters which can

be set independently in each table:

PH – High Pressure Setpoint

•

PL – Low Pressure Setpoint

•

Pm – Minimum pressure warning level

•

SQ – Sequence Rotation Strategy

•

01 – Compressor 1 Priority

•

02 – Compressor 2 Priority

•

03 – Compressor 3 Priority

•

04 – Compressor 4 Priority

•

The “maximum” pressure fault level and the rotation

interval, or rotation time, are set independently in a

configuration menu and are unchanging regardless of the

table selected.

When the X8I is instructed to change between tables,

it will not abruptly change the system operating

parameters. The X8I will adjust the system target pressure

upward or downward to the next table’s settings.

This transition will occur gradually to preserve energy

efficiency and safe, reliable control:

Two independently rotating compressor groups

16

Page 17

PC

1

2

Changing Target Pressures

! X

A

CAP

The time the system is allotted to change the target

pressure is known as the Pressure Change Time (PC). This

is a value that is adjustable in the system settings screen.

See the Quick Setup Manual.

If the X8I is able to complete the transition in less time

than is allotted without threatening energy efficiency

then PC will be automatically shortened.

An aggressively short time setting will compromise

energy efficiency.

PRESSURE SCHEDULE

The X8I is equipped with a real-time clock feature

and pressure schedule functionality. The pressure

schedule function can be used to provide enhanced

system automation.

The pressure schedule consists of 28 individual settings

that instruct the system to change from one table to

another, or put the system into standby mode dependent

on the time of day and the day of the week. The pressure

schedule will cycle from 00:00 hours Monday (day #1) to

23:59 hours on Sunday (day #7) each calendar week.

The pressure schedule has the capability of changing

tables based on the time of day, once each day, or once

each day except weekends. Please see the Quick Setup

Manual for detailed information on how to configure the

pressure schedule.

At system start (manual start or automated start from

standby) the X8I will only load compressors that have

been pre-determined for prefill operation, for a pre-set

period of time. The prefill time (PT) can be adjusted to suit

system characteristics. The aim is to increase pressure to

normal operational levels, using only the pre-determined

compressors, prior to the prefill time expiring.

If normal operational pressure is reached prior to the

set prefill time, the prefill function will automatically

cease and normal operational control begin. If normal

operational pressure is not reached by the end of

the prefill time the P4 will utilize as many available

compressors as required to achieve normal operational

pressure as quickly as possible. Normal operational

control will then begin.

Three prefill modes are available. ‘Backup’ and ‘Standard’

modes require compressor pre-selection and function in

the same way; differing only in response to a failure, or

loss, of a prefill compressor. Automatic mode requires no

compressor pre-selection.

Backup Mode: Compressor(s) can be pre-selected

as ‘Primary Prefill’ compressor(s) or ‘Backup Prefill’

compressor(s). If a primary prefill compressor experiences

a shutdown, or is stopped, a pre-defined backup

compressor replaces it and prefill continues.

Standard Mode: If one or more of the predefined prefill compressors experiences a shutdown, or

is stopped, the prefill function is cancelled and normal

operation begins.

Automatic Mode: No Prefill compressor

selection is necessary; any selection set is ignored. The

management unit automatically selects compressor(s)

dynamically to achieve pressure in accordance with

the set Prefill time. If a compressor is stopped, or shuts

down, it is automatically substituted with an alternative

compressor.

The Prefill feature provides a controlled and energy

efficient method of increasing pressure to normal

operating levels at system start. This feature avoids the

inefficient potential for all available system compressors

to start and load before pressure reaches the normal

operating level.

To manually skip Prefill mode, press and hold Start

for several seconds.

Insufficient Capacity Alarm

The X8I is equipped with a dedicated ‘Insufficient

Capacity’ Advisory Alarm (Warning) indication.

This indication will illuminate if all available compressors

are loaded and system pressure is continuing to decrease.

The indication will generally occur prior to any set low

pressure Alarm (Warning) and is intended to provide an

advanced warning of a potential ‘Low Pressure’ situation.

17

Page 18

The ‘Insufficient Capacity’ advisory alarm is intended as an

CAP

1 2 3 4

#1

#2

#3

#4

A B C D

D A B C

C D A B

B C D A

advanced warning and is not recorded in the fault history

log but is included as a Group Alarm (Warning), or Group

Fault item.

‘Insufficient Capacity’ is available as a dedicated data

communications item.

ALTERNATE CONTROL FEATURES AND

FUNCTIONALITY

Energy Control Mode (ENER) is the STANDARD control

mode of the X8I. Alternate control strategies of the X8I are

the basic FILO (First in / Last Out) and EHR (Equal Hours

Run) EHR

The ‘Insufficient Capacity’ advisory alarm function

can be de-activated. In this instance the unit’s Alarm

indicator will still illuminate but no group alarm, group

fault, or a remote indication is generated.

Restricted Capacity Alarm

The X8I is equipped with a dedicated ‘Restricted Capacity’

Advisory Alarm (Warning) indication.

This indication will flash if all available compressors are

loaded and further capacity is required but one or more,

compressors are: 21

a) inhibited from use in a ‘Table’ priority setting

b) inhibited from use by the short-term Service/

Maintenance function

c) inhibited from use in the long term maintenance menu.

FILO: TIMER ROTATION MODE

The primary function of Timer Rotation mode is to

efficiently operate a compressed air system consisting of

fixed capacity output compressors. The routine rotation

assignments can be modified using ‘Priority’ settings

to accommodate for a differentially sized or variable

capacity output compressor(s).

Rotation:

Each time the rotation interval elapses, or the rotation

time is reached, a sequence rotation occurs and the

sequence assignment for each compressor is re-arranged.

The compressor that was assigned for duty (A) is reassigned as last standby (D) and all other compressor

assignments are incremented by one.

The ‘Restricted Capacity’ advisory alarm is intended to

indicate that all available compressors are already loaded

and further capacity is required but one or more, system

compressor(s) have been restricted from use.

The ‘Restricted Capacity’ advisory alarm is not recorded

in the fault history log but is included as a Group Alarm

(Warning), or Group Fault item.

‘Restricted Capacity’ is available as a dedicated data

communications item.

The ‘Restricted Capacity’ advisory alarm function can

be de-activated. In this instance the unit’s Alarm indicator

will still flash but no group alarm, group fault, or a remote

indication is generated.

The sequence assignment pattern can be modified by

‘Priority’ settings.

Tables; Priority Settings

Control:

Compressors are utilized, in response to changing

demand, using a ‘FILO’ (First In, Last Out) strategy.

The ‘duty’ compressor (A) is utilized first followed by (B)

if demand is greater than the output capacity of (A). As

demand increases (C) is utilized followed by (D) if demand

increases further.

As demand reduces (D) is the first compressor to be

unloaded, followed by (C) and then (B) if demand

continues to reduce.

The last compressor to be unloaded, if demand reduces

significantly, is (A). The compressor assigned as (A) in

the sequence is the first to be loaded and the last to be

unloaded.

18

Page 19

SEQUENCE ROTATION EVENTS

A sequence rotation event can be triggered in the

following ways: a periodic interval, a pre-determined

time each day, or a pre-determined time day and time

each week. Please refer to the Quick Setup Manual to

determine how to configure the rotation events.

EQUAL HOURS RUN MODE

The primary function of EHR mode is to keep the

running hours of all compressors in the system as close

as possible. This provides the opportunity to service

all of the compressors at the same time, given that the

expected service interval for the compressors is similar.

EHR is not an energy efficient focused mode of

operation.

Each time the rotation interval elapses, or the rotation

time is reached, the sequence order of compressors is

reviewed and re-arranged dependant on the running

hours recorded for each compressor. The compressor with

the least recorded running hours is assigned as the ‘duty’

compressor, the compressor with the greatest recorded

running hours is assigned as the ‘last standby’ compressor.

For systems with more than two compressors, the

remaining compressor(s) are assigned in accordance with

there recorded running hours in the same way.

If a compressor is operated independently from

the X8I the running hours record may not be accurately

updated.

The running hours meter display on most

compressors are intended for approximate service

interval indication only and may deviate in accuracy over

a period of time.

Control:

Compressors are utilized, in response to changing

demand, using a ‘FILO’ (First In, Last Out) strategy. The

‘duty’ compressor (A) is utilized first followed by (B) if

demand is greater than the output capacity of (A).

As demand increases (C) is utilized followed by (D) if

demand increases further. As demand reduces (D) is the

first compressor to be unloaded, followed by (C) and then

(B) if demand continuous to reduce.

The last compressor to be unloaded, if demand reduces

significantly, is (A). The compressor assigned as (A) in

the sequence is the first to be loaded and the last to be

unloaded.

Example: The compressors in a four compressor system

have the following recorded running hours when a

rotation event occurs:

Compressor 1 = 2200 hours

•

Compressor 2 = 2150 hours

•

Compressor 3 = 2020 hours

•

Compressor 4 = 2180 hours

•

The new sequence order after the rotation event would

be:

Compressor 1 = D

•

Compressor 2 = B

•

Compressor 3 = A

•

Compressor 4 = C

•

Compressor 3, which has the fewest running hours, will

now be utilized more frequently in the new sequence,

allowing running hours to accumulate at a faster rate.

The X8I continuously monitors the running status of each

compressor and calculates the accumulated running

hours. These readings are viewable and adjustable

in the X8I C01 setting screens. The X8I will use these

values during EHR mode. The running hours on the X8I

should be routinely checked to see that they match the

compressors’ local calculations, and adjusted if necessary.

19

Page 20

SECTION 7 DISPLAY AND MENU OPERATION

a

b

c

d

f

g

h

e

Ingersoll Rand

102

psi

A: 85%

1

CAP

1

5

2

6

3

7

4

8

102

PSI

1

a

b

c

d

e

17:30 #1

a

b

c

CAP

a

b

c

1

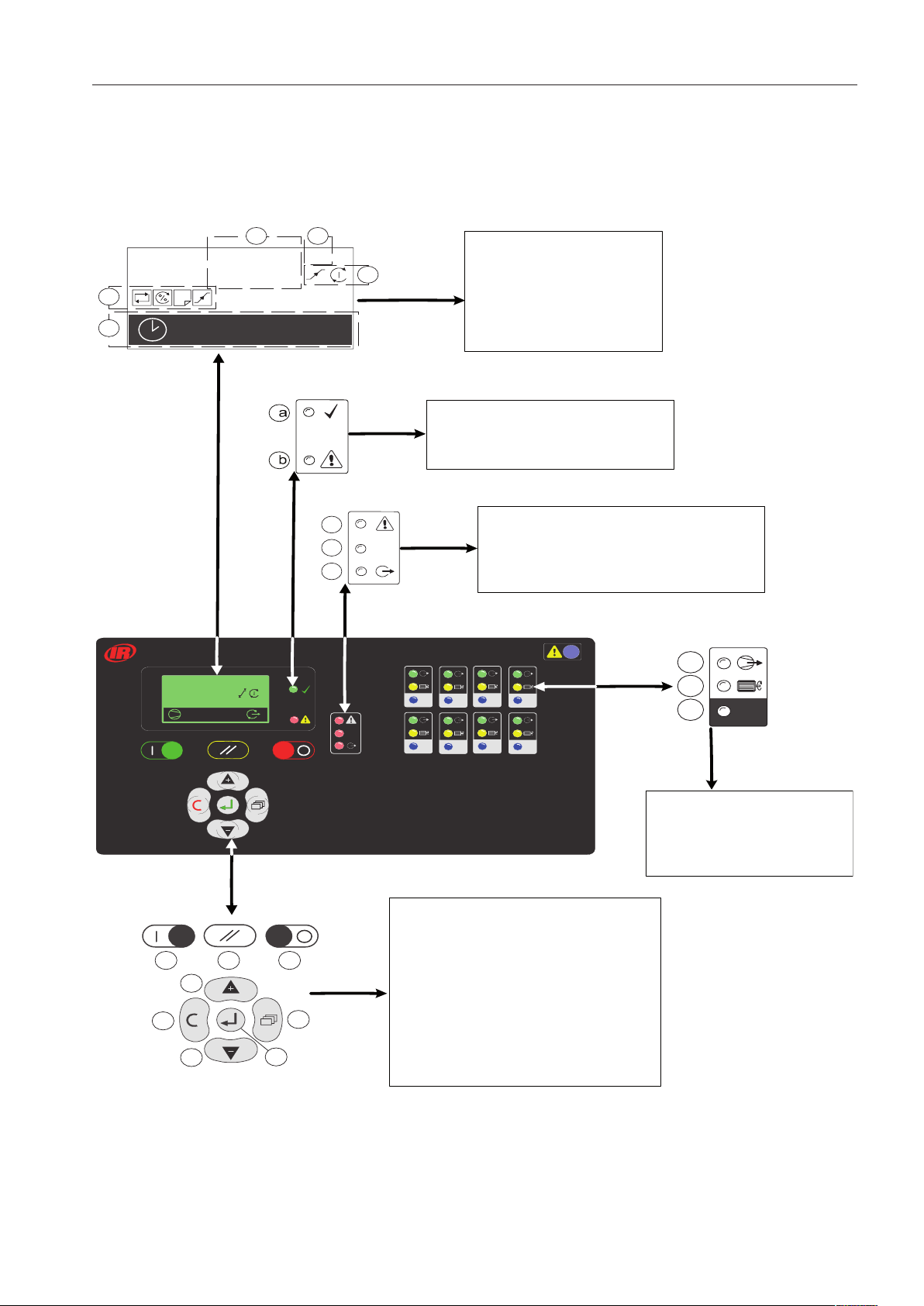

Keypad and Navigational Keys Functionality

a) Start

b) Reset

c) Stop

d) Menu

e) Enter

f) Escape

g) Up (Plus)

h) Down (minus)

Compressor Status Indicators :

a) Load Status

b) Run Status

c) Compressor Availability

System Alarms (Warning) :

a) Group Compressor Fault

b) Insufficient Capacity Alarm (Warning)

c) Restricted Capacity Alarm (Warning)

System Alarms (Warning) :

a) Unit Run Indicator (green LED)

b) Unit Alarm Indicator (Red LED)

User Interface :

a) System Pressure Value

b) System Pressure Units

c) Unit Status

d) Unit Active Functions

e) User Menu Item

The Main Display and the keypad and navigation buttons on the X8I are depicted below and provide the following

functionality:

20

Page 21

1

2

3

4

Unit Functions:

The following Icons are used by the X8I to

display the Controller Active Functions.

EHR - Equal Hours Run

Increasing to normal operational levels (Prefill,

target pressure change or at system start)

Below the active lower, or load, pressure set point

Above the upper, or unload, active pressure set point

The following Icons are used by the X8I to

display the Controller Status.

Stopped

Standby

Started and Running

Alarm (Warning)

Shutdown (Trip)

Day of the week

#1 = Monday

#2 = Tuesday

#3 = Wednesday

#4 = Thursday

#5 = Friday

#6 = Saturday

#7 = Sunday

Between the lower, or load, and upper, or unload,

active pressure set points

FILO - Timer Rotation

ENER - Energy Control

Active Functions :

Operating Mode :

System Pressure Status :

Units Status :

Power Failure Auto-Restart

Table #1

Table #2

Table #3

Table #4

Standby Mode Active

Prefill Function

Pressure Schedule

Function Inhibited (Manual Override)

Remote Manual Override

System Pressure Value

System Pressure Units

Real Time Clock

24 Hour Format

21

Page 22

17:30 #1

A: 100%

1

#

102 psi

00:00 #1

Main Manu

Real Time Clock

Compressor Detailed Status:

Compressor Status Symbols

Primary Detected Pressure

Next Scheduled Sequence Rotation

The Pressure detected on the unit’s

primary pressure sensor.

The next scheduled sequence rotation:

00 : 00 Time (24 hr system)

#1 Monday

A setting of zero hundred hours (00:00hrs)

on Monday (#1) equates to a sequence

rotation at one second past midnight on

Sunday.

17.30 (24r system)

# 1 = Monday to # 7 = Sunday

Standby (or Auto restart)

Running Offload

Running Loaded

Removed From Service in Table Priority Selection (# = Table Number)

Removed From Service in Long Term Maintenance Menu

Alarm (Warning) Standby (or Auto Restart)

Not Available(Stopped Shutdown, Trip Standby (or Auto Restart)

Network Communication Error (RS485 Connectivity Only)

A number of User menu information displays are

available that can be accessed directly from the

front panel using the Up and Down navigation

buttons.

User Manu

22

Page 23

INDICATORS

1sec

1sec

1sec

a

b

c

1

a

b

c

CAP

Indicators

The X8I indicators are as follows.

ON – Loaded

b) Run Status

OFF – Not Running

Off

On

Intermittent:

Slow Flash:

Fast Flash:

Unit Indicators

Unit Run Indicator (Green LED)

Slow Flash – The compressor has been requested

to load but is not running (blowdown delay or

other start delay)

ON – Running

c) Compressor Availability

OFF – No Compressor Connected

Fast Flash – Not Available, Shutdown Fault or

Stopped

Slow Flash – Alarm (Warning)

Intermittent Flash – The compressor has been

intentionally removed from service.

Available, OK

System Alarms (Warnings):

OFF – Not Active, Stopped

Slow Flash: Active, Standby Mode

ON – Active, Running

Unit Fault Indicator (Red LED)

Fast Flash: Shutdown (Trip)

Slow Flash: Alarm (Warning)

The X8I fault indicator does not indicate compressor

fault states; see Compressor Status Indicators.

Compressor Status Indicators:

Each compressor in the system has a set of dedicated

status indicators. The indicators will continuously show

the status of each compressor at all times.

a) Load Status

OFF – Not Loaded, Offload

a) Group Compressor Fault

OFF – All Compressors OK

Fast Flash – One or more compressors Not

Available, Shutdown Fault or Stopped

Slow Flash – One or more compressors Alarm

(Warning)

b) Insufficient Capacity Alarm (Warning)

On – Insufficient Capacity

c) Restricted Capacity Alarm (Warning)

Slow Flash – Restricted Capacity

Slow Flash – The compressor has been requested

to load but is not loaded (load or re-load delay

period)

23

Page 24

Information Displays

P00

#1 18:30

T2

3

4

1

1

2

P00

IRV-485

100 %

1

4

20 %

30 %

5

6

7

1

1

1

3

2

P00

1

102

98

80

psi

psi

psi

2

3

4

1

P00

#4 18:00

18 / 05 / 2006

A B C D

To view detailed information applicable to the

selected User menu display item press Enter.

To view detailed information applicable to the

selected User menu display item press Enter.

Real Time Clock:

Shows the next Pressure Schedule event.

1: The Current Active Table

2: Day (#1=Monday, #7=Sunday)

3: Time (24hr system)

4: Table

Primary Detected Pressure:

1: Active Table

2: Upper (Unload) Pressure Set Point

3: Lower (Load) Pressure Set Point

4: Minimum Pressure Alarm (Warning)

Sequence Rotation:

Items 2 and 3 show the day and time that the unit

will change to use the ‘Table’ shown in item 4.

Compressor Status:

1: Compressor Number

2: Priority Setting

3: Zone Allocation Setting

4: Compressor/Connection Type

5: Maximum Capacity % Setting

6: Minimum Capacity % Setting

7: Minimum Efficiency % Setting

Item values 6 and 7 are only shown if compressor

type is IRV-485 (variable capacity/speed).

Day of the week (#4: Thursday), the time of day

(18:00) and the date (18/05/2006) of the next automated

sequence rotation event.

The active ‘mode’ of operation

“ABCD” The current active rotation sequence assignment.

Manual Sequence Rotation:

The sequence assignment can be manually rotated at any

time. When viewing the ‘Sequence Rotation’ information

screen press Enter:

The manual rotation symbols will appear and

flash. Press Enter again to execute a manual rotation or

Escape to abandon the manual rotation.

Automated sequence rotation is not disrupted by

a manual rotation; the next scheduled automated

sequence rotation event will still occur.

Compressor Identification

Each compressor connected to the X8I will have a unique

assigned compressor identification number; starting at

compressor 1 increasing sequentially to the number of

compressors connected to the X8I.

24

Page 25

1 2 3 4

A: 85%

Stop:

To stop the X8I press Stop.

The X8I will respond dependant on the setup of item ‘CF’

in menu S02:

Pressure regulation control is automatically transferred

back to each compressor. The compressor(s) will continue

to operate using the pressure settings programmed or set

in the individual compressor controller(s).

The X8I will hold each compressor in an offload state.

If the compressor is equipped with a main motor run-ontime function the compressor will run offload for a period

of time and then stop in to a ‘standby’ or ‘auto restart’

state.

Power Failure Auto-Restart

If the power failure auto-restart function is enabled

the X8I will automatically start, when power is restored

after a disruption or failure, if the X8I was in a ‘started’

state when the power disruption or failure occurred.

The X8I will not automatically restart if the X8I was in

a stopped state when the power disruption or failure

occurred.

Failure Mode

If the X8I experiences a disruption to normal control, or

an X8I shutdown fault occurs, pressure regulation control

is automatically transferred back to each compressor. The

compressor(s) will continue to operate using the pressure

settings programmed or set in the individual compressor

controller(s).

Reset

To reset an X8I Alarm (Warning) or Shutdown

condition press Reset.

The design of some air compressor control systems

may inhibit automatic transfer of pressure regulation

control to local operation mode. In this instance the

compressor will not continue production of compressed

air – consult the air compressor manual or your air

compressor supplier / specialist for details before

installing the IAX4.

Start:

To start the X8I press Start.

If the Prefill function is enabled, and system pressure is

below the set prefill pressure, the system will enter Prefill

mode for the set Prefill time.

Prefill

To manually skip the Prefill function, press and hold

Start for several seconds.

When Prefill is complete, if applicable, the X8I will enter

normal operating mode.

The X8I will operate in accordance with the parameters

and options set in the active ‘Table’.

Tables

Each compressor in the system must be started

(running or in a standby or auto restart condition) before

X8I control of the compressor can be established. The X8I

will not start a compressor that is in a stopped condition.

25

Page 26

SECTION 8 COMMISSIONING

When commissioning the X8I, carry out the following

procedures before attempting to start.

It is recommended that an authorized and trained

service technician perform the commissioning.

PHYSICAL CHECKS

1. Before applying power to the X8I, ensure the

power supply connections are correct and secure

and the operating voltage selector is set correctly

for the power supply voltage in use (115Vac or

230Vac (+-10%), 50/60Hz).

2. Open the front panel of the X8I and check the

location of the link wire(s) connected to the

“Voltage Selection” terminals of the power supply

PCB. If necessary, change the link wire locations to

those illustrated for the voltage in use.

See the section on Installation for more

information.

3. Switch on the power supply to the X8I.

4. The control program identification will be

displayed for a short period followed by the normal

operational user display.

PRESSURE DISPLAY

Check the displayed system pressure. If the pressure is

incorrect, or inaccurate, check the type and range of the

sensor and carry out the pressure sensor commissioning

and calibration procedure. If the display shows an error,

this will need to be corrected before continuing. See the

Operator’s Manual for troubleshooting and correcting the

fault/error condition.

X8I QUICK SETUP CONFIGURATION

Before successful basic operation can be established

specific parameters must be entered prior to startup.

Please refer to the X8I Quick Setup Manual for instruction

to accomplish this.

OPTIONAL FEATURES AND FUNCTIONS

Installation requirements may involve the

implementation of additional or optional functions and

features. Please refer to the appropriate Guide or Manual

as required.

26

Page 27

SECTION 9 SYSTEM CONFIGURATION

Access Code Accepted

Access Code Rejected

Access Code = 0032

P00

DISPLAY ITEM STRUCTURE

Operational system status and values are accessible from

the normal user display. To view status or values that are

not normally visible on the default screen, press UP or

DOWN. All standard user display items are viewable only

and cannot be adjusted. The standard user display items

are regarded as “Menu Page 00” items.

All adjustable value, parameter or option item displays

are grouped into “menu mode” lists. Items are assigned

to a list according to type and classification. Item lists

are identified by page number (or menu number). All

adjustable parameters and options are assigned to menu

mode pages “P01” or higher.

NORMAL OPERATIONAL DISPLAY MENU

PAGE P00

At controller initialization, all display elements and LED

indicators are switched on for three seconds and then the

normal operating display is shown. In normal operational

display mode, the main display will continuously show

the detected system pressure and the Item display will

show the first item of the “Page 00” menu. User menu

“items” can be selected using the UP or DOWN buttons at

any time. Pressing the ENTER button will lock any selected

item display and inhibit return to the default display.

When an item display is locked, the “lock key” symbol

will be shown. To unlock an item display, press UP or

DOWN to view an alternative item display or press RESET

or ESCAPE. No item values, options or parameters can

be adjusted in “Page P00”. If a fault condition occurs, the

fault code becomes the first list item and the display will

automatically jump to display the fault code. More than

one active fault code item can exist at any one time and

can be viewed by pressing UP or DOWN. The most recent

“active” fault will be at the top of the list.

ACCESSING THE X8I CONFIGURATION

SCREENS

Access Code:

Access to adjustable menu page items is restricted by

access code. To access menu mode pages press MENU (or

UP and DOWN together); an access code entry display is

shown and the first code character will flash.

Use UP(plus) or DOWN(minus) to adjust the value of the

first code character then press ENTER. The next code

character will flash; use UP or DOWN to adjust then press

ENTER. Repeat for all four code characters.

If the code number is less than 1000 then the first code

character will be 0(zero). To return to a previous code

character press ESCAPE. When all four code characters

have been set to an authorized code number press

ENTER. An invalid code will return the display to normal

operational mode; page ‘P00’.

Access Code Timeout:

When in menu mode, if no key activity is detected for

a period of time the access code is cancelled and the

display will automatically reset to the normal operational

display.

Menu Mode Navigation:

In menu mode the menu ‘page’ number will be

highlighted at the top of the display.

To select a menu ‘page’ press UP or DOWN. To enter the

highlighted menu ‘page’ press ENTER; the first item of the

menu ‘page’ will be highlighted. Press UP or DOWN to

scroll though the selected menu ‘page’ items.

27

Page 28

To select an item value or parameter for modification’

Page 3

Page 2

Page 1

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Page 0

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value

Page 5

Page 4

Page 3

Page 2

Page 1

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Page 0

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value

Page 5

Page 4

P01

01.02 AB

a b c

press ENTER; an adjustment screen for the item will be

displayed.

The value or option can now be modified by pressing

UP(Plus) or DOWN(Minus). To enter a modified value or

option in to memory press, ENTER.

Press ESCAPE at any time in menu mode to step

backwards one stage in the navigation process. Pressing

ESCAPE when the page number is flashing will exit menu