Page 1

Before installing or starting this unit for the first time, this

manual should be studied carefully to obtain a working

knowledge of the unit and/or the duties to be performed

while operating and maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

hould be kept with the unit at all times. s

More Than Air, Answers.

Online answers: http://www.air.irco.com

Ingersoll Rand

System Automation

X12I

Operator’s Manual

C.C.N. : 80445075

REV. A

DATE DECEMBER 2008

Page 2

TABLE OF CONTENTS

TABLEOFCONTENTS..................................................2

SECTION1—INTRODUCTION....................................3

SECTION2—SAFETYPRECAUTIONS...........................3

INSTALLATION.................................................................3

OPERATION....................................................................3

SERVICEMAINTENANCEANDREPAIR...................................4

SECTION3—COMPRESSORCONNECTIONAND

CONTROL...................................................................5

COMPRESSORCONNECTION..............................................5

STANDARDCONNECTIONMETHODS...................................5

OPTIONALCONNECTIONMETHODS....................................6

PRESSUREDETECTIONANDCONTROL.................................10

X12IMAINDISPLAYOVERVIEW.........................................11

X12ISYSTEMOVERVIEW.................................................12

X12IINSTALLATIONOVERVIEW.........................................13

SECTION4—INSTALLATION....................................14

UNITLOCATION............................................................14

POWERSUPPLY.............................................................14

PRESSURESENSORLOCATION..........................................15

PRESSURESENSORCONNECTION......................................15

IR‐485ANDIRV‐485GATEWAYMODULE.........................16

IR485COMMUNICATIONPROTOCOL.................................16

RS485NETWORK.........................................................16

COMPRESSORINTERFACEIR‐PCB.....................................18

IR‐PCBEXPBOX(OPTION).............................................18

ONBOARDI/OOPTIONS..................................................19

SECTION5—CONTROLFEATURESANDFUNCTIONS.21

PRESSURECONTROL.......................................................21

ANTI‐CYCLINGCONTROL..........................................21

TOLERANCE..............................................................22

DAMPING.................................................................22

SYSTEM

VOLUME......................................................23

SEQUENCECONTROLSTRATEGIES.....................................24

S

TANDARDCONTROLFEATURESANDFUNCTIONALITY..........24

ALTERNATECONTROLSTRATEGIES.....................................28

ADDITIONALCONTROLFEATURESANDFUNCTIONALITY..........29

SECTION6—DISPLAYANDMENUOPERATION........31

SERMENU.................................................................33

U

NFORMATIONDISPLAYS.................................................34

I

INDICATORLED’S..........................................................36

COMPRESSORIDENTIFICATION.........................................37

X12ICONTROLKEYPADFUNCTIONS.................................37

SECTION8—SYSTEMCONFIGURATION...................40

DISPLAYITEMSTRUCTURE................................................40

ACCESSINGTHEX12ICONFIGURATIONSCREENS....................40

USERLEVELMENUS.......................................................42

SERVICELEVELMENUS(0021)........................................43

HIGHLEVELMENUS(0032)............................................44

X12ICONFIGURATIONSCREENS.........................................45

X12ICOMPRESSORCONNECTIVITYANDFUNCTIONALSETTINGS

..................................................................................56

SECTION9‐VIRTUALRELAYAUTOMATION..............59

VIRTUALRELAYCONFIGURATION......................................62

FUNCTIONLISTS.............................................................67

VIRTUALRELAYAUTOMATIONEXAMPLES...........................71

SECTION10—DIAGNOSTICS....................................73

SECTION11—X12IFAULTINDICATIONS..................77

ERRORLOG...................................................................77

FAULTCODES.................................................................78

INTERNALCONTROLLERFAULT‘E’CODES.............................79

SECTION12—PARTSLIST........................................80

SECTION13—TECHNICALDATA..............................80

SECTION14—WIRINGDIAGRAM............................81

X12ISCHEMATIC...........................................................81

X12IXPM‐AI4&XPM‐DI8R4......................................82

X12ITERMINALPCB.....................................................83

XPM‐TAC24...............................................................84

SECTION15—COMMISSIONINGFORM...................85

NOTES.....................................................................91

Refer to Section Indicated

Note

Important or Caution, Safety

SECTION7—COMMISSIONING................................39

PHYSICALCHECKS..........................................................39

PRESSUREDISPLAY........................................................39

X12IQUICKSET‐UPCONFIGURATION...............................39

OPTIONALFEATURESANDFUNCTIONS...............................39

2

Page 3

SECTION 1 — INTRODUCTION

The X12I is an advanced system controller designed to

provide safe, reliable, and energy-efficient management

of your compressed air system. The X12I is capable of

controlling up to twelve (12) positive displacement air

compressors. The compressors may be fixed speed,

variable speed or multi-step and have electro-pneumatic

or microprocessor based controls.

SECTION 2 — SAFETY PRECAUTIONS

ALWAYS EMPLOY SAFE WORKING PRACTISE

AND PROCEDURES

WARNING: Risk of Danger

WARNING: Risk of Electric Shock

WARNING: Risk of High Pressure

WARNING: Consult Manual

Before installing or operating the product, take time to

carefully read all the instructions contained in this

manual, all compressor manuals, and all manuals of any

other peripheral devices that may be installed or

connected to the unit.

When installing, commissioning, operating or carrying out

service or maintenance on a product, personnel must use

safe working practice and observe all relevant local

health and safety requirements and regulations.

Electricity and compressed air have the potential to

Lethal voltages are used within the product. Use extreme

caution when carrying out electrical checks. Isolate the

power supply before starting any maintenance work.

Maintenance must be performed by adequately qualified

personnel that are equipped with the proper tools. If the

user employs an operating procedure, an item of

equipment, or a method of working which is not

specifically recommended, the user must ensure the

product will not be damaged or made unsafe and that

there is no risk to persons or property.

It is not possible to anticipate every circumstance that

might represent a potential hazard. Failure to observe

safety precautions or implement safe working practices

may be considered dangerous practice or misuse of the

roduct. p

ere personal injury or property damage cause sev

The X12I is uniquely configurable and customizable to

meet the specific needs of some of the most complex

compressed air system. Additionally, the X12I control

network can expand to include monitoring and control of

arious compressed air system components. v

INSTALLATION

Installation work must only be carried out by a competent

n under qualified supervision. perso

A fused isolation switch must be fitted between the main

wer supply and the product. po

The product should be mounted in such a location as to

allow operational and maintenance access without

obstruction or hazard and to allow clear visibility of

ators at all times. indic

If raised platforms are required to provide access to the

product they must not interfere with normal operation or

obstruct access. Platforms and stairs should be of grid or

late construction with safety rails on all open sides. p

OPERATION

The product must only be operated by competent

nnel under qualified supervision. perso

Never remove or tamper with safety devices, guards or

nsulation materials fitted to the unit. i

The product must only be operated at the supply voltage

and frequency for which it is designed.

When mains power is switched on, lethal voltages are

present in the electrical circuits and extreme caution must

be exercised whenever it is necessary to carry out any

work on the unit.

Do not open access panels or touch electrical

components while voltage is applied unless it is

necessary for measurements, tests or adjustments. This

work must only be carried out by a qualified electrician or

technician equipped with the correct tools and

appropriate protection against electrical hazards.

All air compressors and/or other machine equipment

connected too, and controlled by, the product should

have a warning sign attached stating ‘THIS UNIT MAY

ART WITHOUT WARNING' next to the display panel. ST

If an air compressor and/or other machine equipment

connected too, and controlled by, the product is to be

started remotely, attach warning signs to the machine

stating ‘THIS UNIT CAN BE STARTED REMOTELY’ in a

prominent location, one on the outside of the machine,

he other inside the machine control compartment. t

3

Page 4

SERVICE MAINTENANCE AND REPAIR

Service, maintenance, repairs or modifications must only

be carried out by competent personnel under qualified

supervision.

If replacement parts are required use only genuine parts

from the original equipment manufacturer, or an

ative approved source. altern

Carry out the following operations before opening or

removing any access panels or carrying out any work on

• Isolate from the main electrical power supply. Lock

• Attach a label to the isolator switch and to the

Ensure that all instructions concerning operation and

maintenance are strictly followed and that the complete

product, with all accessories and safety devices, is kept

in good working order.

The accuracy of sensor devices must be checked on a

regular basis. They must be renewed when acceptable

tolerances are exceeded. Always ensure any pressure

within a compressed air system is safely vented to

atmosphere before attempting to remove or install a

The product must only be cleaned with a damp cloth,

using mild detergents if necessary. Avoid the use of any

Do not paint the control facial or obscure any indications,

controls, instructions or warnings.

uct:- the prod

the isolator in the 'OFF' position and remove the

fuses.

product stating ‘WORK IN PROGRESS - DO NOT

APPLY VOLTAGE'. Do not switch on electrical

power or attempt to start the unit if such a warning

label is attached.

evice. sensor d

ubstances containing corrosive acids or alkalis. s

4

Page 5

SECTION 3 — COMPRESSOR CONNECTION AND CONTROL

COMPRESSOR CONNECTION

Each air compressor in your system must be interfaced

to the X12I. Interface methods may vary depending on

the compressor type and/or local control configuration.

The following are main methods for interfacing

ompressors to the X12I: c

1) The ir-PCB Interface

2) The ir-485 Gateway Interface

3) The irV-485 Gateway Interf

4) Direct Connect via RS485

5) Special Application Interface

Consult the air compressor manual or your air

compressor supplier/specialist for details before installing

he X12I. t

Consult the X12I Interconnect and Application

uide

G

ace

STANDARD CONNECTION METHODS

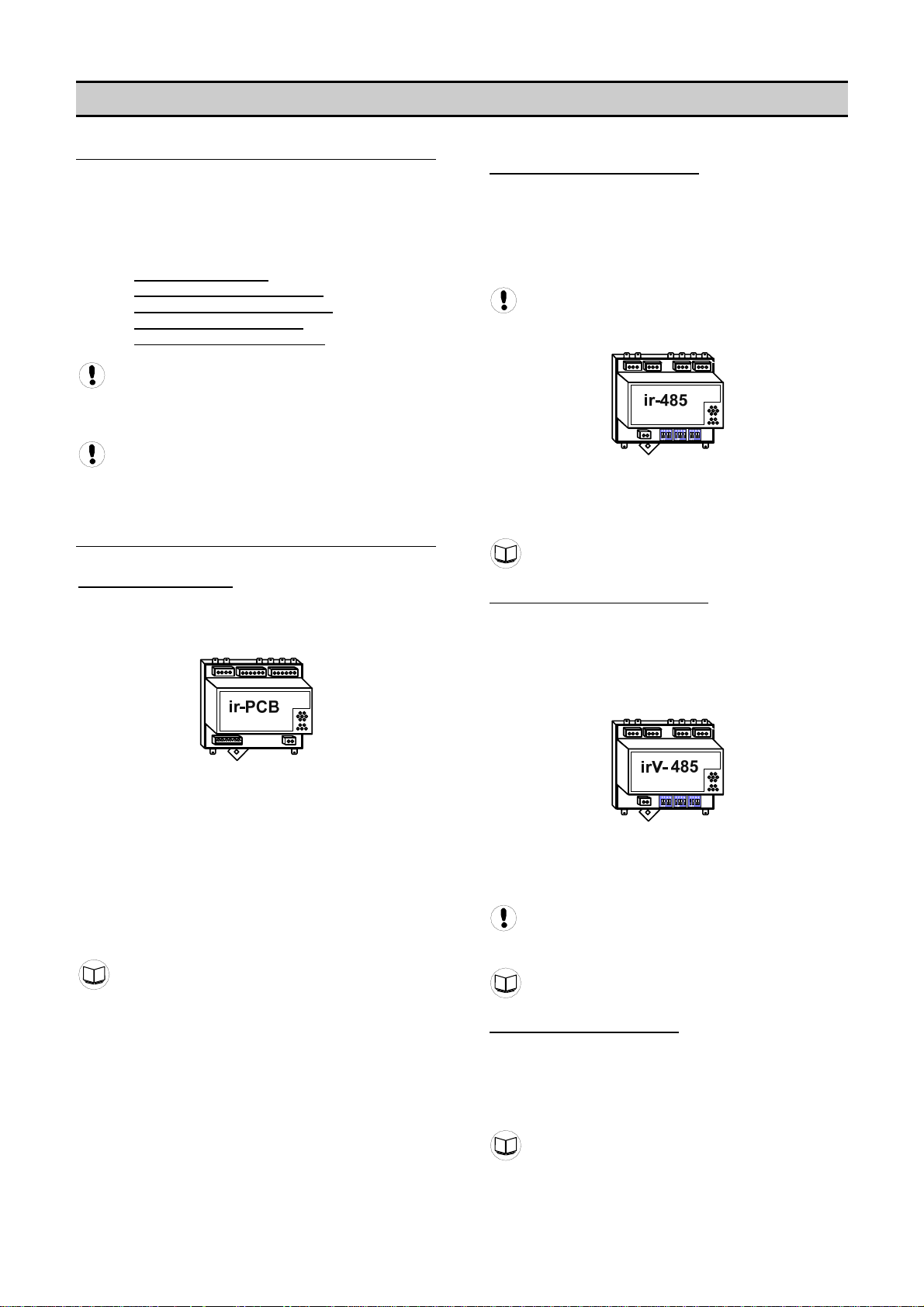

1) The ir-PCB Interface module that is designed to

interface to any positive displacement air compressor

(regardless of make or manufacturer) with an available

c

ontrol voltage of 12-250V (either 50Hz or 60Hz).

2) The ir-485 Gateway Interface

designed to interface to any Ingersoll Rand Intellisys

controlled (Non-Nirvana) compressor. The X12I

communicates to the ir-485 Gateway via a two wire,

RS485 network utilizing the ir485 protocol. All IR

compressors equipped with Intellisys controllers (Non-

irvana and Recips) require this interface.

N

All Nirvana Compressors, 20 HP (15KW) and

bove require the irV-485 Gateway.

a

The ir-485 Gateway interface module is installed within

the compressor control cabinet and connected to the

12I using Belden 9841 or equivalent RS485 cable.

X

ir-485 & irV485 Manual

3) The irV-485 Gateway Interface module that is

designed to interface to any Ingersoll Rand Nirvana

compressor. The X12I communicates to the irV-485

Gateway via a two wire, RS485 network utilizing the ir485

protocol. All Nirvana Compressors, 20 HP (15KW) and

above, and Recips, with Redeye and SG controllers,

equire this interface.

r

module that is

The ir-PCB interface module is installed within the

compressor control area and connected to the X12I using

a six (6) wire cable, (seven (7)-wire cable for Nirvana 7.5

o 15HP (5.5 to 11KW).

t

Each air compressor must be equipped with an

online/offline pressure regulation system capable of

accepting a remote load/unload signal through a volt-free

switching contact or a single electro-mechanical pressure

s

witch.

ir-PCB Manual

The irV-485 Gateway interface module is installed within

the compressor control cabinet and connected to the

12I using Belden 9841 or equivalent RS485 cable.

X

Nirvana 7.5 to 15HP (5.5 to 11KW) connect via the

-PCB using seven (7)-wire cable.

ir

ir-485 & irV485 Manual

4) Direct Connect via RS485

compressor (R-Series) that has an integrated RS485

network port utilizing the ir485 protocol. The X12I

communicates to these compressors via a two wire,

RS485 network. The compressor is connected to the

12I using Belden 9841 or equivalent RS485 cable. X

R-Series Manual

to any Ingersoll Rand

5

Page 6

OPTIONAL CONNECTION METHODS

5) Special Application Interface uses integration boxes

designed to accommodate various types of compressor

nd regulation methods and system monitoring. a

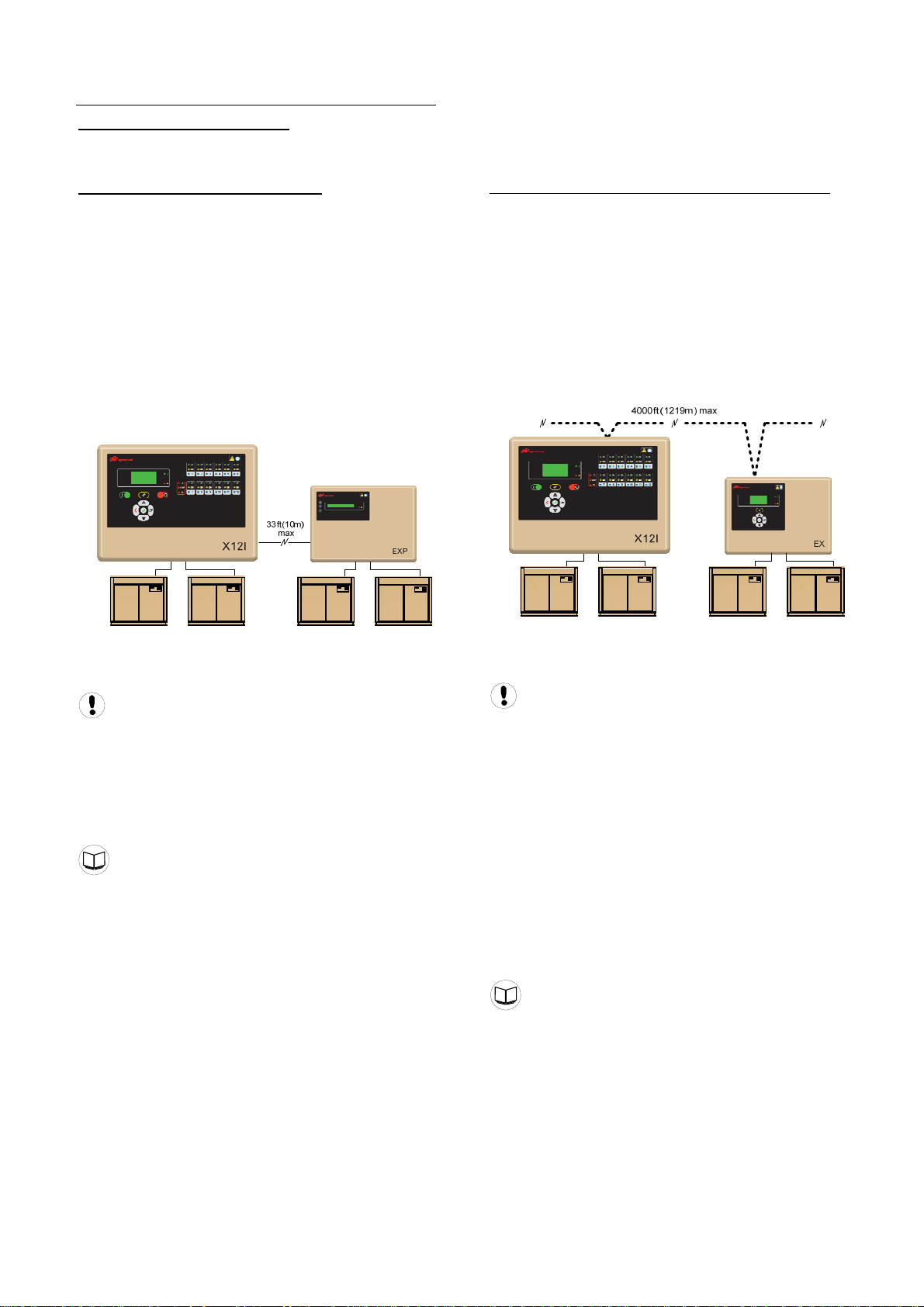

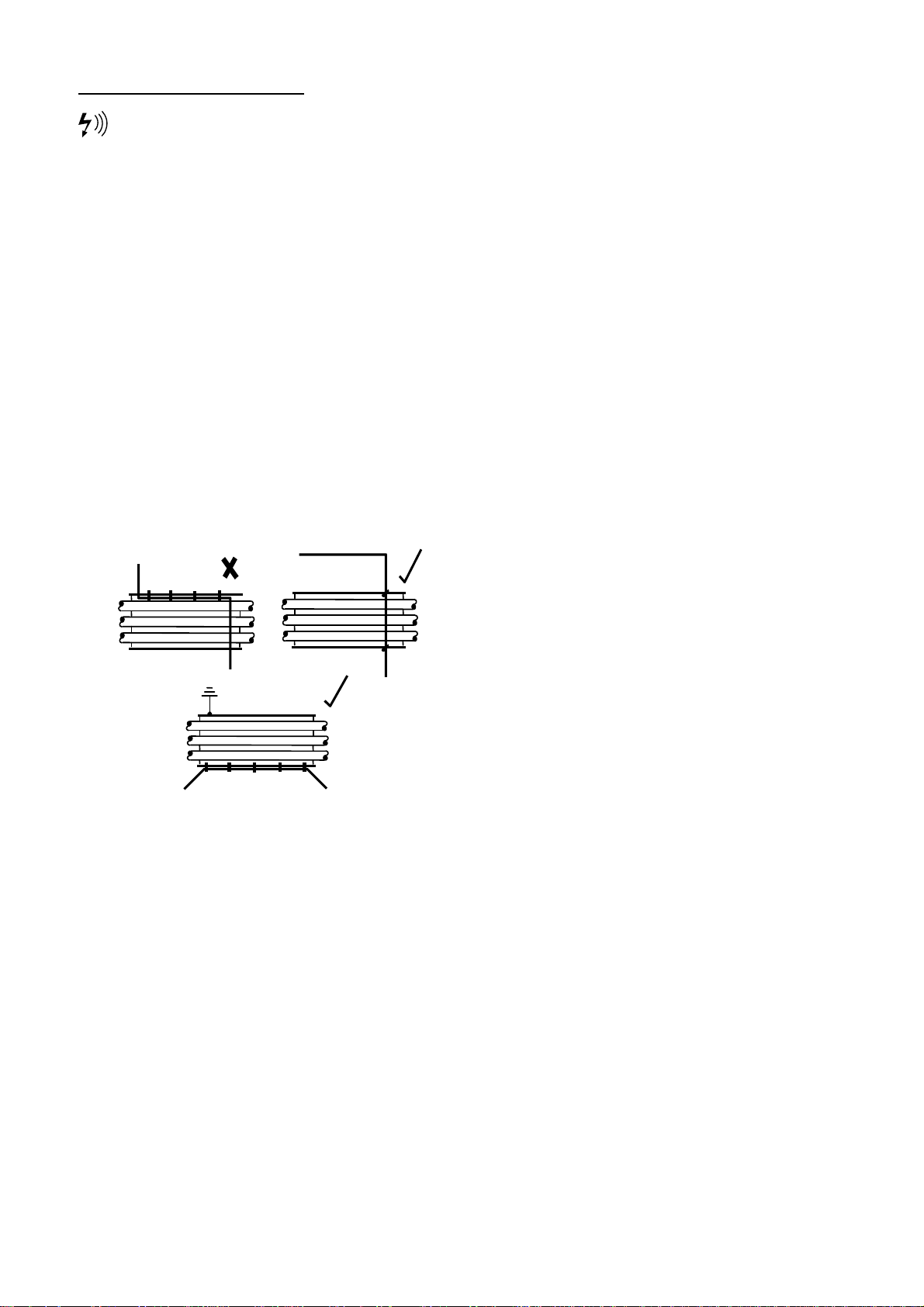

Expansion Module: EXP Box (Option)

As standard the X12I has four direct connect ‘ir-PCB’

terminal connections. This capability can be extended

with the use of tw0 (2) optional EXP Boxes. Each EXP

Box will add another four direct connect ‘ir-PCB’

connection terminals. This would allow a total of 12

compressors to connected and controlled via ‘ir-PCB’

ntegration. i

Compressors 1-4 connect via the X12I

Compressors 5-8 connect via EXP Box #1

ompressors 9-12 connect via EXP Box #2 C

The EXP Box is suitable for wall mounting and must be

located adjacent to the X12I unit (max 33ft or 10m).

on) Remote Compressor Management; EX Box (opti

The EX Box is an ‘EXtension’ to the X12I providing

additional ‘ir-PCB’ connectivity.

The EX Box will typically be used to provide ‘ir-PCB’

connectivity at a remote location beyond the maximum

distance specification of compressors that require ‘irPCB’ type connection; 330ft (100m). This effectively

expands the hardwire connection scheme of the ‘ir-PCB”

o the full RS485 distance specification. t

The EX box is suitable for wall mounting and can be

cated up to 4000ft (1219m) from the X12I unit. lo

The EXP Box connects to the X12I controller via a two

ire, dedicated RS485 network w

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 33ft (10m)

Up to four air compressors can be connected to the EXP

Box using a 6 or 7 wire cable and a compressor interface

ir-PCB (330ft (100m) max). The ‘ir-PCB’ connections are

dentical to the X12I. i

EXP Box Manual

The EX Box connects to the X12I controller via a two

ire, RS485 network utilizing the ir485 protocol w

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

One (1) or two (2) air compressors can be connected to

the EX Box using a 6-wire cable and a compressor

interface ir-PCB (330ft (100m) max). The ‘ir-PCB’

onnections are identical to the X12I. c

The EX Box also provides optional ‘local pressure

sensor’ connections. The compressor delivery pressure,

local system pressure and air treatment differential

ressure can be displayed. p

Multiple EX Boxes can be connected to the X12I as long

as the number of compressors does not exceed the

maximum number of compressors (12).

EX Box Manual

6

Page 7

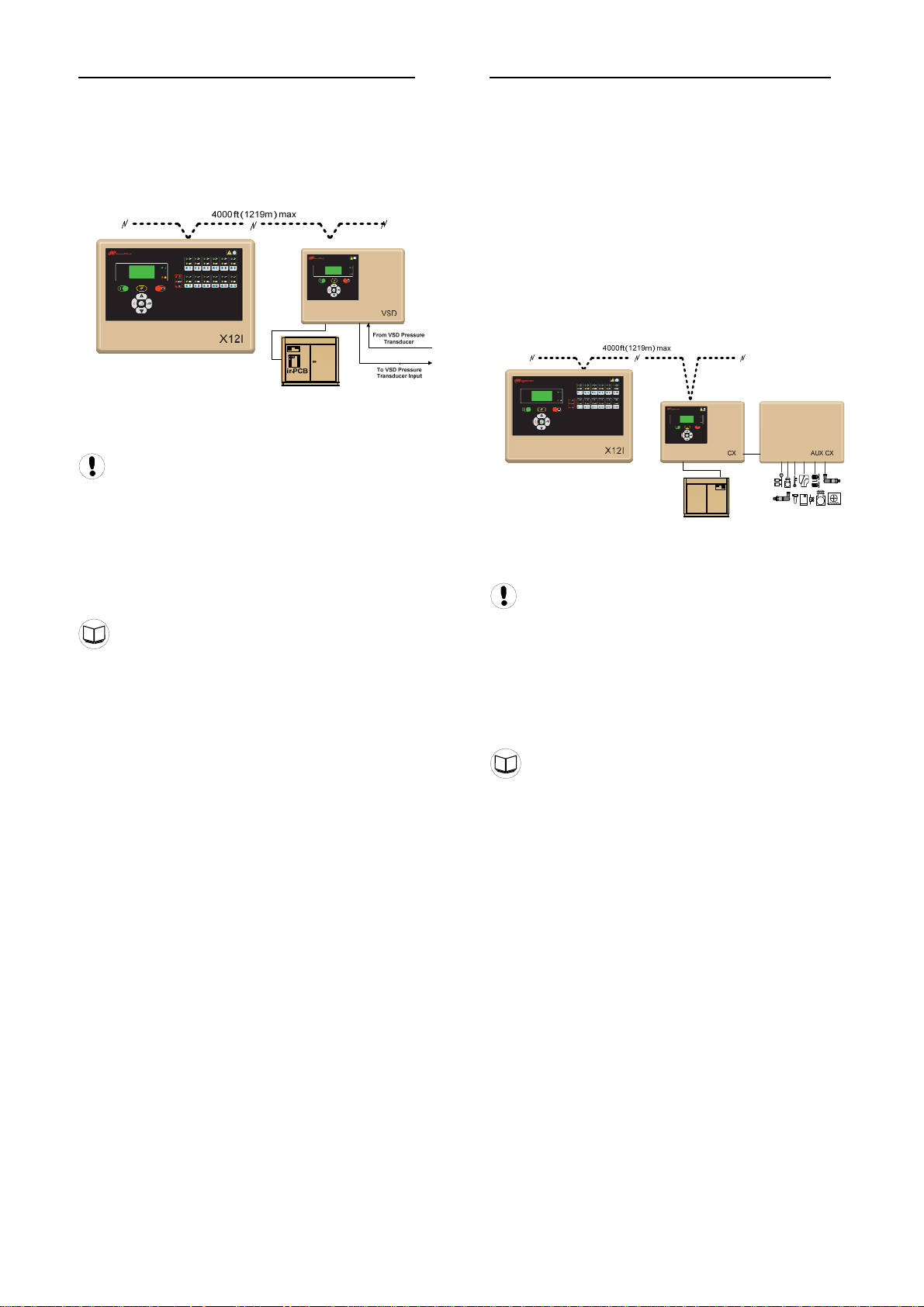

Bolt-On VSD Control Integration: VSD Box (option)

The VSD Box is intended to provide a method of system

integration for a VSD (Variable Speed Drive) air

compressor that is not equipped with any accessible

means of remote connectivity (such as IR- Nirvana). The

VSD Box will provide required functionality to enable

system integration and efficient control using the X12I

utomation system.

a

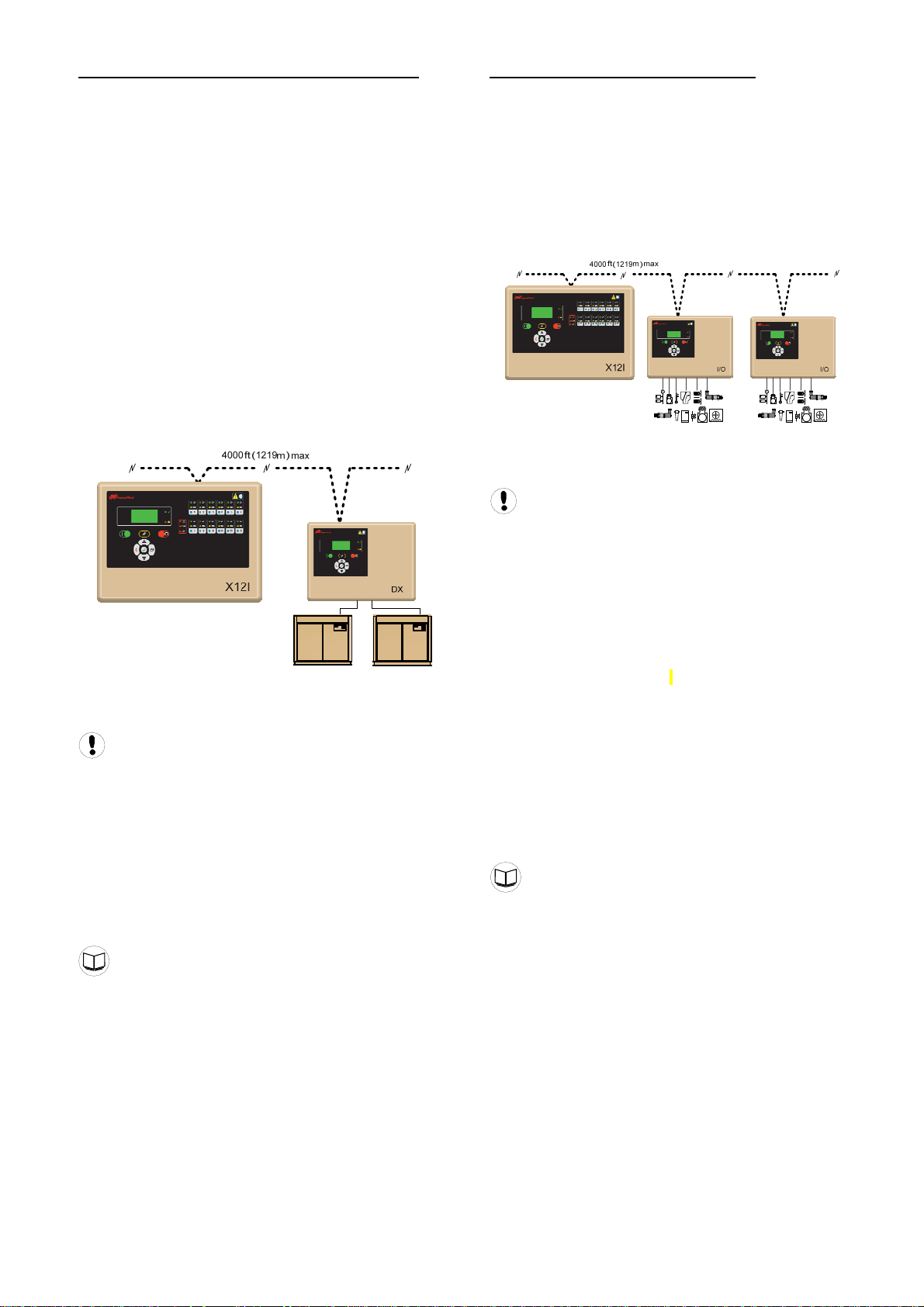

Remote Compressor Management; CX Box (option)

The CX Box is intended to provide a method of system

integration for non-Ingersoll Rand air compressors that

are not equipped with any accessible means of remote

onnectivity. c

The CX Box provides advanced monitoring and control

unctionality for the following compressor types: f

• Load/Unloa•d

3-Step

• 5-Step

• Poppet Valve

• Modulation Valve

• Spiral Valve

• Variable Speed Inverter Drive

The VSD Box connects to the X12I controller via a two

ire, RS485 network utilizing the ir485 protocol w

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

Each air compressor in a system, that requires VSD Box

integration, must be equipped with an individual VSD

Box. Multiple VSD Boxes can be connected to the X12I

as long as the number of compressors does not exceed

he maximum number of compressors (12). t

VSD Box Manual

The CX Box connects to the X12I controller via a two

ire, RS485 network utilizing the ir485 protocol w

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

Each air compressor in a system that requires CX Box

integration must be equipped with an individual CX Box.

Multiple CX Boxes can be connected to the X12I as long

as the number of compressors does not exceed the

aximum number of compressors (12). m

CX Box Manual

7

Page 8

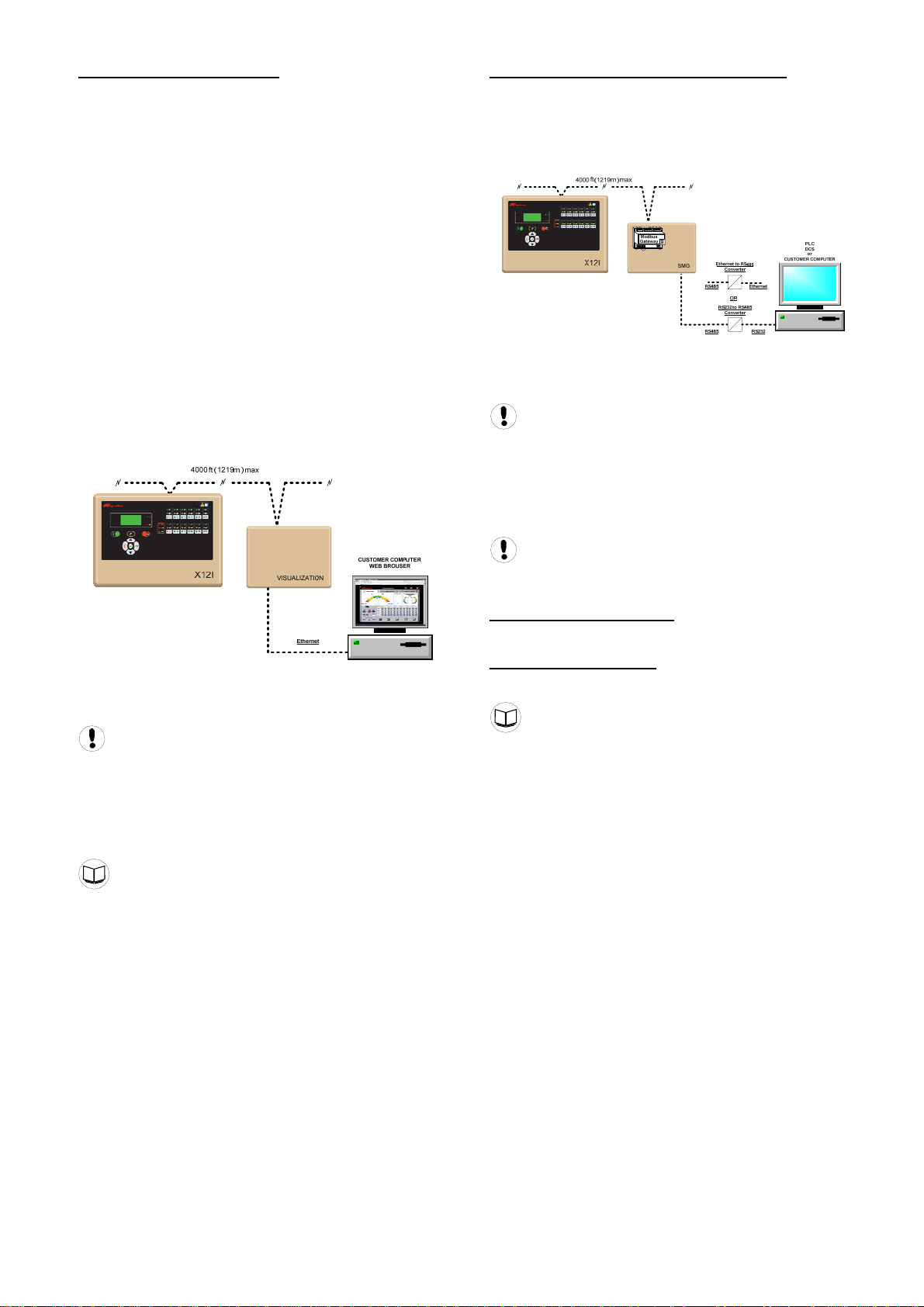

tion) Remote Compressor Management; DX Box (op

The DX Box is designed to allow two fixed speed

online/offline air compressors to be seen as one

ompressor by the X12I. c

This c fun tionality provides the ability to:

a) Group two adjacent air compressors together as

a single coherent unit.

b) Combine two similar capacity compressors

together to form a three-step variable output

group acting as a single coherent variable

output unit.

c) Take advantage of a small or minimal capacity

compressor, grouped together with a medium or

higher capacity compressor, to form a high

capacity, variable output, group acting as a

single variable output ‘top-up’ compressor.

The DX Box also provides optional local pressure sensor

connections. The compressor discharge pressures, local

system pressure and air treatment differential pressures

can be displayed. The monitored local pressure is

available on the system network and can be utilized by

he X12I for advanced pressure related functions. t

Remote Input & Output: I/O Box (option)

An I/O Box provides additional general purpose I/O

(input/output) for a system enhancing monitoring

apabilities and providing distributed system automation. c

Up to twelve I/O Boxes can be connected to the X12I

ontroller. Each I/O Box features: c

• 8 Digital Inputs

• 5 Analog Inputs

• 6 Relay Outputs

The I/O Box connects to the X12I controller via a two

ire, RS485 network utilizing the ir485 protocol w

The DX Box connects to the X12I controller via a two

ire, RS485 network utilizing the ir485 protocol w

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

The DX Box provides for two ‘ir-PCB’ connections. The

DX Box can also be used to provide ‘ir-PCB’ connectivity

at a remote location beyond the maximum distance

pecification of direct X12I connection. s

Multiple DX Boxes can be connected to the X12I as long

as the number of compressors does not exceed the

aximum number of compressors (12). m

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

Digital inputs can be used to monitor switching contact

devices. Each input can be set to act as an Alarm or High

Level Alarm input. Digital inputs can also be used for

metering (for example m

ccumulative count of pulses from a metering device. a

Analog inputs can be used to monitor sensor devices (for

example: pressure differential, temperature, dewpoint,

flow, current, power, and bearing condition). Each input is

equipped with adjustable high or low level detection that

an be used to activate an Alarm or High Level Alarm. c

Relay outputs use ‘Virtual Relay Automation’ technology

and are totally configurable with duel input logic

functions. Relay functions can be assigned utilizing any

status or condition information available on a system

network from any compatible unit connected to the

etwork. n

I/O Box Manual

3

, ft3, kWh) providing an

DX Box Manual

8

Page 9

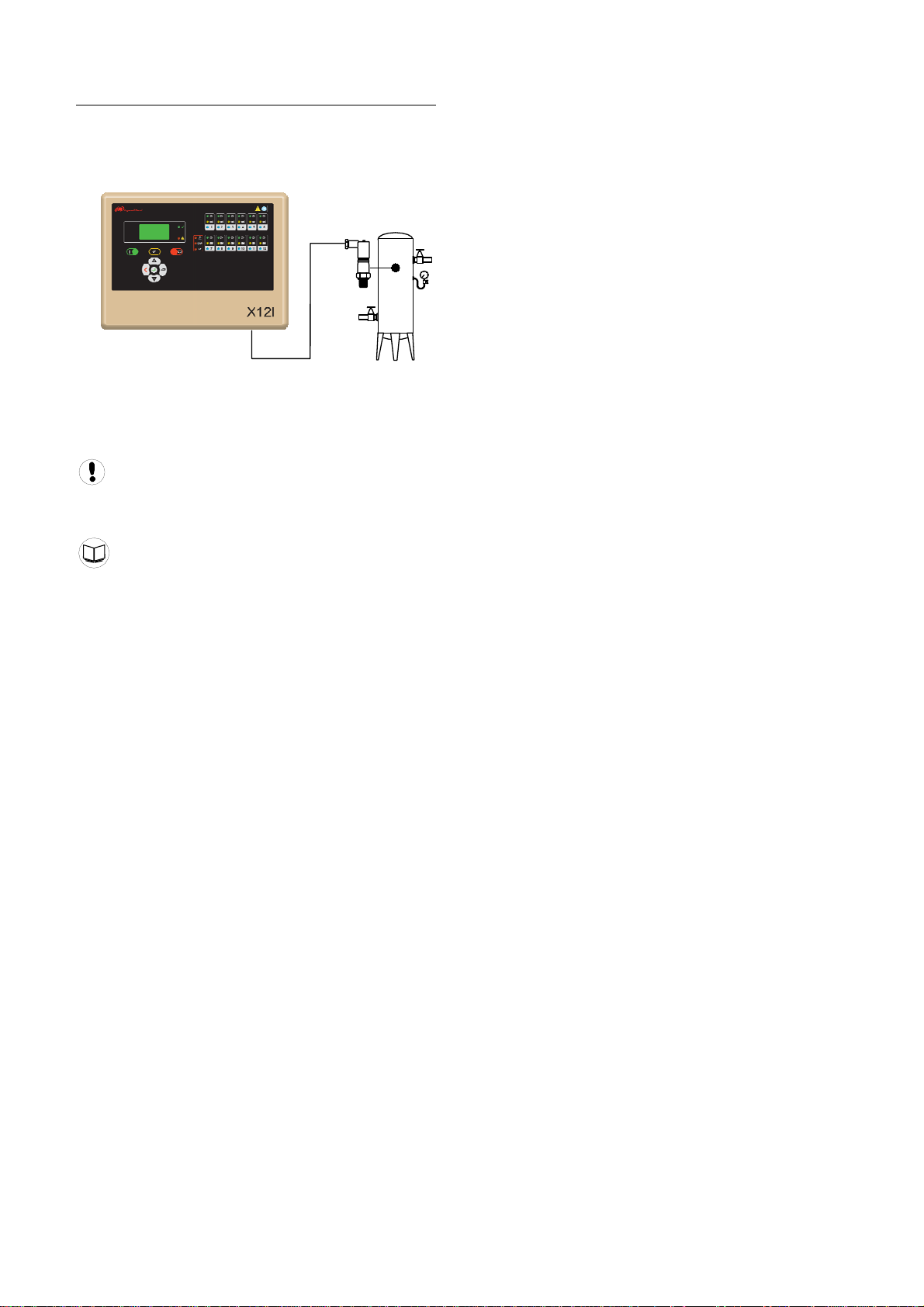

Visualization: VX Box (Option)

The VX Box provides “visualization” of the X12I

Automation System. The VX Box incorporates hardware

and software to allow monitoring of the X12I Automation

system and equipment in a simple format. To access the

application running in the VX Box, simply connect via a

Web Browser from any PC using an Ethernet connection.

he PC can be local “stand alone” or part of a LAN. T

Once logged into the VX Box, the following items are

vailable to the user: a

System status & control

g System performance reportin

Equipment status monitoring

heduler Equipment maintenance sc

ding tools Graphing & Tren

Reporting tools

monitoring Warning & Alarm

SMS messaging

Email messaging

The VX Box is fully field configurable using standard

creen templates. s

System Modbus Gateway: SMG Box (Option)

The SMG Box is designed to provide a RS485 Modbus

connection to the X12I Automation System. This allows

a customer’s computer, PLC, or DCS to connect to,

monitor, and control the X12I Automation System from a

emote location. r

The SMG Box connects to the X12I controller via a two

ire, RS485 network utilizing the ir485 protocol w

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

The SMG Box communicates to the customer’s

computer, PLC, DCS via a two wire, RS485 network

tilizing the Modbus protocol. u

The VX Box connects to the X12I controller via a two

ire, RS485 network utilizing the ir485 protocol w

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

The VX Box connects to the customer’s PC or LAN via

Ethernet, using a RJ45 connector, Cat5e 10/100BaseT

cable.

VX Box Manual

Use Belden 9841 or Equivalent In Grounded

Conduit No Greater Than 4000ft (1219m)

Ethernet to RS485 Converter:

Lantronix XSDRIN-02 Xpress-DR-IAP or equivalent

Serial to RS485 Converter:

&B Electronics 4WSD9OTB or equivient B

SMG Box Manual

9

Page 10

PRESSURE DETECTION AND CONTROL

The X12I utilizes the signal from an electronic pressure

sensor that can be mounted remotely from the X12I in a

suitable location in the compressed air system.

The default setup of the X12I is for operation with a

232psi (16bar) 4-20ma pressure sensor. The X12I can

accept an input from any 4-20mA type pressure sensor

ith a range from 14.5psi (1bar) up to 8700psi (600bar). w

Consult the Pressure Sensor Calibration Procedure

for information regarding the use and setup of the

ressure sensor. p

Pressure Sensor Calibration Procedure

10

Page 11

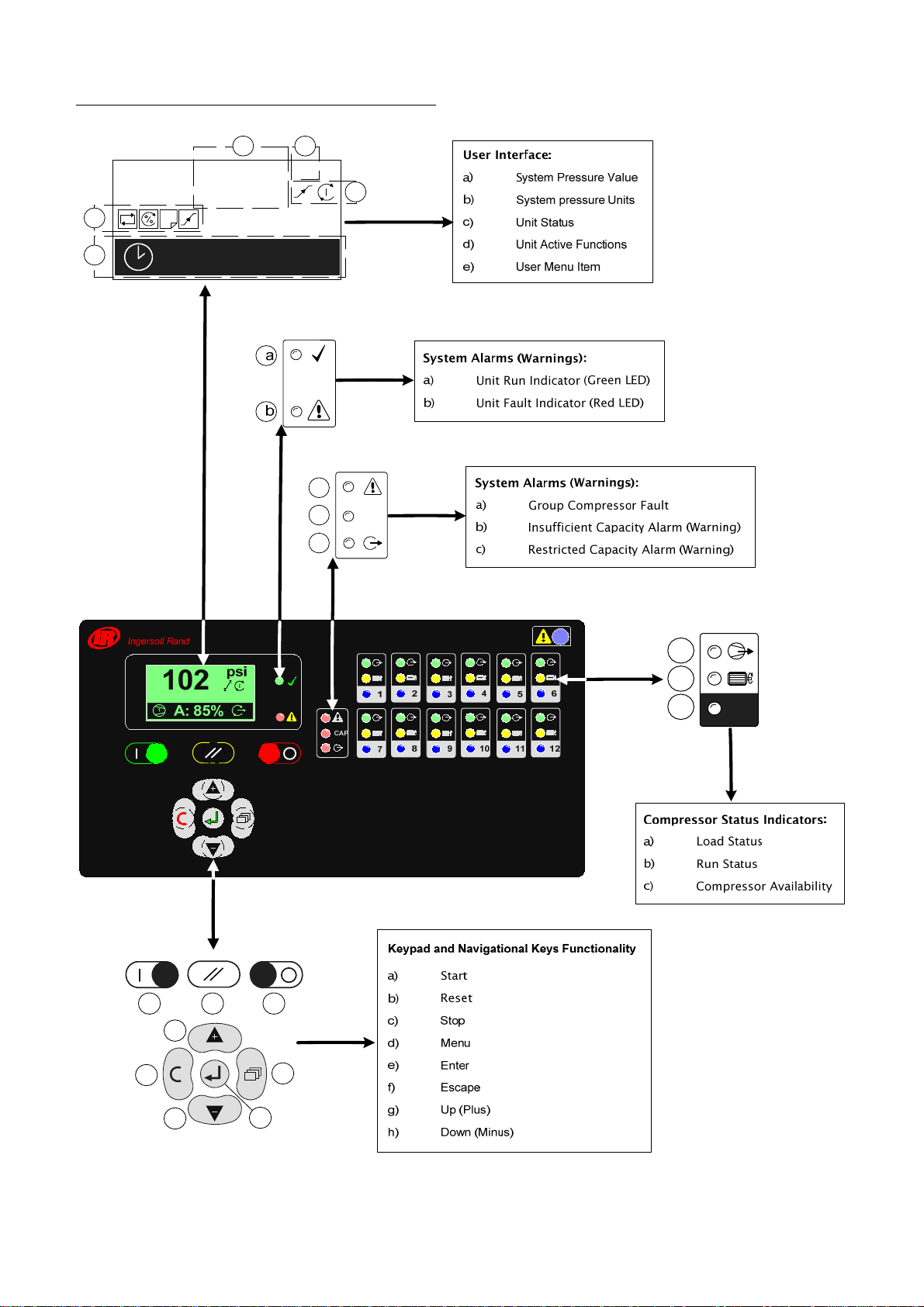

X12I MAIN DISPLAY OVERVIEW

a

b

PSI

102

d

1

c

e

17:30 #1

a

b

CAP

c

a

b

c

a

f

b

g

h

c

d

e

1

11

Page 12

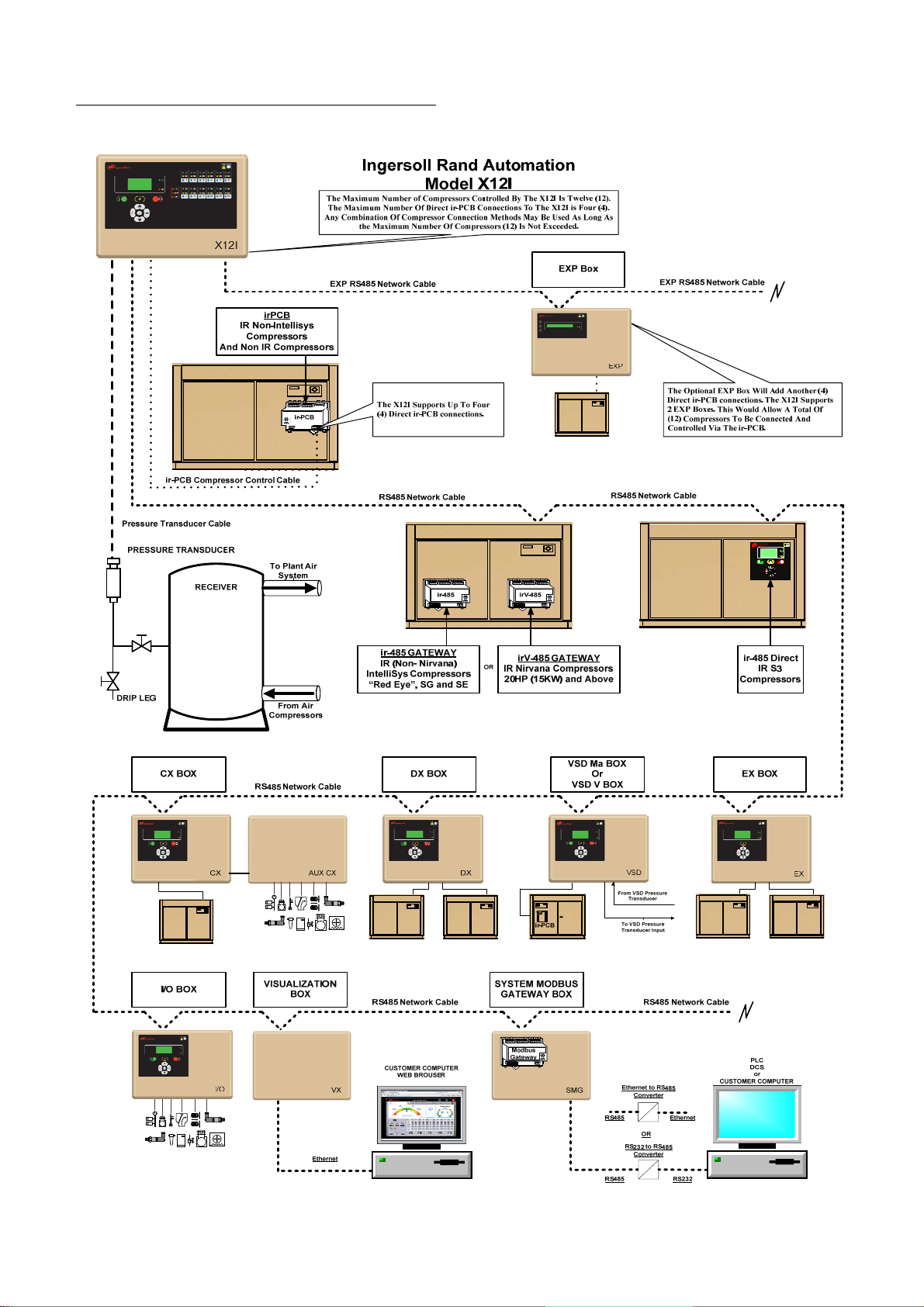

X12I SYSTEM OVERVIEW

12

Page 13

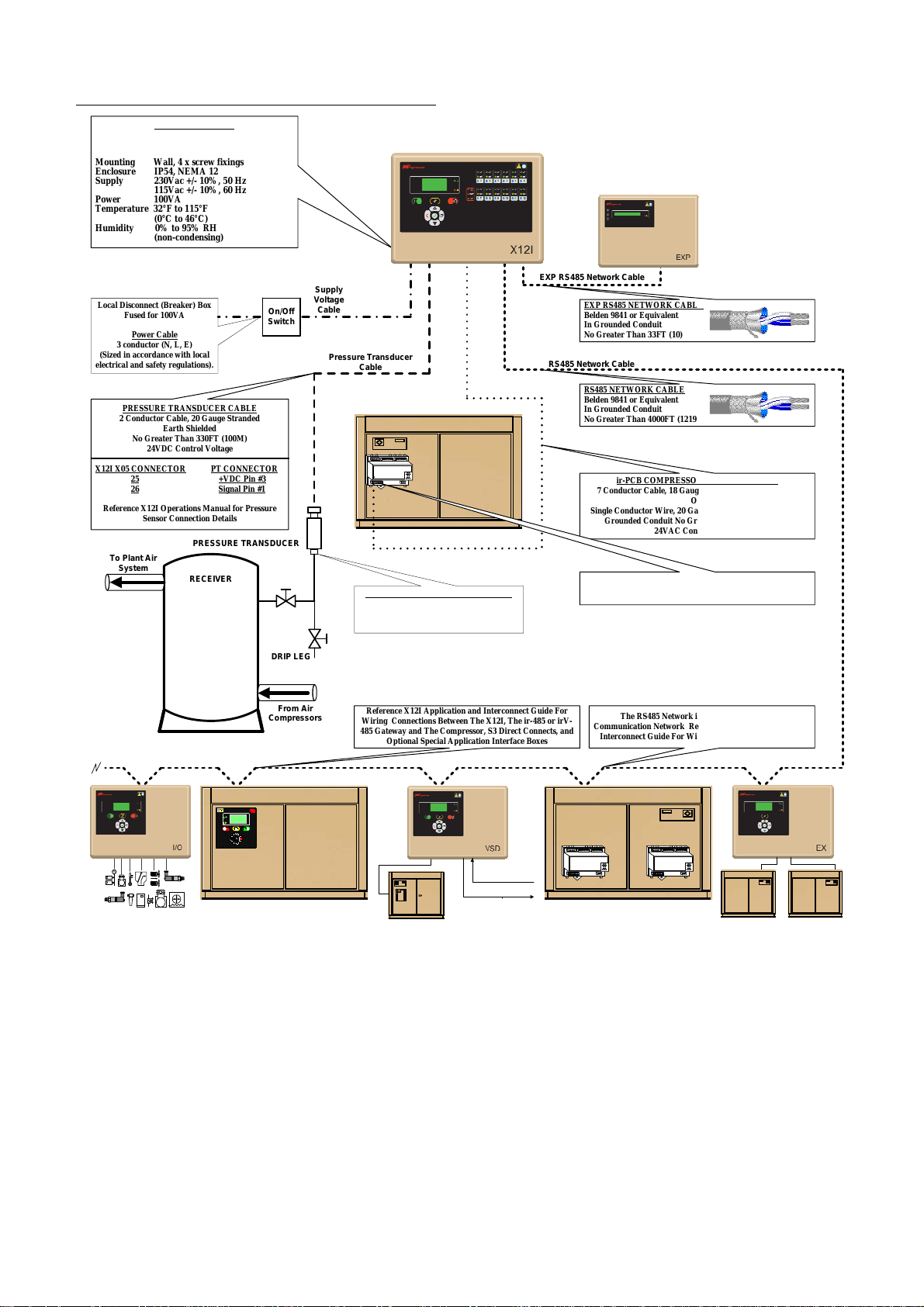

X12I INSTALLATION OVERVIEW

Dimensions 13.4” x 9.45” x 6.0”

Weight 16.5lb (7.5kg)

Mounting Wall, 4 x screw fixings

Enclosure IP54, NEMA 12

Supply 230Vac +/- 10%, 50 Hz

Power 100VA

Temperature 32°F to 115°F

Humidity 0% to 95% RH

Local Disconnect (Breaker) Box

(Sized in accordance with local

electrical and safety regulations).

X12I X05 CONNECTOR

Reference X12I Operations Manual for Pressure

SPECIFICATIONS

340mm x 241mm x 152mm

115Vac +/- 10%, 60 Hz

(0°C to 46°C)

(non-condensing)

Fused for 100VA

Power Cable

3 conductor (N, L, E)

PRESSURE TRANSDUCER CABLE

2 Conductor Cable, 20 Gauge Stranded

Earth Shielded

No Greater Than 330FT (100M)

24VDC Control Voltage

25 +VDC Pin #3

26 Signal Pin #1

Sensor Connection Details

To Plant Air

System

PT CONNECTOR

PRESSURE TRANSDUCER

RECEIVER

On/Off

Switch

Ingersoll Rand Automation

Supply

Voltage

Cable

Pressure Transducer

Cable

PRESSURE TRANSDUCER THREADS

Model X12I

ir-PCB

ir-PCB Compressor Control Cable

BPT G1/4” DIN3852,

Form E, Inox 1, 4305 STainless

Equivalent of ¼” NPT.

EXP RS485 Network Cable

EXP RS485 NETWORK CABLE

Belden 9841 or Equivalent

In Grounded Conduit

No Greater Than 33FT (10)

RS485 Network Cable

RS485 NETWORK CABLE

Belden 9841 or Equivalent

In Grounded Conduit

No Greater Than 4000FT (1219M)

ir-PCB COMPRESSOR CONTROL CABLE

7 Conductor Cable, 18 Gauge, Stranded, Earth Shielded

Single Conductor Wire, 20 Gauge Stranded, Quantity (7) In

Grounded Conduit No Greater Than 330FT (100M)

Reference X12I Application and Interconnect Guide For

Wiring Connections Between The X12I, The ir-PCB, and The

OR

24VAC Control Voltage

Compressor

DRIP LEG

I l

ngersol

Rand

From Air

Compressors

Reference X12I Application and Interconnect Guide For

Wiring Connections Between The X12I, The ir-485 or irV-

485 Gateway and The Compressor, S3 Direct Connects, and

Optional Special Application Interface Boxes

From VSD Pressure

Transducer

ir-PCB

To VSD Pressure

Transducer Input

The RS485 Network is a Serial, Point to Point

Communication Network Refer to the X12I Application and

Interconnect Guide For Wiring Details and Connectivity.

ir-485

irV-485

13

Page 14

SECTION 4 — INSTALLATION

It is recommended that installation and

commissioning be carried out by an authorized and

trained product supplier.

UNIT LOCATION

The X12I can be mounted on a wall using conventional

bolts. The X12I can be located remotely from the

compressors as long as it is within 330 feet (100 meters)

of cable length when connecting compressors directly

with an ir-PCB. When connecting the X12I over the

RS485 communication network the distance is up to

4000 feet (1219 meters) The X12I must be located within

30 feet (100 meters) of the system pressure transducer. 3

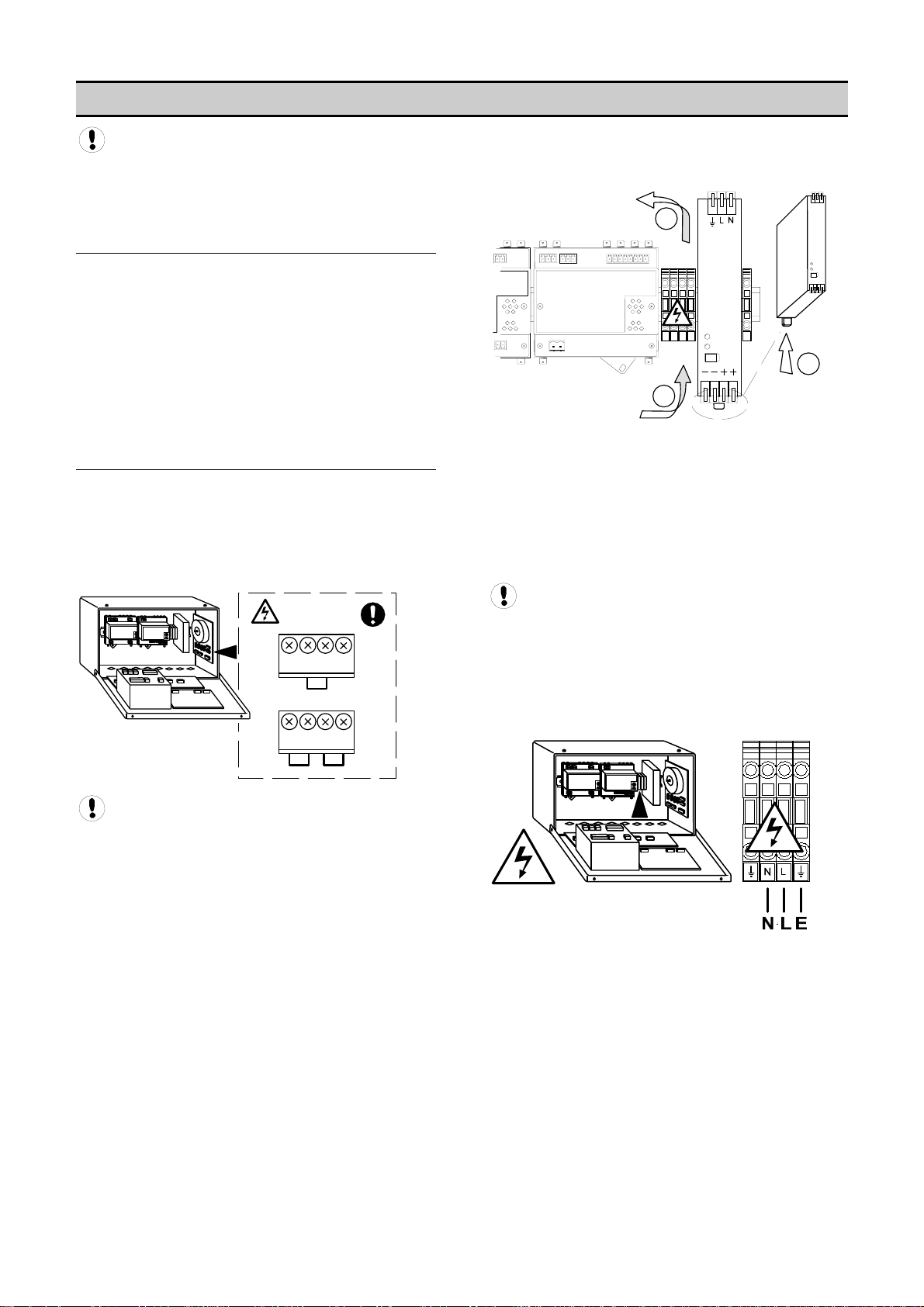

POWER SUPPLY

A fused switching isolator must be installed to the main

incoming power supply, external to the X12I. The isolator

must be fitted with a fuse of the correct rating to provide

adequate protection to the power supply cable used (in

ccordance with local electrical and safety regulations). a

XPM-TAC24

1

X04

X04

23 4

VOLTAGE SELECT

1

23 4

VOLTAGE SELECT

230Vac

115Vac

If it is necessary to adjust the link wires access to the link

terminals can be achieved by temporarily removing the

C Power supply unit (DC) located on the main DIN Rail. D

B

DC

A

C

A) Push the DIN Rail mount button located at the bottom

of the DC Power supply unit. This action can be

achieved by hand; no tooling is required.

B) Remove the DC power supply unit from the DIN Rail

and carefully maneuver to the left. There is no need

to disconnect any wiring.

C) Click the DC power supply unit back in place when

voltage select link adjustment is complete.

The DC power supply unit is mounted in an

inverted orientation on the DIN Rail; this is an

intentional design feature.

Connect the incoming power supply wires to the

power supply terminal blocks located on the main

DIN Rail.

Ensure that the voltage select input is properly

jumpered for the incoming power. Default voltage

onfiguration is 230Vac. c

14

Page 15

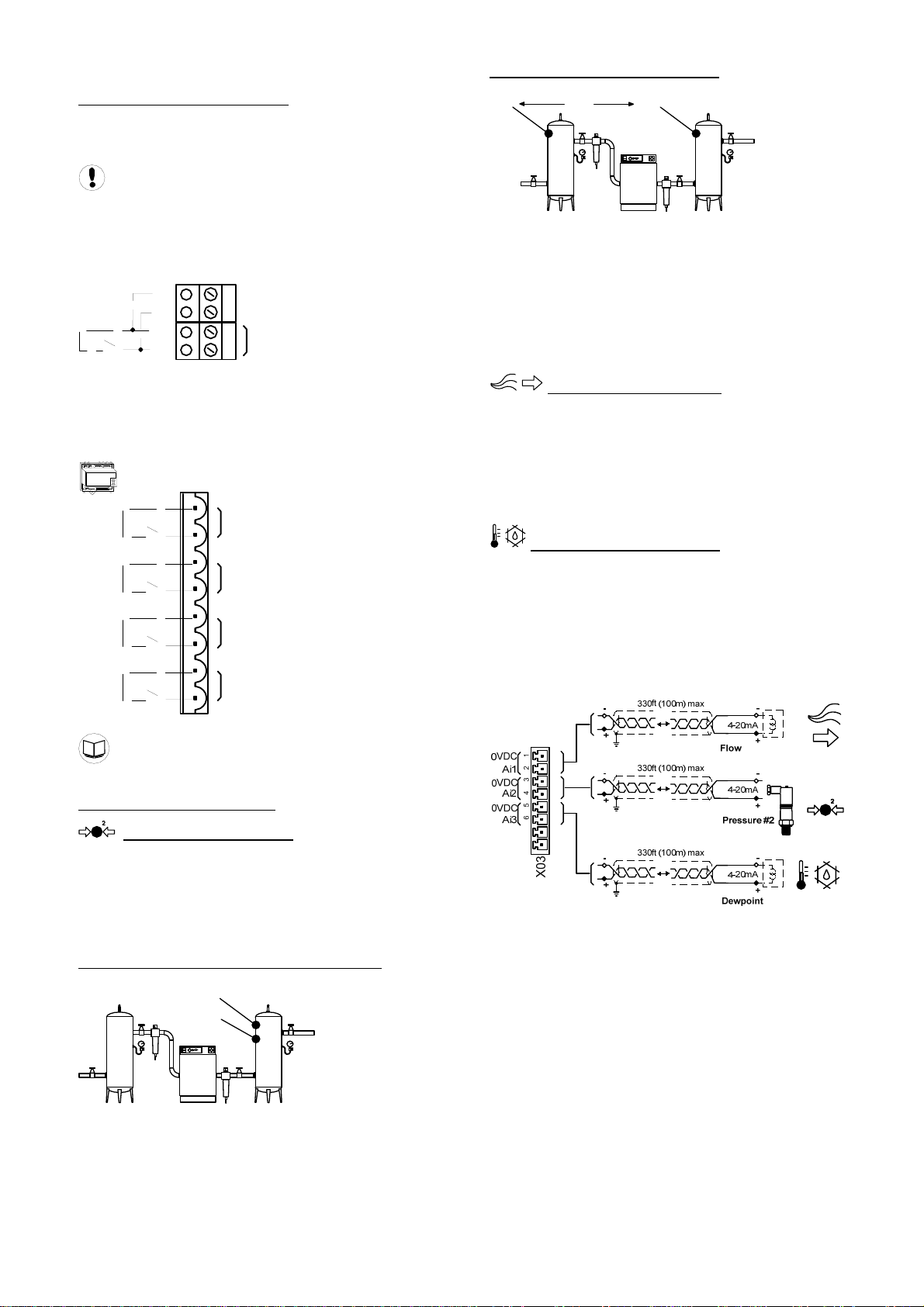

PRESSURE SENSOR LOCATION

The system pressure sensor (P) must be located where it

will see the air pressure that is common to all of the

ompressors. c

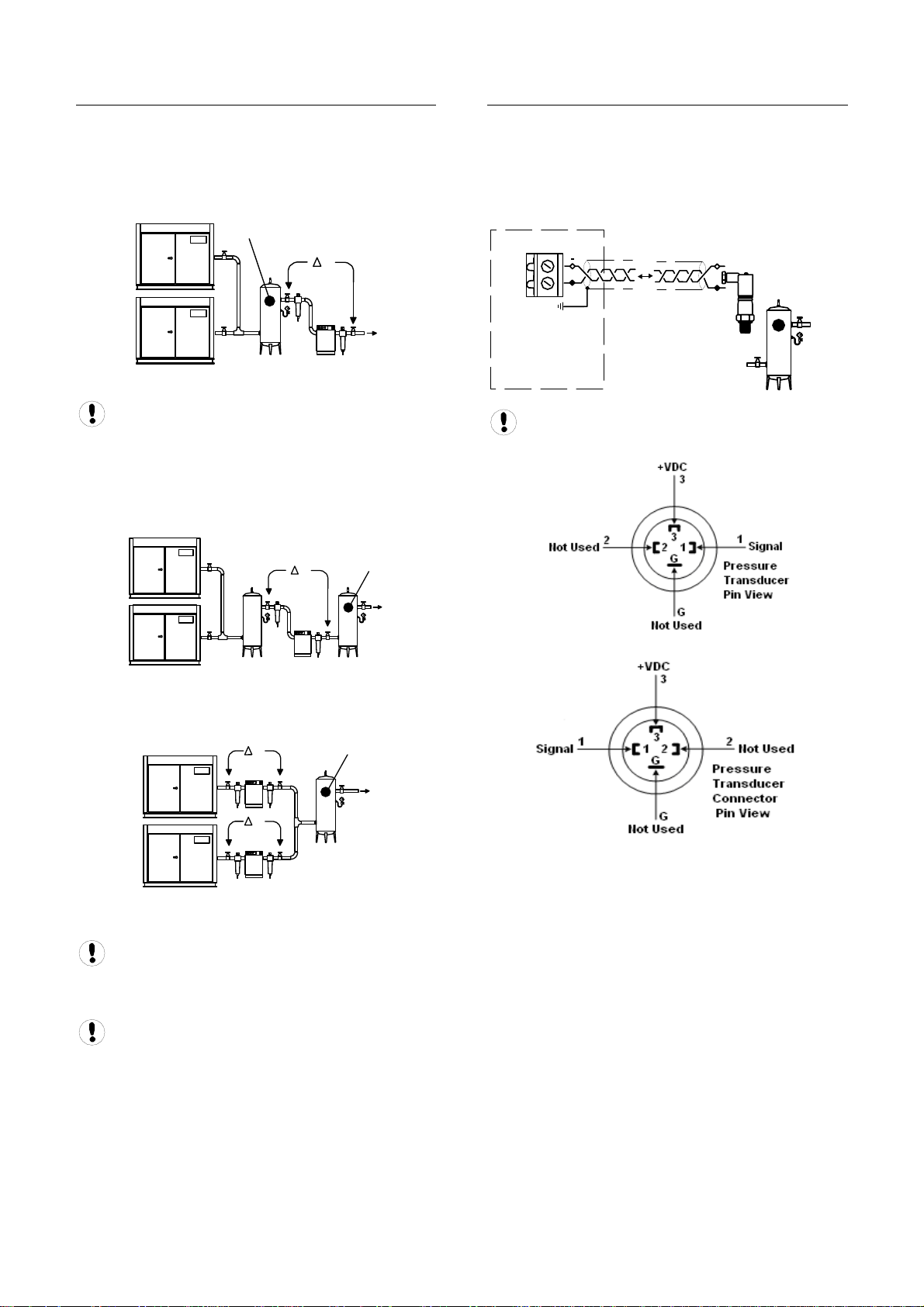

SUPPLY (WET) Side Pressure Control

P

1

P

2

Pressure Sensor Located Before Cleanup Equipment

Dry side pressure will be lower than the system

pressure due to pressure differential losses across air

treatment equipment. The nominal system pressure will

reduce as the air treatment differential pressure

ncreases. i

DEMAND (DRY) Side Pressure Control

PRESSURE SENSOR CONNECTION

The pressure sensor must be connected to terminal X05

of the X12I Terminal PCB using a shielded (earth

screened), two-conductor (2 core), 20 gauge (0.5mm2

CSA minimum), cable no greater than 330ft (100m) in

ngth. le

X05

26

25

+

Wire polarity is important.

-

+

4-20mA

1

P

P

2

Pressure Sensor Located After Shared Cleanup

Equipment

P

P

1

P

2

Pressure Sensor Located After Individual Cleanup

Equipment

Ensure each compressor is equipped with

independent excess pressure shutdown. An increase in

pressure differential across air treatment equipment can

result in excess compressor discharge pressure.

Pressure Sensor Wiring and Location

The pressure transducer threads are BPT G1/4”

DIN3852, Form E, Inox 1, 4305 stainless. It is the

quivalent of ¼” NPT. e

Regular routine monitoring of pressure differential

across air treatment equipment is recommended.

15

Page 16

IR-485 AND IRV-485 GATEWAY

MODULE

The ir-485 and irV-485 Gateways are designed to

interface the Intellisys Controller on the Ingersoll Rand

Compressors and the Nirvana compressors, 20 HP

(15KW) and above, with the X12I via the RS485 Network

utilizing the ir485 protocol. The ir-485 and irV-485

Gateways are DIN Rail mounted and can be located

within the compressor control gear enclosure or remotely

within a separately enclosure.

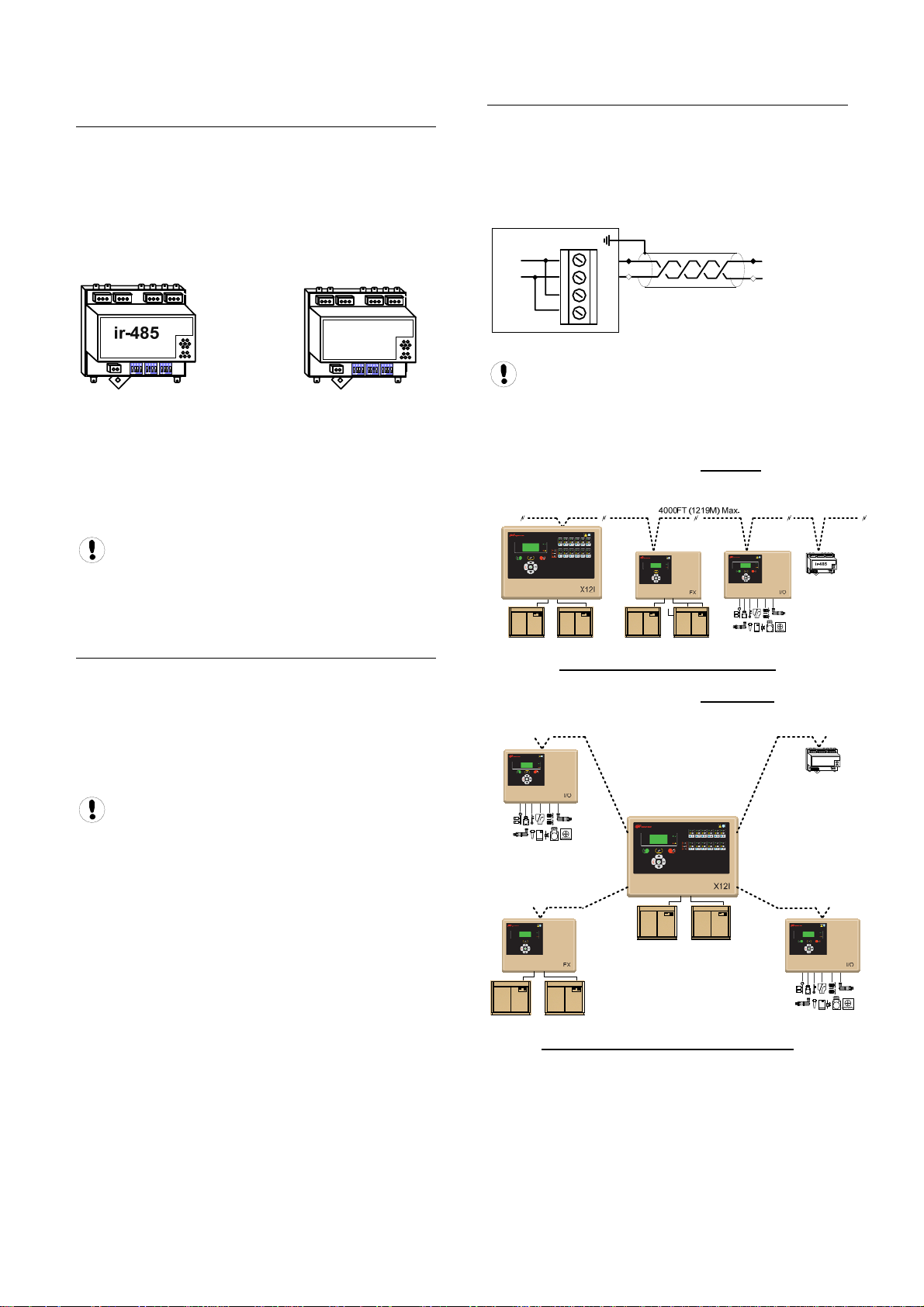

irV-485

ir-485 Gateway irV-485 Gateway

The cable used between the X12I and the ir-485 and irV485 Gateways is Belden 9841 (or equivalent). It should

be run in grounded conduit and should not be greater

than 4000 feet (1219 meters) in length.

The cable used between the ir-485 Gateway and irV-485

Gateways and the Intellisys Controller is included with

the Installation Kit

Consult the X12I Interconnect and Application

Guide and the ir-485 or irV-485 Gateway Manual prior to

the installation of the X12I and the Compressor Gateway

to the air compressor.

IR485 COMMUNICATION PROTOCOL

ir485 is a unique communication protocol designed

specifically for Compressor and Air System control. ir485

is a Multi-Master vs. a Master–Slave protocol that

enables faster, more effective control of network

components. ir485 also features distributed control

capabilities and has inherent resistance to

ommunication faults due to noise c

RS485 NETWORK

The X12I is equipped with an RS485 network

communications capability using the ir485 protocol. This

facility can be used for remote connectivity to optional

networked units and modules with ir485 communications

capabilities or compressor controllers equipped with the

485 capability. ir

X06

L2

L1

The RS485 Network is a Serial, Point to Point

Communication Network. Refer to the X12I Application

and Interconnect Guide For Wiring Details and

onnectivity. C

The following example details the “correct”

iring the RS485 Network w

The following example details the “incorrect” method of

iring the RS485 Network w

30

29

28

27

RS485

method of

Correct RS485 Network Example

L2

L1

ir-485

Follow RS485 Network installation

recommendations

Incorrect RS485 Network Example

16

Page 17

S485 Installation ConsiderationsR

RS485 data communications and other low voltage

signals can be subject to electrical interference. This

potential can result in intermittent malfunction or anomaly

that is difficult to diagnose. To avoid this possibility

always use earth shielded cables, securely bonded to a

known good earth at one end. In addition, give careful

onsideration to cable routing during installation. c

a) Never route an RS485 data communications or low

voltage signal cable alongside a high voltage or 3-phase

power supply cable. If it is necessary to cross the path of

power supply cable(s), always cross at a right angle. a

b) If it is necessary to follow the route of power supply

cables for a short distance (for example: from a

compressor X12I to a wall along a suspended cable tray)

attach the RS485 or signal cable on the outside of an

earthed cable tray such that the cable tray forms an

earthed electrical interference shield.

c) Where possible, never route an RS485 or signal cable

near to equipment or devices that may be a source of

electrical interference (for example: 3-phase power

supply transformer, high voltage switchgear unit,

frequency inverter drive module, radio communications

ntenna). a

17

Page 18

COMPRESSOR INTERFACE IR-PCB

The ‘ir-PCB’ is designed to interface a compressor with

the X12I using a 6-core (or 7-core for IRV-PCB

operation), earth shielded, cable no greater than 330ft

100 meters) in length. (

Each compressor in the system must be assigned a

unique identification number from 1 up to the number of

compressors in the system. The identification number

should be clearly indicated on each compressor for

perational reference. o

For each compressor connected to the X12I utilizing an

‘ir-PCB,’ the signal wires must be connected to the X12I

terminals dedicated for the assigned compressor

eference number. r

C01 C02 C04

i-PCB

C03

V

24613 5

#1

C05

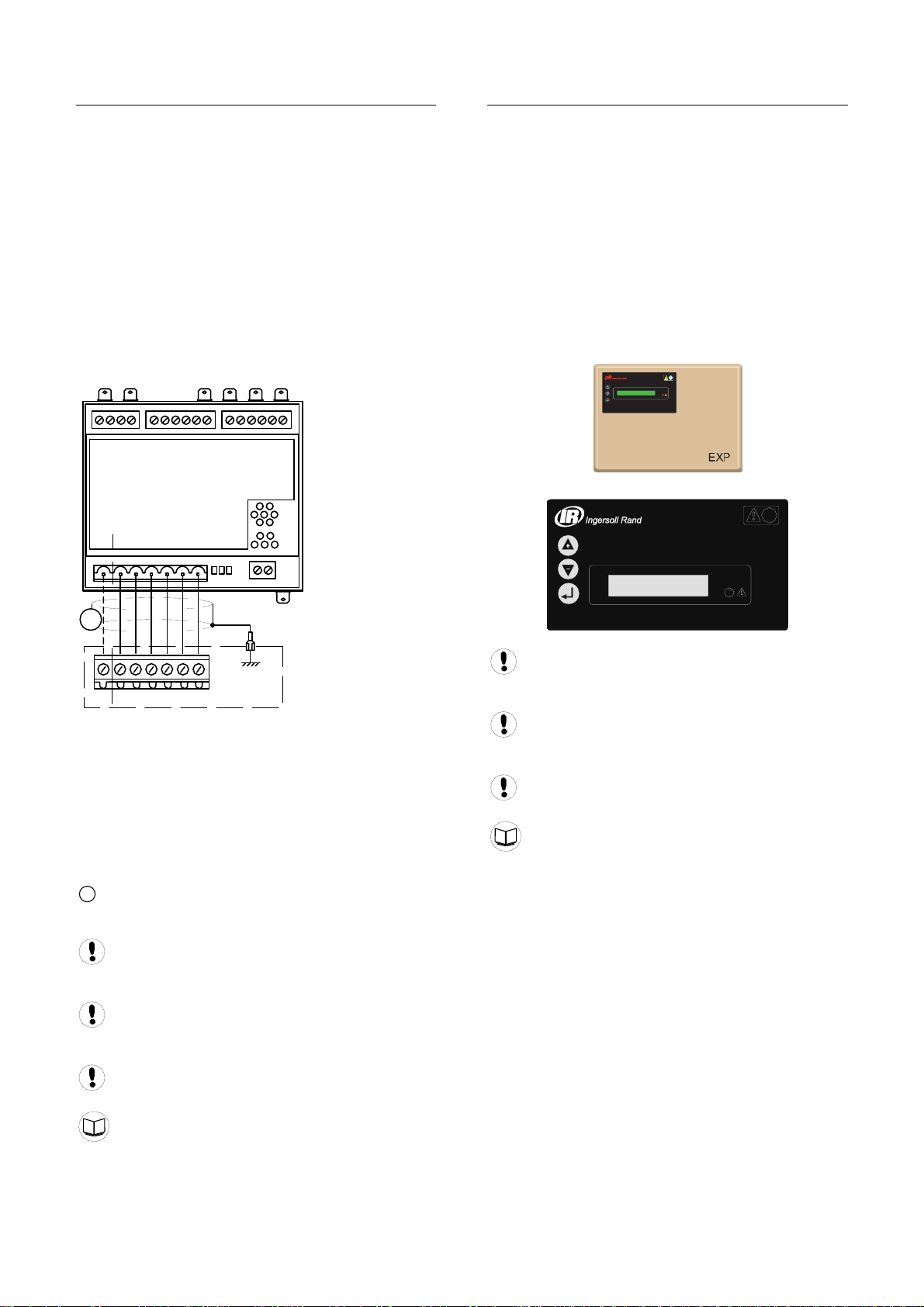

IR-PCB EXP BOX (OPTION)

As standard the X12I has four direct connect ‘ir-PCB’

terminal connections. This capability can be extended

with the use of optional ir-PCB EXP Box(s). Each box

adds another four direct connect ‘ir-PCB’ terminals. Up to

two ir-PCB EXP Boxes can be connected to the X12I to

provide a maximum of 12 direct connect ‘ir-PCB’

erminals. t

The ir-PCB EXP Box is wall mounting and must be

located adjacent to the X12I unit. The distance between

the X12I and the ir-PCB EXP Box is no greater than 33ft

10m). (

LED 1 LED 2

V

X01

246135

V1

The ‘ir-PCB’ is a DIN rail mountable module designed to

be installed within the compressor control or switchgear

rea. a

Each air compressor must be equipped with a

load/unload regulation system and, if not regulated with a

single electro-mechanical pressure switch, have a facility

for a remote load/unload control with the ability to accept

volt-free switching contact input for remote load/unload. a

V

For variable speed compressor(s) equipped with a

‘variable/fixed’ digital input function; Install a 7-core cable

from the ‘ir-PCB’ to the X12I.

Consult the air compressor manual or your air

compressor supplier/specialist for details before installing

the X12I.

Consult the X-Series Interconnect and Application

Guide prior to the installation of the X12I and the ir-PCB

to the air compressor.

C: 5 - 8

Consult the air compressor manual or your air

compressor supplier/specialist for details before installing

the X12I.

Consult the X12I Interconnect and Application

Guide prior to the installation of the X12I and the ir-PCB

to the air compressor.

Consult the EXP Box Instruction Manual for

information regarding the use of the EXP Box.

EXP Box Instruction Manual

Consult the ir-PCB Instruction Manual for

information regarding the use of the ir-PCB.

ir-PCB Instruction Manual

18

Page 19

ON BOARD I/O OPTIONS

DIGITAL INPUTS (OPTIONS)

T he X12I is equipped with ten auxiliary inputs.

Each input is designed to detect a remote ‘volt-free’

switching contact (rated for a minimum 24VDC @ 10mA)

ith a cable length of 330ft (100m) maximum. w

D i1: Digital Input 1, Menu Configurable

X07

32

31

Menu Items – S02:D1

he functions of Di2 to Di10 are fixed. T

ange Di2: Force Sequence Ch

Di3: Remote Start/Stop

Di4: Standby Override

Di5: Table 1 Override

Di6: Table 2 Override

Di7: Table 3 Override

Di8: Table 4 Override

Di9: Table 5 Override

i10: Table 6 Override D

XPM-Ai4

X03

Di1

Di2: Force Sequence Change

Initiates an immediate change/review of the compressor

sequence assignment. The input must be activated for a

minimum of two second. Routine scheduled sequence

change events are not disrupted and will still occur as

ormal. n

Di3: Remote Start/Stop

A start command is generated when the input changes

state from open to closed. The input must remain closed

while running. A stop command is generated when the

put changes state from closed to open. in

Local and Communications Start and Stop remain

active. If the Stop button is pressed while this input is

eld closed, the unit will stop. h

Di4: Standby Override

All compressors are unloaded and continuously held

offloaded. Any active ‘Table’ override input has priority

ver the standby override input. o

Di5 to Di10: Table 1 to 6 Override

The X12I will select the applicable ‘Table’ when a table

input is activated. The X12I will return to normal table

selection, in accordance with pressure schedule or menu

etting, when no table input is activated. s

When a table override input is activated the display

will show a manual table override symbol adjacent to the

able’ symbol. ‘t

If more than one table override input is activated at the

same time the X12I will give priority to the lowest table

number. For example: If table 2 and 3 override inputs are

activated at the same time the X12I will use table 2.

0VDC

Ai4

7

8

Di2

XPM-Di8R4

X03

1

Di1

2

3

Di2

4

5

Di3

6

7

Di4

8

9

Di5

10

11

Di6

12

13

Di7

14

15

Di8

16

Di3

Di4

Di5

Di6

Di7

Di8

Di9

Di10

19

Page 20

DIGITAL OUTPUTS (OPTIONS)

The X12I is equipped with five remote relay contact

utput. o

Remote output relay contacts are rated for 240V

‘CE’ / 115V ‘UL’ @ 4A maximum.

1: Relay Output 1, Menu Configurable R

X08

36

35

34

33

R1

R2: Relay Output 2, Menu Configurable

R3: Relay Output 3, Menu Configurable

R4: Relay Output 4, Menu Configurable

5: Relay Output 5, Menu Configurable R

XPM-Di8R4

X03

1

R1

2

3

R2

4

5

R3

6

7

R4

8

R2

R3

R4

R5

P2+>DP: Pressure Differential Mode

P1P2 DP

The second pressure sensor can be used to monitor

pressure downstream, or upstream, of air treatment

equipment. The pressure differential (DP) between the

primary control pressure sensor (P1) and the second

pressure sensor (P2) can be displayed on the screen. A

pressure differential Alarm (Warning) level can also be

set to indicate when differential pressure exceeds the set

mit. li

Airflow Sensor Monitoring

The X12I is equipped with a 4-20mA input dedicated for

optional airflow sensor monitoring. Any airflow sensor,

that is equipped with a ‘loop powered’ 4-20mA output,

can be connected to the X12I. The airflow sensor value

can be displayed on the X12I screen and is available on

emote communications. r

Dewpoint Sensor Monitoring

The X12I is equipped with a 4-20mA input dedicated for

optional dewpoint sensor monitoring. Any dewpoint

sensor, that is equipped with a ‘loop powered’ 4-20mA

output, can be connected to the X12I. The dewpoint

sensor value can be displayed on the X12I screen and is

available on remote communications.

Virtual Relay Automation – R1 to R5

ANALOG INPUTS (OPTIONS)

Second Pressure Sensor:

The X12I is equipped with a 4-20mA input dedicated for

n optional second pressure sensor. a

The second pressure sensor (P2) can be utilized for one

f two available functions: o

1<>P2: Redundant Pressure Transducer ModeP

P1

P2

If the primary control pressure sensor (P1) fails the

management unit will automatically switch to the ‘backup’

ressure sensor (P2). p

20

Page 21

SECTION 5 — CONTROL FEATURES AND FUNCTIONS

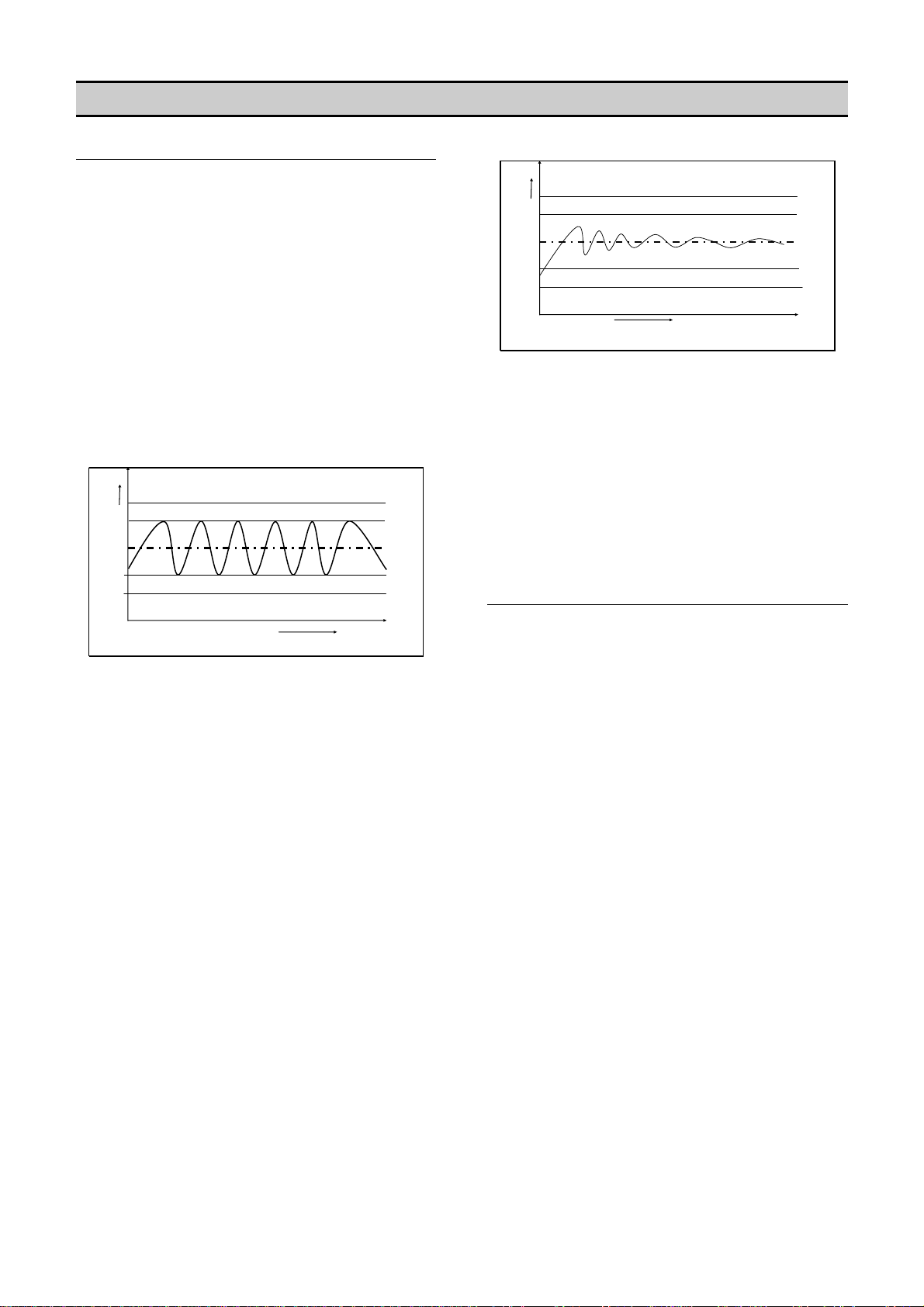

PRESSURE CONTROL

Pressure control is achieved by maintaining the system

pressure within an acceptable range, or pressure band,

which is defined and programmed by the user. Pressure

will rise in the band when system demand is less than

the loaded compressor’s output. Pressure will fall in the

band when system demand is greater than the loaded

ompressor’s output. c

Simply stated, pressure control is achieved by unloading

and loading compressors to closely match compressor

output with system demand within a specified pressure

and defined by PL and PH. See Figure 1. b

Variable speed compressors also operate within the

pressure band and actively match compressor output

with system demand by speeding up and slowing down

around a target pressure defined by the exact midpoint of

the pressure band defined by PT. See Figure 2.

a

b

PH

PT

PL

PH

PT

PL

Figure 2 — Typical VSD Pressure Control vs. Time

The variable speed compressors in the system will run on

their target pressure and smooth out the variations in

system pressure. This assumes that system demand

does not vary more than the capacity of the variable

peed compressor. s

A variable speed compressor will be included in the

load/unload sequence and be controlled exactly as a

fixed speed machine with the exception of speed control

to maintain target pressure.

ANTI-CYCLING CONTROL

Figure 1 — Typical System Pressure vs. Time

As pressure rises to point “a”, the compressor will unload

based on the sequencing algorithm. System pressure is

then allowed to decrease due to the drop in supply until

point “b” is reached. Once point “b” is reached, the X12I

will load the next compressor in the sequence to match

the air demand. This cycle will repeat as long as the X12I

is able to keep the system air pressure between PH and

PL.

The most efficient way to utilize most air compressors is

either fully loaded or off, with the exception of variable

speed compressors which can operate efficiently at

reduced loading. Compressor cycling (start-load-unloadstop, etc.) is essential to maintain pressure control.

Excessive cycling, however, can result in poor

ompressor efficiency as well as increased maintenance.

c

Anti-cycling control is incorporated to help ensure that

only the compressors that are actually required are

started and operating while all others are kept off. Anticycling control includes a pressure tolerance range or

band, defined by the user, which is outside of the primary

pressure band. Inside the tolerance band, an active

control algorithm continually analyzes pressure dynamics

to determine the last possible second to add or cycle

another compressor into the system. This control is

further enhanced by the ability to fine tune the tolerance

and settings and algorithm processing time (Damping). b

21

Page 22

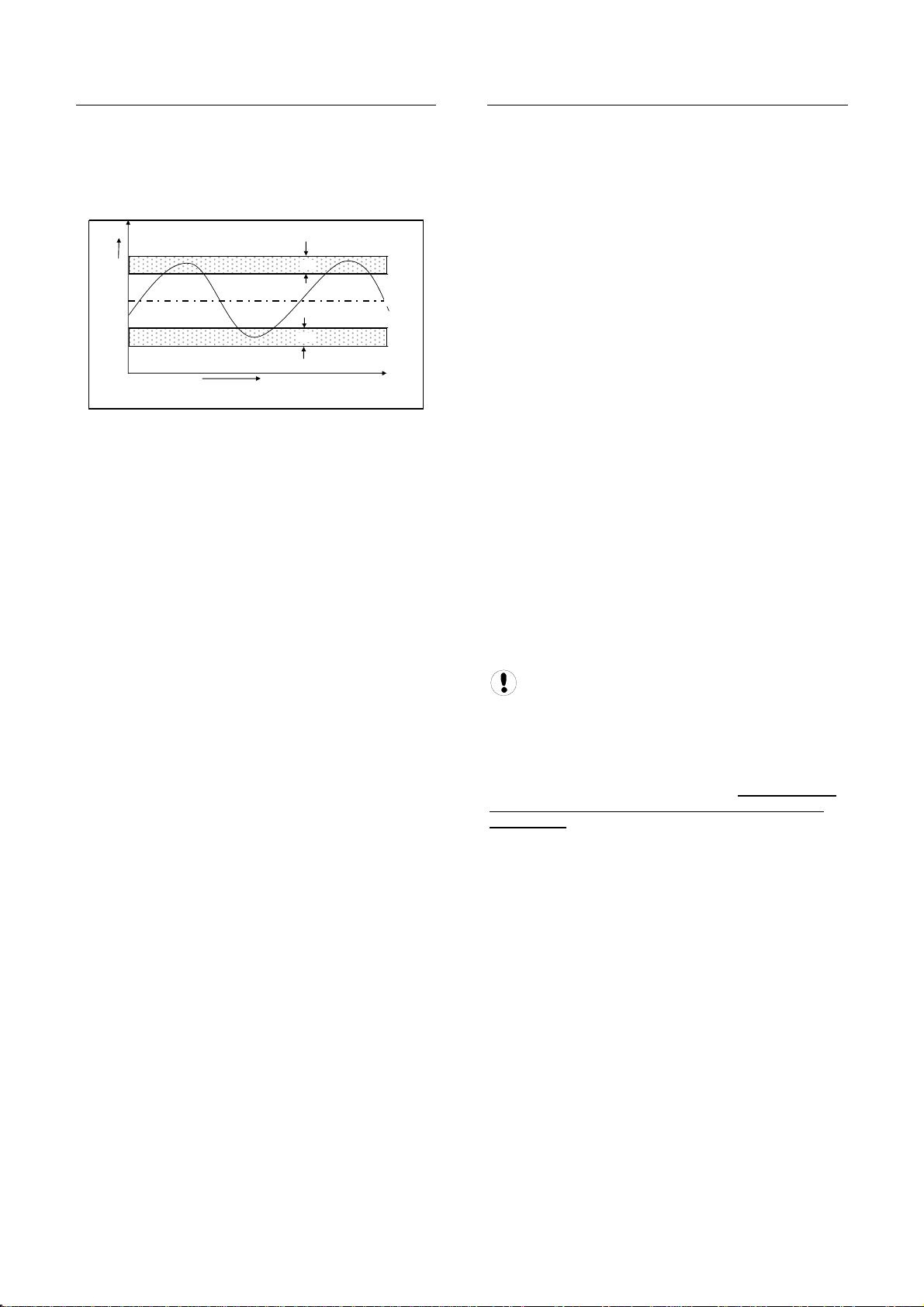

TOLERANCE

Tolerance is a user adjustable setting that determines

how far above the PH Setpoint and below the PL

Setpoint system pressure will be allowed to stray.

Tolerance keeps the X12I from overcompensating in the

event of a temporary significant increase or decrease in

system demand.

TO

TO

Figure 3 — Tolerance in Relation to PH and PL

Tolerance (TO) is expressed as a pressure defining the

width of the band above PH and below PL in which

energy efficient control will be in effect.

When system pressure is in the tolerance band, the X12I

will continuously calculate the moment at which

compressors will be loaded or unloaded based on the

rate of change of system pressure. When the system

pressure strays outside of the tolerance band, the X12I

will abandon energy efficiency and begin to protect the

system air pressure by loading or unloading the

ompressors. Loading will be delay controlled. c

When the compressed air system storage is relatively

small compared to the system demand, and fluctuations

are large and quick, the tolerance band setting should be

increased to maintain energy efficient operation and

avoid a situation in which multiple compressors are

oaded just to be unloaded moments later. l

When the compressed air system is relatively large

compared to system demand and fluctuations are smaller

and slower, the tolerance band can be reduced to

improve pressure control and maintain energy efficient

operation.

The factory default setting for tolerance is 3.0 PSI

0.2Bar). This setting is user adjustable. (

PH + TO

PH

PT

PL

PL - TO

DAMPING

Any time the pressure is within the Tolerance band the

Anti-Cycling algorithm is active, sampling the rate of

pressure change and calculating when to load or unload

the next compressor. The damping (DA) setting is a user

adjustable Setpoint that determines how quickly the

controller samples and recalculates, effectively speeding

p or slowing down the reaction time. u

The X12I’s factory default DA setting of “1” is adequate

for the majority of compressed air systems but may need

to be adjusted in the following circumstances involving

aggressive and disproportionate system pressure

hanges: c

• Inadequate air storage

• High pressure differential across the air

treatment equipment

• Incorrectly sized piping

• Slow or delayed compressor response

In these circumstances, the X12I may overreact and

attempt to load additional compressors that may not be

necessary if the system was given time to allow the

system pressure to stabilize after the initial compressor is

given time to load. If the tolerance has already been

increased and the X12I is still overreacting, then

creasing the damping factor is the next step. in

Damping is adjustable and is scaled from 0.1 to 10 with a

factory default of 1. A factor of 0.1 is a reaction time 10

times faster than the default and a factor of 10 is a

eaction time 10 times slower than the default. r

There are many variables that go into

determining the stability and control of the system

pressure, only some of which are able to be

controlled by the X12I. System storage, air

compressor capacity, and air demand all need to be

analyzed by experienced professionals to determine

the best installation for your system. Tolerance (TO)

and damping (DA) can be used for minor tuning of

the system.

22

Page 23

SYSTEM VOLUME

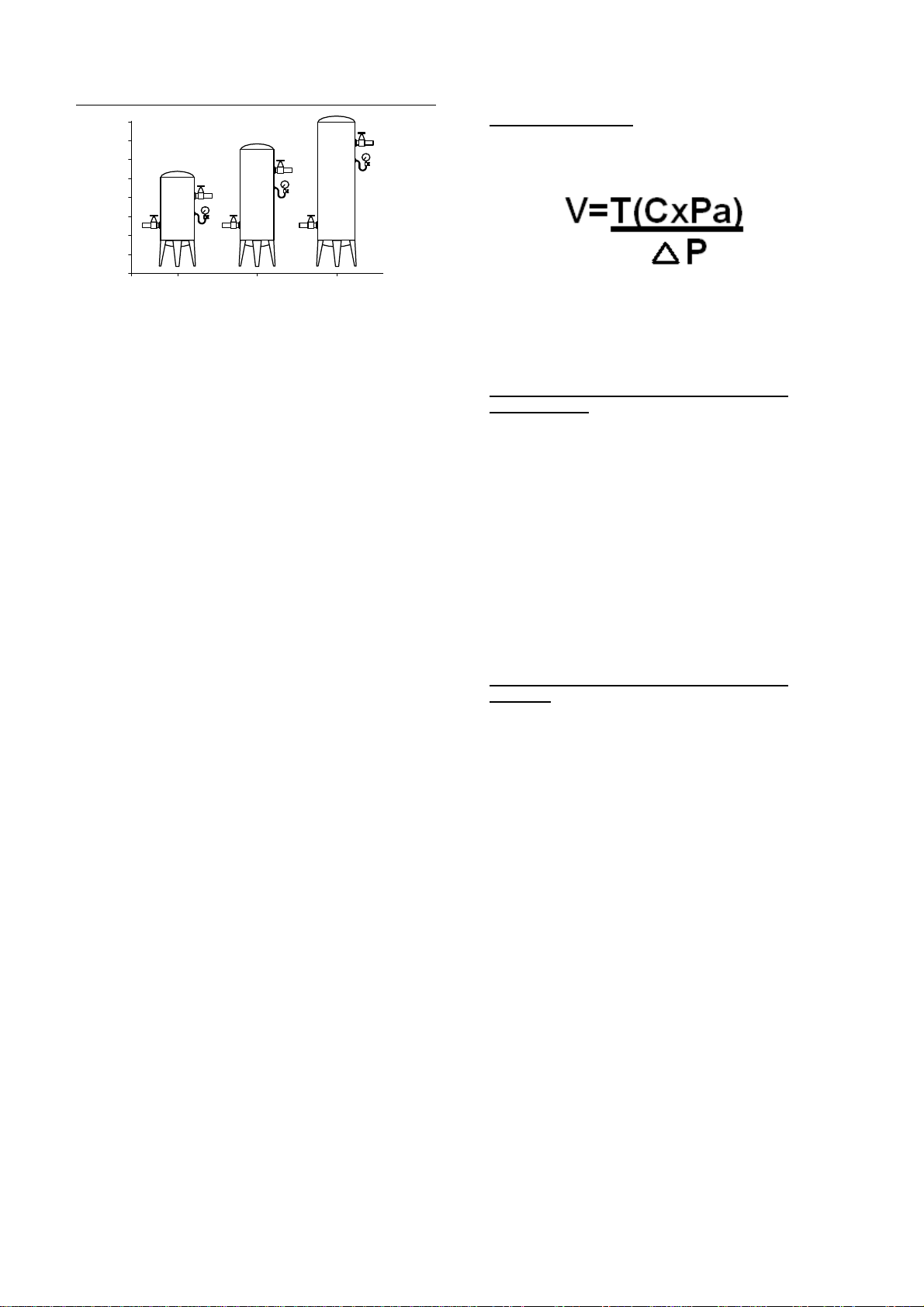

torage Calculations:S

The following formula determines the recommended

inimum storage volume for a compressed air system: m

-

+

Assorted Receiver Tanks

System volume defines how fast system pressure will

rise or fall in reaction to either increased/decreased

demand or increased/decreased supply. The larger the

system volume, the slower the pressure changes in

relation to increased/decreased demand or supply.

Adequate system volume enables effective pressure

control and avoids system over-pressurization in

response to abrupt pressure fluctuations. Adequate

system volume is created by correctly sizing and utilizing

ir receivers. a

The most accurate way to determine the size of air

receivers or the additional volume required would be to

measure the size and duration of the largest demand

event that occurs in the system, then size the volume

large enough to ride through the event with an

acceptable decrease in system pressure. Sizing the

volume for the worst event will ensure system stability

and effective control over all other normal operating

onditions. c

If measurement is not available, then estimating the

largest event is a reasonable alternative. For example,

assume that the largest demand event could be equal to

the loss of the largest operating air compressor. System

volume would be sized to allow time for a back-up

compressor to be started and loaded with an acceptable

decrease in pressure.

V — “Volume of Required Storage” (Gal, Ft , m , L)

T — “Time to Start Back-up Compressor” (Minutes)

3 3

M, m

3

Pa — “Atmospheric pressure” (PSIa, BAR)

P — “Allowable Pressure Drop” (PSI, BAR) ∆

3

Ft

and US Gal.

(4) - 100 Hp Compressors at 450 CFM (12.7 m

Required Storage Volume in Example 1: Find

3

) each

15 seconds to start and load a compressor.

5PSIG pressure drop. is the maximum allowable

nds (.25 minute) T=15 Seco

C=450 ft

3

Pa = 14.5 PSI

Delta P = 5 PSI

.5)]/5 V = [.25 x (450 x 14

525)/5 V = (.25 x 6

V = 1631/5

V = 326 Ft

1 ft = 7.48 Gal

3

3

3

x 7.48 Gal= 326 Ft

Gal = 2440

: Find Required Storage Volume in Example 2

3

) each 4) - 100 Hp Compressors at 450 CFM (12.7 m

m

(

3

and L.

15 seconds to start and load a compressor.

0.34 B essure drop. AR is the maximum allowable pr

ds (.25 minute) T=15 Secon

C=12.7 m3

Pa = 1BAR

Delta P = .34 BAR

]/.34 V = [.25 x (12.7 x 1)

2.7)/.34 V = (.25 x 1

V = 3.2/.34

V = 9.33m

1m = 1000 L

3

3

3

x 1000 L= 9.33

m

L = 933

/min) C — “Lost Capacity of Compressed Air” (CF

23

Page 24

SEQUENCE CONTROL STRATEGIES

The X12I provides three basic sequence control

strategies or modes. Each sequence control strategy

onsists of two sub strategies: c

1) The compressor ‘Rotation’ strategy

2) The compressor load ‘Control’ strategy

The ‘Rotation’ strategy defines how the compressors

are re-arranged, or re-ordered, in to a new sequence at

each routine ‘Rotation’ event. Rotation events are

triggered by a cyclic interval time, a set time of day each

ay, or a set time of day once a week. d

The compressor load ‘Control’ strategy defines how

the compressors are utilized in response to variations in

ystem pressure. s

ompressor Sequence Arrangements: C

Each compressor in a system is initially assigned to the

X12I with a fixed and unchanging number reference, 1 to

2. 1

The ‘duty’ that a compressor is assigned in any set

‘Rotation’ sequence arrangement is defined by a letter, A

o L. t

For example:

A = the ‘Duty’ compressor, the first to be utilized.

d. B = The ‘Standby’ compressor, the second to be utilize

C = The ‘Second Standby’ compressor, the third to be

utilized.

D = The ‘Third Standby’ compressor, the forth to be

tilized. u

Compressor ‘duty’ assignments are reviewed, and rearranged as appropriate in accordance with the selected

rotation strategy, at each rotation event.

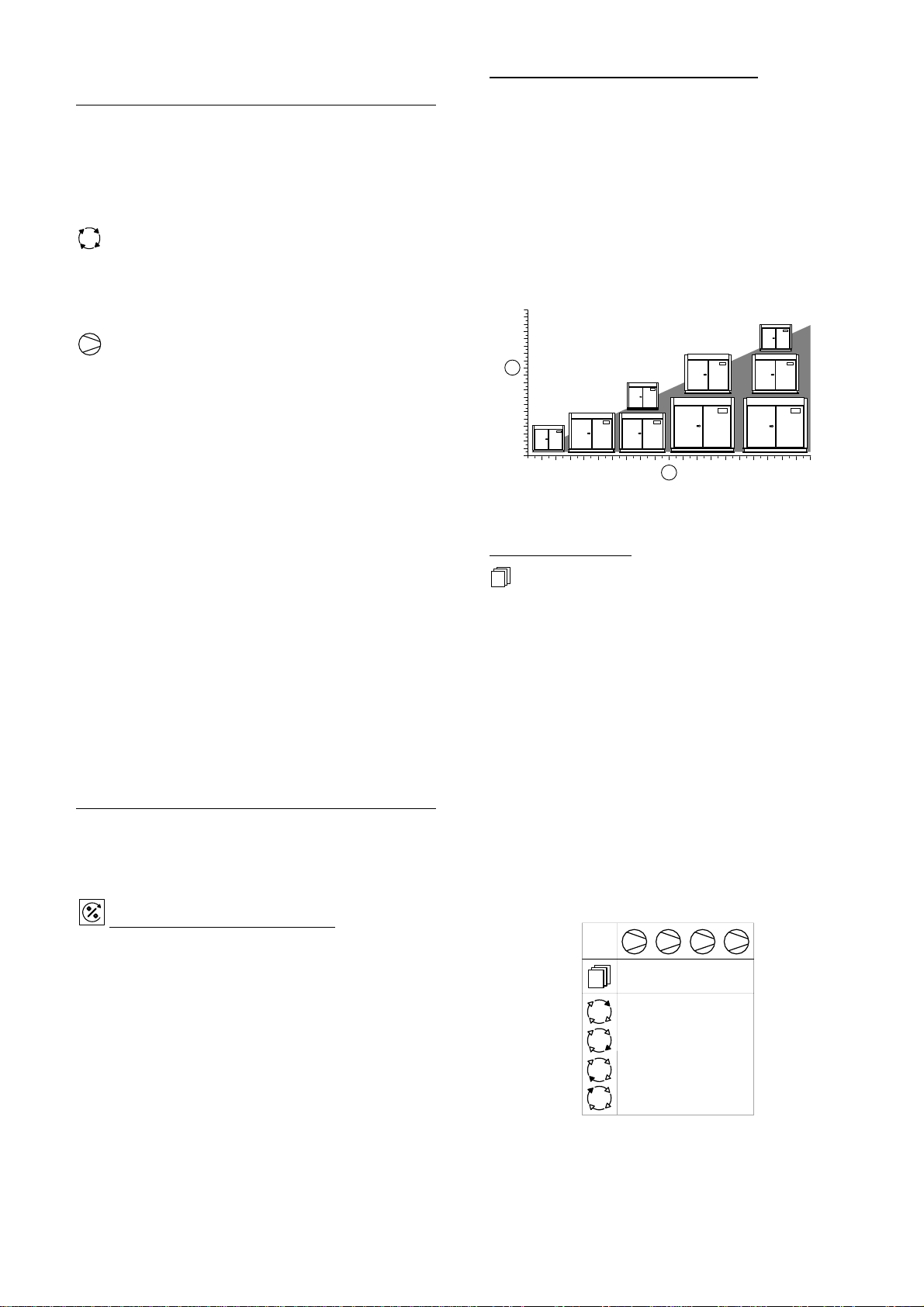

STANDARD CONTROL FEATURES AND

FUNCTIONALITY

The standard (default) configuration of the X12I provides

ENER (Energy Control) sequence control strategy,

Priority Settings, Table Selection, Pressure Schedule,

nd Pre-fill operation. a

ENER: ENERGY CONTROL MODE

he primary function of Energy Control mode is to: T

1/ Dynamically match compressed air supply with

compressed air demand.

2/ Utilize the most energy efficient set/combination of air

ompressors to achieve 1/. c

Energy Control mode is designed to manage systems

that include compressors of different capacities and

different air compressor types (fixed speed, variable

speed and variable capacity) in any combination or

onfiguration. c

Energy Control Mode Control and Rotation:

Compressor control and utilization is dynamically

automated with adaptive control logic and therefore does

not follow pre-determined schedules, rotation

configurations or time intervals. Energy Control mode

can, however be operator influenced by the Priority

unctionality which is discussed later in this manual. f

Energy Control mode is enabled by the ability of the X12I

to process individual compressor capacity, variable

capacity capabilities, and changes in system pressure to

dynamically implement and continuously review ‘best fit’

onfigurations as demand variations occur. c

100%

80%

2

40%

20%

0%

0%

1: Demand

1

100%

2: Supply

PRIORITY SETTINGS

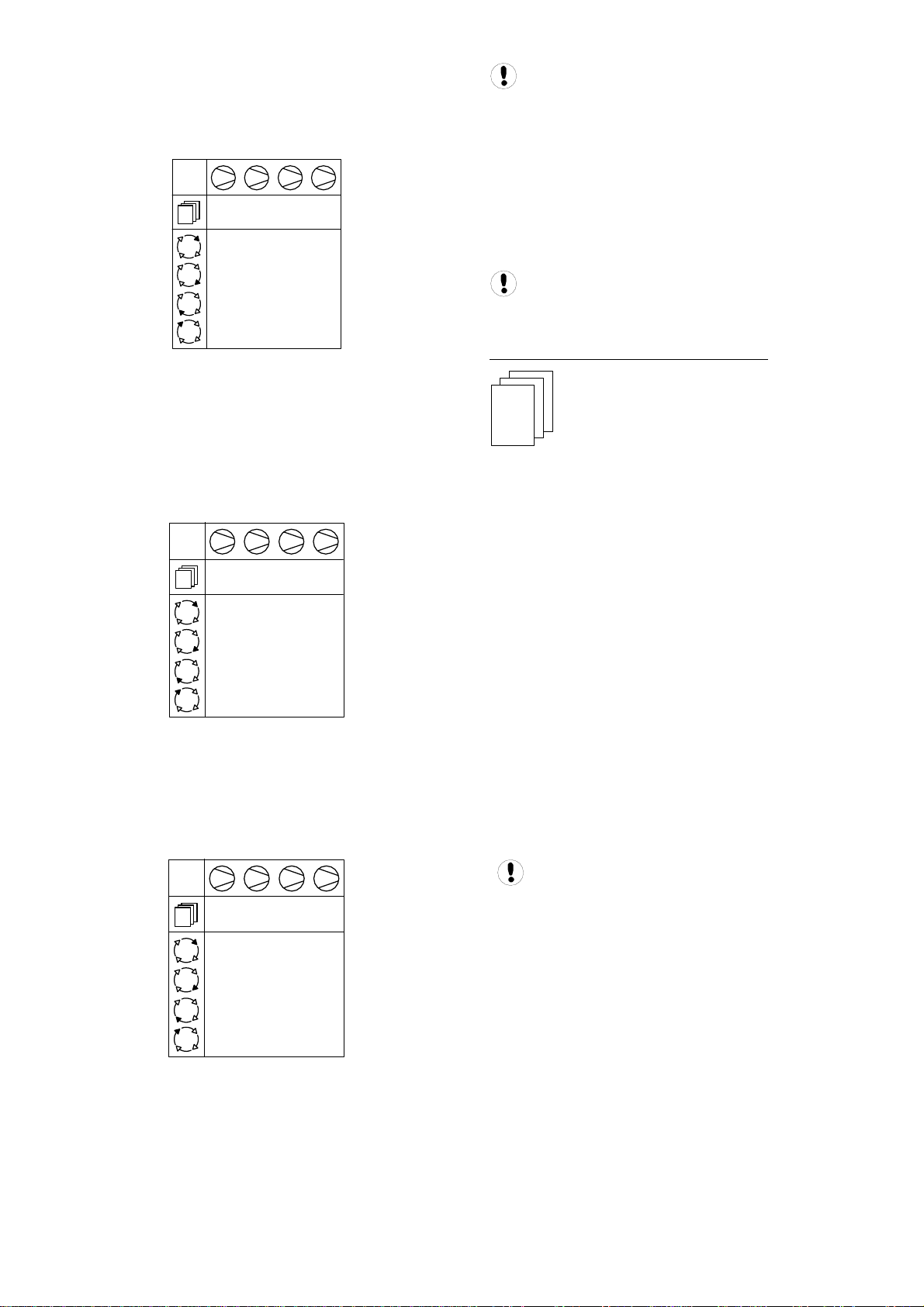

The sequence assignment pattern can be modified

y using the priority settings. b

Priority settings can be used to modify the rotation

sequence assignments. Compressors can be assigned a

priority of 1 to 12, where 1 is the highest priority. Any

compressor can be assigned any priority and any number

of compressors can share the same priority.

Priorities allow you to set up rotation groups. All

compressors that have the same priority number will

rotate inside their own group. The group with the highest

riority will always be in the front of the sequence. p

For example, in a four compressor system including one

variable speed compressor in the compressor 1 position

you may want the variable speed compressor to always

be in the Lead position. By assigning compressor 1 a

priority of 1 and the other three compressors a priority of

2, the variable speed compressor will always remain at

the front of the sequence:

1 2 3 4

1222

#1

ABCD

#2

ACDB

#3

ADBC

#4

ABCD

Compressor 1 has priority 1, all other compressors

have priority 2

24

Page 25

In another example, there is a four compressor system

that includes a compressor in the compressor 4 spot that

is used only as an emergency backup compressor. To

accomplish this, simply assign compressor 4 a lower

priority than any other compressor in the system:

1 2 3 4

1112

#1

ABCD

#2

BCAD

#3

CABD

#4

ABCD

Compressor 4 has priority 2, all other

compressors have priority 1

In a third example, there is a four compressor system

that includes a variable speed compressor designated

compressor 1 and a fixed speed compressor that is an

emergency backup assigned as compressor 4. To ensure

that compressor 1 is always at the front of the sequence

and compressor 4 is always at the end of the sequence,

set the priority as shown below:

1 2 3 4

1223

#1

ABCD

#2

ACBD

#3

ABCD

#4

ACBD

Compressor 1 has priority 1, compressor 4 has

priority 3 and all other compressors have priority 2

A last example involves another four compressor system

that will be assigned into two independently rotation

groups. Compressors 1 and 2 are given priority 1 and

compressors 3 and 4 are given priority 2. This results in

the rotation sequence shown below:

Priority control will also work with ENER control

mode. Recall that ENER control automatically selects the

most efficient set of compressors to dynamically match

compressed air demand. Priority will force the X12I

controller to select from all “priority 1” compressors and

make sure that they are loaded in the sequence before

utilizing any priority 2 compressors. All priority 2

compressors must be utilized before priority 3

compressors can be loaded and so on. Priority allows a

system to be segregated to backup and primary use

ompressors when using ENER control. c

Using the Priority function with ENER Control can

affect system efficiency.

TABLES AND THE PRESSURE SCHEDULE

T01

- - - -

PH

- - - -

PL

- - - -

Pm

- - - -

SQ

The X12I operates based on settings that are

configured into one of six tables. Each table defines the

operational settings and sequence control mode of the

X12I. The X12I can be instructed to change among the

tables at any time based on the configuration of the

ressure schedule. p

This functionality allows the X12I to switch among

multiple different system configurations without any

disruption to control. This is particularly useful in the case

of shift changes, or weekends when the system is to be

deactivated.

Each table consists of the following parameters which

can be set independently in each table:

• PH – High Pressure Setpoint

• PL – Low Pressure Setpoint

• Pm – Minimum pressure warning level

• SQ – Sequence Rotation Strategy

• 01 – Compressor 1 Priority

• to

• 12 – Compressor 12 Priority

1 2 3 4

1122

#1

ABCD

#2

BADC

#3

ABCD

#4

BADC

Two independently rotating compressor groups

The “maximum” pressure fault level and the

rotation interval, or rotation time, are set independently

in a configuration menu and are unchanging regardless

of the table selected.

25

Page 26

PRESSURE CHANGE TIME:

When the X12I is instructed to change between tables, it

will not abruptly change the system operating

parameters. The X12I will adjust the system target

pressure upward or downward to the next table’s

settings. This transition will occur gradually to preserve

energy efficiency and safe, reliable control:

Adjust the ‘day of the week’ sub-setting first and then

press Enter to increment to the next setting. Repeat until

all item sub-settings are entered. The complete ‘Pressure

Schedule’ item will not be set in X12I memory until the

last sub-setting is entered. Press Escape to step back

one sub-item if required.

SEQUENCE ROTATION:

1

The time the system is allotted to change the target

pressure is known as the Pressure Change Time (PC).

This is a value that is adjustable in the system settings

screen.

If the X12I is able to complete the transition in less time

than is allotted without threatening energy efficiency then

PC will be automatically shortened.

An aggressively short time setting will compromise

energy efficiency.

PRESSURE SCHEDULE:

The X12I is equipped with a real time clock feature

and pressure schedule facility. The ‘Pressure Schedule’

function can be used to provide automation of the

ystem. s

The pressure schedule consists of 28 individual settings

that instruct the system to change from one ‘Table’ to

another, or put the system in to ‘Standby’ mode,

dependant on time of day and day of the week. The

pressure schedule will cycle from 00:00 hours Monday

(day #1) to 23:59 hours on Sunday (day #7) each

alendar week. c

P01

01.0# 01

2

PC

Changing Target Pressures

A sequence ‘Rotation’ event can be automatically

triggered on a routine basis using a pre-determined

interval, a pre-determined time each day or a pre-

etermined day and time each week. d

S01

04.01 RP

#1 18:00

Enter the rotation period menu item (RP); the ‘day’

etting will flash. s

Select the ‘day’ or day function as required:

#1 = Monday to #7 = Sunday

#8 = each working day of the week, excluding Saturday

and Sunday

of the week. #9 = each working day

- (dash) = deactivate #

Select the required hour and minutes of the day(s) using

he same method. t

A day starts at 00:00hrs and ends at 23:59hrs (24hr

lock system). c

To define an interval time (more than one

rotation event a day) select ‘#t’ for the day function and

ress Enter: p

S01

04.02 RP

# - - - : - -

- - -

01 02 03040# =

01) Day of the Week

#1 = Monday to #7 = Sunday

#8 = every working day of the week; Monday to

ay. Friday, excluding Saturday and Sund

#9 = every working day of the week.

Select “-“ (dash) and enter to delete a setting from

he schedule. t

4hr format) 02) Hours; time of day (2

03) Minutes; time of day

04) The required table, T01 to T04, or

“-X-“ = Standby (unload all compressors).

# t 12:00

2

An ‘intervals per day’ value will appear and flash. Select

the required number of rotation events per day (1 to 96).

The hour and minutes display will now show the interval

time between each rotation event; 1 = every 24hrs to 96

every 15 minutes (example: 2 = every 12hrs). =

The first automated rotation event each day will

occur at 00:00hrs and then every set rotation interval

time throughout the day.

26

Page 27

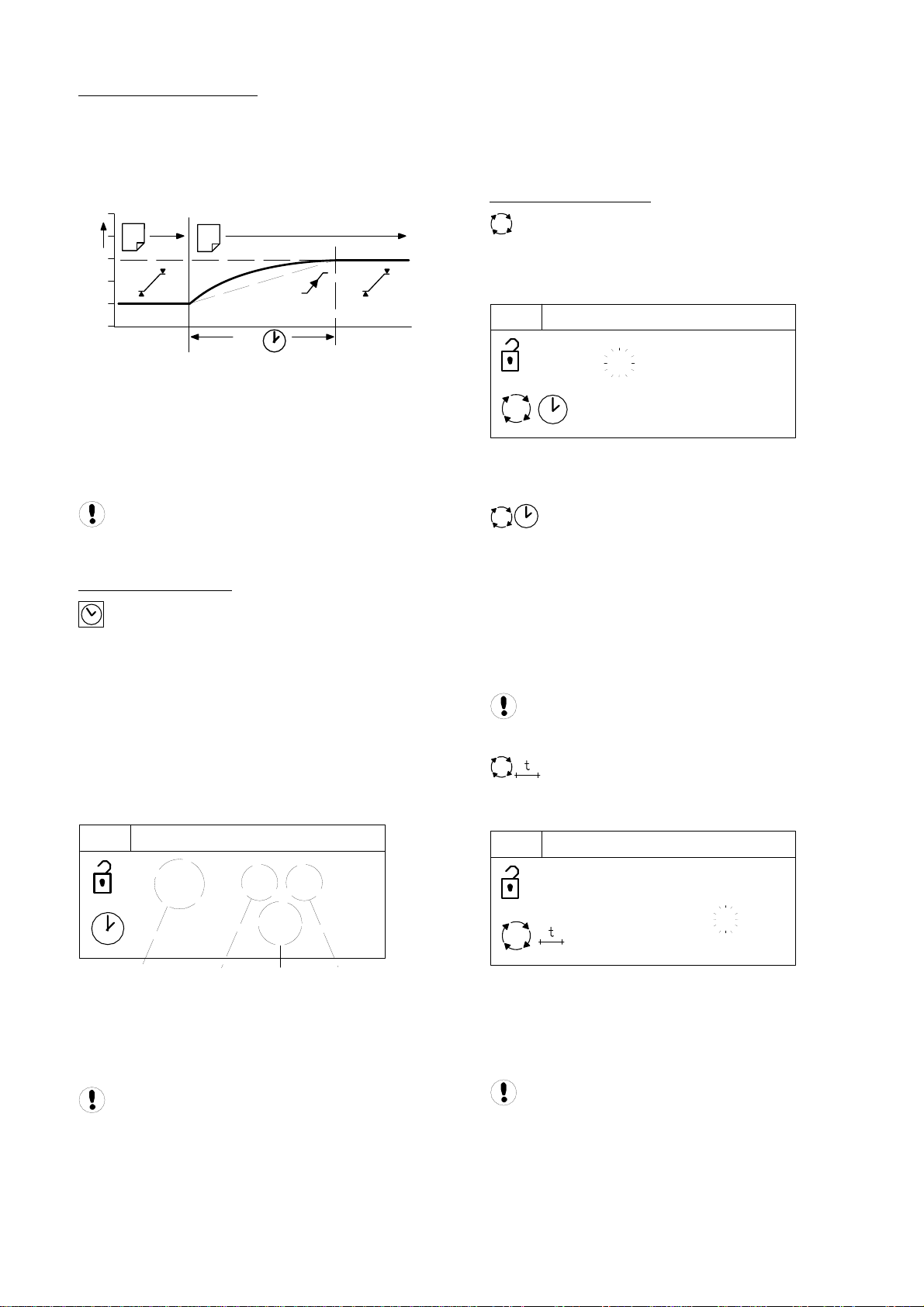

PREFILL

The Prefill feature provides a controlled and energy

efficient method of increasing pressure to normal

operating levels at system start. This feature avoids the

inefficient potential for all available system compressors

to start and load before pressure reaches the normal

perating level. o

At system start (manual start or automated start from

standby) the X12I will only load compressors that have

been pre-determined for prefill operation, for a pre-set

period of time. The prefill time (PT) can be adjusted to

suit system characteristics. The aim is to increase

pressure to normal operational levels, using only the pre-

etermined compressors, prior to the prefill time expiring. d

If normal operational pressure is reached prior to the set

prefill time, the prefill function will automatically cease

and normal operational control begin. If normal

operational pressure is not reached by the end of the

prefill time, the X12I will utilize as many available

compressors as required to achieve normal operational

pressure as quickly as possible. Normal operational

ontrol will then begin. c

Three prefill modes are available. ‘Backup’ and

‘Standard’ modes require compressor pre-selection and

function in the same way; differing only in response to a

failure, or loss, of a prefill compressor. Automatic mode

equires no compressor pre-selection. r

Backup Mode: Compressor(s) can be pre-selected as

‘Primary Prefill’ compressor(s) or ‘Backup Prefill’

compressor(s). If a primary prefill compressor

experiences a shutdown, or is stopped, a pre-defined

ackup compressor replaces it and prefill continues. b

! X

Standard Mode: If one or more of the predefined prefill compressors experiences a shutdown, or is

stopped, the prefill function is cancelled and normal

peration begins. o

A

Automatic Mode: No Prefill compressor

selection is necessary; any selection set is ignored. The

management unit automatically selects compressor(s)

dynamically to achieve pressure in accordance with the

set Prefill time. If a compressor is stopped, or shuts

down, it is automatically substituted with an alternative

ompressor. c

To manually skip Prefill mode, press and hold Start

or several seconds. f

INSUFFICIENT CAPACITY ALARM

CAP

The X12I is equipped with a dedicated ‘Insufficient

Capacity’ Advisory Alarm (Warning) indication. This

indication will illuminate if all available compressors are

loaded and system pressure is continuing to decrease.

The indication will generally occur prior to any set low

pressure Alarm (Warning) and is intended to provide an

dvanced warning of a potential ‘Low Pressure’ situation. a

The ‘Insufficient Capacity’ advisory alarm is intended as

an advanced warning and is not recorded in the fault

history log but is included as a Group Alarm (Warning), or

roup Fault item. G

‘Insufficient Capacity’ is available as a dedicated data

communications item.

can be de-activated. In this instance the unit’s Alarm

indicator will still illuminate but no group alarm, group

fault, or a remote indication is generated.

RESTRICTED CAPACITY ALARM

The ‘Insufficient Capacity’ advisory alarm function

CAP

The X12I is equipped with a dedicated ‘Restricted

Capacity’ Advisory Alarm (Warning) indication. This

indication will flash if all available compressors are

loaded and further capacity is required but one or more,

ompressors are: c

a) inhibited from use in a ‘Table’ priority setting

b) inhibited from use by the short-term Service /

Maintenance function

) inhibited from use in the long term maintenance menu. c

The ‘Restricted Capacity’ advisory alarm is intended to

indicate that all available compressors are already loaded

and further capacity is required but one or more, system

ompressor(s) have been restricted from use. c

The ‘Restricted Capacity’ advisory alarm is not recorded

in the fault history log but is included as a Group Alarm

(Warning), or Group Fault item.

‘Restricted Capacity’ is available as a dedicated data

ommunications item. c

be de-activated. In this instance the unit’s alarm indicator

will still flash but no group alarm, group fault, or a remote

indication is generated.

The ‘restricted capacity’ advisory alarm function can

27

Page 28

ALTERNATE CONTROL STRATEGIES

Energy Control Mode (ENER) is the STANDARD control

mode of the X12I. Alternate control strategies of the X12I

are EHR (Equal Hours Run) and the basic FILO (First in /

ast Out). L

EHR: EQUAL HOURS RUN MODE

The primary function of EHR mode is to maintain a close

relationship between the running hours of each

compressor in the system. This provides an opportunity

to service all compressors at the same time (providing

the service interval times for all compressors are the

ame or similar). s

EHR is not an energy efficient focused mode of

peration. o

EHR Rotation:

Each time the rotation interval elapses, or the rotation

time is reached, the sequence order of compressors is

reviewed and re-arranged dependant on the running

hours recorded for each compressor. The compressor

with the least recorded running hours is assigned as the

‘duty’ compressor, the compressor with the greatest

recorded running hours is assigned as the ‘last standby’

compressor. For systems with more than two

compressors, the remaining compressor(s) are assigned

in accordance with their recorded running hours in the

ame way. s

Example: The compressors in a four-compressor system

have the following recorded running hours at the

Rotation’ time. ‘

Compressor 1 = 2200 hrs

Compressor 2 = 2150 hrs

Compressor 3 = 2020 hrs

ompressor 4 = 2180 hrs C

The new sequence order arrangement after a rotation

vent would be: e

Compressor 1 = D

Compressor 2 = B

Compressor 3 = A

ompressor 4 = C C

Compressor 3, which has the least recorded running

hours, will now be utilized to a greater extent in the new

sequence arrangement; potentially increasing the running

ours at a faster rate. h

The X12I continuously monitors the running status of

each compressor and maintains a record of the

accumulated running hours. These are available, and

adjustable, in the X12I’s compressor running hour’s

menu. The X12I uses these values in EHR mode. The

X12I’s running hours record should be routinely checked,

and adjusted if necessary, to ensure a close match with

he actual run hours displayed on each compressor. t

If a compressor is operated independently from the

X12I the running hours record may not be accurately

updated.

The running hours meter display on most

compressors are intended for approximate service

interval indication only and may deviate in accuracy over

period of time. a

EHR Control:

Compressors are utilized, in response to changing

demand, using a ‘FILO’ (First In, Last Out) strategy. The

‘duty’ compressor (A) is utilized first followed by (B) if

demand is greater than the output capacity of (A). As

demand increases (C) is utilized followed by (D) if

demand increases further. As demand reduces (D) is the

first compressor to be unloaded, followed by (C) and then

(B) if demand continuous to reduce. The last compressor

to be unloaded, if demand reduces significantly, is (A).

The compressor assigned as (A) in the sequence is the

rst to be loaded and the last to be unloaded. fi

FILO: TIMER ROTATION MODE

The primary function of Timer Rotation mode is to

efficiently operate a compressed air system consisting of

fixed capacity output compressors. The routine rotation

assignments can be modified using ‘Priority’ settings to

accommodate for a differentially sized or variable

apacity output compressor(s). c

FILO Rotation:

Each time the rotation interval elapses, or the rotation

time is reached, a sequence rotation occurs and the

sequence assignment for each compressor is rearranged. The compressor that was assigned for duty (A)

is re-assigned as last standby (D) and all other

ompressor assignments are incremented by one. c

#1

#2

#3

#4

The sequence assignment pattern can be modified by

‘Priority’ settings.

Tables; Priority Settings

FILO Control:

Compressors are utilized, in response to changing

emand, using a ‘FILO’ (First In, Last Out) strategy. d

The ‘duty’ compressor (A) is utilized first followed by (B) if

demand is greater than the output capacity of (A). As

demand increases (C) is utilized followed by (D) if

emand increases further. d

As demand reduces (D) is the first compressor to be

unloaded, followed by (C) and then (B) if demand

continues to reduce.

The last compressor to be unloaded, if demand reduces

significantly, is (A). The compressor assigned as (A) in

the sequence is the first to be loaded and the last to be

unloaded.

1 2 3 4

ABCD

DABC

CDAB

BCDA

28

Page 29

ADDITIONAL CONTROL FEATURES AND

FUNCTIONALITY

ZONE CONTROL FUNCTION

Compressors can be assigned to one of three ‘zones’.

The X12I will always attempt to balance utilization across

the zones to maintain, as near as possible, an equal

umber of utilized compressors in each zone. n

2

PRESSURE BALANCE FUNCTION

rP1

P

rP2

1

3

This function is intended for installations that have

ultiple areas of compressor(s) distributed across a site. m

In some instances, large pressure differentials can

develop in remote areas of an air network if air

generation is concentrated in one area. The aim of the

‘zone’ function is to facilitate a balanced pressure across

a site air network by ensuring air generation is

istributed. d

The ‘zone’ function will operate with all available

sequence strategy modes and will work in conjunction

ith the priority and/or pressure balance function. w

The priority function will override ‘zone’ control

where a conflict in compressor selection occurs. This

may result in unexpected compressor utilization; this

hould not be considered abnormal. s

The X12I has the capability to monitor up to two remote

pressures values. These remote pressures can be

integrated with the primary X12I System pressure value,

using one of three available functions, to produce a

calculated ‘balanced’ system pressure for system

ressure control. The three functions to control from are: p

The lowest pressure

The highest pressure

An average of the X12I and the remote pressures

These pressure values can be obtained from Ingersoll

Rand compressor controllers, compressor management

boxes or I/O Boxes.

This function can be used to control to a ‘balanced’

system pressure across an air system that has multiple

remote compressor rooms and/or where pressure

ifferentials across an air system might vary. d

The ‘zone’ function can modify compressor selection

when using ‘Energy Control’ mode. This may

compromise optimum system efficiency in some

instances – use ‘zone’ control with caution where system

fficiency is important. e

29